Patents

Literature

757 results about "Thin line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

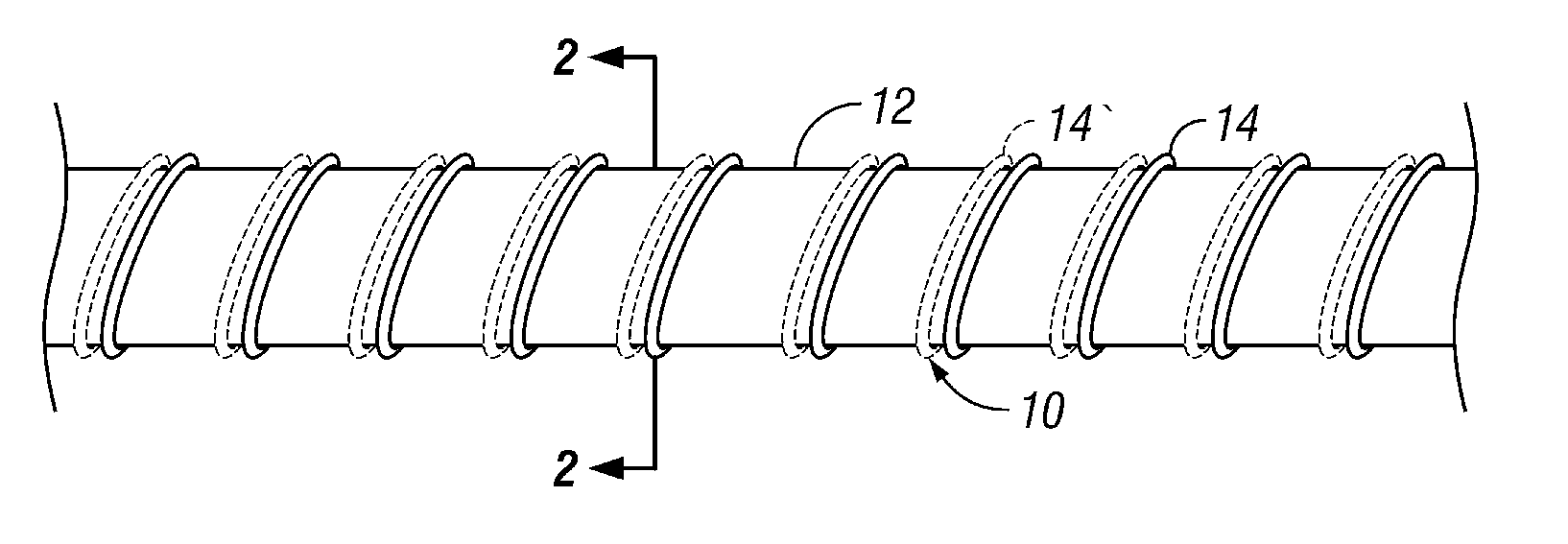

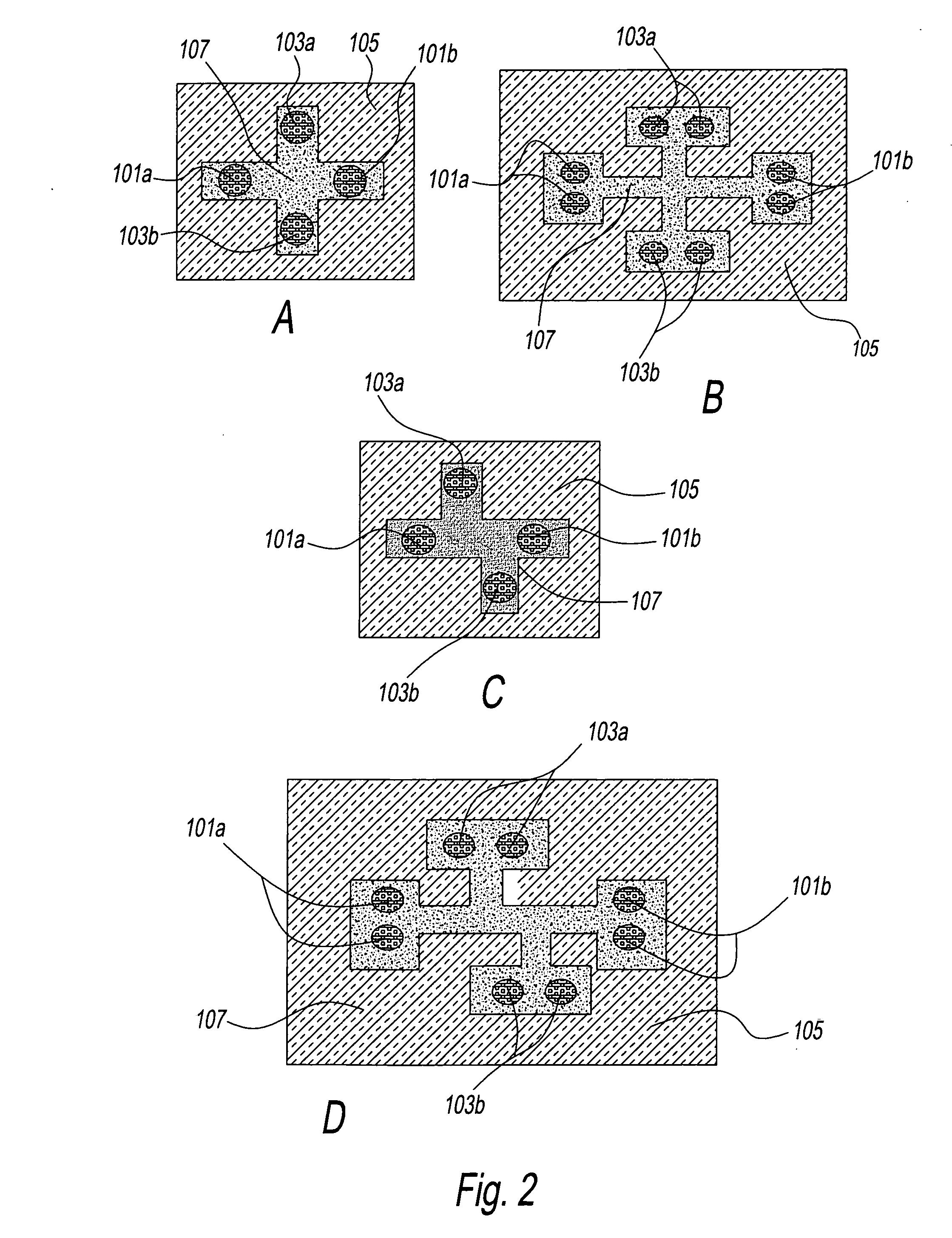

Micro-helix antenna and methods for making same

InactiveUS7183998B2Loop antennas with ferromagnetic coreLogperiodic antennasElectrical conductorThree dimensional shape

A micro-helix antenna. The antenna comprises a helically-shaped conductive element disposed on a dielectric core. The diameter of the helix formed by the conductive element is very small relative to the wavelength of the antenna, preferably no more than about 1 / 100th of the wavelength. Having such a small diameter, this micro-helix antenna can be further compressed into two- and three-dimensional shapes, such as spirals, helices and meandering or stochastic patterns. The micro-helix antenna can be created by pressing a fine wire into a helical shape. Alternately, the helical conductor can be formed by a laser ablation process or laying down the helical shape using a direct-write process.

Owner:SCIPERIO

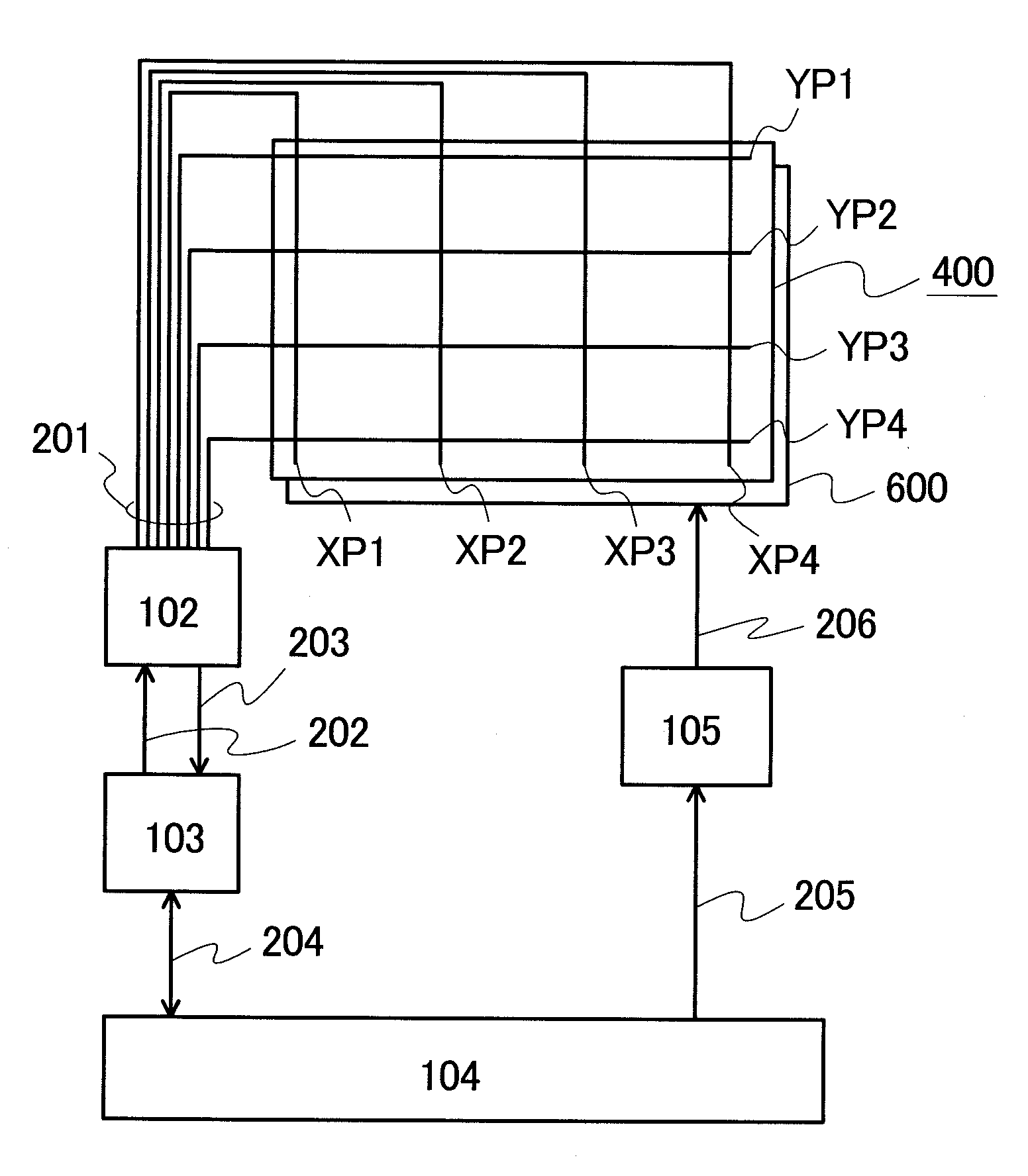

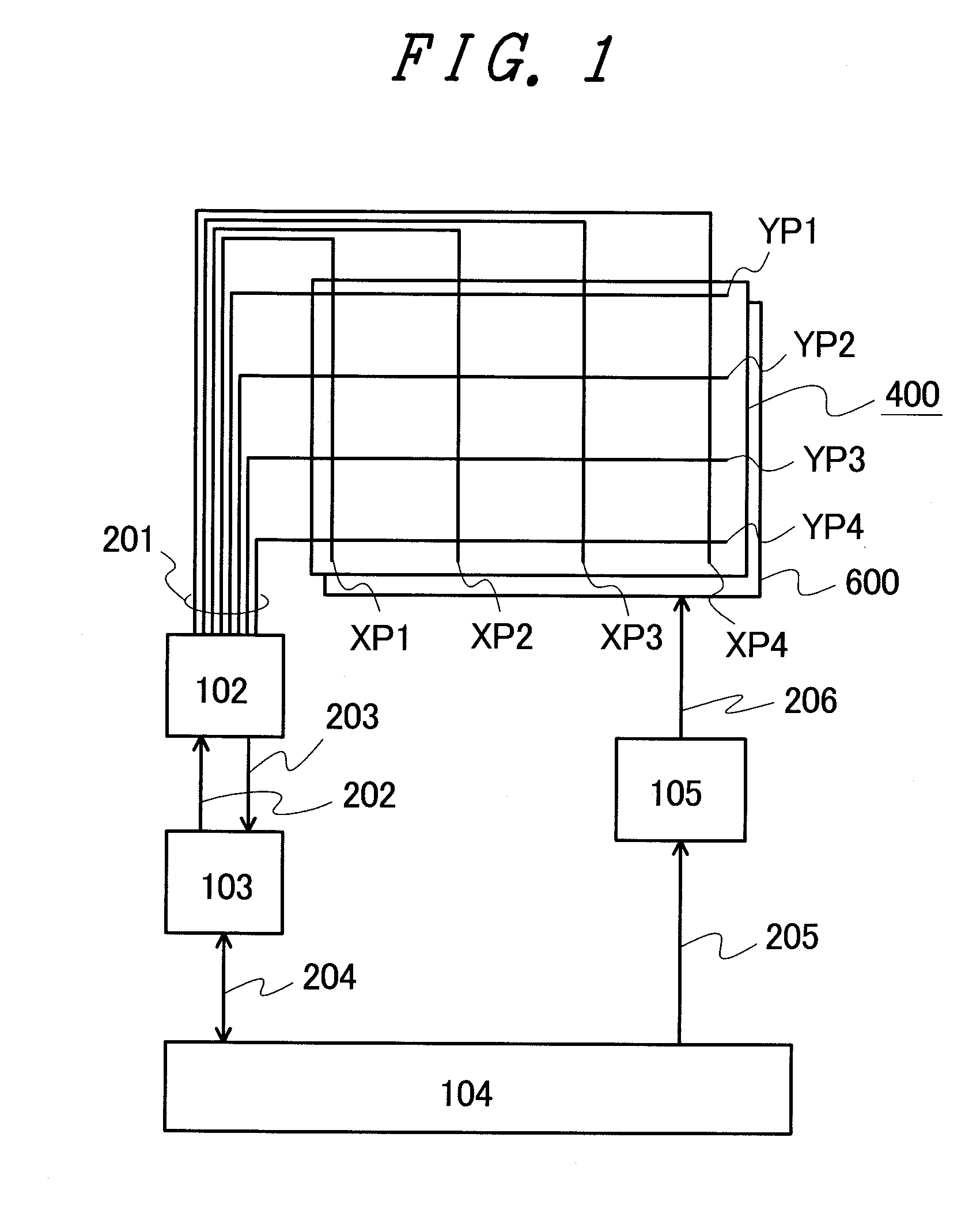

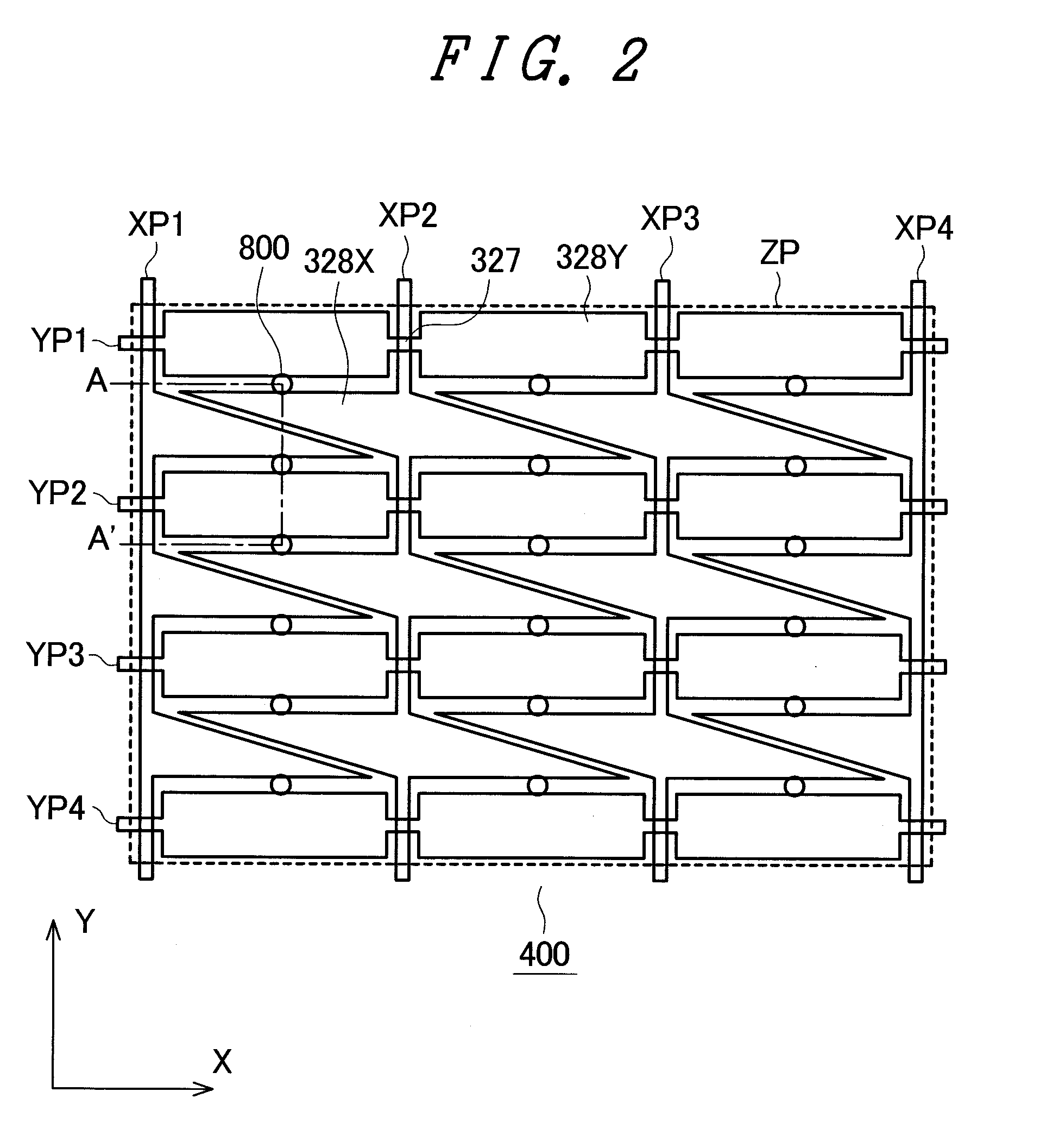

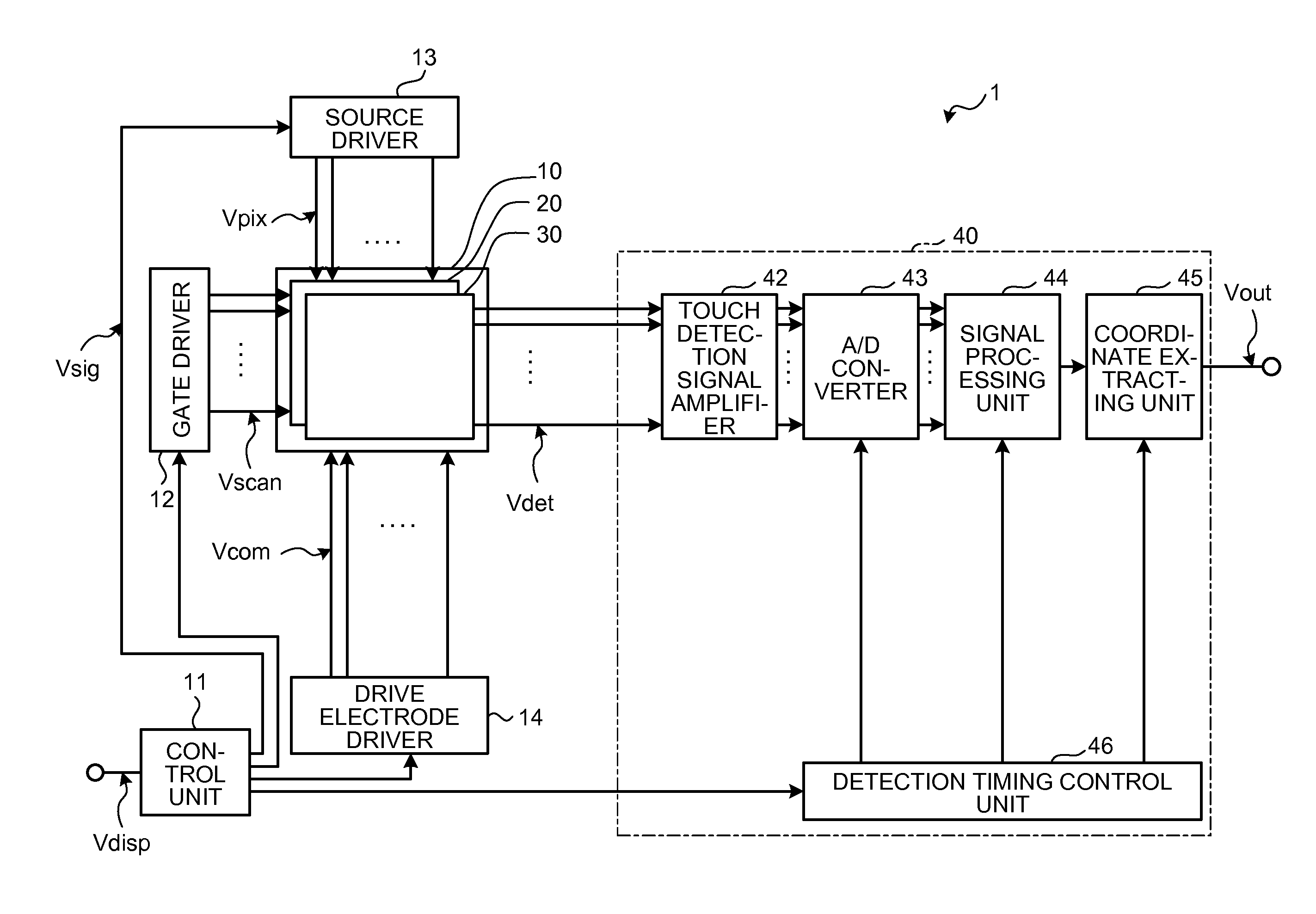

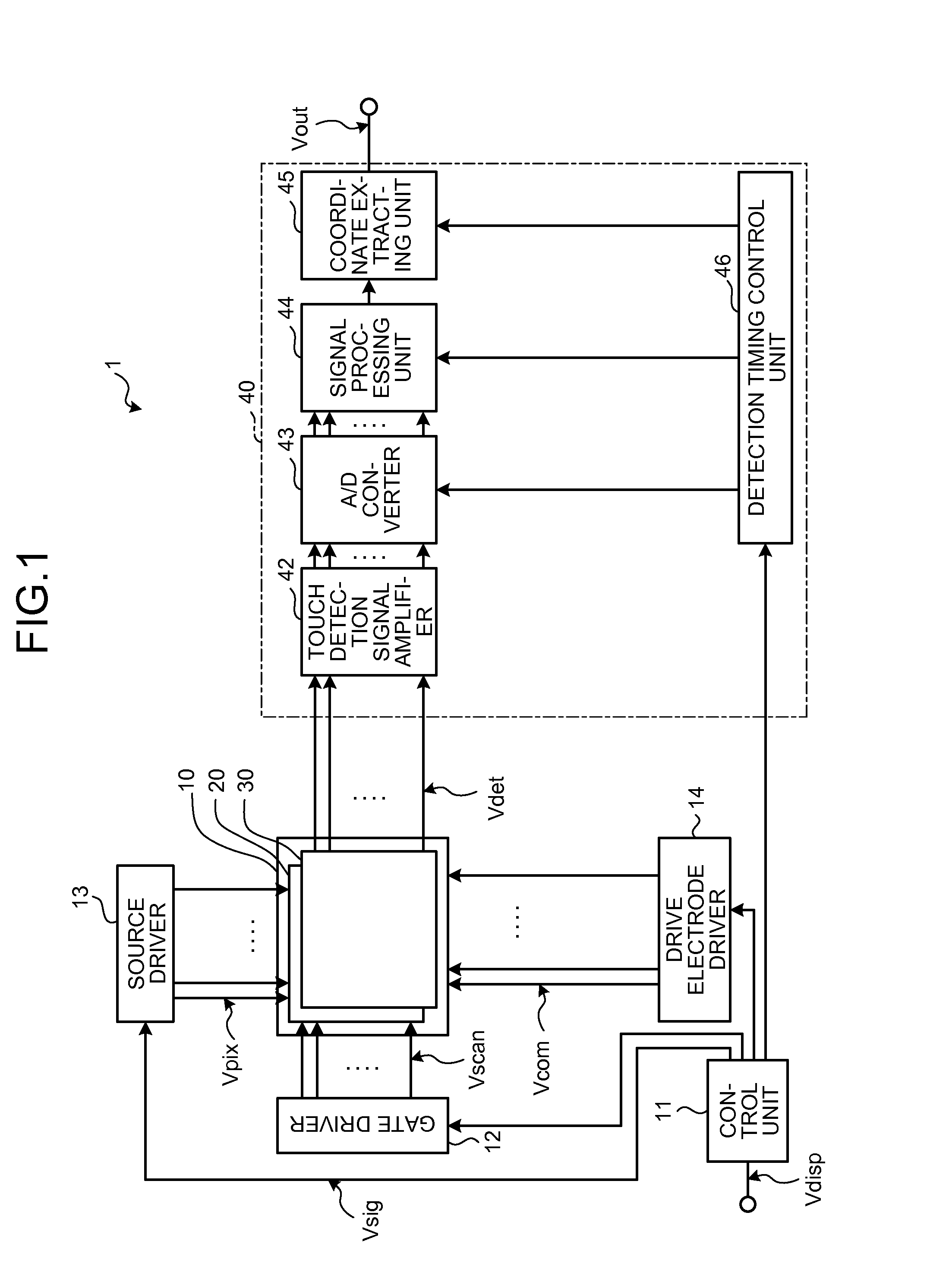

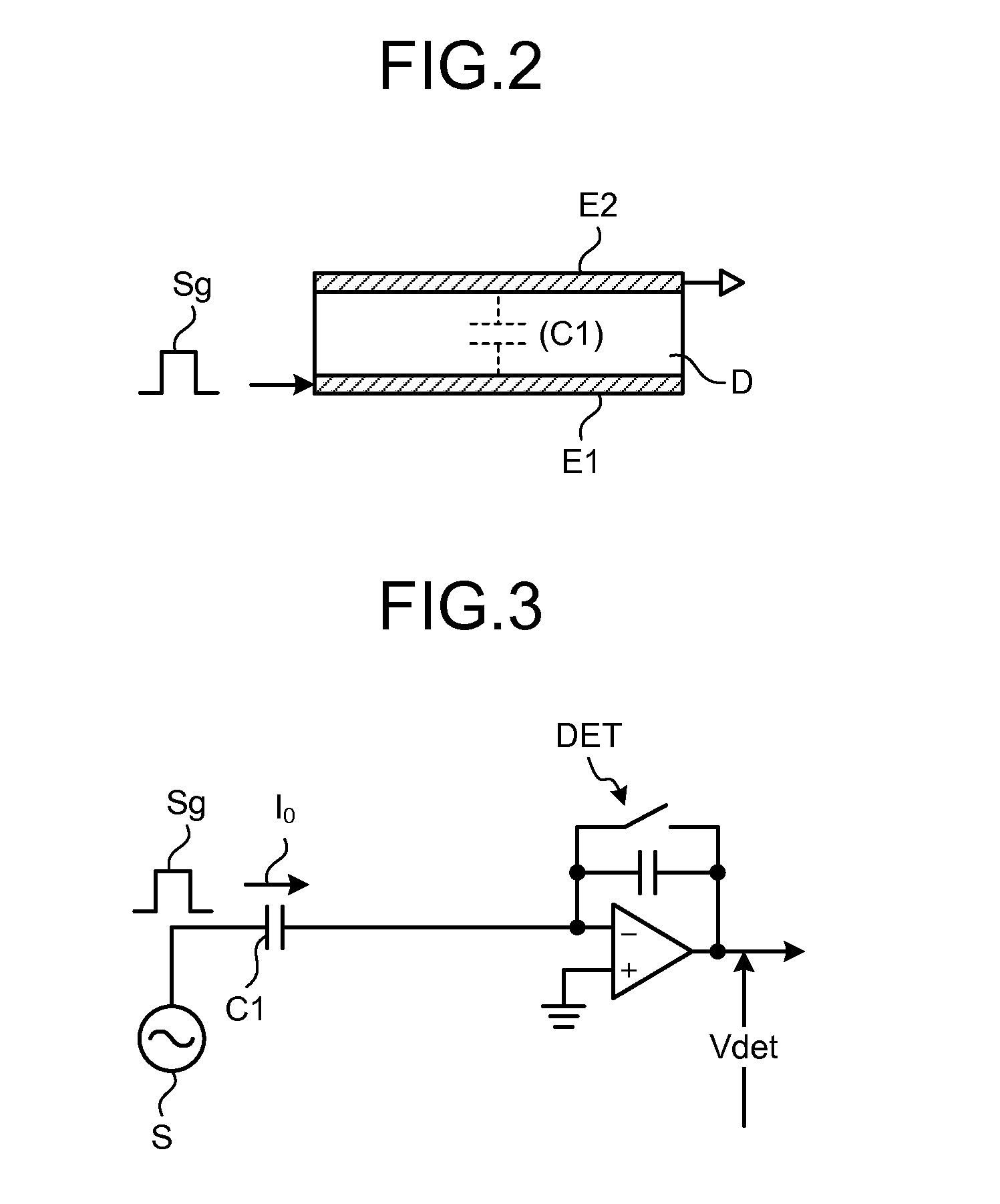

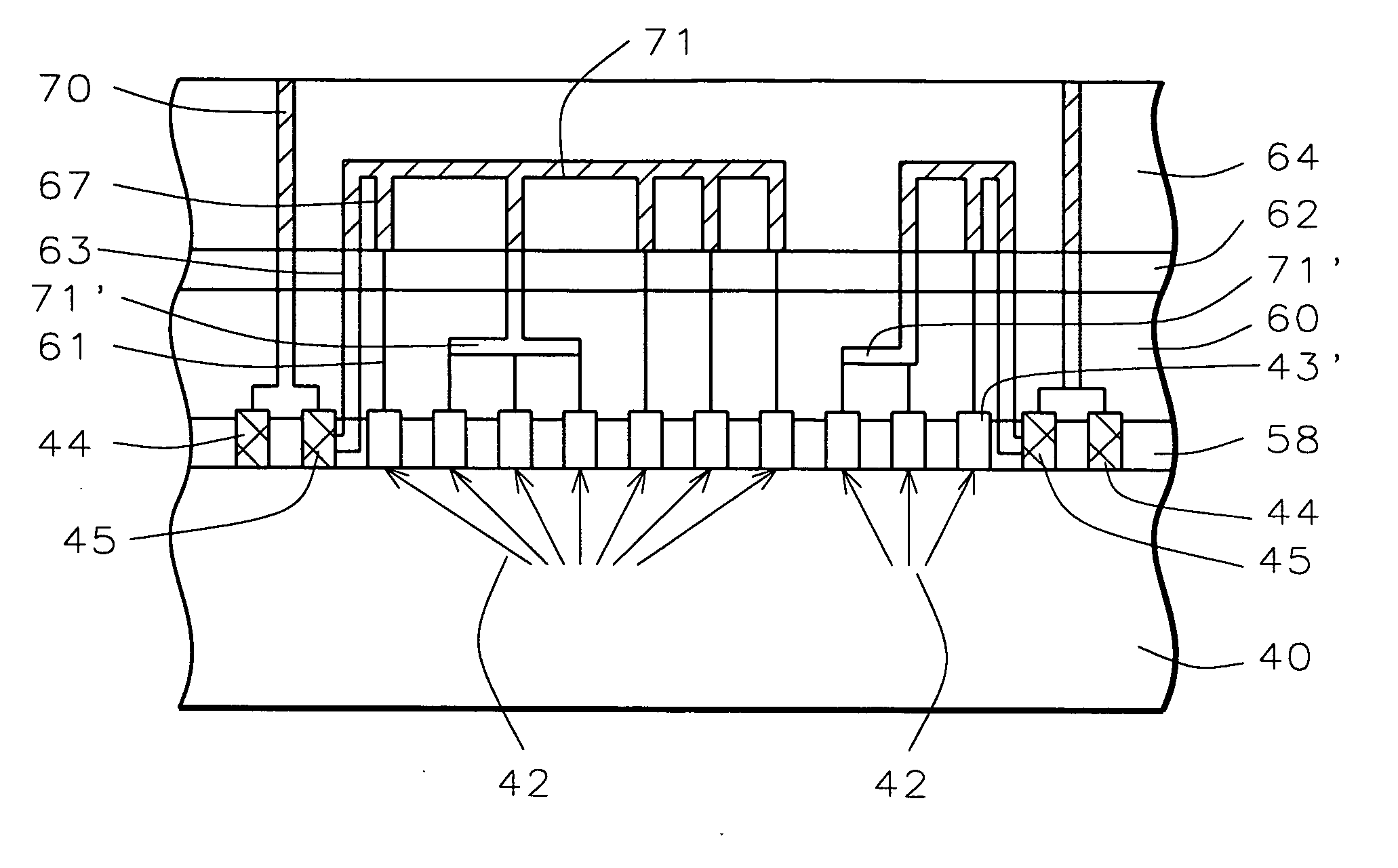

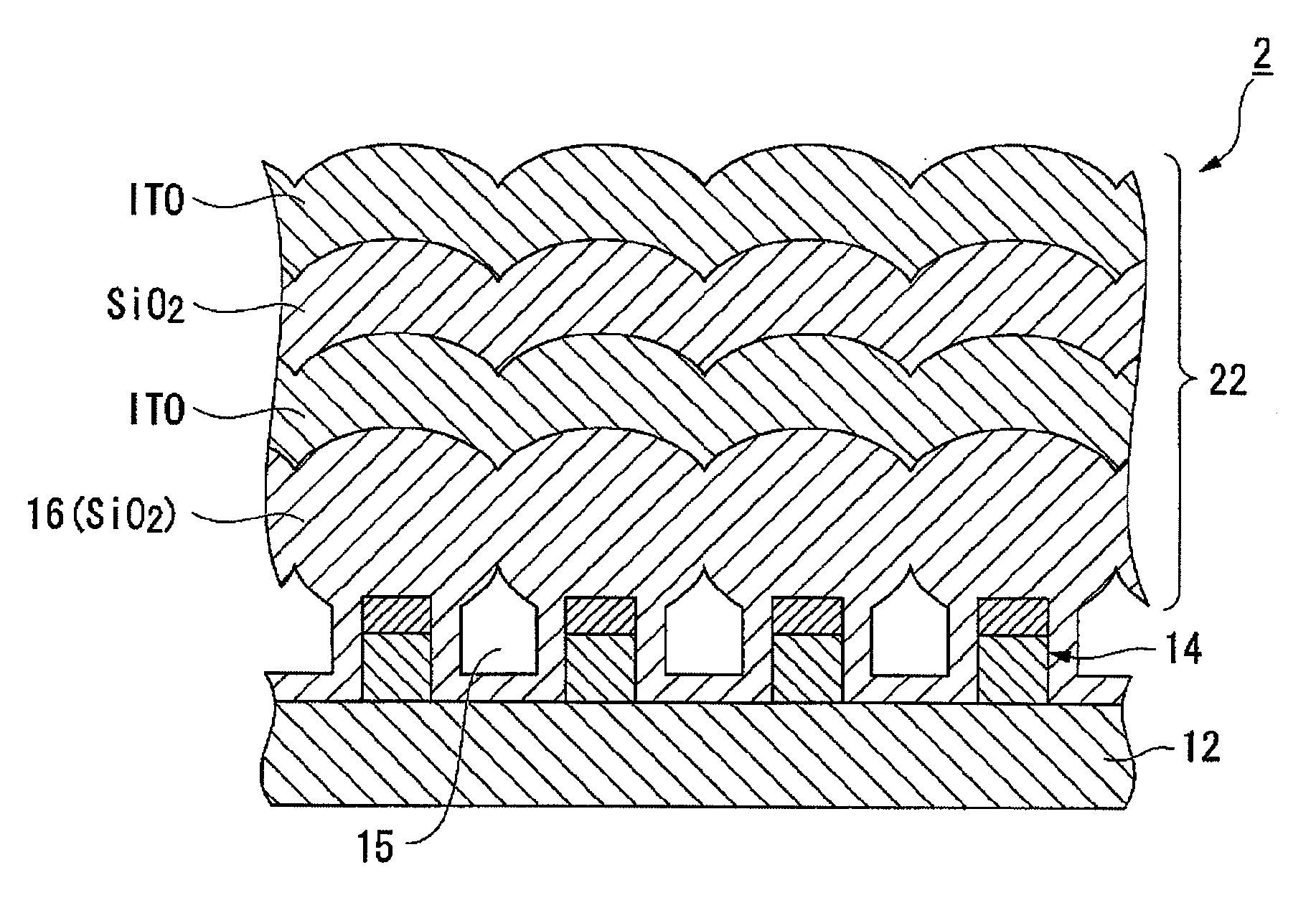

Display device

InactiveUS20110069036A1High-precision position detectionImprove accuracyInput/output processes for data processingCapacitanceCapacitive coupling

In a display device including a capacitive coupling touch panel, reaction to touch with nonconductive input means is achieved, and highly accurate position detection is realized with a small number of electrodes even with a small touch area. X-electrodes and Y-electrodes which intersect with each other via a first insulating layer and a Z-electrode which is in a floating state via a second insulating layer are disposed. For the Z-electrode, a material whose thickness changes by pressing due to touch, such as an elastic conductive material, is used. The Z-electrode is arranged so as to overlap both the X-electrode and the Y-electrode neighboring to each other. A pad portion of the X-electrode has a shape such that an area is maximized in the vicinity of a fine line portion of the relevant X-electrode.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

