Honeycomb three-dimensional porous silicon/carbon composite material and preparation method thereof

A silicon-carbon composite material and three-dimensional porous technology are applied in the field of preparation of nanoporous composite materials to achieve the effects of precise regulation of pore distribution and size, stable structure and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

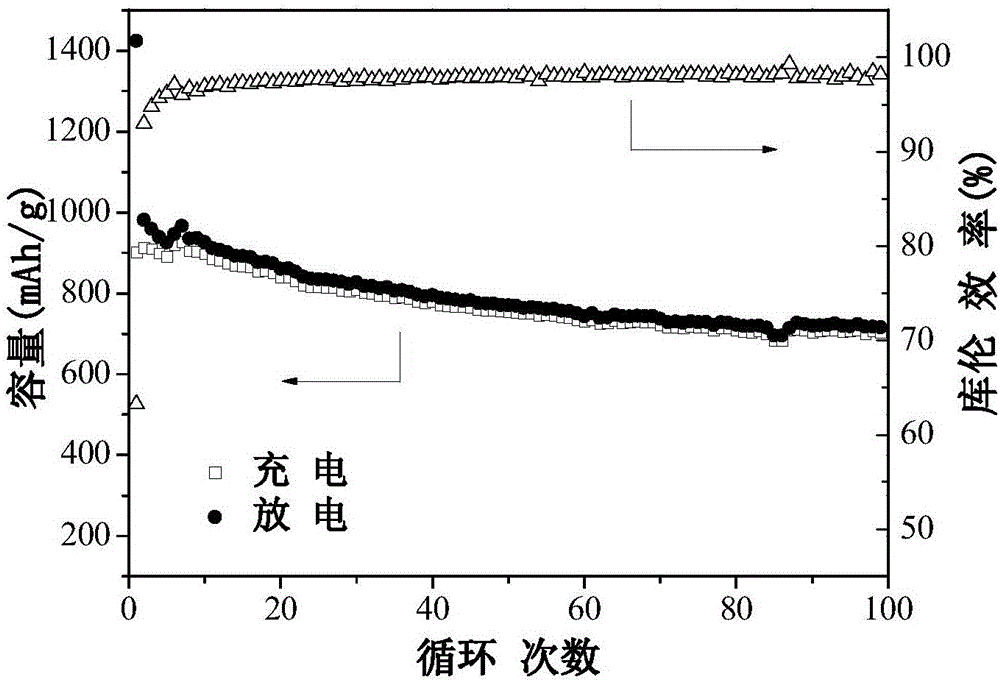

Examples

preparation example Construction

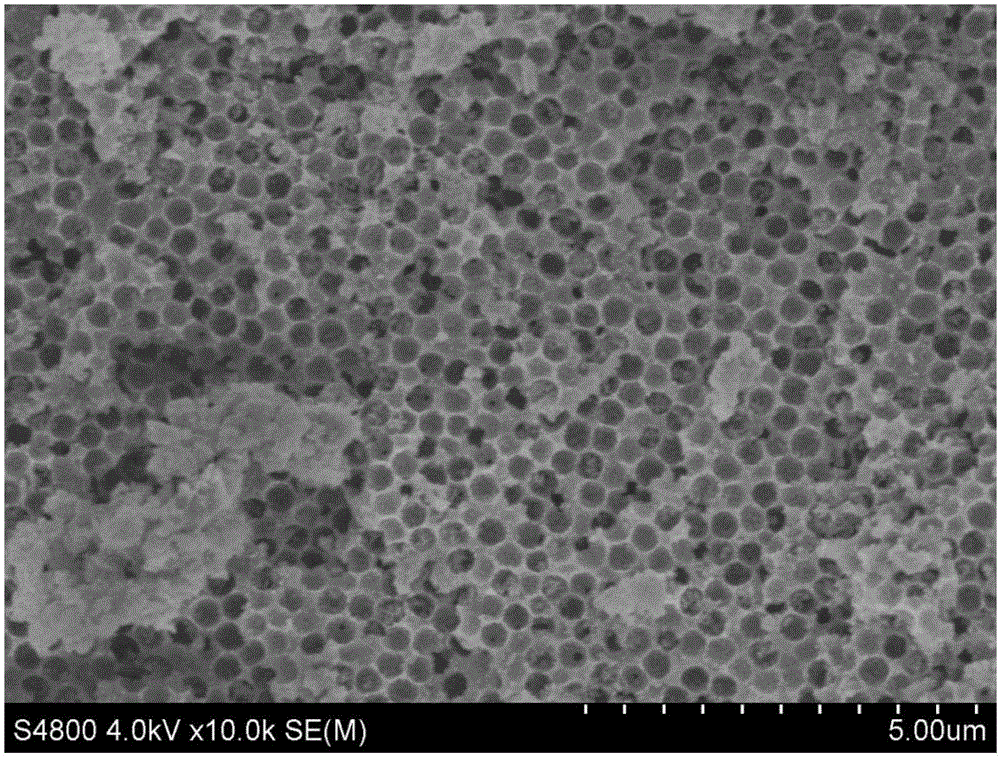

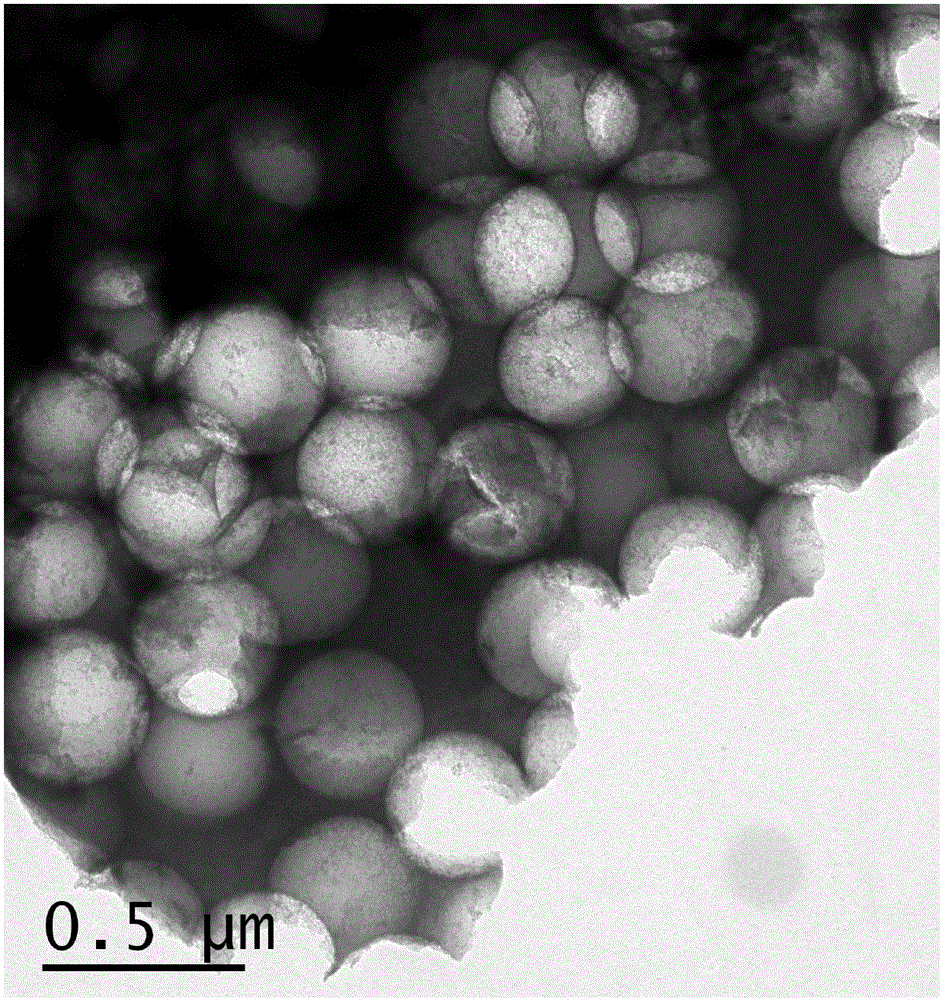

[0032] The preparation method of silicon-carbon composite material of the present invention, the concrete steps of this method are:

[0033] Step (1), preparation of silica: use Stober method in alcohol phase medium, catalyze tetrabutyl orthosilicate (TEOS) with ammonia water, form monodisperse spherical silica particles through hydrolysis-condensation, and adjust the pH value Control the particle size at 80-800 nanometers;

[0034] Step (2), stirring and mixing the acrylate unsaturated resin monomer and the photoinitiator at normal temperature to 80° C. to obtain a mixed solution; the mass content of the photoinitiator in the mixed solution is 0.2 to 2.0%;

[0035] The acrylate unsaturated resin monomer is a vinyl thermosetting resin, specifically bisphenol A-diglycidyl methacrylate, triethylene glycol dimethacrylate, diethylene glycol dimethacrylate One or more of esters, ethylene glycol dimethacrylate, tetraethylene glycol dimethacrylate, 1,6-hexanediol dimethacrylate, eth...

Embodiment 1

[0048] Step (1), preparation of silica: use Stober method in alcohol phase medium, catalyze tetrabutyl orthosilicate (TEOS) with ammonia water, form monodisperse spherical silica particles through hydrolysis-condensation, and adjust the pH value The control particle size is 400 nanometers;

