Patents

Literature

2780 results about "Gear pump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gear pump uses the meshing of gears to pump fluid by displacement. They are one of the most common types of pumps for hydraulic fluid power applications. The gear pump was invented around 1600 by Johannes Kepler.

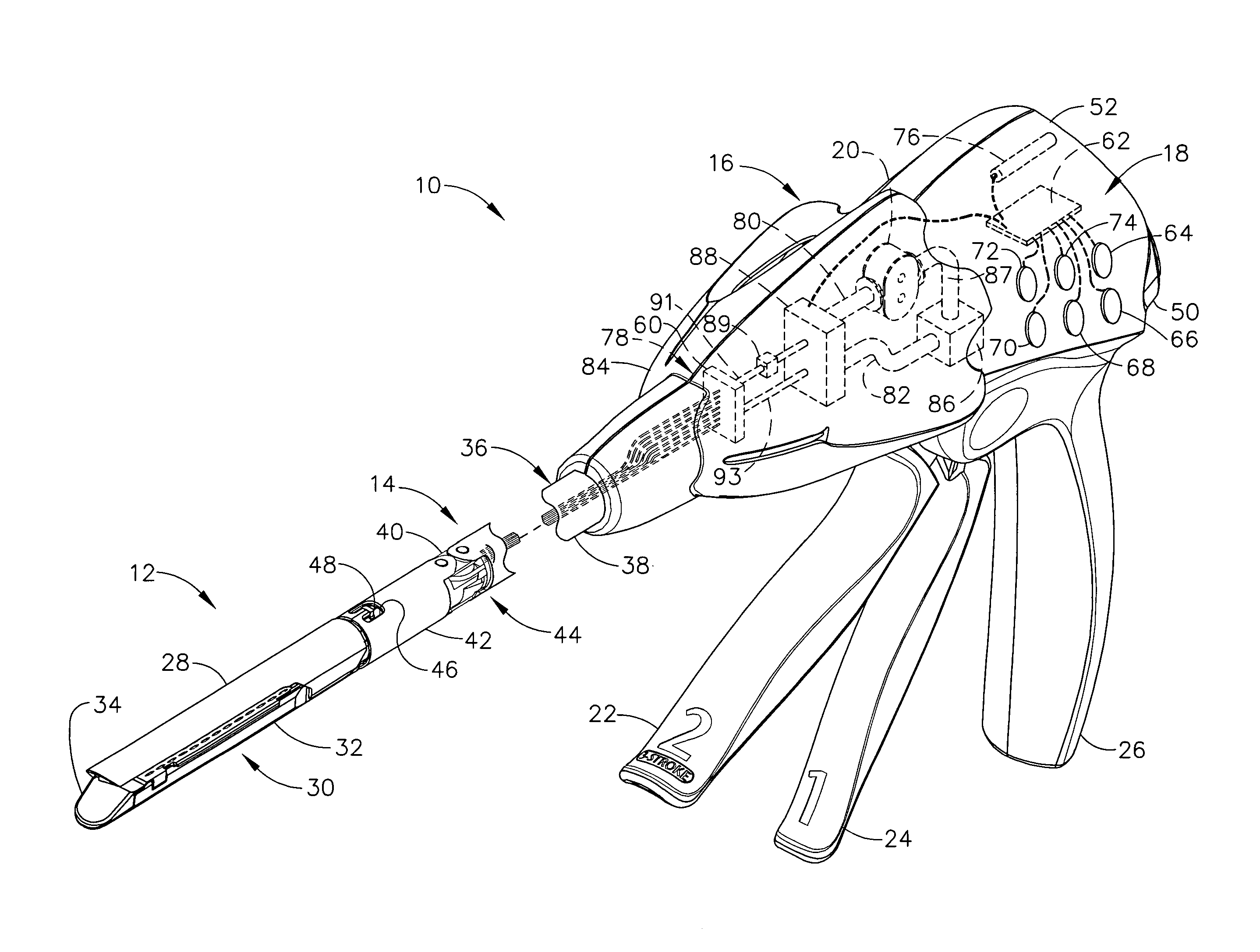

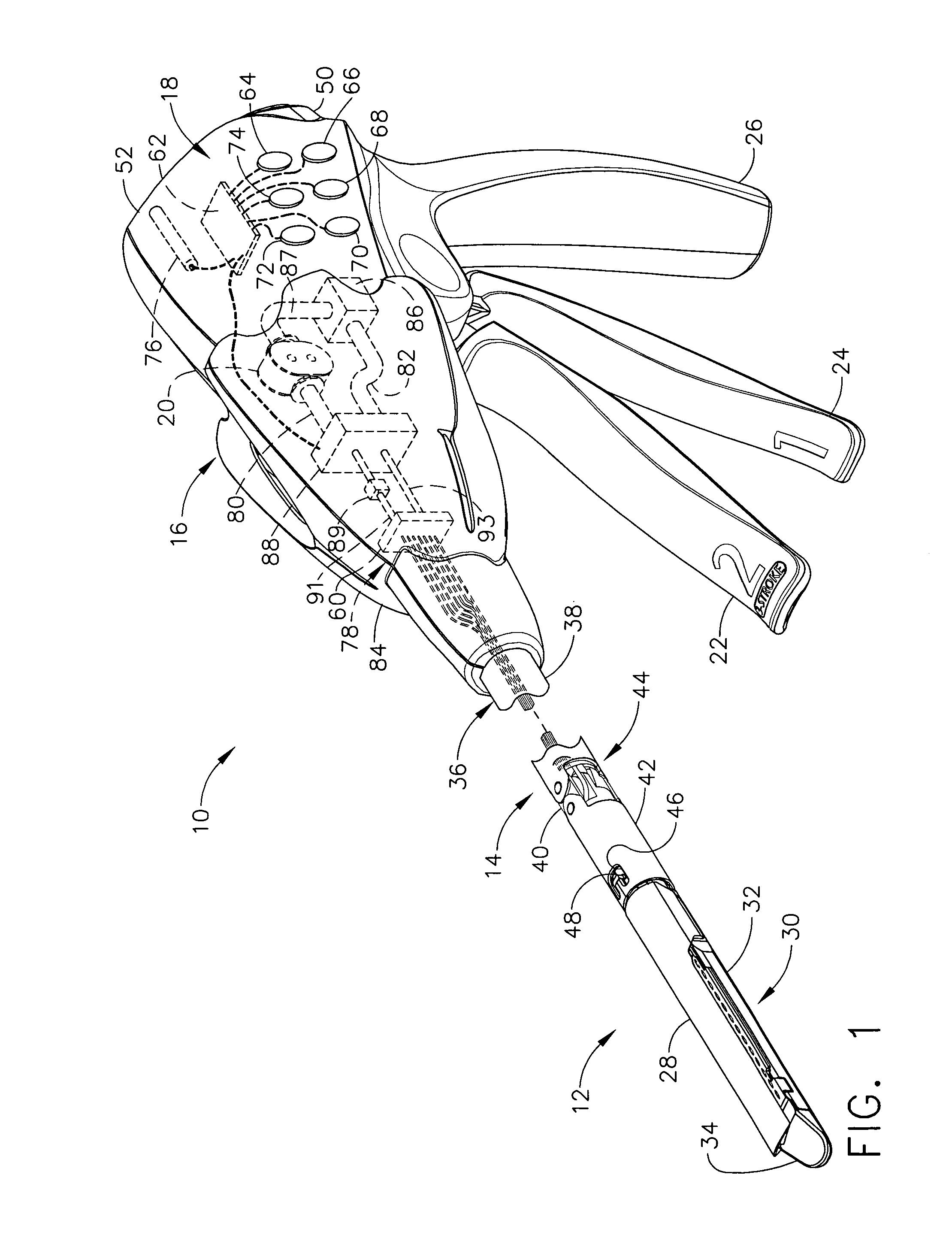

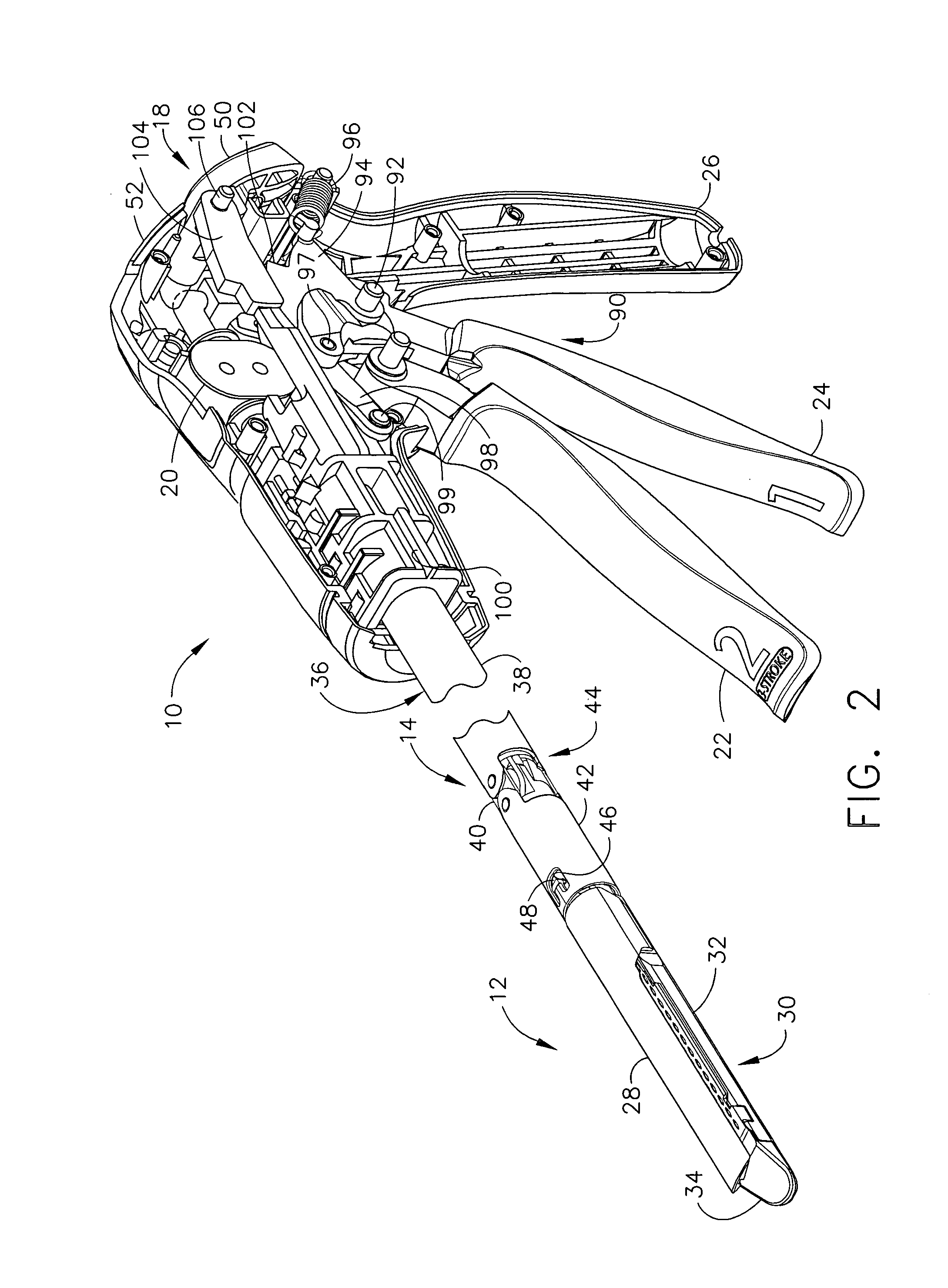

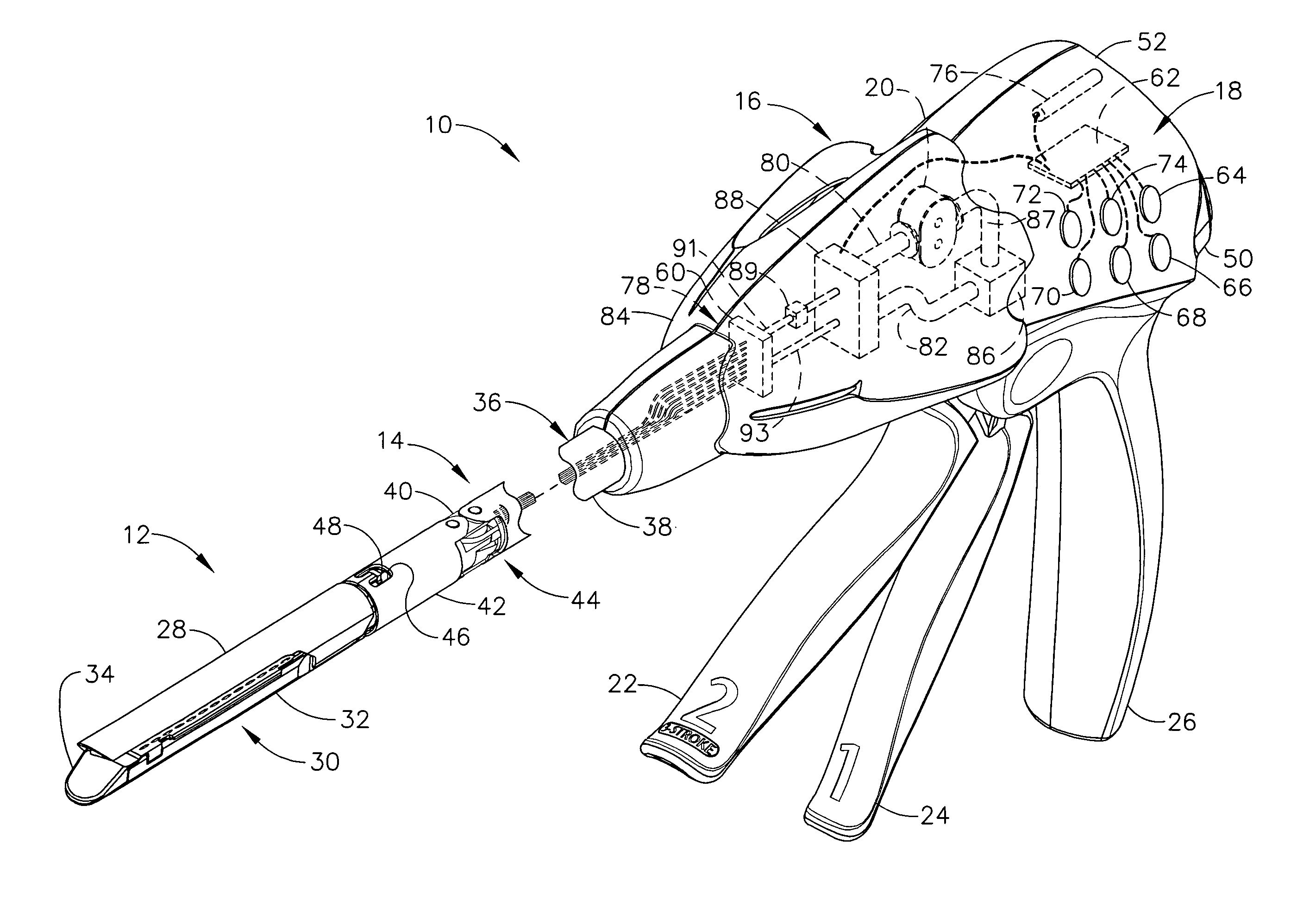

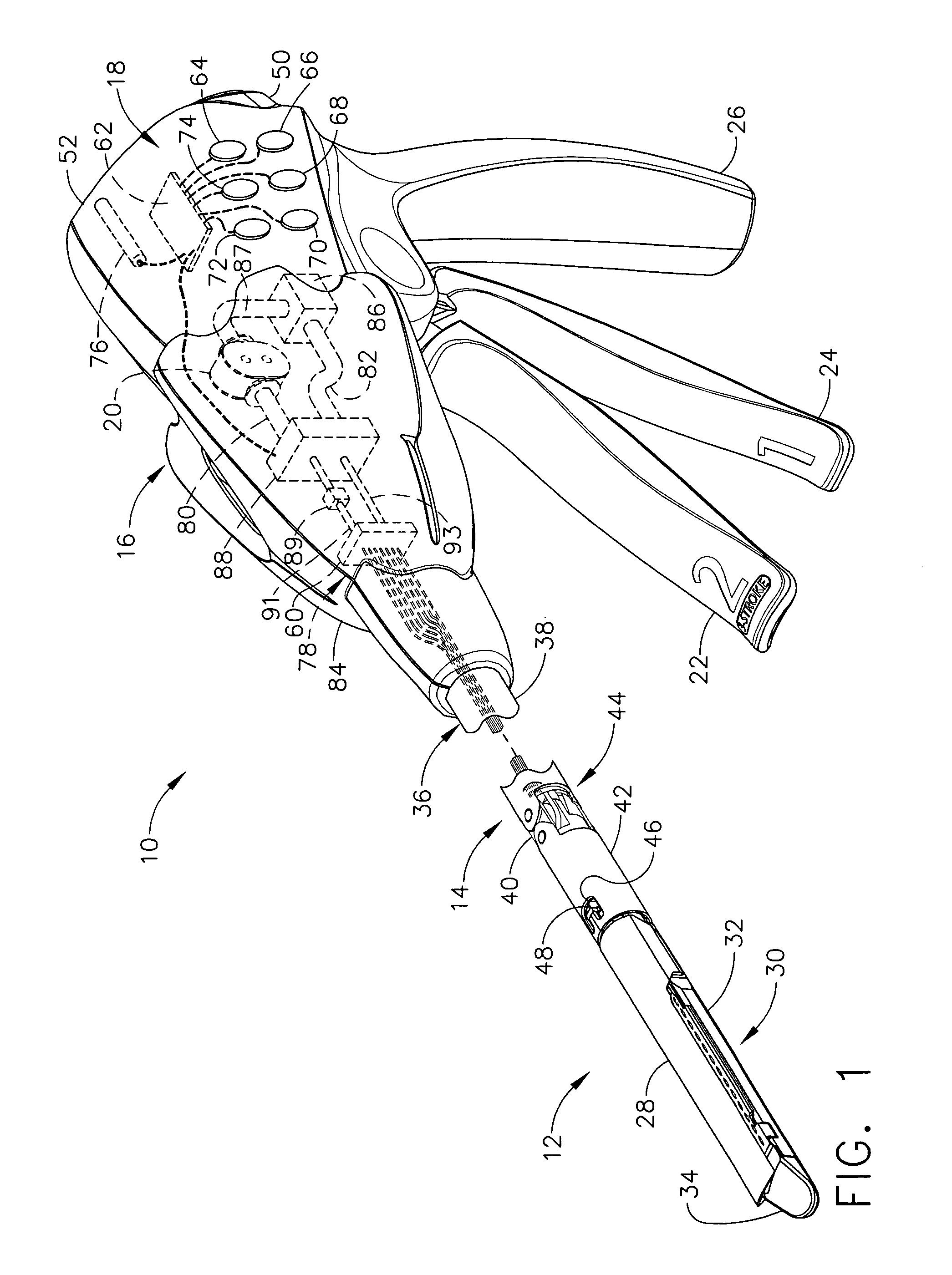

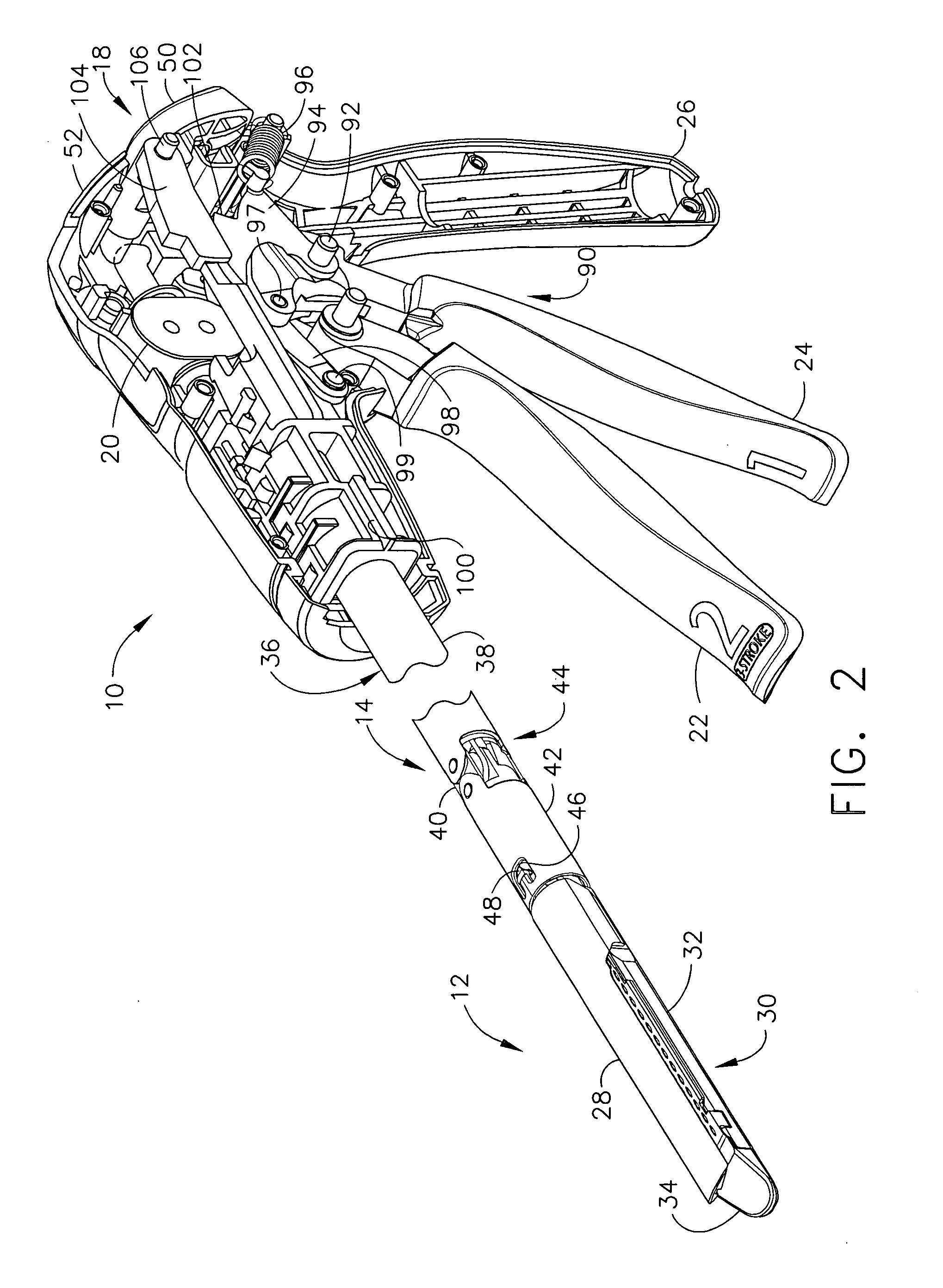

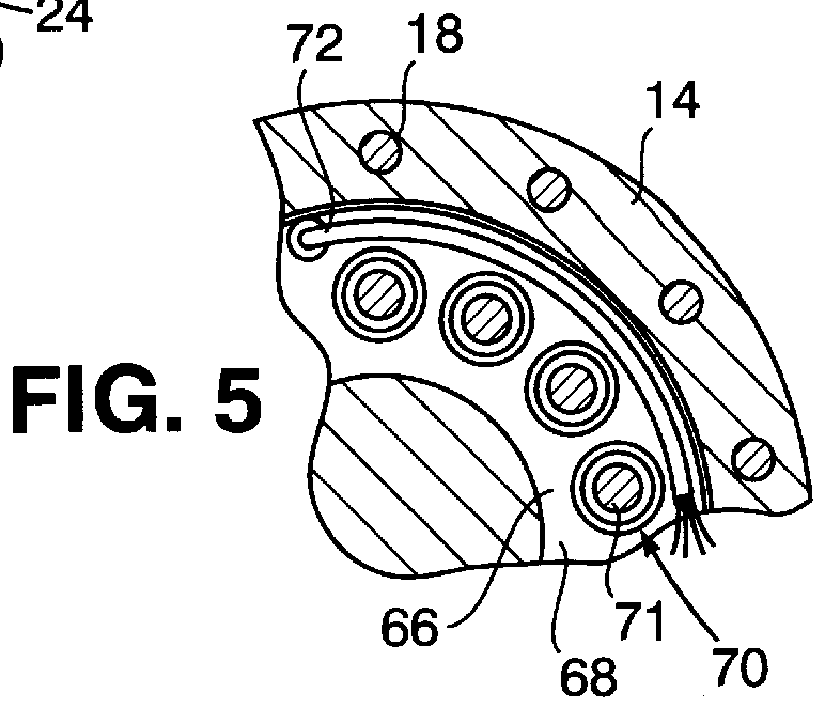

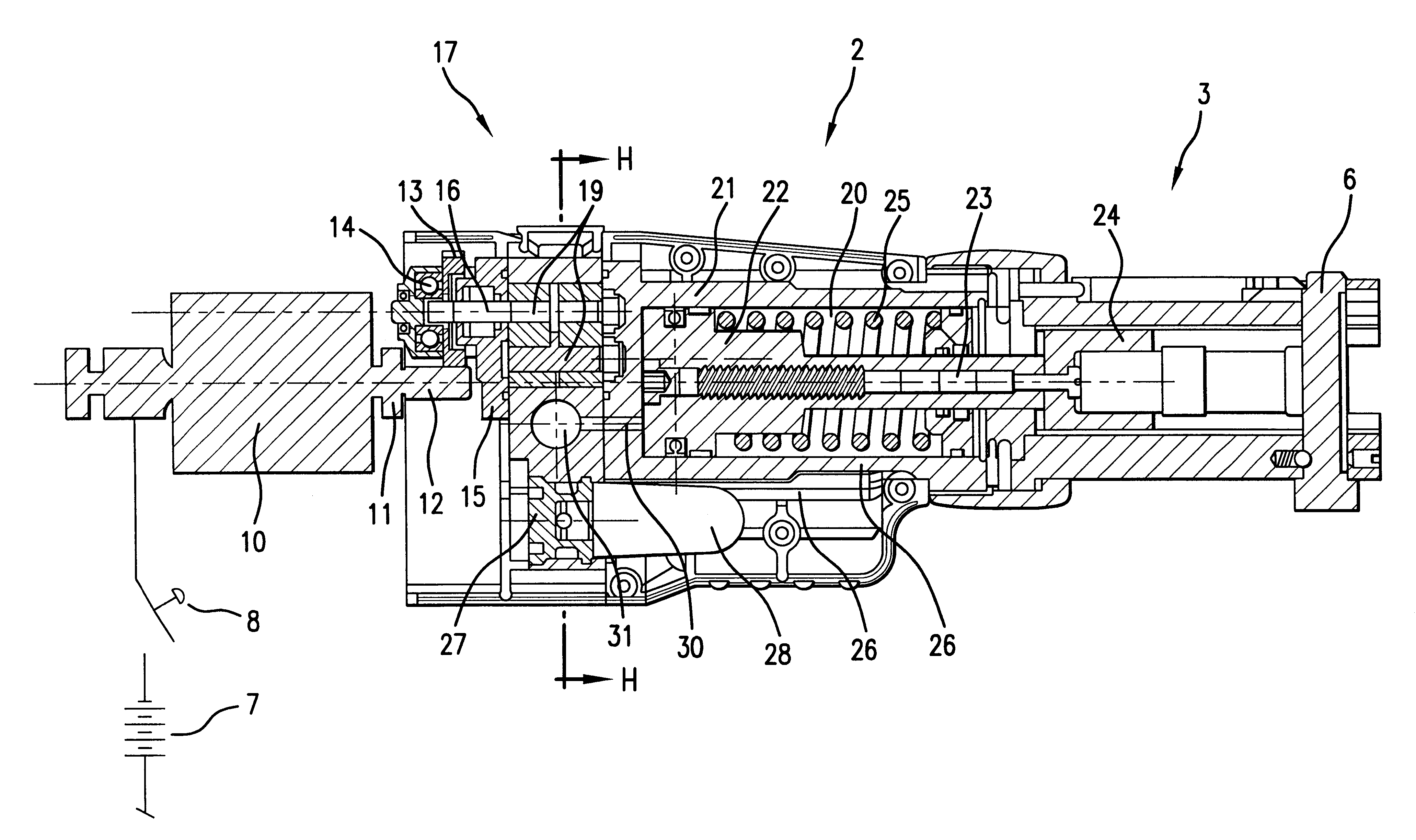

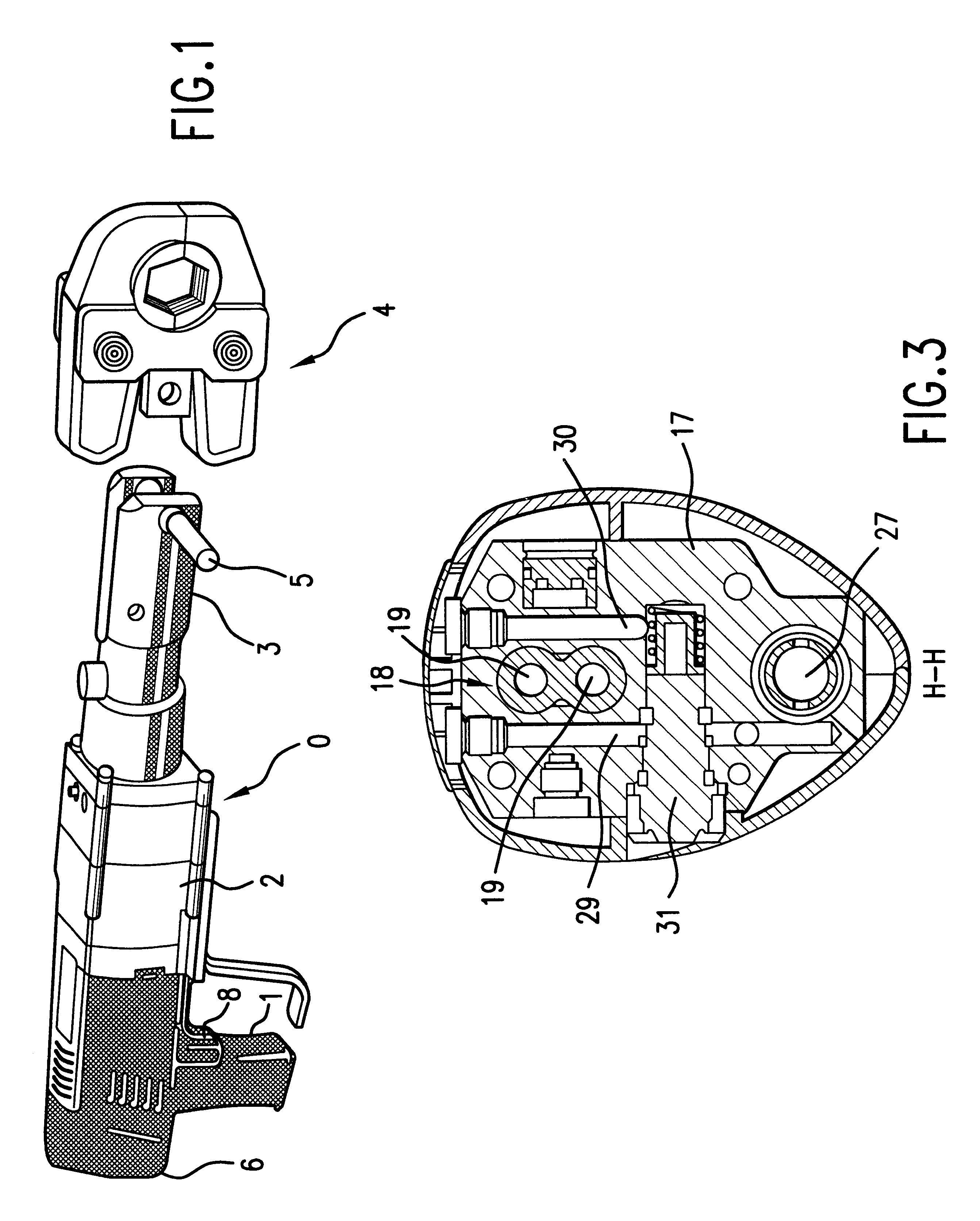

Rotary hydraulic pump actuated multi-stroke surgical instrument

A surgical instrument (e.g., endocutter, grasper, cutter, staplers, clip applier, access device, drug / gene therapy delivery device, and energy device using ultrasound, RF, laser, etc.) may benefit from having a plurality of hydraulically actuated subsystems (e.g., severing, stapling, articulation, locking / unlocking, lockout enabling / disabling, grasping, etc.) supplied with hydraulic power from a trigger actuated rotary pump (e.g., lobe pump, rotary gear pump, internal rotating gear pump, flexible vane rotor pump, rotary vane pump). Thereby, an available amount of mechanical advantage available at a firing trigger may be optimally distributed to various end effector components, perhaps sequenced by an electroactive polymer or piezoelelectrically actuated function switch block.