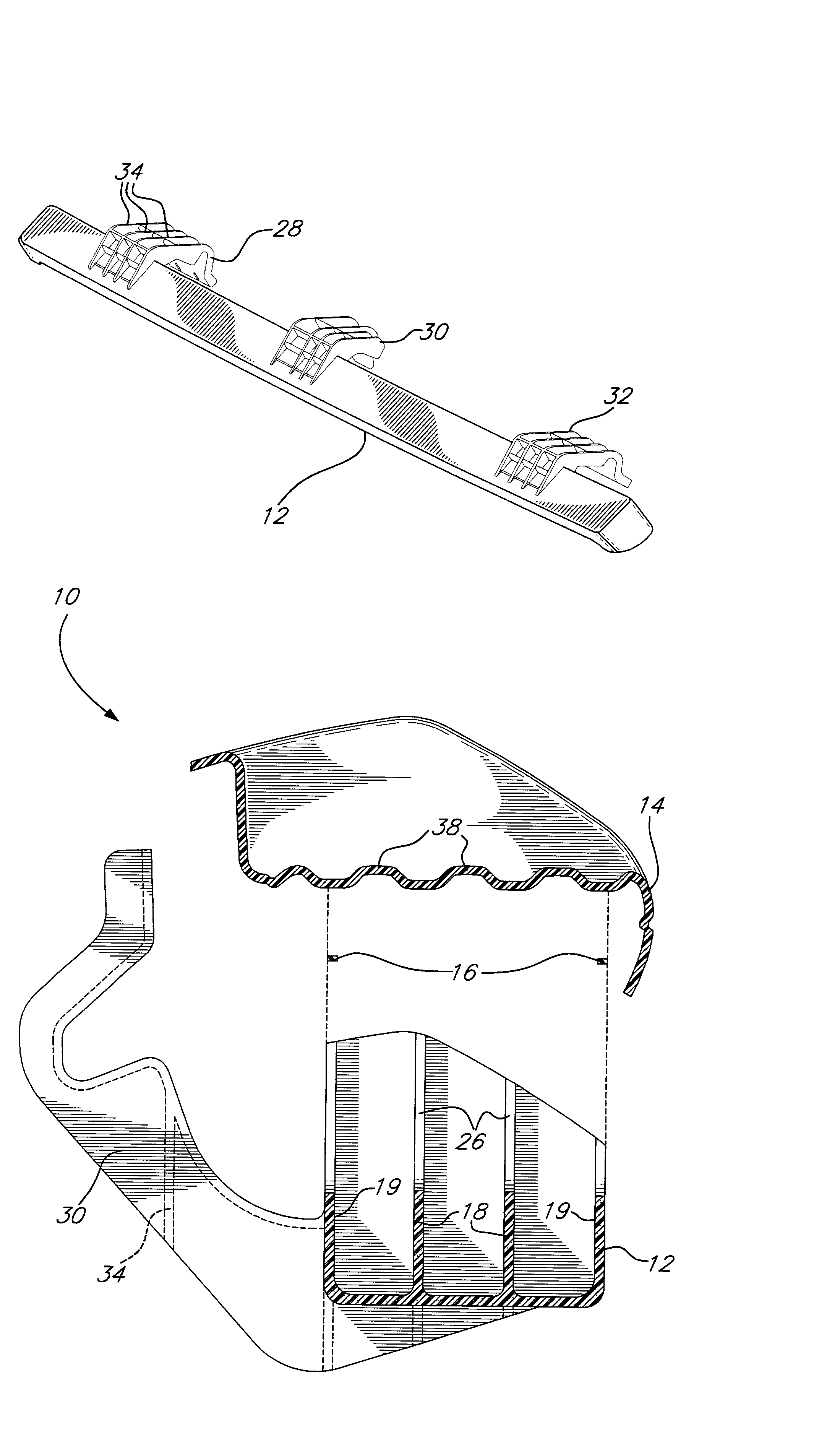

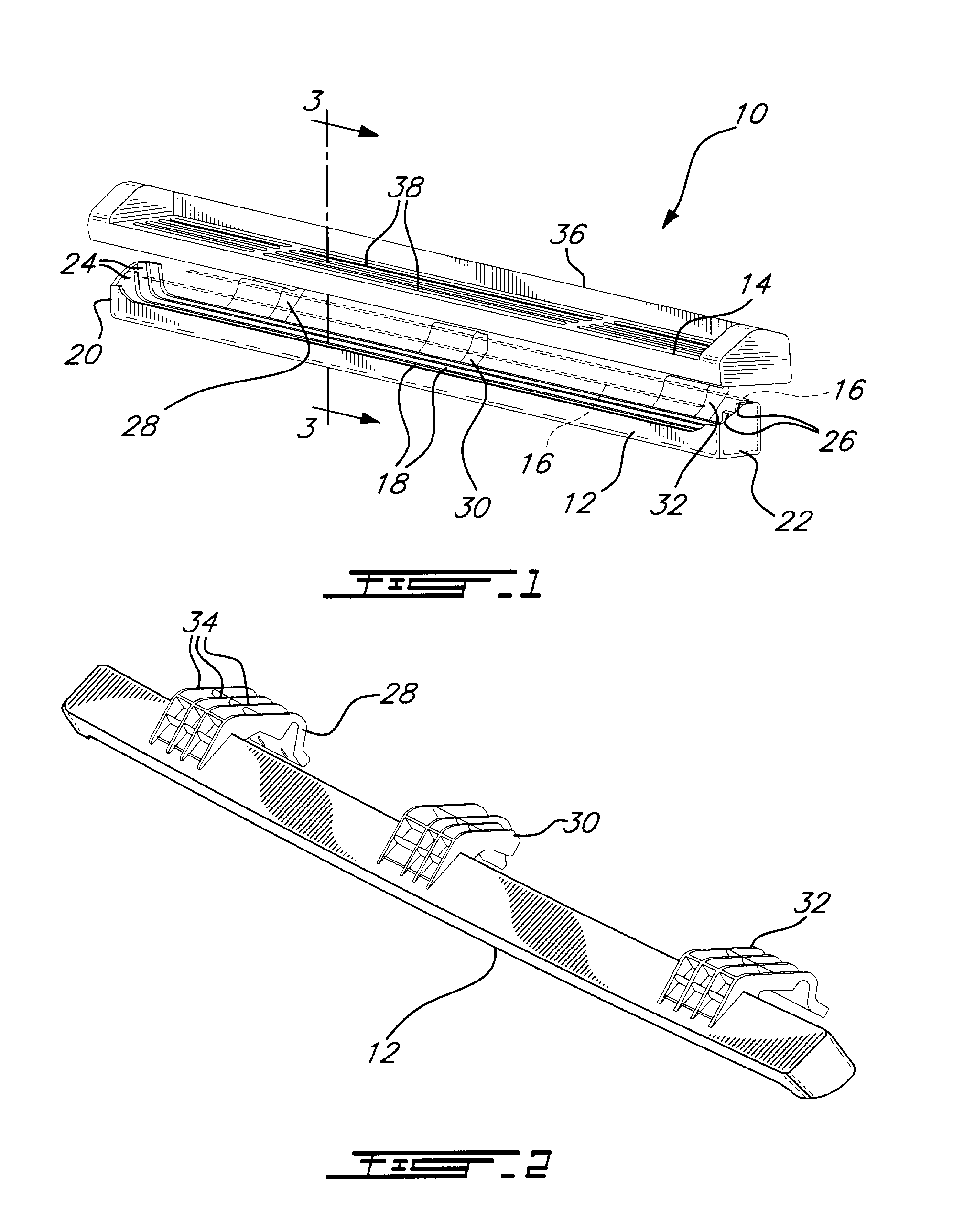

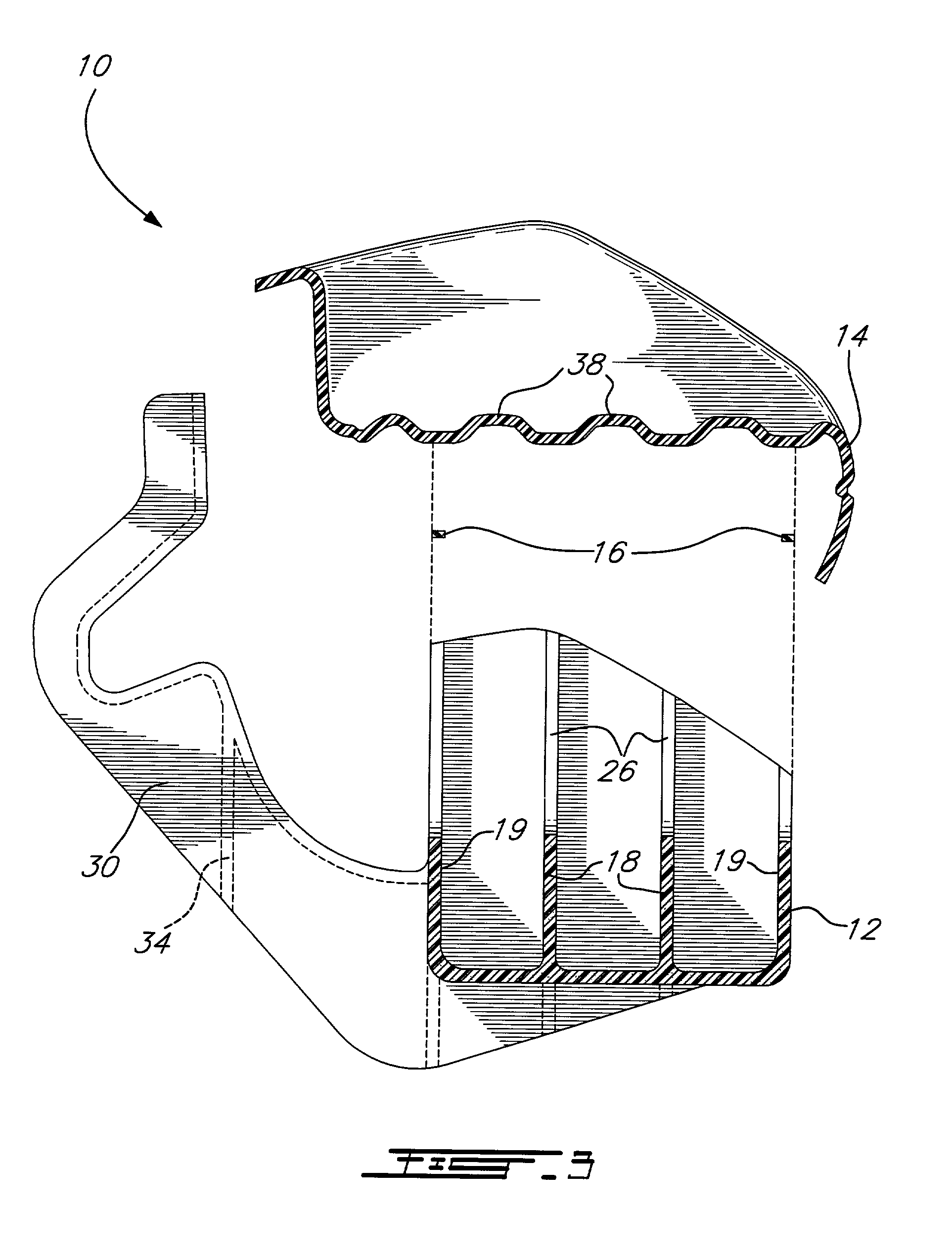

Molded running board

A molded running board provided with a support portion and a top portion is described herein. The support portion is made of plastic material and provided with reinforcing ribs and the top portion is made of a plastic material that is advantageously compatible with the plastic material forming the support portion. A method for the assembly of such a molded running board is also described herein. This method includes the welding of a top portion to a support portion via the use of a thin strand of plastic material compatible with material used in the top portion and the support portion and metallic particles in an electromagnetic press, for example.

Owner:DECOMA INT

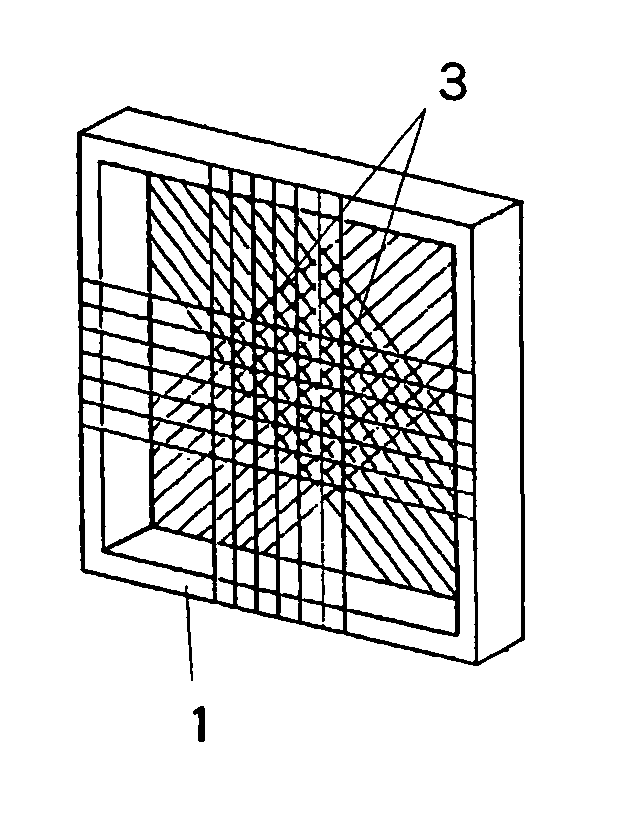

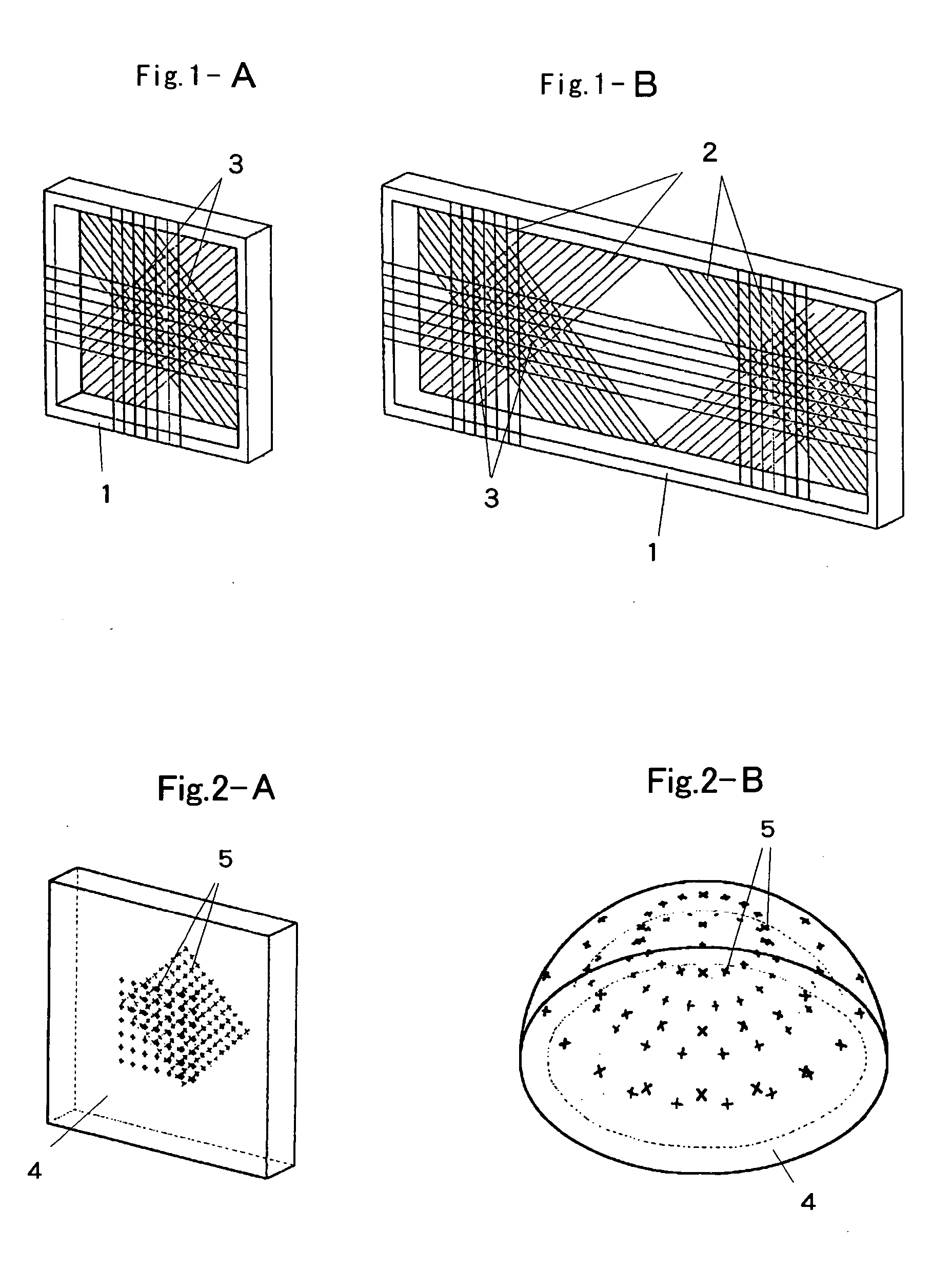

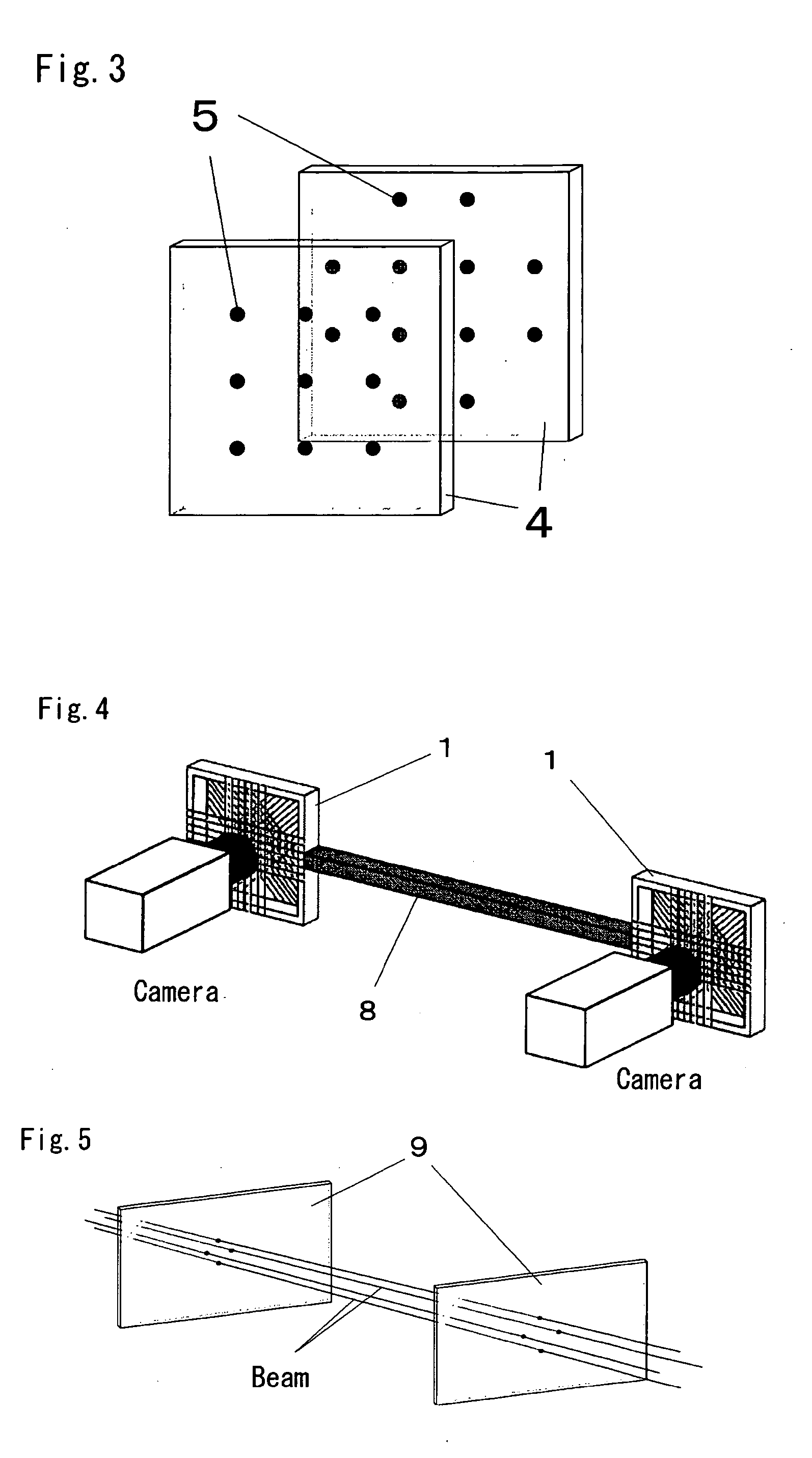

Transparent camera calibration tool for camera calibration and calibration method thereof

InactiveUS20050280709A1Accurate CalibrationTelevision system detailsImage analysisLight beamComputer vision

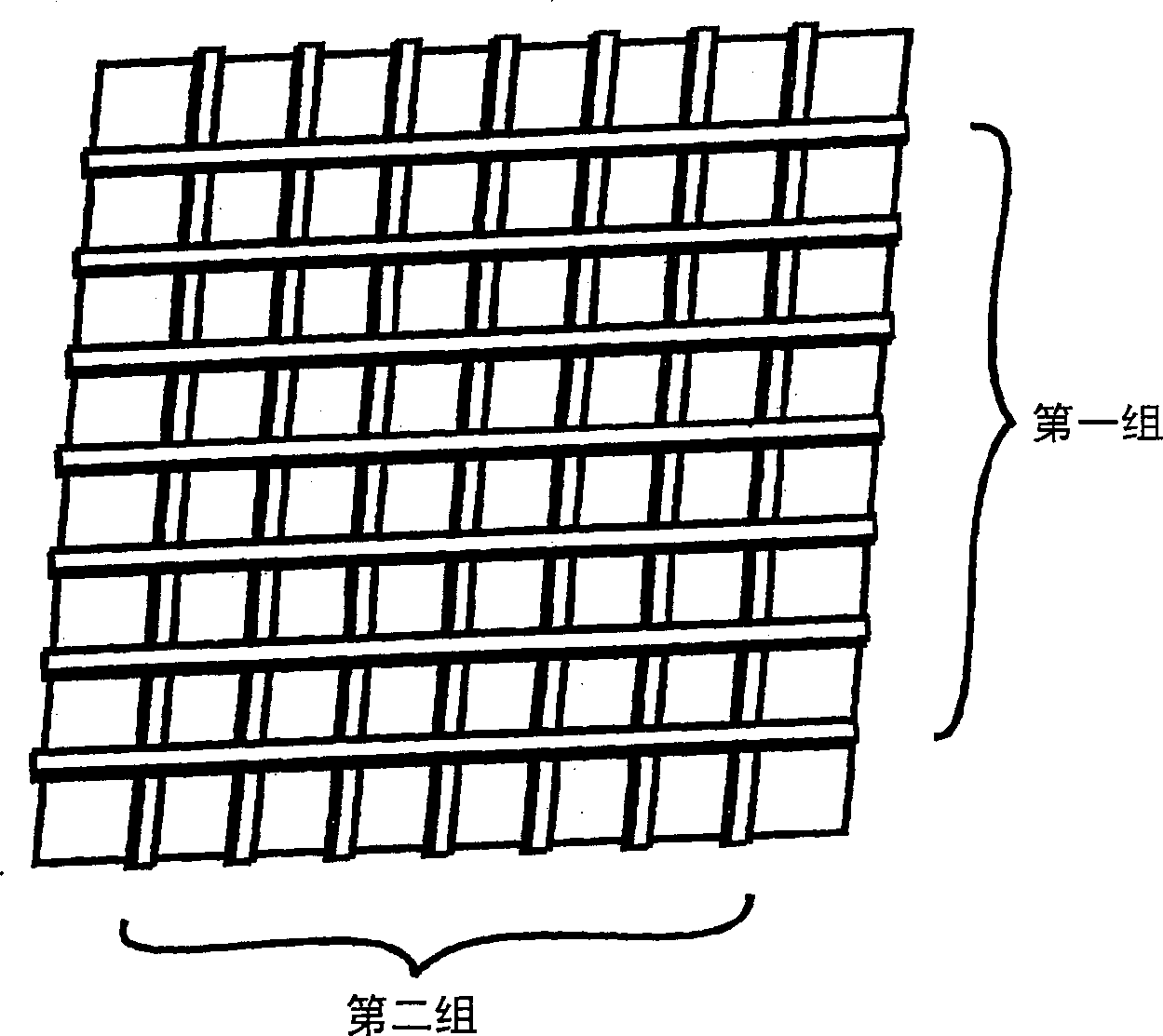

The calibration tool of the present invention is a transparent camera calibration tool in which a plurality of indicator points is spatially distributed and fixed, wherein the indicator points are formed as intersecting points of thin wires extended to the frame by varying the position of the thin wires in the thickness direction and the indicator points are formed as groups of intersecting points of thin wires rendered by extending a plurality of parallel thin wire groups in different directions. The indicator groups are arranged in at least two sets in a non-coplanar relationship and embodied by distributing distinguishable minute particles in a transparent raw material or by marks or similar in the surface of the raw material. Further, a plurality of cameras arranged separately from one another are calibrated in the same coordinate system by using the transparent camera calibration tool, plate tools that are added thereto, and light beams.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

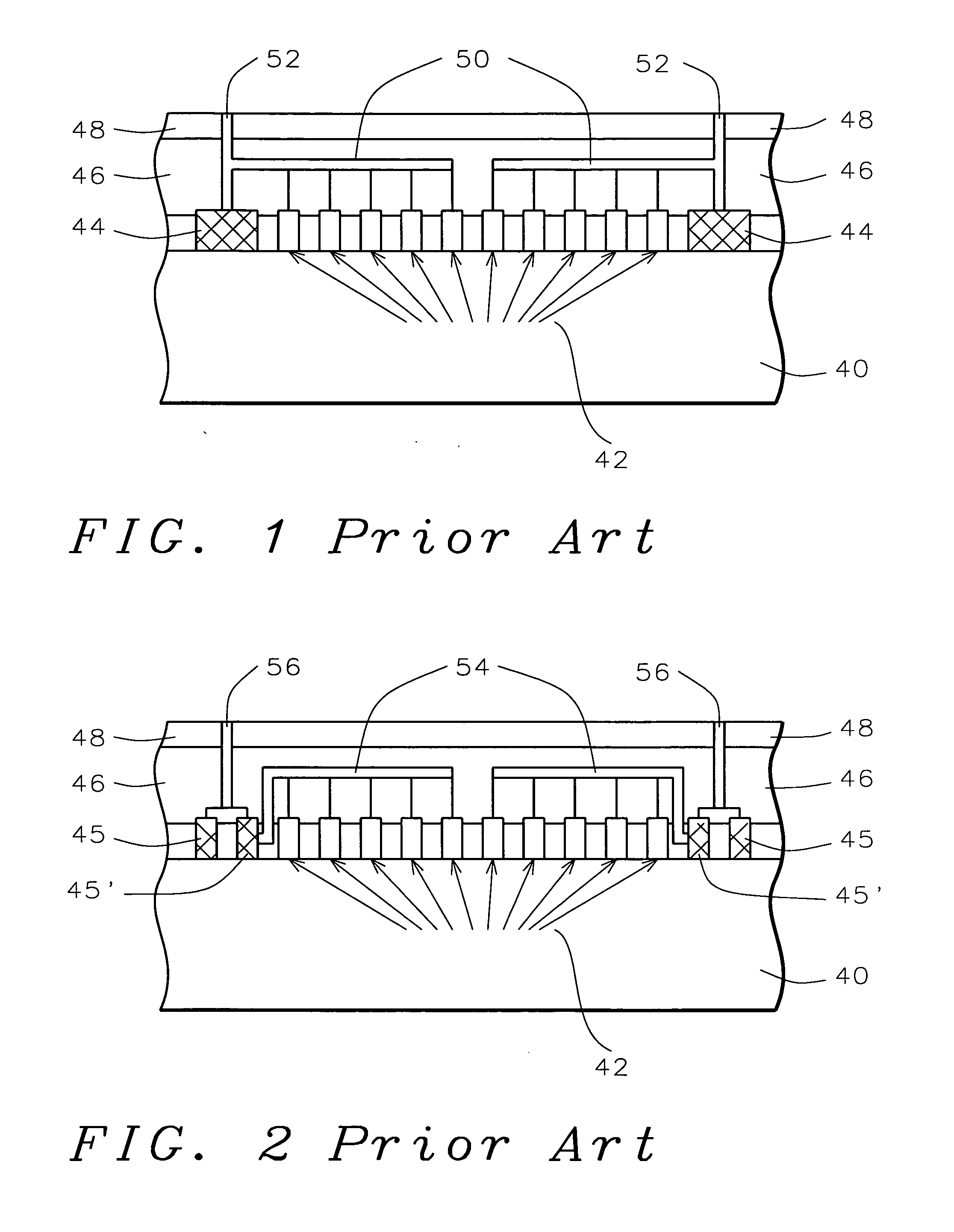

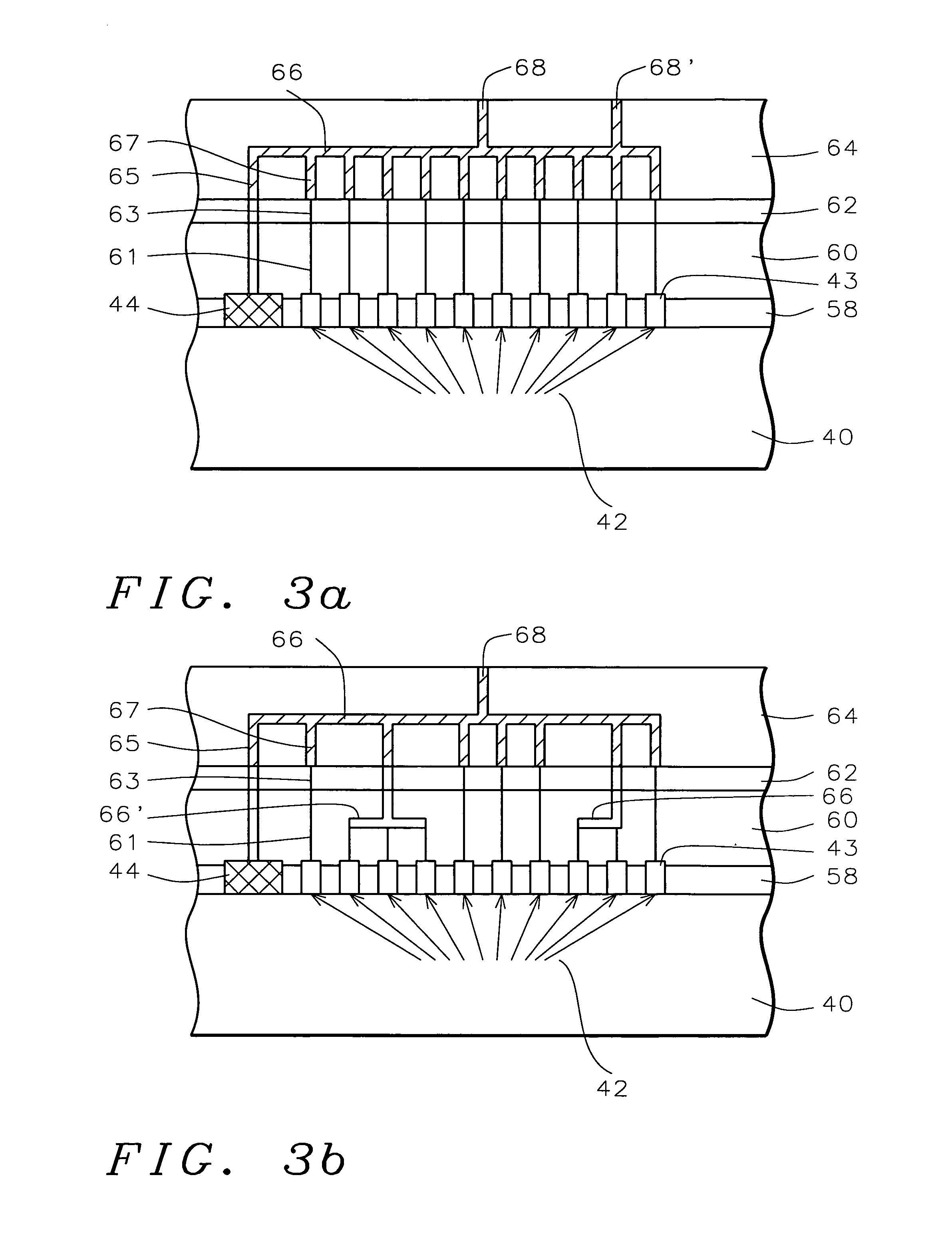

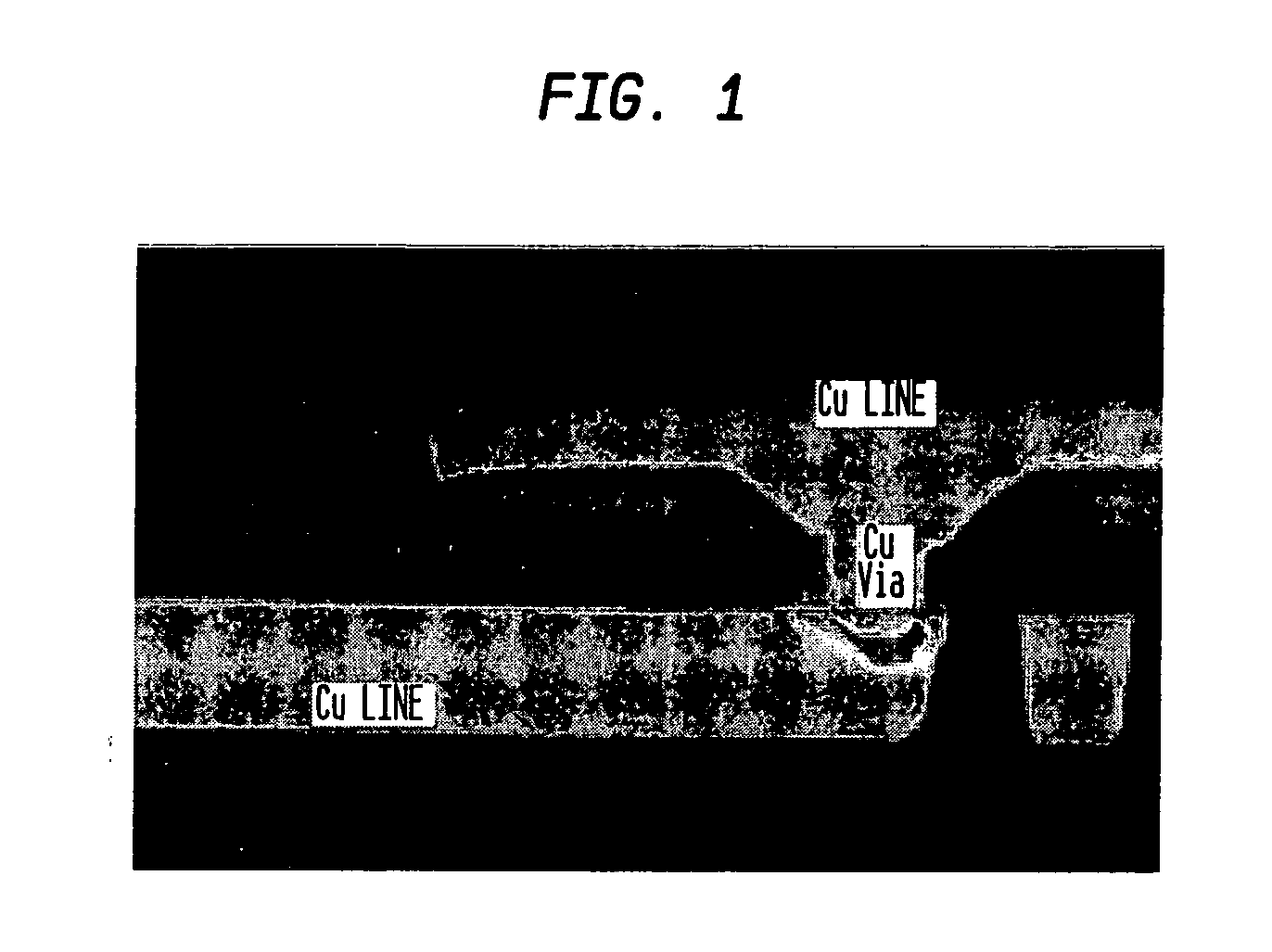

Post passivation interconnection schemes on top of the IC chips

InactiveUS7271489B2Increase resistanceIncrease capacitanceSemiconductor/solid-state device detailsSolid-state devicesDielectricNetwork on

A new method is provided for the creation of interconnect lines. Fine line interconnects are provided in a first layer of dielectric overlying semiconductor circuits that have been created in or on the surface of a substrate. A layer of passivation is deposited over the layer of dielectric and a thick second layer of dielectric is created over the surface of the layer of passivation. Thick and wide post-passivation interconnect lines are created in the thick second layer of dielectric. The first layer of dielectric may also be eliminated, creating the wide thick passivation interconnect network on the surface of the layer of passivation that has been deposited over the surface of a substrate.

