Preparation method of high-conductivity high-strength copper chromium zirconium alloy thin line conductor

A high-conductivity, copper-chromium-zirconium technology, applied in the direction of metal/alloy conductors, cable/conductor manufacturing, circuits, etc., can solve the problem that the conductivity is only 80-85%, the conductivity cannot be obtained, and the secondary solid solution is not considered Solve and other problems to achieve the effect of ensuring operation safety, high tensile strength and good elongation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

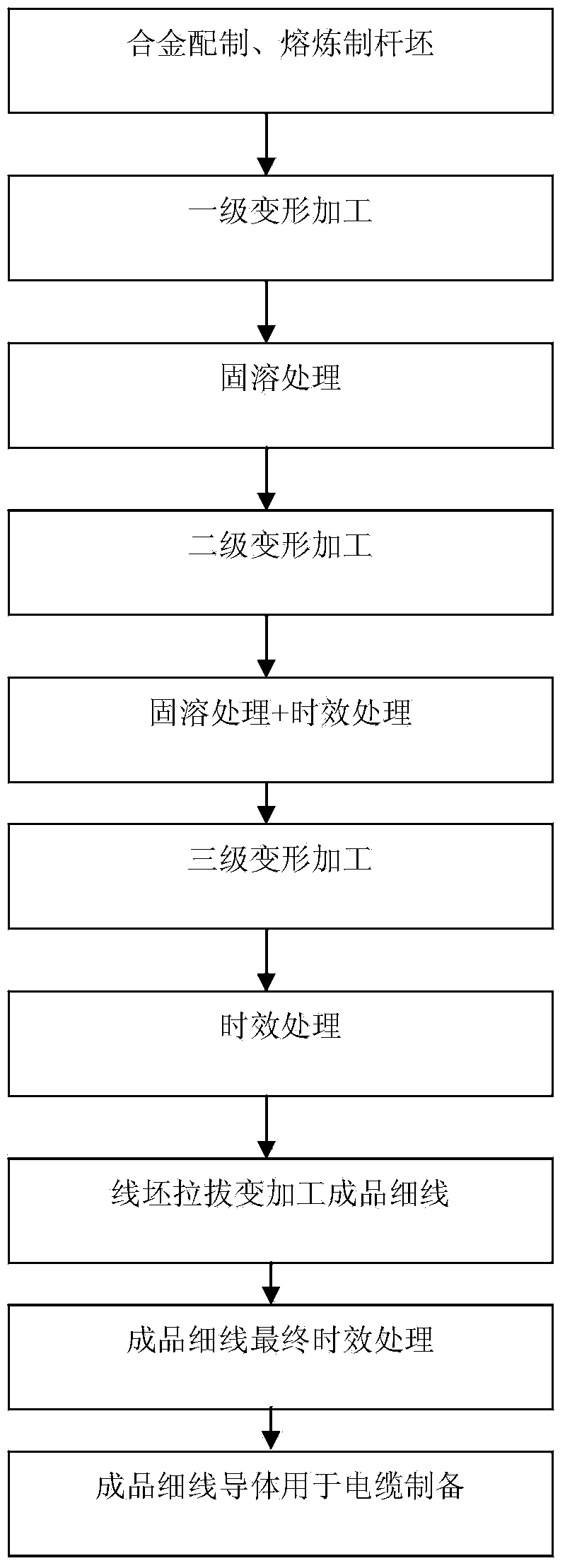

Method used

Image

Examples

Embodiment 1

[0034] The prepared alloy adopts electrolytic copper plate and Cu-Cr, Cu-Zr master alloy according to mass percentage proportioning, the content of Cr is 0.65%, the content of Zr is 0.06%, and the rest is Cu.

[0035] 1. The copper content of the electrolytic copper plate used is not less than 99.95%, and the composition of the master alloy is: Cu-10%Cr, Cu-40%Zr. The electrolytic copper plate is cut into strips, dried and placed in a crucible in a vacuum induction melting furnace. The copper-chromium and copper-zirconium intermediate alloys are cut into pieces and dried in the feeding mechanism. The vacuum degree does not exceed 1×10 -2 Under the condition of Pa, induction heating is started to melt the electrolytic copper, and the temperature of the copper liquid is heated to 1250°C, and the copper-chromium and copper-zirconium intermediate alloy blocks are put into the copper liquid through the feeding mechanism, and the intermediate alloy blocks are dissolved into the coppe...

Embodiment 2

[0041] The prepared alloy is prepared by electrolytic copper plate and Cu-Cr, Cu-Zr master alloy according to the mass percentage, the content of Cr is 0.16%, the content of Zr is 0.09%, and the rest is Cu.

[0042] 1. The copper content of the electrolytic copper plate used is not less than 99.95%, and the composition of the master alloy is: Cu-8%Cr, Cu-35%Zr. The electrolytic copper plate is cut into strips, dried and placed in a crucible in a vacuum induction melting furnace. The copper-chromium and copper-zirconium intermediate alloys are cut into pieces and dried in the feeding mechanism. The vacuum degree does not exceed 1×10 -2 Under the condition of Pa, induction heating is started to melt the electrolytic copper, and the temperature of the copper liquid is heated to 1200°C, and the copper-chromium and copper-zirconium intermediate alloy blocks are put into the copper liquid through the feeding mechanism, and the intermediate alloy blocks are dissolved into the copper l...

Embodiment 3

[0048] The prepared alloy adopts electrolytic copper plate and Cu-Cr, Cu-Zr master alloy according to mass percentage proportioning, the content of Cr is 0.7%, the content of Zr is 0.01%, and the rest is Cu.

[0049] 1. The copper content of the electrolytic copper plate used is not less than 99.95%, and the composition of the master alloy is: Cu-12%Cr, Cu-45%Zr. The electrolytic copper plate is cut into strips, dried and placed in a crucible in a vacuum induction melting furnace. The copper-chromium and copper-zirconium intermediate alloys are cut into pieces and dried in the feeding mechanism. The vacuum degree does not exceed 1×10 -2 Under the condition of Pa, induction heating is started to melt the electrolytic copper, and the temperature of the copper liquid is heated to 1230°C, and the copper-chromium and copper-zirconium intermediate alloy blocks are put into the copper liquid through the feeding mechanism, and the intermediate alloy blocks are dissolved into the copper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com