Patents

Literature

1136 results about "Zirconium alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zirconium alloys are solid solutions of zirconium or other metals, a common subgroup having the trade mark Zircaloy. Zirconium has very low absorption cross-section of thermal neutrons, high hardness, ductility and corrosion resistance. One of the main uses of zirconium alloys is in nuclear technology, as cladding of fuel rods in nuclear reactors, especially water reactors. A typical composition of nuclear-grade zirconium alloys is more than 95 weight percent zirconium and less than 2% of tin, niobium, iron, chromium, nickel and other metals, which are added to improve mechanical properties and corrosion resistance.

Niobium-containing zirconium alloy for nuclear fuel claddings

InactiveUS6261516B1Improve corrosion resistanceIncrease resistanceOptical rangefindersFuel elementsNiobiumManganese

The invention presented herein relates to a niobium-containing zirconium alloy for use in nuclear fuel cladding. The Zr alloy of this invention with superior corrosion resistance is characterized as comprising an alloy composition as follows:1) niobium (Nb), in a range of 0.8 to 1.2 wt. %; one or more elements selected from the group consisting of iron (Fe), molybdenum (Mo), copper (Cu) and manganese (Mn), in a range of 0.1 to 0.3 wt. %, respectively; oxygen (O), in a range of 600 to 1400 ppm; silicon (Si), in a range of 80 to 120 ppm; and the balance being of Zr,2) Nb, in a range of 1.3 to 1.8 wt. %; tin (Sn), in a range of 0.2 to 0.5 wt. %; one element selected from the group consisting of Fe, Mo, Cu and Mn, in a range of 0.1 to 0.3 wt. %; O, in a range of 600 to 1400 ppm; Si, in a range of 80 to 120 ppm; and the balance being of Zr,3) Nb, in a range of 1.3 to 1.8 wt. %; Sn, in a range of 0.2 to 0.5 wt. %; Fe, in a range of 0.1 to 0.3 wt. %; one element selected from the group consisting of chromium (Cr), Mo, Cu and Mn, in a range of 0.1 to 0.3 wt. %; O, in a range of 600 to 1400 ppm; Si, in a range of 80 to 120 ppm; and the balance being of Zr, and4) Nb, in a range of 0.3 to 1.2 wt. %; Sn, in a range of 0.4 to 1.2 wt. %; Fe, in a range of 0.1 to 0.5 wt. %; one element selected from the group consisting of Mo, Cu and Mn, in a range of 0.1 to 0.3 wt. %; O, in a range of 600 to 1400 ppm; Si, in a range of 80 to 120 ppm; and the balance being of Zr.

Owner:KOREA HYDRO & NUCLEAR POWER CO LTD +1

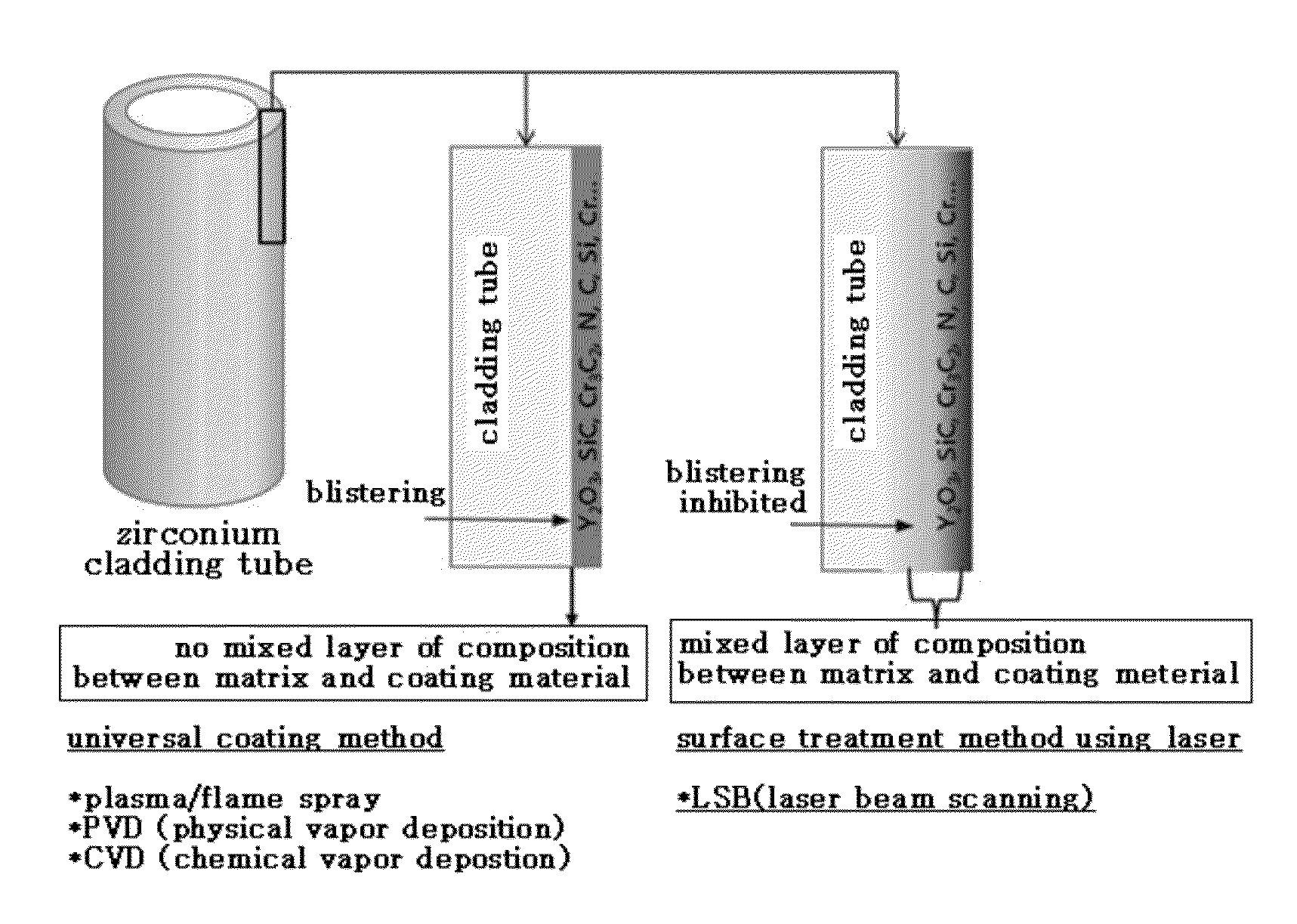

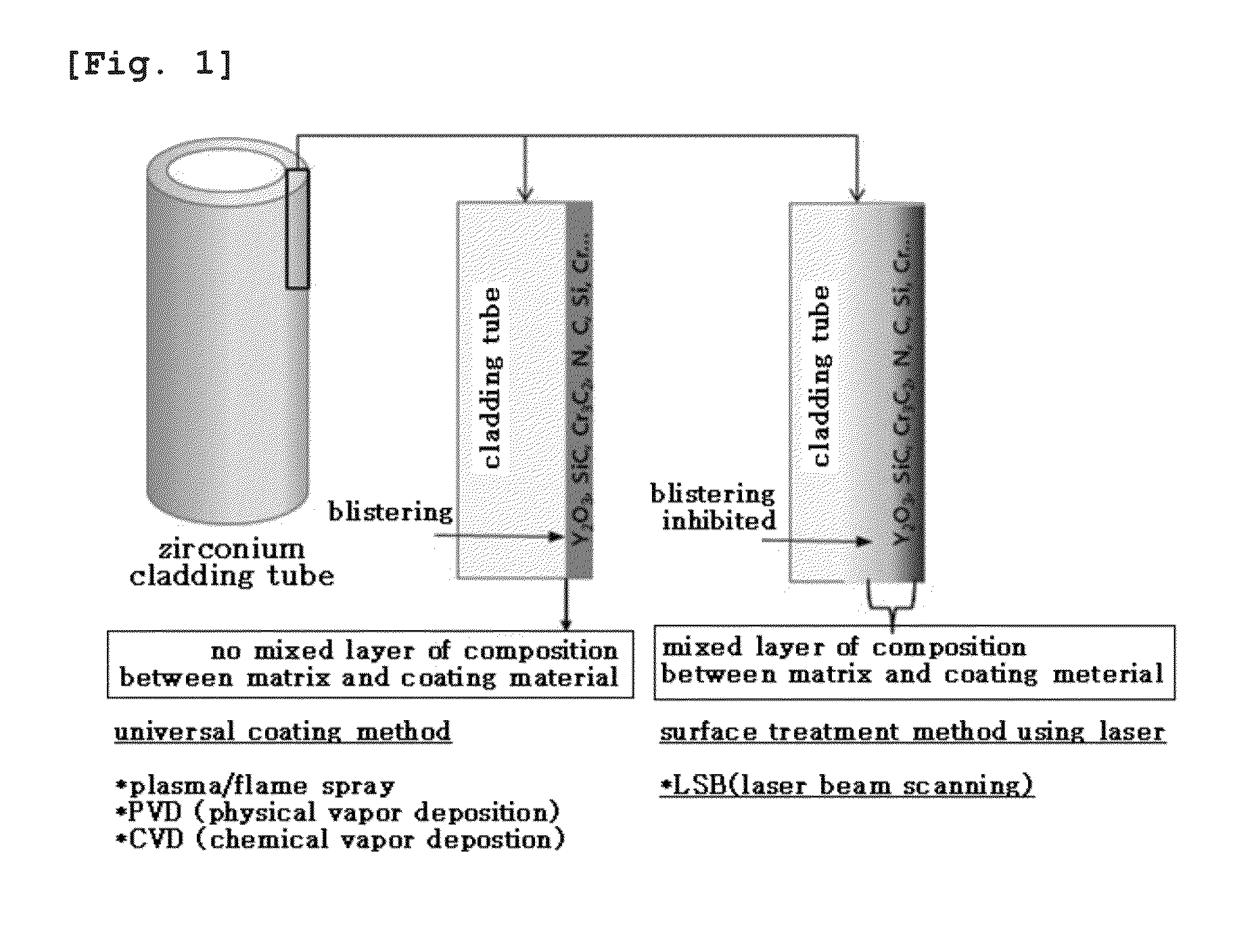

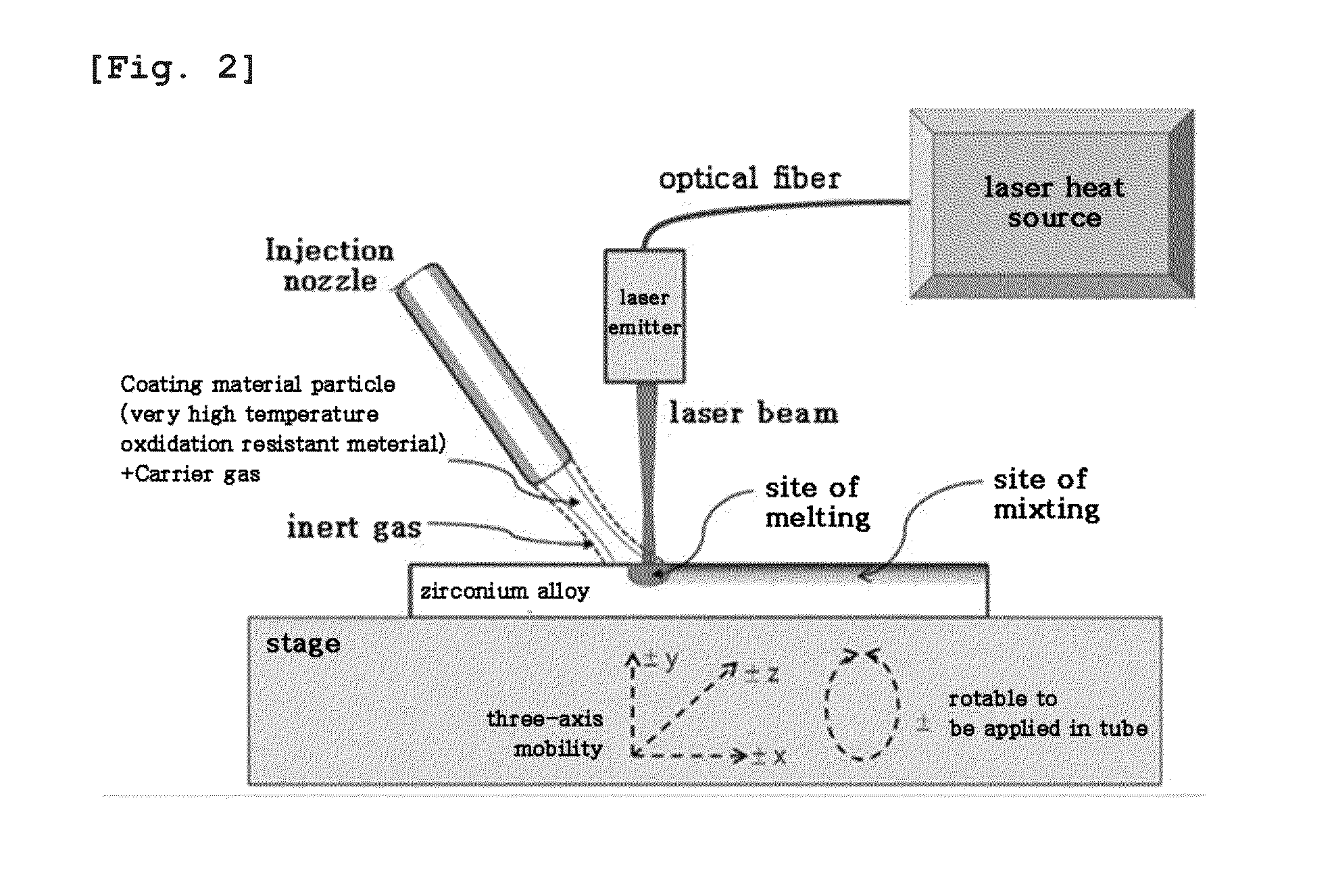

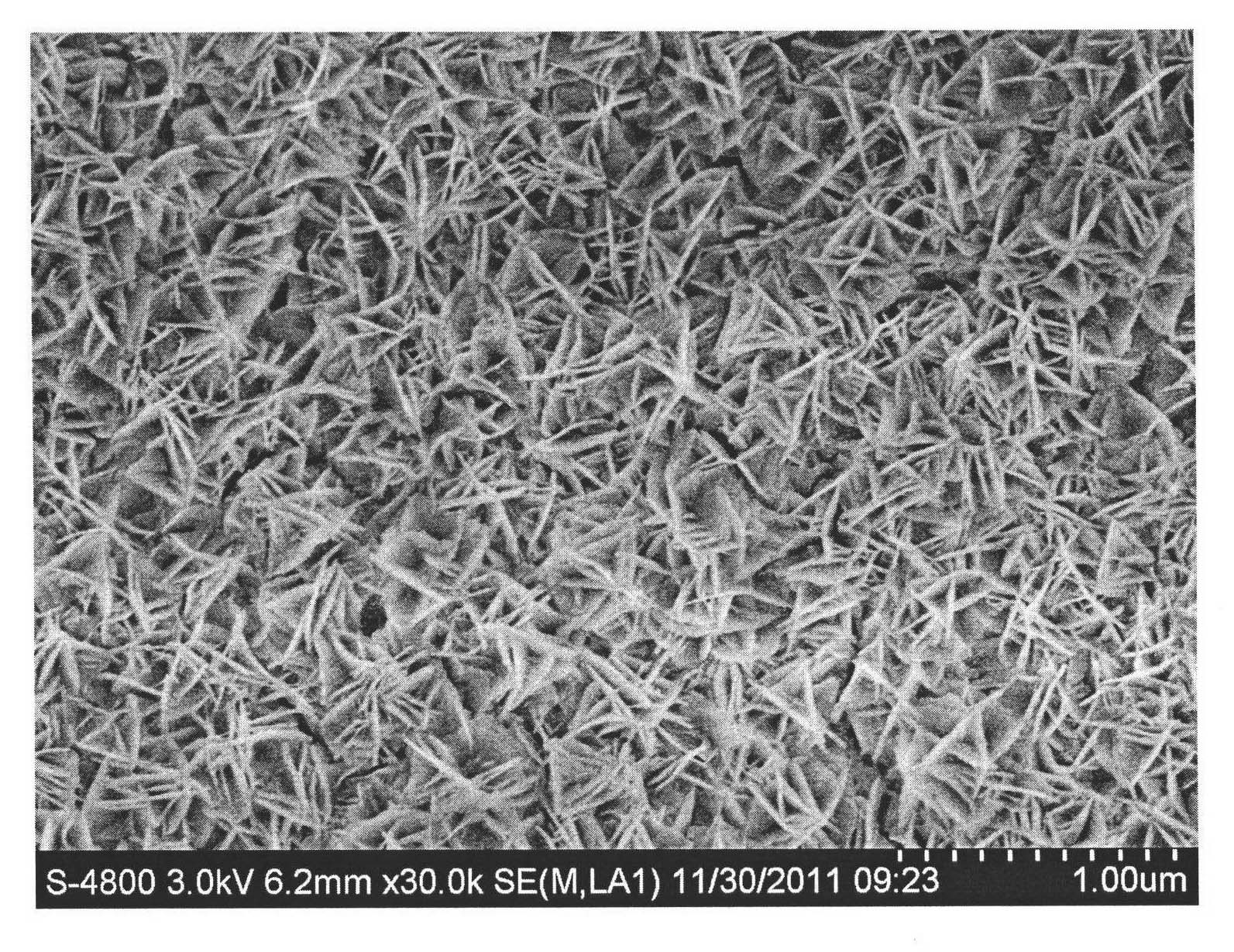

Zirconium alloy with coating layer containing mixed layer formed on surface, and preparation method thereof

InactiveUS20130344348A1High-temperature anticorrosiveAvoid physical damageAdditive manufacturingPretreated surfacesOxidation resistantZirconium alloy

A zirconium alloy with a coating layer formed on a surface comprising a mixed layer, the mixed layer comprises one or more very high temperature oxidation resistant material and zirconium alloy parent material selected from the group consisting of Y2O3, SiO2, ZrO2, Cr2O3, Al2O3, Cr3C2, SiC, ZrC, ZrN, Si and Cr, and in a vertical direction on a boundary between the mixed layer and the zirconium alloy parent material is formed a gradient of compositions between the very high temperature oxidation resistance material and the zirconium alloy parent material.

