Patents

Literature

82 results about "Ferrimagnetism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

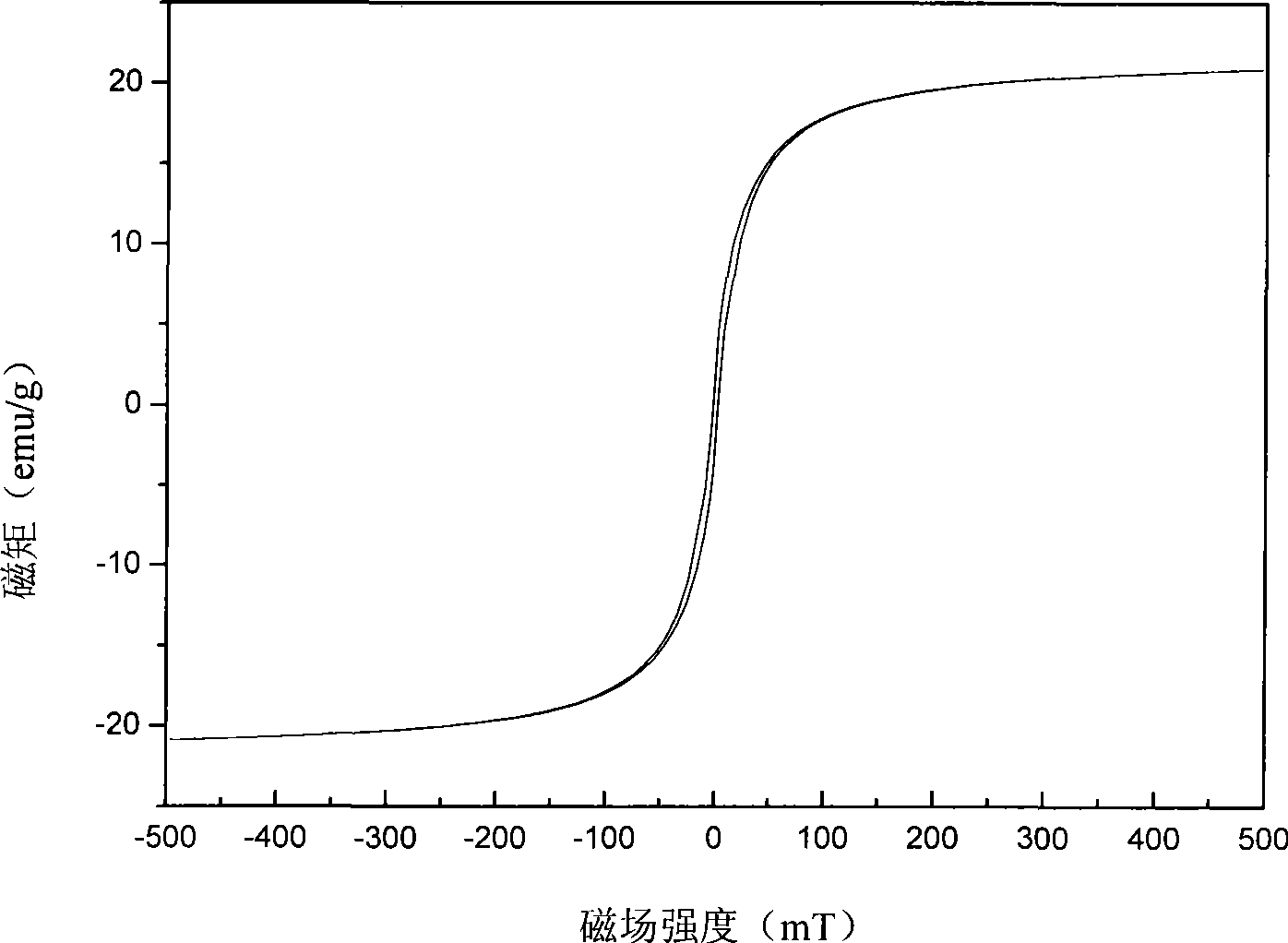

In physics, a ferrimagnetic material is one that has populations of atoms with opposing magnetic moments, as in antiferromagnetism; however, in ferrimagnetic materials, the opposing moments are unequal and a spontaneous magnetization remains. This happens when the populations consist of different materials or ions (such as Fe²⁺ and Fe³⁺).

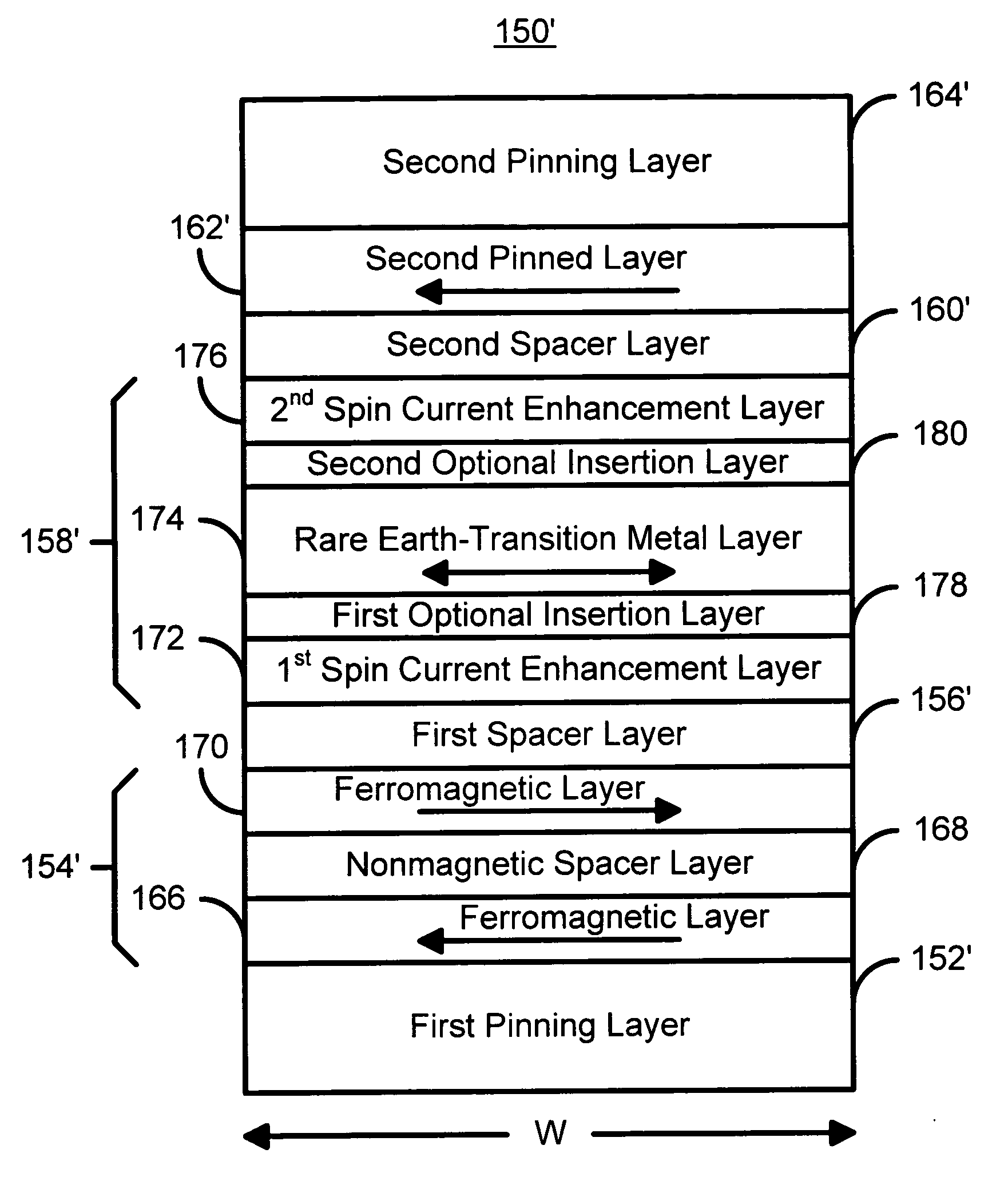

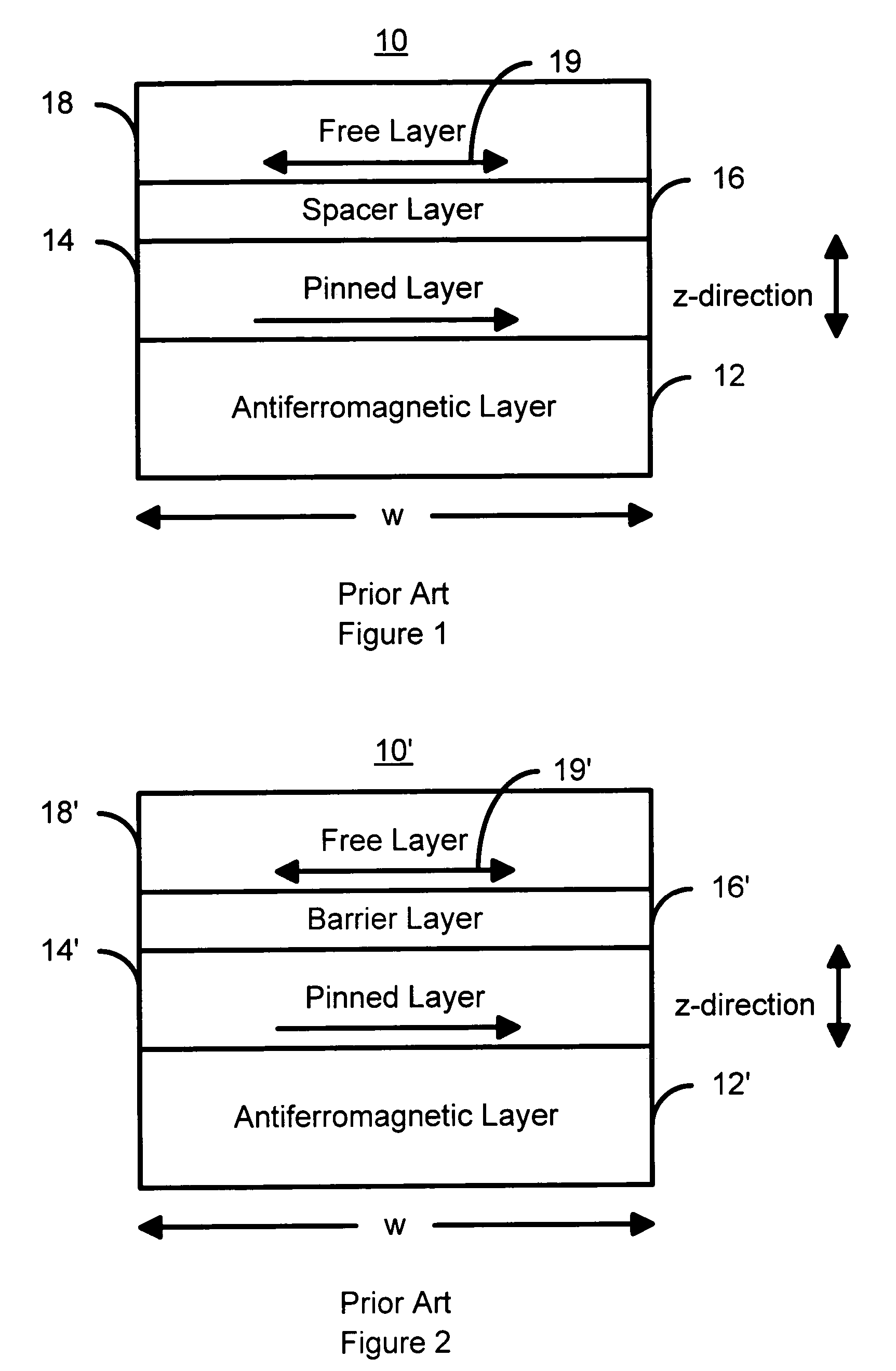

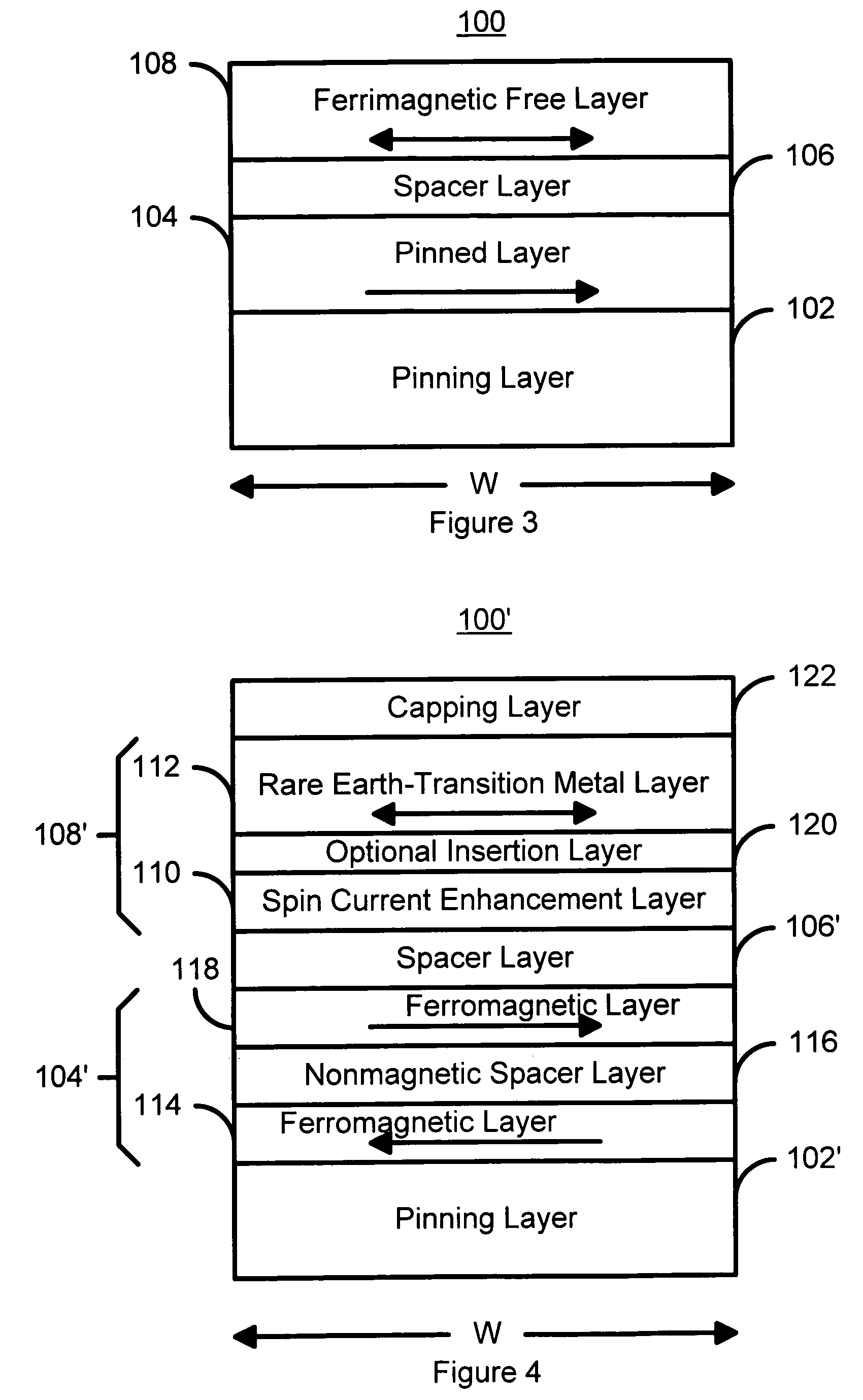

Spin-transfer switching magnetic elements using ferrimagnets and magnetic memories using the magnetic elements

Owner:SAMSUNG SEMICON

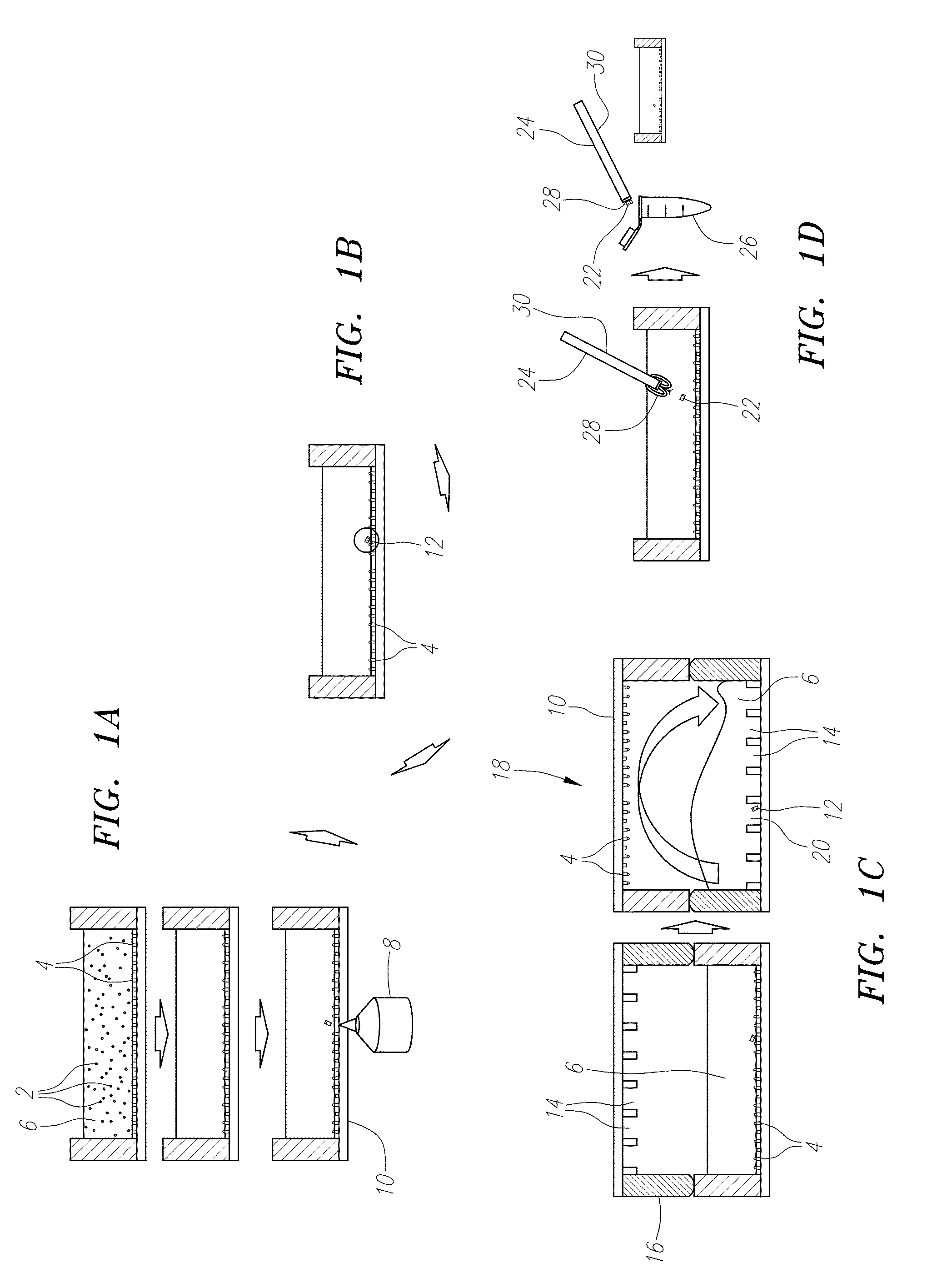

Induction cured power coatings for temperature sensitive substrates

According to the present invention, powder coating compositions comprise one or more than one thermoplastic or thermosetting polymer or resin and one or more than one finely divided magnetic material, such as a ferromagnetic material. Preferred magnetic materials include Ni1−xZnxFe2O4 compounds, wherein 0.4≦X≦0.75, piezoelectric compounds, ferrimagnetic δFeOOH, Fe—Ni—B, Cu2MnIn, transparent polymer-Cobalt oxide nanocomposites and soft ferrites. In addition, the present invention provides methods of making powder coatings on a substrate comprising applying to a substrate a resinous powder coating composition comprising one or more than one magnetic material to form a powder coating layer, followed by induction heating to melt the applied powder coating to form a coating film and, optionally, to cure the powder coating. The powder coatings remain at a pre-selected temperature equal to or less than the Curie temperature (TC) of the one or more than one finely divided magnetic material during induction heating of the powder coating without directly heating the substrate. Powder coatings on metal parts may also be induction heat cured.

Owner:ROHM & HAAS CO

Induction cured powder coatings for temperature sensitive substrates

According to the present invention, powder coating compositions comprise one or more than one thermoplastic or thermosetting polymer or resin and one or more than one finely divided magnetic material, such as a ferromagnetic material. Preferred magnetic materials include Ni1−xZnxFe2O4 compounds, wherein 0.4≦X≦0.75, piezoelectric compounds, ferrimagnetic δFeOOH, Fe—Ni—B, Cu2MnIn, transparent polymer-Cobalt oxide nanocomposites and soft ferrites. In addition, the present invention provides methods of making powder coatings on a substrate comprising applying to a substrate a resinous powder coating composition comprising one or more than one magnetic material to form a powder coating layer, followed by induction heating to melt the applied powder coating to form a coating film and, optionally, to cure the powder coating. The powder coatings remain at a pre-selected temperature equal to or less than the Curie temperature (TC) of the one or more than one finely divided magnetic material during induction heating of the powder coating without directly heating the substrate. Powder coatings on metal parts may also be induction heat cured.

