Patents

Literature

1778 results about "Ferromagnetism" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ferromagnetism is the basic mechanism by which certain materials (such as iron) form permanent magnets, or are attracted to magnets. In physics, several different types of magnetism are distinguished. Ferromagnetism (along with the similar effect ferrimagnetism) is the strongest type and is responsible for the common phenomenon of magnetism in magnets encountered in everyday life. Substances respond weakly to magnetic fields with three other types of magnetism—paramagnetism, diamagnetism, and antiferromagnetism—but the forces are usually so weak that they can only be detected by sensitive instruments in a laboratory. An everyday example of ferromagnetism is a refrigerator magnet used to hold notes on a refrigerator door. The attraction between a magnet and ferromagnetic material is "the quality of magnetism first apparent to the ancient world, and to us today".

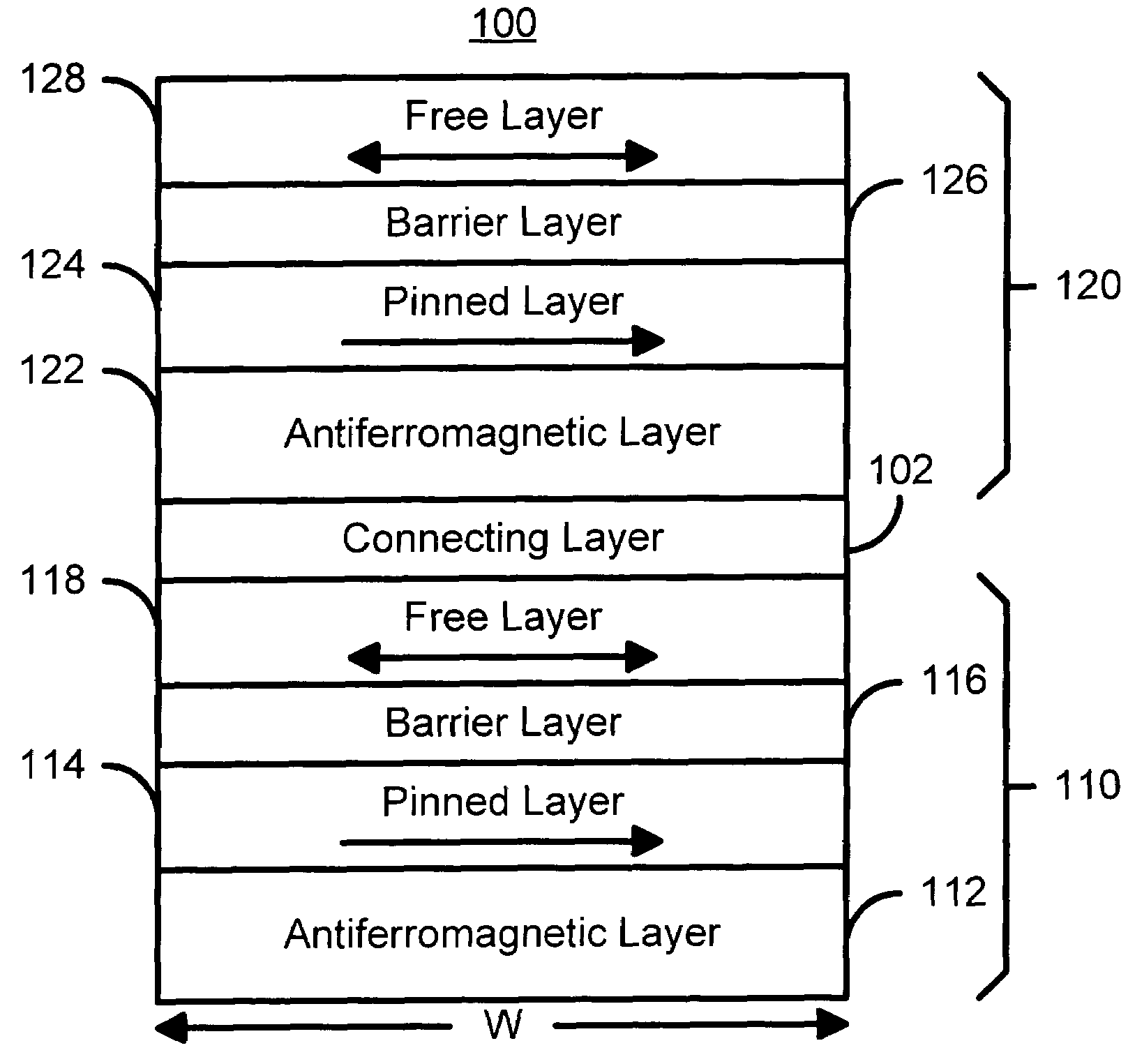

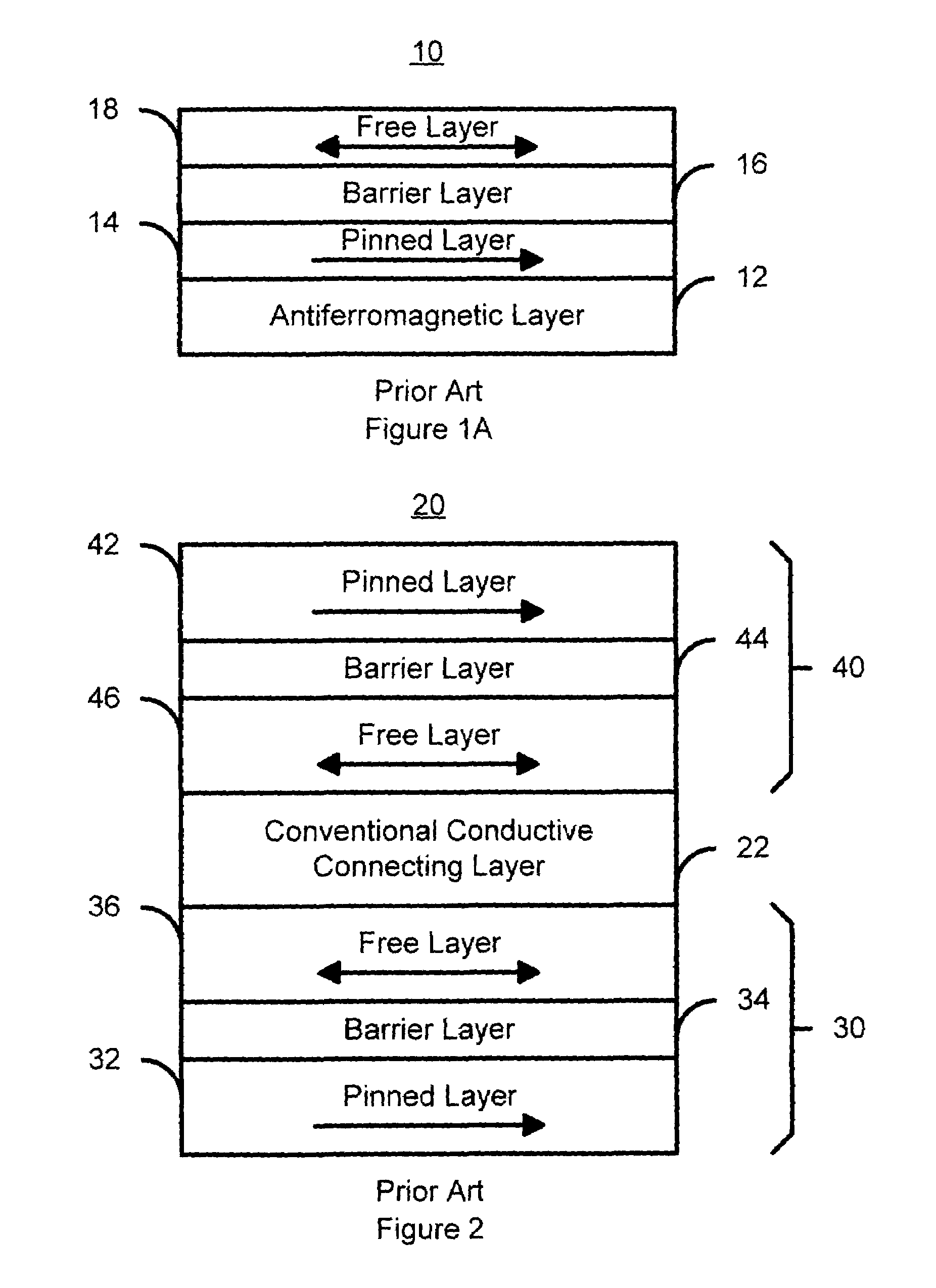

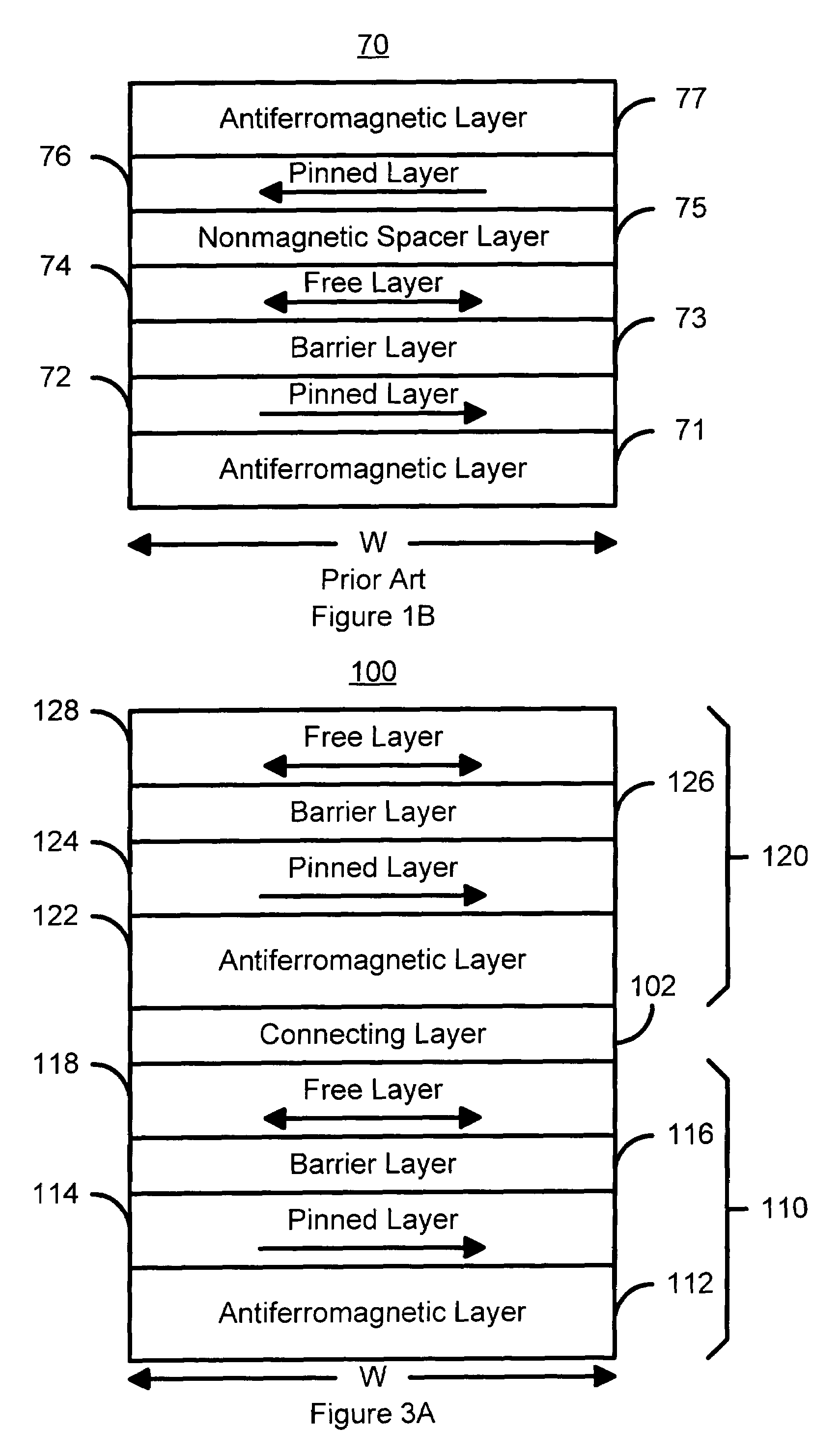

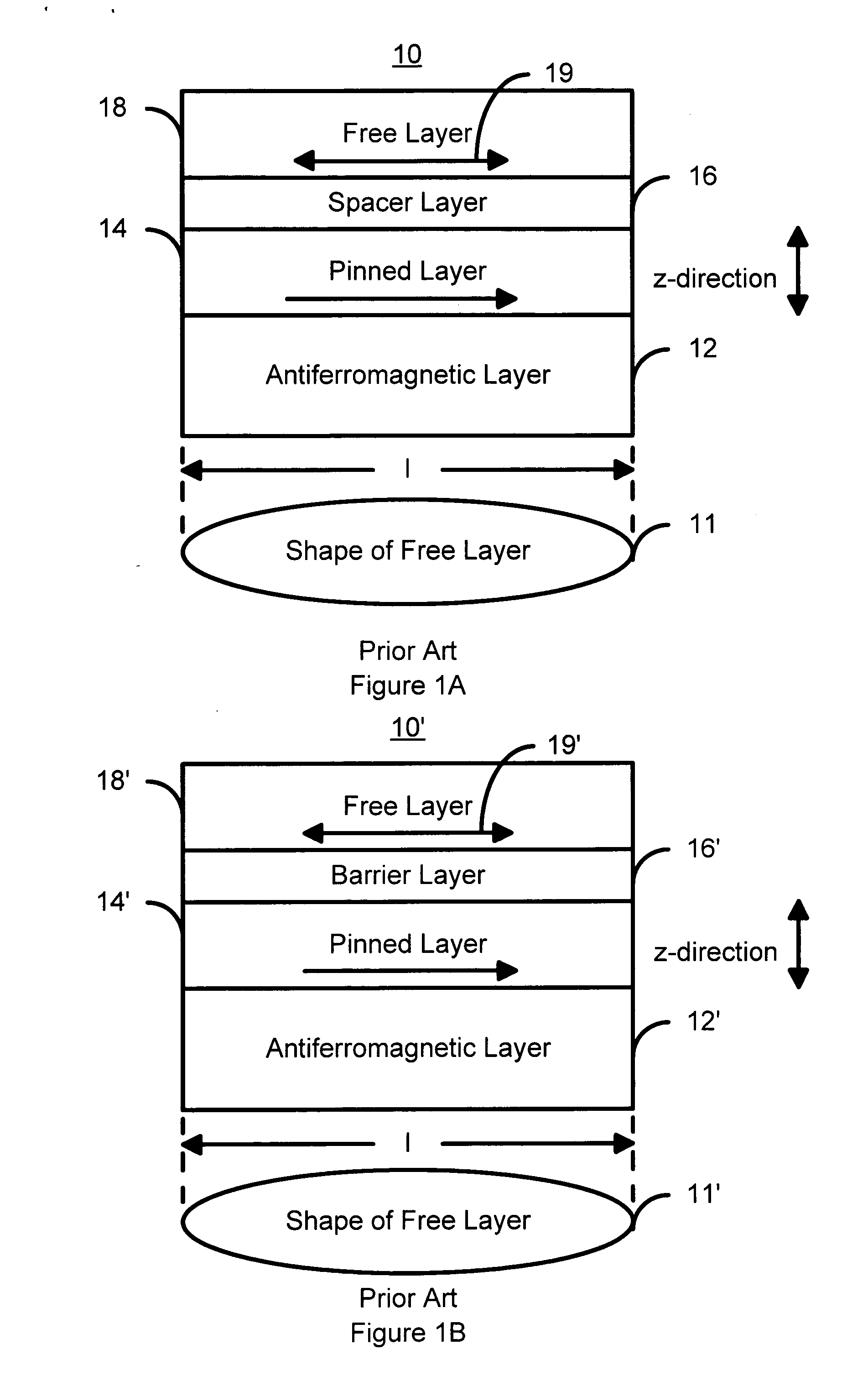

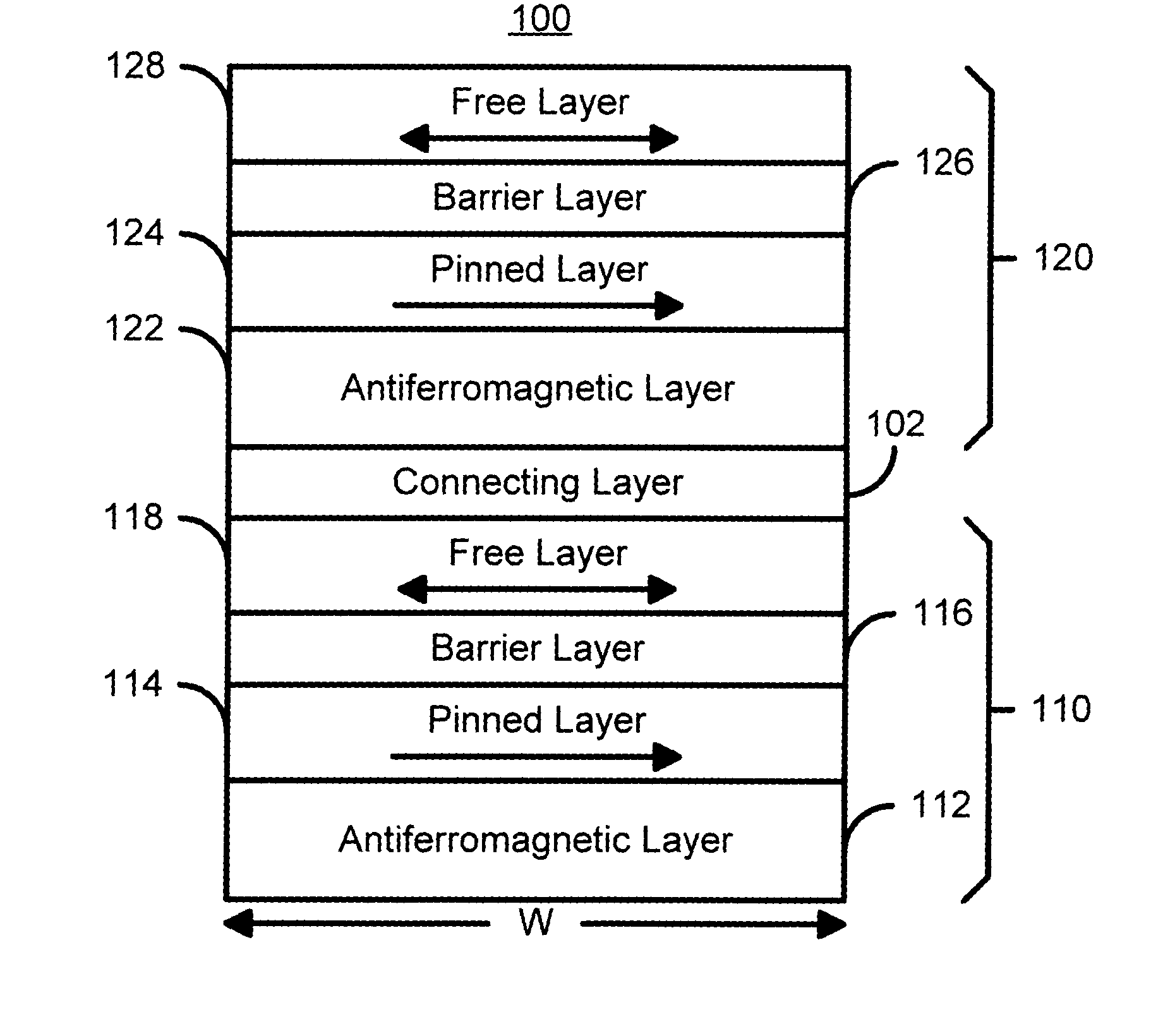

Magnetic memory element utilizing spin transfer switching and storing multiple bits

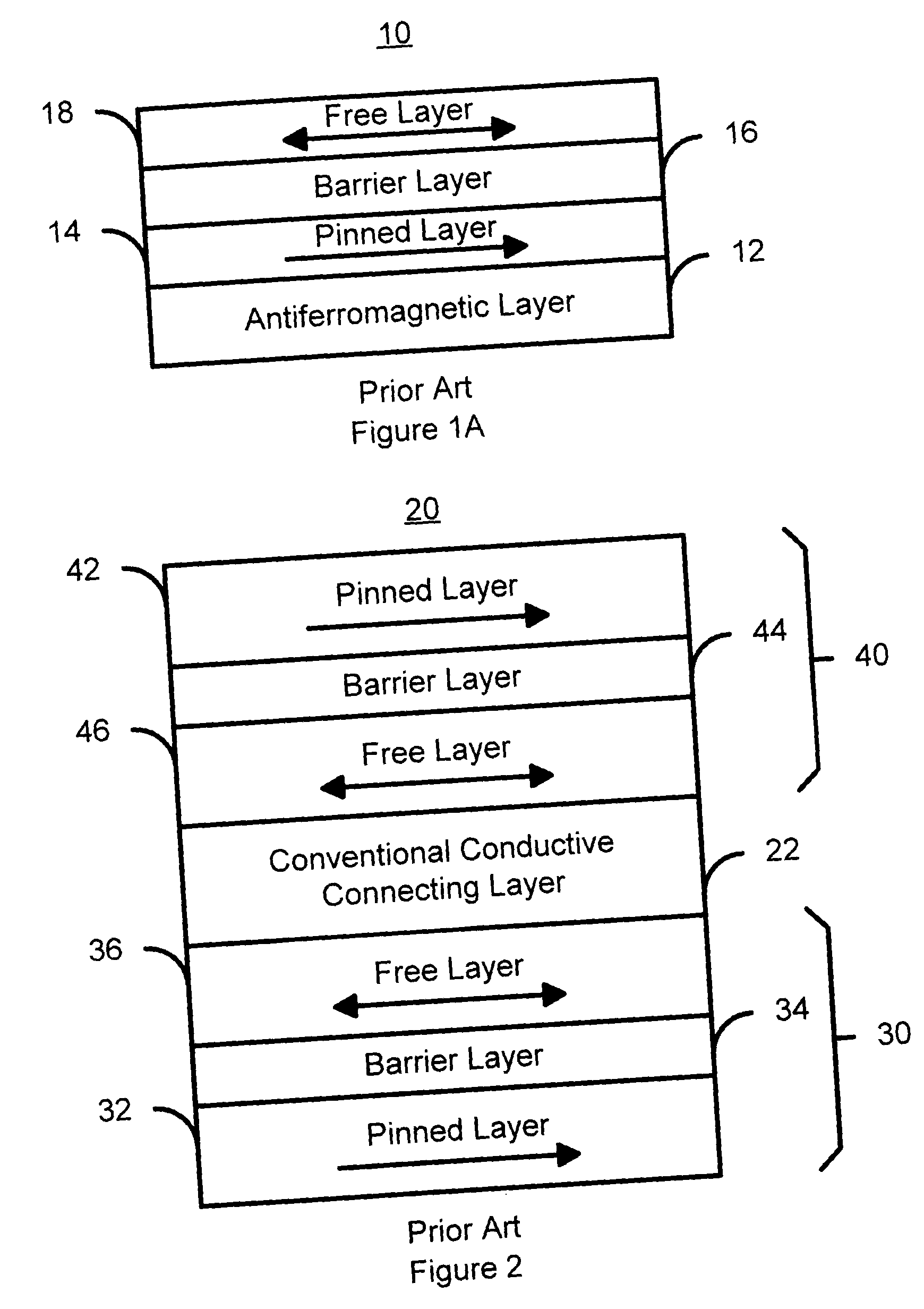

A method and system for providing a magnetic element capable of storing multiple bits is disclosed. The method and system include providing first pinned layer, a first nonmagnetic layer, a first free layer, a connecting layer, a second pinned layer, a second nonmagetic layer and a second free layer. The first pinned layer is ferromagnetic and has a first pinned layer magnetization pinned in a first direction. The first nonmagnetic layer resides between the first pinned layer and the first free layer. The first free layer being ferromagnetic and has a first free layer magnetization. The second pinned layer is ferromagnetic and has a second pinned layer magnetization pinned in a second direction. The connecting layer resides between the second pinned layer and the first free layer. The second nonmagnetic layer resides between the second pinned layer and the second free layer. The second free layer being ferromagnetic and having a second free layer magnetization. The magnetic element is configured to allow the first free layer magnetization and the second free layer magnetization to change direction due to spin transfer when a write current is passed through the magnetic element.

