Patents

Literature

103 results about "Tetramethylsilane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tetramethylsilane (abbreviated as TMS) is the organosilicon compound with the formula Si(CH₃)₄. It is the simplest tetraorganosilane. Like all silanes, the TMS framework is tetrahedral. TMS is a building block in organometallic chemistry but also finds use in diverse niche applications.

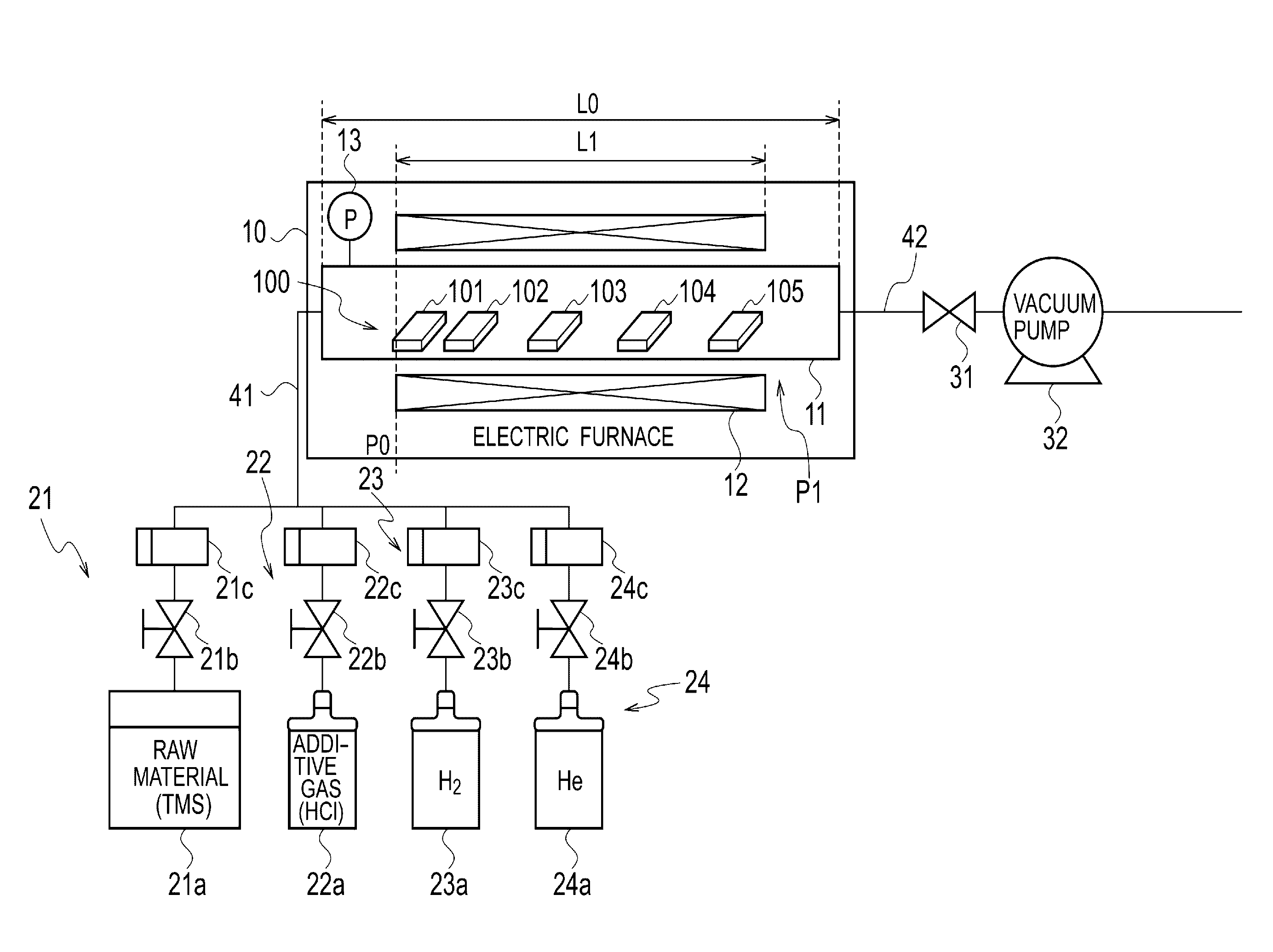

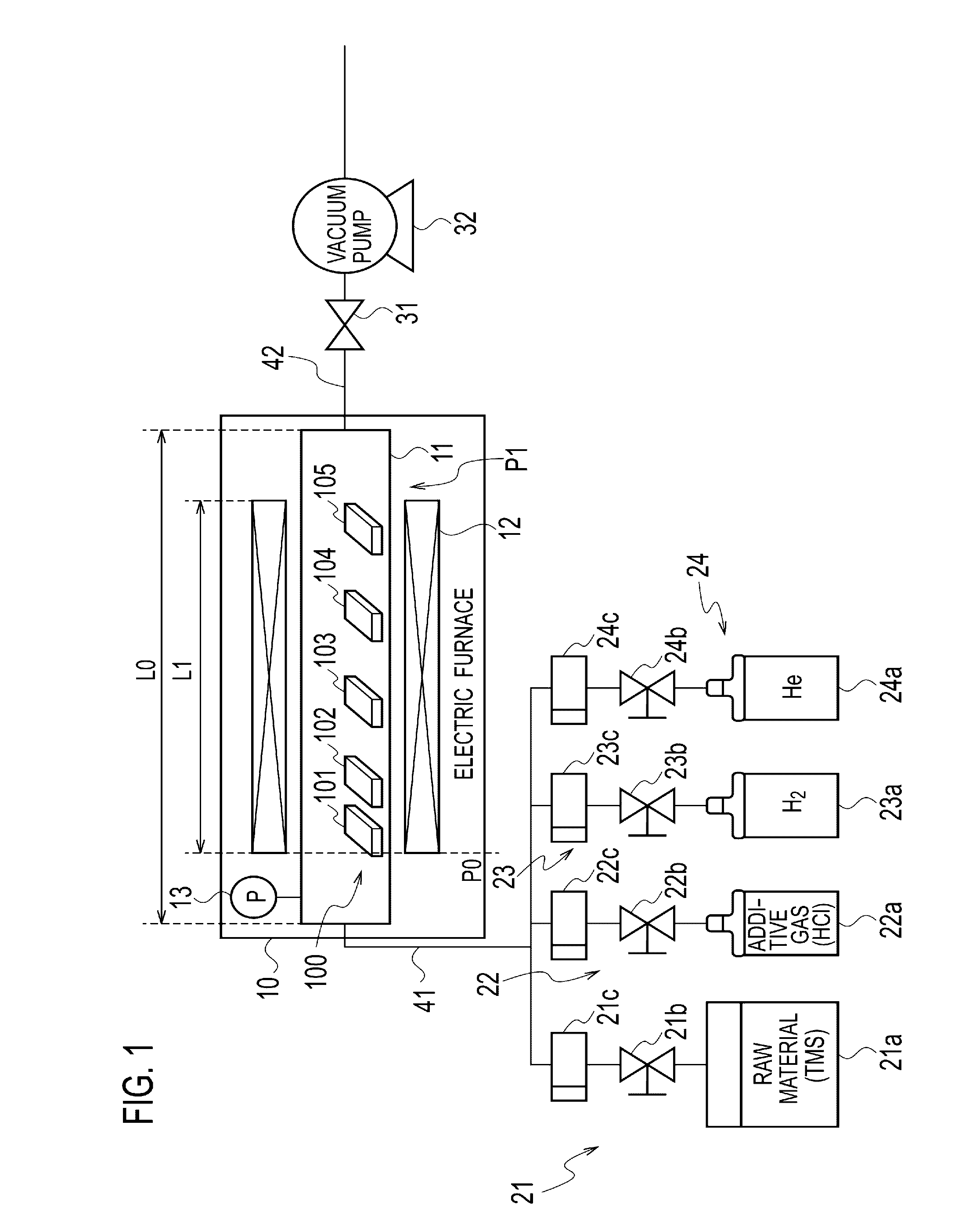

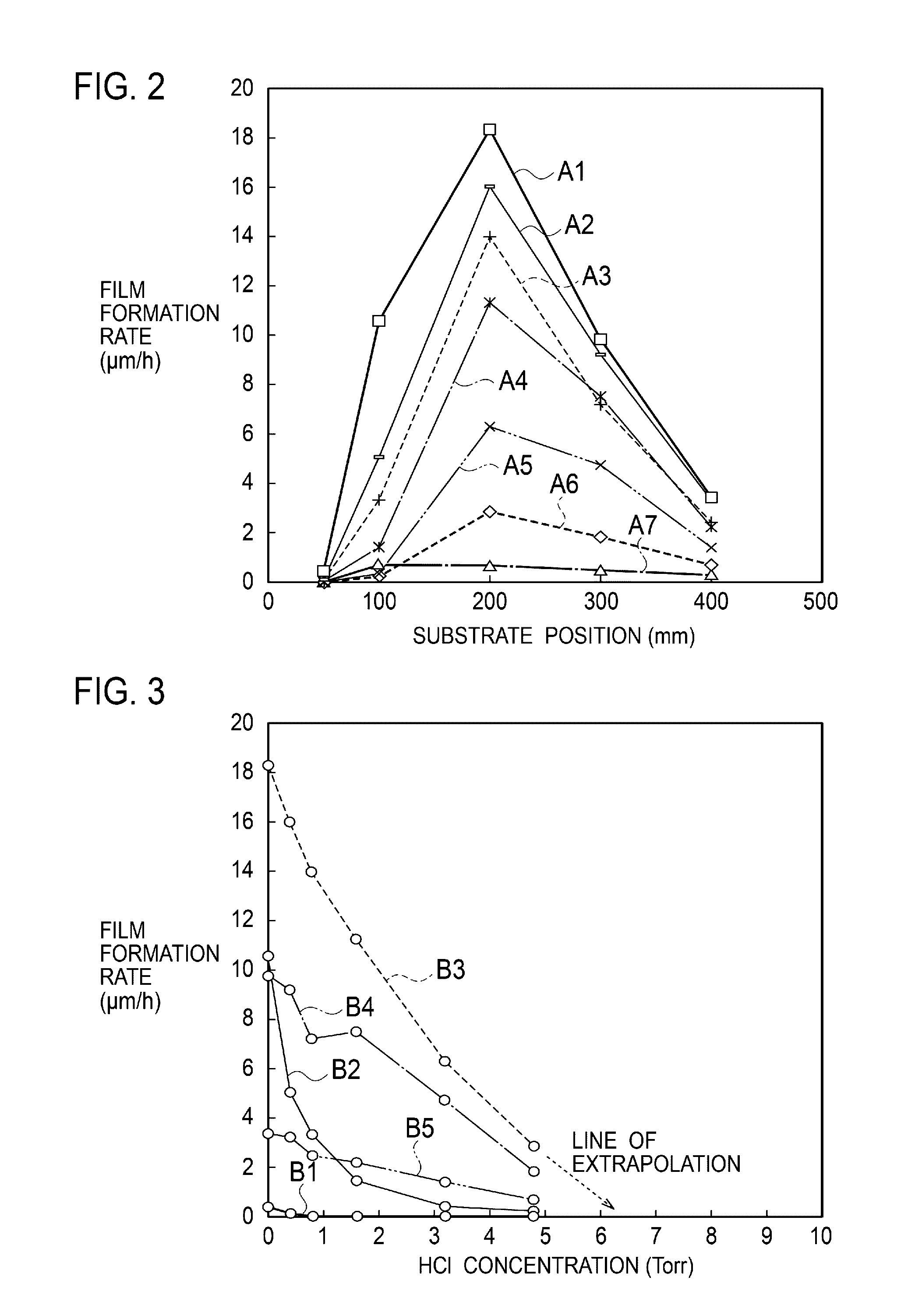

Heat-resistant composite material production method and production device

ActiveUS20160305015A1Reduce generationImprove mass productionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChlorideChemical vapor deposition

In the present embodiment, in the production of a heat-resistant composite material resulting from impregnating a ceramic fiber preform with silicon carbide, a mixed gas containing starting material gas, an additive gas, and a carrier gas is supplied to a substrate having a minute structure such as a preform stored in an electric furnace, silicon carbide is deposited to form a film by means of a chemical vapor deposition method or a chemical vapor infiltration method, and the film formation growth speed and embedding uniformity are controlled by means of the amount of additive gas added to the starting material gas, the starting material gas contains tetramethylsilane, and the additive gas contains a molecule containing chlorine such as methyl chloride or hydrogen chloride. The film formation growth speed and embedding uniformity of the silicon carbide are both achieved.