Owner:ETHICON ENDO SURGERY INC

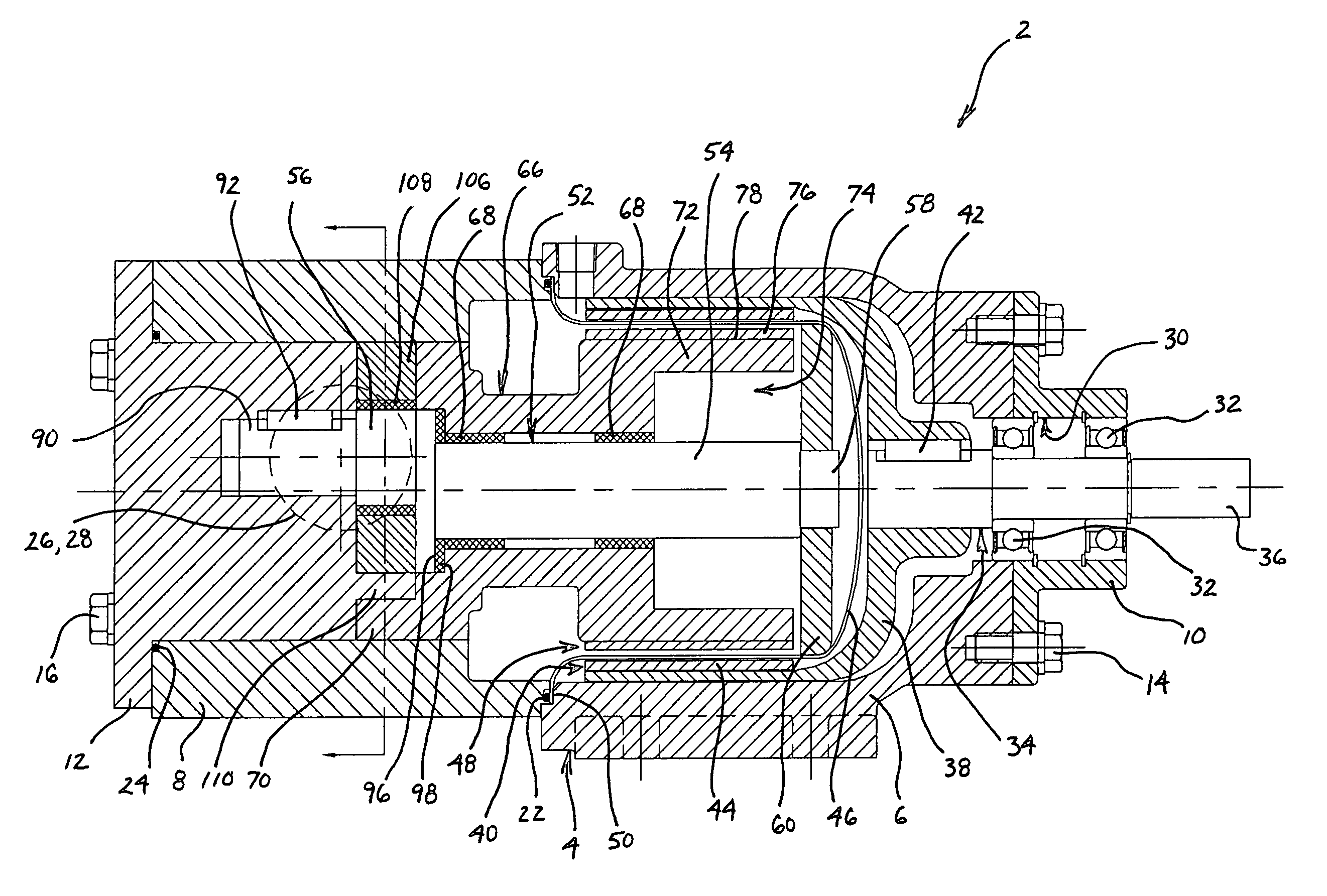

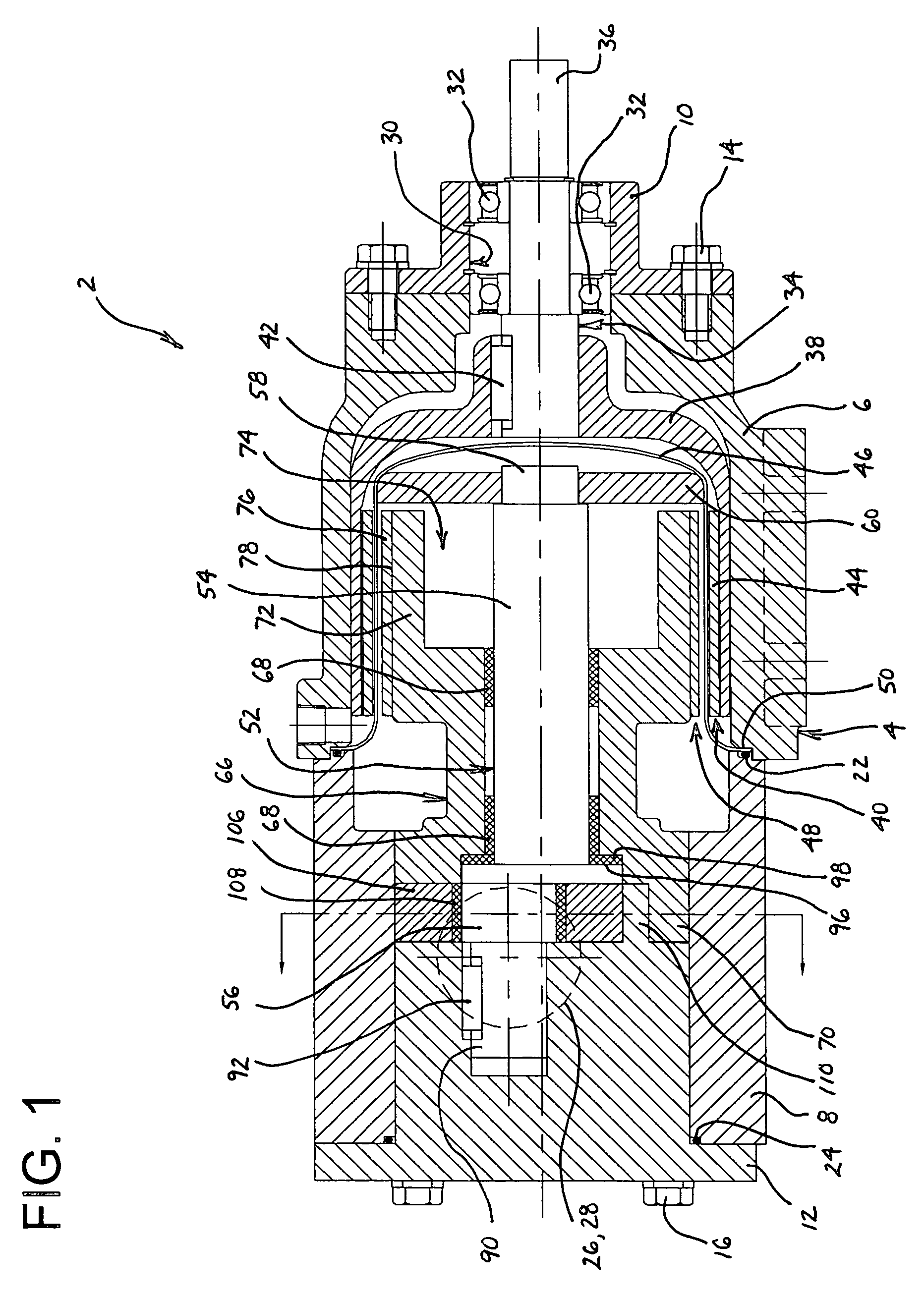

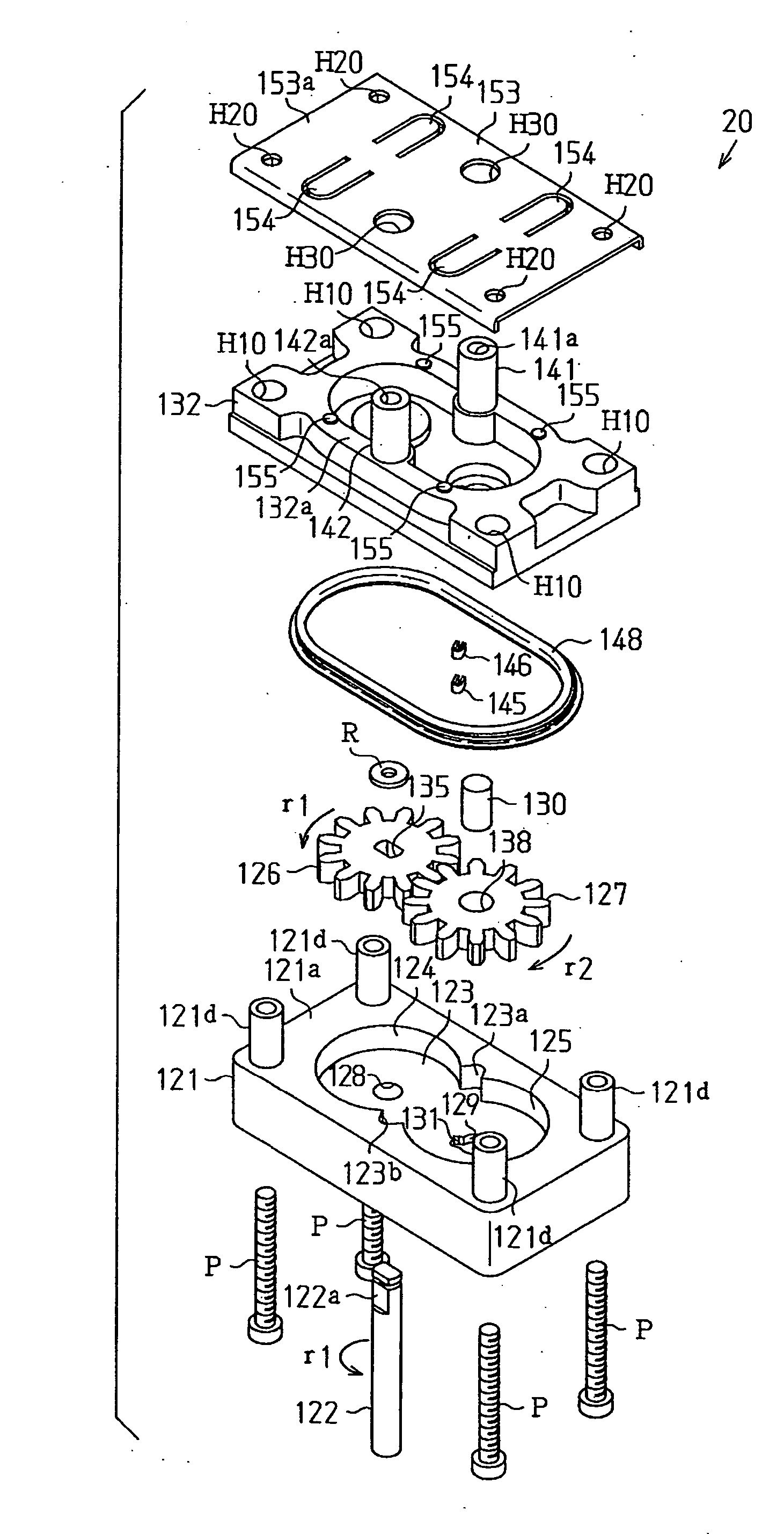

Rotary hydraulic pump actuated multi-stroke surgical instrument

A surgical instrument (e.g., endocutter, grasper, cutter, staplers, clip applier, access device, drug / gene therapy delivery device, and energy device using ultrasound, RF, laser, etc.) may benefit from having a plurality of hydraulically actuated subsystems (e.g., severing, stapling, articulation, locking / unlocking, lockout enabling / disabling, grasping, etc.) supplied with hydraulic power from a trigger actuated rotary pump (e.g., lobe pump, rotary gear pump, internal rotating gear pump, flexible vane rotor pump, rotary vane pump). Thereby, an available amount of mechanical advantage available at a firing trigger may be optimally distributed to various end effector components, perhaps sequenced by an electroactive polymer or piezoelectrically actuated function switch block.

Owner:ETHICON ENDO SURGERY INC

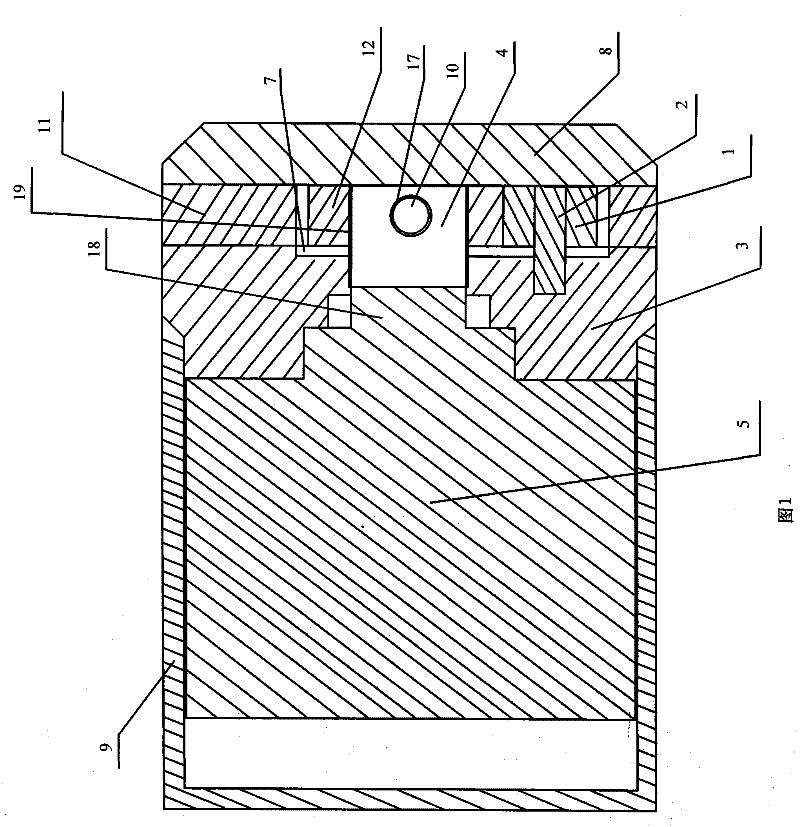

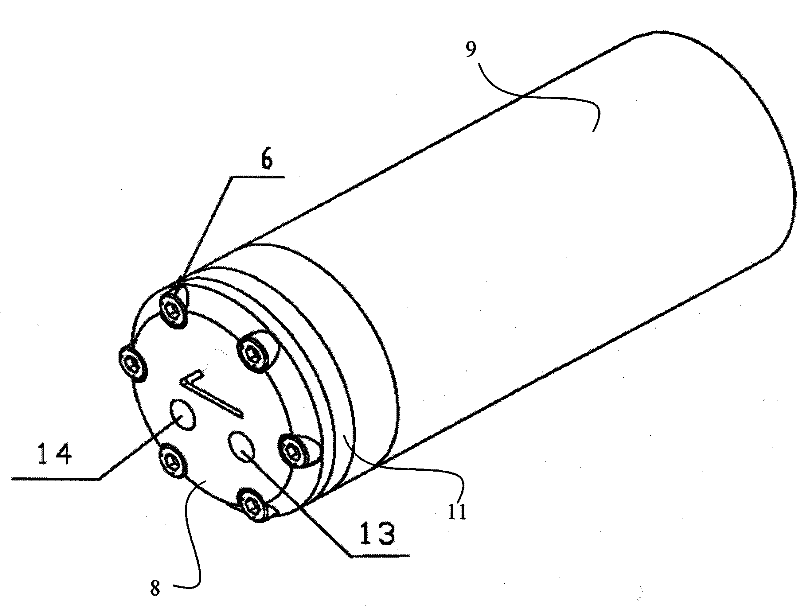

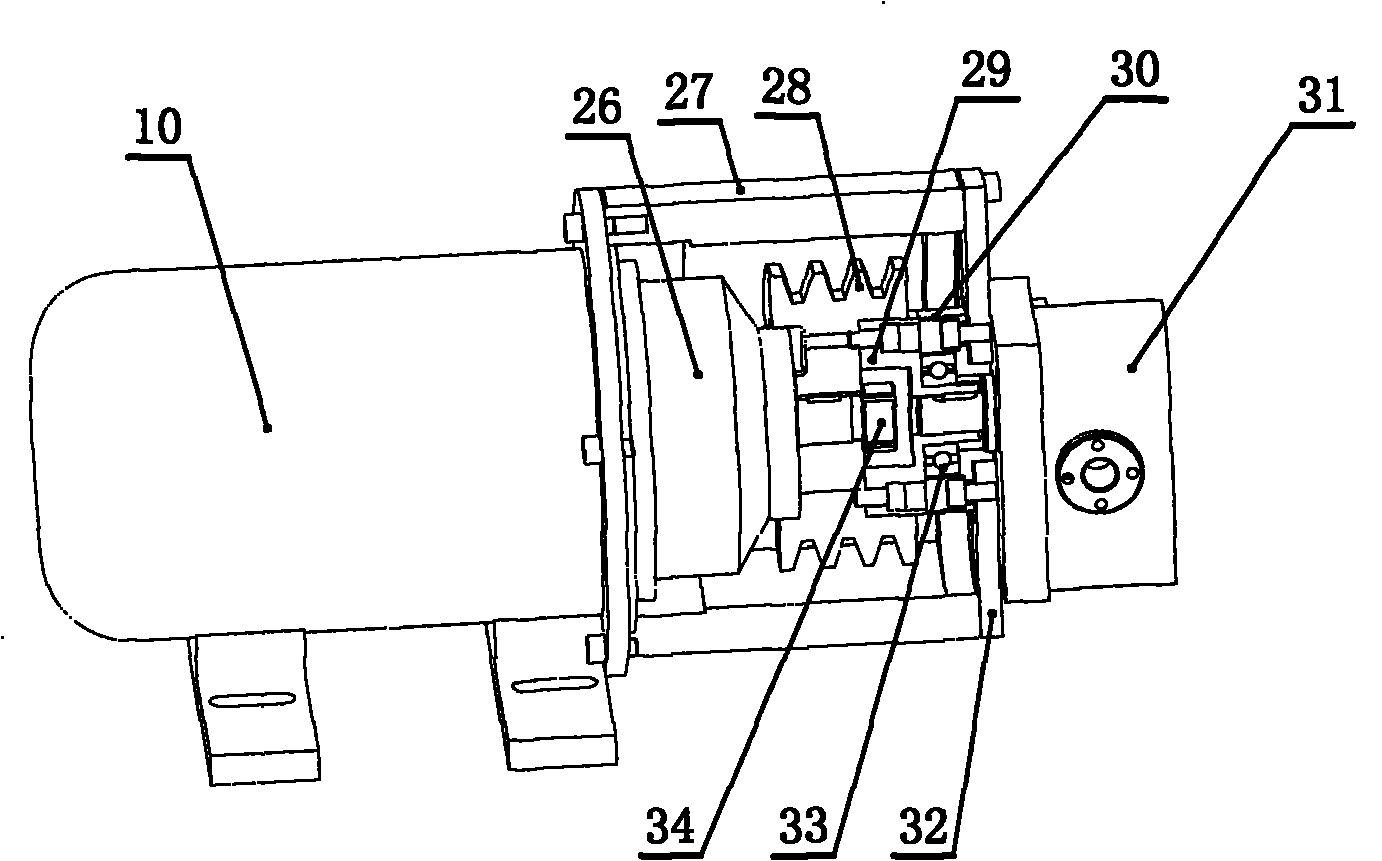

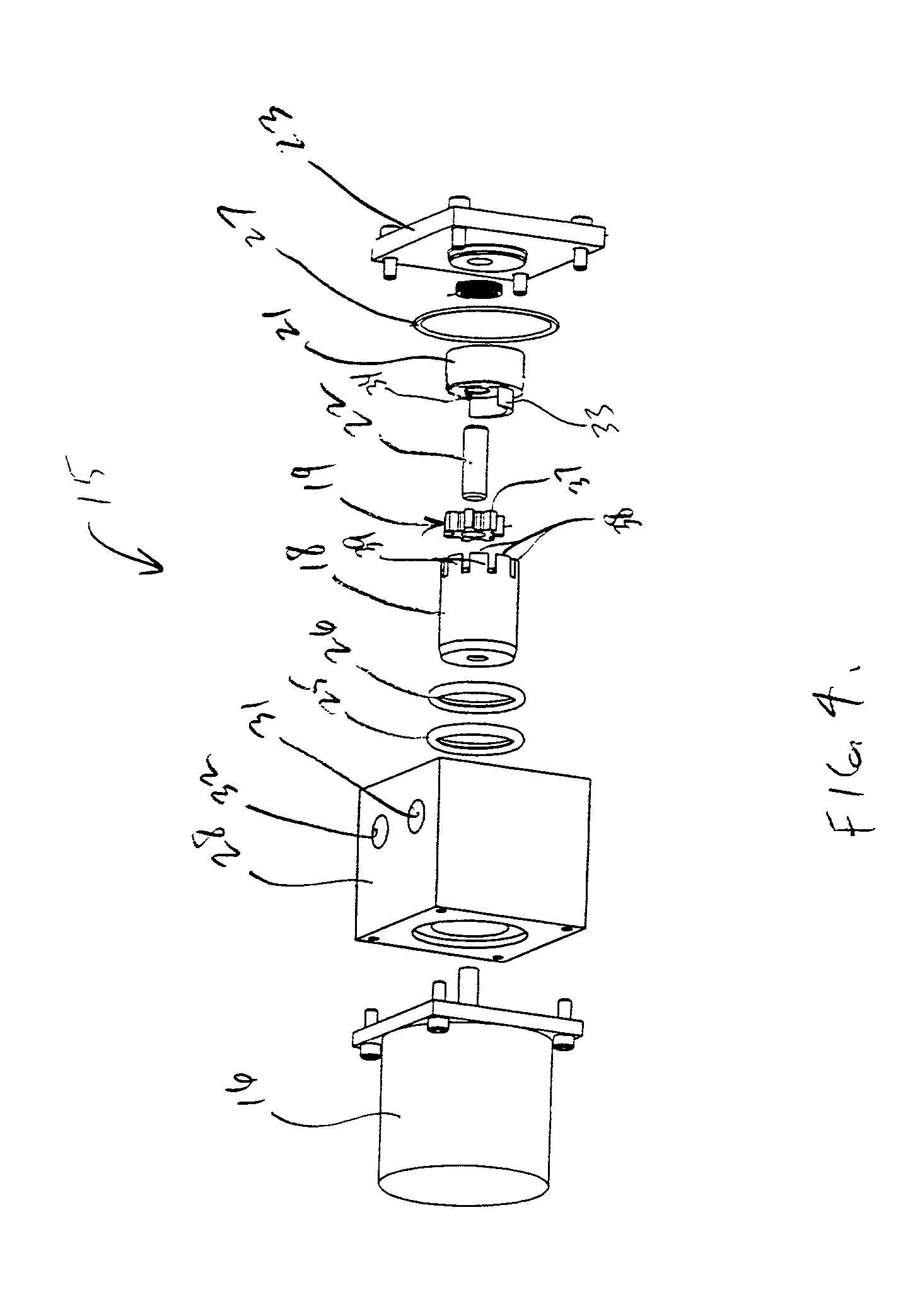

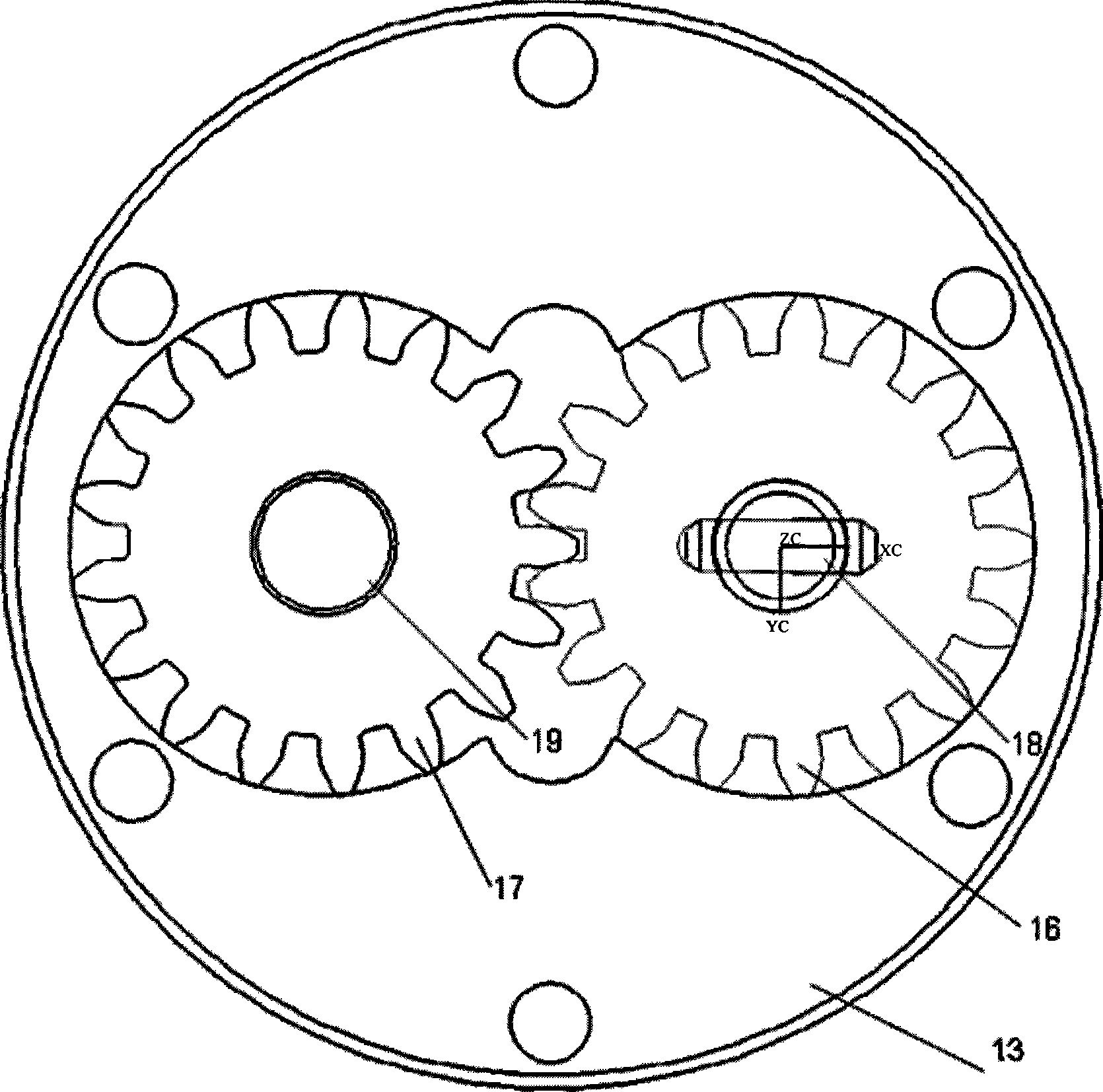

Gear pump for micro-miniature turbojet engine

ActiveCN101403382BReduce weightReduce leakageRotary piston pumpsRotary piston liquid enginesMicrocontrollerJet engine

The invention discloses a gear pump used for a microminiature turbo-jet engine, comprising a direct current motor, a pump body, an upper pump cover, a lower pump cover, a shell, a pair of driving and driven gears which are meshed and a driving shaft and a driven shaft. The driving gear is arranged on the driving shaft; the driven gear is arranged on the driven shaft and is aligned and meshed withthe driving gear; the lower pump cover is fixed on the direct current motor, the upper pump cover is connected to the lower pump cover and the plane of the pump body is pressed tightly and sealed so as to lead the structure to be simple; the shell is sleeved at the outside of the lower pump cover; the driving gear and the driving shaft adopt a method of combining clearance fit and a transmission pin to eliminate the installation error of an output shaft of the direct current motor; and an antifriction material is embedded at the positions on the lower pump cover and the upper pump cover corresponding to the driving gear and the driven gear so as to increase the reliability and durability of the gear pump. Most parts of the gear pump adopt aluminium alloy so as to reduce the weight furthest. The gear pump can control the rotating speed of the direct current motor by pulse-width modulation of a single-chip microcontroller and control the flow rate of the gear pump precisely.

Owner:北京领动国创科技有限公司

Oil pump

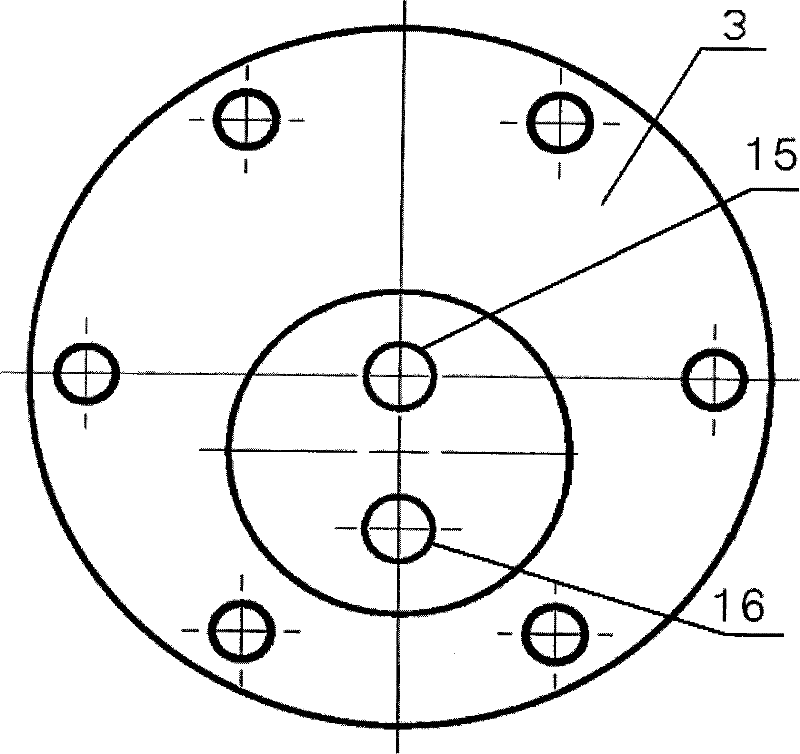

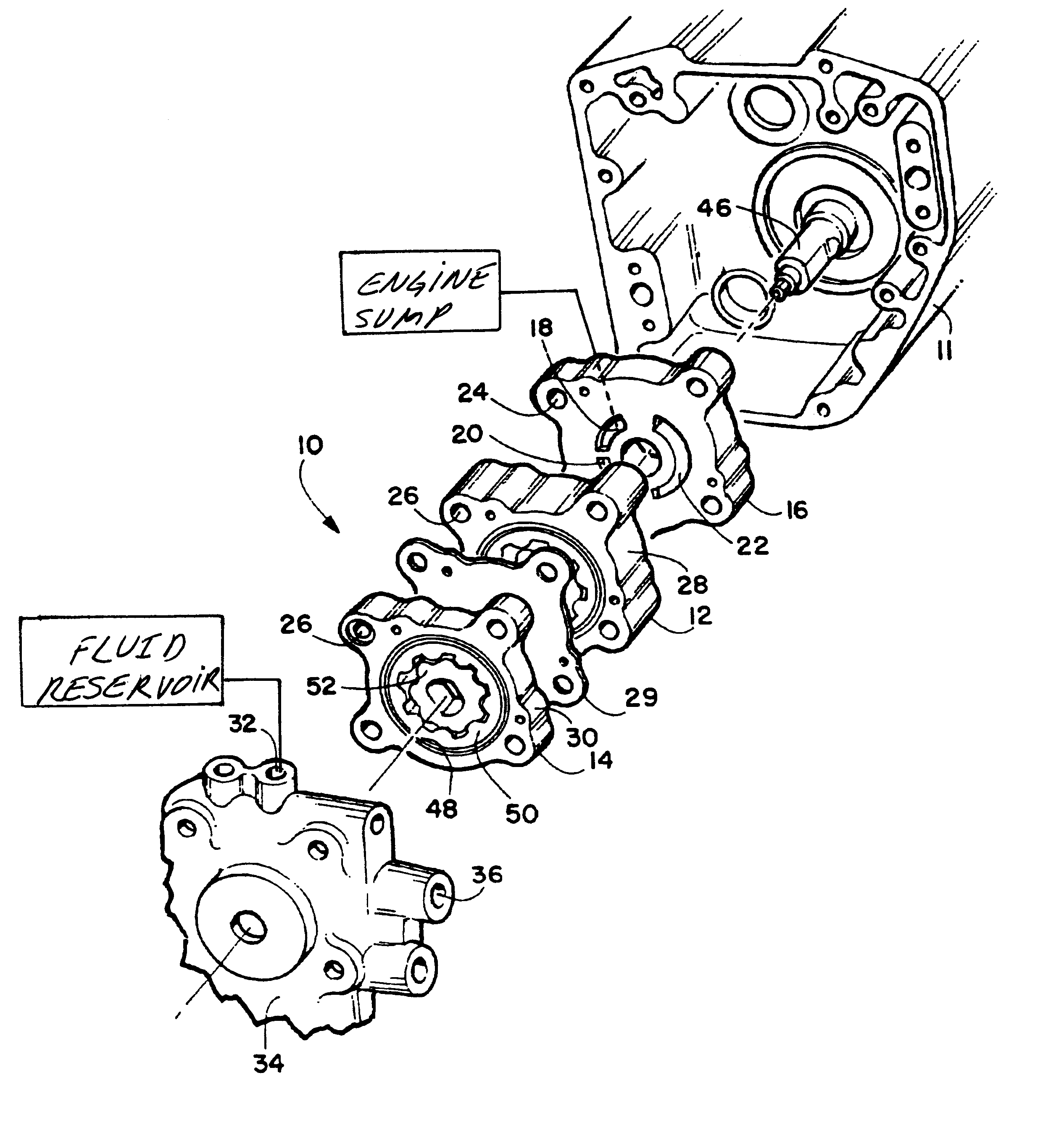

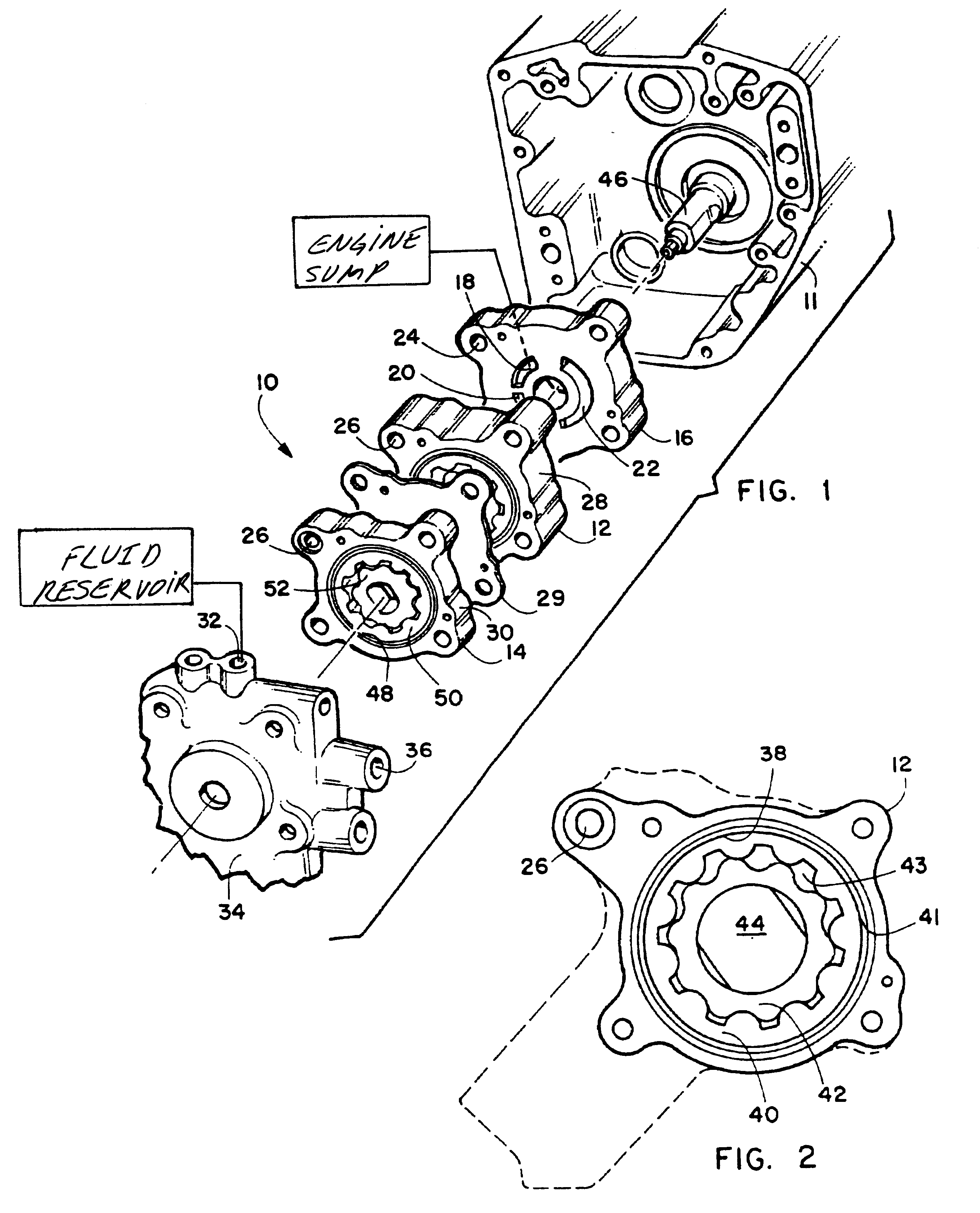

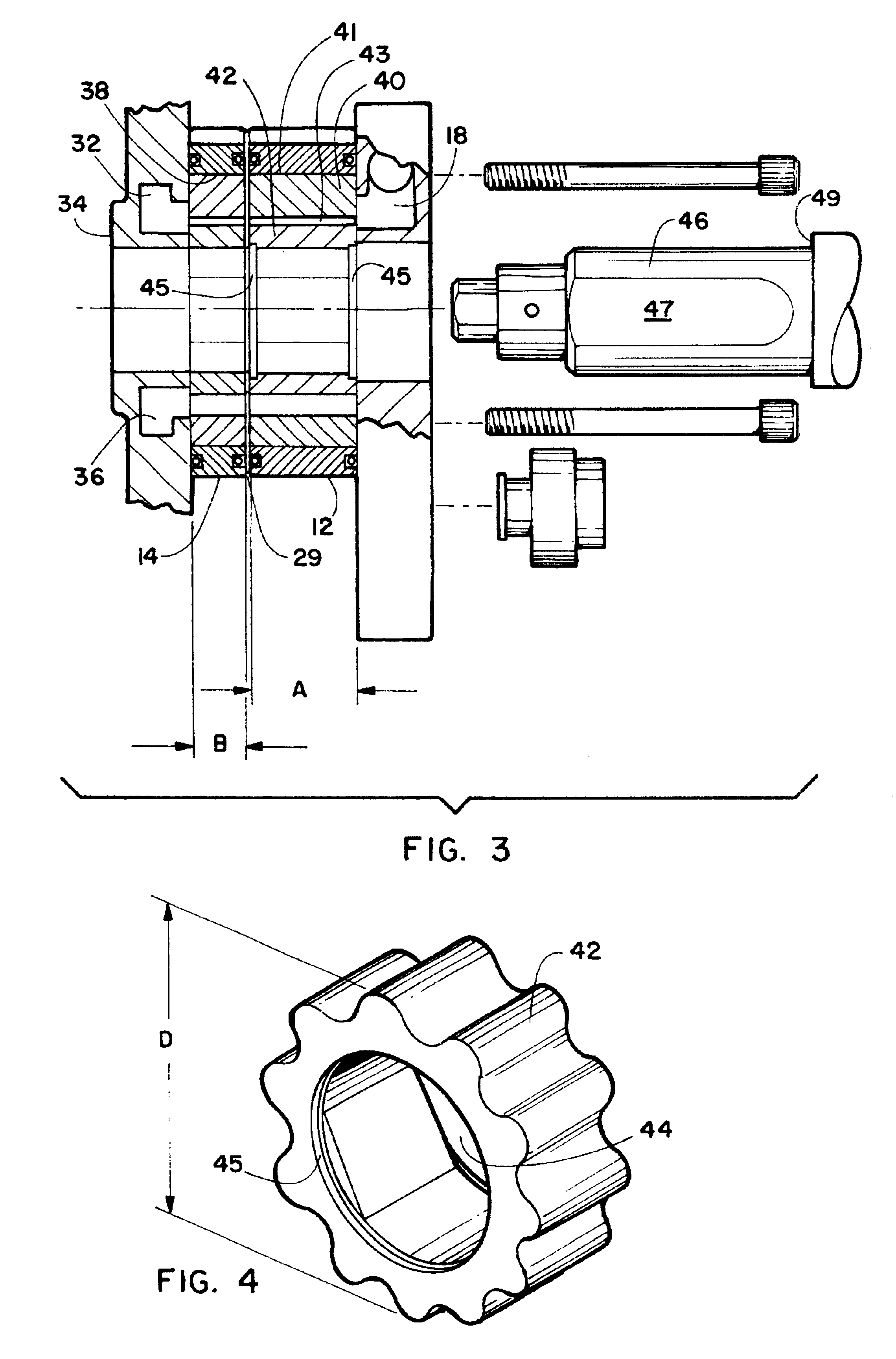

InactiveUS6679692B1Easy to replacePromote repairRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesFuel tankEngineering

A modular oil pump for use in combination with an internal combustion engine having a dry sump lubrication system. The device features a first gerotor pump having an intake port engageable in communication with at least one engine sump and having an discharge port engageable in sealed communication with a fluid reservoir for the dry sump system. A second gerotor pump, engageable in sealed communication with the fluid reservoir has a discharge port fluidly engageable with the engine lubrication system oil supply conduit. Both the first pump and second pump are assembled from separate housings, and cooperatively engaged inner and outer gears sized for rotation and in line mounting on the engine crankshaft inside a cavity in the housings. The volume pumping capacity of the first pump at a ratio to efficiently drain fluid and gas from the engine sumps and supply the reservoir with a constant supply of lubrication fluid. The device may be assembled from a kit having a plurality of different sized components to adjust the ratio of the pumping volume of the first pump to the second pump.

