Patents

Literature

636 results about "Tube cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tube cleaning describes the activity of, or device for, the cleaning and maintenance of fouled tubes. The need for cleaning arises because the medium that is transported through the tubes may cause deposits and finally even obstructions. In system engineering and in industry, particular demands are placed upon surface roughness or heat transfer. In the food and pharmaceutical industries as well as in medical technology, the requirements are germproofness, and that the tubes are free from foreign matter, for example after the installation of the tube or after a change of product. Another trouble source may be corrosion due to deposits which may also cause tube failure.

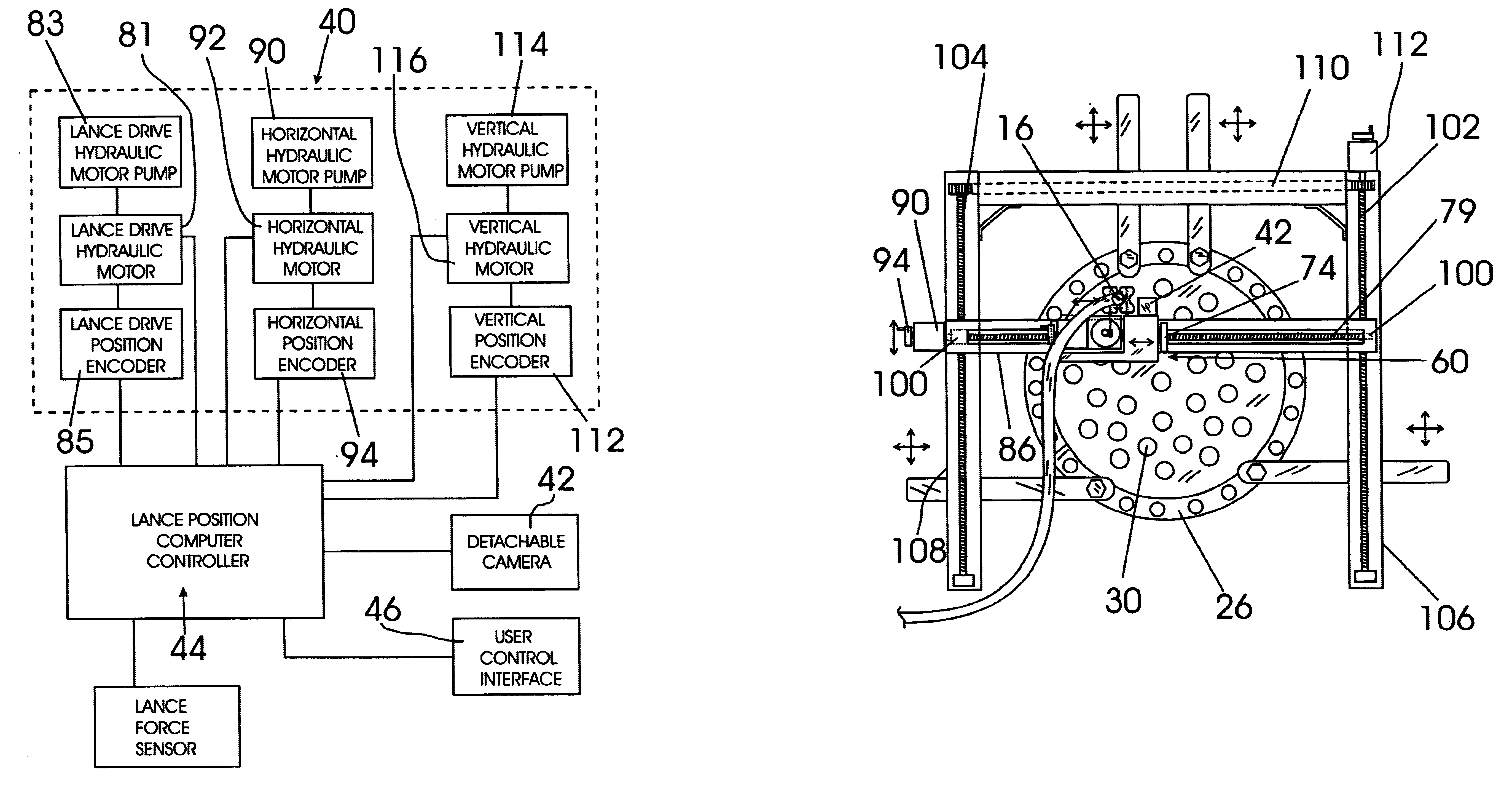

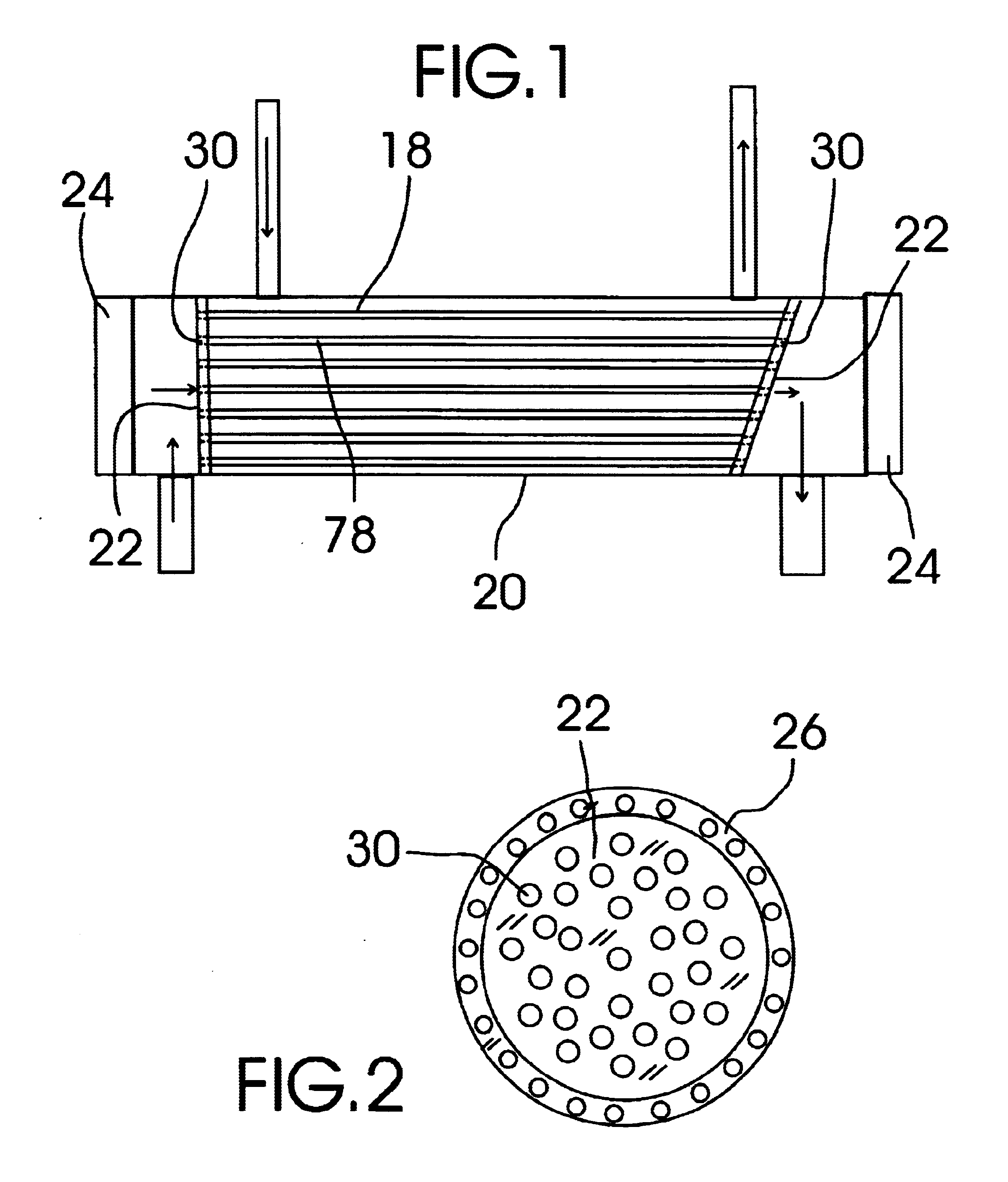

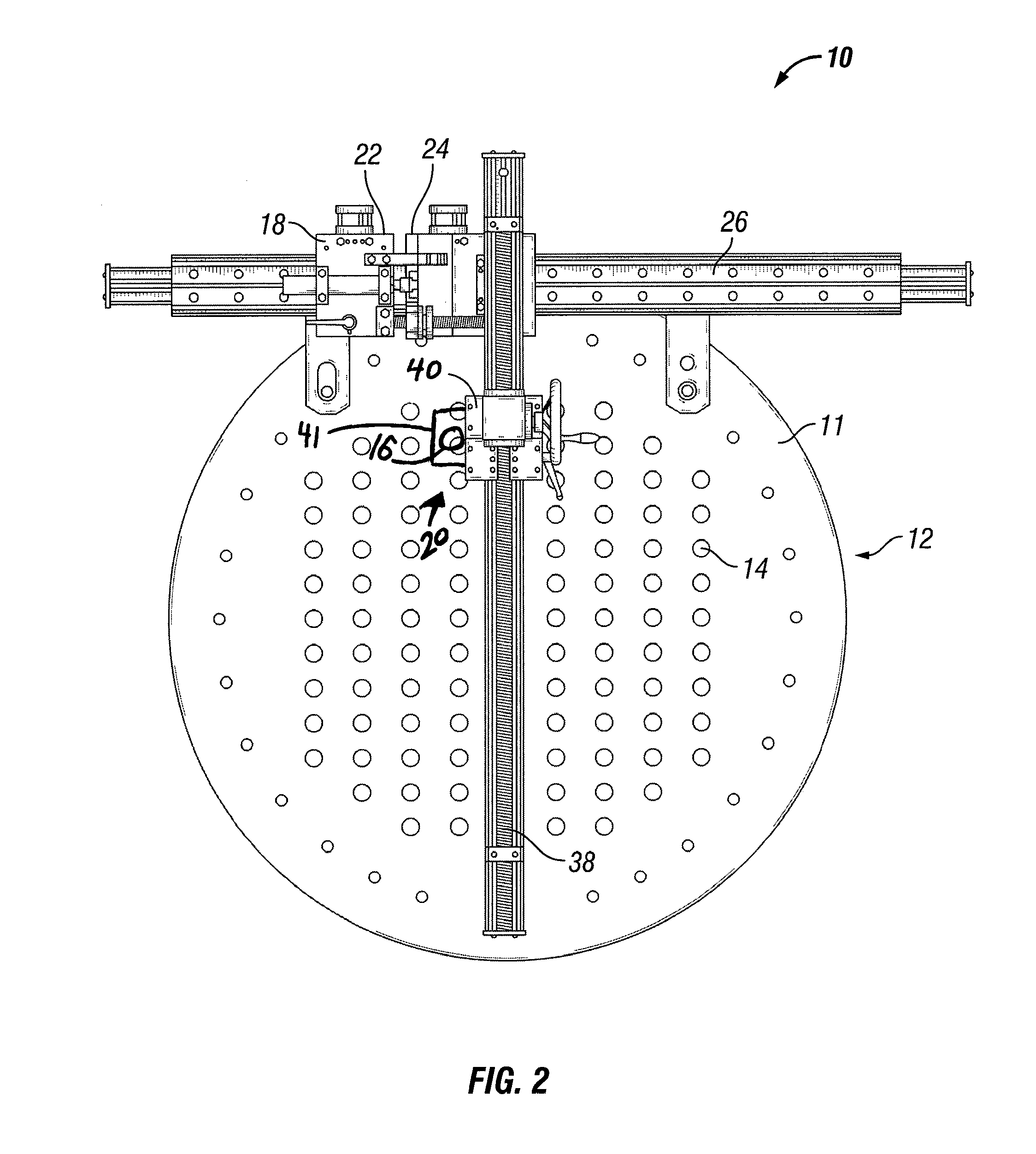

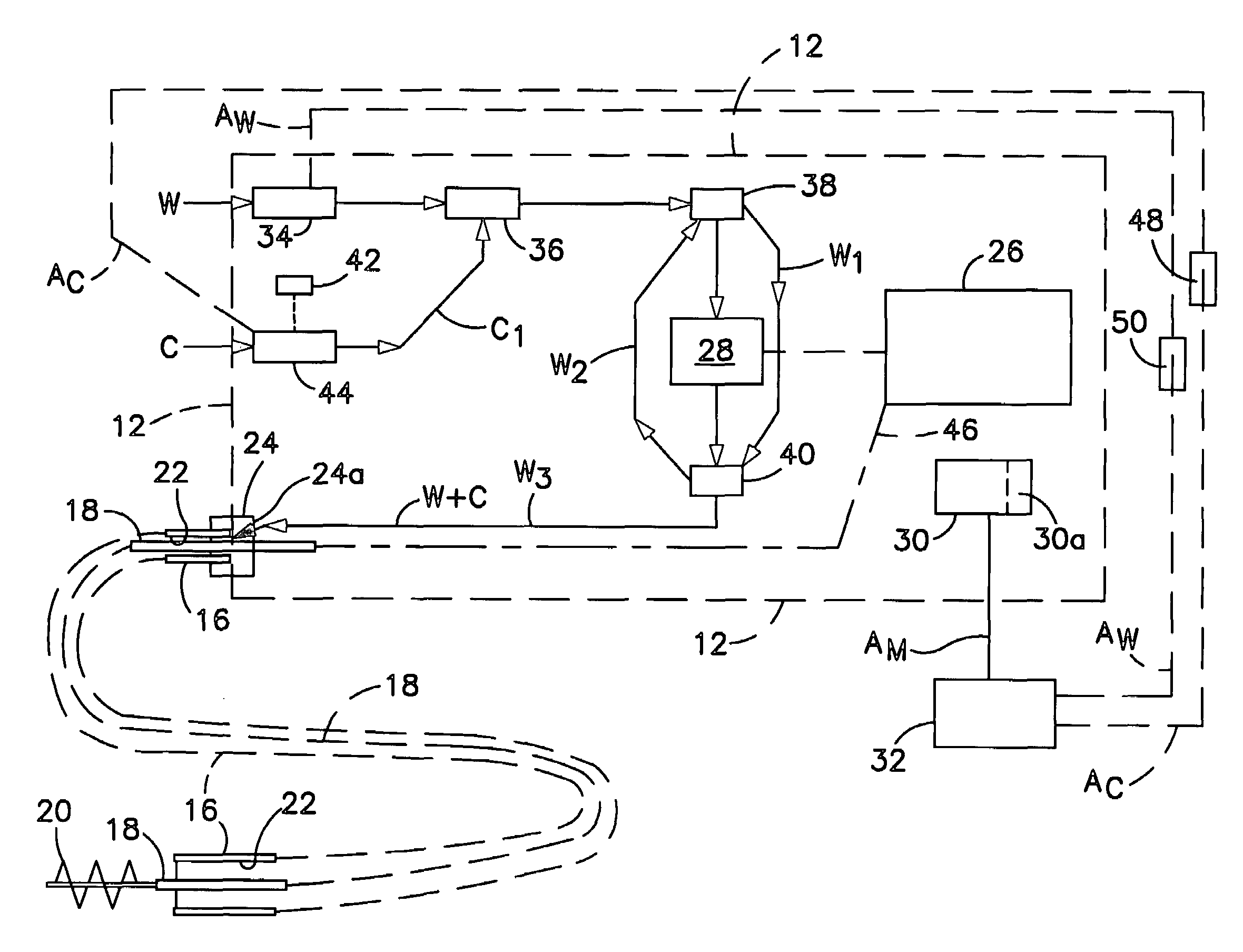

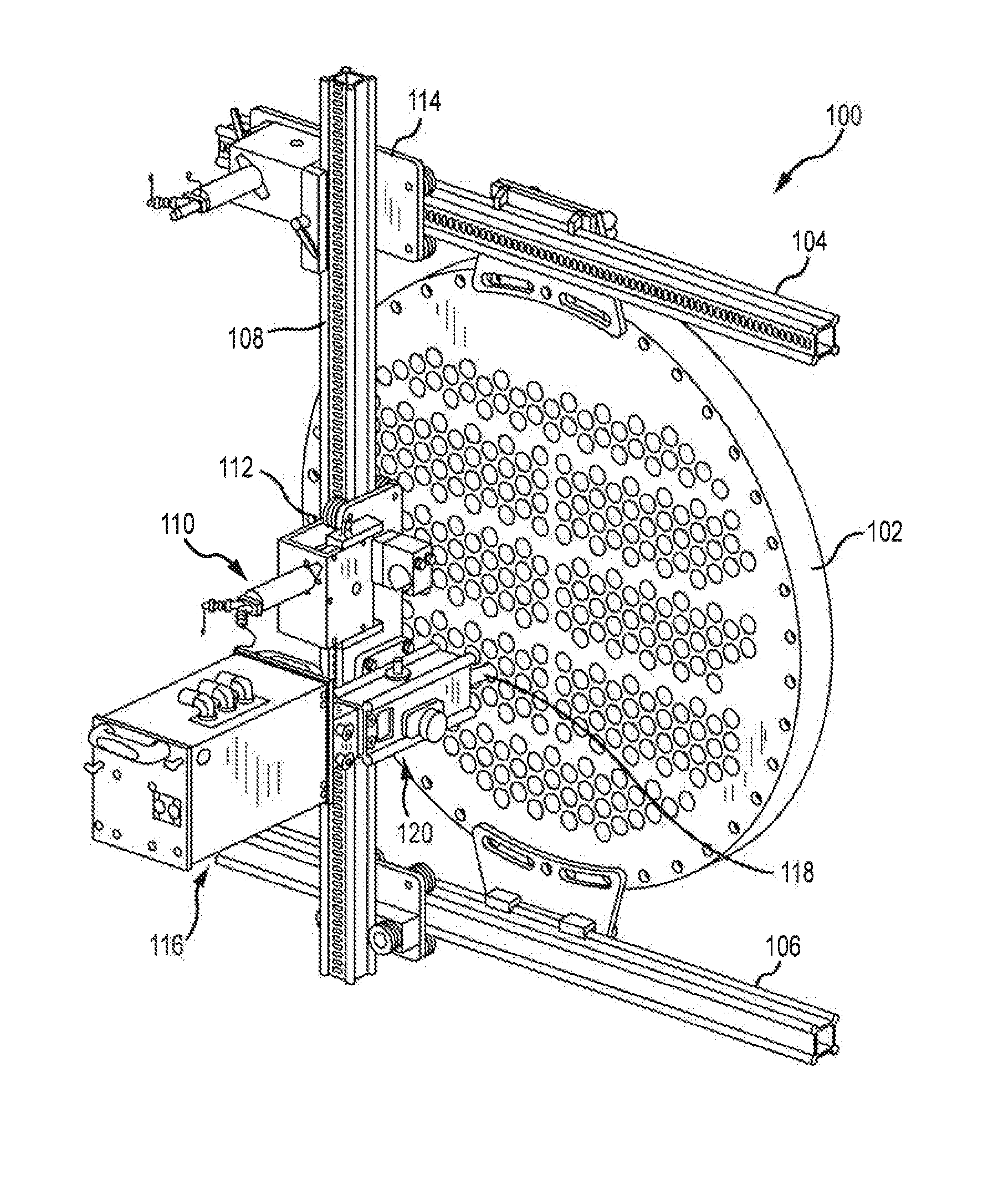

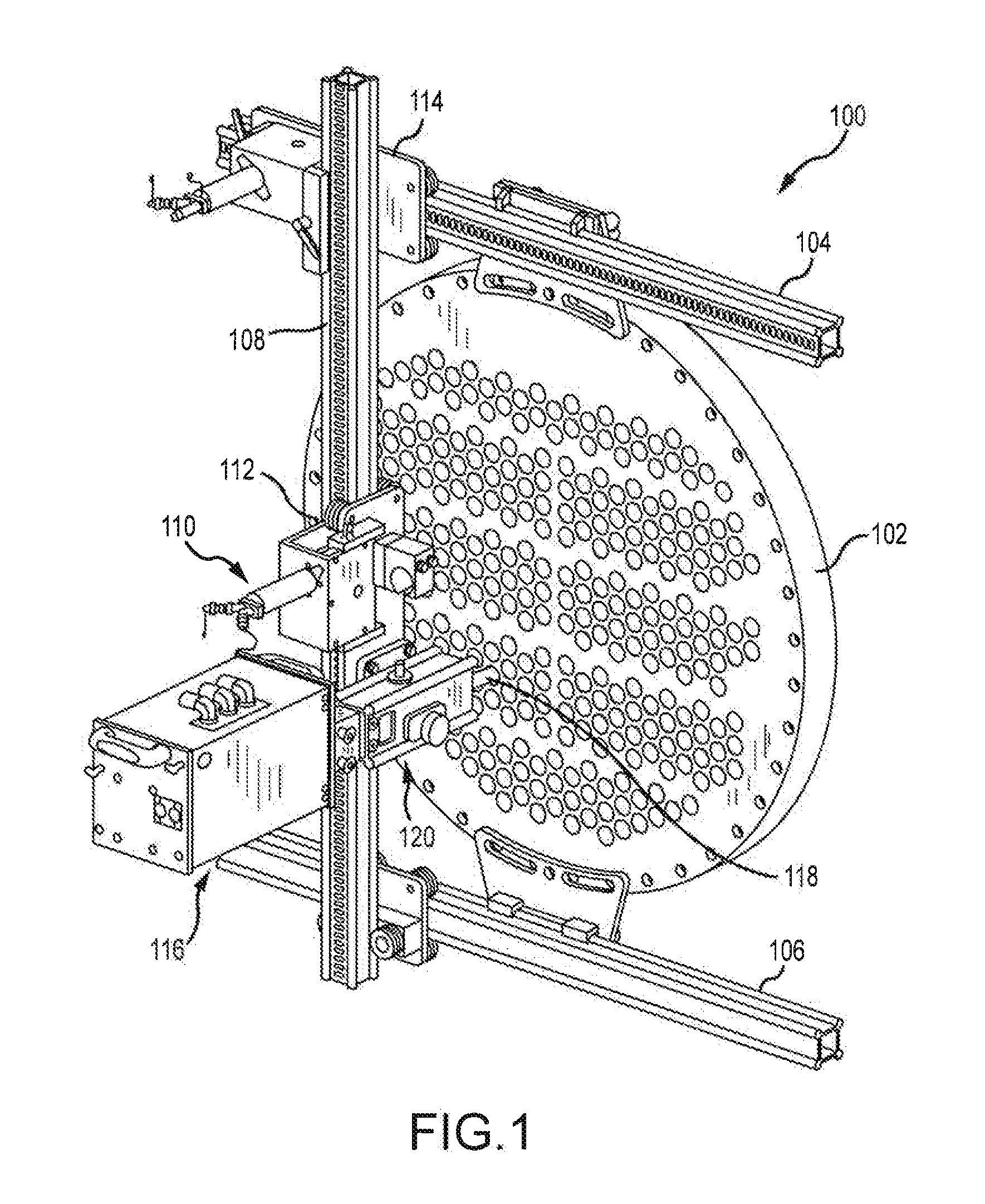

Heat exchanger exchange-tube cleaning lance positioning system

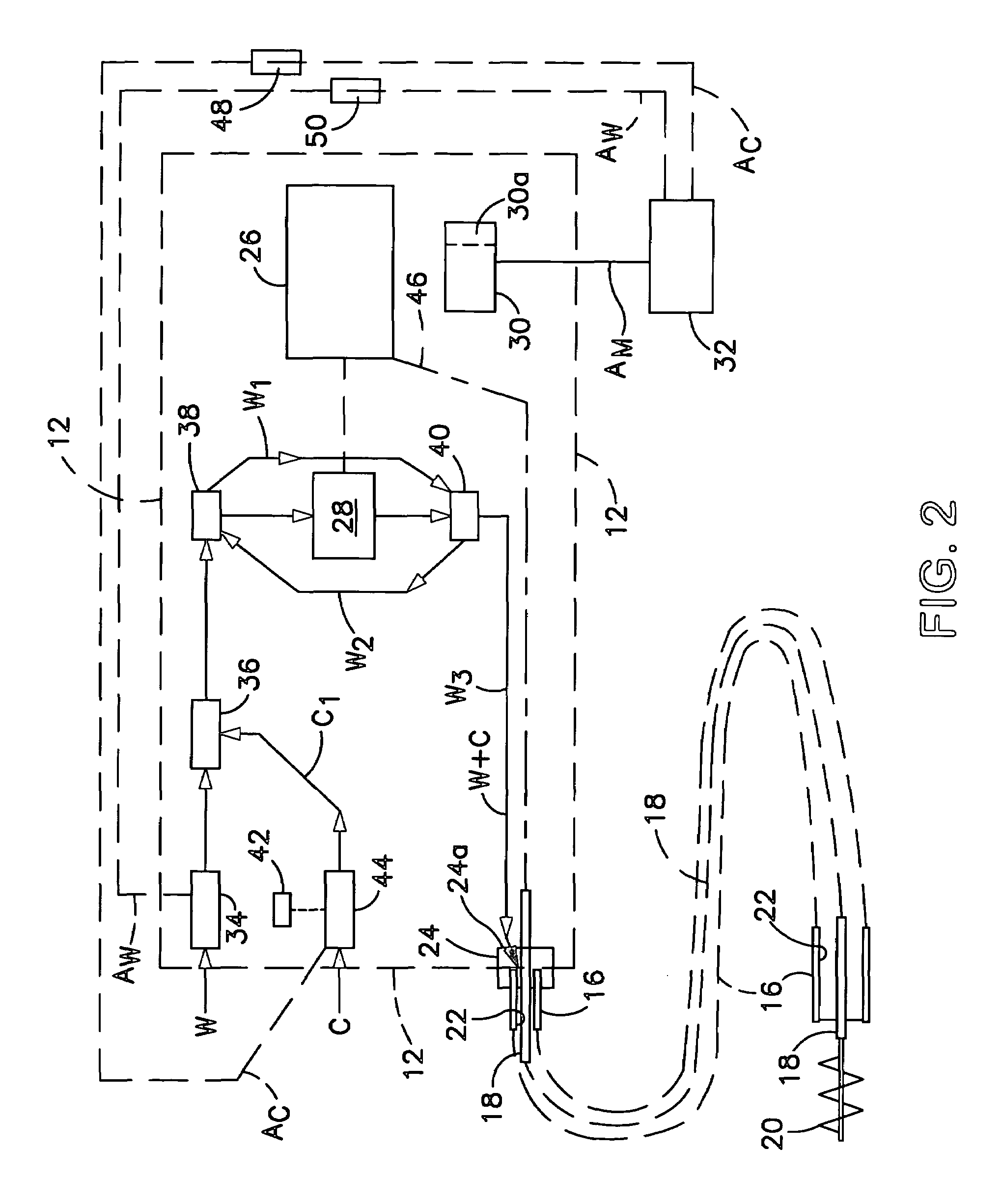

A heat exchanger exchange-tube cleaning lance positioning system that includes a three axis cleaning lance positioning mechanism that is attachable to the end of a heat exchanger and that is controlled by a lance position computer controller that determines the locations of each of the openings of the exchange-tubes of the heat exchanger by analyzing an image signal generated by a camera mounted to the three axis cleaning lance positioning mechanism and then positions a connected exchange tube cleaning lance into and through each of the exchange-tube passageways to clean the exchange-tube passageways automatically.