Owner:IHI CORP +1

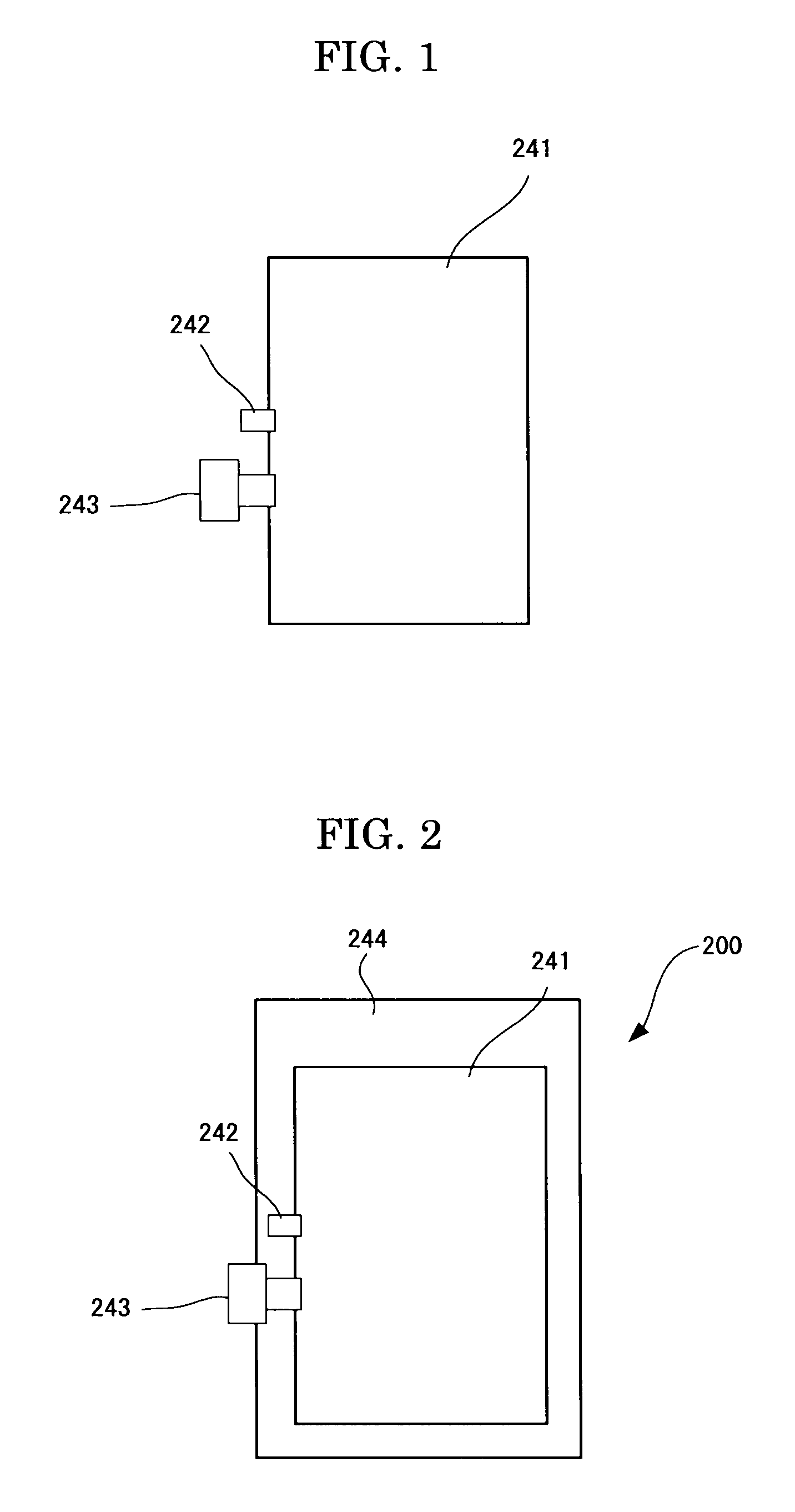

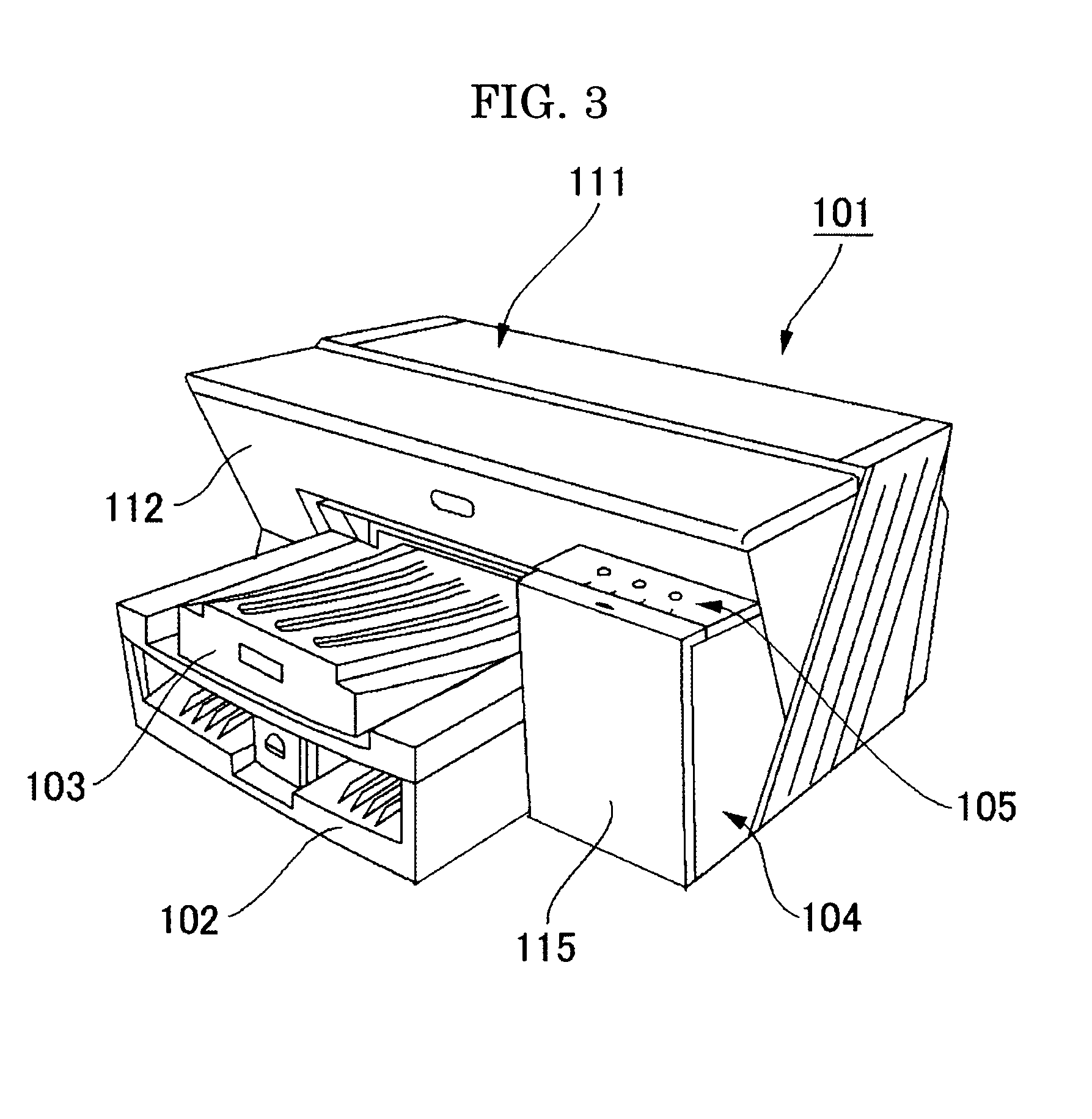

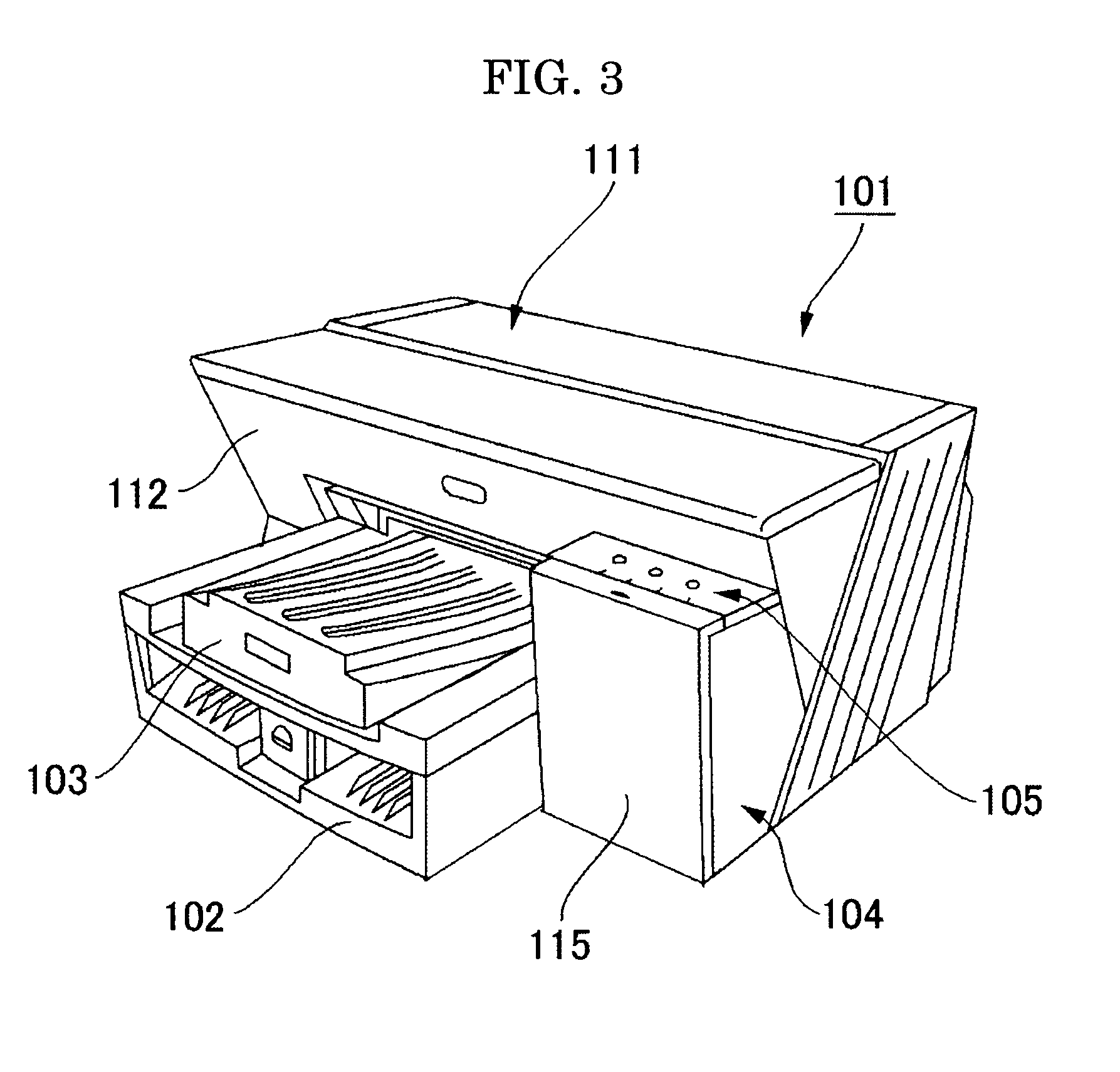

Inkjet ink, and ink cartridge, inkjet recording method, inkjet recording apparatus and ink record using the same

ActiveUS20090047431A1Improve discharge stabilityAvoid fixationMeasurement apparatus componentsInksWater insolublePeak area

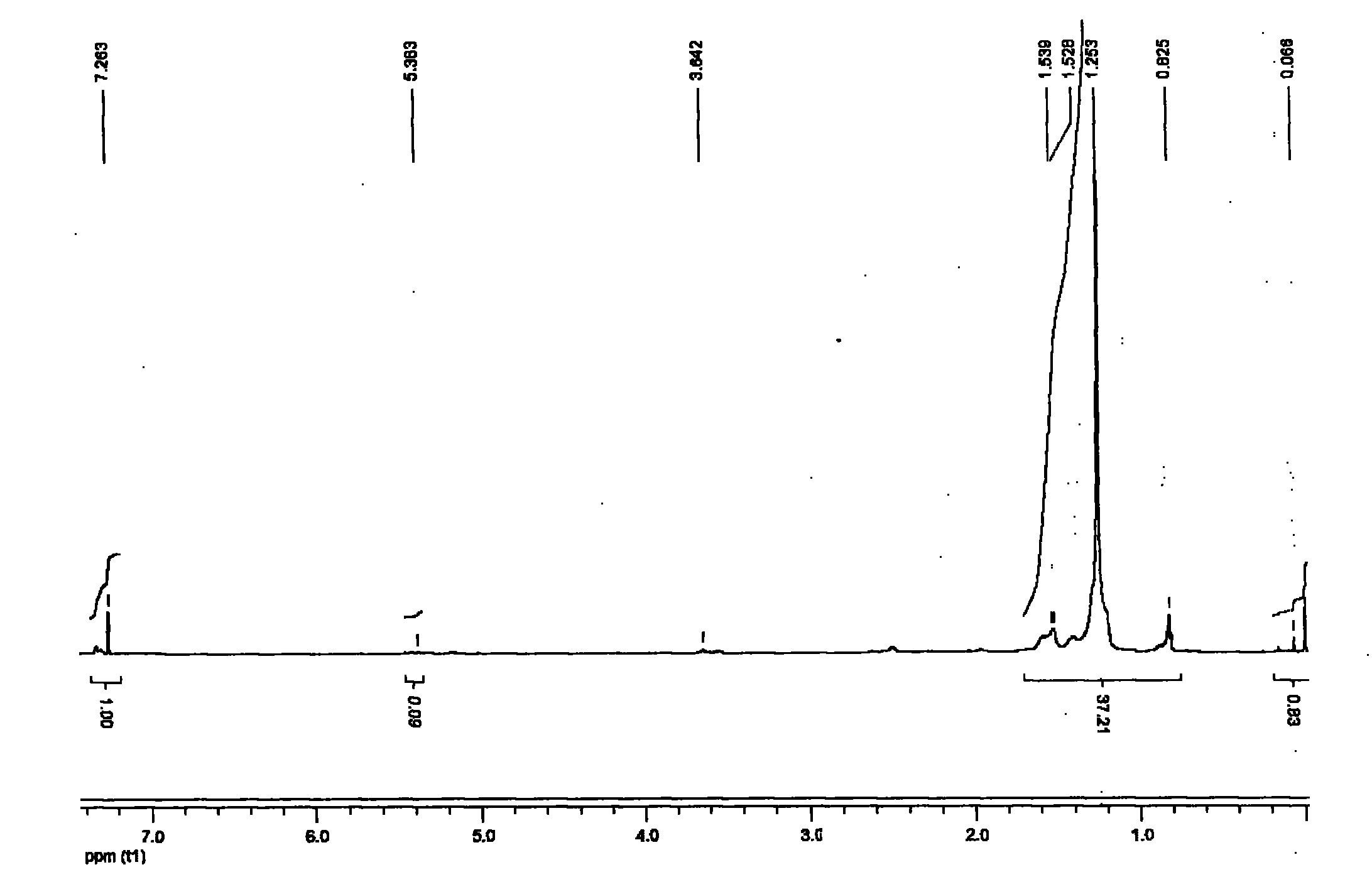

The present invention provides an inkjet ink containing at least a colorant, water, a water insoluble resin, a fluorine surfactant, and a polyether-modified silicone oil, wherein the polyether-modified silicone oil has a hydrophobic value of 0.40 to 1.5, and the hydrophobic value is expressed by Equation 1:Hydrophobic value=A / B Equation 1where “A” represents an integration value of a peak area from 0 ppm to 0.3 ppm in a 1H-NMR spectrum of the polyether-modified silicone oil using tetramethylsilane as a reference substance; and “B” represents an integration value of a peak area from 3.5 ppm to 4.0 ppm in the 1H-NMR spectrum.