Owner:SAMSUNG SEMICON

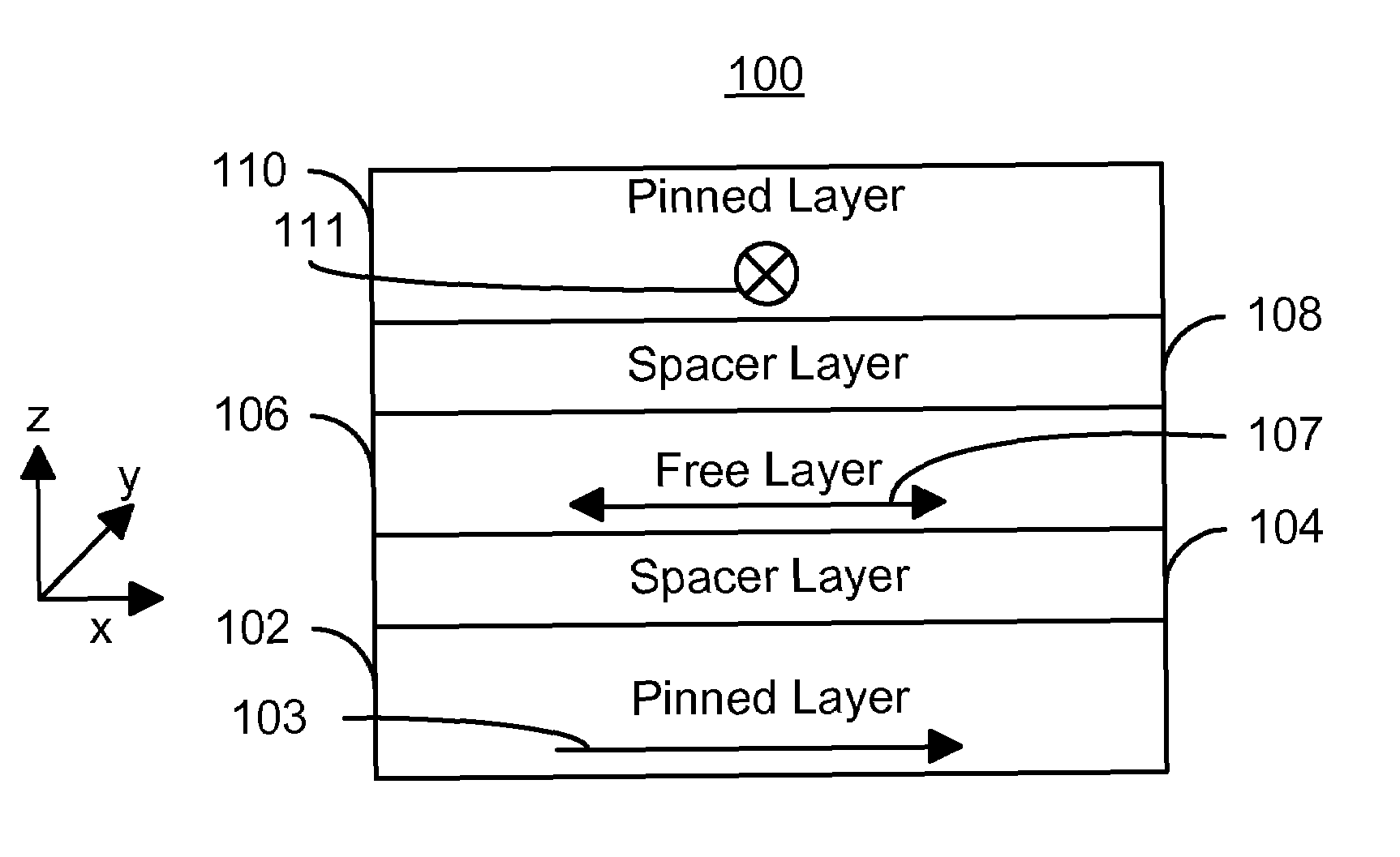

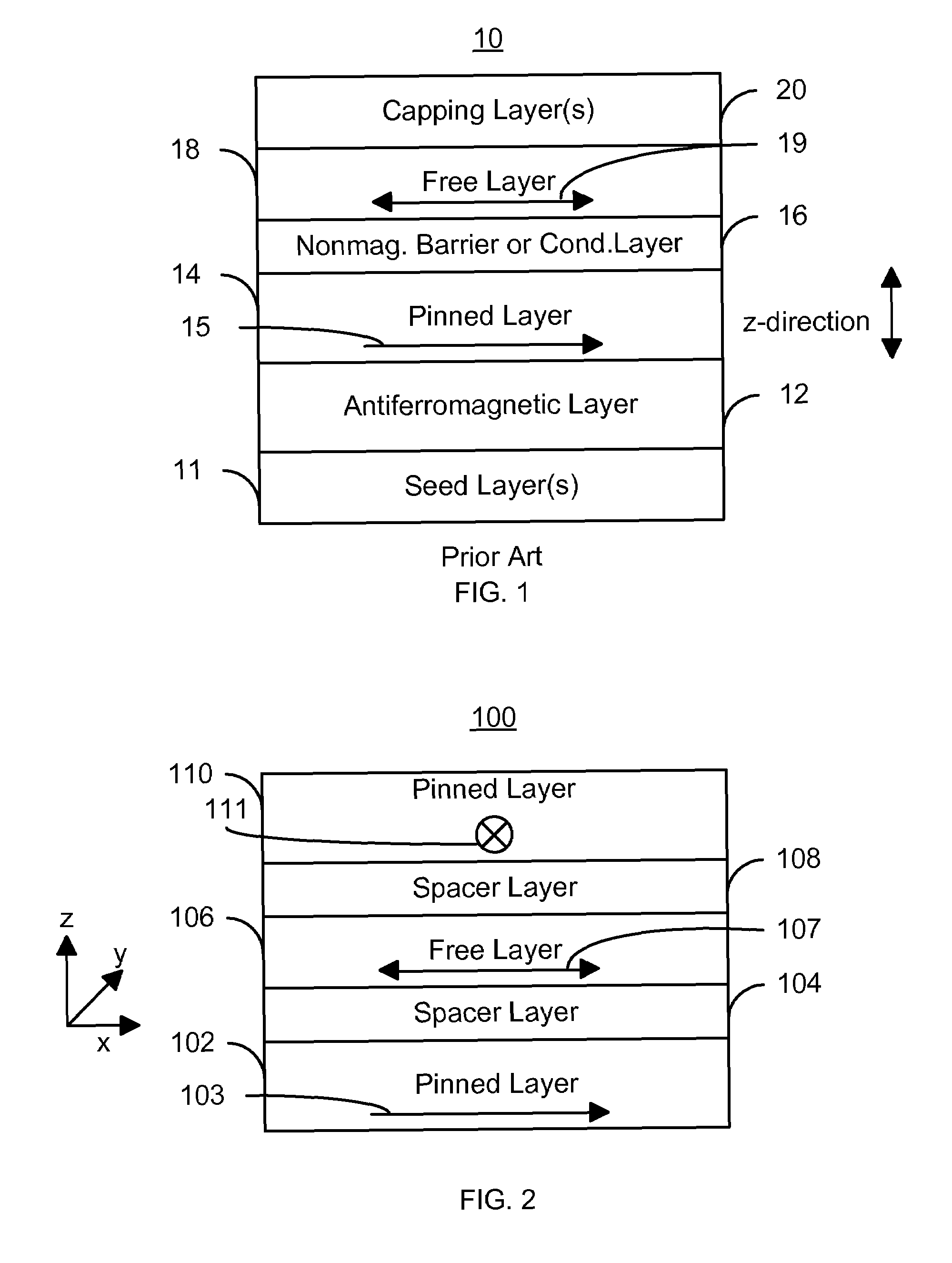

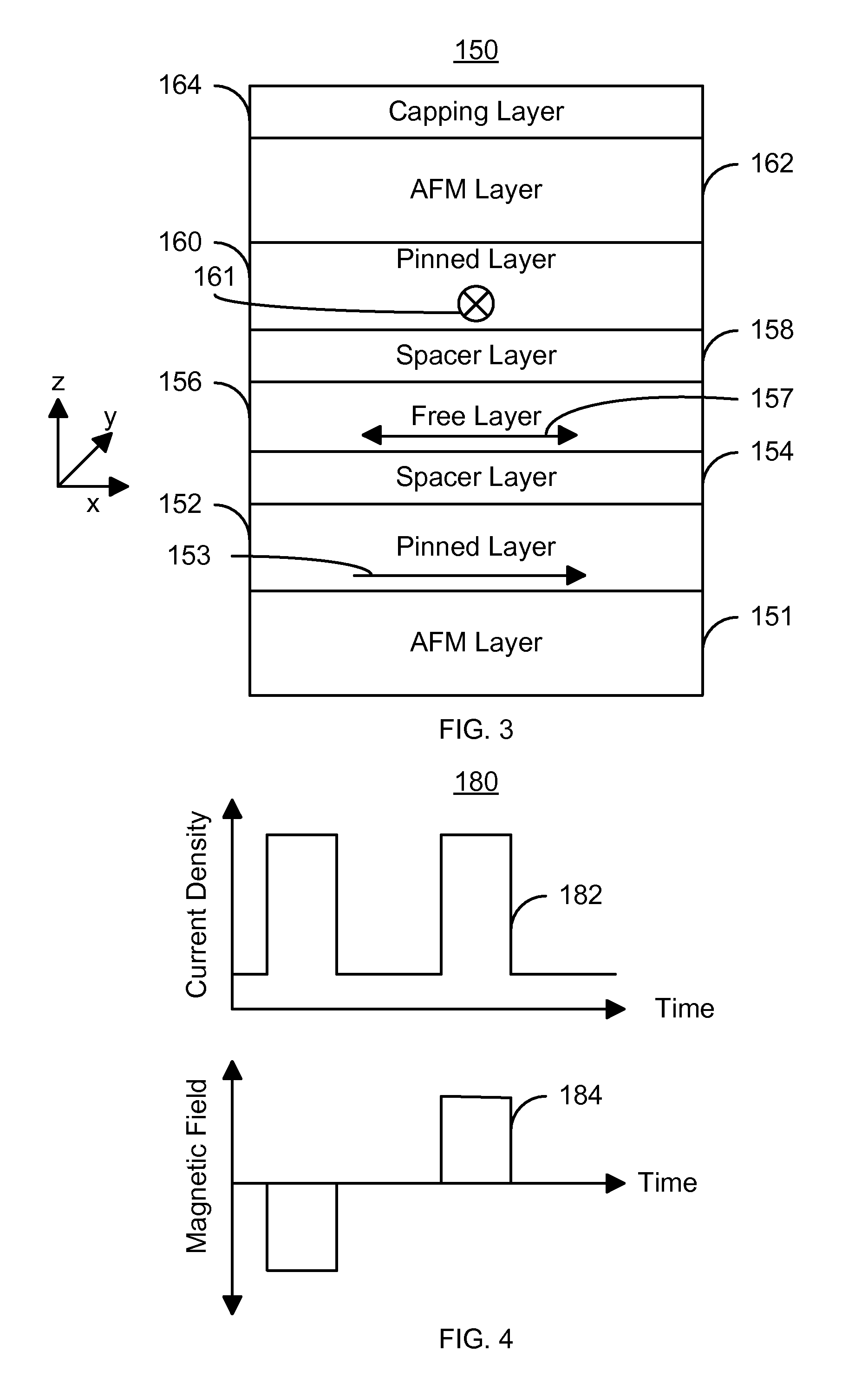

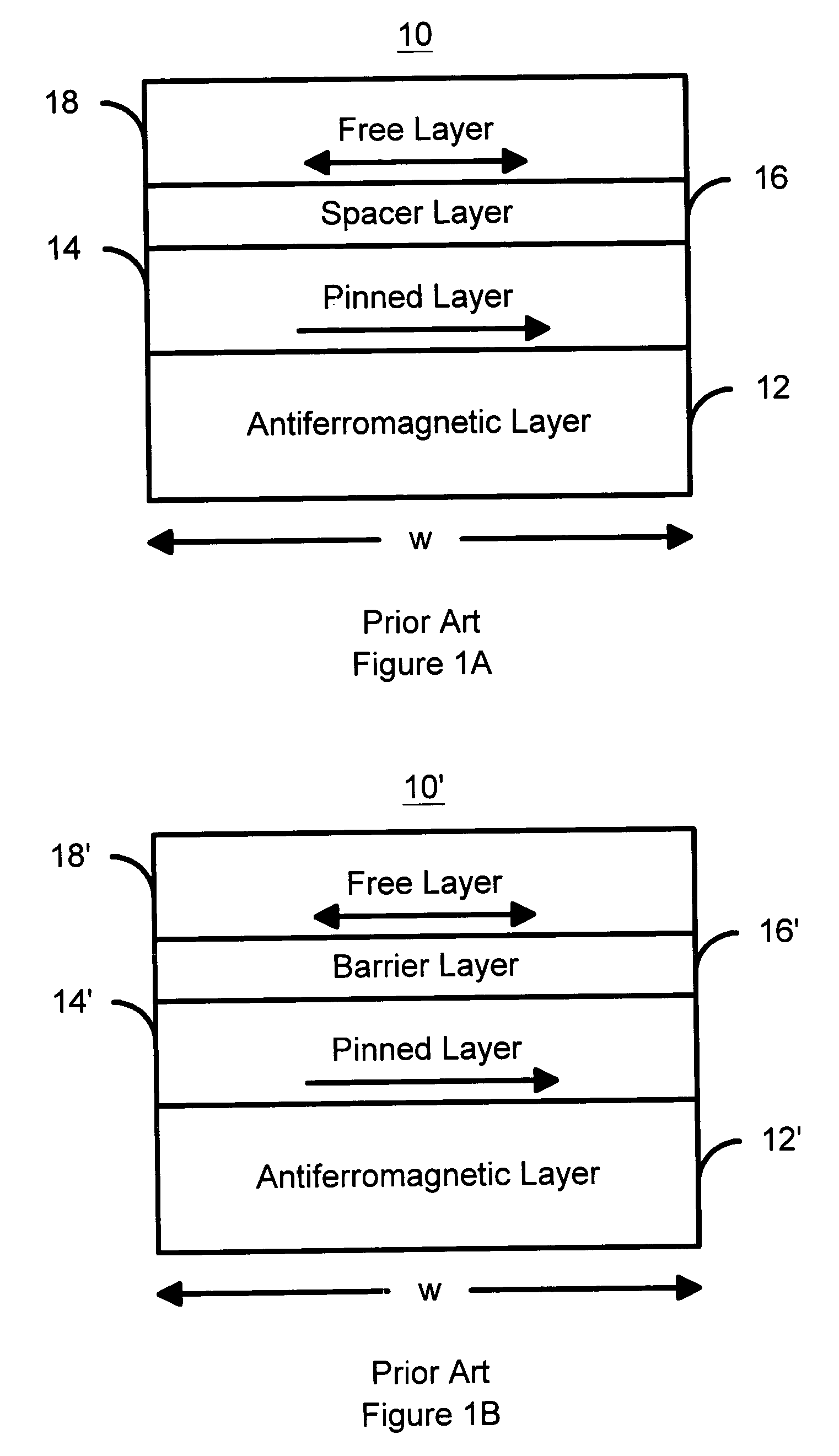

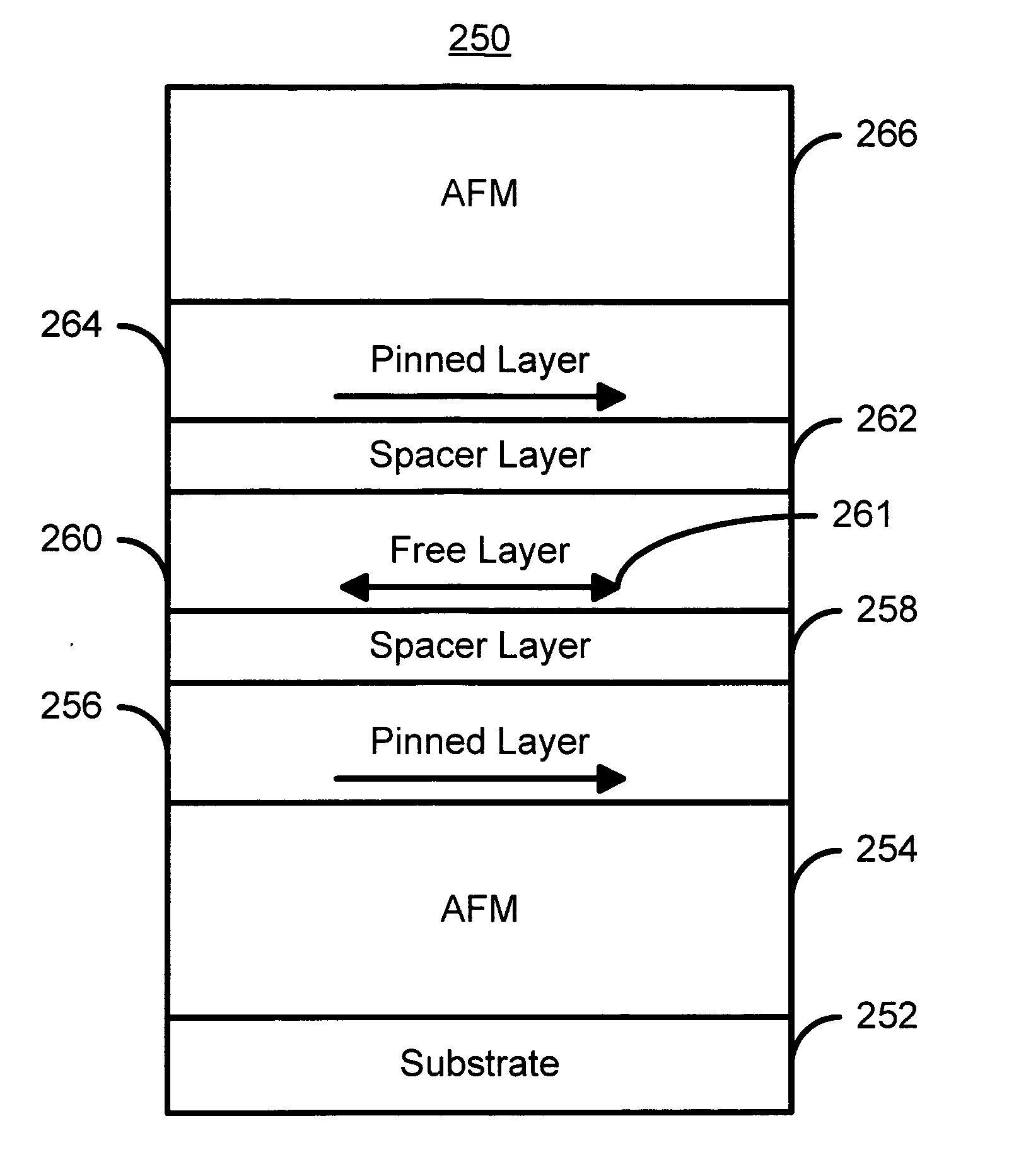

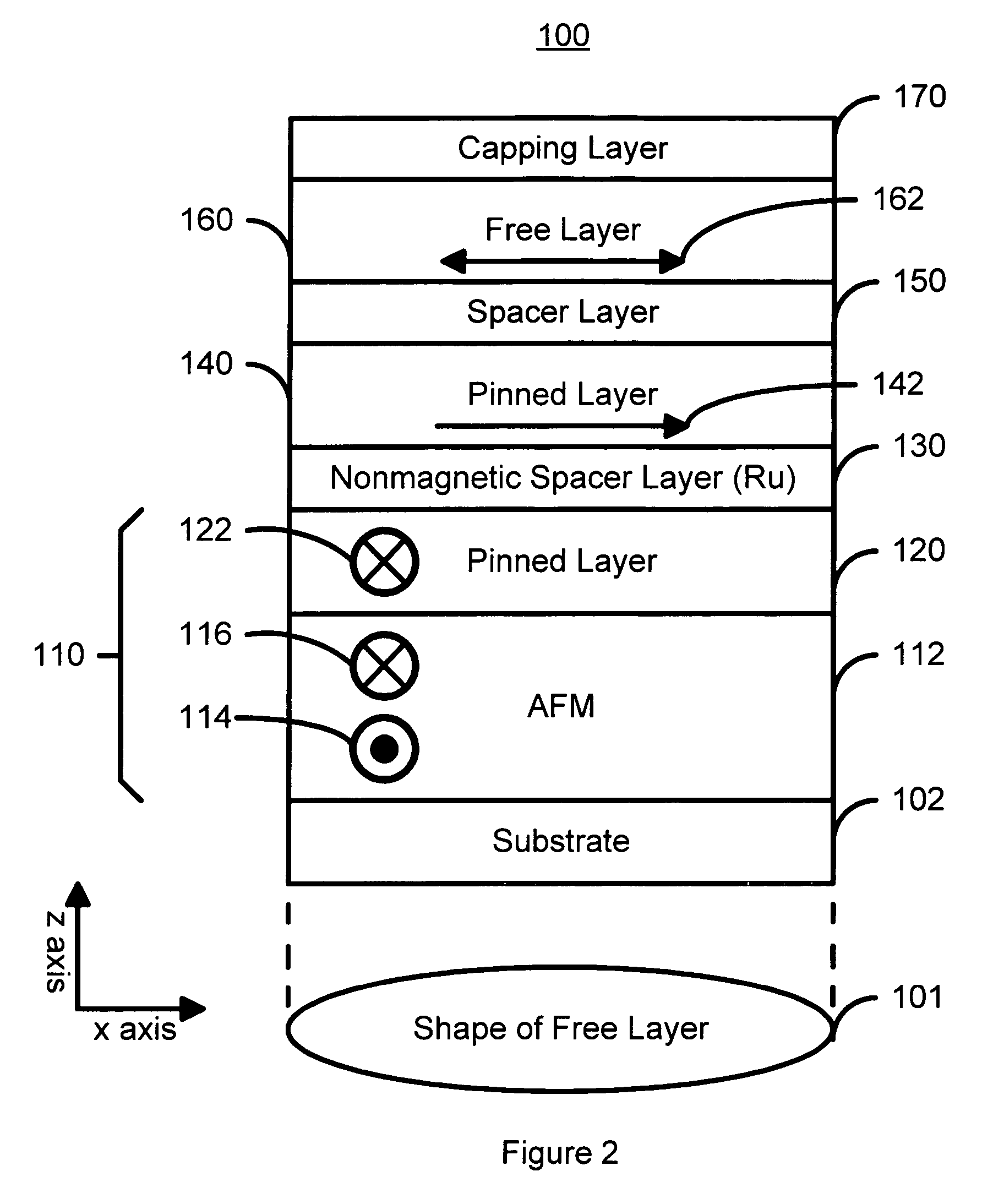

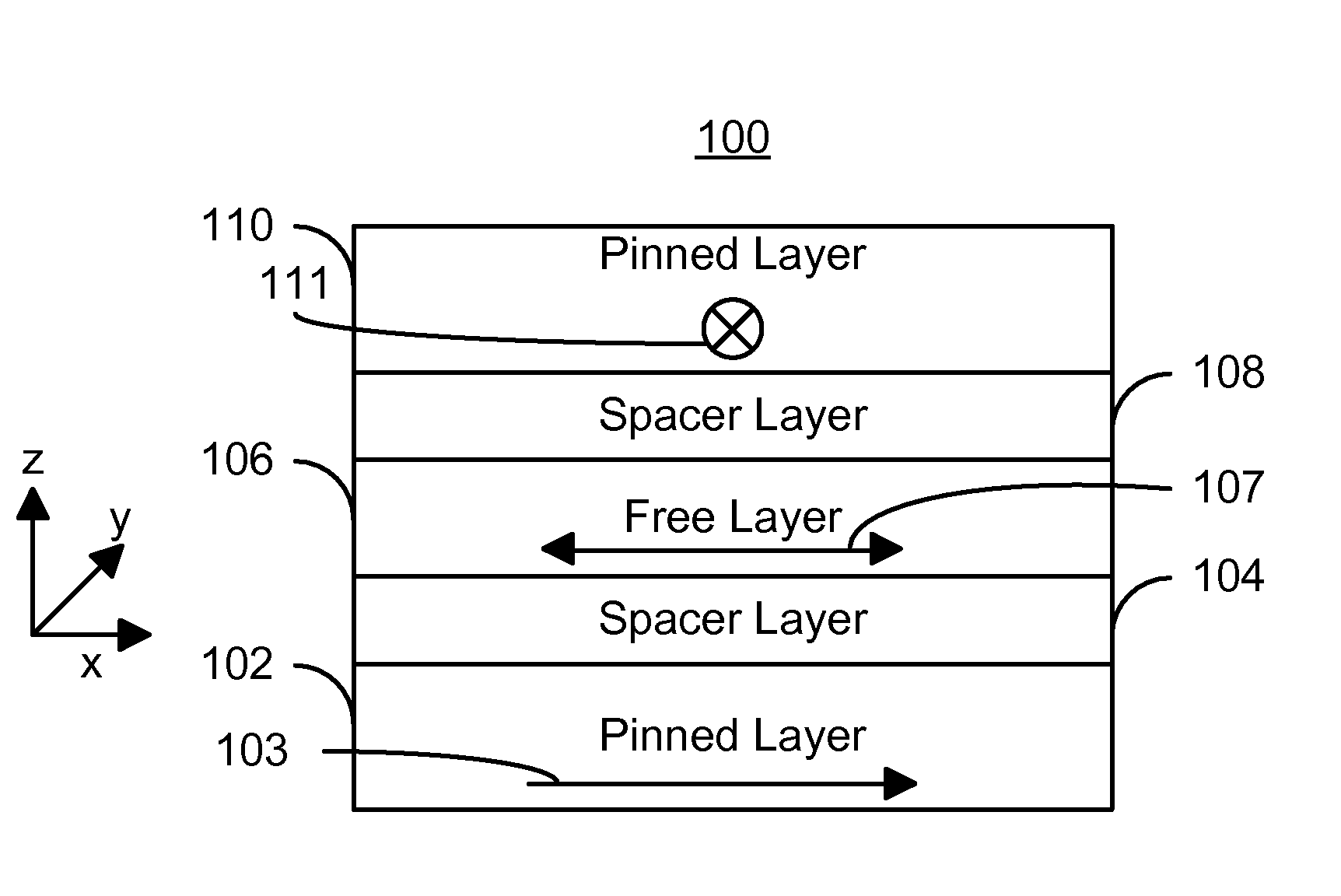

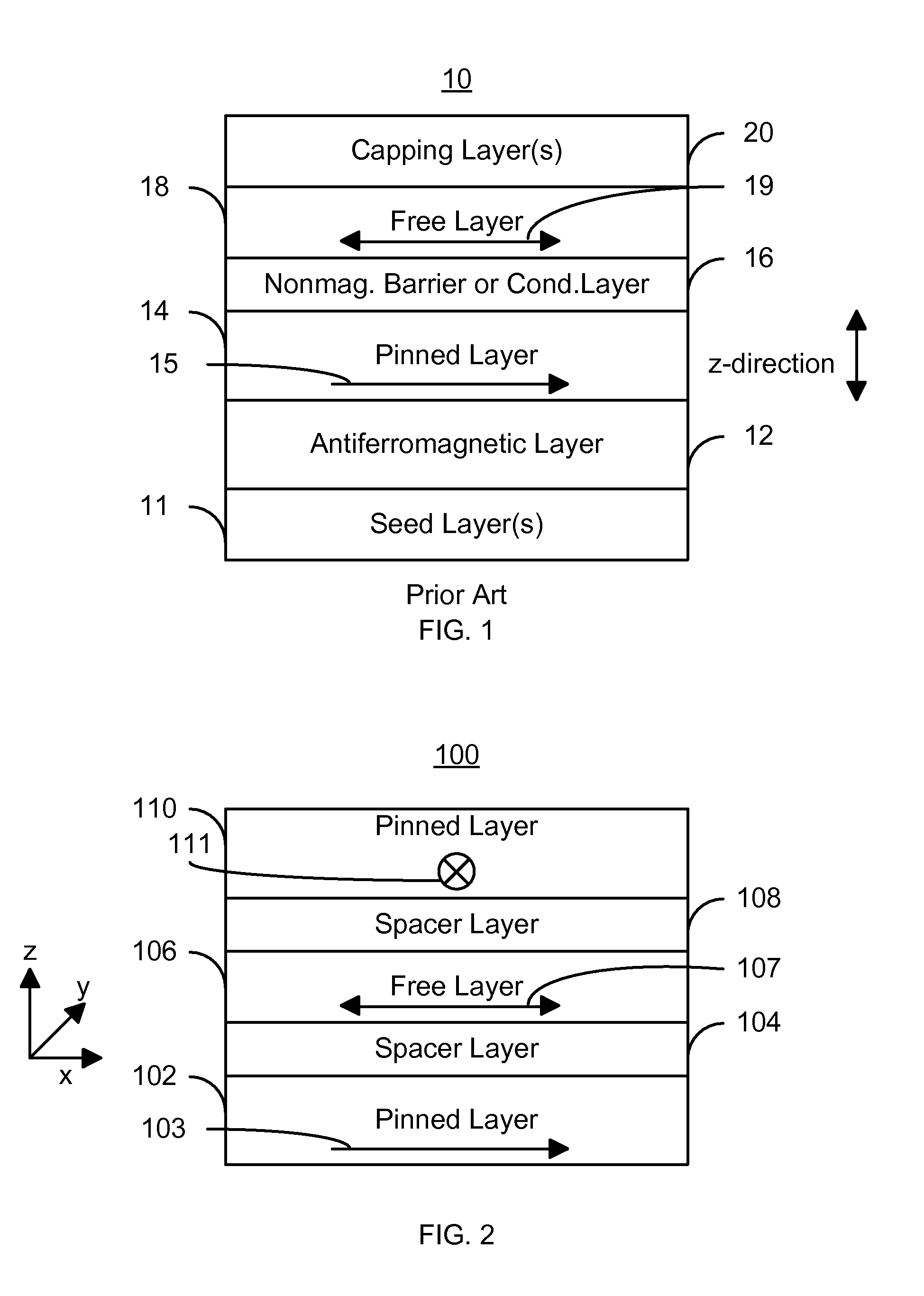

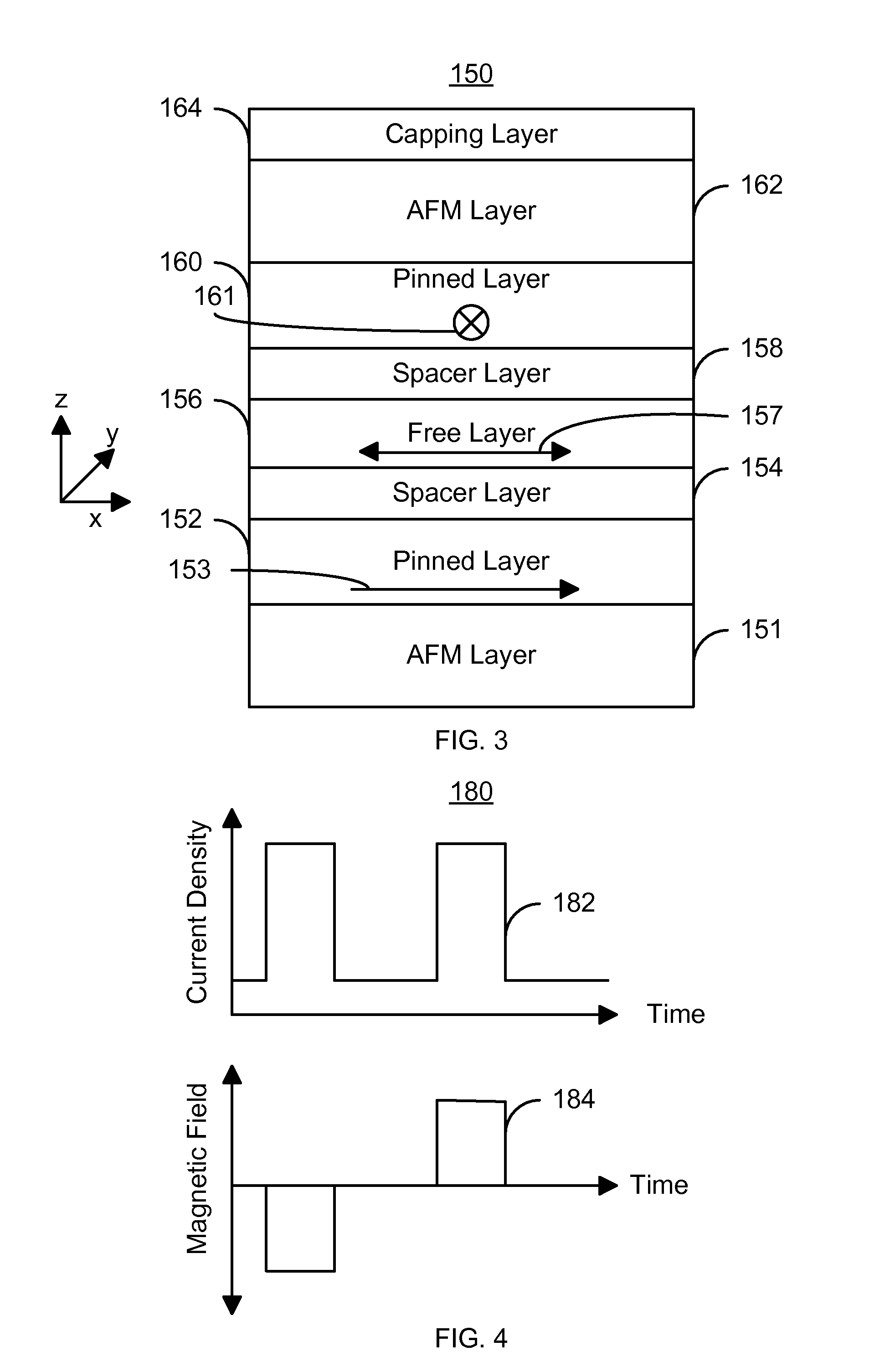

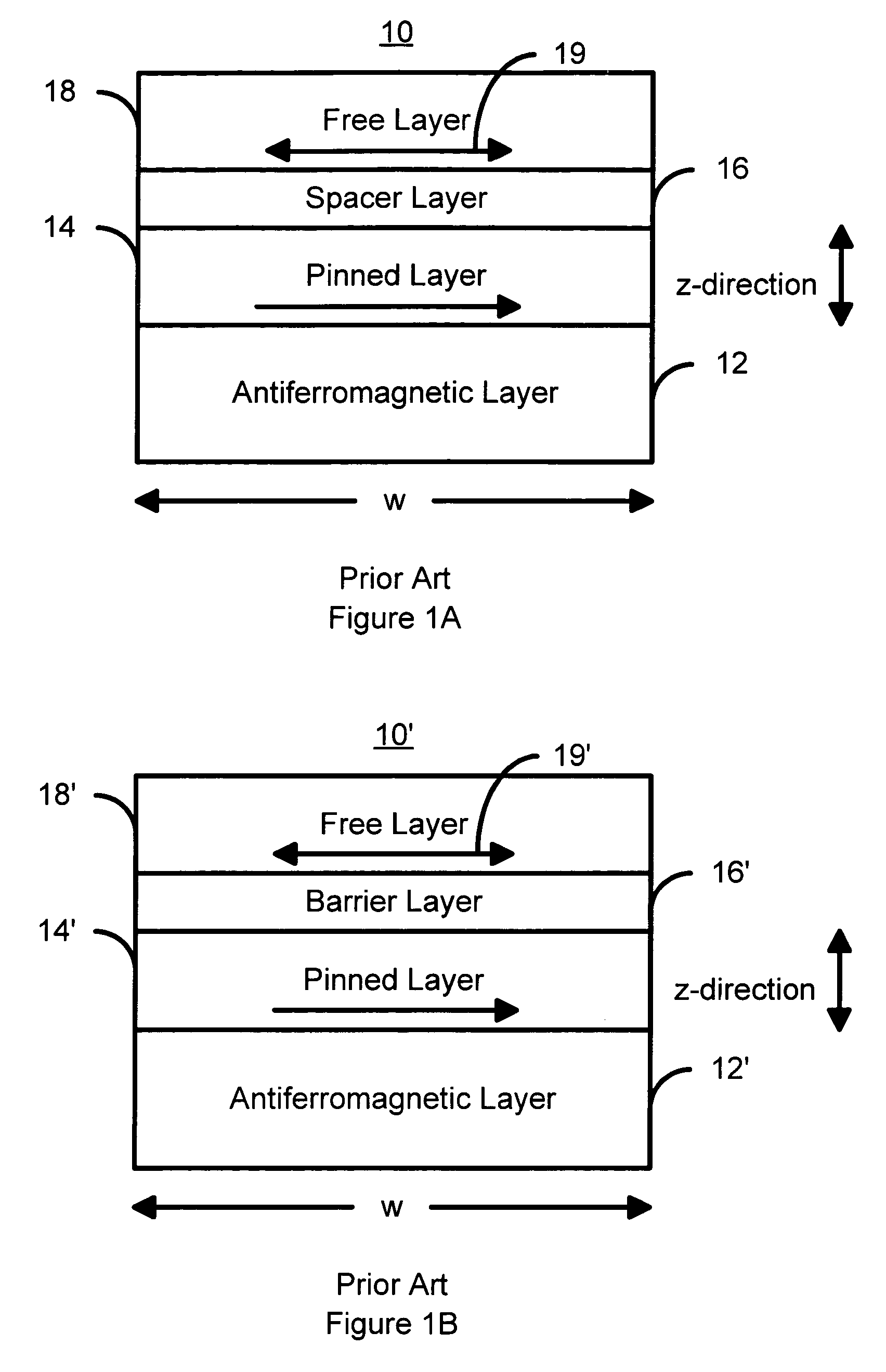

Method and system for providing a spin transfer device with improved switching characteristics

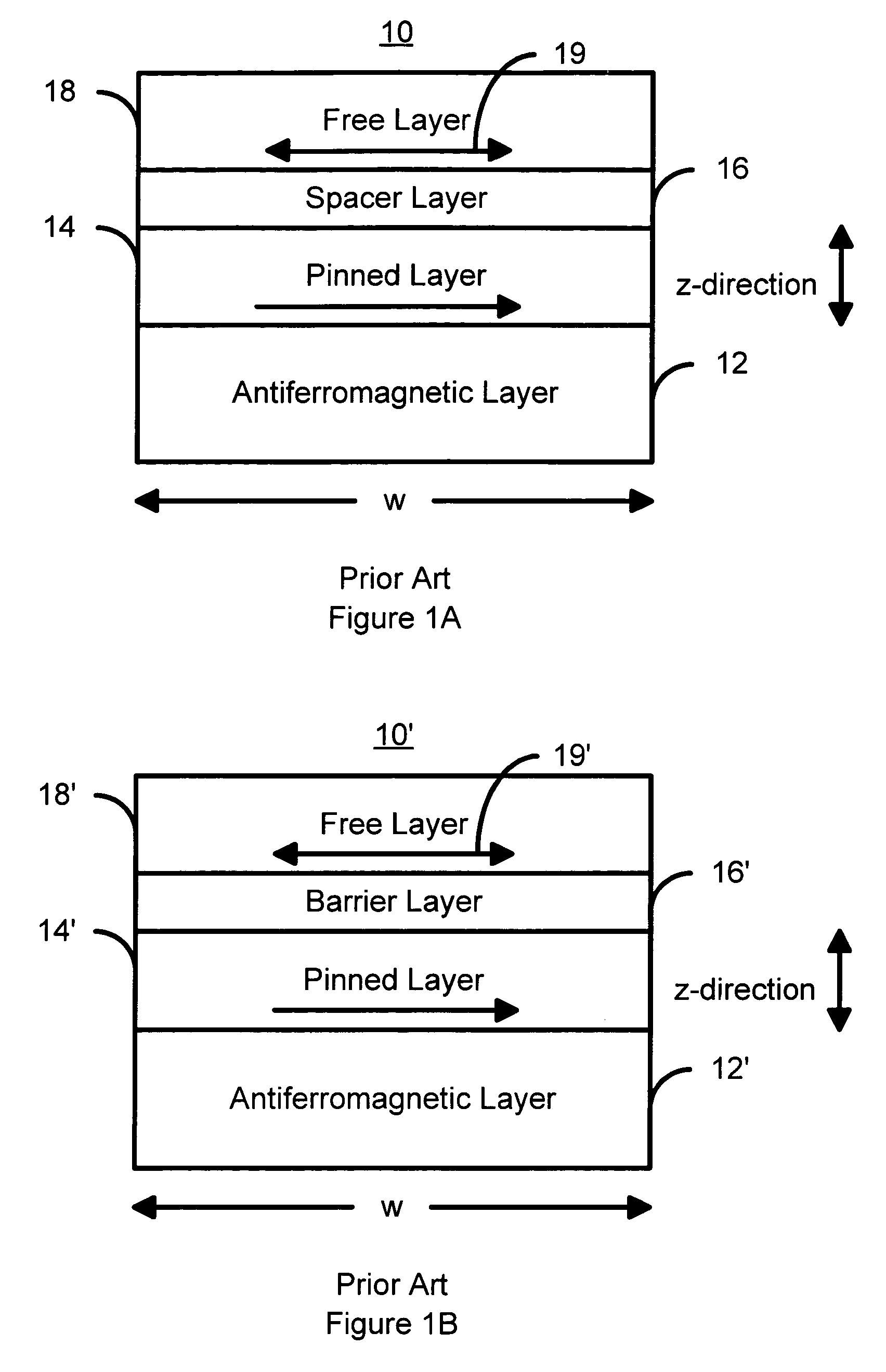

A method and system for providing a magnetic element is described. The magnetic element includes a first pinned layer, a first spacer layer, a free layer, a second spacer layer, and a second pinned layer. The first and second pinned layers have first and magnetizations oriented in first and second directions, respectively. The first and second spacer layers are nonferromagnetic. The first and second spacer layers are between the free layer and the first and second pinned layers, respectively. The magnetic element is configured either to allow the free layer to be switched to each of multiple states when both a unidirectional write current is passed through the magnetic element and the magnetic element is subjected to a magnetic field corresponding to the each states or to allow the free layer to be switched to each of the plurality of states utilizing a write current and an additional magnetic field that is applied from at least one of the first pinned layer and the second pinned layer substantially only if the write current is also applied.