Owner:ROHM & HAAS CO

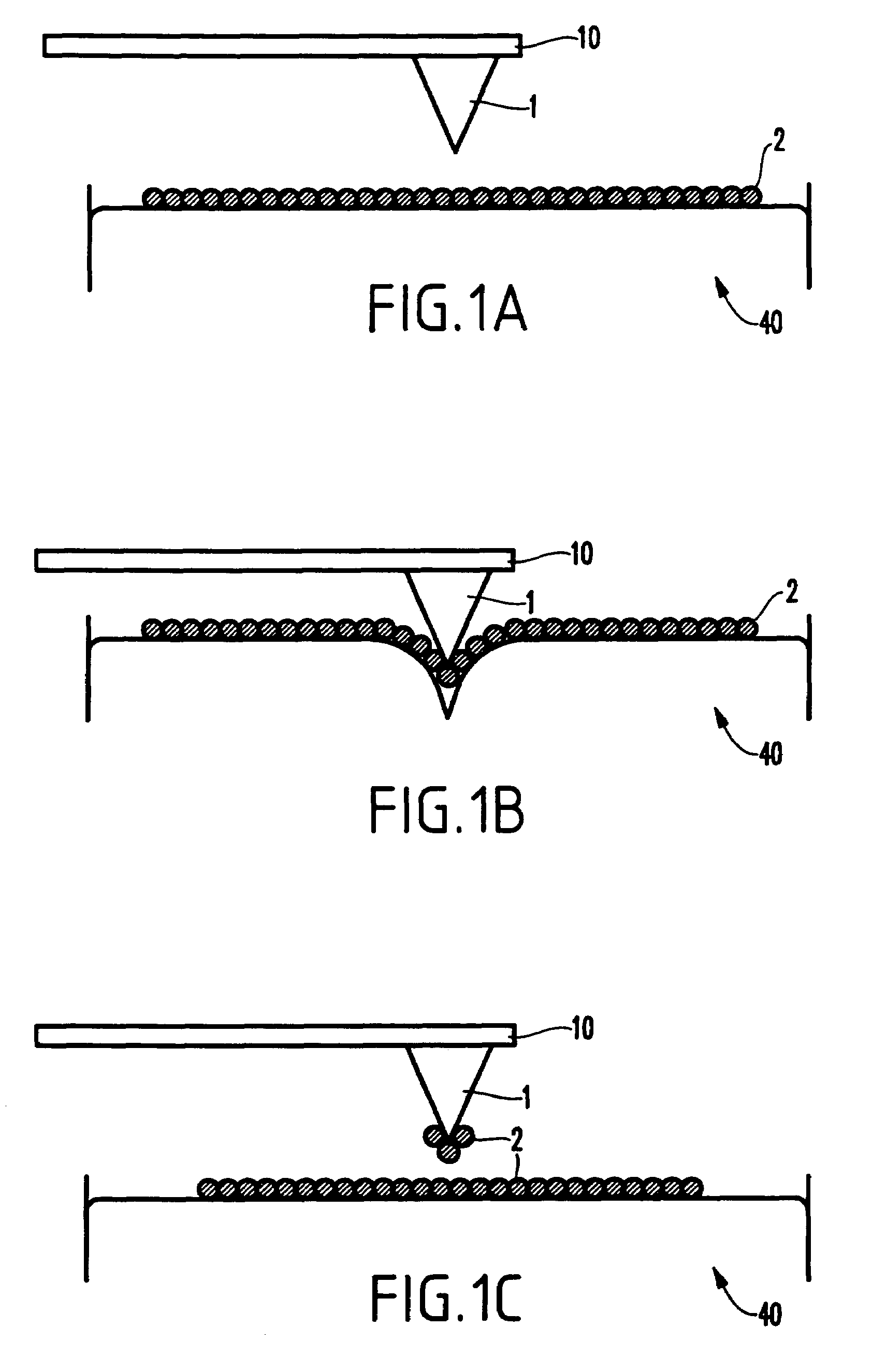

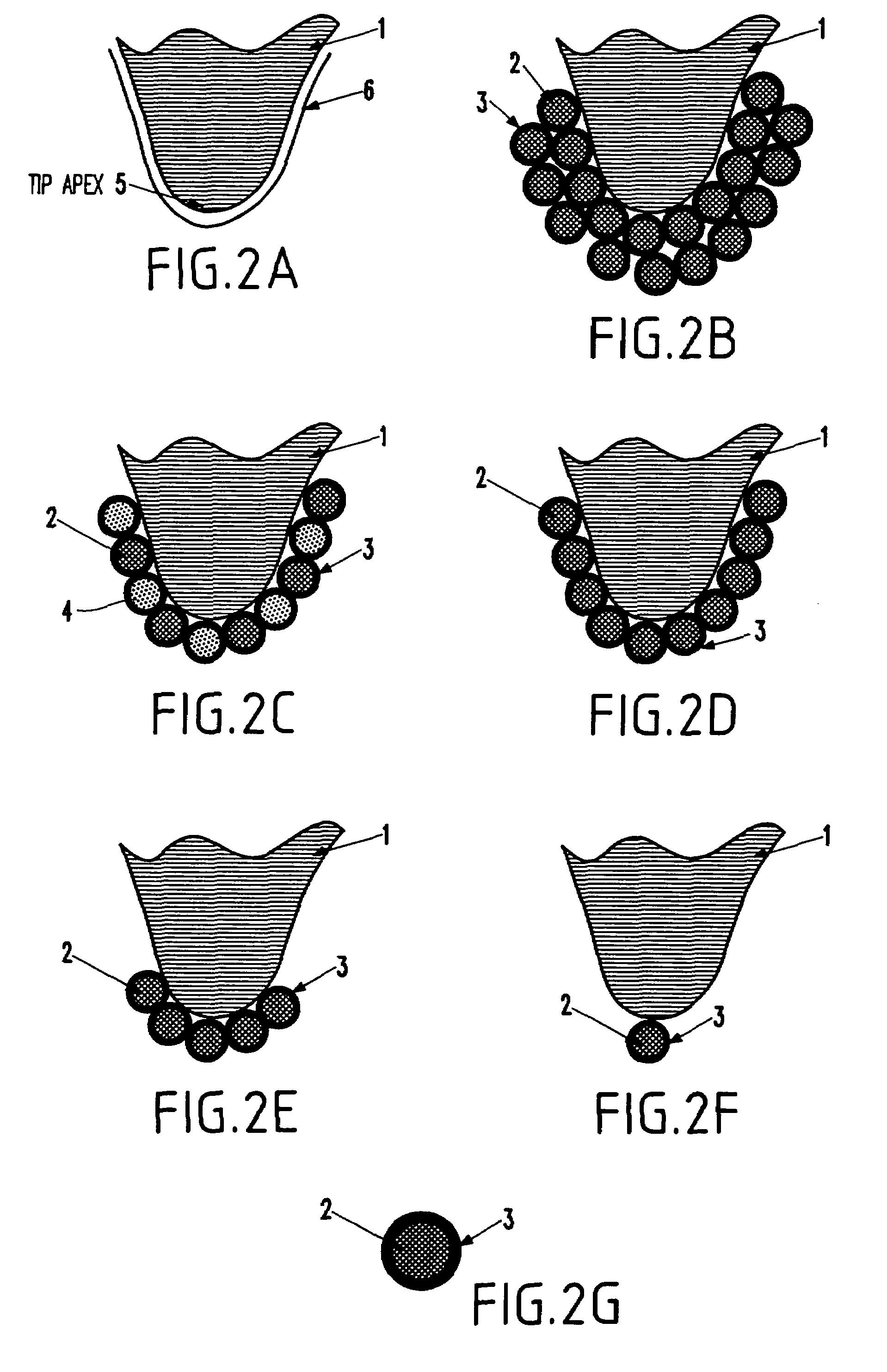

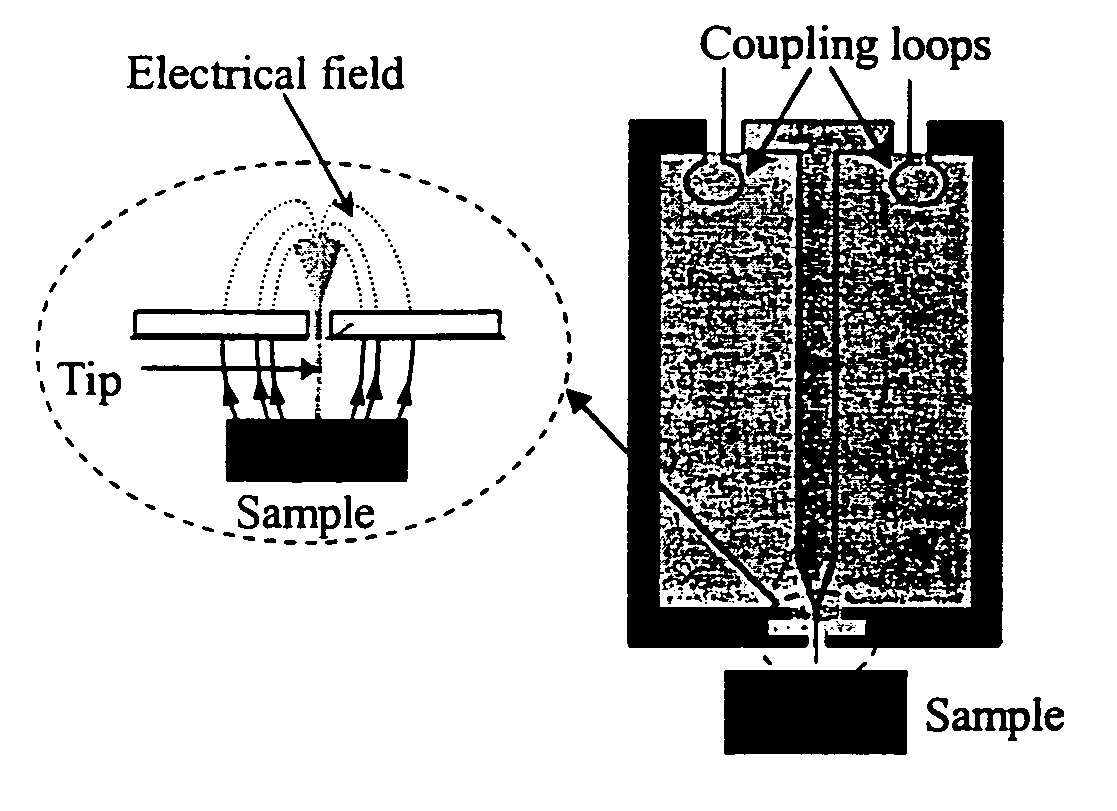

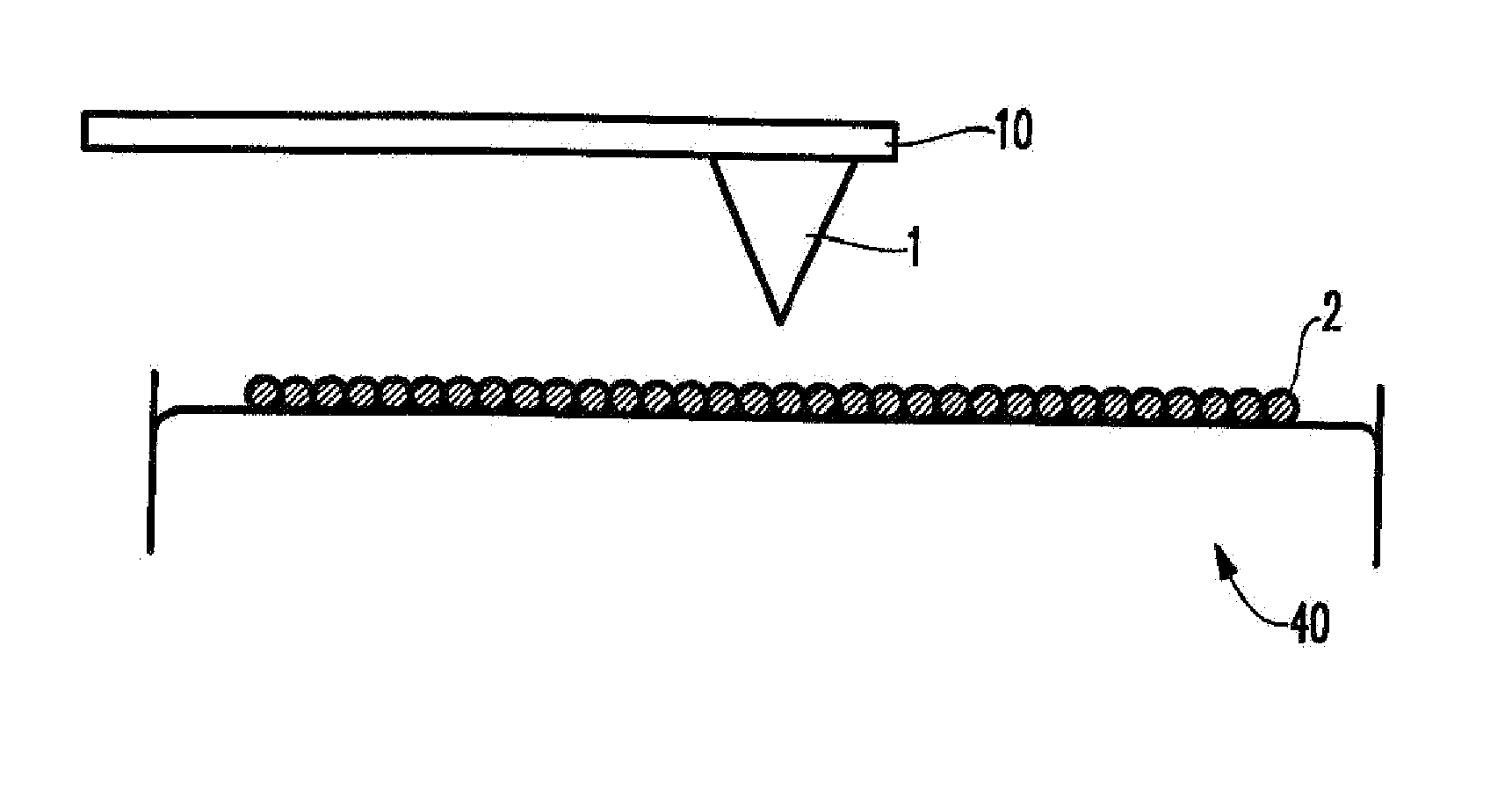

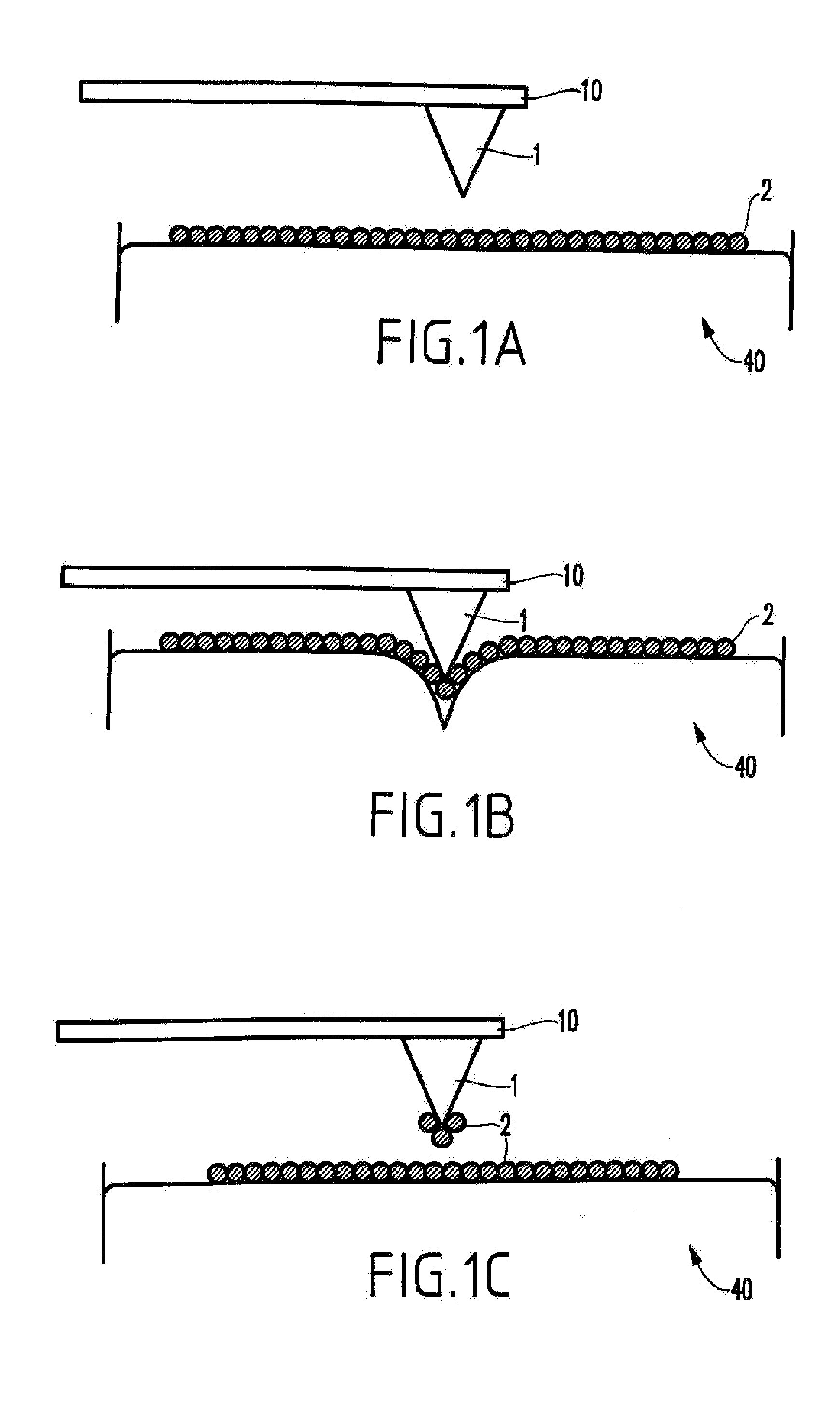

Scanning probe microscopy tips composed of nanoparticles and methods to form same

InactiveUS7282710B1Improve spatial resolutionImprove adhesionMaterial analysis using wave/particle radiationLayered productsChemical synthesisFluorescence

A structure and method for improving the spatial resolution of a scanning probe microscope (SPM) tip, which has been coated with a layer of chemically-synthesized nanoparticles. The nanoparticles are either single-species or heterogeneous, such that the single-species nanoparticles can be either ferromagnetic, paramagnetic, superparamagnetic, antiferromagnetic, ferrimagnetic, magneto-optic, ferroelectric, piezoelectric, superconducting, semiconducting, magnetically-doped semiconducting, insulating, fluorescent, or chemically catalytic. The layer of nanoparticles is at least two nanoparticles thick, or alternatively, is a single layer of nanoparticles thick, or alternatively, is a single layer of nanoparticles thick and covers only the tip apex portion of the tip, or alternatively, only a single nanoparticle is affixed to the tip apex. Alternatively, the layer of nanoparticles is transformed into an electrically-continuous magnetic film by annealing at a high temperature.

Owner:IBM CORP

Magnetoresistive effect element, magnetic head and magnetic reproducing apparatus

In a CPP element using a metal intermediate layer excellent in shot noise and response to high frequencies unlike a TMR element, its magnetoresistive effect film includes a magnetic layer mainly made of a half-metal exhibiting ferromagnetism, ferrimagnetism or antiferromagnetism, and largely variable in way of conduction in response to spin direction of electrons.

Owner:KK TOSHIBA

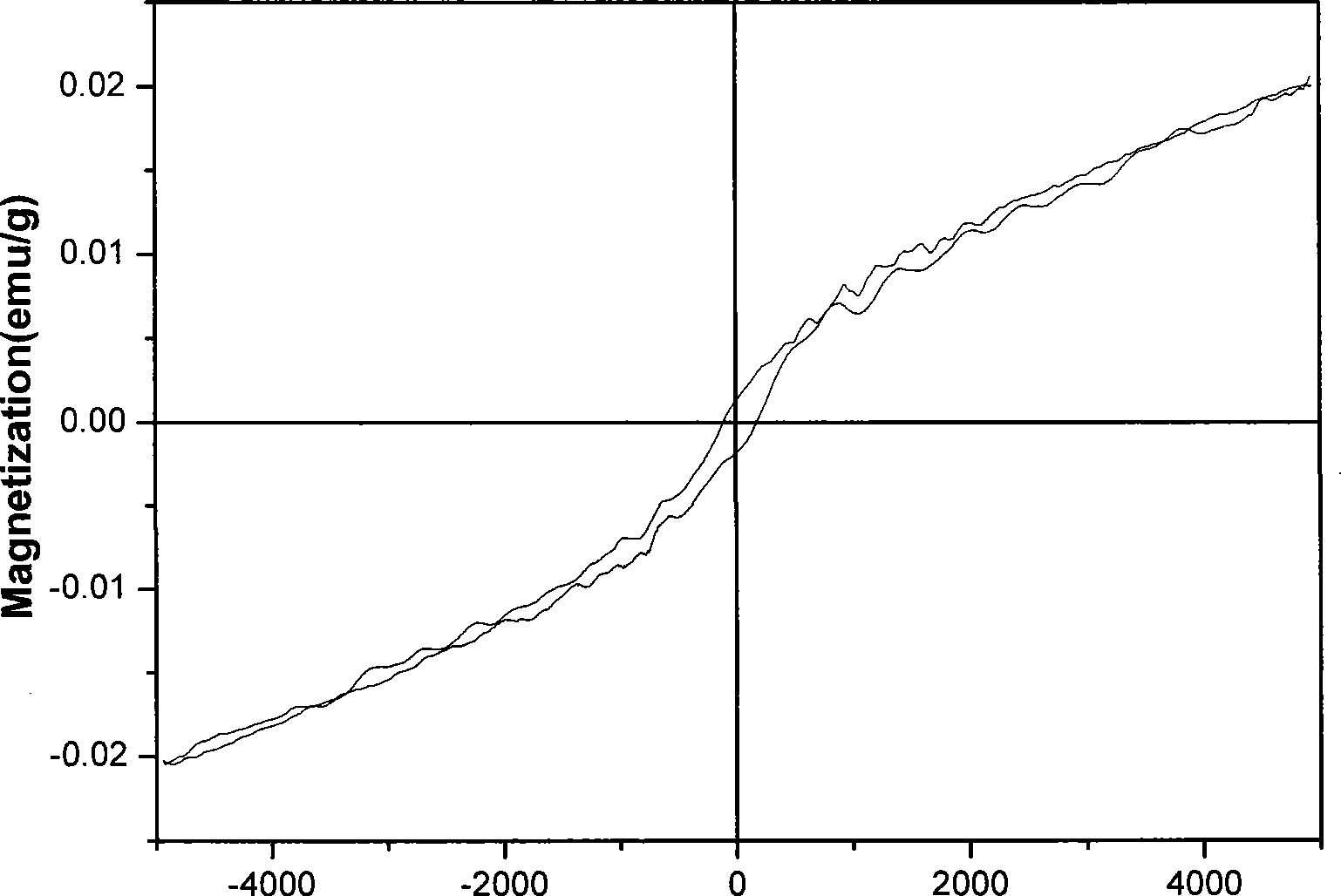

Composites and electrodes for electrochemical devices and processes for producing the same

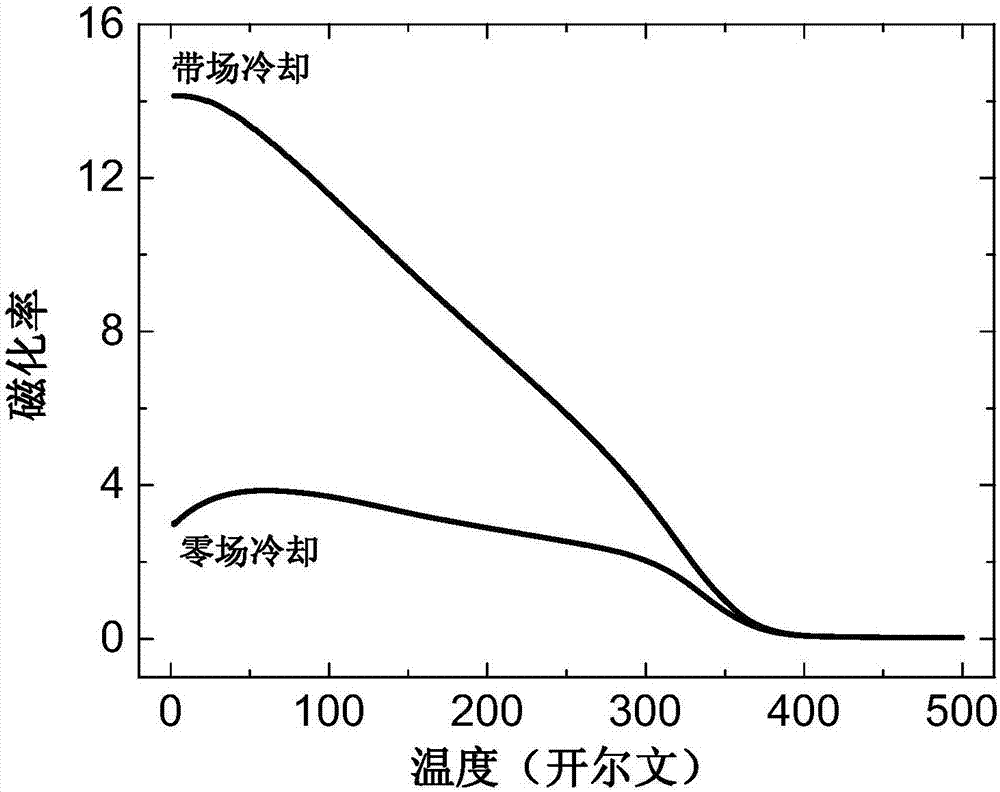

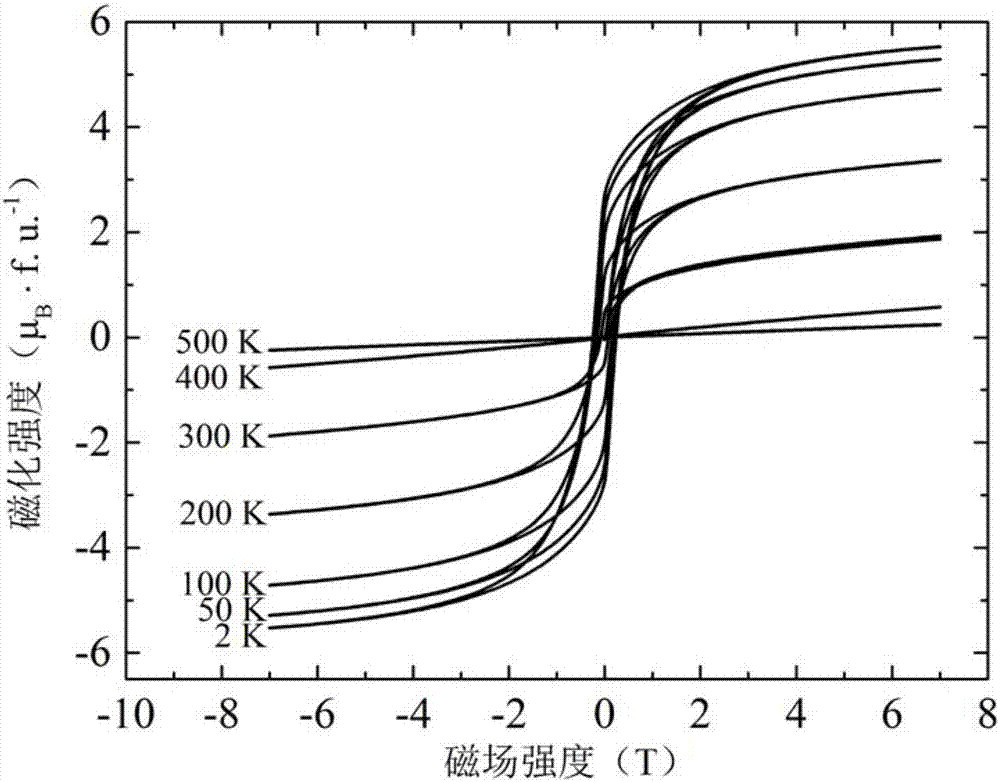

The present invention is directed to a composite including a substrate and a film deposited on a surface of the substrate, and processes for producing the composites. The deposited film includes at least one metal oxide having the formula: MxOy, wherein M is a first, second, or third row transition metal, x is a positive integer from 1 to 7. The film is ferromagnetic, ferrimagnetic, or both ferromagnetic and ferrimagnetic at temperatures greater than 0° C. and has a zero field magnetization of 0.001 emu / g or greater at a temperature of 26.85° C. (300 K). Composites of the present invention may be used, for example, as electrodes in electrochemical devices.

