Patents

Literature

353 results about "Magnetic particle inspection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

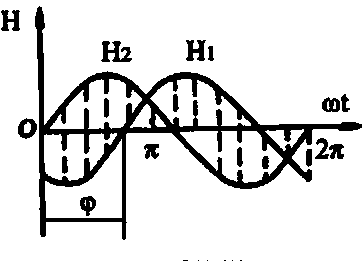

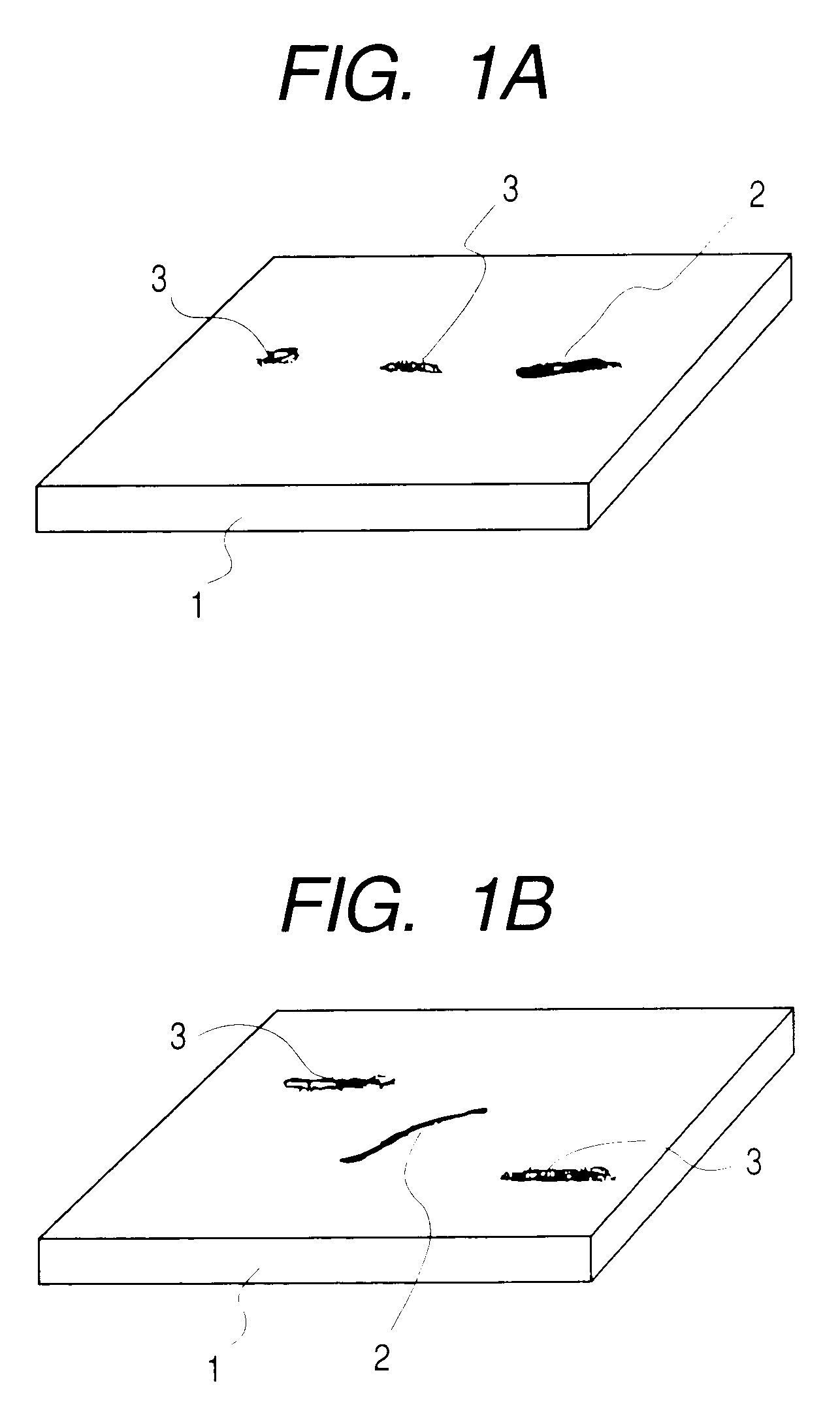

Magnetic particle Inspection (MPI) is a non-destructive testing (NDT) process for detecting surface and shallow subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part. The piece can be magnetized by direct or indirect magnetization. Direct magnetization occurs when the electric current is passed through the test object and a magnetic field is formed in the material. Indirect magnetization occurs when no electric current is passed through the test object, but a magnetic field is applied from an outside source. The magnetic lines of force are perpendicular to the direction of the electric current, which may be either alternating current (AC) or some form of direct current (DC) (rectified AC).