Owner:SAMSUNG SEMICON

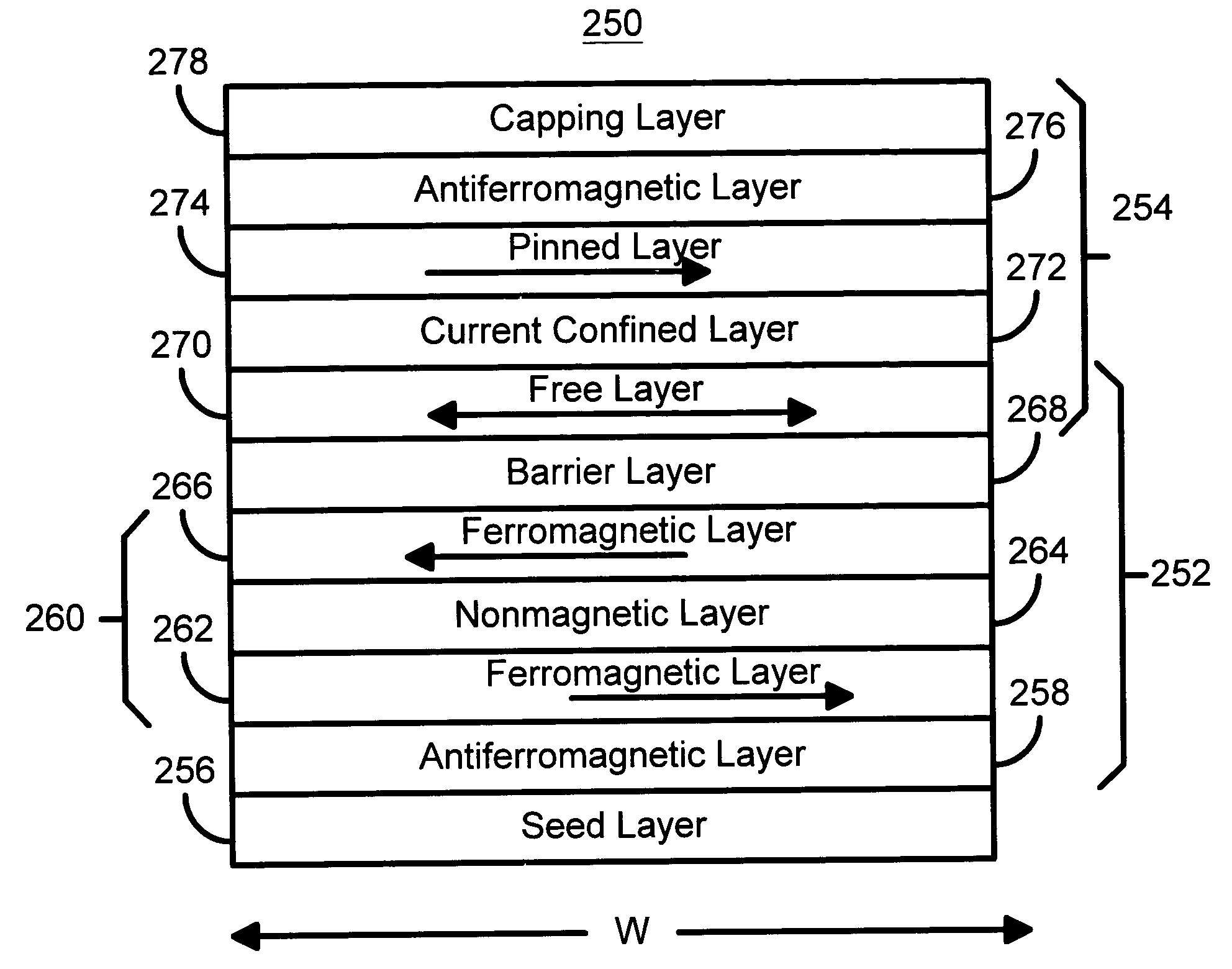

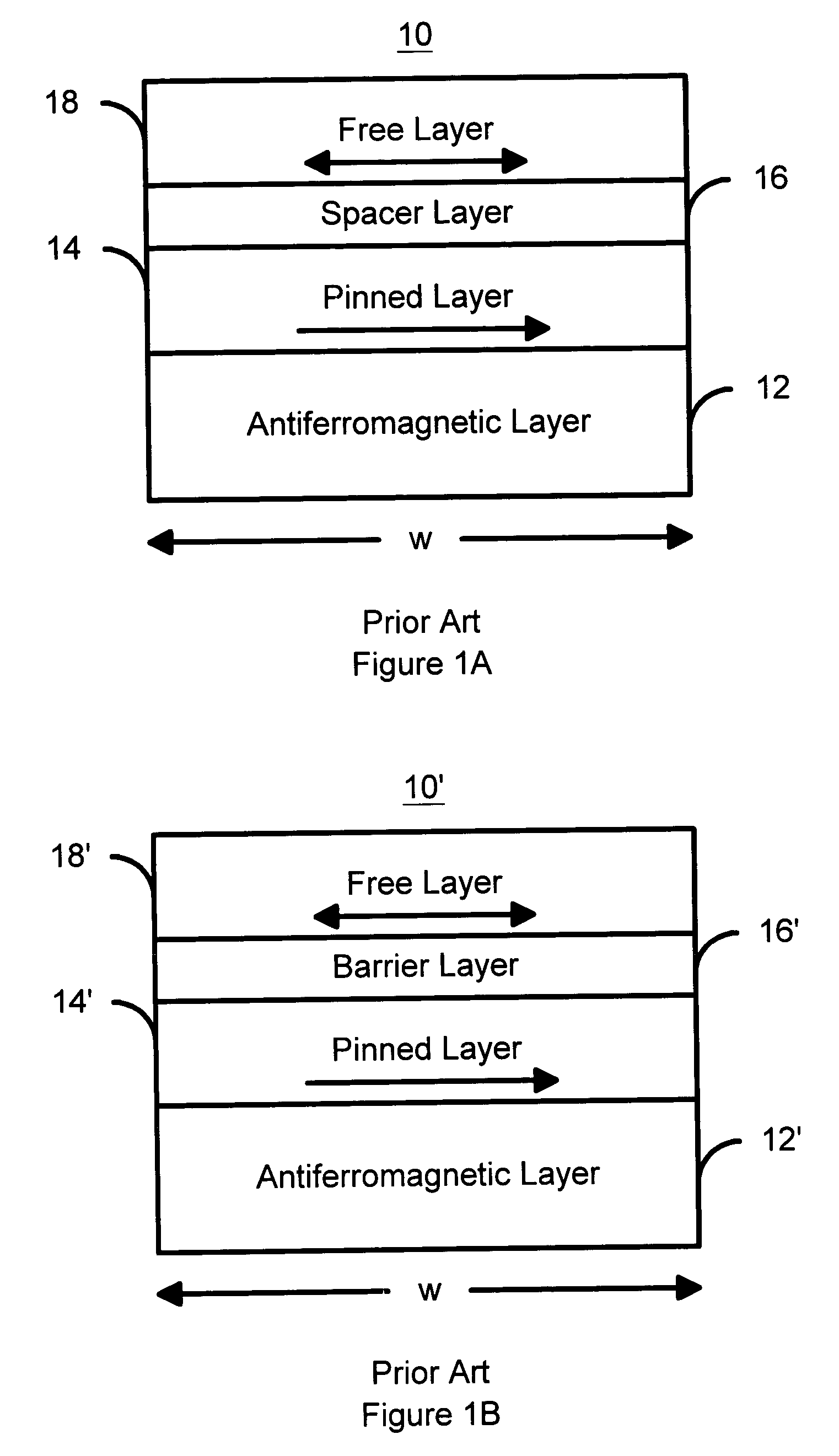

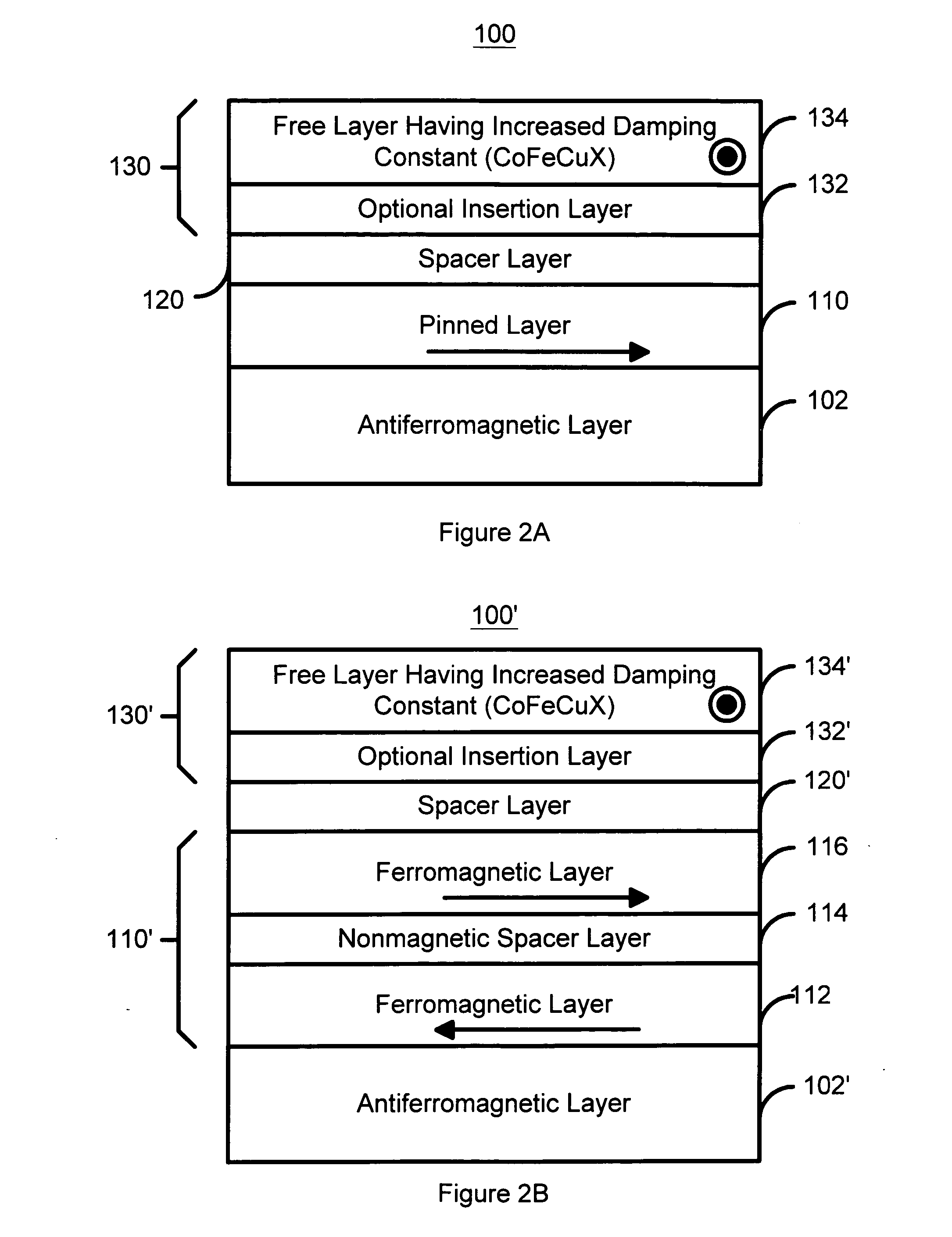

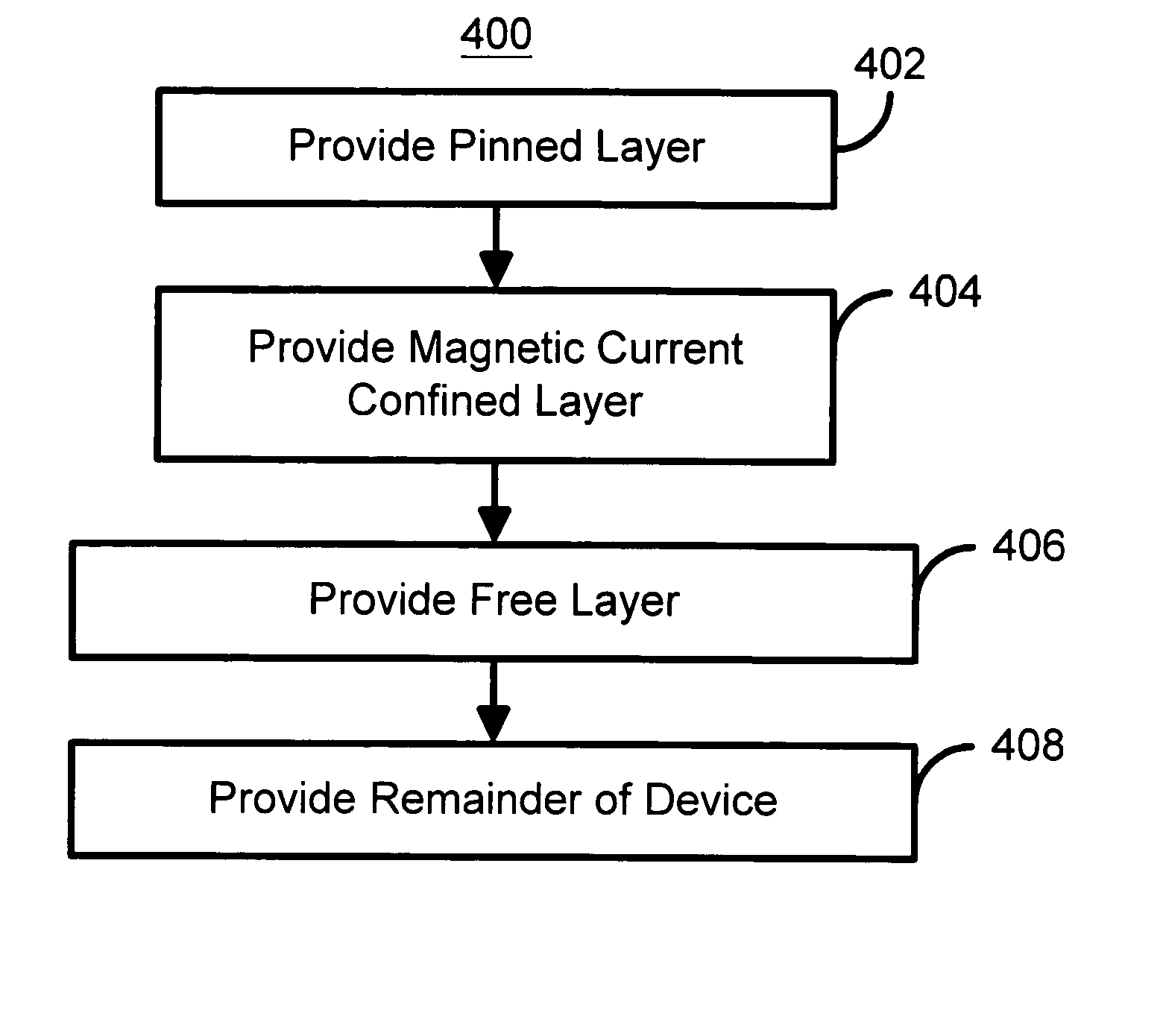

Current confined pass layer for magnetic elements utilizing spin-transfer and an MRAM device using such magnetic elements

ActiveUS20050063222A1Total current dropFunction increaseDigital storageCurrent limitingSpin tunneling

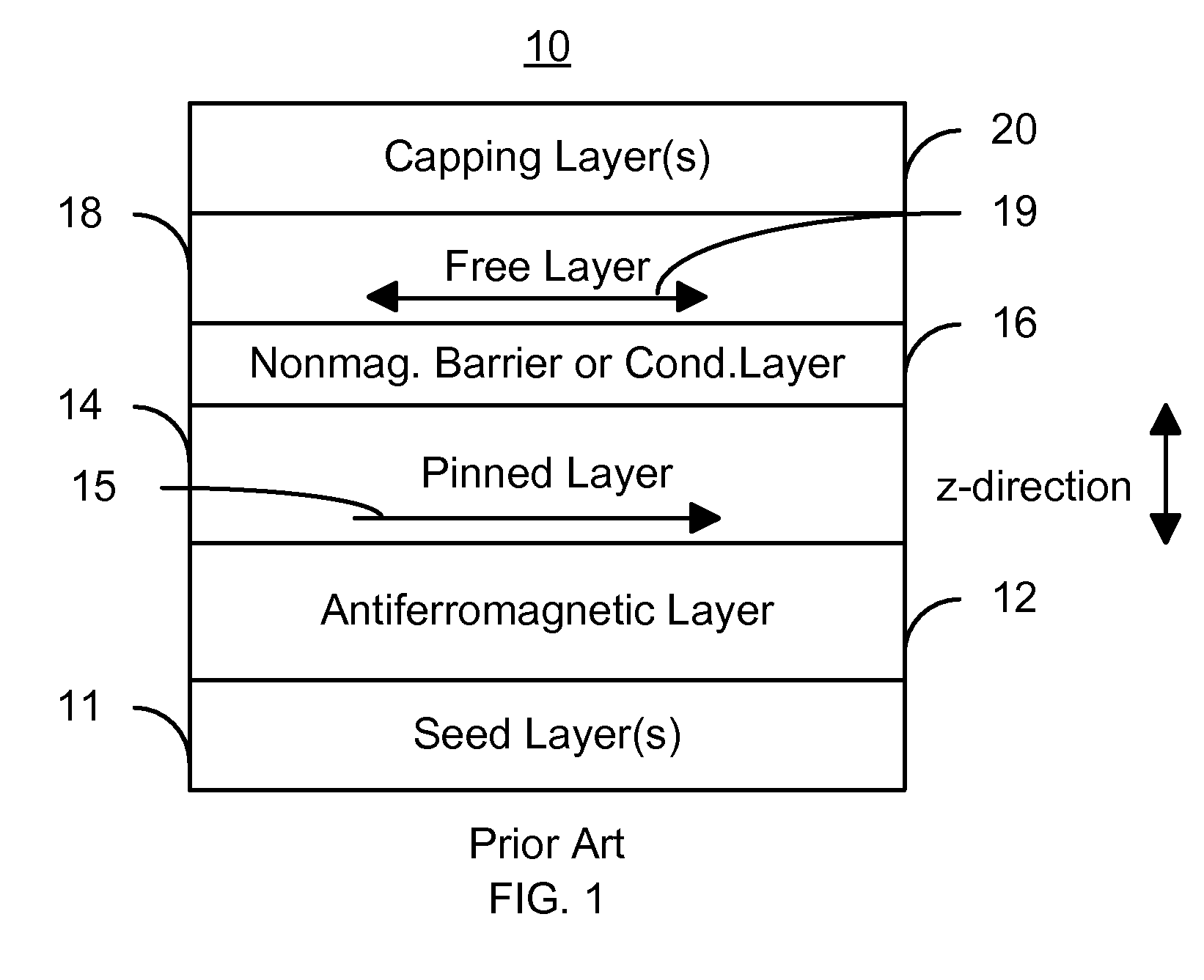

A method and system for providing and magnetic element is disclosed. In one aspect, the magnetic element includes at least a pinned layer, a free layer, and a current confined layer residing between the pinned layer and the free layer. The pinned layer is ferromagnetic and has a first magnetization. The current confined layer has at least one channel in an insulating matrix. The channel(s) are conductive and extend through the current confined layer. The free layer is ferromagnetic and has a second magnetization. The pinned layer, the free layer, and the current confined layer are configured to allow the magnetization of the free layer to be switched using spin transfer. The magnetic element may also include other layers, including layers for spin valve(s), spin tunneling junction(s), dual spin valve(s), dual spin tunneling junction(s), and dual spin valve / tunnel structure(s).

Owner:SAMSUNG SEMICON

Current confined pass layer for magnetic elements utilizing spin-transfer and an MRAM device using such magnetic elements

Owner:SAMSUNG SEMICON

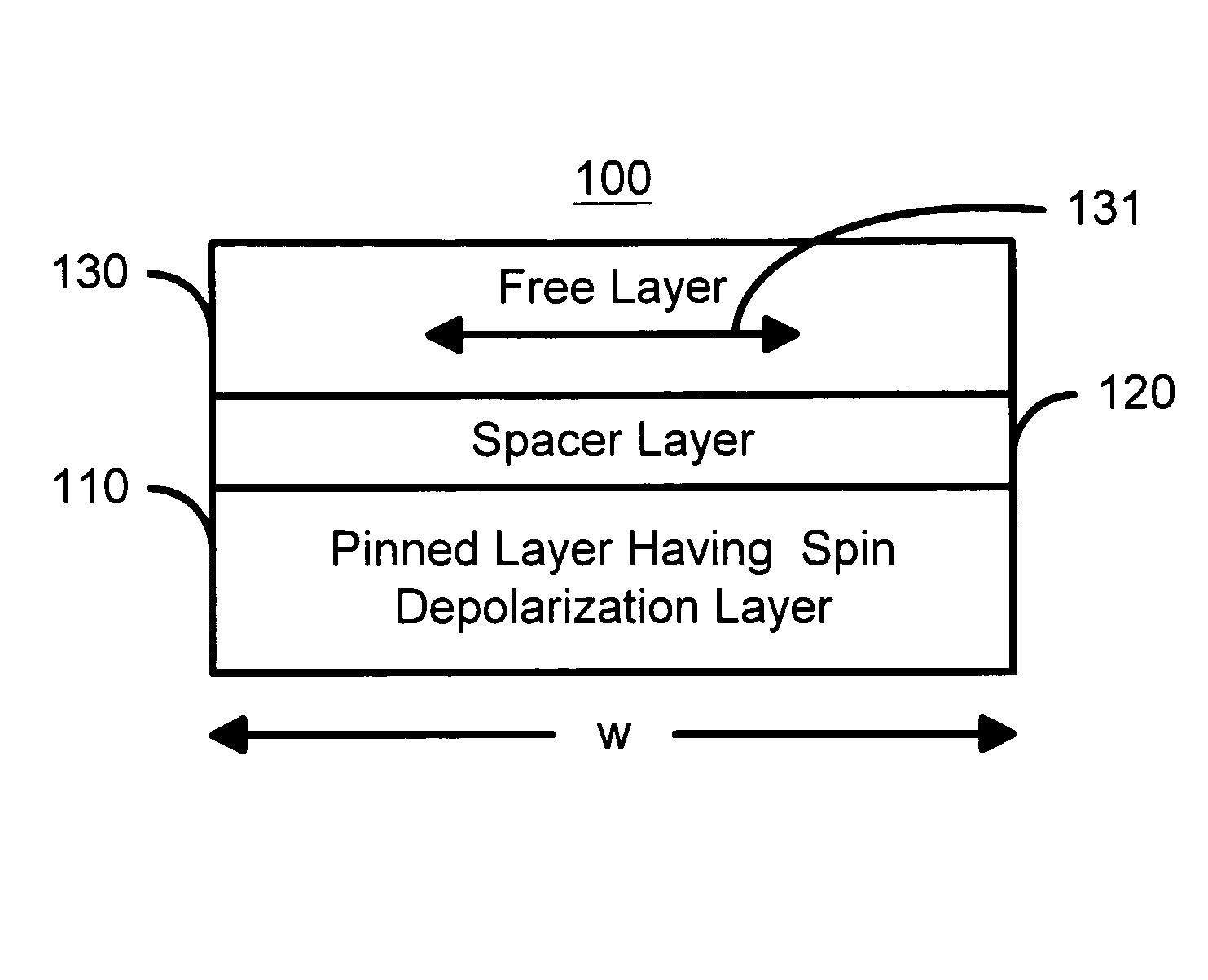

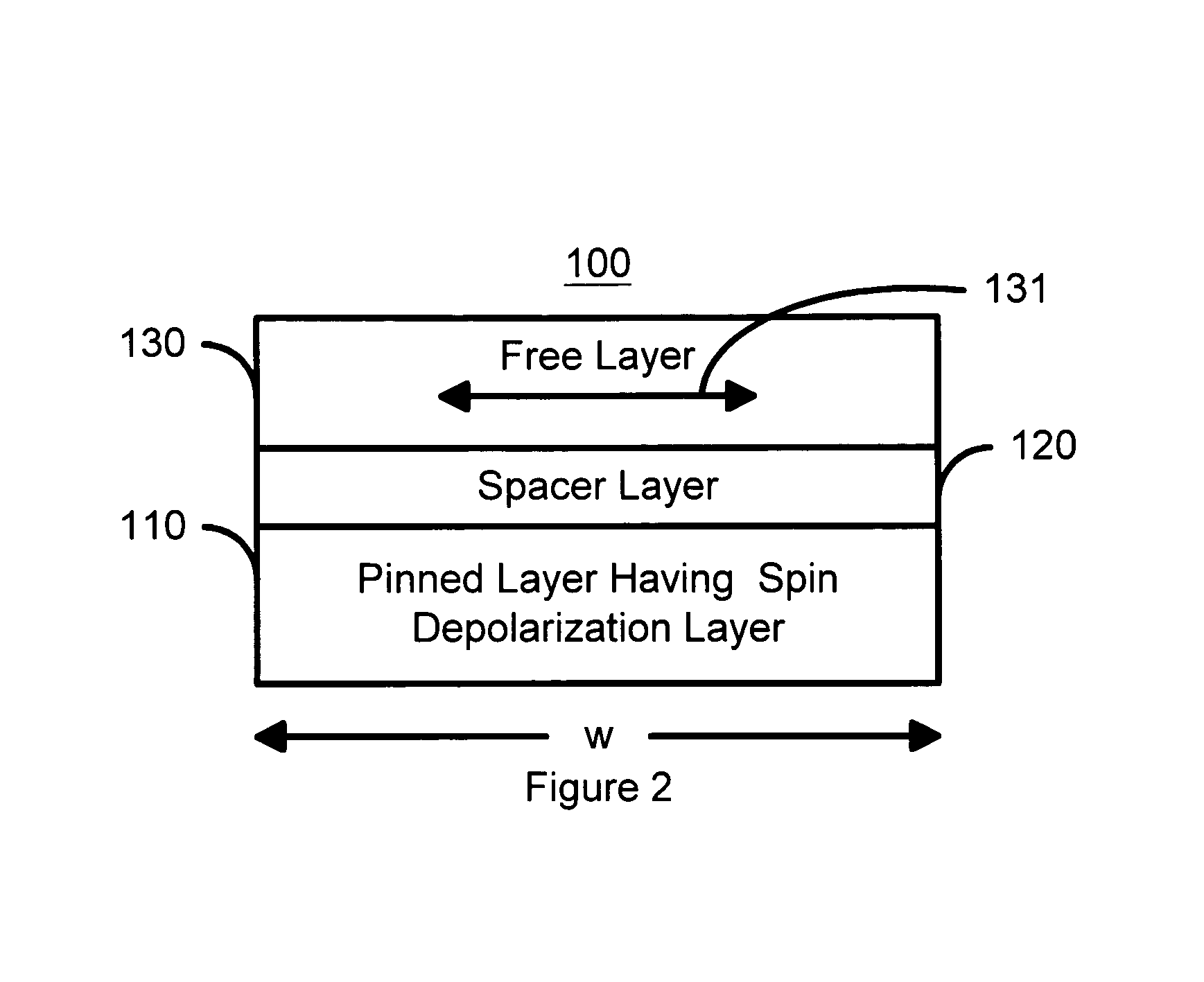

Spin transfer magnetic elements with spin depolarization layers

A method and system for providing a magnetic element is disclosed. The method and system include providing a free layer, a spacer layer, and a pinned layer. The free layer is ferromagnetic and has a free layer magnetization. The spacer layer is nonmagnetic and resides between the pinned and free layers. The pinned layer includes first and second ferromagnetic layers having first and second magnetizations, a nonmagnetic spacer layer, and a spin depolarization layer. Residing between the first and second ferromagnetic layers, the nonmagnetic spacer layer is conductive and promotes antiparallel orientations between the first and second magnetizations. The spin depolarization layer is configured to depolarize at least a portion of a plurality of electrons passing through it. The magnetic element is also configured to allow the free layer magnetization to change direction due to spin transfer when a write current is passed through the magnetic element.