Owner:FEULING JAMES J

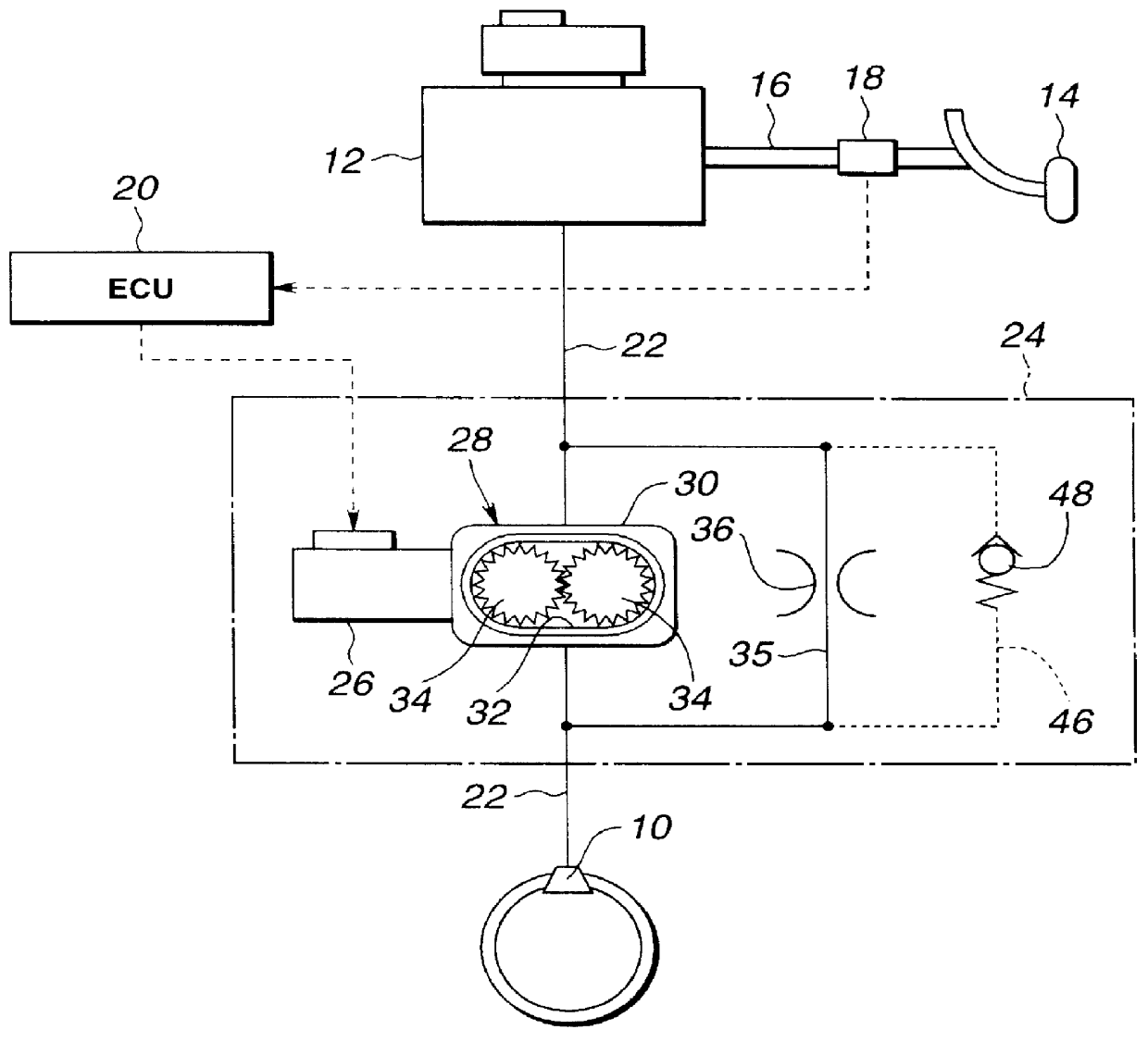

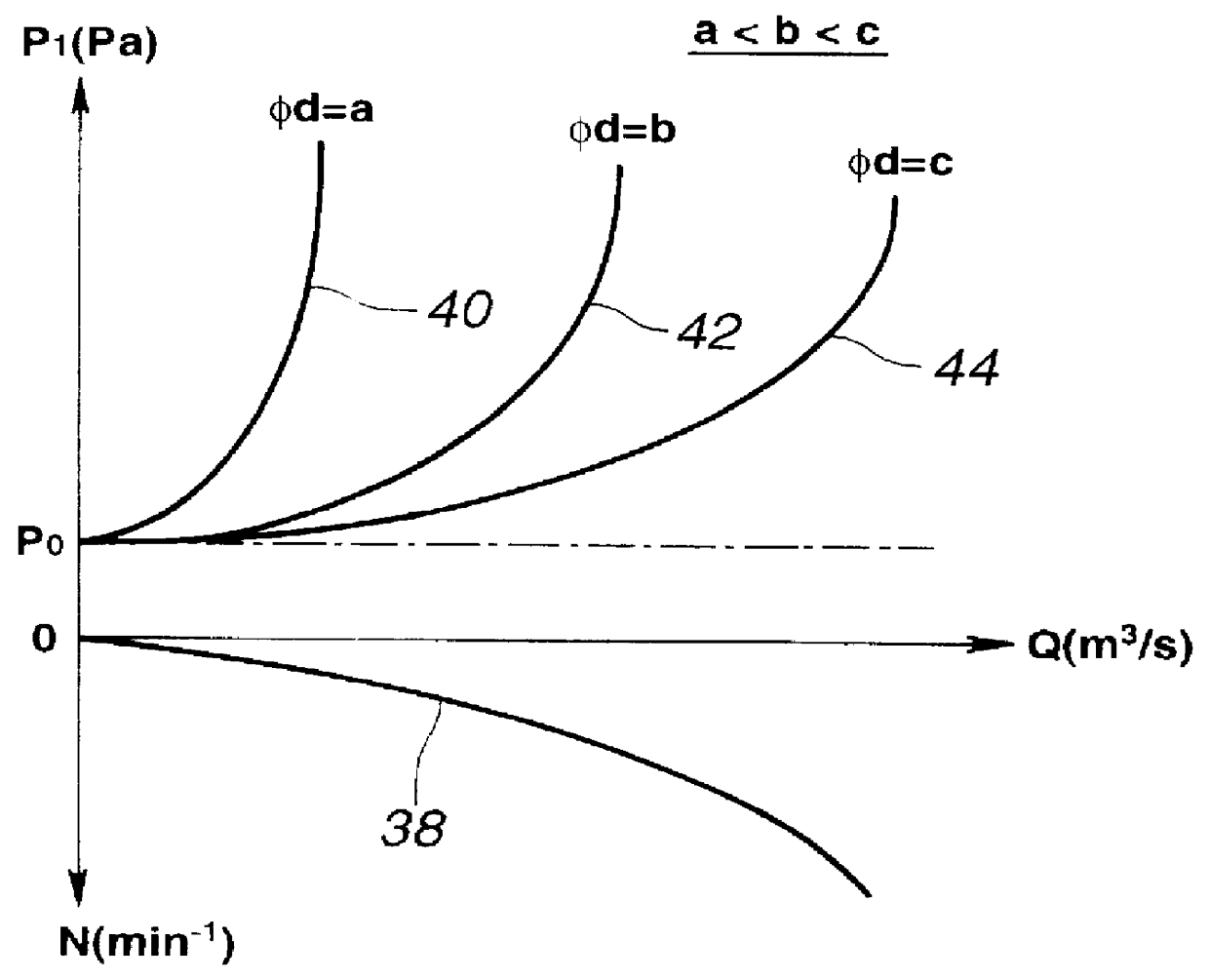

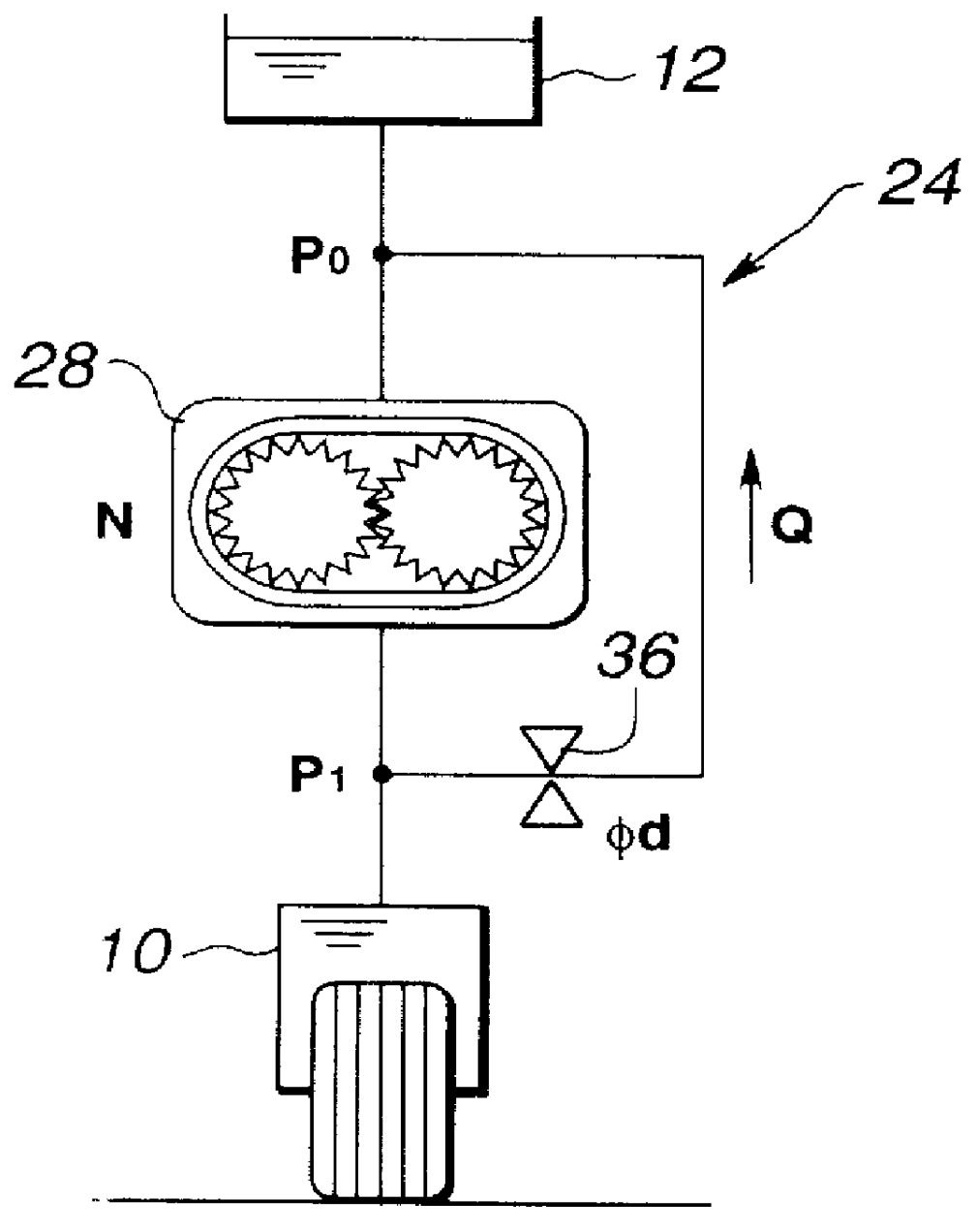

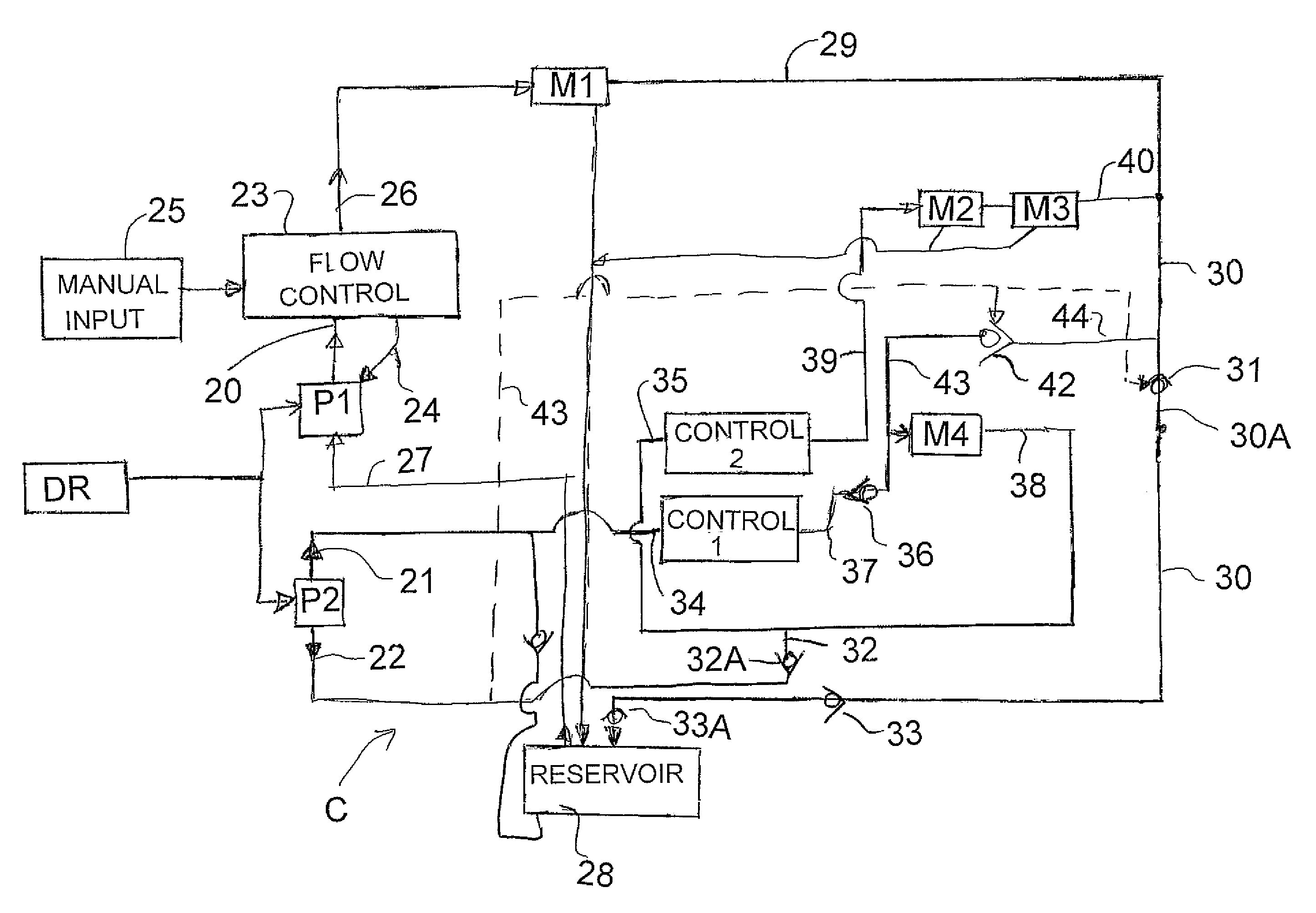

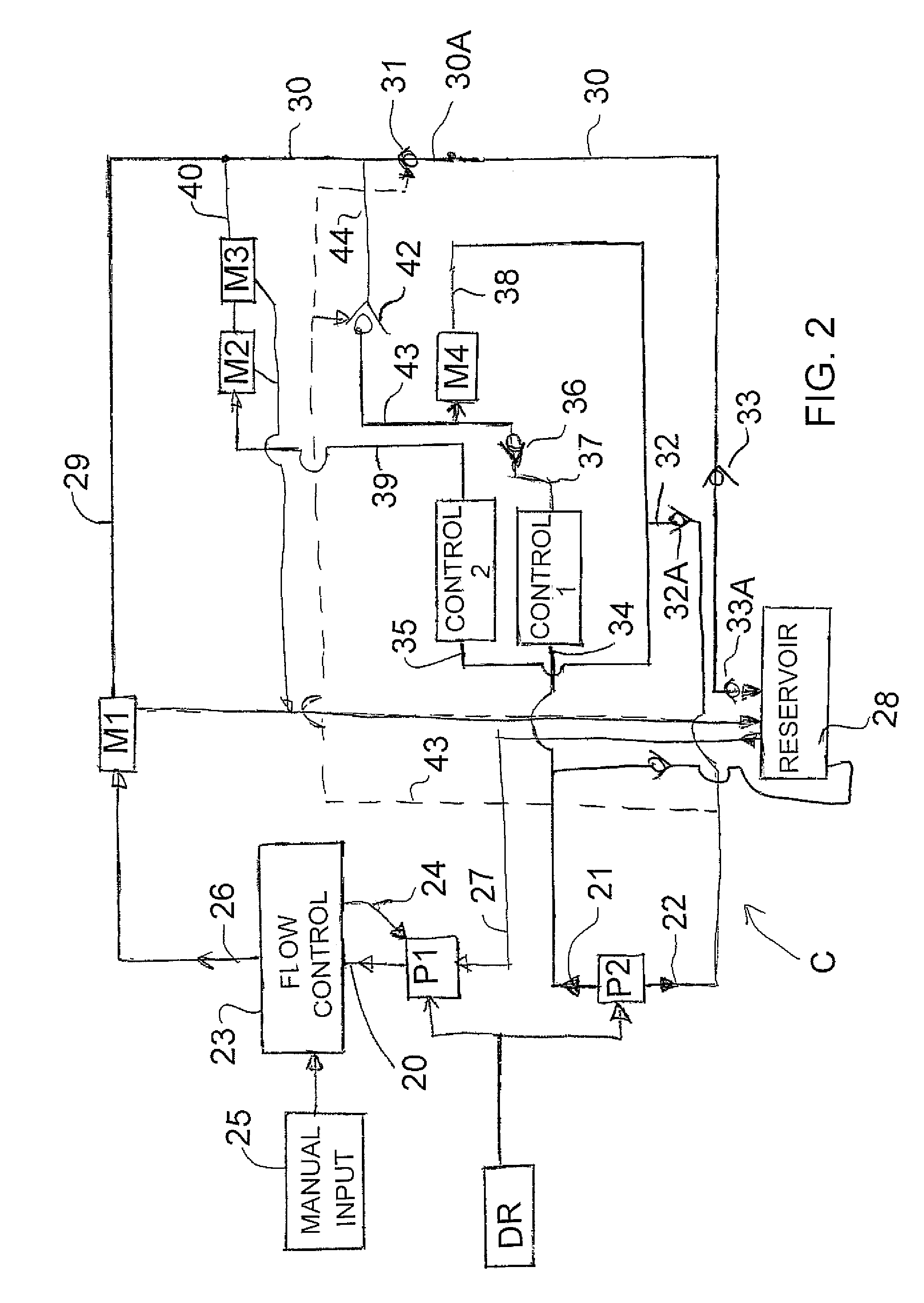

Wheel braking system

A wheel braking system comprises a motor driven gear pump, a relief line connecting the pump discharge to the pump intake, a wheel brake unit connected to the pump discharge, and a flow restriction in the relief line. A control unit controls the motor for the pump in response to an output signal of a brake pedal sensor. The brake pedal sensor generates the output signal indicative of the brake pedal stamping force. The control unit determines a desired motor speed for the sensed brake pedal stamping force and operates the motor.

Owner:UNISIA JECS CORP

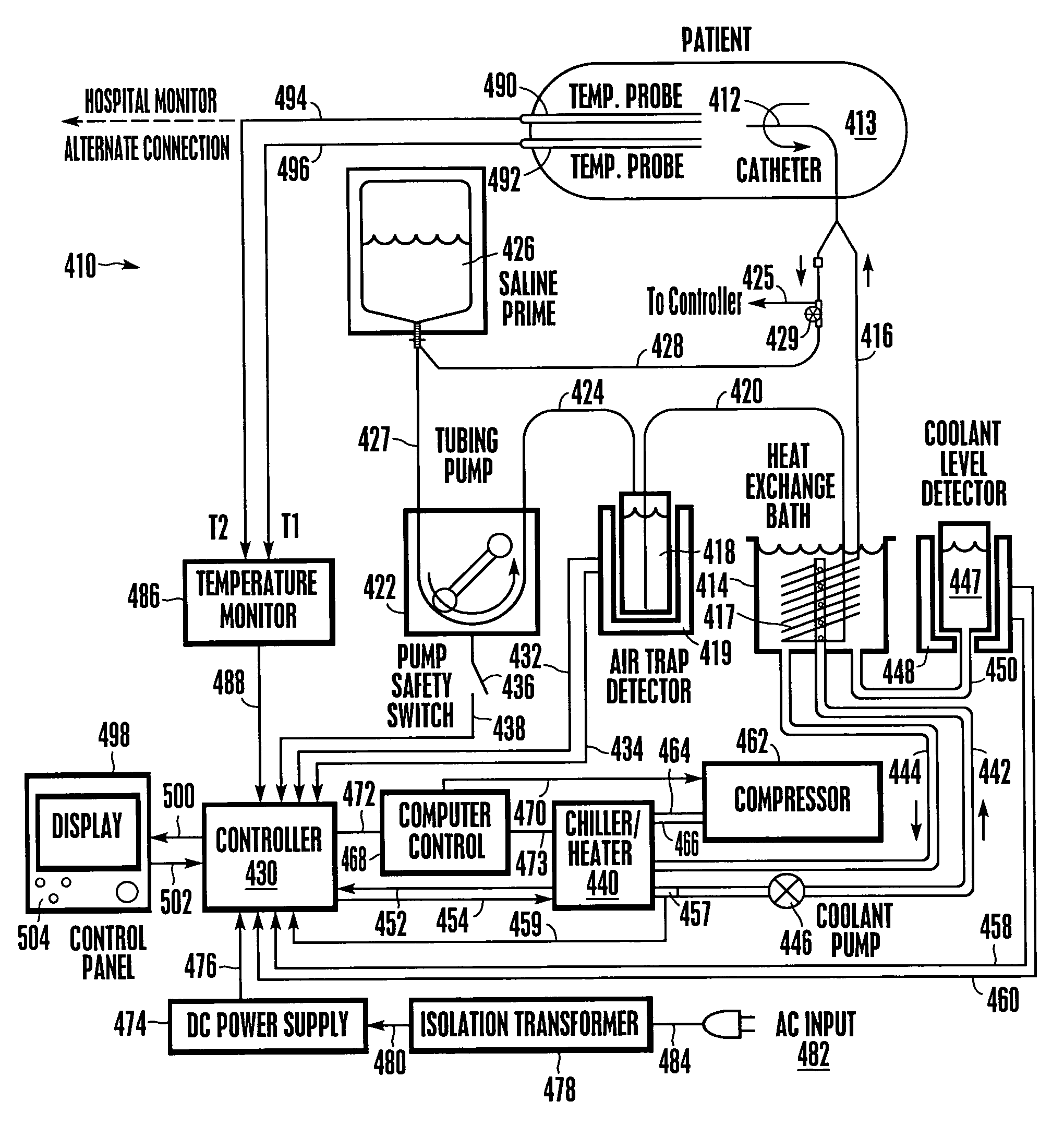

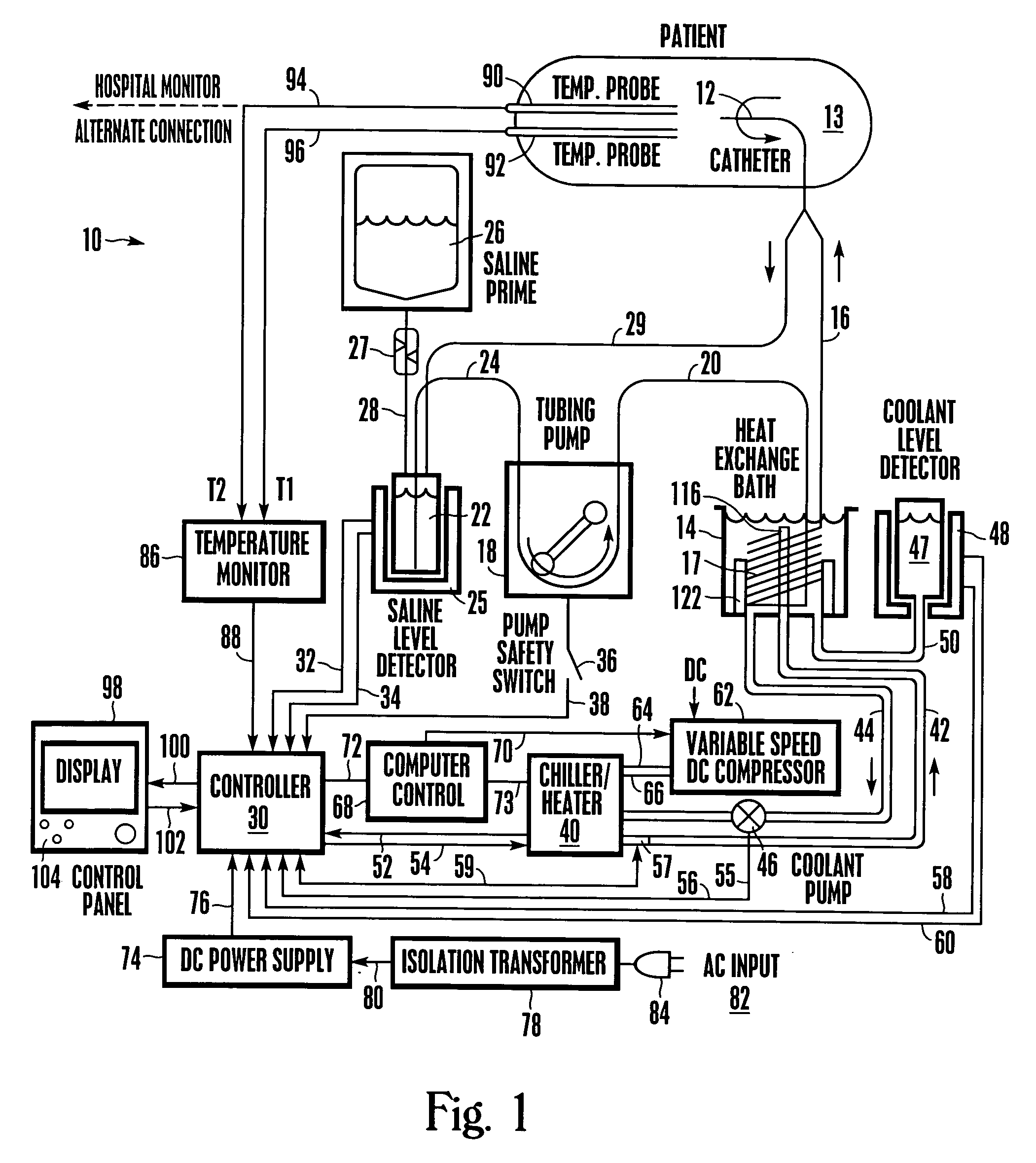

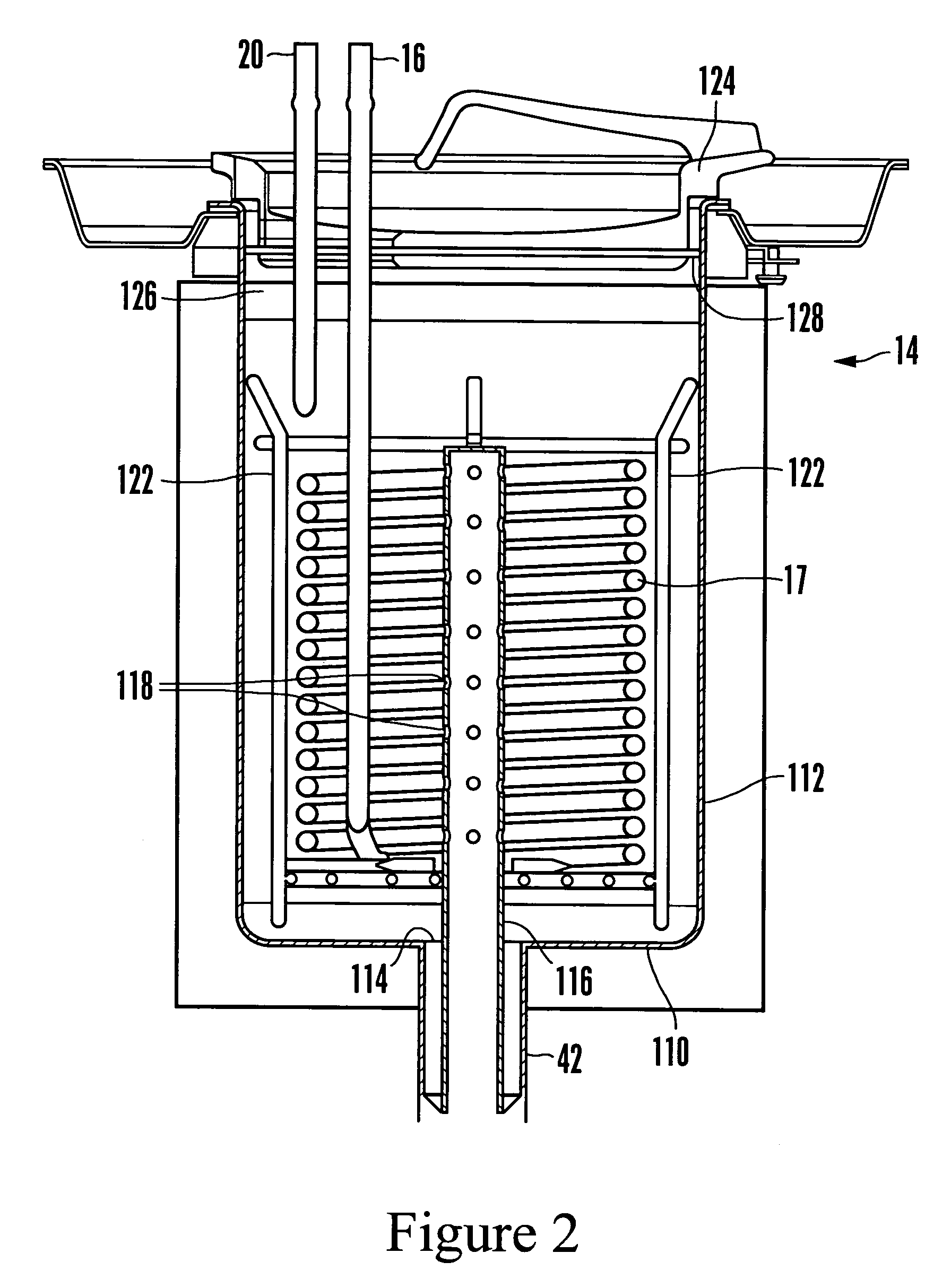

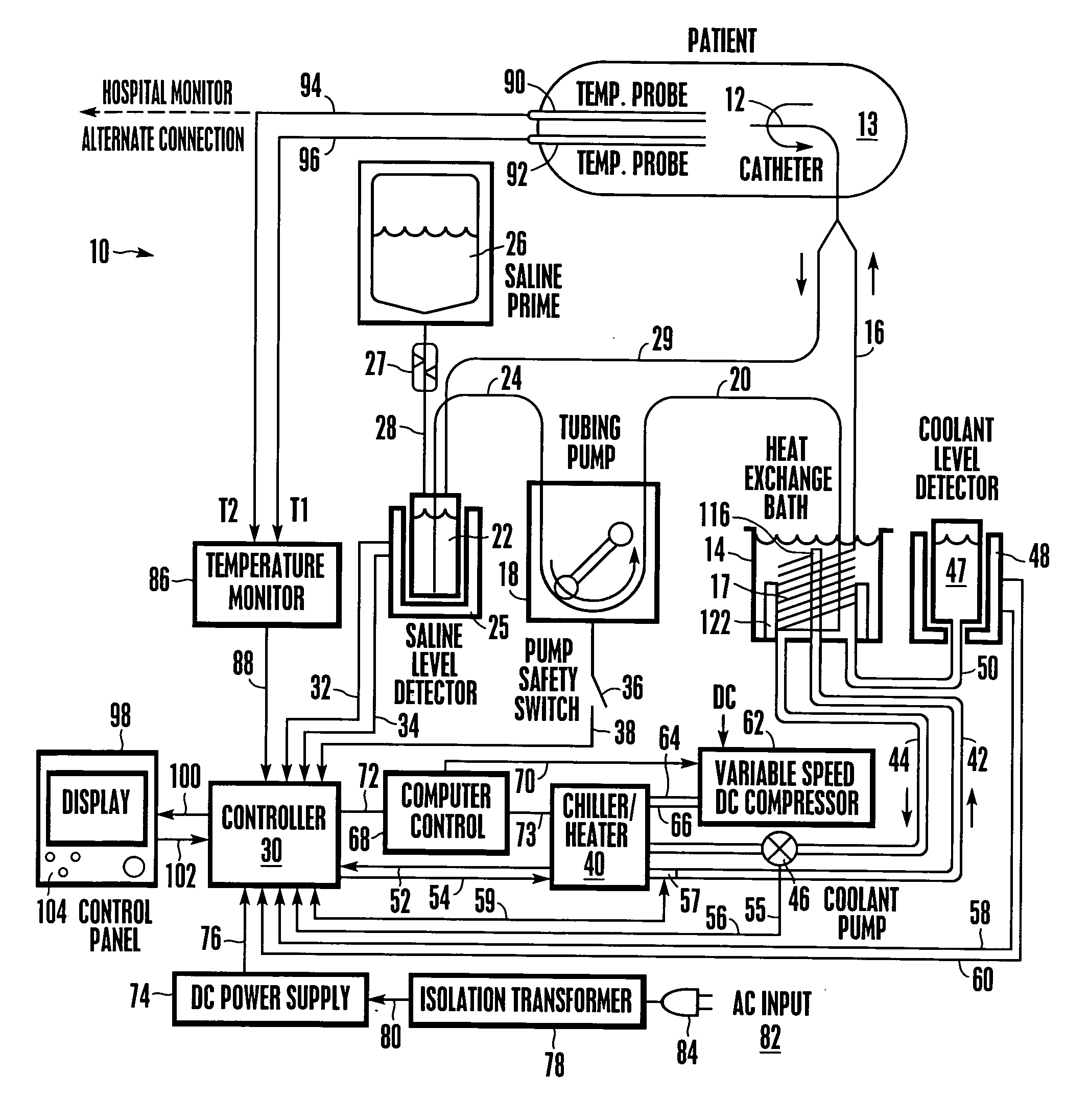

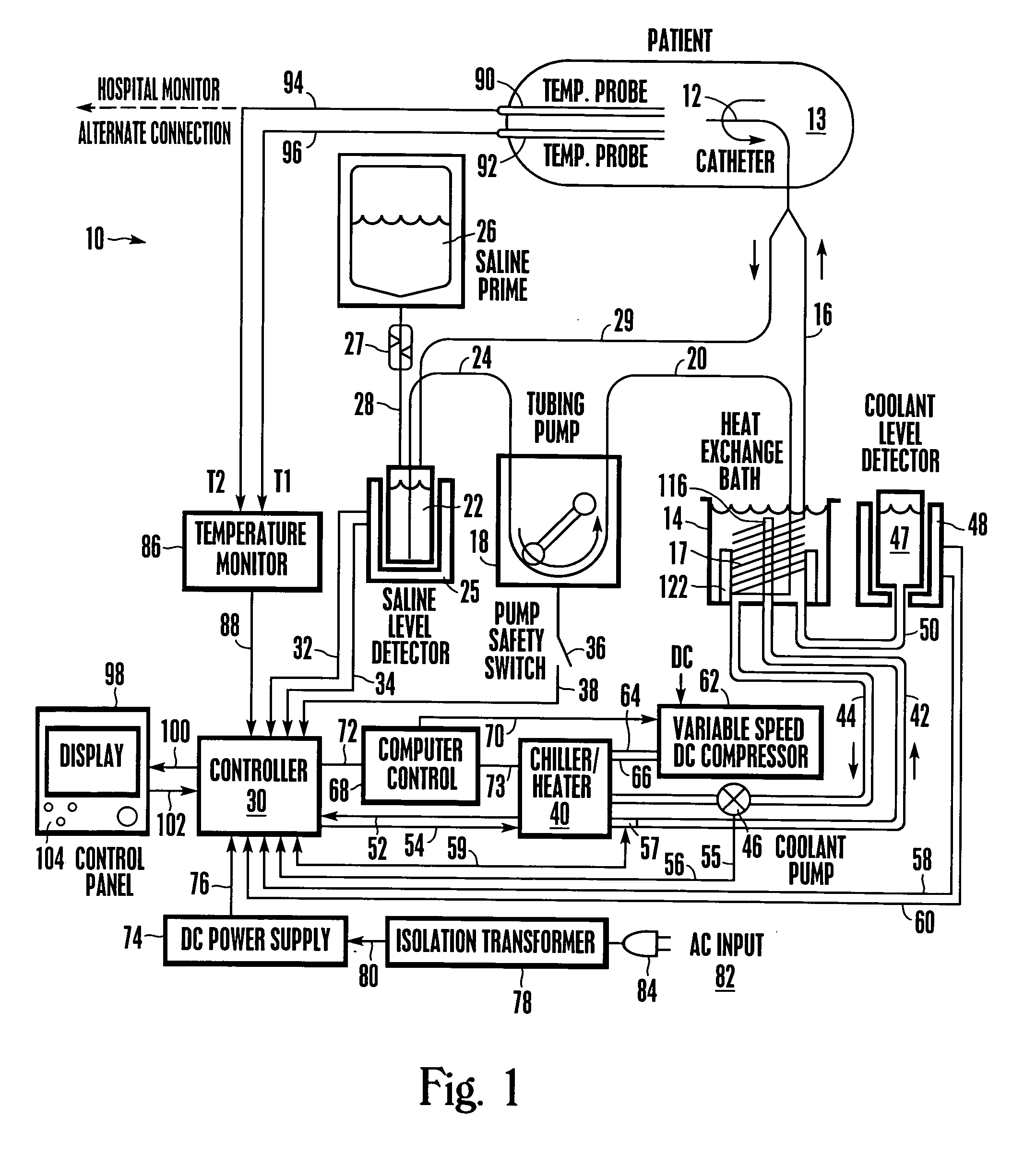

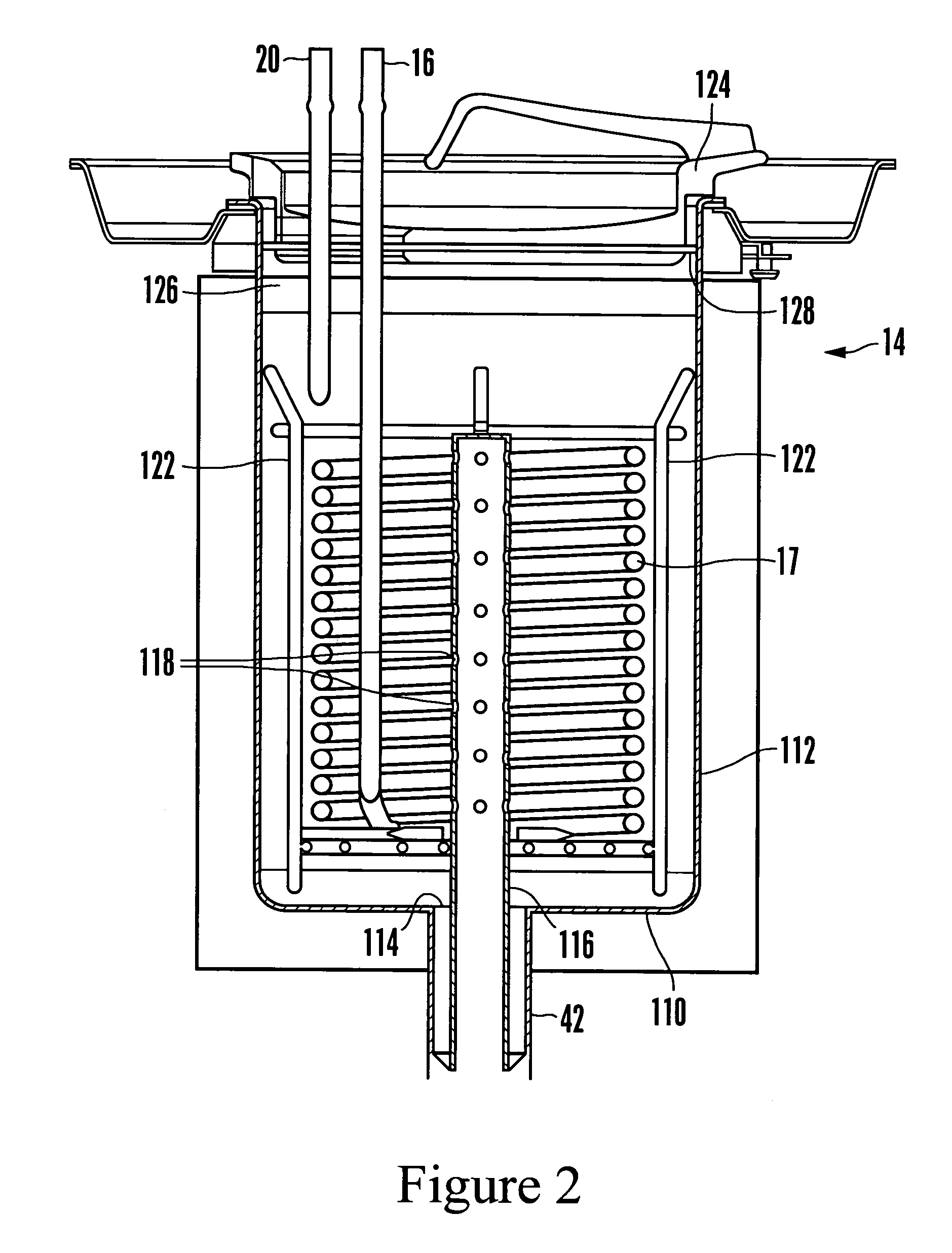

Heating/cooling system for indwelling heat exchange catheter

A cooling system for an indwelling heat exchange catheter includes a heat exchange bath that is configured to receive a conduit that carries saline to and from the catheter. A heating / cooling fluid is in the bath and exchanges heat with the saline. The heating / cooling fluid flows through a heat exchanger that includes a refrigerant and two variable speed DC compressor for removing heat from the refrigerant. A gear pump circulates the working fluid to and from the catheter and is removably engaged with a pump support platform.

