Patents

Literature

138results about How to "Reduce stack height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

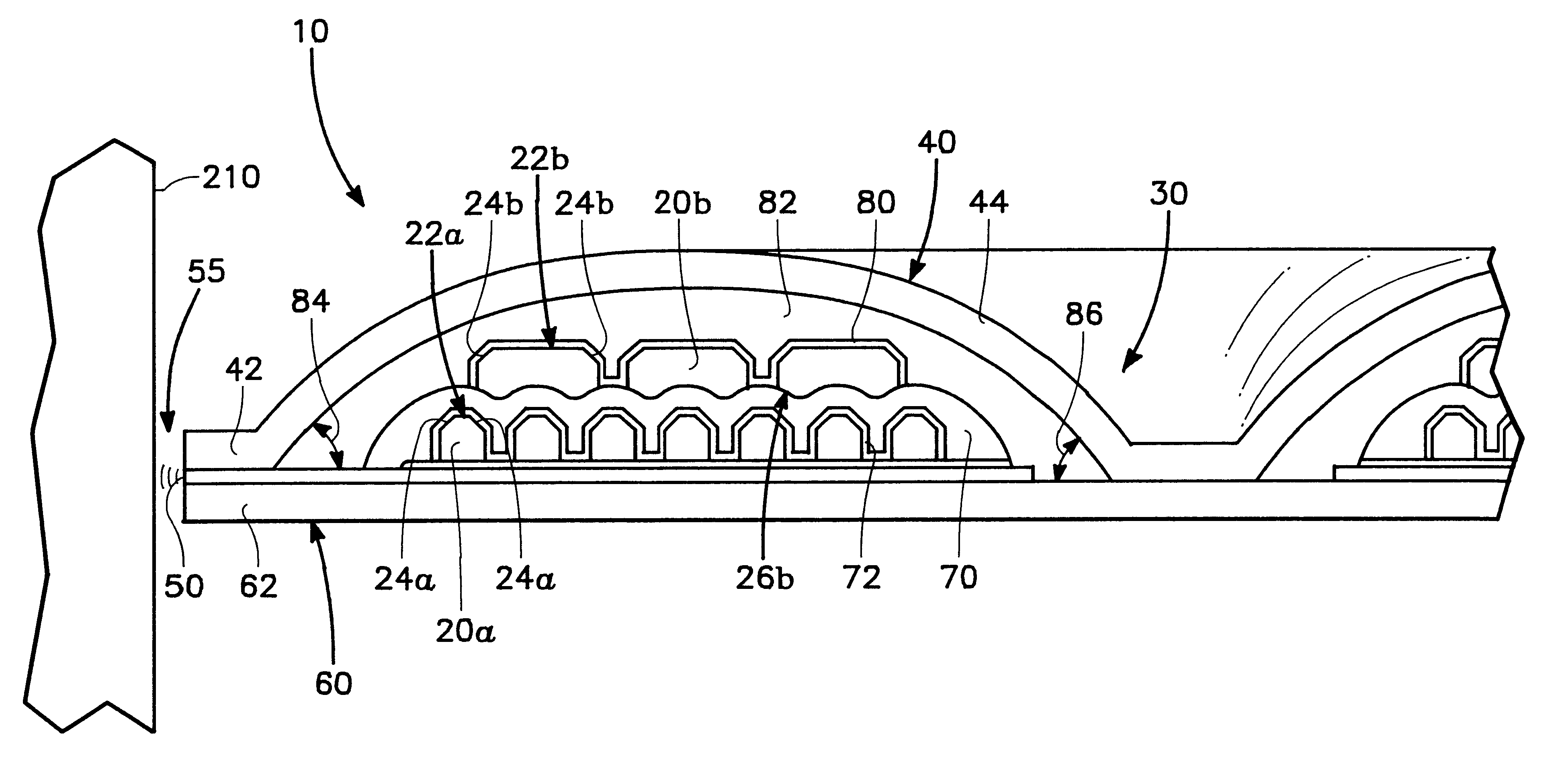

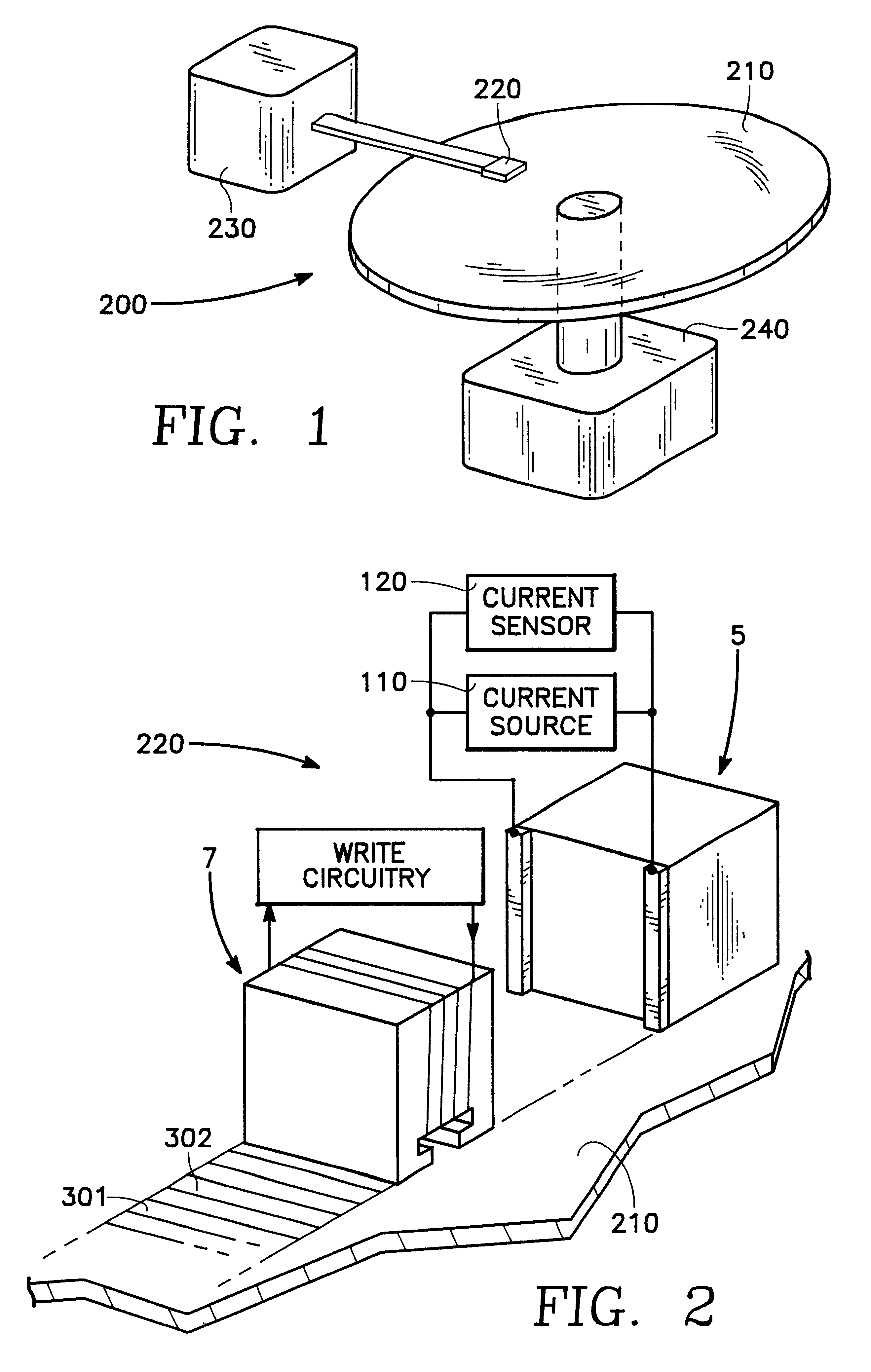

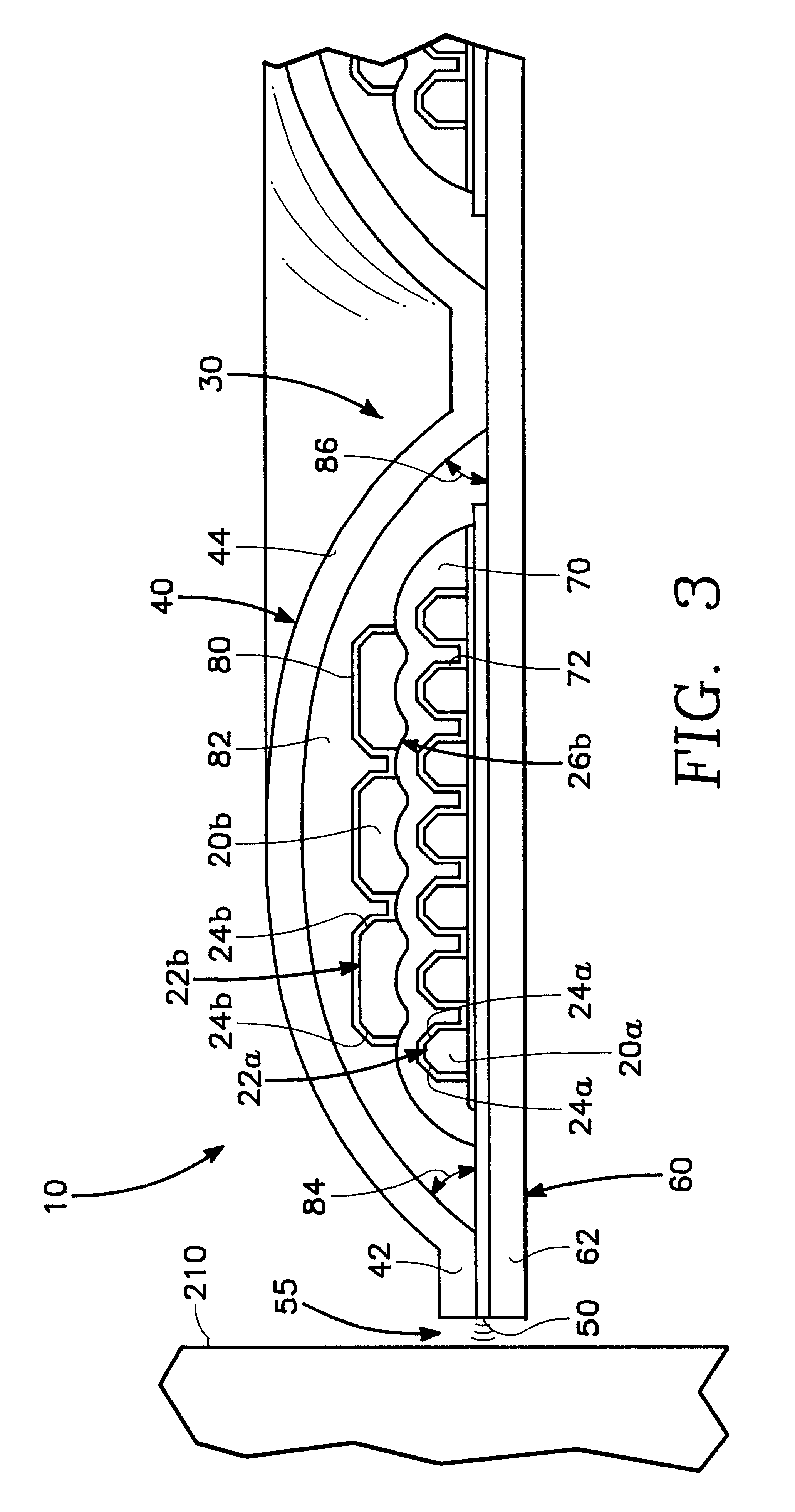

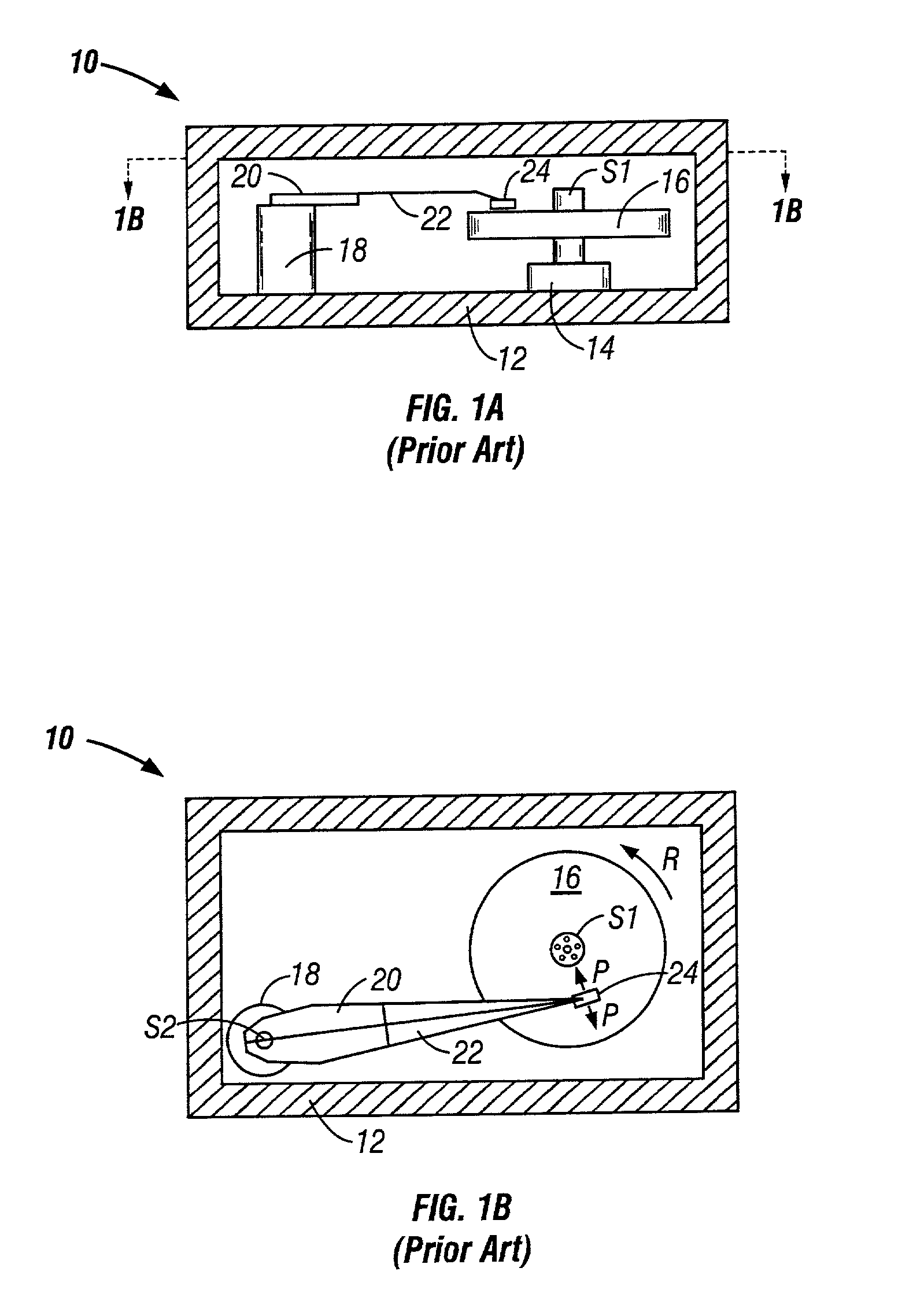

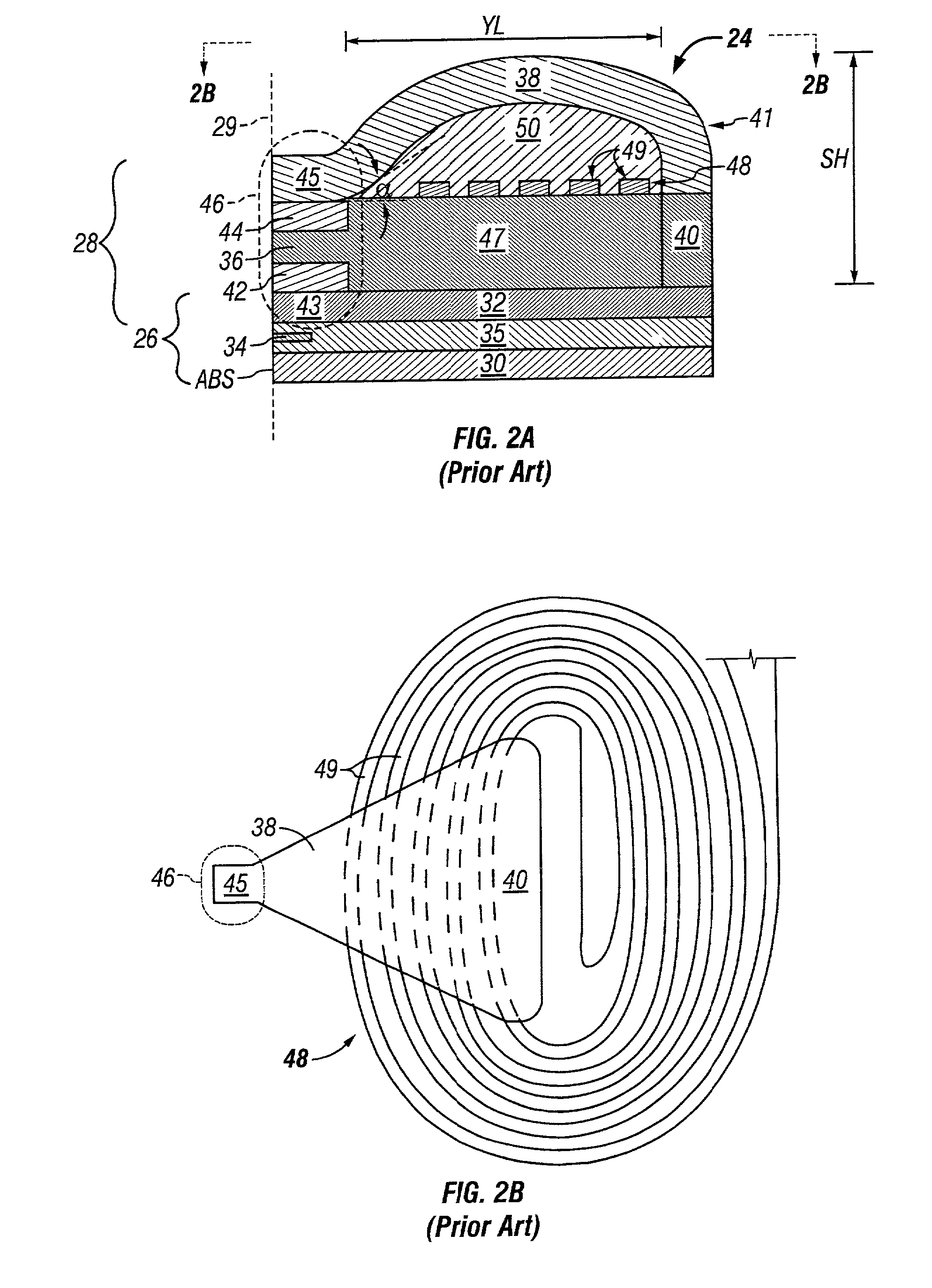

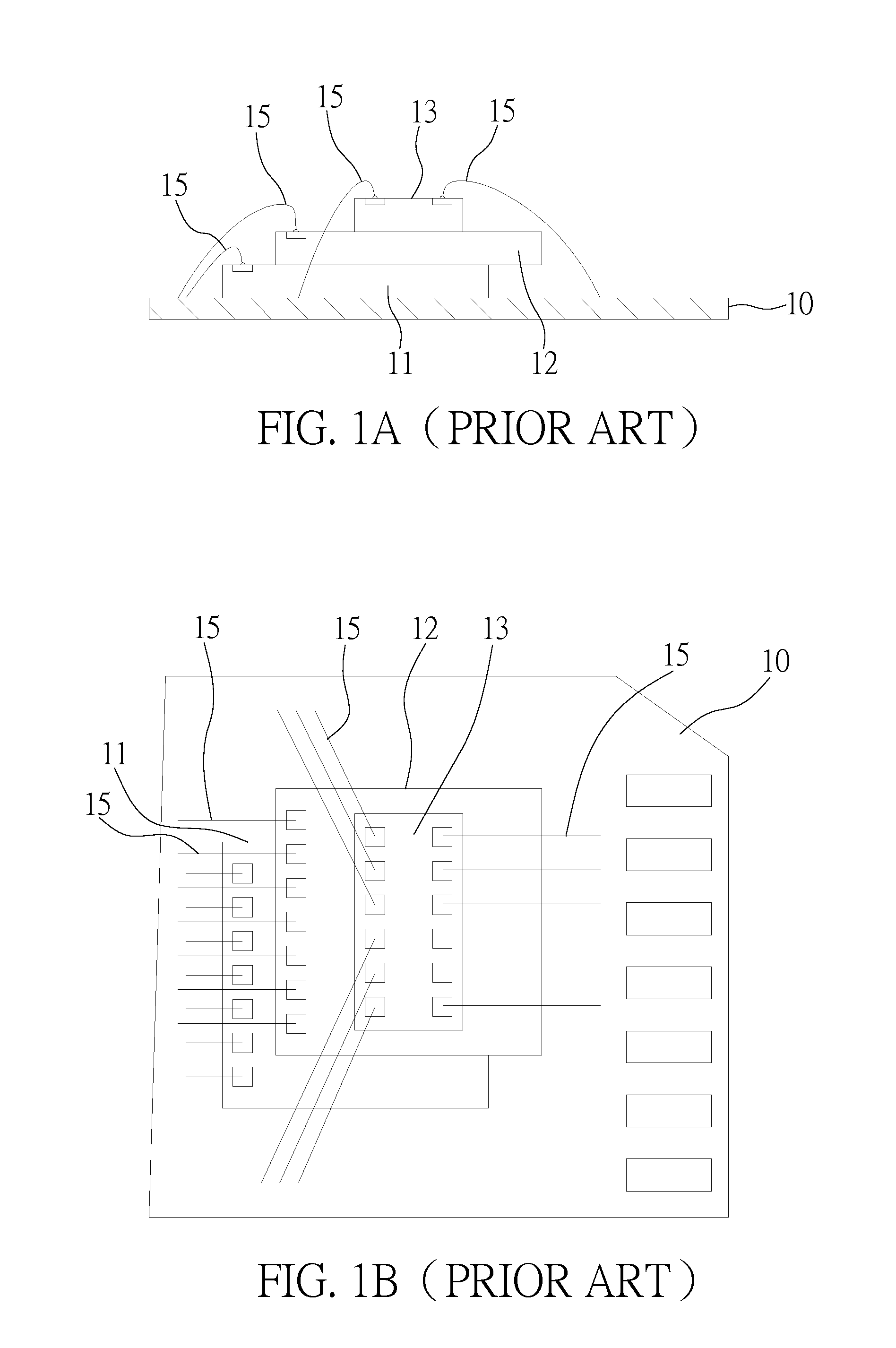

Low resistance coil structure for high speed writer

InactiveUS6333830B2Lower coil resistanceReduce dissipationConstruction of head windingsHeads using thin filmsElectrical conductorLower pole

The present invention provides a thin film write head having an upper and lower pole structures and conductor turns forming a winding for generating magnetic flux. The conductor is formed with a non-planar top surface. The winding of the present invention may be formed of lower and upper turns. The upper turns may be formed with a non-planar top surface, a non-planar bottom surface, or both. It is preferred that the bottom surface of the upper conductor turns be coherent with the non-planar top surface of the lower conductor turns. The non-planar top surface may be formed by removing corners formed during deposition between a generally planar top surface and abutting side walls. The corners may be removed by ion milling to form the non-planar top surface. The conductor may be copper with the non-planar top surface having sloping facets. The thin film write head of the present invention may be utilized to provide an improved data storage and retrieval apparatus. The preferred embodiment provides reduced coil resistance thereby reducing Johnson Thermal Noise and power dissipation. It also allows for reduced yoke length and reduced stack height while providing low apex angles to expand and improve yoke material deposition thereby improving head response and operational frequency.

Owner:WESTERN DIGITAL TECH INC

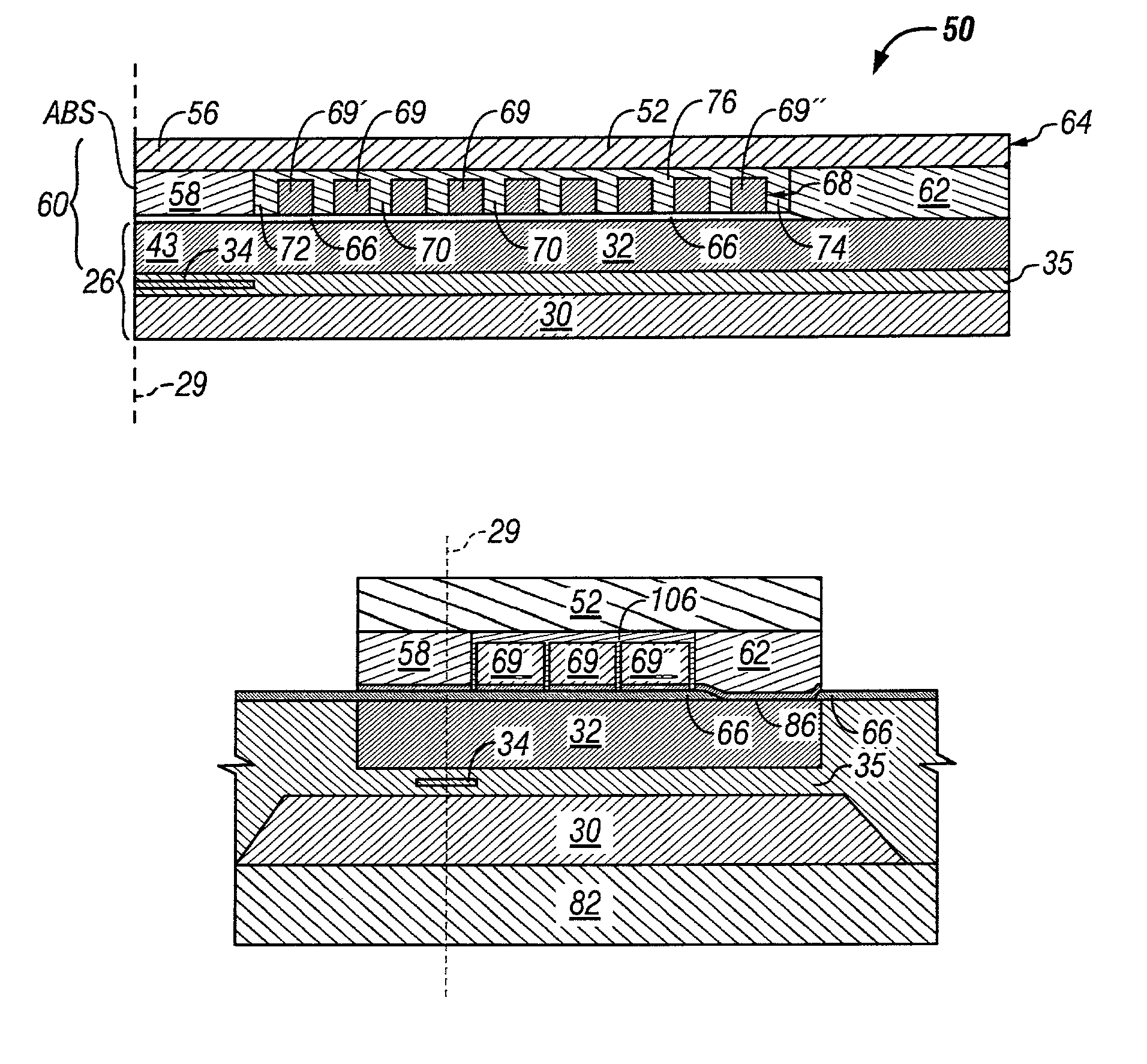

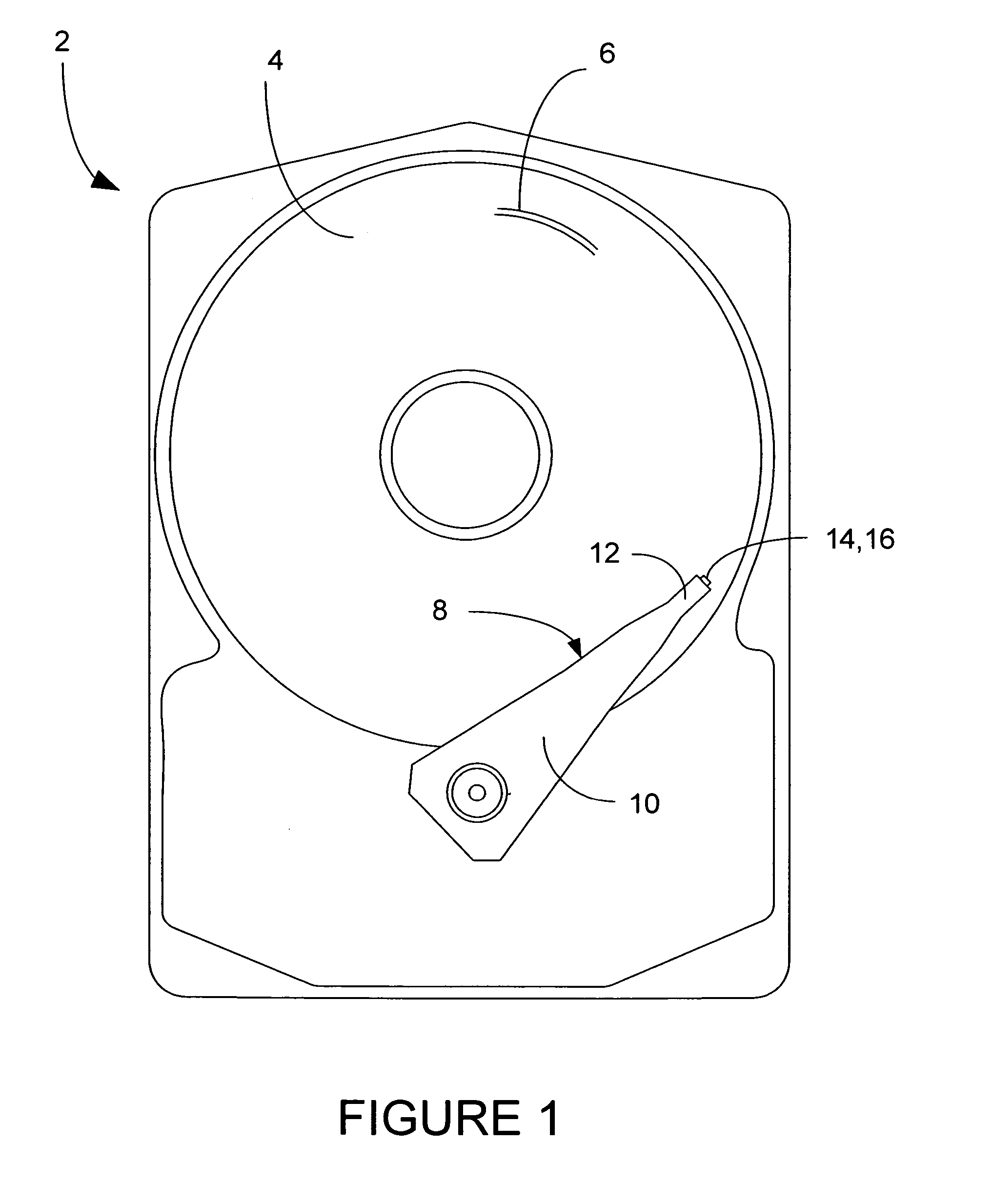

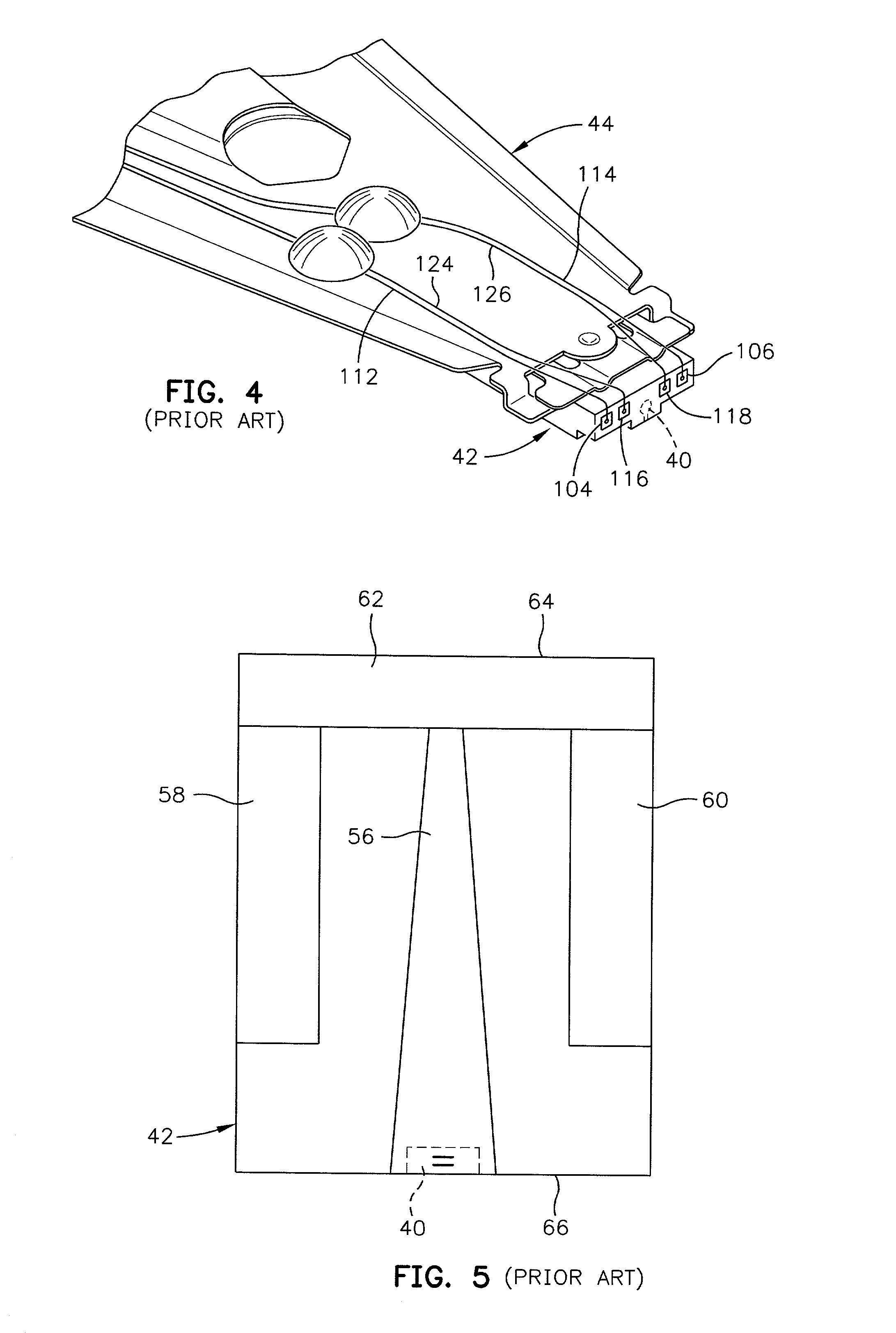

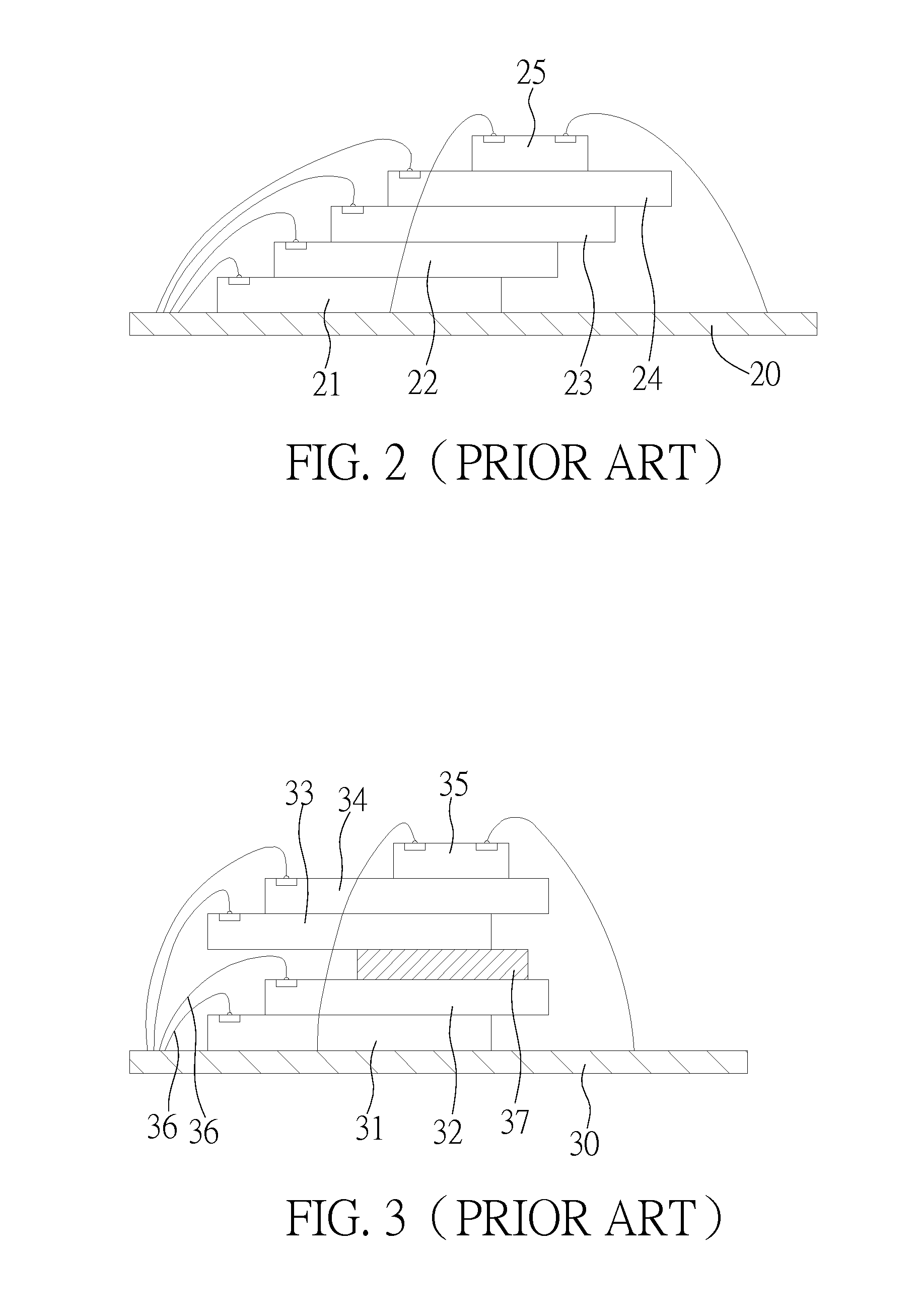

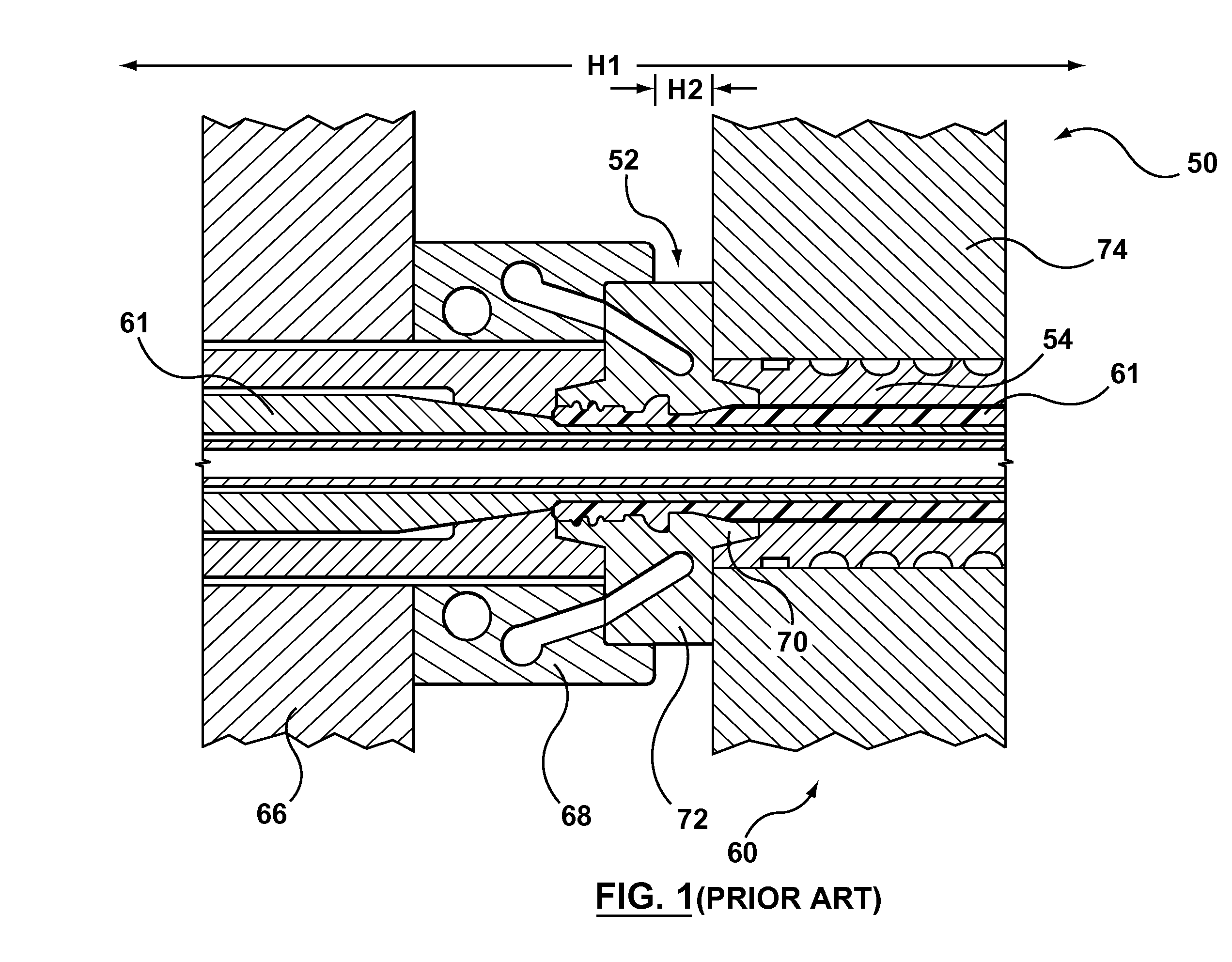

Compact MR write structure

InactiveUS6894877B1Less spaceCompact structureConstruction of head windingsManufacture head surfaceEngineeringBackplane

A compact write element includes a conductive shield layer, an insulating write gap layer, a pole pedestal, a coil, and a conductive pole layer, and, in some embodiments also includes a backgap. The pole pedestal and the coil, and, in some embodiments the backgap, constitute a self-aligned array of components that may be formed in a single masking operation to allow for very tight tolerances between the components for a shorter yoke length. The pole layer is substantially flat and parallel to the conductive shield layer, providing for a shorter stack height. Also, a compact MR read / write head includes such a write element and a magnetic data storage and retrieval system includes the compact MR read / write head having such a write element.