Owner:KOREA ATOMIC ENERGY RES INST +1

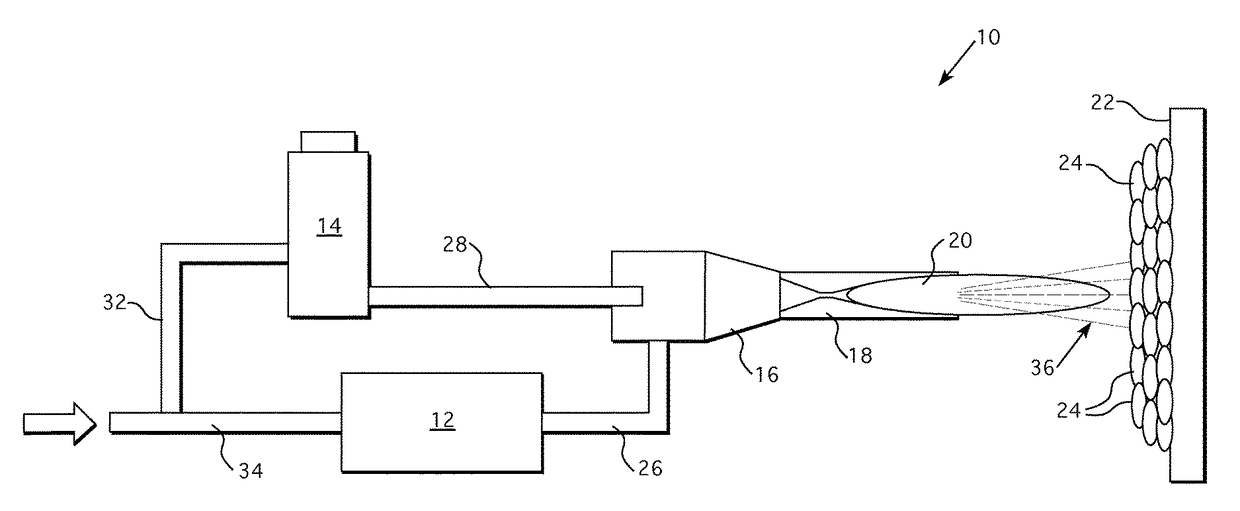

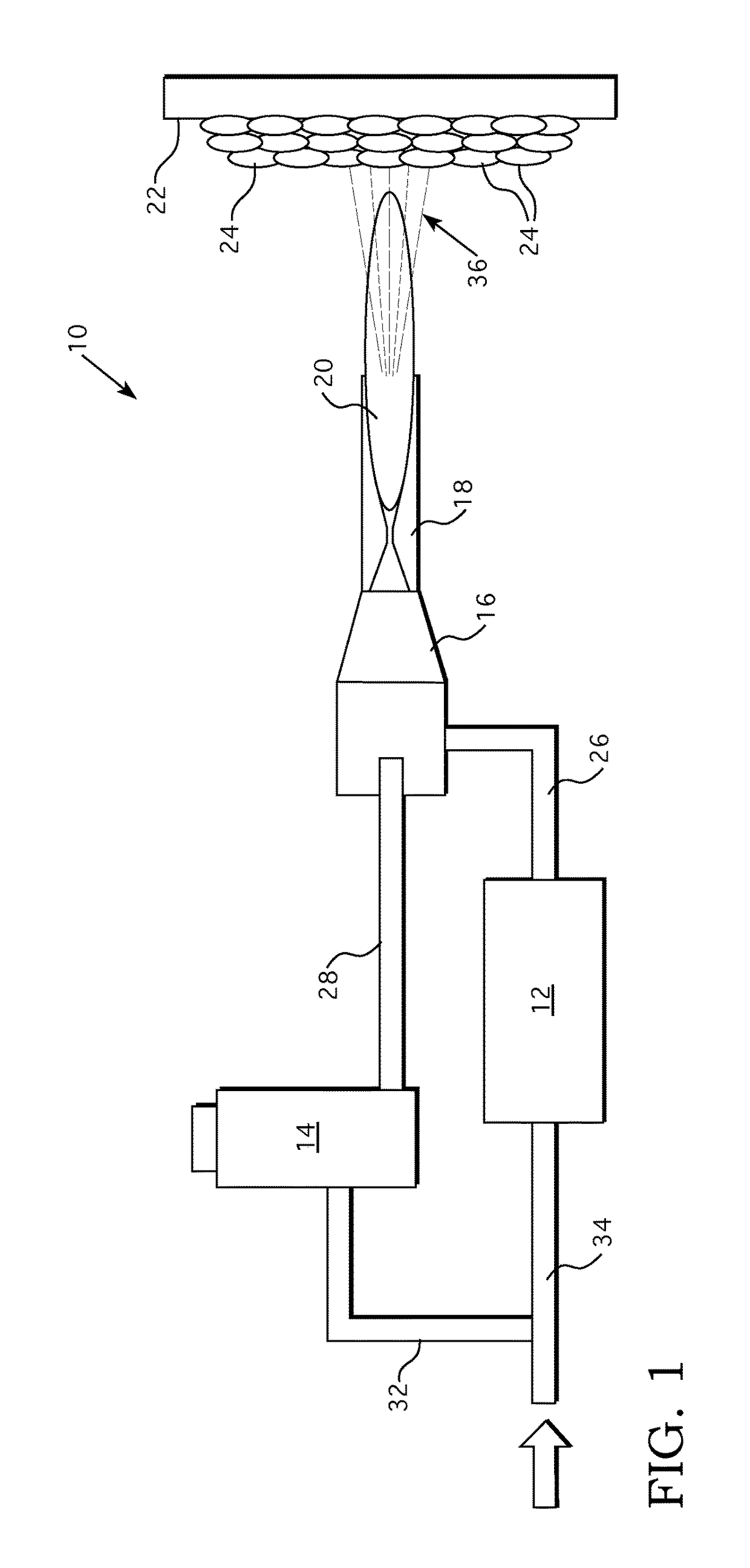

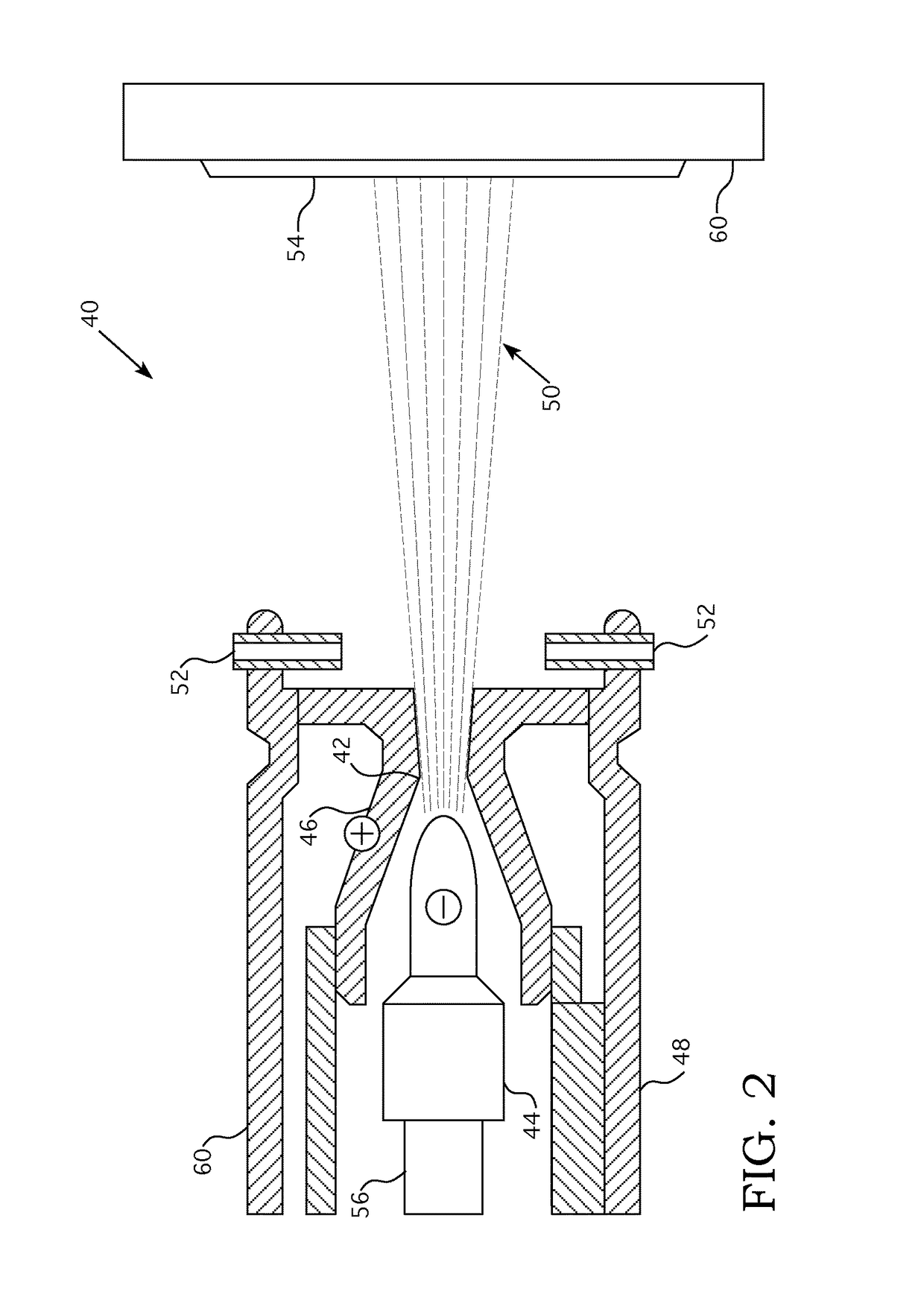

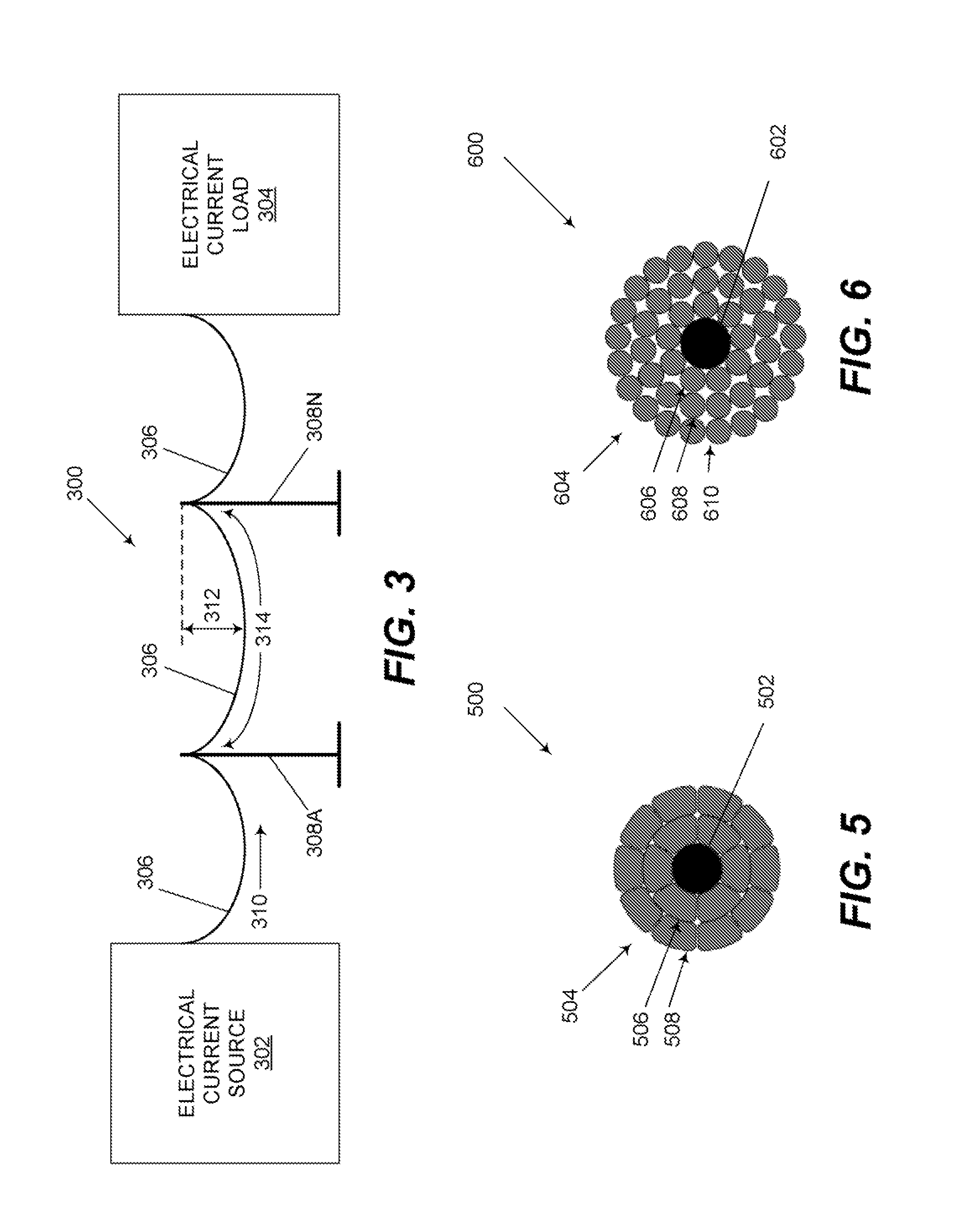

Spray methods for coating nuclear fuel rods to add corrosion resistant barrier

InactiveUS20180025794A1Increase entropyPrevent and to mitigate diffusionMolten spray coatingOptical rangefindersHigh entropy alloysZirconium alloy

A method is described herein for coating the substrate of a component for use in a water cooled nuclear reactor to provide a barrier against corrosion. The method includes providing a zirconium alloy substrate; and coating the substrate with particles selected from the group consisting of metal oxides, metal nitrides, FeCrAl, FeCrAlY, and high entropy alloys. Depending on the metal alloy chosen for the coating material, a cold spray or a plasma arc spray process may be employed for depositing various particles onto the substrate. An interlayer of a different material, such as a Mo, Nb, Ta, or W transition metal or a high entropy alloy, may be positioned in between the Zr-alloy substrate and corrosion barrier layer.

