Patents

Literature

700 results about "Porous microspheres" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

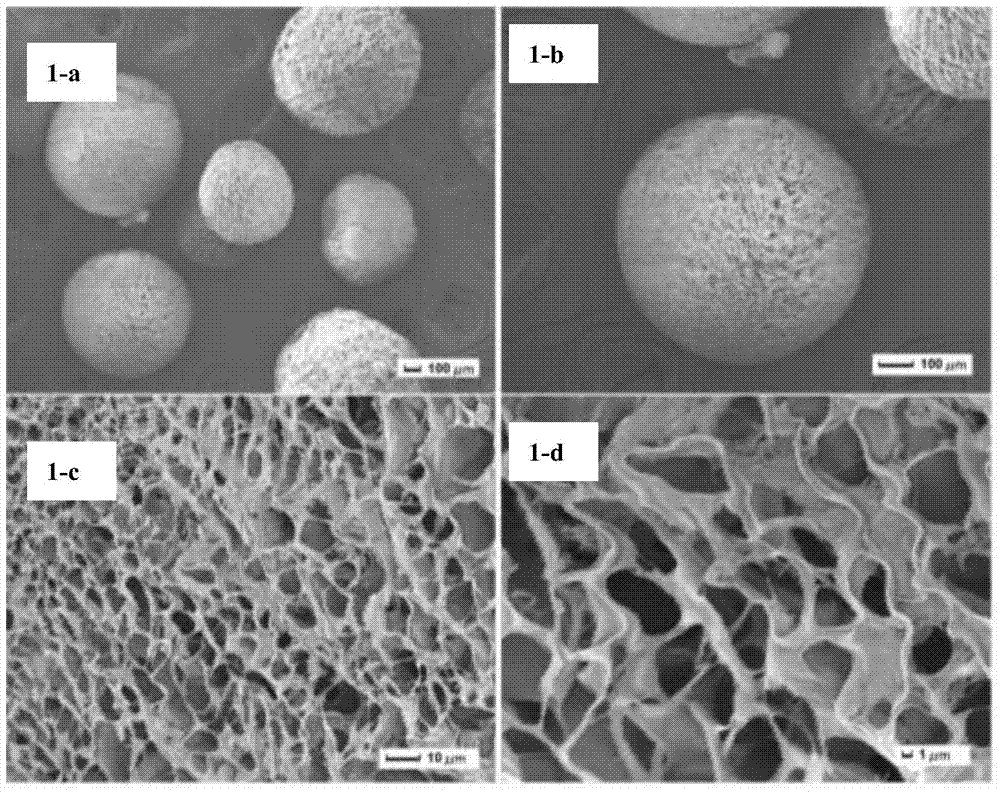

Improved process for preparing porous microsphere active carbon

The improved process for preparing high strength porous microsphere active carbon includes the following steps: oxidizing thermosetting resin ball at 60-400 deg.c in oxygen containing atmosphere or pre-treating thermosetting resin ball at 60-300 deg.c in oxidizing acid, SO2 or SO3; carbonizing at 600-1200 deg.c in helium, nitrogen or their mixture atmosphere; and activating at 600-1200 deg.c in activating water vapor atmosphere to obtain high strength porous microsphere active carbon with grain size of 10 micron to 2 mm, BET specific surface area of 500-4000 sq m / g, and grain strength of 50-200 MPa. The process is simple, low in cost and high in yield, and the prepared microsphere active carbon has high strength and high purity and is one excellent medical active adsorption material.

Owner:EAST CHINA UNIV OF SCI & TECH

Preparation of degradable pollutant polyalcohol stephanoporate microballoons and uses thereof

InactiveCN101249077ALarge specific surface areaImprove loading performancePeptide/protein ingredientsPharmaceutical non-active ingredientsPolyvinyl alcoholFreeze-drying

A preparation method for porous microspheres of a biodegradable polymer is provided. The method comprises the following steps: (a) dissolving a biodegradable polymer in an organic solvent to form an oil phase of 1-30% (g / ml) concentration; (b) selecting a pore-forming agent 1-50% of the biodegradable polymer in the step (a) and dissolving the pore-forming agent in water to form an internal water phase; (c) adding dropwise the internal water phase into the oil phase at a volume ratio of (1-30):100, and stirring to form a primary emulsion; (d) preparing a polyvinyl alcohol aqueous solution of 0.5-10% (g / ml) concentration, which serves as an external water phase; (e) pouring the primary emulsion into the external water phase at a volume ratio of (3-30):100, stirring or performing ultrasonic treatment to form a double-emulsion, and allowing the polymer in the double-emulsion to solidify, thereby forming microspheres; (f) freeze-drying the microspheres to obtain the final product. The obtained porous microspheres of the biodegradable polymer have high porosity, large specific surface area and good adsorption and encapsulation properties; and are used for the adsorption and encapsulation of unstable protein drugs, polypeptide drugs and growth factors and can retain pharmaceutical activity and effectiveness thereof.

Owner:SOUTHWEST JIAOTONG UNIV

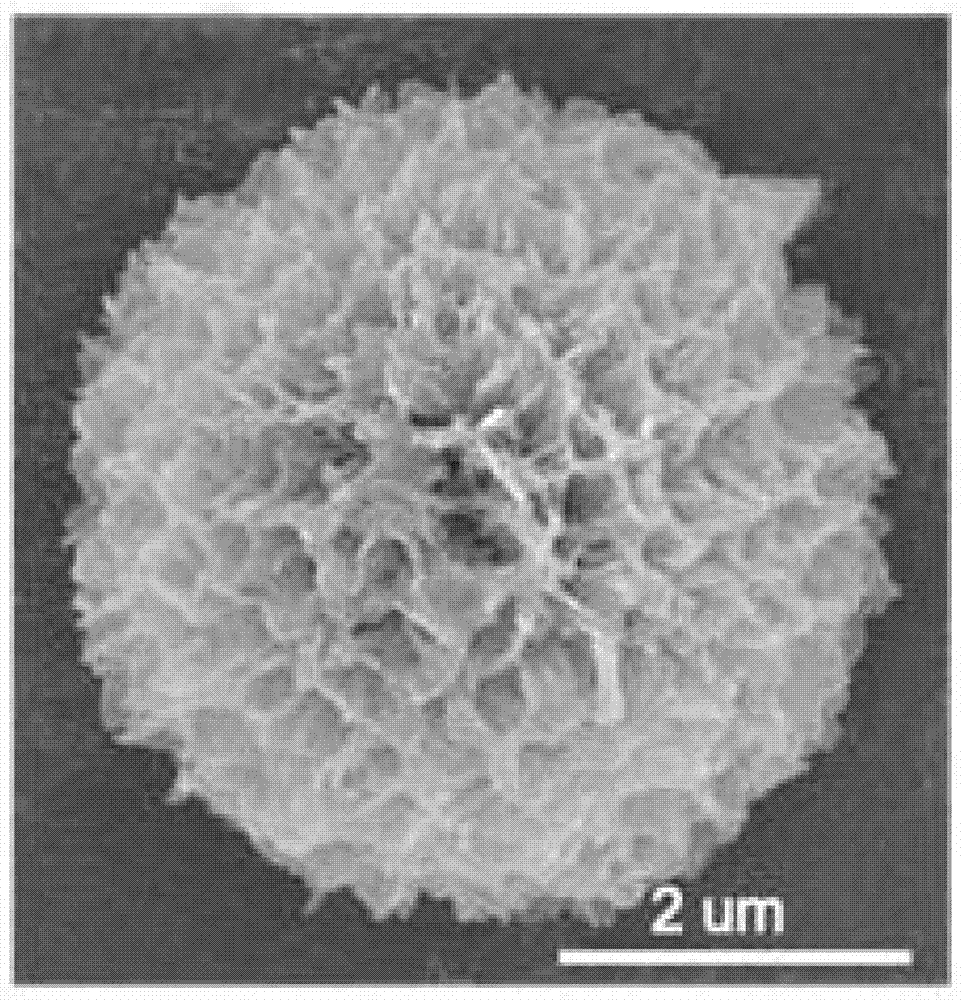

Preparation method of alumina porous microsphere

The invention discloses a preparation method of an alumina porous microsphere. The preparation method comprises the following steps: 1) dissolving a surfactant in deionized water, stirring the solution, and using the solution as a water phase; 2) mixing a chelating agent, an alumina precursor and octanol, stirring the materials, and using the mixture as an oil phase; 3) adding Span80 and a pore-forming agent to the oil phase, and stirring the materials; 4) pouring the clear oil phase obtained in the step 3) into the water phase, and continuously stirring and emulsifying the materials; 5) carrying out vacuum filtration on the product obtained in the step 4), and washing and then drying the obtained filter cake, thus obtaining the alumina porous microsphere. The microsphere has an internally closed macroporous structure and has a microsphere dimension of 1-100mu m and an internally closed pore diameter of 50nm-5mu m.