Owner:ZOLL CIRCULATION

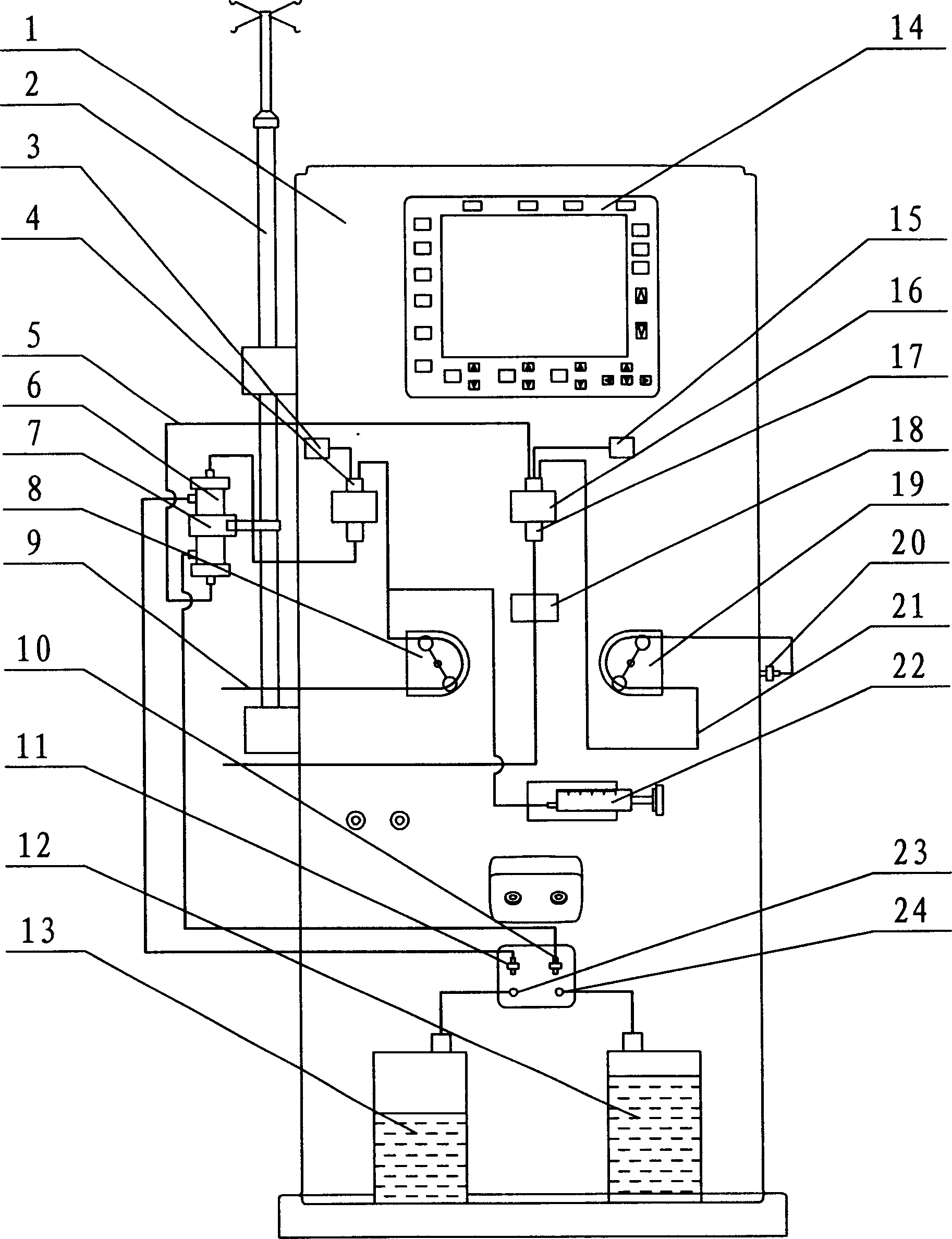

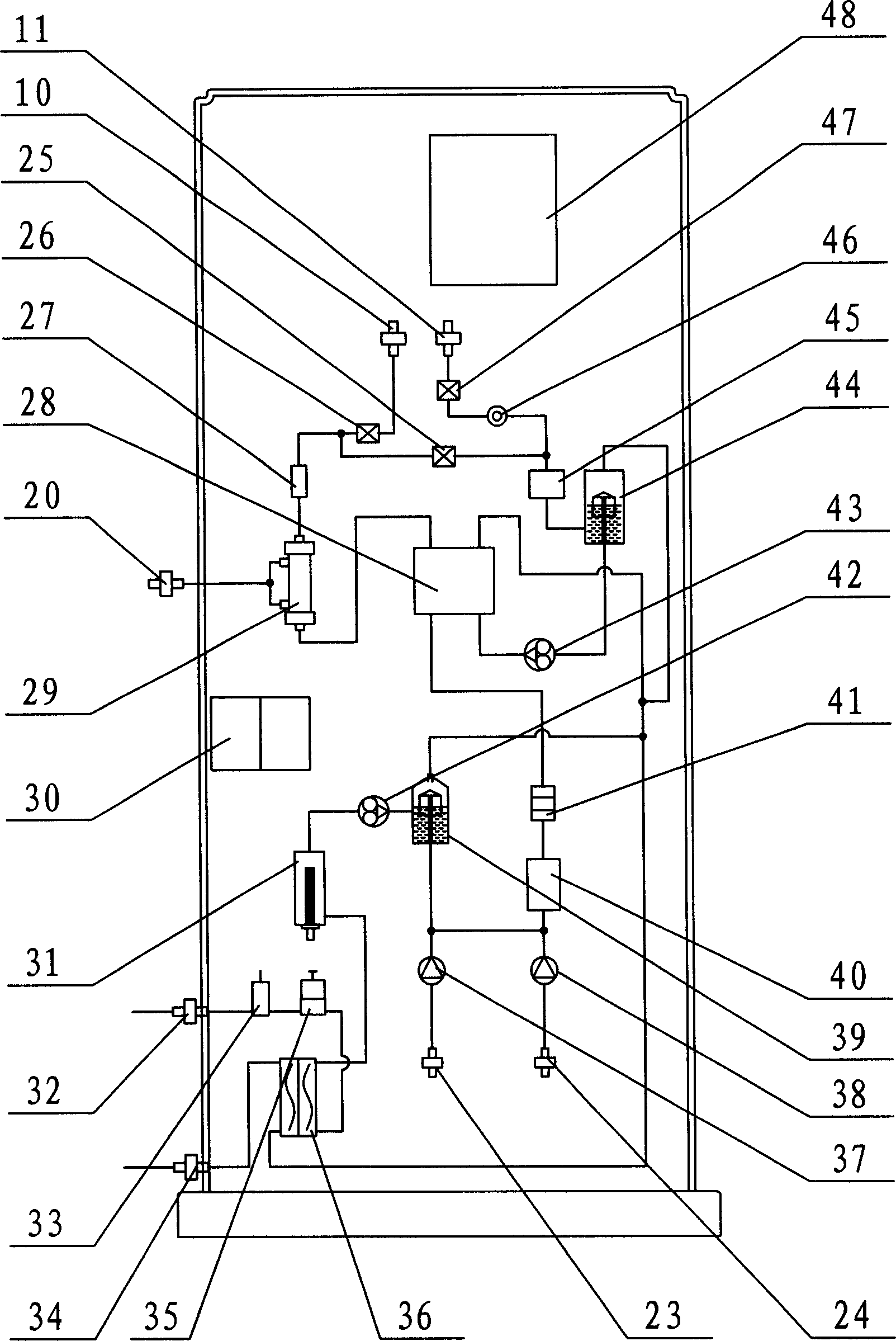

Medical hemodialysis filter

ActiveCN1830494AAvoid air embolismSolve unstable flowHaemofiltrationDialysis systemsHemodialysisGear pump

A medical filtering machine for the hemodialysis is composed of main body with console panel, blood loop consisting artery loop and vein loop, liquid-supplementing loop, water channel system and operation-control system. Said water channel system consists of reverse osmosis jointer, heat exchanger, heater, gear pump, deaerating unit, two concentrated liquid pumps, mixer, ion concentration monitor, volume balance and ultrafiltration unit, and endotoxin filter.

Owner:SWS HEMODIALYSIS CARE CO LTD

Method of controlling a gear pump as well as an application of the method

ActiveUS20100322805A1Reduce impactOscillating piston enginesEngine of counter-engagement typeGear pumpGear wheel

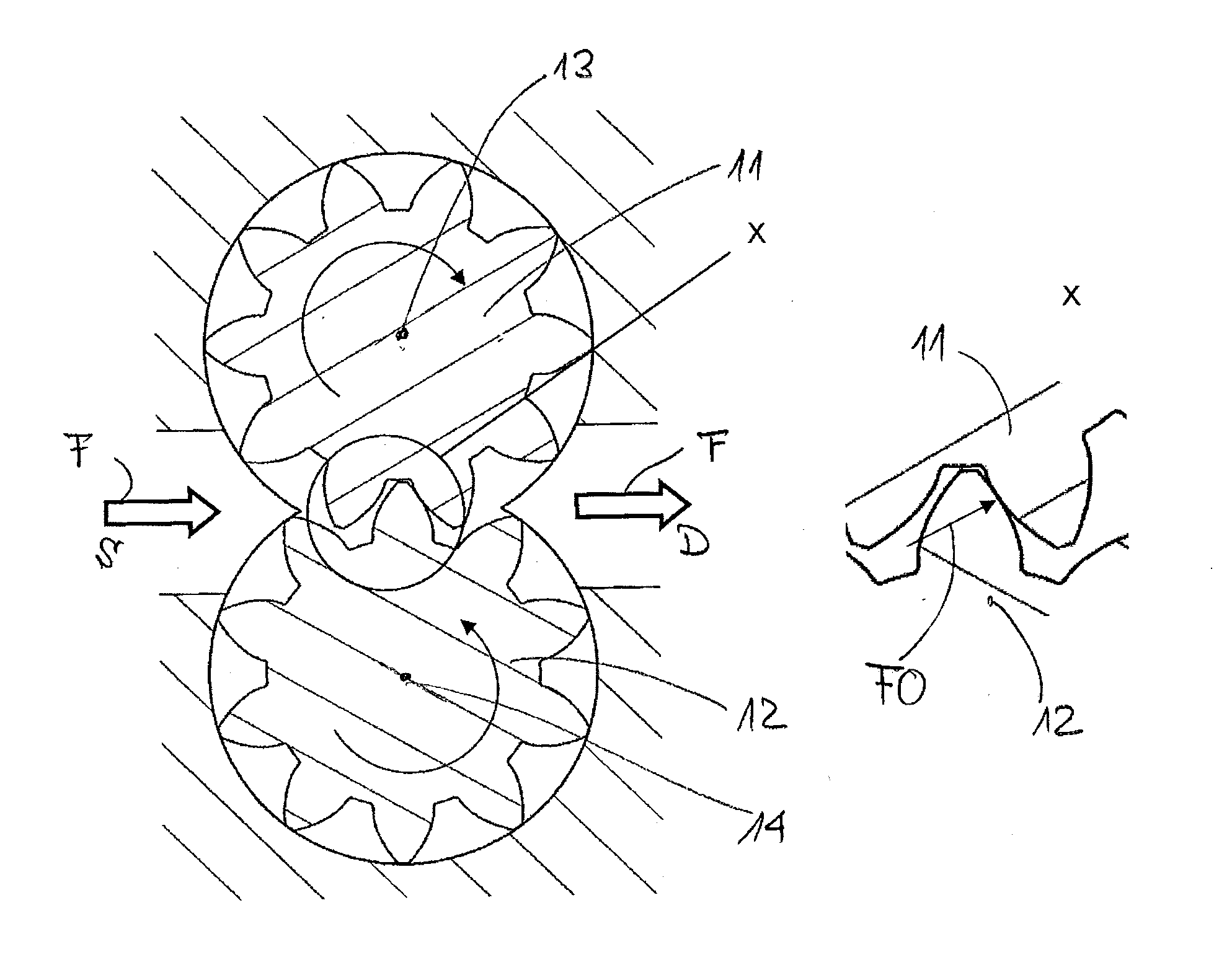

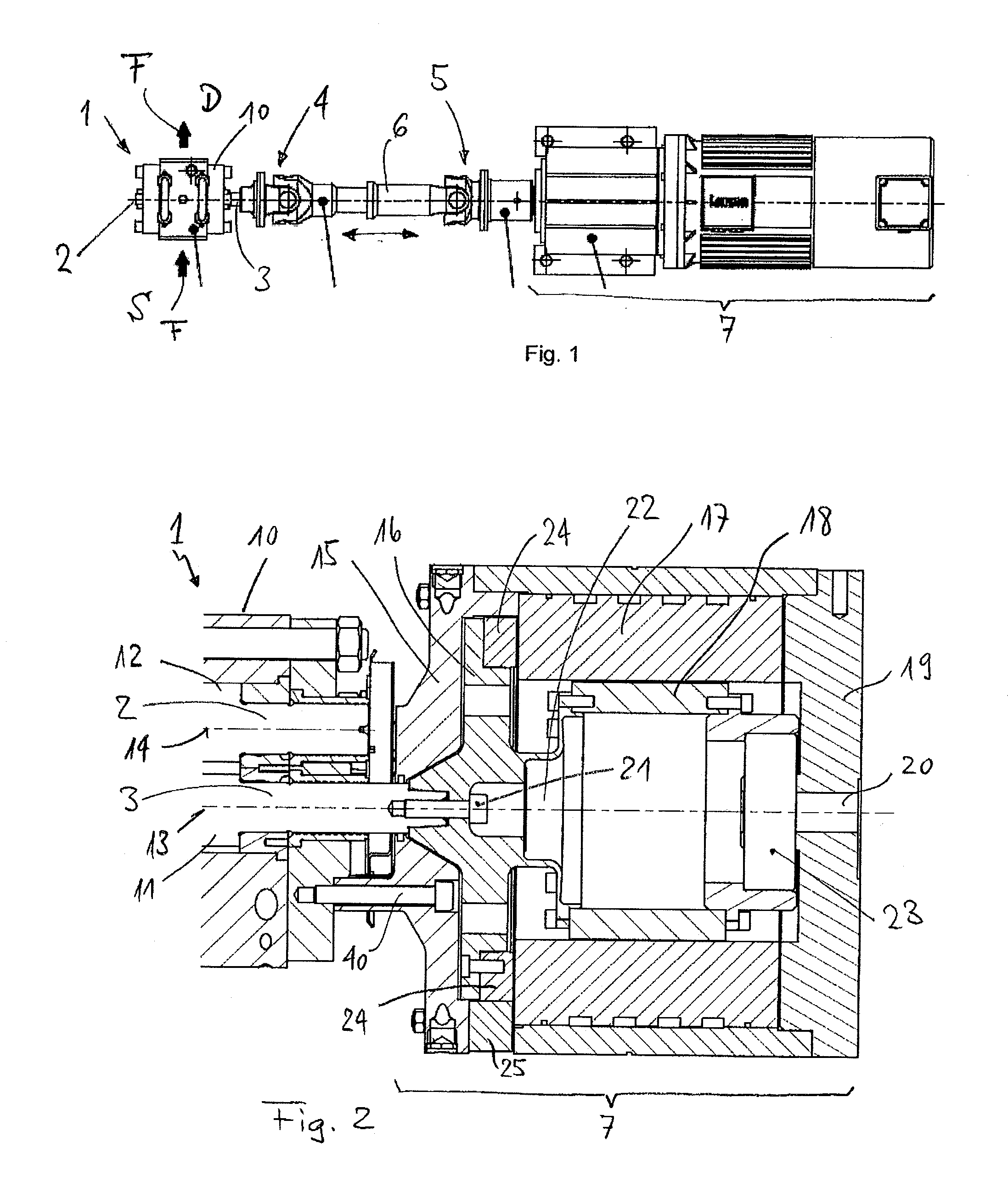

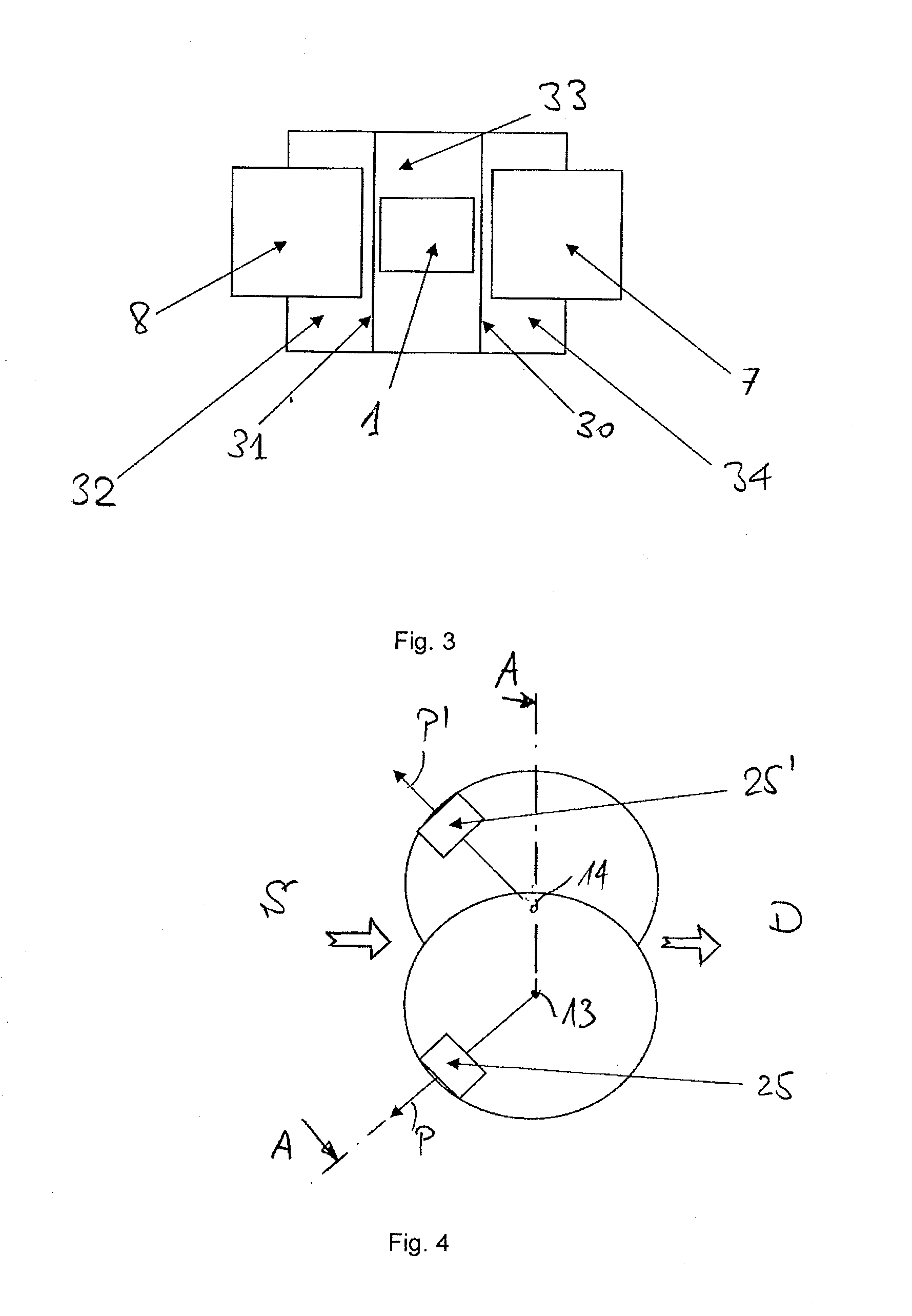

A method of controlling a gear pump comprising two meshing gear wheels (11, 12), wherein the two gear wheels (11, 12) are driven via respective shafts (2, 3) each by a drive unit (7, 8). A current position of the one gear wheel (11, 12) is determined with respect to the current position of the other gear wheel (12, 11), and the current position of the one gear wheel (11, 12) is continuously adjusted with respect to the current position of the other gear wheel (12, 11) according to specified predefined operating conditions.

Owner:MAAG PUMP SYST TEXTRON

Heating/cooling system for indwelling heat exchange catheter

A cooling system for an indwelling heat exchange catheter includes a heat exchange bath that is configured to receive a conduit that carries saline to and from the catheter. A heating / cooling fluid is in the bath and exchanges heat with the saline. The heating / cooling fluid flows through a heat exchanger that includes a refrigerant and two variable speed DC compressor for removing heat from the refrigerant. A gear pump circulates the working fluid to and from the catheter and is removably engaged with a pump support platform.

Owner:ZOLL CIRCULATION

Integrated motor/gear pump

Pinion and ring gears intermeshed at one location within a pump chamber are rotationally supported therein by a cylindrical bearing portion of a housing sealingly enclosing said pump chamber between side plates of the housing within which stator windings are mounted in operative alignment with permanent magnets carried in one of the gears acting as a motor rotor as a result of interaction between such magnets and magnetic fields produced by electrical input power fed to the stator windings.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

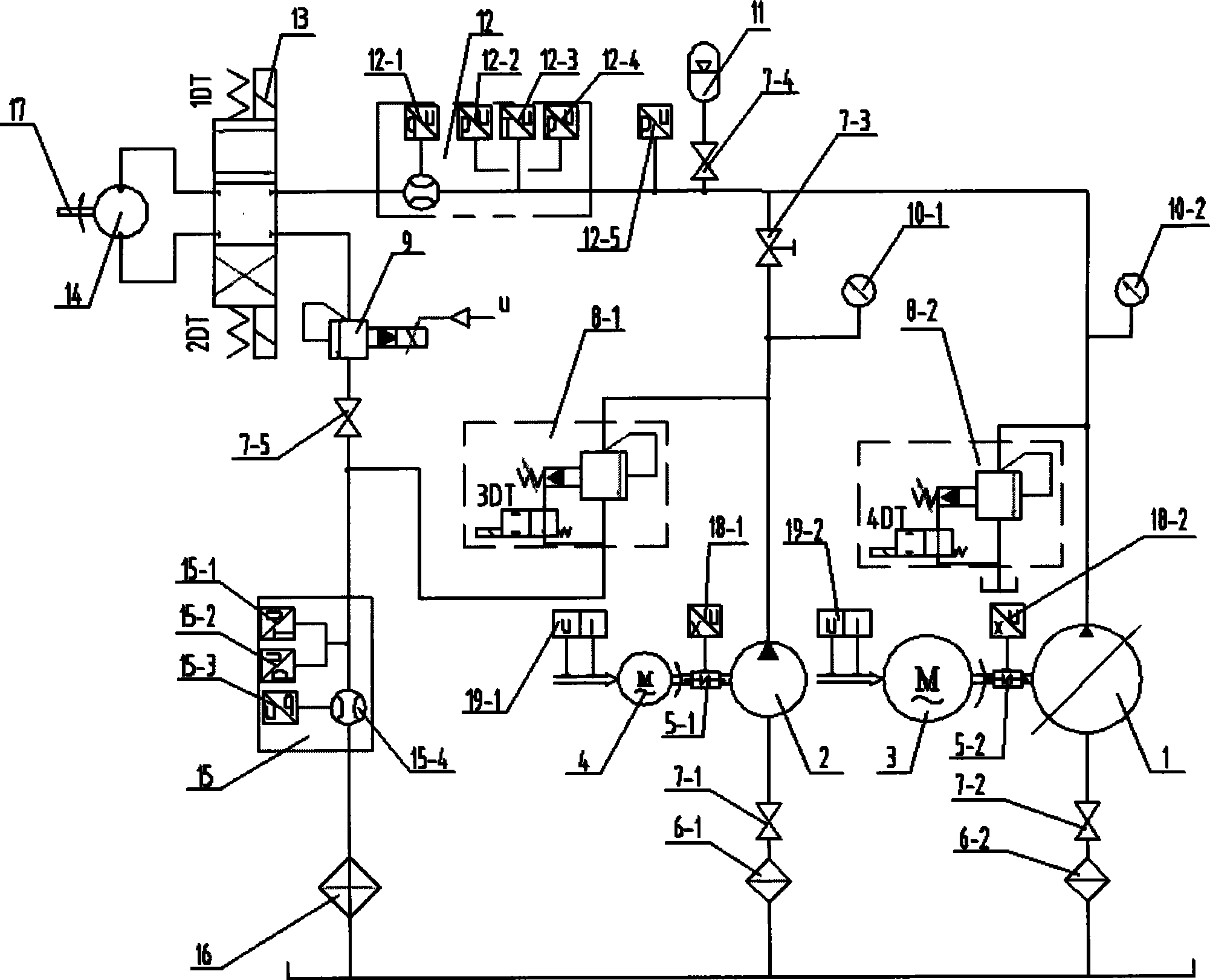

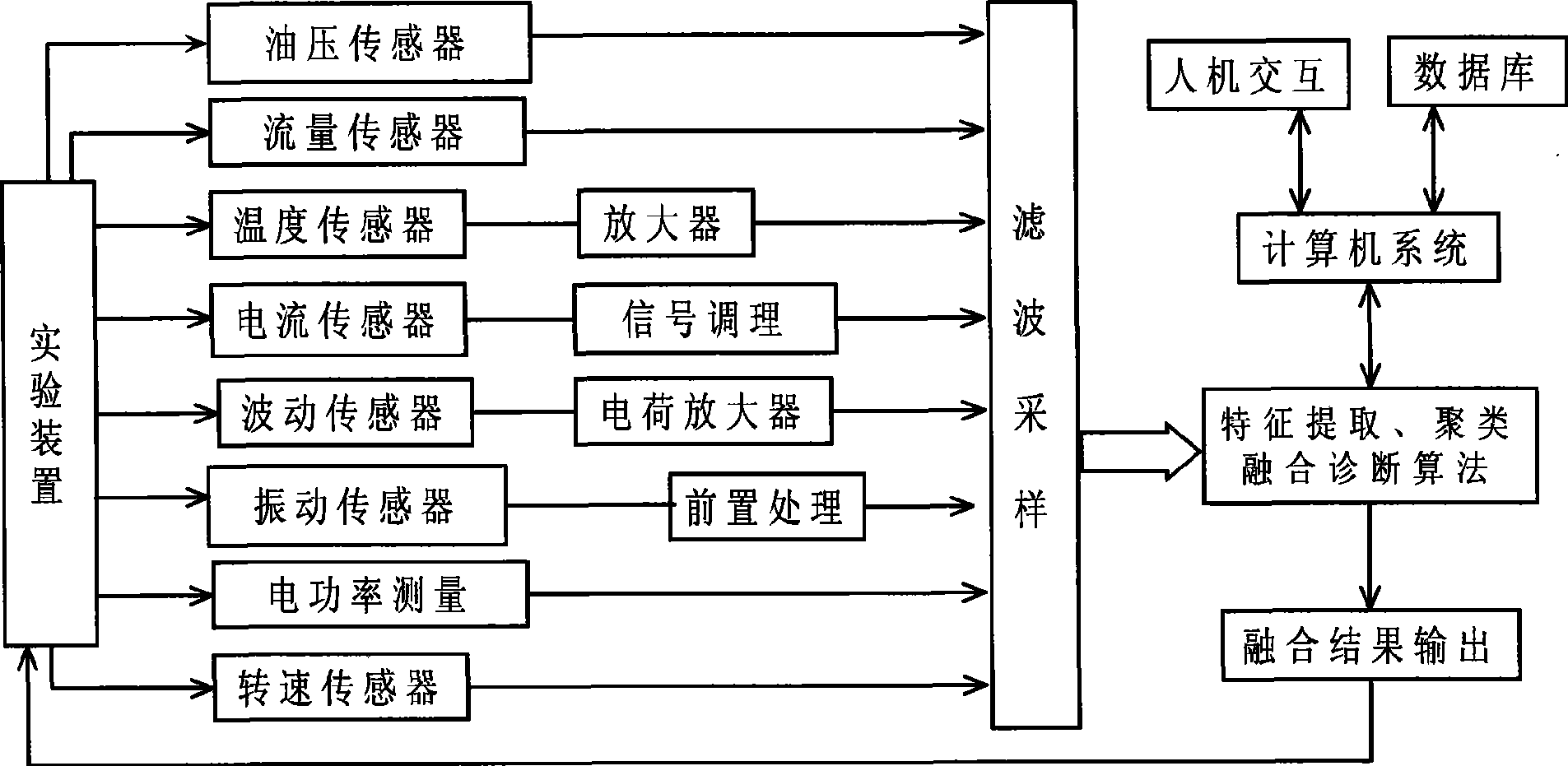

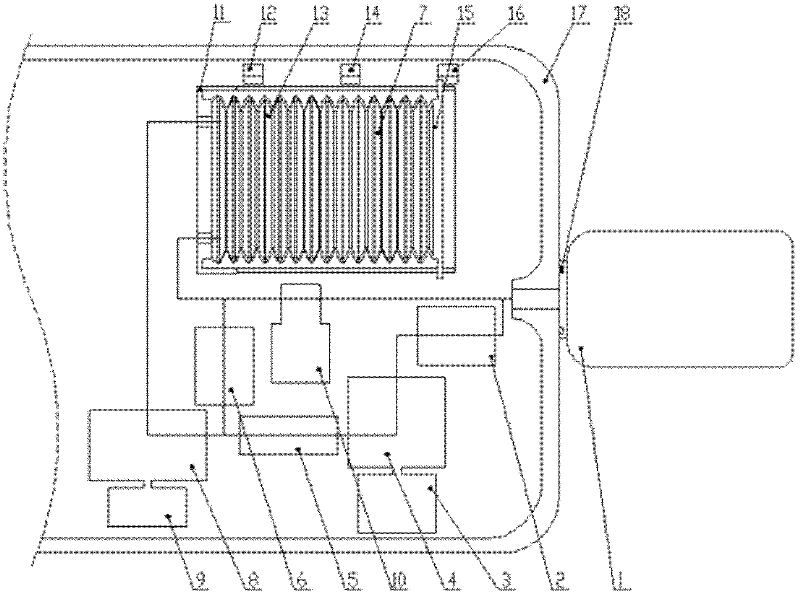

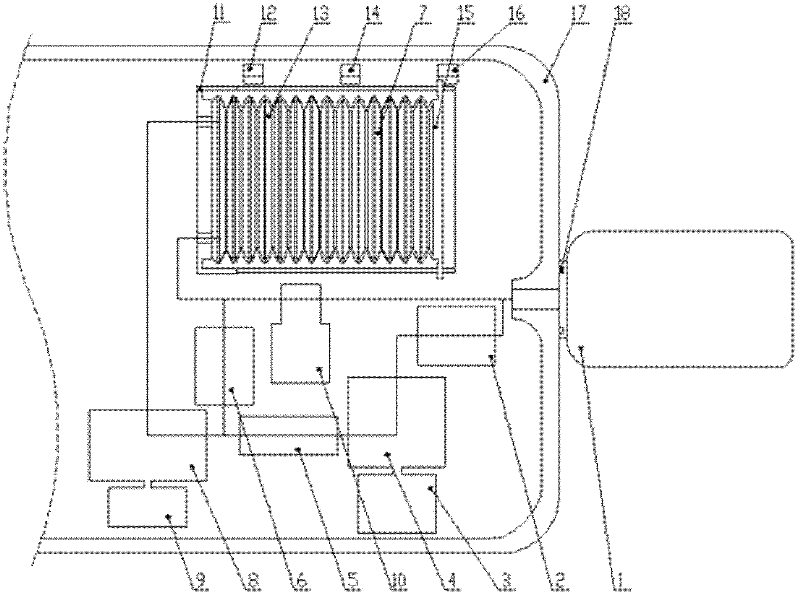

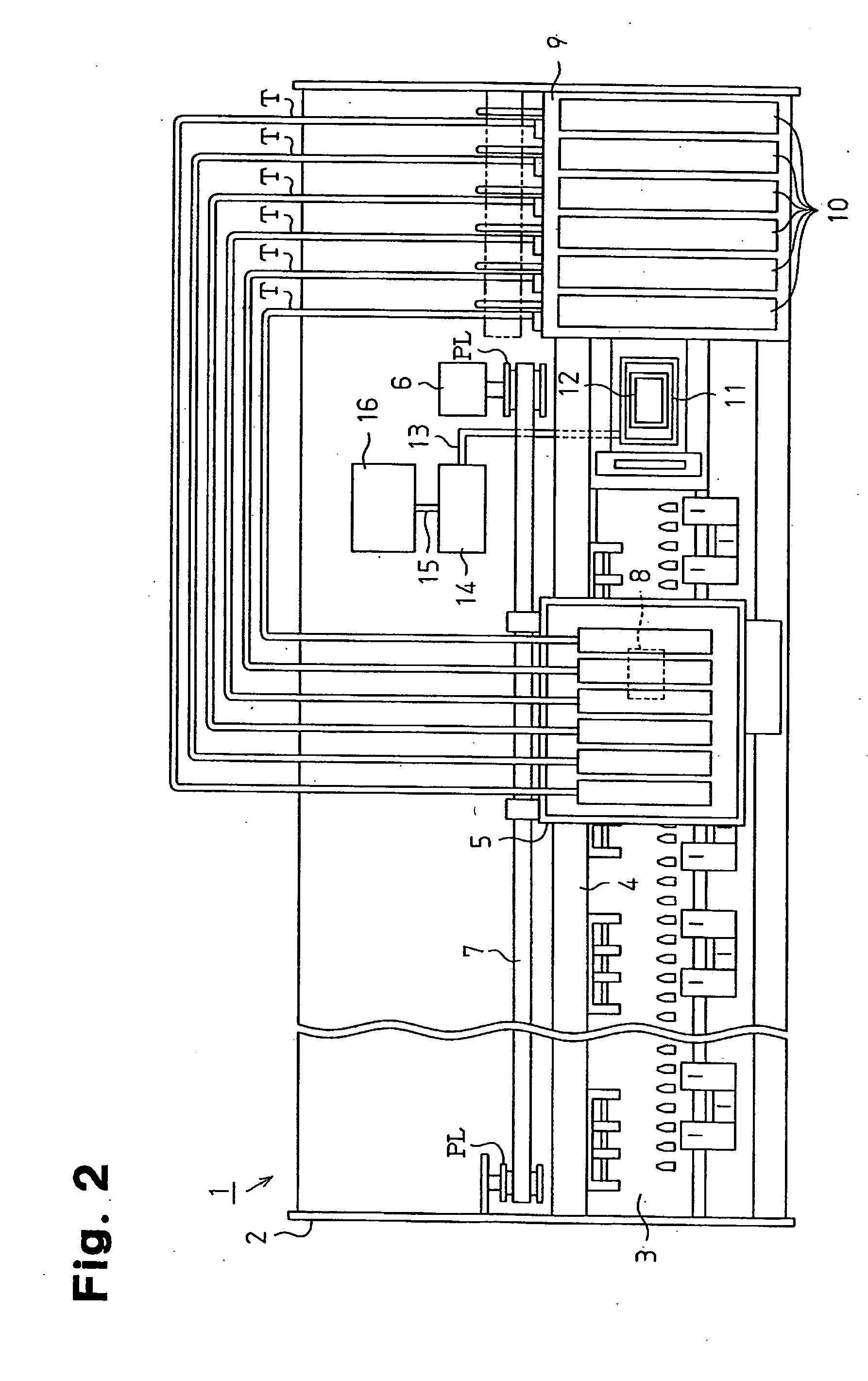

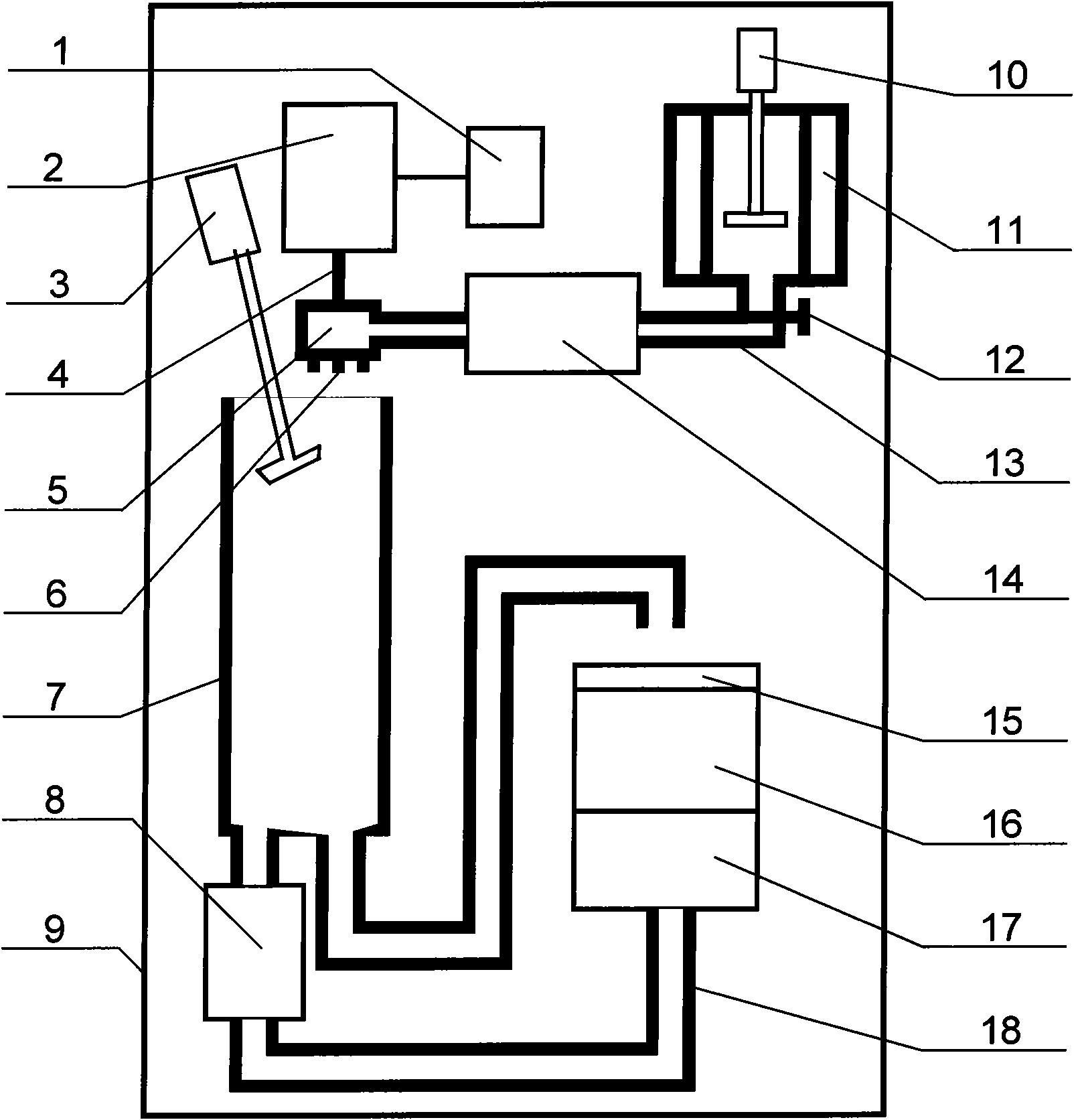

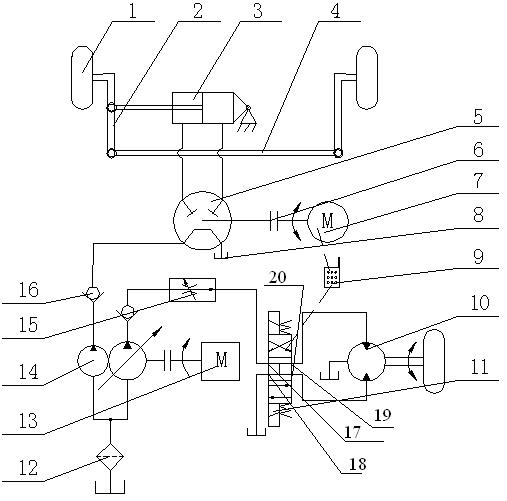

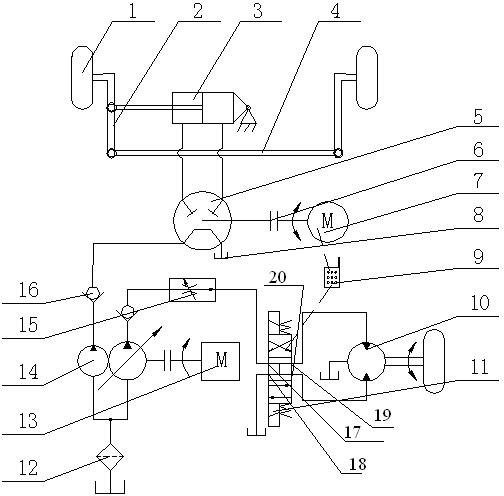

Experimental apparatus and method for obtaining multi-source diagnostic information of hydraulic equipment

