Patents

Literature

274 results about "Tetraethylene glycol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

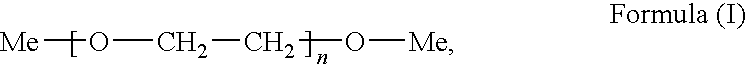

Used for the synthesis of tetraethylene glycol metha acrylate monomer. Glow discharge plasma deposition of TEG renders surfaces resistant to protein adsorption and cellular attachment. General description An oligomer of polyethylene glycol, tetra (ethylene glycol) (TEG) is a transparent, colorless, odorless, low volatility, hygroscopic liquid ...

Non-flammable Quasi-Solid Electrolyte and Lithium Secondary Batteries Containing Same

PendingUS20180277913A1Reduce electrical conductivityLow ionic conductivityFuel and secondary cellsCell electrodesSolid state electrolyteCelsius Degree

A rechargeable lithium cell comprising a cathode, an anode, a non-flammable quasi-solid electrolyte containing a lithium salt dissolved in a mixture of a liquid solvent and a liquid additive having a salt concentration from 1.5 M to 5.0 M so that said electrolyte exhibits a vapor pressure less than 0.01 kPa, a vapor pressure less than 60% of the vapor pressure of the liquid solvent alone, a flash point at least 20 degrees Celsius higher than the flash point of the liquid solvent alone, a flash point higher than 150° C., or no flash point, wherein the liquid additive is selected from Hydrofluoro ether (HFE), Trifluoro propylene carbonate (FPC), Methyl nonafluorobutyl ether (MFE), Fluoroethylene carbonate (FEC), Tris(trimethylsilyl)phosphite (TTSPi), Triallyl phosphate (TAP), Ethylene sulfate (DTD), 1,3-propane sultone (PS), Propene sultone (PES), Diethyl carbonate (DEC), Alkylsiloxane (Si—O), Alkylsilane (Si—C), liquid oligomeric silaxane (—Si—O—Si—), Tetraethylene glycol dimethylether (TEGDME), or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

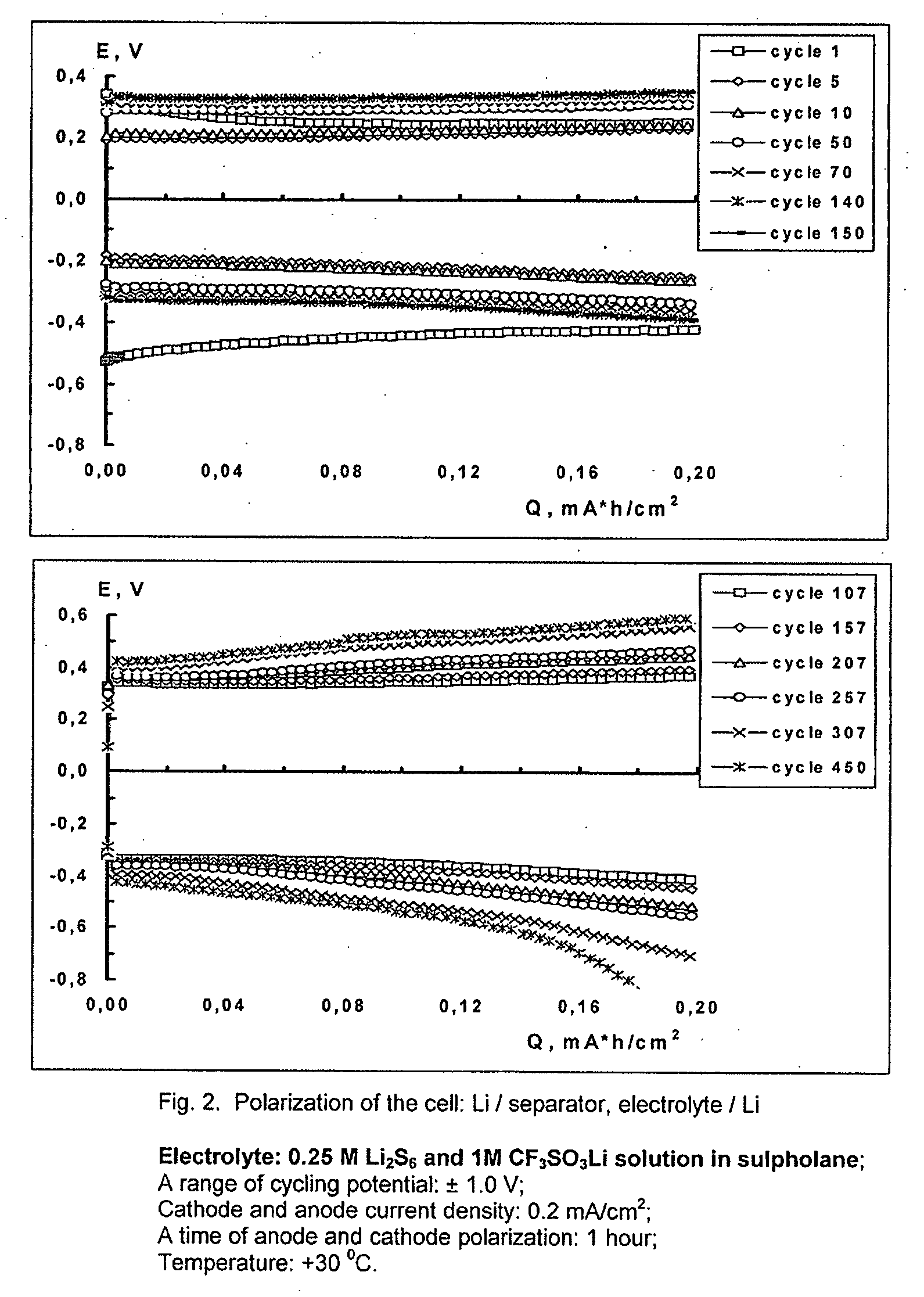

Cell or battery with a metal lithium electrode and electrolytes therefor

InactiveUS20080038645A1Improve cycle lifeOrganic electrolyte cellsLi-accumulatorsSulfolaneMetallic lithium

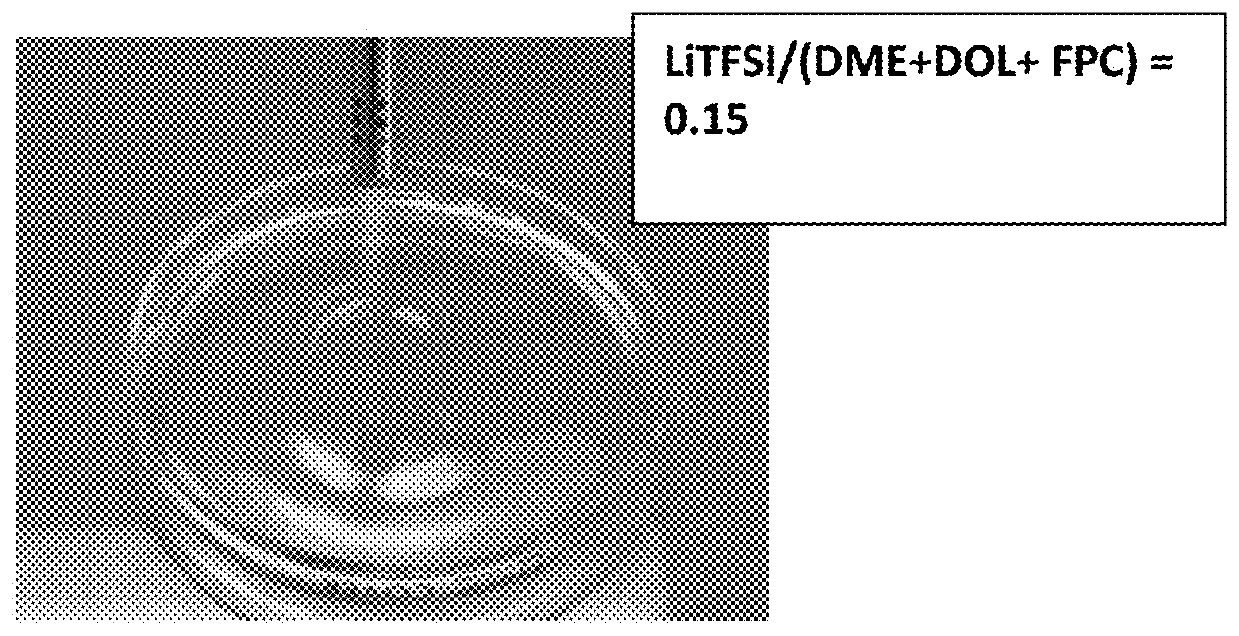

An electrolyte for rechargeable batteries with a negative electrode of lithium or lithium containing alloys comprising: one or several non-aqueous organic solvents, one or several lithium salts and one or several additives increasing the cycle life of the lithium electrode. The electrolyte solution may comprise one or several solvents selected from the group comprising: tetrahydrofurane, 2-methyltetrahydrofurane, dimethylcarbonate, diethylcarbonate, ethylmethylcarbonate, methylpropylcarbonate, methylpropylpropyonate, ethylpropylpropyonate, methylacetate, ethylacetate, propylacetate, dimetoxyethane, 1,3-dioxalane, diglyme (2-methoxyethil ether), tetraglyme, ethylenecarbonate, propylencarbonate, γ-butyrolactone, and sulfolane. The electrolyte solution may further comprise at least one salt or several salts selected from the group consisting of lithium hexafluorophosphate (LiPF6), lithium hexafluoroarsenate (LiAsF6), lithium perchlorate (LiClO4), lithium sulfonylimid trifluoromethane (LiN(CF3SO2)2)) and lithium trifluorosulfonate (CF3SO3Li) or other lithium salts or salts of another alkali metal or a mixture thereof. Also disclosed is an electrochemical cell or battery with an anode of metallic lithium or a lithium-containing alloy, and such an electrolyte.

Owner:OXIS ENERGY

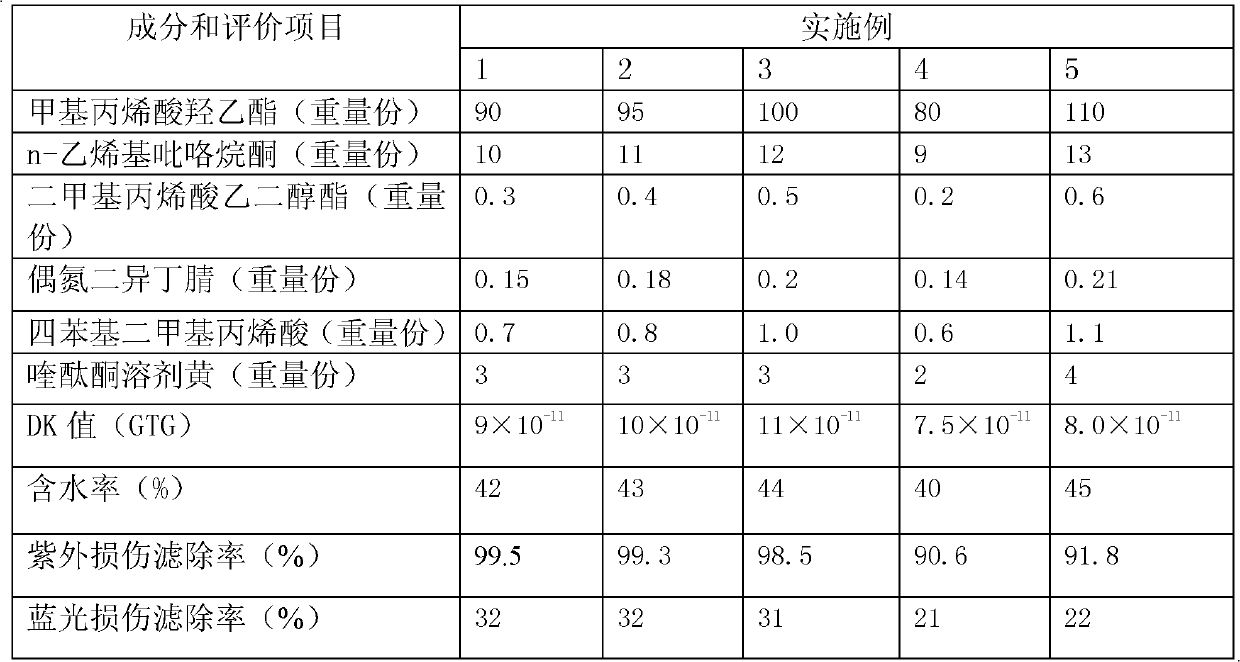

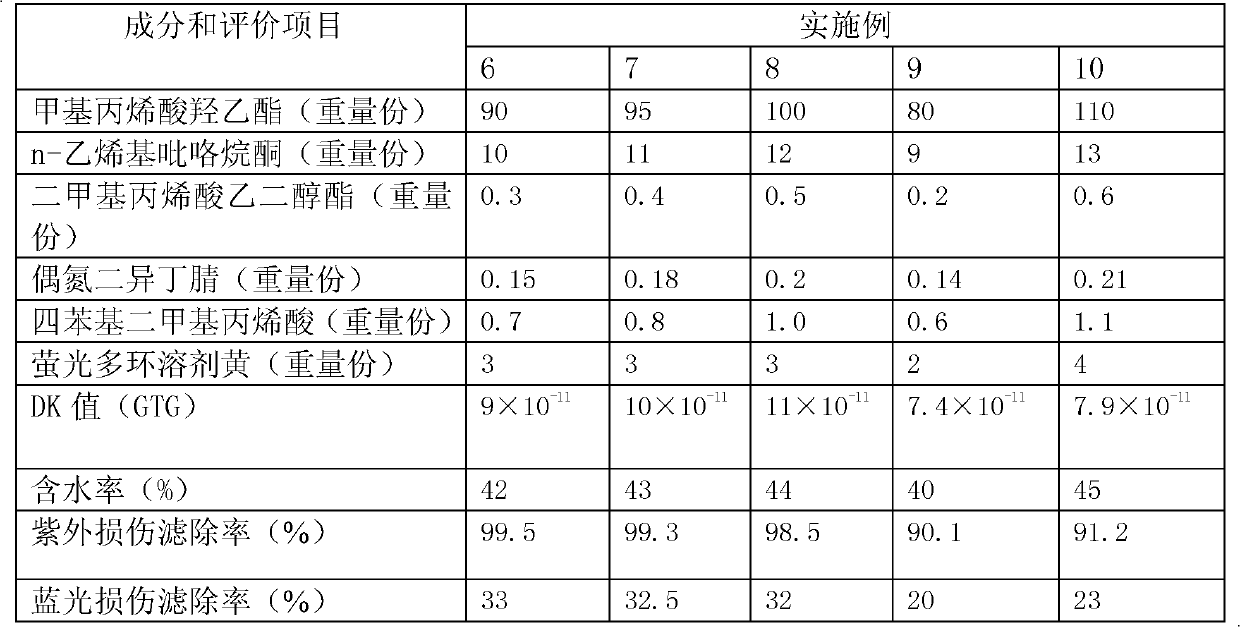

Radiation-proof light-filtering contact lens and production method thereof

ActiveCN102382237AGood oxygen transmission coefficientIncrease moisture contentOptical articlesOptical parts(Hydroxyethyl)methacrylateUltraviolet

A radiation-proof light-filtering contact lens is characterized in that the weight ratio of each component of liquid material is as follows: 90 to 100 parts of hydroxyethyl methacrylate; 10 to 12 parts of ethenyl pyrrolidinone; 0.3 to 0.5 part of 2-propenoic acid, oxybis(2,1-ethanediyloxy-2,1-ethanediyl)ester; acrylic acid, diester with tetraethylene glycol; 0.15 to 0.2 part of 2,2'-dicyano-2,2'-azopropane azobisisbutyronitrile; 0.7 to 1 part of 4-[(E)-phenyldiazenyl]phenyl-2-methacrylate; and 3 parts of yellow pigment and dye for contact lenses. The contact lens has a good oxygen permeation coefficient, high moisture content, moderate hardness and fewer residues, and also has a good ultraviolet radiation protection effect and a good filtering effect on purple light and blue light.

Owner:北京自然美光学有限公司

Diverting compositions, fluid loss control pills, and breakers thereof

A method of treating a well that includes selectively emplacing a fluid loss pill into the well, wherein the fluid loss pill includes at least one of diethylene glycol, triethylene glycol, and tetraethylene glycol, and wherein the at least one of diethylene glycol, triethylene glycol, and tetraethylene glycol reacts with a calcium brine present in the well to form a plug is disclosed.

Owner:MI

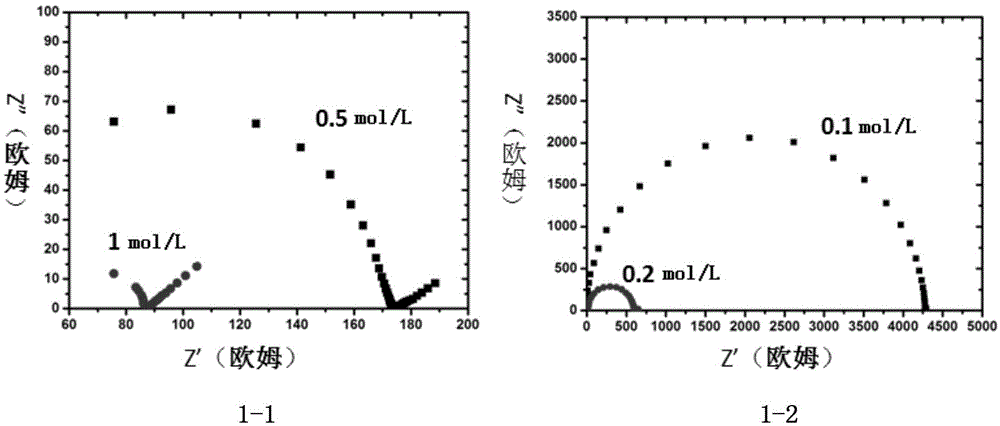

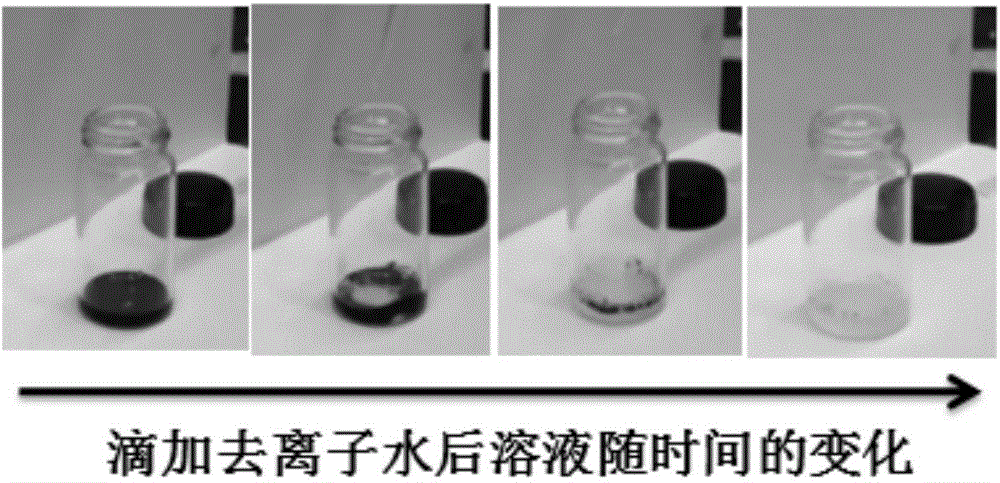

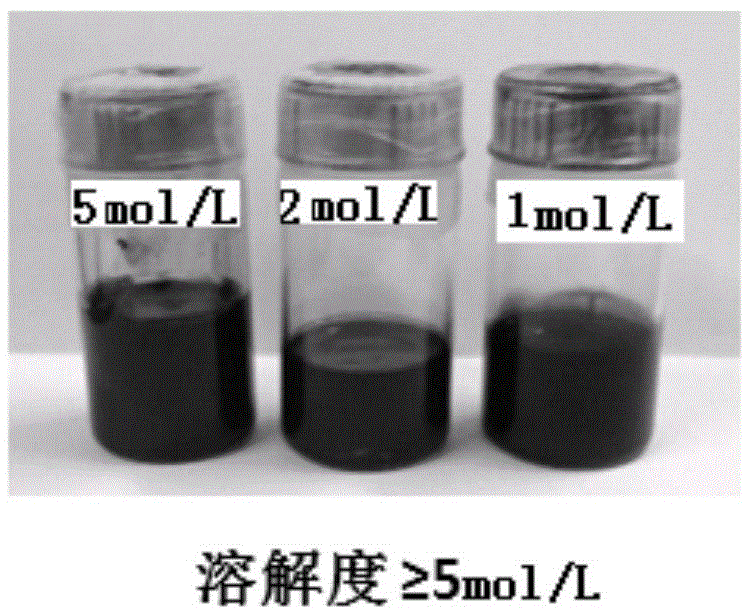

Liquid metal anode material, room-temperature liquid metal battery, and preparation method and application

