Tube cleaner speed controller with hydraulic system

A speed controller, hydraulic system technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem of expensive rental of pigs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

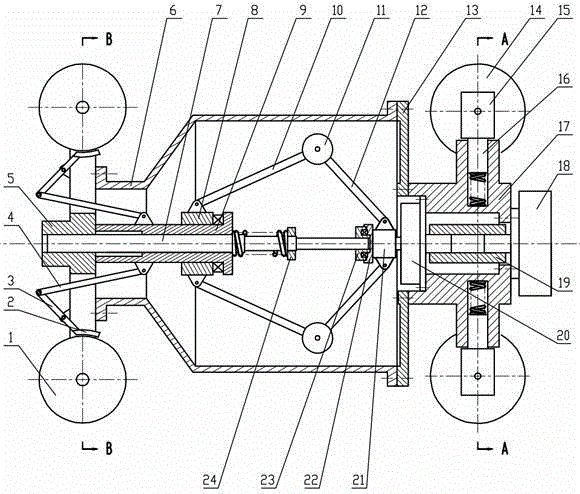

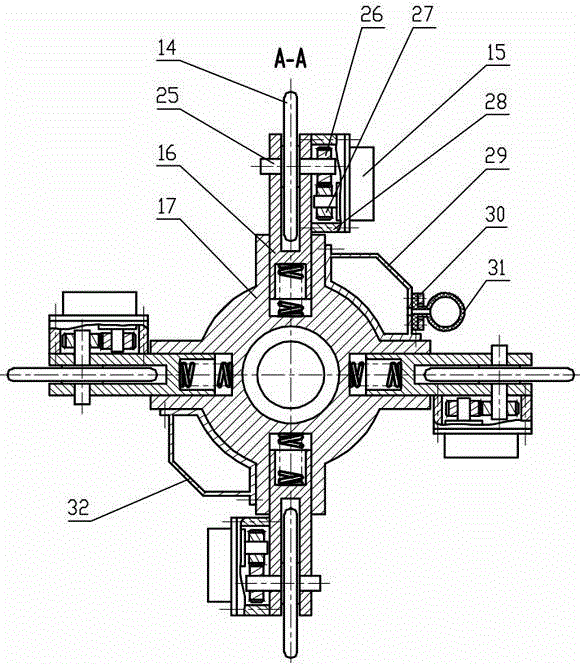

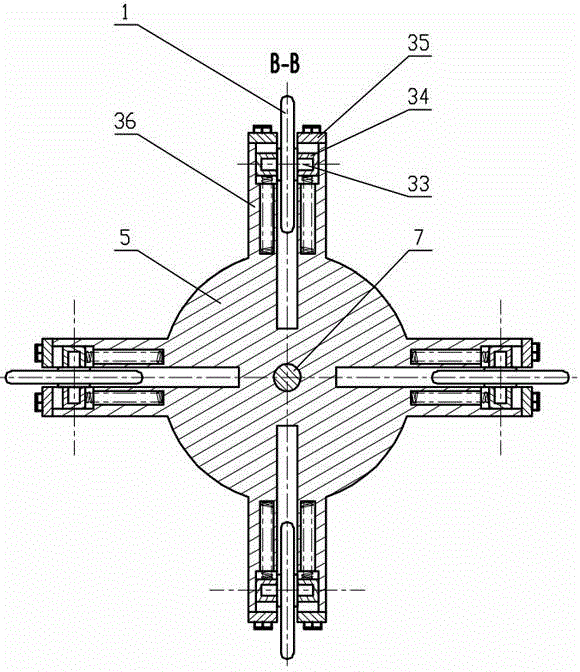

[0024] The present invention is not limited by the following implementation examples, and specific implementation manners can be determined according to the technical solutions of the present invention and actual conditions. Combine below figure 1 , 2 , 3 The present invention is described below. The positional relationship of up, down, left, right, etc. is based on the attached figure 1 determined by the layout direction.

[0025] Such as figure 1 As shown, the friction plate 2 is fixed on the end of the connecting rod A3, the middle of the connecting rod A3 is hinged to the rear end cover 5, the other end of the connecting rod A3 is hinged to the end of the connecting rod B4, and the other end of the connecting rod B4 is hinged to the fixed on cylinder 9. The fixed cylinder 9 is sleeved on the central shaft 7 and connected by splines, the fixed cylinder 9 is covered with the rotating cylinder 8, the end of the fixed cylinder 9 is provided with a step, and the rotating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com