Owner:WESTINGHOUSE ELECTRIC CORP +1

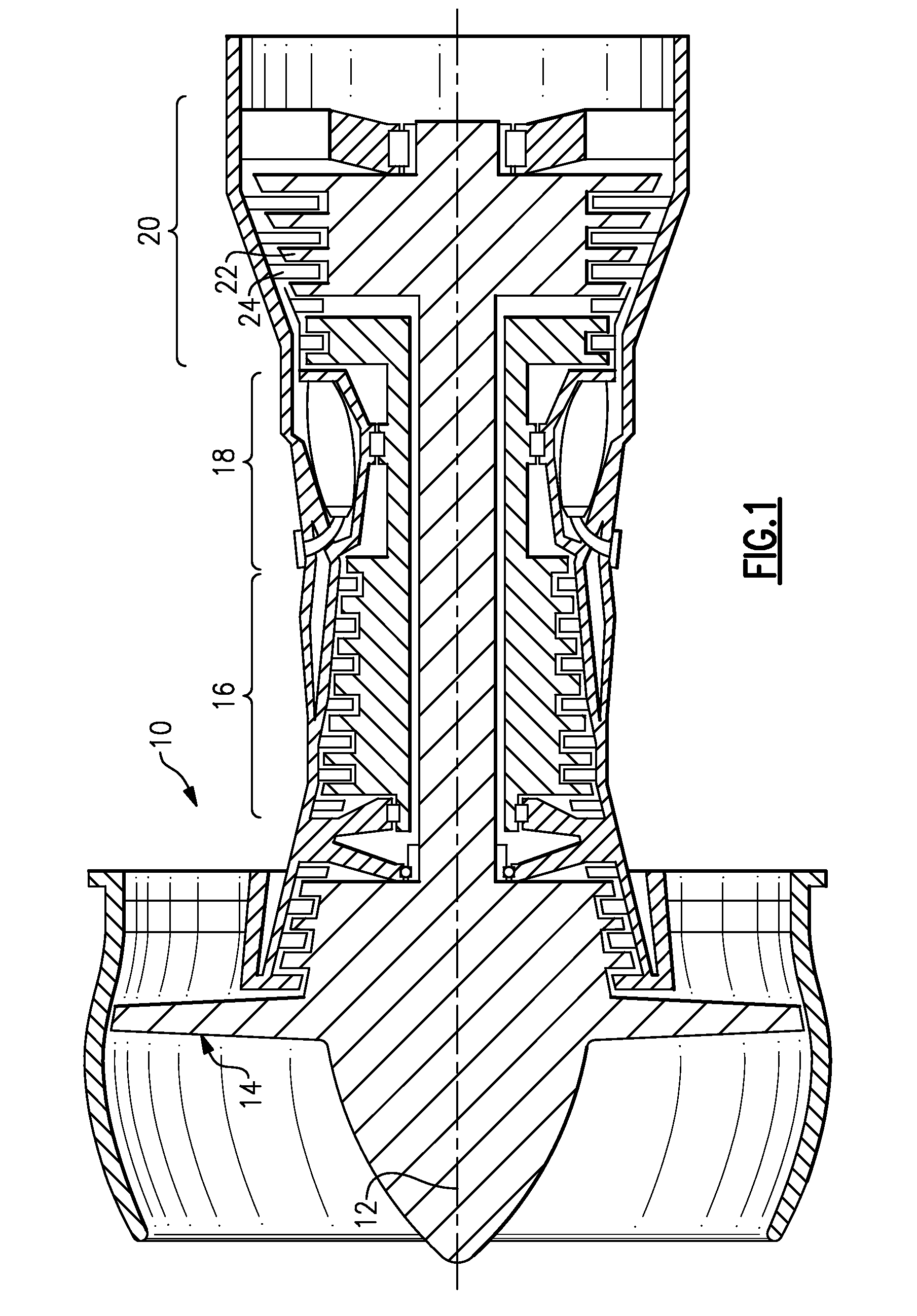

Method of surface oxidizing zirconium and zirconium alloys and resulting product

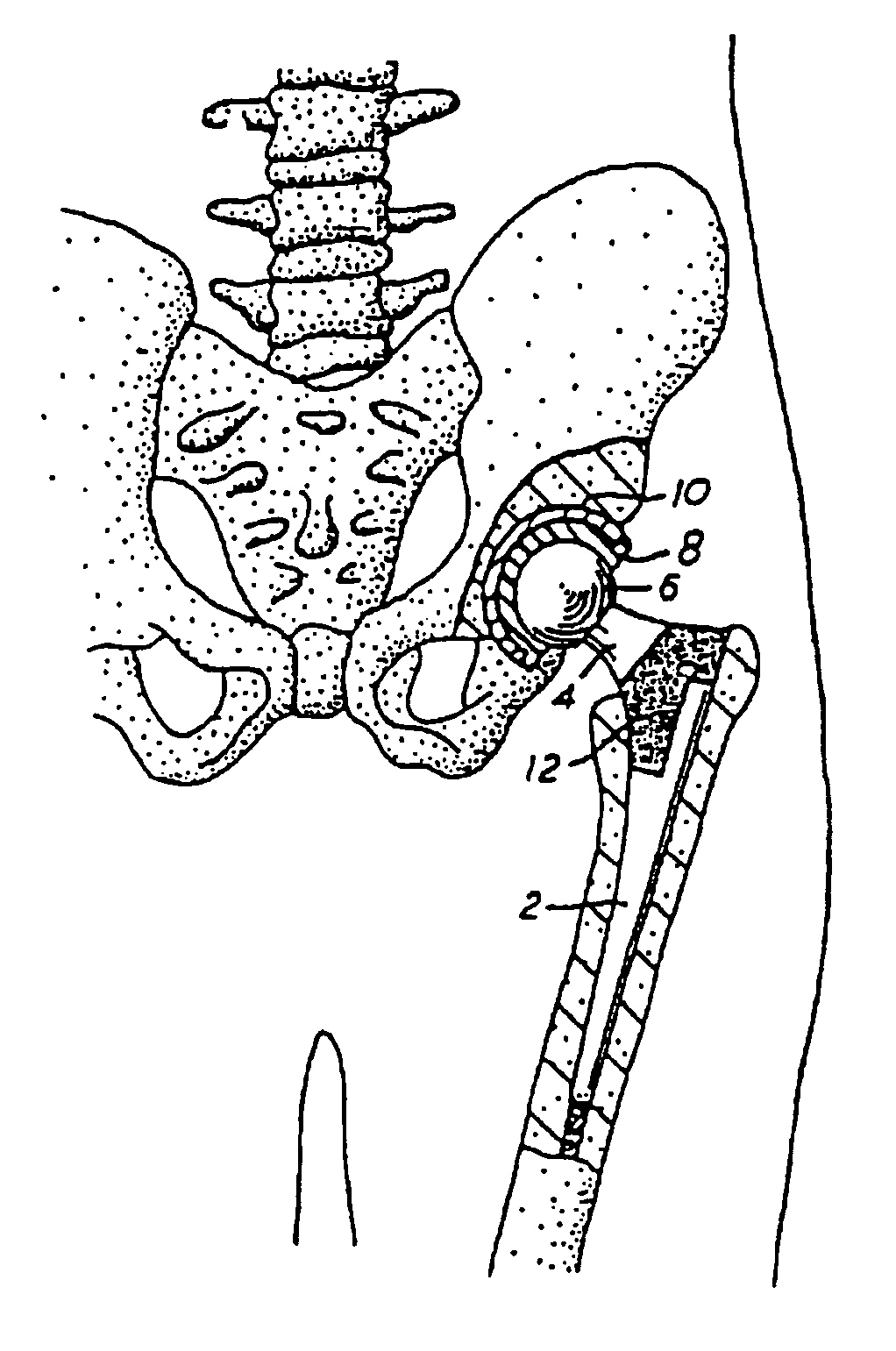

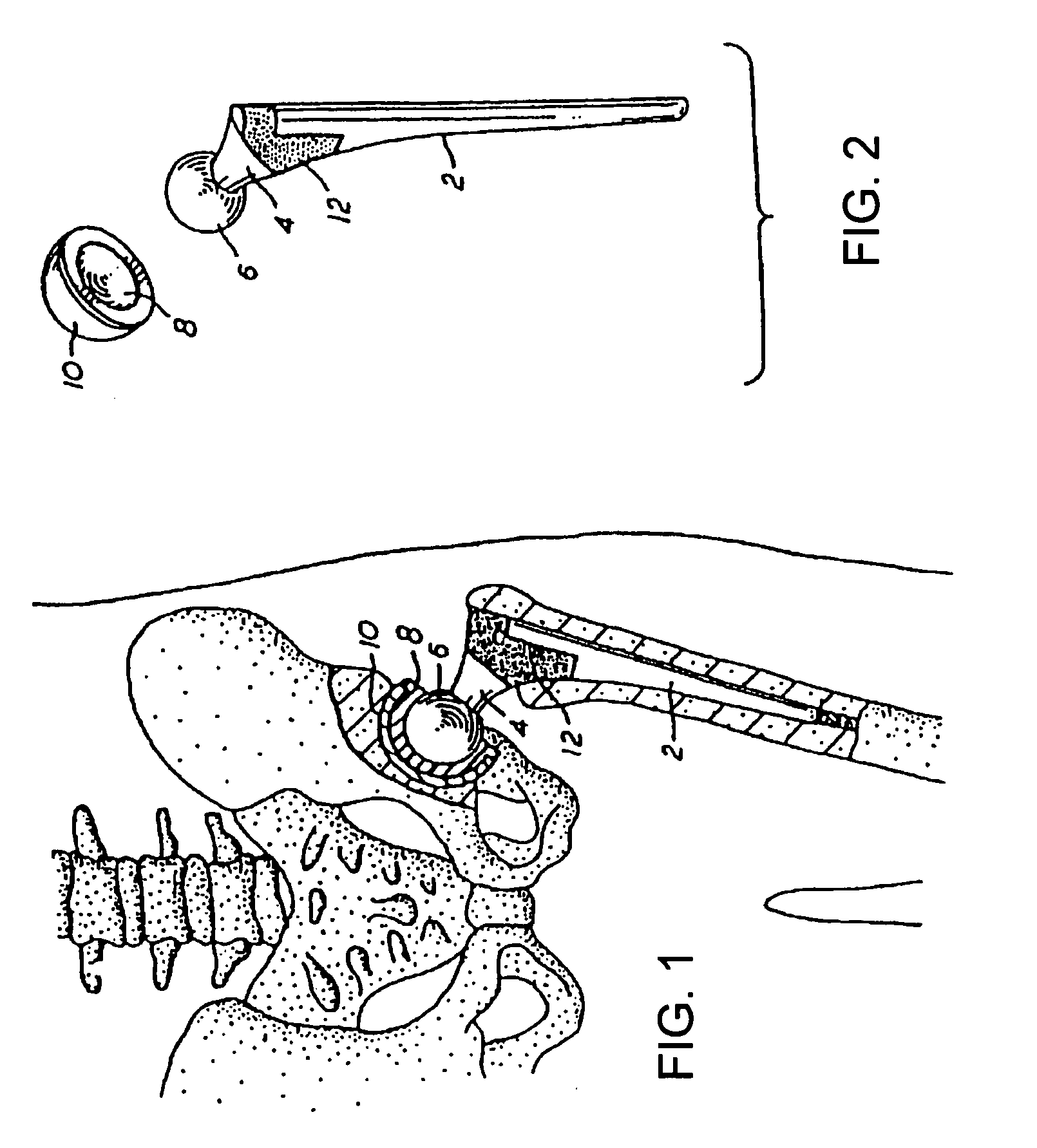

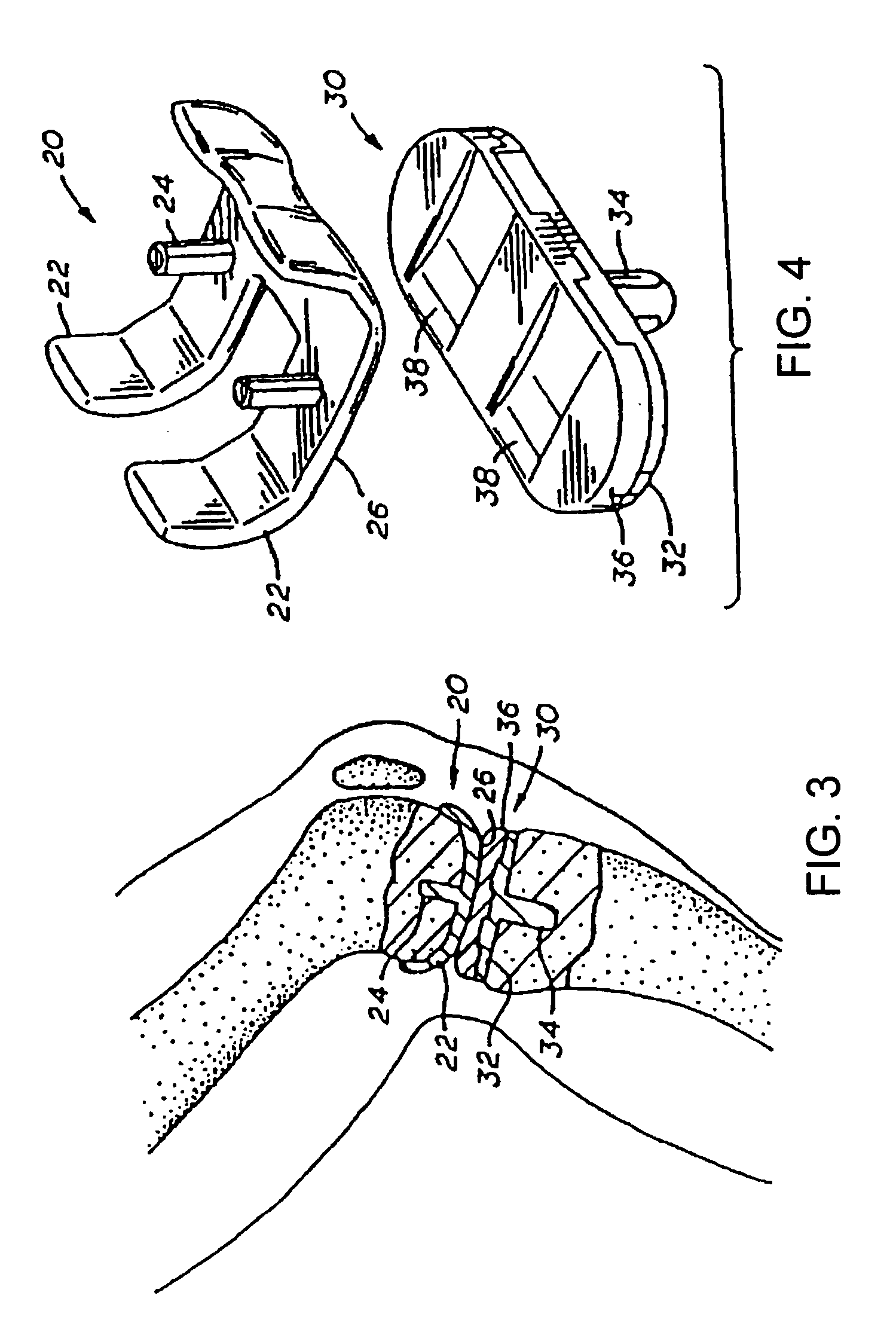

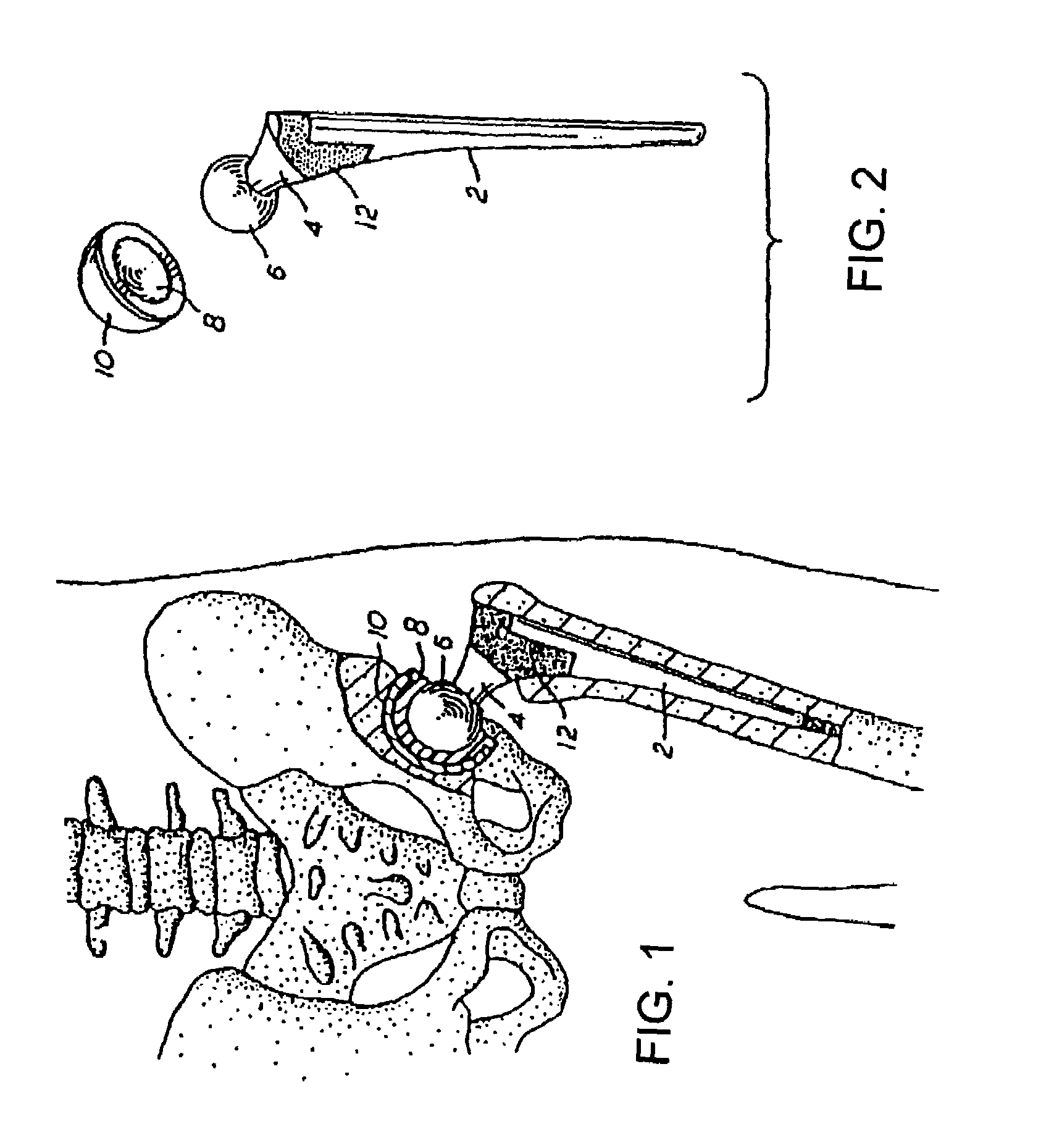

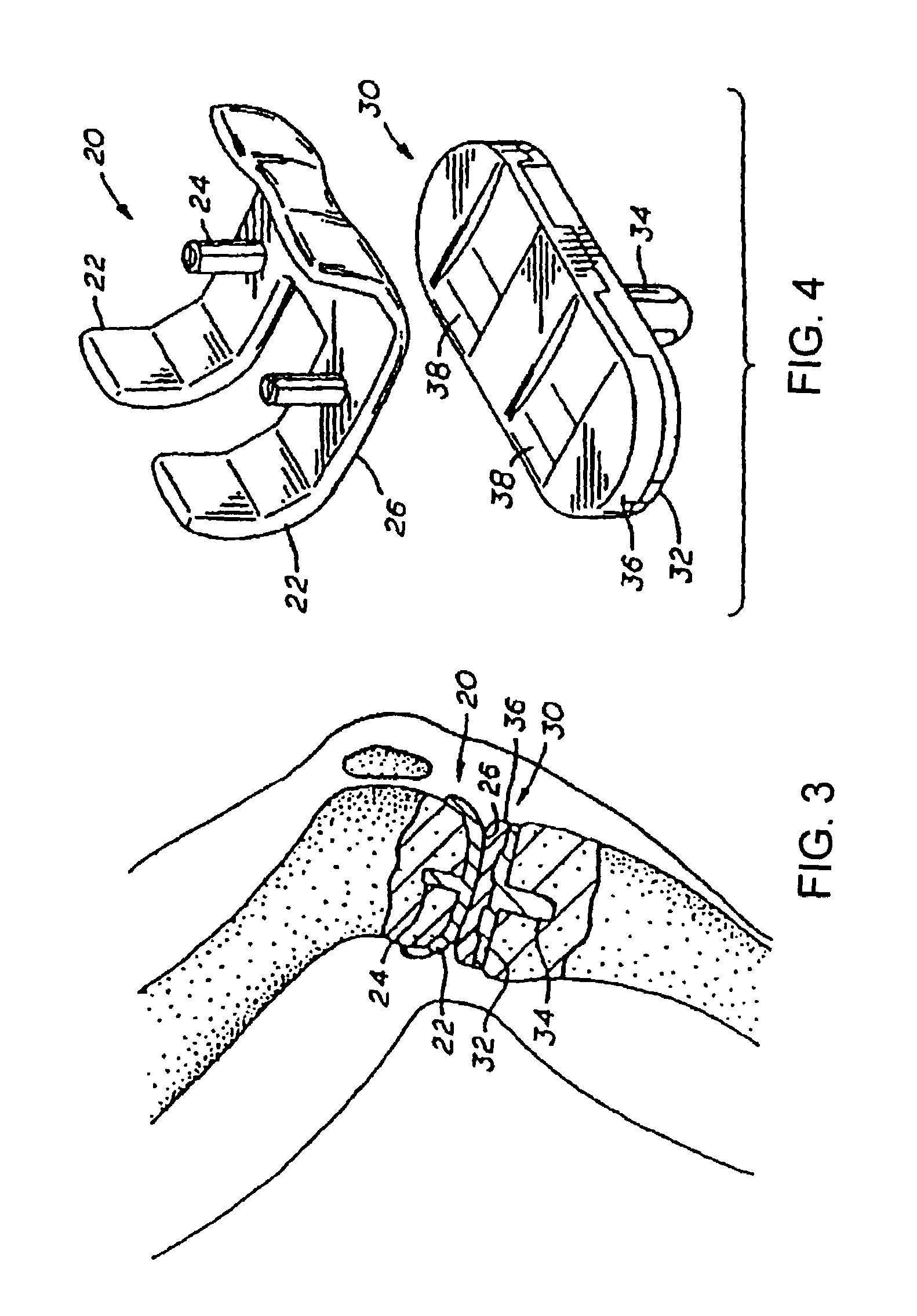

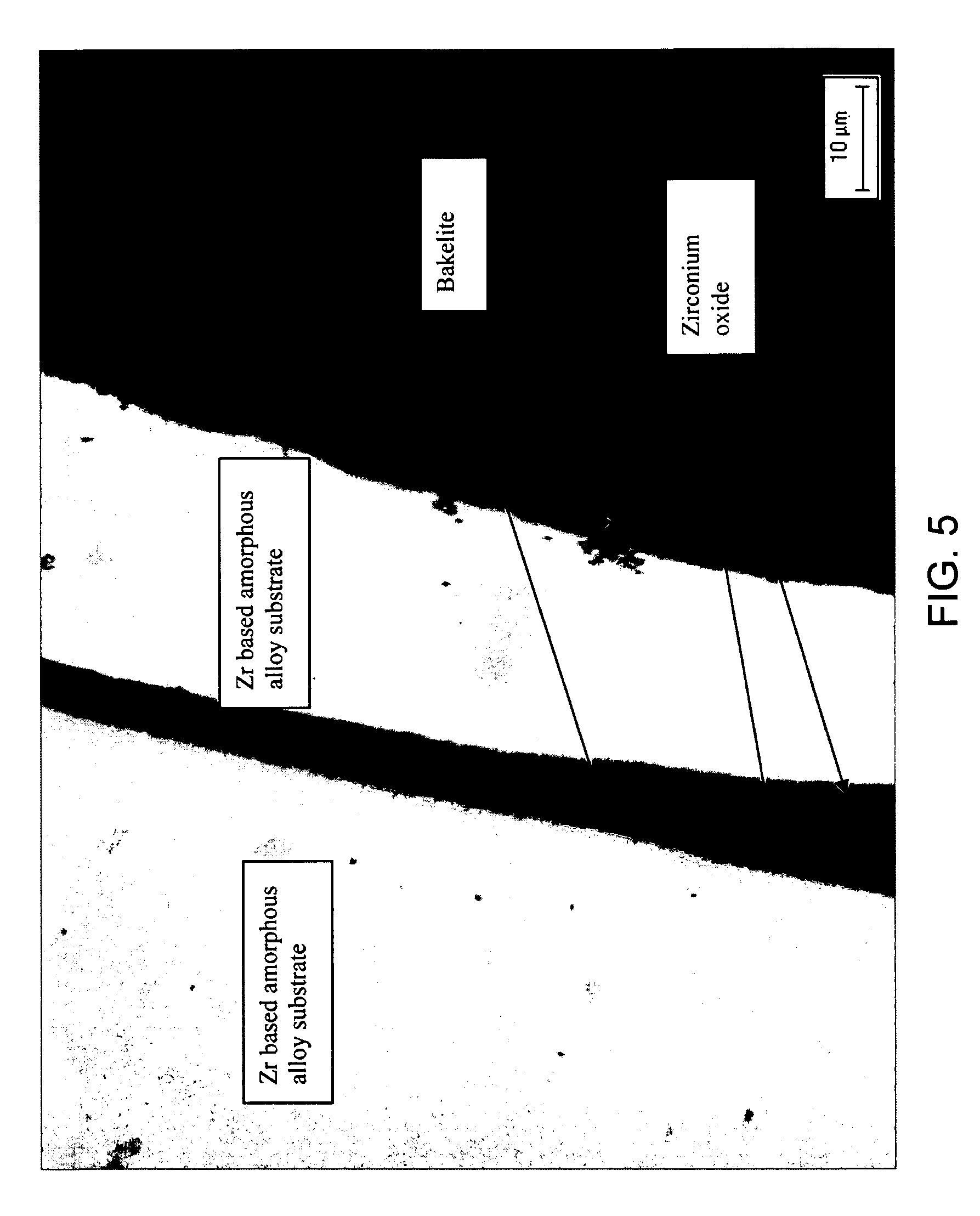

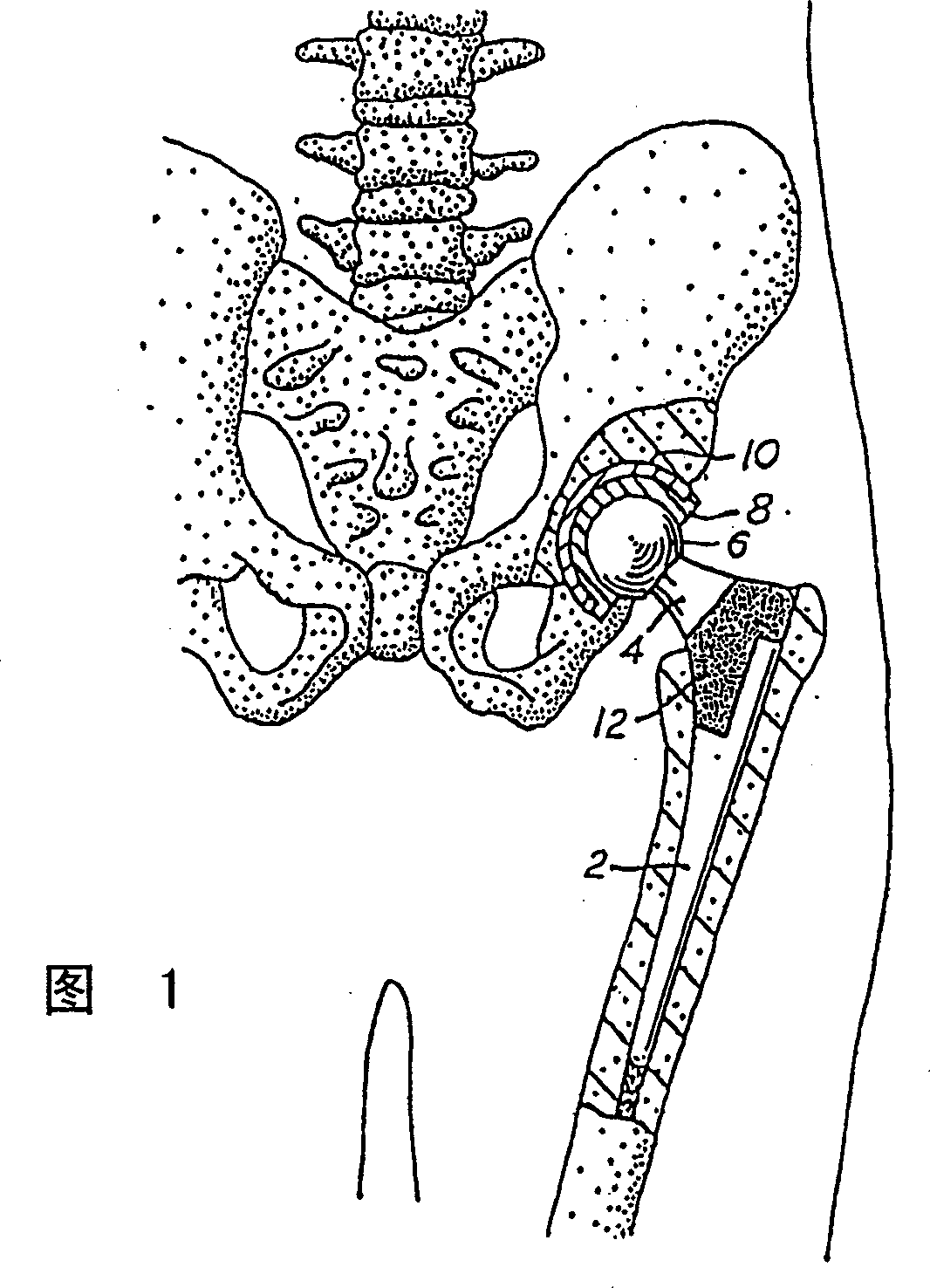

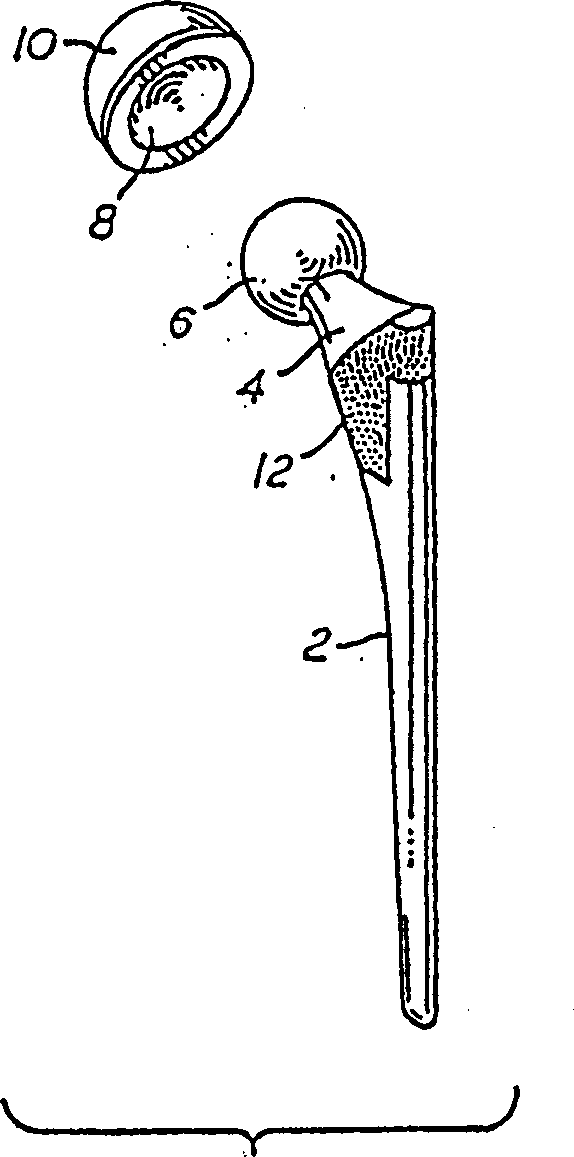

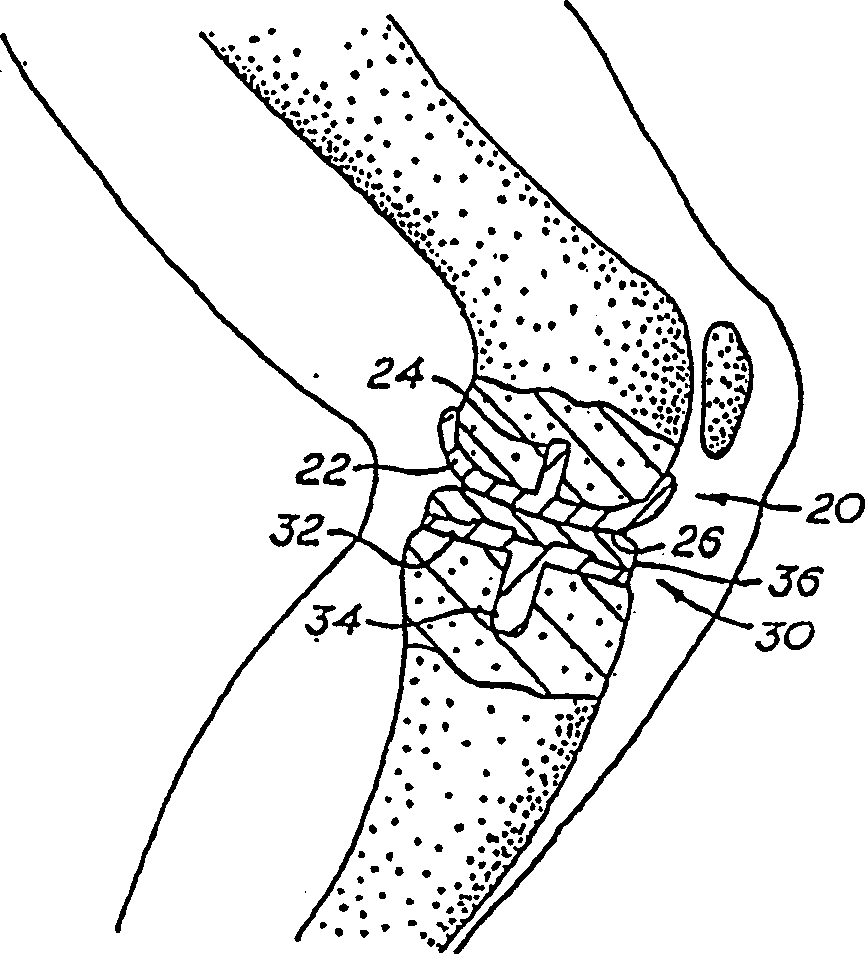

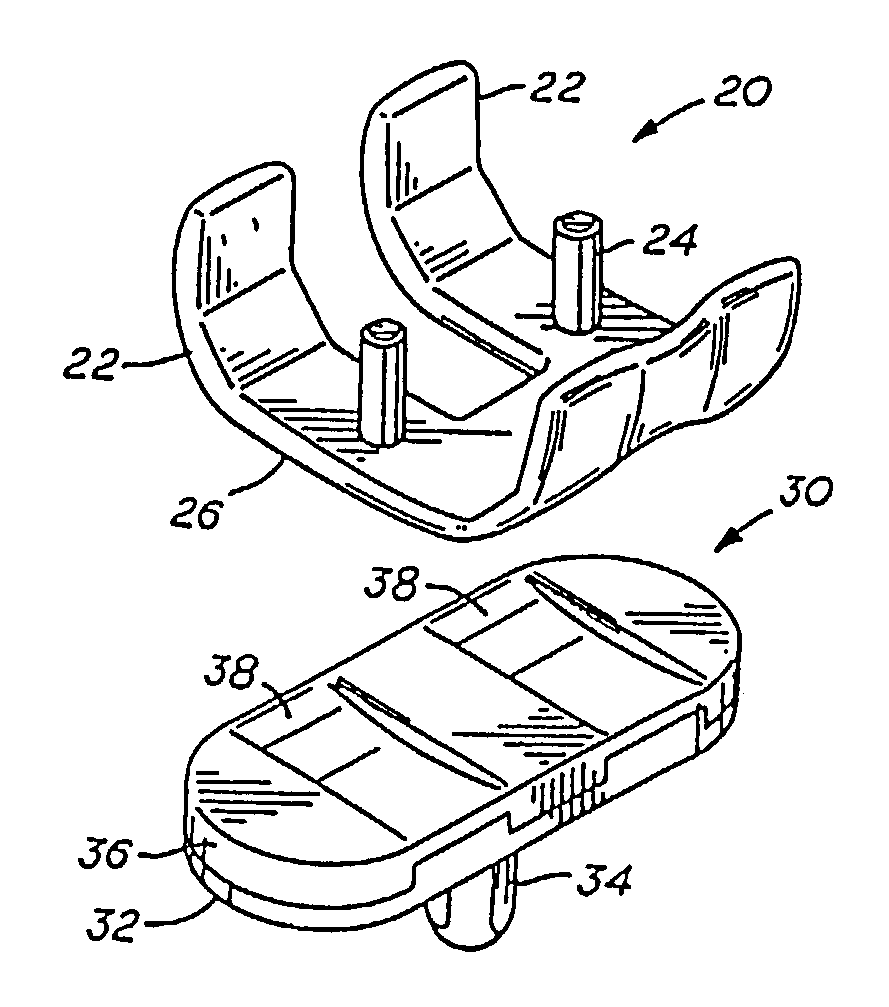

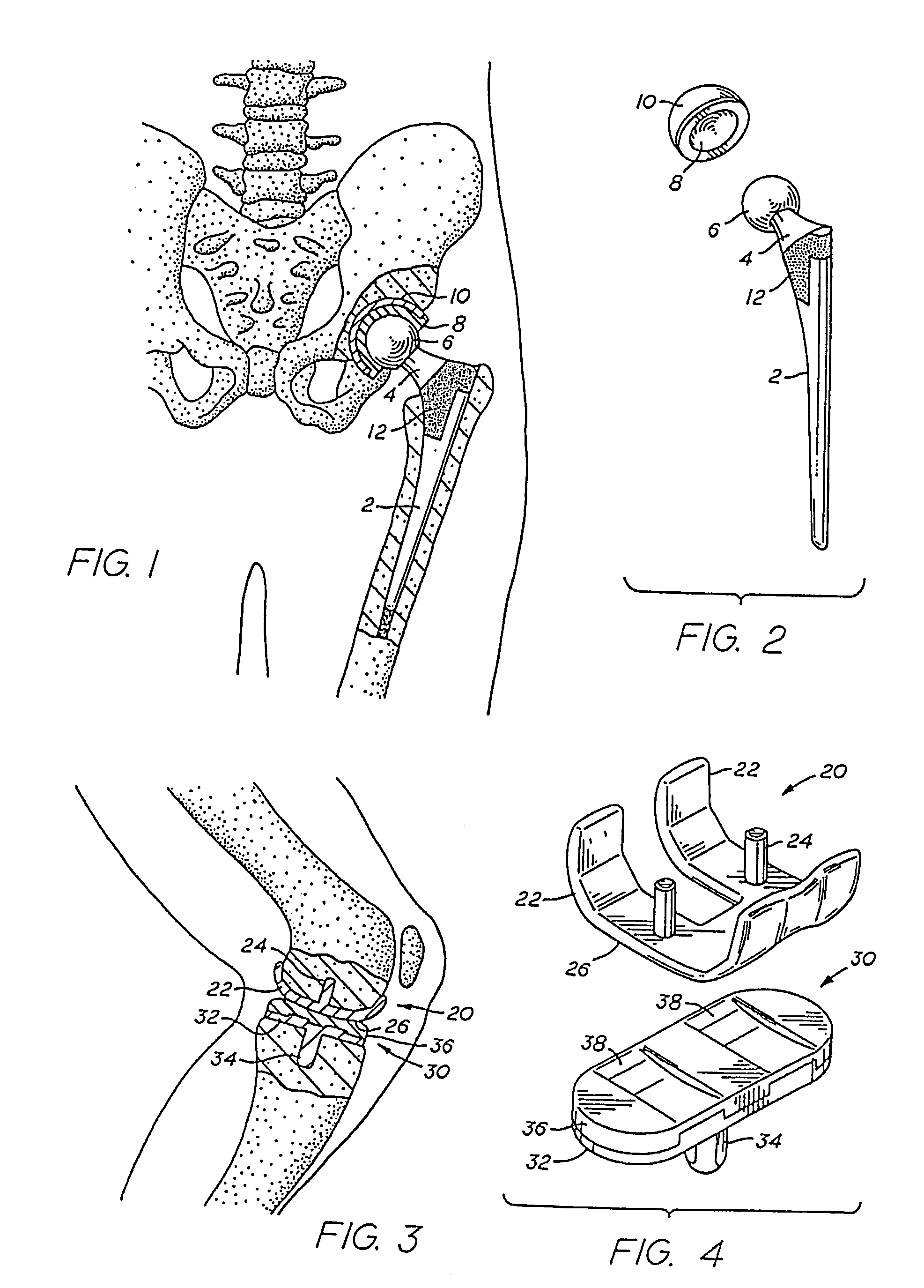

ActiveUS20060058888A1Bone implantSurface reaction electrolytic coatingWear resistantSurface oxidation

A coating of blue-black or black oxidized zirconium of uniform and controlled thickness on a zirconium or zirconium alloy material is accomplished through the oxidative treatment of an amorphous zirconium or zirconium alloy substrate having an altered surface roughness. An oxidized zirconium coating of uniform and controlled thickness is especially useful on orthopedic implants of zirconium or zirconium-based alloys to provide low friction, highly wear resistant surfaces on artificial joints, such as, but not limited to, hip joints, knee joints, shoulders, elbows, and spinal implants. The uniformly thick oxidized zirconium surface of controlled depth on prostheses provide a barrier against implant corrosion caused by ionization of the metal prostheses. The invention is also useful in non-articulating implant devices such as bone plates, bone screws, etc.

Owner:SMITH & NEPHEW INC

Process for the production of a composite component that can resist high thermal stress

InactiveUS6443354B1Without effectOptimal high-temperature strength characteristicWelding/cutting media/materialsWelding/soldering/cutting articlesGraphiteZirconium alloy

The invention provides a process for the production of a composite structural part which can withstand high thermal stress, consisting of at least one graphite part and at least one metal part made of a hardenable copper alloy. In accordance with the invention, the metal part is bonded, by a hot isostatic press process, with the graphite part, which has a layer made of copper or a copper alloy on the bonding surface. In this way, it is possible to use copper-chromium-zirconium alloys with more complex composite structural part constructions and with thin-wall parts of the metal component, without the good mechanical characteristics of the copper-chromium-zirconium alloy being destroyed.

