Patents

Literature

164results about How to "Impurities increase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

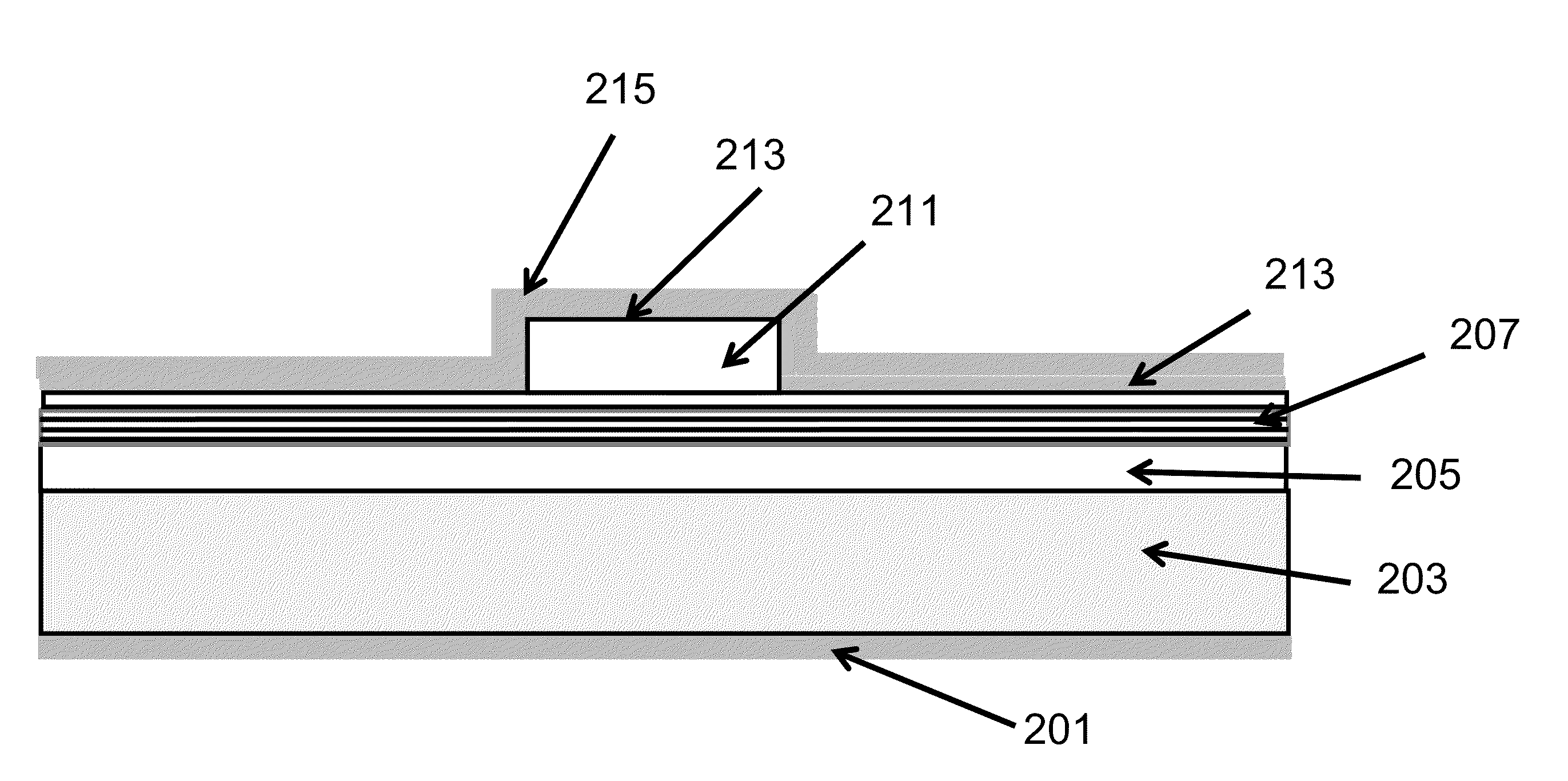

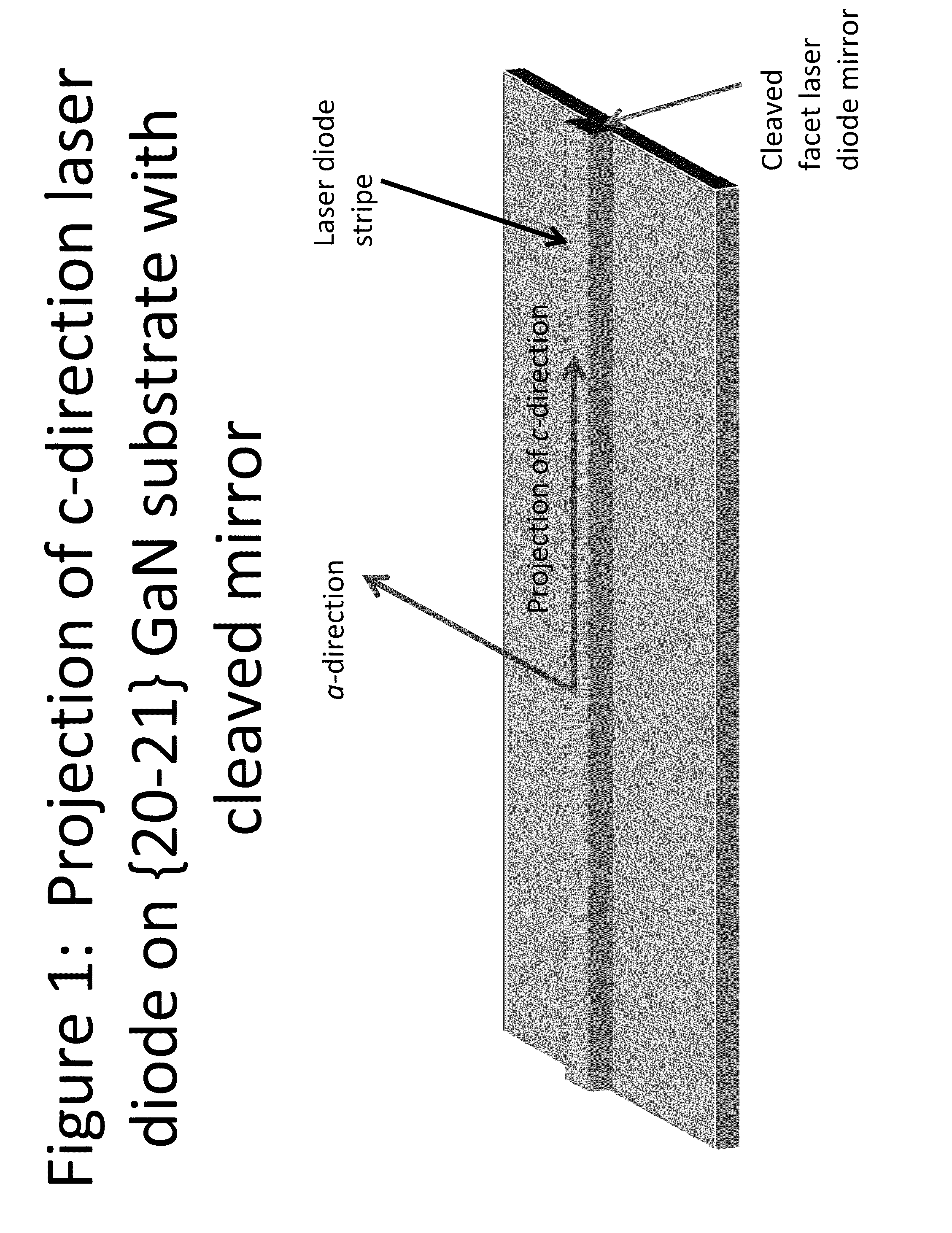

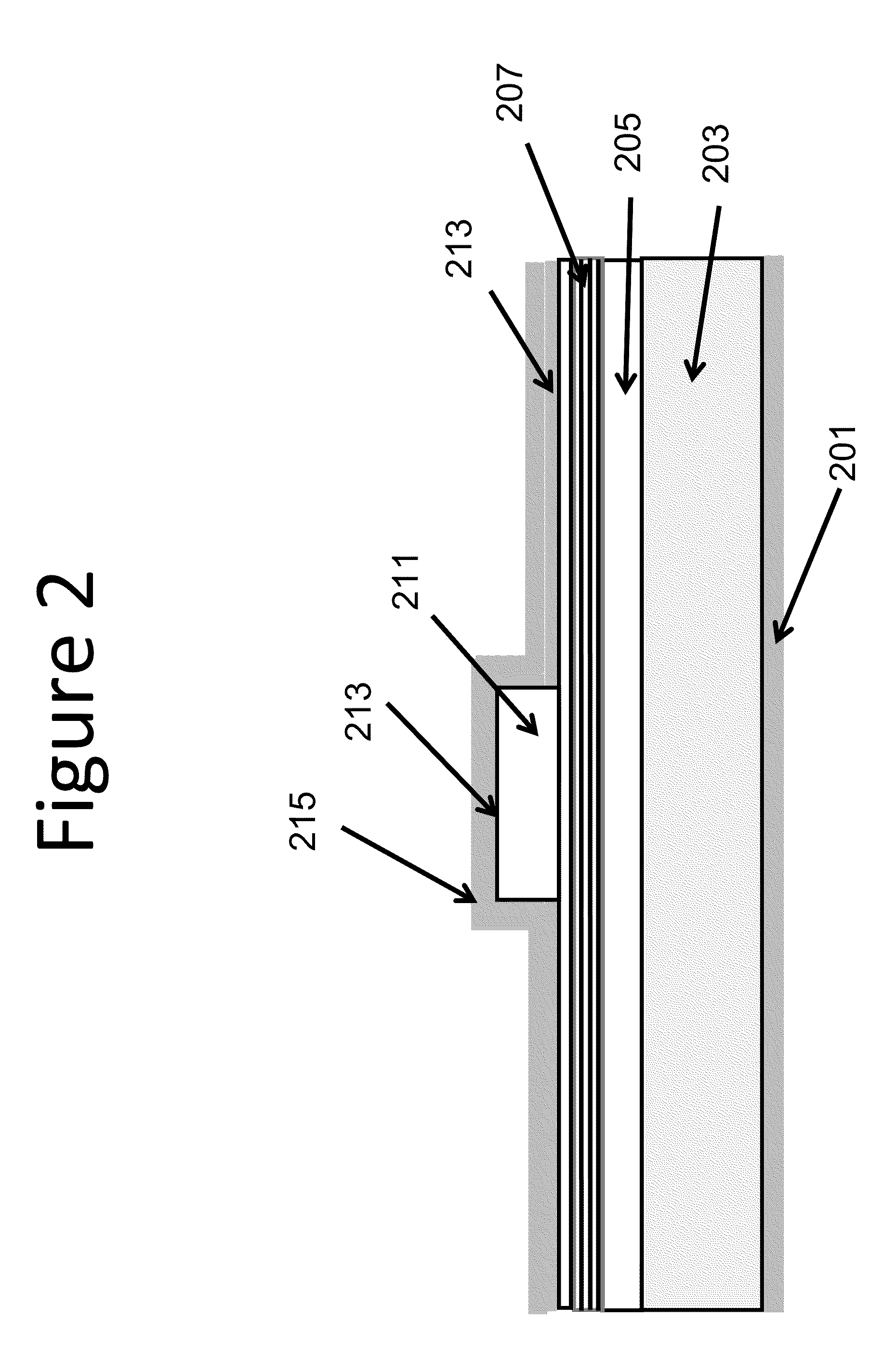

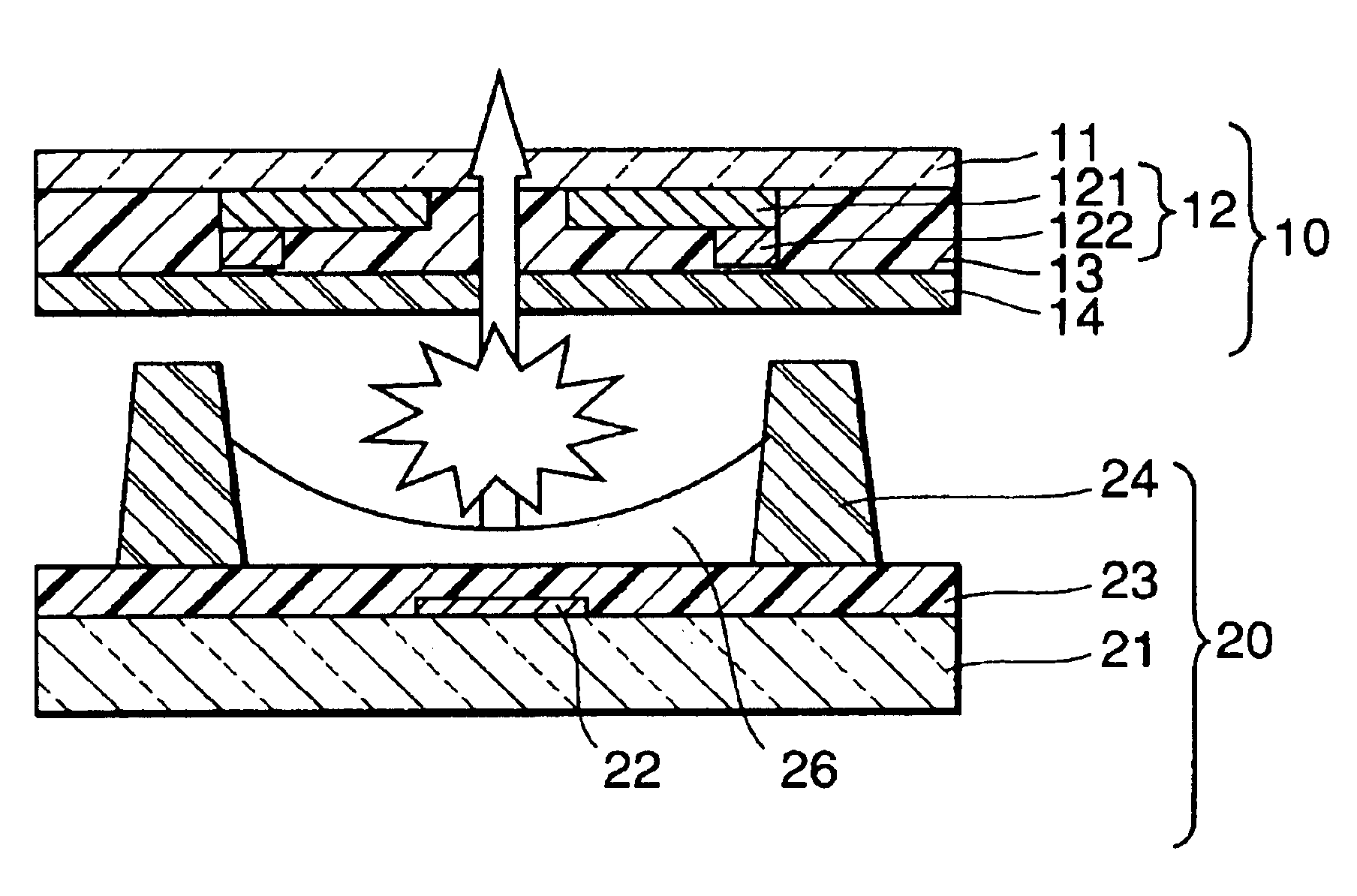

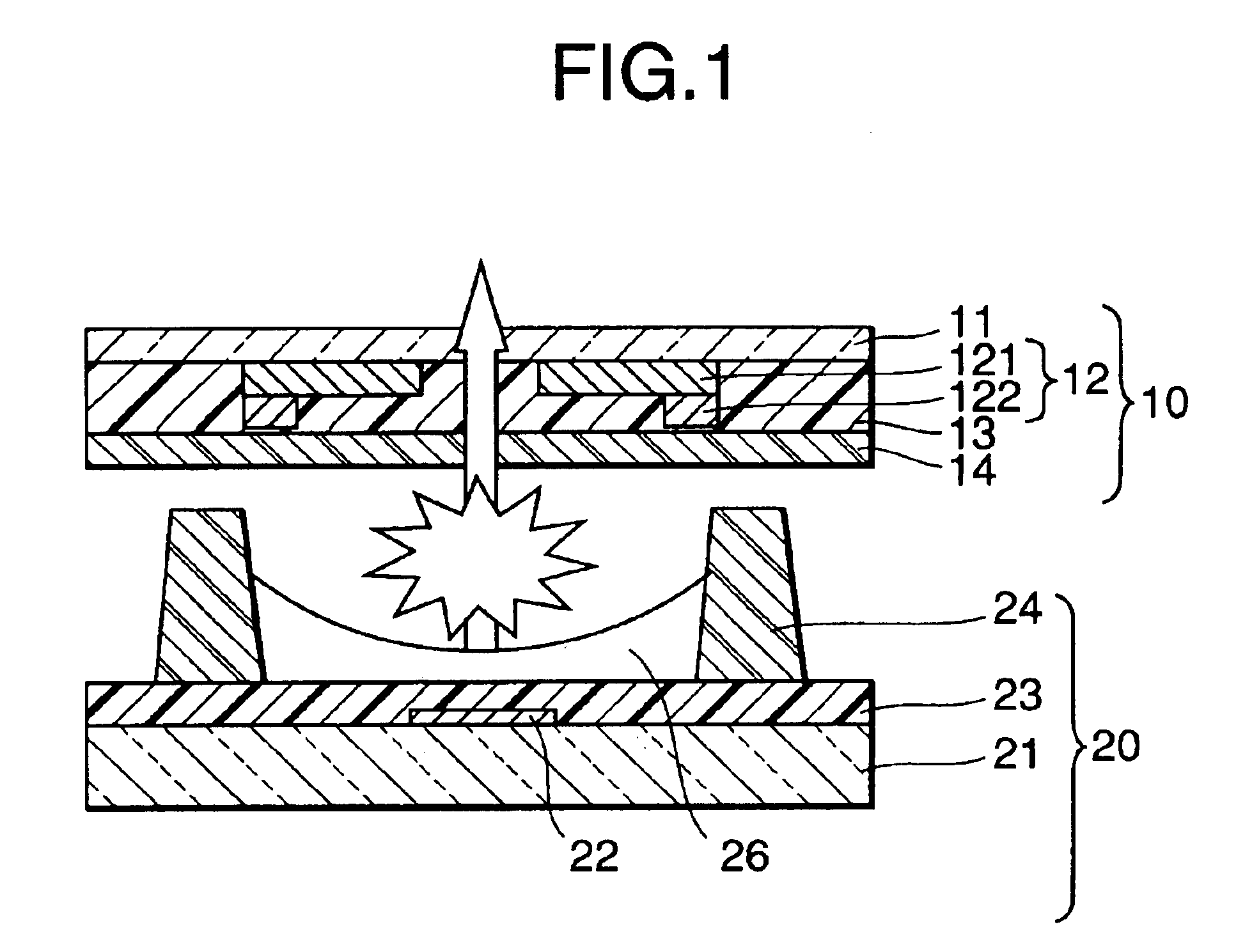

Low Voltage Laser Diodes on Gallium and Nitrogen Containing Substrates

ActiveUS20110064101A1Improved cleavesSimple and cost-effectiveOptical wave guidanceLaser detailsLow voltageNitrogen

A low voltage laser device having an active region configured for one or more selected wavelengths of light emissions.

Owner:KYOCERA SLD LASER INC

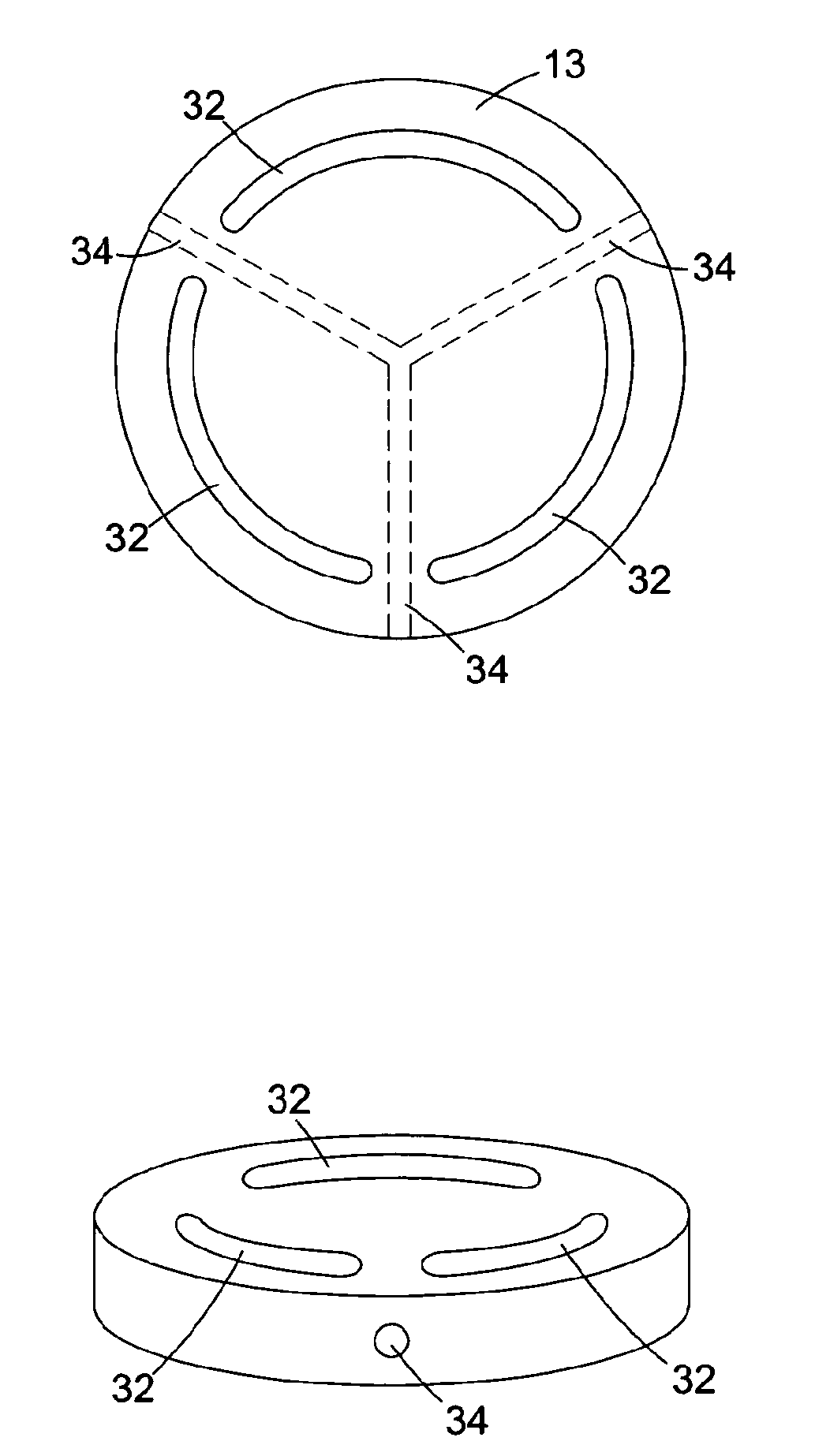

Large area optical quality synthetic polycrystalline diaond window

ActiveUS20140349068A1Improve optical qualityPrecise design toleranceSynthetic resin layered productsDiamondDielectric lossRoom temperature

A polycrystalline chemical vapour deposited (CVD) diamond wafer comprising: a largest linear dimension equal to or greater than 70 mm; a thickness equal to or greater than 1.3 mm; and one or both of the following characteristics measured at room temperature (nominally 298 K) over at least a central area of the polycrystalline CVD diamond wafer, said central area being circular, centred on a central point of the polycrystalline CVD diamond wafer, and having a diameter of at least 70% of the largest linear dimension of the polycrystalline CVD diamond wafer: an absorption coefficient ≦0.2 cm−1 at 10.6 μm; and a dielectric loss coefficient at 145 GHz, of tan δ≦2×10−4.

Owner:ELEMENT SIX TECH LTD

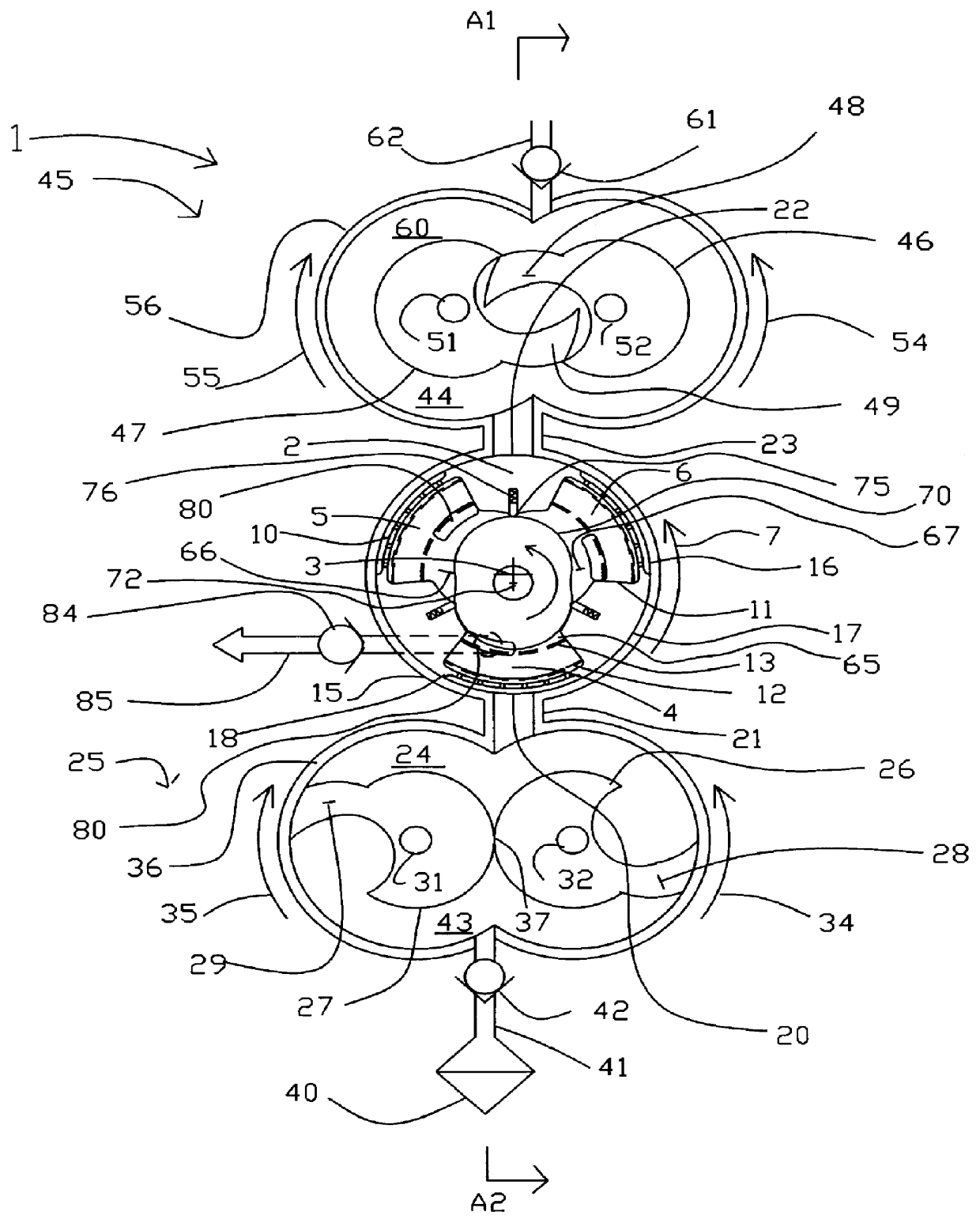

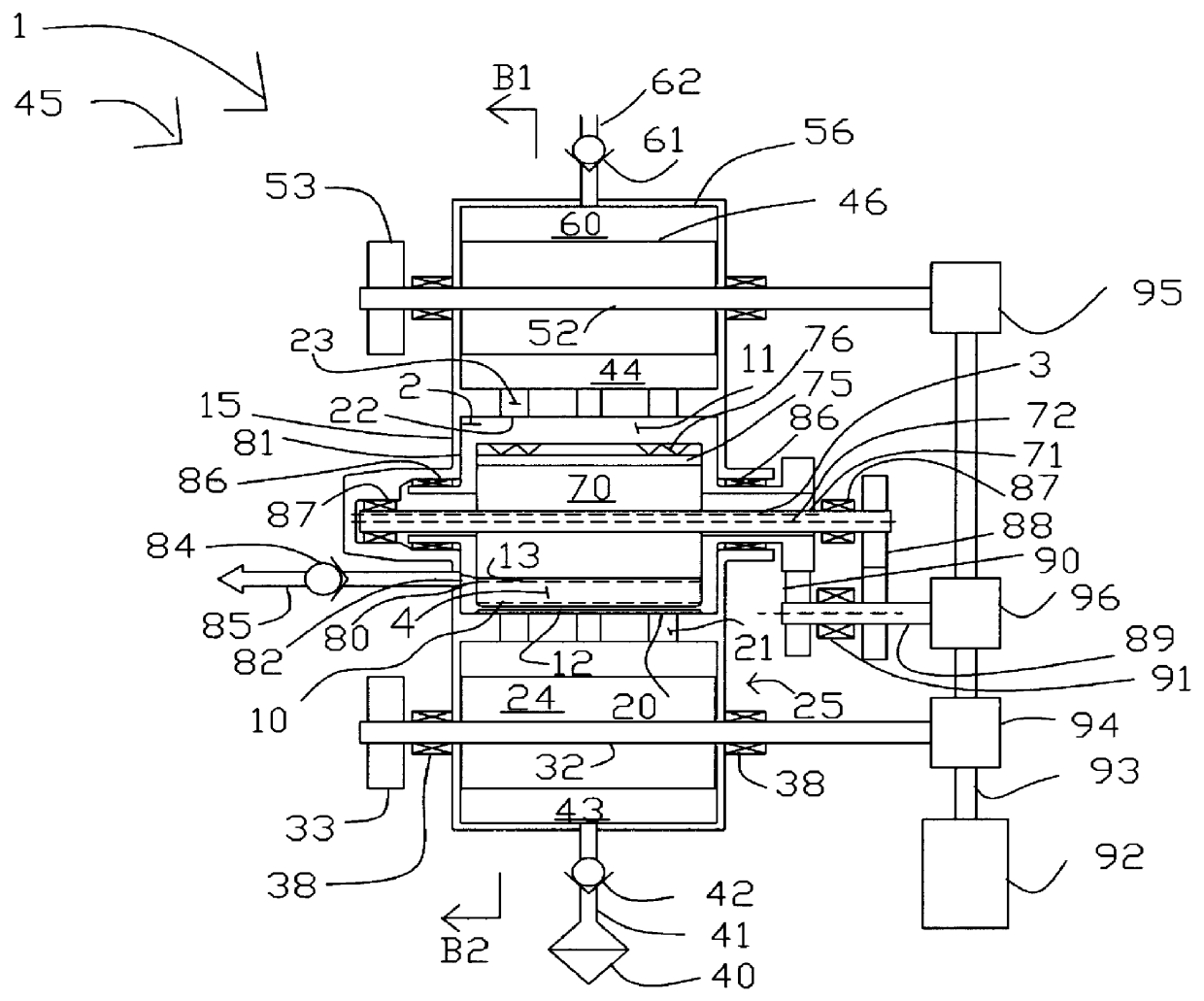

High frequency rotary pressure swing adsorption apparatus

InactiveUS6056804AHigh-frequency operationCompact equipmentGas treatmentIsotope separationProduct gasDistributor

Pressure swing adsorption separation of a feed gas mixture, to obtain a purified product gas of the less strongly adsorbed fraction of the feed gas mixture, is performed with a cooperating set of "N" adsorbers in a rotary assembly, with each adsorber communicating at its product end directly to a rotary cyclic displacement chamber, and at its feed end by rotary distributor valve ports to a rotary piston feed compressor and a rotary piston exhaust vacuum pump. The compressor and vacuum pump are integrated with the cycle, and rotate at "N" times the cycle frequency. Alternative adsorber configurations for high frequency operation are disclosed.

