Patents

Literature

100results about How to "Regulatory Topography" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

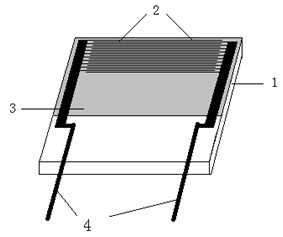

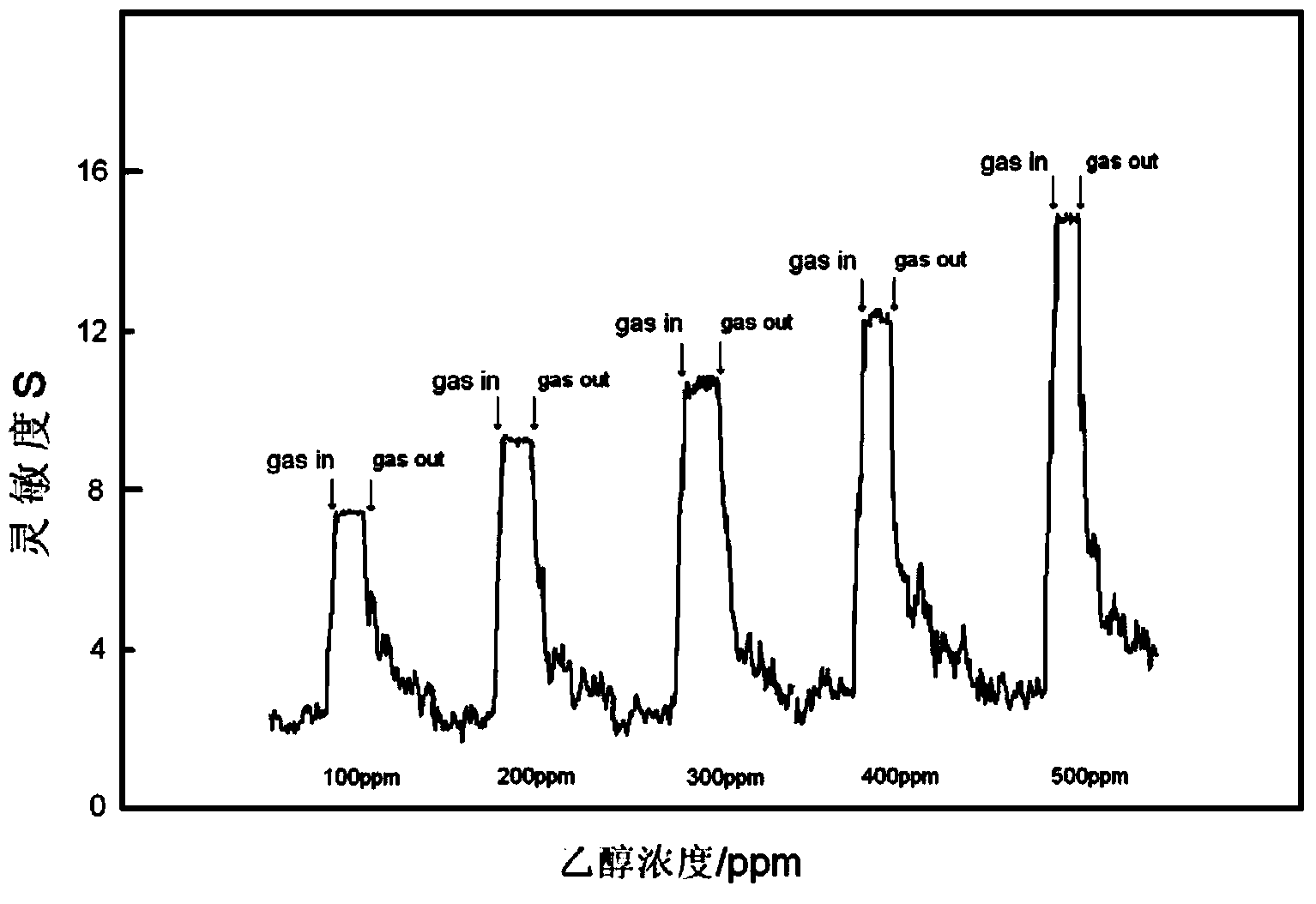

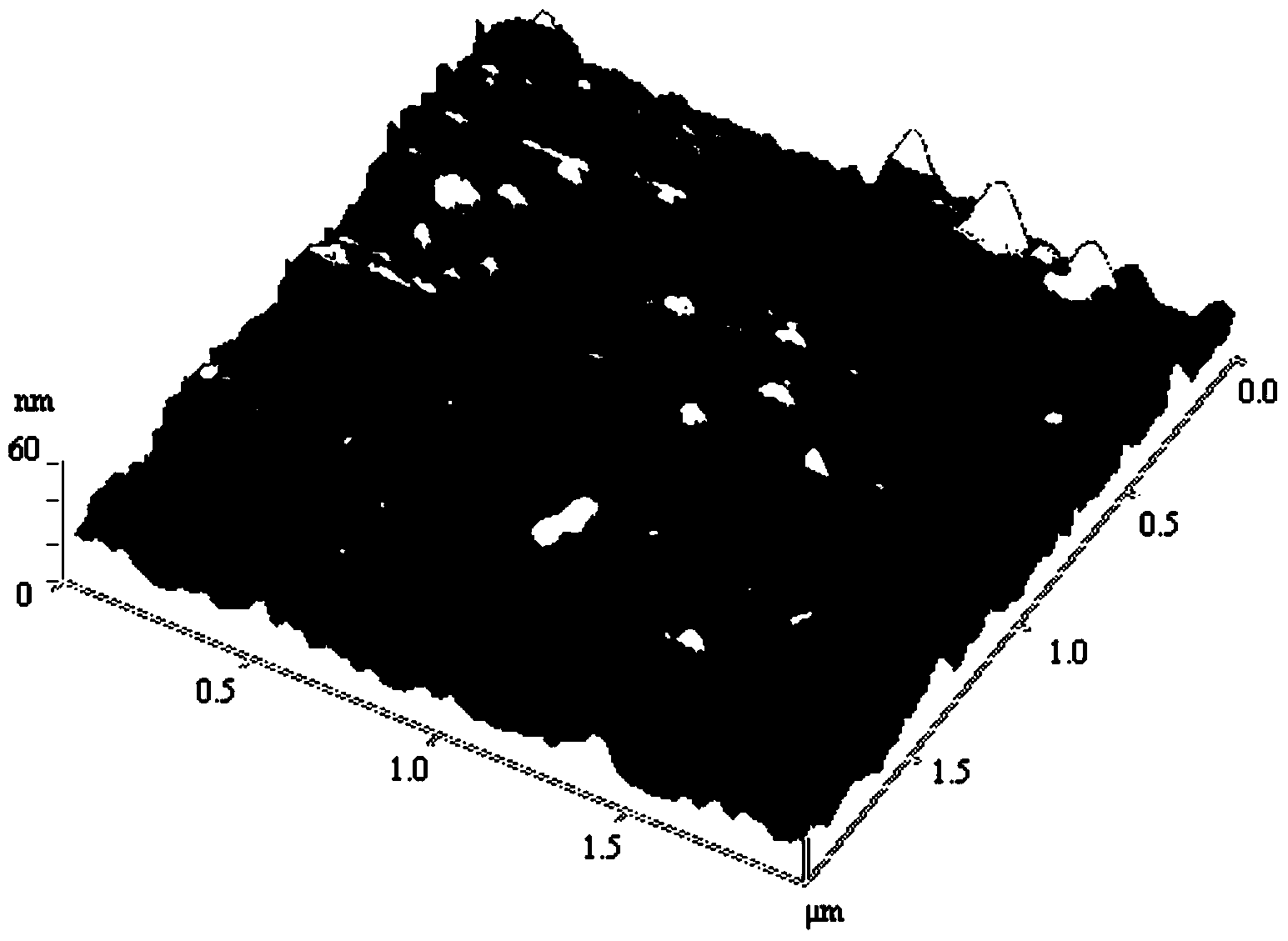

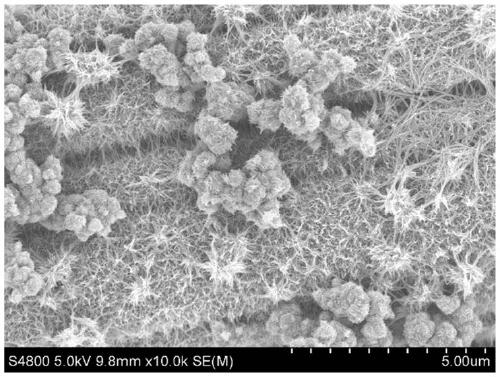

Graphene/ stannic oxide nanometer compounding resistance type film gas sensor and manufacturing method thereof

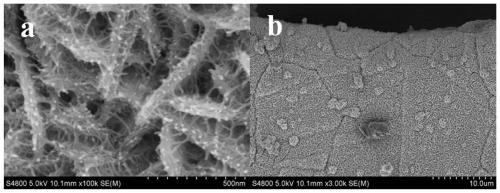

InactiveCN102636522AFine 3D NanostructuresLarge specific surface areaMaterial resistanceResponse sensitivityNano structuring

The invention discloses a graphene / stannic oxide nanometer compounding resistance type film gas sensor, which takes ceramics as a basal body. The surface of the ceramic basal body is photo-etched and evaporated with multiple pairs of interdigital gold electrodes, and is coated with gas-sensitive films of graphene and stannic oxide nanometer composite, and the manufactured resistance type film gas sensor has the advantages of simple manufacturing process and low cost. The gas-sensitive film is composed of a grapheme namosheet layer in a three-dimensional nano-structure and stannic oxide crystal particle composite with an orientated growth characteristic, the introduction of the graphene can favorably reduce the resistance of sensor elements, and the formation of the three-dimensional nano-structure can obviously enhance the specific surface area of the composite, thus the absorption and the diffusion of the gas can be promoted so as to greatly enhance the room temperature gas sensitive response sensitivity of elements. The graphene / stannic oxide nanometer compounding resistance type film gas sensor has the characteristics of high response sensitivity to low concentration ammonia, fast response, favorable recovering performanc, capability of carrying out the detection at the room temperature, and the like, which can be widely applied in the agricultural and industrial production process, and the room temperature detection and control of the concentration of ammonia in the atmospheric environment.

Owner:ZHEJIANG UNIV

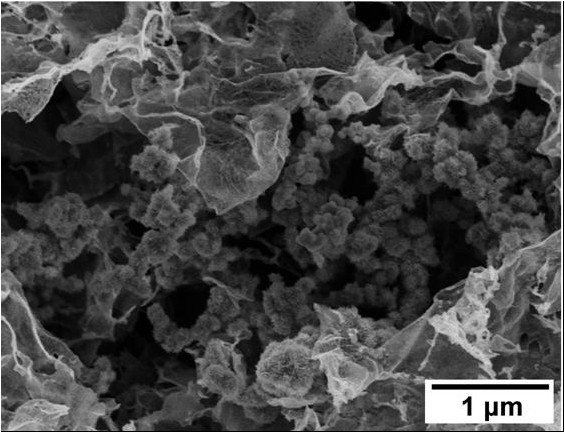

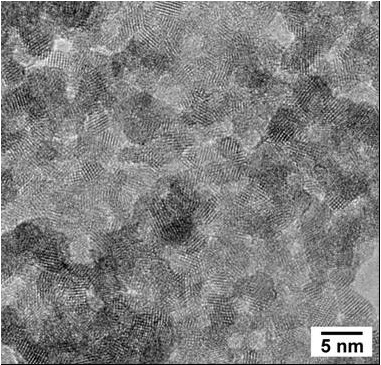

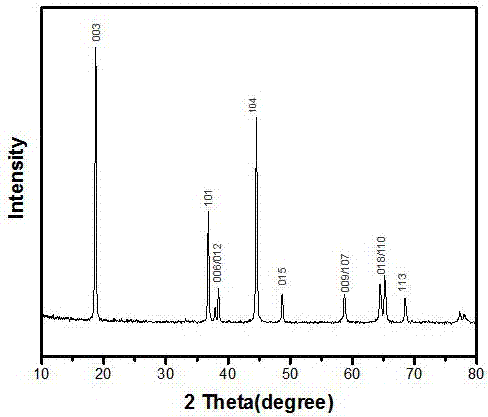

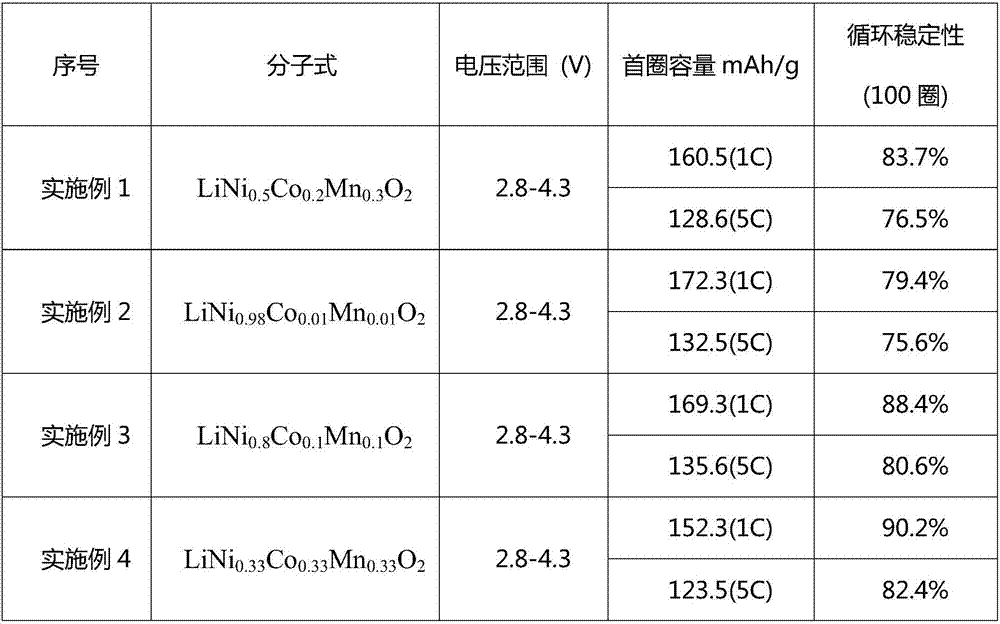

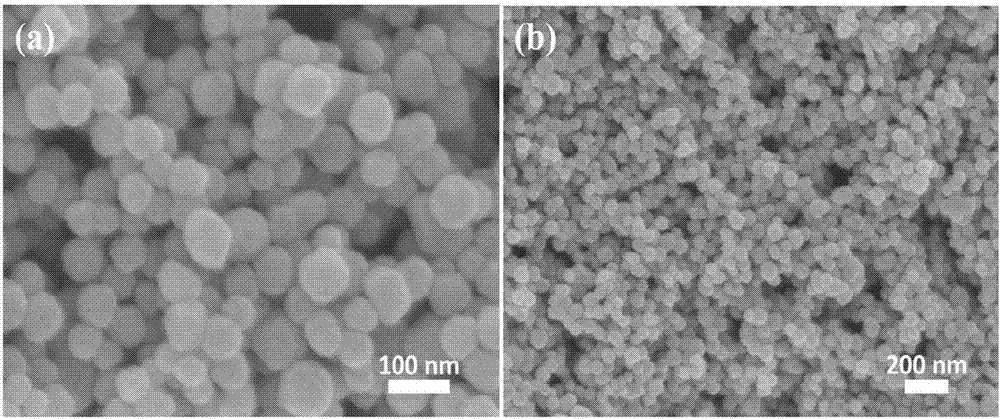

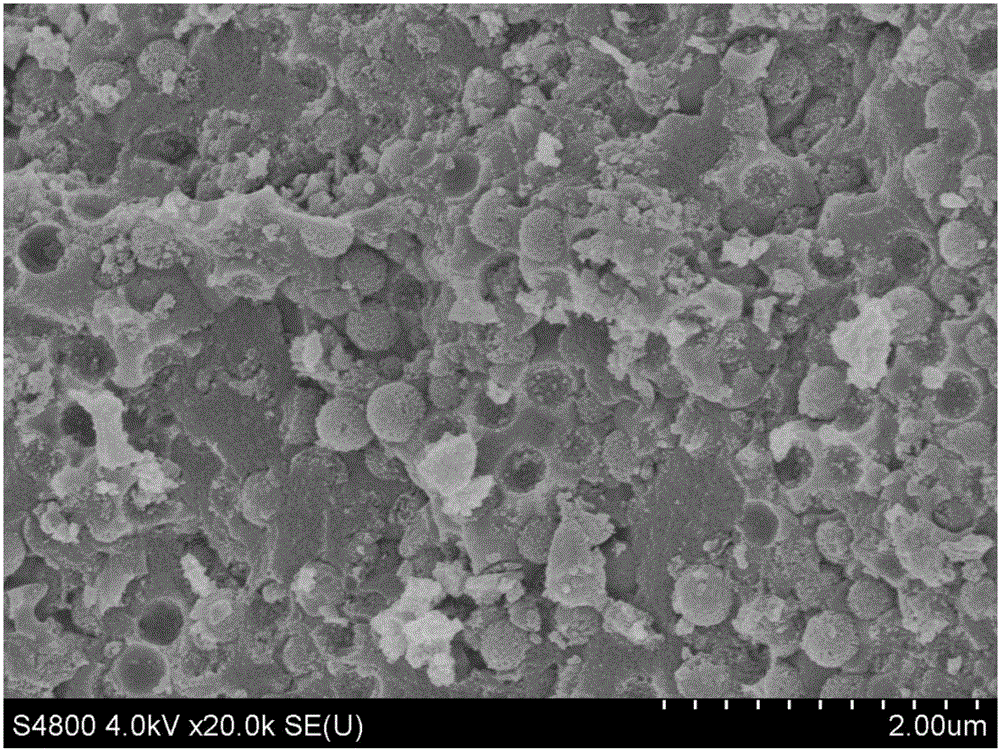

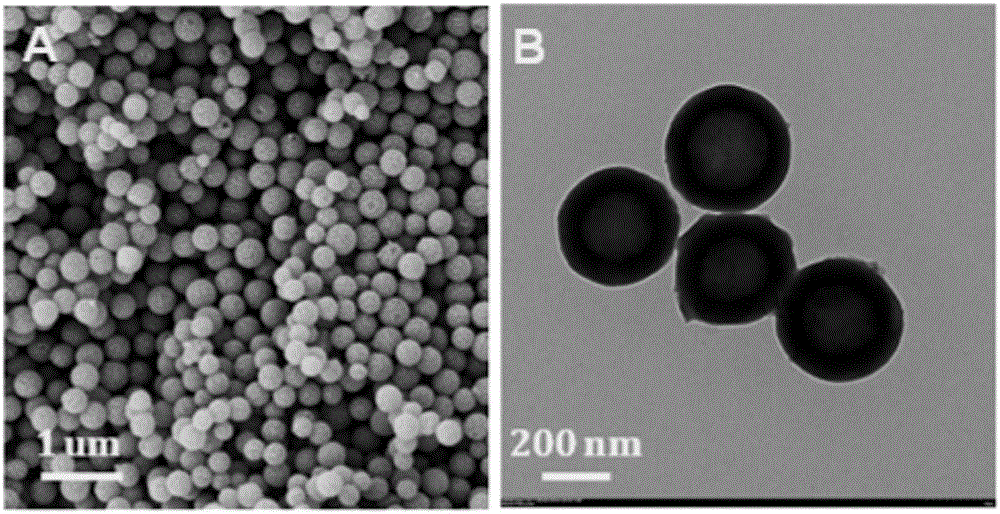

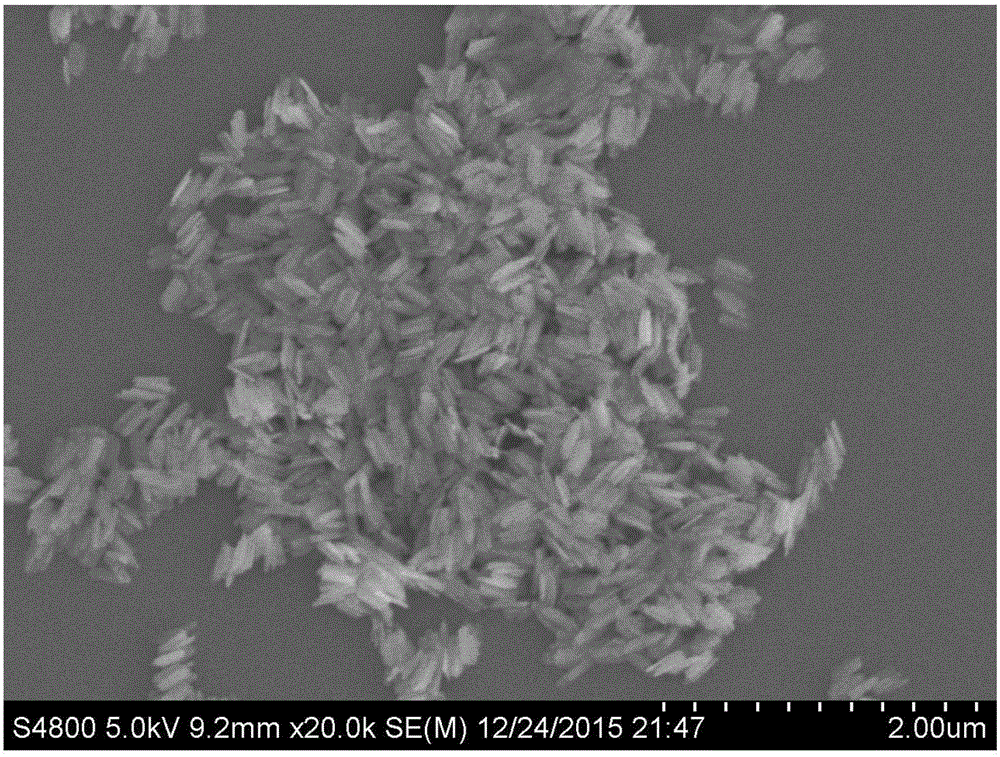

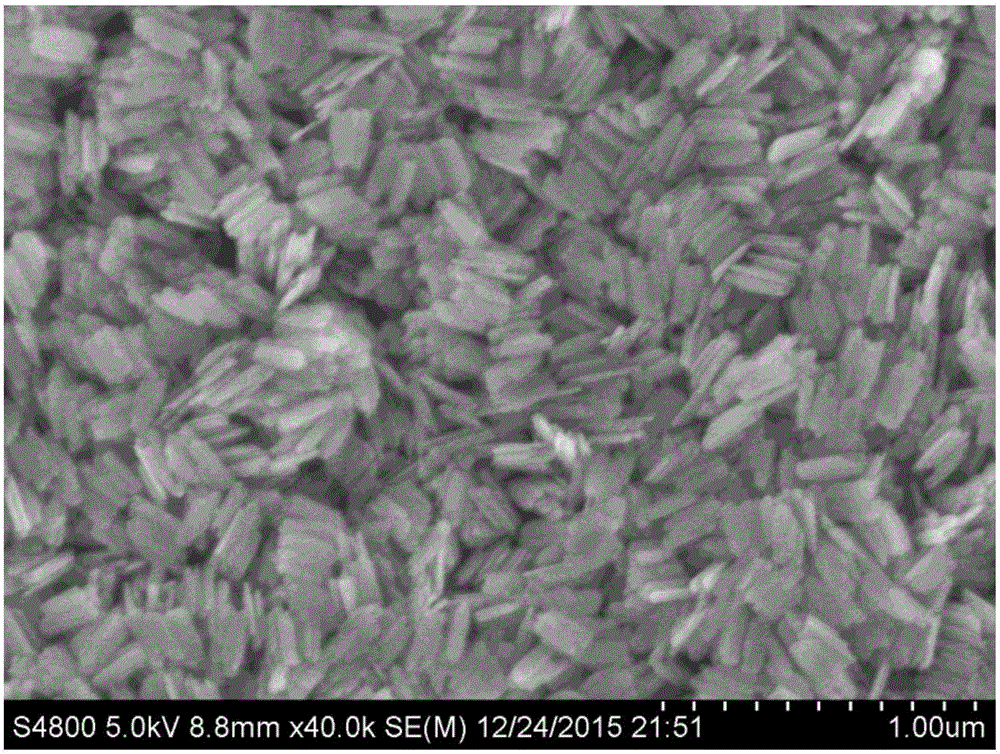

Ternary positive-electrode material prepared by solvothermal method and preparation method thereof