Owner:SAMSUNG SEMICON

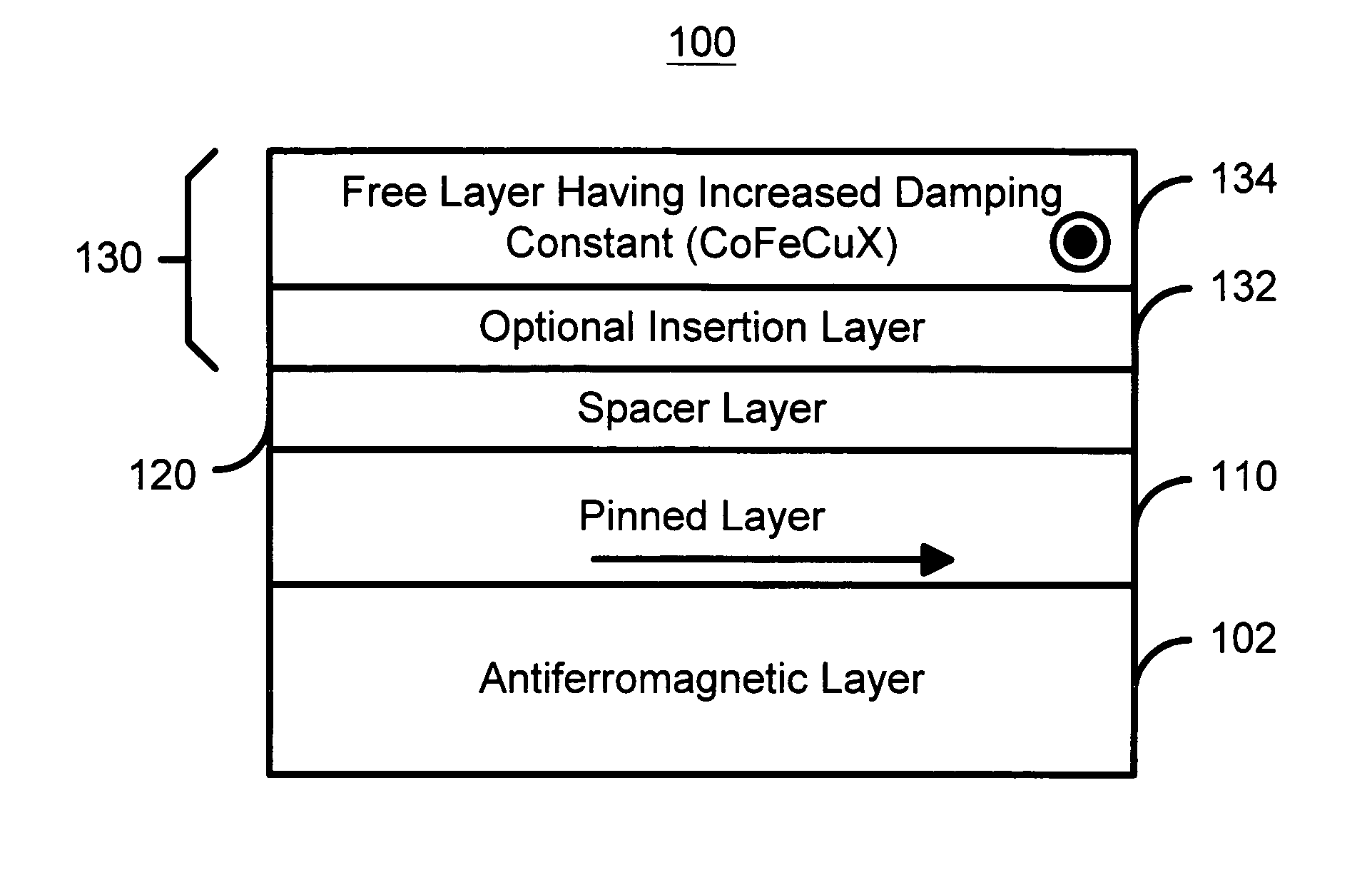

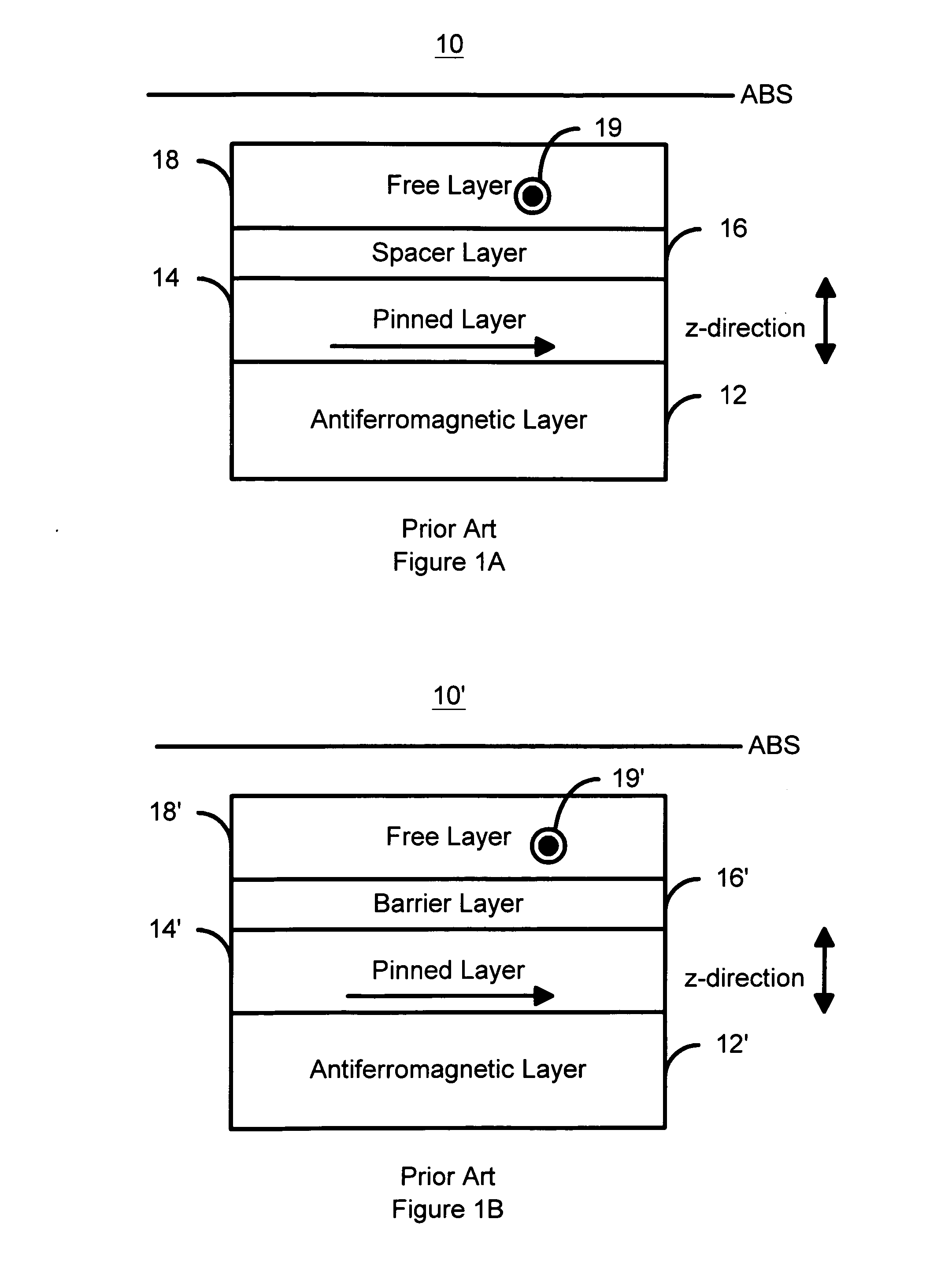

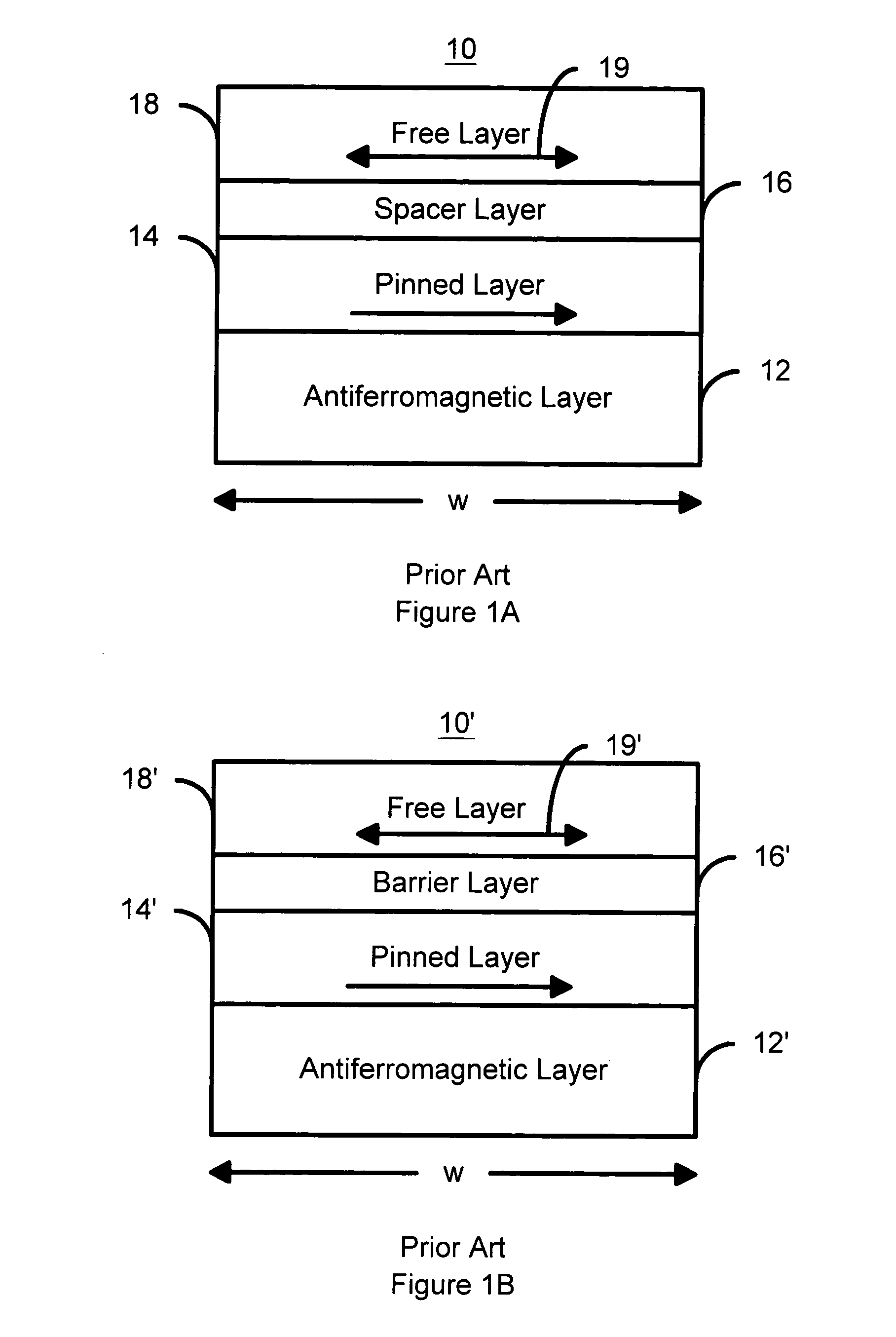

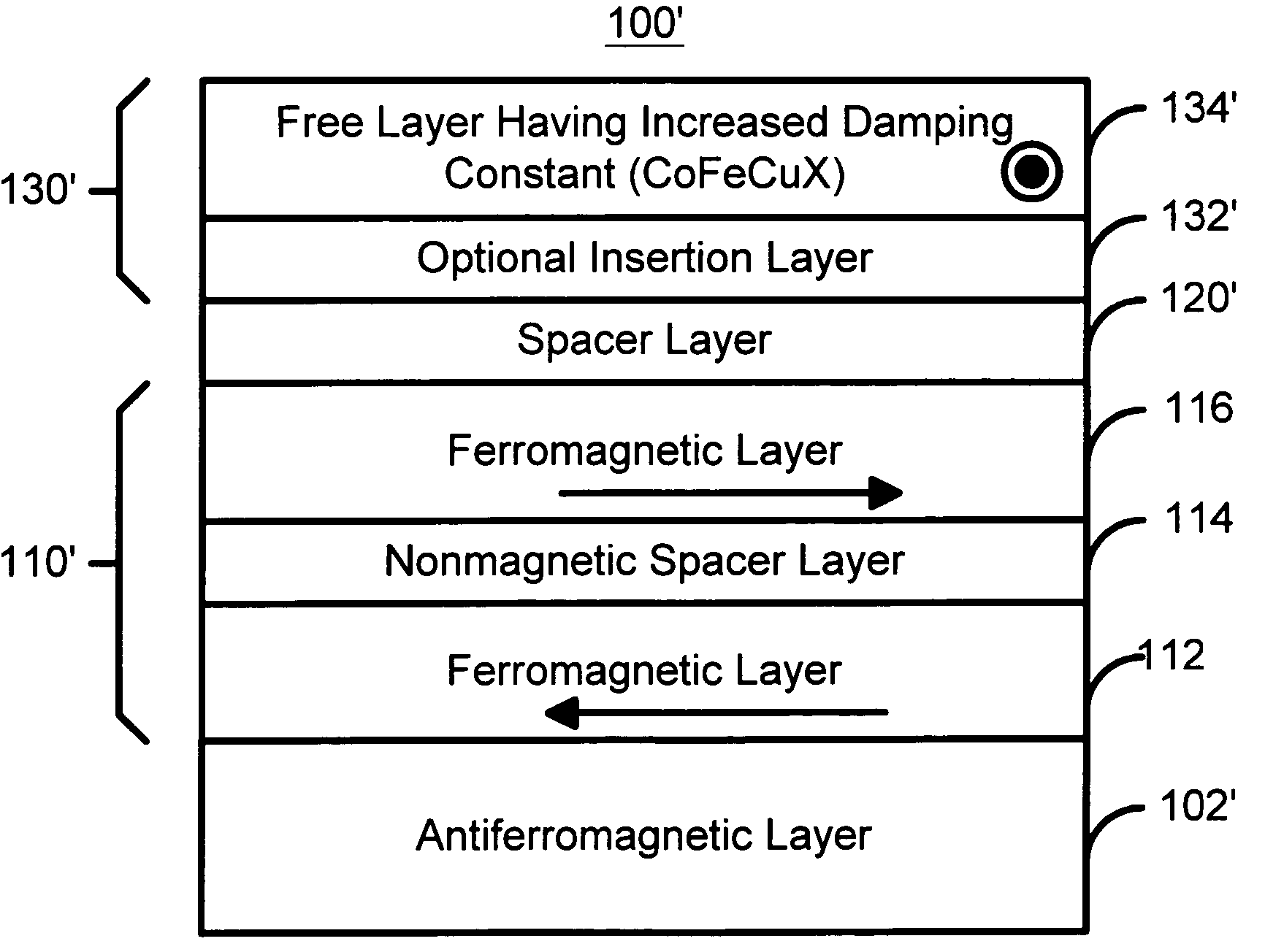

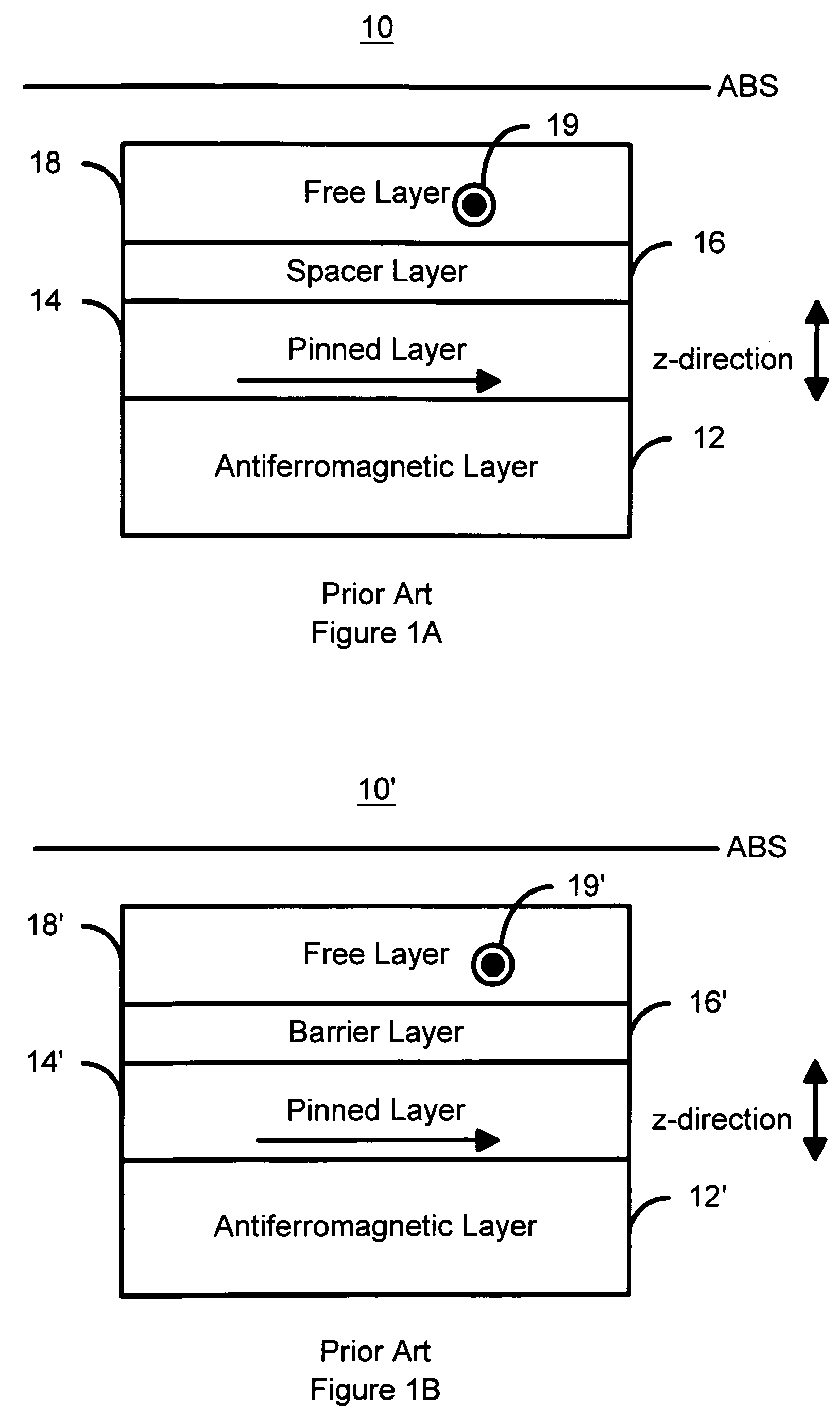

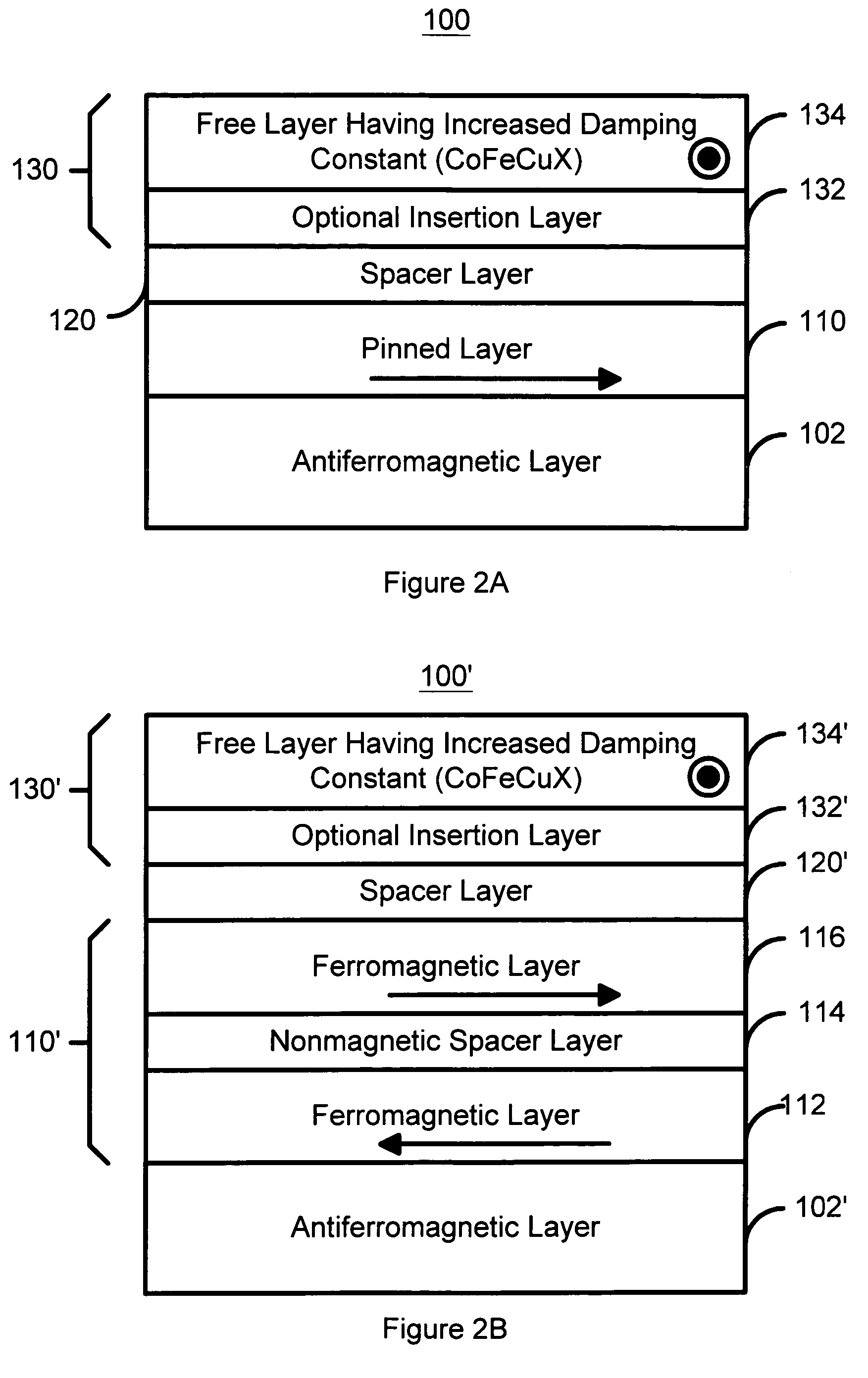

Magnetoresistive element having reduced spin transfer induced noise

InactiveUS20050041342A1Increased magnetic damping constantNanomagnetismMagnetic measurementsMagnetic reluctanceSpin transfer

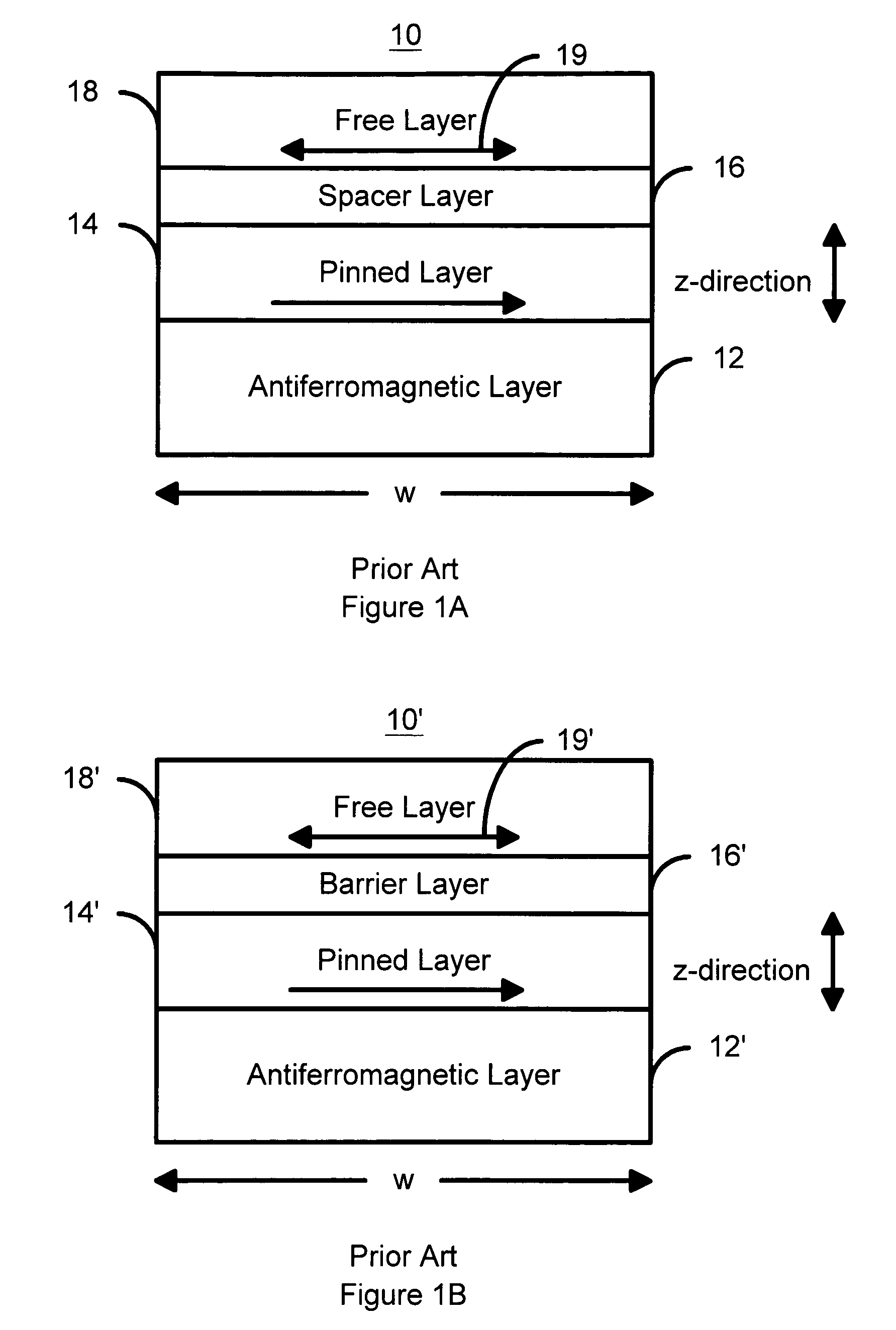

A method and system for providing a magnetic element is disclosed. The method and system include providing a ferromagnetic pinned layer, providing a free layer, and providing a spacer layer between the pinned layer and the free layer. The pinned layer and free layer are ferromagnetic and have a pinned layer magnetization and a free layer magnetization, respectively. The spacer layer is nonmagnetic. In one aspect, the free layer is configured to have an increased magnetic damping constant. In another aspect, the method and system also include providing a second pinned layer and a second spacer layer between the free layer and the second pinned layer. In this aspect, the first pinned layer and / or the second pinned layer are configured such that a forward torque and a reflected torque due to a current driven through the magnetic element in a current-perpendicular-to-plane configuration are substantially equal and opposite.

Owner:SAMSUNG SEMICON

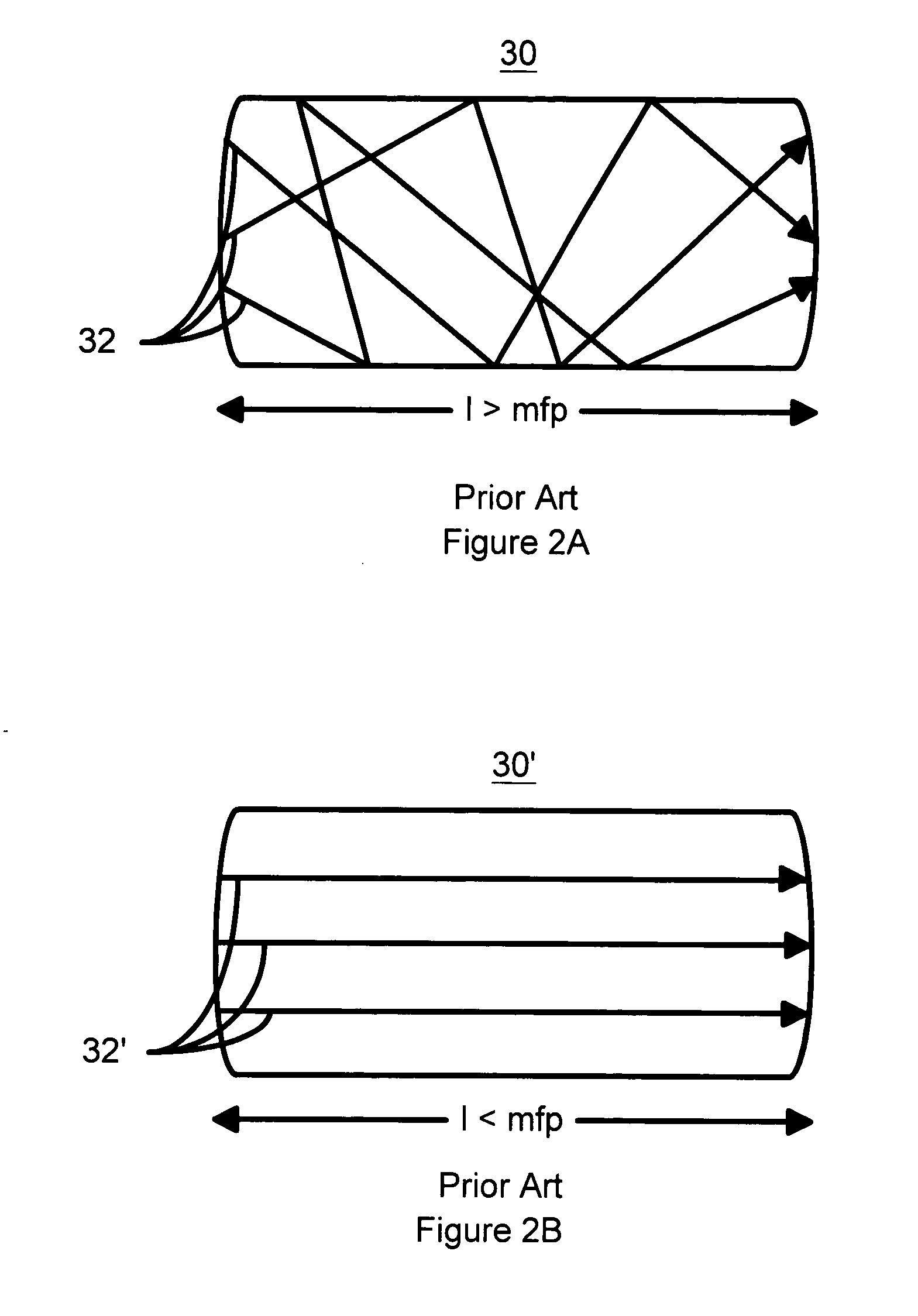

Magnetic elements with ballistic magnetoresistance utilizing spin-transfer and an MRAM device using such magnetic elements

InactiveUS20050136600A1Improve signal outputTransistorNanostructure applicationMagnetic currentCharge carrier

A method and system for providing a magnetic element is disclosed. The method and system include providing a pinned layer, a magnetic current confined layer, and a free layer. The pinned layer is ferromagnetic and has a first pinned layer magnetization. The magnetic current confined layer has at least one channel in an insulating matrix and resides between the pinned layer and the free layer. The channel(s) are ferromagnetic, conductive, and extend through the insulating matrix between the free layer and the pinned layer. The size(s) of the channel(s) are sufficiently small that charge carriers can give rise to ballistic magnetoresistance in the magnetic current confined layer. The free layer is ferromagnetic and has a free layer magnetization. Preferably, the method and system also include providing a second pinned layer and a nonmagnetic spacer layer between the second pinned layer and the free layer. In this aspect, the magnetic element is configured to allow the free layer magnetization to be switched using spin transfer.

