Patents

Literature

377 results about "Chemical test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, a chemical test is a qualitative or quantitative procedure designed to identify, quantify, or characterise a chemical compound or chemical group.

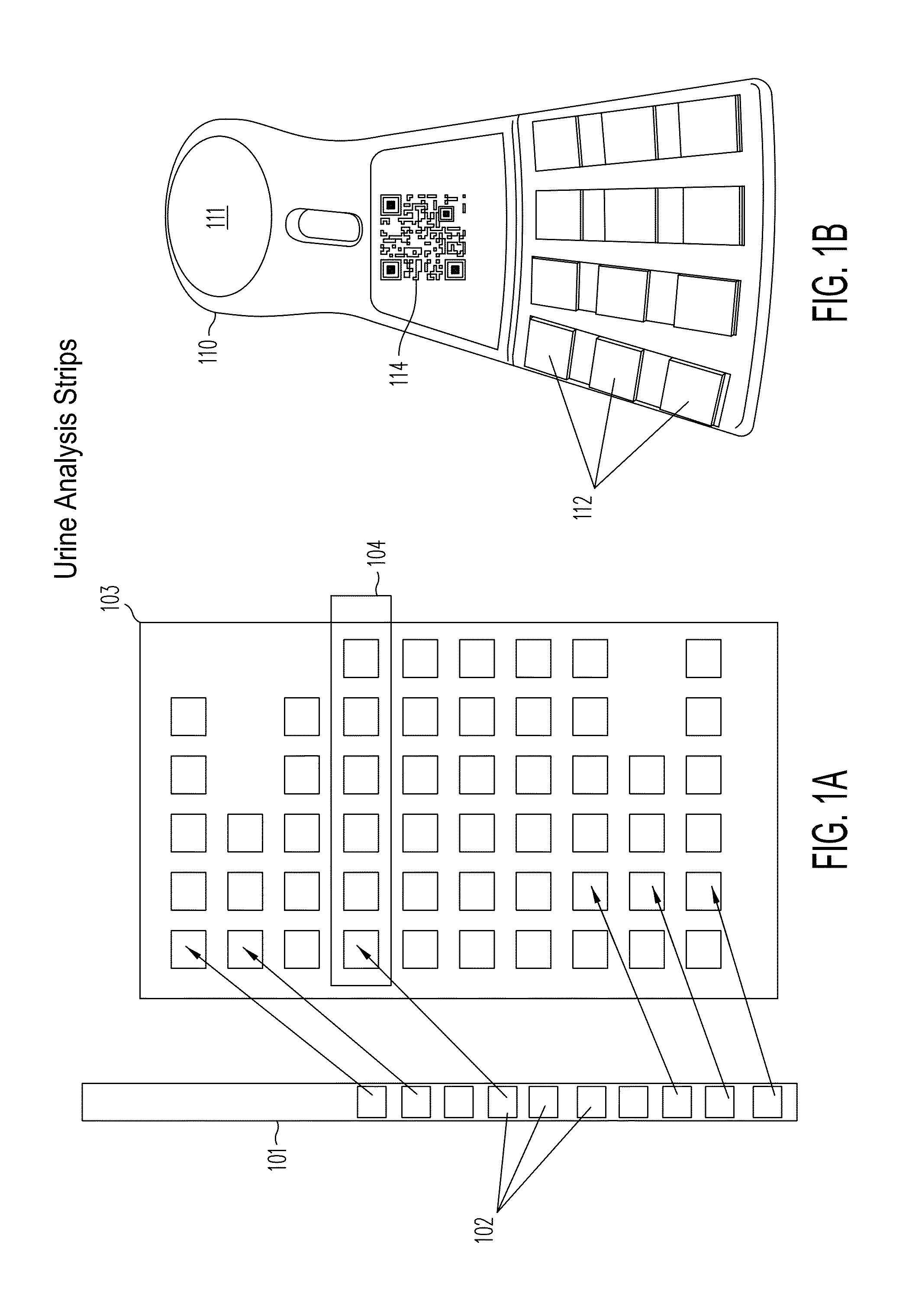

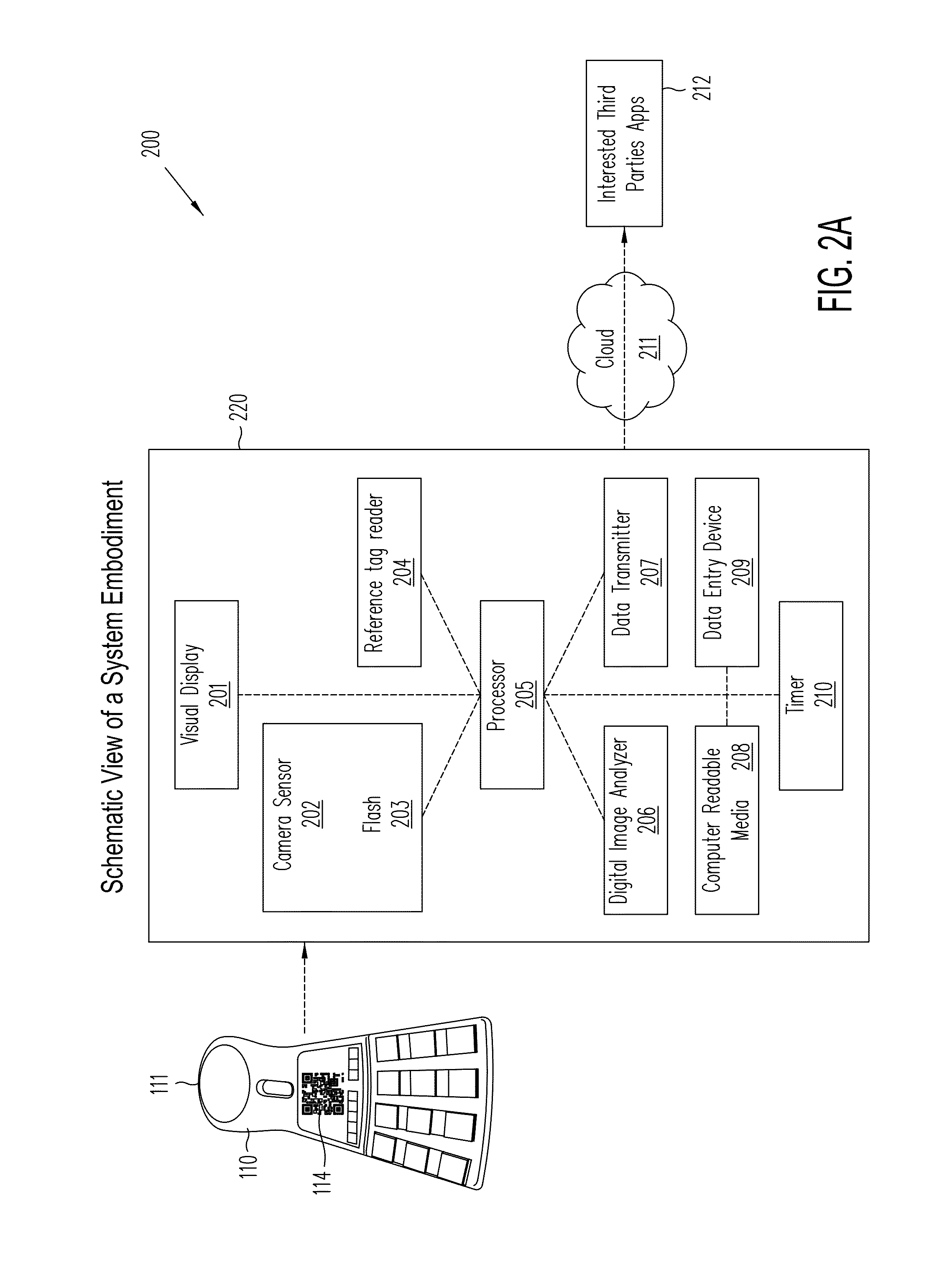

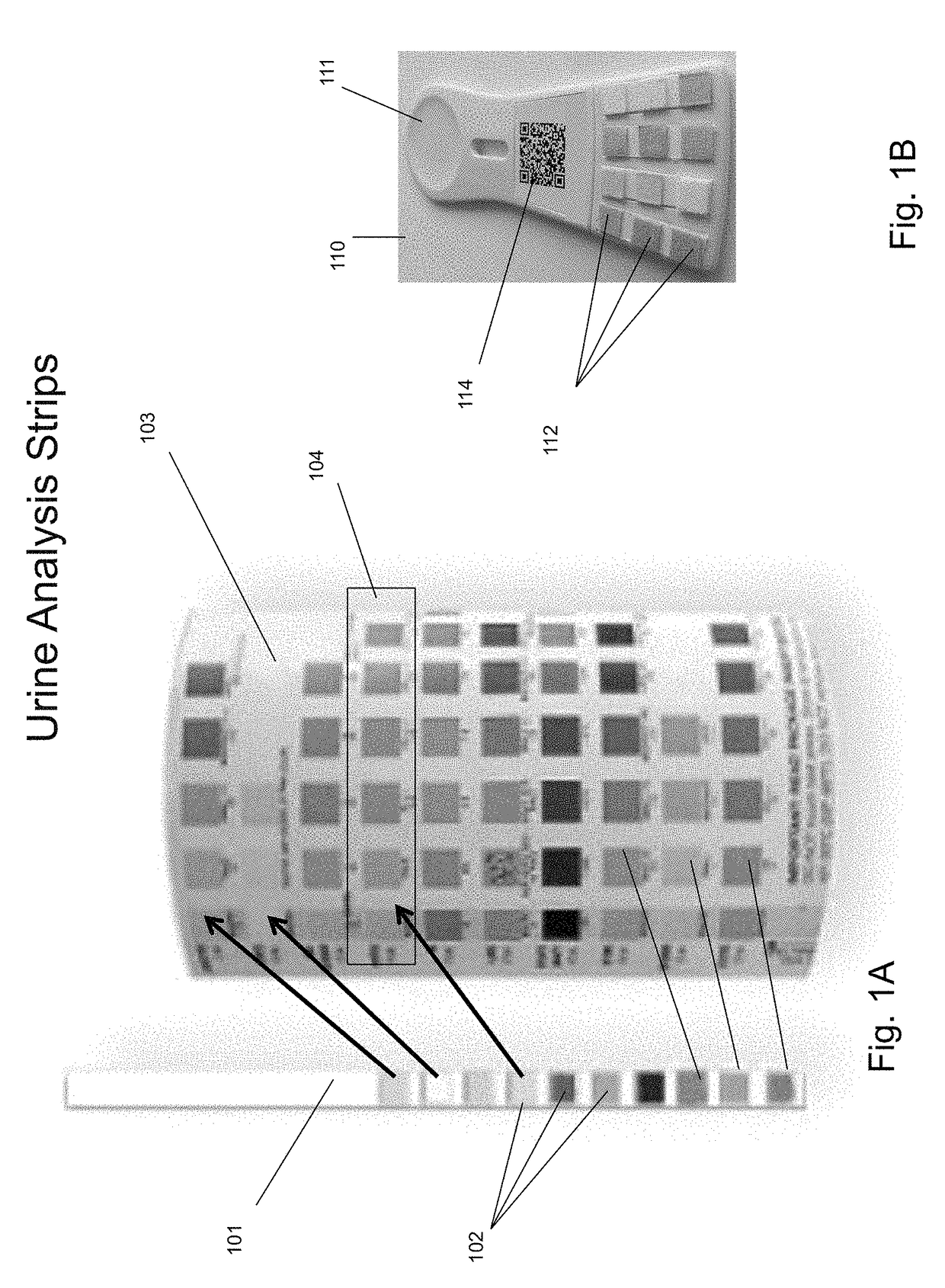

Method and apparatus for performing and quantifying color changes induced by specific concentrations of biological analytes in an automatically calibrated environment

ActiveUS20150211987A1Accurate and precise and cost-effective measurementMinimizing user interactionImage enhancementRadiation pyrometryColor changesColor calibration

