Gear pump for micro-miniature turbojet engine

A turbojet and engine technology, which is used in machines/engines, liquid fuel engines, rotary piston/oscillating piston pump components, etc., can solve the problem of affecting engine performance, heavy weight, difficult to meet micro-small turbojet engines, and complex structure. and other problems, to achieve the effect of solving motion interference, reducing cross-section leakage, and simplifying oil control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

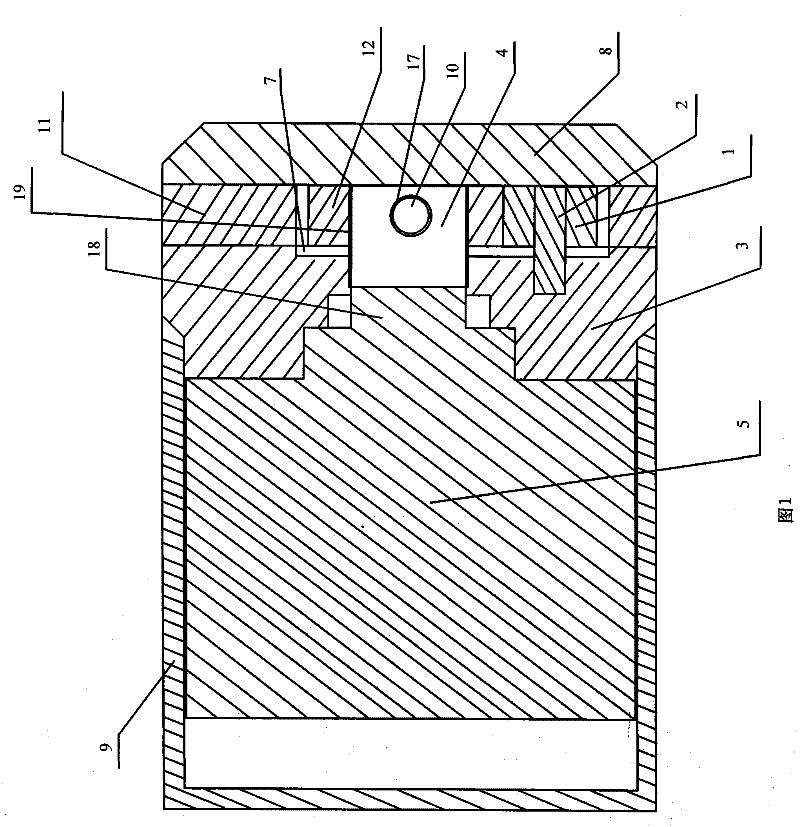

[0024] The present invention will be further described in detail below with reference to the accompanying drawings.

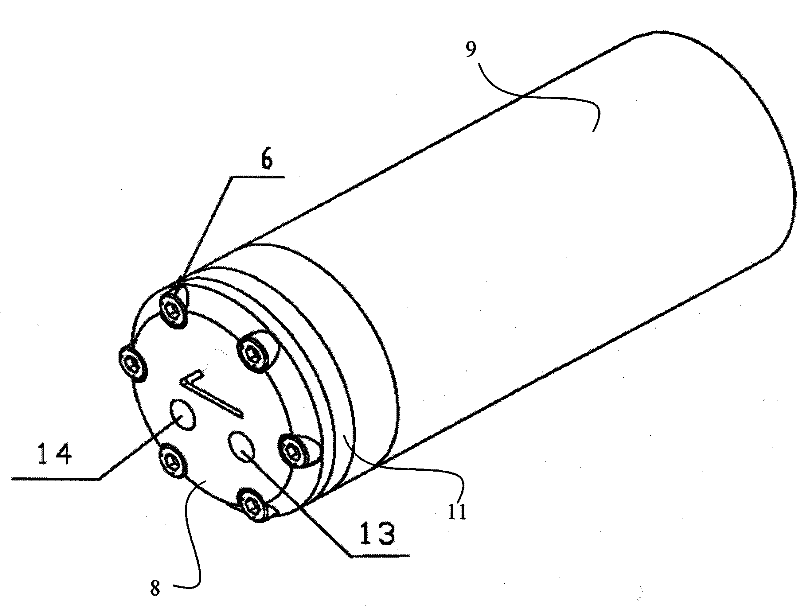

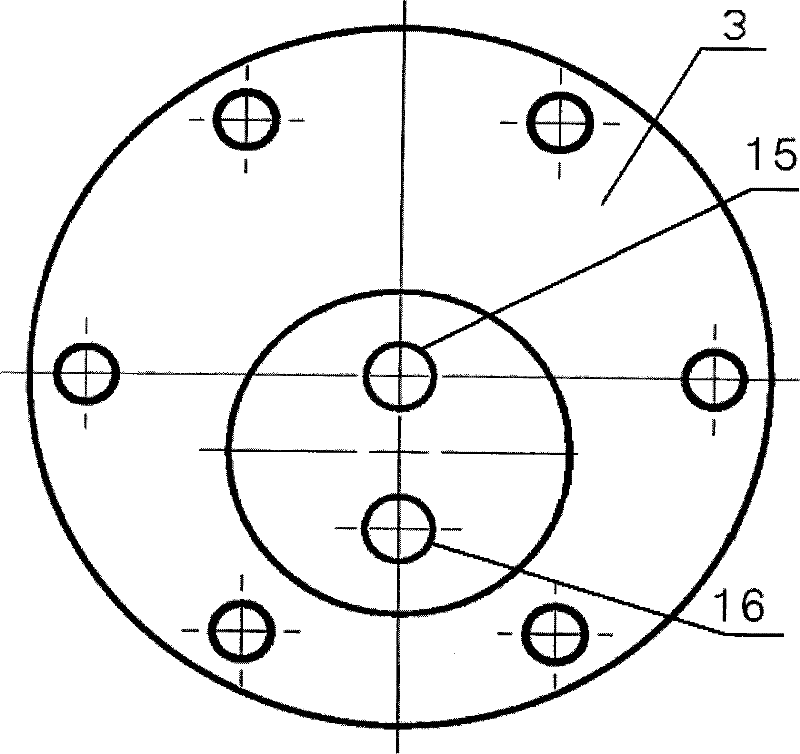

[0025] The present invention provides a gear pump for a miniature turbojet engine, such as figure 1 , including the DC motor 5, the pump body 11, the upper pump cover 8, the lower pump cover 3, the casing 9, the driving gear 12, the driven gear 1 and the driving shaft 4, the driven shaft 2, the cavity in the pump body 11 Align a pair of meshed driving gear 12 and driven gear 1, and fit with the lower pump cover 3. The driving gear 12 is installed on the driving shaft 4 through the transmission pin 10; the driven gear 1 is installed on the driven shaft 2, and Align and engage with the driving gear 12; the lower pump cover 3 is fixed on the DC motor 5 through bolts, and the upper pump cover 8 is connected to the lower pump cover 3 through bolts 6, such as figure 2 , press and seal the plane of the pump body 11; the outer casing 9 is sleeved on the outer side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com