InactiveCN101413521ALow efficiencySimple and fast operationFluid-pressure actuator testingSelf organizing map neural networkGear pump

The invention relates to an experimental device and an experimental method for multi-source information fusion for fault diagnosis of a hydraulic device. The device comprises the following elements: a variable plunger pump, a gear pump, two motors, two suction filters, five throttle and stop valves, two electromagnetic relief valves, an electromagnetic proportional relief valve, two pressure meters, an energy accumulator, two sets of combined sensors, a three-position four-way electromagnet directional valve, a hydraulic motor and a cooler. The experimental device can simulate eight typical running states (faults) of the hydraulic device, including low efficiency, oil and liquid pollution, air suction, leakage, oil pump fault, relief valve failure, motor failure and mechanical failure and can perform cluster analysis and fusion diagnosis to characteristics of the eight faults through a self organizing maps neural network.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

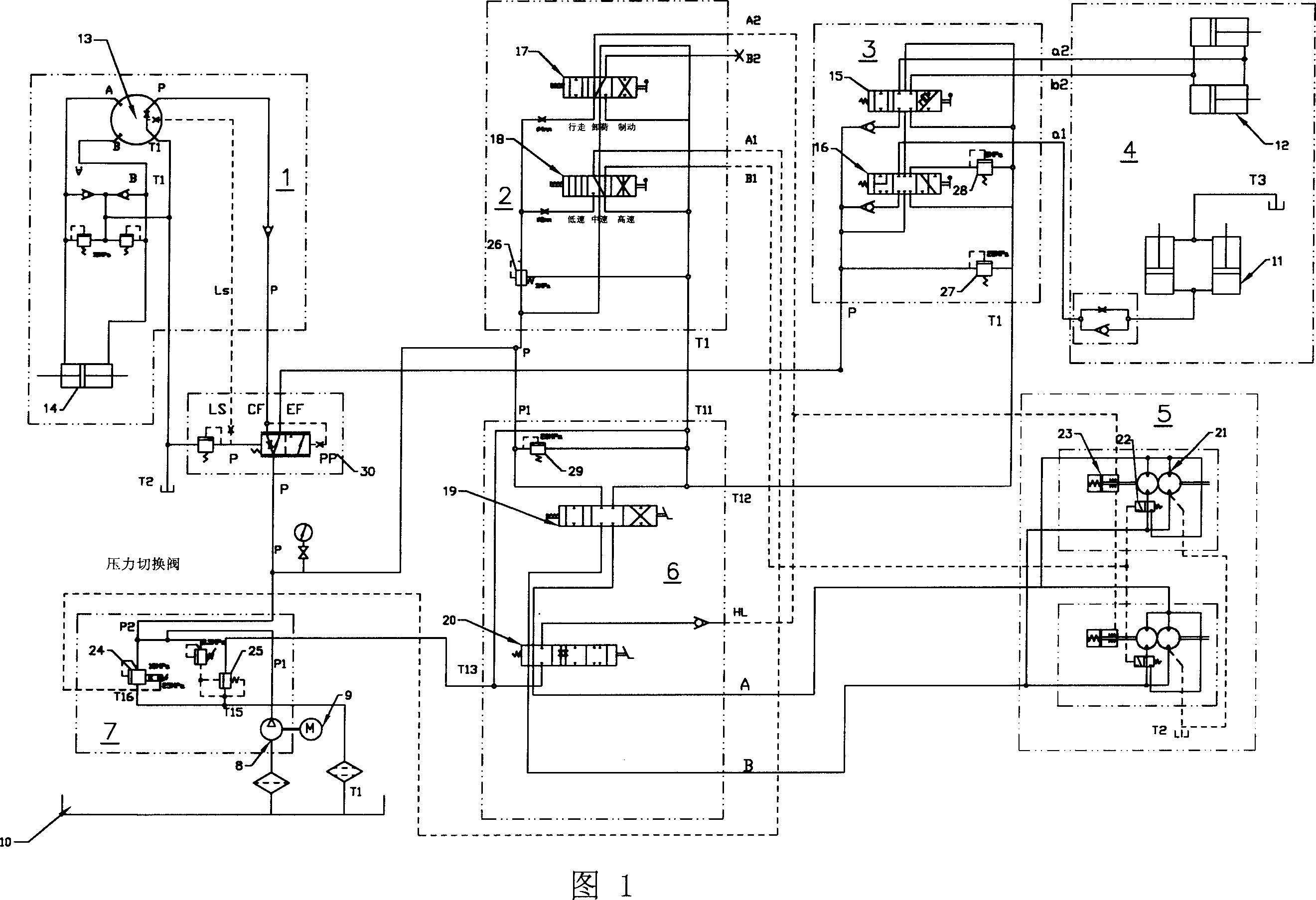

Full hydraulic electric forklift hydraulic system

InactiveCN101058395AEasy to controlImprove operational efficiencyLifting devicesHydraulic motorElectricity

The overall hydraulic electric forklift hydraulic system comprises the hoist oil cylinder, slanting oil cylinder formed slanting lifting device, steering device mainly made of the deflector and the steering oil cylinder, hydraulic motor, hydraulic motor brake and its speed regulating valve. The above mentioned three devices can get hydraulic energy form a generator driven gear pump, the said gear pump generated hydraulic energy divided into two ways, one passing through the optimal valve supplying to the said steering device and several valve controlled lifting device, the other way going to the control valve and converting brake valve drive device through change-over valve. It can replace variable pump for the control of the generator gear pump through electricity, getting rid of the low efficiency, big energy consumption, high oil temperature, long time damage to the hydraulic motor, traveling, and poor brake stability.

Owner:ZHEJIANG JIALI TECH

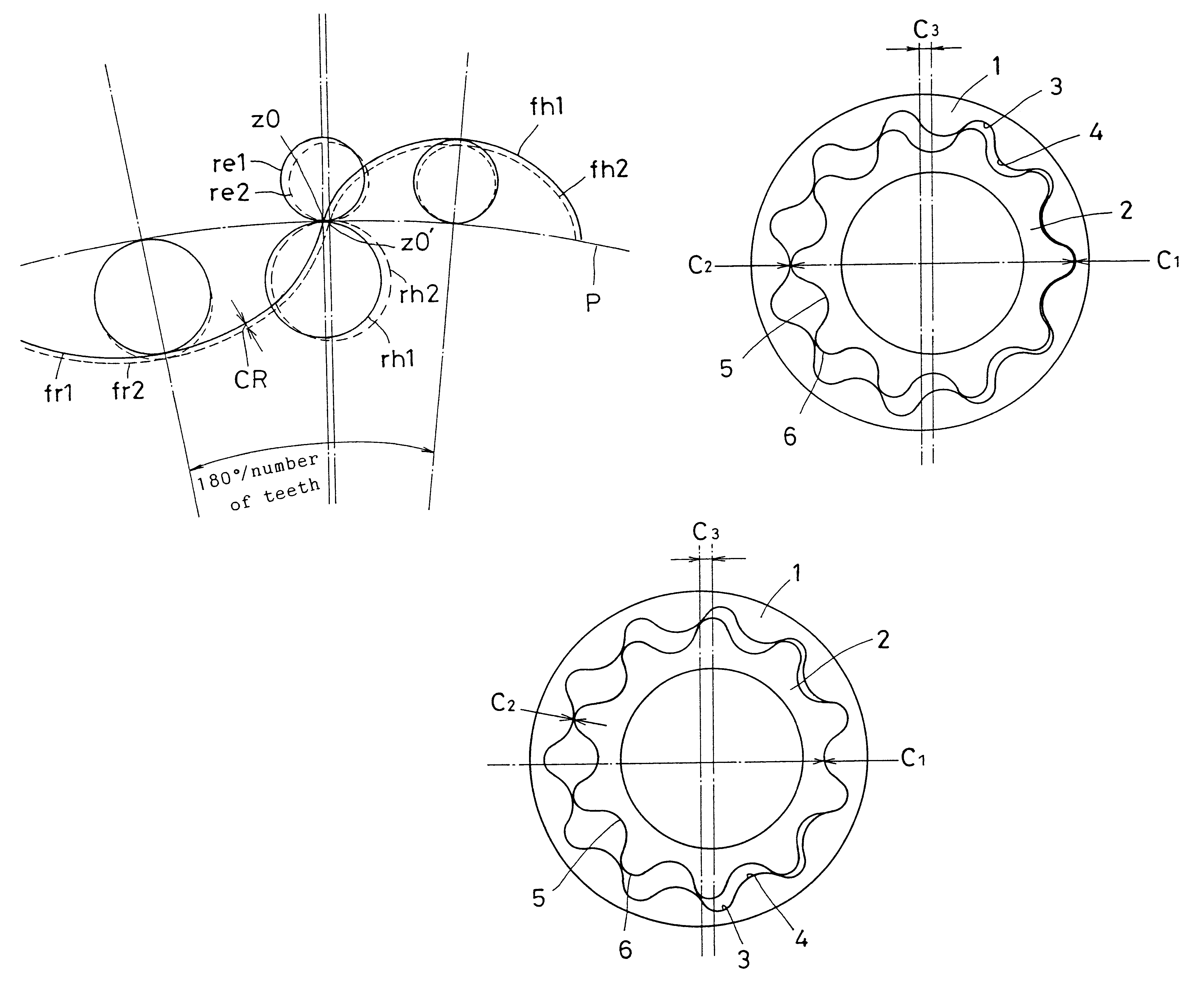

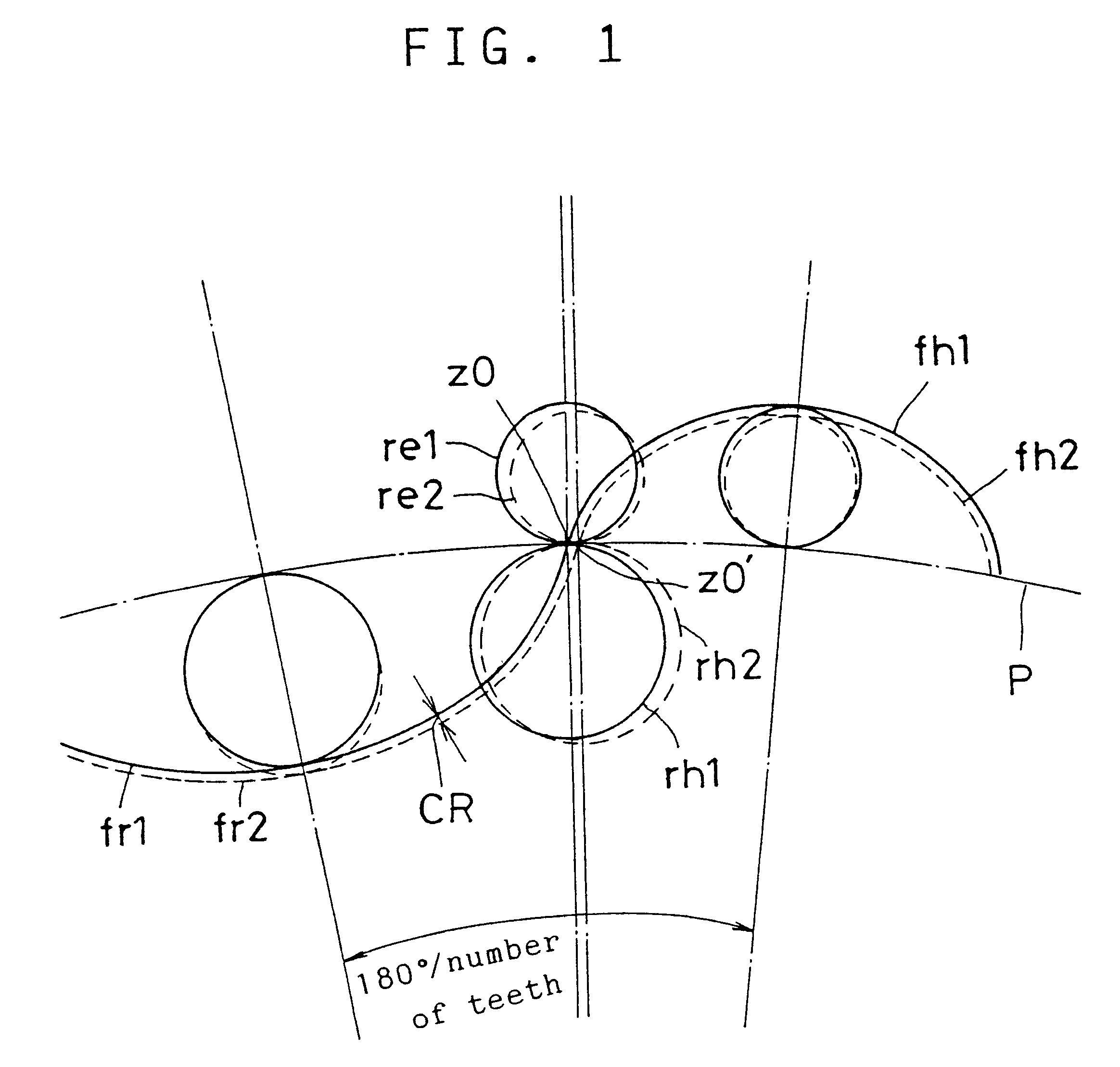

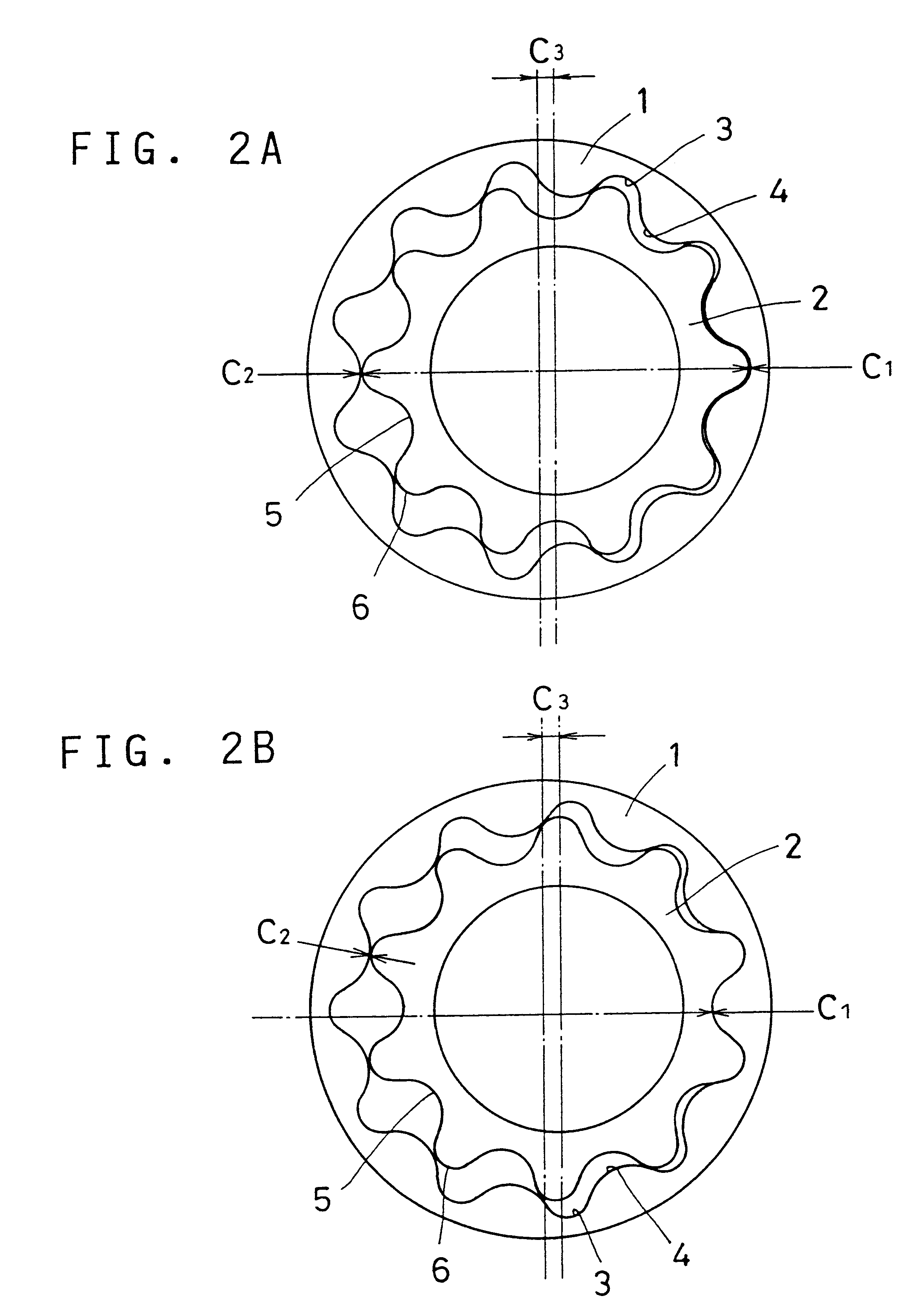

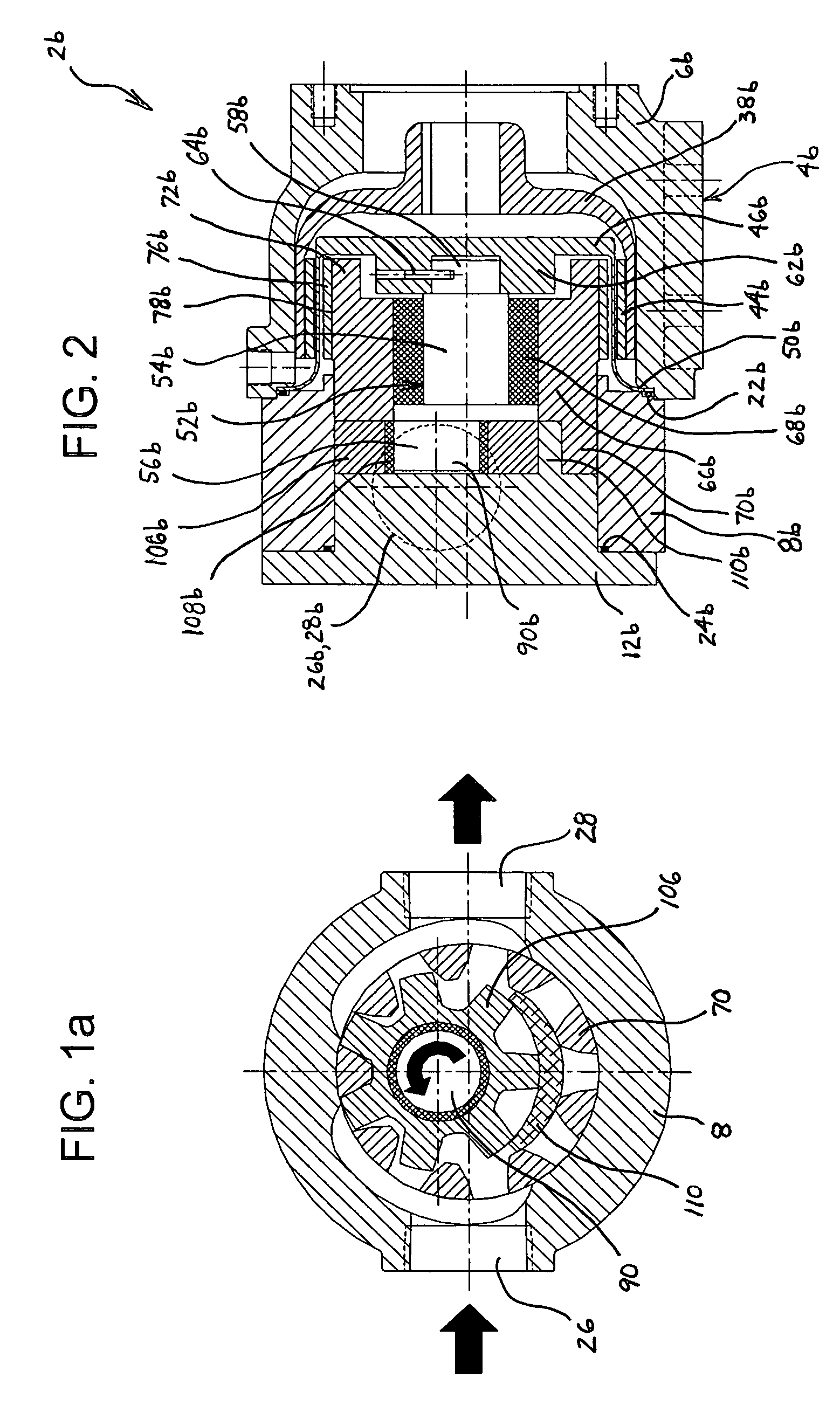

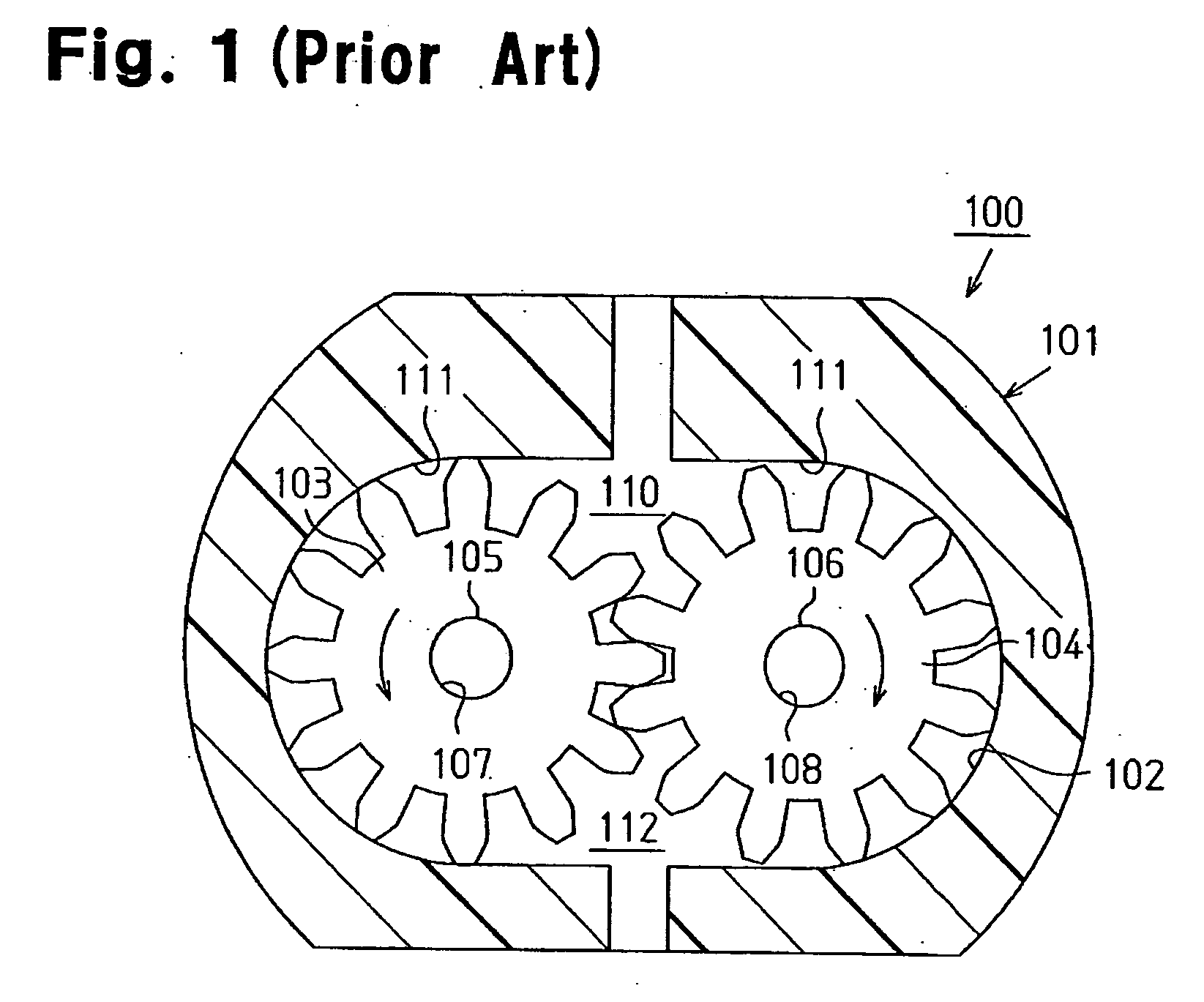

Internal gear pump

InactiveUS6244843B1Oscillating piston enginesEngine of intermeshing engagement typeGear pumpEngineering

An internal gear pump which improves the mechanical efficiency and the life and reduces noises by eliminating non-uniformity of the gaps between teeth. In the internal gear pump wherein the tooth spaces of the outer gear and the tooth tips of the inner gear form an epicycloid and the tooth tips of the outer gear and the tooth spaces of the inner gear form a hypocycloid, these cycloids are formed by four circles that roll on the pitch circle of each gear such that the gap between teeth in a region where the outer and inner gears mesh most deeply with each other is substantially equal to the gap between teeth in a region where the depth of mesh between the outer and inner gears are the shallowest.

Owner:SUMITOMO ELECTRIC SINTERED ALLOY LTD

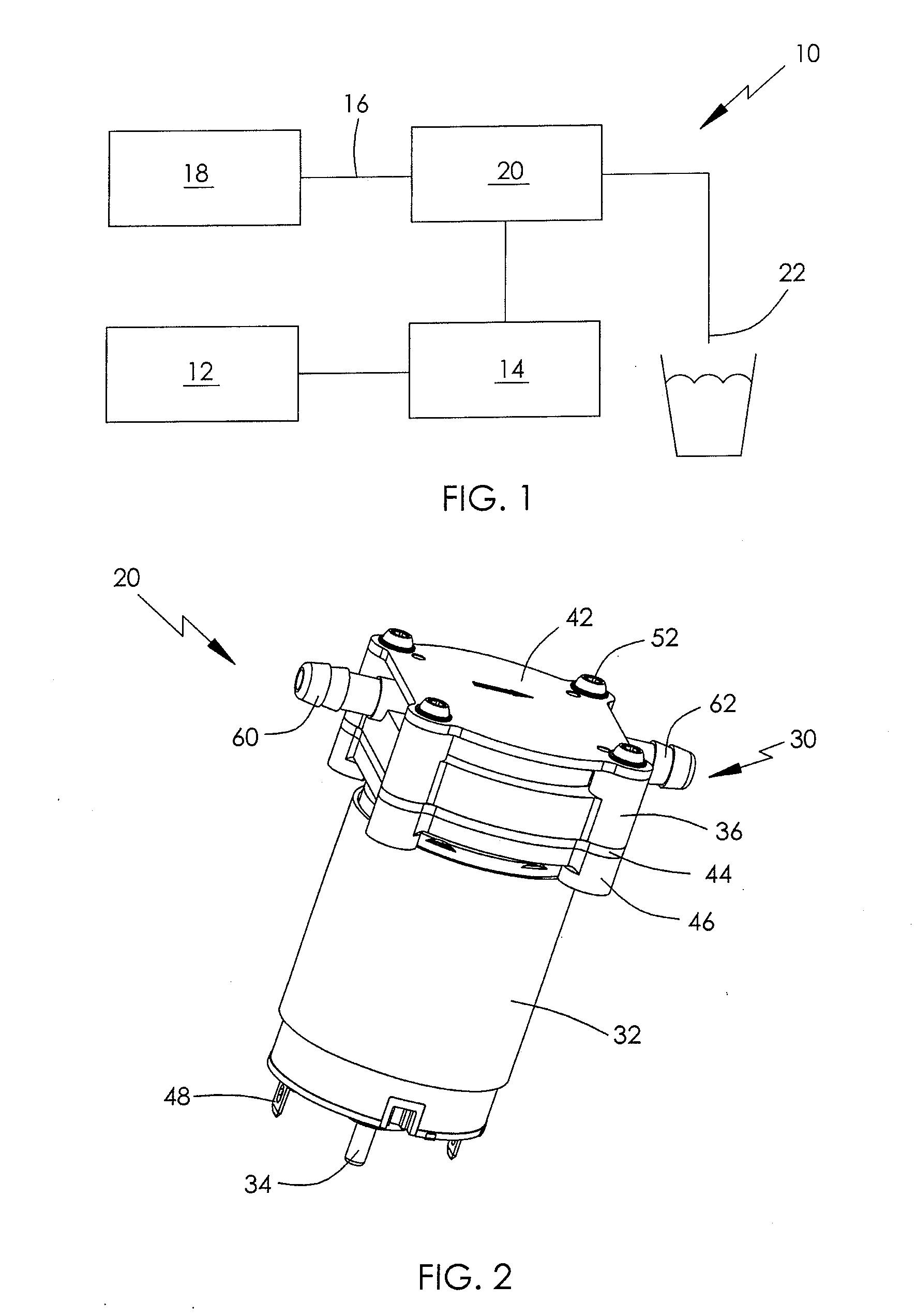

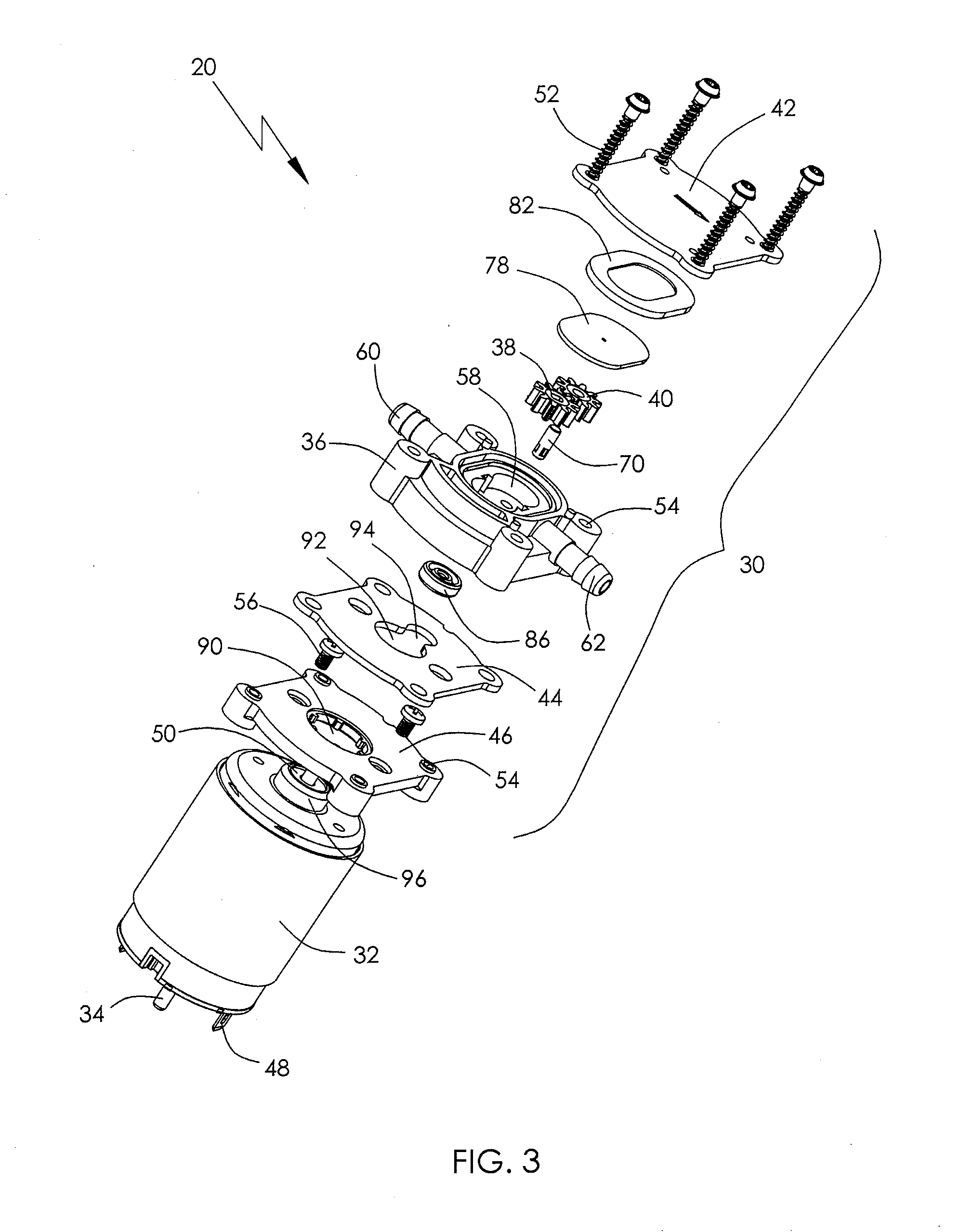

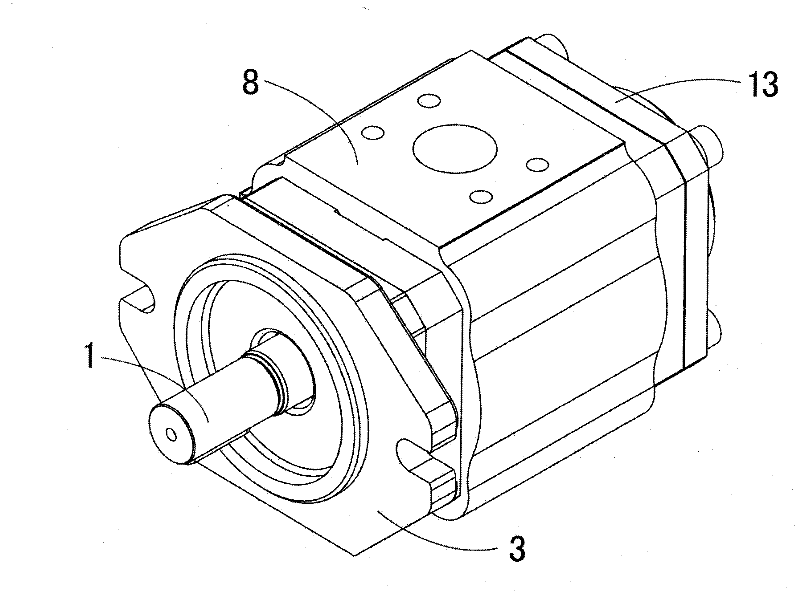

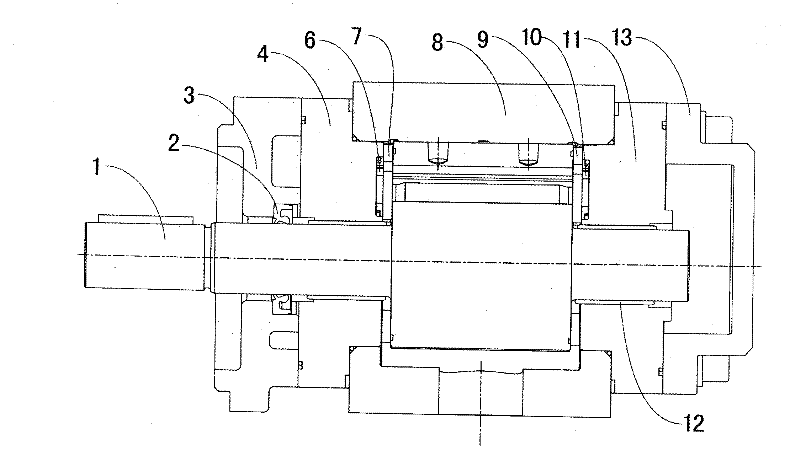

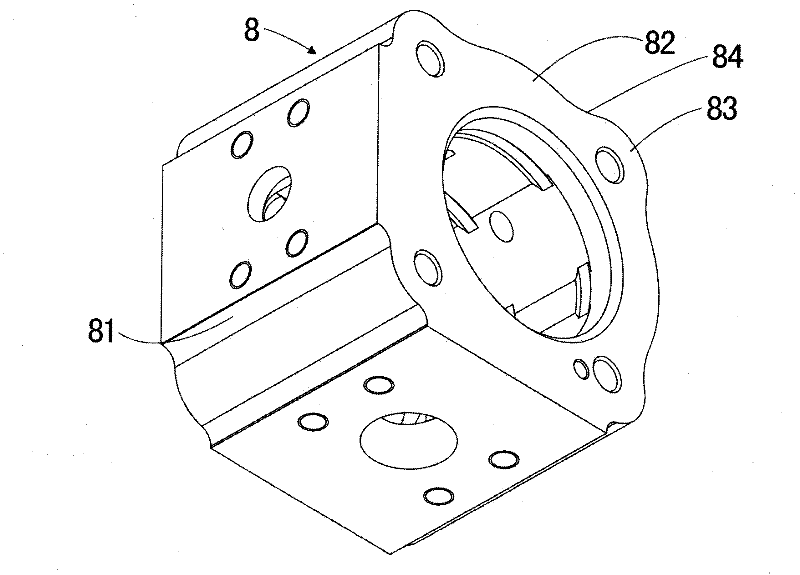

Liquid gear pump

ActiveUS20120305603A1Excellent low water absorptionHigh mechanical strengthPump componentsDispensing apparatusGear pumpPump chamber

A liquid gear pump includes a gear pump assembly and an electric motor with an motor shaft. The gear pump assembly includes a pump housing which defines a pump chamber, an inlet and an outlet which are in fluid communication with the pump chamber, and a driving gear and an idle gear which are received in the pump chamber. The driving gear is driven by the motor shaft. The idle gear is supported on an idle shaft and engaged with the driving gear. The driving gear and the idle gear are made of a material with a main component of PPS.