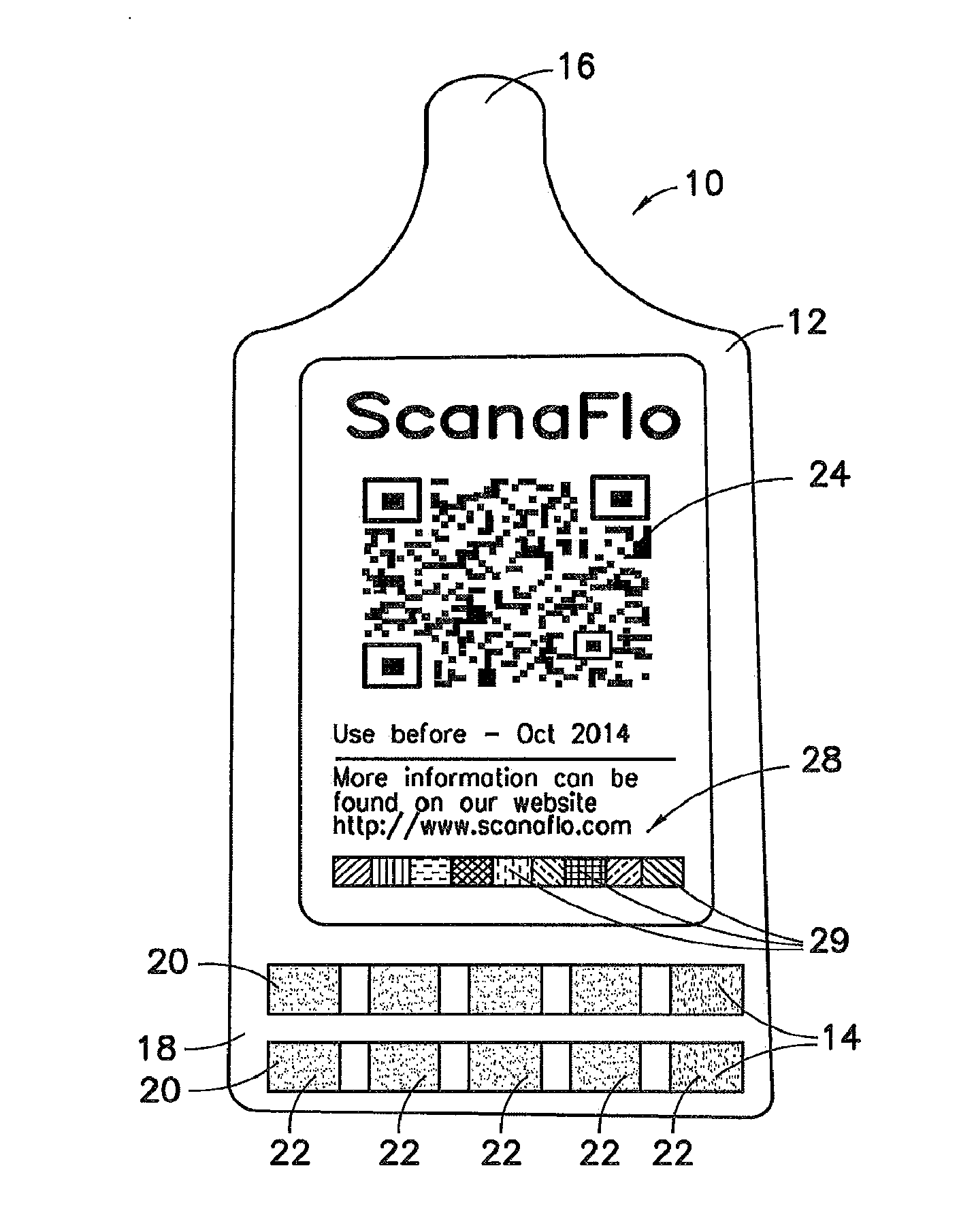

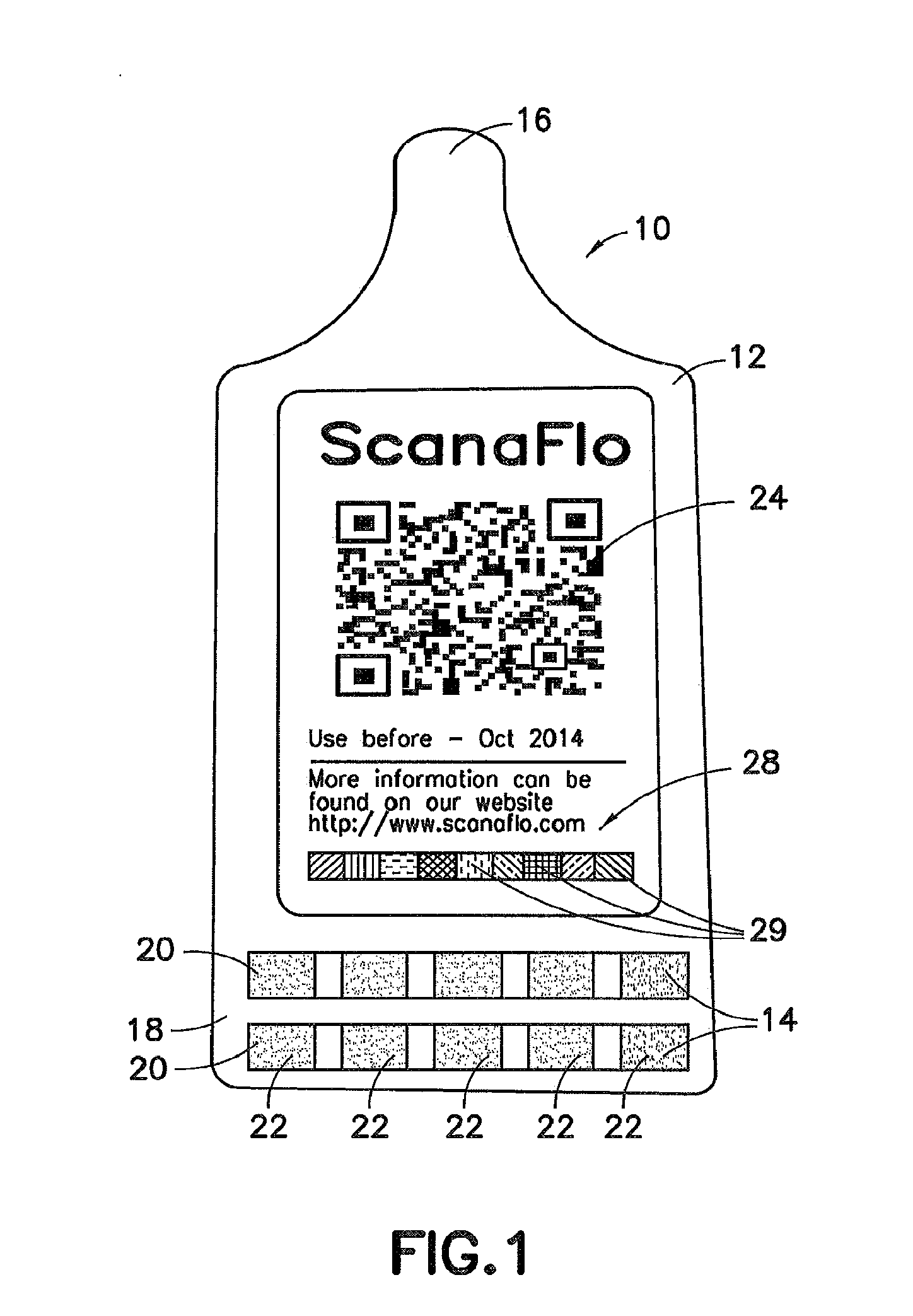

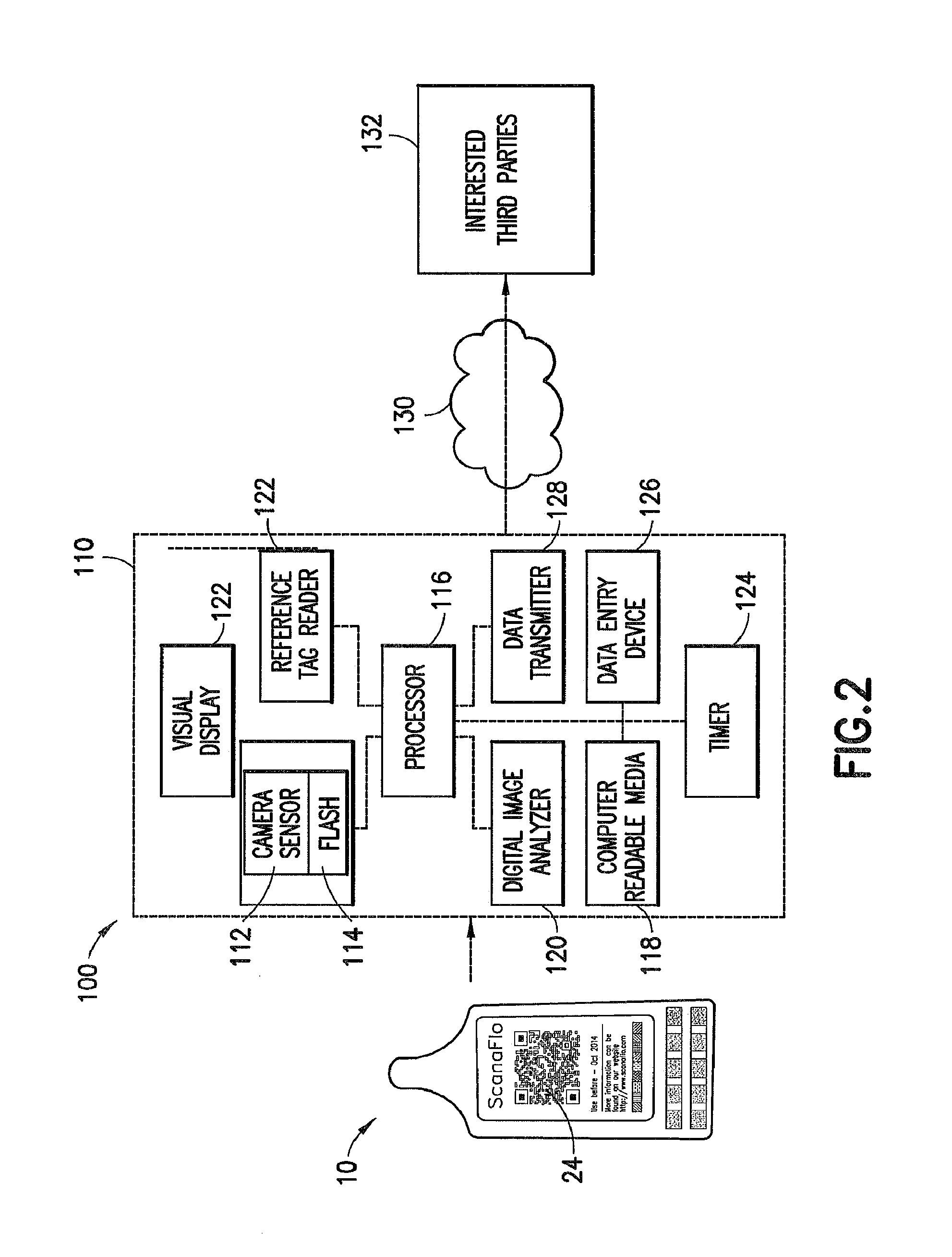

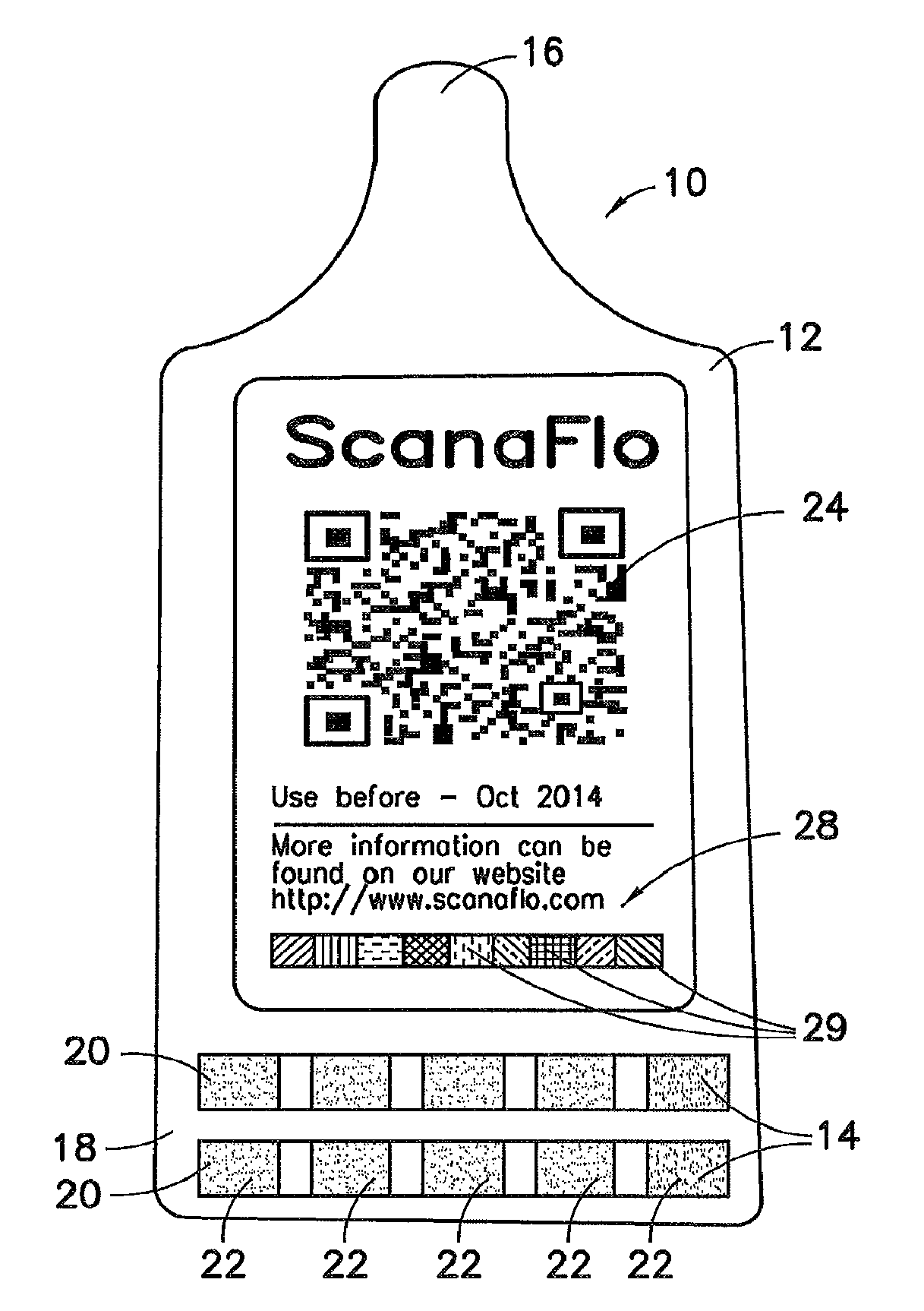

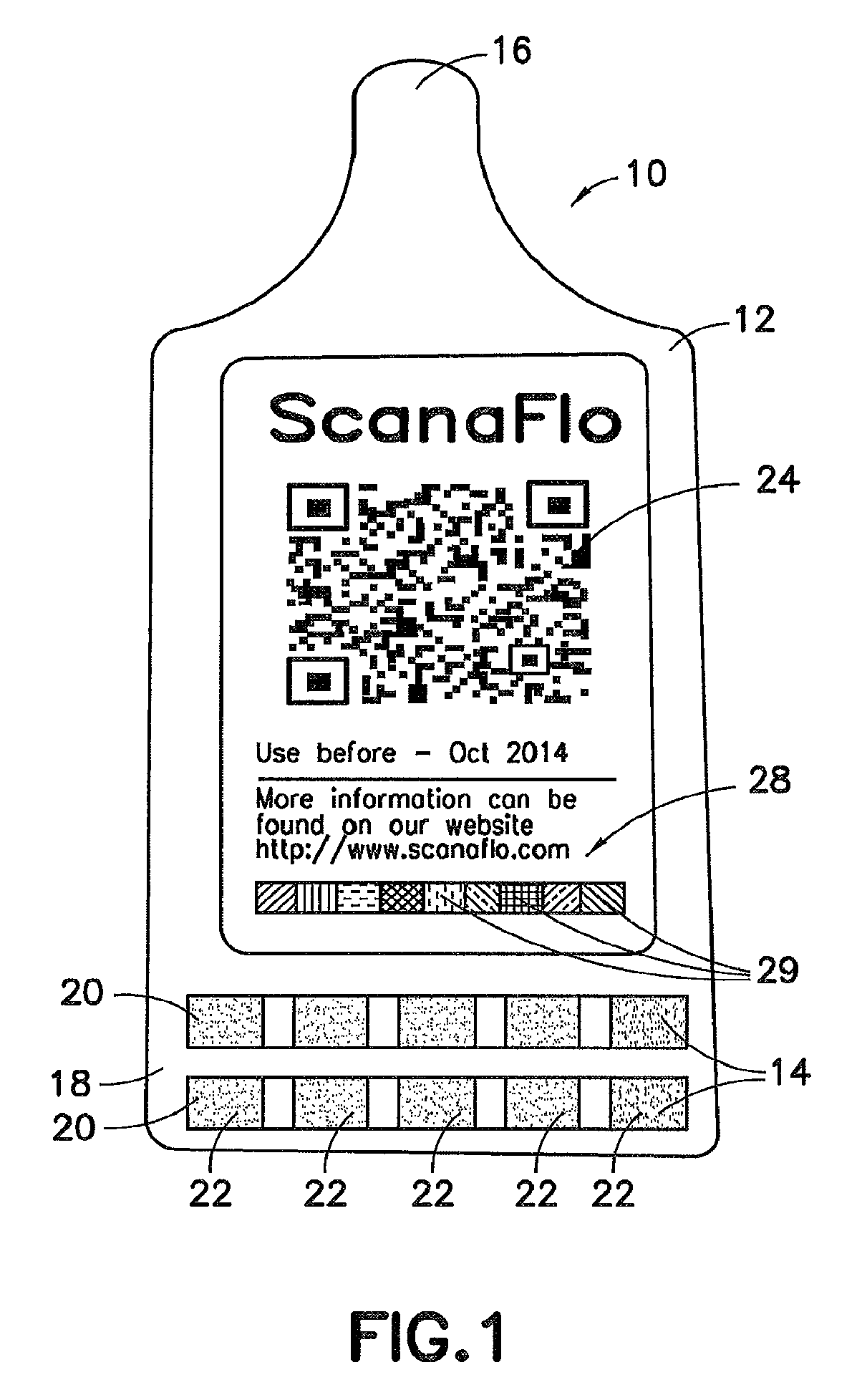

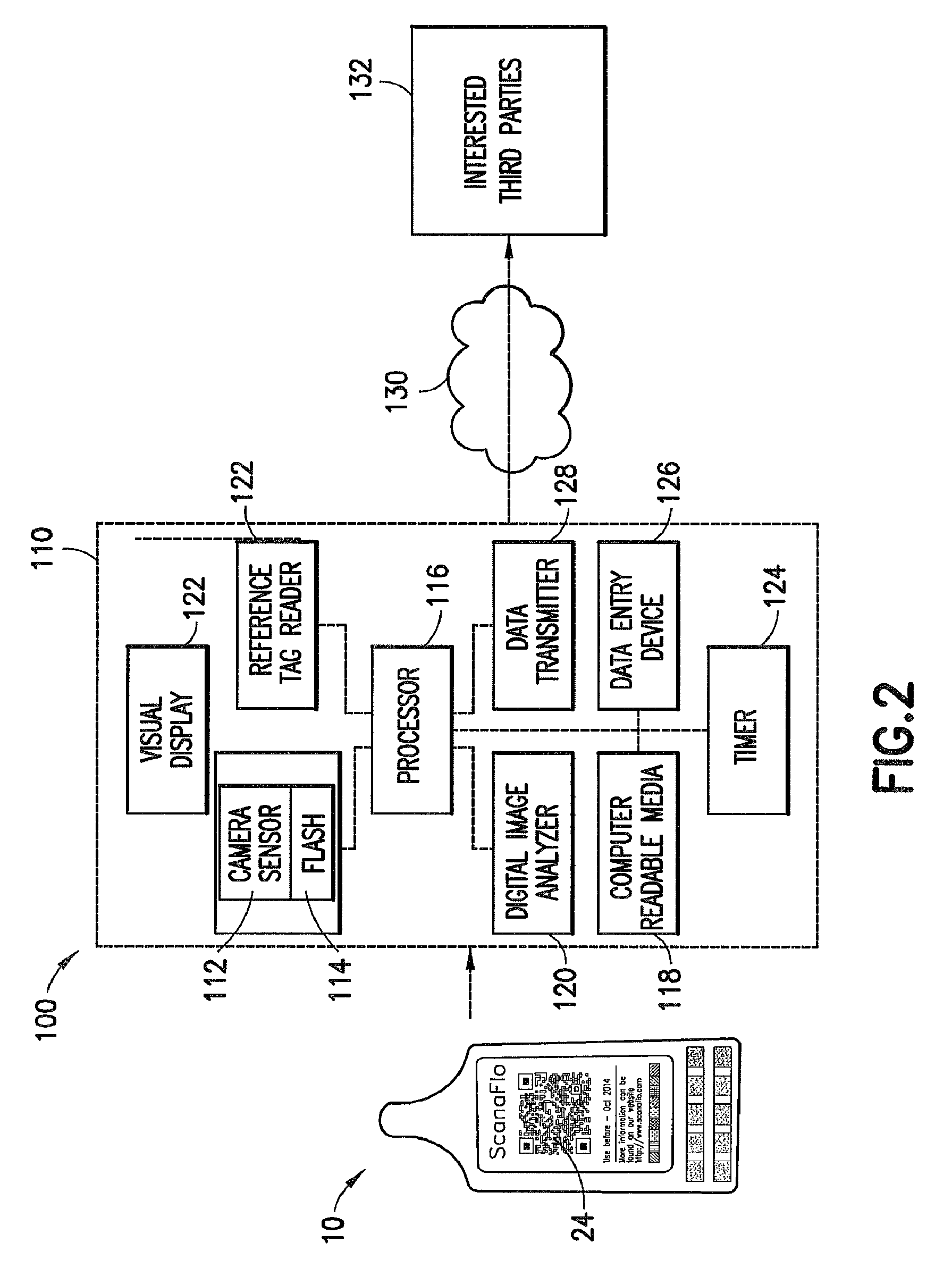

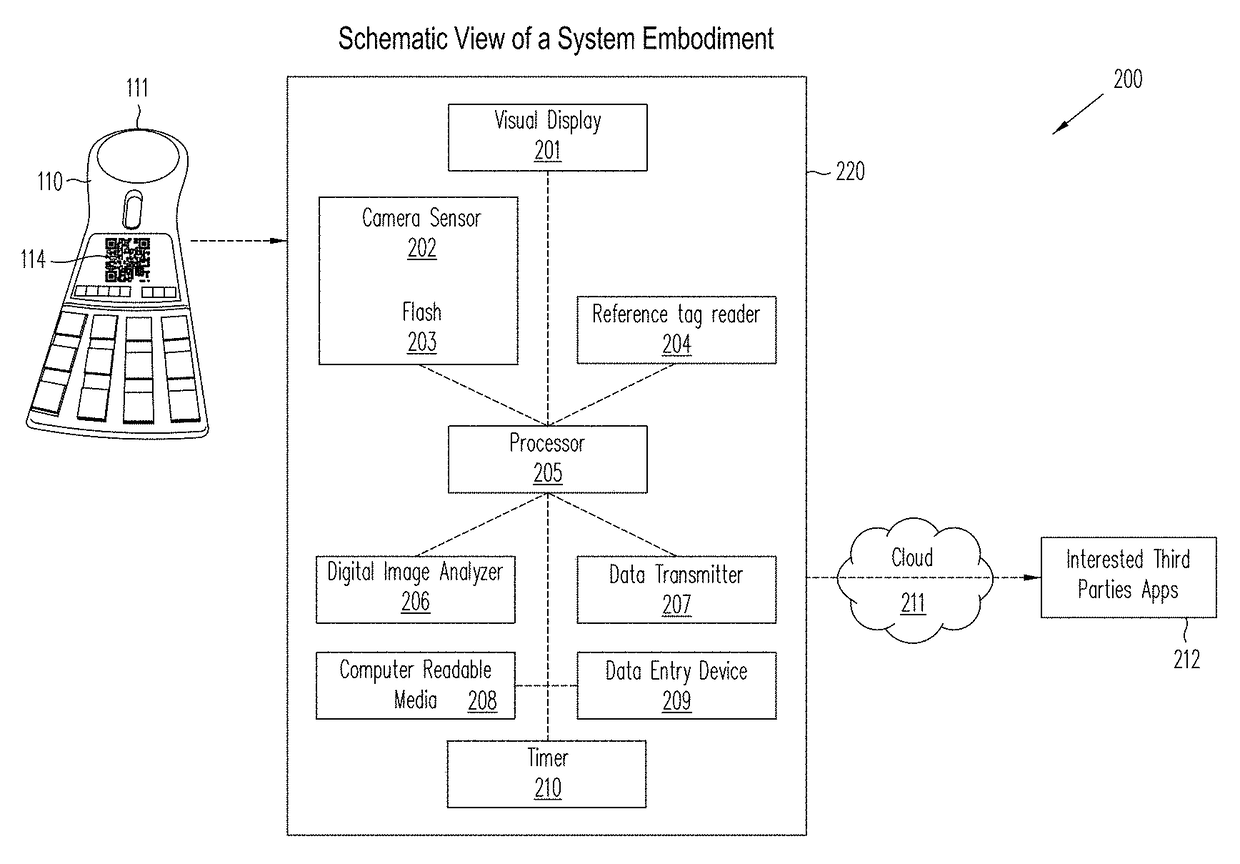

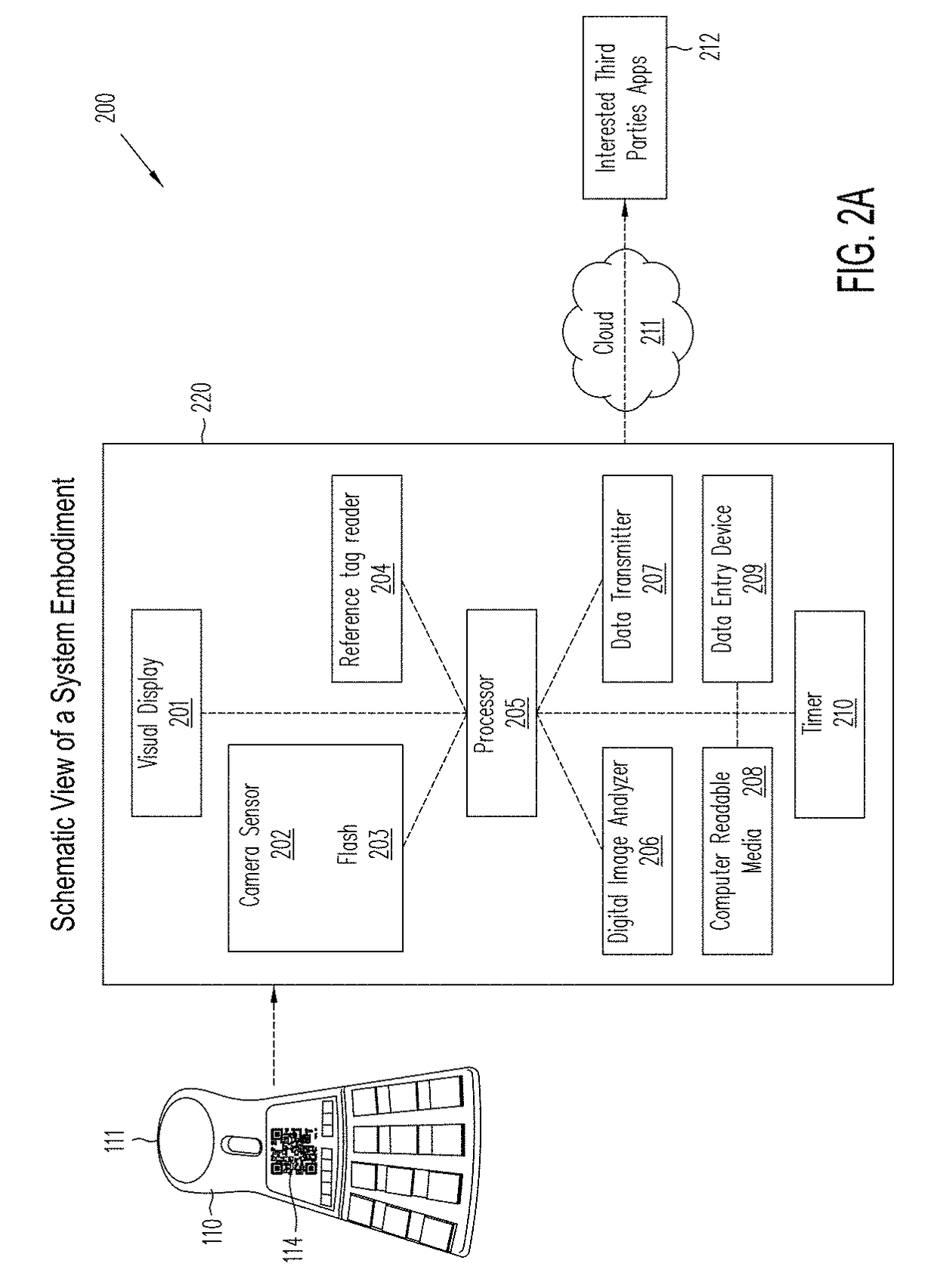

Methods and electronic devices for performing color-based reaction testing of biological materials. The method includes capturing and interpreting digital images of an unexposed and later exposed paddle at various delay times within an automatically calibrated environment. The test paddle includes a unique identification mechanism (UID), a Reference Color Bar (RCB) providing samples of standardized colors for image color calibration, compensation and corrections, and several test-specific sequences of Chemical Test Pads (CTP). The method further includes locating the paddle in the image, extracting the UID and validating the paddle, extracting the RCB and locating the plurality of CTP in each image. The method further reduces image noise in the CTP and calibrates the image automatically according to lighting measurements performed on the RCB. To determine test results, the method further determines several distances between the CTP and its possible trajectory in the color space described by the Manufacturer Interpretation Color Chart.

Owner:HEALTHY IO LTD

Test paper reading method and test paper reading device

InactiveCN104198482ASuitable for popular promotion and useEasy to operateMaterial analysis by observing effect on chemical indicatorPesticide residueTest card

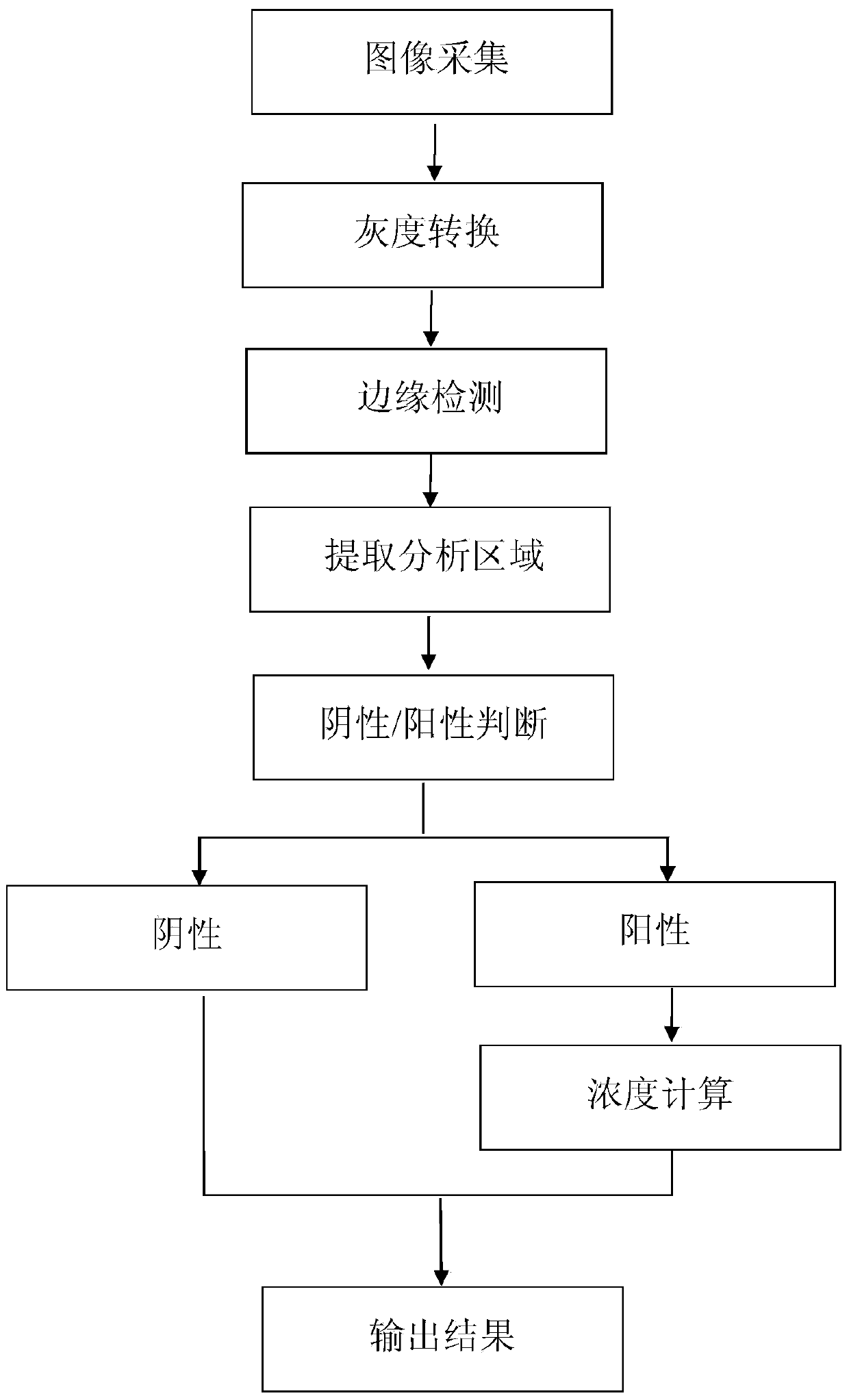

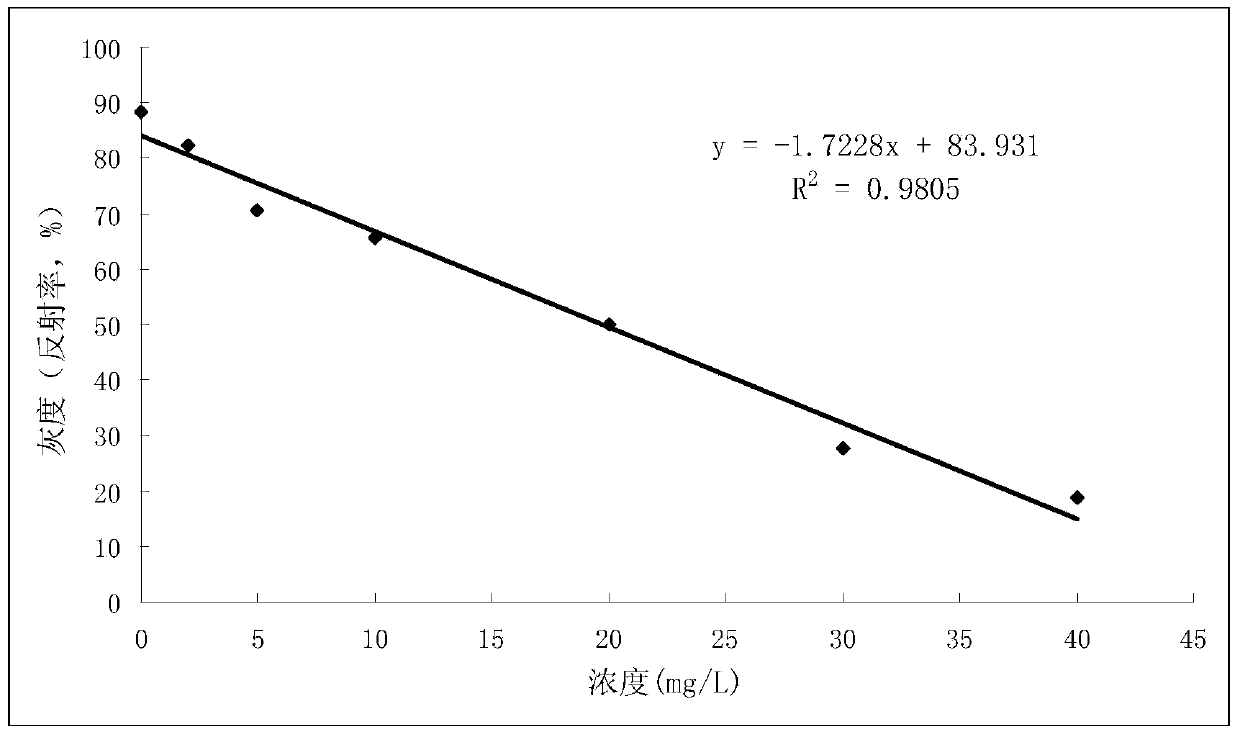

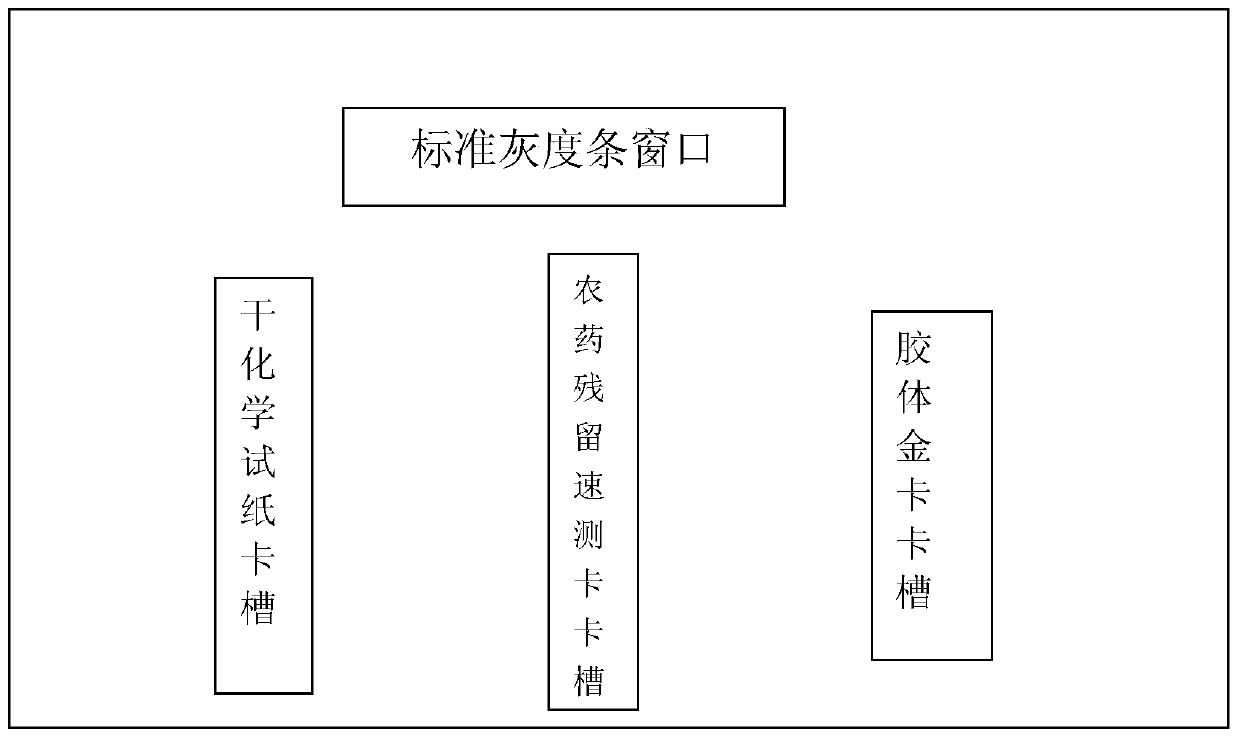

The invention provides a test paper reading method and a test paper reading device, which can read dry chemical test paper strips, colloidal gold immunochromatograohic assay test paper strips / cards and rapid pesticide residue test cards, are easy to operate, need no extra detection instrument and equipment, can automatically judge and read the detection result by only acquiring corresponding developing pictures through electronic equipment such as computers or mobile phones, have reliable testing accuracy and are particularly suitable for personal and household wide application. The method comprises the following steps: A. acquiring images; B. processing the acquired images; C. performing negative and positive discrimination; and D. performing concentration conversion on a sample which is discriminated to be positive in the step C through a concentration-gray scale relation to obtain a concentration value of the to-be-tested paper card / strip. The device comprises a shell and a built-in standard gray scale strip, wherein the shell is provided with a standard gray scale strip display window and is also provided with a first card slot, a second card slot and a third card slot for arranging the colloidal gold card, the rapid pesticide residue test card and the dry chemical test paper respectively.

Owner:BEIJING ZHIYUNDA TECH CO LTD

Lateral flow assay devices and methods of use

ActiveUS20050079629A1Prevent backflowGuarantee smooth developmentAnalysis using chemical indicatorsSamplingChemical testBody fluid

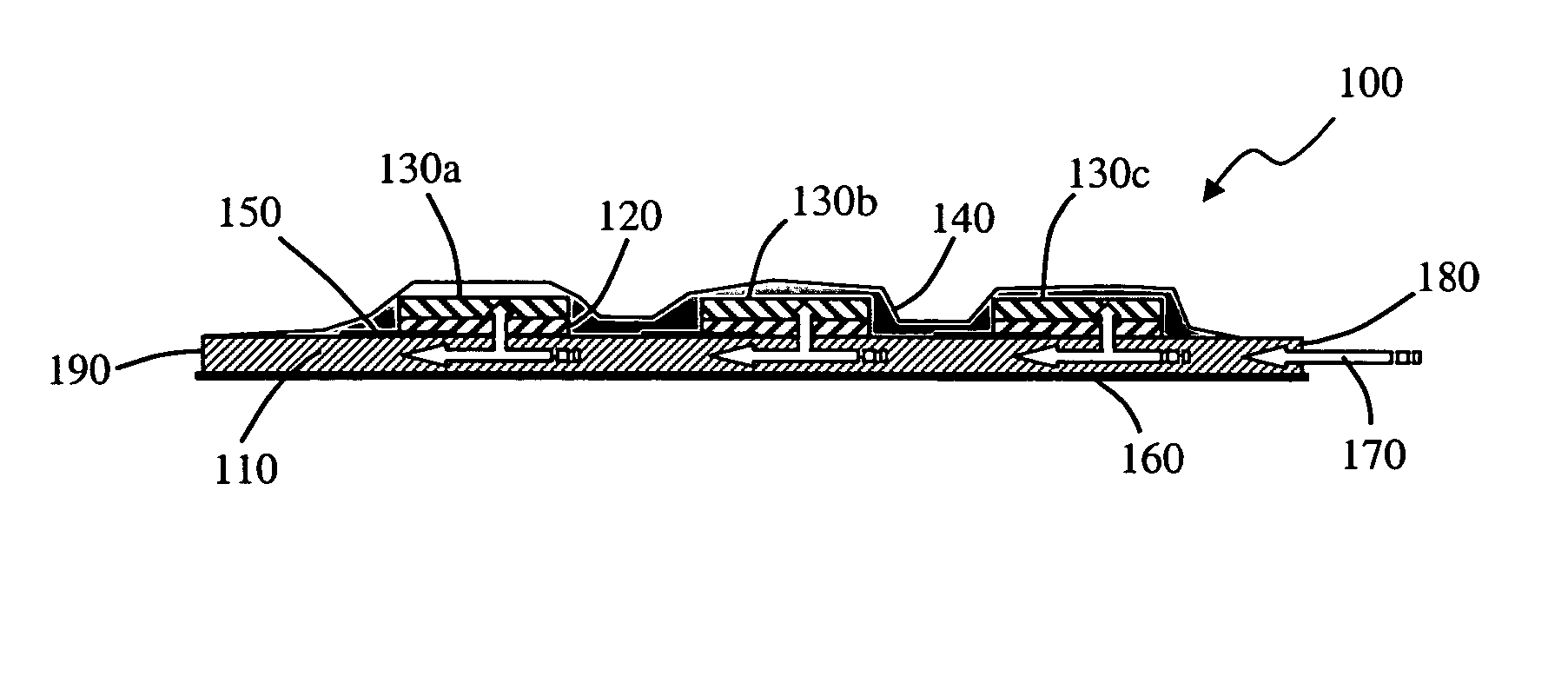

The present invention is directed novel lateral flow devices for analyzing liquid samples. The devices contain chemical test strips and are useful for testing liquids for physical properties, such as pH, specific gravity, contamination or adulteration, the presence of proteins or blood, and the like. The test strips contain a bibulous material, a filter element, a reagent pad, and in some embodiments also contain a hydrophobic member and a cover. Any fluid can be tested, for example, urine or other body fluids, environmental samples, biological samples, clinical samples, or food and beverage samples.