Owner:WESTERN DIGITAL TECH INC

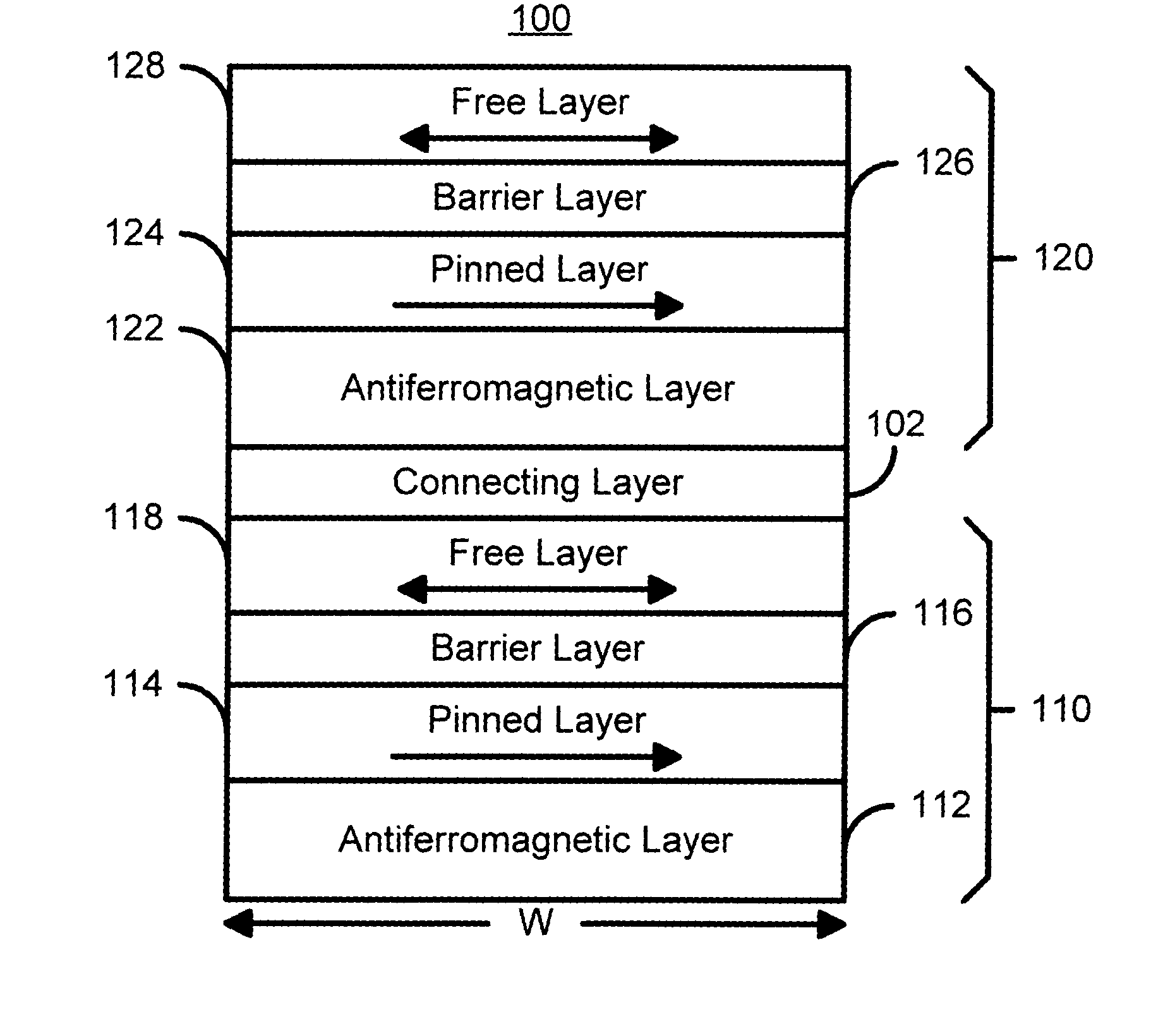

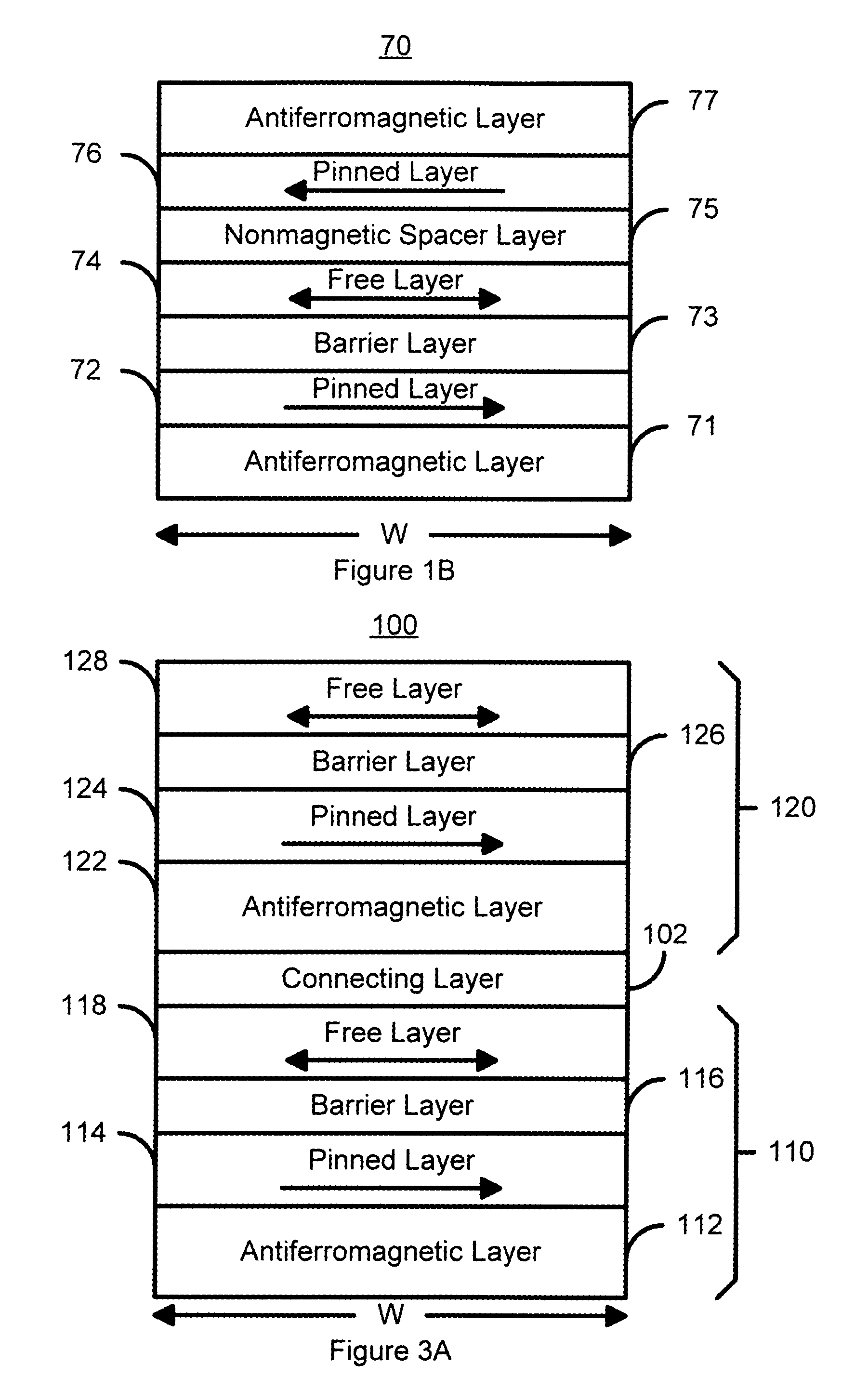

Magnetic memory element utilizing spin transfer switching and storing multiple bits

ActiveUS20050045913A1Reduce stack heightNanomagnetismMagnetic-field-controlled resistorsMagnetic memorySpin transfer

A method and system for providing a magnetic element capable of storing multiple bits is disclosed. The method and system include providing first pinned layer, a first nonmagnetic layer, a first free layer, a connecting layer, a second pinned layer, a second nonmagetic layer and a second free layer. The first pinned layer is ferromagnetic and has a first pinned layer magnetization pinned in a first direction. The first nonmagnetic layer resides between the first pinned layer and the first free layer. The first free layer being ferromagnetic and has a first free layer magnetization. The second pinned layer is ferromagnetic and has a second pinned layer magnetization pinned in a second direction. The connecting layer resides between the second pinned layer and the first free layer. The second nonmagnetic layer resides between the second pinned layer and the second free layer. The second free layer being ferromagnetic and having a second free layer magnetization. The magnetic element is configured to allow the first free layer magnetization and the second free layer magnetization to change direction due to spin transfer when a write current is passed through the magnetic element.

Owner:SAMSUNG SEMICON

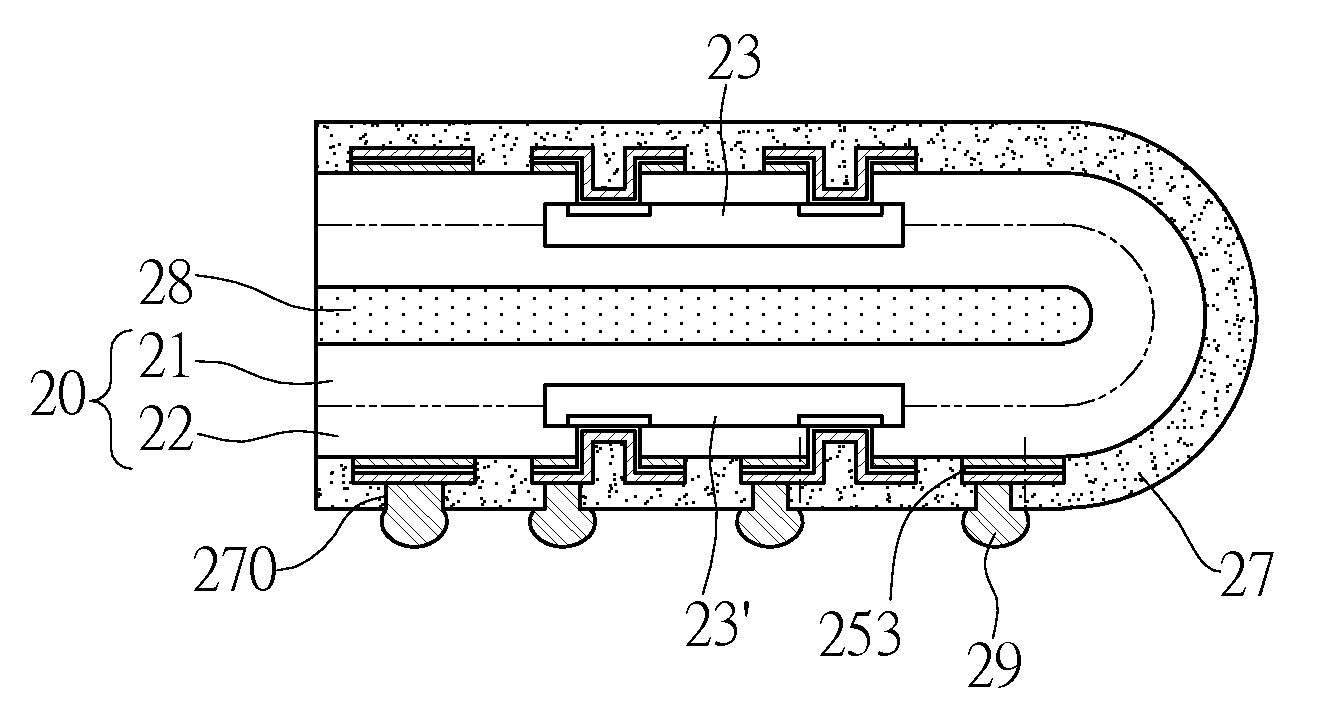

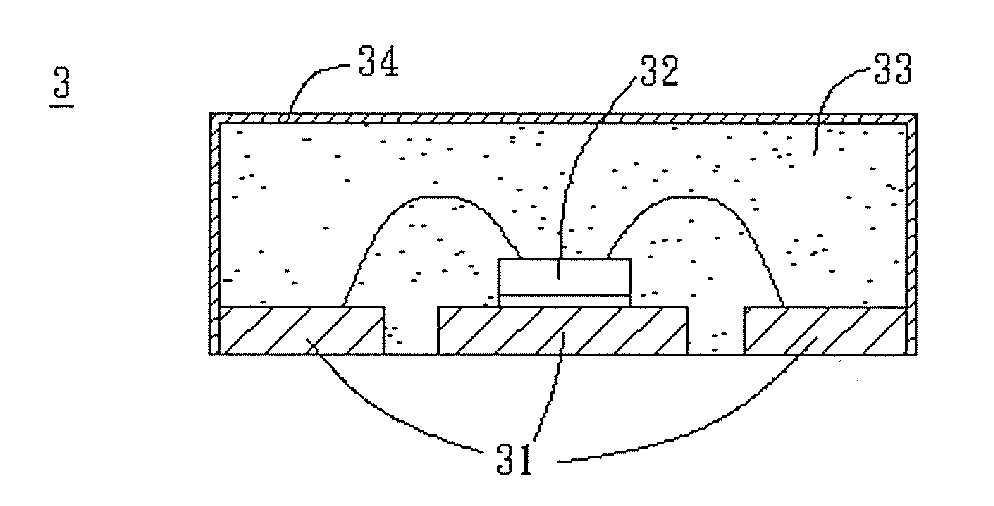

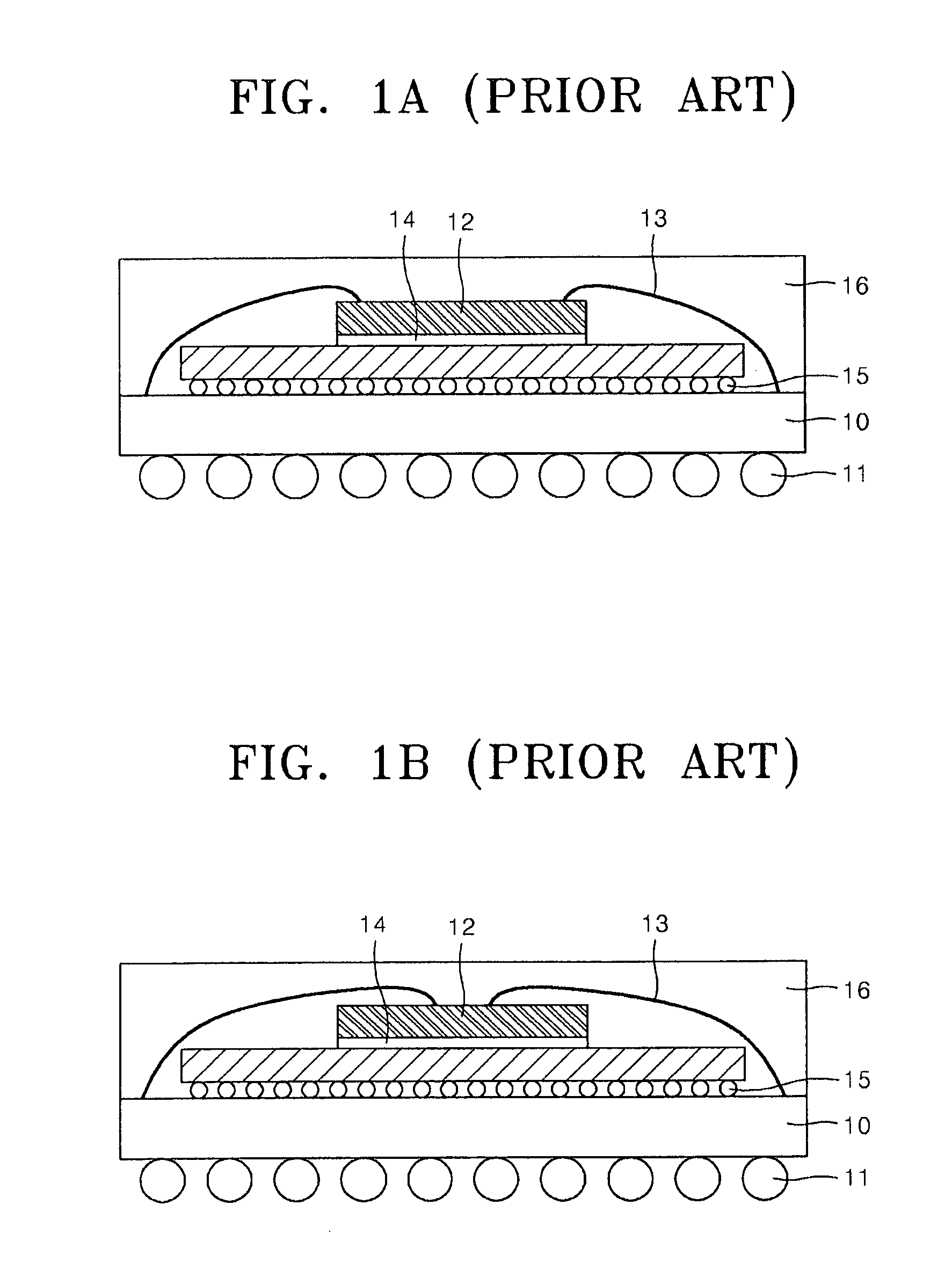

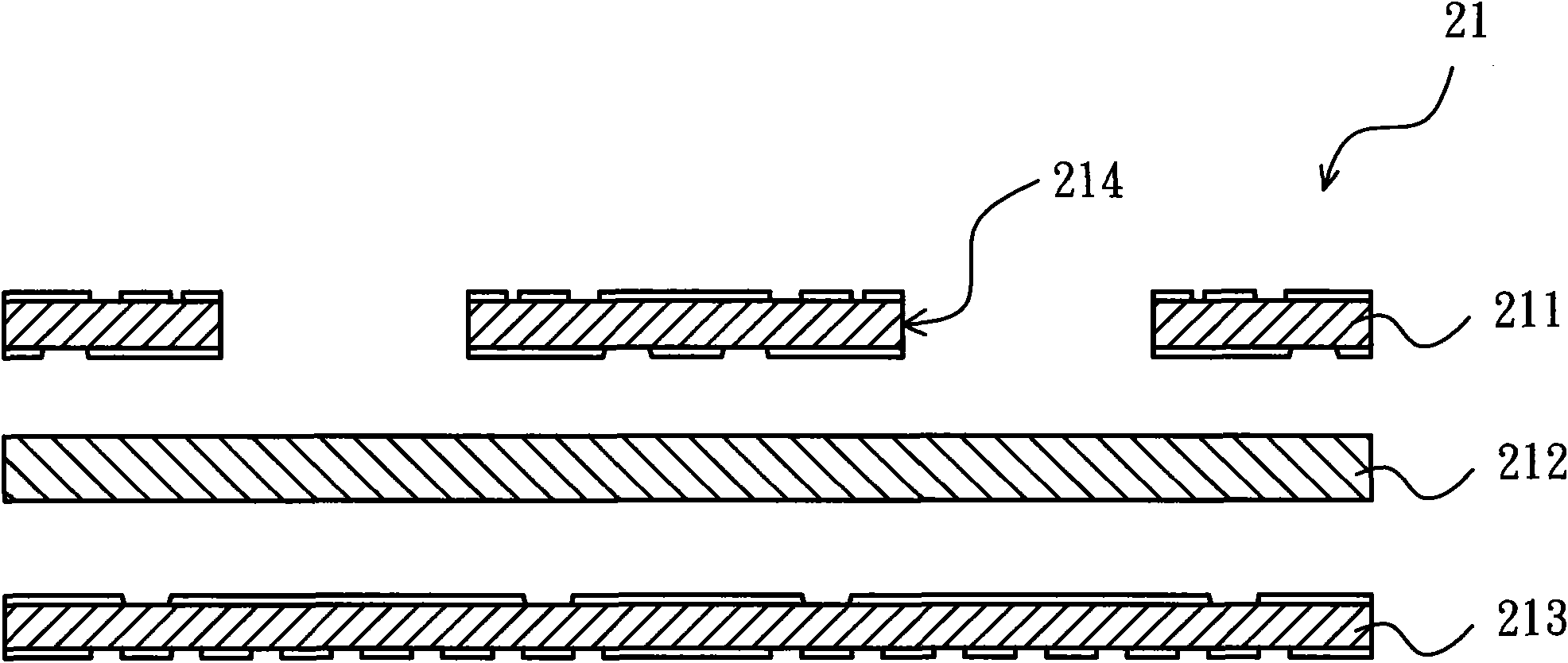

Stacked semiconductor device and fabricating method thereof

ActiveUS20090090541A1Reduce package heightReduction of package miniaturizationSemiconductor/solid-state device detailsPrinted circuit aspectsMiniaturizationSemiconductor chip

Provided is a stacked semiconductor device including a first flexible layer and a second flexible layer combined together, serving as a flexible substrate body being bent somewhere such that a surface of the first flexible layer itself is face-to-face clipped, two semiconductor chips each embedded in the flexible substrate body, and an adhesive layer sandwiched in a gap between the face-to-face surface of the first flexible layer. The active surface of each of the semiconductor chips has plurality of electrode pads thereon electrically connected to a first circuit layer on the second flexible layer. The semiconductor chips are stacked up and embedded in the flexible substrate body, thereby reducing package height to achieve miniaturization of electronic products. A method for fabricating the stacked semiconductor device is also provided.

Owner:UNIMICRON TECH CORP

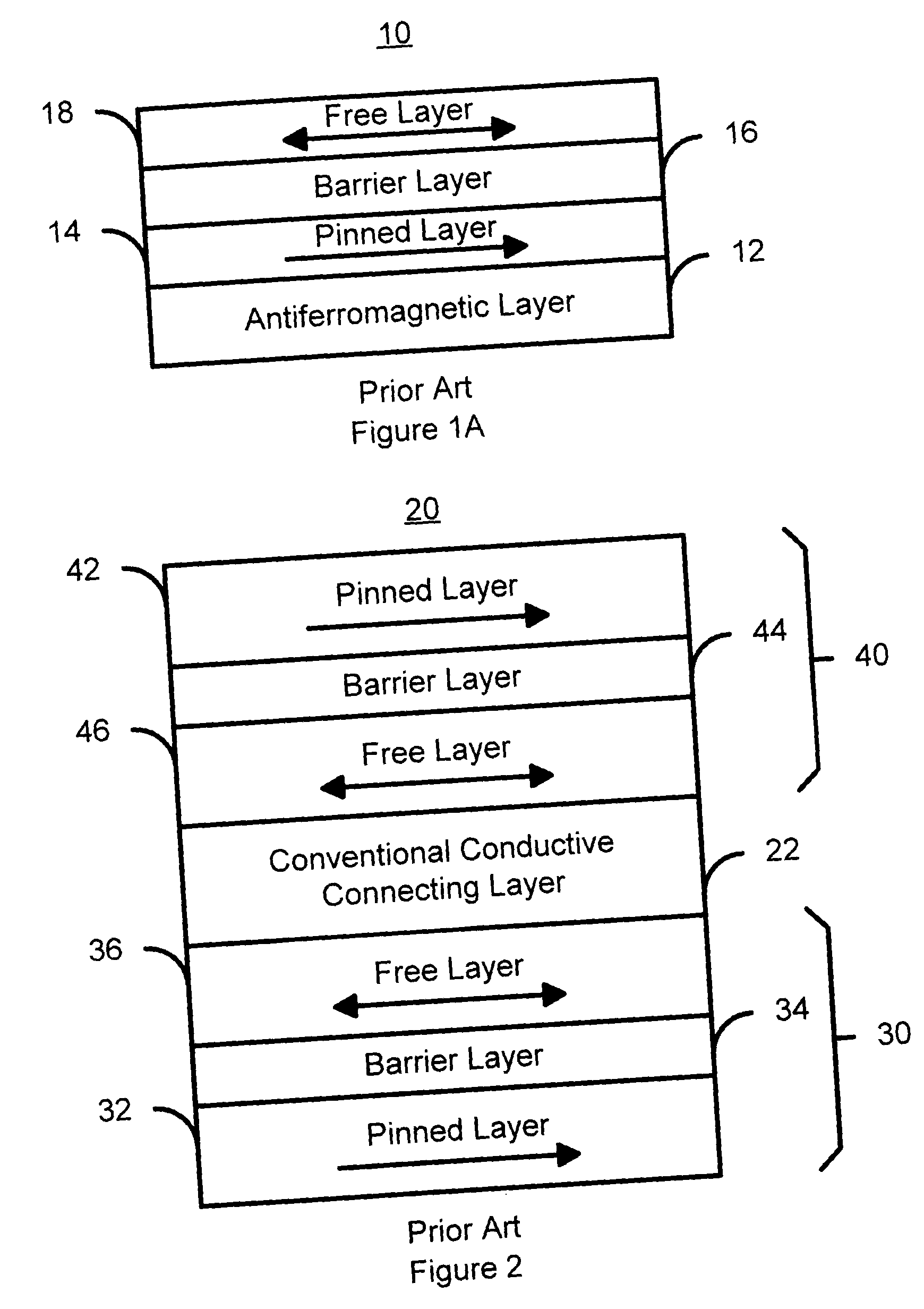

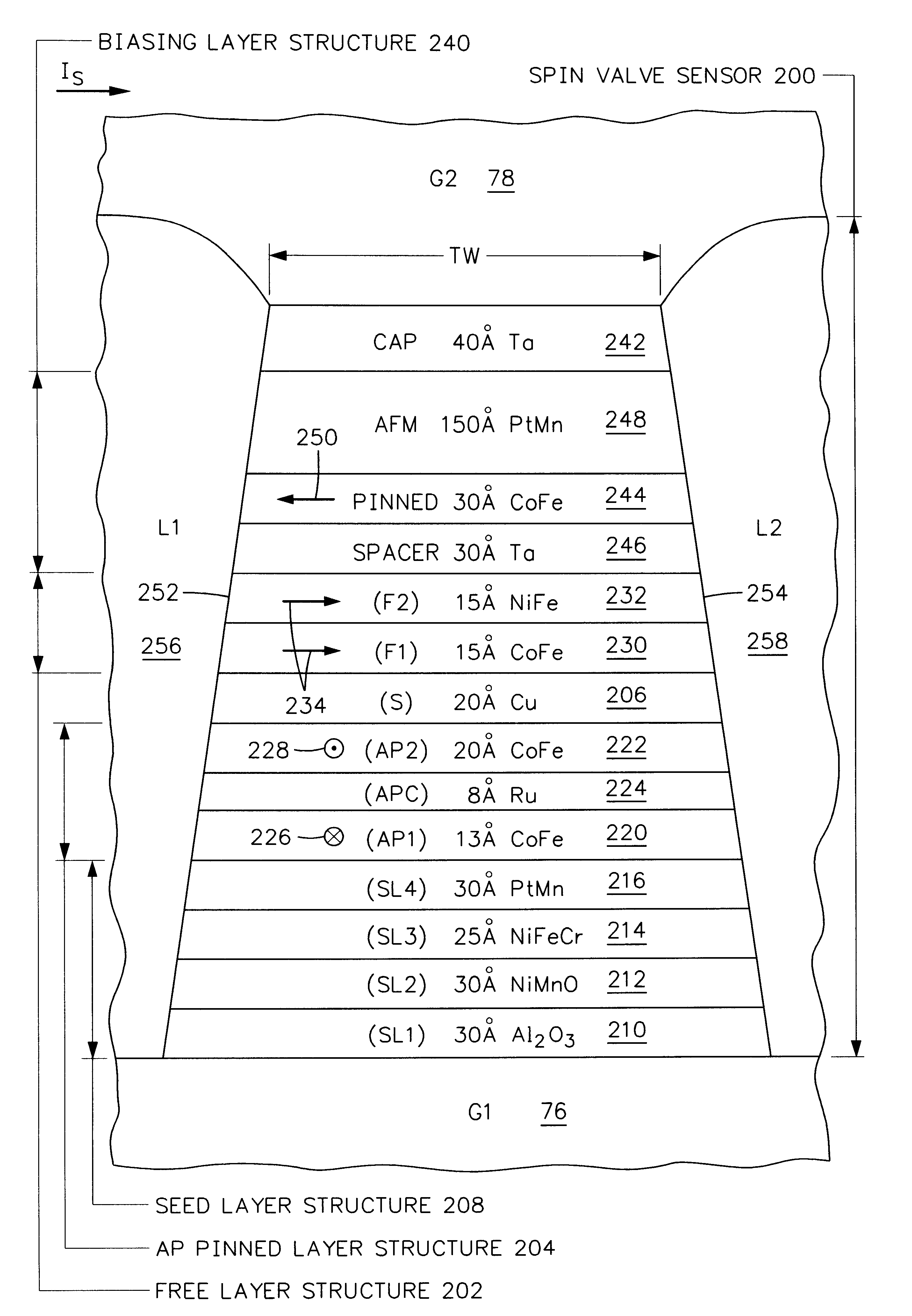

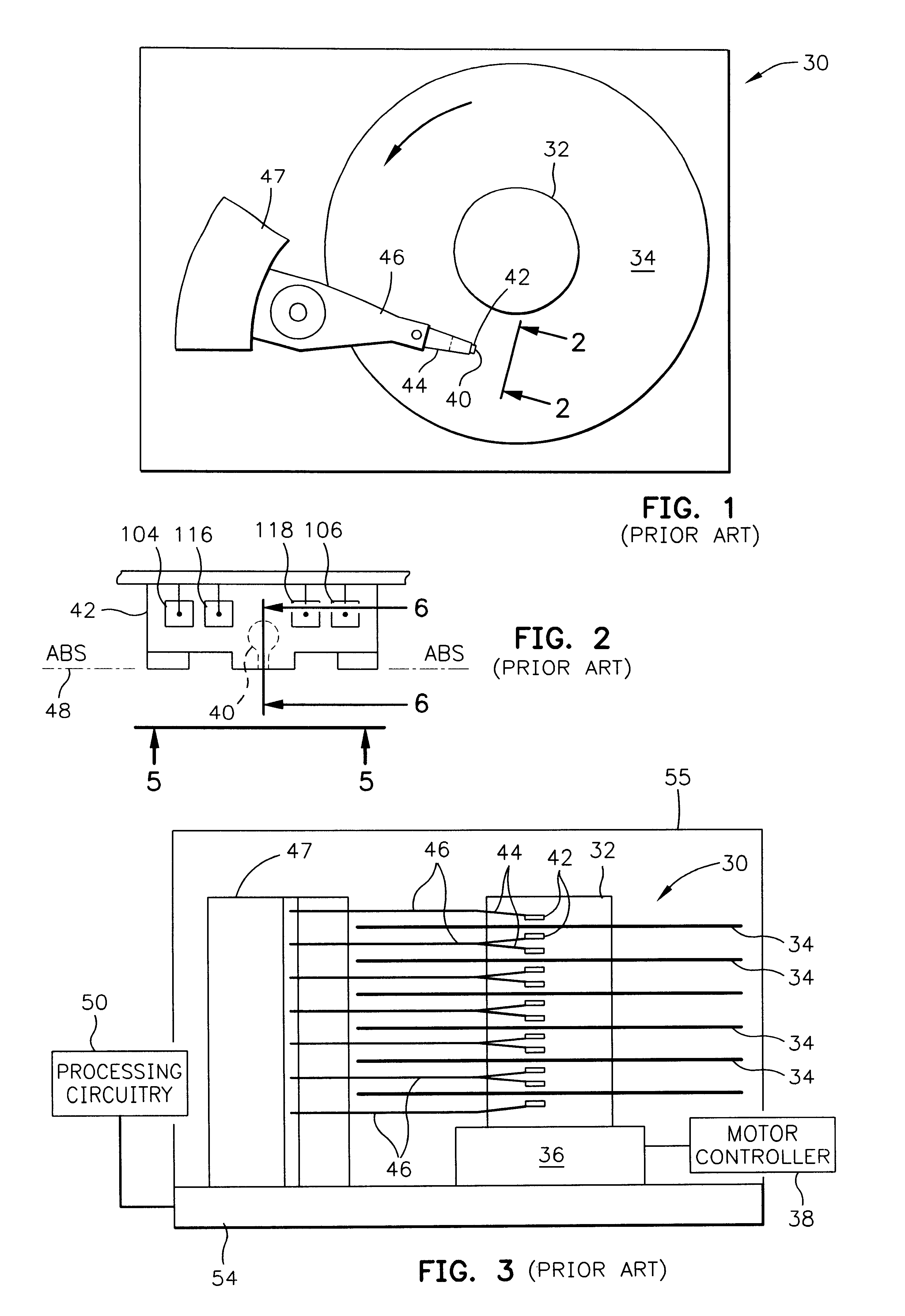

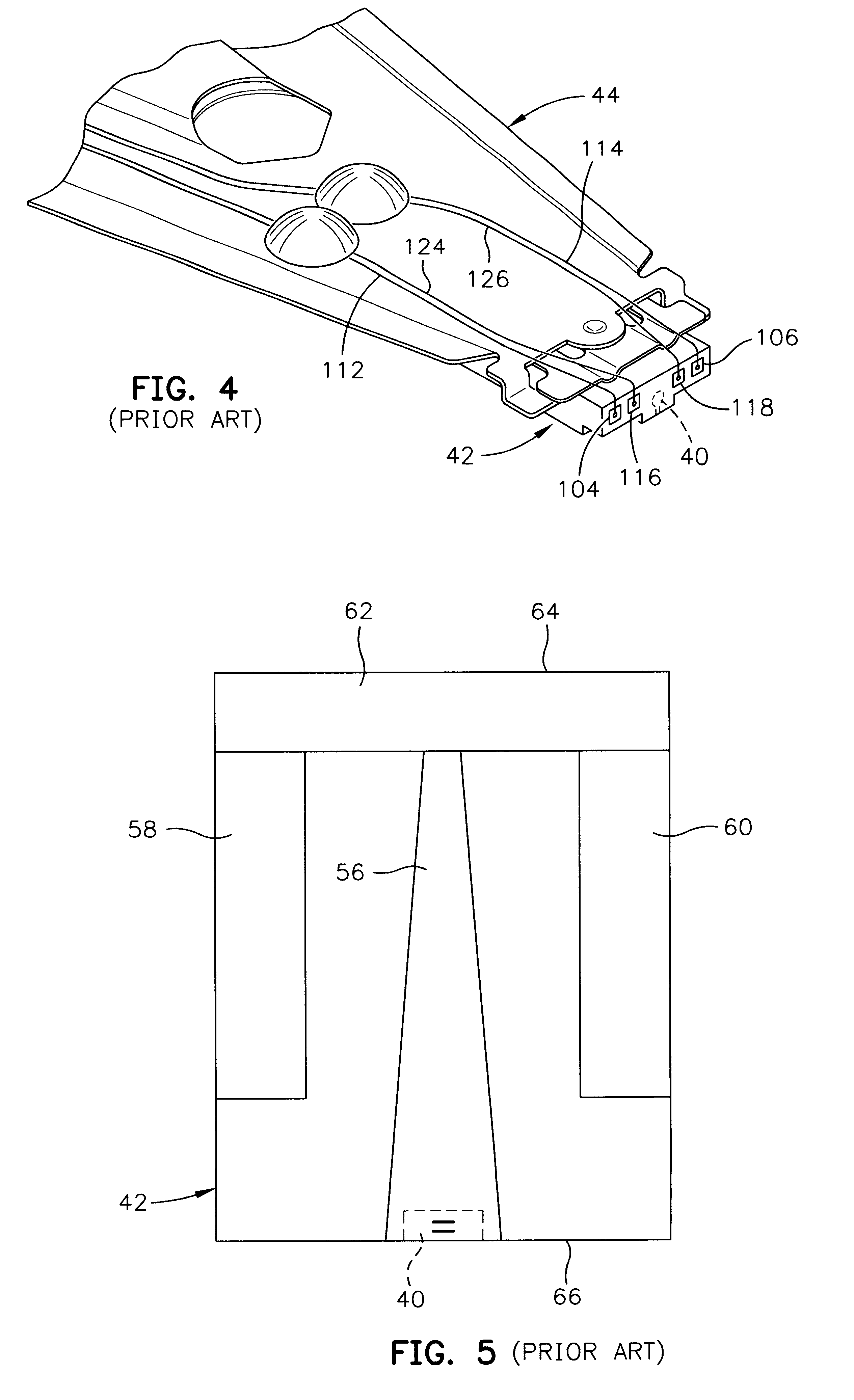

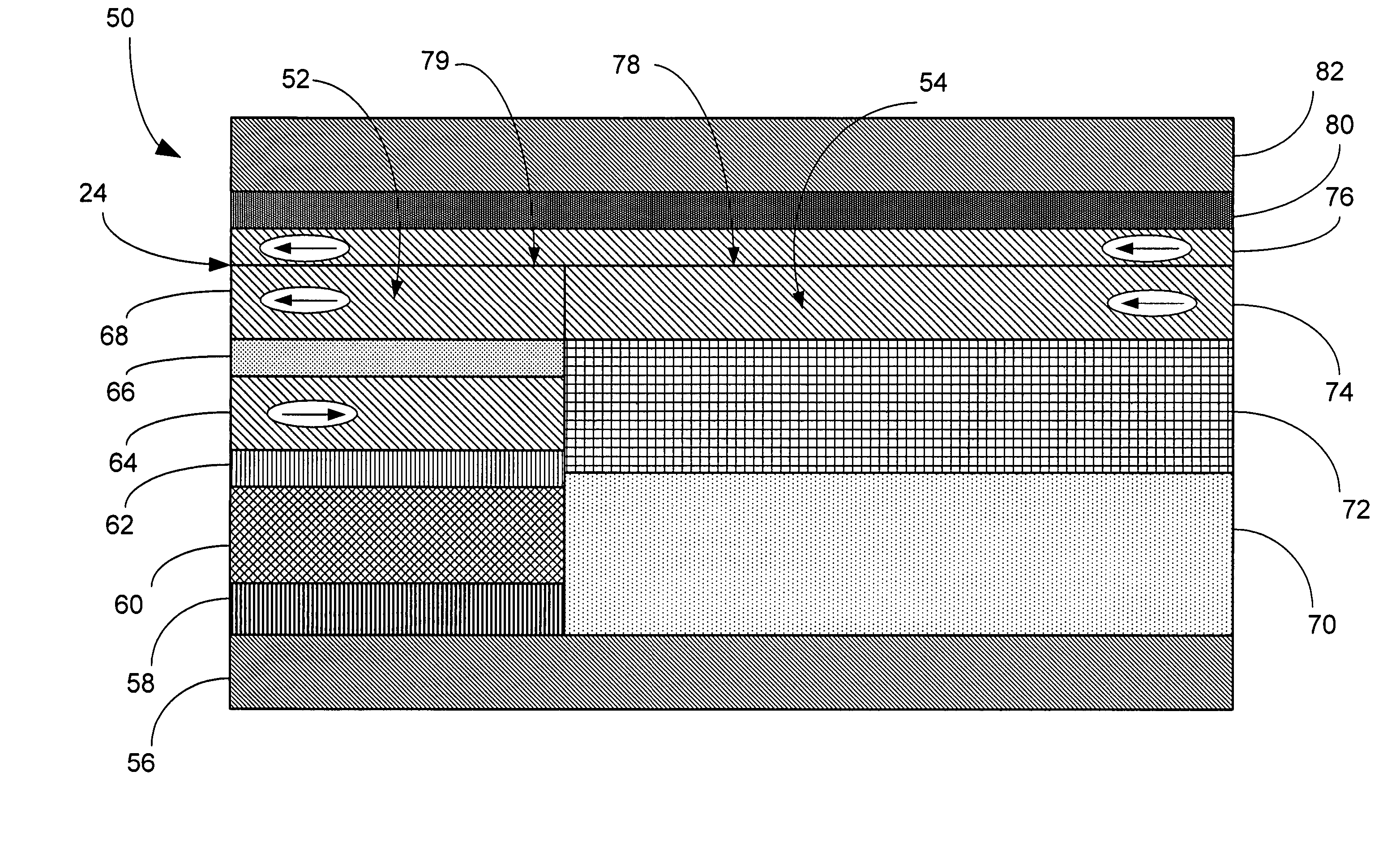

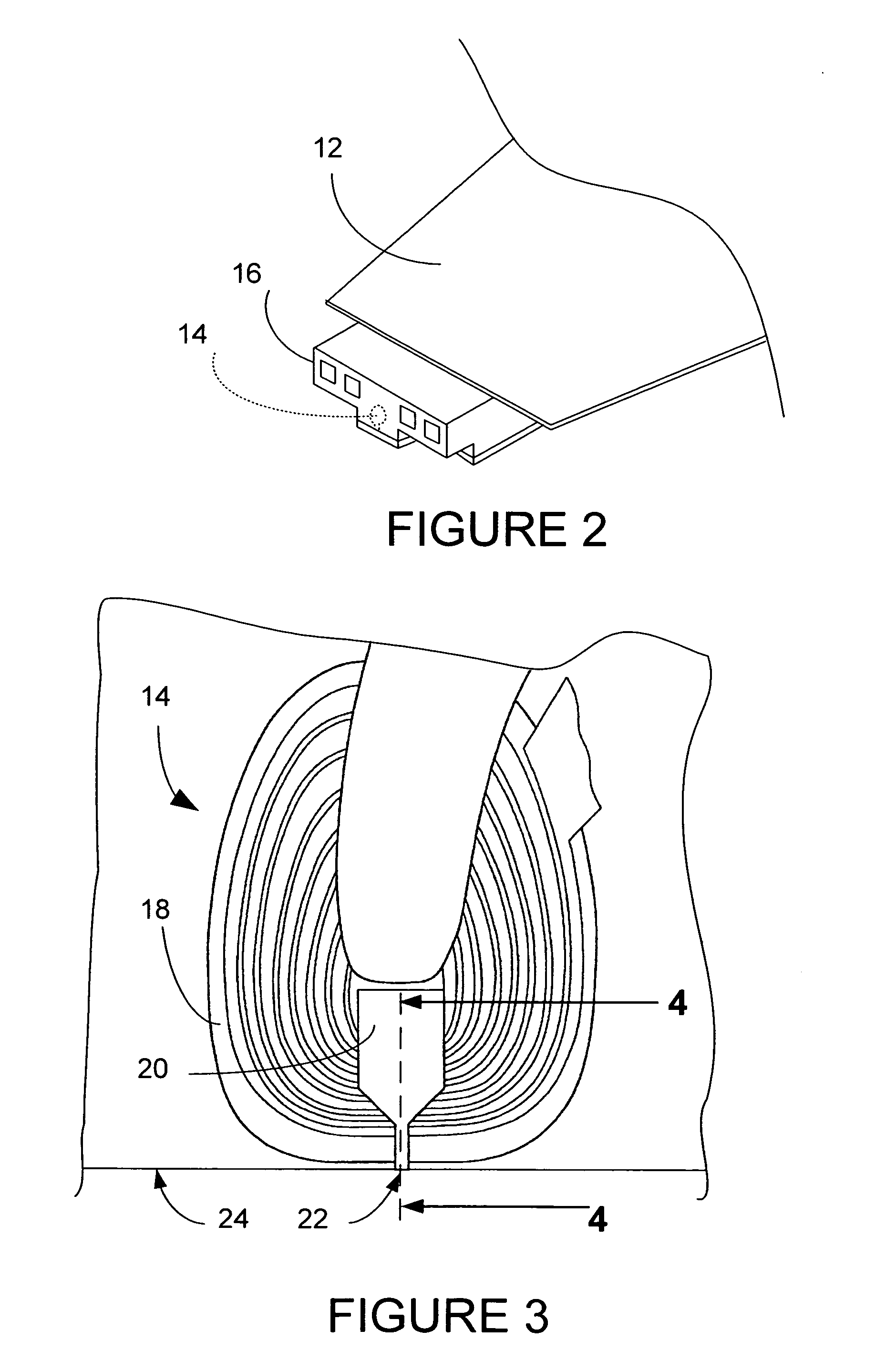

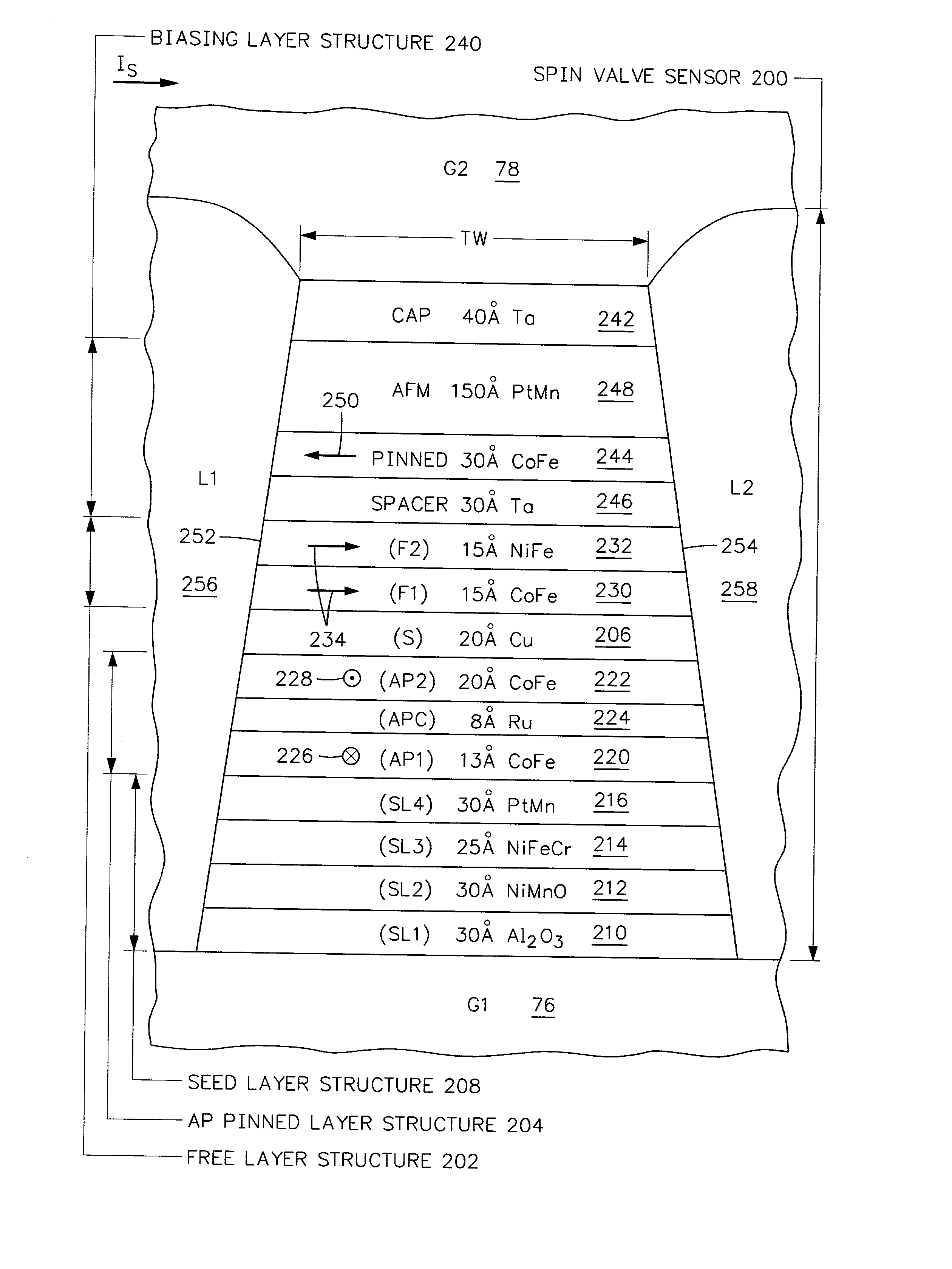

Spin valve sensor with in-stack biased free layer and antiparallel (AP) pinned layer pinned without a pinning layer

InactiveUS6856493B2Improved magnetostrictionImprovement factorNanoinformaticsHeads using thin filmsCouplingOptoelectronics

A spin valve sensor has an antiparallel (AP) pinned layer structure which has ferromagnetic first and second AP pinned layers that are separated by an antiparallel coupling layer. The first and second AP pinned layers are self-pinned antiparallel with respect to one another without the assistance of an antiferromagnetic (AFM) pinning layer. The spin valve sensor further includes an in-stack longitudinal biasing layer structure which is magnetostatically coupled to the free layer for longitudinally biasing a magnetic moment of the free layer parallel to an air bearing surface and parallel to major planes of the layers of the sensor. The only AFM pinning layer employed is in the biasing layer structure so that when the magnetic spins of the AFM pinning layer are set the orientations of the magnetic moments of the AP pinned layer structure are not disturbed.