Owner:JOHNSON ELECTRIC SA

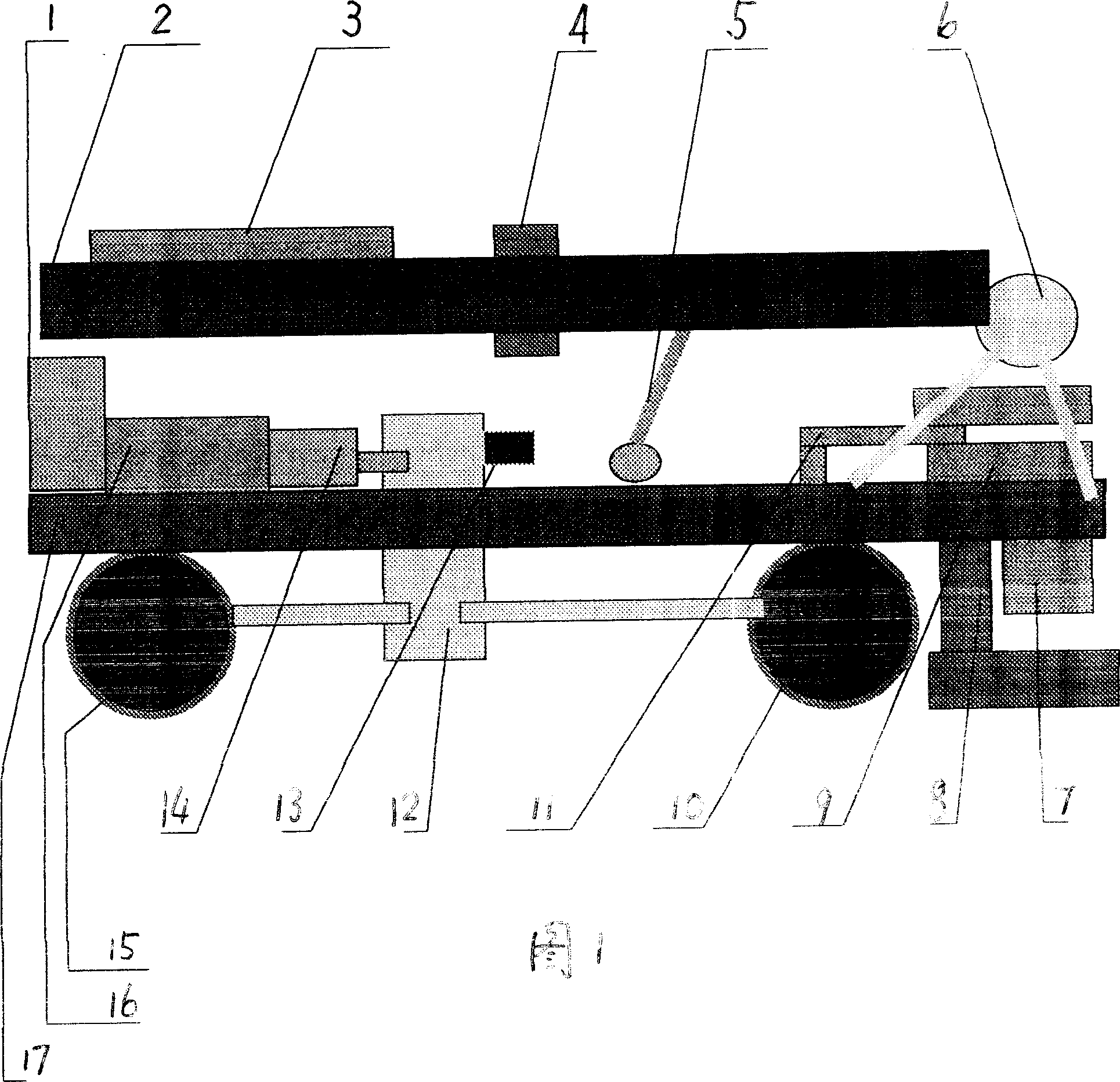

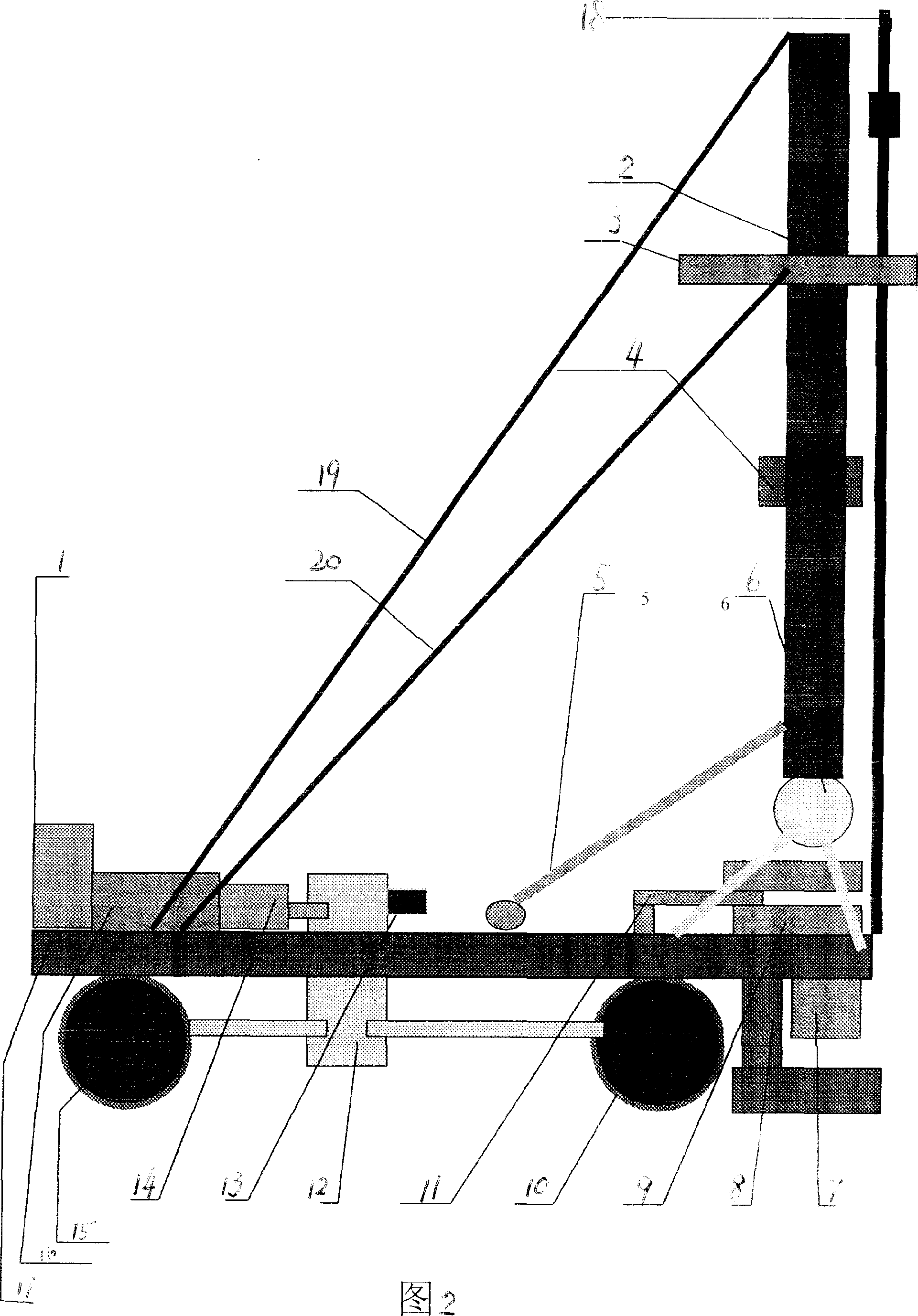

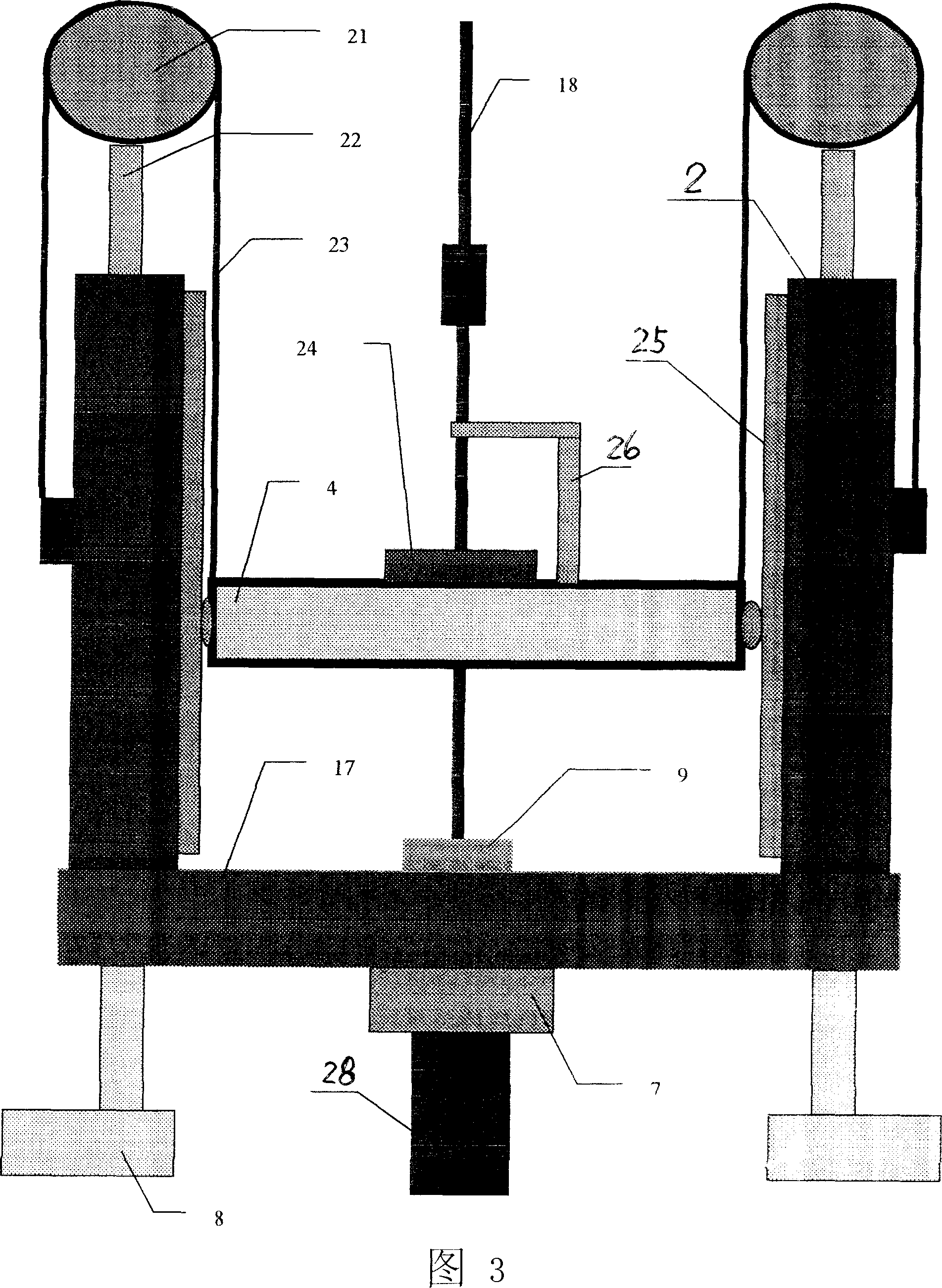

Drill floor well repairing machine without manual operation in well mouth

InactiveCN1920239AReduce labor intensityImprove workover efficiencyDrilling rodsDrilling casingsHydraulic cylinderVehicle frame

The invention relates to a workover device in drill floor type, used in non-manned operation under the oil well, wherein it is formed by driving control room 1, thick support post 2, discharge tube 3, lifter 4, amplitude-variable hydraulic cylinder 5, support post base 6, well-open hydraulic blowout preventer 7, drill floor hydraulic base 8, fixing hydraulic clamp disc 9, back tyre, back driving bridge 10, hydraulic clamper 11 with flexible sliding channel 11, hydraulic gear box 12, high-pressure gear pump 13, hydraulic torque converter 14, front tyre, front driving bridge 15, engine 16, frame and drill floor 17; the front part of frame 17 is arranged with driving control room 1, engine 16, hydraulic torque converter 14, hydraulic gear box 12 and high-pressure gear pump 13, while the back part has fixing hydraulic clamp disc 19, support post base 6, and hydraulic clamper 11; the support post base 6 is mounted with thick support post 2, discharge tube 3 and lifter 4. The invention can automatically set discharge tube and improve the working efficiency.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

Buoyancy driving device of deep-sea underwater glider

InactiveCN102501955ARealize the development to the deep seaLarge oil flowUnderwater vesselsUnderwater equipmentGear pumpFuel tank

The invention discloses a buoyancy driving device of a deep-sea underwater glider, which comprises an oil tank, a high-pressure plunger pump, a gear pump and a normally closed electromagnetic valve. The oil tank is mounted in a pressure-resistant shell and consists of a shell fixedly connected with the pressure-resistant shell, a corrugated pipe type leather sac is mounted in the shell, one end of the corrugated tube type leather sac is hermetically fixedly connected with the bottom end of the shell, the other end of the corrugated tube type leather sac is hermetically fixedly connected with a movable end cover, the movable end cover is slidably connected into the shell, an end cover photoelectric sensor and a top end photoelectric sensor are mounted on the shell, an oil outlet of the oil tank is connected with an oil inlet of the gear pump, an oil outlet of the gear pump is connected with an oil inlet of the high-pressure plunger pump, an oil outlet of the high-pressure plunger pump is connected with an oil inlet of an outer oil sac, the oil outlet of the gear pump is connected with an oil inlet of the oil tank by a check valve communicated with the gear pump, and an oil outlet of the outer oil sac is connected with the oil inlet of the oil tank by the normally closed electromagnetic valve. By the aid of the buoyancy driving device, underwater gliders can run in the deep sea, and requirements on deep-sea operation for a long time and at high depth are met.

Owner:TIANJIN UNIV

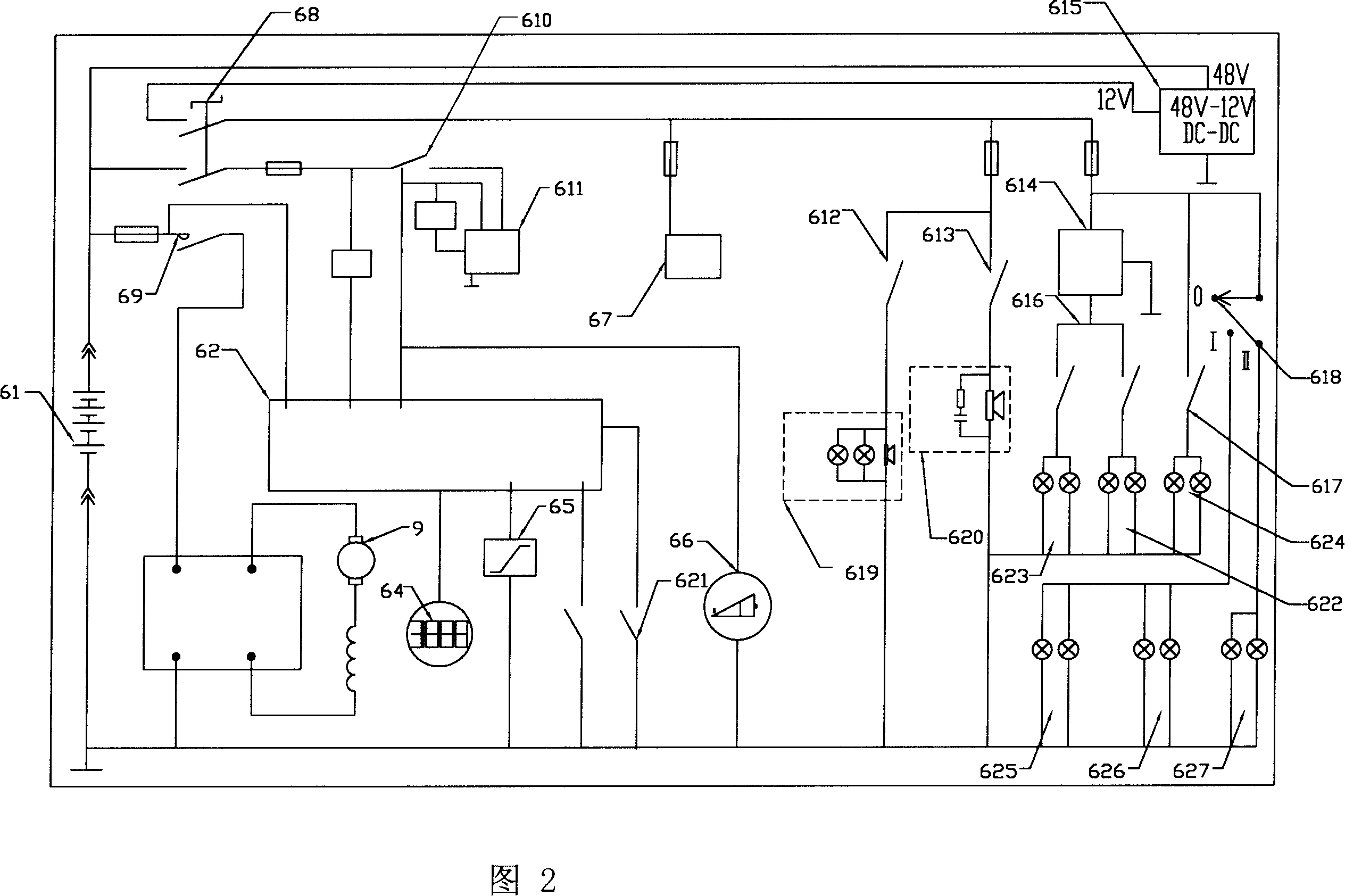

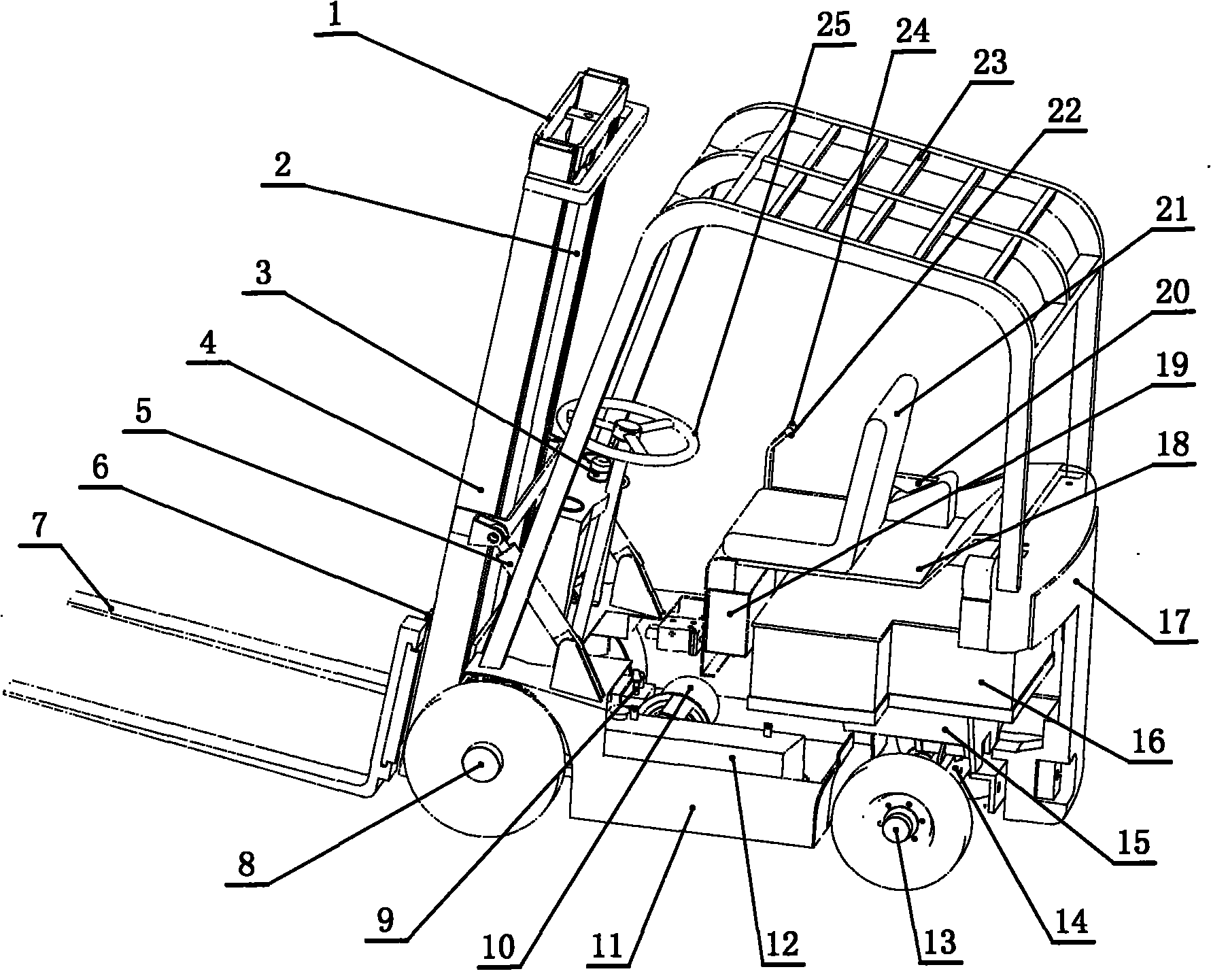

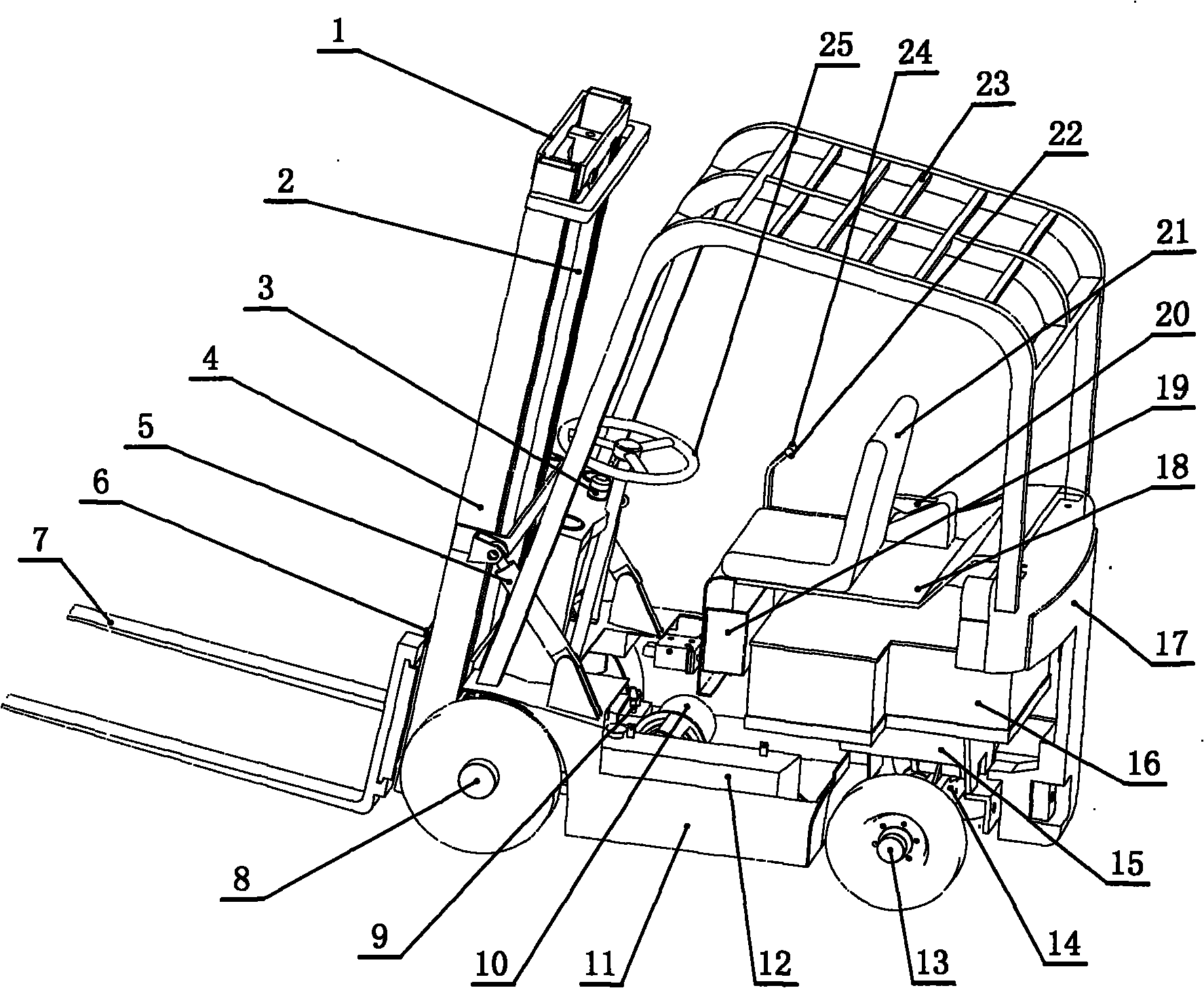

Electric forklift

InactiveCN101811652AReduce consumptionImprove battery lifeElectric propulsion mountingLifting devicesVehicle frameGear pump

The invention relates to an electric forklift with low energy consumption, high efficiency, simple structure and convenient use. A transmission shaft of a motor is in transmission connection with a gear pump, an oil tank is fixedly mounted on a frame and communicated with a gear pump, a lifting cylinder is movably connected between a movable gantry and a fixed gantry, a lifting pipeline is communicated between the lifting cylinder and the oil tank, an inclined cylinder is fixedly connected with the fixed gantry and the frame, an inclined pipeline is communicated between the inclined cylinder and the oil tank, a multi-way valve is communicated between the lifting pipeline and the inclined pipeline and provided with a lifting rod and an inclined rod, the lifting rod corresponds to the lifting pipeline and is provided with a lifting control rod, the inclined rod corresponds to the inclined pipeline and is connected with an inclined control rod, an rear axle is articulated with a rear wheel, a steering cylinder is fixedly connected between the rear axle and the rear wheel, and a steering pipeline is communicated between the steering cylinder and the oil tank and communicated with a steering gear.

Owner:JIANGSU WEISIDENG CARRYING MACHINERY

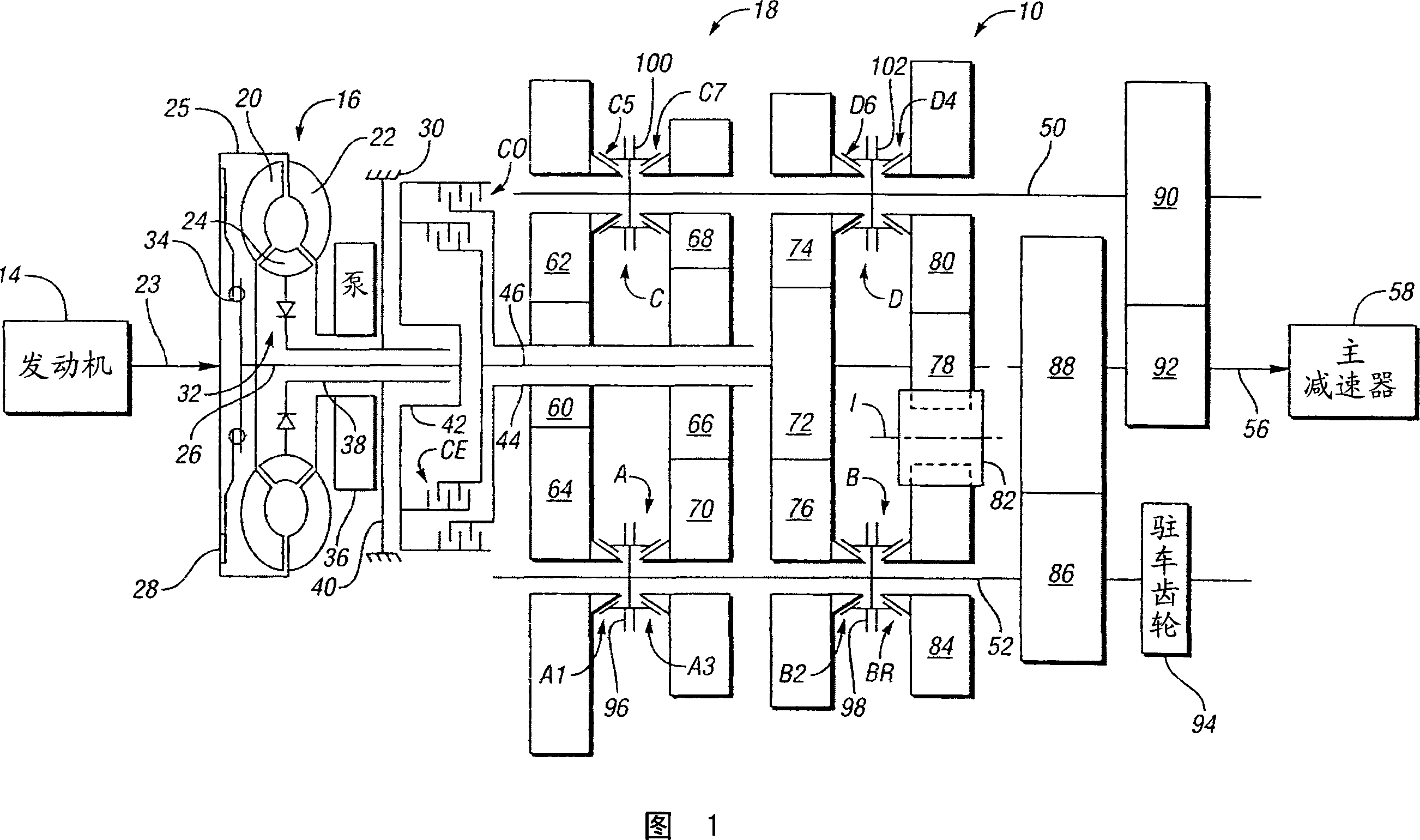

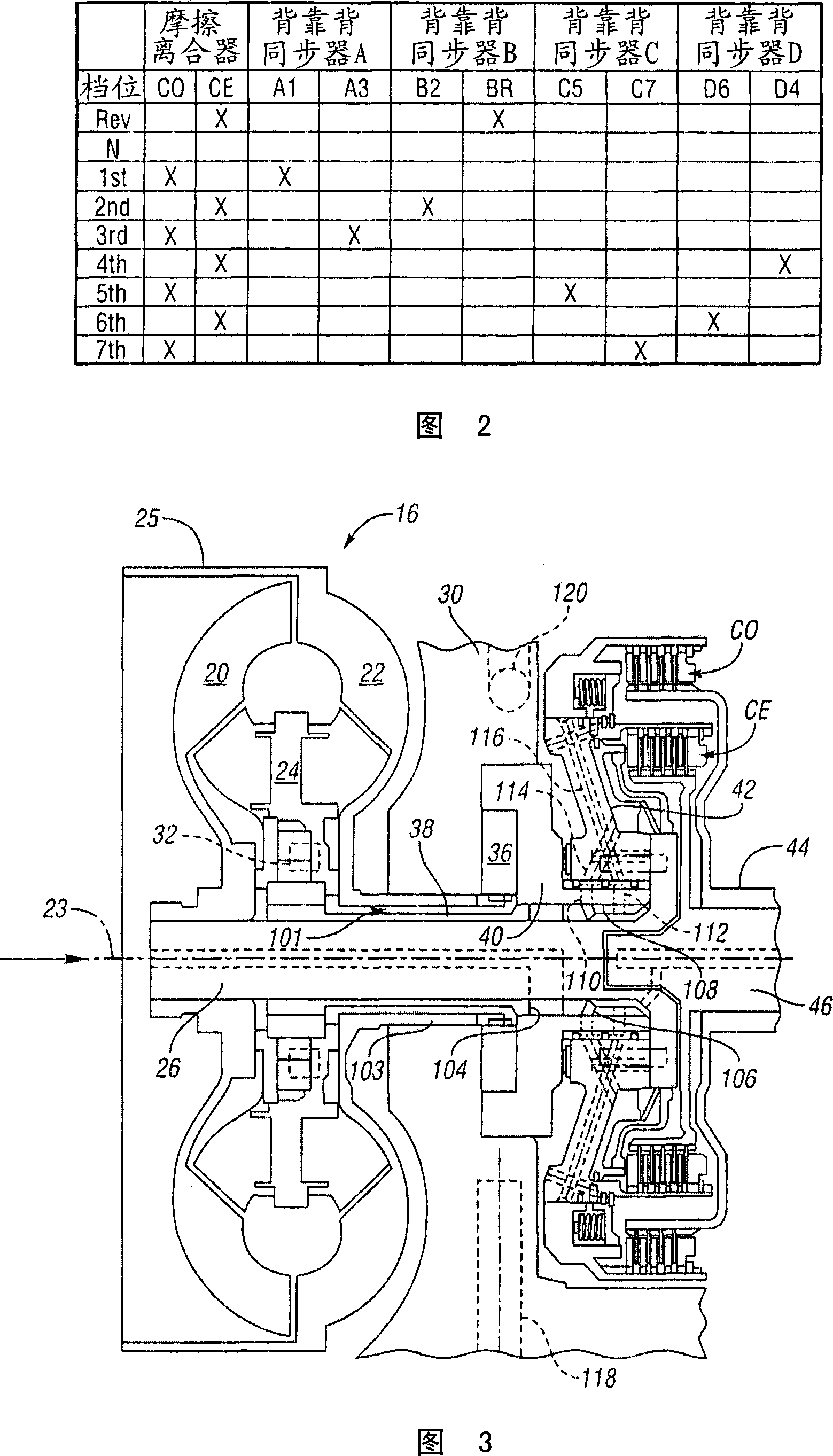

Powertrain with torque converter and axially compact seven speed dual clutch transmission

InactiveCN101131198AEasy transferCompact bootToothed gearingsTransmission elementsGear pumpControl theory

A powertrain having a torque converter, a friction input shift clutch, and a shared drive gear, and having an axially compact structure, encapsulating a transmission pump between the torque converter and a clutch hub and utilizing four back-to-back synchronized The engine achieves seven forward speed ratios.