Owner:ABBOTT RAPID DIAGNOSTICS INT UNLTD

Method and apparatus for performing and quantifying color changes induced by specific concentrations of biological analytes in an automatically calibrated environment

ActiveUS9311520B2Minimizing user interactionAccurate and precise and cost-effective measurementImage enhancementRadiation pyrometryColor calibrationColor changes

Owner:HEALTHY IO LTD

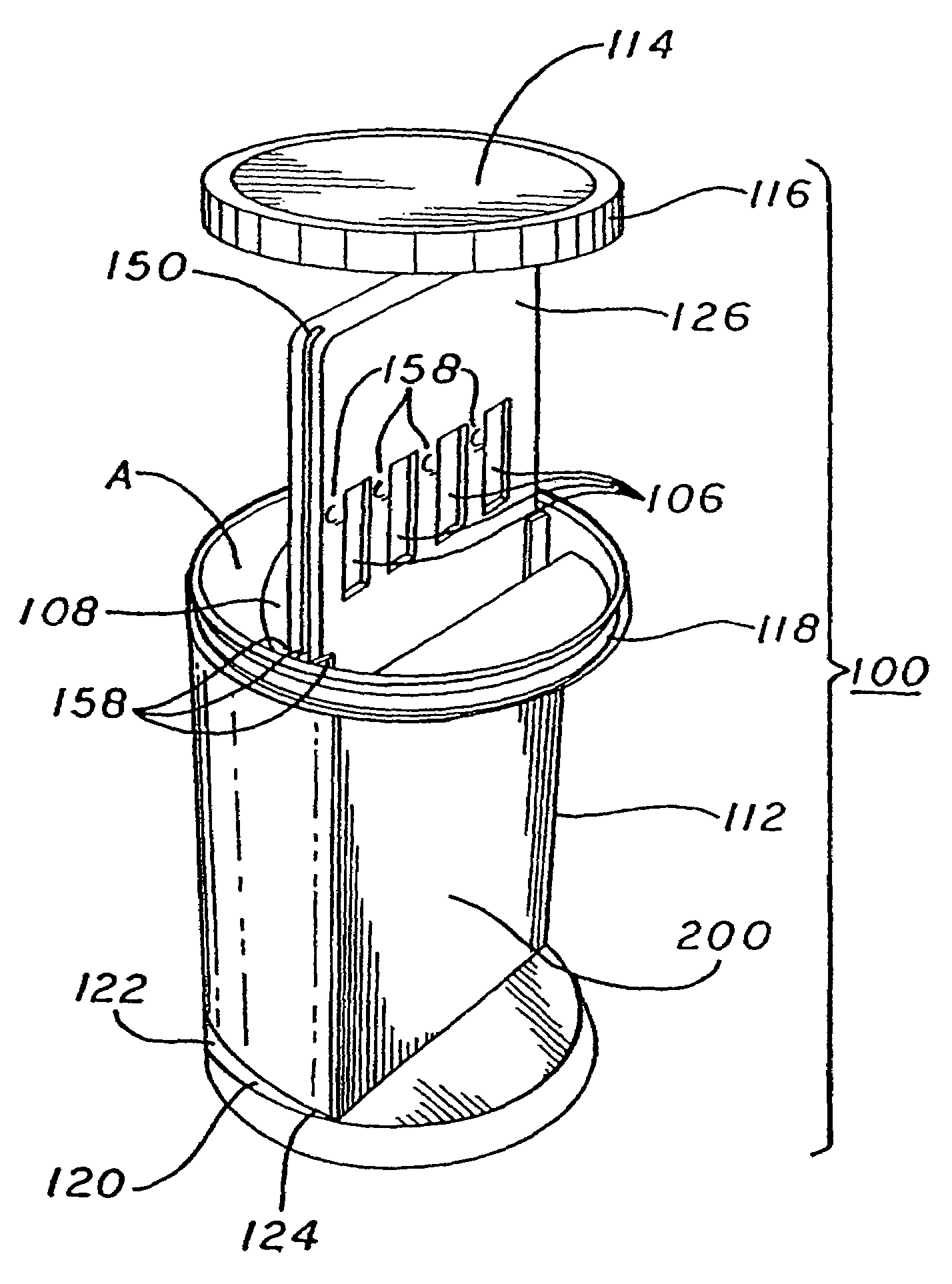

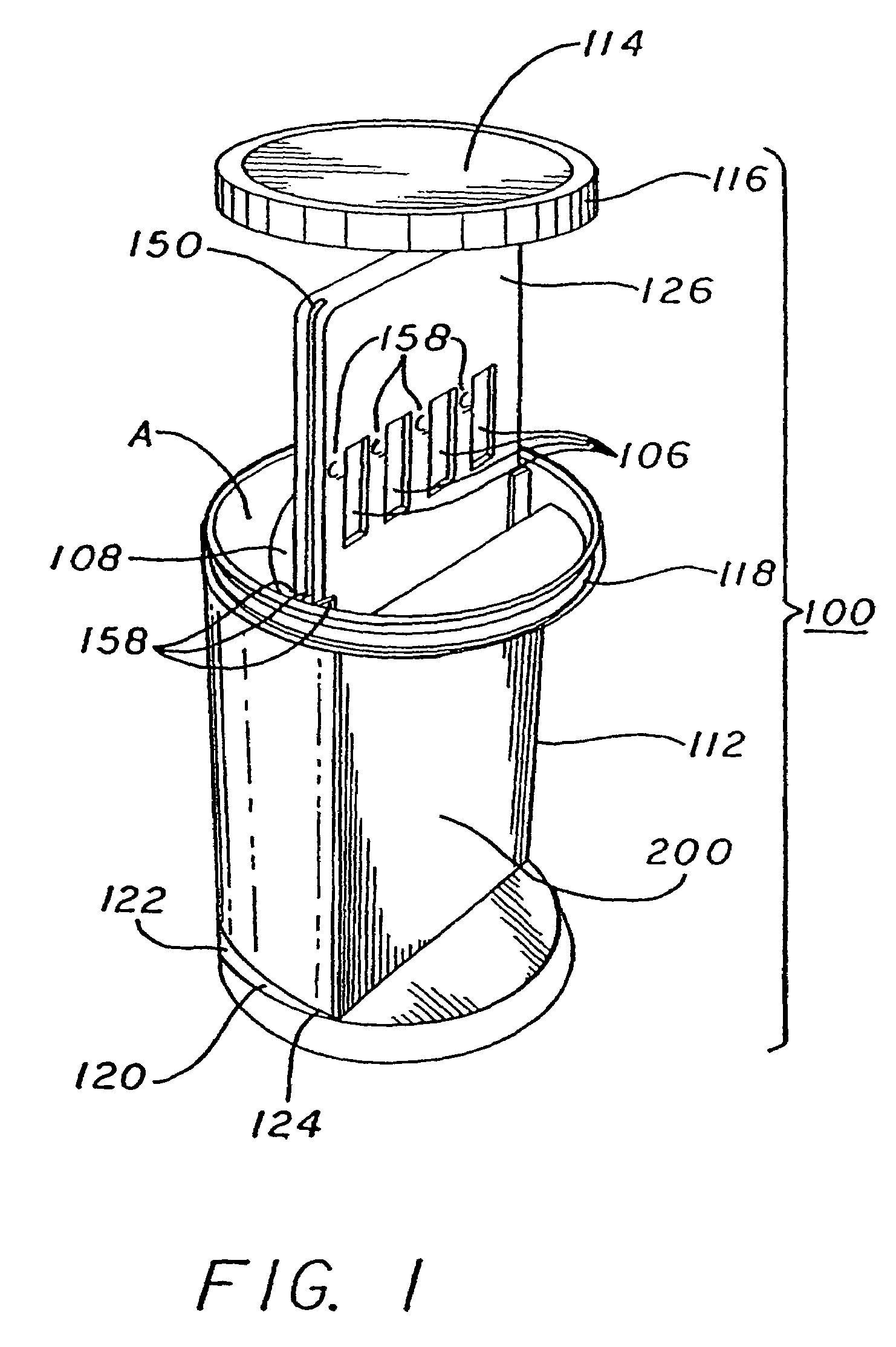

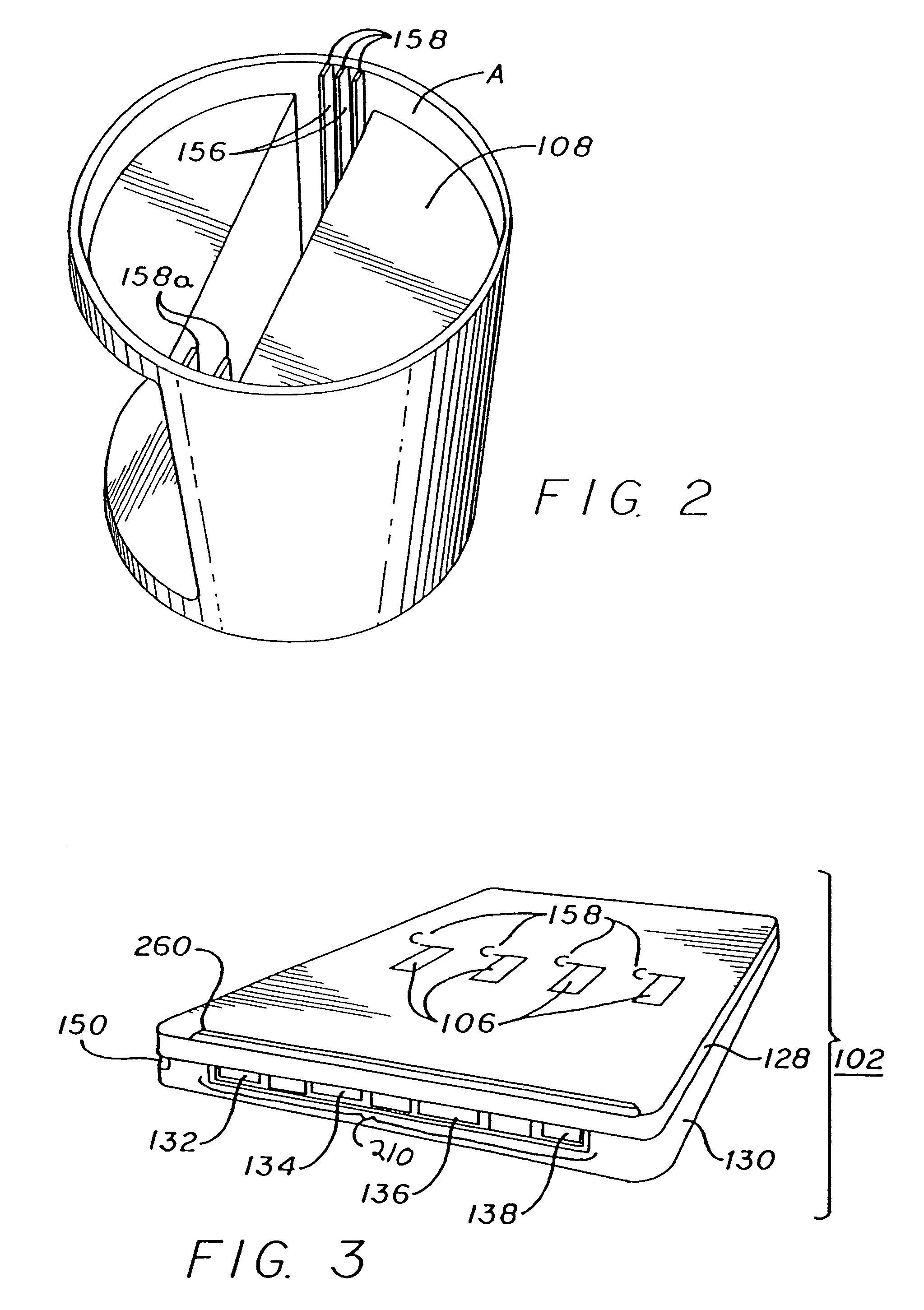

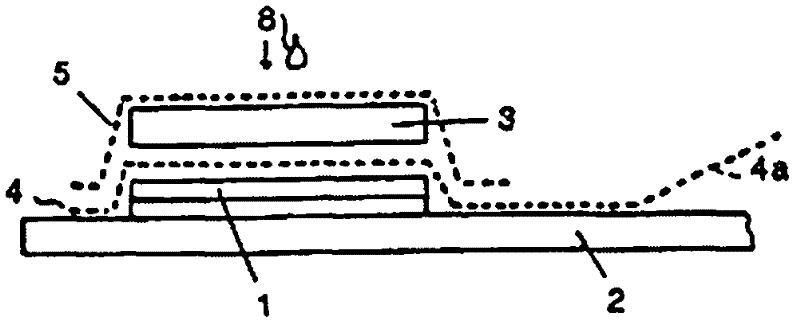

Slide-in cassette for a cup for testing of drugs of abuse

InactiveUS7244392B1Cut off available spaceEase of use and stabilityAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorMagnetic tapeHermetic seal

A specimen cup (100) has slide-in cassette (102) hermetically sealed in a chamber (104), with a outer partition being transparent. The cassette comprised chemical test strips (106) used to provide testing of drugs of abuse or other chemical or biological substances. The cassette is designed to draw urine up from the front bottom of the cup, thereby reduces the amount of urine required to perform the test. Further the cassette is designed to form isolated test channels through the use of strategically placed vertical and horizontal bars which are hermetically sealed. The cup further comprises a spill prevention flap or float (108) and an optionally enlarged sample collection portion (110) for its operation. The windows of the test cassette are covered with transparent fluid-resistant plate to prevent urine from accidentally spill onto the strips.

Owner:ABBOTT RAPID DIAGNOSTICS INT UNLTD

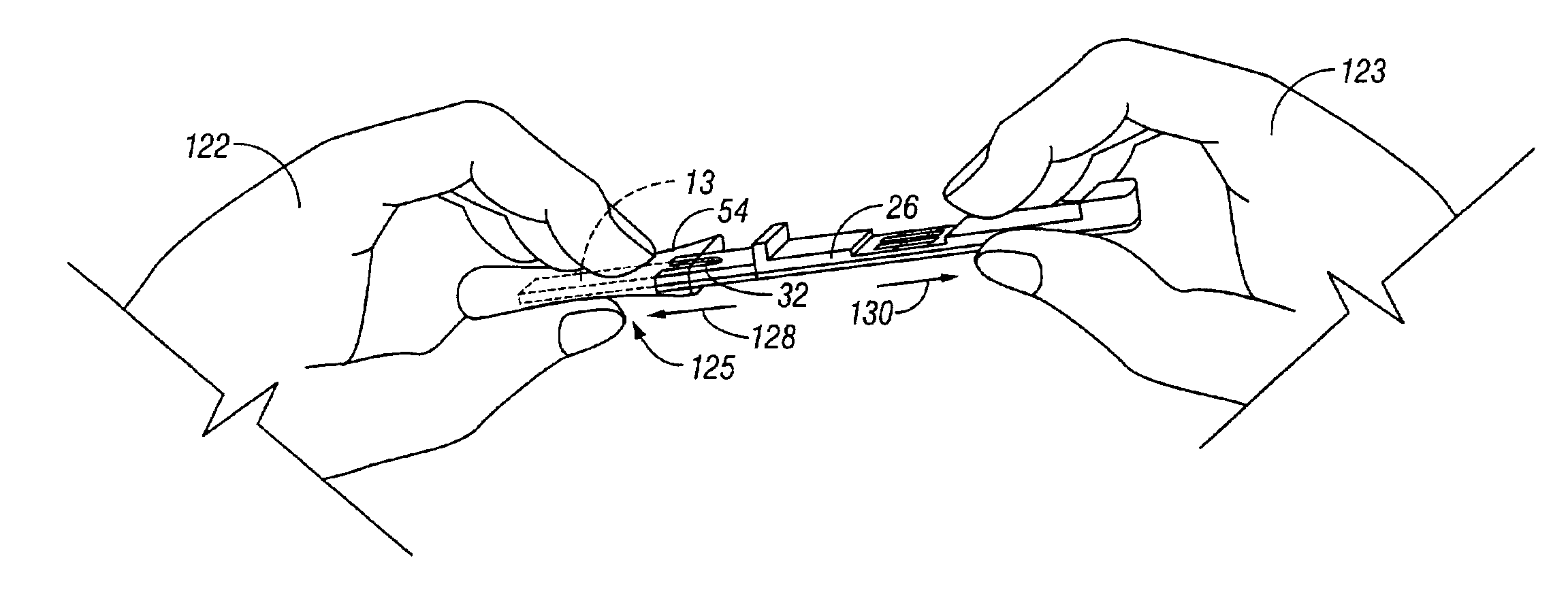

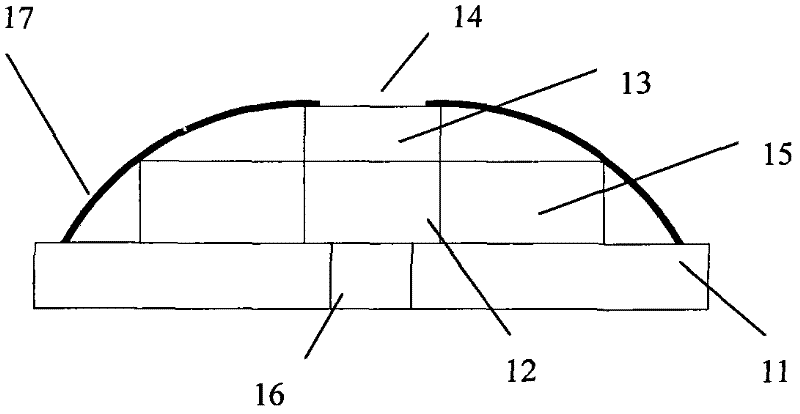

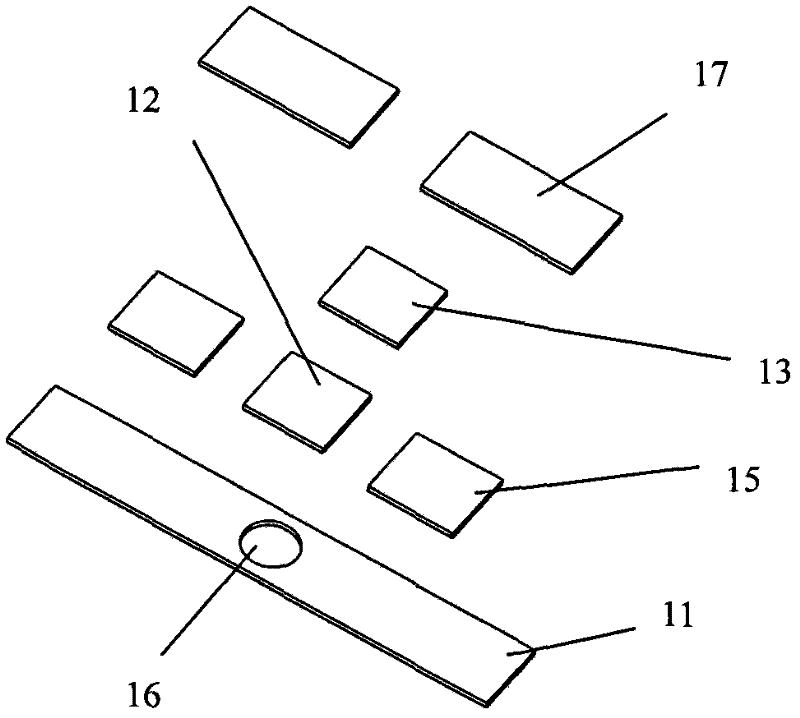

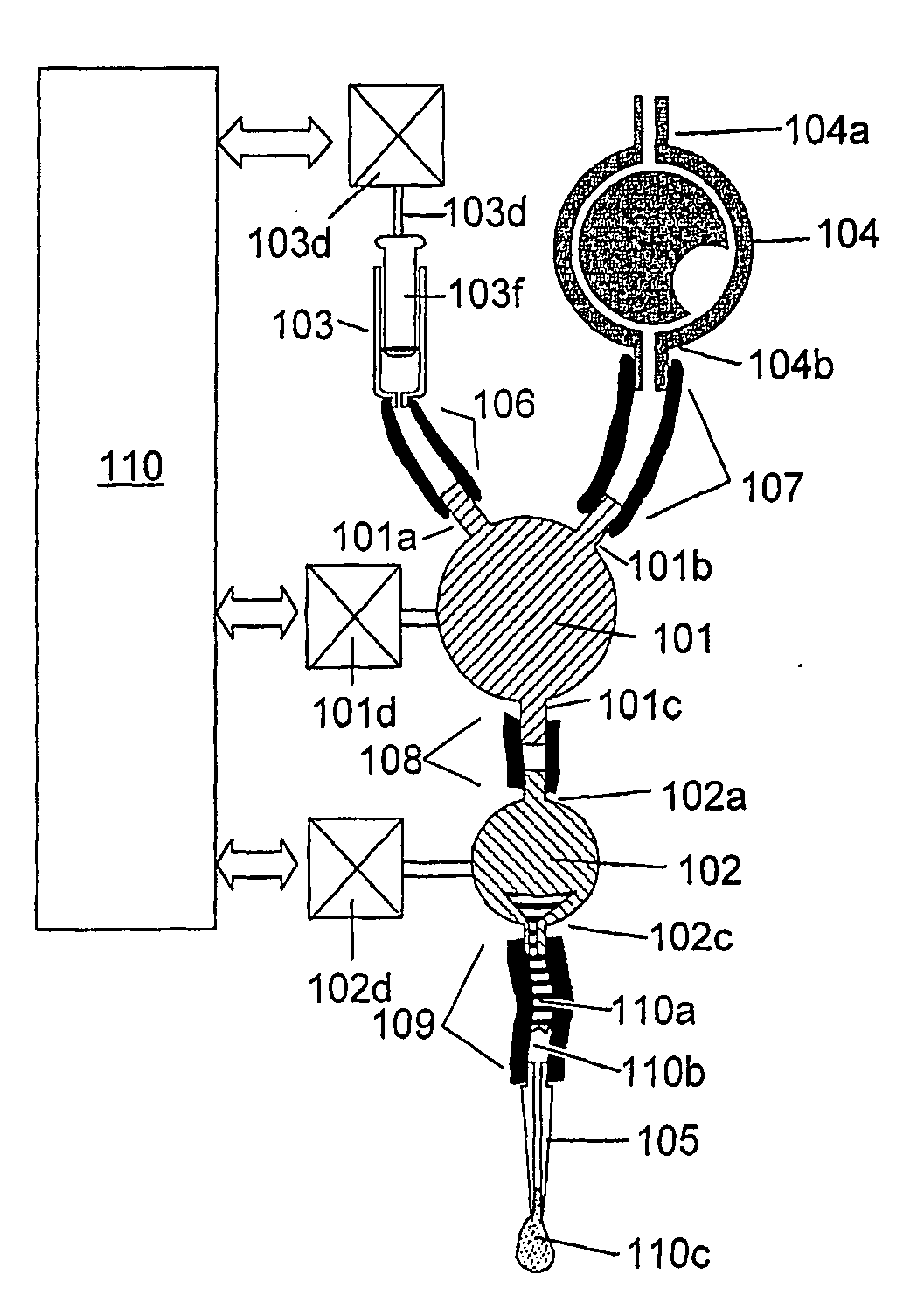

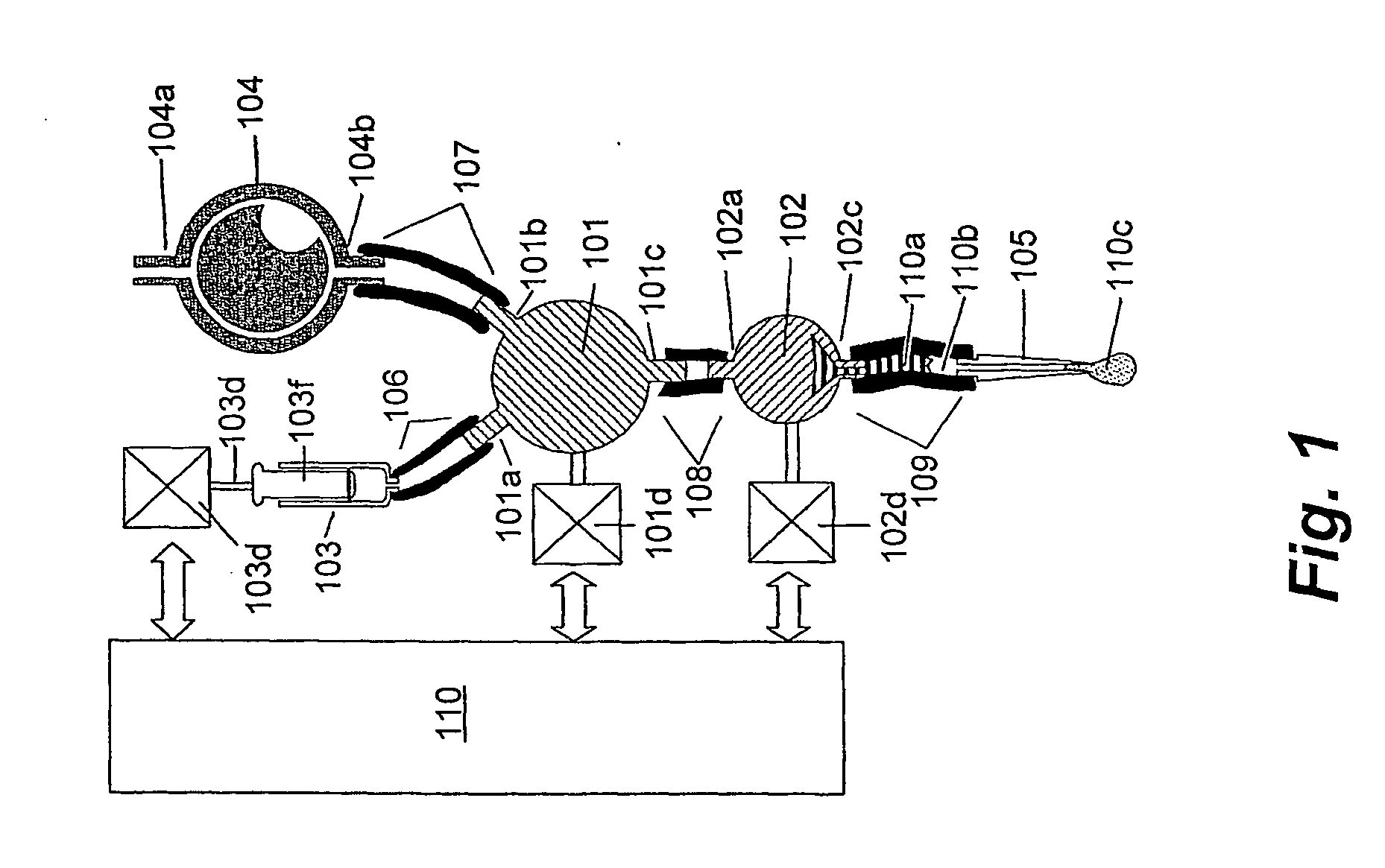

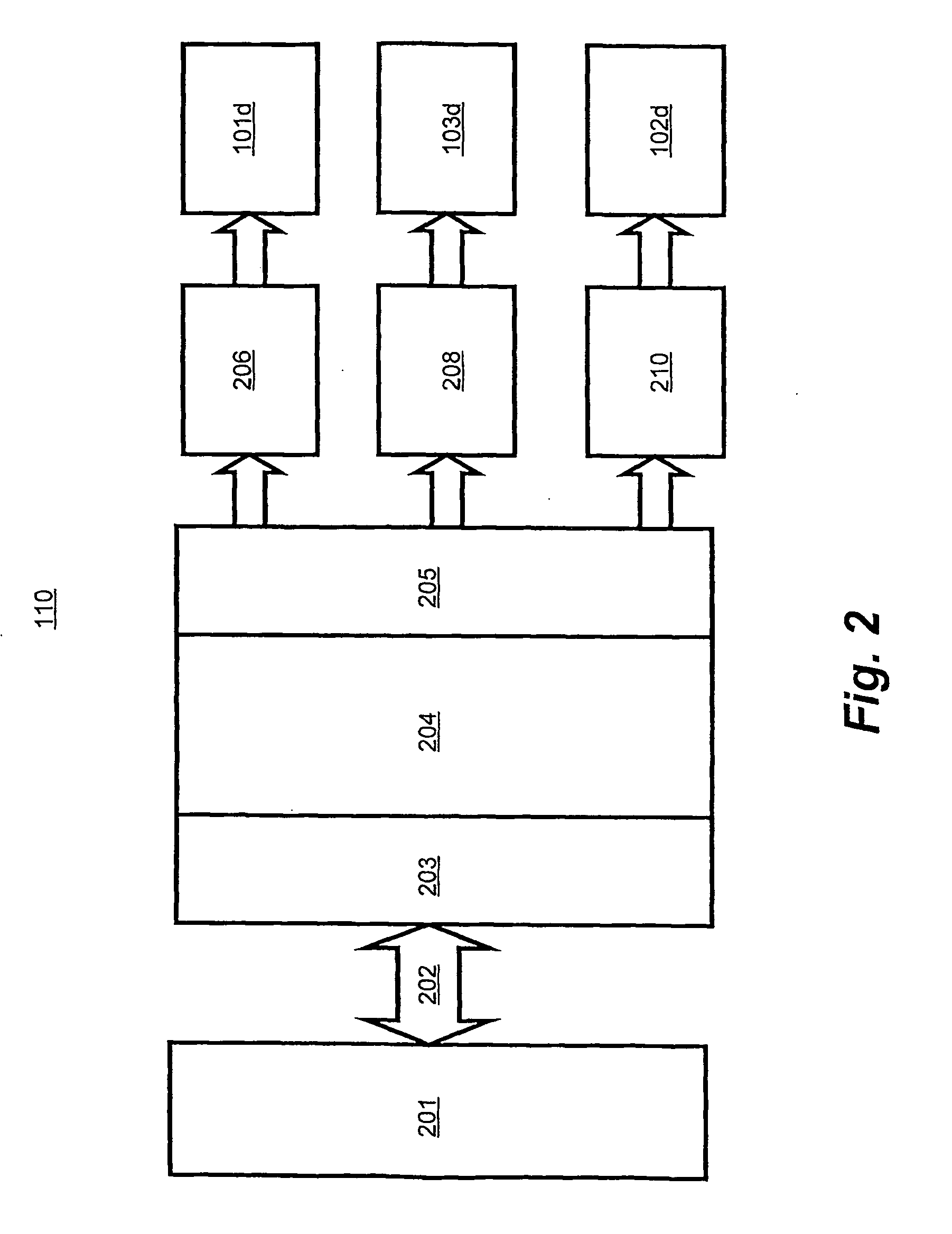

Integrated confirmation sample in a body fluid test device and method of using

InactiveUS6875185B2Small sizeEasy to useAnalysis using chemical indicatorsVaccination/ovulation diagnosticsAntigenSingle sample