Owner:FLORIDA STATE UNIV RES FOUND INC

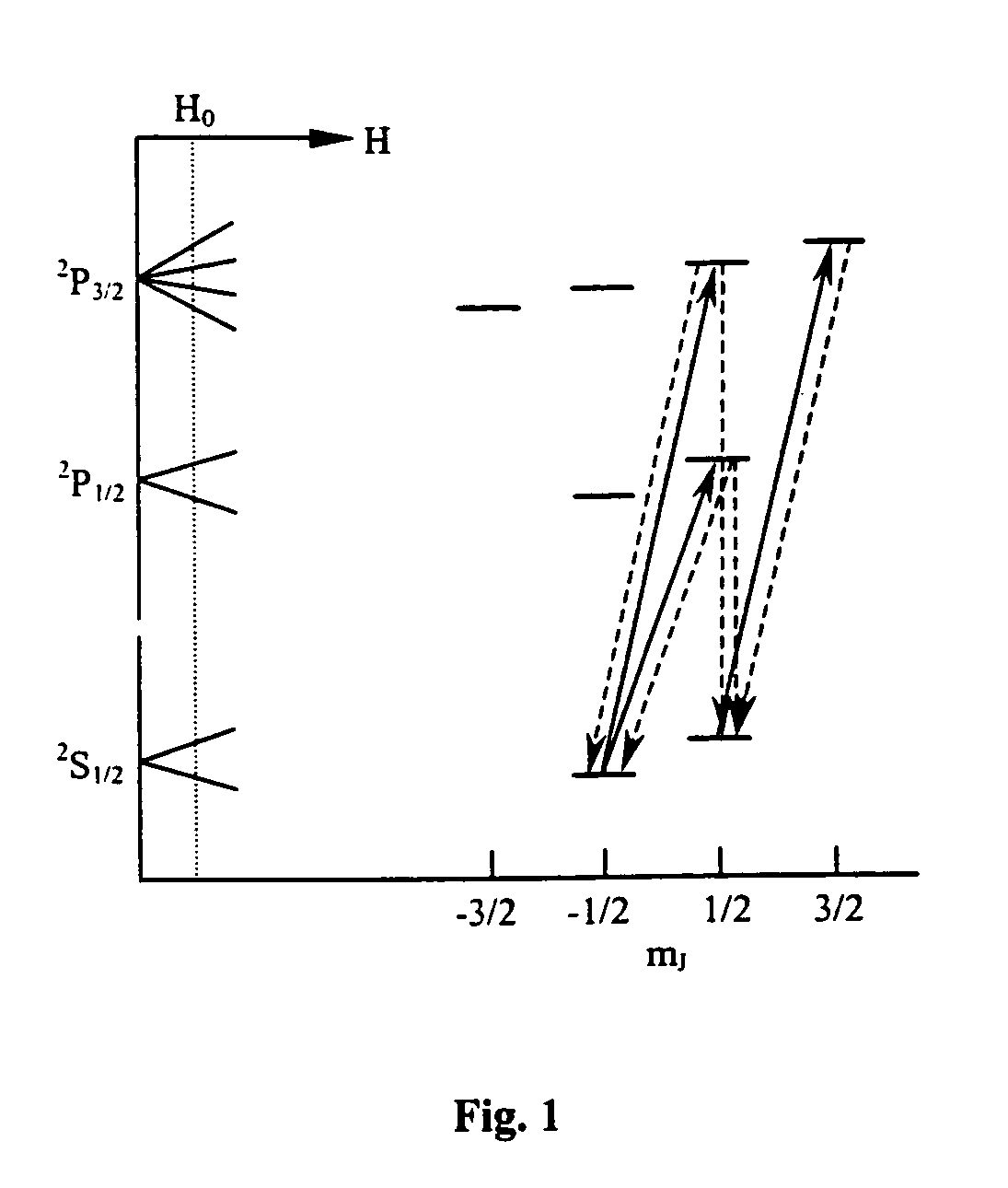

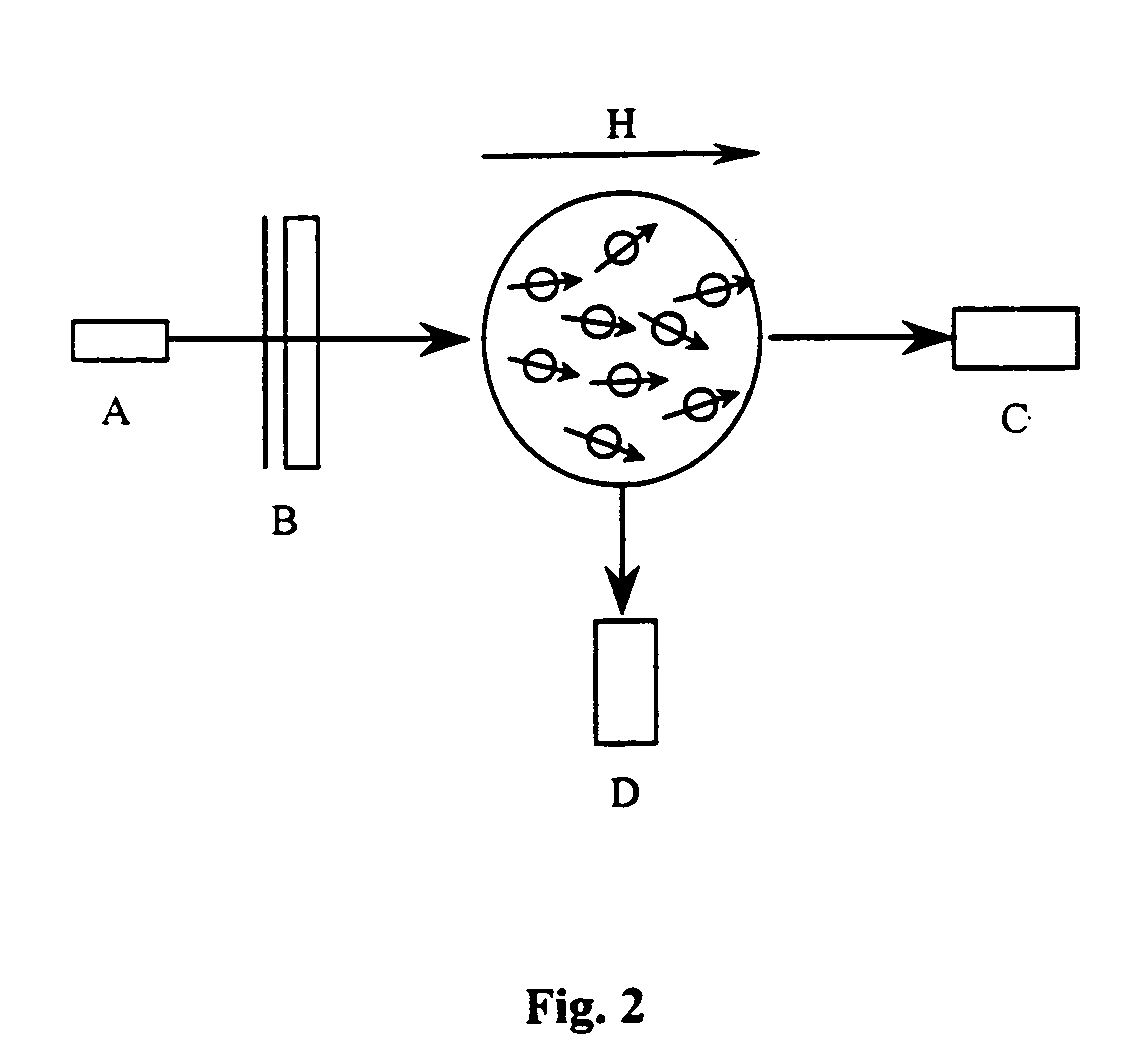

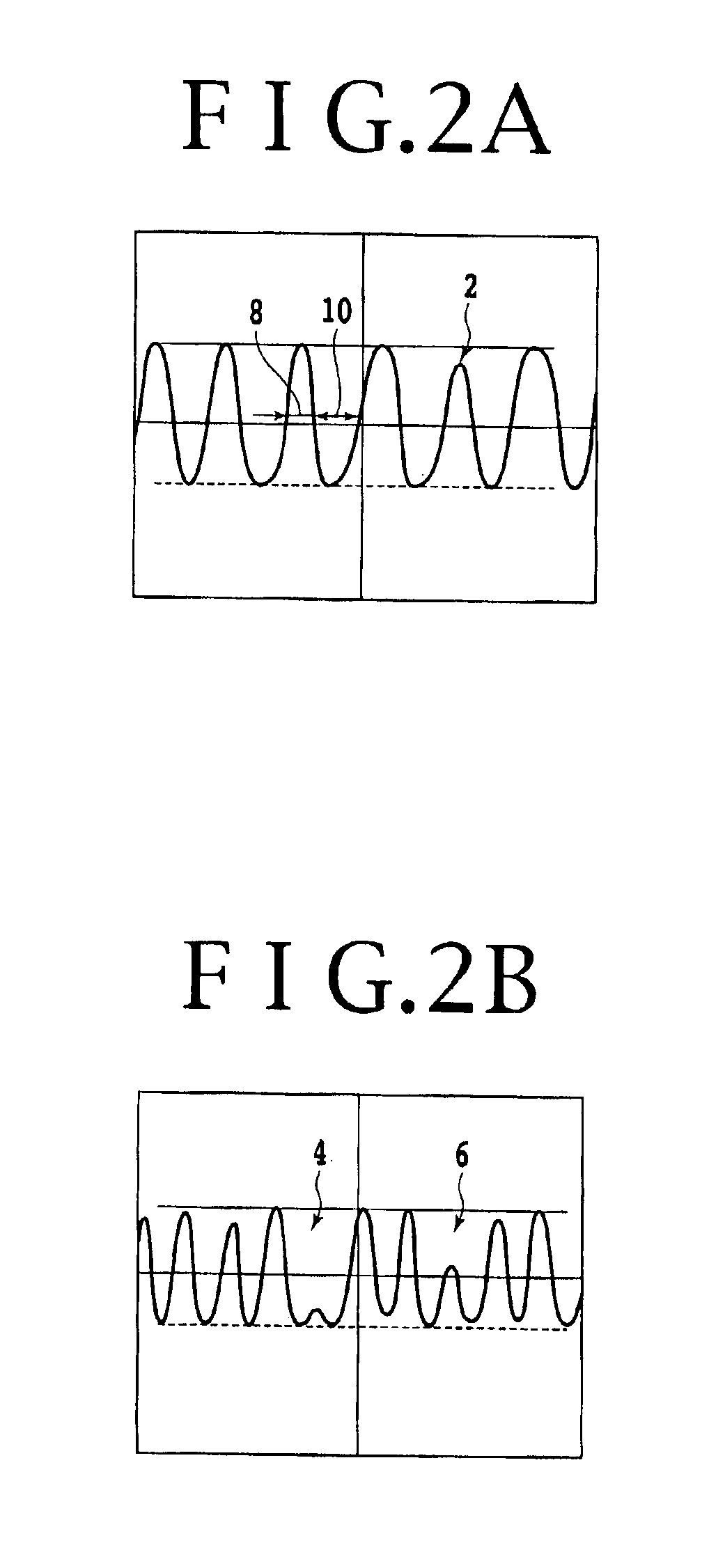

Spatially resolved spin resonance detection

InactiveUS6946835B1High sensitivityImprove spatial resolutionMagnetic measurementsMaterial analysis by using resonanceBio moleculesBeam polarization

Methods for spatially resolved spin resonance detection in a sample of material, with a resolution as small as 0.5 μ m –1 mm. In one embodiment, a coupler having at least one pair of degenerate orthogonal modes provides an evanescent input signal along one coupler axis to the sample, to which a magnetic field is applied, and senses a spin interaction signal along another coupler axis. In another embodiment, an evanescent input signal is applied to the sample along one of two identical transmission line resonators, and a difference of the two resonator signals provides a spin interaction signal. In another embodiment, a polarized laser beam provides an evanescent input signal to the sample, and the spin interaction signal is sensed according to a second beam polarization direction. Certain ferromagnetic or ferrimagnetic molecules, such as YIG, can be used to tag selected chemical and biological molecules, using spatially resolved spin resonance detection for interrogation.

Owner:INTEMATIX

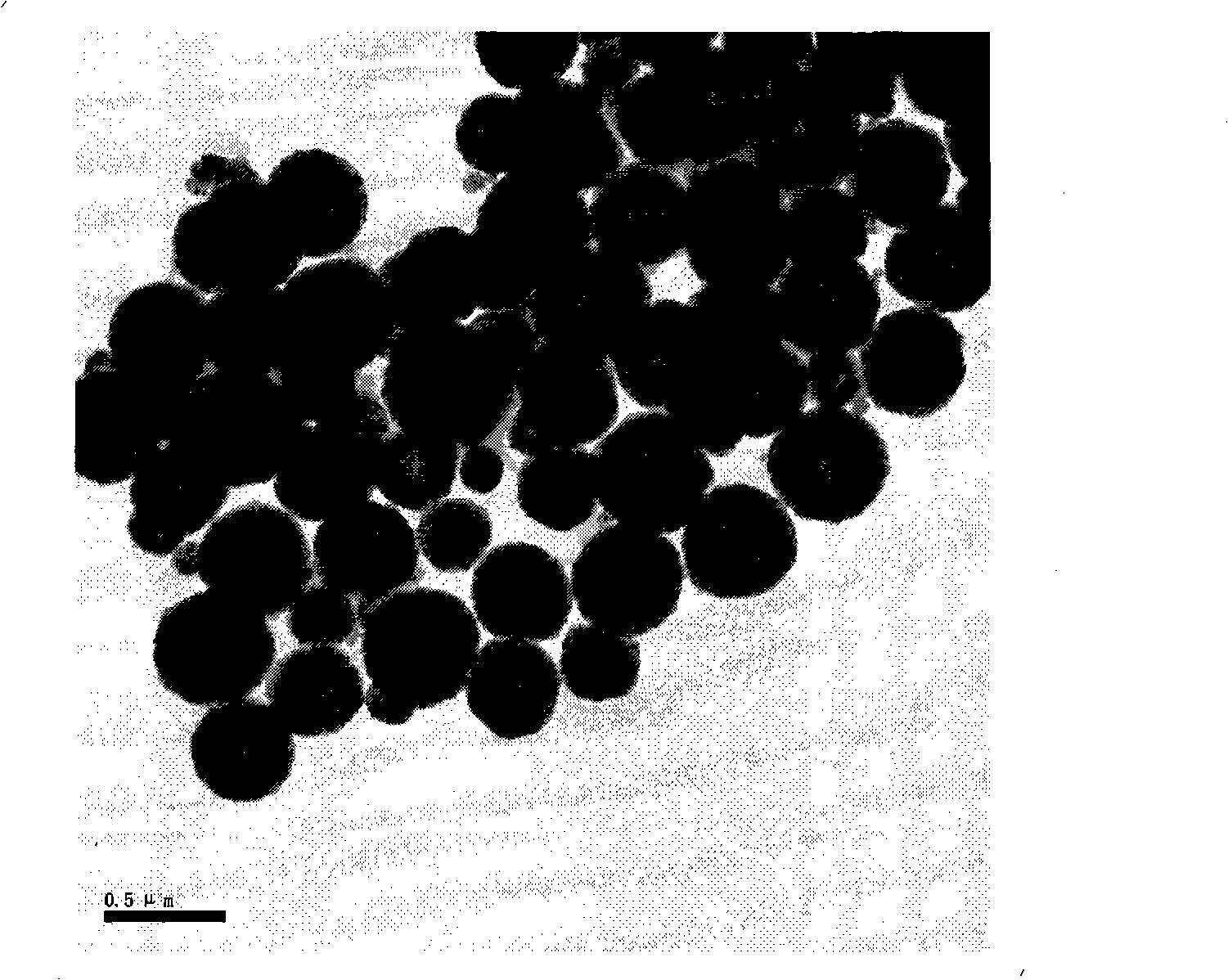

Method for synthesizing ferrimagnetism hollow microballoons

The invention belongs to the preparation field of magnetic materials, comprising the following steps: firstly, adding the metal ion salt to organic polar solvent for complete dissolution, and then adding solid alkali metal salt and surfactant; the composed mixed solution is reacted at 140-200 DEG C so as to get ferrimagnetic hollow microspheres; the mass ratio between the surfactant and the organic polar solvent is 0.02-0.2:1; the concentration of the metal ion solution is 0.025-0.625mol / L; the molar ratio between the alkali metal salt and the metal ions is 5-20:1; the metal ion is selected from one or more among the iron, cobalt, nickel, manganese, zinc and magnesium ions; the surfactant can be polyethylene glycol series or tween series; the organic polar solvent can be glycol, ethanol, diethylene glycol, triethylene glycol, tetraethylene glycol or glycerol. The method of the invention is simple and the raw materials are cheap and can be easily obtained; the method has good process repeatability, high yield, safety, low cost and wide applicability, which generates no toxic substances and pollutants.

Owner:溧阳常大技术转移中心有限公司

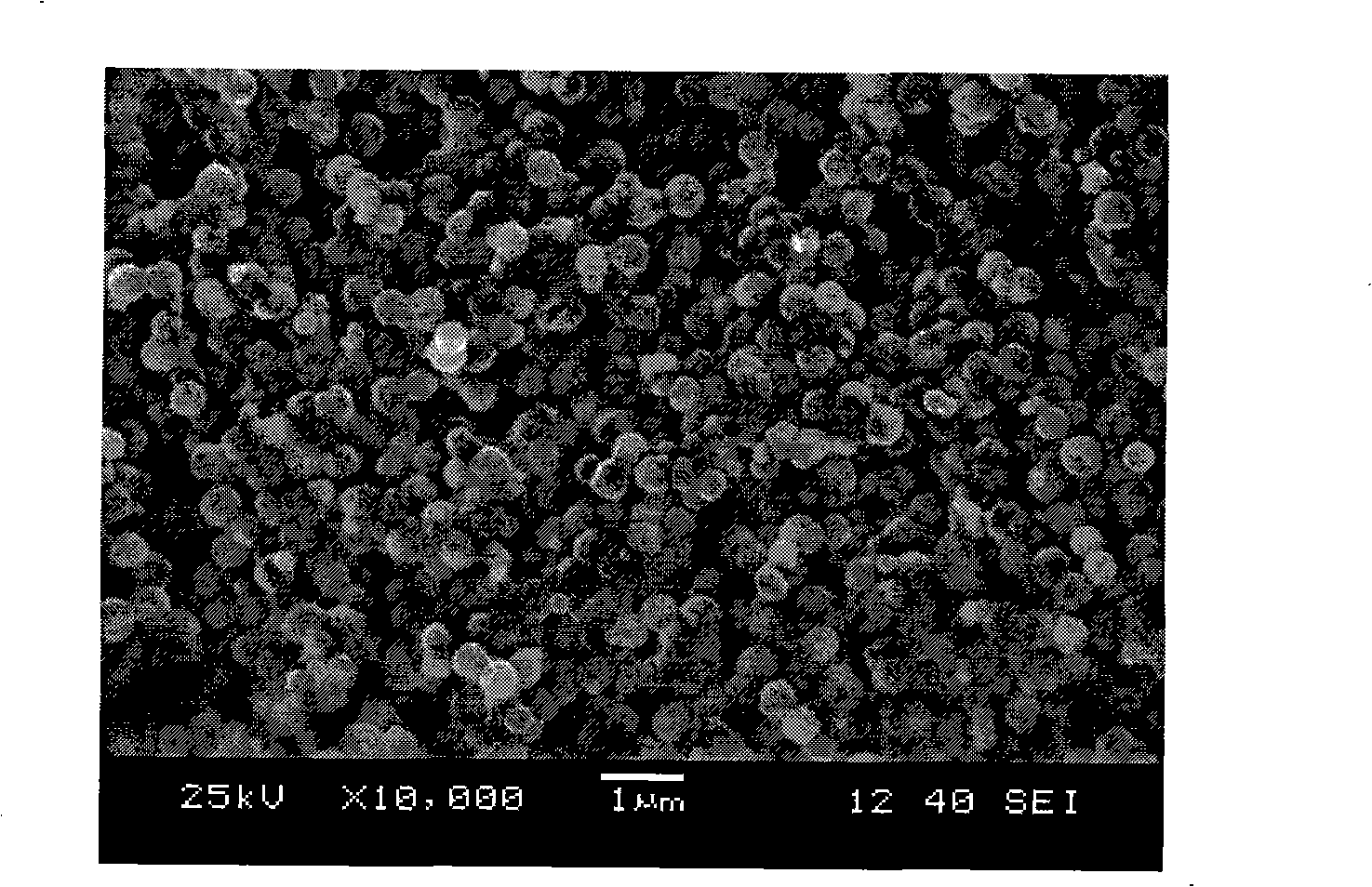

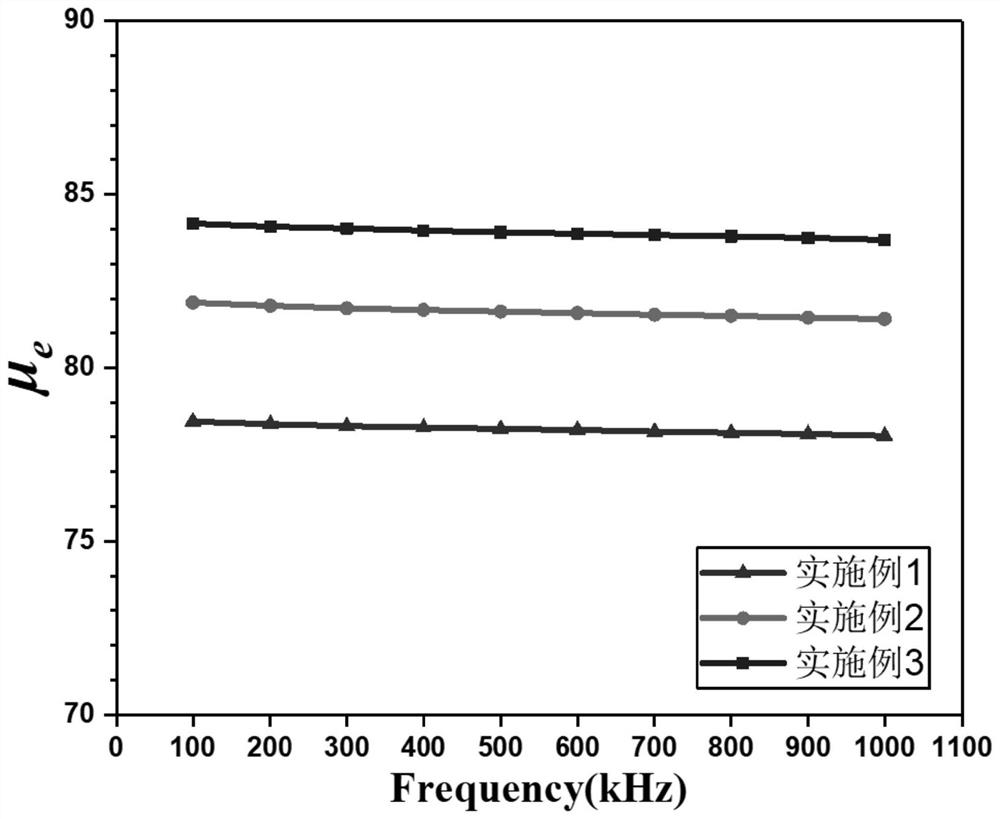

Preparation method of soft magnetic composite material

ActiveCN104028762ANo magnetic dilutionImprove permeabilityInorganic material magnetismCompression moldingFerrous

The invention discloses a preparation method of a soft magnetic composite material. The surface of soft magnetic alloy powder is coated with a coating layer with a sol-gel method, wherein the coating layer is formed by nanometer Fe3O4 particles with the uniform sizes; the processes of bonding, compression molding and heat treatment are carried out, and the novel soft magnetic composite material is prepared. The preparation method has the advantages that the surface of the soft magnetic alloy powder can be uniformly coated with Fe3O4 prepared with the sol-gel method; the Fe3O4 with ferrimagnetism serves as an insulating coating agent, so that a magnetic dilution phenomenon occurring when a traditional non-magnetic material serves as a coating agent is avoided, and higher magnetic conductivity and magnetization intensity can be obtained.

Owner:ZHEJIANG UNIV

Hollow silicon dioxide/magnetic composite microsphere and its production method

InactiveCN101499348ALow densityImprove mechanical stabilityInorganic material magnetismSilicon oxidesIron saltsMicrosphere

The invention belongs to the technical field of a composite material and a functional material, particularly relates to a hollow silica / magnetic composite microsphere and a preparation method thereof. The magnetic composite microsphere is formed by embedding a layer of magnetic particles on the surface of the hollow silica microsphere with sulfonic acid groups. The composing raw materials are hollow silica microspheres with sulfonic acid groups, trivalent iron salts, divalent transition metal salts, oxidizing agents, dispersing agents, and alkali, according to a suitable weight ratio, and by steps such as ultrasonic dispersion, particle embedding, post processing and the like, the composite microsphere is prepared. The prepared hollow silica / magnetic composite microsphere has small density, good mechanical and chemical stability, controllable particle size, and excellent magnetic property which can be used for obtaining ferrimagnetism or for superparamagnetism by adjusting the ratio of the trivalent iron salts and the divalent transition metal salts.

Owner:TONGJI UNIV

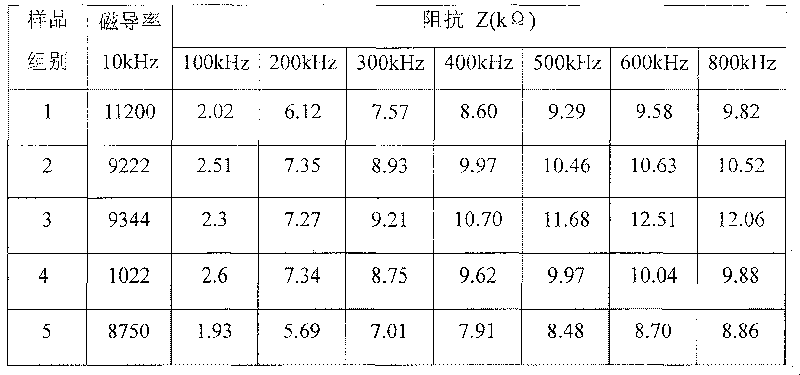

Mn-Zn ferrite magnetic material with high magnetoconductivity and high impedance and method for making the same

ActiveCN101231902AImprove permeabilityHigh impedance characteristicInorganic material magnetismFerrimagnetismMaterials science

The invention relates to a Mn and Zn ferrimagnetism material and a preparation method thereof. The Mn and Zn ferrimagnetism material is made of principal ingredients and subsidiary ingredients. The weight percentages of the principal ingredients which are oxides are calculated as follows: Fe2O3 accounts for 61 percent to 75 percent by weight; ZnO accounts for 12 percent to 30 percent by weight; the rest principal ingredient is Mn3O4. The subsidiary ingredients are one or a plurality of kinds of CaCO3 accounting for 0 to 300ppm by weight; SiO2 accounting for 50ppm to 250ppm by weight; Bi2O3 accounting for 0 to 500ppm by weight. The Mn and Zn ferrimagnetism material has both high magnetic permeability and high impedance.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