Owner:RICOH KK

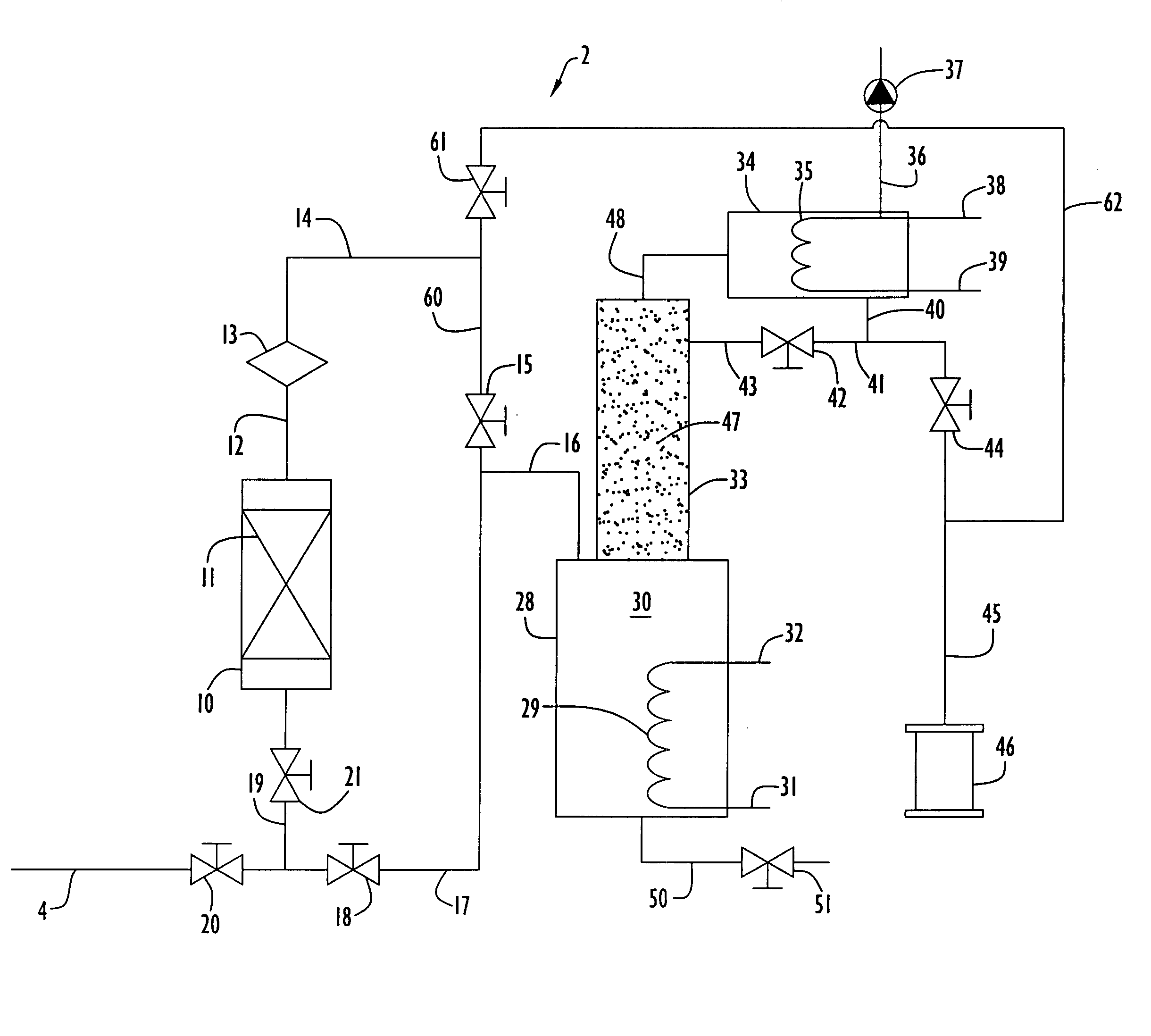

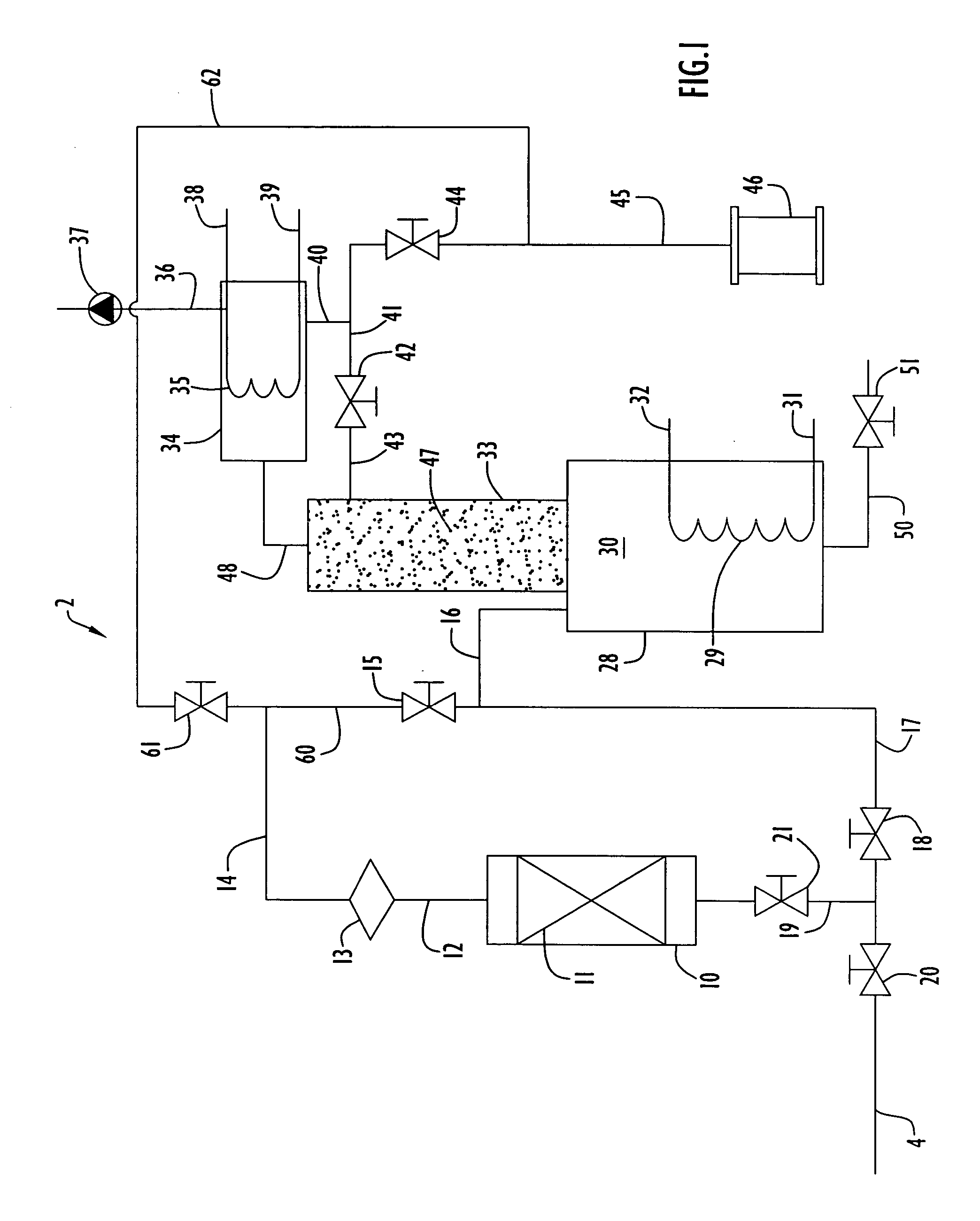

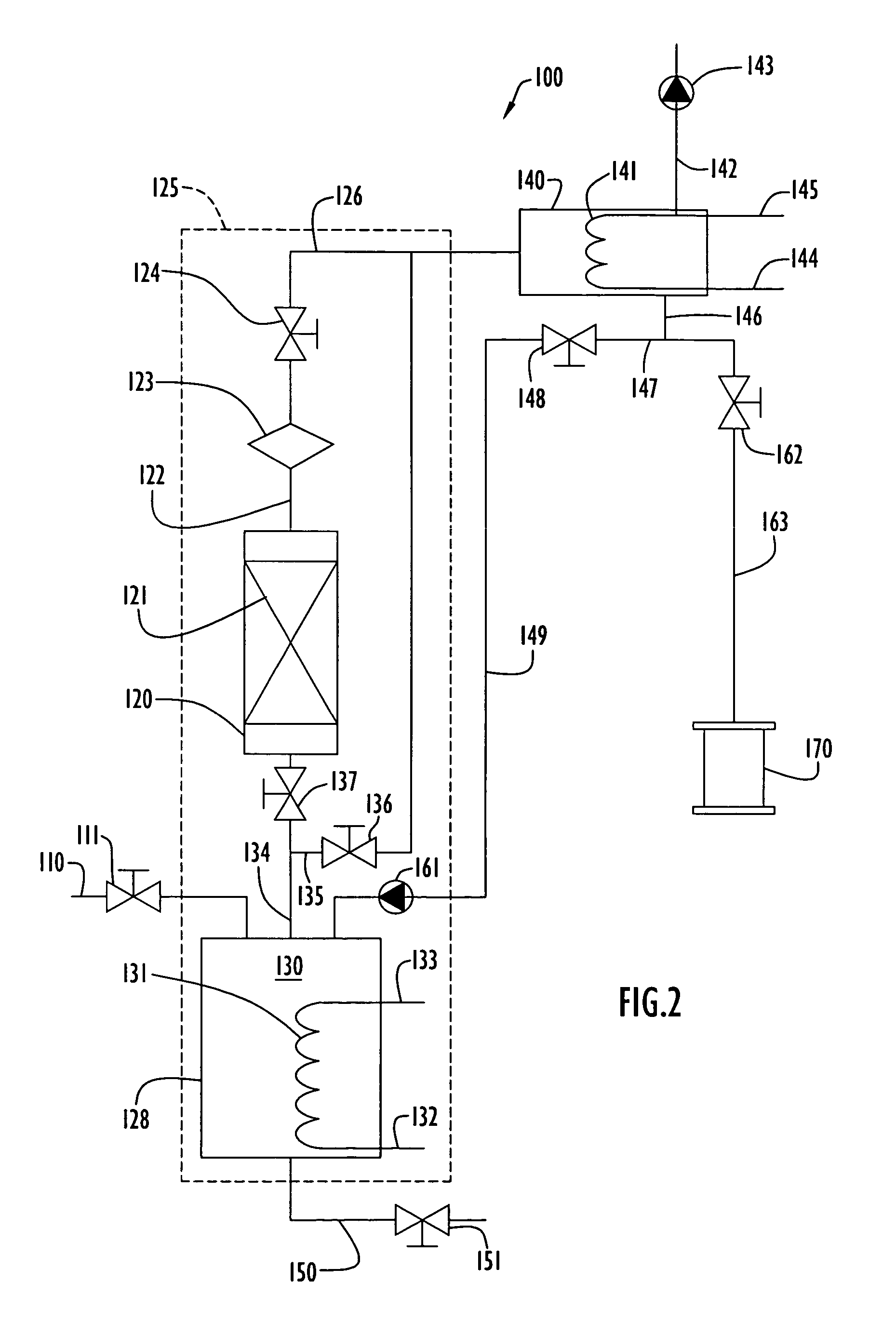

Purification of silicon-containing materials

InactiveUS20050054211A1Impurities increaseSilicon organic compoundsSemiconductor/solid-state device manufacturingSilanesLiquid state

Systems and methods of purifying a silicon-containing material include the step of directing the silicon-containing material in a liquid state through an adsorption unit including an adsorbent material to facilitate adsorption of at least one component from the silicon-containing material. Alternatively, the silicon-containing material is directed, in liquid state and / or gaseous state, through two or more purification units, including an adsorption unit, a vaporization unit, a filter unit and a condenser. The silicon-containing material can be a low-k silicon-containing material such as trimethylsilane, tetramethylsilane, dimethyldimethoxysilane, tetramethylcyclotetrasiloxane, octamethylcyclotetrasiloxane, dimethylphenyl silane, and dimethyldivinyl silane.

Owner:XU MINDI +2

Method for manufacturing gradient hard composite coating on surface of hard alloy

ActiveCN105386049ASmall coefficient of thermal expansionHigh bonding strengthSuperimposed coating processGlow plasmaAlloy

The invention relates to a method for manufacturing a gradient hard composite coating on the surface of a hard alloy. A dual-layer glow plasma surface alloying device is used, argon serves as plasma stimulation gas, a composite target manufactured through a refractory metal wire and a graphite plate serves as a source electrode, and refractory metal and a carbide composite cementation layer of the refractory metal are manufactured on the surface of the hard alloy; then mixed gas of tetramethylsilane and hydrogen is led in, and the gradient composite coating comprising refractory metal carbide and silicon carbide is prepared by continuously increasing the flow of the tetramethylsilane; and finally methane is led in, the flow of the methane is gradually increased, the flow of the tetramethylsilane is reduced at the same time, and the silicon carbide and diamond gradient hard composite coating is prepared. The coating prepared with the method and a base body are in metallurgical bonding, the coefficients of thermal expansion from the base body to the coating are distributed in a gradient manner, and the method has the characteristics of being small in stress, high in binding intensity and the like. Meanwhile, the overall coating is continuously prepared in one device, the process is simple, and the cost is low.

Owner:TAIYUAN UNIV OF TECH

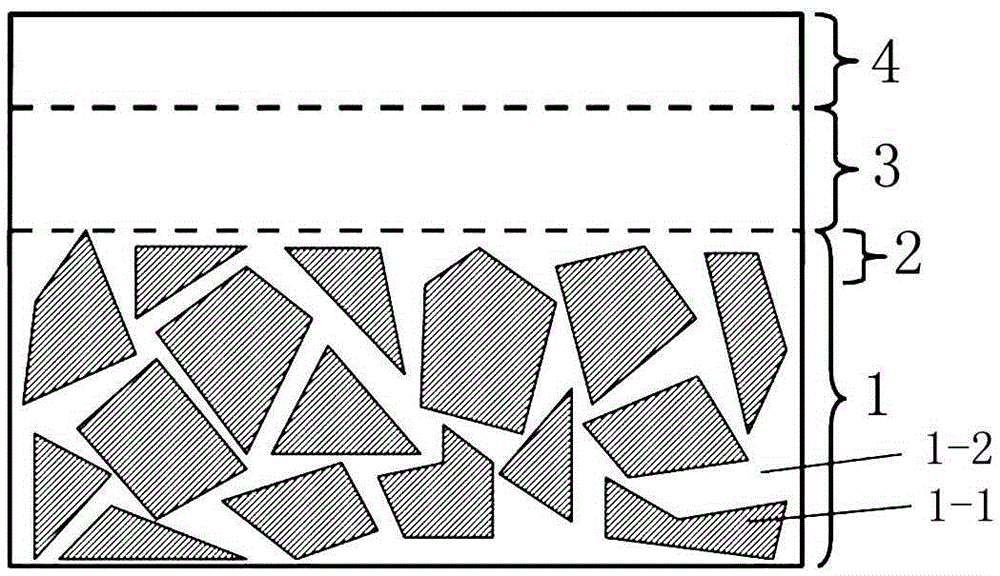

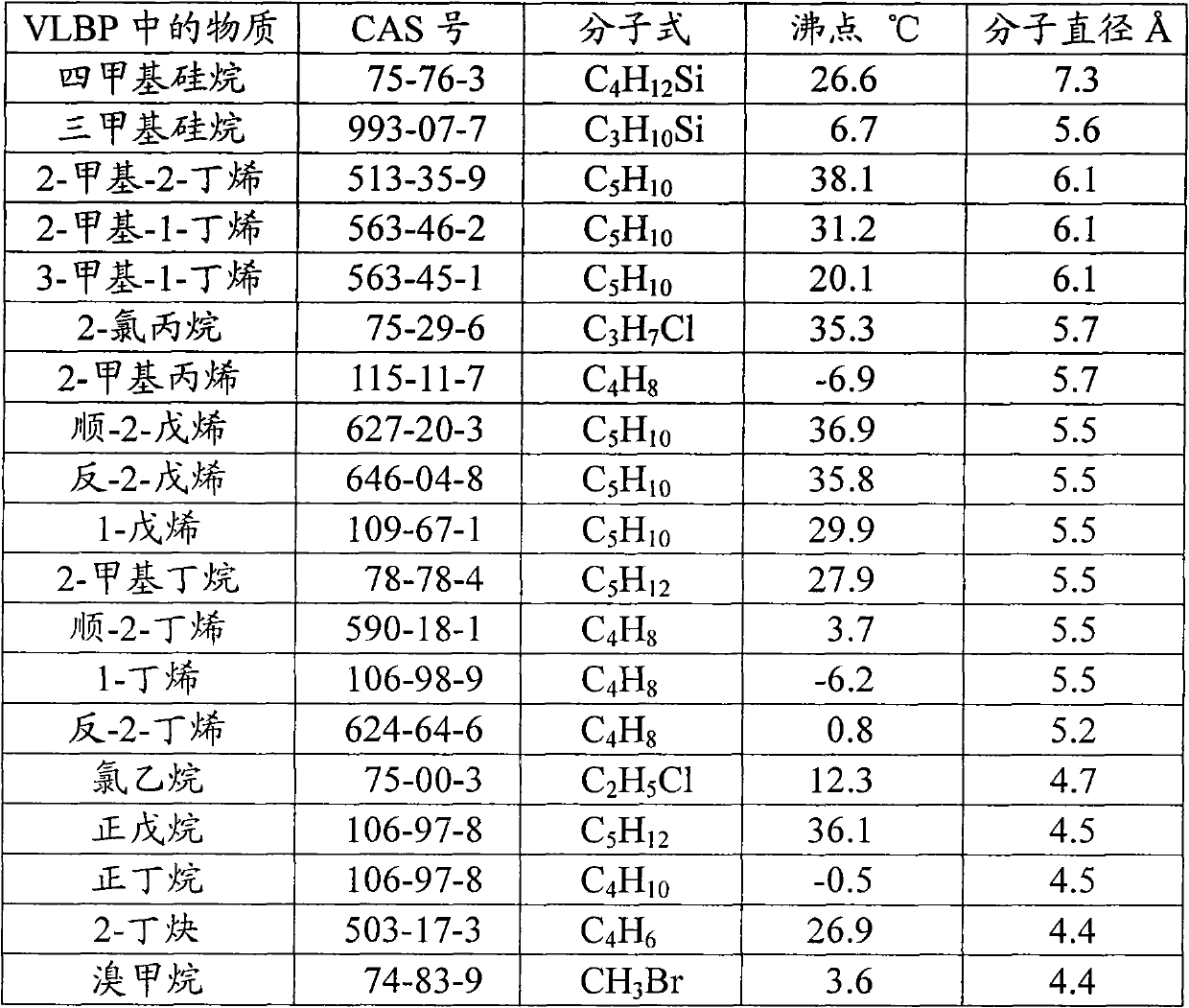

Process for purifying tetramethylsilane

ActiveCN101955496ALow costHighly selective adsorptionSilicon organic compoundsDispersed particle separationMolecular sieveAlkane

The invention discloses a process for purifying tetramethylsilane, which comprises the following steps of: (1) pretreating fractions of a low-boiling-point substance after synthesizing methyl chlorosilane by a direct method and separating to remove a compound containing a Si-Cl bond; and (2) adsorbing impurities in separated fractions in the step (1) by using a molecular sieve and purifying to obtain the tetramethylsilane, wherein the channel diameter of the molecular sieve is 4.5 to 7.2 angstroms. The impurities in the fractions of the low-boiling-point substance are adsorbed by the molecular sieve; the molecular sieve has good selective adsorption effect on alkane, olefin, chloroalkane and trimethylsilane in the fractions of the low-boiling-point substance; the tetramethylsilane can be purified to have high purity and other impurities are not introduced; in addition, the molecular sieve can be reused after being activated and has low cost.