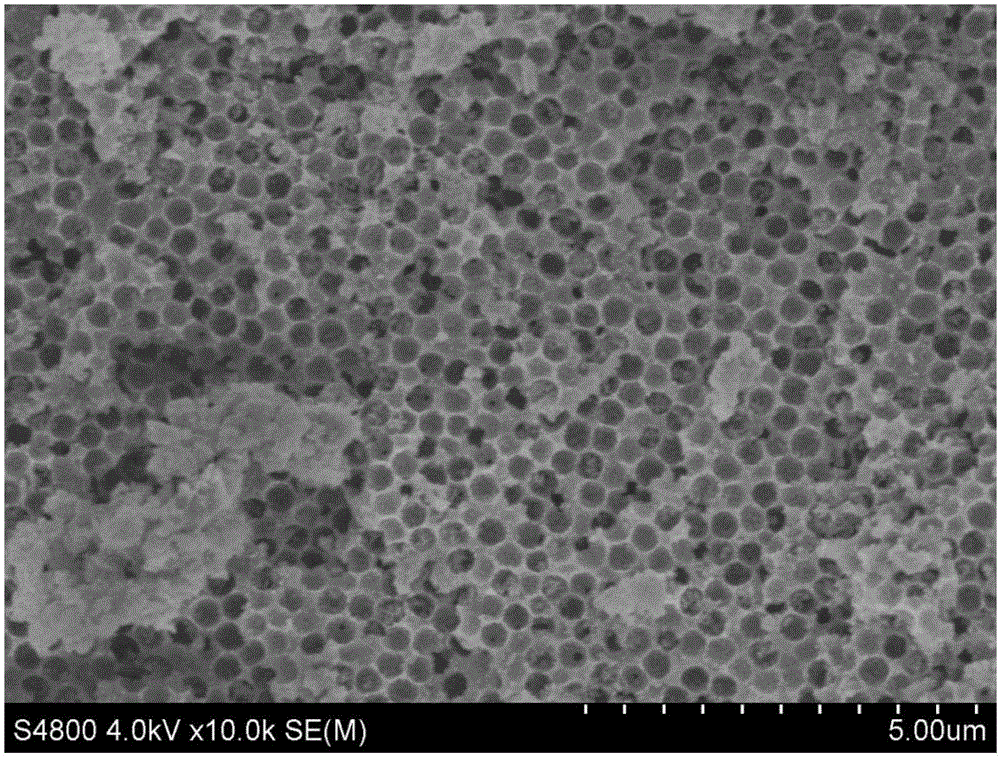

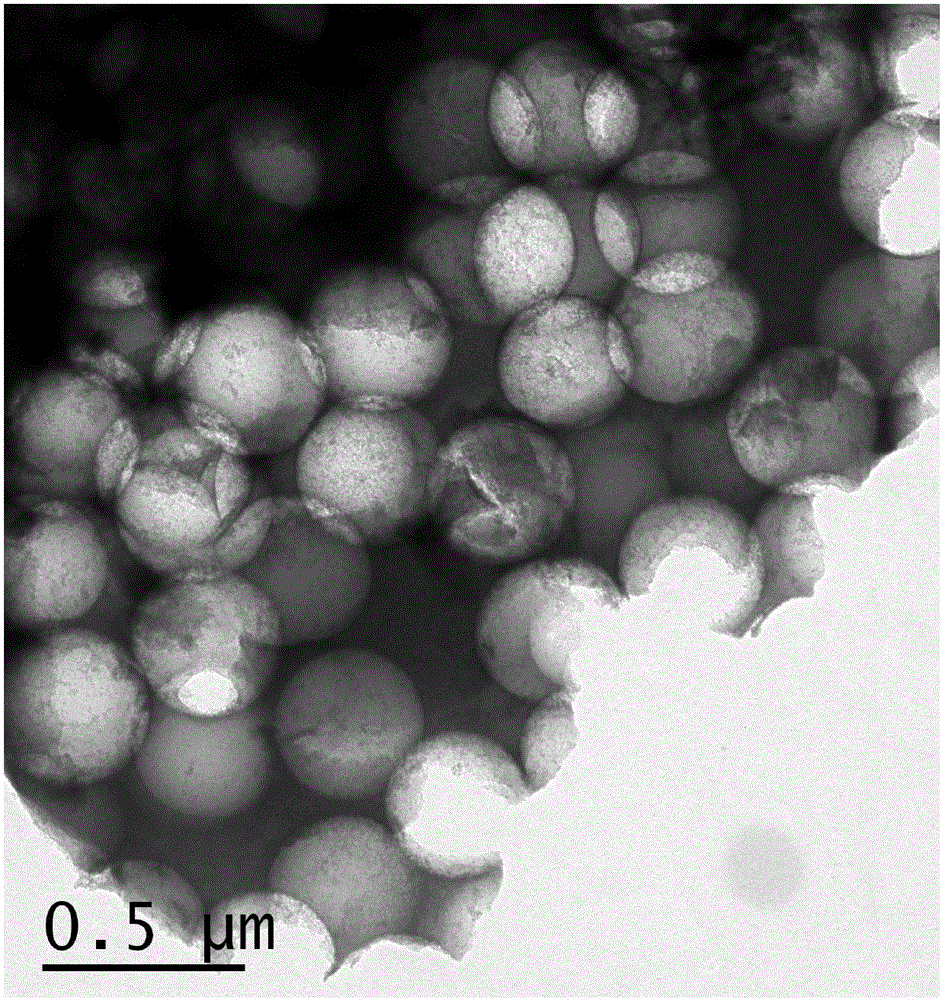

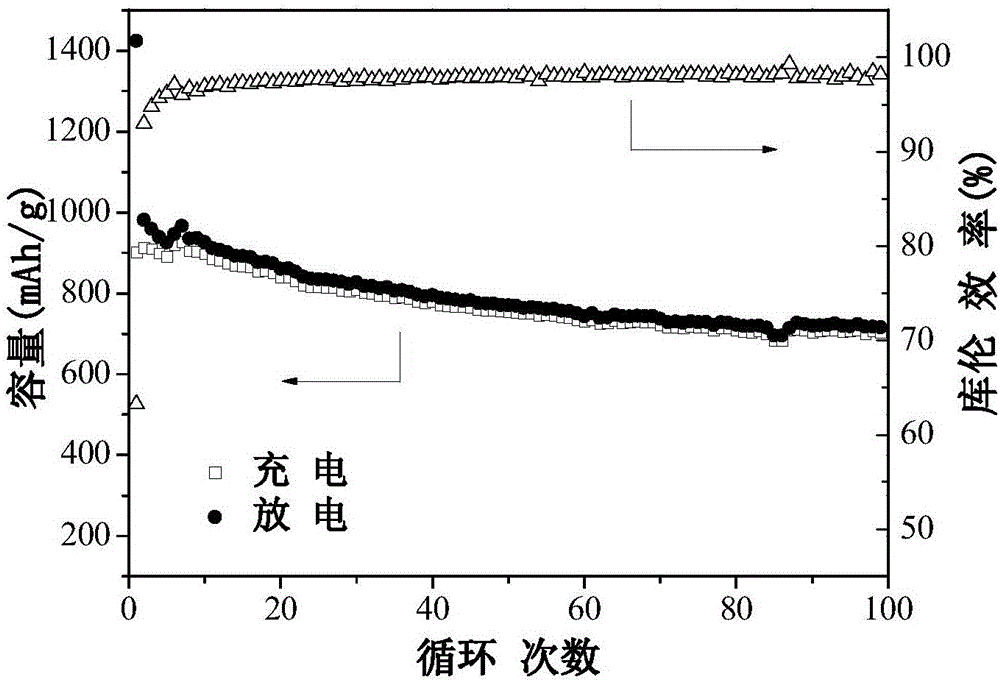

InactiveCN107959022ARegulatory TopographySmall sizeCell electrodesSecondary cellsFiltrationManganese

The invention discloses a ternary positive-electrode material prepared by a solvothermal method and a preparation method thereof. The preparation method includes: dissolving nickel cobalt manganese salt in a solvent, adding a surfactant and hydrolysis auxiliaries, sufficiently stirring, transferring into a reaction kettle, performing solvothermal reaction under certain temperature for 2-24 hours,cooling to room temperature, using a suction filtration method to separate out a nickel cobalt manganese ternary product, washing, drying, and pre-calcining in air to obtain a precursor; grinding andmixing the precursor and a lithium compound, and calcining to obtain the ternary positive-electrode material. The ternary positive-electrode material and the preparation method thereof have the advantages that the ternary oxide precursor prepared by the solvothermal method is small in particle size, uniform in particle distribution and controllable in morphology as compared with a ternary precursor prepared by a conventional precipitation method, so that the finally prepared ternary material is small in granularity, uniform in particle size distribution and controllable in morphology and has excellent electrochemical performance, and the capacity and stability of the prepared ternary material are better than those of a ternary positive-electrode material prepared by the precipitation method.

Owner:SOUTH CHINA UNIV OF TECH

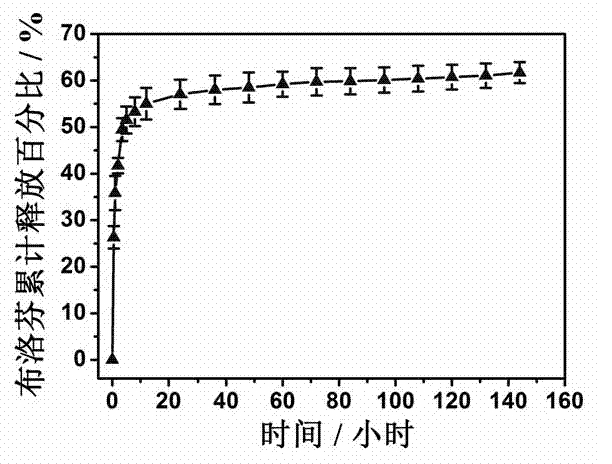

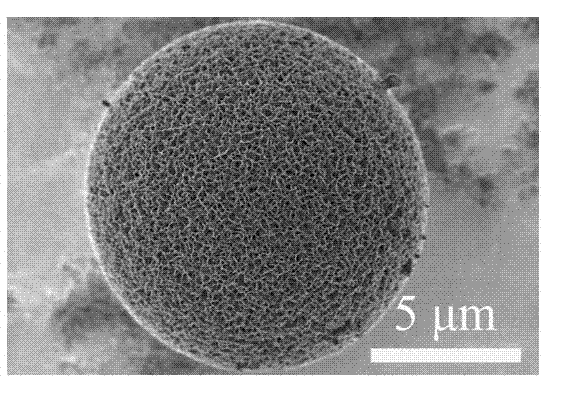

Microwave-assisted preparation method of hydroxylapatite nanometer structure porous microspheres

ActiveCN103110952ASimple processCraft shortPeptide/protein ingredientsPharmaceutical non-active ingredientsApatiteHydroxylapatite

The invention discloses a microwave-assistant preparation method of hydroxylapatite nanometer structure porous microspheres. The microwave-assistant preparation method comprises the following steps of: mixing water-soluble calcium salt as a calcium source with pyridoxal phosphate as a phosphor source under an acidic condition; preparing hydroxylapatite nanometer structure porous microspheres as a carrier through a microwave-assistant hydrothermal reaction; adding the hydroxylapatite nanometer structure porous microspheres to organic solvent containing a hydrophobic drug or an aqueous solution containing hydrophilic protein; and oscillating the solution for 24-60 hours at 20-40 DEG C, and centrifuging, washing and drying the products to obtain the hydroxylapatite nanometer structure porous microspheres which are loaded with the hydrophobic drug or adsorbed with the hydrophilic protein.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Cuprous oxide nanocrystalline with adjustable morphology and dimension as well as preparation method and application thereof

ActiveCN107473257AMorphology regulationParticle Size ControlNanotechnologyCopper oxides/halidesPhotocatalytic degradationReaction system

The invention discloses a cuprous oxide nanocrystalline with adjustable morphology and dimension as well as a preparation method and an application thereof. The preparation method comprises the following steps: copper hydroxide which is used as a precursor is synthesized; the pH value of the system is regulated; the system whose pH value is regulated is reduced in order to obtain cuprous oxide nanocrystalline. A surfactant is not needed to add, the cuprous oxide nanocrystalline with specific morphology and dimension can be obtained by adjusting the pH value of the reaction system, and the nanocrystalline can be used for photocatalytic degradation of organic pollutants, and the method is a rapid, simple and green preparation method of cuprous oxide nanocrystalline.

Owner:INST OF CHEM CHINESE ACAD OF SCI

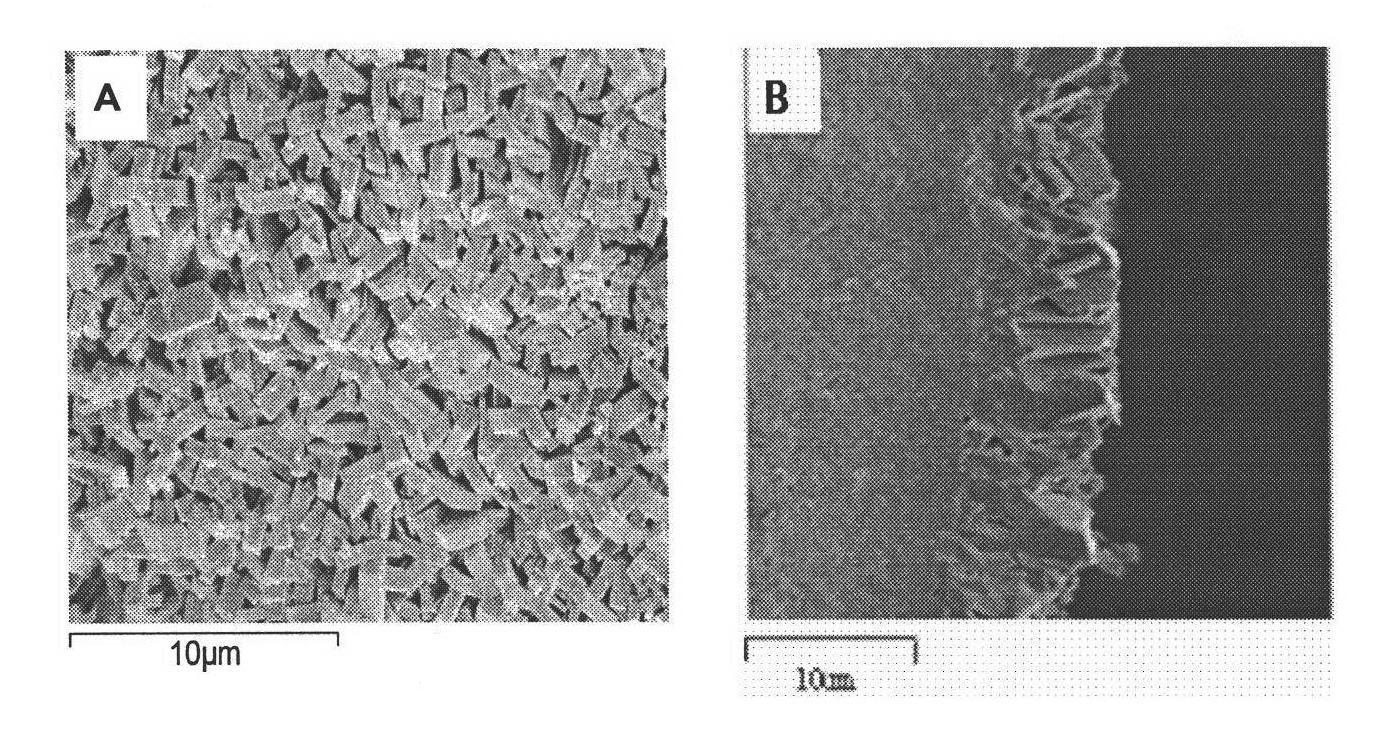

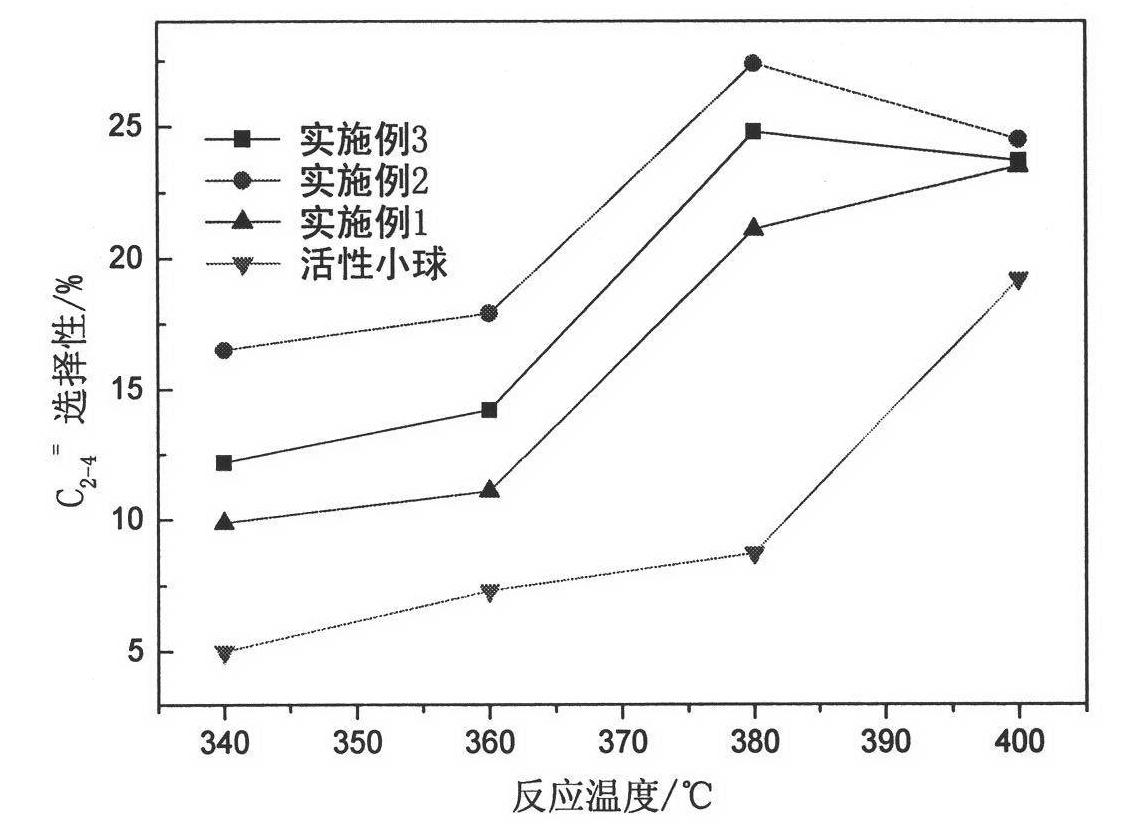

Capsule type catalyst for preparing low-carbon olefin by catalyzing synthesis gas and preparation method thereof

InactiveCN101767040AControl thicknessRegulatory TopographyHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sieveDesorption

The invention relates to a capsule type catalyst for preparing low-carbon olefin by catalyzing synthesis gas and a preparation method thereof. The catalyst is characterized in that the surfaces of spherules with the activity of preparing hydrocarbons through catalytic conversion of synthesis gas are coated with inert molecular sieve membranes with shape selectivity. The preparation method is characterized by coupling molecular sieve seed crystals on the active spherules and then further growing the molecular sieve membranes by a hydrothermal process. The thickness and morphology of the molecular sieve membranes can be controlled by regulating the ratios of H2O / SiO2 and H2O / template agent in molecular sieve precursor solution and the crystallization temperature and time, thereby affecting the desorption shape selectivity of the products and further improving the selectivity of the low carbon olefins.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Preparation method for large-area nano zinc oxide directional array

InactiveCN101122020AUniform shapeSimple processZinc oxides/hydroxidesVacuum evaporation coatingHexamethylenetetramineZno nanoparticles

A method of preparing large scale nano zinc dioxide directional array belongs to the technical field of preparation of nano material directional arrays. The technology subsequently includes the following procedures: the silver nitrate and hexamethylenetetramine are diluted into water as a reacting solution, and the pH value of the solution can be regulated by adding alkaline substances; a cleaned basal is provided; a layer of zinc oxide film is deposited on the surface of the basal, or the zinc salt solution well prepared is evenly applied on the surface of the basal and sintered; the treated basal is put into the reacting solution and the temperature is preserved for a period of time; the basal is taken out, cleaned and dried, and the nano zinc dioxide array is obtained. The invention has advantages that high orientation and high purity nano zinc dioxide arrays can be rapidly prepared on a large area, the shape and appearance can be controlled, the technology is simple and the cost is low.

Owner:UNIV OF SCI & TECH BEIJING

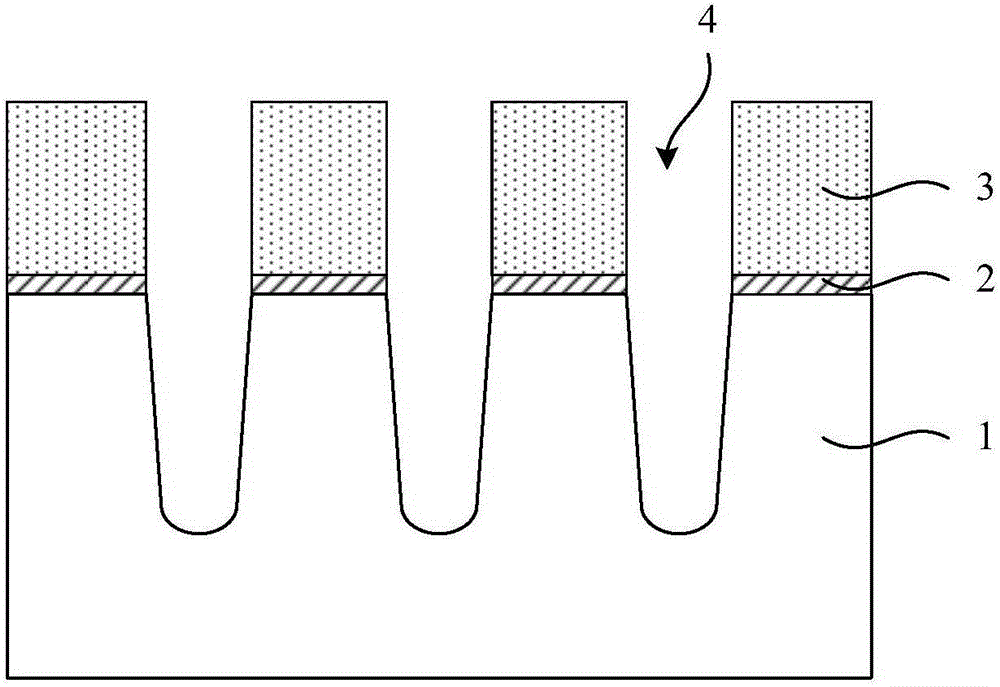

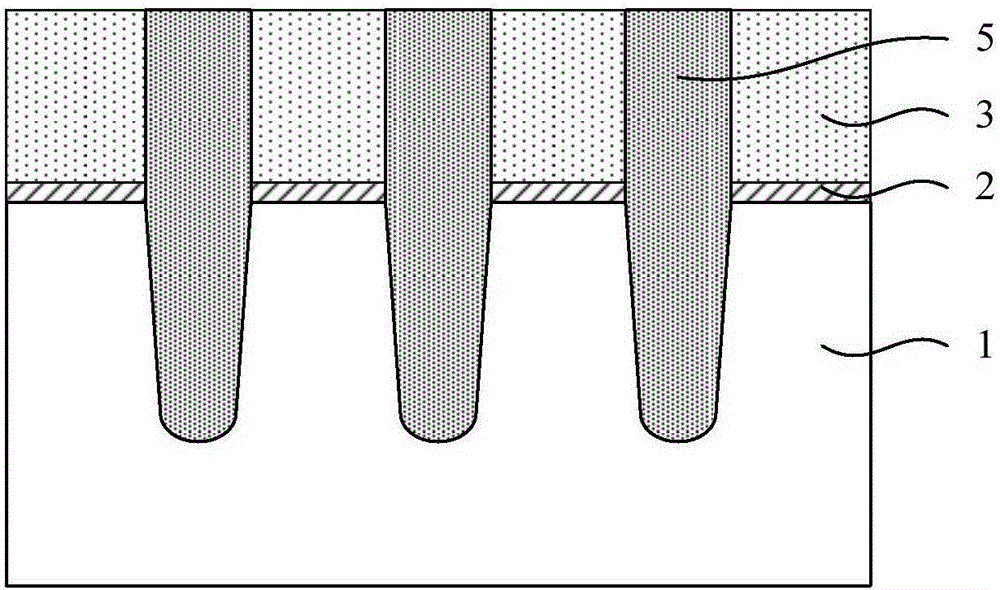

Semiconductor structure manufacturing method

ActiveCN106469730ARegulatory TopographyEasy to fillSolid-state devicesSemiconductor devicesSemiconductor structureEngineering

The invention discloses a semiconductor structure manufacturing method, which comprises the following steps: 1) forming at least one concave groove that penetrates a silicon nitride layer and goes deep into a substrate; 2) forming an isolation structure; 3) removing from the top a first thickness silicon nitride layer so as to expose the first section of the isolation structure; and conducting an etchback to the isolation structure to reduce the width of the first section; 4) further removing a second thickness silicon nitride layer so as to expose the second section of the isolation structure; and conducting an etchback to the isolation structure to reduce the width of the second section; 5) repeating the step 4 at least one time until the remaining silicon nitride layer is provided with a third thickness; 6) removing the remaining silicon nitride layer; and 7) depositing and obtaining a floating gate structure. According to the invention, in the manufacturing process of the floating gate, the floating gate is gradually enlarged to fill the upper opening while the active region CD at the bottom does not have to be enlarged. In this way, it is possible to enlarge the processing window and effectively avoid the appearance of holes in the floating gate. And it is also possible to better regulate the shape and appearance of the floating gate, increase the coupling rate of components and improve the breakdown performance between the active region and the control gate.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Honeycomb porous silicon/carbon composite material and preparation method thereof

ActiveCN105958047AAvoid the hassle of using solventsEffectively control the distributionMaterial nanotechnologyCell electrodesCarbon compositesPorous carbon

The invention discloses a honeycomb porous silicon / carbon composite material and a preparation method thereof. The silicon-carbon composite material is of a hybrid structure that nano silicon spheres are distributed in a honeycomb three-dimensional continuous porous carbon matrix. The method comprises the steps of: adopting spherical silicon dioxide nanoparticles as a silicon source and thermosetting difunctional acrylate unsaturated resin as a carbon source; firstly, mixing silicon dioxide and magnesium powder and then carrying out magnesiothermic reduction in an inert atmosphere to form a continuous porous silicon matrix containing the silicon dioxide nanoparticles; pickling a product obtained by reduction by a hydrochloric acid, evenly dispersing the product into a resin monomer for solidifying, and carrying out high-temperature calcination in the inert atmosphere for in situ carbon formation; and finally etching silicon dioxide which does not completely react by a hydrofluoric acid to obtain the honeycomb porous silicon / carbon composite material and applying the honeycomb porous silicon / carbon composite material to a negative electrode material of a lithium-ion battery. Through in-situ polymerization of vinyl thermosetting resin, the cumbersome problem that traditional thermosetting resin needs to utilize a solvent is solved; post-treatment is not needed; the operation is simple and convenient; and the honeycomb porous silicon / carbon composite material is green and environment-friendly.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

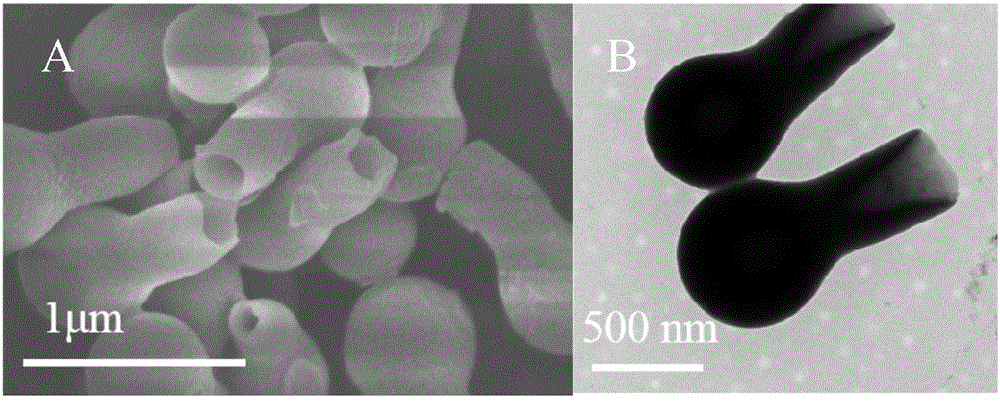

Preparation method for hollow carbon material and product

A disclosed preparation method for a hollow carbon material comprises taking a biomass raw material as a carbon source and a surfactant as a template, combining a hydrothermal process and a soft template process, and performing a hydrothermal reaction, so as to obtain a hollow polymer material, and then performing high-temperature calcining, so as to obtain the corresponding hollow carbon material. The invention also discloses a product prepared according to the above method. The method enables the biomass carbon source and the surfactant to be subjected to self-assembled for obtaining a hollow structure, and is capable of obtaining hollow carbon materials with different morphologies (spherical or racket-shaped) by changing variety of the carbon source.

