Patents

Literature

2390results about How to "Good release effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rapidly releasing and taste-masking pharmaceutical dosage form

InactiveUS6221402B1Inhibition releaseGood drug release profilePowder deliveryBiocideTaste maskingDosage form

A rapidly-releasing and taste-masking pharmaceutical dosage form and a process for preparing such oral dosage form are disclosed.

Owner:PFIZER PHAMACEUTICALS INC

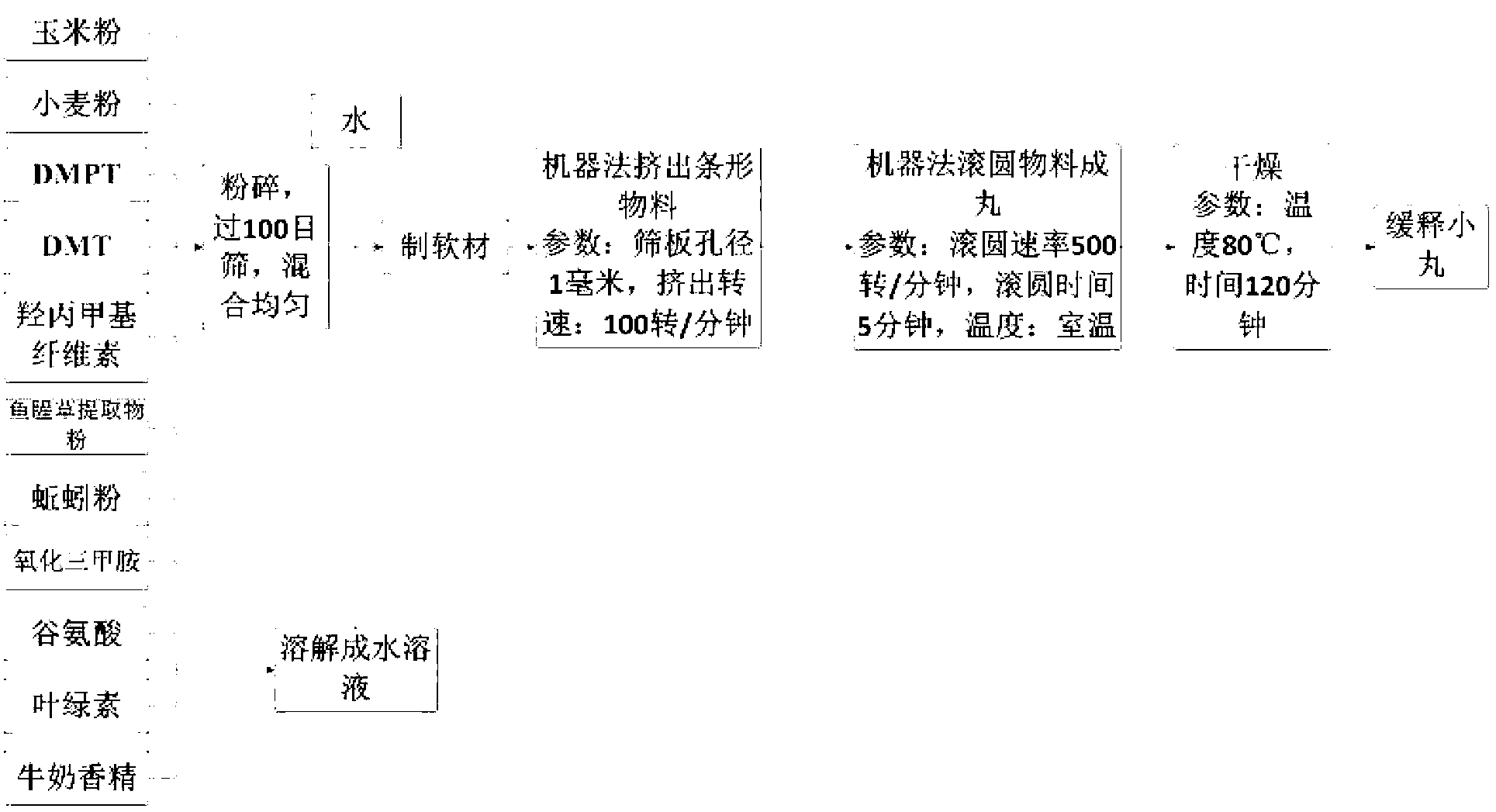

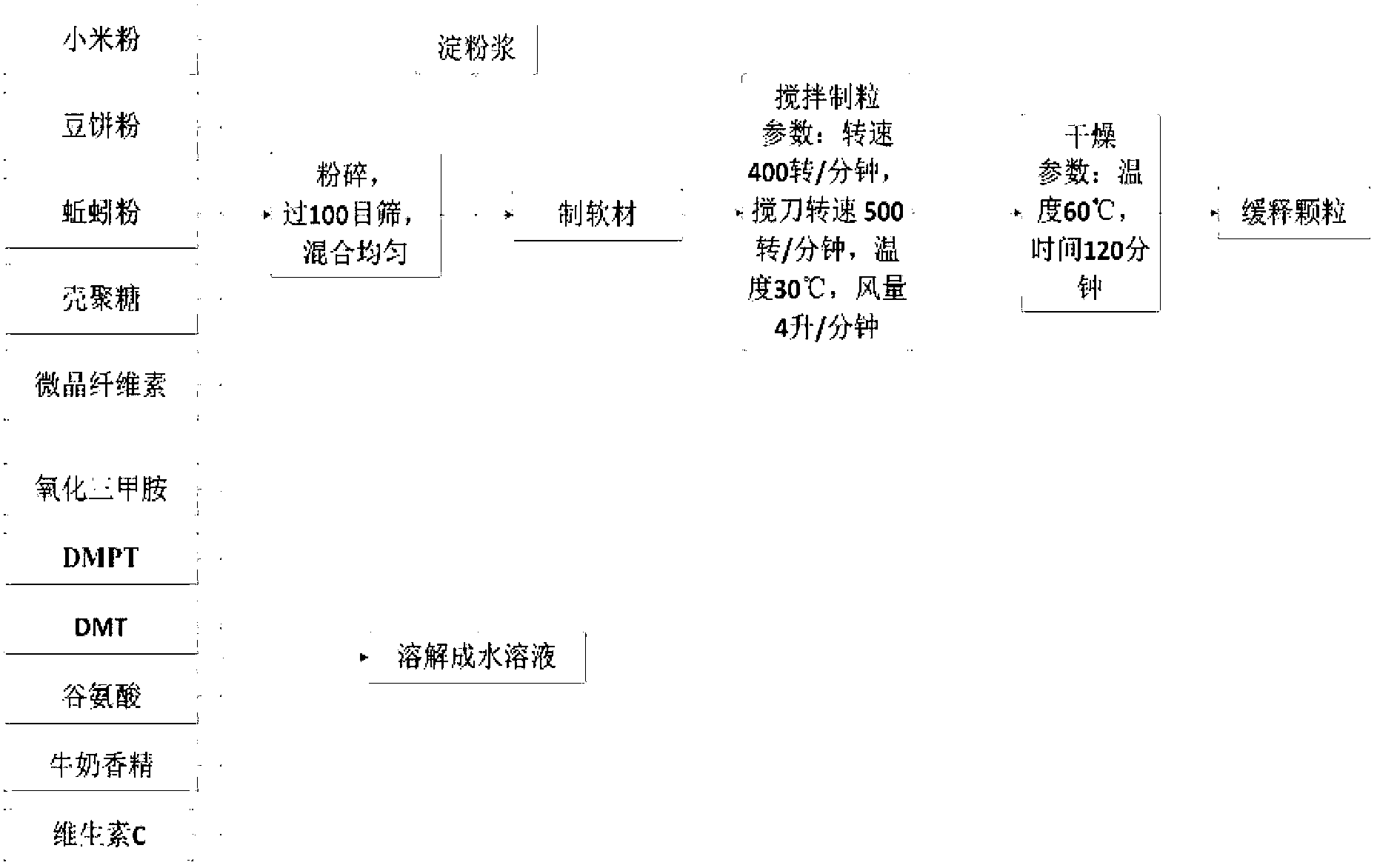

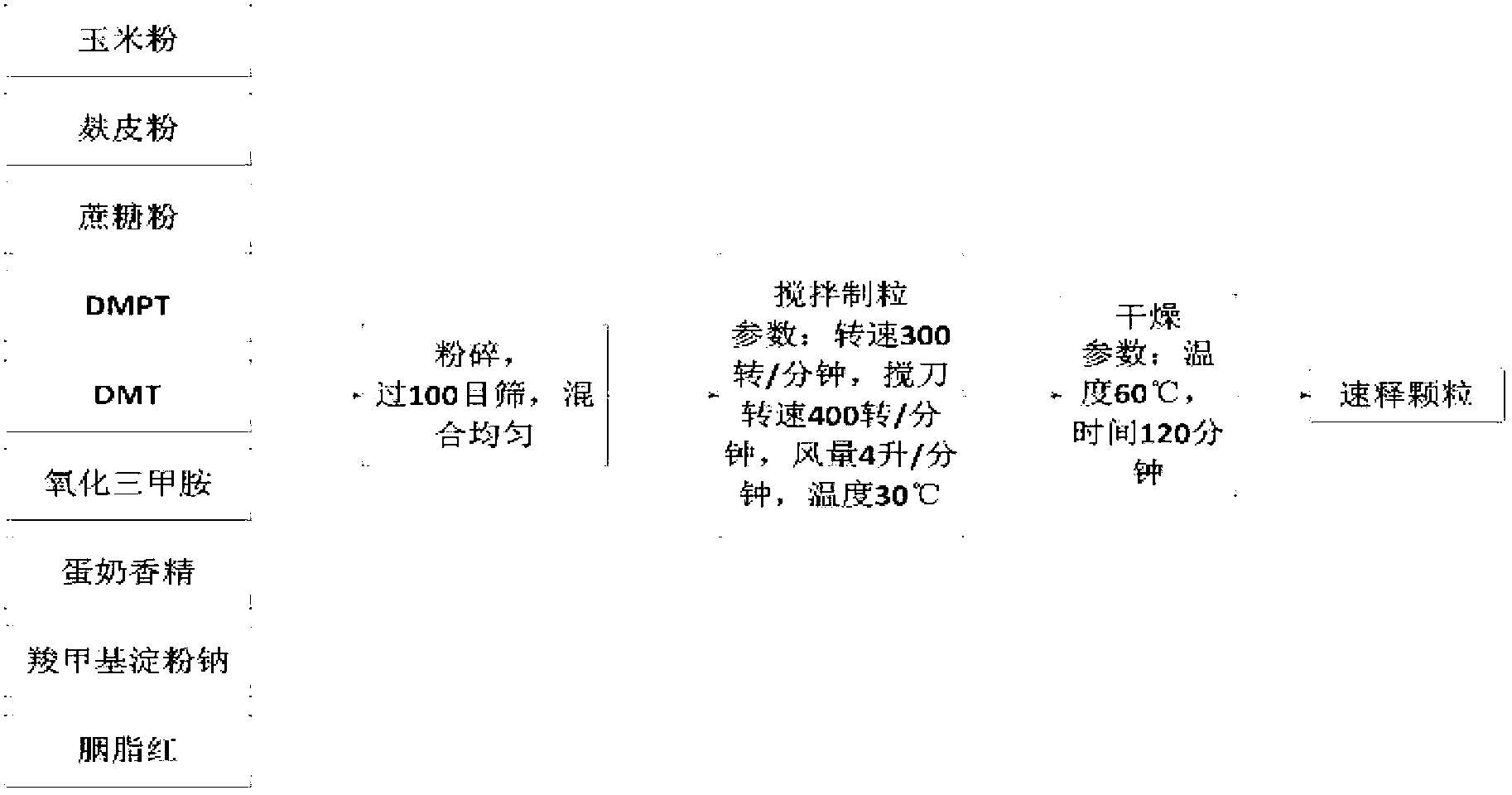

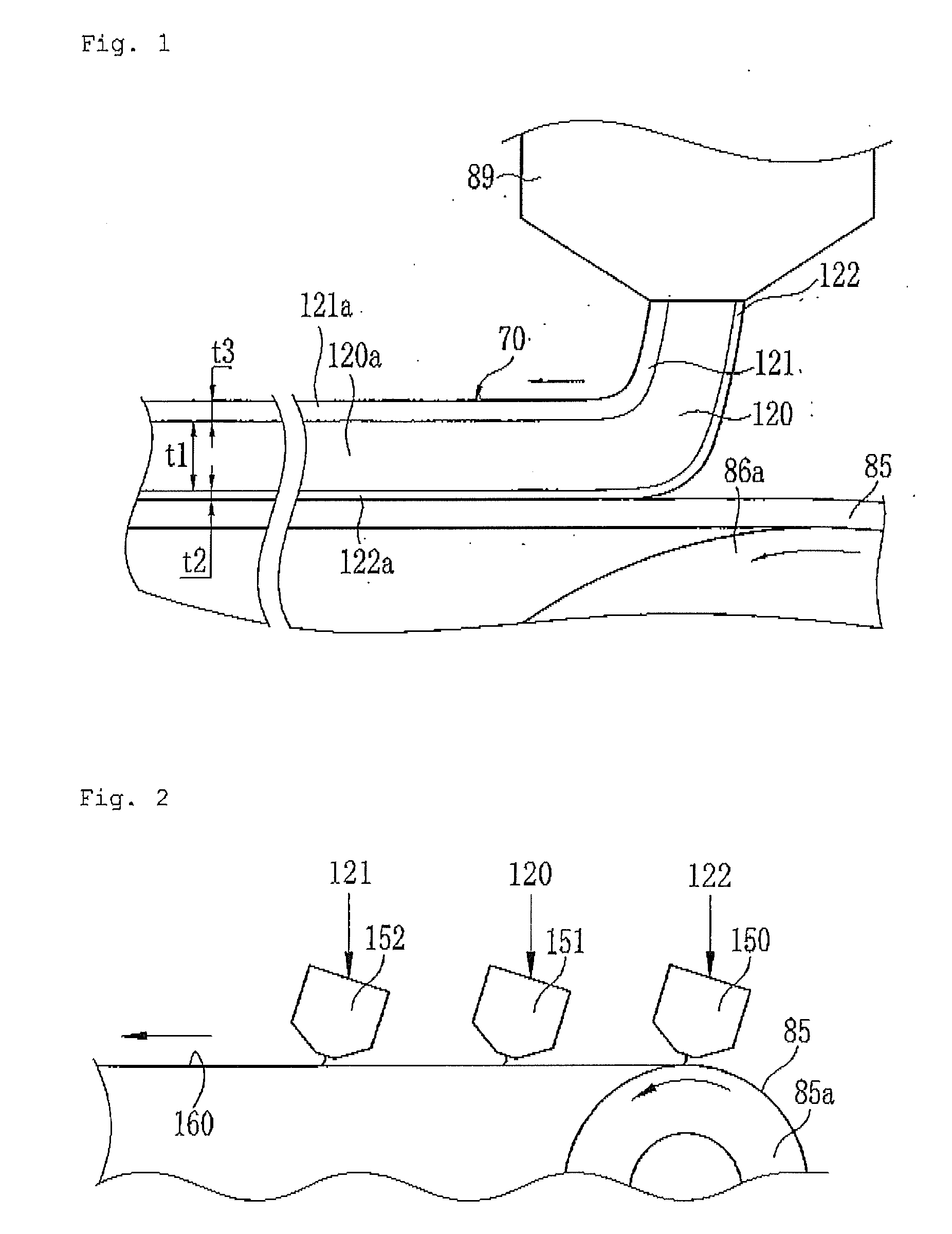

Controlled release bait material and preparation method thereof

InactiveCN103004717AQuick and long-lasting releaseFast and long-lasting effectOther angling devicesWater insolubleMicrosphere

The invention relates to a controlled release bait material and a preparation method thereof. The controlled release bait material refers to small pills, micro-pills, microcapsules, microspheres, particles or sticks prepared from raw materials including a basic material, a feed attractant, a bonding agent, a hydrophilic high-polymer material, a water-insoluble high-polymer material, a quick-release material, a filler, a colorant, a flavoring agent and the like through a preparation means; and the controlled release bait material can be coated for improving the controlled release effect. The invention further discloses a preparation method of the bait material. The controlled release material has rapid and lasting attracting force on fishes, the fish attracting time can be adjusted according to the habit of a fisherman and the habits of fishes, the food ration and frequency of fishes are increased, the fishing success rate can be increased, the food intake of fishes in cultivation of fishes can be increased, the corrosion ratios of remnant feeds and feeds in water bodies are reduced, the utilization ratios of feeds is increased, and the water body environmental pollution is lowered. The preparation method provided by the invention is suitable for industrial production.

Owner:李群益 +2

Powder material capable of producing anion and preparation method thereof

The present invention discloses one kind of powder material capable of generating negative ion and its preparation process. The powder material consists of tourmaline material 20-70 wt%, mixed RE material or mixed RE oxide material 20-60 wt%, semiconductor catalyst material 5-20 wt%, and auxiliary exciting material 4-15 wt%. Its preparation process includes the following steps: 1. crushing and roasting tourmaline material; 2. grinding tourmaline material in a grinding set into superfine powder; 3. adding surface treating agent for surface treatment; 4. grinding the other materials to size smaller than 1 micron; and 5. dispersing all the materials inside one high speed dispersing machine, sieving and drying. The powder material has a negative ion releasing rate up to 6000-10000 / cu cm.

Owner:常州众普环保新材料科技有限公司

Jelly composition

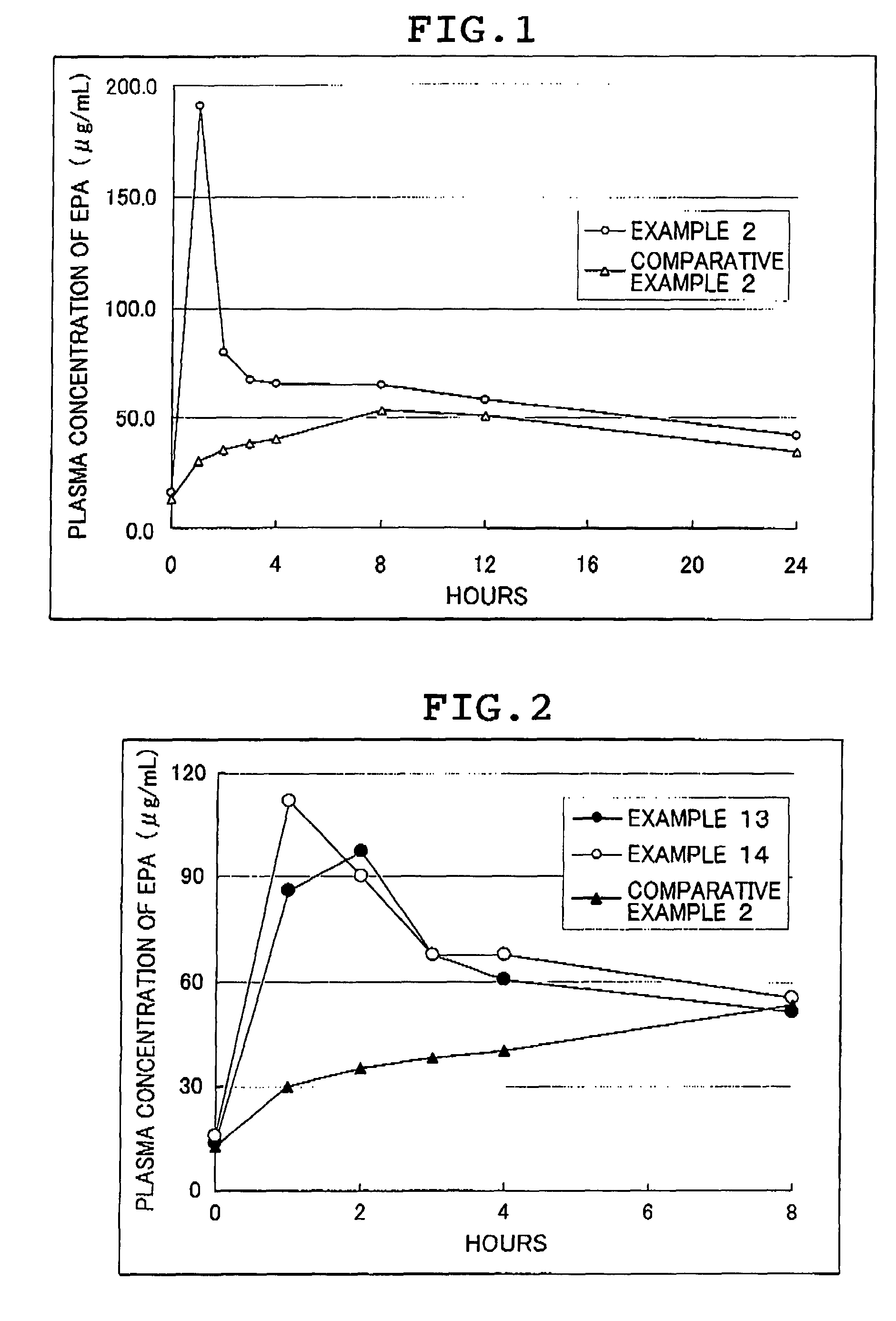

InactiveUS9452150B2Easy to carryEasily administered without waterBiocideAntipyreticBULK ACTIVE INGREDIENTActive ingredient

A composition in which a preparation of the composition itself has an excellent disintegratability in the right place and excellent active ingredient releasability within the digestive tract, the active ingredient and the preparation itself have long-term stability, excellent ease of operation such as manufacturability and filling into containers, an amount sufficient for achieving physiological effects can be easily taken and swallowed, and can be absorbed rapidly from the digestive tract, thus the physiological effect can be expected. The composition is an easy-release jelly composition containing an emulsified polyvalent unsaturated fatty acid or derivative thereof in an amount exceedingly 10 mass % and further containing an emulsifying agent and a gallant. The easy-release jelly composition includes an emulsified polyunsaturated fatty acid or derivative thereof in an amount greater than 10 wt %, an emulsifying agent, and a gelling agent.