Owner:AIR PROD & CHEM INC +1

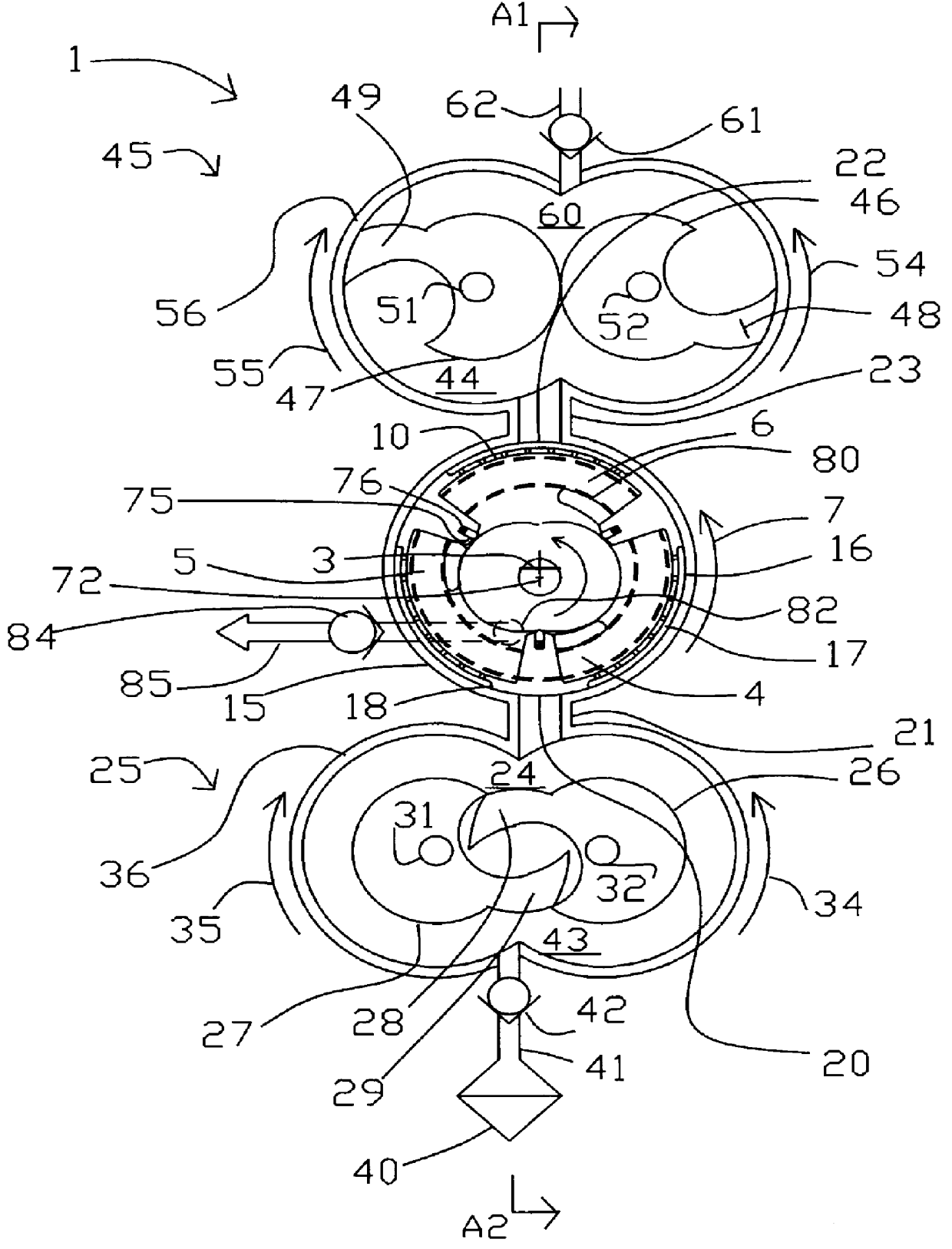

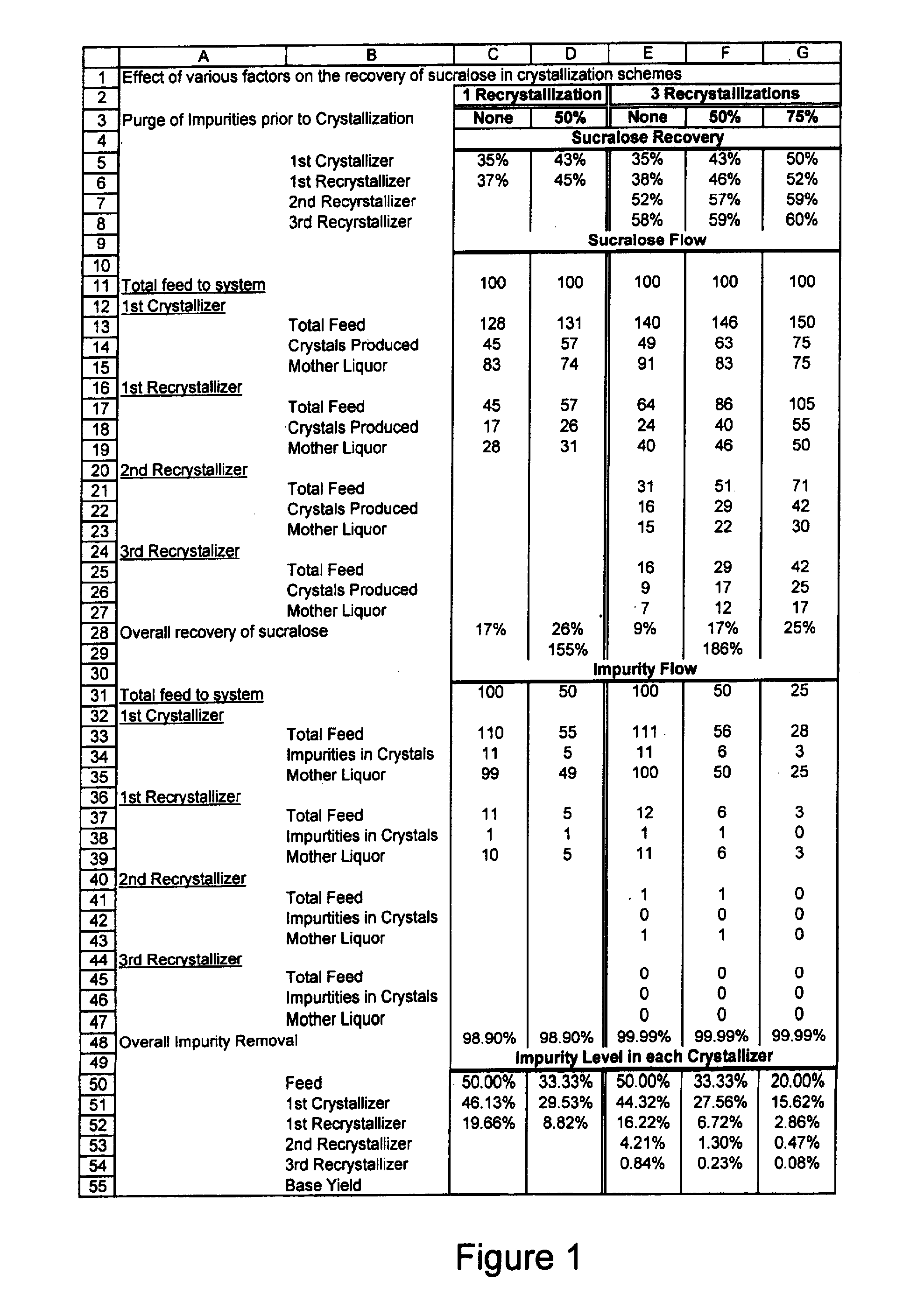

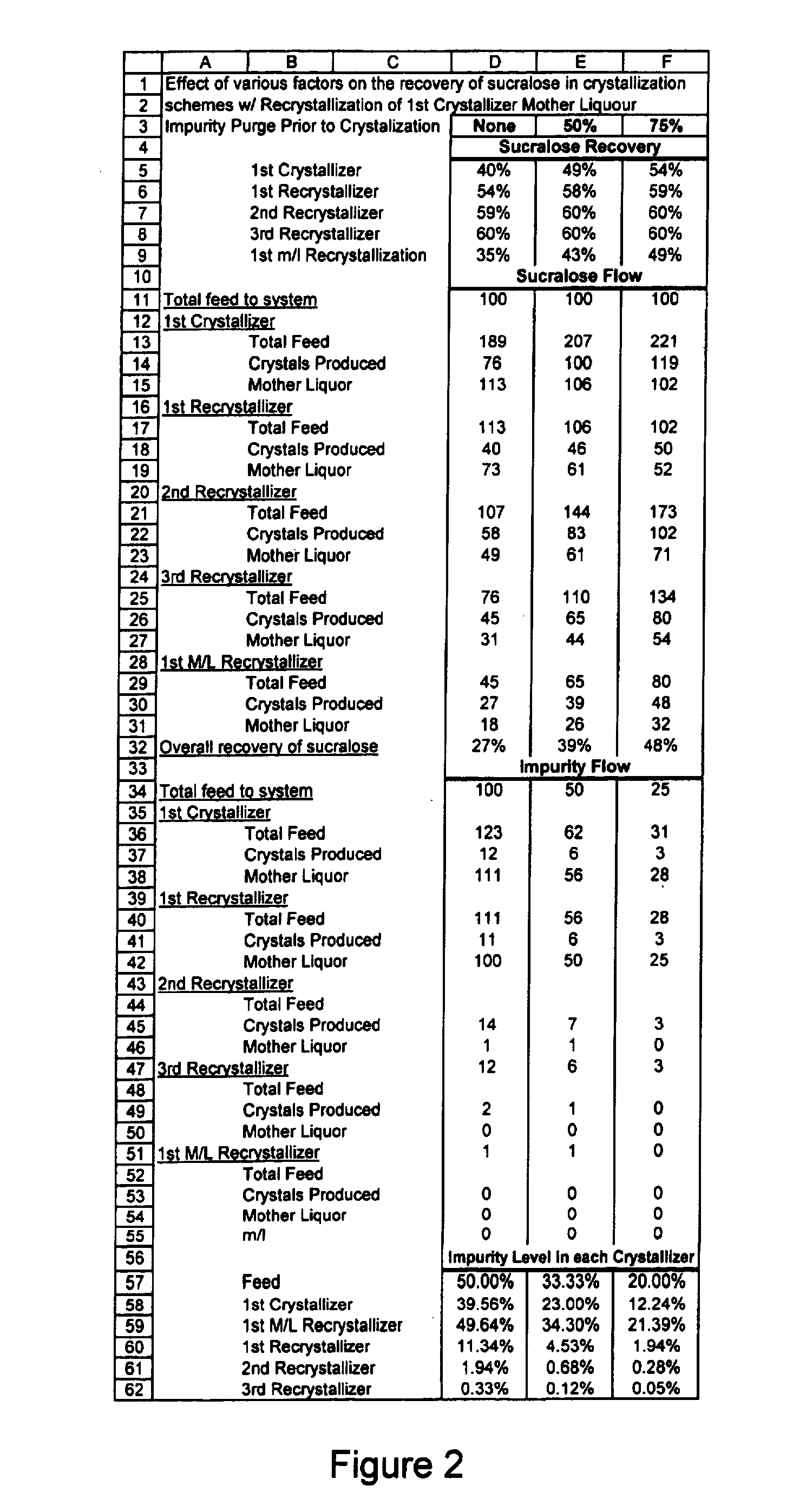

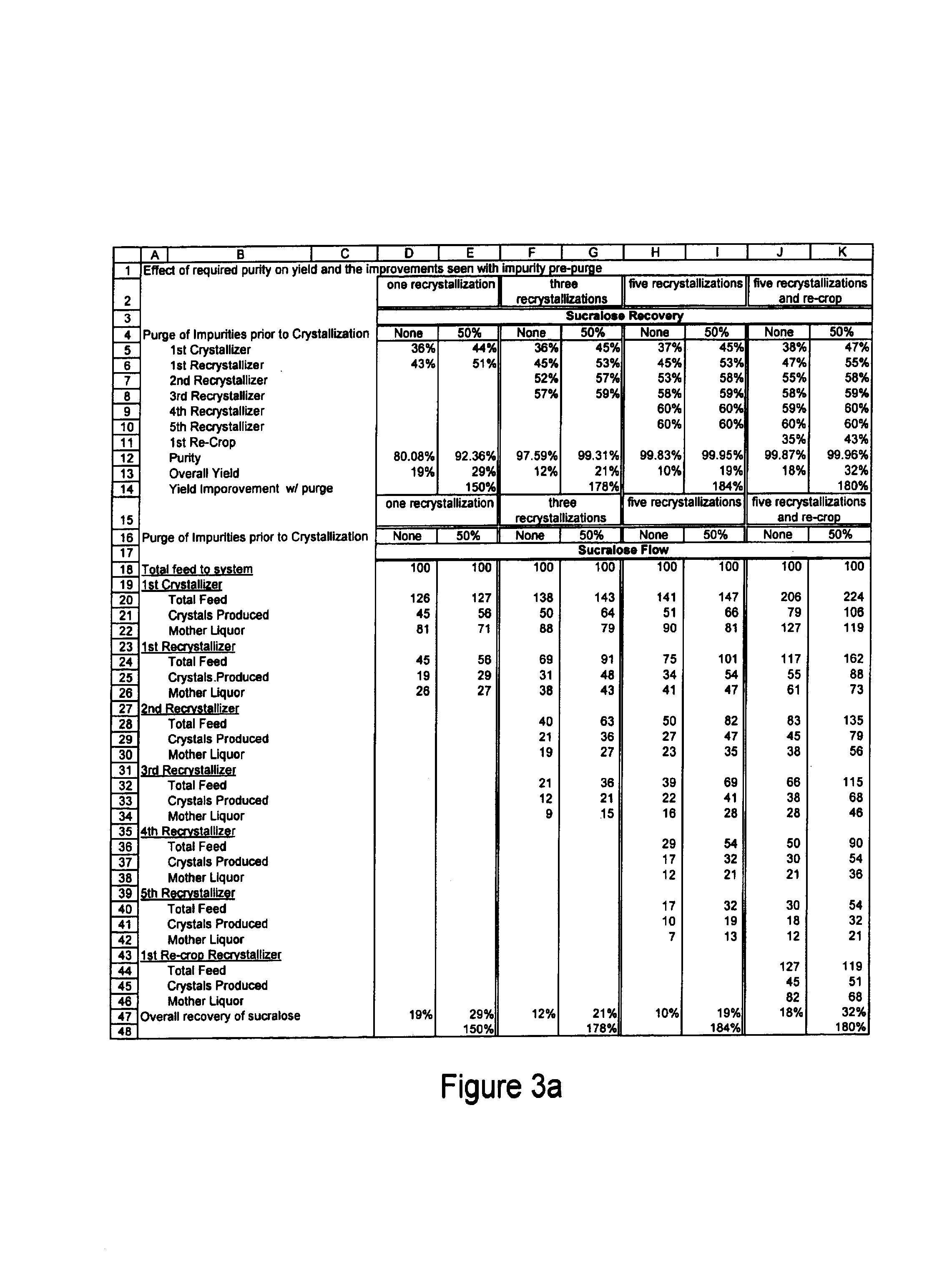

Process for improving sucralose purity and yield

InactiveUS6998480B2Improve efficiencyHigh purityEsterified saccharide compoundsSugar derivativesSucraloseCrystallization Purification

This invention relates to processes for purifying sucralose by the use of an initial non-crystallization purification procedure followed by three or more sequential crystallization steps and recycle of the mother liquor remaining from each crystallization step to the feed of another crystallization or purification step. This invention also relates to sucralose compositions as well as compositions comprising the sucralose compositions of the present invention. These compositions may be highly pure and have a superior taste profile.

Owner:TATE & LYLE TECH LTD

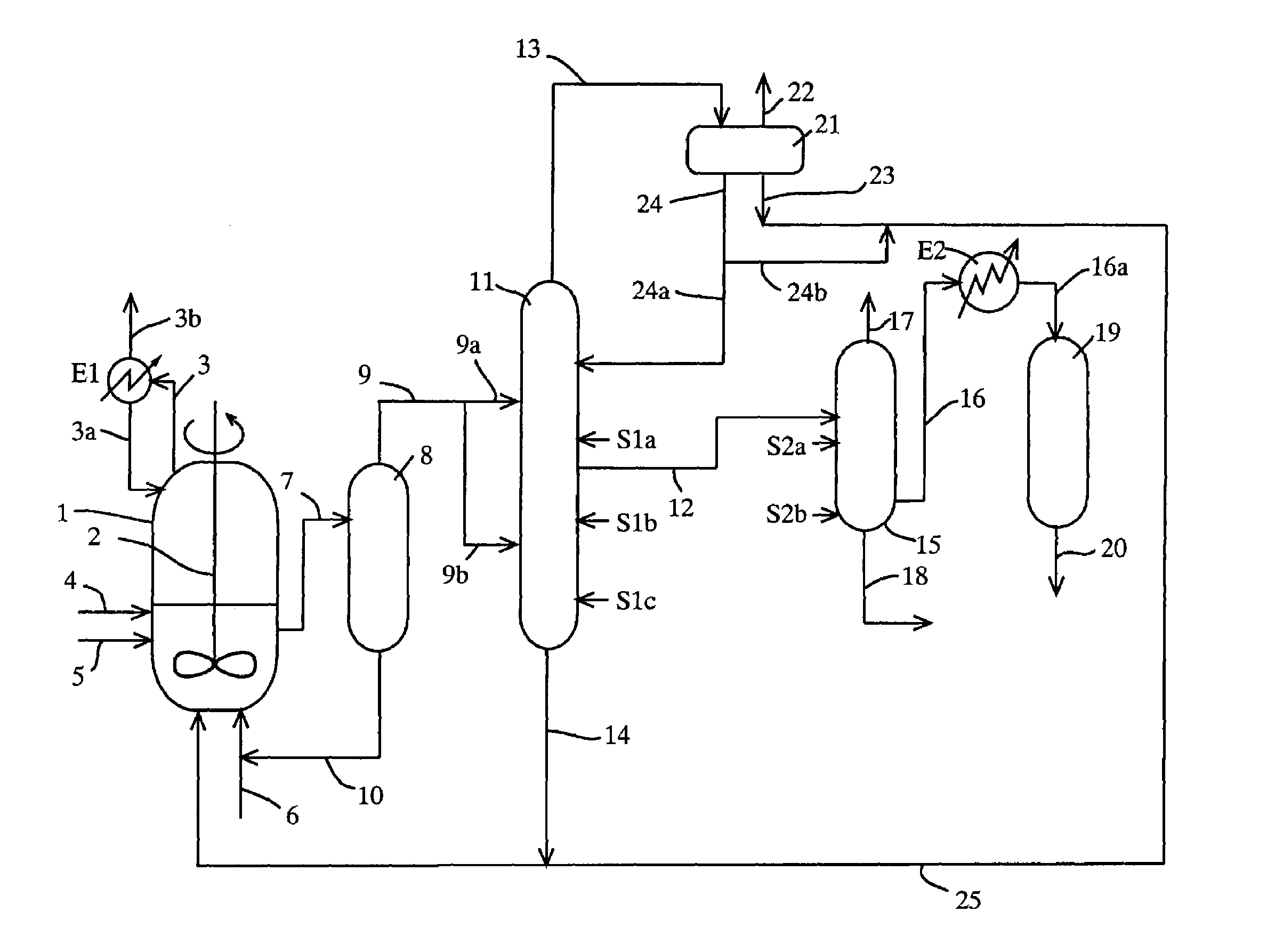

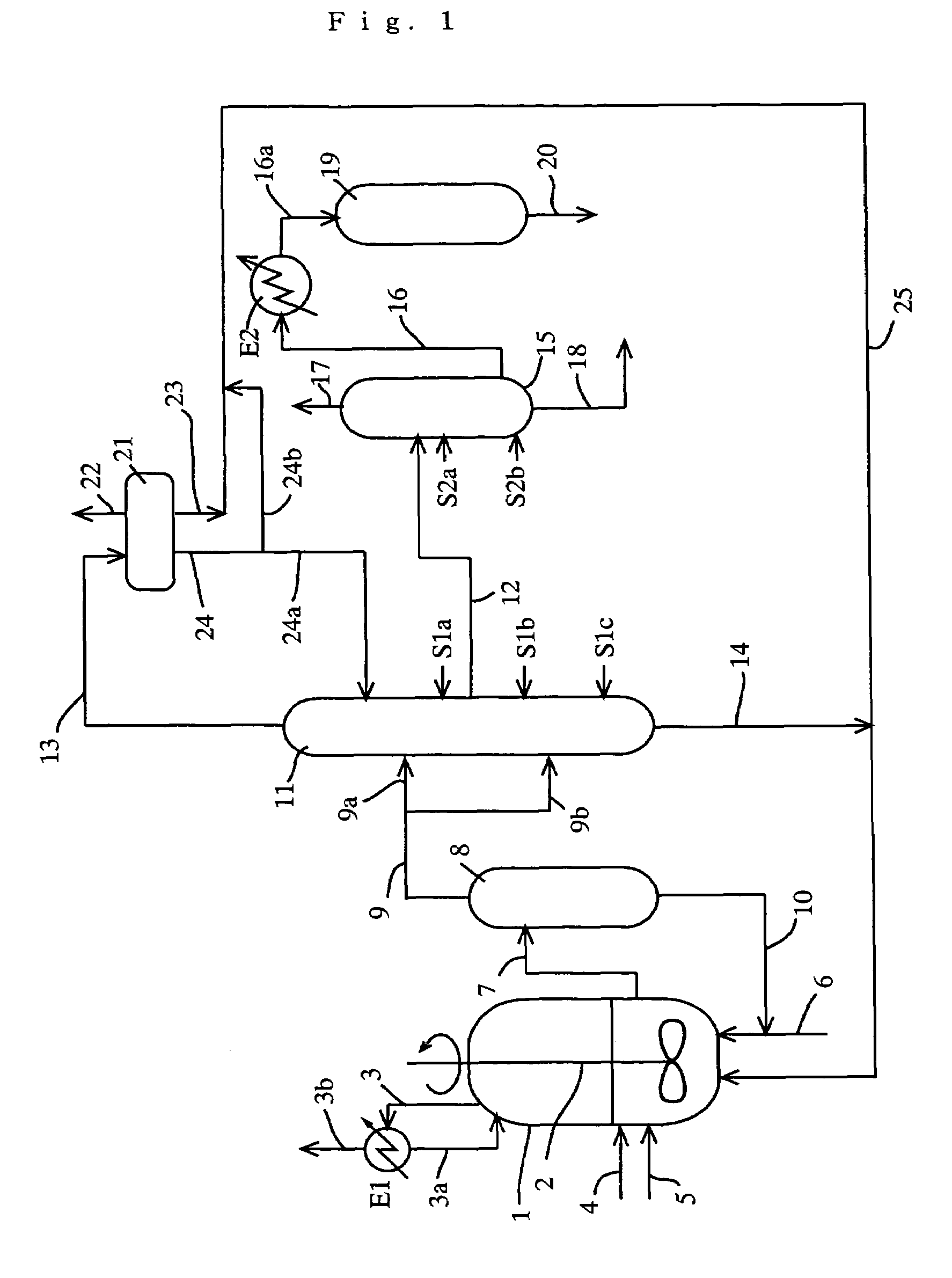

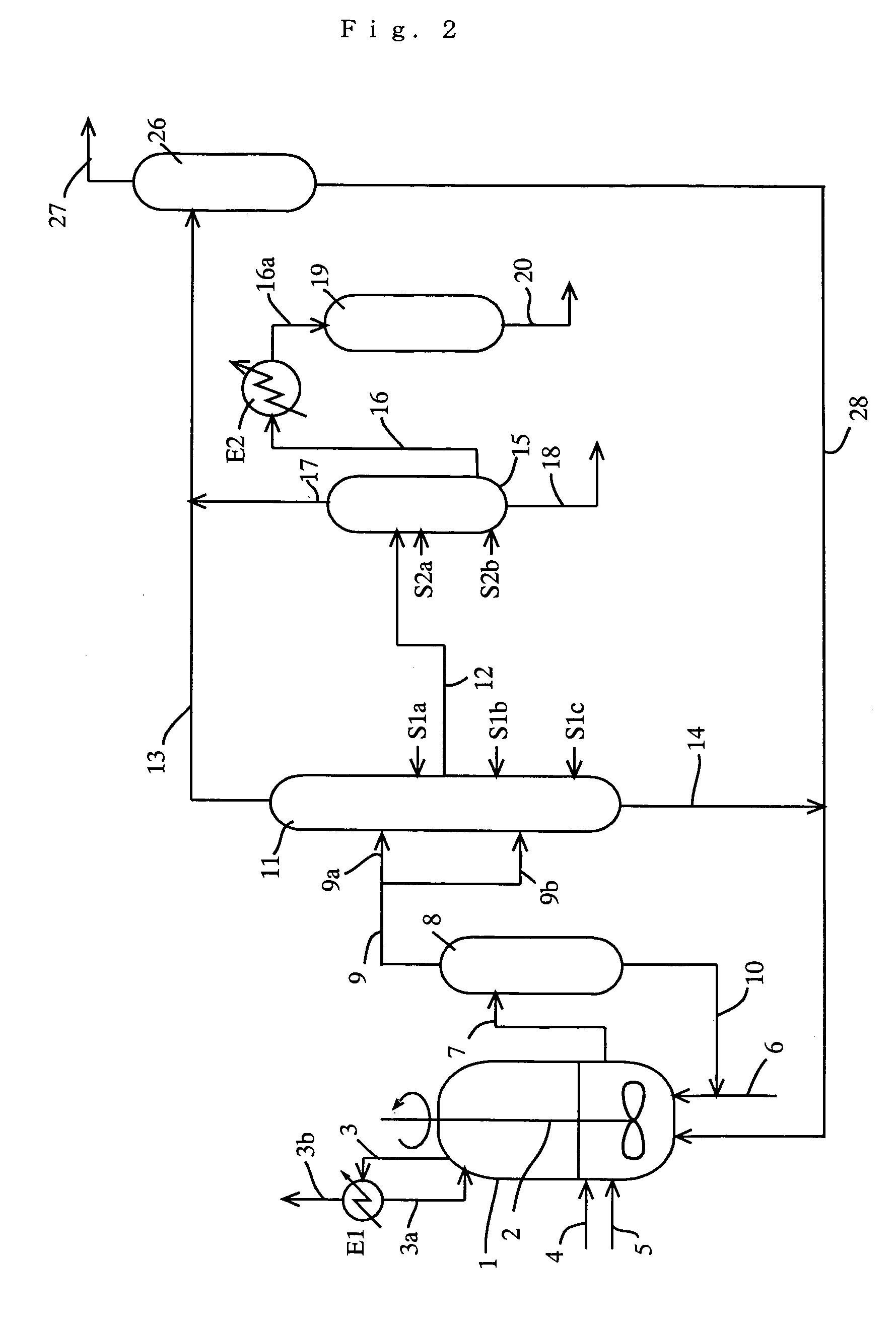

Process for producing carboxylic acid

InactiveUS7678940B2Efficient separationHigh purityOrganic compound preparationCarboxylic compound separation/purificationHydrogen halideAlcohol

A process for producing a purified carboxylic acid having “n+1” carbon atoms comprises feeding a carboxylic acid stream containing a carboxylic acid having “n+1” carbon atoms, a hydrogen halide, a lower boiling point (bp) component, a higher bp component, and others to a first distillation column; separating a lower bp fraction containing part of the lower bp component and a higher bp fraction containing part of the higher bp component in the first column; withdrawing a side stream containing at least the carboxylic acid by side cut from the first column; feeding the side stream to a second distillation column; separating a lower bp fraction containing part of the lower bp component and a higher bp fraction containing part of the higher bp component in the second column; and withdrawing a side stream containing the carboxylic acid by side cut from the second column to recover a purified carboxylic acid; and the process further comprises feeding at least one first component (A) selected from the group consisting of an alcohol, corresponding to the carboxylic acid, having “n” carbon atom(s), and an ester of the alcohol with the carboxylic acid to the first column, and if necessary water. Such a process ensures reduction of the concentration of the hydrogen halide in the purified carboxylic acid.

Owner:DAICEL CHEM IND LTD

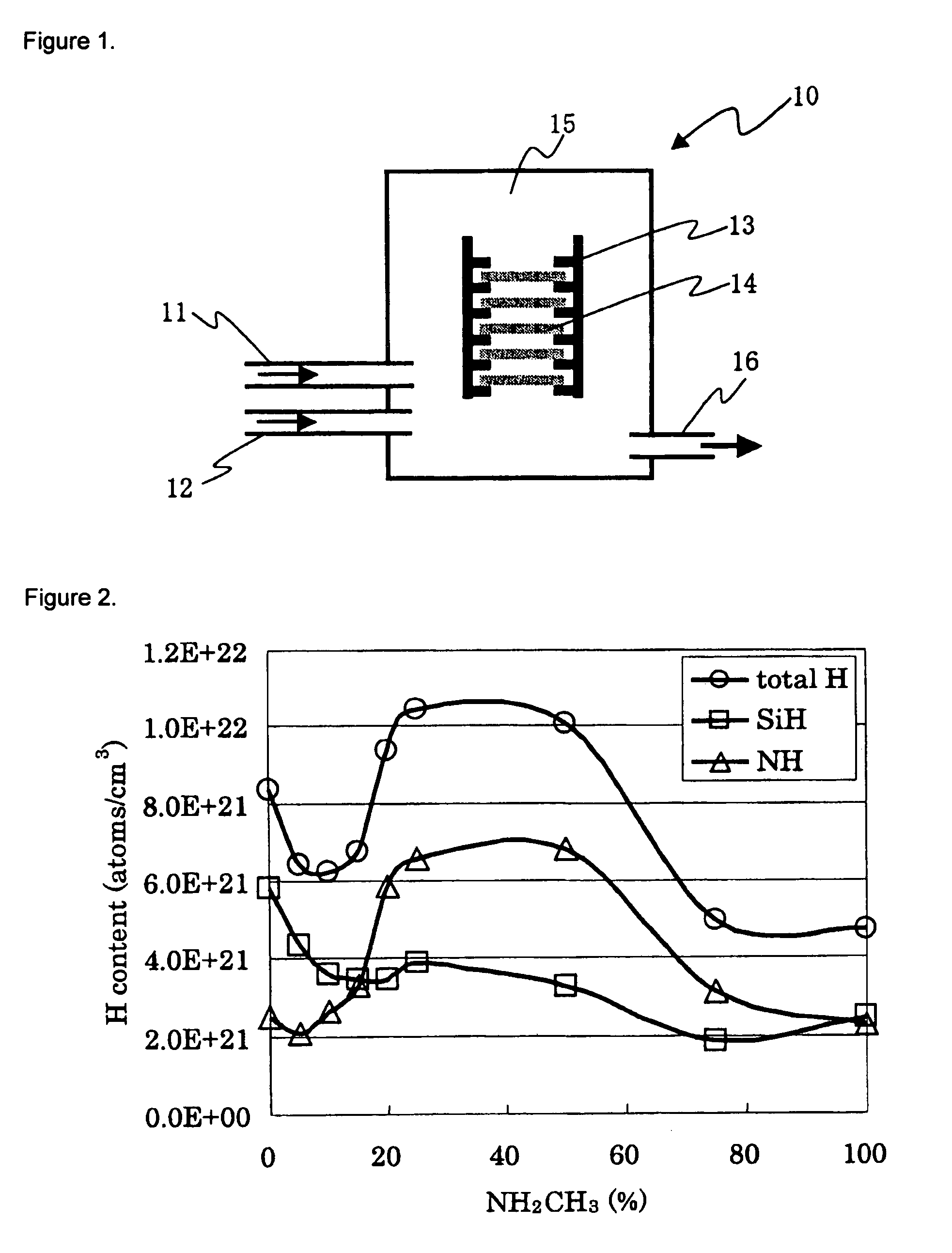

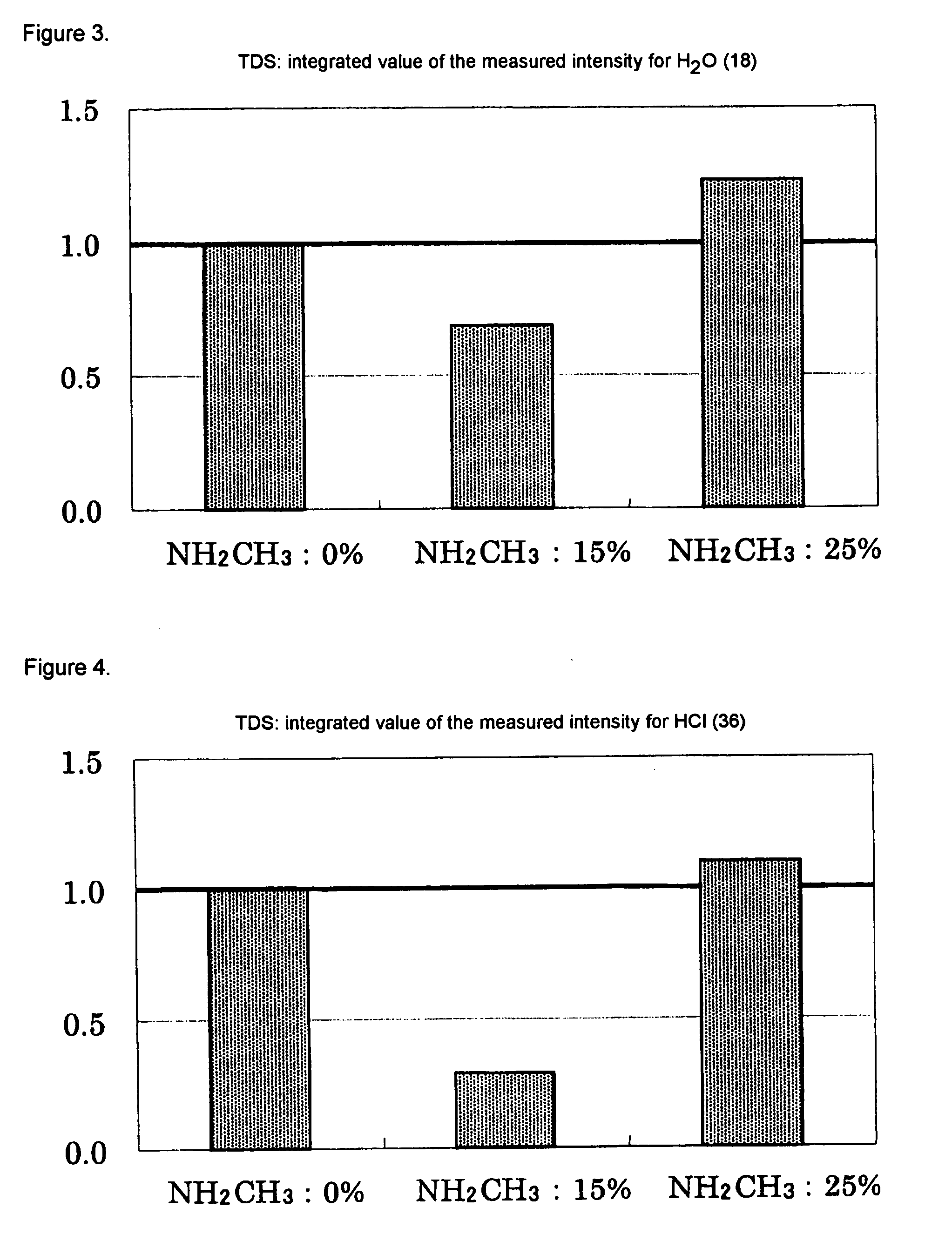

Method for producing silicon nitride films and process for fabricating semiconductor devices using said method

InactiveUS20050158983A1Reduction in thermal budgetImprove film propertiesSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogen sourceAmmonia

Silicon nitride film is formed on a silicon wafer mounted in a boat in an LPCVD tool by feeding a silicon source (SiH2Cl2, SiCl4, Si2Cl6, etc.) from an injector and feeding a mixed gas of monomethylamine (CH3NH2) and ammonia (NH3) as the nitrogen source from an injector. This addition of monomethylamine to the source substances for film production makes it possible to provide an improved film quality and improved leakage characteristics even at low temperatures (450-600° C.).