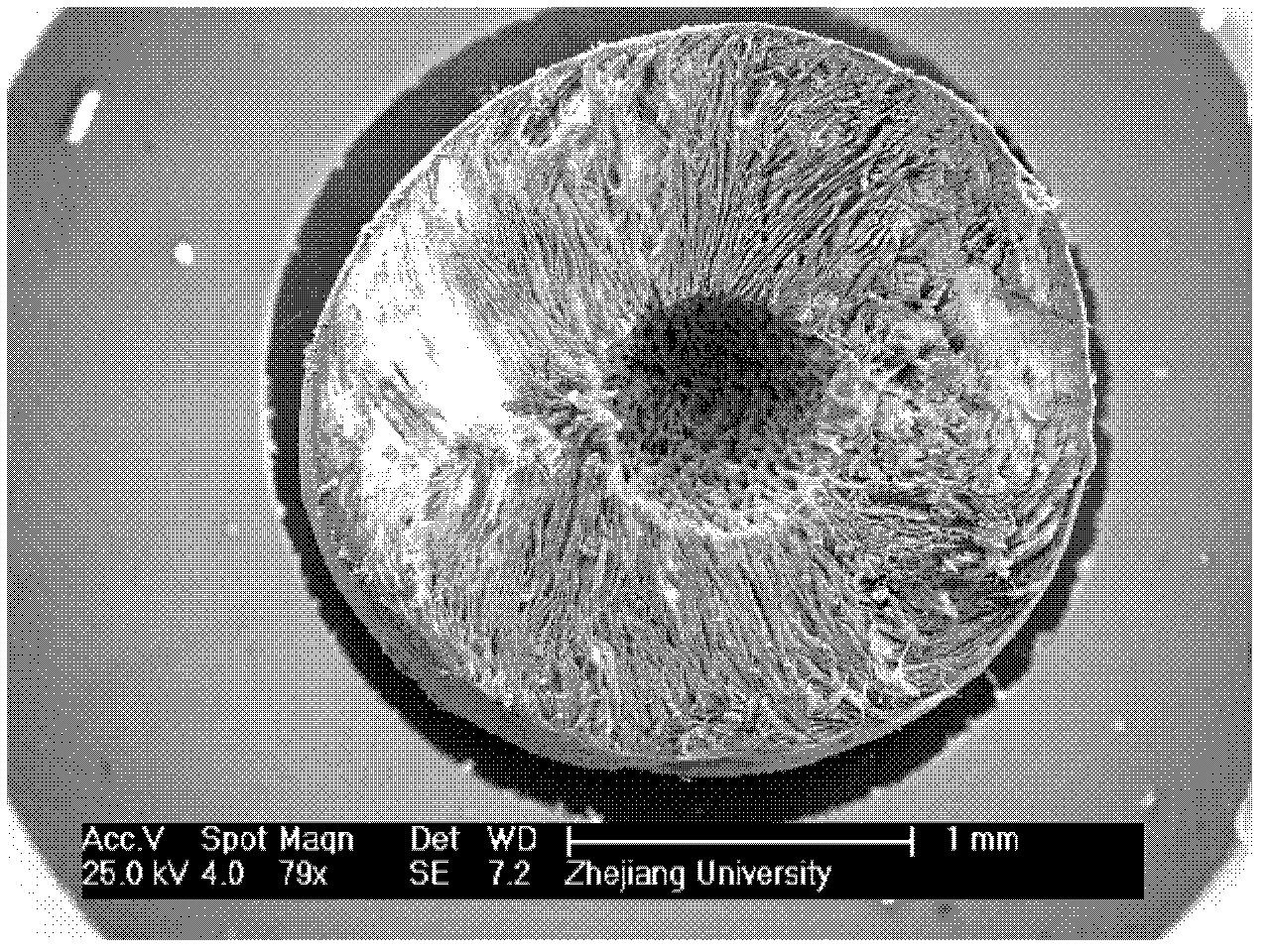

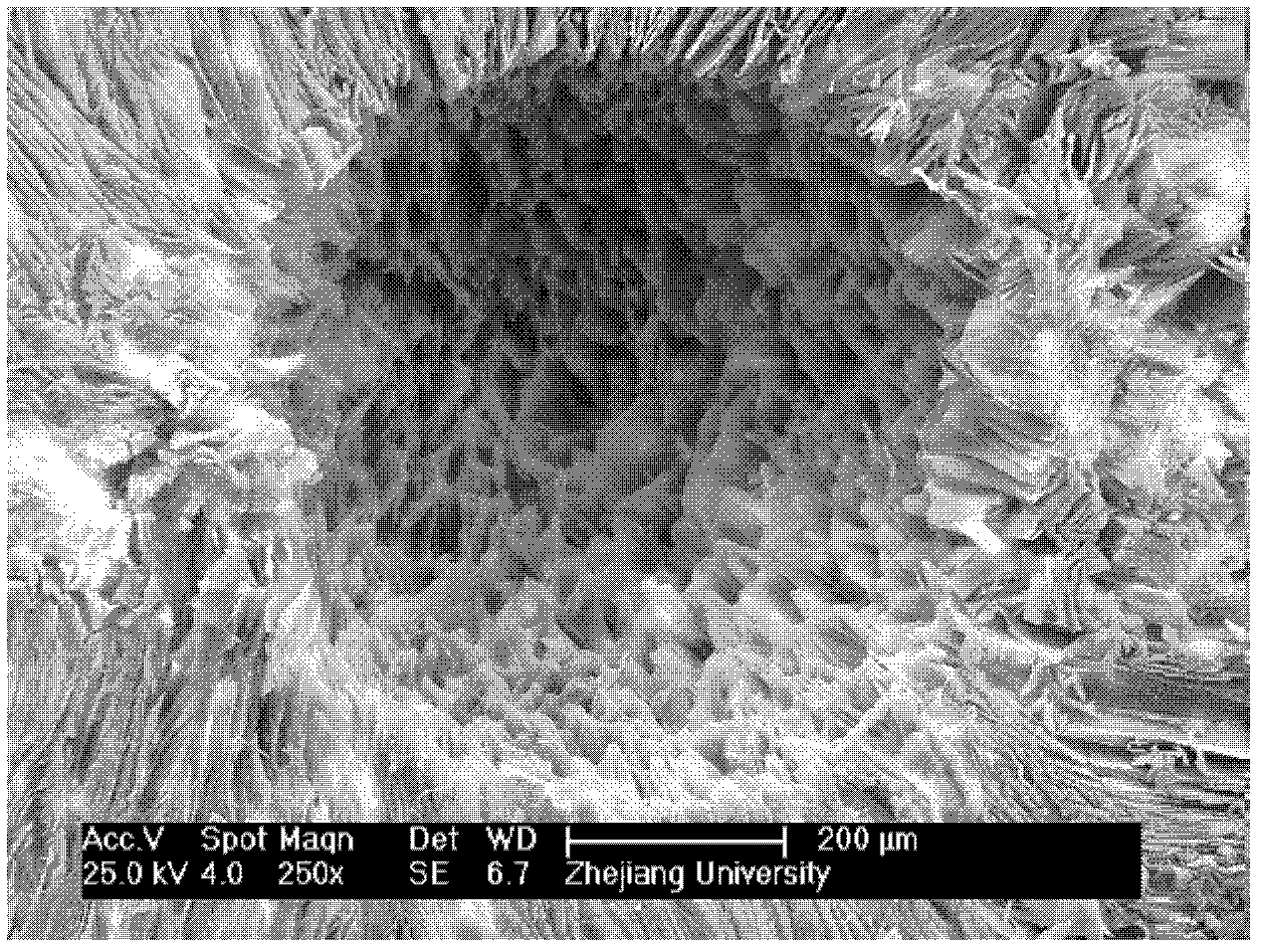

Owner:ZHEJIANG UNIV

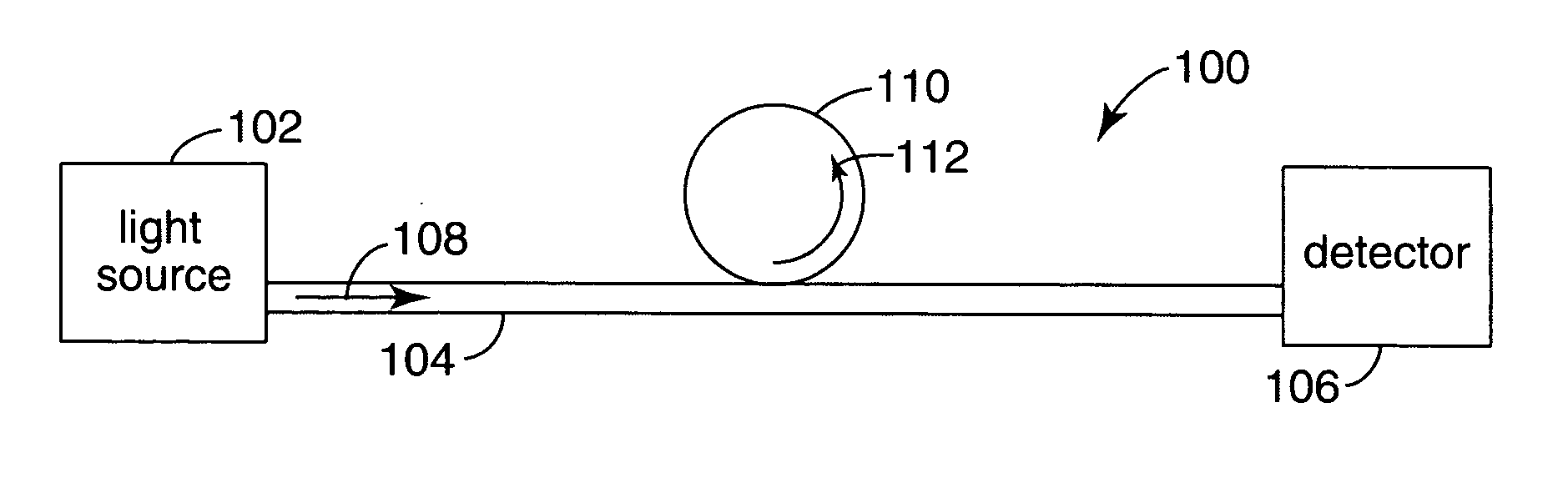

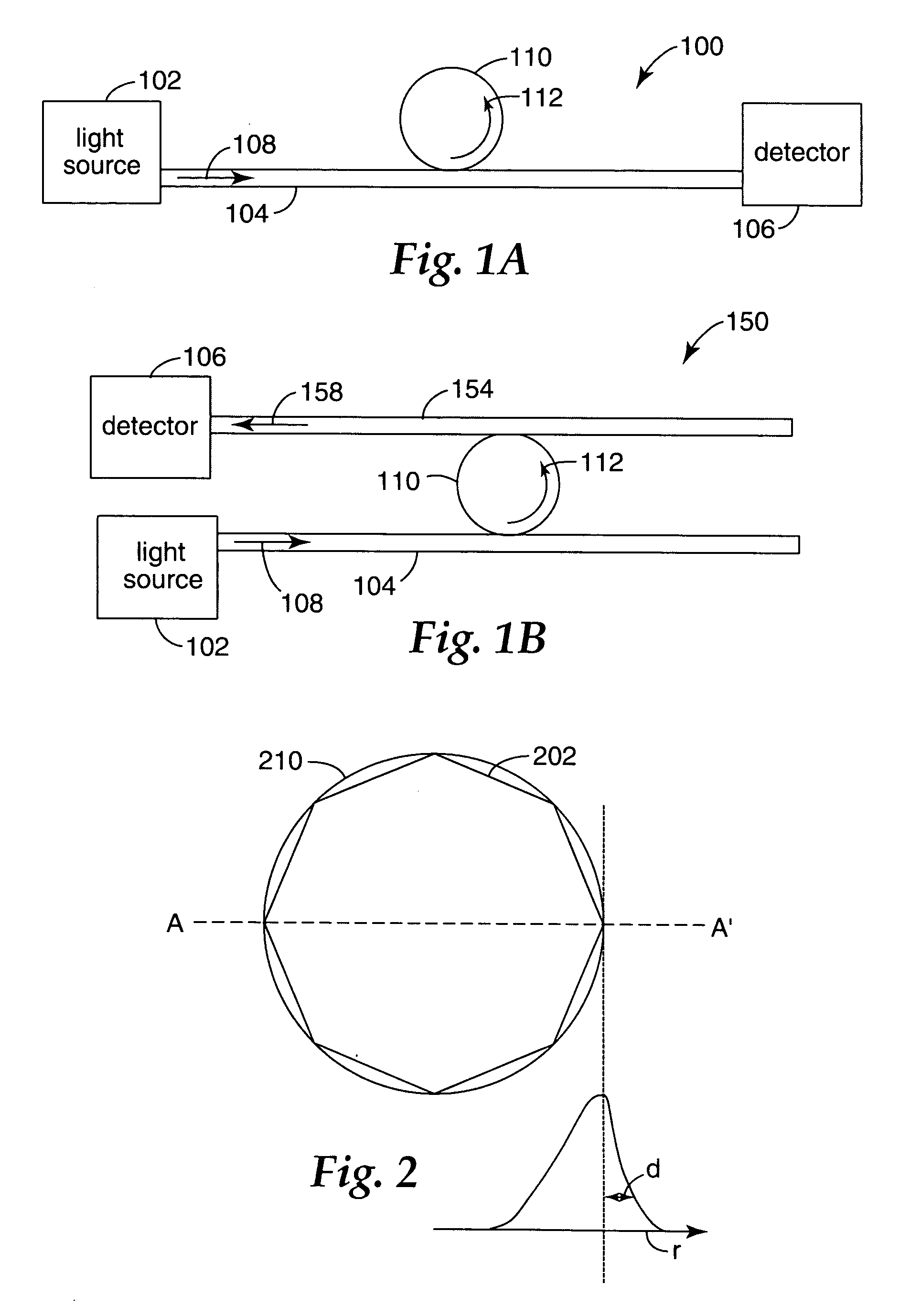

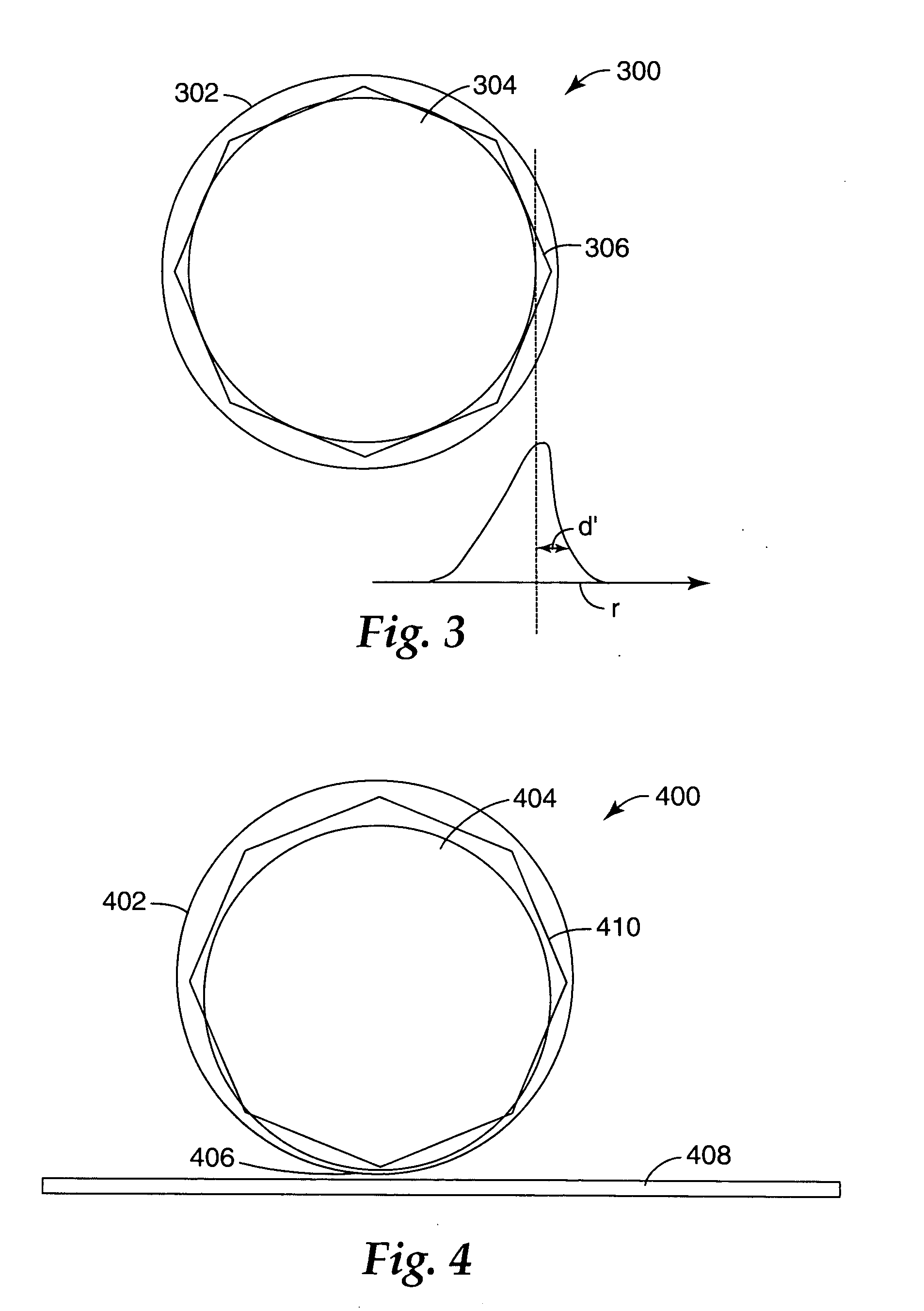

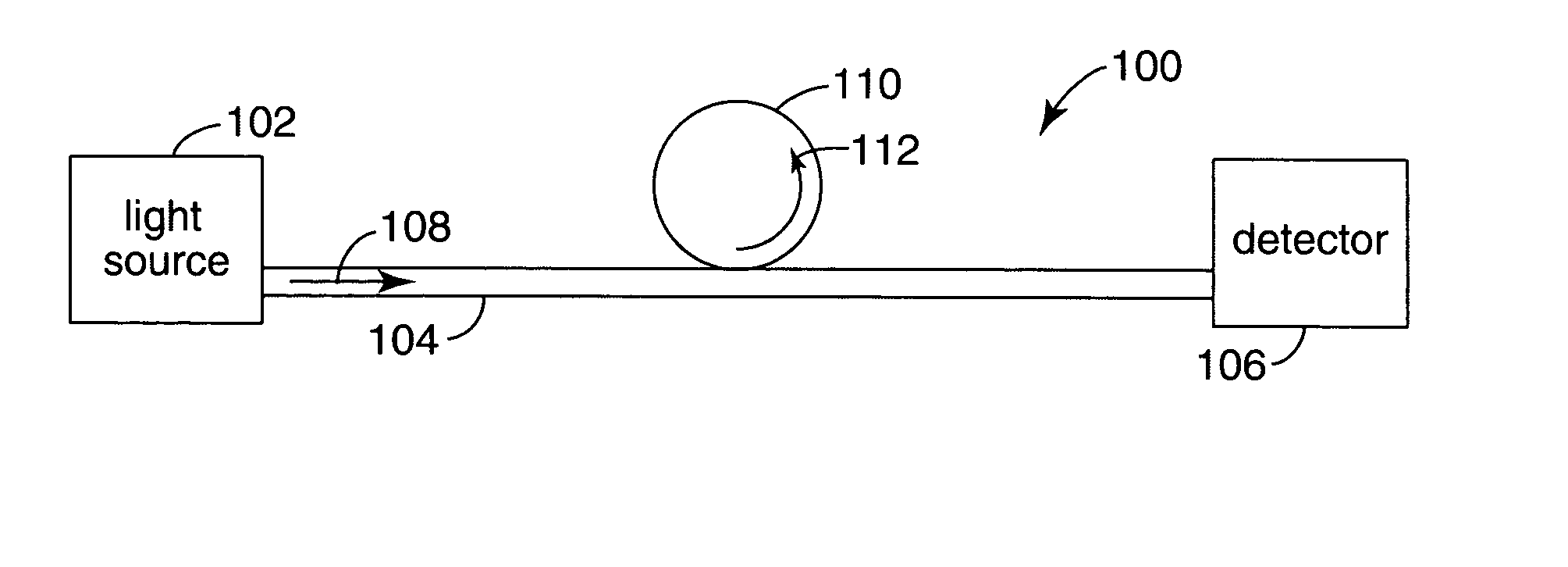

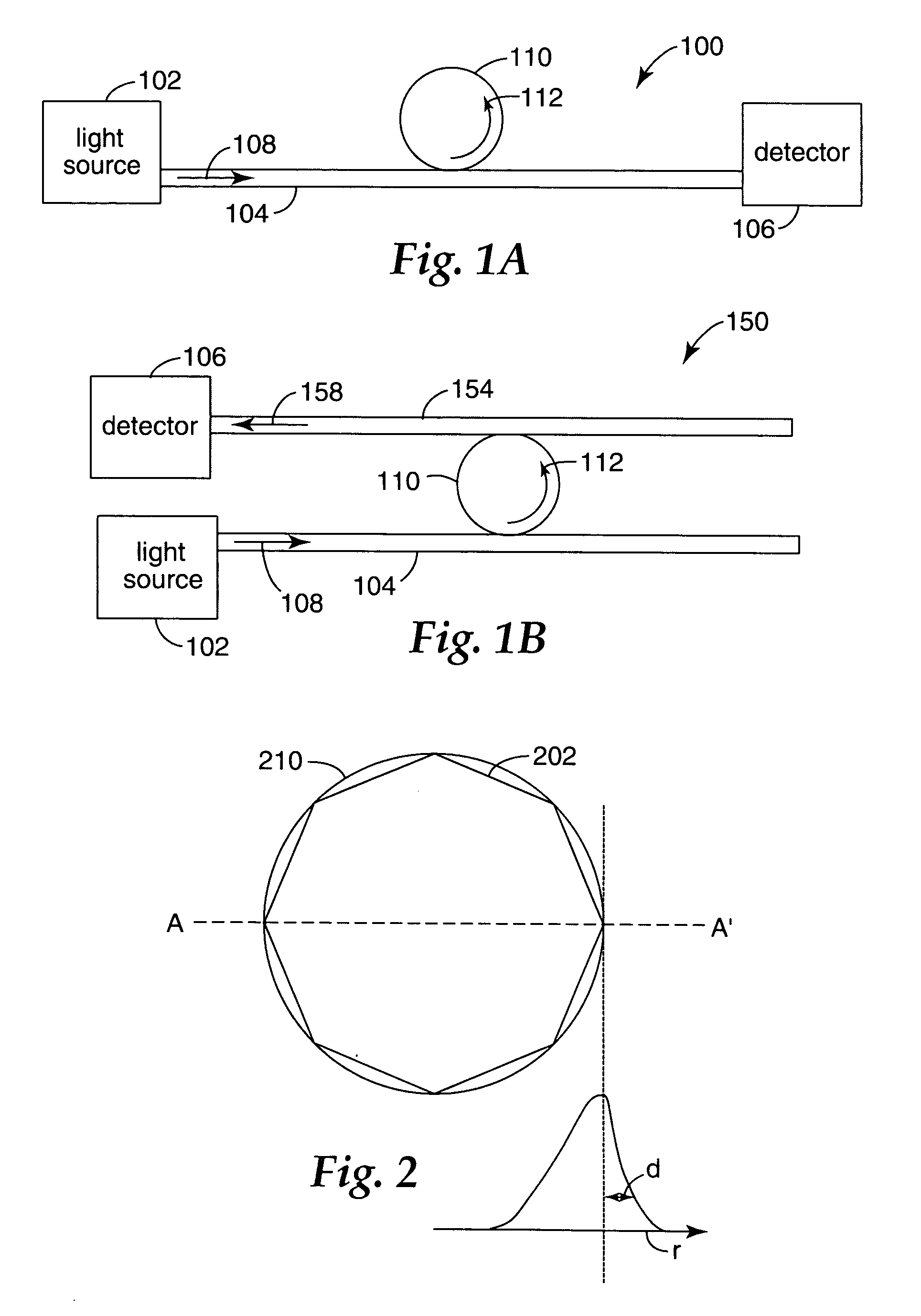

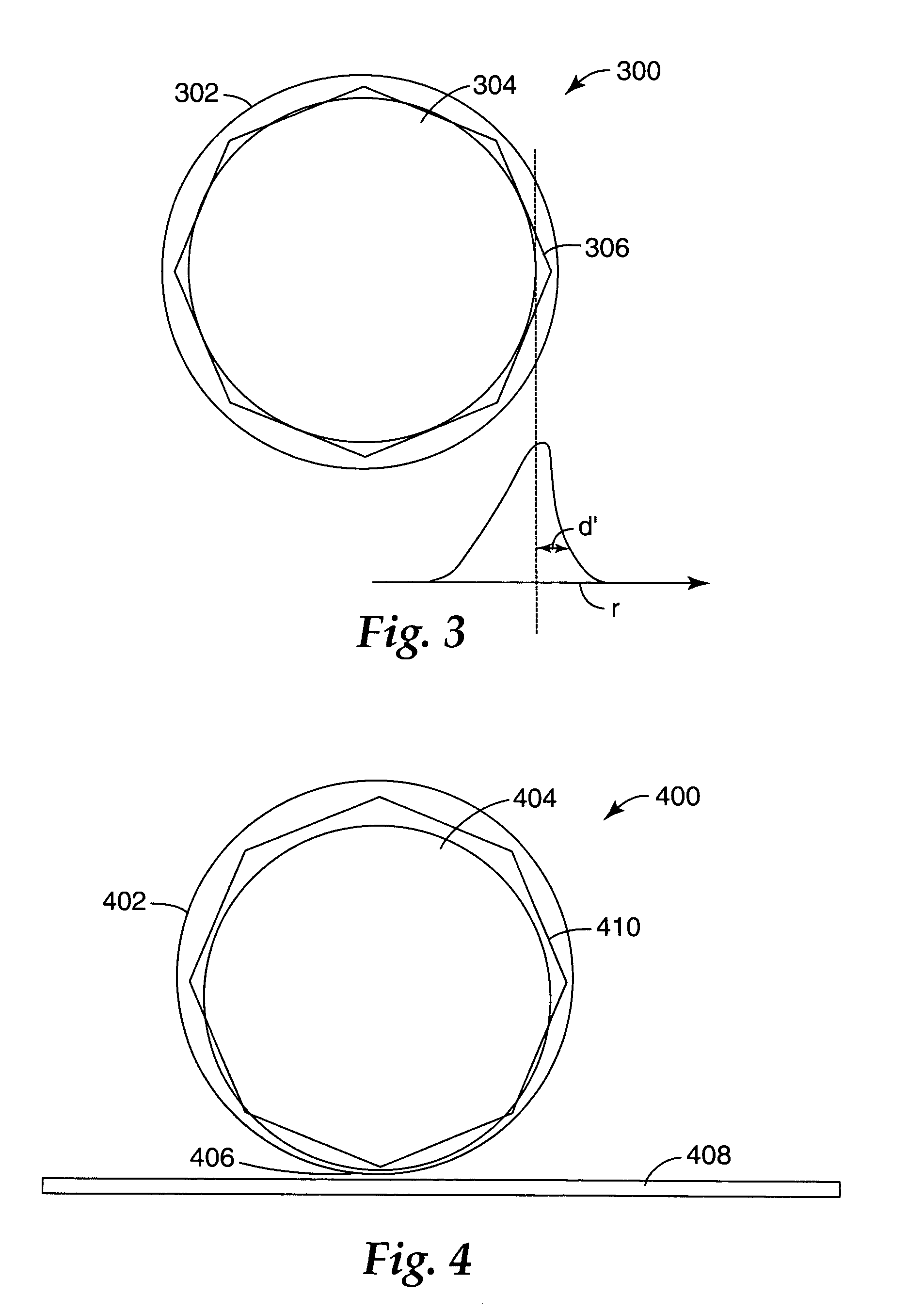

Porous microsphere resonators

InactiveUS20050078731A1Increase volumeEnhanced interactionMaterial analysis by observing effect on chemical indicatorActive medium shape and constructionWhispering galleryOptical interaction

There are several different applications where it is desirable to increase the amount of material that can be introduced to the surface of a microresonator that has whispering gallery modes. The use of a porous surface on the microresonator permits greater amounts of the material to be captured on or near the surface of the microresonator, resulting in an increased optical interaction between the material and the light propagating in the whispering gallery mode(s) of the microresonator.

Owner:3M INNOVATIVE PROPERTIES CO

Injectable composite material capable of promoting bone regeneration and repair and preparation method thereof

The invention discloses an injectable composite material capable of promoting bone regeneration and repair. The injectable composite material is prepared by mixing sodium alginate, chitosan, multiple trace element, calcium phosphate porous microsphere and bioactive glass nanometer granules, preparing the mixture by using deionized water and cell culture fluid, and compounding the prepared mixture. The injectable composite material comprises the following components in percentage by mass: 0.10 to 0.50 percent of sodium alginate, 0.01 to 0.20 percent of chitosan, 5 to 30 percent of multiple trace element codoped calcium phosphate porous microsphere, 0.05 to 0.50 percent of bioactive glass, 25 to 55 percent of cell culture fluid and 30 to 45 percent of deionized water. The preparation process is simple; the prepared injectable composite material has the characteristics of excellent injectability and quick degradation; and a hydrogel network can concentrate calcium, phosphorous ion and trace elements degraded and released by inorganic particles and can promote the migration, growth, multiplication and differentiation of bone cell, thereby having effects of quickly inducing bone regeneration and promoting bone repair on endosteal microdamage, fracture or bone defect.

Owner:ZHEJIANG UNIV

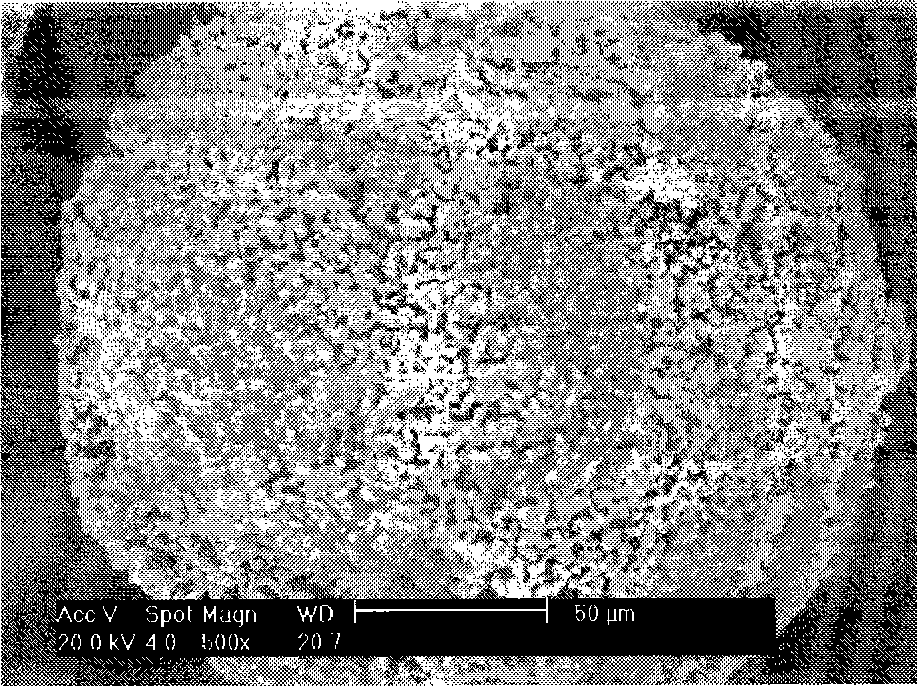

Chitosan/sheet silicate nano compound stephanoporate crosslinked microsphere sorbent and preparation method thereof

InactiveCN101347719AImprove adsorption capacityLow priceOther chemical processesSilicon compoundsSorbentLow molecular weight chitosan

The invention discloses a chitosan / layered silicate nano composite porous crosslinked microsphere adsorbent and a preparation method thereof; in the adsorbent, the layered silicate which is in nano-state is dispersed in the chitosan microsphere which is treated with chemical crosslinking. The preparation method is as follows: the chitosan with low molecular weight / layered silicate intercalation solution is prepared, the intercalation solution is blended with the chitosan with high molecular weight and is contacted with alkaline coagulant to prepare the microsphere, the microsphere is treated with pre-crosslinking and crosslinking, acid solution is used for removing pre-crosslinking agent to obtain the chitosan / layered silicate nano composite porous crosslinked microsphere adsorbent. By comprehensively utilizing the characters of chitosan and layered silicate in terms of adsorption property and jointly applying intercalation composition, solidification and granulation by alkali solution, and pre-crosslinking and crosslinking techniques, a porous microsphere adsorbent which has low price and excellent adsorption performance for heavy metal ions and organic pollutants can be prepared.

Owner:SOUTH CHINA NORMAL UNIVERSITY

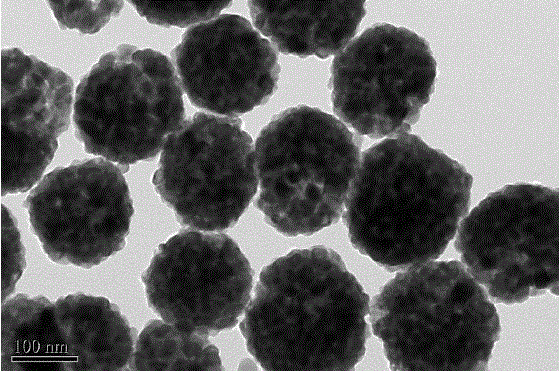

Porous carbon microsphere with surface covered with graphene, and preparing method and application of porous carbon microsphere

The invention discloses a porous carbon microsphere with the surface covered with graphene, and a preparing method and application of the porous carbon microsphere. The polymer porous microsphere with the surface provided with the amination perssad serves as a template, the polymer microsphere is fully soaked in a sulfonation graphene water solution and dried, the sulfonation graphene and the polymer microsphere are combined, the polymer porous microsphere with the surface covered with sulfonation graphene is obtained and is carbonized at a high temperature in the protective atmosphere, and a target product, namely the porous carbon microsphere with the surface covered with graphene is obtained. The diameter of the target product is in the controllable range of 5 nm to 1,000 microns, a porous structure is achieved, the aperture is in the controllable range of 5 nm to 100 nm, a very large specific area is achieved, a very high electron transfer rate and good electrical conductivity are presented, the porous carbon microsphere can be widely applied to many fields such as catalyst loads, lithium ion batteries, supercapacitors, adsorption, sea water desalination and sensing, the preparing technology is simple, controllability of the reaction process is high, and industrial large-scale production is facilitated.