Owner:JIAXING UNITED CHEM +1

High-temperature-resistant corrosion-resistant coating for aluminum plate

InactiveCN104017466AImprove adhesionImprove high temperature resistanceAnti-corrosive paintsPolyether coatingsEpoxyChlorinated paraffins

The invention discloses a high-temperature-resistant corrosion-resistant coating for an aluminum plate. The coating is prepared from the following raw materials in parts by weight: 30-50 parts of epoxy resin E20, 15-20 parts of furan resin, 8-10 parts of flame retardant polyether polyol, 3-5 parts of nano calcium carbonate, 3-5 parts of tetramethylsilane, 5-8 parts of barium sulfate, 8-10 parts of n-butyl acetate, 10-12 parts of propylene glycol, 10-15 parts of modified zeolite powder, 1-3 parts of di-n-butyltin dilaurate, 5-7 parts of silane coupling agent, 3-5 parts of chlorinated paraffin, 8-12 parts of chlorinated olefins and 5-8 parts of modified straw ash. According to the high-temperature-resistant corrosion-resistant coating for an aluminum plate disclosed by the invention, the modified zeolite powder is added into the formula, so that the adhesive force, the high temperature resistance and resistance to acid and base of the corrosion-resistant coating are greatly improved, and the formula is reasonable. In the aluminum plate preparing process, the aluminum plate is treated, and the corrosion-resistant coating formed on the surface of the aluminum plate is stable in performance, good in adhesive force, high-temperature-resistant, acid-resistant, base-resistant and good in corrosion resistance.

Owner:HEFEI TAITONG REFRIGERATION TECH CO LTD

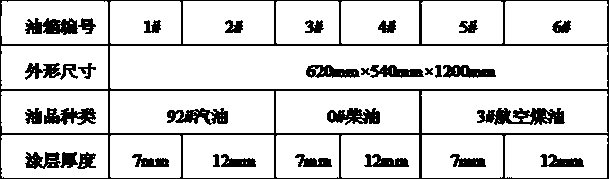

Self-repair material and preparation method and repairing coating layer thereof

ActiveCN108250937APromote repairAvoid lostFireproof paintsPolyurea/polyurethane coatingsEpoxyPolyvinyl alcohol

The invention belongs to the technical field of high molecular materials and discloses a self-repair material which is composed of a recovery unit, a swelling and filling unit and a self repairing andreinforcing unit. In parts by weight, the recovery unit is prepared from 5 to 10 parts of amine-terminated polyether and 4 to 6 parts of isocyanate; the swelling and filling unit is prepared from 4 to 10 parts of olefin and 3 to 5 parts of alkyl acrylate; the self repairing and reinforcing unit is composed of a capsule wall and a core material, wherein the capsule wall is prepared from 3 to 5 parts of paraffin, 5 to 8 parts of polyvinyl alcohol and 2 to 5 parts of polyacrylate, and the capsule core is prepared from 5 to 10 parts of epoxy-contained polysiloxane and 3 to 5 parts of tetramethylsilane. The invention further discloses a preparation method of the self-repair material and a repairing coating layer of the self-repair material. The self-repair material disclosed by the inventioncan be applied to a fuel oil system (an oil tank); under the situation that a net-shaped high-molecular explosion inhibiting material is fed in the fuel oil system, a damaged opening can be quickly repaired when the fuel oil system is shot by bullets or collided; thus, oil loss and fire occurrence caused by fuel oil leakage are avoided.

Owner:深圳市国志汇富高分子材料股份有限公司

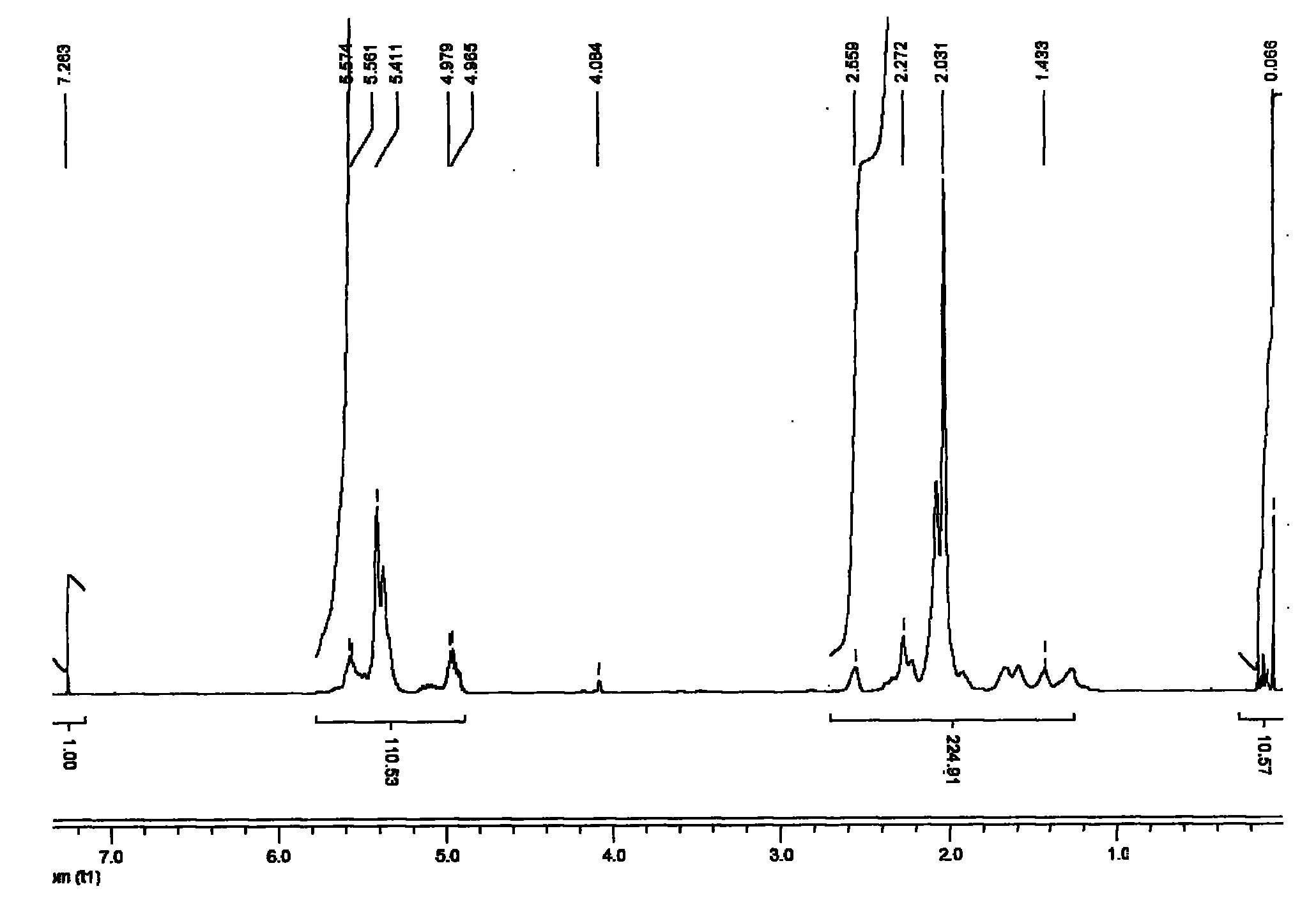

Inkjet ink, and ink cartridge, inkjet recording method, inkjet recording apparatus and ink record using the same

ActiveUS20130023614A1Avoid fixationImprove discharge stabilitySpecial tyresInksWater insolublePeak area

The present invention provides an inkjet ink containing at least a colorant, water, a water insoluble resin, a fluorine surfactant, and a polyether-modified silicone oil, wherein the polyether-modified silicone oil has a hydrophobic value of 0.40 to 1.5, and the hydrophobic value is expressed by Equation 1;Hydrophobic value=A / B Equation 1where “A” represents an integration value of a peak area from 0 ppm to 0.3 ppm in a 1H-NMR spectrum of the polyether-modified silicone oil using tetramethylsilane as a reference substance; and “B” represents an integration value of a peak area from 3.5 ppm to 4.0 ppm in the 1H-NMR spectrum.