ActiveCN105098140ALow costAbundant resourcesElectrode manufacturing processesNon-aqueous electrolyte accumulator electrodesPotassiumLiquid metal

The invention discloses a liquid metal anode material, a room-temperature liquid metal battery, and a preparation method and an application. The anode material is a black green liquid which is formed by mixing alkali metal, an aromatic compound and an ether solvent, wherein the alkali metal is any one of metal sodium, metal lithium or metal potassium; and the aromatic compound is any one of biphenyl, derivatives of the biphenyl, naphthaline, derivatives of the naphthaline and anthracene or derivatives of the anthracene; and the ether solvent comprises one or more of glycol dimethyl ether, diethylene glycol dimethyl ether or tetraethylene glycol dimethylether and the like.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

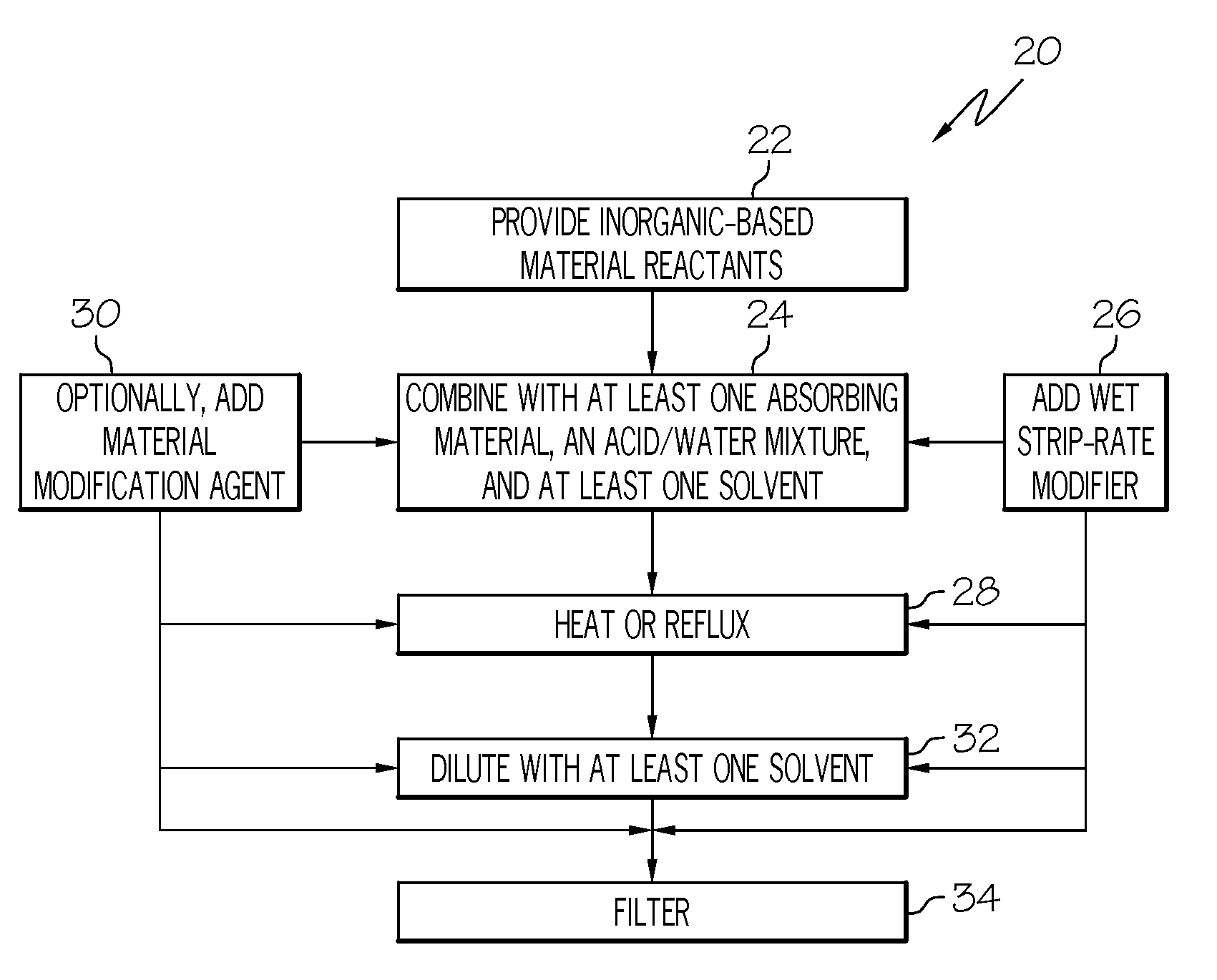

Bottom antireflective coatings exhibiting enhanced wet strip rates, bottom antireflective coating compositions for forming bottom antireflective coatings, and methods for fabricating the same

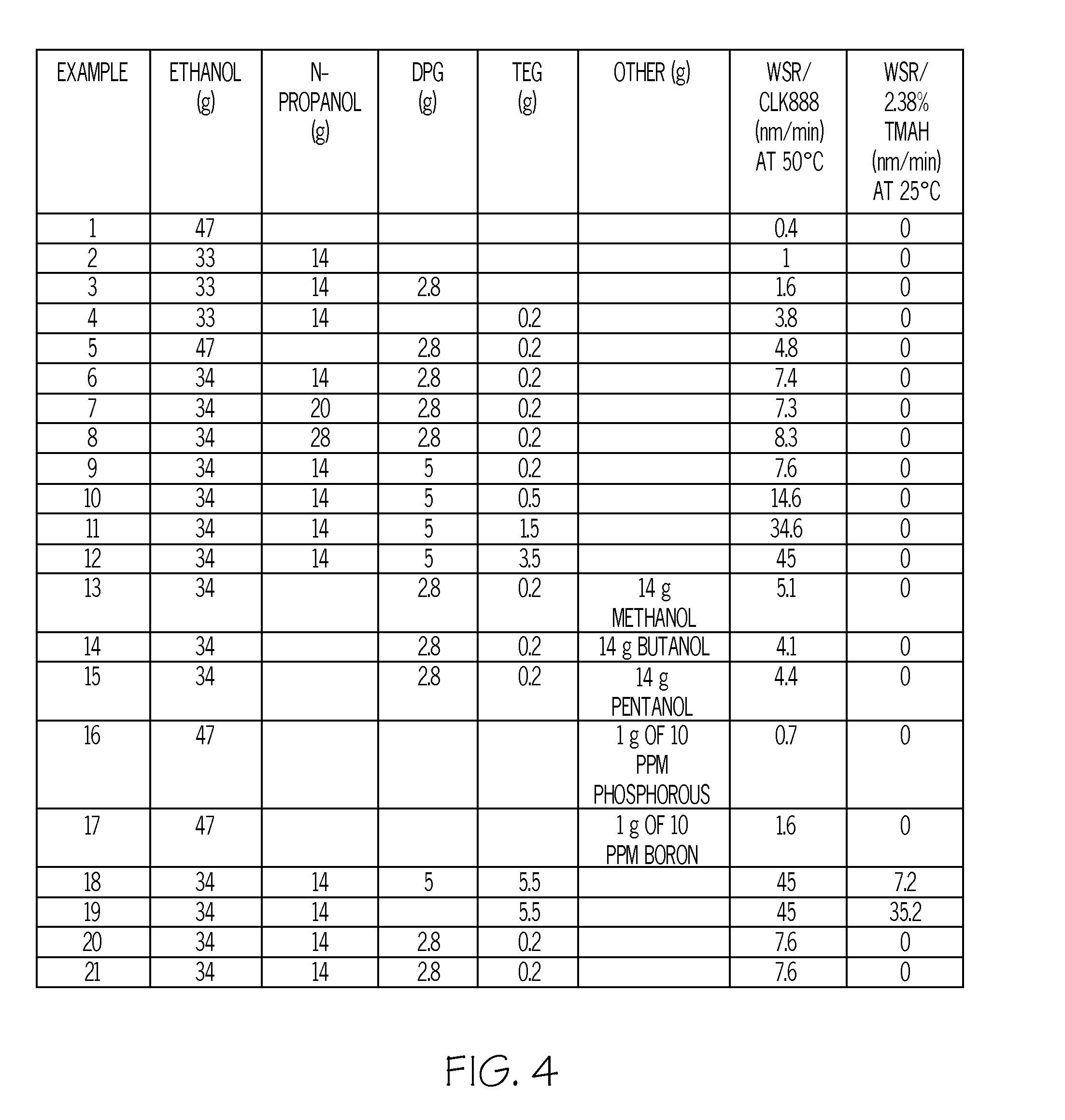

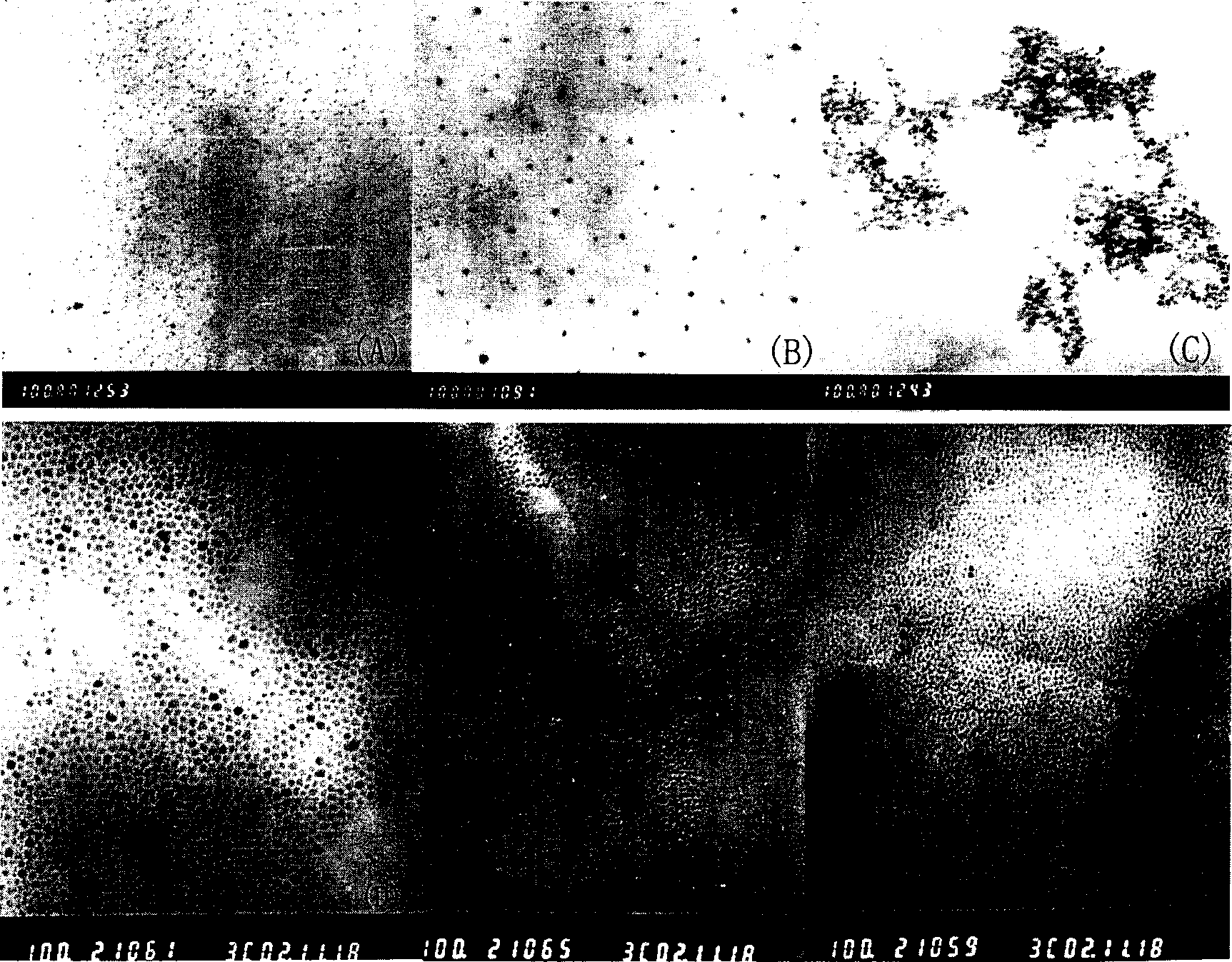

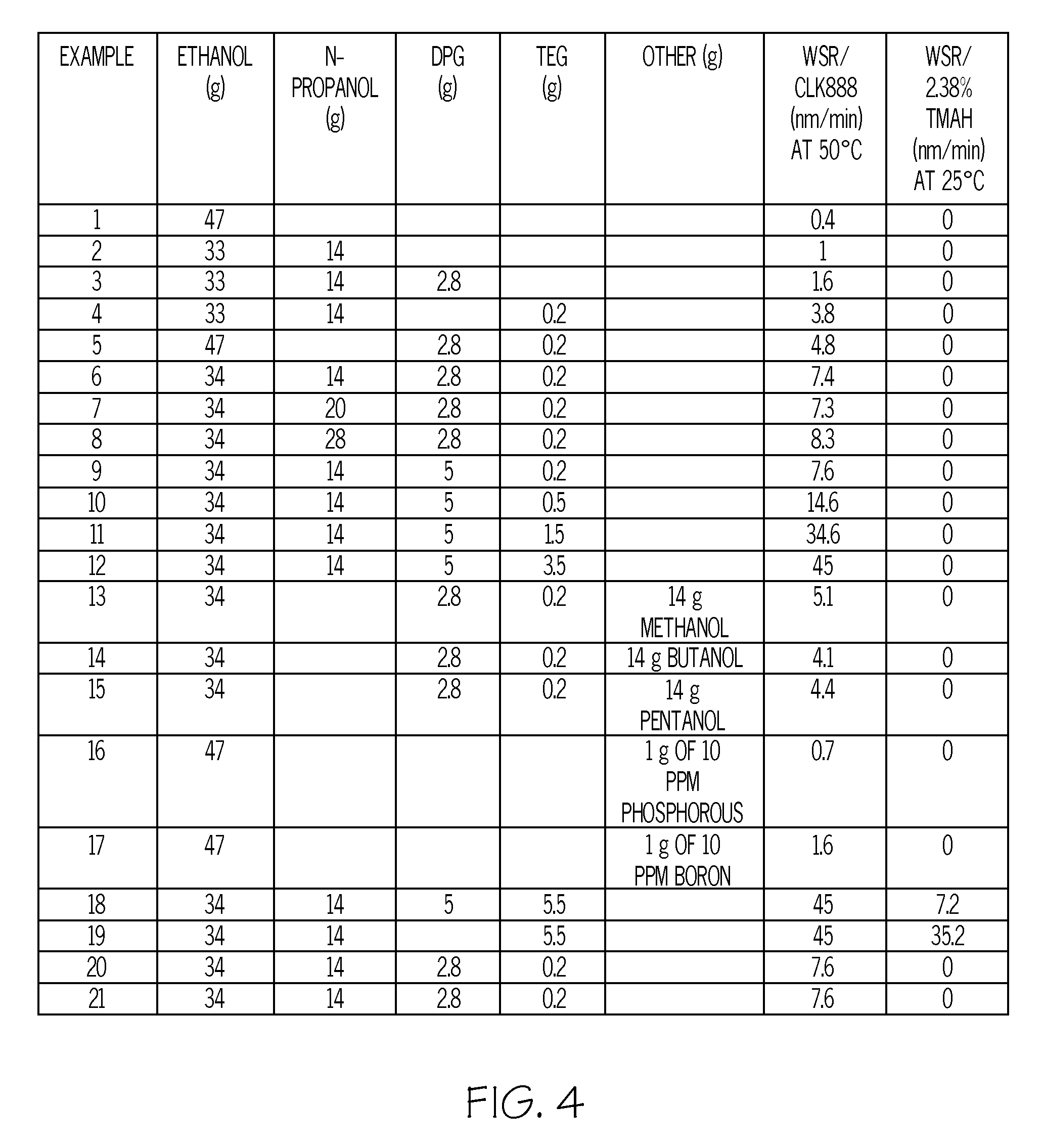

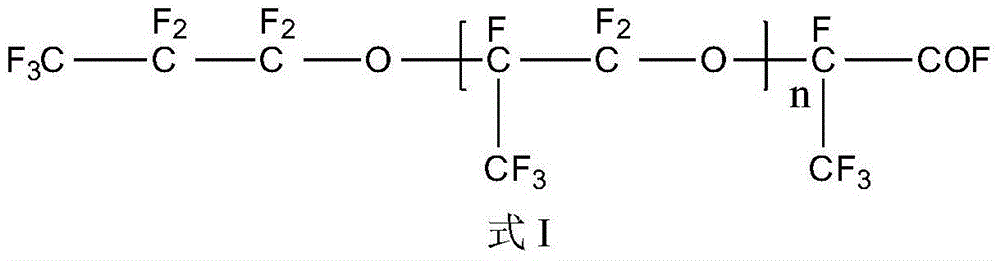

Bottom antireflective coating (BARC) that exhibit enhanced wet strip rates, BARC compositions for fabricating such BARCs, and methods for manufacturing such BARC compositions are provided. According to one exemplary embodiment, a bottom antireflective coating (BARC) composition comprises an inorganic-based compound, an absorbing material, and a wet strip-rate modifier combination. The wet strip-rate modifier composition comprises a combination of a short chain linear alcohol and dipropylene glycol (DPG), a combination of the short chain linear alcohol and tetraethylene glycol (TEG), a combination of DPG and TEG, or a combination of the short chain linear alcohol, DPG, and TEG.