Owner:QUALCOMM INC

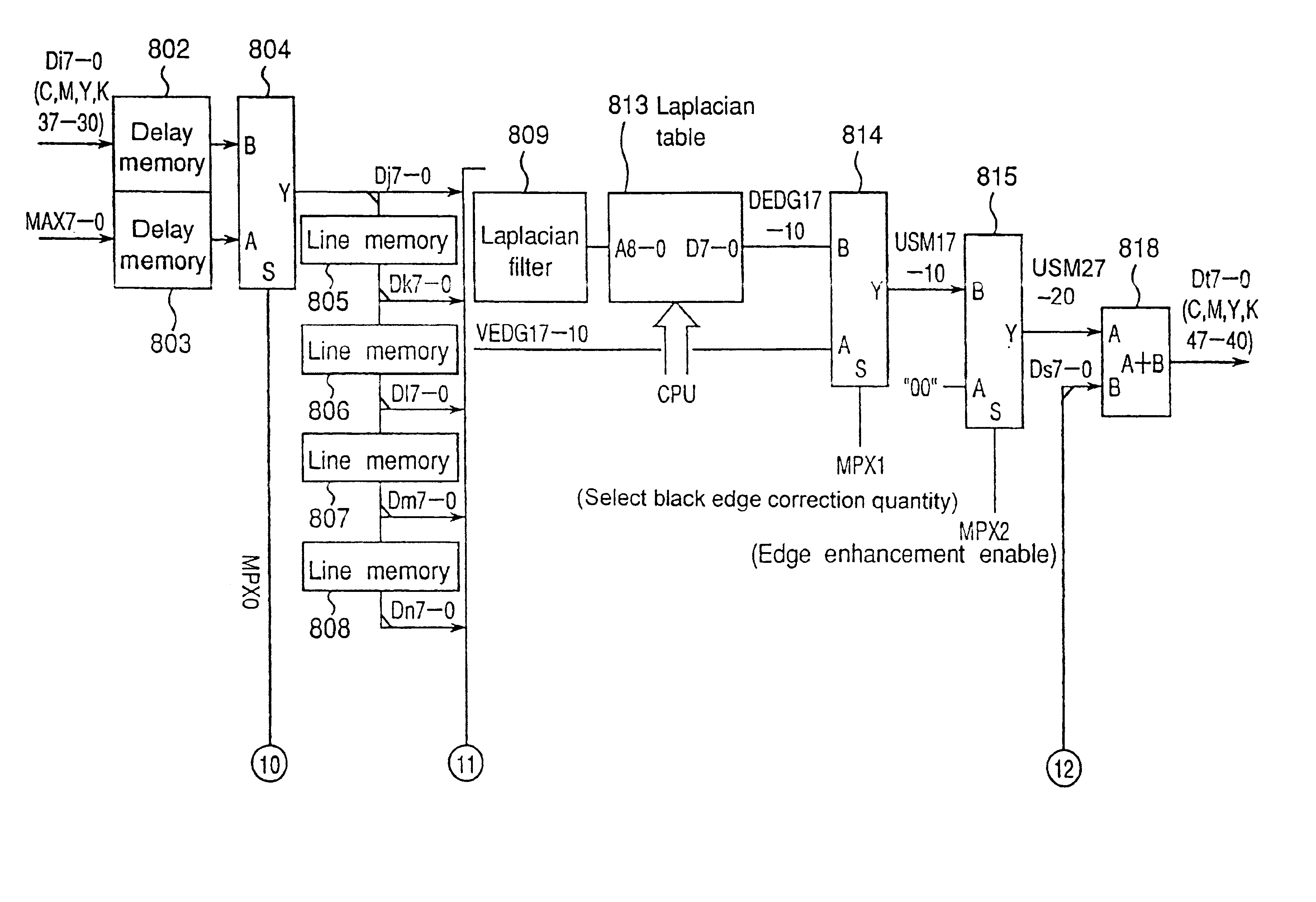

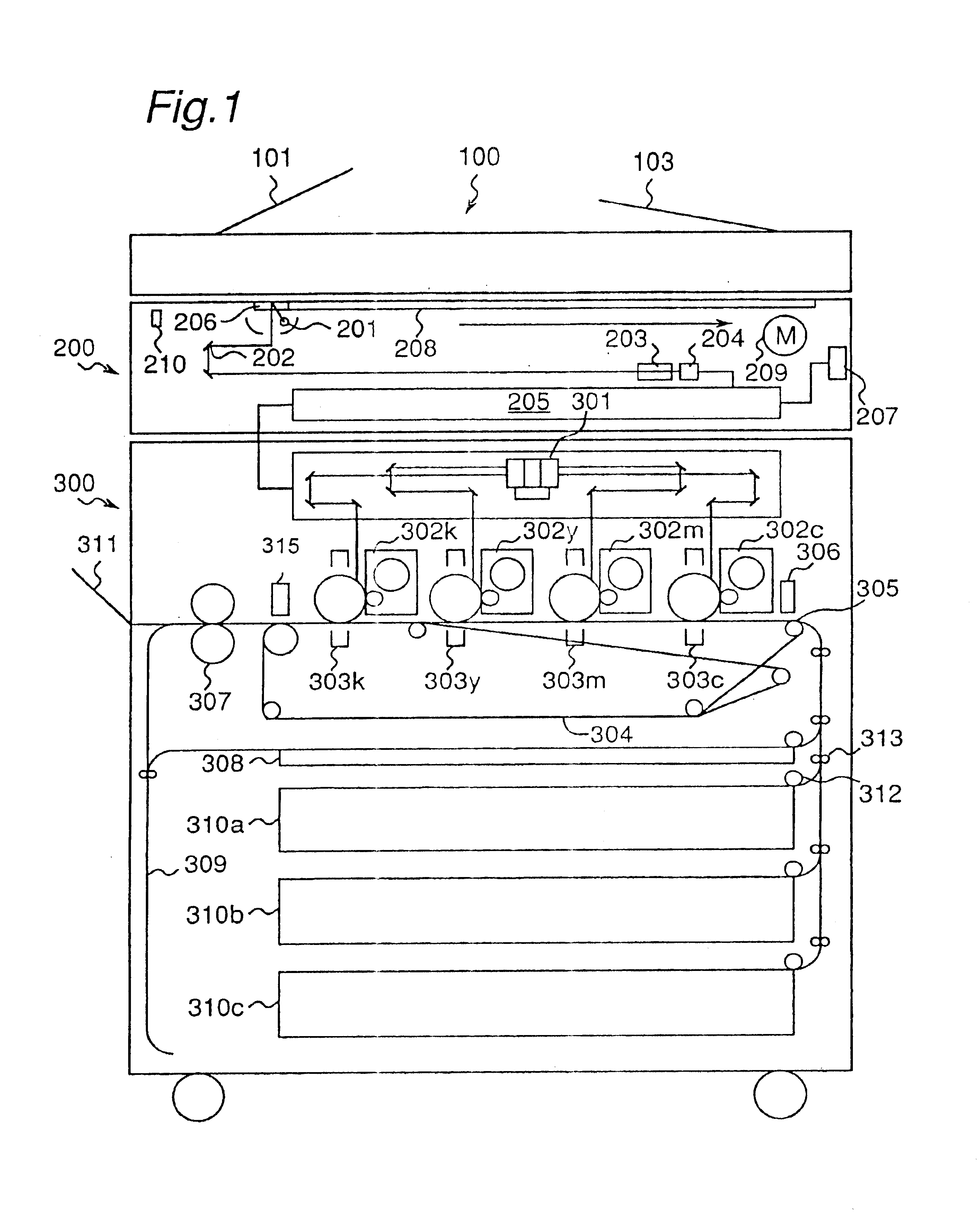

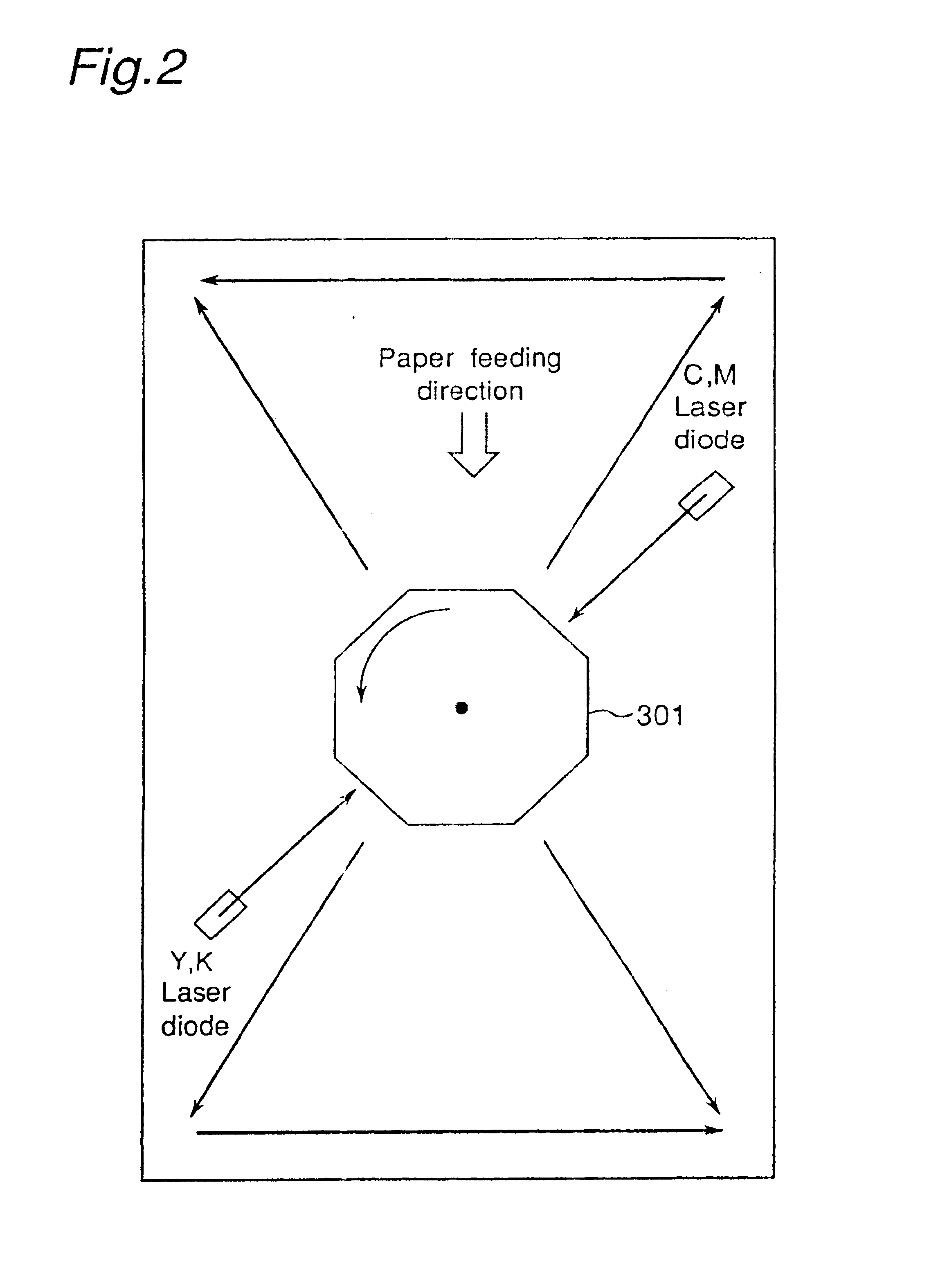

Method and apparatus for image processing, including processing for reproducing black character areas of color and monochromatic images

InactiveUS7079685B1Solve the lack of densityCharacter and pattern recognitionPictoral communicationColor imageImaging processing

In an image processor which converts color image data to image data of cyan, magenta, yellow and black necessary for forming an image, a black character edge is discriminated in R, G, B image data. The edge component in a black character area is deleted by narrowing on image data of cyan, magenta and yellow. Further, in a black character area, K data is replaced with maximum density data in the R, G, B data, and edge emphasis is performed on the substituted data. Then, reproducibility of a thin line portion in a character is improved largely.

Owner:MINOLTA CO LTD

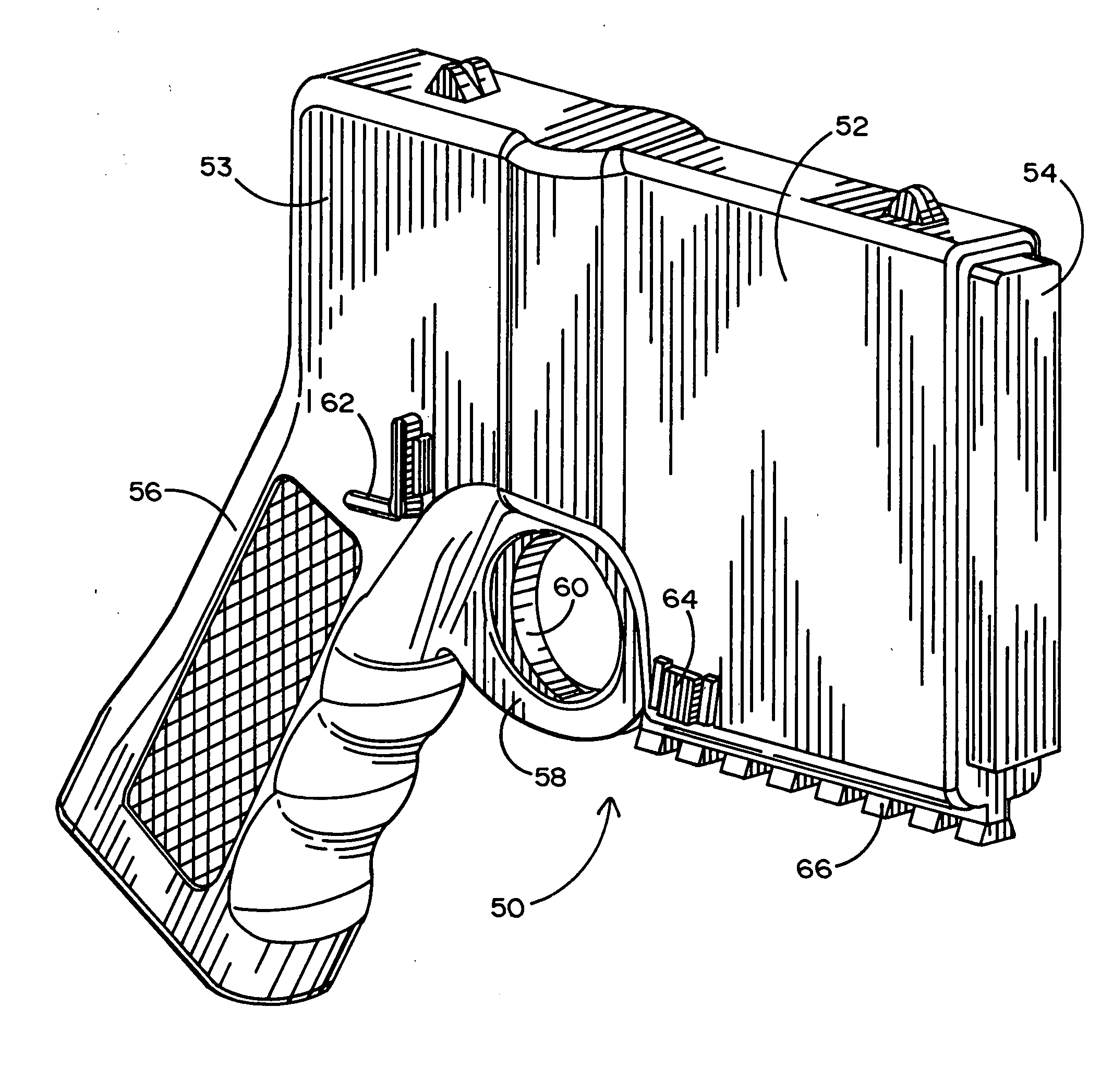

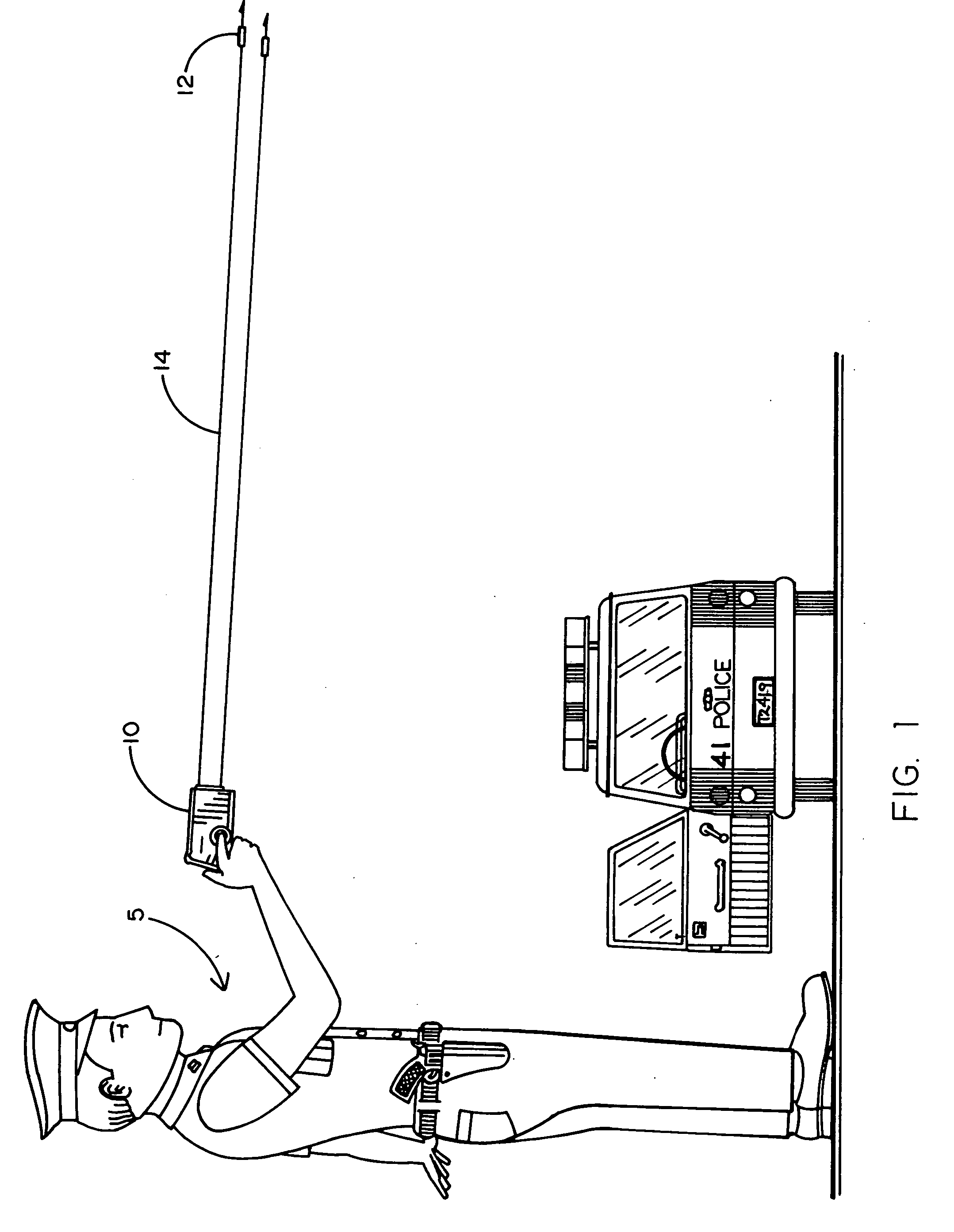

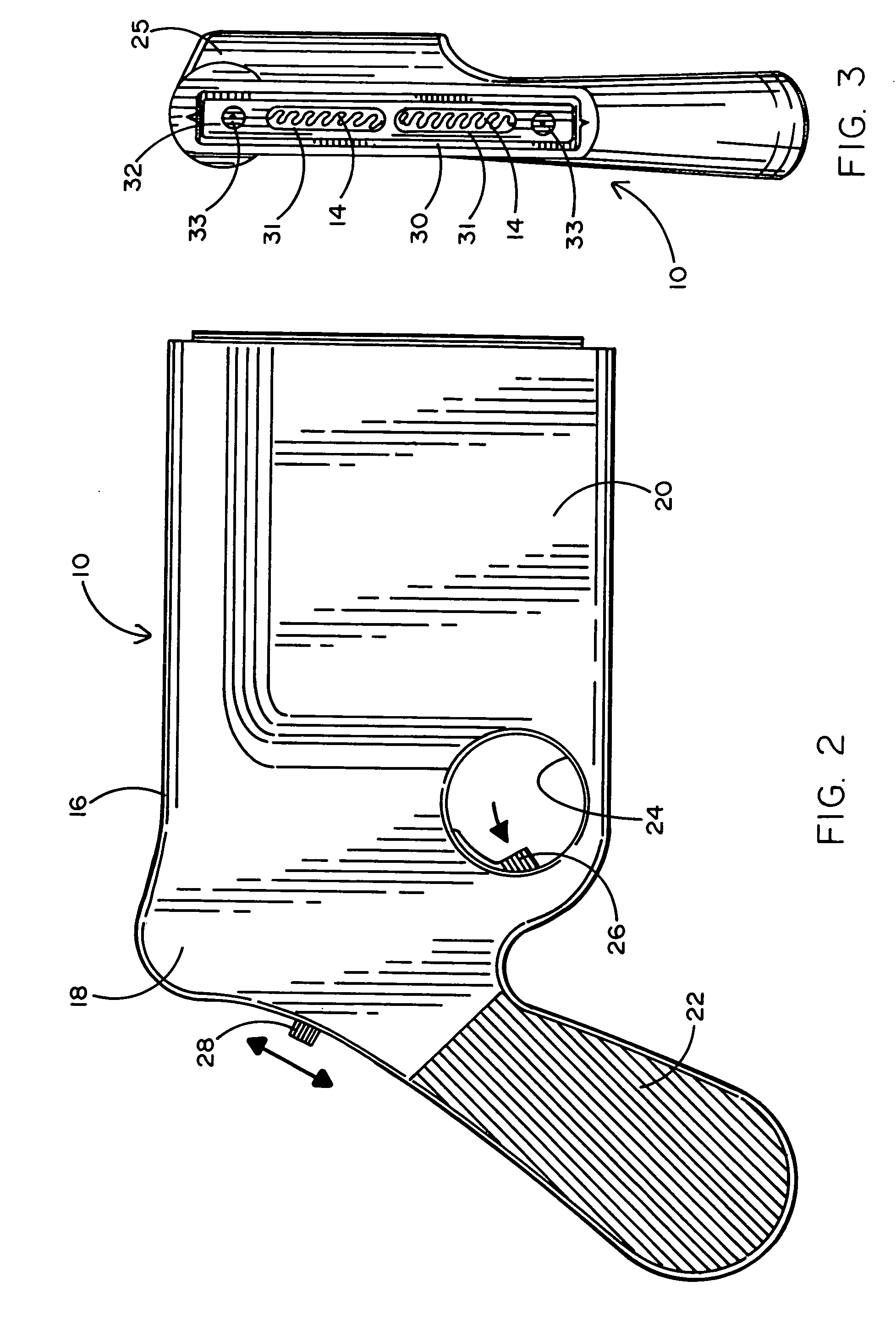

Non-lethal electrical discharge weapon having a slim profile

InactiveUS20060120009A1Easy to placeAssure effectivenessElectrical apparatusSmallarmsPower flowPush off

An electrical discharge weapon configured as a lightweight, slim profile gun-shaped weapon which is less than one inch thick along the cartridge receiving chamber so that it can be readily placed in a police officer's uniform pocket or in a slim-line holster for easy deployment. All of the major internal components, including battery and transformer, are positioned above or behind the trigger aperture so that even with the dart cartridge in the chamber, the weapon's center of gravity is through the hand so that it is balanced and easily aimed at the target. The invention employs a specially configured chamber to receive a unique cartridge with widely separated darts. As a result, the electrodes may be also widely separated so that current will not jump the electrode gap even when the impacted darts leave a substantial gap to a suspect's skin. Thus, the present invention is more likely to be effective against suspect's wearing thick outerwear. The spent cartridge may be expelled by a spring-activated release for quick ejection and rapid reload. A bottom rail permits connection of another non-lethal device such as a mace canister for use as a secondary weapon or the attachment of tactical lighting or laser aiming devices. A push-on / push-off trigger switch is combined with a mechanical safety device to assure weapon effectiveness and safety for the police officer. Quick disconnect battery clip allows for rapid battery replacement.

Owner:LAW ENFORCEMENT ASSOC

Network conductor and its production method and use

ActiveUS7172822B2Maintain good propertiesLow resistivityConductive layers on insulating-supportsSolid-state devicesNetwork structureConductive materials

Owner:FUJIFILM CORP +1

Display device with touch detecting function and electronic apparatus

ActiveUS20140292713A1Reduce the possibilityNon-linear opticsInput/output processes for data processingDisplay deviceThin line

According to an aspect, a display device with a touch detecting function includes: a substrate; a display area; a touch detection electrode provided with a plurality of conductive thin wires, each of the conductive thin wires including a plurality of thin wire pieces each having a linear shape and including a first end and a second end; a drive electrode; and a display functional layer. The adjacent thin wire pieces are arranged so as to be bent at a bent portion serving as a portion at which the second end of the one thin wire piece of the adjacent thin wire pieces is connected to the first end of the other thin wire piece of the adjacent thin wire pieces, and the conductive thin wires include a bent portion having an angle formed by the adjacent thin wire pieces different from angles of the other bent portions.

Owner:JAPAN DISPLAY INC

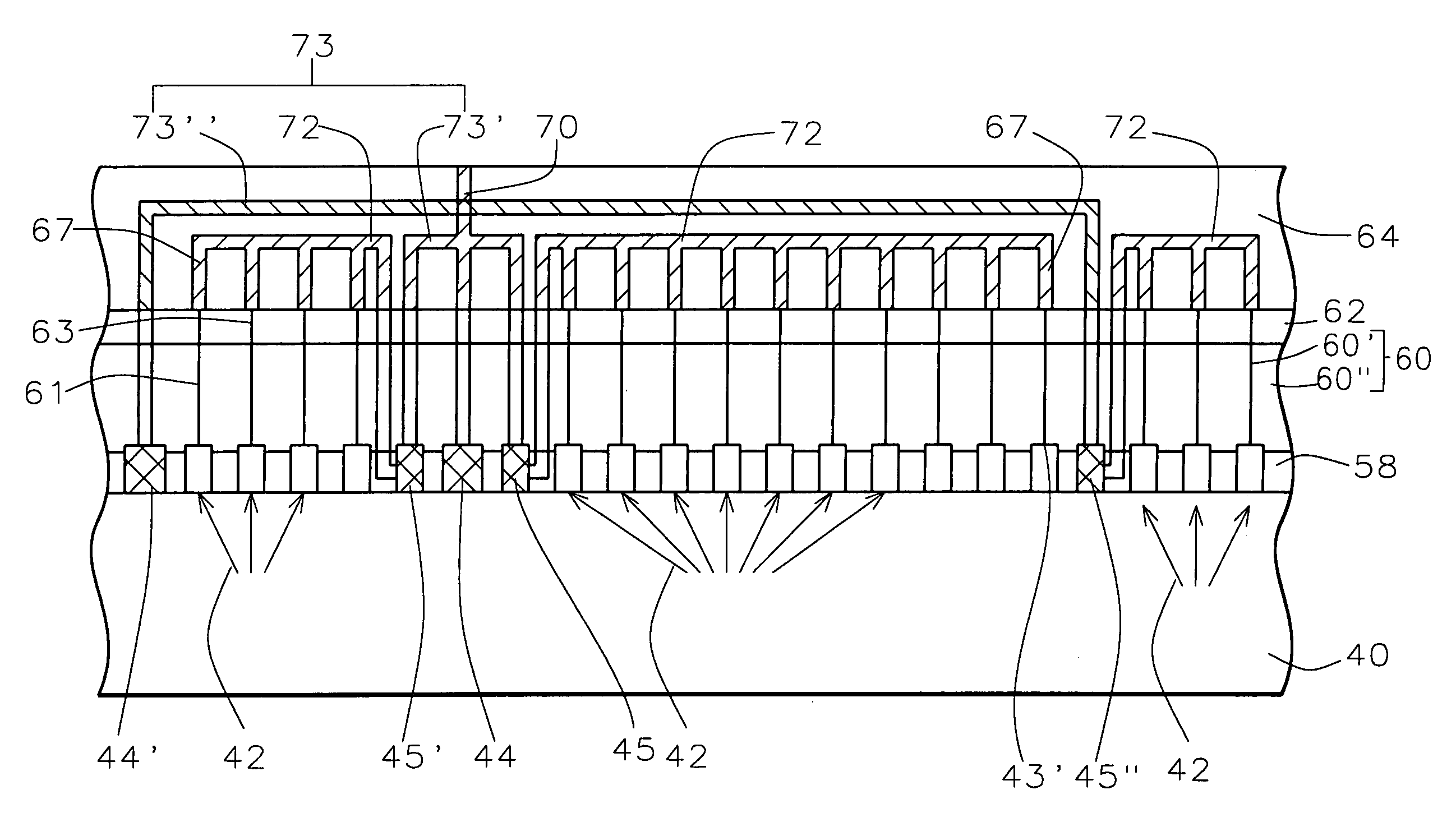

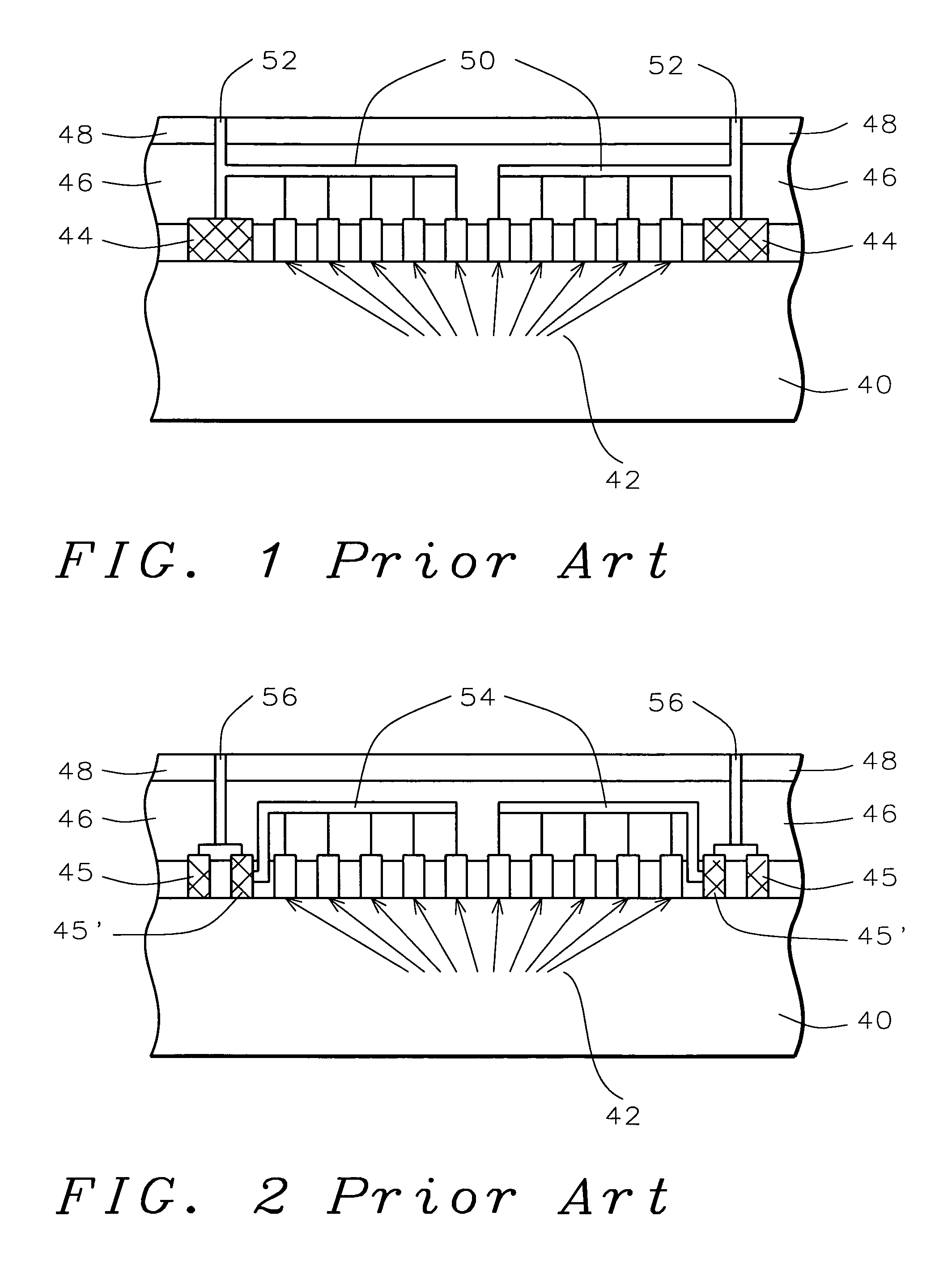

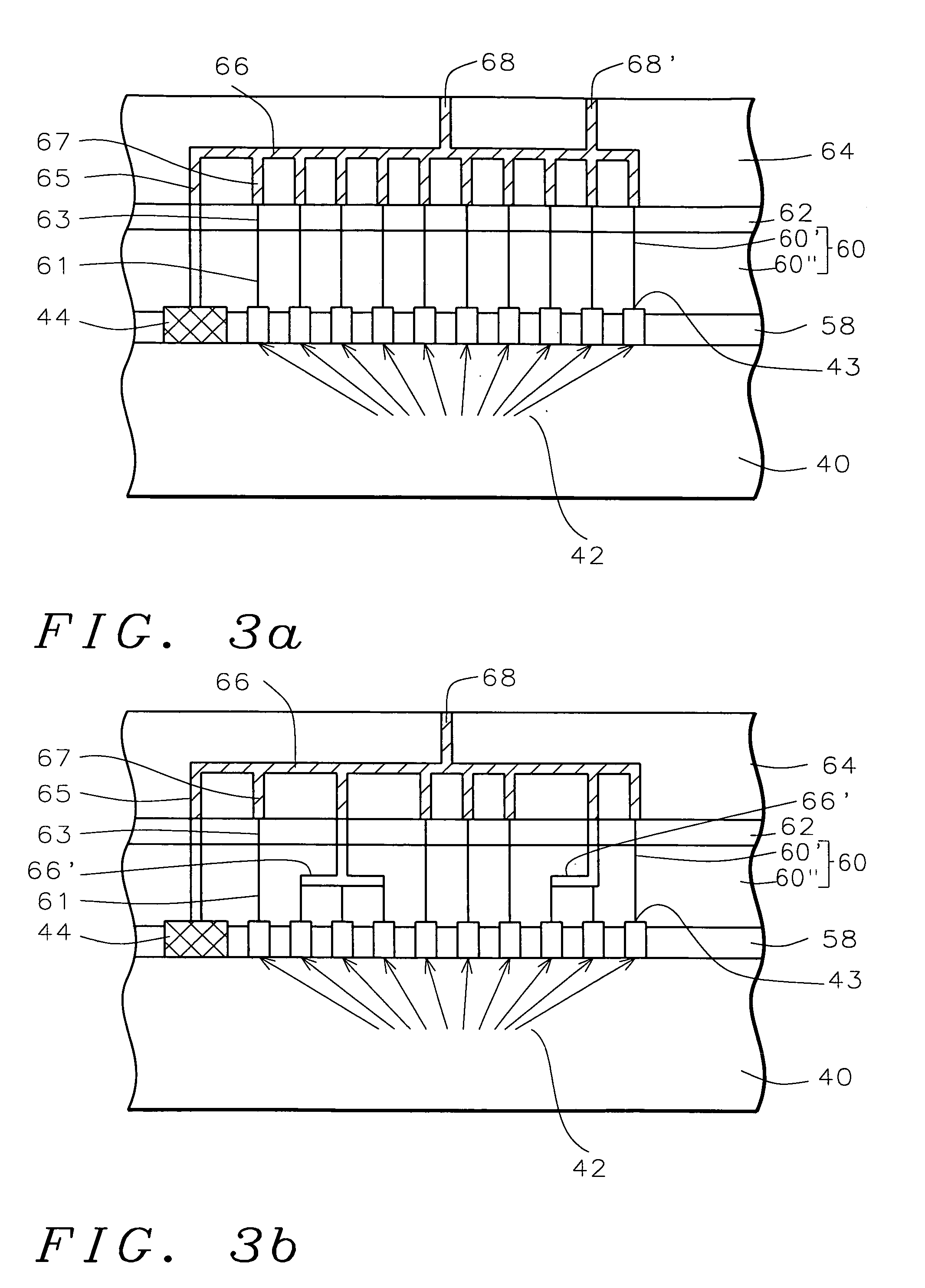

Post passivation interconnection schemes on top of the IC chips

InactiveUS20060076687A1Increase resistanceIncrease capacitanceSemiconductor/solid-state device detailsSolid-state devicesDielectricNetwork on

A new method is provided for the creation of interconnect lines. Fine line interconnects are provided in a first layer of dielectric overlying semiconductor circuits that have been created in or on the surface of a substrate. A layer of passivation is deposited over the layer of dielectric and a thick second layer of dielectric is created over the surface of the layer of passivation. Thick and wide post-passivation interconnect lines are created in the thick second layer of dielectric. The first layer of dielectric may also be eliminated, creating the wide thick passivation interconnect network on the surface of the layer of passivation that has been deposited over the surface of a substrate.