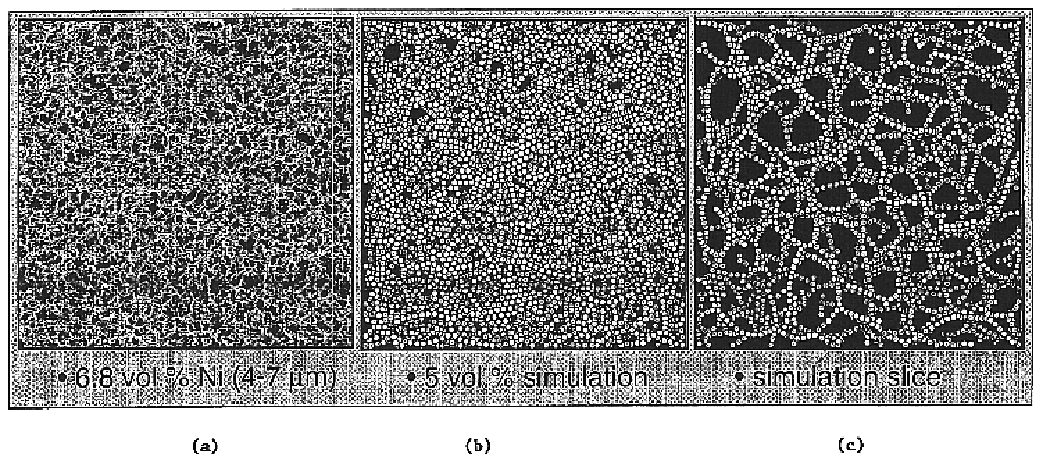

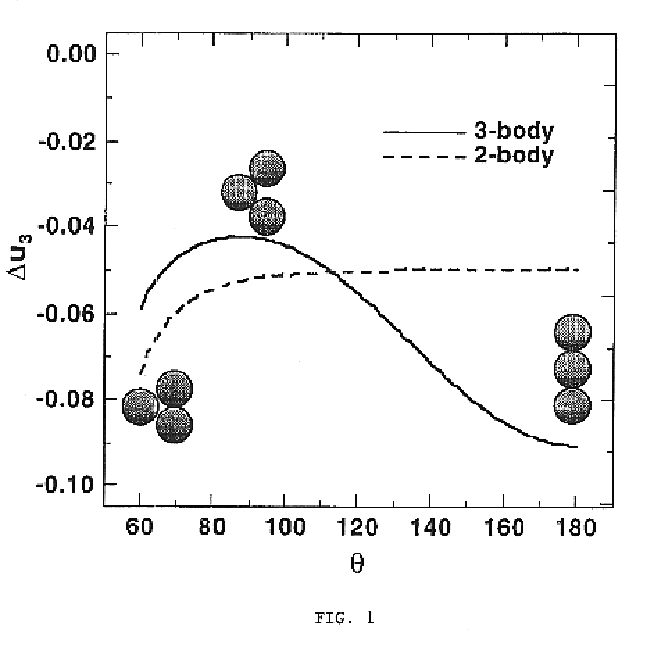

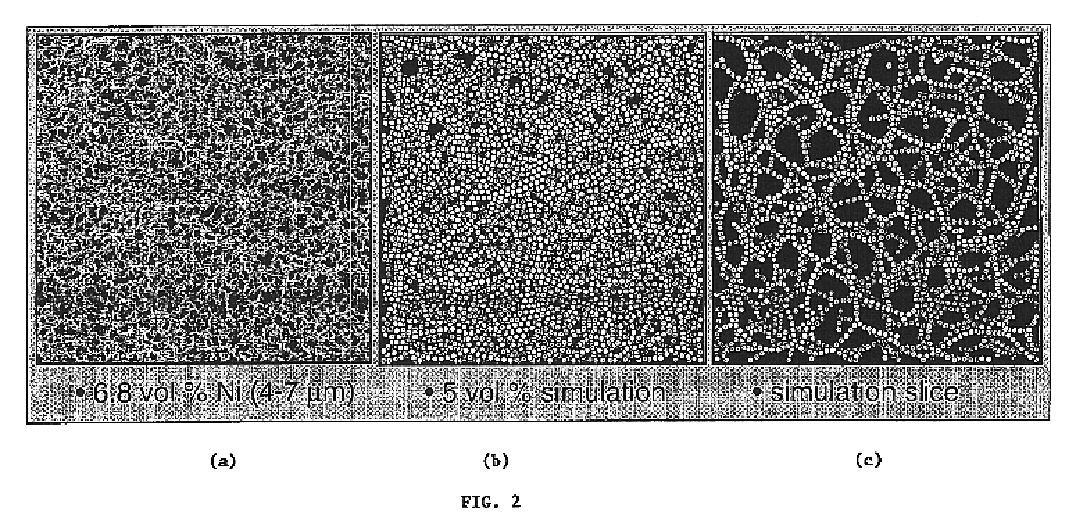

Method of using triaxial magnetic fields for making particle structures

A method of producing three-dimensional particle structures with enhanced magnetic susceptibility in three dimensions by applying a triaxial energetic field to a magnetic particle suspension and subsequently stabilizing said particle structure. Combinations of direct current and alternating current fields in three dimensions produce particle gel structures, honeycomb structures, and foam-like structures.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