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

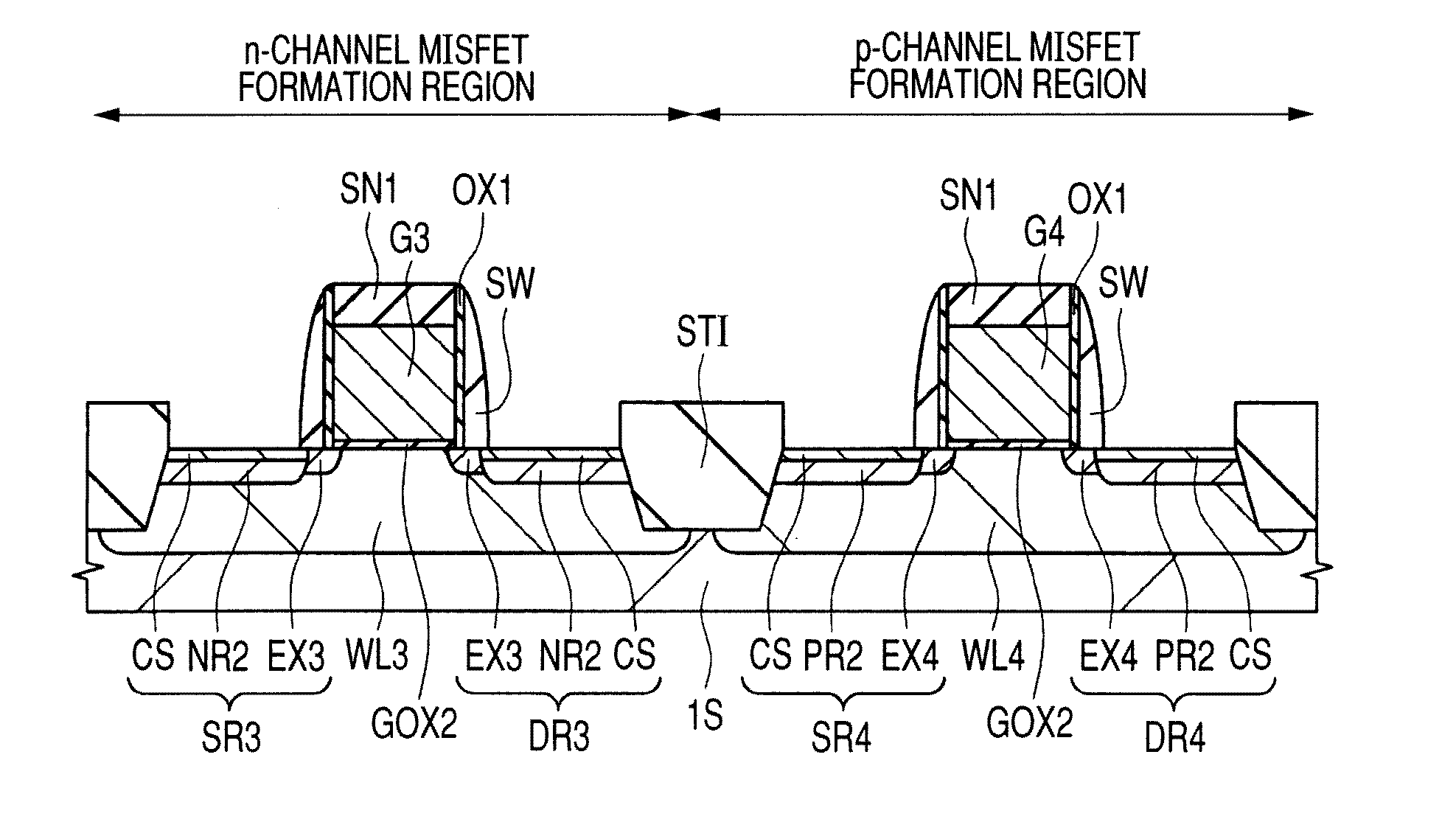

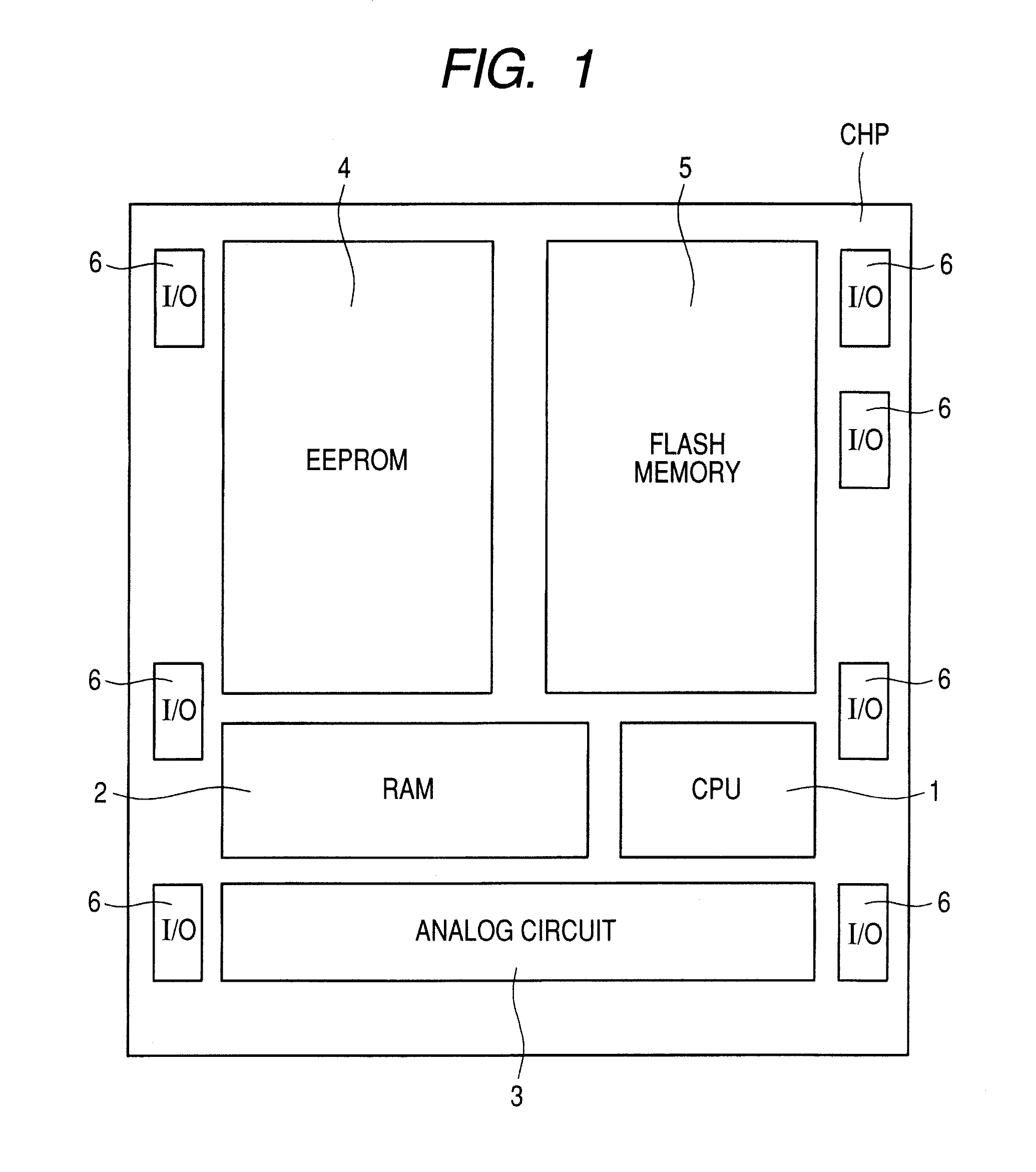

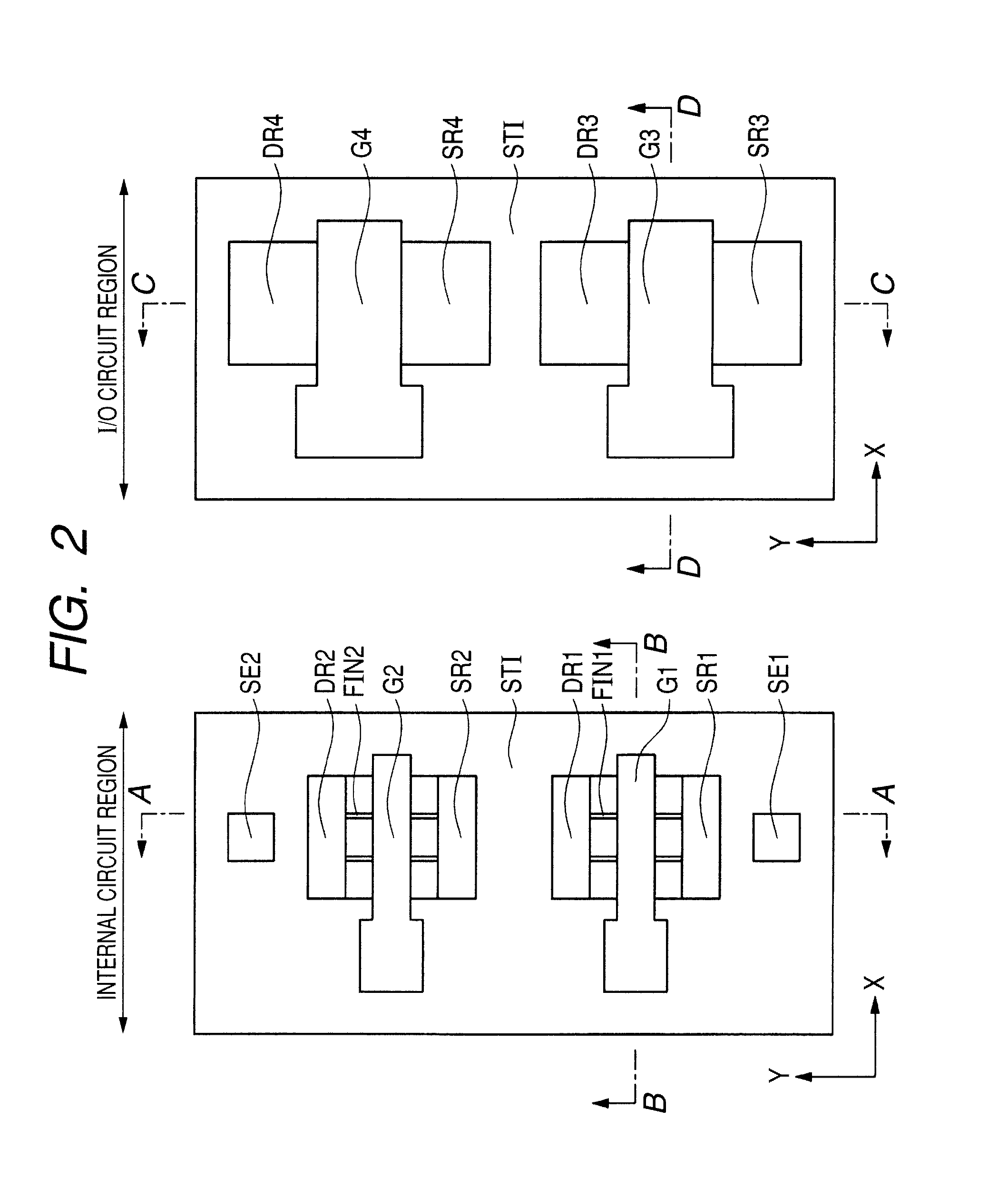

Semiconductor device and manufacturing method thereof

InactiveUS20110031552A1Improve breakdown resistanceEliminate the effects ofSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialWork function

To provide, in FINFET whose threshold voltage is determined essentially by the work function of a gate electrode, a technology capable of adjusting the threshold voltage of FINFET without changing the material of the gate electrode. FINFET is formed over an SOI substrate comprised of a substrate layer, a buried insulating layer formed over the substrate layer, and a silicon layer formed over the buried insulating layer. The substrate layer has therein a first semiconductor region contiguous to the buried insulating layer. The silicon layer of the SOI substrate is processed into a fin. A ratio of the height of the fin to the width of the fin is adjusted to fall within a range of from 1 or greater but not greater than 2. In addition, a voltage can be applied to the first semiconductor region.

Owner:RENESAS ELECTRONICS CORP

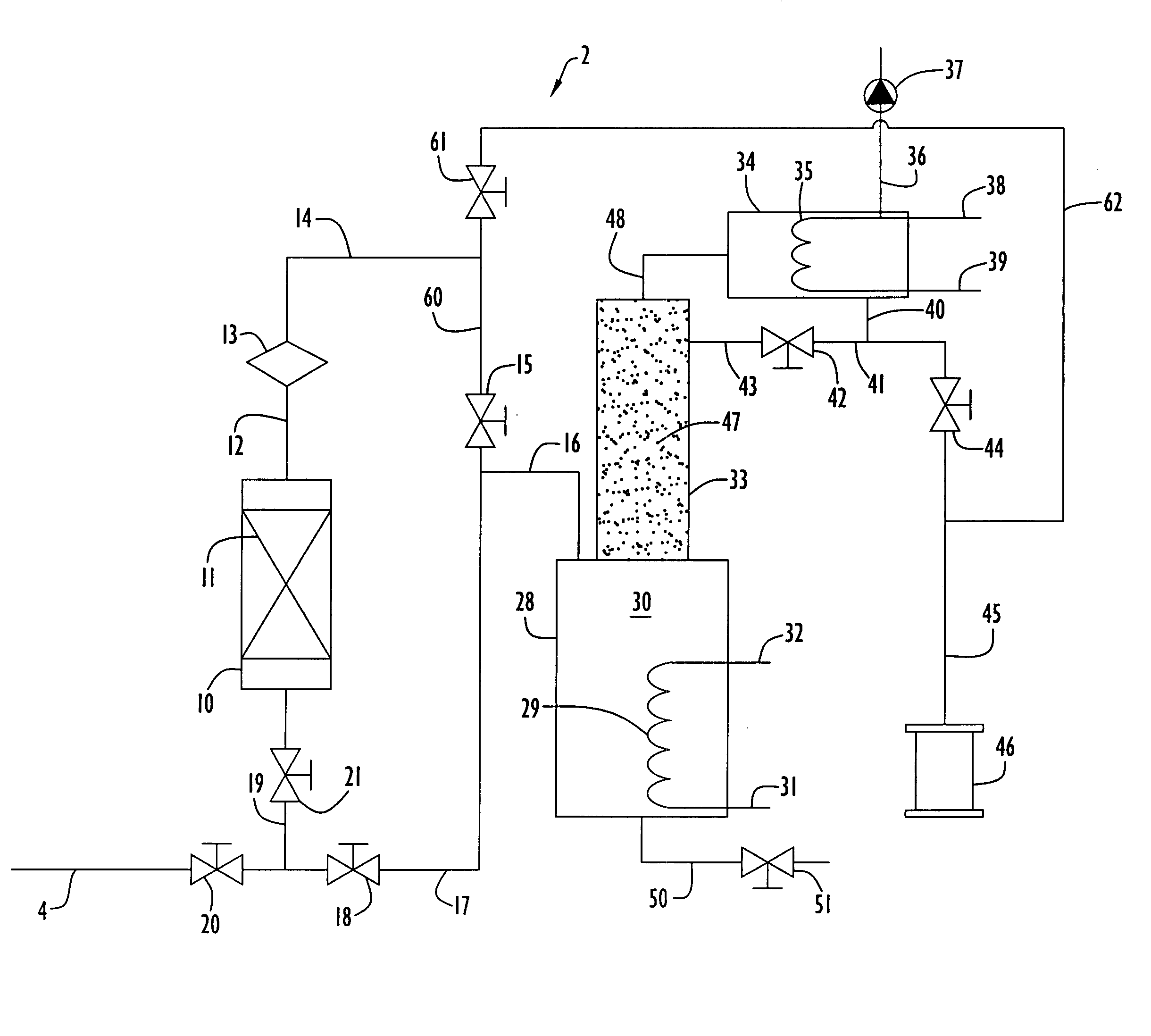

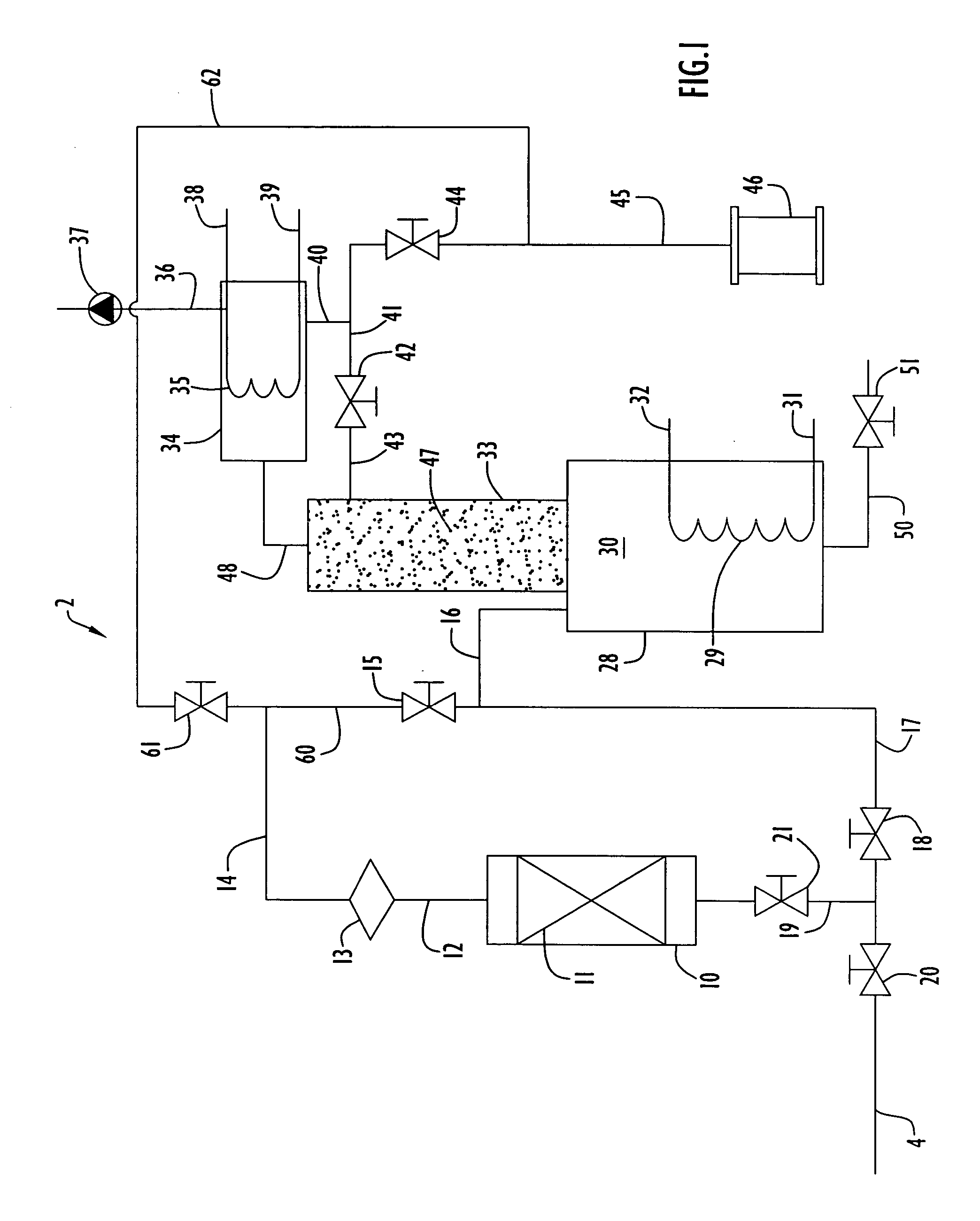

Purification of silicon-containing materials

InactiveUS20050054211A1Impurities increaseSilicon organic compoundsSemiconductor/solid-state device manufacturingSilanesLiquid state

Systems and methods of purifying a silicon-containing material include the step of directing the silicon-containing material in a liquid state through an adsorption unit including an adsorbent material to facilitate adsorption of at least one component from the silicon-containing material. Alternatively, the silicon-containing material is directed, in liquid state and / or gaseous state, through two or more purification units, including an adsorption unit, a vaporization unit, a filter unit and a condenser. The silicon-containing material can be a low-k silicon-containing material such as trimethylsilane, tetramethylsilane, dimethyldimethoxysilane, tetramethylcyclotetrasiloxane, octamethylcyclotetrasiloxane, dimethylphenyl silane, and dimethyldivinyl silane.

Owner:XU MINDI +2

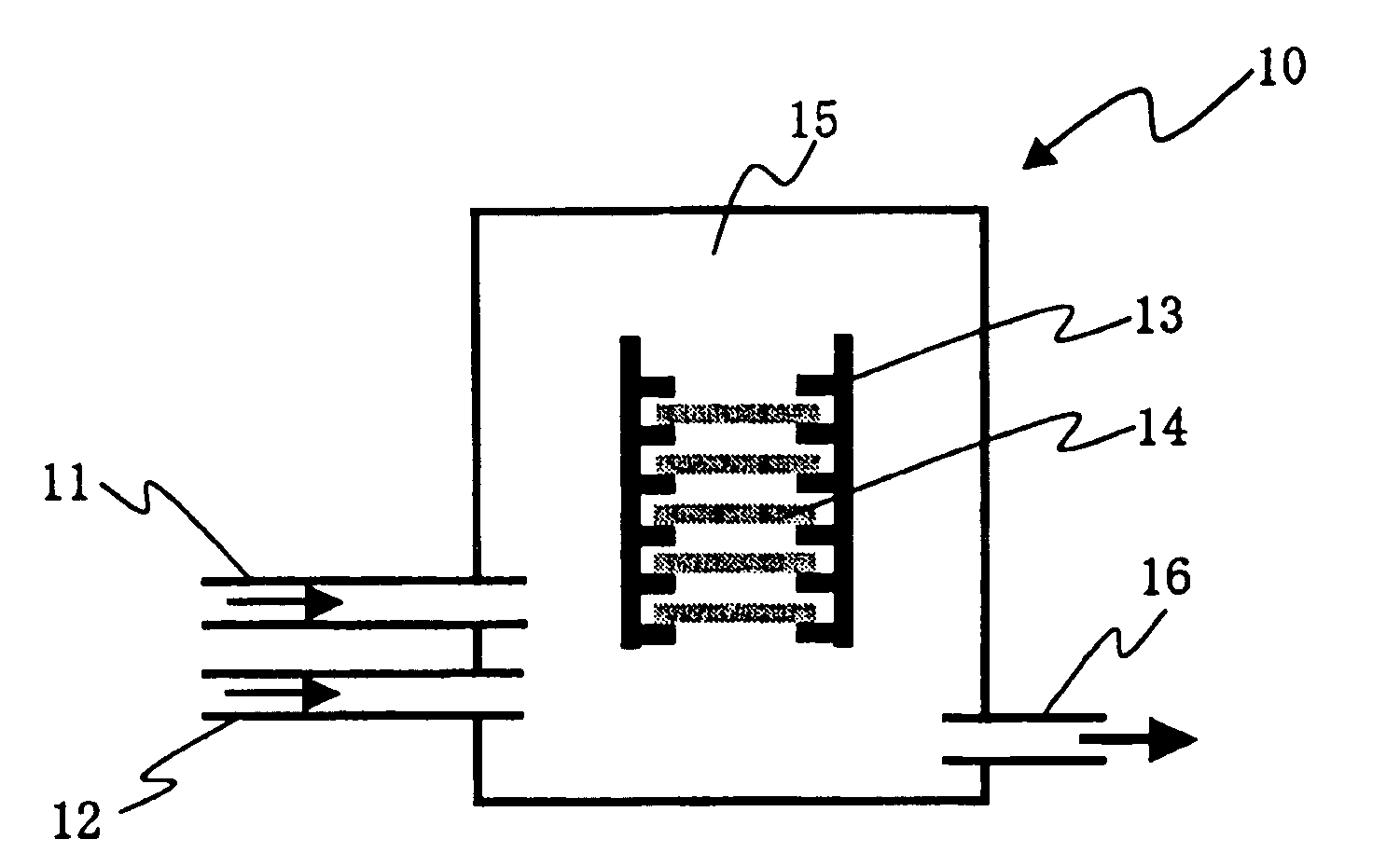

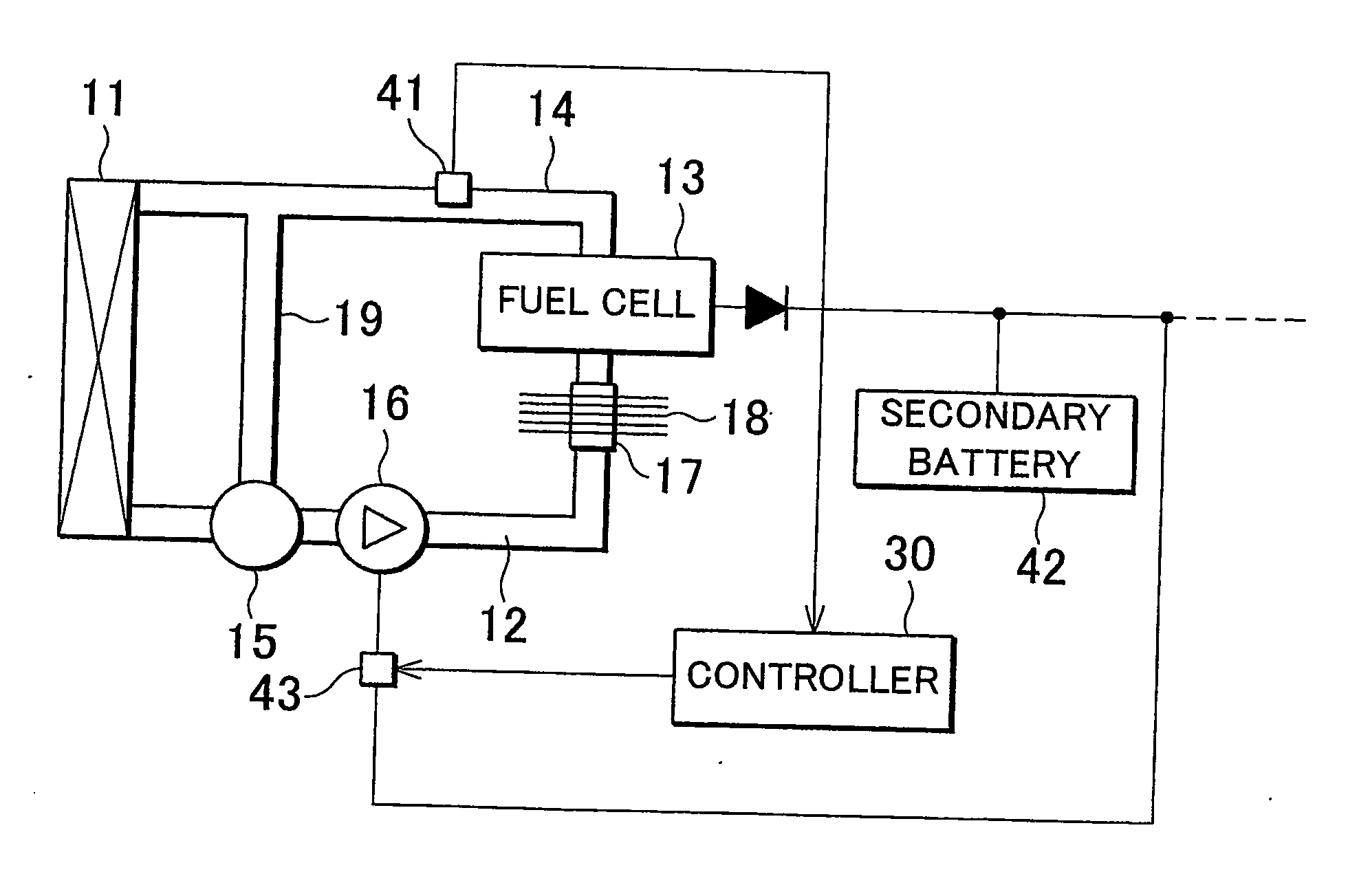

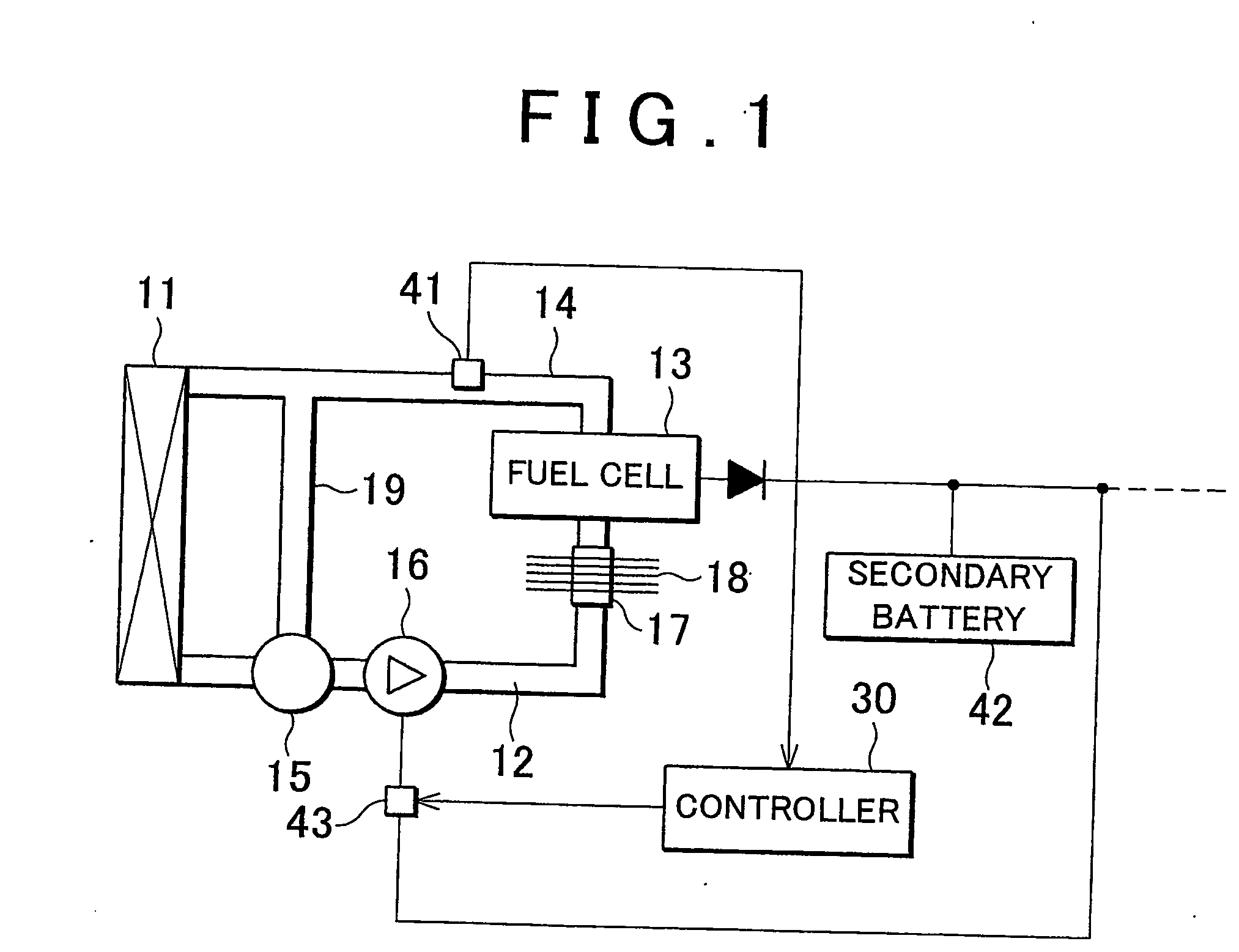

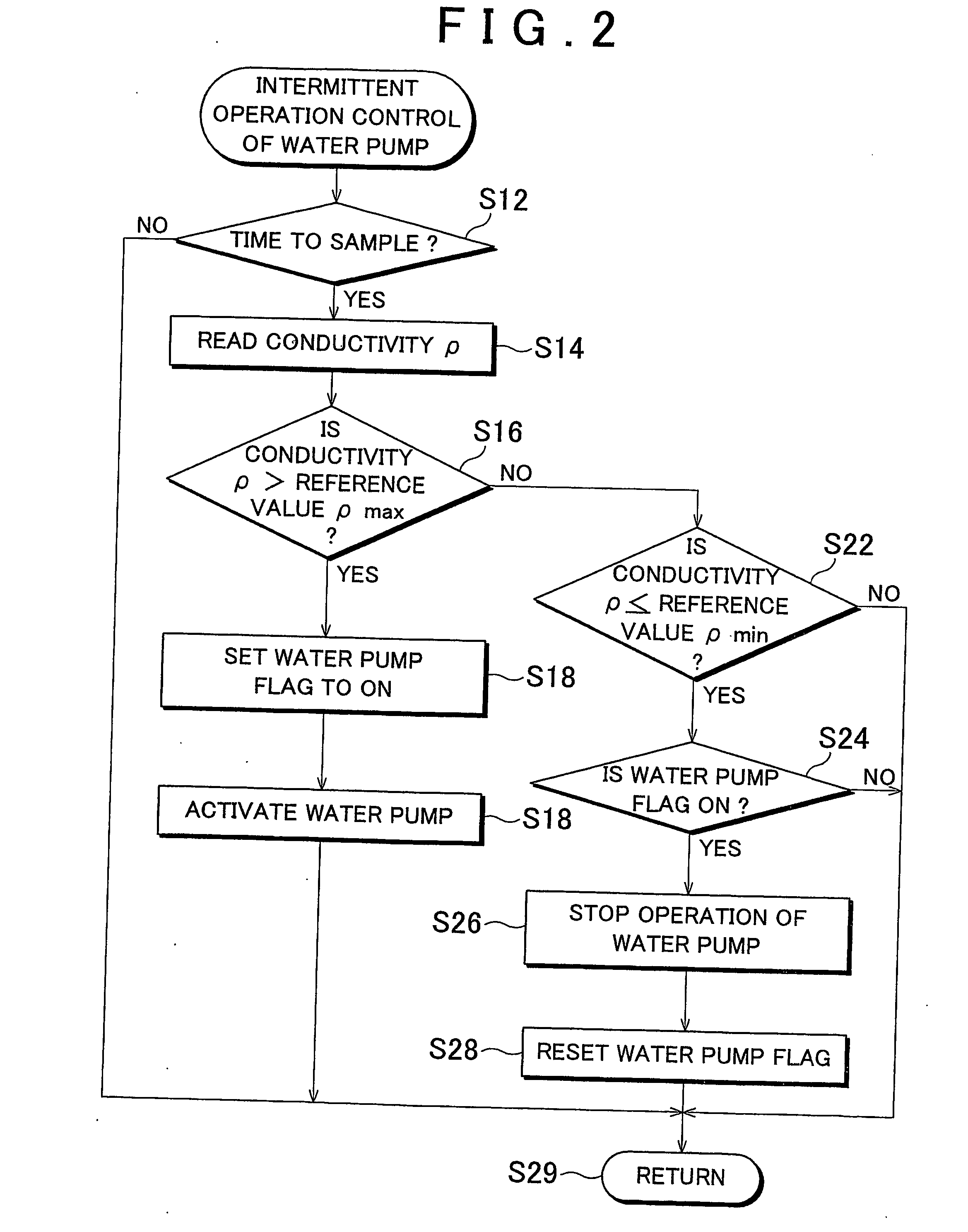

Fuel cell cooling system and method for controlling circulation of cooling liquid in fuel cell

ActiveUS20060269807A1Reduce startup timeImpurities increaseFuel cell auxillariesSolid electrolyte fuel cellsFuel cellsNuclear engineering

A cooling system for a fuel cell is provided with a cooling apparatus that regulates the temperature of the fuel cell by supplying the fuel cell with a cooling liquid via a cooling liquid passage by means of a water pump; an impurity-removing device which is provided in the cooling liquid passage and which removes impurities from within the cooling liquid; and flow generating means for causing the cooling liquid in the cooling liquid passage to flow through the impurity-removing device when the fuel cell is not operating.