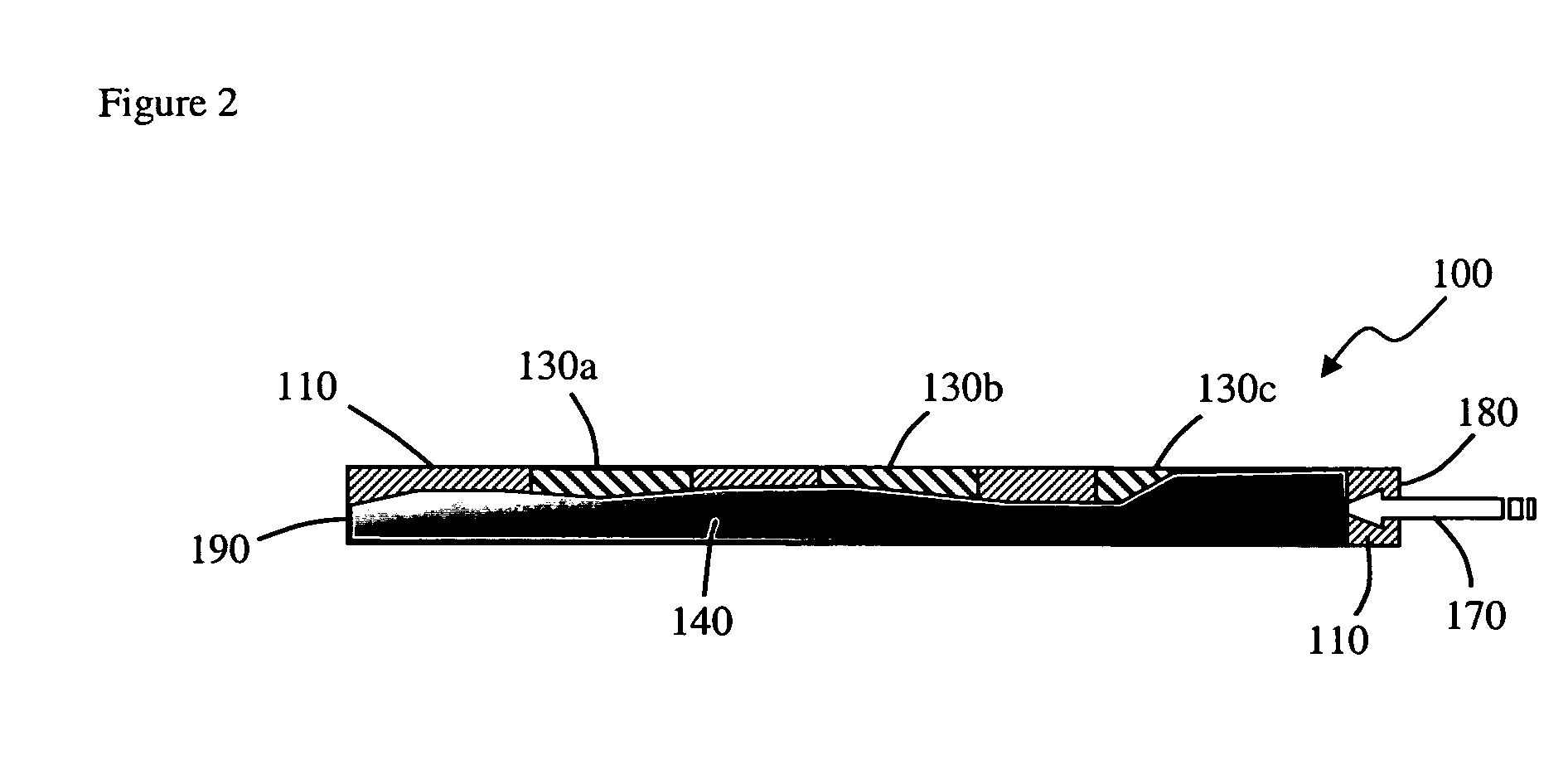

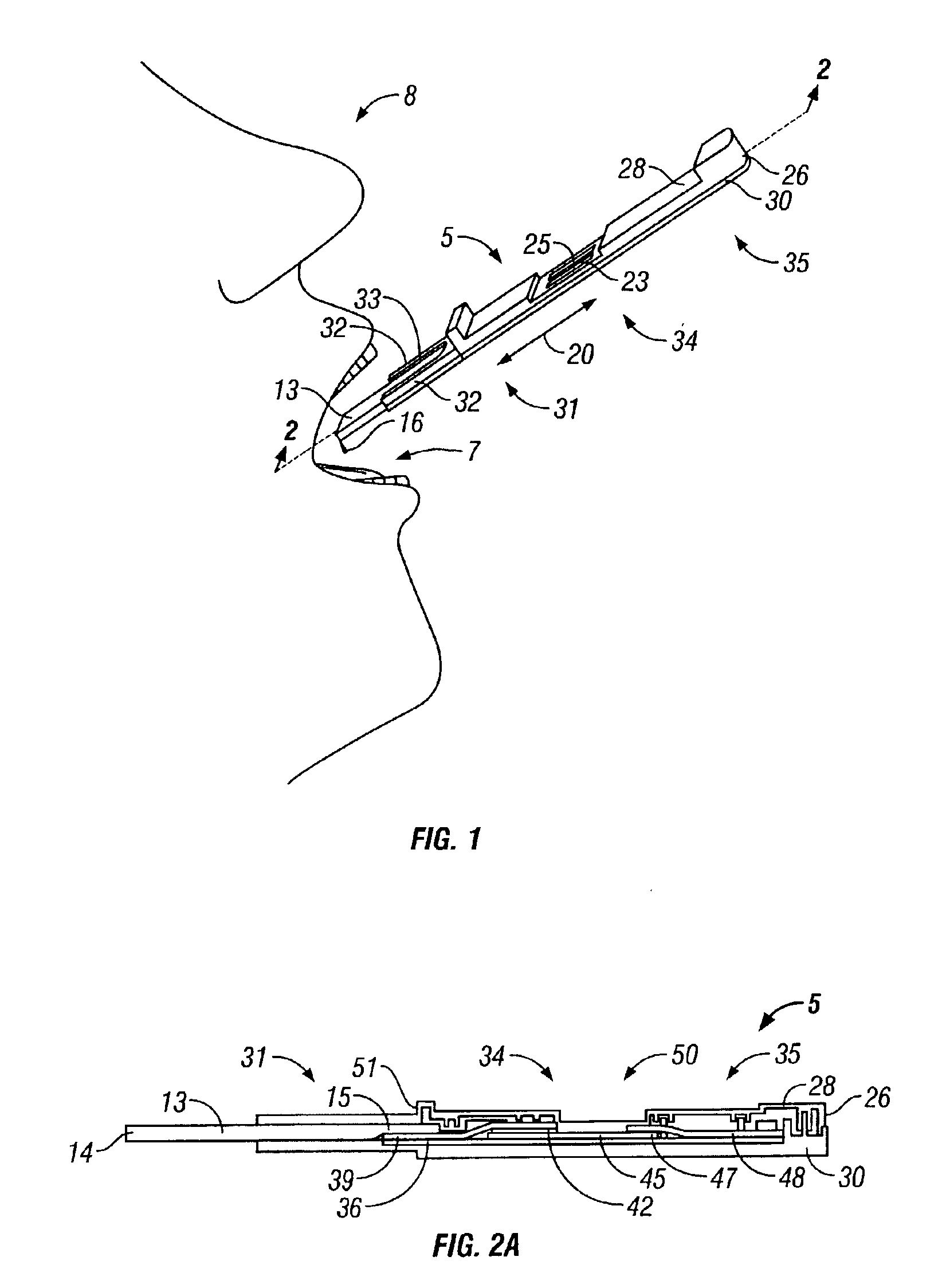

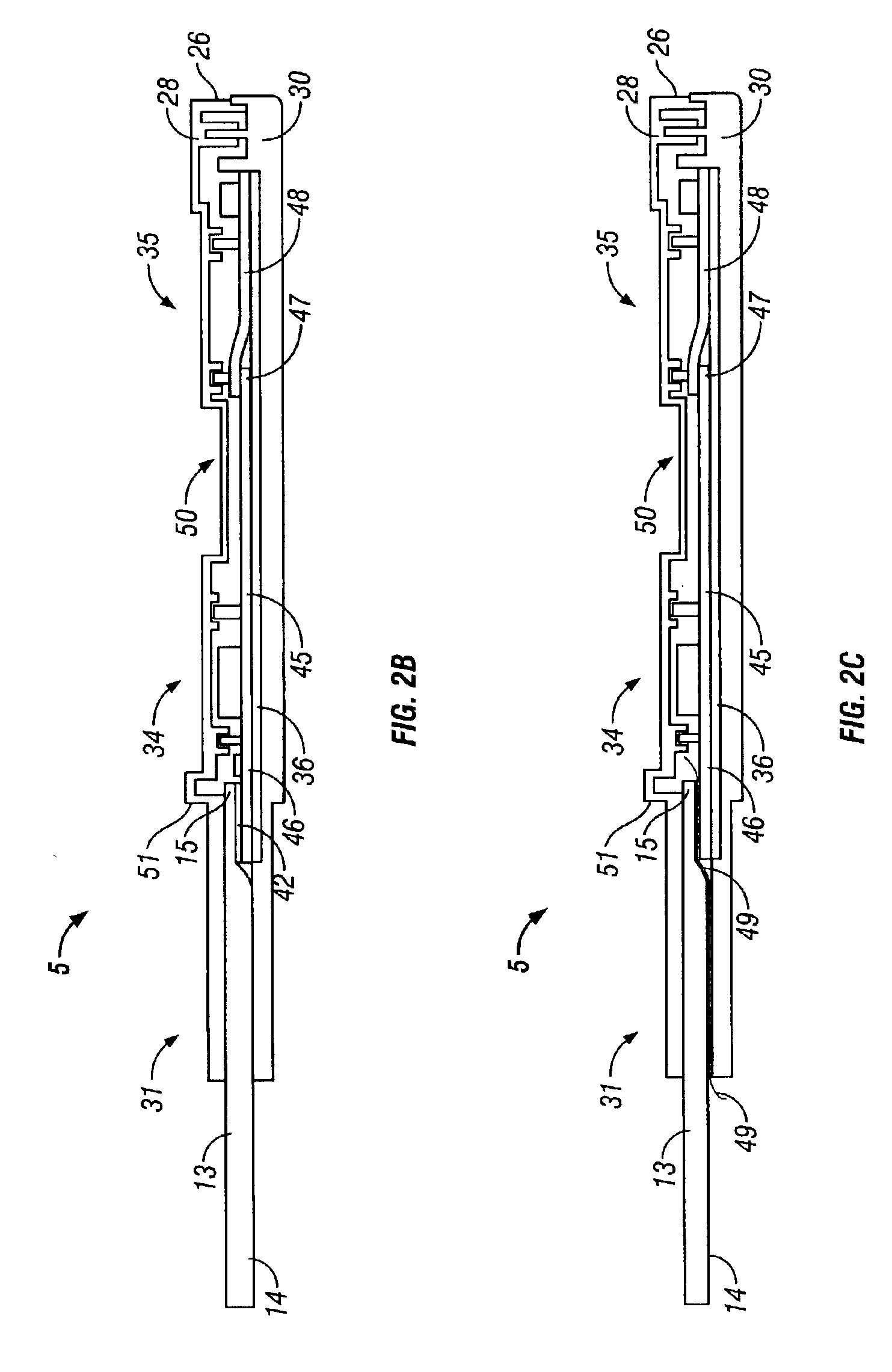

A lateral flow immunoassay contact chemical test device and method integrates sample collection, prescreen testing, and confirmation sample collecting and storing with a single device and a minimum of steps. While particularly advantageously used with an oral fluid sample absorbed directly from a person's mouth, (in which constant monitoring of a collection process is made possible), the test device may be used with any of a variety of sample fluids. Prescreen testing and confirmation testing are performed on a single sample. Prescreen testing is performed by a lateral flow assay. The sample collection pad is subsequently separated from the wicking path to prevent continued migration from, and backflow into the sample collection pad, so that the confirmation sample is preserved in the sample collection pad. A multitude of antigens can be detected with a single device.

Owner:BRANAN MEDICAL

Rhamnolipid-based formulations

InactiveUS20080213194A1Improve skin appearanceHigh purity rhamnolipidBiocideCosmetic preparationsRhamnolipidWorking environment

The present invention relates to rhamnolipid-based formulations to clean, disinfect, deodorize, and act as an antimicrobial and antifungal agent for living and working environments. In addition, the present invention relates to the use of rhamnolipids to create a bio-film when applied to a surface, which prevents the growth of bacteria and fungus. This technique is especially useful to create clean surface areas for medical procedures, chemical testing, during food preparation, as well as for daycare centers and hospitals.

Owner:AURORA ADVANCE BEAUTY LABS

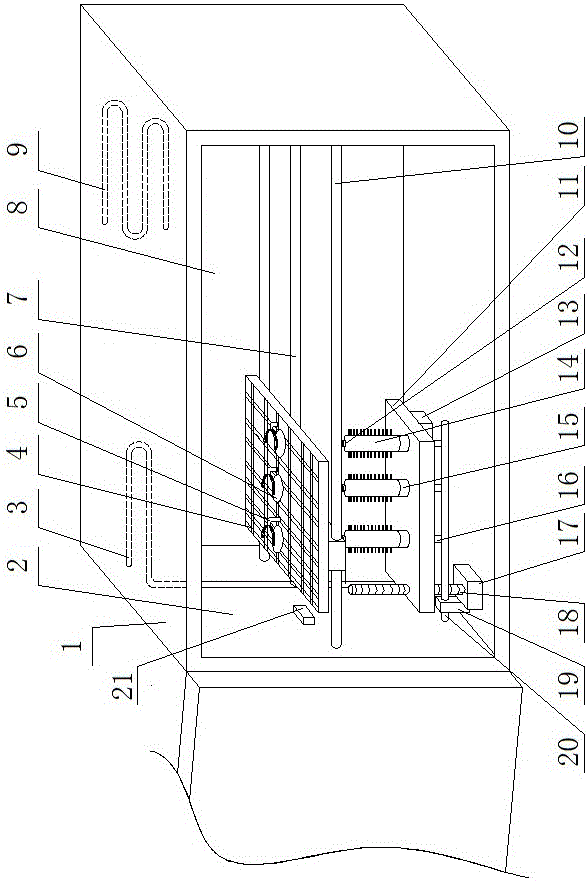

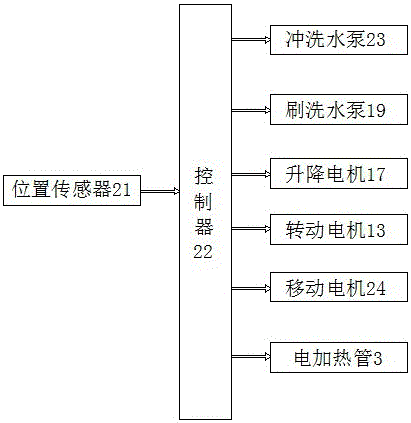

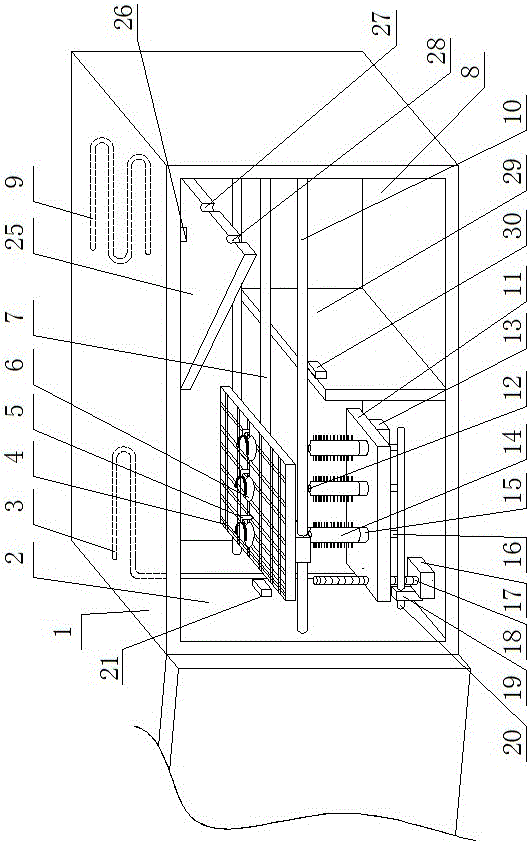

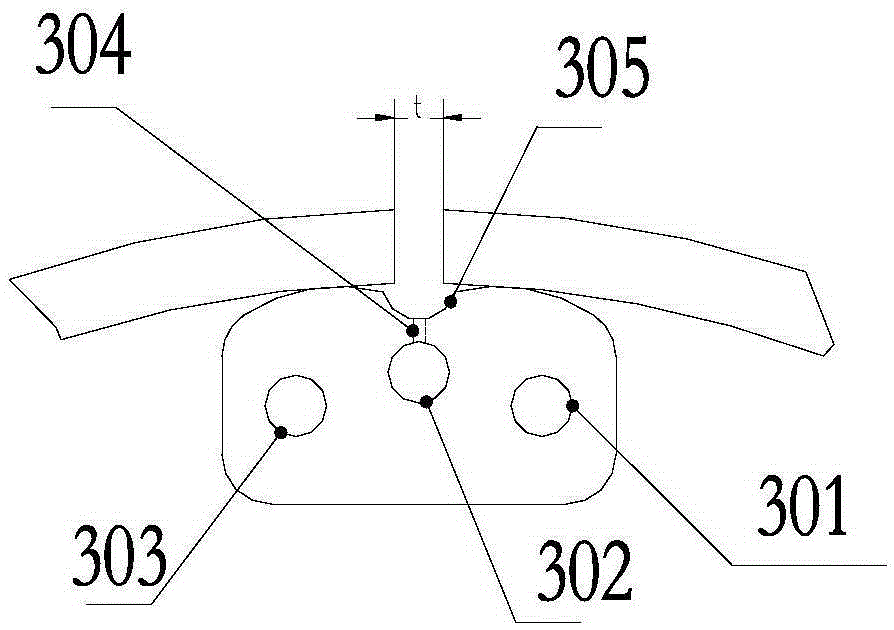

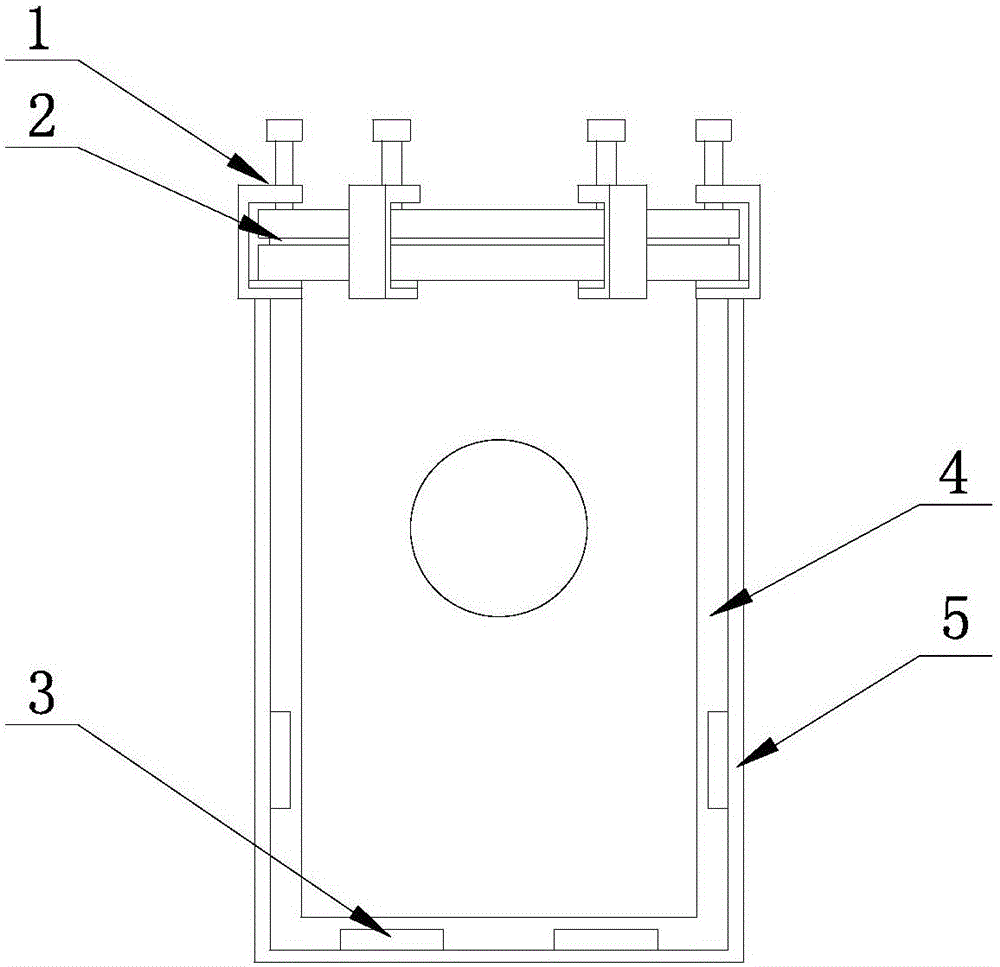

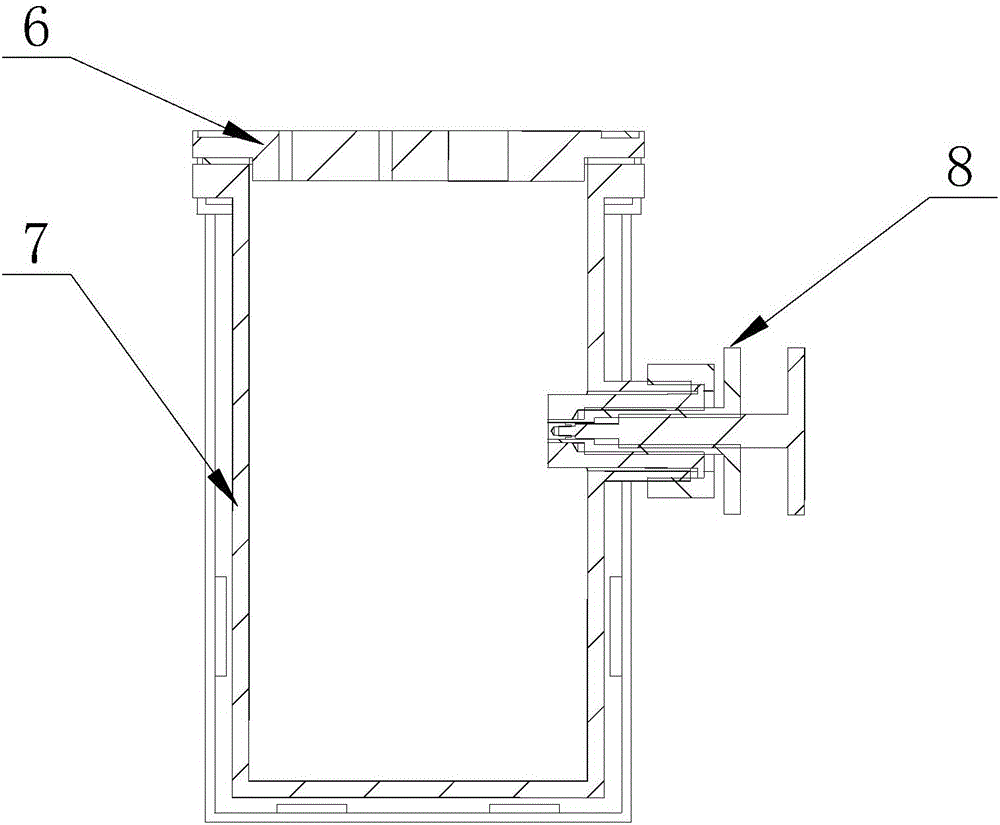

Test tube cleaning and drying device for chemical tests

InactiveCN106363000AAchieve cleaningAchieve immediate storageHollow article cleaningHeating arrangementChemical testEngineering

The invention discloses a test tube cleaning and drying device for chemical tests and belongs to the field of test tube cleaning and drying devices. The technical problems that test tubes cannot be cleaned thoroughly and cannot be stored immediately after being cleaned are solved. As for the structure, the test tube cleaning and drying device comprises a box body. The interior of the box body is divided into a cleaning cavity and a drying cavity, and the cleaning cavity communicates with the drying cavity in the left-right direction. A test tube moving device is fixed in the box body. A grid-shaped test tube fixing plate is fixed to the test tube moving device. A plurality of brushing holes are formed in the test tube fixing plate. A test tube fixing clip is fixed in the position of each brushing hole in the test tube fixing plate. The cleaning device comprises a flushing device and a brushing device. The flushing device is fixed to the position above the test tube fixing plate. The brushing device is fixed below the test tube fixing plate. A drying device body is fixed to the position above the test tube fixing plate. The test tube moving device, the flushing device, the brushing device and the drying device body are all connected to a controller. By the adoption of the test tube cleaning and drying device, the test tubes can be cleaned thoroughly and dried.