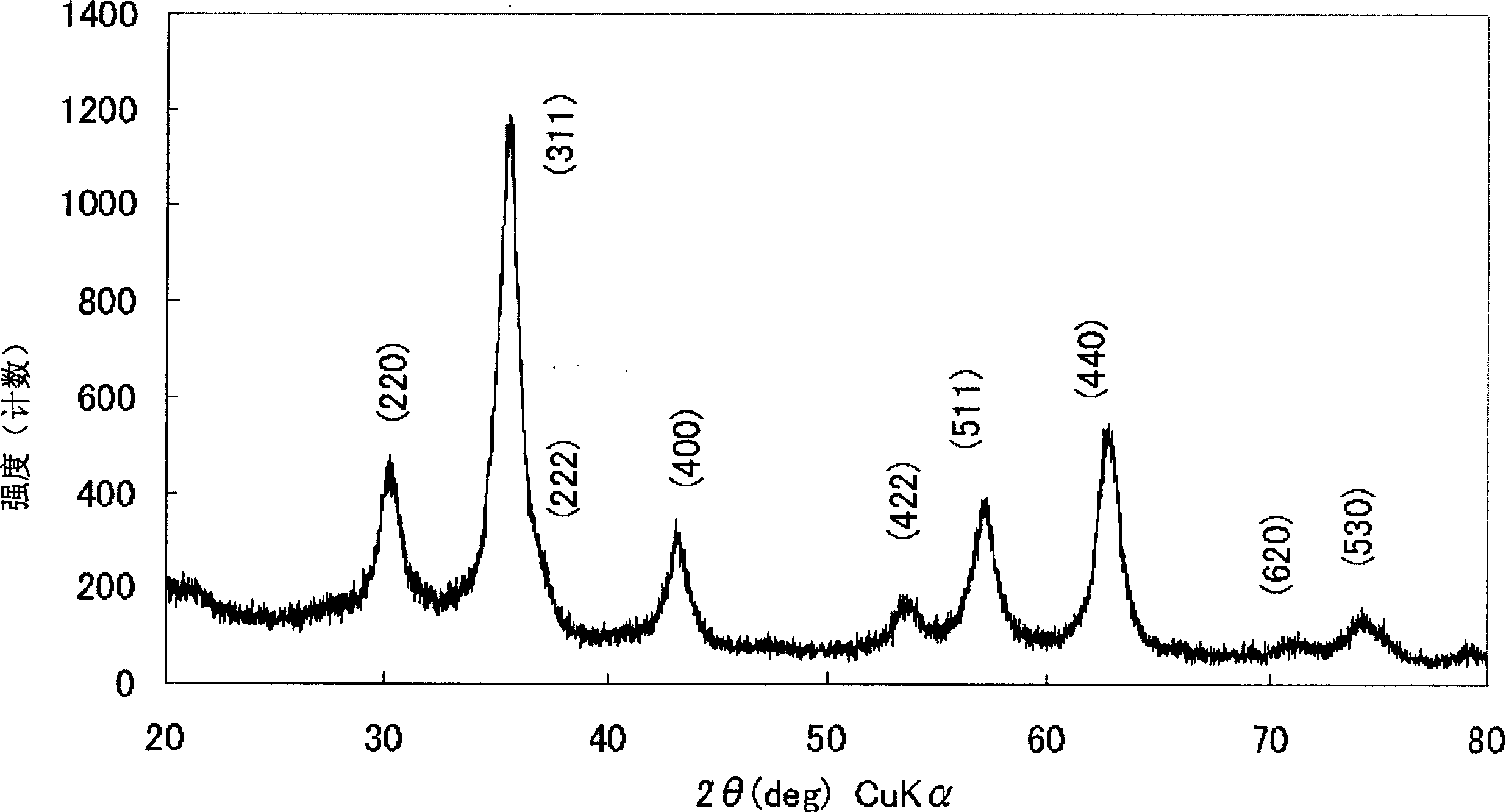

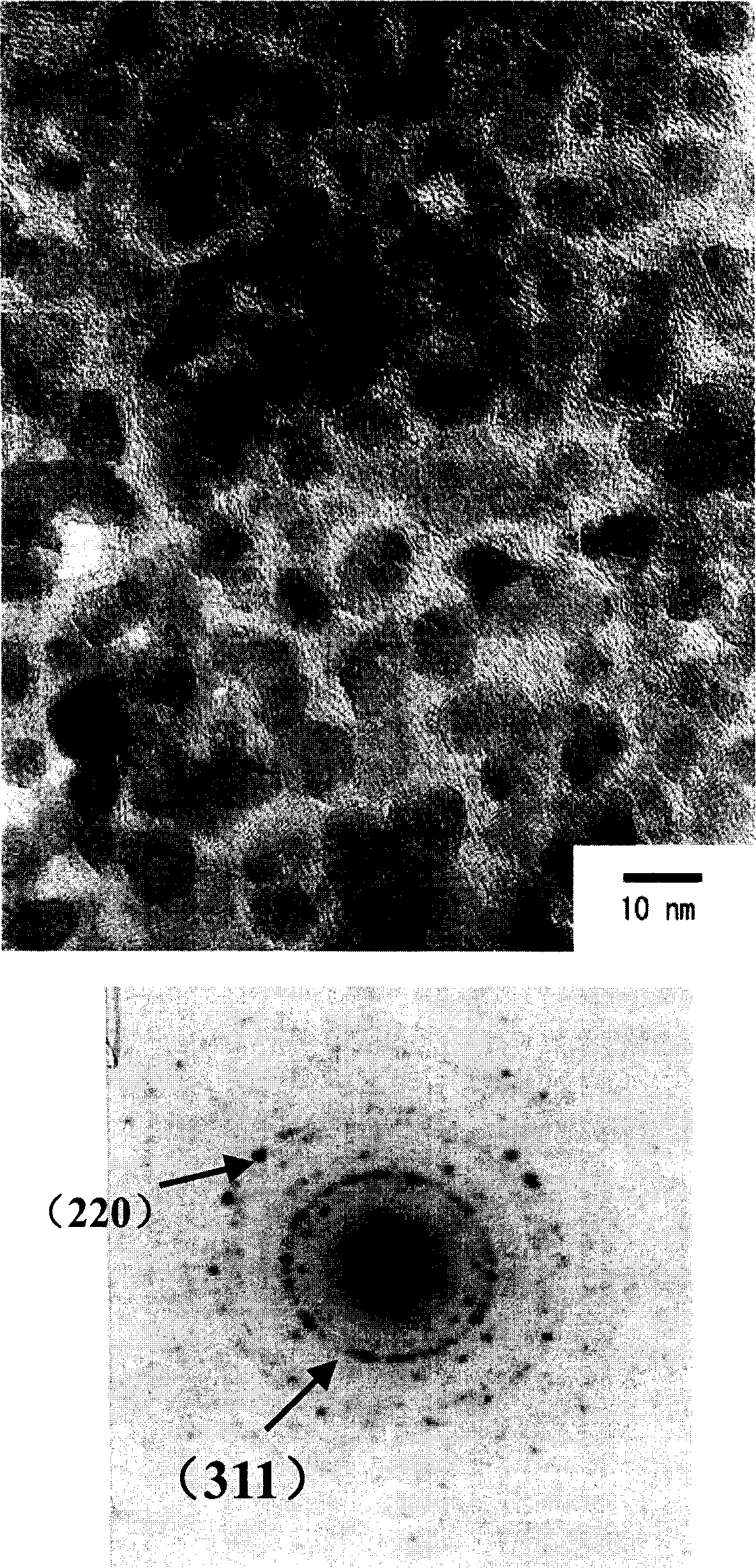

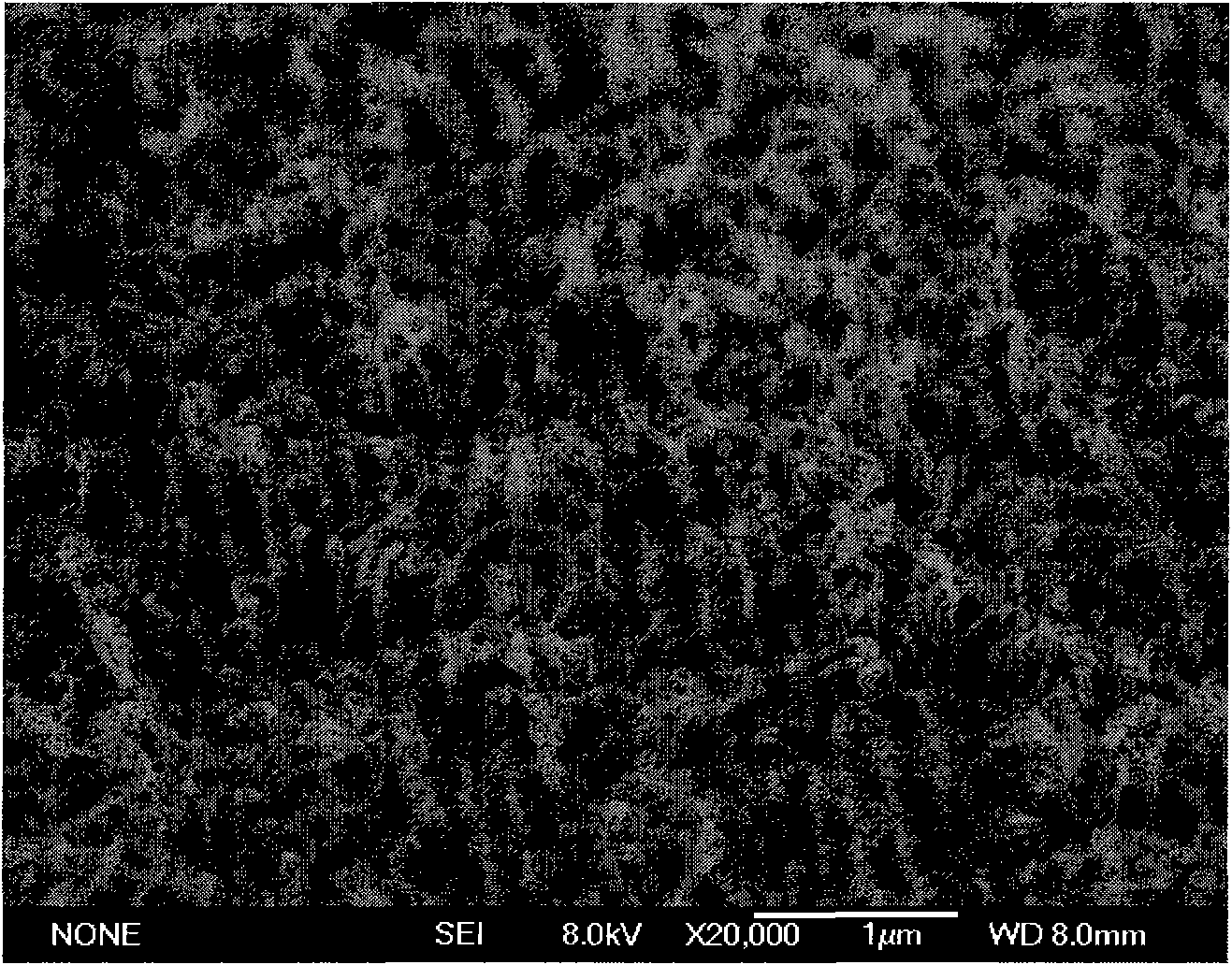

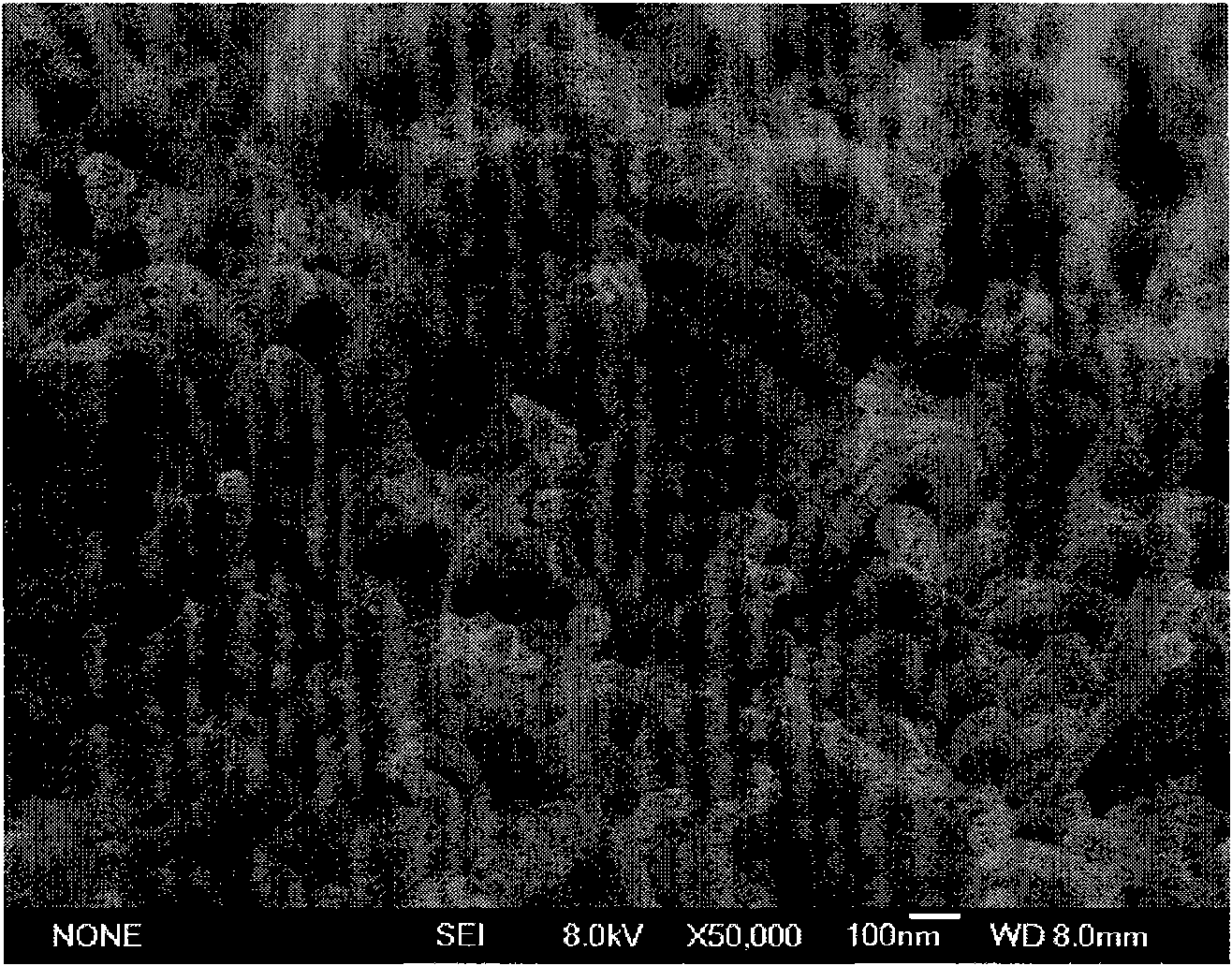

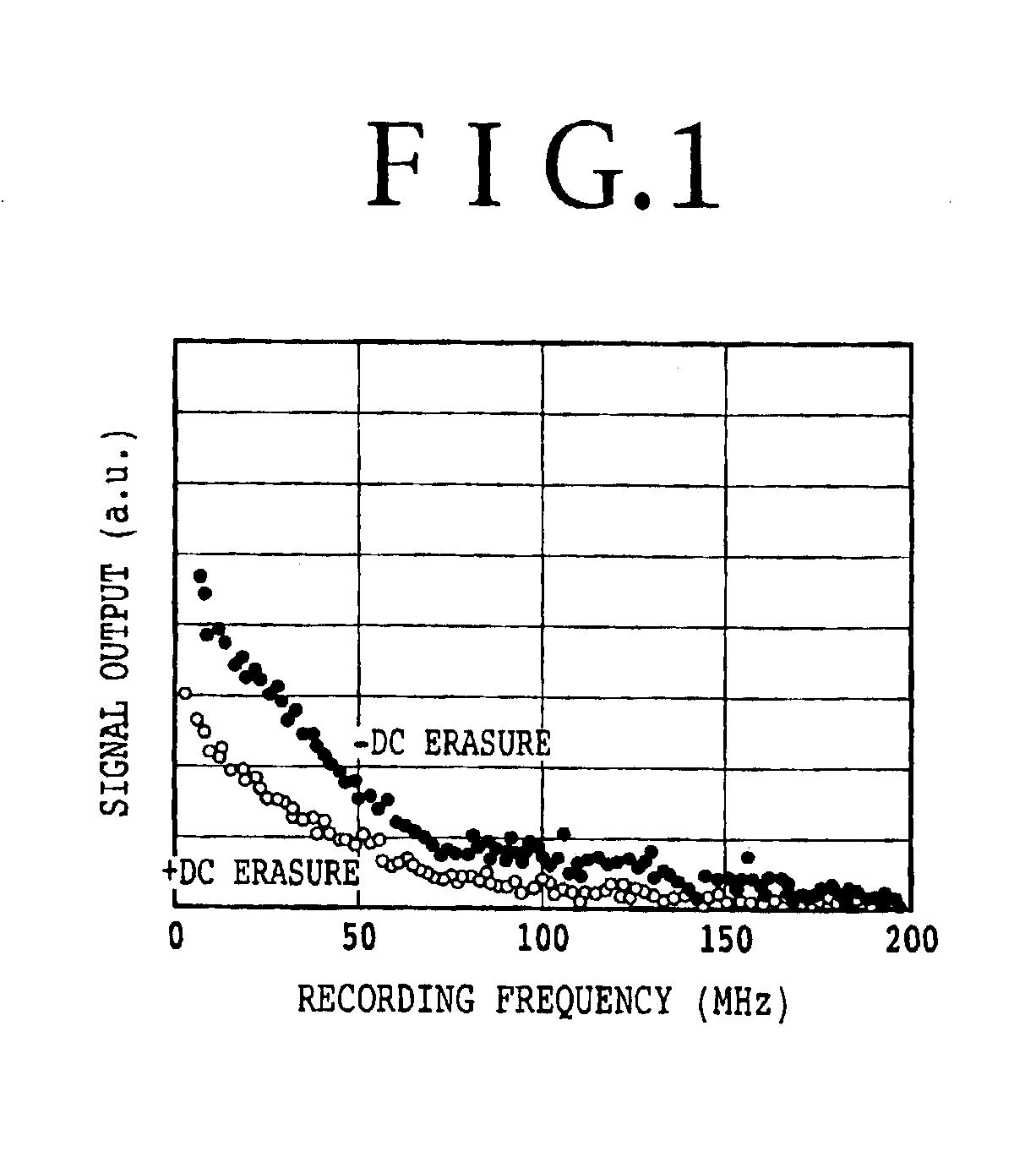

Spinel-type ferrimagnetic particles process for producing the same, and magnetic recording medium using the same

InactiveUS20060188755A1Improve coercive forceGood dispersionMaterial nanotechnologyRecord information storageHigh densityWeather resistance

Spinel-type ferrimagnetic particles having a composition represented by the formula: (MO).n / 2(Fe2O3) wherein M is a divalent metal; and n is a molar ratio of Fe to M (n=Fe / M) which is from more than 2.05 to less than 2.5 (2.05<n<2.5), containing a superparamagnetic component in an amount of not more than 2% by mass, and having an average particle diameter of 5 to 30 nm, said spinel-type ferrimagnetic particles being respectively coated on surface thereof with a hydroxide of at least one metal selected from the group consisting of Si, Al, P and Zn in an amount of not more than 10% by mass, calculated as the metal, as well as a magnetic recording medium containing the spinel-type ferrimagnetic particles. The spinel-type ferrimagnetic particles can exhibit a high coercive force irrespective of fine particles, and are excellent in dispersibility and chemical stability, as well as the magnetic recording medium for high-density recording can exhibit not only excellent frequency characteristics and high output characteristics, but also an excellent weather resistance and a high reliability.

Owner:MEIJI UNIV

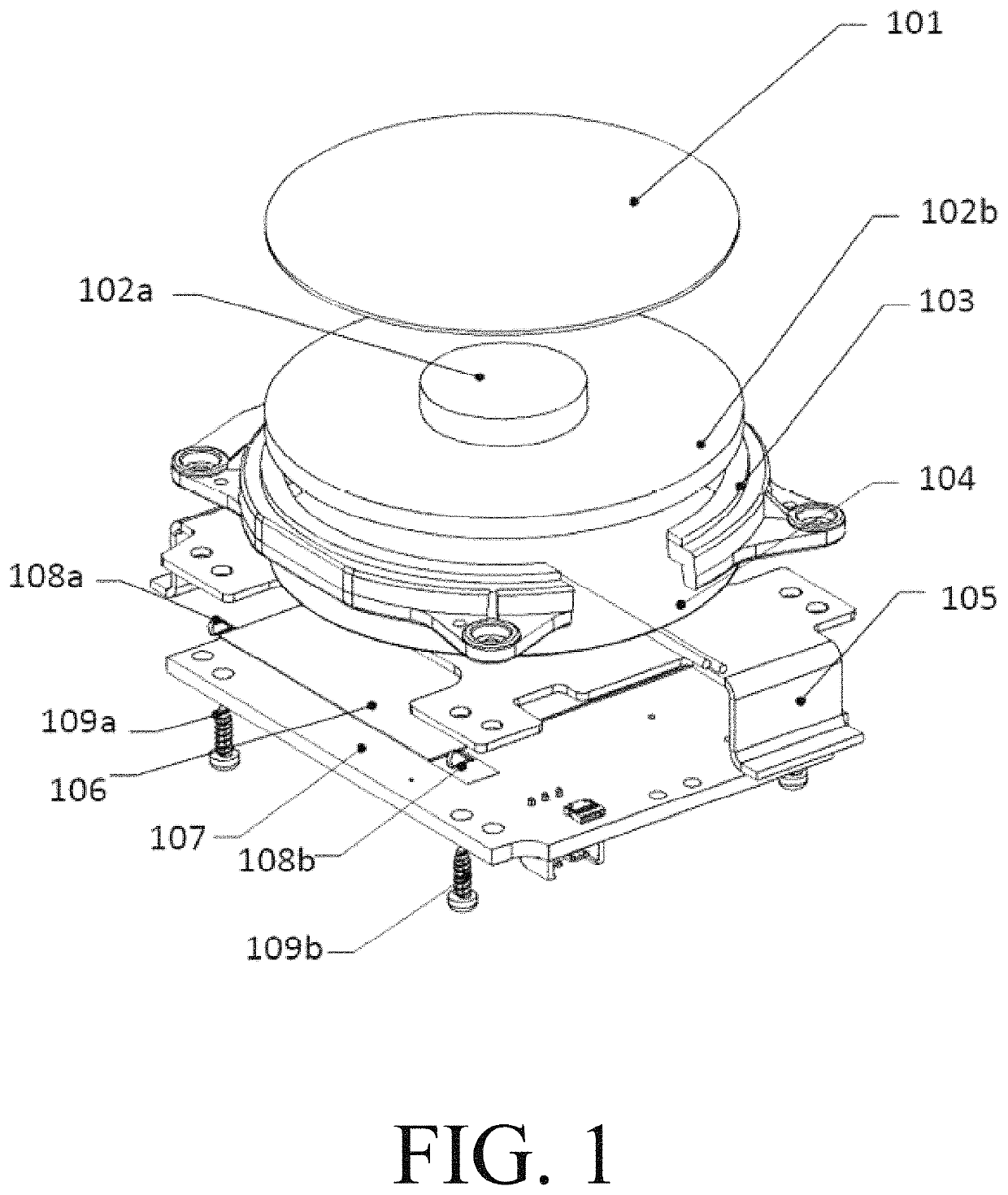

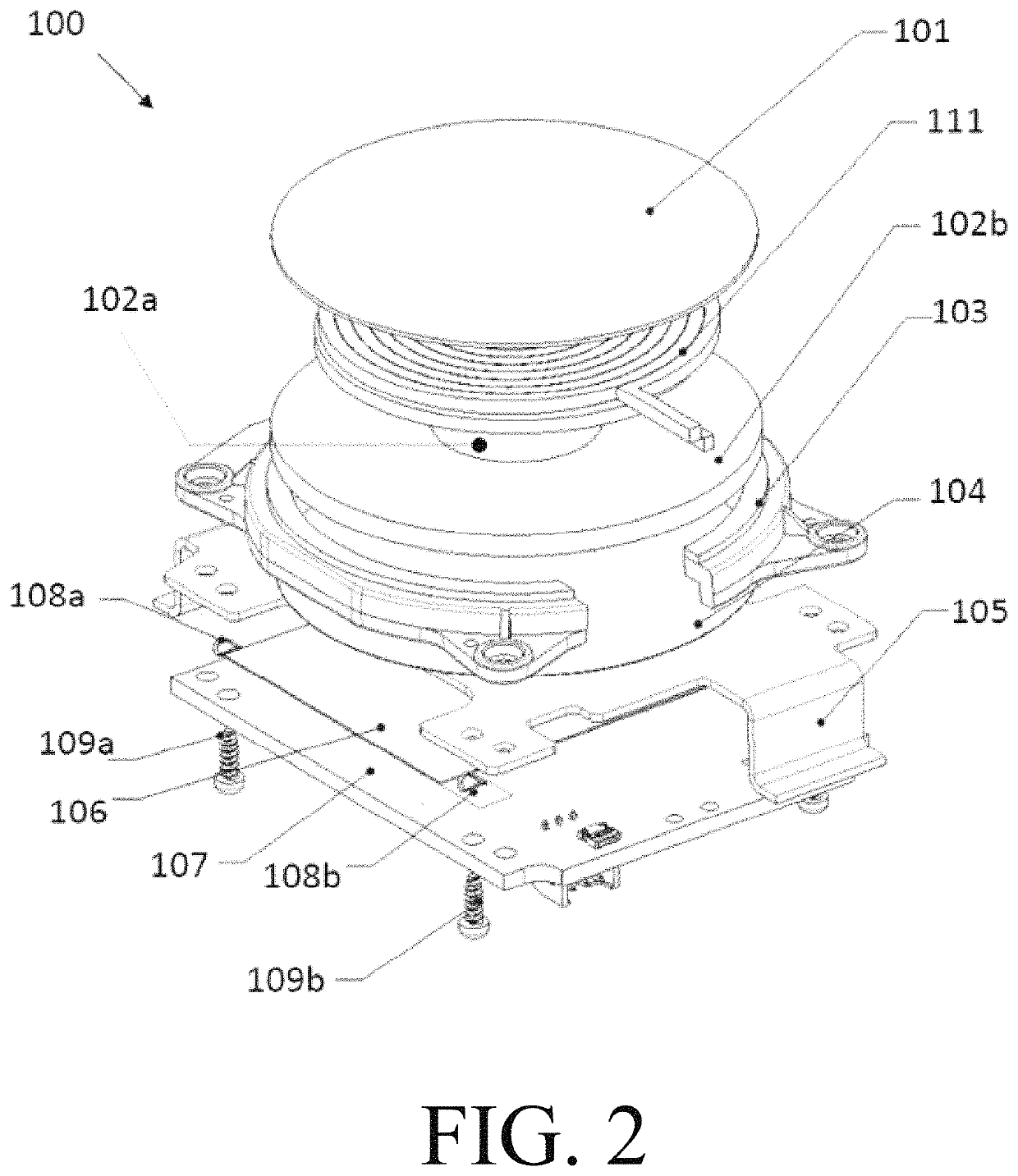

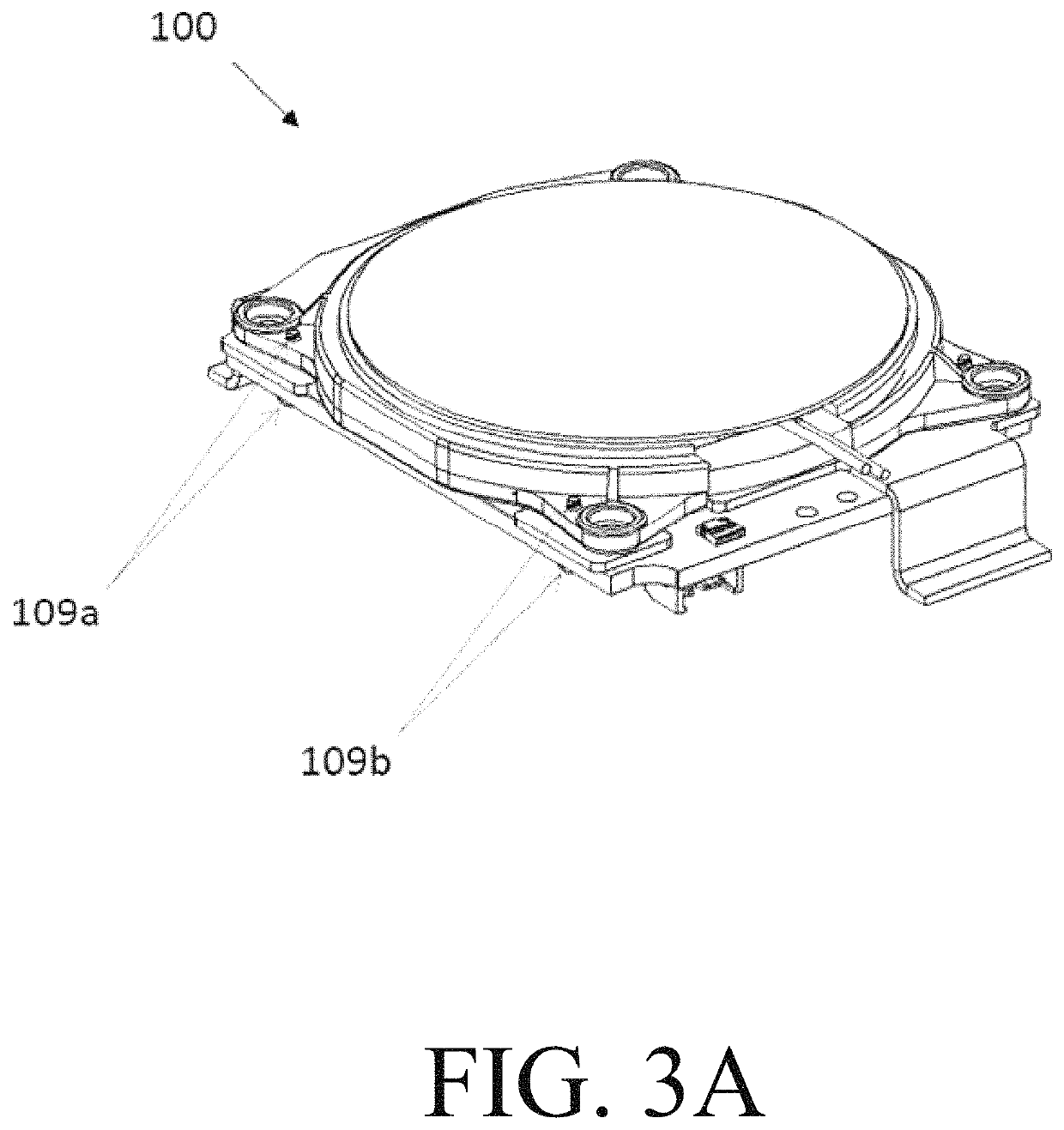

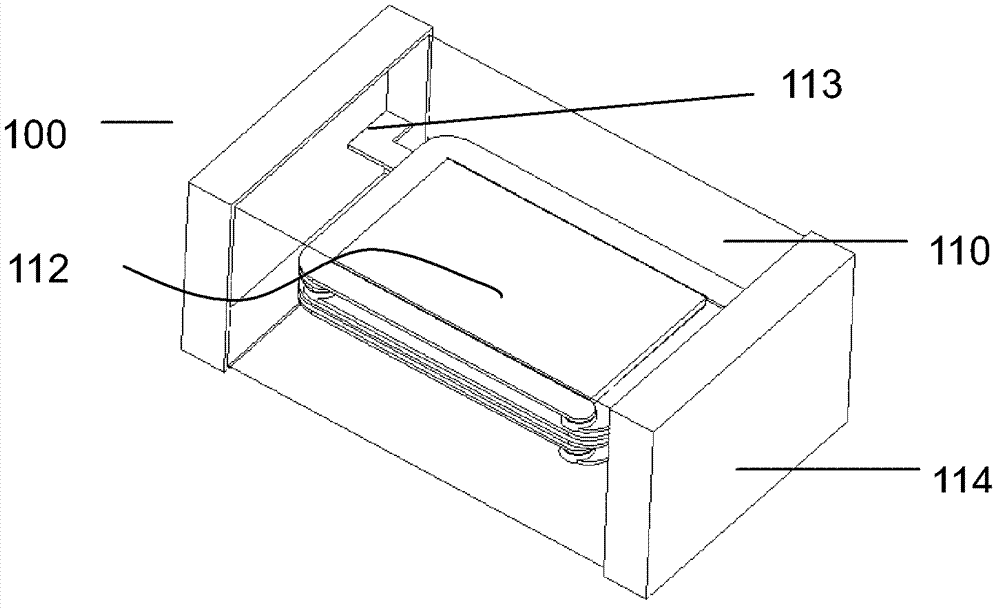

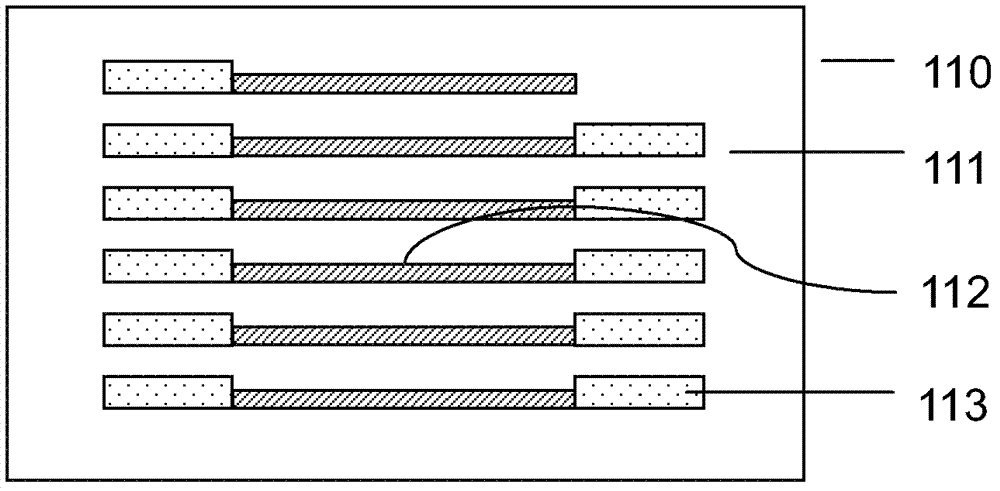

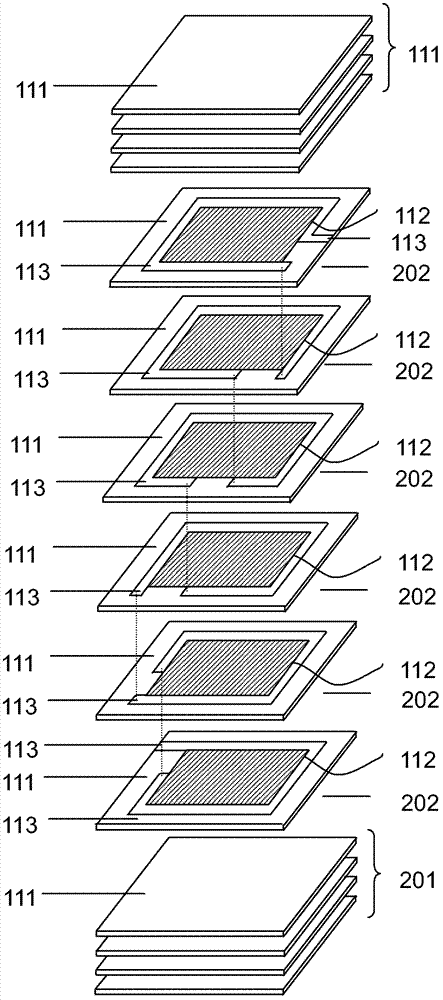

Wireless power transfer system for simultaneous transfer to multiple devices

ActiveUS11056922B1Noise minimizationMitigate and/orCircuit arrangementsBatteries circuit arrangementsElectric power transmissionOvervoltage

The present application relates to an apparatus which comprises a wireless power transmission system. This system comprises features which allow it to transfer more power wirelessly to multiple devices simultaneously, each at extended distances than other systems operating in the same frequency range. The system including heat dissipation features, allowing the system to operate effectively in elevated-temperature environments and to transfer power at higher levels and / or greater distances than a typical power-transfer system. The system also may include design features to withstand mechanical shocks, stresses, and impacts for use in a rugged environment. The system may include features to reduce electromagnetic interference (EMI) and / or specially shaped components with magnetic / ferrimagnetic properties that enhance performance. Other potential features include power conditioning by combining, within one circuit or one board, multiple elements that protect against excessive current, over-voltage, and / or reverse voltage.