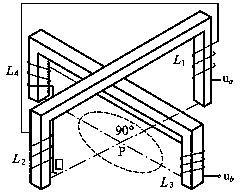

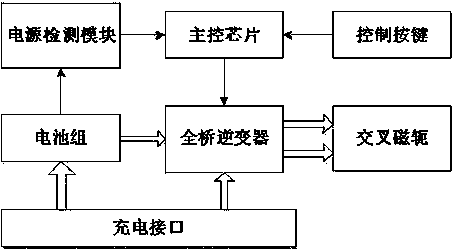

Electromagnetic inspection method based on hall sensor array and electromagnetic inspection system based on hall sensor array

The invention relates to an electromagnetic inspection system which comprises a magnetic field generation device and a magnetic field detection device, wherein the magnetic field detection device inspects a magnetic induction component through detecting a magnetic field generated by the magnetic field generation device; the magnetic field generation device mainly comprises a full-bridge inverter, a main control chip, a cross magnet yoke and a power supply detection module, and is mainly used for generating an electromagnetic field for magnetizing a workpiece; and the magnetic field detection device comprises a hall sensor array, a data acquisition module, a data processing module and a data display module, and is used for detecting and displaying magnetic lines generated around the workpiece by the magnetic field generation device. By virtue of the electromagnetic inspection system, the defects of a magnetic powder inspection mode in a nondestructive detection process are overcome; the detection time and detection range of single charging are prolonged and improved; and the detection rate and detection speed of the single charging are increased.

Owner:河南省锅炉压力容器安全检测研究院

Method for repairing roller sleeve of continuous casting roller

InactiveCN102728993AExtended service lifeReduce consumptionWelding/cutting media/materialsSoldering mediaHigh power lasersAlloy

The invention discloses a method for repairing a roller sleeve of a continuous casting roller. The method comprises the following steps of: preliminarily checking the roller sleeve; measuring the size of each part of the roller sleeve, removing a fatigue layer on the surface of the roller sleeve, and performing magnetic particle inspection and ultrasonic flaw detection; preparing Ni45 and WC alloy powder by adopting a mechanical mixing method, preheating the roller sleeve, coating the alloy powder on the surface of the roller sleeve by adopting a coaxial powder feeding method and scanning with a high-power CO2 laser device, thermally treating the whole roller sleeve, and slowly cooling together with a furnace; and performing rough machining and precision machining on the roller sleeve of the continuous casting roller meeting the requirements by using a lathe. Compared with the prior art, the method has the advantages that the service life of the roller sleeve is prolonged; consumption is reduced; the roller sleeve is high in abrasion resistance and heat resistance; and the method is simple, strong in controllability and low in cost, and saves the alloy material.