Owner:TOYOTA JIDOSHA KK

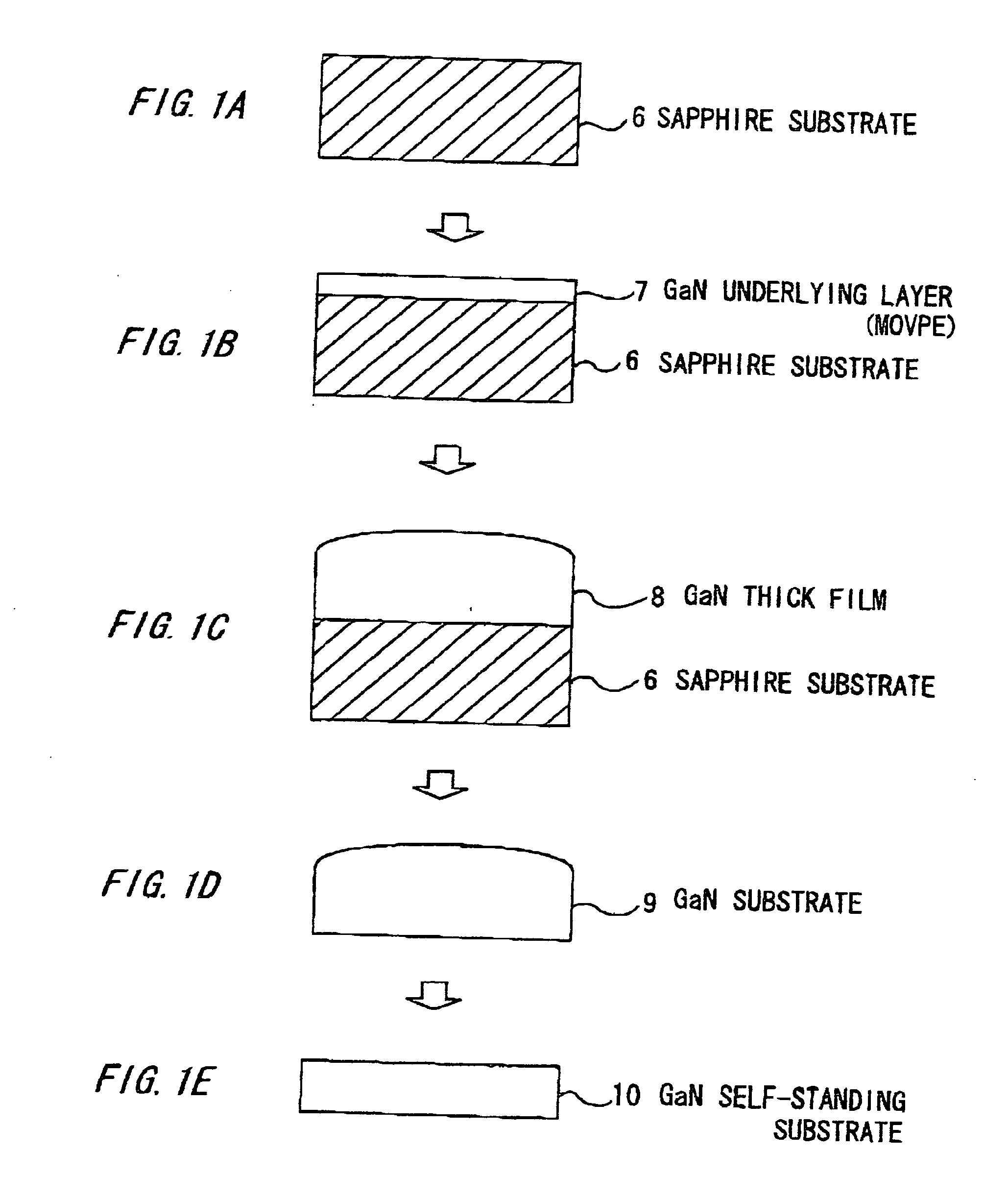

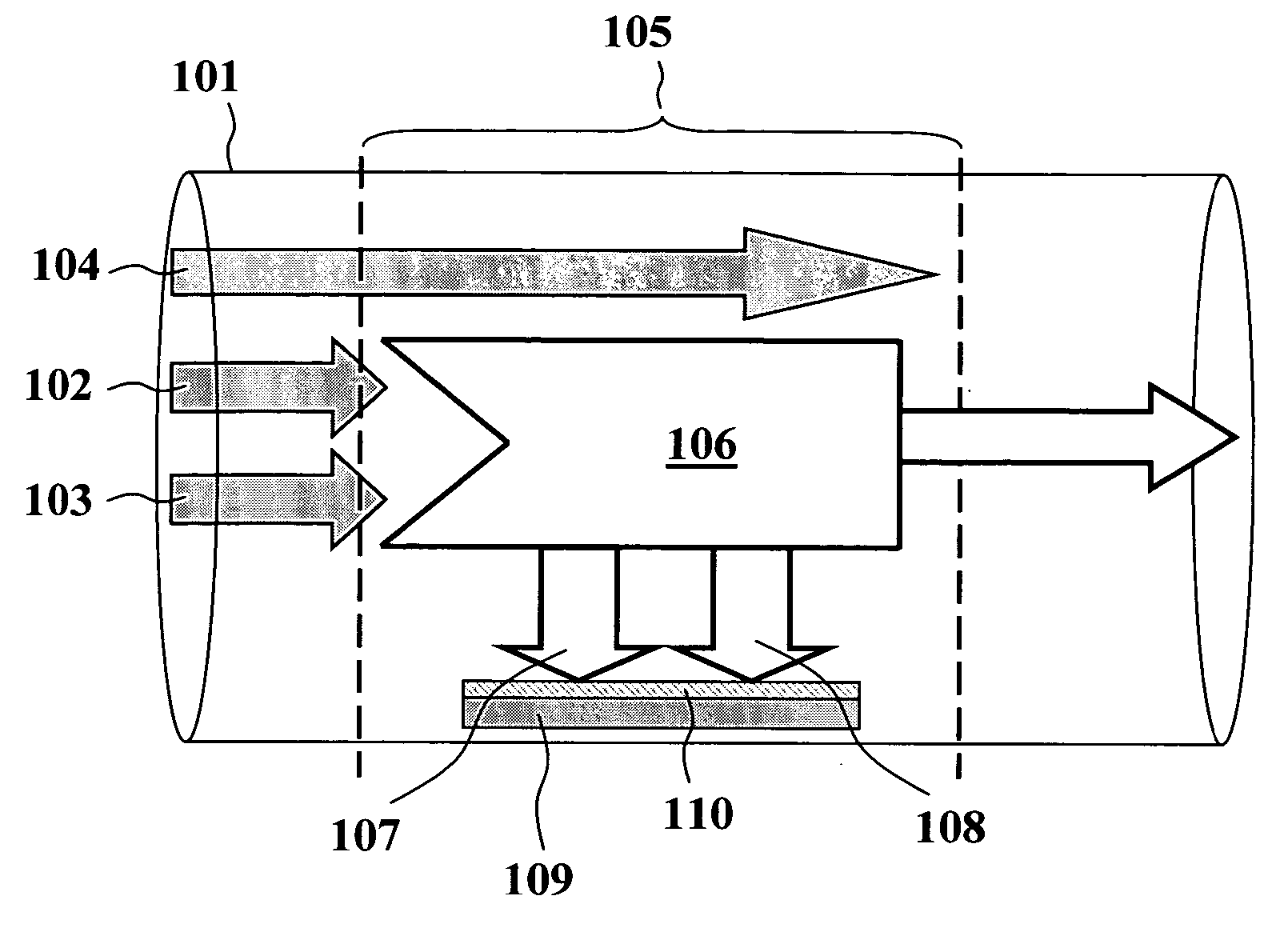

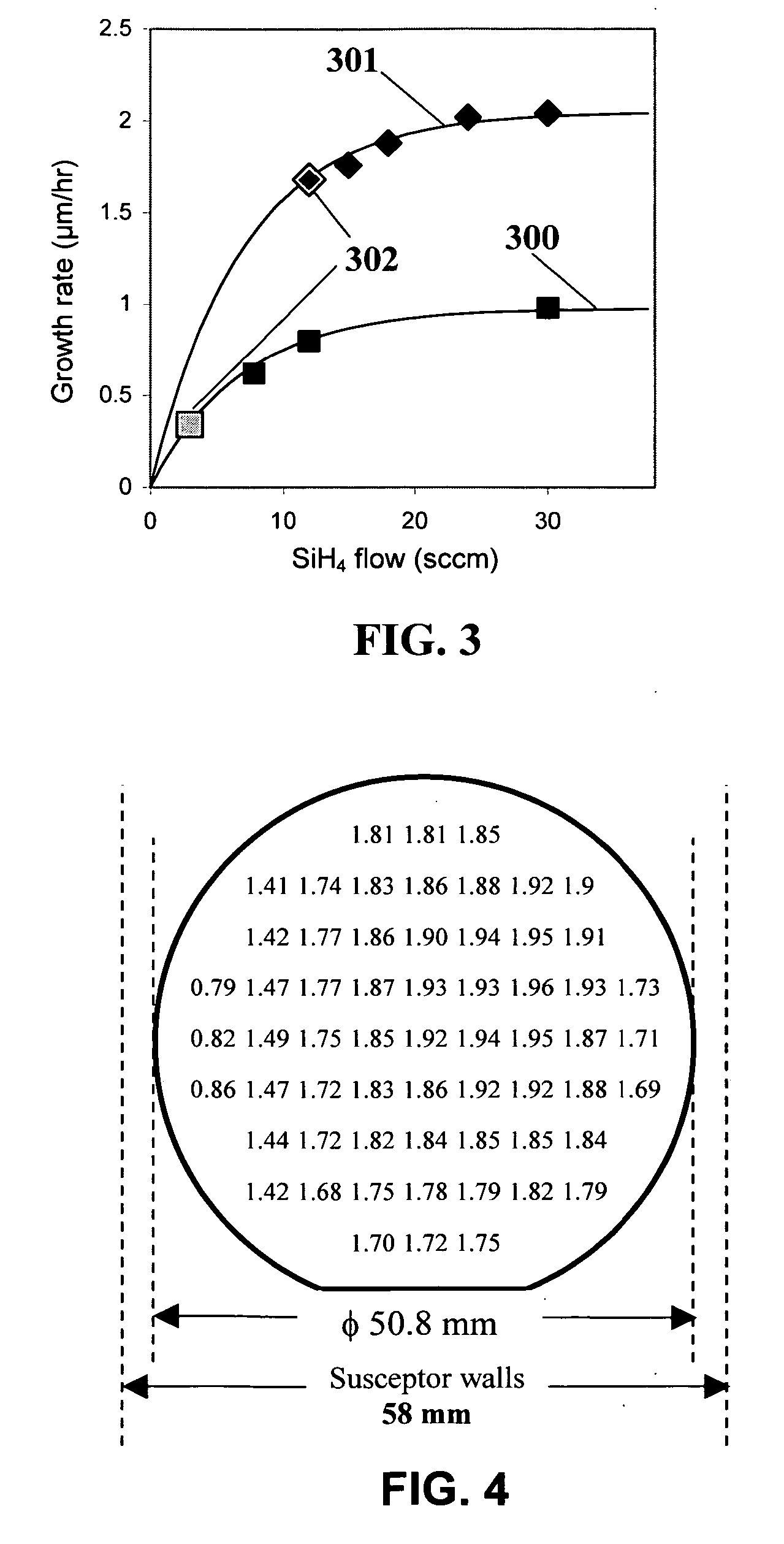

Group III-V nitride-based semiconductor substrate and method of making same

InactiveUS20060226414A1Improve uniformityUniform propertyPolycrystalline material growthSemiconductor/solid-state device manufacturingSusceptorNitride

A method of making a group III-V nitride-based semiconductor substrate has the steps of: providing a first crystal substrate; placing the first crystal substrate on a susceptor; holding down the first crystal substrate on the susceptor; and growing a first group III-V nitride-based semiconductor crystal on the first crystal substrate.

Owner:HITACHI CABLE

Phthalocyanine compound, method for production thereof, and use thereof

InactiveUS6069244AImprove solubilityImprove efficiencyOrganic chemistryReactive dyesHeat resistancePhthalocyanine

A phthalocyanine compound possessing an excellent ability to absorb near infrared ray, exhibiting excellent compatibility with resin, and excelling in such special qualities as heat resistance, light resistance, and resistance to weather conditions is provided. This phthalocyanine compound is represented by the following general formula (1) wherein Z2, Z3, Z6, Z7, Z10, Z11, Z14, and Z15 are independently SR1, OR2, or a fluorine atom, and at least one of them is for SR1 or OR2, Z1, Z4, Z5, Z8, Z9, Z12, Z13, and Z16 independently stand for NHR3, SR1, OR2, or a fluorine atom and at least one of them is NHR3, at least one of Z1 to Z16 is a fluorine atom or OR2, R1, R2, and R3 are independently a substituted or non-substituted phenyl group, a substituted or non-substituted aralkyl group, or a substituted or non-substituted alkyl group of 1 to 20 carbon atoms, and M is for a nonmetal, a metal, a metal oxide, or a metal halide.

Owner:NIPPON SHOKUBAI CO LTD

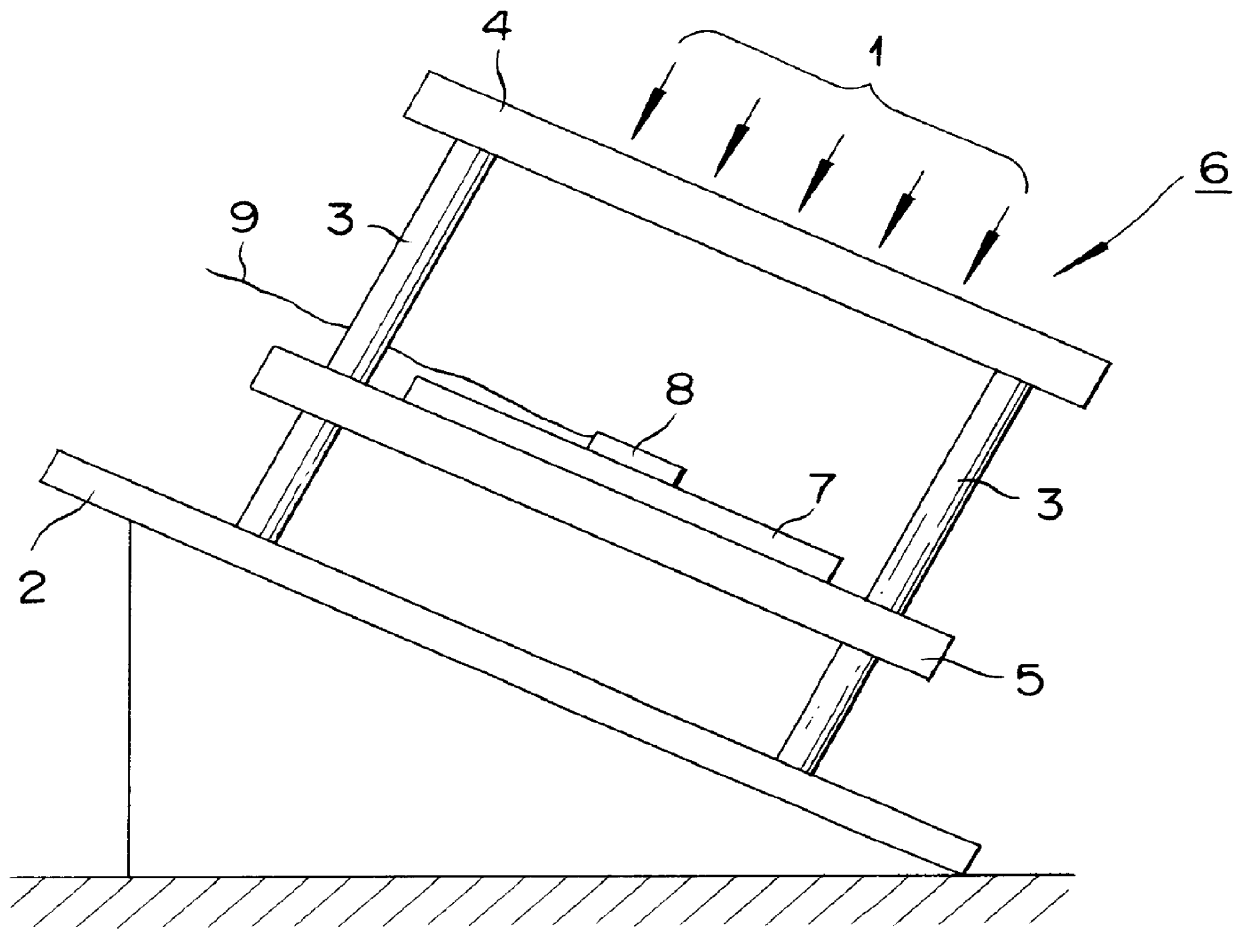

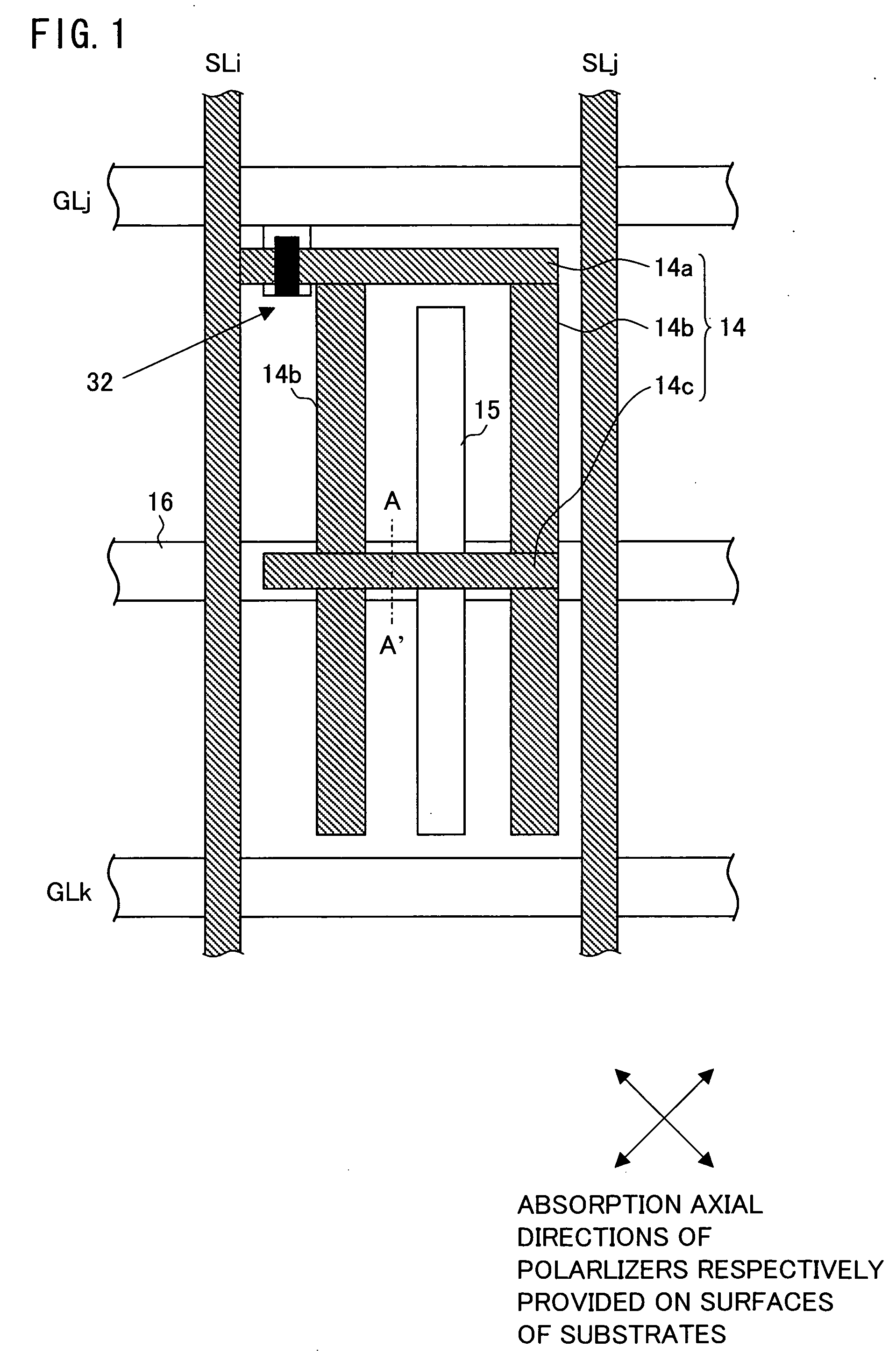

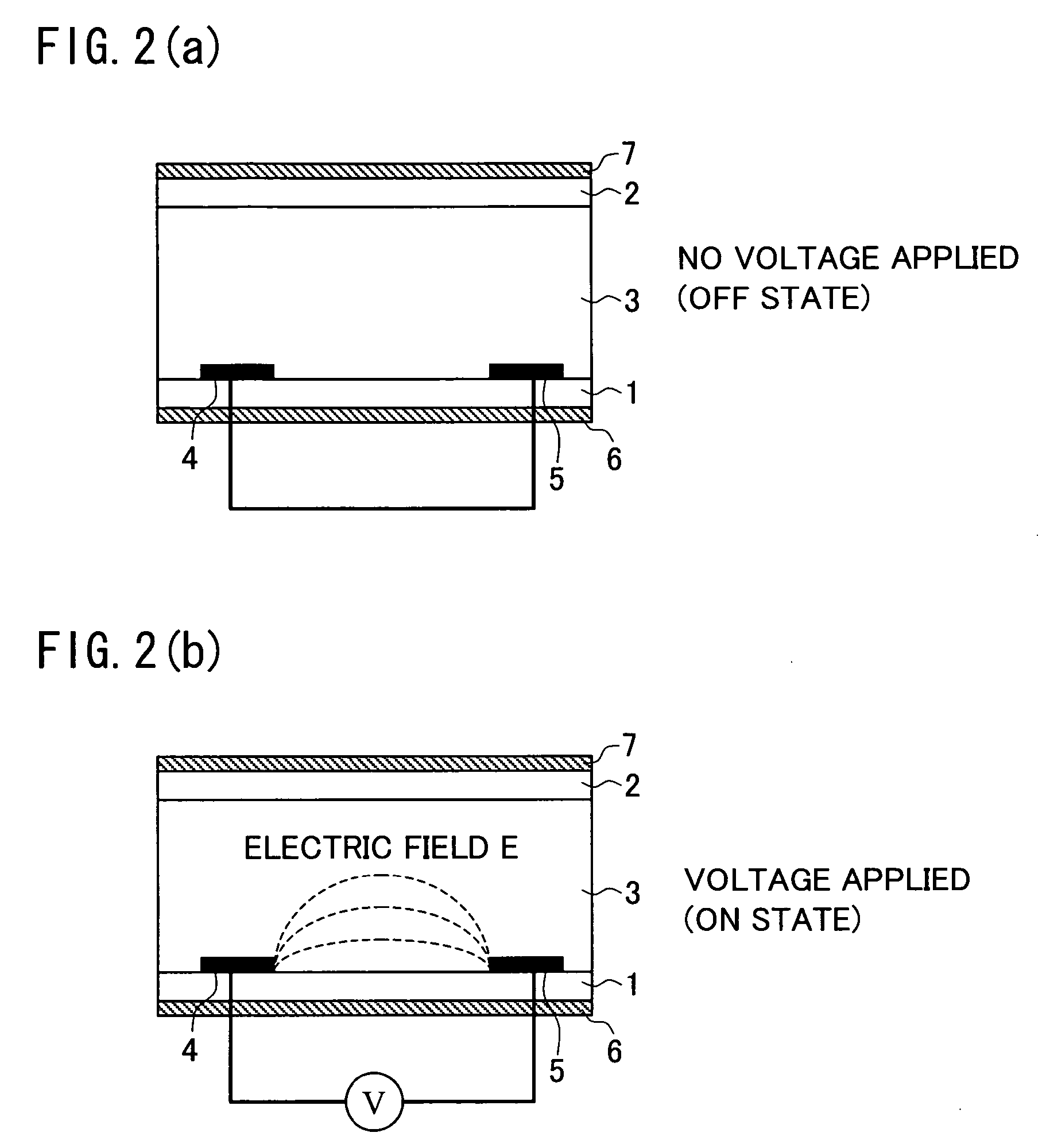

Display element and display apparatus

InactiveUS20050179632A1Reduce degree changeDegree of change is smallStatic indicating devicesNon-linear opticsElectric fieldPhysics

A display element includes: a pair of substrates, at least one of which is transparent; a medium, between the substrates, the medium being changeable in an optical anisotropy magnitude by and according to electric field application; and a region in which a pixel electrode and a counter electrode overlap with each other with an insulating layer therebetween.

Owner:SHARP KK

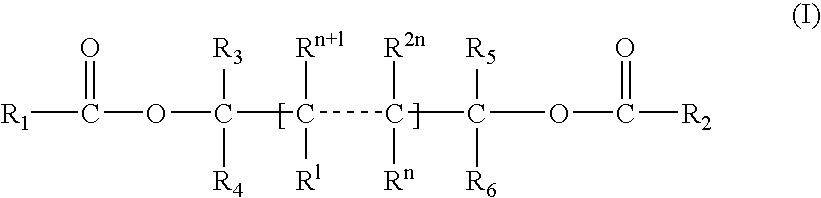

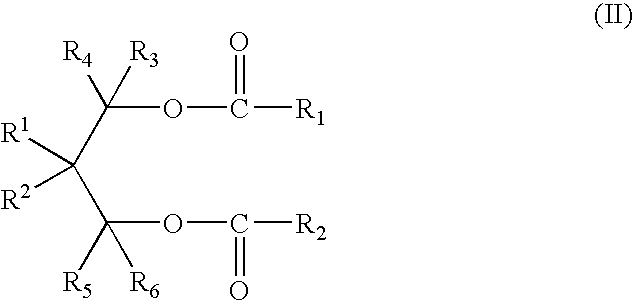

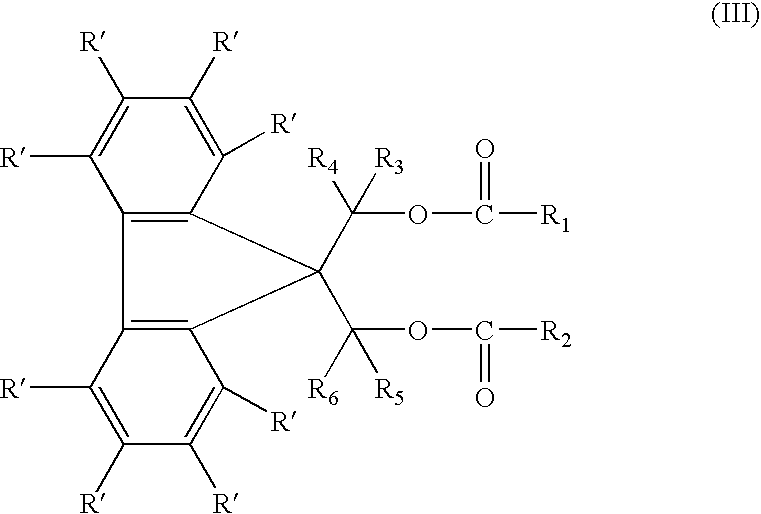

Catalyst component for olefin (Co)polymerization, preparation thereof, a catalyst comprising the same and use thereof

ActiveUS20070155616A1High catalytic activityParticles in good shapeOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationHalogenAlkoxy group

The invention relates to a catalyst component for olefin (co)polymerization, to preparation thereof, to a catalyst comprising the same, and to use thereof in olefin (co)polymerization. The catalyst component of the invention comprises magnesium, titanium, halogen, inner electron donor compound, and alkoxy group derived from a surface modifier, wherein the content of the alkoxy group derived from the surface modifier is in a range of from 0.01 to 3 percent by weight, based on the weight of the catalyst component.

Owner:CHINA PETROCHEMICAL CORP +1

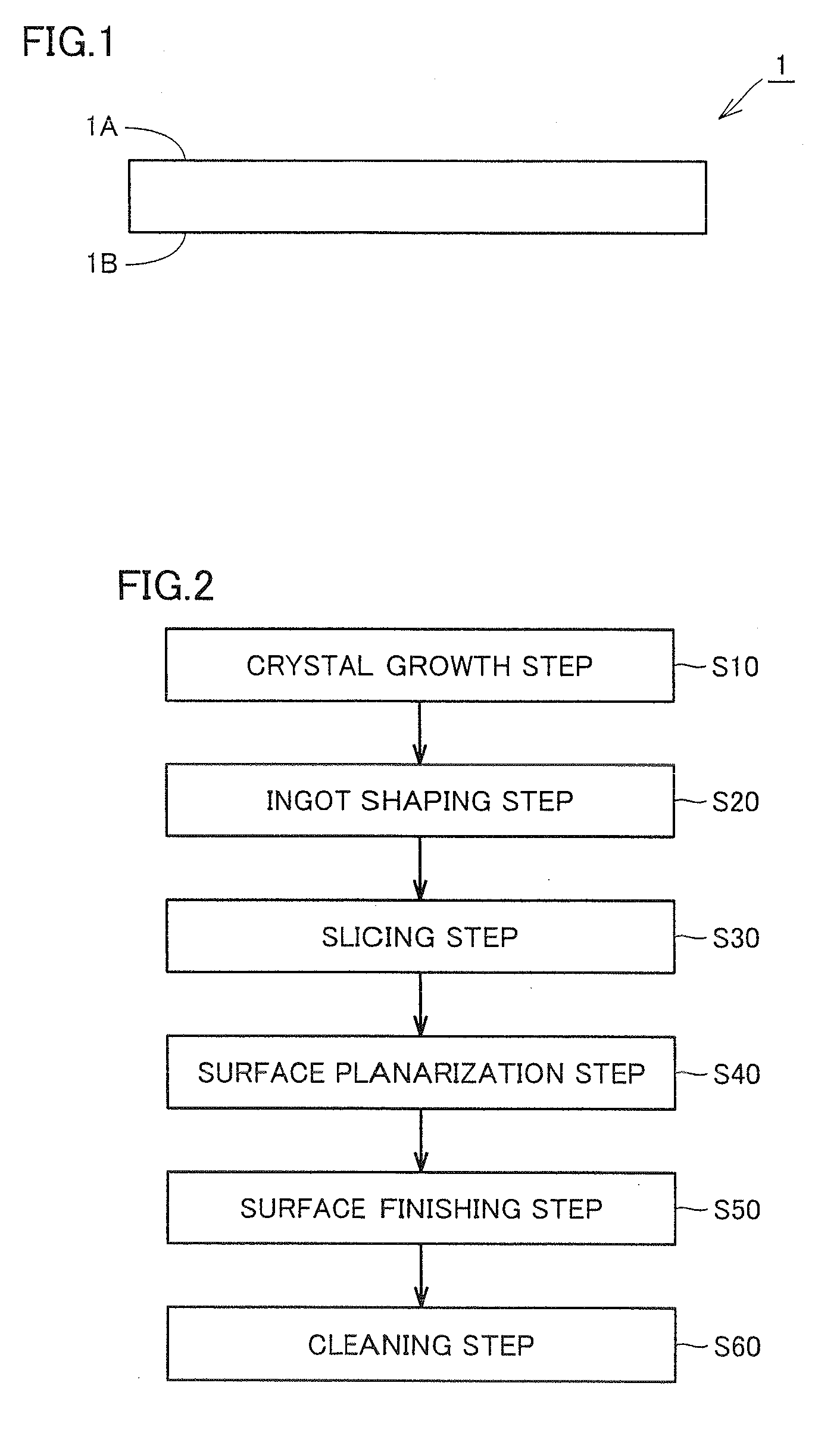

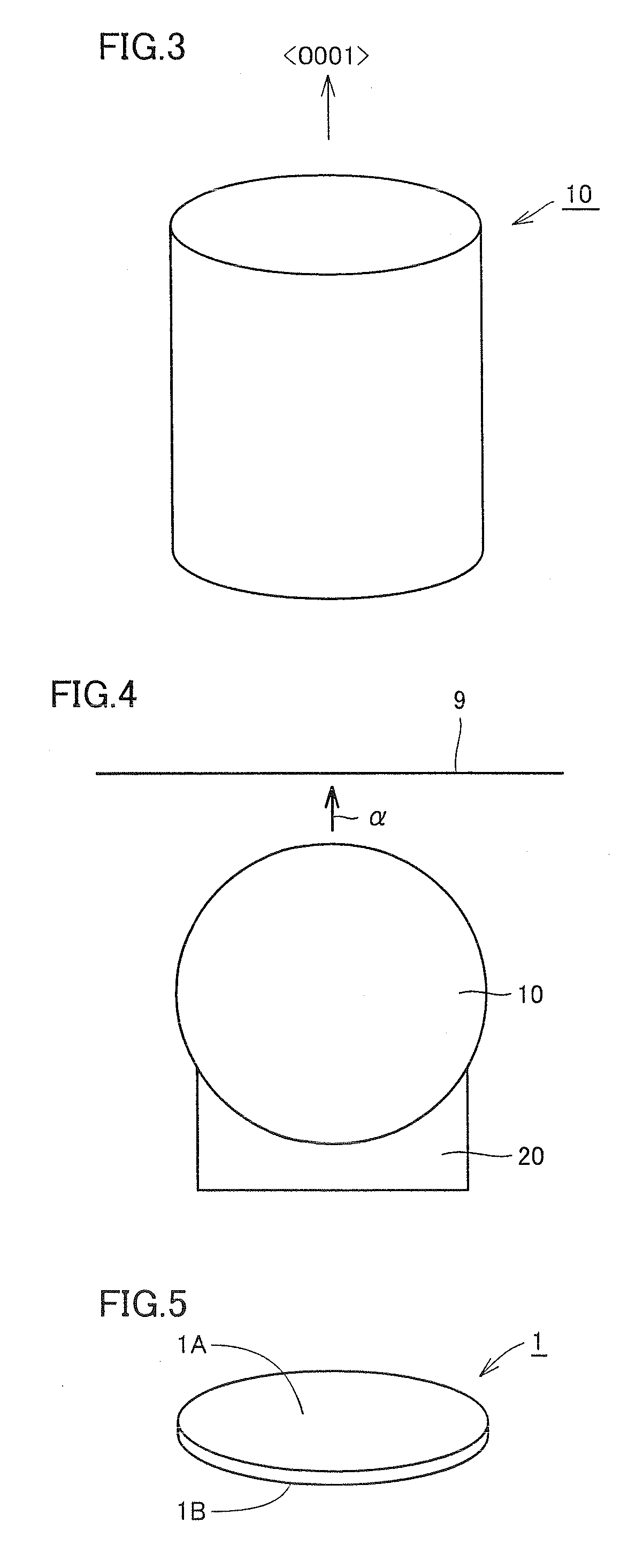

Silicon carbide substrate, semiconductor device, and methods for manufacturing them

ActiveUS20130256700A1Improve production efficiencySuppress manufacturing costPolycrystalline material growthDiffusion/dopingPower semiconductor deviceSulfur

A silicon carbide substrate has a first main surface, and a second main surface opposite to the first main surface. A region including at least one main surface of the first and second main surfaces is made of single-crystal silicon carbide. In the one main surface, sulfur atoms are present at not less than 60×1010 atoms / cm2 and not more than 2000×1010 atoms / cm2, and carbon atoms as an impurity are present at not less than 3 at % and not more than 25 at %. Thereby, a silicon carbide substrate having a stable surface, a semiconductor device using the substrate, and methods for manufacturing them can be provided.

Owner:SUMITOMO ELECTRIC IND LTD

Synthetic method of cyclosulphate

InactiveCN110386916AHigh reaction conversion rateImpurities increaseOrganic chemistrySecondary cellsCatalytic oxidationOrganic layer

The invention discloses a synthetic method of cyclosulphate. A peroxysulfate solution is pre-synthesized through sulfuric acid and hydrogen peroxide, then under existence of an organic solvent, a metal inorganic compound and a catalyst, the peroxysulfate solution is dropwise added to generate a catalytic oxidation reaction with cyclosulfite, after the reaction is completed, salt residue is filtered out, still standing for layering is conducted, an organic layer is taken to be distilled, concentrated and purified, and a cyclosulphate high-quality product is obtained. According to the syntheticmethod of the cyclosulphate, the cheap sulfuric acid and hydrogen peroxide are used as the raw materials, the peroxysulfate solution is prepared to conduct catalytic oxidation on the cyclosulfite, onthe one hand, the reaction is mild, control is easy, and the reaction conversion rate is high; on the other hand, the evaporation capacity of water is small, energy consumption is low, generated wastewater is less, and a synthetic process is more environmentally friendly; and the prepared cyclosulphate is few in impurity, high in purity and wide in market prospect.

Owner:CHANGSHU CHANGJI CHEM

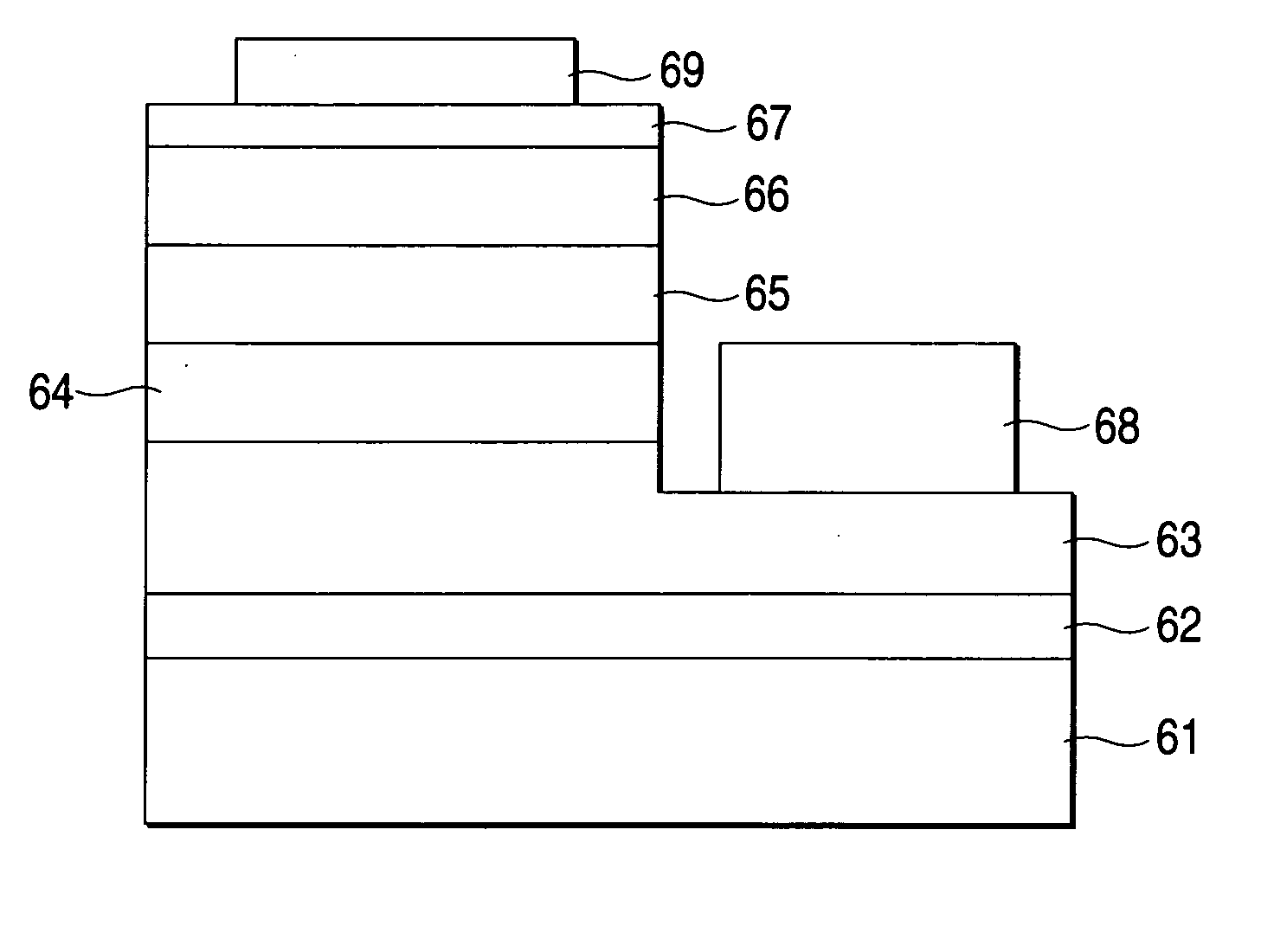

Method for producing p-type Group III nitride compound semiconductor

InactiveUS20040058465A1Reduce resistanceFacilitated DiffusionLaser detailsSemiconductor/solid-state device manufacturingNitrideImpurity

A second Group III nitride compound semiconductor layer not doped with any impurities or doped with n-type impurities or with n-type and p-type impurities is formed on a first Group III nitride compound semiconductor layer doped with p-type impurities. Resistance is reduced by a heat treatment after or during the formation of the second Group III nitride compound semiconductor layer.

