Microwave-assisted preparation method of hydroxylapatite nanometer structure porous microspheres

A technology of hydroxyapatite and nanostructures, applied in chemical instruments and methods, phosphorus compounds, pharmaceutical formulations, etc., can solve the problems of increasing process complexity and production costs, and achieve good protein adsorption and drug loading and sustained release performance , simple process, environment-friendly appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Mix 20mL of 4mg / L pyridoxal phosphate aqueous solution with 10mL of 0.05M calcium chloride aqueous solution, adjust the pH value of the mixed solution to 4.5 with ammonia water, place the mixed solution in a microwave reactor, and heat the microwave at a temperature of 180°C. After 5 minutes, the precipitate after the reaction was collected by centrifugation, washed with water, dried in air at 60° C., and then ground to obtain hollow microspheres assembled with hydroxyapatite nanorods.

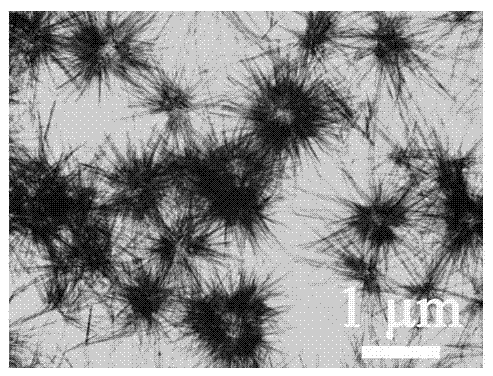

[0039] The sample was characterized by TEM, such as figure 1 shown. It can be seen from the figure that the prepared sample structure is hollow microspheres assembled with nanorods, and the size of the microspheres is 0.5–2 μm.

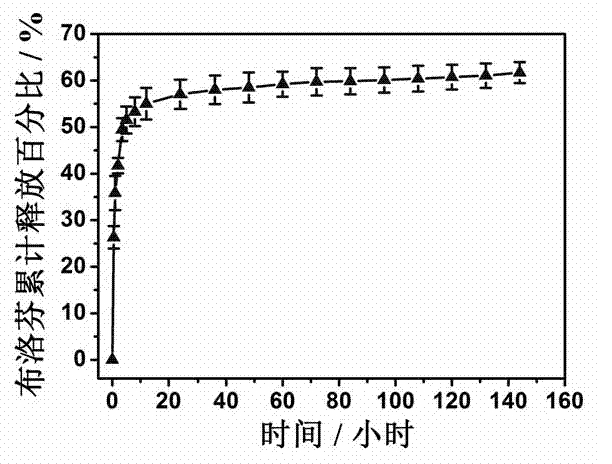

[0040] After the obtained sample was dried and ground, it was added to a solution of ibuprofen with a concentration of 40 mg / mL in n-hexane, and shaken for 24 hours at a rate of 160 rpm at 37°C. Then the sample was centrifuged, dried and ground at 60°C in air...

Embodiment 2

[0043] Mix 20mL of 4mg / L pyridoxal phosphate aqueous solution with 10mL of 0.05M calcium chloride aqueous solution, adjust the pH value of the mixed solution to 4.5 with ammonia water, place the mixed solution in a microwave reactor, and heat the microwave at a temperature of 140°C. After 5 minutes, the precipitate after the reaction was collected by centrifugation, washed with water, dried in air at 60° C., and then ground to obtain hydroxyapatite nanosheet-assembled microspheres.

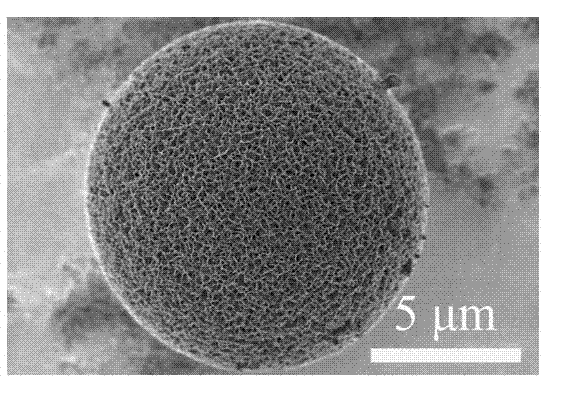

[0044] The sample was characterized by SEM, such as image 3 shown. It can be seen from the figure that the prepared sample structure is nanosheet-assembled microspheres, and the size of the microspheres is about 10 μm.

Embodiment 3

[0046] Mix 20mL of 4mg / L pyridoxal phosphate aqueous solution with 10mL of 0.05M calcium chloride aqueous solution, adjust the pH value of the mixed solution to 4.5 with ammonia water, place the mixed solution in a microwave reactor, and heat the microwave at a temperature of 160°C. After 5 minutes, the precipitate after the reaction was collected by centrifugation, washed with water, dried in air at 60° C., and then ground to obtain hydroxyapatite nanorod assembly microspheres.

[0047] The sample was characterized by SEM, such as Figure 4 shown. It can be seen from the figure that the prepared sample structure is a nanorod-assembled microsphere, and the size of the microsphere is about 14 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com