Owner:YANSHAN UNIV

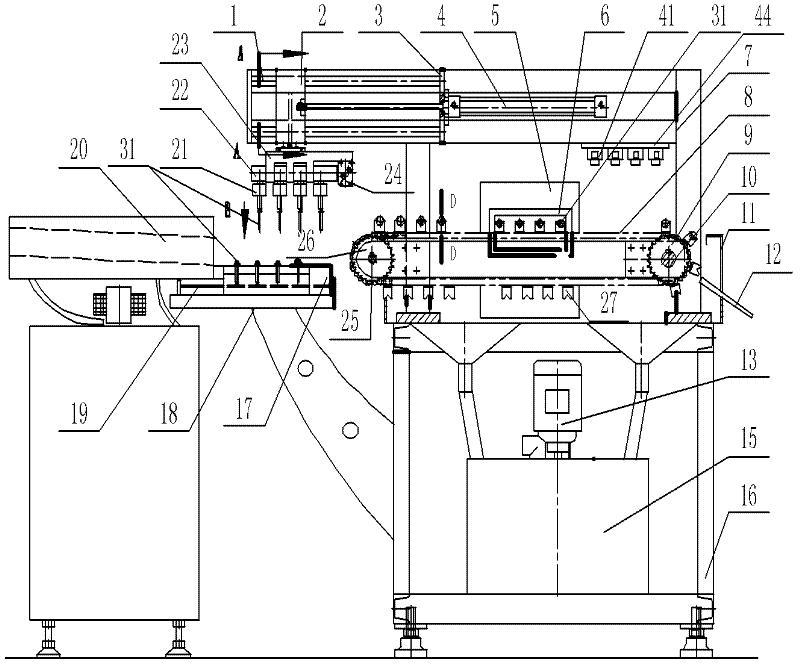

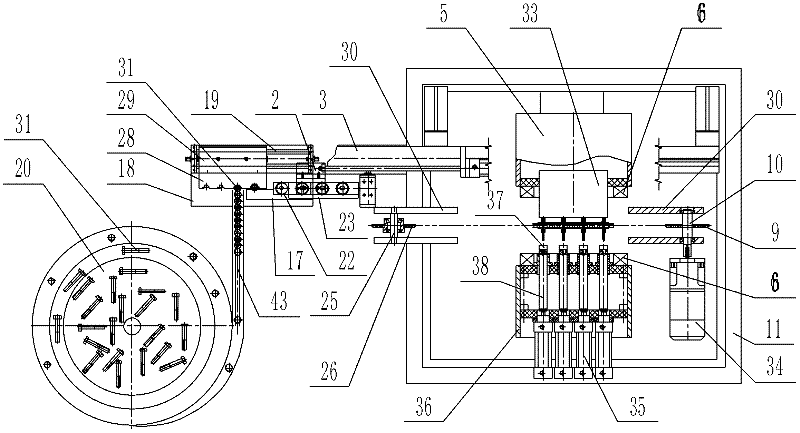

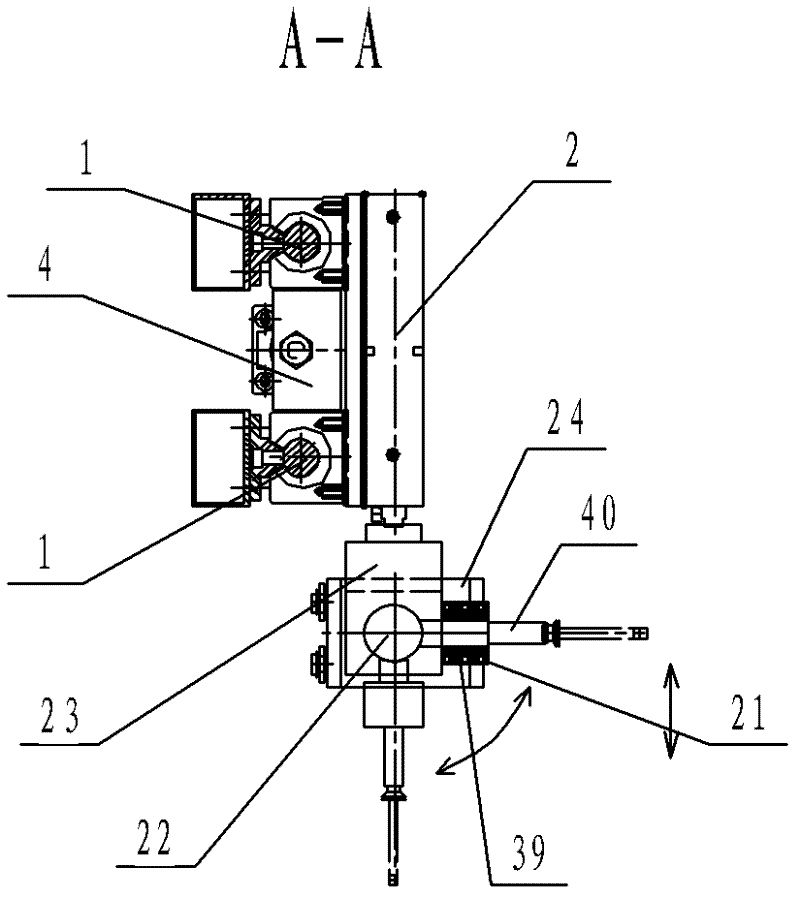

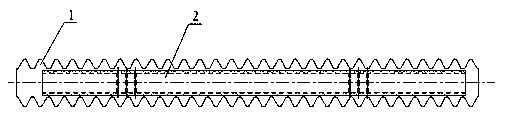

Automatic-bolt-feeding magnetic powder flaw detecting line

The invention relates to an automatic-bolt-feeding magnetic powder flaw detecting line, which is characterized in that a mechanical hand device is arranged above a chain wheel conveying device, a displacement air cylinder and a lifting air cylinder are arranged on a cross beam of a mechanical hand support, and an ultraviolet lamp and a camera are arranged below the cross beam; a piston rod extruding end of the lifting air cylinder is connected with the top of a rotary support, and rotary shafts are in movable fit with the inner holes of a plurality of vertical plates which are arranged at the left part of the lower face of the rotary support; a rotating air cylinder is fixed at the right part of the lower face of the rotary support, and the extending end of a piston rod of the rotating air cylinder is connected with one ends of the rotary shafts; a plurality of electromagnetic finger clamps are fixed on the rotary shafts; and a conveying device is arranged at the left side of a chain wheel conveying device and below the lifting air cylinder. Because a full-automatic feeding system is adopted to replace manual operation, high speed and high efficiency are achieved; and an automatic defect sorting system replaces manual sorting, the advantages of good reliability, time-saving and labor-saving performances and high speed are achieved, and the requirements for detecting large-batch products are met completely.