Owner:HONEYWELL INT INC

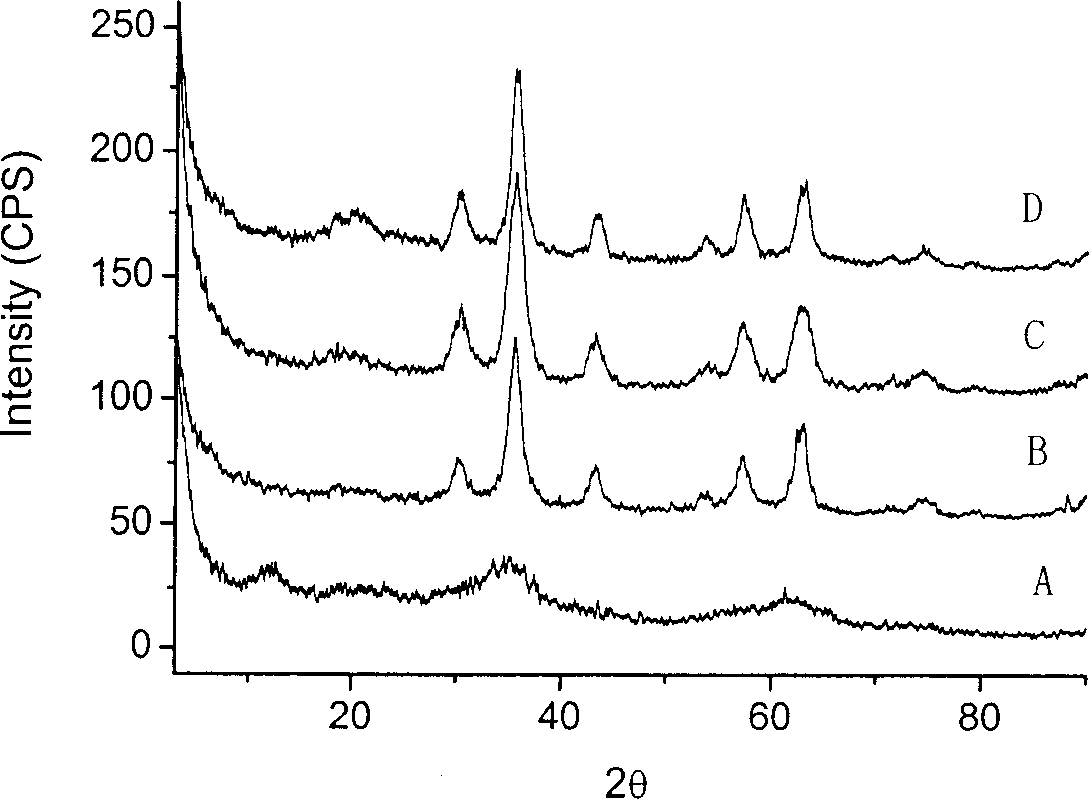

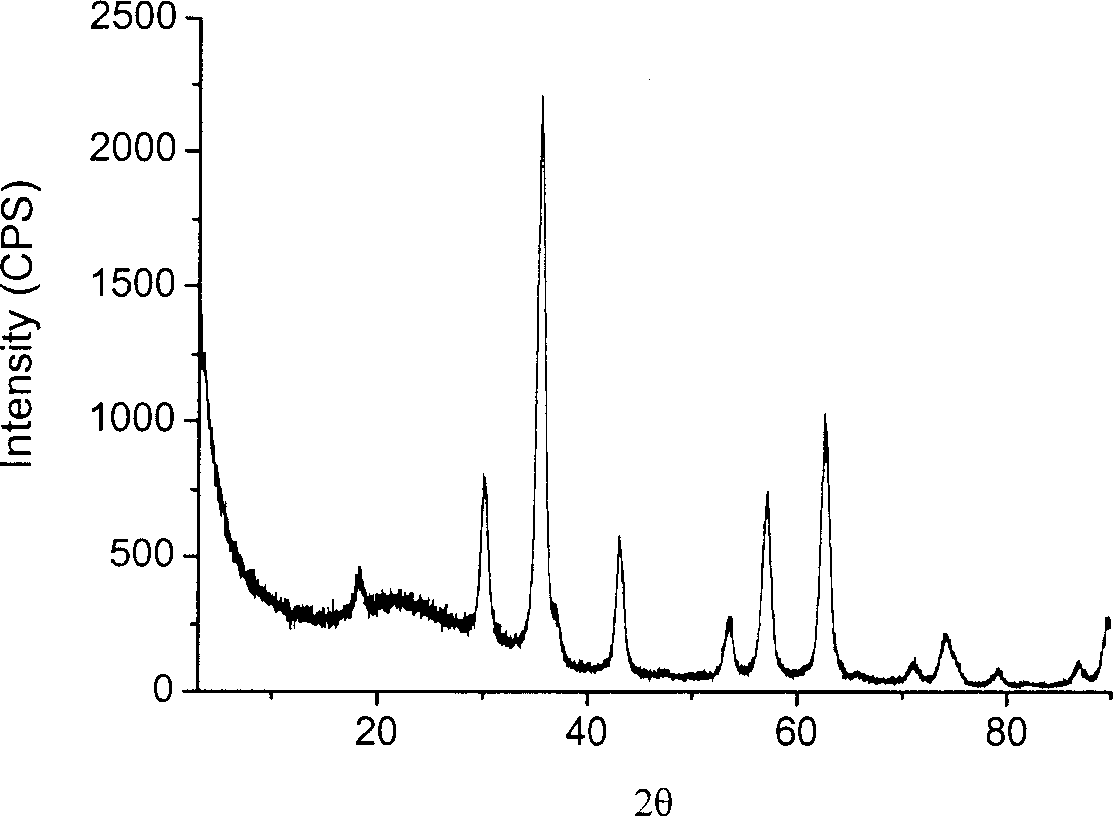

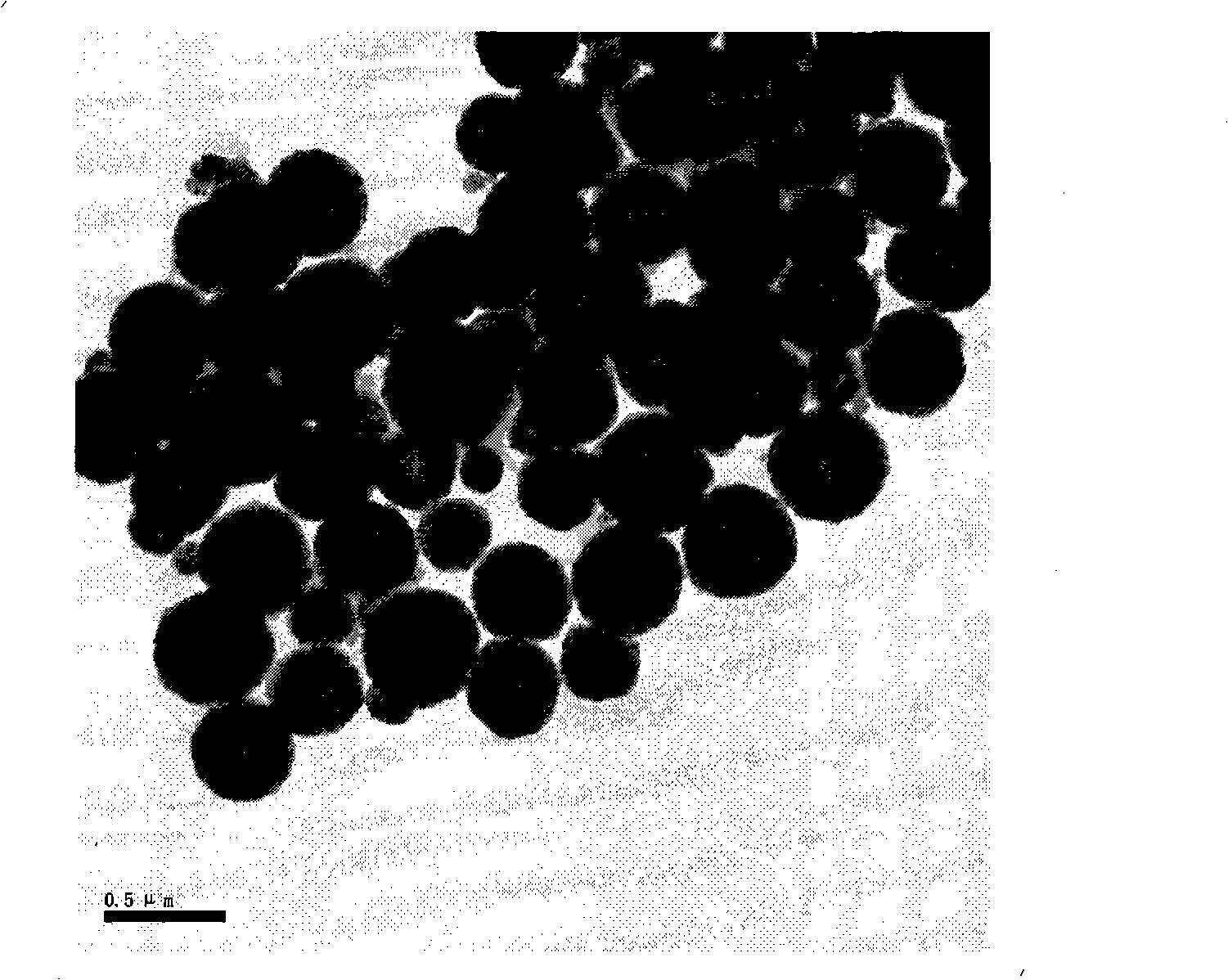

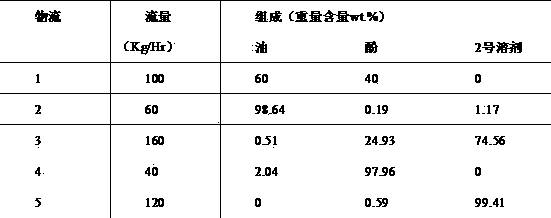

Method for producing water dispersing magnetic nano particle with high-crystallinity

InactiveCN1549283AUniform and controllable particle sizeHigh crystallinityNanostructure manufactureInductances/transformers/magnets manufactureFerric oxalateIron salts

The new method for preparing high crystallinity monodisperse water-soluble magnetic nano microparticles is characterized by that it selects the inorganic iron salts of anhydrous iron trichloride and iron chloride, etc. or metal organic iron compounds (such as iron pentacarbonyl, iron triacetylacetonate, iron biacetylacetonate, complex of cupferron and iron salt, iron octoate and ferric oxalate, etc.) as iron raw material, and utilizes high-temp. decomposition of them in high boiling point polar solvent (for example alpha-pyrrolidone and its derivatives (N-methyl-2-pyrrolidone and N-ethyl-2-pyrrolidone, etc.), N,N-dimethyl-2-imidazolone, hexametapol, gamma-butyrolactone and its derivative and low molecular weight (molecular weight M is less than or equal to 5000) polyglycol and its derivatives) to prepare magnetic nano microparticles. Said invention can adopts different iron raw materials and high boiling point polar solvents so as to obtain different types of magnetic nano microparticles (Fe, Fe2O3 and Fe3O4) with different sizes and crystallinities and different crystal structures.

Owner:苏州欣影生物医药技术有限公司

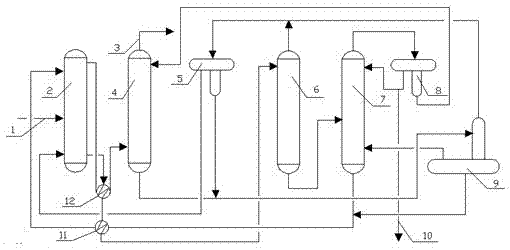

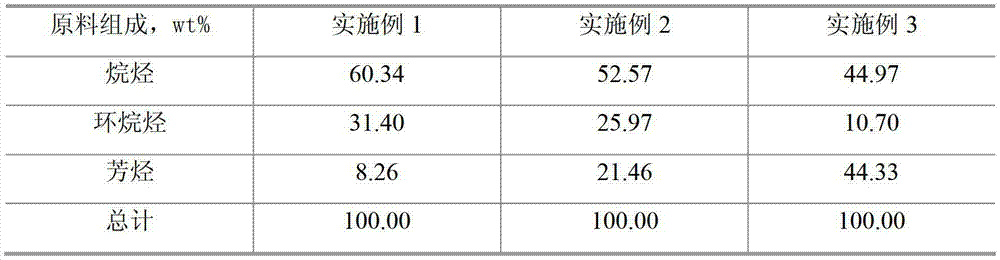

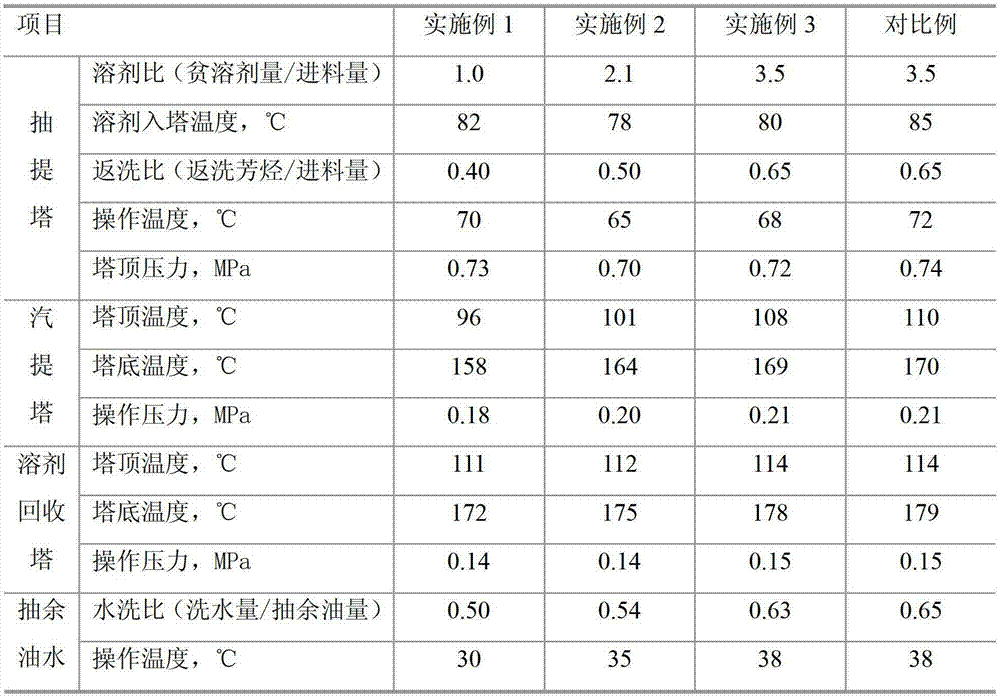

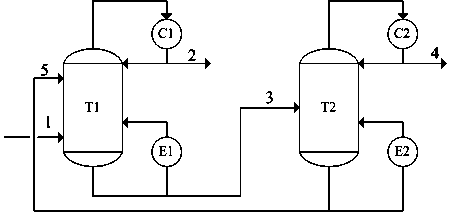

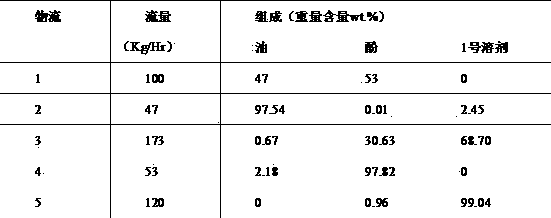

Composite solvent and extraction method for extracting and separating aromatic hydrocarbons

InactiveCN103160310AReduce dosageImprove solubilityExtraction purification/separationHydrocarbon oils refiningSolubilitySulfolane

The invention relates to a composite solvent and extraction method for extracting and separating aromatic hydrocarbons from a hydrocarbon mixture in industries of oil refining and chemical engineering, which can achieve the advantages of high aromatic hydrocarbon separation efficiency, favorable heat stability and convenient recovery process. The technical scheme is as follows: the composite solvent comprises the following solvents in percentage by mass: 45-95% of main solvent, 4.5-40% of auxiliary solvent and 0.5-15% of modifier, wherein the main solvent is one of sulfolane or N-formyl morpholine or dimethylsulfoxide or tetraethylene glycol, the auxiliary solvent is one of N-methylpyrrolidone or N,N-dimethylformamide, and the modifier is one of ethylene glycol or polyethyleneglycol; and a preparation method of the composite solvent comprises the following steps: proportionally adding the modifier into the auxiliary solvent, evenly mixing, proportionally adding the mixed solvent into the main solvent, and evenly mixing to prepare the composite solvent. The composite solvent obviously enhances the solubility and selectivity of the solvent on aromatic hydrocarbons, avoids the increase of energy consumption and the occurrence of hydrolysis reaction caused by the situation that water is contained in the solvent, reduces the consumption of the solvent and increases the aromatic hydrocarbon recovery rate.

Owner:SOUTHWEST PETROLEUM UNIV

Stable non-aqueous inkjet inks

InactiveUS20090176926A1Improve dispersion qualityImprove stabilityInksGranular deliveryEthylene glycolPigment

A non-aqueous ink not curable by UV radiation includes an organic color pigment and between 12 to 98 wt % of tetraethylene glycol dimethylether based on the total weight of the inkjet ink. Also, a method for preparing a non-aqueous inkjet ink is provided.

Owner:AGFA NV

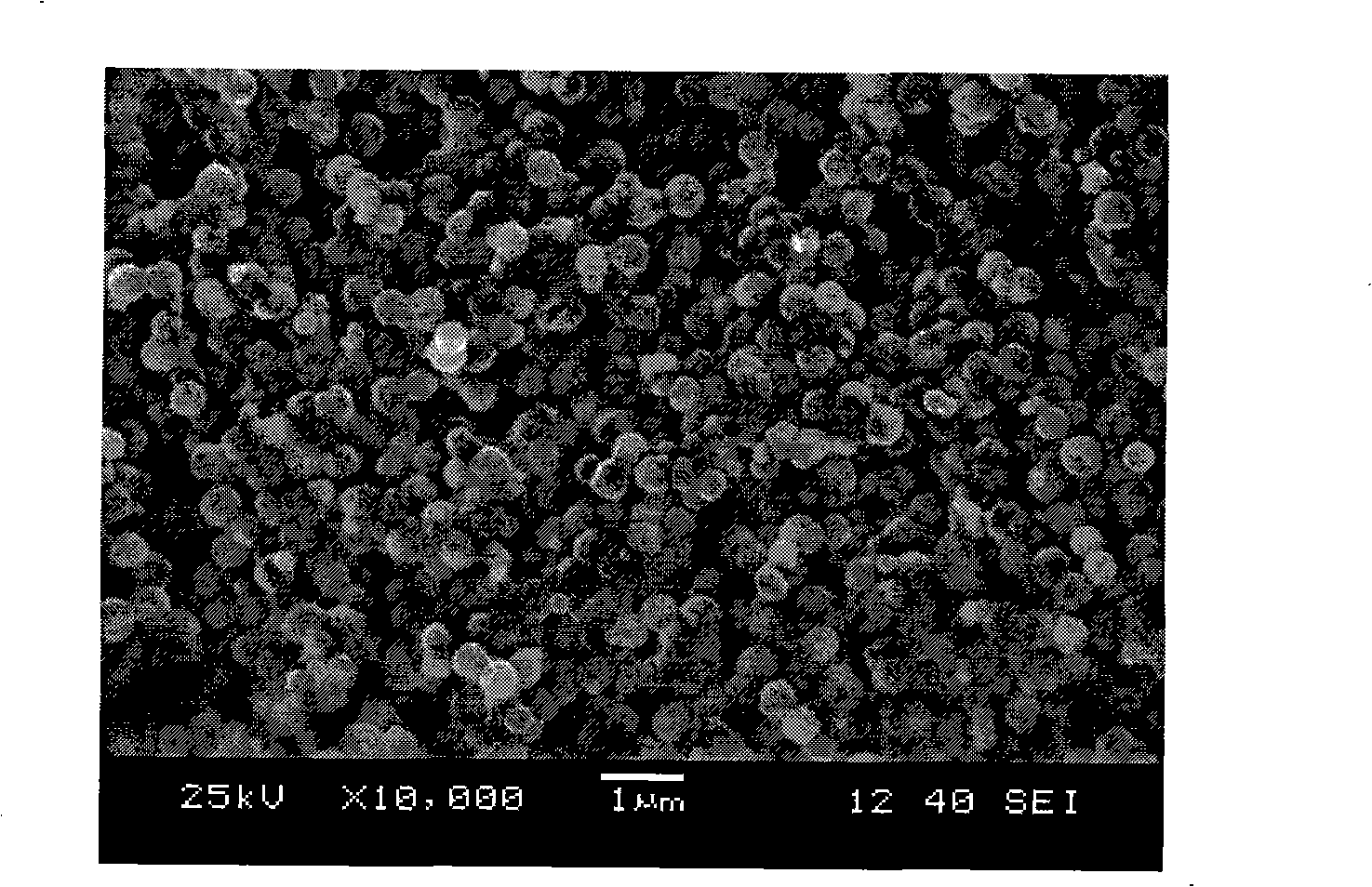

Method for synthesizing ferrimagnetism hollow microballoons

The invention belongs to the preparation field of magnetic materials, comprising the following steps: firstly, adding the metal ion salt to organic polar solvent for complete dissolution, and then adding solid alkali metal salt and surfactant; the composed mixed solution is reacted at 140-200 DEG C so as to get ferrimagnetic hollow microspheres; the mass ratio between the surfactant and the organic polar solvent is 0.02-0.2:1; the concentration of the metal ion solution is 0.025-0.625mol / L; the molar ratio between the alkali metal salt and the metal ions is 5-20:1; the metal ion is selected from one or more among the iron, cobalt, nickel, manganese, zinc and magnesium ions; the surfactant can be polyethylene glycol series or tween series; the organic polar solvent can be glycol, ethanol, diethylene glycol, triethylene glycol, tetraethylene glycol or glycerol. The method of the invention is simple and the raw materials are cheap and can be easily obtained; the method has good process repeatability, high yield, safety, low cost and wide applicability, which generates no toxic substances and pollutants.