Owner:BALZER BRENT A

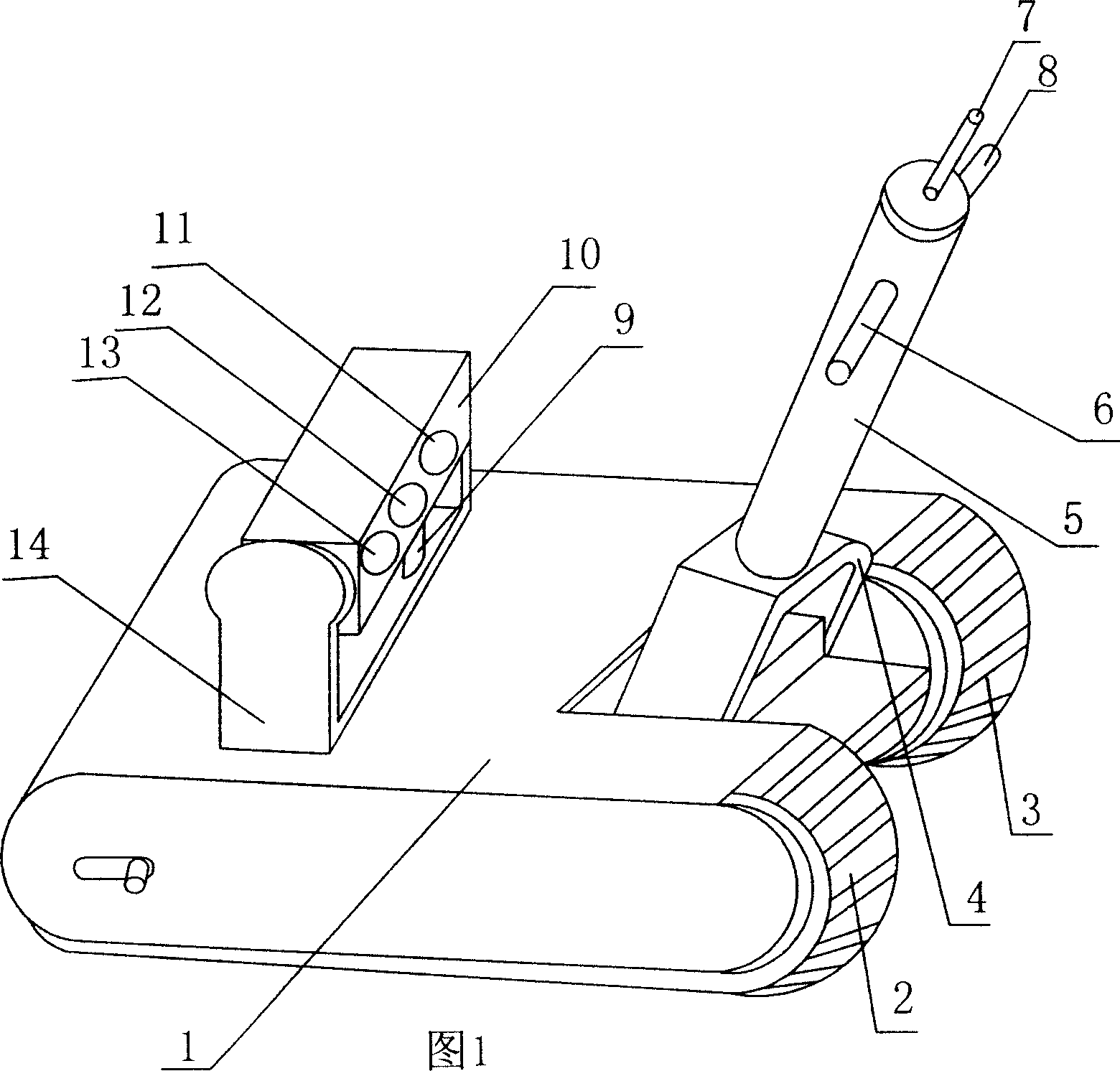

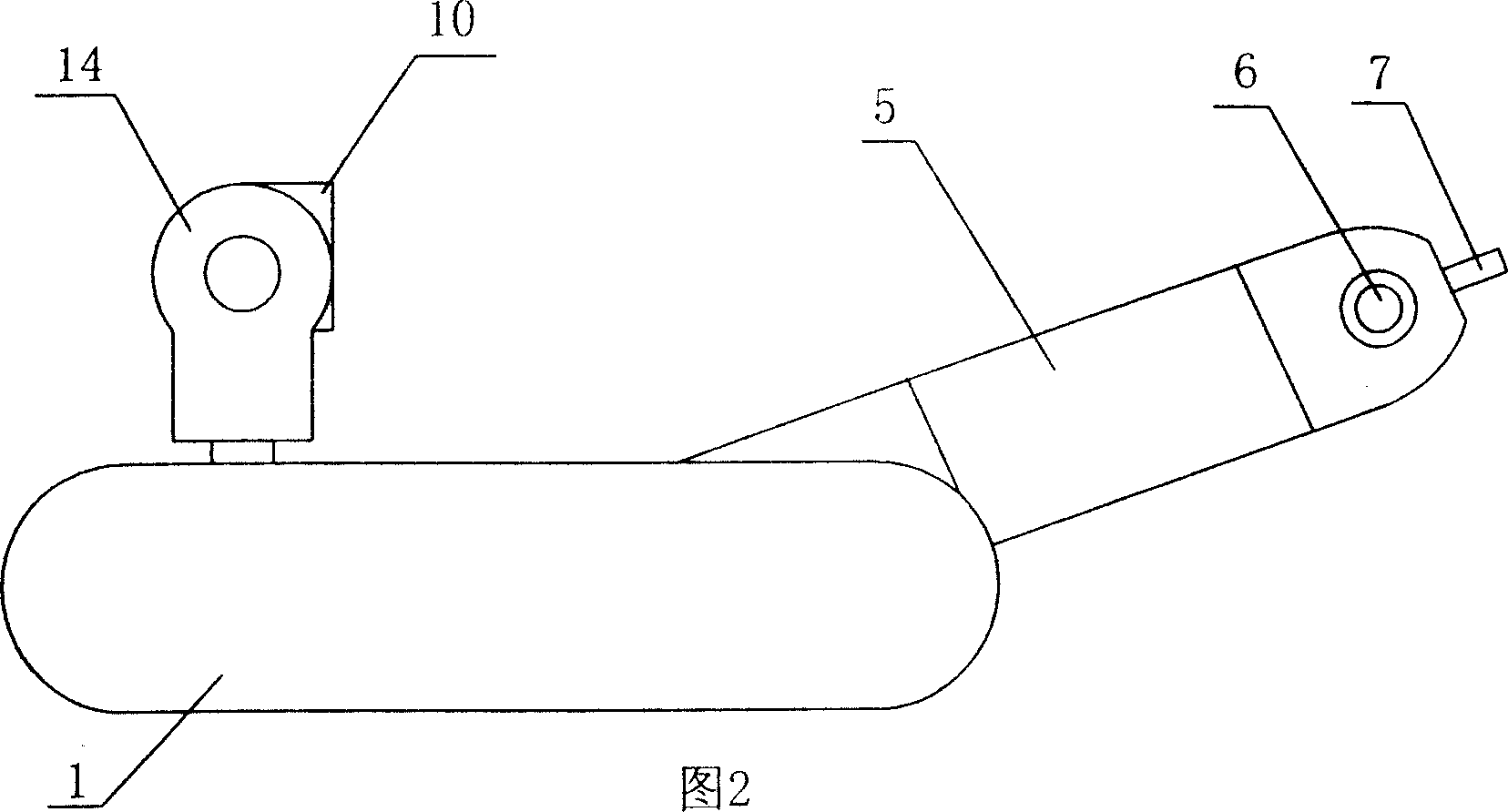

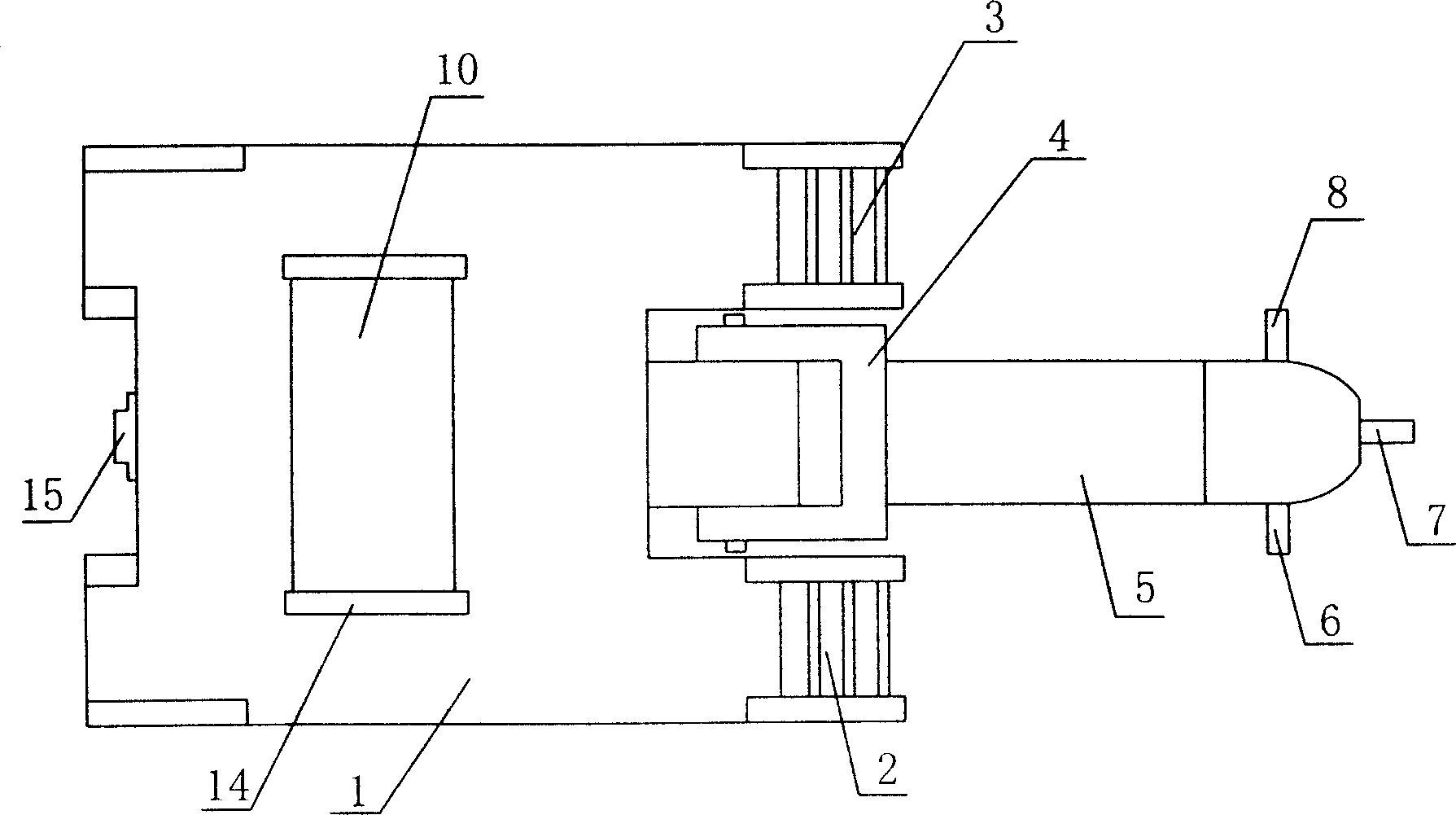

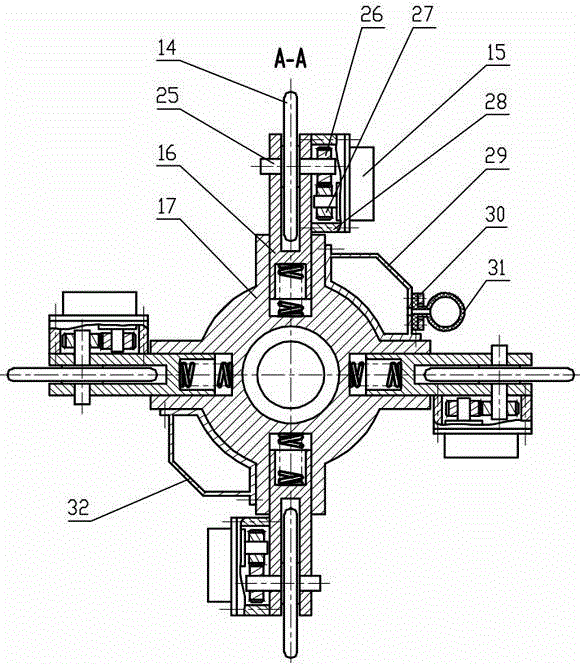

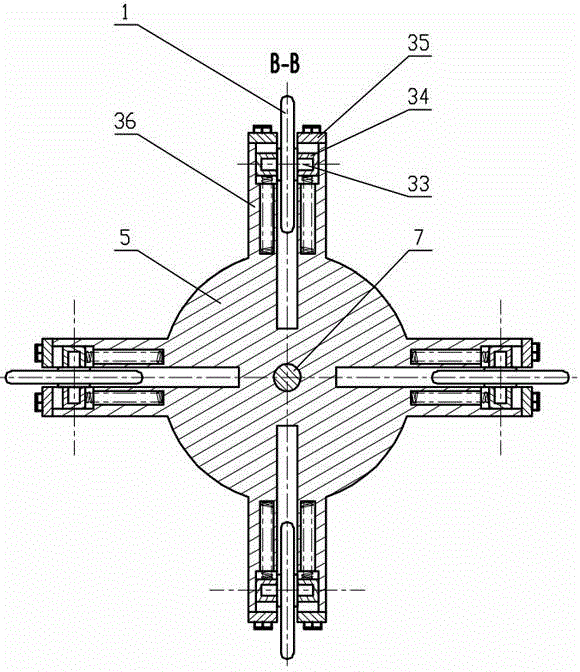

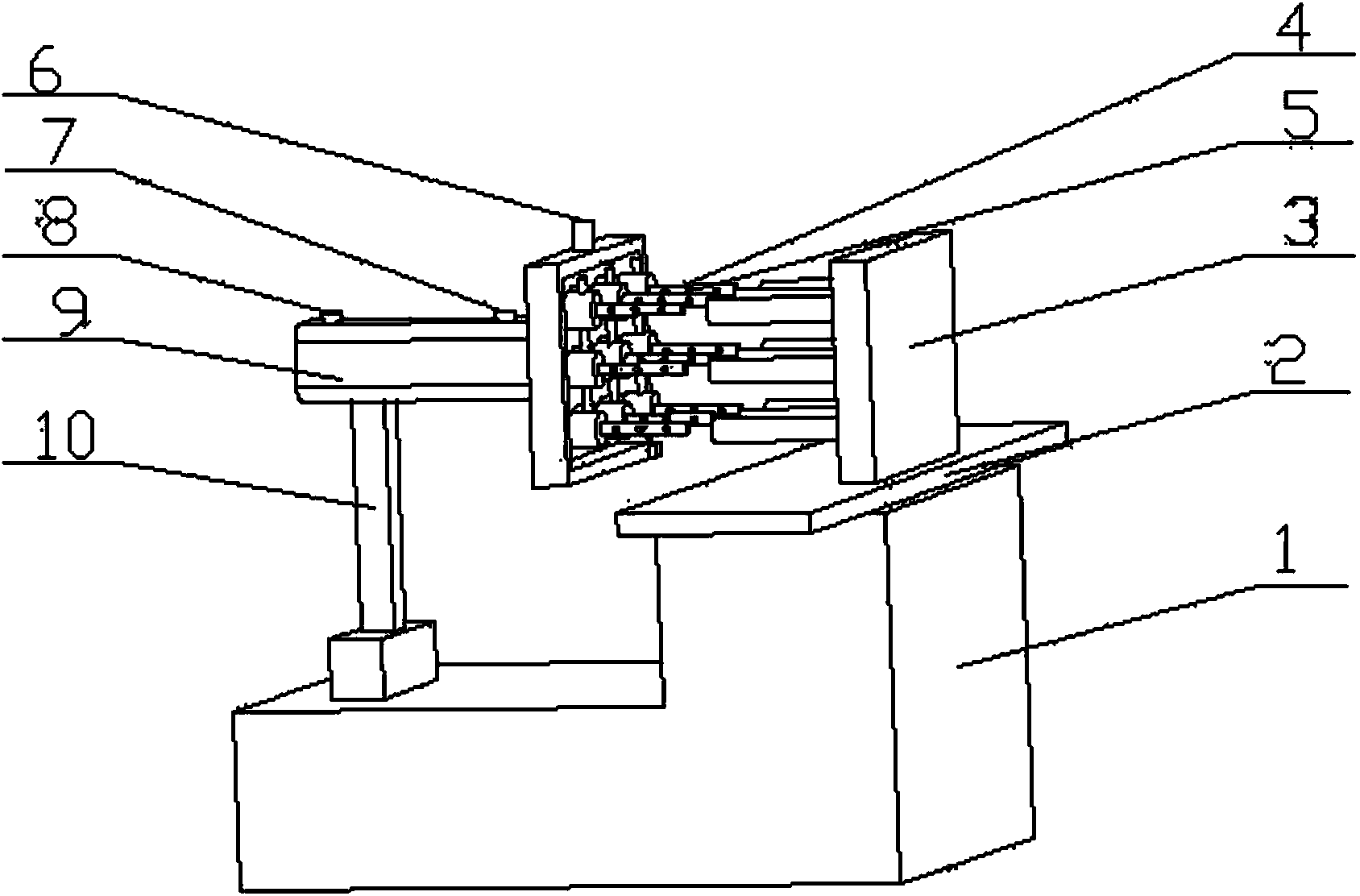

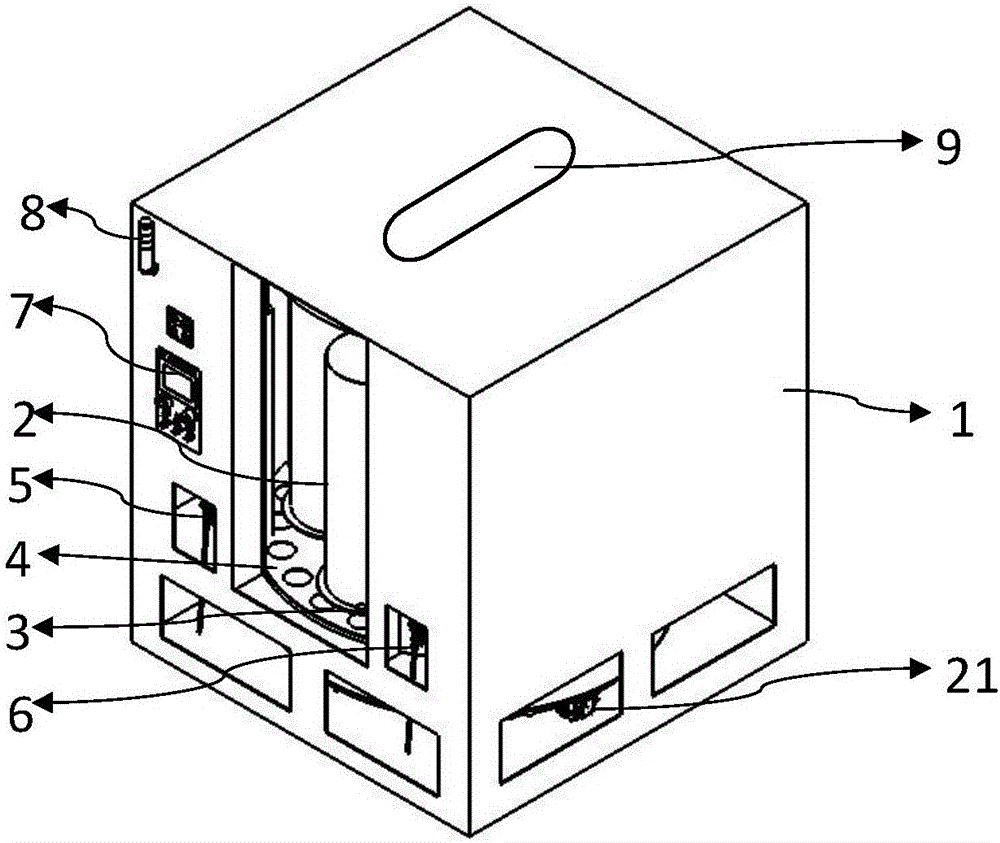

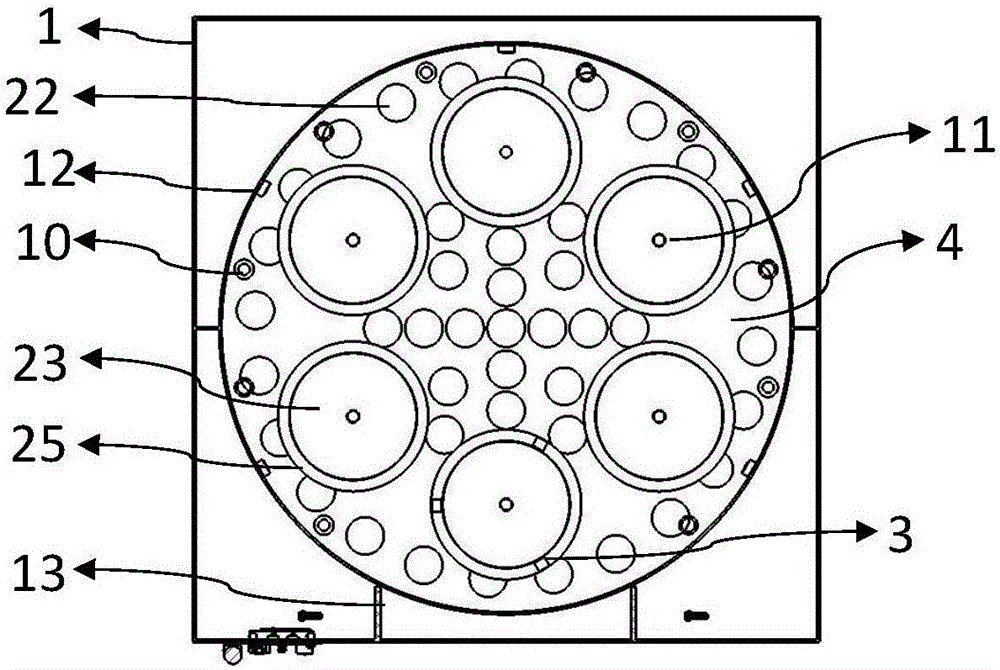

Multifunctional pipeline cleaning robot

InactiveCN1907583AGood effectImprove performanceHollow article cleaningManipulatorSprayerTube cleaning

The invention relates to a multifunctional tube cleaning robot which can wash, adsorb dust and disinfect the tube of central air conditioner, wherein the front part of main body with two side walking tracks has lifting arm or disinfection liquid sprayer and dust absorber; the front end of lifting arm has left, right, and front outlet axles that synchronously rotate and the brush; the top of main body has U-shaped support rotationally mounted on the upright axle, with camera and lighting tank; said tank can rotate and is mounted with camera and lighting lamp. The invention has stable property, simple operation and low weight.

Owner:金银龙 +6

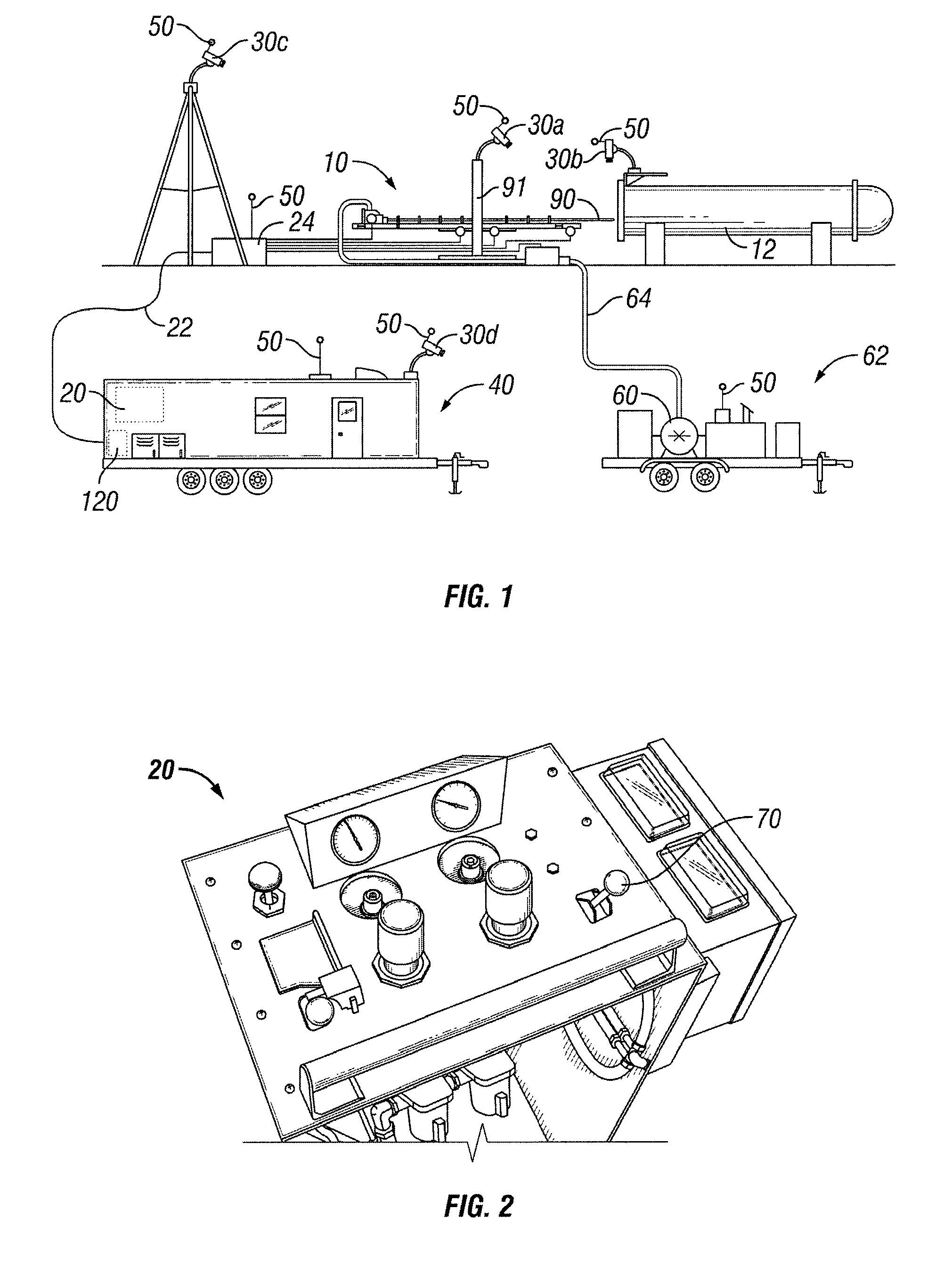

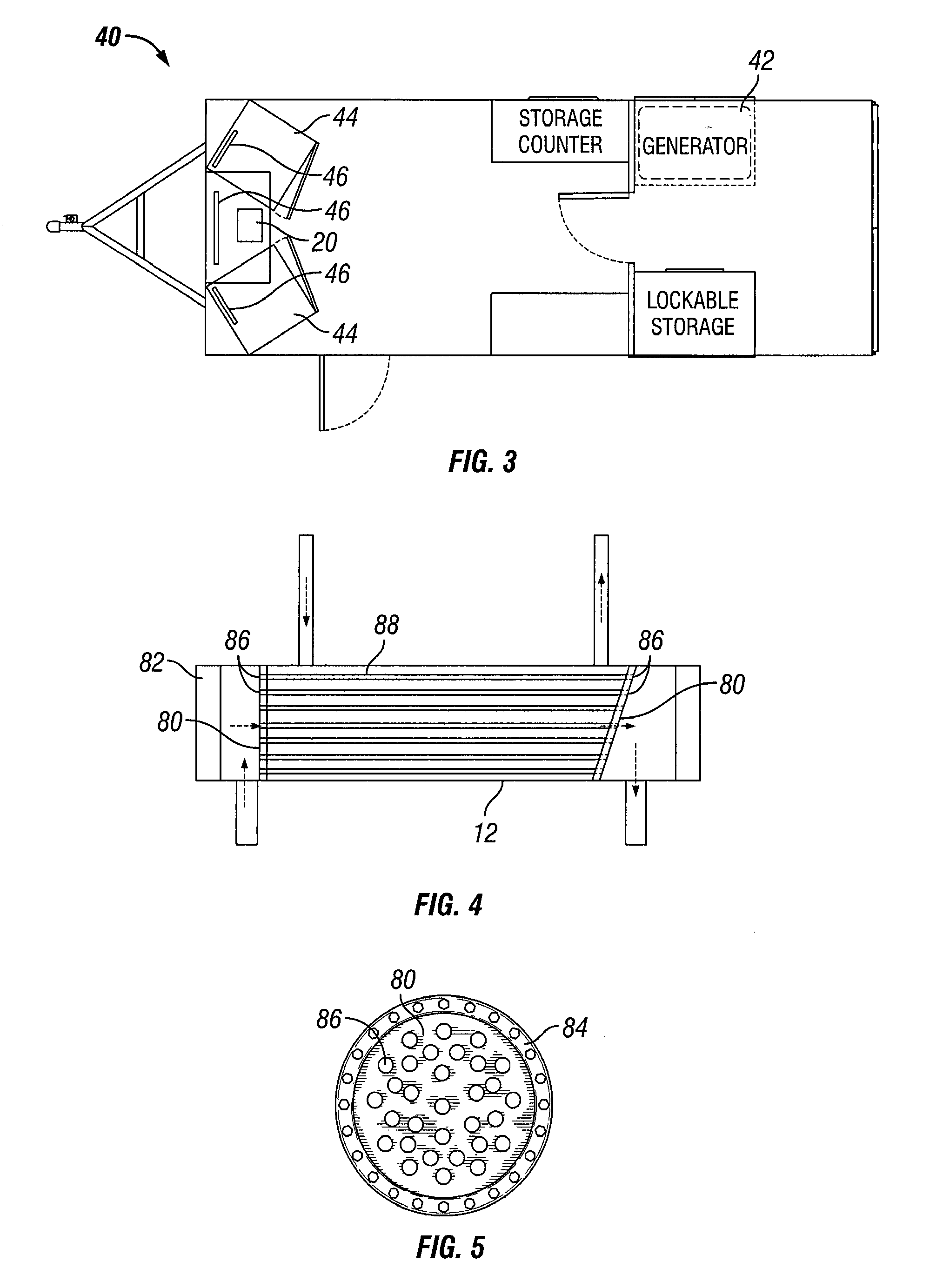

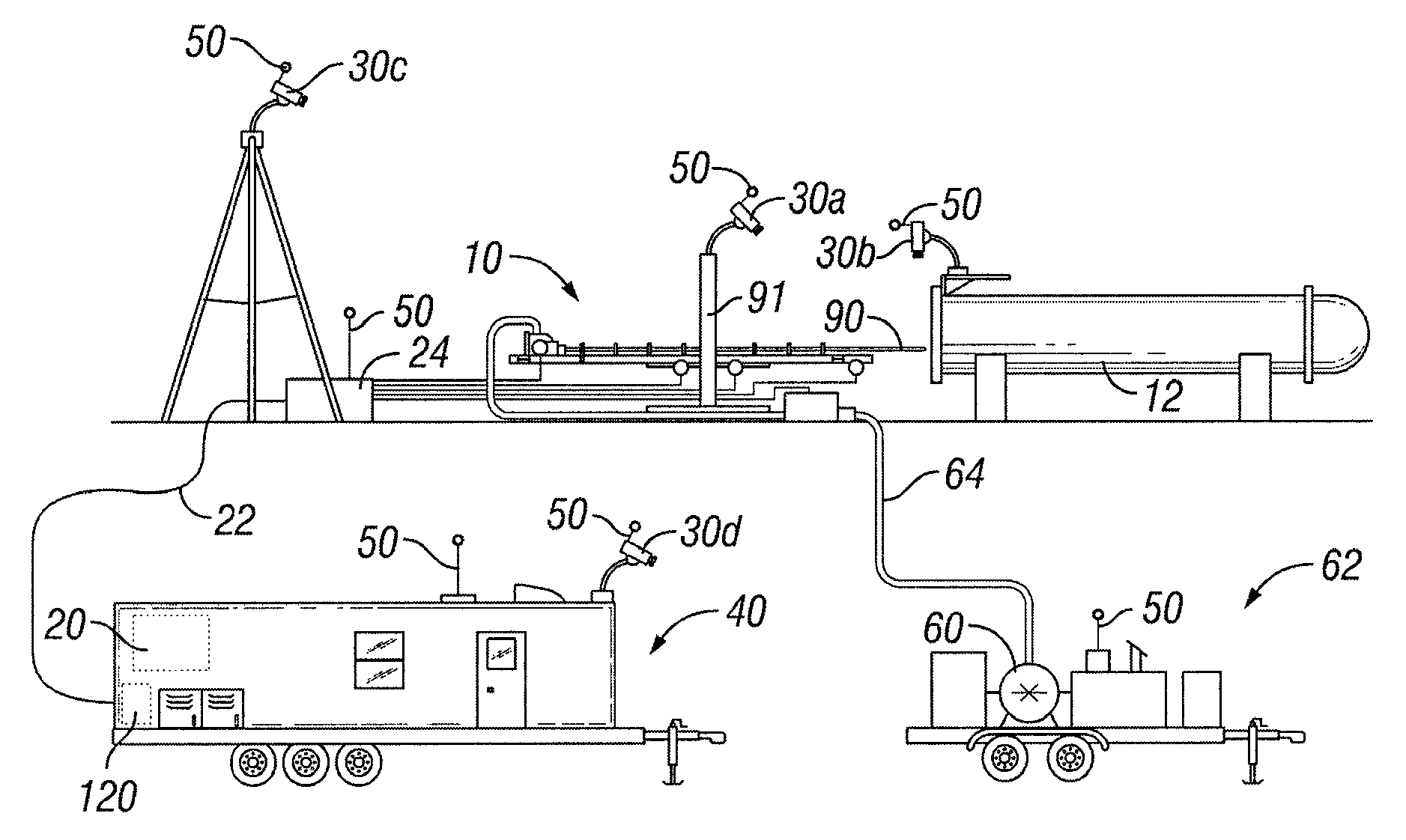

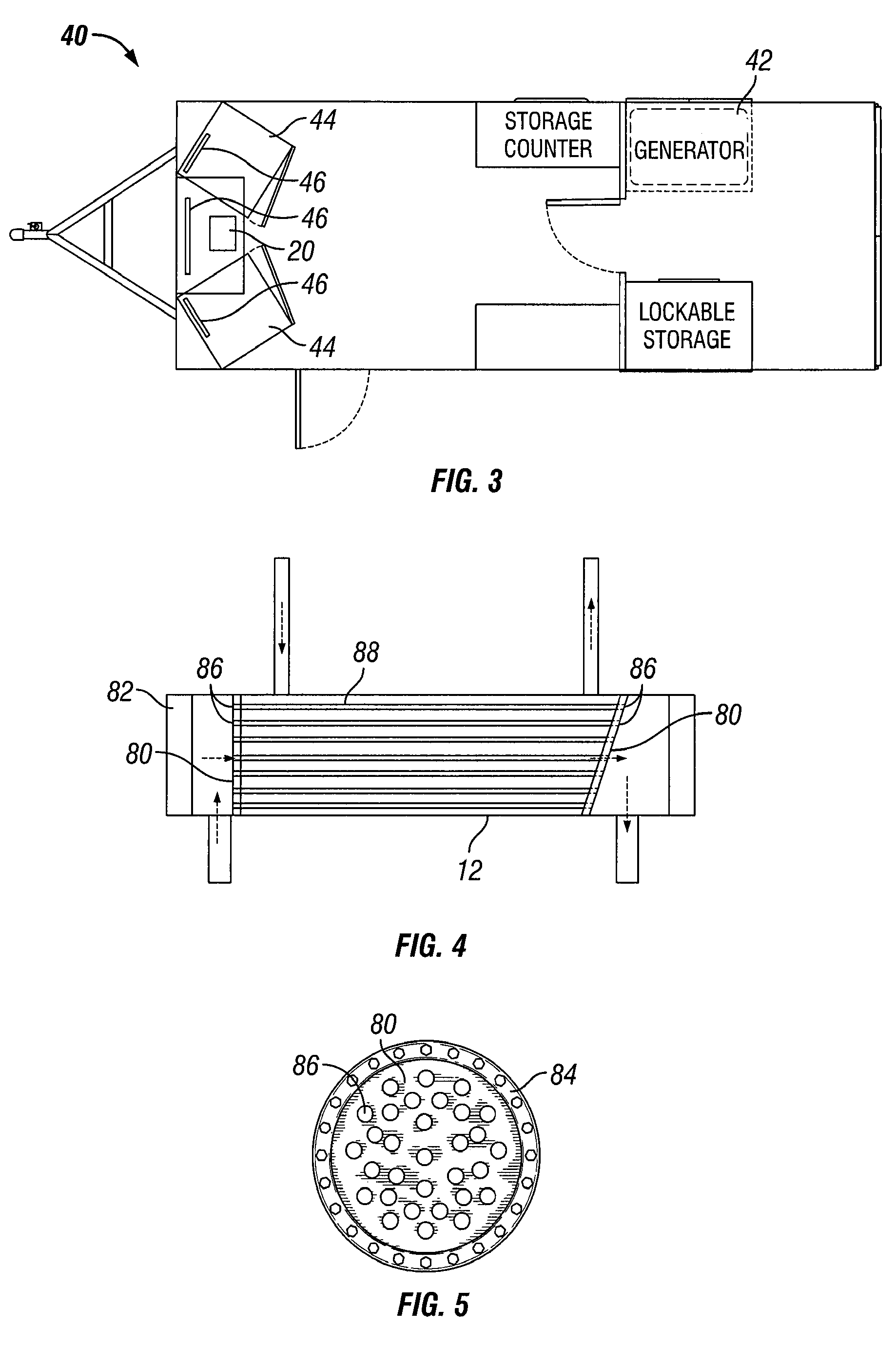

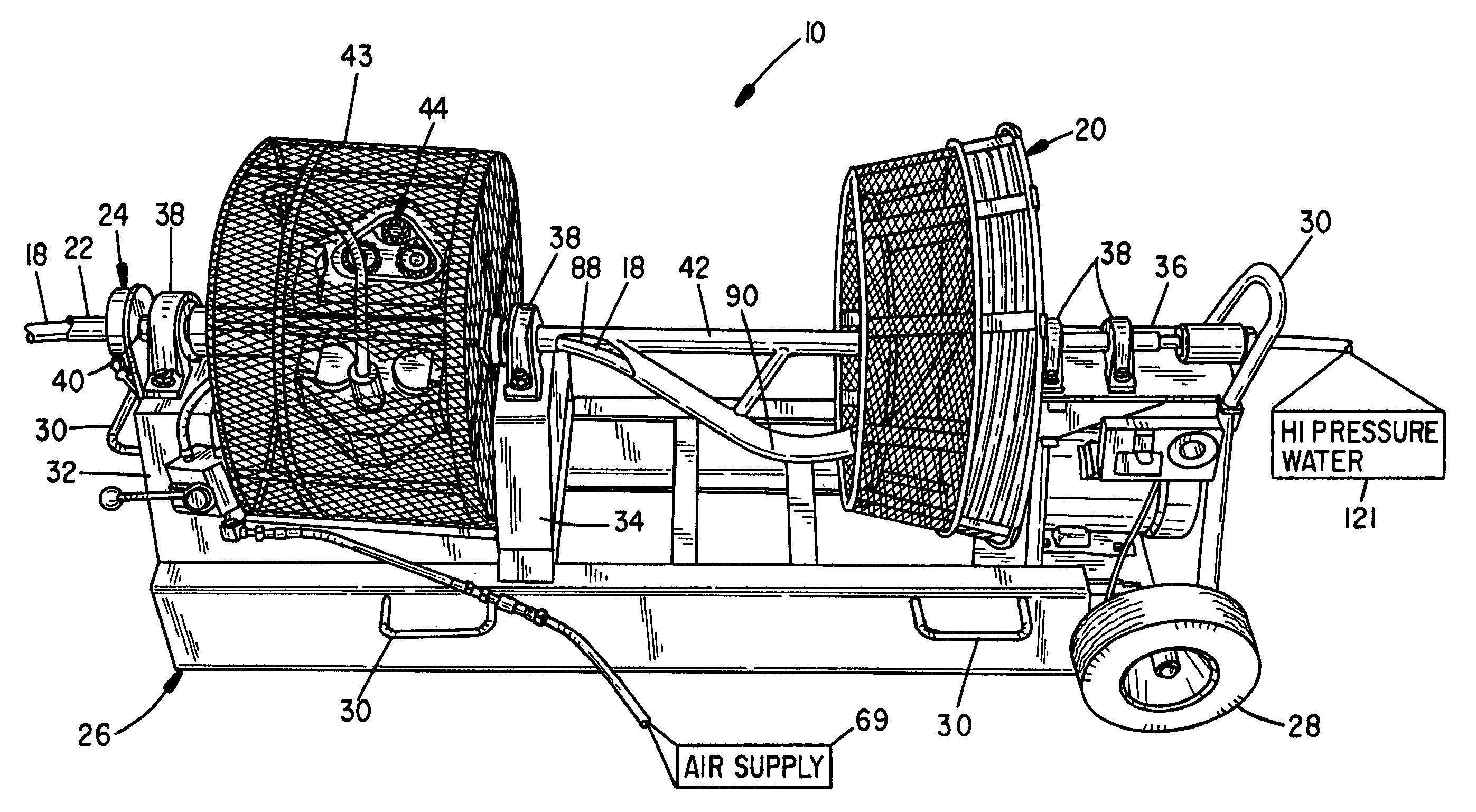

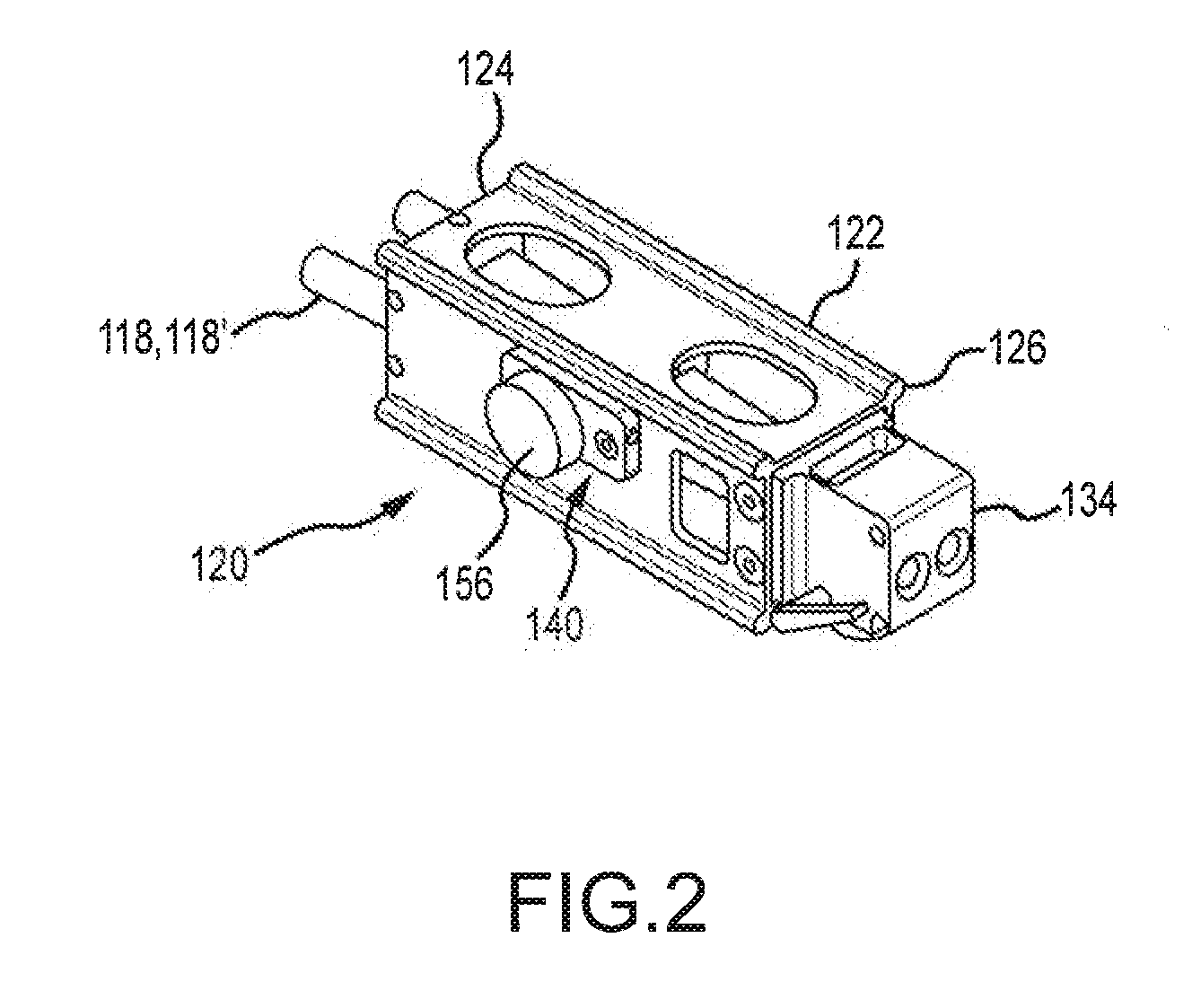

Semi-automated heat exchanger tube cleaning assembly and method

ActiveUS20120067370A1Adjustable distanceHollow article cleaningHair combsPetrochemicalProcess engineering