Owner:QUALCOMM INC

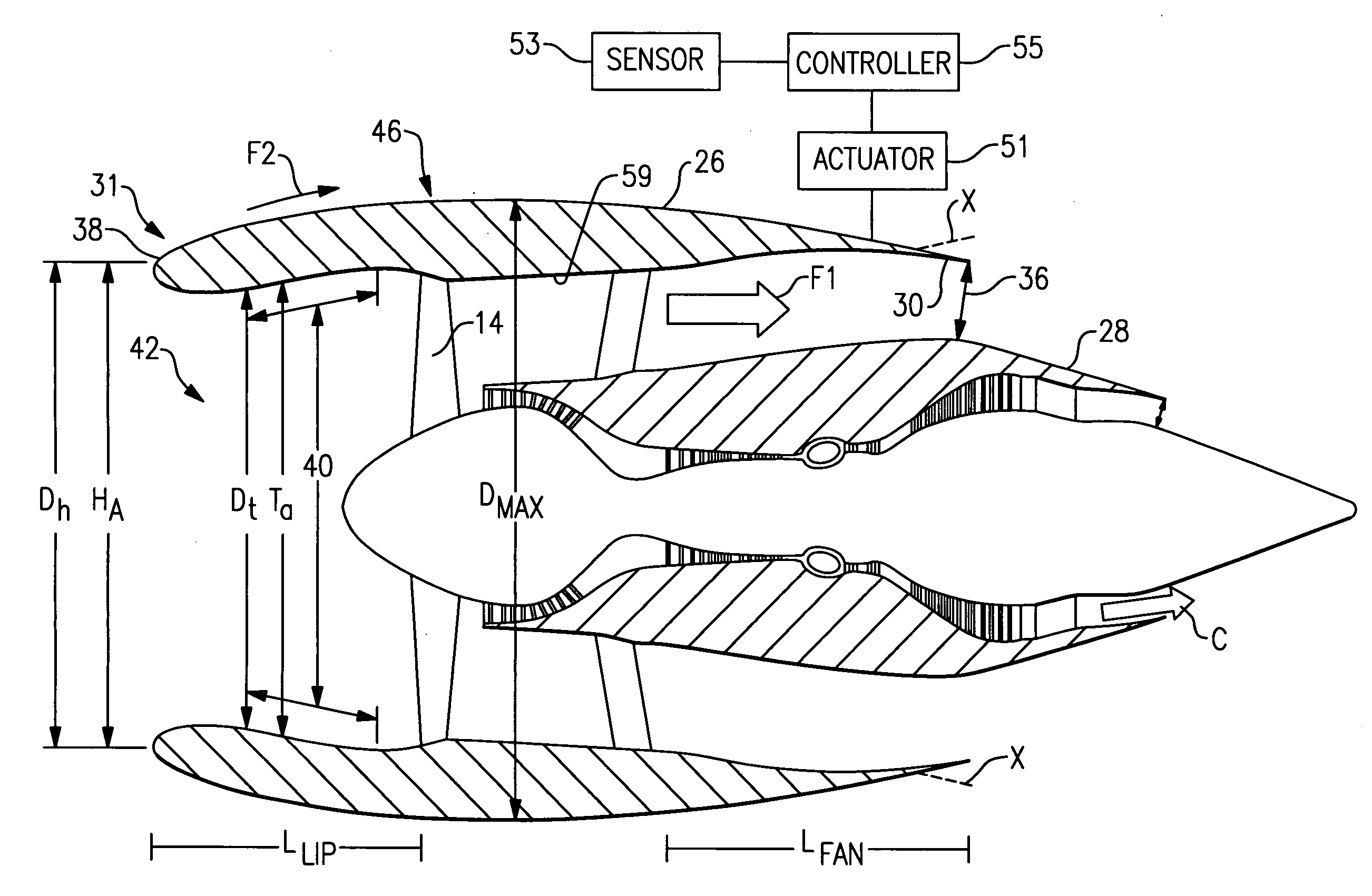

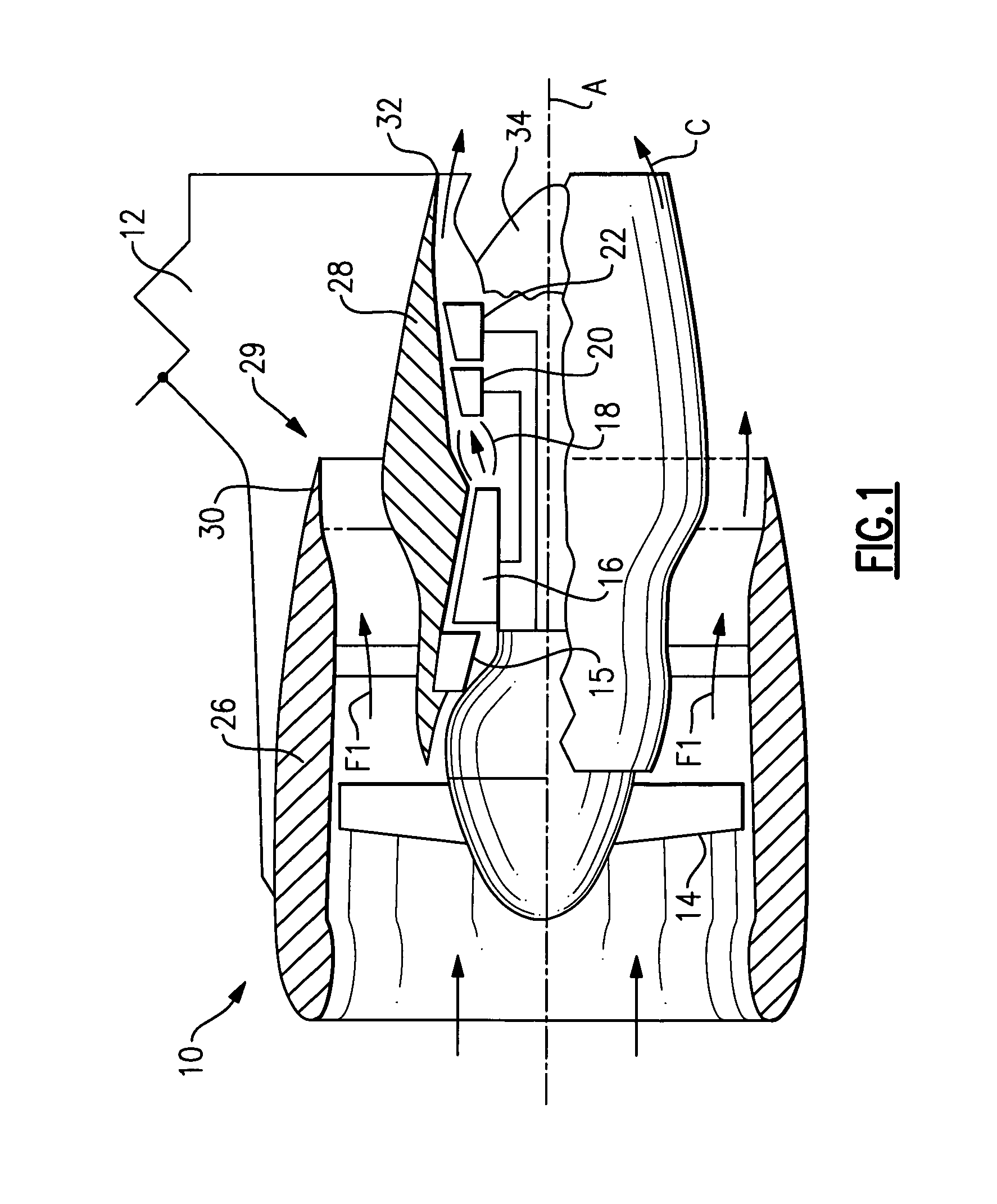

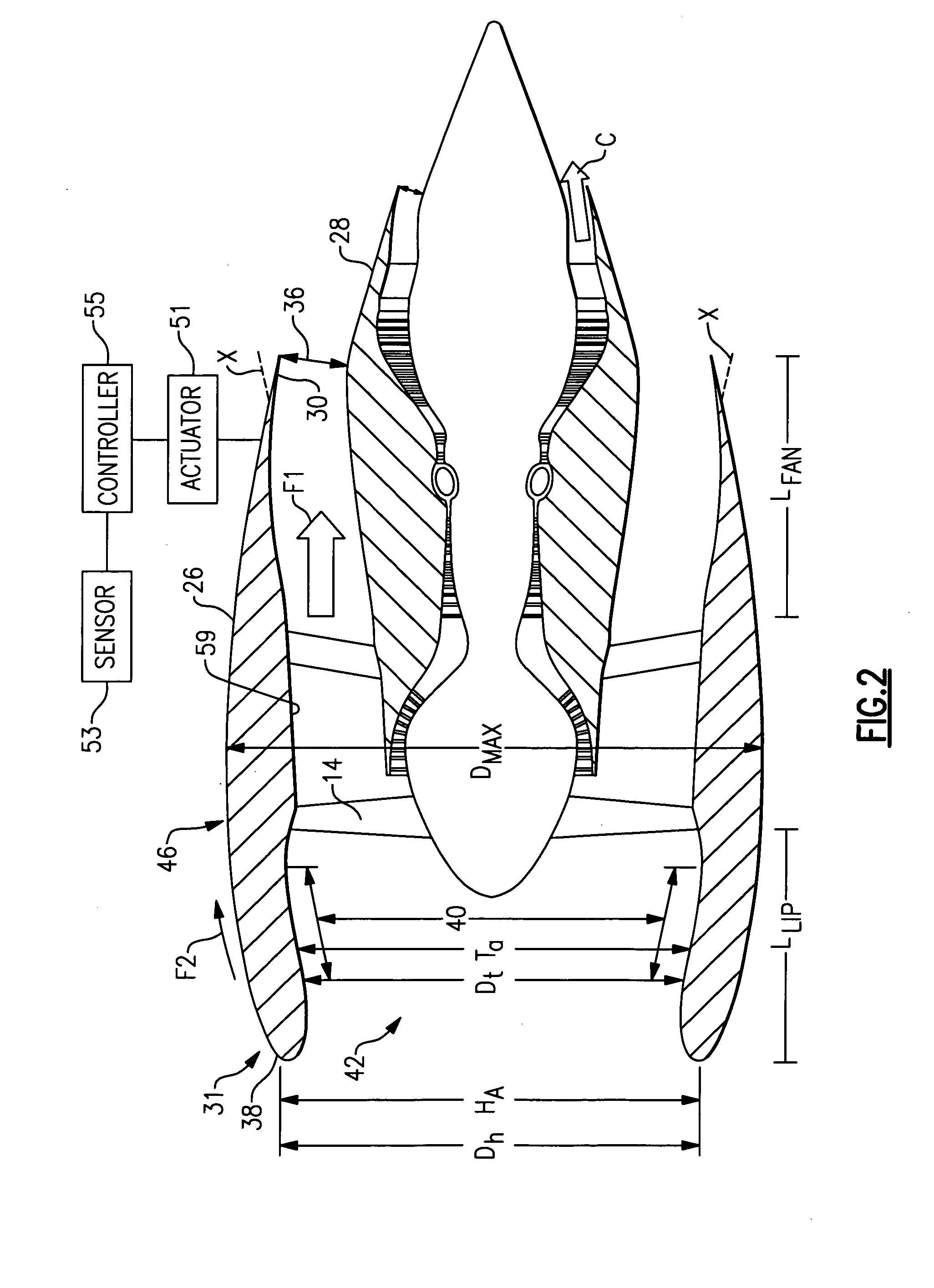

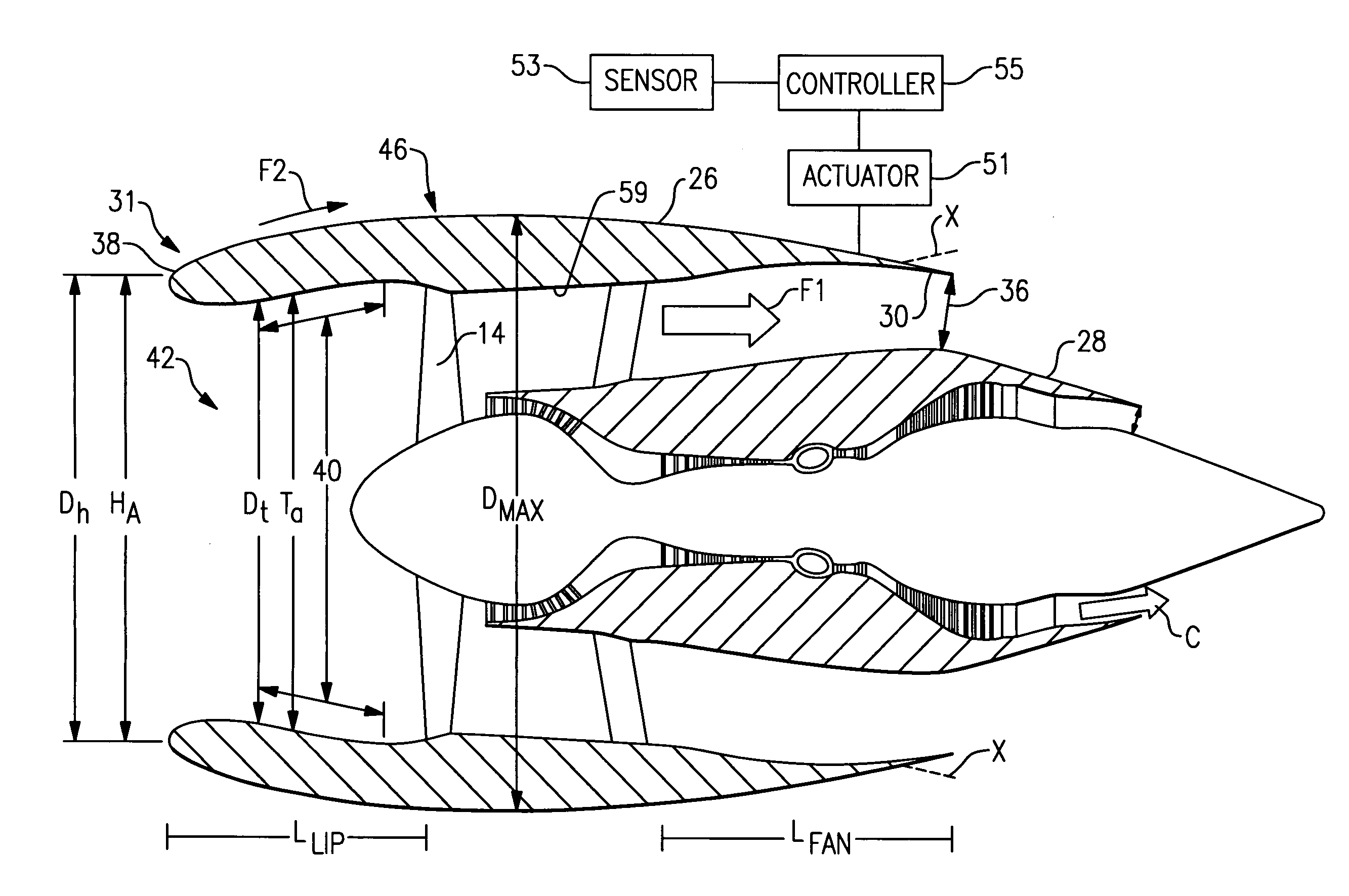

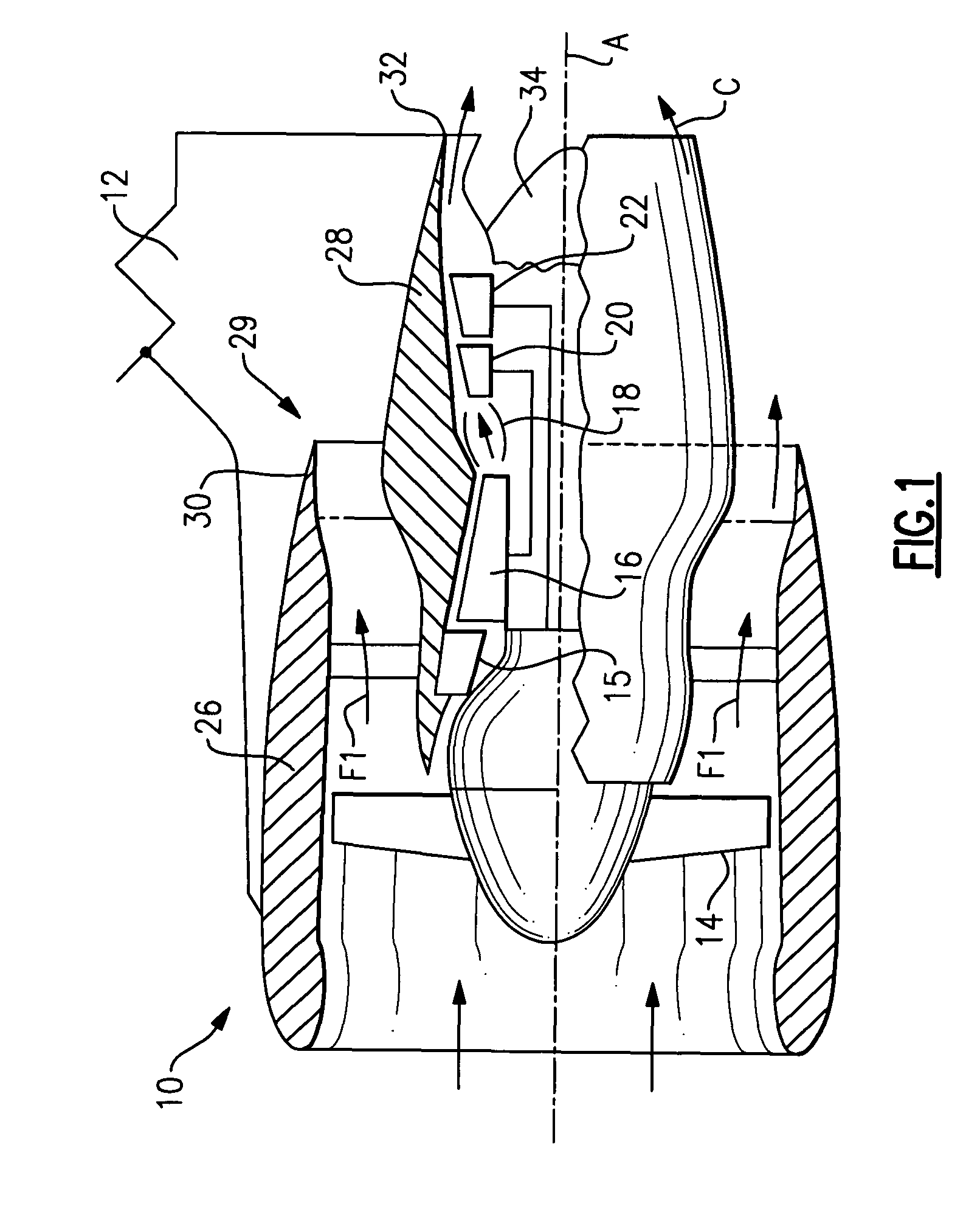

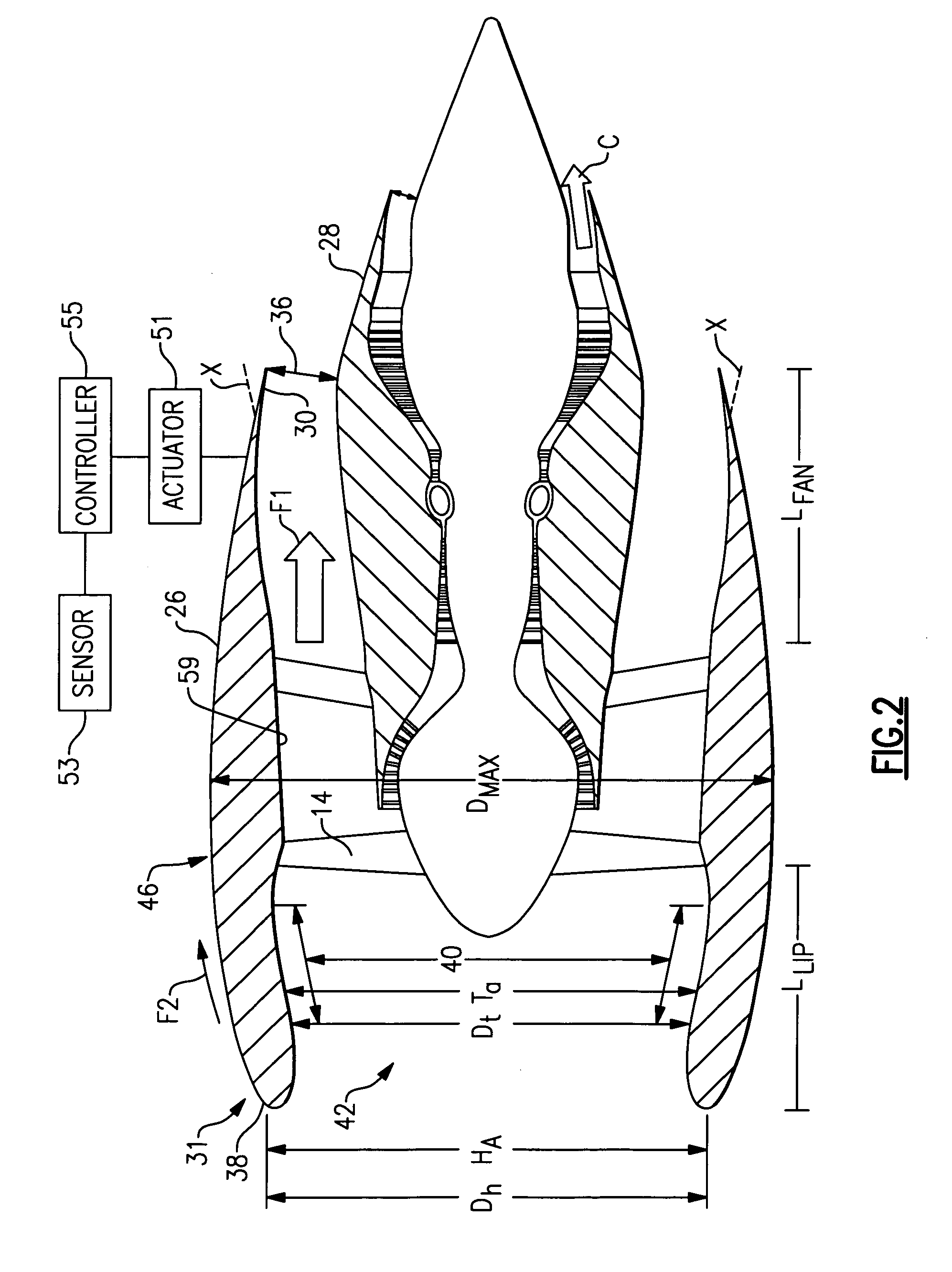

Gas turbine engine having slim-line nacelle

A nacelle assembly for a gas turbine engine includes a nacelle, a variable area fan nozzle, a sensor that detects a windmilling condition and a controller that communicates with the sensor. The variable area fan nozzle is moveable between a first position having a first discharge airflow area and a second position having a second discharge airflow area greater than the first discharge airflow area in response to detecting the windmilling condition.

Owner:RAYTHEON TECH CORP

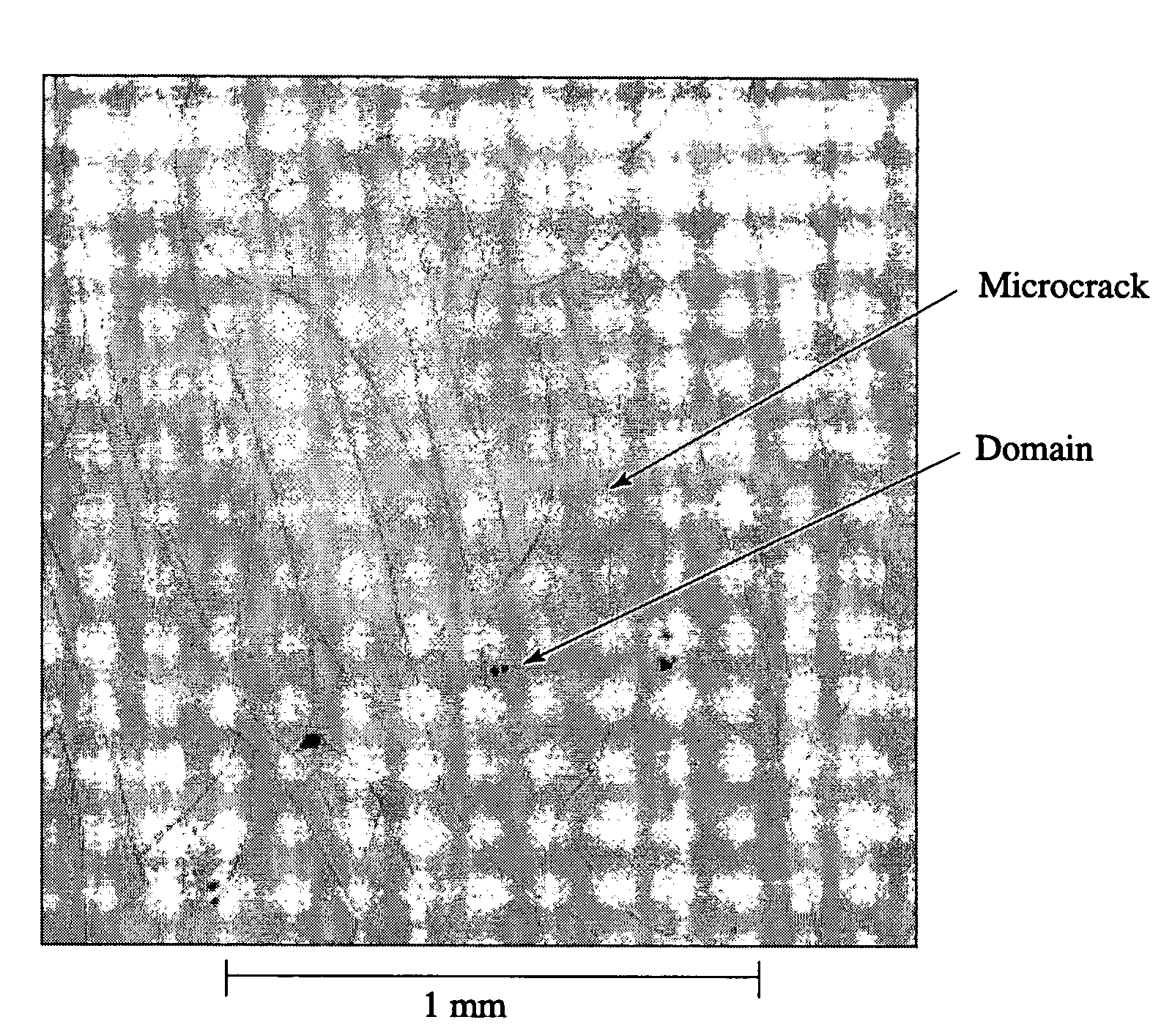

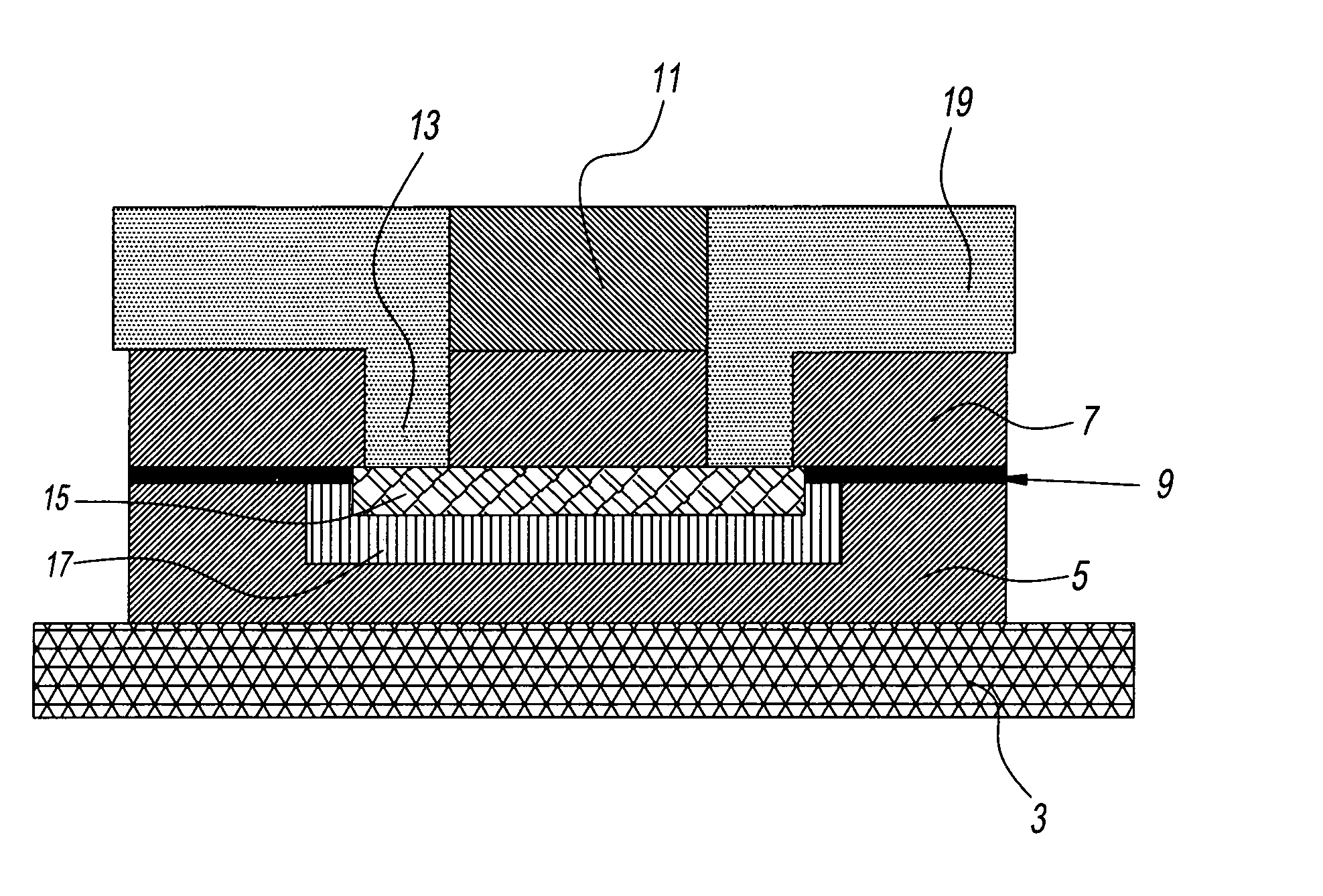

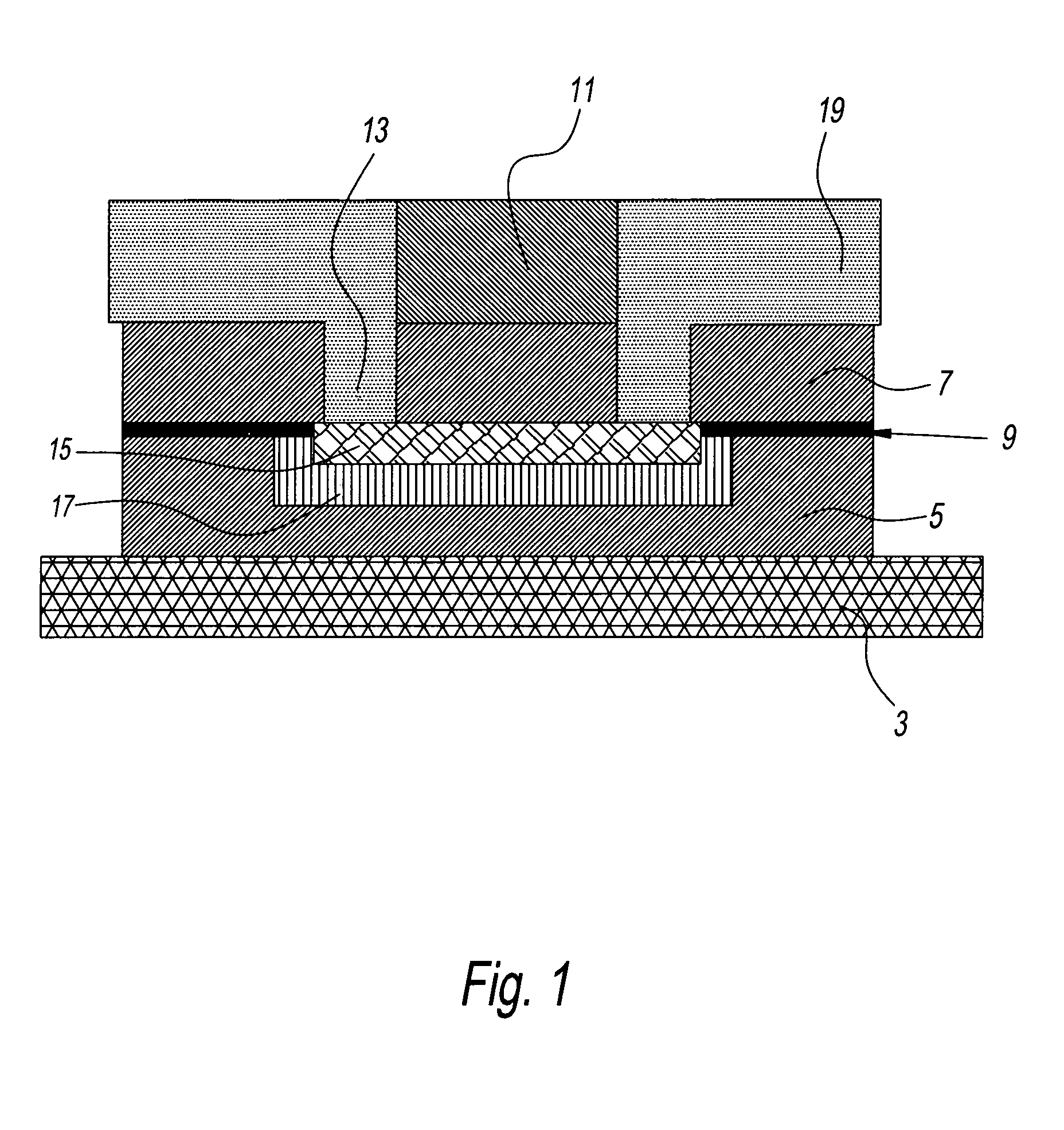

Reprogrammable fuse structure and method

InactiveUS20060278895A1Reduce voltageMinimizes additional processing stepTransistorSemiconductor/solid-state device detailsElectrical resistance and conductanceCrystalline materials

A reversible fuse structure in an integrated circuit is obtained through the implementation of a fuse cell having a short thin line of phase change materials in contact with via and line structures capable of passing current through the line of phase change material (fuse cell). The current is passed through the fuse cell in order to change the material from a less resistive material to a more resistive material through heating the phase change material in the crystalline state to the melting point then quickly quenching the material into the amorphous state. The reversible programming is achieved by passing a lower current through the fuse cell to convert the high resistivity amorphous material to a lower resistivity crystalline material. Appropriate sense-circuitry is integrated to read the information stored in the fuses, wherein said sense circuitry is used to enable or disable circuitry.

Owner:GLOBALFOUNDRIES INC

Magnetic random access memory array with thin conduction electrical read and write lines

InactiveUS7067330B2Data efficientSmall sizeSemiconductor/solid-state device manufacturingDigital storageBit lineCell free

Owner:HEADWAY TECH INC +1

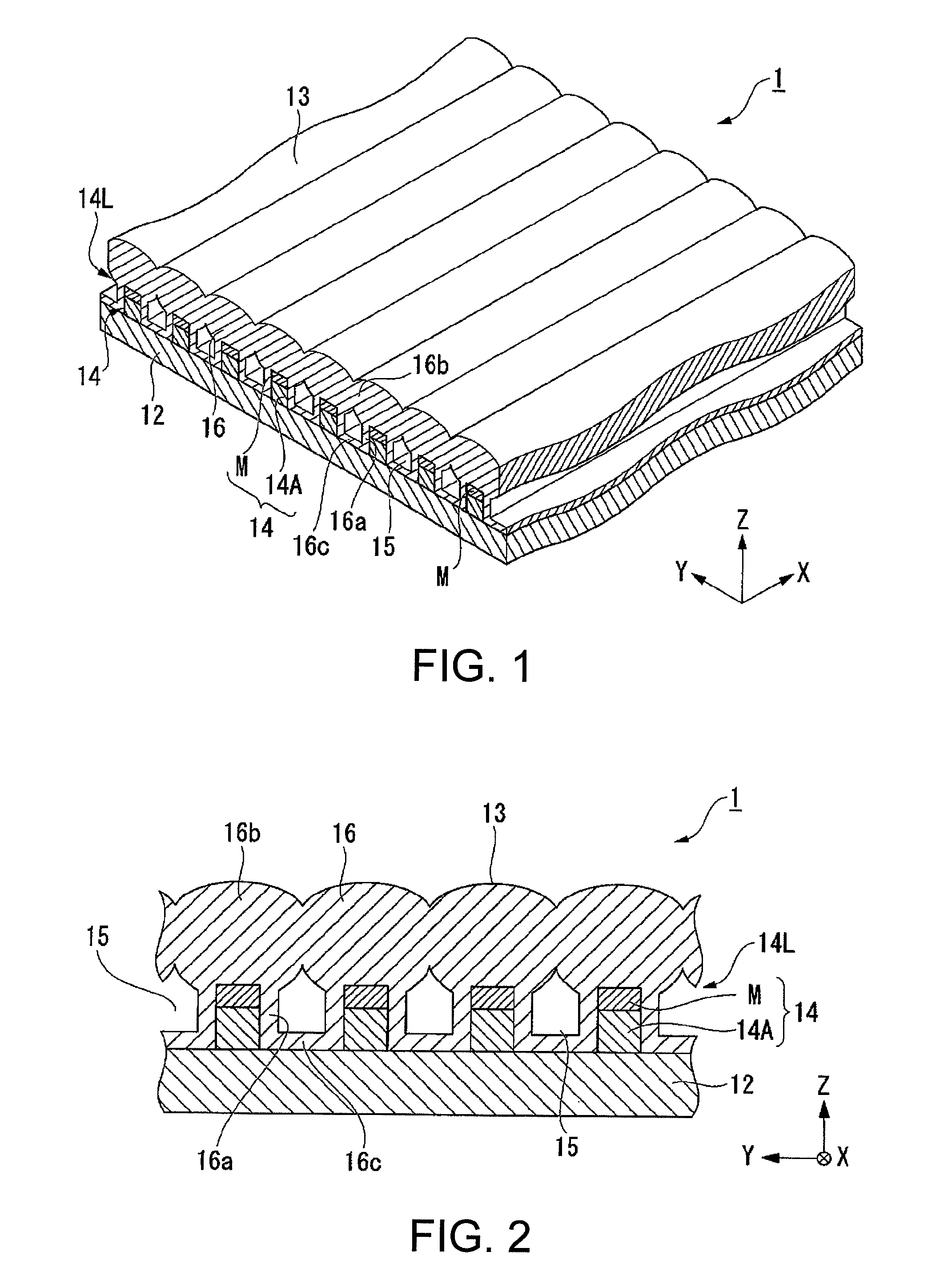

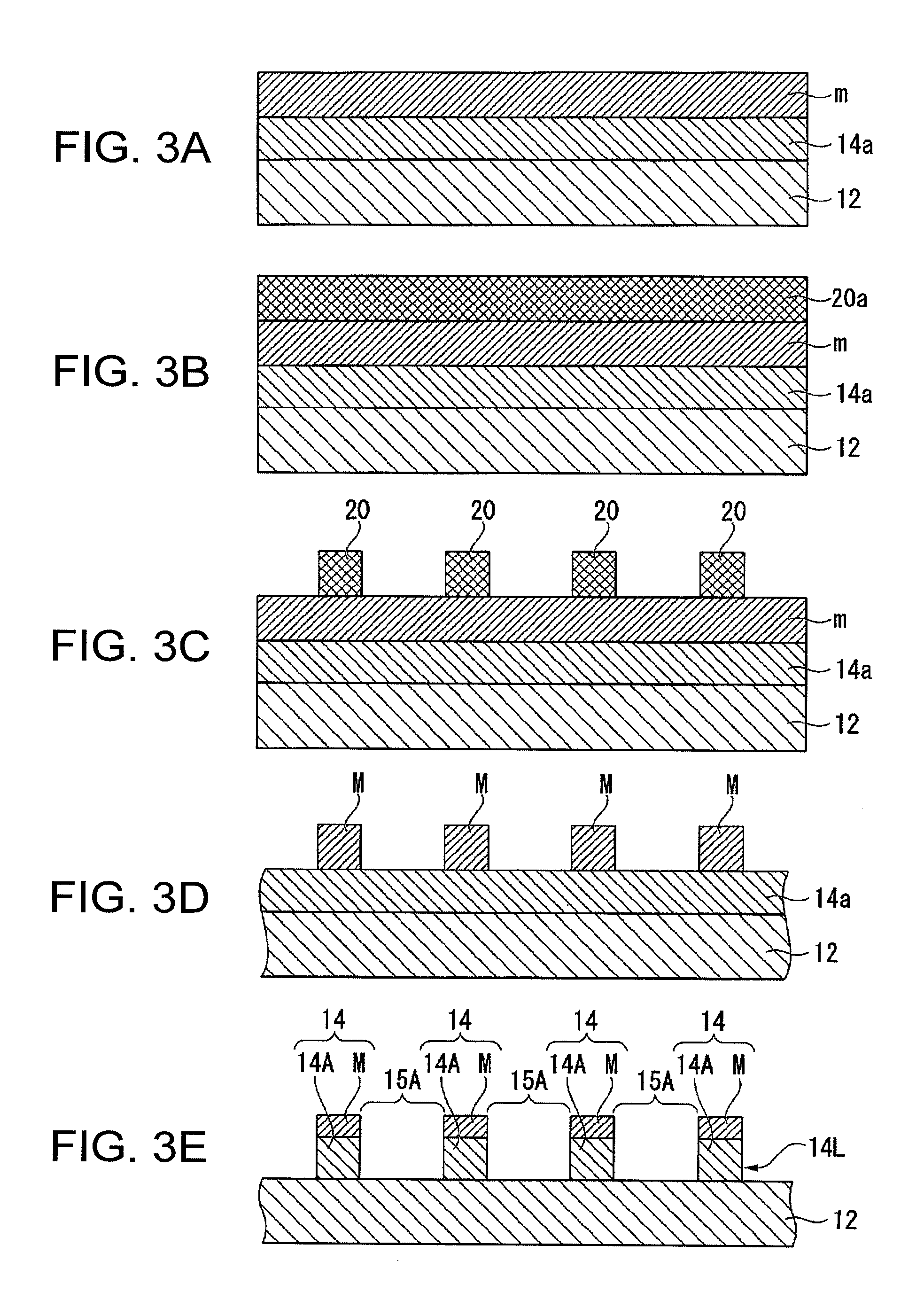

Polarization element, method for manufacturing the same, liquid crystal device, and electronic apparatus

ActiveUS20090066885A1Inhibit deteriorationImprove display qualityPolarising elementsSpecial surfacesTectorial membraneThin line

A polarization element includes: a base; a plurality of metal thin wires provided on the base along a predetermined alignment axis; and a plurality of protection films covering each of the plurality of metal thin wires. In the element, each of the protection films covers an upper end and both sidewalls of one of the metal thin wires. Further, a width of a part, which is on the upper end of the one of the metal thin wires, of the each of the protection films in a direction of the alignment axis is larger than a width obtained by summing a width of the one of the metal thin wires in the direction of the alignment axis and widths of parts, which are on the both sidewalls of the one of the metal thin wires, of the each of the protection films in the direction of the alignment axis.The protection films on sidewalls, which are opposed to each other, of the metal thin wires that are adjacent form an air gap.