Owner:NUCURRENT INC

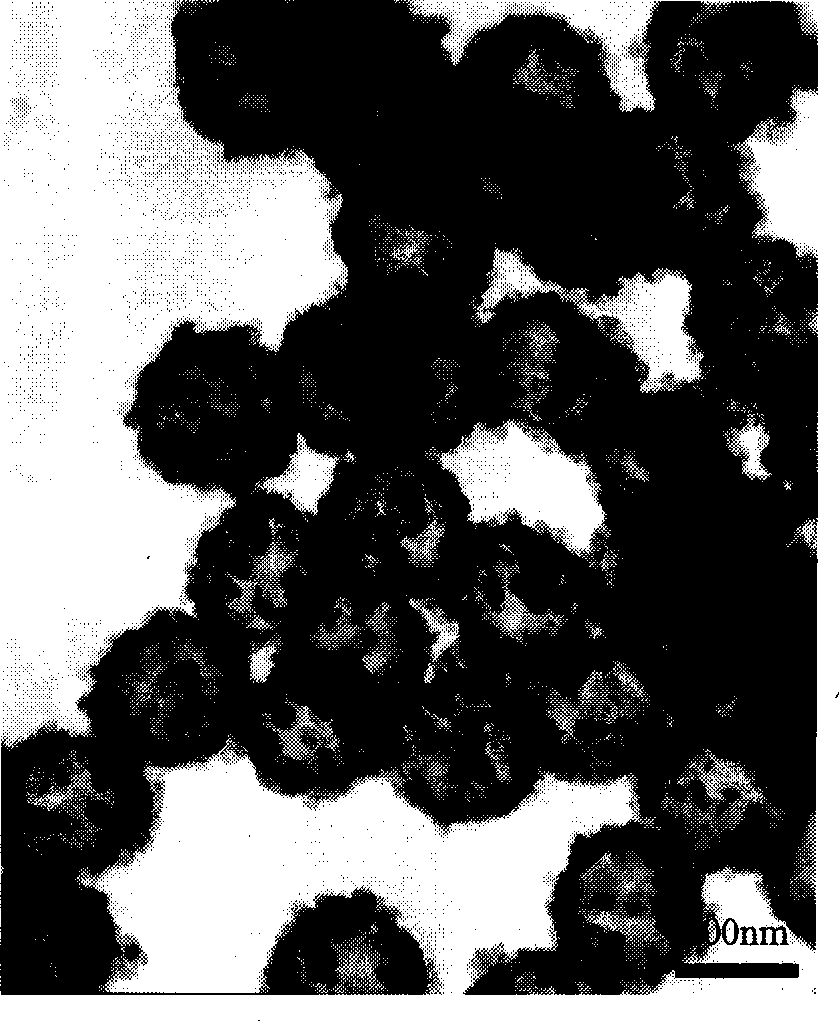

Ferrimagnetism fluid

InactiveCN1797624AImprove flow characteristicsExcellent magnetic propertiesMagnetic liquidsInductances/transformers/magnets manufactureIron saltsManganese

The method includes following steps: using chemical coprecipitation method to prepare mixed liquor of ammonia (or sodium hydroxide), bivalent iron salt (manganese, nickel, cobalt etc.) and tervalent iron salt; dropping the mixed liquor to ion exchange water, and keeping pH of solution at 7; mixing round the solution to generate suspending liquid of ferrite; using ultrasonic to coat a layer of surface active agent on surfaces of fine grains evenly; finally, using ultrasonic to disperse fine grains on solvent evenly.

Owner:巨东英 +1

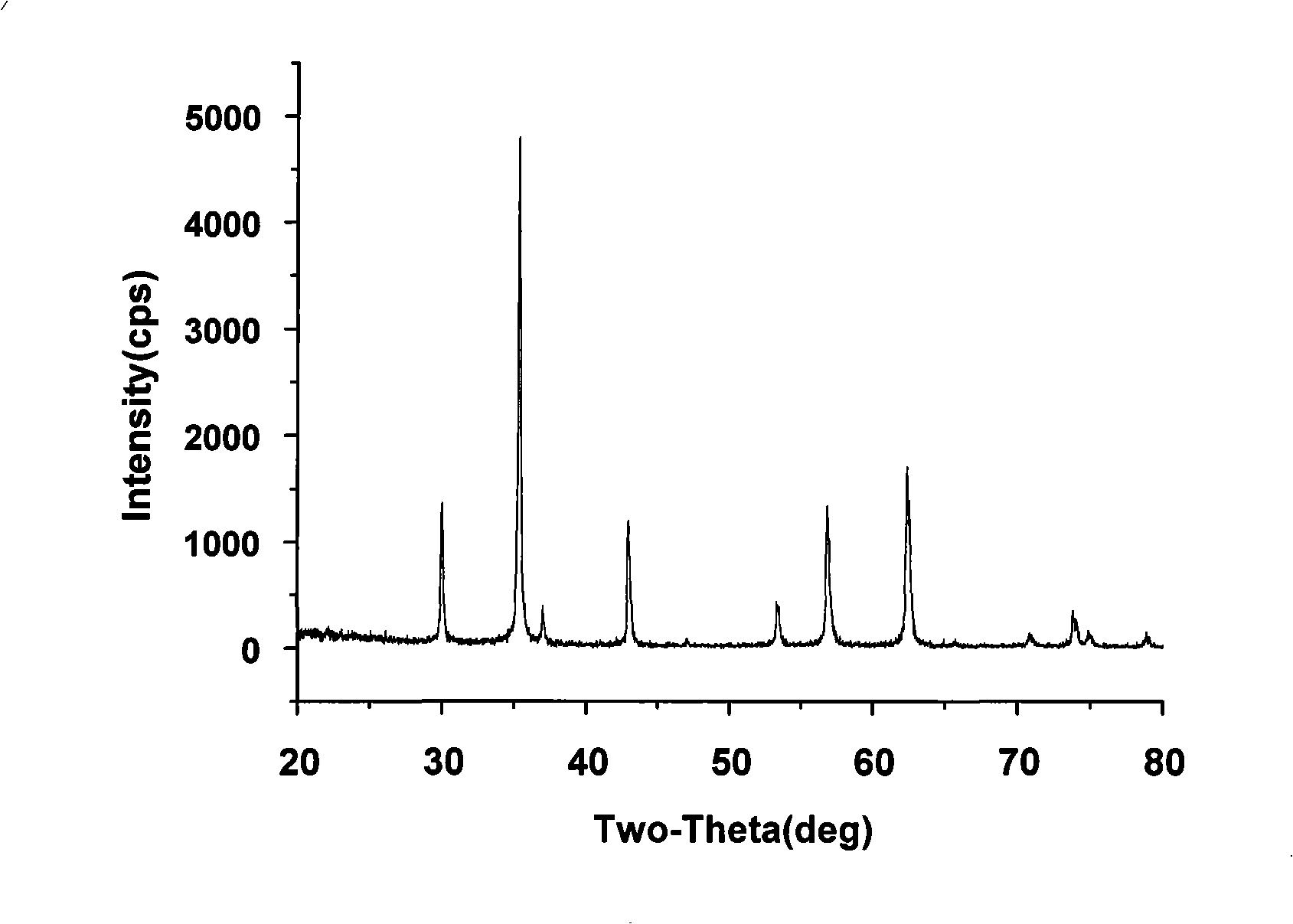

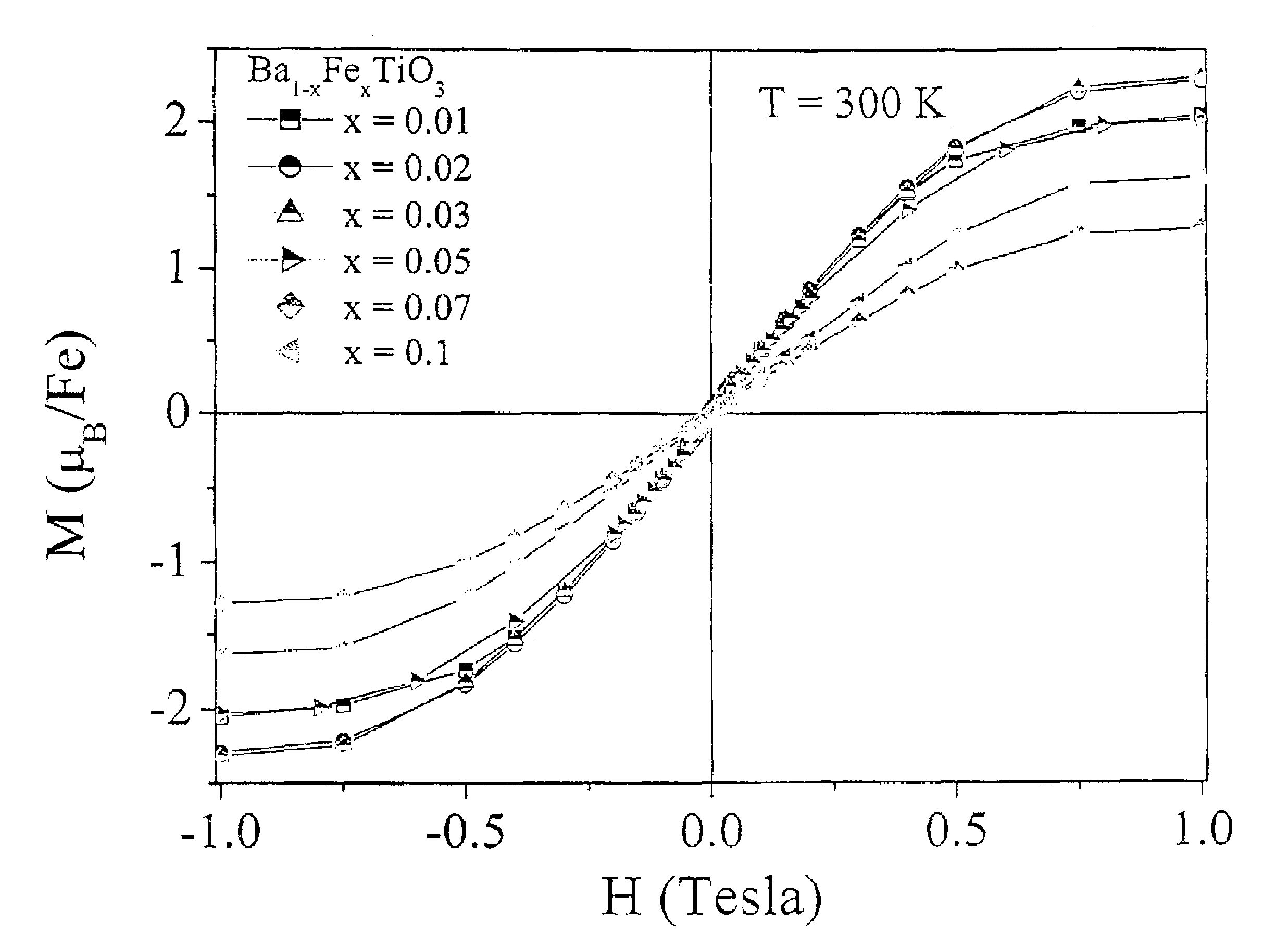

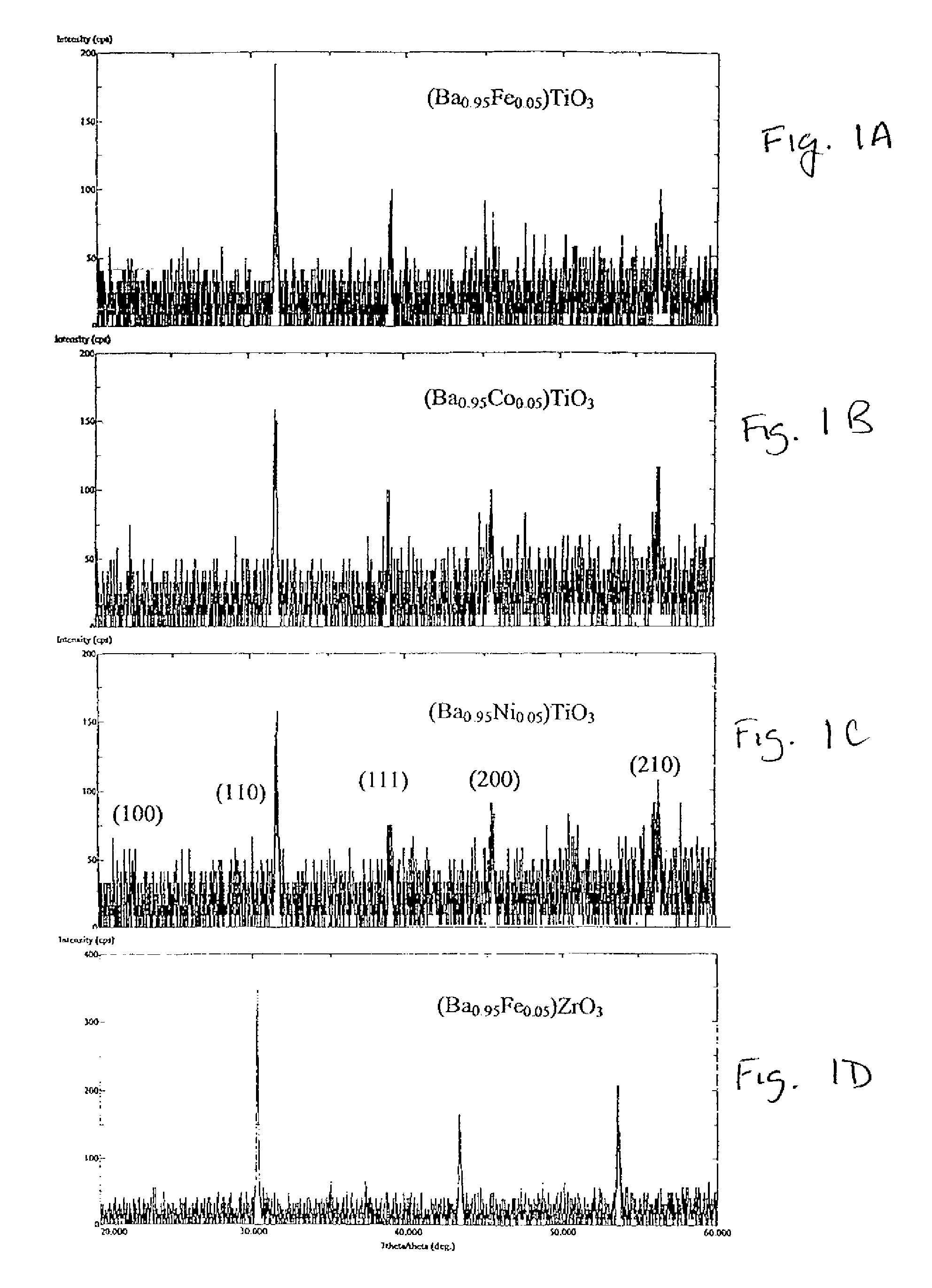

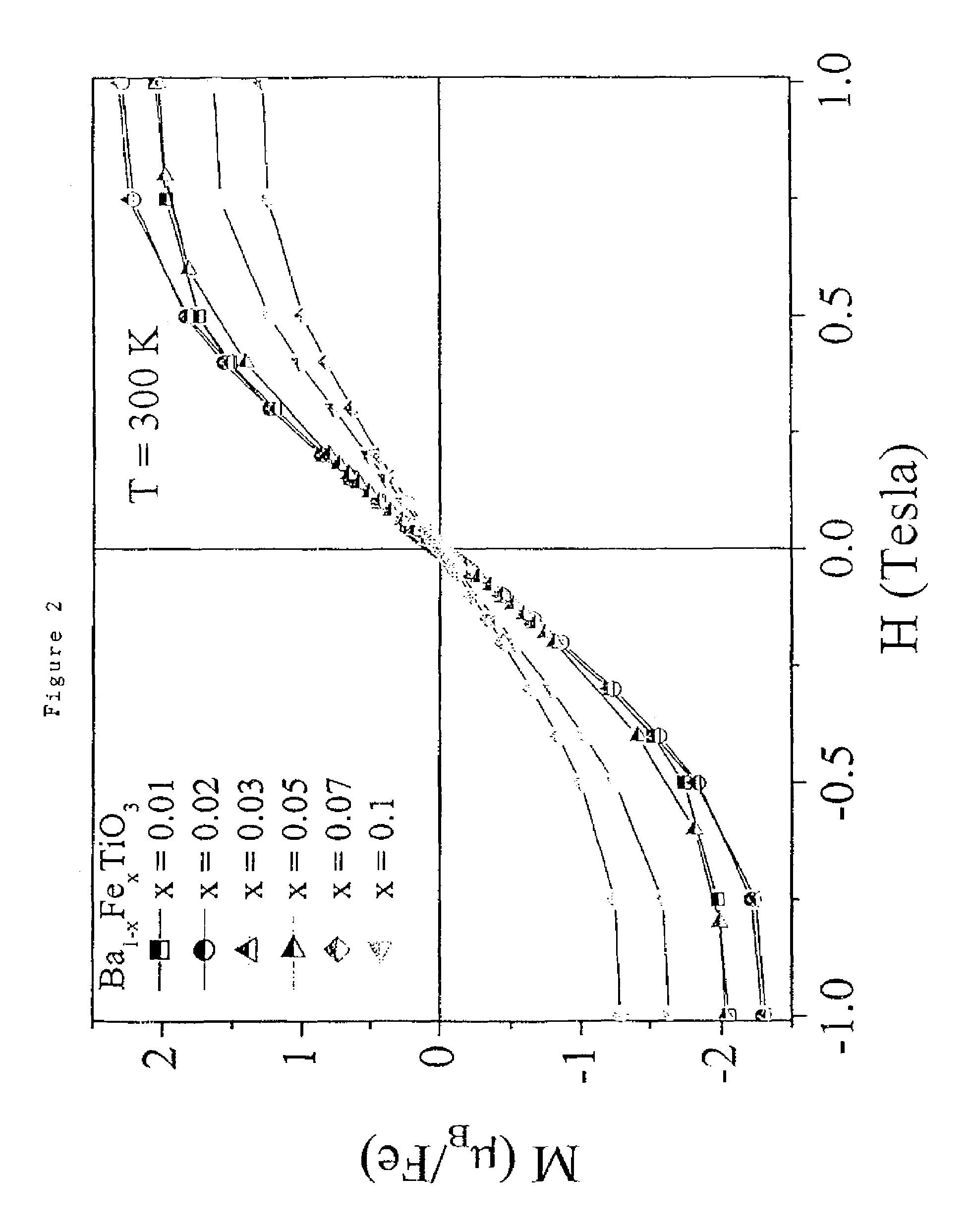

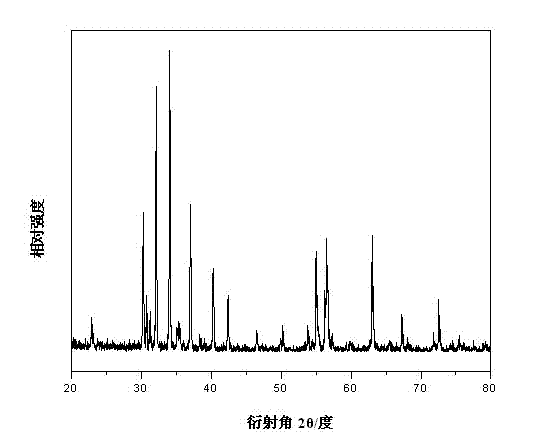

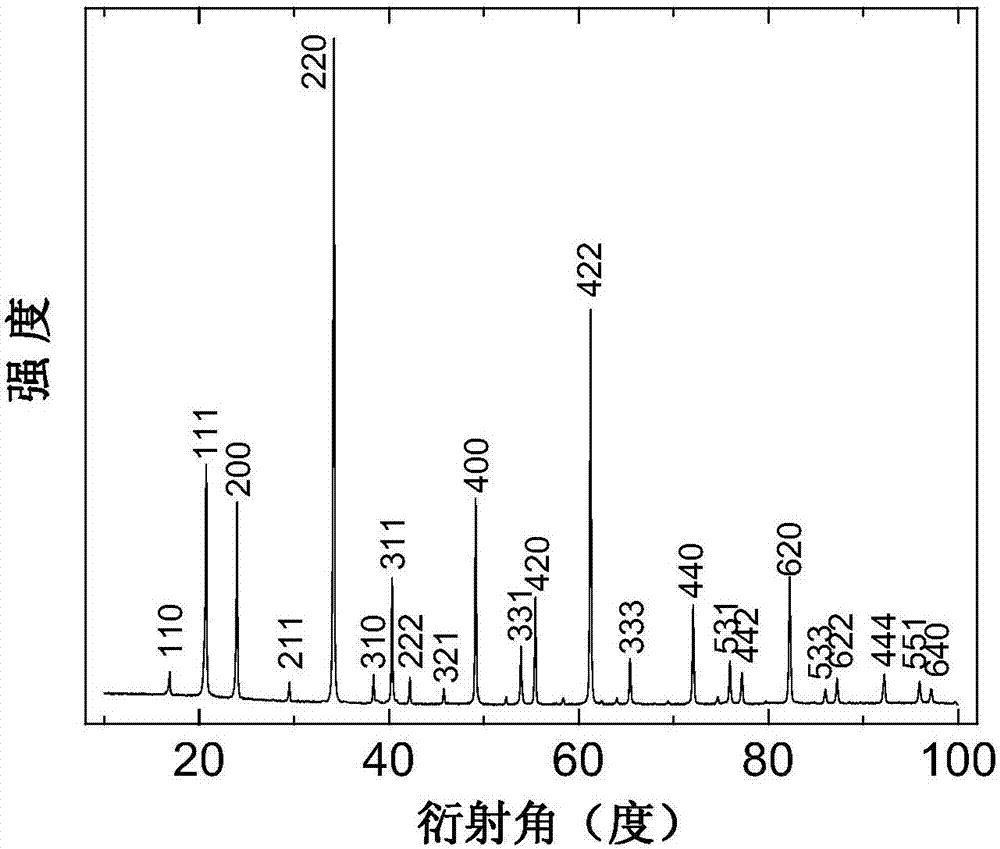

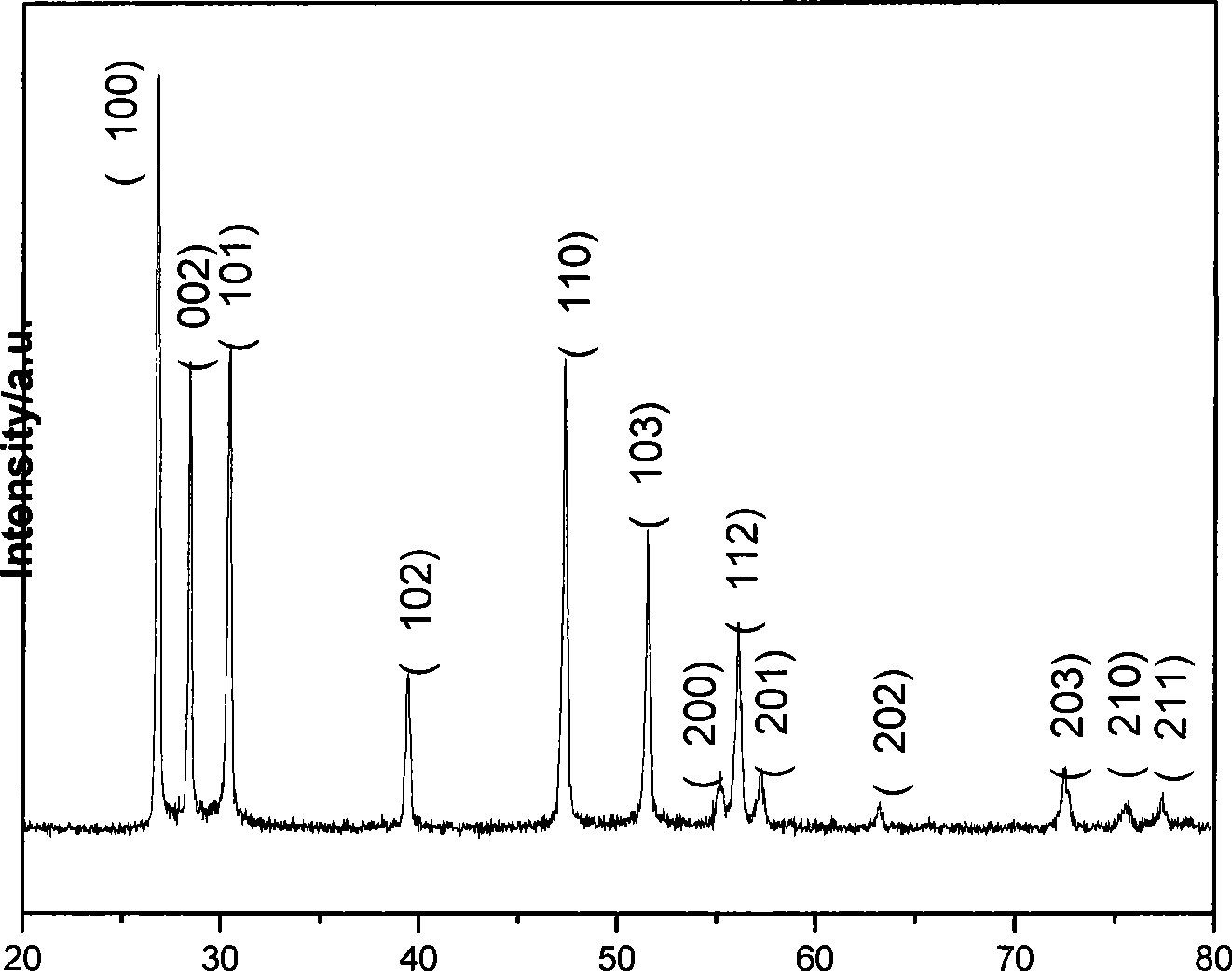

Magnetic doped perovskite oxides

Novel metal oxide compositions are disclosed. These ferromagnetic or ferrimagnetic compositions have resitivities that vary between those of semiconducting and insulating materials, and they further exhibit Curie temperatures greater than room temperature (i.e., greater than 300 K). They are perovskite structures with the general chemical formulas (A1-xMx)BO3, (A1-xMx)(B′B″)O3 or A(B1-xMx)O3, where A can be a 1+, 2+ and 3+ charged ion; B can be a 5+, 4+, 3+ charged ion; B′ and B″ can be 2+, 3+, 4+, 5+ and 6+ charged ion. M is a magnetic ion dopant. X-ray diffraction patterns are presented for exemplary compositions.