Owner:RICOH KK

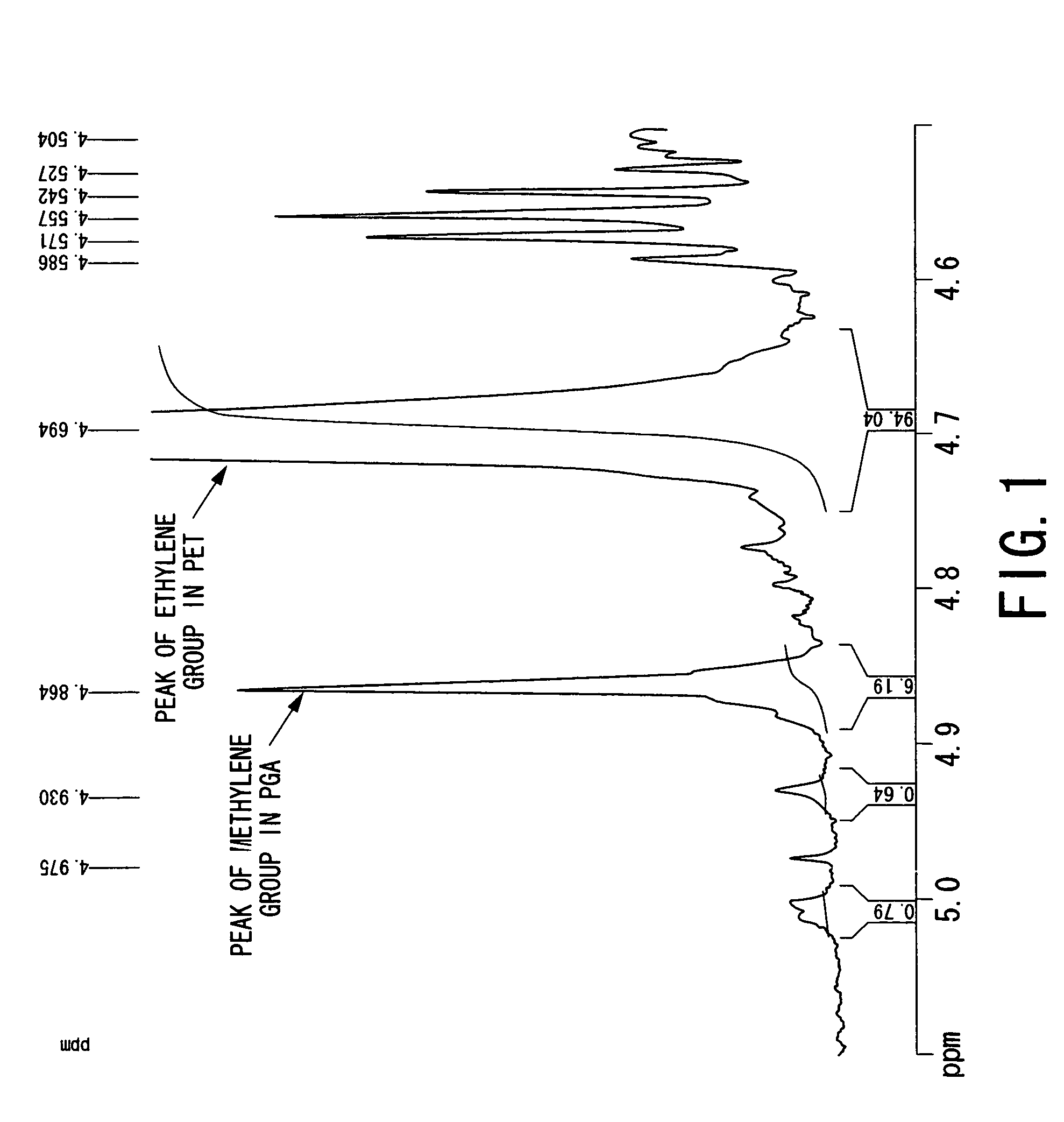

Aromatic polyester resin composition and process for production thereof

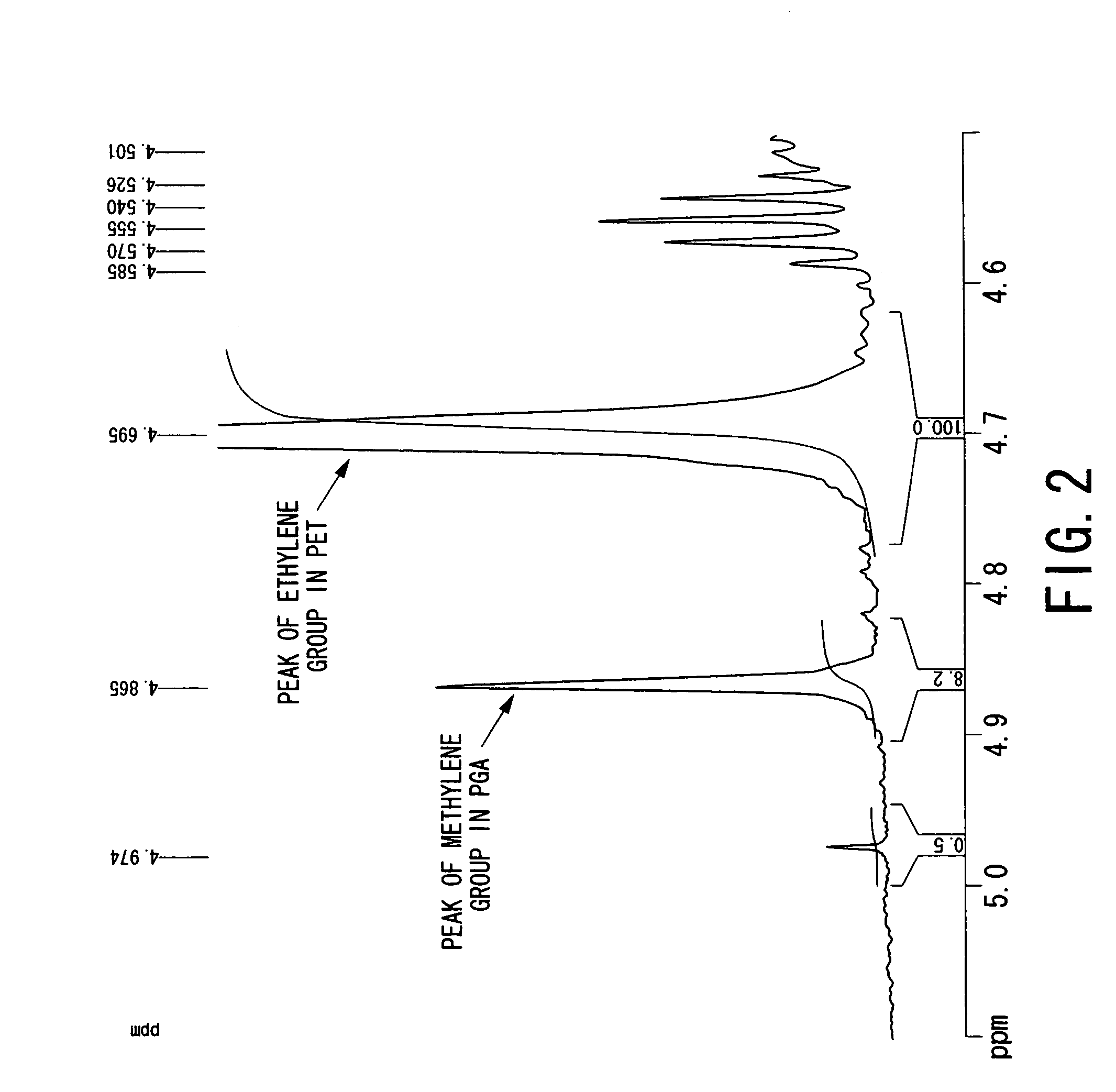

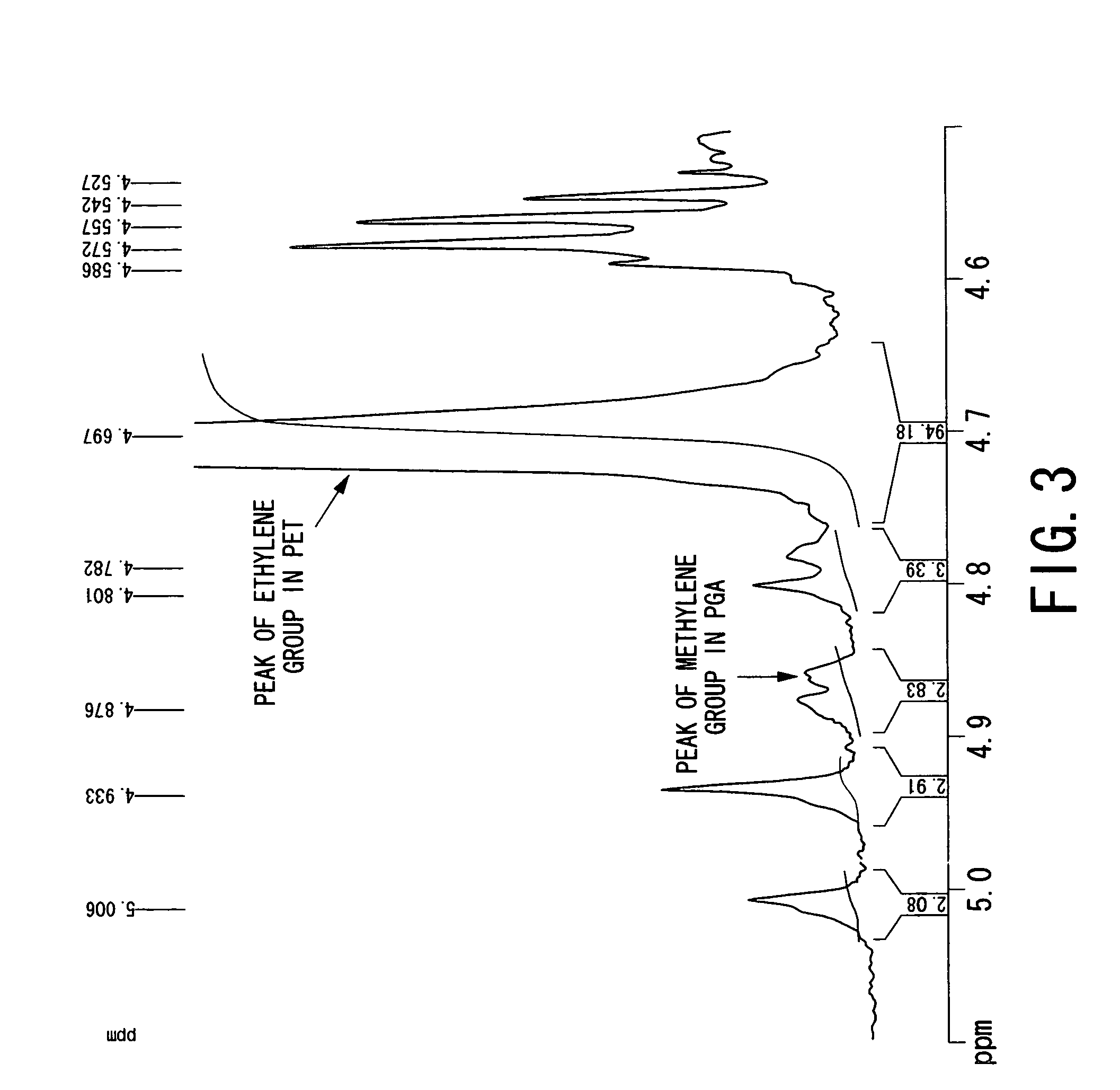

An aromatic polyester resin composition, comprising: a melt-kneaded product of 99-70 weight parts of an aromatic polyester resin and 1-30 wt. parts (providing a total of 100 wt. parts together with the aromatic polyester resin) of a polyglycolic acid resin, wherein the composition is characterized by a transesterification rate CTE (%) of 20-60% determined by formula (1) below based on a peak integration ratio of methylene group in polyglycolic acid appearing at σ4.87 ppm with reference to tetramethylsilane according to 1H-NMR measurement:CTE (%)=(1−I(B) / I(A))×100 (1),wherein I (A): a peak integration ratio of the methylene group of the polyglycolic acid main chain with respect to the alkylene group of the aromatic polyester main chain calculated from the components weight ratio; and I (B): a peak integration ratio of the methylene group of polyglycolic acid main chain to the alkylene group of the aromatic polyester main chain in the resin composition. As a result, the aromatic polyester resin composition obtained by adding a relatively small amount of polyglycolic acid resin is provided with a good harmony of gas-barrier property and transparency.

Owner:KUREHA KAGAKU KOGYO KK

Process for preparing diamond-like coating doped with silicon element

InactiveCN104593724AReduce coefficient of frictionImprove corrosion resistanceVacuum evaporation coatingSputtering coatingGas phaseOxidation resistant

The invention relates to a process for preparing a diamond-like coating doped with silicon element. The adopted equipment refers to physical vapor deposition equipment and a light discharge device. The process comprises the following steps: pretreating the surface of a workpiece, introducing argon into a vacuum furnace, and performing plasma cleaning on the workpiece; introducing nitrogen into the vacuum furnace chamber, taking Cr as a target, and depositing a CrN transition layer on the surface of the workpiece by adopting a physical vapor deposition technology; introducing acetylene and tetramethylsilane into the vacuum furnace, and preparing the diamond-like coating of which the top is doped with silicon element by virtue of a plasma glow discharge technology. The diamond-like coating is prepared by controlling the vacuum degree, substrate bias voltage, nitrogen flow, tetramethylsilane flow, acetylene flow and target current size. The prepared diamond-like coating doped with silicon element has the advantages of low deposition temperature (lower than 180 DEG C), high binding force, high hardness (Vickers hardness of more than HV2800), low friction coefficient (less than 0.05), corrosion resistance, oxidation resistance and the like.

Owner:SHANGHAI INST OF TECH

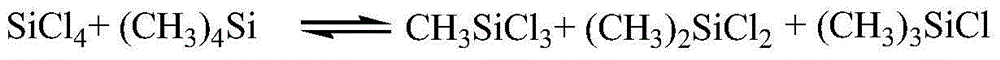

Method for preparing dimethyl dichlorosilane

ActiveCN104945428AAvoid the downside of reactingIncrease contentGroup 4/14 element organic compoundsTrimethylsilyl chlorideMethyltrichlorosilane

The invention discloses a method for preparing dimethyl dichlorosilane, which is implemented through carrying out disproportionation reaction on methyl trichlorosilane, trimethylchlorosilane, azeotrope and tetramethylsilane under the catalysis of aluminum chloride, and carrying out rectification treatment after the disproportionation reaction is completed, so that dimethyl dichlorosilane is obtained, wherein the mass ratio of methyl trichlorosilane to trimethylchlorosilane to azeotrope to tetramethylsilane is 1:(0.3-0.5):(0.6-0.8):(0.4-0.6), the temperature of the disproportionation reaction is 100-180 DEG C, and the reaction time is 4-16 h. The method for preparing dimethyl dichlorosilane, disclosed by the invention, is mild in conditions, simple in operation, high in product purity, safe and stable in synthesis process, low in energy consumption, and easy to realize industrialization.

Owner:JIAXING UNIV +1

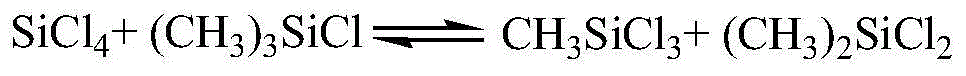

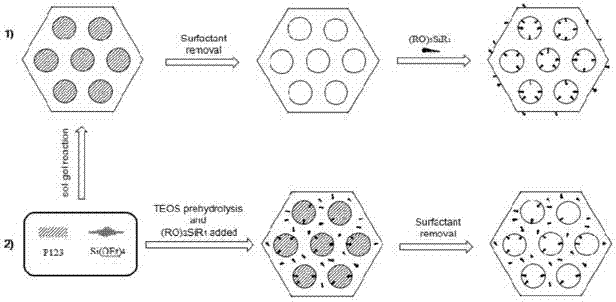

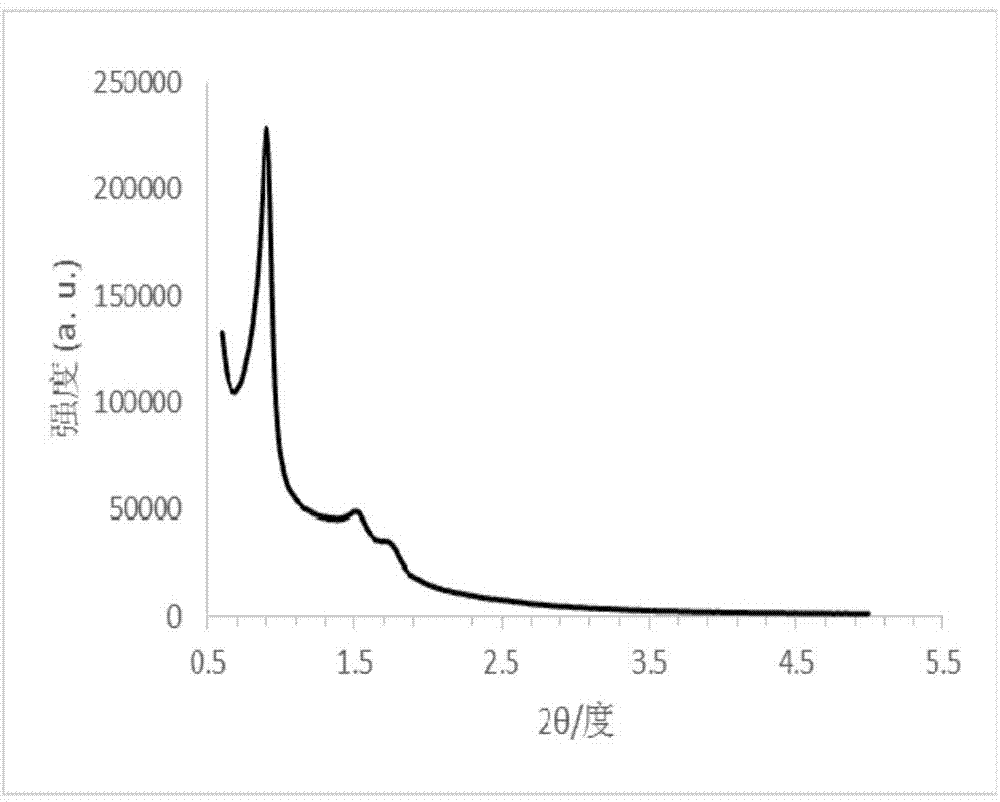

Preparation method of surface amino-group functionalization SBA-15 mesoporous silica

InactiveCN104841481AImprove orderHigh hydrothermal stabilitySilicaOther chemical processesSilanesMesoporous silica

The invention discloses a preparation method of surface amino-group functionalization SBA-15 mesoporous silica, and belongs to the technical field of organic functionalization ordered mesoporous materials synthetic method. The method comprises the following steps of taking aryl groups of different structures as protecting groups to react with silane coupling agents to prepare alkyl group trialkoxysilane functional precursor; under an acidic condition, taking tri-block non-ionic surface active agents as structure directing agents, and after pre hydrolyzing precursor, carrying out copolymerization with tetraethoxysilane or tetramethylsilane. The preparation method is characterized in that the aryl groups of different structures are taken as the protecting groups, so the functional precursor can be simply, conveniently and quickly prepared, and through the co-template role of the aryl groups and the structure directing agents, SBA-15 mesoporous silica, of which amino height is located at the inner surface of a duct, the microstructure is ordered and the bore diameters are different, is obtained.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