Owner:MOCHIDA PHARM CO LTD

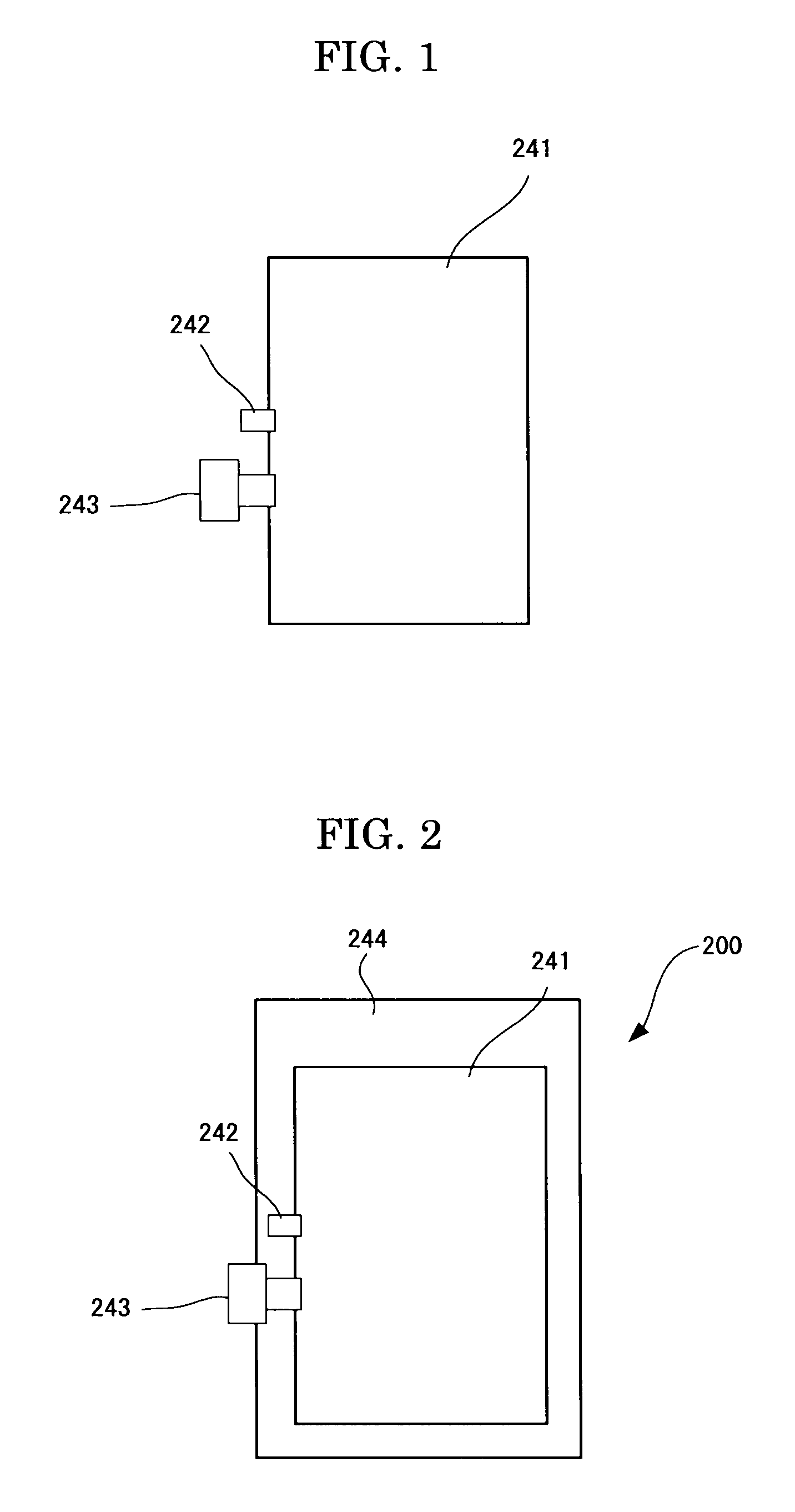

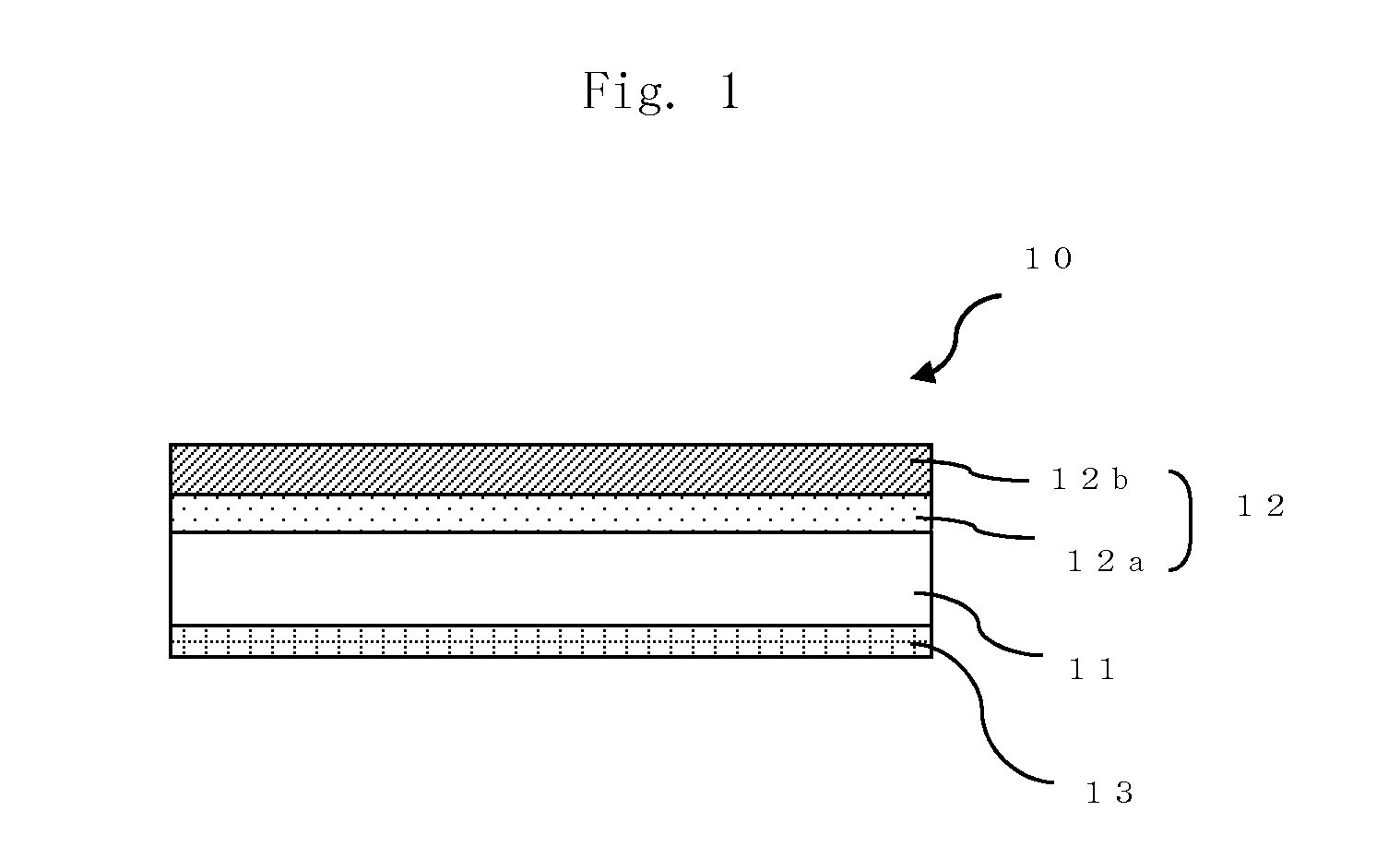

Cellulose acylate laminate film, method for producing same, polarizer and liquid crystal display device

InactiveUS20100055356A1High degree of substitutionExcellent releasabilityLiquid crystal compositionsCellulosic plastic layered productsPolarizerLiquid-crystal display

A stretched cellulose acylate laminate film having a skin layer containing a cellulose acylate with a total degree of acyl substitution of more than 2.7 and a core layer containing a cellulose acylate with a total degree of acyl substitution of 2.0-2.7 wherein the core layer is thicker than the skin B layer and at least one of these layers contains a retardation-controlling agent, is excellent in high expressibility, little optical unevenness and good releasability from a support.

Owner:FUJIFILM CORP

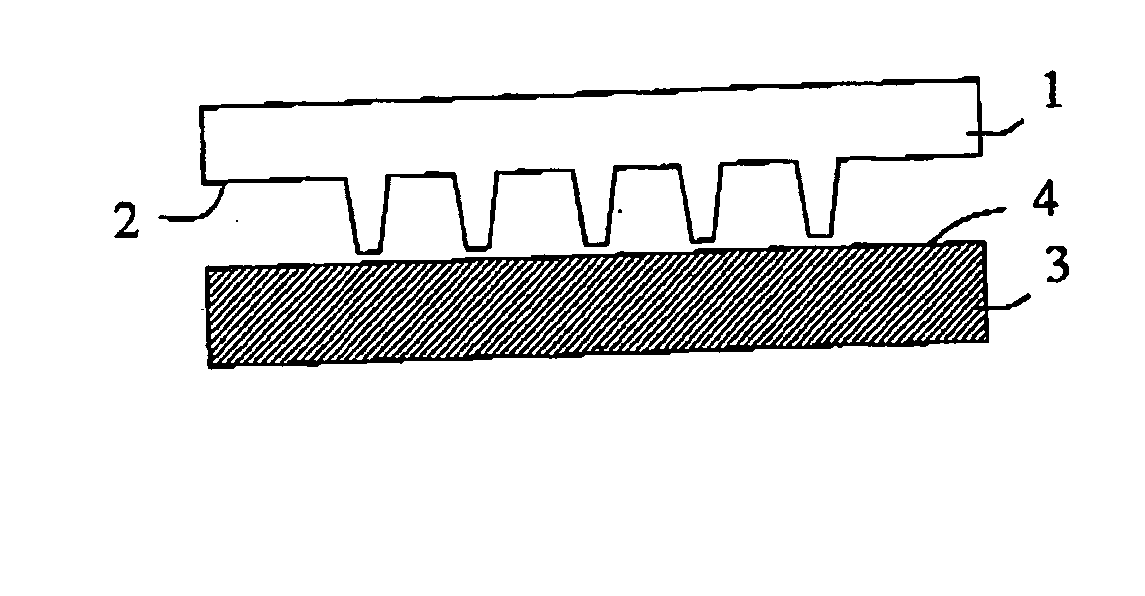

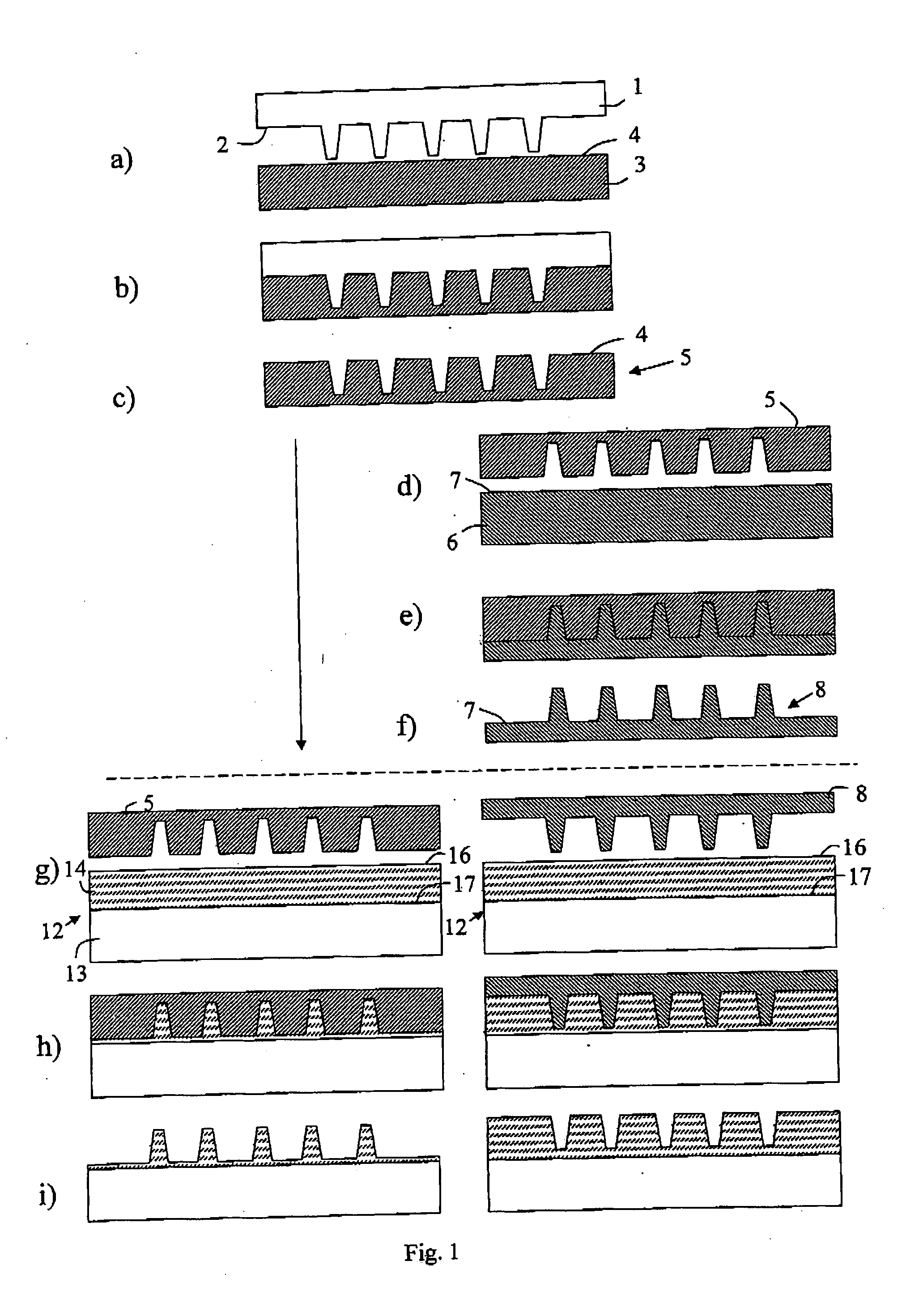

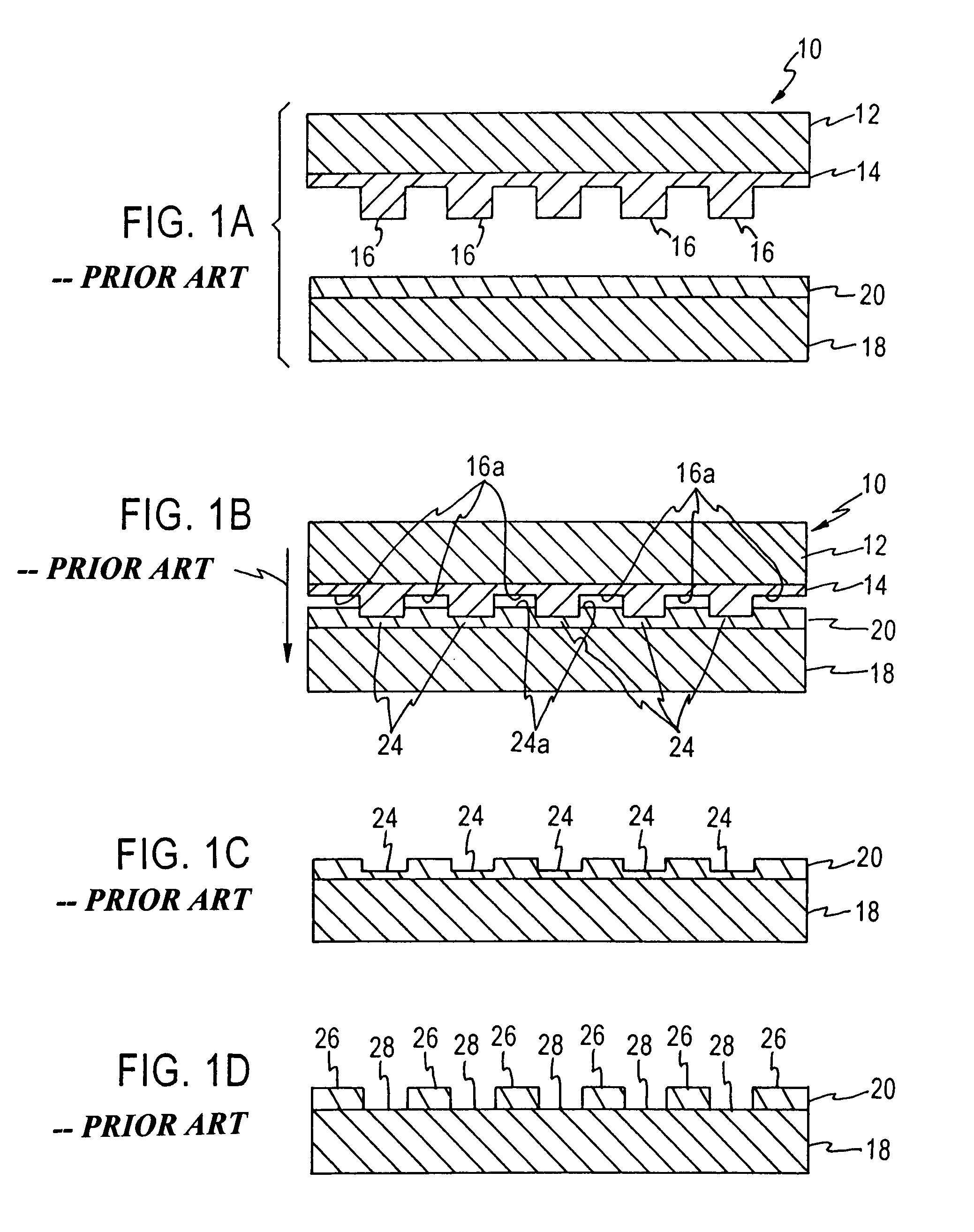

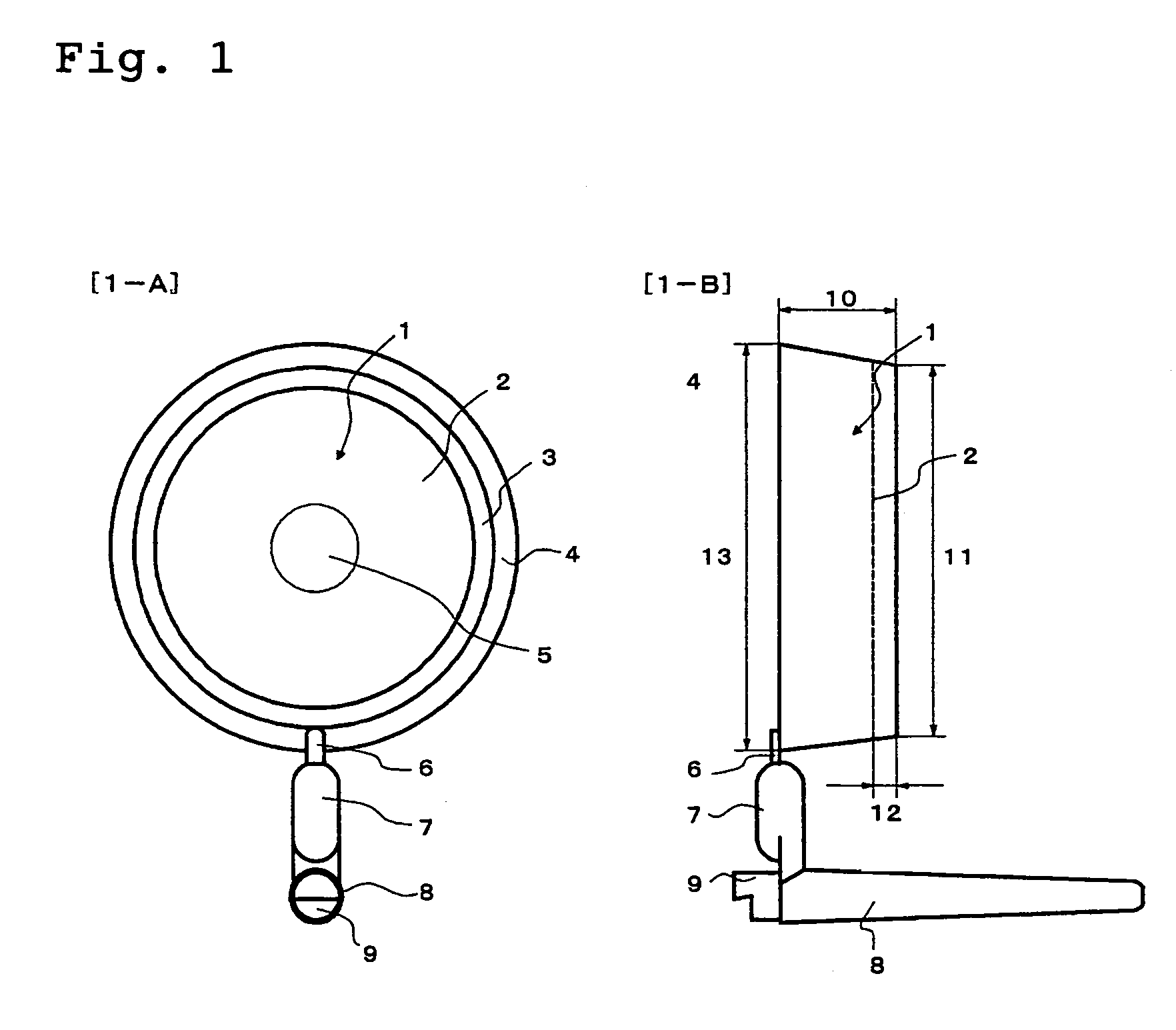

Imprint stamp comprising Cyclic Olefin copolymer

ActiveUS20070212522A1Easy and suitable to employ industriallyImprove fidelityLayered productsNanoinformaticsResistCyclic olefin copolymer

A method is provided for transferring a pattern from a template (1) to an object (12) in an imprint process, using a two-step process. The first step includes contacting a pattern of the template surface with a polymer material comprising one or more Cyclic Olefin Copolymers (COCs), to produce a flexible polymer replica having a structured surface with an inverse of the pattern of the template surface. In a second step, after releasing the flexible polymer replica from the template, the inverse pattern of the flexible polymer replica is pressed into a resist layer on a substrate, to imprint a replica of the pattern of the template surface in therein.

Owner:OBDUCAT AB SE

Polycarbonate resin composition, pellets thereof and molded article thereof

InactiveUS20040152806A1Increased durabilityHigh transparencySynthetic resin layered productsAbsorbent padsAlcoholCrack resistance

The object of the present invention is to provide a polycarbonate resin composition which has excellent transparency and durability against molding heat, which gives a molded article having an excellent mold release property, reduced strains, improved cracking resistance and, preferably, weatherability, and which is particularly suitable for a transparent member for a vehicle, pellets thereof and a molded article thereof, and the present invention provides a polycarbonate resin composition obtained by blending 100 parts by weight of a polycarbonate resin (Component A) and 0.005 to 2 parts by weight of a full ester (Component B) from an aliphatic polyhydric alcohol having 4 to 8 hydroxyl groups and 5 to 30 carbon atoms and an aliphatic carboxylic acid having 10 to 22 carbon atoms, said Component B having a 5% weight loss temperature, measured by TGA (thermogravimetric analysis), of 250 to 360° C. and having an acid value of 4 to 20, pellets thereof and a molded article thereof.