Owner:YANCHENG WEIYA ELECTROMAGNETIC TECH

Overall heating automatic welding process of spud leg main coil of offshore drilling platform and special tool of overall heating automatic welding process

ActiveCN102699494AIncrease productivityImprove welding qualityWelding/cutting auxillary devicesArc welding apparatusWeld seamEngineering

The invention relates to an overall heating automatic welding process of a spud leg main coil of an offshore drilling platform and a special tool of the overall heating automatic welding process. The process steps include that after a primary preheating, toothed bars and string pipes on two sides of the toothed bars are positioned and are subjected to a backing weld by the special tool; primary postweld treatment is performed, a backing weld seam is subjected to an appropriate polishing, and then the backing weld seam is subjected to a heat magnetic particle inspection after the polishing; a secondary preheating is performed, and the toothed bars and the string pipes which are subjected to the backing weld are placed in an electric furnace to be preheated again; a secondary welding is performed, an automatic submerged arc welding is utilized to perform filling and capping on the toothed bars and the string pipes which are subjected to the preheating again; and finally heat treatment is performed. By means of a mode of combining a plurality of times of the preheating and welding, and by means of reasonable control of welding temperatures and speeds, the manufacturing of spud leg main coil of the offshore drilling platform is achieved, and design requirements of welding qualities, welding deformation control and postwelding dimensional accuracy are met, so that the production efficiency and welding qualities are remarkably improved, and an effective and practical producing and manufacturing mode is provided for the production of a spud leg main coil of a self-elevating drilling platform.

Owner:SHANGHAI ZHENHUA HEAVY IND GRP NANTONG TRANSMISSION MACHINERY

Image processing-based magnetic particle inspection defect intelligent identification detection system

The invention discloses an image processing-based magnetic particle inspection defect intelligent identification detection system. A communication module, a CCD (Charge Coupled Device) camera, a CCD control module, a crack identification module, an image processing module, an image alarm terminal and a memory are integrated in the system; a surface image of a workpiece is acquired by the CCD camera and is stored in a memory card; the image processing module is used for segmentation, defect identification processing and storage of the image in the memory card and transferring defect information of the surface of the workpiece to the crack identification module; and the defect information of the surface of the workpiece is fed back to the image alarm terminal by the crack identification module to finish the final display alarm. By improving a segmentation algorithm, the problems such as imaging fuzziness caused by motion, imaging region selection and false alarm caused by pseudo-crack signal existing in the system are solved excellently.