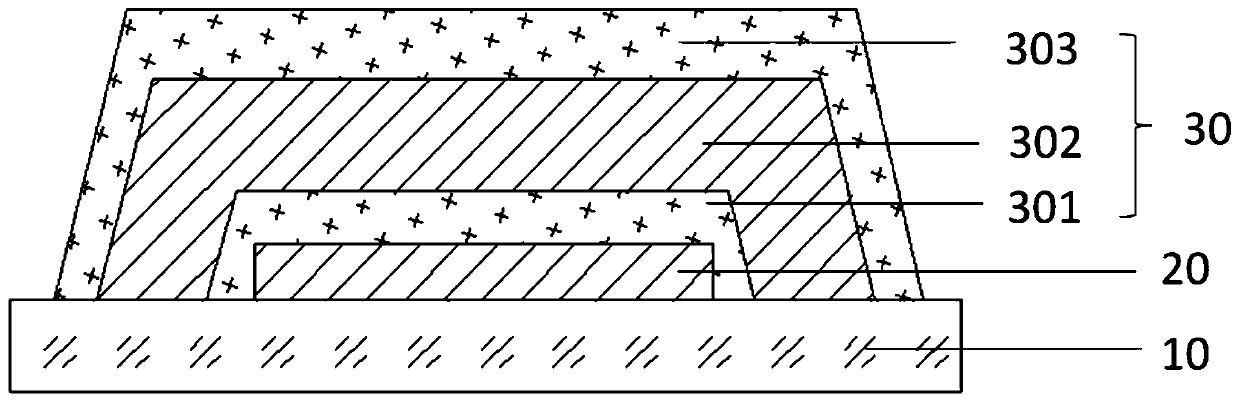

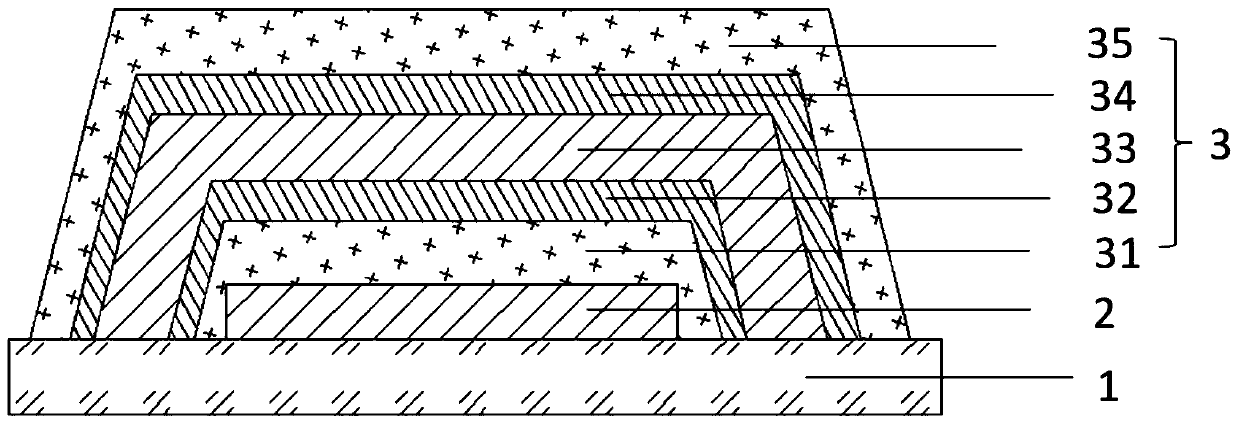

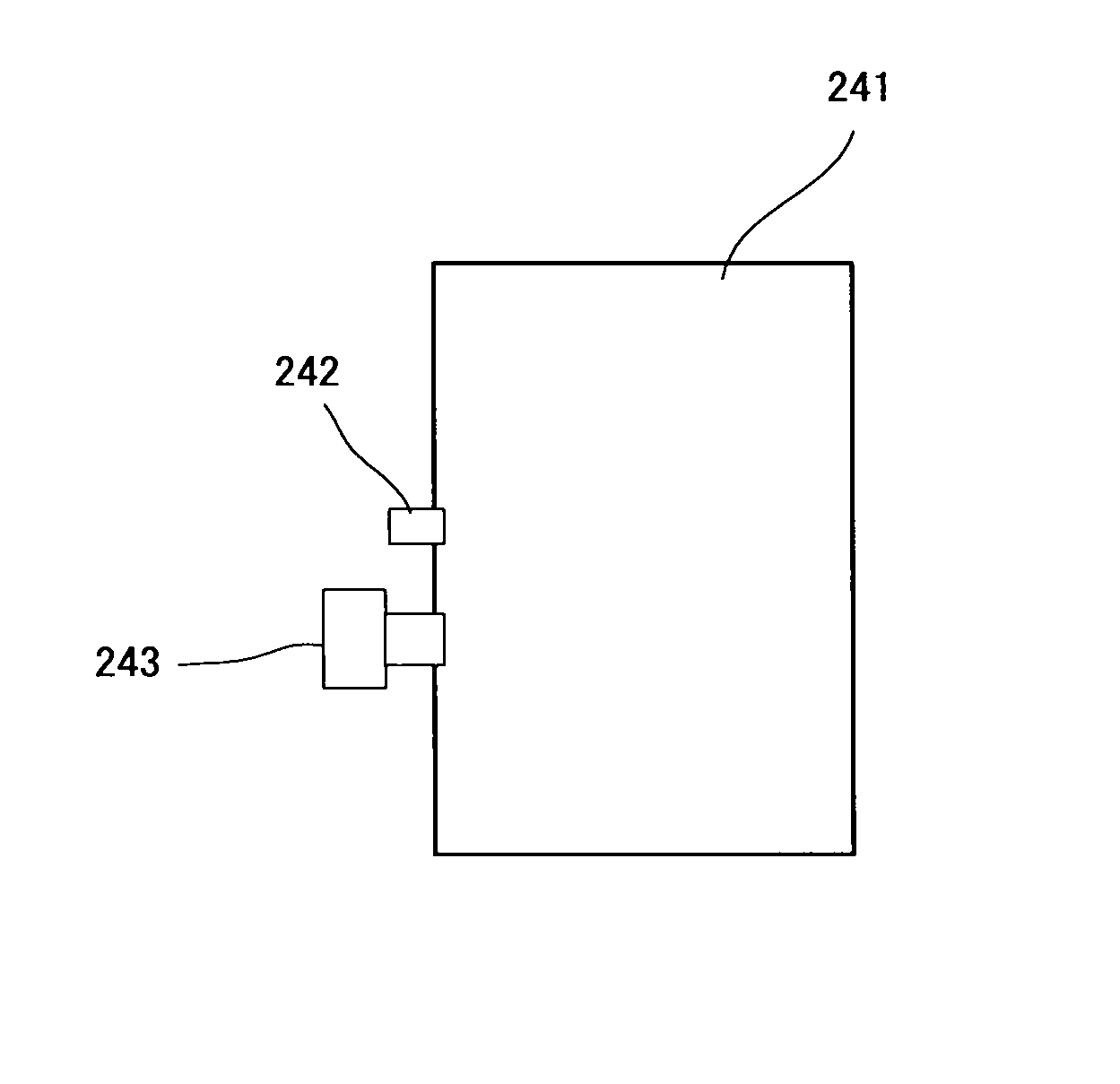

Organic electroluminescent device

InactiveCN110943182AImprove bending performanceImprove impact resistanceSolid-state devicesSemiconductor/solid-state device manufacturingCarbide siliconPolyamide

The invention discloses an organic light-emitting device. The organic light-emitting device includes: an organic light-emitting device arranged on a substrate, and a packaging layer which covers a light-emitting layer. The packaging layer comprises at least one inorganic layer and at least one organic layer. Wherein a buffer layer is arranged between one inorganic layer and one organic layer whichare adjacent to each other; wherein the buffer layer is made of at least one of a tetramethylsilane monomer, an ethoxysilane monomer and a silicon oxycarbide monomer, and the buffer layer is used forenhancing the bonding strength between the inorganic layer and the organic layer and improving the bending resistance of the organic light-emitting device; moreover, the organic layer is made of thetransparent polyamide resin material, so that the impact resistance of the organic light-emitting device is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Method of fixing glucose oxidase by organic modification sol-gel

InactiveCN101054574AImprove adhesionSolve the swelling problemOxidoreductasesOn/in organic carrierWater bathsPolyvinyl alcohol

The present invention provides a method for fixing glucose oxidase using organic modified sol- gelatin. Mixing evenly of oxygen radix silane and dimethyl dimethoxy silane, adding HCl aqueous solution of same volume with tetramethyl silane, placing mixing liquor in bottle, covering with lid mounted with a hole, stirring in water bath, placing for 3-5min, reserving gel liquor, mixing prepared gel and polyvinyl alcohol water solution, placing for 3-5min, taking upper clear solution after lamination and mixing with phosphate buffer dissolved with glucose oxidase, applying it on surface of matrix, drying for molding. The invention successfully solves the problem of swelling property derived from using individual PVA embedment. The glucose oxidase is embedded in porous matrix hybridized by gel solution and PVA so it is not easy to be lost and can be stored in a long-term and keeps the activity and stability.

Owner:FUZHOU UNIV

Hydrogenation method of hydroxyl terminated butyl nitrile (HTBN)

The invention relates to a hydrogenation method of hydroxyl terminated butyl nitrile (HTBN), in particular to a hydrogenation method of liquid nitrile containing terminated hydroxyl. The method is characterized by comprising the following steps: reacting terminated hydroxyl and silane of an unsaturated polymer before hydrogenation to obtain an unsaturated polymer capped with tetramethylsilane, dissolving hydroxyl terminated butyl nitrile in a benzene solvent according to the mass concentration of 5-30%, adding in a hydrogenated kettle, and performing hydrogenation reaction for 2-20h, wherein the temperature is 65-165 DEG C, the pressure is 0.4-5.0 MPa, the rotation speed is 200-400r / min, and the dosage of a catalyst is 0.1-5%. The invention has the advantages that the hydrogenated polymer is a novel polymer, and the hydrogenation degree can be more than 98%.

Owner:BEIJING UNIV OF CHEM TECH

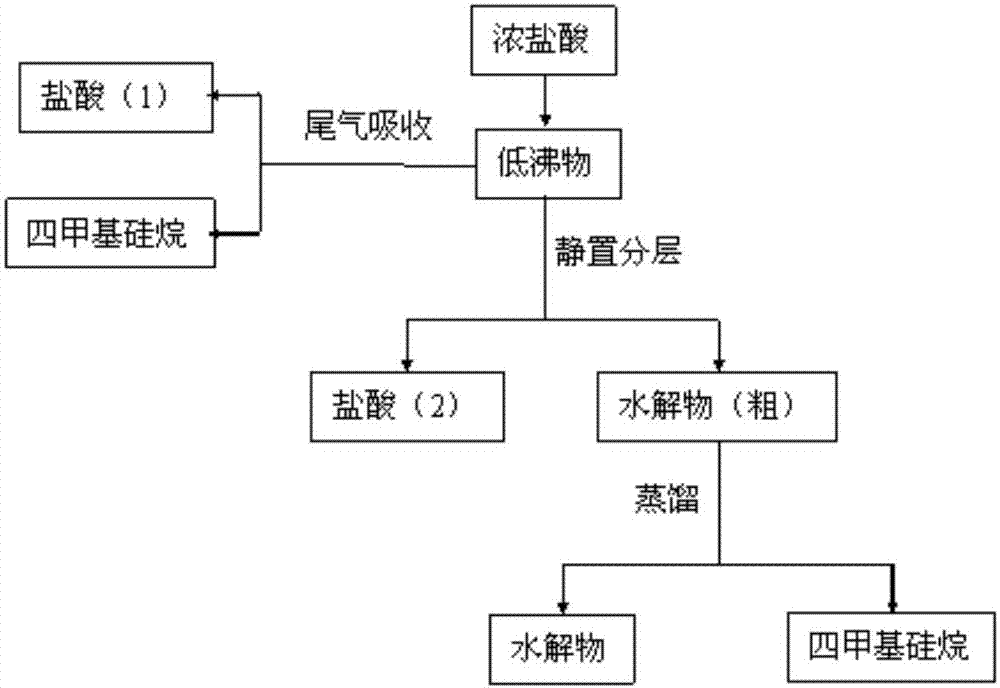

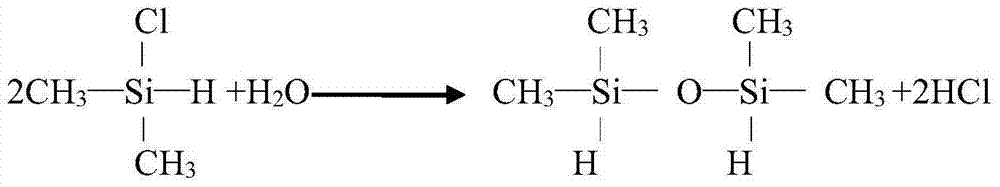

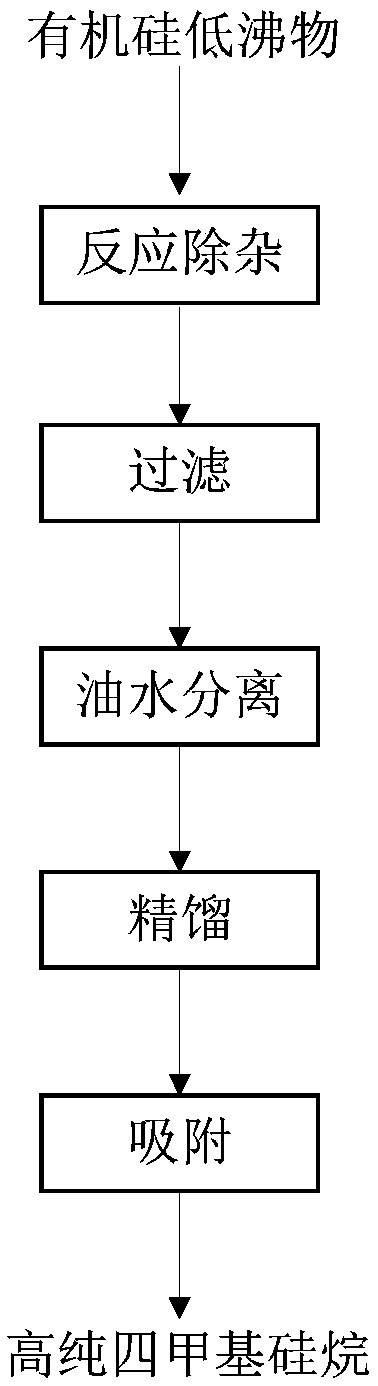

Treatment method of organic silicon low-boiling-point substance

InactiveCN103539810AHigh market valueSilicon organic compoundsPreparation from chloridesHydrolysateDistillation

The invention discloses a treatment method of an organic silicon low-boiling-point substance and particularly relates to a method of treating an organic silicon low-boiling-point substance by utilizing reverse dropwise adding of concentrated hydrochloric acid. The method comprises the following steps: a, adding the organic silicon low-boiling-point substance into a reaction kettle with a filled column and stirring, and then, dropwise adding concentrated hydrochloric acid from the middle part of the filled column while stirring to carry out reaction; 1.5-1 hour after dropwise adding the concentrated hydrochloric acid, heating a reaction system to 40 DEG C-50 DEG C to continuously react for 1-2 hours; b, ventilating tail gas generated by reaction into a hydrochloric acid absorbing device, an organic absorbing device and a tetramethylsilane condensing and recycling device in sequence; c, after the reaction in the step a is finished, standing for a certain time, and discharging the hydrochloric acid from the reaction kettle; and d, heating the reaction kettle, keeping the temperature in the kettle at 60 DEG C-70 DEG C for carrying out distillation to obtain tetramethylsilane. According to the treatment method disclosed by the invention, three products of the tetramethylsilane, the hydrochloric acid and hydrolysate can be obtained, so that a novel method is provided for treating the organic silicon low-boiling-point substance.

Owner:LUZHOU NORTH CHEM IND

Oxidation-resistant polymer film with memory function

InactiveCN105670128ASimple componentsLow costFixed capacitor dielectricBulk chemical productionPolymer scienceOxidation resistant

Owner:汤卓群

Polymer article having a thin coating formed on at least one of its sides by plasma and method for producing such an article

ActiveUS20090042025A1Reduce thicknessImprove surface propertiesSynthetic resin layered productsRecord information storageCoated surfacePolymer

Polymer article having a thin coating on at least one of its side, characterized in that said coating comprises a first coating of SiOxCyH2 which is a plasma polymerized tetramethylsilane deposited on the surface on said polymer article, the x value being between 0 and 1.7, the y value being between 0.5 and 0.8, the z value being between 0.35 and 0.6 for said first SiOxCyHzcoating and a second coating of SiOxCyHz which is a plasma polymerized tetramethylsilane deposited on the surface on said first coating, the x value being between 1.7 and 1.99, the y value being between 0.2 and 0.7, the z value being between 0.2 and 0.35 for said second SiOxCyHz coating and in that the thickness of said first coating is from about 1 nanometer to about 15 nanometers and in that the thickness of said second coating is from about 10 nanometers to about 100 nanometers, preferentially around 30 nanometers.