Owner:溧阳常大技术转移中心有限公司

Solutions and Catalysts Comprising Group VI Metal, Group VIII Metal, Phosphorus and An Additive

ActiveUS20120145600A1Organic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolyethylene glycolMonoethylene Glycol

This invention provides a process for forming a solution composition, which process comprises forming a primary solution by bringing together, in an aqueous medium, i) at least one phosphorus compound, ii) at least one Group VI metal compound, iii) at least one Group VIII metal compound, and iv) an additive which is a) tetraethylene glycol, b) polyethylene glycol having an average molecular weight in the range of about 200 to about 400, c) a mixture of tetraethylene glycol and polyethylene glycol having an average molecular weight in the range of about 200 to about 400, or d) a mixture of (1) tetraethylene glycol and / or polyethylene glycol having an average molecular weight in the range of about 200 to about 400 and (2) one or more of monoethylene glycol, diethylene glycol, and triethylene glycol. The molar ratio of additive to the total moles of Group VI metal and Group VIII metal is above 0.30:1, and the atomic ratio of phosphorus to Group VI metal is at least about 0.33:1. Optionally, the primary solution is heated at a temperature above about 40° C. to form a heated solution. The heated solution is optionally cooled to form a cooled solution. Also provided are compositions formed by such processes, processes for forming catalyst compositions from these compositions, and catalyst compositions formed by these processes.

Owner:ALBEMARLE EURO

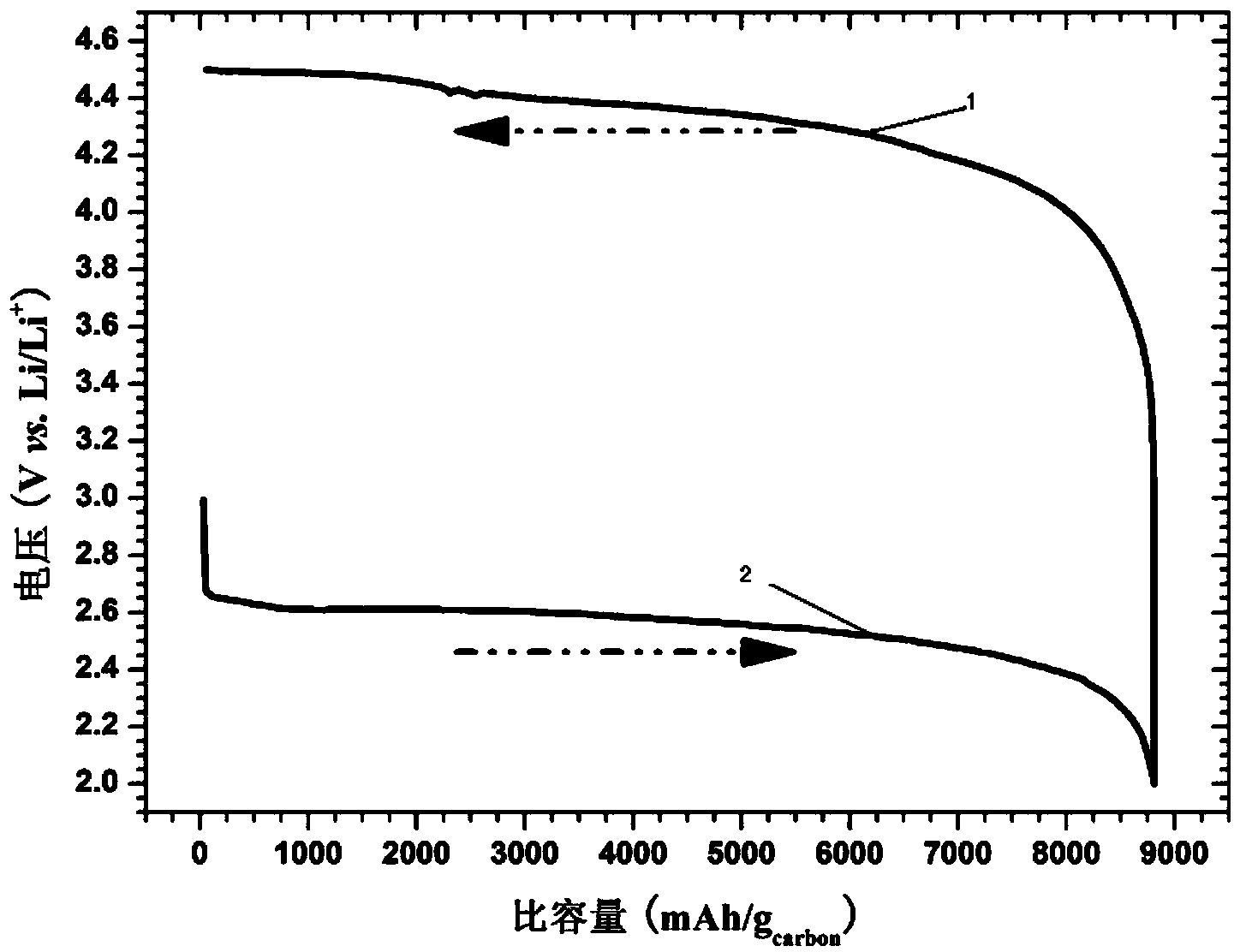

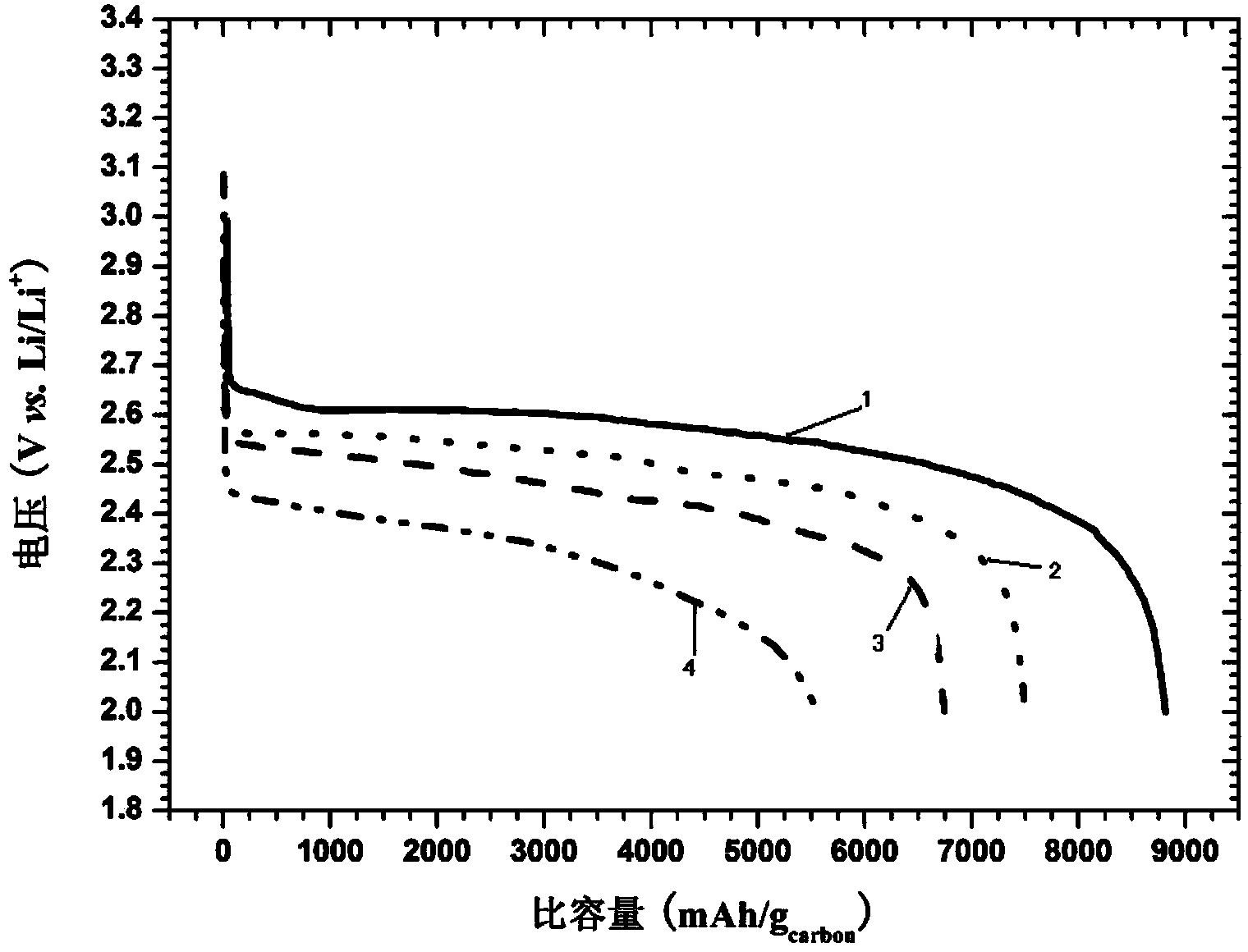

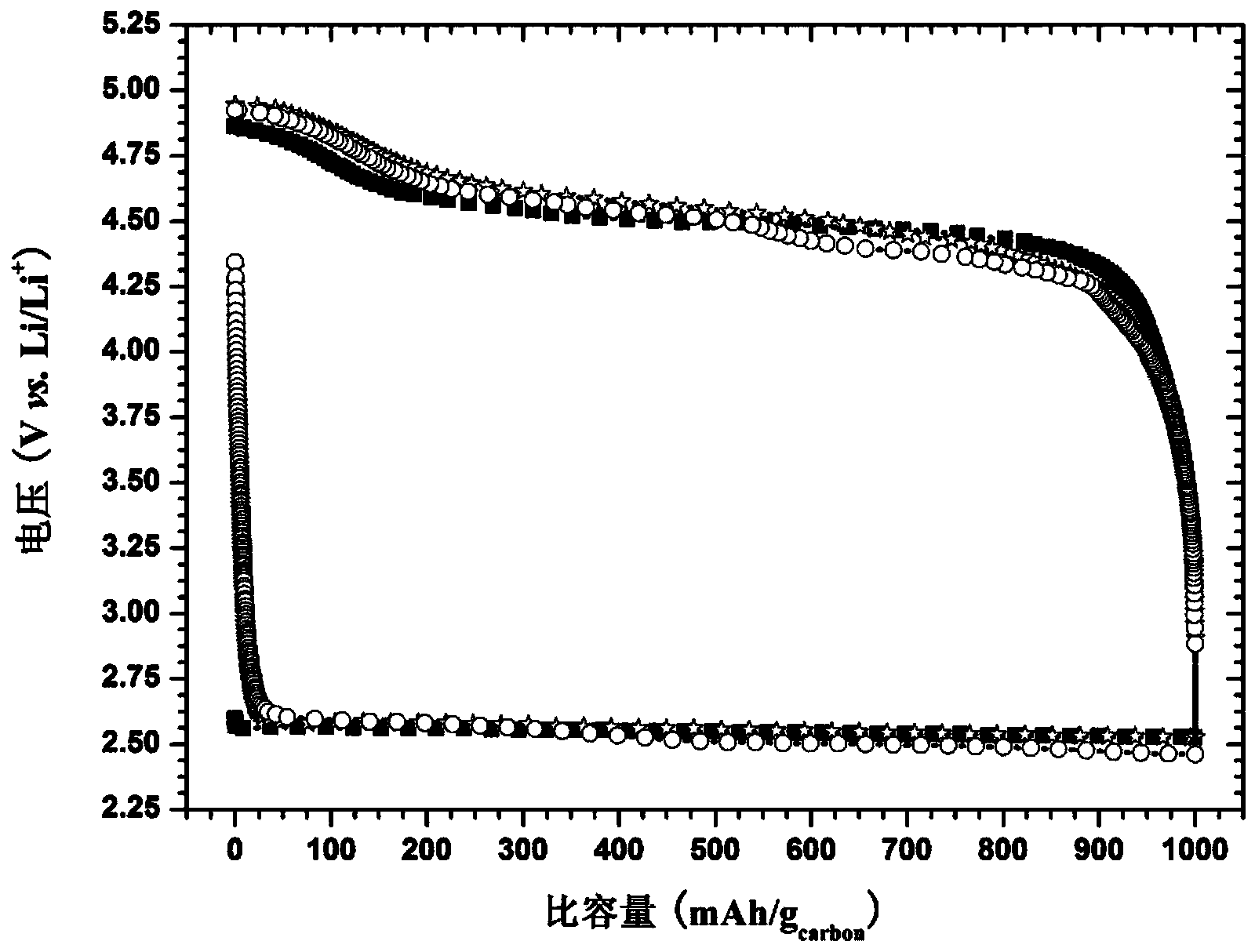

Ether electrolyte and lithium air battery

InactiveCN103996892ANot volatileImprove oxygen solubilityFuel and primary cellsFuel and secondary cellsCharge dischargeOxygen

The invention provides ether electrolyte. The ether electrolyte comprises lithium salt and an organic solvent, wherein the organic solvent comprises one or more of 1,2-dimethoxyethane, diethylene glycol dimethyl ether, triethylene glycol dimethyl ether and tetraethylene glycol dimethyl ether. The ether electrolyte has advantages that the ether electrolyte is unlikely to volatize, the oxygen dissolving degree is high, the electrochemical stable window is wide, and the like, and has excellent chemical stability for a discharging intermediate product O2<-1> or LiO2 and a discharging final product Li2O2. The lithium air battery prepared by utilizing the ethers electrolyte is excellent in long cycling stability. The experimental result shows that a charging-discharging curve is not obviously changed after the lithium air battery assembled by utilizing the ether electrolyte is circularly charged and discharged for 30 times at a limit capacity of 1,000mAh / g under the current density of 100mA / g.

Owner:常州盈华高科储能材料科技有限公司 +1

Ink composition, recording method using the same, and recorded matter

ActiveUS20100247874A1Small difference in viscosityImprove featuresCosmetic preparationsMeasurement apparatus componentsGlycerolTrimethylolpropane