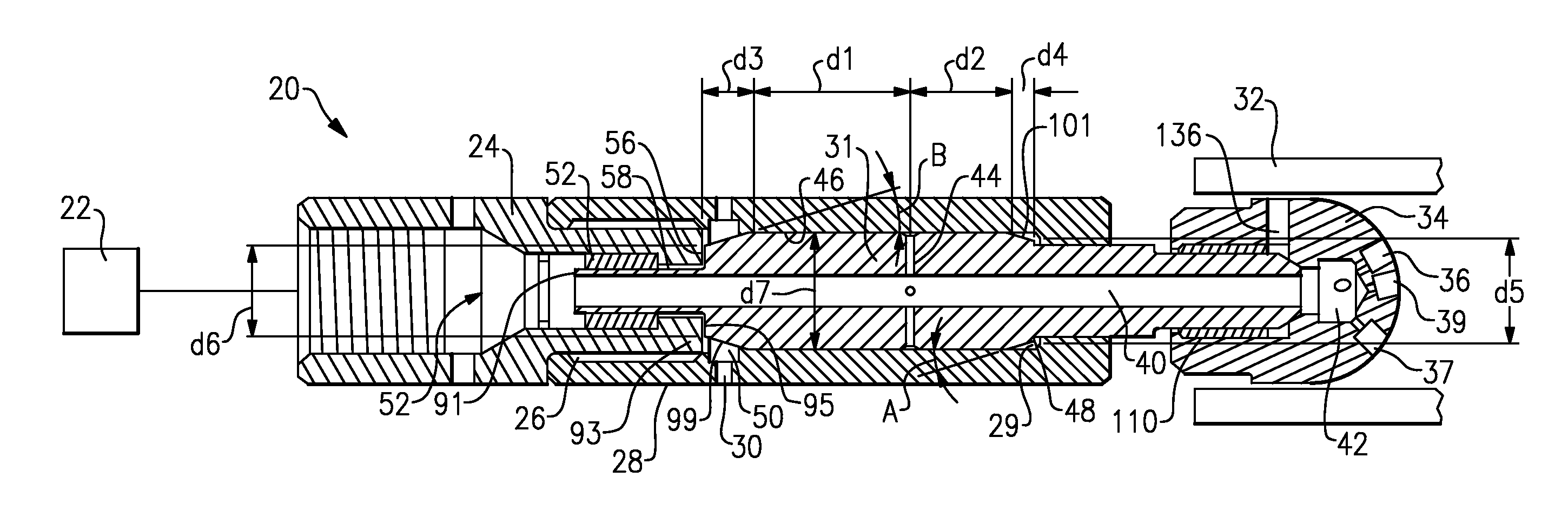

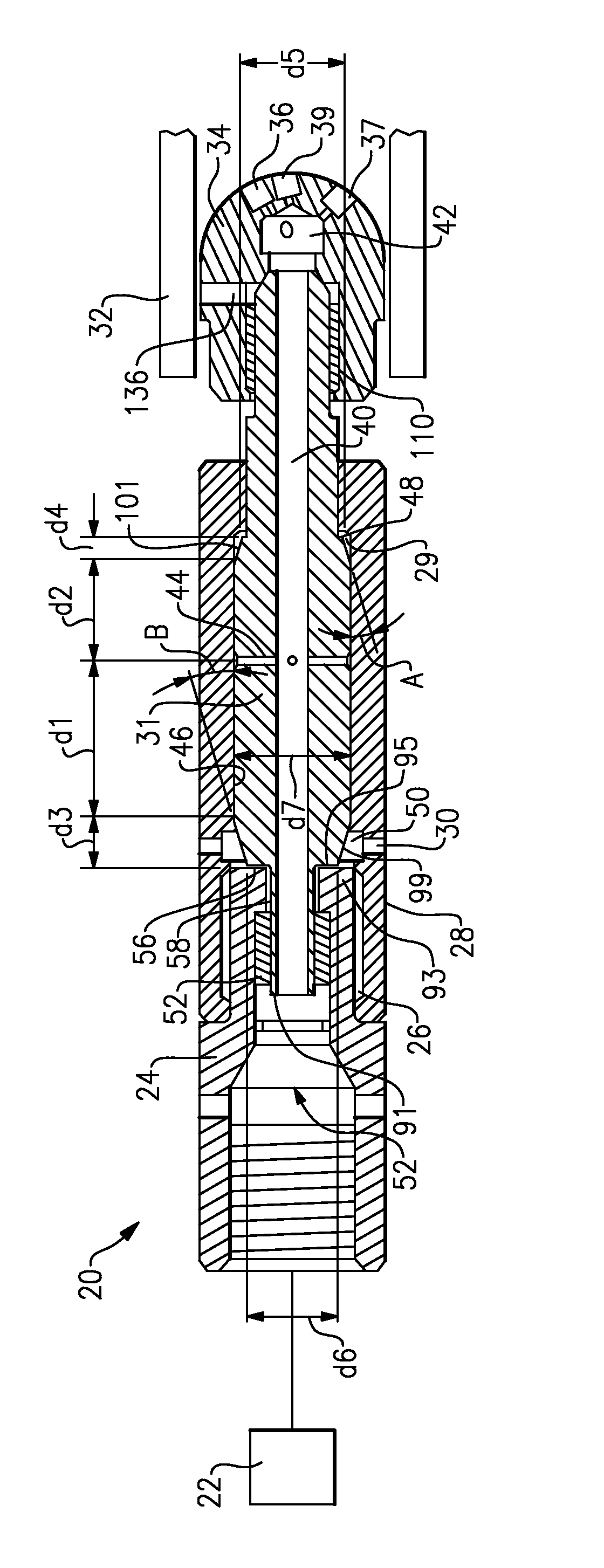

A heat exchanger tube cleaning assembly and method is provided. The assembly can allow for semi-automated tube cleaning of a heat exchanger or other piping or equipment used in an industrial facility such as, for example, a petrochemical plant or oil refinery.

Owner:HYDROCHEM

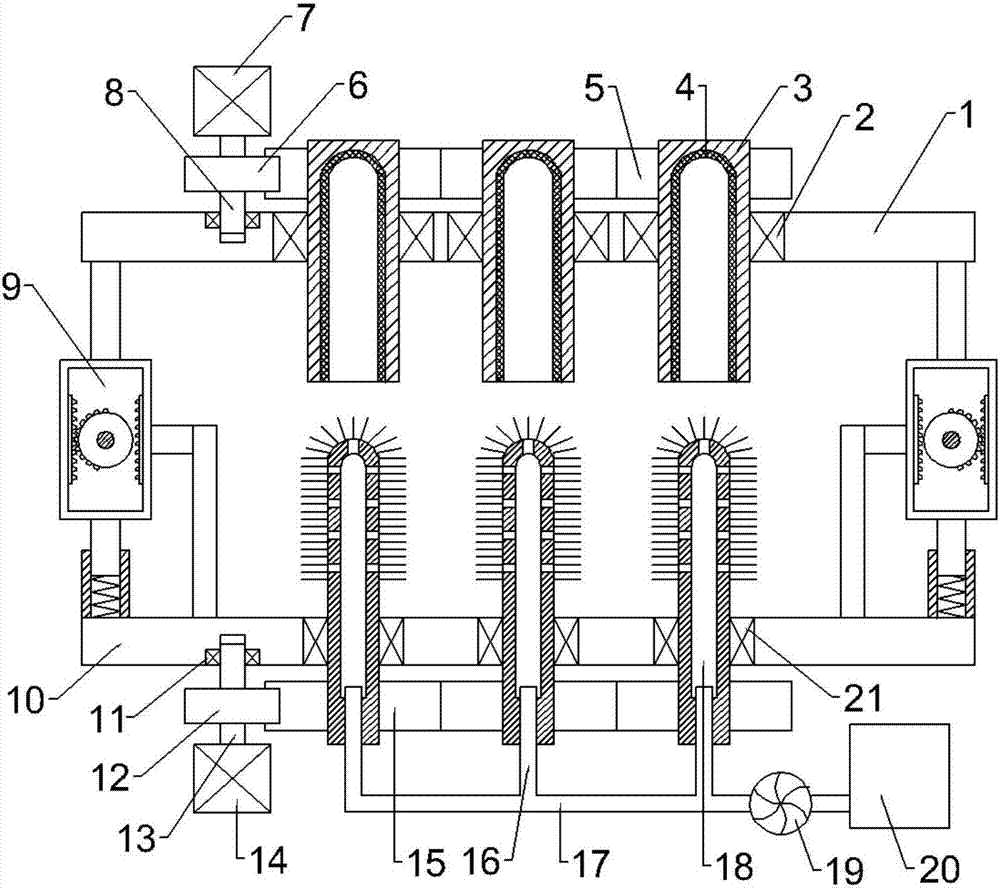

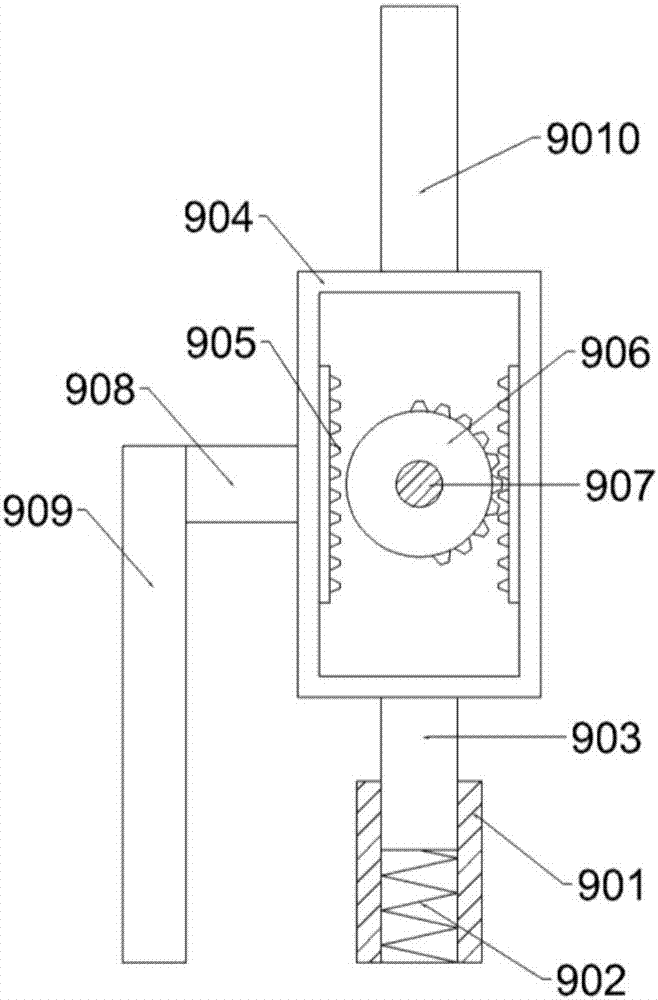

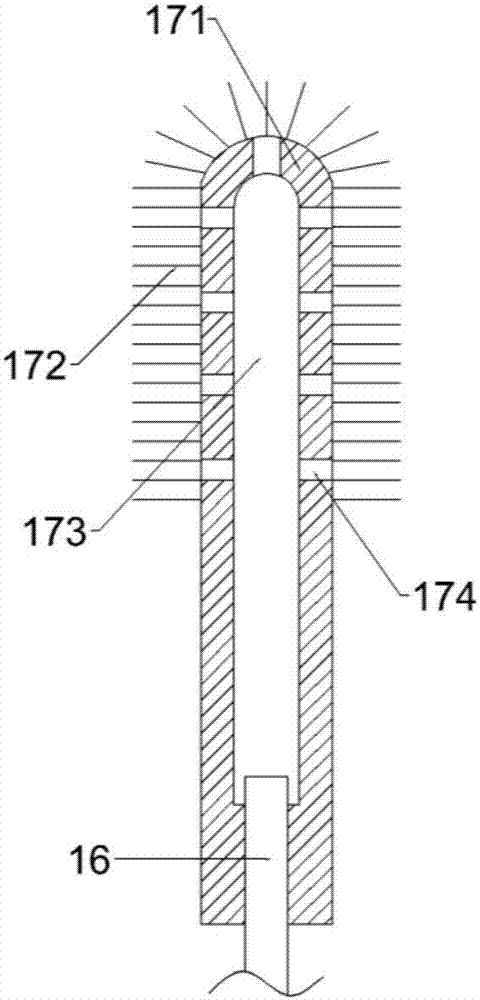

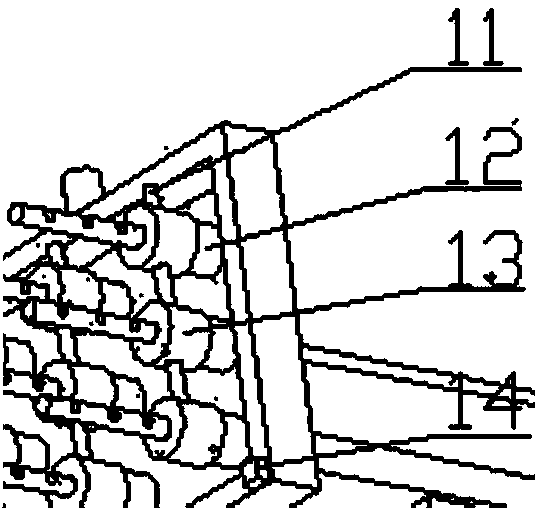

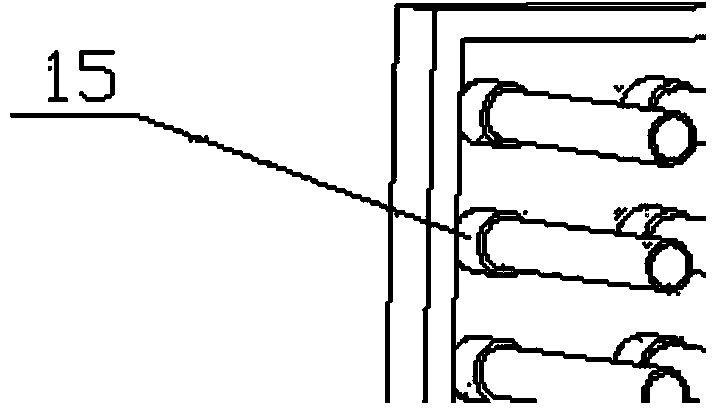

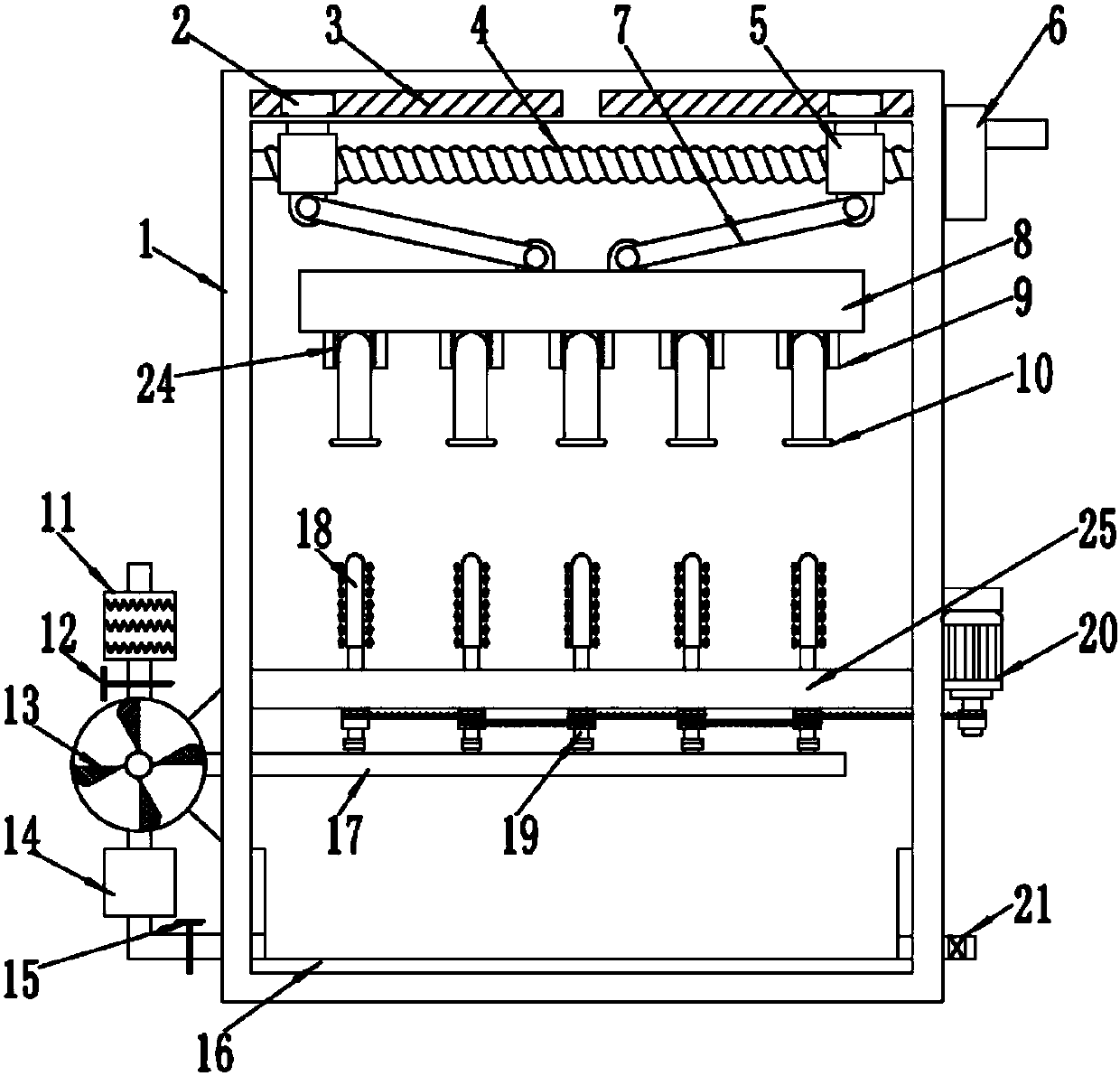

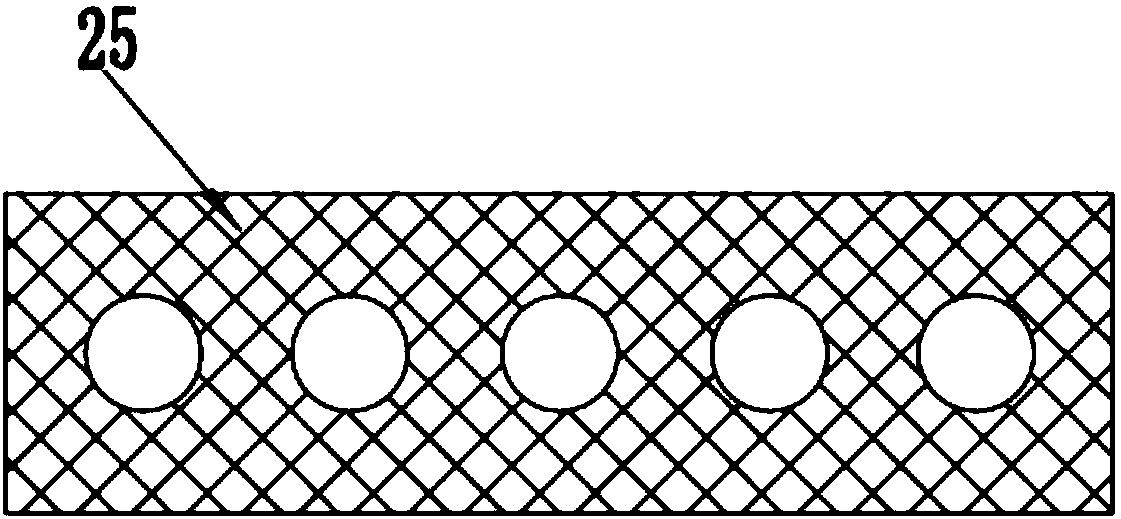

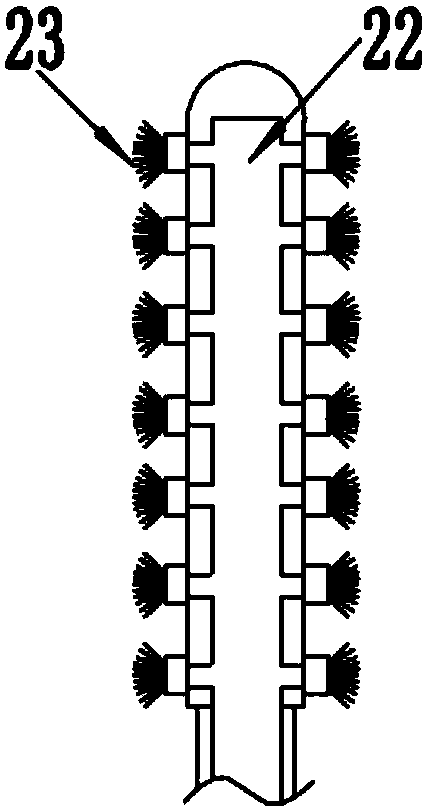

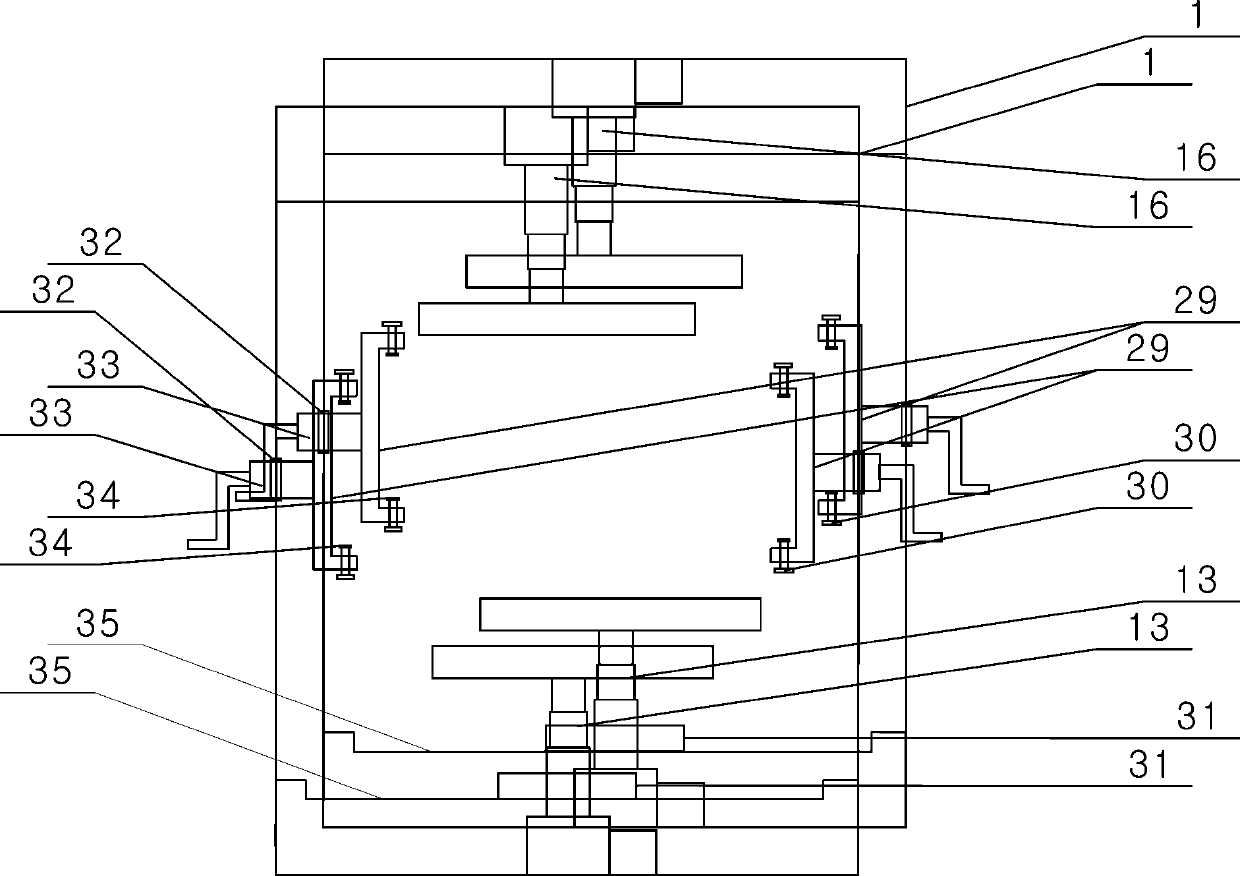

College chemistry teaching test tube cleaning device based on opposite rotation principle

InactiveCN107138496AEasy to cleanRealize up and down reciprocating motionHollow article cleaningElectric machineryTube cleaning

A test tube cleaning device for university chemistry teaching based on the principle of counter-rotation, comprising an upper base plate and a lower base plate, the upper base plate and the lower base plate are connected by two reciprocating lifting devices; the upper base plate is embedded with several The first bearing, the inner ring of the first bearing is fixedly connected with a support sleeve, the top of the support sleeve is sealed, and a rubber pad is arranged on the inner side wall of the support sleeve; the upper part of the support sleeve is fixedly connected with the first driven Gears, the adjacent first driven gears mesh with each other, the first driven gear located on the far left meshes with the first driving gear, the first driving gear is arranged on the upper base plate through the first support shaft, and the first support shaft The top end is fixedly connected with the output shaft of the first motor; a plurality of second bearings are embedded on the lower bottom plate, and the inner ring of the second bearings is fixedly connected with a scrubbing body. The invention has the advantages of reasonable structural design, simple and convenient operation, good cleaning effect, etc., and has certain popularization and application value.

Owner:黄海

Gun barrel and tube cleaning device

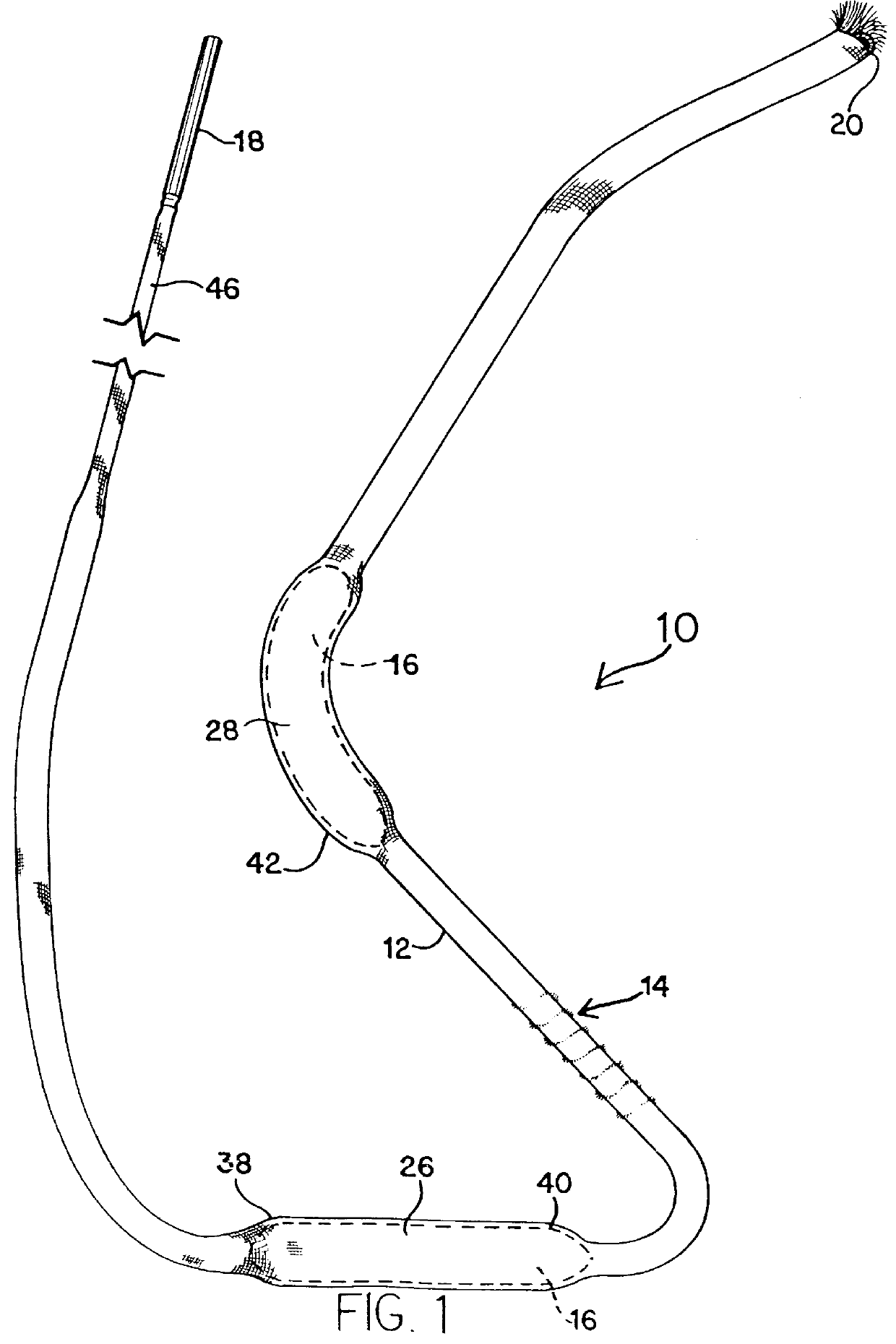

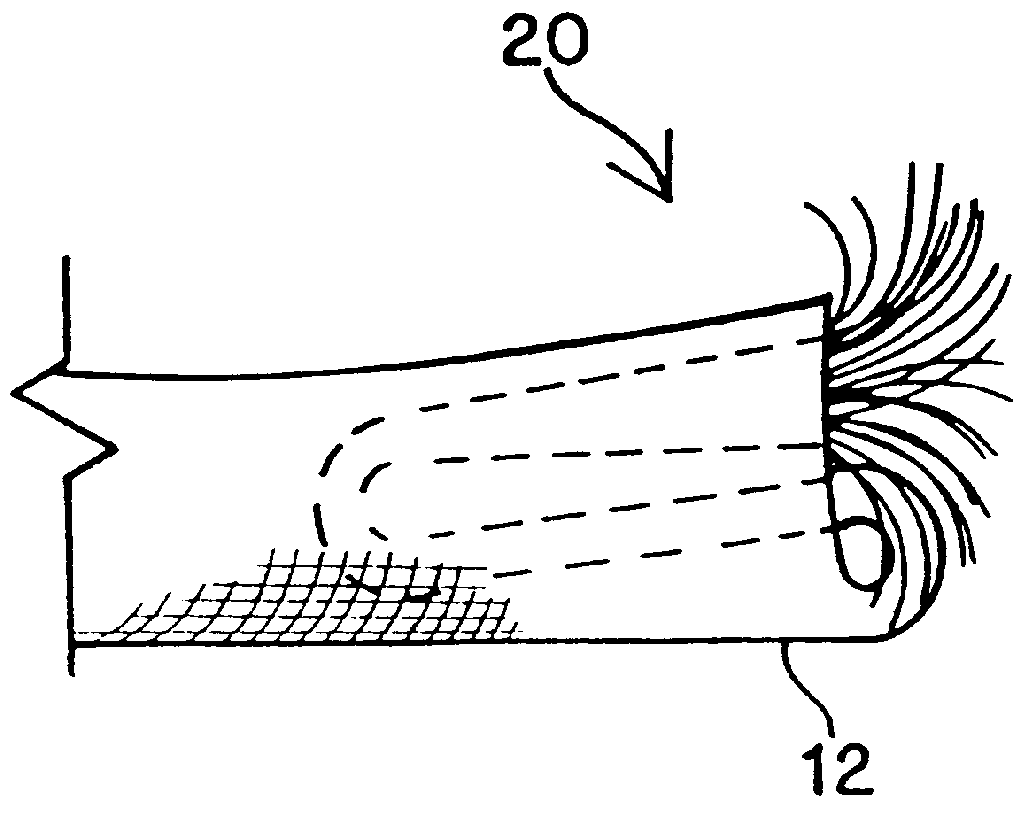

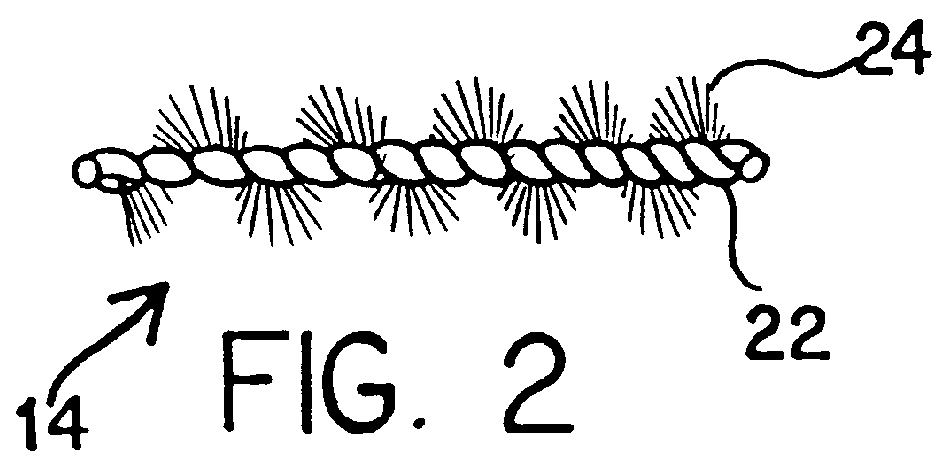

InactiveUS6088866AEliminates scratching, scarring, or uneven abrasionCarpet cleanersFloor cleanersBristleCombustion

This device is a cleaning tool for cleaning the inside of gun barrels. The device consists of a metal brush which is enclosed within a tubular sheath of material, typically a woven fabric. The bristles of the brush extend through the wall of the woven sheath of fabric. The tubular sheath is pulled through a gun barrel and the bristles of the brush clean the inside of the gun barrel. Also enclosed within the tubular sheath are one or more foam inserts, or one or more cleaning regions formed by folding the cord within itself, either of which creates a bulge in the tubular sheath and cleans debris from the gun barrel, spreads gun cleaning solvent in the gun barrel, absorbs solvent and combustion and bullet residues, and spreads a layer of gun oil in the gun barrel.