Owner:EURATOM +1

High-strength high-toughness amorphous zirconium alloy

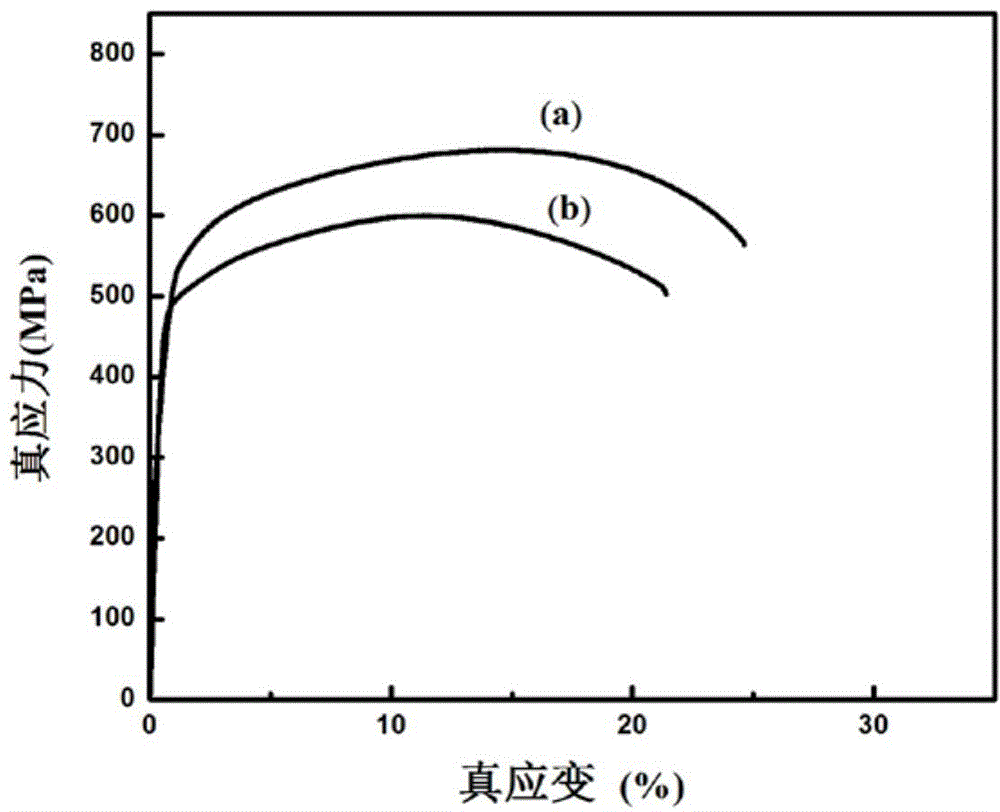

An amorphous Zr alloy has a composition expressed as Zr-Ala-Nib-Cuc-Md. M is one or more elements selected from Ti, Nb and Pd. The a, b, c, and d are amounts in atomic %, and satisfy the following formulas. 5<=a<=0; 30<=b+c<=50; b / c<=1 / 3; and 0<d<=7. The remainder are Zr and inevitable impurities. The alloy contains a non-crystalline phase of 90% or higher by volume. Also, the amorphous alloy indicates an excellent glass-forming ability with a supercooled liquid range over 100° C. (indicated by a difference between the crystallization temperature and the glass transition temperature) and which has a thickness of 1 mm or thicker. Further, it has excellent strength and toughness indicated by the following mechanical characteristics: tensile strength of 1800 MPa or higher; flexural strength of 2500 MPa or higher; Charpy impact value of 100 kJ / m2 or higher; and fracture toughness value of 50 MPa*m1 / 2 or higher.

Owner:JAPAN SCI & TECH CORP

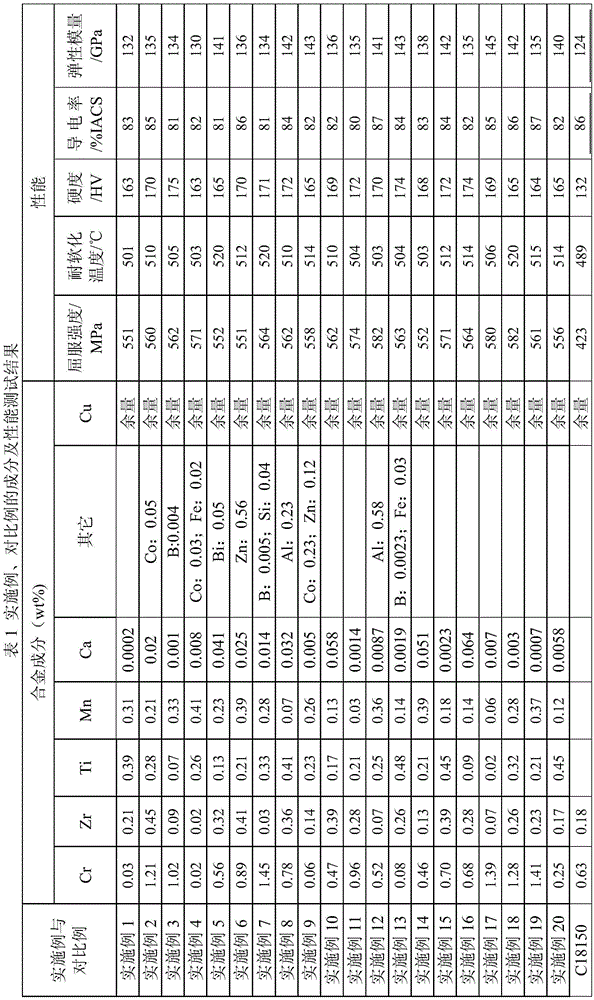

High-strength high-conductivity copper-chromium-zirconium alloy and preparation method of plate/strip thereof

The invention discloses a high-strength high-conductivity copper-chromium-zirconium alloy and a preparation method of a plate / strip thereof. This alloy comprises the chemical composition: 0.01-1.5 wt% of Cr, 0.01-0.5 wt% of Zr, 0.001-0.5 wt% of Ti, 0.01-0.5 wt% of Mn, 0.0001-0.07 wt% of Ca, and the balance of copper and unavoidable impurities; the position and process of the Cu-Cr-Zr alloy are optimized, the provided high-strength high-conductivity copper-chromium-zirconium alloy retains high conductivity (above 80% IACS), elastic modulus up to higher than 130 GPa, softening temperature resistance up to higher than 500 DEG C, yield strength up to higher than 550 MPa and hardness up to 160 HV, the copper-chromium-zirconium plate / strip is imparted high strength, high conductivity and excellent comprehensive performance, this comprehensive performance meets the requirements of products such as a lead frame and a connector upon base material stamping and machining performances, and this plate / strip material is mainly applied to electronic components such as connectors and lead frames.

Owner:NINGBO POWERWAY ALLOY PLATE & STRIP CO LTD

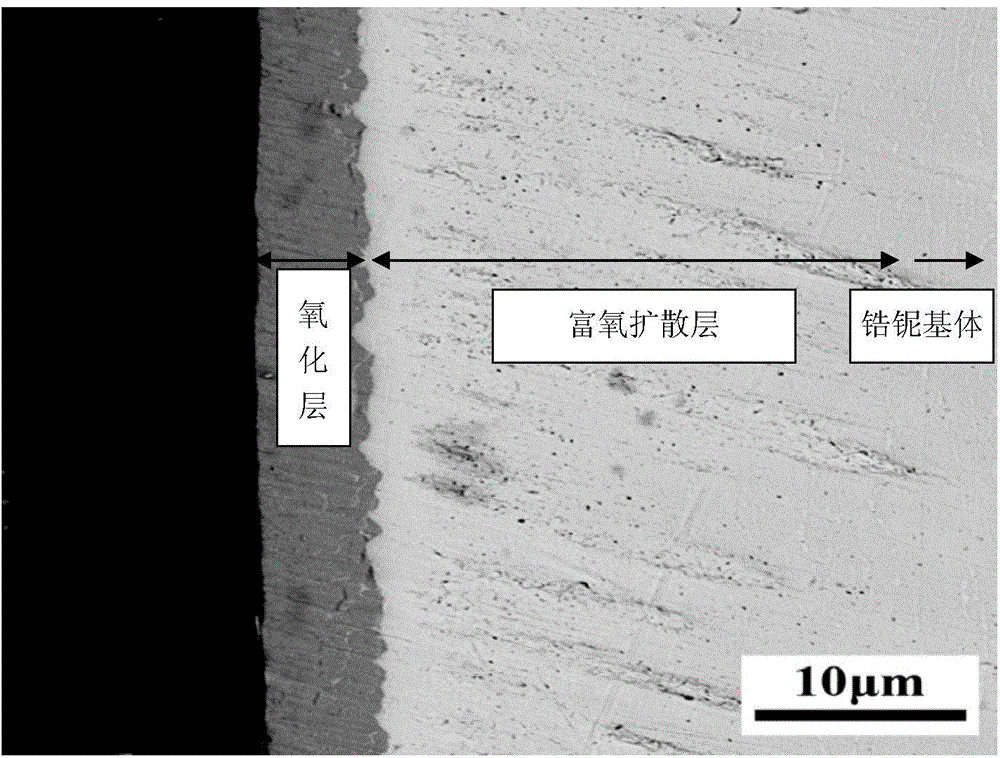

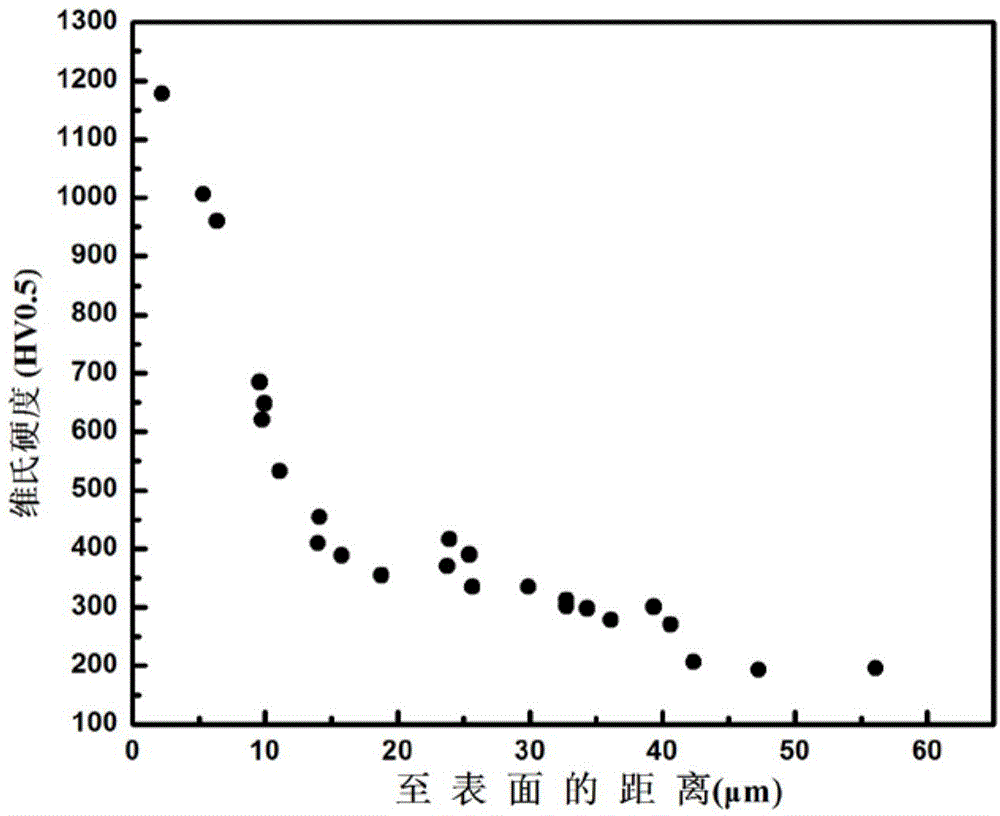

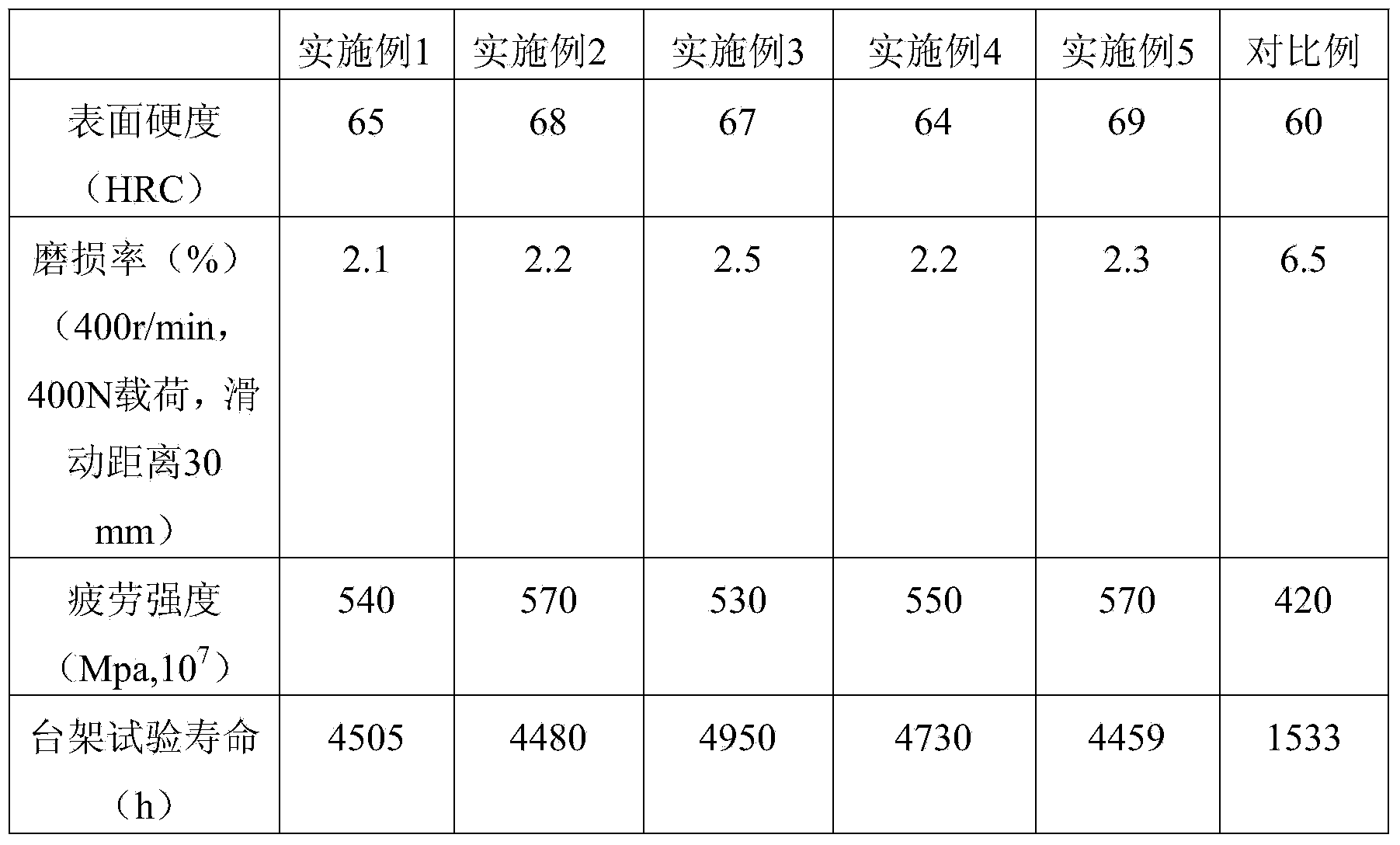

High-wear-resistance and high-tenacity medical zirconium alloy and preparation method and application thereof

The invention belongs to the technical field of high-performance medical alloy materials and particularly relates to a medical zirconium alloy high in surface wear resistance and integral tenacity and a preparation method and application thereof. The surface of the medical zirconium alloy is provided with a micron-level thick oxide ceramic layer is mainly composed of nonoclinic-system zirconia and a small amount of tetragonal-system zirconia; the matrix of the medical zirconium alloy is zirconium alloy, which is specifically composed of, by weight percentage, 76.5-100 wt.% of Zr, 0-19 wt.% of Nb, 0-4.5 wt.% of Hf and inevitable trace impurities as balance; an oxygen-enriched transition layer is arranged between the oxide ceramic layer and the matrix alloy, namely, oxygen is dissolved inside the matrix to form zirconium-oxygen solid solution. The high-wear-resistance and high-tenacity medical zirconium alloy combines the plastic deformation technology and the high-temperature oxidation technology and greatly improves the surface hardness, the wear resistance and the alloy strength, thereby having a broad application prospect in biomedicine, particularly in the aspect of biomedical implants.

Owner:SOUTH CHINA UNIV OF TECH

Method of surface oxidizing zirconium and zirconium alloys and resulting product

A coating of blue-black or black oxidized zirconium of uniform and controlled thickness on a zirconium or zirconium alloy material is accomplished through the oxidative treatment of an amorphous zirconium or zirconium alloy substrate having an altered surface roughness. An oxidized zirconium coating of uniform and controlled thickness is especially useful on orthopedic implants of zirconium or zirconium-based alloys to provide low friction, highly wear resistant surfaces on artificial joints, such as, but not limited to, hip joints, knee joints, shoulders, elbows, and spinal implants. The uniformly thick oxidized zirconium surface of controlled depth on prostheses provide a barrier against implant corrosion caused by ionization of the metal prostheses. The invention is also useful in non-articulating implant devices such as bone plates, bone screws, etc.

Owner:SMITH & NEPHEW INC

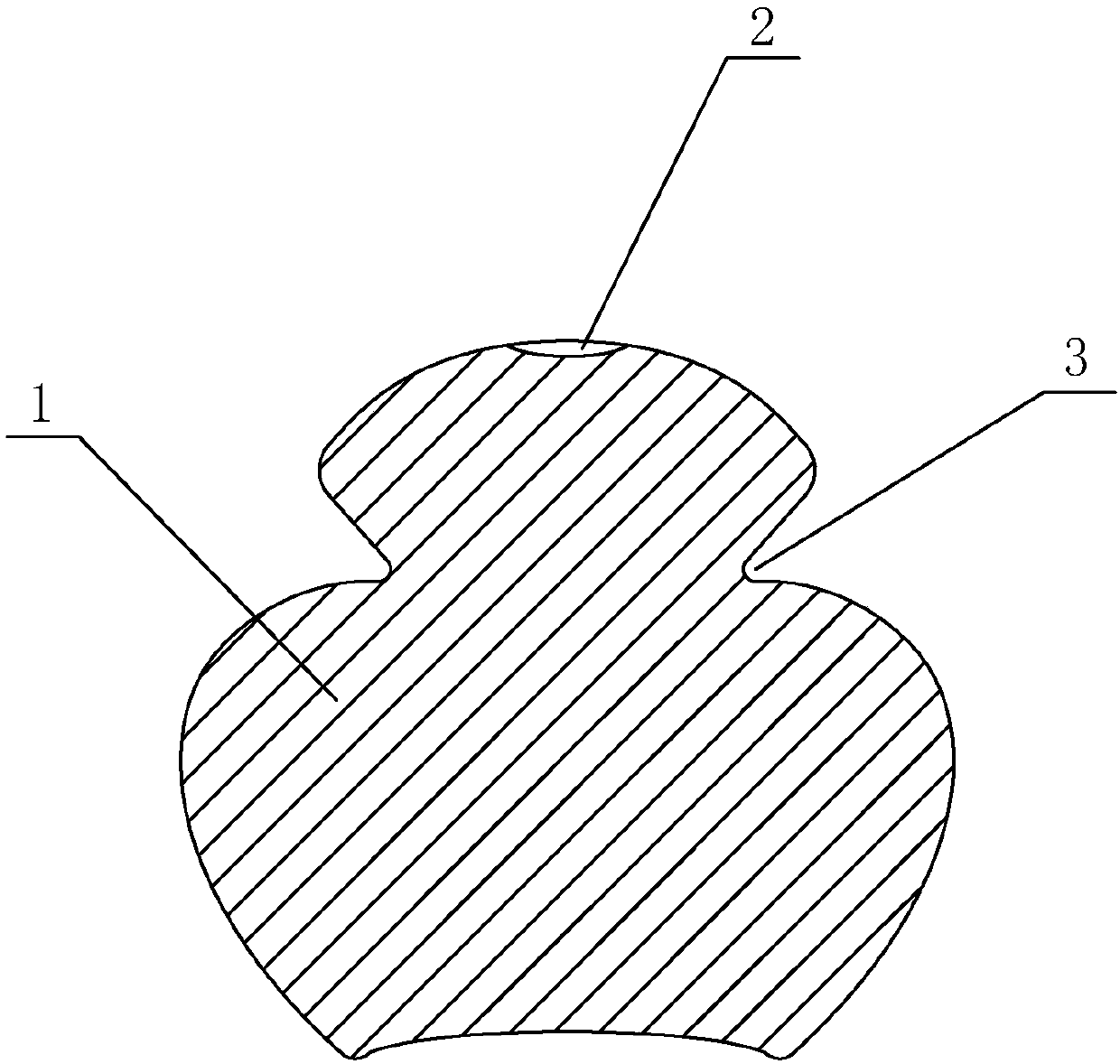

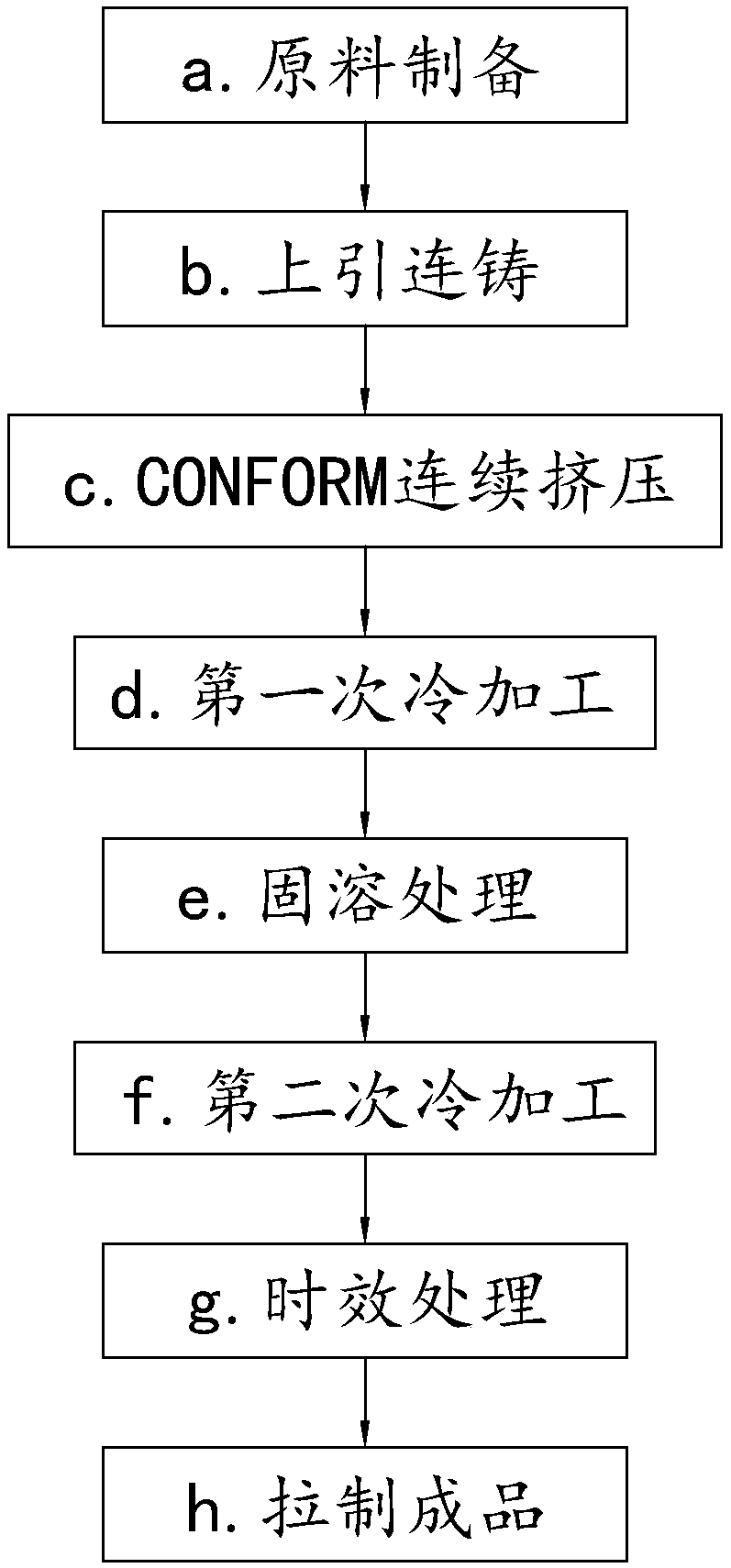

Copper-chromium-zirconium alloy contact wire and production technique thereof

ActiveCN107739872AMeet the needs of rapid developmentConductive materialMetal/alloy conductorsZirconium alloyImpurity

The invention discloses a copper-chromium-zirconium alloy contact wire and a production technique thereof. The copper-chromium-zirconium alloy contact wire is composed of copper, chromium, zirconium and inevitable impurity elements according to the set mass percentages. In preparation, the main technique comprises the steps of raw material preparation, up-drawing continuous casting, CONFORM continuous squeezing, primary cold machining, solution treatment, secondary cold machining, aging treatment and finished product drawing. According to the copper-chromium-zirconium alloy contact wire manufactured by the technique and materials, the matching of the contact wire raw materials is reasonably adjusted, the ratio of all element components in the contact wire is adjusted, and the special production technique is combined so that a high-strength high-conductivity contact wire product can be produced, wherein the weight of one single contact wire product is larger than two tons, the IACS electrical conductivity of the contact wire product is 75-90%, and the tensile strength of the contact wire product is 550-700 MPa; and the requirement of current electric railway high-speed development can be better met.