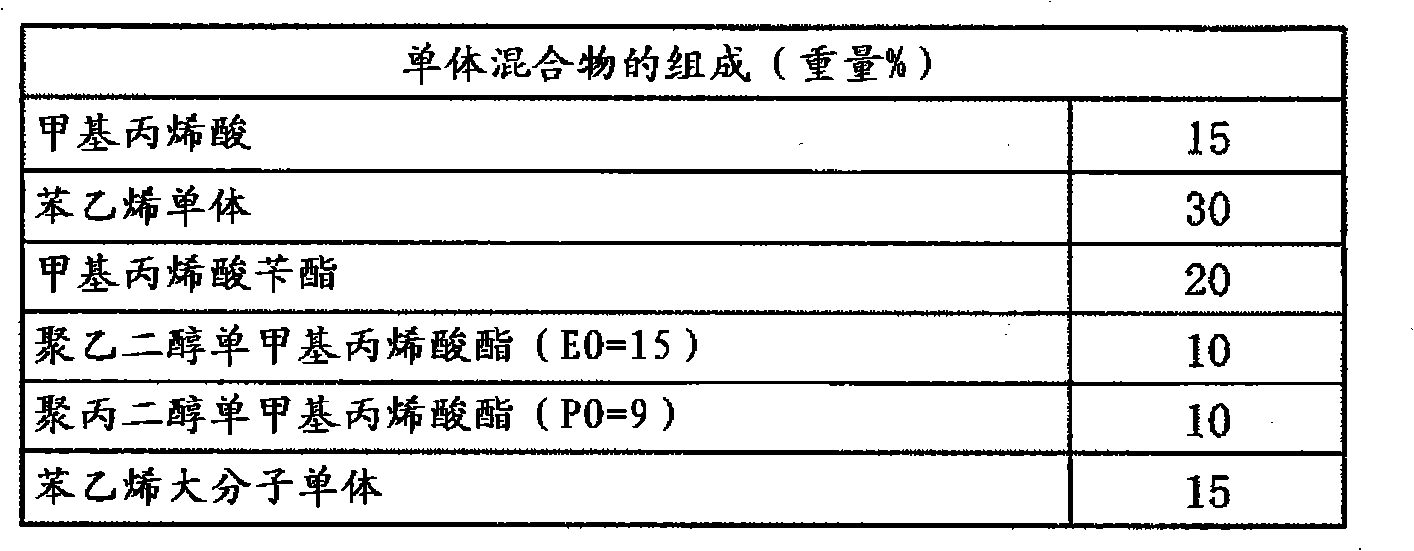

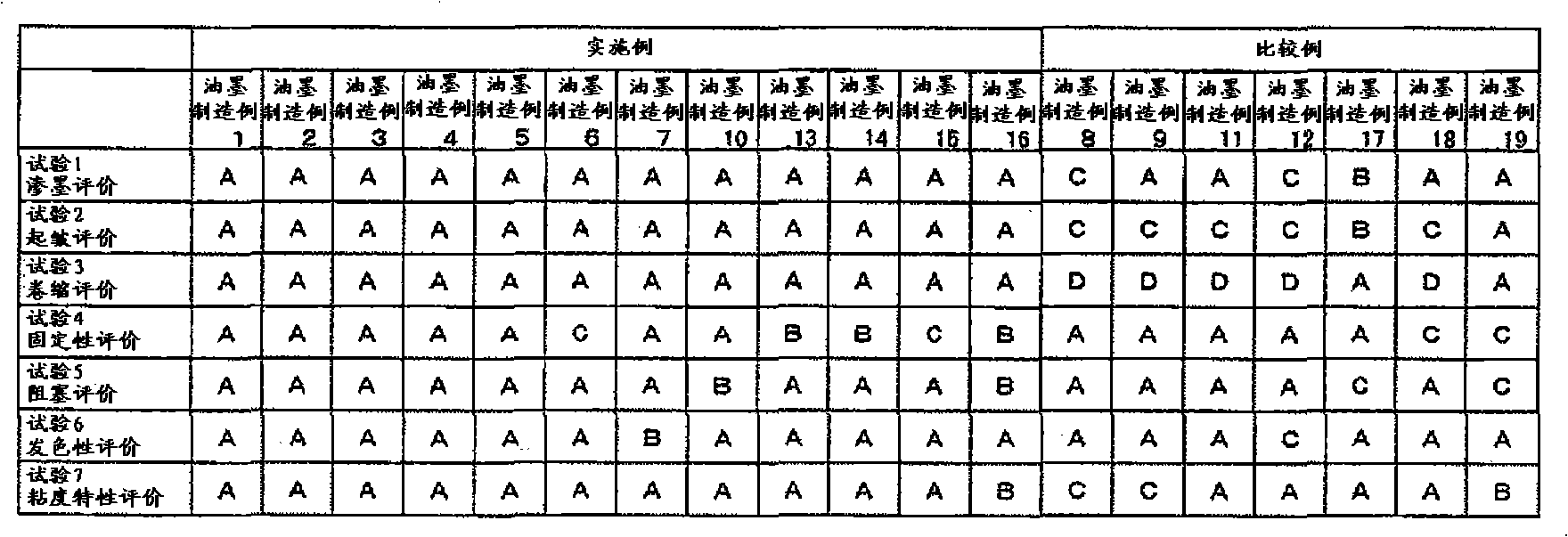

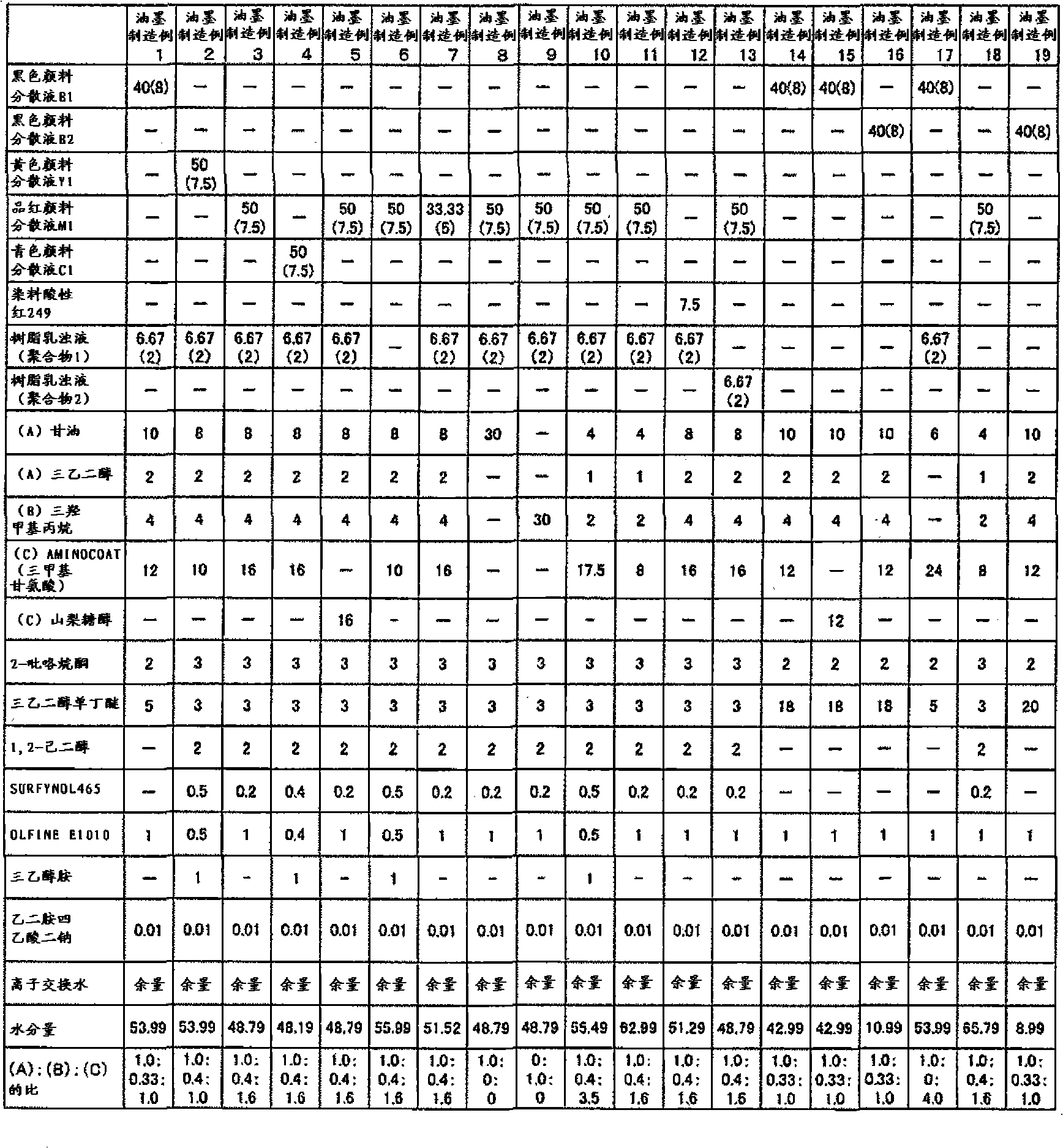

An ink composition includes at least a pigment, a humectant, and water in from 10 to 60% by weight to the total amount of ink. The humectant is a mixture of (A) at least one compound selected from glycerin, 1,2,6-hexanetriol, diethylene glycol, triethylene glycol, tetraethylene glycol, and dipropylene glycol; (B) either trimethylol propane or trimethylol ethane, or a mixture thereof; and (C) at least one compound selected from betaines, saccharides, and ureas and having a molecular weight in the range of from 100 to 200, at a content weight ratio of (A):(B):(C) of 1.0:0.1 to 1.0:1.0 to 3.5.

Owner:SEIKO EPSON CORP

Electronic mouth cavity atomized liquid using multi-element ethanediol series lower alcohols as base solution

The invention discloses electronic mouth cavity atomized liquid using multi-element ethanediol series lower alcohols as a base solution. The electronic mouth cavity atomized liquid is composed of 3%w / v to 5%w / v of tobacco leaf extracts, 30%w / v to 80%w / v of the lower alcohols, 5%w / v to 10%w / v of pure water, 3%w / v to 5%w / v of tobacco essence, 0%w / v to 3%w / v of nicotine, 0.2%w / v to 1.0%w / v of stabilizers, 3%w / v to 8%w / v of thickeners and 15%w / v to 20%w / v of taste modifiers, wherein the lower alcohols are the mixtures of triethylene glycol and / or tetraethylene glycol and / or pentaethylene glycol and / or hexaethylene glycol and / or heptaethylene glycol and / or octaethylene glycol and / or nonaethylene glycol. The electronic mouth cavity atomized liquid has the advantages that remaining taste is clear, fragrance lasts for a long time, and safety is realized after the electronic mouth cavity atomized liquid is used.

Owner:FEELLIFE BIOSCI INT

Method for extracting phenol compounds from direct coal liquefied oil through extractive distillation

ActiveCN103896739AHigh recovery rateIncrease relative volatilityOrganic chemistryOrganic compound preparationSulfolaneExtractive distillation

The invention relates to a method for extracting phenol compounds from direct coal liquefied oil through extractive distillation. An extractive distillation solvent (hereinafter referred to as solvent) adopted in the method is glyceryl triacetate and / or sulfolane, or a mixed solvent formed by mixing glyceryl triacetate and / or sulfolane and one or more selected from glycerol, triethanolamine, triethylene glycol, tetraethylene glycol, dimethyl sulfoxide and diethanol amine according to any proportion. The method is used for extracting phenol compounds from direct coal liquefied oil in an extraction distillation tower by using the solvent, then, a solvent flow rich in the phenol compounds enters a recovery tower and is separated, the phenol compounds discharged from the top of the recovery tower are recovered after being cooled to obtain phenol products, and the solvent is recycled after being discharged from the bottom of the recovery tower. The method has the characteristics of high product purity, low system energy consumption, no wastewater generation, no acid and alkaline waste and no corrosion to equipment.

Owner:TAIYUAN UNIV OF TECH

Embossed printing paste for velvet fabric and preparation method thereof

The invention relates to an embossed printing paste for velvet fabrics and a preparation method thereof. The embossed printing paste is prepared by blending an emulsion and a thickening agent, wherein the emulsion is prepared by triggering and polymerizing itaconic acid, butyl acrylate, acrylic acid ethyl ester, dimethylacrylic acid tetraethylene glycol ester, acrylonitrile, fatty alcohol-polyoxyethylene ether XL-90, ammonium persulfate and deionized water. The embossed printing paste has the characteristics of good transparency, high temperature non-yellowing, good fastness, soft hand feel,bright color, non-formaldehyde, no APEO (Alkylphenol Ethoxylates), good luster and simple production technology. The embossed printing paste is used for printing on the velvet fabrics so that the valve fabrics have very prominent concave-convex effect, clear pattern contours and good degree of finish.

Owner:LIAONING FIXED STAR FINE CHEM

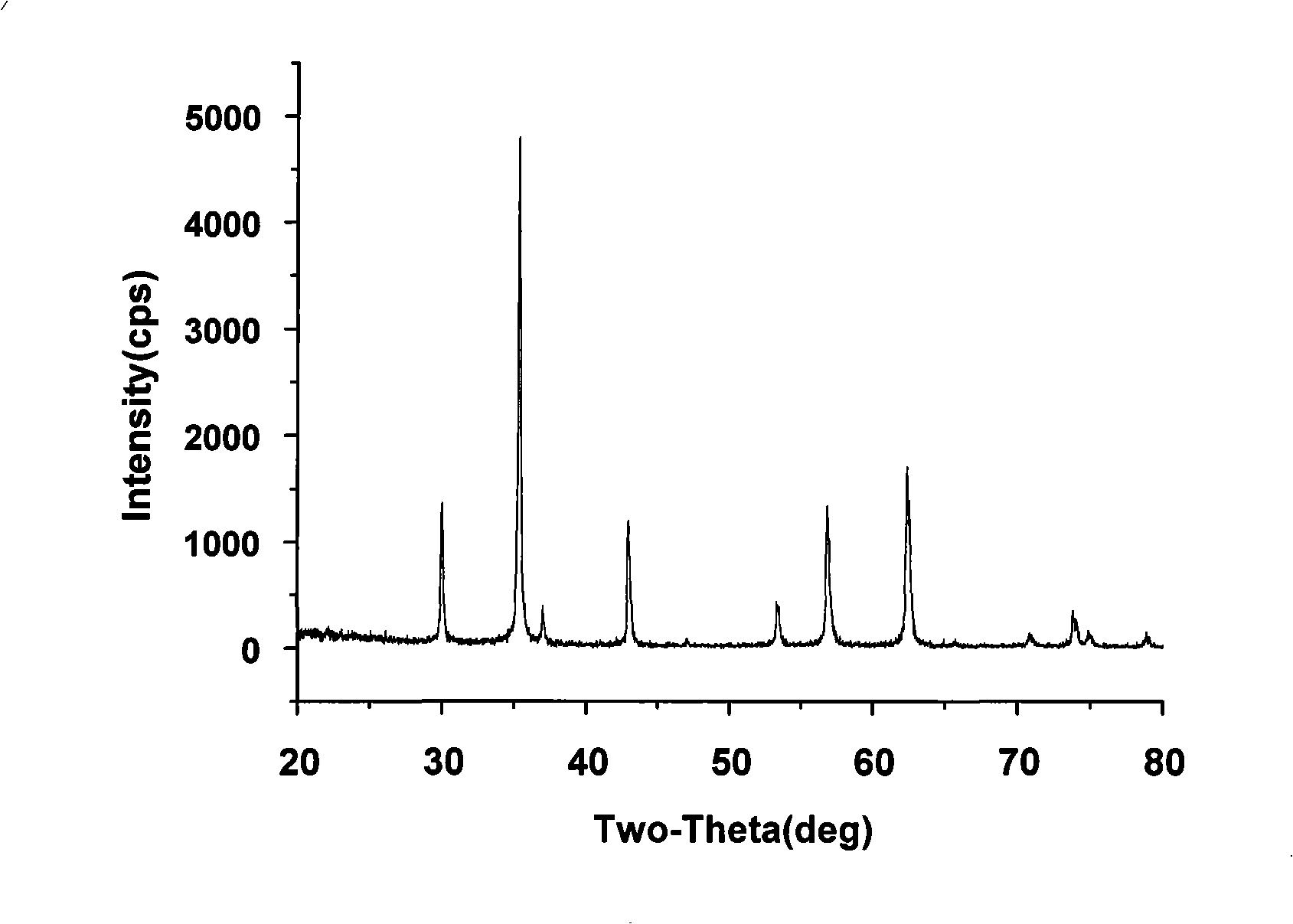

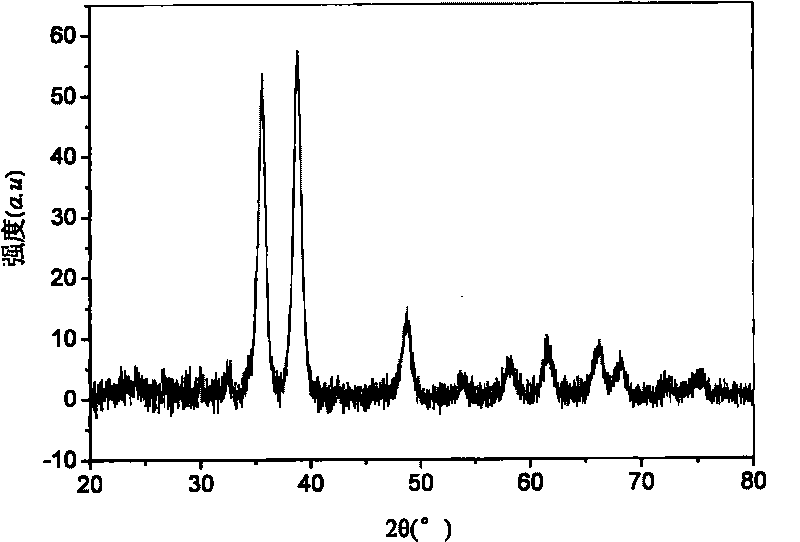

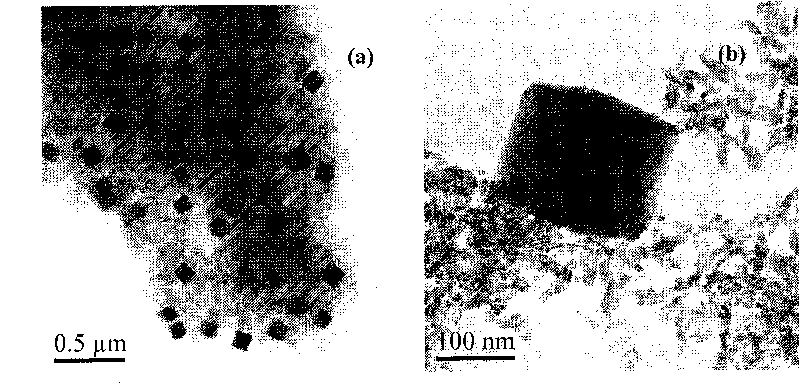

Cubic copper oxide nano particle and synthesizing method and application thereof

InactiveCN101696027AAvoid reaction conditionsExtended reaction timeIndividual molecule manipulationCopper oxides/halidesTetraglycolMicrowave

The invention relates to a cubic copper oxide nano particle and a preparation method and application thereof. The method comprises the following steps: uniformly mixing copper acetate aqueous solution, sodium hydroxide tetraglycol solution and polyvinylpyrrolidone aqueous solution by a microwave as a heating medium; heating by the microwave by stirring till the color of the solution is changed into transparent dark brown; and then obtaining the cubic copper oxide nano particle. The method has simple experiment process without complicated and rigorous process condition, and the obtained product can be used for preparing an air-sensitive element.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