Owner:INT BUSINESS MASCH CORP

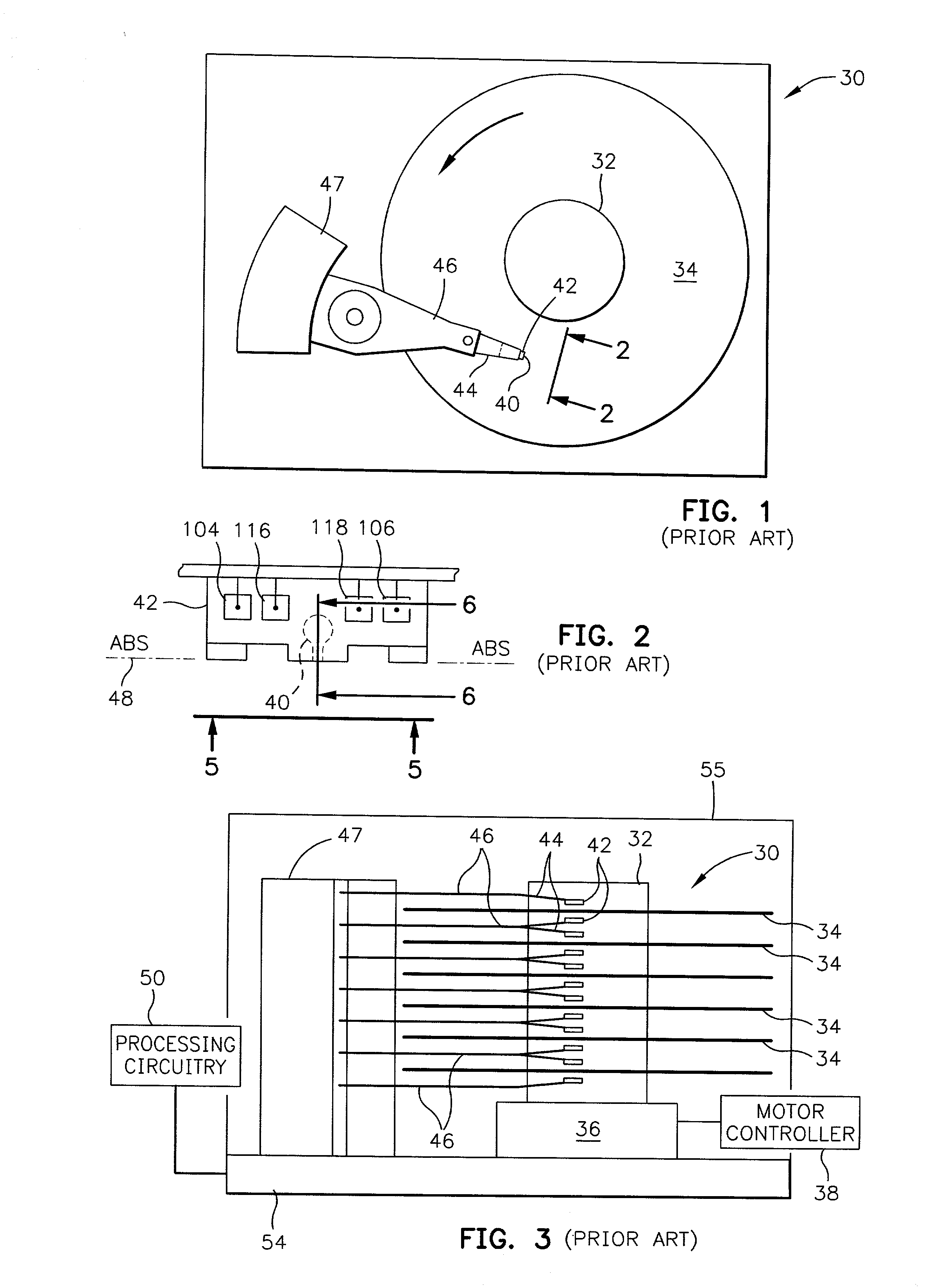

Top CPP GMR/TV with back end of stripe pinned by insulating AFM

InactiveUS7092221B2Reduce stack heightLess heatRecord information storageManufacture of flux-sensitive headsElectrical and Electronics engineeringSoftware engineering

A magnetic head includes a read sensor having a primary stack, a secondary stack and an exchange layer. The primary stack includes one or more primary pinned layers having a top surface, a barrier layer, a free layer, and a seed layer. The secondary stack includes one or more layers of antiferromagnetic (AFM) material, and a secondary pinned layer, which is pinned by said AFM material. The secondary pinned layer has a top surface which is substantially level with the top surface of the primary pinned layer. An exchange layer contacts the top surface of the secondary pinned layer and is pinned thereby, and also contacts the top surface of the primary pinned layer and acts to pin the primary pinned layers. The secondary stack is removed from the ABS, but is in proximity to the primary stack.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Spin valve sensor with in-stack biased free layer and antiparallel (AP) pinned layer pinned without a pinning layer

InactiveUS20030179513A1Improved magnetostrictionImprovement factorNanoinformaticsHeads using thin filmsCouplingOptoelectronics

A spin valve sensor has an antiparallel (AP) pinned layer structure which has ferromagnetic first and second AP pinned layers that are separated by an antiparallel coupling layer. The first and second AP pinned layers are self-pinned antiparallel with respect to one another without the assistance of an antiferromagnetic (AFM) pinning layer. The spin valve sensor further includes an in-stack longitudinal biasing layer structure which is magnetostatically coupled to the free layer for longitudinally biasing a magnetic moment of the free layer parallel to an air bearing surface and parallel to major planes of the layers of the sensor. The only AFM pinning layer employed is in the biasing layer structure so that when the magnetic spins of the AFM pinning layer are set the orientations of the magnetic moments of the AP pinned layer structure are not disturbed.

Owner:IBM CORP

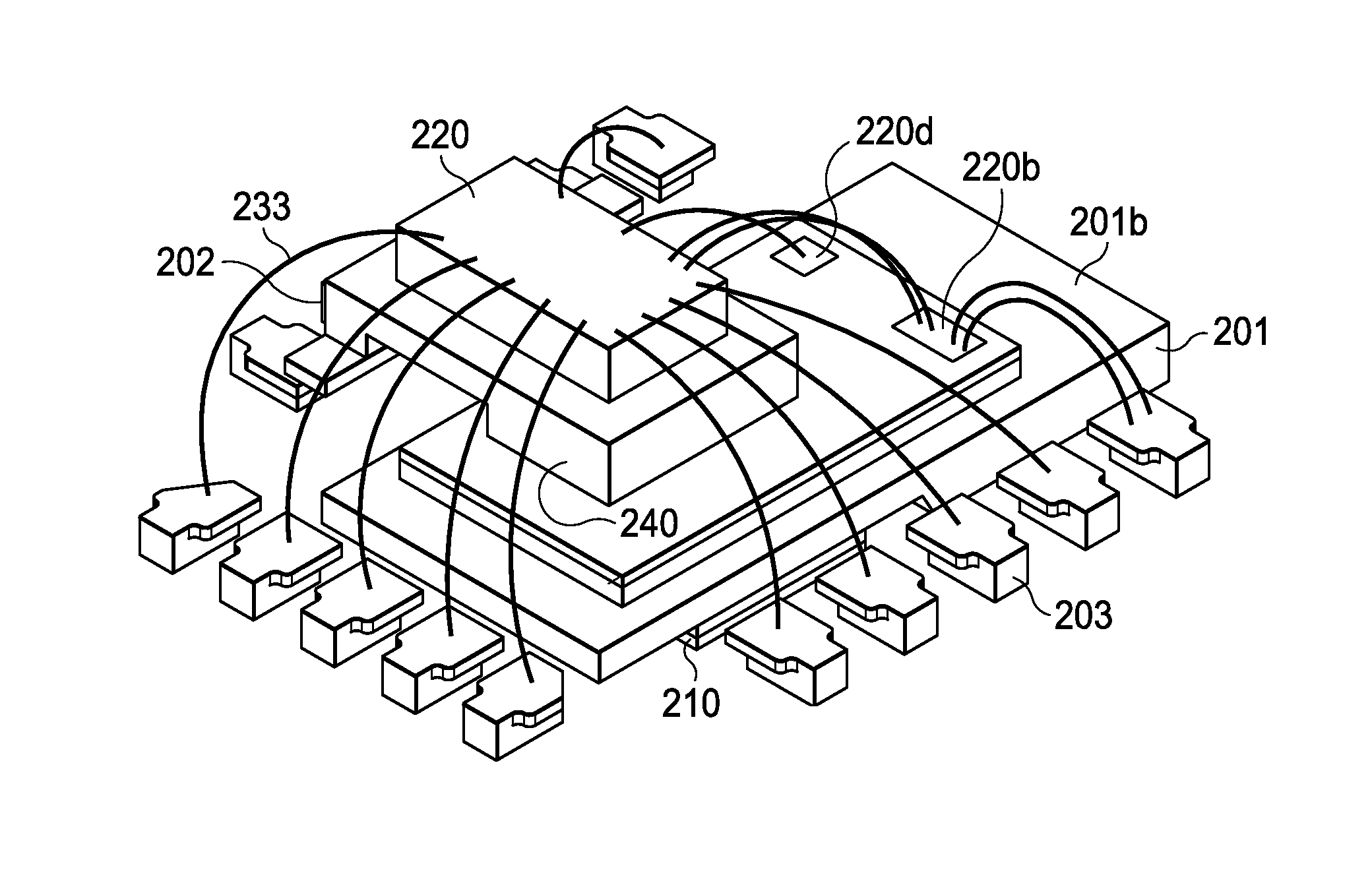

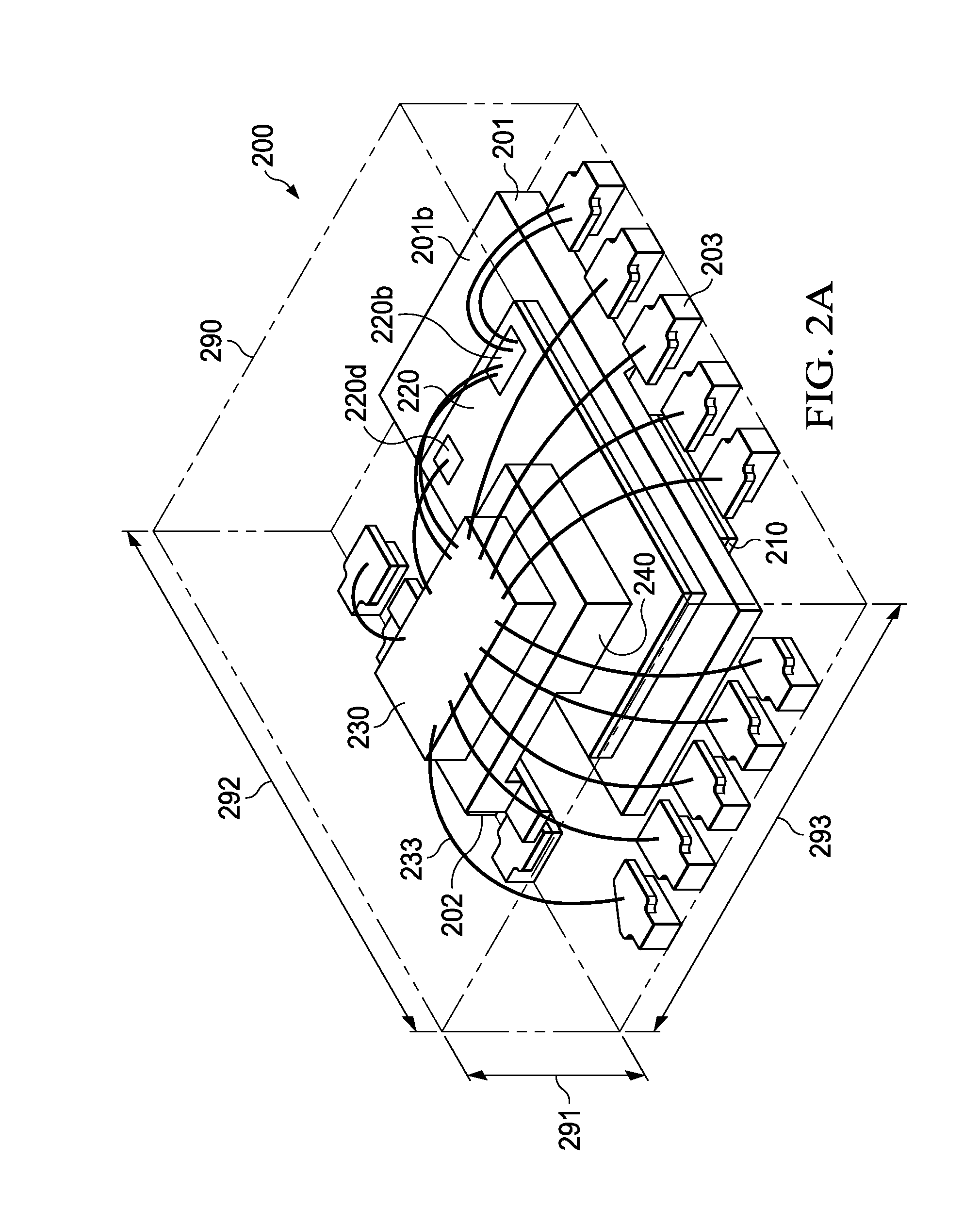

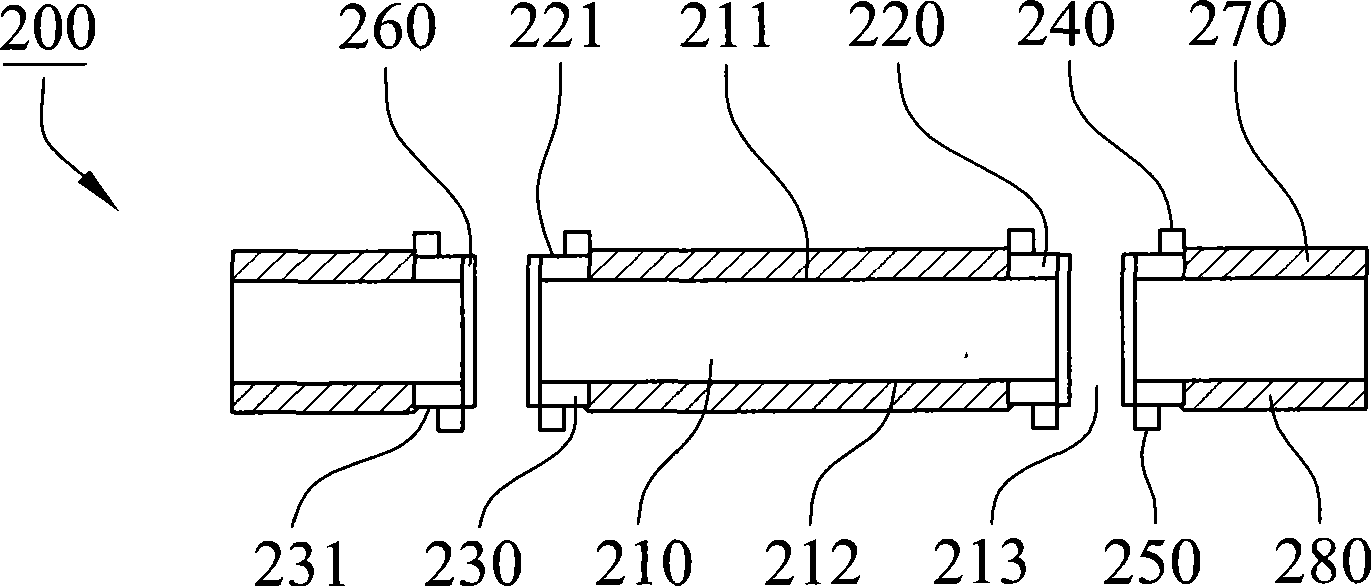

Stacked Synchronous Buck Converter Having Chip Embedded in Outside Recess of Leadframe

ActiveUS20150221584A1Reduce the overall heightLow powerSemiconductor/solid-state device detailsSolid-state devicesBuck converterSemiconductor chip

A power supply system (200) has a QFN leadframe with leads and a pad (201, switch node terminal); a pad surface having a portion recessed with a depth (270) and an outline suitable for attaching a semiconductor chip. A first FET chip (220) is vertically stacked to the opposite pad surface. A clip (240) is vertically stacked on the first FET chip and tied to a lead (202, grounded output terminal). A second FET chip (210) has its source terminal attached to the recessed portion and its drain (210a, input terminal) and gate (210b) terminals co-planar with the un-recessed portion. A driver-and-controller chip (230) is attached to the clip. Packaging compound (290) encapsulates the parts but leaves a pad surface and the drain and gate terminals of the second FET chip un-encapsulated.