Owner:SUZHOU GRAPHENE NEW MATERIAL TECH

Process for manufacture and use of improved attrition resistant catalyst

A method for manufacturing of an improved attrition resistant catalyst having an oxide-rich surface layer involving forming a slurry comprising; catalyst, catalyst precursor or catalyst support particles (e.g., transition metal oxides), a colloidal oxide sol (e.g., colloidal silica), and a solution of a solvent and solute wherein the solute consist essentially of a precursor of said oxide-rich surface with particle size no greater than 5 nm (e.g., aqueous silicic acid or polysilicic acid) and then spray drying the slurry to form porous microspheres of attrition resistant catalyst; and, calcining the spray dried microspheres. Such a catalyst is particularly useful in oxidation processes wherein the oxidation is performed by an oxidized form of the catalyst and the resulting reduced form of the catalyst is separately regenerated (e.g., two-step vapor phase processes carried out in recirculating solids reactors, transport bed reactors or circulating fluidized bed reactors and the like).

Owner:EI DU PONT DE NEMOURS & CO

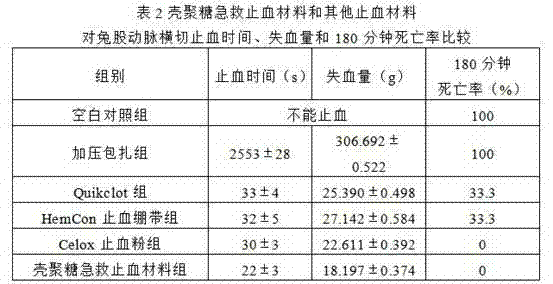

Chitosan emergent hemostasis material

ActiveCN102648985AStrong water absorptionSpeed up penetrationAbsorbent padsBandagesSuction forceTissue repair

The invention provides a chitosan emergent hemostasis material, which is provided with at least two layers of structures: a chitosan hemostasis layer as an upper layer, and a polyacrylic acid grafting chitosan lining layer as a lower layer, wherein the chitosan hemostasis layer is of a structure of a porous microsphere, porous fiber, porous sponge, or a compound of the porous microsphere, the porous fiber and the porous sponge; and the polyacrylic acid grafting chitosan lining layer is of a structure of porous fiber, porous sponge, or a compound of the porous fiber and the porous sponge. According to the chitosan emergent hemostasis material, the polyacrylic acid grafting chitosan is used as the lining layer of the chitosan, so that powerful water suction force can be provided, seepage velocity of blood in the chitosan hemostasis material is improved, blood is further concentrated, the density of the hemostasis material is improved simultaneously, the hemostasis material is easier to sink to arrive at a bleeding point, gravity press of a bleeding part is formed, pressurization is convenient, and the hemostasis effect is improved. Meanwhile, the polyacrylic acid grafting chitosan layer also can be used as a medicine-carrying substrate, can be used for carrying antibacterial drug, acesodyne, factors for promoting tissue repair and the like, and is good for preventing and controlling infection while stopping bleeding, relieving pains, and accelerating wound tissue healing.

Owner:欣乐加生物科技温州有限公司

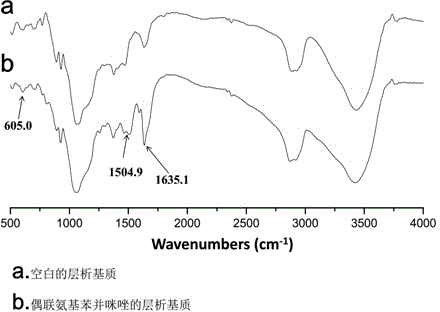

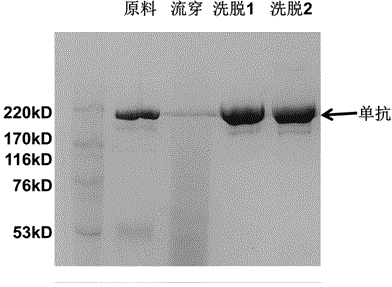

Chromatographic medium using amino benzimidazole as function ligand and preparation method thereof

ActiveCN104096544ALarge adsorption capacityReduce adverse effectsOther chemical processesPeptide preparation methodsChromatographic separationDesorption

The invention discloses a chromatographic medium using amino benzimidazole as a function ligand and a preparation method thereof. Hydrophilic porous microspheres are used as a chromatographic medium, activated by allyl bromide, and coupled with the amino benzimidazole to obtain a medium using the amino benzimidazole as the function ligand; dimethyl sulfoxide and the allyl bromide are sequentially added into a chromatographic matrix for activation; the activated chromatographic matrix is reacted with N-bromo-succinimide for bromo-alcoholization; the bromo-alcoholized chromatographic matrix is mixed with an amino benzimidazole solution for coupling the amino benzimidazole ligand; finally an aqueous ethanol amine solution is used for sealing unreacted bromo-alcoholized ends to obtain a hydrophobic charge induced chromatographic medium using the amino benzimidazole as the function group. The new chromatographic medium is simple in preparation process and high in antibody adsorption capacity, and has the characteristics of non salt dependent adsorption, can realize desorption and recovery by changing the solution pH to weak acid, and can be used for hydrophobic charge induction chromatographic separation of antibodies.