Owner:TOYODA GOSEI CO LTD

Cleaning composition for semiconductor components and process for manufacturing semiconductor device

InactiveUS20050284844A1High cleaning effectLittle burdenDecorative surface effectsDetergent mixture composition preparationWater soluble polymersWater soluble

A cleaning composition for semiconductor components comprises a water-soluble polymer (a) having a specific molecular weight and a compound (b) represented by the following formula (1): NR4OH (1) wherein each R is independently a hydrogen atom or an alkyl group of 1 to 6 carbon atoms. A process for manufacturing a semiconductor device comprises chemical mechanical polishing a semiconductor component, and cleaning the semiconductor component with the cleaning composition for semiconductor components. The cleaning composition exerts a high cleaning effect on impurities remaining on a polished surface of a semiconductor component after chemical mechanical polishing, and becomes little burden on the environment.

Owner:JSR CORPORATIOON

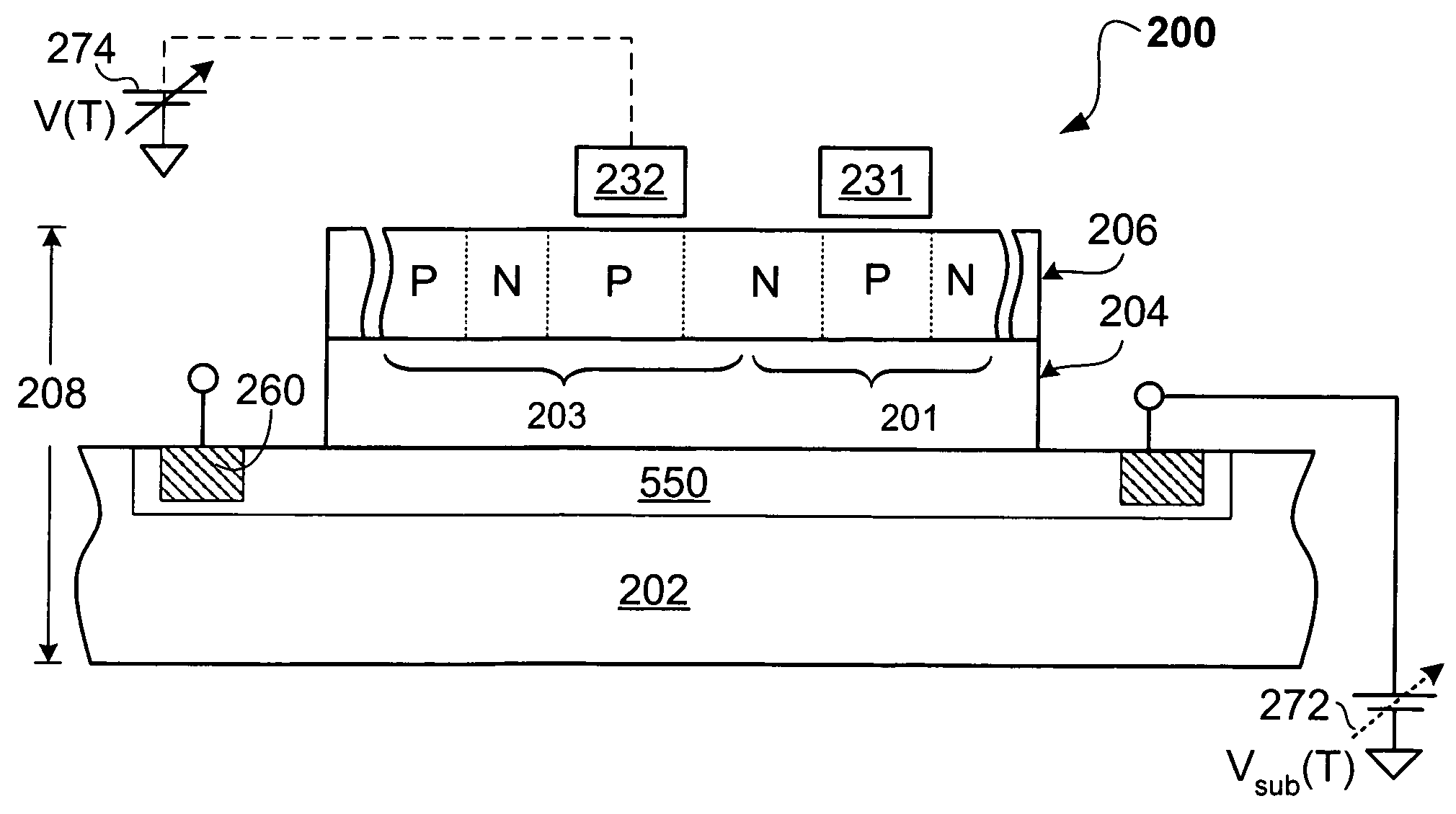

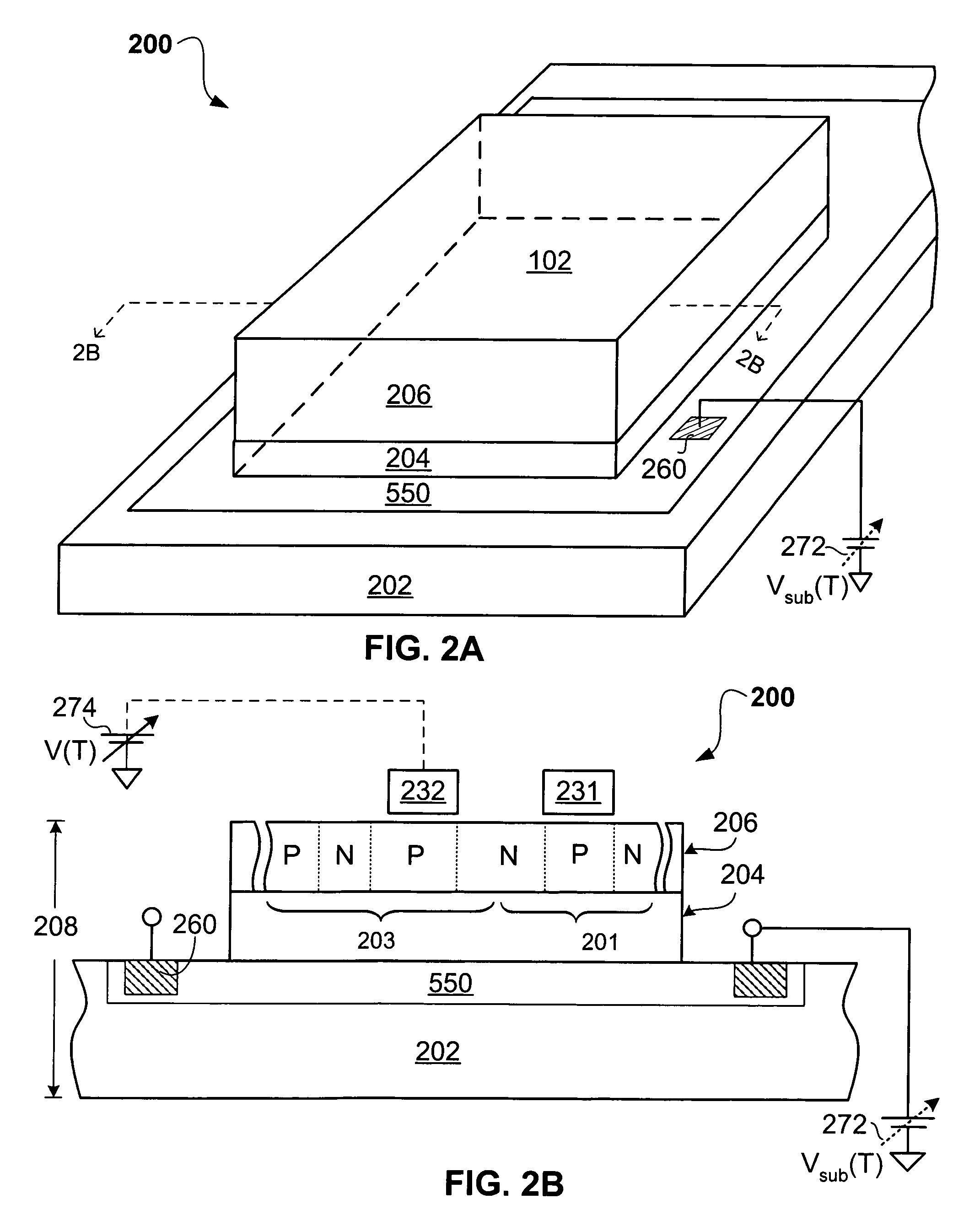

Thyristor-based semiconductor memory device with back-gate bias

InactiveUS7573077B1High density of impurityAvoid voltage dropThyristorDc-dc conversionThyratronEngineering

In accordance with an embodiment of the present invention, a thyristor-based semiconductor memory device may comprise an array of thyristor-based memory formed in an SOI wafer. A supporting substrate may be formed with a density of dopants sufficient to assist delivery of a bias level to the backside of an insulating layer beneath a thyristor. Such conductivity within the substrate may allow reliable back-gate control for the gain of a component bipolar device of the thyristor.

Owner:T RAM ASSIGNMENT FOR THE BENEFIT OF CREDITORS LLC +1

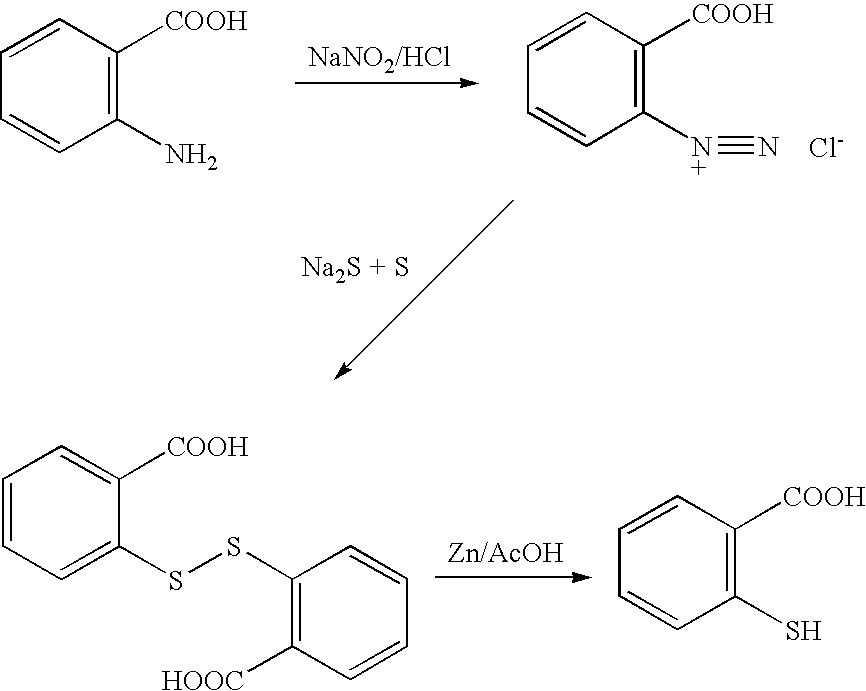

Method for producing thiosalicylic acid

InactiveUS20040116734A1Reduce production efficiencyLow yieldThiol preparationOrganic compound preparationSulfurAnthranilic acid

The present invention relates to a method for causing sodium sulfide or a mixture of sodium sulfide and sulfur to react with diazonium salt formed by diazotizing anthranilic acid, wherein the Na / S atomic ratio as calculated on the basis of the employed sodium sulfide and sulfur is adjusted to within the range of 1.33 to 2.0 during the reaction. Thus is made practicable the manufacture of thiosalicylic acid in a high yield without going through the individual route of isolating and reducing dithiosalicylic acid.

Owner:AIR WATER INC

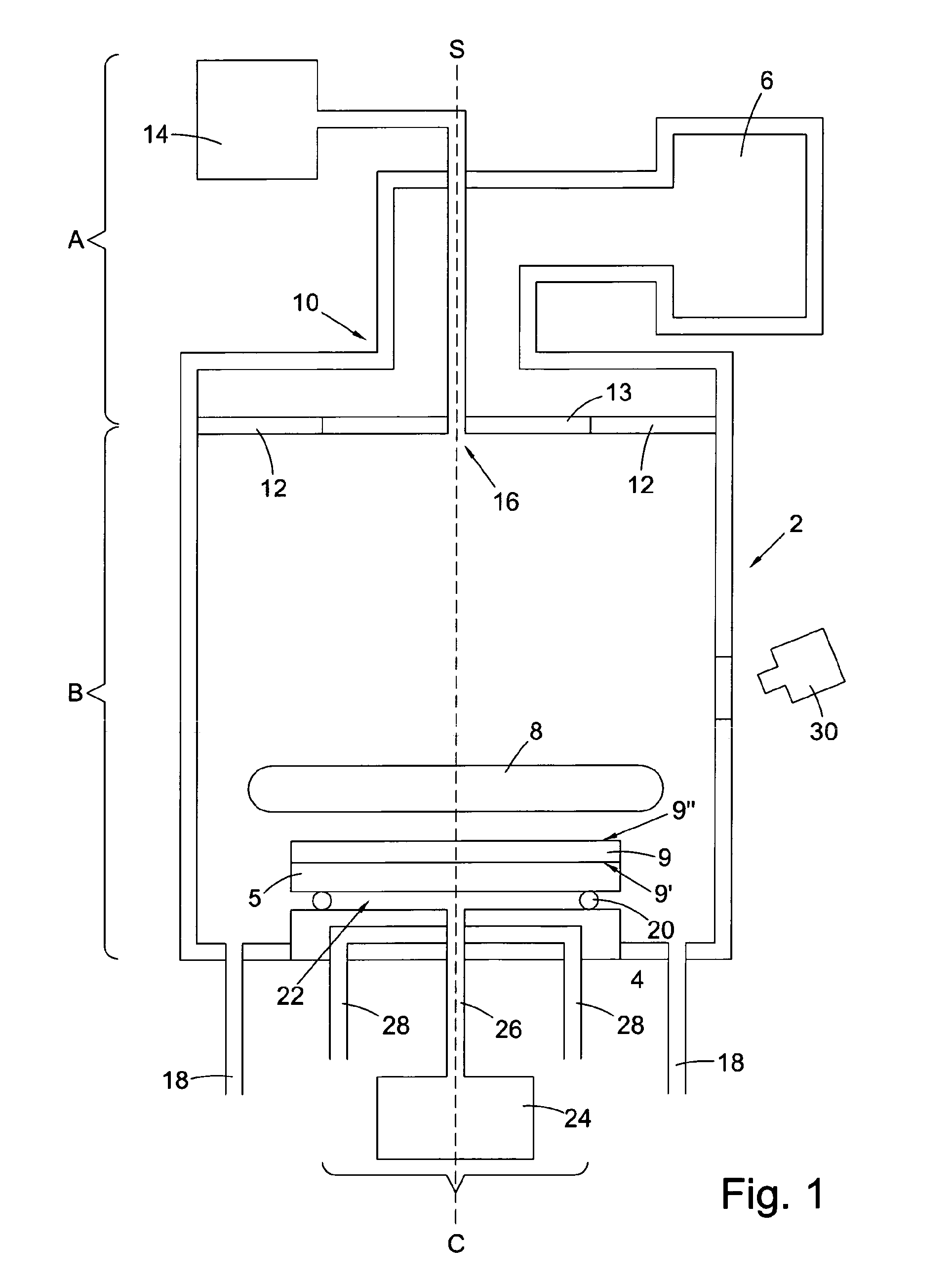

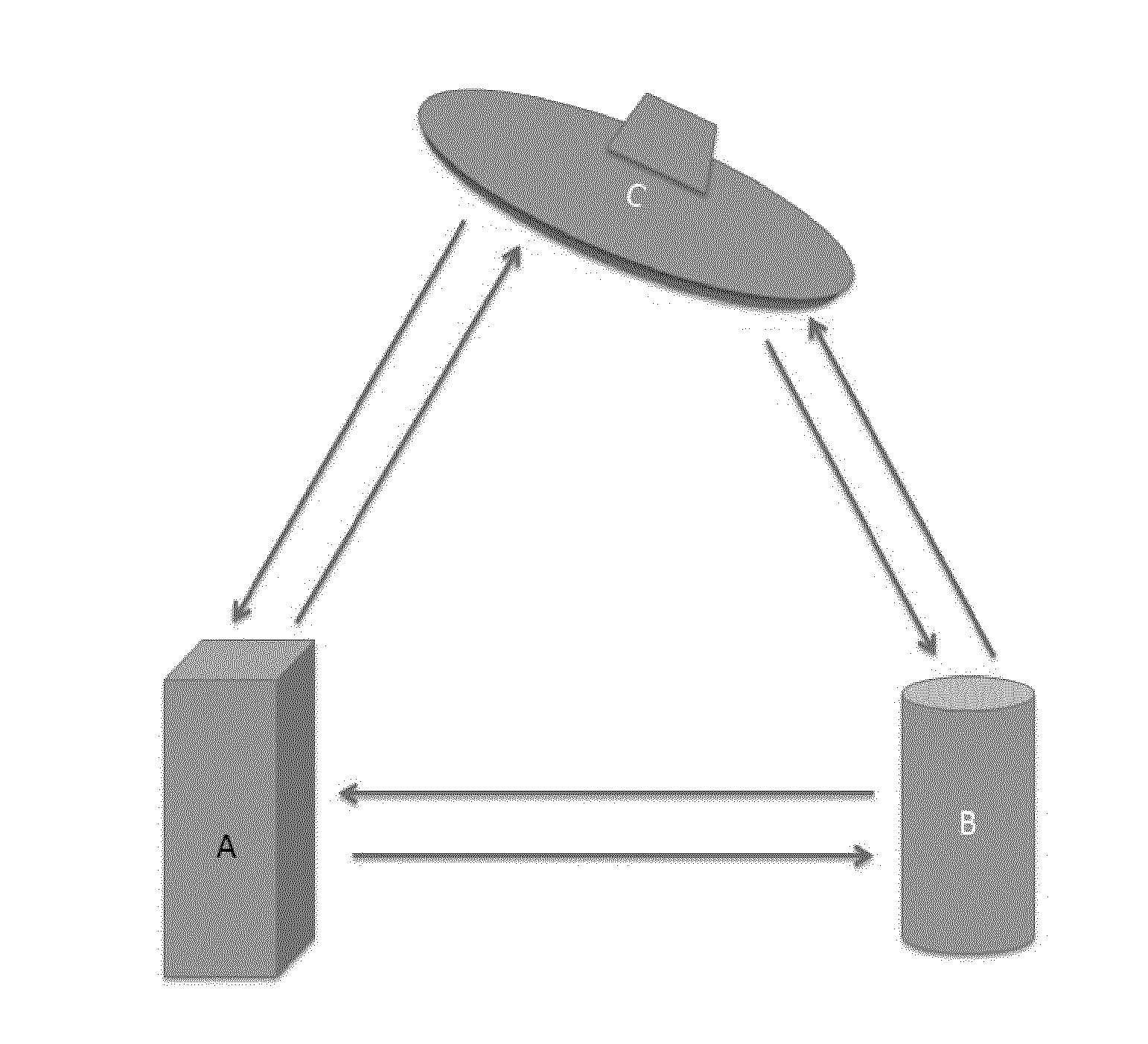

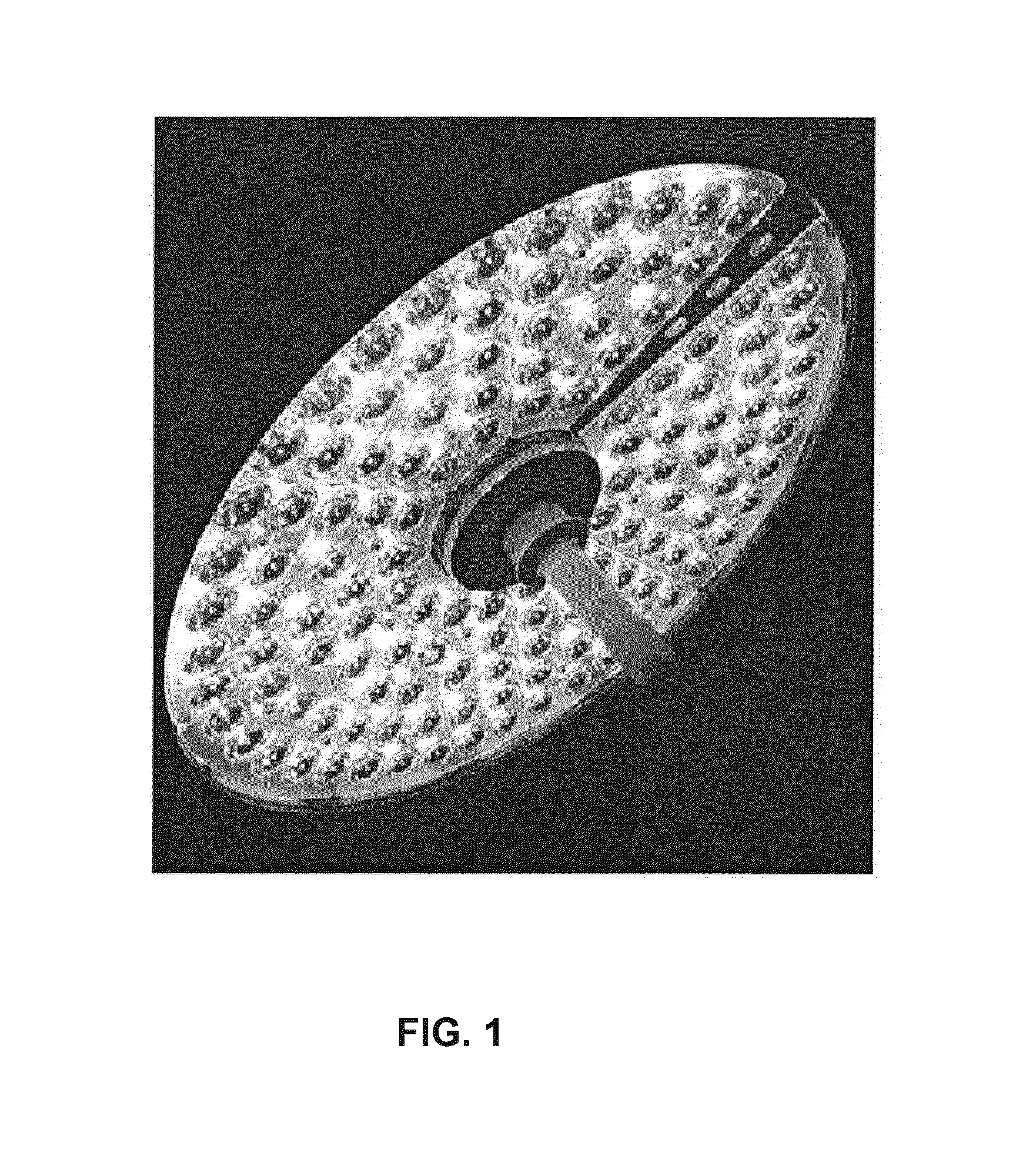

Innovative Operation Room Light System Capable of Wireless Data Exchange Between Operating Room Devices

ActiveUS20160301471A1Impurities increaseQuality improvementNon-electrical signal transmission systemsDiagnosticsCommunications systemDevice form

The invention relates to a communication system and devices forming part of this system, wherein light is used for the transmission signal. The communication system includes an apparatus for forwarding operating room device signals to a device which apparatus is configured to receive an analog signal comprising the operating room device signal and to produce a digital signal based upon the analog signal, the apparatus further being configured to produce a signal based upon the digital signal, wherein the signal is for modulating the output of a light source. This invention includes a device for managing access and priority of traffic within this system according to a specific hierarchy of priority starting with safety and ending with administrative information.

Owner:KUNZ GMBH & CO +1

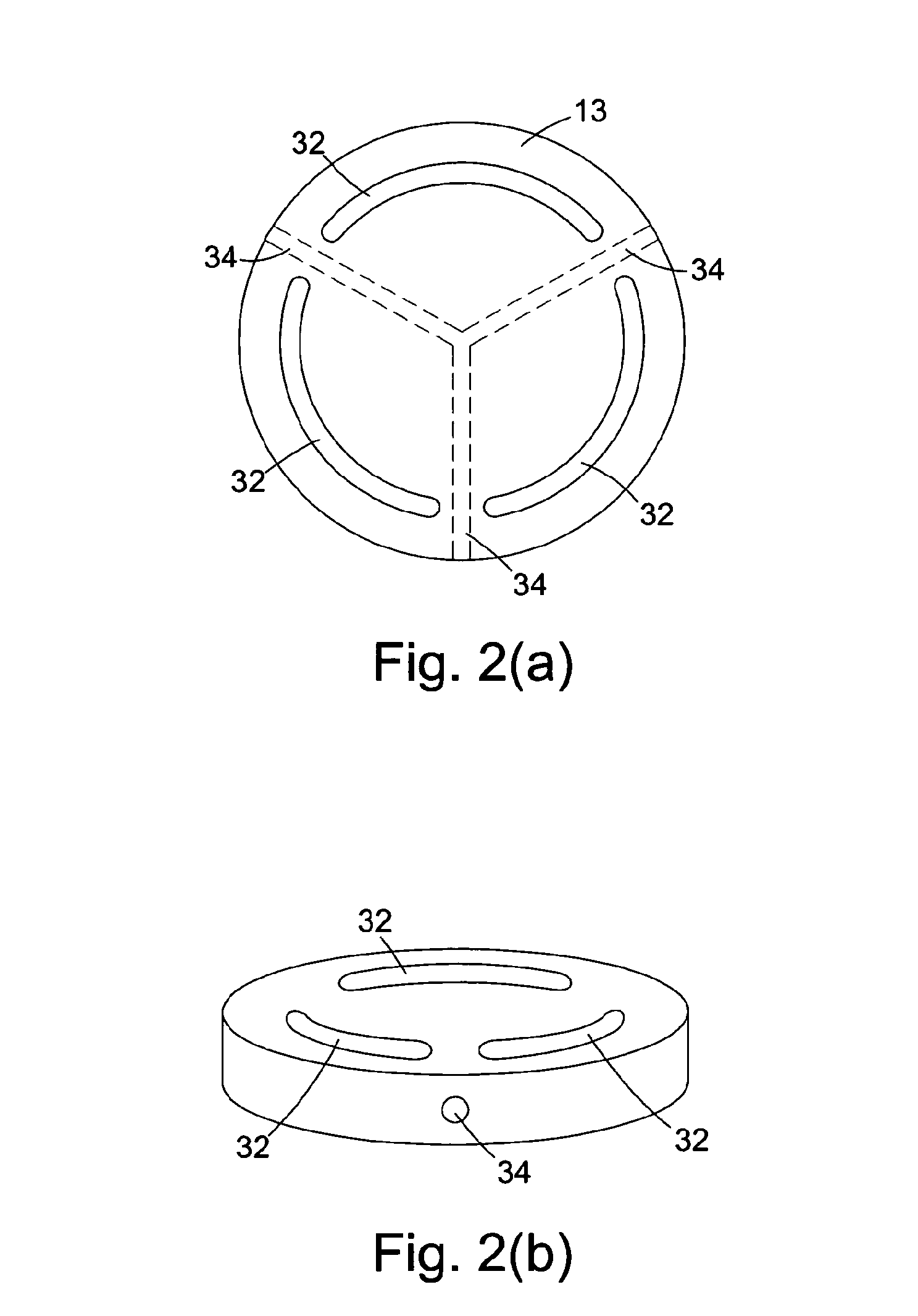

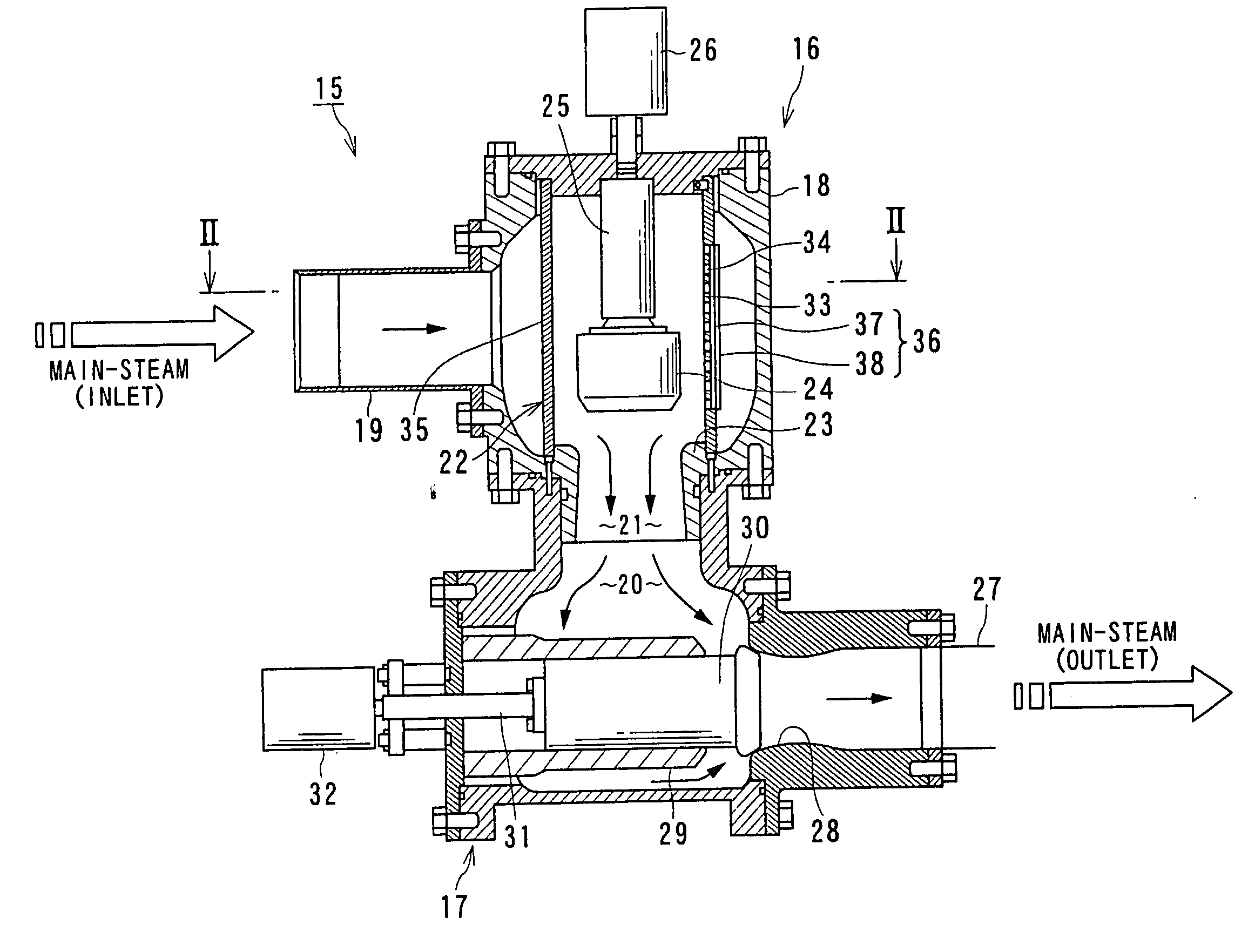

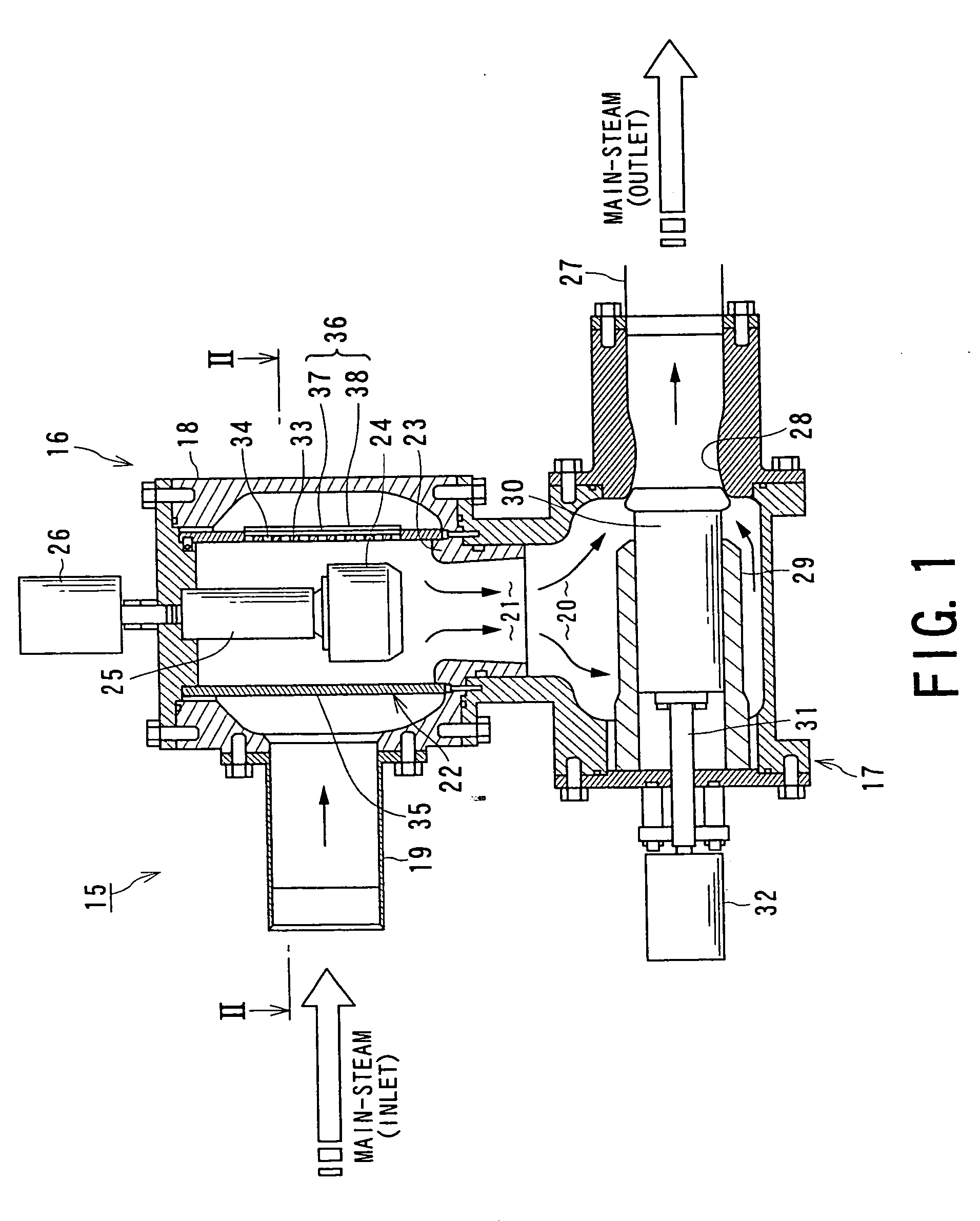

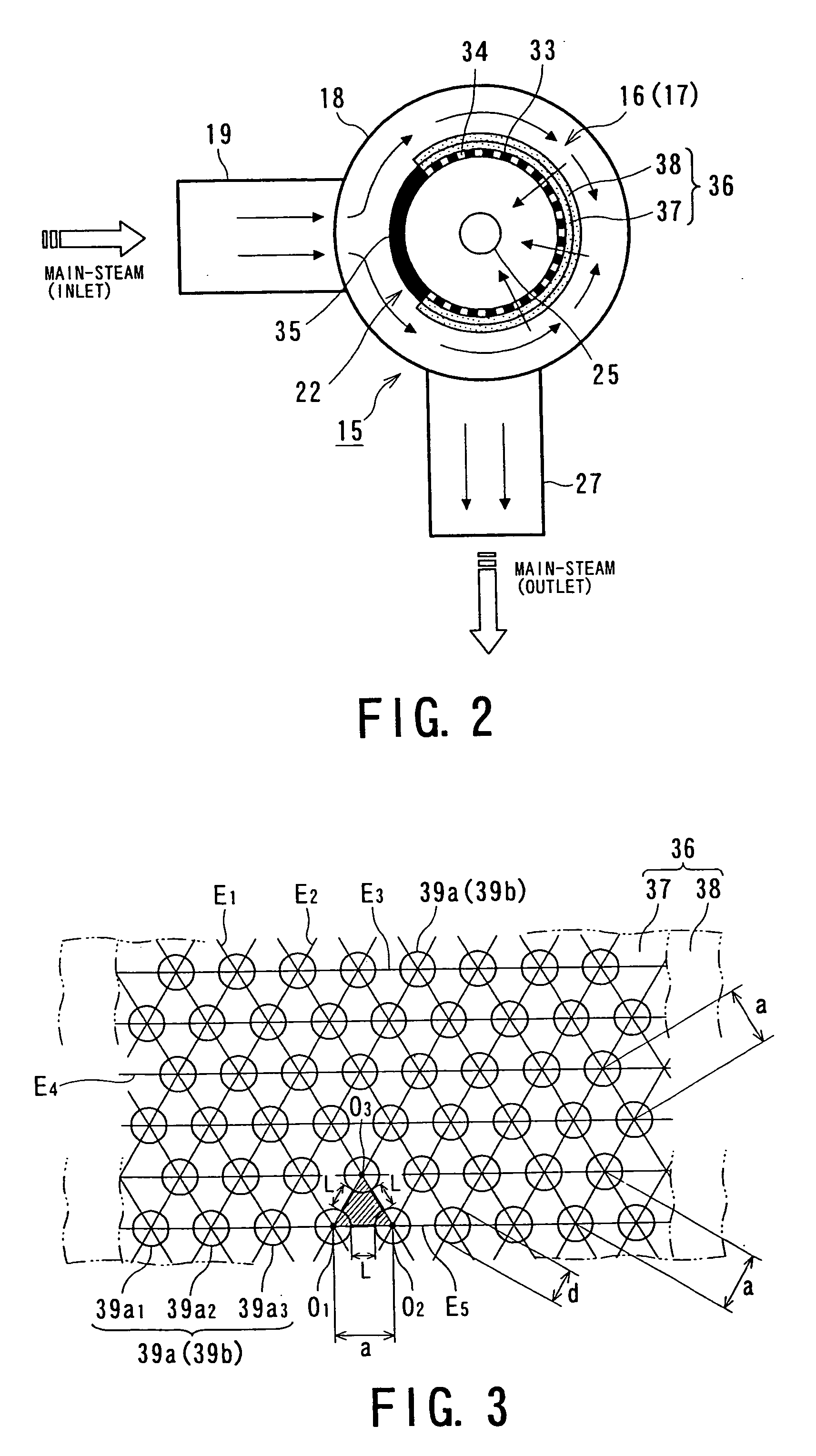

Steam valve

ActiveUS20060070666A1Eliminate defect and drawbackHigh strengthDispersed particle filtrationValve members for absorbing fluid energyEngineeringMaterial Perforation

In a steam valve, a strainer is arranged between a valve body and a valve casing in which the valve body is accommodated, and a screen assembly is mounted on an outer peripheral portion of the strainer. The screen assembly includes a temporary screen unit and a permanent screen unit which is arranged inside the temporary screen unit. Each of the screen units is a substantially cylindrical structure made of a plate formed with perforations.