Owner:ZHEJIANG UNIV

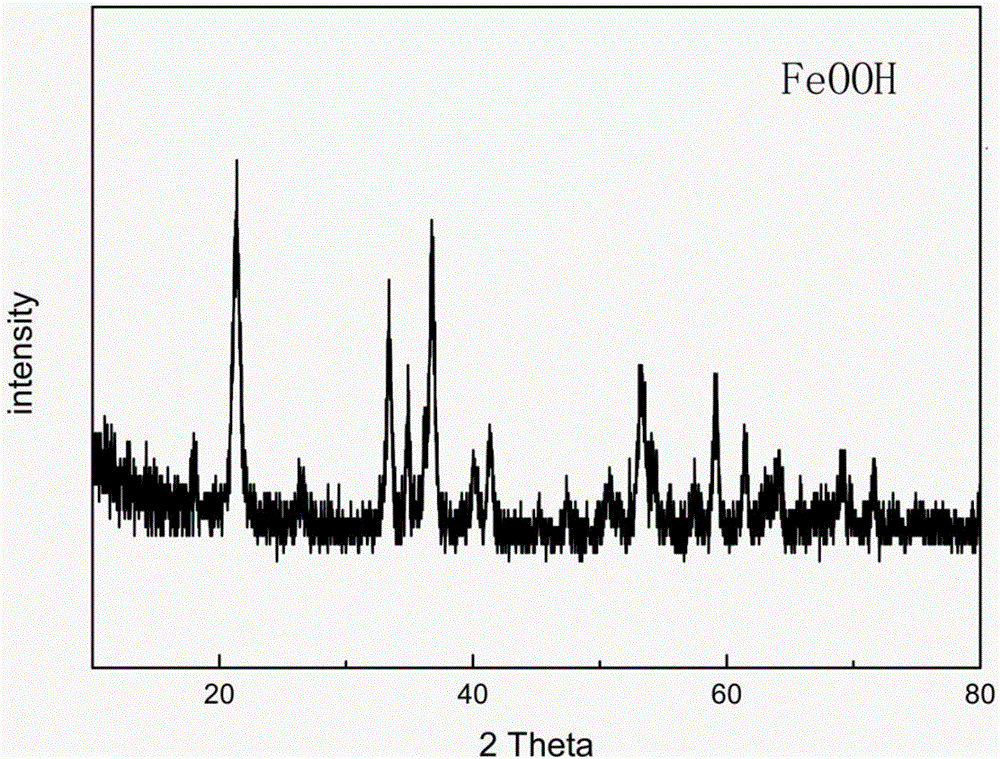

Method for preparing iron oxyhydroxide nanosheet and its product

InactiveCN106082351AHigh crystallinityStable structureIron oxides/hydroxidesTetramethylammonium hydroxideNitrate

The invention relates to a method for preparing iron oxyhydroxide nanosheet and its product. The method comprises the following steps: 1) mixing iron nitrate nonahydrate, tetramethylammonium hydroxide and deionized water to obtain a precursor solution; the concentration of the iron nitrate nonahydrate in the precursor solution is 0.25-0.3 mol / L, and the concentration of tetramethylammonium hydroxide is 0.25-1 mol / L; 2) performing a hydrothermal reaction on the precursor solution obtained in the step 1) at the temperature of 100-120 DEG C for 6-8 hours, filtering the material, cleaning the material, and drying the material to obtain the iron oxyhydroxide nanosheet. The size of the iron oxyhydroxide nanosheet is small, and the other metal impurity in the products can be avoided.

Owner:ZHEJIANG UNIV

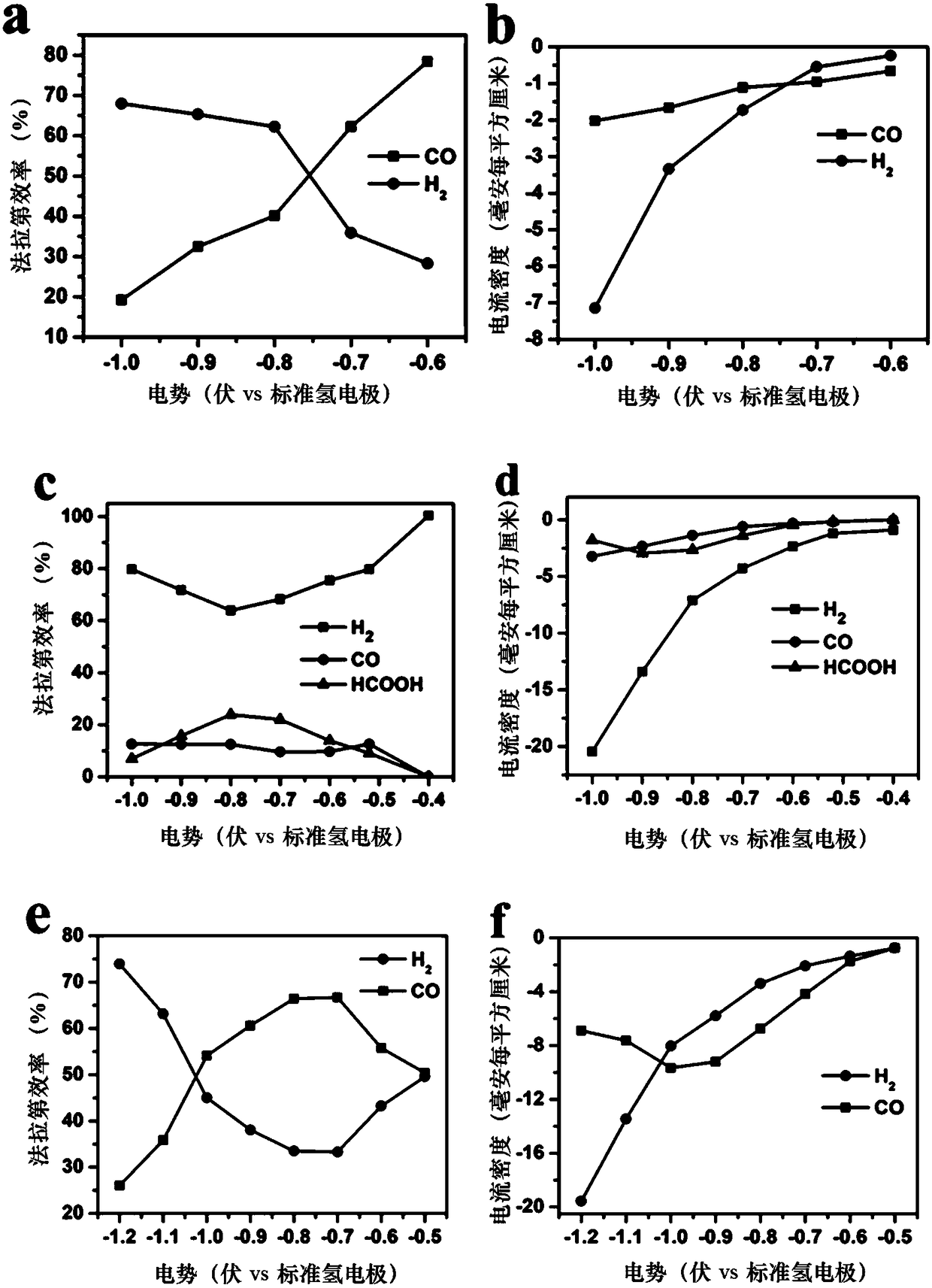

Au-Ir nano alloy, preparation method of Au-Ir nanometer alloy and application of Au-Ir nanometer alloy used as catalyst

ActiveCN109175347AControl element ratioRegulatory TopographyMaterial nanotechnologyTransportation and packagingAlloyActive site

The invention discloses an Au-Ir nano alloy. The particle size of the Au-Ir nano alloy is 5-10nm; and the molar ratio of Au to Ir in the Au-Ir nano alloy is (1:3)-(9:1). The particle size of the Au-Irnano alloy is small, the Au-Ir nano alloy has an extremely large specific surface area and more active sites, the morphology of the Au-Ir nano alloy is adjustable, and different product selectivity is shown in electro-catalysis carbon dioxide.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