Owner:GRANDIS

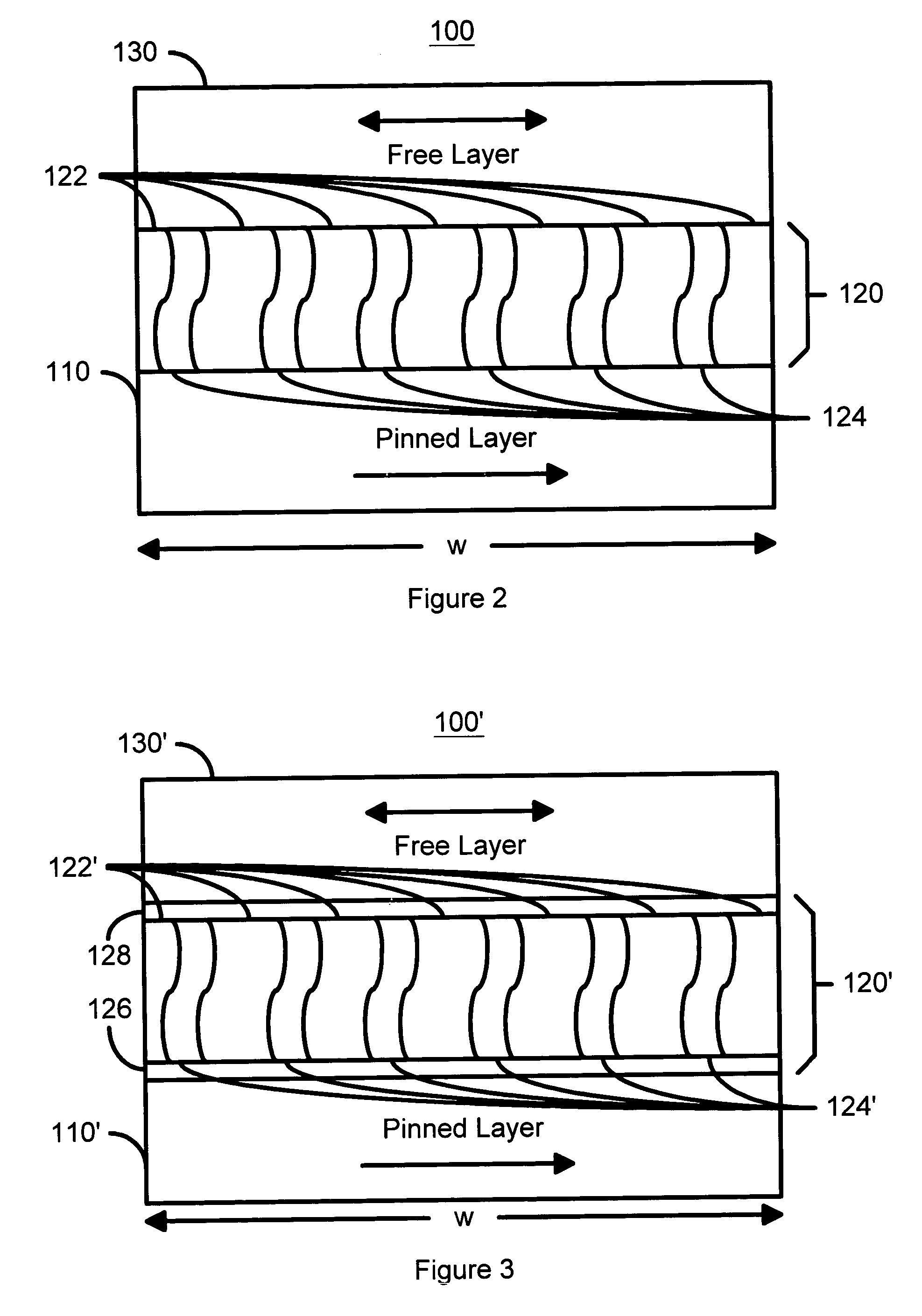

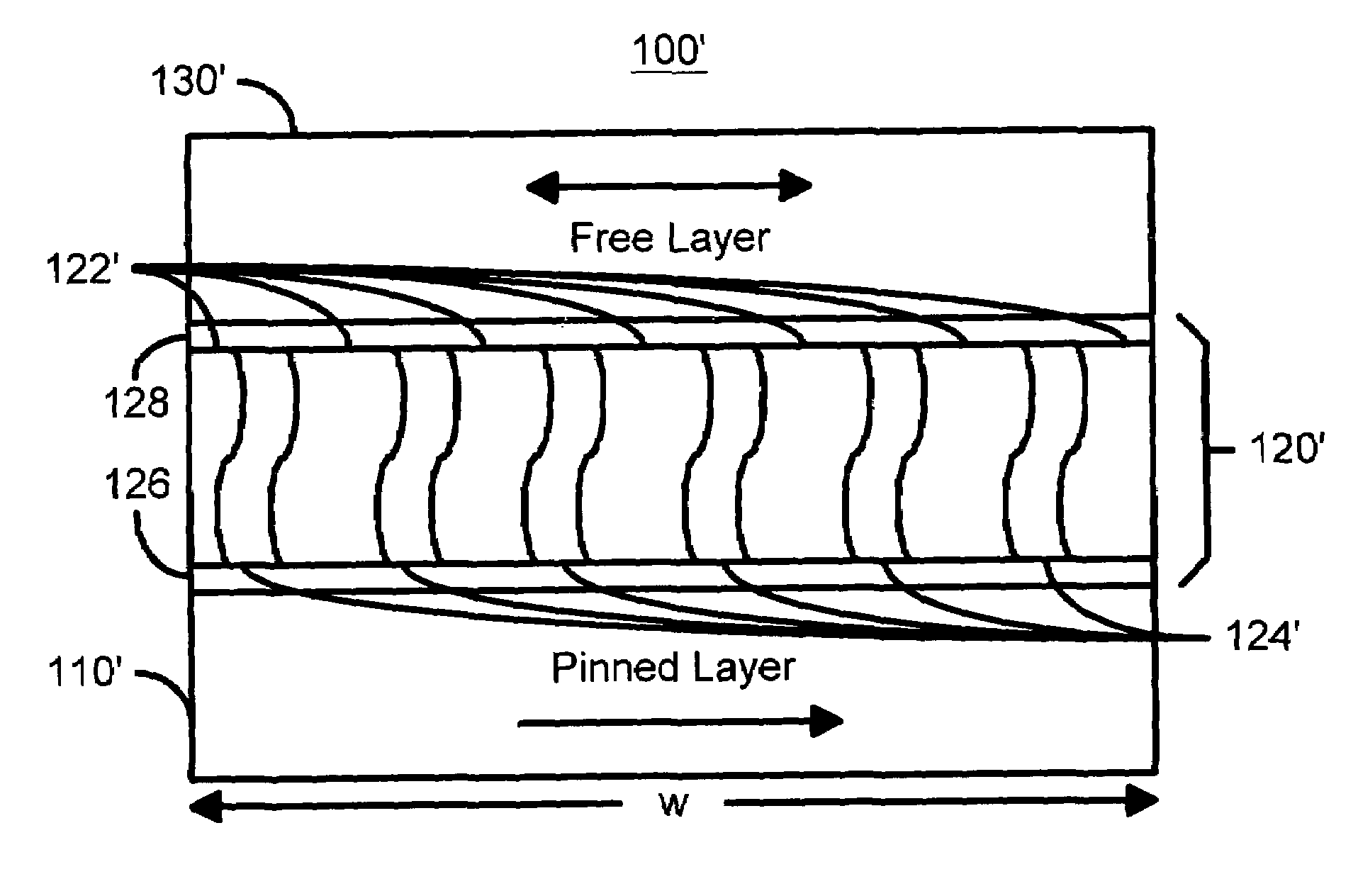

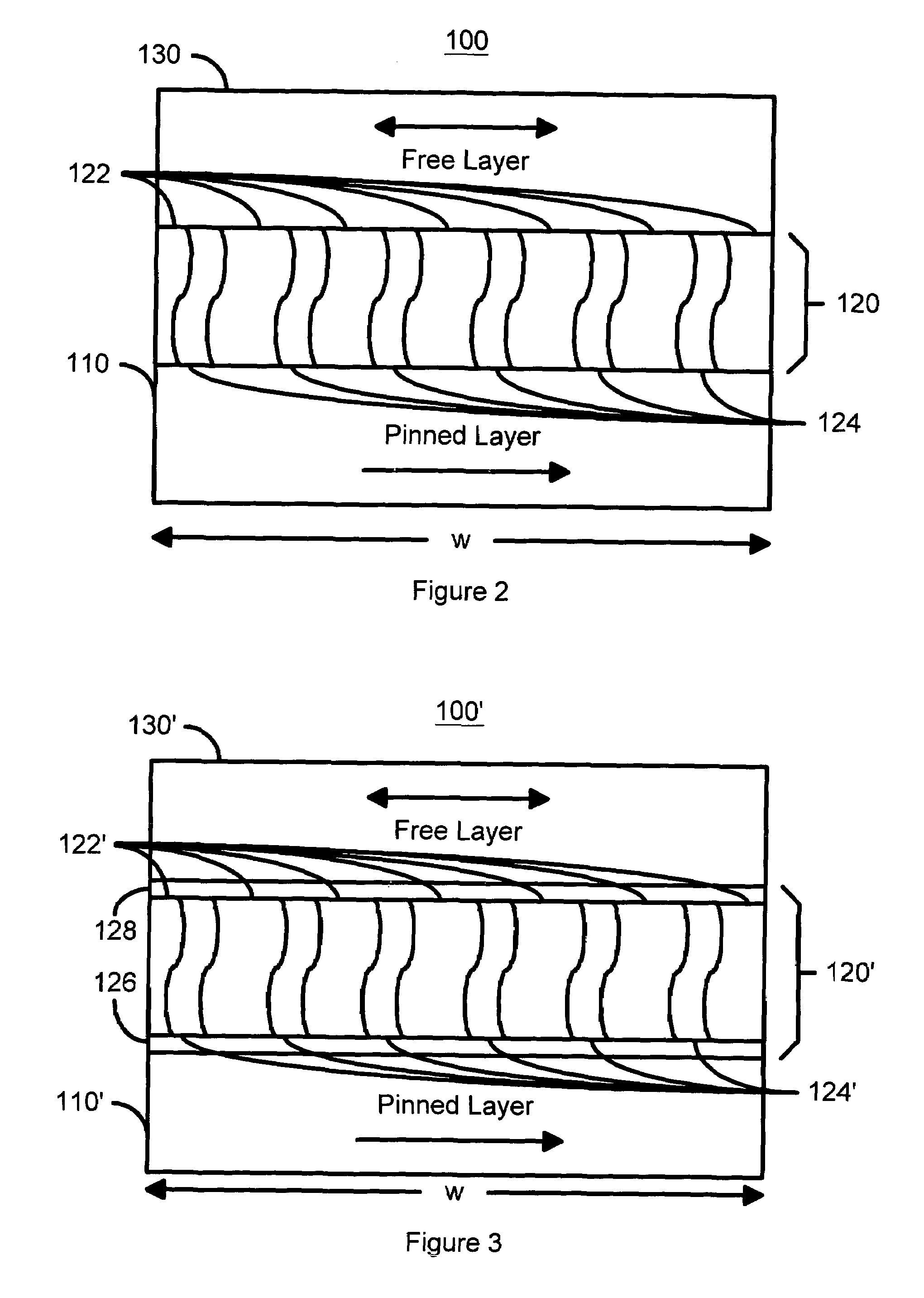

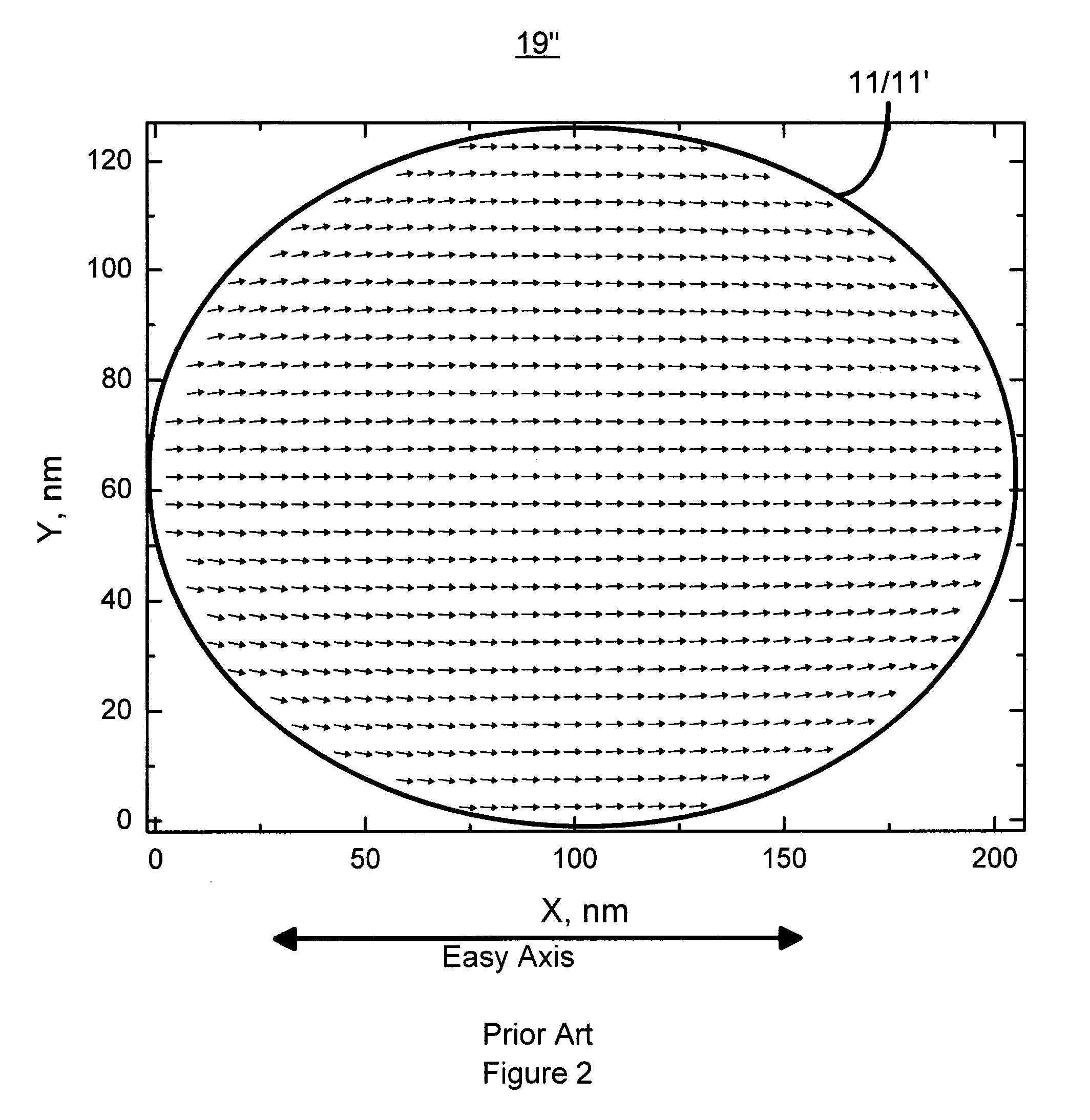

Magnetic elements having improved switching characteristics and magnetic memory devices using the magnetic elements

InactiveUS20070019337A1Magnetic measurementsSemiconductor/solid-state device manufacturingMagnetic memorySpin transfer

A method and system for providing a magnetic element and a memory using the magnetic element are described. The method and system include providing a pinned layer, providing a spacer layer, and providing a free layer. The spacer layer is nonferromagnetic and resides between the pinned layer and the free layer. At least the free layer has a first end portion, a second end portion and a central portion between the first end portion and the second end portion. The first end portion, the second end portion and the central portion form an S-shape. At least one of the first end portion and the second end portion includes a curve. The magnetic element is also configured to allow the free layer to be switched at least in part due to spin transfer when a write current is passed through the magnetic element.

Owner:GRANDIS

Magnetoresistive element having reduced spin transfer induced noise

A method and system for providing a magnetic element is disclosed. The method and system include providing a ferromagnetic pinned layer, providing a free layer, and providing a spacer layer between the pinned layer and the free layer. The pinned layer and free layer are ferromagnetic and have a pinned layer magnetization and a free layer magnetization, respectively. The spacer layer is nonmagnetic. In one aspect, the free layer is configured to have an increased magnetic damping constant. In another aspect, the method and system also include providing a second pinned layer and a second spacer layer between the free layer and the second pinned layer. In this aspect, the first pinned layer and / or the second pinned layer are configured such that a forward torque and a reflected torque due to a current driven through the magnetic element in a current-perpendicular-to-plane configuration are substantially equal and opposite.

Owner:SAMSUNG SEMICON

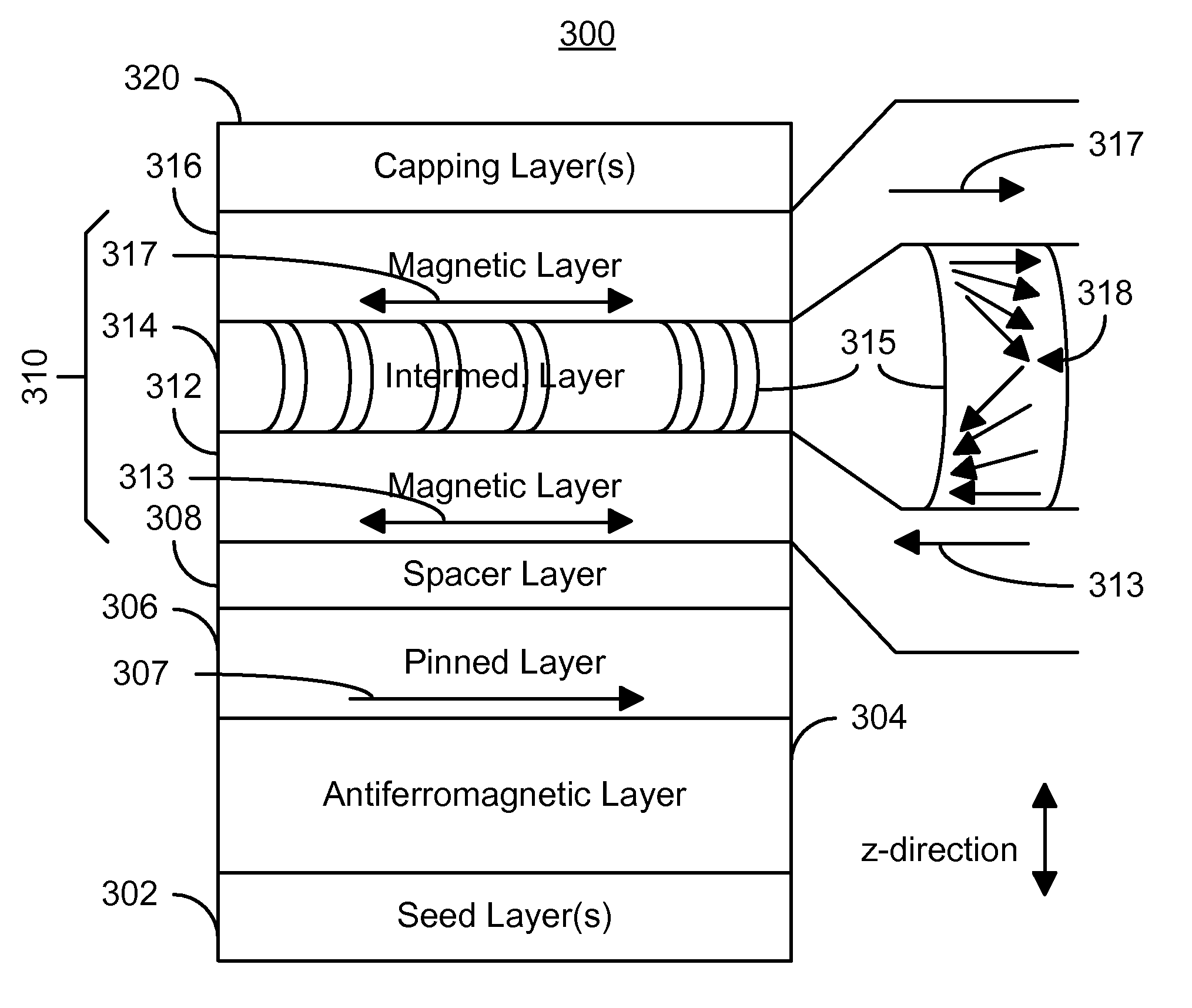

Method and system for providing domain wall assisted switching of magnetic elements and magnetic memories using such magnetic elements

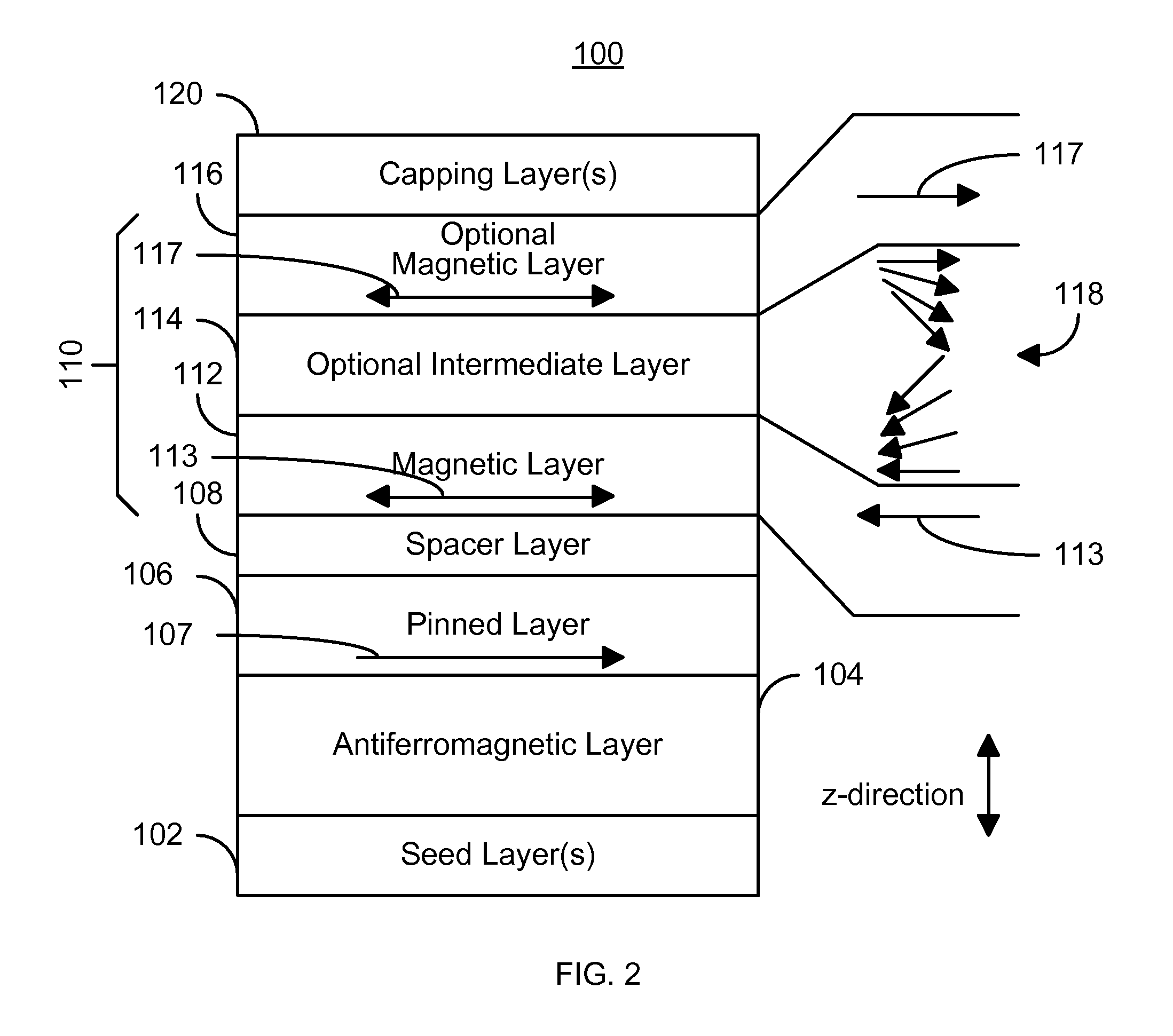

A method and system for providing a magnetic element is described. The magnetic element includes a pinned layer, a spacer layer, and a free layer. The spacer layer is nonferromagnetic and resides between the pinned layer and the free layer. The free layer includes a first magnetic layer and at least one of a second magnetic layer and an intermediate layer. The intermediate layer would reside between the first and second magnetic layers. The free layer also includes at least one domain wall therein during switching. In addition, the magnetic element is configured to allow the free layer to be switched at least in part due to spin transfer when a write current is passed through the magnetic element.

Owner:SAMSUNG SEMICON

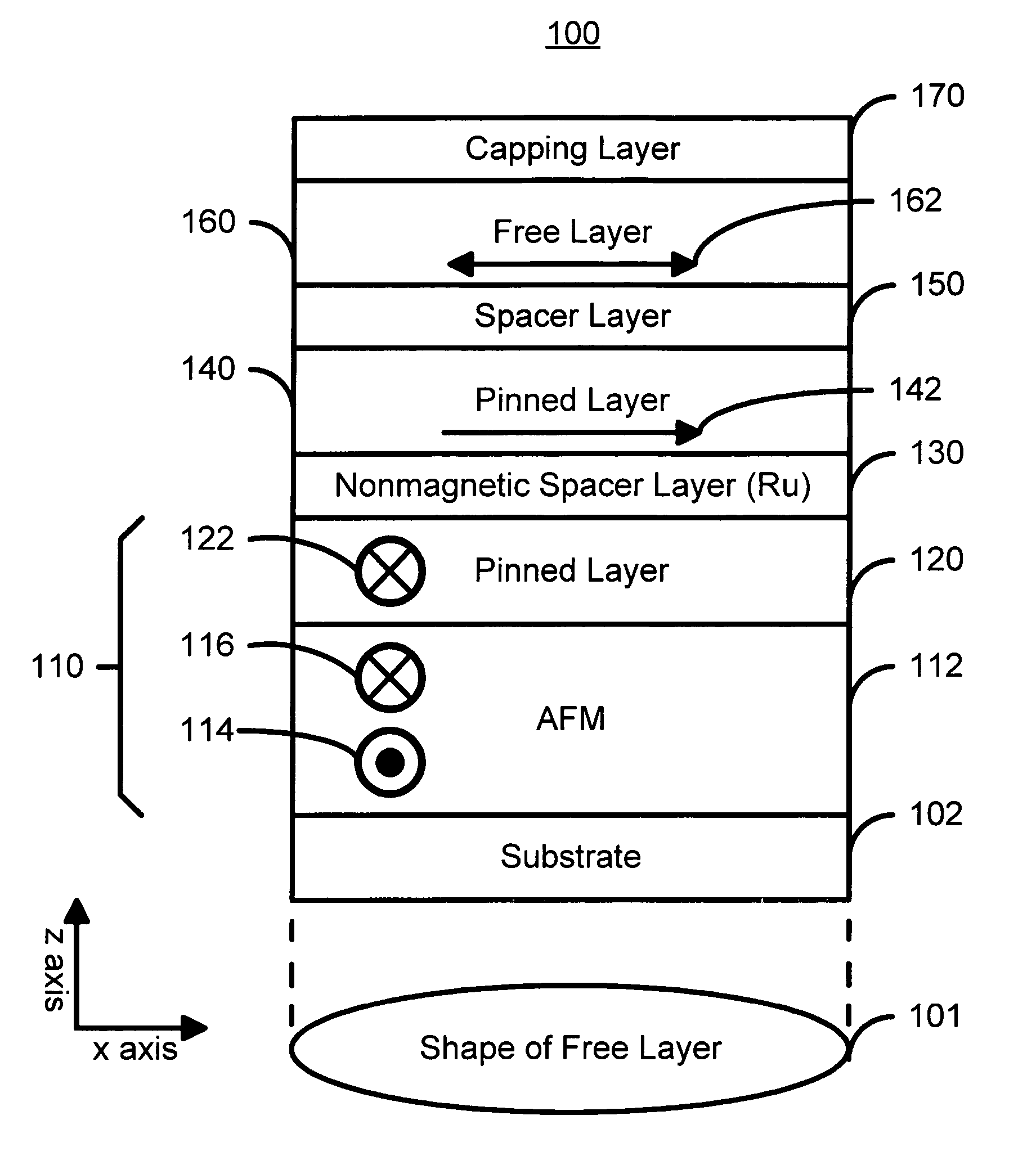

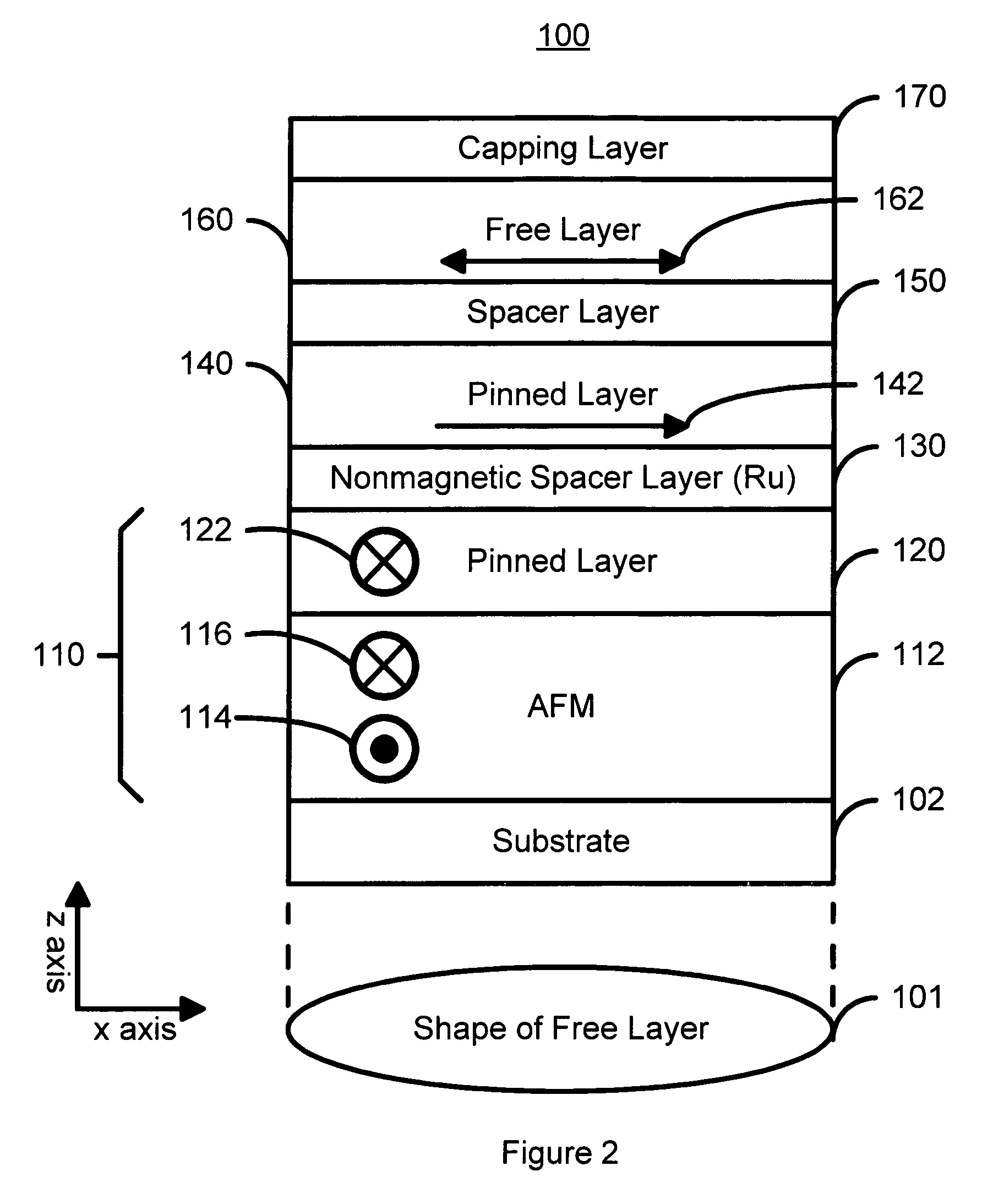

Magnetic elements having a bias field and magnetic memory devices using the magnetic elements

ActiveUS7518835B2Improve switching characteristicsLower average currentRecord information storageManufacture of flux-sensitive headsMagnetic memoryBias field

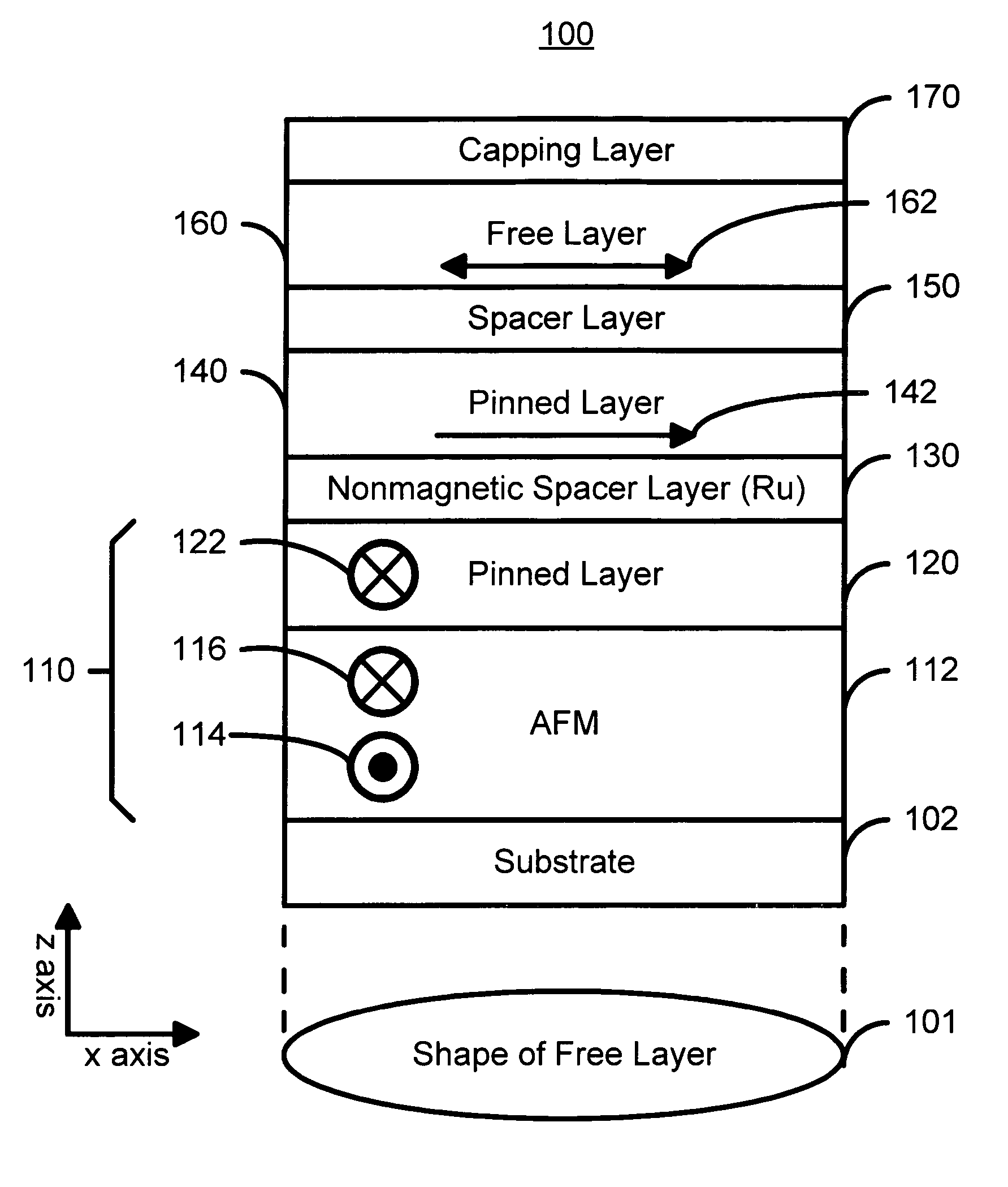

A method and system for providing a magnetic element are disclosed. The method and system include providing a magnetic biasing structure having a first pinned layer, a second pinned layer, a spacer layer, and a free layer. The first pinned layer has a first magnetization pinned in the first direction. The second pinned layer has a second magnetization in a second direction that is substantially perpendicular or along the first direction. The spacer layer is nonferromagnetic, resides between the second pinned layer and the free layer, and is configured such that the free layer is substantially free of exchange coupling with the second pinned layer. The free layer has a shape anisotropy with a longitudinal direction substantially in the second direction. The magnetic biasing structure provides a bias field for the free layer along the hard or easy axis. In one aspect, the second pinned layer resides between the first pinned layer and the free layer.

Owner:SAMSUNG SEMICON

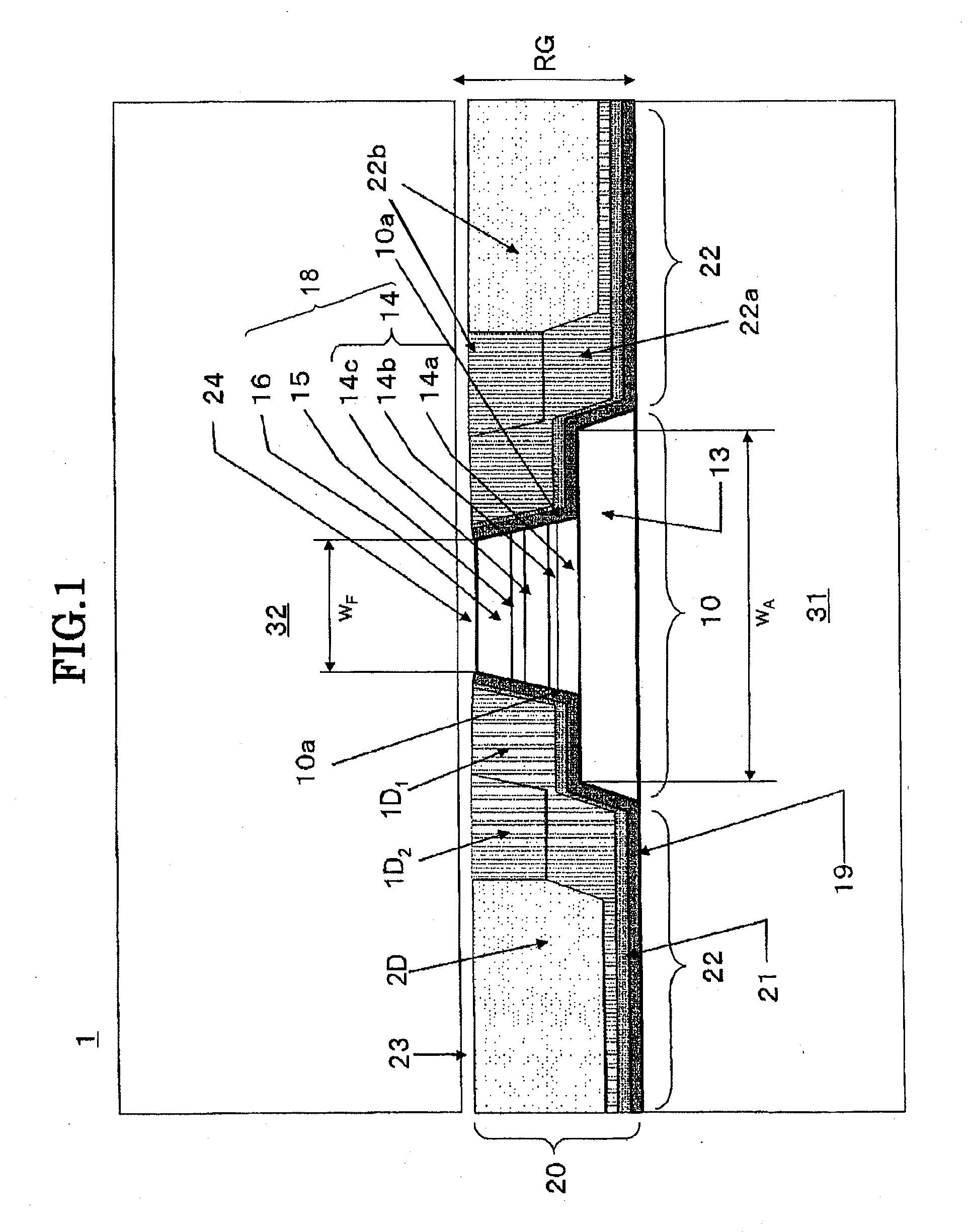

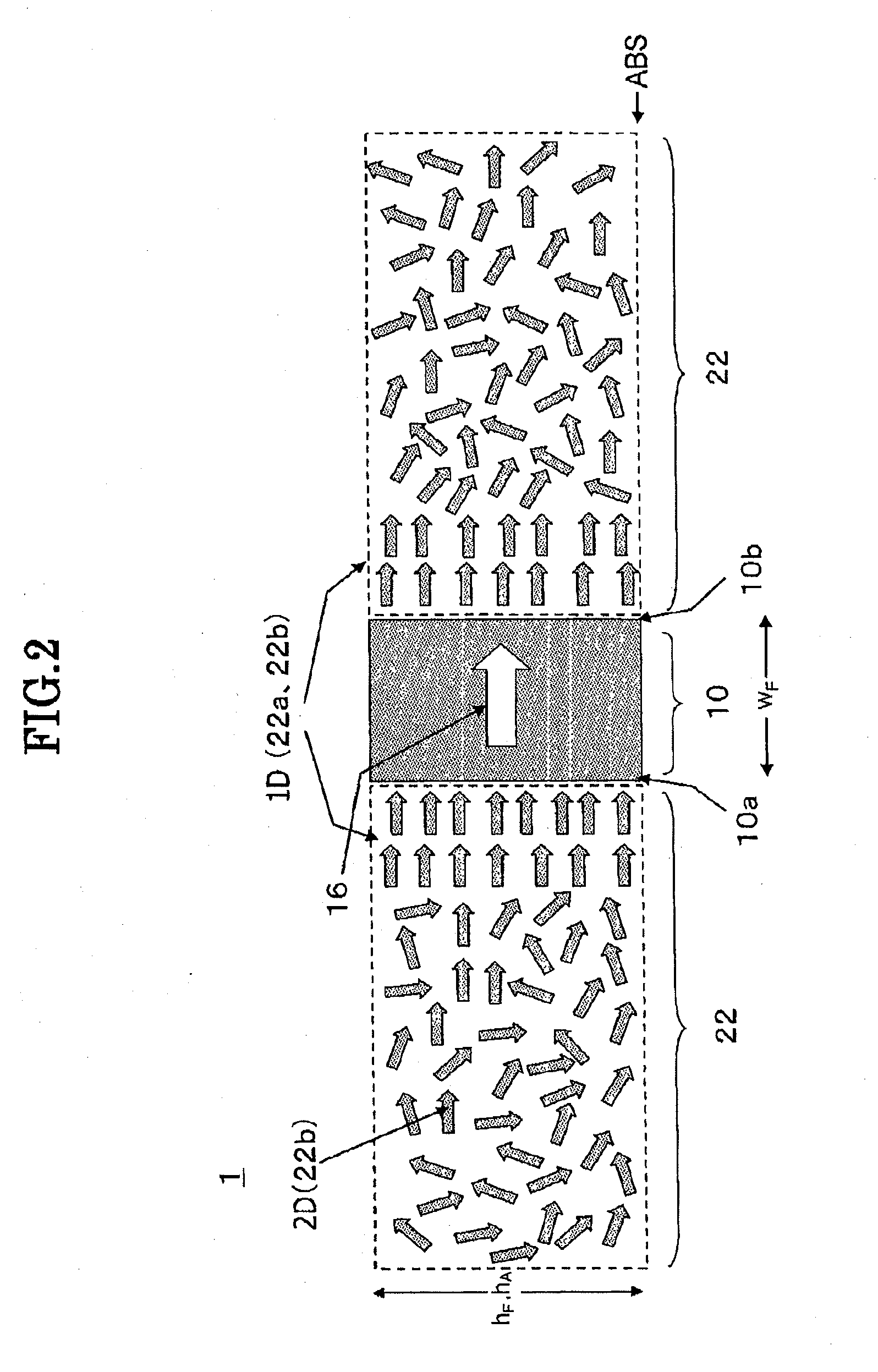

Magnetic sensor stack body, method of forming the same, film formation control program, and recording medium

ActiveUS20110032645A1Good effectEnhance layeringMagnetic measurementsDecorative surface effectsElectrical resistance and conductanceFerromagnetism

The present invention is directed to align crystal c-axes in magnetic layers near two opposed junction wall faces of a magnetoresistive element so as to be almost perpendicular to the junction wall faces. A magnetic sensor stack body has, on a substrate, a magnetoresistive element whose electric resistance fluctuates when a bias magnetic field is applied and, on sides of opposed junction wall faces of the magnetoresistive element, field regions including magnetic layers for applying the bias magnetic field to the element. The magnetoresistive element has at least a ferromagnetic stack on a part of an antiferromagnetic layer, and width of an uppermost face of the ferromagnetic stack along a direction in which the junction wall faces are opposed to each other is smaller than width of an uppermost face of the antiferromagnetic layer in the same direction.