Owner:KK TOSHIBA

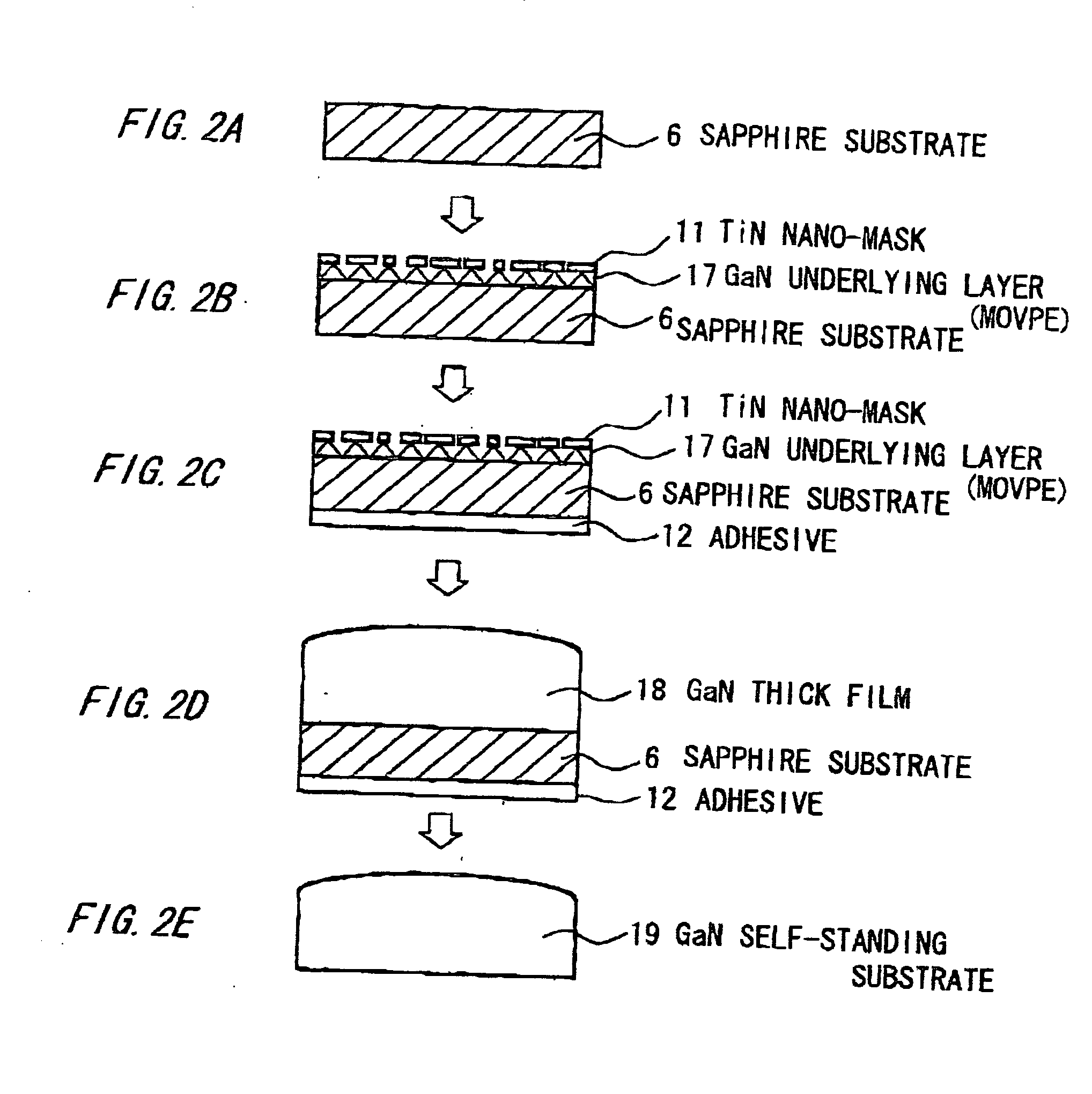

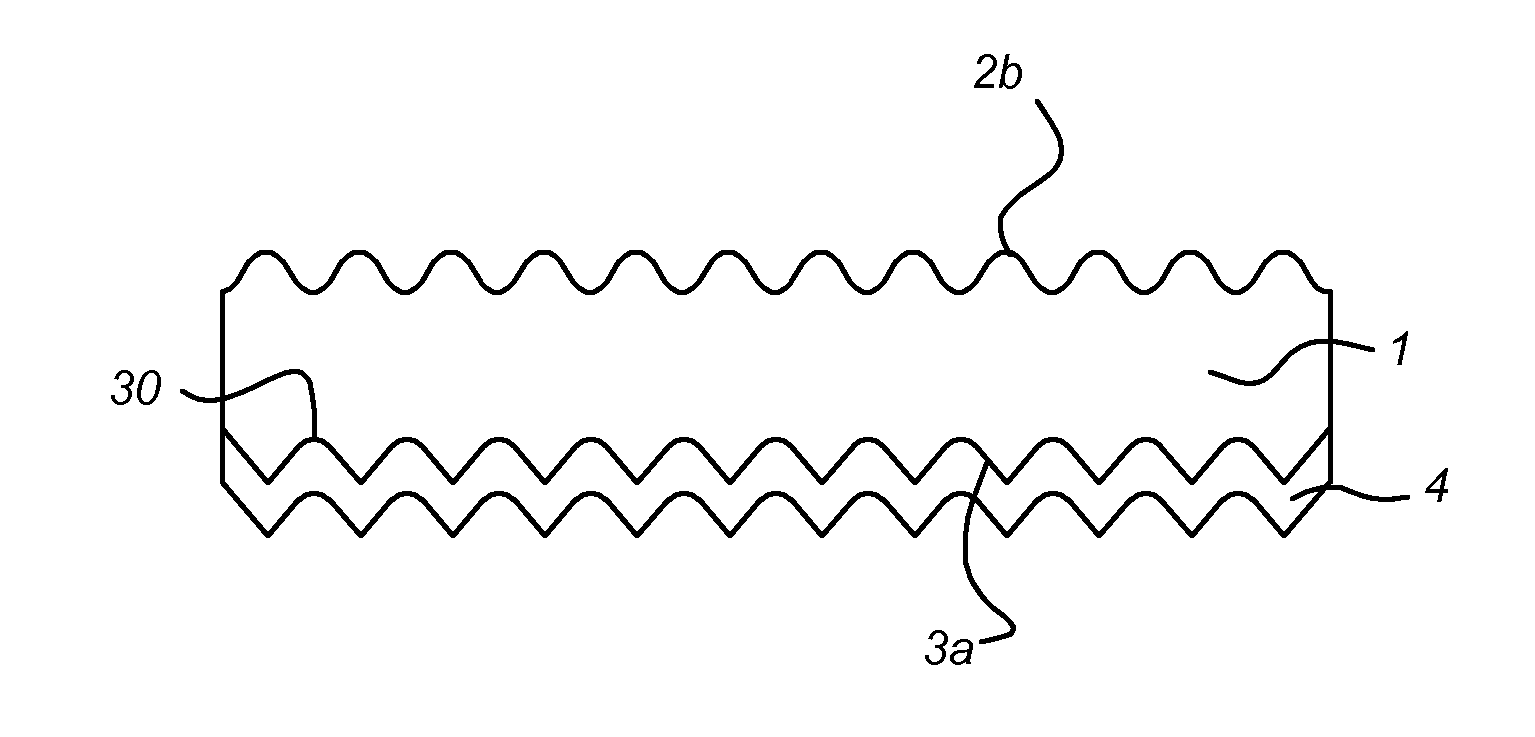

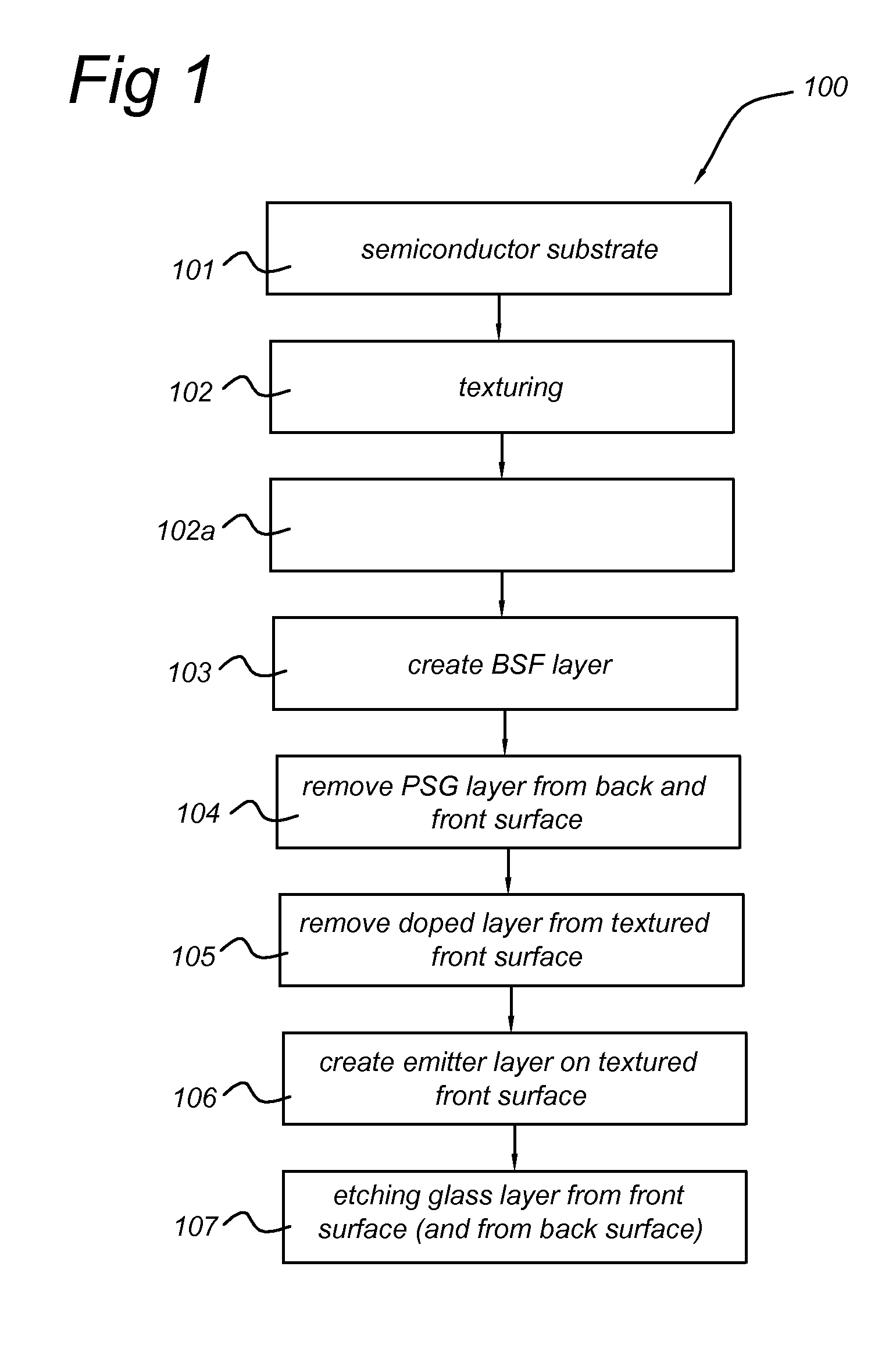

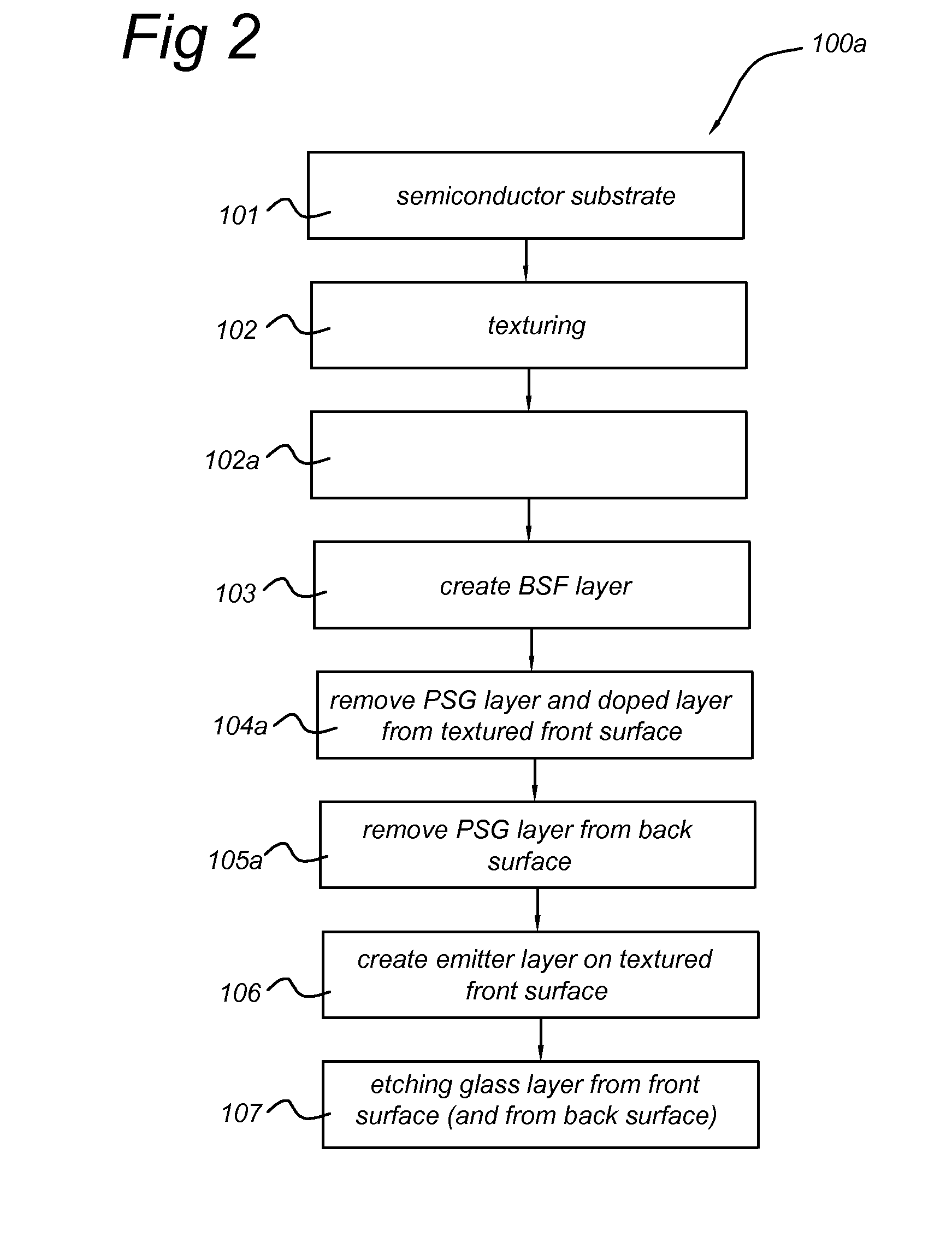

Solar cell and method for manufacturing such a solar cell

ActiveUS20120181667A1Reduce creationHigh budgetSemiconductor/solid-state device manufacturingPhotovoltaic energy generationDopantBack surface field

A method for manufacturing a solar cell from a semiconductor substrate (1) of a first conductivity type, the semiconductor substrate having a front surface (2) and a back surface (3). The method includes in a sequence: texturing (102) the front surface to create a textured front surface (2a); creating (103) by diffusion of a dopant of the first conductivity type a first conductivity-type doped layer (2c) in the textured front surface and a back surface field layer (4) of the first conductivity type in the back surface; removing (105; 104a) the first conductivity-type doped layer from the textured front surface by an etching process adapted for retaining texture of the textured front surface; creating (106) a layer of a second conductivity type (6) on the textured front surface by diffusion of a dopant of the second conductivity type into the textured front surface.

Owner:NEDERLANDSE ORG VOOR TOEGEPAST-NATUURWETENSCHAPPELIJK ONDERZOEK (TNO)

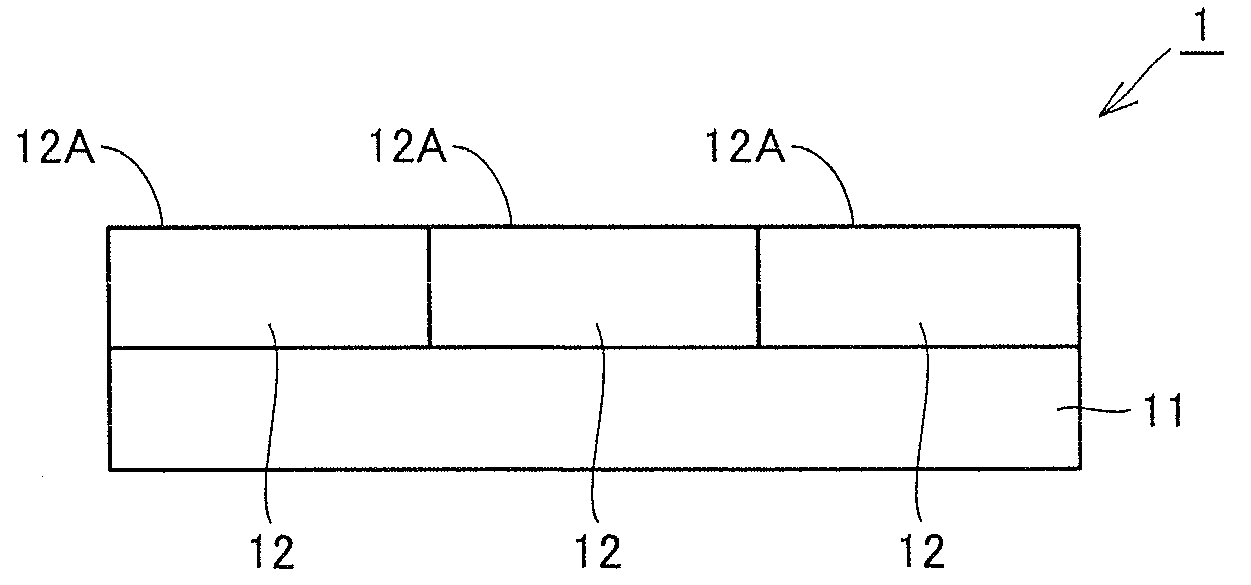

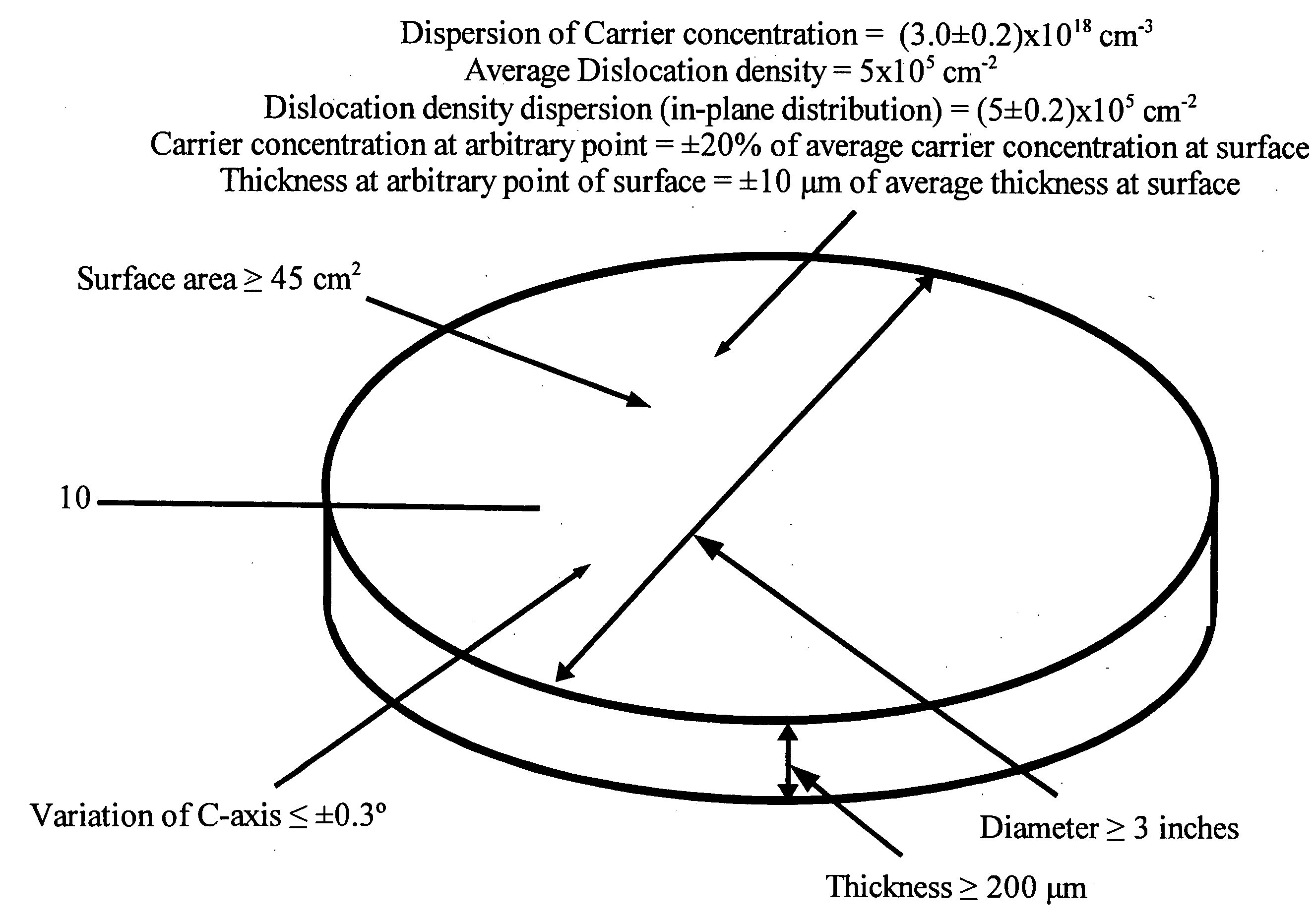

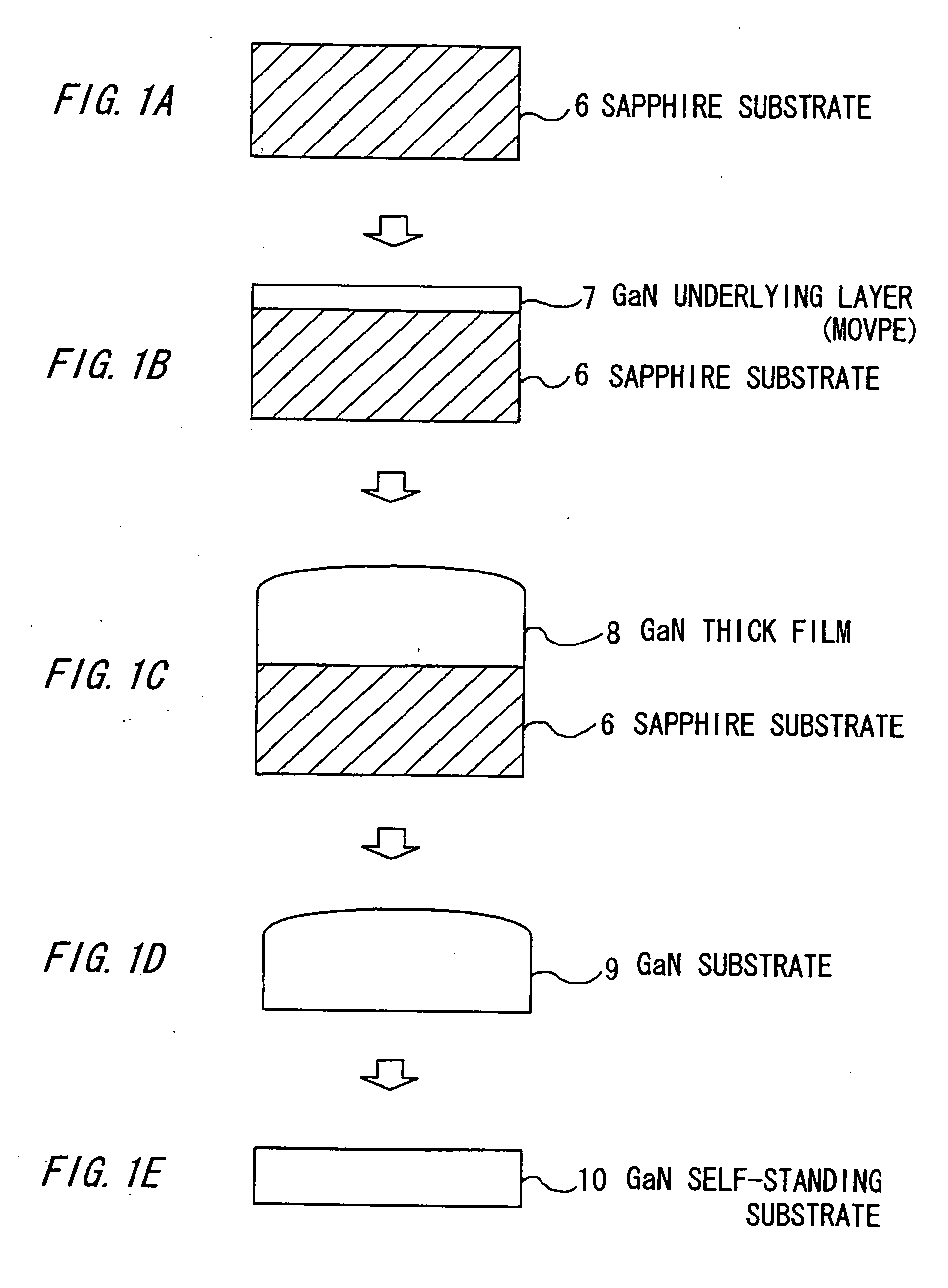

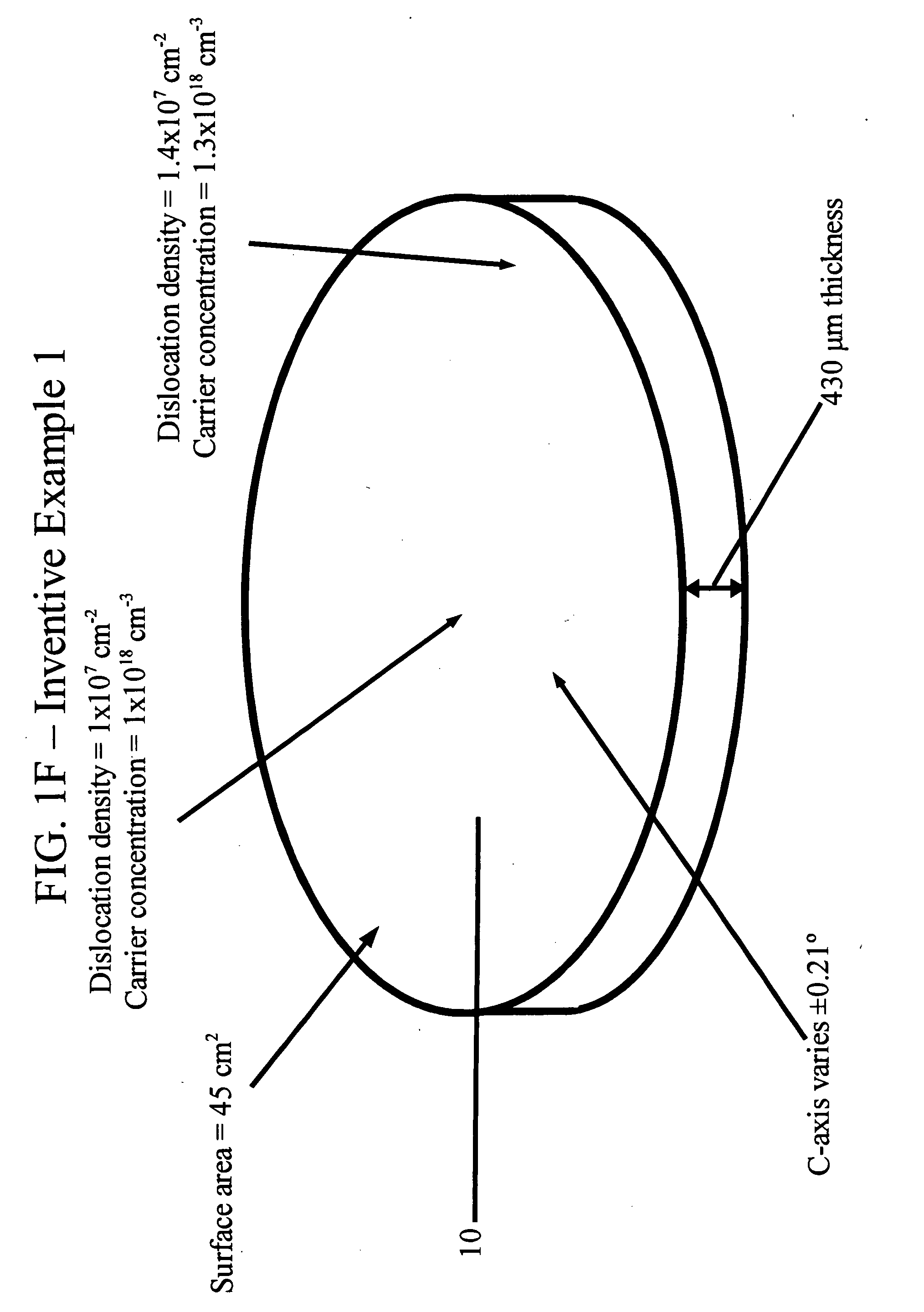

Group III-V nitride based semiconductor substrate and method of making same

ActiveUS20100200955A1Uniform propertyImpurities increasePolycrystalline material growthSemiconductor/solid-state device manufacturingIn planeDislocation

A group III-V nitride-based semiconductor substrate includes a group III-V nitride-based semiconductor crystal. A surface area of the substrate is greater than or equal to 45 cm2. A thickness of the substrate is greater than or equal to 200 μm. An in-plane dislocation density of the substrate is less than or equal to 2×107 cm−2 in average. The in-plane dislocation density of the substrate is less than or equal to 150% of the average at maximum.