Owner:INTEMATIX

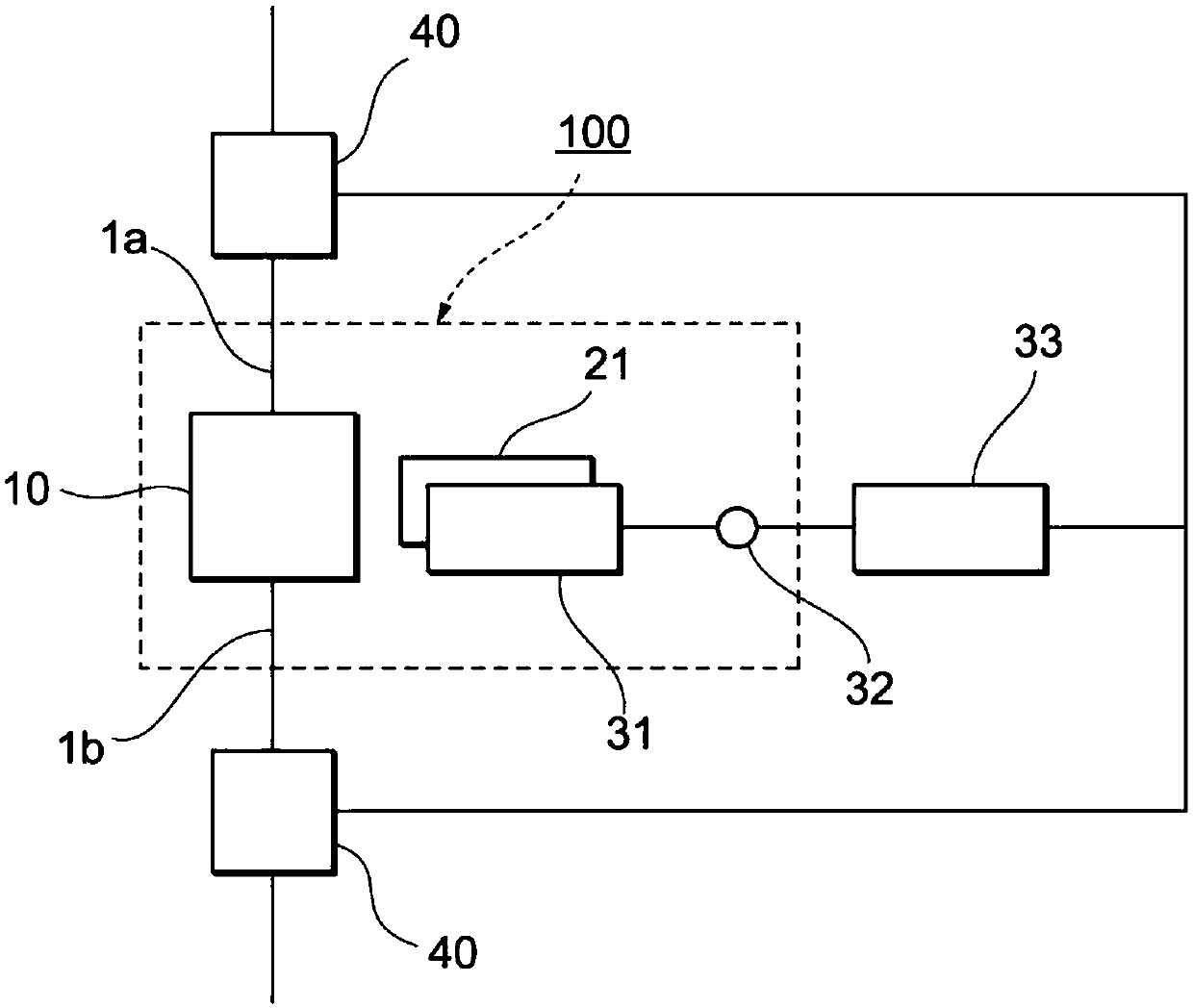

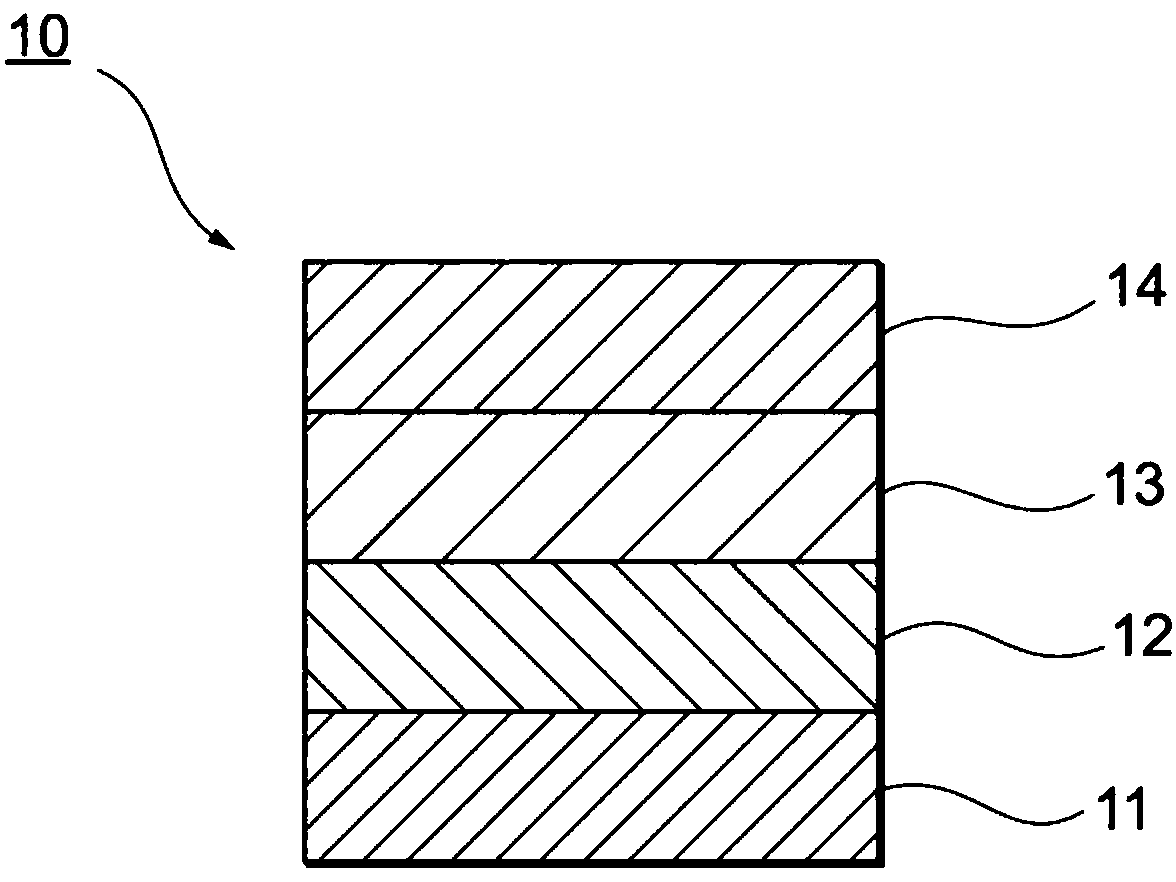

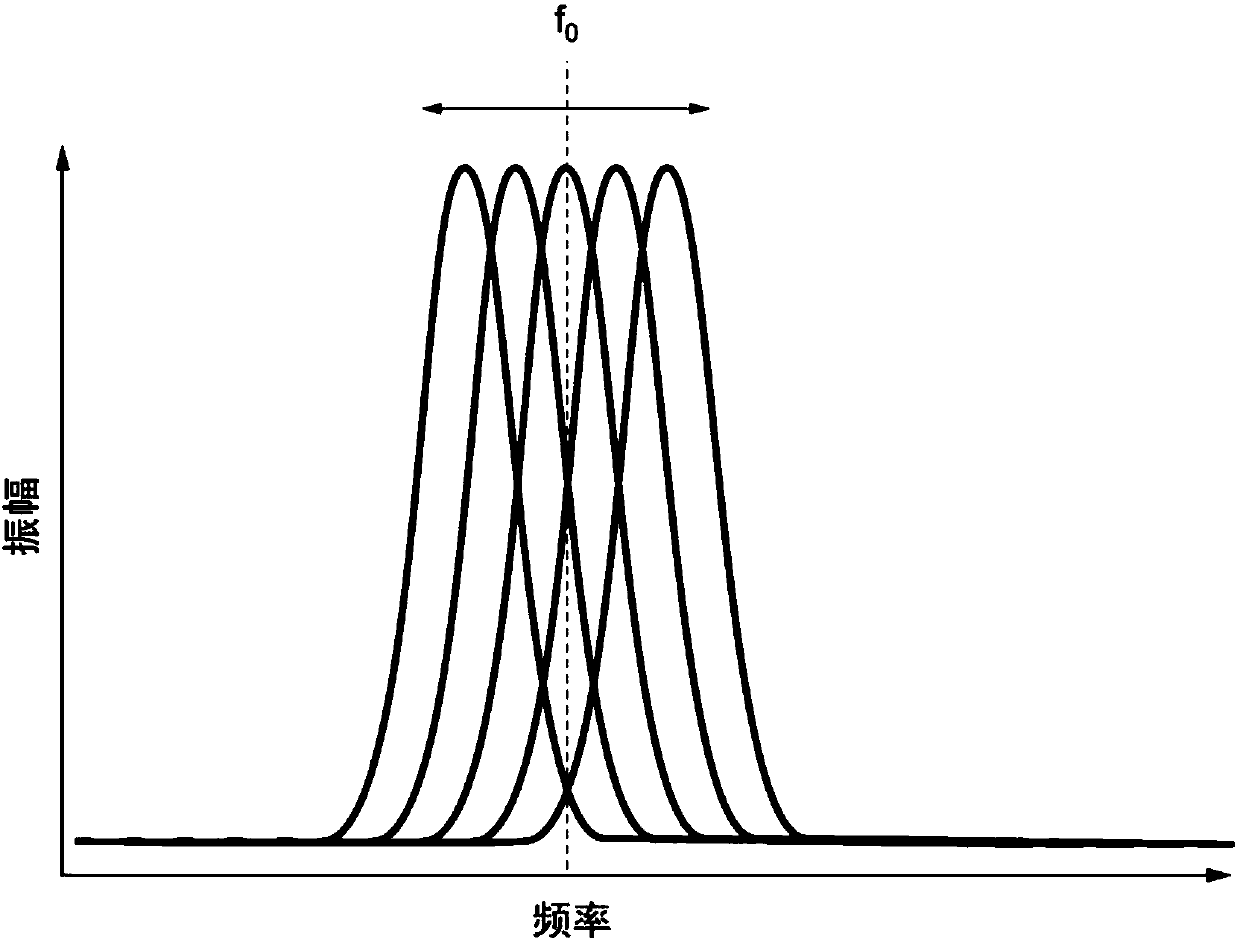

Variable-frequency magnetoresistive effect element and oscillator, detector, and filter using the same

ActiveCN107919434AReduce work energyMagnetic measurementsMagnetic-field-controlled resistorsMagnetic effectElectrical resistance and conductance

The invention aims to provide a variable-frequency magnetoresistive effect element stable in frequency feature and substantially reduced in working energy and a device employing the same. The variable-frequency magnetoresistive effect element includes a magnetoresistive effect element, a magnetic-field applying mechanism that applies a magnetic field to the magnetoresistive effect element, an electric-field applying mechanism that applies an electric field to the magnetoresistive effect element, and a control terminal connected to the electric-field applying mechanism and used for applying a voltage that varies in at least one of magnitude and polarity to the electric-field applying mechanism. The magnetoresistive effect element contains an antiferromagnetic material or ferrimagnetic material having a magnetoelectric effect. A spin torque oscillation frequency or spin torque resonance frequency of the magnetoresistive effect element is controlled by varying the voltage applied via thecontrol terminal in at least one of magnitude and polarity.

Owner:TDK CORPARATION

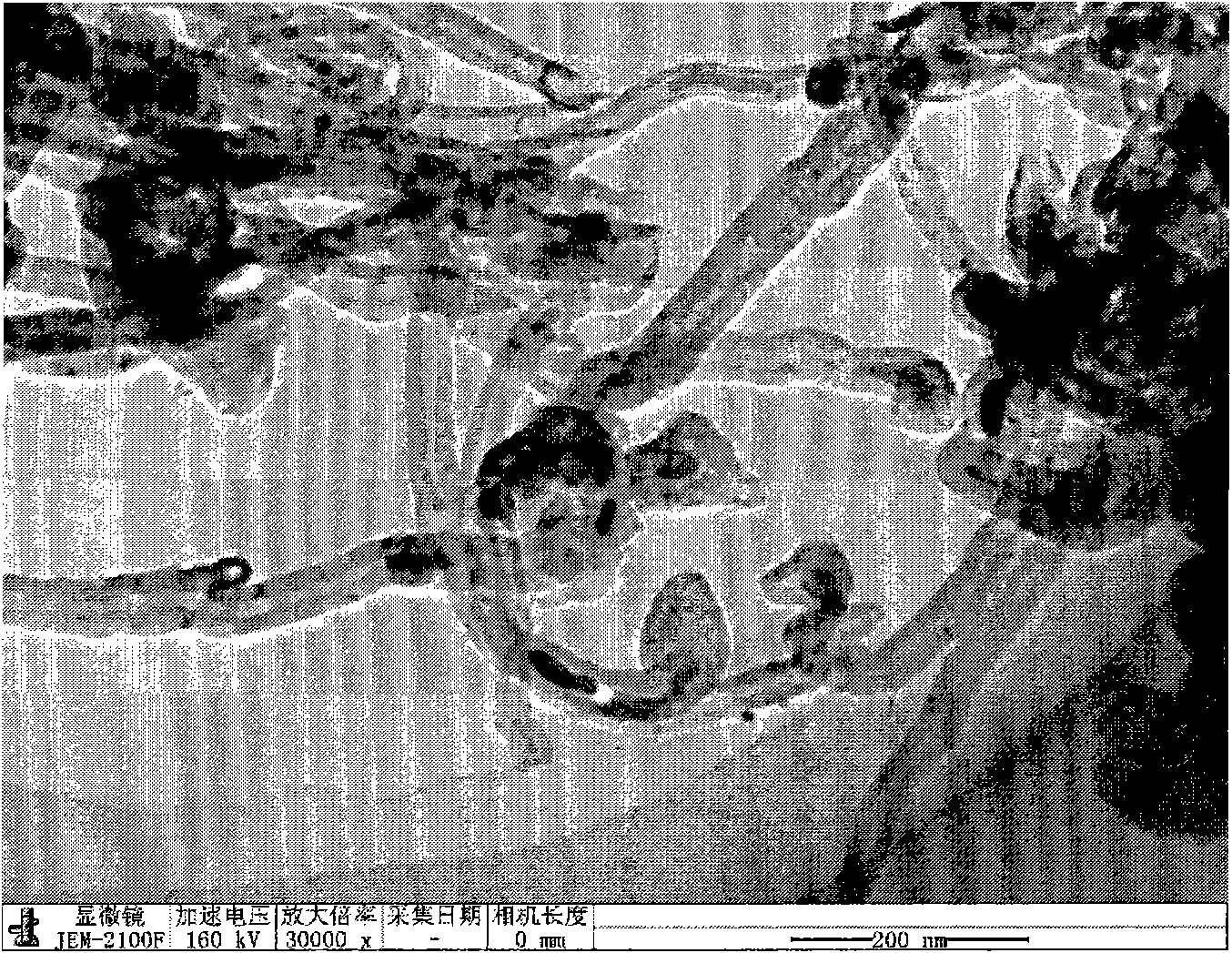

Method for preparing gamma-Fe2O3 nanometer wire filling carbon nitrogen multi-wall nanometer tubes through one-step reaction

The invention relates to a method for preparing gamma-Fe2O3 nanometer wire filling carbon nitrogen multi-wall nanometer tubes through one-step reaction. Particularly, the invention belongs to a method for preparing metal oxide nanometer wire filling carbon nitrogen nanometer tubes under the condition of the existence of FeNi (50 percent of Fe and 50 percent of Ni in mass percent) catalyst thin films in the plasma body chemical gas phase deposition process of paraffin gas (preferably methane), air and hydrogen (according to a flow rate ratio of 80 / 10 / 20 with the unit of ml / minute in a standard state). The products prepared by the invention have good orientation effect and high yield. The single crystal nanometer wires filled to the inside have ferrimagnetism, and the multi-wall tubular structures at the outer layer have the special nitrogen doped bamboo joint type structures. The invention has the advantages of simple method, one-step completion, easy control and convenient industrial production. The prepared magnetic nanometer materials have wide application prospects in the fields of biological medicine, field generation devices, catalytic materials and the like.

Owner:JILIN UNIV

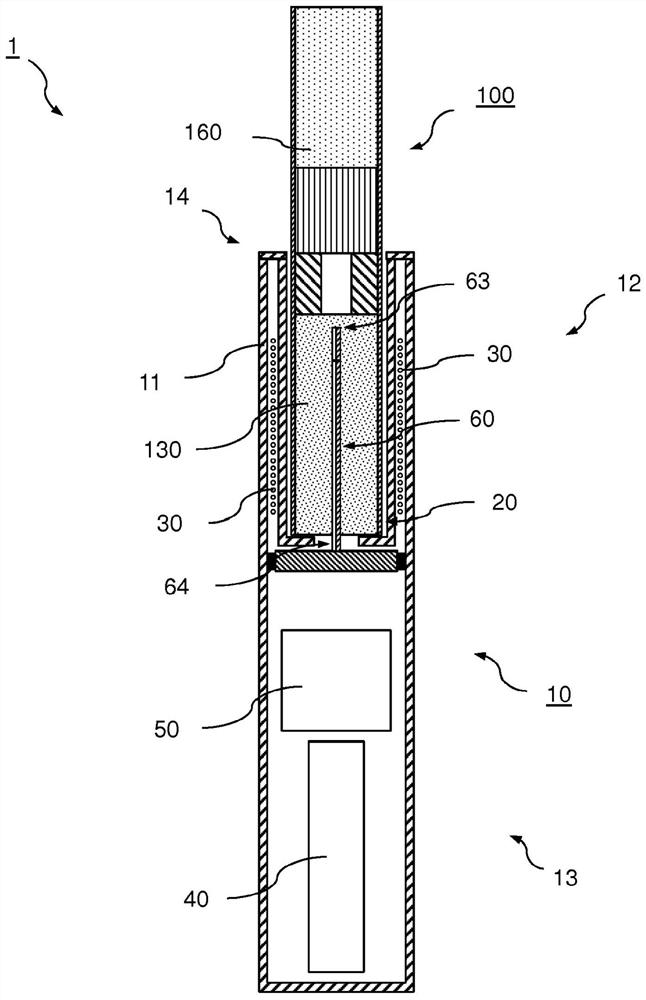

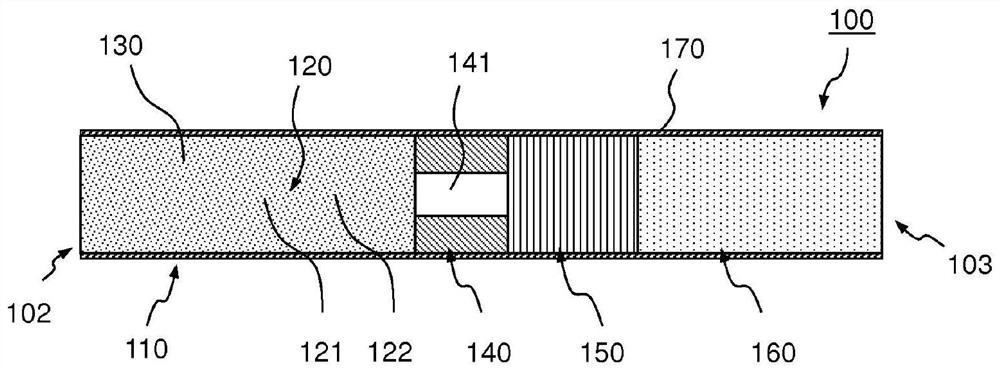

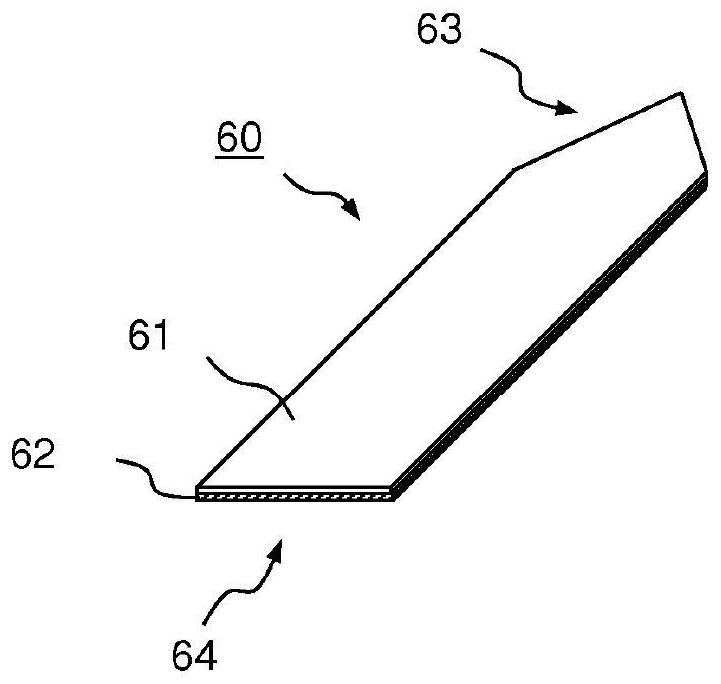

Inductively heated aerosol-generating device comprising a susceptor assembly

The present invention relates to an inductively heated aerosol-generating device (10) for generating an aerosol by heating an aerosol-forming substrate. The device comprises a receiving cavity (20) for receiving the aerosol-forming substrate (130) to be heated. The device further comprises an induction source (30) which is configured to generate an alternating electromagnetic field. Moreover, the device comprises a susceptor assembly (60) which his configured and arranged to inductively heat the aerosol-forming substrate within the receiving cavity under the influence of the alternating magnetic field generated by the induction source. The susceptor assembly comprises a first susceptor (61) and a second susceptor (62). The first susceptor comprises a first susceptor material having a positive temperature coefficient of resistance, and the second susceptor comprises a second ferromagnetic or ferrimagnetic susceptor material having a negative temperature coefficient of resistance. The invention further relates to an aerosol-generating system comprising such an aerosol-generating device and an aerosol-generating article (100) for use with the device which comprises the aerosol-forming substrate to be heated.

Owner:PHILIP MORRIS PROD SA

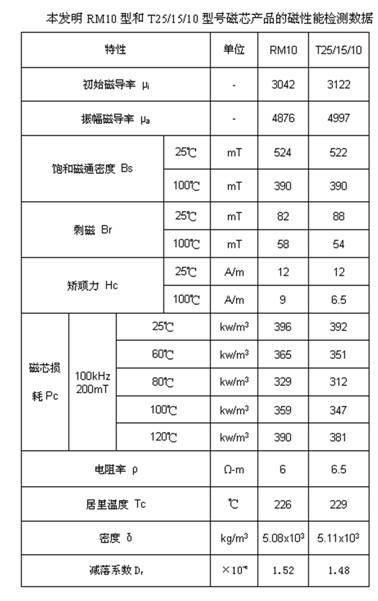

Wide-temperature low-power consumption ferrimagnetism material

ActiveCN102097195AEliminate negative effectsReduce porosityInorganic material magnetismTransformerFerrimagnetism

The invention relates to a wide-temperature low-power consumption ferrimagnetism material, prepared by adopting a method comprising the following steps: (1) burdening, namely preparing 52-58mol% of Fe2O3, 6-13mol% of ZnO, 29-42mol% of metal Mn powder and 0.1-1.0mol% of Co2O3; (2) adding the metal Mn powder and ZnO into a reaction tank filled with deionized water for carrying out binary reaction, then respectively adding Fe2O3 and Co2O3, and mixing; (3) drying the synthesized size obtained in the step (2) until the water content is lower than 0.7%; (4) placing the material obtained in the step (3) in a rotary kiln to be pre-burned until more than 90% of the material is subjected to ferro-oxidization; (5) respectively adding 100-1000ppm of trace elements Ca, Zr, Nb, Sn, Ti and Ta, and stirring to be uniform; (6) ball milling; (7) pelleting; (8) shaping; (9) sintering; and (10) grinding. The magnetic material in the invention has high magnetic conductivity and wide use temperature range, the power consumption at normal temperature is reduced by 30% when the magnetic material is in a standby state; the energy conversion efficiency of the material is improved by 25% and the volume is reduced by one third when the material is applied to an LCD (liquid crystal display) backlight power converter and a POP power transformer; and the material is beneficial to miniaturization and lightening of an automobile power.