Owner:GM GLOBAL TECHNOLOGY OPERATIONS LLC

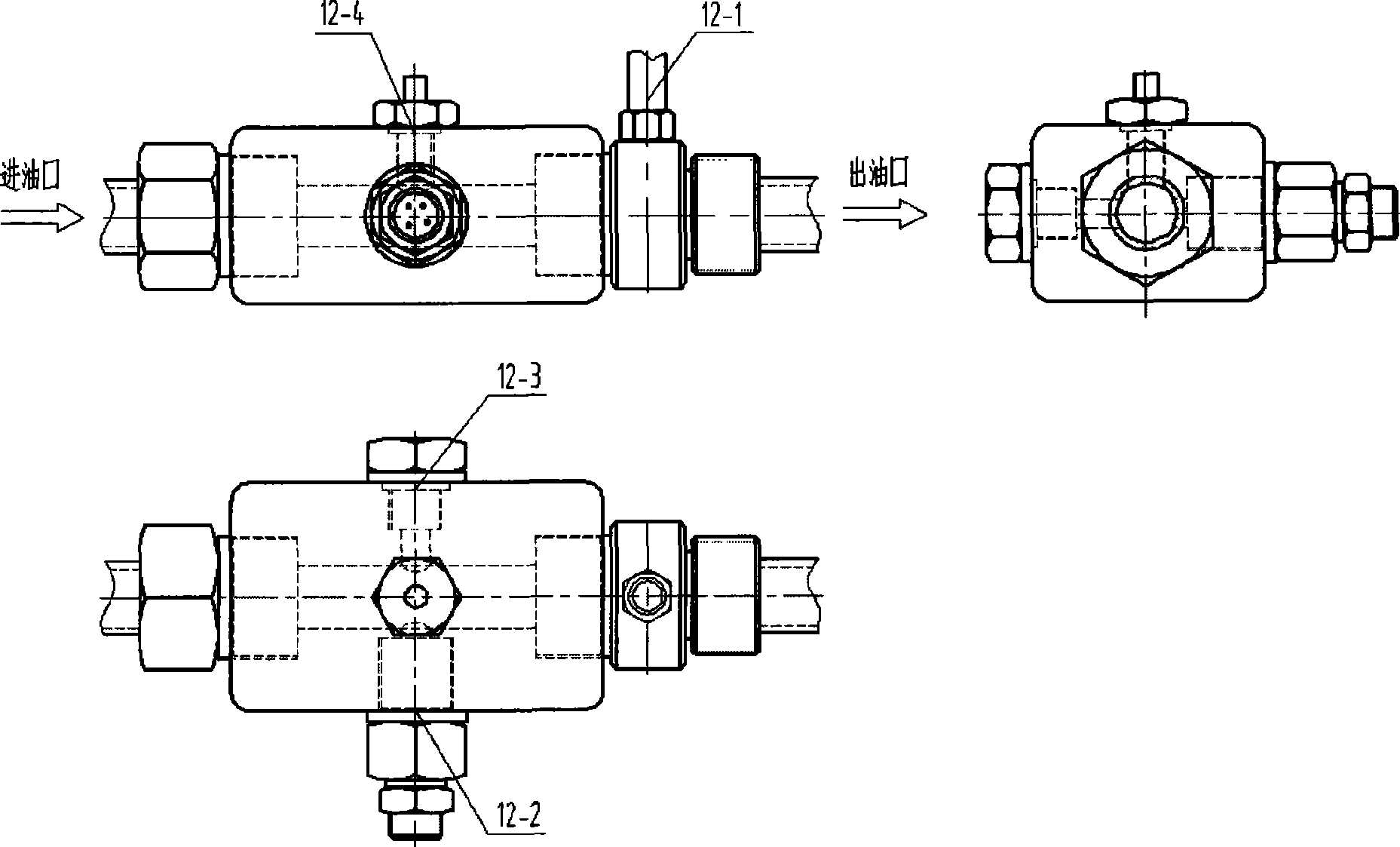

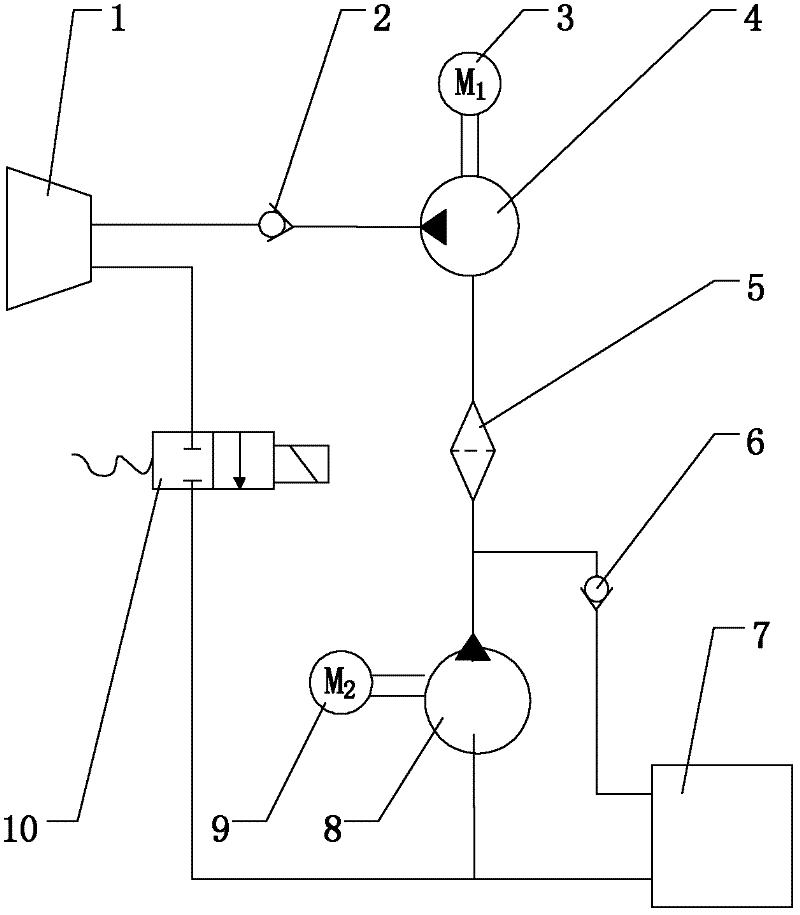

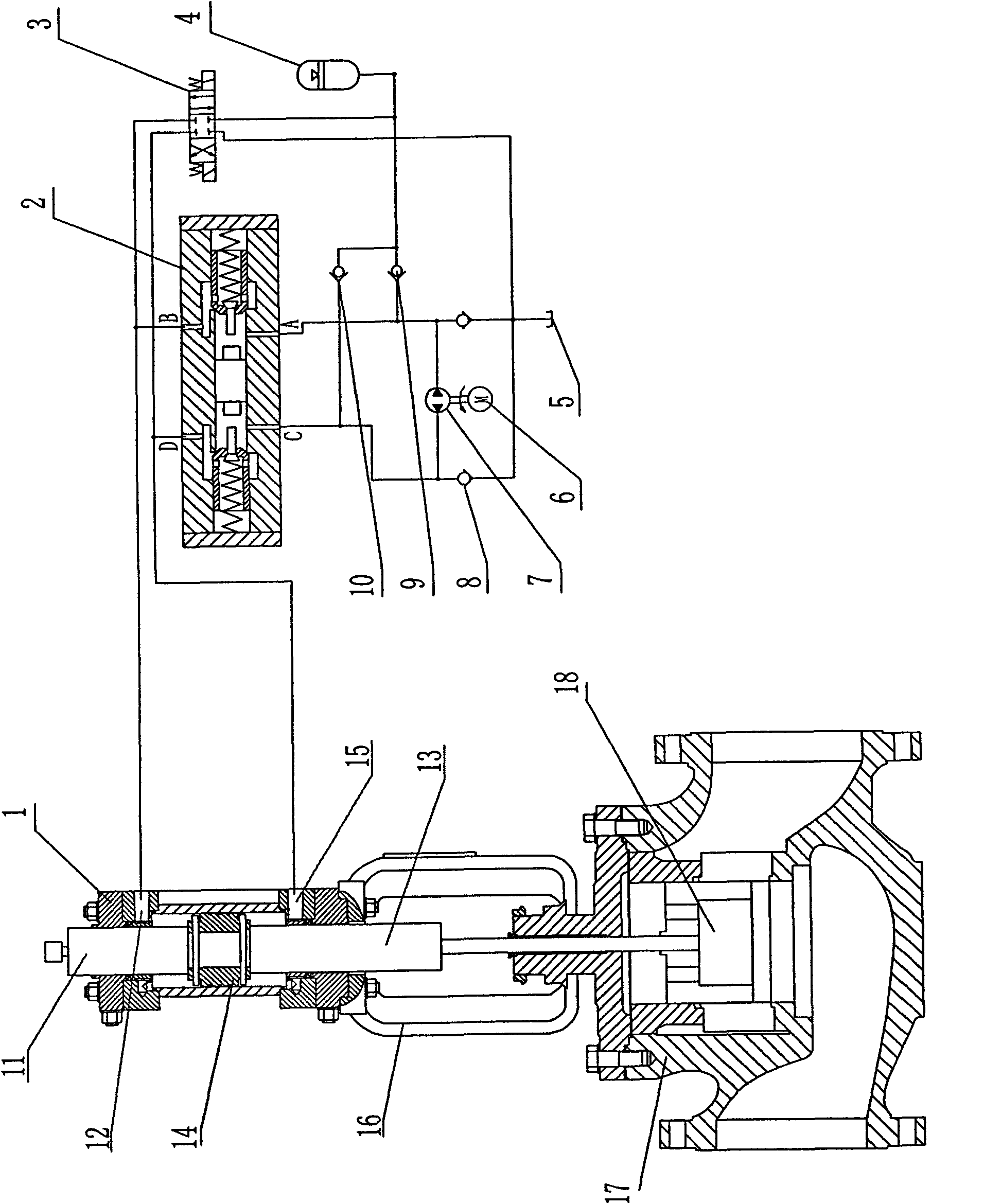

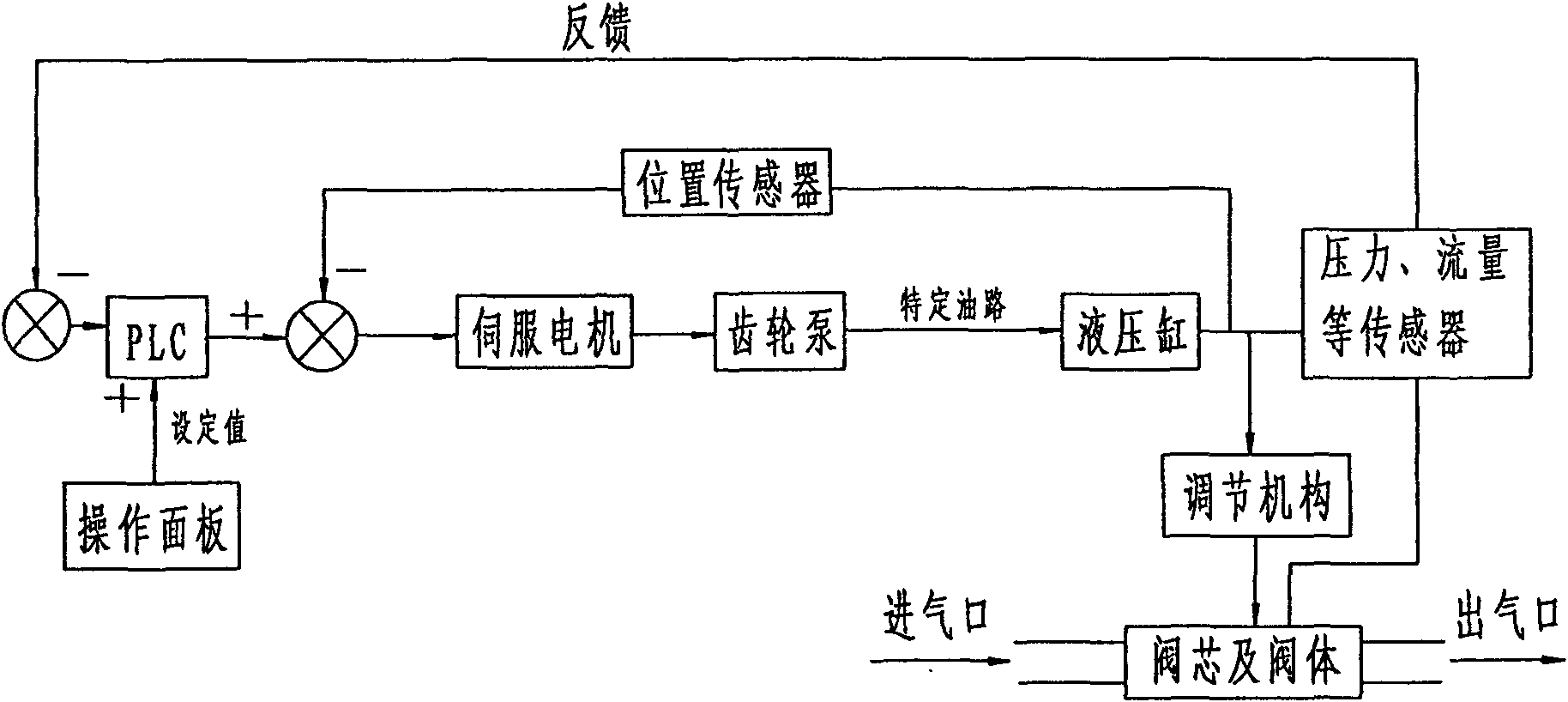

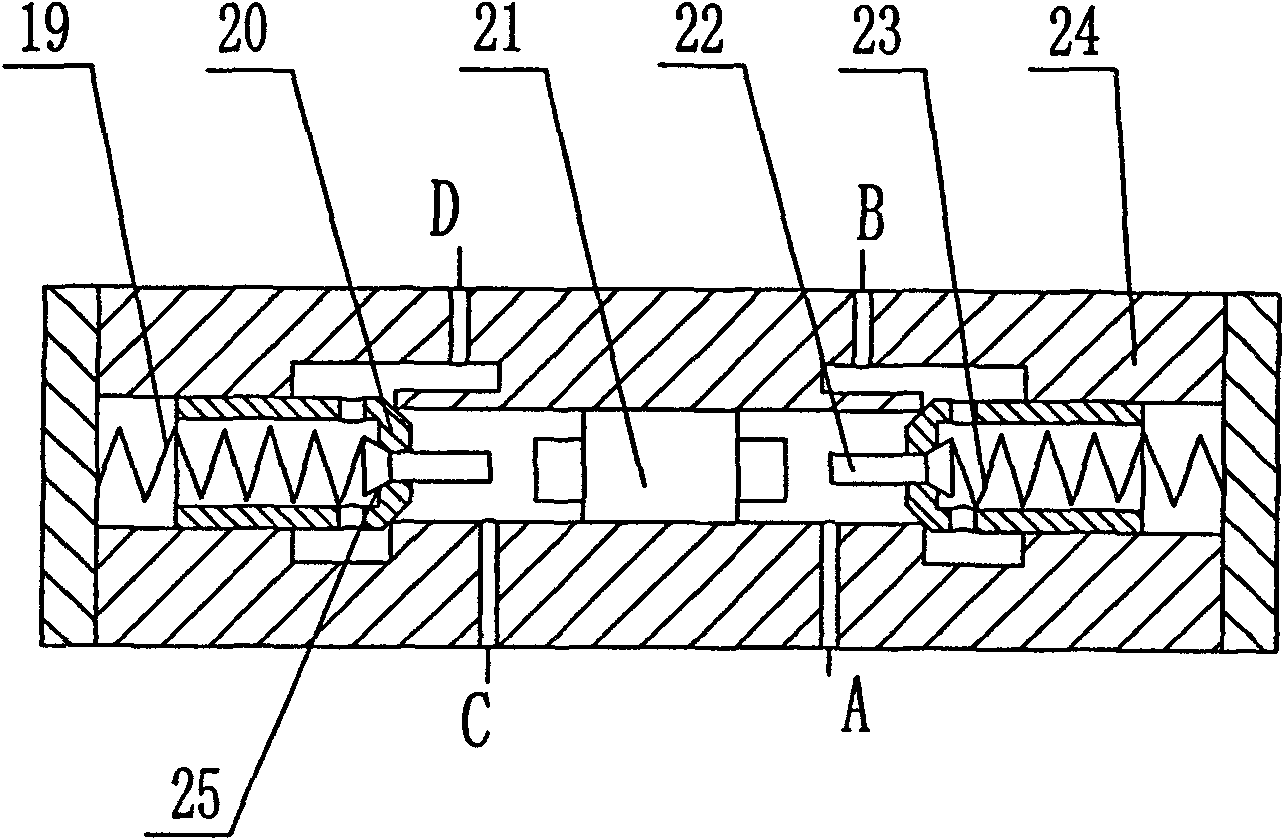

Electro-hydraulic driver of control valve

InactiveCN101598232AImprove reliabilityResponsive compactOperating means/releasing devices for valvesGear pumpFuel tank

The invention provides an electro-hydraulic driver of a control valve, which comprises a hydraulic driving system, a pressure sensor, a flow sensor, a position sensor and a control unit; wherein, the hydraulic driving system is used for driving a valve core of the control valve and comprises a bidirectional driving cylinder, a directional control valve, a three-position four-way reversing valve, an energy accumulator, a servo motor and a bidirectional gear pump; the pressure sensor and the flow sensor are installed on a fluid output pipeline, are used for detecting the pressure and the flow of the output fluid in the pipeline and are connected with the control unit; the position sensor is used for detecting the valve core position of the control valve to be controlled and is connected with the control unit. The electro-hydraulic driver realizes that hydraulic oil can flow out of an oil outlet cavity and directly enter an oil inlet cavity without passing through an oil tank, and has simple and compact structure; the motor and the oil pump do not need to continuously run but operate intermittently, which can not only save energy but also prolong the service life of the system, thus realizing stable operation for extra-long time and quick response of the control valve with high reliability.

Owner:SHANDONG UNIV

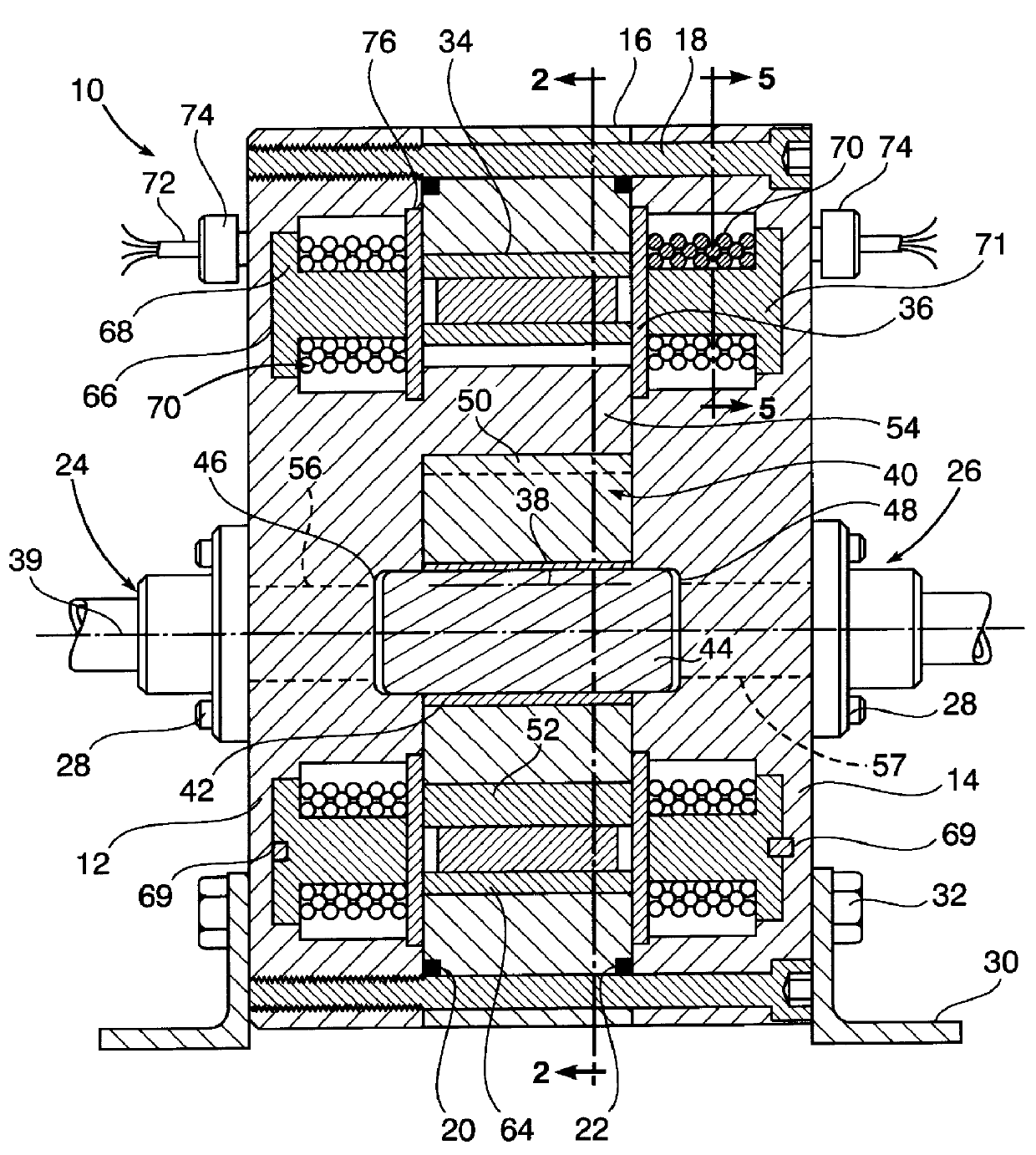

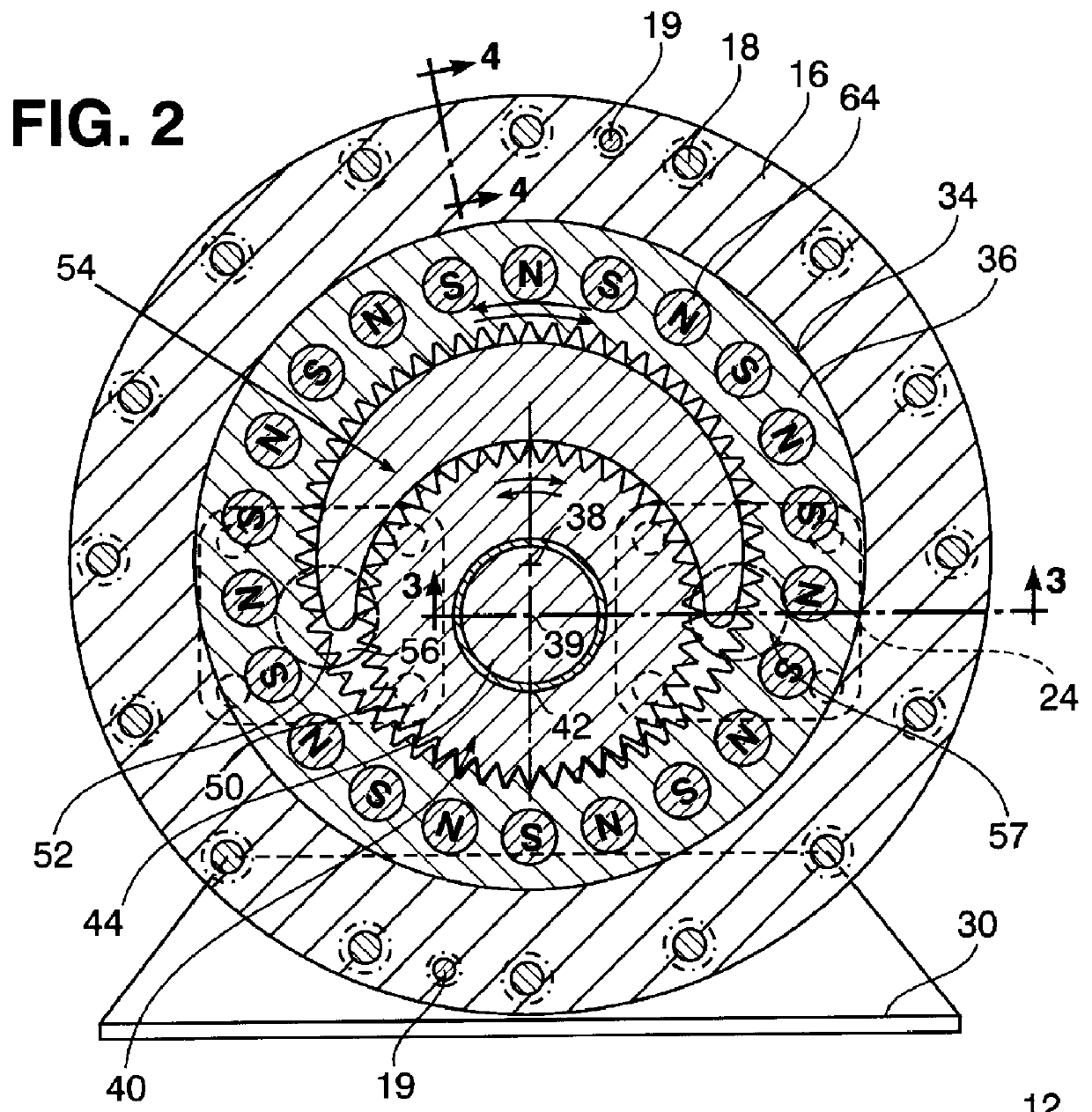

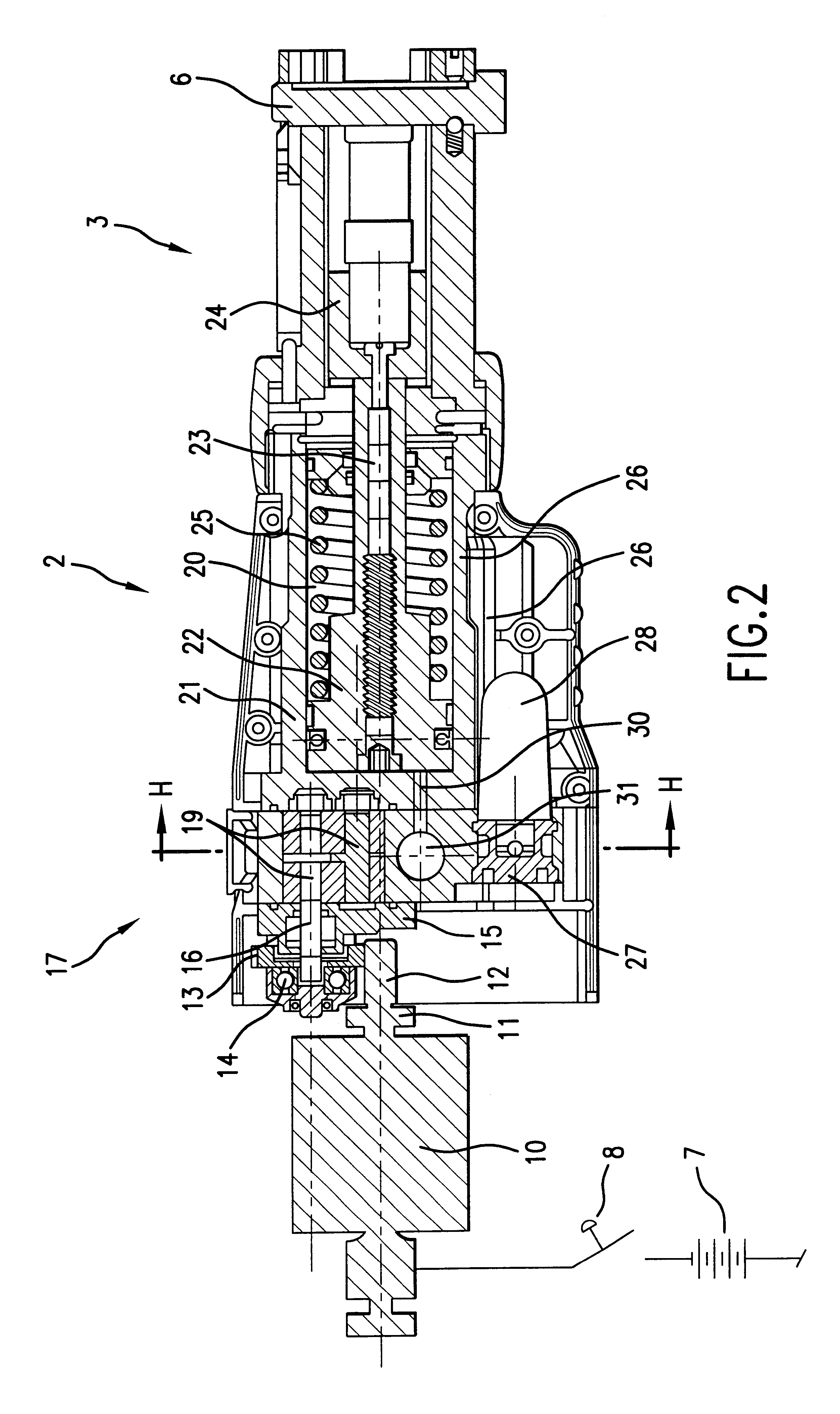

Magnetically driven gear pump

ActiveUS7137793B2Simple structureEngine of arcuate-engagement typeOscillating piston enginesGear driveGear pump

A magnetically driven gear pump having a housing, a rotatable annular magnetic drive assembly magnetically coupled to but spaced from an annular driven magnet and rotor gear assembly with an annular canister disposed therebetween, and wherein when the annular magnetic drive assembly is rotated, the annular driven magnet and rotor gear assembly rotate on a first shaft portion of an offset stationary shaft and the rotor gear drives an idler gear that rotates on a second shaft portion of the offset stationary shaft.

Owner:PSG CALIFORNIA LLC

Pressing tool for pressing coupling elements

Owner:VON ARX AG

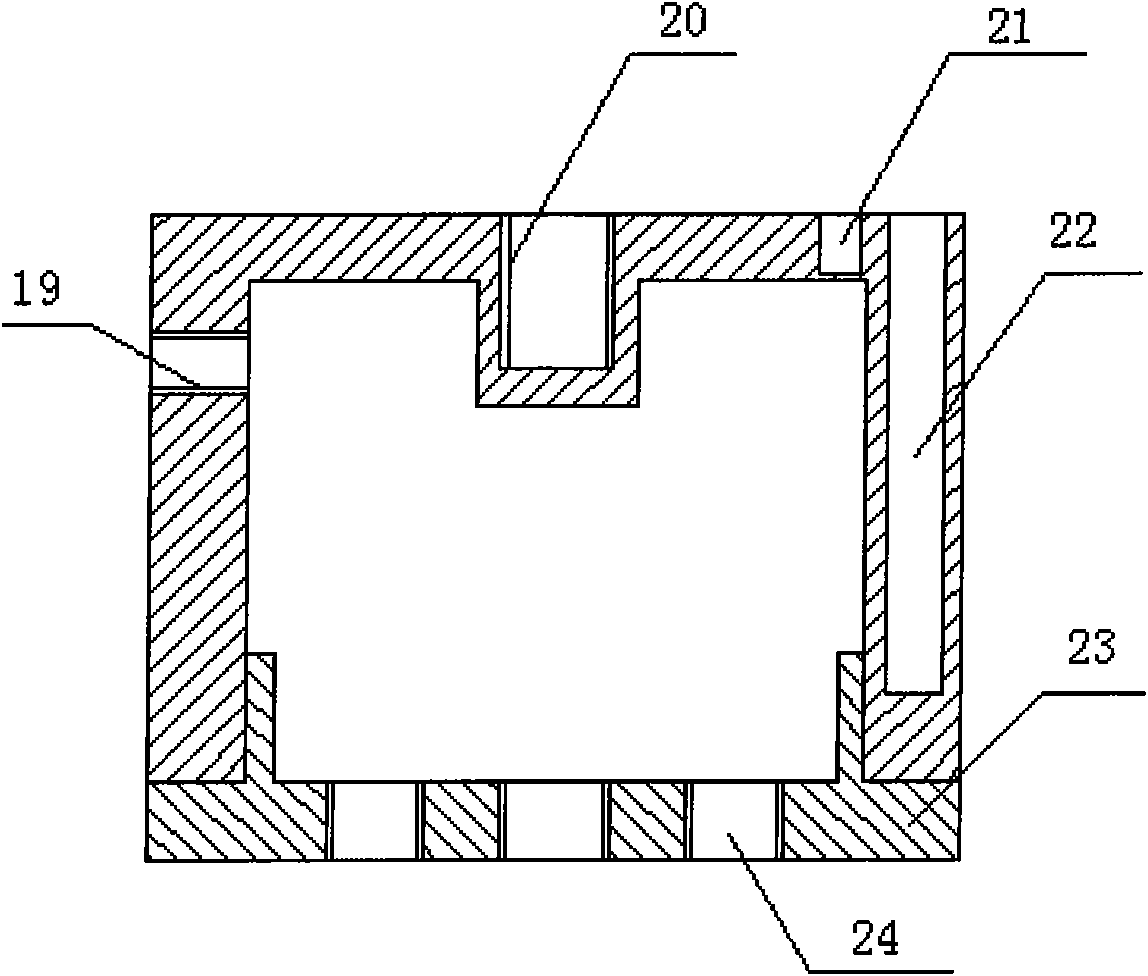

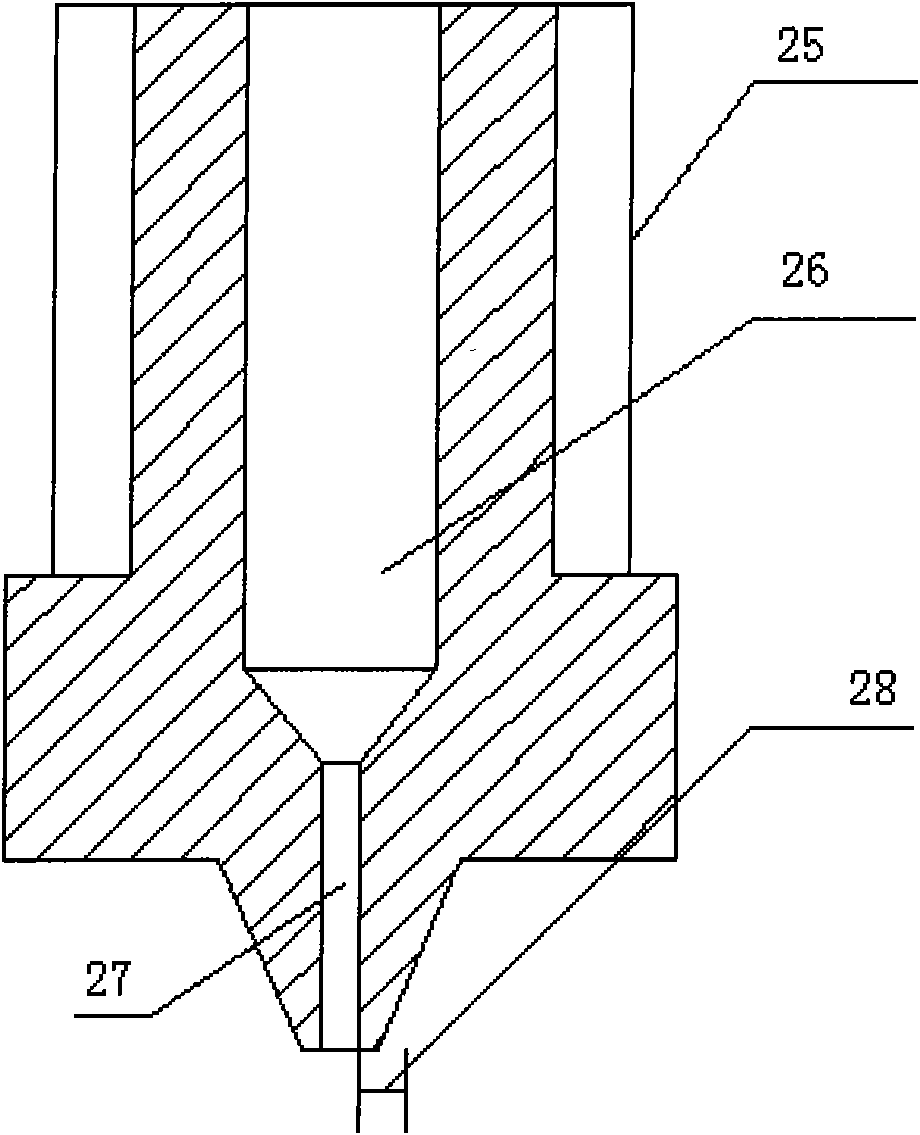

Gear pump and liquid injection apparatus

InactiveUS20050238505A1Close openingAvoid positioningOscillating piston enginesEngine of counter-engagement typeGear pumpDrive shaft

A high-performance gear pump that does not require highly accurate machining is disclosed. The gear pump includes a housing having an accommodation chamber. A drive gear and a driven gear are positioned in contact with an inner surface of the accommodation chamber. The drive shaft is loosely received by the shaft hole of the drive gear, and the driven shaft is loosely received by the shaft support formed in the housing and the cover.

Owner:SEIKO EPSON CORP

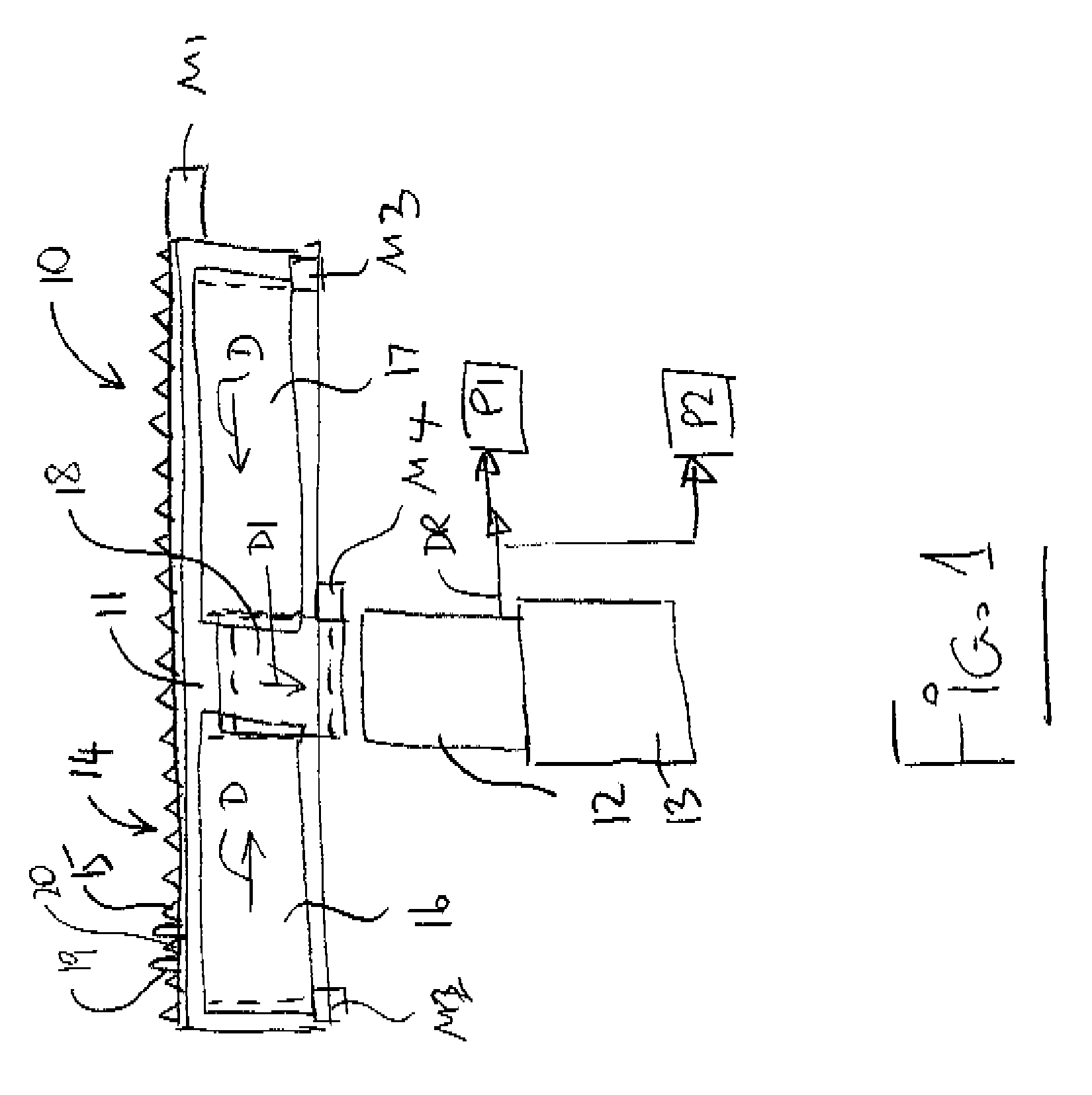

Crop harvesting header with reversible drive to the sickle knife

A crop harvesting header includes a sickle knife driven by a first hydraulic motor and a crop transfer system including three conveying drapers which is driven by at least one second hydraulic motor. A mechanical drive input from the combine harvester drives a first pressure regulated piston pump generating flow for the first motor and a second gear pump for the second motor. When the drive input is driven in the reverse direction, hydraulic fluid is supplied from the second pump in the reverse direction for driving the second motor in the reverse direction. As the first pump does not pump in the reverse direction the hydraulic control circuit is arranged such that, when the second pump is driven by the drive input in the reverse direction, hydraulic fluid is supplied from the second pump to the first motor for driving the first motor in the reverse direction.