Owner:MICHAELS OF OREGON

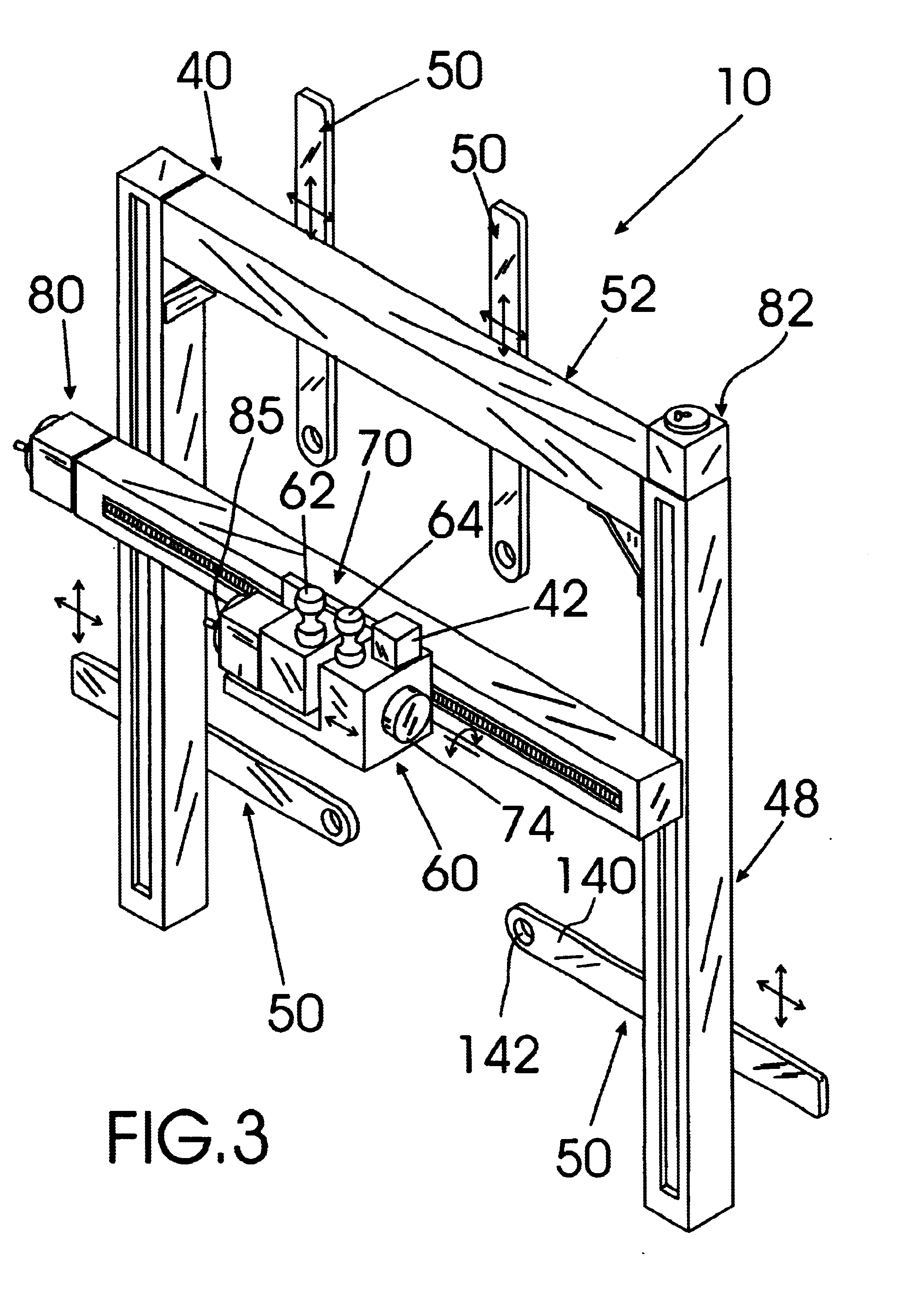

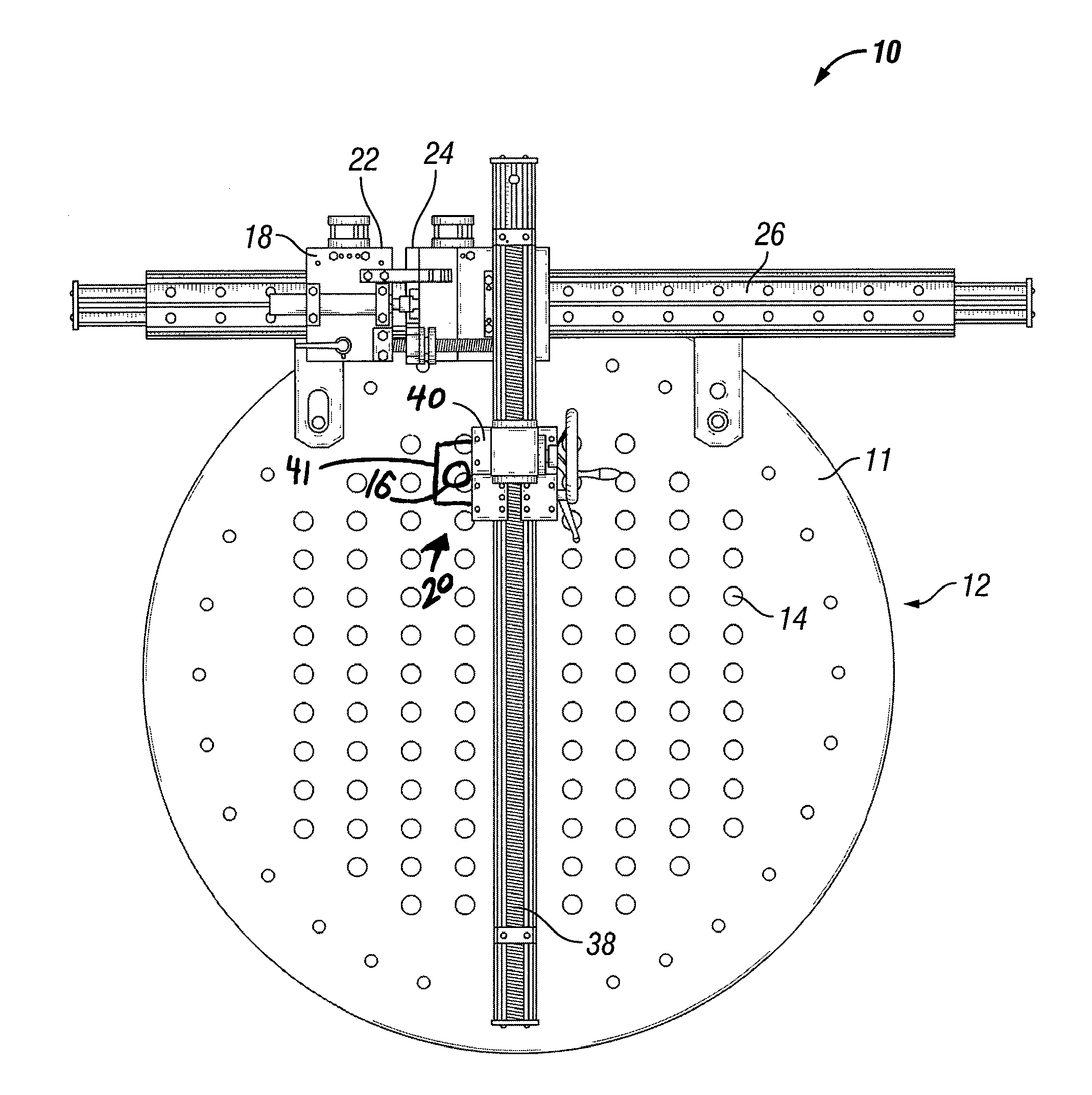

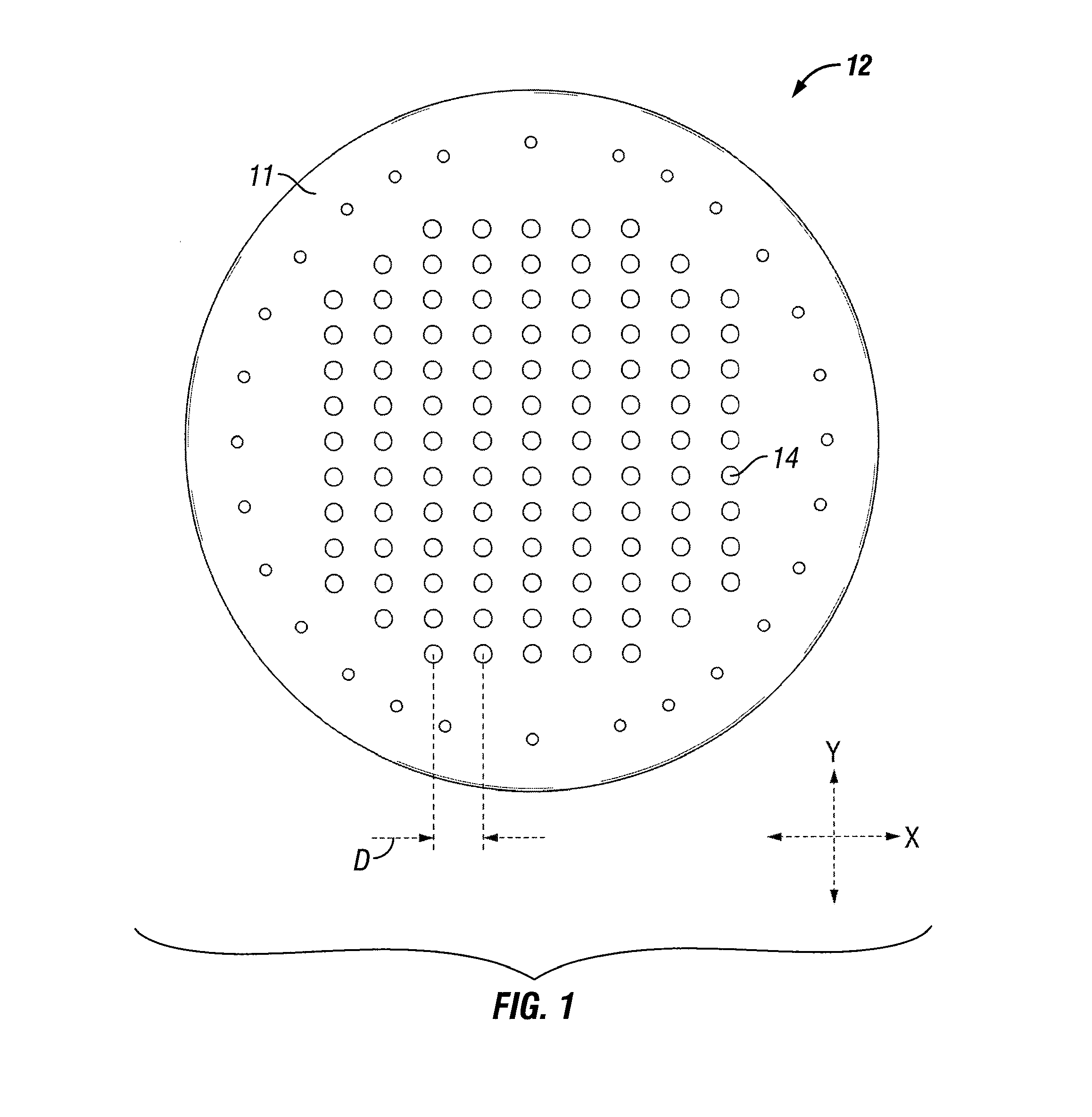

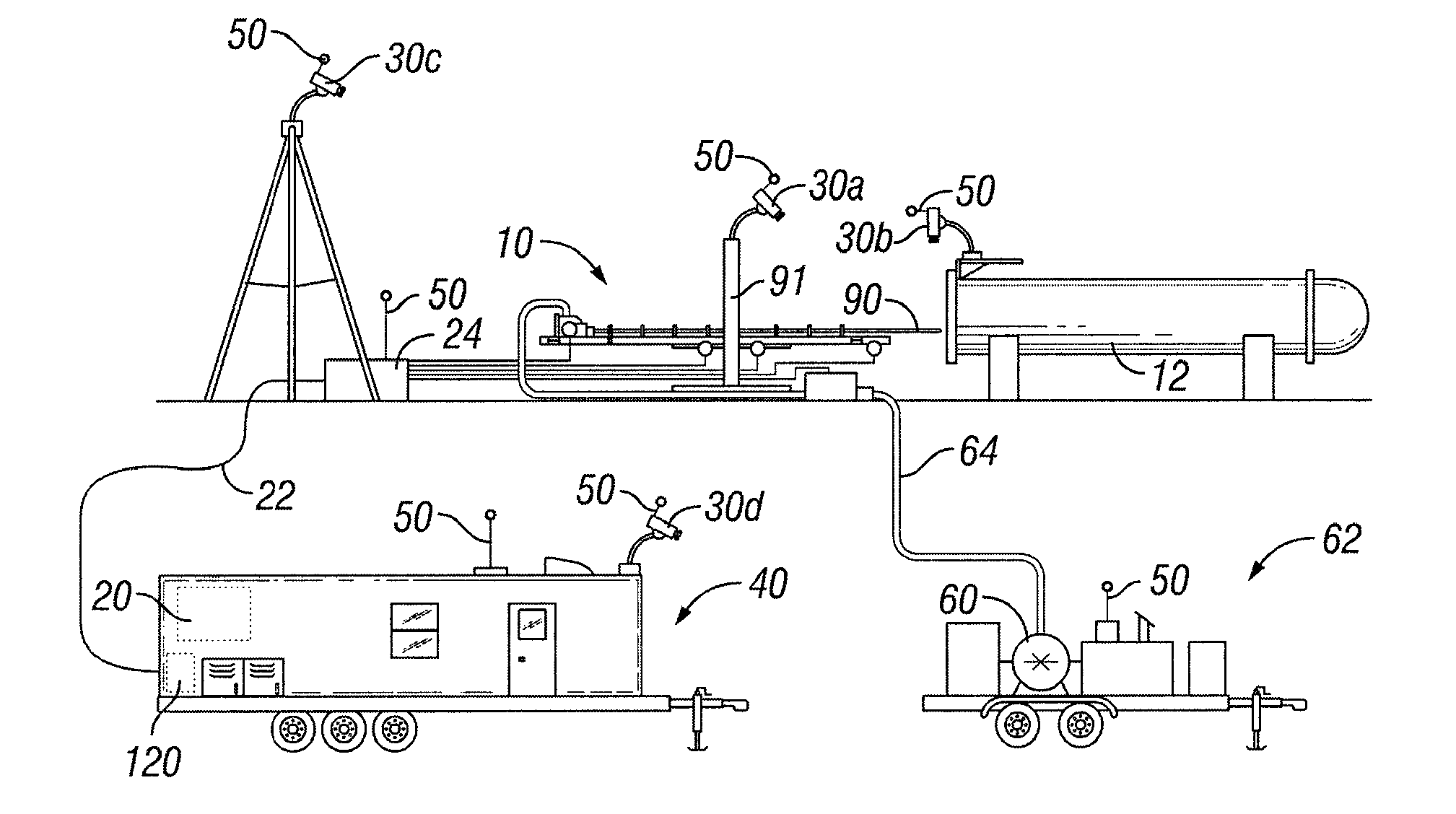

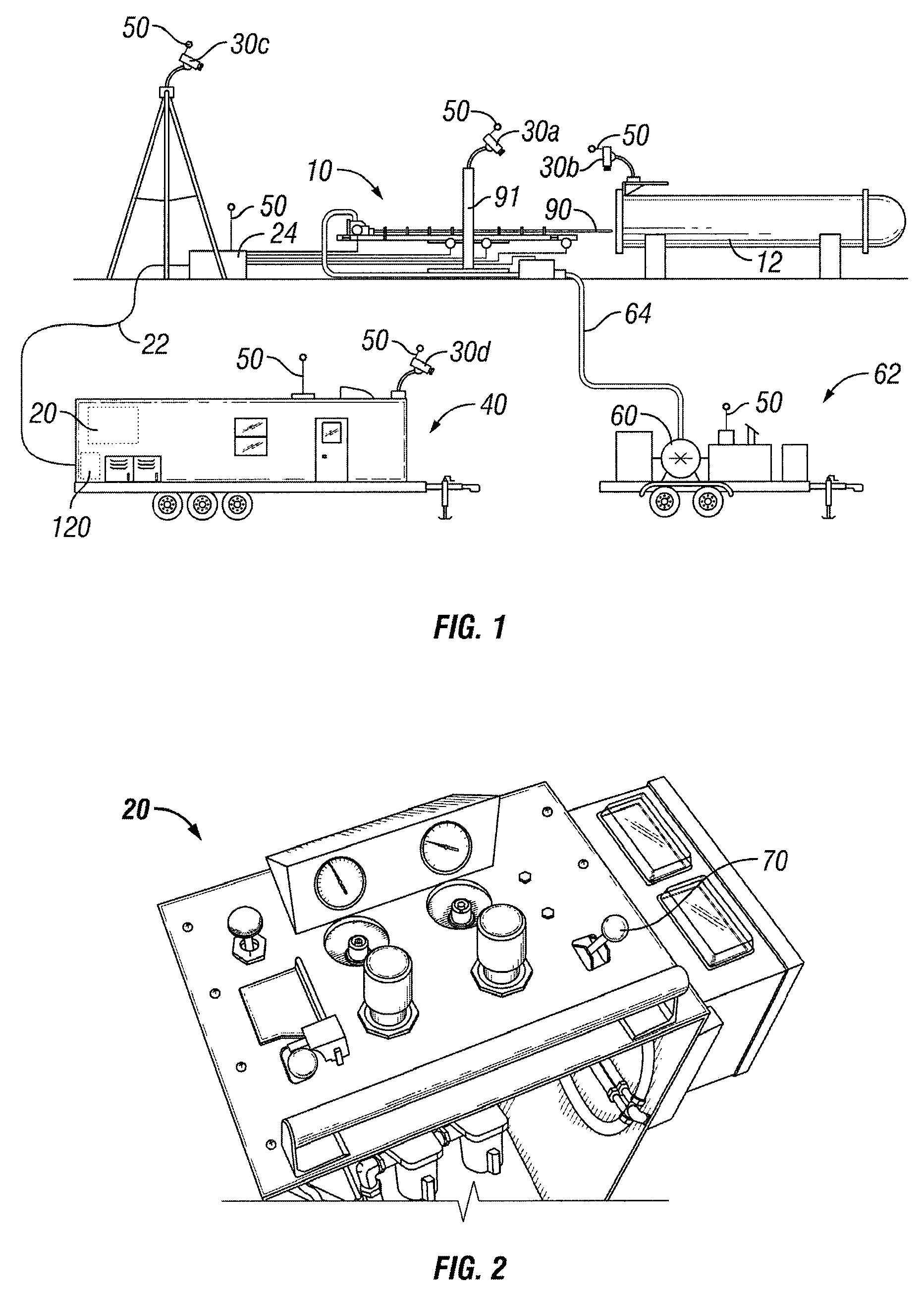

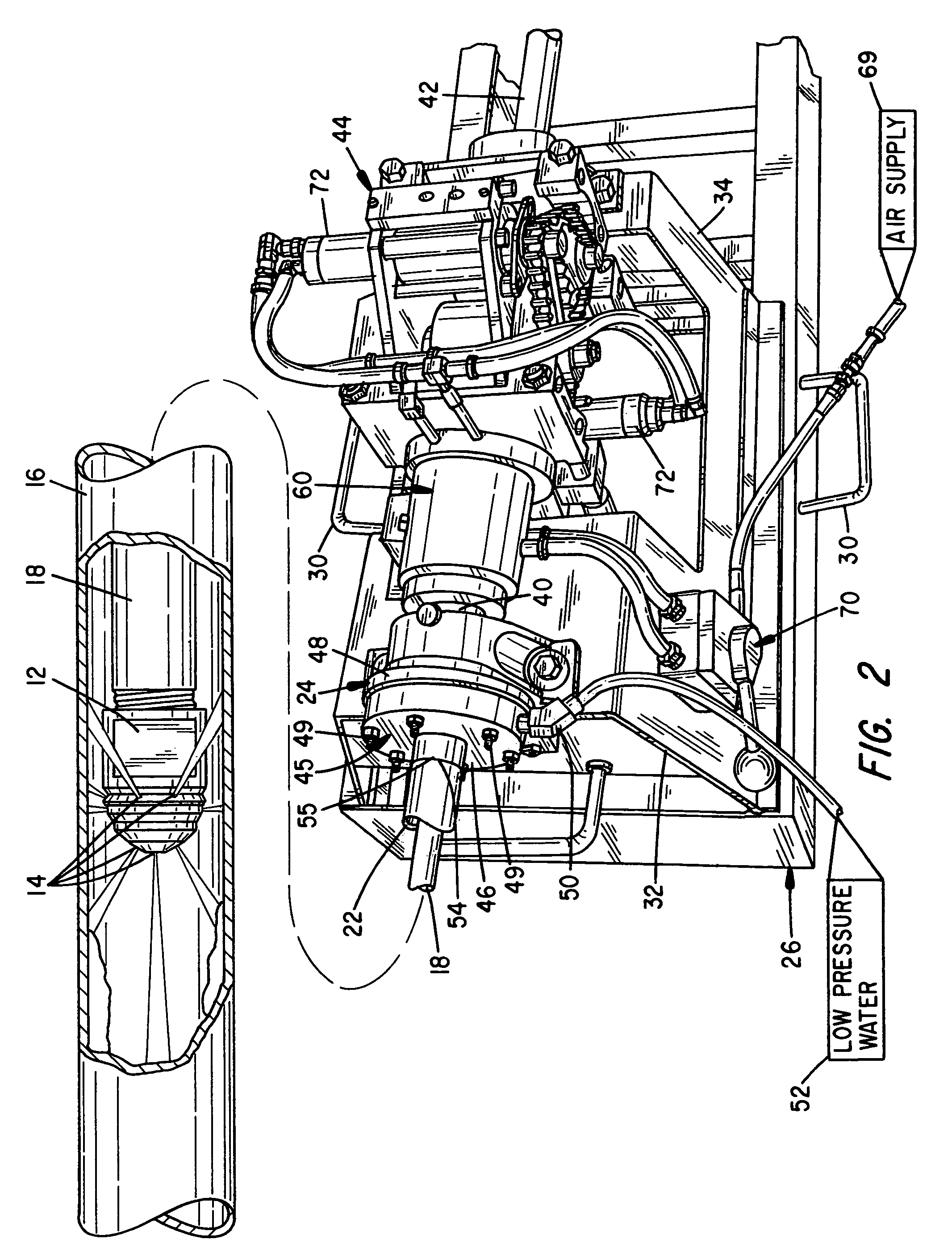

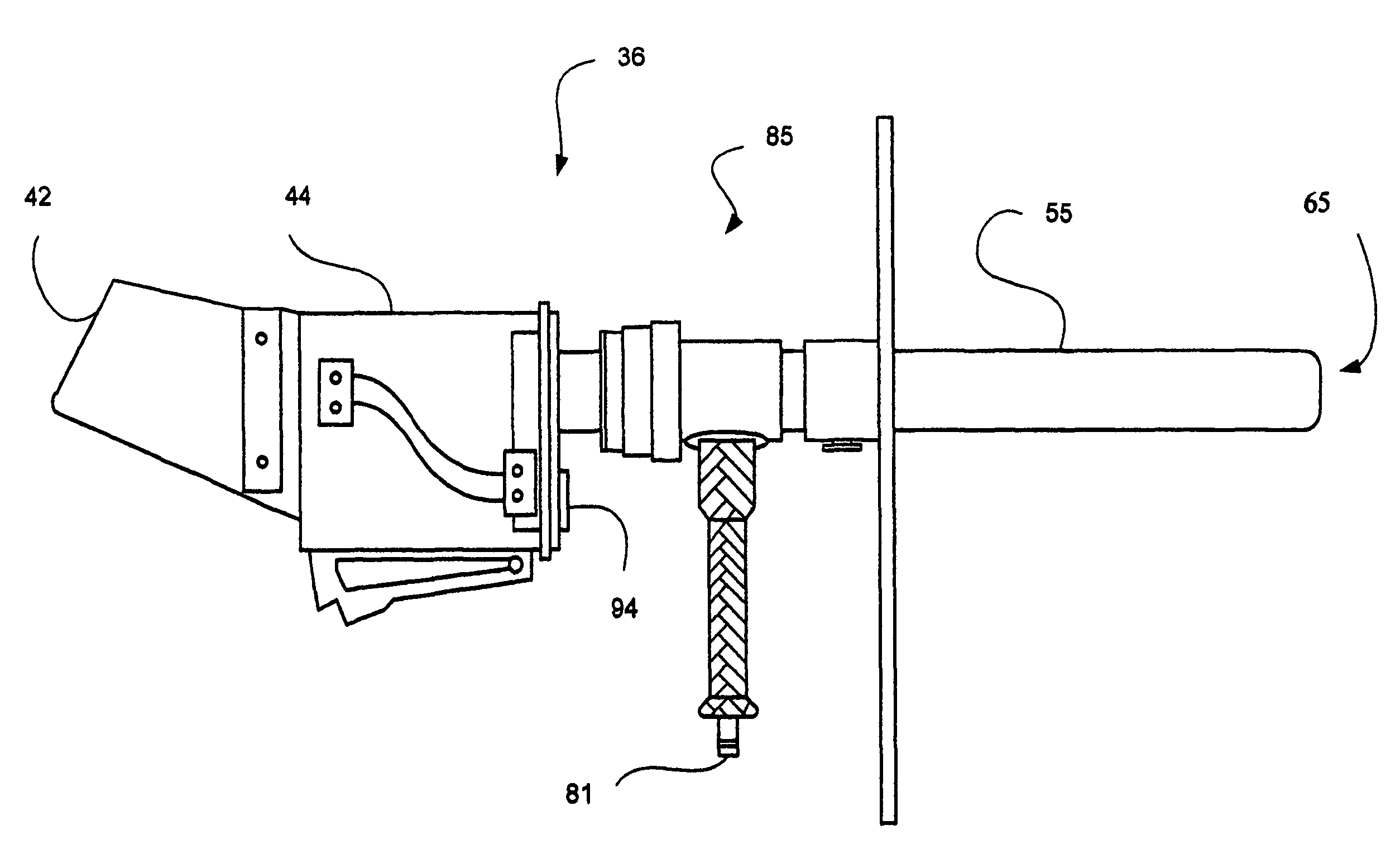

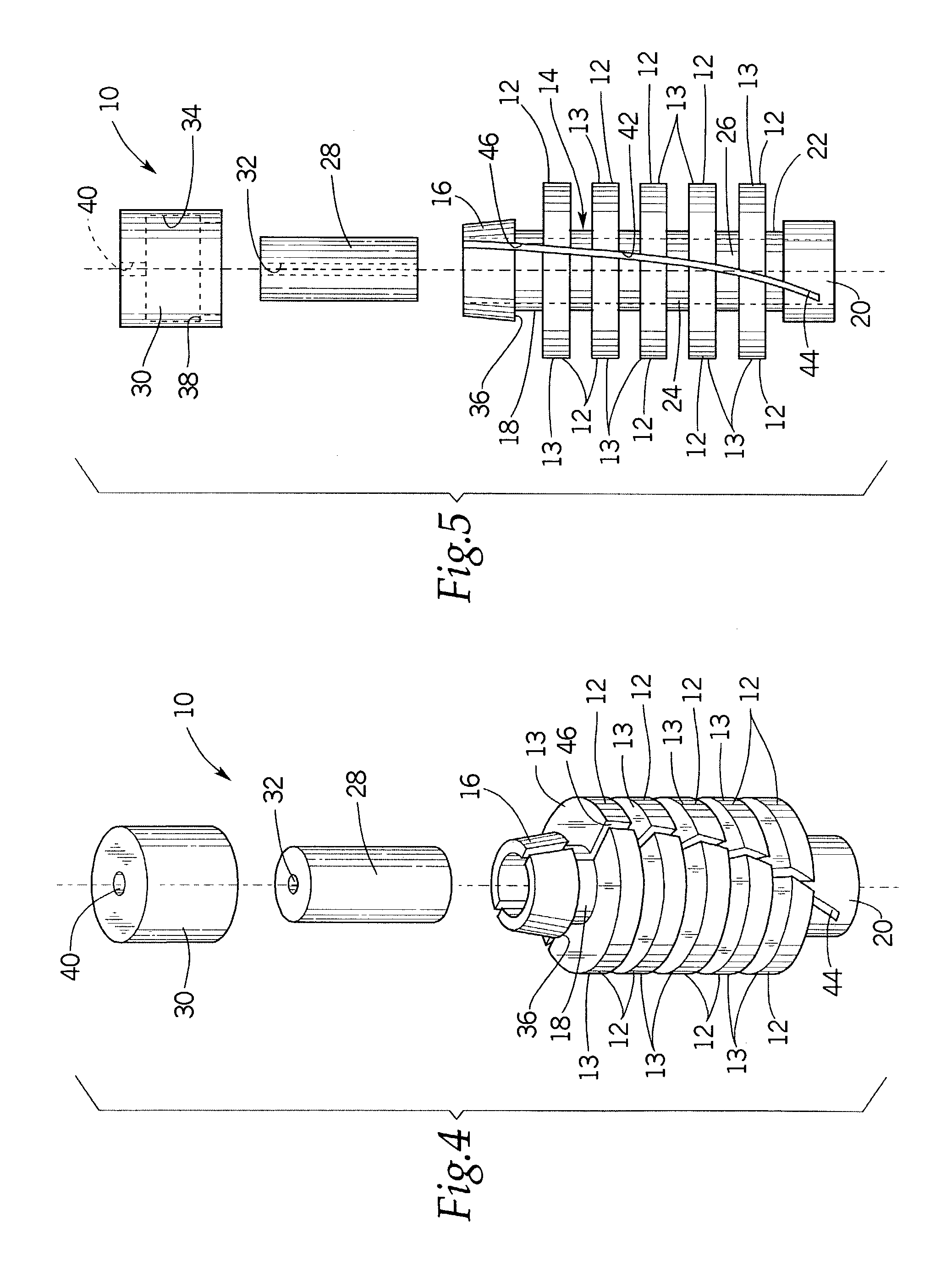

Automated heat exchanger tube cleaning assembly and system

ActiveUS20090255557A1Clean effectHollow article cleaningVehicle position/course/altitude controlSurvey resultThree dimensional measurement

An automated heat exchanger tube cleaning assembly and system are provided. The present system can automatically (without ongoing human intervention) survey the tube sheet of a heat exchanger in three-dimensions, convert and record the survey results as a digital file in three-dimensions, and then, according to sequential parameters input via custom software, automatically coordinate via computer one or more cleaning devices to effect the cleaning of each desired tube of the heat exchanger.

Owner:HYDROCHEM

Automated heat exchanger tube cleaning assembly and system

ActiveUS8057607B2Hollow article cleaningVehicle position/course/altitude controlThree dimensional measurementSurvey result

An automated heat exchanger tube cleaning assembly and system are provided. The present system can automatically (without ongoing human intervention) survey the tube sheet of a heat exchanger in three-dimensions, convert and record the survey results as a digital file in three-dimensions, and then, according to sequential parameters input via custom software, automatically coordinate via computer one or more cleaning devices to effect the cleaning of each desired tube of the heat exchanger.