Owner:CENTURAY TECH CO LTD

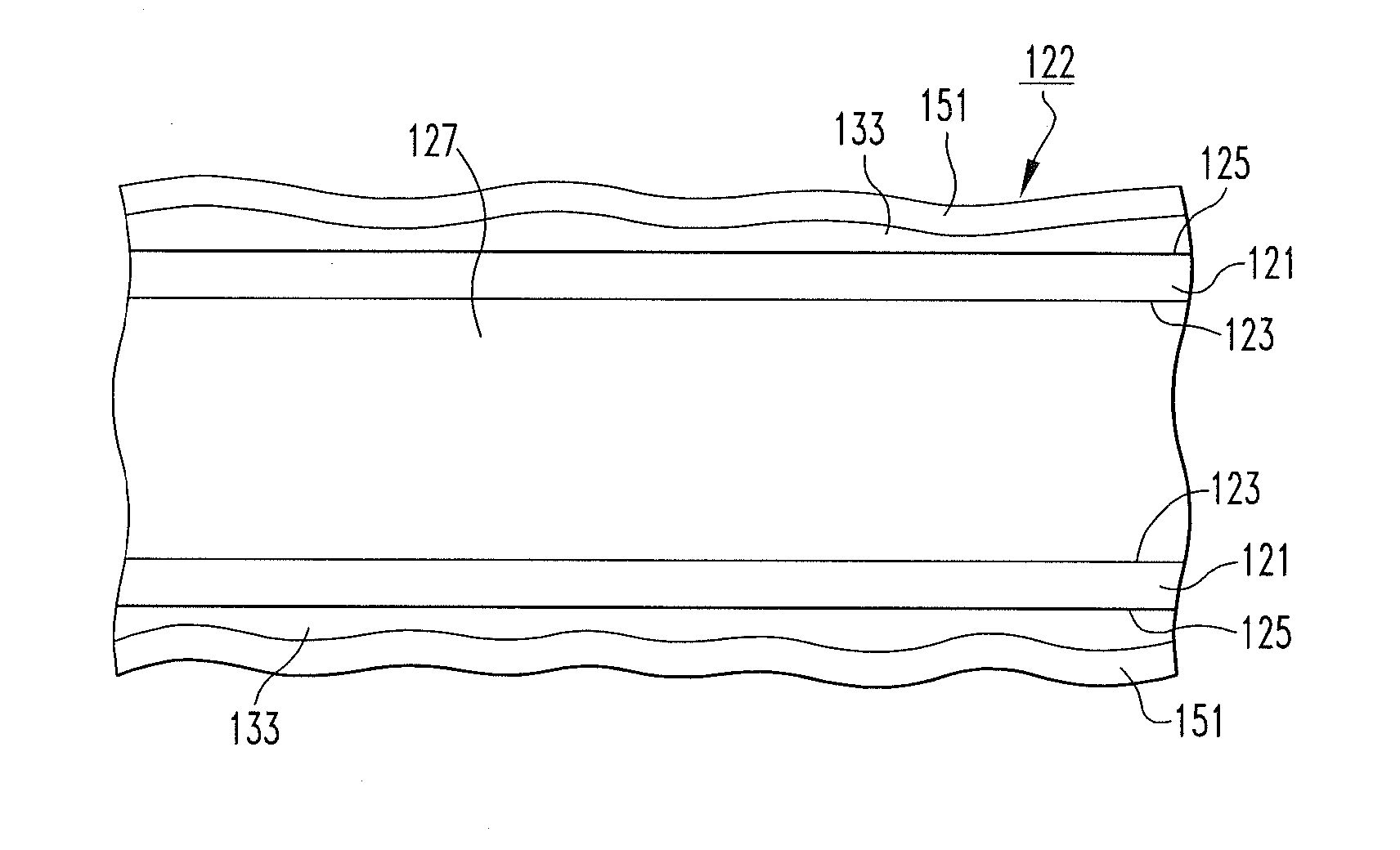

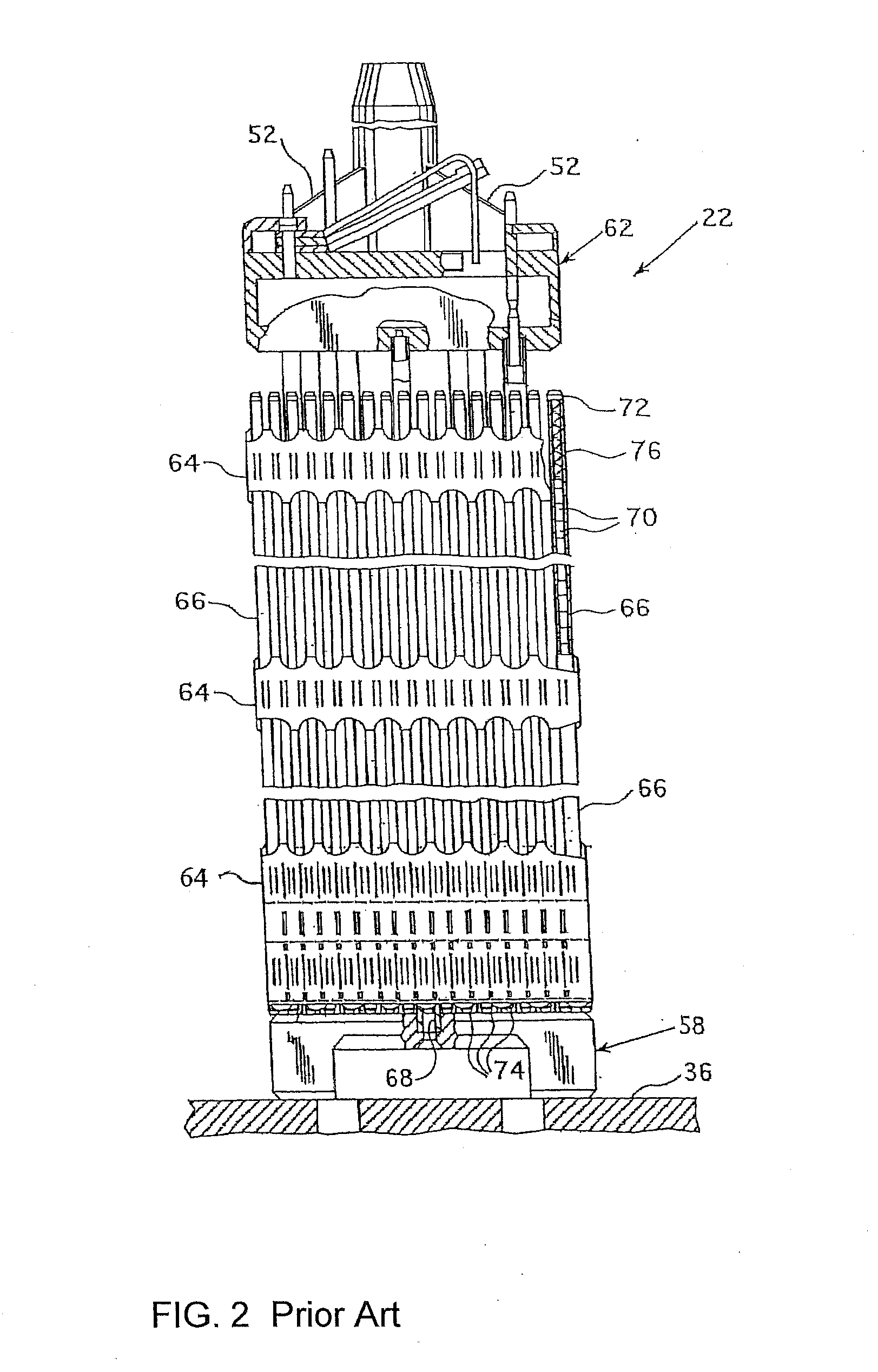

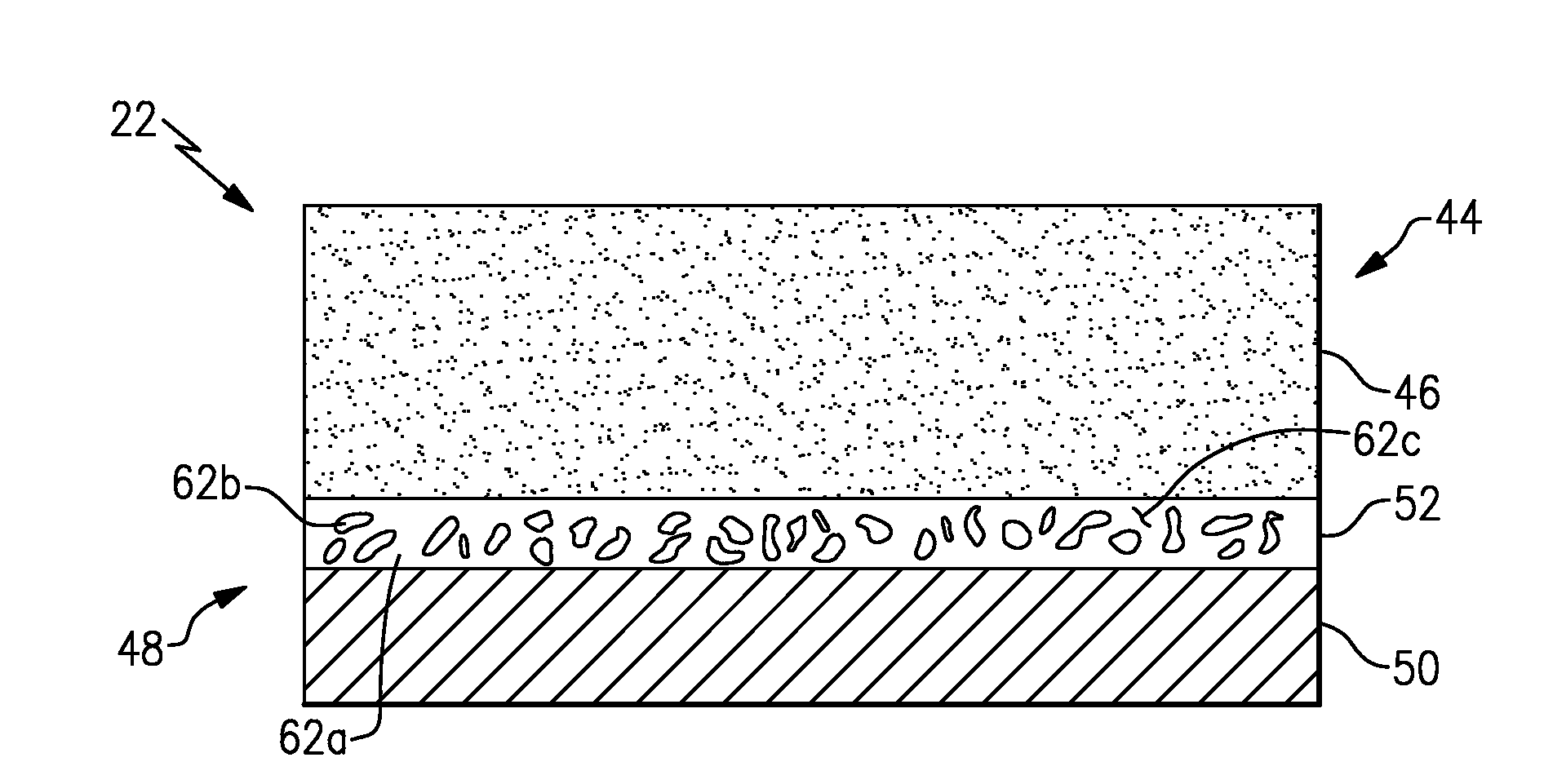

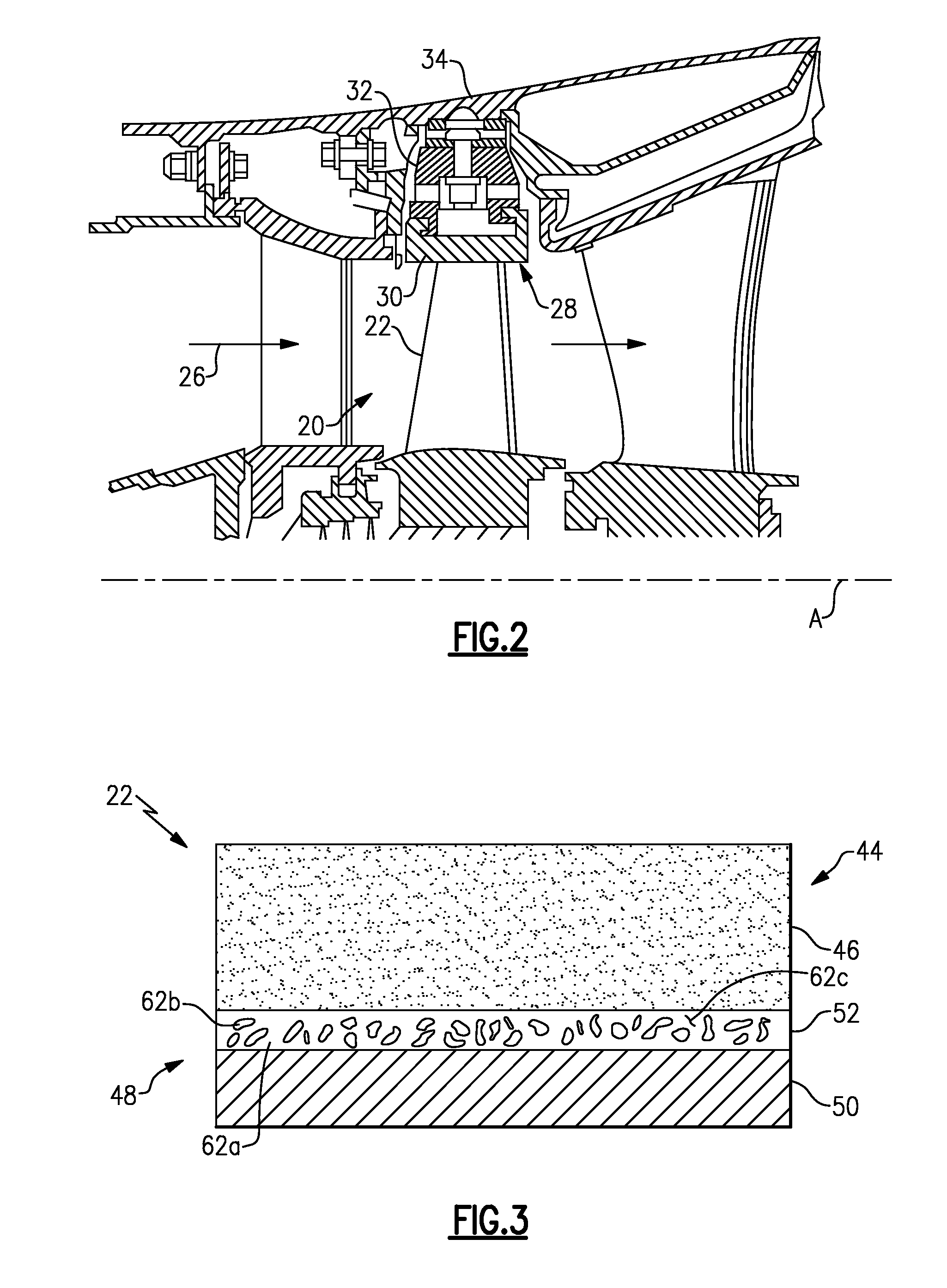

Deposition of a protective coating including metal-containing and chromium-containing layers on zirconium alloy for nuclear power applications

ActiveUS20150348652A1Low neutron absorption cross-sectionLiquid surface applicatorsMolten spray coatingNuclear reactorNuclear power

The invention relates to compositions and methods for coating a zirconium alloy cladding of a fuel element for a nuclear water reactor. The coating includes a first tier or layer and a second tier or layer. The first layer includes an elemental metal and the second layer is an oxidation-resistant layer that includes elemental chromium. The first layer serves as an intermediate layer between the zirconium alloy substrate and the second layer. This intermediate layer can be effective to improve adhesion of the second layer to the zirconium alloy substrate. The multilayer coating forms a protective layer which provides improved capability for the zirconium alloy cladding to withstand normal and accident conditions to which it is exposed in the nuclear reactor.

Owner:WESTINGHOUSE ELECTRIC CORP

Method of surface oxidizing zirconium and zirconium alloys and resulting product

A coating of blue-black oxidized zirconium of uniform and controlled thickness on a zirconium or zirconium alloy material is accomplished through the use of a single phase crystalline material substrate having an altered surface roughness. An oxidized zirconium coating of uniform and controlled thickness is especially useful on orthopedic implants of zirconium or zirconium-based alloys to provide low friction, highly wear resistant surfaces on artificial joints, such as, but not limited to, hip joints, knee joints, shoulders, elbows, and spinal implants. The uniformly thick oxidized zirconium surface of controlled depth on prostheses provide a barrier against implant corrosion caused by ionization of the metal prostheses. The invention is also useful in non-articulating implant devices such as bone plates, bone screws, etc.

Owner:SMITH & NEPHEW INC

Magnesium-calcium-carbon refractory material

The invention relates to a magnesium-calcium-carbon refractor material, in particular to a refractory material for smelting, which belongs to the technical field of refractory materials for smelting. The magnesium-calcium-carbon refractor material contains 1-25 parts of carbon, 0.2-6 parts of a magnesium-zirconium alloy, 60-96 parts of a mixture of dolomite sand, magnesium-calcium sand and magnesium sand, and 2-5 parts of a carbon-containing bonding agent, wherein the magnesium-zirconium alloy contains 3-35 percent of a zirconium element and the balance of magnesium and a small quantity of impurities. The magnesium-calcium-carbon refractor material provided by the invention can be taken as a refractory material for smelting, and has the advantages of oxidation resistance, high temperature resistance, slag permeation resistance, thermal shock resistance and easiness in producing.

Owner:江苏苏嘉集团新材料有限公司

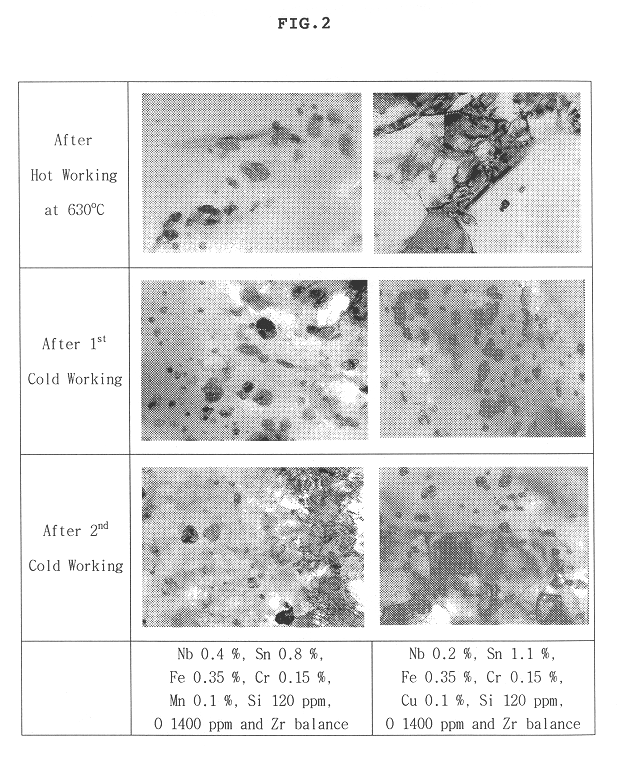

Zirconium alloys with improved corrosion resistance and method for fabricating zirconium alloys with improved corrosion

InactiveUS20060243358A1Improve corrosion resistanceReduced intermediate anneal temperatureNuclear energy generationReactor fuel elementsNiobiumZirconium alloy