Owner:MACDON INDS

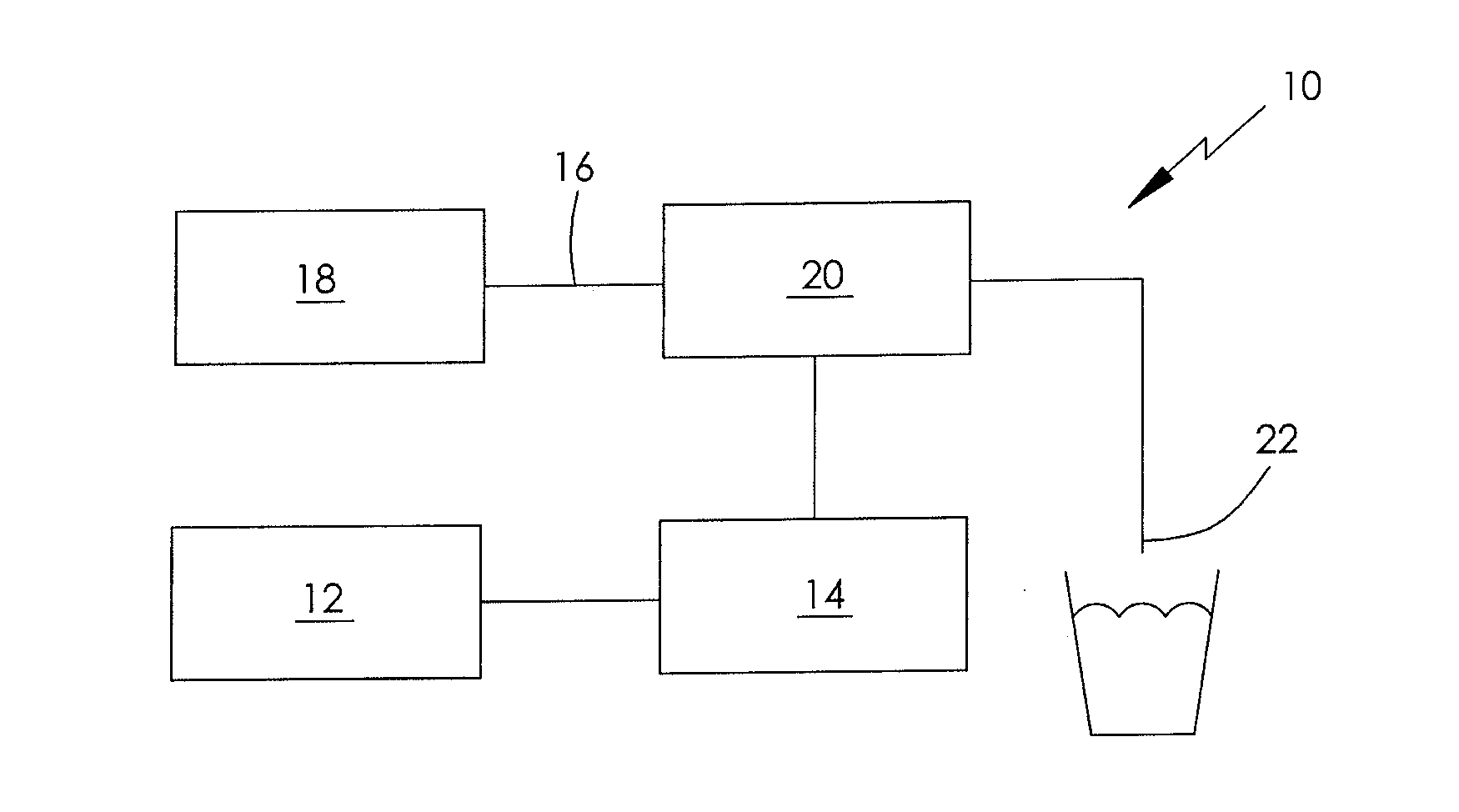

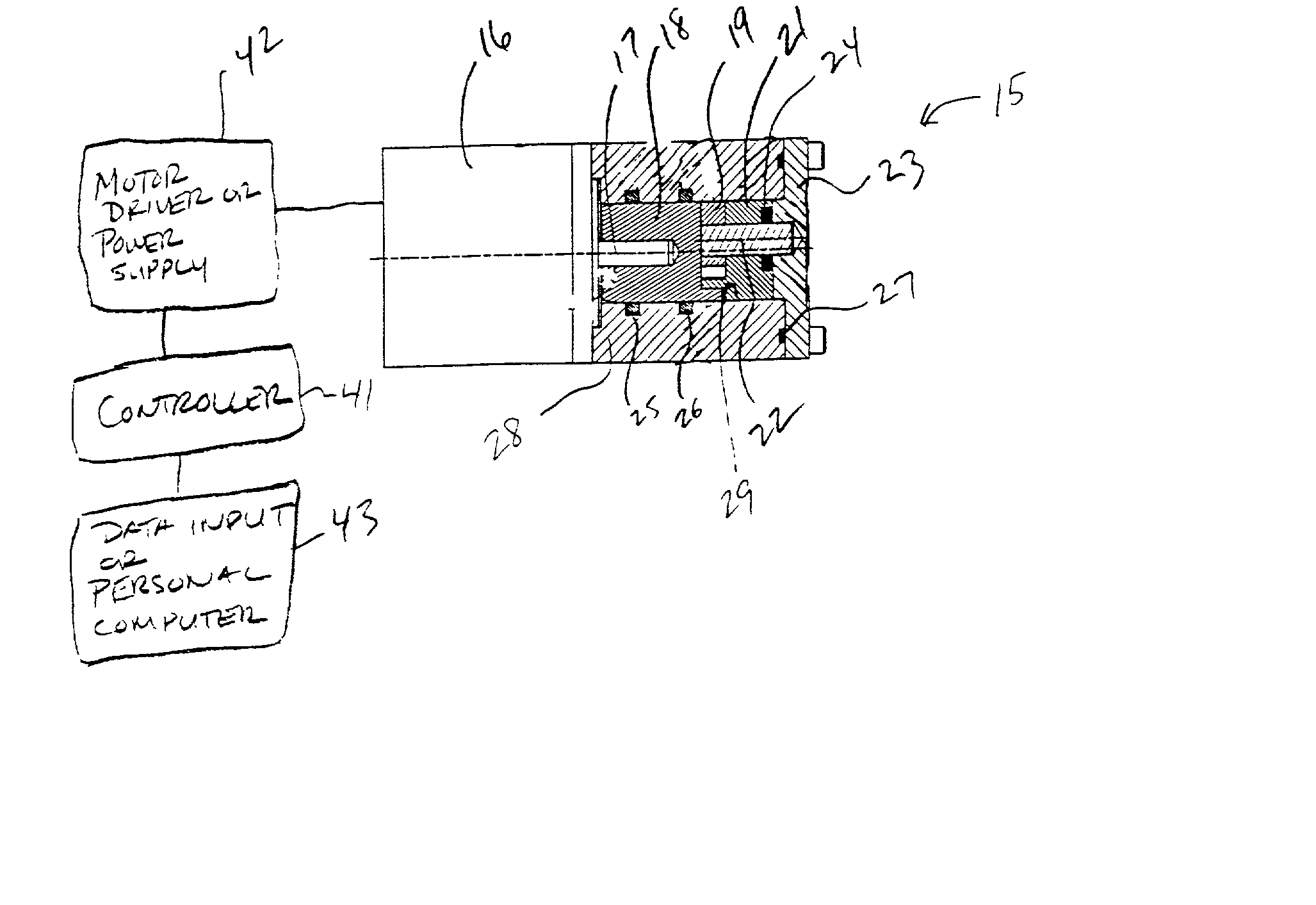

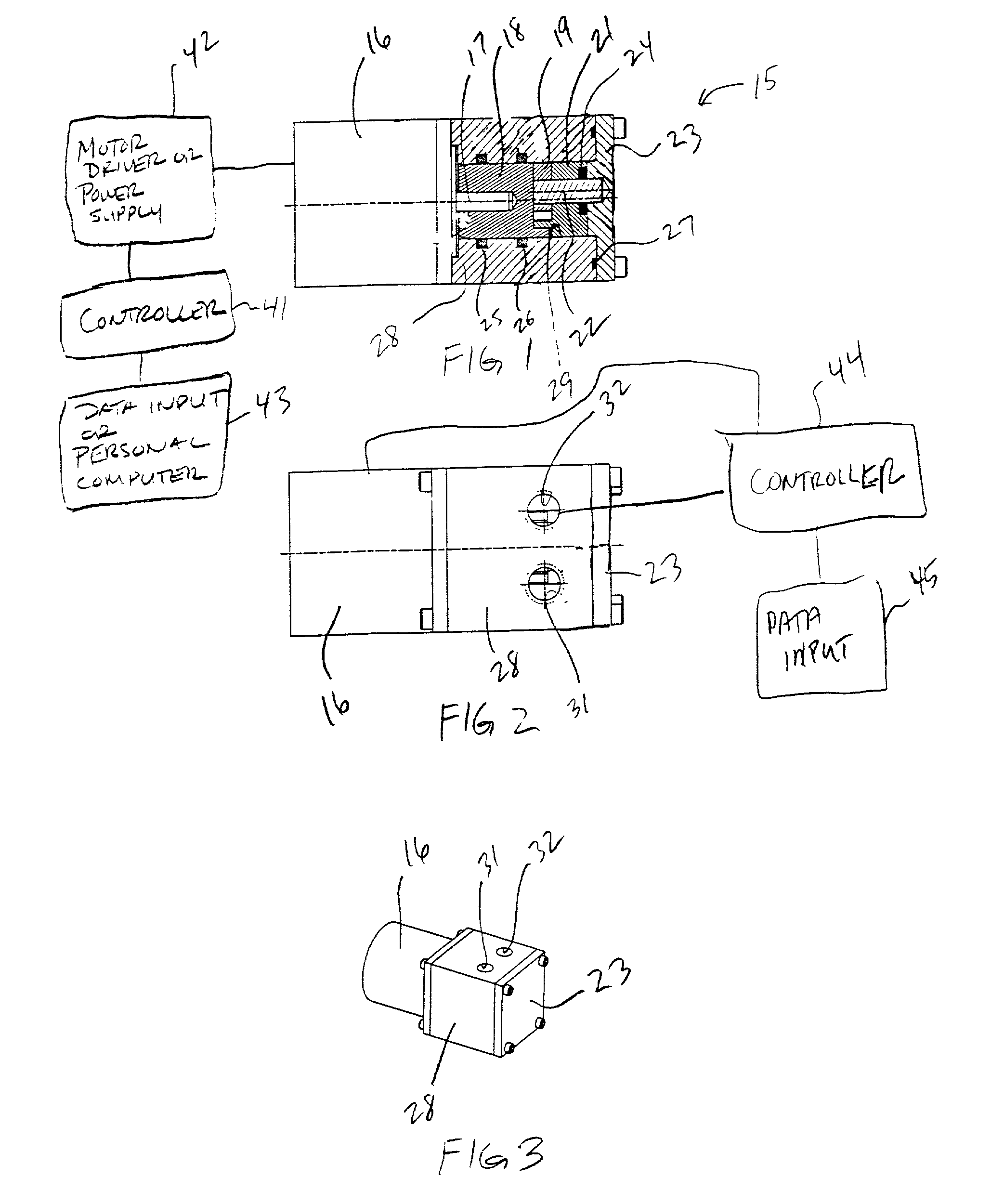

Liquid dispensing pump system

An internal gear pump including a stepper motor coupled to a drive shaft that is coupled to a rotor and meshed with an idler is disclosed. A controller is linked to the stepper motor. The stepper motor imparts a stepped rotational movement to the drive shaft wherein a single 360° rotation of the drive shaft comprises a plurality of steps. The controller sends a signal to the stepper motor to rotate the drive shaft a predetermined number of steps, based upon an inputted dispense amount. The signal causes the stepper motor to rotate the drive shaft a predetermined number of steps. The controller calculates the predetermined number of steps based upon the inputted dispense amount using an algorithm that is derived experimentally that defines a relationship between dispense amount and the number of steps required for each dispense amount. The algorithm is unique for each fluid to be pumped. A head surface area that is planar with the exception of an aperture for receiving the idler pin and a crescent is provided for increased accuracy.

Owner:FLUID MANAGEMENT LLC

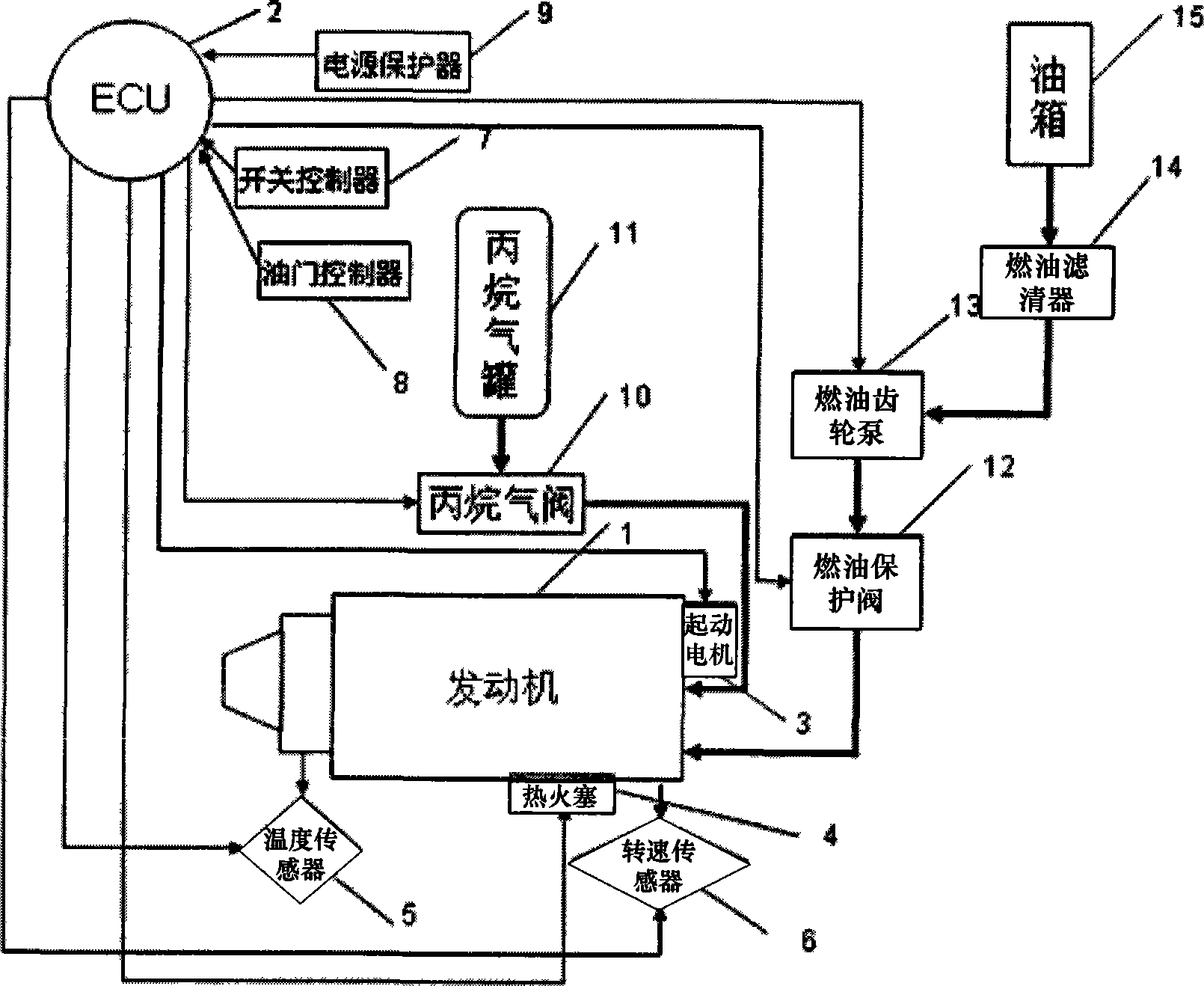

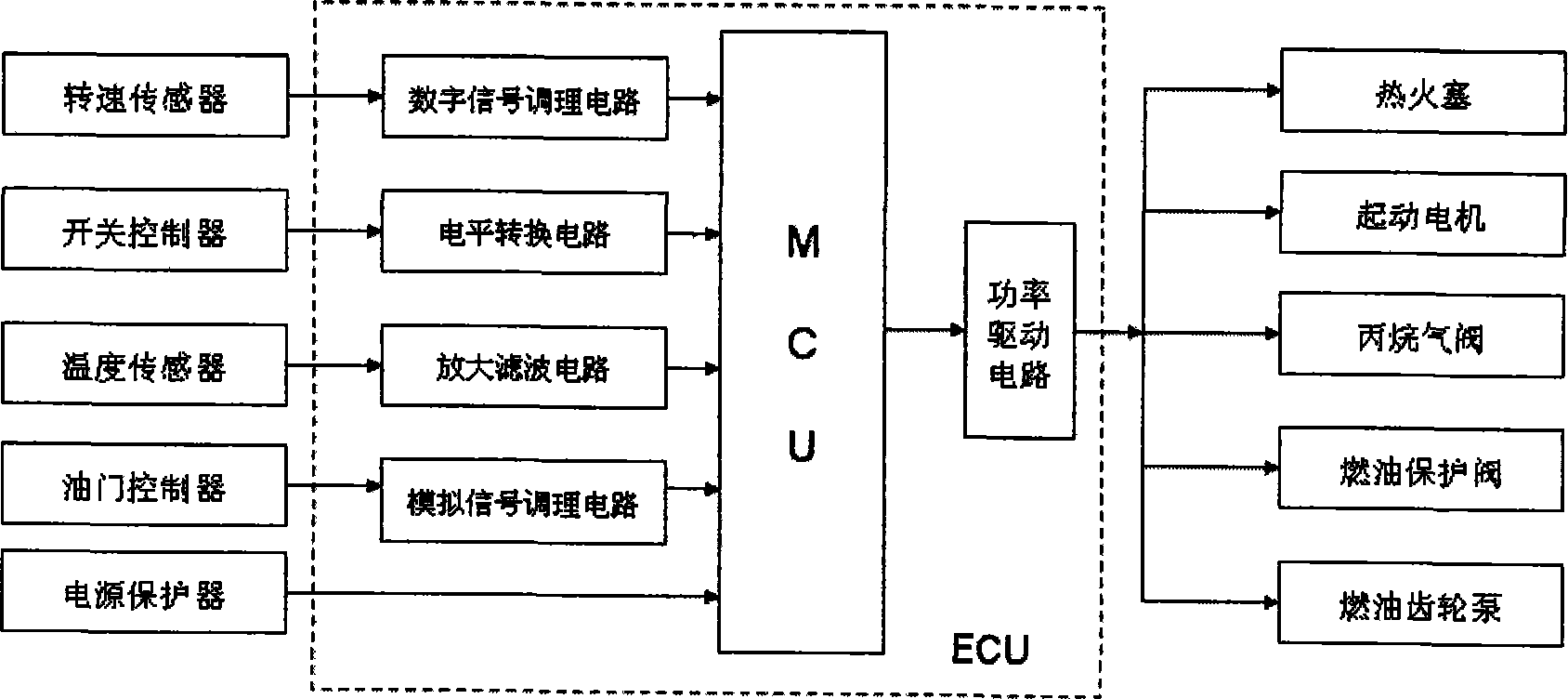

Control device of microminiature turbojet and starting control method thereof

The invention discloses a control device for a microminiature turbojet engine and a starting control method thereof. The device comprises a rotating speed sensor for collecting the rotating speed of an engine, a temperature sensor for collecting exhaust temperature, a switch controller, a throttle controller, an electronic control unit (ECU) and an executing mechanism, wherein the executing mechanism comprises a starting motor, a hot piston, a propane gas valve, a fuel protective valve and a fuel gear pump. The control method comprises the following steps: the ECU monitors the working state of the engine through the sensor, and outputs a pulse-width modulation signal to a power drive circuit to control the starting motor, the hot piston, the propane gas valve, the fuel protective valve and the fuel gear pump so as to complete starting control to the engine; functions of establishing fuel pressure and adjusting fuel quantity can be realized by the fuel gear pump after starting of the engine is completed; and fuel can be accurately supplied to ensure that the engine operates in an expected working state. The device can be used for a microminiature delivery vehicle, and the executing mechanism of the device has the advantages of simple structure, small volume and light weight, and easily realization of reliable and efficient control to the engine.

Owner:北京领动国创科技有限公司

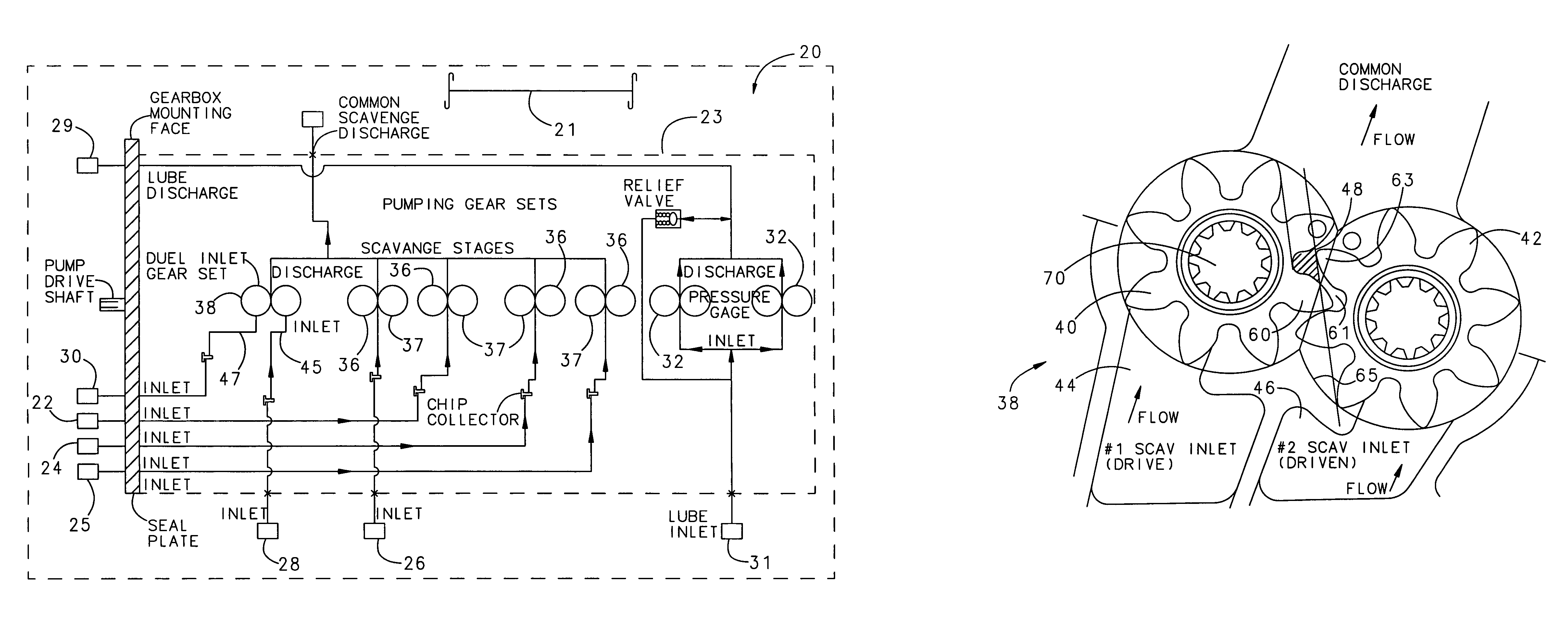

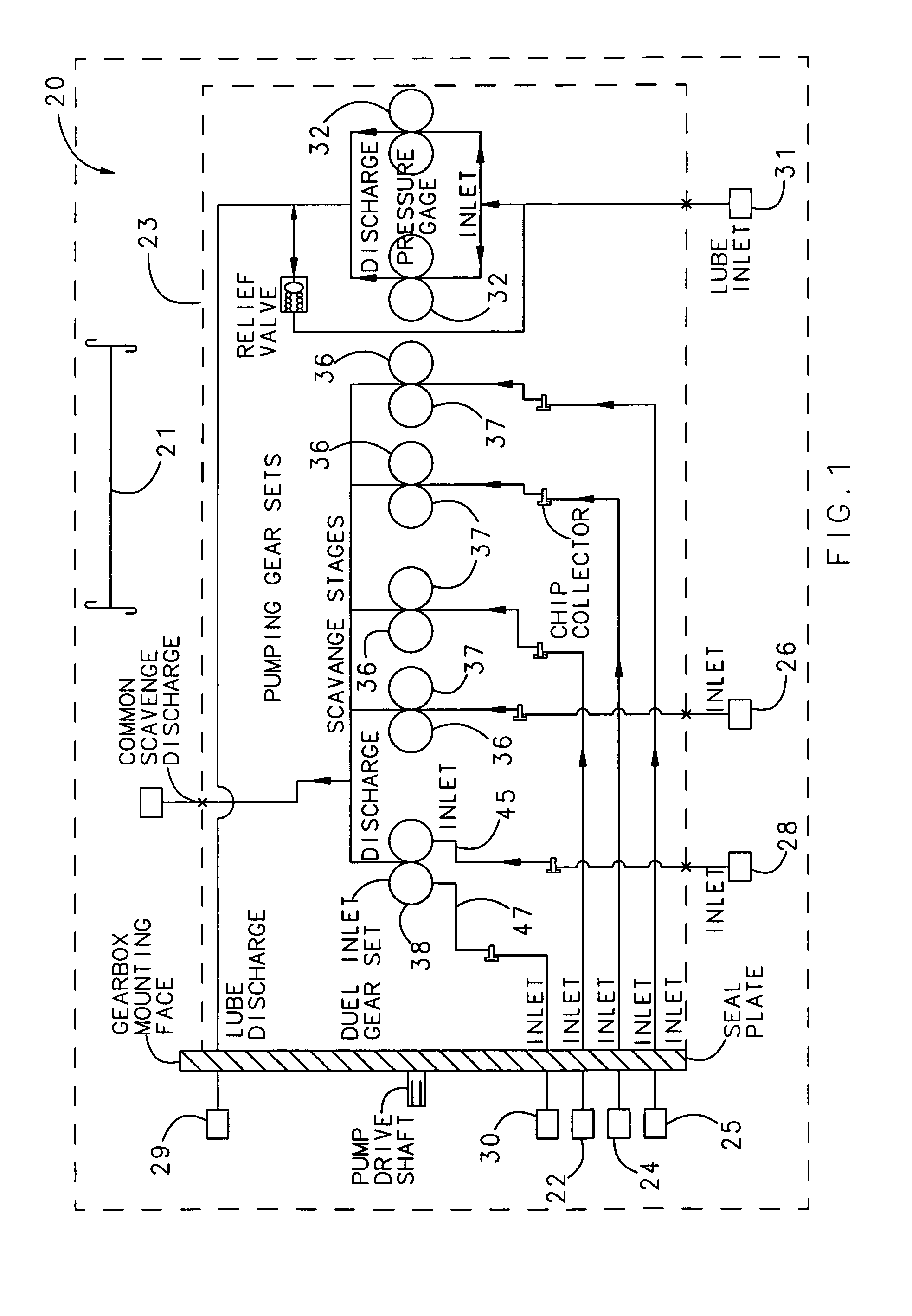

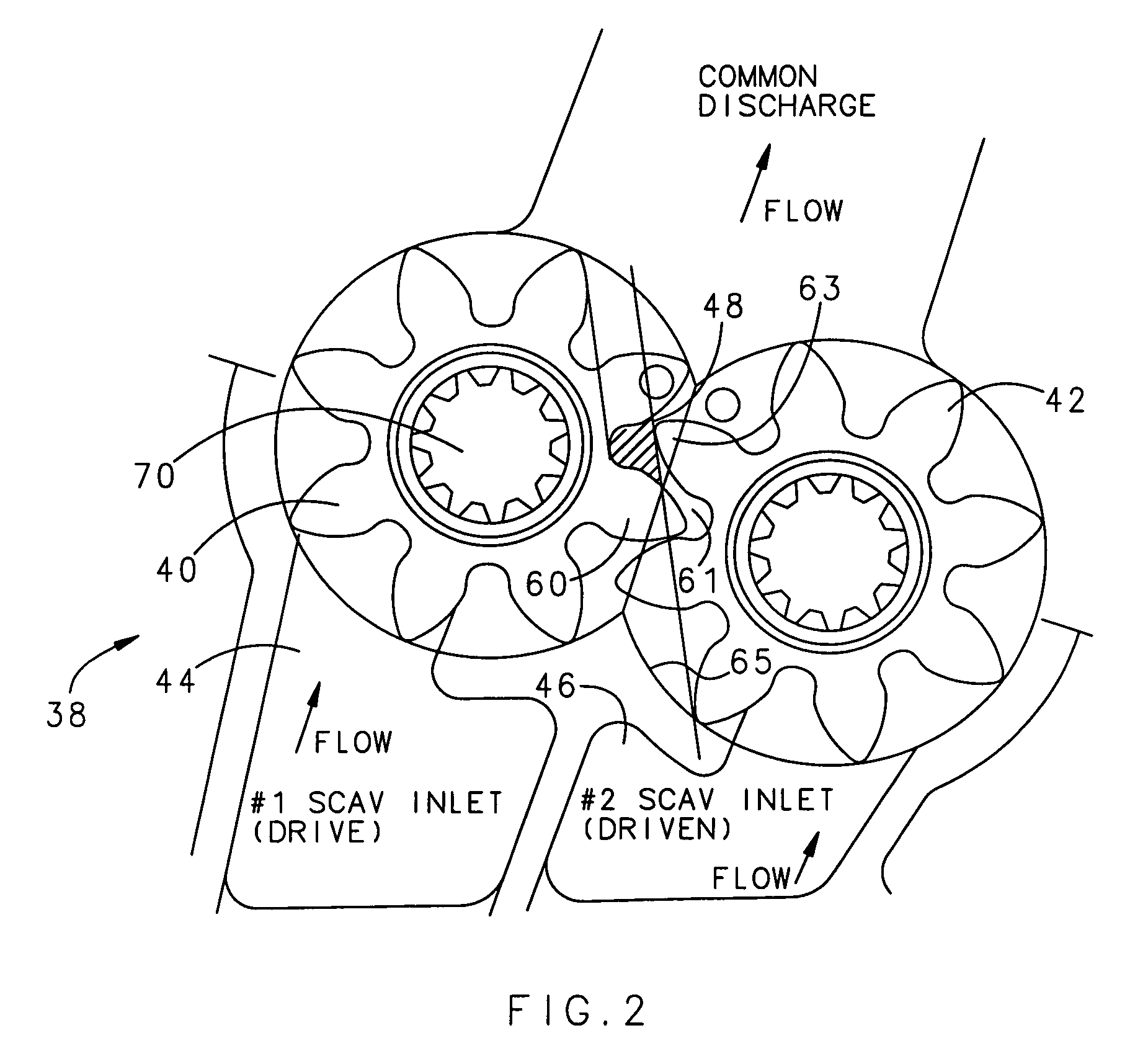

Dual-inlet gear pump with unequal flow capability

A dual-inlet gear pump includes a drive gear and a driven gear. The invention utilizes the discovery that the drive gear will typically move a higher flow volume than does the driven gear, particularly when the fluid being moved is an air / oil mixture. The present invention takes advantage of this discovery to communicate a first higher expected flow source to the drive gear, and to separately communicate a second, relatively lower expected flow rate to the driven gear. A particular application is in a scavenging pump for a jet engine.

Owner:HAMILTON SUNDSTRAND CORP

Vibration-crushing micro-pill machine

InactiveCN101574305AGood molding effectEasy to operatePharmaceutical product form changeTemperature controlGear pump

The invention pertains to the technical field of medicine preparation and relates to a vibration-crushing micro-pill machine which comprises a liquid storage pot, a pill dripping system, a cooling circulation device, a micro-pill collecting machine and a control circuit, wherein the pill dripping system comprises a dropper, a jet hole, a vibration exciter and a gear pump. The dropper is connectedwith the vibration exciter by a rigid connecting rod. The lower part of the dropper is provided with one or more jet holes, the upper part of which is a liquid inlet and the lower part thereof is a nozzle. The dropper is connected with an electric valve at the lower part of the liquid storage pot by pipes on which the gear pump is arranged. The side wall of the dropper is provided with two insertion holes in which a heater and a temperature sensor respectively connected with the control circuit are arranged. The control circuit controls the make-and-break of the heater according to the detected temperature of the temperature sensor. The cooling circulation device comprises a condensation column, a stirring device, a filter, a cooling cylinder, a cooling pump and an electromagnetic pump. The vibration-crushing micro-pill machine has the advantages of chance of batch production of micro-pills, high production efficiency, simple equipment structure and convenient control.

Owner:TIANJIN UNIV

Tube cleaner speed controller with hydraulic system

InactiveCN104438251AApplicable to various types of pigging operationsHollow article cleaningGear pumpEngineering

The invention relates to a tube cleaner speed controller with a hydraulic system. By means of the tube cleaner speed controller, the defects of a bypass valve control mode can be overcome. According to the technical scheme, front wheels are arranged on a base through supports and are arranged in the radial direction of the base, the lower ends of the supports are provided with compression springs, and the front wheels are connected with gear pumps; a radial plunger motor is arranged at the end of the base through a bolt, a speed changer is arranged at the center of the base, and an output shaft of the speed changer drives a mass block in a cylinder body to rotate; rear wheels are arranged on a rear end cover, the ends of connection rods A are fixedly provided with friction pieces, the friction pieces are closely attached to the outer edges of the rear wheels, the middle of each connection rod A is hinged to the rear end cover, the other end of each connection rod A is connected with the end of each connection rod B in a hinged mode, the other end of each connection rod B is hinged to a safety barrel, and the safety barrel is connected with a central shaft through a spline. The tube cleaner speed controller can be used just by being arranged on the rear side of a tube cleaner and can be suitable for various types of tube cleaning works.

Owner:SOUTHWEST PETROLEUM UNIV

Internal gear pump

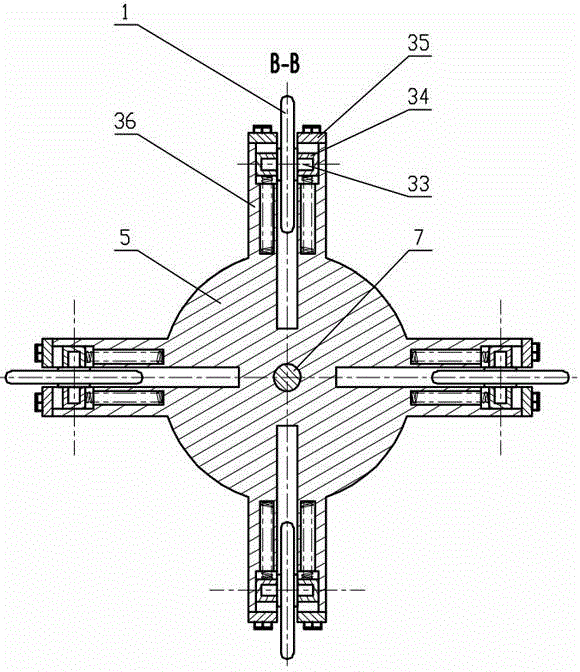

ActiveCN102400907AReduce leakageIncrease pressureRotary piston pumpsRotary piston liquid enginesGear pumpPre compression

The invention discloses an internal gear pump with low leakage rate, high feeding power, high pressure and energy-saving capability. The internal gear pump comprises a pump body, a front cover, a rear cover, an internal gear, an internal gear shaft, an irregular sheet, a front valve plate, a rear valve plate, a front support, a rear support, and elastic sealing members, wherein the front cover and the rear cover are arranged at two ends of the pump body; the internal gear and the internal gear pump shaft are eccentrically meshed inside the pump body; the irregular sheet is used for dividing a cavity formed by meshing the internal gear and the internal gear shaft in the pump body into two parts; the front valve plate and the rear valve plate as well as the front support and the rear support are respectively and sequentially arranged between the irregular sheet and the front cover as well as between the irregular sheet and the rear cover; the elastic sealing members are respectively arranged between the front cover and the rear cover as well as between the front support and the rear support; a crescent sheet is further arranged on the irregular sheet and is matched with the irregular sheet to divide the cavity in the pump body into two parts; and a spring is arranged between the irregular sheet and the crescent sheet. According to the invention, the pre-compression amount of the elastic sealing members and the pre-pressure of the spring are utilized to fulfill an axial compensation function and a radial compensation function respectively, so that the internal leakage of the entire pump is prevented.

Owner:重庆沃菲特泵业有限公司 +1

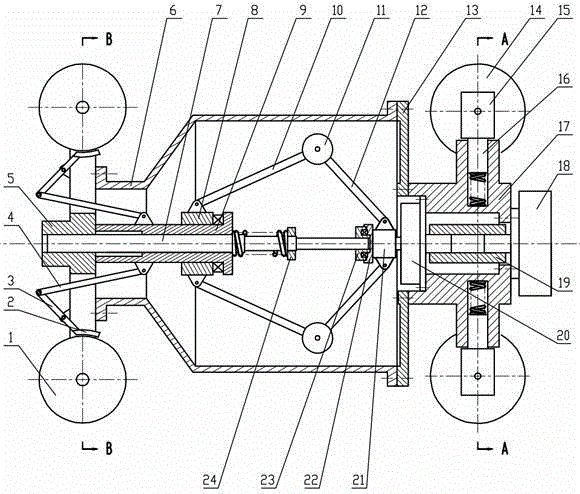

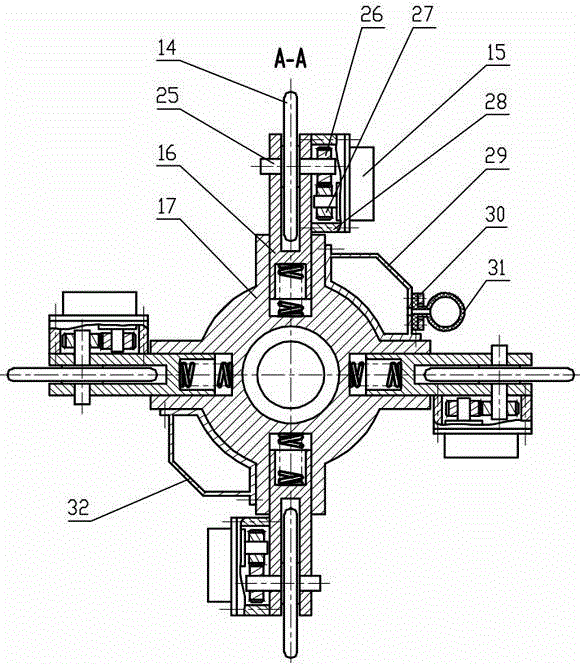

Electrically-controlled hydraulically-driven steering device for mobile platform of agricultural robot

InactiveCN102501917AConvenient and flexible operationAdjustable forwardFluid steeringVehiclesGear pumpFuel tank

The invention relates to a hydraulically-driven steering device, in particular to an electrically-controlled hydraulically-driven steering device for a mobile platform of an agricultural robot, which comprises a supporting plate, a double-acting single-piston-rod cylinder, a connecting rod, a hydraulic steering gear, a coupler, a stepping motor, an oil tank, a remote controller, a three-position four-way electromagnetic directional valve, a gerotor motor, a filter, a gasoline engine, a dual gear pump, a speed regulating valve and a one-way valve. The stepping motor is connected to a power input shaft of the steering gear through the coupler, the steering gear is a parallel four-rod steering gear, and the remote controller is used for controlling steering and turn angles of the stepping motor to change the expansion length of a piston rod, so that turn directions and the turn angles of wheels are controlled. The remote controller is used for adjusting the position of a valve spool of the three-position four-way electromagnetic directional valve to control steering of the hydraulic motor, so that advancing, retreating and stopping of a four-wheeled vehicle are realized. The speed regulating valve is added in front of the stepping motor so that stepless speed regulating can be realized, and the electrically-controlled hydraulically-driven steering device is simple in structure, convenient in operation and low in cost.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com