Owner:ZHEJIANG UNIV

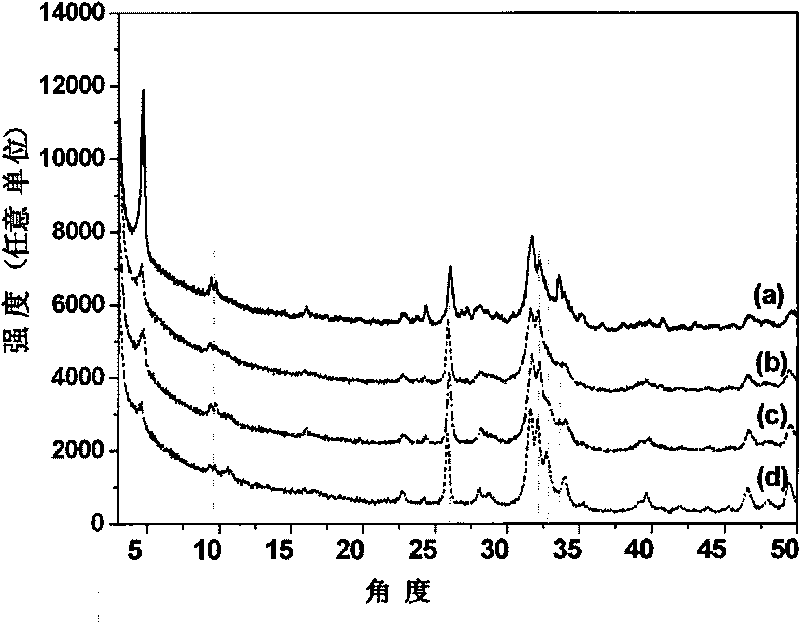

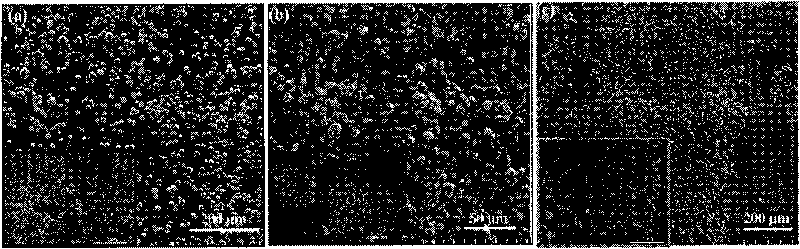

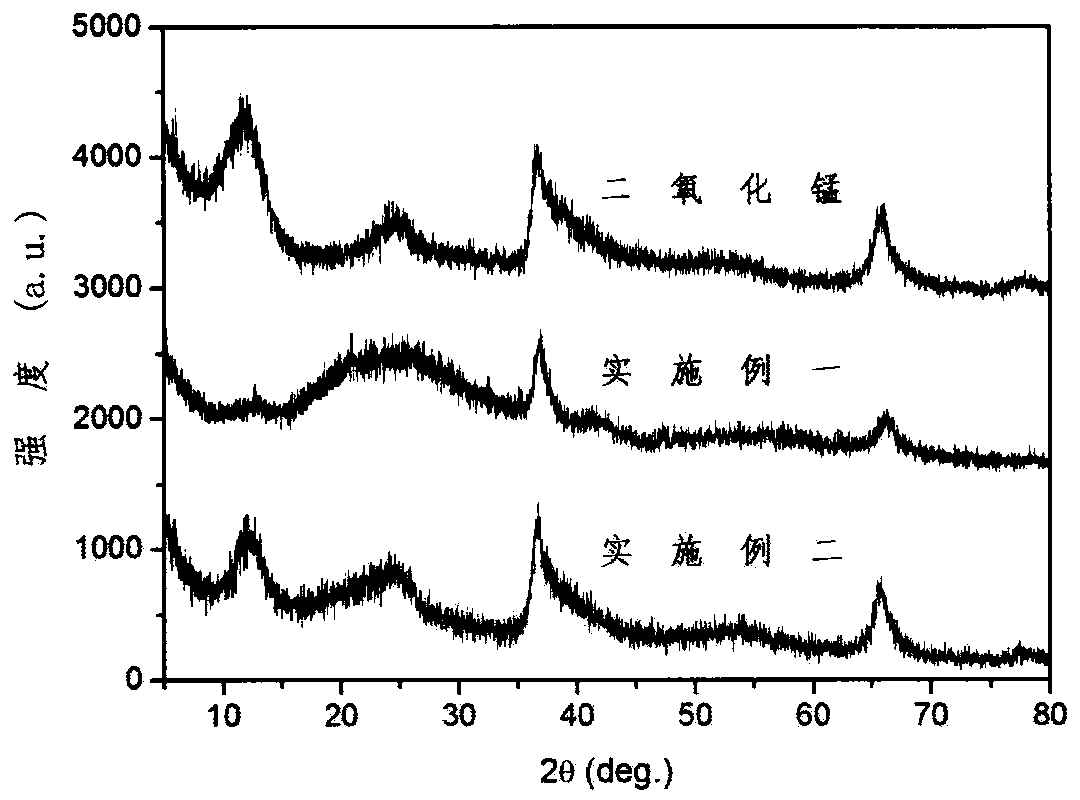

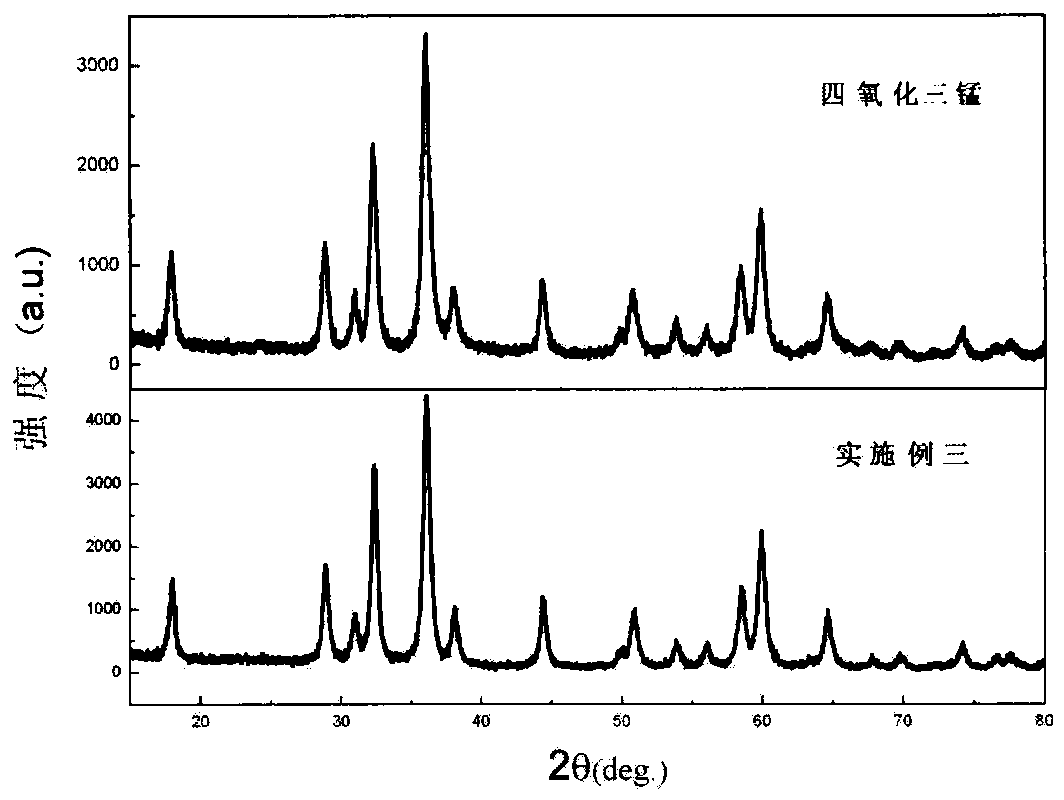

Manganese oxide/graphene porous microspheres, preparation method and energy storage application thereof

The invention discloses a manganese oxide / graphene porous microspheres, a preparation method and energy storage application of the manganese oxide / graphene porous microspheres. The preparation method includes the concrete steps that nano manganese oxide particles or precursor is mixed with aqueous suspension of graphene according to the mass ratio of manganese oxide / graphene 1:10-20:1; after the mixed solution is dispersed evenly through ultrasound or stirring, spray drying is conducted on the mixed solution through a spray drier, temperature at an inlet ranges from 100 DEG C to 280 DEG C, and temperature at an outlet is controlled between 30 DEG C 120 DEG C; after the collected solid powder is heated under 80 DEG C to 350 DEG C, manganese oxide / graphene secondary microsphere structure composite material is obtained. The manganese oxide / graphene composite material prepared through the method has excellent energy storage performance.

Owner:TIANJIN POLYTECHNIC UNIV

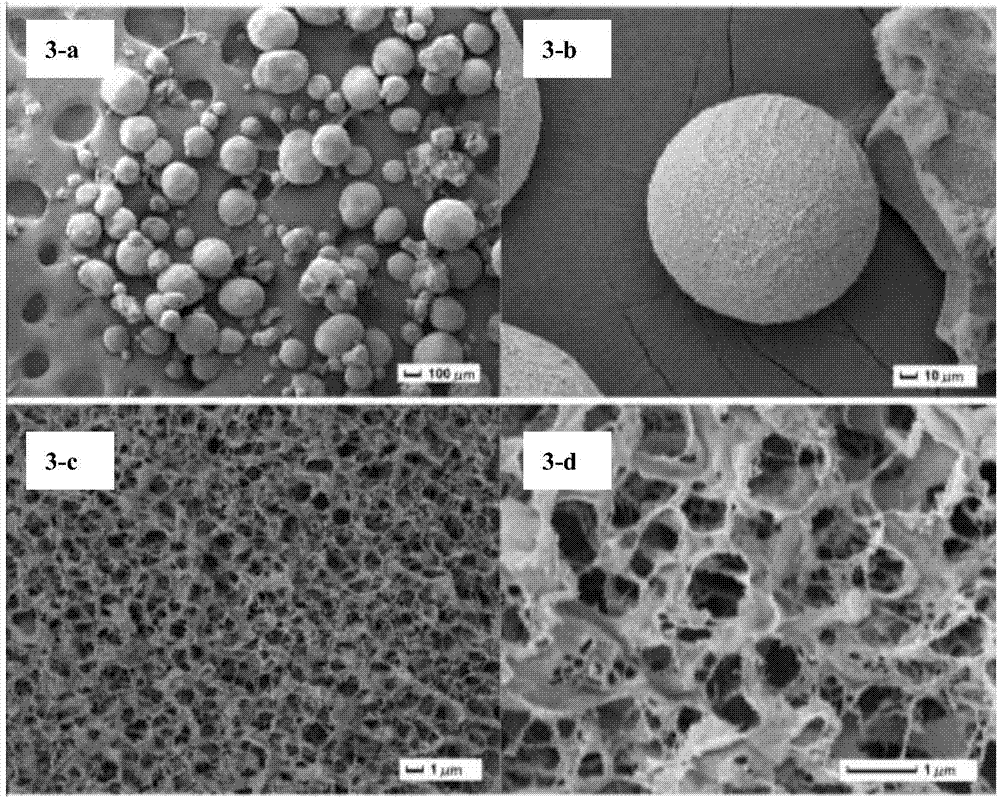

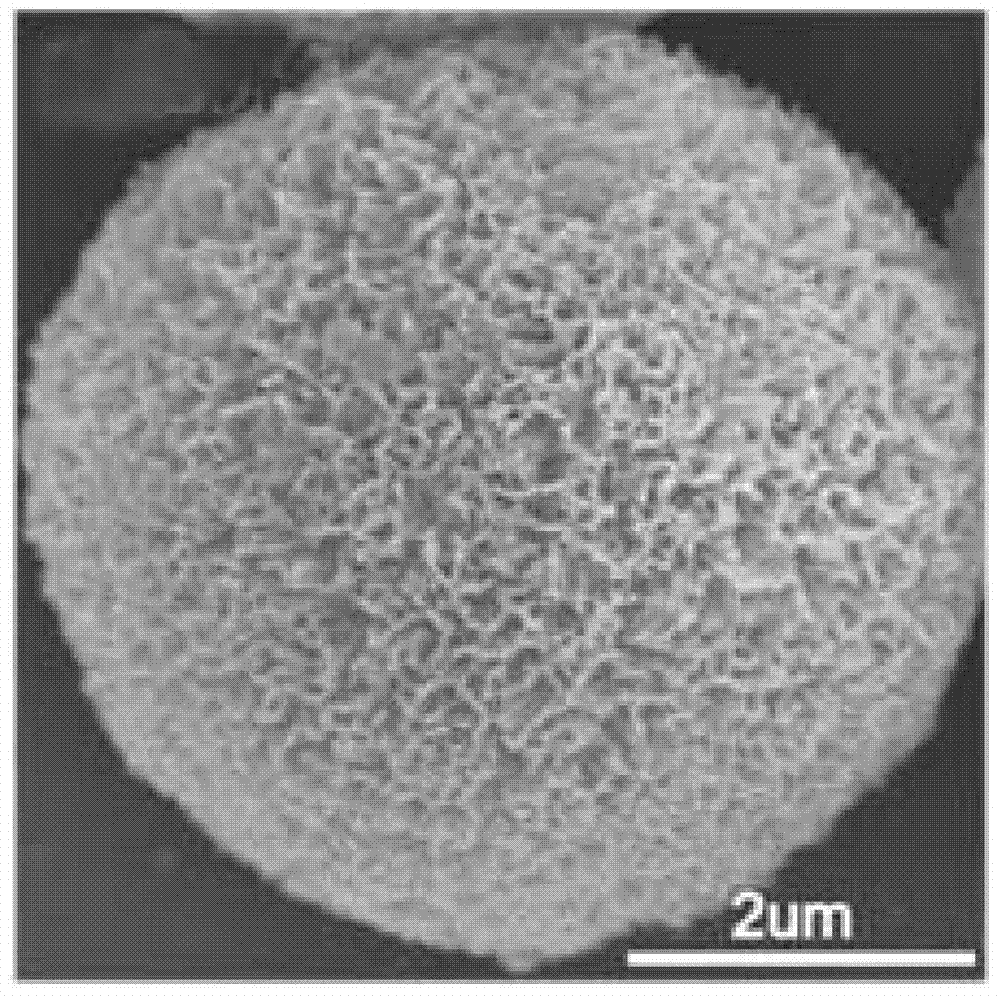

Preparation method of porous chitosan-based microspheres

ActiveCN104722251AUniform particle sizeRich sourcesOther chemical processesMicroballoon preparationWound dressingEmulsion

The invention relates to the field of high-molecular porous materials and particularly relates to a preparation method of porous chitosan-based microspheres for medicine carriers, adsorption and separation, hemostasis and wound dressing. The preparation method comprises the following steps: (a) respectively preparing solidification liquid, an emsulsifying-agent solution and a diluted-acid solution of pelletizing materials and precooling the solidification solution to minus 20 DEG C; (b) dripping the chitosan diluted-acid solution into the emsulsifying-agent solution, homogenizing and stirring to form emulsion; and (c) carrying out thermally-induced phase separation on the emulsion under the temperature ranging from minus 60 DEG C to minus 10 DEG C, adding precooled solidification liquid, carrying out reverse-phase regeneration and thus obtaining the chitosan-based porous microspheres. The preparation method has the beneficial effect that the surfaces and the inner parts of the porous microspheres have porous structures with communicated heights.

Owner:福建梅生药业有限公司

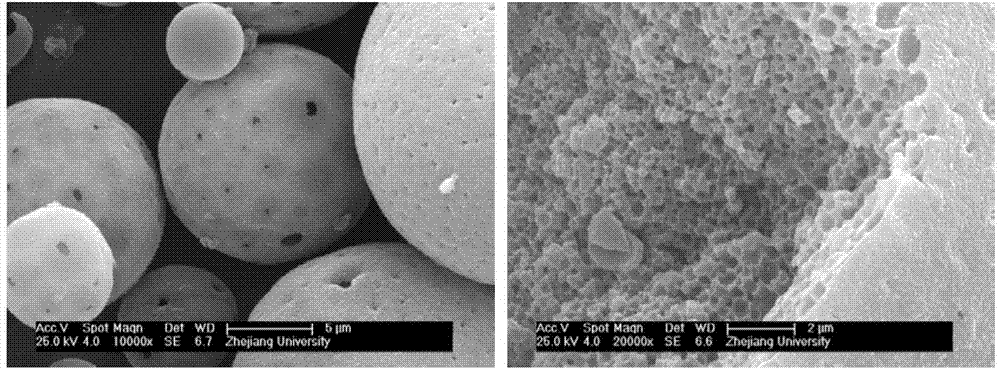

Preparation method of drug-carrying hydroxylapatite microspheres and bone cement composite porous microspheres

InactiveCN101361715AThe release rate is easy to controlLarge and adjustable drug loadingInorganic non-active ingredientsGranular deliveryApatiteHydroxylapatite

The invention discloses a preparation method of porous microspheres composite with hydroxyapatite microspheres being capable of carrying drugs and bone cement, which belongs to the technical field of biological material preparation. The method comprises the following steps: the preparation of nano hydroxyapatite powders; the preparation of Alpha- tricalcium phosphate powders; the preparation of the hydroxyapatite microspheres; and the preparation of the porous microspheres composite with the hydroxyapatite microspheres and the bone cement. The method has the advantages that: the porosity of the porous microspheres composite with the hydroxyapatite microspheres and the bone cement, and the size of the microspheres can be easily controlled; the composite of the drugs can be carried out by the preparation process of the bone cement stuff, the drug-carrying rate is large and controllable; and the composite porous microspheres can be served as drug carriers or stents with integration of bone restoration and cure.