Owner:TEXAS INSTR INC

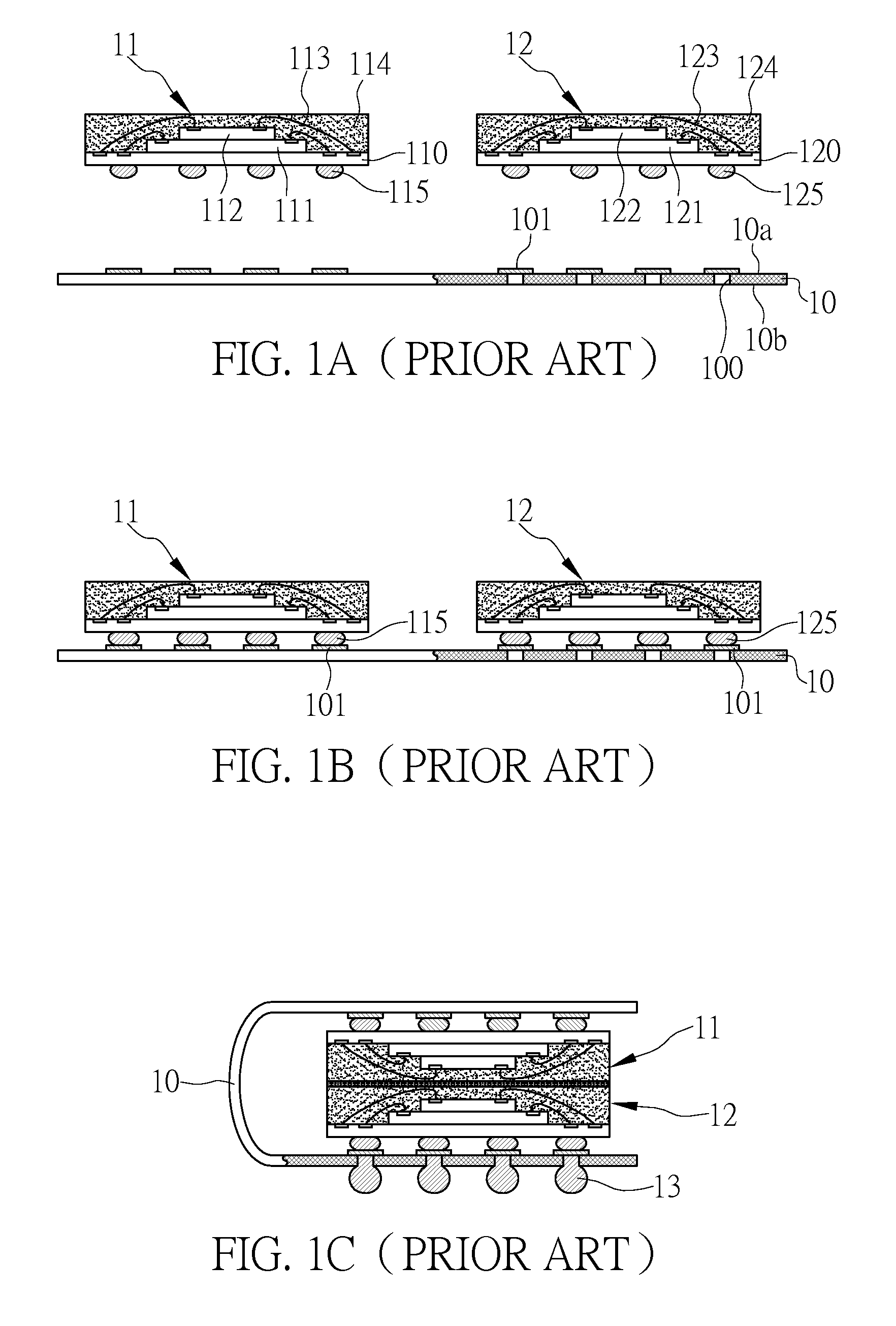

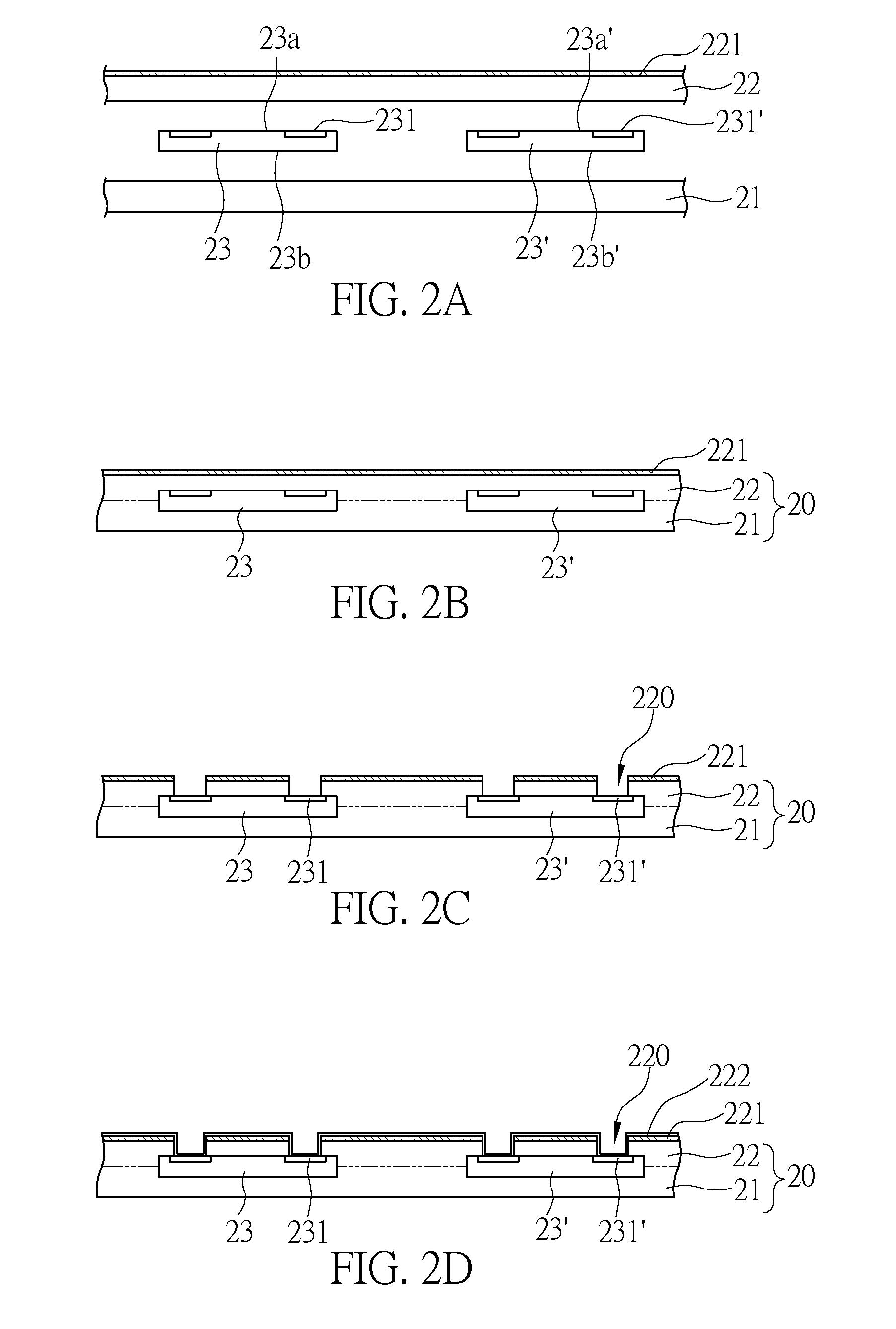

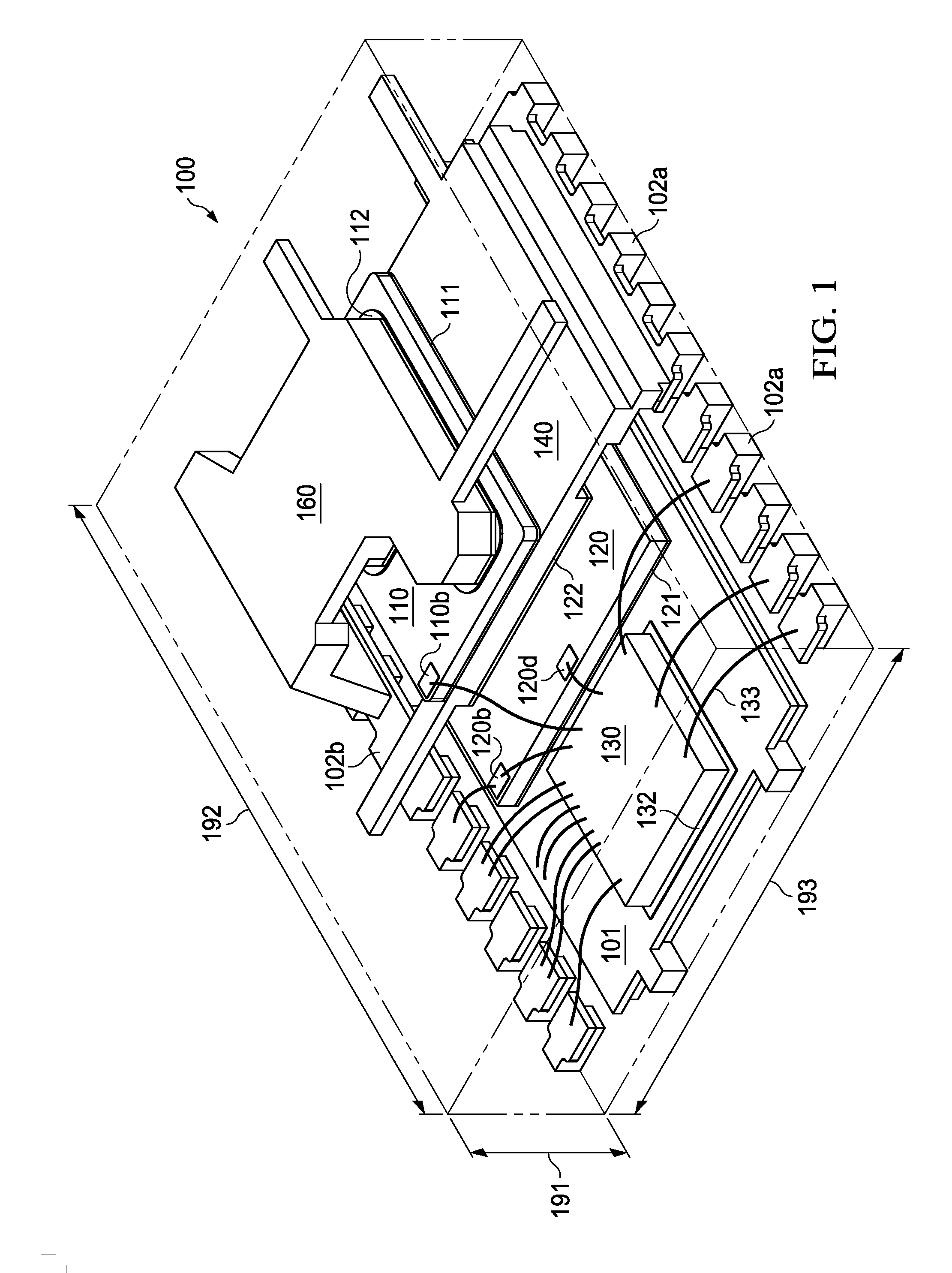

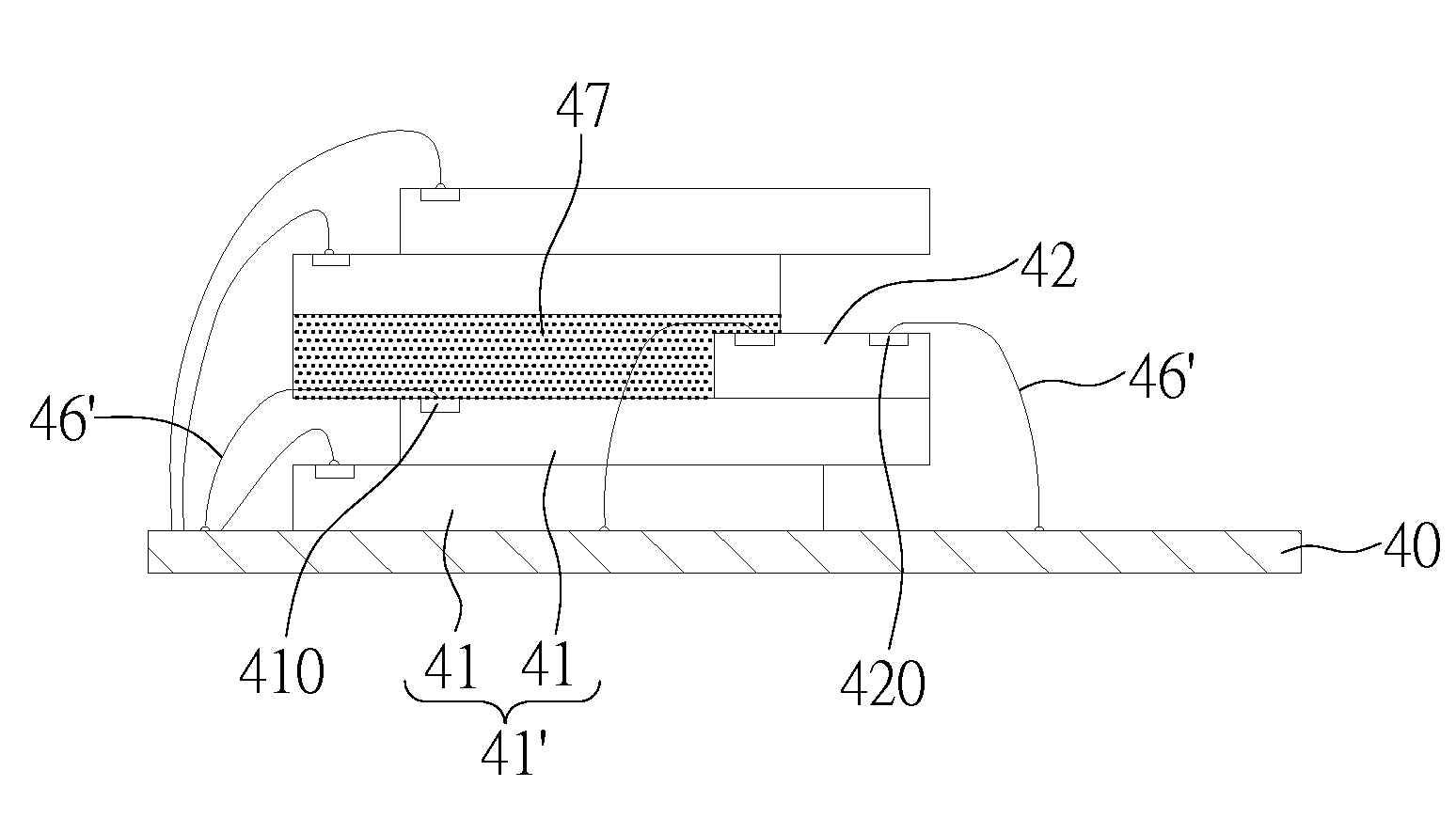

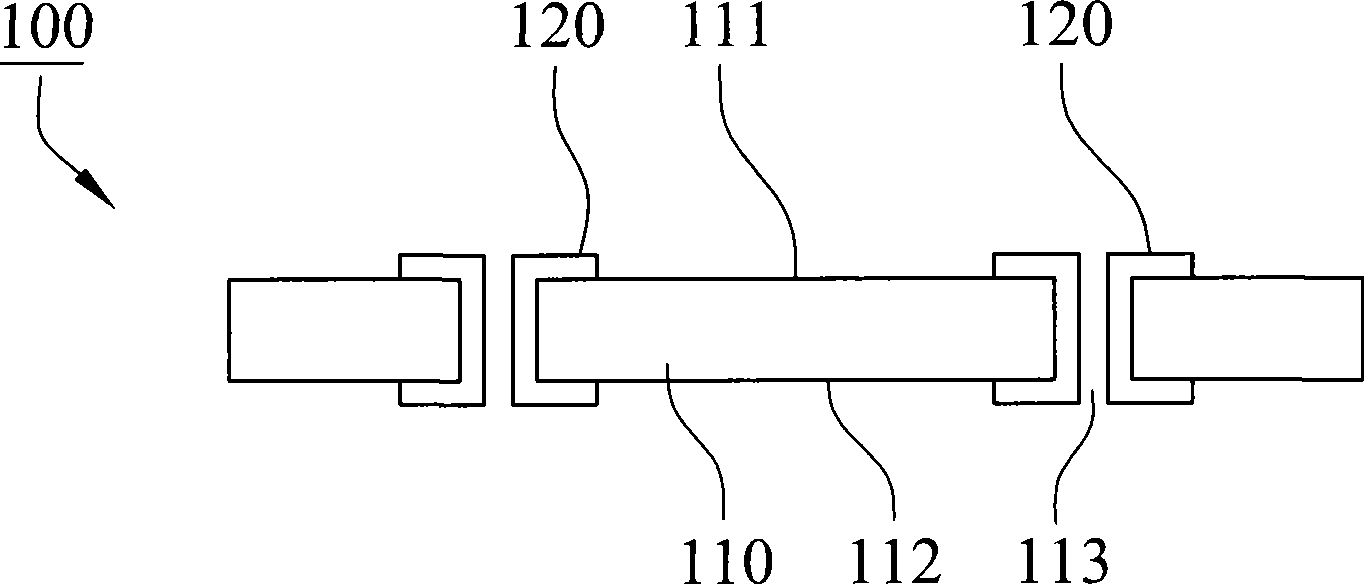

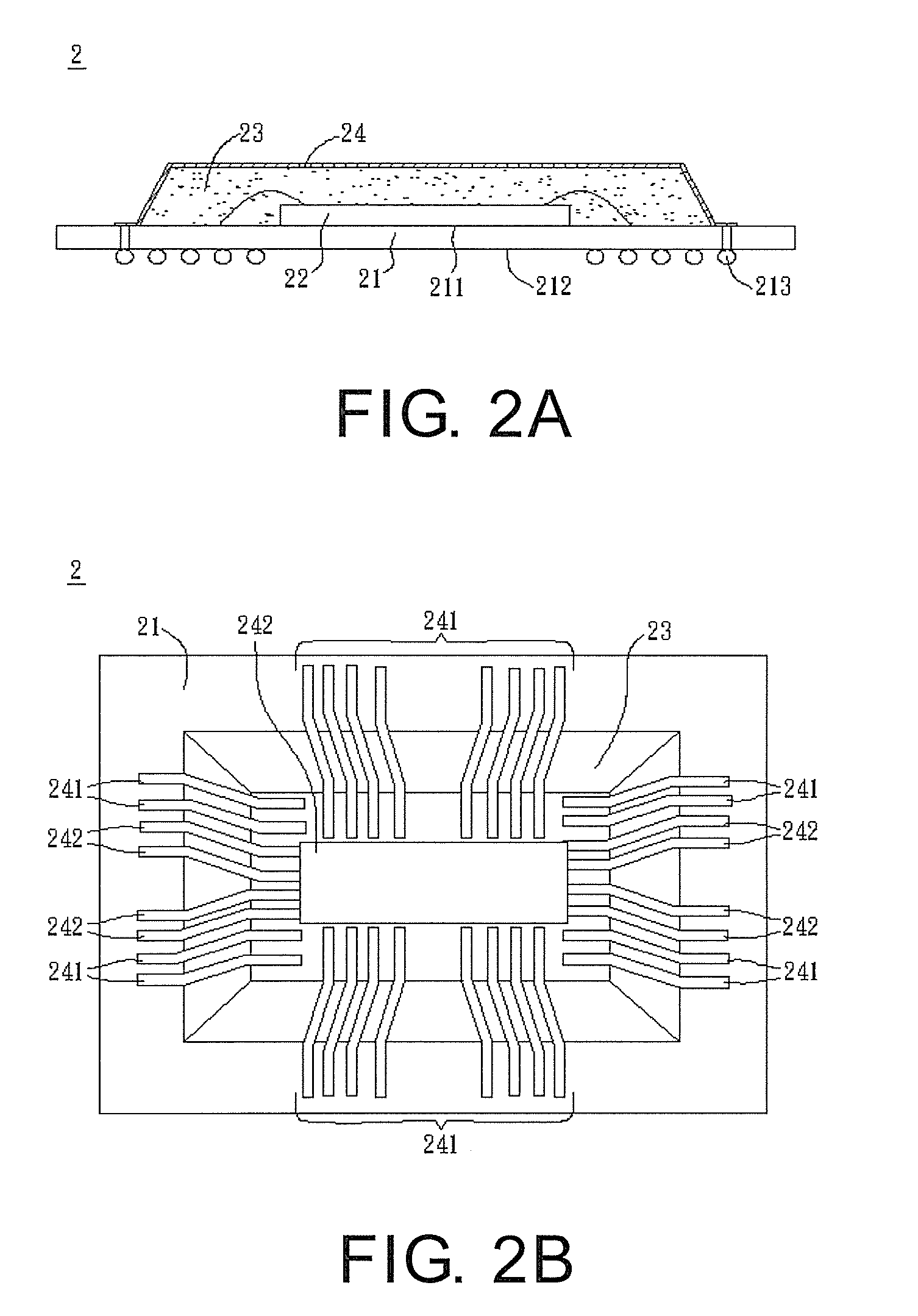

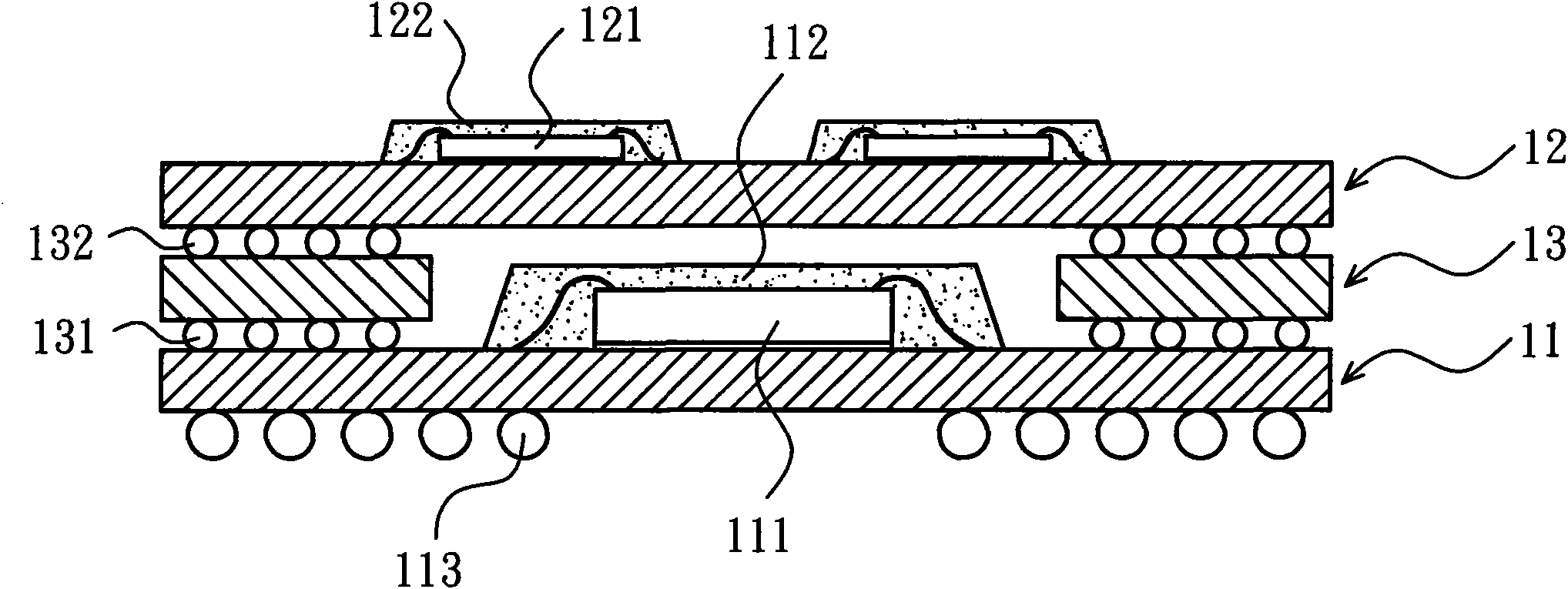

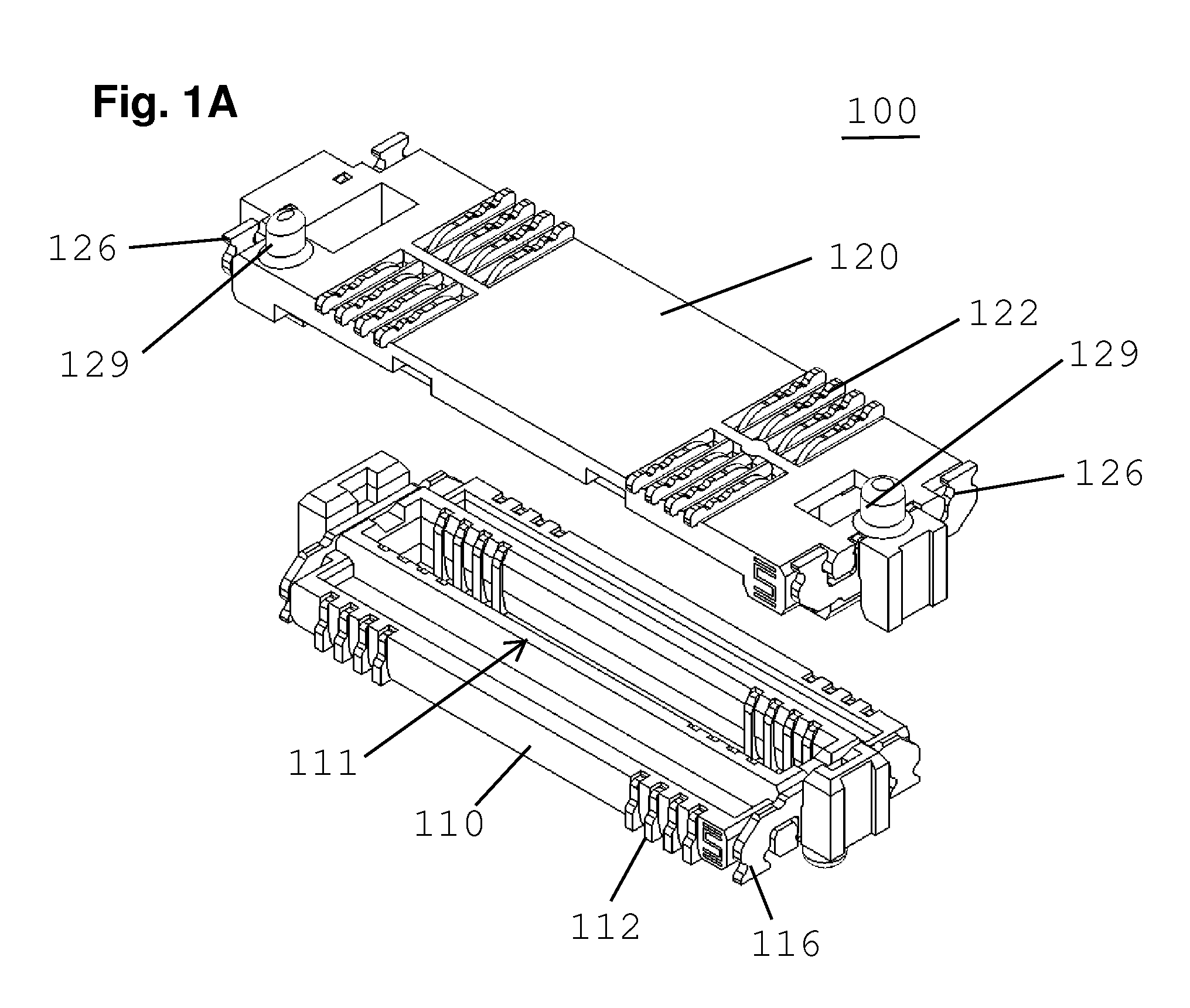

Multi-chip stack structure and method for fabricating the same

ActiveUS20090140440A1Reduce the overall heightReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesChip stackingChip carrier

A multi-chip stack structure and a method for fabricating the same are provided. The method for fabricating a multi-chip stack structure includes disposing a first chip group comprising a plurality of first chips on a chip carrier by using a step-like manner, disposing a second chip on the first chip on top of the first chip group, electrically connecting the first chip group and the second chip to the chip carrier through bonding wires, using film over wire (FOW) to stack a third chip on the first and the second chips with an insulative film provided therebetween, wherein the insulative film covers part of the ends of the bonding wires of the first chip on the top of the first group and at least part of the second chip, and electrically connecting the third chip to the chip carrier through bonding wires, thereby preventing directly disposing on a first chip a second chip having a planar size far smaller than that of the first chip as in the prior art that increases height of the entire structure and increases the wiring bonding difficulty.

Owner:SILICONWARE PRECISION IND CO LTD

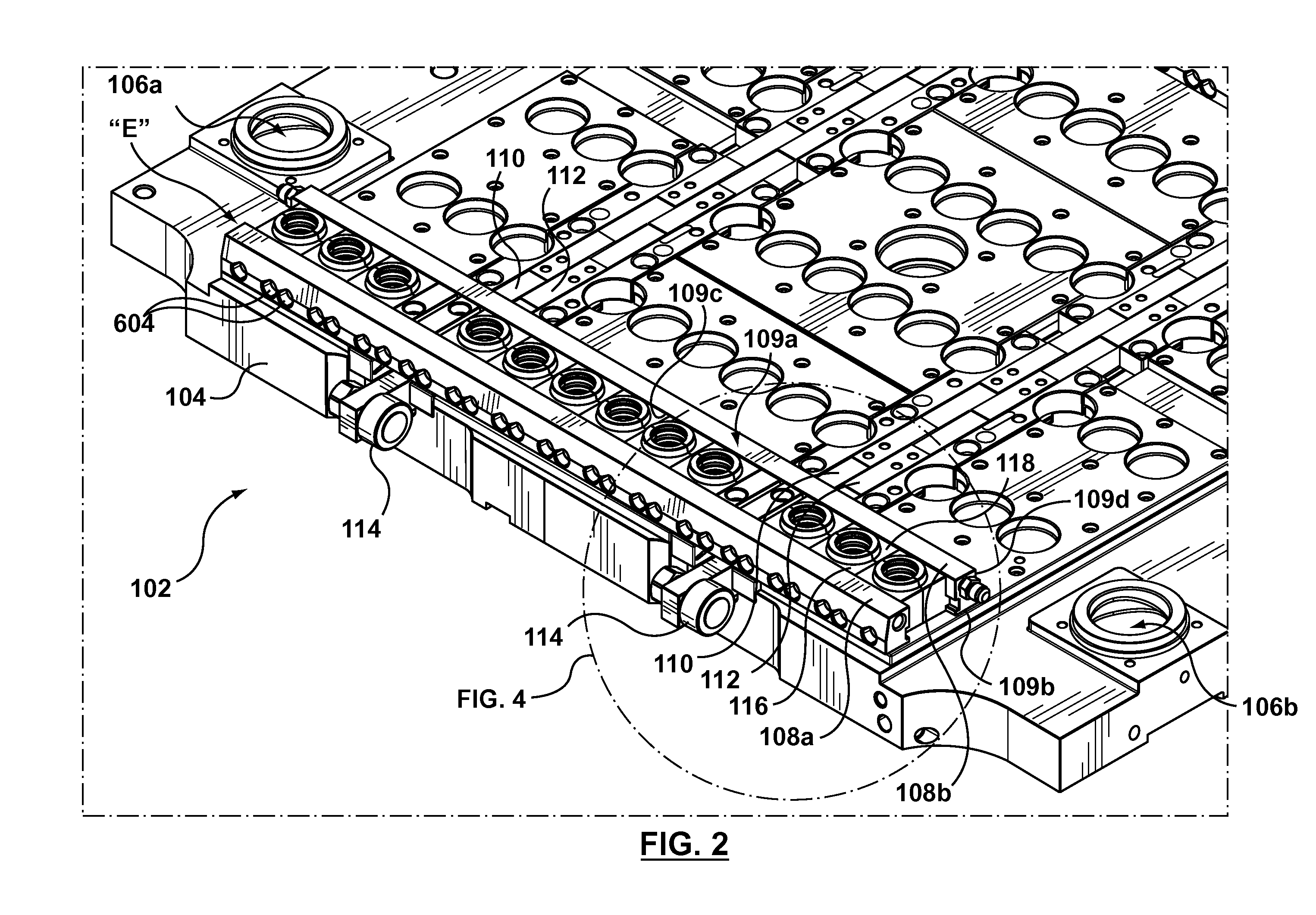

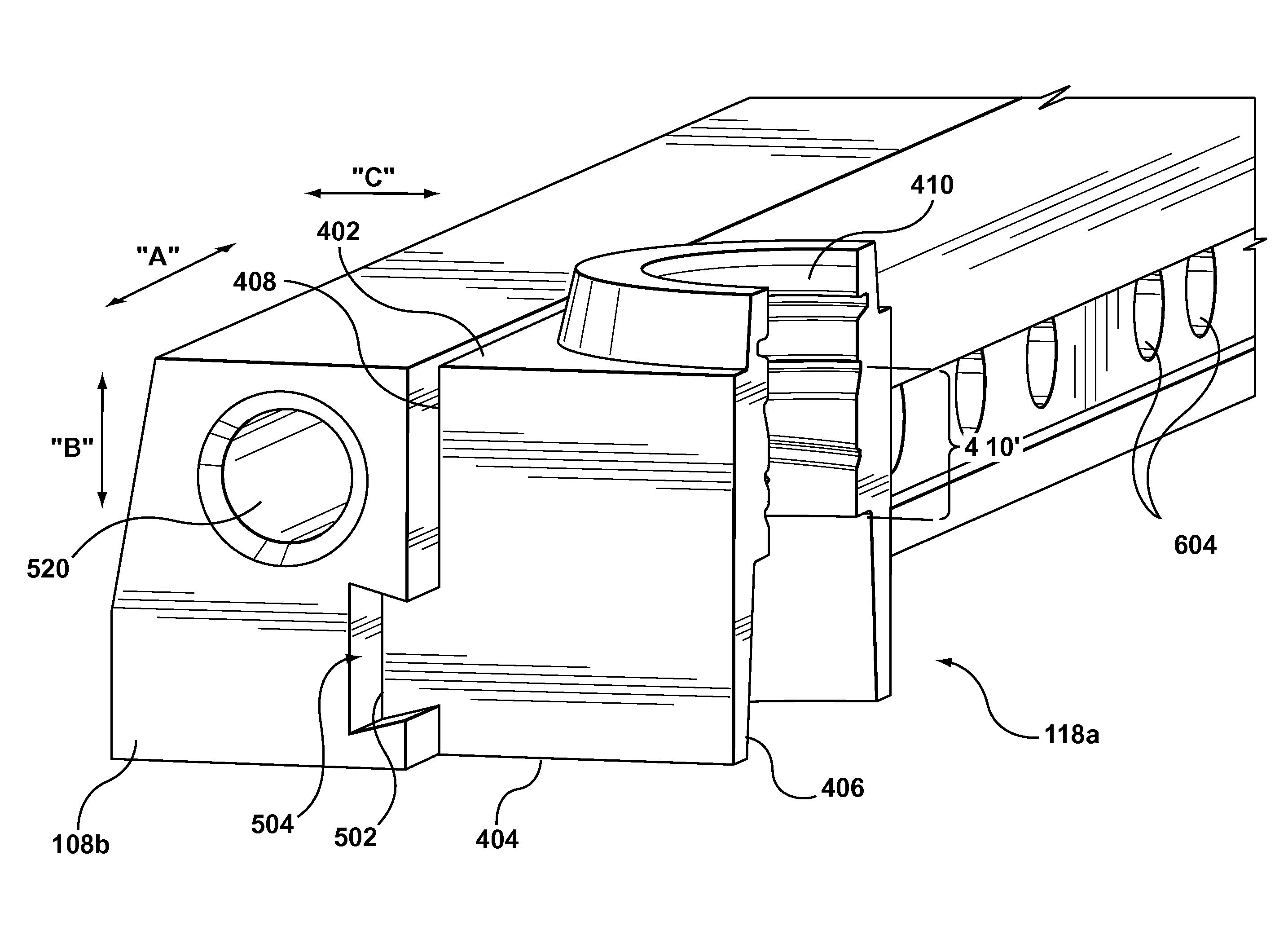

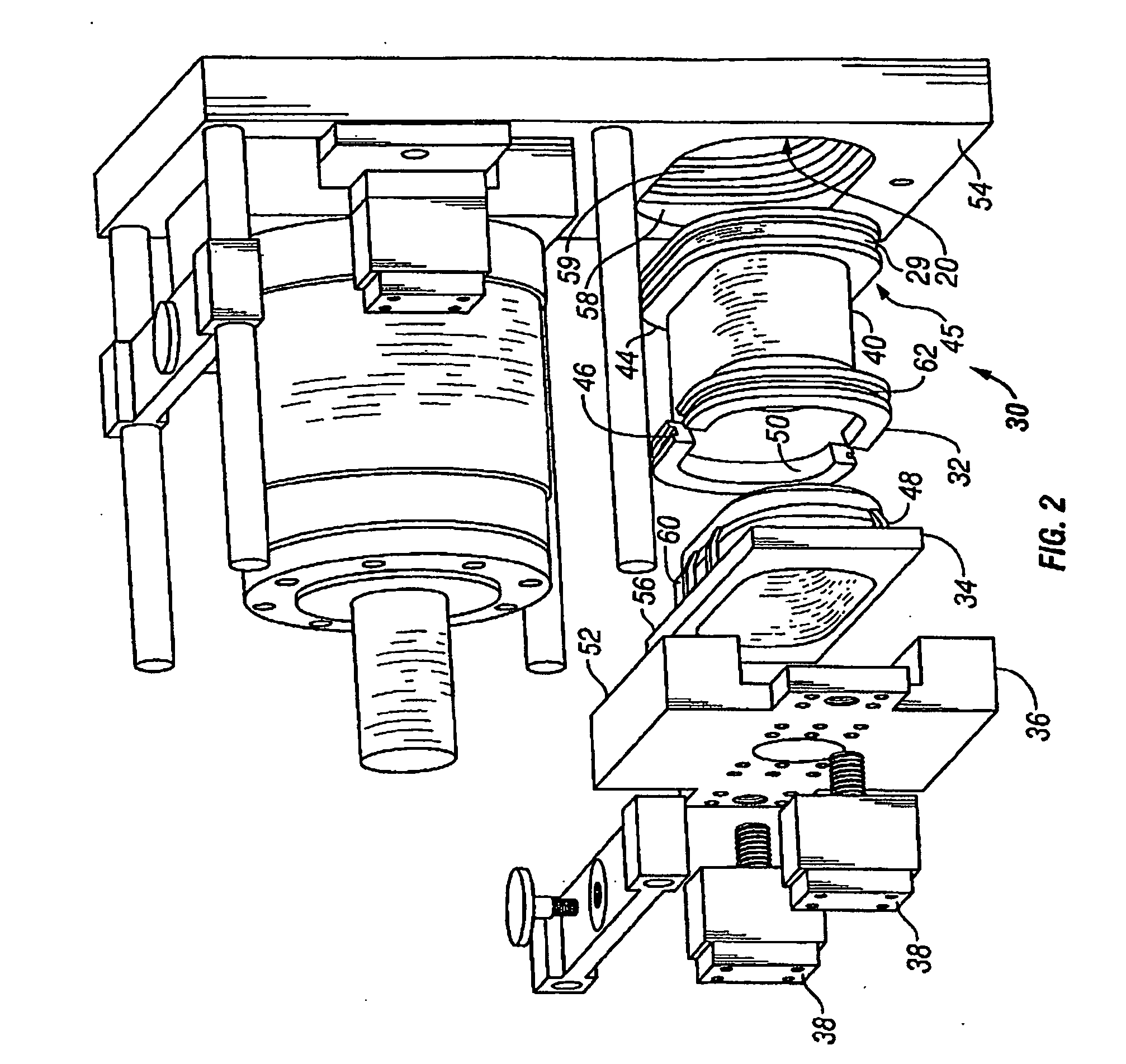

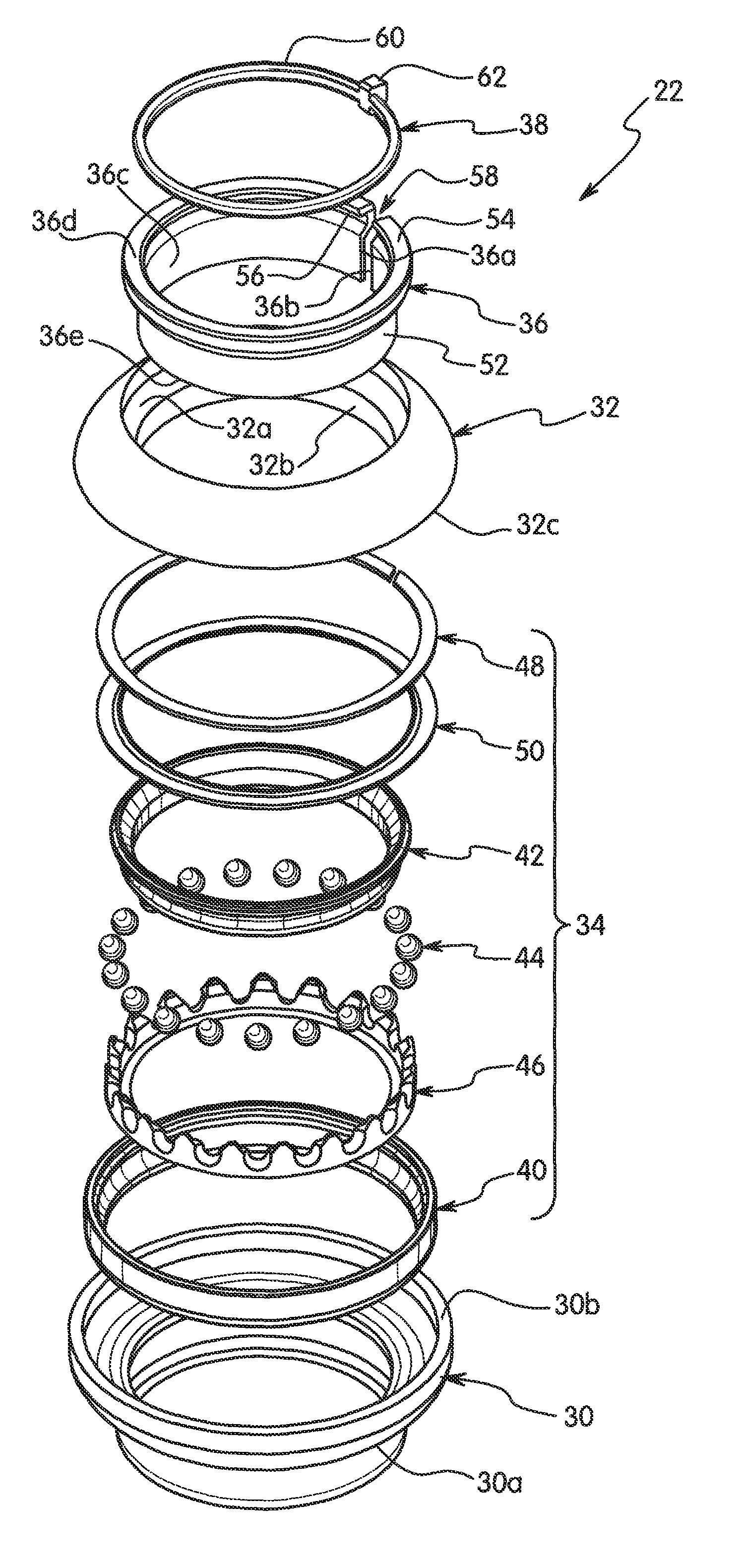

Split Mold Insert for a Molding System

InactiveUS20080268086A1Reduce wearReduce stack heightDomestic articlesEngineeringMechanical engineering

According to embodiments of the present invention, there is provided a split mold insert for a molding system. A first split mold insert complementary to a second split mold insert, the first and second split mold inserts configured, in use, to form a neck region of a preform capable of being blow-molded. The first split mold insert comprises a top portion and a bottom portion; the top portion for abutting, in use, a cavity plate assembly and the bottom portion being at an opposite extreme relative to the top portion; a back portion and a face portion opposite each other, extending between the top and bottom portions, the face portion defining a molding surface defining portion for forming, in use, at least a portion of the neck region of the preform; the back portion comprising a connecting interface for connecting, in use, to a slide bar.

Owner:HUSKY INJECTION MOLDING SYST LTD

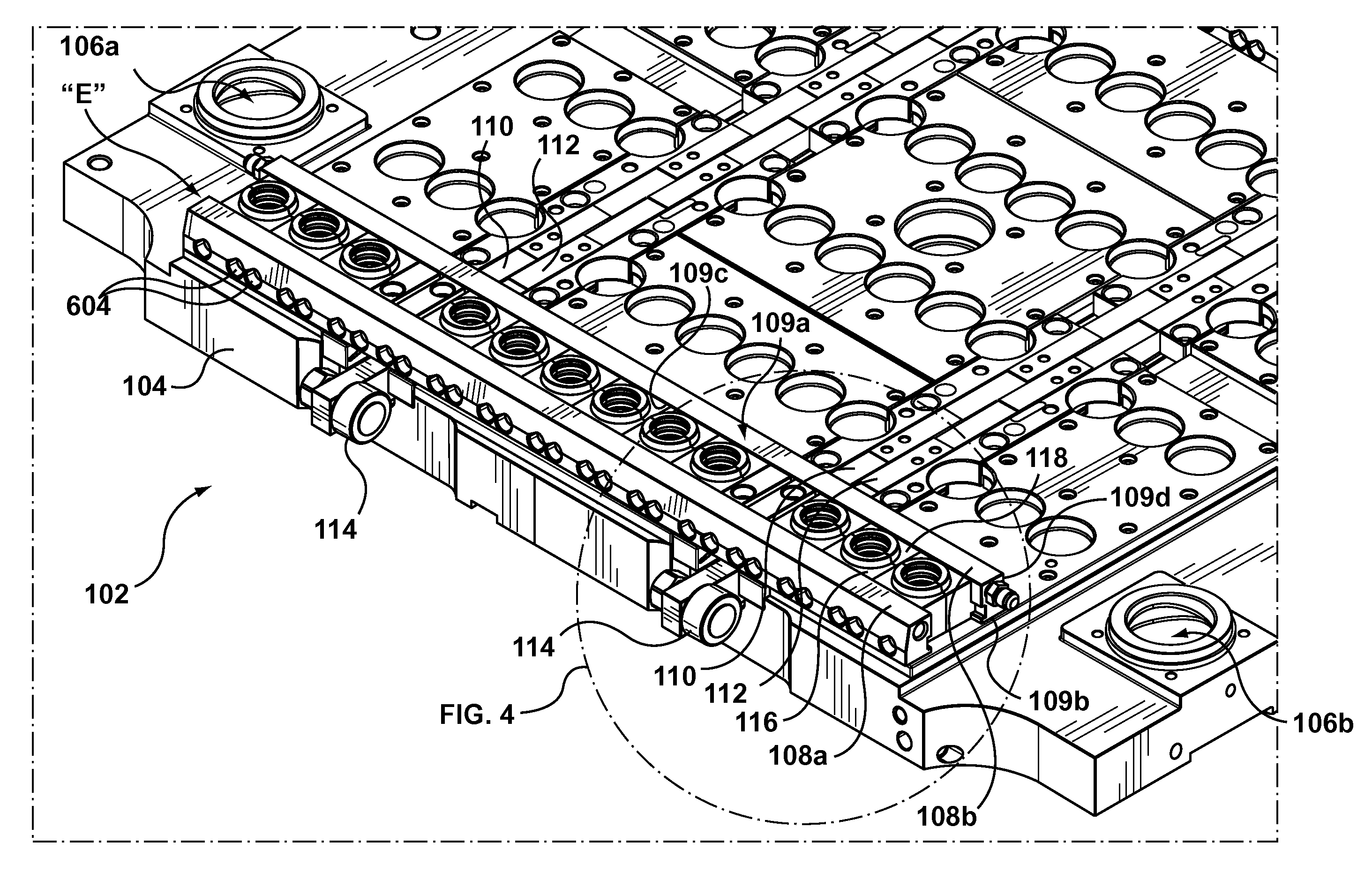

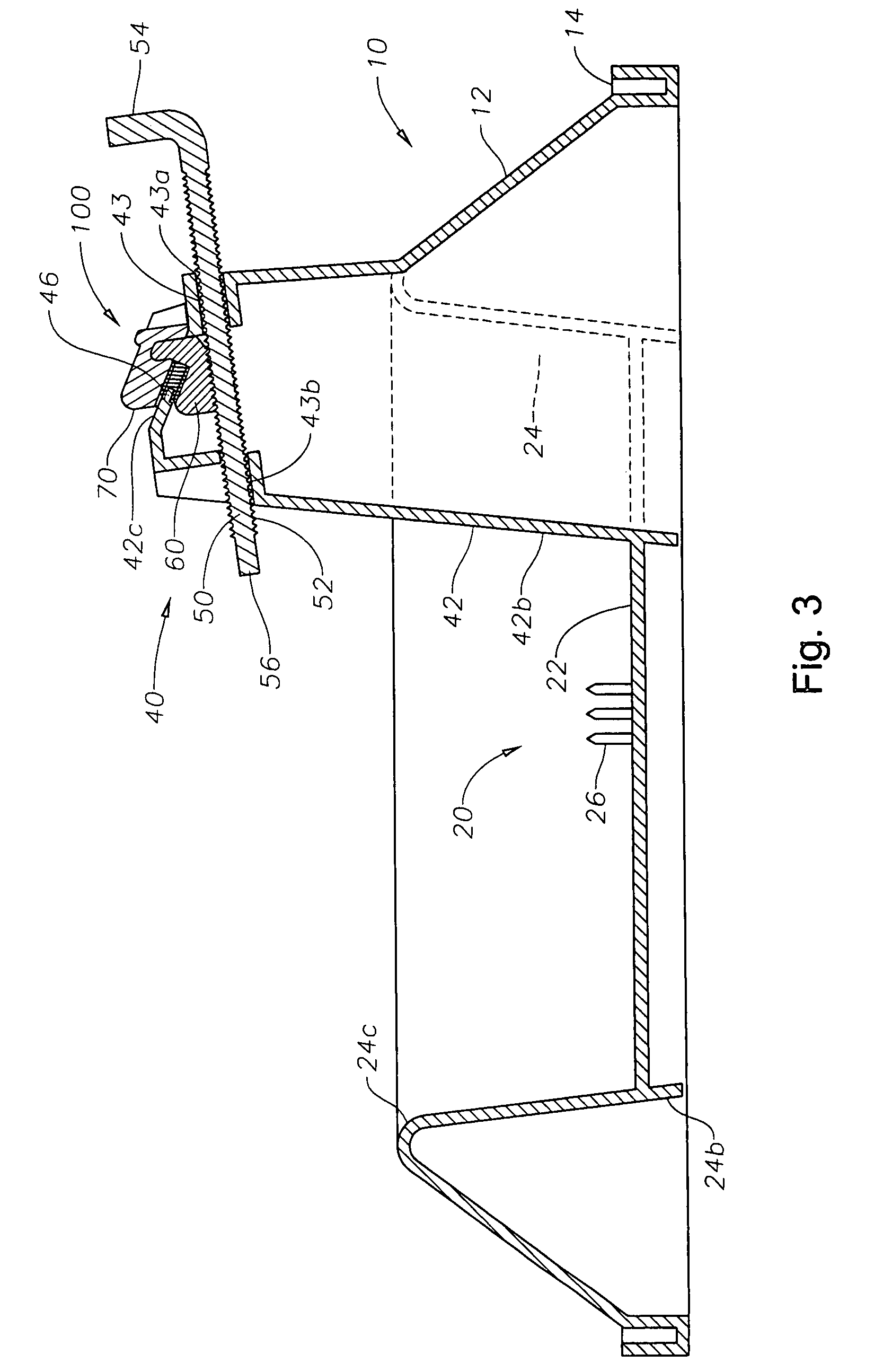

Multiple bore termination system having an integrally formed component

ActiveUS7381103B2Easy to installLess componentsCouplings bases/casesClamped/spring connectionsEngineeringFastener

A cable termination housing for terminating a cable to one or more devices includes a bore for receiving a device mating portion, a component portion integrally formed within the housing, the component portion having a fastener that is slidable between a retracted position wherein fastener does not extend into the lug aperture of the cable assembly and an extended position wherein the fastener extends into the lug aperture. Preferably, the fastener is rotatable while in its extended position so as to couple with the device mating portion.

Owner:RICHARDS MFG CO INC

Split mold insert for a molding system

InactiveUS7798804B2Reduce wearReduce stack heightMouldsConfectioneryEngineeringMechanical engineering

According to embodiments of the present invention, there is provided a split mold insert for a molding system. A first split mold insert complementary to a second split mold insert, the first and second split mold inserts configured, in use, to form a neck region of a preform capable of being blow-molded. The first split mold insert comprises a top portion and a bottom portion; the top portion for abutting, in use, a cavity plate assembly and the bottom portion being at an opposite extreme relative to the top portion; a back portion and a face portion opposite each other, extending between the top and bottom portions, the face portion defining a molding surface defining portion for forming, in use, at least a portion of the neck region of the preform; the back portion comprising a connecting interface for connecting, in use, to a slide bar.

Owner:HUSKY INJECTION MOLDING SYST LTD

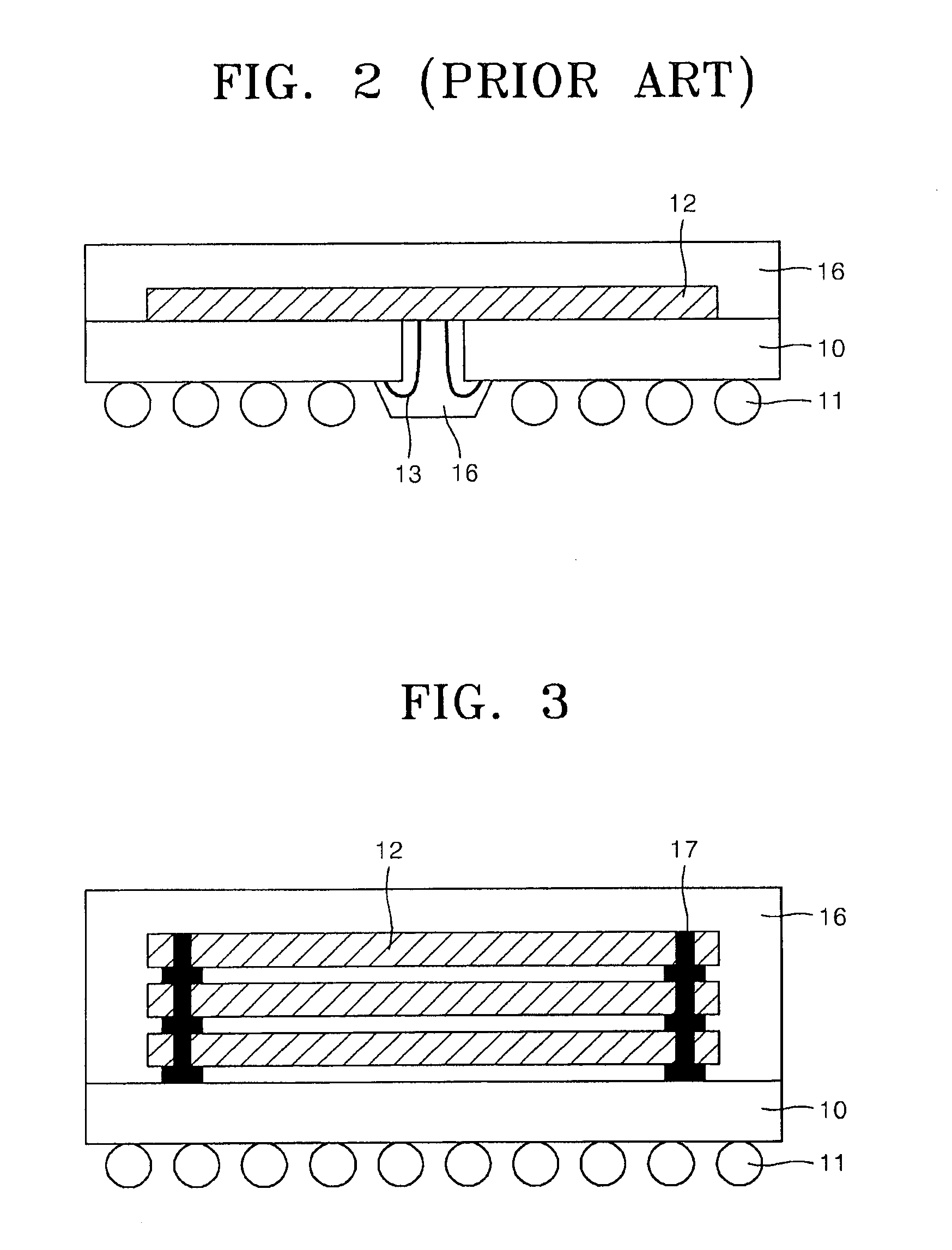

Structure of semiconductor chip with silicon through hole and stacking assembly thereof

InactiveCN101533811AReduce stack heightImprove manufacturing yieldSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEmbedment

The invention provides a structure of a semiconductor chip with silicon through holes and stacking assembly thereof; two or more through holes vertically penetrate bonding pads on the upper surface and the lower surface of a semiconductor substrate; two or more first flange rings are convexly arranged on the bonding pad which is arranged on the upper surface of the semiconductor substrate, thus leading the corresponding bonding pad to be provided with a contact surface which is arranged between the first flange rings and the through holes; two or more second flange rings are convexly arranged on the bonding pad which is arranged on the lower surface of the semiconductor substrate, thus leading the corresponding bonding pad to be provided with a contact surface which surrounds the outside of the second flange rings; and the second flange rings can be embedded in the first flange rings due to the dimension thereof. By utilizing the embedment of the flange rings, the invention can realize the accurate matchup of the chips and avoid displacement, and also can realize a chip stacking technique of stacking the chips first and then filling the through holes with materials for filling holes, wherein the materials for filling holes does not flow out and no electrical short circuit of the adjacent through holes exists, thus meeting the requirements of micro-interval between silicon through holes.