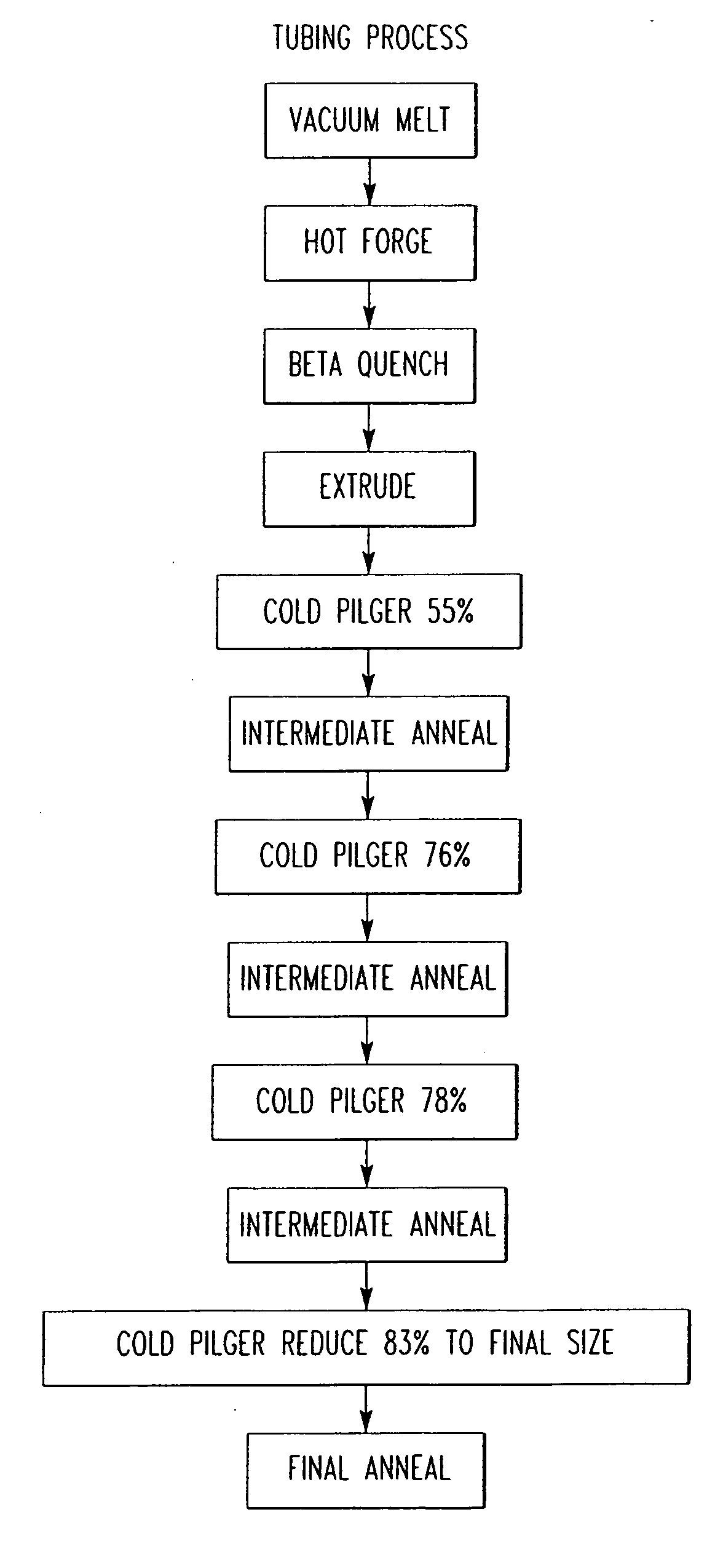

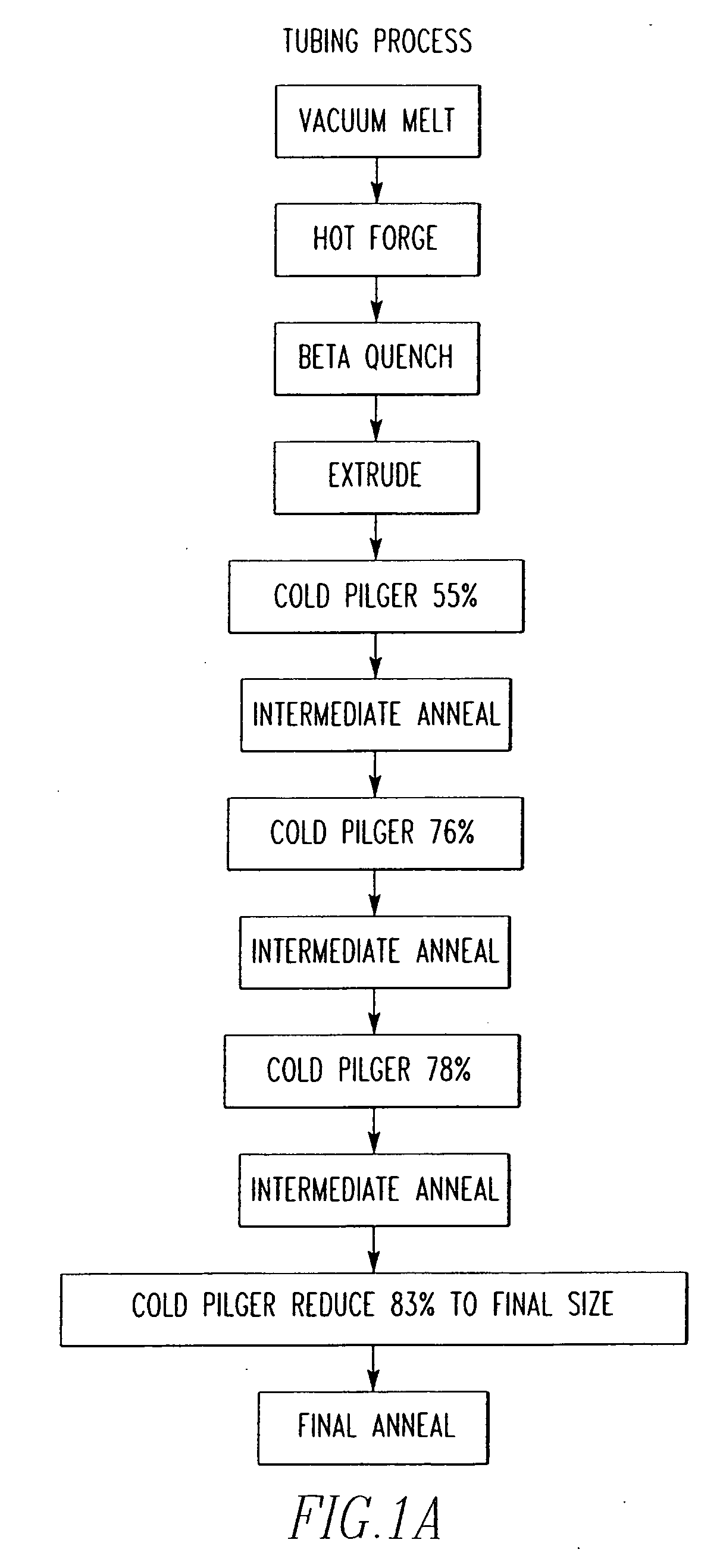

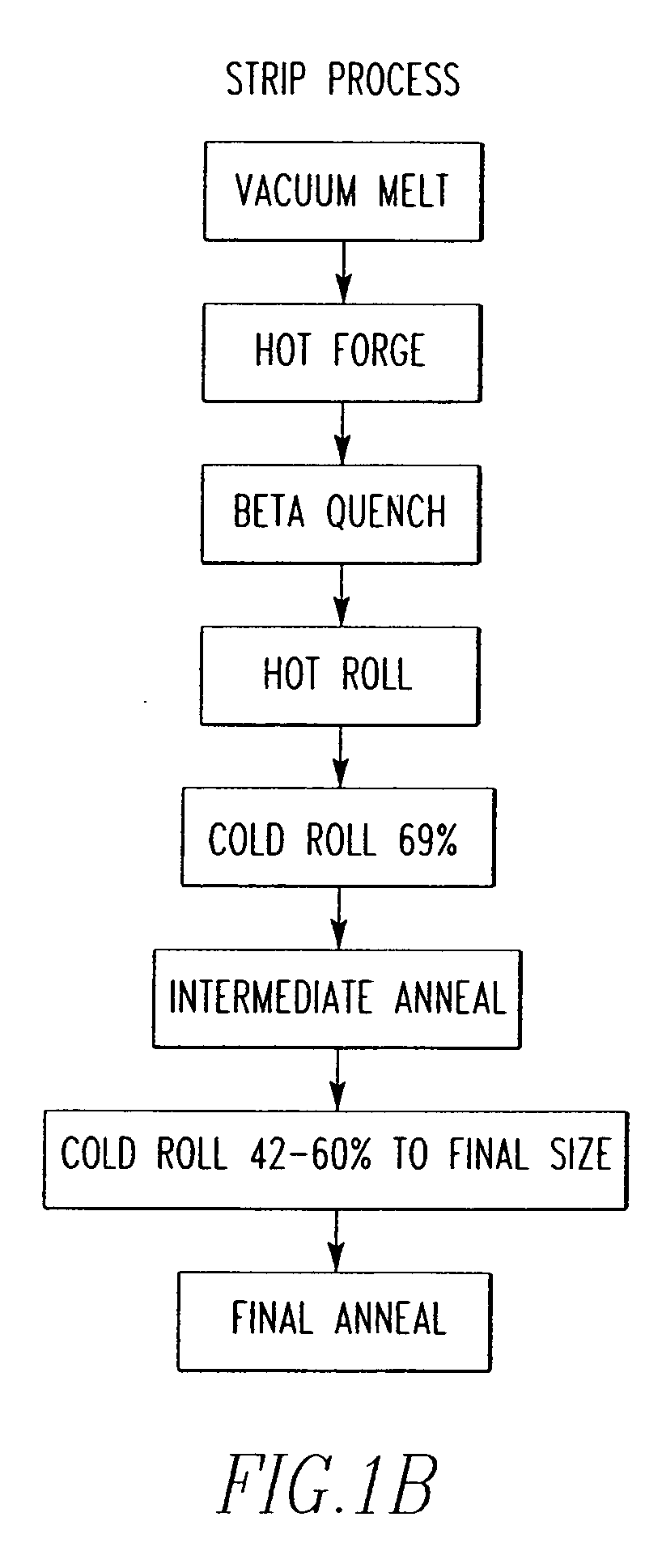

Articles, such as tubing or strips, which have excellent corrosion resistance to water or steam at elevated temperatures, are produced from alloys having 0.2 to 1.5 weight percent niobium, 0.01 to 0.45 weight percent iron, at least one additional alloy element selected from 0.02 to 0.8 weight percent tin, 0.05 to 0.5 weight percent chromium, 0.02 to 0.3 weight percent copper, 0.1 to 0.3 weight percent vanadium, 0.01 to 0.1 weight percent nickel, the balance at least 97 weight percent zirconium, including impurities, wherein the alloy may be fabricated from a process of forging the zirconium alloy into a material, beta quenching the material, forming the material by extruding or hot rolling the material, cold working the material with one or a multiplicity of cold working steps, wherein the cold working step includes cold reducing the material and annealing the material at an intermediate anneal temperature of 960°-1105° F., and final working and annealing of the material. The articles formed also show improved weld corrosion resistance with the addition of chromium.

Owner:WESTINGHOUSE ELECTRIC CORP

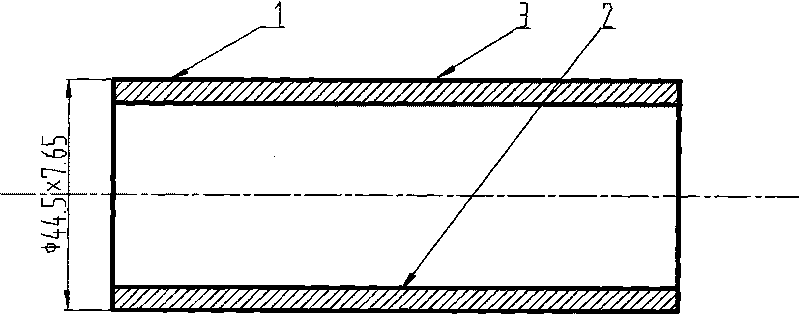

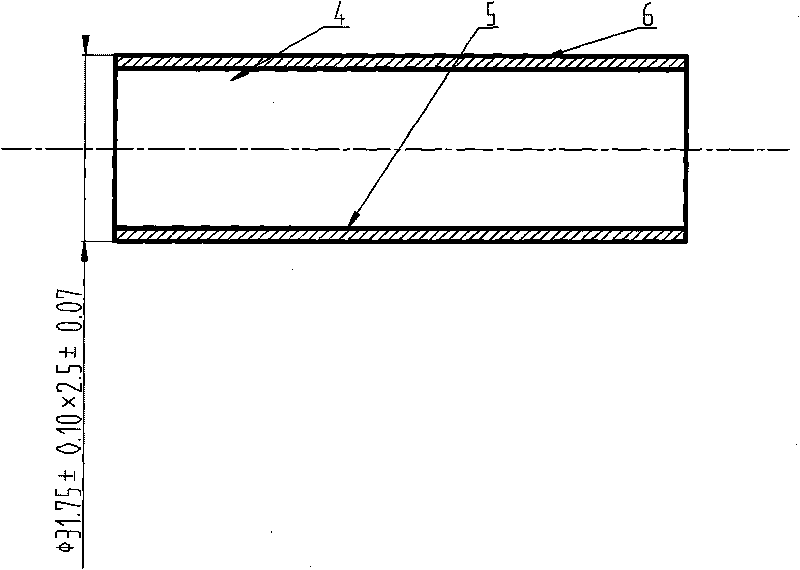

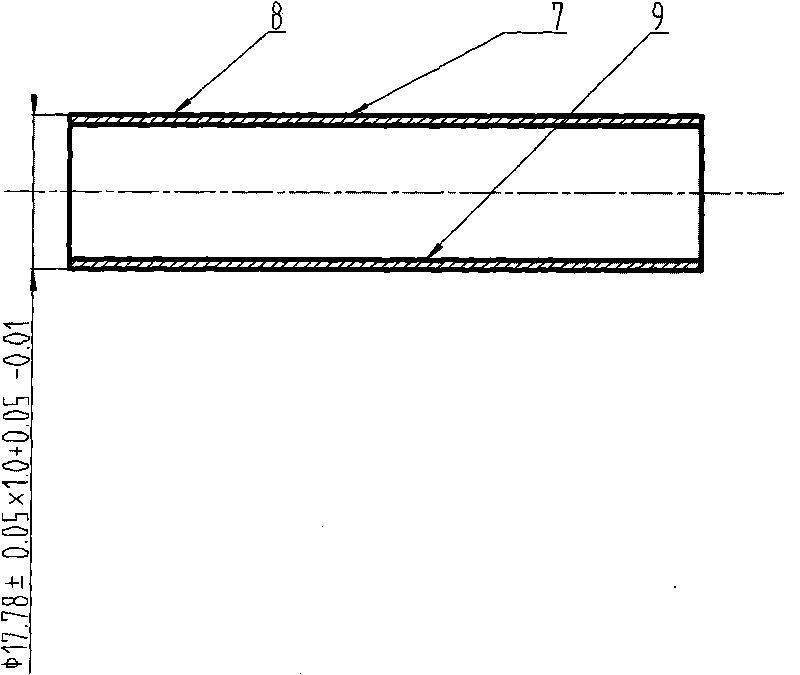

Method for processing thin-walled tube of zirconium alloy specially used by nuclear reactor

ActiveCN101704178AMeet the use requirementsChange the unfavorable situationNuclear reactor coreNuclear reactor

The invention relates to a method for processing a thin-walled tube of zirconium alloy specially used by nuclear reactor with the specification of Phi 12.8 multiplied by 0.25mm. The adopted technical scheme is characterized by comprising the following steps: selecting and using a zircaloy tube (1) with a certain length of Phi 44.5 multiplied by 7.65 mm, then conducting the steps such as cold rolling, primary intermediate annealing, primary acid cleaning, second pass cold rolling, secondary intermediate annealing, secondary acid cleaning, final cold rolling, final annealing, straightening and then polishing, acid cleaning and complexing treatment, detection and then cutting constant length, and the like on the zircaloy tube, and finally completing the process of the thin walled tube of zirconium alloy specially used by the nuclear reactor. The thin-walled tube of zirconium alloy specially used by the nuclear reactor which is processed by the method reaches the requirement of the required machining accuracy, meets the operating requirement of the nuclear reactor, and changes the unfavorable situation that in China, the thin-walled tube of zirconium alloy specially used by the nuclear reactor, which has the specification and the machining accuracy, depends on import.

Owner:西北锆管有限责任公司

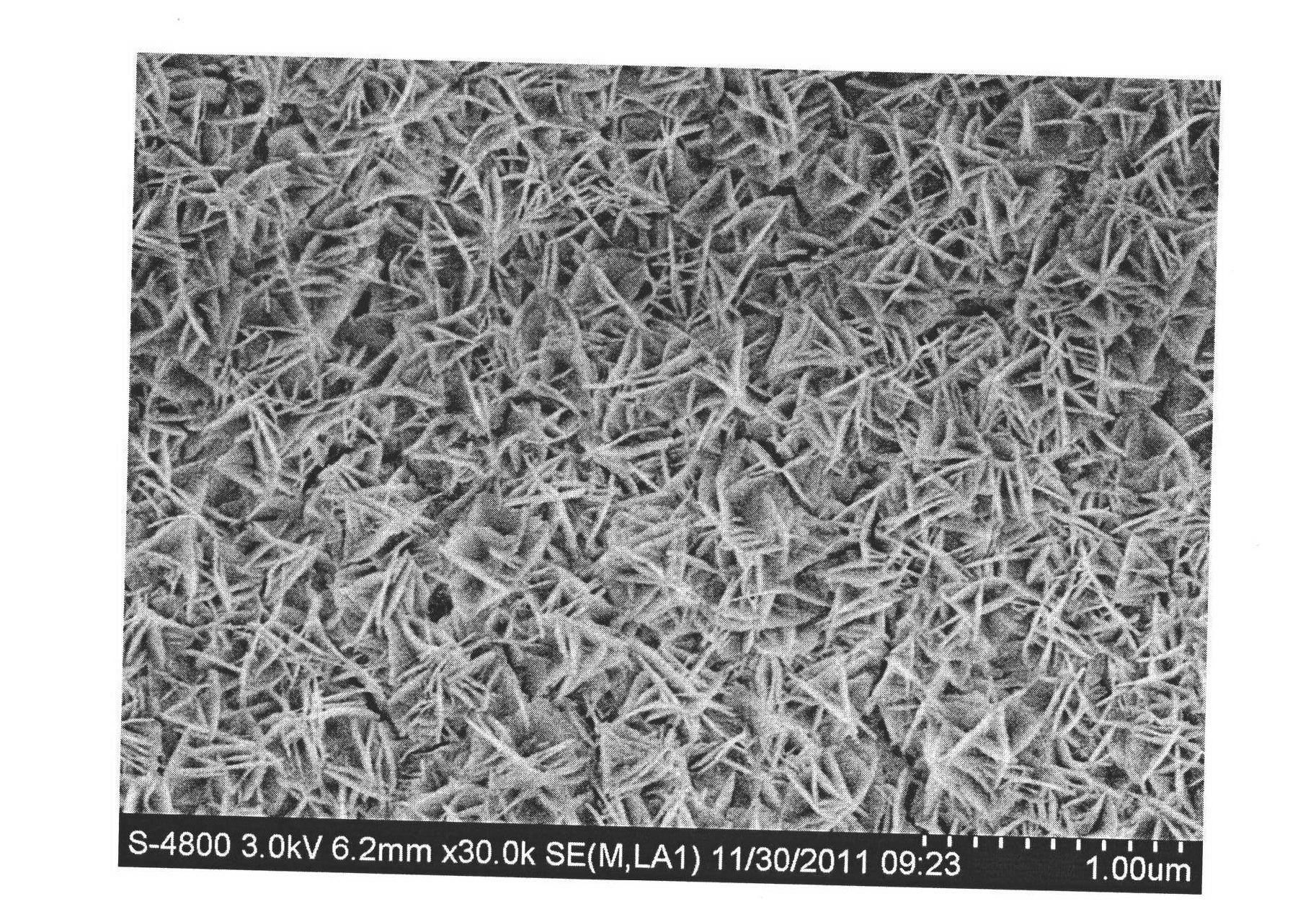

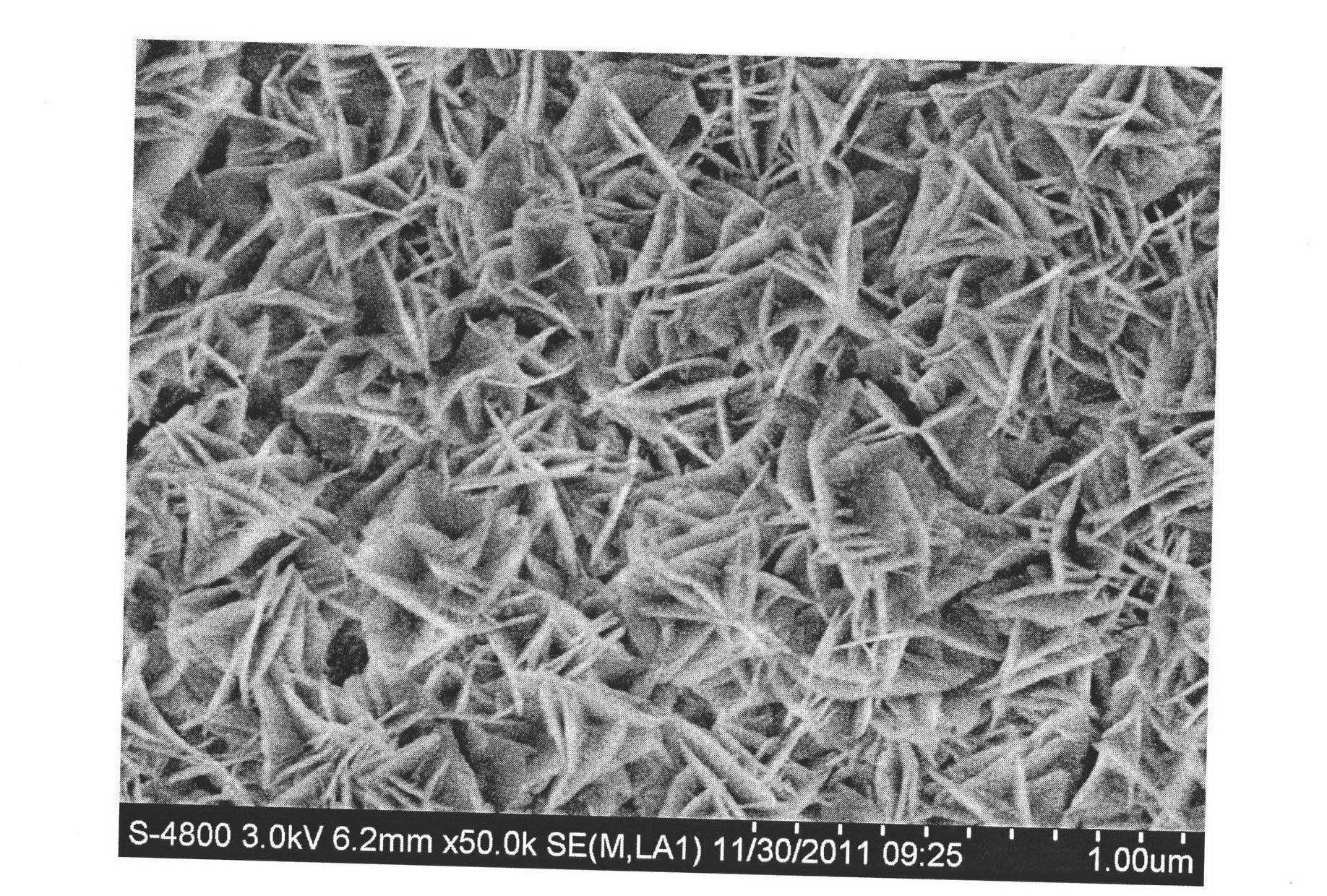

Zirconium and zirconium alloy zinc-manganese composite phosphating solution and phosphating method thereof

InactiveCN102560461AImprove protectionRealize environmental friendlinessMetallic material coating processesPhosphatePhosphoric acid

The invention discloses a zirconium and zirconium alloy zinc-manganese composite phosphating solution and a phosphating method thereof. The zirconium and zirconium alloy zinc-manganese composite phosphating solution is an aqueous solution comprising the following components of: 0.001-10g of zinc salts, 0.001-5g of manganese salts, 5-30g of phosphoric acid, 1-8g of accelerator, 0.001-15g of complexing agent, 0.001-10g of anionic surface agent and 0.001-5g of corrosion inhibitor in each liter of phosphating treatment solution. The phosphating method of the zirconium and zirconium alloy zinc-manganese composite phosphating solution comprises the steps of preliminary grinding, water washing, chemical degreasing, water washing, acid pickling, water washing, phosphating, water washing and drying, wherein the phosphating treatment temperature is 50-90DEG C, the pH value is 1.5-3.5 and the treatment time is 1-30 minutes. According to the zirconium and zirconium alloy zinc-manganese composite phosphating solution and the phosphating method thereof disclosed by the invention, a phosphate conversion coating with favorable protective performance, favorable wear resistance, fineness and uniformity can be obtained from the surfaces of zirconium and zirconium alloy workpieces. The phosphate conversion coating is stable and strong in a binding force and can be used for improving the service performances of zirconium and zirconium alloy and prolonging the service life of the zirconium and zirconium alloy. The phosphating method disclosed by the invention is stable in process, easy to control and is environment-friendly.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method of surface oxidizing zirconium and zirconium alloys and resulting product

A coating of blue-black or black oxidized zirconium of uniform and controlled thickness on a zirconium or zirconium alloy material is accomplished through the use of a single phase crystalline material substrate having an altered surface roughness. An oxidized zirconium coating of uniform and controlled thickness is especially useful on orthopedic implants of zirconium or zirconium-based alloys to provide low friction, highly wear resistant surfaces on artificial joints, such as, but not limited to, hip joints, knee joints, shoulders, elbows, and spinal implants. The uniformly thick oxidized zirconium surface of controlled depth on prostheses provide a barrier against implant corrosion caused by ionization of the metal prostheses. The invention is also useful in non-articulating implant devices such as bone plates, bone screws, etc.

Owner:SMITH & NEPHEW INC

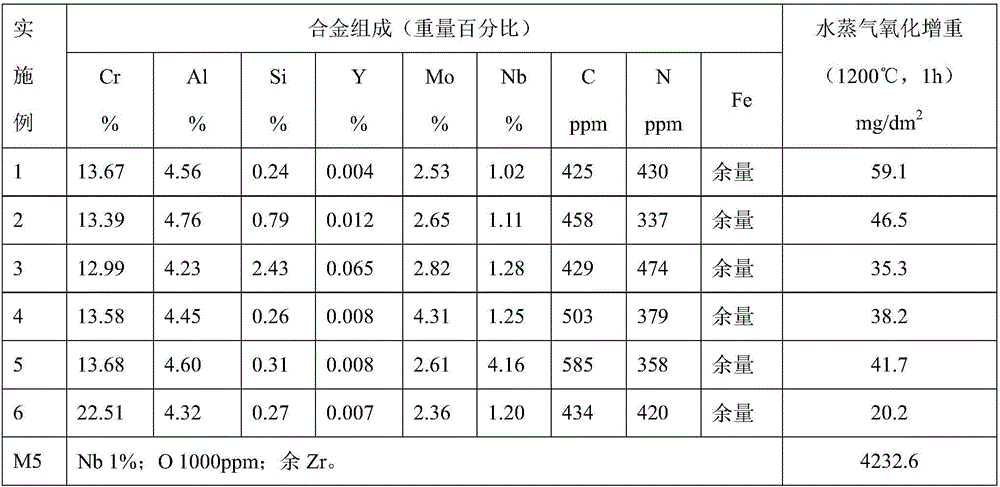

FeCrAl alloy material for preparing Nuclear reactor fuel cladding material

InactiveCN106399846AImprove performanceImprove resistance to water vapor oxidationOptical rangefindersNuclear energy generationNuclear reactor coreWater vapor

The invention relates to a FeCrAl alloy material for preparing a Nuclear reactor fuel cladding material. By taking the total weight of the FeCrAl alloy material as a benchmark, the FeCrAl alloy material is composed of the following components: 5%-25% of Cr, 3%-15% of Al, 0.01%-3.3% of Si, 0.001%-1% of Y, 5% or less of Mo, 5% or less of Nb, 1000 ppm or less of C, 1000 ppm or less of N and the balance of Fe and inevitable trace elements. The nuclear fuel cladding FeCrAl alloy has excellent oxidation resistance at the 1200 DGE C water vapor environment, which is obviously better than commercial M5 zirconium alloys, and the requirement for accident fault tolerance of the nuclear power plant is met. The alloy can be used for the preparation of oxide dispersion strengthened iron-base alloy base materials for fuel element cladding pipes, composite cladding pipes, zirconium alloy coatings and nuclear fuel cladding pipes, and core structural materials of positioning grid stripes and the like.

Owner:SUZHOU NUCLEAR POWER RES INST +3

Air inlet valve and manufacturing method thereof

InactiveCN103627961AImprove heat resistanceImprove fatigueMachines/enginesLift valveHardnessHigh surface

The invention discloses an air inlet valve and a manufacturing method thereof. Alloy for manufacturing the air inlet valve comprises the following components in percentage by weight: 0.32-0.40% of C, 0.17-0.37% of Si, 2.5-3.5% of Mo, 0.50-0.80% of Mn, 0.80-1.10% of Cr, 0.50-1.0% of W, less than or equal to 0.030% of Ni, less than or equal to 0.015 of P, less than or equal to 0.015 of S, less than or equal to 0.010% of Cu and the balance of Fe. The air inlet valve is manufactured by the technologies such as surface nanocrystallization, low-temperature nitriding and surfacing of tungsten-zirconium alloy and the like. The air inlet valve has high surface strength, high hardness, good abrasion performance and long service life.