Owner:CHANGSHU RES INSTITUE OF NANJING UNIV OF SCI & TECH +1

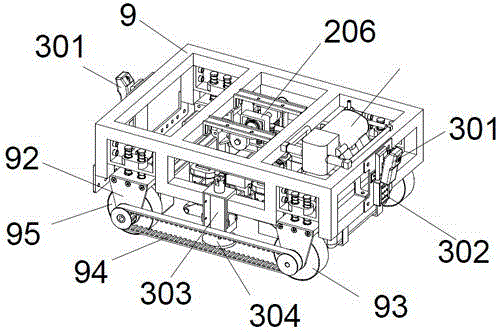

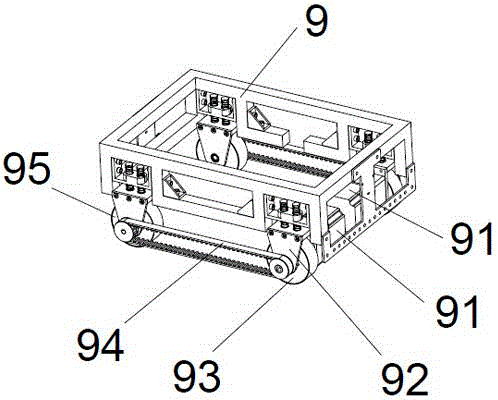

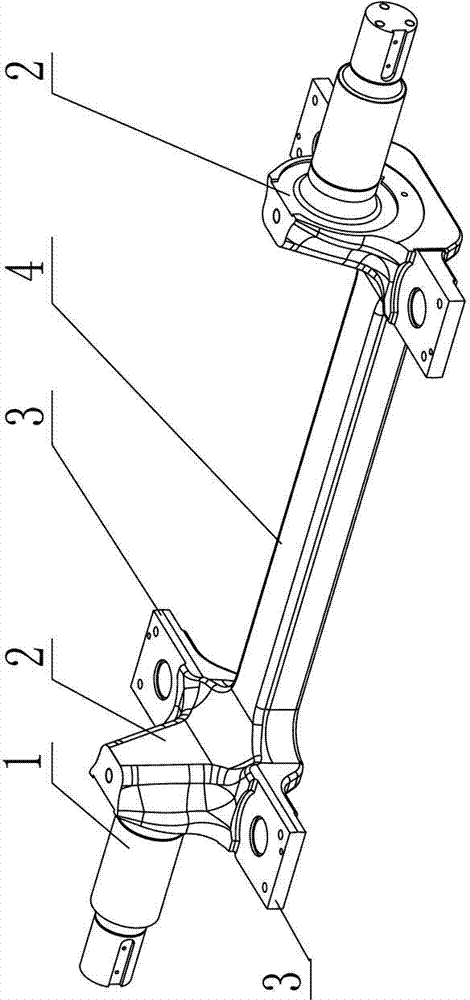

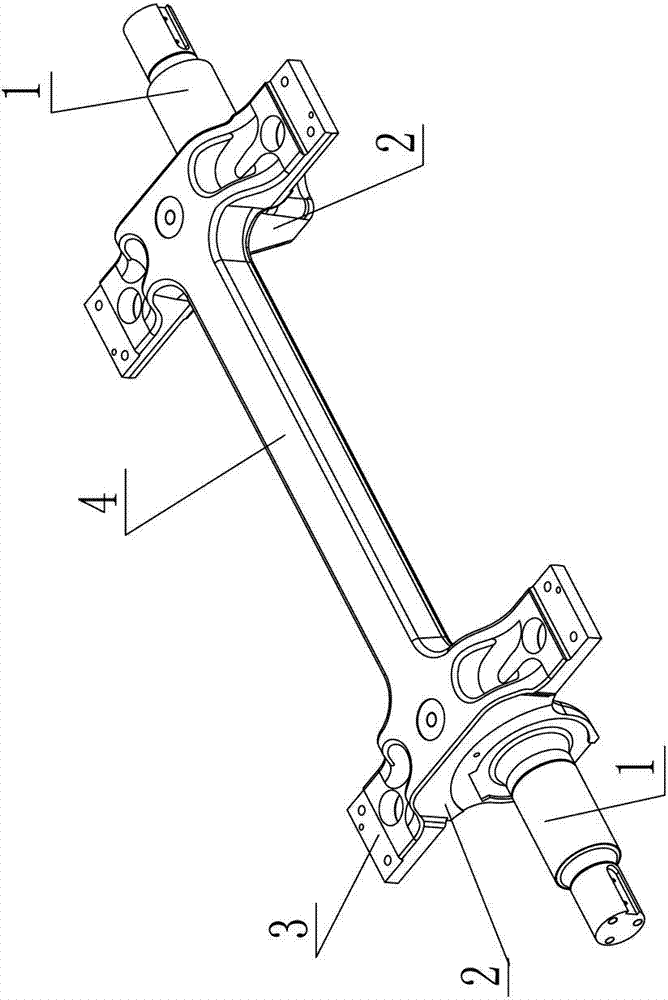

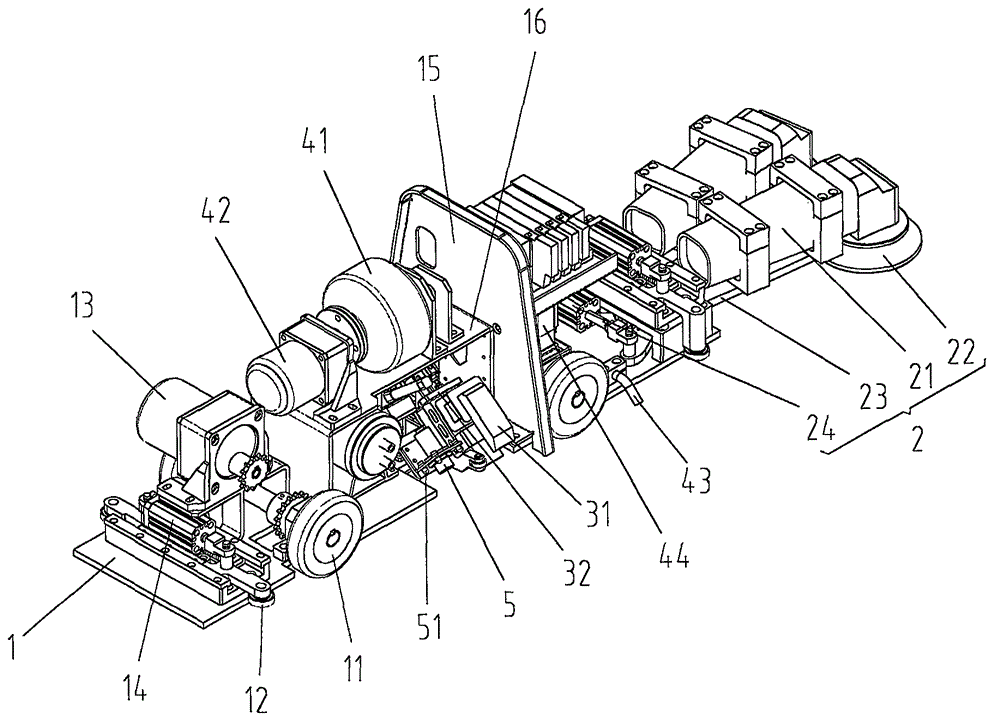

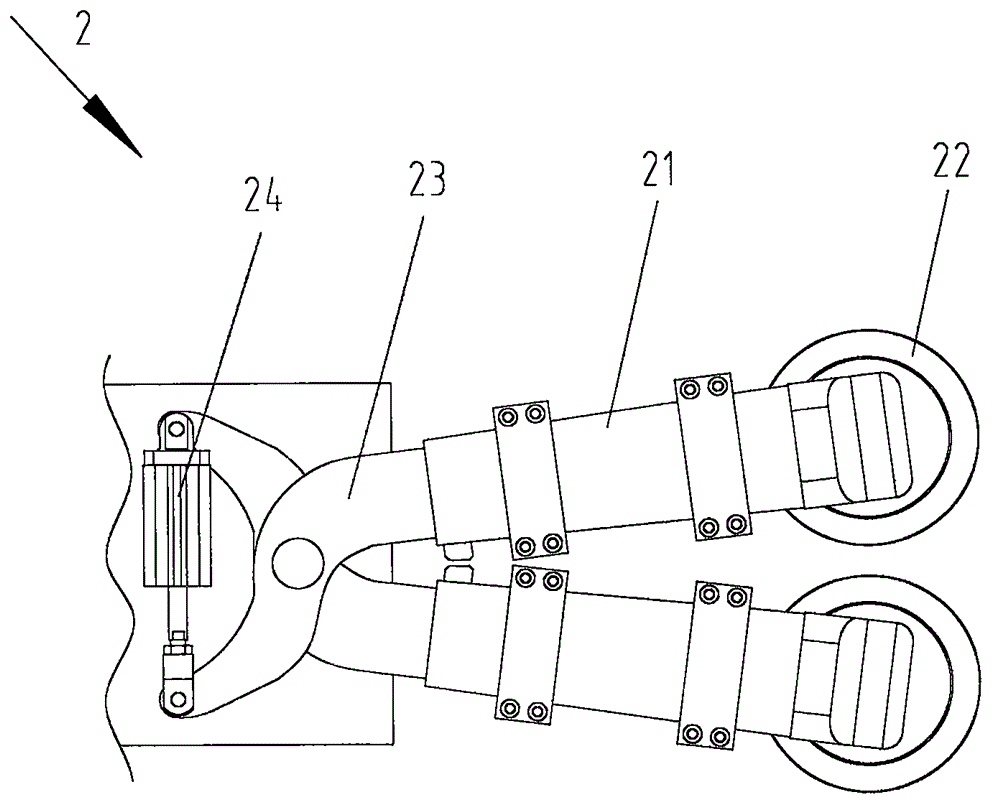

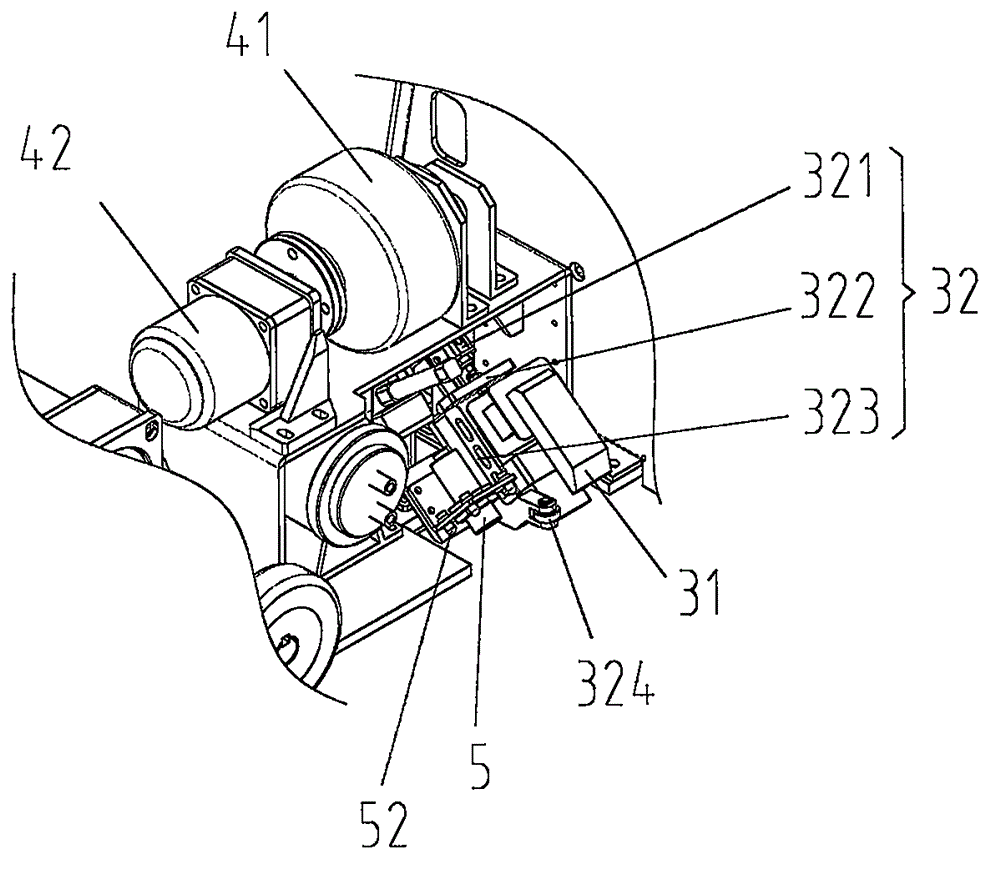

Wall-climbing robot for magnetic particle defect testing

InactiveCN104875808AImprove magnetic attractionSimple structureVehiclesMaterial magnetic variablesPush pullEngineering