Owner:SEIKO EPSON CORP

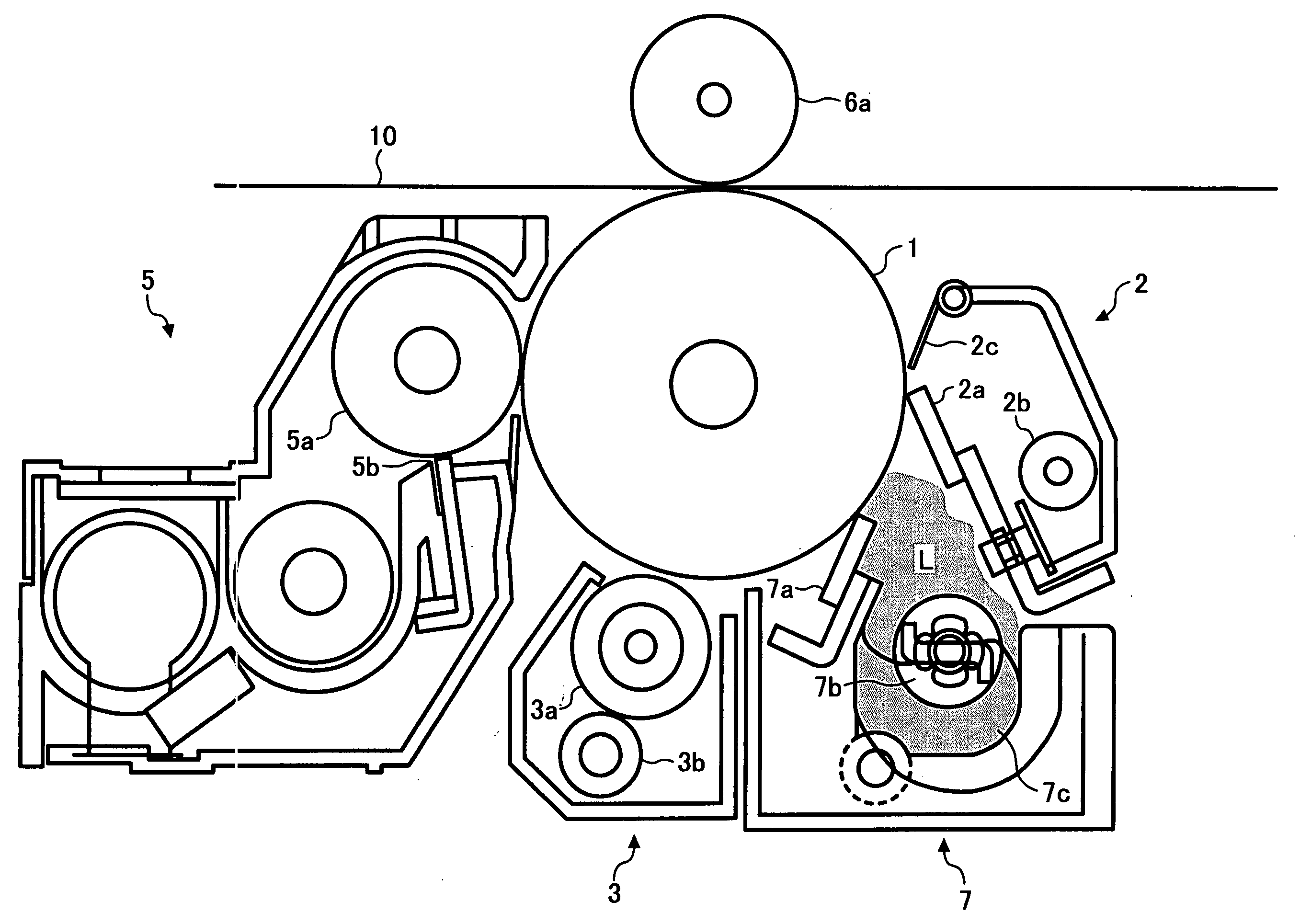

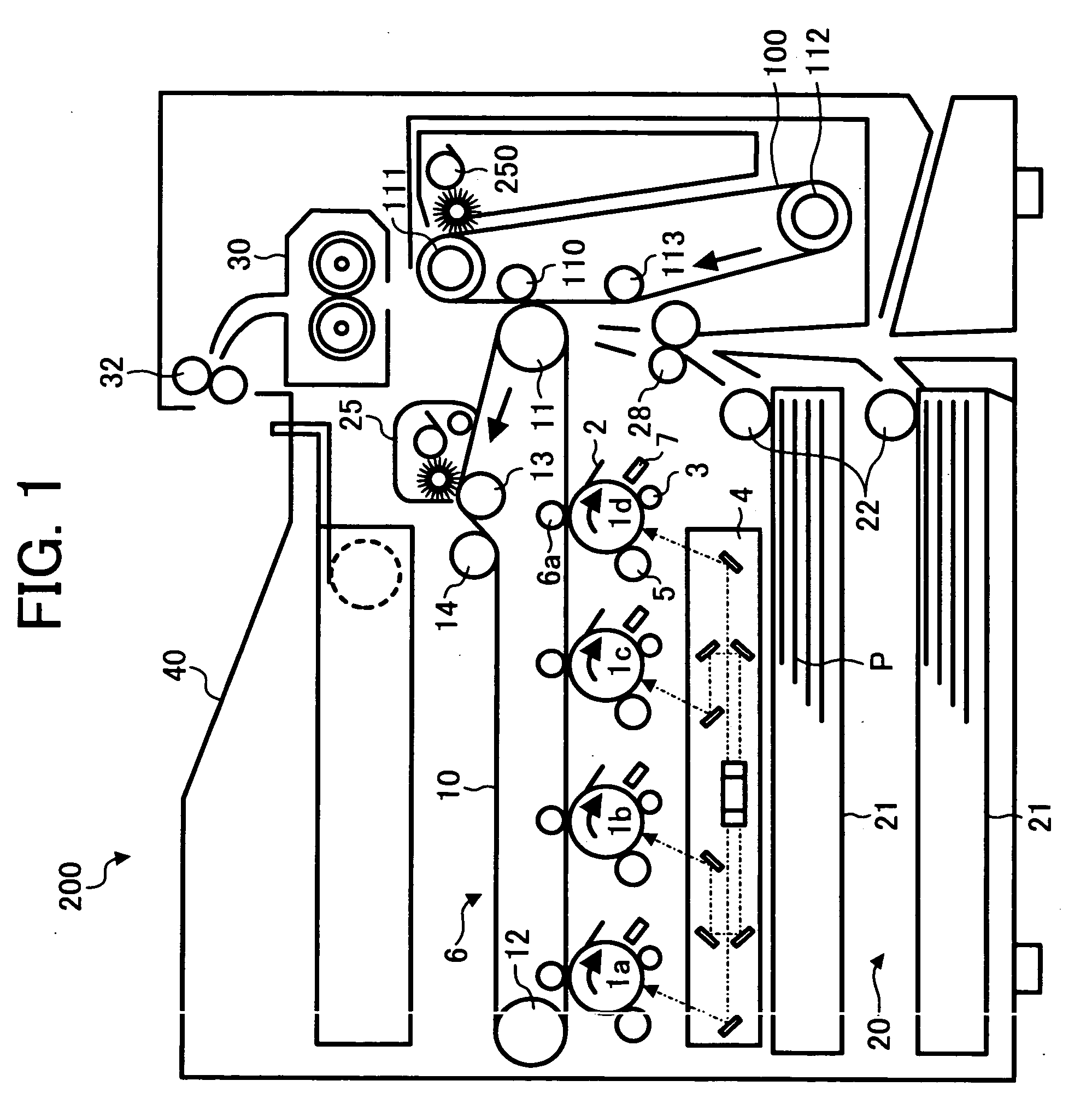

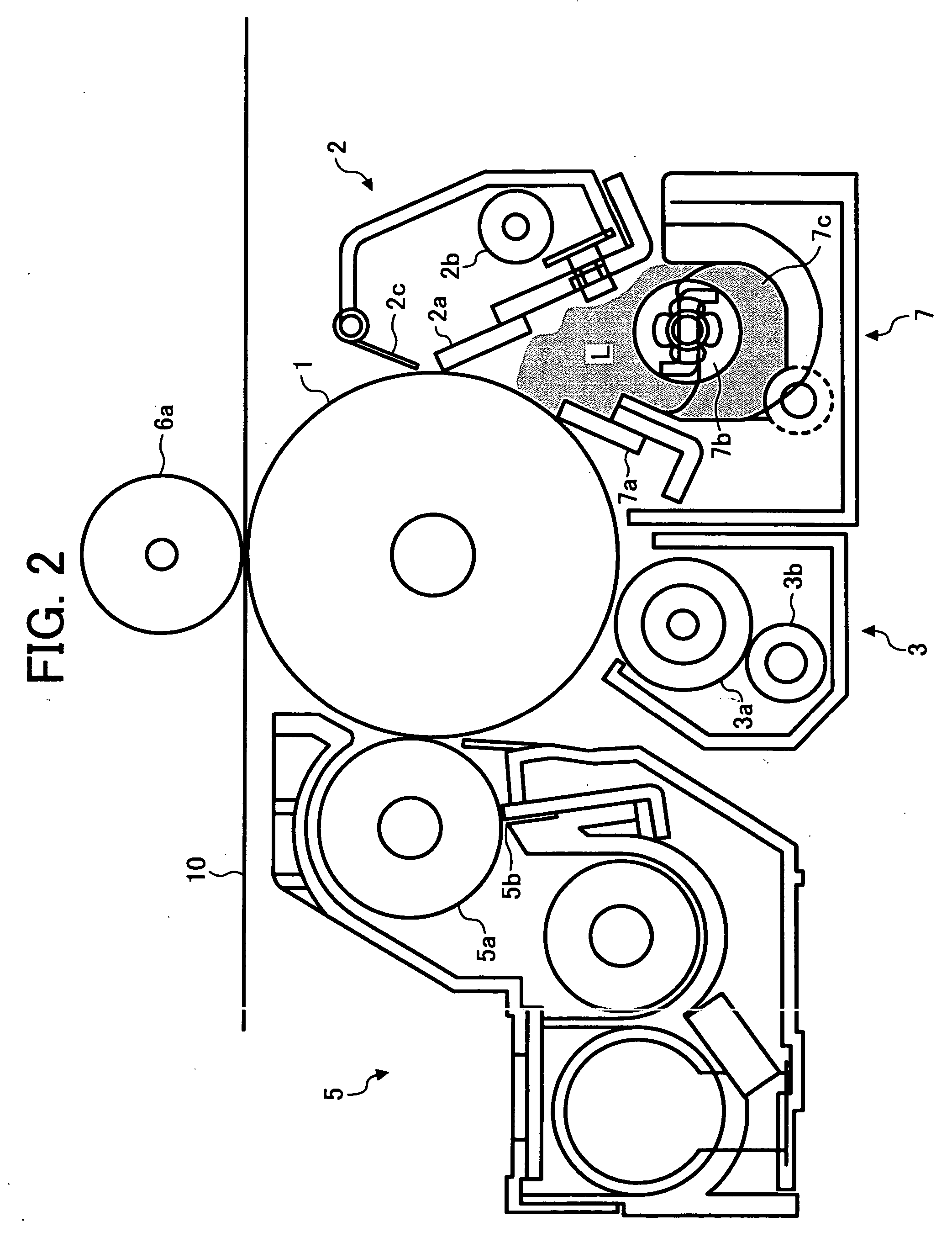

Method and apparatus for image forming capable of using minuscule spherical particles of toner, a process cartridge in use for the apparatus and a toner used in the image forming for obtaining an image with a high thin line reproducibility

ActiveUS20050152722A1Quality improvementExcellent thin line reproducibilityDevelopersElectrographic process apparatusImage formationThin layer

An image forming apparatus includes an image bearing member configured to bear a toner image on a surface thereof. A charging mechanism is configured to uniformly charge the surface of the image bearing member. An intermediate transfer mechanism is configured to transfer the toner image from the image bearing member onto an image receiver. A cleaning mechanism is configured to clean the surface of the image bearing member after the toner image is transferred onto the image receiver. A lubricant supplying mechanism is configured to supply a lubricant contained therein onto the surface of the image bearing member and form a thin layer using a lubricating blade. The lubricant supplying mechanism is disposed between the cleaning mechanism and the charging mechanism.

Owner:RICOH KK

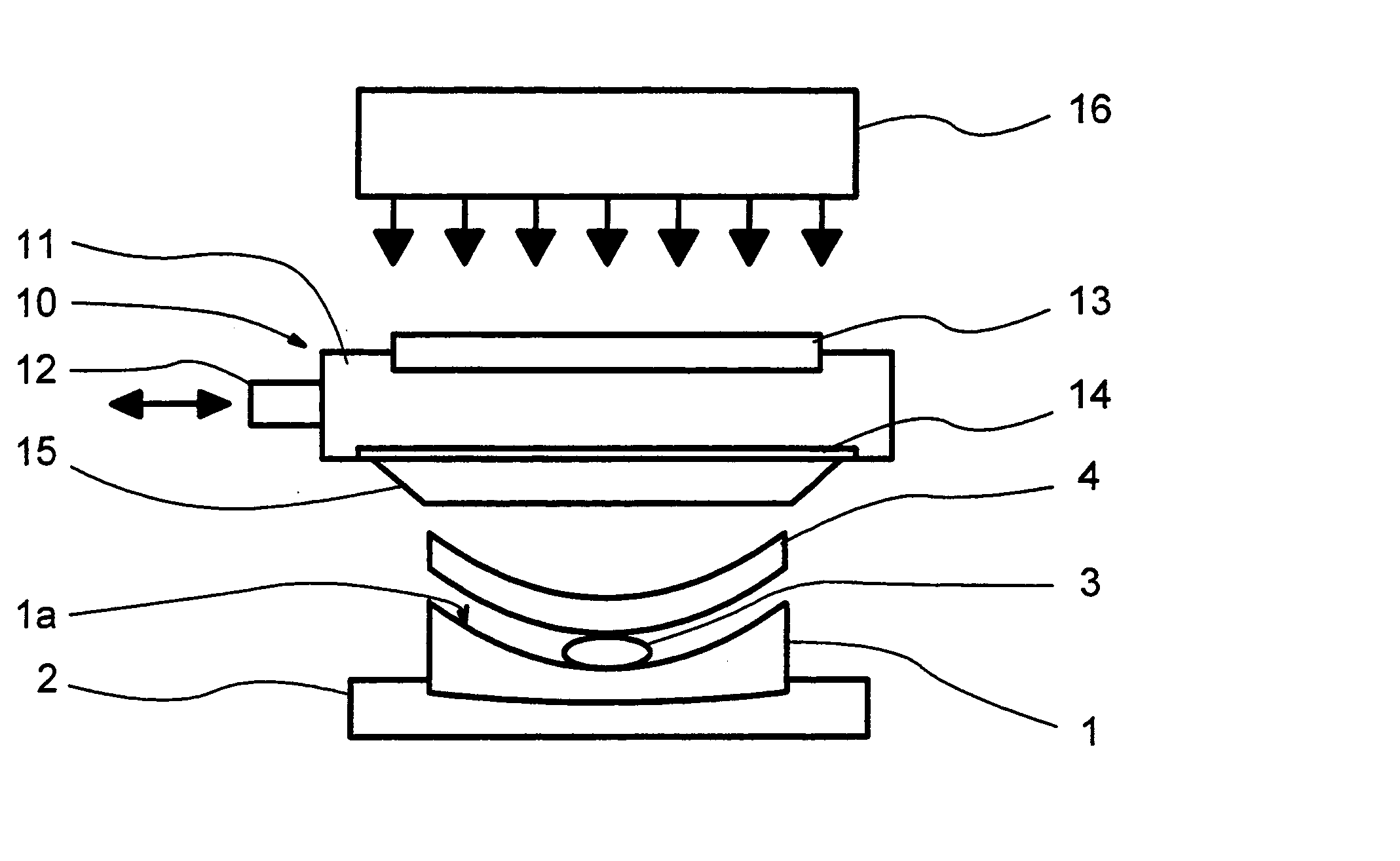

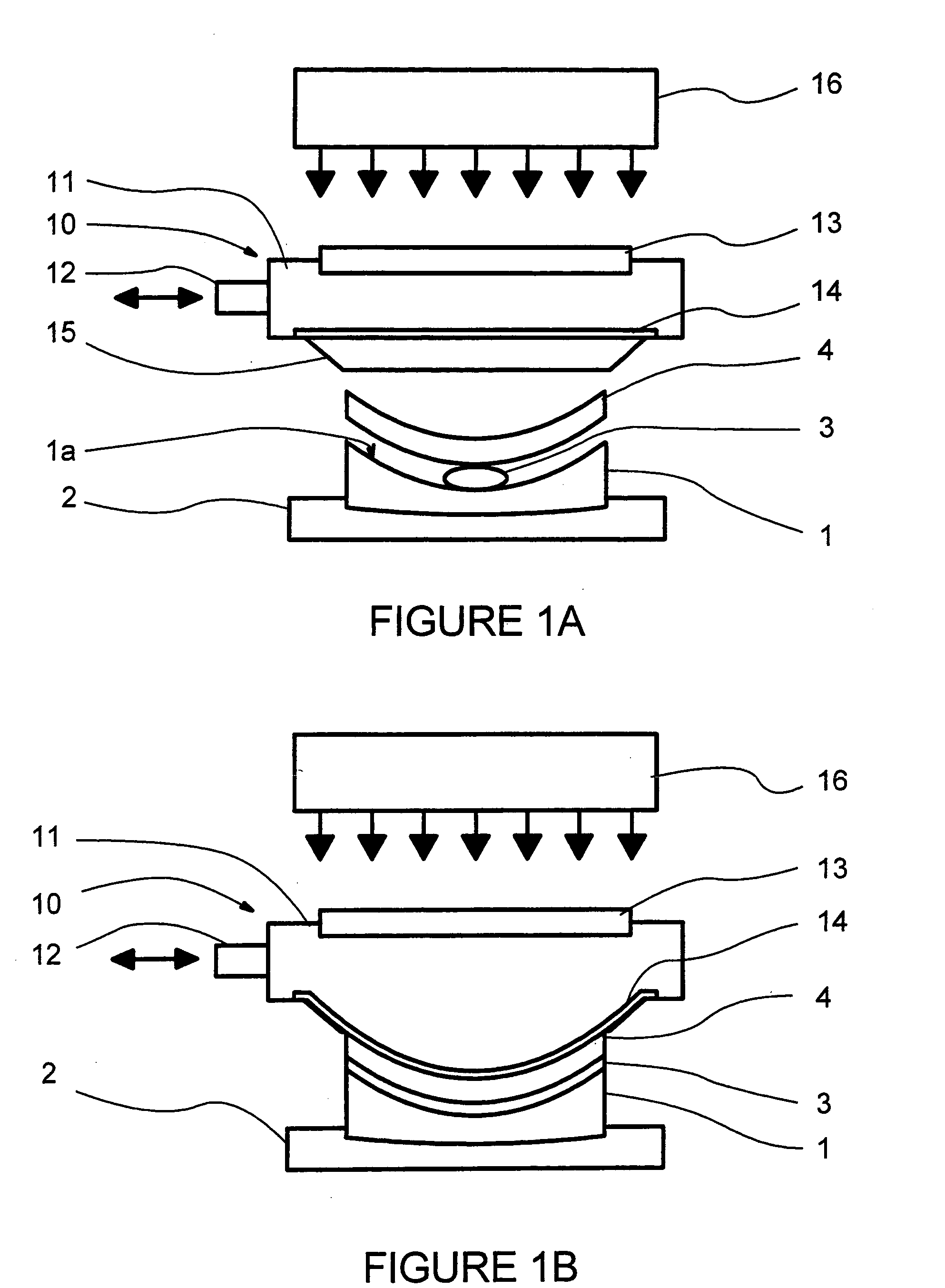

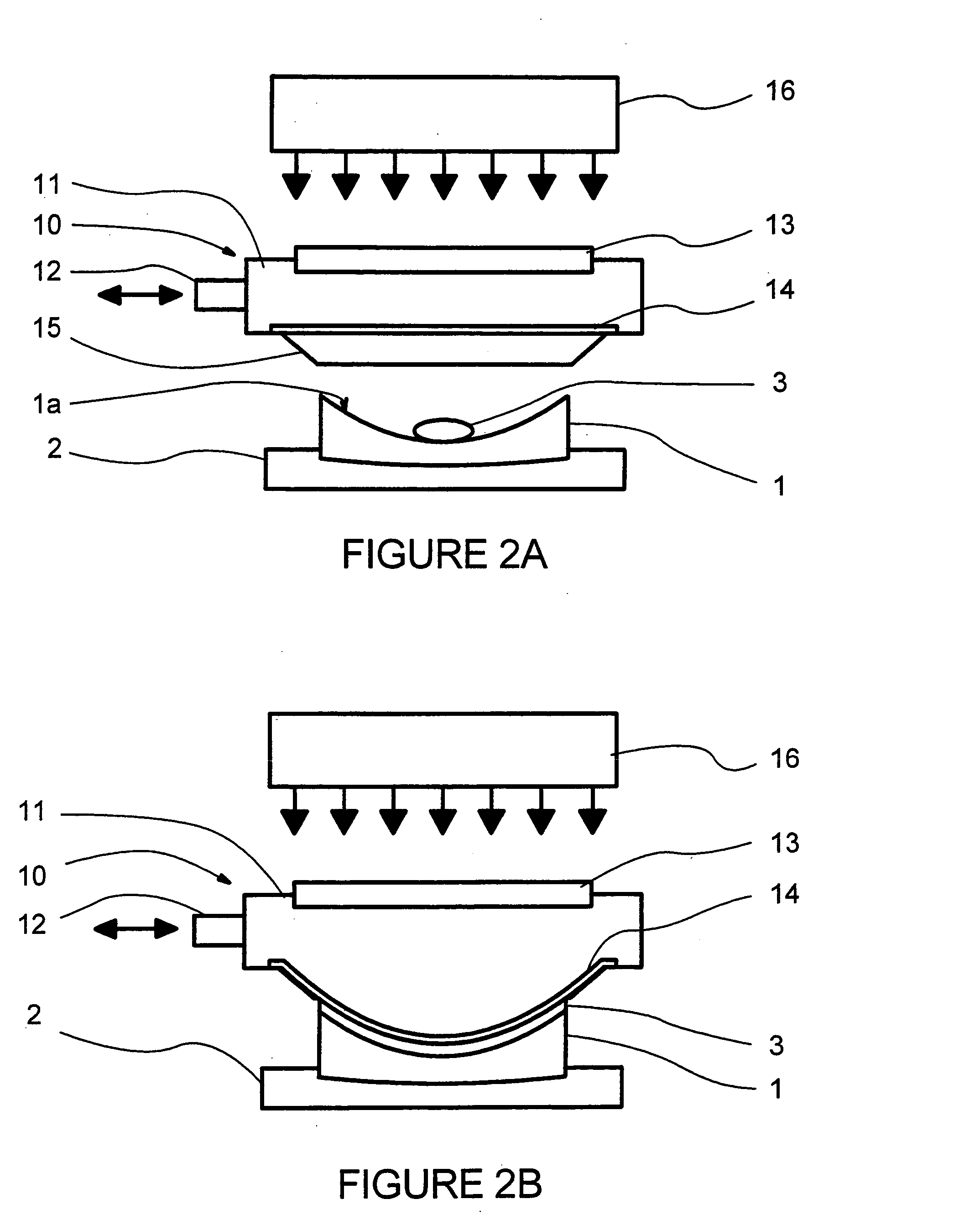

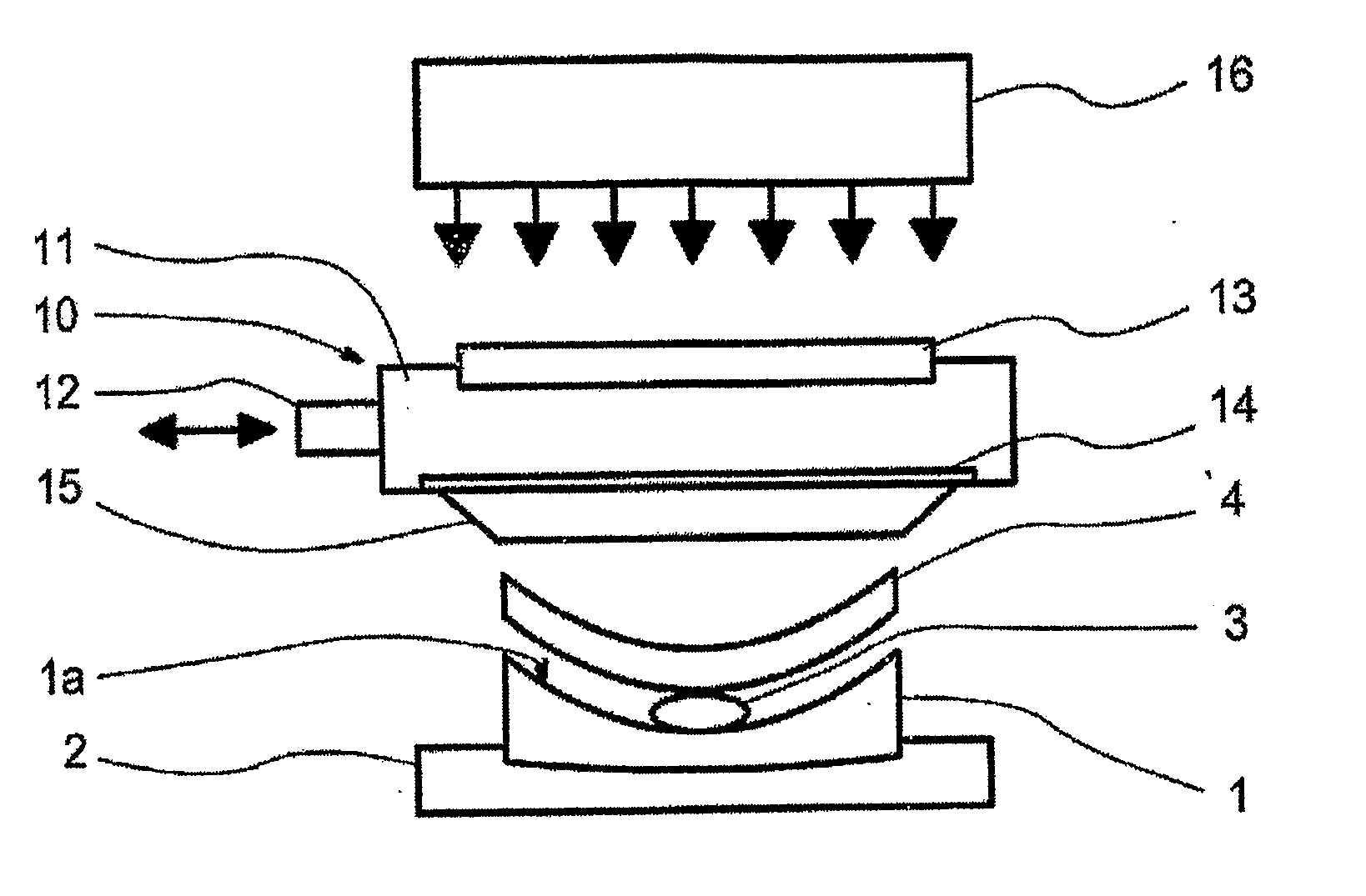

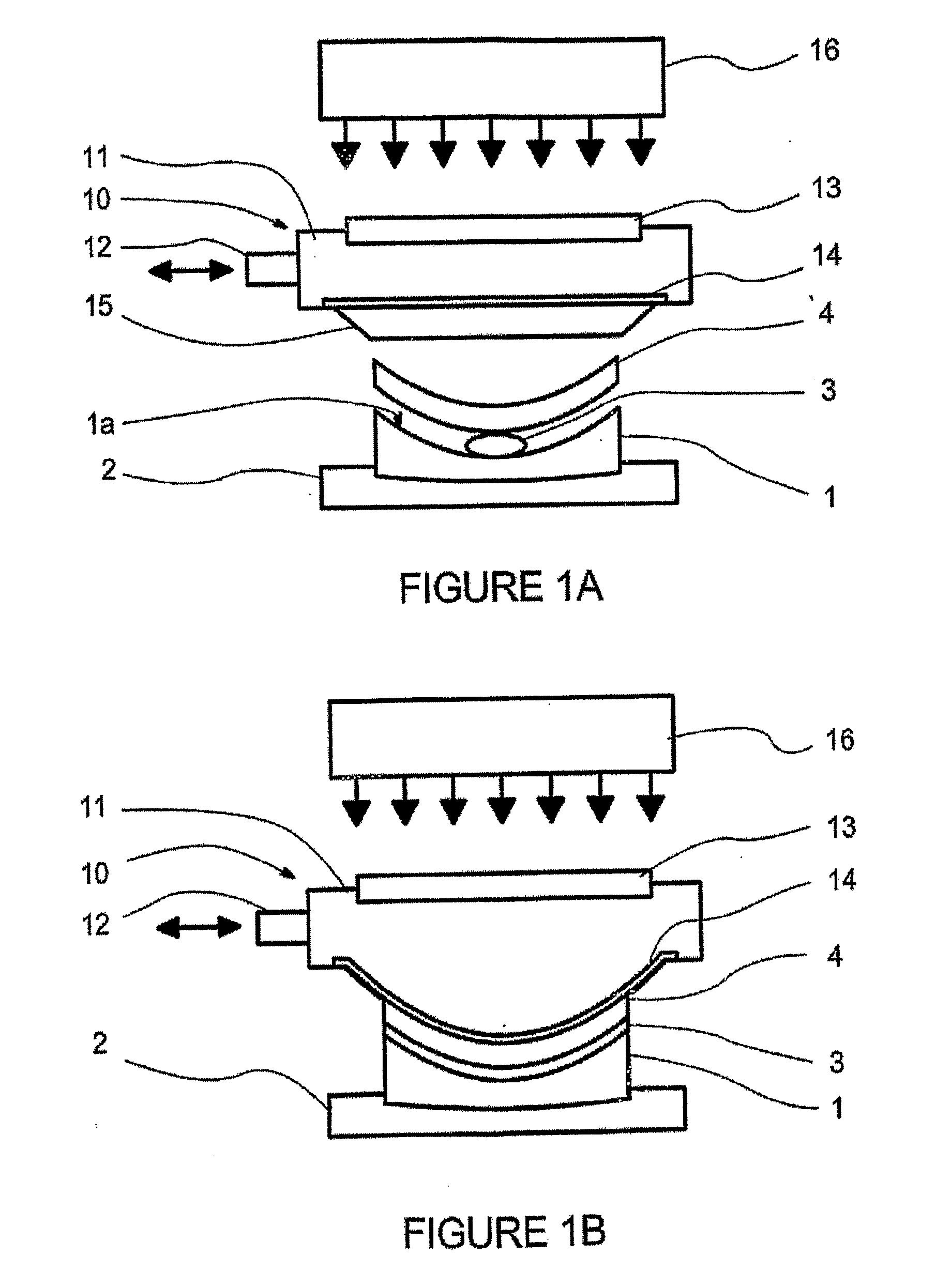

Process for making a coated optical article free of visible fining lines

InactiveUS20050140033A1Fine surfaceImprove optical qualityMouldsOptical articlesLiquid stateEngineering

The invention concerns a process for making a coated optical lens blank free of visible fining lines which comprises: (i) providing an optical article having at least one fined but unpolished geometrically defined main face; (ii) providing a mold part having an internal and external surface; (iii) depositing on said main face of said optical article or on the internal surface of the mold part a requisite amount of a liquid curable coating composition; (iv) moving relatively to each other the optical article and the mold part to either bring the coating composition into contact with the main face of the optical article or into contact with the internal face of the mold part; (v) applying pressure to the mold part to spread the liquid curable coating composition on said main face and form a uniform liquid coating composition layer onto the main face; (vi) curing the liquid coating composition layer; (vii) withdrawing the mold part; and (viii) recovering the free of visible fining lines coated optical article.

Owner:ESSILOR INT CIE GEN DOPTIQUE

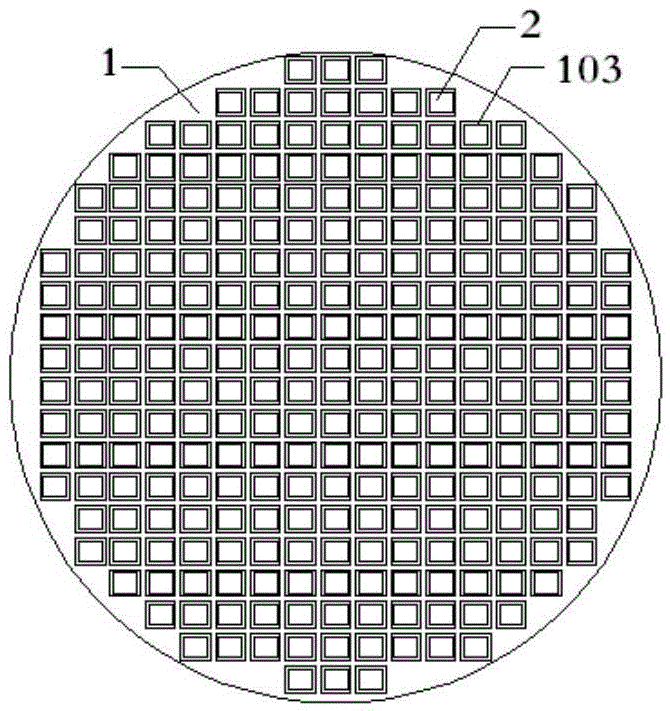

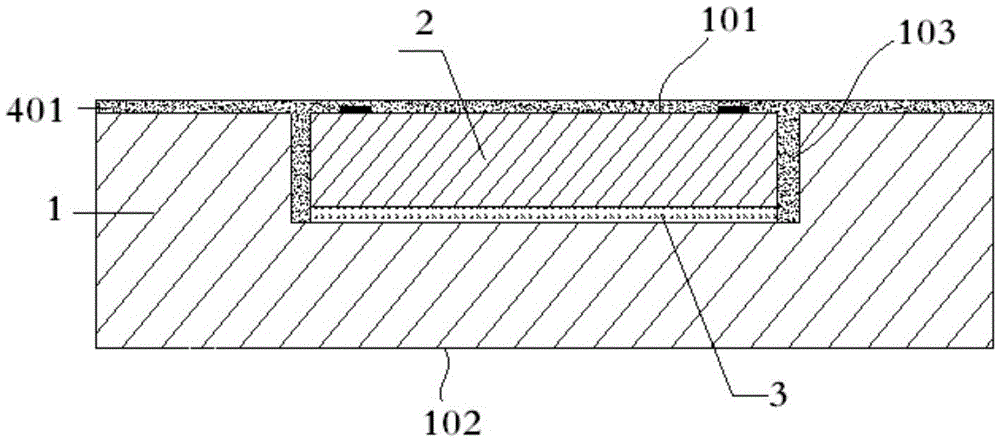

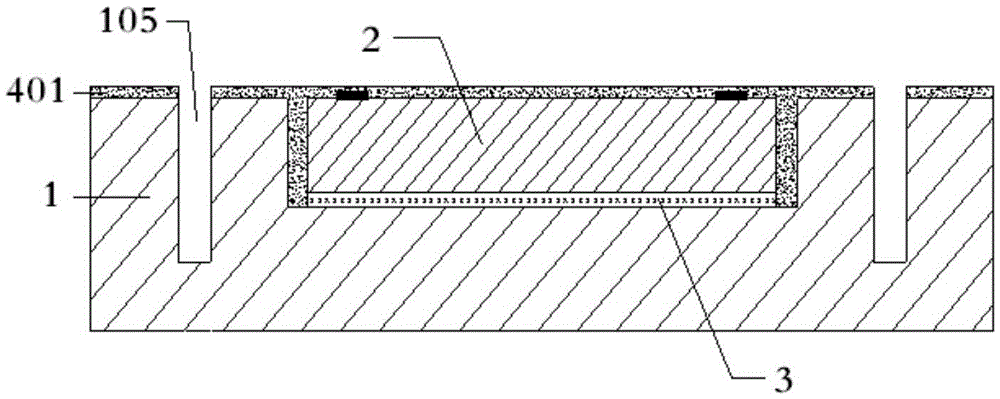

Fan-out type 3D packaging structure embedded in silicon substrate

ActiveCN105575913AImprove reliabilityMiniaturizationSemiconductor/solid-state device detailsSolid-state devicesElectricityHigh density

The invention discloses a fan-out type 3D packaging structure embedded in a silicon substrate. In the packaging structure, a functional chip is embedded into a groove formed in the front surface of the silicon substrate; vertical conductive through holes are formed in a region outside the groove formed in the front surface of the silicon substrate; the functional chip can be used for conducting electricity to the back surface of the silicon substrate; and a rearrangement wire and a welding ball are arranged on the front surface and back surface of the silicon substrate. The structure has the advantages that the thermal expansion coefficients of the silicon substrate and the chip are close so that the packaging structure has good reliability; the structure can realize 3D packaging interconnection; the silicon substrate is adopted, a thin-line and high-density rearrangement wire can be produced, and the requirements on high-density interconnection can be met; and the packaging structure can relatively easily realize miniaturization and thinness, a preparation method is developed and a process is feasible.

