Alkane and polyamine solvent compositions for liquid delivery chemical vapor deposition

a technology of solvent compositions and polyamines, applied in the field of solvents, can solve the problems of difficult control of bi.sub.2o.sub.3, premature decomposition, and unsuitable overall compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

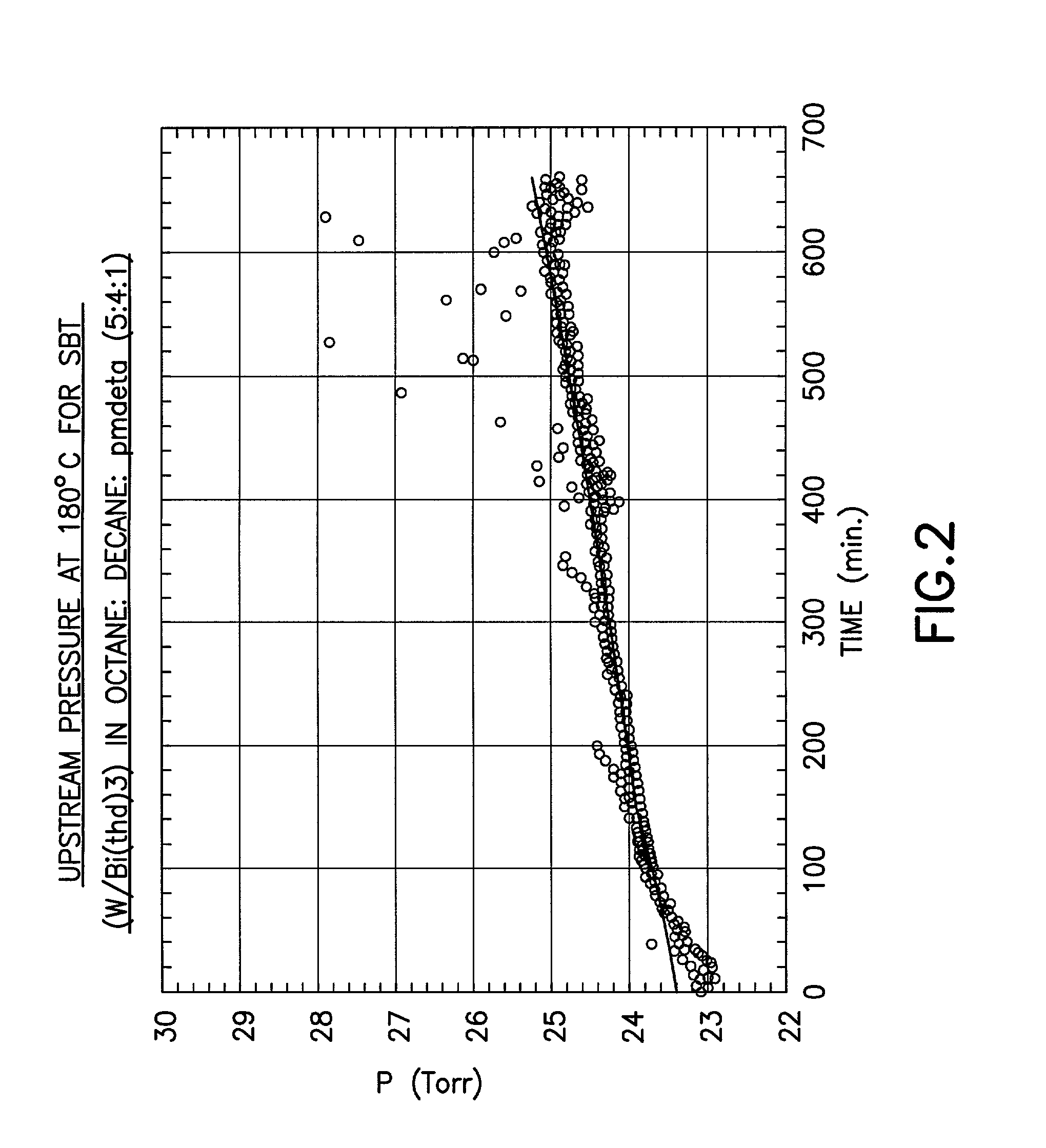

[0073] A solution containing 7 atomic percent Sr(thd).sub.2(pentamethyldie-thylenetriamine), 55 atomic percent Bi(thd).sub.3 and 38 atomic percent Ta(OiPr).sub.4(thd), wherein thd=2,2,6,6-tetramethyl-3,5-heptanedionato, in a solvent mixture of 5:4:1 octane:decane:pentamethyldiethylenetriamine is metered to the liquid delivery chemical vapor deposition system where the precursor solution is flash vaporized at 190.degree.C. and then carried to the CVD chamber in 400 sccm argon.

[0074] The precursor vapor is mixed with 1100 sccm oxygen and then additional 100 sccm argon for a combined for a 7:3 oxygen:argon ratio, and is passed through a showerhead disperser to the chemical vapor deposition chamber which is maintained at 1 torr. Decomposition occurs on a substrate heated to a surface temperature of 385.degree.C. The substrate is a 0.5 micron linewith SiO.sub.2 (TEOS) structure covered with platinum. The SBT film produced on the substrate is highly conformal, exhibiting a minimum SBT thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com