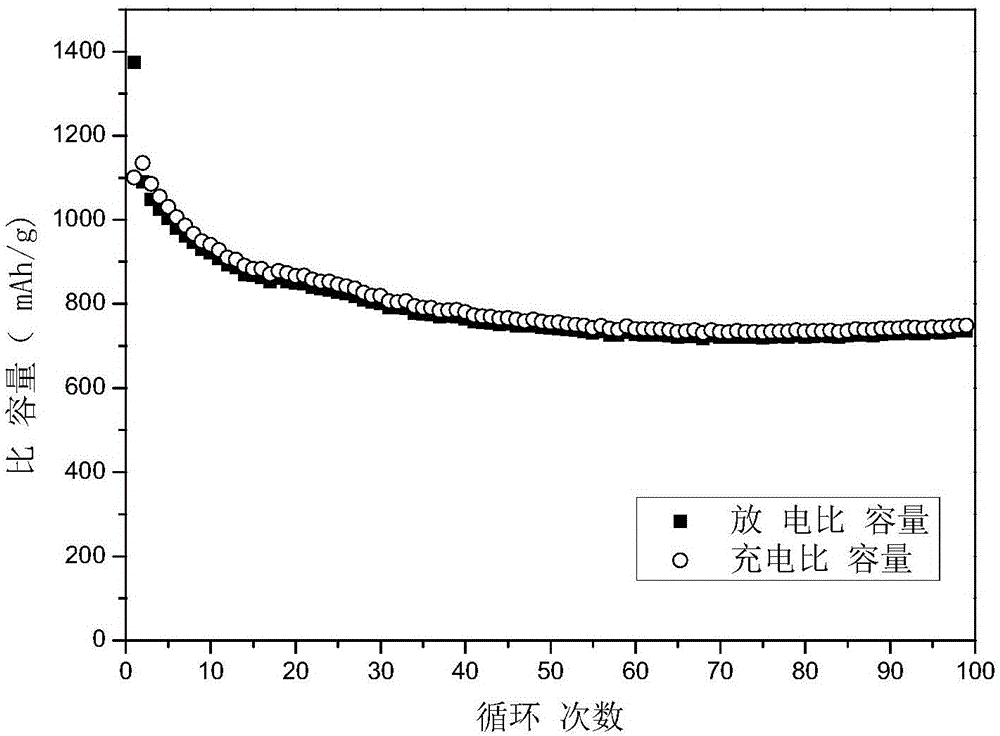

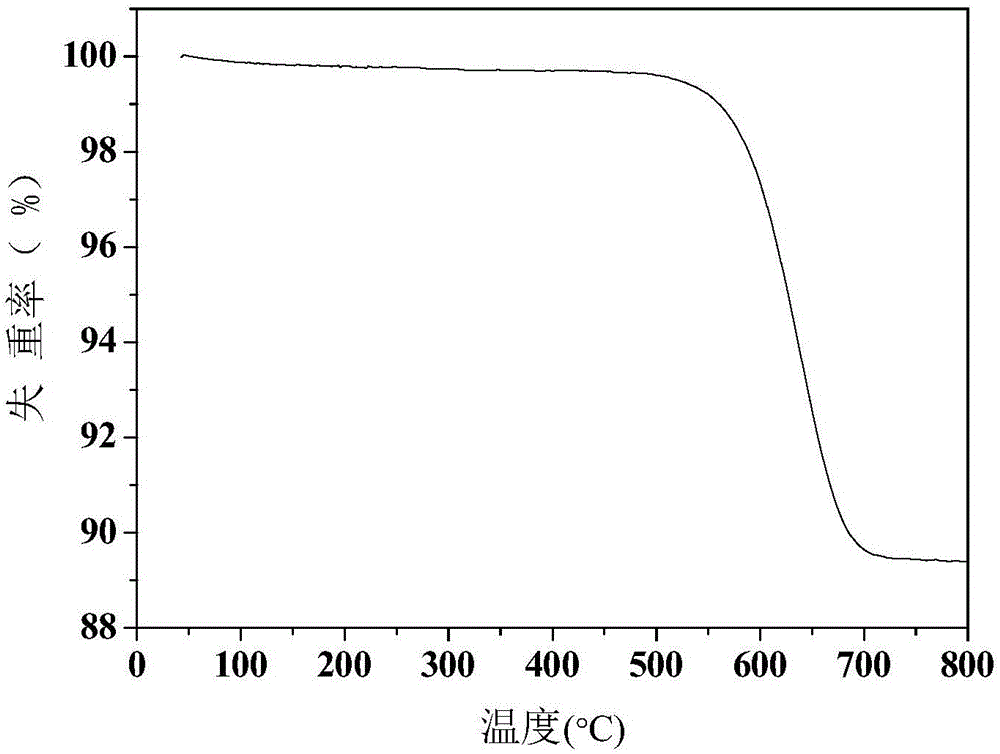

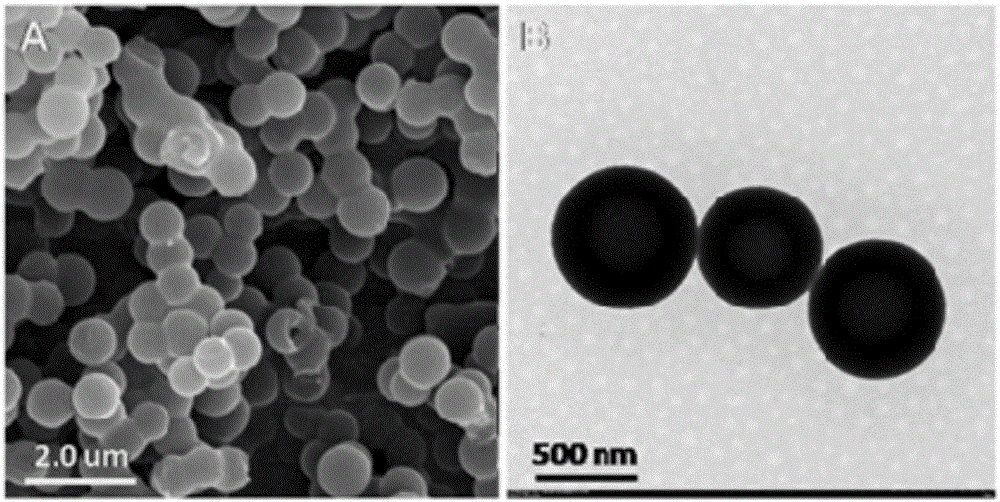

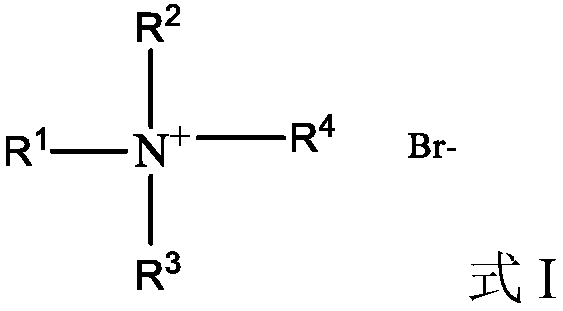

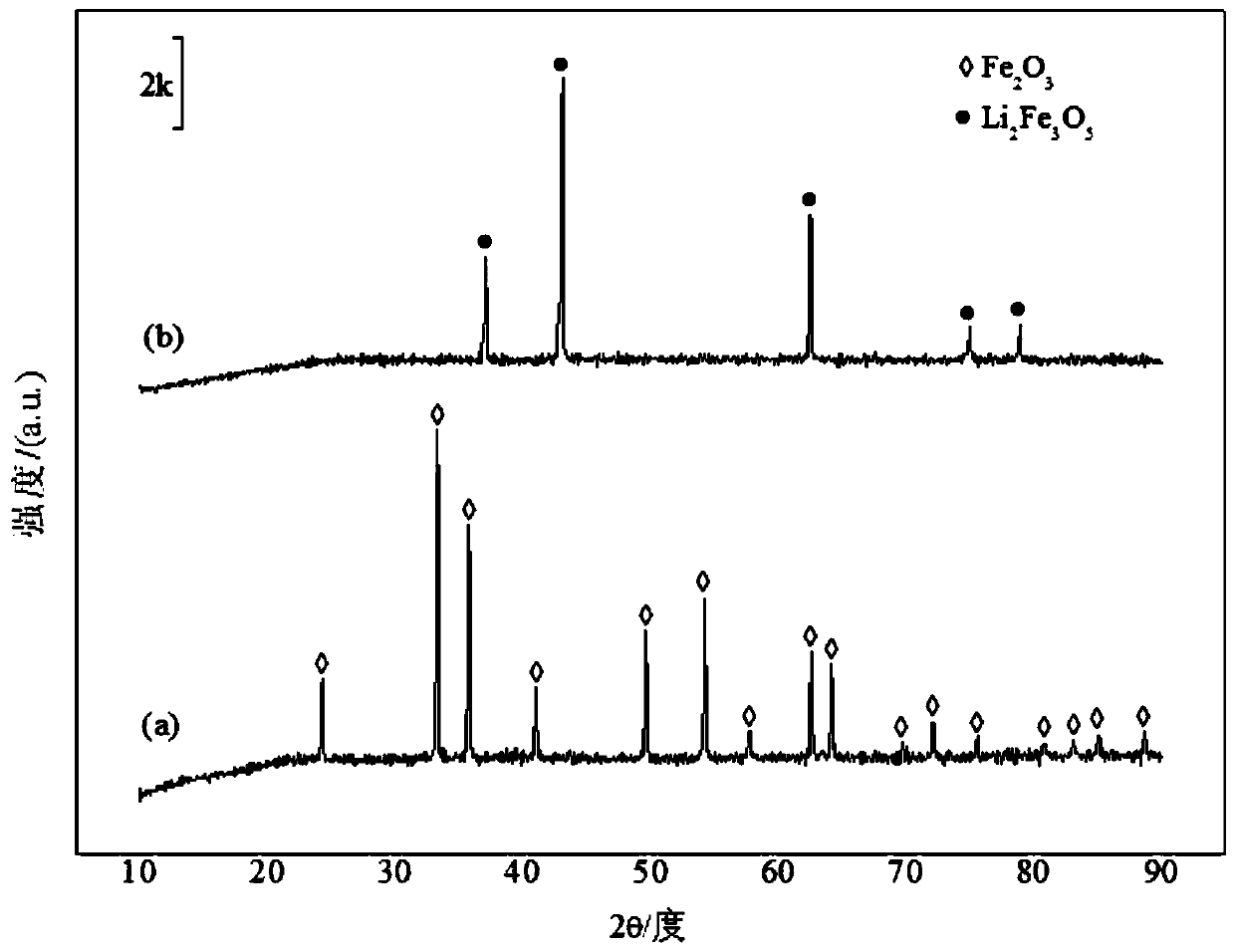

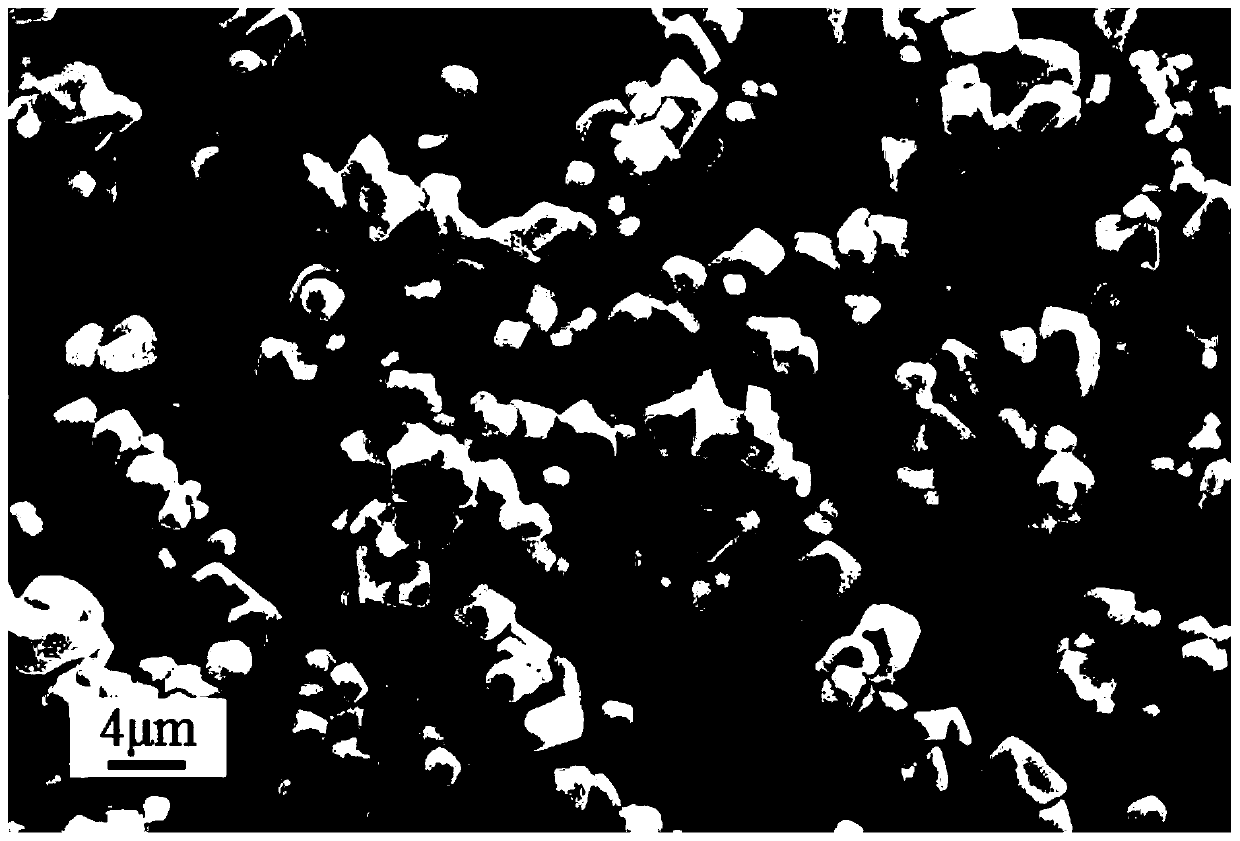

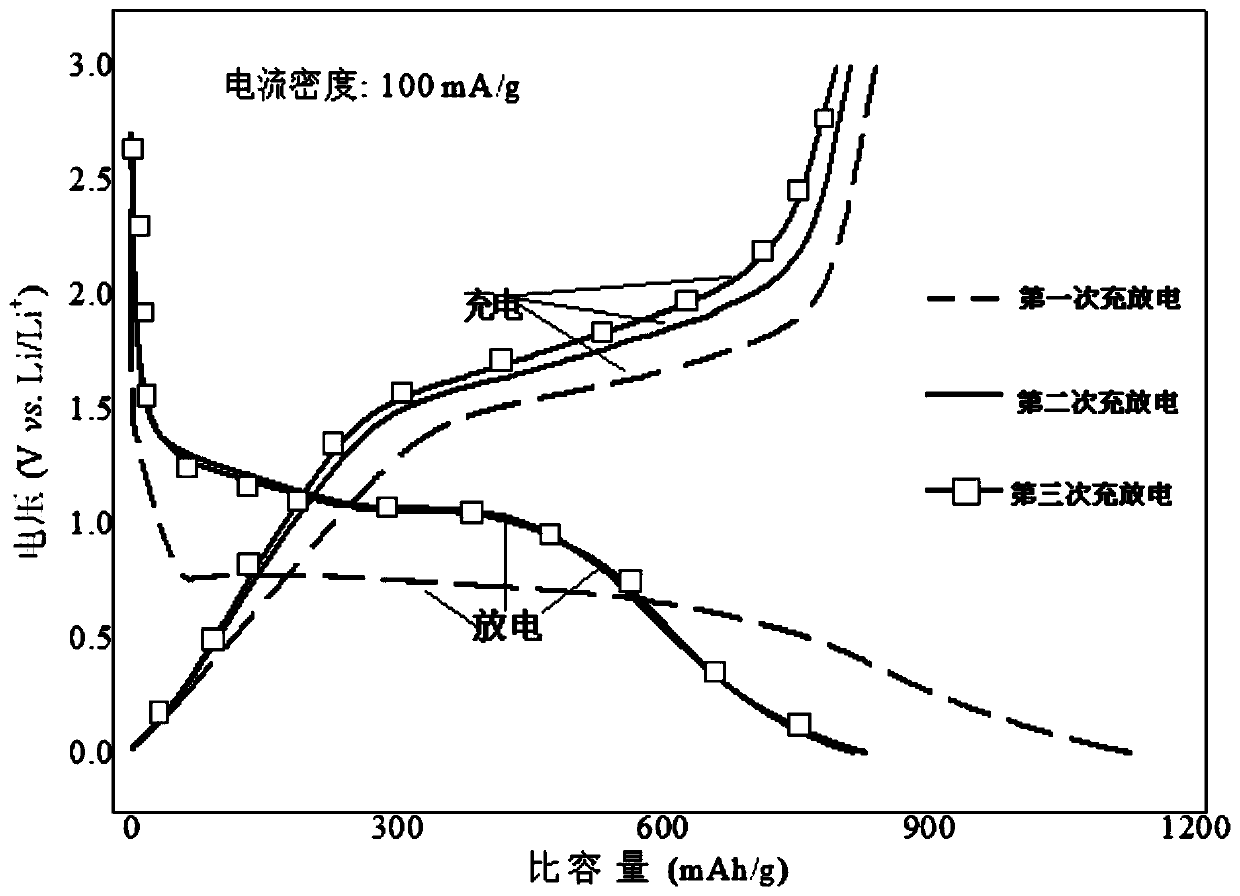

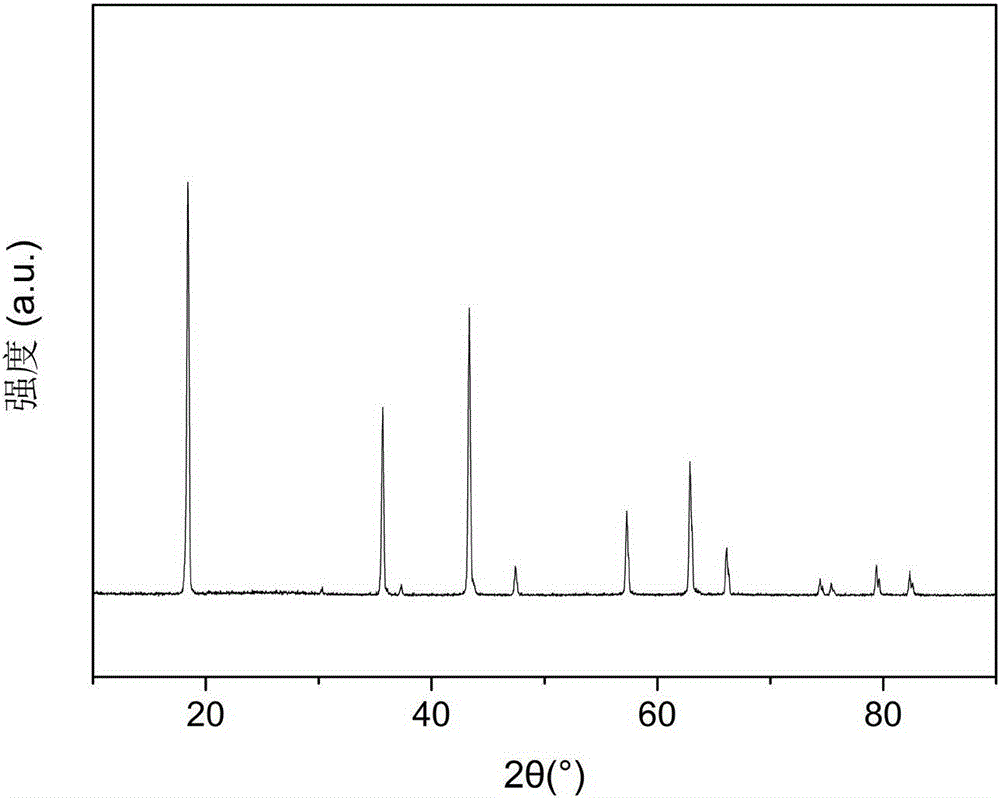

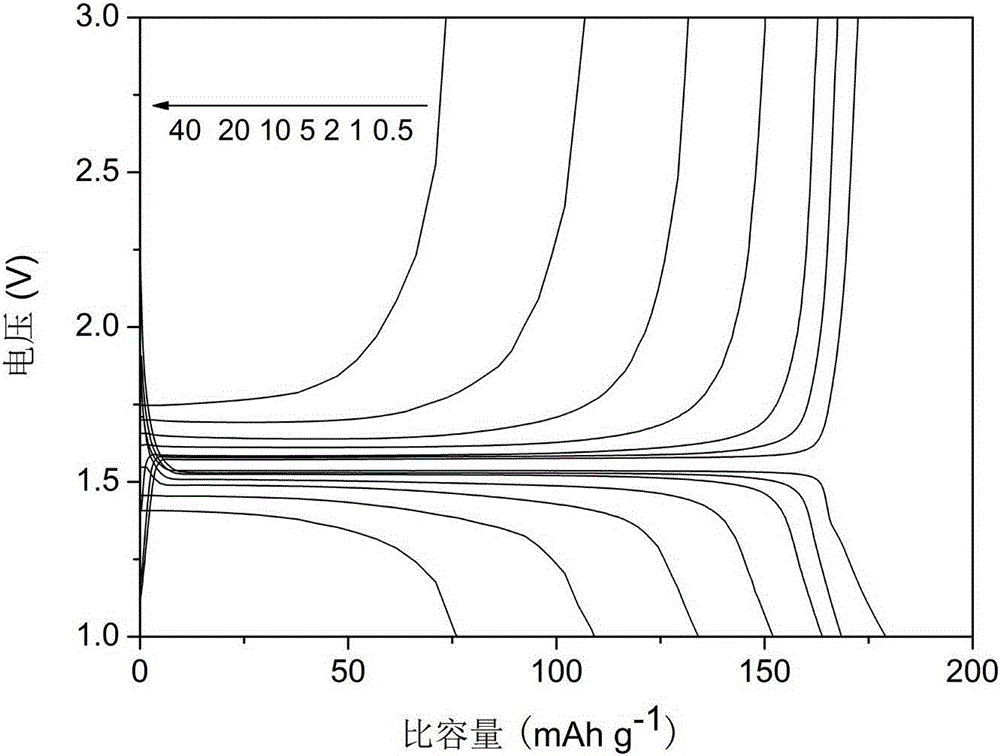

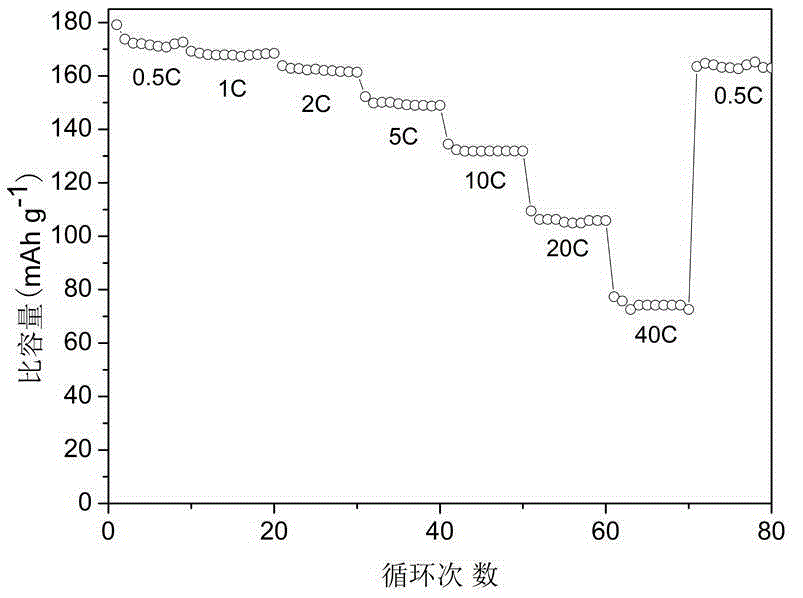

Lithium battery anode material based on lithium ferrite as well as preparation method and application thereof

ActiveCN109755471ARegulatory TopographyRegulatory granularitySecondary cellsNon-aqueous electrolyte accumulator electrodesGraphiteSolvent

The invention relates to a lithium battery anode material based on lithium ferrite as well as a preparation method and application thereof and belongs to the field of preparation and application of lithium ion battery electrode materials. The lithium battery anode material based on lithium ferrite comprises lithium ferrite as well as conductive carbon, a binder and a solvent, wherein a chemical formula of lithium ferrite is Li2Fe3O5, morphology of lithium ferrite is particles of an octahedral structure, and particle size is 0.2-10[mu]m. The preparation method of the lithium battery anode material comprises the following steps: mixing all the substances, and stirring, so that the lithium battery anode material is obtained. A lithium battery can be prepared by adopting the anode material. The method provided by the invention prepares a lithium ion anode material on the basis of a lithium ferrite material of the octahedral structure, not only conductivity is improved, but also great volume change of lithium ions in intercalation and deintercalation processes is alleviated, so that electrochemical stability of the lithium ion anode material is improved, the problem that graphite has relatively low theoretical specific capacity when being taken as the traditional lithium ion battery anode material can be thoroughly solved, and the development obstacle that specific capacity of a lithium ion battery is relatively low is overcome.

Owner:NORTHEASTERN UNIV

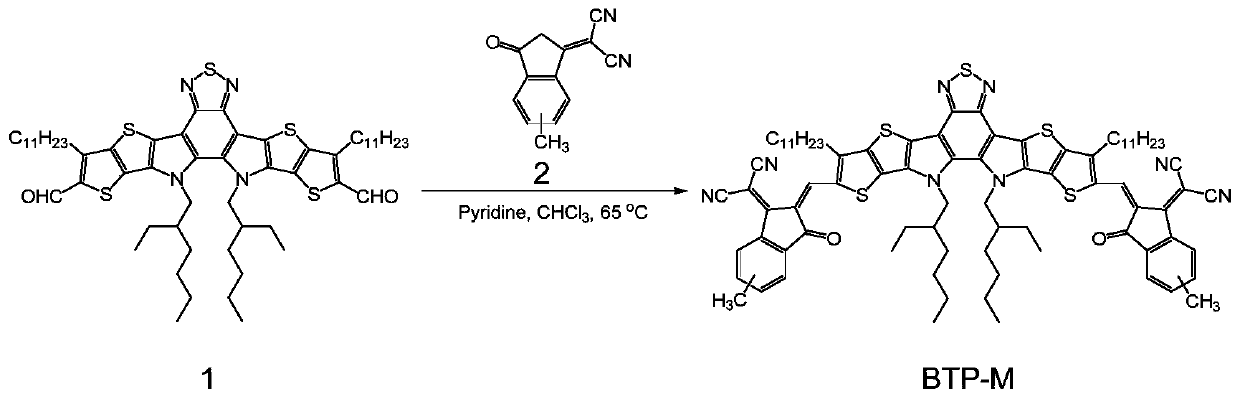

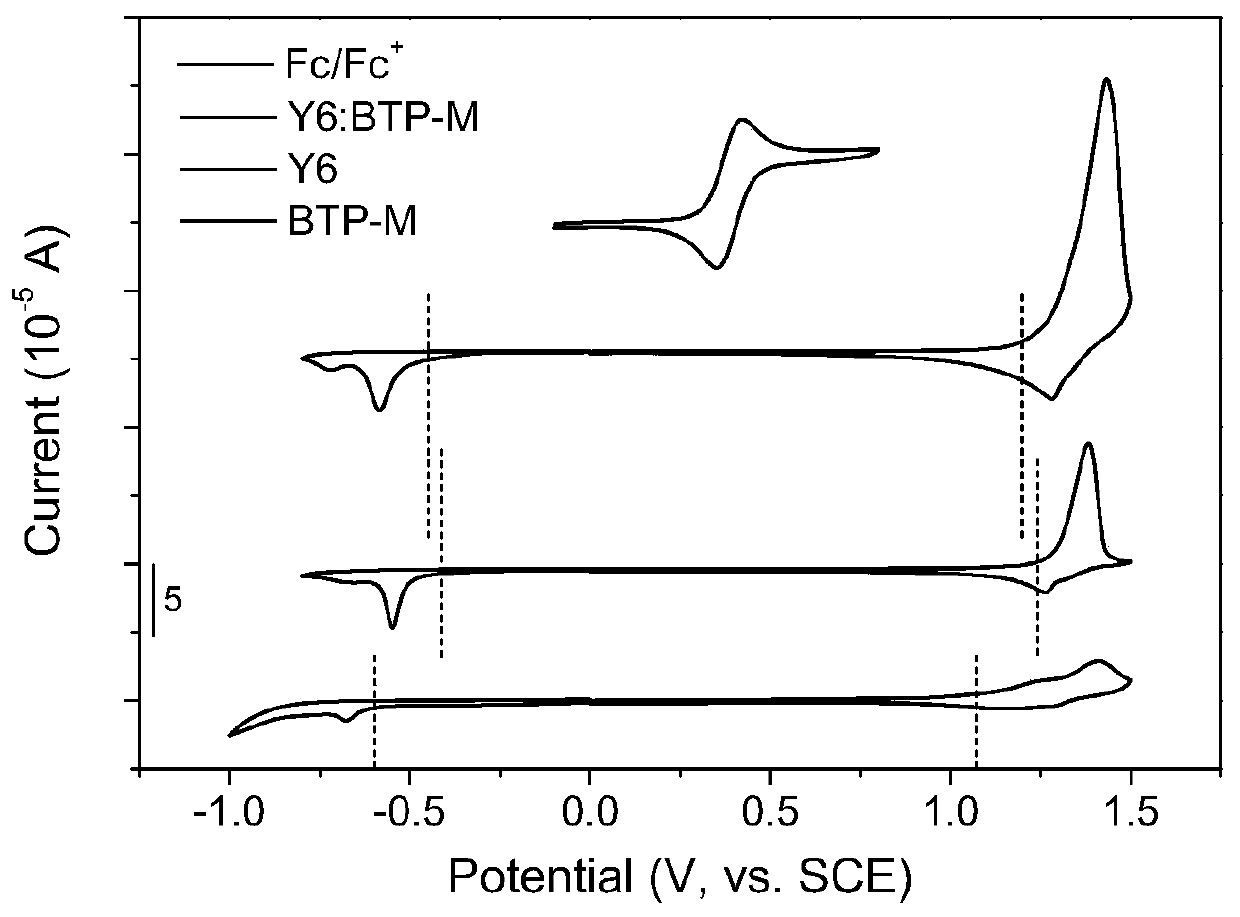

High-efficiency ternary organic solar cell based on non-fullerene acceptor alloy

ActiveCN110690349AWide absorption rangeHigh crystallinitySolid-state devicesSemiconductor/solid-state device manufacturingOrganic solar cellAcceptor

The invention discloses a high-efficiency ternary organic solar cell based on a non-fullerene receptor alloy, which comprises a substrate, an anode, an anode modification layer, an active layer, a cathode modification layer and a cathode, and is characterized in that the active layer is a polymer donor PM6 and non-fullerene receptor alloy blended film; and the non-fullerene receptor alloy is a Y6:BTP-M alloy formed by mixing two non-fullerene receptors Y6 and BTP-M according to a certain proportion. By using the higher energy level and weaker crystallinity of BTP-M relative to Y6, the Y6: BTP-M alloy optimizes the energy level and morphology of the active layer at the same time, so that the PM6: Y6: BTP-M ternary organic solar cell obtains higher voltage and current than a PM6: Y6 binarycell; and finally, the highest energy conversion efficiency (PCE = 17.03%) of the existing single-junction organic solar cell is realized. Besides, the performance of the ternary organic solar cell isnot sensitive to the thickness of the active layer, and the PCE is 14% or above when the thickness of the active layer is 120-300 nm.

Owner:ZHEJIANG UNIV

Preparation method of p-n junction type ZnO-CoTiO3 room temperature gas-sensitive film

ActiveCN104020193AEasy to prepareWide range of raw materialsVacuum evaporation coatingSputtering coatingSputteringWorking temperature

A preparation method of a preparation method of a p-n junction ZnO-CoTiO3 room temperature gas-sensitive film. The method is as below: placing a TiO2 target and a Co3O4 target into two radio frequency target positions of a magnetron sputtering instrument, and placing a Zn target into a direct current sputtering target position; then placing a Si substrate on a coating sample stage of the magnetron sputtering instrument, then vacuumizing, introducing Ar gas, then conducting pre-sputtering, introducing O2 gas, and finally conducting sputtering coating on the Si substrate to obtain a precursor film; calcining the precursor film, controlling the calcination temperature at 300-700 DEG C and calcination time at 0.5-3 h, and then cooling to room temperature in the furnace to obtain the p-n junction type ZnO-CoTiO3 room temperature gas-sensitive film. The method can effectively control the composition of the film, has good film forming property, convenient operation and short production cycle; and the prepared p-n junction type ZnO-CoTiO3 gas-sensitive thin has uniform distribution, and excellent room temperature gas-sensitive property and can effectively reduce the working temperature.

Owner:SHAANXI UNIV OF SCI & TECH

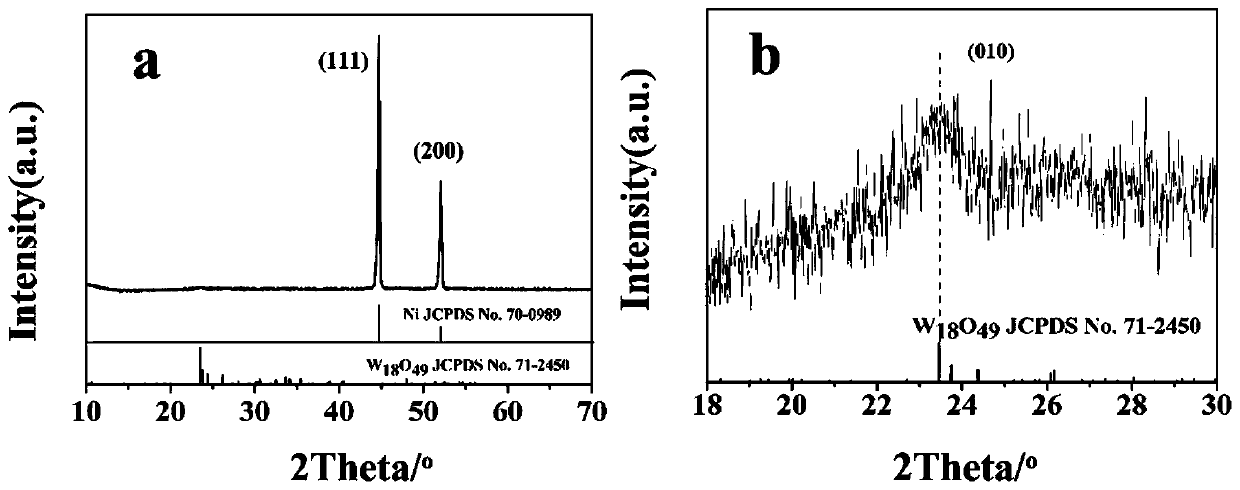

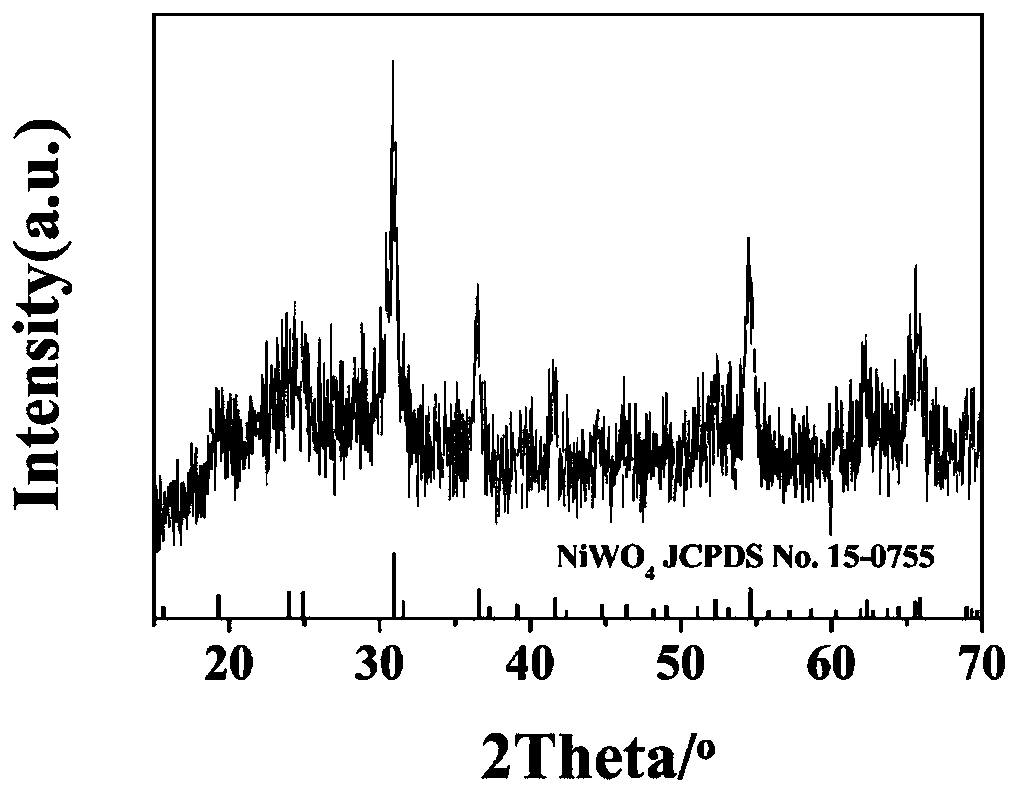

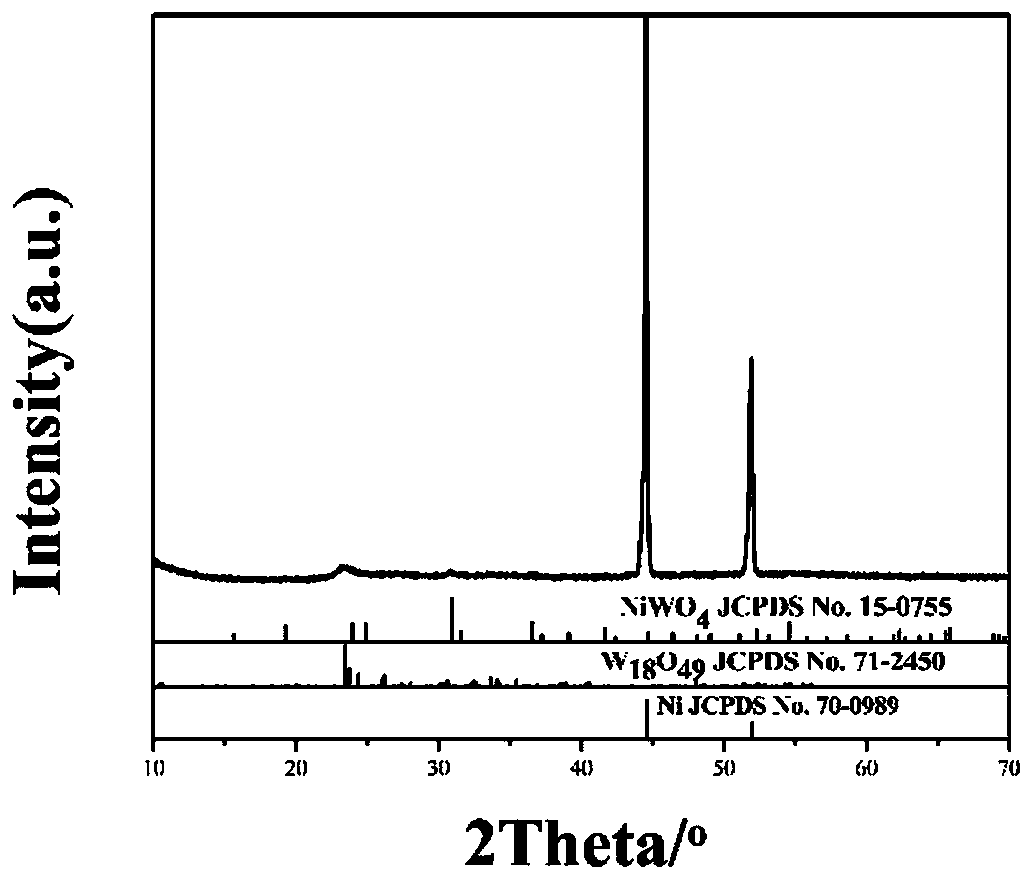

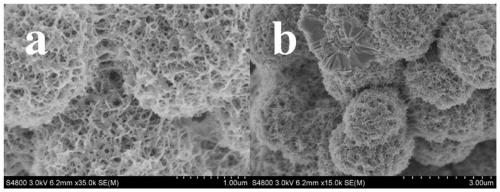

Preparation method of W18O49/NiWO4/NF self-supporting electrocatalytic material

ActiveCN109806902ALow reaction temperatureLow costPhysical/chemical process catalystsElectrode shape/formsReaction temperatureHigh pressure

The invention relates to a preparation method of a W18O49 / NiWO4 / NF self-supporting electrocatalytic material. The preparation method includes the steps that Na2WO4.2H2O and Ni(CH3COO)2.4H2O are successively added to deionized water to obtain a mixed solution A; the mixed solution A is loaded into the a polytetrafluoroethylene lined high-pressure reactor for a hydrothermal reaction, and NiWO4 crystals are obtained by washing, drying and calcining reactants; the NiWO4 crystals and a WCl6 are successively added to absolute ethyl alcohol to obtain a solution C; the solution C is poured into the polytetrafluoroethylene lined high-pressure reactor, then foamed nickel is placed in the polytetrafluoroethylene lined high-pressure reactor for the hydrothermal reaction, final reactants are subjectedto centrifugal washing and drying with the absolute ethyl alcohol to obtain the W18O49 / NiWO4 / NF self-supporting electrocatalytic material. According to the preparation method of the W18O49 / NiWO4 / NF self-supporting electrocatalytic material, the reaction temperature is low, the condition is mild, and implementation is easy; and the preparation process is simple, the cost is low, the process is easyto control, environmental protection is achieved, the prepared W18O49 / NiWO4 / NF electrocatalytic material shows excellent properties of electrocatalytic hydrogen and oxygen production.