Owner:INNOVATIVE SYST & TECH

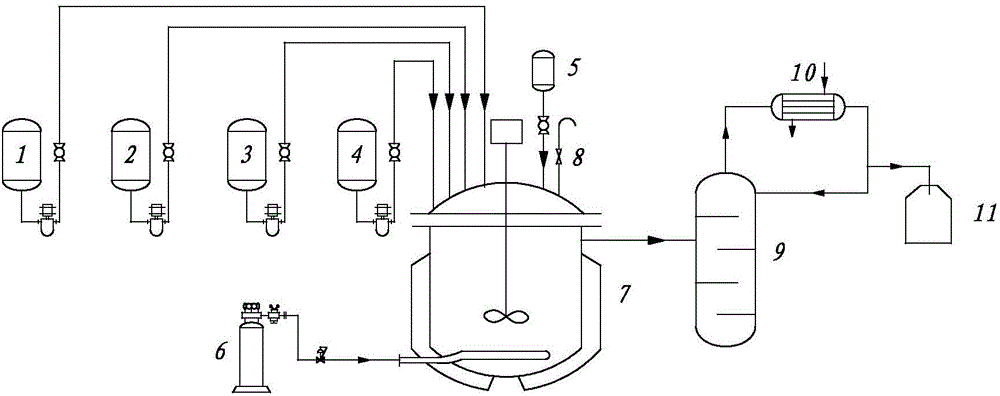

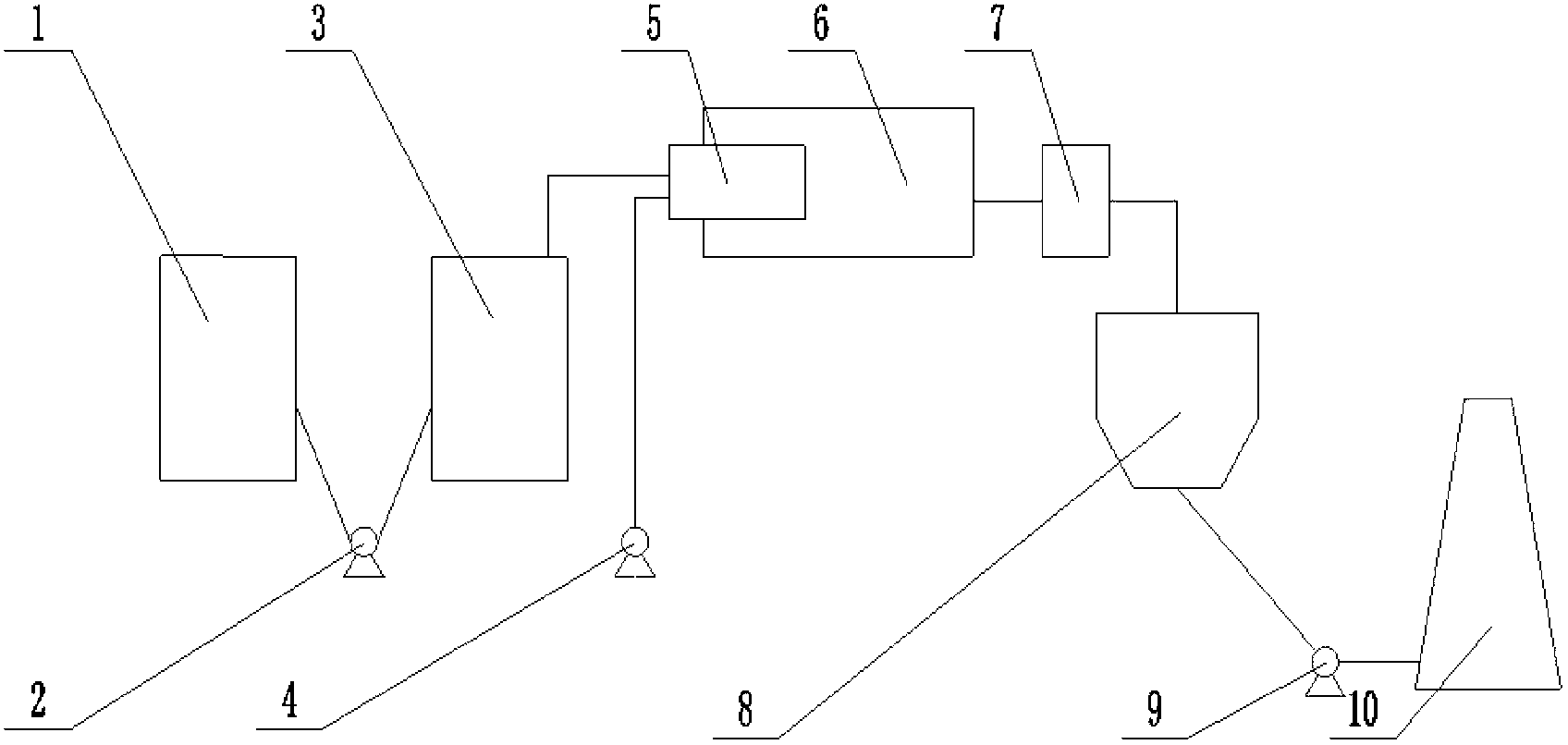

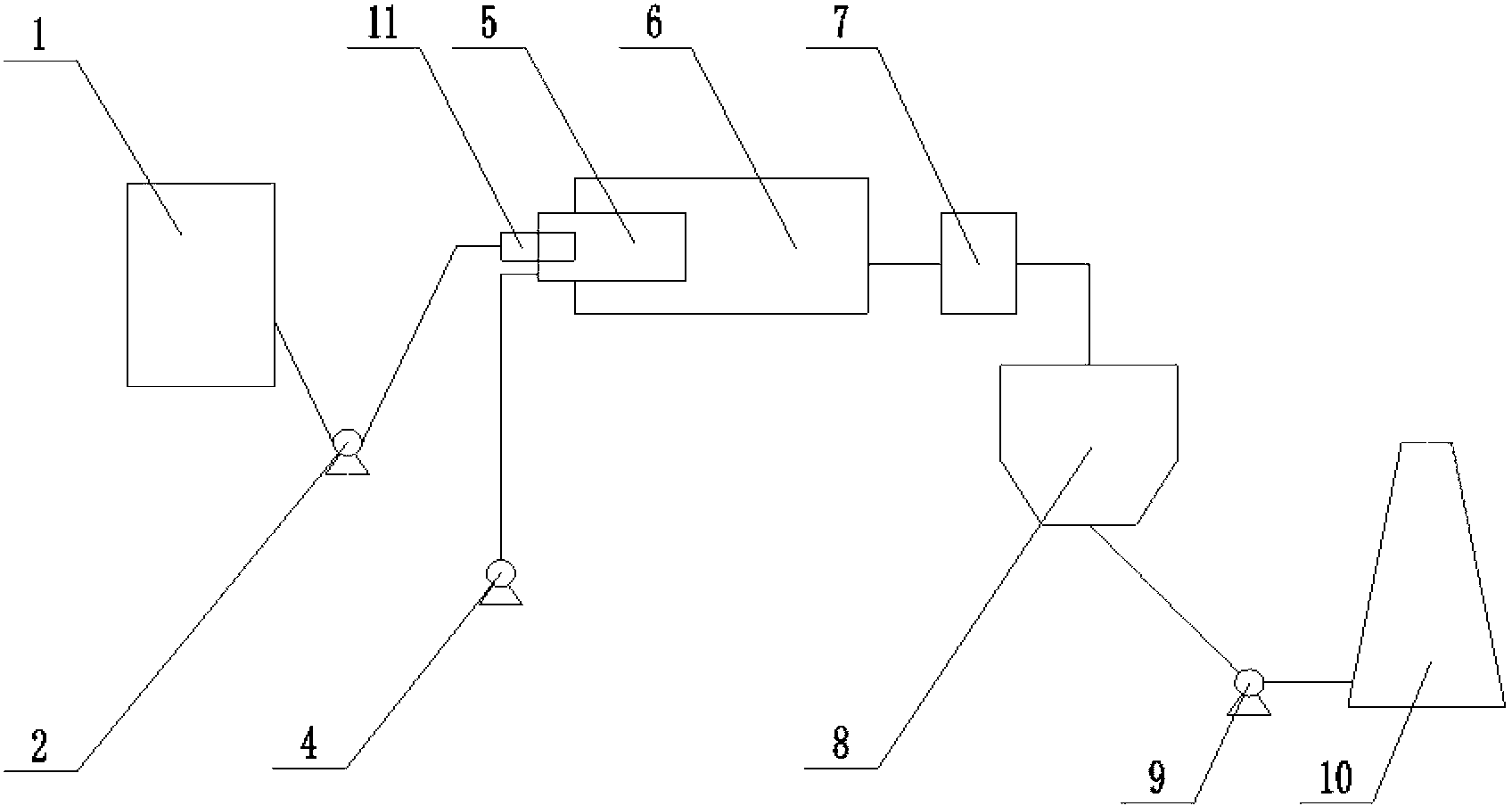

Method for preparing white carbon black by combusting tetramethylsilane and preparation device thereof

The invention relates to the field of material preparation, and aims at providing a method for preparing white carbon black by combusting tetramethylsilane and a preparation device thereof. The method comprises the following steps: atomizing the tetramethylsilane, then sending into a hearth for sufficient combustion, trapping the white carbon black from combustion products through a trap, and finally discharging tail gas into the atmosphere. The preparation device needed by the method comprises a combustor, a storage tank, a delivery pump, an atomization device, a forced draught blower, the hearth, a gas cooler, the trap, an induced draft fan and a chimney. The method combusts the tetramethylsilane (C4H12Si) to obtain the white carbon black, the temperature is much lower than 1,800 DEG C, the equipment requirement is also reduced, the energy is effectively saved, and the cost is saved. The products include the white carbon black, water and carbon dioxide, the method is relatively environmental-friendly, and the produced white carbon black has a good quality.

Owner:ZHEJIANG UNIV

Application of amino aryloxy rare-earth metal-lithium amide used as catalyst

InactiveCN102755906AGood substrate adaptabilityHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsRare earthMethyl group

The invention discloses application of amino aryloxy rare-earth metal-lithium amide used as a catalyst to catalyze amidation reaction of aldehyde and amine to prepare acid amide or bisamide. A general formula of the amino aryloxy rare-earth metal-lithium amide is [NO]2Ln[N(TMS)2][Li9(THF)]2; in the formula, [NO] represents amino aryloxy ligand; X is selected from one of hydrogen, C1-C4 saturated alkyl or halogen; R2 and R3 are respectively selected from one of methyl or tertiary butyl; Ln represents a central ion and is selected from one of praseodymium, neodymium, samarium, ytterbium or yttrium, and TMS (tetramethylsilane) is tetramethylsilane. The complex is used as the catalyst for catalyzing the aldehyde and amine to synthetize the acid amide. The dosage of the catalyst is less, the reaction condition is mild and the reaction time is short.

Owner:SUZHOU UNIV

Multi-component metal antirust painting and preparation method thereof

InactiveCN102352169AImprove adhesionDry fastAnti-corrosive paintsEpoxy resin coatingsPolymer scienceEthylic acid

The invention discloses a multi-component metal antirust painting and a preparation method thereof. The materials of the multi-component metal antirust painting, i.e. epoxy resin E20, bisphenol A type epoxy resin, nano calcium carbonate, silica flour, tetramethylsilane, straw ash, butyl acetate, glycol, chlorcosane, attapulgite and chlorinated olefin, are mixed according to certain parts by weight and are dispersed, and thereby the finished product is prepared. The multi-component metal antirust painting prepared by the method provided by the invention has the advantages of high adhesive force of the painting film, fast drying, high heat resistance, environment-friendliness and no pollution, and moreover, the preparation method is simple, is low in cost and is suitable for mass production.

Owner:ANHUI YIDA ELECTRONICS

Inkjet ink, and ink cartridge, inkjet recording method, inkjet recording apparatus and ink record using the same

ActiveUS8317913B2Avoid fixationImprove discharge stabilityMeasurement apparatus componentsInksWater insolubleSilicone oil

The present invention provides an inkjet ink containing at least a colorant, water, a water insoluble resin, a fluorine surfactant, and a polyether-modified silicone oil, wherein the polyether-modified silicone oil has a hydrophobic value of 0.40 to 1.5, and the hydrophobic value is expressed by Equation 1:Hydrophobic value=A / B Equation 1where “A” represents an integration value of a peak area from 0 ppm to 0.3 ppm in a 1H-NMR spectrum of the polyether-modified silicone oil using tetramethylsilane as a reference substance; and “B” represents an integration value of a peak area from 3.5 ppm to 4.0 ppm in the 1H-NMR spectrum.

Owner:RICOH KK

Polymer epoxy resin metal anticorrosion paint and preparation method thereof

InactiveCN102286239AImprove adhesionDry fastAnti-corrosive paintsEpoxy resin coatingsEpoxyPolymer science

The invention discloses a high molecular epoxy resin metal anticorrosion paint and a preparation method thereof. The preparation method mainly comprises the steps of mixing and stirring raw materials of epoxy resin E20, nanometer calcium carbonate, quartz powder, tetramethylsilane, straw ashes, butyl acetate, ethylene glycol, dinbutyltin dilaurate, attapulgite and chlorinated alkene in parts by weight and then dispersing the mixed raw materials to obtain a finished product. The high molecular epoxy resin metal anticorrosion paint prepared by using the invention has the advantages of good filmadhesion, rapidness in drying, good thermal resistance, environment friendliness and no pollution; moreover, the preparation method disclosed by the invention has the advantages of simplicity, low cost and suitability for large-scale production.

Owner:ANHUI YIDA ELECTRONICS

A kind of polymer metal anticorrosion paint and preparation method thereof

InactiveCN102286237AImprove adhesionDry fastAnti-corrosive paintsEpoxy resin coatingsEthylic acidChlorinated paraffins

The invention discloses a high molecular metal anticorrosion paint and a preparation method thereof. The preparation method mainly comprises the steps of mixing and stirring raw materials of bisphenol A type epoxy resin, nanometer calcium carbonate, tetramethylsilane, straw ashes, butyl acetate, propylene glycol, vermiculite powder, dibutyltin dilaurate, chlorinated paraffin and chlorinated alkene in parts by weight and then dispersing the mixed raw materials to obtain a finished product. The high molecular metal anticorrosion paint prepared by using the invention has the advantages of good film adhesion, rapidness in drying, good thermal resistance, environment friendliness and no pollution; moreover, the preparation method disclosed by the invention has the advantages of simplicity, lowcost and suitability for large-scale production.

Owner:ANHUI YIDA ELECTRONICS

Environmentally-friendly laminating coating for aluminum capacitor shell and preparation method thereof

InactiveCN102417764AEffective protectionExtended service lifeCapacitorsCoatingsStearic acidDimethyl siloxane

The invention discloses an environmentally-friendly laminating coating for an aluminum capacitor shell and a preparation method thereof. The environmentally-friendly laminating coating is mainly obtained by mixing and stirring a composition A and a composition B in composition raw materials in part by weight, wherein the composition A consists of polyethylene resin, ketone, polyethylene wax, isopropanol and attapulgite; and the composition B consists of phenolic resin, polydimethylsiloxane, a silane coupling agent, stearic acid, graphite powder and tetramethylsilane. The environmentally-friendly laminating coating has a reasonable formula, a simple preparation method and a good curing effect on the aluminum capacitor shell; a capacitor is protected effectively; and the obtained laminating coating has heat resistance and wear resistance performance, and contributes to prolonging the service life of the capacitor.

Owner:TONGLING XINTAI ELECTRIC APP & CAPACITOR

Polyamide resin capacitor aluminium shell film mulching paint and its preparation method

The invention discloses a polyamide resin capacitor aluminium shell film mulching paint and its preparation method. The polyamide resin capacitor aluminium shell film mulching paint is mainly prepared by mixing raw materials of a composition A and a composition B, wherein the composition A is composed of polyamide resin, ketone, polyethylene wax, nanometer powdered carbon, ethanol, glycerol and attapulgite; and the composition B is composed of an acrylic acid ester copolymer modifier, a silane coupling agent, graphite and tetramethylsilane. The formulation provided by the invention is reasonable and the preparation method is simple. The film mulching paint has a good curing effect on the capacitor aluminium shell and has heat-resistant and wear-resistant performance, and can be used to effectively protect the capacitor and increase the service life of the capacitor.