Owner:HUATIAN TECH KUNSHAN ELECTRONICS

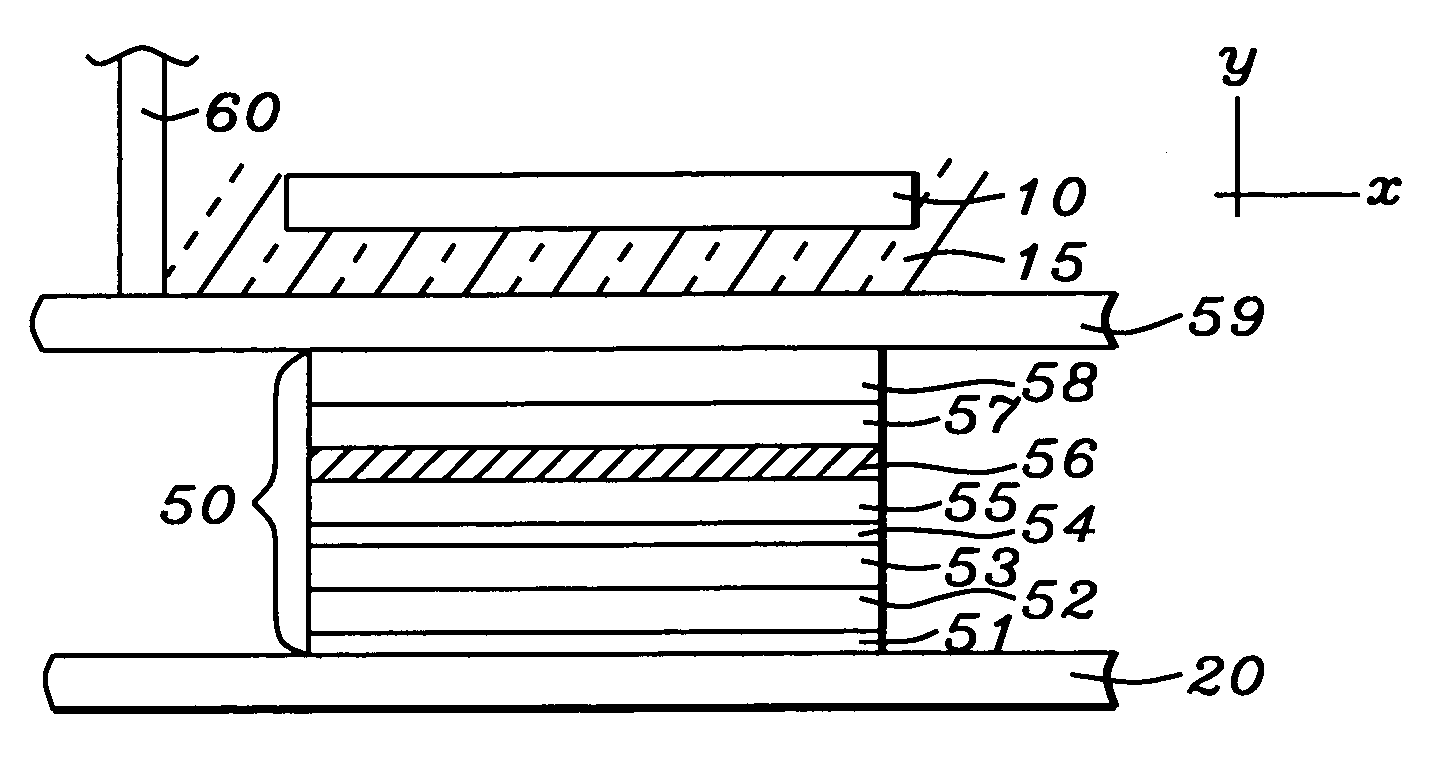

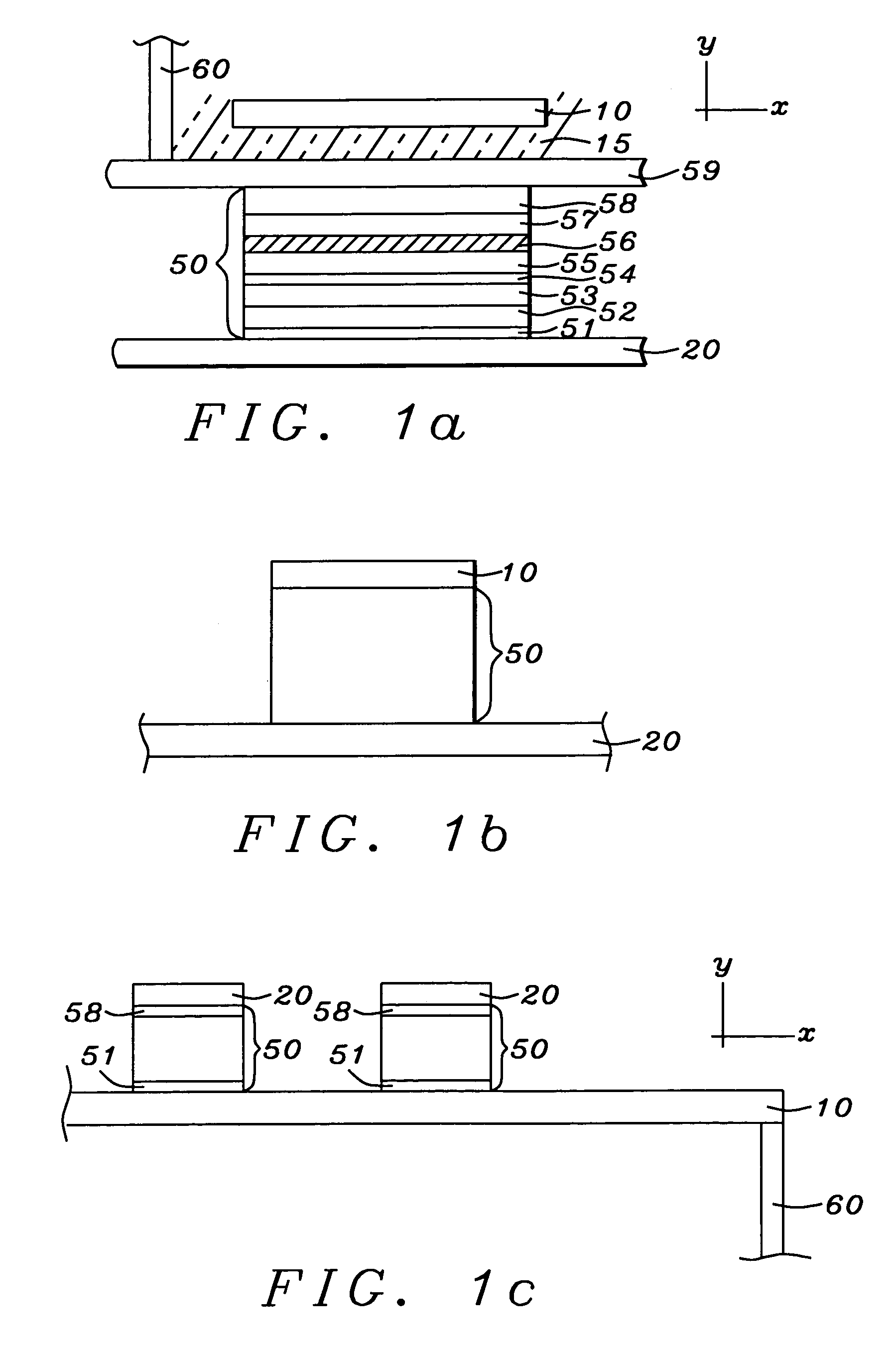

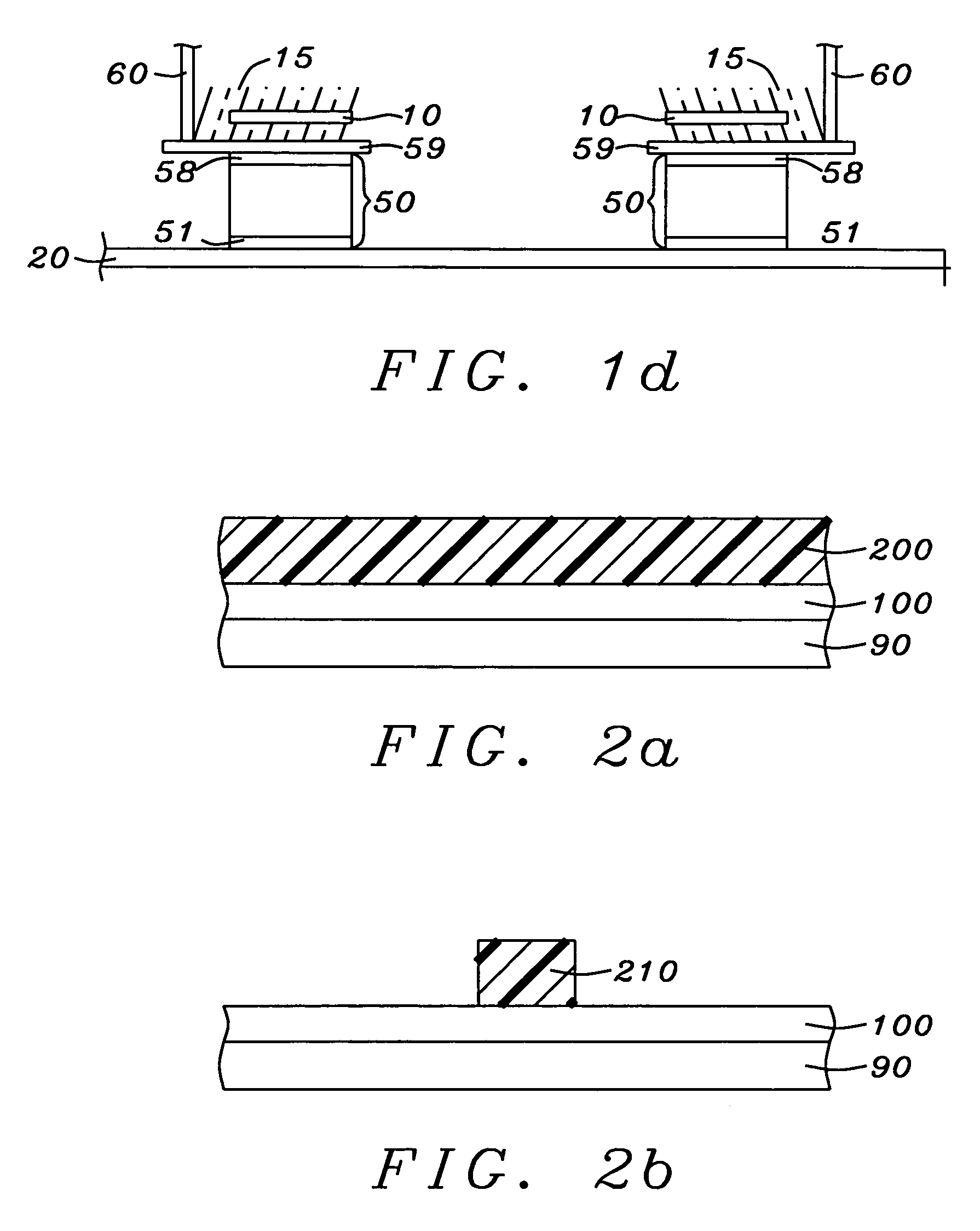

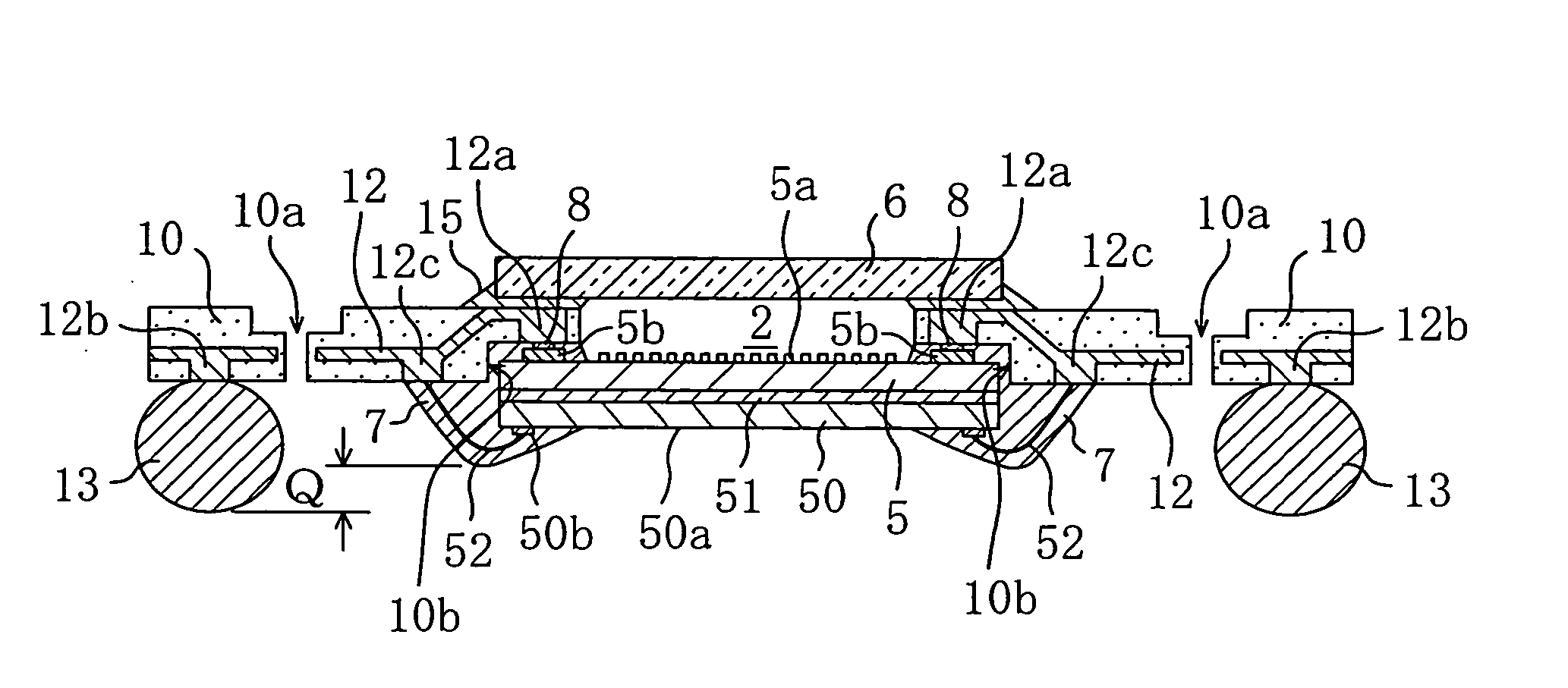

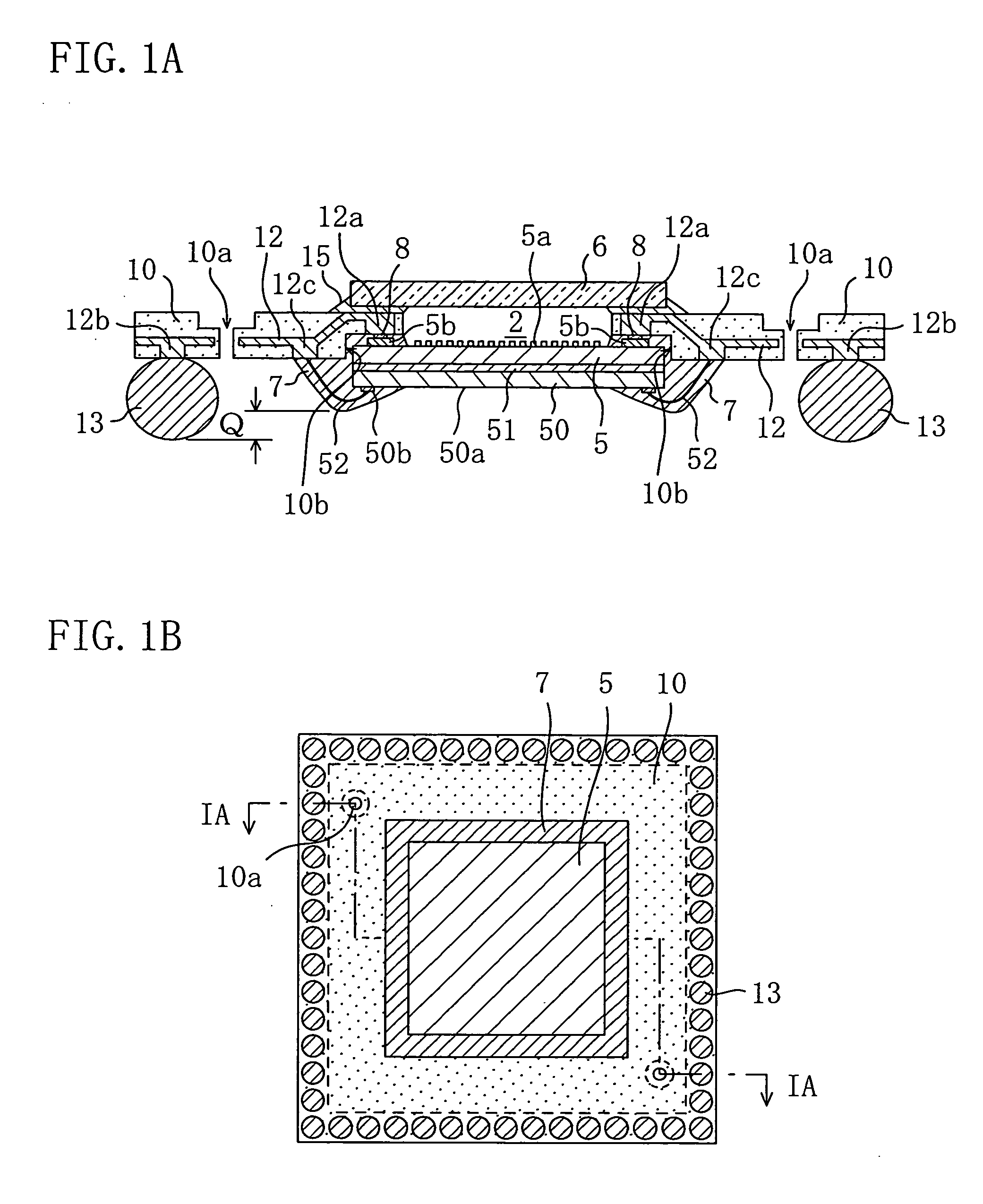

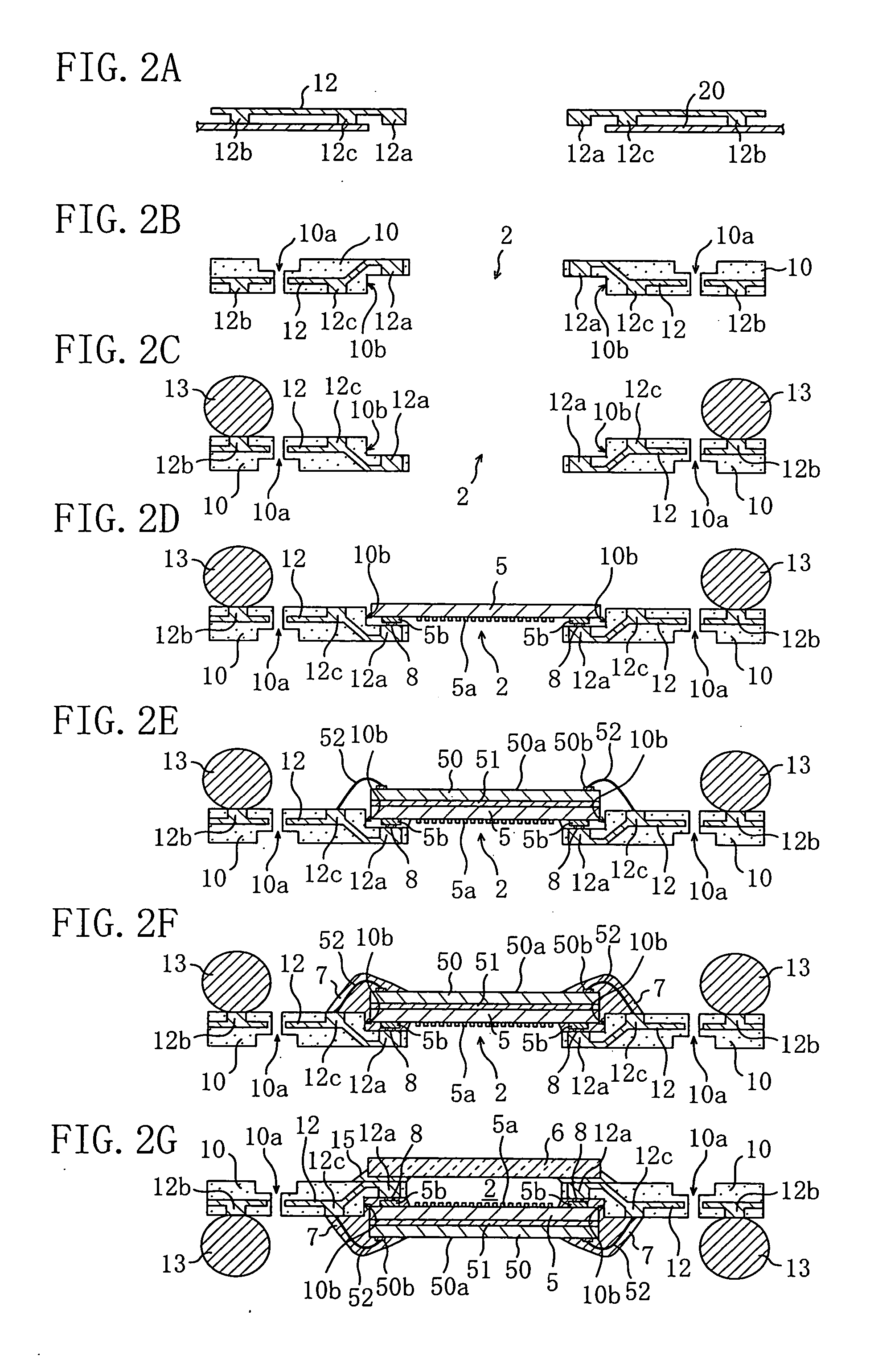

Optical device and method for fabricating the same

InactiveUS20050253211A1Small thicknessEasy to integrateSemiconductor/solid-state device detailsSolid-state devicesEngineeringThin line

An optical device includes a base, an optical element chip attached to the base, an integrated circuit chip attached onto the back surface of the optical element chip, and a translucent member (window member). A wire is buried within the base, and the wire has an internal terminal portion, an external terminal portion, and a midpoint terminal portion. A pad electrode of the optical element chip is connected to the internal terminal portion through a bump, and a pad electrode of the integrated circuit chip is connected to the midpoint terminal portion through a fine metal wire.

Owner:COLLABO INNOVATIONS INC

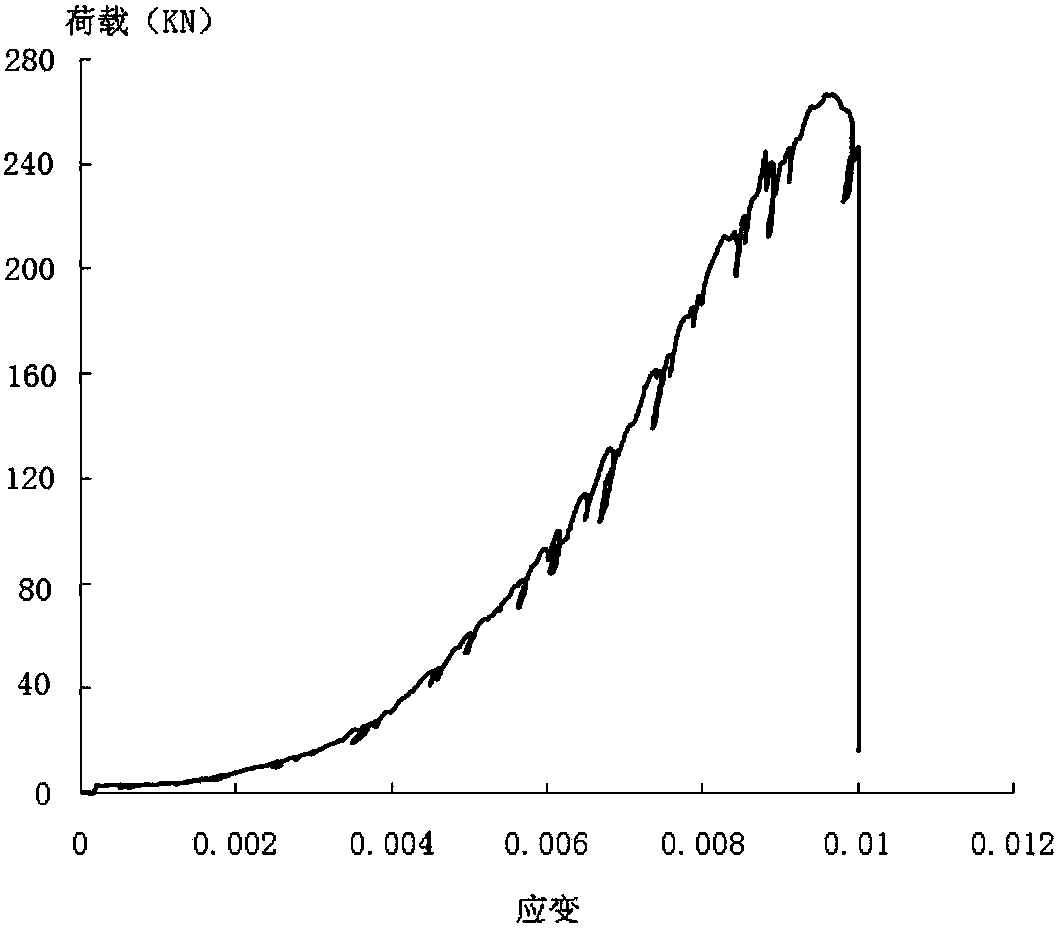

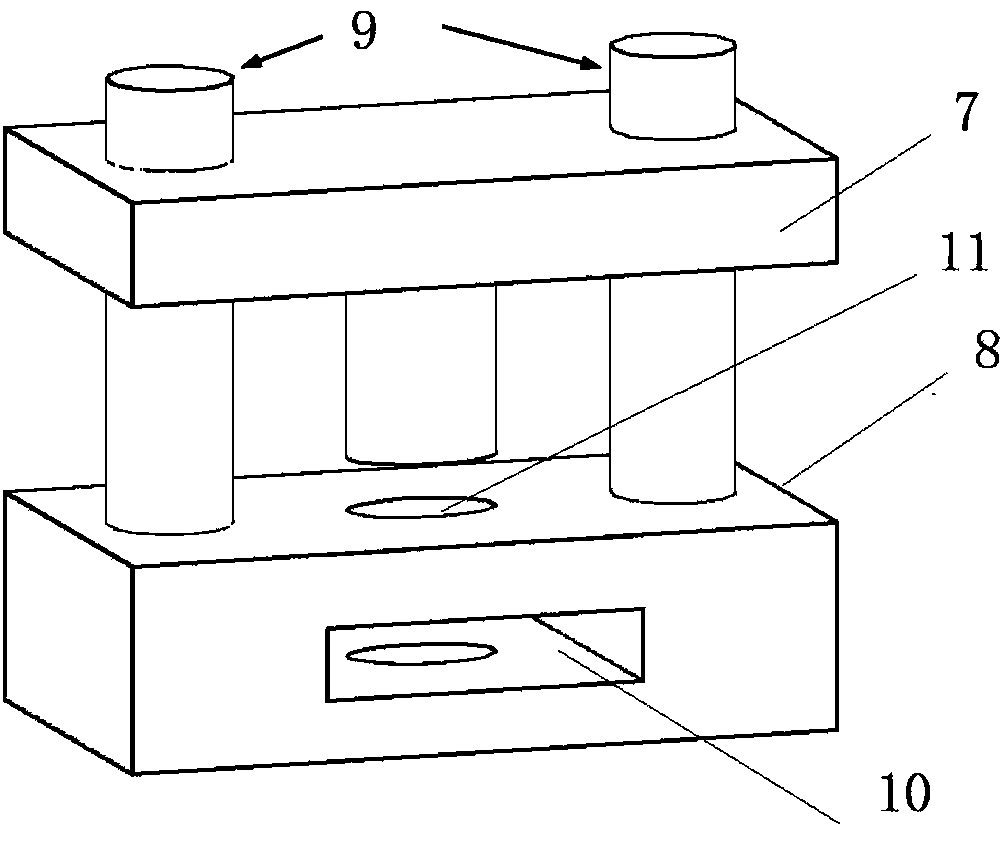

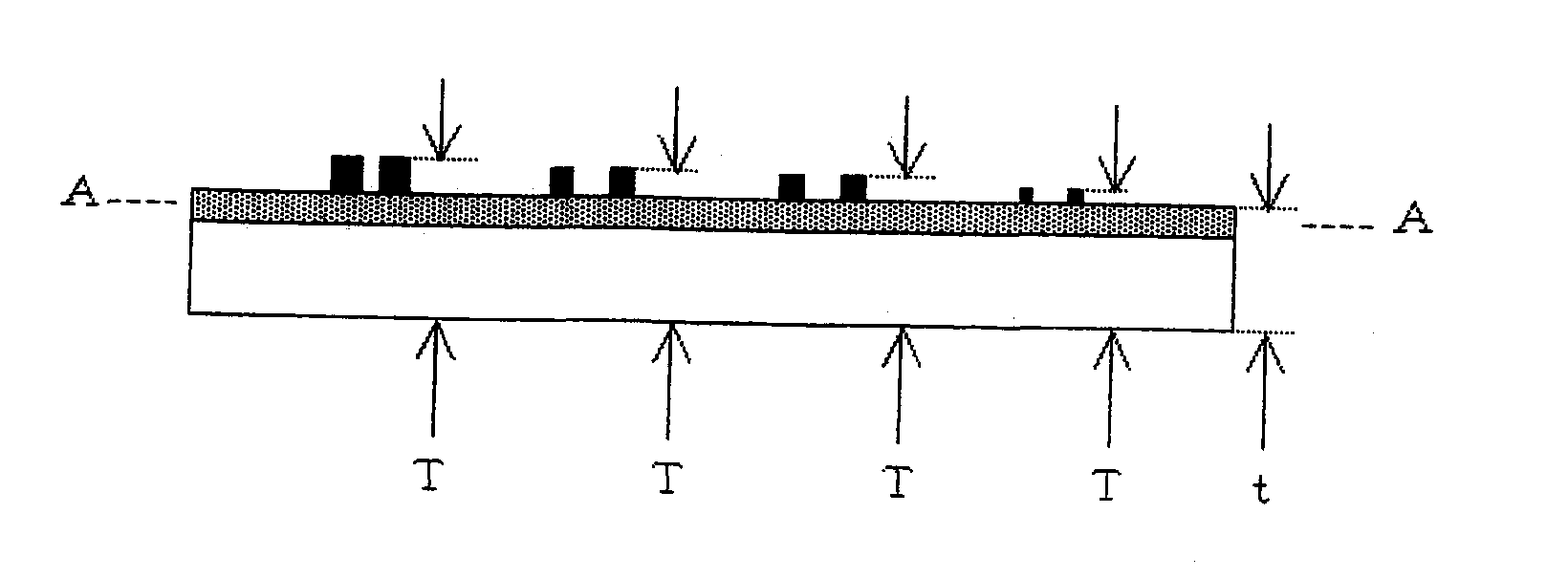

Preparation method of high-brittleness transparent rock material test piece

The invention discloses a preparation method of a high-brittleness transparent rock material test piece. The preparation method comprises the steps of resin material selection, selection of materials for forming three-dimensional prefabricated built-in elliptical cracks, molding and space location. Raw materials comprise CY-39 type resin and YS-T31 type curing agent, wherein the mass ratio of the CY-39 type resin to the YS-T31 type curing agent is 100: 34, or and the volume ratio of the CY-39 type resin to the YS-T31 type curing agent is 100: 41. The preparation method comprises the following general steps: (1) weighing the materials; (2) mixing the materials; and (3) casting, molding and maintaining. Mica plates with the thickness of 0.12mm are used for forming the prefabricated cracks, and an elliptical steel mold with the corresponding size is used for cutting the mica plates into the required accurate size. The preparation method is characterized in that different parts of a left side face plate and a right side face place of the mold are drilled, a thin line is used for pulling, fixing and connecting the prefabricated cracks, the two ends of the thin line are fixed in holes of the two side face plates so as to play a role of accurate location, and three-dimensional crack test pieces with different numbers of cracks at different angles and different opposite locations are manufactured. The test piece prepared by the method has the characteristics of good brittleness, high transparency, easiness for molding and observing crack extension process and the like.

Owner:SHANDONG UNIV

Three-dimensionally patterned natural leather

A natural leather having a three-dimensional pattern formed on the surface thereof is provided. The three-dimensionally patterned natural leather permits a minute three-dimensional expression such as small dots and thin lines, is high in the degree of freedom of the three-dimensional pattern, can retain the three-dimensional pattern even with the lapse of time and retain the characteristics peculiar to the natural leather. The three-dimensional pattern is formed by a resin portion which covers by coating the surface of an undercoating layer of the natural leather partially in a pattern shape. The resin portion has a maximum thickness of 20 to 400 μm.

Owner:SEIREN CO LTD

Manufacturing process for step circuit of PCB (Printed Circuit Board)

InactiveCN102651946AReduce copper thickness dropEliminate poor quality defectsConductive material chemical/electrolytical removalProduction scheduleEngineering

The invention discloses a manufacturing process for a step circuit of a PCB (Printed Circuit Board). According to the manufacturing process, different film patterns are adopted twice for manufacturing the circuit, during the primary film pattern circuit manufacture, a positive film circuit pattern is adopted, compensation is carried out a film substrate circuit at different positions according to copper thickness so as to manufacture a special circuit, and sunk copper plate electrification is carried out on the special circuit, so that the copper thickness meets the requirement; then board grinding is carried out by a twice board grinding mode so as to reduce the copper thickness difference of step positions; a dry film is enabled to be fully combined with the step positions by virtue of a film attaching and air compressing mode; and finally, normal circuit pattern manufacturing is carried out by utilizing a high-precision LDI (Laser Direct Imaging) exposure machine. Compared with the prior art, the manufacturing process for the step circuit can be used for eliminating the defects of open circuit at the position of the step circuit, notches, large deckle edges, serious lateral erosion, halfway etching and poor quality of thin lines and the like existing in the step circuit manufacturing process, improving the production efficiency and the production quality, quickening the production schedule and lowering the production cost.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

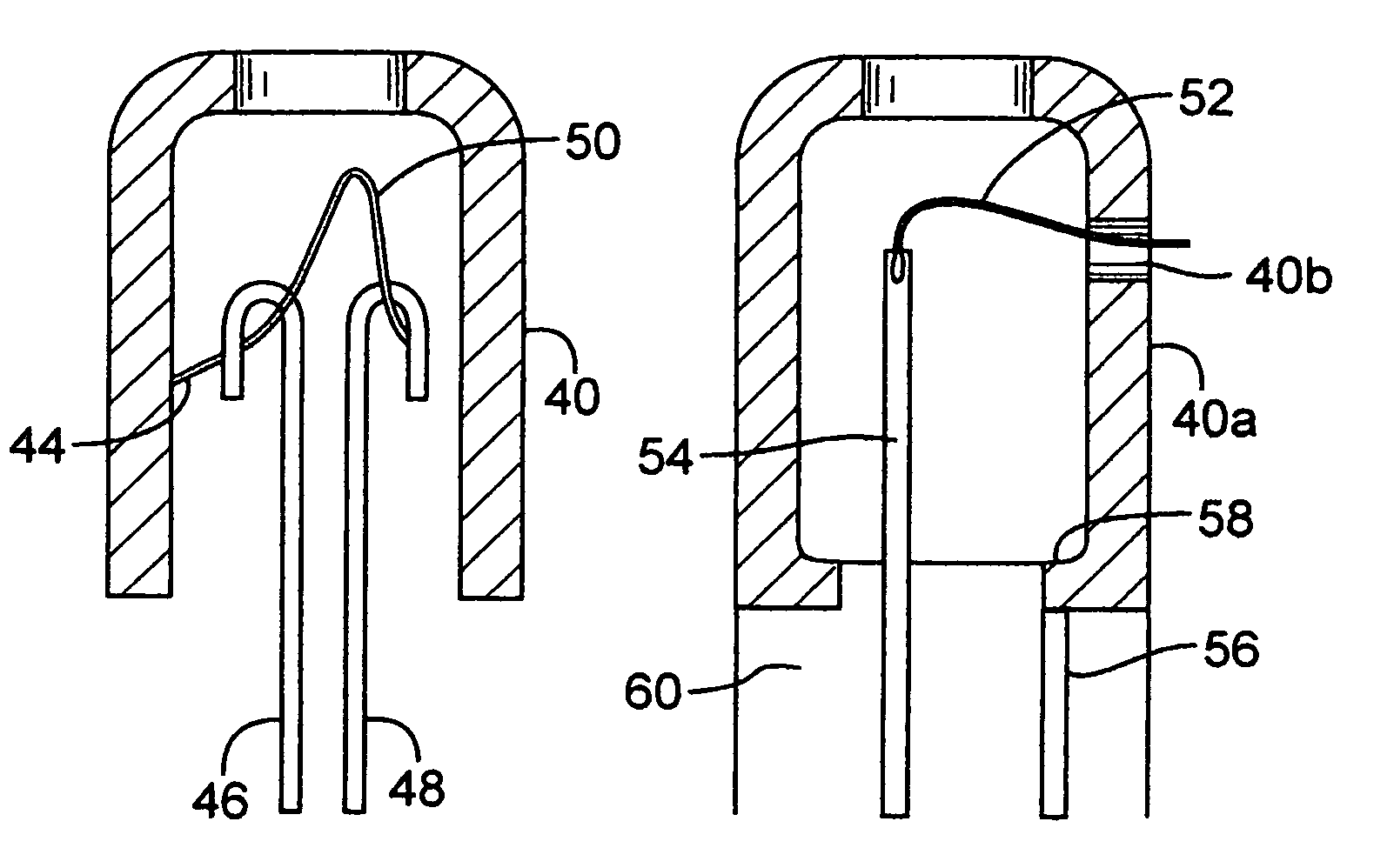

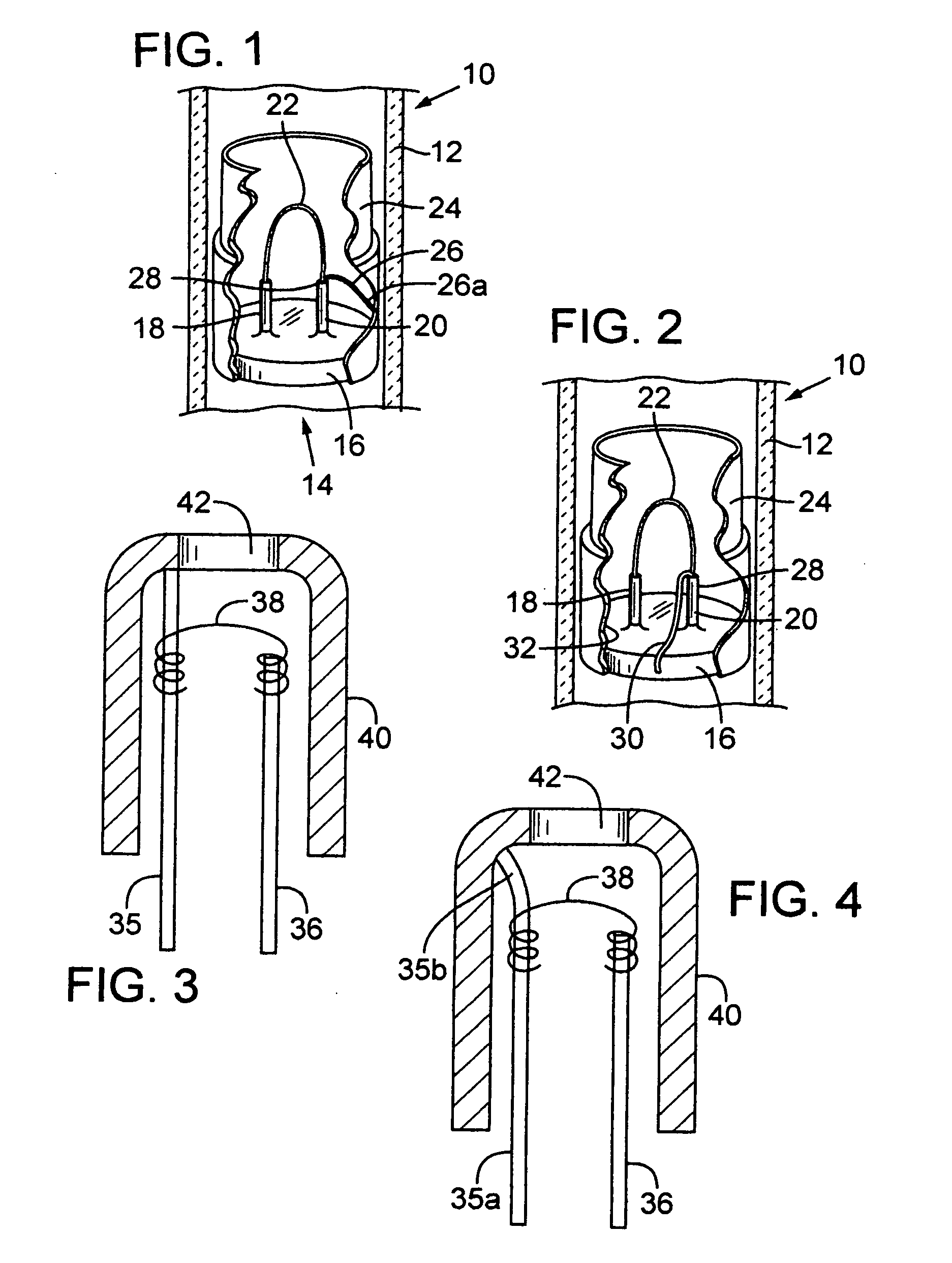

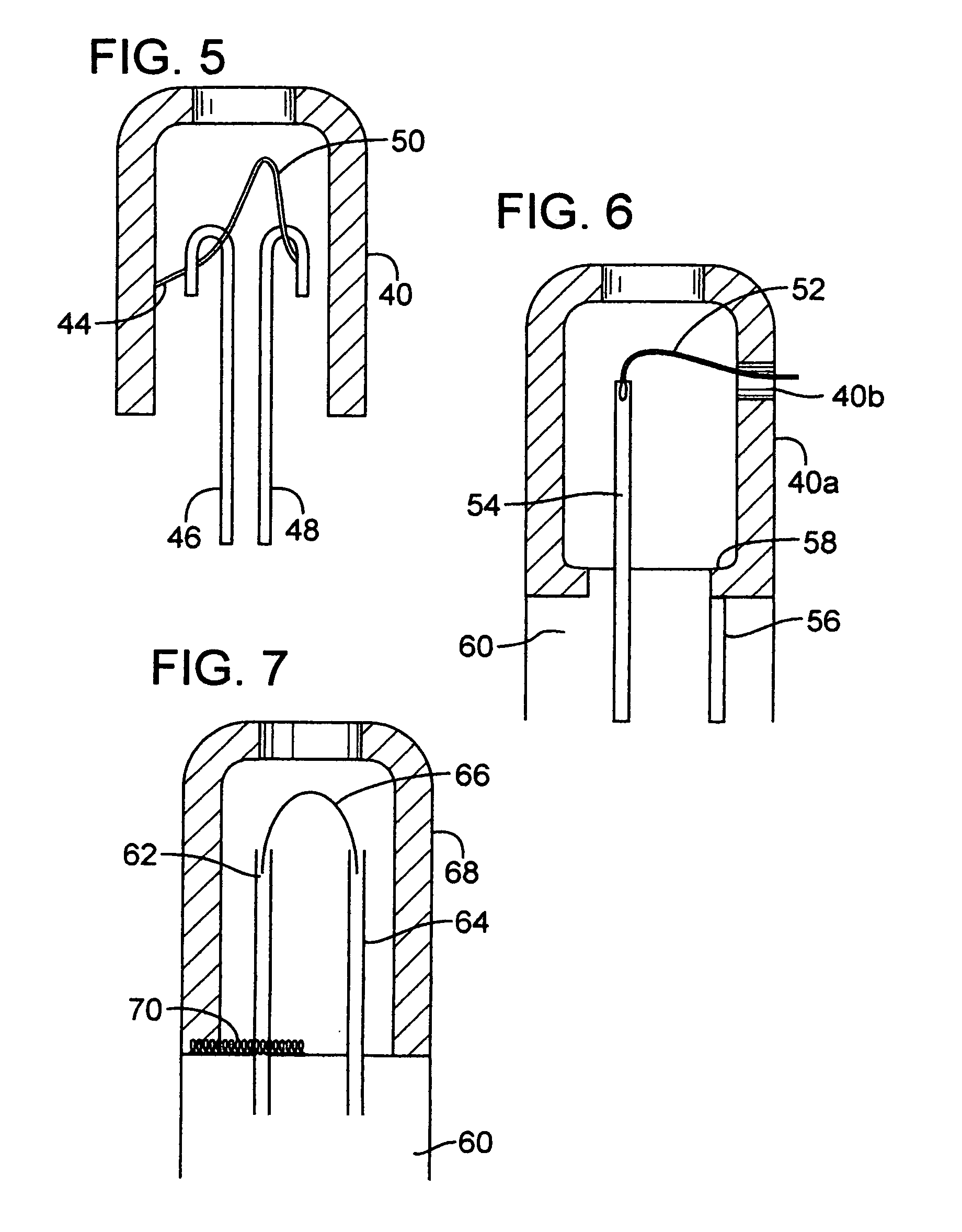

Extractor cup on a miniature x-ray tube

ActiveUS7130380B2Increase resistanceElectrode assembly support/mounting/spacing/insulationIncadescent body mountings/supportEvaporationThin line

Methods for connecting electrical potential to an extractor cup at the cathode of a miniature x-ray tube are disclosed. The various connection schemes are designed to form a rugged and conveniently manufacturable connection between the metal extractor cup and one side of the cathode filament, so that the extractor cup shapes the path of electrons as desired en route to the anode of the tube. Some of the disclosed connections involve evaporation of conductive metal or other materials off the filament when the filament is first activated. Others involve applying a paste or paint conductive precursor directly to a base to connect a post and the extractor, the paste being heat-cured after the completion of assembly. Others involve a fine wire or spring strip from one filament post to the walls of the extractor cup. Other schemes include welded or brazed wires or foil, crimping, pinching, swaging and other connections, all made inside the tube enclosure.