Owner:娄底市玖鑫电子科技有限公司

Magnetic recovery method of magnetically responsive high-aspect ratio photoresist microstructures

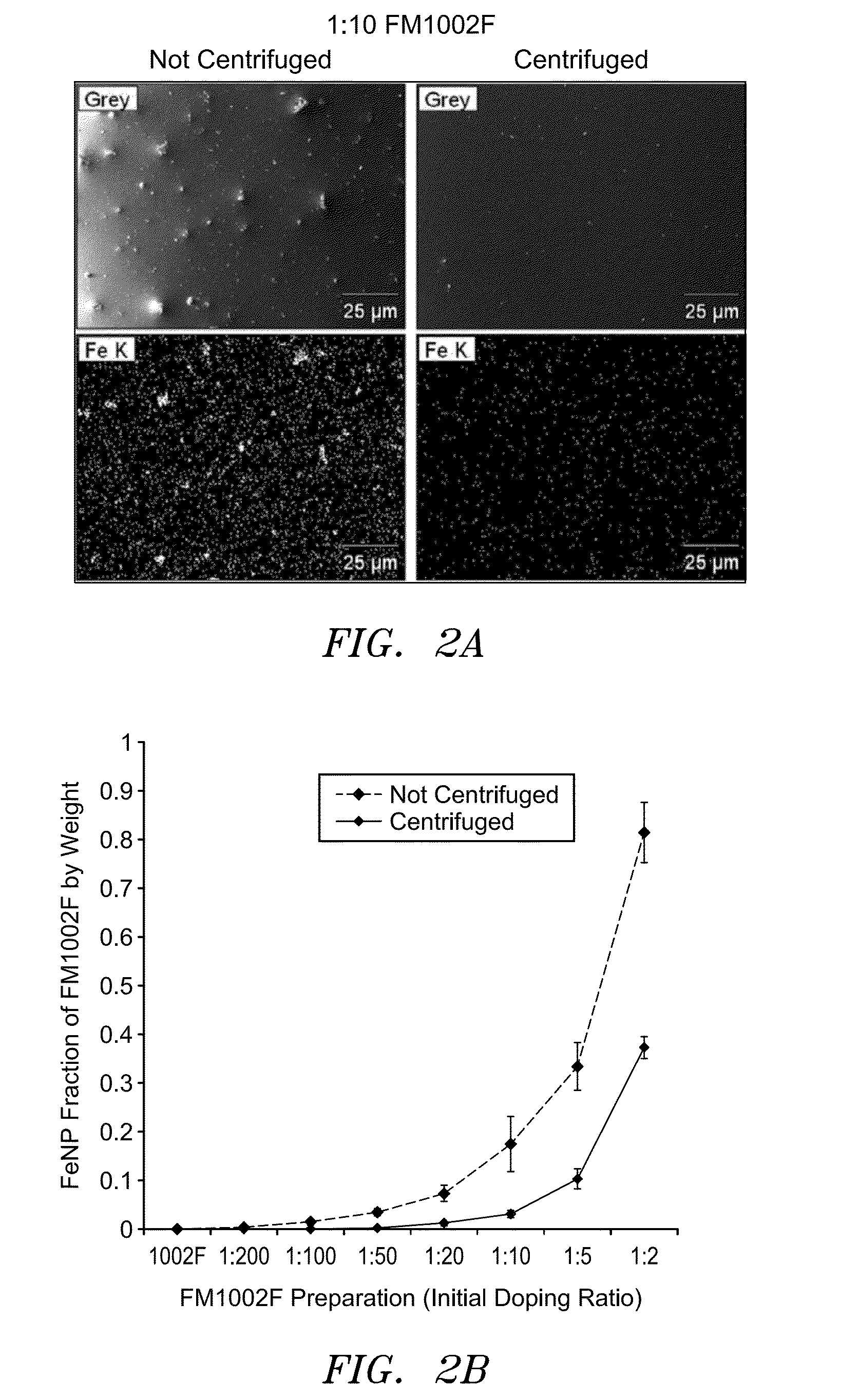

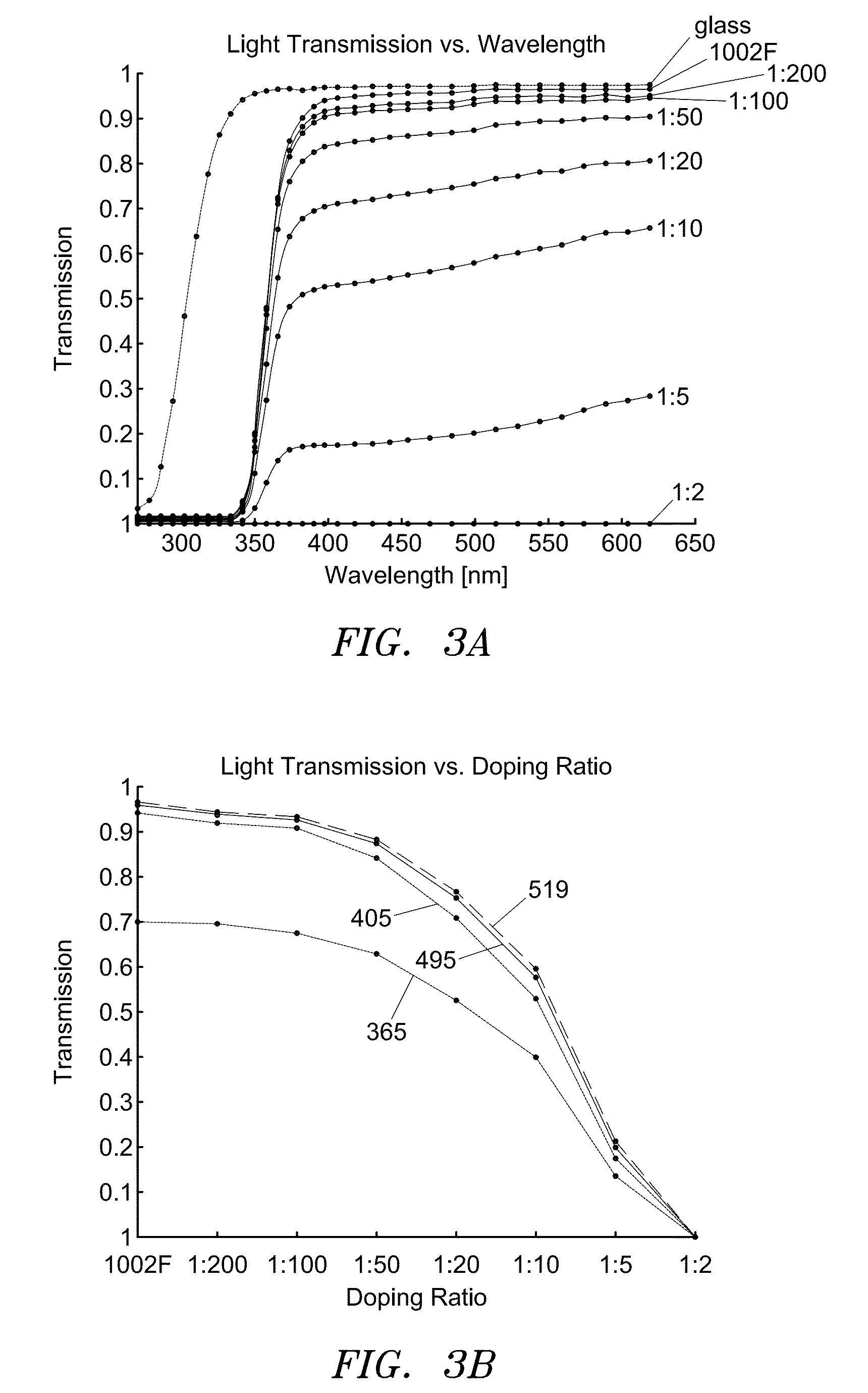

ActiveUS20130023438A1Facilitate magnetic collectionFacilitate manipulationLibrary screeningNanosensorsRecovery methodResist

Systems and methods that facilitate magnetic collection and / or manipulation of individual micropallets are provided. The embodiments provided herein are directed to a new method for collecting micropallets once released from a substrate. It is accomplished by endowing the micropallets with magnetic properties by incorporating ferromagnetic or superparamagnetic nanoparticles into the photoresist material or otherwise incorporating magnetically responsive material into the micropallet structure. The magnetic particles, which posses magnetic qualities, e.g., ferromagnetism, ferrimagnetism, paramagnetism, and are composed of iron, nickel, and / or other magnetic materials, are mixed into the bulk photoresist prior to its use in the fabrication of microstructures. Also covered are other methods of incorporating magnetically-attractable material into the micropallet structure, such as plating of the micropallets with a material that is magnetically responsive, such as nickel. Additionally, the embodiments provided include a “collection probe” that is used to collect the released magnetic micropallets.

Owner:RGT UNIV OF CALIFORNIA

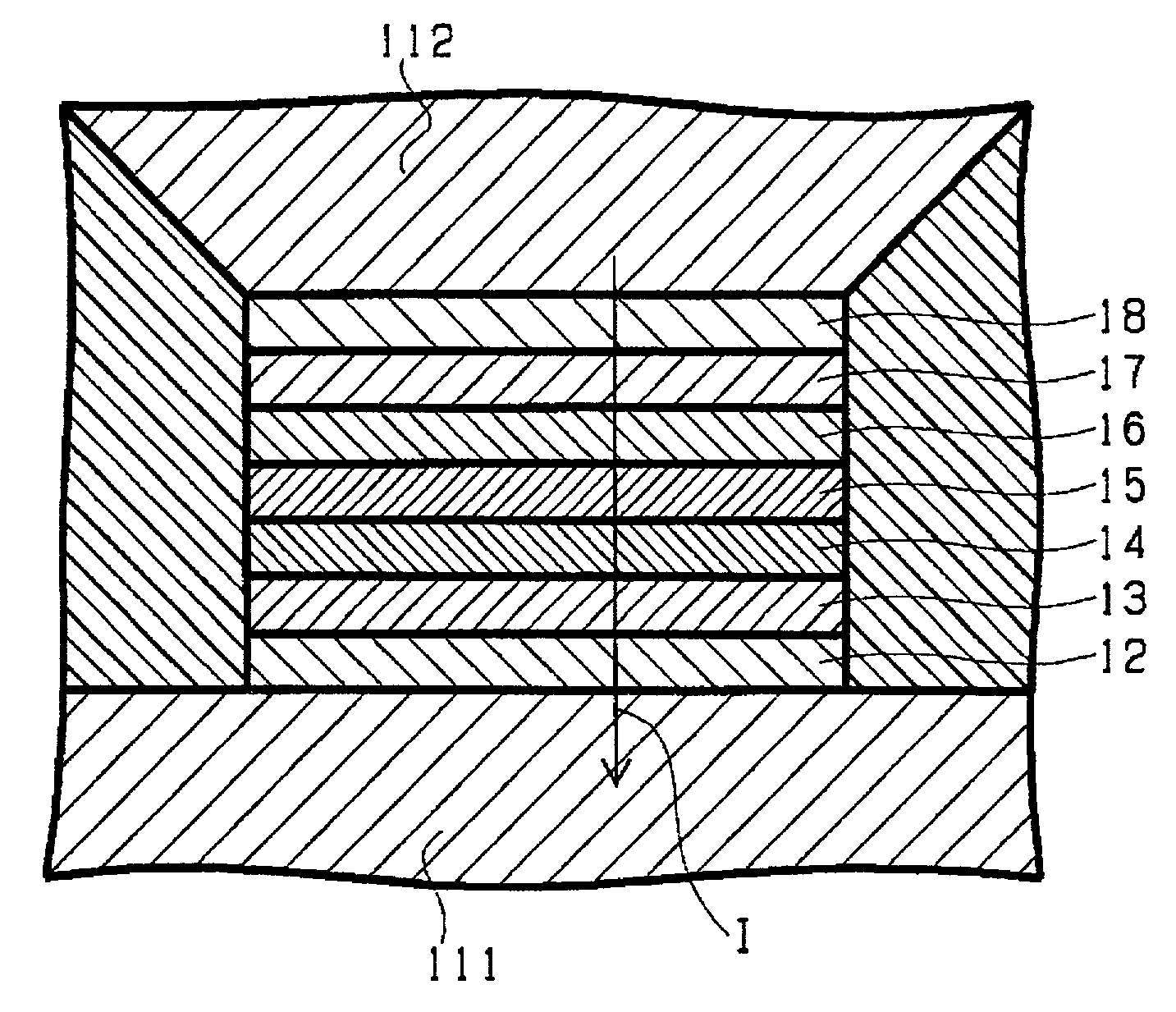

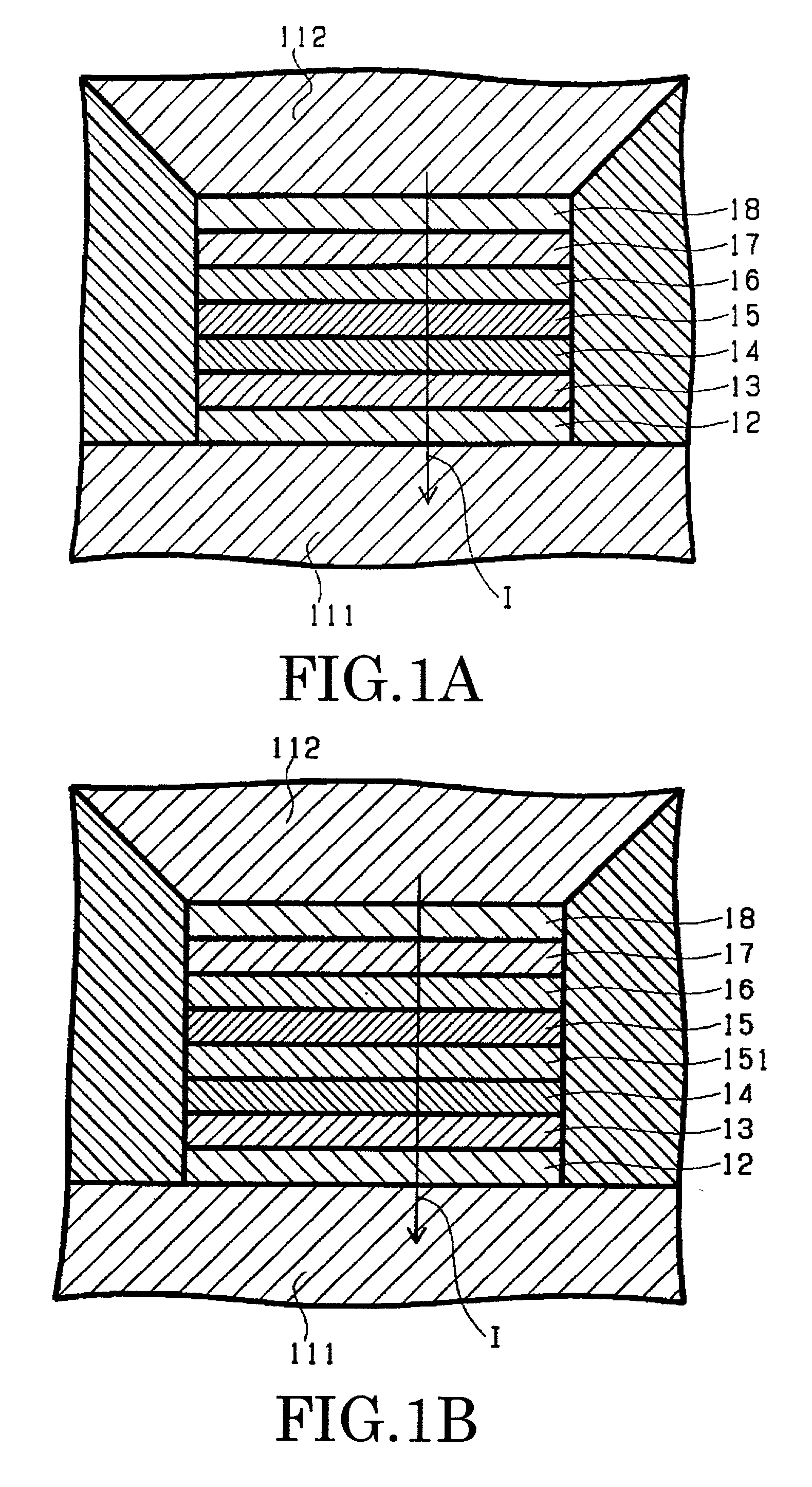

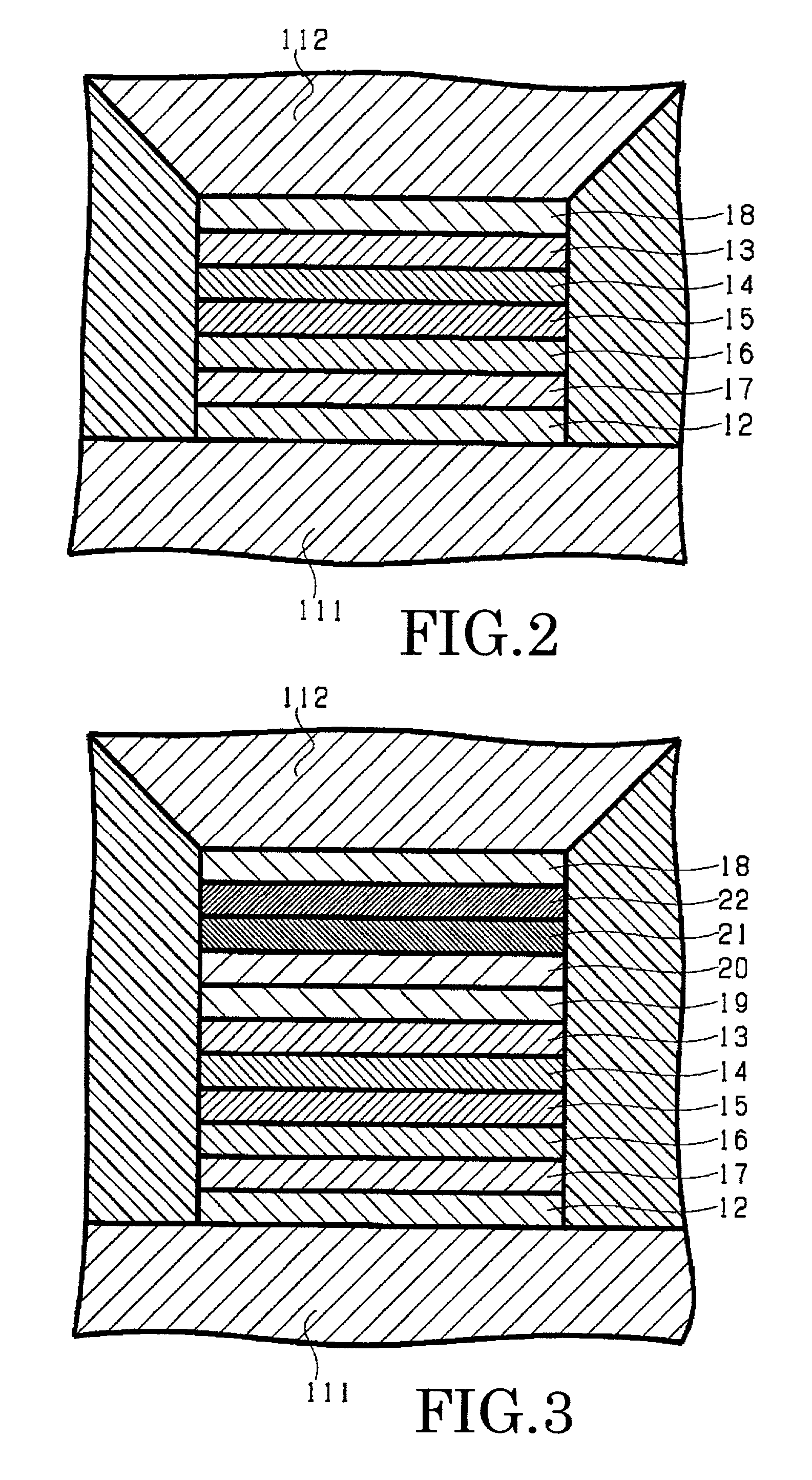

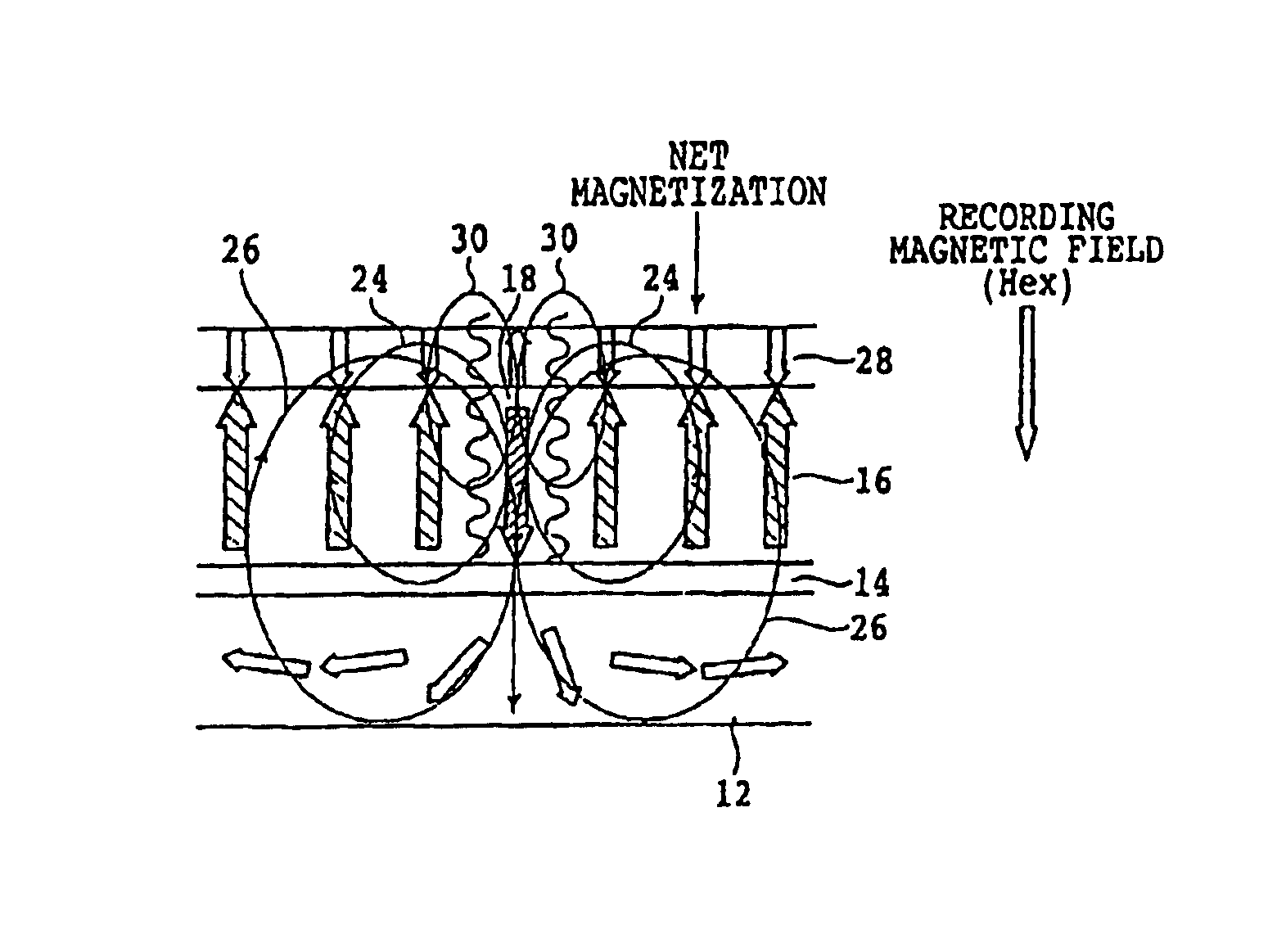

Information recording medium and information storing device

A perpendicular magnetic recording medium including a substrate, a soft-magnetic backing layer formed on the substrate, a magnetic recording layer having perpendicular magnetic anisotropy formed on the backing layer, and a leakage magnetic field control layer having ferrimagnetism formed on the magnetic recording layer. The leakage magnetic field control layer is exchange-coupled to the magnetic recording layer antiferromagnetically or ferrimagnetically to thereby suppress the influence of leakage magnetic fields from the backing layer and the magnetic recording layer and reduce the medium noise.

Owner:SHOWA DENKO KK

Laminated magnetic bead with large high-frequency impedance

InactiveCN102709462AIncrease high frequency impedanceLow dielectric constantTransformers/inductances coils/windings/connectionsPiezoelectric/electrostrictive/magnetostrictive devicesCapacitanceElectrical conductor

The invention provides a laminated magnetic bead with large high-frequency impedance. A lamination body is in a structure formed by laminating at least two types of insulator thin sheets as a whole body; one type is a first insulator thin sheet which is made of a ferrimagnetism material and used for forming upper and lower substrates of the lamination body; and the other type is a second insulator thin sheet which is close to an internal electrode and is used for forming the lamination body; the main body of the lamination body is provided with a plurality of first insulators made of the ferrimagnetism material and at least one layer of a second insulator which is arranged at a specific position inside a first insulating layer and is made of a material with low dielectric constant and low consumption; and a coil conductor of a coil layer is arranged in each first insulator; and the dielectric constant and the consumption of the entire material of the laminated magnetic bead can be reduced by adjusting a layer quantity and the thickness of the second insulator, namely the stray capacitance is reduced, so that the high-frequency impedance of the laminated magnetic bead can be increased. Furthermore, a series of the laminated magnetic beads with the different high-frequency impedances can be obtained by only using one kind of ferrite slurry. Compared with the design of the traditional various ferrite materials, the cost can be greatly reduced.

Owner:SHENZHEN SUNLORD ELECTRONICS

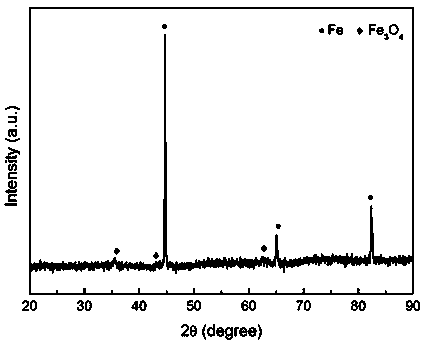

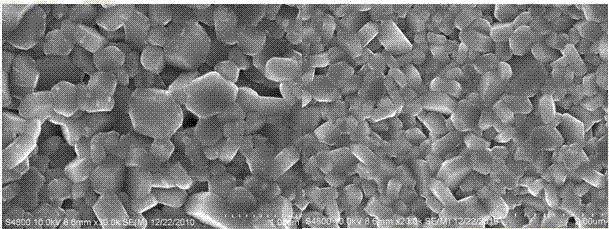

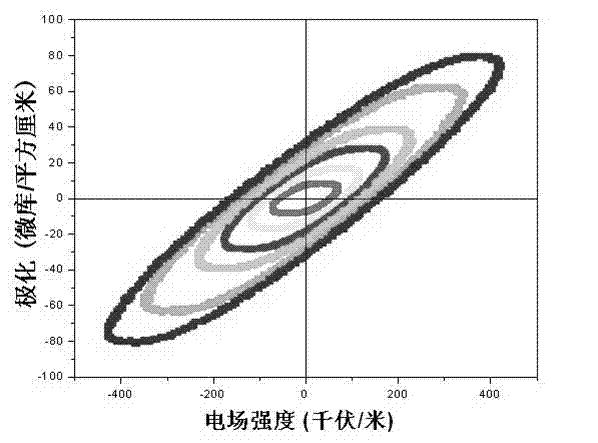

Single-phase multiferroic barium ferrite ceramic material and preparation method thereof

The invention relates to a single-phase multiferroic barium ferrite ceramic material and a preparation method thereof. The preparation method comprises the following steps: weighing barium salt and ferric salt, forming a barium precursor solution and a ferric precursor solution, weighing polyethylene glycol, and dissolving the polyethylene glycol in deionized water for later use; mixing the precursor solutions, adding a mixed solution of ammonia water and polyethylene glycol, and mixing to obtain a suspension; centrifugalizing, pouring out the supernatant, washing the centrifugalized precipitate, calcining, and removing organic substances to obtain initial powder; and grinding, tabletting, and sintering at high temperature to obtain the target product. The barium ferrite ceramic material has multiferroic performance, and has excellent ferroelectricity and ferrimagnetism at room temperature; and the average particle size is 2 mu m or so, and, the particle distribution is uniform. The barium ferrite ceramic material has excellent ferroelectricity, ferrimagnetism and obvious multiferroic performance, and thus, is a practicable multiferroic material. In addition, the invention has the advantages of simple preparation technique, low facility request, accessible raw materials, low price and the like.