Owner:SHAANXI UNIV OF SCI & TECH

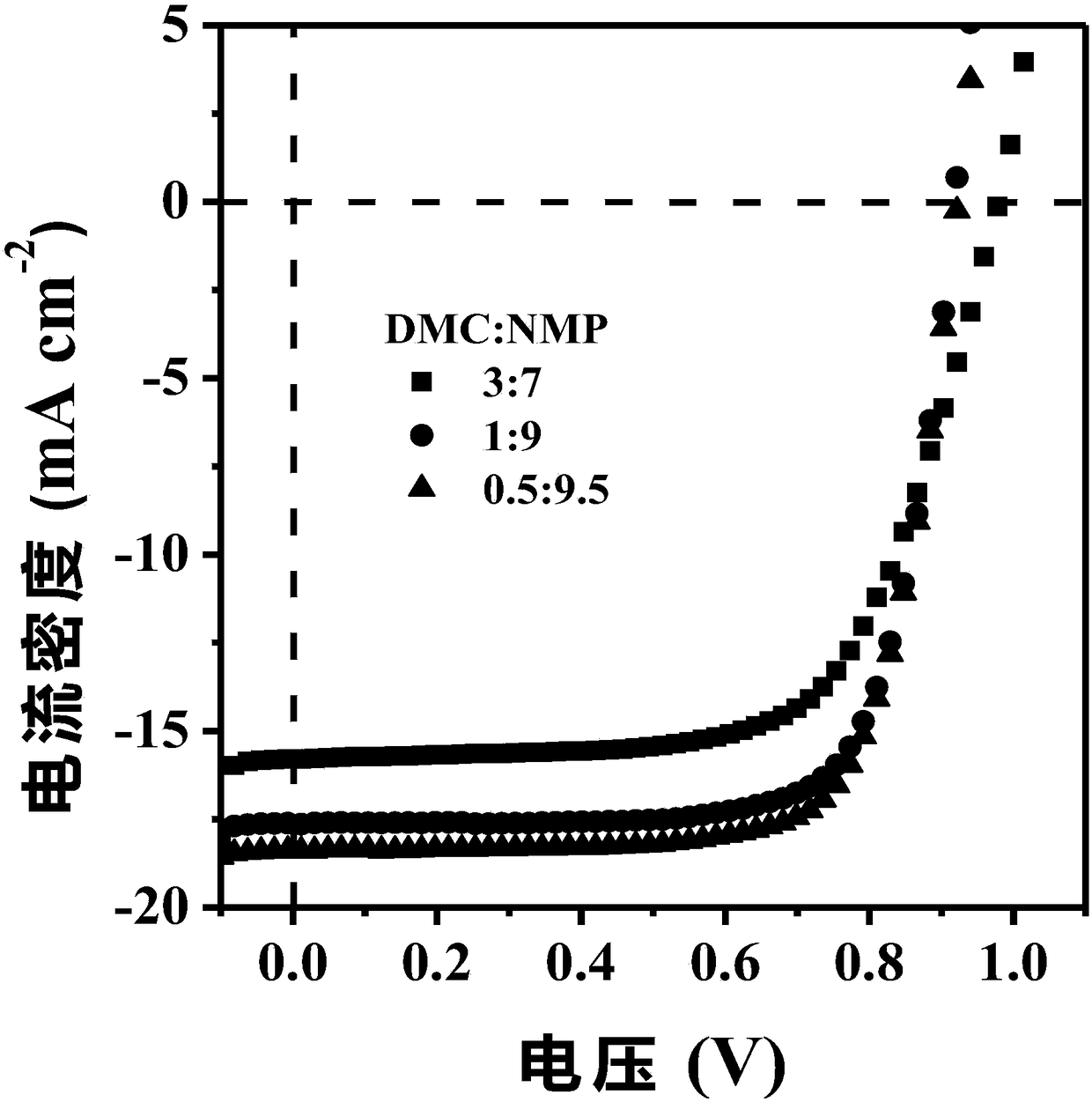

Green solvent system for preparing perovskite layer of perovskite solar cell and mixed solution

ActiveCN108389969ARegulatory TopographySolid-state devicesSemiconductor/solid-state device manufacturingEnvironmental resistancePerovskite solar cell

The invention provides a solvent system for preparing a perovskite layer of a perovskite solar cell. The system comprises dimethyl carbonate and another solvent; and the other solvent comprises one ormultiple selected from N-methyl 2 pyrrolidone, gamma-butanolide, isopropanol and acetone. The dimethyl carbonate is used in cooperation with the other solvent of N-methyl 2 pyrrolidone and the like,the solvent system is green and degradable, and the environment can be protected. The perovskite solar cell prepared by the solvent system can regulate the morphology of the perovskite layer effectively under the condition of short-time thermal annealing or event without thermal annealing, the problem that technology is hard to control accurately during annealing by solvent steam, and requirementsfor high-flux coil-to-coil printing in future can be met. The preparation technology is simple, conditions are mild, and the system and solution have significance in the commercialized progress of the perovskite solar cell.

Owner:GUANGDONG UNIV OF TECH

Method using emulsion electricity texture to prepare beaded filaments

InactiveCN102926021AThe preparation process is simpleMild conditionsFilament/thread formingMonocomponent synthetic polymer artificial filamentNanofiberWater contact

The invention provides a method using emulsion electricity texture to prepare beaded filaments. The method specifically comprises the following steps of using emulsion polymerization method to prepare polymer emulsion, preparing spinning emulsion dispersion liquid, using high voltage static spinning to process the emulsion dispersion liquid, collecting fiber through flat plates or drums and obtaining different-shaped micro nanometer fiber of beaded structure. Different-shaped fiber of the beaded structure can be prepared by changing emulsion dispersion liquid proportioning and spinning work parameters. The method using emulsion electricity texture to prepare beaded filaments is simple in structure, moderate in condition, environmental-protection and safe and easy to produce in large scale. Raw materials of the preparation method are easy to obtain. The method uses the emulsion electricity spinning method to prepare beaded filament membranes which are super-hydrophilicity through water contact angle tests. The method is wide in application prospect in field of absorbent materials.

Owner:BEIJING UNIV OF CHEM TECH

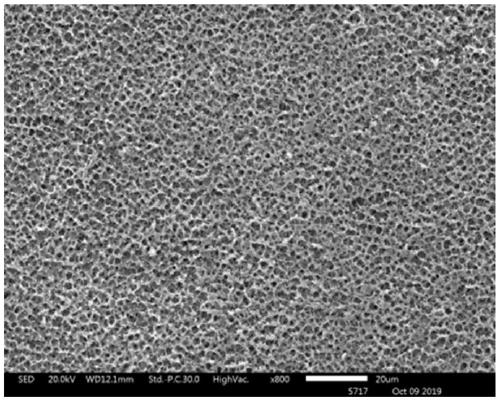

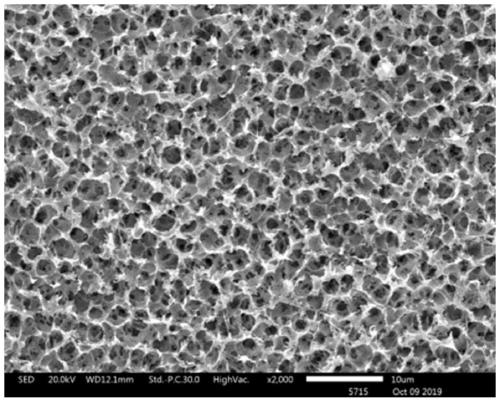

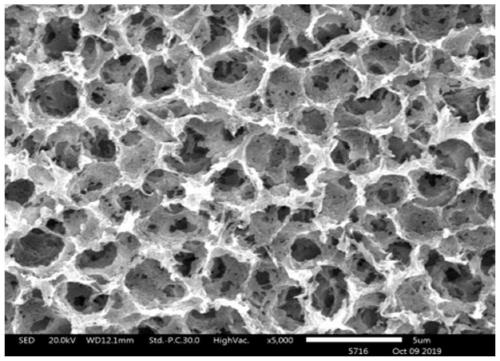

Polyvinyl alcohol-ethylene copolymer honeycomb porous membrane and preparation method thereof

ActiveCN111346522AImprove controllabilityImprove uniformitySemi-permeable membranesMembranesPolyvinyl alcoholPorous membrane

The invention provides a polyvinyl alcohol-ethylene copolymer honeycomb porous membrane and a preparation method thereof. The preparation method comprises the following steps: firstly, a polyvinyl alcohol-ethylene copolymer is dissolved in a mixed solvent of isopropanol and water in a mass ratio of (1: 2)-(2: 1) to prepare a polyvinyl alcohol-ethylene copolymer solution with the mass fraction of 7%-12%; then, after a polyvinyl alcohol-ethylene copolymer film is prepared through spin coating, heat treatment is conducted at the temperature 1 to 10 DEG C lower than the boiling point of an azeotrope of isopropanol and water, a solvent phase is removed, and a honeycomb-shaped porous film is formed; and finally, annealing treatment is carried out to obtain the polyvinyl alcohol-ethylene copolymer honeycomb porous membrane. The molecular chain of the selected polyvinyl alcohol-ethylene copolymer comprises a hydrophilic polyvinyl alcohol chain segment and a hydrophobic polyethylene chain segment, and the honeycomb porous membrane with uniform distribution, small pore diameter and uniform pore diameter is prepared through multi-stage solvent volatilization by utilizing the difference of solubility and boiling points of isopropanol and water on the polyvinyl alcohol-ethylene copolymer.

Owner:武汉维晨科技有限公司

Method for preparing negative electrode material mono-dispersed nano-crystalline lithium titanate by using nanometer microreactor

InactiveCN105261748AReduce sizeRegulatory TopographyMaterial nanotechnologyCell electrodesMesoporous silicaSilicon oxide

The invention provides a method for preparing negative electrode material mono-dispersed nano-crystalline lithium titanate (Li4Ti5O12) by using a nanometer microreactor. The method comprises the steps of coating the mono-dispersed TiO2 with an organic acid, adding tetraethyl orthosilicate (TEOS) into a water / ethanol solution containing a surfactant; dispersing the TiO2 coated with the organic acid into the solution, wherein a hydrolysis reaction and a condensation reaction are performed by the TEOS on the oil-water / ethanol interface, fully mixing the hollow TiO2@SiO2 core-shell structure with lithium salt, and calcining at the temperature of 800-1000 DEG C for formation; and dissolving the Li4Ti5O12@Li2SiO3 into a hot NaOH solution to form the mono-dispersed nano-crystalline Li4Ti5O12. In the preparation process, the hollow mesoporous silicon oxide is used as the nanometer microreactor, so that the sizes and the appearances of the particles can be regulated and controlled to prevent from particle aggregation so as to further improve the electromechanical property of the materials.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Metal phase molybdenum disulfide nano-structure and preparation method thereof

ActiveCN108557888ARegulatory TopographyIncrease the active siteMaterial nanotechnologyMolybdenum sulfidesIonChemistry

The invention provides a metal phase molybdenum disulfide nano-structure and a preparation method thereof. The method comprises the steps that 1, molybdate and molecules containing sulfur are dissolved into deionized water according to the ratio larger than the molar ratio of sulfur to molybdenum in molybdenum disulfide, and stirring is performed to form a homogeneous solution; 2, the homogeneoussolution is heated to the temperature of 180-200 DEG C for heat preservation for 6-30 h, and after the reaction is stopped, natural cooling is performed to reach the room temperature; 3, sediments obtained after the reaction are centrifuged and separated, after repeated washing, a supernate is removed, and the metal phase molybdenum disulfide nano-structure is obtained. Hydro-thermal synthesis ofthe metal phase molybdenum disulfide nano-structure of the small size is achieved, and the surface of the synthesized metal phase molybdenum disulfide has multiple edge states, defects and other active sites.