Owner:HYDROCHEM

Medical tube cleaning apparatus

ActiveUS8458844B2Avoid accumulationAdequate airflowBronchoscopesTracheal tubesTracheal tubeEngineering

Owner:SUNMED GRP HLDG LLC

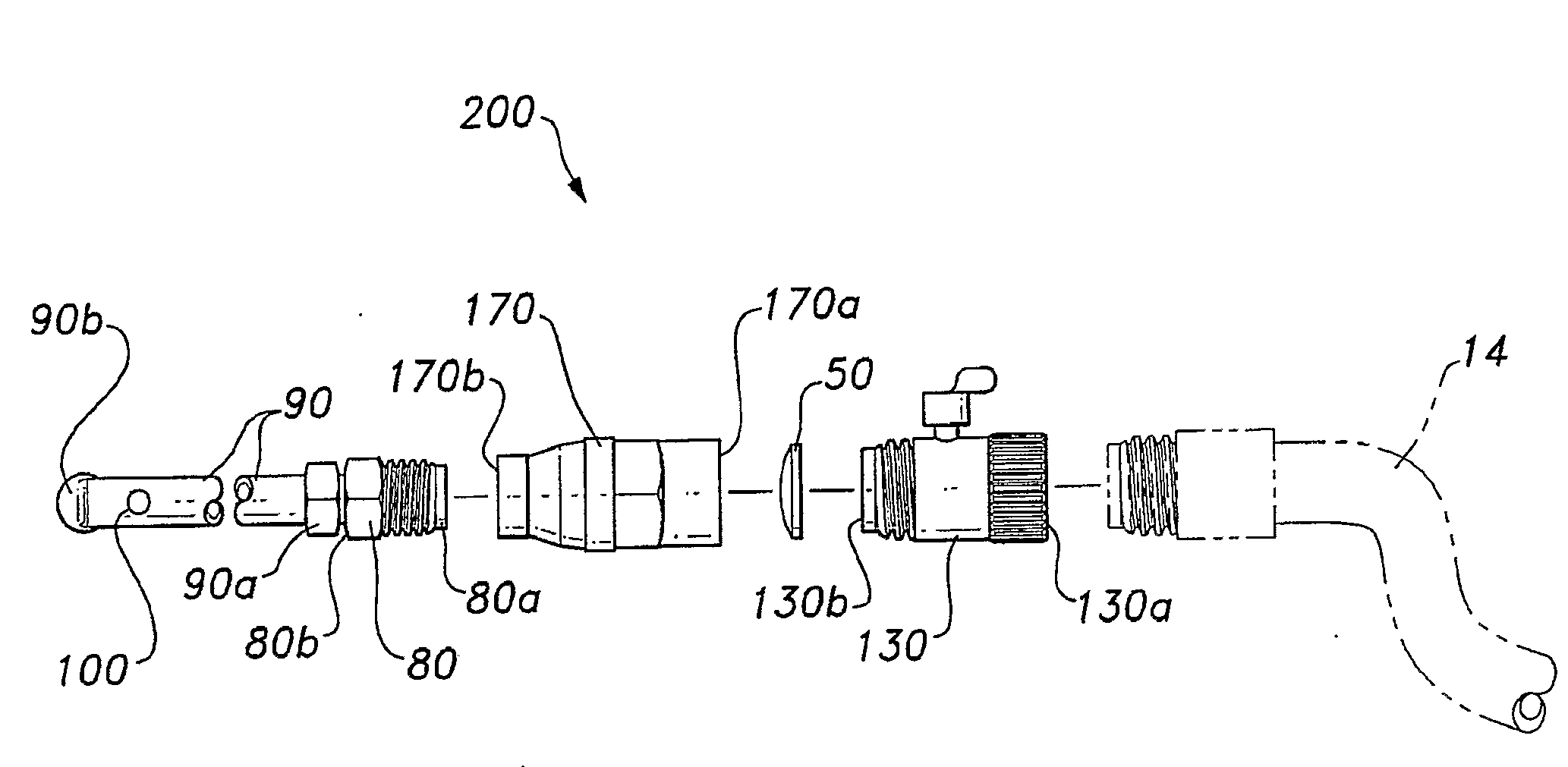

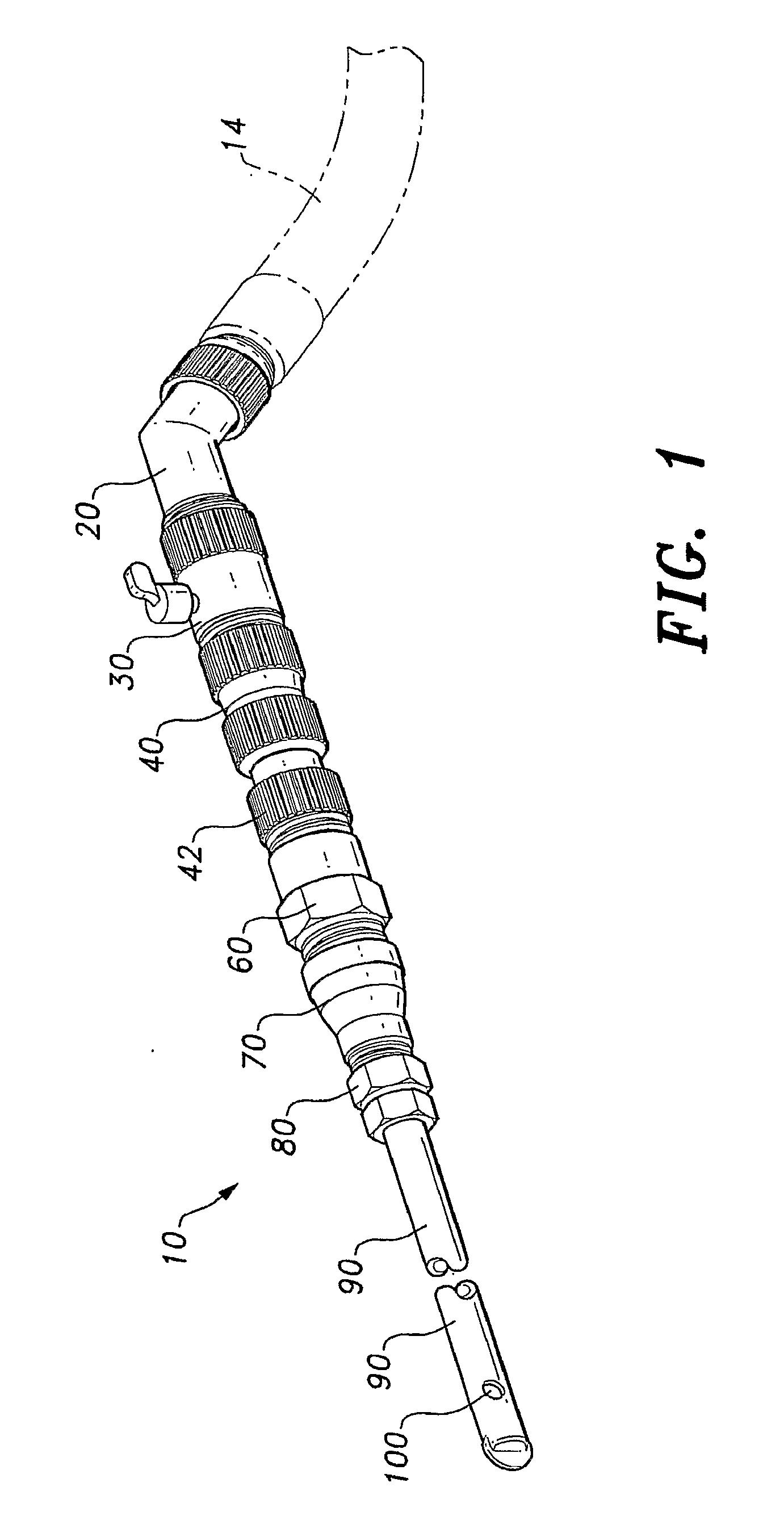

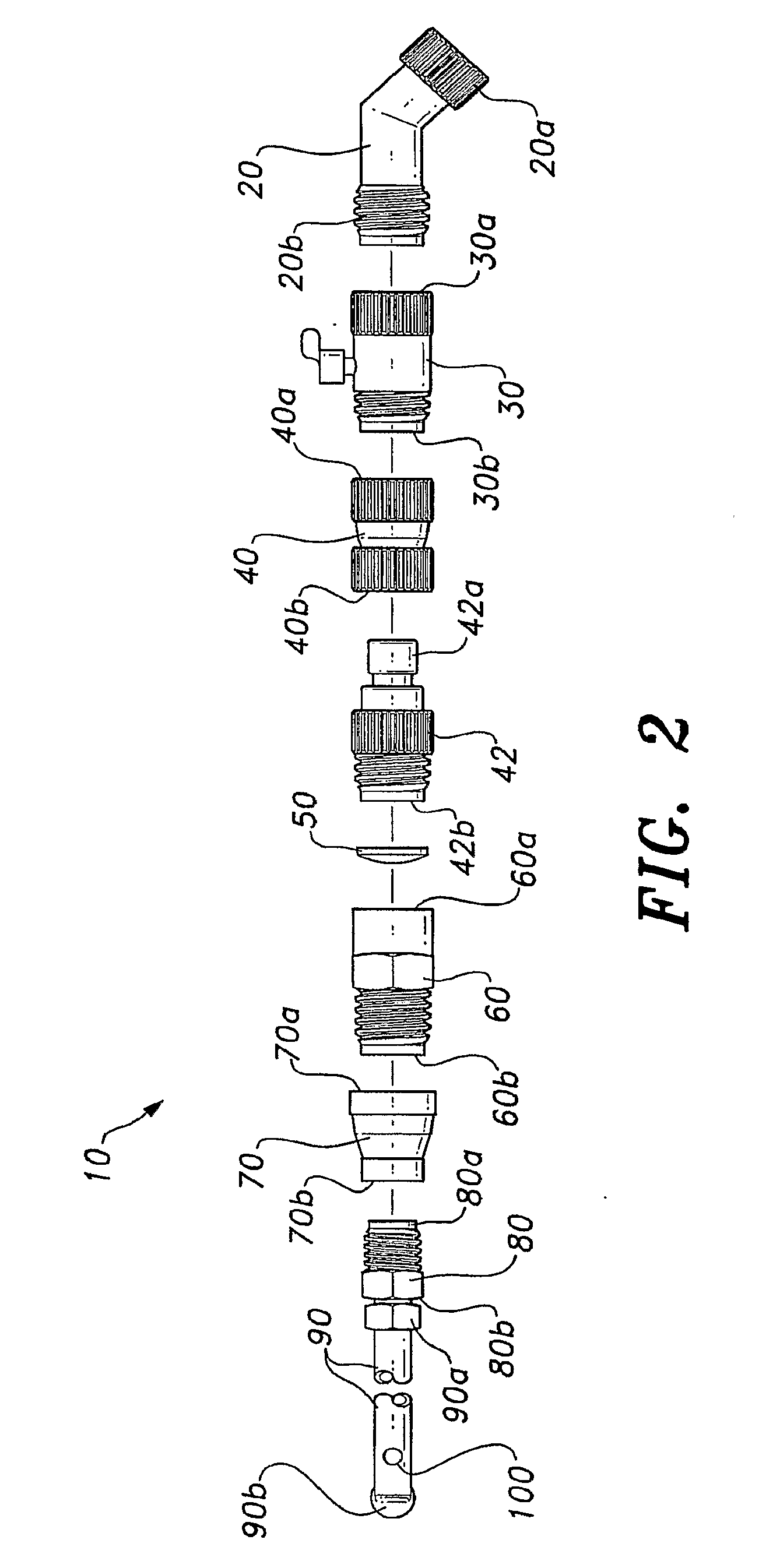

Cleaning Attachment for Water Hose

The cleaning attachment (10) for use with a water hose (14) includes an angle adapter (20), a water control valve (30), a quick connect coupling (40, 42), a first thread adapter (60), a debris screen, a second thread adapter (70), a compression fitting adapter (80), and a hollow wand (90). The cleaning attachment (10) is designed to act as a nozzle for directing and dispensing water from a conventional water hose (14). Specifically, the cleaning attachment (10) is designed for effectively cleaning air conditioner coils, particularly condenser coils and evaporator coils. Cleaning attachment (10) allows a user to clean a coil with a flow of water through openings in the coil, eliminating the conventional need to disassemble the coil. The cleaning attachment (10) may also be used for a variety of other purposes for which a flow of pressurized water is needed.

Owner:AUER JR JOHN

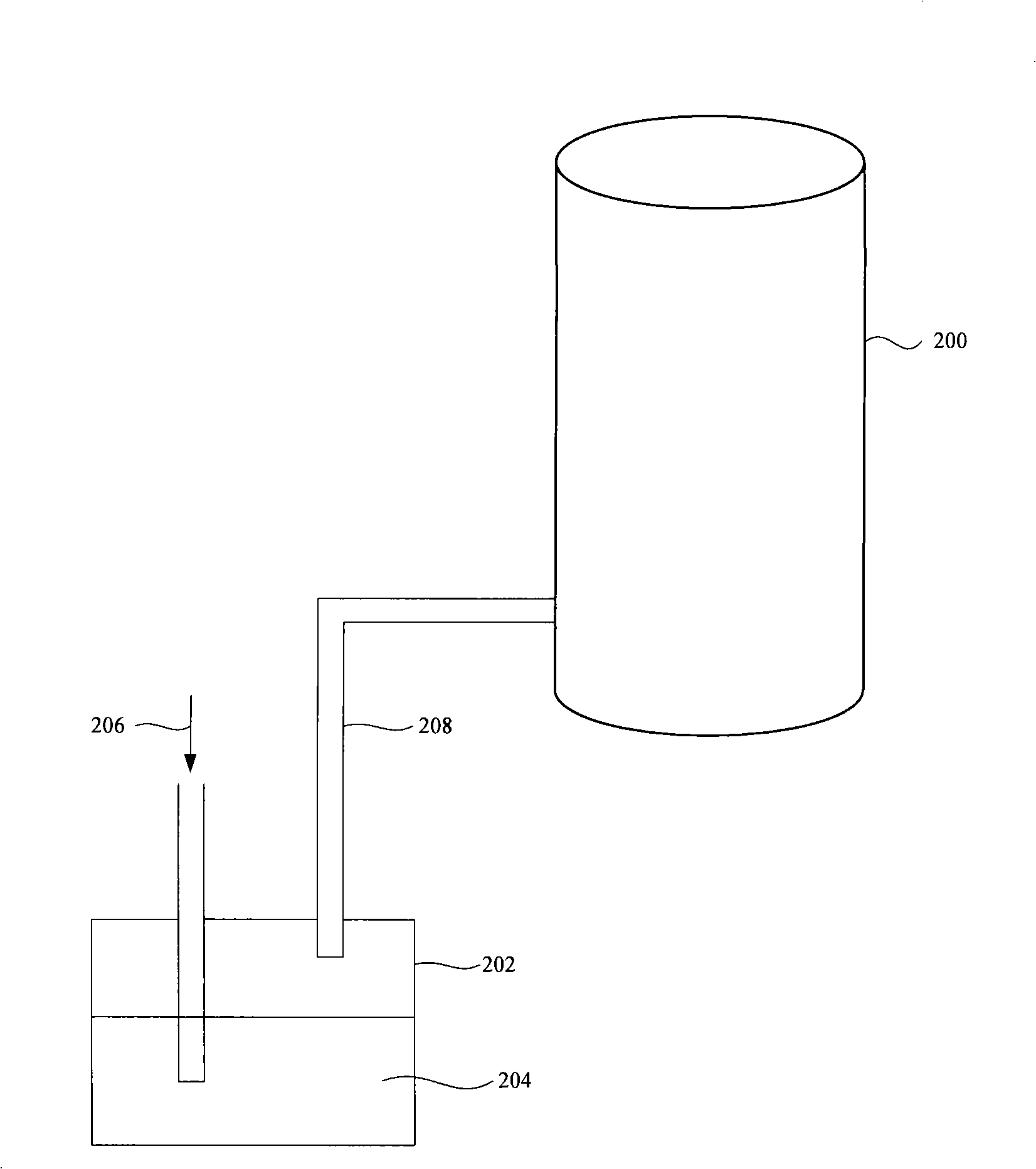

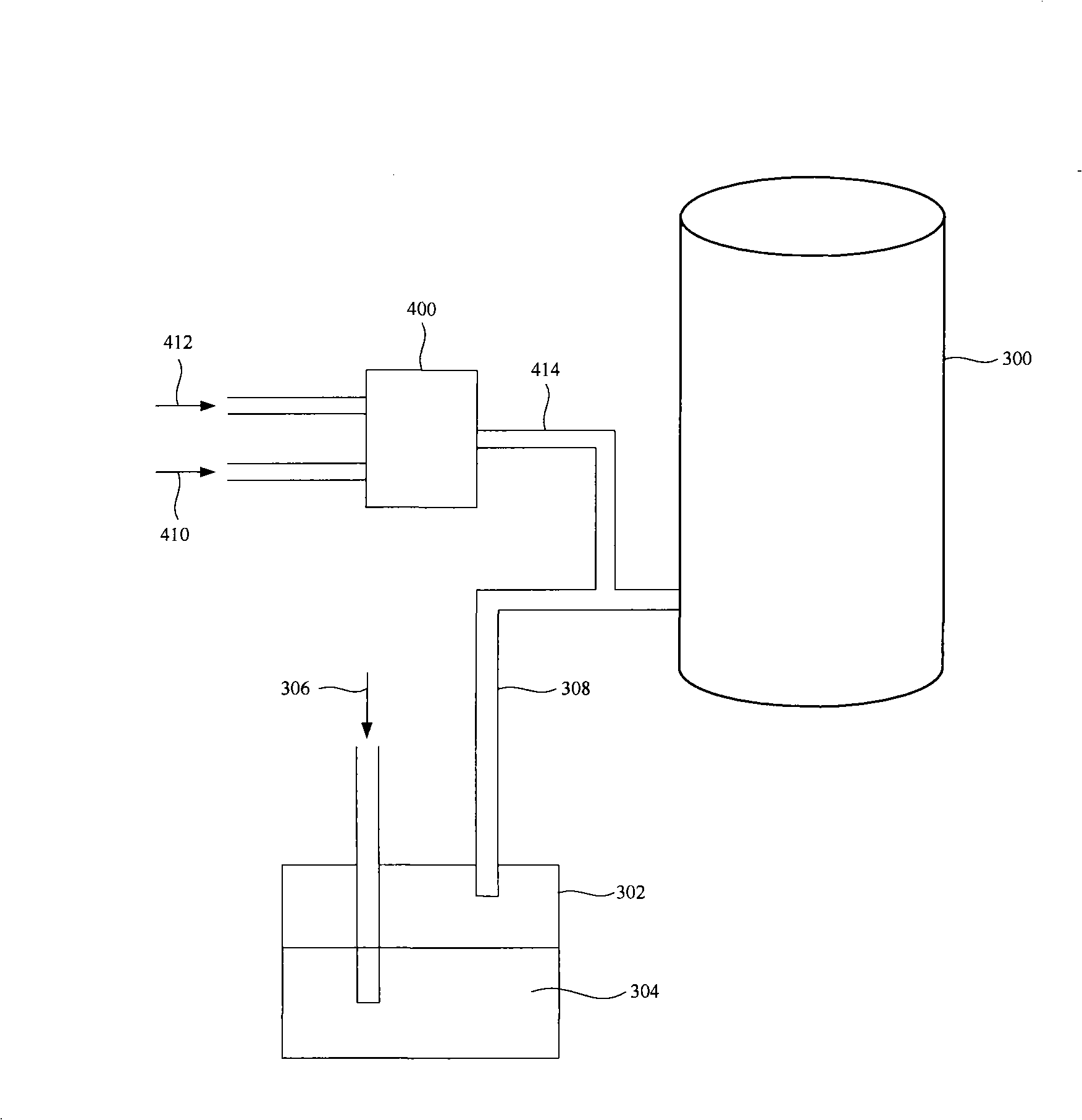

Method and system for cleaning boiler tube

InactiveCN101327487AEasy to cleanHigh purityHollow article cleaningMaintainance of heating chambersEngineeringCleaning methods

The invention discloses a furnace tube cleaning system and method. Nitrogen gas enters into a cleaning agent tank, wherein, the cleaning agent carried by the nitrogen gas enters into the furnace tube via a pipeline to clean the furnace tube; hydrogen and oxygen are mixed to produce water vapor which enters into the furnace tube to clean the furnace tube. The furnace tube cleaning method of the invention is capable of effectively removing the metallic and non-metallic impurity sediments inside the furnace tubes in the semiconductor calcar pipes.