Owner:WUHAN UNIV OF TECH

Mn-Zn ferrite magnetic material with high magnetoconductivity and high impedance and method for making the same

ActiveCN101231902BImprove permeabilityHigh impedance characteristicInorganic material magnetismFerrimagnetismMaterials science

The invention relates to a Mn and Zn ferrimagnetism material and a preparation method thereof. The Mn and Zn ferrimagnetism material is made of principal ingredients and subsidiary ingredients. The weight percentages of the principal ingredients which are oxides are calculated as follows: Fe2O3 accounts for 61 percent to 75 percent by weight; ZnO accounts for 12 percent to 30 percent by weight; the rest principal ingredient is Mn3O4. The subsidiary ingredients are one or a plurality of kinds of CaCO3 accounting for 0 to 300ppm by weight; SiO2 accounting for 50ppm to 250ppm by weight; Bi2O3 accounting for 0 to 500ppm by weight. The Mn and Zn ferrimagnetism material has both high magnetic permeability and high impedance.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

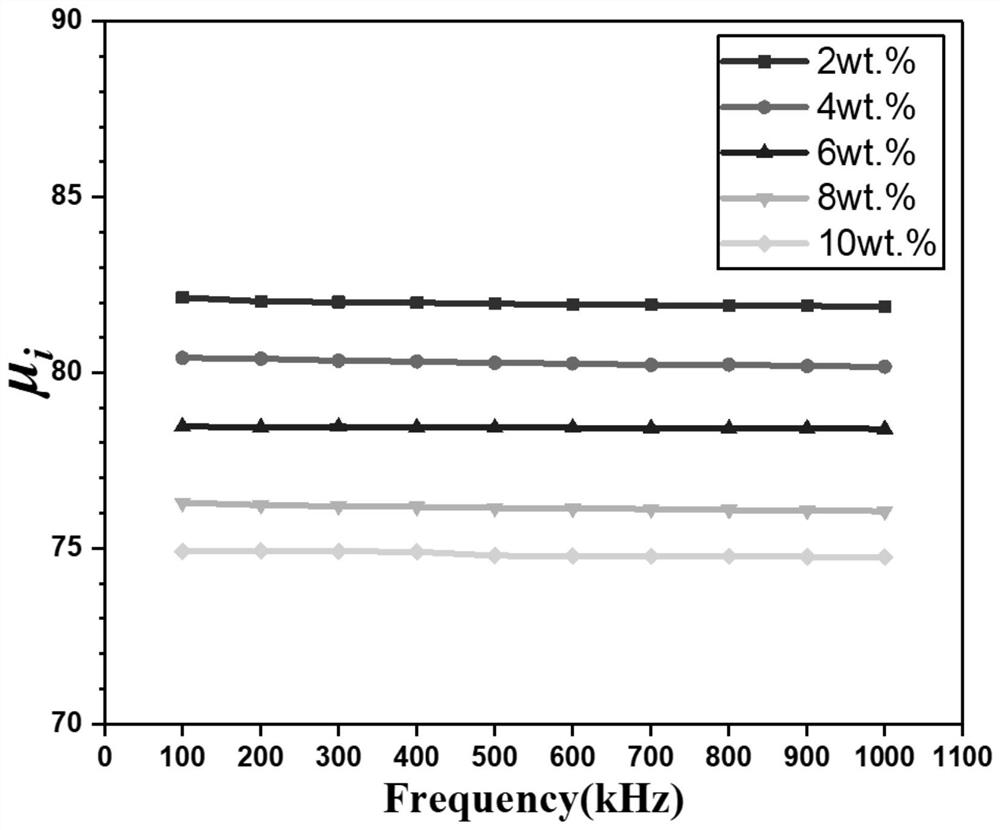

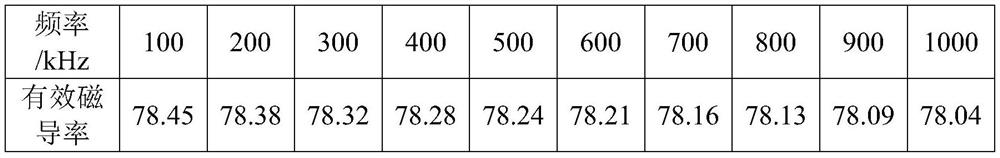

Low-loss FeSiAl/MnZn ferrite soft magnetic composite magnetic powder core with stable magnetic conductivity and preparation method of low-loss FeSiAl/MnZn ferrite soft magnetic composite magnetic powder core with stable magnetic conductivity

PendingCN113658768AGood effectReduce power lossInorganic material magnetismInductances/transformers/magnets manufactureFerrite layerAdhesive

The invention discloses a low-loss FeSiAl / MnZn ferrite soft magnetic composite magnetic powder core with stable magnetic conductivity and a preparation method of the low-loss FeSiAl / MnZn ferrite soft magnetic composite magnetic powder core with stable magnetic conductivity. The raw materials of the magnetic powder core comprise an adhesive, a lubricant and FeSiAl / MnZn ferrite composite magnetic powder; the FeSiAl / MnZn ferrite composite magnetic powder comprises phosphatized FeSiAl magnetic powder and a MnZn ferrite layer, and the surface of the phosphatized FeSiAl magnetic powder is coated with the MnZn ferrite layer through ball milling. According to the preparation method, a phosphoric acid / MnZn ferrite composite coating process is mainly adopted, and MnZn ferrite coating is carried out on the phosphorized FeSiAl powder through the high-energy ball milling method. The preparation method has the advantages of convenience in material preparation, simple operation, uniform coating and good coating effect, and can better facilitate industrial popularization; the MnZn ferrite with ferrimagnetism serves as an insulating coating agent, so that the magnetic dilution phenomenon caused by a non-magnetic substance serving as the coating agent is reduced. The high-frequency performance of the FeSiAl magnetic powder core can be improved, and the provided FeSiAl / MnZn ferrite soft magnetic composite magnetic powder core is low in loss and stable in magnetic conductivity under high frequency.

Owner:西安锐磁电子科技有限公司

Ferrimagnetism semimetal NaCu3Fe2Os2O12 and preparation method thereof

ActiveCN107162068AHigh saturation magnetizationWith temperatureRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsInorganic material magnetismSemimetalSpace group

The invention discloses a ferrimagnetism semimetal. The chemical formula of the ferrimagnetism semimetal is NaCu3Fe2Os2O12, the space group is Pn-3, the lattice constant is as shown in the specification, and the Curie temperature is 380 K. The ferrimagnetism semimetal is a high-temperature ferrimagnetism semimetal. The invention further discloses a preparation method for the ferrimagnetism semimetal. The preparation method comprises the following steps: (1) grinding and mixing NaOH, Fe2O3, CuO, Os and an oxygen source, to obtain a mixture; (2) filling the mixture in a gold or platinum capsule, sealing; (3) processing the gold or platinum capsule in 6-10 GPa of the pressure and 1000-1200 DEG C of the temperature; and (4) cooling a reaction product obtained in the step (3) to be the room temperature, releasing the pressure, and taking out from the gold or platinum capsule, grinding and washing, to obtain the ferrimagnetism semimetal NaCu3Fe2Os2O12. The ferrimagnetism semimetal NaCu3Fe2Os2O12 has the high Curie temperature, and has the potential application value in a future spinning electron device.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

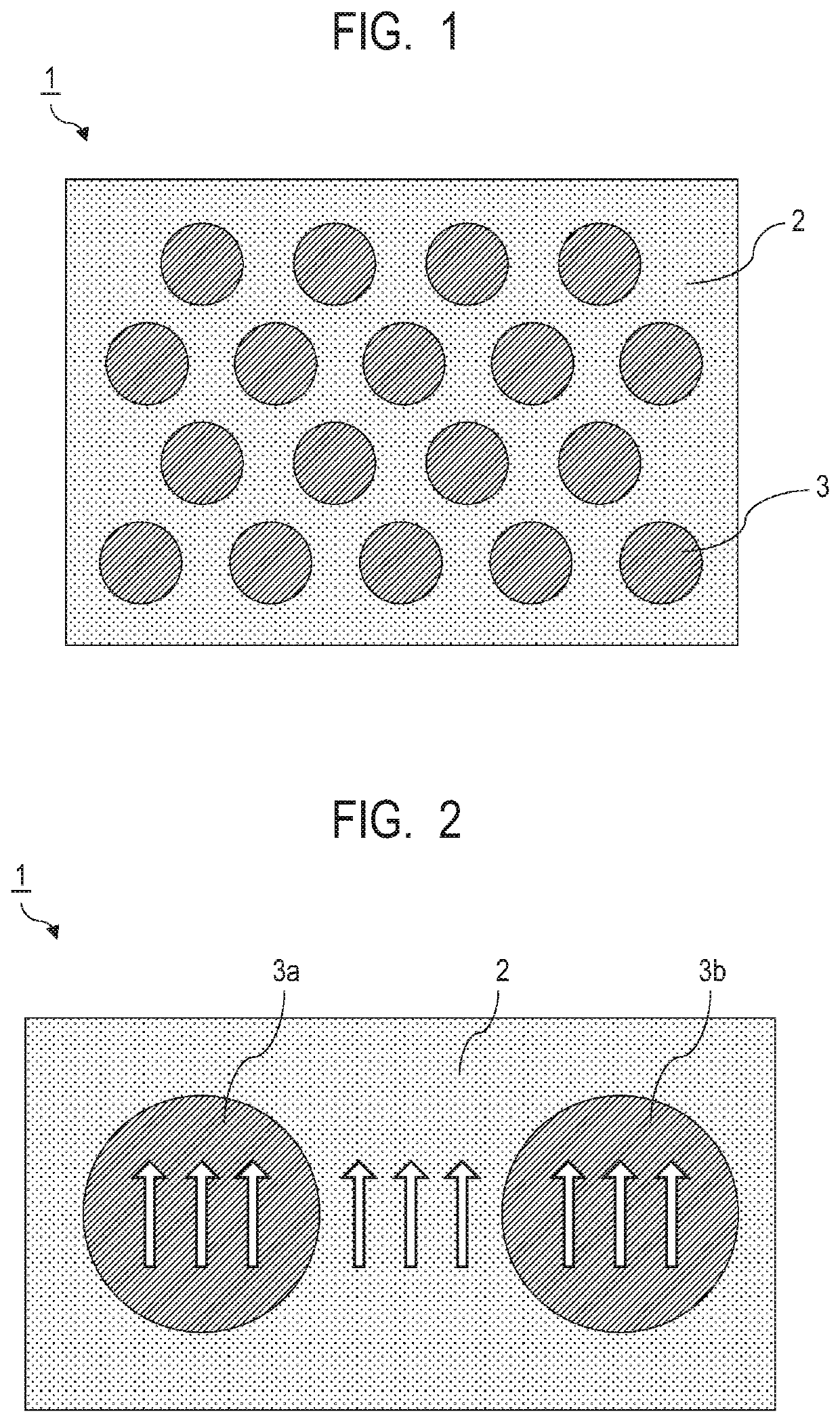

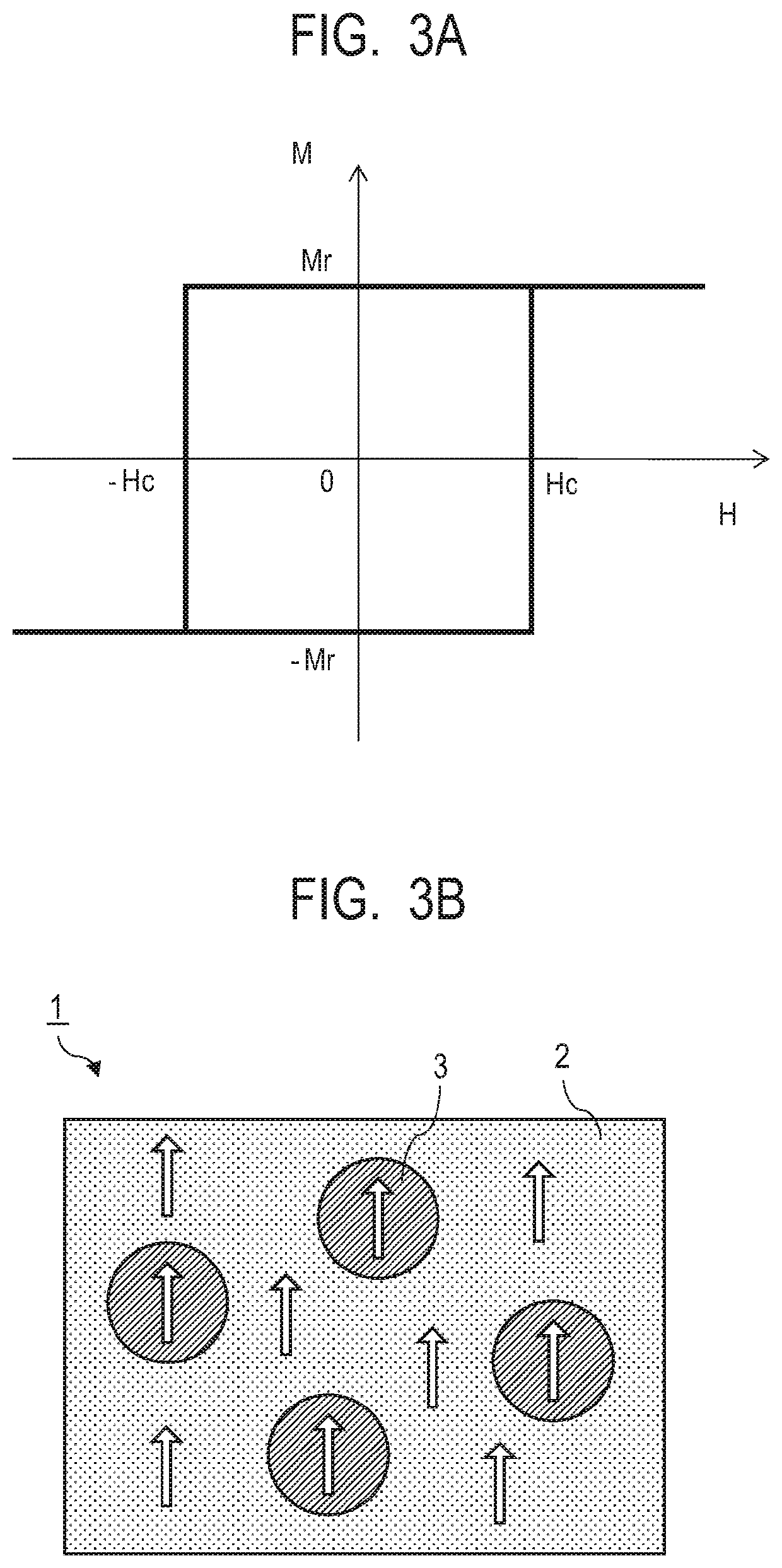

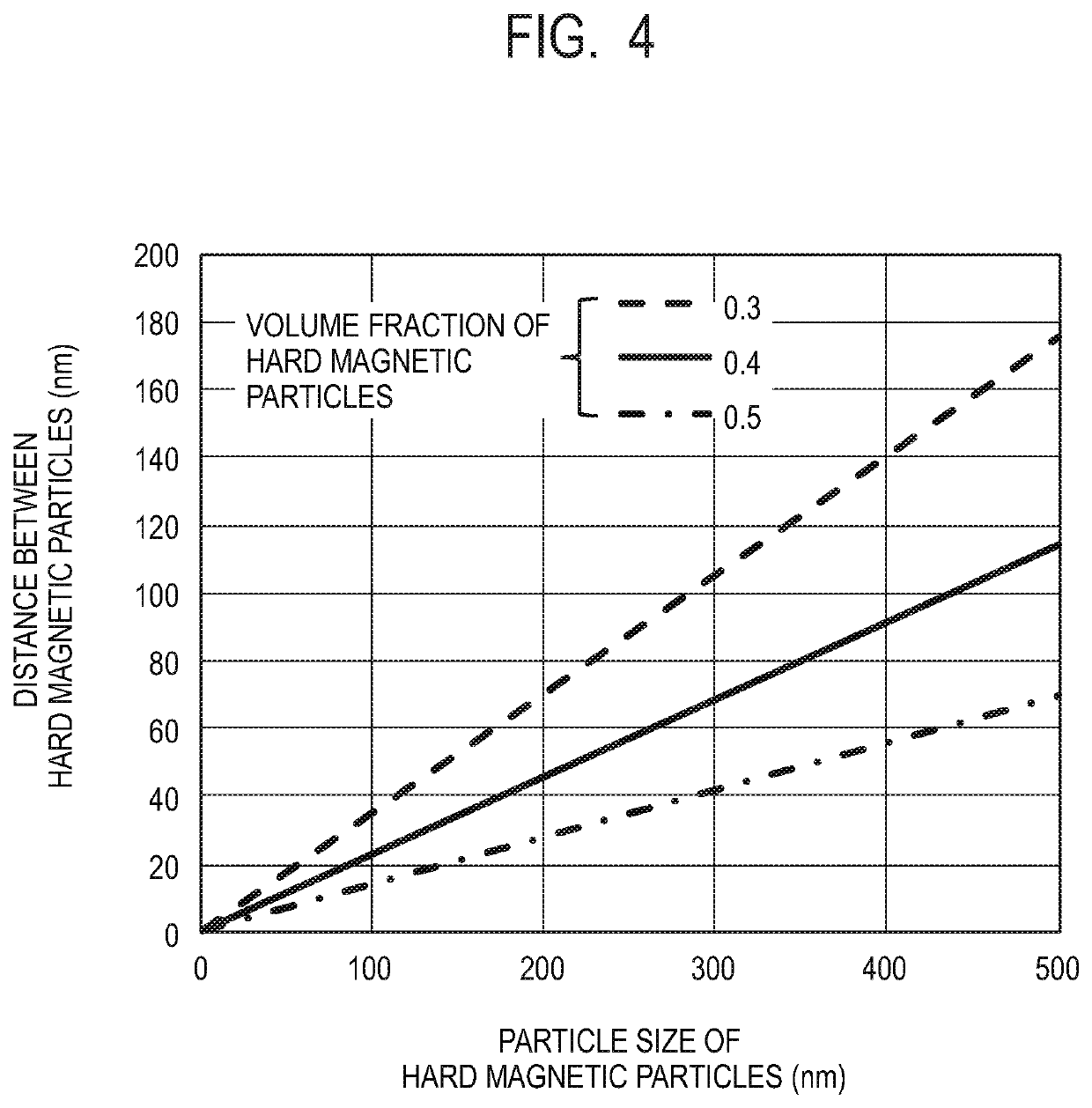

Composite magnetic material, magnet comprising the material, motor using the magnet, and method of manufacturing the composite magnetic material

InactiveUS20200243231A1Association with control/drive circuitsInorganic material magnetismMagnetic phaseElectric machine

A composite magnetic material includes a soft magnetic phase including a magnetic material containing a ferromagnetic material including Fe or Co as a main component and a plurality of hard magnetic particles present and dispersed in a form of islands in the soft magnetic phase. The hard magnetic particles have an average particle size of 2 nm or more and include a magnetic material containing a ferrimagnetic material or an antiferromagnetic material as a main component while they are present with an average inter-particle distance of 100 nm or less in the soft magnetic phase. The composite magnetic material has excellent magnetic properties and can be made into a lightweight magnet to be used e.g. in a motor of an aircraft.

Owner:CANON KK

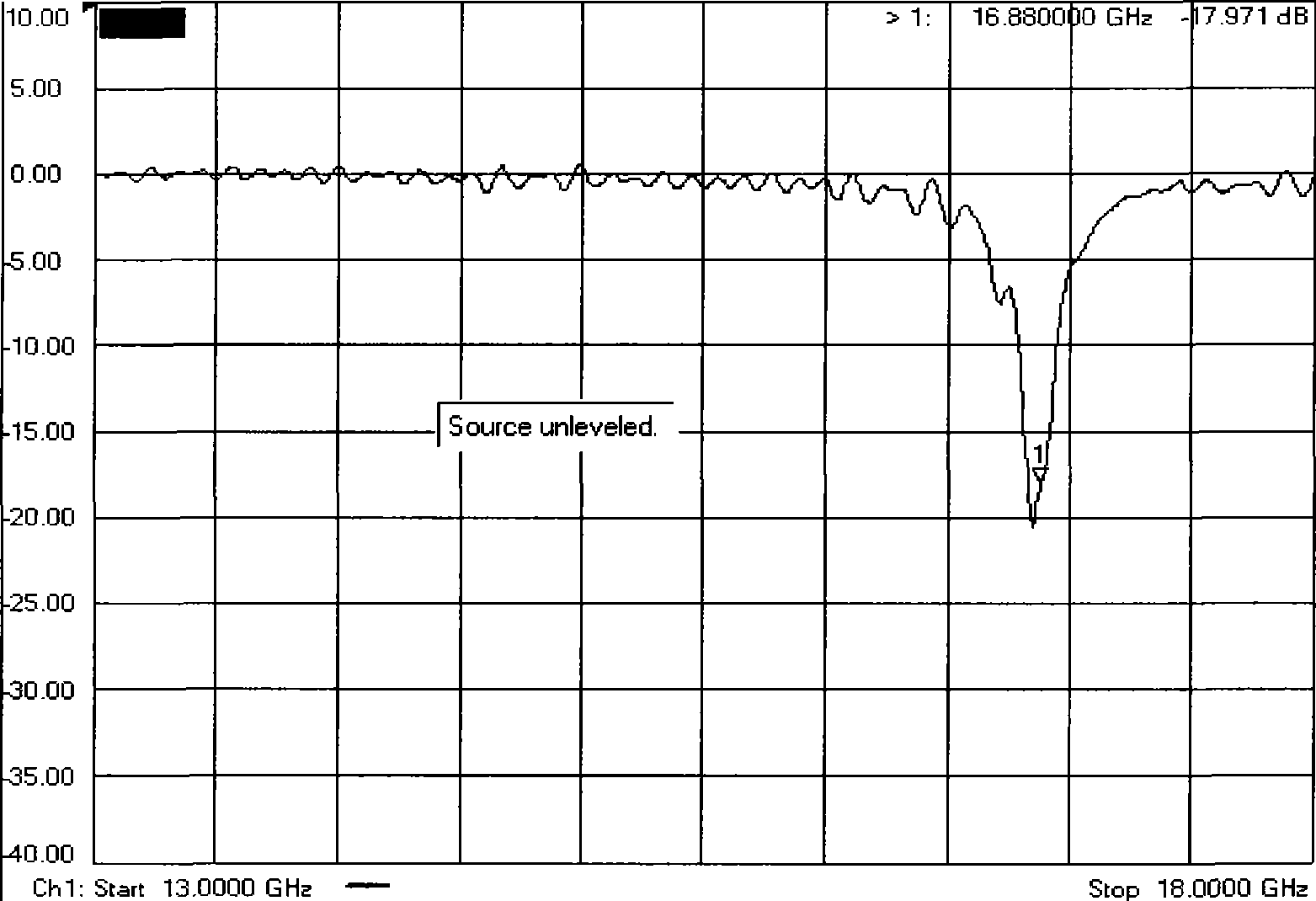

Novel wave-absorbing material and preparation method thereof

InactiveCN101445716ALight in massWith fluorescent effectOther chemical processesFerrousRoom temperature

The invention relates to a novel wave-absorbing material and a preparation method thereof. The novel wave-absorbing material comprises a base material and a wave-absorbing agent, wherein, the wave-absorbing agent is pure cubic phase or hexagonal phase manganese-doped zinc sulfide microcrystal with ferromagnetism or ferrimagnetism at the room temperature. The weight ratio of the cubic phase or hexagonal phase manganese-doped zinc sulfide microcrystal is 10 to 15 percent, and the weight ratio of base material is 50 to 90 percent. The preparation method comprises the following steps: the manganese-doped zinc sulfide precursor is obtained by hydrothermal synthesis, then the heat treatment is performed to the sprecursor within the temperature range of 600 to 700 DEG C under the protection of argon gas atmosphere to obtain cubic phase manganese-doped zinc sulfide microcrystal powder, the heat treatment is performed to the cubic phase manganese-doped zinc sulfide microcrystal powder within the temperature range of 1000 to 1200 DEG C to obtain hexagonal phase manganese-doped zinc sulfide microcrystal powder, and the obtained powder is added in the base material and solidified to obtain the wave-absorbing material.

Owner:ANHUI UNIVERSITY

Scanning probe microscopy tips composed of nanoparticles and methods to form same

InactiveUS20070256480A1Improve spatial resolutionImprove adhesionNanosensorsThin material handlingChemical synthesisFluorescence

A structure and method for improving the spatial resolution of a scanning probe microscope (SPM) tip, which has been coated with a layer of chemically-synthesized nanoparticles. The nanoparticles are either single-species or heterogeneous, such that the single-species nanoparticles can be either ferromagnetic, paramagnetic, superparamagnetic, antiferromagnetic, ferrimagnetic, magneto-optic, ferroelectric, piezoelectric, superconducting, semiconducting, magnetically-doped semiconducting, insulating, fluorescent, or chemically catalytic. The layer of nanoparticles is at least two nanoparticles thick, or alternatively, is a single layer of nanoparticles thick, or alternatively, is a single layer of nanoparticles thick and covers only the tip apex portion of the tip, or alternatively, only a single nanoparticle is affixed to the tip apex. Alternatively, the layer of nanoparticles is transformed into an electrically-continuous magnetic film by annealing at a high temperature.

Owner:BLACK CHARLES T +3

Preparation method of titanium dioxide photocatalysis composite material

InactiveCN108816212AImprove adsorption capacityLarge specific surface areaMaterial nanotechnologyWater/sewage treatment by irradiationActivated carbonMagnetic media

The invention relates to a preparation method of a porous recyclable ferromagnetic ferrite / titanium dioxide (TiO2) photocatalysis composite material. The material takes an active carbon template and apore-forming agent and is prepared through modification, magnetic medium filling, titanium dioxide loading and template removal, and has the advantages of high photocatalysis efficiency and good magnetic separation efficiency. The preparation method comprises the following steps: 1) nitric acid backflow modification of active carbon; 2) a solvothermal method is employed for appropriate filling ofa ferrite magnetic medium on the modified active carbon to obtain a ferrite / active carbon composite material having magnetic responsiveness; 3) an immersion method is employed for loading TiO2 nano particles by taking butyl titanate as a precursor to obtain a TiO2 / ferrite / active carbon composite material; and 4) the TiO2 / ferrite / active carbon composite material is calcined in air to obtain the porous recyclable ferromagnetic ferrite / titanium dioxide photocatalysis composite material with easy magnetic separation. The titanium dioxide photocatalysis composite material has the advantages of simple preparation technology, cycle utilization, and high catalysis efficiency.

Owner:CHINA JILIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com