Owner:SHAANXI NORMAL UNIV

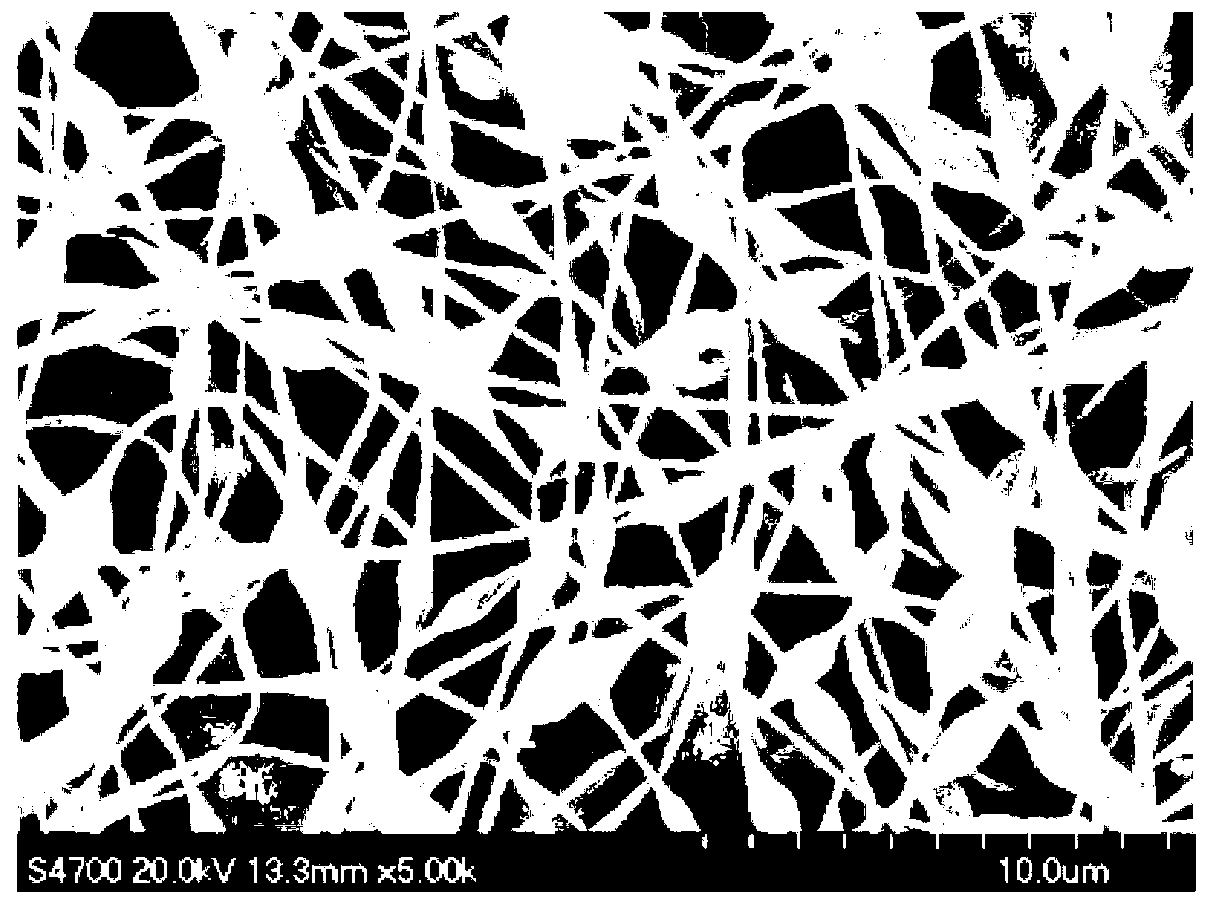

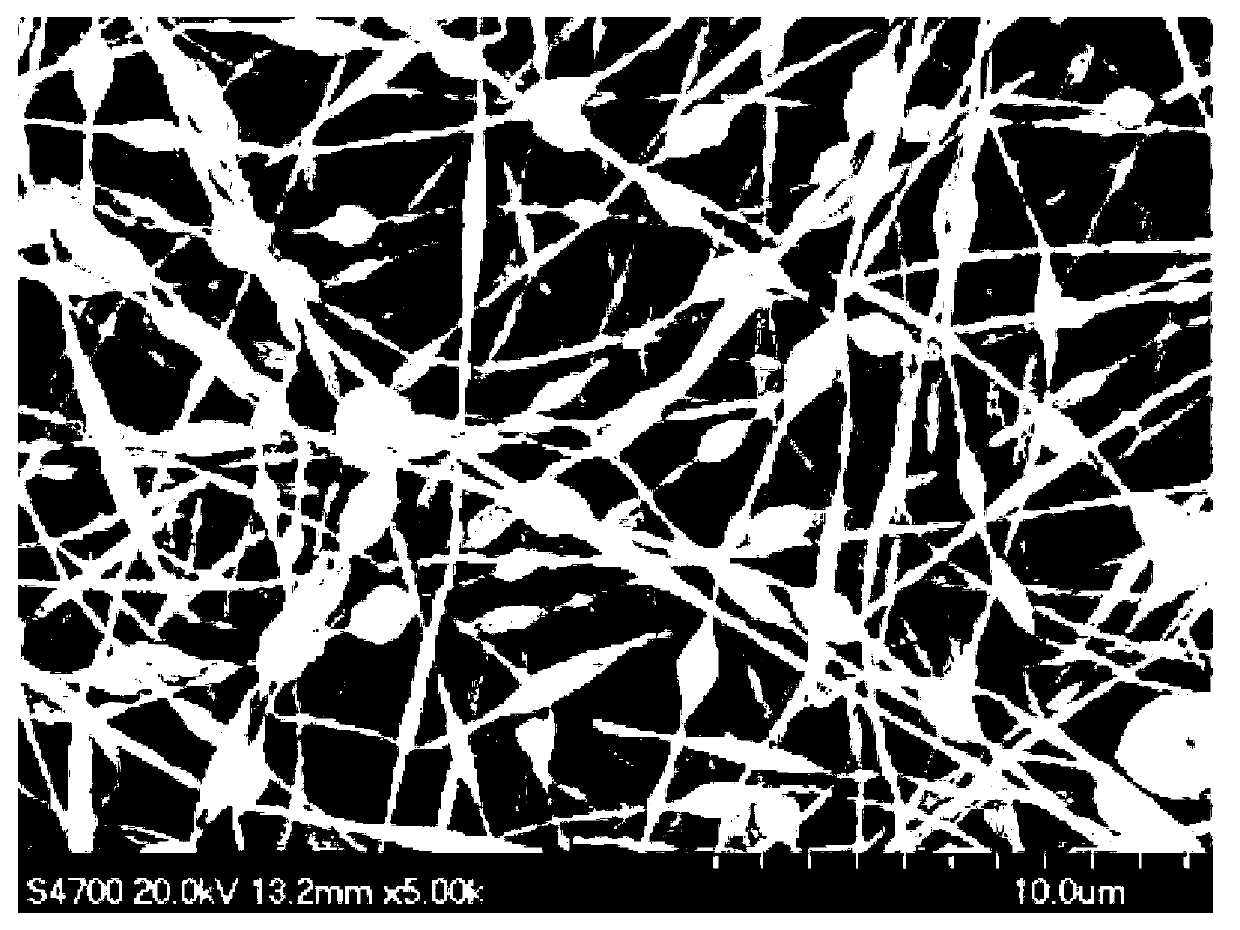

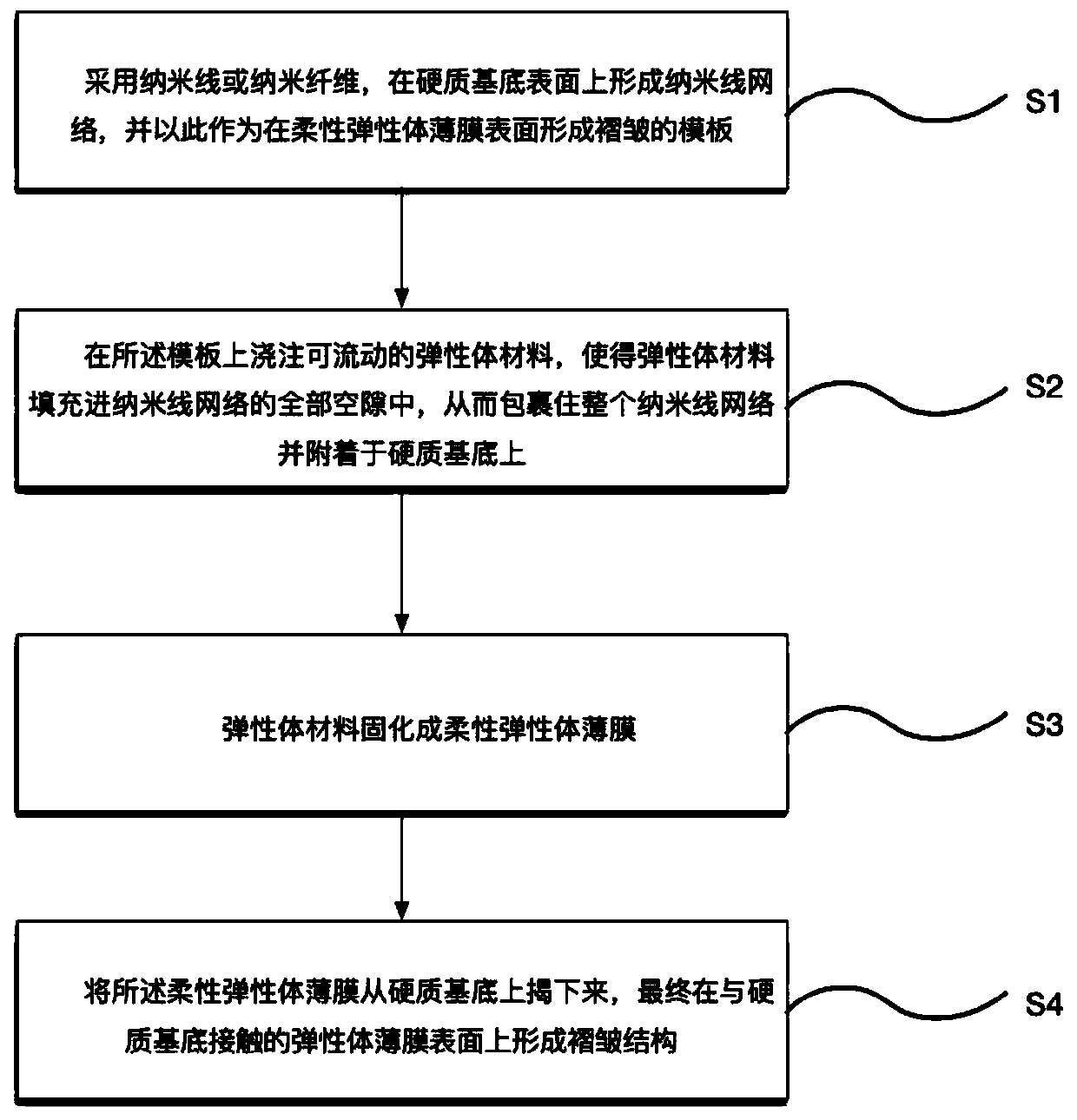

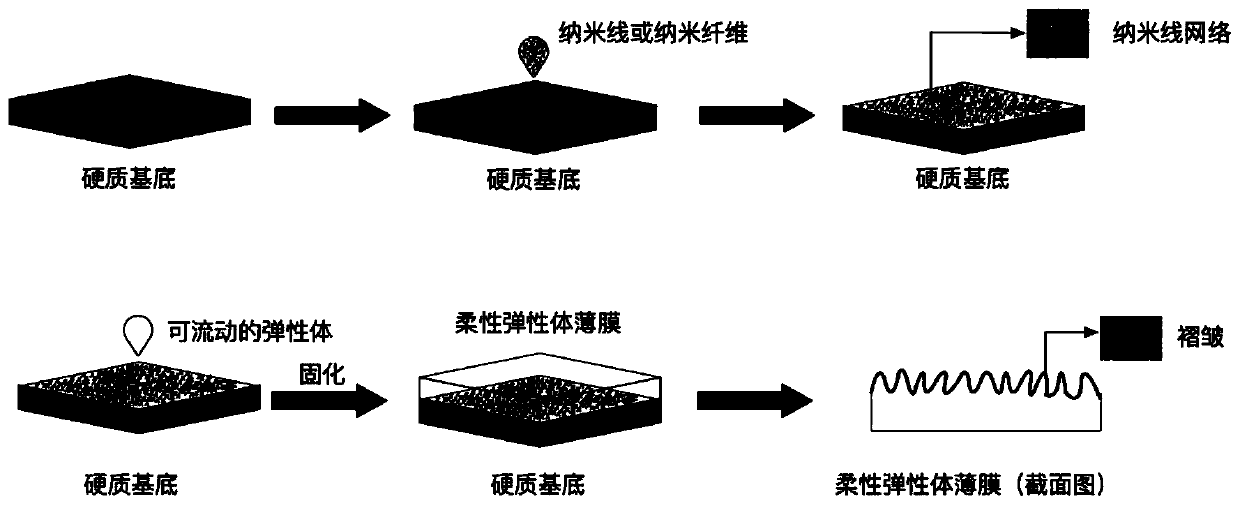

Method for forming pleats on surface of elastomer film

The invention provides a method for forming pleats on the surface of an elastomer film. The method comprises the following steps: (1) forming a nanowire network on the surface of a hard substrate as atemplate; (2) covering the nanowire network containing surface of the template with a flowing elastomer material until the elastomer material is filled into all voids of the nanowire network and attached to the hard substrate; (3) curing the elastomer material; and (4) removing the hard substrate so as to obtain the elastomer film with a nanometer pleat containing surface. According to the invention, the nanowire network constructed by nanowires or nanofibers is transferred into the elastomer film; a nano-scale pleat structure is prepared on the surface of the elastomer film in a large area;and the morphology of nanometer pleats is simple and convenient to be adjusted and controlled. By utilization of the method provided by the invention for preparation of a pleat structure, no micro-nano processing technologies like photolithography, nanoimprinting and electron beam lithography are needed; and the method provided by the invention is simple and rapid in preparation process and has low cost and good repeatability.

Owner:BEIJING UNIV OF POSTS & TELECOMM

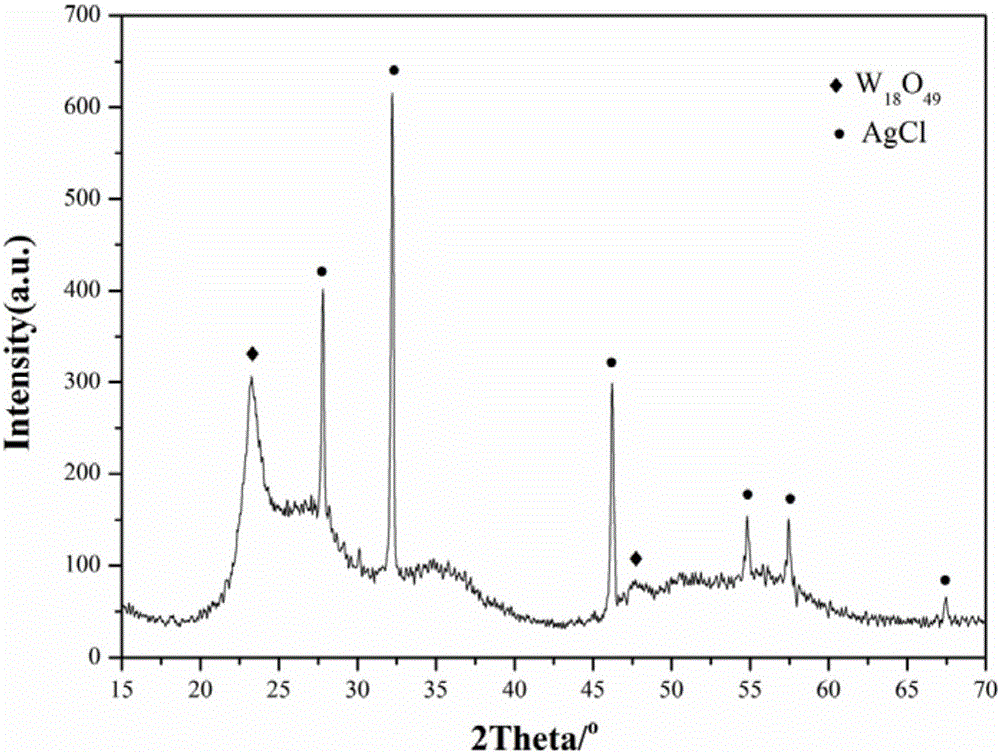

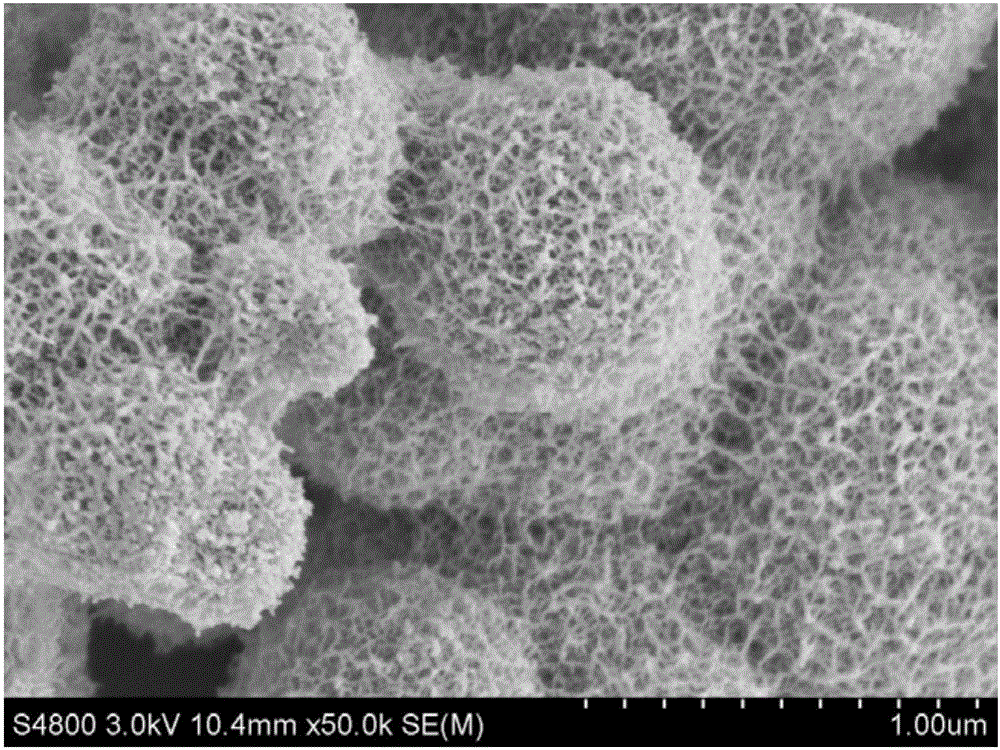

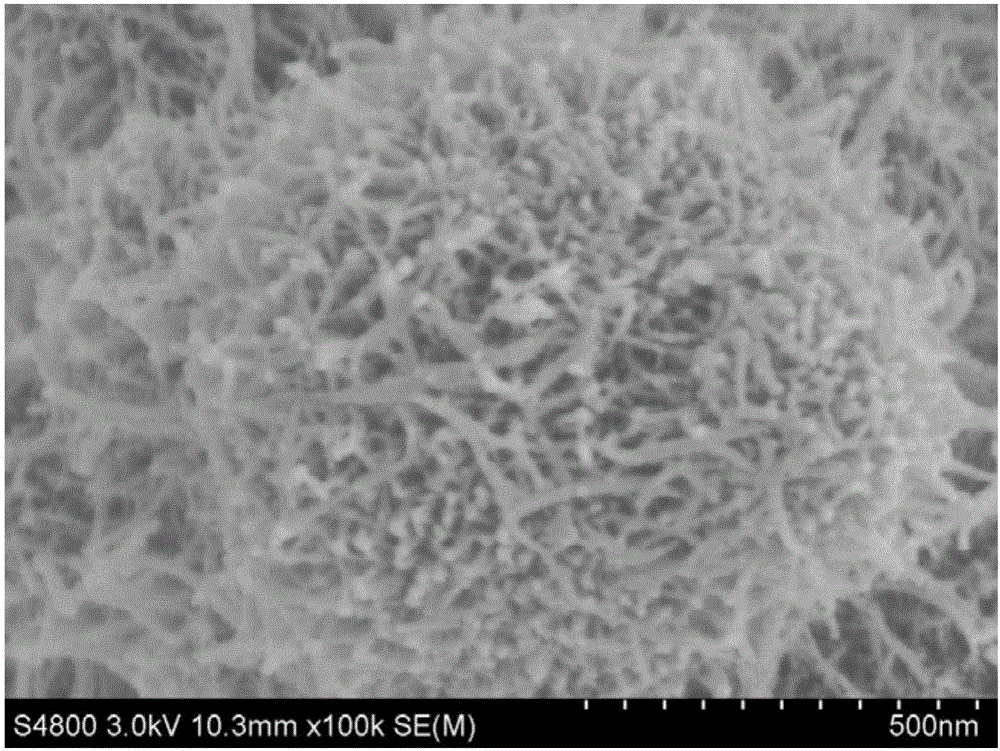

Method for preparing spherical AgCl/W18O49 composite material

ActiveCN105148952ARegulatory TopographySmall sizeMaterial nanotechnologyPhysical/chemical process catalystsNanowireReaction temperature

A method for preparing spherical AgCl / W18O49 composite material includes: pouring solution containing AgNO3 and WCl6 into a high-pressure reaction kettle, feeding nitrogen into the high-pressure reaction kettle to reduce oxygen in the reaction kettle, placing the sealed reaction kettle into a homogeneous reactor, reacting under 150-180 DEG C, cooling to room temperature after the reaction, separating, and drying. The method has the advantages that the self-assembling spherical AgCl / W18O49 prepared by the method is microcrystal-shaped, uniform in chemical component, high in purity and uniform in morphological structure, and the AgCl / W18O49 is of a loose structure formed by the self-assembling of nanowires with the diameter of 0.4-1 micrometers; the product is high in methylene blue absorption performance; the method is low in reaction temperature, mild in reaction condition, low in energy consumption, easy to realize, simple in preparation process, low in cost, easy in process control and short in preparation cycle.

Owner:SHAANXI UNIV OF SCI & TECH

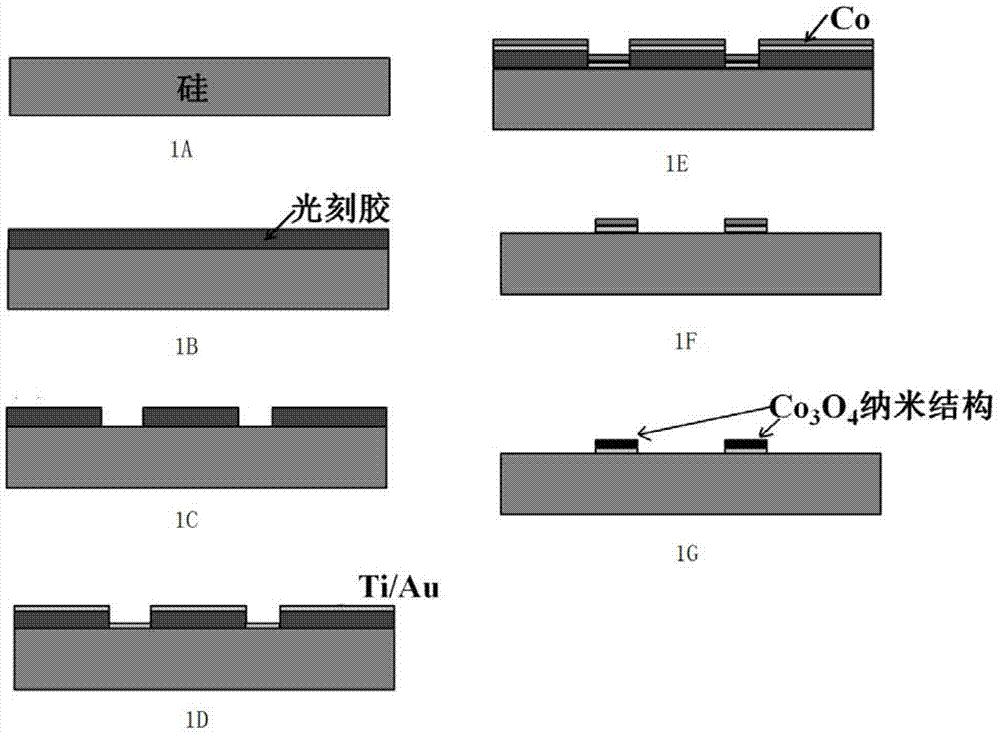

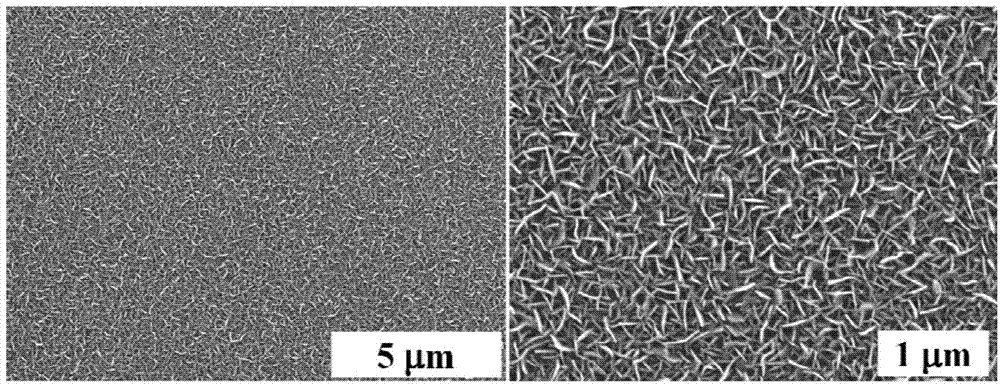

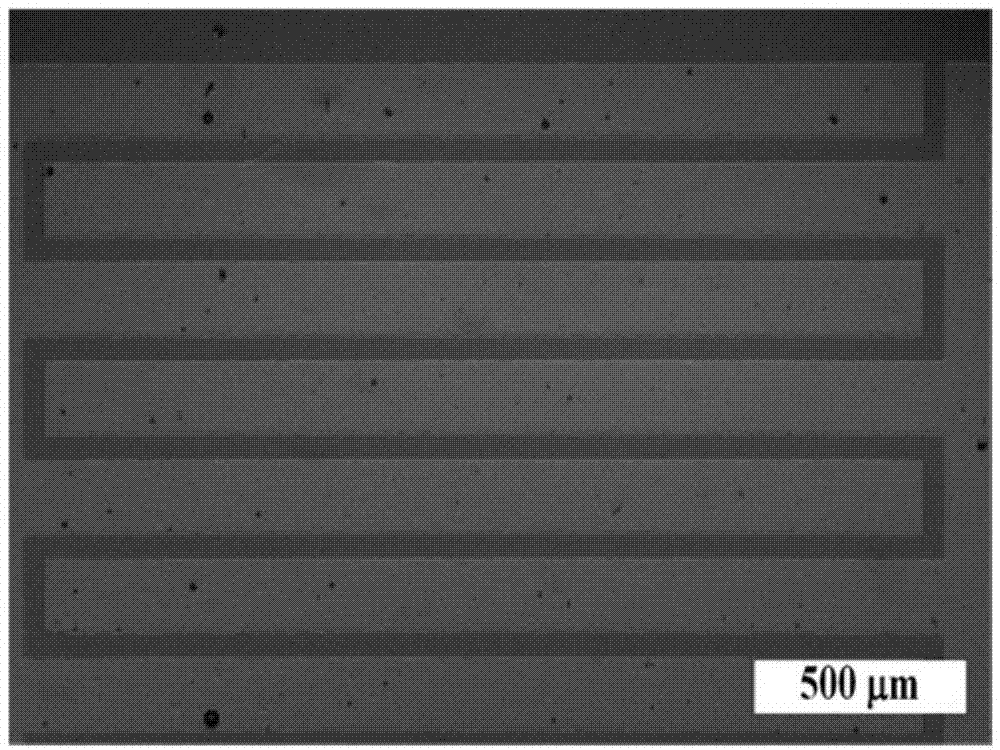

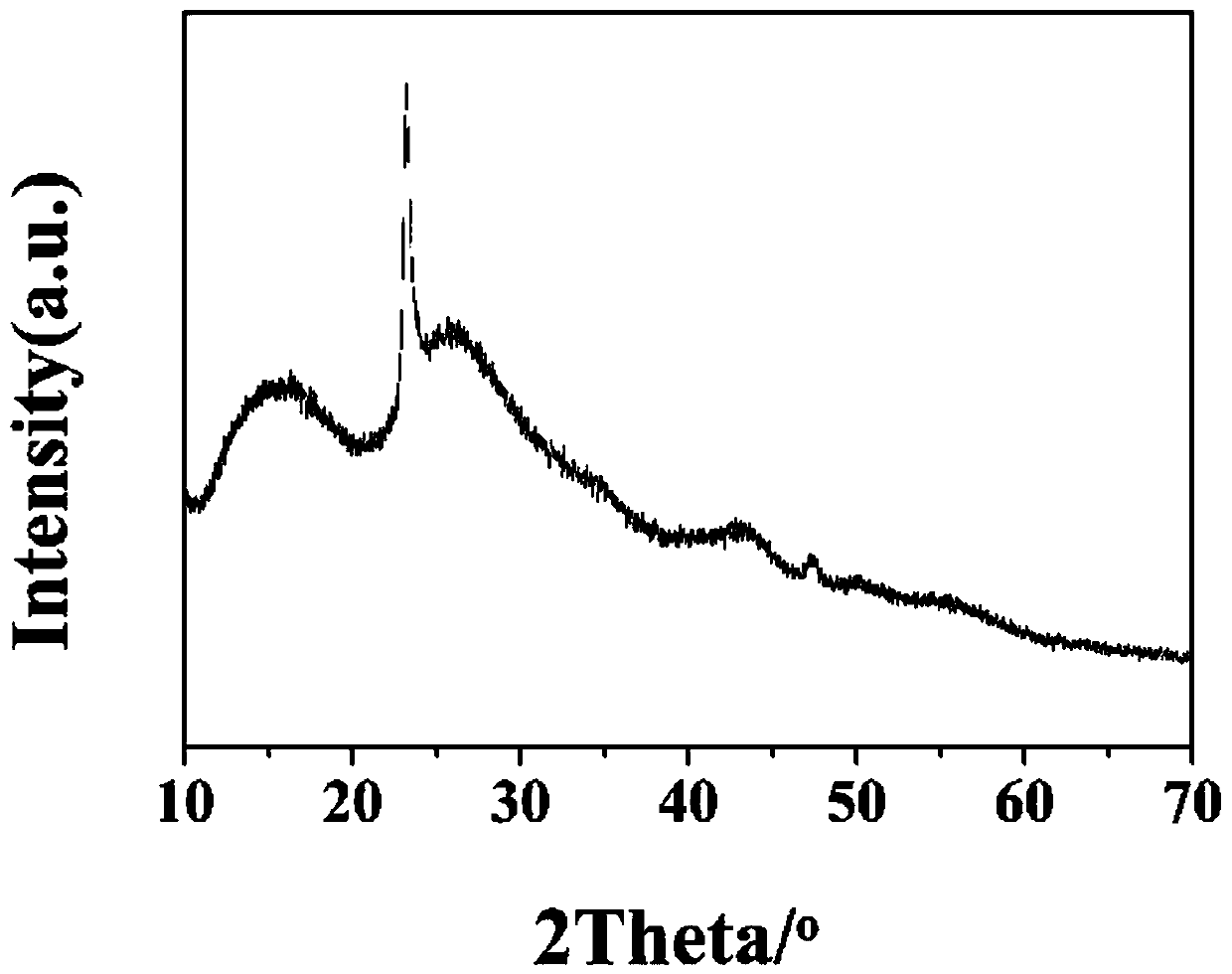

Microfabrication process for micro capacitor based on cobaltosic oxide nano structure

InactiveCN104766724AImprove electrochemical performanceGood adhesionHybrid/EDL manufactureMicro nanoNanowire

The invention provides a microfabrication process for a micro capacitor based on a cobaltosic oxide nano structure. The micro capacitor microfabrication process includes the steps of mask manufacturing, ultraviolet photolithography, physical vapor deposition, stripping flotation and fast annealing treatment, the photosensitive property of photoresist is used, a sample with photoresist microstructural patterns is manufactured through mask manufacturing, ultraviolet photolithography and semiconductor machining processes, and the micro capacitor based on the cobaltosic oxide nano structure is manufactured through physical vapor deposition, stripping flotation and fast annealing treatment. The optimal process based on fast annealing and oxidizing is provided to manufacture the patterned cobaltosic oxide nanowire microstructure, the process fuses and uses related technologies in the semiconductor field and a micro-nano structure synthesizing method, the process is concise, the related technologies are mature, the process can be applied to mass production, and the obtained cobaltosic oxide nanowire microstructure is high in chemical stability and electrochemical performance.

Owner:WUHAN UNIV OF TECH

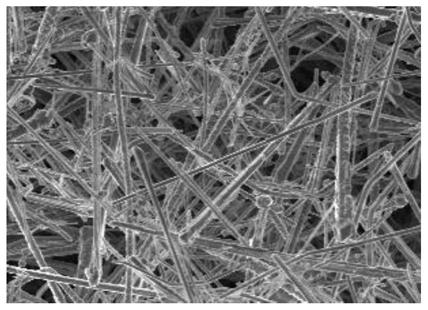

Preparation method for W18O49 self-supporting electrode material grown on carbon cloth surface in situ

ActiveCN109706476AIncrease abundanceLow priceElectrode shape/formsMetal/metal-oxides/metal-hydroxide catalystsEthylenediamineSolvent

The invention provides a preparation method for a W18O49 self-supporting electrode material grown on a carbon cloth surface in situ. The method comprises the following steps: adding an analytically-pure tungsten source into a mixed alcohol to obtain a solution A, and adding analytically-pure ethylenediamine and citric acid into the solution A to obtain a solution B; pouring the solution B into a polytetrafluoroethylene-lined high-pressure reaction kettle, and placing a carbon cloth into the polytetrafluoroethylene reaction kettle; placing the sealed reaction kettle into a homogeneous hydrothermal reactor, and performing a hydrothermal reaction; and performing centrifugal washing on the final reactant by using absolute ethanol, and drying the centrifugal washed material to obtain the W18O49self-supporting electrode material grown on the surface of the carbon cloth in situ. According to the method provided by the invention, the carbon cloth has high abundance, a lower price, a larger specific surface area, higher electron conductivity and an ideal 3D open-hole structure; and the method prepares the W18O49 / carbon cloth nano material with better electrocatalytic performance by using the carbon cloth as a supporting material and using a solvothermal method to grow W18O49 on the supporting body in situ.