Owner:SEMICON MFG INT (SHANGHAI) CORP

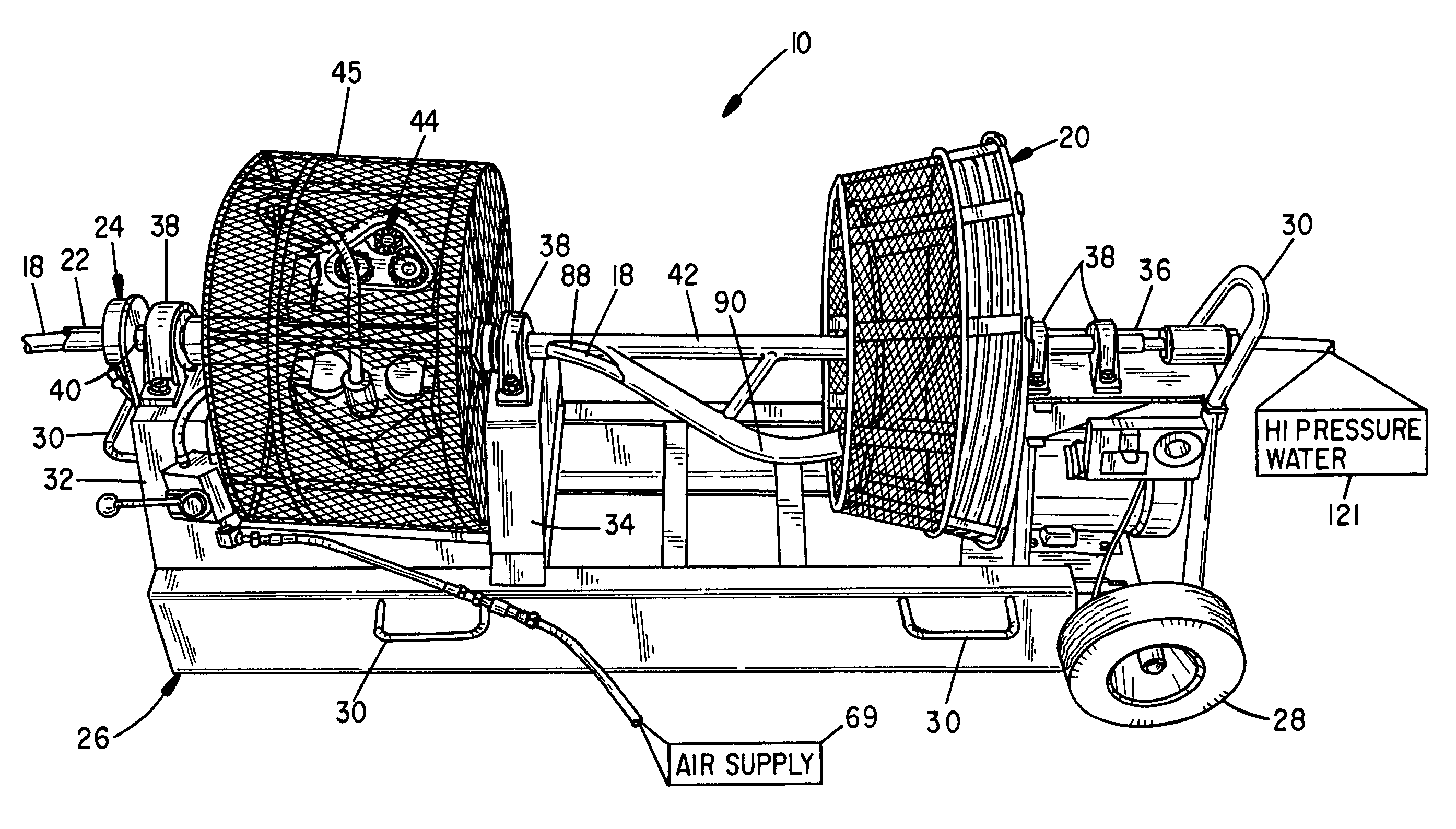

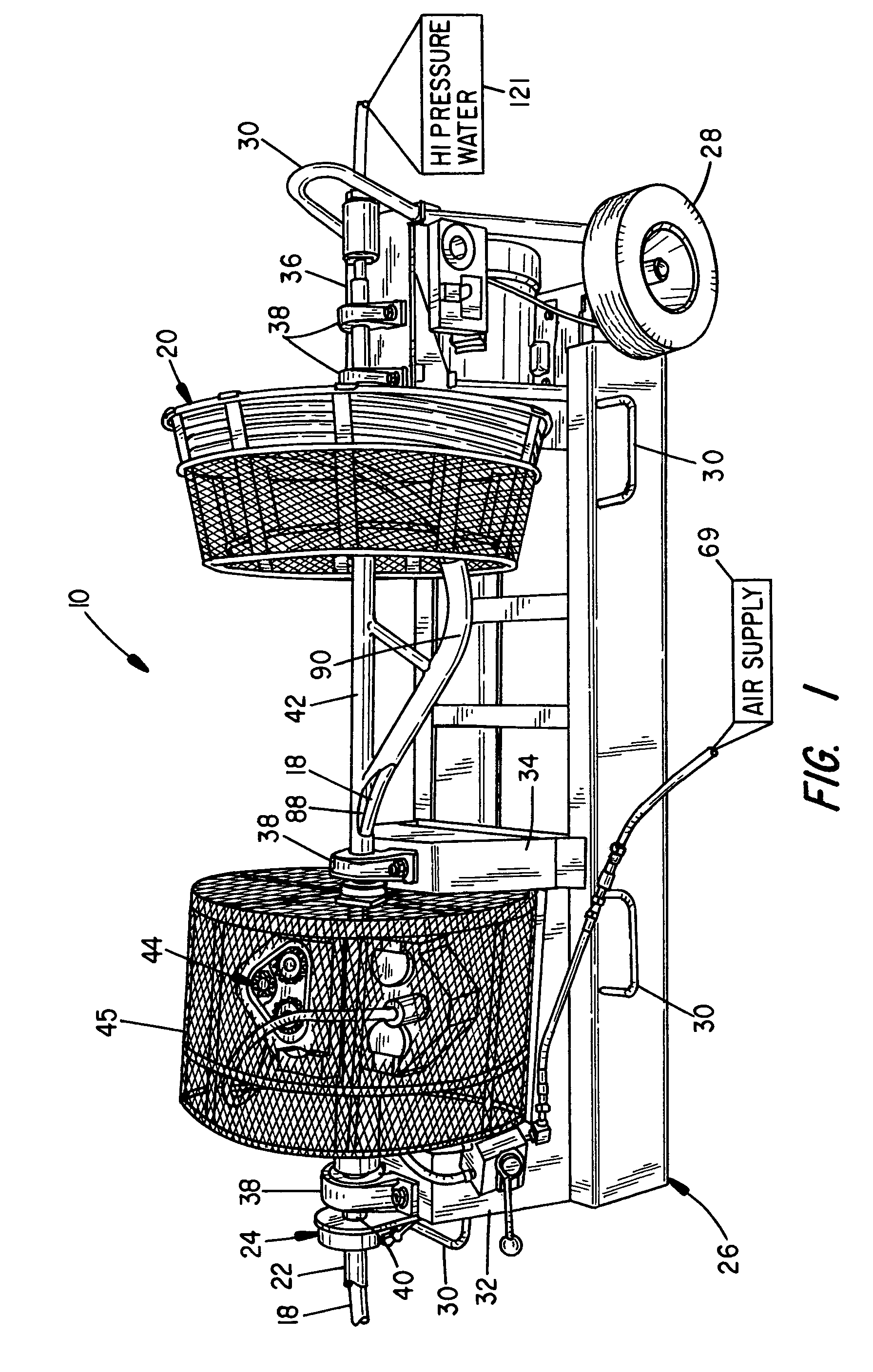

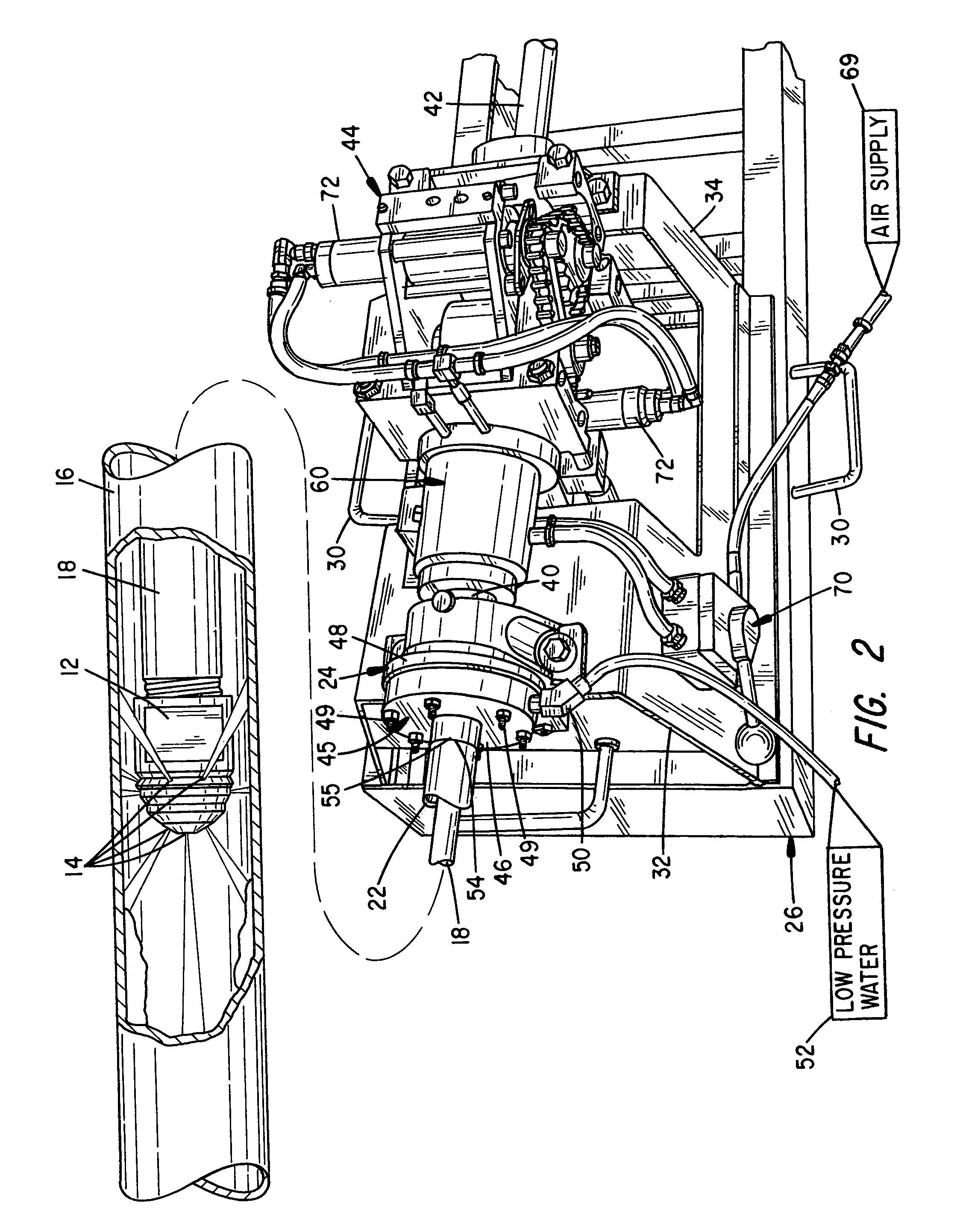

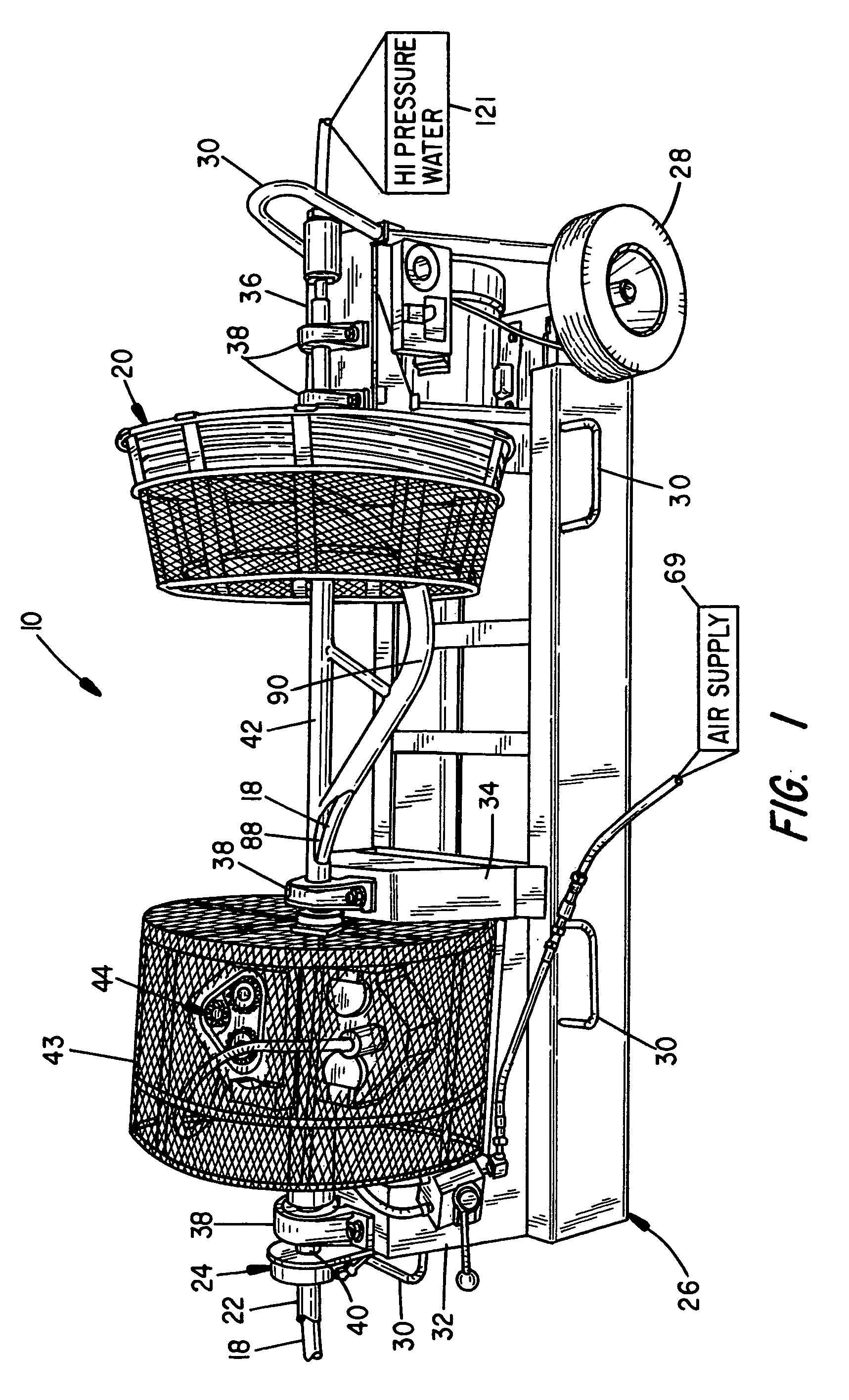

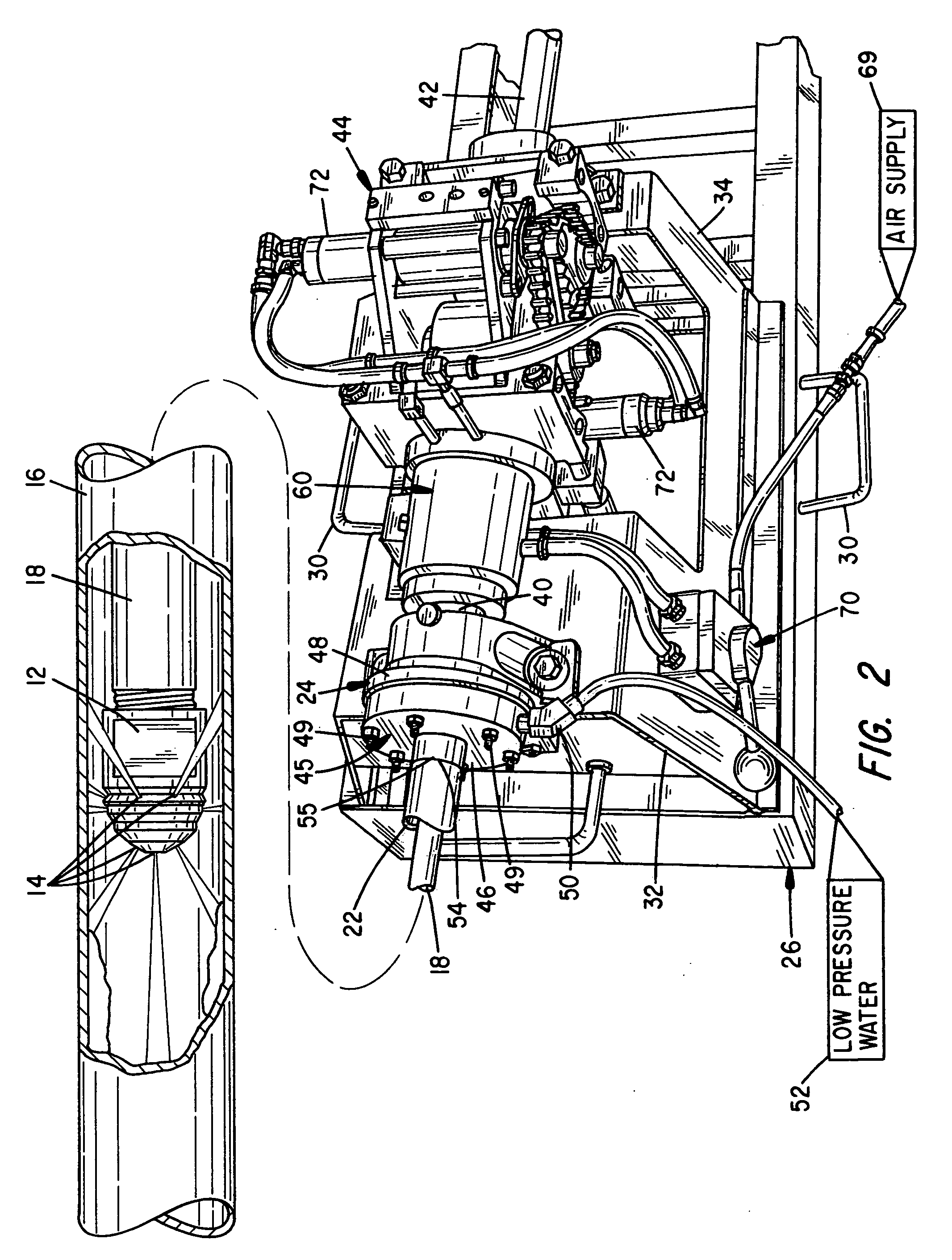

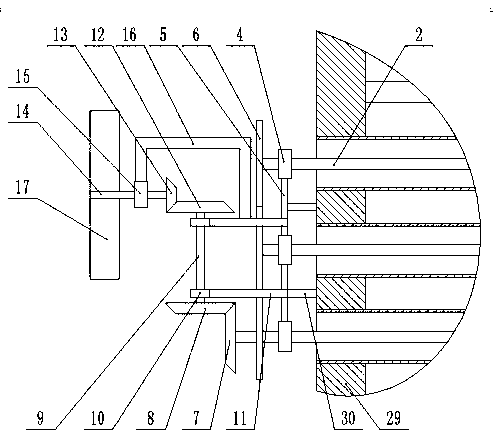

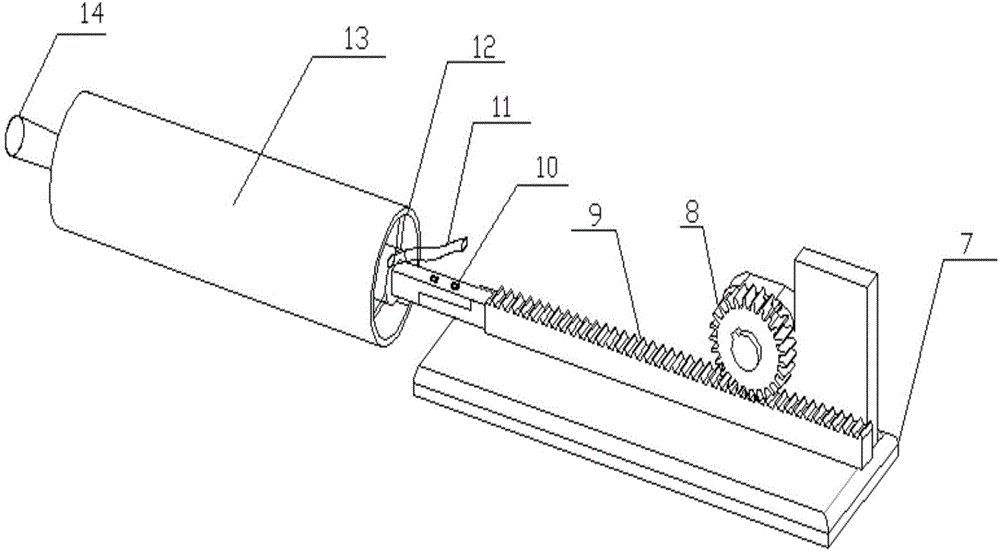

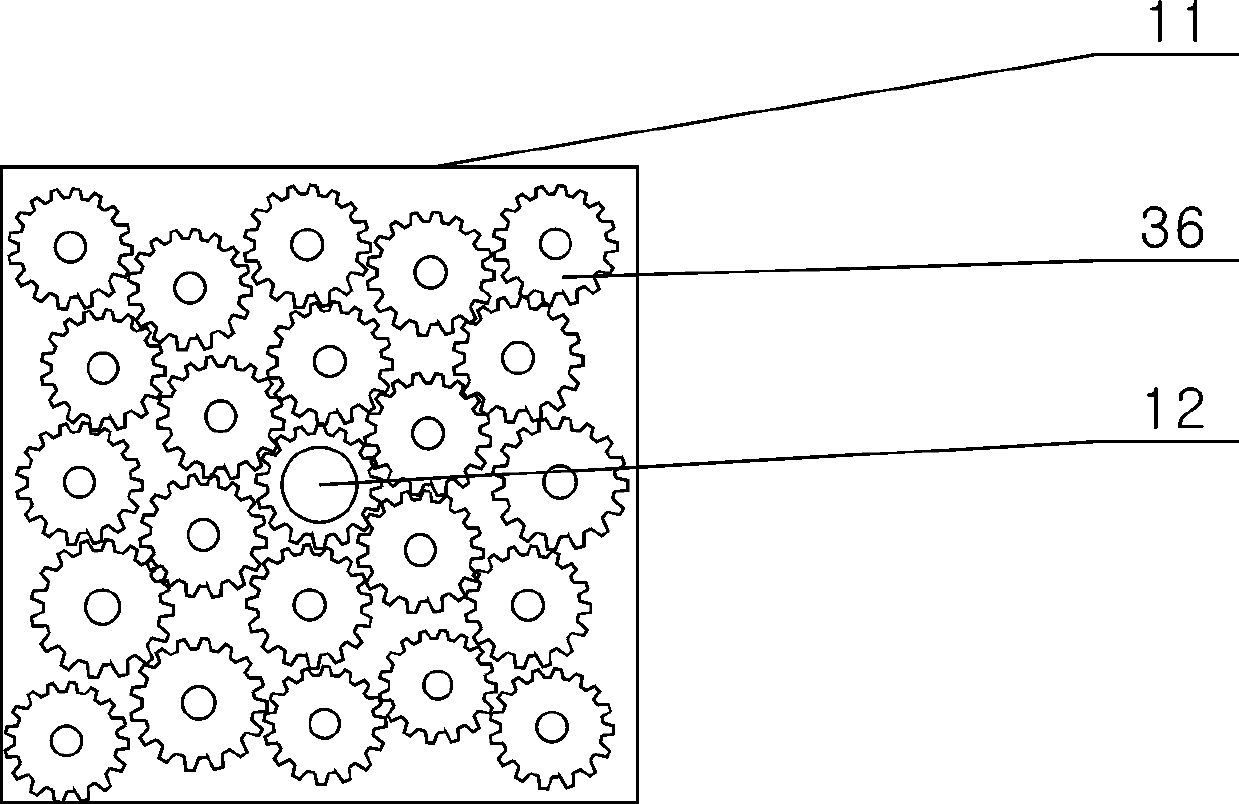

High pressure tube cleaning apparatus

InactiveUS7040331B2Increase chanceUnbalanced blockCarpet cleanersFloor cleanersGear wheelEngineering

An assembly for rotating and axially directing a high pressure spray hose and spray head to clean residue from the bores of thermal transfer tubes. The assembly includes a number of subassemblies that are concentrically aligned and mounted to rotate in synchrony and direct a high-pressure hose and spray head. A hose cleaning subassembly washes and / or brushes the hose exterior with a low-pressure spray. A hose drive assembly controls axial hose movement via driven gears and chains and four polyurethane pinch wheels that abut the hose. Spring tensioners control the wheel-to-hose pressure. A layering arm extends from a driven reel axle and stacks the hose in uniform layer onto an adjustable hub at a driven reel. The diameter of the reel hub can adjusted relative to an outer cage. The hose reel, axial hose drive and hose cleaner assemblies can be operated at speeds rotational speeds of 60 rpm to 650 rpm and whereby tubes from ½ to 6-inch diameters can be cleaned at rates of 1 to 80 feet per minute.

Owner:AQUA DYNAMICS

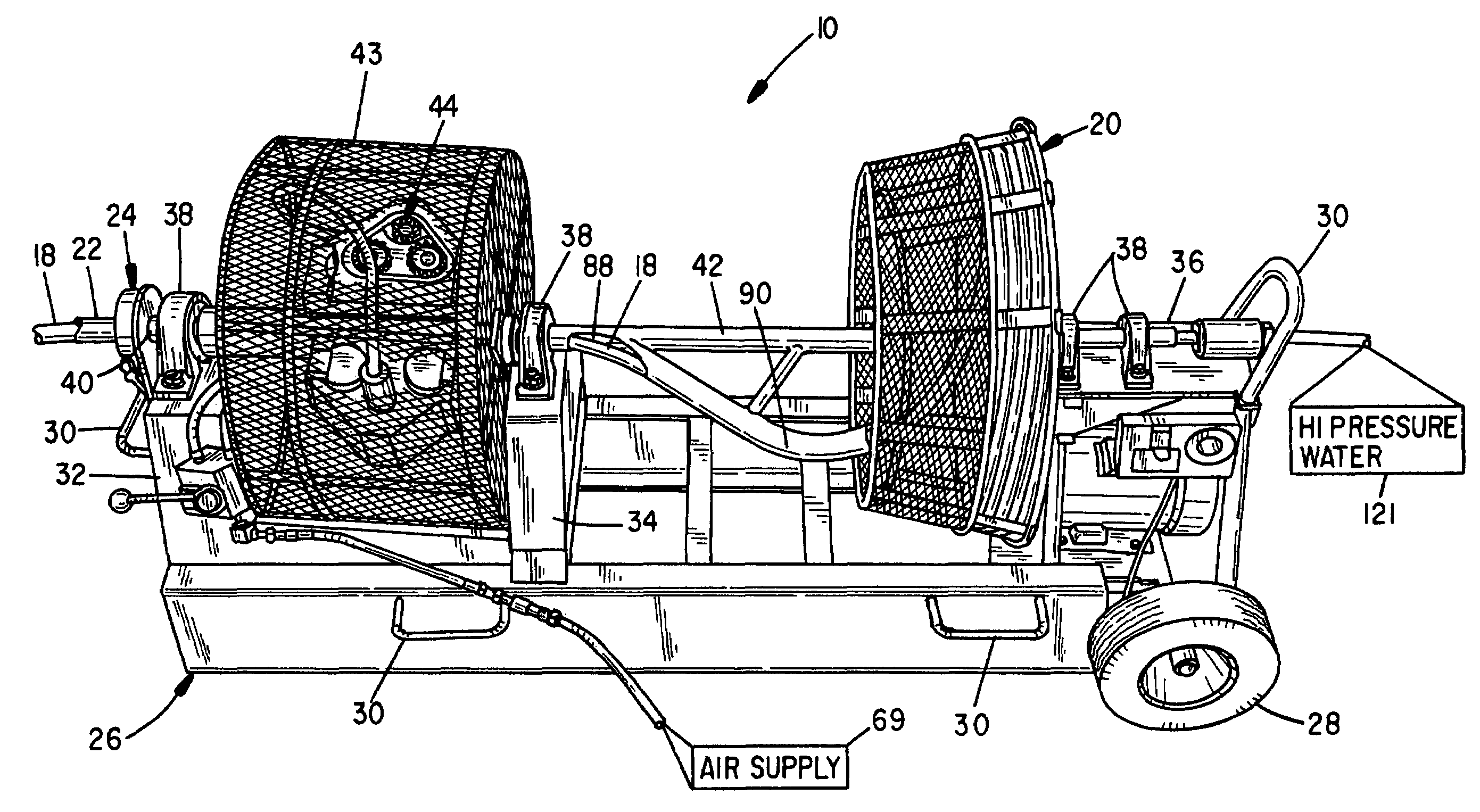

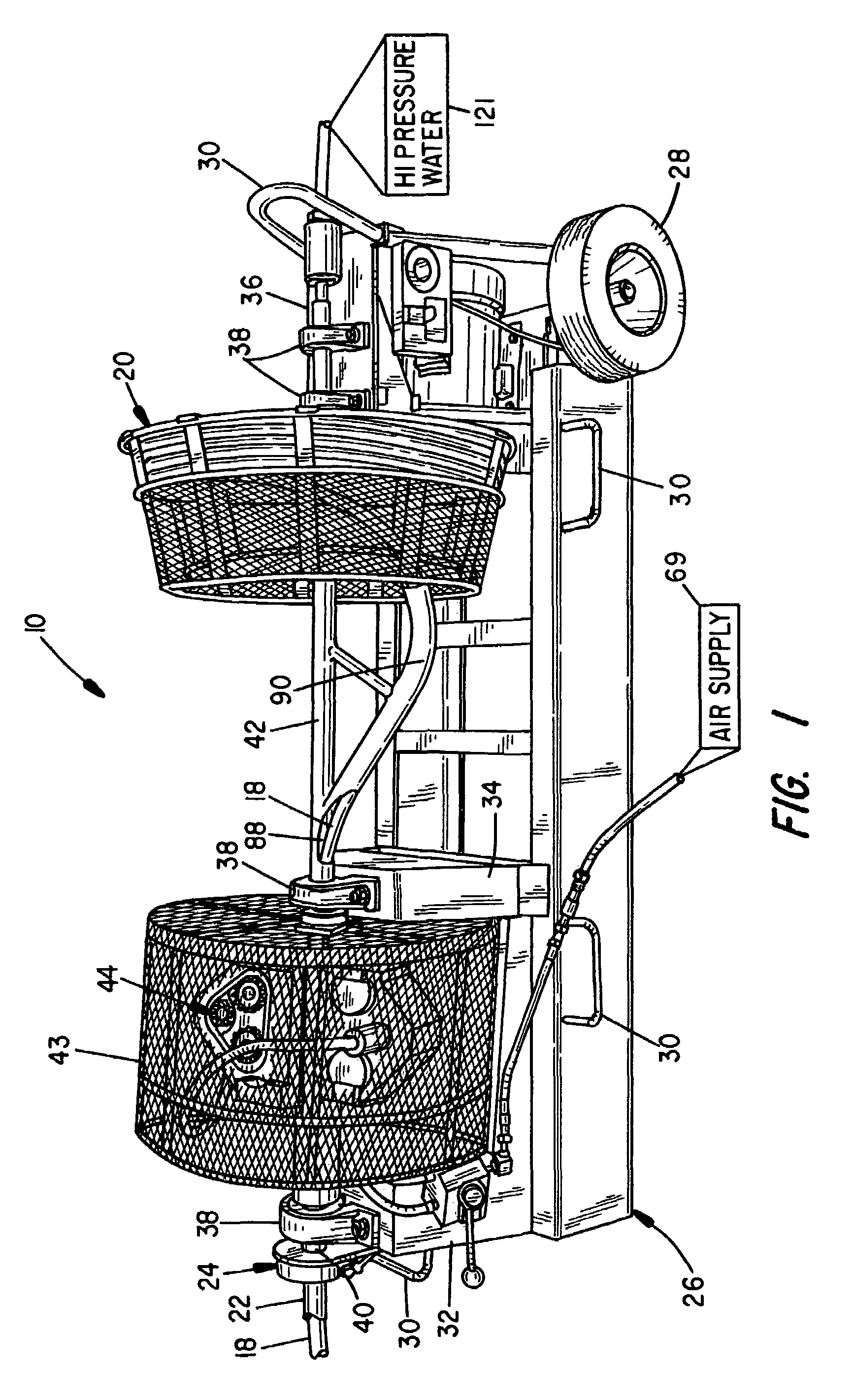

High pressure tube cleaning apparatus

InactiveUS20060249185A1Increase chanceUnbalanced blockHollow article cleaningCleaning using toolsEngineeringHigh pressure water

An assembly for rotating and axially directing a high pressure spray hose and spray head to clean residue from the bores of thermal transfer tubes. Modular subassemblies are concentrically aligned and mounted to rotate in synchrony and direct a high-pressure water hose and spray head. Air controlled operator gun and remote controllers control assembly operation. A hose cleaning subassembly washes and / or brushes and cleans the hose exterior with a low-pressure spray. A hose drive assembly controls hose rotation and axial hose movement via biased pinch wheels. A resilient, eccentric linkage controls pinch wheel pressure. A layering arm uniformly layers the hose at an adjustable hose reel. Rotational sensors and / or a pneumatic booster and a disk brake assembly facilitate non-kinking hose collection and release without spillage. A channeled, re-configurable, extruded framework, and manual and pneumatic support carriages support a walking beam and the spray hose to automatically index the hose along the walking beam and vertically adjust and tilt the beam.

Owner:GARMAN DANIEL T

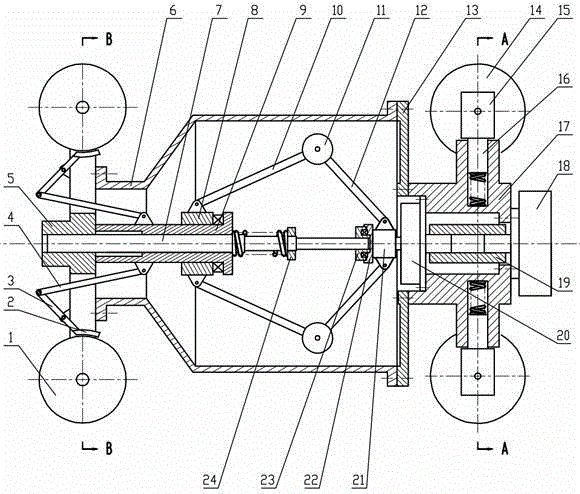

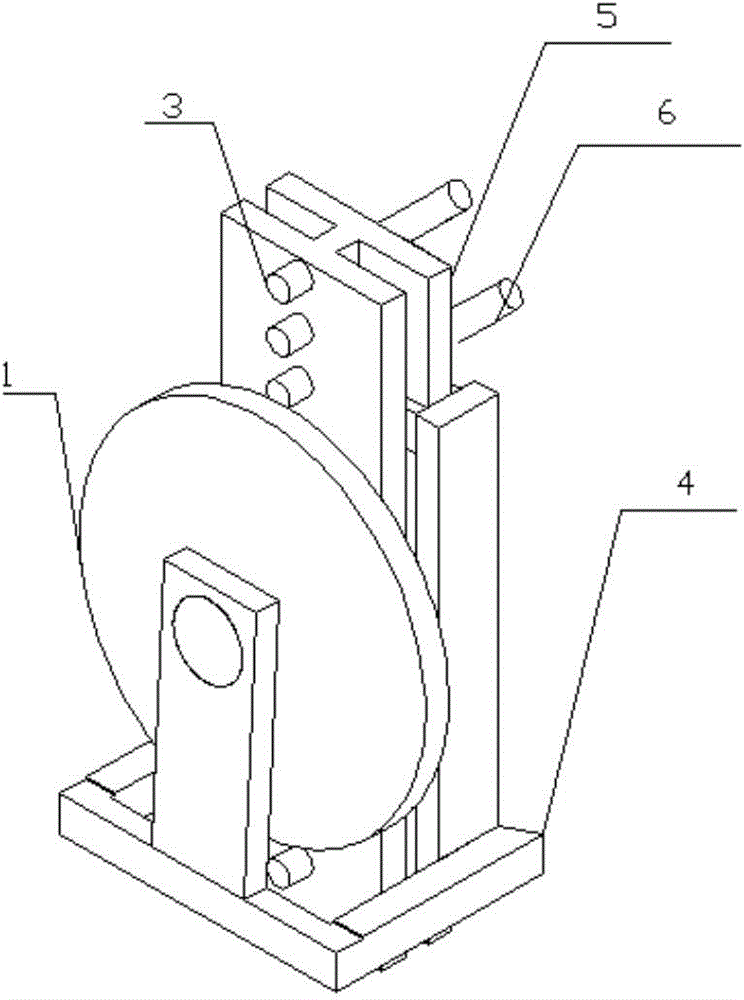

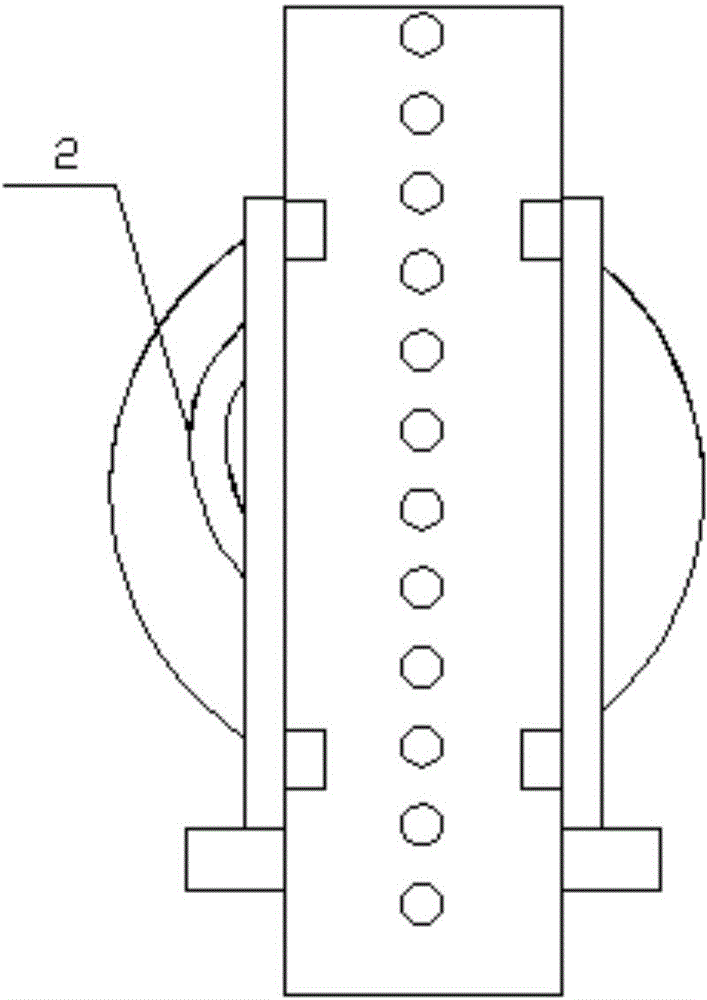

Tube cleaner speed controller with hydraulic system

InactiveCN104438251AApplicable to various types of pigging operationsHollow article cleaningGear pumpEngineering

The invention relates to a tube cleaner speed controller with a hydraulic system. By means of the tube cleaner speed controller, the defects of a bypass valve control mode can be overcome. According to the technical scheme, front wheels are arranged on a base through supports and are arranged in the radial direction of the base, the lower ends of the supports are provided with compression springs, and the front wheels are connected with gear pumps; a radial plunger motor is arranged at the end of the base through a bolt, a speed changer is arranged at the center of the base, and an output shaft of the speed changer drives a mass block in a cylinder body to rotate; rear wheels are arranged on a rear end cover, the ends of connection rods A are fixedly provided with friction pieces, the friction pieces are closely attached to the outer edges of the rear wheels, the middle of each connection rod A is hinged to the rear end cover, the other end of each connection rod A is connected with the end of each connection rod B in a hinged mode, the other end of each connection rod B is hinged to a safety barrel, and the safety barrel is connected with a central shaft through a spline. The tube cleaner speed controller can be used just by being arranged on the rear side of a tube cleaner and can be suitable for various types of tube cleaning works.

Owner:SOUTHWEST PETROLEUM UNIV

High pressure tube cleaning apparatus

InactiveUS7530363B2Increase chanceUnbalanced blockHollow article cleaningCleaning using toolsEngineeringHigh pressure water

An assembly for rotating and axially directing a high pressure spray hose and spray head to clean residue from tubing bores. Modular, remotely controlled subassemblies are concentrically aligned and mounted to a hose drive framework to rotate in synchrony and direct a high-pressure water hose and spray head. A hose drive assembly controls hose rotation and axial hose movement via biased pinch wheels. A resilient, eccentric linkage controls pinch wheel pressure. A layering arm uniformly layers the hose at a hose reel. Rotational sensors and / or a pneumatic booster and a disk brake assembly facilitate non-kinking hose collection and release without spillage. A re-configurable hose support framework contains a driven walking beam having drive assemblies that laterally and vertically index a hose support and control the inclination of the walking beam.

Owner:GARMAN DANIEL T

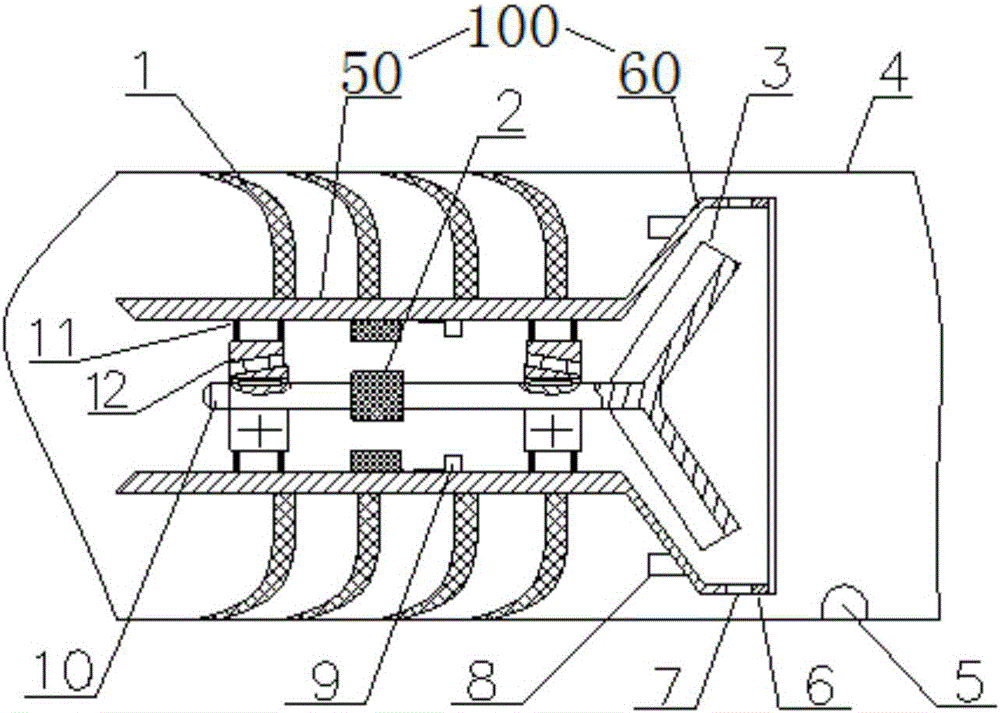

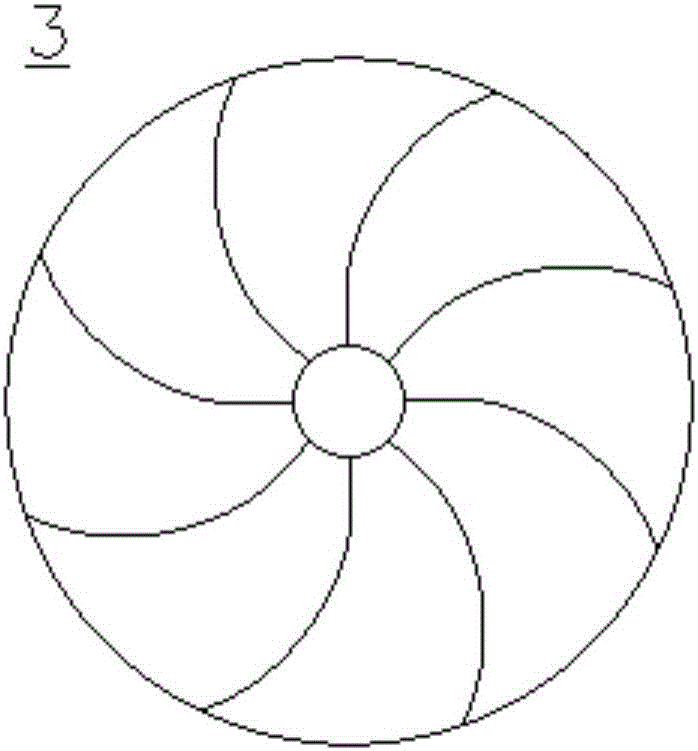

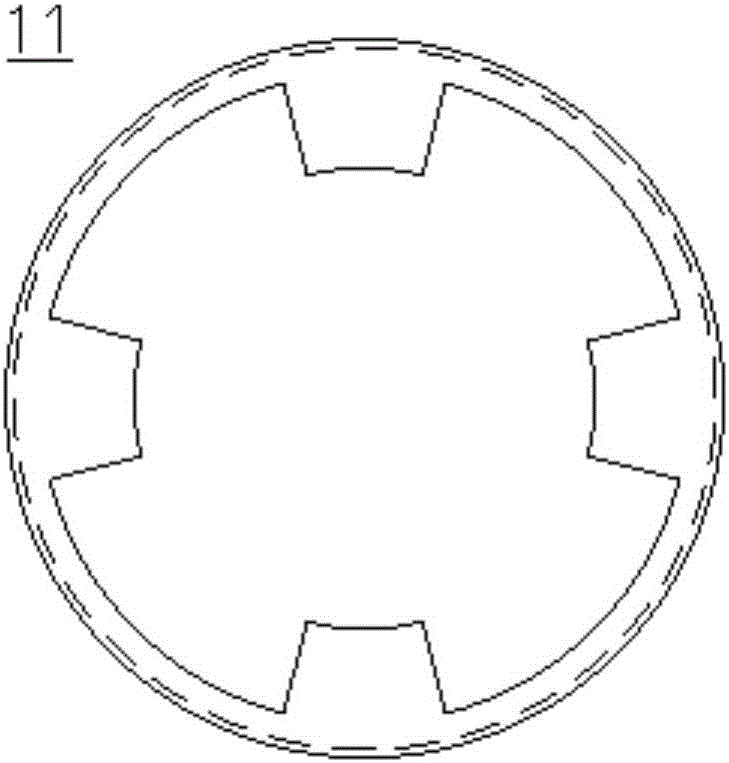

Self-powered ultrasonic scale removal tube cleaner

InactiveCN106269730AReduce mechanical damageGood pigging effectHollow article cleaningImpellerWater quality

The invention discloses a self-powered ultrasonic scale removal tube cleaner. The self-powered ultrasonic scale removal tube cleaner comprises a body, and an ultrasonic generation apparatus, an electromagnetic induction power generation apparatus, a power supply apparatus and a protection apparatus, which are arranged on the body, wherein the body comprises a barrel and a cone; the ultrasonic generation apparatus comprises an ultrasonic generator; the electromagnetic induction power generation apparatus comprises a transmission connecting rod, an induction coil and a converter; the power supply apparatus comprises a packing cup and an impeller with a runner; and the protection apparatus is a metal protection cover, and the metal protection cover is provided with a leak flow hole. The tube cleaner is adopted as a carrier to be combined with the ultrasonic scale removal apparatus, so that the ultrasonic scale removal effect is more remarkable than the scale removal effect by only adopting the tube cleaner; and meanwhile, the self-powered ultrasonic scale removal tube cleaner carries a self-powered power generation apparatus, the automation degree is relatively high, scales are automatically removed, and the tube cleaner is only required to be transmitted and received by a tube cleaner receiving and transmitting barrel. Compared with a chemical tube cleaning way, the problem of changing the water quality is avoided, the phenomenon that a great amount of scales are dropped is avoided, and the tube cleaner plugging phenomenon is avoided.

Owner:SOUTHWEST PETROLEUM UNIV

Chemical test tube cleaning device

The invention discloses a chemical test tube mechanical cleaning device, and belongs to the field of chemical supplies. The chemical test tube cleaning device is composed of an automatic rotation water spraying hairbrush, motors, small-sized cylindrical water channels, a stand column, a tube brushing machine base platform, an air cylinder, air holes, a conveyor belt, an operating platform and a micro sensor. The stand column is used for supporting the upper air cylinder, an air cylinder piston is connected with a tube brushing device, and one end of a test tube brush is connected with the motors. The motors are separated from a water inlet in the tail portion of the test tube brush through the small-sized cylindrical water channels. The rotation hairbrush is in a thin-wall hollow type, six small water spraying holes are punched in the working position of the hairbrush, two water inlet holes are punched in the hollow positions, corresponding to the small-sized cylindrical water channels, of the hairbrush, an outer water inlet is formed in the upper portion of a test tube brush box, and the micro sensor is placed at the lower right corner of the test tube brush box. Nine novel rubber plugs are mounted inside a test tube clamping box, and the conveyor belt is used for conveying the test tube box so that cleaning can be achieved. The chemical test tube cleaning device has the advantage that a large number of test tubes can be efficiently cleaned through the device.

Owner:孙香兰

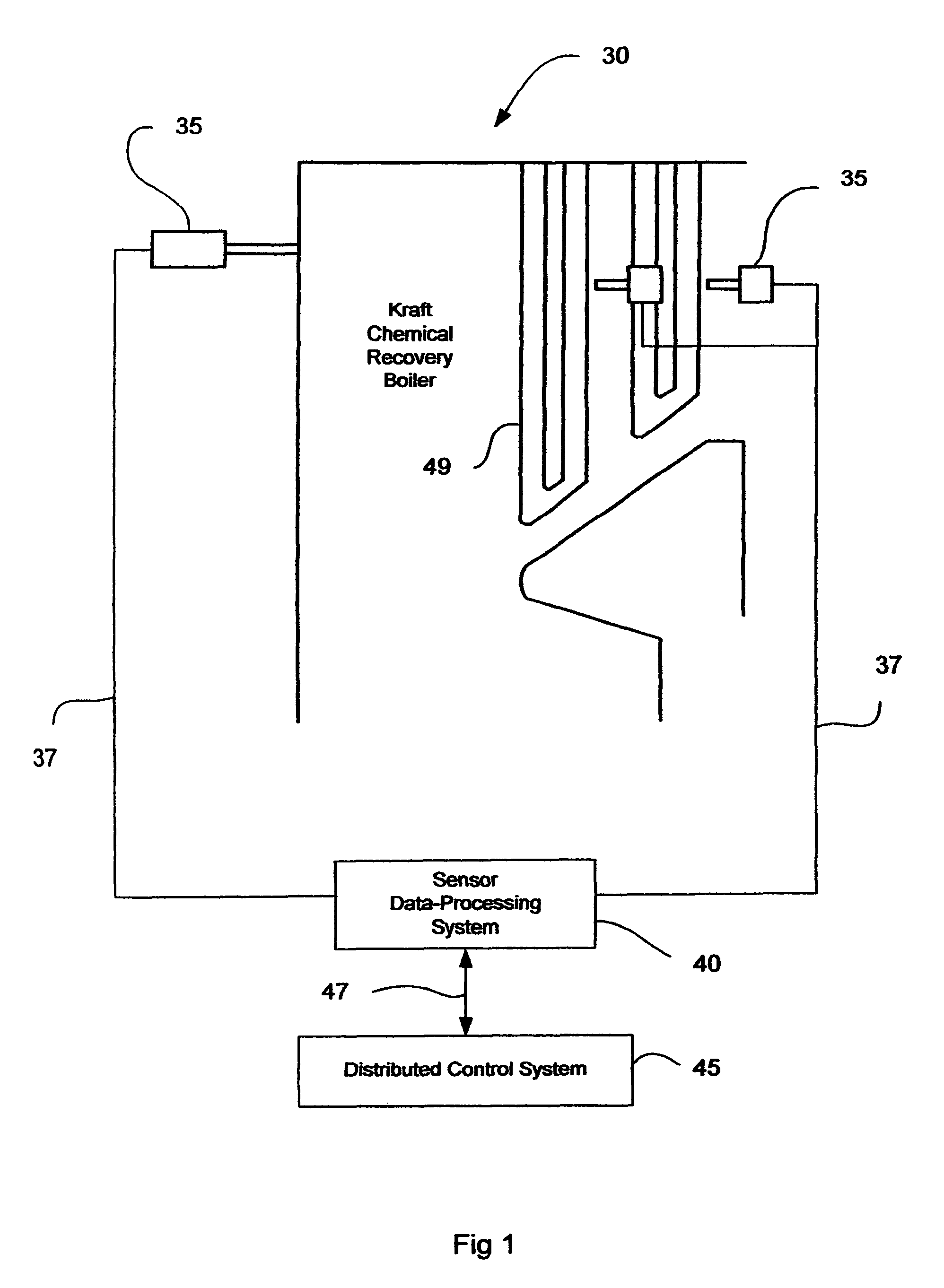

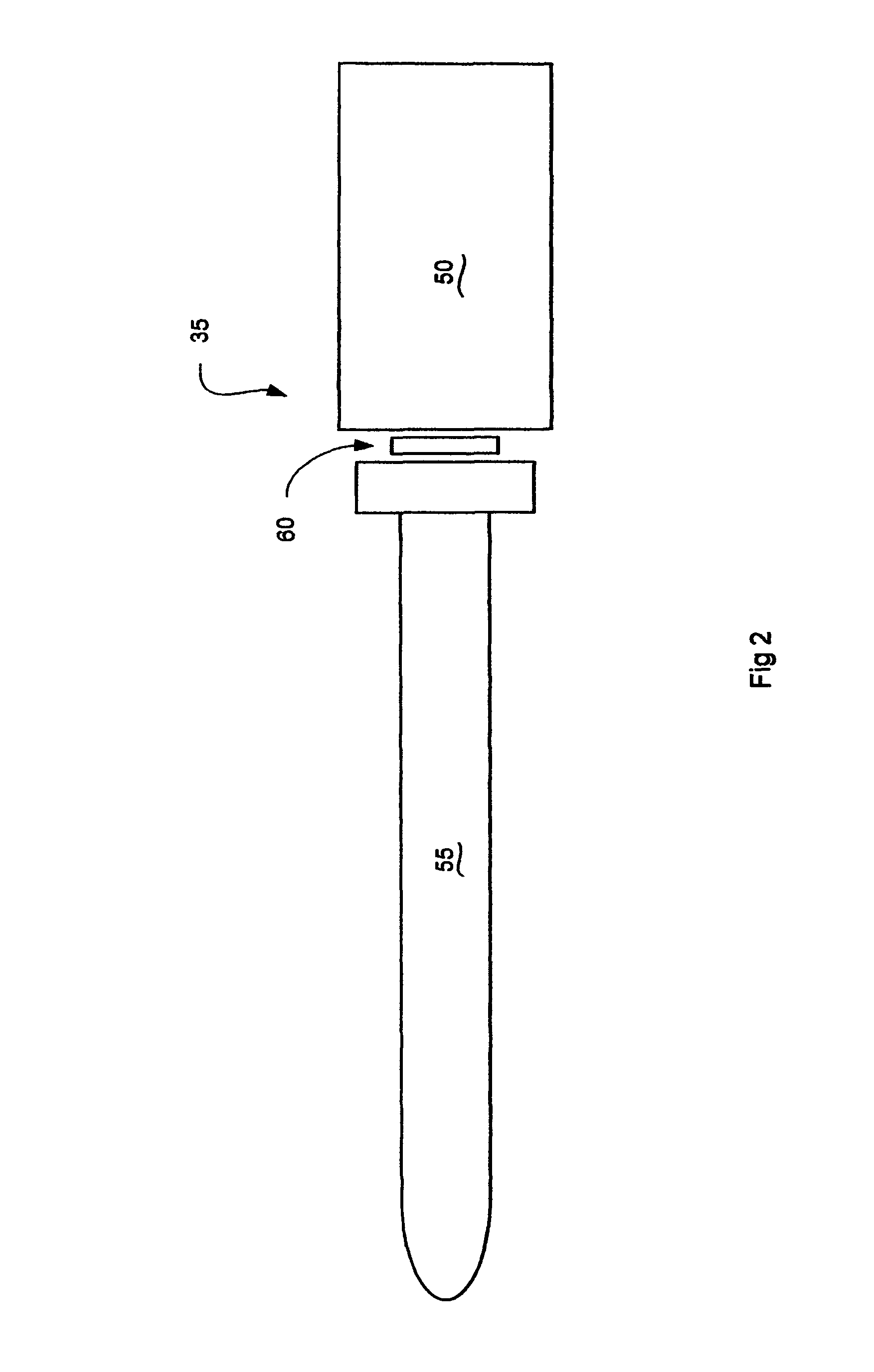

Infrared imaging sensor

InactiveUS7956326B1Low costReduce absorptionRadiation pyrometryWeather/light/corrosion resistanceLow-pass filterImage segmentation

A system for detection and control of deposition on pendant tubes in recovery and power boilers includes one or more deposit monitoring sensors operating in infrared regions of about 4 or 8.7 microns and directly producing images of the interior of the boiler, or producing feeding signals to a data processing system for information to enable a distributed control system by which the boilers are operated to operate said boilers more efficiently. The data processing system includes an image pre-processing circuit in which a 2-D image formed by the video data input is captured, and includes a low pass filter for performing noise filtering of said video input. It also includes an image compensation system for array compensation to correct for pixel variation and dead cells, etc., and for correcting geometric distortion. An image segmentation module receives a cleaned image from the image pre-processing circuit for separating the image of the recovery boiler interior into background, pendant tubes, and deposition. It also accomplishes thresholding / clustering on gray scale / texture and makes morphological transforms to smooth regions, and identifies regions by connected components. An image-understanding unit receives a segmented image sent from the image segmentation module and matches derived regions to a 3-D model of said boiler. It derives a 3-D structure the deposition on pendant tubes in the boiler and provides the information about deposits to the plant distributed control system for more efficient operation of the plant pendant tube cleaning and operating systems.

