Conductive pressure sensitive textile

A technology of conductors and fabrics, used in textiles and papermaking, textiles, fabrics, etc., to achieve the effect of high discrimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

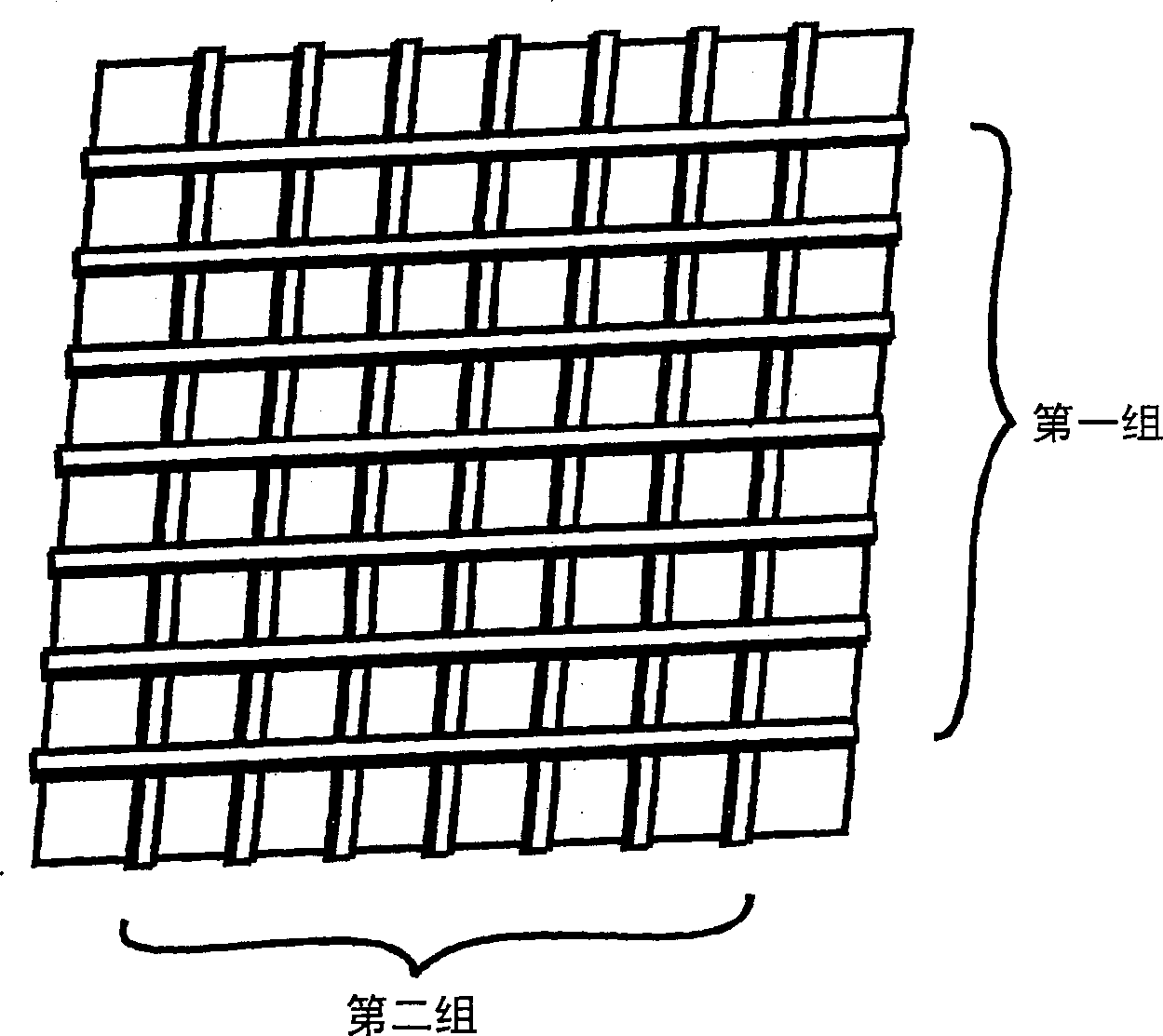

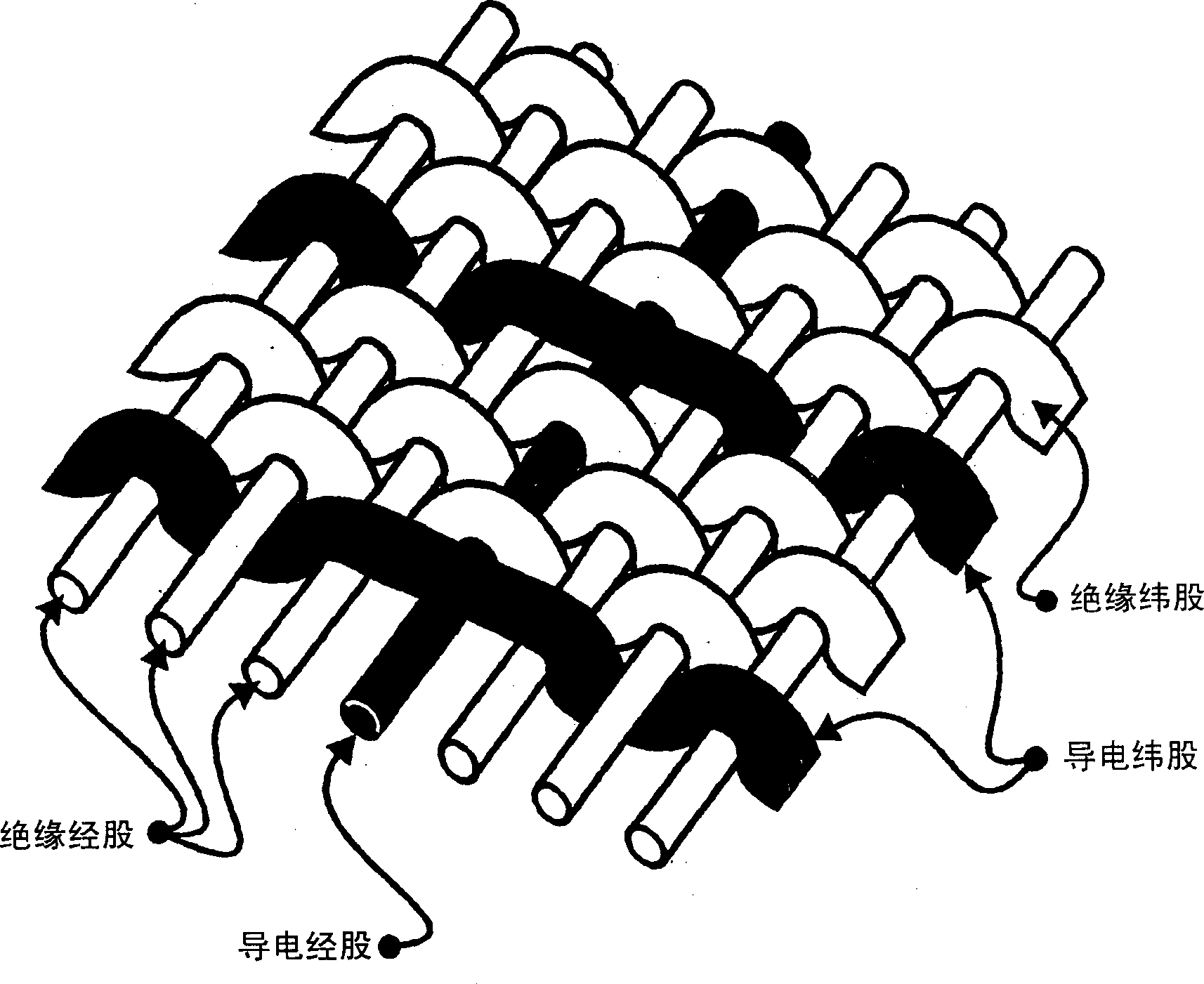

[0034] Refer to attached picture, in figure 1 In the preferred embodiment, it is desirable that the fabric includes at least two sets of elongated conductors. Typically, the conductors in each group are arranged parallel to each other, and one group of conductors is arranged perpendicular to the other to form an artificially spaced grid, such as figure 1 shown in . The elongated conductors are generally single or multi-wire conductive fibers, while the remainder of the deposit consists of insulating fibers.