Owner:TEIJIN KASEK KK

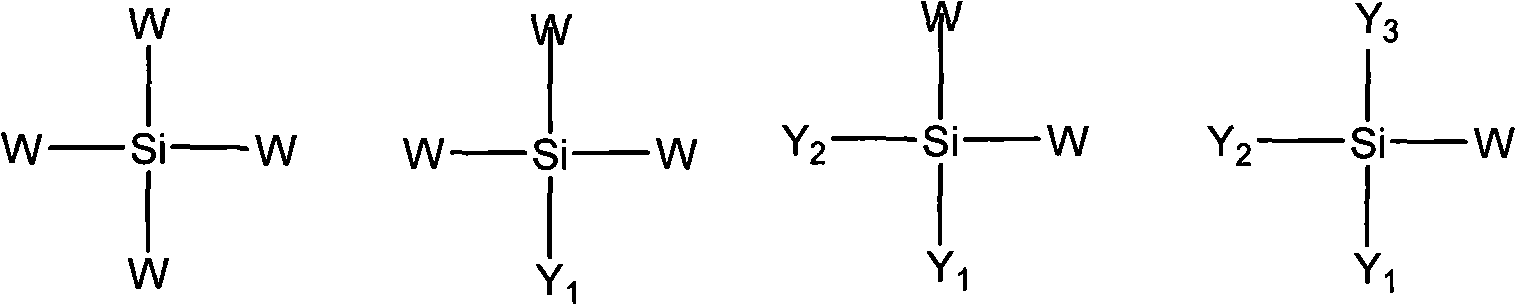

Curable Siloxane Composition With Modified Surface Properties

ActiveUS20070275255A1Little force requiredGuaranteed flatnessLayered productsSpecial tyresPolymer sciencePolymer chemistry

The present invention relates to new curable siloxane compositions, and their use for the manufacture of cured products thereof having modified release properties. The modified release forces are achieved by incorporating a selected pressure sensitive adhesive additive.

Owner:MOMENTIVE-PERFORMANCE MATERIALS GMBH

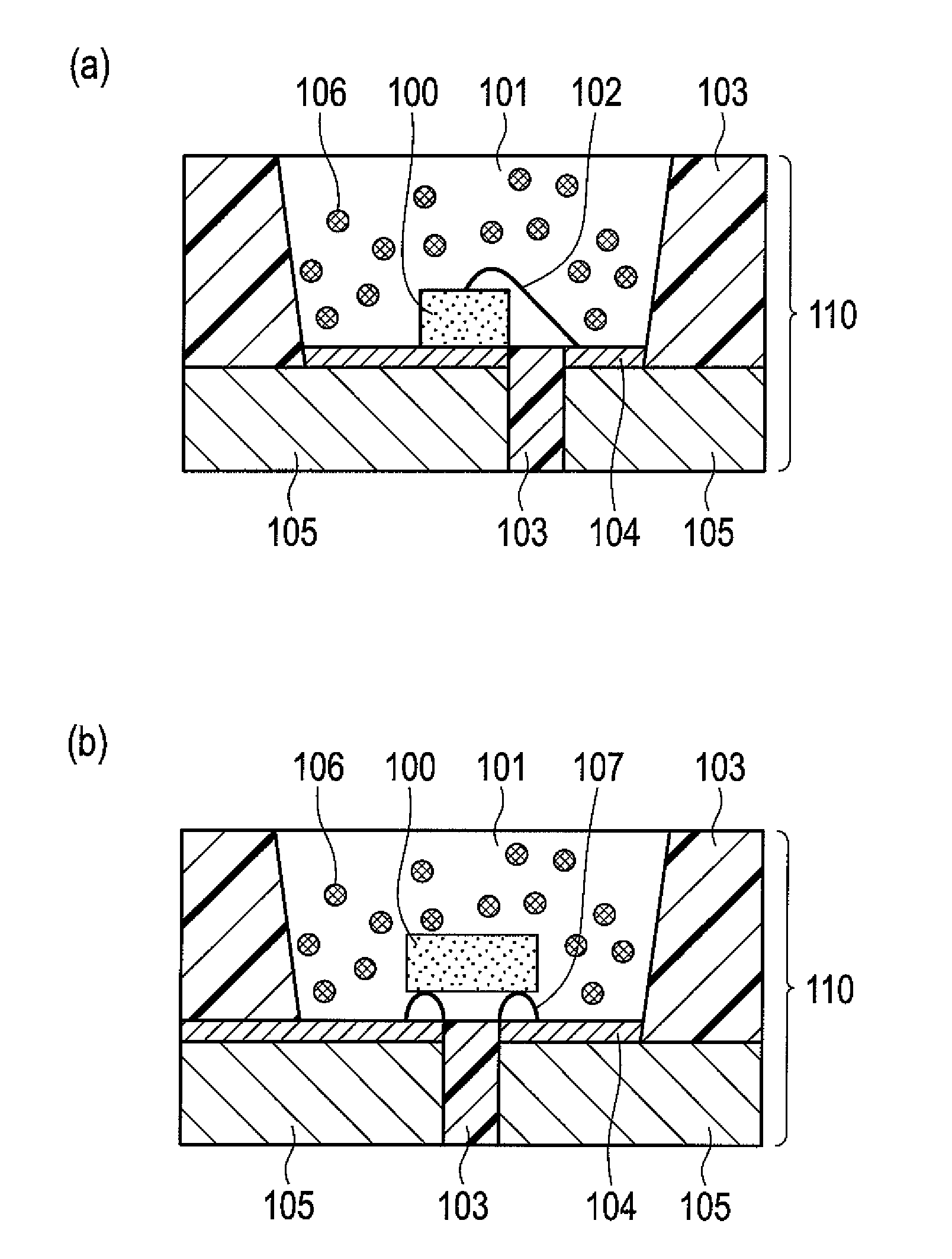

Thermosetting light-reflecting resin composition, optical semiconductor element mounting board produced therewith, method for manufacture thereof, and optical semiconductor device

ActiveUS20100200882A1High levelHigh releasabilityLiquid crystal compositionsDiffusing elementsReflectivityLight wave

There is provided a thermosetting light-reflecting resin composition that has a high level of various characteristics required of optical semiconductor element mounting boards, such as optical properties and thermal discoloration resistance, provides high releasability during molding such as transfer molding, and allows molding processes to be performed continuously. There are also provided a highly-reliable optical semiconductor element mounting board and an optical semiconductor device each produced with the resin composition, and methods for efficient production thereof. A thermosetting light-reflecting resin composition is prepared and used, which includes (A) an epoxy resin, (B) a curing agent, (C) a curing catalyst, (D) an inorganic filler, (E) a white pigment, (F) an additive, and (G) a release agent as major components, wherein the resin composition, after curing, has a diffuse reflectance of 80% or more at a light wavelength of 400 nm; and the resin composition is possible to perform transfer molding 100 times or more continuously.

Owner:RESONAC CORP

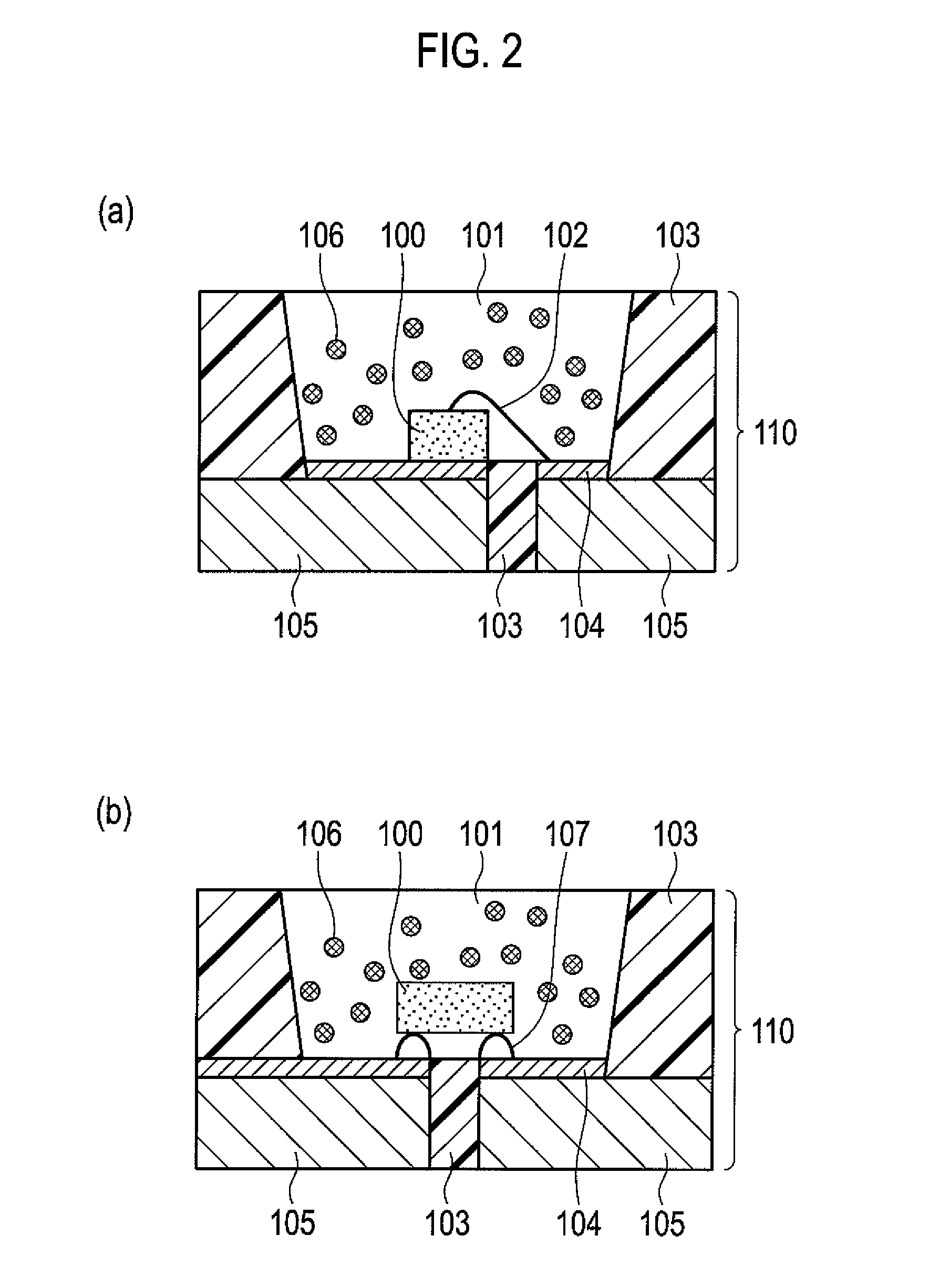

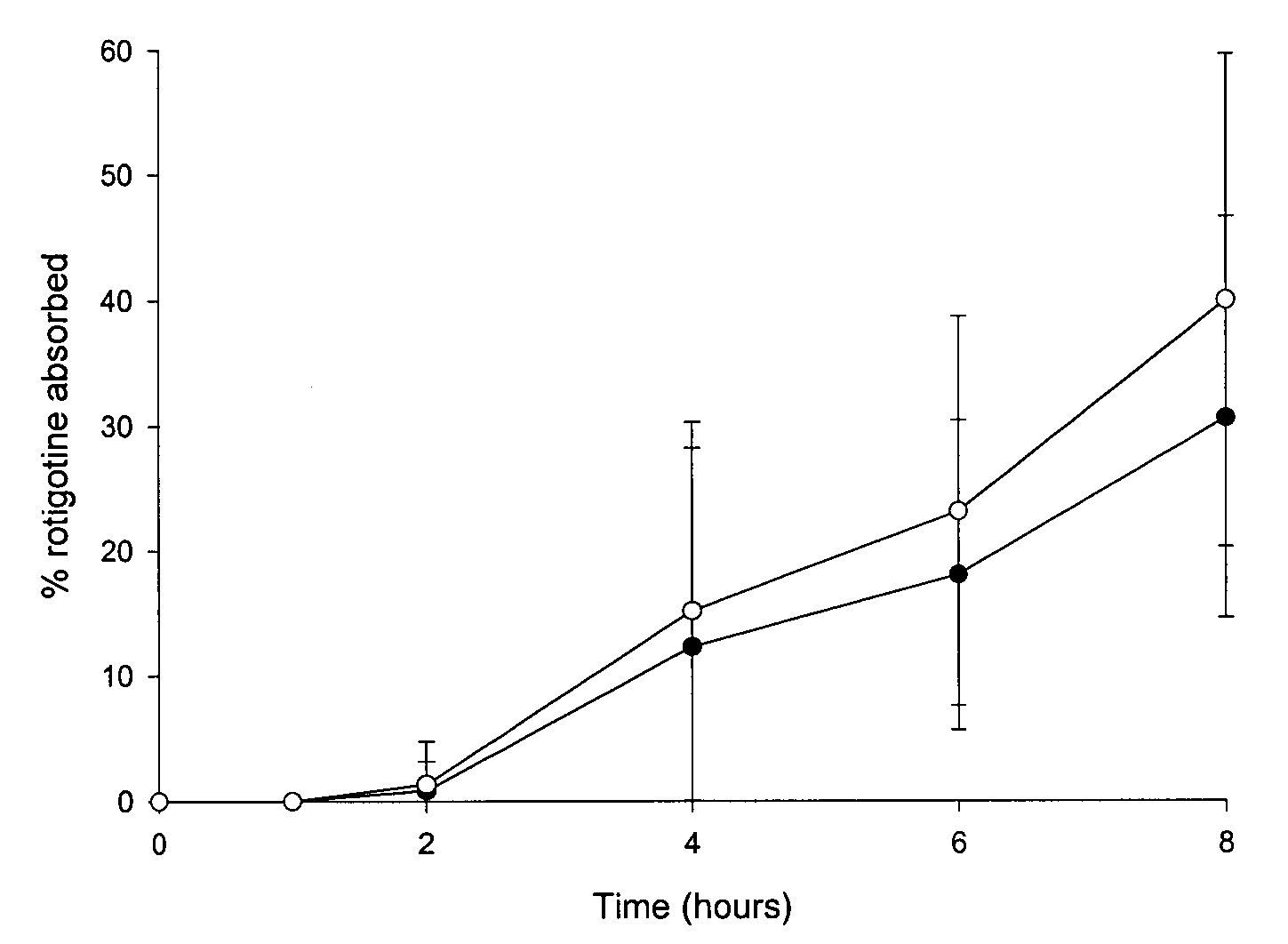

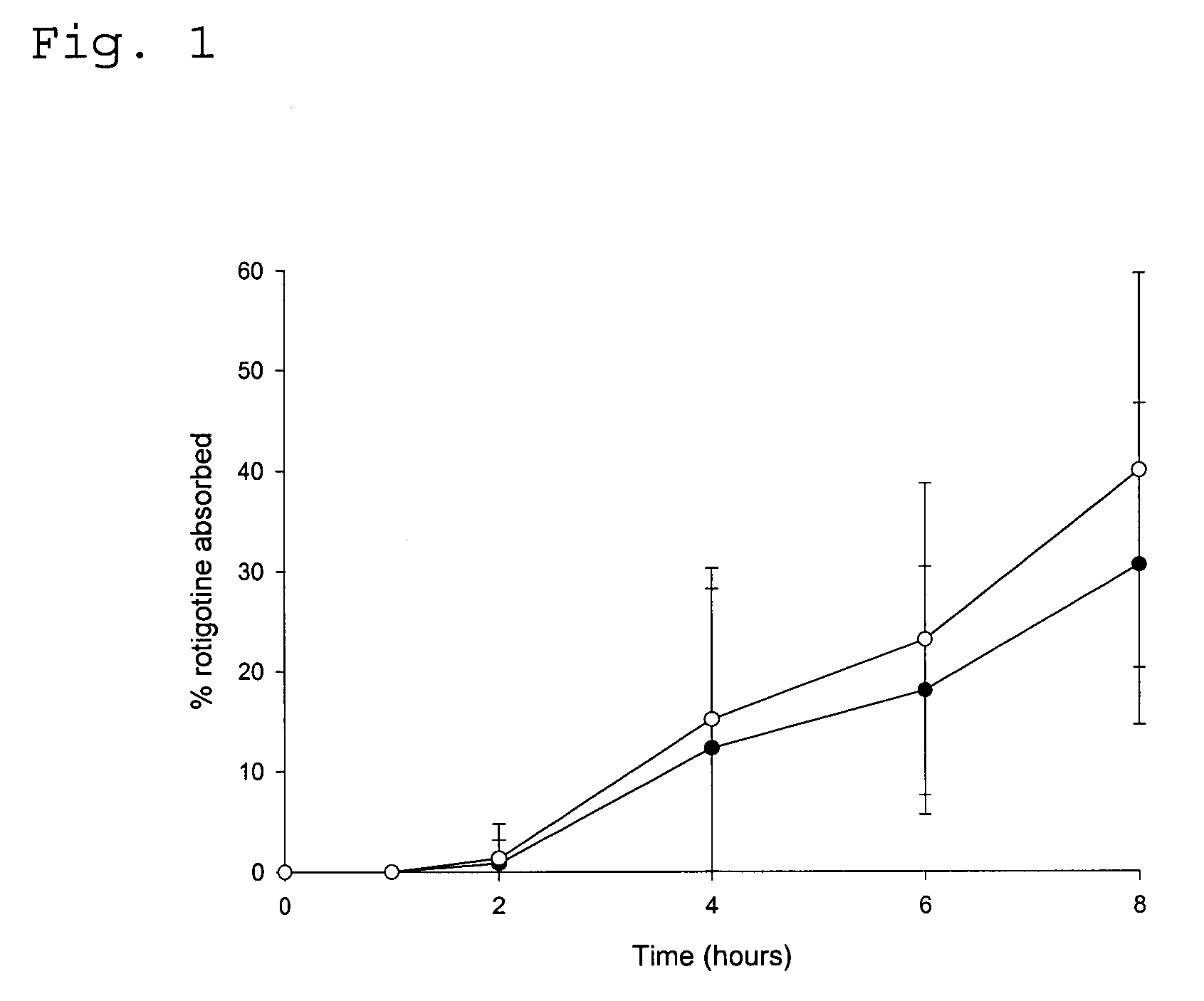

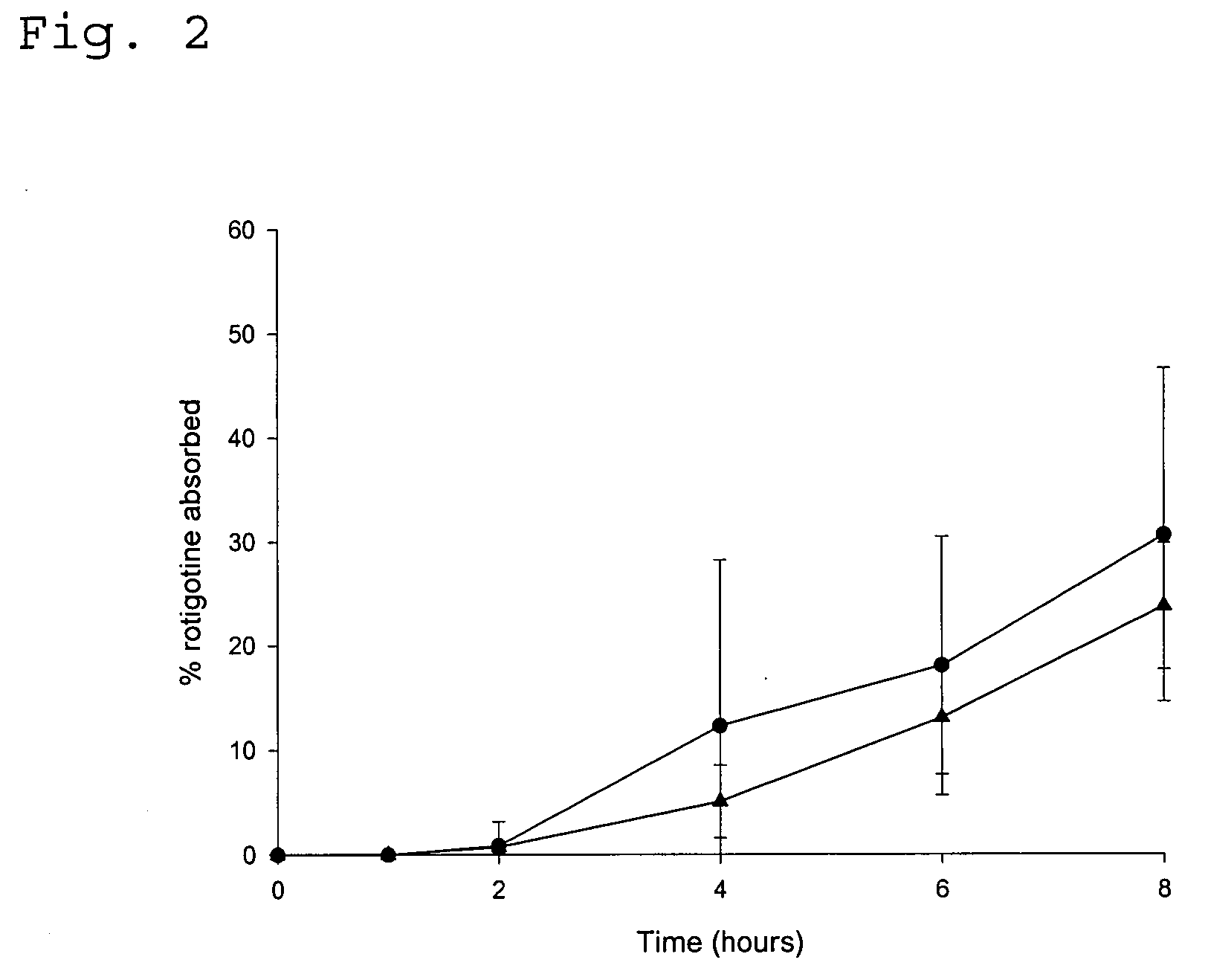

Transdermal delivery system

ActiveUS20040081683A1Facilitated releaseGood release effectPowder deliveryBiocideProtonationMedicine

An improved Transdermal Delivery System (TDS) comprising a backing layer inert to the components of the matrix, a selfadhesive matrix containing an amine-functional drug and a protective foil or sheet to be removed prior to use, characterized in that the self-adhesive matrix consists of a solid or semi-solid semi-permeable polymer (1) wherein an amine functional drug in its free base form has been incorporated, (2) which is saturated with the amine functional drug and contains said drug as a multitude of microreservoirs within the matrix, (3) which is highly permeable for the free base of the amine functional drug, (4) which is impermeable for the protonated form of the amine functional drug, (5) wherein the maximum diameter of the microreservoirs is less than the thickness of the matrix. is provided. Said TDS provides for enhanced flux of the amine functional drug across the TDS / skin interface.

