Method for synthesizing ferrimagnetism hollow microballoons

A technology of hollow microspheres and ferrite, applied in the field of magnetic material preparation, can solve the problems of high price, unfavorable batch production, and many steps of triblock polymer PEO-PPO-PEO, and achieve low cost and simple method , wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

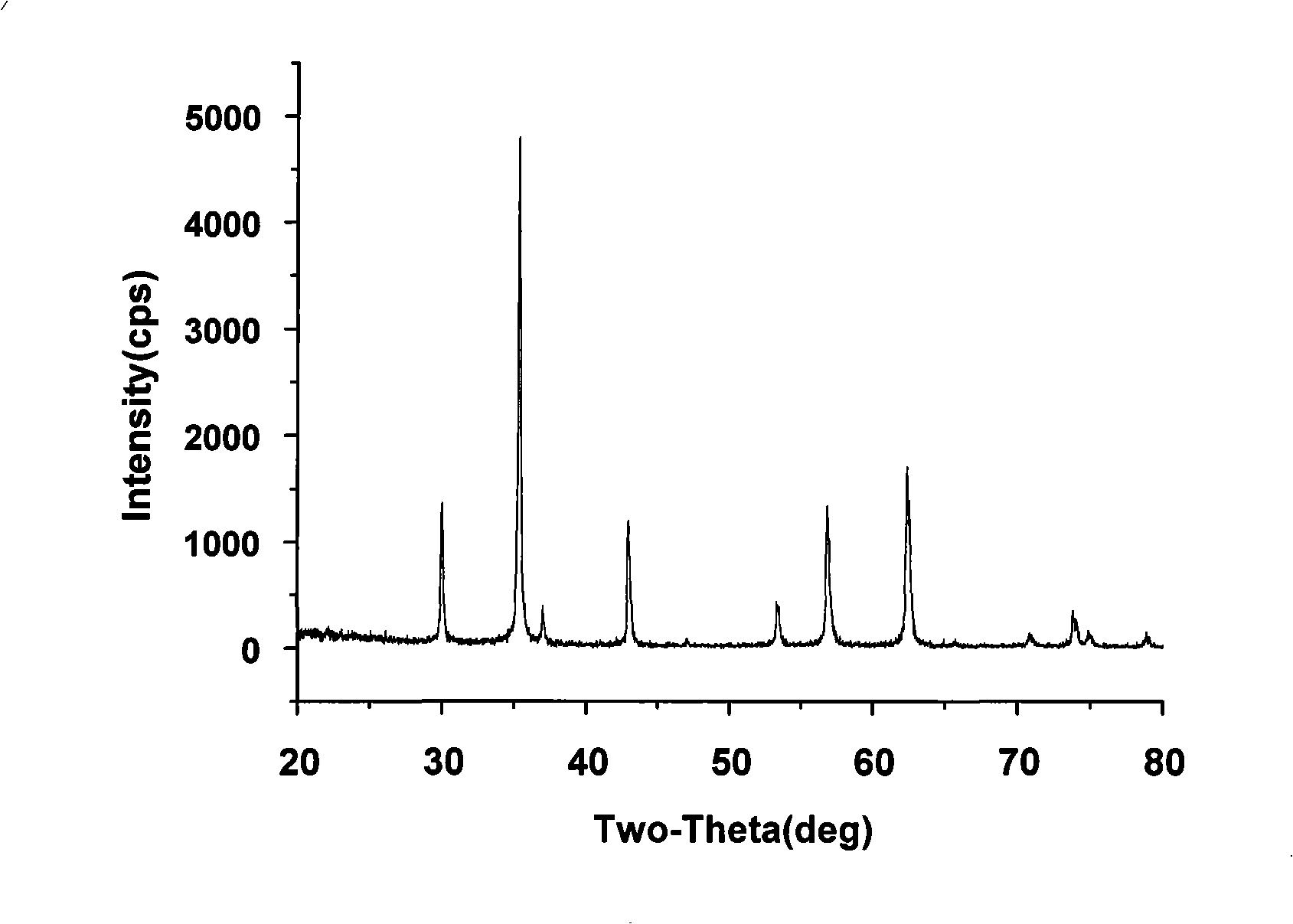

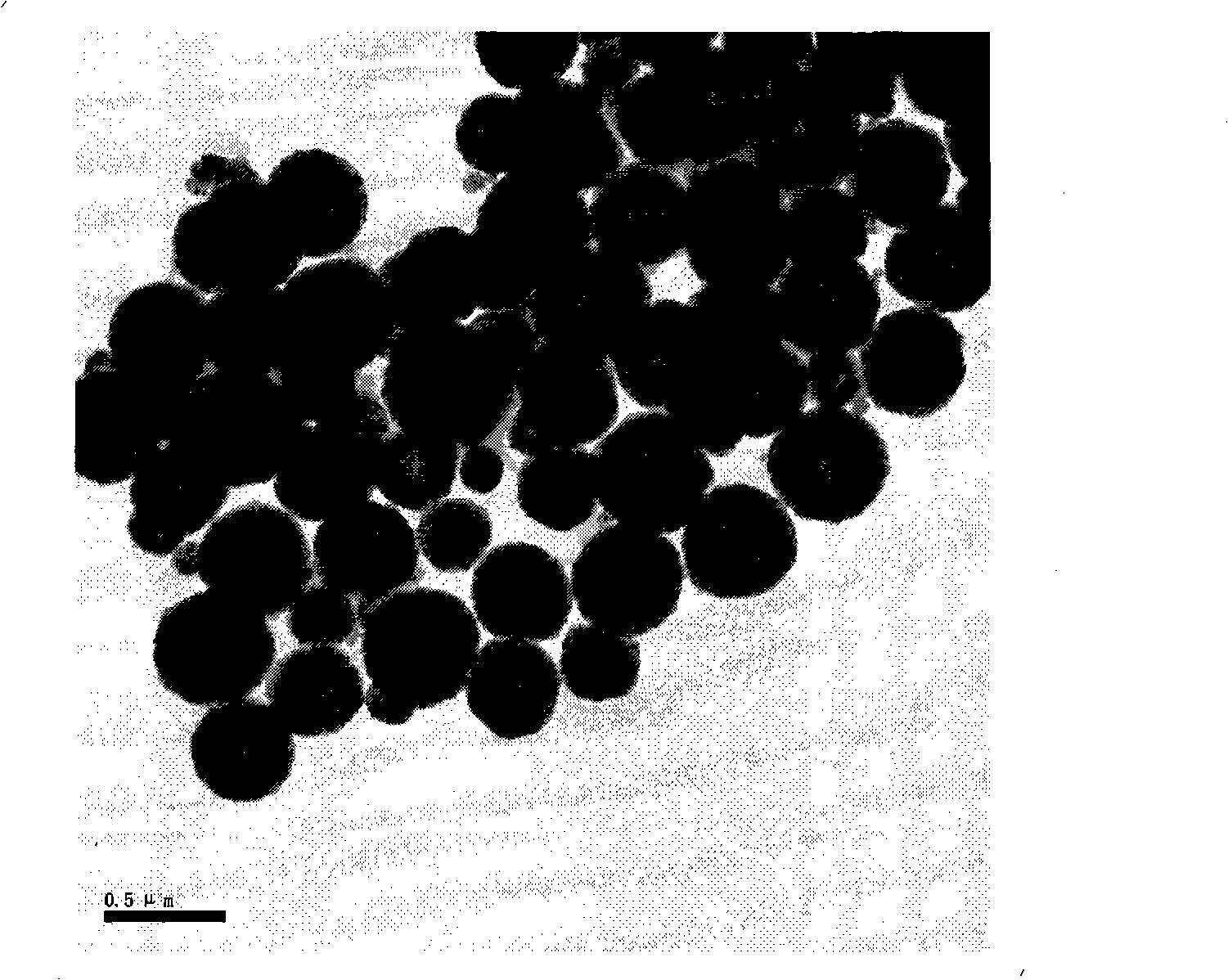

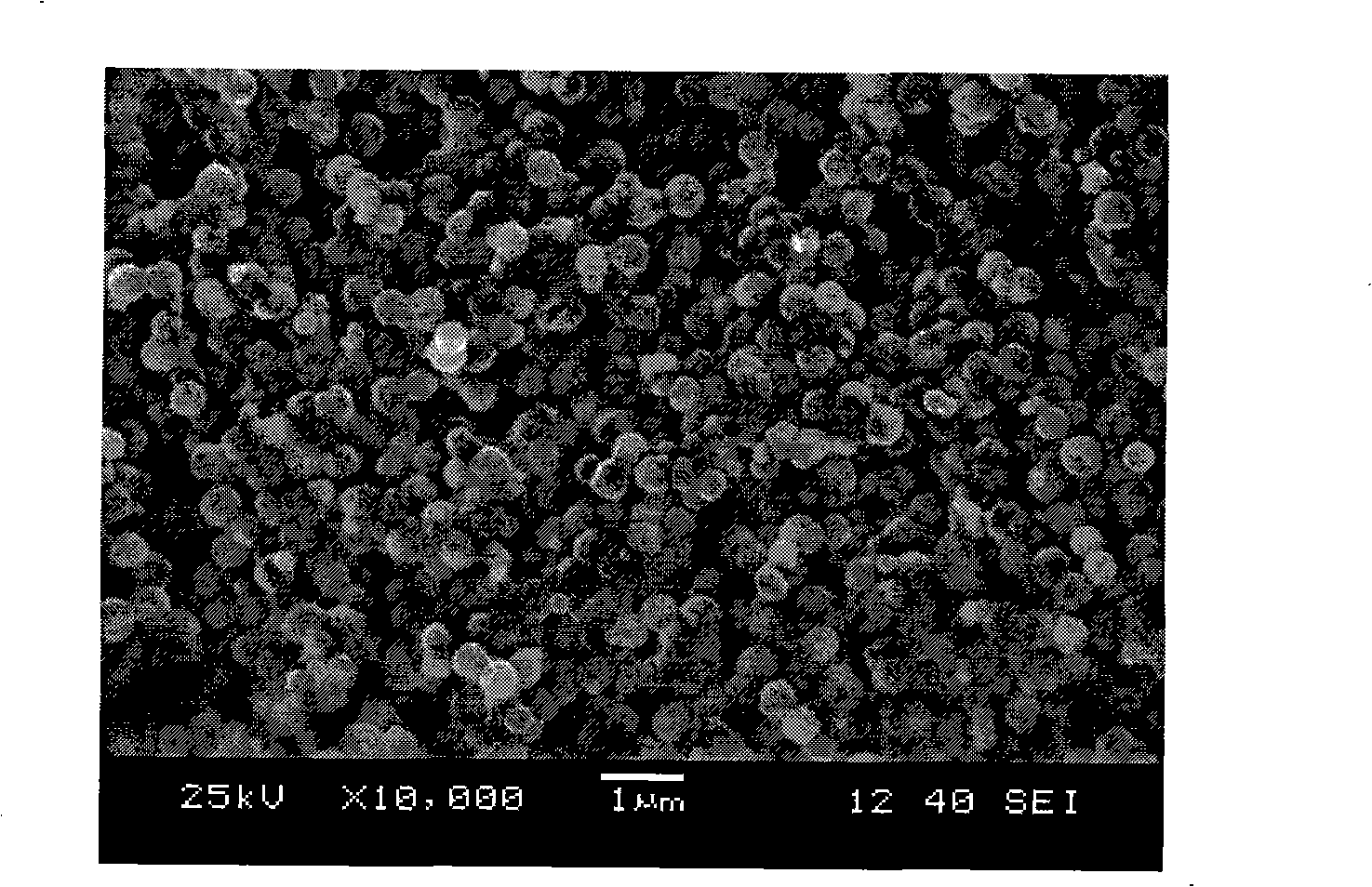

[0016] Embodiment 1 weighs 0.675g FeCl 3 ·6H 2 O, add to 20ml ethylene glycol to dissolve completely. Then weigh 0.9-3.6g sodium acetate and 0.1-2.0g polyethylene glycol 1000 and add to FeCl 3 ·6H 2 O, in the ethylene glycol solution, stir vigorously for about 30 minutes, stir evenly, place in a 30ml stainless steel pressure-resistant reaction kettle, react at 200°C for 6 hours, and obtain a black powder after centrifugation, washing and drying of the obtained precipitate . Such as figure 1 The shown product is identified as ferric oxide by X-ray diffraction (XRD); its shape and size are observed with a transmission electron microscope (TEM), and the product is a hollow microsphere with a particle diameter between 150-500nm.

Embodiment 2

[0017] Example 2 The test method is the same as in Example (1), except that 0.1-2.0 g of polyethylene glycol 6000 is used to replace 0.1-2.0 g of polyethylene glycol 1000, and black powder is also obtained.

Embodiment 3

[0018] Example 3 The test method is the same as in Example (1), except that 0.1-2.0 g of polyethylene glycol 10000 is used instead of 0.1-2.0 g of polyethylene glycol 1000, and black powder is also obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com