Owner:NUCLETRON OPERATIONS +1

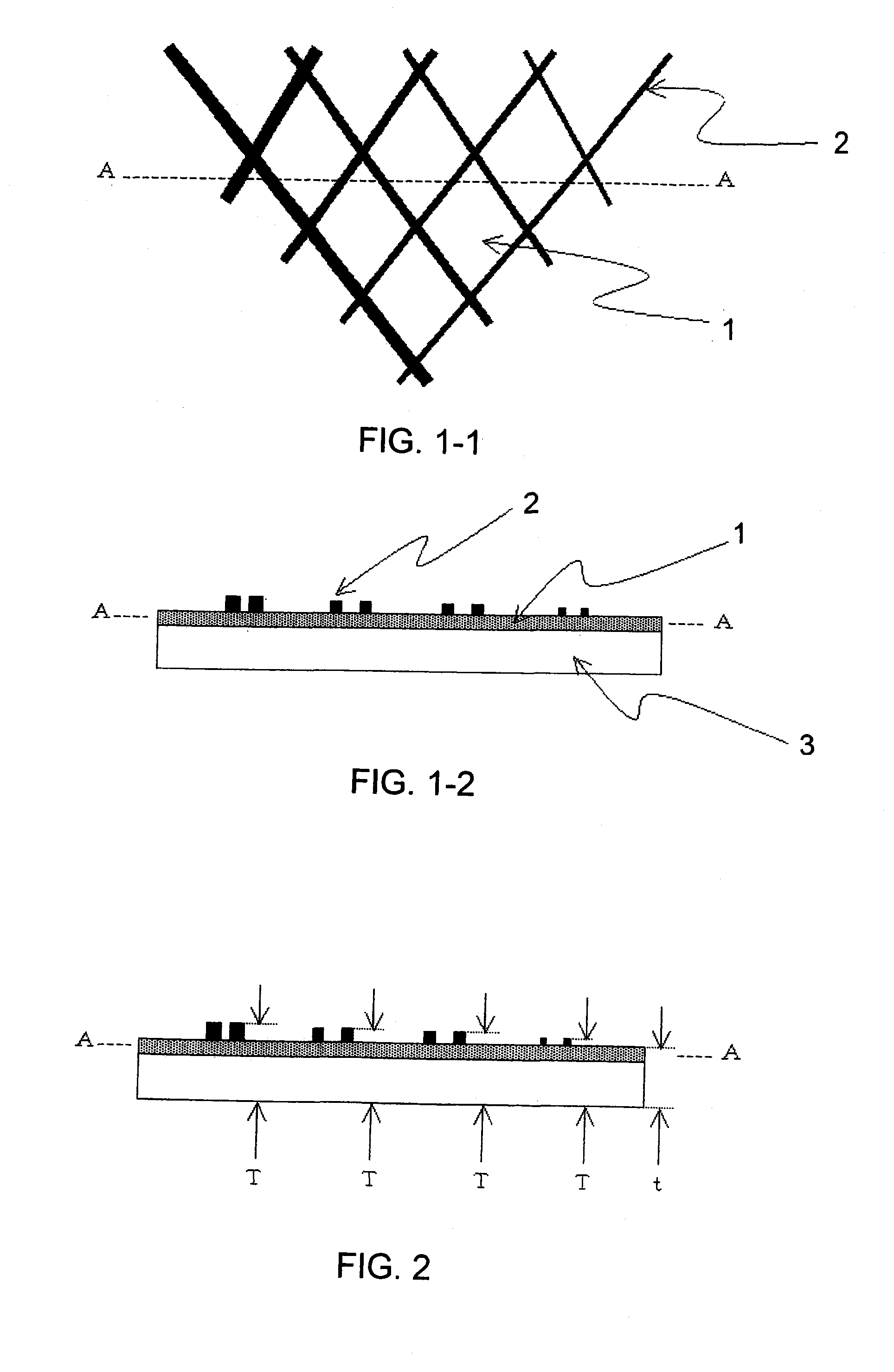

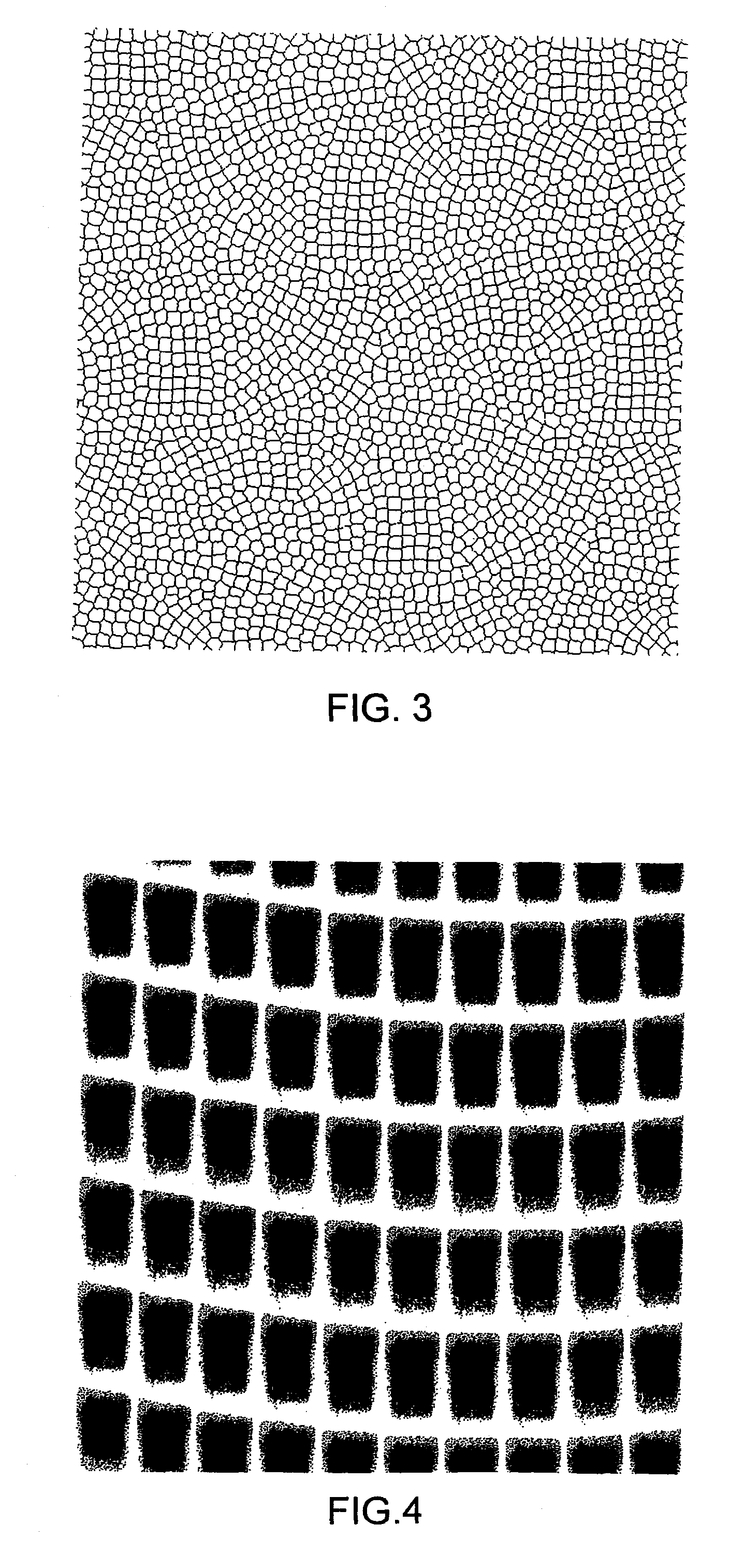

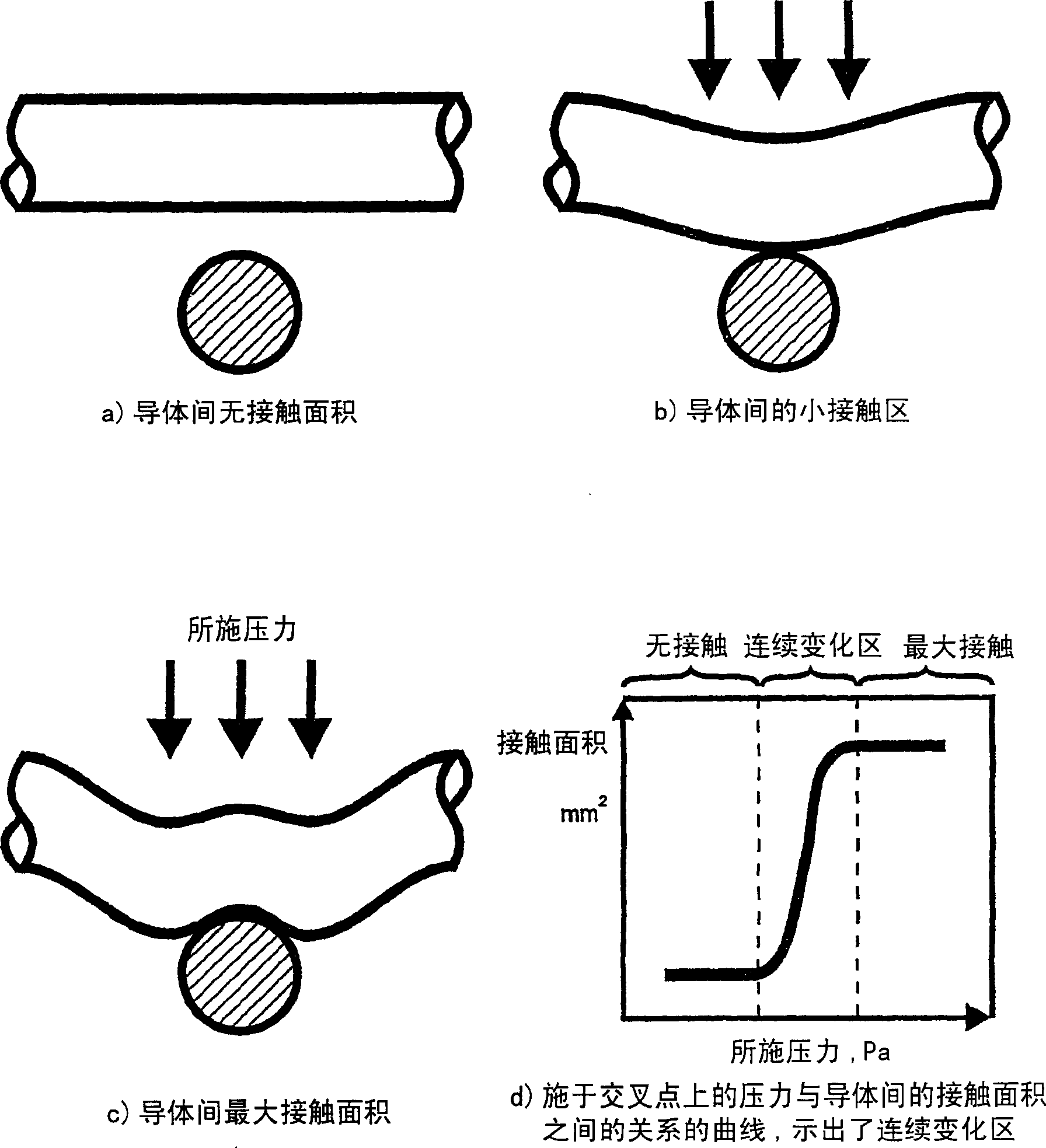

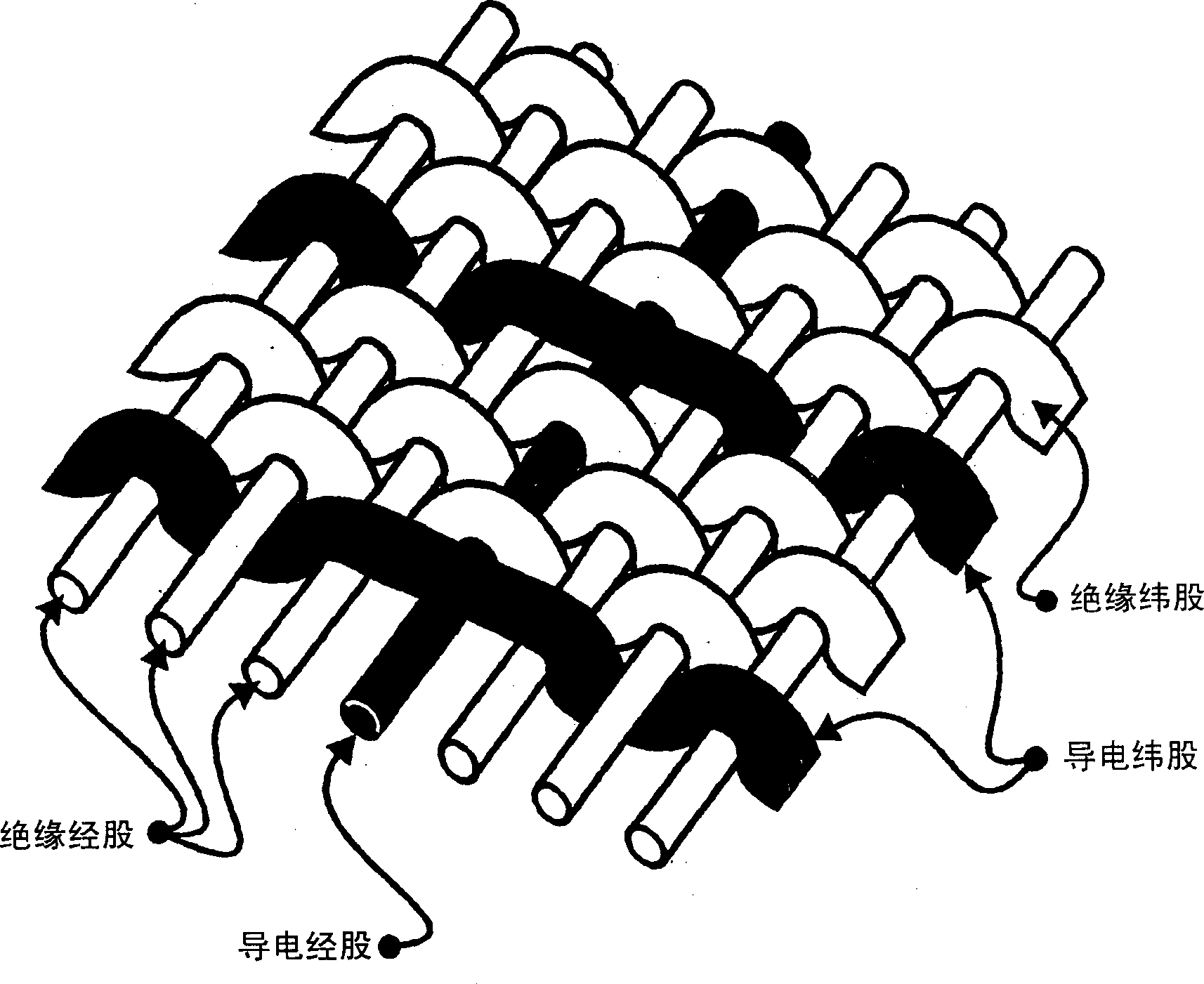

Conductive pressure sensitive textile

InactiveCN1430765AAvoid edge effectsImprove discriminationContact surface shape/structureGarmentsElectrical conductorThin line

A fabric including within its construction a first elongated electrical conductor crossed by a second elongated electrical conductor, the conductors being normally biased apart at a crossover point of said fibres with an air gap between them, whereby application of pressure in a direction substantially normal to a plane of the fabric causes the conductors to make contact. The fabric may be woven, knitted, non-woven or plaited. The fabric can be used as a pressure sensor, switch or other sensor.

Owner:INTELLIGENT TEXTILES

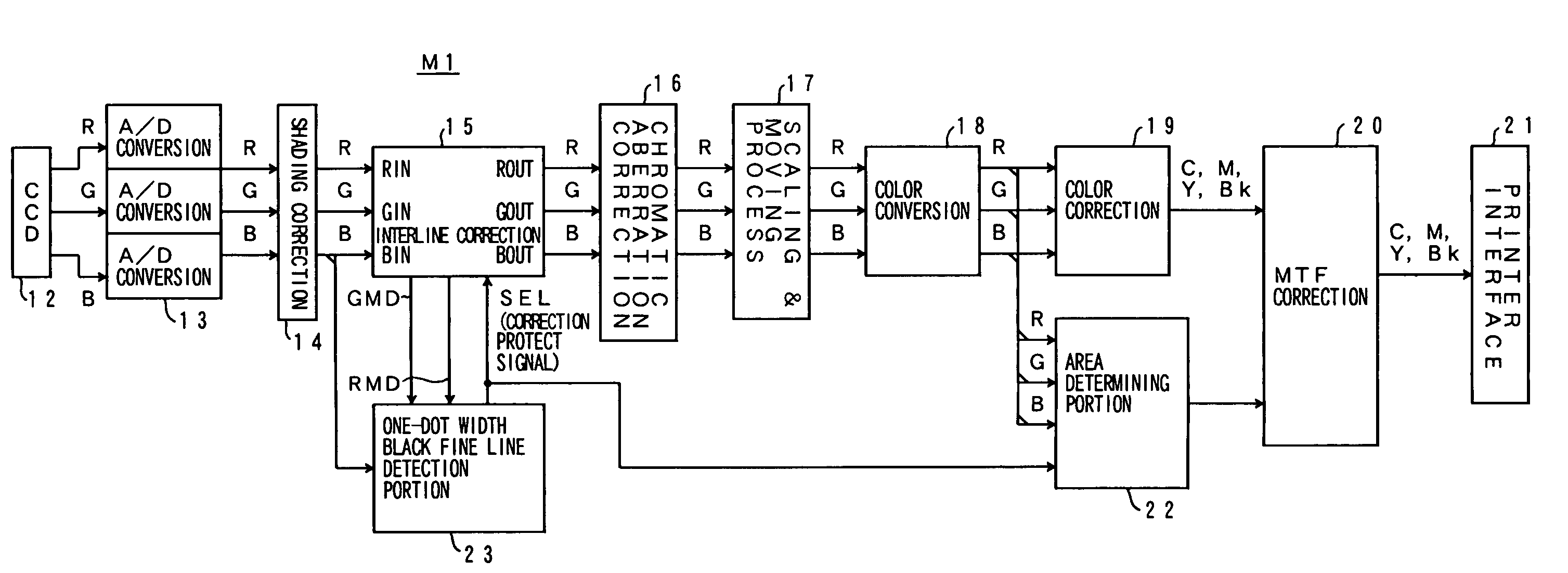

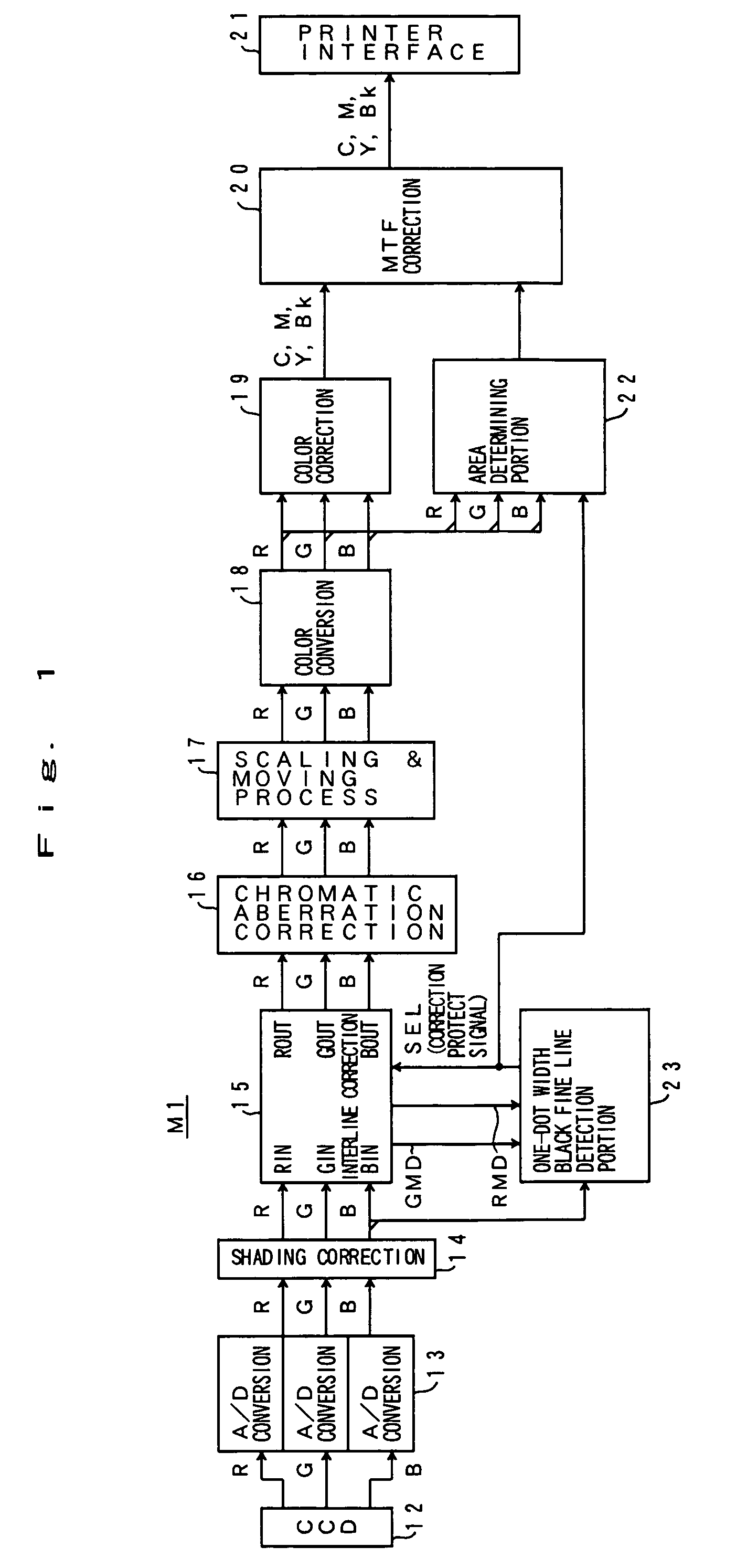

Image processing apparatus

InactiveUS7339699B1Good reproducibilityDigitally marking record carriersDigital computer detailsPhase shiftedImaging processing

An image processing apparatus includes a first sensor having a plurality of reading elements arranged in the primary scanning direction, a second sensor disposed in parallel with the first sensor and by a predetermined lines in the secondary scanning direction, an integral correction portion for correcting a time difference of data output due to a position difference between the first sensor and the second sensor by a line unit, and a fractional correction portion for correcting a time difference of data output due to a position difference between the first sensor and the second sensor by a sub line unit. Thus, the correction of the phase shift between element arrays can be performed as precisely as possible and the reproducibility of a black fine line is increased.

Owner:MINOLTA CO LTD

Process for Making a Coated Optical Lens Free of Visible Fining Lines

The invention concerns a process for making a coated optical lens blank free of visible fining lines which comprises: (ix) providing an optical article having at least one fined but unpolished geometrically defined main face; (x) providing a mold part having an internal and external surface; (xi) depositing on said main face of said optical article or on the internal surface of the mold part a requisit amount of a liquid curable coating composition; (xii) moving relatively to each other the optical article and the mold part to either bring the coating composition into contact with the main face of the optical article or into contact with the internal face of the mold part; (xiii) applying pressure to the mold part to spread the liquid curable coating composition on said main face and form a uniform liquid coating composition layer onto the main face; (xiv) curing the liquid coating composition layer; (xv) withdrawing the mold part; and recovering the free of visible fining lines coated optical article.