Owner:POWERTECH TECHNOLOGY

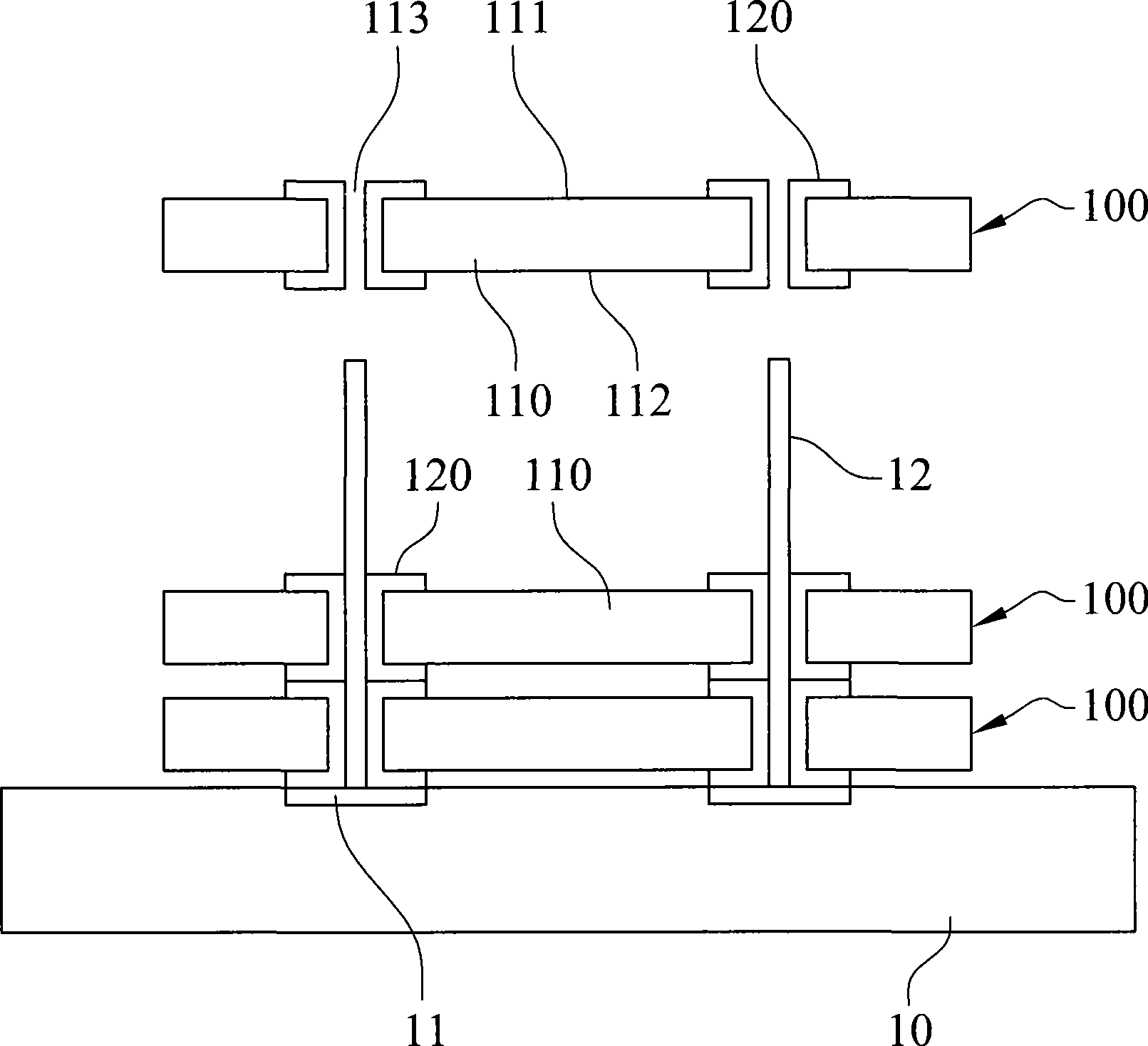

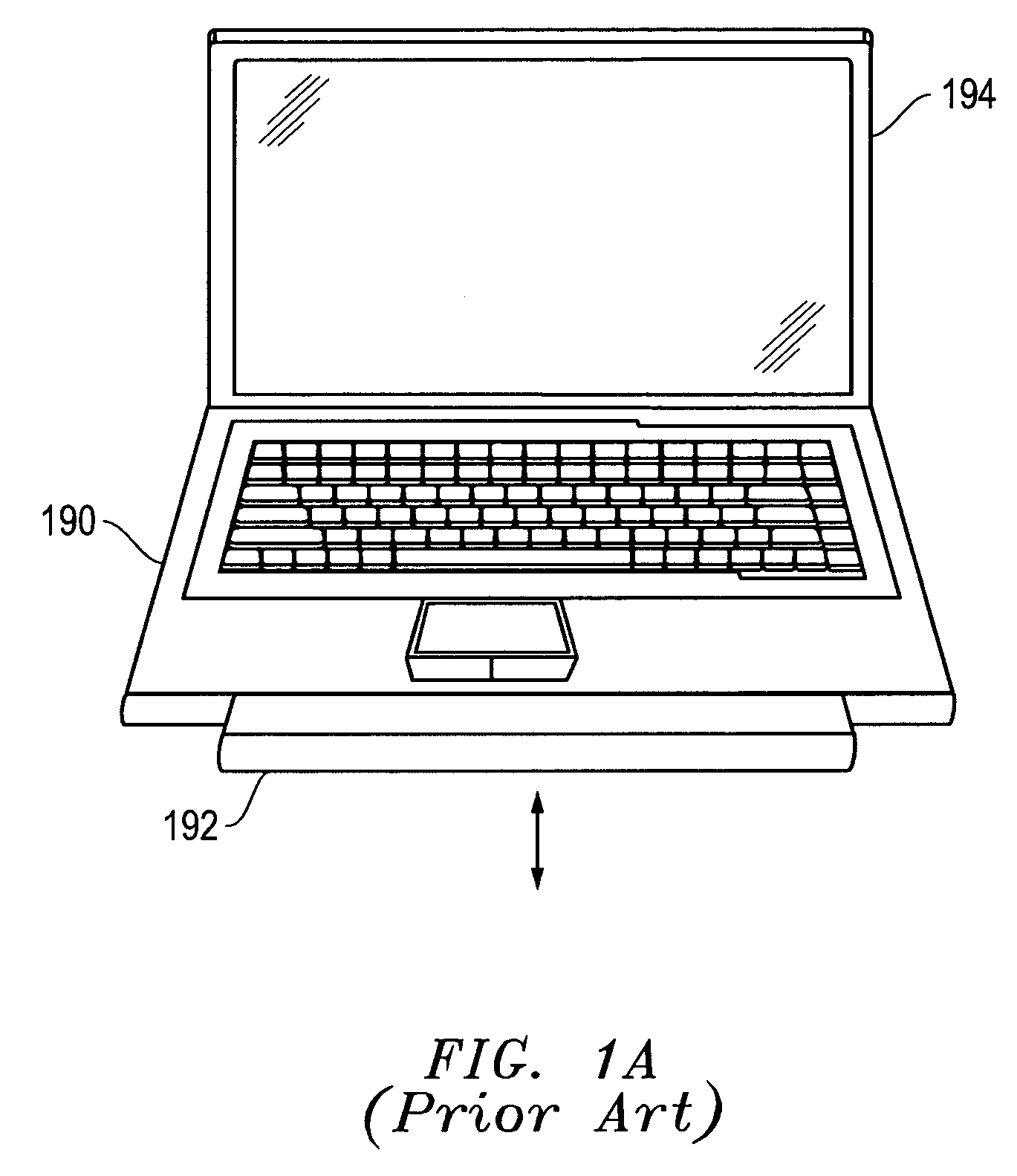

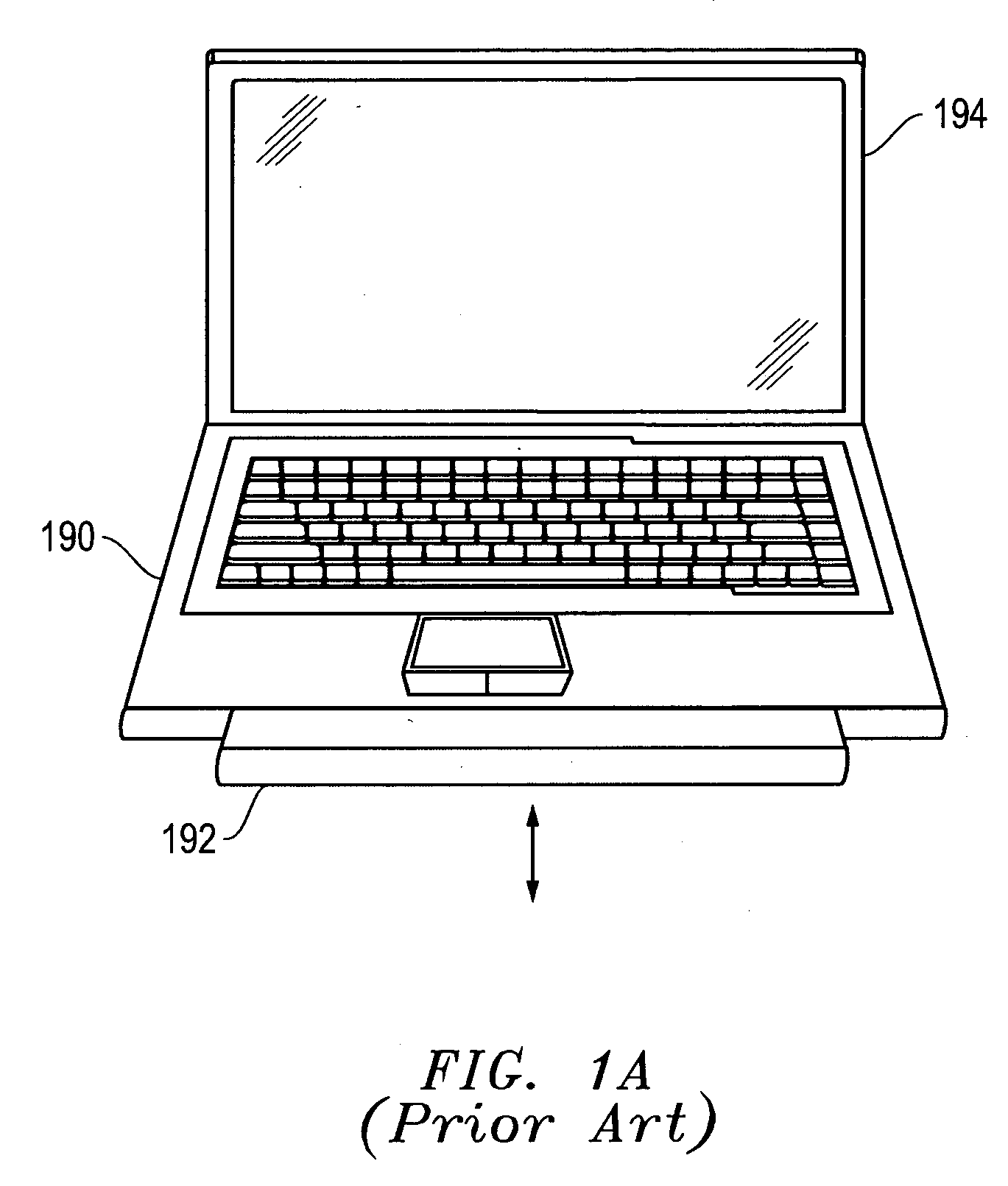

Apparatus and methods for battery installation

ActiveUS8399117B2Small sizeImprove usabilityDigital data processing detailsSecondary cells charging/dischargingDisplay deviceHandling system

Apparatus and methods for placement of battery packs in portable information handling systems such as notebook and netbook computers. A first set of pivot features may be provided on opposing sidewalls of a battery well that interface with a corresponding set of mating pivot features provided on exterior end surfaces of a battery pack such that the battery pack may be pivoted into and out from the battery well to install or release it from the system, e.g., pivoted from the bottom of the portable information handling system in a manner that does not interfere with, or require modification to, the lid and display of the portable information handling system. A latch mechanism and battery release feature may be further provided that acts to transfer horizontal manipulation (e.g., horizontal sliding motion) of the battery release feature to a vertical latching action that acts to lift the battery pack out from the portable information handling system chassis when releasing the battery pack from the chassis.

Owner:DELL PROD LP

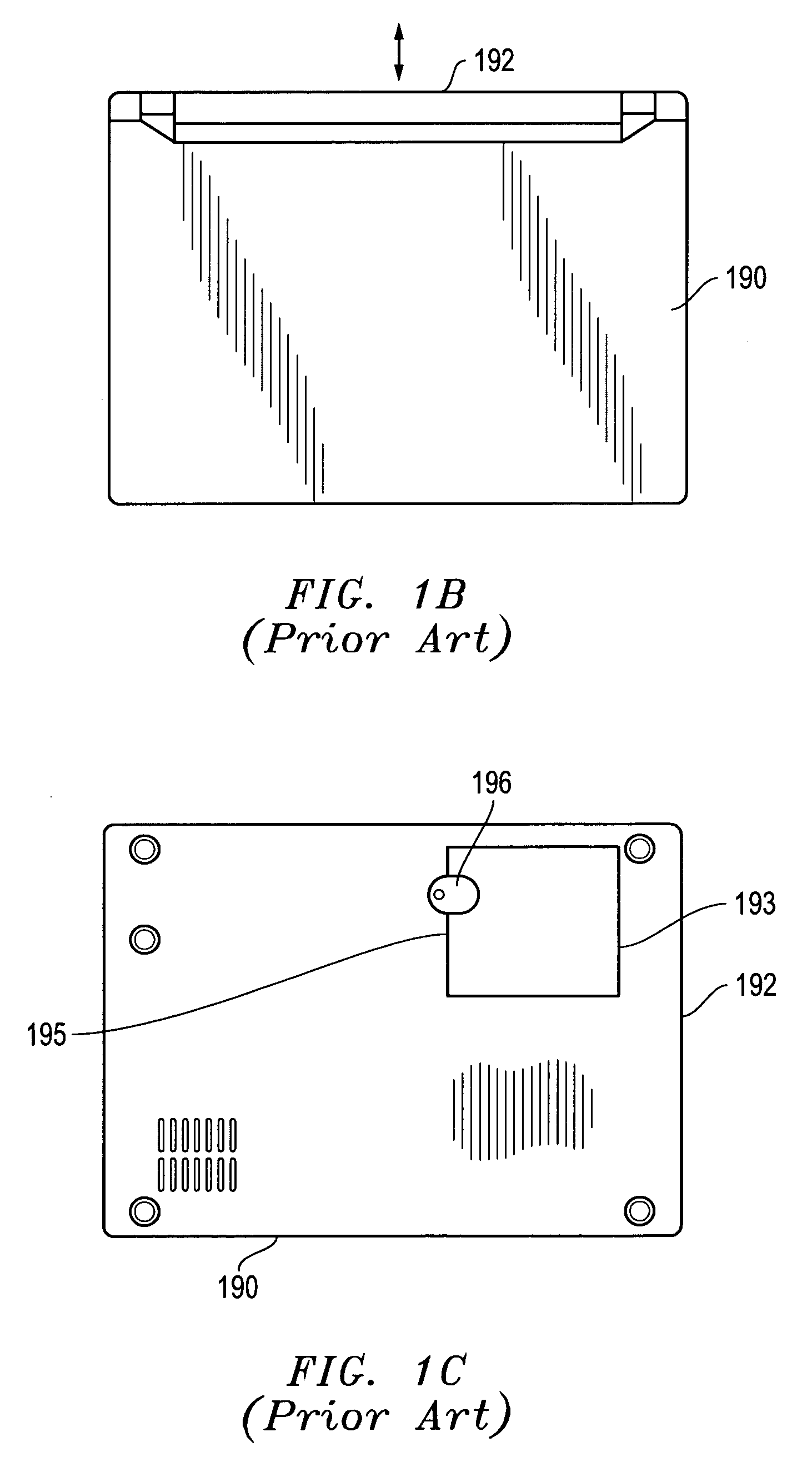

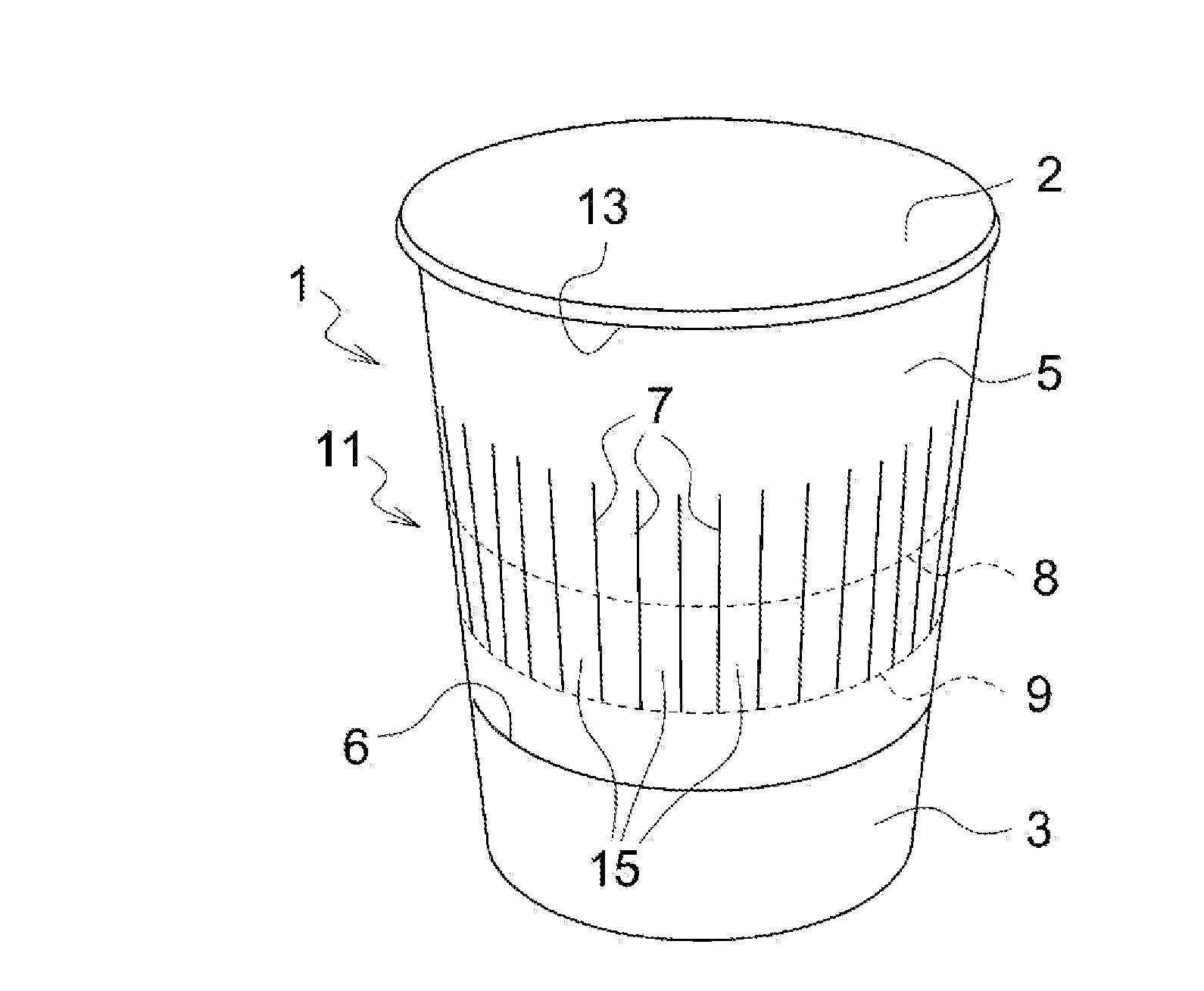

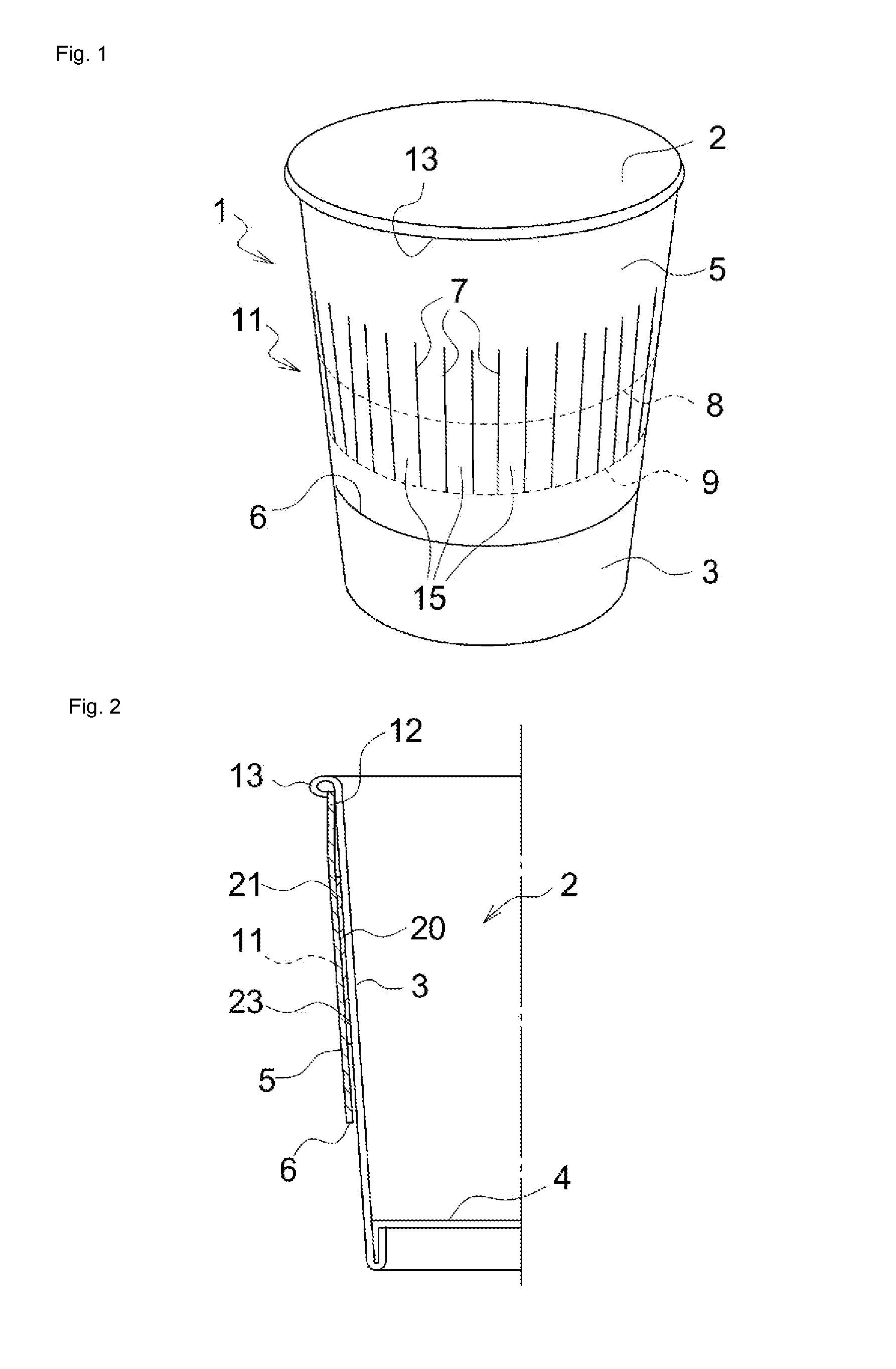

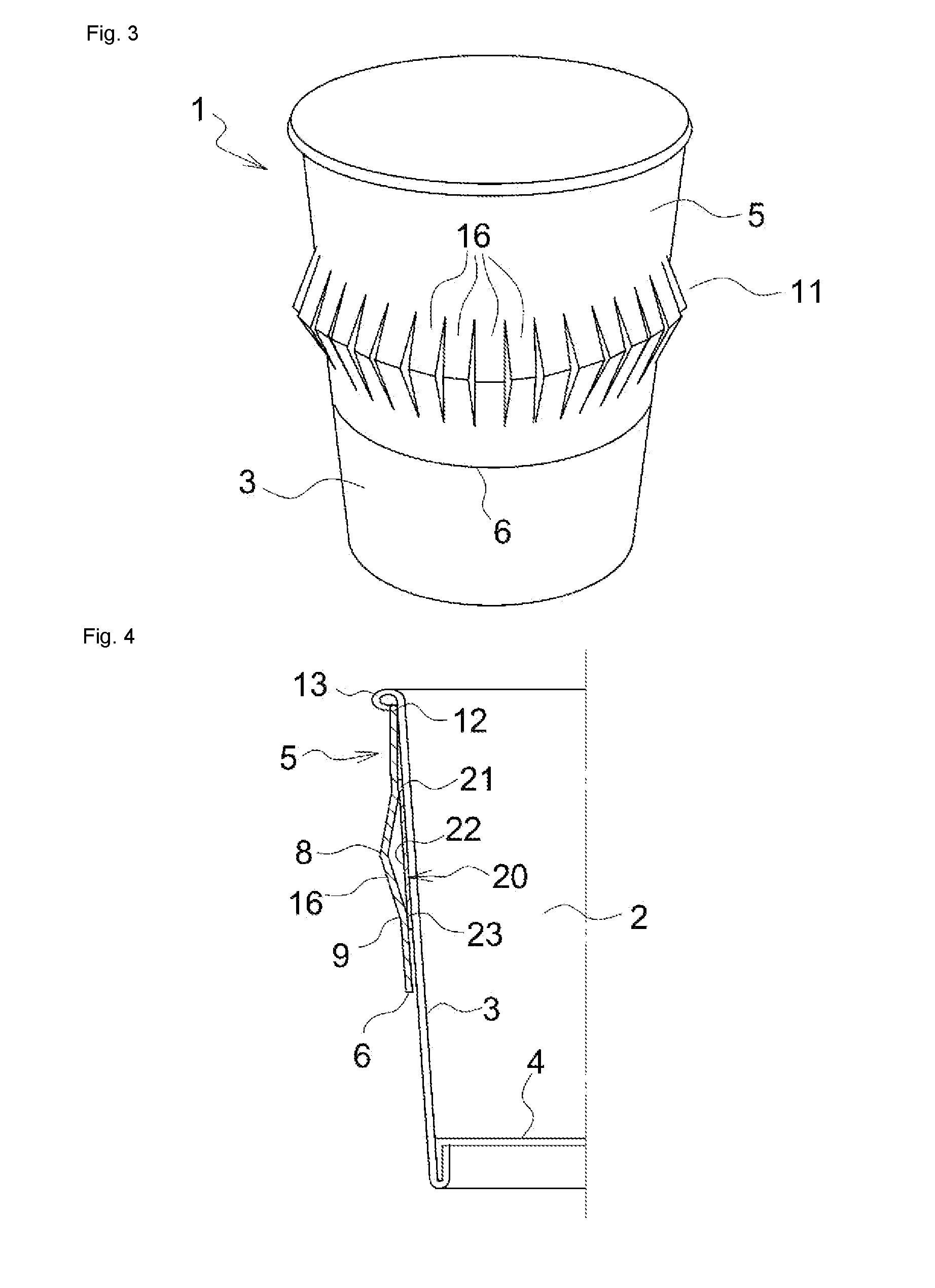

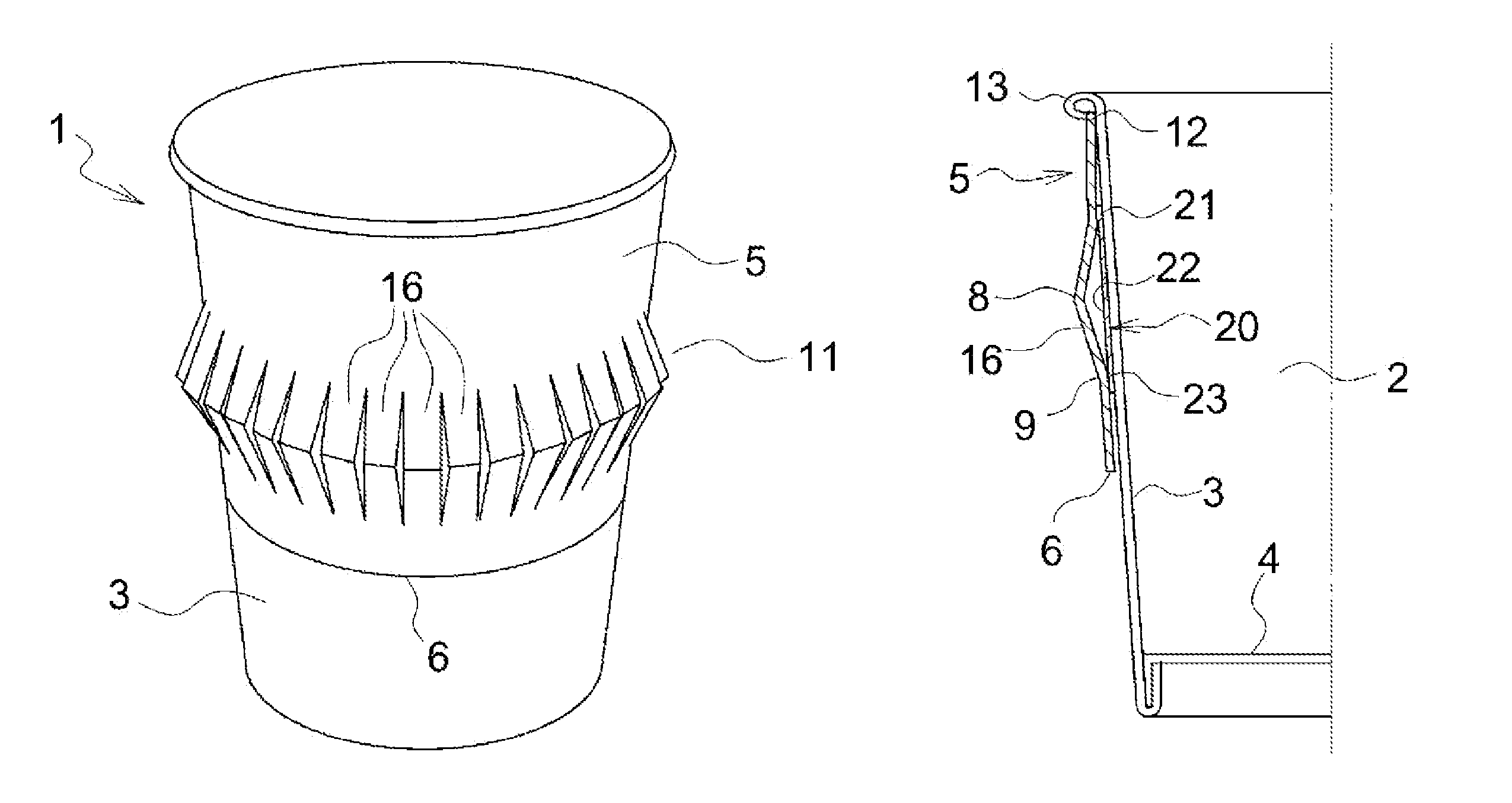

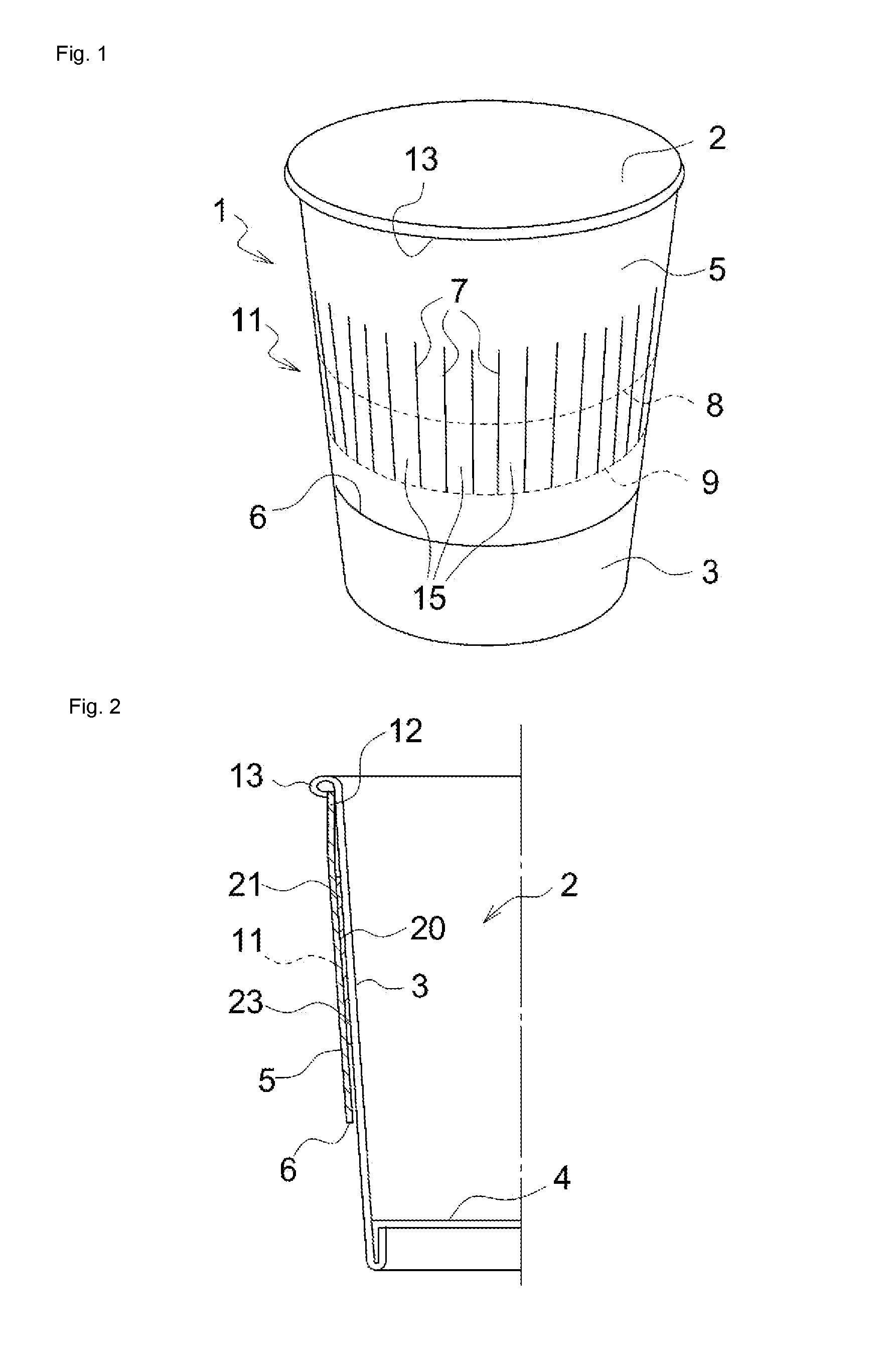

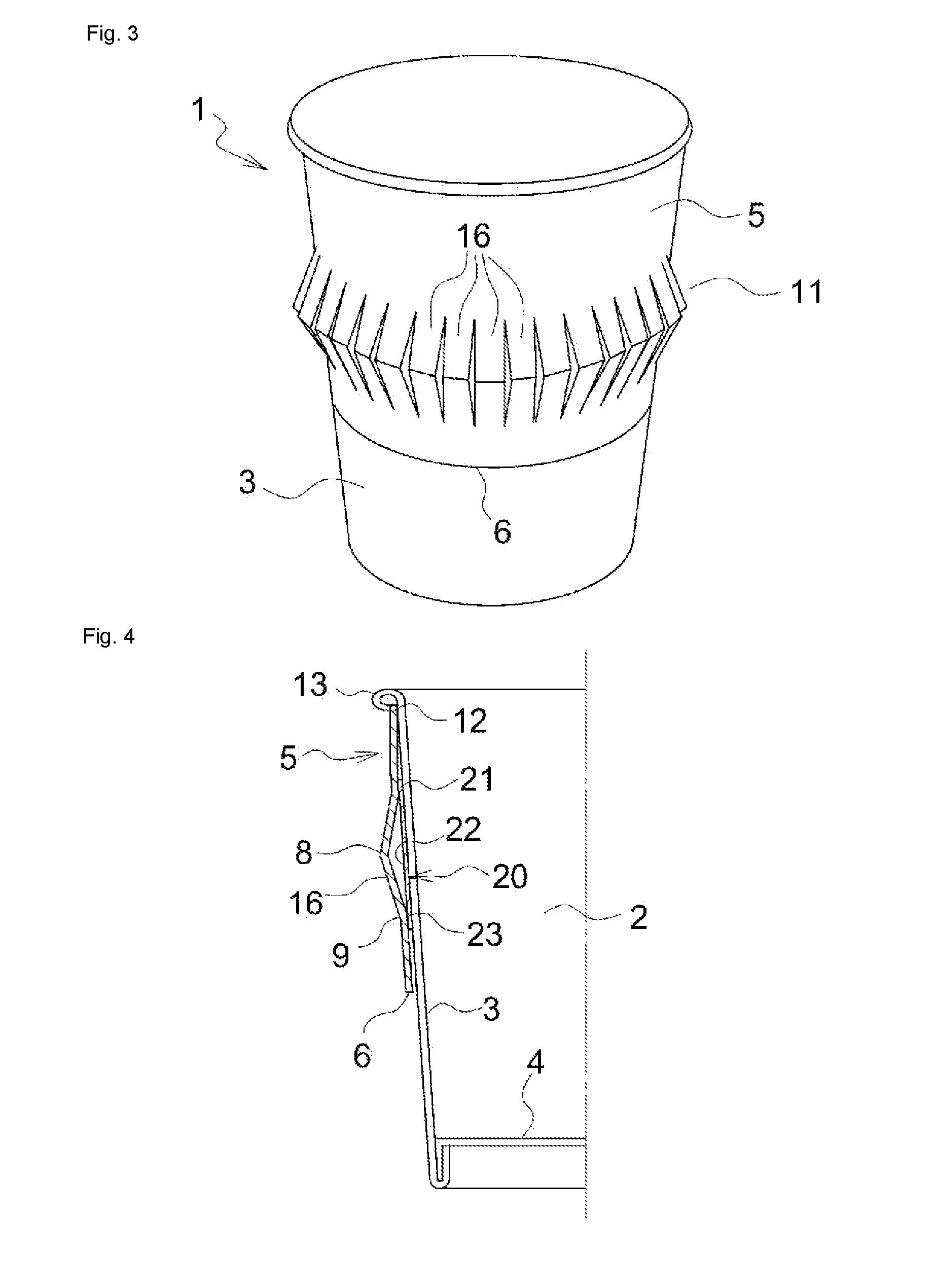

Heat insulated container

ActiveUS20100224637A1Improve cooling effectReduce stack heightDomestic cooling apparatusLighting and heating apparatusEngineeringBiomedical engineering

Owner:TOKAN KOGYO CO LTD

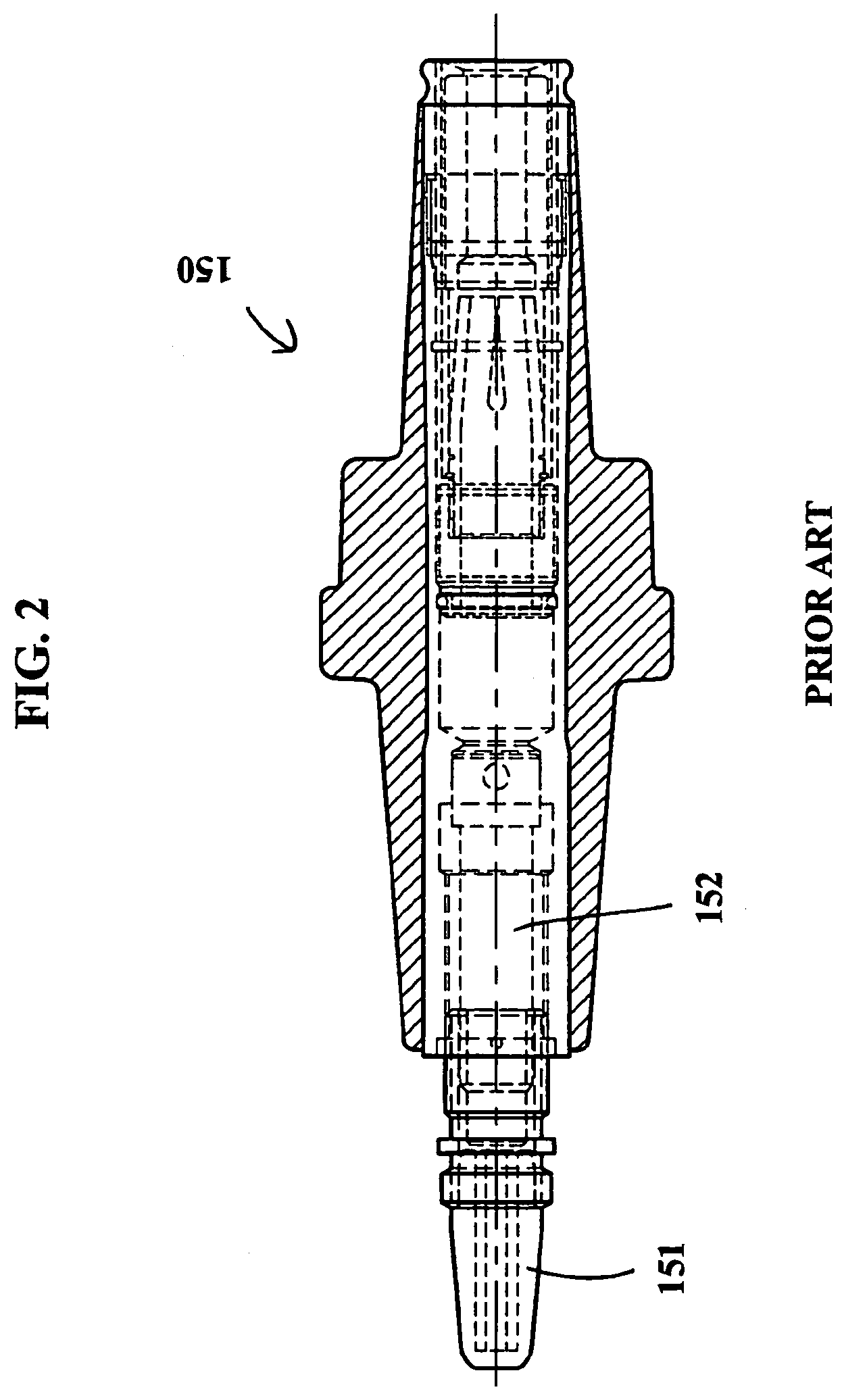

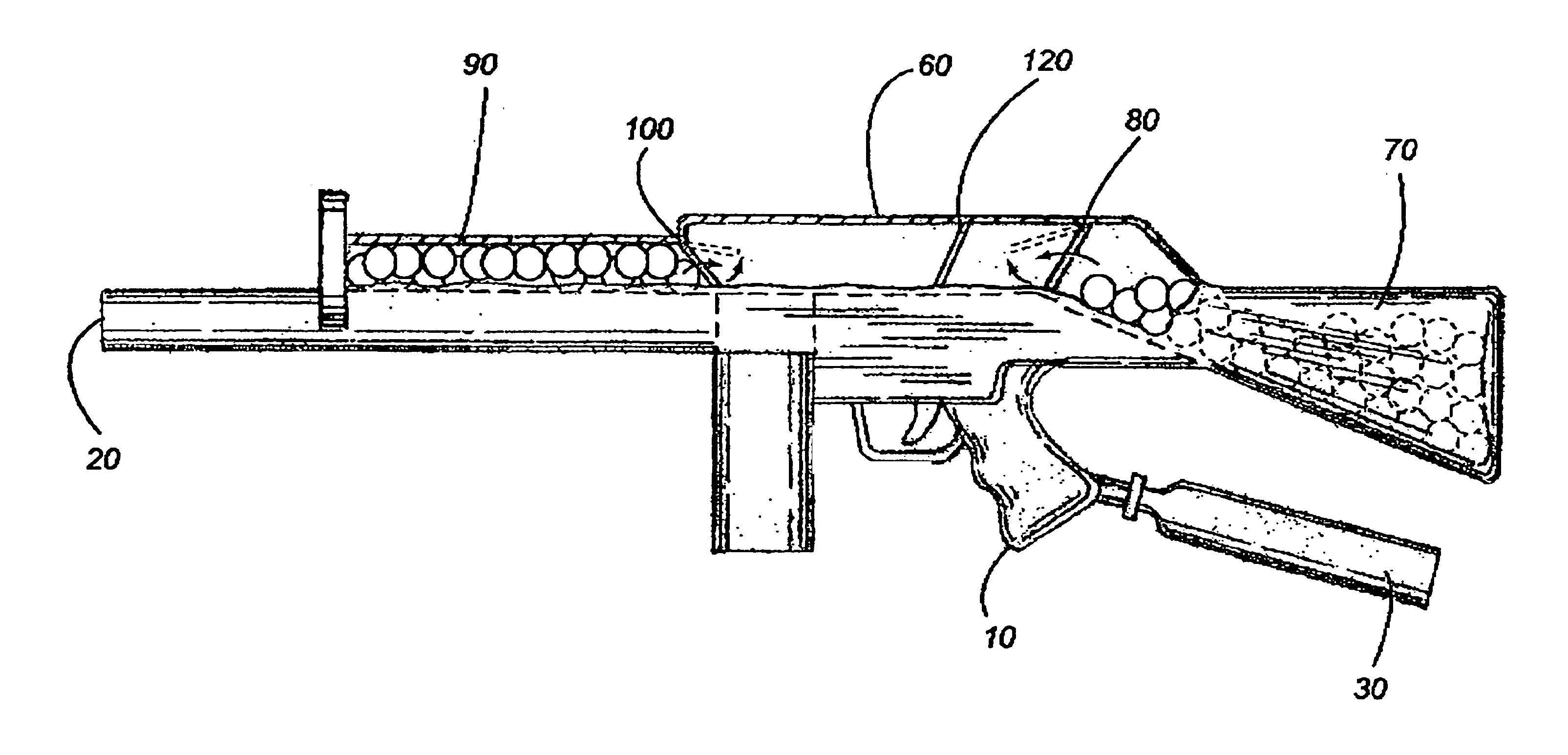

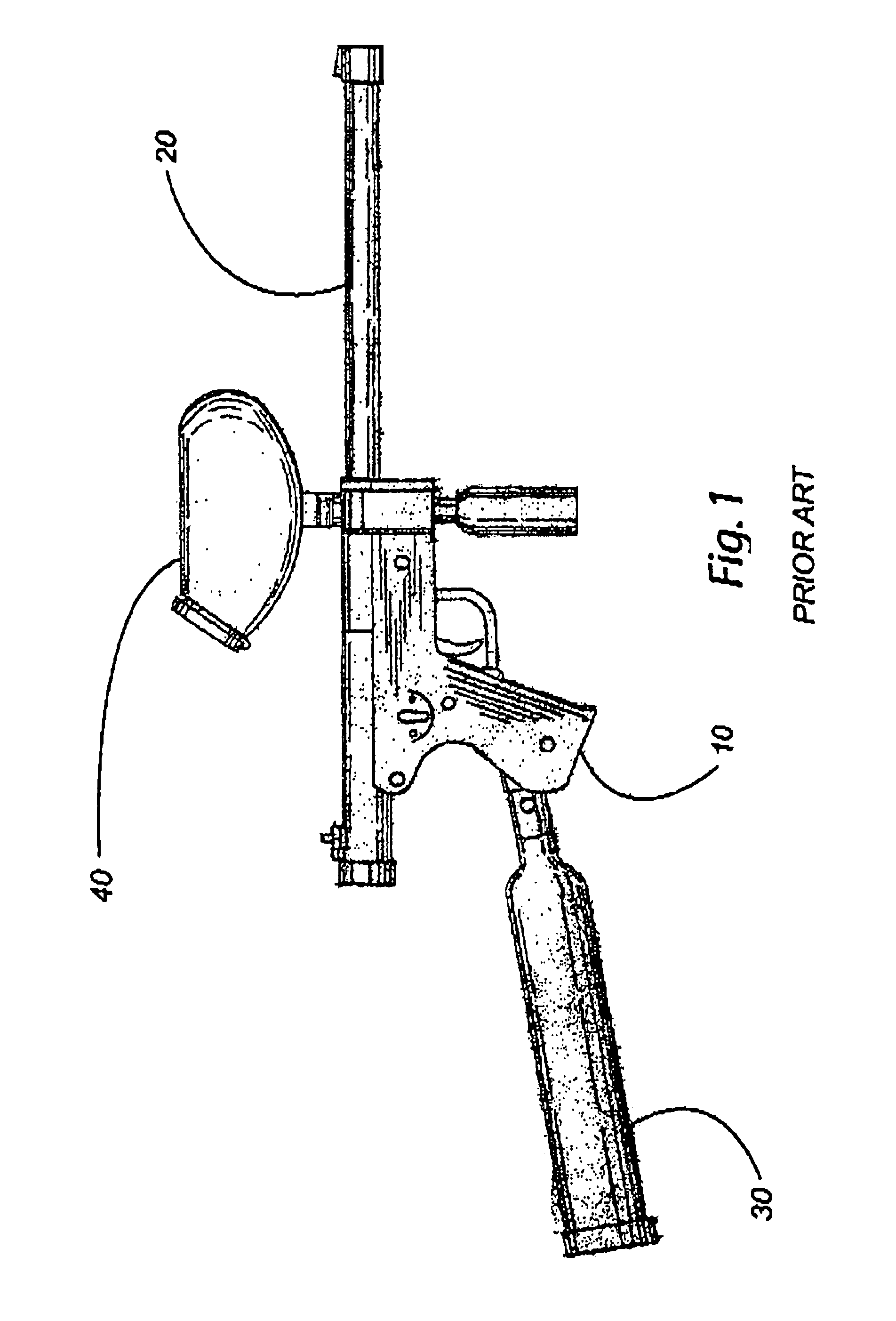

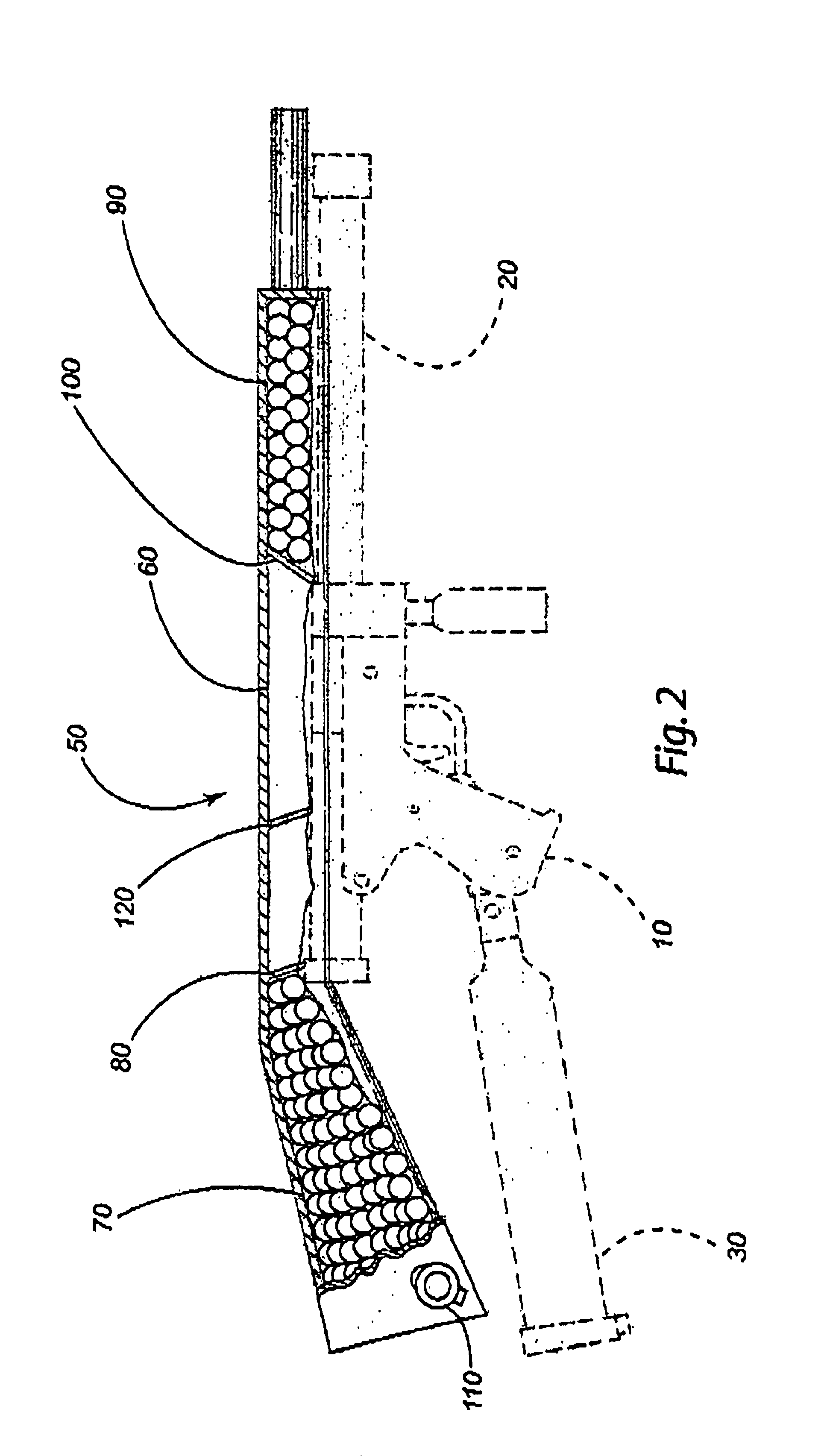

Paintball munition chamber and paintball gun utilizing the same

InactiveUS6935324B2Fit tightlyPrevent returnAmmunition loadingCompressed gas gunsState of artEngineering

A hopper for a paintboll gun is disclosed. The hopper is a gravity feed hopper and has a lower profile than those in the previous art. The hopper fits closely to the profile of the paintball gun and may have multiple chambers along with unidirectional gates to control the flow between chambers and within chambers as well. This invention may take the form of a hopper mounted onto a previous type of paintboll gun as an aftermarket add-on or it may be built into the paintball gun itself as part of its construction.