Owner:赵靖宇

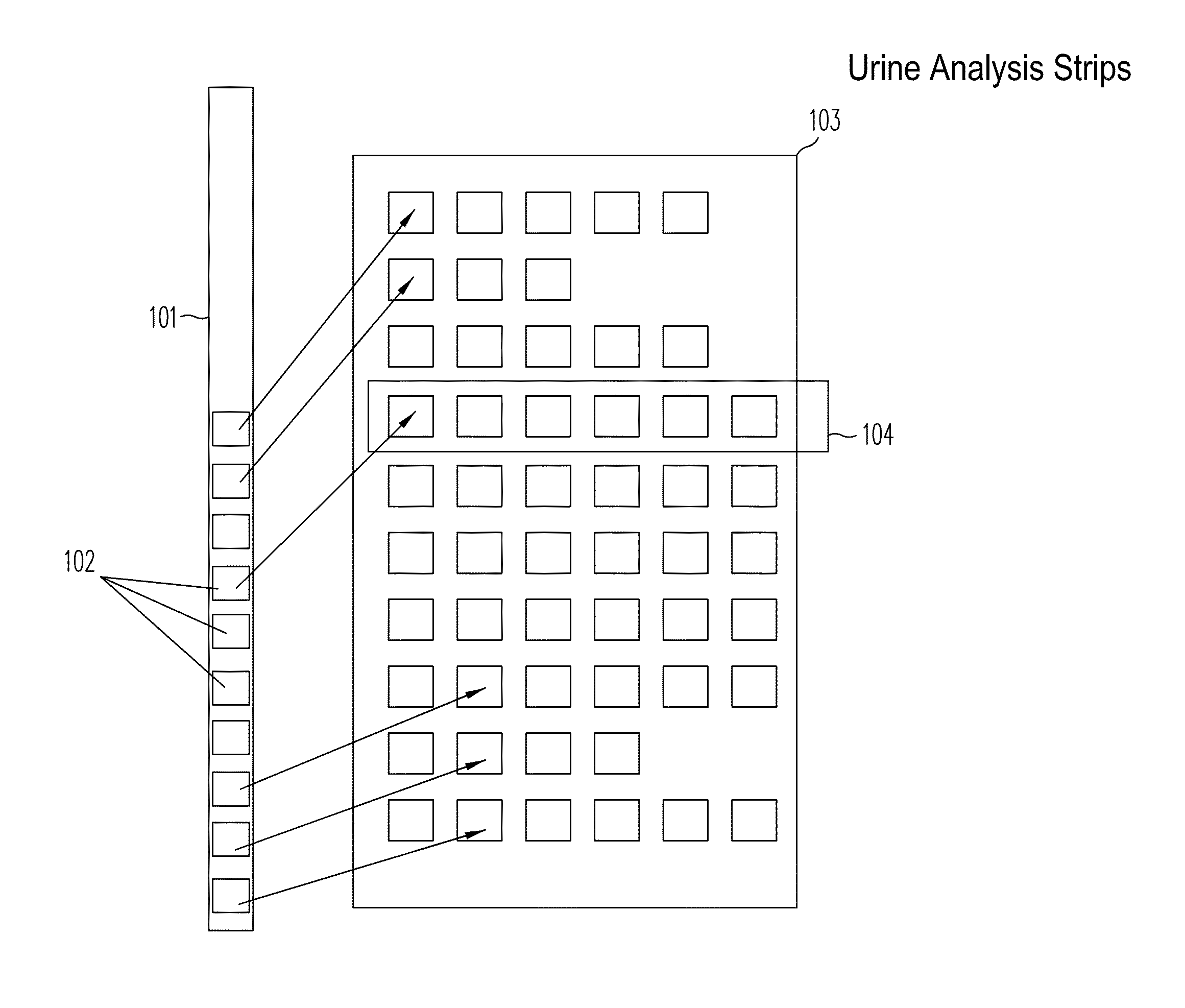

Precision luxmeter methods for digital cameras to quantify colors in uncontrolled lighting environments

ActiveUS20160048739A1Improve accuracyImprove color quantificationImage enhancementImage analysisColor changesDiagnostic instrument

In one embodiment, a diagnostic system for biological samples is disclosed. The diagnostic system includes a diagnostic instrument, and a portable electronic device. The diagnostic instrument has a reference color bar and a plurality of chemical test pads to receive a biological sample. The portable electronic device includes a digital camera to capture a digital image of the diagnostic instrument in uncontrolled lightning environments, a sensor to capture illuminance of a surface of the diagnostic instrument, a processor coupled to the digital camera and sensor to receive the digital image and the illuminance, and a storage device coupled to the processor. The storage device stores instructions for execution by the processor to process the digital image and the illuminance, to normalize colors of the plurality of chemical test pads and determine diagnostic test results in response to quantification of color changes in the chemical test pads.

Owner:HEALTHY IO LTD

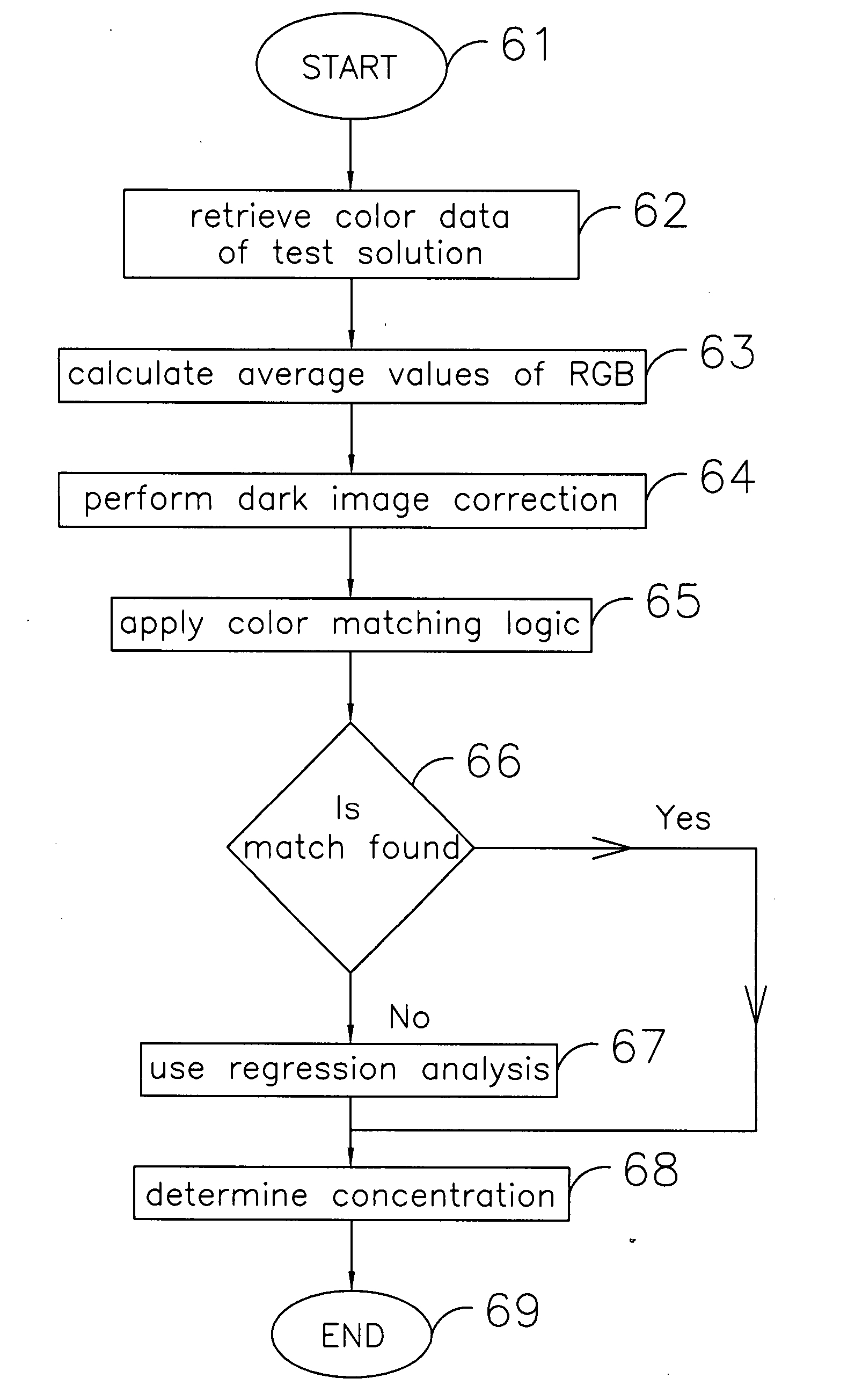

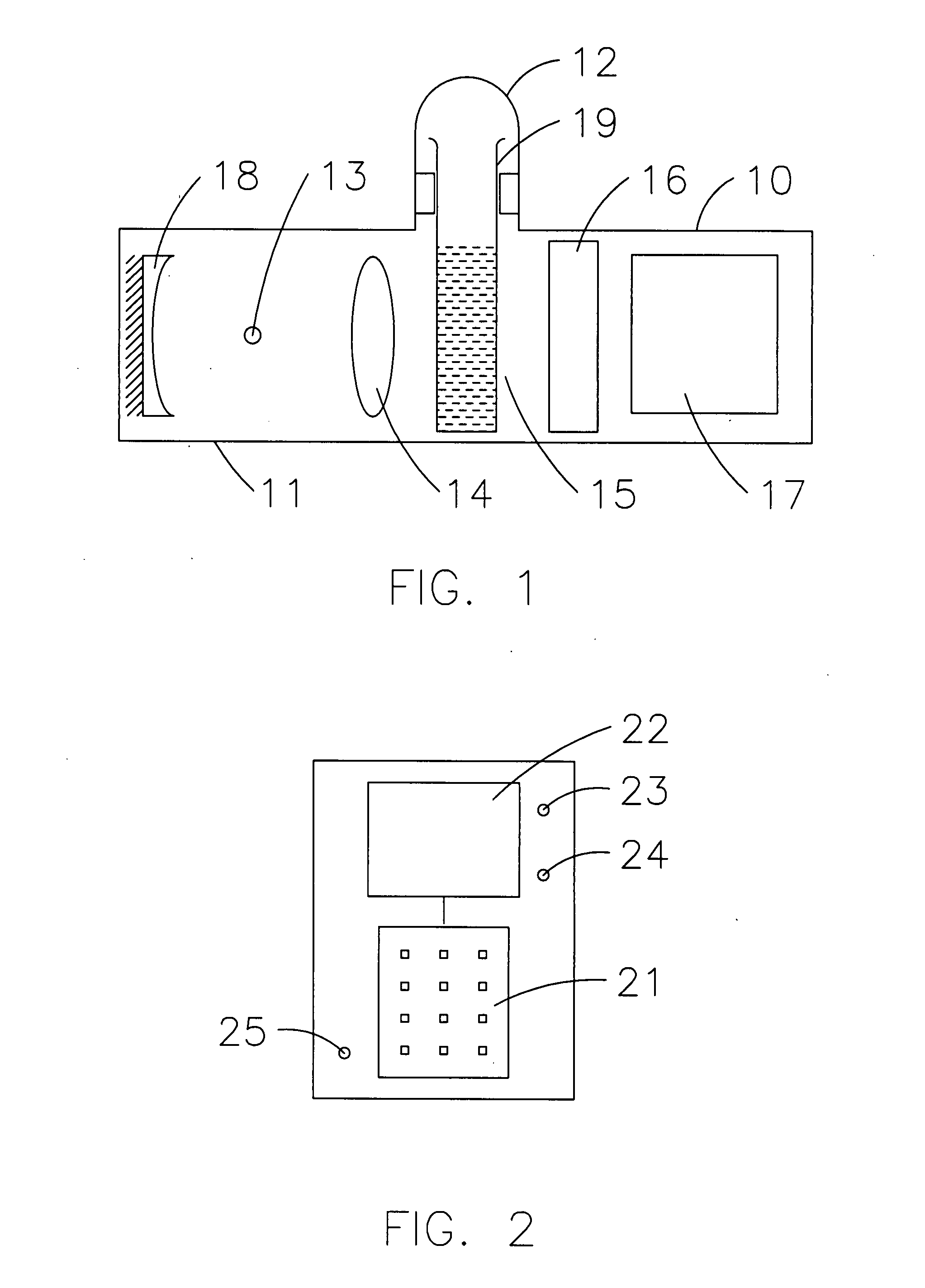

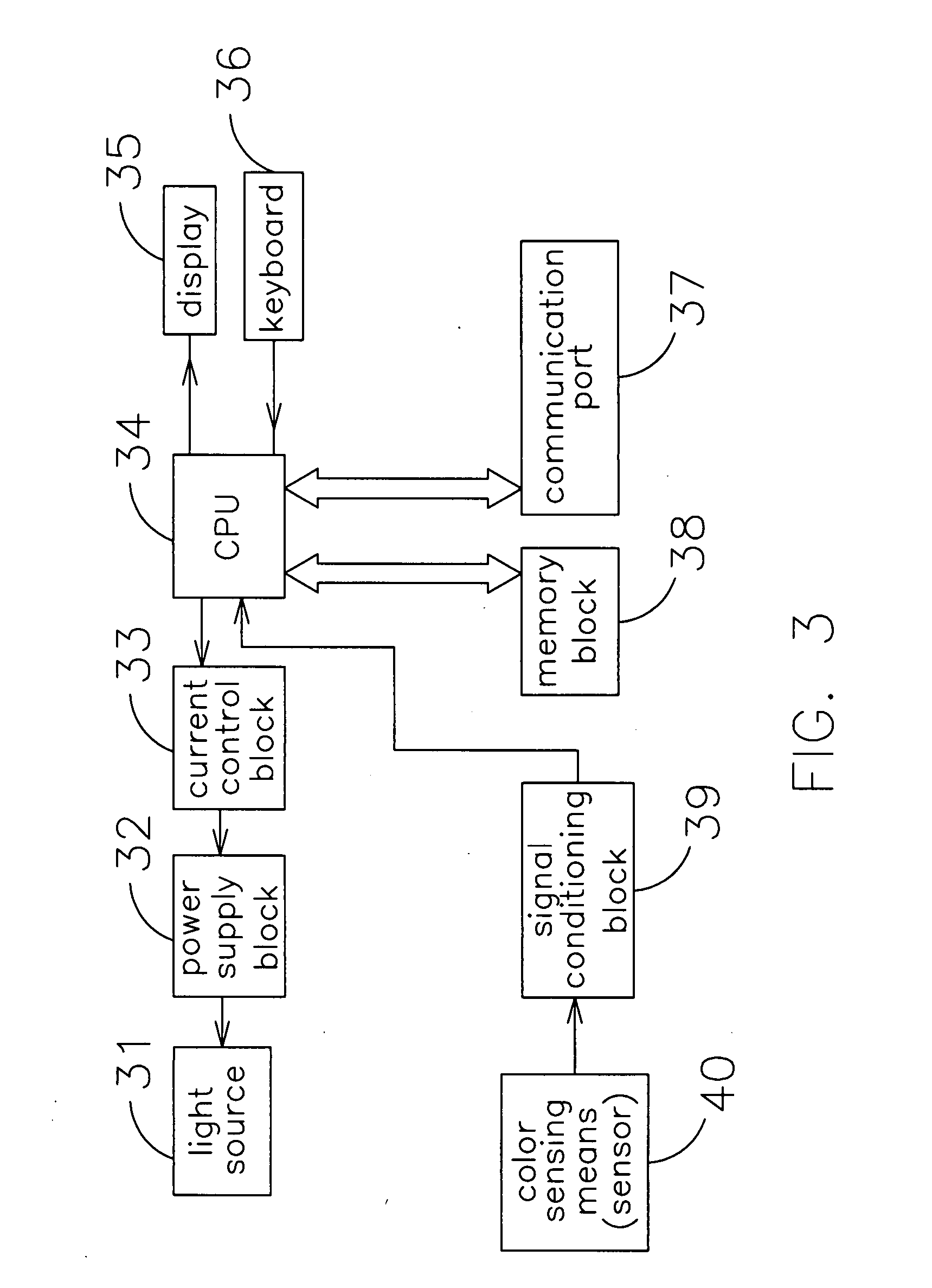

Colorimeter operating on color matching logic

InactiveUS20070188759A1Material analysis by observing effect on chemical indicatorAnalysis by thermal excitationChemical testComputer science

A colorimeter operating on color matching logic concerned with a process of quantitatively analyzing a known substance by finding the color signature of the colored solution of that substance and matching it or interpolating it with the color values provided in the look-up table for that substance for determining the concentration of the substance in question. A memory means coupled with a microprocessor or a computer stores the calibration commands, computational routines and comparison logic and stores a plurality of color data corresponding to each biochemical, clinical pathological or chemical test for the substances that can possibly be quantitatively determined by the said colorimeter and the said data is stored in the form of look-up tables.

Owner:MEHENDALE DHANANJAY +2

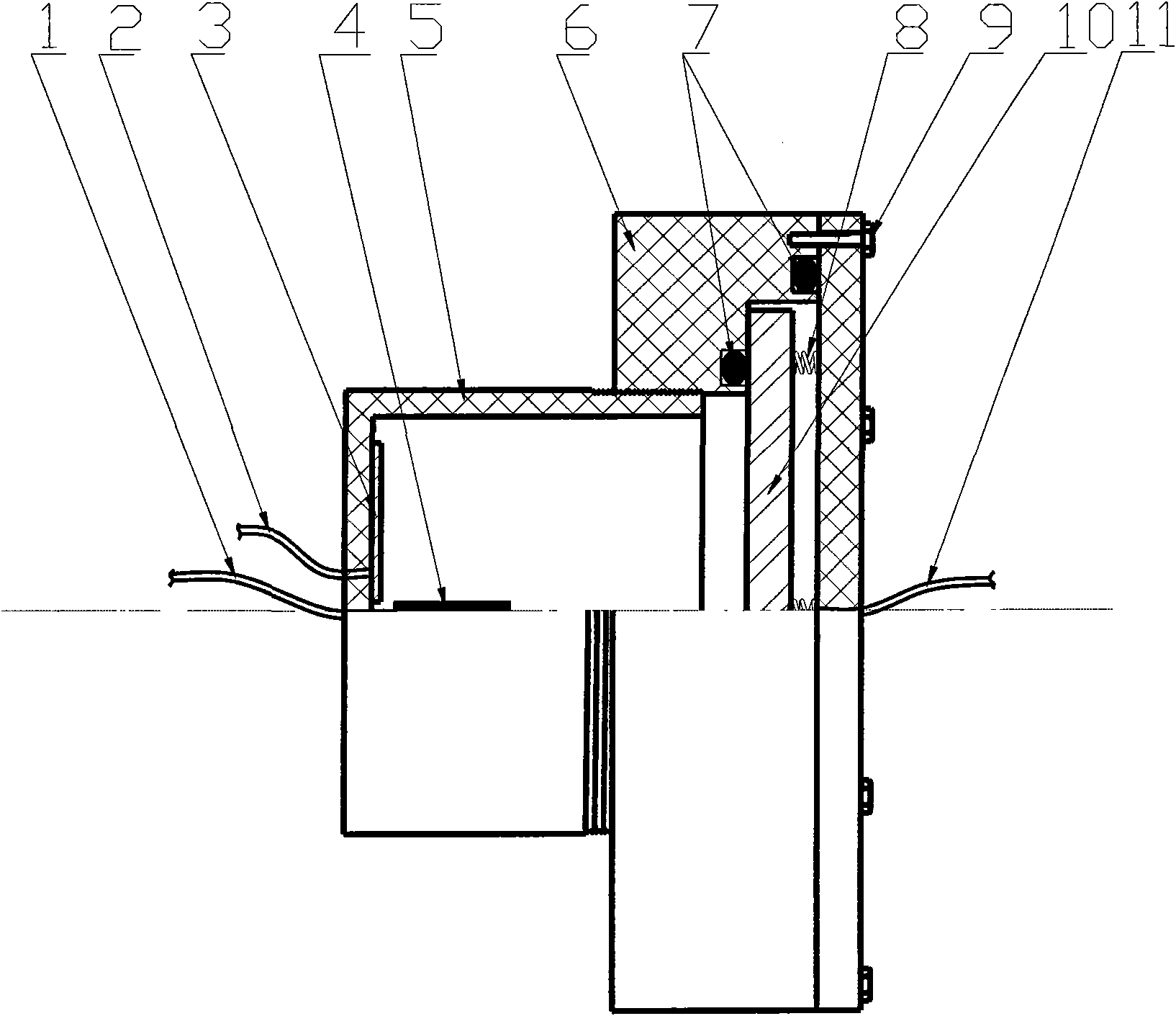

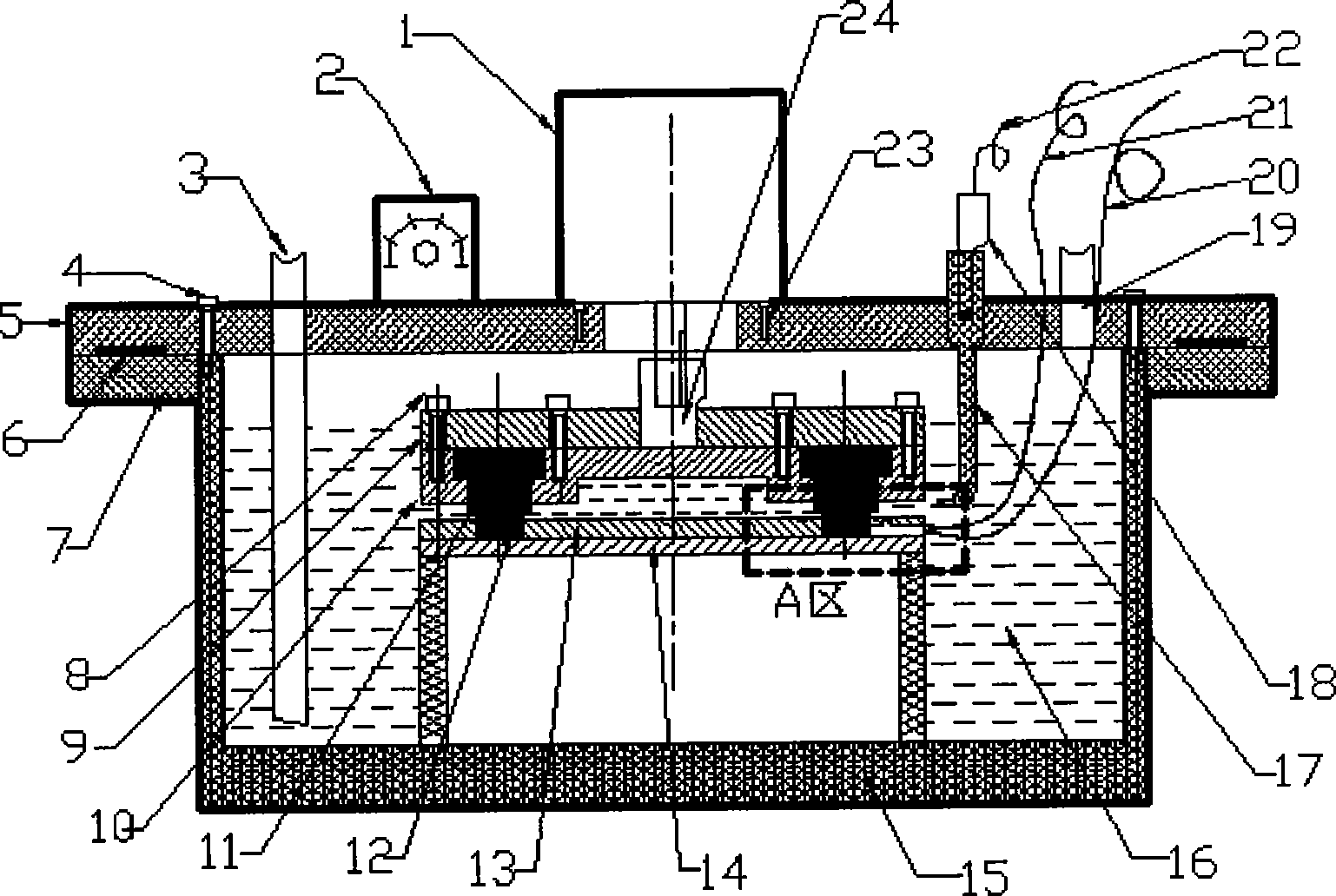

Corrosion test device with in-situ electrochemical test function

InactiveCN101644653AReduce distractionsReduce adverse effectsWeather/light/corrosion resistanceMetallic materialsAuxiliary electrode

The invention relates to a corrosion test device with a field in-situ electrochemical test function in a natural sea area environment, belonging to the technical field of electrochemical corrosion tests. The main structure of the corrosion test device comprises a reference electrode lead wire, an auxiliary electrode lead wire, an auxiliary electrode, a reference electrode, a probe shell, a samplesealing structure shell, a sealing ring, a pressure spring, a fastening bolt, a sample and a sample lead wire, wherein an electrochemical test probe and a sample sealing structure are designed into split type structures; the electrochemical test probe consists of the reference electrode, the reference electrode lead wire, the auxiliary electrode and the probe shell and is rotated to the sample sealing structure through screw threads positioned at the front of the probe shell; the sample sealing structure shell is processed by and made of plastic and nylon or other non-metal materials; and thesample or the researched electrode is hermetically fixed by the O-shaped sealing ring and sealing stuffing. The invention has simple and reliable structural principle, convenient use and operation andgood test accuracy.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