Owner:SHAANXI UNIV OF SCI & TECH

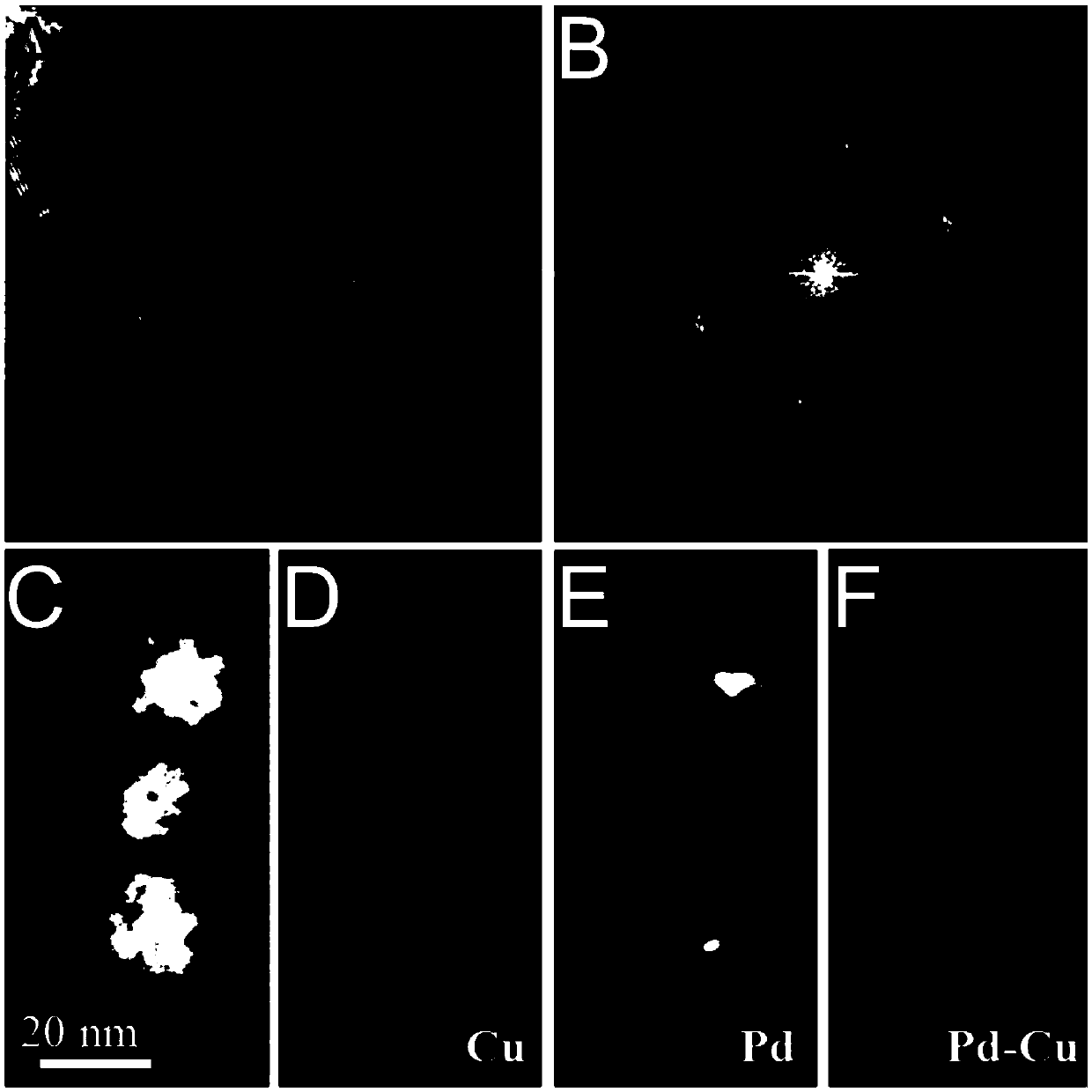

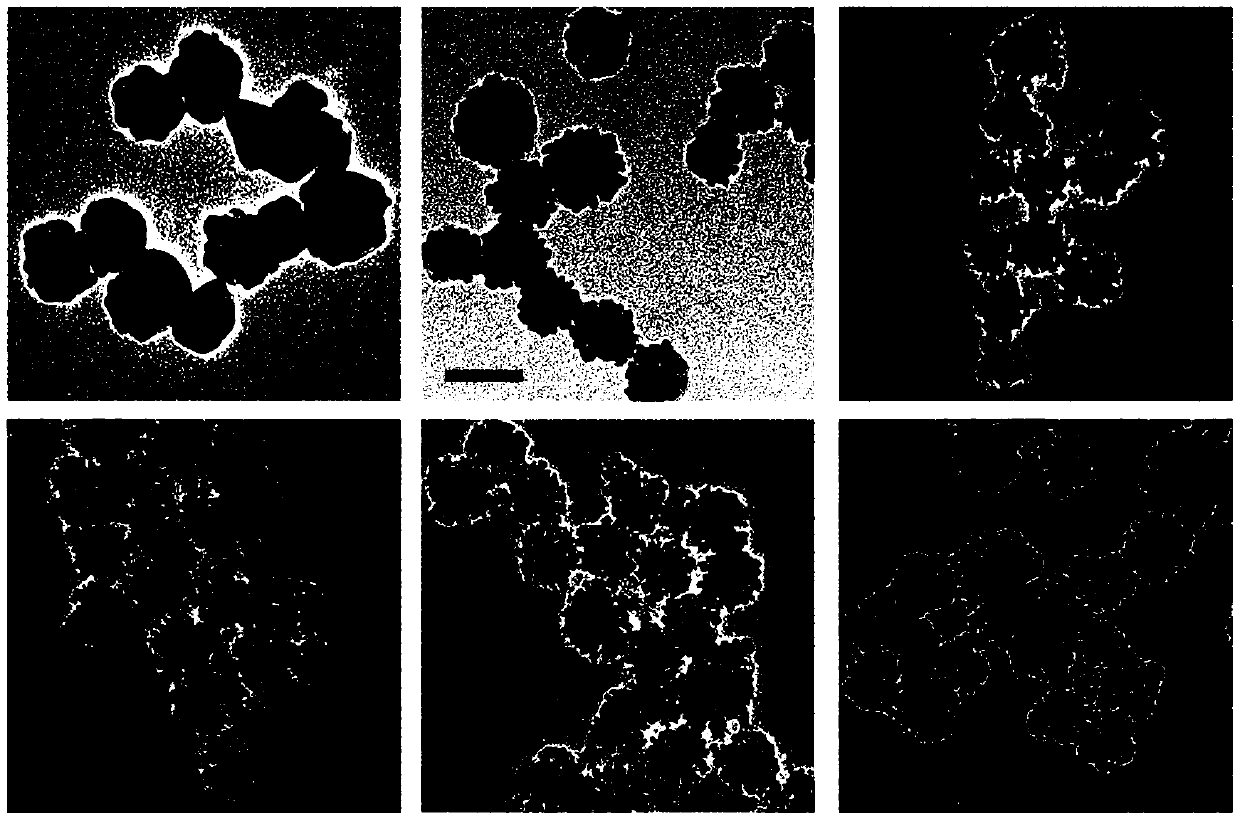

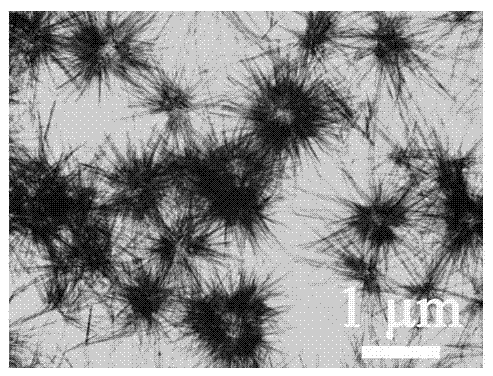

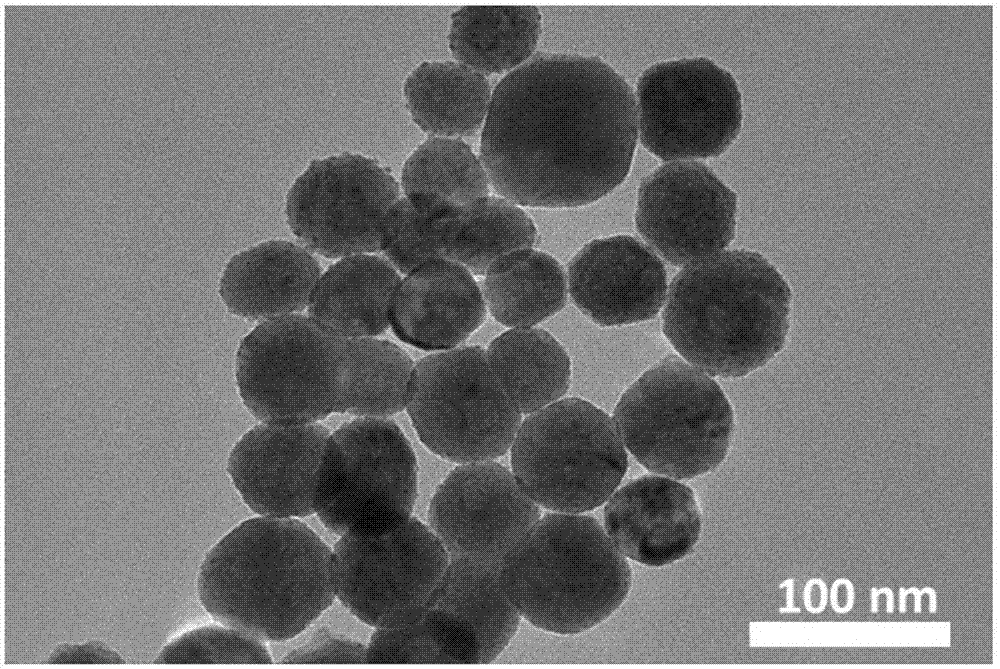

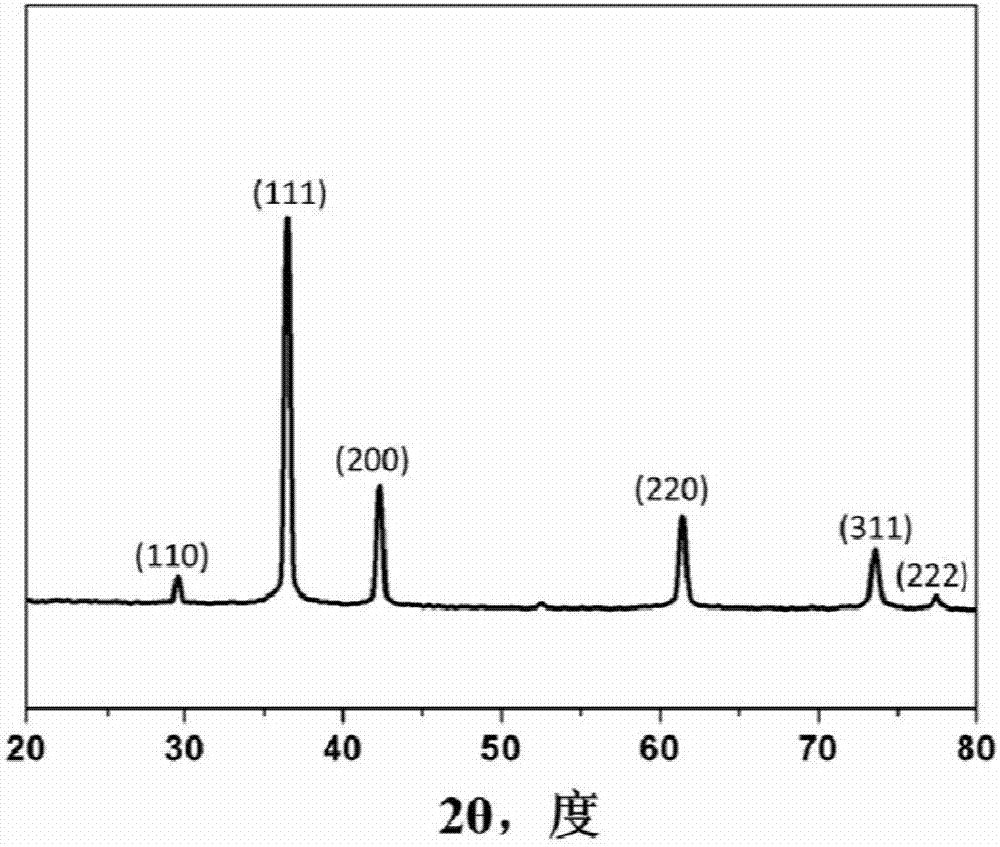

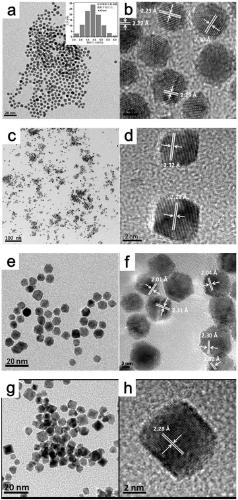

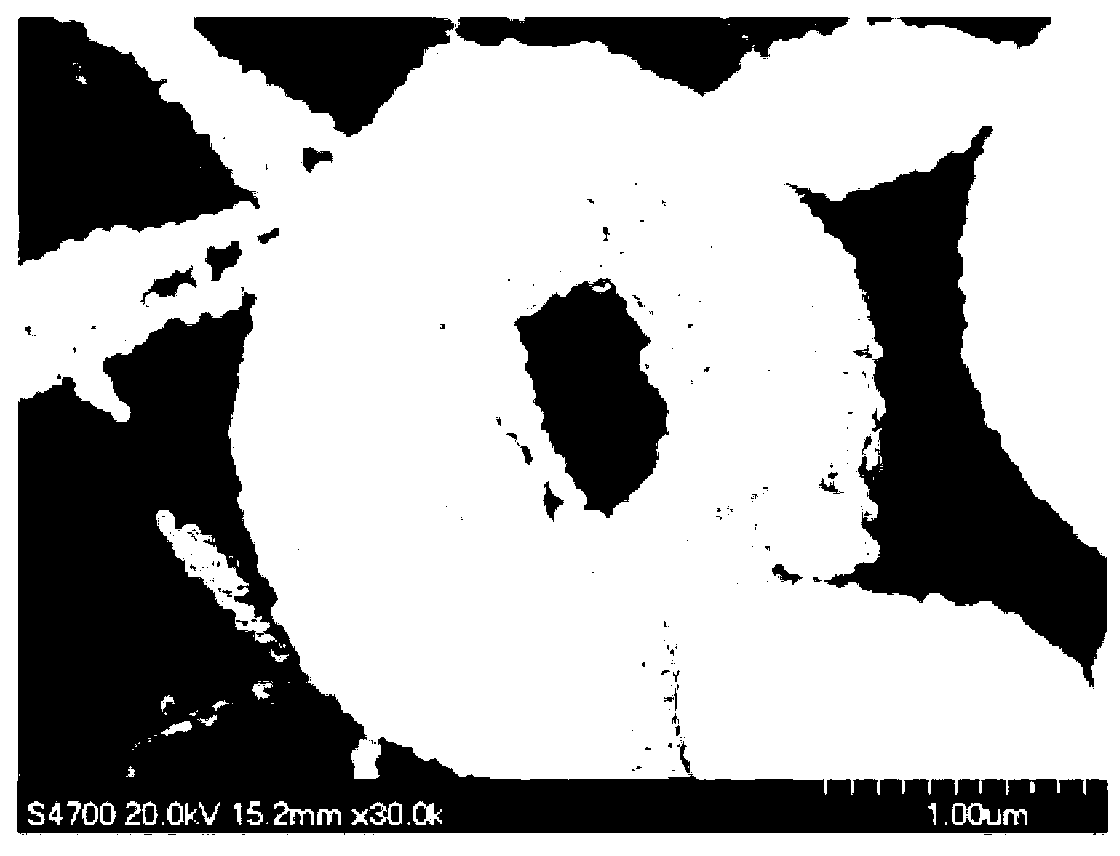

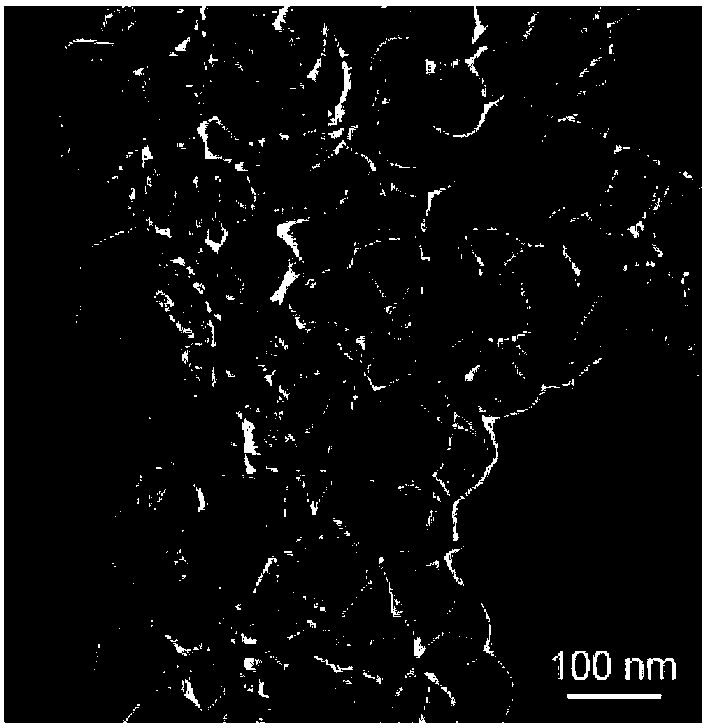

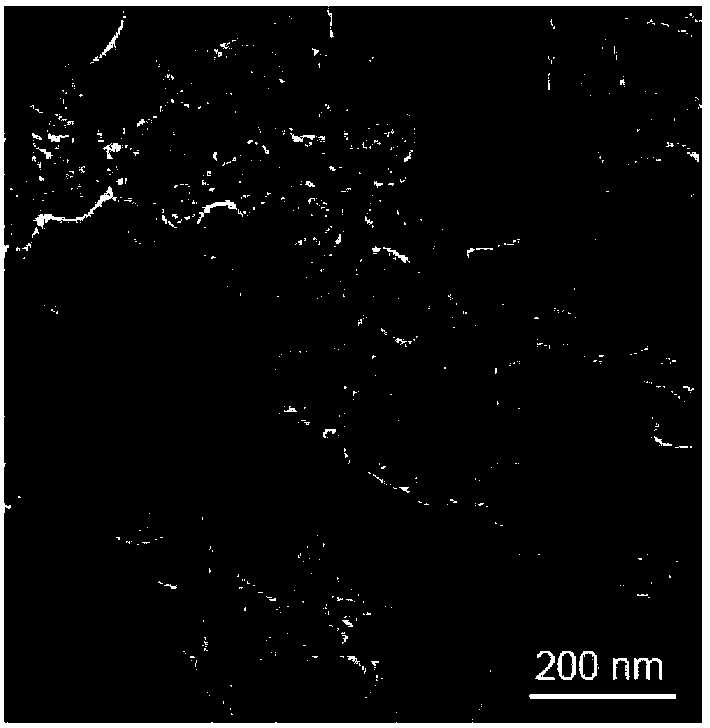

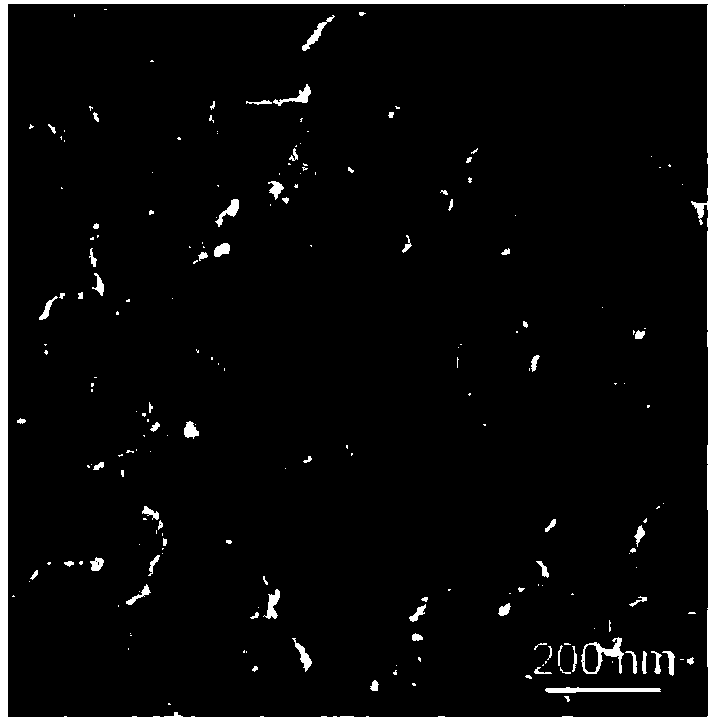

Preparation and usage of nanoribbon-shaped Cucurbit[6]uril carried cubic palladium nanoparticles

ActiveCN103594718AExplain the stabilizing effectEffective regulationCell electrodesFuel cellsDirect-ethanol fuel cell

The invention discloses preparation and usage of cubic palladium nanoparticles carried by nanoribbon-shaped Cucurbit[6]uril. Cucurbit[6]uril is used as a nanoparticle stabilizer and a carrier, and cubic palladium nanoparticles serve as the active substance of a catalyst, can be used for a direct ethanol fuel cell catalyst, and belongs to the field of fuel cell catalyst. The cubic palladium nanoparticles are 5 to 7 nano in particle diameters, and have the advantages that the particle diameters of the particles are uniform, one-dimensional space distribution is achieved, the distribution is uniform, the catalytic activity is high, and the stability is good.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Nanometer aluminum carbide particle reinforced aluminum matrix composite material and manufacturing method thereof

ActiveCN109680188ASolve the problem of hydrolysisFix stability issuesArgon atmosphereMetallic materials

The invention belongs to the field of metal materials, and particularly relates to an aluminum oxide layer cladding type nanometer aluminum carbide particle reinforced aluminum matrix composite material and a manufacturing method of the aluminum oxide layer cladding type nanometer aluminum carbide particle reinforced aluminum matrix composite material. The aluminum oxide layer cladding type nanometer aluminum carbide particle reinforced aluminum matrix composite material is characterized in that according to the mass percentage of various chemical components, the mass percentage of aluminum ranges from 65% to 99.5%, the mass percentage of carbon ranges from 0.5% to 15.0%, and the balance is at least one of the magnesium element, the copper element, the silicon element, the zinc element, the ferrum element, the manganese element, the chromium element and the titanium element. Aluminum oxide cladding type nanometer aluminum carbide particles which are formed in an in-situ synthesis modeare distributed on an aluminum or aluminum alloy matrix. The manufacturing method of the aluminum oxide layer cladding type nanometer aluminum carbide particle reinforced aluminum matrix composite material comprises the steps that raw materials are prepared in proportion, and graphite powder and activated carbon are subjected to vacuum drying, and then are mixed and reserved; and commercial purityaluminum and at least one of magnesium, copper, silicon, zinc, ferrum, manganese, chromium and titanium are molten in a smelting furnace, after the temperature is stabilized, the mixed powder of thegraphite powder and the activated carbon are uniformly blown to the molten body in the argon atmosphere by a rotary blowing device, then the temperature is rapidly reduced until solidification is achieved, the materials are transferred to a resistance furnace to conduct a liquid-solid reaction, and therefore the nanometer aluminum carbide particle reinforced aluminum matrix composite material is obtained. The manufacturing method is low in cost, is green and environmentally friendly, and has the good industrial production prospect.