Owner:TIANJIN UNIV

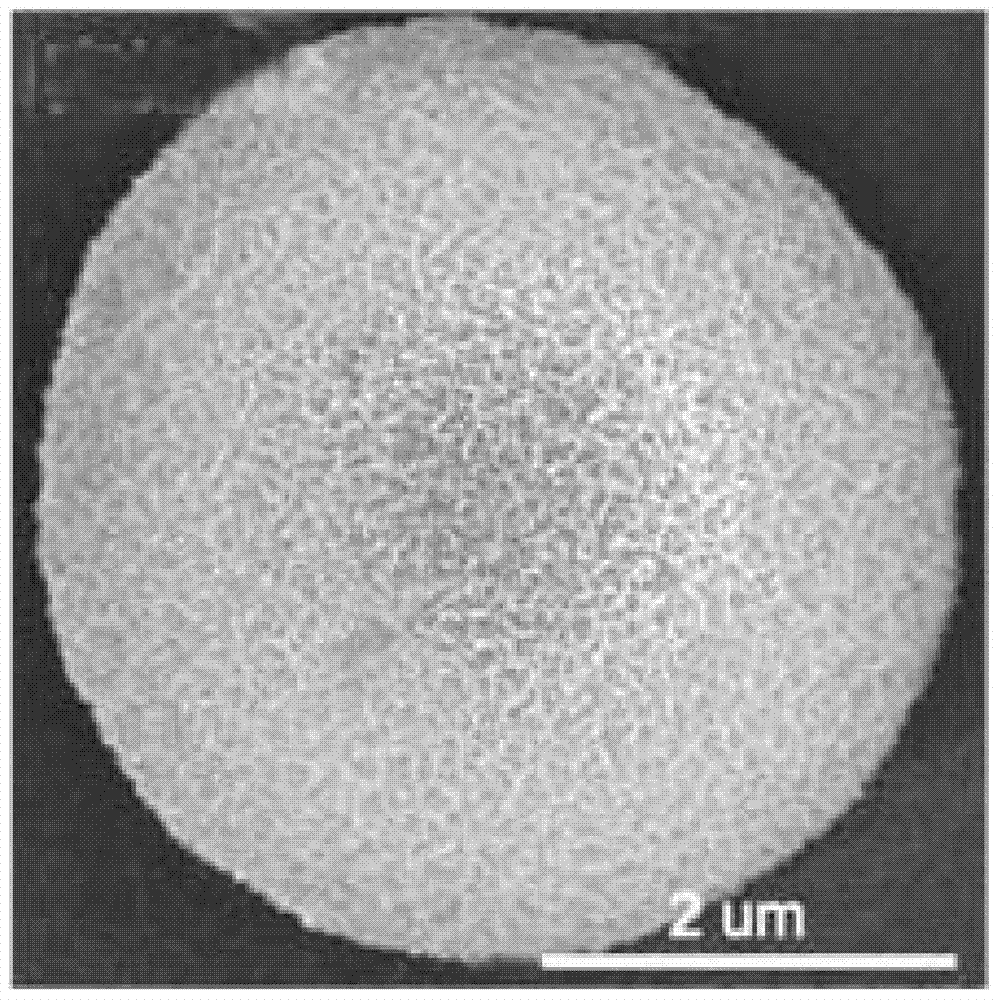

Preparation method of composite porous microspheres of core-shell structure

InactiveCN105534952AGood dispersionNo agglomerationMacromolecular non-active ingredientsMicrocapsulesDispersityWater in oil emulsion

The invention provides a preparation method of composite porous microspheres of a core-shell structure. The method comprises the following steps that a shell material solution, oil-phase dispersion liquid of porous microspheres and an oil-phase solution containing an emulsifying agent are prepared separately; the shell material solution is added into the oil-phase solution containing the emulsifying agent and mixed, and a water-in-oil emulsion is obtained; the oil-phase dispersion liquid of the porous microspheres is added into the water-in-oil emulsion, stirring is conducted, and the porous microspheres coated with shell materials are collected. Compared with the prior art, the preparation method of the composite porous microspheres of the core-shell structure has the advantages that the composite porous microspheres are good in dispersity and free of gathering agglomeration; the preparation technology is simple; the microspheres each has the structure with a dense shell layer and a porous kernel, and improvement of drug-loading capacity and slow release of a drug are facilitated.

Owner:FUJIAN NORMAL UNIV

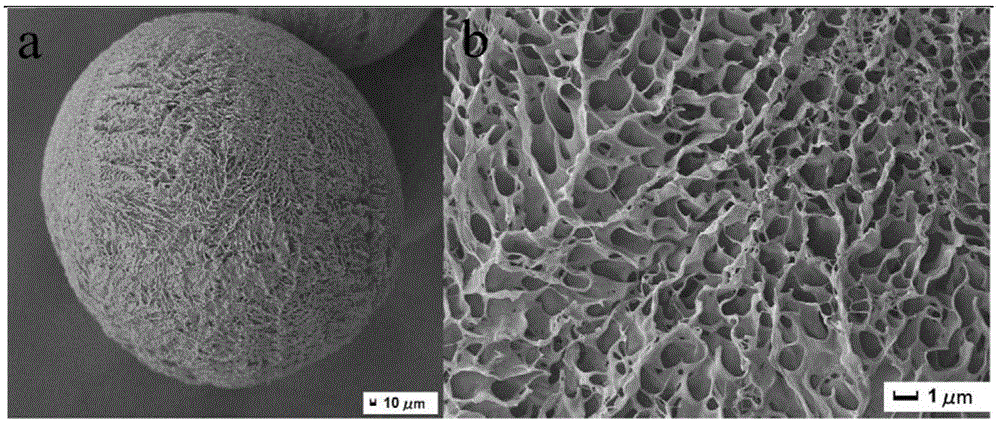

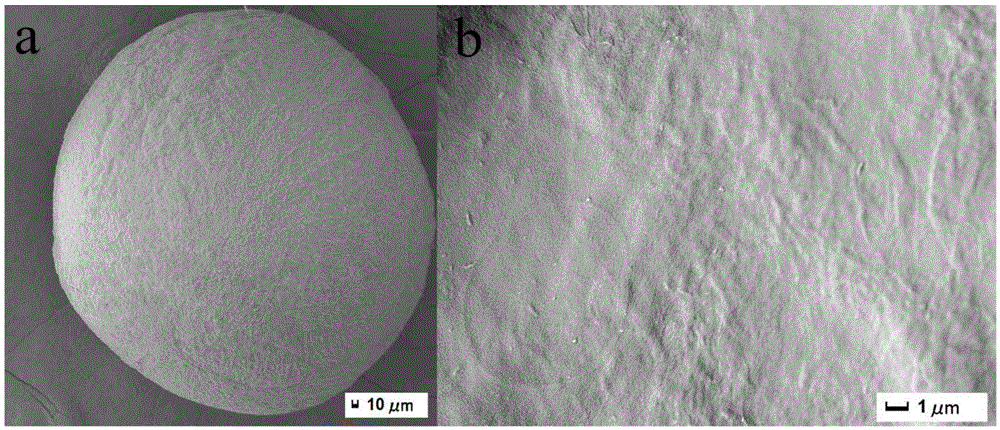

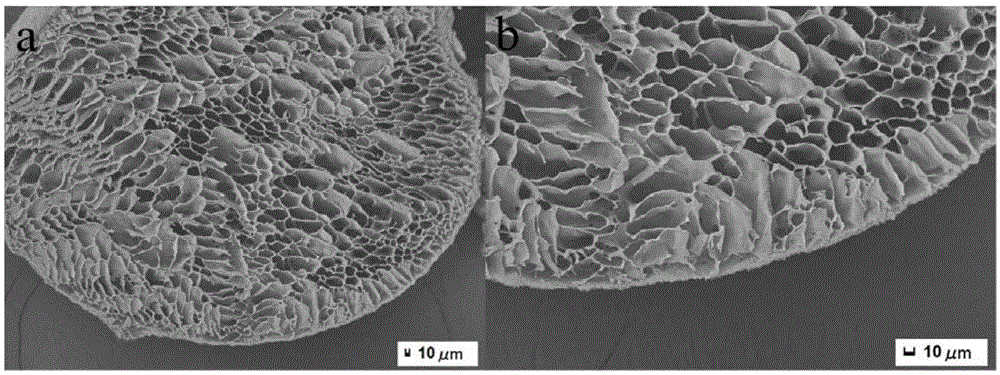

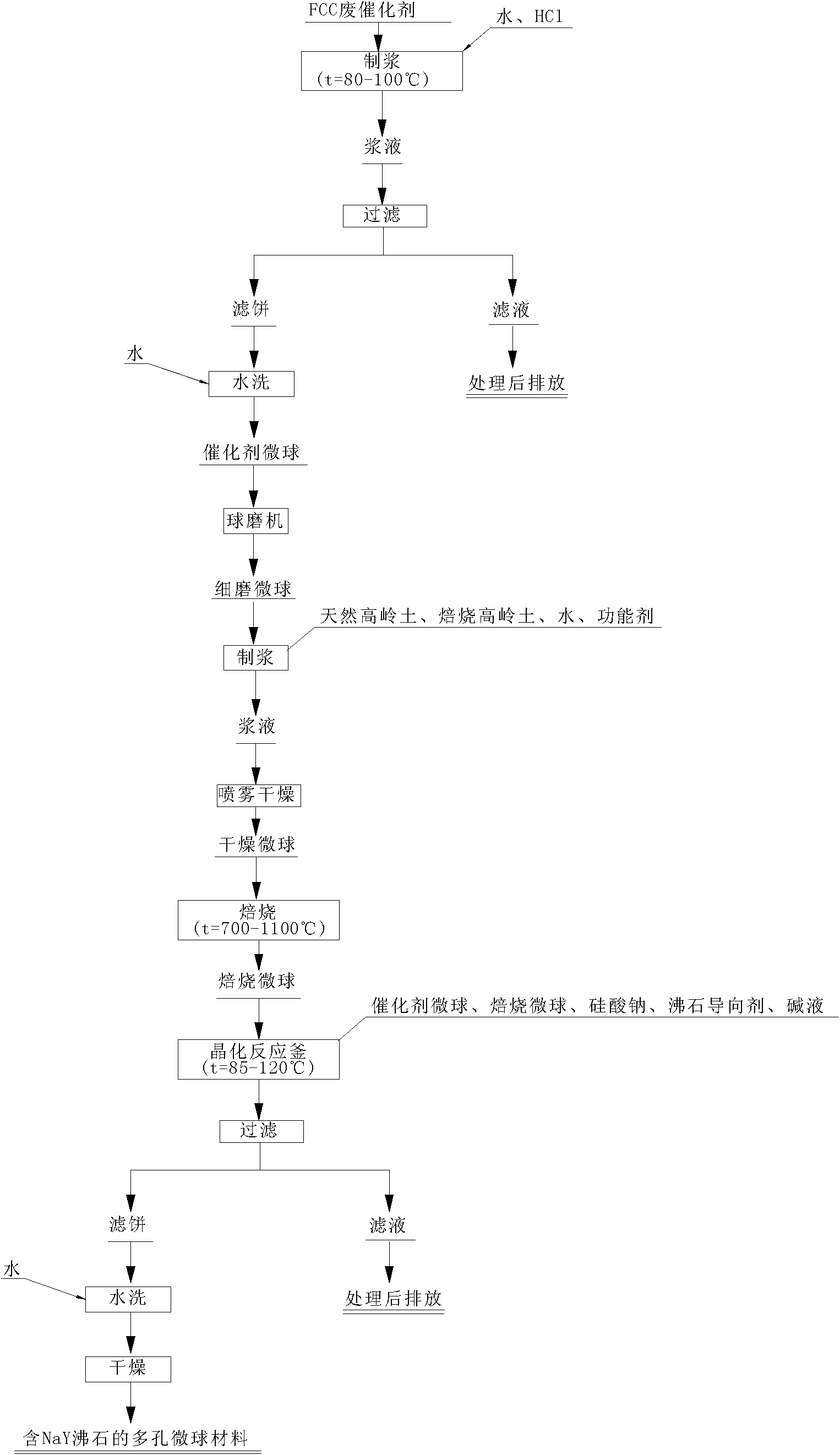

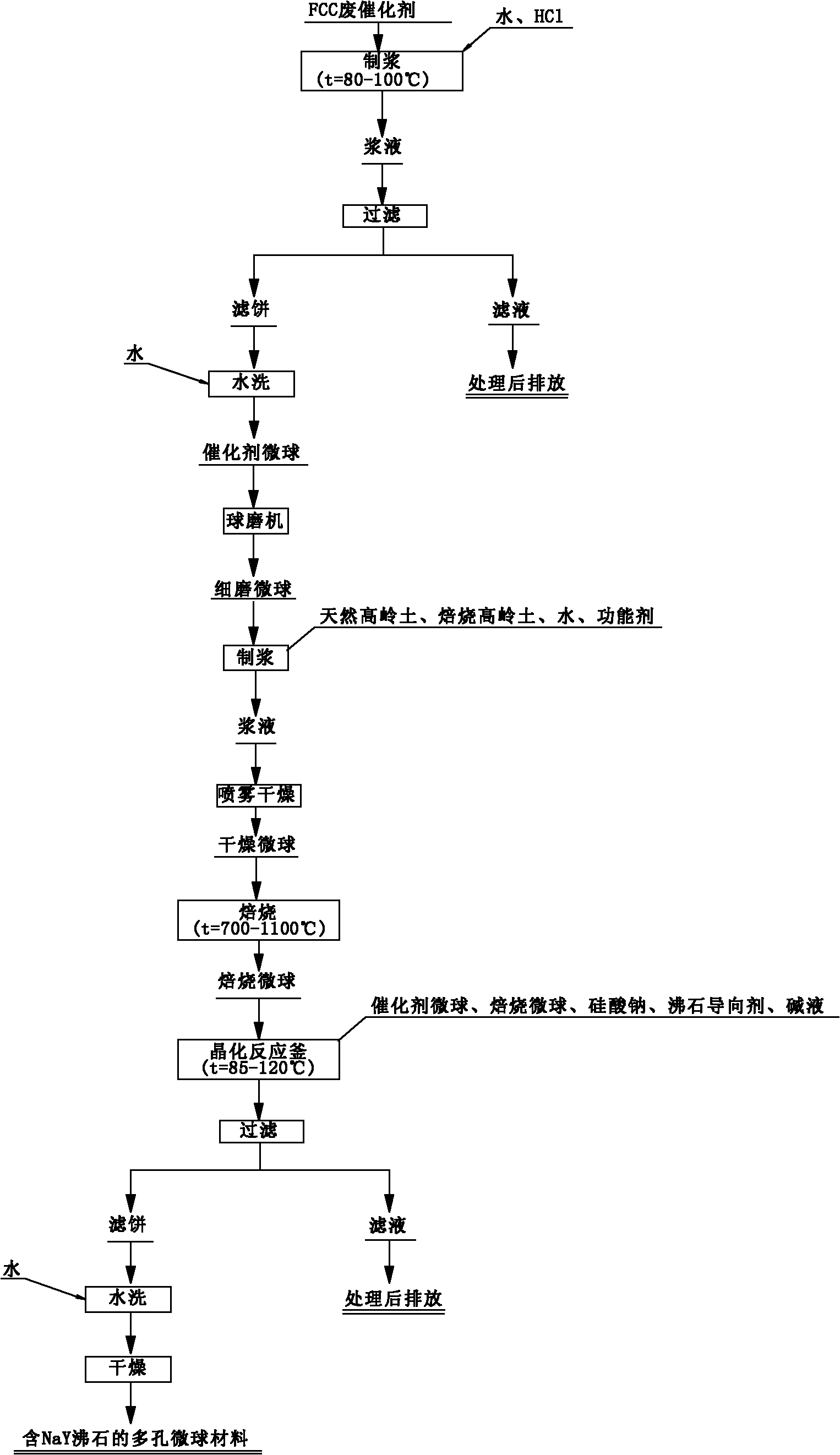

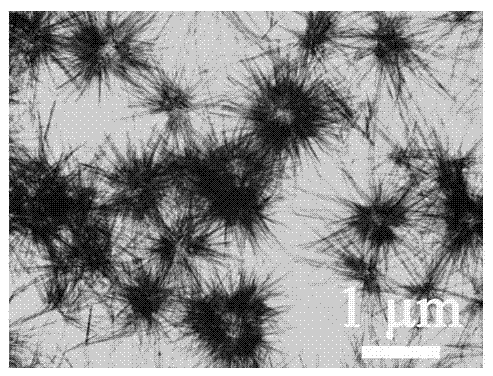

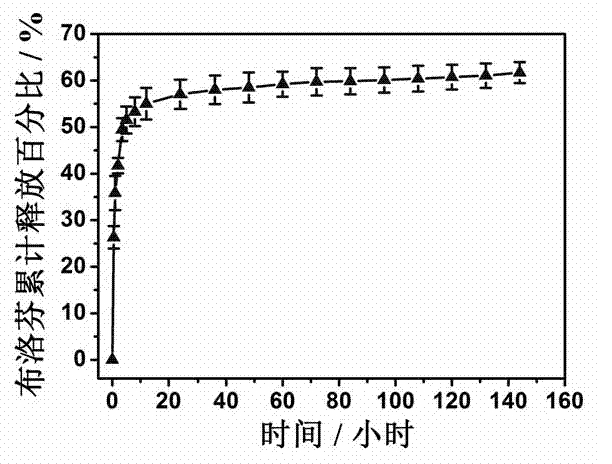

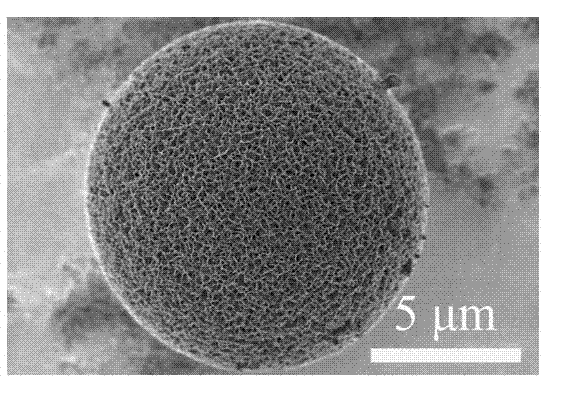

Method for synthesizing porous microsphere material containing NaY zeolite by waste FCC (fluid catalytic cracking) catalyst

ActiveCN102125872AReduce pollutionImprove performanceCatalytic crackingMolecular sieve catalystsSlurrySodium silicate

The invention discloses a method for synthesizing a porous microsphere material containing NaY zeolite by a waste FCC (fluid catalytic cracking) catalyst, which is a catalytic cracking process. The method is characterized by comprising the following steps: A. adding water and hydrochloric acid to the waste FCC catalyst for mixing slurry and acidizing to obtain catalyst microspheres; B. mixing thecatalyst microspheres with one or a combination of natural kaolin and roasted kaolin, adding water to obtain slurry containing 30-50% of solid, adding a functional agent to the slurry and then forming dried microspheres through spray drying, and roasting the dried microspheres at the temperature of 700-1100 DEG C for 0.5-10 hours to obtain roasted microspheres; and C. adding sodium silicate, a zeolite directing agent and alkali liquor to the catalyst microspheres and / or the roasted microspheres, adding the obtained mixed solution to a crystallization reaction kettle, performing hydrothermal crystallization at the temperature of 85-120 DEG C for 10-30 hours, filtering out a mother liquid, washing the obtained filter cake with deionized water, and then drying to finally obtain the finished product. The method is mainly used for synthesizing the porous microsphere material containing the NaY zeolite.