Owner:SUMITOMO CHEM CO LTD

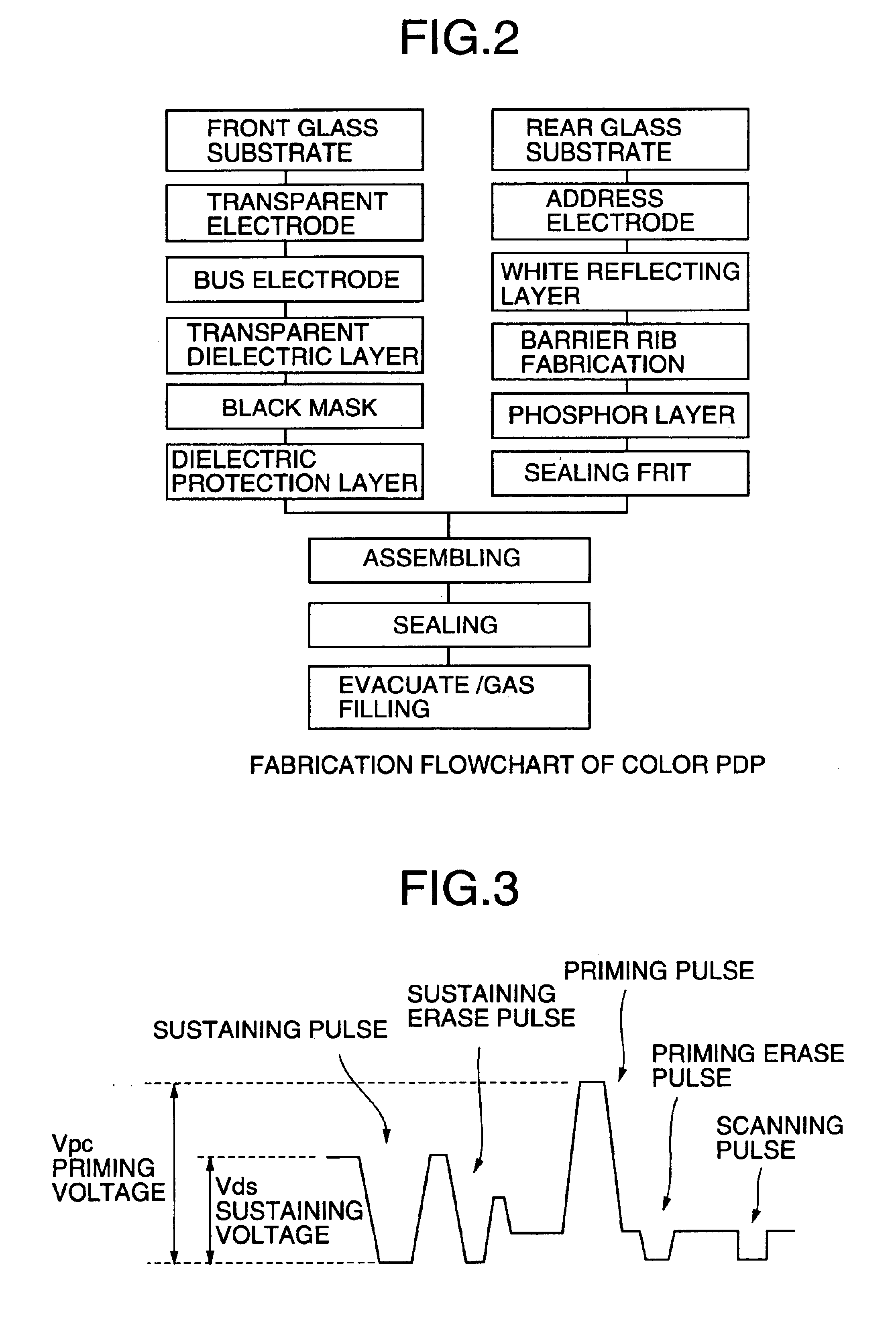

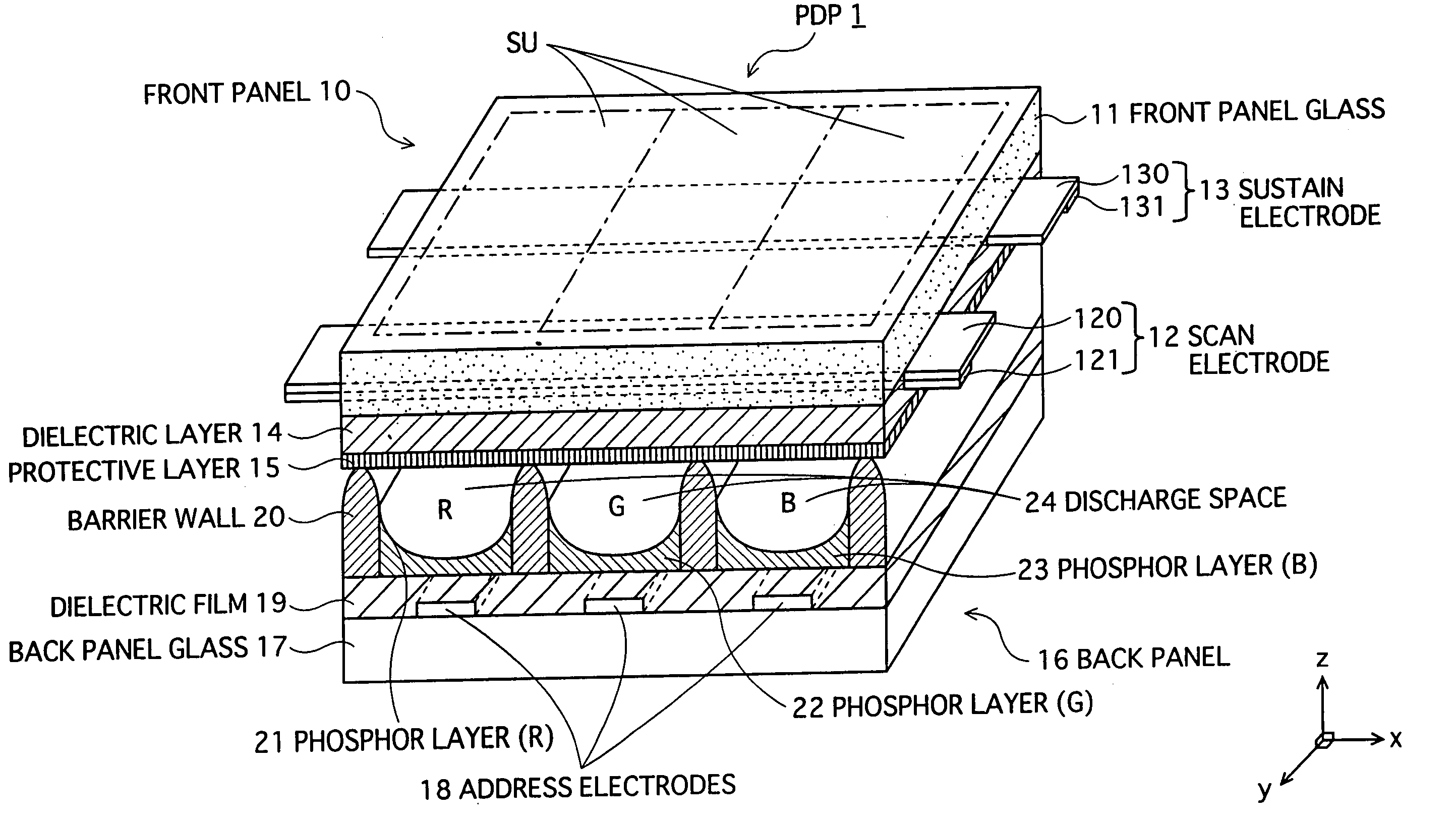

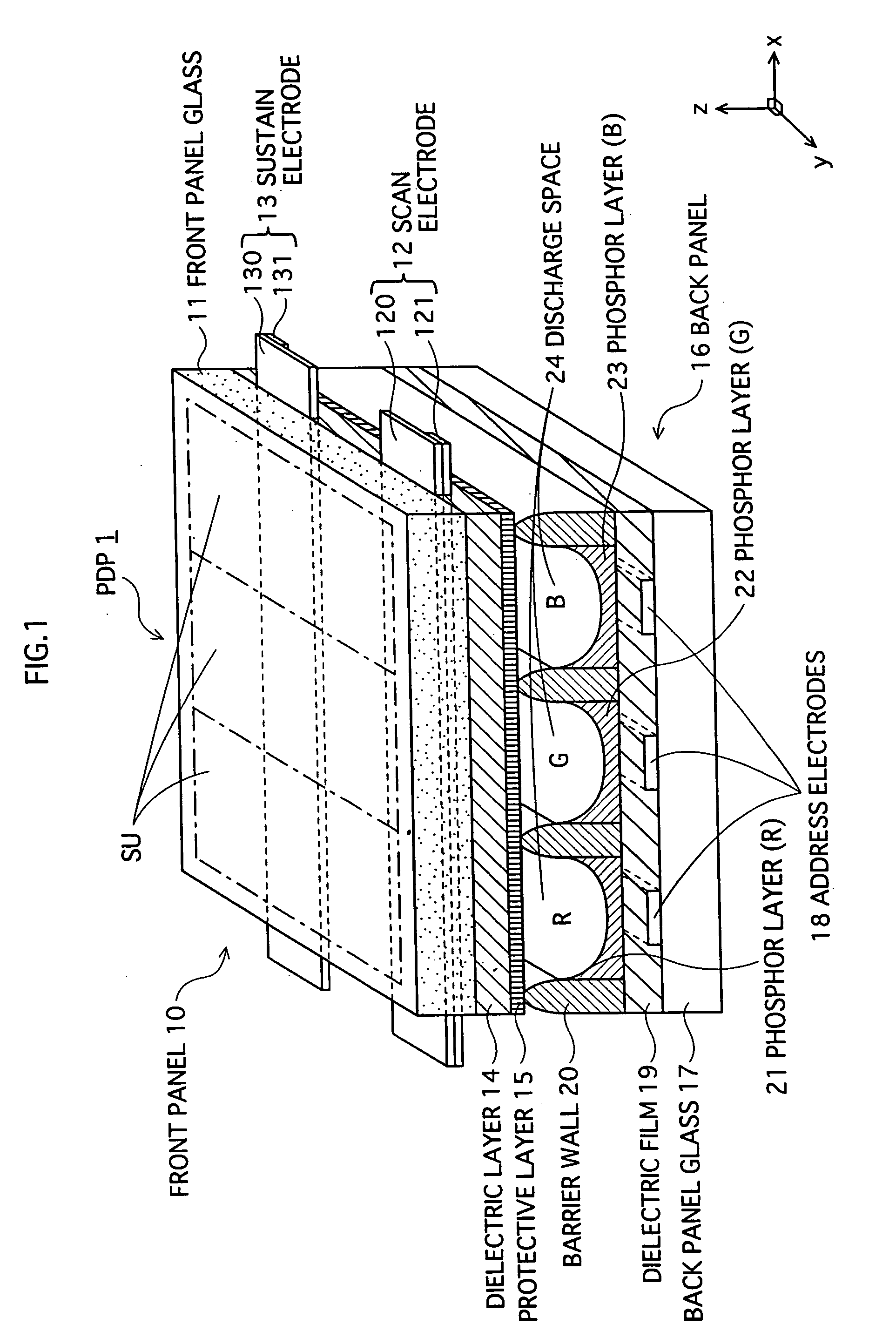

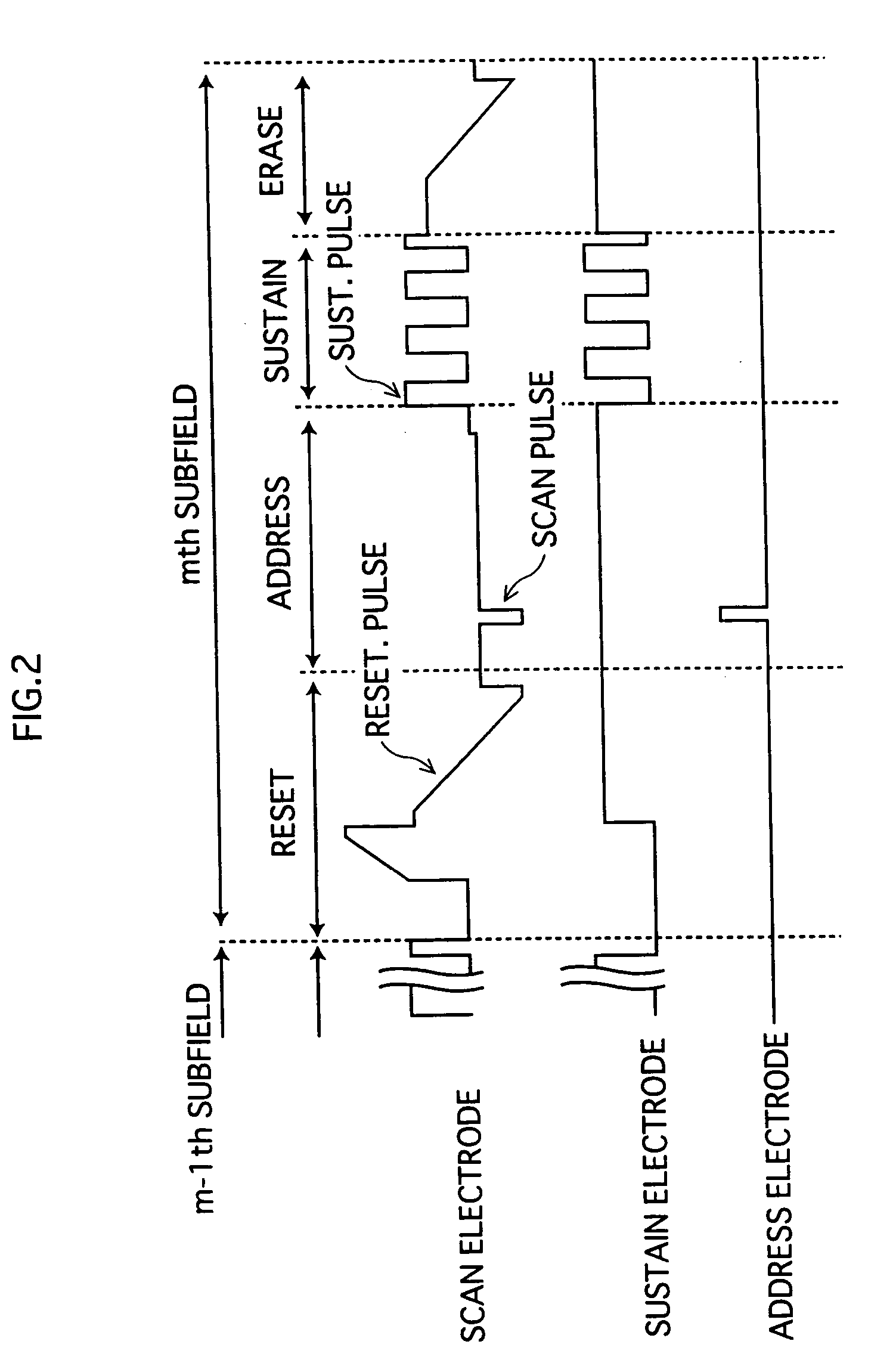

Plasma display panel and fabrication method of the same

InactiveUS6879107B2High contrast display without erroneous lightening or flickerReduce voltageAddress electrodesSustain/scan electrodesHydrogenHydrogen atom

A protection film for protecting a dielectric layer of an AC type PDP is formed such that impurity metal ion densities of the protection film of the PDP, which is aged, become 400 ppm or less, respectively, and the protection film contains three or more hydrogen atoms assuming that the total number of atoms of the protection film is 100.

Owner:PANASONIC CORP

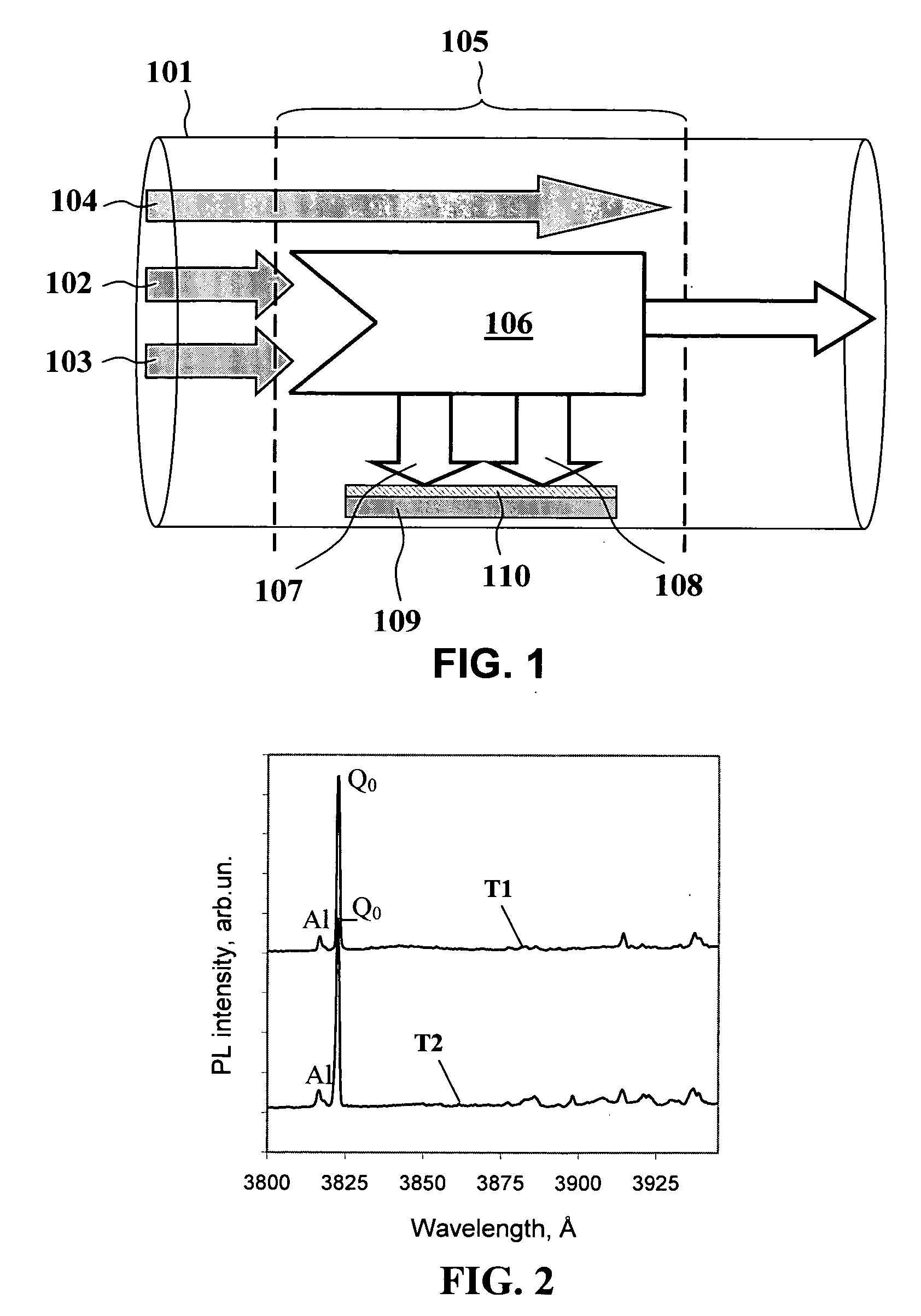

Method for epitaxial growth of silicon carbide

InactiveUS20070062441A1Promote growthEasy to controlPolycrystalline material growthFrom chemically reactive gasesHalogenGas phase

A method for epitaxial growth of silicon carbide using chemical vapor deposition (CVD) is provided. This method utilizes halogenated carbon precursors and control of the gas-phase interaction of halogen-containing intermediate chemical products involving silicon and carbon, which ensures quality and homogeneity across the silicon carbide crystals. It also ensures a possibility to achieve device-quality epitaxial layers at lower growth temperatures as well as on on-axis or low off-angle substrate surfaces. The growth method can be applied to forming SiC device regions of desirable shape and dimensions by restricting the growth into windows formed in non-silicon carbide region on the top of SiC substrate. Application of the methods described herein will greatly benefit the production of high quality silicon carbide materials and devices.

Owner:MISSISSIPPI STATE UNIVERSITY

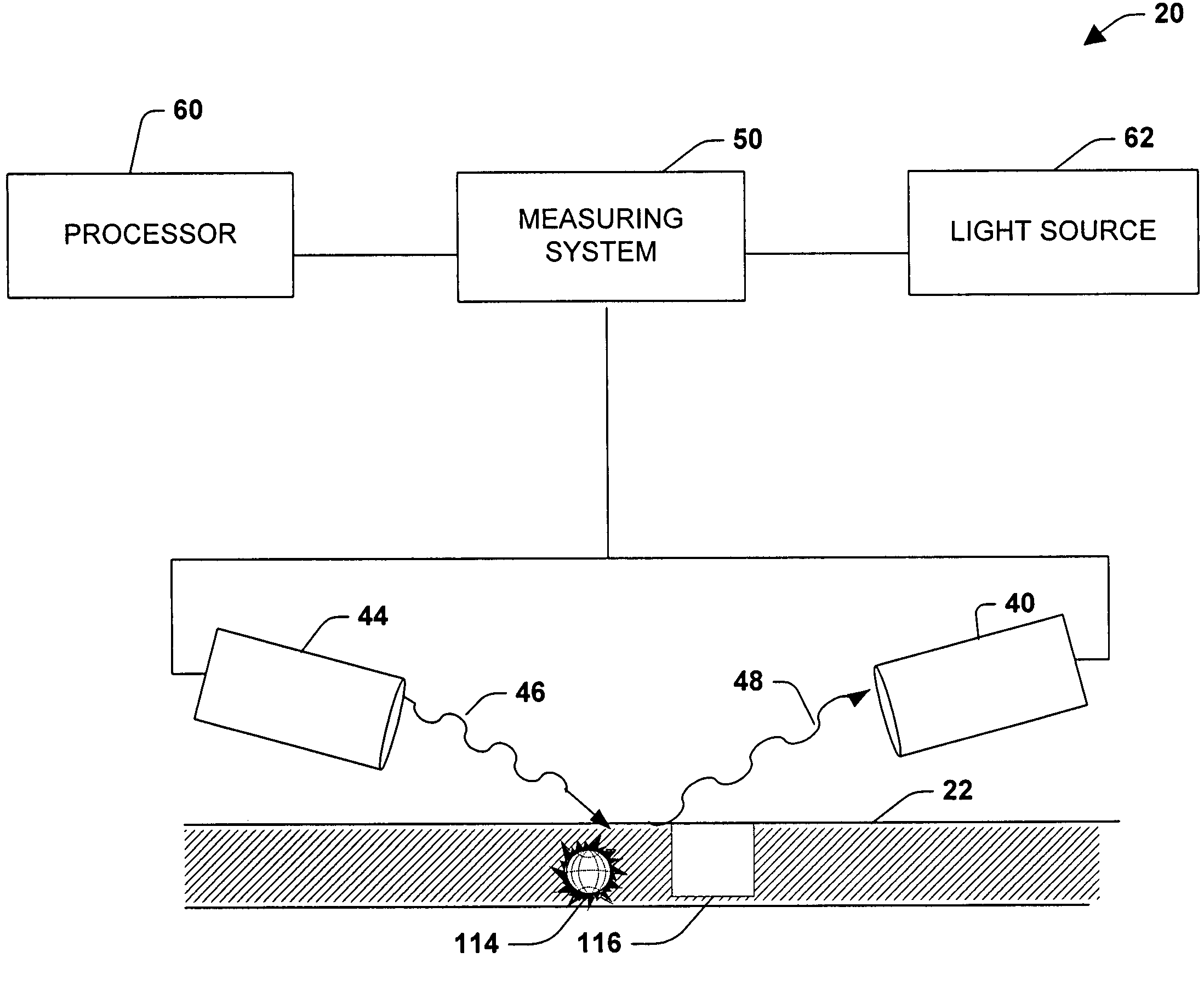

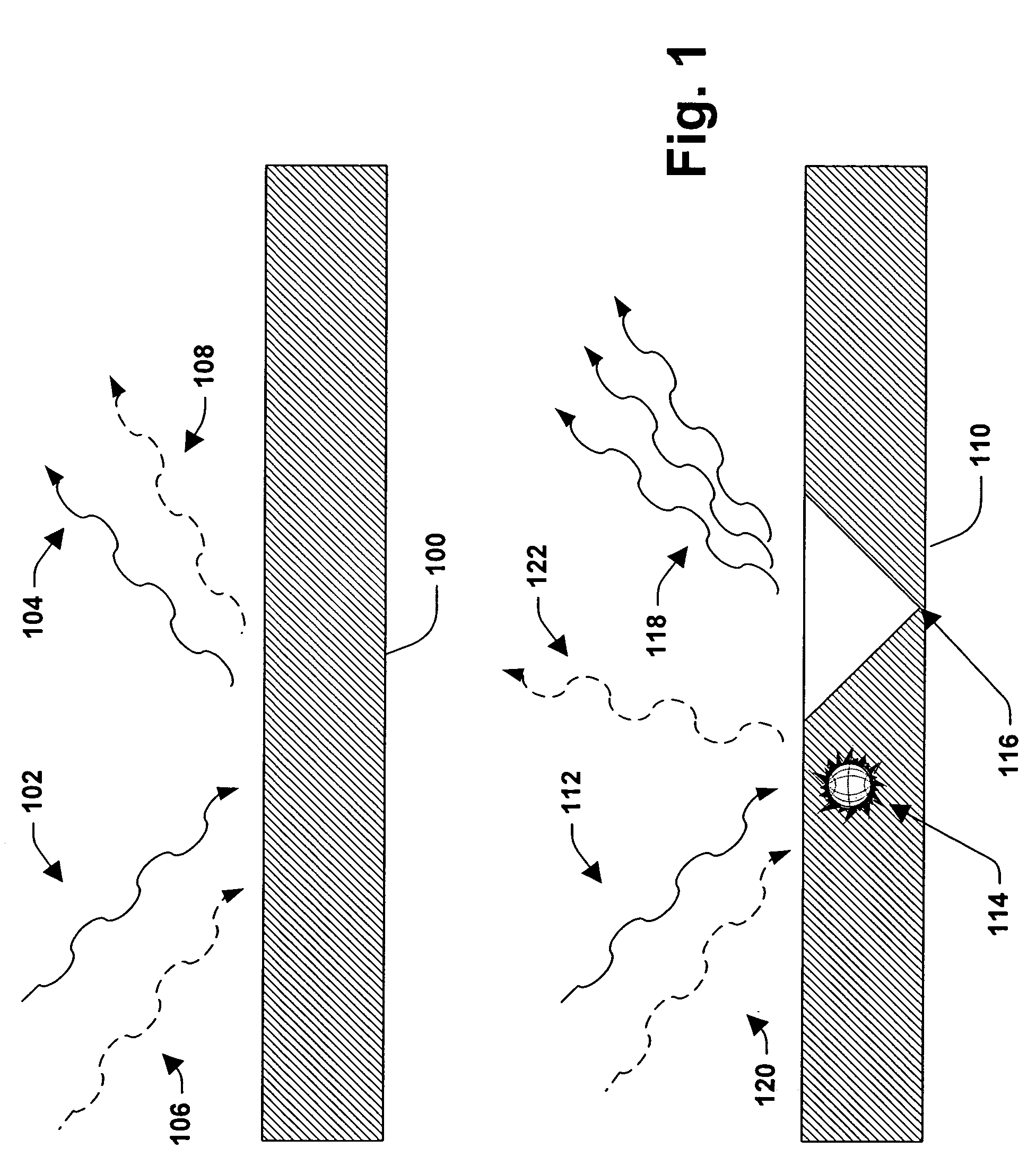

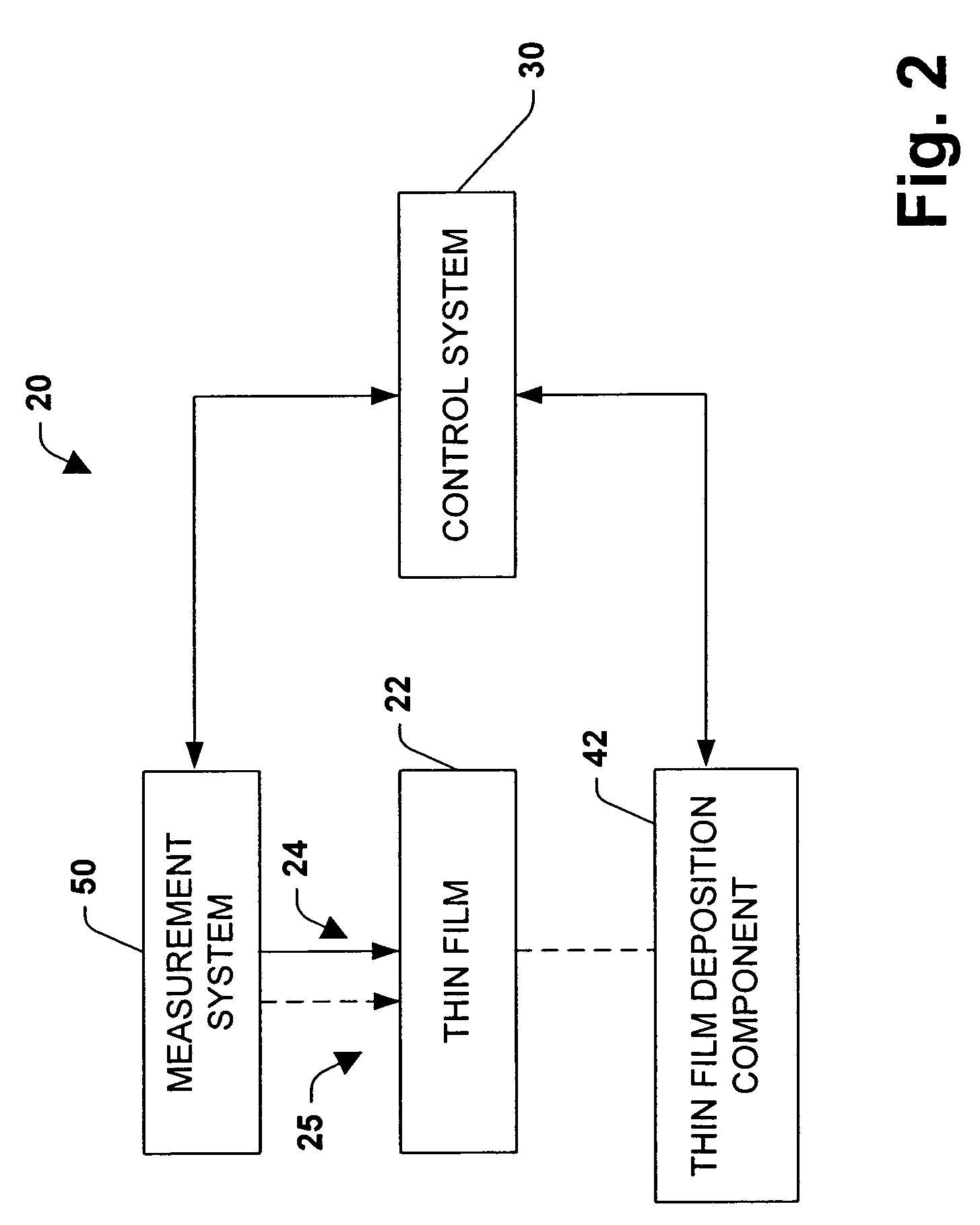

Scatterometry and acoustic based active control of thin film deposition process

InactiveUS7079975B1Faster and high densityEnhanced vapor depositionSemiconductor/solid-state device testing/measurementScattering properties measurementsSystems analysisMonitoring system

A system for monitoring and controlling the deposition of thin films employed in semiconductor fabrication is provided. The system includes one or more acoustic and / or ultrasonic wave sources, each source directing waves onto one or more thin films deposited on a wafer. Waves reflected from the thin film is collected by a monitoring system, which processes the collected waves. Waves passing through the thin film may similarly be collected by the monitoring system, which processes the collected waves. The collected waves are indicative of the presence of impurities and / or defects in the deposited thin film. The monitoring system analyzes and provides the collected wave data to a processor, which determines whether adjustments to thin film deposition parameters are needed. The system also includes a plurality of thin film deposition devices associated with depositing thin films on the wafer. The processor selectively controls thin film deposition parameters and devices to facilitate regulating deposition.

Owner:GLOBALFOUNDRIES INC

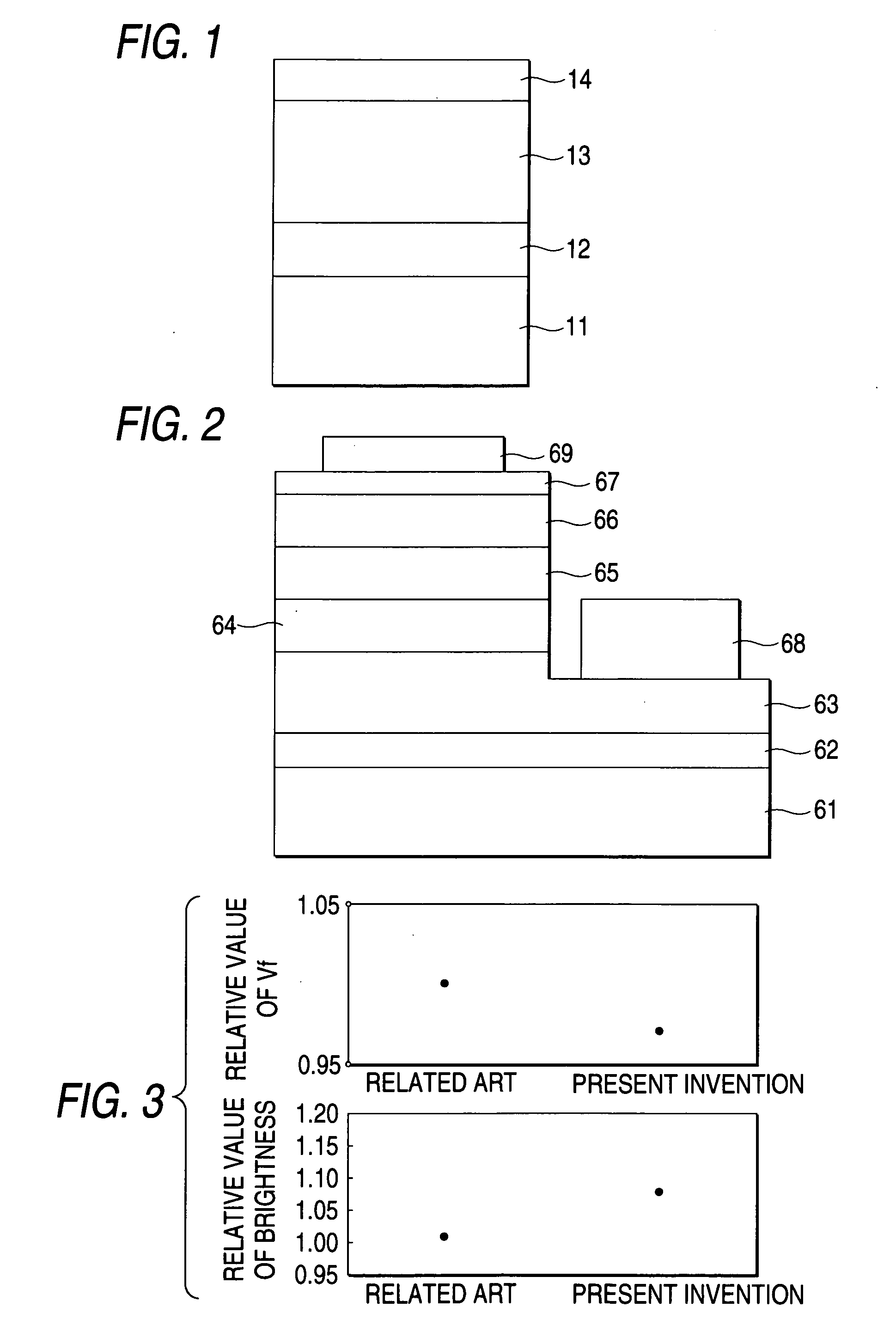

Plasma display panel and method for manaufacturing same

InactiveUS20060012721A1Good secondary electron emission propertyVoltage Vf can be reducedTelevision system detailsAddress electrodesElectronAtomic physics

A plasma display panel in which a first substrate having a protective layer formed thereon opposes a second substrate across a discharge space, with the substrates being sealed around a perimeter thereof. At a surface of the protective layer, first and second materials of different electron emission properties are exposed to the discharge space, with at least one of the materials existing in a dispersed state. The first and second materials may be first and second crystals, and the second crystal may be dispersed throughout the first crystal.