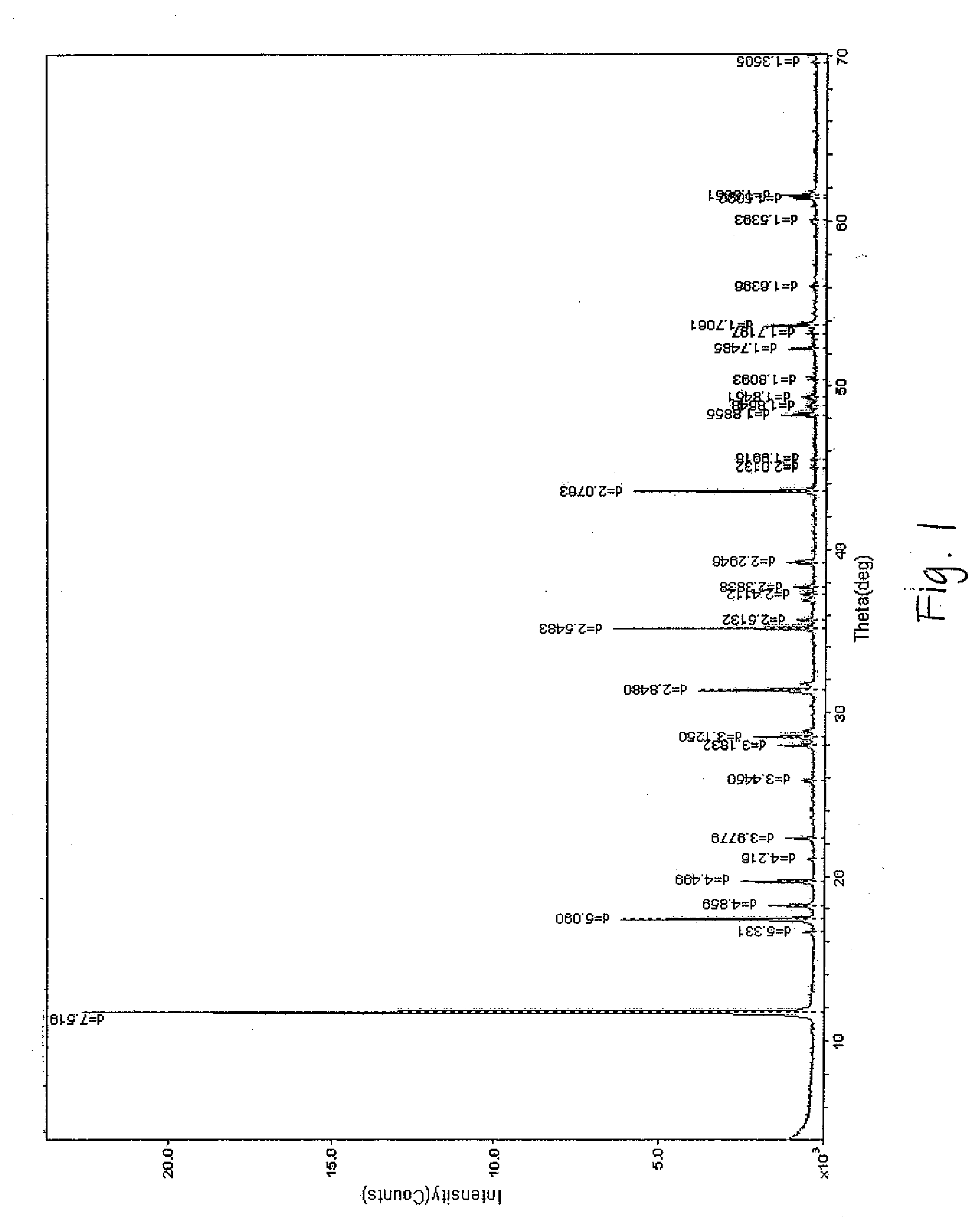

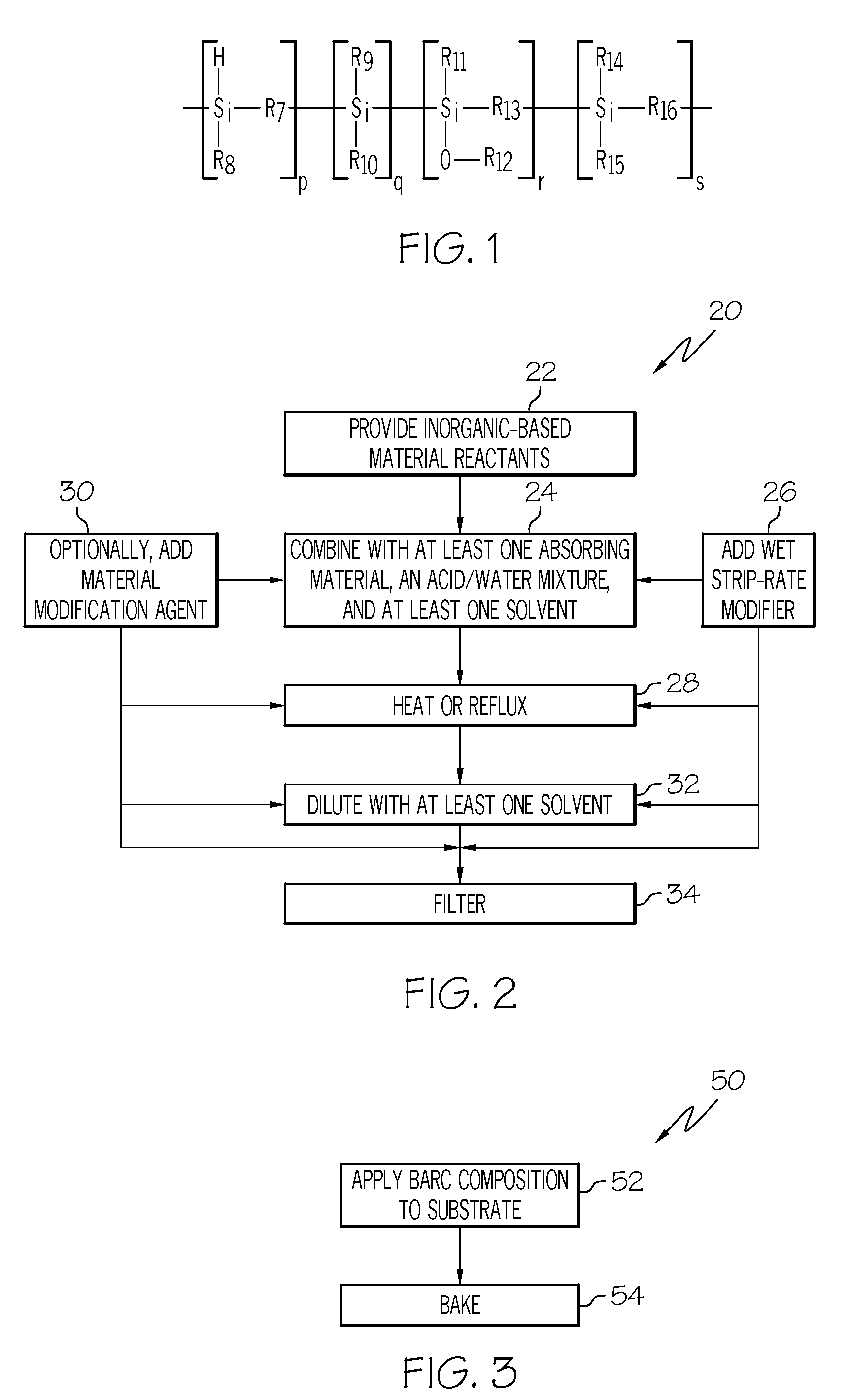

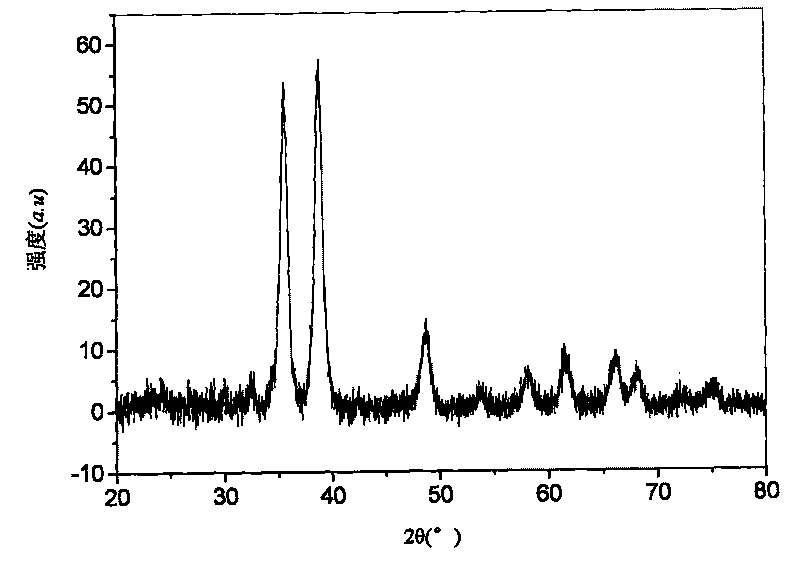

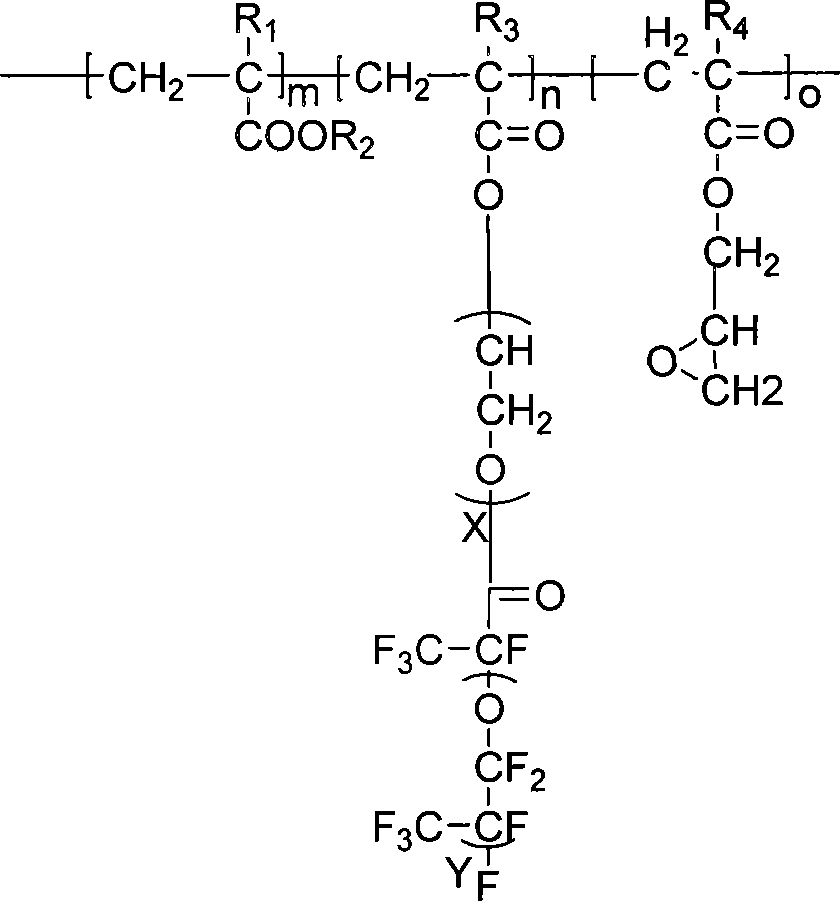

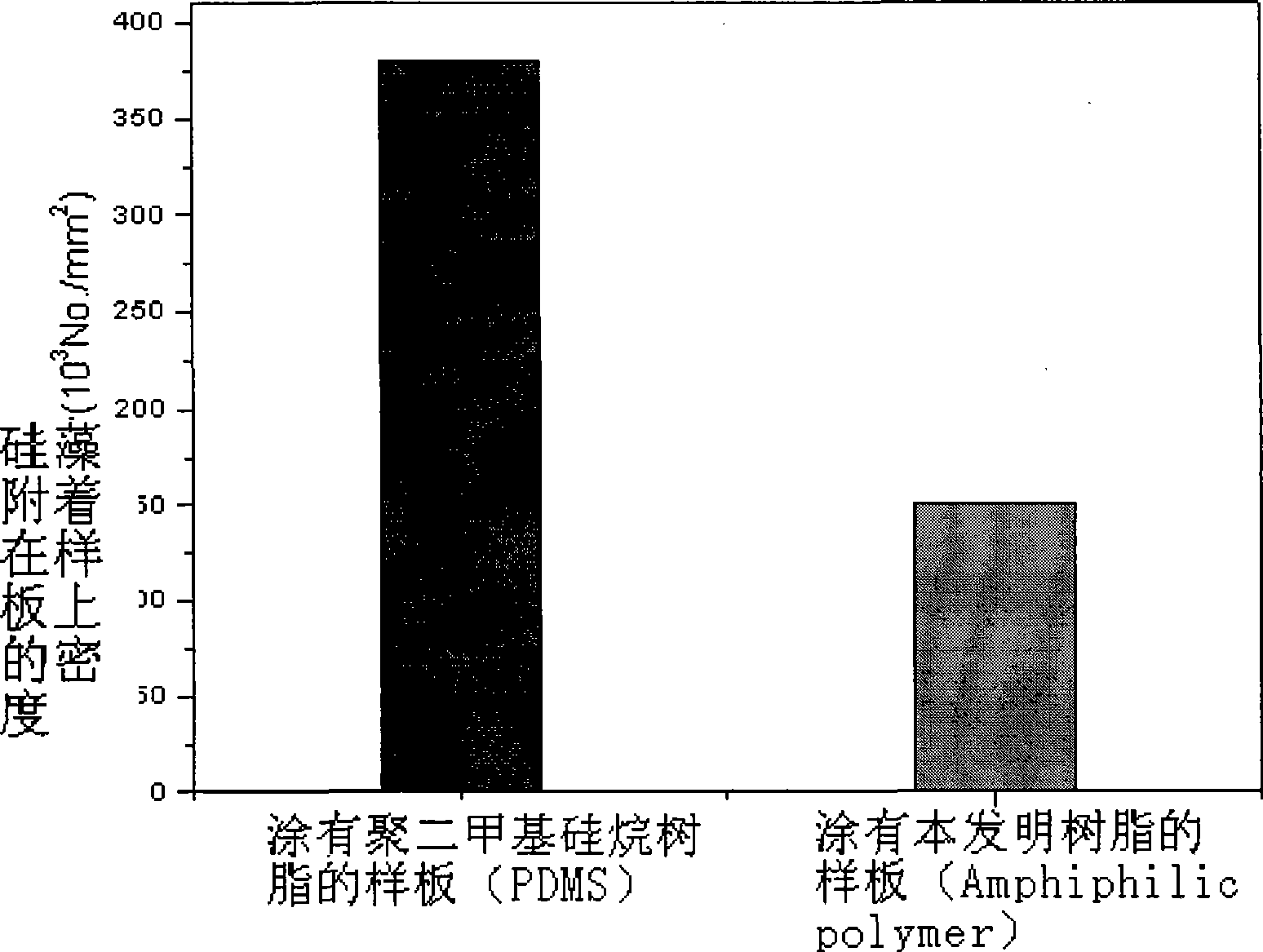

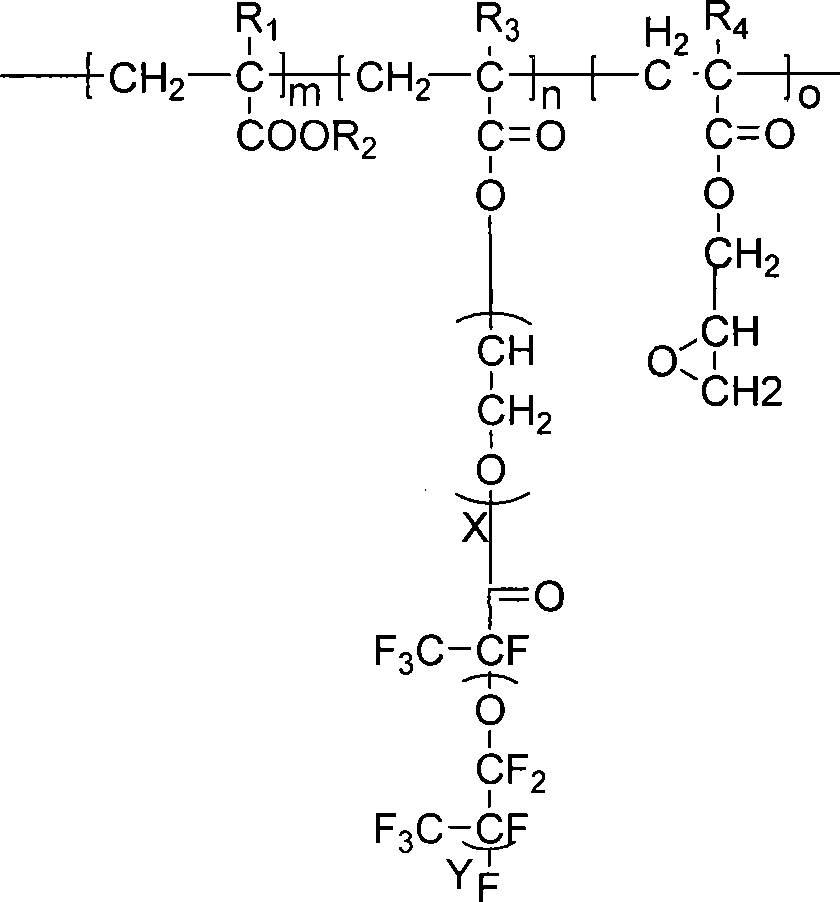

Acrylic resin containing amphipathic lateral chain, and preparation and use thereof

InactiveCN101412779AGood antifouling activityExcellent marine antifouling activityAntifouling/underwater paintsPaints with biocidesMethacrylateAcrylic resin

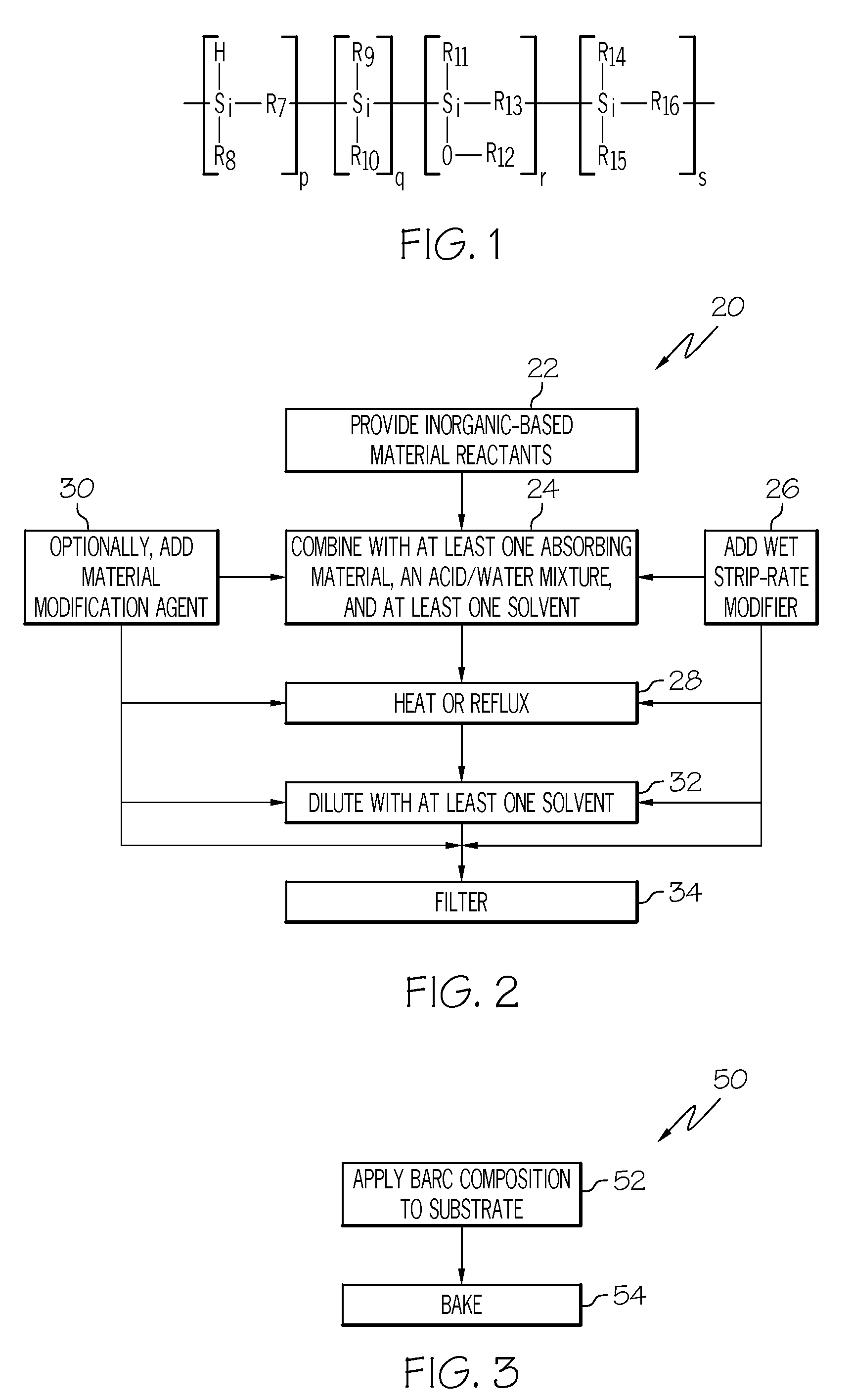

The invention relates to acrylic resin containing amphiphilic lateral chains, a preparation method thereof and application of the acrylic resin containing the amphiphilic lateral chains. The general structural formula of the acrylic resin containing the amphiphilic lateral chains is as shown in a figure 1. The preparation method comprises the following steps: (1) dichloromethane, tetraethylene glycol and triethylamine are added, acryloyl chloride is slowly dripped into the mixture under the protection of nitrogen, and the mixture is subjected to temperature rise and stirring; (2) ester obtained in the step (1) is dissolved in anhydrous dichloromethane, dipped with acyl fluoride containing perfluor polyether chains, and stirred at a temperature of 80 DEG C below zero and 25 DEG C; and (3) 100 to 150 millimeters of tetrahydrofuran and 800 to 900 milligrams of initiator are added, and the mixture is subjected to temperature rise to between 60 and 80 DEG C, added with 15 to 20 grams of methacrylic ester, 12 to 15 grams of glycidyl methacrylate and 15 to 25 grams of acrylic acid derivatives under the protection of the nitrogen, stirred, subjected to temperature rise to between 65 and 80 DEG C, maintained at a constant temperature for 48 to 72 hours to obtain the acrylic resin containing the amphiphilic lateral chains. The resin not only can be taken as a film former of marine antifouling coating but also has nontoxic and eco-friendly performance.

Owner:DONGHUA UNIV

Eight-foot-shaped Pt-Cu alloy nanometer material and synthetic method and application of eight-foot-shaped Pt-Cu alloy nanometer material

ActiveCN108161025AShort synthesis timePromote formationTransportation and packagingMetal-working apparatusSynthesis methodsMetallurgy

The invention belongs to the field of the preparation technology and catalysis of nanometer materials and particularly discloses an eight-foot-shaped Pt-Cu alloy nanometer material and a synthetic method of the eight-foot-shaped Pt-Cu alloy nanometer material. In the method, chloroplatinic acid and copper chloride serve as precursors, tetraethylene glycol serves as a solvent and a reducing agent,polyvinylpyrrolidone serves as a stabilizing agent, potassium iodide serves as a morphological control agent, and the eight-foot-shaped Pt-Cu alloy nanometer material is synthesized in a microwave assisting method. The synthetic method is quick and simple, high in energy efficiency and small in pollution, and the obtained eight-foot-shaped Pt-Cu alloy nanometer material is single in shape and evenin size; and the prepared eight-foot-shaped Pt-Cu alloy nanometer material has good electro-catalysis activity and can be applied to the fields such as bio-sensing, optical conduction and electrochemistry.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

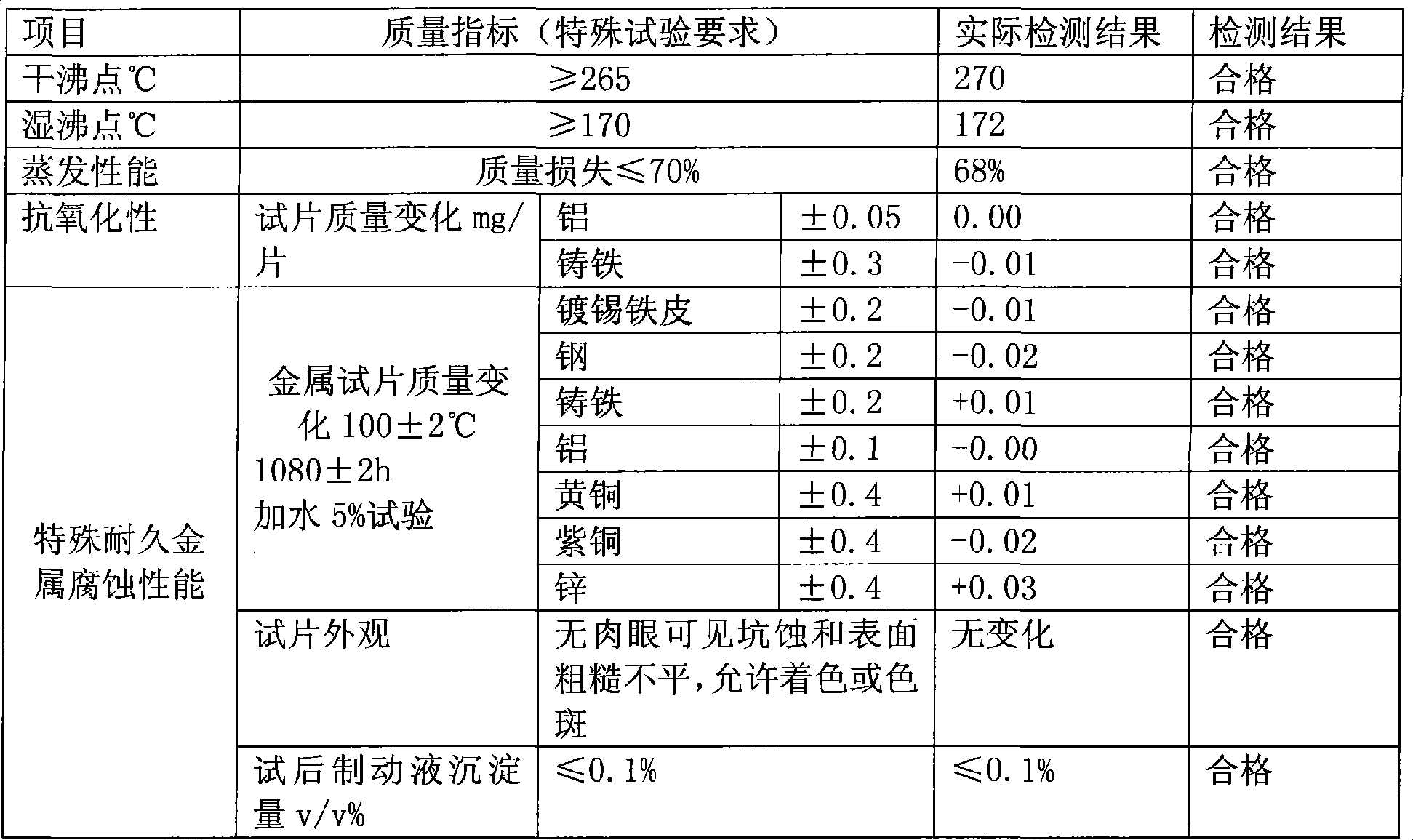

DOT4 boric acid ester type brake fluid

ActiveCN101418249ASolve the problem of long-term storage hydrolytic stabilityAdditivesBase-materialsMorpholinePhenol

The invention discloses a DOT4 boric acid ester type brake fluid, which comprises the following components in weight percentage: 4.3 to 4.7 percent of triethylene glycol methyl ether, 15 to 17 percent of tetraethylene glycol methyl ether, 1.9 to 2.1 percent of diethylene glycol, 74 to 76 percent of alcohol ether borate, 0.19 to 0.21 percent of benzotriazole, 0.33 to 0.37 percent of N-phenyl morpholine, 0.76 to 0.84 percent of tri-n-butylamine, 0.57 to 0.63 percent of 2, 2-di (4-hydroxyl phenyl) propane (bisphenol A), 0.057 to 0.063 percent of thiodipropionic acid didodecyl alcohol ester, 0.19 to 0.21 percent of 2.6-di-tert-butyl-4-methyl phenol, 0.095 to 0.105 percent of mercapto styrene-acrylic thiazole, and 0.38 to 0.42 percent of dodecatylene butane diacid (T746). The DOT4 boric acid ester type brake fluid has the advantages that the DOT4 boric acid ester type brake fluid can thoroughly solve the problem of hydrolytic stability of boric acid ester for long term storage by using a formulation technology of combining organic substances and additives.