Owner:HUNAN JULI CATALYST

Microwave-assisted preparation method of hydroxylapatite nanometer structure porous microspheres

ActiveCN103110952ASimple processCraft shortPeptide/protein ingredientsPharmaceutical non-active ingredientsApatiteHydroxylapatite

The invention discloses a microwave-assistant preparation method of hydroxylapatite nanometer structure porous microspheres. The microwave-assistant preparation method comprises the following steps of: mixing water-soluble calcium salt as a calcium source with pyridoxal phosphate as a phosphor source under an acidic condition; preparing hydroxylapatite nanometer structure porous microspheres as a carrier through a microwave-assistant hydrothermal reaction; adding the hydroxylapatite nanometer structure porous microspheres to organic solvent containing a hydrophobic drug or an aqueous solution containing hydrophilic protein; and oscillating the solution for 24-60 hours at 20-40 DEG C, and centrifuging, washing and drying the products to obtain the hydroxylapatite nanometer structure porous microspheres which are loaded with the hydrophobic drug or adsorbed with the hydrophilic protein.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

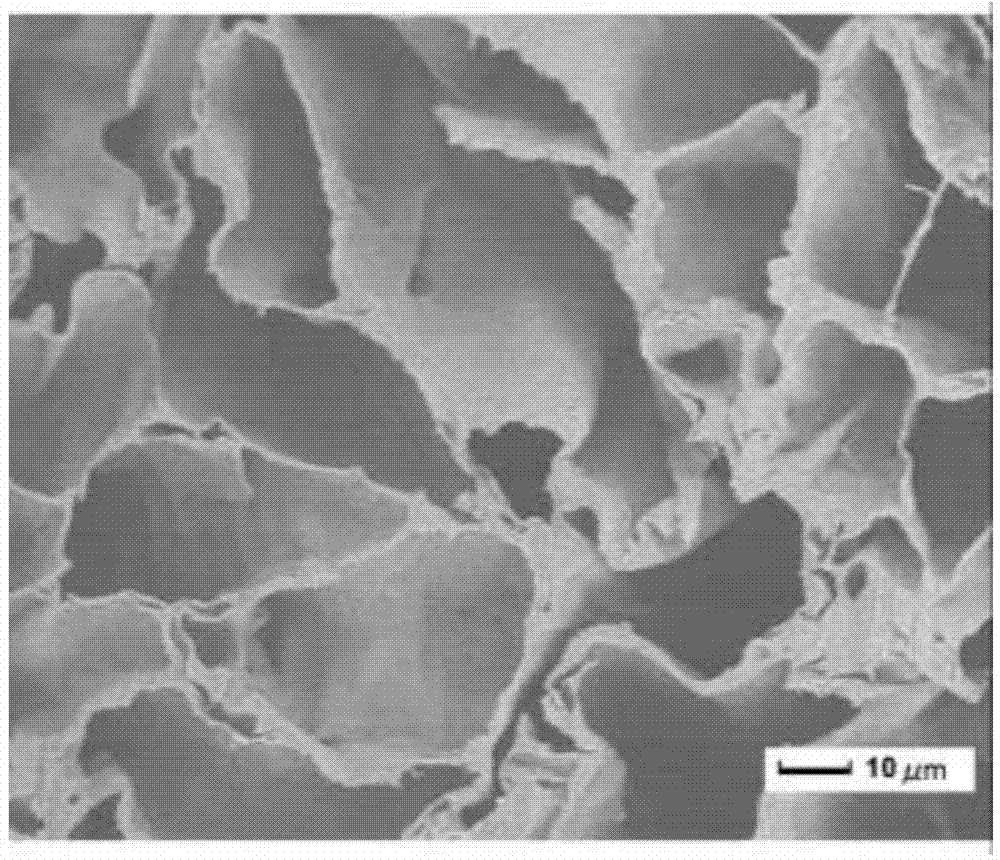

Method for preparing polymer porous microspheres through mixed phase separation

InactiveCN102500300AReduce restrictionsImprove pore structureMicroballoon preparationMicrocapsule preparationNon solventIce water

The invention discloses a method for preparing polymer porous microspheres through mixed phase separation. The method comprises the following steps: 1), dissolving a polymer and an additive into a solvent, and heating and stirring until the polymer and the additive are completely dissolved to form a transparent solution; 2), injecting a high-temperature polymer solution into a low-temperature non-solvent such as ice water or water and the like by using a syringe needle and inducing thermally induced phase separation and non-solvent induced separation to form pores; and 3), washing, drying and the like to obtain the polymer porous microspheres. The characteristics that the thermally induced phase separation is easy to control, pore-forming rate is high and the non-solvent induced separation has high applicability are exerted; the preparation method is simple, high in efficiency and low in cost; and the invention provides the method for preparing the polymer porous microspheres with various pore structures and high porosity. The preparation method has a huge application prospect in the aspects of gas separation, water treatment, biological active substances, catalyst carriers and the like.

Owner:ZHEJIANG UNIV

Porous microsphere resonators

InactiveUS7259855B2Enhanced interactionIncrease volumeRadiation pyrometryMaterial analysis by observing effect on chemical indicatorWhispering galleryOptical interaction

There are several different applications where it is desirable to increase the amount of material that can be introduced to the surface of a microresonator that has whispering gallery modes. The use of a porous surface on the microresonator permits greater amounts of the material to be captured on or near the surface of the microresonator, resulting in an increased optical interaction between the material and the light propagating in the whispering gallery mode(s) of the microresonator.

Owner:3M INNOVATIVE PROPERTIES CO

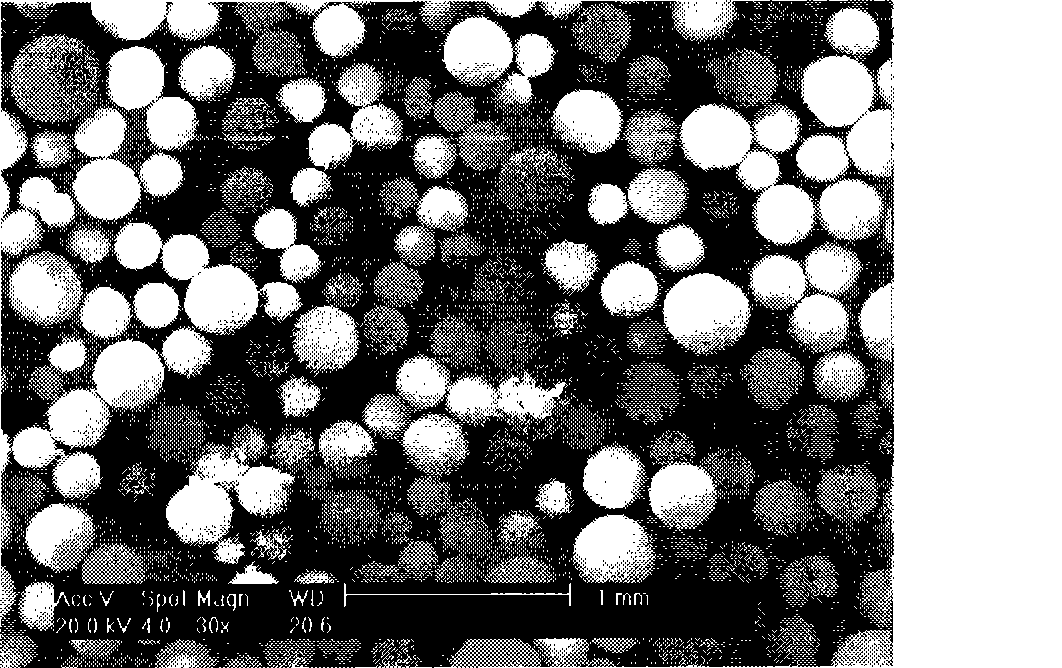

Method for preparing chitosan porous microsphere sorbent by metal ion imprinting and crosslinking methods as well as use

InactiveCN101347720AEfficient selection of separation functionsOther chemical processesWater/sewage treatment by sorptionHigh resistanceCrosslinked chitosan

The invention discloses a preparation method of a metallic ion blotting crosslinked chitosan porous spherical adsorbent and the application thereof; the method is as follows: the chitosan in solution state and metallic ions jointly form a composition which is prepared into microspheres with diameters from 1.0mm to 10.0mm, the prepared microspheres are treated with pre-crosslinking reaction and then crosslinking reaction in water solution, after crosslinking reaction, the metallic ions and pre-crosslinking agent used for blotting are removed and the metallic ion blotting crosslinked chitosan porous spherical adsorbent is obtained. The method of the invention jointly applies metallic ion blotting and the formaldehyde pre-crosslinking method and matches the technique of solidification and granulation in alkali solution to prepare the metallic ion blotting crosslinked chitosan porous spherical adsorbent with the diameter of 1.0-10.0mm. The spherical adsorbent has large size and high specific surface area, and can be applied to efficient selective separation of heavy metal ions; furthermore, the spherical adsorbent can solve the problems that the existing chitosan microsphere is mostly powder, and has small size and high resistance to water flows, and the speed of sewage treatment is affected, etc.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Process for manufacture of an attrition resistant catalyst

InactiveUS6362128B1Organic compound preparationHeterogenous catalyst chemical elementsColloidal silicaSilicic acid

A method for manufacturing of an improved attrition resistant catalyst having an oxide-rich surface layer involving forming an aqueous slurry comprising; catalyst, catalyst precursor or catalyst support particles (e.g., vanadium / phosphorus oxide, V / P / O catalyst), a large particle colloidal oxide sol (e.g., 200 Å, 600 Å, 750 Å colloidal silica, sodium stabilized) as the major oxide-rich surface layer forming component, and a second oxide-rich surface layer forming component solution wherein the solute is selected from the group consisting essentially of a precursor of the oxide-rich surface with average particle size no greater than 5 nm (e.g., aqueous silicic acid or polysilicic acid), a colloidal oxide sol wherein oxide particles in the sol have an average size below 10 nm (e.g., 50 Å colloidal silica), and mixtures thereof and then spray drying the slurry to form porous microspheres of attrition resistant catalyst; and, calcining / activating the spray dried microspheres. Such a catalyst is particularly useful and exhibits improved performance in oxidation processes such as the catalytic air oxidation of butane to maleic anhydride.

Owner:THE CHEMOURS CO FC LLC

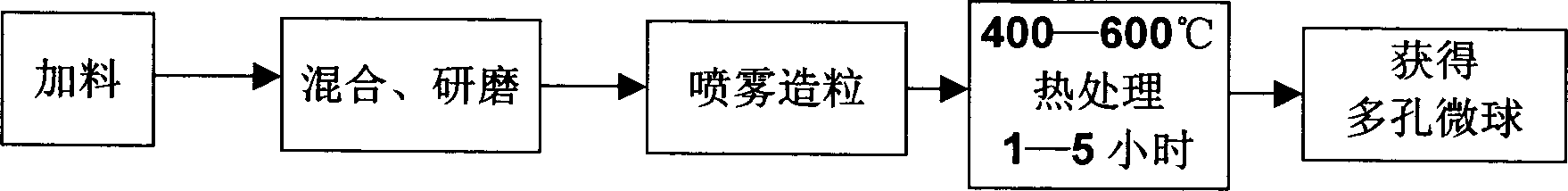

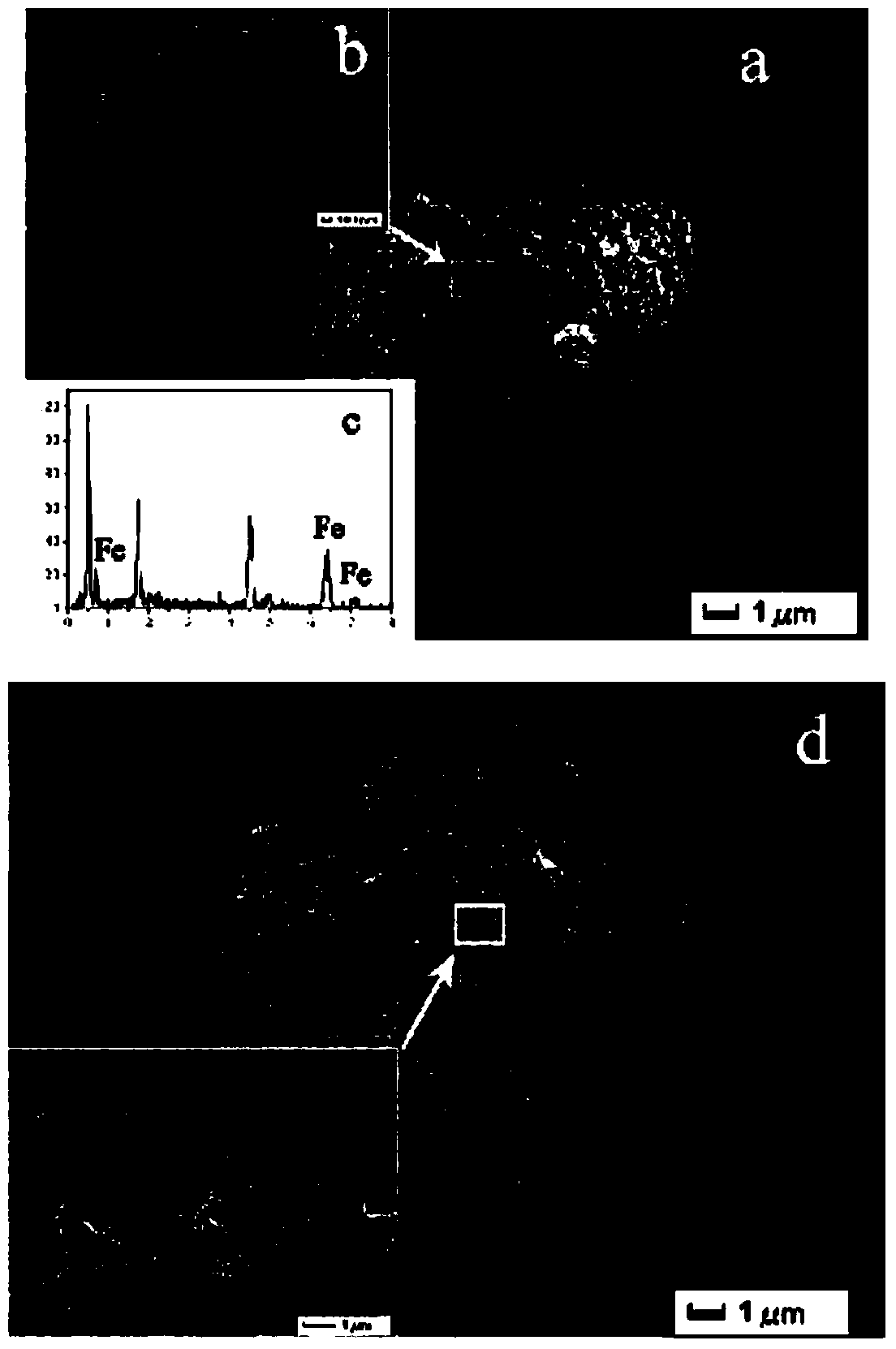

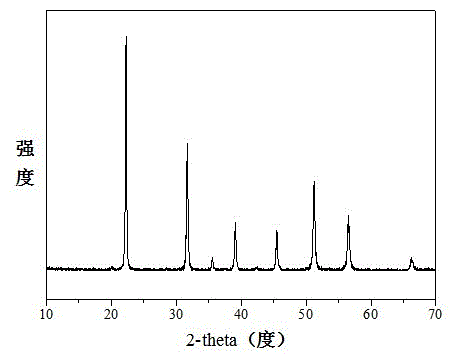

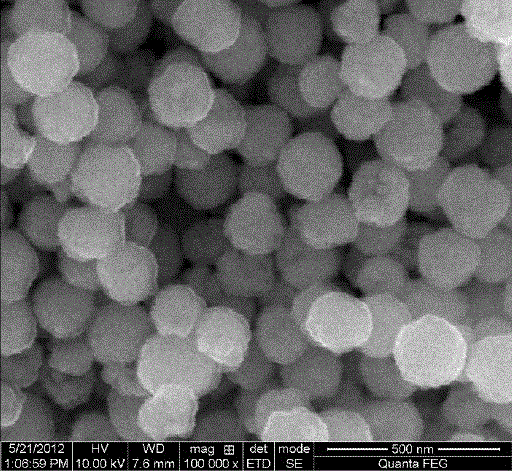

Nano titanium dioxide porous microsphere and its production method

InactiveCN1443601ARaise quality standardsSimple structureCatalyst activation/preparationGranulation by liquid drop formationWastewaterColloid