Owner:JIANGSU UNIV OF SCI & TECH

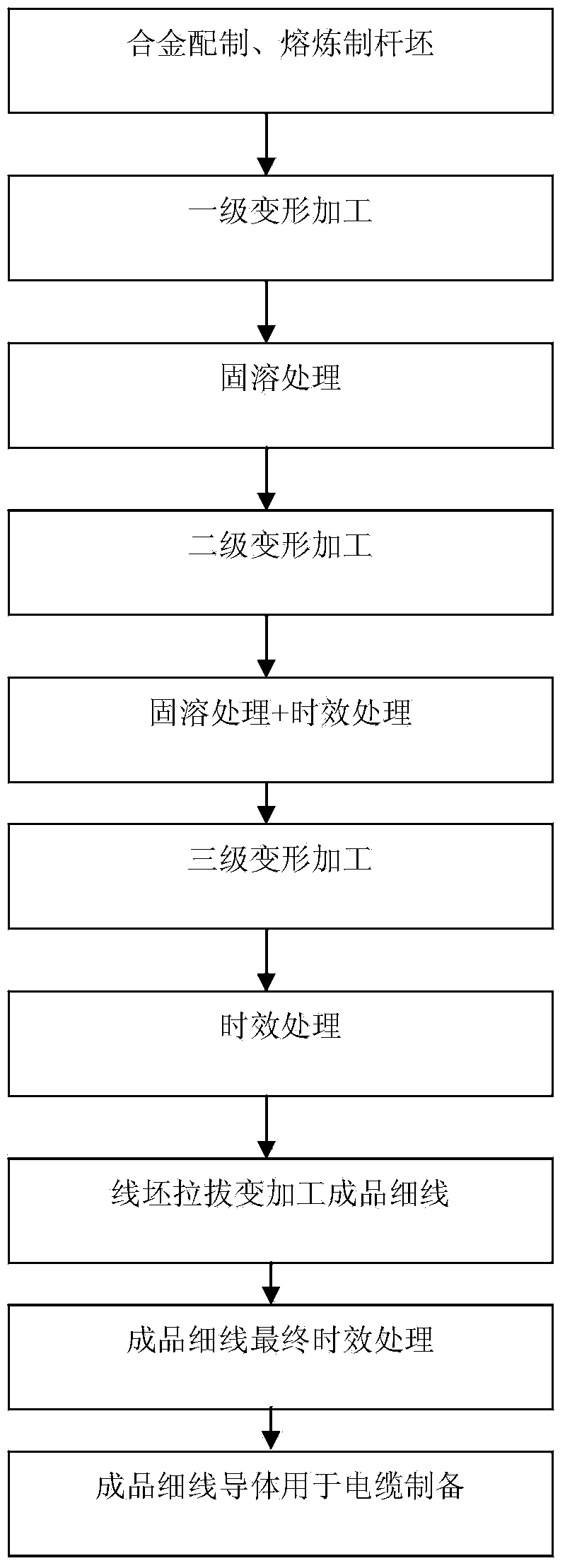

Preparation method of high-conductivity high-strength copper chromium zirconium alloy thin line conductor

ActiveCN103695825AReduce lossImprove conductivityMetal/alloy conductorsCable/conductor manufactureSolution treatmentSmelting process

The invention relates to the technical field of material processing, in particular to a preparation method of a high-conductivity high-strength copper chromium zirconium alloy thin line conductor. The preparation method comprises the following main steps: performing alloy smelting and blank forming, performing cold deformation processing on rod blanks and line blanks, performing multi-stage solution treatment, and performing aging treatment. According to the preparation method, the copper chromium zirconium alloy rod blanks obtained through a specific preparation formula and a smelting process are subjected to the multi-stage solution treatment and the aging treatment in multi-stage rolling and drawing cold-working processes, so that the sizes, shapes and distribution of precipitated phases in the copper chromium zirconium alloy processing process are effectively controlled, the mechanical performance of materials is improved, and good conductivity of copper-based alloy is kept.

Owner:SHANGHAI ELECTRIC CABLE RES INST

Zirconium modified protective coating

A protective coating system includes a nickel-aluminum-zirconium alloy coating having at least one phase selected from gamma phase nickel, gamma prime phase nickel-aluminum, or beta phase nickel-aluminum in combination with the gamma phase nickel or the gamma prime phase nickel-aluminum. For example, the nickel-aluminum-zirconium alloy coating includes about 0.001 wt % to 0.2 wt % zirconium.

Owner:RTX CORP

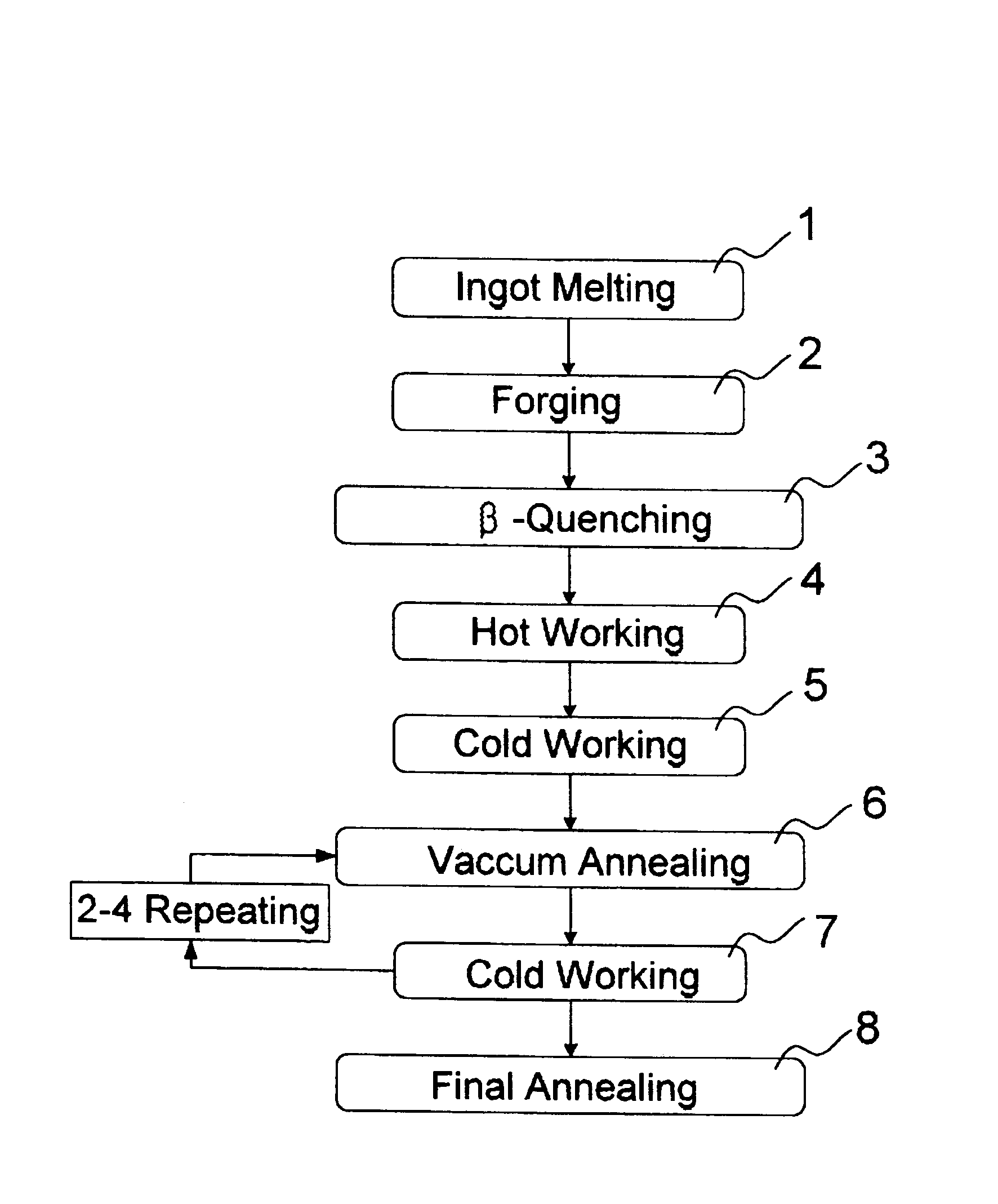

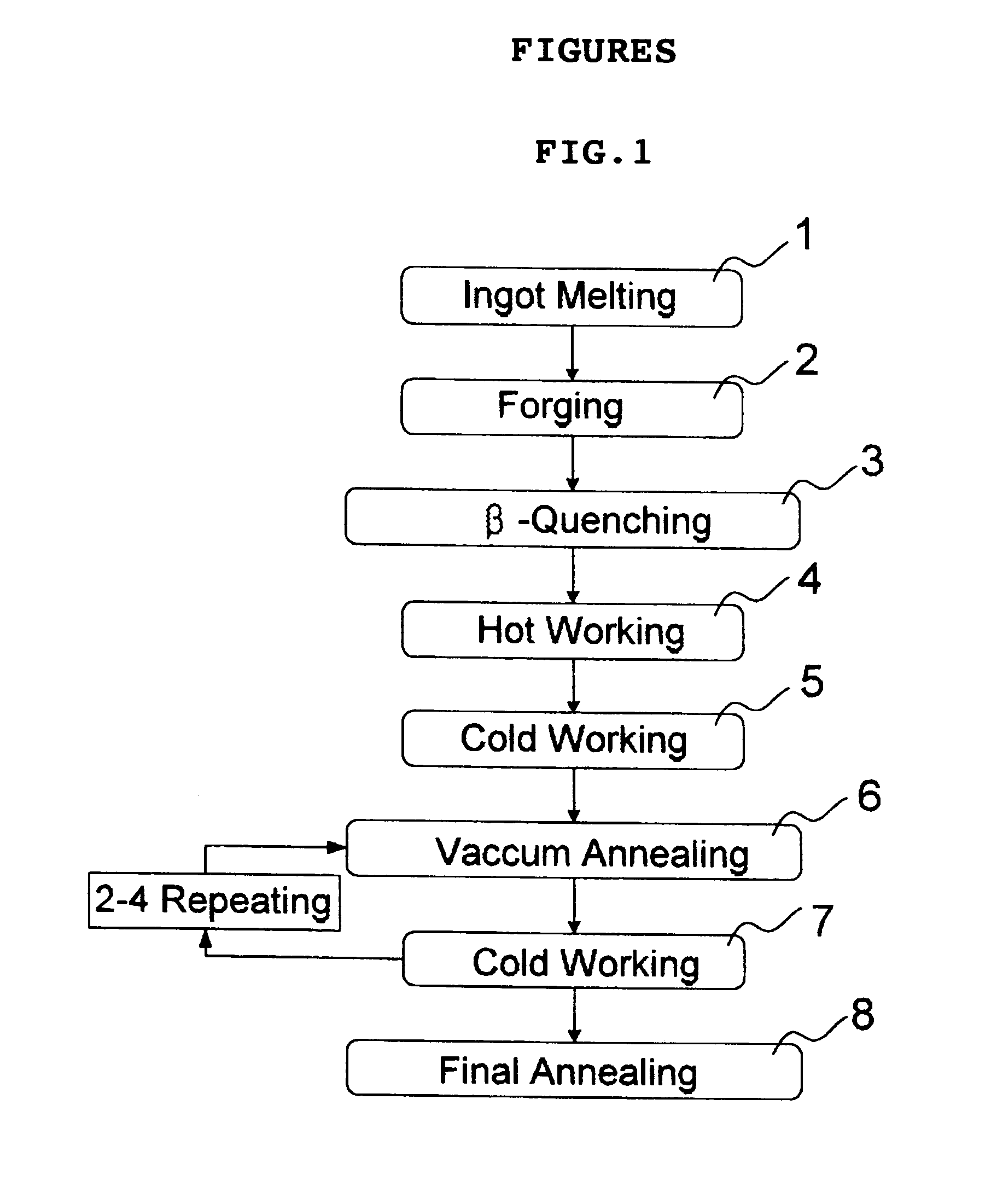

Method for manufacturing a tube and a sheet of niobium-containing zirconium alloy for a high burn-up nuclear fuel

Disclosed is a method for manufacturing a tube and a sheet of niobium-containing zirconium alloys for the high burn-up nuclear fuel. The method comprises melting Nb-added zirconium alloy to ingot; forging the ingot at beta phase range; beta-quenching the forged ingot after solution heat-treatment at 1015-1075° C.; hot-working the quenched ingot at 600-650° C.; cold-working the hot-worked ingot in three to five passes, with intermediate vacuum annealing; and final vacuum annealing the cold-worked ingot at 440-600° C., wherein temperatures of intermediate vacuum annealing and final vacuum annealing after beta-quenching are changed so as to attain the condition under which precipitates in the alloy matrix are limited to an average diameter of 80 nm or smaller and the accumulated annealing parameter (SIGMA A) is limited to 1.0x10-18 hr or lower.

Owner:KEPCO NUCLEAR FUEL CO LTD +1

Zirconium cladding surface resistant to high temperature and oxidation ZrCrFe/AlCrFeTiZr composite gradient coating preparing technology

ActiveCN107513694AImprove the interface binding forceHigh strengthVacuum evaporation coatingSputtering coatingHigh entropy alloysAlloy coating

The invention discloses a zirconium cladding surface resistant to high temperature and oxidation ZrCrFe / AlCrFeTiZr composite gradient coating preparing technology. Ultrahigh vacuum multitarget co-sputtering technique is adopted, a ZrCrFe / AlCrFeTiZr composite gradient alloy resistant to high temperature and oxidation protecting coating is prepared on the surface of a zirconium alloy base body, and the zirconium cladding surface resistant to high temperature and oxidation ZrCrFe / AlCrFeTiZr composite gradient coating preparing technology comprises the steps of predepositional treatment, bias voltage anti-splash washing and ZrCrFe / AlCrFeTiZr composite gradient alloy coating deposition. The preparing process of the composite coating is divided into two steps, the first step is to prepare ZrCrFe gradient transition layer coating, in a deposited ZrCrFe transition layer, the atomic percentage content of Zr element is changed from the gradient of 100 at%-35 at% in the thickness direction, the atomic percentage content of Cr element is changed from the gradient of 0 at%-33 at% in the thickness direction, and the atomic percentage content of Fe element is changed from the gradient of 0 at%-33 at% in the thickness direction; the second step is to prepare a AlCrFeTiZr high-entropy alloy coating, in a deposited AlCrFeTiZr high-entropy alloy coating, the atomic percentage content of Al element is controlled in 0.5 at%-1.0at %, and the atomic percentage of other elements is between 10 at%-35 at%. Bonding force of the coating prepared by the technology is excellent, the surface is dense and uniform, and the coating has excellent performance such as high strength, resistance to high temperature and oxidation and irradiation resistance.

Owner:田雨

Laser cladding method for preparing nickel-based heat-resisting and wear-resisting coating on surface of zirconium alloy

InactiveCN103866319AExtended service lifeLow costMetallic material coating processesZirconium alloyRadiation

The invention discloses a laser cladding method for preparing a nickel-based heat-resisting and wear-resisting coating on the surface of a zirconium alloy. The laser cladding method comprises the steps of polishing and washing the surface of a zirconium alloy matrix to be subjected to laser cladding; fully mixing nickel-based alloy powder and an organic binder, blending into a uniform paste, and uniformly coating the paste on the surface of the zirconium alloy matrix to be subjected to laser cladding in advance; introducing argon in advance before performing laser cladding; performing single-channel radiation scanning cladding on a powder pre-placing area on the surface of the zirconium alloy matrix by using laser beams, wherein technological parameters are as follows: the laser power is 2.0-3.8kW, the beam spot diameter is 5mm, the scanning speed is 3-5mm / s, the shielding gas flow rate is 8-15L / min, the laser cladding process is continuously operated, and the dilution rate is not more than 10%. By adopting the laser cladding method disclosed by the invention, the nickel-based heat-resisting and wear-resisting coating is prepared in situ on the surface of the zirconium alloy by using a laser in-situ cladding technique; the laser cladding method is simple and easy in operation process, noise-free, environment-friendly and pollution-free, and can reduce the energy consumption and production cost; the wear-resisting coating is excellent in performance, and can meet operating requirements.

Owner:SHANDONG UNIV

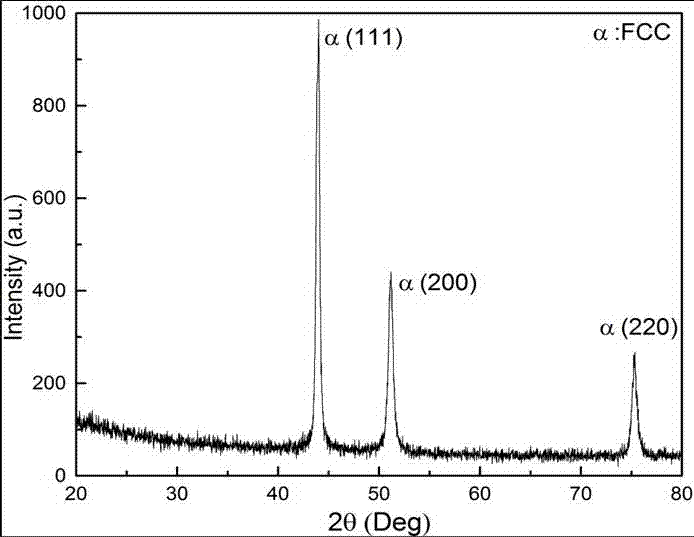

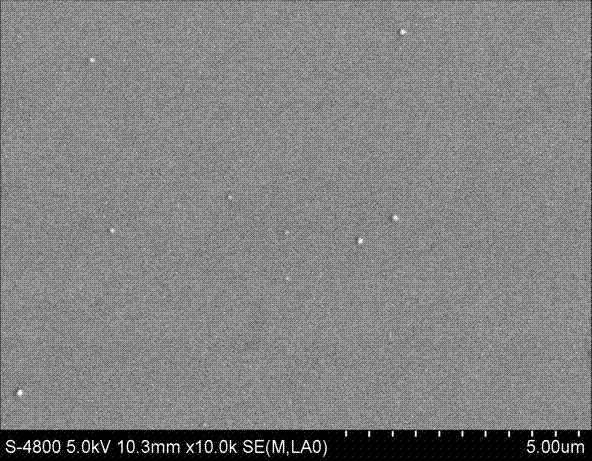

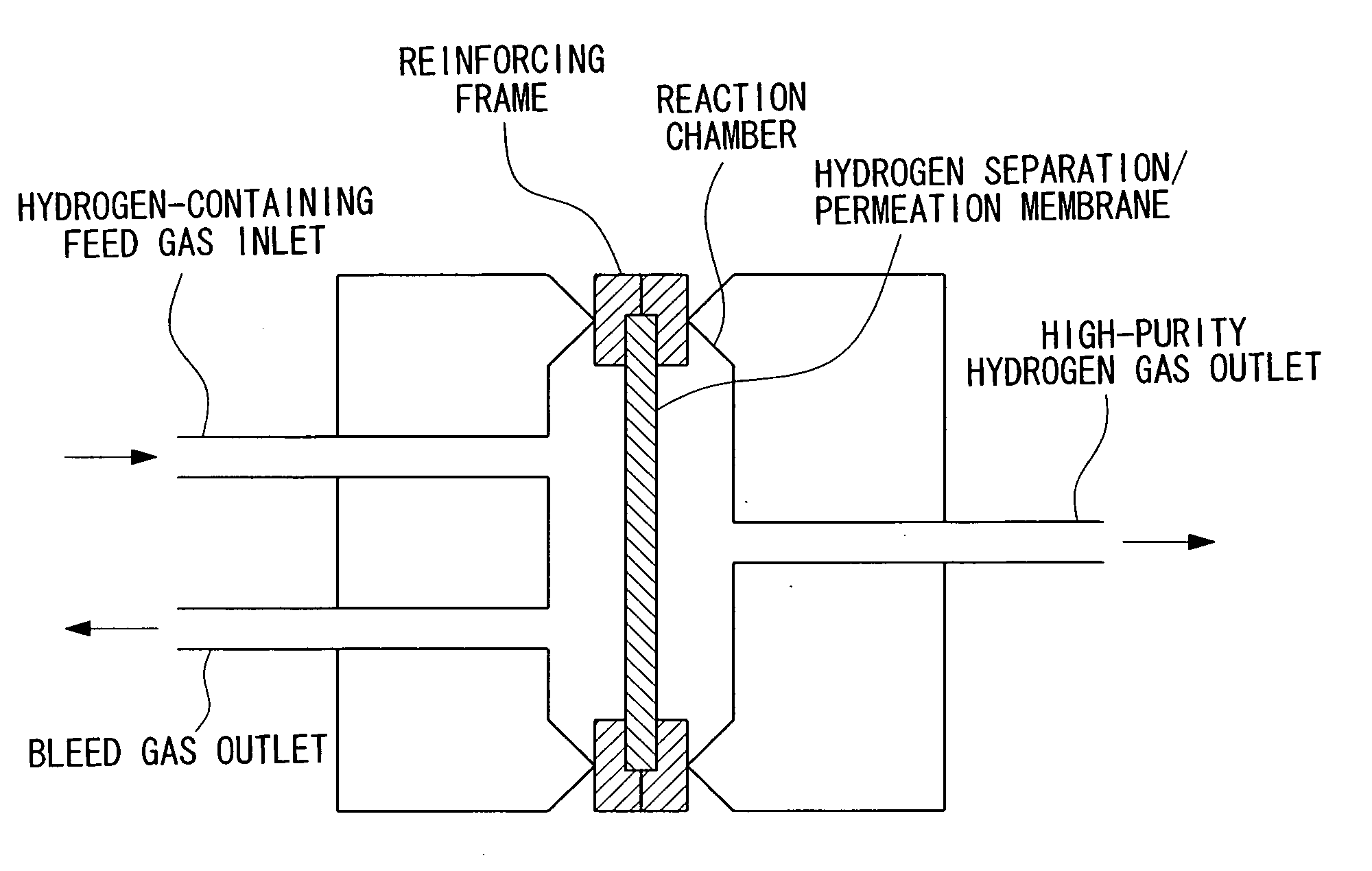

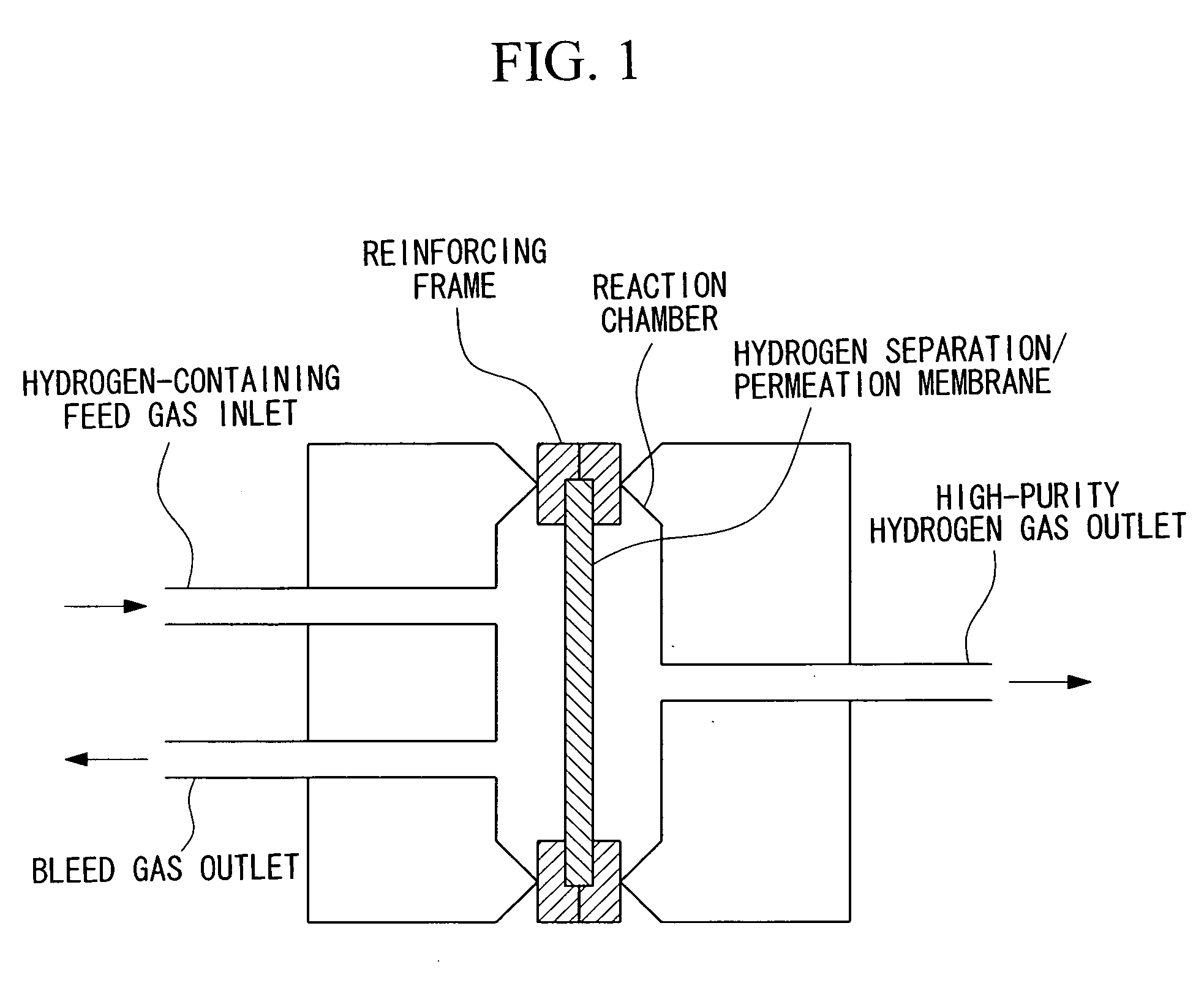

Permeable film for separating hydrogen

ActiveUS20060213368A1Improves high-temperature amorphous stabilityGuaranteed stabilityMembranesSemi-permeable membranesHydrogenNiobium

A hydrogen permeable membrane which has an excellent high-temperature amorphous stability and a long lifetime under high-temperature heating operation and which can be miniaturized for use in a high-performance hydrogen purifier. The hydrogen permeable membrane is made of a non-crystalline nickel-zirconium alloy or zirconium-nickel alloy composed of 44 to 75 atom % of nickel or zirconium; and 0.2 to 16 atom % of aluminum, 0.2 to 12 atom % of vanadium and / or niobium, or 0.2 to 12 atom % of niobium and 0.1 to 10 atom % of phosphorus (provided that the combined amount of niobium and phosphorus is not more than 18 atom %); with the balance being zirconium or nickel and unavoidable impurities.