Owner:UCB SA

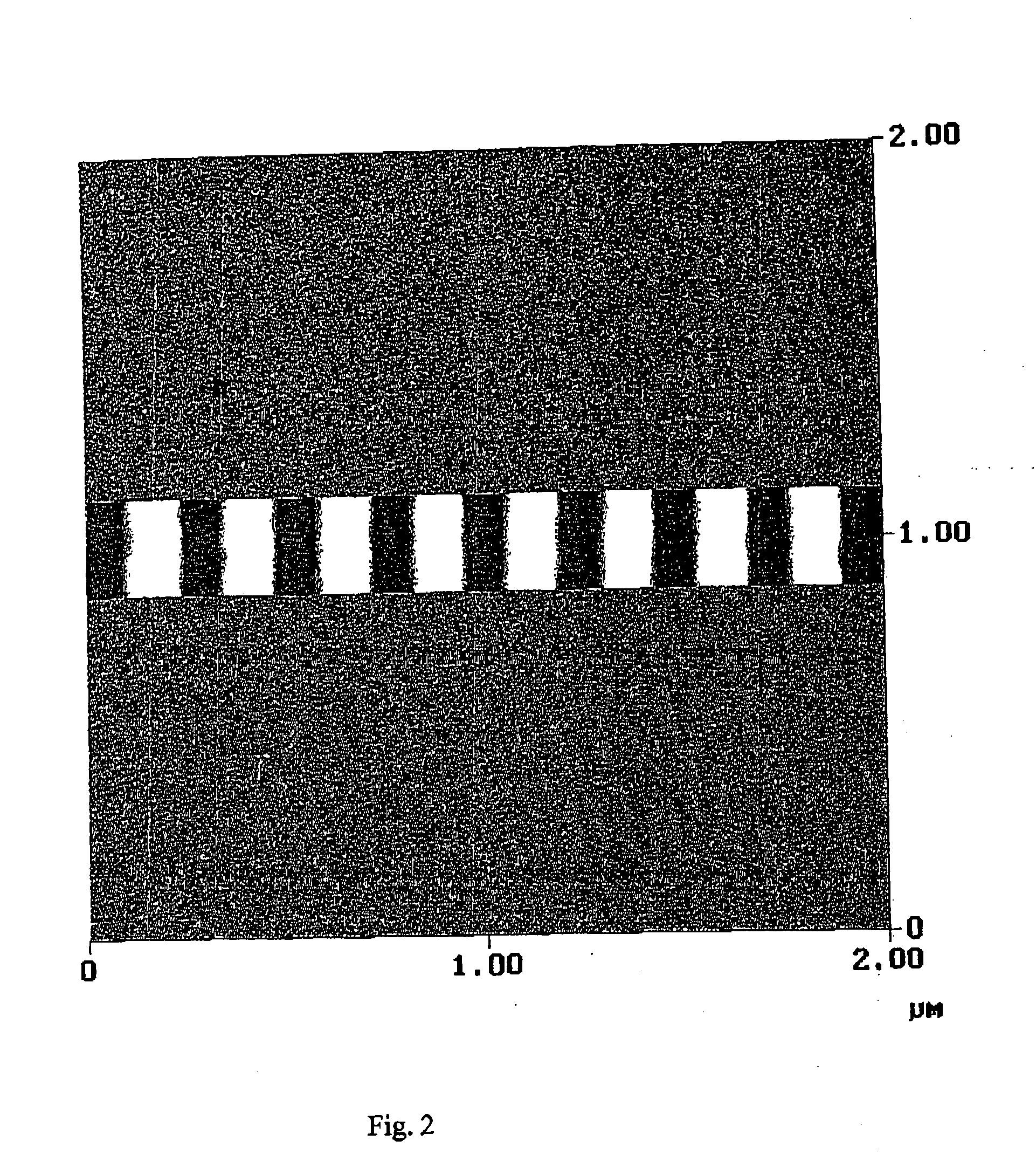

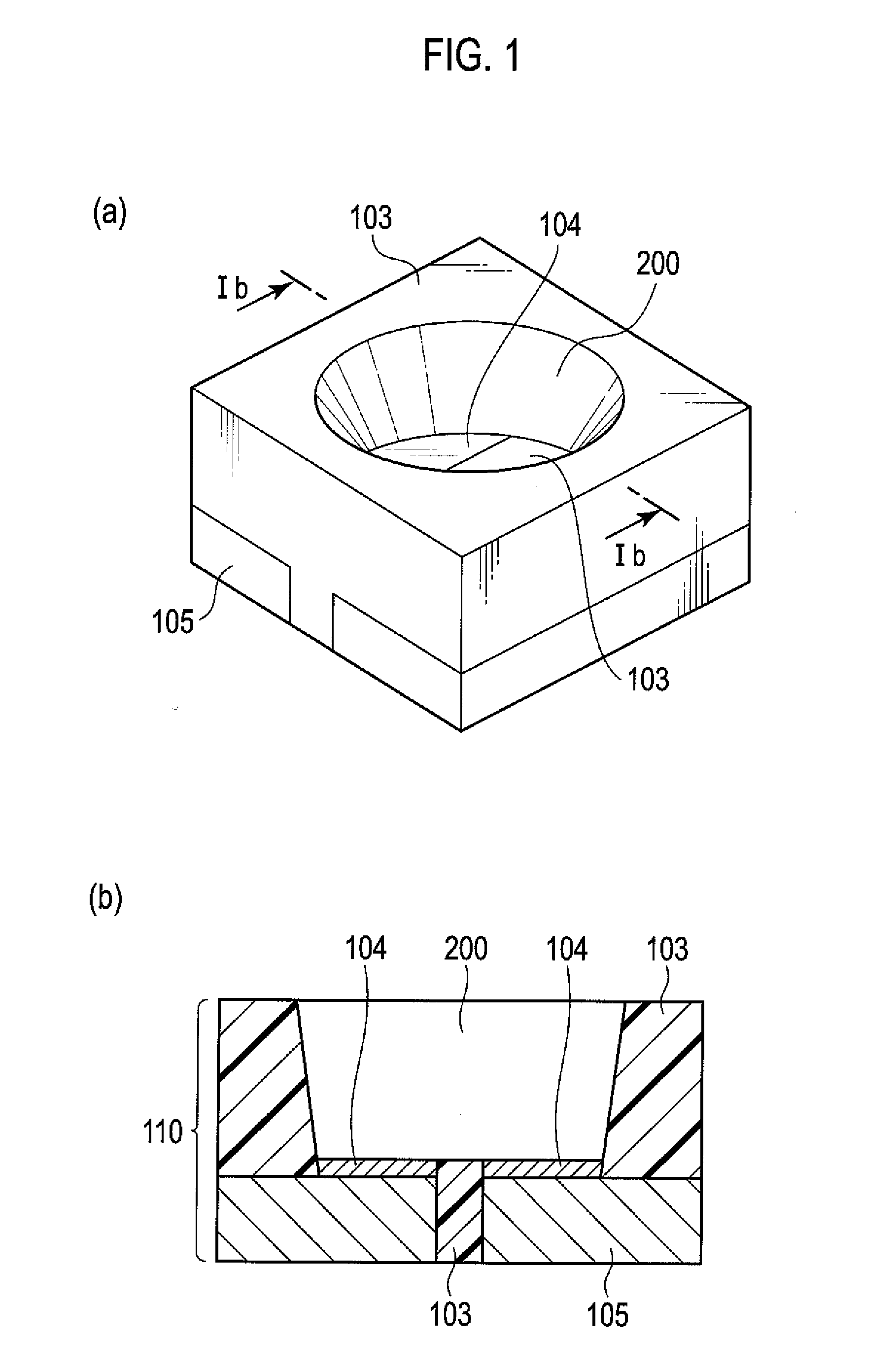

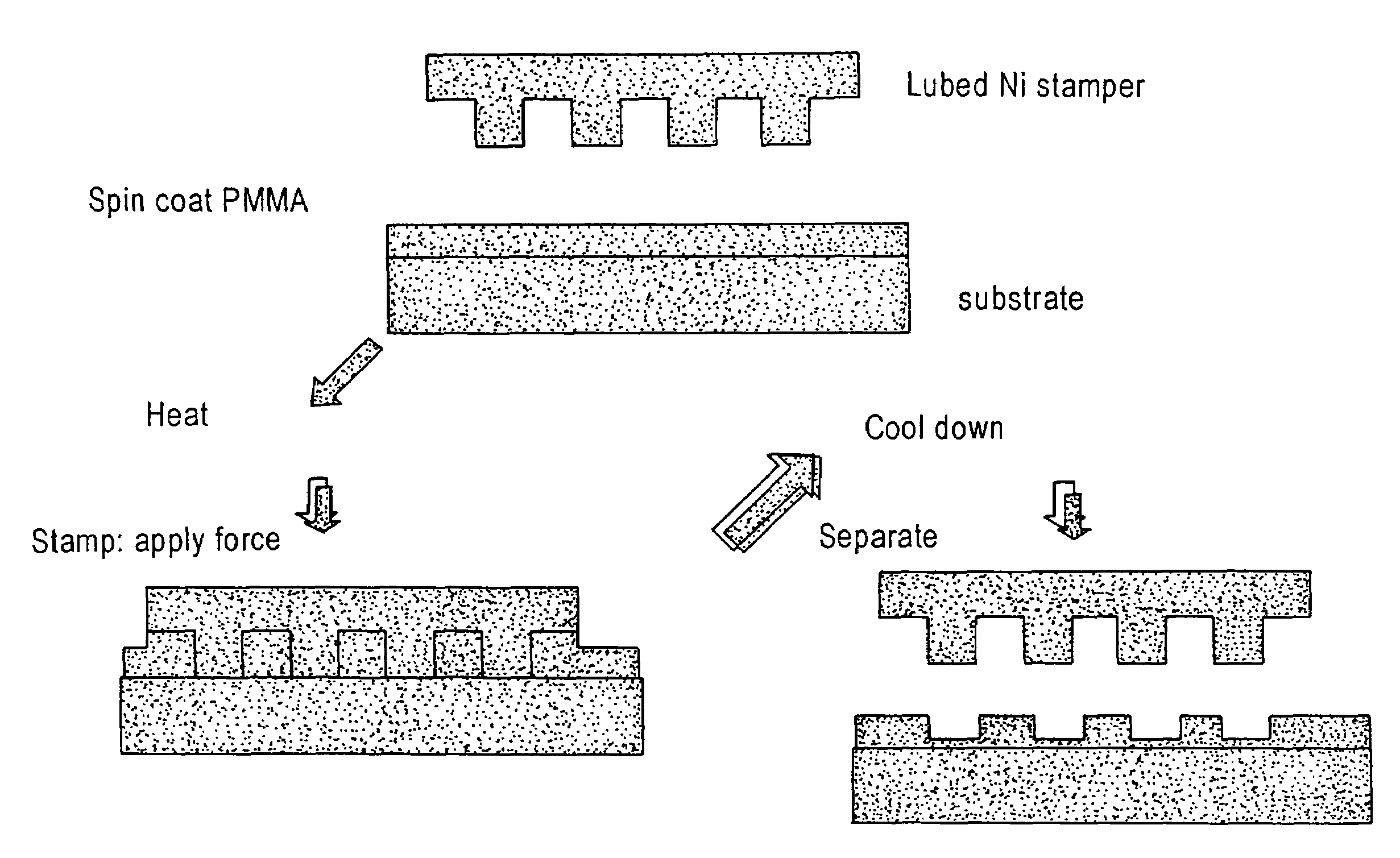

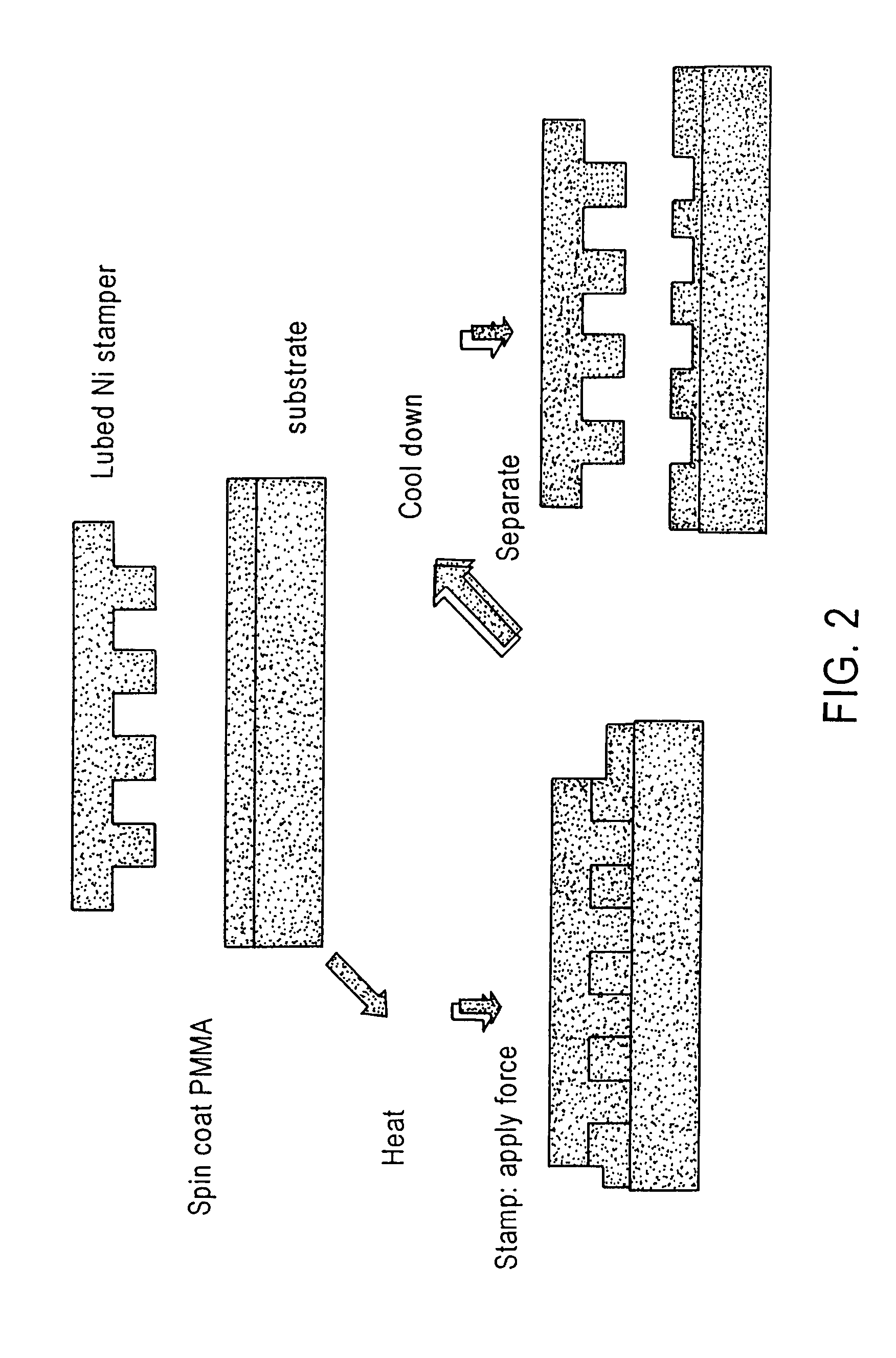

Surface modified stamper for imprint lithography

InactiveUS7294294B1Good release effectMinimize peelingRecord carriersNanoinformaticsLithographic artistEngineering

A method of performing imprint lithography of a surface substrate includes a stamper having a thin lubricant coating thereon to facilitate release of the stamper from the imprinted surface to reduce degradation of image replication. Embodiments of the invention include stampers suitable for use in patterning servo information on magnetic recording media having a lubricant coating of from about 1 nm to about 20 nm.

Owner:SEAGATE TECH LLC

Release agent and application thereof

The invention discloses a release agent. The release agent comprises polysiloxane compound of which the molecule has more than three silicon-hydrogen (Si-H) bonds, semigloss particles, an emulsifying agent and water. The invention also provides the application of the release agent in the preparation of semigloss type rubber products, semigloss type plastic products or semigloss type composite material products. The release agent of the invention has simple construction, high release property and a good semigloss effect, and can form a harder film after being cured, so that the semigloss particles are fixed on the film without being transferred to the molded products, and semi-permanent demoulding is realized; the obtained products after multiple demoulding still have basically constant glossiness and high storage stability without being influenced on the product property. The release agent of the invention is almost suitable for all moulds, particularly has higher caking property with metal moulds and has a wide application range.

Owner:HENKELCHINAINVESTMENT

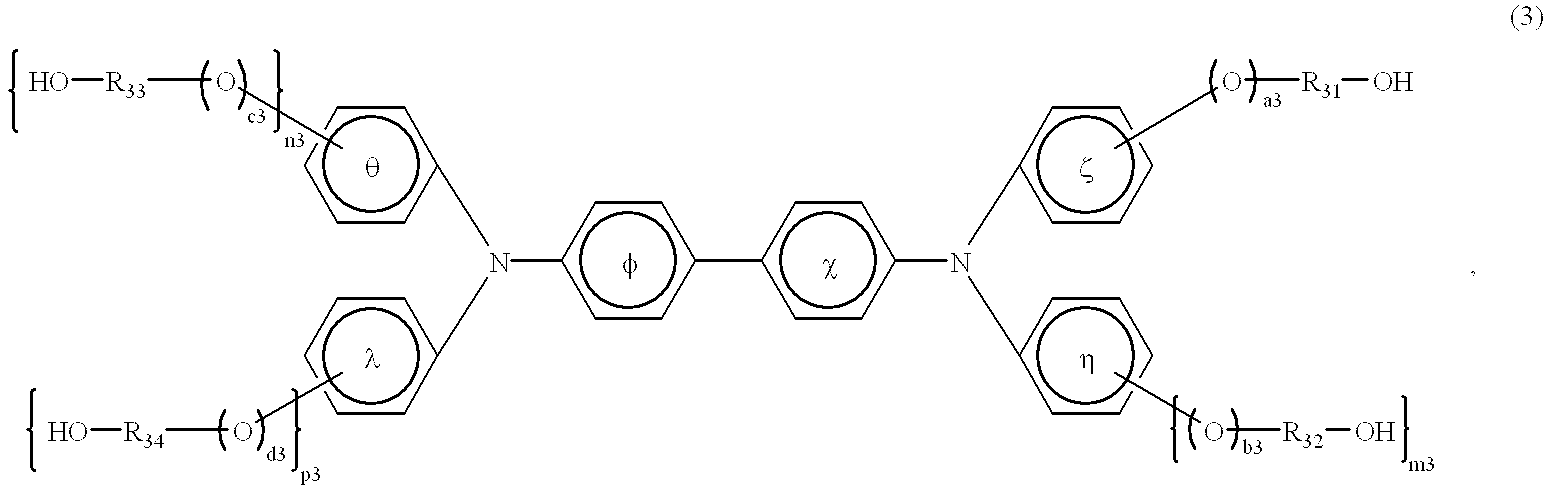

Electrophotographic photosensitive member, process cartridge and electrophotographic apparatus

InactiveUS20020119382A1Reduce photosensitivityIncrease in residual potentialElectrographic process apparatusCorona dischargeProtection layerElectric charge

An electrophotographic photosensitive member exhibiting a good durability and stable electrophotographic performances regardless of environmental change is provided by coating the photosensitive layer with a specific protective layer. The protective layer comprises a cured phenolic resin and a charge-transporting compound having at least one group selected from the group consisting of hydroxyalkyl groups, hydroxyalkoxy groups and hydroxyphenyl groups capable of having a substituent.

Owner:CANON KK

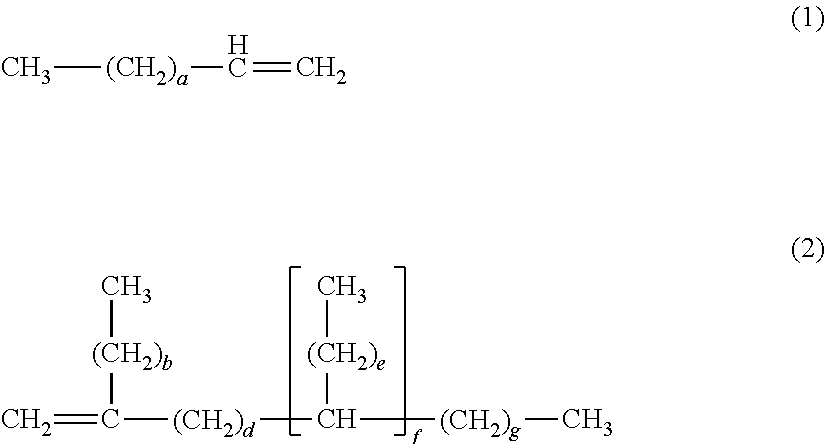

Toner, image forming apparatus, image forming method, and process cartridge using the toner

ActiveUS20080280219A1High quality imagingDecrease in image densityDevelopersElectrographic processes using charge patternImage formationCarboxylic acid

The present invention provides a toner containing at least a binder resin, a releasing agent, and a colorant, wherein the binder resin contains at least a polyester resin (A) having a softening point Tm(A) of 120° C. to 160° C., a polyester resin (B) having a softening point Tm(B) of 80° C. or more and less than 120° C. and a composite resin (C) containing a condensation polymerization monomer and an addition polymerization monomer, at least any one of the polyester resins (A) and (B) is a polyester resin prepared by condensation-polymerizing an alcohol component substantially composed of only aliphatic alcohol with a carboxylic acid component, and 65% or more of the alcohol component is 1,2-propanediol.