The present invention relates to a nano titanium dioxide porous microsphere, and is characterized by that its main component is nano titanium dioxide of anatase phase, grain size is 60-mesh to 180-mesh, its micropore pore size is 20 nano to 80 nano, its specific surface area is 80 sq.m / g to 140 se.m / g, and its preparation method includes the following steps: mixing nano titanium dioxide powder and nano titanium dioxide colloid, grinding to obtain its mixed pulp material, spray-pelleting, heat-treatment so as to obtain the nano titanium dioxide porous microsphere. Said invented porous microsphere is a high-effective light-catalyst.

Owner:JIANGSU SUJING GROUP +1

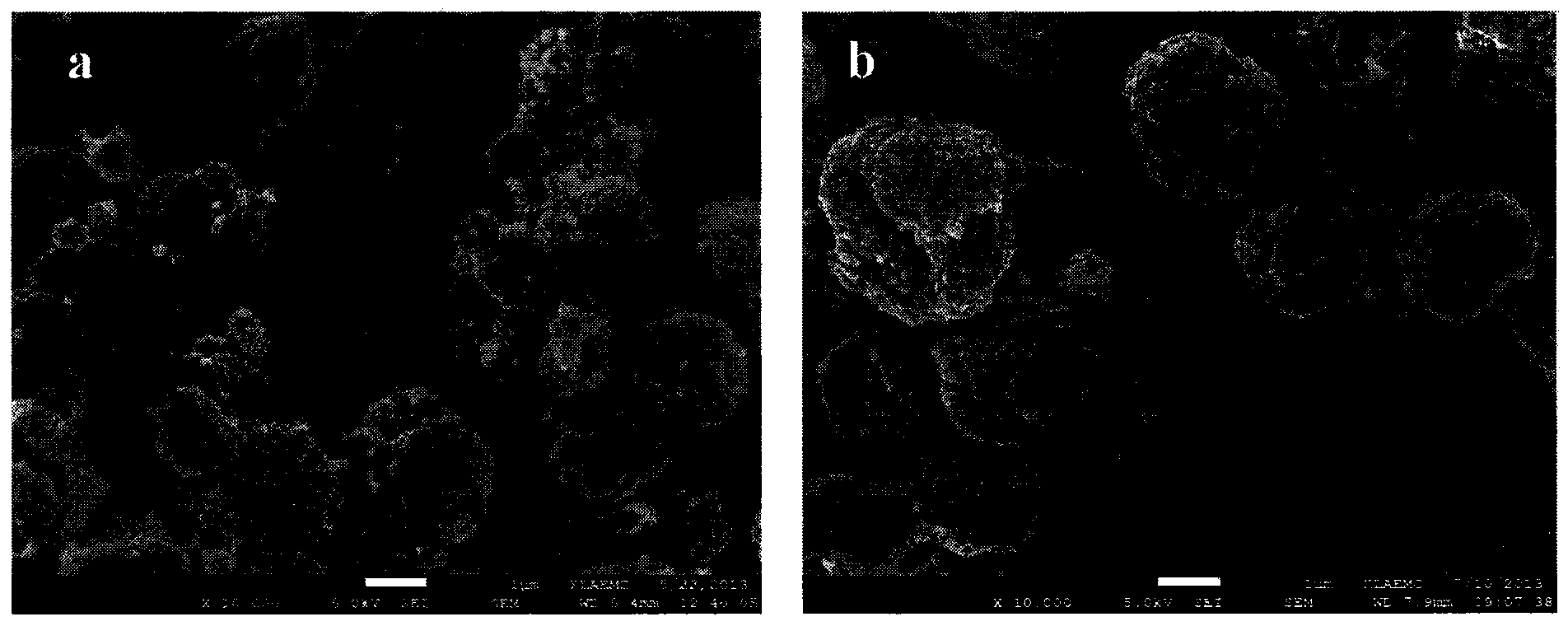

Method for preparing magnetic porous polystyrene microspheres on basis of suspension polymerization

InactiveCN103627022AIncrease productionHigh mechanical strengthOther chemical processesAlkali metal oxides/hydroxidesMagnetic stabilityPolymer science

The invention relates to a method for preparing magnetic porous polystyrene microspheres on the basis of suspension polymerization, belonging to the technical field of preparation of environmental functional materials. The method comprises the following steps: synthesizing Fe3O4 magnetic particles by a solvothermal process; and preparing magnetic porous polystyrene microspheres by suspension polymerization by using styrene and divinylbenzene as functional monomers, azodiisobutyronitrile as an initiator and toluene and cyclohexanol as pore-forming agents. The obtained microspheres have abundant pores on the surface, thereby being beneficial to enhancing adsorbability; and the Fe3O4 magnetic particles inside the microspheres have magnetic stability, and can be quickly separated under the action of an external magnetic field. The adsorbent is used in a water environment for selectively adsorbing 2,4-dichlorophenol and 2,6-dichlorophenol. The static adsorption experiment result indicates that the magnetic porous microspheres prepared by the method have the advantages of favorable adsorption capacity, quick adsorption kinetic property and favorable regenerability.

Owner:JIANGSU UNIV

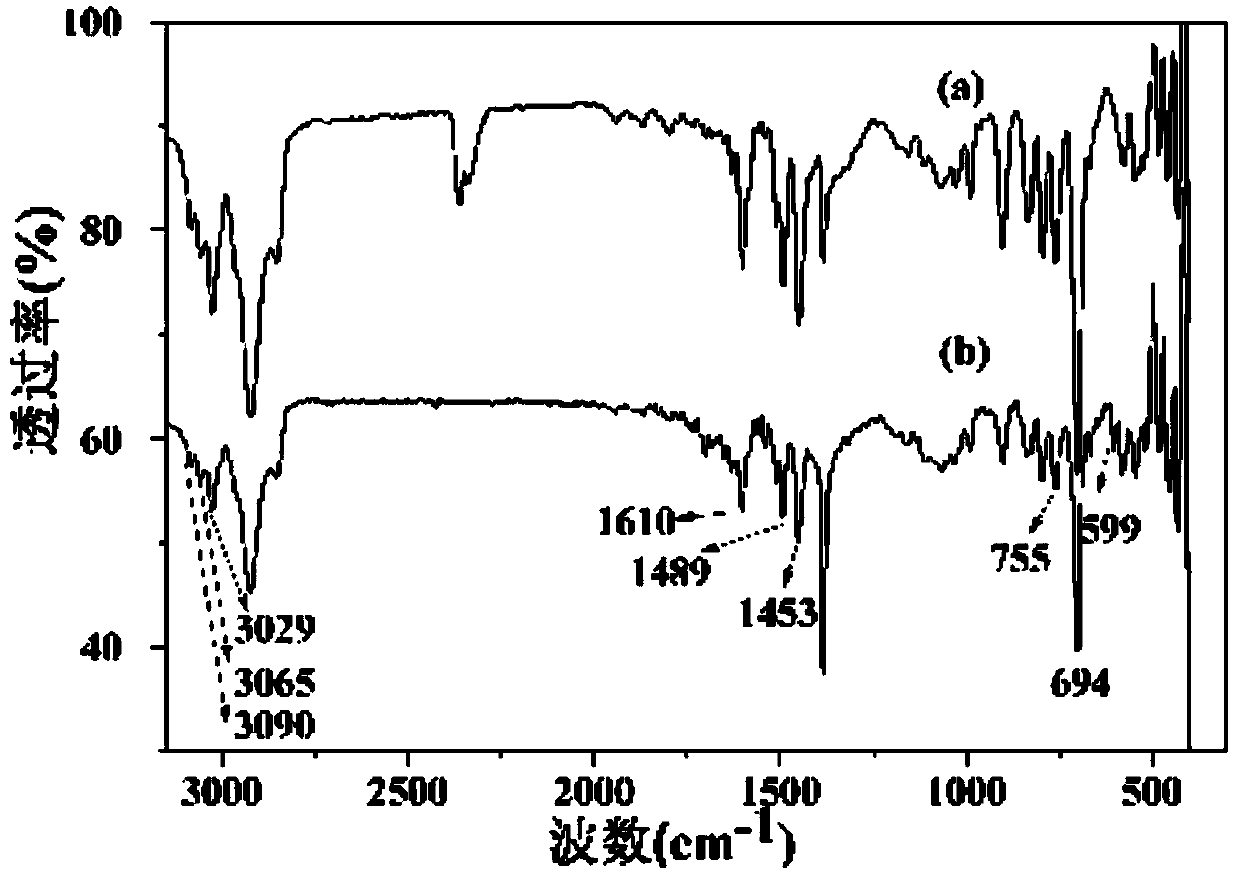

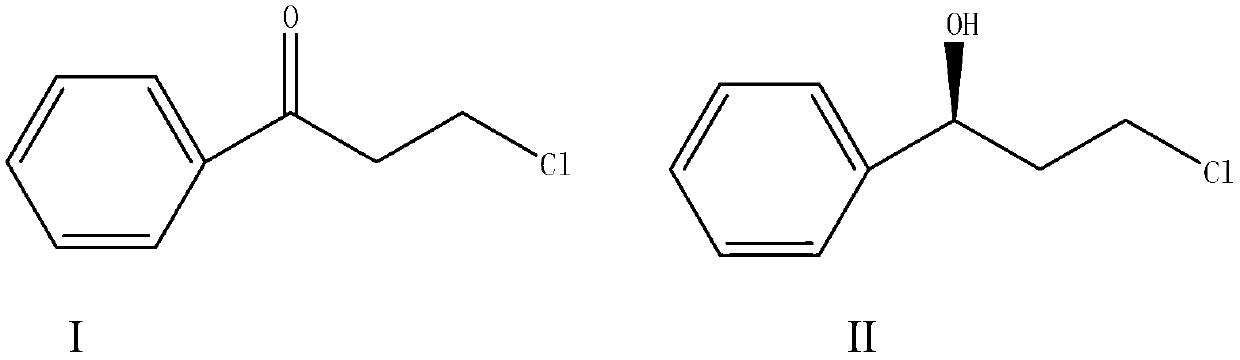

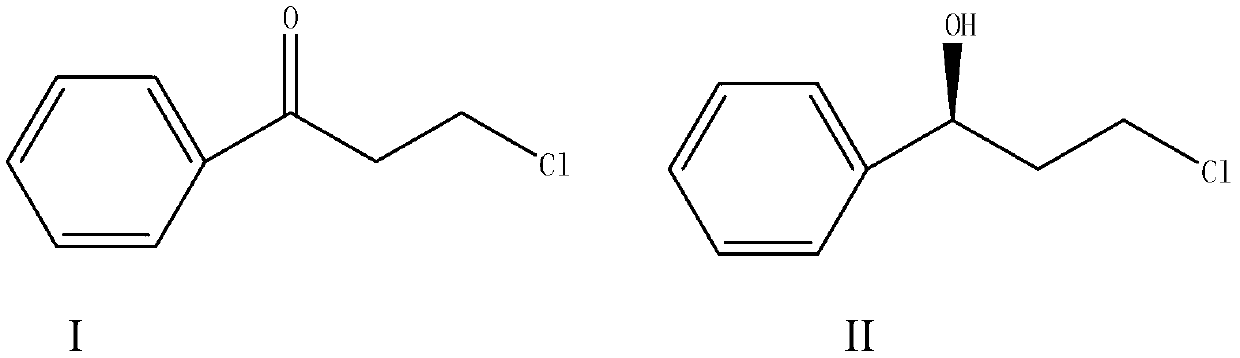

Magnetic porous supported metallic chiral catalyst and application thereof

InactiveCN103272648AReduce lossesHigh catalytic efficiencyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSilanesPolyacrylamide

The invention discloses a magnetic porous supported metallic chiral catalyst and an application thereof. The support of the catalyst is an amino-modified magnetic porous microsphere, and a preparation method of the amino-modified magnetic porous microsphere comprises the following steps: heating iron chloride in an aqueous solution comprising sodium citrate, urea and polyacrylamide for carrying out a hydrothermal reaction to prepare a ferriferrous oxide nanosphere, preparing a magnetic porous microsphere through a sol-gel process by using the ferriferrous oxide nanosphere as a magnetic core and tetrahexyl orthosilicate as a silicon source and adding a template cetyltrimethylammonium bromide, and carrying out a silane coupling reaction of the magnetic porous microsphere and 3-aminopropyltriethoxysilane to prepare the amino-modified magnetic porous microsphere. The catalyst provided by the invention is magnetic, allows reaction products to be easily separated through applying a magnetic field, and can be recycled several times, so the catalyst loss is reduced. The catalyst has a high catalytic efficiency, allows the e.e. values of the products to be high, and still has a very good catalytic capability in the repeated use.