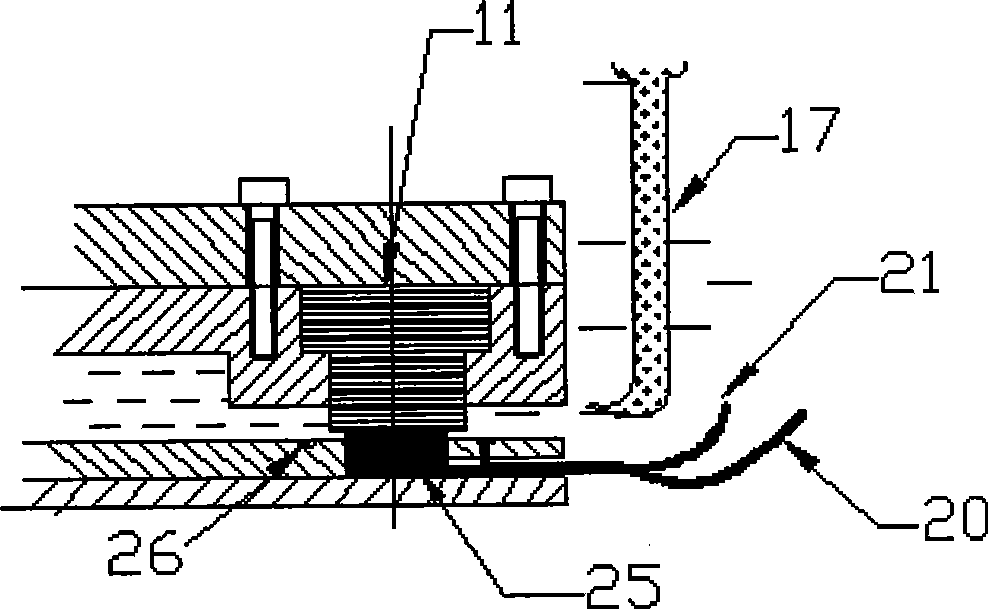

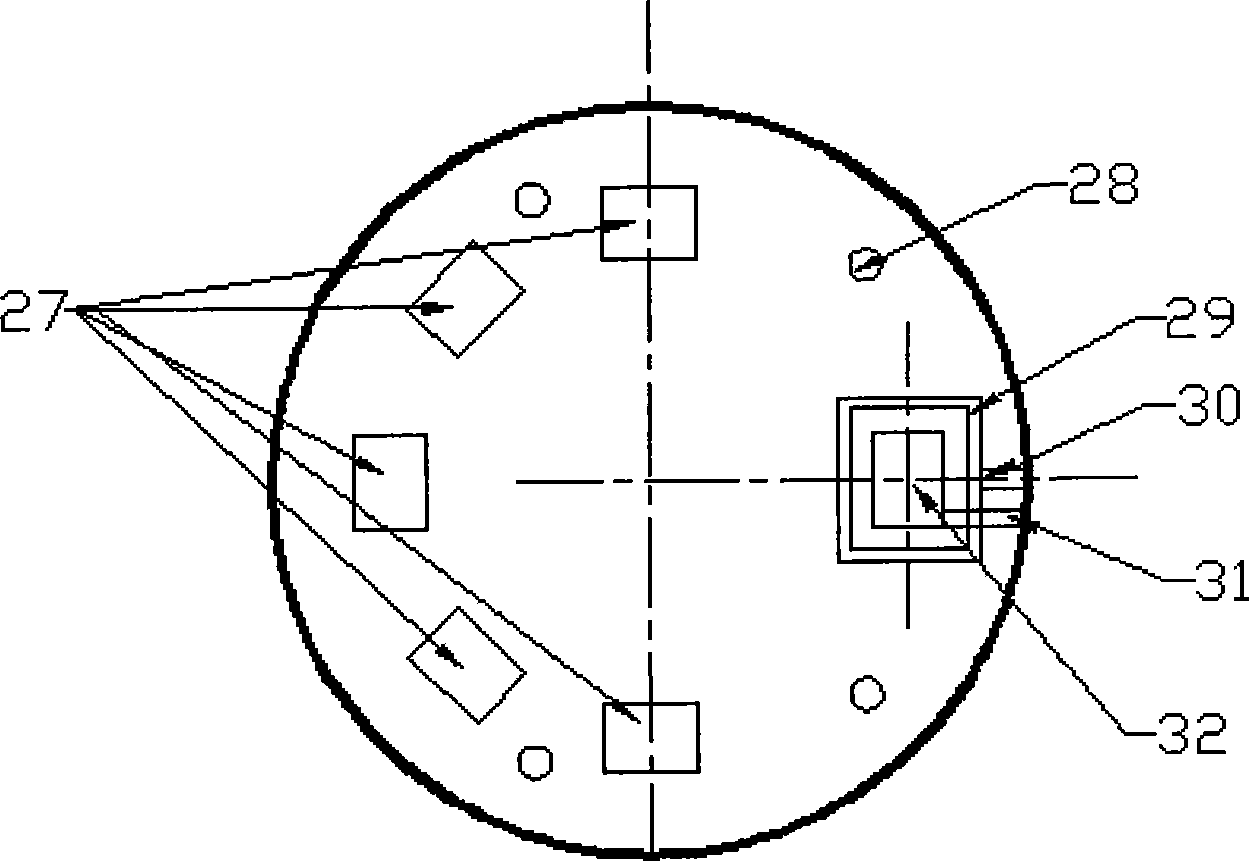

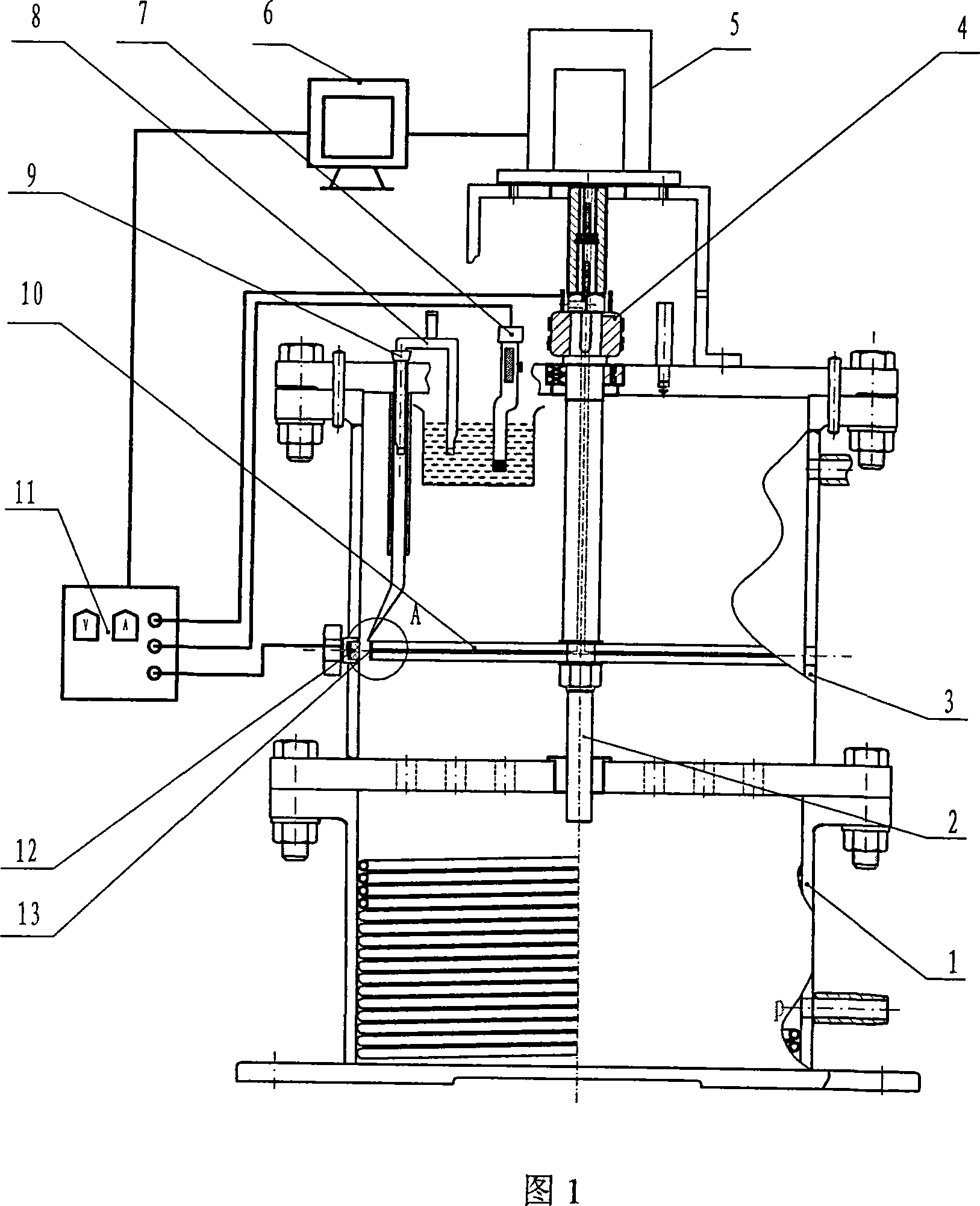

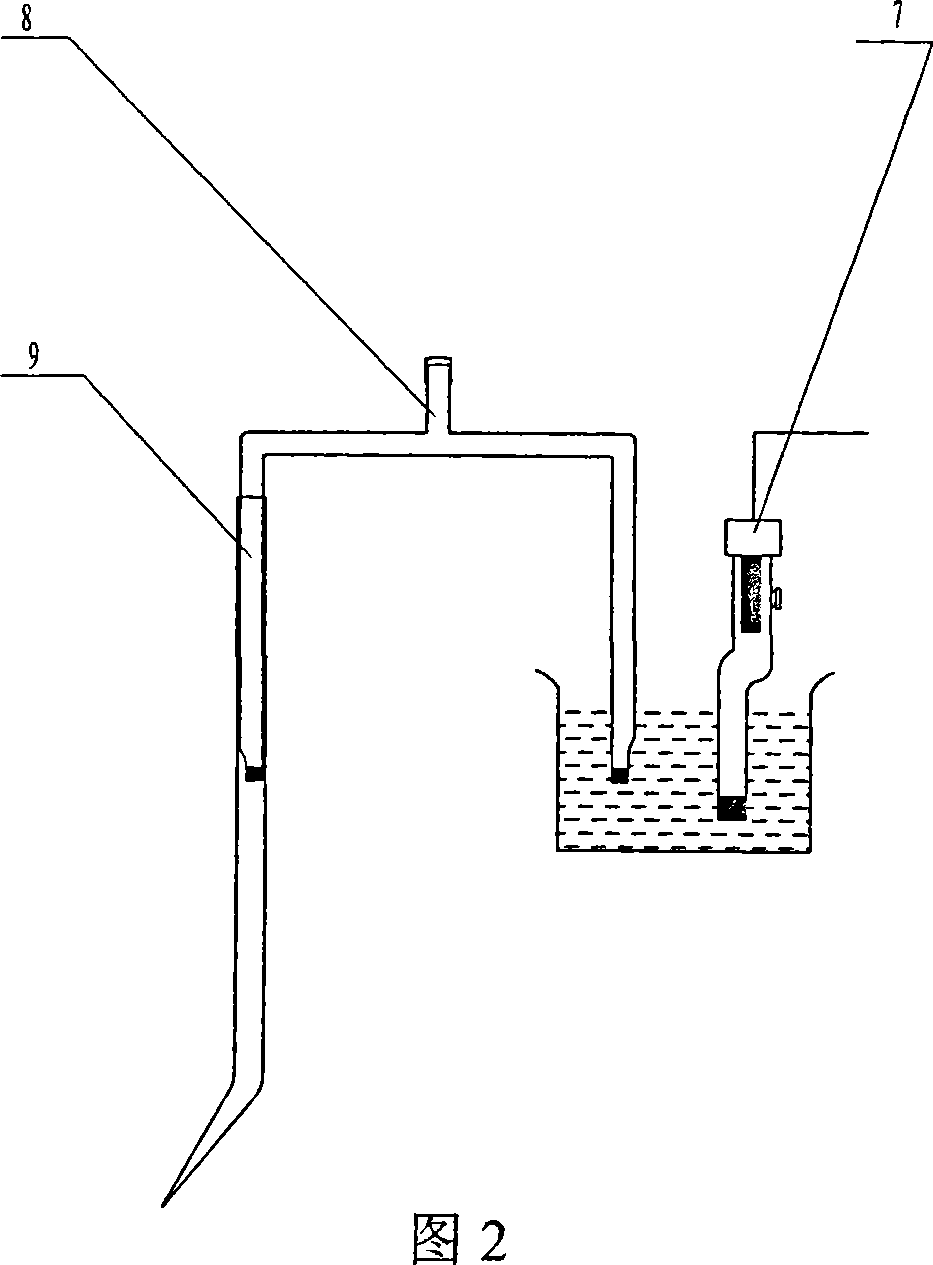

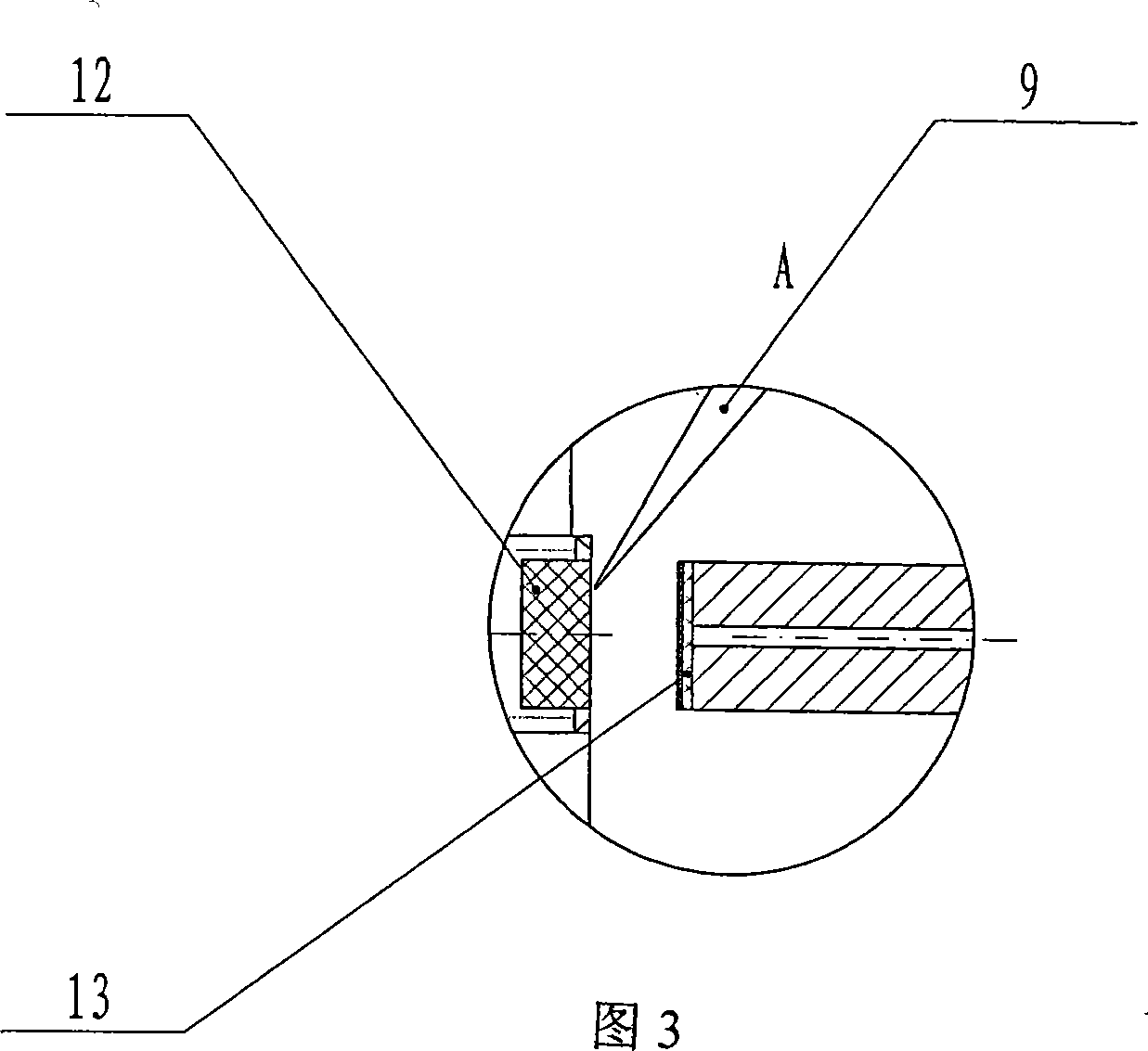

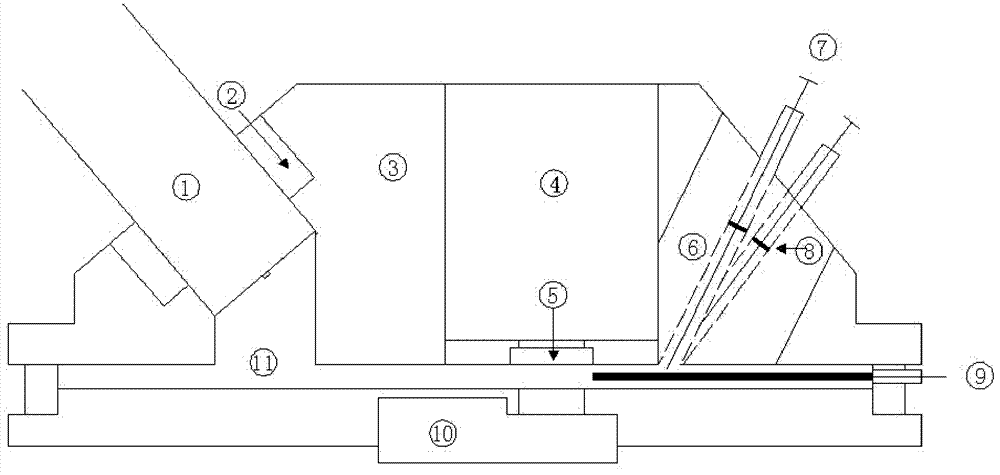

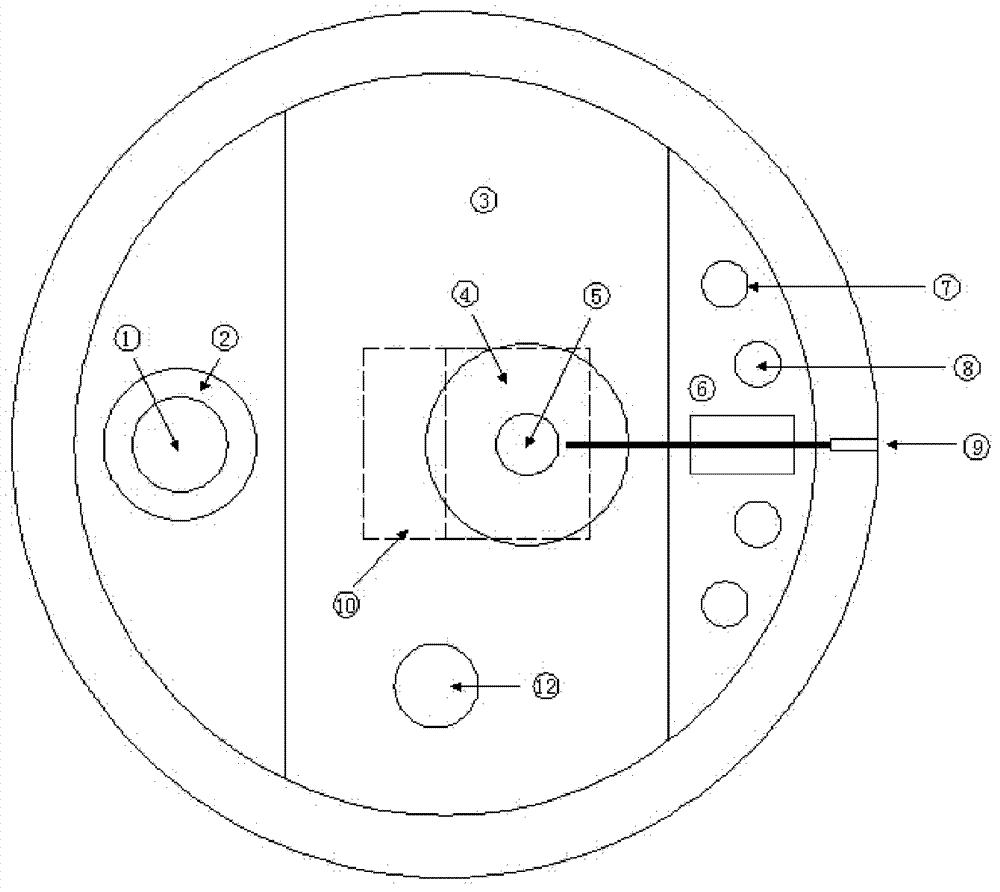

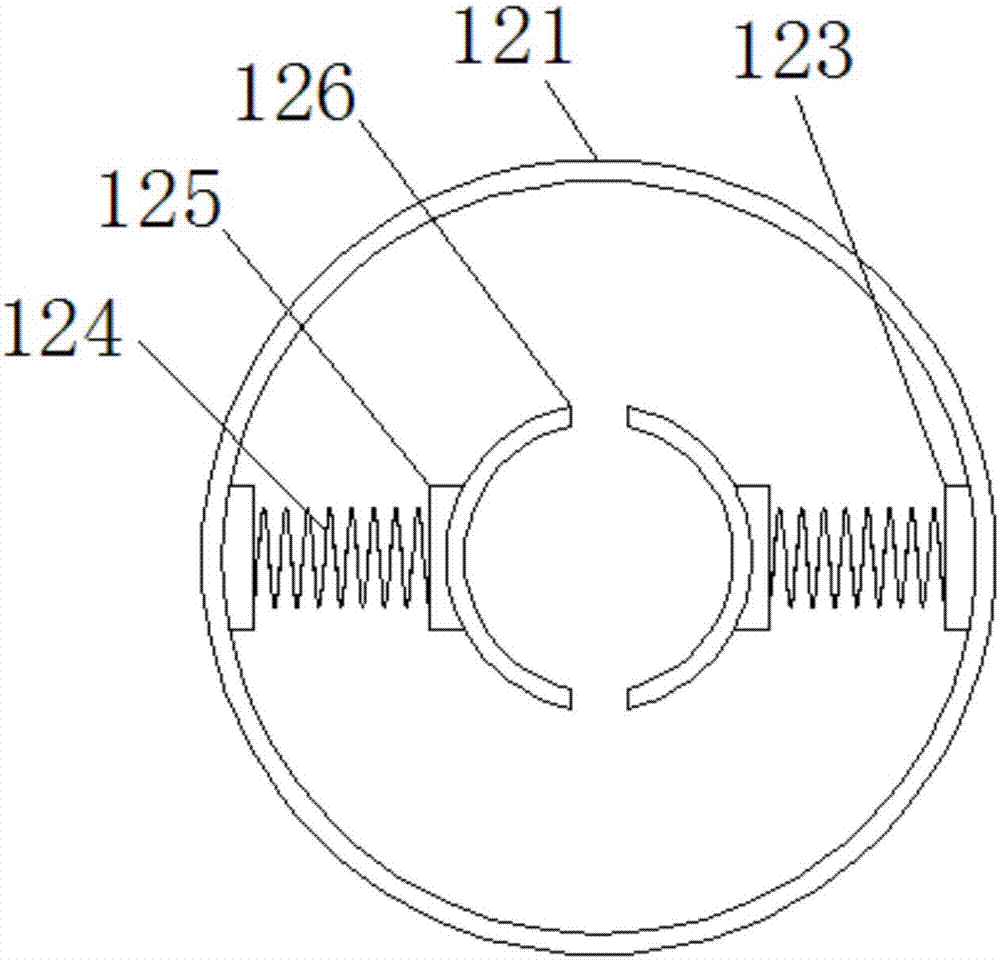

Corrosion product film wear property and corrosion electro-chemistry test device

InactiveCN101477010AMeasuring wear resistanceWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceWater bathsCircular disc

The invention relates to a device for testing abrasion property and corrosion electrochemistry of a corrosion product film, and belongs to the technical field of corrosion simulation experiment and electrochemistry test. The device consists of main parts such as an electric motor, a sealing cover, a rotary disc, a friction block, a sample table, a three-electrode electrochemistry test system, an external electrochemistry test instrument, a thermostatic water bath, and the like; and the rotary friction block of the rotary disc abrades a sample, an electrochemistry test adopts a three-electrode system, and the electrochemistry sample as a working electrode, a platinum wire as a reference electrode surrounding the periphery of the electrochemistry sample and a saturated calomel electrode to form the three-electrode system. The device can measure the abrasion resistant property of the formed corrosion product film, and simultaneously measure electrochemical parameters for the samples covered by the corrosion product film during abrasion to obtain electrochemical parameter values at different time of abrasion of the corrosion product film.

Owner:UNIV OF SCI & TECH BEIJING

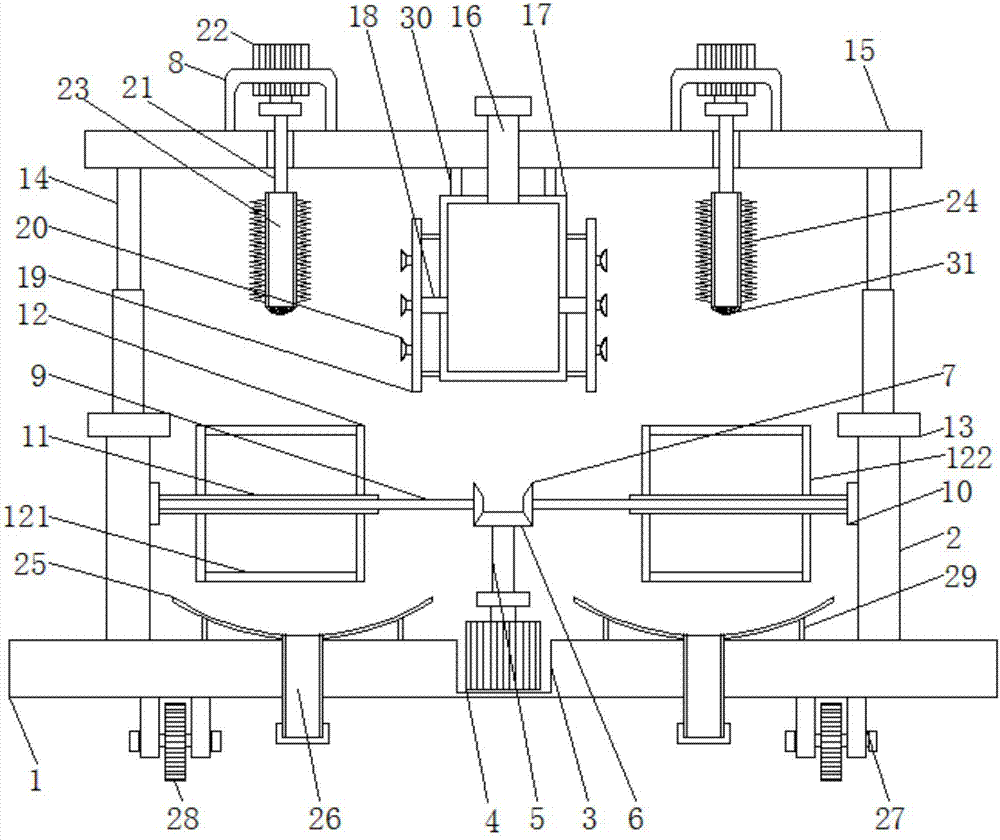

Chemical test tube cleaning device

The invention discloses a chemical test tube mechanical cleaning device, and belongs to the field of chemical supplies. The chemical test tube cleaning device is composed of an automatic rotation water spraying hairbrush, motors, small-sized cylindrical water channels, a stand column, a tube brushing machine base platform, an air cylinder, air holes, a conveyor belt, an operating platform and a micro sensor. The stand column is used for supporting the upper air cylinder, an air cylinder piston is connected with a tube brushing device, and one end of a test tube brush is connected with the motors. The motors are separated from a water inlet in the tail portion of the test tube brush through the small-sized cylindrical water channels. The rotation hairbrush is in a thin-wall hollow type, six small water spraying holes are punched in the working position of the hairbrush, two water inlet holes are punched in the hollow positions, corresponding to the small-sized cylindrical water channels, of the hairbrush, an outer water inlet is formed in the upper portion of a test tube brush box, and the micro sensor is placed at the lower right corner of the test tube brush box. Nine novel rubber plugs are mounted inside a test tube clamping box, and the conveyor belt is used for conveying the test tube box so that cleaning can be achieved. The chemical test tube cleaning device has the advantage that a large number of test tubes can be efficiently cleaned through the device.