Owner:CANON ANELVA CORP

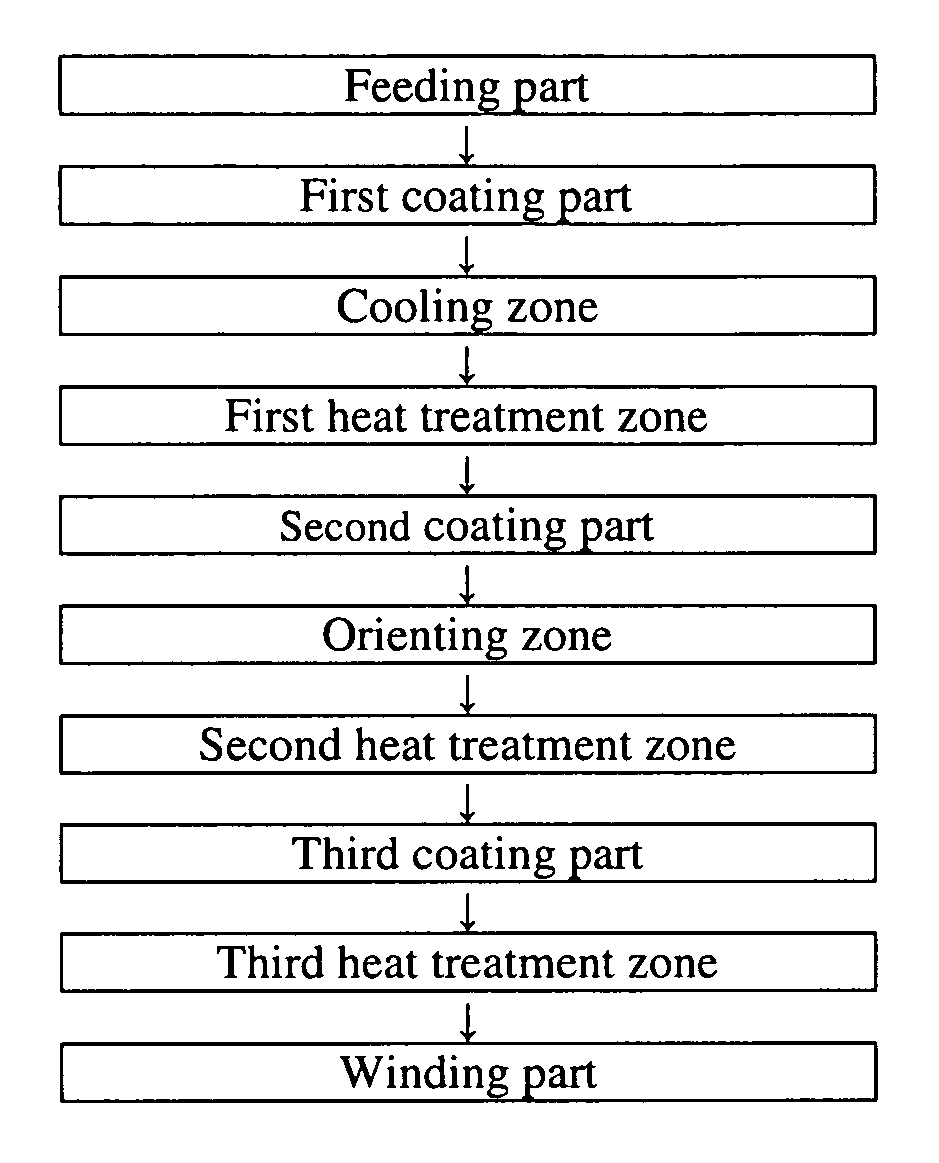

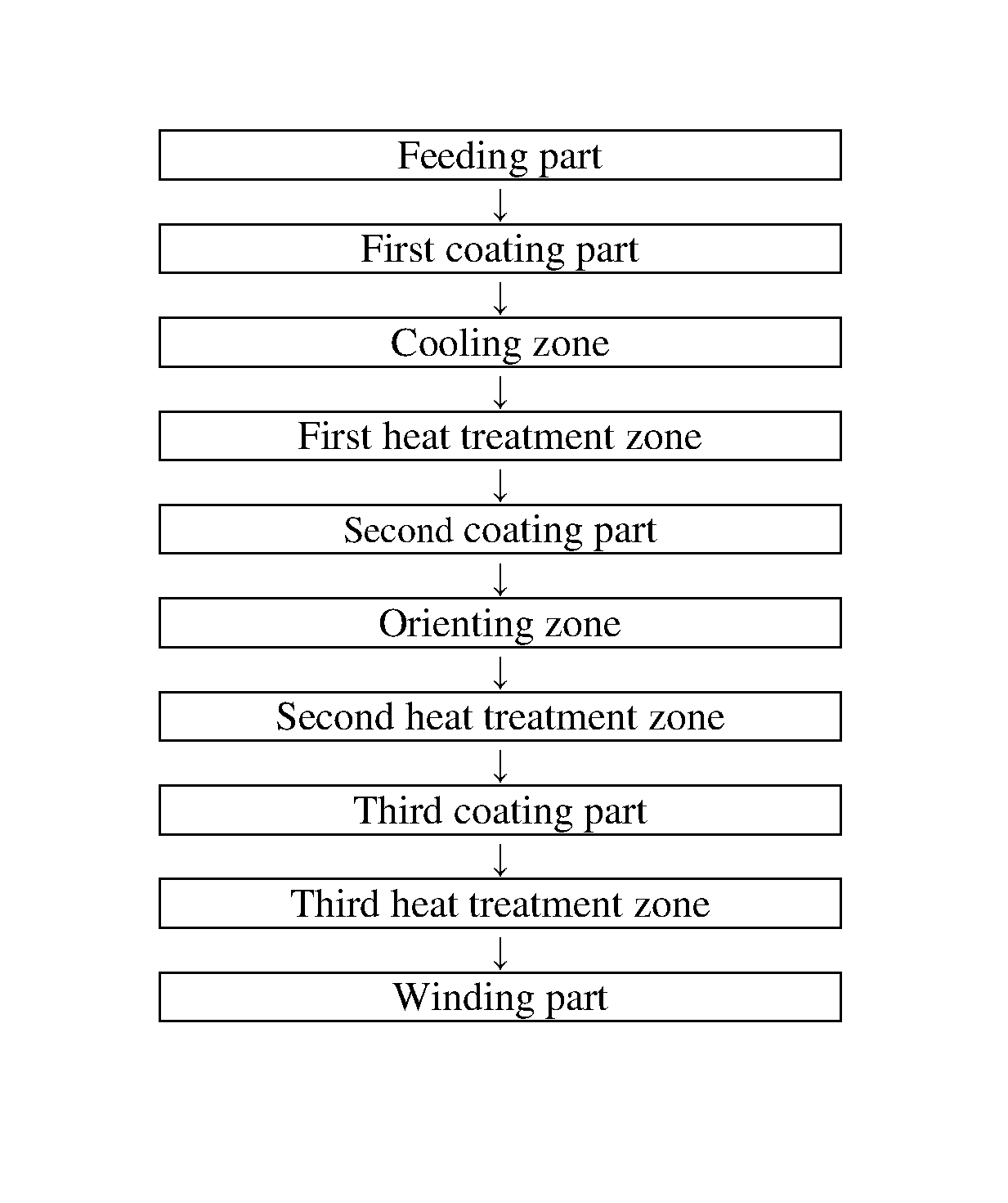

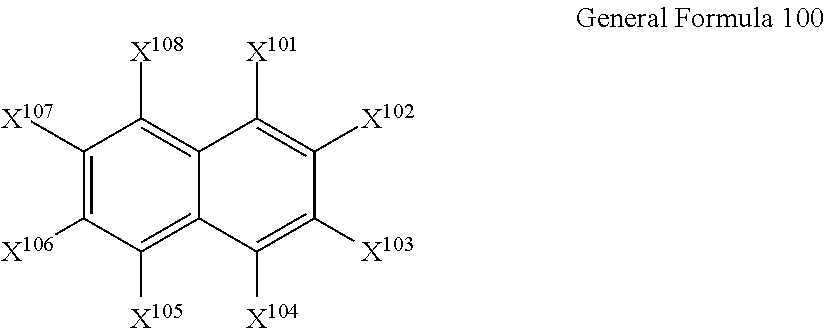

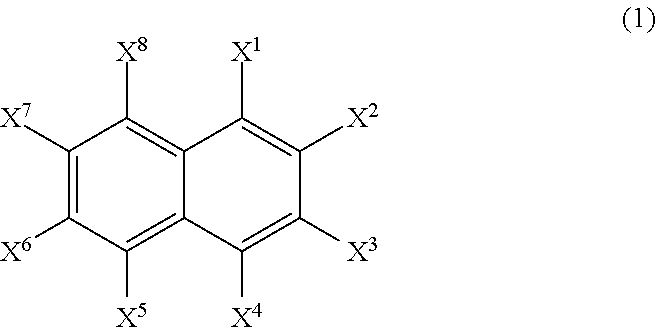

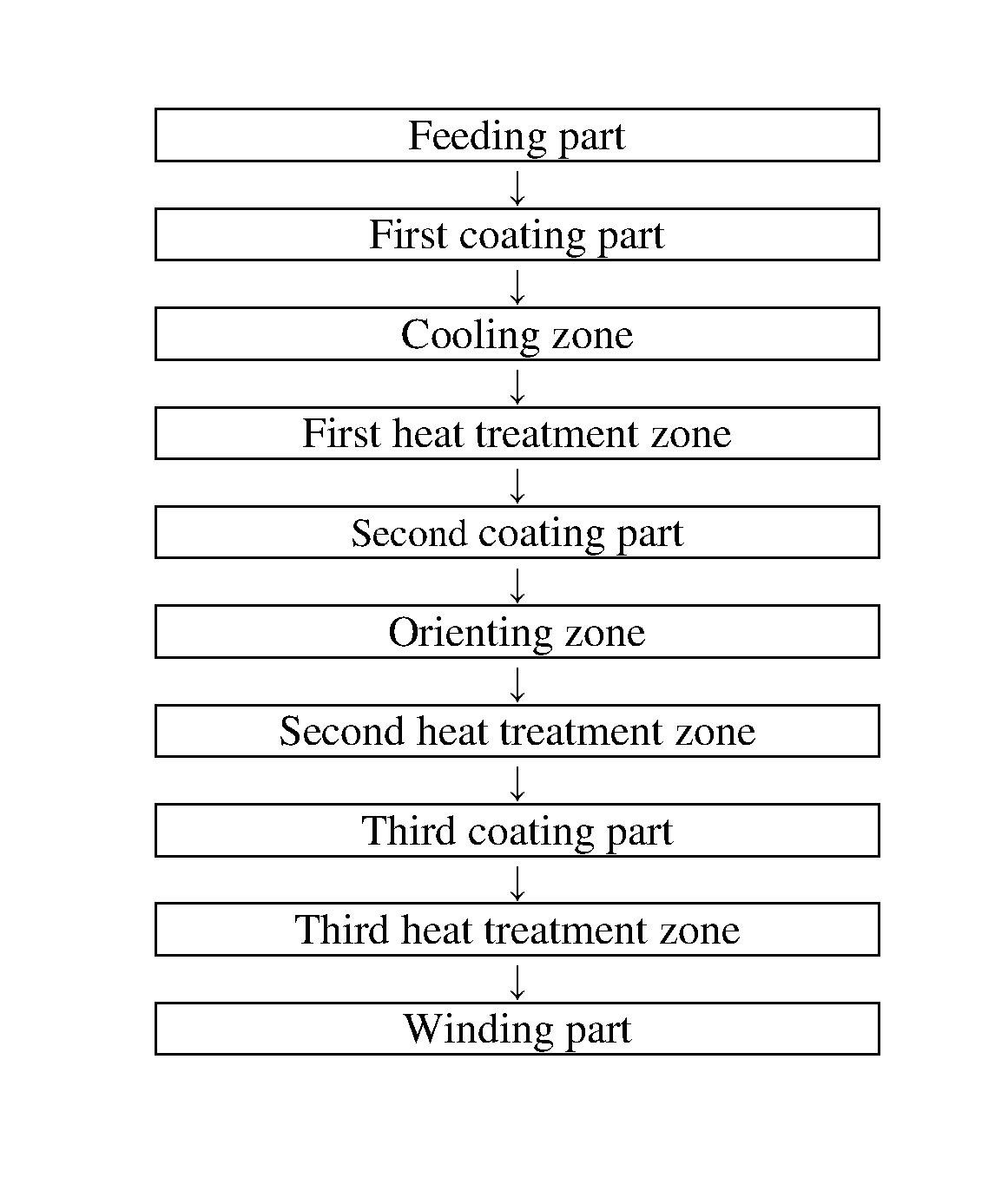

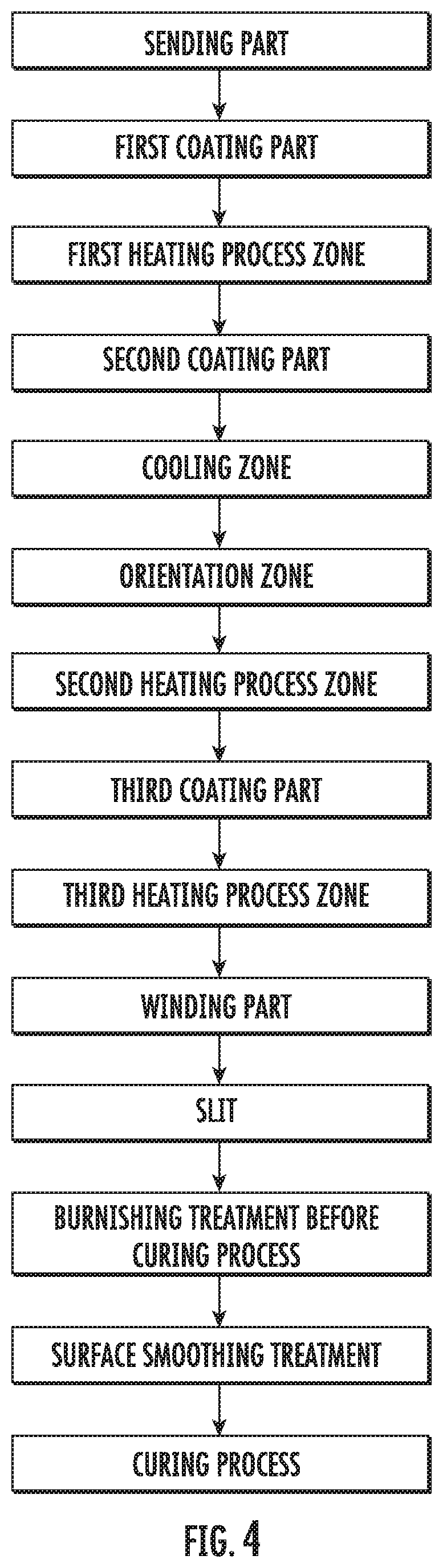

Magnetic tape and method of manufacturing the same

ActiveUS9711174B2Reduce thicknessIncrease recording capacityBase layers for recording layersTape carriersMagnetic tapeNon magnetic

Provided is a magnetic tape, which comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder and binder; wherein a total thickness of the magnetic tape is less than or equal to 4.80 μm; at least the magnetic layer comprises one or more components selected from the group consisting of a fatty acid and a fatty acid amide; and a C—H derived carbon, C, concentration calculated from a C—H peak area ratio in a C1s spectrum obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on a surface on the magnetic layer side of the magnetic tape is greater than or equal to 45 atom %.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS9721605B2Avoid it happening againImprove the immunityBase layers for recording layersRecord information storageMedicineMagnetic tape

Provided is a magnetic tape, which comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder and binder; wherein at least the magnetic layer comprises one or more components selected from the group consisting of a fatty acid and a fatty acid amide; a quantity of components selected from the group consisting of a fatty acid and a fatty acid amide per unit area of the magnetic tape among components that are extracted from a surface on the magnetic layer side of the magnetic tape is less than or equal to 15.0 mg / m2, and a concentration of carbon, C, that is obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on the surface on the magnetic layer side of the magnetic tape is greater than or equal to 50 atom %.

Owner:FUJIFILM CORP

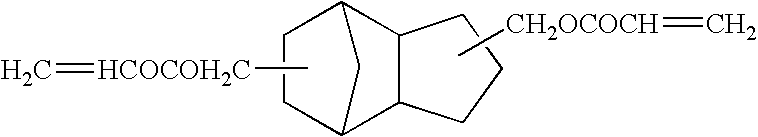

Magnetic recording medium

InactiveUS6939606B2Excellent characteristicsImprove smoothnessMagnetic materials for record carriersBase layers for recording layersNon magneticFerromagnetism

A magnetic recording medium is provided that includes, in order, (1) a non-magnetic support, a radiation-cured layer formed by applying a layer containing a radiation curing compound and curing by exposure to radiation, and a magnetic layer having a ferromagnetic powder dispersed in a binder, or (2) a non-magnetic support, a radiation-cured layer formed by applying a layer containing a radiation curing compound and curing by exposure to radiation, a non-magnetic layer having a non-magnetic powder dispersed in a binder, and a magnetic layer having a ferromagnetic powder dispersed in a binder; the radiation-cured layer including 0.3 to 30 parts by weight of an inorganic powder relative to 100 parts by weight the radiation curing compound.

Owner:FUJIFILM CORP +1

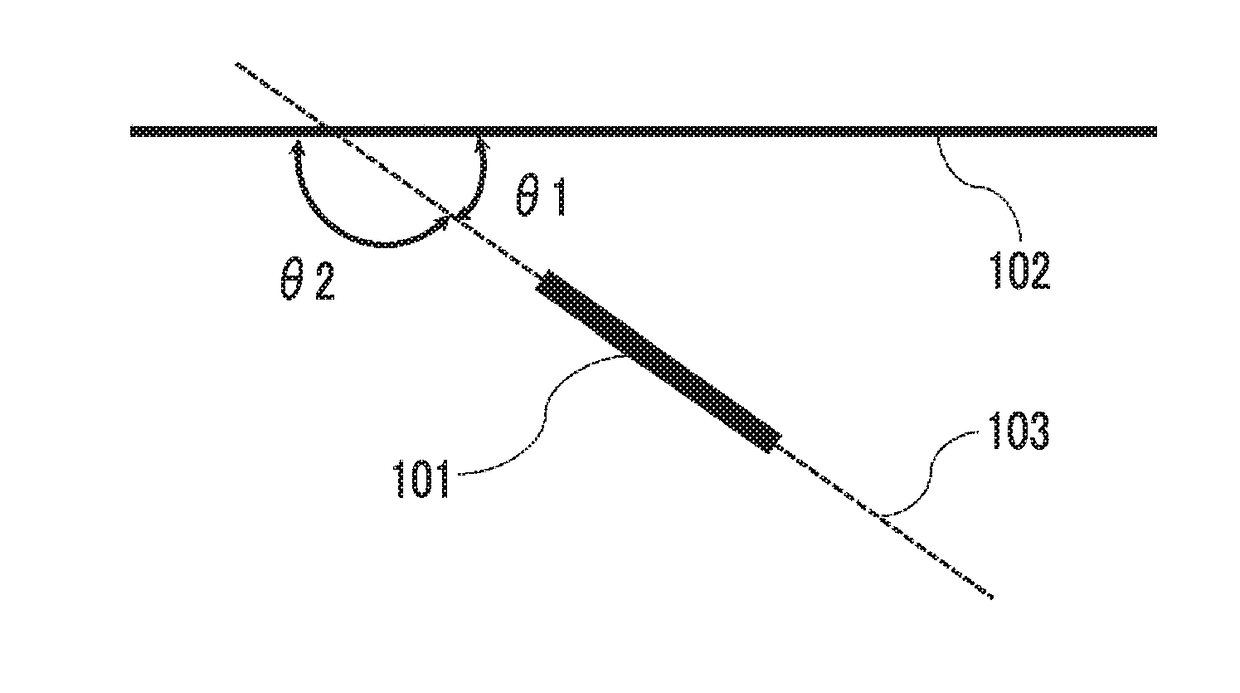

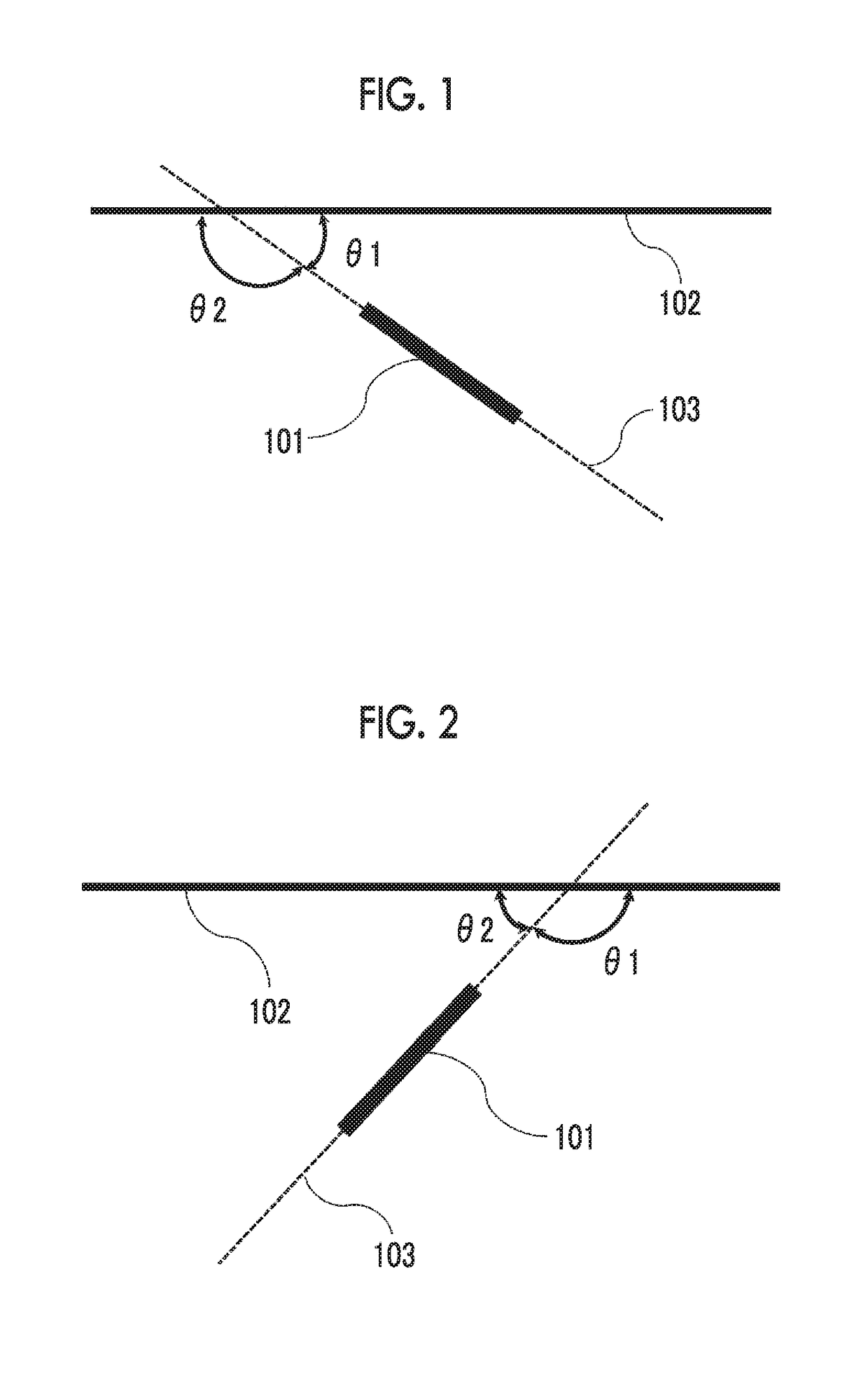

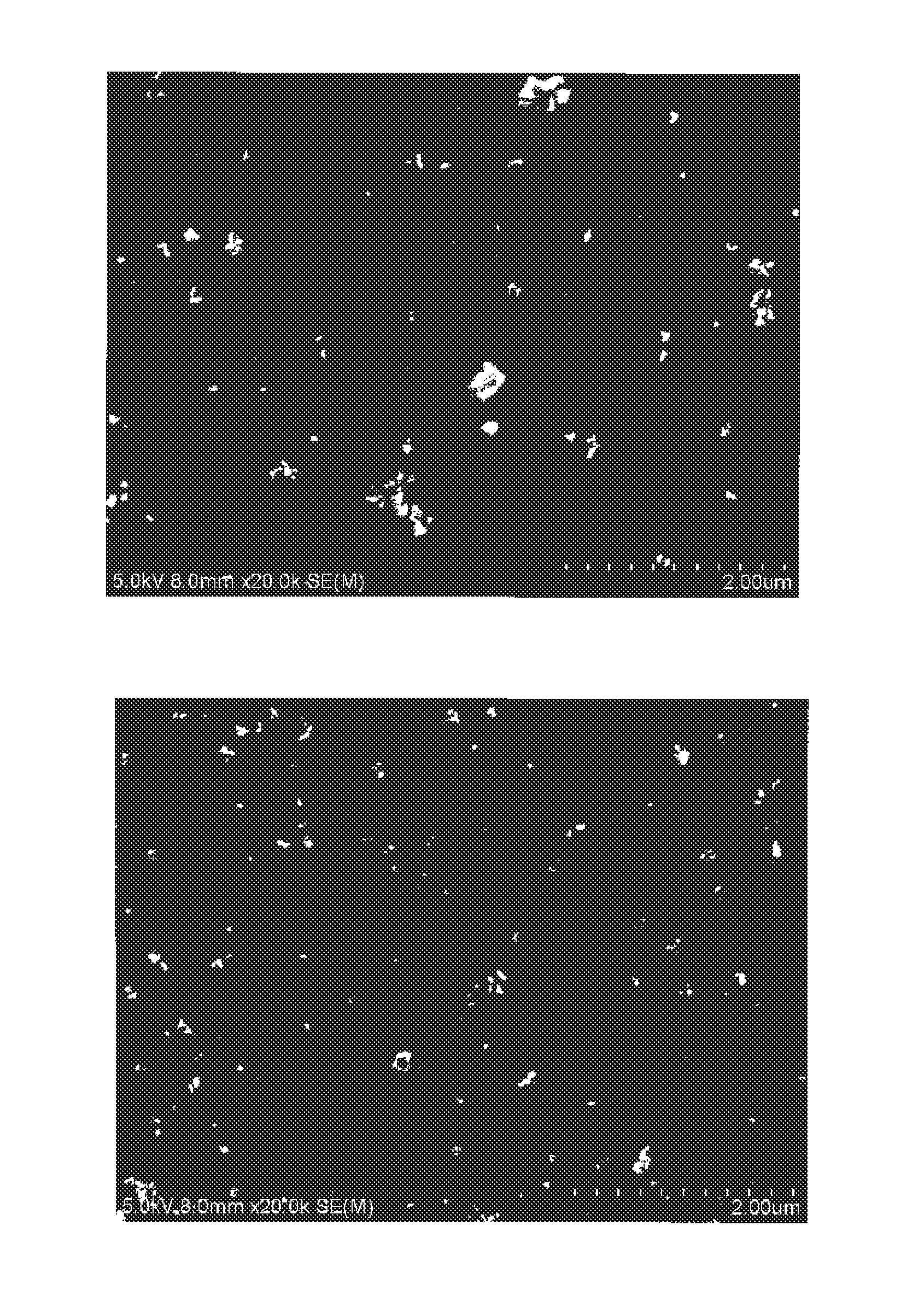

Magnetic tape

ActiveUS20180061446A1Deterioration of characteristicMagnetic materials for record carriersTape carriersConventional transmission electron microscopeScanning tunneling microscope

Provided is a magnetic tape in which the total thickness of the non-magnetic layer and the magnetic layer is equal to or smaller than 0.60 μm, the magnetic layer includes ferromagnetic hexagonal ferrite powder and an abrasive, a percentage of a plan view maximum area of the abrasive confirmed in a region having a size of 4.3 μm×6.3 μm of the surface of the magnetic layer by plane observation using a scanning electron microscope, with respect to the total area of the region is equal to or greater than 0.02% and less than 0.06%, and a tilt cos 0 of the ferromagnetic hexagonal ferrite powder with respect to a surface of the magnetic layer acquired by cross section observation performed by using a scanning transmission electron microscope is 0.85 to 1.00.

Owner:FUJIFILM CORP

Magnetic recording medium

ActiveUS9530444B2Increased durabilityReduce runningMagnetic materials for record carriersRecord information storageScanning electron microscopeElectron microscope

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS20160189740A1Avoid it happening againImprove the immunityBase layers for recording layersTape carriersMagnetic tapeNon magnetic

Provided is a magnetic tape, which comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder and binder; wherein at least the magnetic layer comprises one or more components selected from the group consisting of a fatty acid and a fatty acid amide; a quantity of components selected from the group consisting of a fatty acid and a fatty acid amide per unit area of the magnetic tape among components that are extracted from a surface on the magnetic layer side of the magnetic tape is less than or equal to 15.0 mg / m2, and a concentration of carbon, C, that is obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on the surface on the magnetic layer side of the magnetic tape is greater than or equal to 50 atom %.

Owner:FUJIFILM CORP

Magnetic recording medium and process for producing the same

InactiveUS20070231606A1Improve the overall coefficientHead contaminationMaterials with cobaltRecord information storageMetal powderCobalt

A magnetic recording medium comprising a substrate and a magnetic layer containing ferromagnetic metal powder and a binder, wherein the ferromagnetic metal powder contains iron, cobalt and form 2 to 20 atom % of yttrium based on a total of iron and cobalt contained in the ferromagnetic metal powder and has an average length of 50 nm or smaller, and the magnetic recording medium has a test value of at least 100 passes in a magnetoresistive head resistance reduction test performed as defined herein.

Owner:FUJIFILM CORP

Magnetic recording medium

InactiveUS20060187589A1High reproductive outputHigh outputRecord information storageManufacture of flux-sensitive headsMetallurgyMicrometer

Provided is a magnetic recording medium capable of achieving high reproduction output in a short wavelength region. The magnetic recording medium comprises a nonmagnetic layer comprising a nonmagnetic powder and a binder and a magnetic layer comprising a ferromagnetic powder and a binder in this order on a nonmagnetic support. The magnetic layer has a squareness ranging from 0.6 to 1.0 in a perpendicular direction, and the magnetic recording medium is employed for recording a magnetic signal on the medium in a longitudinal direction at a linear recording density of equal to or greater than 300 Kbpi using a recording head with a gap length of equal to or less than 0.3 micrometer, and reproducing the magnetic signal using a magnetoresistive head with a shield spacing of equal to or less than 0.2 micrometer.

Owner:FUJIFILM CORP +1

Magnetic tape and method of manufacturing the same

ActiveUS20170186456A1Increase frictionImprove featuresRecord information storageTape carriersMagnetic tapeMagnetization

The magnetic tape has a nonmagnetic layer containing nonmagnetic powder and binder on a nonmagnetic support and a magnetic layer containing ferromagnetic powder and binder on the nonmagnetic layer, wherein a fatty acid ester is contained in at least the magnetic layer, the ferromagnetic powder is ferromagnetic hexagonal ferrite powder, the ferromagnetic hexagonal ferrite powder has a crystallite volume as determined by X-ray diffraction analysis ranges from 1,000 nm3 to 2,400 nm3, and a ratio of the crystallite size Dx(107) obtained from a diffraction peak of a (107) plane to a particle size in a direction of an easy axis of magnetization DTEM as determined by observation with a transmission electron microscope, Dx(107) / DTEM, is greater than or equal to 1.1, and ΔSFD in a longitudinal direction of the magnetic tape as calculated with Equation 1: ΔSFD=SFD25° C.−SFD−190° C., ranges from 0.50 to 1.60.