Owner:RICOH KK

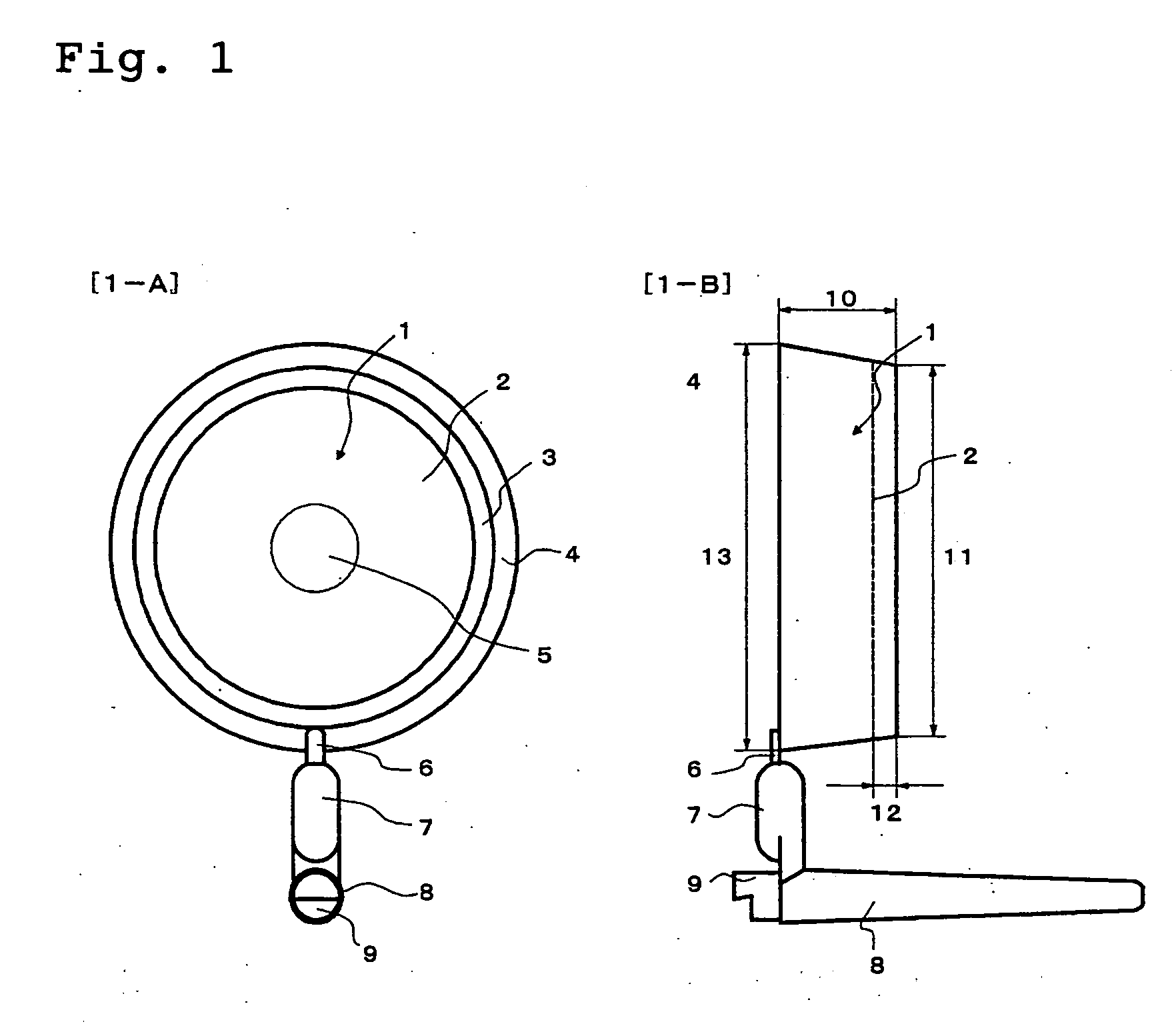

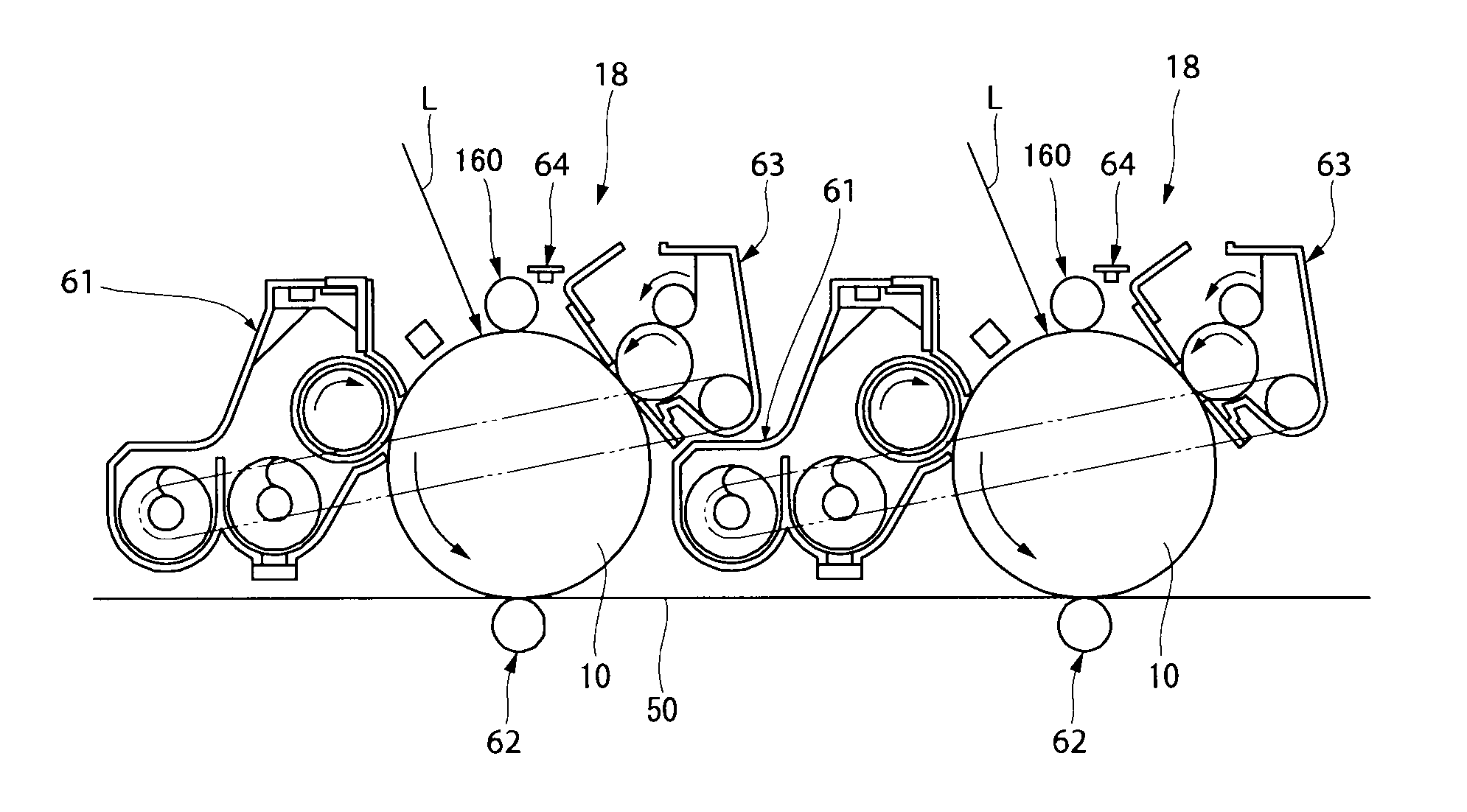

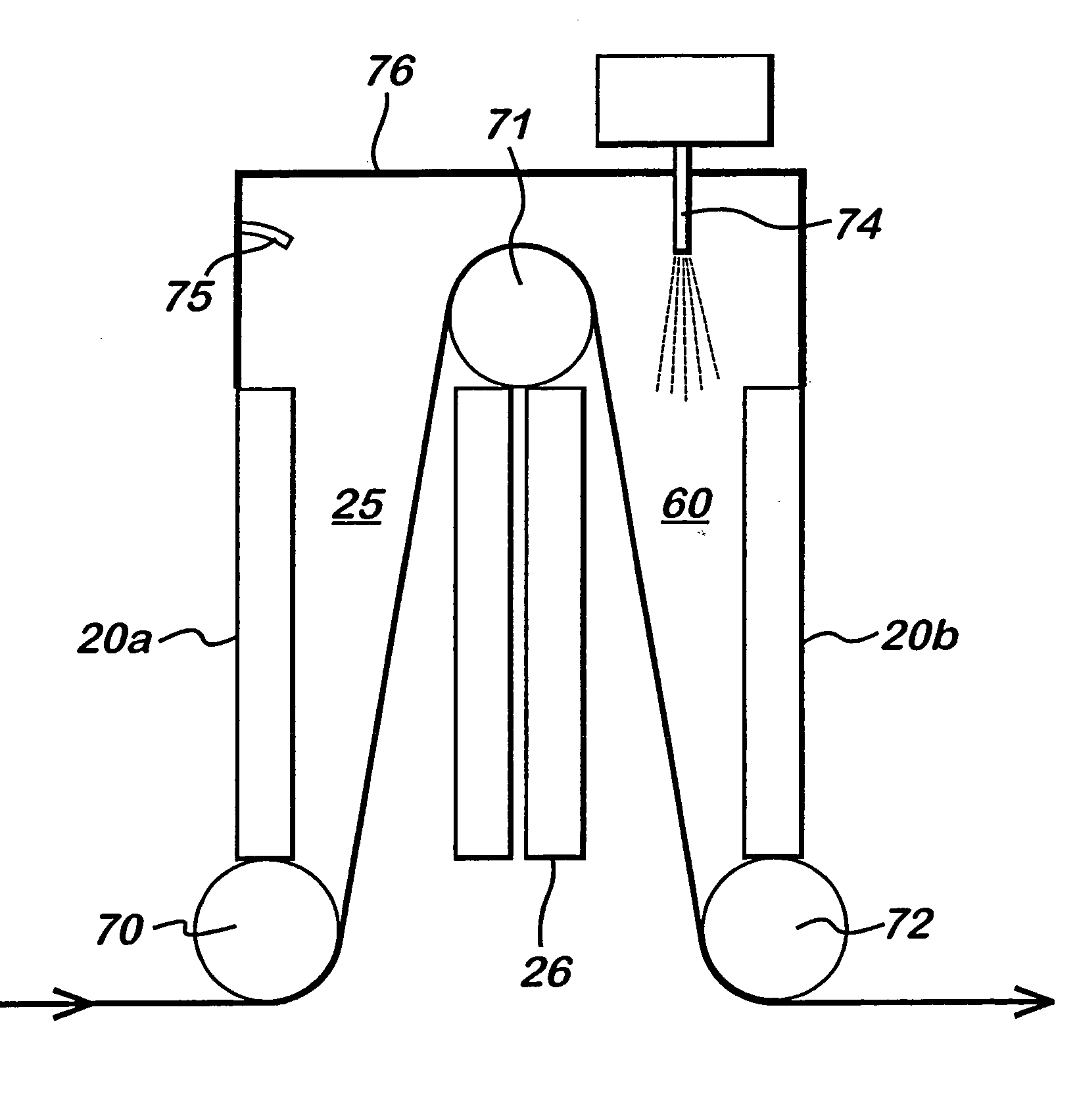

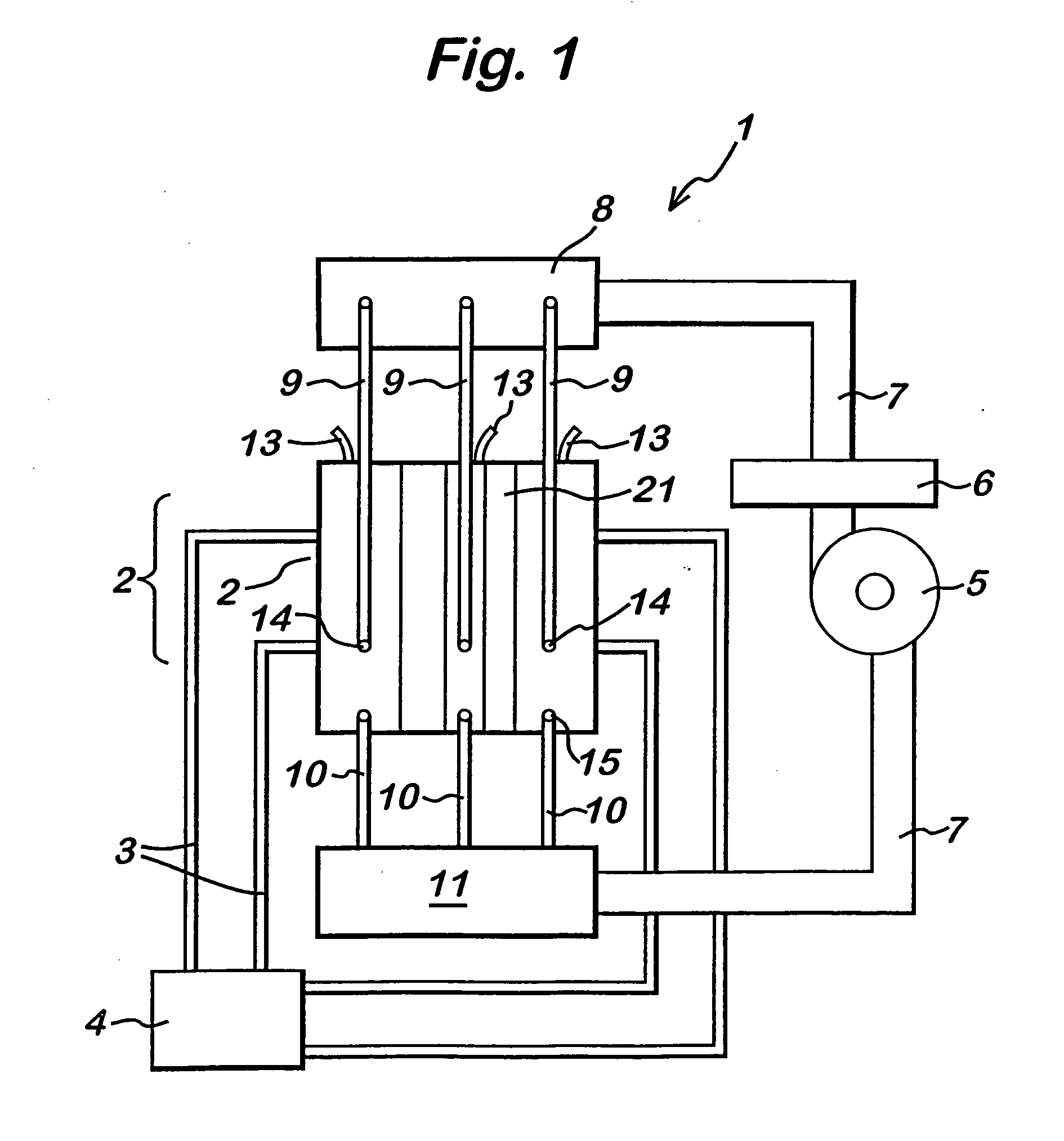

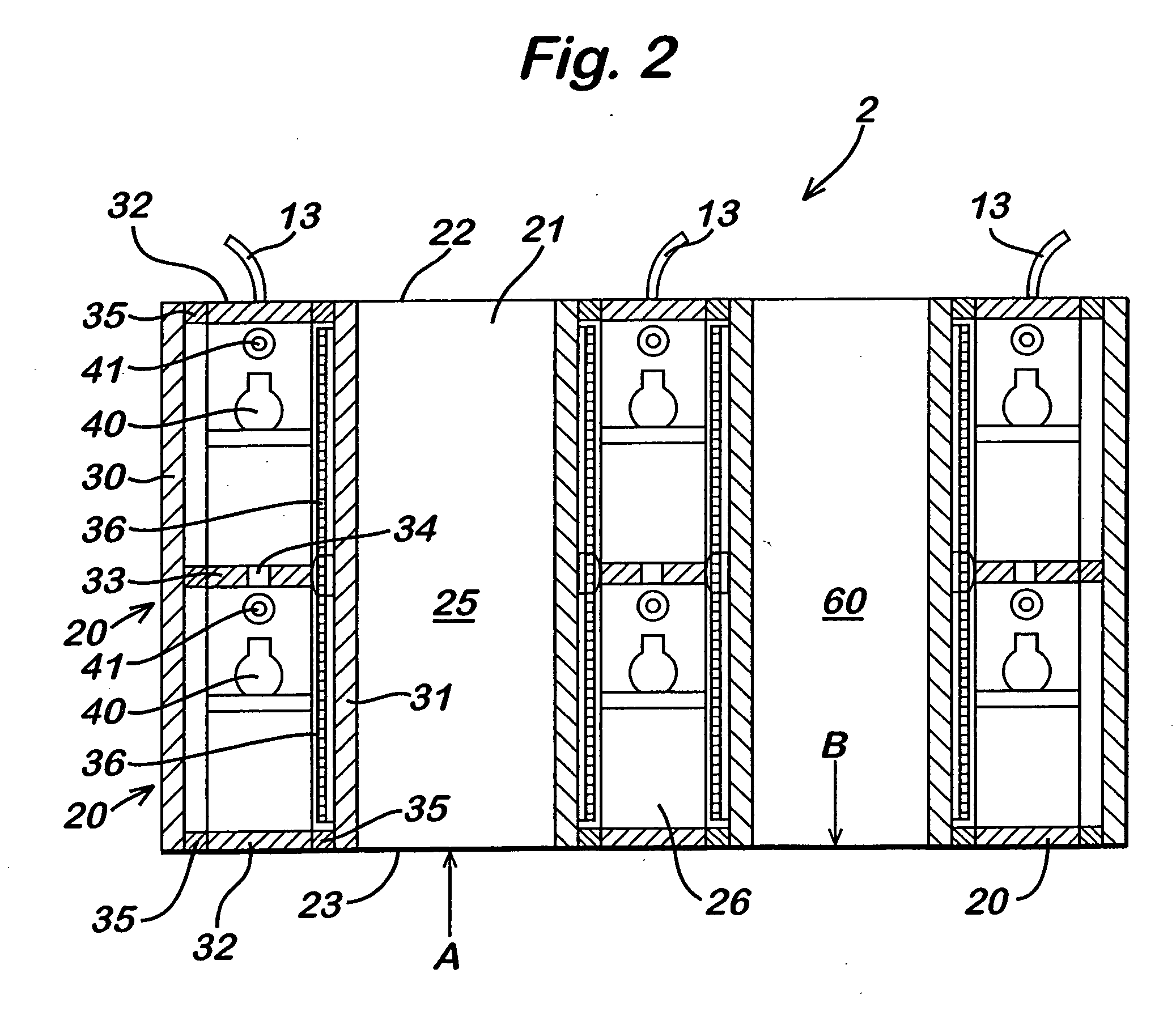

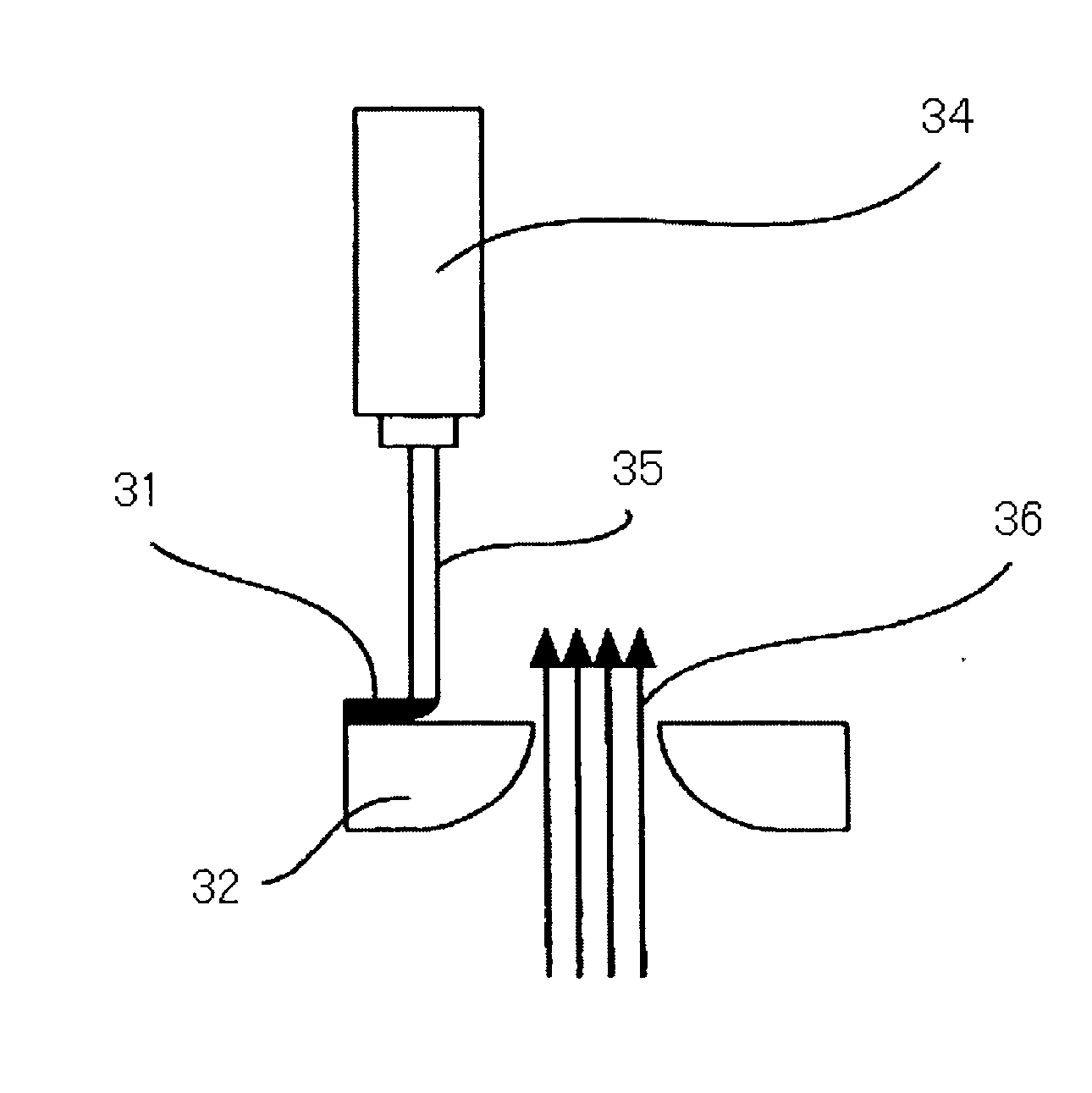

Atmospheric pressure plasma assembly

InactiveUS20050178330A1Efficient cooling agentEfficient electrodeElectric discharge tubesSurgeryPlanar electrodeDielectric plate

An atmospheric pressure plasma assembly (1) comprising a first and second pair of vertically arrayed, parallel spaced-apart planar electrodes (36) with at least one dielectric plate (31) between said first pair, adjacent one electrode and at least one dielectric plate (31) between said second pair adjacent one electrode, the spacing between the dielectric plate and the other dielectric plate or electrode of each of the first and second pairs of electrodes forming a first and second plasma regions (25,60) characterised in that the assembly further comprises a means of transporting a substrate (70,71,72) successively through said first and second plasma regions (25,60) and an atomiser (74) adapted to introduce an atomised liquid or solid coating making material into one of said first or second plasma regions.