Owner:孙香兰

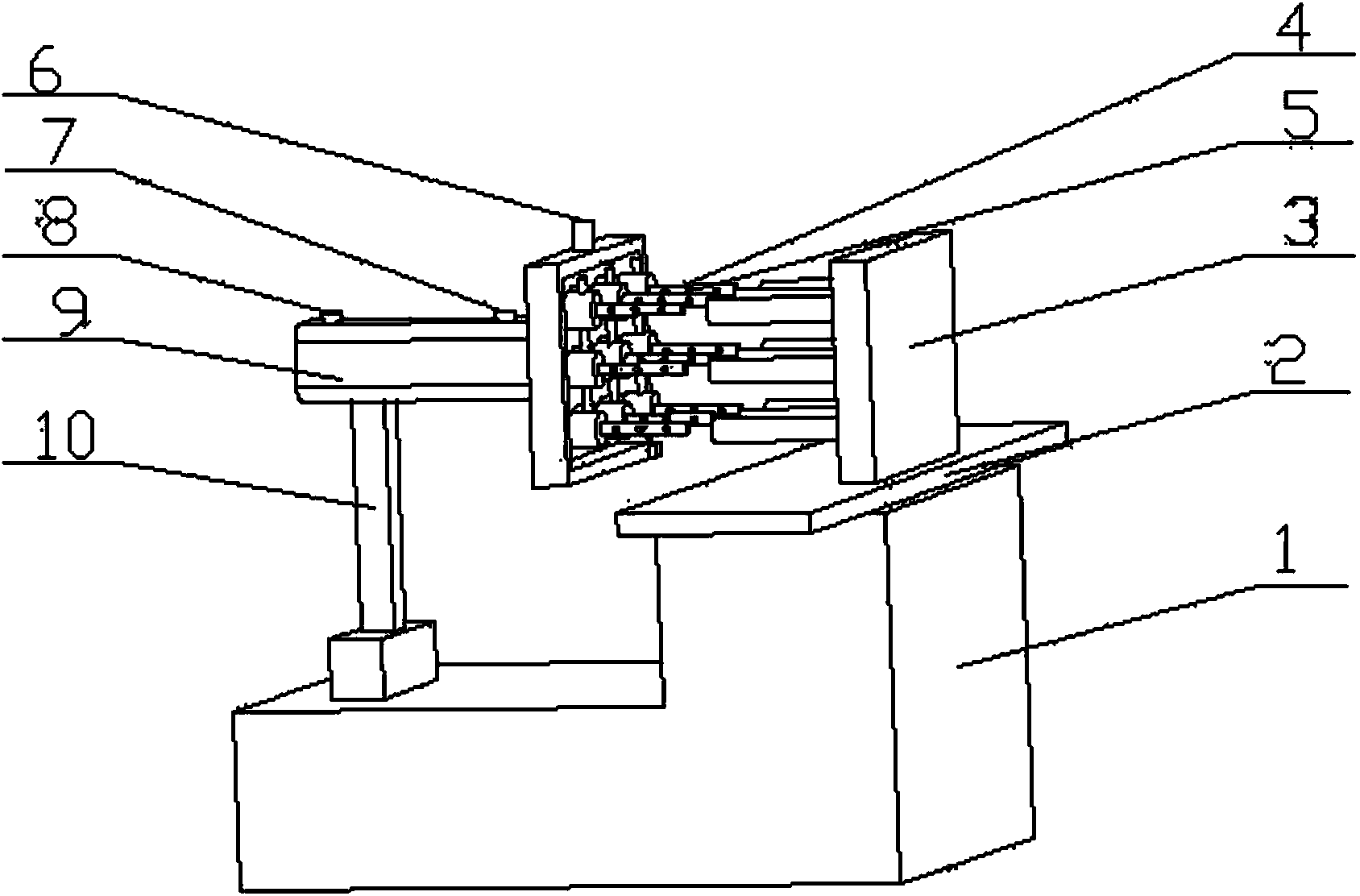

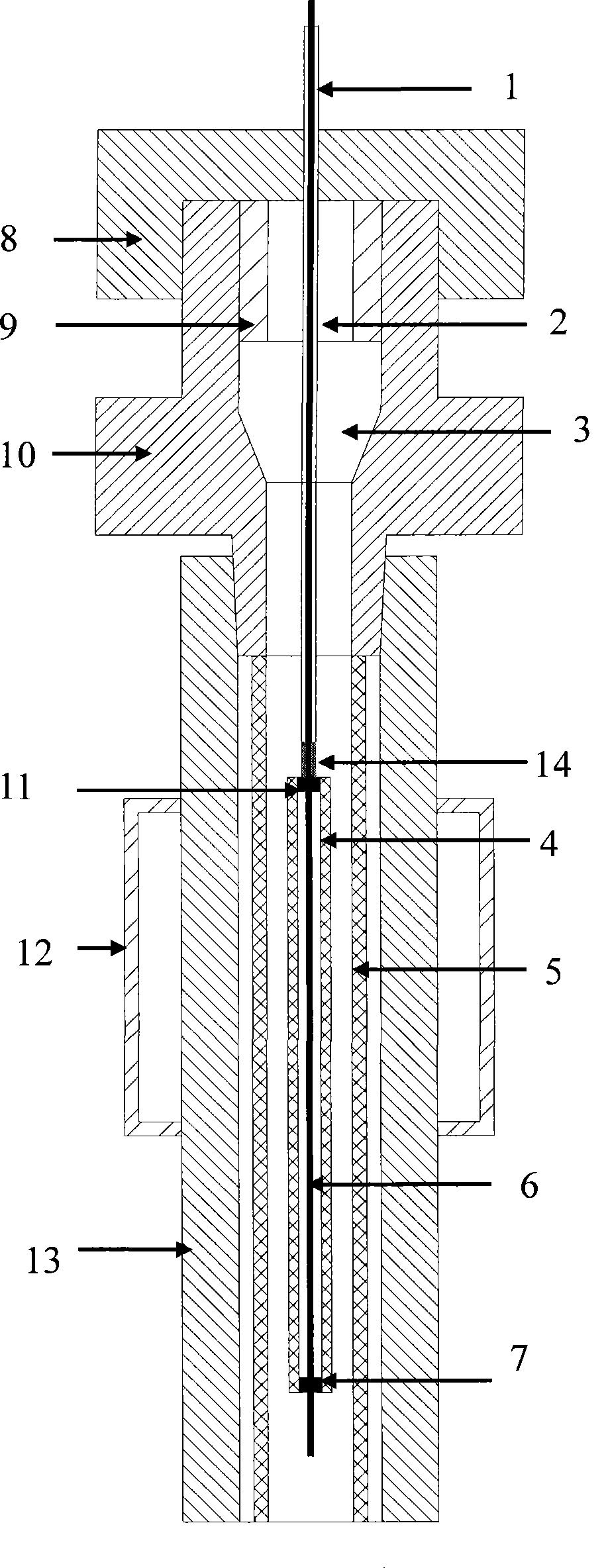

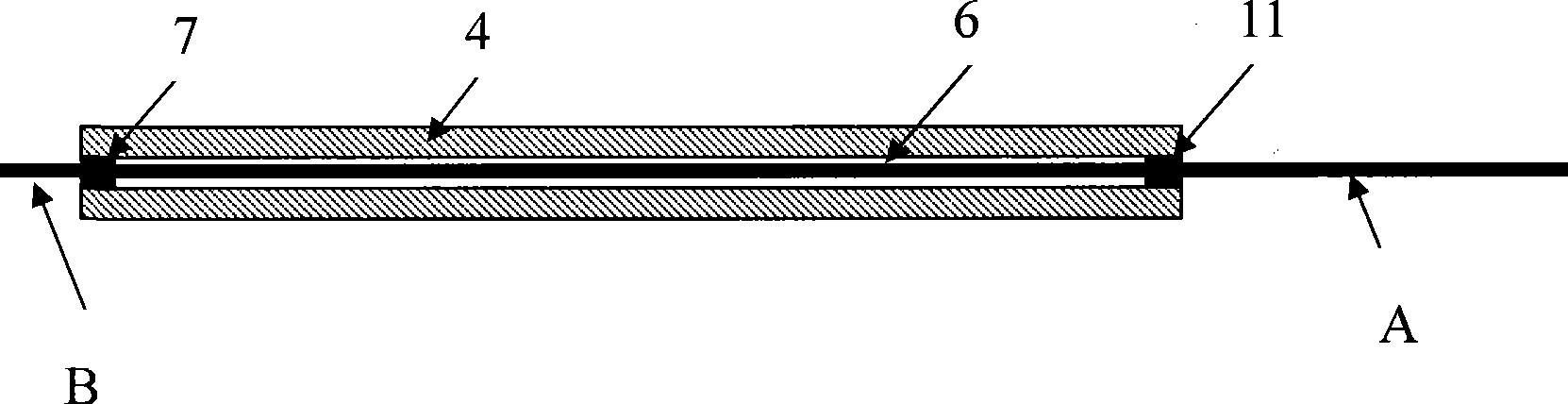

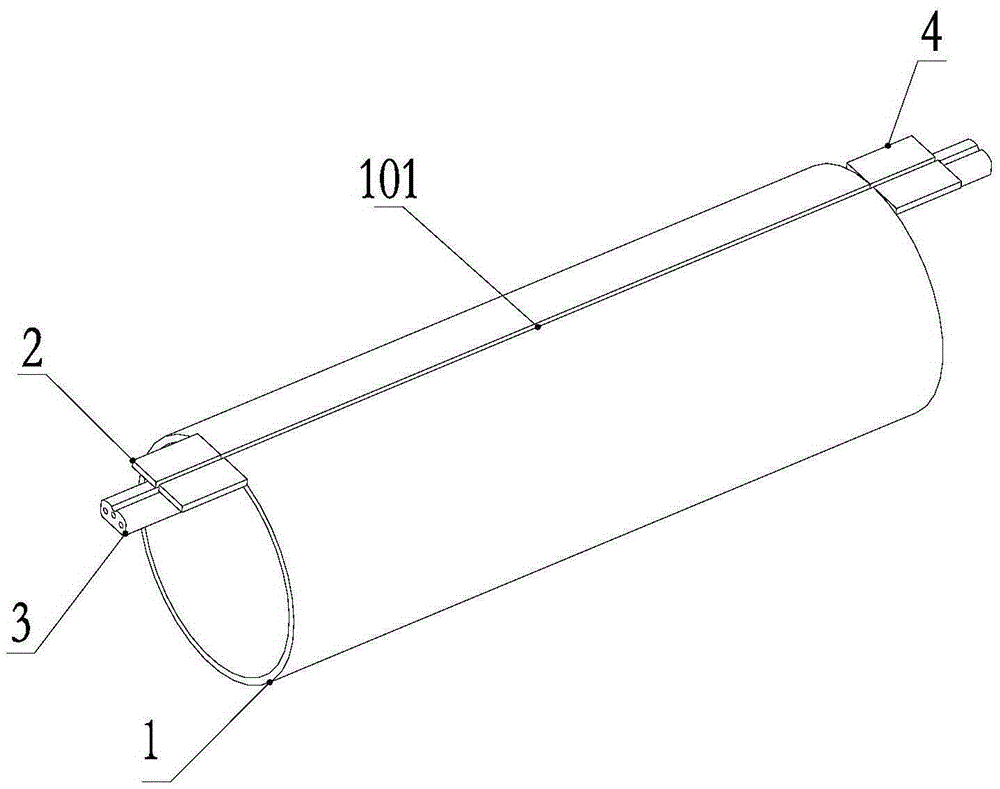

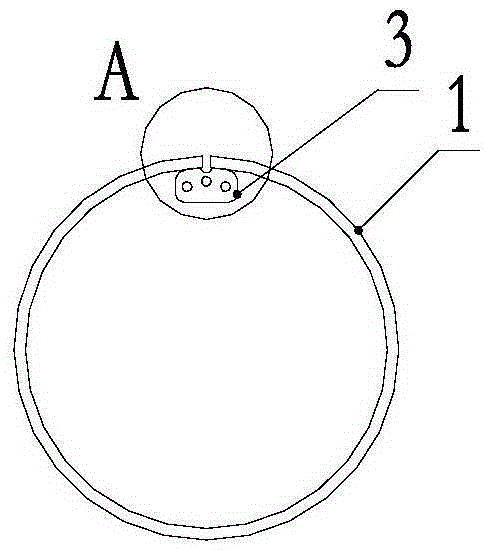

Working electrode for implementing electro-chemical test of high-temperature high-pressure water solution system

ActiveCN101470093AHigh temperature resistantGuaranteed high temperature performanceWeather/light/corrosion resistanceMaterial electrochemical variablesEpoxyCore component

The invention relates to a working electrode for realizing the electrochemical test of high temperature high pressure water solution system and a preparation technology thereof, belonging to the electrochemical test field of high temperature high pressure water solution. The working electrode is composed of a core component and a sealing component, wherein the insulation unit of the core component is composed of a high temperature part and a low temperature part; the high temperature part is made from corundum tube and is penetrated by a working electrode wire, and the port of the high temperature is sealed with the working electrode wire via high temperature glue; the low temperature part is made from polytetrafluoroethylene tube and is penetrated by a working electrode wire, the port of the low temperature part is sealed with the working electrode wire via high temperature epoxy resin; the high temperature part and the low temperature part are sealed by high temperature epoxy resin; the electrode and a high pressure autoclave are sealed of high temperature and high pressure via the sealing component. The electrode prepared by the technology has high sealing performance, resists high temperature and high pressure, and can be applied in the weak acidic, neutral and weak alkaline mediums for realizing electrochemical test of filamentous metal material in high temperature high pressure water solution system at room temperature to 350 DEG C and normal temperature to 20MPa.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Electrochemistry test method used for rotary type single-phase flow erosion testing

InactiveCN101042330AProtect critical featuresSimple designWeather/light/corrosion resistanceTransducerAuxiliary electrode

This invention discloses one electrical chemical test method for rotation single phase impulse erosion test, which comprises the following steps: processing the specimen into work electrode fixed onto test device and adjusting work, reference and aid electrode distance and the capacitor top is added with test erosion liquid with 75mm higher than the liquid; in static erosion medium liquid adopting electrical chemical method for anti-erosion till the current reduces to small to make the work electrode surface form even erosion product protection film; starting transducer motor and pre-setting acceleration curve through computer to observe constant level current curve change till there is burst.

Owner:ZHEJIANG SCI-TECH UNIV

Detecting test paper

ActiveCN102128918AAvoid pollutionAvoid touchingBiological testingBiochemical engineeringChemical test

The invention relates to a detecting test paper, in particular to a dry chemical test paper for detecting the content of the analyzed object in the blood sample. The detecting test paper comprises a sample adding layer, a reacting layer, a base plate and a liquid-locking component, wherein the sample adding layer, the reacting layer and the base plate are vertically arranged from the top to bottom; at least one side of the reacting layer is provided with the liquid-locking component; and the speed of the liquid-locking component for absorbing the liquid is less than or equal to the speed of the reacting layer for absorbing the liquid. As the liquid-locking component is capable of absorbing the redundant liquid sample, the redundant sample does not flow out of the range of the test paper, and the phenomenon of polluting the environment or the sample contacting to the detector is avoided.

Owner:ACON BIOTECH (HANGZHOU) CO LTD

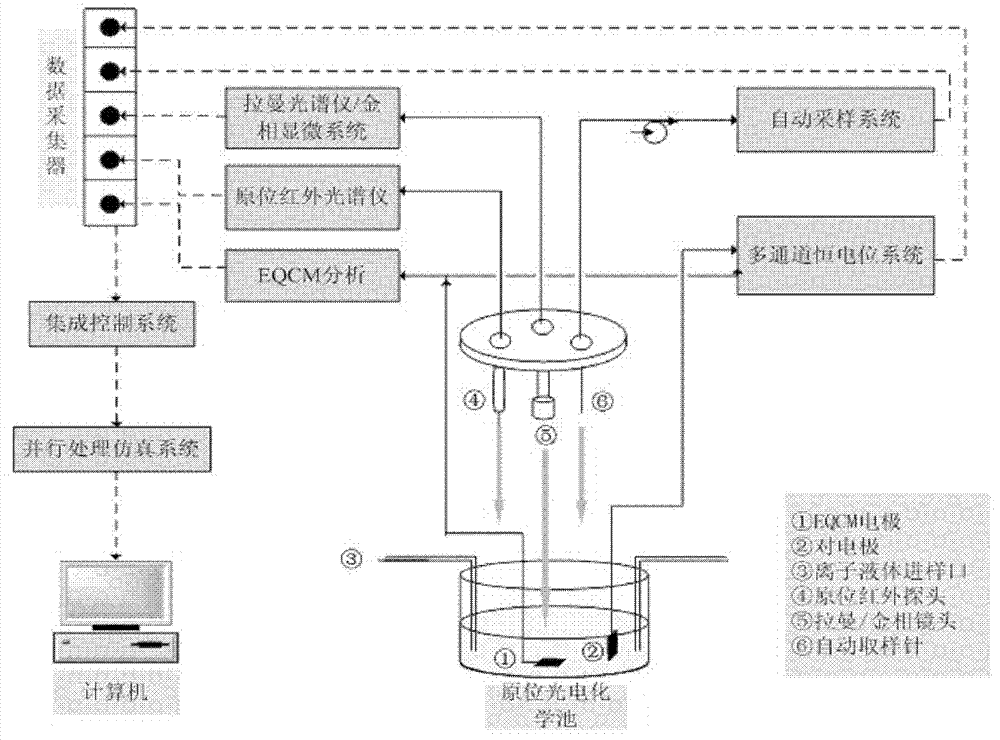

Ionic liquid system electrochemical process in-situ research device

InactiveCN103196963AEasy to set upImprove developmentMaterial electrochemical variablesDecompositionEngineering

The invention relates to an ionic liquid system electrochemical process in-situ research device. According to the device, an in-situ photo-electrochemical tank is adopted as a core. Under the control and adjustment of a multifunctional automatic adjusting rack, devices such as a flow injection analyzer, an in-situ infrared spectrometer, a Raman spectrometer, a metallurgical microscope, a multi-channel electrochemical workstation, a quartz crystal microbalance, and the like can be applied in combination. Detection liquid is placed in the in-situ photo-electrochemical tank, and a reaction process is subjected to real-time monitoring by using a computer control system. With the device provided by the invention, on a basis of conventional electrochemical tests, morphology, structure, composition, concentration change characterizations upon electrode surface / interface sediment, electrolyte, decomposition products, gas product, and the like can be realized, and powerful support can be provided for ionic liquid electrochemical process researches. The device has the characteristics of compact structure, high operation automation degree, precise detection, reasonable design, and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Welding structure for inner container longitudinal seam of stainless steel gas cylinder and welding method

ActiveCN105252121AReduce one-time input costsLow input costShielding gas supply/evacuation devicesWelding/cutting media/materialsButt weldingGas cylinder

The invention discloses a welding structure for an inner container longitudinal seam of a stainless steel gas cylinder and a welding method. The welding structure comprises a strip-shaped auxiliary board, wherein a main gas guide hole and a gas guide groove are formed in the strip-shaped auxiliary boar in the length direction; the main gas guide hole and the gas guide groove are arranged in parallel; a plurality of gas guide small holes are formed between the main gas guide hole and the gas guide groove; the two ends of the gas guide small holes are respectively communicated with the main gas guide hole and the gas guide groove; and the cross section of the gas guide groove and the cross section of the longitudinal seam to be welded are positioned in the same plane. The welding method comprises the following steps: rolling round; carrying out butt welding and spot welding; carrying out spot welding on run-on plates and run-off plates; clamping; and welding. According to the invention, an MIG automatic welding process is adopted, so that the primary input-cost of welding equipment is low; in a later using process, the input using and maintenance costs are relatively low and the working efficiency is improved greatly. By adopting the process in the invention, the qualification rate of nondestructive testing reaches 99.4% or above in an actual longitudinal seam welding process of an insulated gas cylinder and a cylinder for an LNG vehicle; and physical and chemical test projects completely meet standard requirements.

Owner:ANHUI DAPAN SPECIAL EQUIP VEHICLE CO LTD

Precision luxmeter methods for digital cameras to quantify colors in uncontrolled lighting environments

ActiveUS9863811B2Improve accuracyEasy to quantifyImage enhancementRadiation pyrometryColor changesDiagnostic system

In one embodiment, a diagnostic system for biological samples is disclosed. The diagnostic system includes a diagnostic instrument, and a portable electronic device. The diagnostic instrument has a reference color bar and a plurality of chemical test pads to receive a biological sample. The portable electronic device includes a digital camera to capture a digital image of the diagnostic instrument in uncontrolled lightning environments, a sensor to capture illuminance of a surface of the diagnostic instrument, a processor coupled to the digital camera and sensor to receive the digital image and the illuminance, and a storage device coupled to the processor. The storage device stores instructions for execution by the processor to process the digital image and the illuminance, to normalize colors of the plurality of chemical test pads and determine diagnostic test results in response to quantification of color changes in the chemical test pads.

Owner:HEALTHY IO LTD

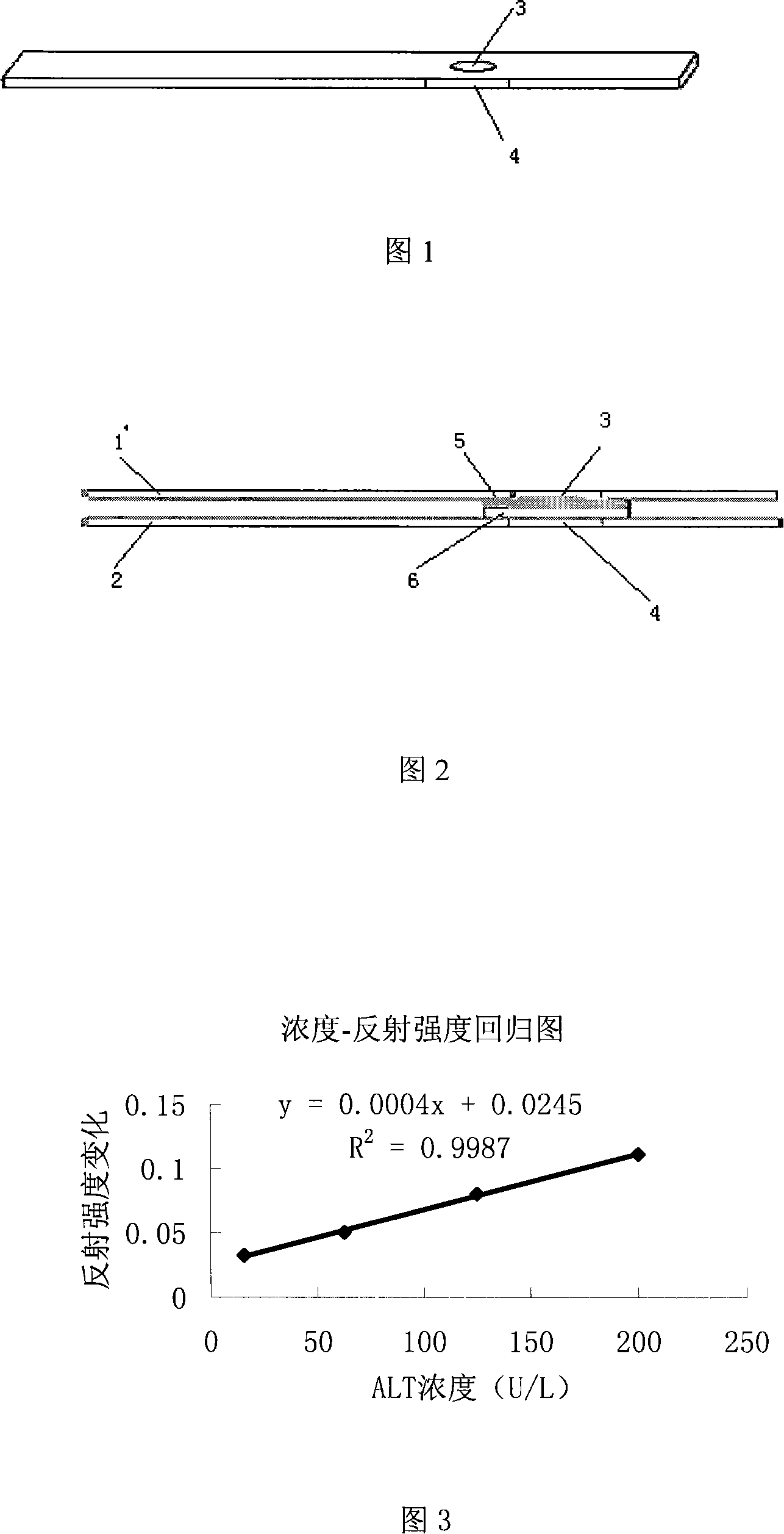

Dry chemical test paper for quantitatively determining human alanine aminotransferase

InactiveCN101105491AImprove stabilityHigh color intensityMaterial analysis by observing effect on chemical indicatorMicrobiological testing/measurementChemical reactionAdditive ingredient

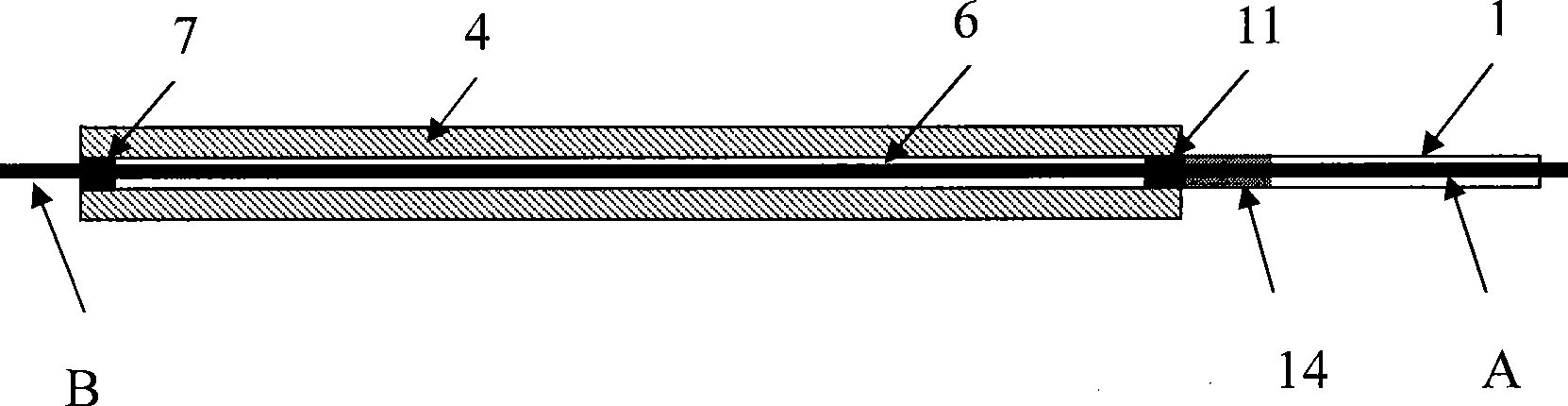

The invention belongs to the in vitro clinical diagnosis reagent field and specifically relates to a dry chemistry test paper which quantitatively determines the activity of alanine aminotransferase in human body; the dry chemistry test paper consists of an upper and a lower supporting layers in long-belt-shapes; a loading hole, a substrate layer, a visualization layer and a test hole are provided in a test area from top to bottom; the substrate layer can adopt the materials such as glass fibre, filter paper and non-woven fabrics and is soaked with reagents such as a substrate; the visualization layer is composed of various filter papers, non-woven fabrics or synthetic film and is soaked with reagents such as chromogen. A sample penetrates into the substrate layer through the loading hole and flows to a sample surface of the visualization layer; a liquid with detected ingredients penetrates to a detecting surface; the color of chromogen is changed under chemical reaction; the liquid penetrates through the test hole on the lower supporting layer and reaches the detecting surface of the visualization layer; the photodensity of the liquid can be determined on the detecting surface. The test paper is used to rapidly test the activity of alanine aminotransferase in whole blood, serum or plasma in the human body, which is one of important indexes of the detection of liver function.

Owner:SHANGHAI KEHUA BIO ENG

Microvalve Controlled Precision Fluid Dispensing Apparatus with a Self-Purging Feature and Method for use

ActiveUS20090301231A1Precise and repeatable dispensingEfficient removalWithdrawing sample devicesVolume measurement and fluid deliveryWorking fluidEngineering

An apparatus and methods for the precise, repeatable dispensing of small, sample fluid volumes, especially as related to the printing of microarrays for biological and / or chemical testing. A pressure tuning module meters fluid volumes for aspiration and dispensation and builds pressure for fluid dispensation, in conjunction with a microvalve that precisely controls the volume of the fluid dispensed under the built pressure. A pressure source can be switched in line to efficiently purge the apparatus of residual sample fluid. A working fluid can be optionally aspirated into the system, prior to aspirating the sample fluid, in order to maximize sample fluid recovery.

Owner:CAPITALBIO CORP +1

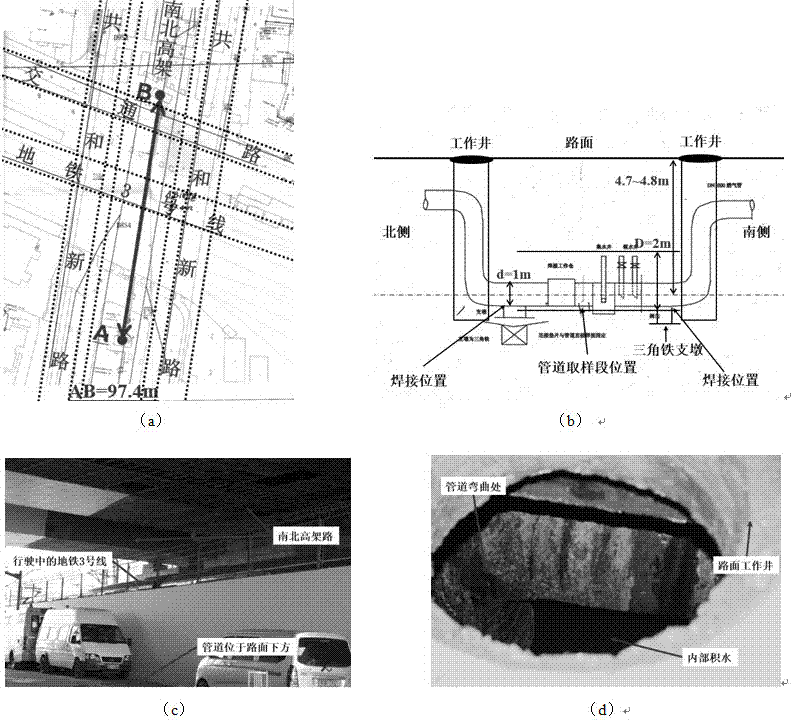

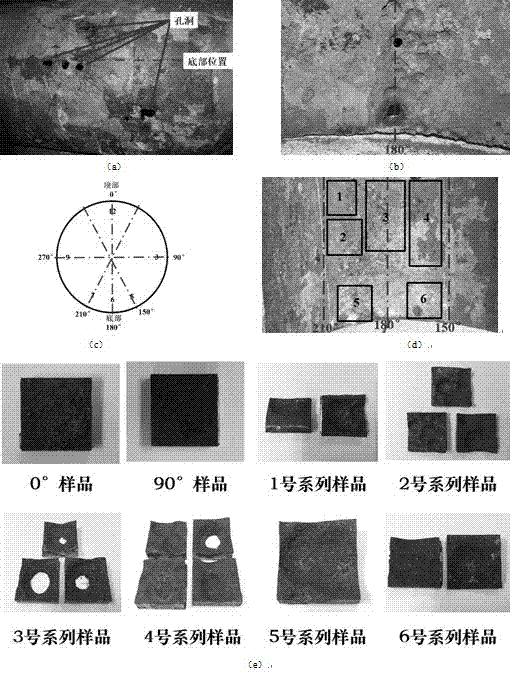

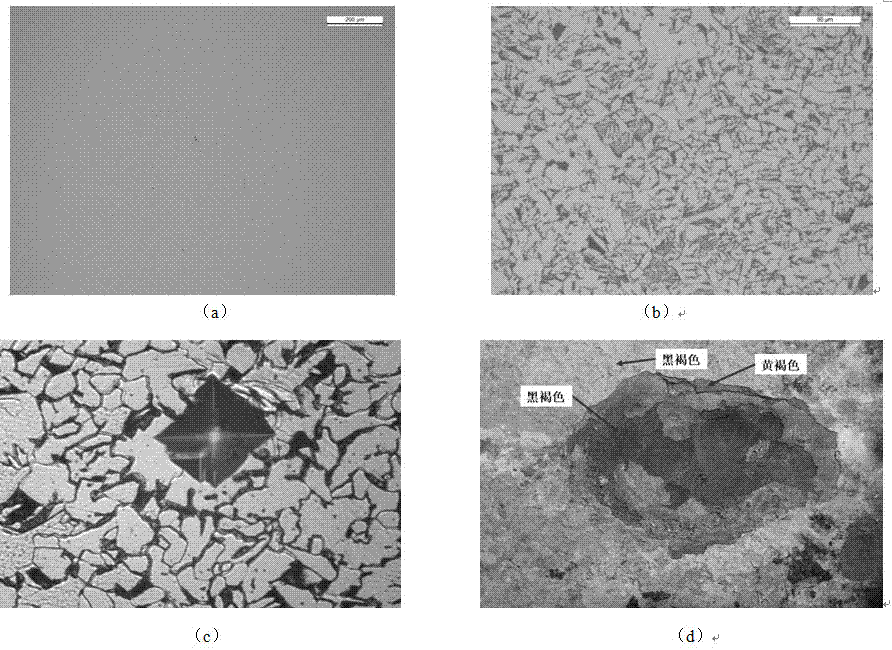

Comprehensive judgment method for buried gas metal pipeline corrosion caused by stray current nearby subway lines

InactiveCN107271359AAccurately determine the failure mechanismDetermining the Cause of Corrosion FailureWeather/light/corrosion resistanceEngineeringSubway line

The invention discloses a comprehensive judgment method for buried gas metal pipeline corrosion caused by stray current nearby subway lines. The method comprises steps as follows: 1, arrangement and analysis of background and general situation: technological parameters, past operation conditions and the like of a pipeline are known; 2, inspection and test analysis: after a faulted pipeline with abnormal leakage is sampled, the sample is subjected to check analysis with various devices and multiple physical and chemical test means; 3, comprehensive discussion, analysis and judgment: an acting form of the stray current on pipeline corrosion morphology is judged, a mutual relation between failure mechanisms is discussed, a failure reason is found out and a solution is given. By means of comprehensive analysis for corrosion failure, caused by the stray current nearby the subway lines, of the buried gas metal pipeline, new stray current corrosion morphology feature reference and failure mechanism theoretical support are provided, the failure reason of the pipeline can be accurately judged, and an effective solution is proposed. The method has great reference significance and practical application value for failure analysis of various oil and gas transmission pipelines and pipelines with different diameters, model and textures in different environments.