Owner:VALMET AUTOMATION OY

Test tube cleaning device with function on simultaneously cleaning inner side wall and outer side wall

A test tube cleaning device with the function of simultaneously cleaning the inner and outer walls, comprising a lower support plate, a height adjustment device is fixedly connected to both sides of the support plate, an upper support plate is fixedly connected to the top of the height adjustment device, and an upper support plate is provided in the middle of the upper support plate A through hole, an annular rubber gasket is fixedly connected to the side wall of the through hole, a test tube is arranged in the annular rubber gasket, the opening of the test tube is arranged downward, a cleaning column is arranged inside the test tube, and a first bristle is arranged on the outer wall of the cleaning column, and The cleaning column extends downward through the lower support plate, and the lower part of the cleaning column is connected with a driving device, and a cavity is arranged inside the cleaning column. The beneficial effect of the present invention is that the first motor drives the first rotating shaft to rotate, the first rotating shaft drives the driving bevel gear to rotate, and the driving bevel gear drives the driven bevel gear to rotate, so that the driven bevel gear drives the threaded rod to rotate. The adjusting rod moves upwards, thereby realizing the raising of the height of the upper support plate.

Owner:上海申第实业有限公司

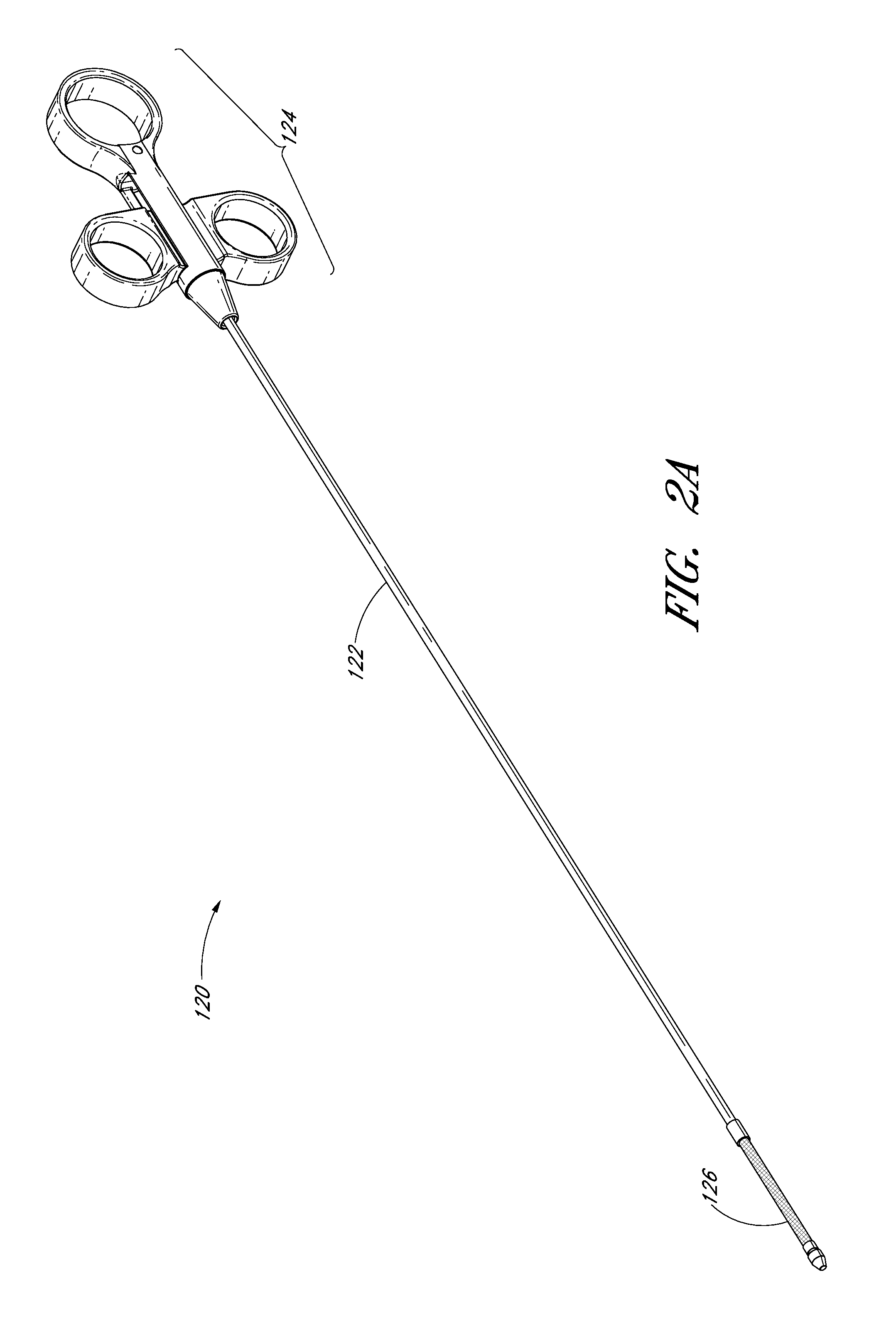

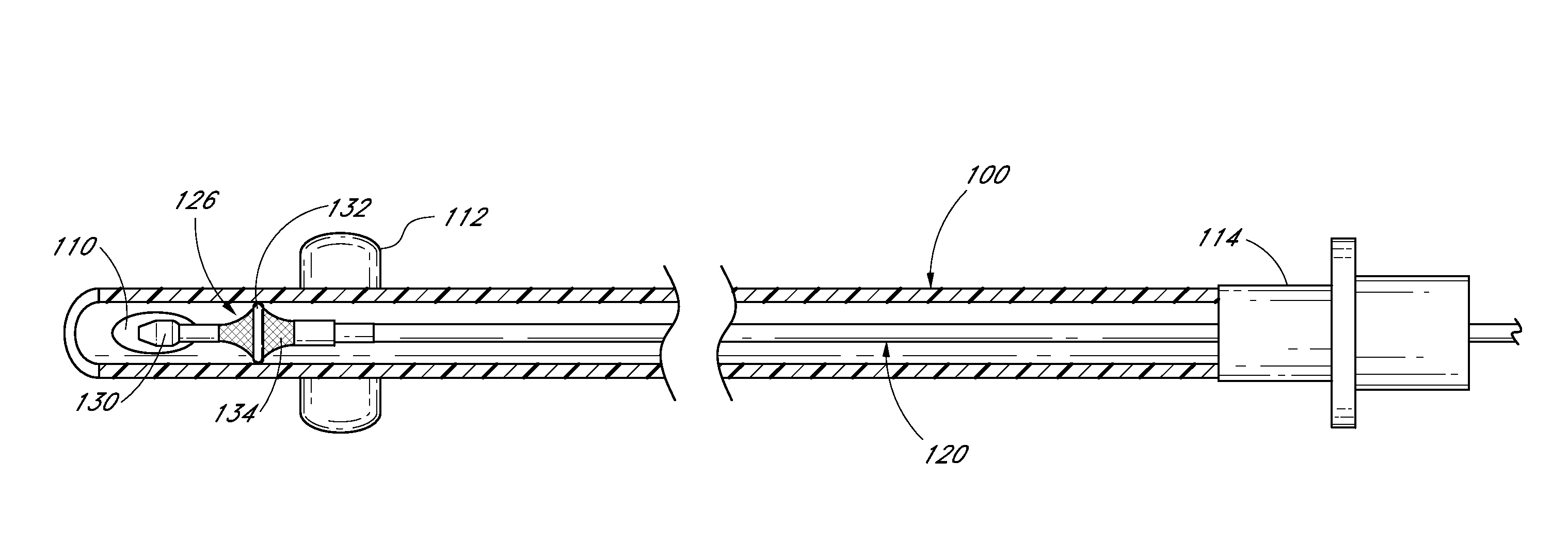

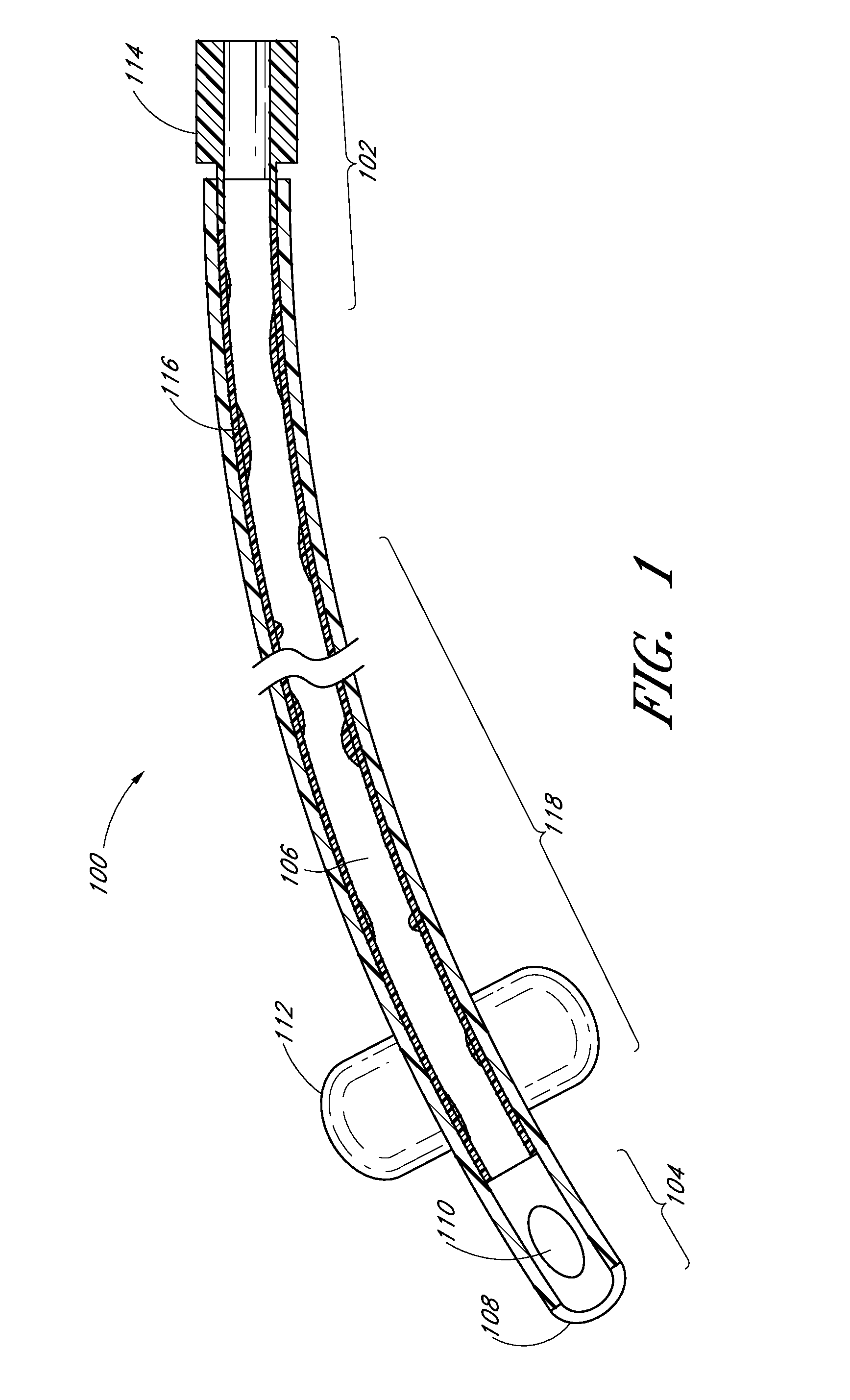

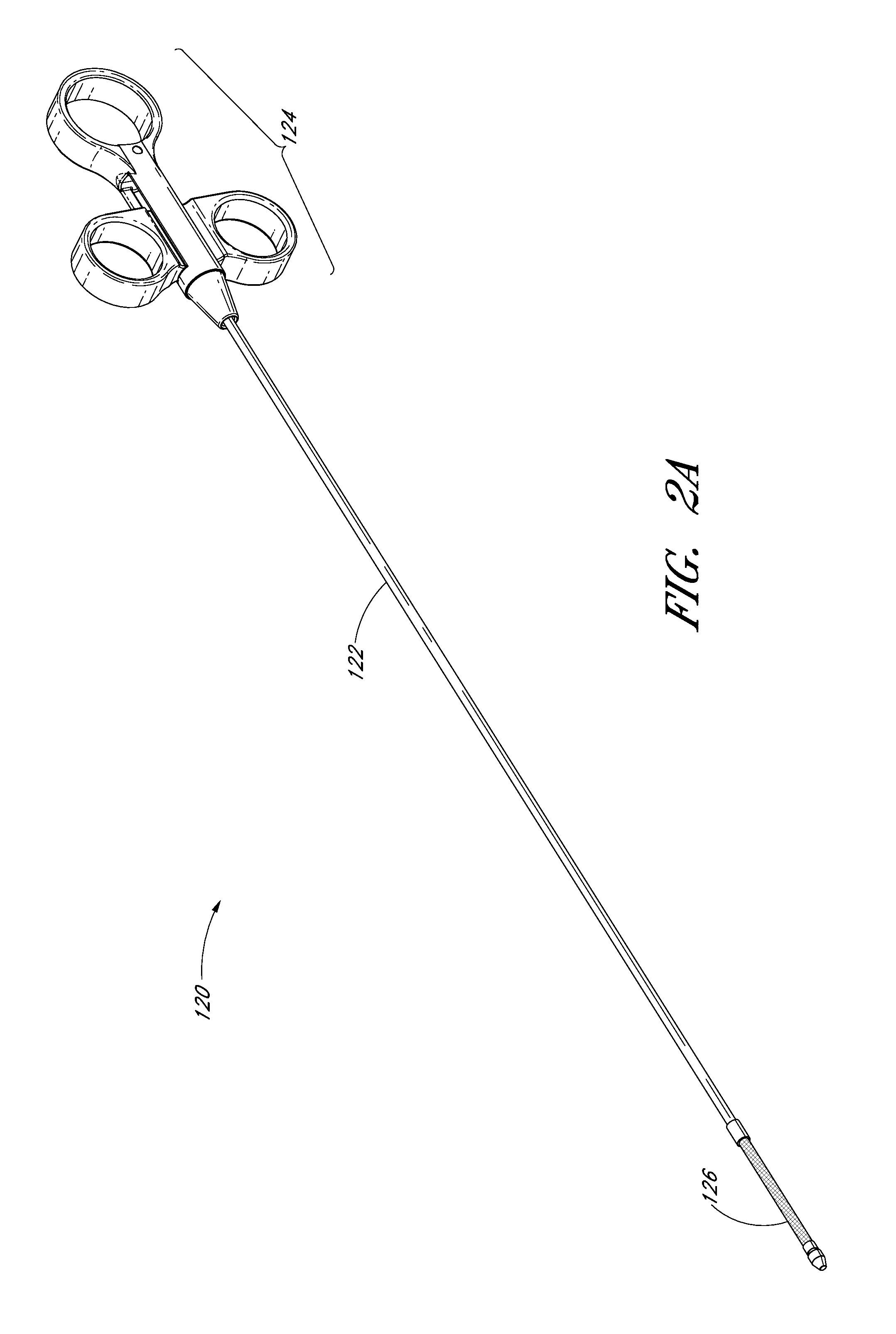

Medical tube cleaning apparatus

ActiveUS20110023886A1Adequate airflowPrevent buildupBronchoscopesTracheal tubesTracheal tubeCatheter

Systems, devices, and methods are disclosed for the cleaning of an endotracheal tube while a patient is being supported by a ventilator connected to the endotracheal tube for the purpose of increasing the available space for airflow or to prevent the build up of materials that may constrict airflow or be a potential nidus for infection. In one embodiment, a mechanically-actuated endotracheal tube cleaning device is configured to removably receive a visualization member to provide cleaning of the endotracheal tube under direct visualization.