Owner:张家港迪克汽车化学品有限公司

Alkane and polyamine solvent compositions for liquid delivery chemical vapor deposition

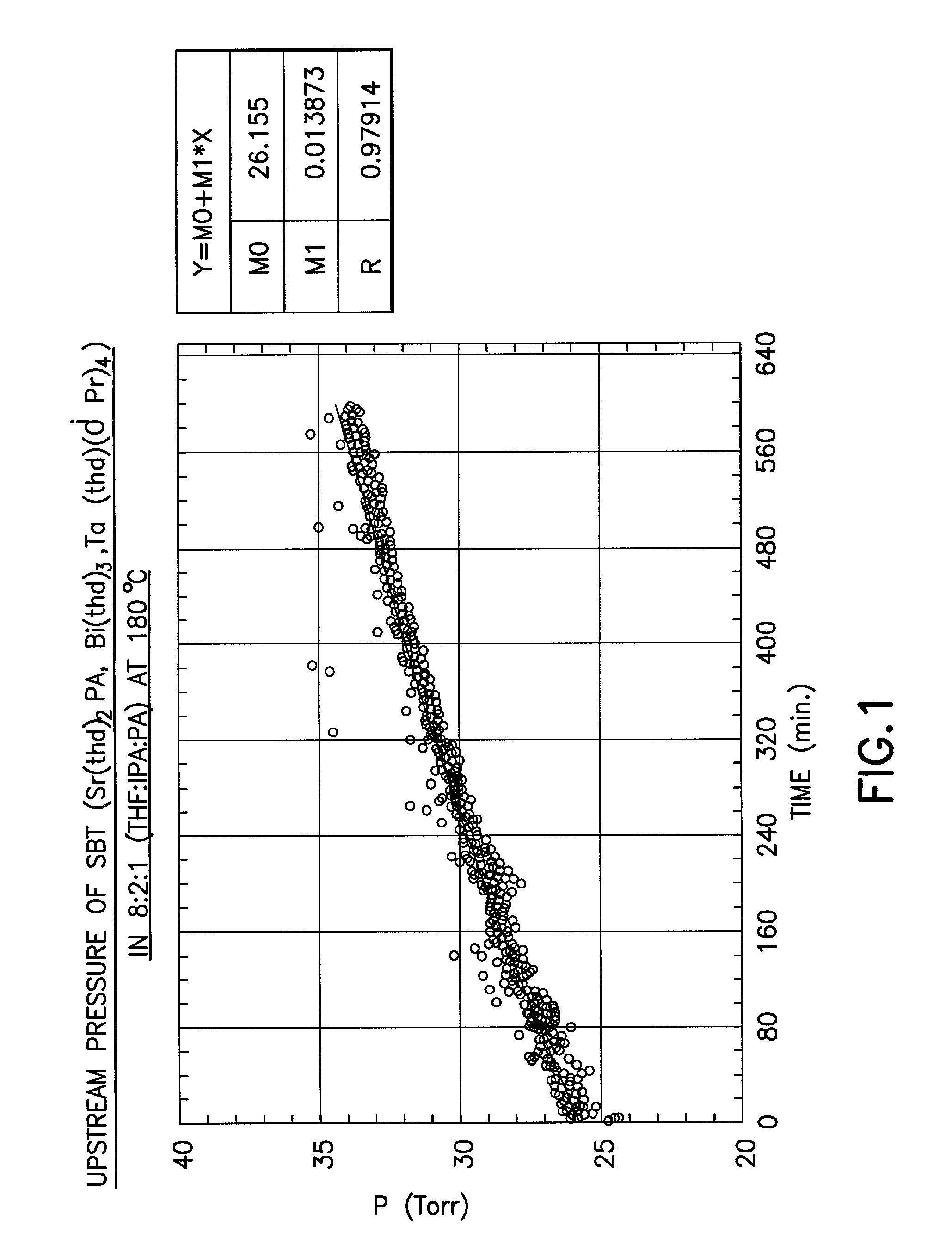

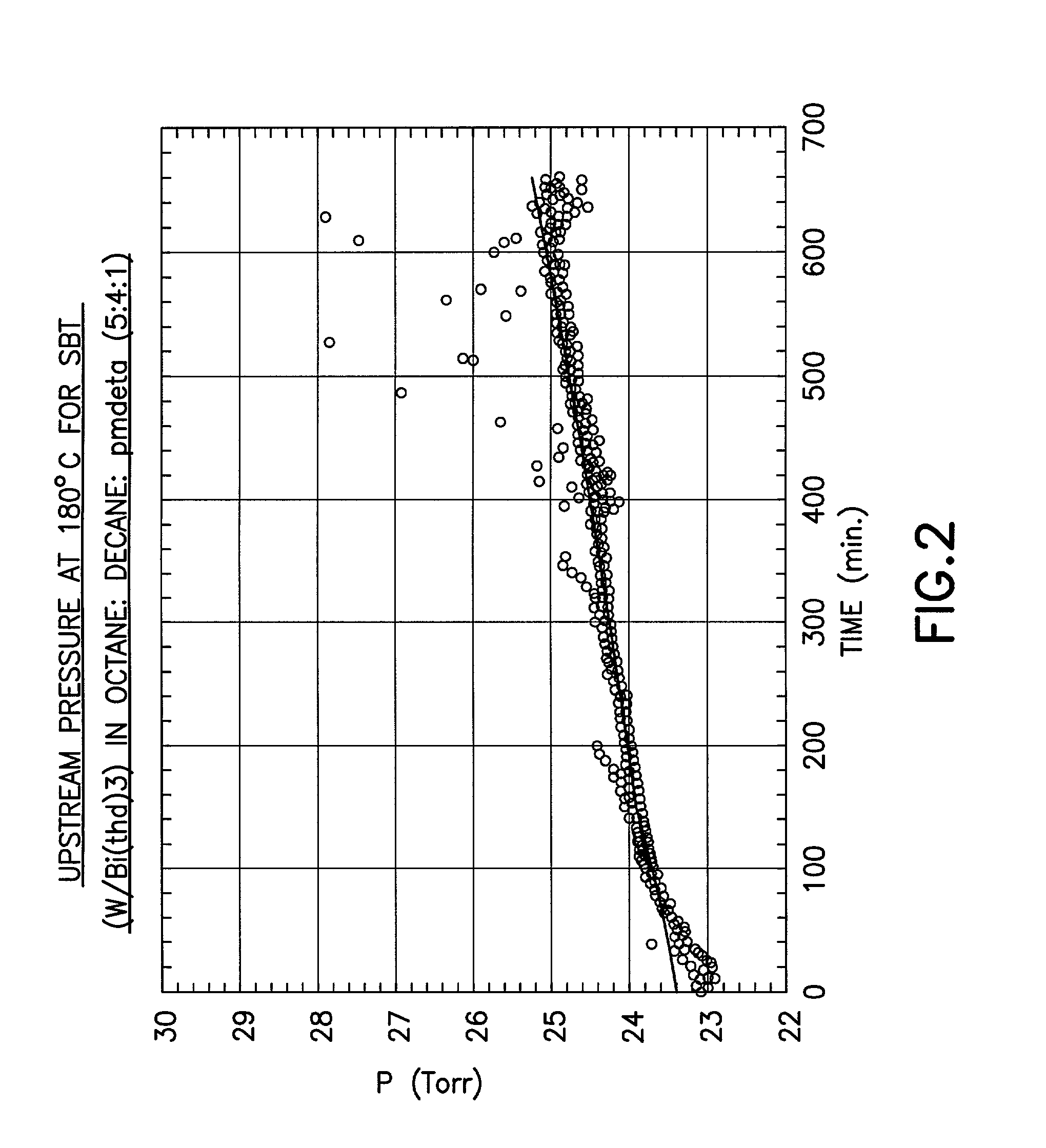

A solvent composition for liquid delivery chemical vapor deposition of metal organic precursors, to form metal-containing films such as SrBi2Ta2O9 (SBT) films for memory devices. An SBT film may be formed using precursors such as Sr(thd)2(tetraglyme), Ta(OiPr)4(thd) and Bi(thd)3 which are dissolved in a solvent medium comprising one or more alkanes. Specific alkane solvent compositions may advantageously used for MOCVD of metal organic compound(s) such as beta-diketonate compounds or complexes, compound(s) including alkoxide ligands, and compound(s) including alkyl and / or aryl groups at their outer (molecular) surface, or compound(s) including other ligand coordination species and specific metal constituents.

Owner:ENTEGRIS INC

Cleaning agent

InactiveCN101784648ACan be cleanedCan detoxifyOrganic detergent compounding agentsUsing liquid separation agentTaurineCleansing Agents

Disclosed is a cleaning agent containing a 0.0001-0.01% by weight aqueous solution or aqueous dispersion (A) of a linear poly(meth)acrylamide having an average molecular weight determined from limiting viscosity of not less than 5 106, a polyhexamethylene biguanide hydrochloride (B) represented by the formula (1) below, and at least one compound (C) selected from the group consisting of propylene glycol, dipropylene glycol, tripropylene glycol, diethylene glycol, triethylene glycol, tetraethylene glycol, ethylene glycol, an ether of propylene glycol and an alcohol having 1-3 carbon atoms, an ester of one of them and a fatty acid having 1-3 carbon atoms, glycine and taurine. Formula (1): [-(CH2)m-NH-C(NH)-NH-C(NH)-NH-(CH2)n-]pHCl. In the formula, m and n respectively represent an integer of 2-5, and p represents an integer of 5-16.

Owner:ESPO CHEM

Bottom antireflective coatings exhibiting enhanced wet strip rates, bottom antireflective coating compositions for forming bottom antireflective coatings, and methods for fabricating the same

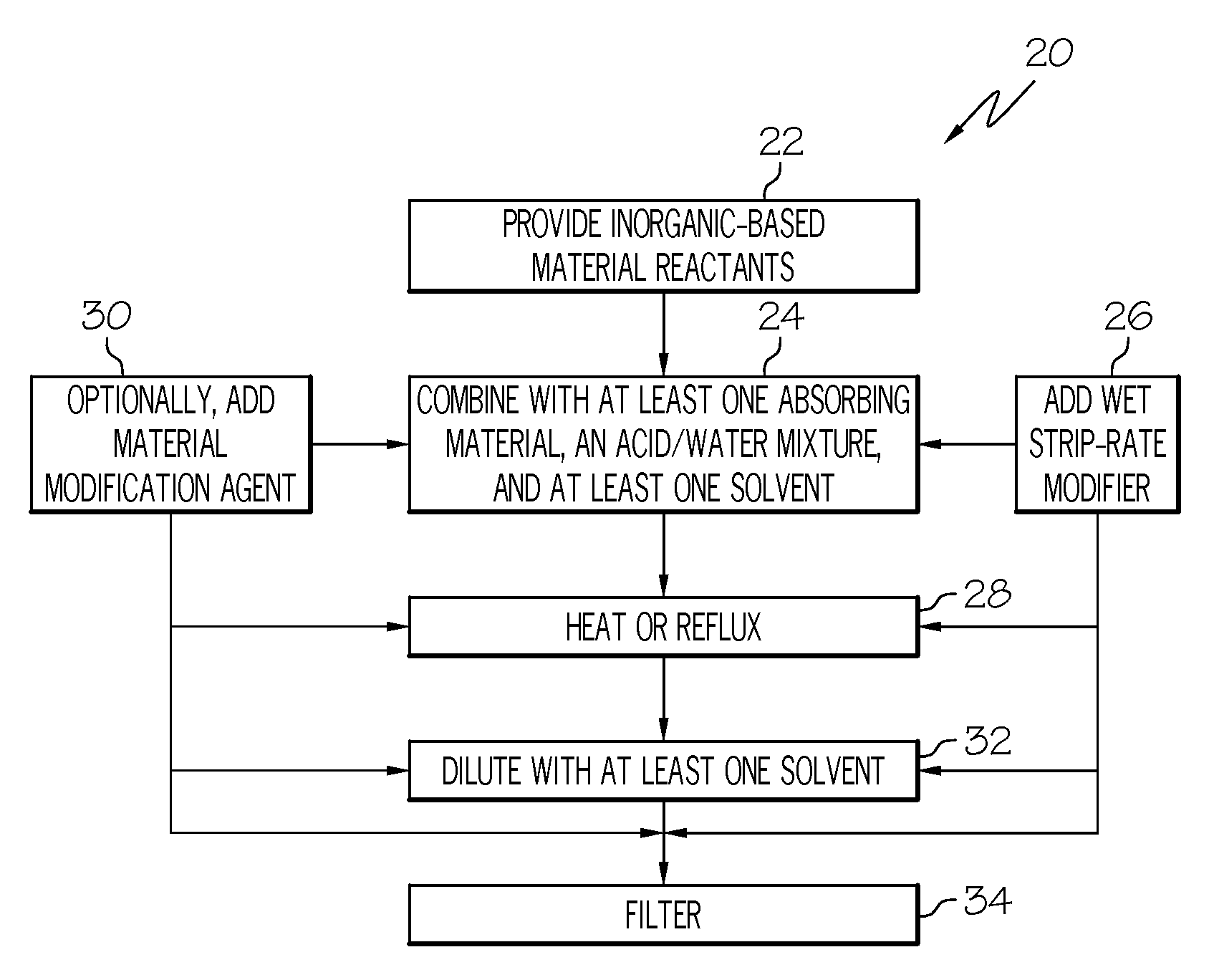

ActiveUS7955782B2Photosensitive materialsSemiconductor/solid-state device manufacturingAlcoholAbsorbent material

Bottom antireflective coating (BARC) that exhibit enhanced wet strip rates, BARC compositions for fabricating such BARCs, and methods for manufacturing such BARC compositions are provided. According to one exemplary embodiment, a bottom antireflective coating (BARC) composition comprises an inorganic-based compound, an absorbing material, and a wet strip-rate modifier combination. The wet strip-rate modifier composition comprises a combination of a short chain linear alcohol and dipropylene glycol (DPG), a combination of the short chain linear alcohol and tetraethylene glycol (TEG), a combination of DPG and TEG, or a combination of the short chain linear alcohol, DPG, and TEG.

Owner:HONEYWELL INT INC

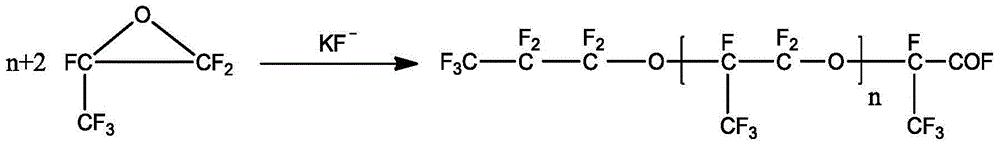

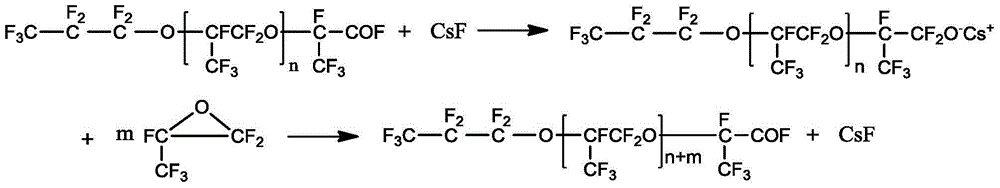

Preparation method for hexafluoropropylene oxide homopolymers

The invention discloses a preparation method for hexafluoropropylene oxide homopolymers. Potassium fluoride is employed as a catalyst to trigger ring-opening polymerisation of hexafluoropropylene oxide, a saturated solution of tetraethylene glycol dimethyl ether and fluorine containing solvent of cesium fluoride is added in batches for multiple times, the reaction temperature is lowered gradually from 0 DEG to -40 DEG C, thus reaction activity of tail end groups of hexafluoropropylene oxide homopolymers is kept, hexafluoropropylene oxide monomers are added continuously on this basis, and through control of addition times of hexafluoropropylene oxide and the cesium fluoride solution, hexafluoropropylene oxide homopolymers with an average polymerization degree of 50 can be synthesized. Through control of addition of monomers, hexafluoropropylene oxide homopolymers with an average polymerization degree of 20-50 can be synthesized selectively, and different industrial production requirements are met.

Owner:DONGGUAN DONGYANG SOLAR SCI RES & DEV CO LTD

Ink composition, recording method using the same, and recorded matter

ActiveCN101845250AReduce viscosity differenceEasy to curlDuplicating/marking methodsInksBetaineEmissivity

The invention provides an ink composition which reduces viscosity difference caused by temperature as well as has excellent suitability for curl and crinkle, excellent ink penetration resistance, suitability for two-sides printing and color emissivity, and also a recording method using the same and a recorded matter are disclosed. The ink composition includes at least a pigment, a humectant, and water in from 10 to 60% by weight to the total amount of ink. The humectant is a mixture of (A) at least one compound selected from glycerin, 1,2,6-hexanetriol, diethylene glycol, triethylene glycol, tetraethylene glycol, and dipropylene glycol; (B) either trimethylol propane or trimethylol ethane, or a mixture thereof; and (C) at least one compound selected from betaines, saccharides, and ureas and having a molecular weight in the range of from 100 to 200, at a content weight ratio of (A):(B):(C) of 1.0:0.1 to 1.0:1.0 to 3.5.