Owner:FUDAN UNIV

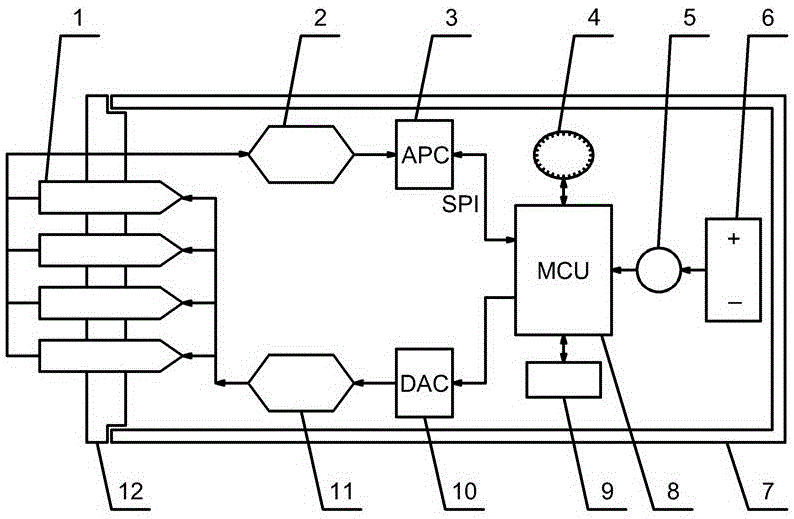

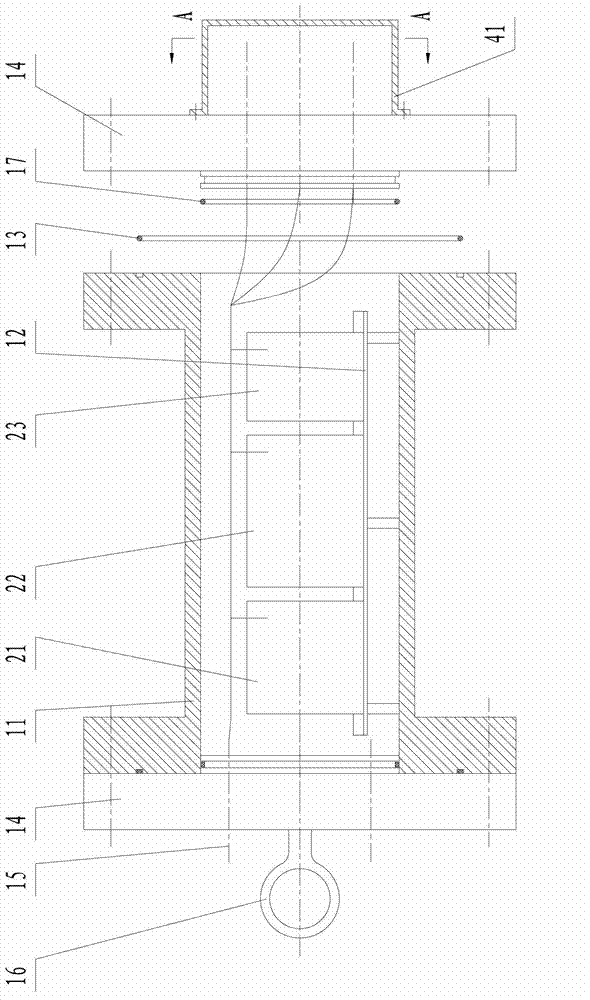

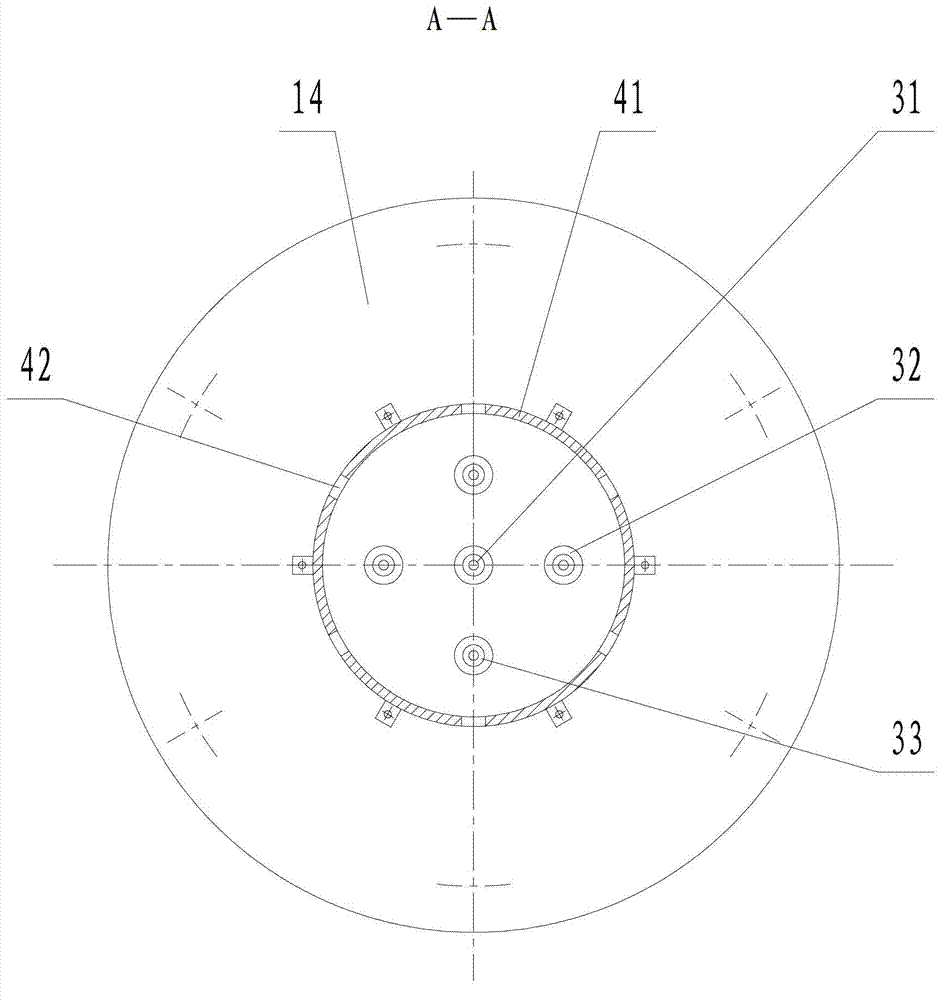

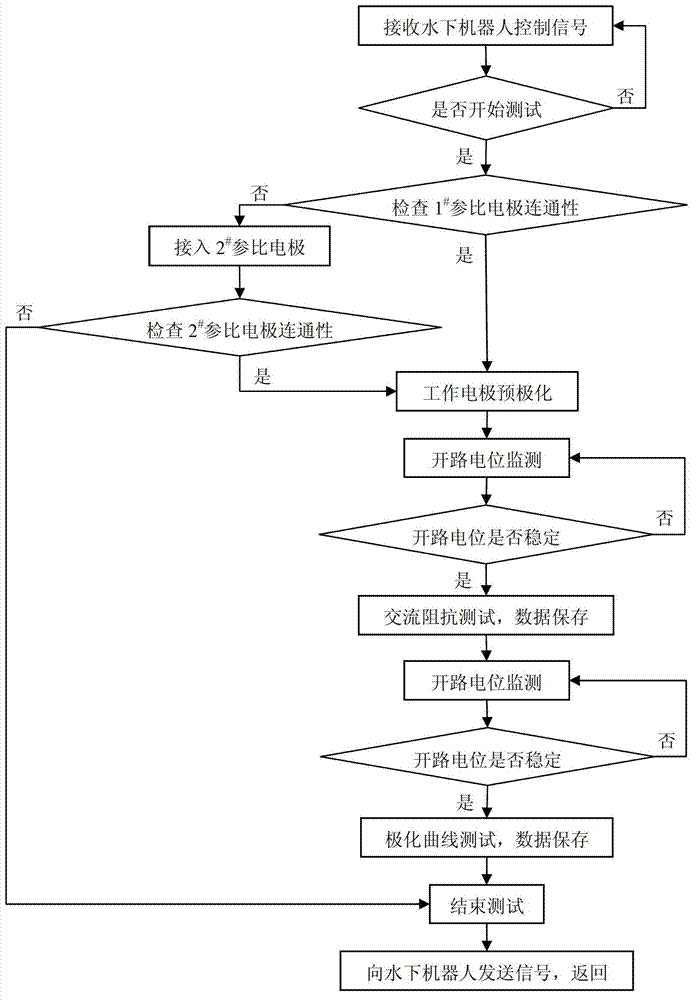

Deep sea multichannel corrosion electrochemical in-situ test device and test method

ActiveCN106198375AEasy to deployEasy to operateWeather/light/corrosion resistanceAlternating currentHigh pressure

The invention provides a deep sea multichannel corrosion electrochemical in-situ test device and test method, and belongs to the field of metal and organic coating material corrosion electrochemical in-situ automatic test in deep sea environment. The test device uses a high-pressure sealing technology for oil field logging; functional elements such as a power supply, a precise analog and digital circuit, a memory and an electrochemical sensor are sealed in a pressure-resistant casing to form a black box type deep sea corrosion electrochemical work station; electrochemical test is performed in seawater with the depth being 3000m; various kinds of measuring data such as corrosion electric potential / current, constant electric potential polarization, cyclic voltammetry curve and alternating current impedance are collected and stored according to set frequencies. The test device has the advantages that the structure is simple and compact; the expandability is high; the in-situ electrochemical test on various metal or organic coating specimens in deep sea environment can be performed at the same time; the storage and recovery operation is simple; the independent power supply is used; high pressure can be resisted; the size is small; the test device can be combined or carried with any deep sea devices in other forms; the service life is long.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Deep-sea field erosion electrochemical testing device and testing method thereof

ActiveCN103712907AReal-time detection jobQuick detection jobWeather/light/corrosion resistanceAnti jammingChemical test

The invention belongs to the field of ocean engineering technology, and specifically relates to a deep-sea field erosion electrochemical testing device and a testing method thereof. The deep-sea field erosion electrochemical testing device comprises a pressure-proof watertight electronic cabin, an erosion electrochemical testing system arranged in the pressure-proof watertight electronic cabin, a plug-in type electrode system integrated outside one end of the pressure-proof watertight electronic cabin, and a porous screening cover; the erosion electrochemical testing system is connected with the plug-in type electrode system through a wire; and the porous screening cover is arranged at one end of the pressure-proof watertight electronic cabin, and the plug-in type electrode system is covered by the porous screening cover. The deep-sea field erosion electrochemical testing device can be used for developing in-situ real-time rapid detection operation under deep-see conditions, and has characteristics of high pressure resistance, water seepage prevention, erosion resistance, strong anti-jamming capability, small size, high strength, good insulating and sealing properties and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for measuring depth of alloy steel decarbonized layer

InactiveCN102221352AAccurate analysisEasy to operateUsing wave/particle radiation meansAdditive ingredientMeasurement point

The invention belongs to physico-chemical test technology, and relates to a method for measuring depth of an alloy steel decarbonized layer. In the invention, the method for measuring the depth of the alloy steel decarbonized layer is characterized in that an image signal output terminal of a scanning electron microscope is connected with an input terminal of an X-ray energy spectrometer, the scanning electron microscope is used for measurement and analysis; and the X-ray energy spectrometer is used for analysis and verification. The method comprises the following steps of firstly cutting a sample; carrying out surface treatment on the sample; cleaning the sample; subsequently placing the sample in the scanning electron microscope and vacuuming the scanning electron microscope; adjusting parameters of the scanning electron microscope and carrying out organization form analysis; subsequently collecting images to carrying out energy spectrum analysis at two sides of a measuring point at a half position of a transition area; verifying a carbon ingredient; and finally completing the measurement on the depth of the decarbonized layer. The method can carry out exact analysis on the depth of the alloy steel decarbonized layer, can be operated simply and conveniently, and can meet the requirement of practical scientific research production and failure analysis.

Owner:HARBIN

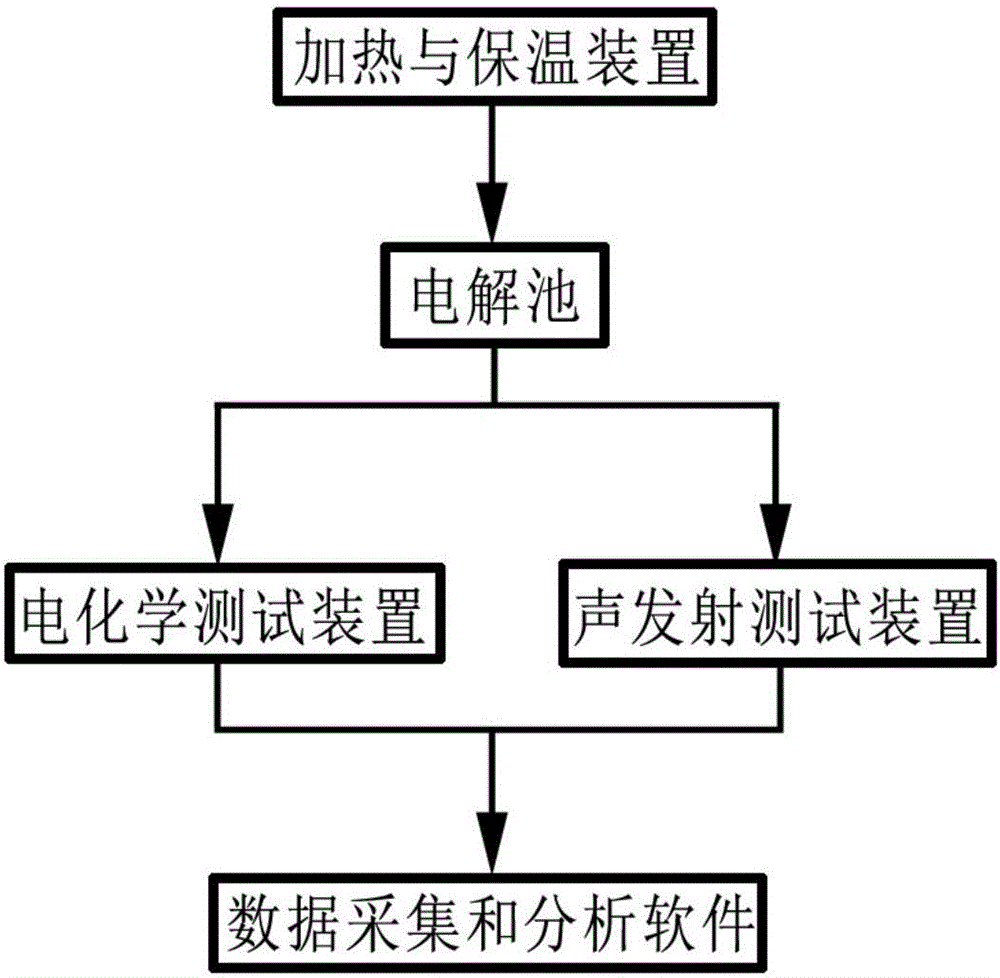

Electrochemical corrosion test apparatus and application method thereof

ActiveCN106525709AAvoid damagePortable and efficient installationMaterial analysis using acoustic emission techniquesWeather/light/corrosion resistanceThermal insulationAuxiliary electrode

The invention discloses an electrochemical corrosion test apparatus and an application method thereof; the apparatus comprises an electrolytic cell, an electrochemical test device, a heating device and a thermal insulation device; the electrolytic cell comprises a reaction cell, a reaction cell cover, a seal gasket, a fastening device, and a sample mounting device; the sample mounting device comprises a step threaded waveguide rod, a primary sleeve, a secondary sleeve, a tertiary sleeve and a seal ring; the electrochemical test device comprises an auxiliary electrode chuck, a reference electrode chuck, a working electrode chuck, and an electrochemical data processing system; the auxiliary electrode is a platinum gauze electrode, the reference electrode is mounted in a Luggin-Haber capillary, the heating device is arranged outside the reaction cell, and the thermal insulation device is arranged outside the heating device. A corrosion process of a material in various complex corrosive gas environments can be simulated, a distance from the tip of the Luggin-Haber capillary to a test sample is fixed, the influences of the distance from the tip of the Luggin-Haber capillary to the test sample upon test results are uniformized, and the apparatus is suitable for use under severe complex conditions.

Owner:TIANJIN UNIV

Artificial intelligent cleaning device used for chemical test tube

The invention discloses an artificial intelligence cleaning device for chemical test tubes, which includes a fixed seat, a bevel gear plate is connected to the top of the first rotating shaft, and transmission gear plates are meshed on both sides of the top of the bevel gear plate , one side of the transmission gear plate is connected with a rotating rod, the clamping device includes a clamping ring, both sides of the bottom of the clamping ring are connected to the connecting plate through a strut, one of the first support The side is connected with a second support through a compression spring, the top of the connection seat is connected with an electric push rod, both sides of the water tank are connected with a spray pipe through a branch pipe, and the top of the second shaft is connected with a second motor. , the bottom of the second rotating shaft is connected with a cleaning rod, and the outside of the cleaning rod is equidistantly provided with bristles. The invention has the advantage of not needing to manually clean the test tubes, and solves the problem that the chemical test tubes are very inconvenient to clean and the cleaning efficiency of the test tubes will be reduced.

Owner:竺林坤

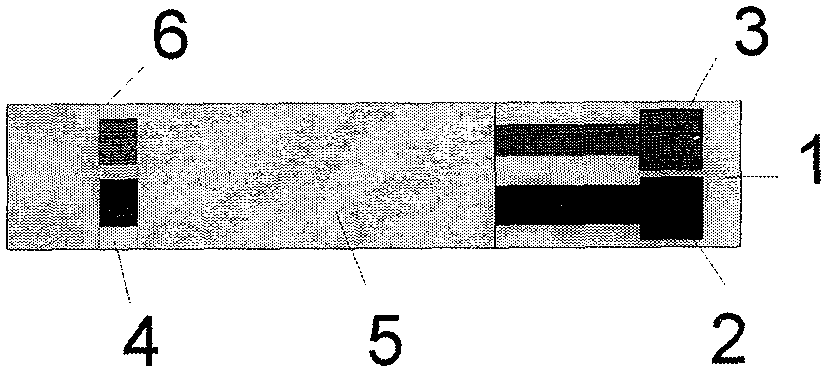

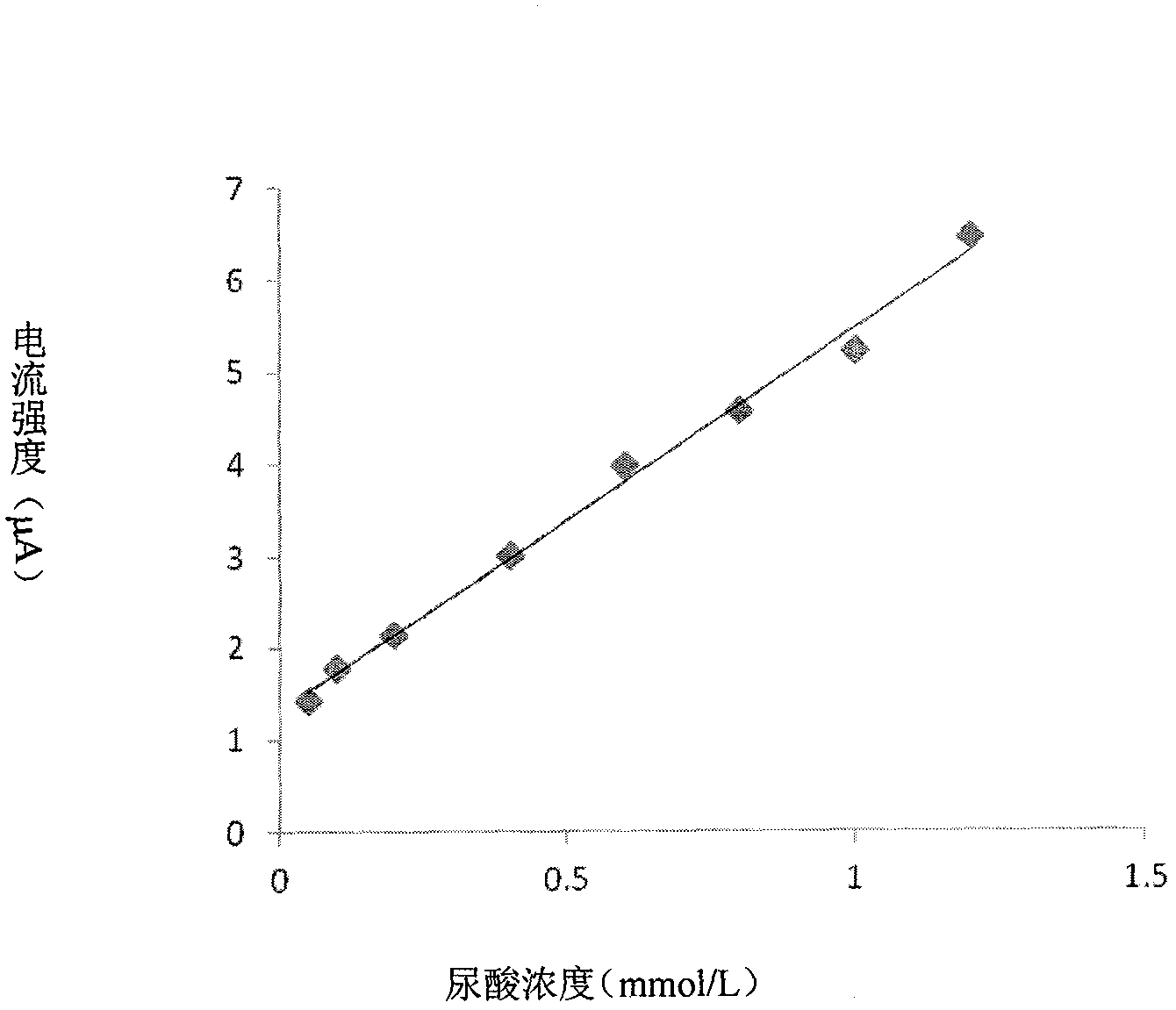

Dry chemical test strip used in quantitative test of uric acid

InactiveCN103235015ADetect uric acid contentMaterial electrochemical variablesScreen printingAdhesive

The invention belongs to the technical field of biosensing, and relates to a dry chemical test strip used in quantitative test of uric acid and a preparation method thereof. The uric acid quantitative-test dry chemical test strip provided by the invention comprises an insulating substrate, electrodes and an anti-interference enzyme layer printed on the insulating substrate with a screen printing technology, and a siphonic reaction cell composed of a double-sided adhesive, a hydrophilic membrane, and the enzyme layer. According to the invention, with an electrochemical method, uric acid oxidation is catalyzed, and urate oxidase is not needed to participate in the reaction. Therefore, testing precision can be improved, cost can be reduced, and uric acid content can be tested in a short time.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

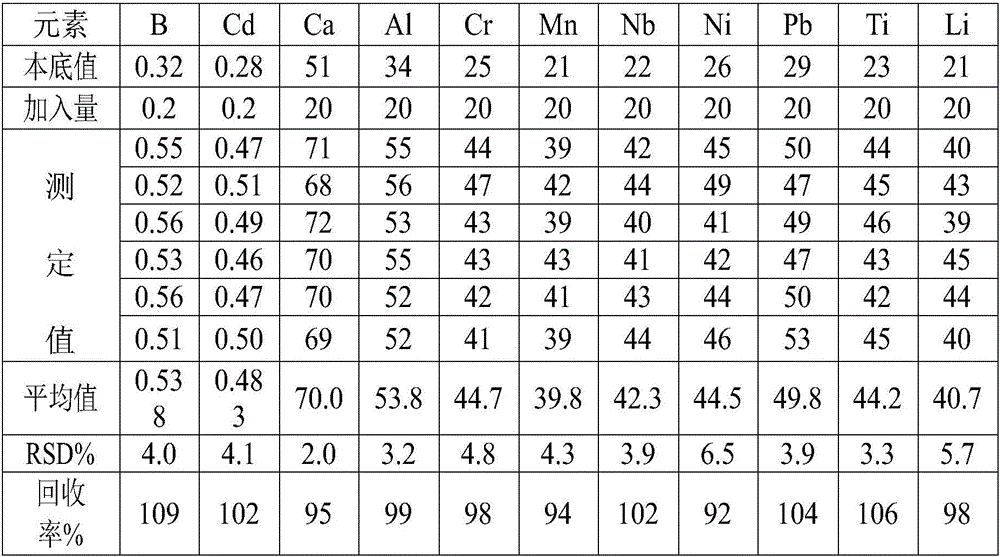

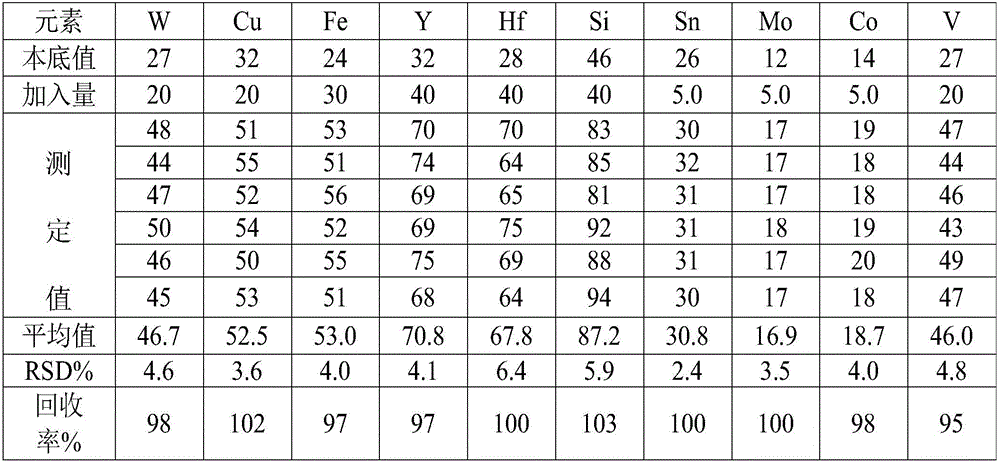

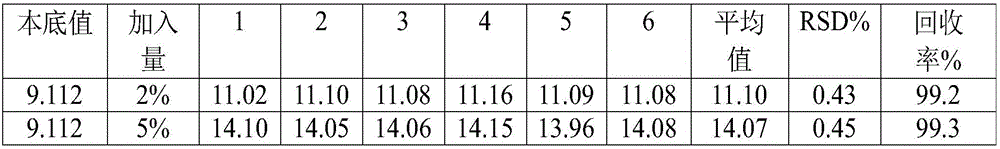

Method for determining zirconium and impurity contents in uranium-zirconium alloy

ActiveCN106596518AAccurate determination of contentThe detection data is accuratePreparing sample for investigationAnalysis by thermal excitationHydrofluoric acidChemical test

The invention belongs to the establishment of a novel chemical test method, and particularly relates to a specific method for determining zirconium and impurity contents in uranium-zirconium alloy by inductively coupled plasma emission spectrometry. The invention establishes the test method for determining impurity elements and zirconium in uranium-zirconium alloy by plasma emission spectrometry. A sample is dissolved by nitric acid-hydrochloric acid mixed acid and hydrofluoric acid, matrix interference is eliminated by a matrix matching method and a multispectral fitting correction method, and a plasma emission spectrometer is used for detecting the contents of elements to be detected. The method is accurate and reliable, and meets the index requirement of the analysis technique of the project.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

Chemical fast determining method of soil and crop nutrition content

InactiveCN1904598AReduce volumeEasy to operateMaterial analysis by observing effect on chemical indicatorWithdrawing sample devicesNutritionPotassium

The invention relates to a chemical test method for earth and crop nutrient. It includes the following steps: earth sample gathering and processing, rapid testing earth alkali-hydrolyzable nitrogen, rapidly available phosphorus, and rapidly available potassium, gaining the tested liquid of earth or crop and dropping into the two holes in dropping board, comparing the standard color gradation and calculating rapid test value by regression equation. The advantages of the invention are easy to operate, rapid, certain accuracy, and convenient to carry, etc.

Owner:李楠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com