[0049] Step (2), 4g of bisphenol A-diglycidyl methacrylate, 6g of triethylene glycol dimethacrylate, and 0.05g of Yanjiagu 819 were stirred and mixed evenly at room temperature to obtain 10.05g of a mixed solution ;

[0050] Step (3), adding 1 g of silicon dioxide obtained in step (1) to the above mixed solution, stirring for 2 hours, to obtain a mixed solution containing silicon dioxide;

[0051] Step (4), injecting the above-mentioned mixed solution containing silicon dioxide into the mold, curing with ultraviolet light, and illuminating for 300 seconds at a power of 50W, to obtain a silicon dioxide / polyacrylate composite solid material;

[0052] Step (5), pulverizing the silica / polyac...

Embodiment 2

[0059] Step (1), preparation of silica: use Stober method in alcohol phase medium, catalyze tetrabutyl orthosilicate (TEOS) with ammonia water, form monodisperse spherical silica particles through hydrolysis-condensation, and adjust the pH value Control the particle size at 80 nanometers;

[0060] Step (2): Stir and mix 9.98g bisphenol A-diglycidyl methacrylate and 0.02g Yanjiagu 1173 at 80°C to obtain a mixed solution;

[0061] Step (3), adding 0.001 g of silicon dioxide obtained in step (1) to 9.999 g of the above mixed solution, stirring for 1 hour, to obtain a mixed solution containing silicon dioxide;

[0062] Step (4), injecting the above-mentioned mixed solution containing silicon dioxide into the mold, curing with blue light, and illuminating for 300 seconds at a power of 5W, to obtain a silicon dioxide / polyacrylate composite solid material;

[0063] Step (5), pulverizing the silica / polyacrylate composite solid material for 5 minutes to obtain solid particles.

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com