Owner:DOW CORNING IRELAND

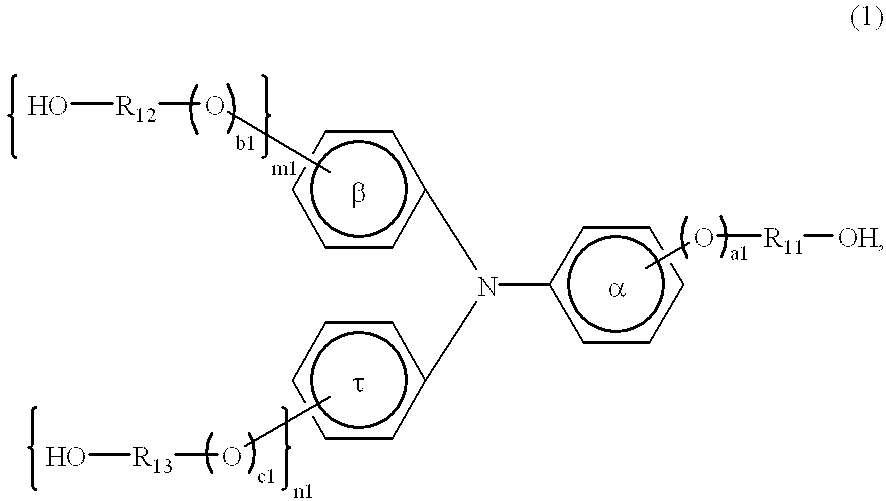

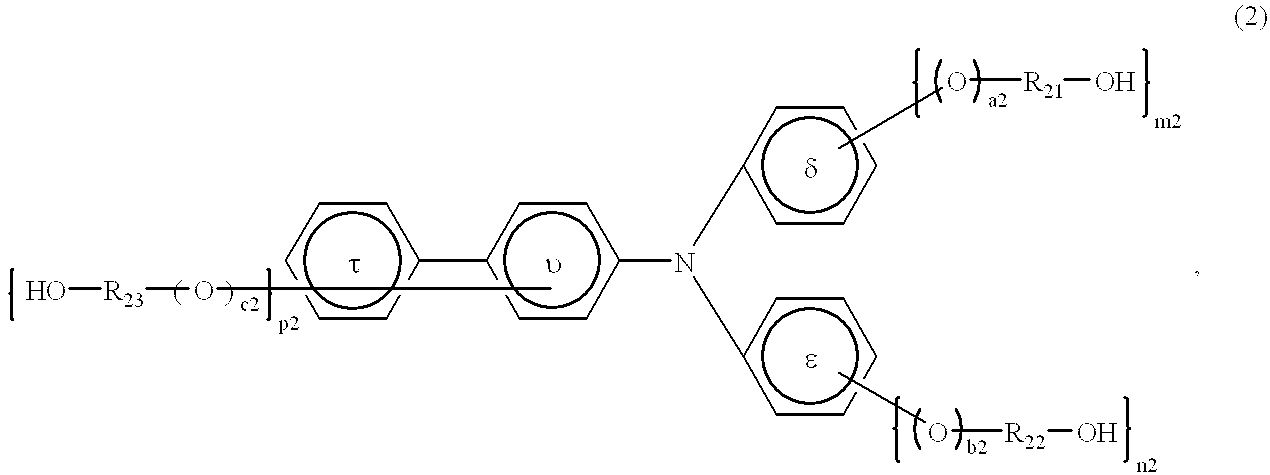

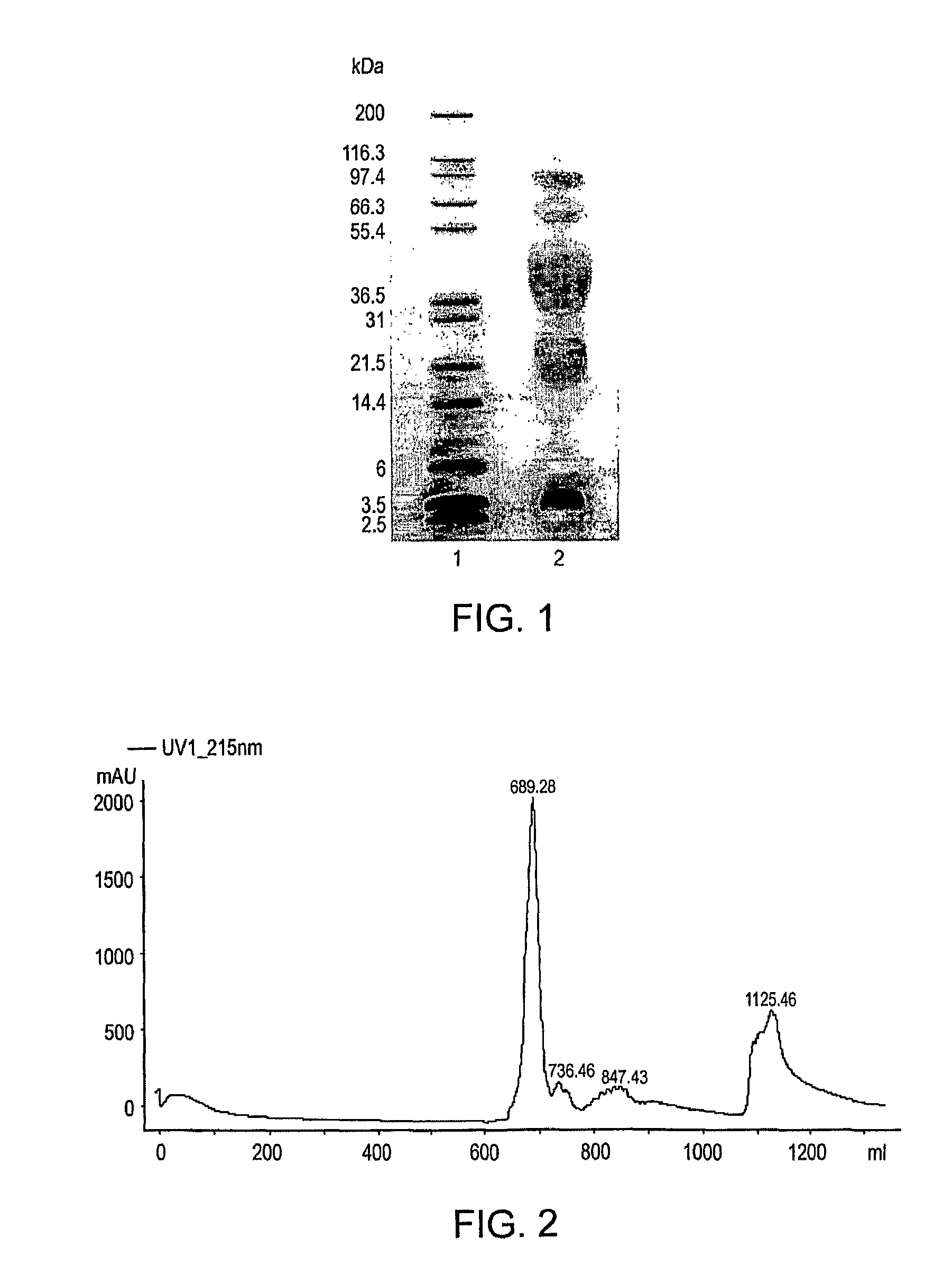

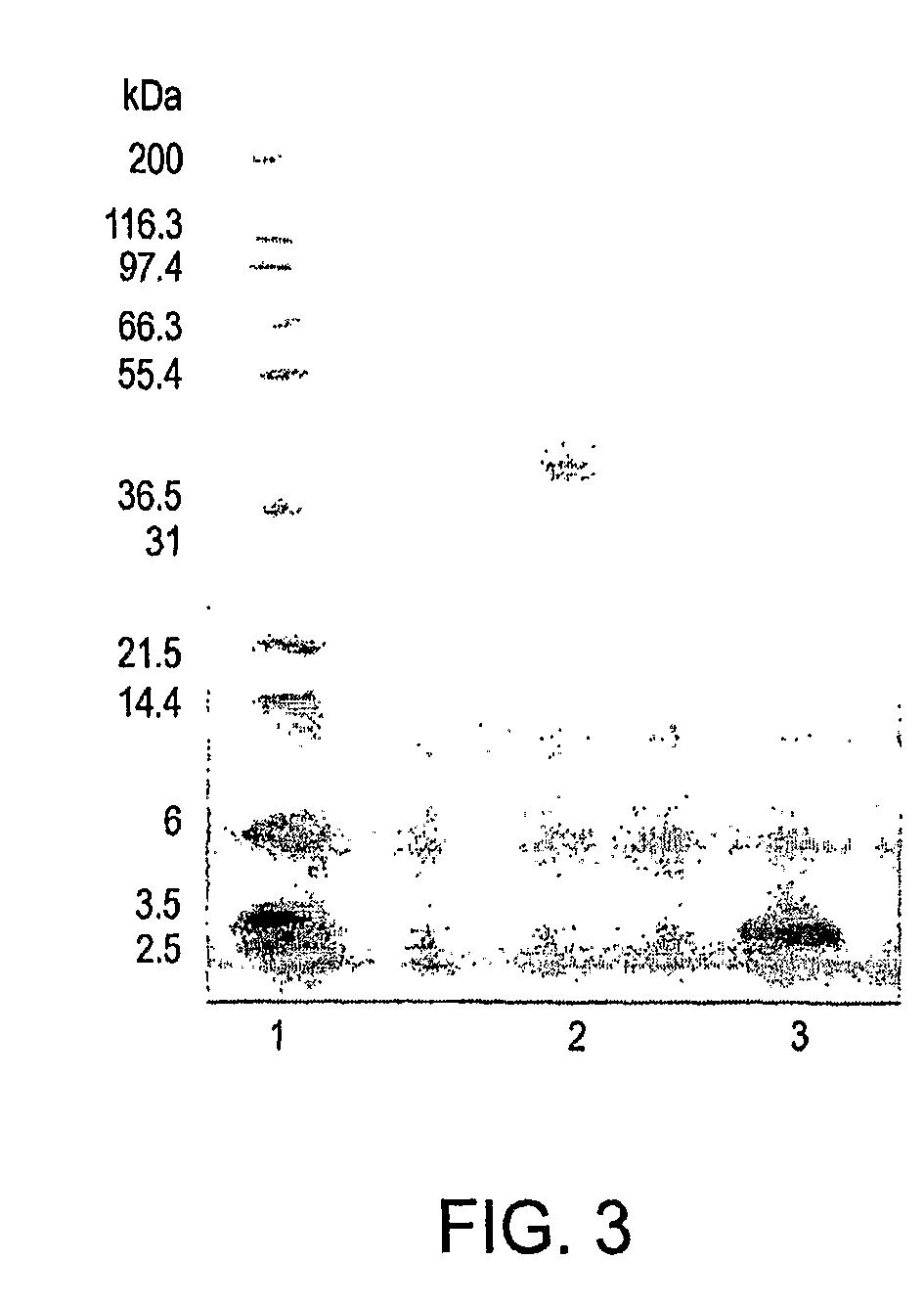

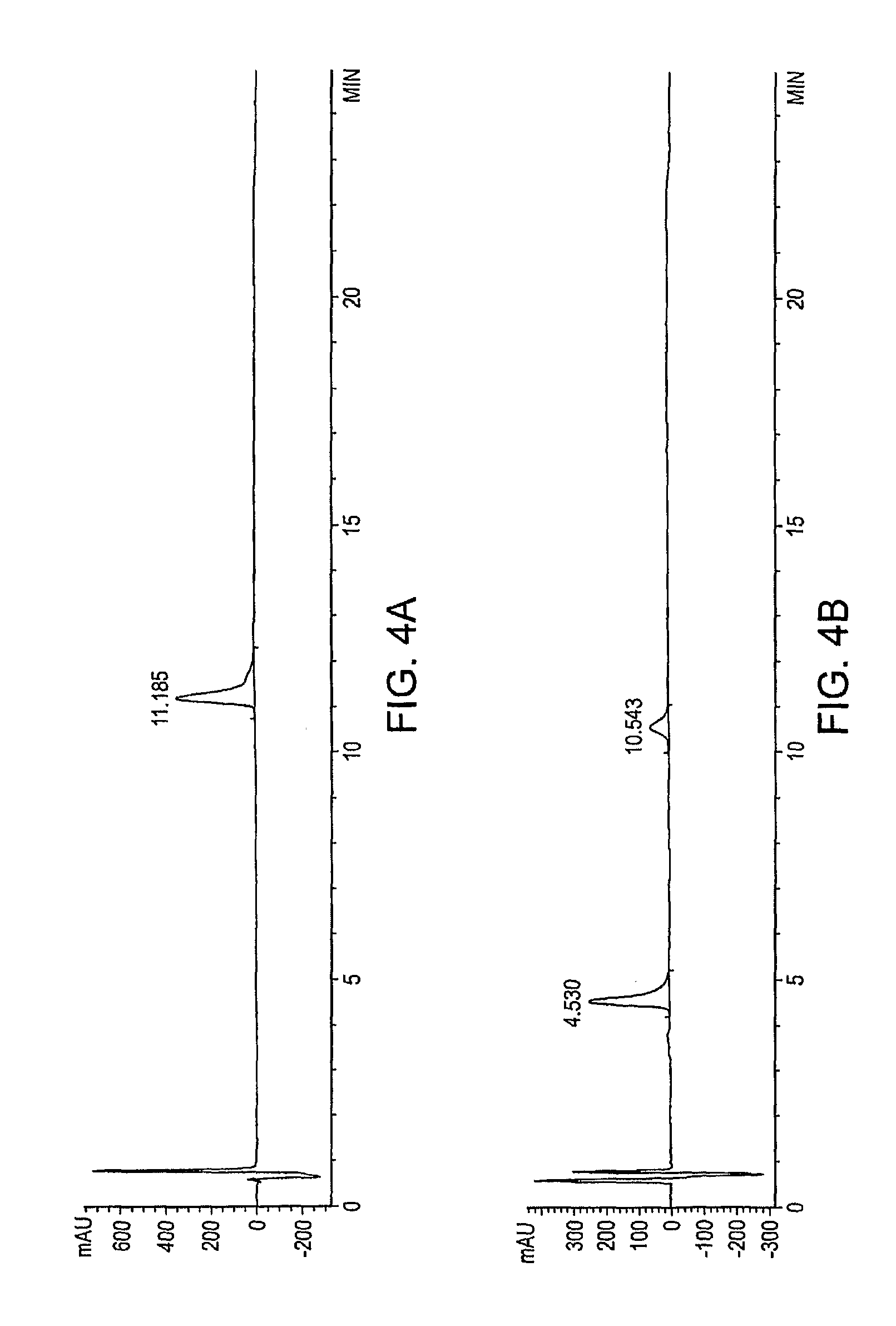

Polymer conjugates of GLP-1

ActiveUS8293869B2Rapid clearanceGood release effectMetabolism disorderSaccharide peptide ingredientsWater solubleMethyl group

Conjugates of a GLP-I moiety may be covalently attached to one or more water-soluble polymers. For instance, a GLP-I polymer conjugate may include a GLP-I moiety releasably attached at its N-terminus to a water-soluble polymer. The GLP-I polymer conjugate may include a GLP-I moiety covalently attached to a water-soluble polymer, wherein the GLP-I moiety possesses an N-methyl substituent. The GLP-I polymer conjugate may include a GLP-I moiety covalently attached at a polymer attachment site to a water-soluble polymer, wherein the GLP-I moiety is glycosylated at a site separate from the polymer attachment site.

Owner:NEKTAR THERAPEUTICS INC

Resin composition for vibration-damping material, vibration-damping material, and sound-insulating member

InactiveUS7041377B2Reduce nipping temperatureGood release effectOther chemical processesFibre treatmentPolymer scienceChlorinated paraffins

The object of the invention is to provide sound insulating members exhibiting both high vibration damping performance and high sound insulation performance, a vibration damping material for affording such members and a resin composition for forming the vibration damping material. The invention provides a first resin composition for vibration damping materials which contains 100 parts by weight of a chlorine-containing thermoplastic resin, and 20 to 200 parts by weight of a chlorinated paraffin having 12 to 16 carbon atoms on average. The thermoplastic resin contains preferably 20 to 70 wt. %, more preferably 30 to 70 wt. %, of chlorine. The chlorinated paraffin is preferably 30 to 70 wt. %, more preferably 35 to 65 wt. %, in chlorination degree.

