Hydrotreating catalyst of catalytic cracking gasoline

a catalyst and cracking technology, applied in the field of hydrotreating catalysts, can solve the problems of further reducing the sulfur content of gasoline, increasing the cleaning performance of high-mileage automobiles with direct injection engines or lean burn engines, and increasing the degree of mos2 dispersion, excellent desulfurization activity, and hydrogenation suppressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

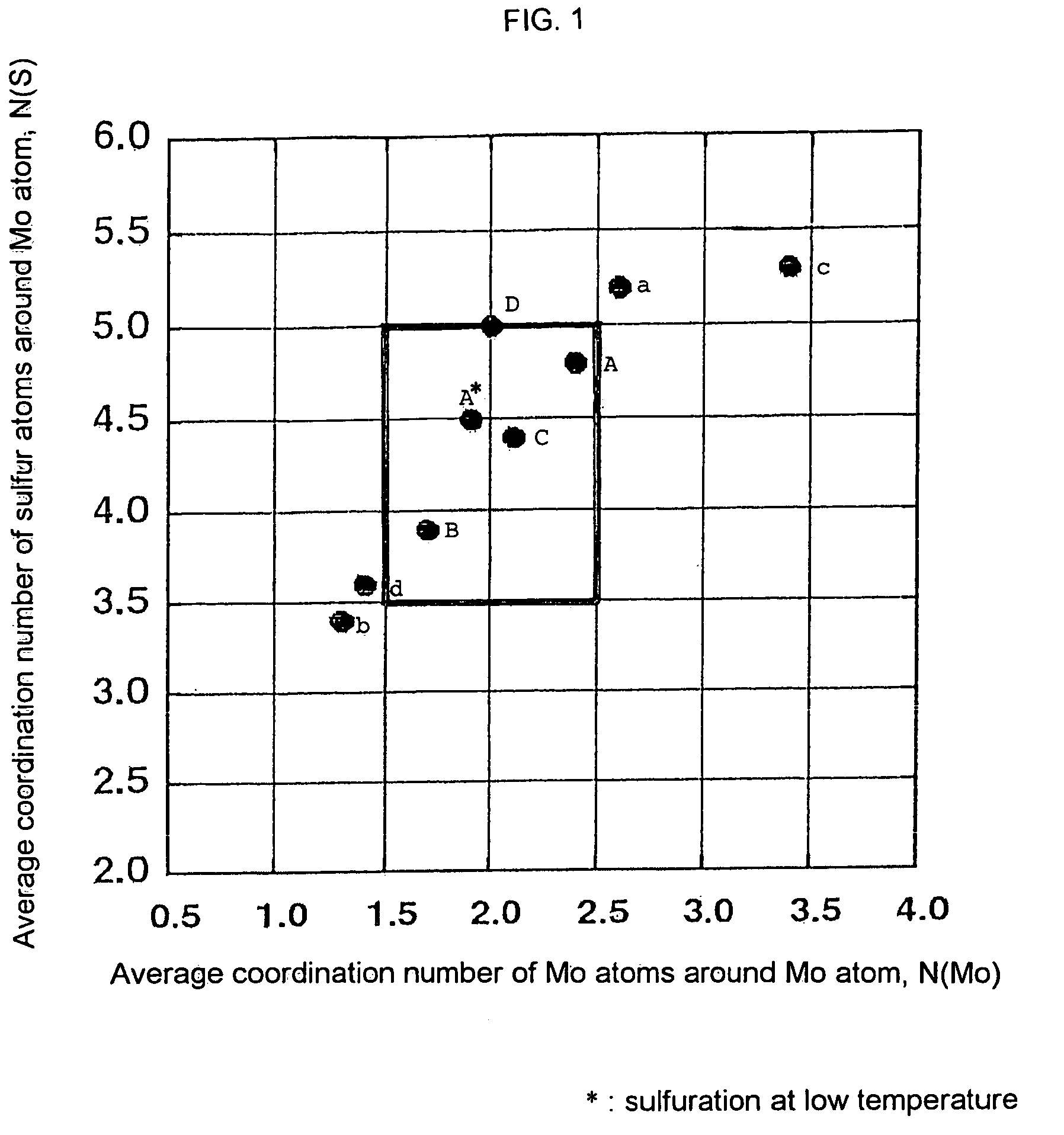

Image

Examples

example 1

Preparation of Catalyst:

(1) Preparation of Support

[0047] At the preparation of a catalyst, γ-alumina (shape: 1 / 16 inch cylinder) which was a porous inorganic oxide was used as a support. The surface area of the support was 195 m2 / g and the pore volume thereof was 0.80 cm3 / g.

(2) Preparation of Impregnating Solution

[0048] To a 2,000 ml beaker were added 1,500 ml of water and 64.0 g of molybdenum trioxide, followed by stirring at 95° C. for 10 hours. Then, 28.0 g of basic cobalt carbonate was added thereto, followed by stirring at 95° C. for 5 hours. The mixture was cooled to 75° C. and 130.0 g of a 50% gluconic acid solution (gluconic acid / cobalt=1.5 / l (mol / mol)) was added thereto, followed by stirring at the same temperature for 5 hours. The resulting solution was concentrated to 320 ml and subsequently 10.0 g of ammonium dihydrogen phosphate was added and dissolved to prepare an aqueous Co—Mo—P-gluconic acid solution.

(3) Preparation of Catalyst

[0049] The aqueous Co—Mo—P-gl...

example 2

Preparation of Catalyst:

(1) Preparation of Support

[0050] The same alumina support as used in Example 1 was employed.

(2) Preparation of Impregnating Solution

[0051] To a 2,000 ml beaker were added 1,500 ml of water and 64.0 g of molybdenum trioxide, followed by stirring at 95° C. for 10 hours. Then, 28.0 g of basic. cobalt carbonate was added thereto, followed by stirring at 95° C. for 5 hours. The mixture was cooled to 75° C. and 130.0 g of a 50% gluconic acid solution (gluconic acid / cobalt=1.5 / l (mol / mol)) was added thereto, followed by stirring at the same temperature for 5 hours. The resulting solution was concentrated to 424 ml and subsequently 10.0 g of ammonium dihydrogen phosphate was added and dissolved to prepare an aqueous Co—Mo—P-gluconic acid solution.

(3) Preparation of Catalyst

[0052] The aqueous Co—Mo—P-gluconic acid solution prepared in (2) was supported on the γ-alumina of (1) by an impregnation method. That is, 50 g of the γ-alumina was impregnated with 40 m...

example 3

Preparation of Catalyst:

(1) Preparation of Support

[0053] A catalyst was prepared by the same operations as in Example 1 except that the catalyst was burned. That is, to a 2,000 ml beaker were added 1,500 ml of water and 64.0 g of molybdenum trioxide, followed by stirring at 95° C. for 10 hours. Then, 28.0 g of basic cobalt carbonate was added thereto, followed by stirring at 95° C. for 5 hours. The mixture was cooled to 75° C. and 130.0 g of a 50% gluconic acid solution (gluconic acid / cobalt=1.5 / l (mol / mol)) was added thereto, followed by stirring at the same temperature for 5 hours. The resulting solution was concentrated to 320 ml and subsequently 10.0 g of ammonium dihydrogen phosphate was added and dissolved to prepare an aqueous Co—Mo—P-gluconic acid solution. With the aqueous Co—Mo—P-gluconic acid solution was impregnated 50 g of the γ-alumina. Then, the impregnated product was irradiated with a microwave having a frequency of 2.45 GHz for 10 minutes to be dried and subseq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com