Owner:WENZHOU UNIVERSITY

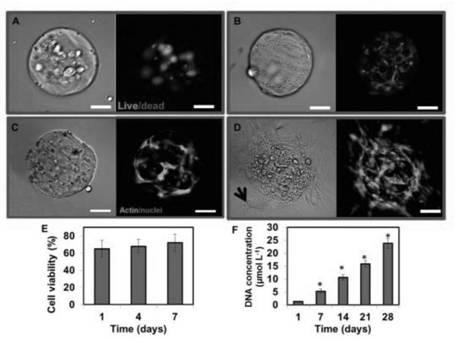

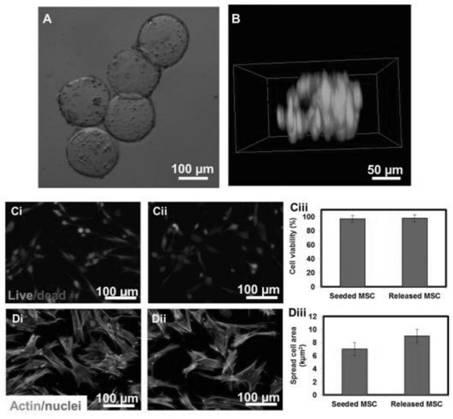

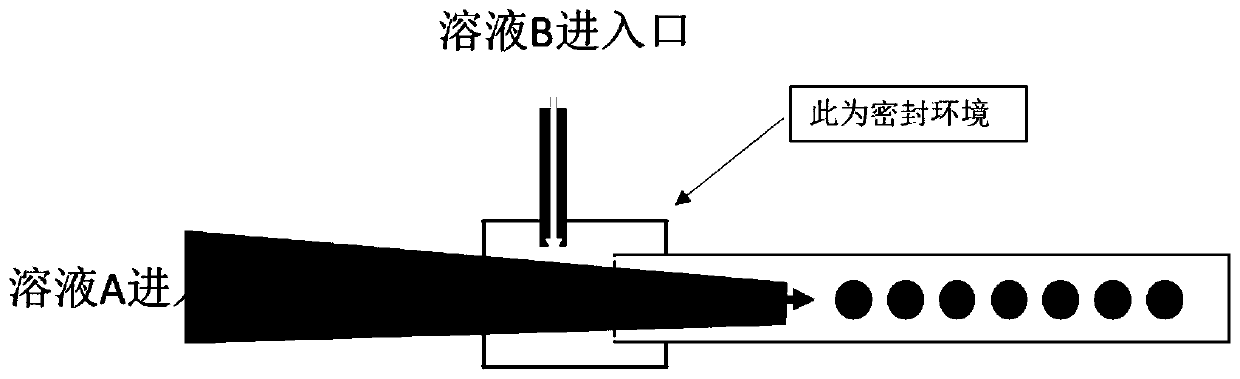

Preparation method of hydrogel porous microspheres and porous scaffold material

InactiveCN109880151AQuick buildGuaranteed survival rateMicroballoon preparationProsthesisFreeze-dryingPorous scaffold

The invention provides a preparation method of hydrogel porous microspheres. The preparation method comprises the following steps: a, a hydrogel material, a buffer solution and a photoinitiator are mixed to obtain a hydrogel solution, and an oily material is mixed with a surfactant to obtain an oily solution; b, a first container is partially nested in a second container, the inner diameter of theinlet end of the first container is larger than the inner diameter of the outlet end of the first container, and the inner diameter of the outlet end of the first container is smaller than the innerdiameter of the second container; the hydrogel solution is injected into the first container, the oily material is injected into the intersection of the first container and the second container, and the oily solution and the hydrogel solution form water-in-oil droplets under the action of a flowing shear force; c, ultraviolet irradiation is performed on the water-in-oil droplets, and crosslinkingis performed to obtain hydrogel microspheres; and d, freezing and freeze-drying are performed on the hydrogel microspheres to obtain the hydrogel porous microspheres. According to the invention, uniform and stable hydrogel porous microspheres are obtained by utilizing a micro-fluidic technology.

Owner:上海市伤骨科研究所

Method for preparing sustained-release fertilizer

ActiveCN101948352AFacilitate inhalationImprove solubilityFertiliser formsFertilizer mixturesPollutionPorous microspheres

The invention relates to a method for preparing a sustained-release fertilizer, and belongs to a method for preparing the sustained-release fertilizer by embedding a fertilizer into the pores of a carrier, in particular a method for preparing the sustained-release fertilizer by embedding the fertilizer into the pores of porous microspheres puffed by mountain flour in a larger amount than that in the prior art. The method comprises the following steps of: putting the porous microspheres puffed by the mountain flour in a vacuum container which is vacuumized; stopping vacuumizing after the air in the pores of the porous microspheres puffed by the mountain flour is pumped out completely; pouring the fertilizer into the vacuum container; uniformly mixing the porous microspheres puffed by the mountain flour and the fertilizer; gradually reducing the vacuum to normal pressure to ensure that the fertilizer is absorbed into the pores of the porous microspheres puffed by the mountain flour as much as possible; and thus, obtaining a sustained-release fertilizer primary product. Compared with the method of simply mixing the porous microspheres puffed by the mountain flour and the fertilizer, the method not only increases the vacuumization process and the cost, but prolongs the utilizable time of the fertilizer in the soil, increases the utilization rate of the fertilizer and reduces the fertilizer pollution.

Owner:河北硅谷肥业有限公司

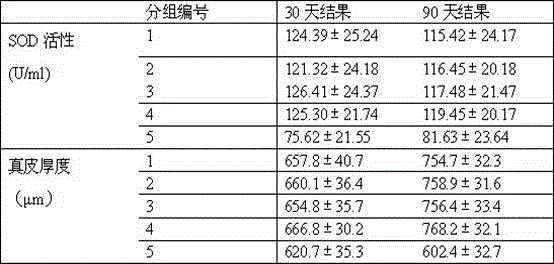

Skin filler used for injection and preparing method and application thereof

InactiveCN105749359AHigh load rateRelease stabilitySurgeryCapsule deliveryMANNITOL/SORBITOLFreeze-drying

The invention discloses skin filler used for injection and a preparing method and application thereof.The skin filler used for injection is composed of sodium carboxymethylcellulose, mannitol and hydrophilic modified polylactic acid microspheres loading an antioxidant factor.Sodium carboxymethylcellulose, mannitol and hydrophilic modified polylactic acid microspheres loading the antioxidant factor are adopted to form the skin filler used for injection, wherein a polyethylene glycol-polylactic acid-hydroxyacetic acid segmented copolymer is adopted as a raw material of the hydrophilic modified polylactic acid microspheres loading the antioxidant factor, the material is good in biocompatibility and moderate in degradation time, and no residue exists in the human body; the preparing method of the skin filler used for injection is easy to operate and facilitates industrial production, activity of the antioxidant factor can be reserved by the process, and by the adoption of the freeze-drying process, the porous microspheres which are high in dissolution speed, uniform in morphology, high in encapsulation efficiency and stable in slow release can be prepared and used for meeting structural design requirements and clinical needs.

Owner:SHANDONG ACADEMY OF PHARMACEUTICAL SCIENCES

Anion resin for bilirubin absorption and preparation method thereof

ActiveCN102049242AHigh affinityGood dispersionOther chemical processesOther blood circulation devicesCross-linkPreferential adsorption

The invention relates to anion resin for bilirubin absorption and a preparation method thereof. According to the invention, in the anion resin for bilirubin absorption, styrene is adopted as monomers, divinyl benzene is adopted as a cross-linking agent, maleic anhydride copolymer microspheres and organic small molecules are adopted as a pore-forming agent, and oil dispersible hyperoxide is adopted as an initiating agent; porous microspheres are prepared through suspension polymerization; and the anion resin with preferential bilirubin adsorption ability is obtained through quaternary ammoniation treatment, wherein the theoretical crosslinking degree of the resin is 4-20%, the average pore size of total pores is 80-120nm, and functional groups are quaternary ammonium salt groups. Accordingto the invention, the anion resin with uniform pore sizes, good permeability, good blood compatibility, high preferential adsorption of bilirubins, is obtained, and the problems in the prior art, such as poor absorption selectivity, high prices of imports, and the like, are solved.

Owner:GUANGZHOU KONCEN BIOSCI

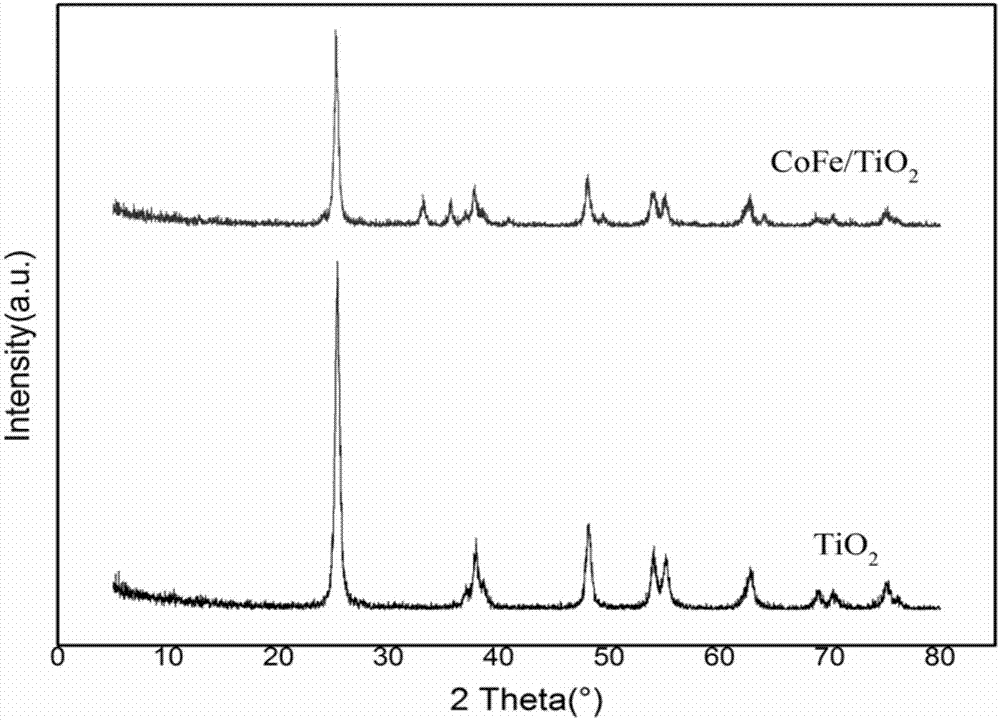

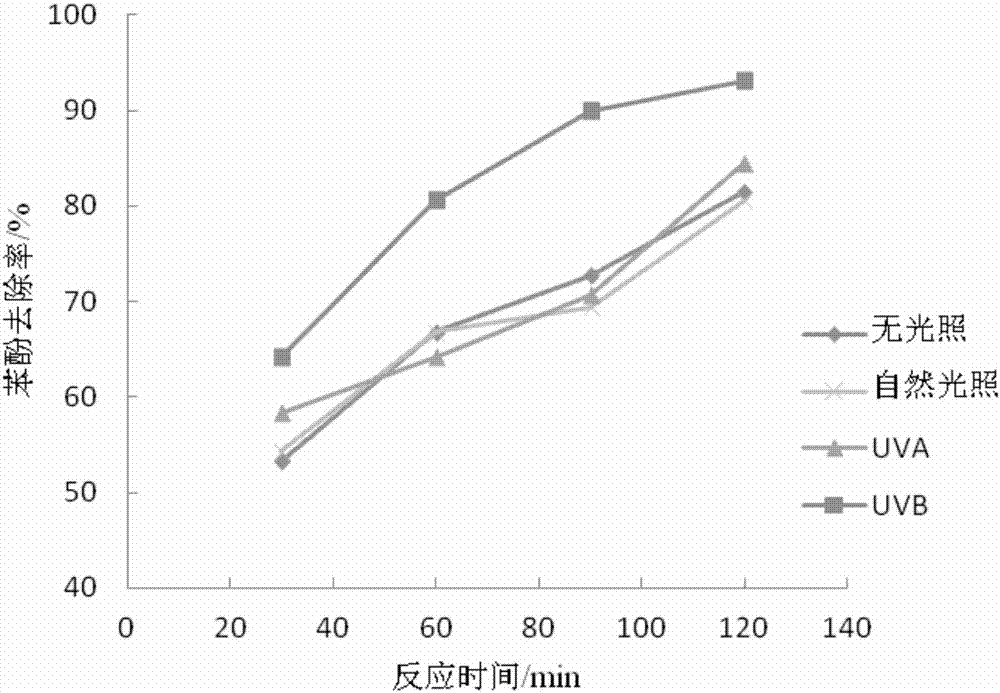

Method for degrading organic matters in water by activated persulfate coupling system

InactiveCN106955708ACompletely degradedReduce secondary pollutionWater/sewage treatment by irradiationWater contaminantsUltraviolet lightsDissolution

The invention discloses a method for degrading organic matters in water by an activated persulfate coupling system, and is realized through the following steps: firstly, preparing TiO2 porous microspheres; then, preparing FeCo / TiO2; finally, fully mixing the FeCo / TiO2 with aqueous solution which contains organic matters, adding the persulfate, meanwhile, irradiating by ultraviolet rays, and activating to generate SO4<->. and.OH under the synergistic effect of the FeCo / TiO2 and ultraviolet light so as to degrade most parts of organic pollutants in wastewater. The method has a simple processing technology, the organic wastewater can be subjected to up-to-standard emission only through one-step reaction, cobalt ion and iron ion dissolution rates are extremely low, environment pollution is lightened, organic matter degradation efficiency in the wastewater is higher under acidic, neutral and alkaline conditions, and the stable treatment of the organic wastewater under a situation of various pH (Potential of Hydrogen) values is realized.

Owner:XIAN UNIV OF SCI & TECH

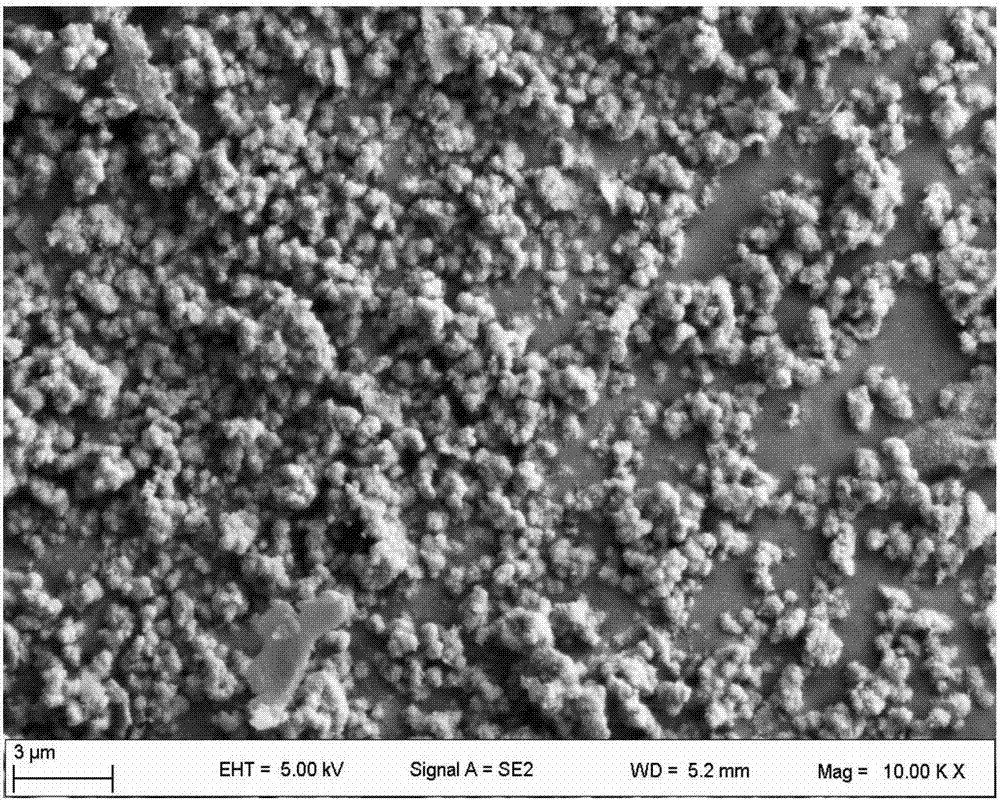

Method for preparing monodisperse indium oxide nanometer porous microsphere

InactiveCN103183374ALow costImprove protectionGallium/indium/thallium compoundsNanotechnologyManufacturing technologyDisplay device

The invention provides a method for preparing a monodisperse indium oxide nanometer porous microsphere, and belongs to the technical field of function materials. The preparation method particularly comprises the following steps: adding citric acid with a certain molar ratio in indium chloride aqueous solution, mixing intensively, adding moderate urea as a precipitant, and dispersing uniformly; sealing the mixed solution in an autoclave and conducting water thermal reaction for a period of time, and then centrifugalizating, washing and drying; calcining in a muffle furnace in air to obtain the monodisperse indium oxide nanometer porous microsphere. The method provided by the invention has low cost, simple manufacturing technology, high productivity, and is easy to realize industrialization and mass production. The indium oxide nanometer microsphere produced by the method has a neat appearance, uniform disperse, has a porous structure and a larger specific surface area, and can be applied in the field of solar cells, FPDs (Flat Panel Display), photo-electron devices, gas sensors and the like.

Owner:UNIV OF JINAN

Graphite phase carbon nitride porous microsphere and preparation method thereof

ActiveCN106938198ALarge specific surface areaRegular structurePhysical/chemical process catalystsNitrogenCarbon nitride

The invention discloses a graphite phase carbon nitride porous microsphere. The graphite phase carbon nitride porous microsphere is a spherical nearly spherical particle, at least the surface of the microsphere has a porous structure, and pores are connected by graphite phase carbon nitride nanosheets. A preparation method of the graphite phase carbon nitride porous microsphere comprises the following steps: carrying out high temperature calcining on a nitrogen-containing compound used as a precursor to obtain graphite phase carbon nitride; dissolving the graphite phase carbon nitride in sulfuric acid; and re-crystallizing the graphite phase carbon nitride through changing the solvent condition of the above obtained graphite phase carbon nitride solution in order to obtain the graphite phase carbon nitride porous microsphere. The porous microsphere is obtained by interconnecting the nanosheets. The porous microsphere has a special porous structure, thereby inhibiting the agglomeration of the nanosheets. Raw materials used in the invention have wide sources, and the prepared graphite phase carbon nitride porous microsphere has the advantages of high specific surface area, regular structure, narrow pore size distribution and low cost.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com