Au-Ir nano alloy, preparation method of Au-Ir nanometer alloy and application of Au-Ir nanometer alloy used as catalyst

A nano-alloy and catalyst technology, applied in nanotechnology, nanotechnology, metal processing equipment, etc., can solve the problems of large difference in reduction potential and difficulty in obtaining controllable morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

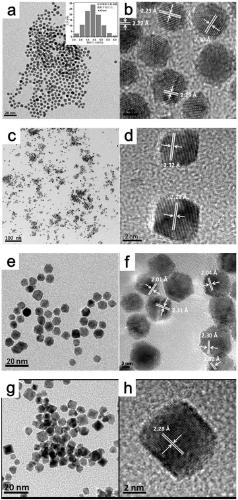

[0117] Embodiment 1: the preparation method of Au-Ir bimetallic nanoparticles

[0118] (1) Add 0.1 mmol of iridium chloride trihydrate and 0.1 mmol of tetrachloroauric acid trihydrate into a 100 ml two-necked flask, then add 35 ml of oleylamine and sonicate for 60 min to obtain mixture A.

[0119] (2) Put mixture A into an oil bath preheated to 200°C, N 2 Under the atmosphere, react for 1h to obtain the product B.

[0120] (3) Naturally cool to room temperature, centrifuge the obtained product B (12000 rpm), and wash 6 times with a mixed solution of ethanol and cyclohexane (the volume ratio of ethanol and cyclohexane is 1:1).

[0121] (4) drying at 70° C. overnight to obtain the Au-Ir bimetallic nanoparticles of the present invention.

Embodiment 2

[0122] Embodiment 2: the preparation method of Au-Ir double metal nano-octahedron

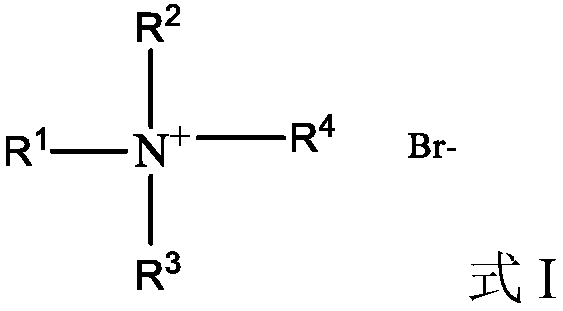

[0123] (1) 0.1mmol of iridium chloride trihydrate, 0.1mmol of tetrachloroauric acid trihydrate, 0.6mmol of tetraethylammonium bromide, 100mg of PVP (molecular weight is 40000) are joined in the 100ml two-necked flask, then add 35ml Oleylamine was sonicated for 60 min and stirred for 4 h to obtain mixture A.

[0124] (2) Put mixture A into an oil bath preheated to 220°C, N 2 Under the atmosphere, react for 1h to obtain the product B.

[0125] (3) Naturally cool to room temperature, centrifuge (12000 rpm) to obtain product B, water, ethanol, hexanaphthene and acetone mixed solution (the volume ratio of water, ethanol, hexanaphthene and acetone is 1:4:1 :2) Wash 14 times.

[0126] (4) drying at 70° C. overnight to obtain the Au-Ir bimetallic nano-octahedron of the present invention.

Embodiment 3

[0127] Embodiment 3: the preparation method of Au-Ir bimetallic nano-truncated octahedron

[0128] (1) 0.1mmol of hydrated hexachloroiridium (IV) acid, 0.1mmol of tetrachloroauric acid trihydrate, 0.6mmol of tetraethylammonium bromide, and 33.3mg of PVP (molecular weight is 55000) are added in a 100ml two-necked flask , then add 30ml oleylamine and sonicate for 60min, stir for 4h to obtain mixture A.

[0129] (2) Put mixture A into an oil bath preheated to 220°C, N 2 Under the atmosphere, react for 1h to obtain the product B.

[0130] (3) naturally cool to room temperature, obtain product B centrifugation (12000 rpm), water, ethanol, cyclohexane and acetone mixed solution (the volume ratio of ethanol, ether, normal hexane and acetone is 5:5:3: 5) Wash 12 times.

[0131] (4) drying at 70° C. overnight to obtain the Au-Ir bimetallic nano-truncated octahedra of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com