Owner:TONGLING XINTAI ELECTRIC APP & CAPACITOR

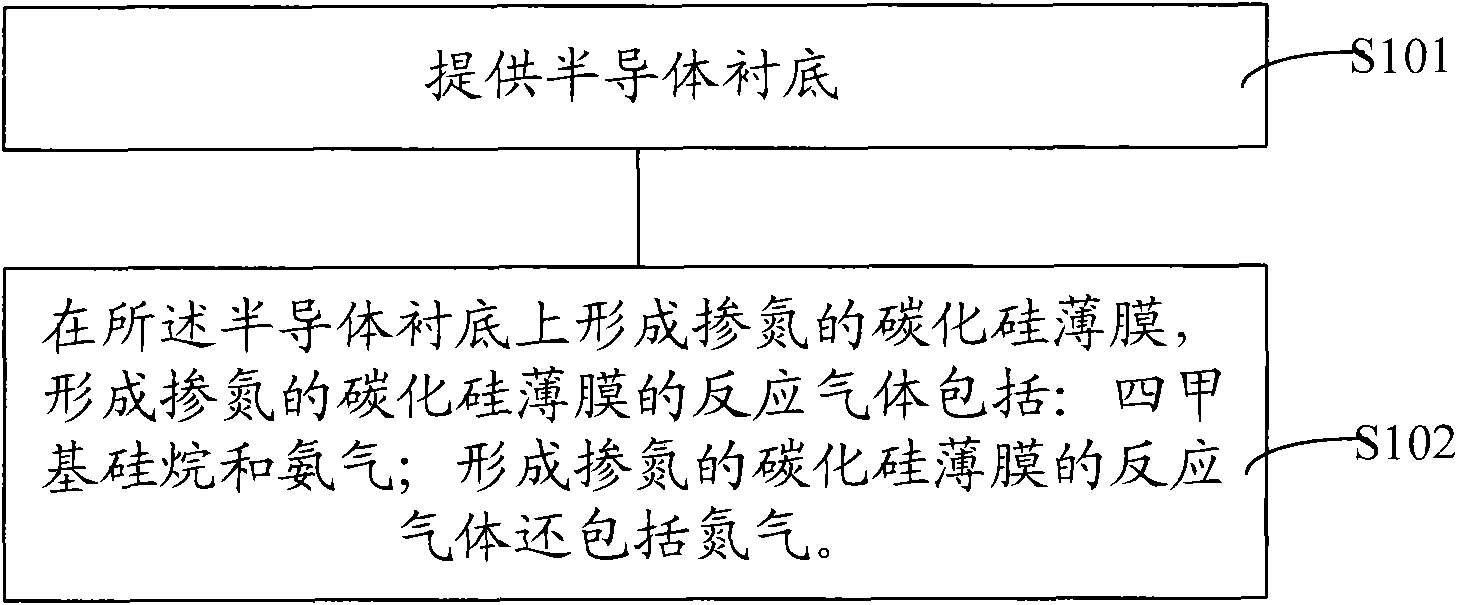

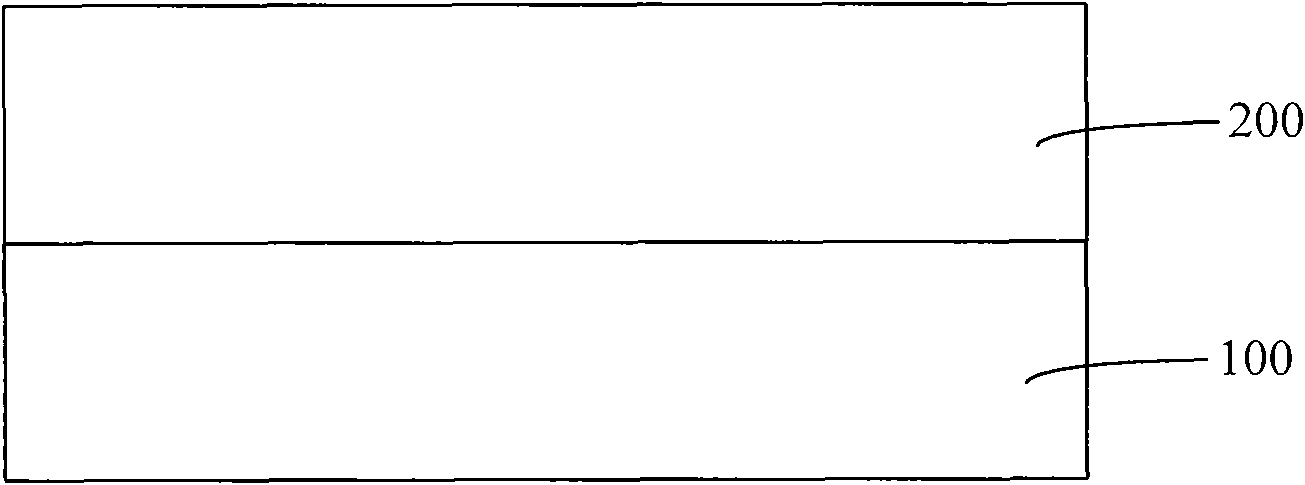

Forming method of nitrogen-doped silicon carbide thin film

InactiveCN102097304AImprove reflectivityIncreased reflectivity varianceSemiconductor/solid-state device manufacturingNitrogen gasSmall range

The invention relates to a forming method of a nitrogen-doped silicon carbide thin film, comprising the following steps of: providing a semiconductor substrate; and forming the nitrogen-doped silicon carbide thin film on the semiconductor substrate, wherein reaction gas used for forming the nitrogen-doped silicon carbide thin film comprises tetramethylsilane, ammonia gas and nitrogen gas. The nitrogen-doped silicon carbide thin film formed with the forming method of the invention has the advantages of small ranges of reflectivity difference values and good uniformity in properties.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

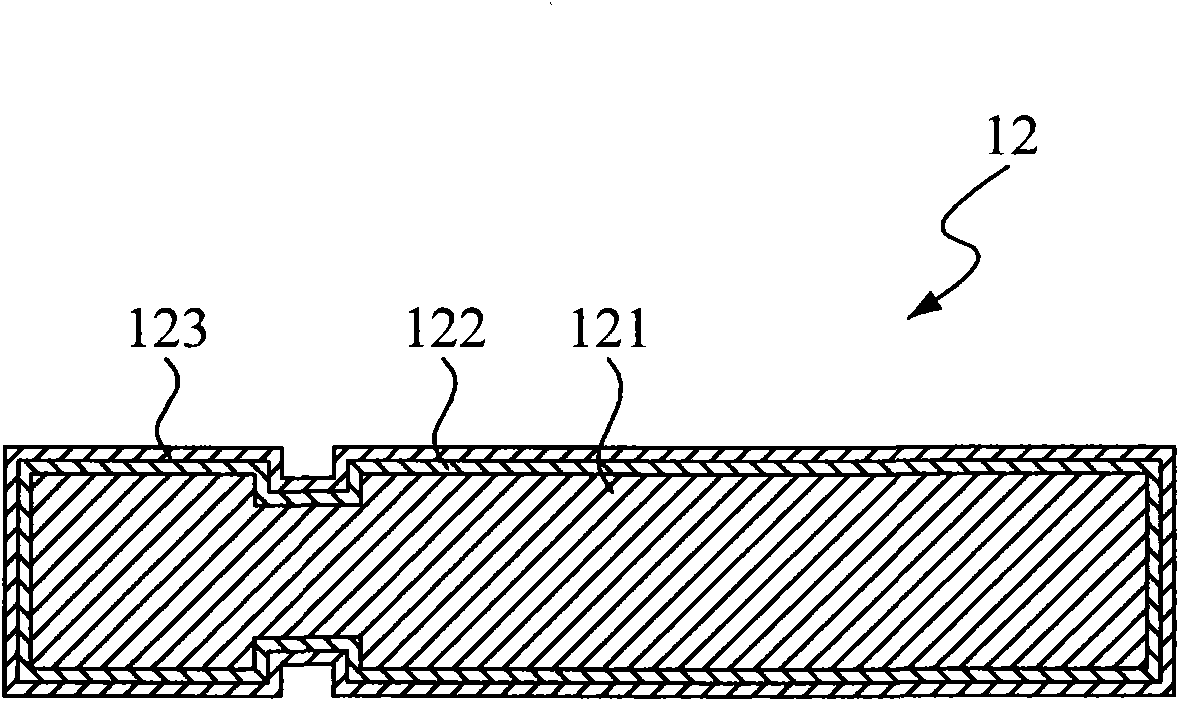

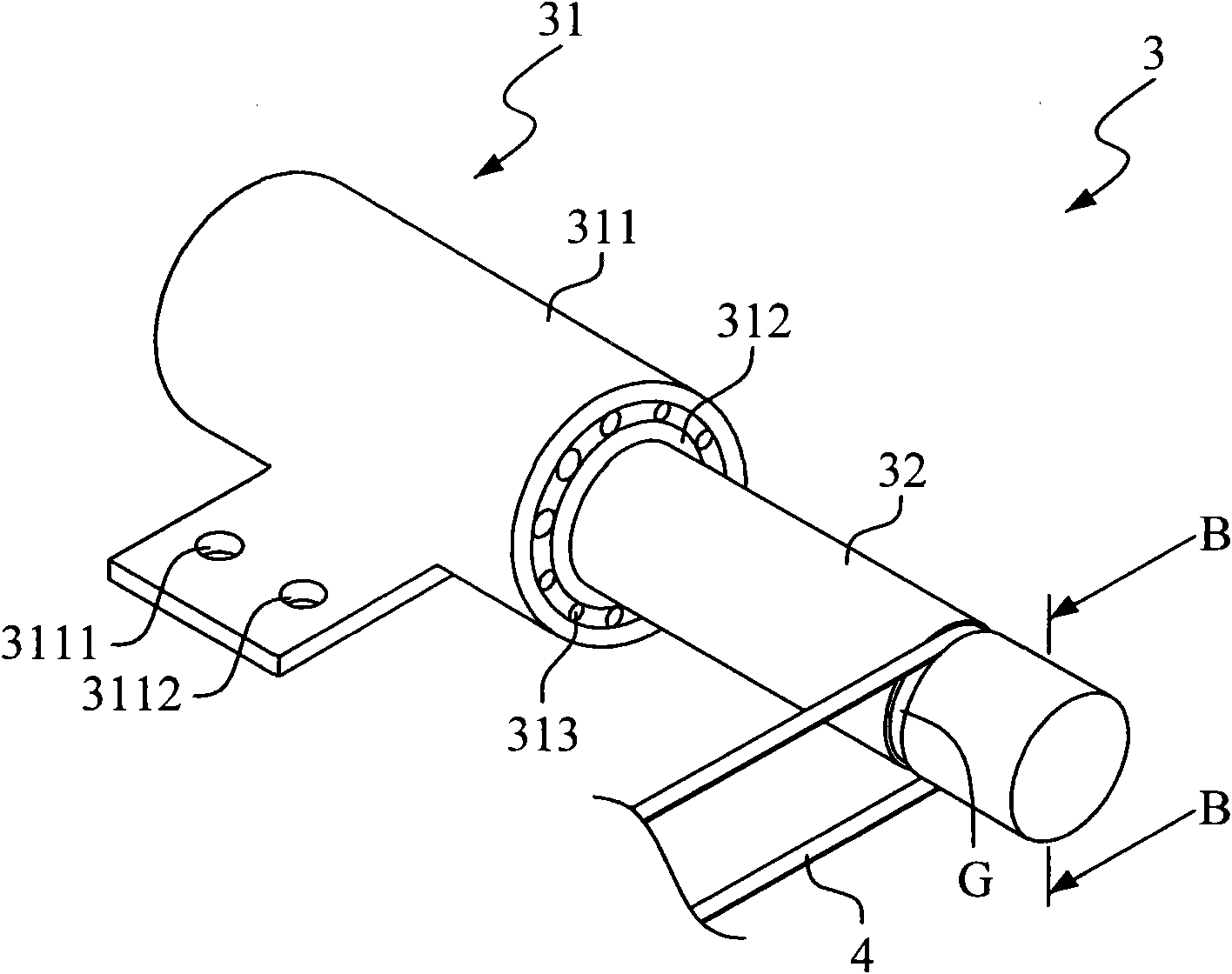

Surface coating method of transmission mechanism

InactiveCN101671814AHigh surface hardnessAvoid the flashback effectChemical vapor deposition coatingDiamond-like carbonHydrogen

The invention provides a surface coating method of a transmission mechanism. The method comprises the following steps of: providing a transmission mechanism; cleaning the surface of the transmission mechanism; placing the transmission mechanism in a working environment in which hydrogen gas, tetra-methylsilane(TMS) and Si(CH3)4 gas are filled, applying an external electric power, of which the power is 800 to 1,500 watts, to generate a bias electric field in the working environment so as to form an attaching film on the surface of the transmission mechanism; forming a mixing film on the surfaceof the attaching film; and forming an amorphous diamond(diamond-like carbon, DLC) film on the surface of the mixing film, and finally manufacturing the coated transmission mechanism. In the mixing film, the content of the amorphous DLC materials increases with the distance from the transmission mechanism. By the method, the high surface hardness of the coated transmission mechanism is ensured, and the anti-wearing ability and life time of the coated transmission mechanism are improved.

Owner:林玉雪

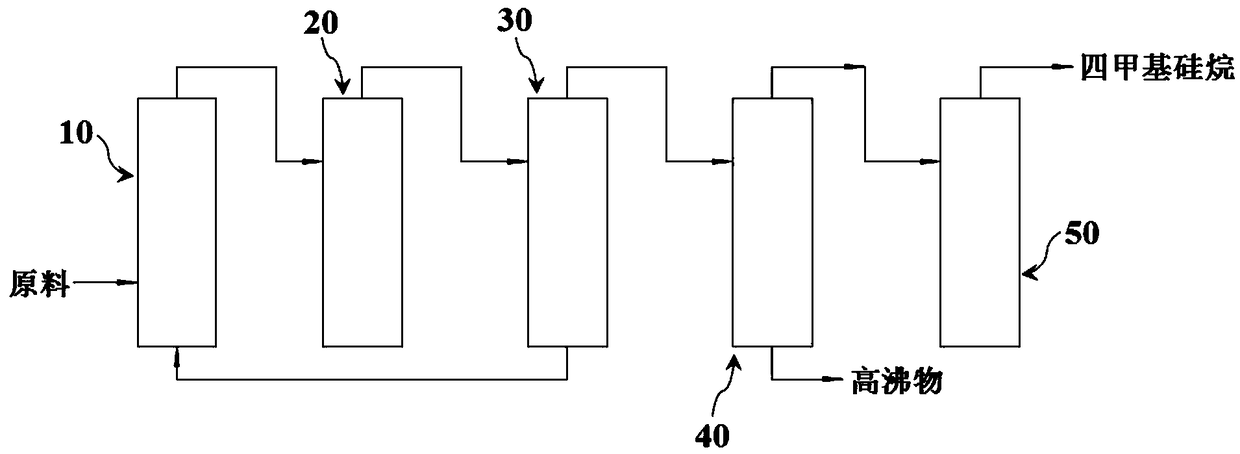

Method for preparing tetramethylsilane

One embodiment of the invention provides a method for preparing tetramethylsilane. The method comprises the following steps: taking a mixture of low-boiling-point substances or methyl chlorosilane produced in the process of synthesizing organosilicone monomers by a direct method as the raw material, and performing purification treatment, thereby obtaining the tetramethylsilane. According to the preparation method in the embodiment of the invention, the mixture of the low-boiling-point substances or methyl chlorosilane produced in the process of synthesizing the organosilicone monomers by the direct method serves as the raw material, the production cost is low, and tetramethylsilane with high purity can be prepared.

Owner:CHINA SILICON CORP LTD +1

Wear-resistant and high-temperature resistant capacitor aluminum case film coating paint and preparation method thereof

InactiveCN102373006AEffective protectionExtended service lifePolyurea/polyurethane coatingsMeth-Ketone

Owner:TONGLING XINTAI ELECTRIC APP & CAPACITOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com