Owner:AVENT INC

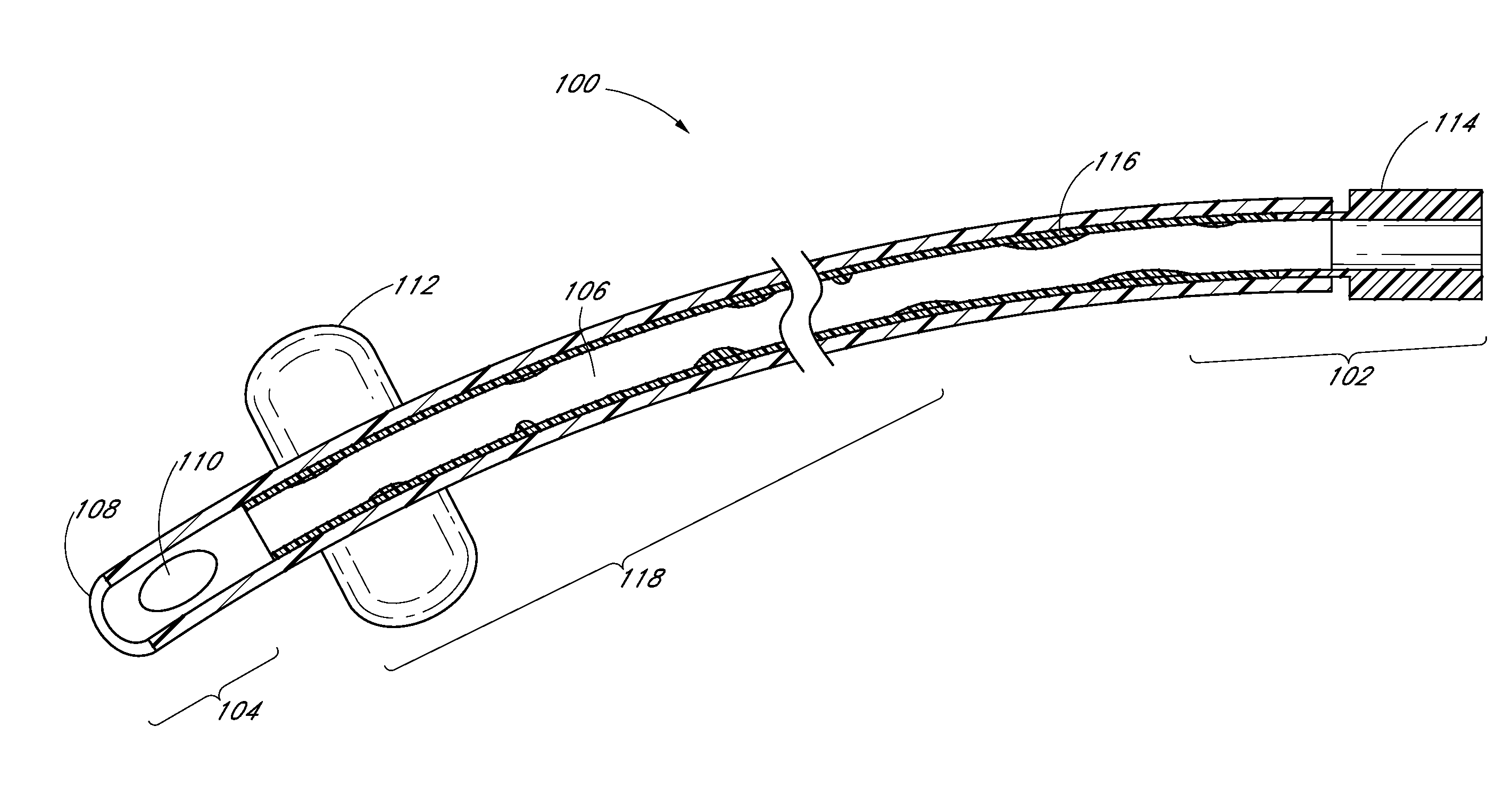

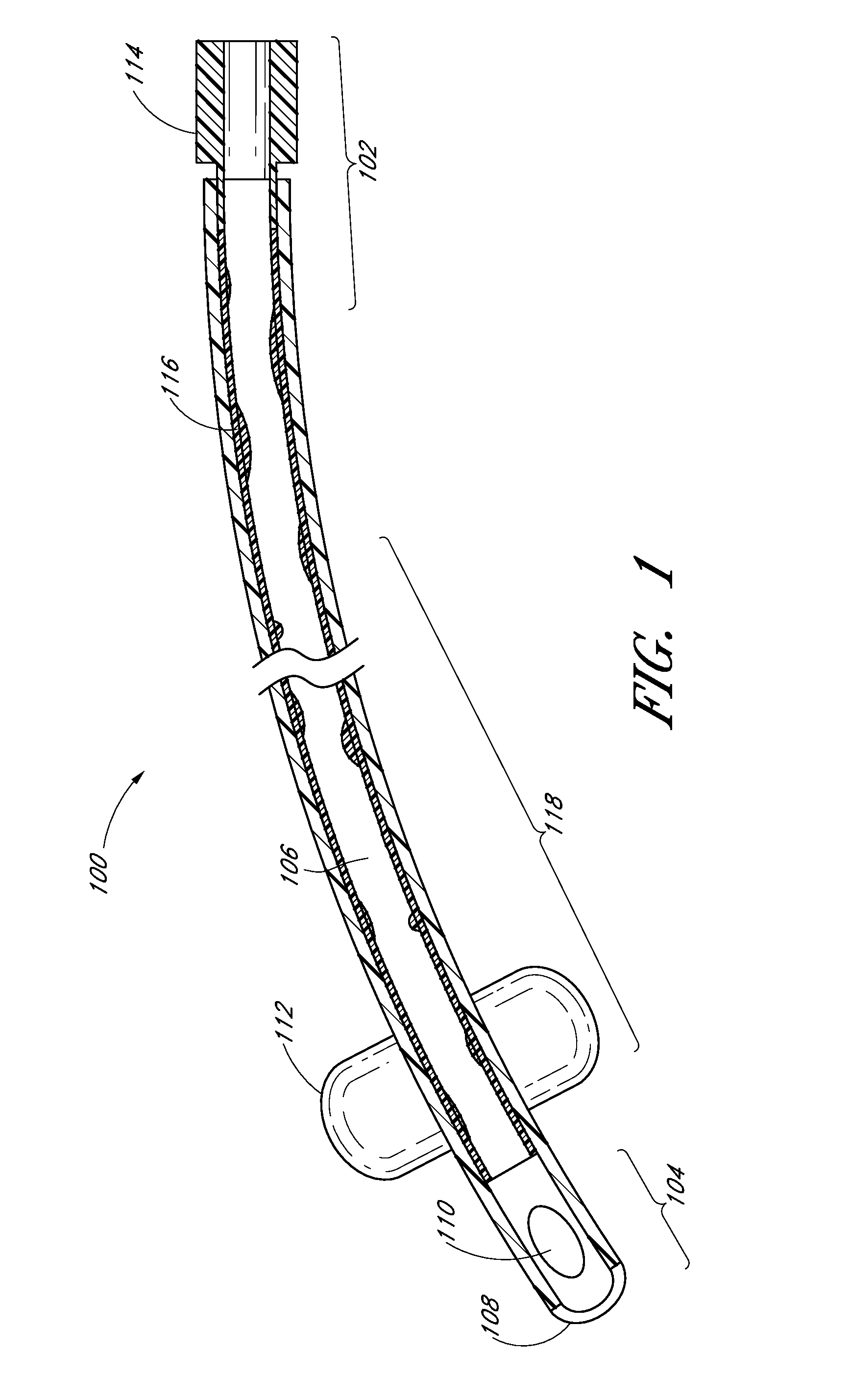

Gun barrel and tube cleaning device

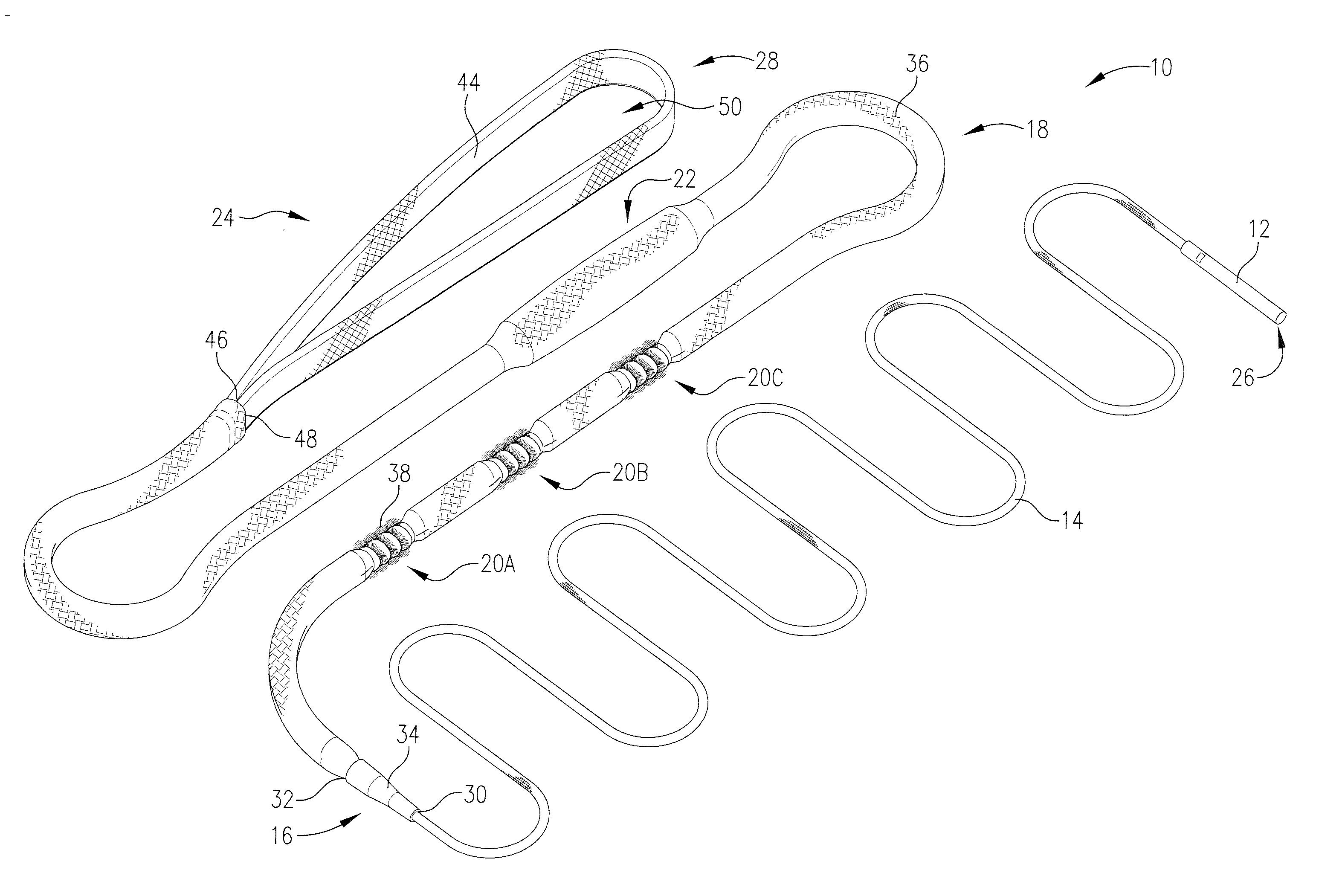

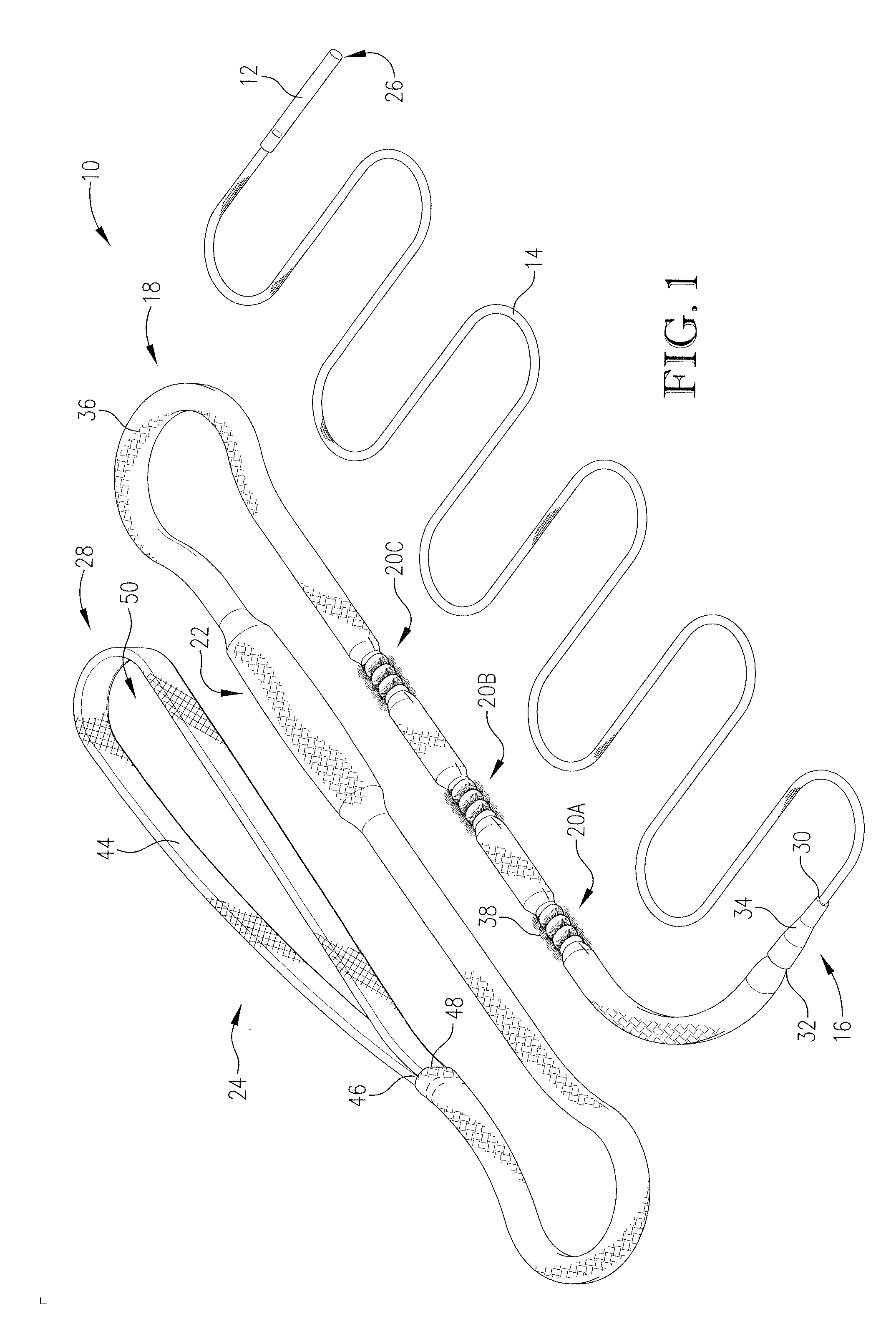

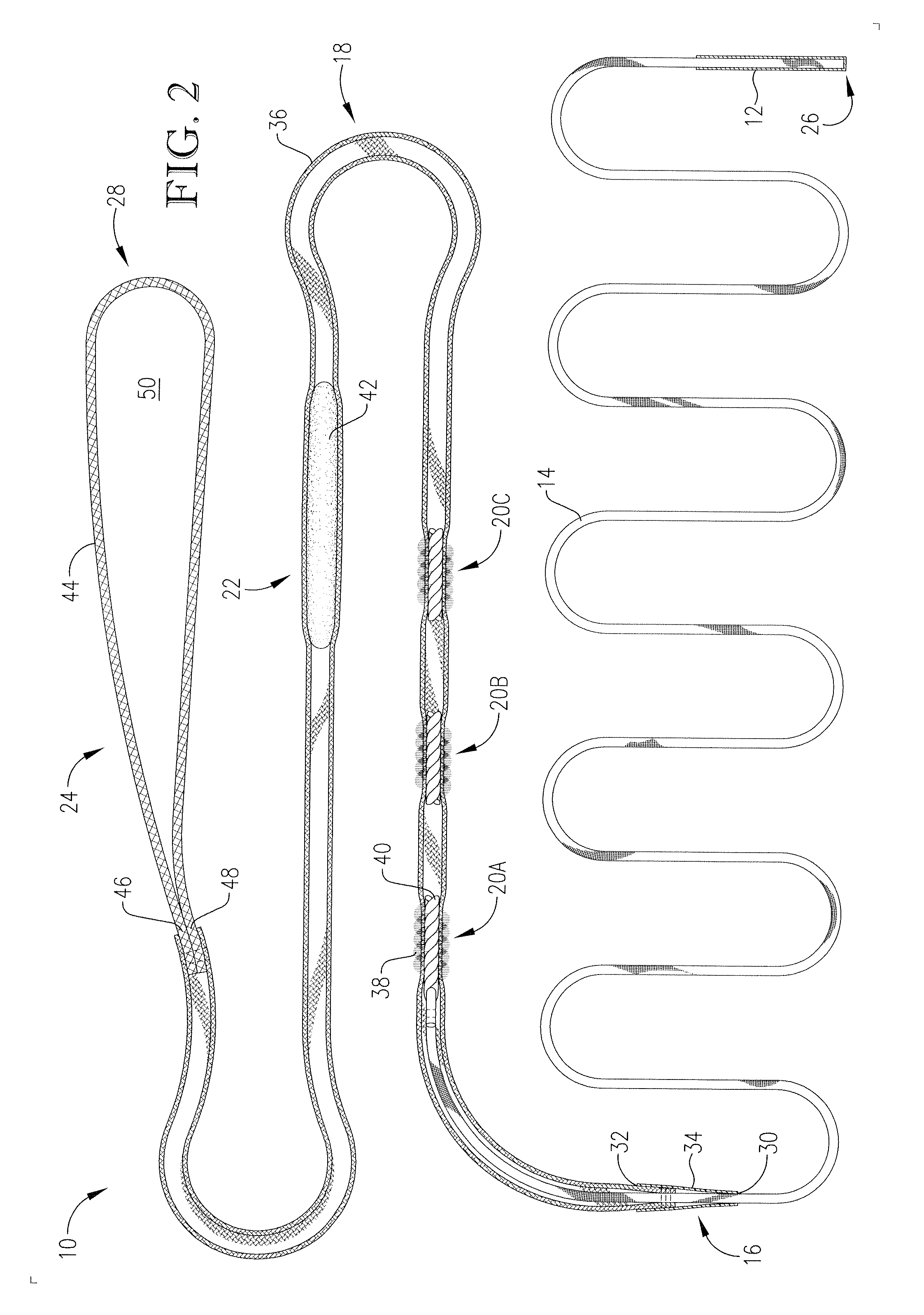

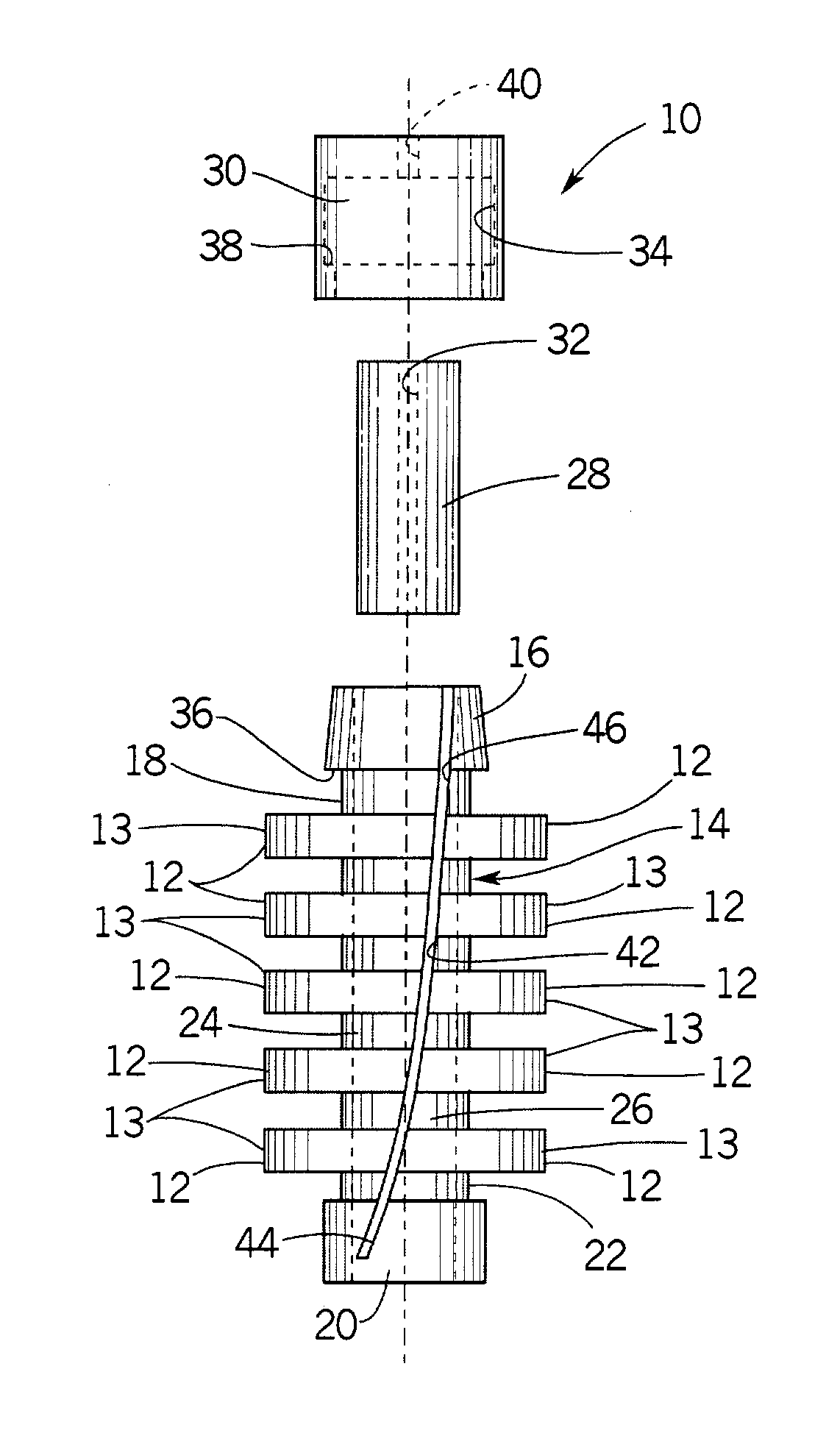

InactiveUS20110099880A1Surface of more easily and moreEntry delayHollow article cleaningWeapon cleaningEngineeringTube cleaning

A gun barrel cleaning device comprises a weight, a cord, a boreguide sleeve, a sheath, a brush, a cleaning element, and a lubrication element. The weight provides a mass that helps to insert the device into the barrel of a gun. The weight may be coupled to the high tensile strength cord, which in turn may be coupled to the tubular sheath. The boreguide sleeve may cover the sheath where it is coupled to the cord to smooth the transition from the cord to the sheath. The brush may be connected to the cord and encased by the sheath. The cleaning element, also encased by the sheath, may remove dirt from the gun barrel. The lubrication element, coupled to the sheath, may deposit lubrication in the gun barrel. The gun barrel may be cleaned and lubricated by pulling the device through the barrel.

Owner:BUSHNELL

Tube cleaning tool

A cleaning device, or projectile, cleans the inside surface of a tube as it is propelled by a liquid through the tube by mechanically scraping and cleaning soft and hard deposits, such as sludge and manganese, from the inner surface of the tube, such as those found in condensers and heat exchangers. The tube cleaning device, or projectile, is propelled forward by a high-pressure fluid spray injected into a tube. This high-pressured fluid injection is sufficient to advance the device through the tube, allowing the device to scrape or otherwise dislodge incrustations or other accumulations from the interior wall of the tube. The tool cleans the inside surface of a tube as the tool travels through the tube and includes a compressible bushing and a series of cutters secured to a split support that defines a cavity for receiving the bushing, the support being adapted to be opened and closed to receive and contain the bushing. Each cutter defines a cutting surface of a diameter that depends on the diameter and hardness of the bushing. Use of bushings with various diameters and hardness provides effective cutting surfaces of various diameters and scraping forces of various magnitudes. Each cutter can define a mounting groove to receive a metal cutter for tougher deposits.

Owner:LYLE DANIEL C

Tube cleaning machine

InactiveUS7055203B1Minimize undesirable slipHollow article cleaningHair combsEngineeringTube cleaning

A tube cleaning machine for industrial smooth bore tubes and enhanced tubes in which the machine includes a rotary brush with means for selecting brush rotary speed for optimum cleaning of the smooth bore and enhanced tubes, and in which the machine includes a water side and a chemical side for supplying a cleaning medium to tubes being cleaned.

Owner:GOODWAY TECH CORP

Rotating fluid nozzle for tube cleaning system

A fluid nozzle for use in a high pressure water jetting system includes a housing to be fixed to a source of high pressure water. The housing receives a rotating member and an inner peripheral bore. The rotating member includes a shaft received within the housing, and a nozzle extending outwardly of the housing, the nozzle having openings extending along a direction having a component both forwardly along an axis of rotation of the shaft and the nozzle, and radially outwardly relative to the central axis. A central passage within the shaft communicates high pressure fluid to the nozzle. The shaft includes leakage paths to provide leakage fluid from the central passage to an interface between an outer peripheral wall of the shaft and an inner peripheral wall of the bore in the housing. The leakage paths communicate fluid to a forward fluid pressure chamber, and to a rearward fluid pressure chamber. A pressure loss to the rearward fluid pressure chamber is greater than a pressure drop at the forward pressure chamber.

Owner:NEW LANTAO BUS

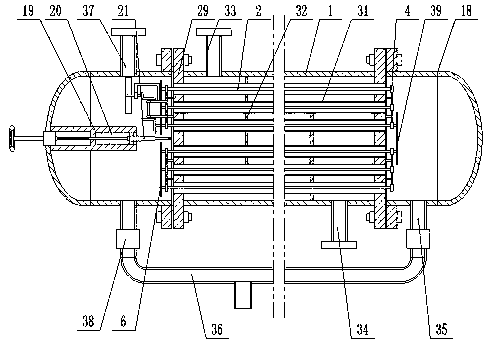

Efficient heat exchanger device

ActiveCN110595235AImprove heat transfer efficiencyImprove heat transfer effectMachines/enginesStationary tubular conduit assembliesImpellerEngineering

The invention discloses an efficient heat exchanger device. The efficient heat exchanger device comprises a tank body, wherein a tube-shell type heat exchanger device is arranged in the tank body, a hydraulic heat exchange tube cleaning device is arranged in the tube-shell type heat exchanger device, and a flow path regulation device is arranged in the tube-shell type heat exchanger device. According to the efficient heat exchanger device, a drive impeller is driven to rotate through power generated when a heat conduction medium flows out from a heat conduction medium inlet tube, and enabled to drive a rotation shaft to rotate, and therefore impurities adhered to the inner wall of a heat exchange tube are quickly cleared through rotation of a spiral scraper blade, and then a heat exchangercan be enabled to efficiently exchange heat, and meanwhile a flow path of the heat conduction medium in the heat exchange tube can be suitably lengthened through the spiral scraper blade, and heat exchange effect of the heat conduction medium is effectively improved, and furthermore by stretching out and drawing back a taper partitioning baffle and a ring sealing piston, an elliptical seal head can be simply and quickly partitioned into two spaces, and therefore the length of the flow path of the heat conduction medium can be selected according to actual conditions, and the device is enabledto preform regulation of multiple heat exchange modes.

Owner:陈庆高

Solar tube cleaning device

The invention relates to a solar tube cleaning device and belongs to the field of mechanical cleaning. The solar tube cleaning device is composed of a solar tube transmission device and a cleaning device. A motor drives a planar slot type cam to rotate, and a cylindrical bump is driven by the rotation of the cam to move down to drive a solar tube in an insertion slot to slide down. During working, a hairbrush of the cleaning device is enabled to be matched with the solar tube transmitted by the insertion slot, and the positions of the hairbrush and the solar tube are fixed. An inner hairbrush enters the inner part of the solar tube and conveys descaling fluid at the same time, and an outer hairbrush covers the outer ring of the solar tube to clean the surface of the solar tube. The solar tube cleaning device has the beneficial effects that the transmission device is relatively slow in running and high in stability; the hairbrush of the cleaning device is designed into an inner layer and an outer layer, which efficiently clean the inner surface and the outer surface of the solar tube simultaneously; the inner brush is hollow and can convey the descaling fluid for the solar tube.

Owner:珠海同德新能源有限公司

Medical test tube cleaning and drying integrated device

InactiveCN107931283AImprove cleaning efficiencyEasy to cleanHollow article cleaningDrying gas arrangementsWater resourcesEngineering

Owner:陈鑫利

Flexible multi-tube cleaning lance positioner guide apparatus

A guide tube pitch adjustment apparatus for aligning distal ends of lance guide tubes in registry with tube openings in a heat exchanger tube sheet is disclosed. A guide tube pitch clamp assembly carried within and supported from a housing. The pitch clamp assembly has at least two V-blocks fastened to a threaded rod. One V-block is fastened to a portion of the threaded rod having right hand threads, and another V-block is fastened to another portion of the threaded rod having left hand threads. Each of the V-blocks supports a portion of one of the guide tubes, and a cross bar clamp within the housing is oriented to span across the V-blocks and adjustably hold the portions of the guide tubes in a spaced relationship such that spacing between the distal ends of adjacent guide tubes may be adjusted by rotation of the threaded rod.

Owner:STONEAGE

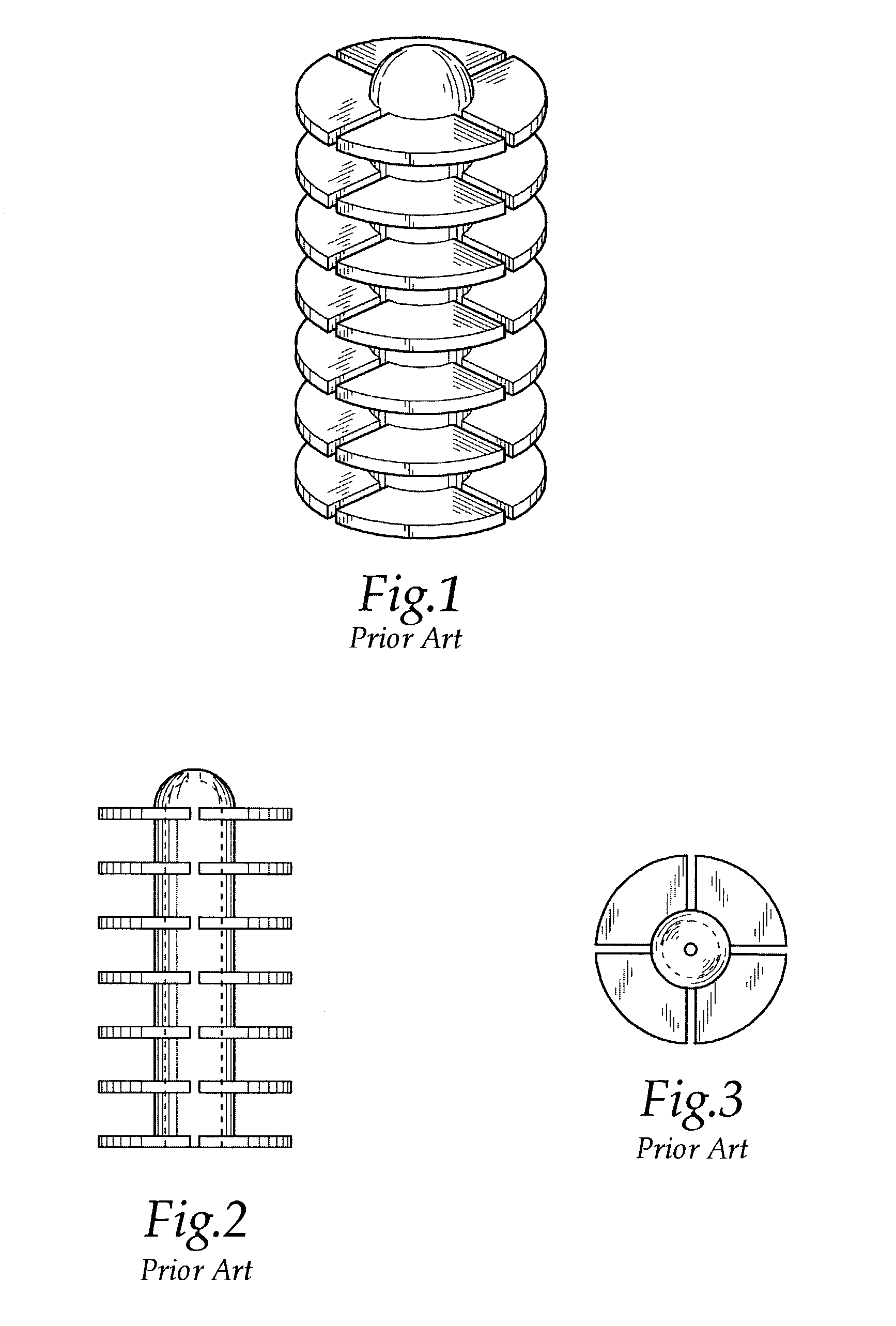

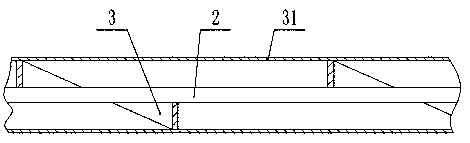

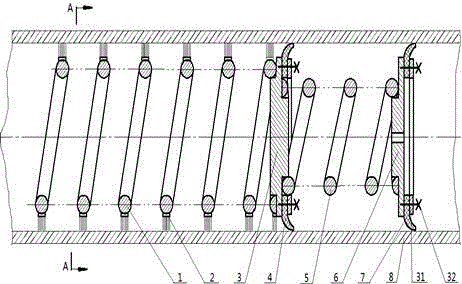

Spiral-spring wire brush type tube cleaner

The invention relates to a spiral-spring wire brush type tube cleaner. The spiral-spring wire brush type tube cleaner consists of springs I, spiral-spring wire brushes, a spring leather bowl seat I, leather bowls I, springs II, a spring leather bowl seat II and leather bowls II and is characterized in that the spiral-spring wire brushes are mounted at the outer edges of the springs I, the spring leather bowl seat I is mounted at one end of the springs I, the leather bowls I are mounted on the spring leather bowl seat I, one end of the springs II is connected with the spring leather bowl seat I, the other end of the springs II is connected with the spring leather bowl seat II, and the leather bowls II are mounted on the spring leather bowl seat II. According to the tube cleaner provided by the invention, the design is ingenious, the structure is simple, and the tube cleaner is impelled in a tube in a spiral rotation manner during tube cleaning operation; the tube cleaner has the advantages that the effect of cleaning dirt from the wall of the tube is good, the wear to the leather bowls is little and uniform, and the tube cleaner easily passes through elbows.

Owner:淮南市申升达玻璃有限责任公司

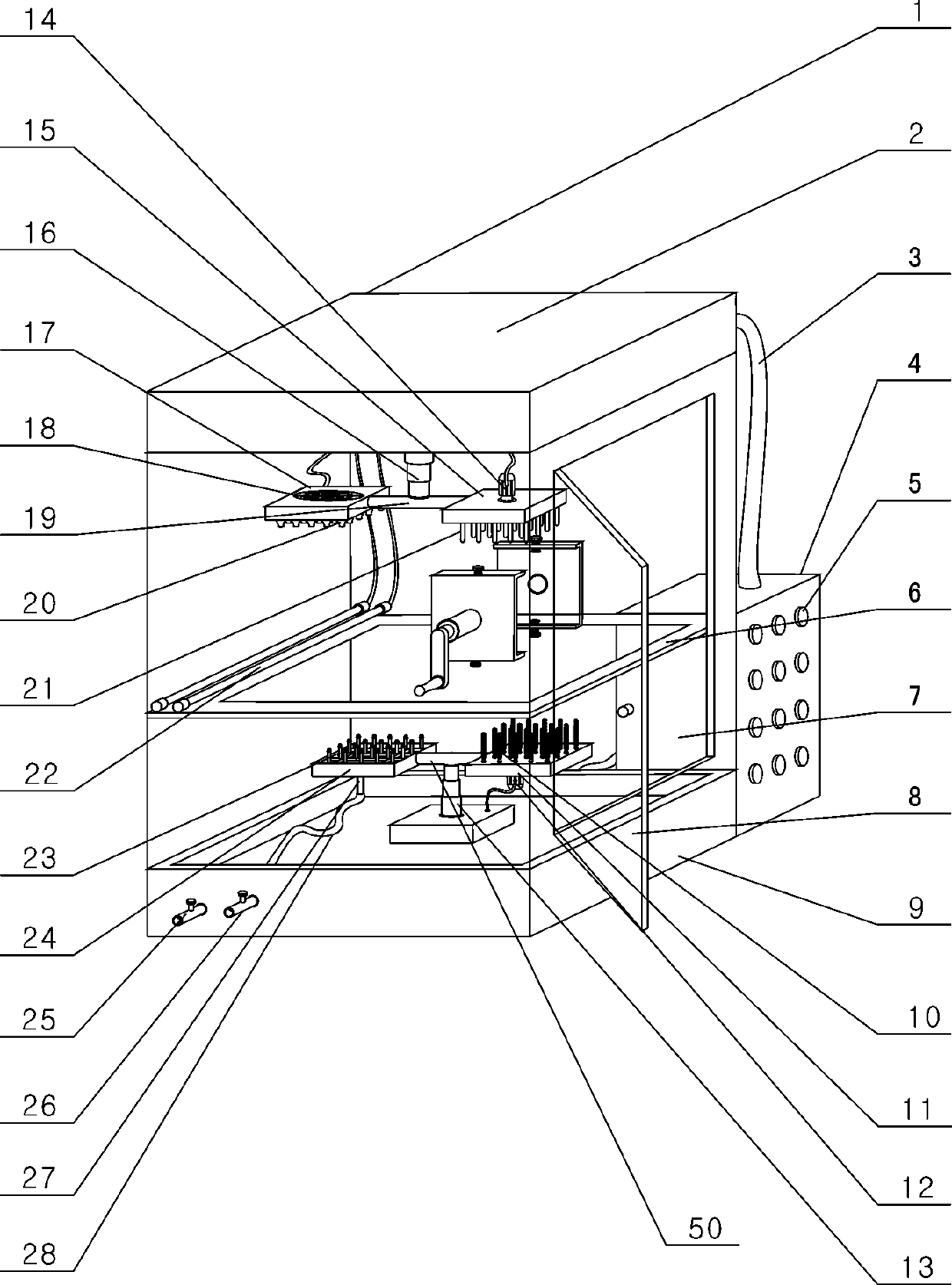

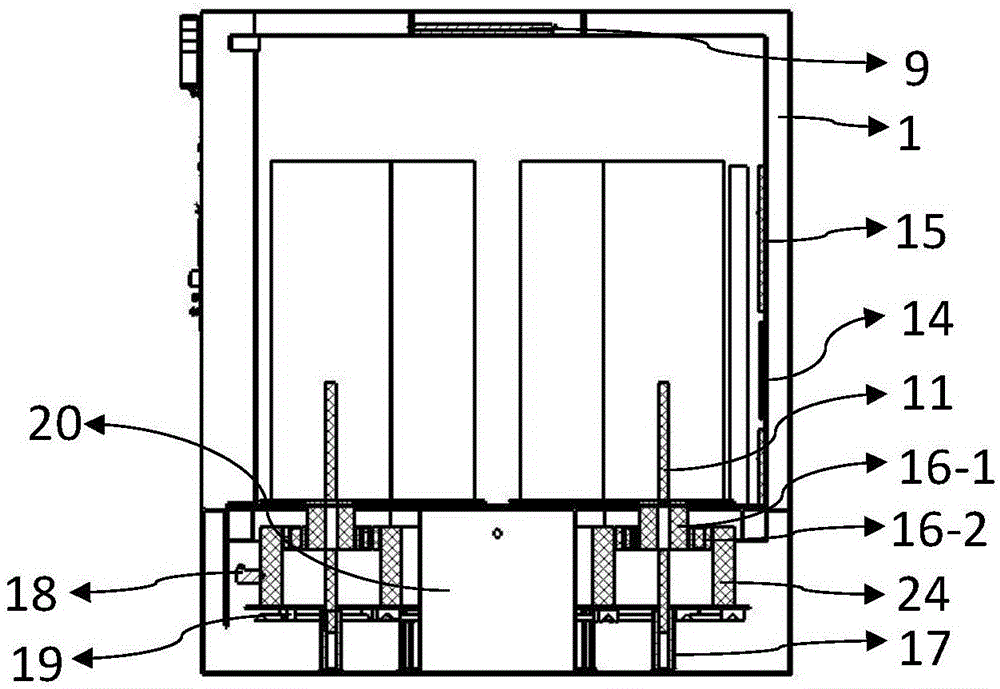

Medical-use integrated device for rapid cleaning and disinfection of test tubes

ActiveCN107649473AKeep dryEnsure health and safetyDrying solid materials without heatHollow article cleaningElectric machineEngineering

The invention provides a medical-use integrated device for rapid cleaning and disinfection of test tubes, and relates to the field of medical-use cleaning devices. The medical-use integrated device for rapid cleaning and disinfection of test tubes includes a tank body (1) and a main control box (4). The device is characterized in that the upper portion of the tank body is provided with an upper-portion start device (2), the upper-portion start device (2) is connected with the main control box (4) through a cable (3), the inside of the upper-portion start device (2) is provided with a rotary telescopic motor B (16), the lower end of a telescopic rod of the rotary telescopic motor B (16) is connected with a cross rod A (19), one side end of the cross rod A (19) is connected with a drying device (17), and the drying device (17) is electrically connected with the upper-portion start device (2). Through the medical-use integrated device, the to-be-cleaned tubes can be placed centrally, rapid brushing, flushing, wiping, drying and disinfection are integrally completed, the cleaning efficiency of the test tubes is greatly improved, the structure is reasonable, and the use process saves time and labor.

Owner:北京华兴康生物科技有限公司

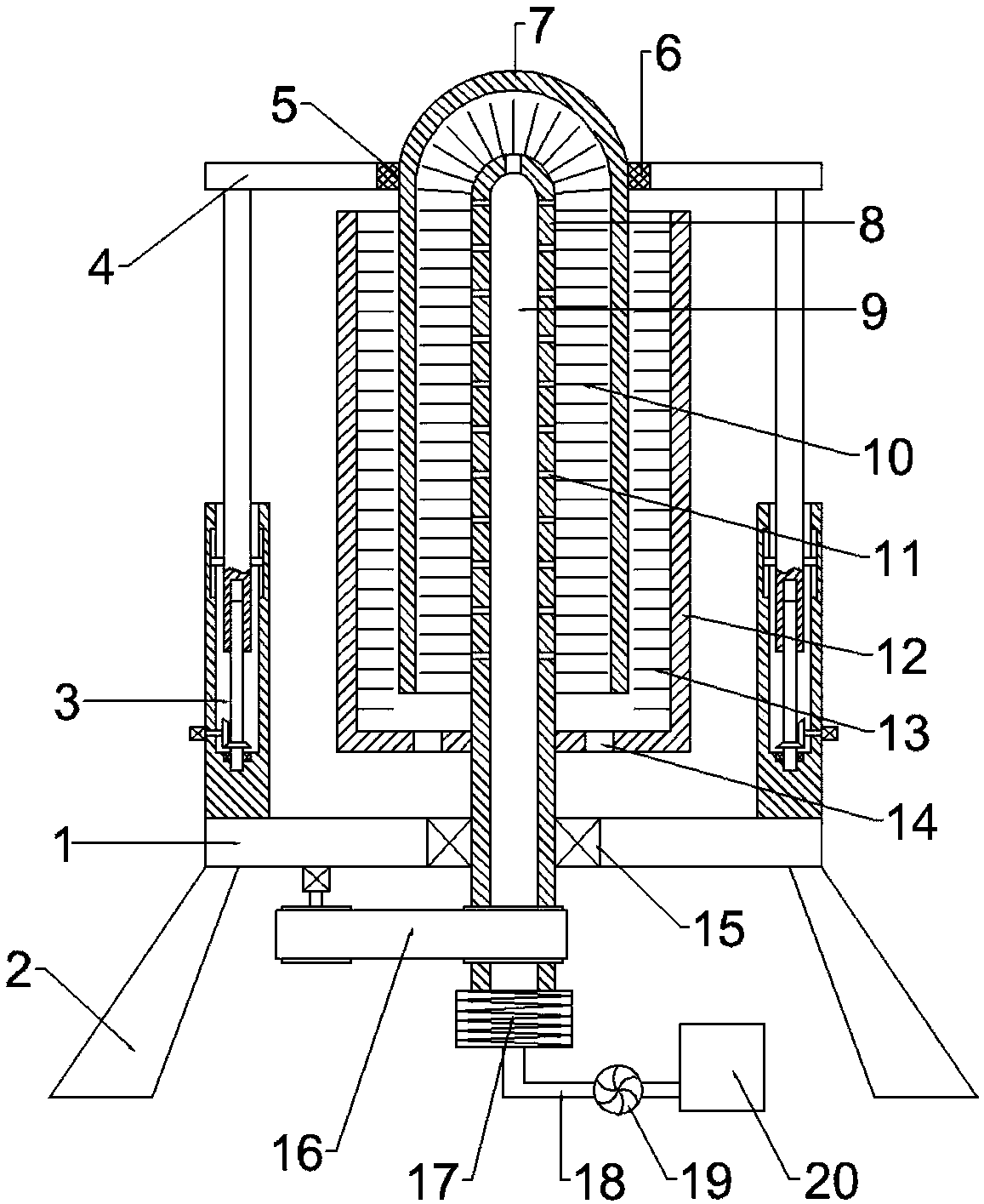

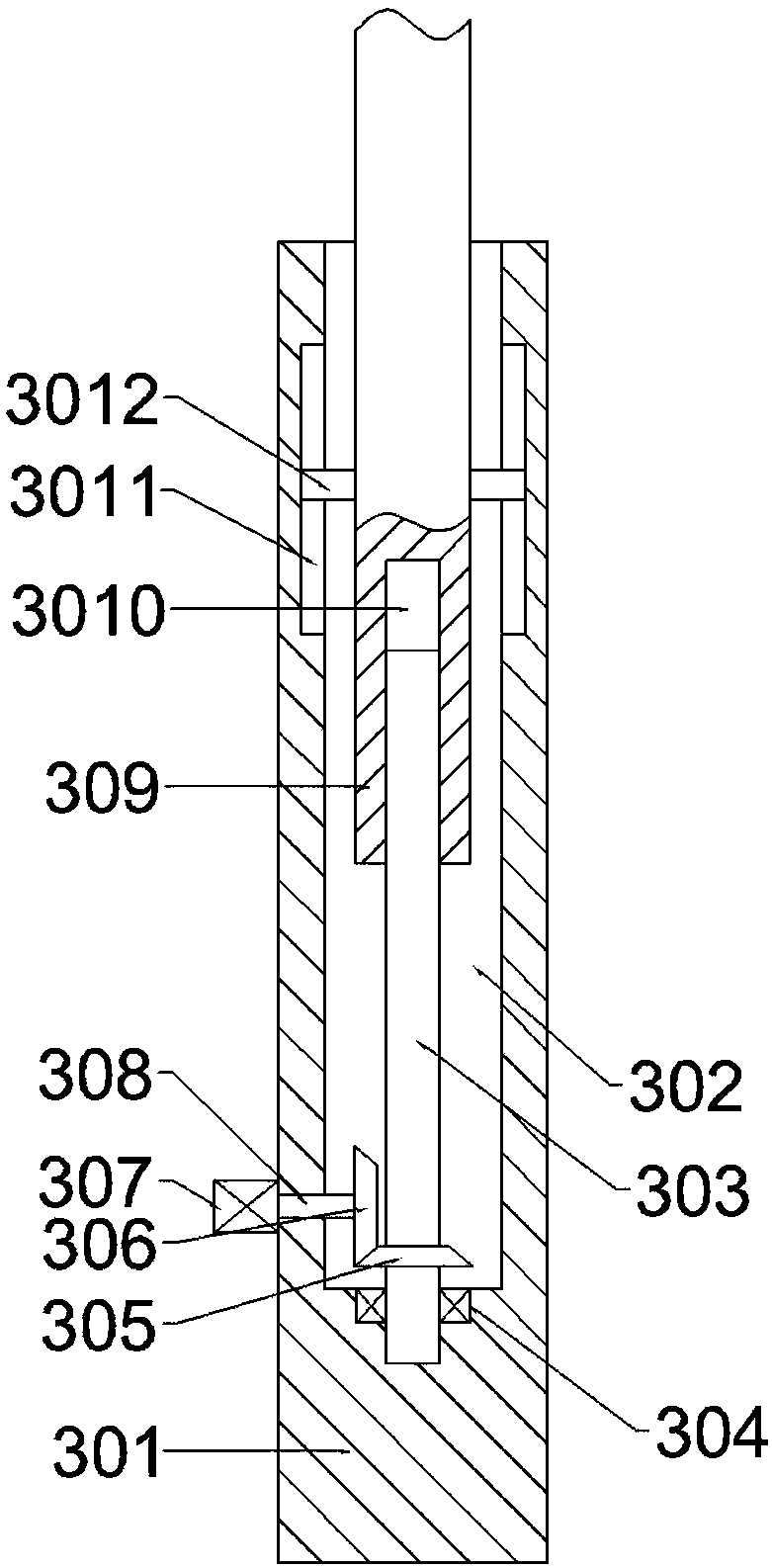

Vertical multi-station quartz tube cleaning machine and cleaning method

ActiveCN106824929AComprehensive cleaningWash thoroughlyHollow article cleaningSpray nozzleEngineering

The invention discloses a vertical multi-station quartz tube cleaning machine. The vertical multi-station quartz tube cleaning machine comprises a cleaning platform rotationally arranged in a body, one or more outer spray pipes and a plurality of inner spray pipes, wherein multiple mounting holes penetrate through the surface of the cleaning platform and surround the center of the surface of the cleaning platform, rotating discs are arranged on the inner sides of the mounting holes, and quartz tubes are fixed on the rotating discs, driven by the rotating discs to conduct autorotation and driven by the cleaning platform to conduct revolution; the outer spray pipes are vertically arranged in the body and located on the outer sides of the quartz tubes, a plurality of spray nozzles are arranged along the side walls of the outer spray pipes and used for spraying a cleaning liquid or gas to clean or dry the outer walls of the quartz tubes; the plurality of inner spray pipes are in one-to-one correspondence to the rotating discs and penetrate into the quartz tubes from the lower sides of the rotating discs, a plurality of spray nozzles are also arranged on the side walls and the tops of the inner spray pipes and used for spraying a cleaning liquid or gas to clean or dry the inner walls of the quartz tubes. The invention further discloses a corresponding cleaning method. Multiple quartz tubes can be comprehensively and effectively cleaned once, waste liquids obtained after cleaning can be recovered in a classified manner, and the vertical multi-station quartz tube cleaning machine is simple in structure and easy to implement.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com