Owner:SEKISUI CHEM CO LTD

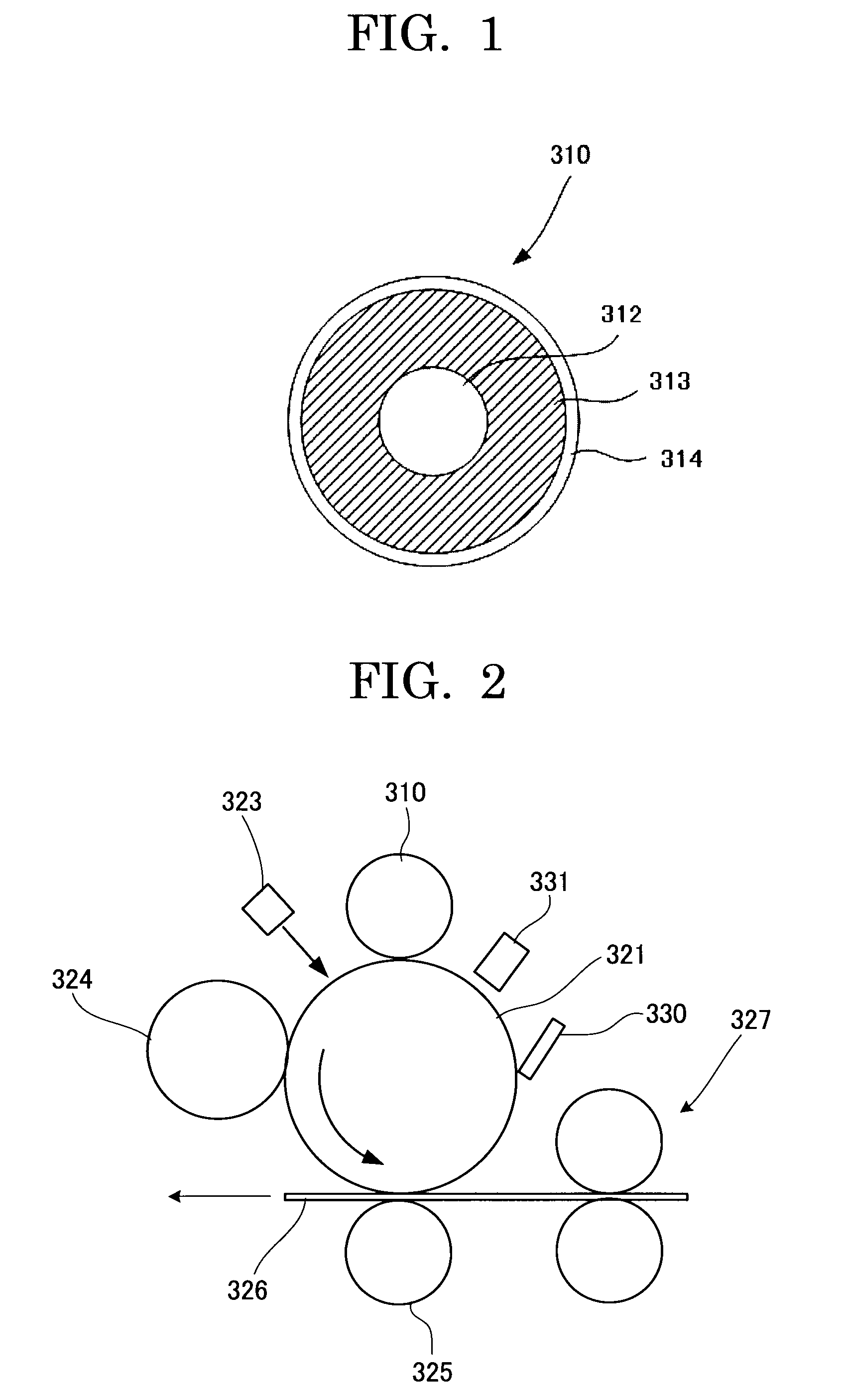

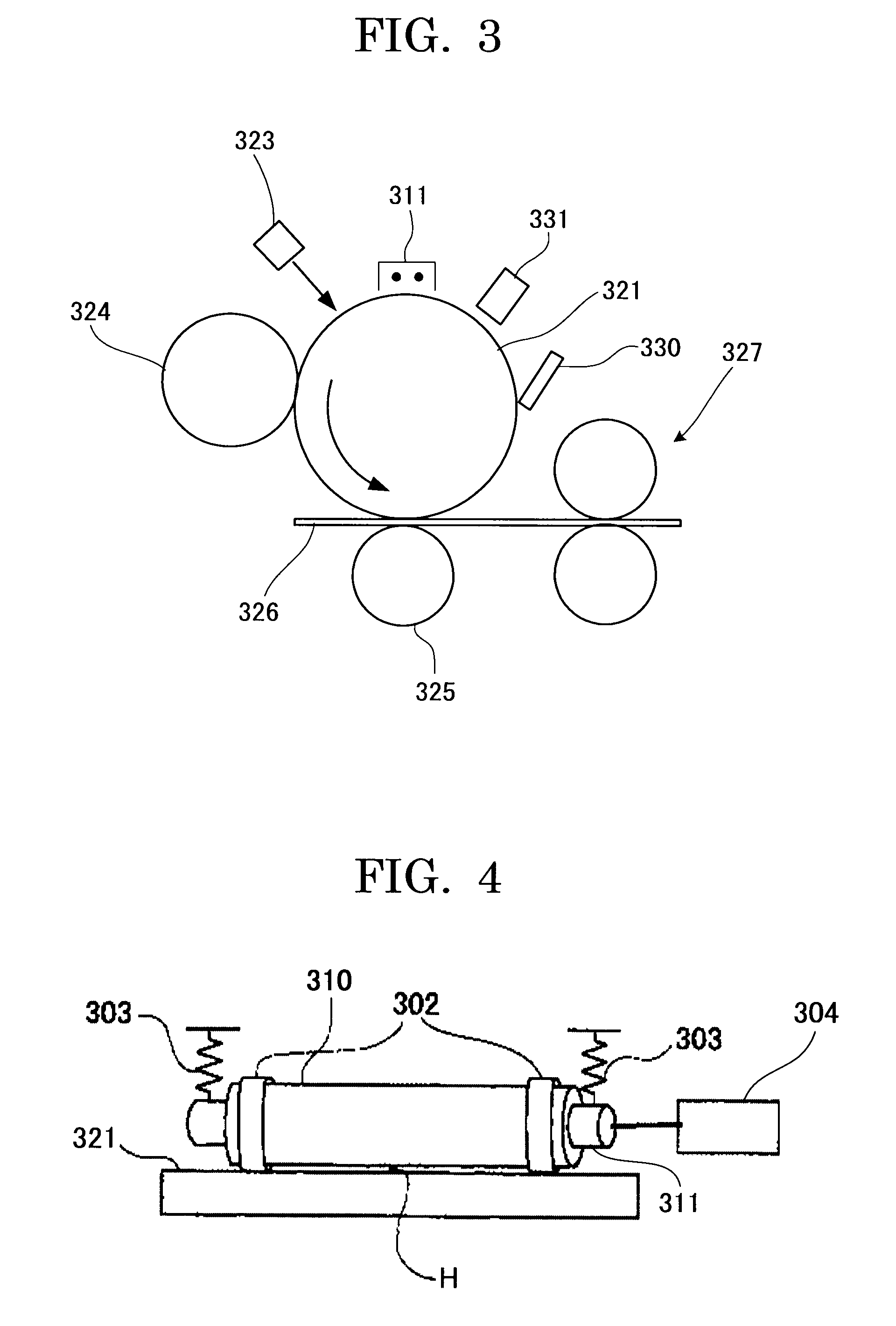

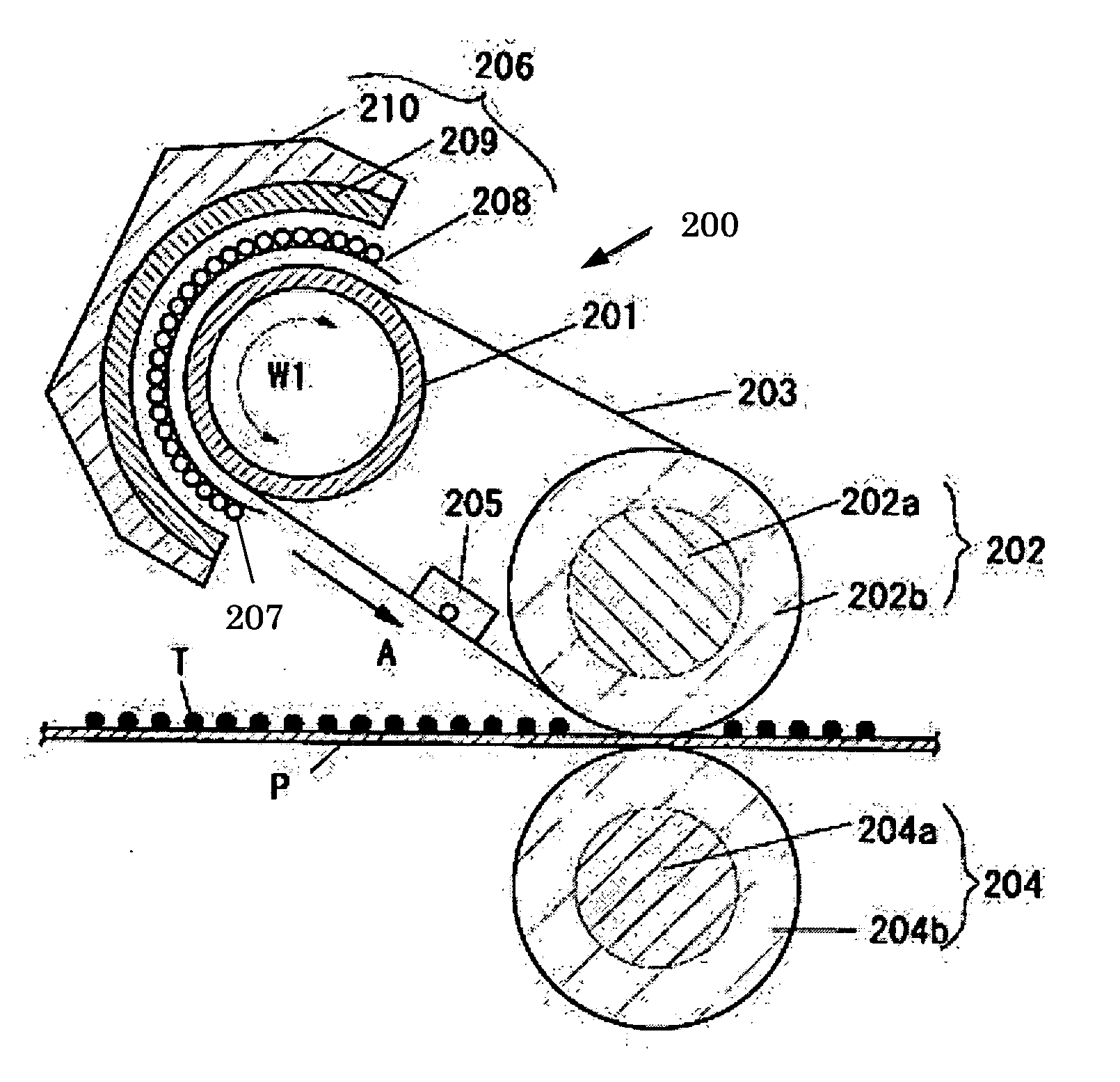

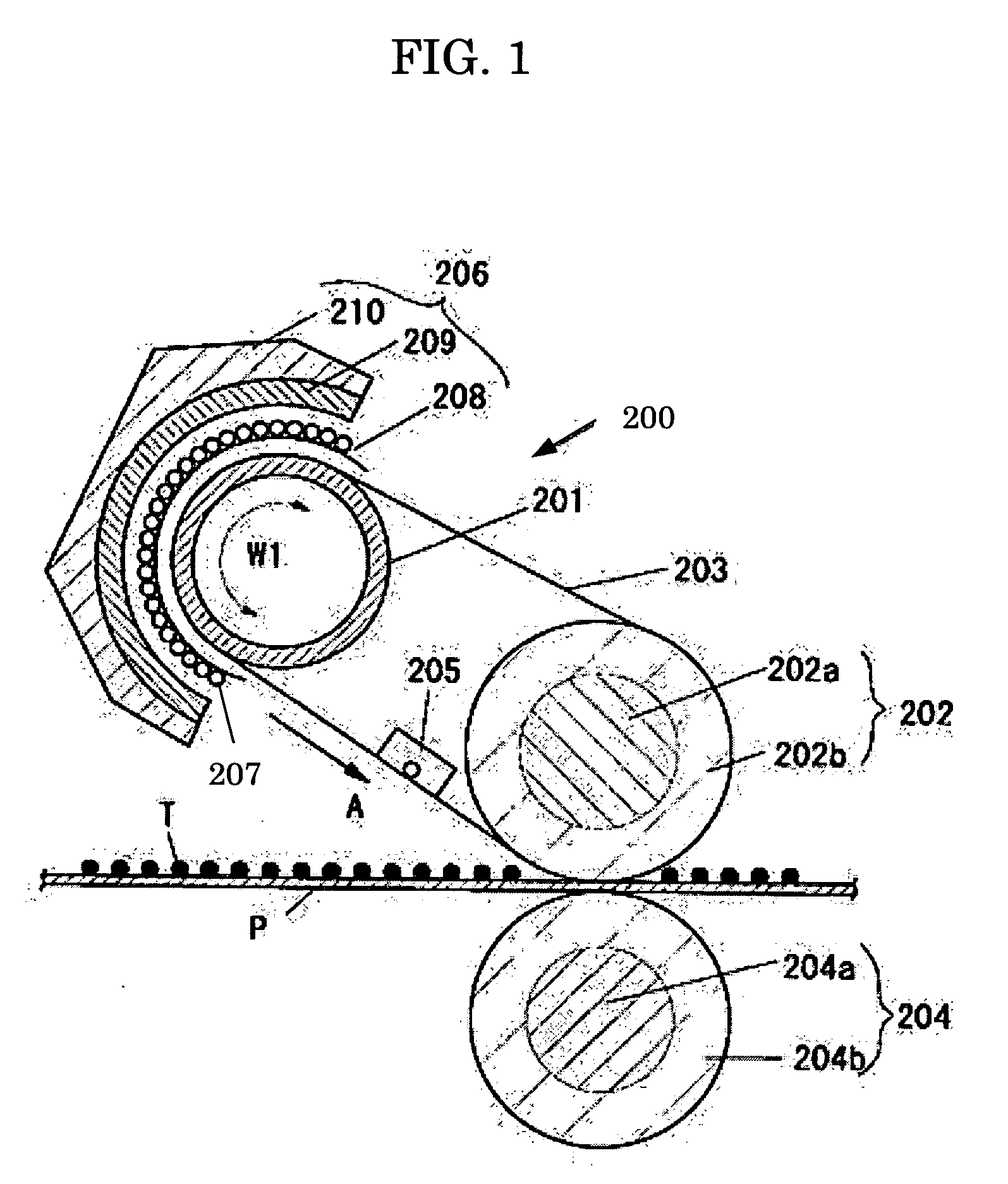

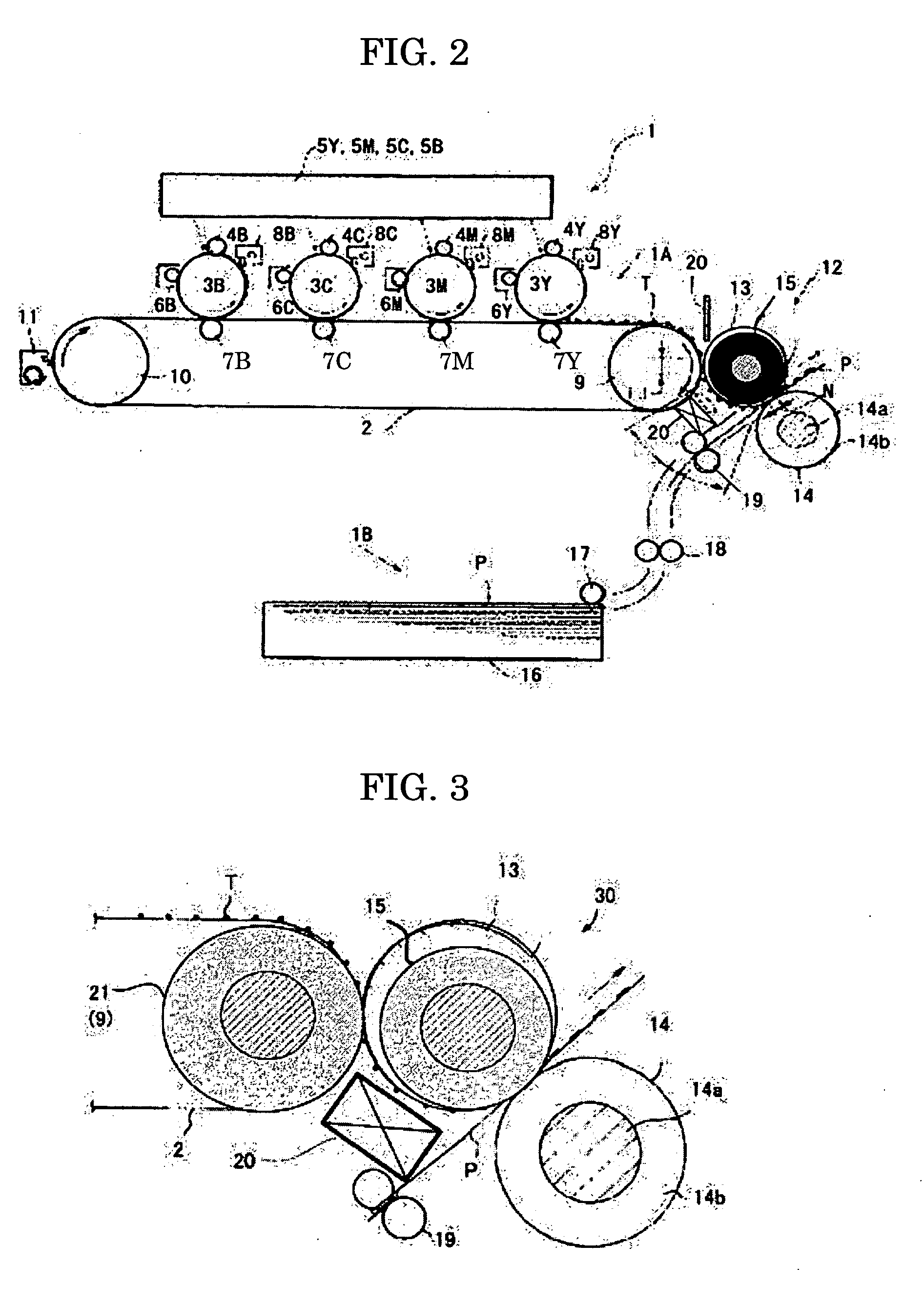

Image-fixing apparatus, and, image-forming apparatus

InactiveUS20060013624A1Excellent releasabilityHigh qualityElectrographic process apparatusElastic modulusEngineering

An image-fixing apparatus including a fixing belt; a fixing member; a pressure member; and a heating source, wherein the fixing belt is heated by the heating source, wherein the fixing member is brought into pressure contact with the pressure member via the fixing belt to form a nip and a paper carrying an unfixed toner is allowed to pass through the nip, thereby fixing the unfixed toner on the paper, and wherein the toner to be used includes a binder resin, a colorant, and a releasing agent, and wherein the toner has a ½ flown-out temperature of 115° C. to 145° C. and has a storage elastic modulus (G′) at 190° C. of 200 Pa or more.

Owner:RICOH KK

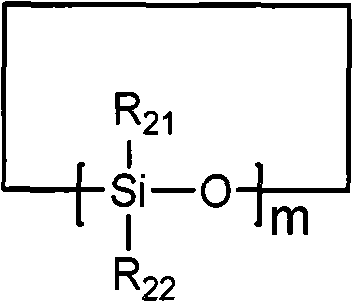

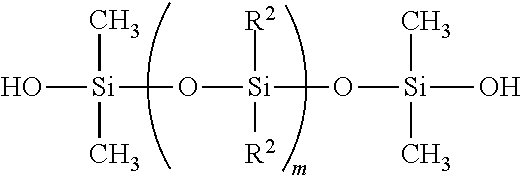

Silicone-Based Releasable Adhesive Composition, Sheet-Form Substrate Having Releasable Adhesive Layer Formed By Curing This Composition, And Use Of Such A Protective Film Or Fixing Sheet

InactiveUS20120328863A1Easy to controlEasy to disassembleSynthetic resin layered productsOrganic non-macromolecular adhesivePolymer scienceAlkoxy group

Problem: To provide a silicone-based releasable adhesive composition that is capable of easily controlling peeling force of a releasable adhesive layer by the composition, and whereby the silicone-based releasable adhesive composition has excellent attachment characteristics and releasability characteristics. A further object is to provide a sheet-form substrate and a releasable adhesive sheet that have a releasable adhesive layer formed by curing this composition.Resolution Means: The silicone-based releasable adhesive composition includes an organopolysiloxane resin-organopolysiloxane condensation reaction product obtained by condensation reaction between (a1) 100 weight parts of an MQ type organopolysiloxane resin containing hydroxyl groups or alkoxy groups in a range of 0.3 to 2.0 weight % and having an M unit to Q unit molar ratio of 0.6 to 1.0, and (a2) 20 to 150 weight parts of a chain-like diorganopolysiloxane having an average degree of polymerization of 100 to 1,000 and having at least one hydroxyl group or alkoxy group, wherein the organopolysiloxane resin-organopolysiloxane condensation reaction product preferably includes a certain hydroxyl group content.

Owner:DOW CORNING TORAY CO LTD

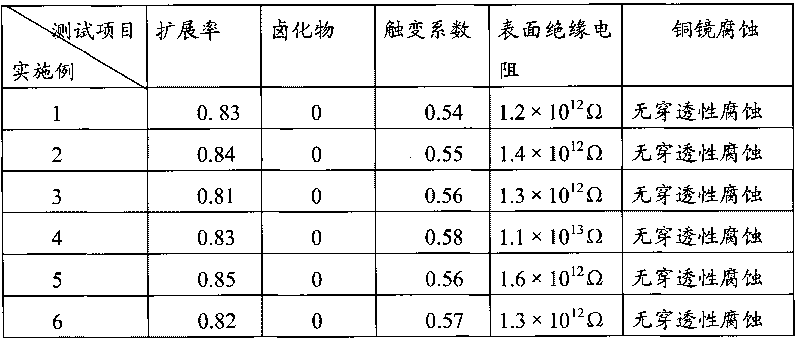

Halogen-free tin-bismuth-copper soldering paste and preparation method thereof

InactiveCN101695794AExtended shelf lifeExtended service lifeWelding/cutting media/materialsSoldering mediaAntioxidantExpansion rate

The invention relates to the technical field of soldering pastes, in particular to a halogen-free tin-bismuth-copper soldering paste and a preparation method thereof. A soldering flux of the halogen-free tin-bismuth-copper soldering paste consists of the following components in percentage by weight: 20 to 40 percent of polymerized rosin, 1 to 6 percent of rosin amine, 4 to 8 percent of thixotropic agent, 5 to 10 percent of organic acid, 5 to 10 percent of organic amine, 1 to 5 percent of antioxidant, 0.5 to 3 percent of surfactant and an organic solvent. The halogen-free tin-bismuth-copper soldering paste is mainly characterized by adopting the organic acid and the organic amine serving as activating agents and comprising no halogens at all, so not only the solderability is not reduced, but also the expansion rate and the insulation resistance value of the soldering paste are improved, and simultaneously the corrosivity of residues after soldering to a base material is reduced and the service life of the soldering paste is prolonged; and particularly, the peak temperature of the soldering paste during soldering is lower in favor of reducing the thermal damages to electronic components.

Owner:东莞市特尔佳电子有限公司

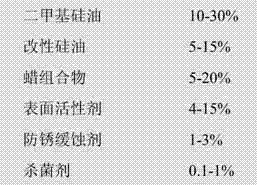

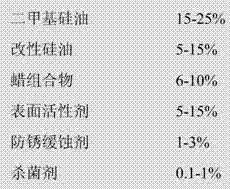

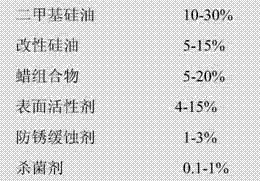

Water-based release agent for aluminum alloy die casting and preparation method thereof

The invention discloses a water-based release agent for aluminum alloy die casting and a preparation method thereof. The release agent comprises, by mass, 10 to 30% of dimethicone, 5 to 15% of modified silicone oil, 5 to 20% of a wax composition, 4 to 15% of a surfactant, 1 to 3% of an anti-rust corrosion inhibitor and 0.1 to 1% of a bactericide, with the balance being deionized water. The preparation method comprises the following steps: heating dimethicone, modified silicone oil, the wax composition and the surfactant to a temperature of 70 to 80 DEG C and carrying out uniform mixing with stirring; slowly adding deionized water accounting for 30 to 40% of the total weight of the release agent with stirring in batches so as to prepare an oil-in-water O / W pre-emulsion; and carrying out grinding by using a colloid mill and adding the anti-rust corrosion inhibitor, the bactericide and residual deionized water so as to obtain the water-based release agent with an emulsion particle size of 0.1 to 0.4 mu m. According to the invention, modified silicone oil is used as main base oil, so emulsification difficulty is lowered down, heat resistance is improved, and good high temperature stability is obtained; the wax composition has excellent lubrication capability and a good film forming effect. The release agent has excellent heat resistance, excellent lubricity and a good film forming effect.

Owner:上海福岛新材料科技有限公司

Self-adhesive addition-crosslinking silicone compositions

The invention relates to self-adhesive addition-crosslinking silicone compositions which comprises(A) diorganopolysiloxanes, (B) organohydrogenpolysiloxanes containing less than 20 SiH bonded hydrogen atoms and less than 12% aryl groups, (C) organosilicon compounds having epoxy groups and hydrolyzable groups and (D) a hydrosilylation catalyst. The compositions are transparent to translucent, exhibit good compositional comparability, and cure to form strongly adhesive elastomers with good physical properties.

Owner:WACKER CHEM GMBH

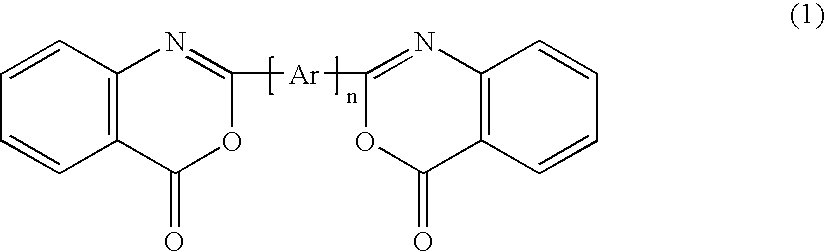

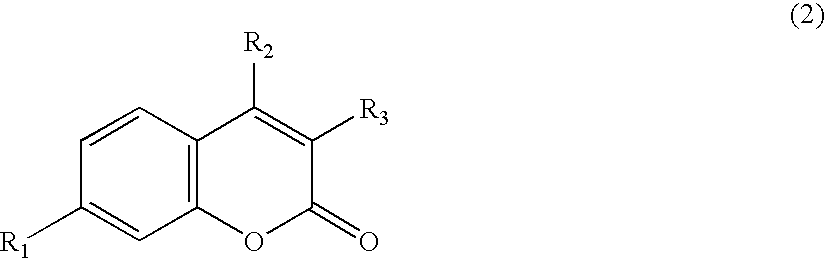

Cellulose acetate and dope containing the same

InactiveUS7122660B1Good release effectSatisfactory optical propertyArtificial filaments from cellulose derivativesCarboxyl radicalCellulose diacetate

Using the dope containing the following cellulose acetate (1), (2), or (3), a film is prepared by the casting process:(1) a cellulose acetate having carboxyl groups binding to at least one member selected from the group consisting of a cellulose acetate and a hemicellulose acetate, wherein at least a part of said carboxyl groups are in an acidic form;(2) a cellulose acetate containing at least one member selected from the group consisting of an acid having an acid dissociation exponent pKa of 1.93 to 4.50 in water, an alkali metal salt of said acid and an alkaline earth metal of said acid; or(3) a cellulose acetate containing an alkali metal or an alkaline earth metal wherein the total content of an alkaline metal and an alkaline earth metal in 1 gram of the cellulose acetate is from an effective amount to 5.5×10−6 equivalent (in terms of ion equivalent). The above cellulose acetate is also useful for spinning process. The cellulose acetate includes a cellulose diacetate and a cellulose triacetate. The cellulose acetate of the present invention has high film-releasability from a support and excellent optical characteristics.