Owner:WATSON JASON D +1

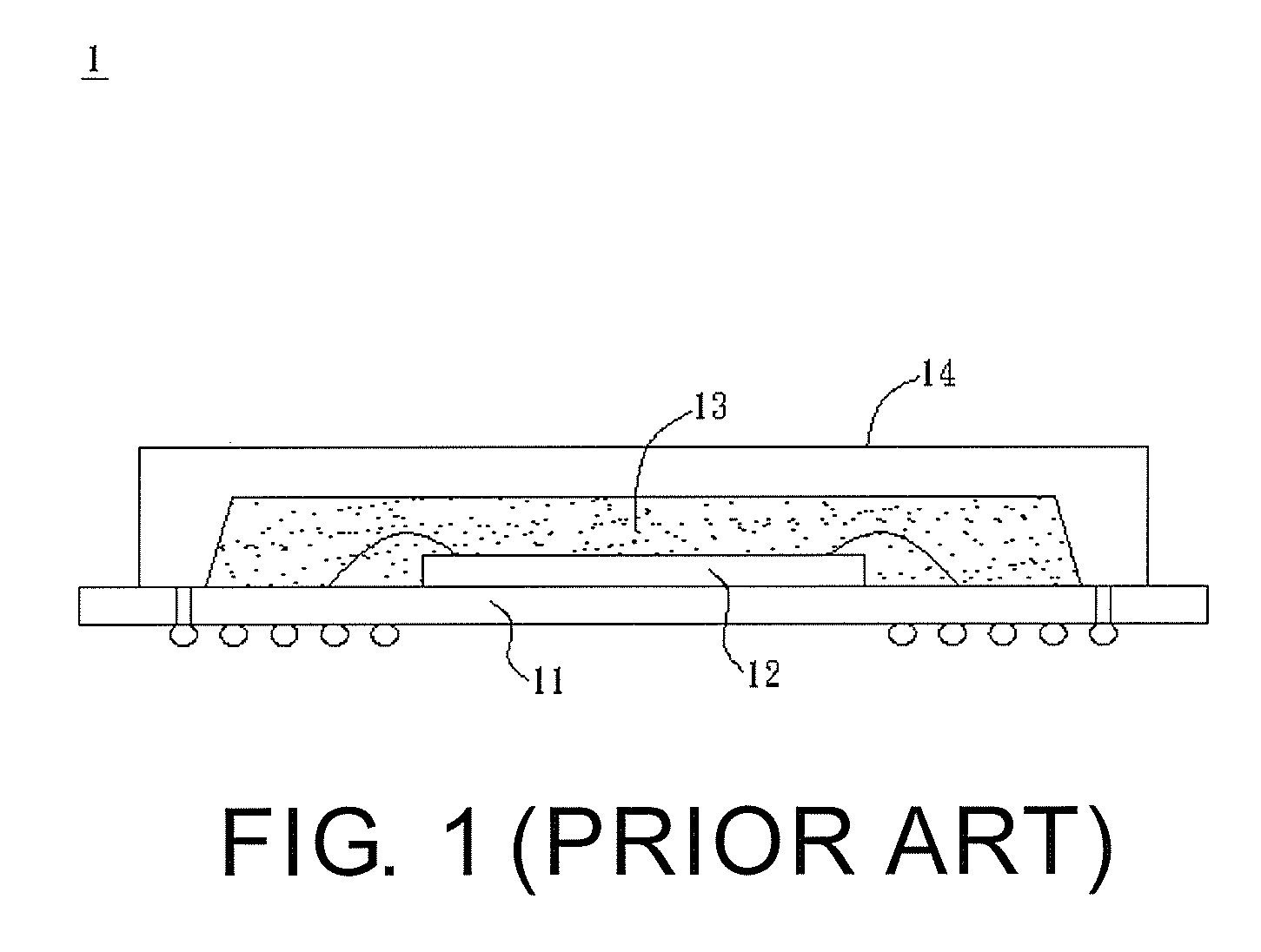

Semiconductor package and manufacturing method thereof

InactiveUS20090065911A1Reduce stack heightSmall sizeSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

A semiconductor package includes a carrier, at least one chip, an encapsulation, and a patterned conductive film. The carrier has a first surface and a second surface opposite to the first surface. The chip is disposed on the first surface of the carrier and electrically connected to the carrier. The encapsulation encapsulates the chip and at least a portion of the first surface of the carrier. The patterned conductive film is disposed on the encapsulation to electrically connect to the carrier. A manufacturing method of the semiconductor package is also disclosed.

Owner:ADVANCED SEMICON ENG INC

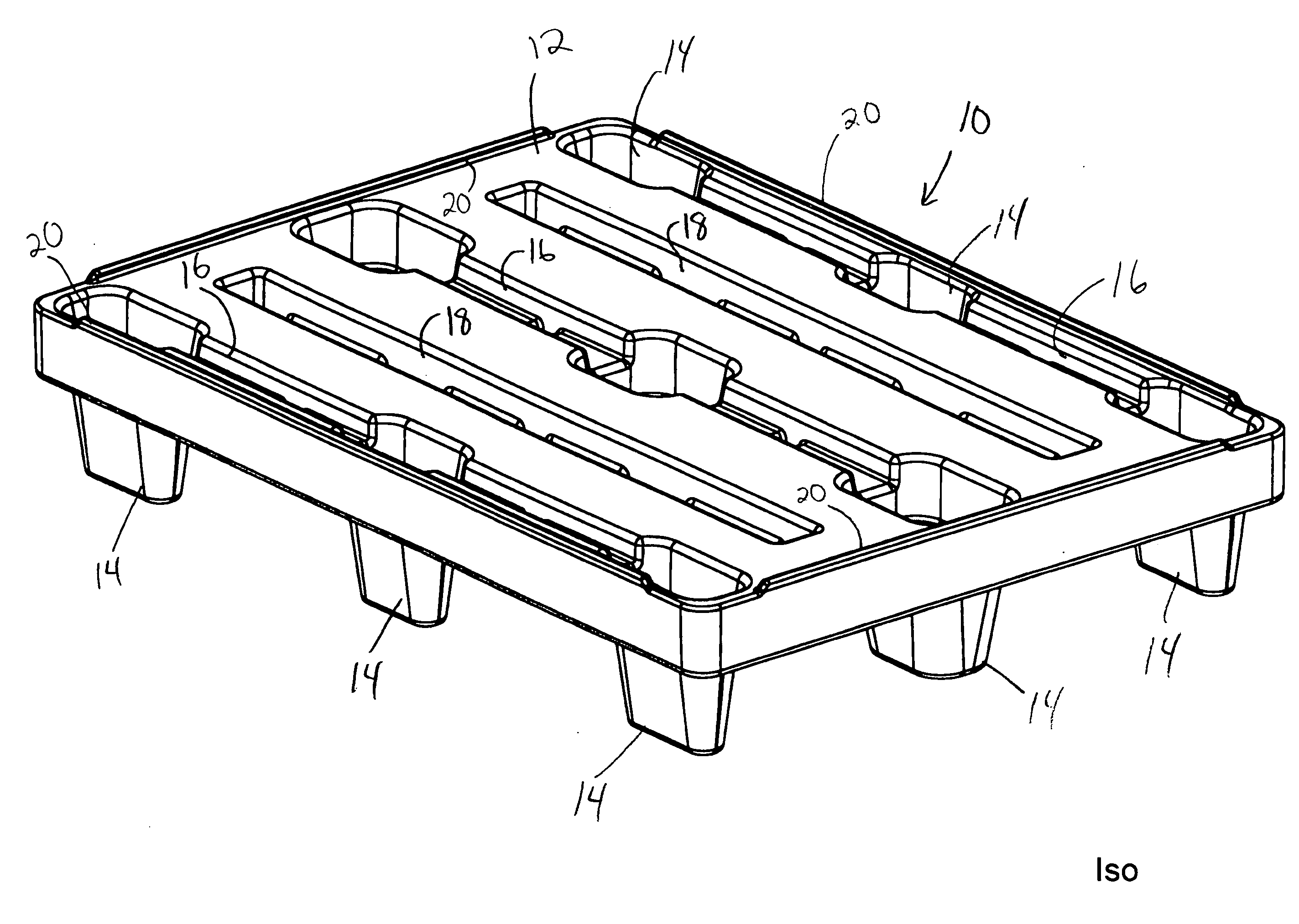

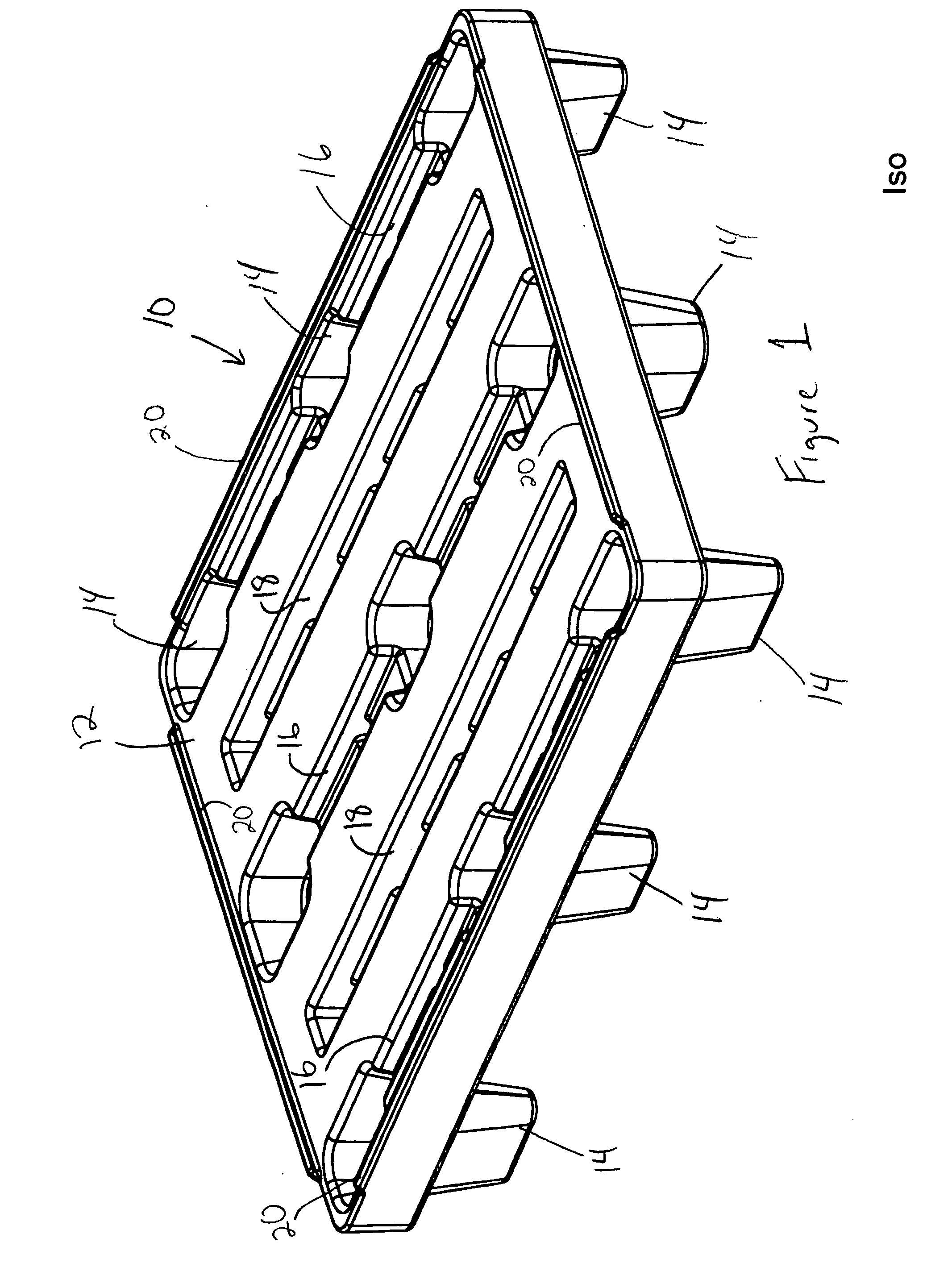

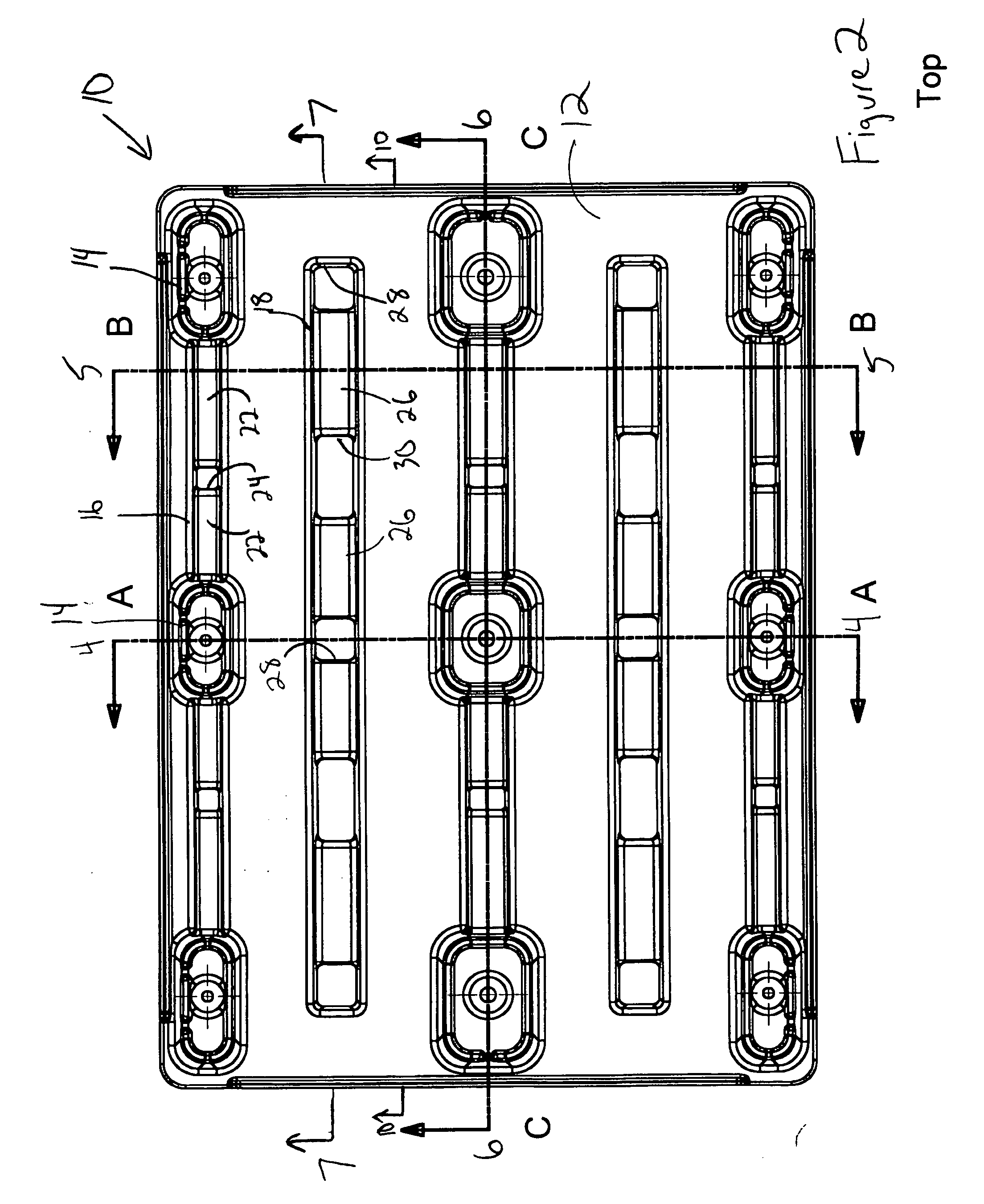

Pallet

ActiveUS20070181045A1Increase stiffnessImproved strength and stiffnessOther manufacturing equipments/toolsCoatingsEngineeringElectrical and Electronics engineering

A pallet includes a plurality of parallel channels or corrugations in an upper surface of the deck. A plurality of perpendicular lower channels or corrugations are formed on a lower surface of the deck. The upper and lower channels or corrugations support one another and provide increased stiffness to the deck. The pallet is designed such that it can be rotomolded.

Owner:REHRIG PACIFIC CO INC

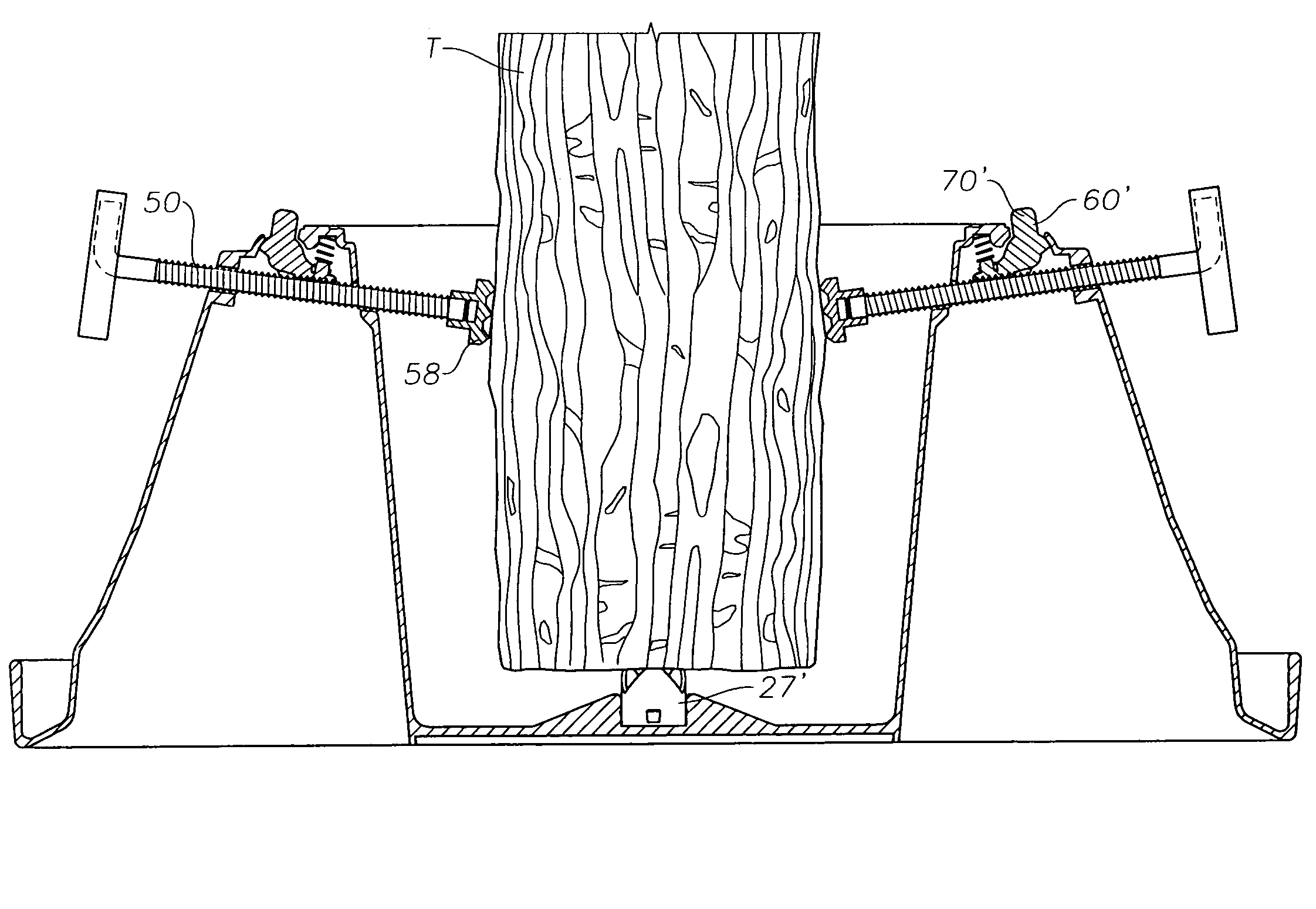

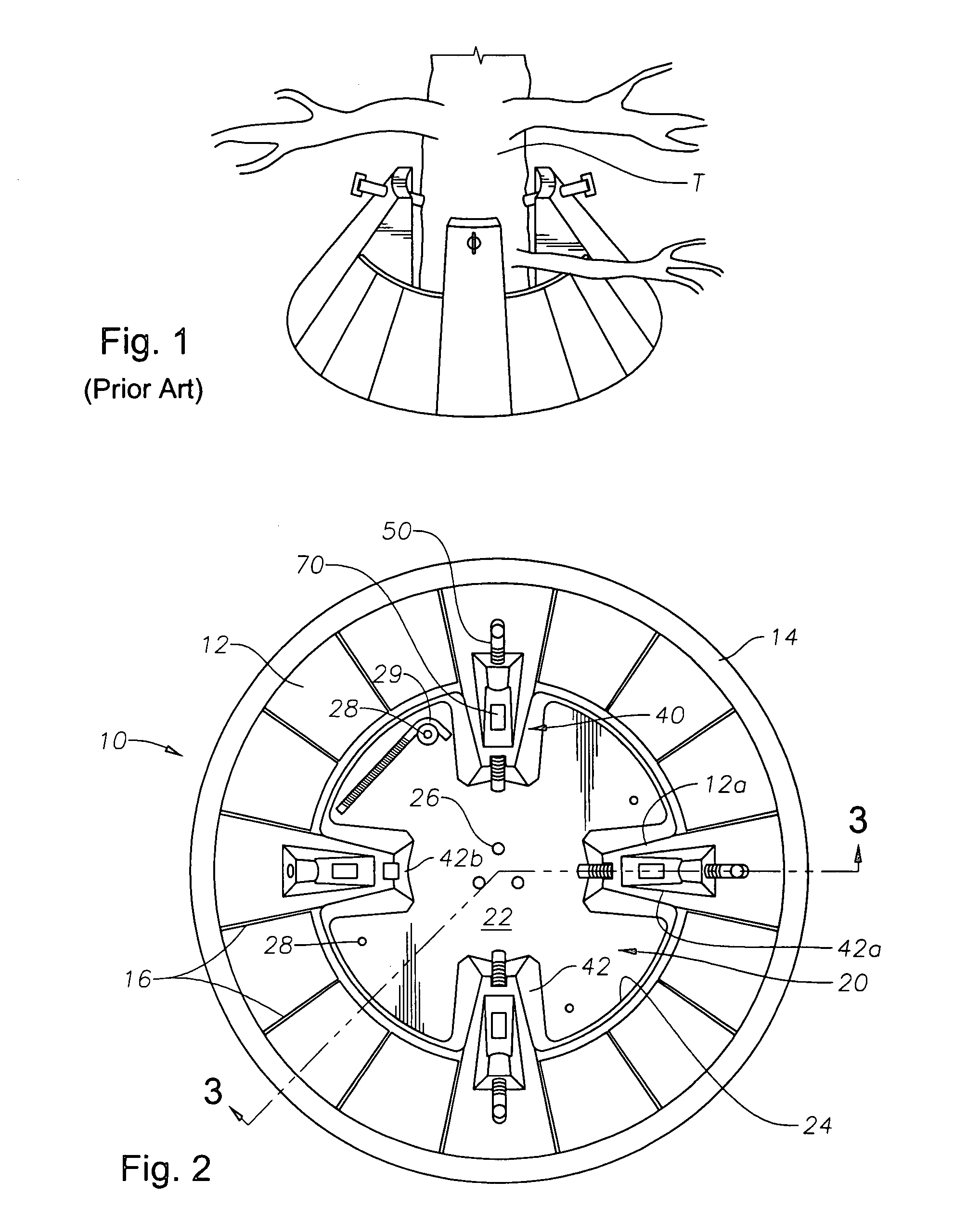

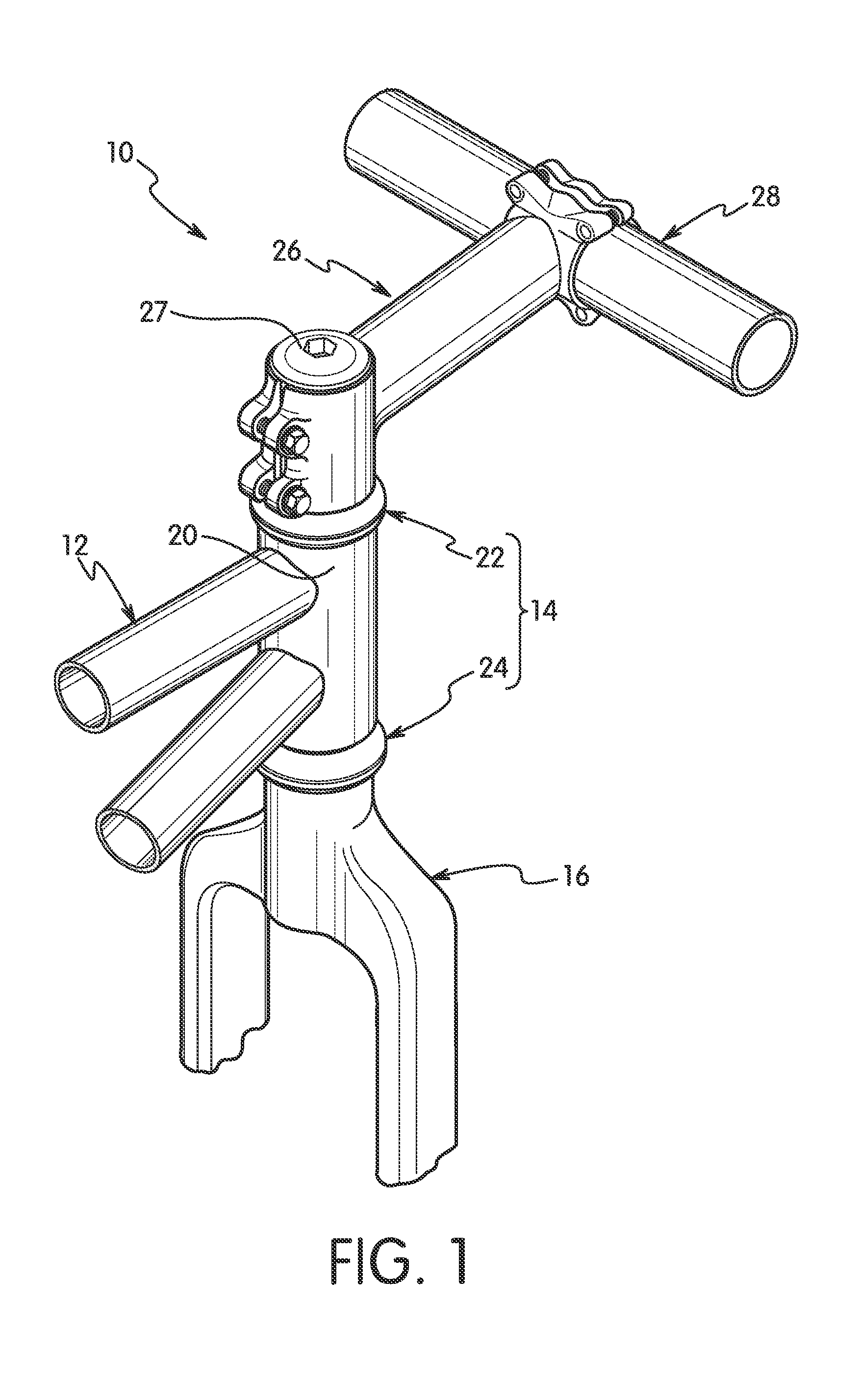

Tree stand with fast-acting screw assembly and method of using same

ActiveUS7600342B2Easy to adjustEasy to assembleFlower holdersReligious equipmentTree trunkEngineering

A tree stand assembly including a container defining a basin and a plurality of securement assemblies attached to the container. The securement assemblies are spaced from each other and define a space within the container for receiving the base of a tree trunk. Each securement assembly has a support member having a passageway in an upper portion thereof and a fast-acting screw assembly. Each fast-acting screw assembly includes an engager having a threaded recess portion, and a bolt having a threaded shank designed to threadedly engage the recess portion threads when the bolt extends through the passageway. The engager has a normal or biased condition allowing the bolt to slide in a first axial direction in the passageway while preventing the bolt from sliding in an opposing second axial direction.

Owner:CINCO PLASTICS INC

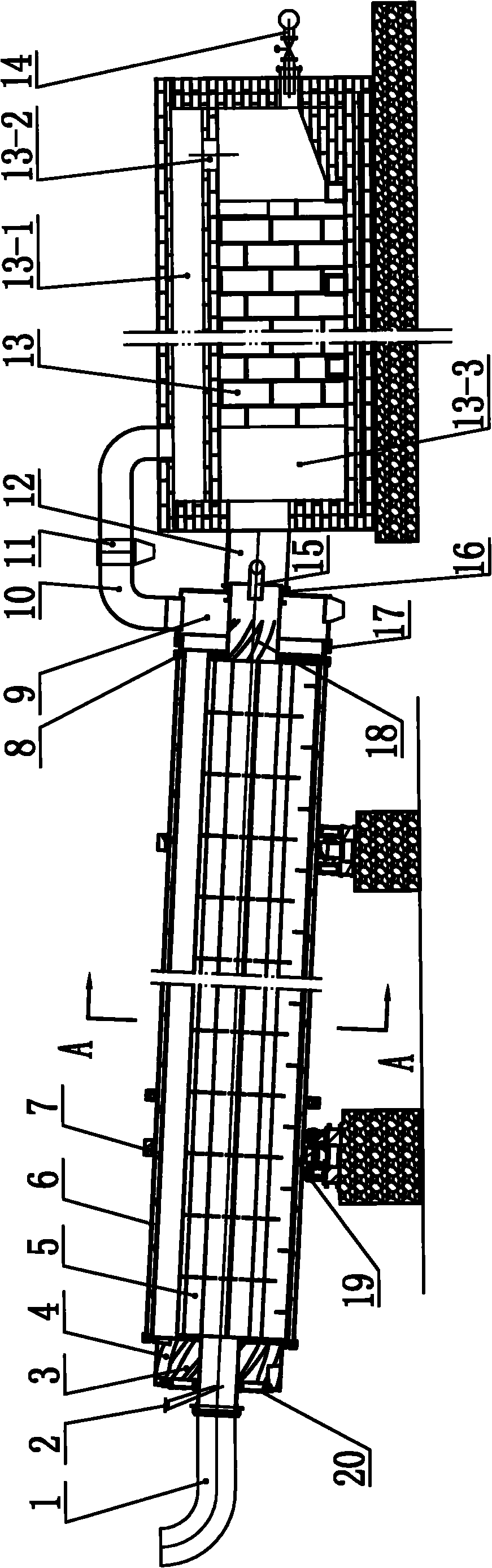

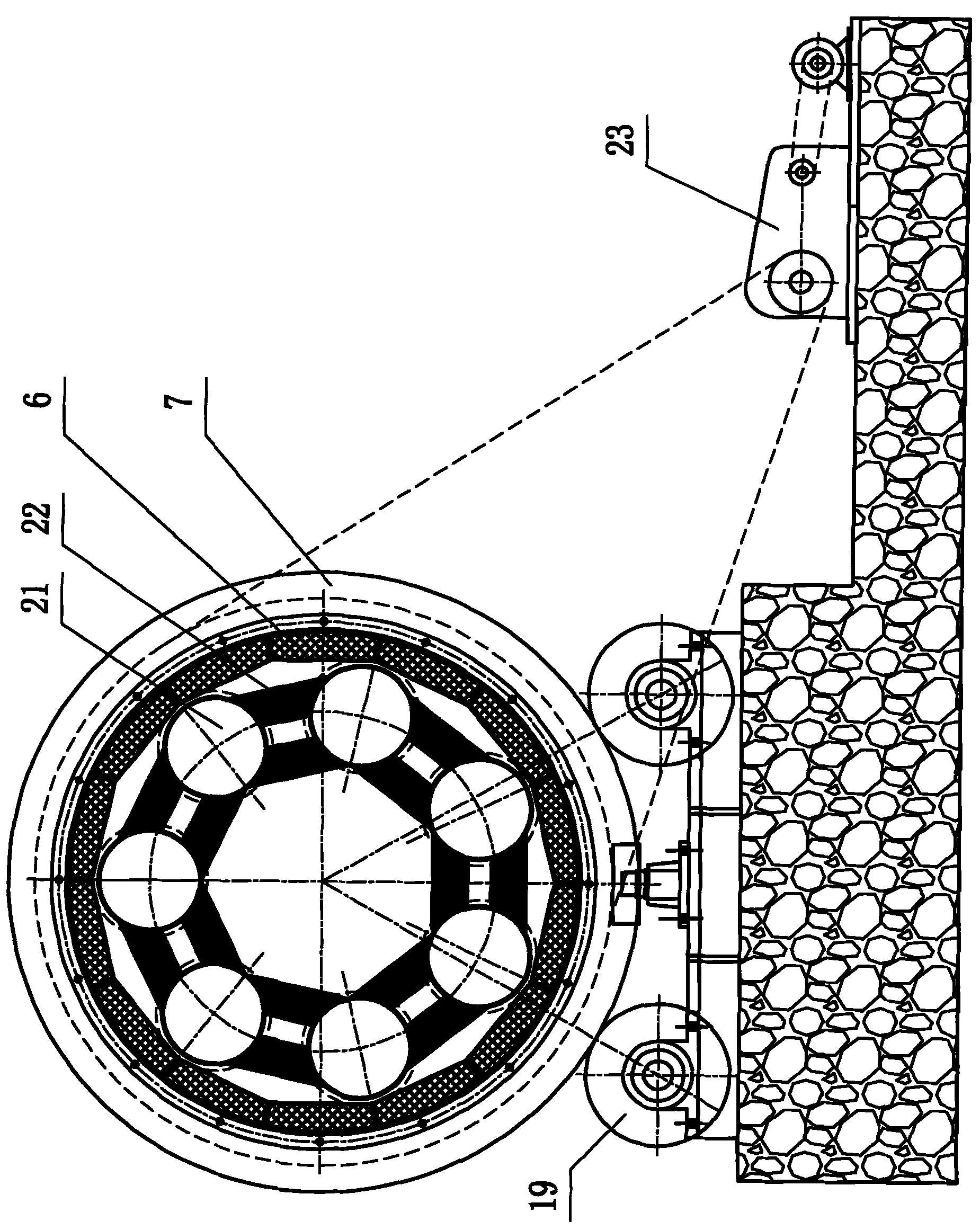

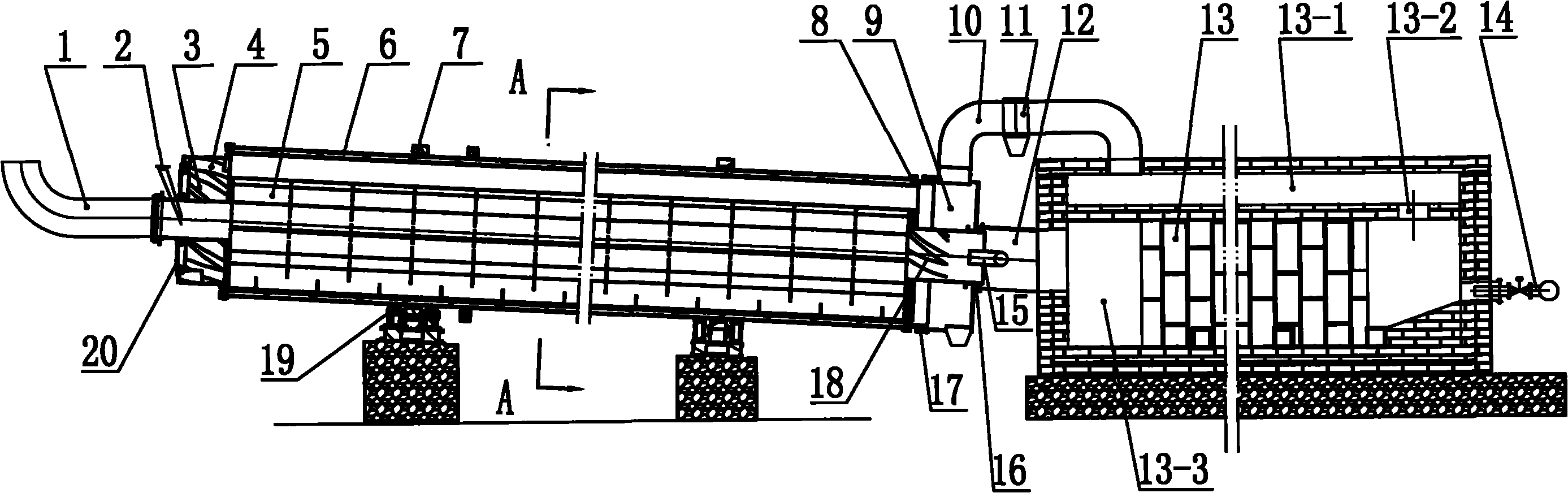

External-heating energy-saving and environment friendly rotary carbonization furnace

InactiveCN102092706AImprove qualityHigh mechanical strengthChemical industryCombustion chamberCarbonization

The invention relates to an external-heating energy-saving and environment friendly rotary carbonization furnace; a furnace body (5) consists of at least three independent material passages (21) that are connected with each other through reinforcing plates (22); the left feed end of the furnace body is sealed with a sealing flange (20), and the right feed end of the furnace body is sealed with a material passage expansion sealing device (8); the left and the right ends of a discharge warehouse are sealed with sealing flanges (16, 17); a feeding warehouse (3), the sealing passage (21), the discharge warehouse (9), a fugitive constituent pipeline (10), a combustion chamber (13), a high-temperature smoke gas pipe (12), a space between the inner part of a furnace housing (6) and the outer part of the material passage (21) and a tail gas exhaust pipe (1) are communicated with each other in sequence; and the temperature of the high-temperature smoke gas of heated material is adjusted through an air distributing pipe (15). In the invention, the temperature and heating rate are easy to control when the material is carbonized, and the material is capable of uniformly and sufficiently absorbing heat with low material ablation, high yield and few energy consumption; and the produced carbonized material has good quality.