Owner:FUJIFILM CORP

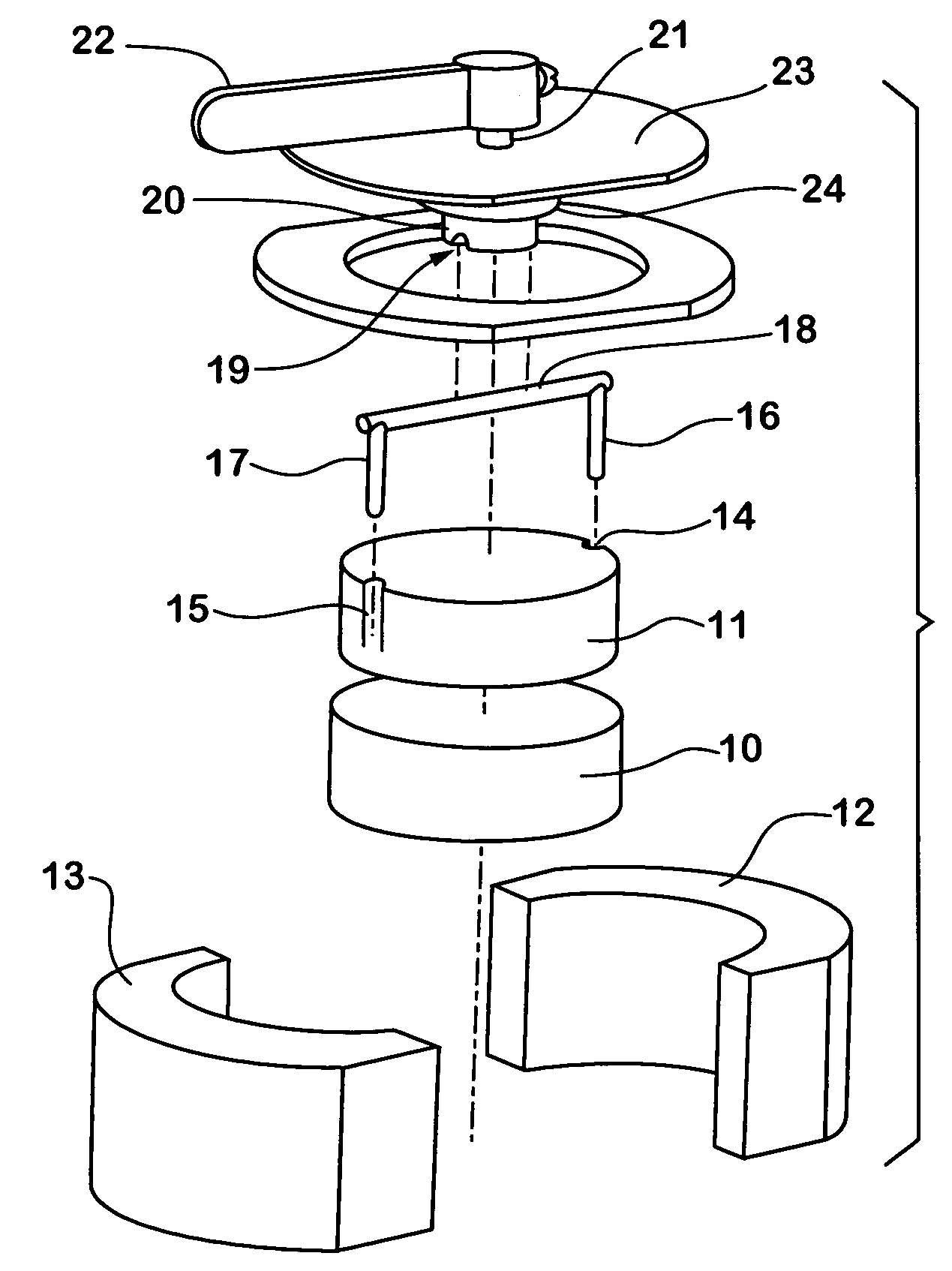

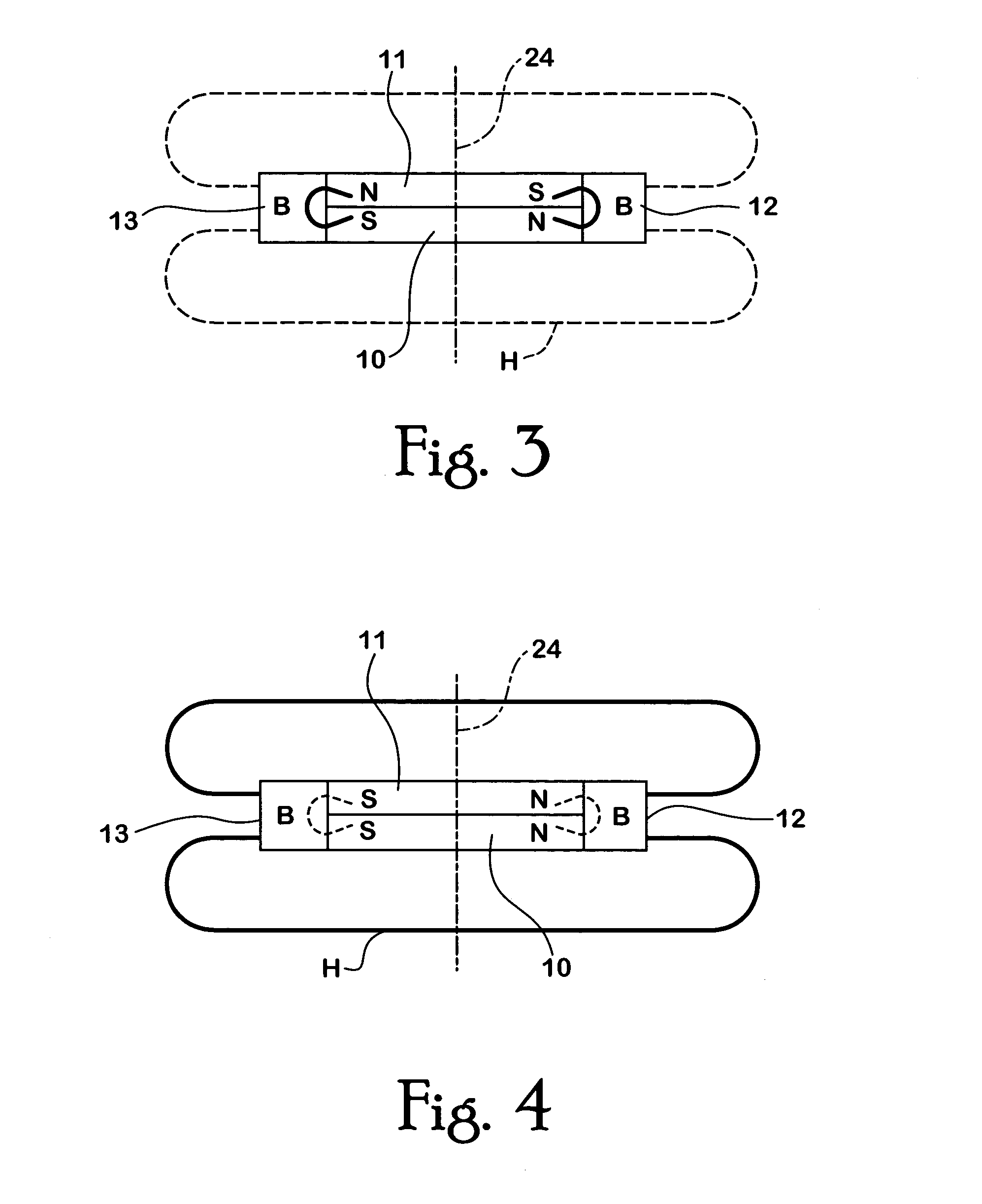

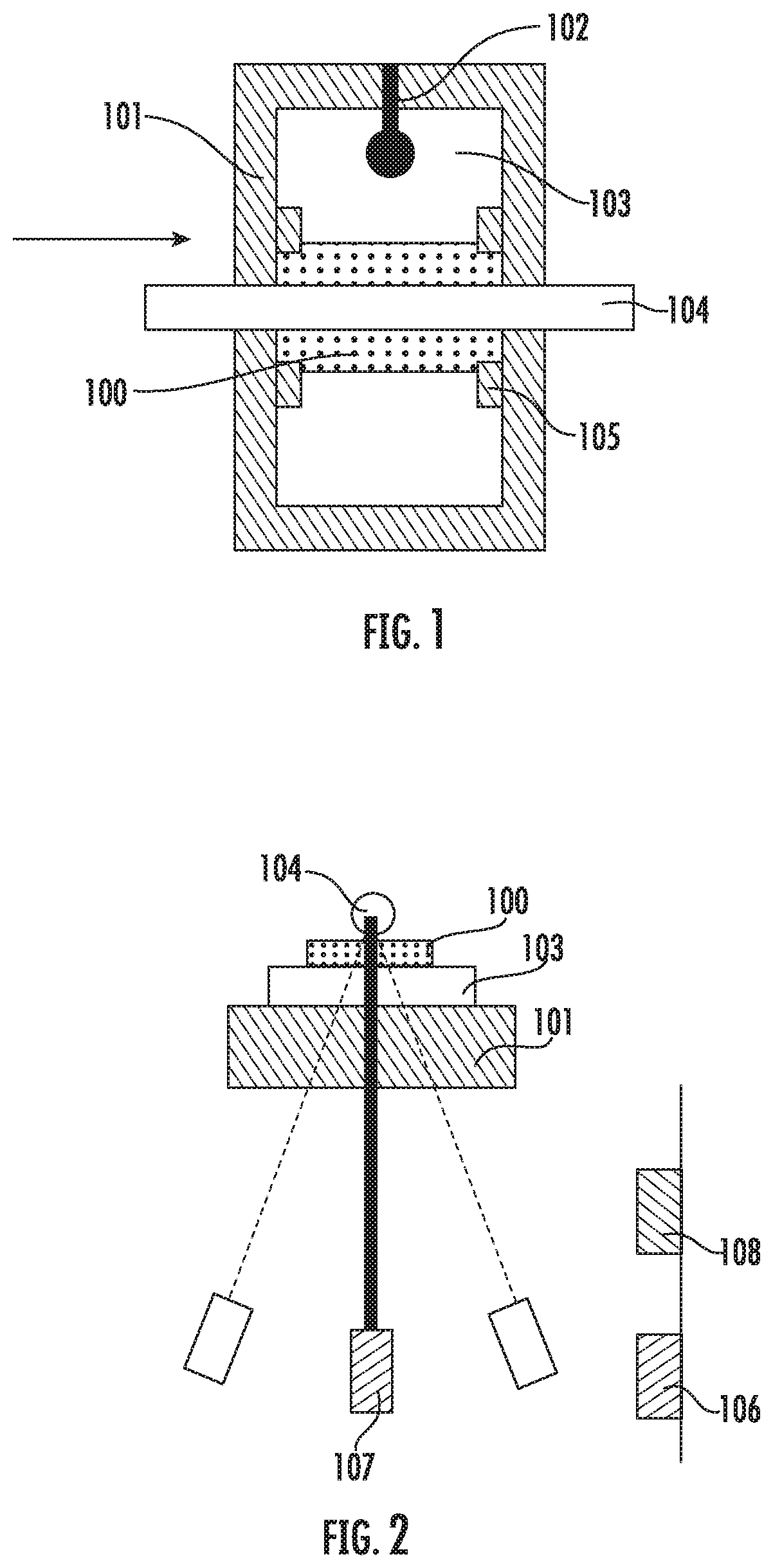

Switchable permanent magnetic device

InactiveUS7012495B2Improve propertiesMaximized strengthElectromagnets without armaturesPermanent magnetsPole pieceFerromagnetism

A switchable magnetic device includes a first magnet and a second magnet, both of which are essentially cylindrical. Magnets are housed in a housing made from pole pieces. Pole pieces are ferromagnetic. Lower magnet is fixedly mounted in the housing while upper magnet can rotate within the housing. Upper magnet is formed with notches or grooves along its vertical side walls. These notches or grooves receive downwardly depending arms of bar. Bar is received inside a groove formed on boss. Boss is connected to a short bar that, in turn, is fixedly connected to a handle or lever. By this means, rotation of handle or lever causes rotation of second magnet. When the upper magnet is positioned such that its north pole substantially overlies the south pole of lower magnet and the south pole of upper magnet substantially overlies the north pole of lower magnet, the first and second magnets act as an internal active magnetic shunt and as a result the external magnetic field strength from the device is quite low. Rotating the upper magnet 180° about its axis of rotation brings the magnets into alignment such that the respective north and south poles of the upper magnet substantially overlie respective north and south poles of lower magnet. In this alignment, the external magnet field from the device is quite strong and the device can be affixed to surfaces or objects.

Owner:MAGSWITCH TECH

Method and system for providing a spin transfer device with improved switching characteristics

A method and system for providing a magnetic element is described. The magnetic element includes a first pinned layer, a first spacer layer, a free layer, a second spacer layer, and a second pinned layer. The first and second pinned layers have first and magnetizations oriented in first and second directions, respectively. The first and second spacer layers are nonferromagnetic. The first and second spacer layers are between the free layer and the first and second pinned layers, respectively. The magnetic element is configured either to allow the free layer to be switched to each of multiple states when both a unidirectional write current is passed through the magnetic element and the magnetic element is subjected to a magnetic field corresponding to the each states or to allow the free layer to be switched to each of the plurality of states utilizing a write current and an additional magnetic field that is applied from at least one of the first pinned layer and the second pinned layer substantially only if the write current is also applied.

Owner:SAMSUNG SEMICON

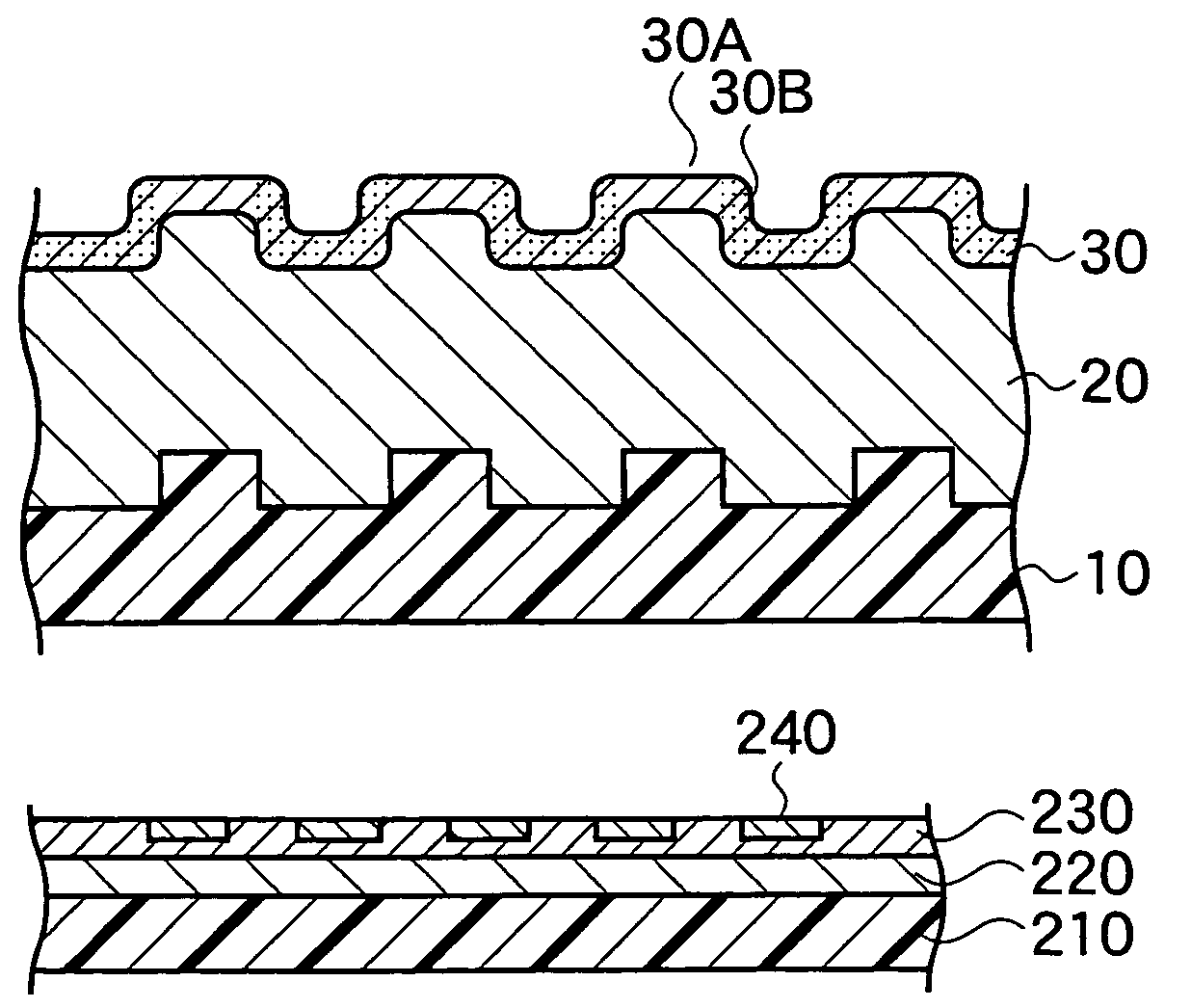

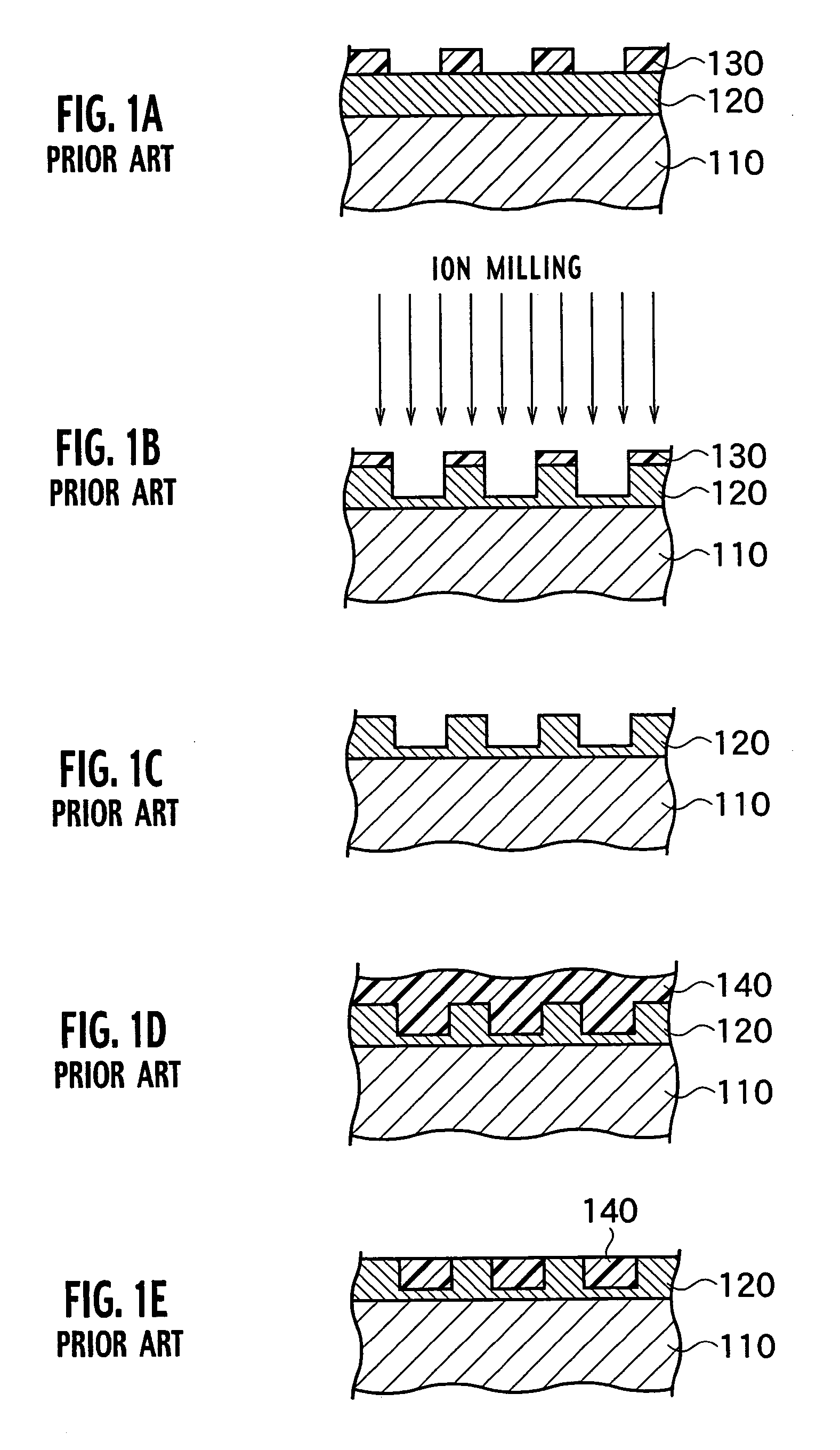

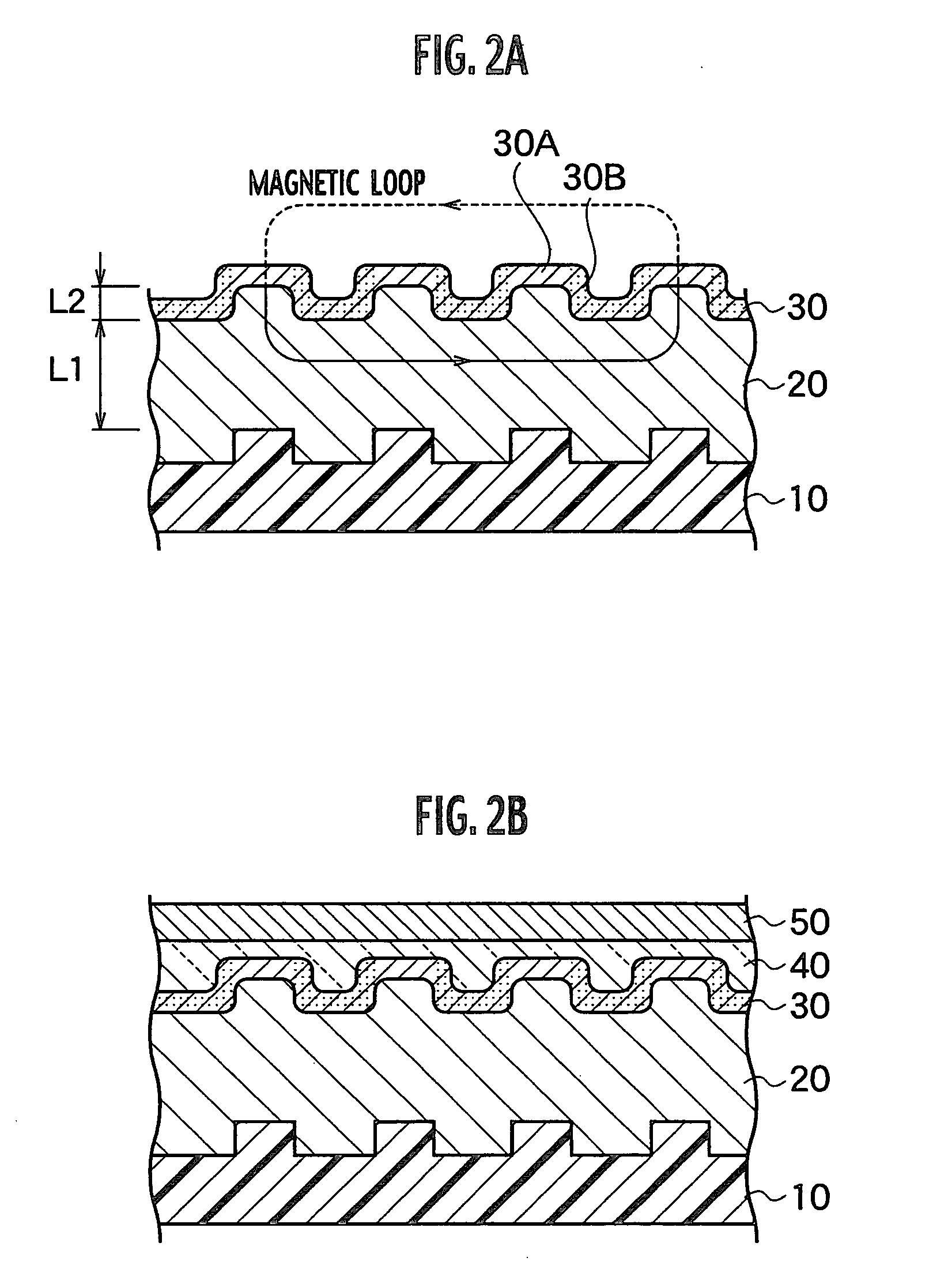

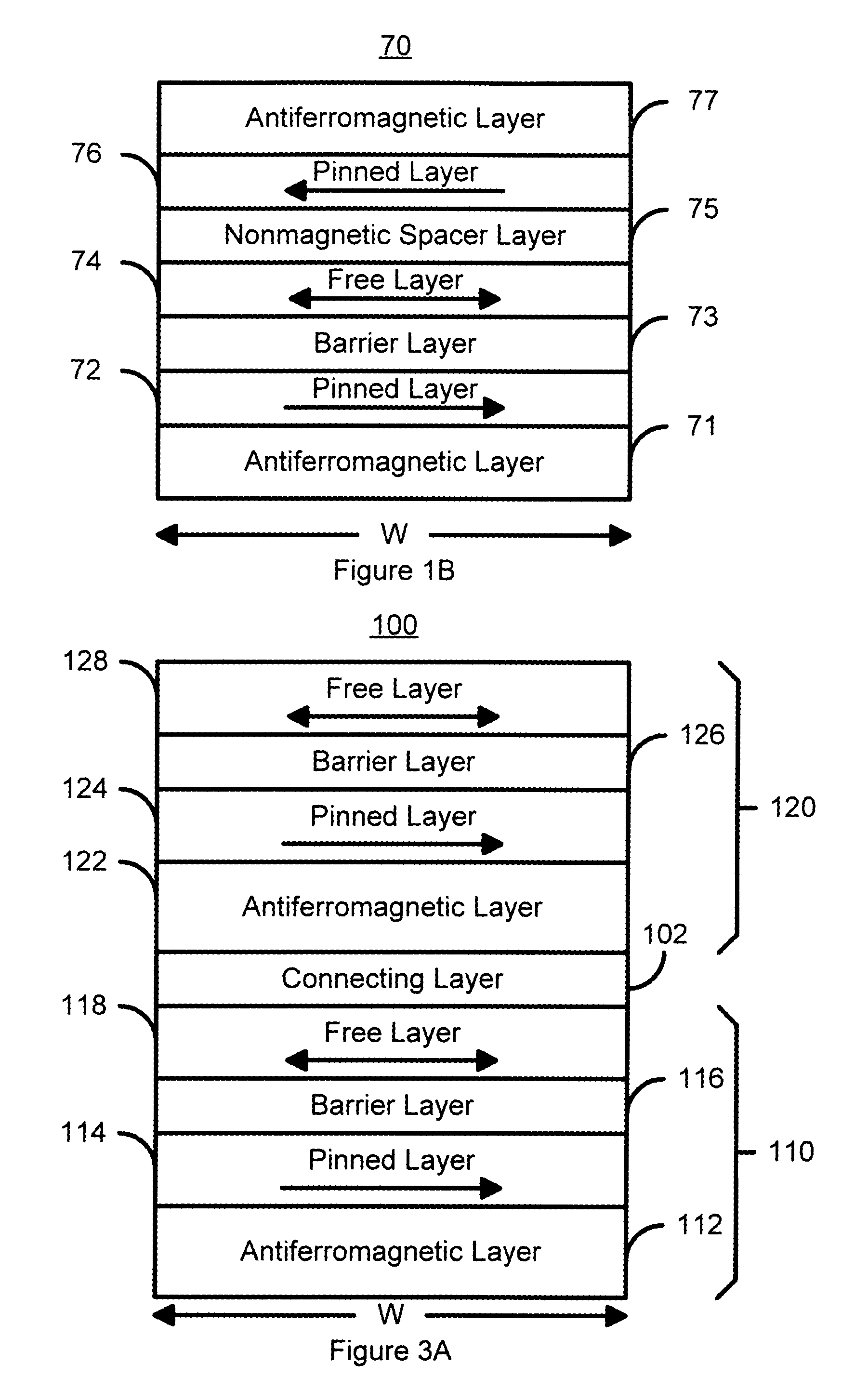

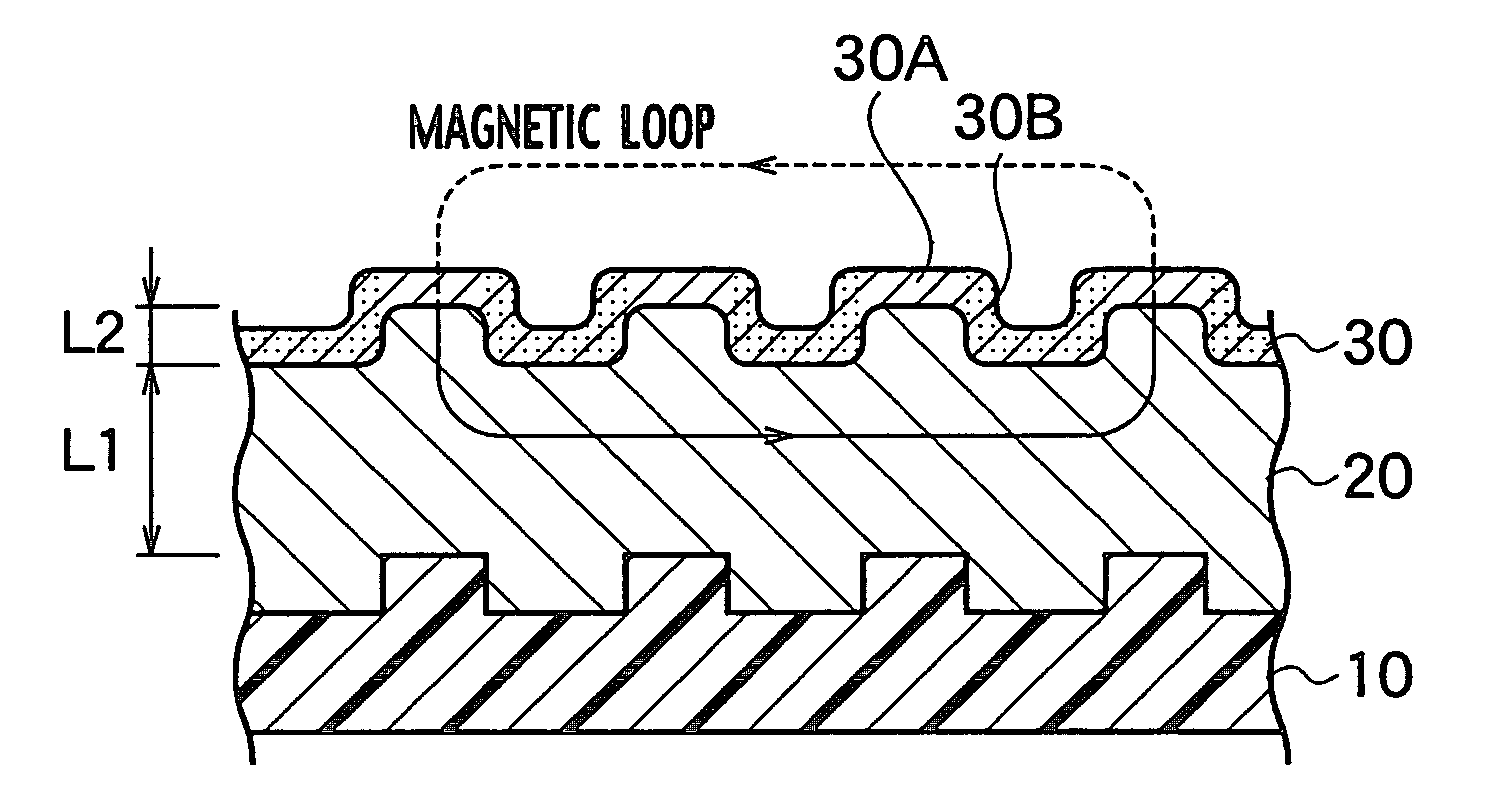

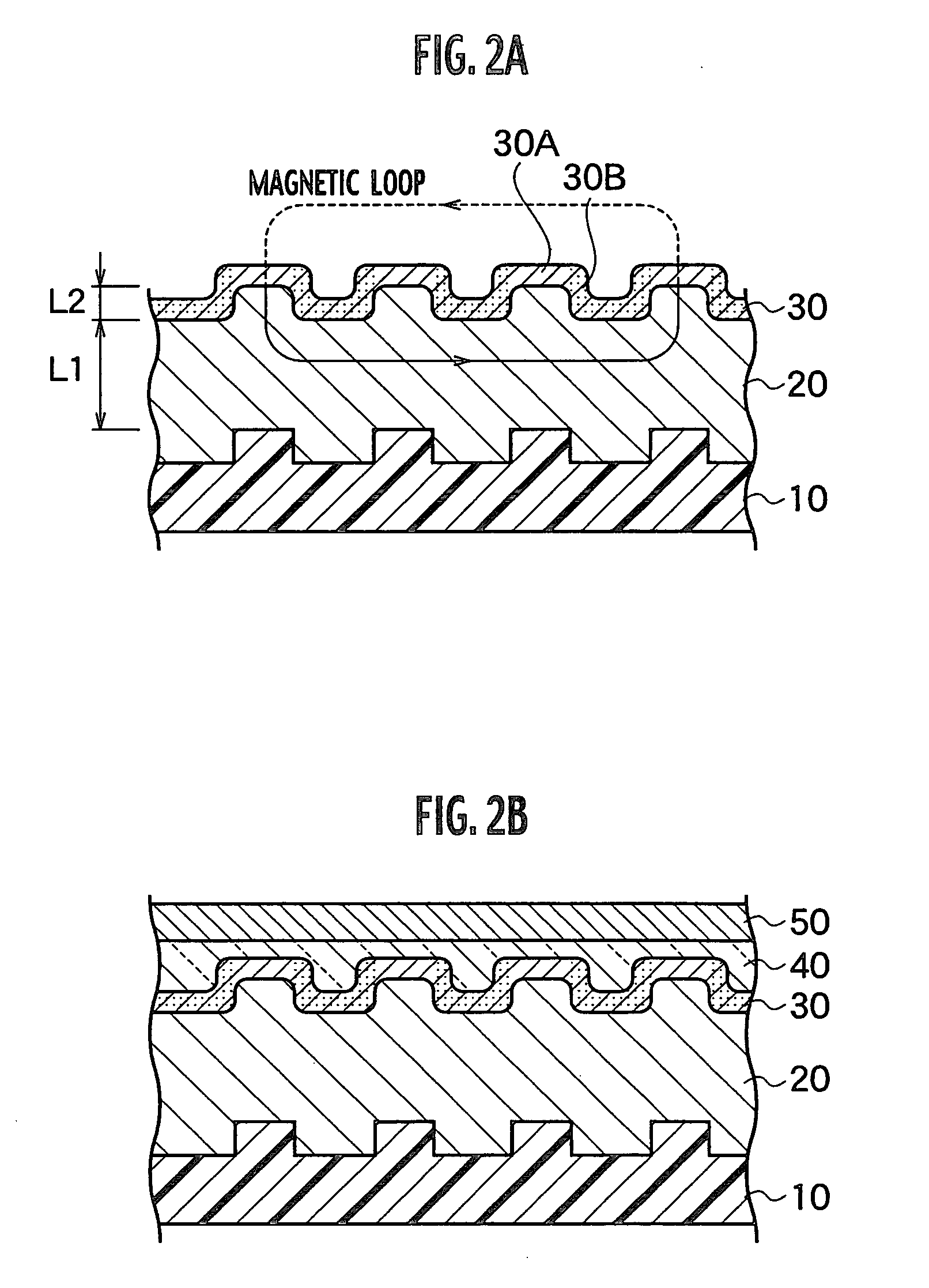

Magnetic recording medium having a patterned soft magnetic layer

InactiveUS7067207B2Reduce noiseMagnetic materials for record carriersBase layers for recording layersNon magneticFerromagnetism

A magnetic recording medium includes a non-magnetic substrate; a soft magnetic layer which is formed on the non-magnetic substrate and which includes projected parts arranged on the surface thereof and recessed parts surrounding each of the projected part; and a ferromagnetic layer which is formed on the soft magnetic layer and which includes projected parts and recessed parts reflecting the projected parts and the recessed parts of the soft magnetic layer. Further the magnetic recording medium includes recording areas which have perpendicular magnetic anisotropy and ferromagnetism, and which are formed of the projected parts of the ferromagnetic layer and separated magnetically from their surroundings. A method for manufacture of the magnetic recording medium includes forming a soft magnetic layer including of projected parts arranged regularly on the surface thereof and recessed parts surrounding each projected part; and forming a ferromagnetic layer having perpendicular magnetic anisotropy on the soft magnetic layer.