Owner:MAGNUM OIL TOOLS +2

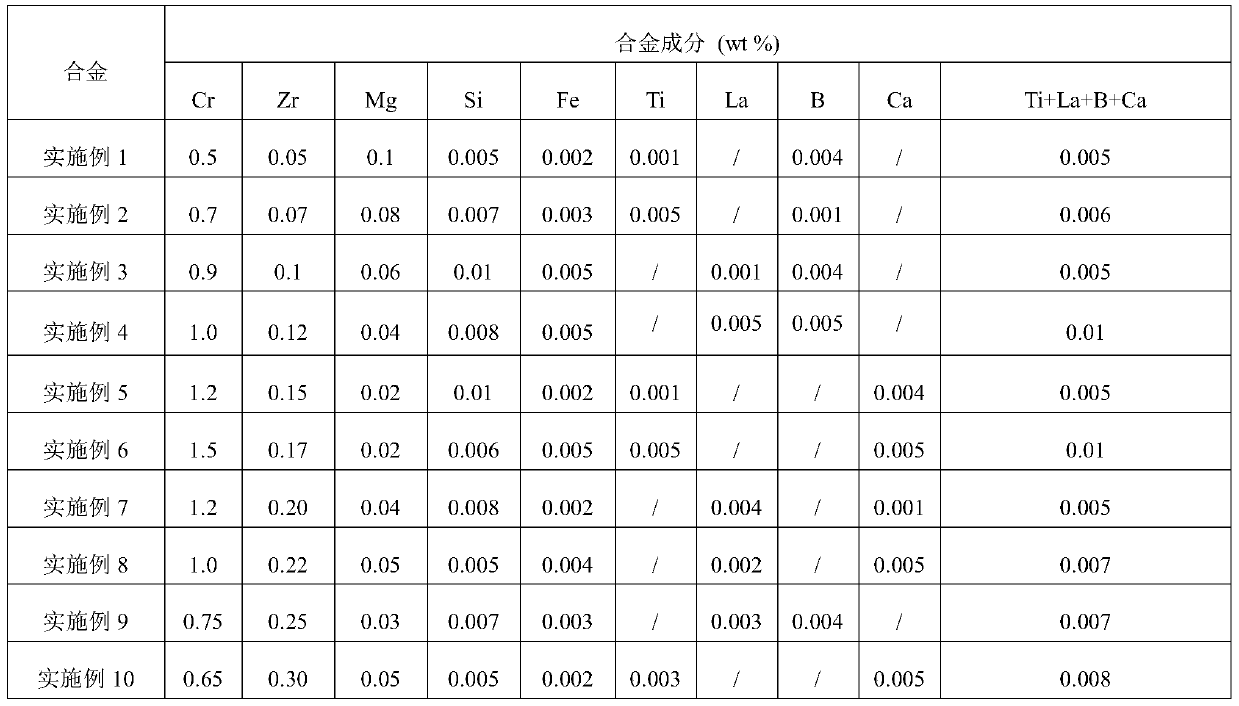

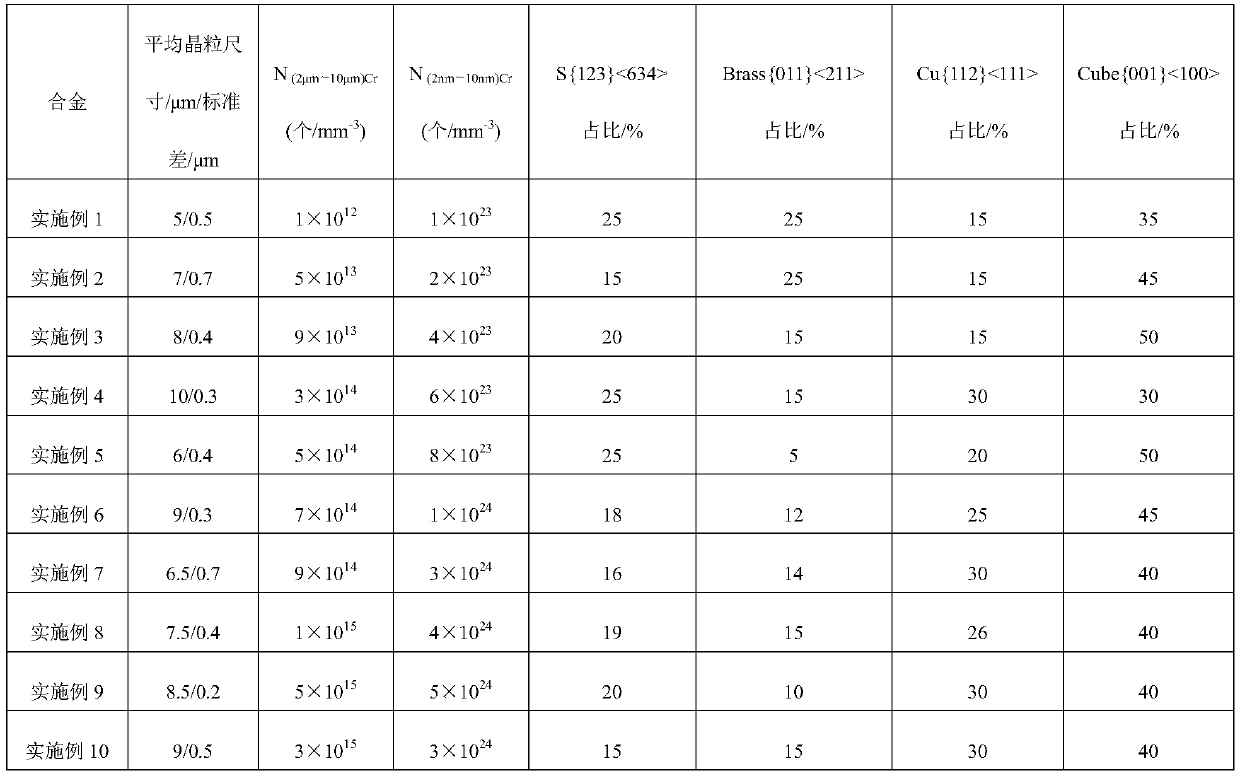

High-strength and high-conductivity copper-chromium-zirconium alloy material and preparation method thereof

The invention relates to a high-strength and high-conductivity copper-chromium-zirconium alloy material and a preparation method thereof. The material is composed of, by weight, 0.5-1.5% of Cr, 0.05-0.3% of Zr, 0.02-0.1% of Mg, 0.005-0.01% of Si, 0.002-0.005% of Fe and the balance Cu. The alloy further includes two of the four elements: Ti, La, B and Ca, the content of each element is 0.001-0.005%, and the total content of the alloy elements is 0.005-0.01%. The material is prepared through smelting and casting, hot rolling, face milling, rough rolling, intermediate annealing, intermediate rolling, high-temperature rapid solution treatment, finish rolling and aging treatment. The high-strength and high-conductivity copper-chromium-zirconium alloy material has the tensile strength of 500-800MPa, the yield strength of 350-700 MPa, the elongation of 3-10%, the electrical conductivity of 75-90% IACS and the softening temperature of 500-600 DEG C, the stress relaxation after treatment for 1000 hours at 150 DEG C is smaller than 10%, and the transverse or longitudinal section does not crack after bending by 90 or 180 degrees under the condition: R / t<=1.5. The use requirements of precision plug-in terminals of high-end electronic components for copper alloy materials are completely met.

Owner:NINGBO XINGYE SHENGTAI GROUP

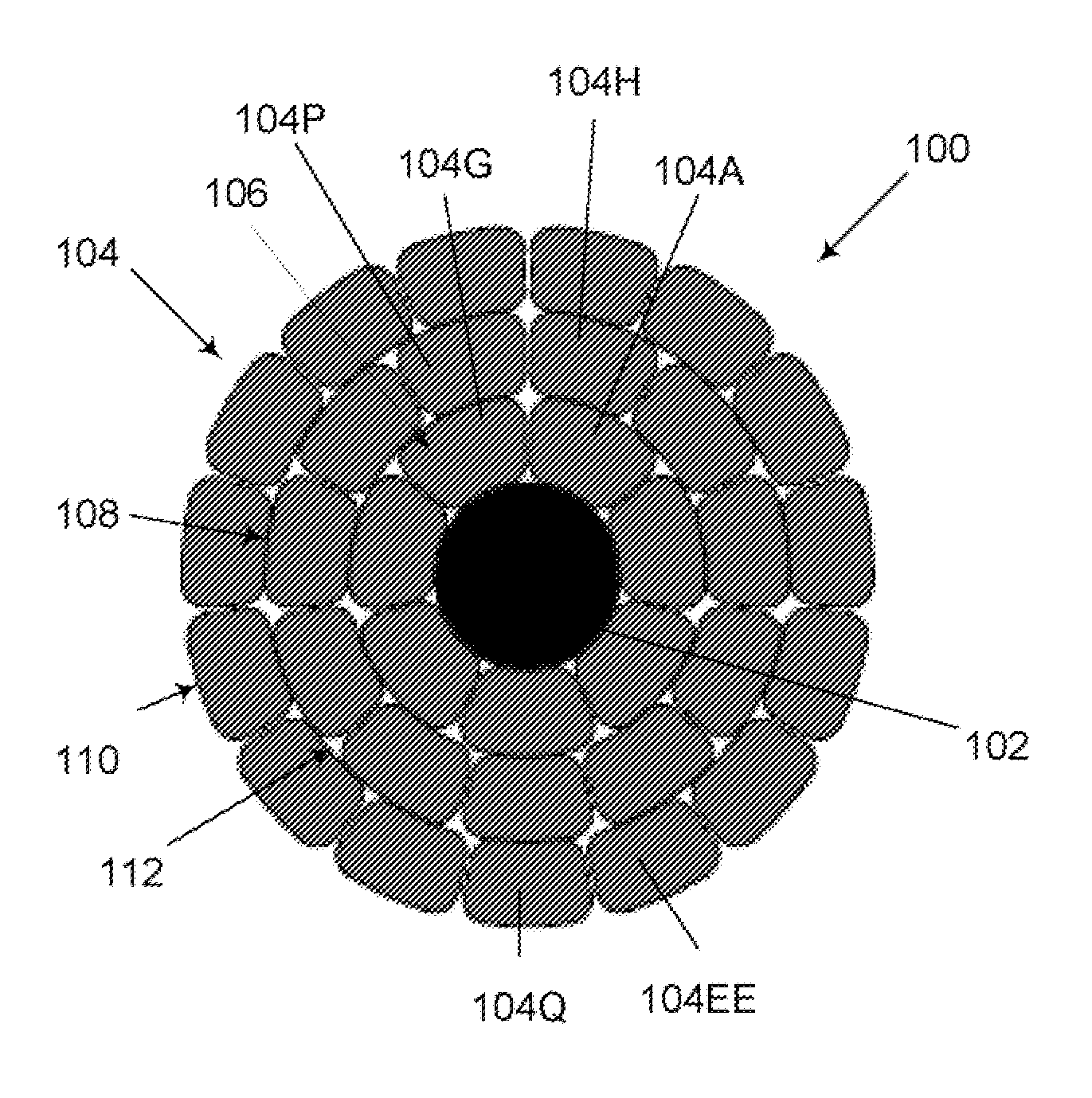

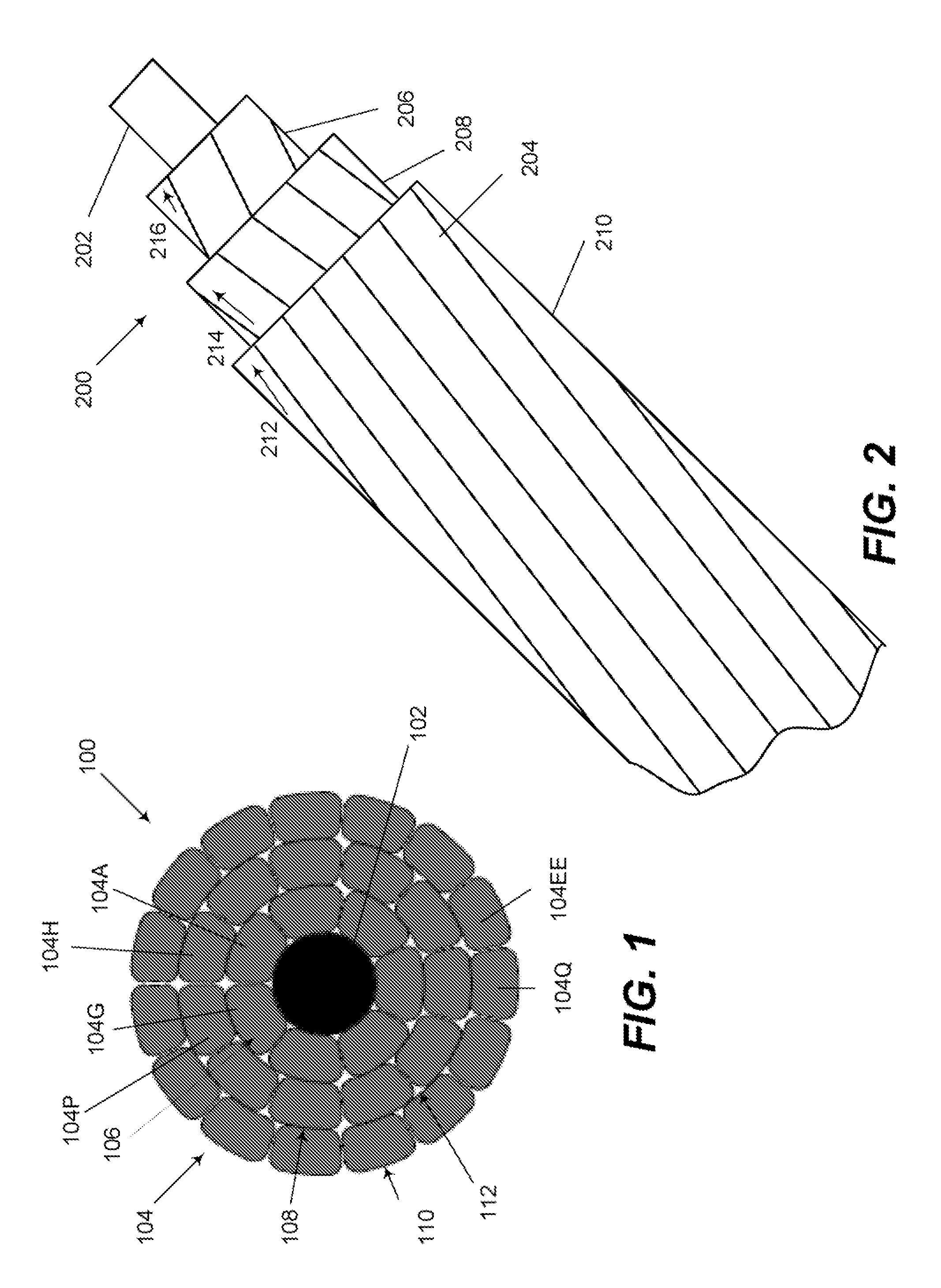

Aluminum Alloy Conductor Composite Reinforced for High Voltage Overhead Power Lines

InactiveUS20120170900A1Non-insulated conductorsLine/current collector detailsElectrical conductorCarbon fibers

Embodiments of the invention relate to aluminum alloy conductor composite reinforced for high voltage overhead power lines and associated methods of use and manufacture. In one embodiment, a transmission cable can be provided. The transmission cable can include a core including at least one of: a composite core, a plurality of fibers in a matrix of one or more materials, or a set of carbon fibers embedded in an epoxy matrix; and a plurality of wires wrapped around the core, wherein the wires comprise at least one of the following: aluminum 6201 T83 alloy, aluminum 6201 T81 alloy, aluminum 1350-H19 alloy, or a heat resistant aluminum-zirconium alloy; wherein the transmission cable has a low sag characteristic.

Owner:GENERAL CABLE TECH CORP

Method for preparing zirconium and zirconium alloy investment precision casting oxide ceramic molding shell

ActiveCN101947640AMaintain stabilityHigh temperature strengthFoundry mouldsFoundry coresOxide ceramicHigh surface

The invention relates to a method for preparing a zirconium and zirconium alloy investment precision casting oxide ceramic molding shell. At present, the most common methods for casting of active organic metal and alloy comprise machining graphite mold casting and investment precision casting. The most serious technological difficulty of the zirconium alloy investment precision casting is to manufacture an investment precision casting molding shell which has the advantages of high-temperature resistance, high chemical stability, high strength and high surface finish. The process of the invention comprises the following steps of: (1) preparing a coating, immersing a wax mould into paste, coating the paste, and coating a back layer; (2) removing wax by drying; and (3) roasting the coating in an electric furnace. The molding shell has the advantages of superior high-temperature chemical stability and high-temperature strength and can bear the high temperature of over 2,000 DEG C. A zirconium and zirconium alloy casting produced by using the shell manufacturing process has high surface quality, surface roughness Ra of less than or equal to 3.2mu m and surface pollution layer thickness of less than 100mu m. The complex zirconium and zirconium alloy casting with wall thickness of less than 3mm can be produced.

Owner:西安泵阀总厂有限公司

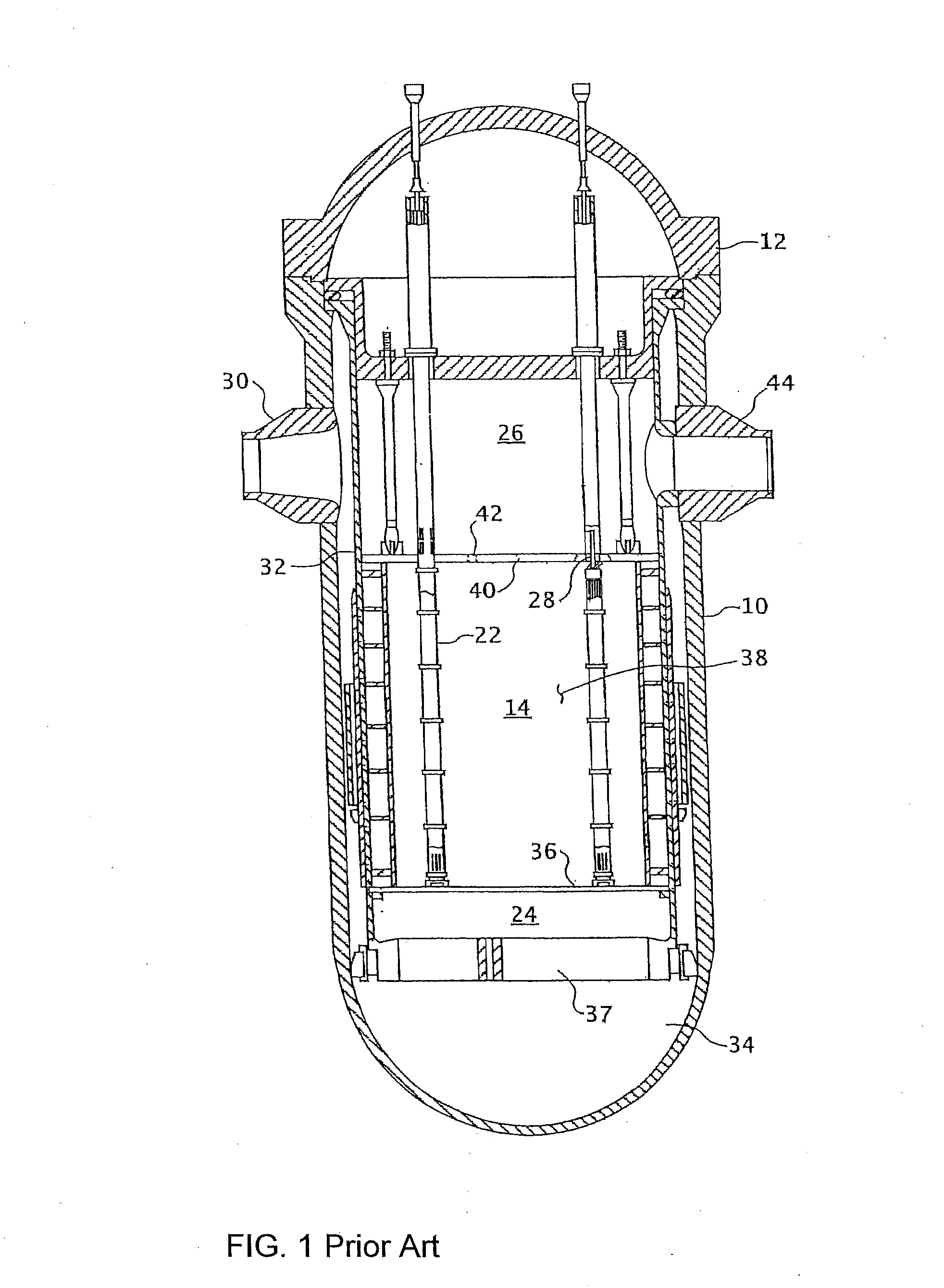

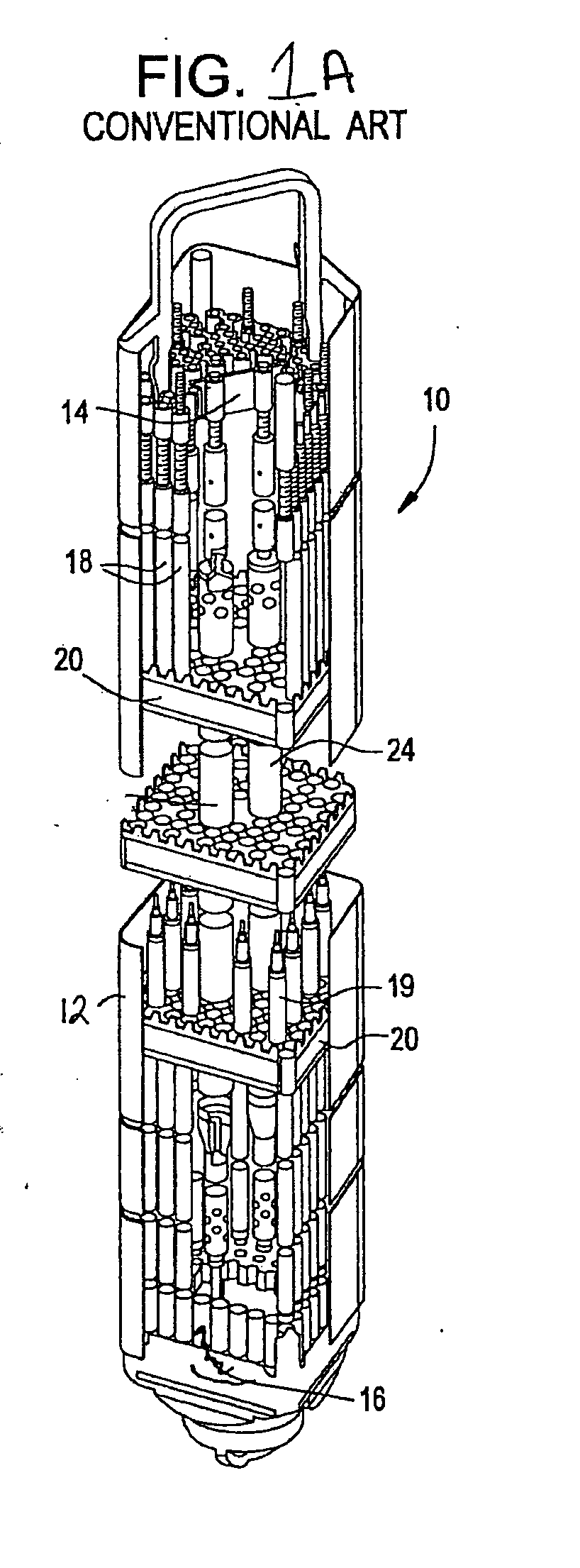

Nuclear reactor components including material layers to reduce enhanced corrosion on zirconium alloys used in fuel assemblies and methods thereof

InactiveUS20100014624A1Reducing increased corrosionIncreased corrosionNuclear energy generationReactors manufactureNuclear reactorZirconium alloy

Example embodiments are directed to providing a thin, adherent coating on the surfaces of nuclear reactor components, which are known to cause increased corrosion on adjacent zirconium alloy structures, and methods of reducing the increased corrosion. Example embodiments include coatings being structurally bonded to components such that the difference in the corrosion potential between a coated component and a zirconium alloy component is less than that between a component without the coating and the zirconium alloy component.

Owner:GLOBAL NUCLEAR FUEL -- AMERICAS

Electrolyte and zirconium or zirconium alloy surface micro-arc oxidation method

ActiveCN101748464AImprove corrosion resistanceSurface reaction electrolytic coatingMicro arc oxidationPlasma electrolytic oxidation

The invention provides electrolyte. The electrolyte is aqueous solution; and the aqueous solution contains fluorozirconate, borofluoride, water-soluble carboxylate of zinc and alkali metal hydroxide. The invention also provides a zirconium or zirconium alloy surface micro-arc oxidation method, wherein the electrolyte adopted by the micro-arc oxidation is the electrolyte provided by the invention. Through the method of the invention, a micro-arc oxidation film is formed on the surface of zirconium or zirconium alloy so as to greatly improve the corrosion resistance of the zirconium or zirconium alloy. In addition, the method of the invention also can further improve stain resistance, compactness, hardness, abrasion resistance and electrical insulating property of the zirconium or zirconium alloy surface.

Owner:BYD CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com