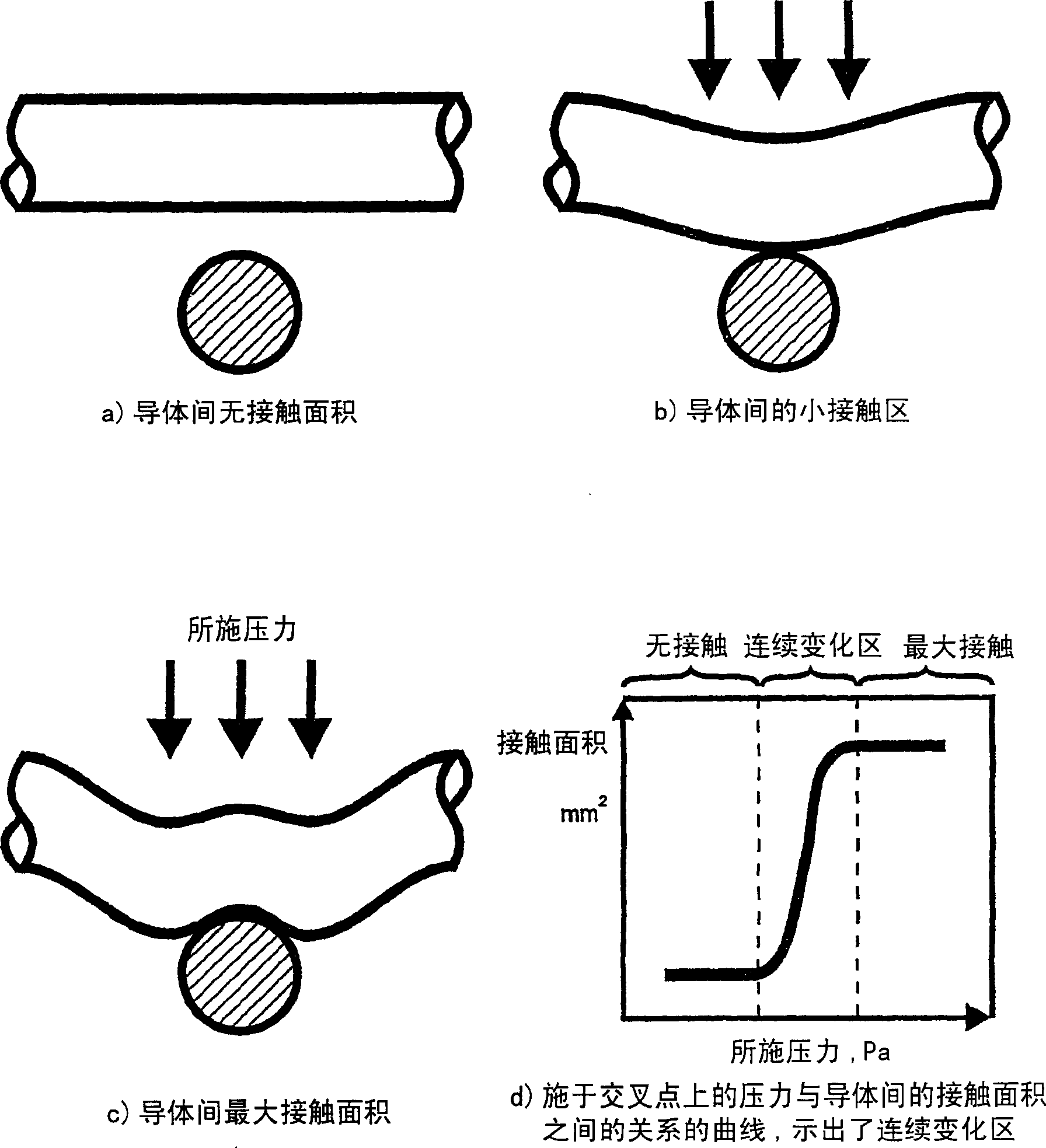

[0035] as in figure 2 As shown in the cross-sectional view of the two conductors in (a), at the point where the two conductors intersect each other, the structure of the fabric and / or conductive fibers maintains their physical separation. When pressure is applied in a direction perpendicular to the plane of the fabric, as shown in Figure (b), the conductive fibers are caused to segregate and make electrical contact. In this way, each intersection creates a momentar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com