Owner:DAICEL CHEM IND LTD

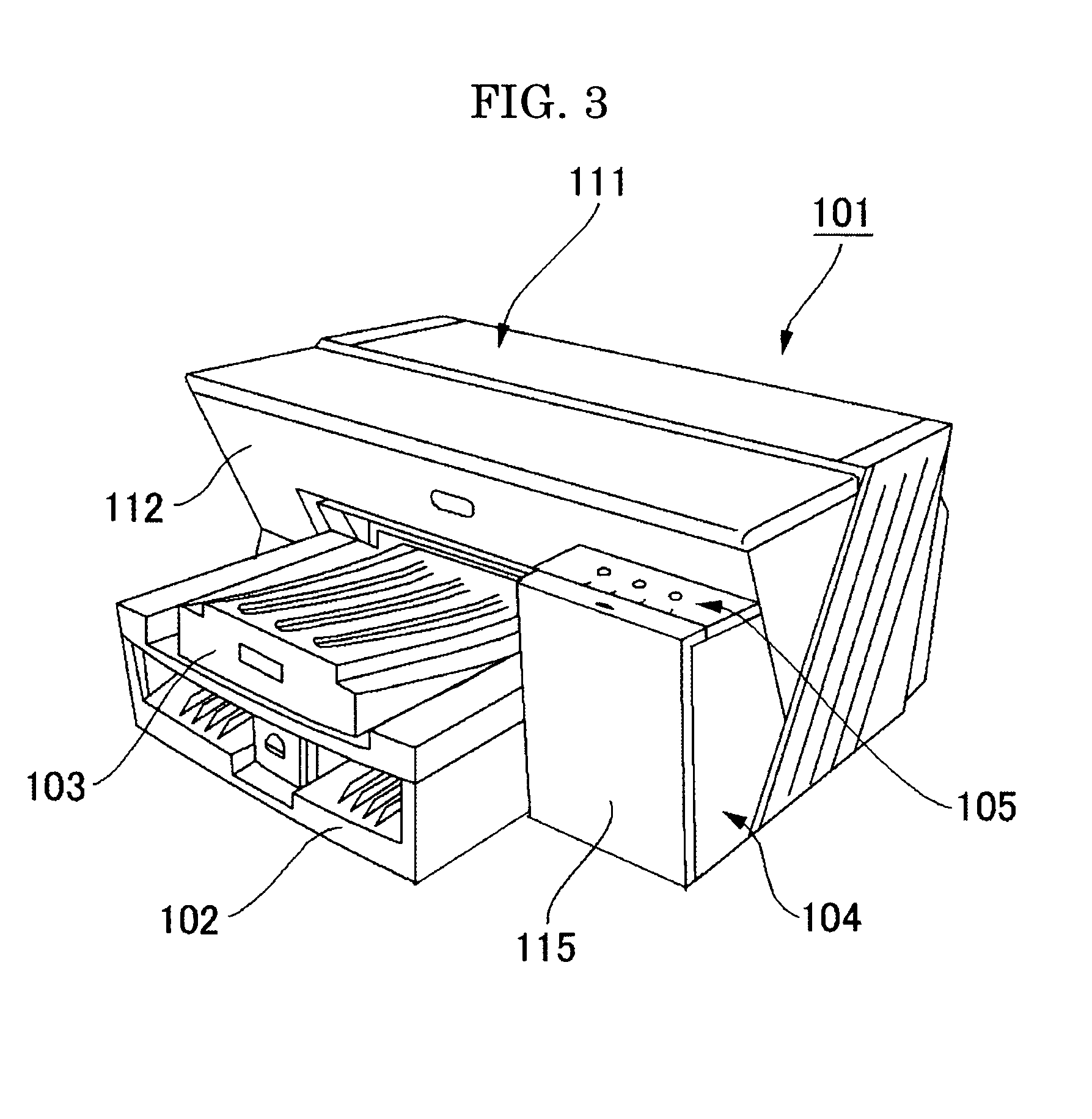

Inkjet ink, and ink cartridge, inkjet recording method, inkjet recording apparatus and ink record using the same

ActiveUS20090047431A1Improve discharge stabilityAvoid fixationMeasurement apparatus componentsInksWater insolublePeak area

The present invention provides an inkjet ink containing at least a colorant, water, a water insoluble resin, a fluorine surfactant, and a polyether-modified silicone oil, wherein the polyether-modified silicone oil has a hydrophobic value of 0.40 to 1.5, and the hydrophobic value is expressed by Equation 1:Hydrophobic value=A / B Equation 1where “A” represents an integration value of a peak area from 0 ppm to 0.3 ppm in a 1H-NMR spectrum of the polyether-modified silicone oil using tetramethylsilane as a reference substance; and “B” represents an integration value of a peak area from 3.5 ppm to 4.0 ppm in the 1H-NMR spectrum.

Owner:RICOH KK

Preparation method of molding sand for gray iron casting

InactiveCN102366811AThe preparation process steps are simpleEasy to operateFoundry mouldsFoundry coresDrying timePollution

The invention discloses a preparation method of molding sand for gray iron casting, comprising the following three steps: preparing raw materials, preparing the molding sand, and mixing the molding sand. The preparation method has the advantages of simple process steps, easy operation, no use of coal dust, clean workshop, little pollution, and low cost and environmental protection by using straw powder, modified starch and other renewable raw materials. The prepared molding sand has small gas content, short drying time, good permeability and high baked tensile strength in casting, and can improve the releasability of the sand mold, further improving the fineness of casts.

Owner:辛培兴

Insulating and environment-friendly PVC modified material and preparation method thereof

The invention relates to the technical field of PVC modified materials and particularly relates to an insulating and environment-friendly PVC modified material and a preparation method thereof. The insulating and environment-friendly PVC modified material contains the following raw materials: 80-120 parts of PVC resin, 40-60 parts of bulking agent, 40-60 parts of plasticizer, 10-15 parts of insulation modifier, 3-7 parts of heat stabilizer and 0.5-1.5 parts of lubricant, wherein the plasticizer is a mixture prepared from dioctyl terephthalate and tri-n-butyl citrate which are in the weight ratio of (5-7): 1; the insulation modifier is a mixture prepared from kaolin, titanium white and glass micro-beads which are in the weight ratio of (2-4): (1.5-2.5): 1, and the particle size of the glass micro-beads is smaller than 20 microns. According to the modified material prepared by the preparation method, all properties exceed the national standards, the insulating property is good, the resistivity reaches up to 5.1*10<14> omega, and the modified material is environment-friendly; the preparation method disclosed by the invention is simple in process, convenient in operation and control, stable in quality and high in production efficiency and can be applied to large-scale industrial production.

Owner:广东祺龙科技有限公司

Polycarbonate resin composition, pellets thereof and molded article thereof

InactiveUS7241825B2Increased durabilityHigh transparencySynthetic resin layered productsAbsorbent padsPolyolCrack resistance

The object of the present invention is to provide a polycarbonate resin composition which has excellent transparency and durability against molding heat, which gives a molded article having an excellent mold release property, reduced strains, improved cracking resistance and, preferably, weatherability, and which is particularly suitable for a transparent member for a vehicle, pellets thereof and a molded article thereof, and the present invention provides a polycarbonate resin composition obtained by blending 100 parts by weight of a polycarbonate resin (Component A) and 0.005 to 2 parts by weight of a full ester (Component B) from an aliphatic polyhydric alcohol having 4 to 8 hydroxyl groups and 5 to 30 carbon atoms and an aliphatic carboxylic acid having 10 to 22 carbon atoms, said Component B having a 5% weight loss temperature, measured by TGA (thermogravimetric analysis), of 250 to 360° C. and having an acid value of 4 to 20, pellets thereof and a molded article thereof.

Owner:TEIJIN KASEK KK

Flame-retardant polycarbonate resin composition and its injection moldings

InactiveUS6150443AImprove antistatic performanceImprove stabilityPlastic/resin/waxes insulatorsDomestic articlesElastomerAntistatic agent

Provided are a flame-retardant polycarbonate resin composition capable of being formed into moldings having good impact resistance, high strength and good thermal stability that are intrinsic to polycarbonate resins and having good antistatic properties and good flame retardancy, and also injection moldings of the composition. The composition comprises 100 parts by weight of a resin or resin mixture of (A) from 50 to 100% by weight of a polycarbonate resin and (B) from 0 to 50% by weight of a styrenic resin, from 1 to 50 parts by weight of (C) a flame retardant, and from 0.1 to 5 parts by weight of (D) an anionic antistatic agent, and has a sodium sulfate content of at most 0.05% by weight. Optionally, the composition may contain (F) a fluoro-olefinic resin, (G) a rubber-like elastomer, and (H) an inorganic filler.

Owner:IDEMITSU KOSAN CO LTD

Processing method of tobacco raw materials for heating non-combustion tobacco products

ActiveCN103445283AIncrease contentGood release effectTobacco preparationTobacco treatmentGlycosideCombustion

A processing method of tobacco raw materials for heating non-combustion tobacco products sequentially includes: adjusting moisture of the tobacco raw materials, heating at 100-300 DEG C for 0.5-8 hours; cooling at room temperature; balancing at 22 DEG C and 60% of moisture for 24-120 hours, applying glycoside aroma precursors, and standing for 48-120 hours to guarantee that the aroma precursors are fully absorbed by the raw materials; applying polyol to the raw materials after perfuming, and standing for 48-120 hours under a seal state to guarantee that the polyol is fully absorbed by the raw materials; balancing for 24-120 hours to obtain the tobacco raw materials for heating the non-combustion tobacco products. The tobacco raw materials processed by the method has the advantages that smoke releasing performance of the tobacco raw materials during heating of the non-combustion tobacco products is increased evidently, sensory quality of the released smoke is improved evidently, and good satisfaction and comfortableness are achieved.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

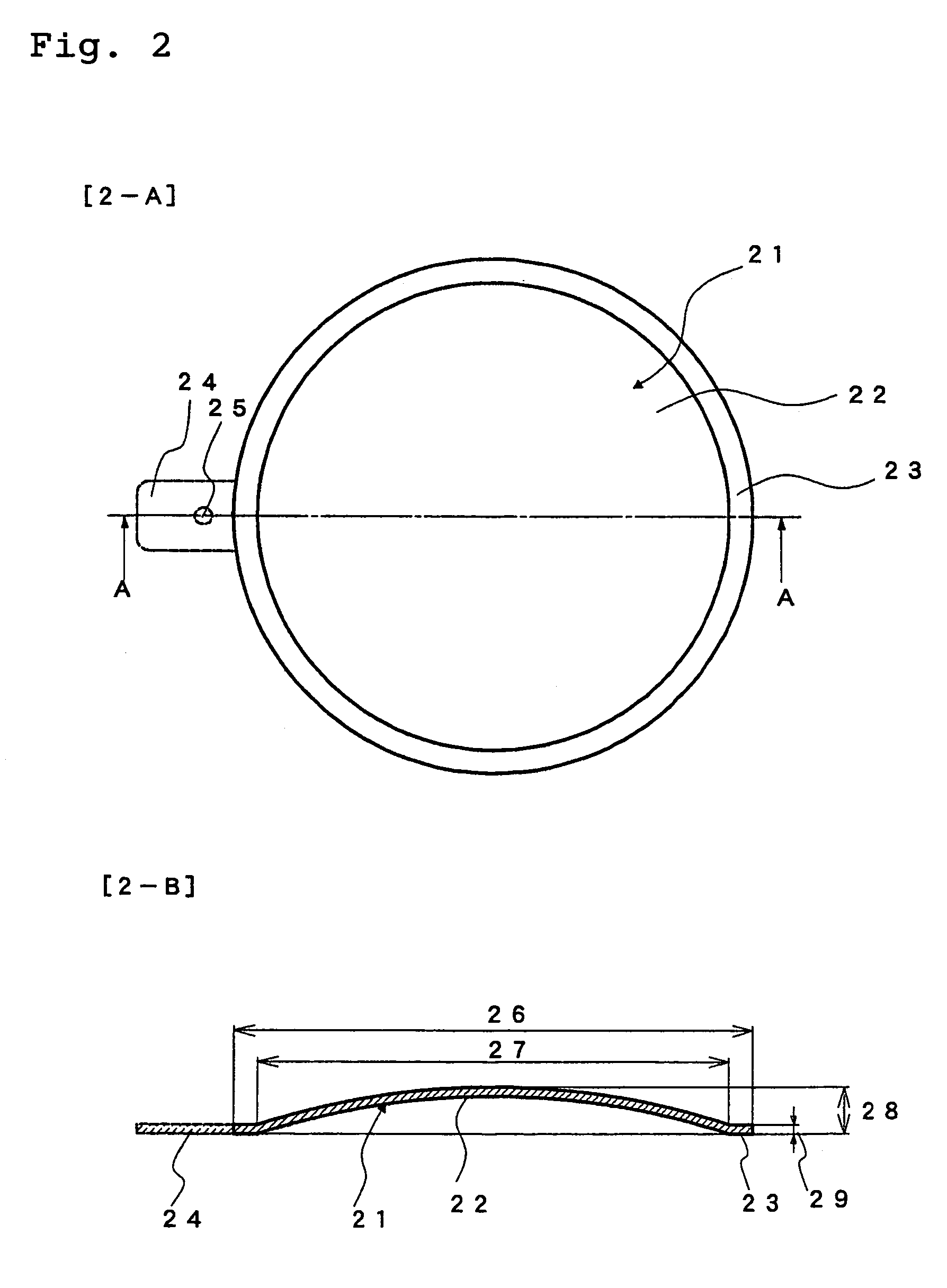

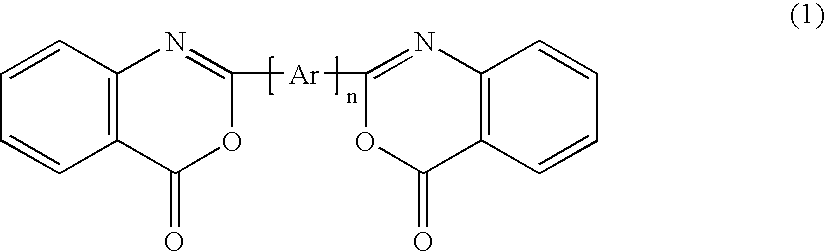

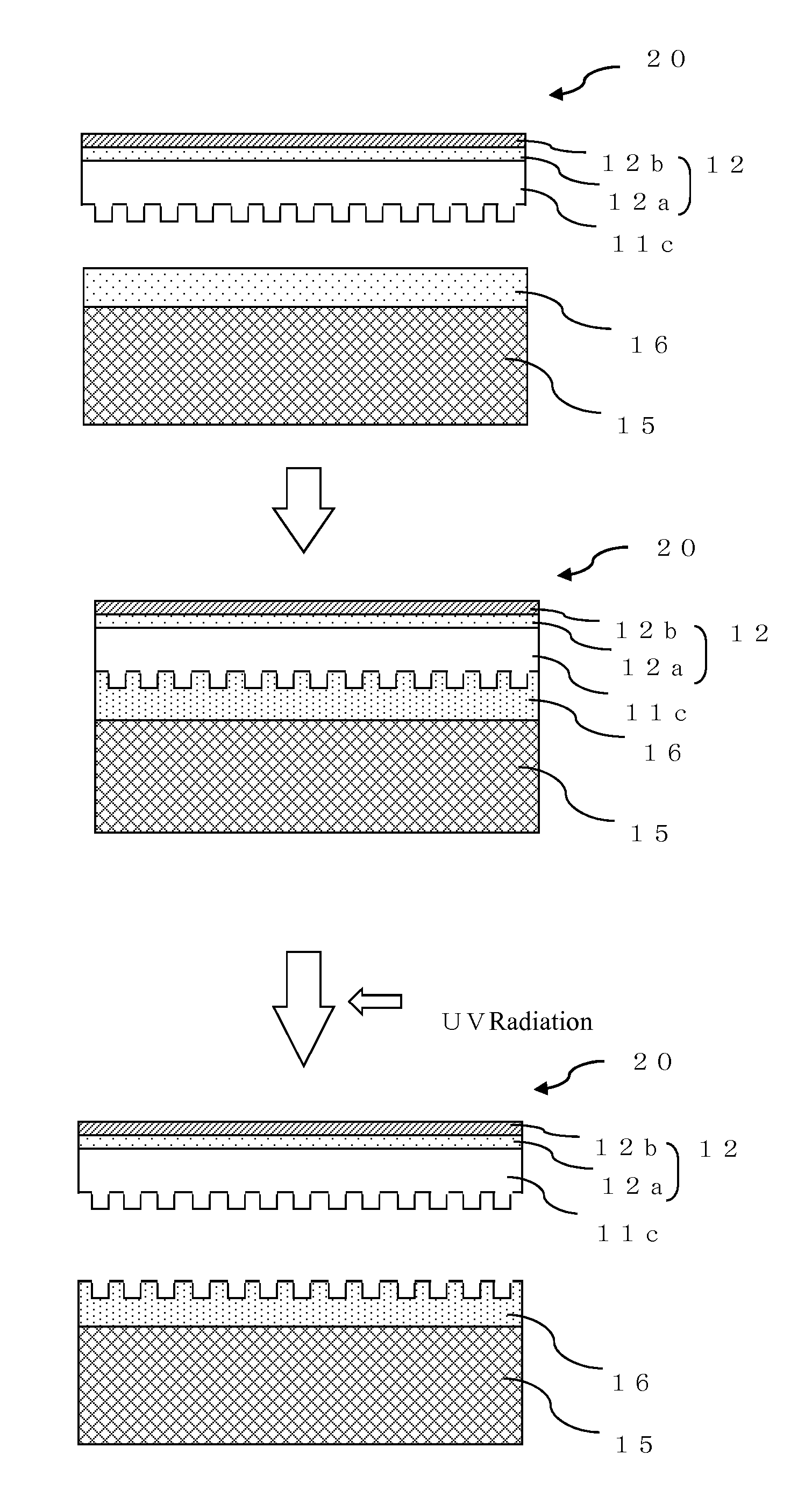

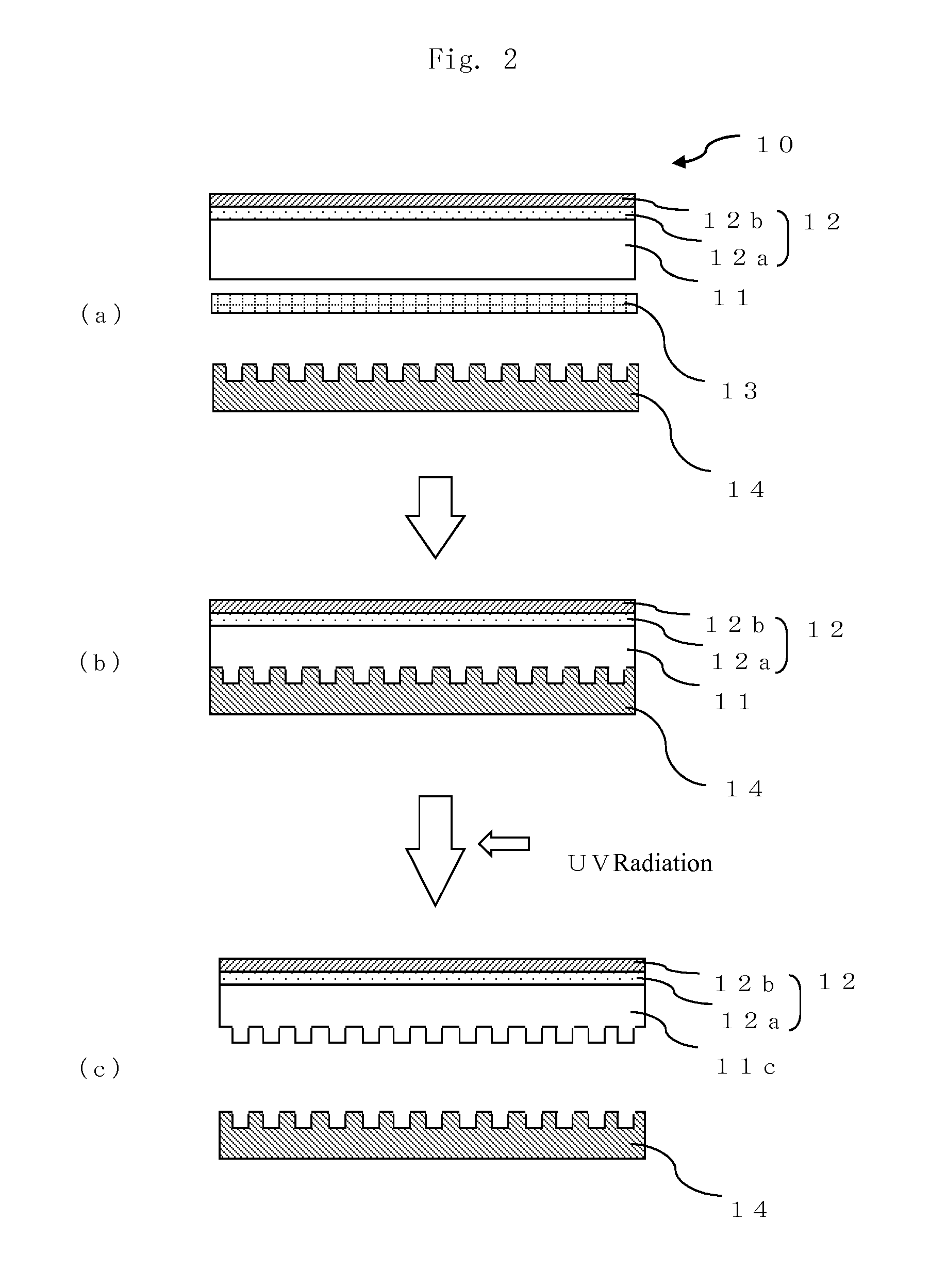

Photo-curable transfer sheet and method for forming concave-convex pattern using the same

InactiveUS20120175822A1Reduce polarityGood transferabilitySemiconductor/solid-state device manufacturingElectric/magnetic/electromagnetic heatingAcrylic resinReactive diluent

The present invention is to provide a photo-curable transfer sheet suitable for the preparation of an intermediate stamper in a nanoimprint method, in which the mold release properties from a mold having a fine concave-convex pattern used in the preparation of the intermediate stamper and the mold release properties of a cured photo-curable resin that is a product having a fine concave-convex pattern transferred from the intermediate stamper are excellent, and the transfer property of the fine concave-convex pattern is good; and a method for forming a concave-convex pattern by using the above-mentioned photo-curable transfer sheet. The photo-curable transfer sheet 10 having a photo-curable transfer layer 11 comprising a photo-curable composition deformable by application of pressure which comprises a polymer and a reactive diluent having a photopolymerizable functional group, wherein the polymer is an acrylic resin comprising a recurring unit derived from (meth)acrylate having an alicyclic group.

Owner:BRIDGESTONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com