Owner:淮北市协力重型机器有限责任公司 +1

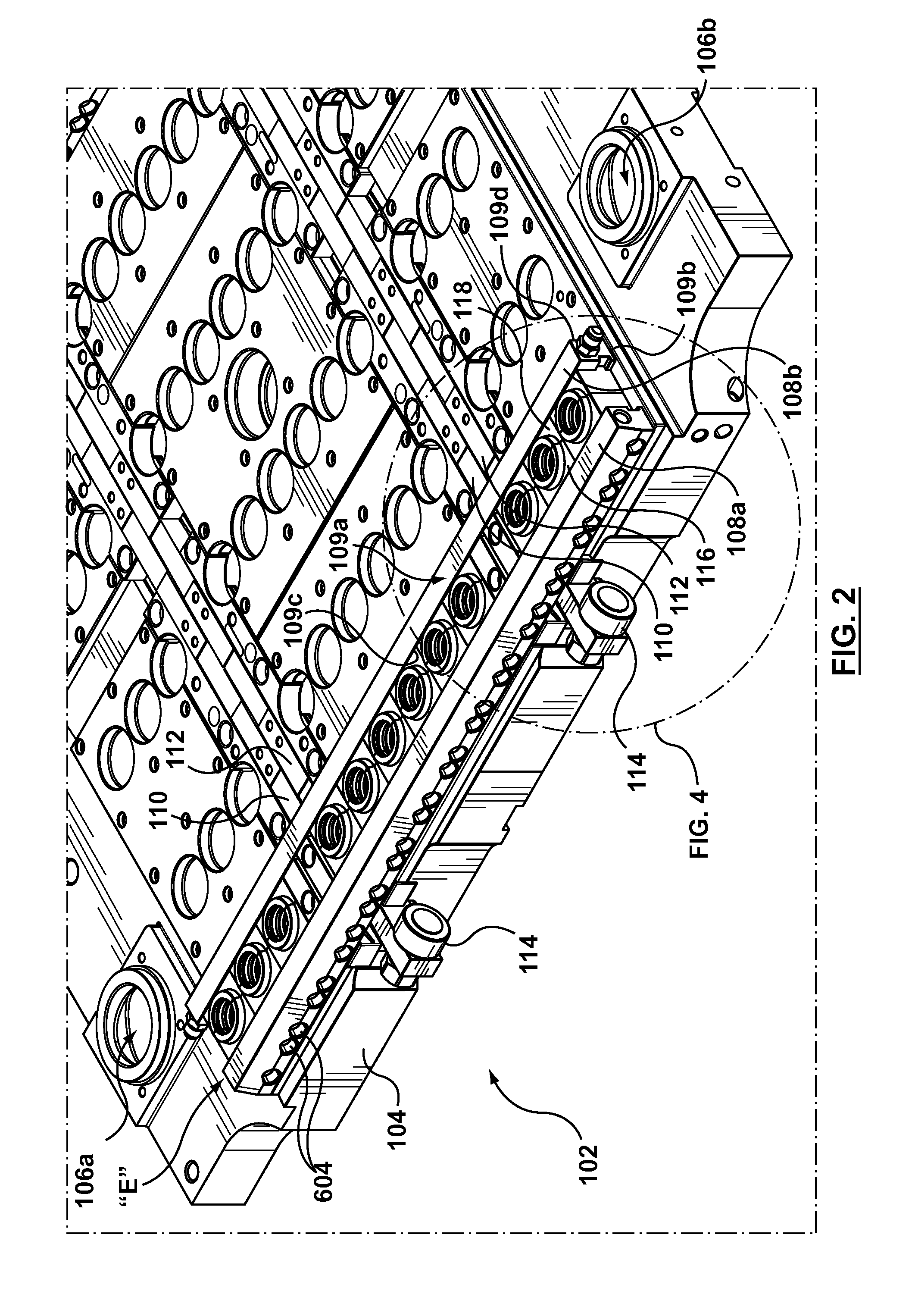

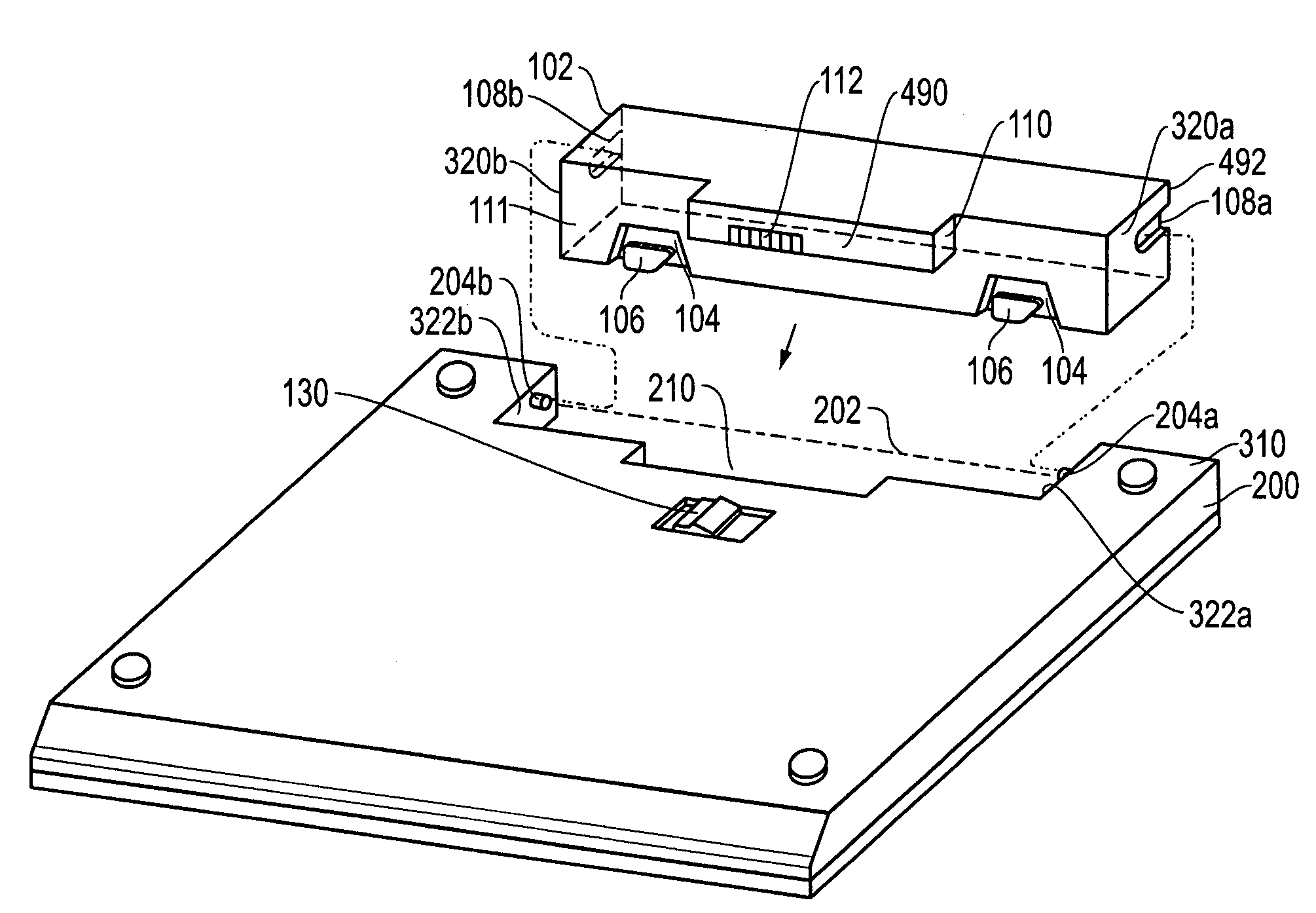

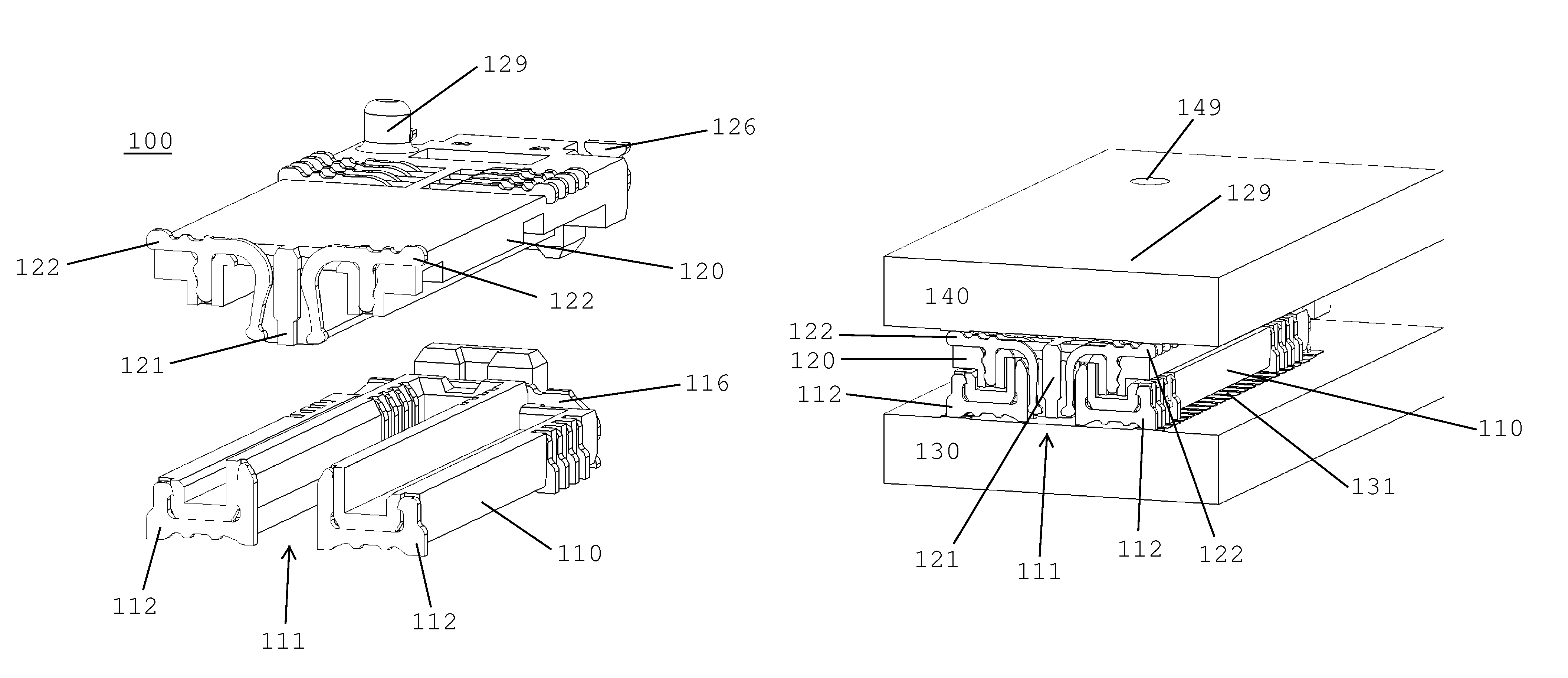

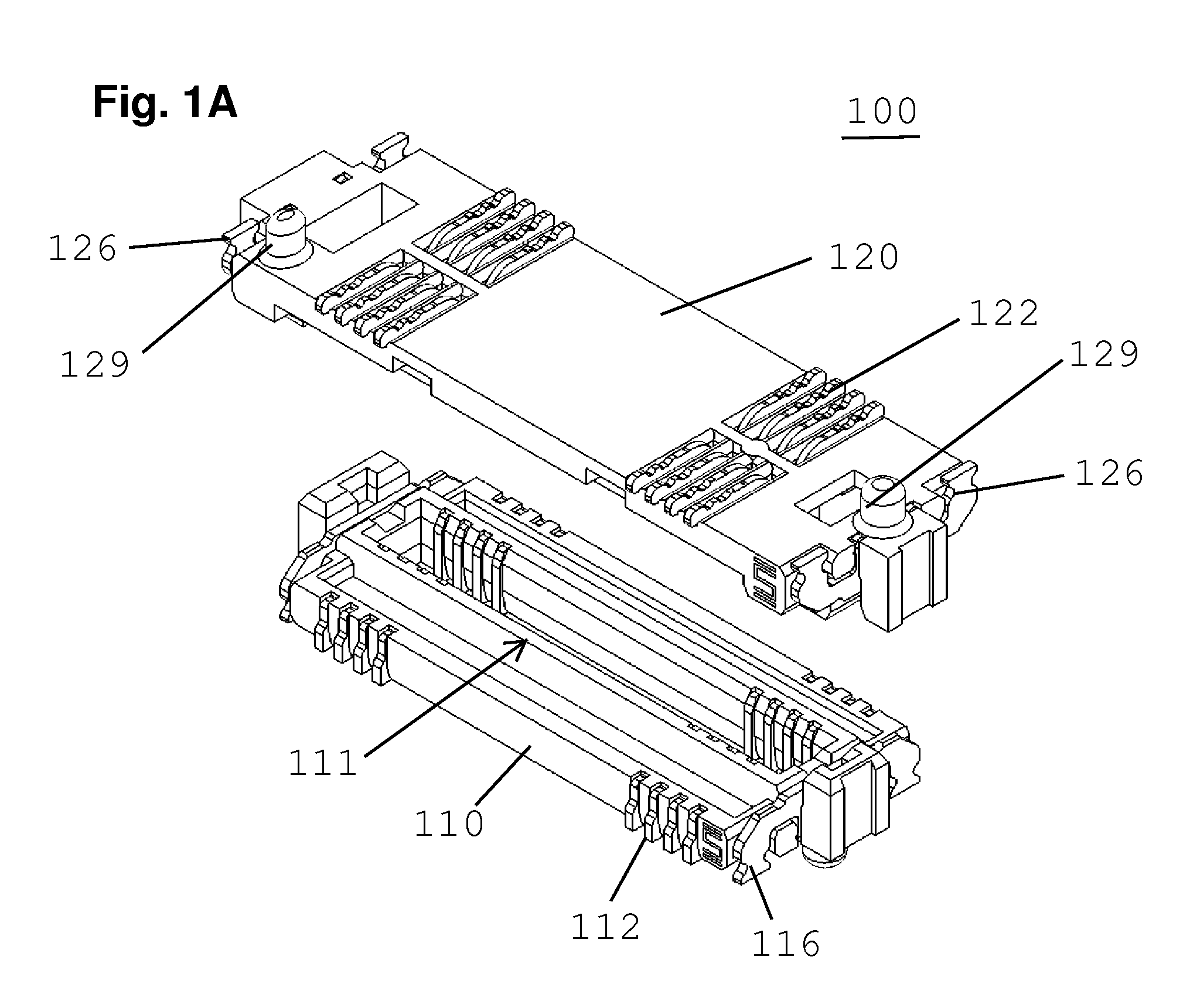

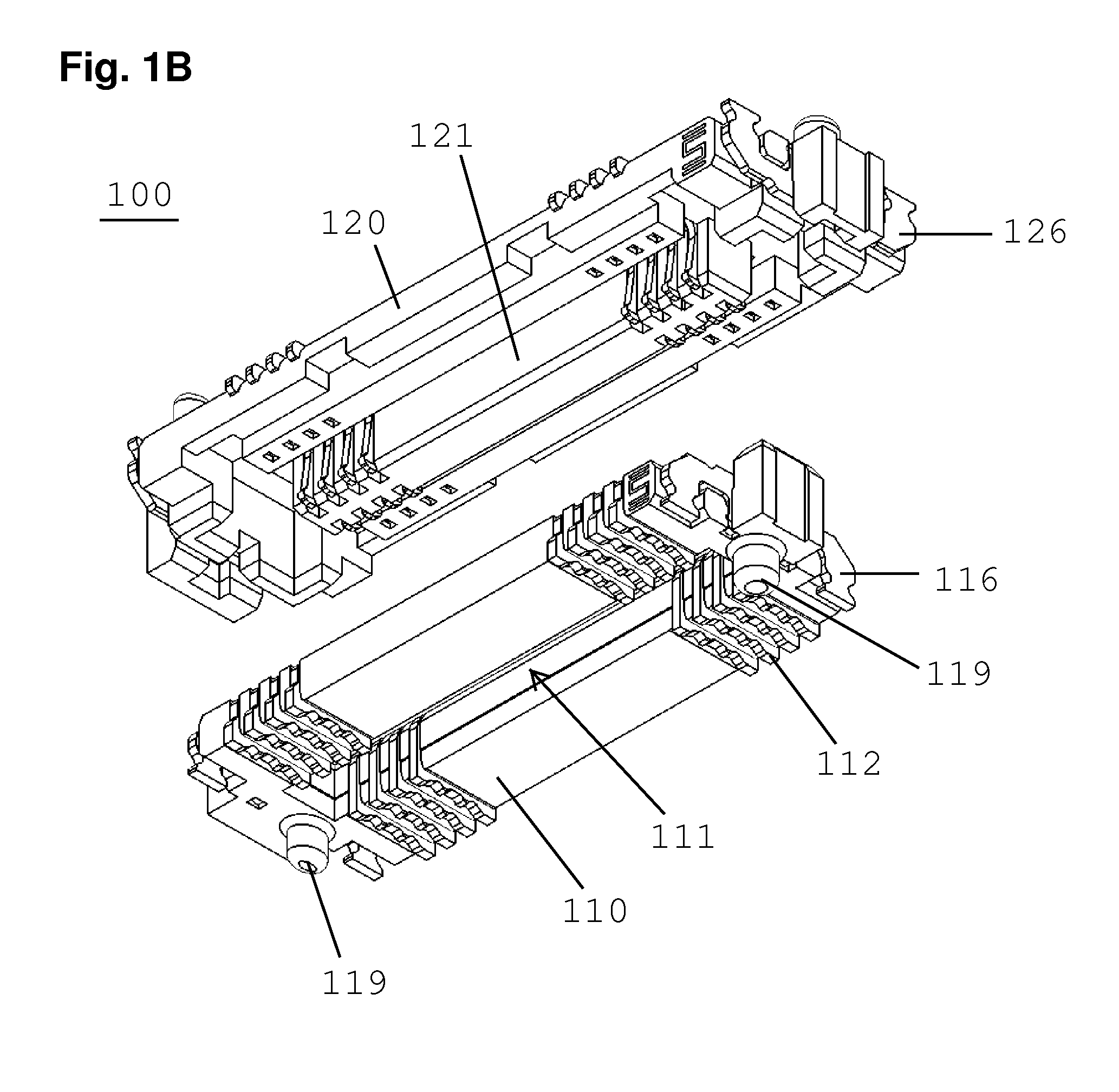

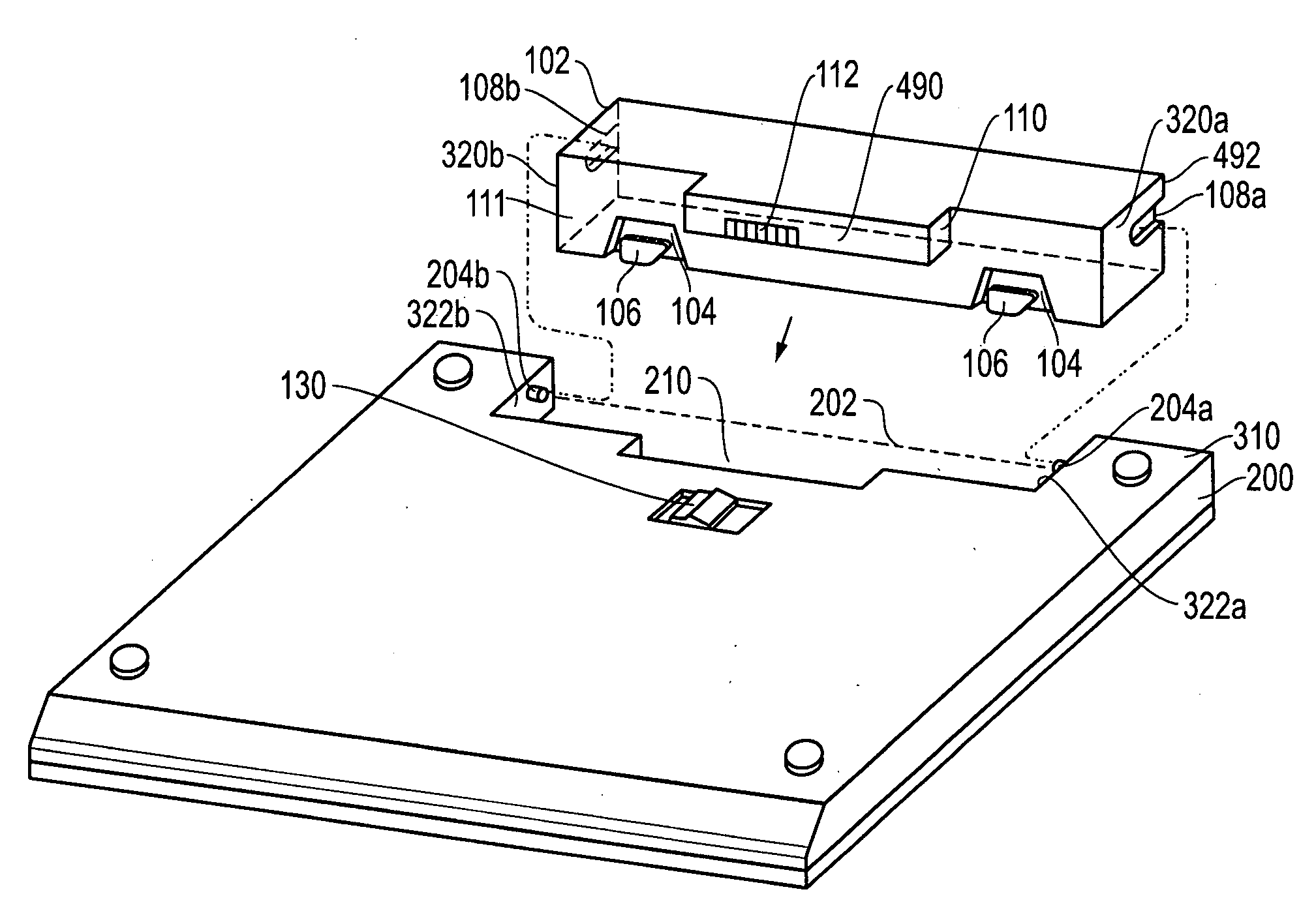

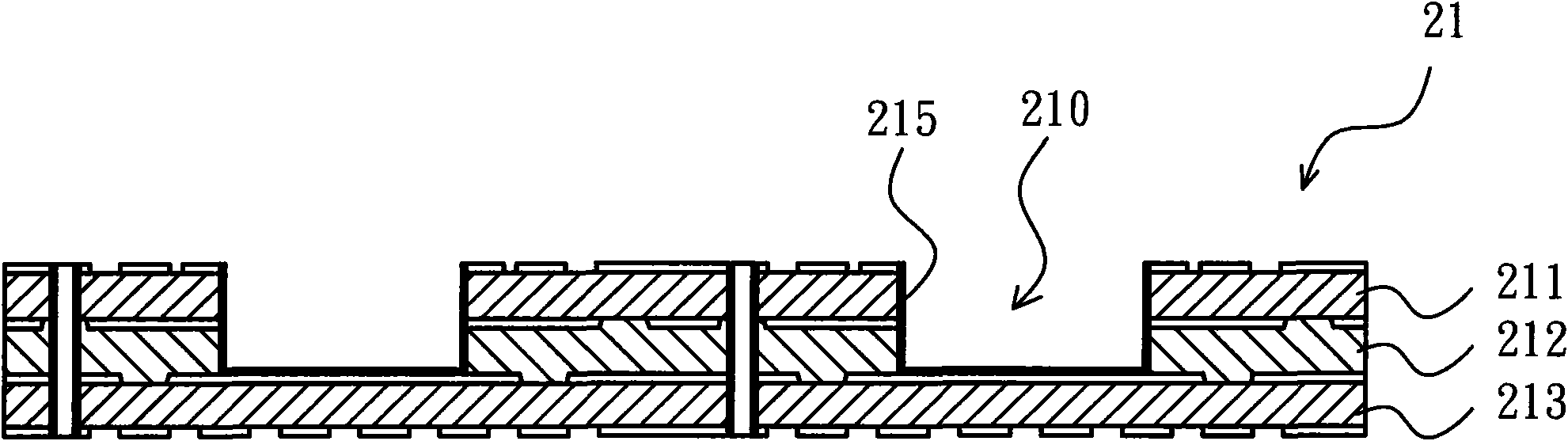

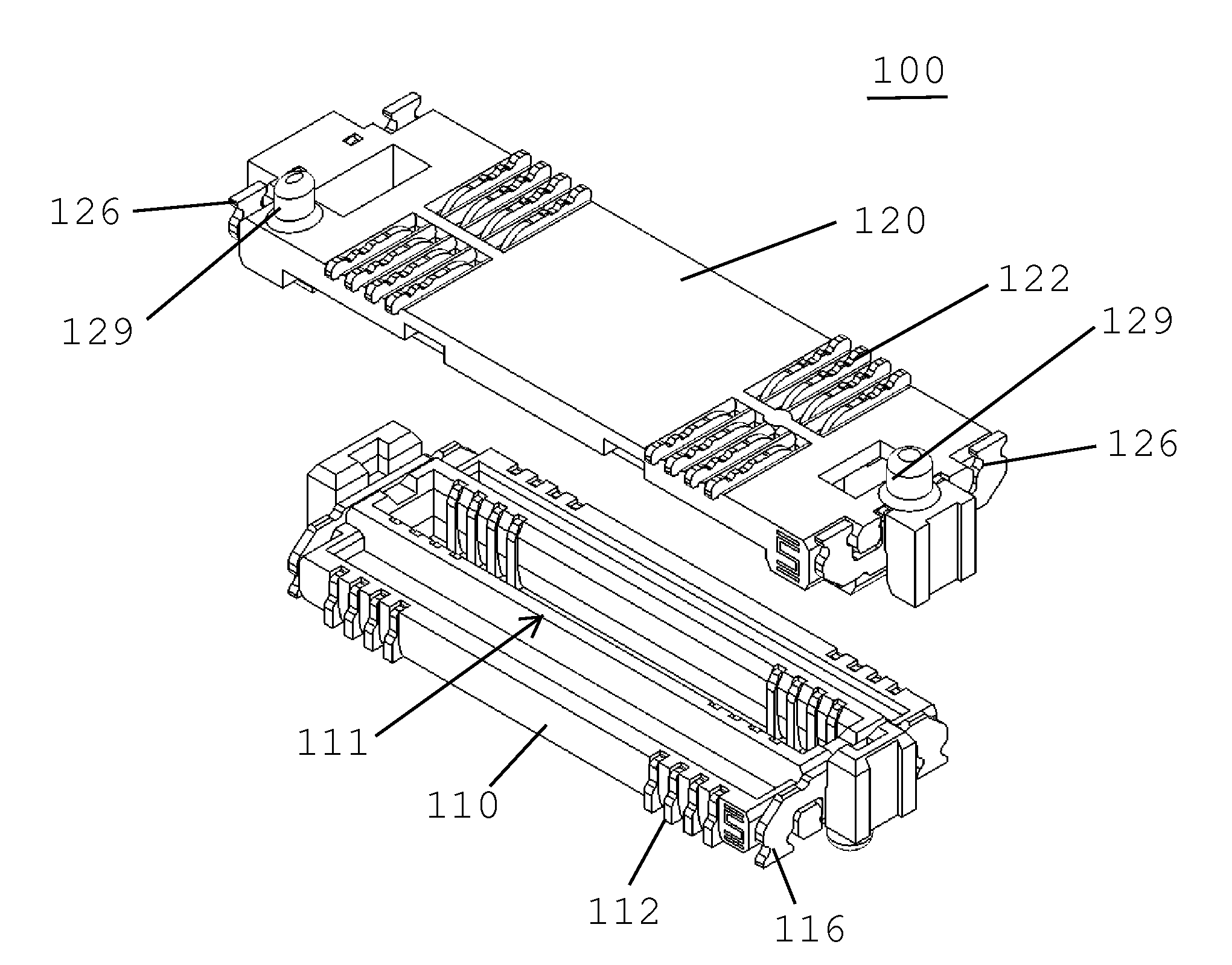

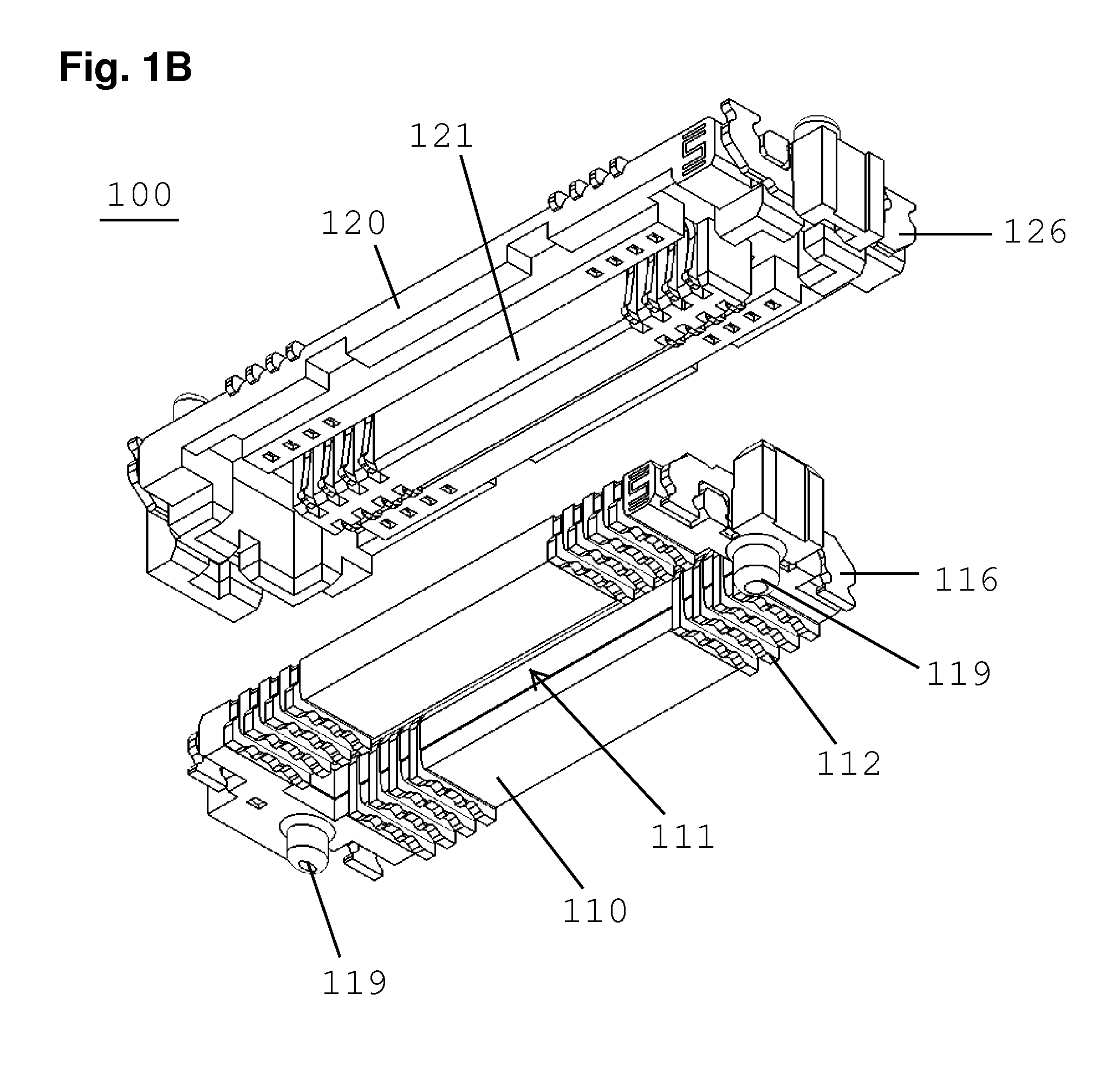

Low-profile mezzanine connector

ActiveUS8979551B2Long contact wipe distanceReduce stack heightCoupling device connectionsPrinted circuitsElectrical and Electronics engineering

A mezzanine connector includes a first connector including a pass-through hole and a first plurality of contacts arranged around the pass-through hole, the first connector arranged to be connected to a first substrate such that the first plurality of contacts are connected to the first substrate, and a second connector including a beam and a second plurality of contacts arranged around the beam, the second connector arranged to be connected to a second substrate such that the second plurality of contacts are connected to the second substrate. The pass-through hole extends fully through the first connector in a mating direction of the first connector and the second connector, and the beam of the second connector is arranged to extend into the pass-through hole of the first connector when the first connector and the second connector are mated.