Owner:SHANDONG UNIV +1

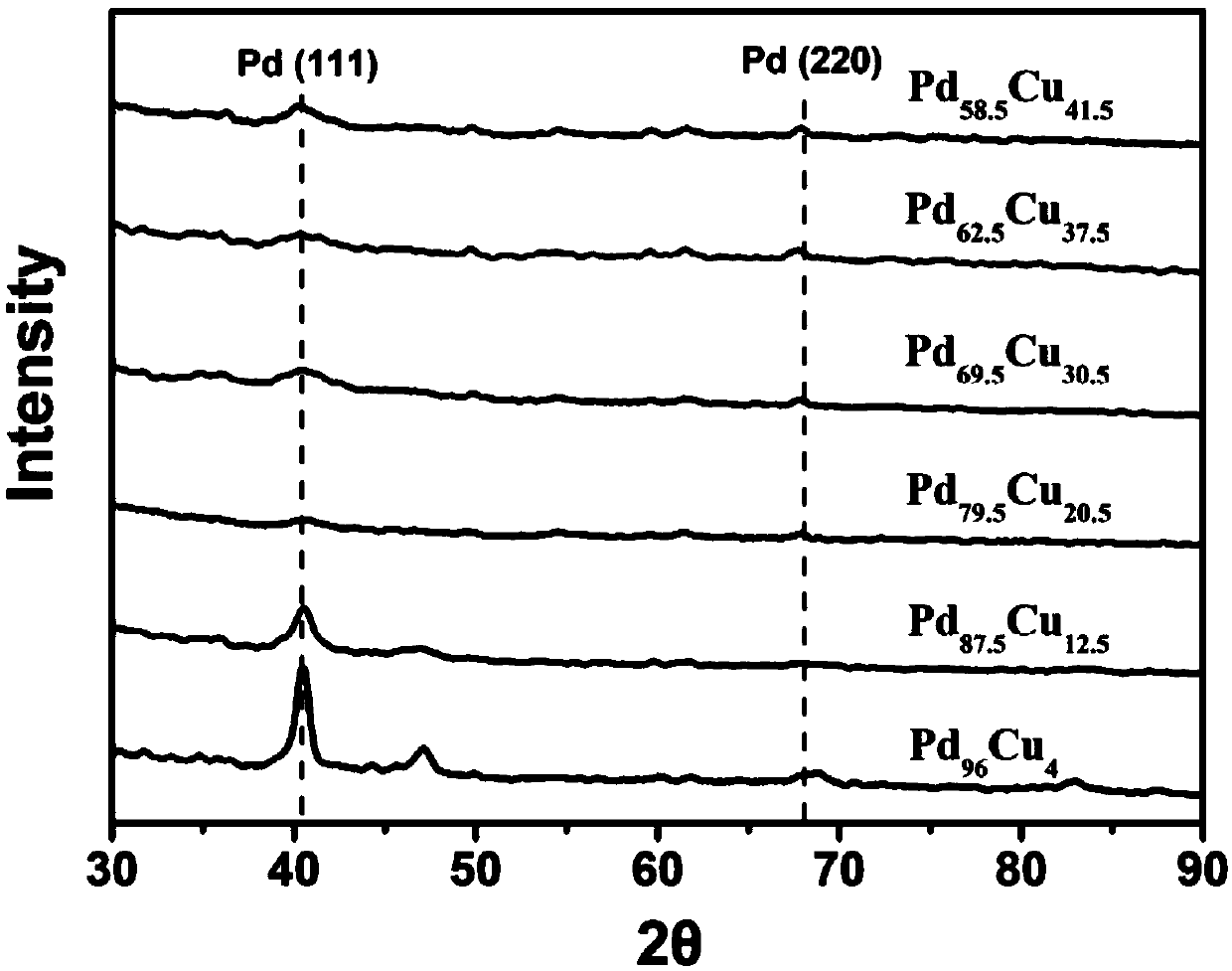

Method of one-step synthesis of cluster type palladium-copper nano particles and application of cluster type palladium-copper nano particles

InactiveCN108672717AGood dispersionImprove uniformityTransportation and packagingMetal-working apparatusOrganic solventRoom temperature

The invention relates to a method of one-step synthesis of cluster type palladium-copper nano particles and application of the cluster type palladium-copper nano particles. The method comprises the following steps that polyvinylpyrrolidone is dissolved in an organic solvent, and Pd(acac)2 and Cu(acac)2 are added under the condition of continuous stir so that a colorless solution is turned into a yellow green solution; then the solution conducts a reaction at the temperature ranging from 100 DEG C to 150 DEG C until the solution is blackened, and cooling is conducted to enable the temperature to be equal to the room temperature; and the mass ratio of polyvinylpyrrolidone to Pd(acac)2 to Cu(acac)2 is 12-17:5-6:4-6. In this way, the oxidation activity and the stability of formic acid can be improved, and compared with the performance of commercial Pd / C, the performance of formic acid is remarkably improved. In addition, the shapes of the synthetic nano particles can be regulated and controlled by changing the concentration of copper ions.

Owner:SUZHOU UNIV

Preparation method of W18o49/NF self-supporting electrocatalytic material

ActiveCN109731580AAvoid conductive propertiesInhibitory activityCatalyst activation/preparationElectrode shape/formsAlcoholAdhesive

A preparation method of a W18o49 / NF self-supporting electrocatalytic material comprises: adding a tungsten source into a mixed alcohol to obtain a solution A; adding analytically pure ethanediamine and cycloheptylamine into the solution A to obtain a solution B; pouring the solution B into a polytetrafluoroethylene-lined high-pressure reactor, subjecting nickel foam to hydrothermal reaction in thepolytetrafluoroethylene-lined high-pressure reactor with the solution B, cooling to room temperature after the reaction is over, centrifugally washing the final reaction product with absolute ethyl alcohol, and drying the centrifugally washed material to obtain the W18o49 / NF self-supporting electrocatalytic material. Since W18O49 having rich oxygen defects is directly grown on NF (nickel foam) through a one-step process, the influence of adhesive upon electrical conductivity and activity of a catalyst during preparation of a working electrode is avoided, with electrocatalytic performance effectively improved.

Owner:SHAANXI UNIV OF SCI & TECH

Honeycomb three-dimensional porous silicon/carbon composite material and preparation method thereof

ActiveCN105977478AStable structurePrecise control of hole distributionCell electrodesCarbon compositesIn situ polymerization

The invention discloses a honeycomb three-dimensional porous silicon / carbon composite material and a preparation method thereof. The porous silicon / carbon composite material is of a hybrid structure that nano silicon spheres are distributed in a honeycomb continuous three-dimensional porous carbon matrix, wherein the mass content of carbon is 99%-1% and controllable. The honeycomb three-dimensional porous silicon / carbon composite material is prepared from 80-800nm spherical silicon dioxide nanoparticles as a silicon source and thermosetting difunctional acrylate unsaturated resin as a carbon source by employing a method of reduction after compounding; and an acrylate unsaturated resin monomer is vinyl thermosetting resin. The cumbersome problem that traditional thermosetting resin needs to utilize a solvent is solved through in-situ polymerization of vinyl thermosetting resin; post-treatment is not needed; the operation is simple and convenient; and the honeycomb three-dimensional porous silicon / carbon composite material is green and environment-friendly. Meanwhile, the thermosetting resin is difficult to melt in the high-temperature calcination process, so that in-situ carbon formation can be achieved; the distribution condition of silicon dioxide can be effectively regulated and controlled; and the shape and form of the final product are regulated and controlled.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

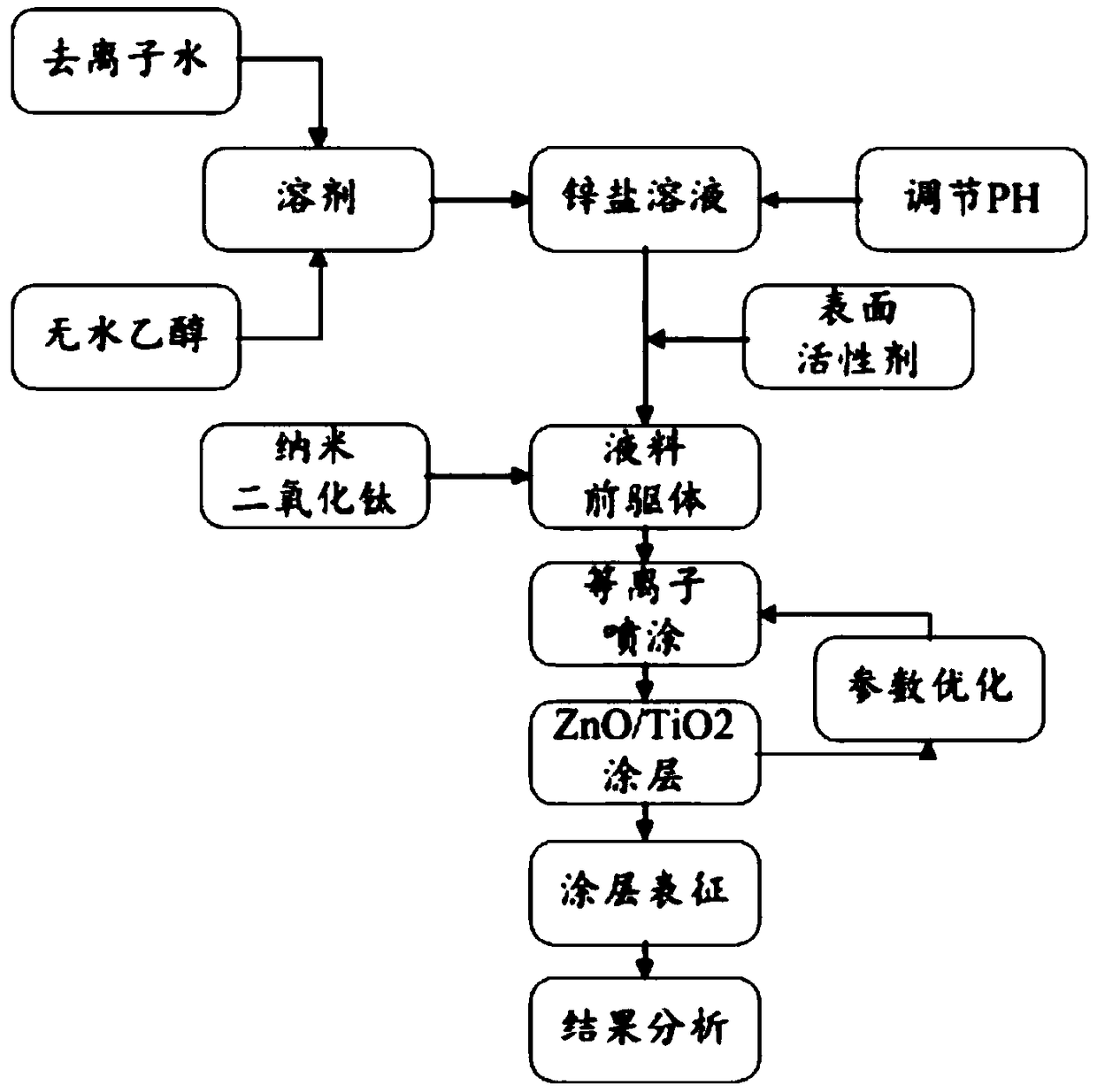

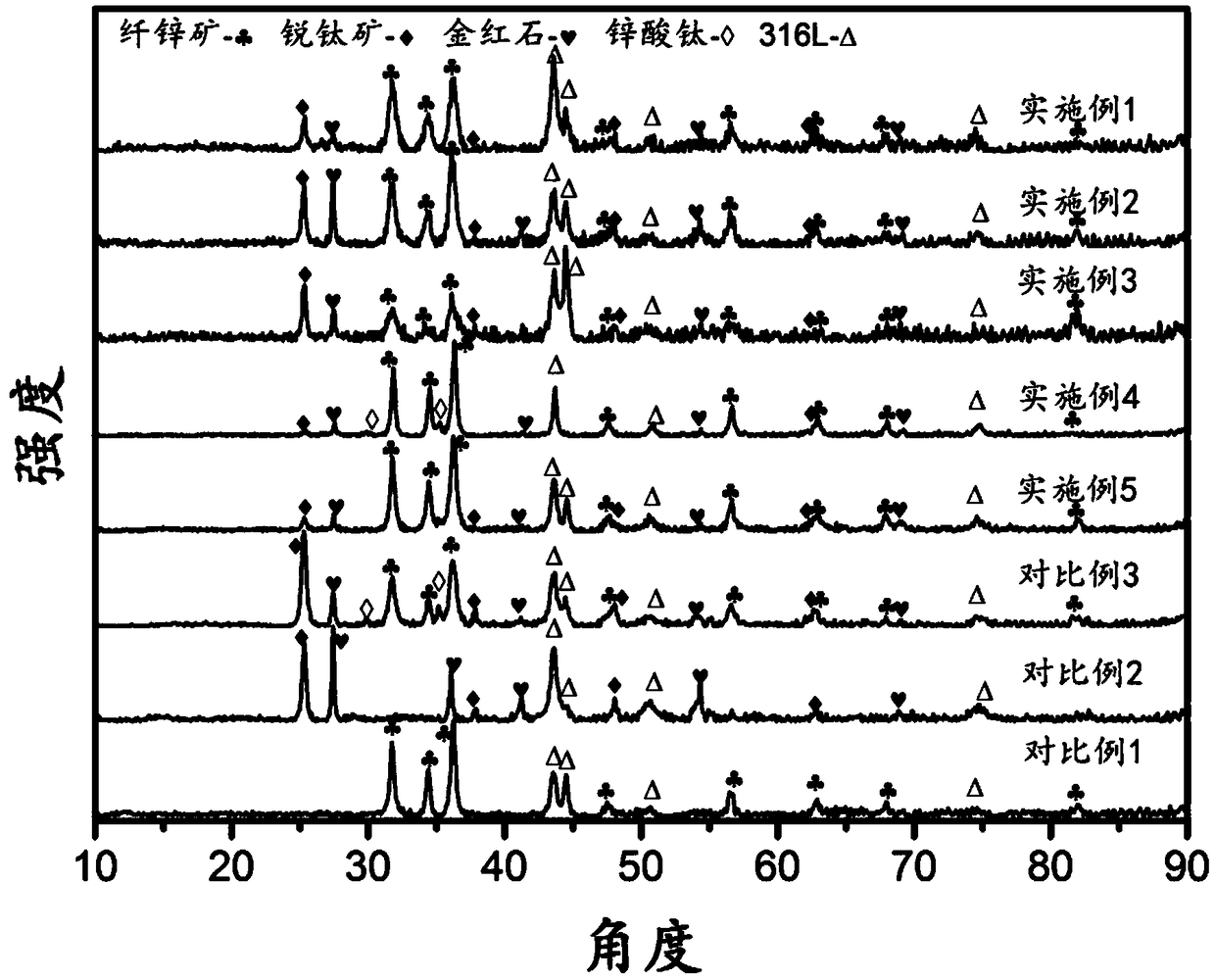

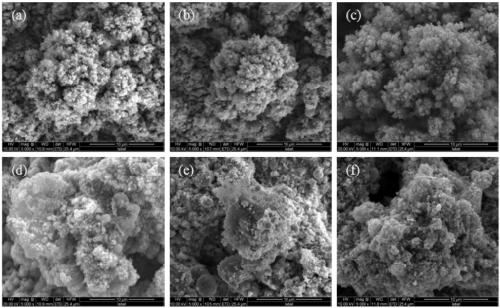

Photocatalytic coating having zinc oxide/titanium dioxide heterostructure and preparation method and application of photocatalytic coating with zinc oxide/titanium dioxide heterostructure

ActiveCN108970601AImprove bindingBroaden the spectral absorption rangeWater/sewage treatment by irradiationWater treatment compoundsThermal sprayingOrganic dye

The invention discloses a photocatalytic coating having a ZnO / TiO2 heterostructure and a preparation method of the photocatalytic coating having the ZnO / TiO2 heterostructure. The photocatalytic coating comprises a ZnO stack cluster formed by stacking nano ZnO crystal grains having a diameter of 10 to 50 nm, and nano TiO2 particles embedded in the ZnO stack cluster, wherein the ZnO stack cluster has a cluster structure, has a loose porous structure, and has a diameter of 3 to 30 mum. The photocatalytic coating is prepared by a thermal spraying process in one step, and the morphology and microscopic size of a product are controllable. The photocatalytic coating disclosed by the invention has high binding force with a matrix and has a larger spectral absorption range, and obvious improvementon efficiency of photocatalytic degradation of pollutants such as organic dyes.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

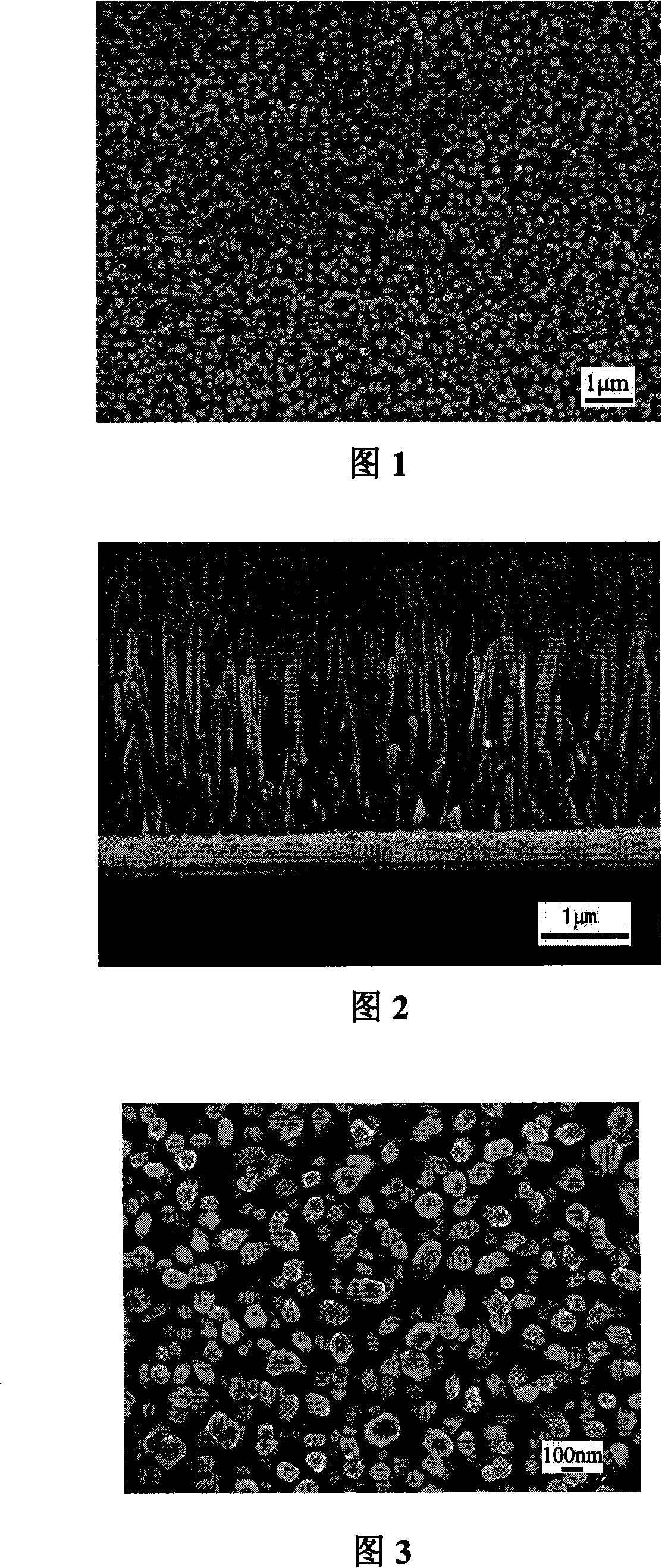

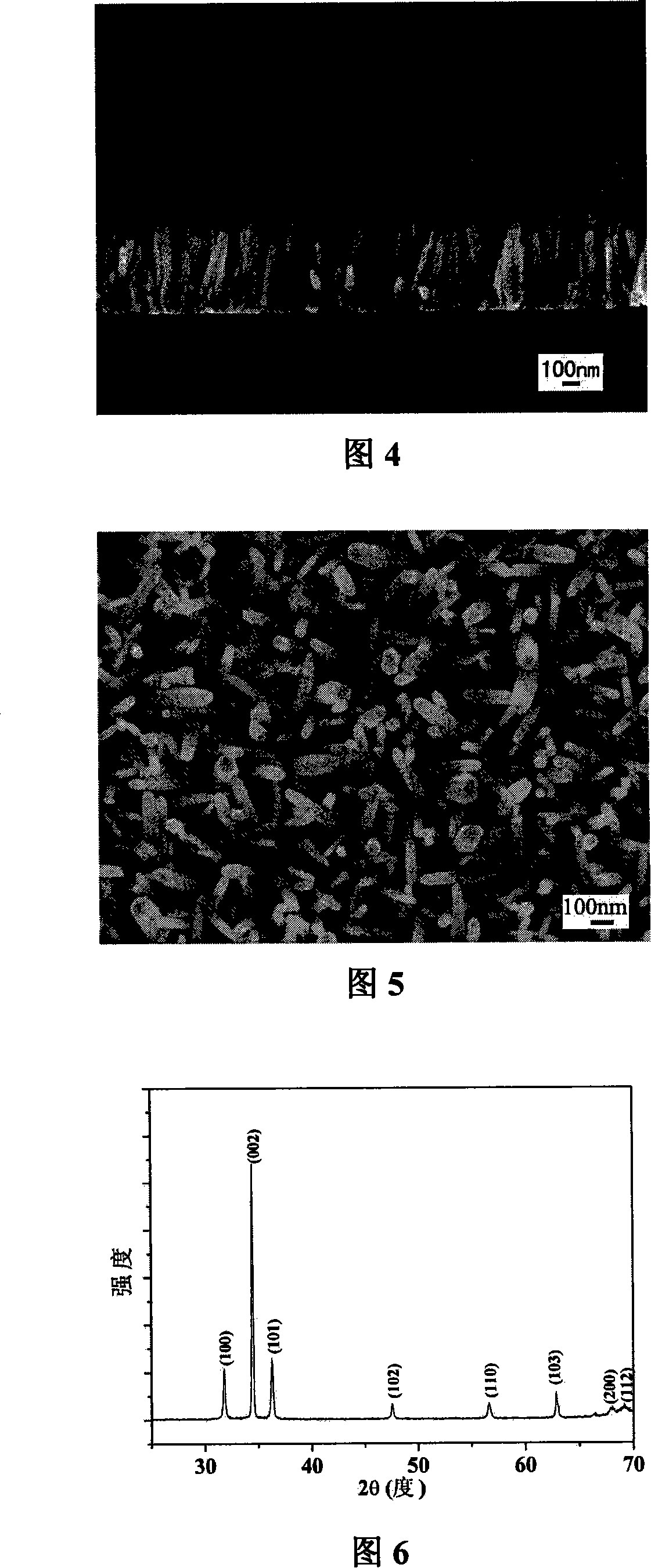

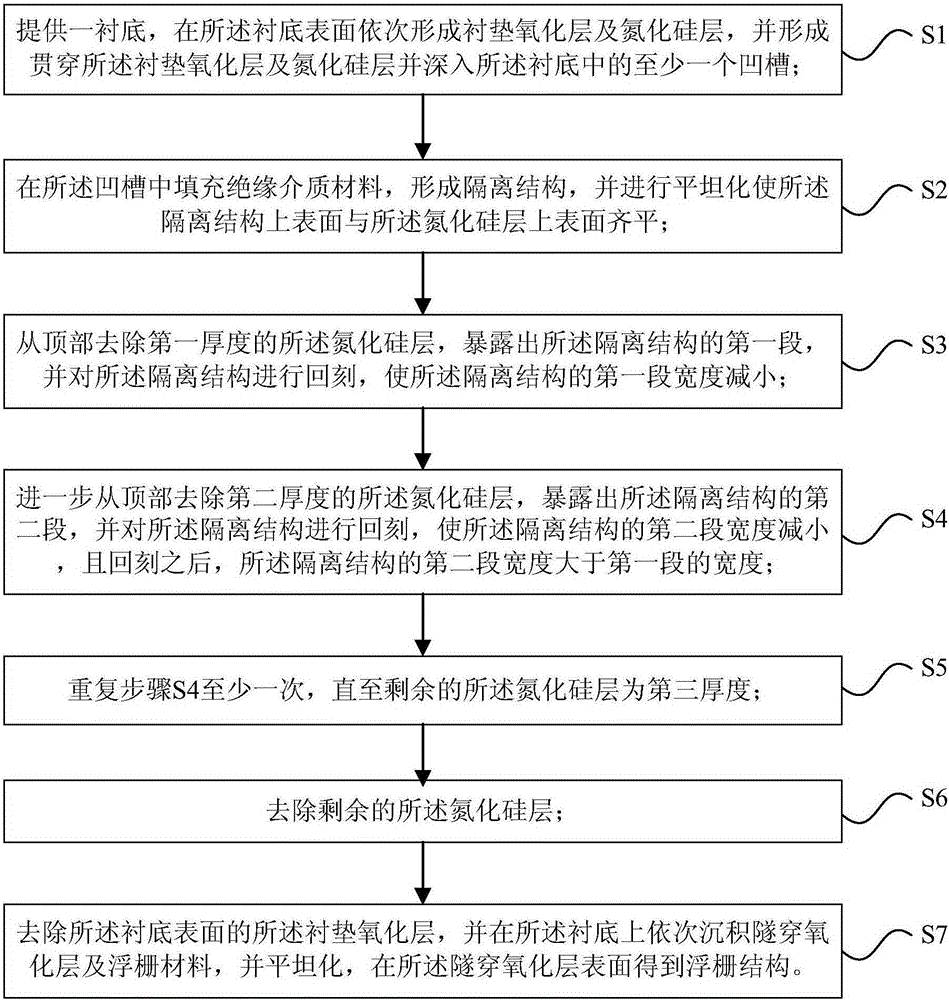

![Preparation and usage of nanoribbon-shaped Cucurbit[6]uril carried cubic palladium nanoparticles Preparation and usage of nanoribbon-shaped Cucurbit[6]uril carried cubic palladium nanoparticles](https://images-eureka.patsnap.com/patent_img/6ff4da62-4db6-4c59-915c-20897b30ac9a/HDA0000421656310000011.PNG)

![Preparation and usage of nanoribbon-shaped Cucurbit[6]uril carried cubic palladium nanoparticles Preparation and usage of nanoribbon-shaped Cucurbit[6]uril carried cubic palladium nanoparticles](https://images-eureka.patsnap.com/patent_img/6ff4da62-4db6-4c59-915c-20897b30ac9a/HDA0000421656310000012.PNG)

![Preparation and usage of nanoribbon-shaped Cucurbit[6]uril carried cubic palladium nanoparticles Preparation and usage of nanoribbon-shaped Cucurbit[6]uril carried cubic palladium nanoparticles](https://images-eureka.patsnap.com/patent_img/6ff4da62-4db6-4c59-915c-20897b30ac9a/HDA0000421656310000021.PNG)