Owner:PANASONIC CORP

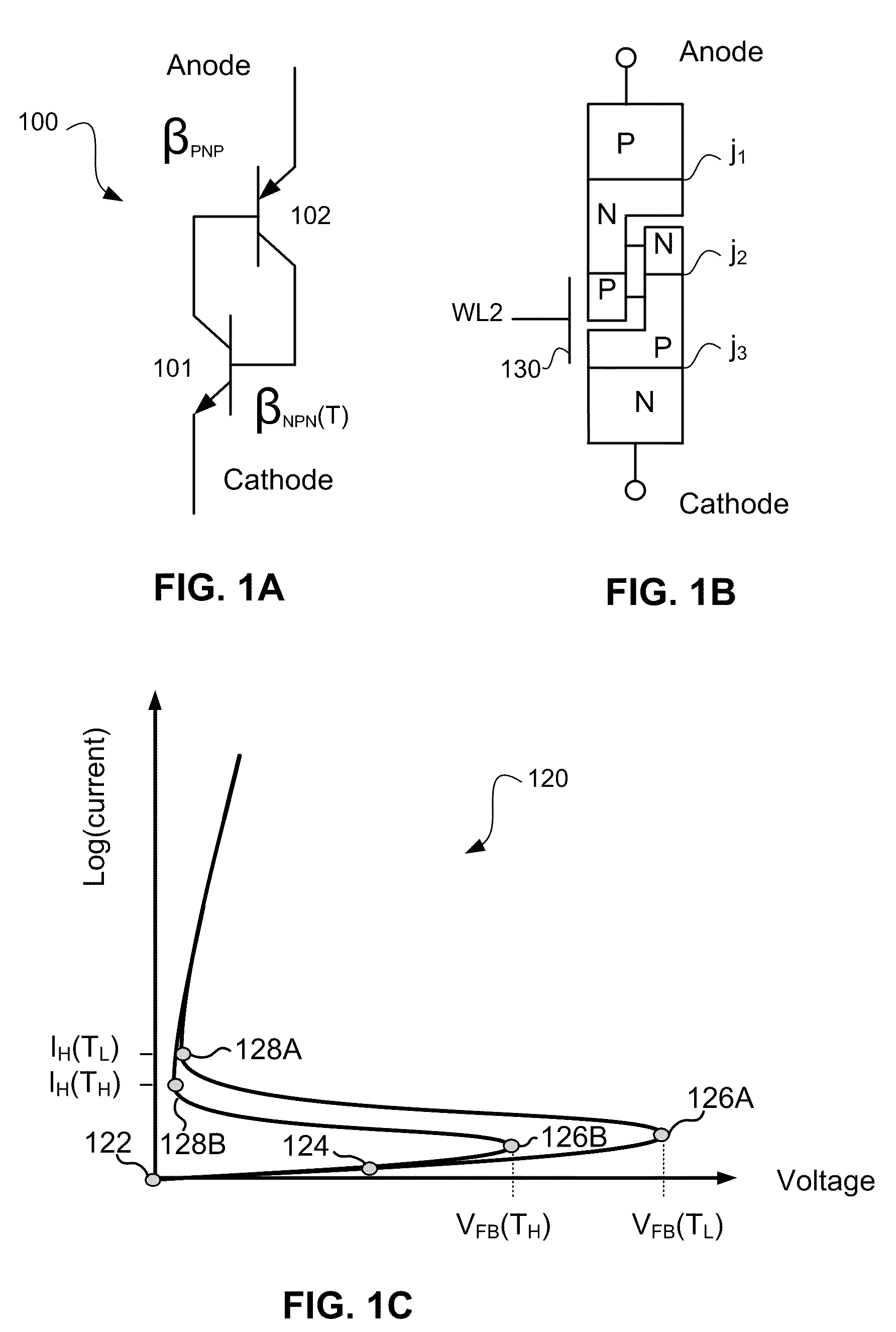

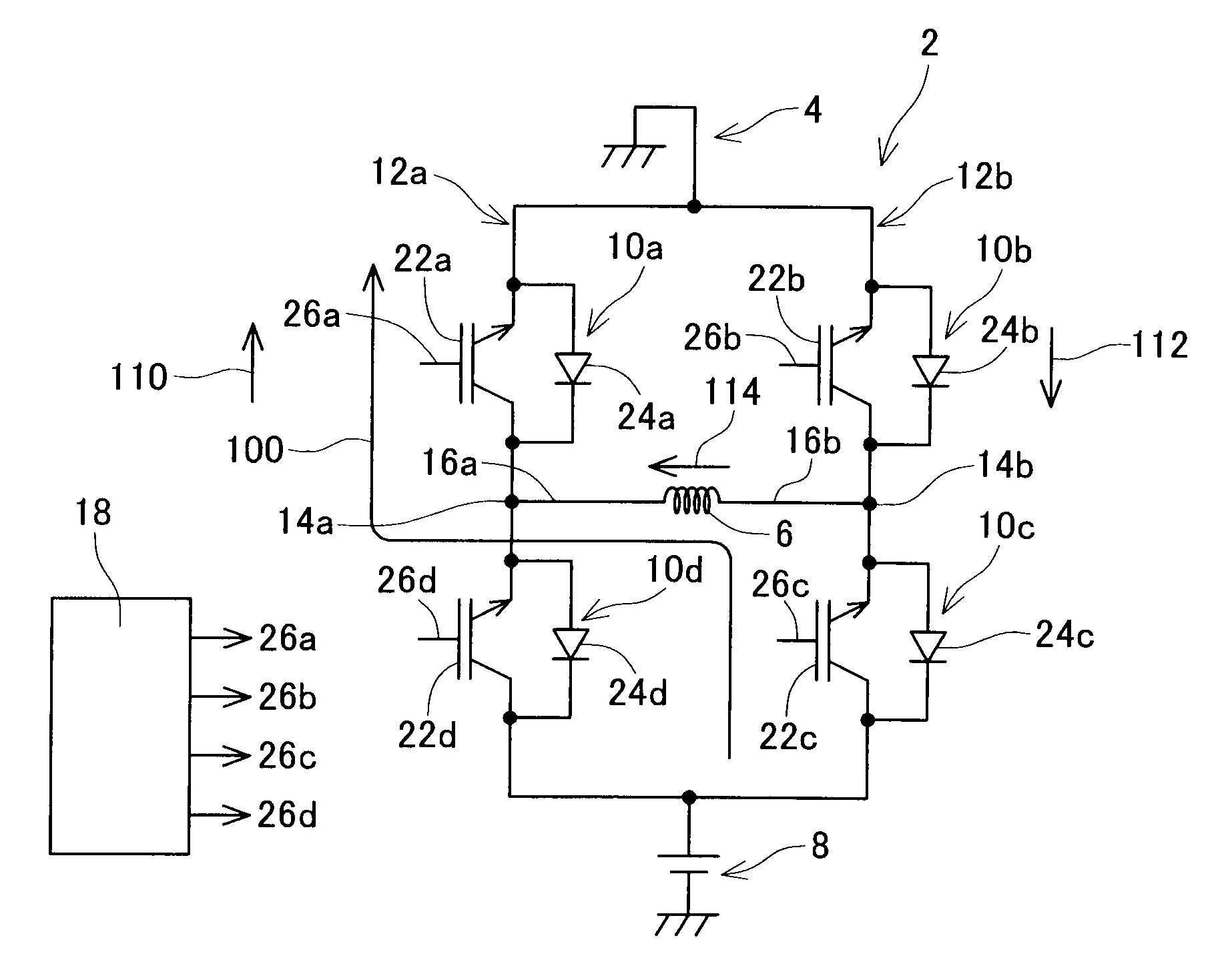

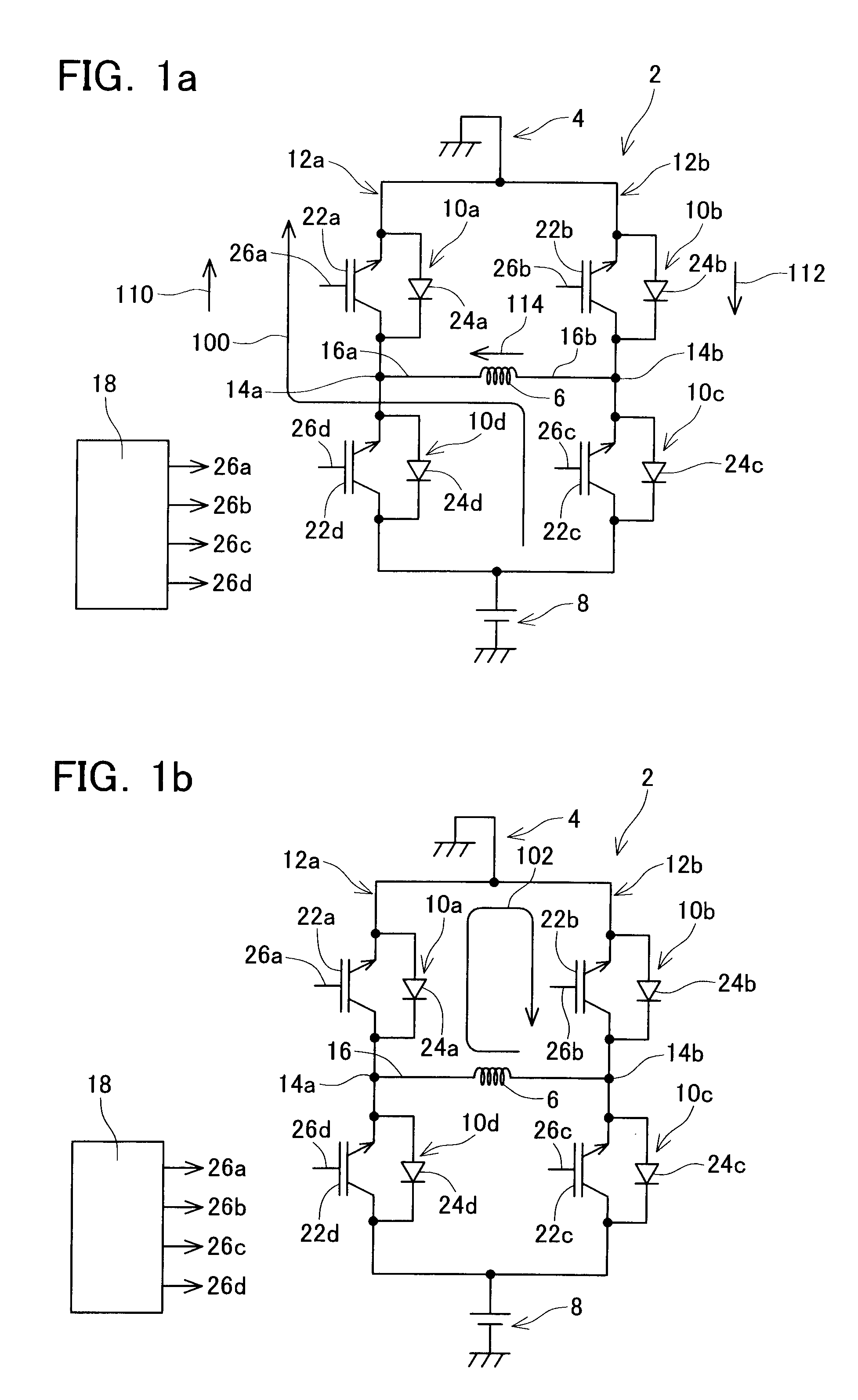

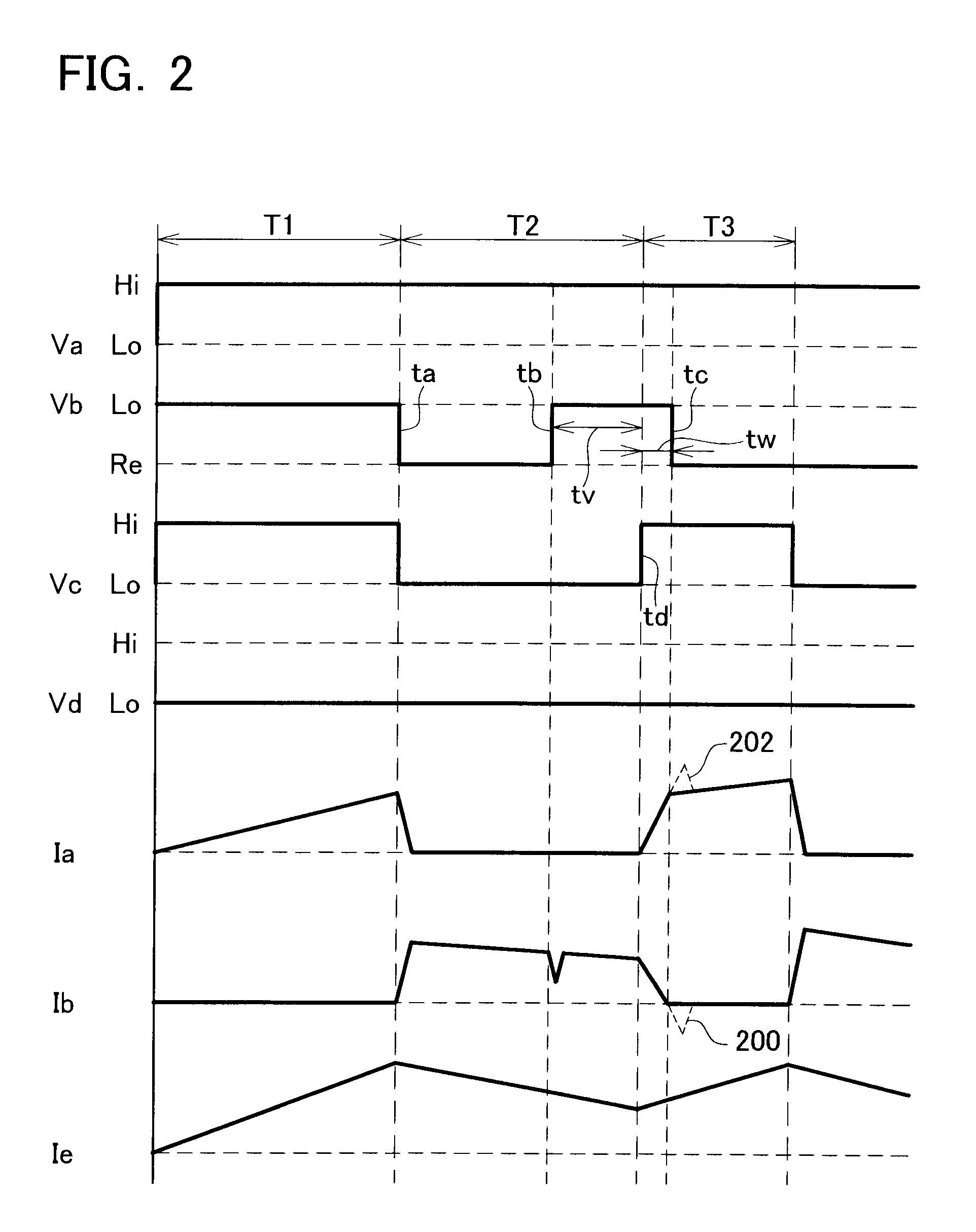

Power supply device and method for driving the same

ActiveUS20100283514A1Lower forward voltage dropGain is not constantAc-dc conversionElectronic switchingBody contactEngineering

In a reverse conducting semiconductor device, which forms a composition circuit, a positive voltage that is higher than a positive voltage of a collector electrode may be applied to an emitter electrode. In this case, in a region of the reverse conducting semiconductor device in which a return diode is formed, a body contact region functions as an anode, a drift contact region functions as a cathode, and current flows from the anode to the cathode. When a voltage having a lower electric potential than the collector electrode is applied to the trench gate electrode at that time, p-type carriers are generated within the cathode and a quantity of carriers increases within the return diode. As a result, a forward voltage drop of the return diode lowers, and constant loss of electric power can be reduced. Electric power loss can be reduced in a power supply device that uses such a composition circuit in which a switching element and the return diode are connected in reverse parallel.

Owner:DENSO CORP

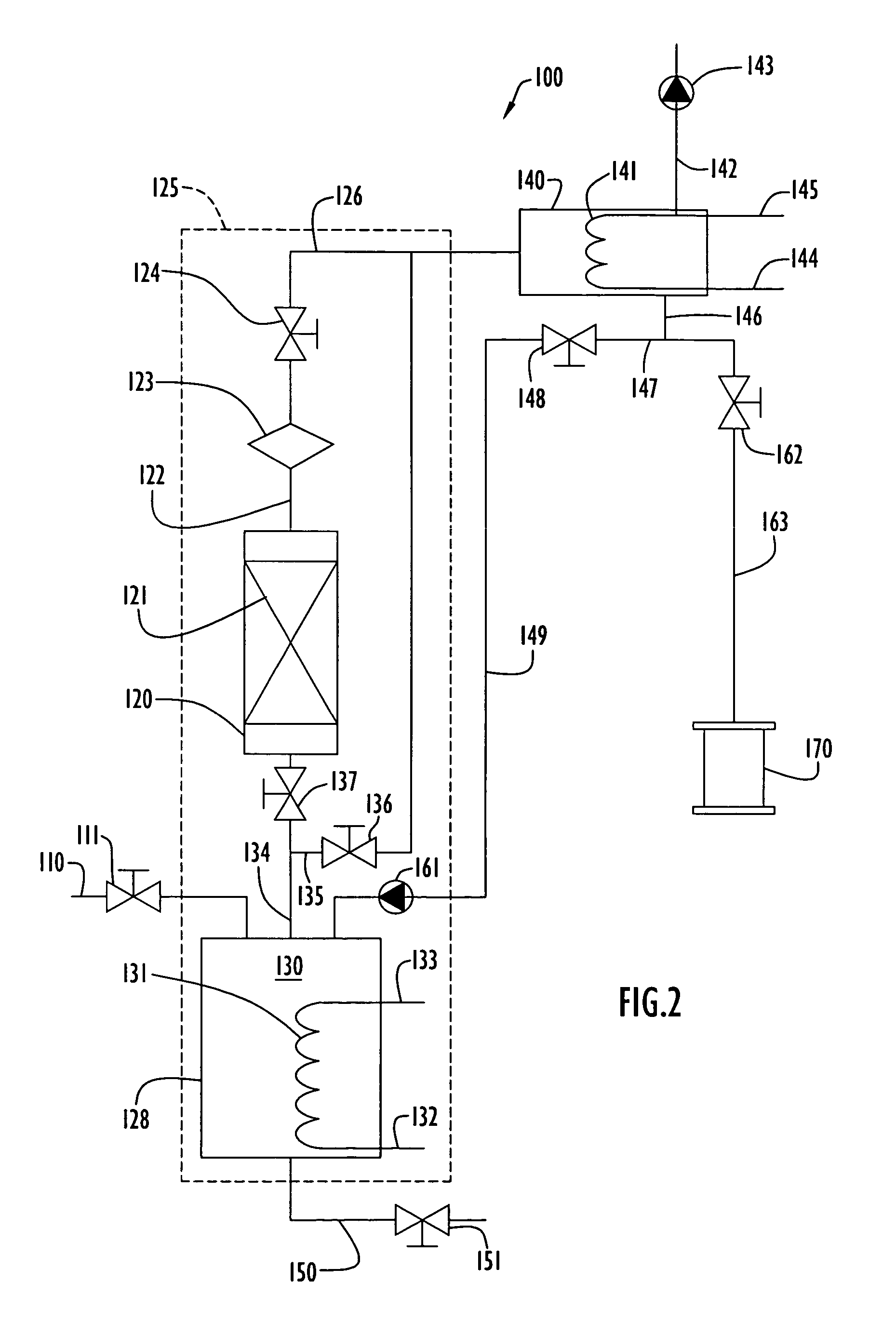

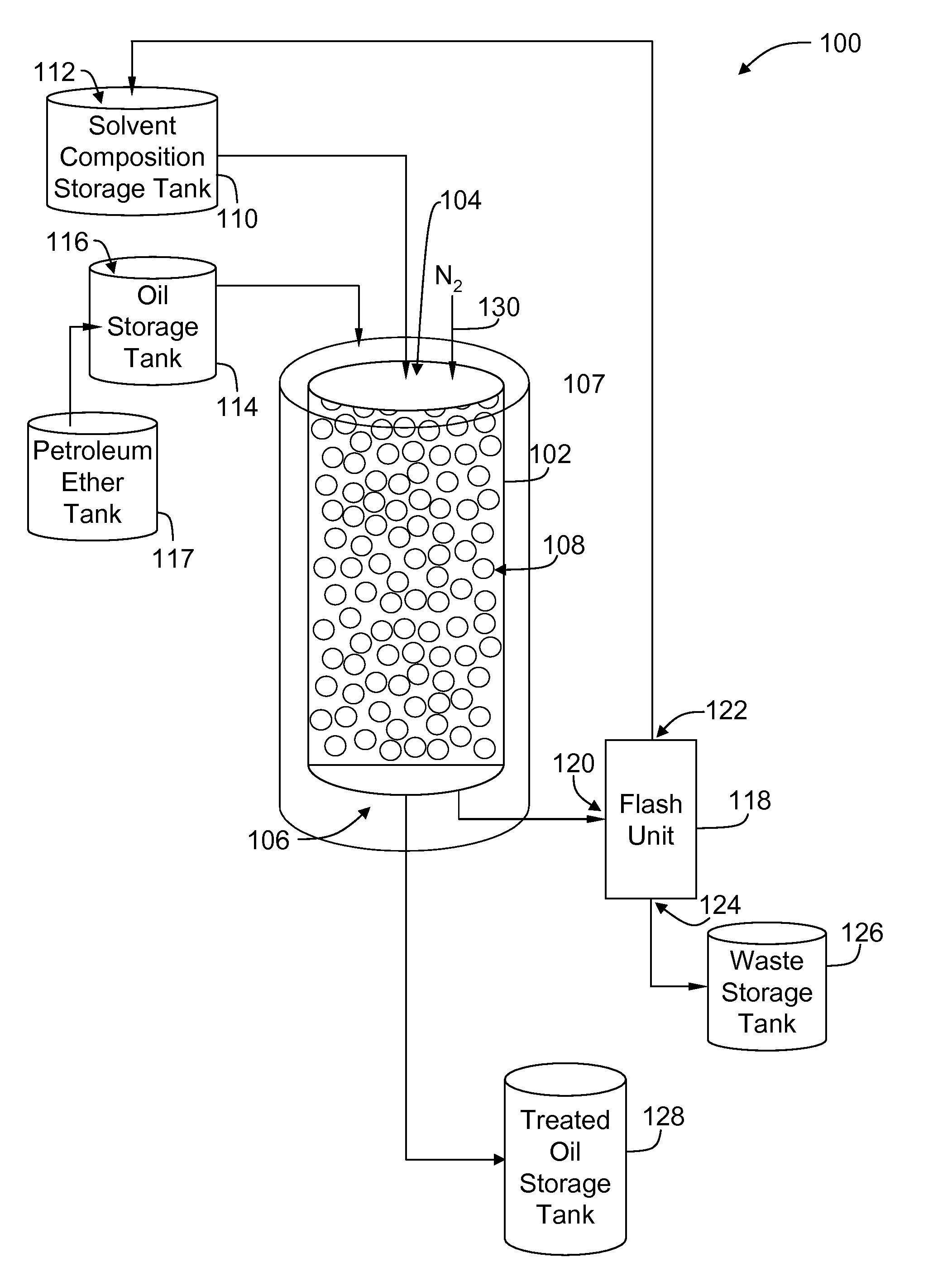

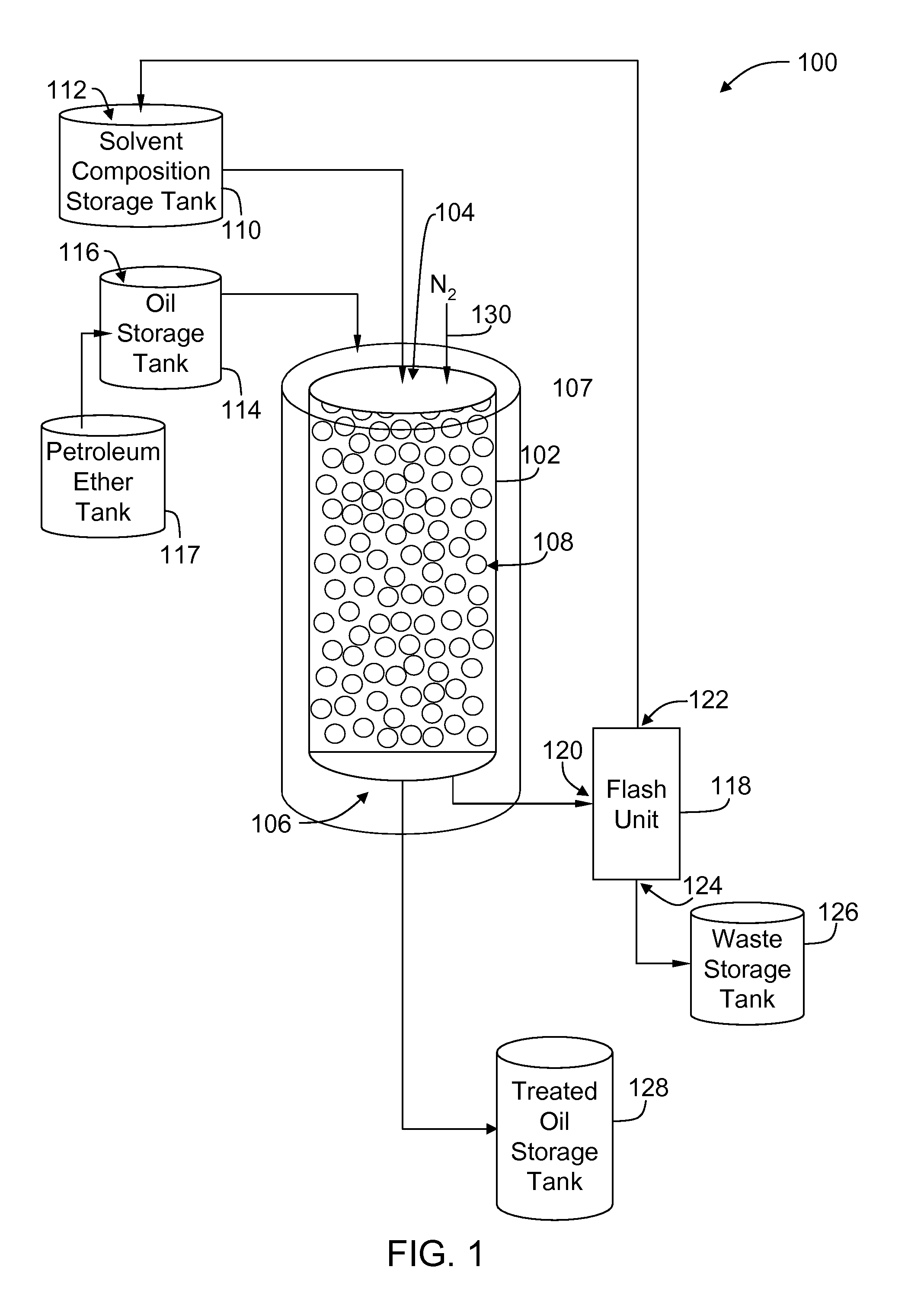

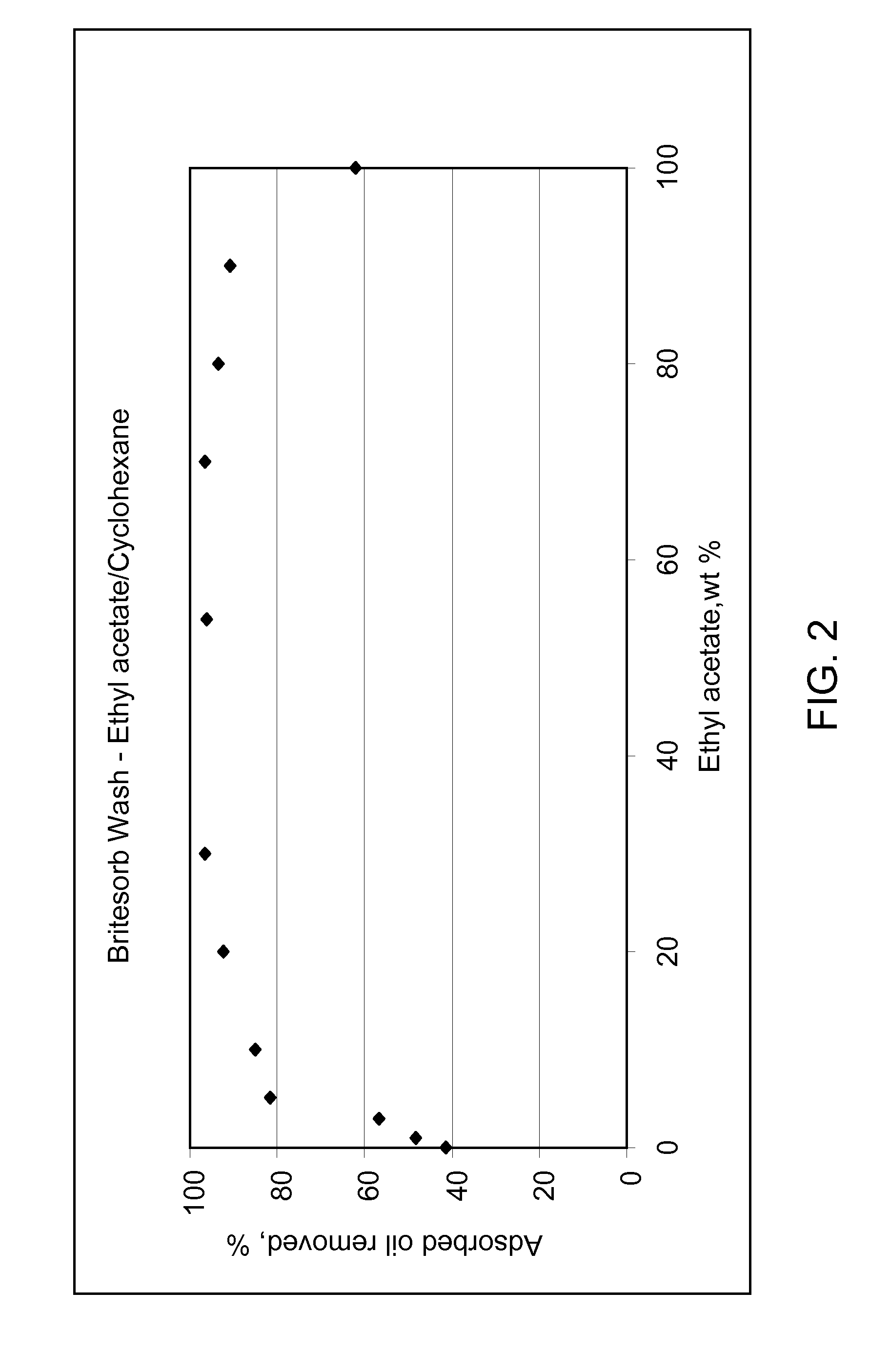

Methods and system for regeneration of adsorbent material

ActiveUS20090312176A1Facilitate removing oilImpurities increaseInorganic chemistryOther chemical processesSorbentImpurity

Owner:GENERAL ELECTRIC CO

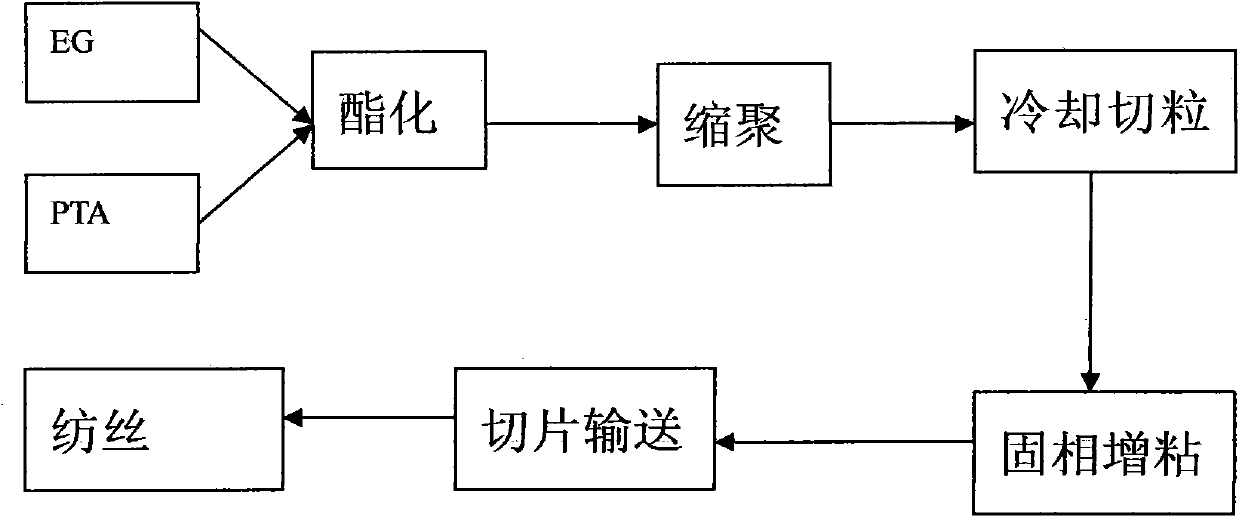

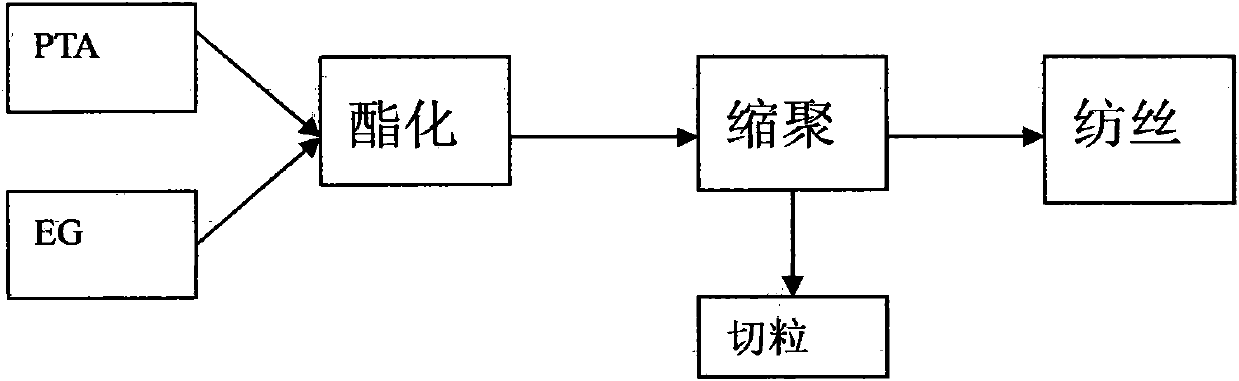

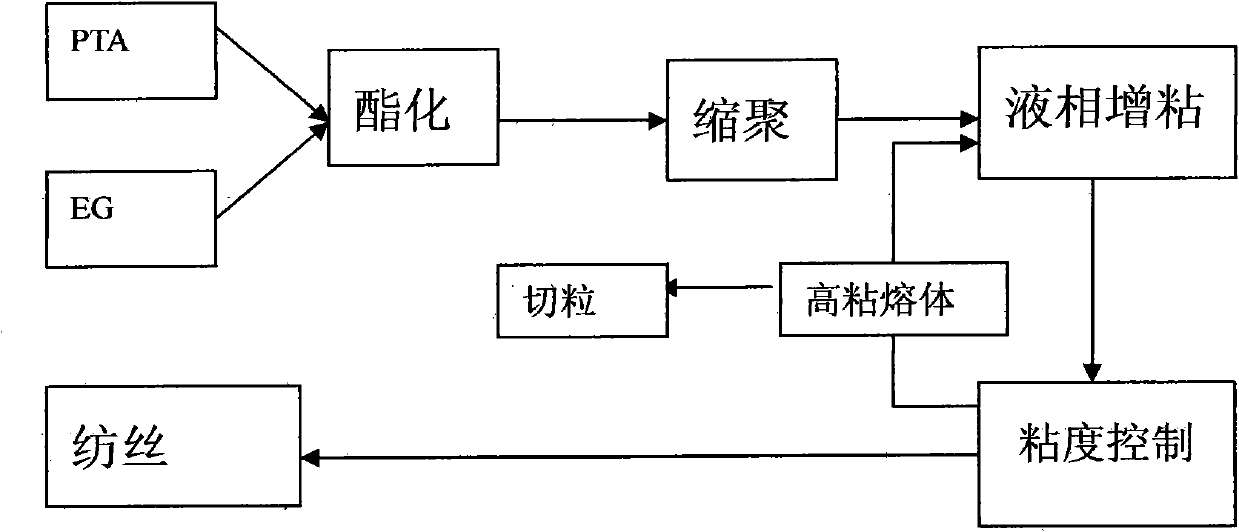

Production process for directly-spun terylene industrial filament of liquid-phase tackifying fusant

ActiveCN101768788AEasy to degradeReduce manufacturing costFilament forming substance formingMelt spinning methodsChemistryPolyester

The invention discloses a production process for a directly-spun terylene industrial filament of a liquid-phase tackifying fusant, belonging to the technical field of spinning. The production process includes the following steps: esterification, polycondensation, liquid-phase tackification and spinning. The production process is characterized in that: in a vertical reaction kettle, liquid-phase tackfication is carried out on the fusant obtained through esterification and polycondensation of glycol and phthalic acid; the vertical reaction kettle adopts a tower type film forming structure; the fusant enters the vertical reaction kettle from the top part for distribution, and the film forming is naturally finished under the action of gravity; a backflow pipeline is provided for the discharging of the reaction kettle, the viscosity and flow rate of the fusant are controlled by the backflow adjusting, the intrinsic viscosity of the polyester fusant after being tackified in a liquid-phase manner is within 0.85 to 1.0dl / g, and the fusant is conveyed to a spinning box body by a gear pump for spinning. By reasonably designing the reaction kettle and allocating the process, the invention effectively solves the consistency between the fusant reacting condition and the staying time; meanwhile, the consumption of a public medium is reduced, and the cost is lowered; by optimizing the process, the invention increases the production efficiency of a system and improves the product quality.

Owner:ZHEJIANG GUXIANDAO POLYESTER DOPE DYED YARN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com