Owner:SAMTEC

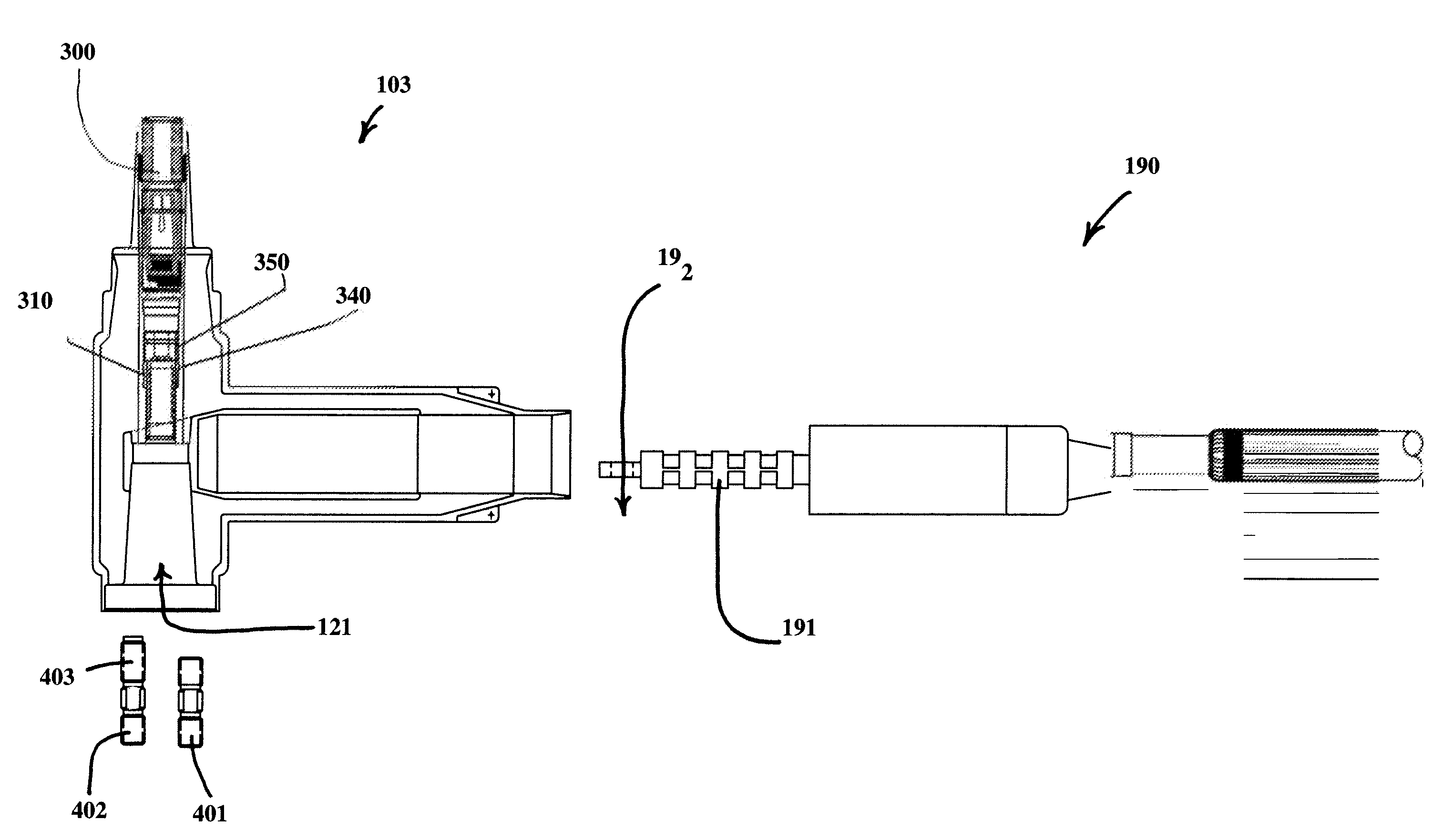

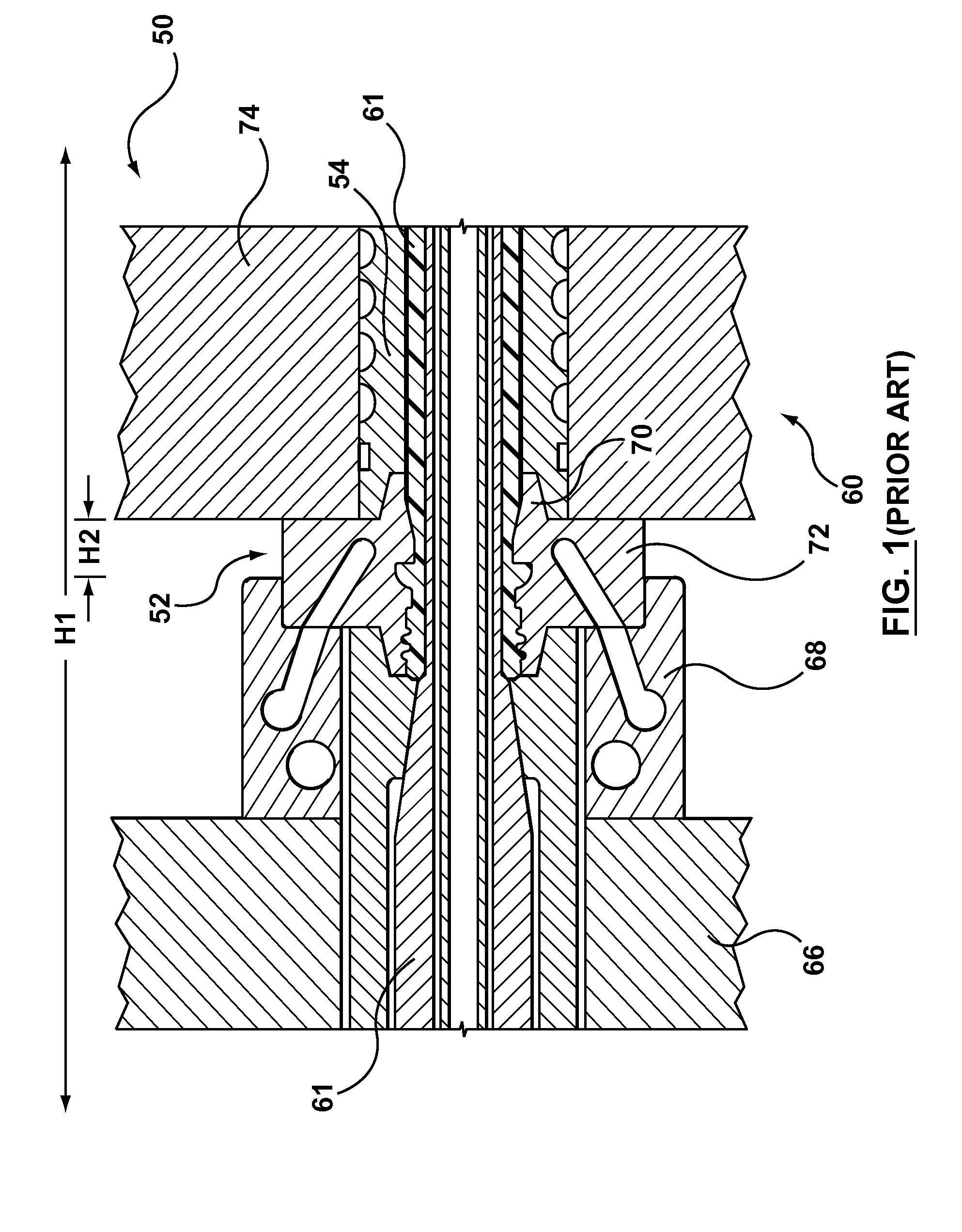

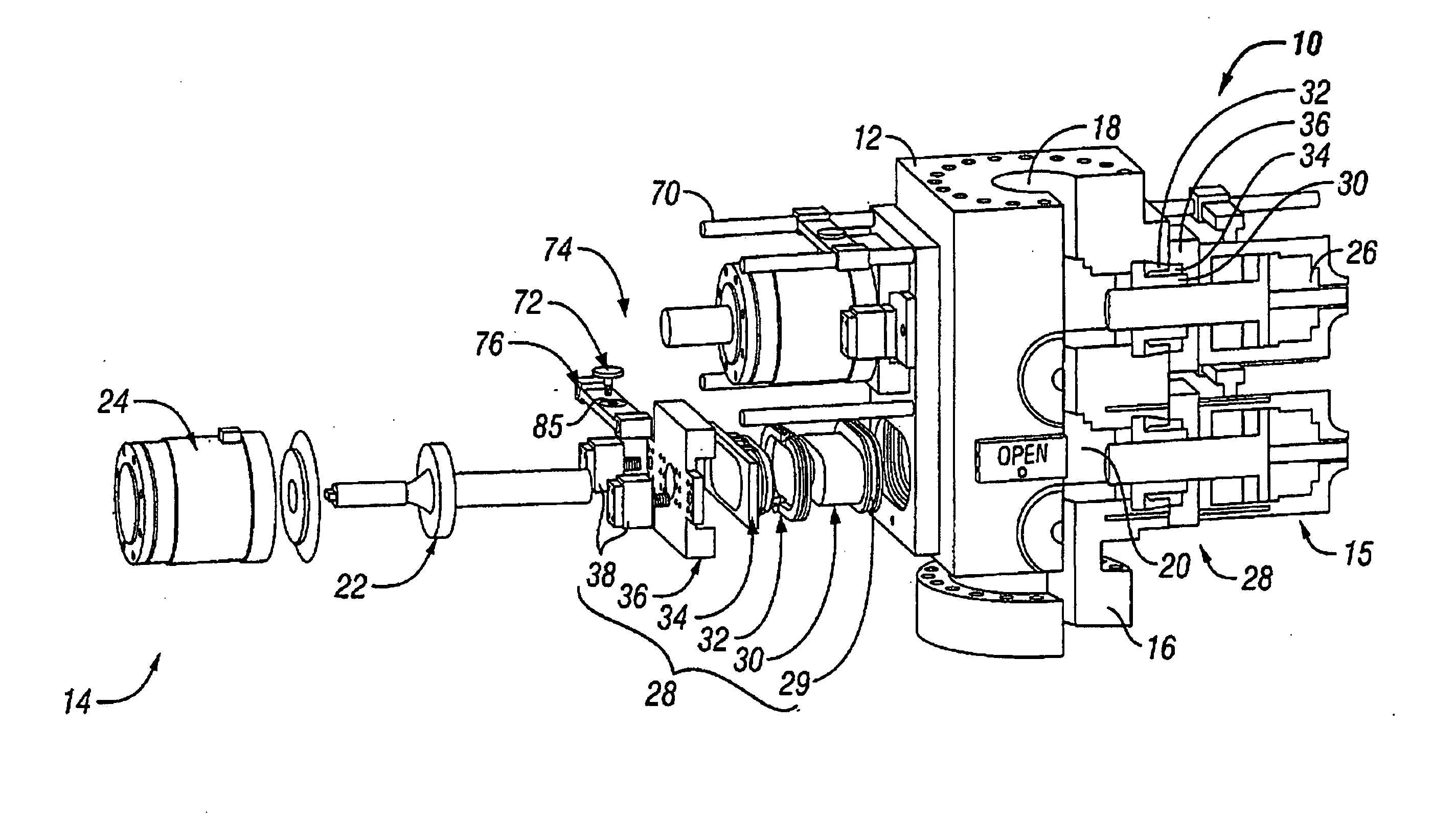

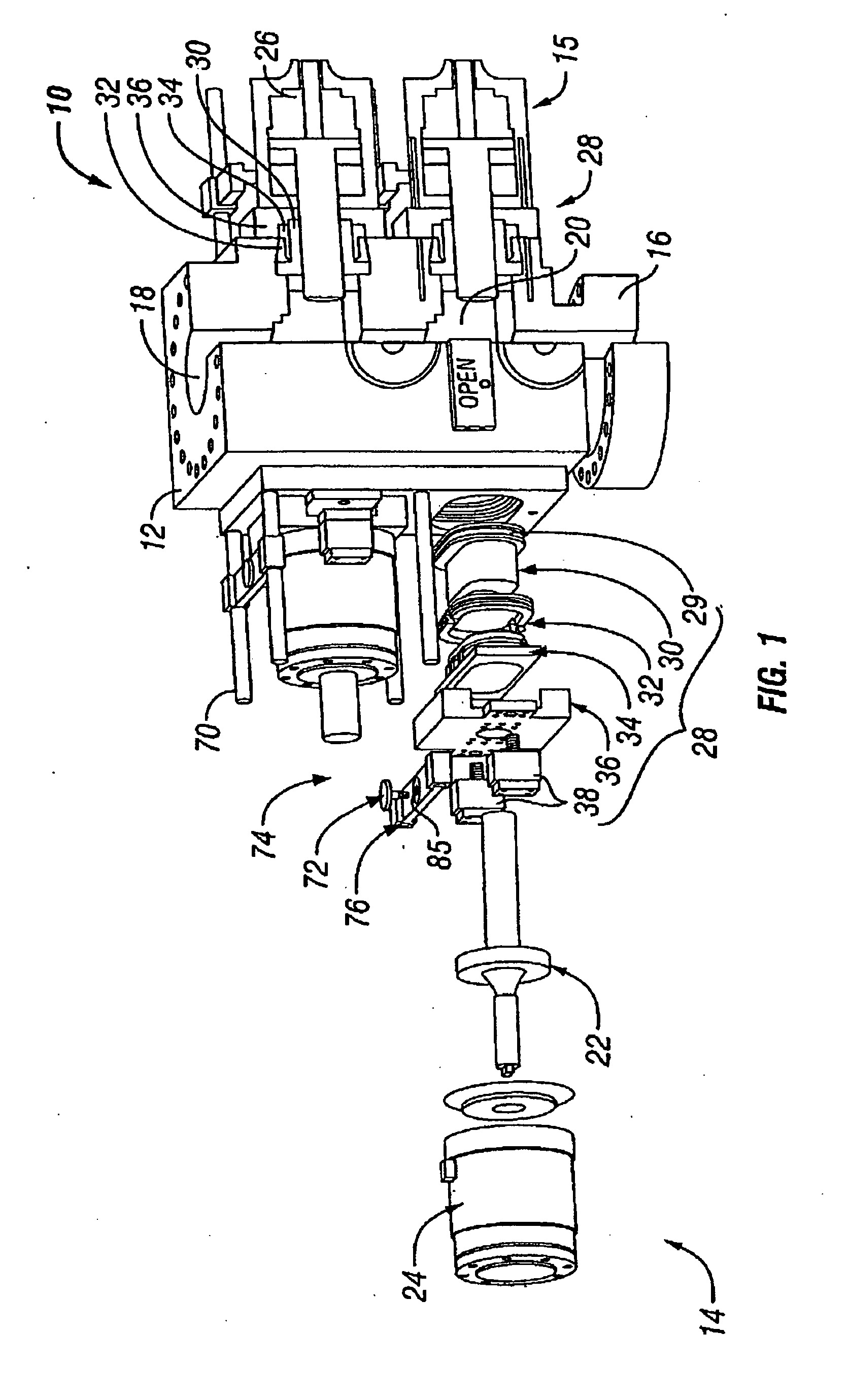

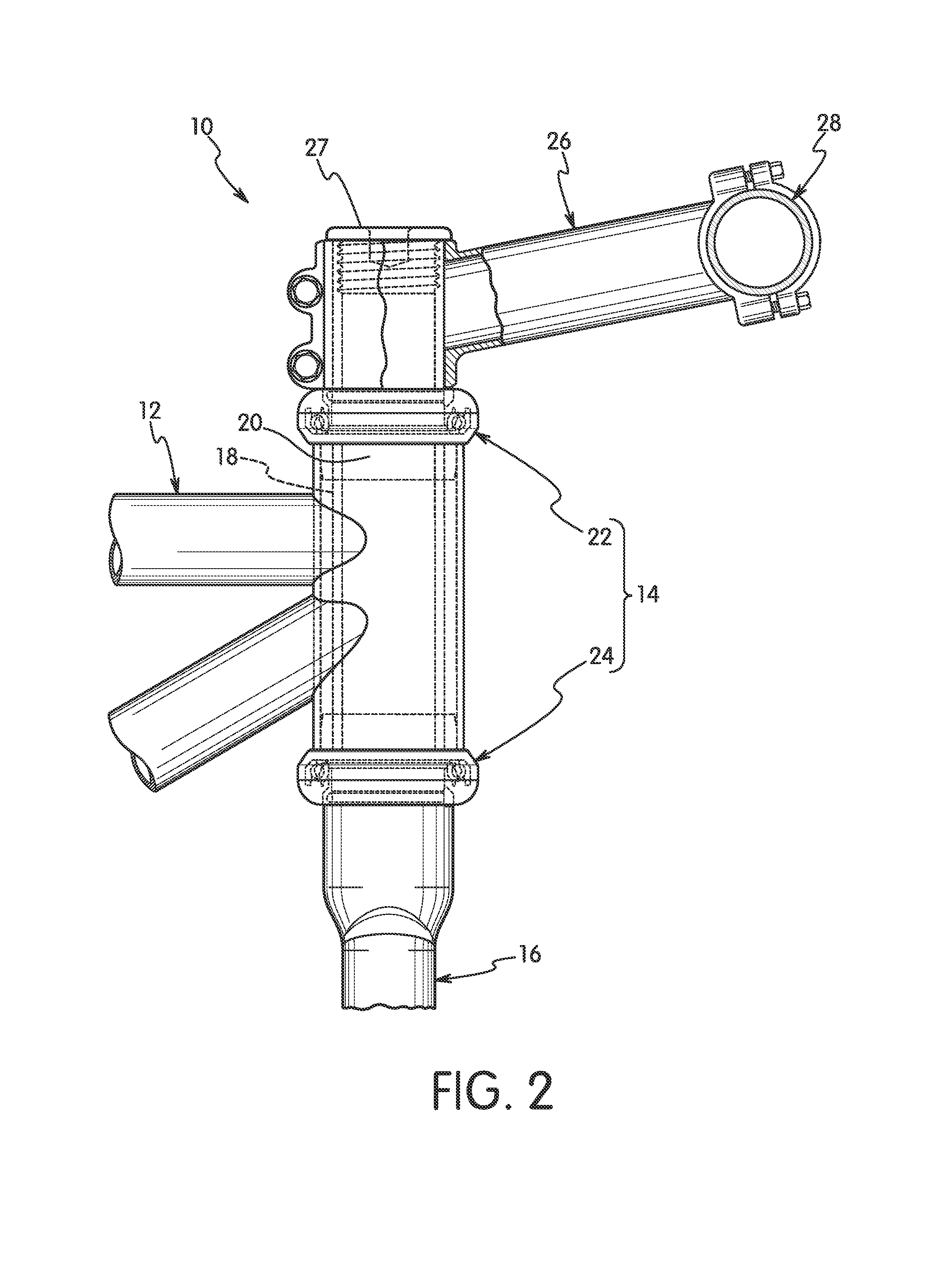

Mounts for blowout preventer bonnets

InactiveUS20060243451A1Easy maintenanceReduce stack heightDrilling rodsFluid removalEngineeringBlowout preventer

A bonnet locking apparatus is disclosed. The bonnet locking apparatus includes a segmented radial lock disposed around a bonnet and configured to engage a corresponding radial lock disposed in a body of a blowout preventer, at least one spring configured to bias at least one segment of the segmented radial lock in a locked position, and a backup sleeve disposed around the bonnet, wherein at least a portion of the backup sleeve is configured to secure engagement of the segmented radial lock with the corresponding radial lock disposed in the body of the blowout preventer. A method of locking a bonnet to a blowout preventer is also disclosed. The method includes assembling a segmented radial lock around a bonnet, wherein at least one segment of the radial lock is biased towards a locked position, inserting the bonnet into an opening in the blowout preventer, wherein an outer surface of the segmented radial lock contacts a surface of the opening, thereby moving the at least one segment of the segmented radial lock radially inward, until the at least one segment of the segmented radial lock extends radially outward into engagement with a corresponding radial lock disposed in the blowout preventer, and position a backup sleeve into a position wherein at least a portion of the backup sleeve is radially inward of the segmented radial lock.

Owner:HYDRIL USA MANUFACTURING LLC

Apparatus and methods for battery installation

ActiveUS20100330400A1Great sizeSmall sizeDigital data processing detailsSecondary cells charging/dischargingEmbedded systemInformation handling system

Apparatus and methods for placement of battery packs in portable information handling systems such as notebook and netbook computers. A first set of pivot features may be provided on opposing sidewalls of a battery well that interface with a corresponding set of mating pivot features provided on exterior end surfaces of a battery pack such that the battery pack may be pivoted into and out from the battery well to install or release it from the system, e.g., pivoted from the bottom of the portable information handling system in a manner that does not interfere with, or require modification to, the lid and display of the portable information handling system. A latch mechanism and battery release feature may be further provided that acts to transfer horizontal manipulation (e.g., horizontal sliding motion) of the battery release feature to a vertical latching action that acts to lift the battery pack out from the portable information handling system chassis when releasing the battery pack from the chassis.

Owner:DELL PROD LP

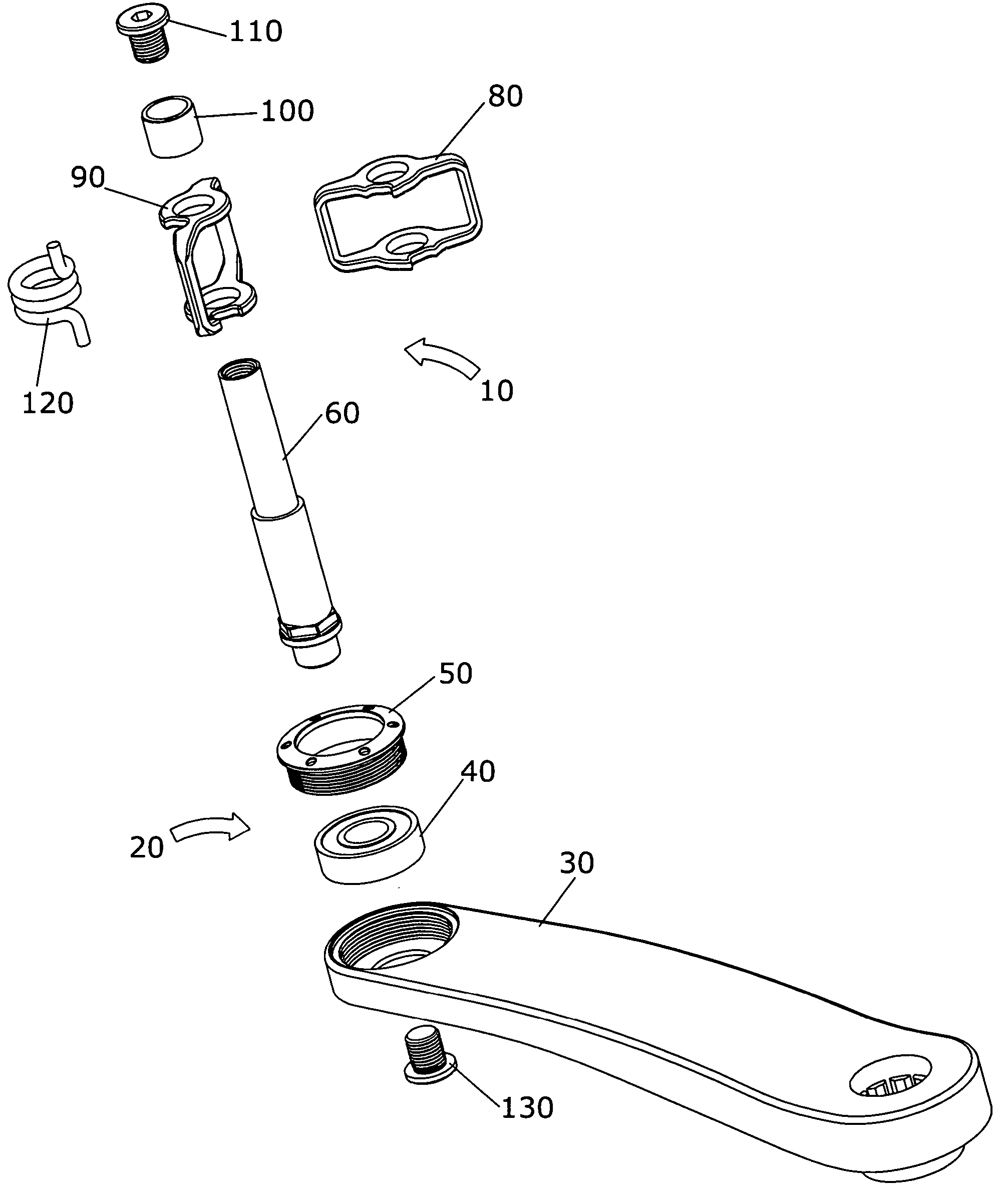

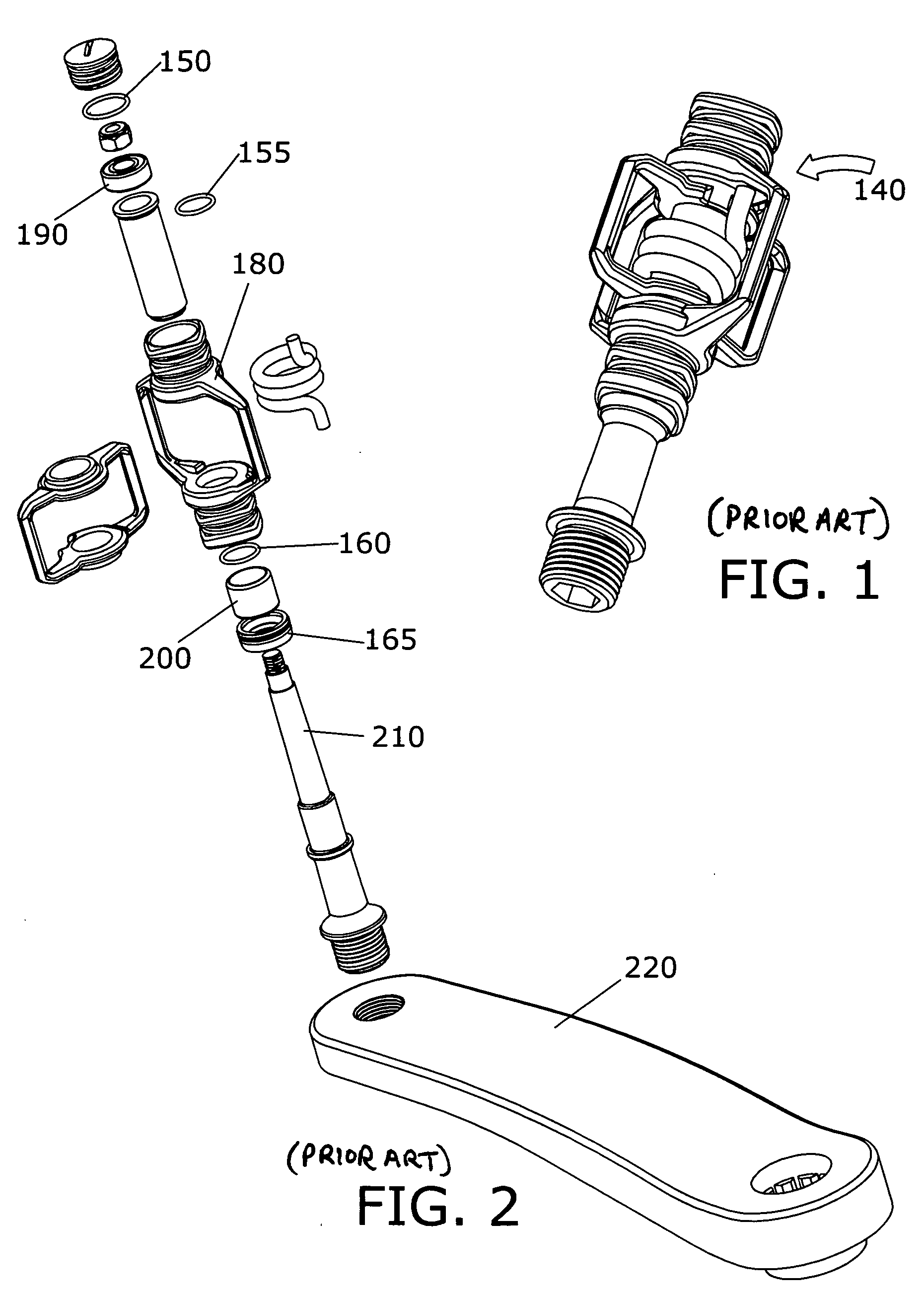

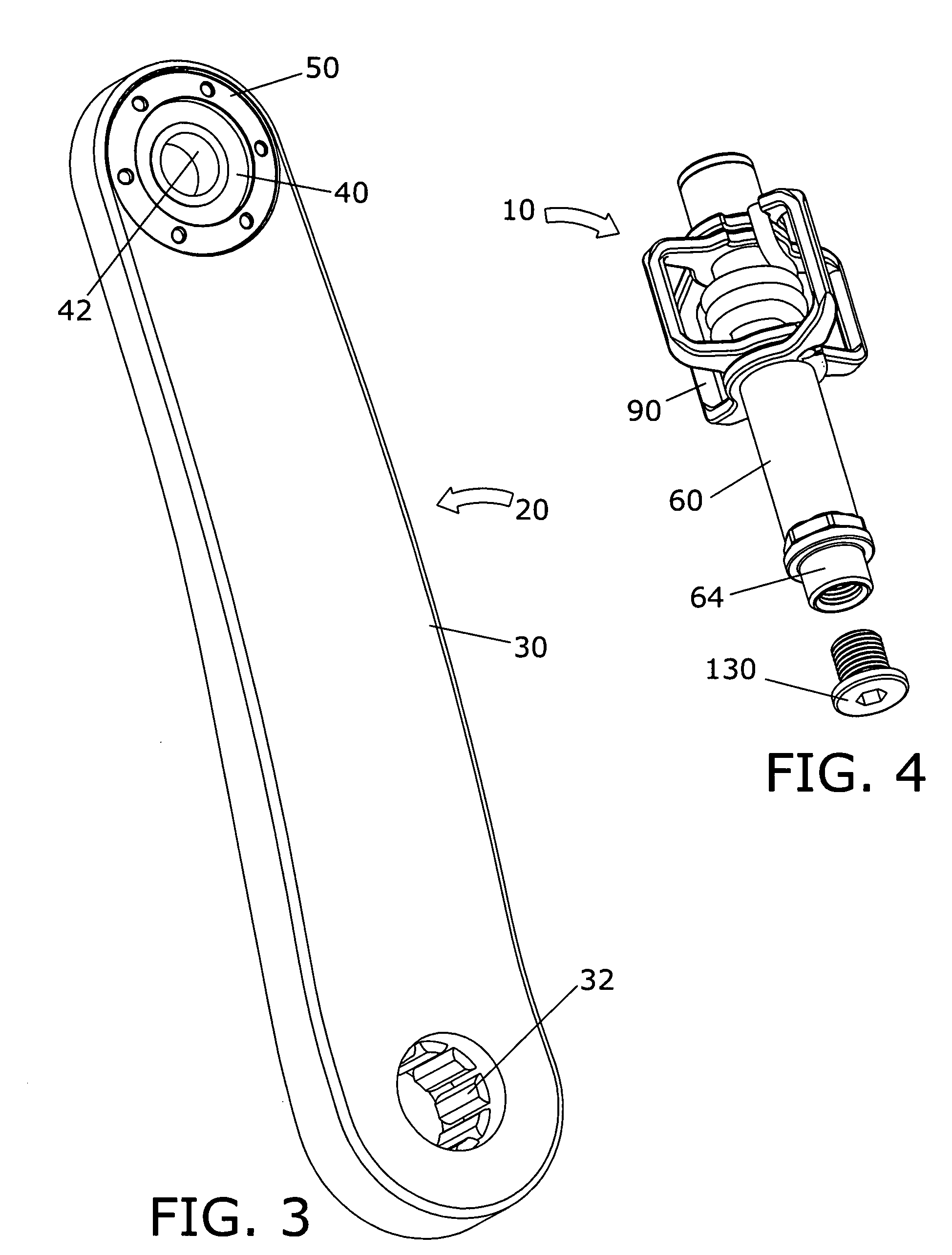

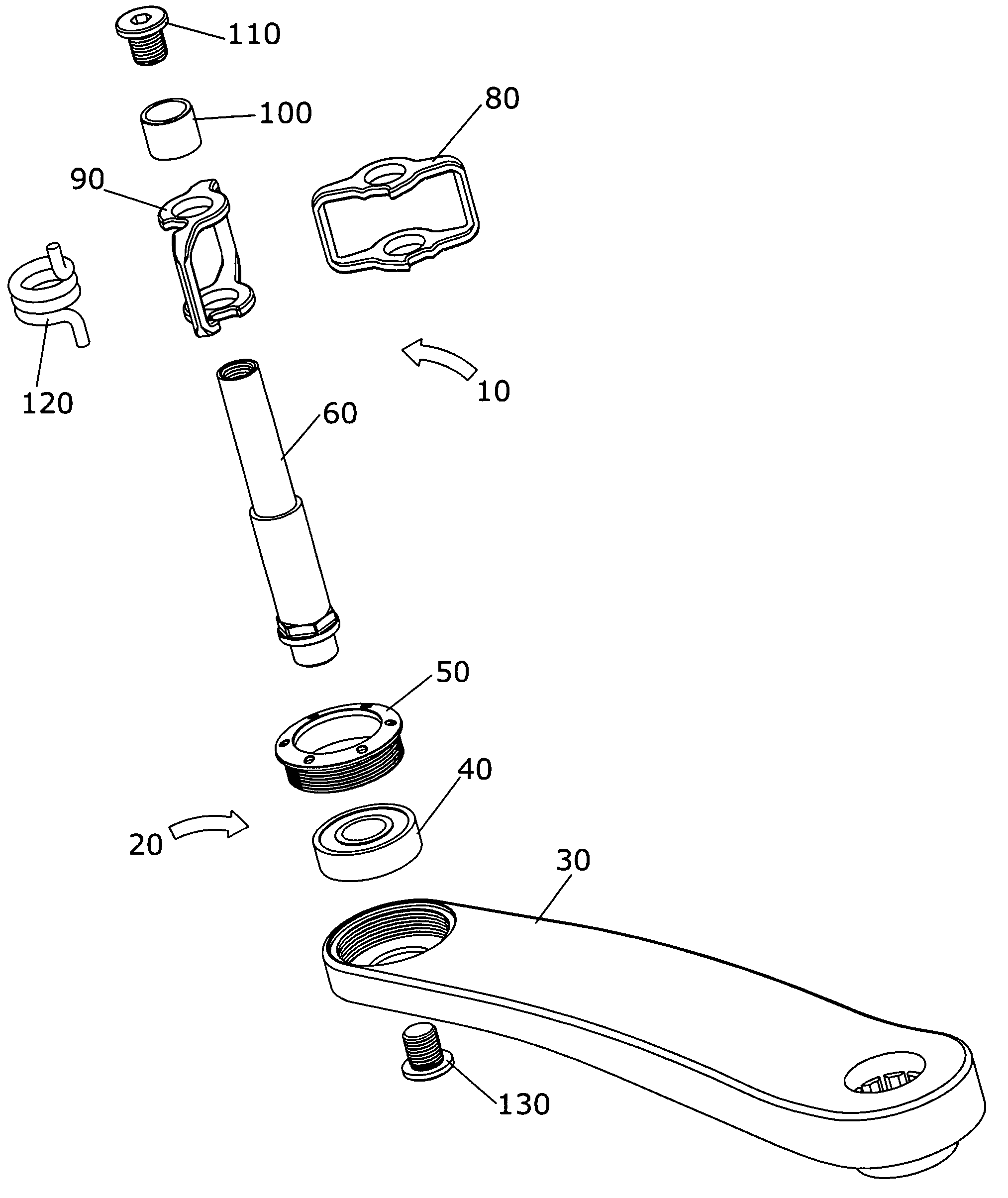

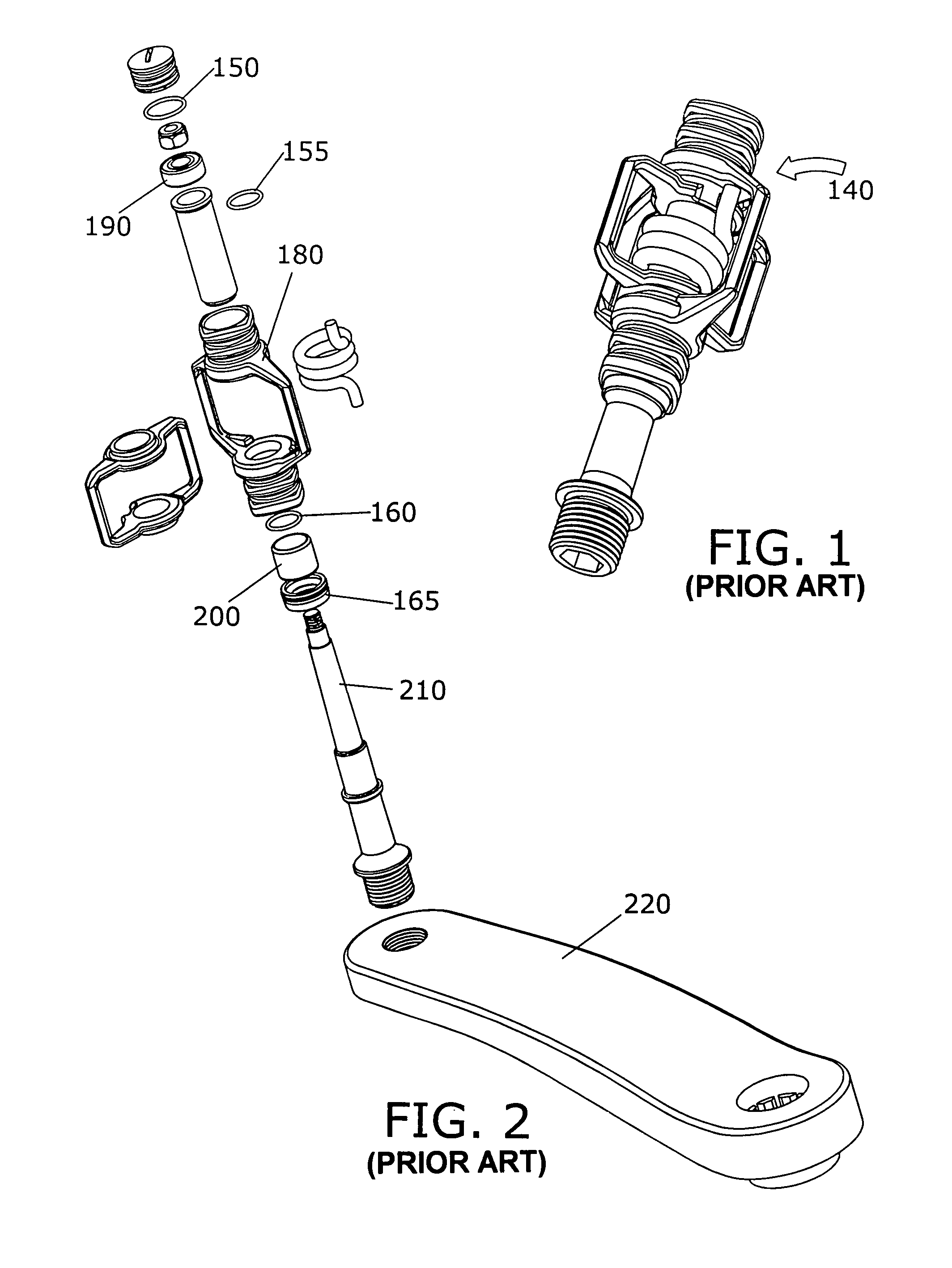

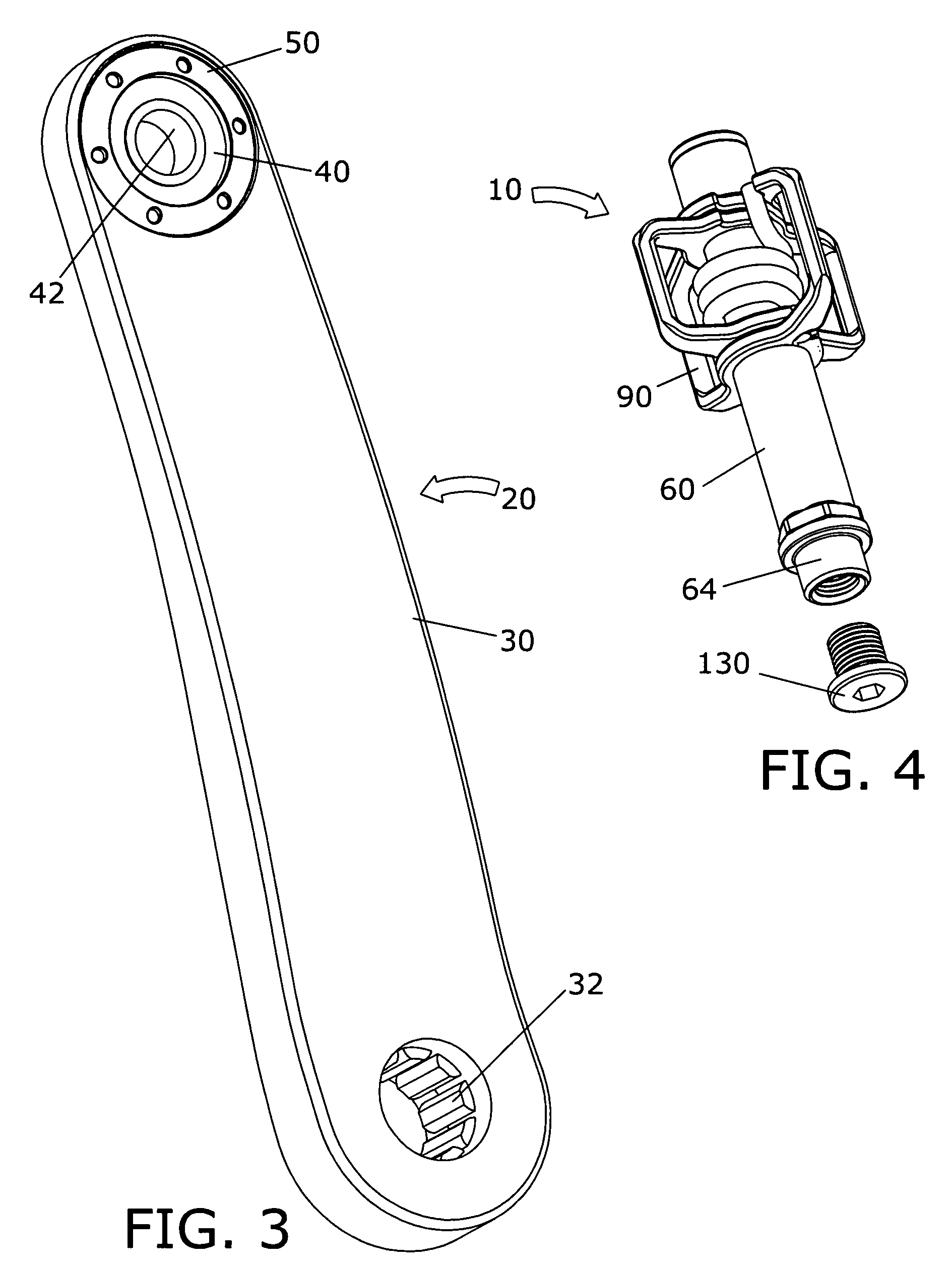

Bicycle pedal and crank apparatus

ActiveUS20050204859A1More freedomMaximize stiffness to weight ratioControlling membersMechanical apparatusBall bearingEngineering

A pedal with a shaft fixed to the pedal body instead of a spindle that turns relative to the pedal body. The shaft is fixed relative to the pedal body. The pedal shaft rotates relative to the crank arm instead. A sealed cartridge ball bearing is mounted to the end of a crank arm and held in position by a retainer. The shaft is fitted through the sealed cartridge ball bearing of the crank arm and a screw secures the shaft in position. This changes the pedal to crank interface. The pedal does not require bearings or bushings or seals as with prior art pedals, because the shaft rotates within the sealed cartridge bearing held within the crank arm. The shaft and pedal body can be combined to create an even simpler pedal.

Owner:CRANK BROS INC

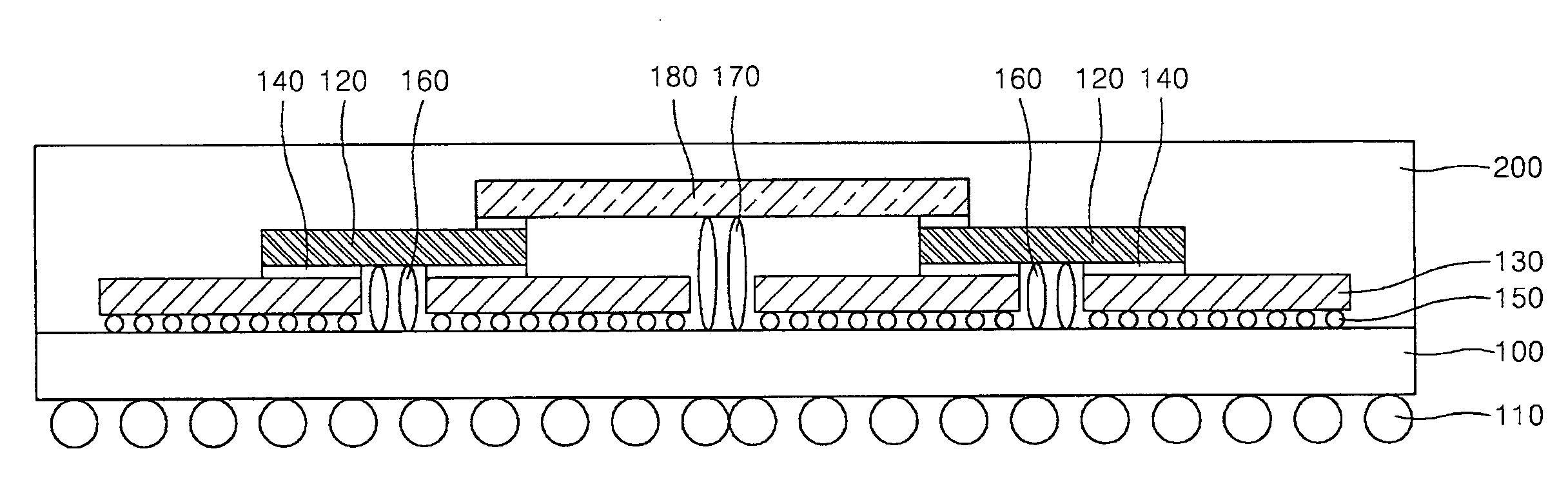

Semiconductor device stack package, electronic apparatus including the same, and method of manufacturing the same

InactiveUS20080258288A1Effective coolingReduce the overall heightSemiconductor/solid-state device detailsSolid-state devicesDevice materialSemiconductor chip

In a semiconductor device stack package and a method of forming the same, the package comprises: a substrate; a plurality of lower chips stacked on the substrate and having an active surface oriented in a direction toward the substrate; and at least one upper chip disposed on the lower chips and connected to the substrate via a bump disposed between the lower chips. As no wire loops are formed, there is no increase in the height of the stack package, and the electrical path is shortened, thereby improving the electric performance of the stack package. Also, the semiconductor device stack package has a flip chip structure, and thus a plurality of semiconductor chips can be stacked in various manners.

Owner:SAMSUNG ELECTRONICS CO LTD

Stacking structure of semiconductor packages

InactiveCN101887885AReduce protrusion heightReduce stack heightSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageColloid

The invention discloses a stacking structure of semiconductor packages, which comprises a first package, a second package and a plurality of switching elements. The first package is provided with a first circuit board, at least one first chip and at least one first package colloid. The first circuit board is provided at least one depression and a plurality of switching solder pads, the depression accommodates the first chip, and the first package colloid fills the depression and covers the first chip. The switching solder pads are formed on the upper surface of the first circuit board where no depression is arranged. The lower surface of the second package is electrically connected with the switching solder pad of the first circuit board of the first package through the switching element. Because the depression accommodates the chip, the protrusion height caused by the chip and the package colloid can be reduced, and the overall stacking height during stacking assembly can be further reduced.

Owner:ASE ASSEMBLY & TEST SHANGHAI

Low-profile mezzanine connector

ActiveUS20140148022A1Long contact wipe distanceReduce stack heightCoupling device connectionsPrinted circuitsEngineeringElectrical and Electronics engineering

A mezzanine connector includes a first connector including a pass-through hole and a first plurality of contacts arranged around the pass-through hole, the first connector arranged to be connected to a first substrate such that the first plurality of contacts are connected to the first substrate, and a second connector including a beam and a second plurality of contacts arranged around the beam, the second connector arranged to be connected to a second substrate such that the second plurality of contacts are connected to the second substrate. The pass-through hole extends fully through the first connector in a mating direction of the first connector and the second connector, and the beam of the second connector is arranged to extend into the pass-through hole of the first connector when the first connector and the second connector are mated.

Owner:SAMTEC

Heat insulated container

ActiveUS8286824B2Good release effectReduce stack heightDomestic cooling apparatusLighting and heating apparatusThin membraneEngineering

Owner:TOKAN KOGYO CO LTD

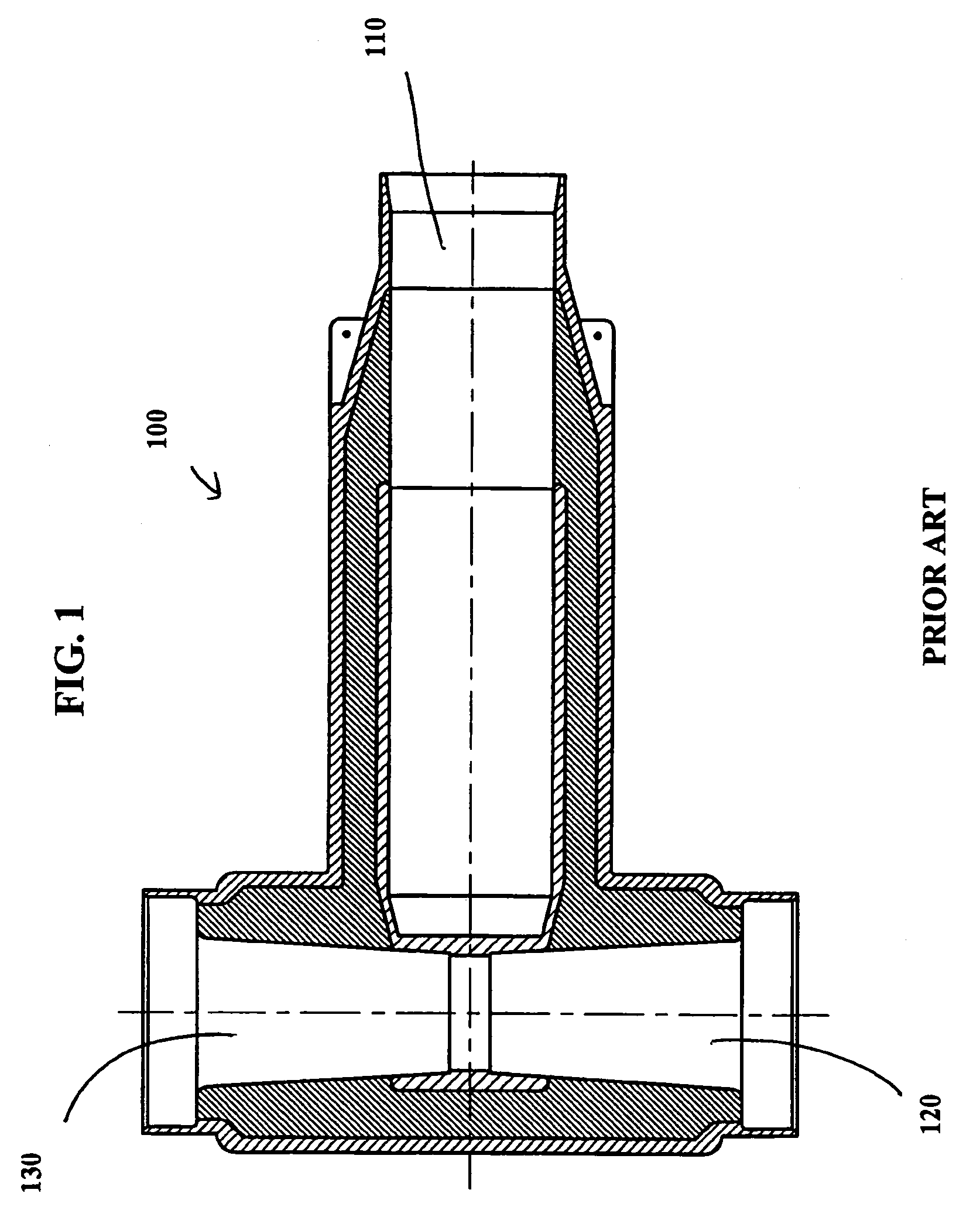

Bicycle headset

InactiveUS8302981B1Reduce stack heightReduce forceFoot-driven leversWheel based transmissionEngineeringMechanical engineering

A bicycle headset includes a first race member, a second race member, at least one rolling member, a compression ring and a sealing ring. The first race member includes a first support surface. The second race member includes a second support surface. The at least one rolling member is disposed between the first and second support surfaces. The compression ring is disposed on the second race member. The sealing ring is disposed on the compression ring.

Owner:SHIMANO SINGAPORE PRIVATE LTD

Bicycle pedal and crank apparatus

ActiveUS7225703B2Improved contamination protectionReduce stack heightControlling membersMechanical apparatusBall bearingEngineering

Owner:CRANK BROS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com