Profiling flexible array eddy current probe and detection method

A flexible array and eddy current probe technology, which is applied in the direction of measuring devices, instruments, and material analysis through electromagnetic means, can solve the problems of large detection blind spots, large detection signal interference, and low detection efficiency, and achieve significant promotion and use. The effect of detection accuracy and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

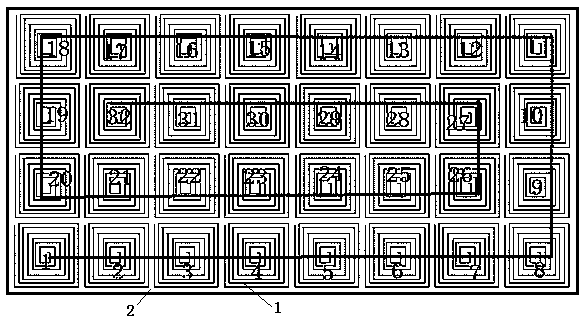

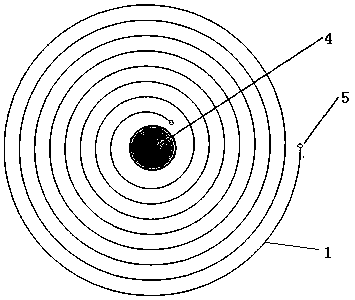

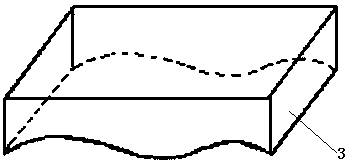

[0032] Such as Figure 1-6 As shown, a plurality of coils 1 with the same size and the same parameters can be used as attached figure 1 Arranged in the manner shown to form an array, polyimide is used as the base material, and the coil 1 is a flat coil, which is fabricated on the flexible circuit board 2 by means of a printed circuit, and the manufactured one has high reliability and good flexibility printed circuit. In order to improve the detection sensitivity of the coil 1 and reduce the mutual influence between the coils 1, the center of the coil 1 is embedded in the magnetic core 4, and its structure is as follows figure 2 As shown, the magnetic core is made of iron-based amorphous alloy with high magnetic permeability, and the two coil terminals 5 of the coil 1 are welded on the flexible circuit board 2, so that the coil 1 has the char...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com