Owner:KK TOSHIBA

Magnetic memory element utilizing spin transfer switching and storing multiple bits

ActiveUS20050045913A1Reduce stack heightNanomagnetismMagnetic-field-controlled resistorsMagnetic memorySpin transfer

A method and system for providing a magnetic element capable of storing multiple bits is disclosed. The method and system include providing first pinned layer, a first nonmagnetic layer, a first free layer, a connecting layer, a second pinned layer, a second nonmagetic layer and a second free layer. The first pinned layer is ferromagnetic and has a first pinned layer magnetization pinned in a first direction. The first nonmagnetic layer resides between the first pinned layer and the first free layer. The first free layer being ferromagnetic and has a first free layer magnetization. The second pinned layer is ferromagnetic and has a second pinned layer magnetization pinned in a second direction. The connecting layer resides between the second pinned layer and the first free layer. The second nonmagnetic layer resides between the second pinned layer and the second free layer. The second free layer being ferromagnetic and having a second free layer magnetization. The magnetic element is configured to allow the first free layer magnetization and the second free layer magnetization to change direction due to spin transfer when a write current is passed through the magnetic element.

Owner:SAMSUNG SEMICON

Magnetic recording medium and method for manufacture thereof

InactiveUS20040091748A1Magnetic materials for record carriersBase layers for recording layersEngineeringNon magnetic

A magnetic recording medium includes a non-magnetic substrate; a soft magnetic layer which is formed on the non-magnetic substrate and which includes projected parts arranged on the surface thereof and recessed parts surrounding each of the projected part; and a ferromagnetic layer which is formed on the soft magnetic layer and which includes projected parts and recessed parts reflecting the projected parts and the recessed parts of the soft magnetic layer. Further the magnetic recording medium includes recording areas which have perpendicular magnetic anisotropy and ferromagnetism, and which are formed of the projected parts of the ferromagnetic layer and separated magnetically from their surroundings. A method for manufacture of the magnetic recording medium includes forming a soft magnetic layer including of projected parts arranged regularly on the surface thereof and recessed parts surrounding each projected part; and forming a ferromagnetic layer having perpendicular magnetic anisotropy on the soft magnetic layer.

Owner:KK TOSHIBA

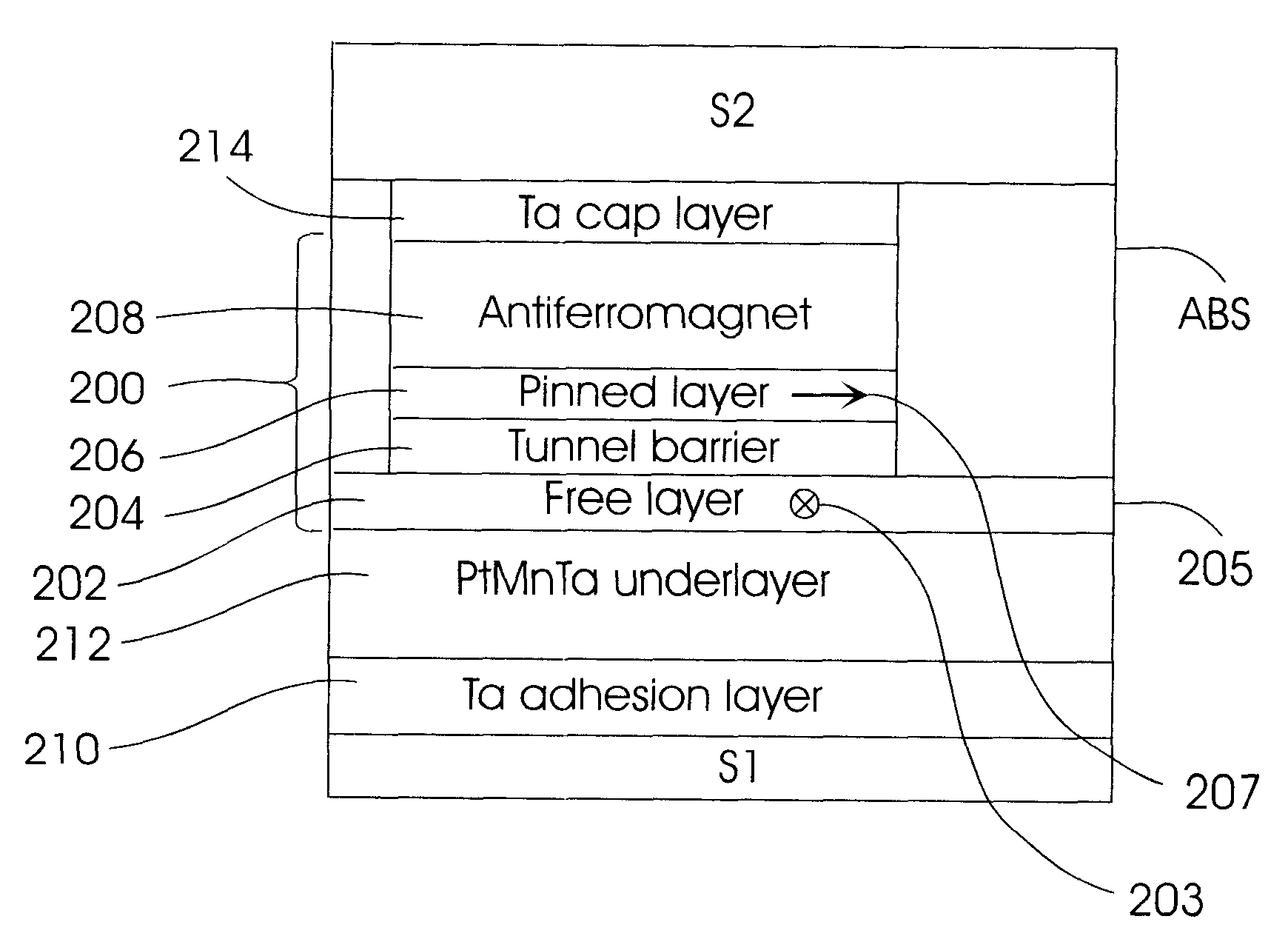

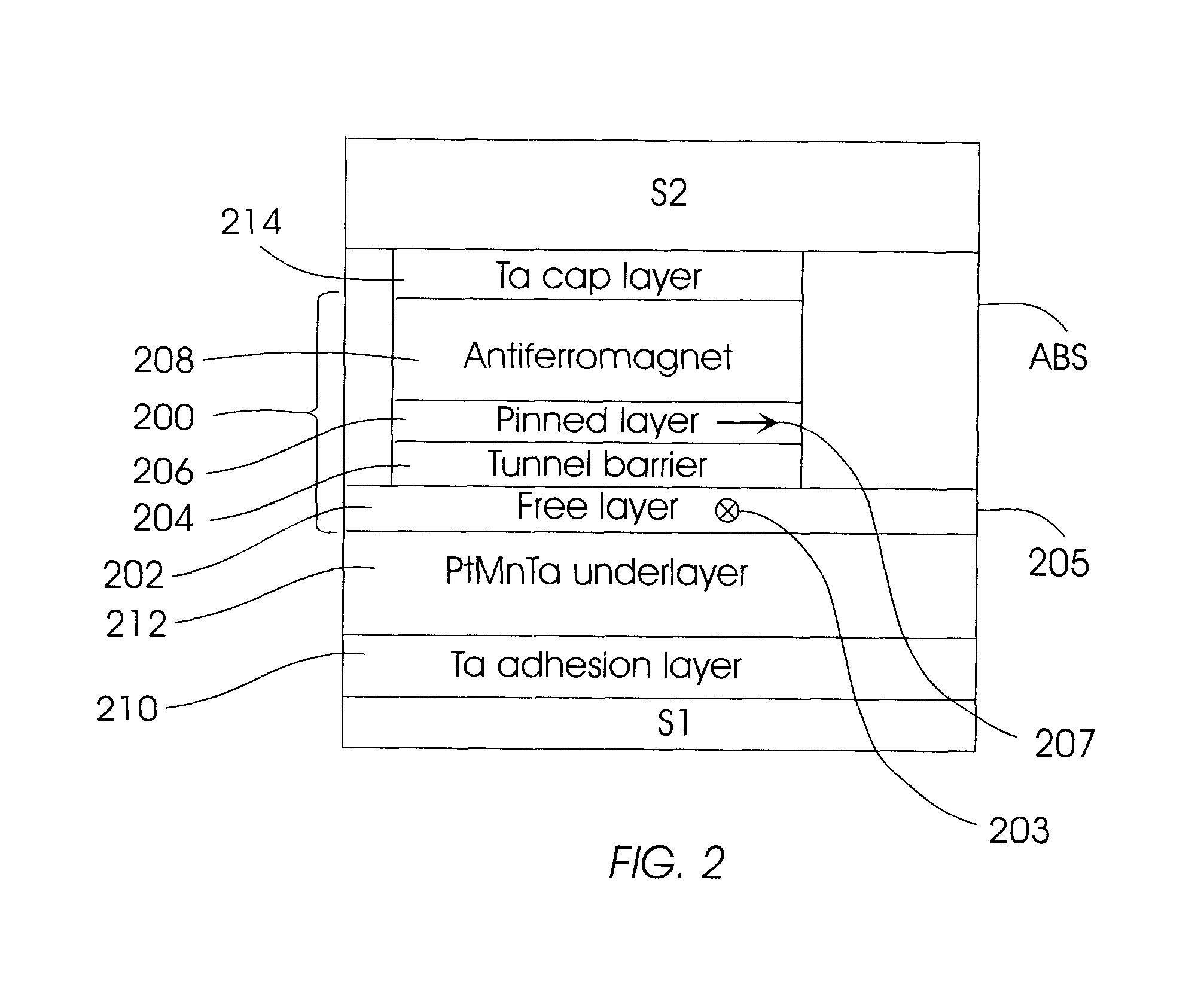

Magnetic tunnel junction device with bottom free layer and improved underlayer

A magnetic tunnel junction (MTJ) device usable as a magnetic memory cell or magnetoresistive sensor, such as a MTJ read head for magnetic recording, has the free ferromagnetic layer located on the bottom of the device, the bottom free layer being formed on a special underlayer. The MTJ read head may be a flux-guided head that uses the free layer as a flux guide for directing magnetic flux from the magnetic media to the sensing region of the MTJ. The special underlayer for the growth of the free layer is an alloy comprising Mn, one of Pt, Ni, Ir and Os, and an additive X selected from Ta, Al, Ti, Cu, Cr and V. Without the additive, the underlayer alloy is antiferromagnetic. The additive is present in an amount sufficient to render the alloy to have no magnetic ordering, i.e., it is neither antiferromagnetic nor ferromagnetic, but without substantially affecting the preferred crystalline texture and unit cell size so that the underlayer is well-suited as a growth-enhancing underlayer for the free layer.

Owner:WESTERN DIGITAL TECH INC

Magnetic elements having a bias field and magnetic memory devices using the magnetic elements

ActiveUS20070002504A1Improve switching characteristicsLower average currentRecord information storageManufacture of flux-sensitive headsMagnetizationMagnetic memory

A method and system for providing a magnetic element are disclosed. The method and system include providing a magnetic biasing structure having a first pinned layer, a second pinned layer, a spacer layer, and a free layer. The first pinned layer has a first magnetization pinned in a first direction. The second pinned layer has a second magnetization in a second direction that is substantially perpendicular or along the first direction. The spacer layer is nonferromagnetic, resides between the second pinned layer and the free layer, and is configured such that the free layer is substantially free of exchange coupling with the second pinned layer. The free layer has a shape anisotropy with a longitudinal direction substantially in the second direction. The magnetic biasing structure provides a bias field for the free layer along the hard or easy axis. In one aspect, the second pinned layer resides between the first pinned layer and the free layer.

Owner:SAMSUNG SEMICON

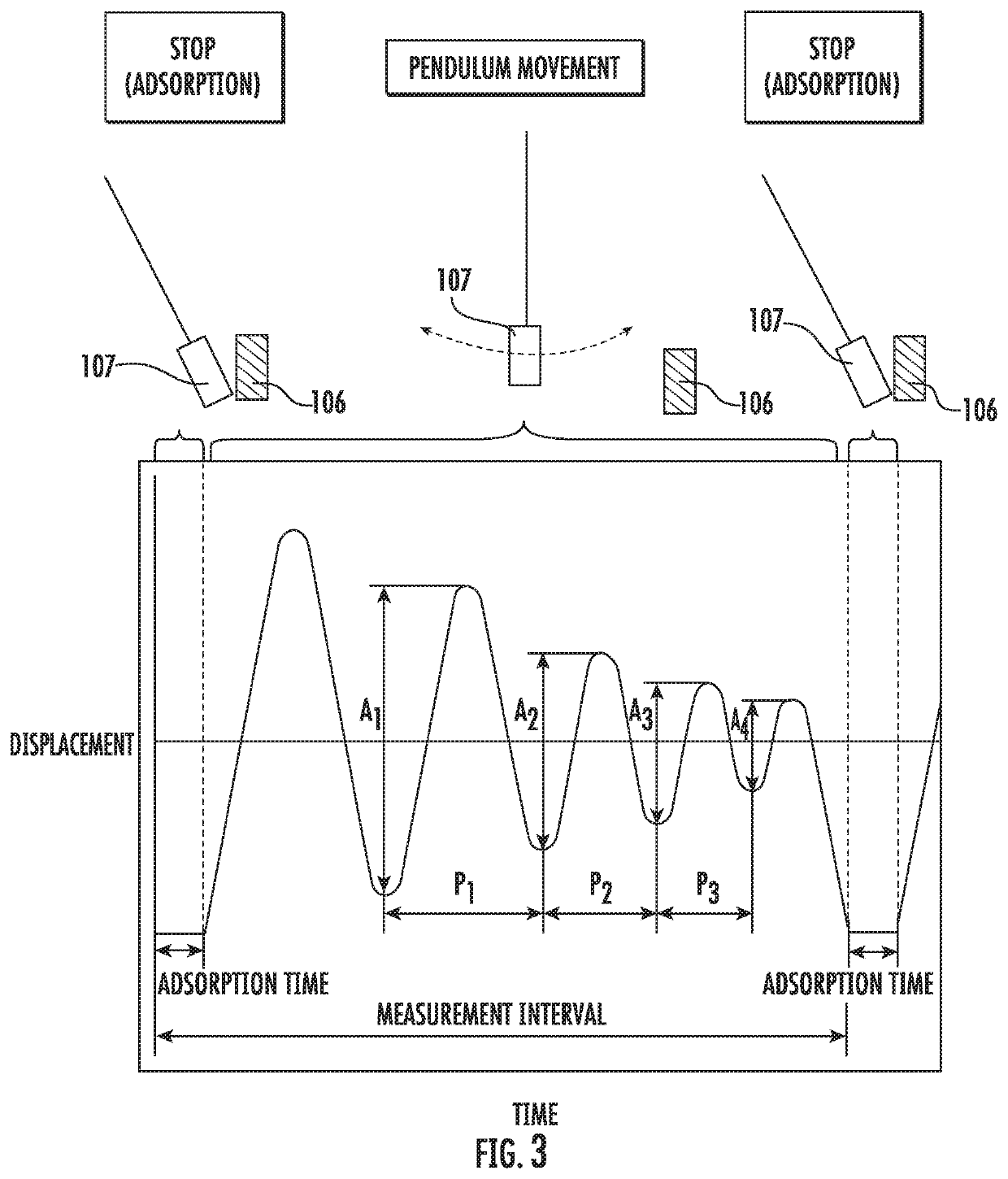

Magnetic tape device and reproducing method employing TMR reproducing head and tape with characterized XRD intensity ratio

ActiveUS10546602B2Improve smoothnessImprove surface smoothnessMagnetic materials for record carriersBase layers for recording layersMagnetic tapeFerrite powder

The magnetic tape device includes a Tunneling Magnetoresistive (TMR) head as a reproducing head; and a magnetic tape which includes a non-magnetic support, and a magnetic layer including ferromagnetic hexagonal ferrite powder and a binding agent on the non-magnetic support, an XRD intensity ratio (Int(110) / Int(114)) of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical direction squareness ratio of the magnetic tape is 0.65 to 1.00, a center line average surface roughness Ra measured regarding a surface of the magnetic layer is equal to or smaller than 2.0 nm, and a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding the surface of the magnetic layer is equal to or smaller than 0.050.

Owner:FUJIFILM CORP

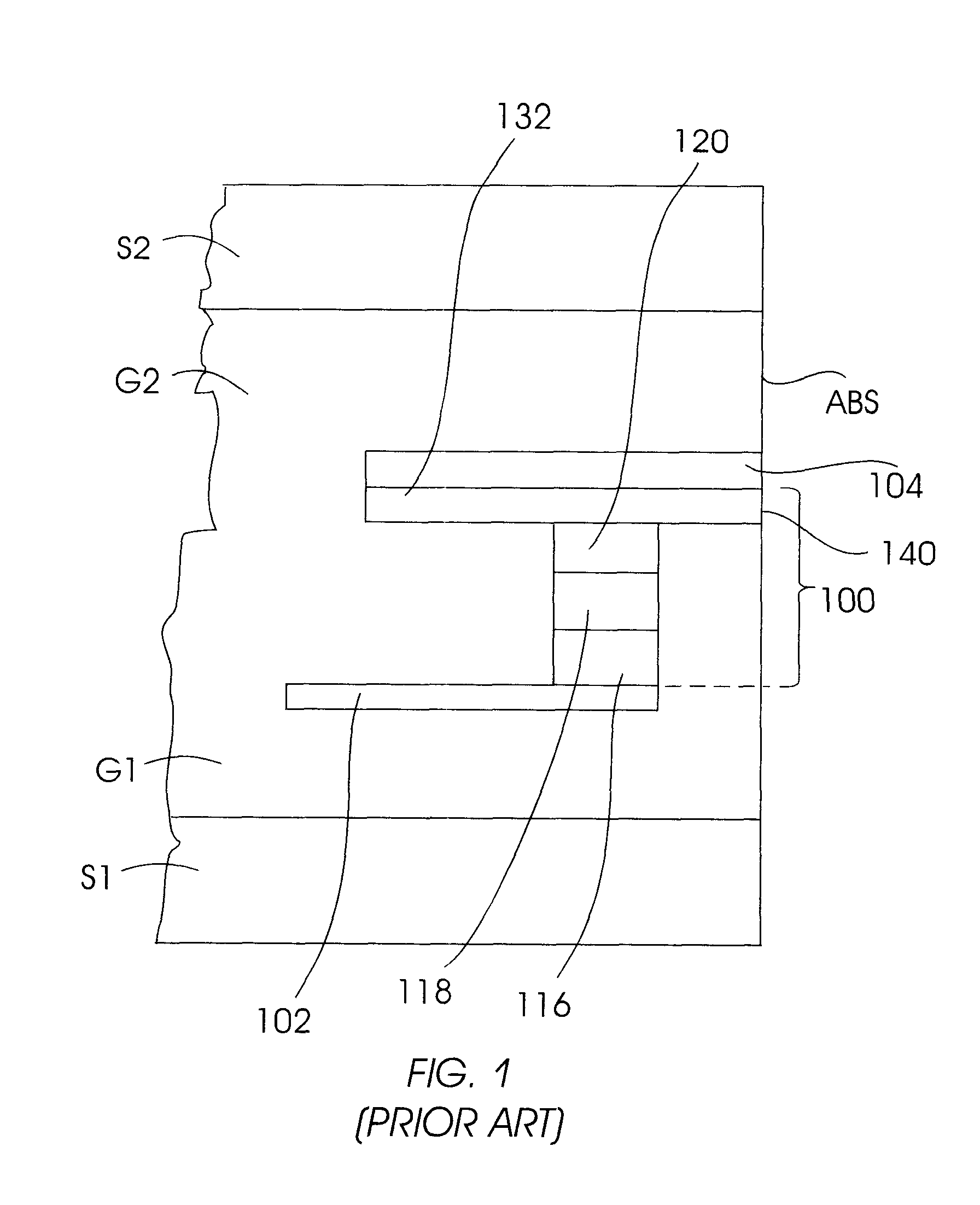

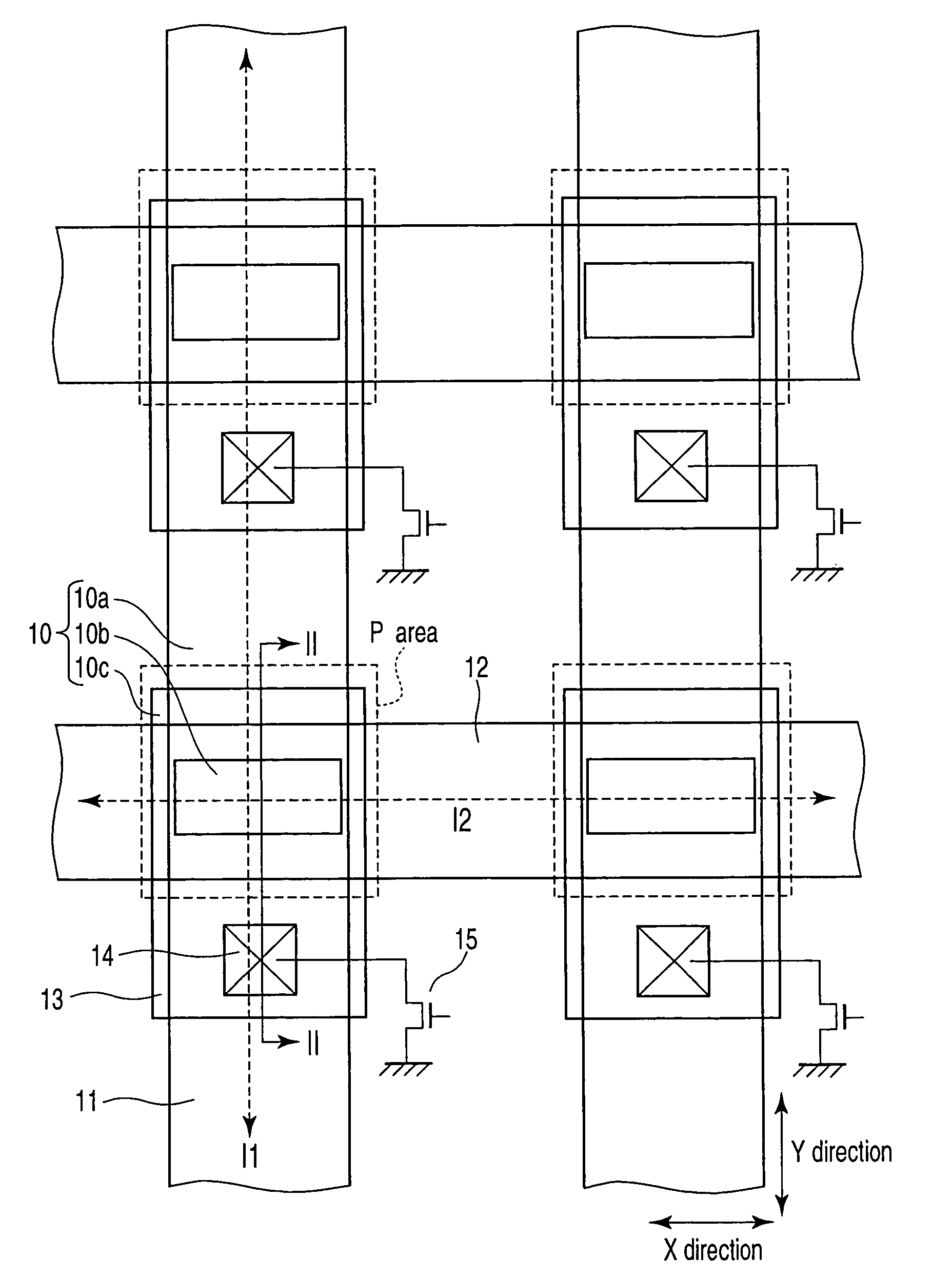

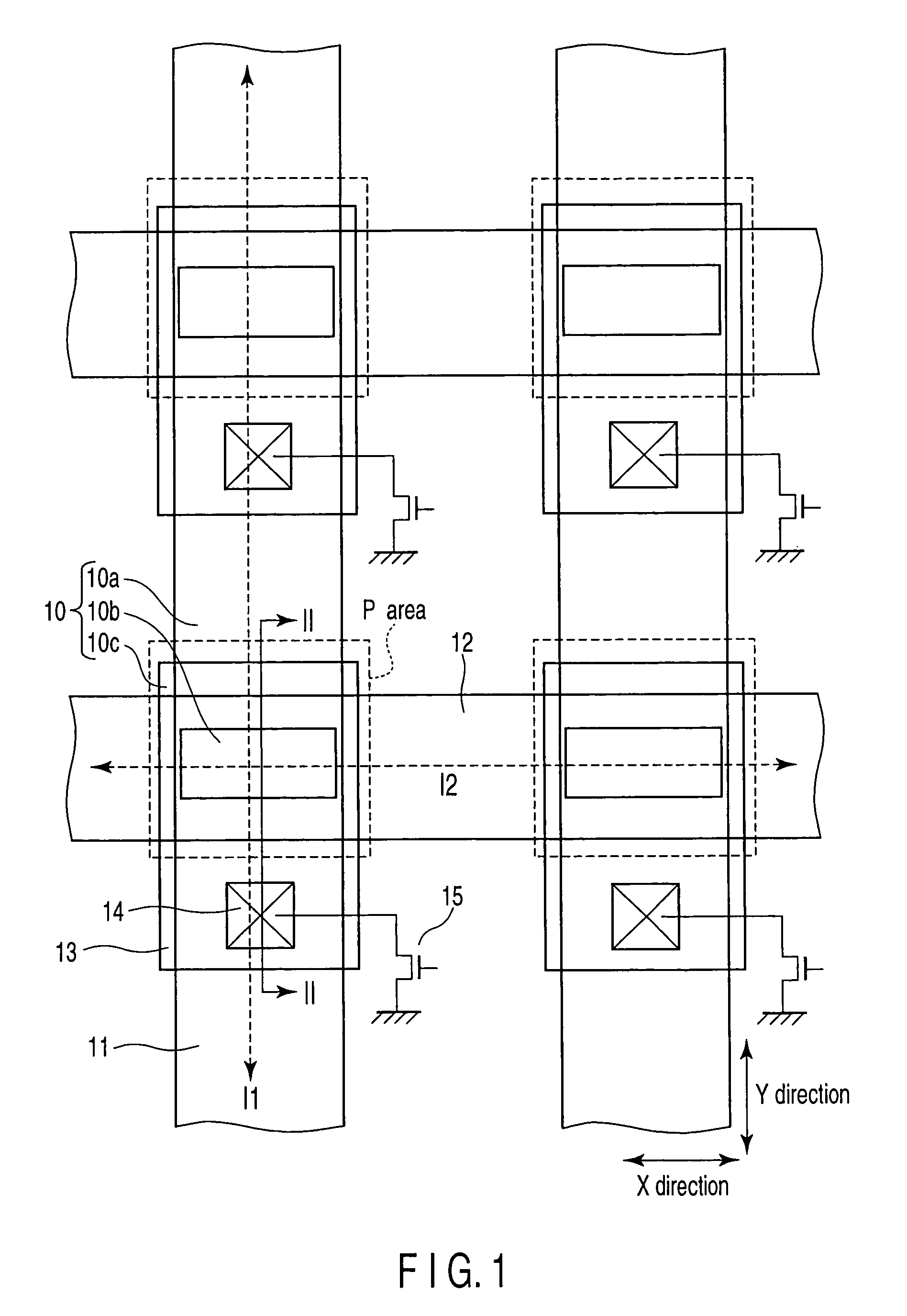

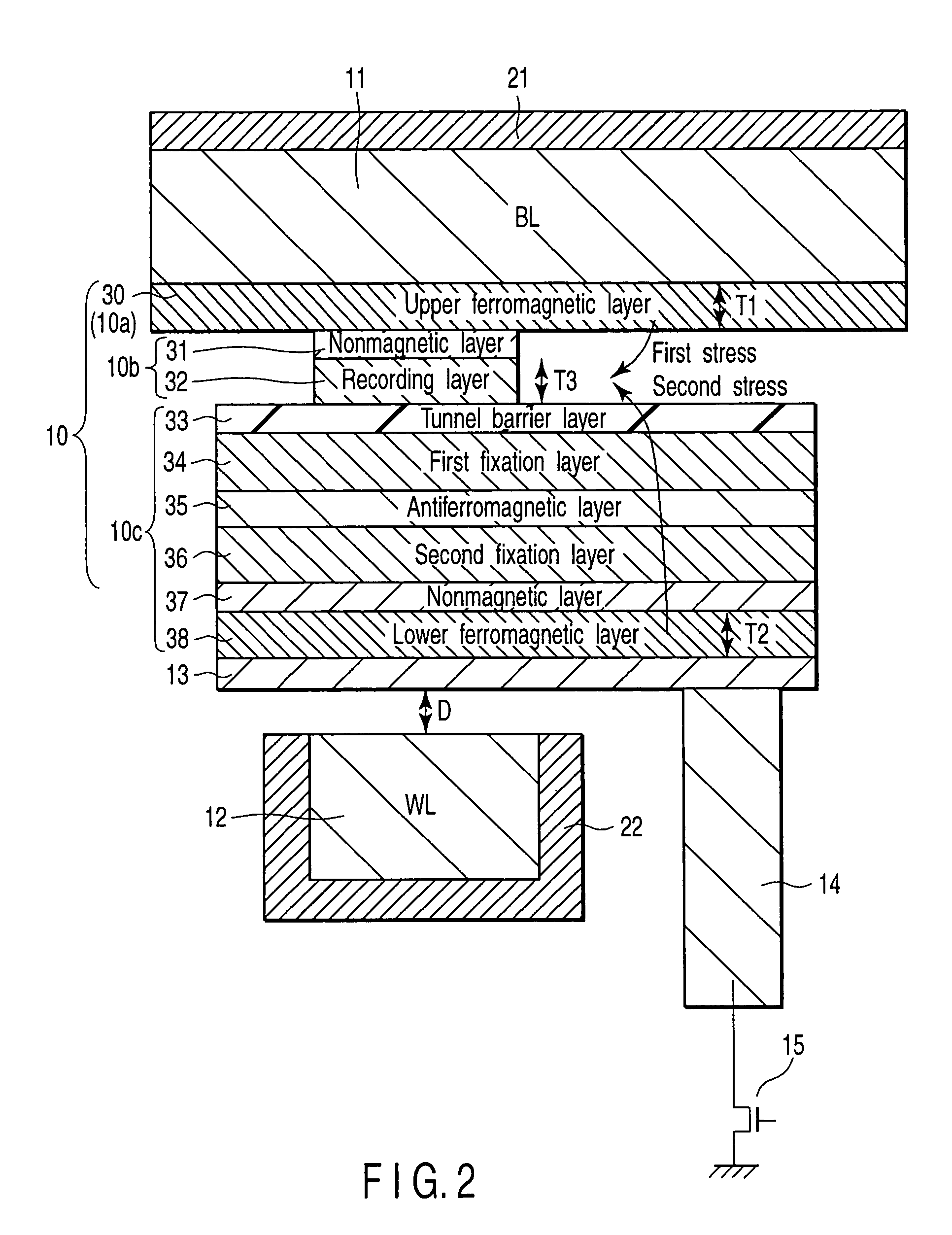

Magnetic random access memory and method of writing data in magnetic random access memory

InactiveUS6970376B1NanomagnetismSemiconductor/solid-state device detailsStatic random-access memoryRandom access memory

A magnetic random access memory includes first and second write wirings extended in first and second directions, a magneto-resistance element located between the first and second write wirings, a first yoke layer provided on a first outer surface and both sides of the first write wiring and being formed of a magnetic layer, and a second yoke layer provided on a second outer surface and both sides of the second write wiring and being formed of a magnetic layer, wherein the magneto-resistance element has a recording layer formed of a ferromagnetic substance and comprising a first surface and a second surface, a first ferromagnetic layer provided on the first surface, a second ferromagnetic layer provided on the second surface, a first nonmagnetic layer provided between the recording layer and the first ferromagnetic layer, and a second nonmagnetic layer provided between the recording layer and the second ferromagnetic layer.

Owner:KK TOSHIBA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com