Owner:SEIKO EPSON CORP

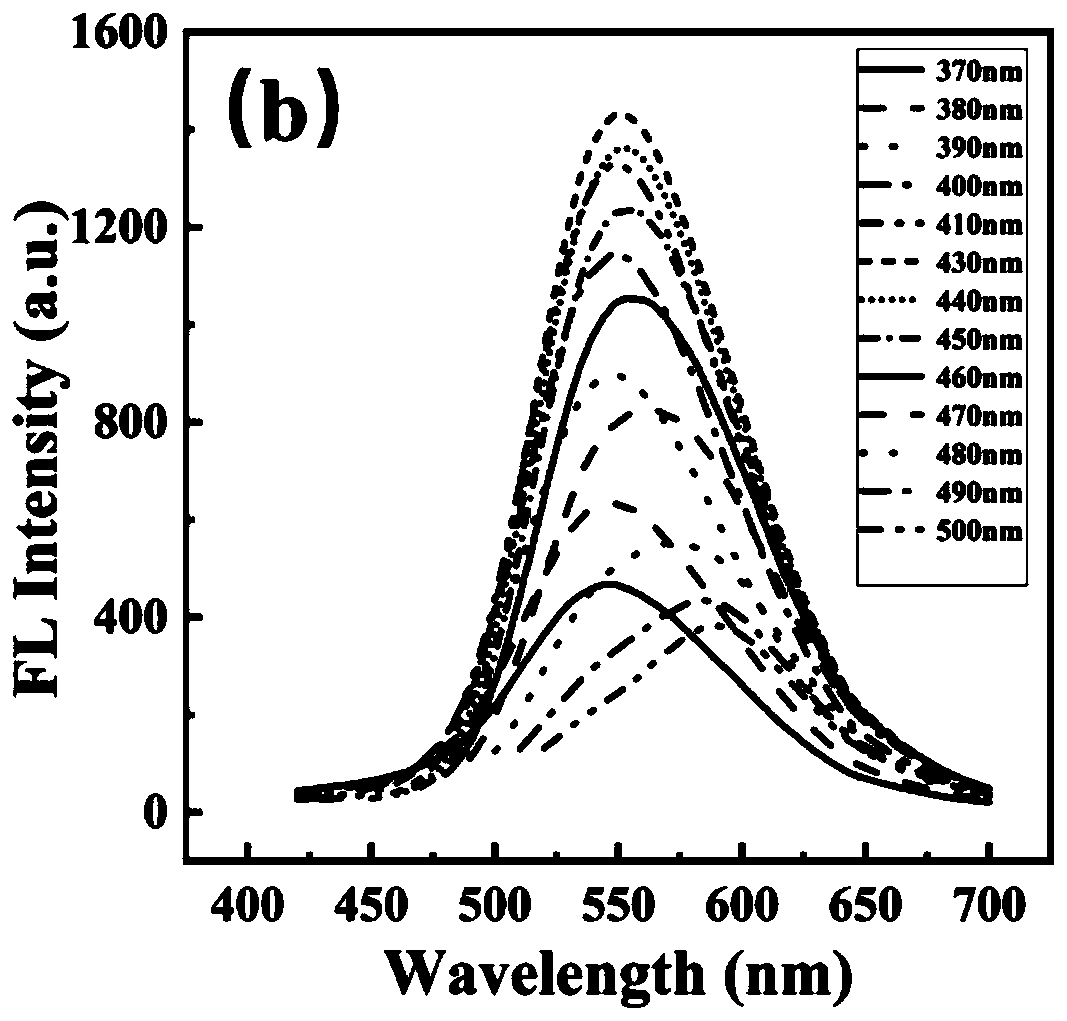

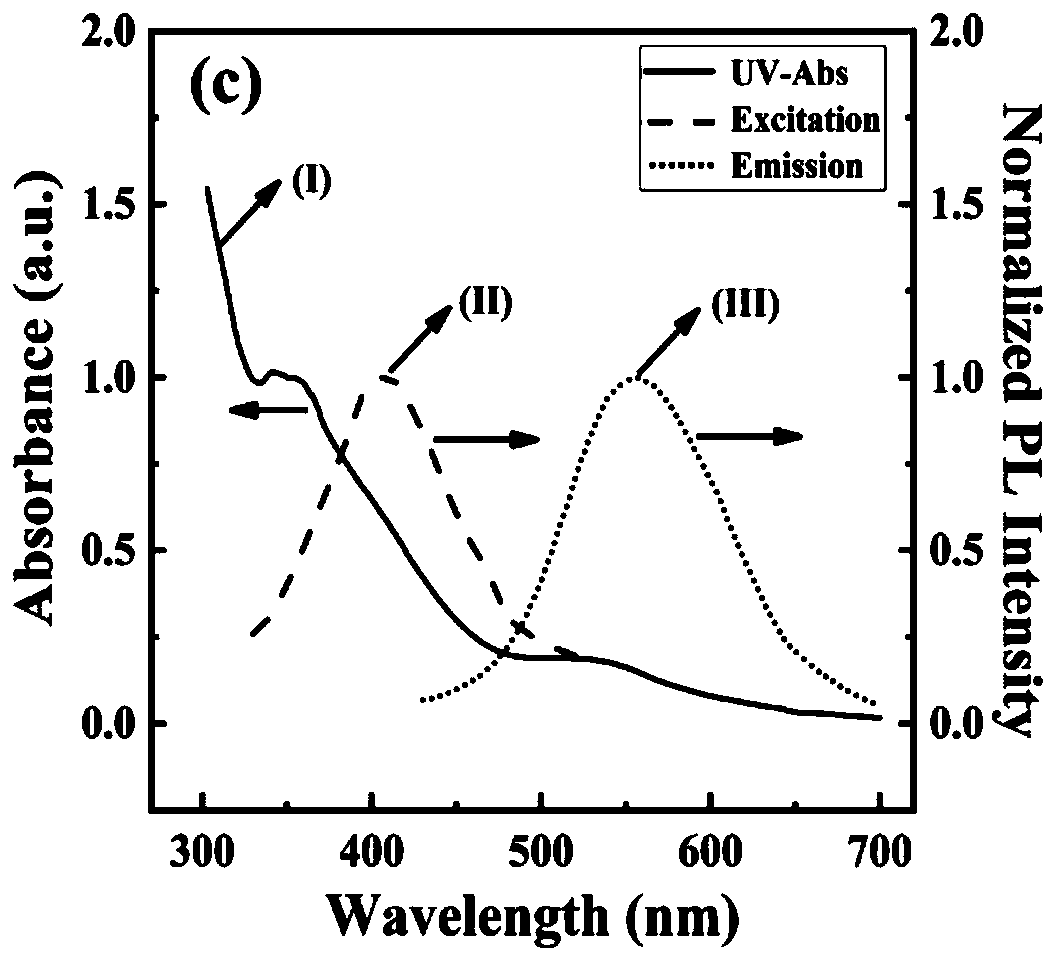

Fluorescent probe for detecting hypochlorite in water environment as well as preparation method and application thereof

PendingCN111286324AGood water solubilityEasy to detectMaterial nanotechnologyNanoopticsFluoProbesHypochlorite

The invention relates to a yellow fluorescent carbon quantum dot fluorescent probe and a preparation method and application thereof. The preparation method comprises the steps that: p-phenylenediamine, tetraethylene glycol, ethyl alcohol and concentrated sulfuric acid are mixed, a mixed reactant is carbonized through a solvothermal method, and then the yellow fluorescent carbon quantum dot fluorescent probe is obtained after separation and purification; the prepared yellow fluorescent carbon quantum dot fluorescent probe can be applied to detection of ClO<-> ions in a water environment. Compared with the prior art, the yellow fluorescent carbon quantum dot fluorescent probe provided by the invention has the advantages of simple and mature preparation method, rapid detection response, highselectivity, strong anti-interference performance, good reproducibility and the like, and has good application prospect and practical value in the fields of environment, chemistry, biology, medicine and the like.

Owner:SHANGHAI INST OF TECH

Prepn of tri-and tetra-glycol methyl ether and utilization of side product polyglycol methyl ether

InactiveCN1403429AImprove performanceReduce unit consumptionEther preparation from oxiranesSodium methoxideEpoxy

The present invention relates to the preparation of tri-and tetra-glycol methyl ether and the utilization of side product poly-glycol methyl ether. Alcohol and epoxy ethane are made to react in the presence of alkali metal compound catalyst and the product is depression rectified to obtain separated di, tri- and tetra-glycol methyl ether as well as side product penta-and over glycol methyl ether. The utilization of the side product includes reaction of poly-glycol methyl ether with sodium hydroxide, potassium hydroxide, sodium methoxide or metal sodium to prepare poly-glycol methyl ether sodium or potassium; Williamson reaction with alkylating agent and filtering to prepare side product sodium or potassium salt; and decoloring, adsorption and high vacuum depression distillation to prepare poly-glycol dimethyl ether.

Owner:JIANGSU YIDA CHEM

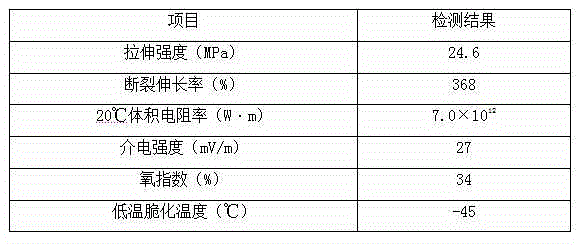

Low-temperature reinforced type heating cable sheathing material and preparation method thereof

InactiveCN104448811AImprove low temperature resistanceHigh mechanical strengthPlastic/resin/waxes insulatorsEpoxyBoride

The invention discloses a low-temperature reinforced type heating cable sheathing material and a preparation method thereof. The low-temperature reinforced type heating cable sheathing material is prepared from the following raw materials in parts by weight: 36-52 parts of nylon 66, 24-48 parts of polytetrafluoroethylene, 18-32 parts of polyamide imide, 10-15 parts of low-molecular-weight polybutylene, 14-18 parts of magnesium borate whiskers, 12-16 parts of illite powder, 10-15 parts of tetraethylene glycol diheptylate, 5-10 parts of nano zirconium boride, 3-5 parts of magnesium oleate, 8-14 parts of diisodecyl adipate, 4-6 parts of aluminum hydroxydistearate, 6-9 parts of caprylic / capric triglyceride, 10-15 parts of dioctyl sebacate, 5-10 parts of epoxy fatty acid methyl ester, 1-2 parts of polyethylene oxide sorbitan monoleate and 3-4 parts of auxiliaries. The low-temperature reinforced type heating cable sheathing material has good low-temperature resistance, a low-temperature brittleness temperature up to -45 DEG C, extremely good mechanical strength and excellent corrosion resistance, ageing resistance and abrasive resistance, and is durable in use and wide in range of application.

Owner:ANBANG ELECTRICAL GRP

Reference electrolyte capable of improving cycling performance of lithium-sulfur battery and preparation method

InactiveCN107819152ALow priceImprove cycle performanceElectrolytesLi-accumulatorsHexamethyldisilaneLithium–sulfur battery

The invention belongs to reference electrolyte capable of improving the cycling performance of a lithium-sulfur battery and a preparation method. The reference electrolyte is prepared from an ether type solvent, lithium salt, lithium nitrate and an additive for improving the cycling performance, wherein the ether type solvent is a mixture of two solvents; a first solvent is any one of 1,3-dioxolane and 1,4-dioxane; a second solvent is any one of ethylene glycol dimethyl ether, diethylene glycol dimethyl ether and tetraethylene glycol dimethyl ether; the lithium salt is any one of LiPF6, LiBF4,LiTFSi, LiFSi and LiBOB; the additive for improving the cycling performance is any one of 3-aminopropyltriethoxysilane, hexamethyldisilane and tetraethyl silicate. The reference electrolyte has the advantages that a preparation process is simple, the prices of the solvents and the additive are cheap, and materials are saved; the reference electrolyte can have a good negative electrode lithium protection effect; after lithium-sulfur battery electrolyte is used in the lithium-sulfur battery, the cycling performance and the safety of the lithium-sulfur battery can be remarkably improved.

Owner:HUARUI XINXIANG CHEM

Sodium ion battery positive electrode material, preparation method thereof and sodium ion battery

ActiveCN107978743AImprove conductivityHigh voltageCell electrodesSecondary cellsSpace groupSodium-ion battery

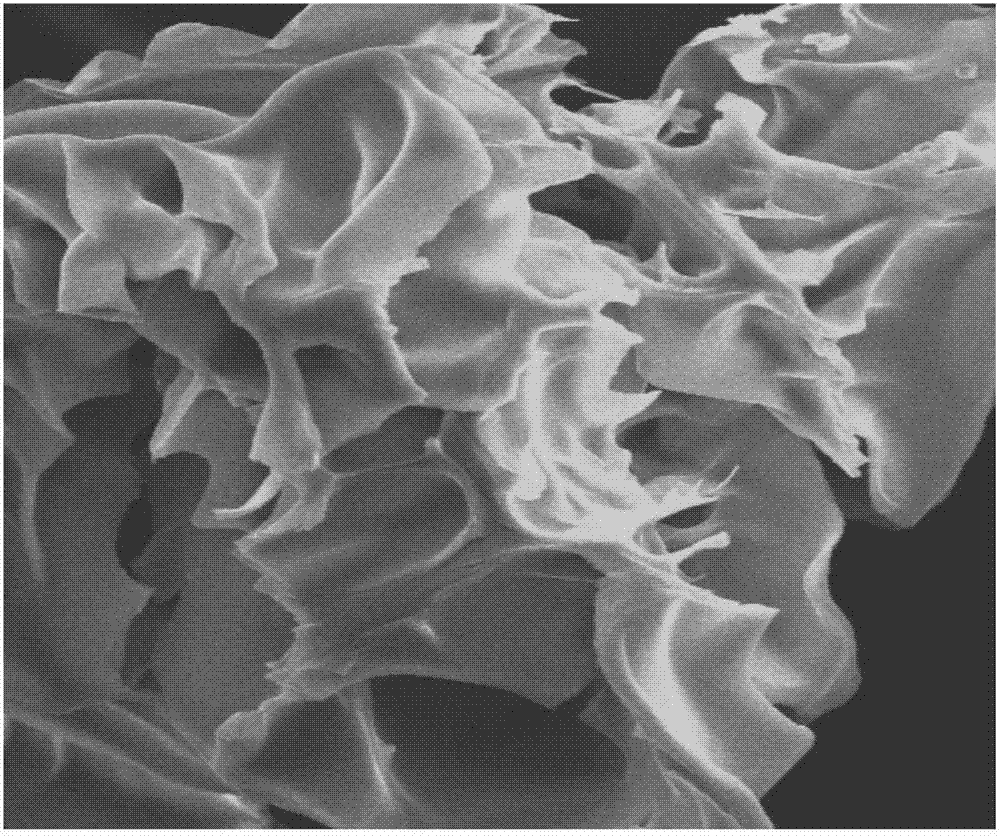

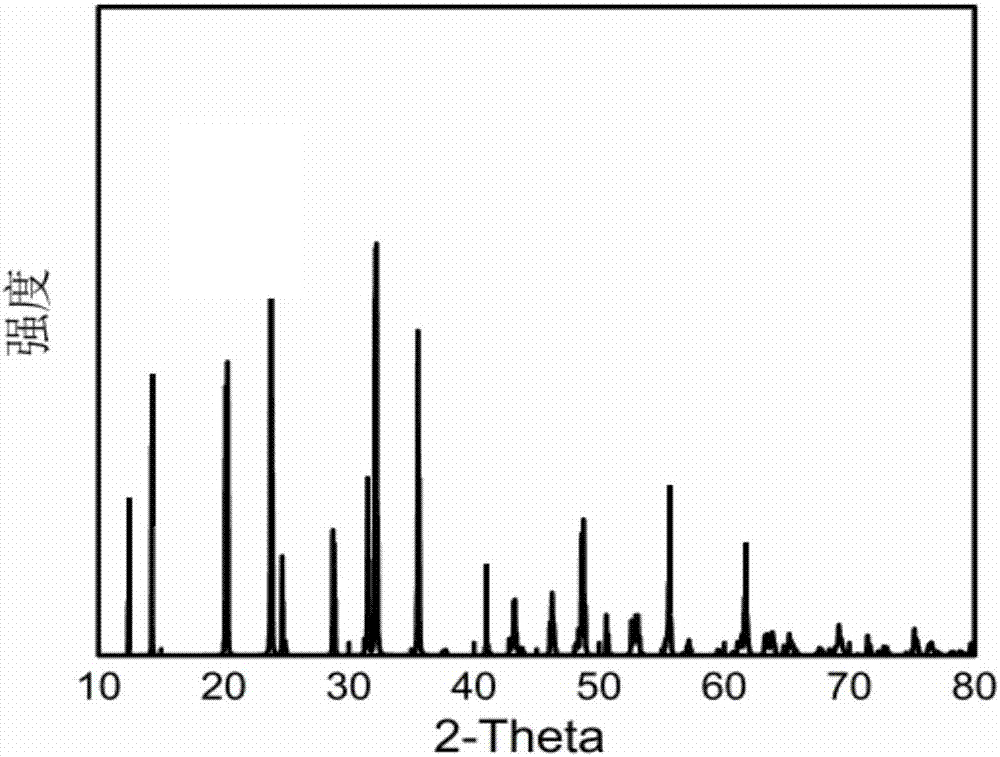

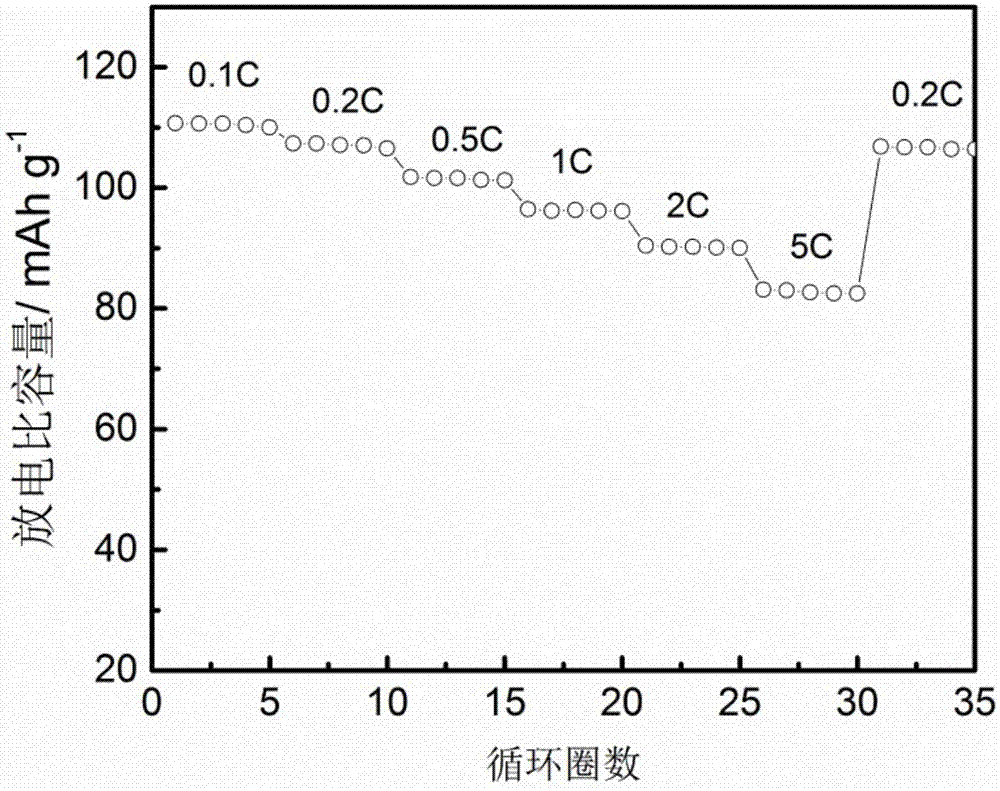

The invention discloses a sodium ion battery positive electrode material. The molecular formula of the sodium ion battery positive electrode material is Na<4>Fe<0.5>Mn<0.5>V(PO<4>)<3>, is a trigonal system and is an irregularly-shaped sheet structure, and the space group is R-3c. The invention also discloses a preparation method of the sodium ion battery positive electrode material. The preparation method comprises the steps of dissolving a sodium source, an iron source, a manganese source, a vanadium source and a phosphate source in deionized water according to a stoichiometric ratio, addinga mixed solution of tetraethylene glycol and ethylene glycol, and performing stirring reaction under a room temperature to obtain a mixed liquid; transferring the mixed liquid to the reaction kettle,performing heating reaction to obtain viscous colloid, and freezing and drying the viscous colloid to obtain precursor powder; and performing high-temperature calcination on the precursor powder underan inert atmosphere to obtain the sheet-shaped sodium ion battery positive electrode. The method is good in repeatability, is simple to operate and has industrial application prospect. The inventionalso provides a sodium ion battery employing the sodium ion battery positive electrode material. The sodium ion battery has excellent electrochemical performance.

Owner:湖南钠邦新能源有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com