Owner:ESSILOR INT CIE GEN DOPTIQUE

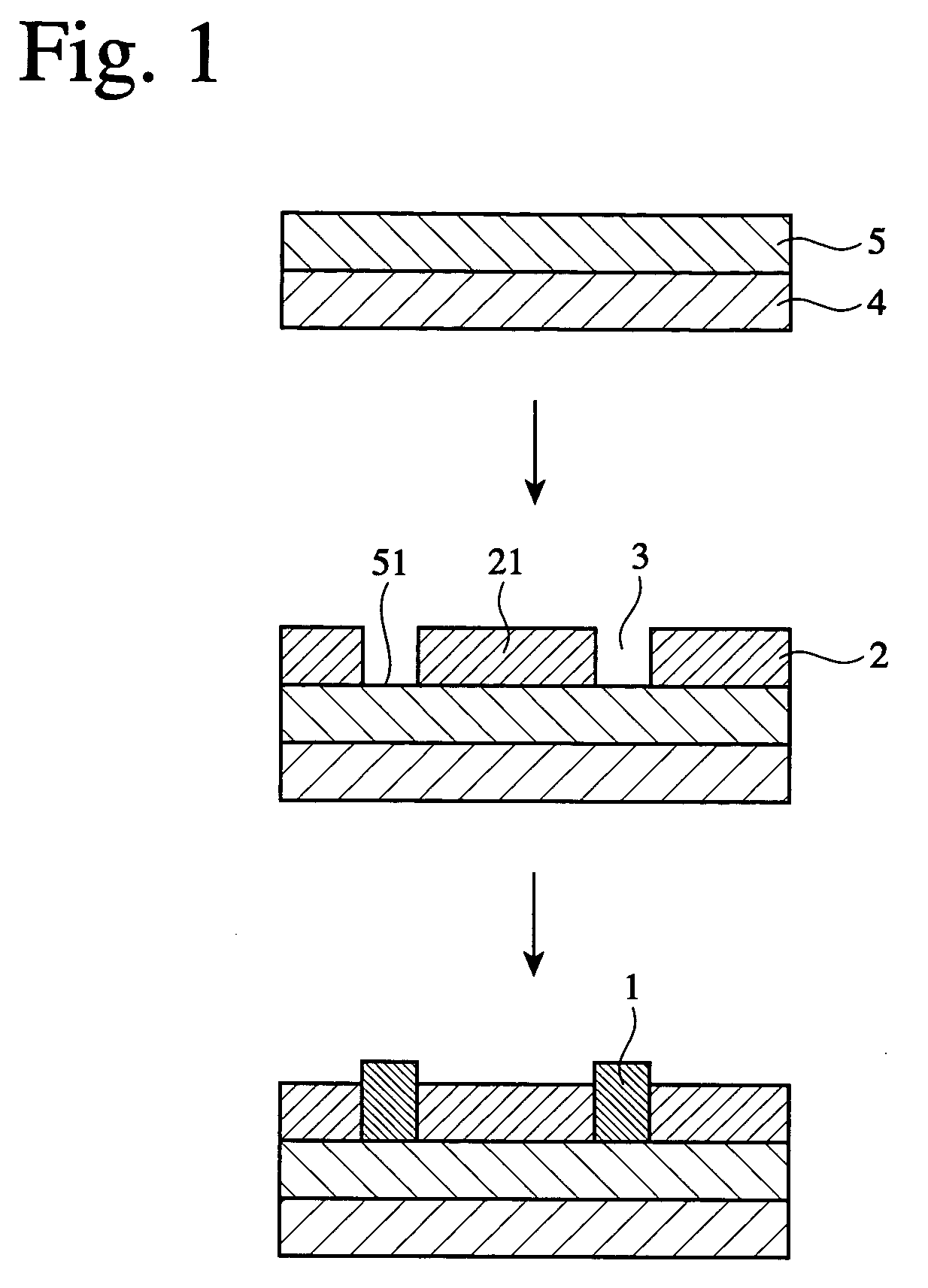

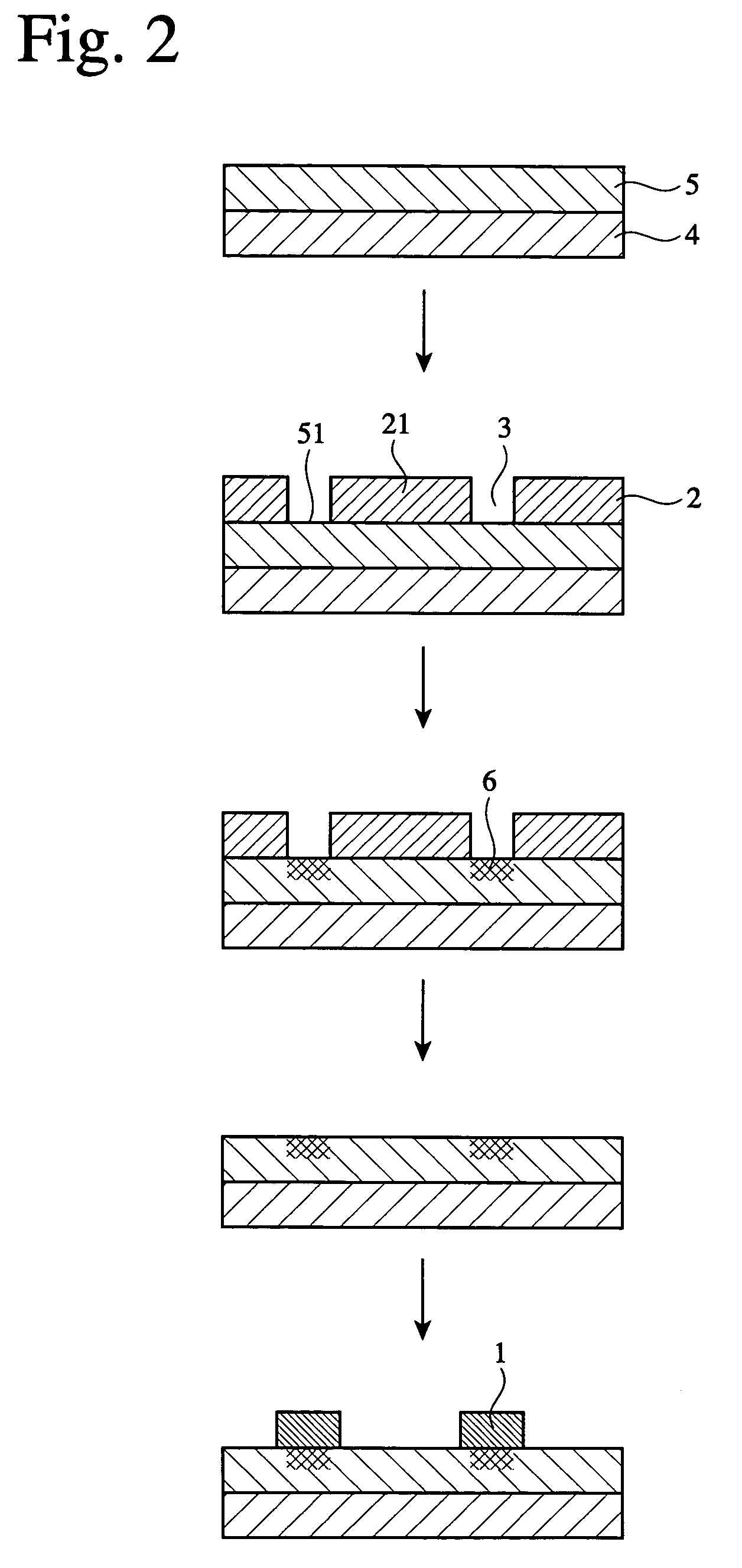

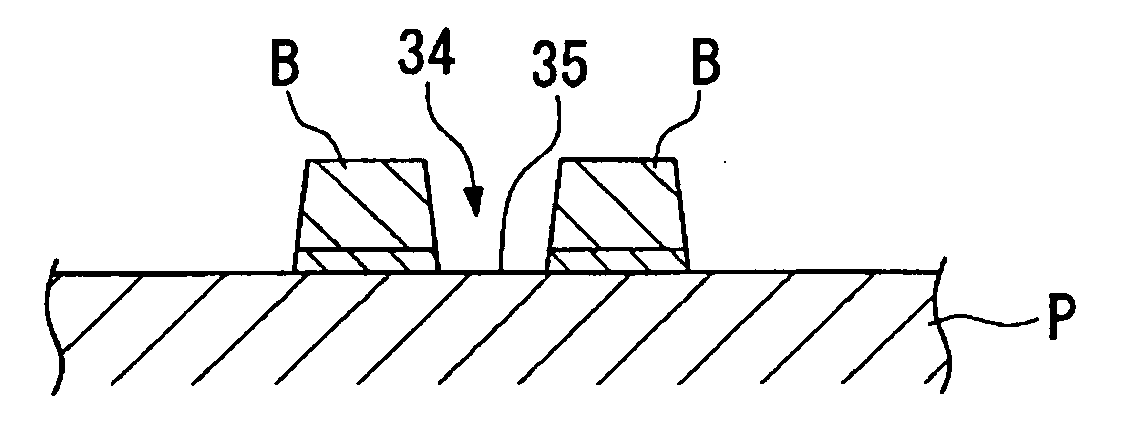

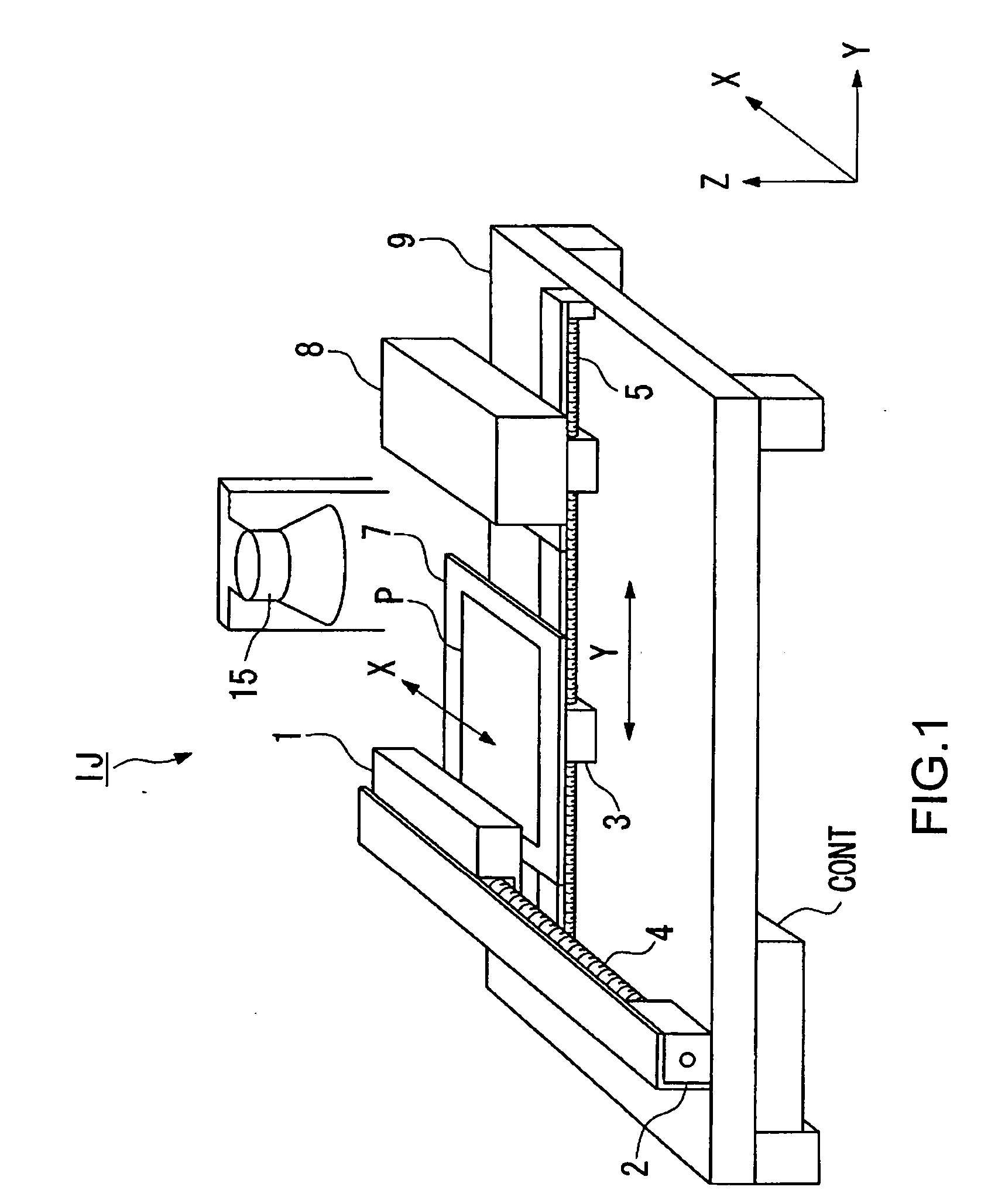

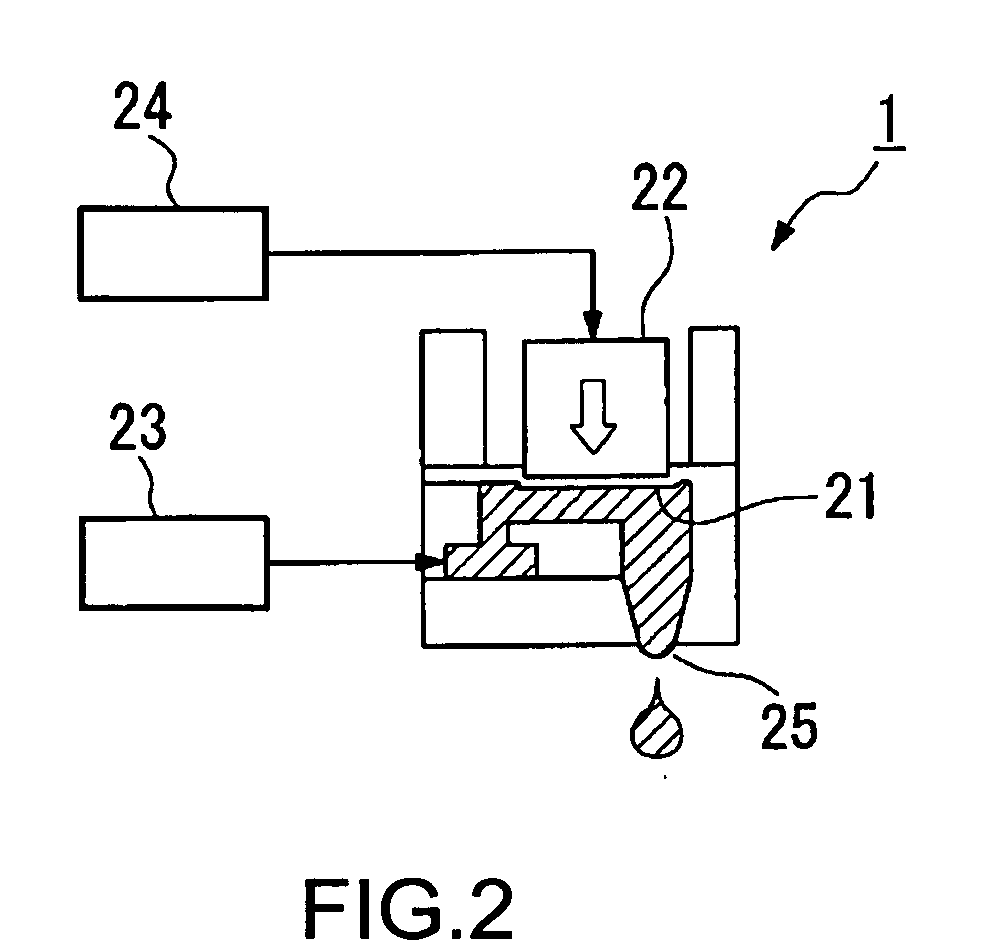

Forming process of thin film pattern and manufacturing process of device, electro-optical apparatus and electronic apparatus

InactiveUS20050003645A1Accurate placementBroaden your optionsPrinted circuit aspectsSolid-state devicesEngineeringThin line

The invention provides a forming process of a thin film pattern capable of properly realizing a thin line. The forming process of a thin film pattern of the invention can be a process of forming a thin film pattern by arranging a functional liquid on a substrate P. The process can include a bank forming step to set up banks protrudingly on the substrate corresponding to the thin film pattern, a repellent liquefaction step of imparting a liquid repellent property to the bank by CF4 plasma processing, and a material arranging step of arranging the functional liquid between the banks imparted with the liquid repellent property.

Owner:SEIKO EPSON CORP

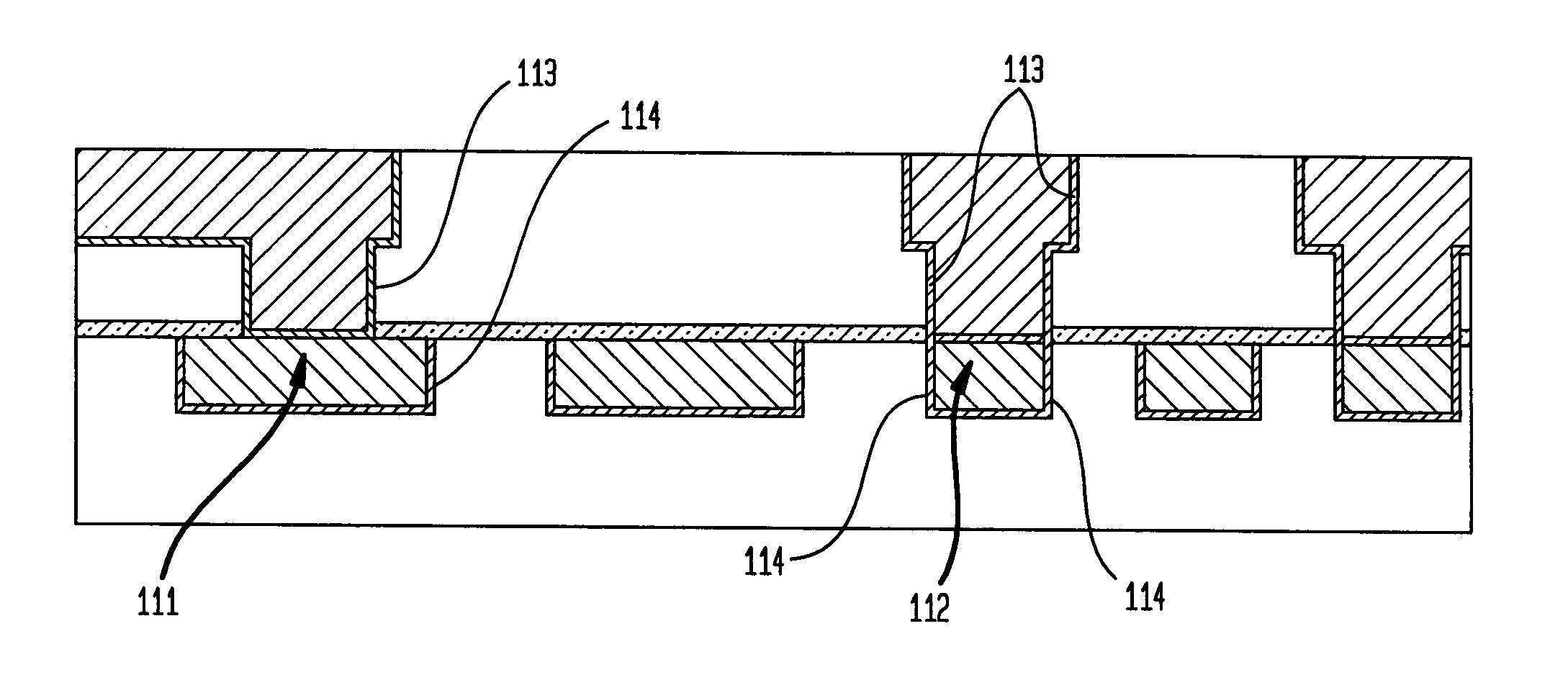

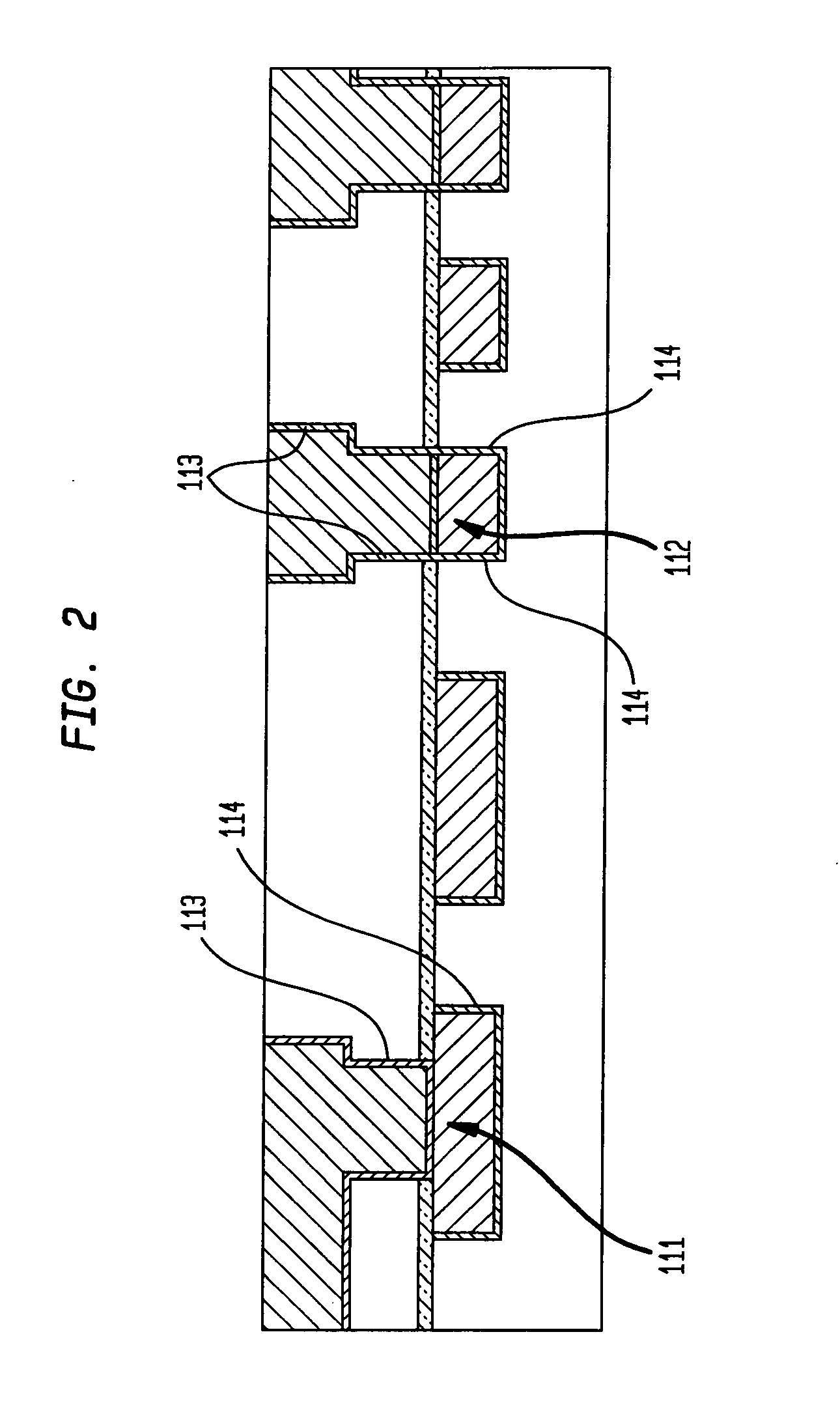

Interconnect structure with a barrier-redundancy feature

ActiveUS20070212870A1Semiconductor/solid-state device detailsSolid-state devicesSufficient timeConductive materials

An interconnect structure that includes a barrier-redundancy feature which is capable of avoiding a sudden open circuit after an electromigration (EM) failure as well as a method of forming the same are provided. In accordance with the present invention, the barrier-redundancy feature is located within preselected locations within the interconnect structure including in a wide line region, a thin line region or any combination thereof. The barrier-redundancy feature includes an electrical conductive material located between, and in contact with, a conductive line diffusion barrier of a conductive line and a via diffusion barrier of an overlying via. The presence of the inventive barrier-redundancy feature creates an electrical path between the via diffusion barrier along the sidewalls of the via and the conductive line diffusion barrier along the sidewalls of the conductive line. This electrical path generated by the inventive barrier-redundancy feature can avoid a sudden open circuit resulting from EM failure at the bottom of the via. The presence of the inventive barrier-redundancy feature within an interconnect structure provides sufficient time for chip replacement or system operation.

Owner:AURIGA INNOVATIONS INC

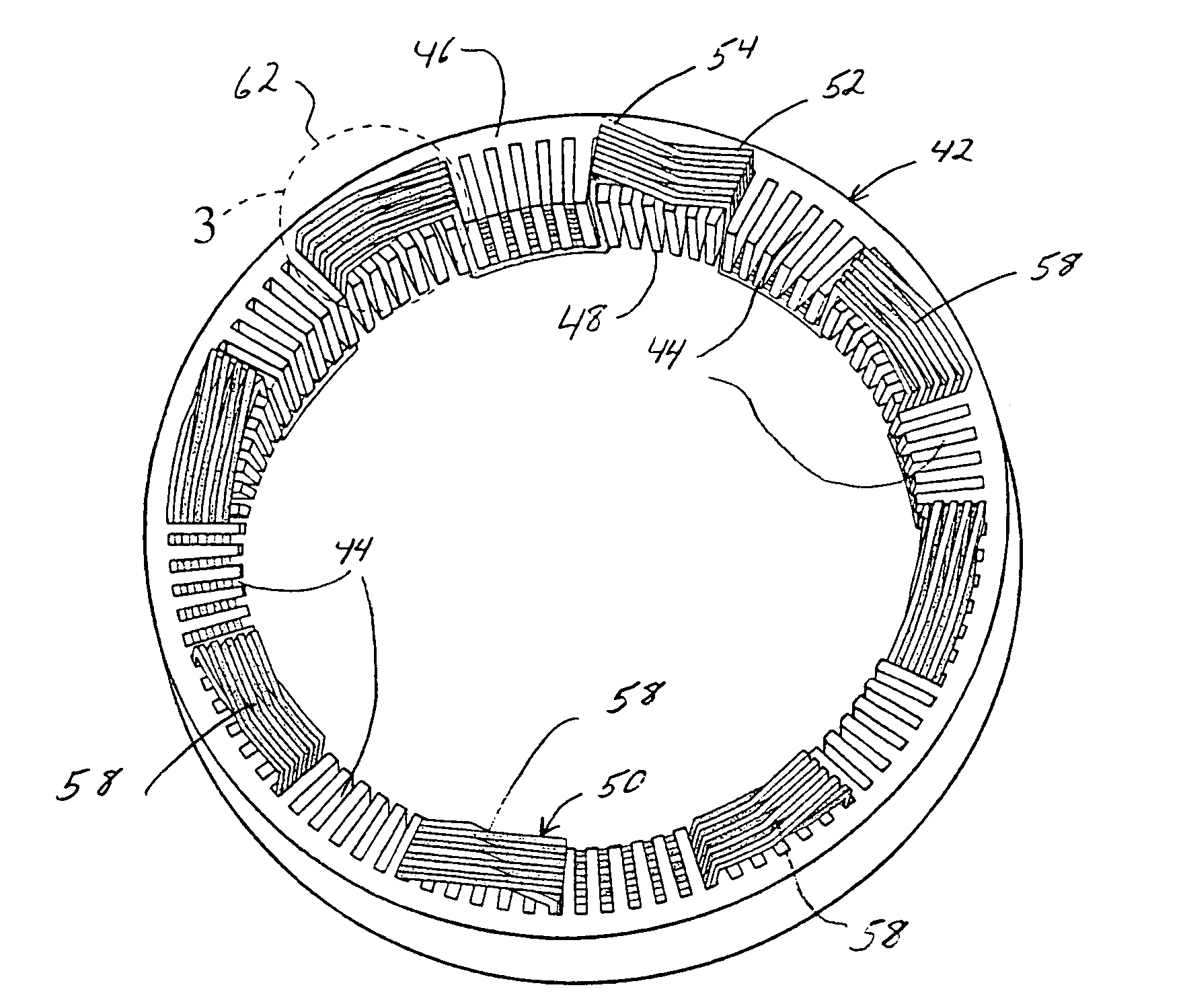

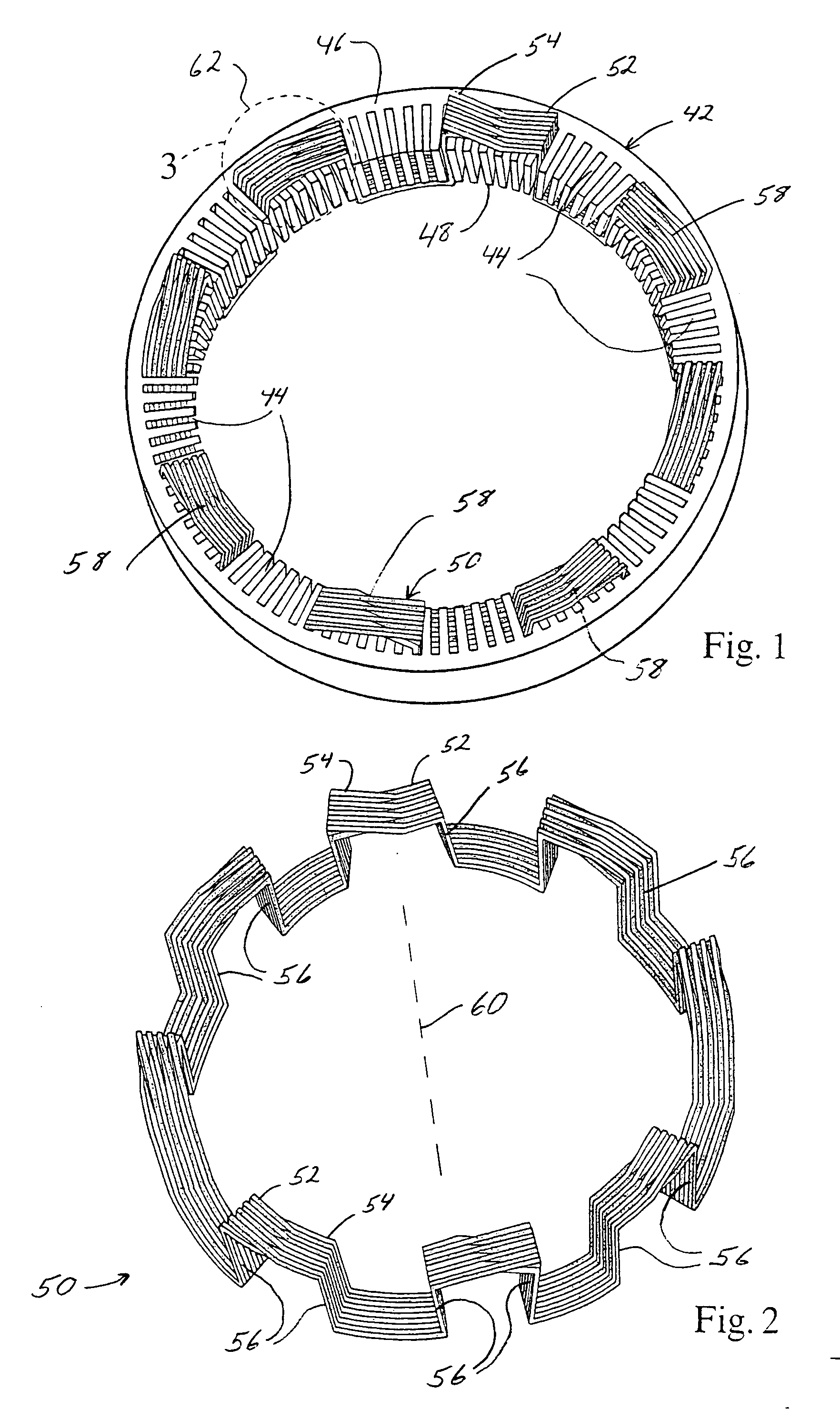

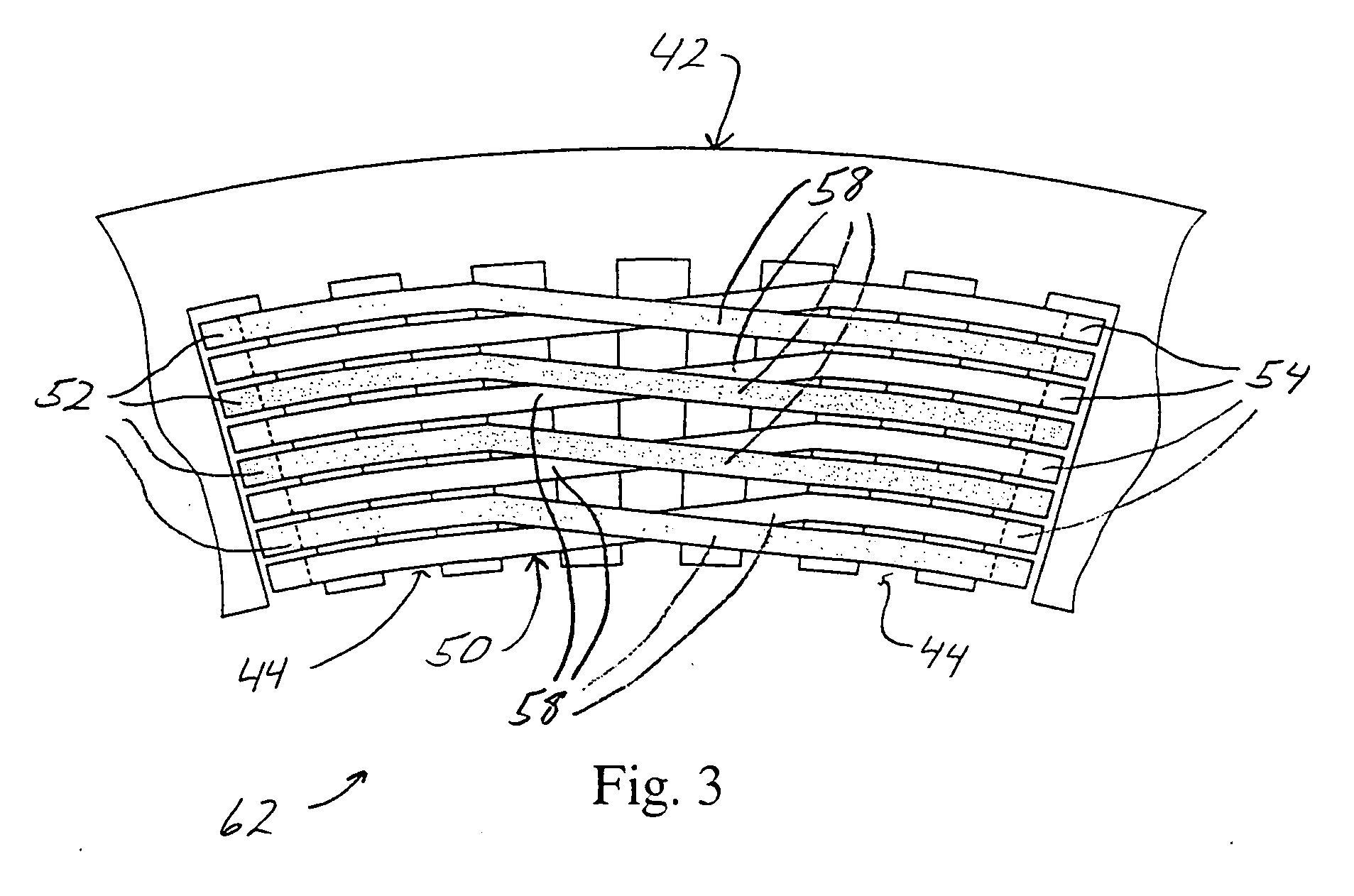

Stator winding having transitions

InactiveUS20050046297A1Reduce the amount requiredReduce heatSynchronous generatorsMagnetic circuitElectrical conductorElectric machine

A stator for an electric machine includes a generally cylindrically-shaped stator core having a plurality of circumferentially spaced core slots. A stator winding includes a plurality of phases, each including at least a first filar and a second filar extending circumferentially around the stator core to form a plurality of layers. Each of the filars is a conductor having a plurality of slot segments disposed in the core slots. The slot segments are alternately connected at the first and second ends of the stator core by a plurality of end loop segments that may form a cascaded winding pattern. The plurality of filars of each phase alternating radial positions with one another within at least one end loop segment at discreet locations around the stator core such that the average radial position of the slot segments of the first filar conductors is substantially equal to that of the second filar.

Owner:REMY TECHNOLOGIES LLC

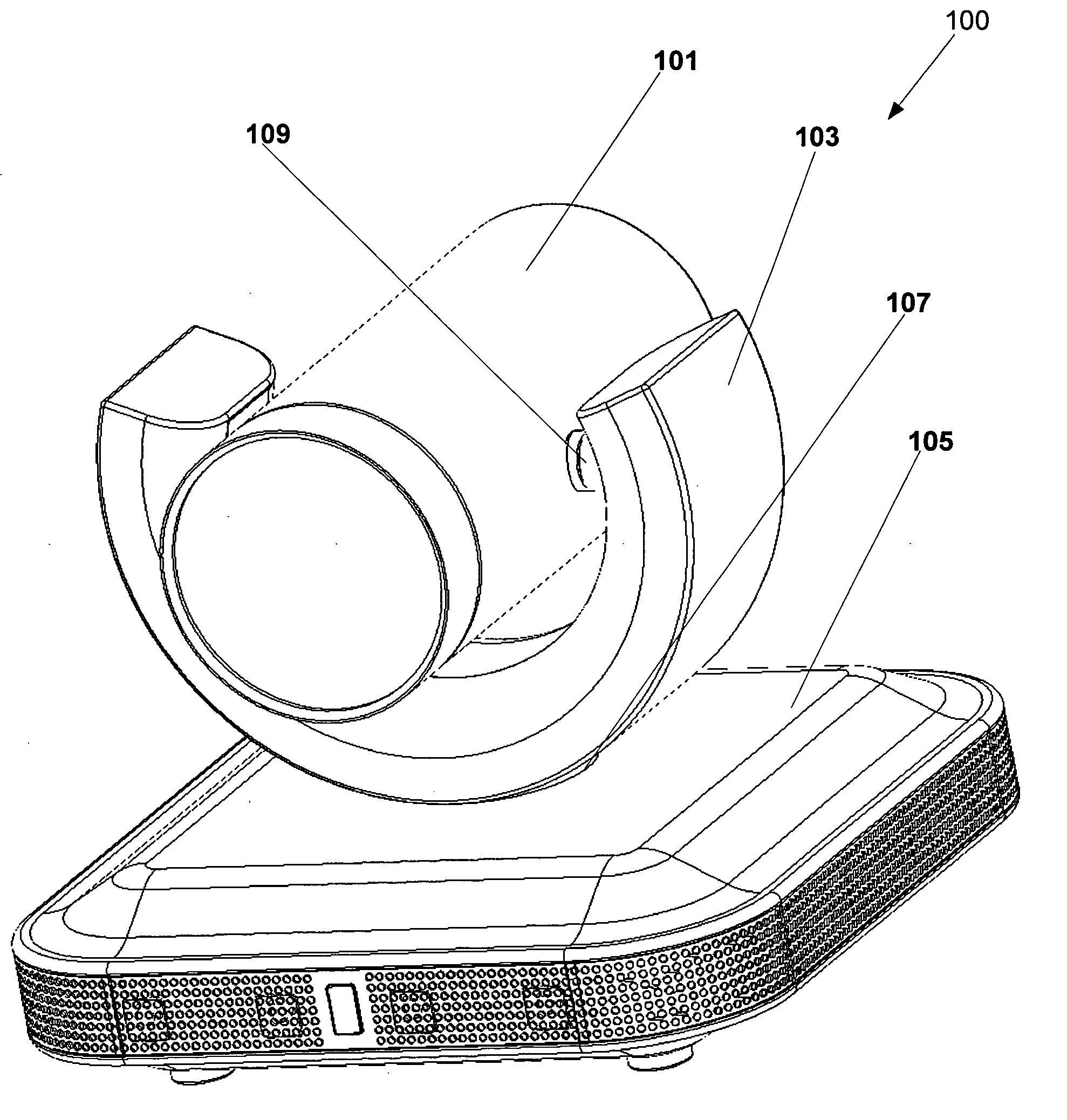

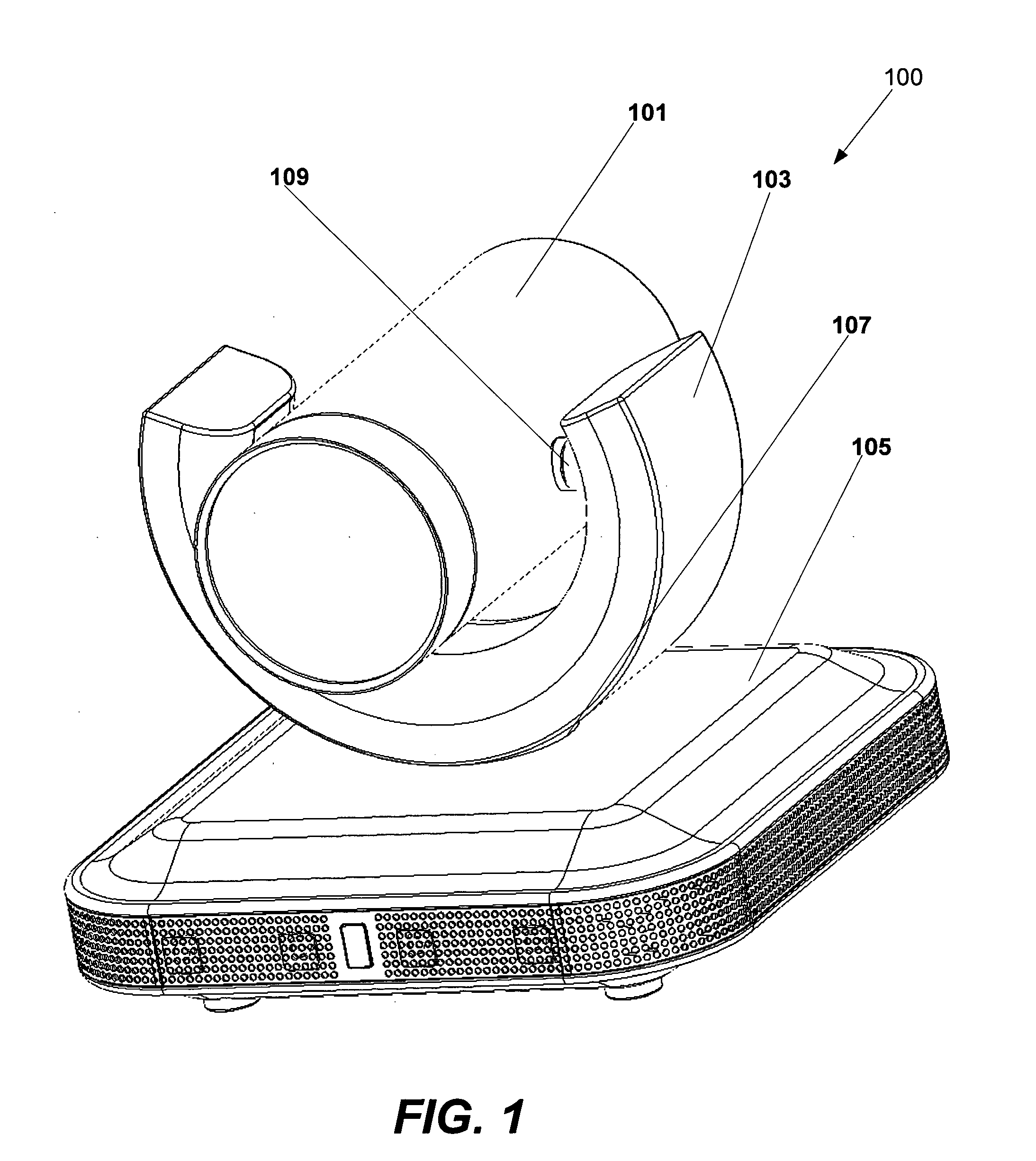

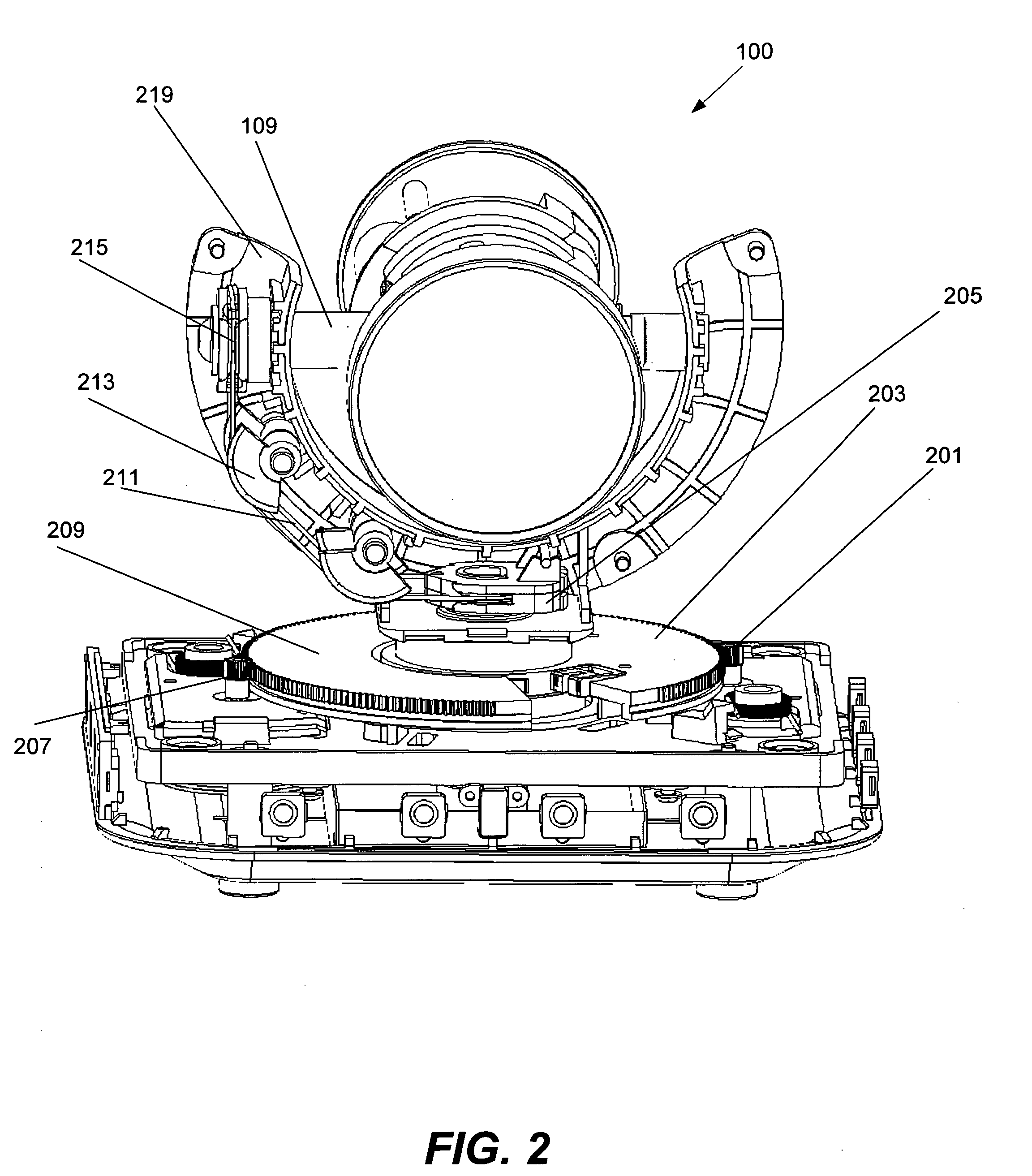

High definition pan tilt zoom camera with embedded microphones and thin cable for data and power

ActiveUS20060082655A1Small sizeImprove stabilityTelevision system detailsPicture signal generatorsCamera lensCable transmission

In various embodiments, a High Definition (HD) camera may be controlled by one or more motors in a base of the HD camera. Cables and other components may be used to manipulate the HD camera lens through the side arms of the HD camera. Putting the motors in the base may reduce the size of the outer case of the HD camera and add stability. In some embodiments, images from the HD camera may be converted into a serialized stream and transported over a cable from the HD camera. Other components may also be used to increase the functionality of the HD camera.

Owner:LIFESIZE INC

Gas turbine engine having slim-line nacelle

A nacelle assembly for a gas turbine engine includes a nacelle, a variable area fan nozzle, a sensor that detects a windmilling condition and a controller that communicates with the sensor. The variable area fan nozzle is moveable between a first position having a first discharge airflow area and a second position having a second discharge airflow area greater than the first discharge airflow area in response to detecting the windmilling condition.

Owner:RTX CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com