A wall-climbing robot for magnetic particle defect testing comprises a running device, a magnet spraying device, a magnetizing device and a marking device, magnetic adsorption wheels with damping structures are mounted on a frame, four E-type probes are connected with eccentric cam driving devices via flexible connectors, the marking device comprises a push-pull electromagnet, and a marking stamper is mounted at the bottom of the electromagnet. The wall-climbing robot can be firmly attracted on the wall face of a tank, the obstacle avoidance capability can be improved effectively by the aid of the magnetic probes through elastic connection, existing manual operation can be substituted completely, defect testing efficiency can be improved, and personal injury can be reduced.

Owner:ZHEJIANG UNIV OF TECH +1

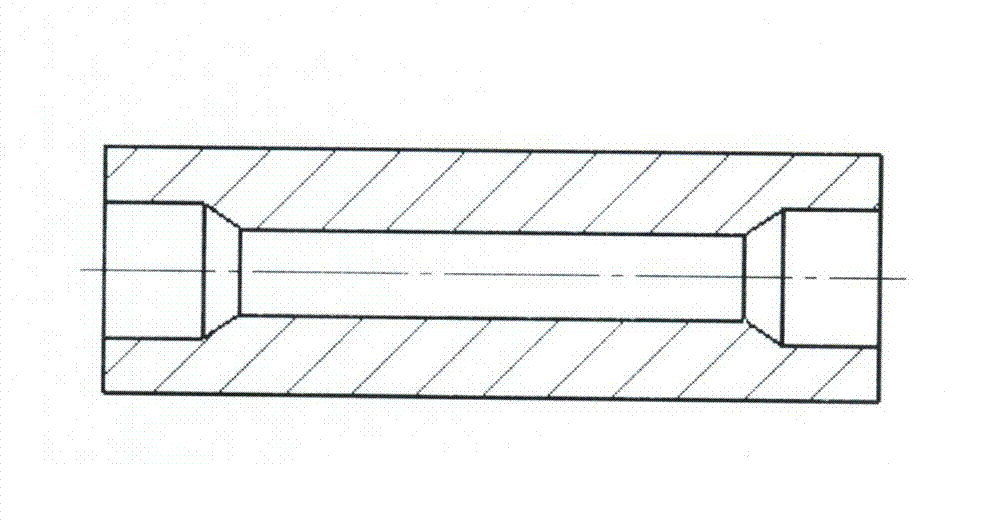

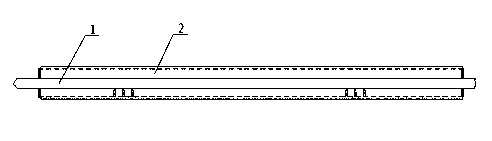

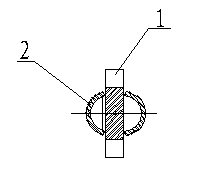

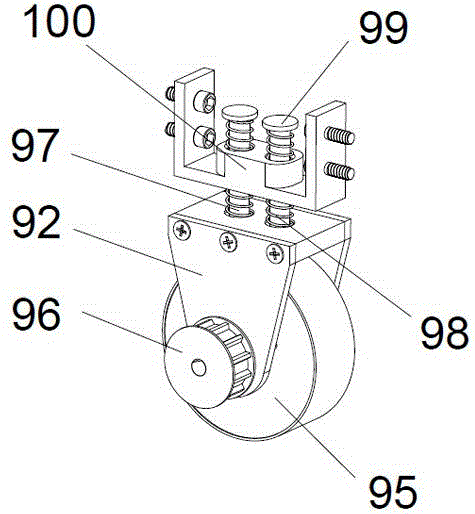

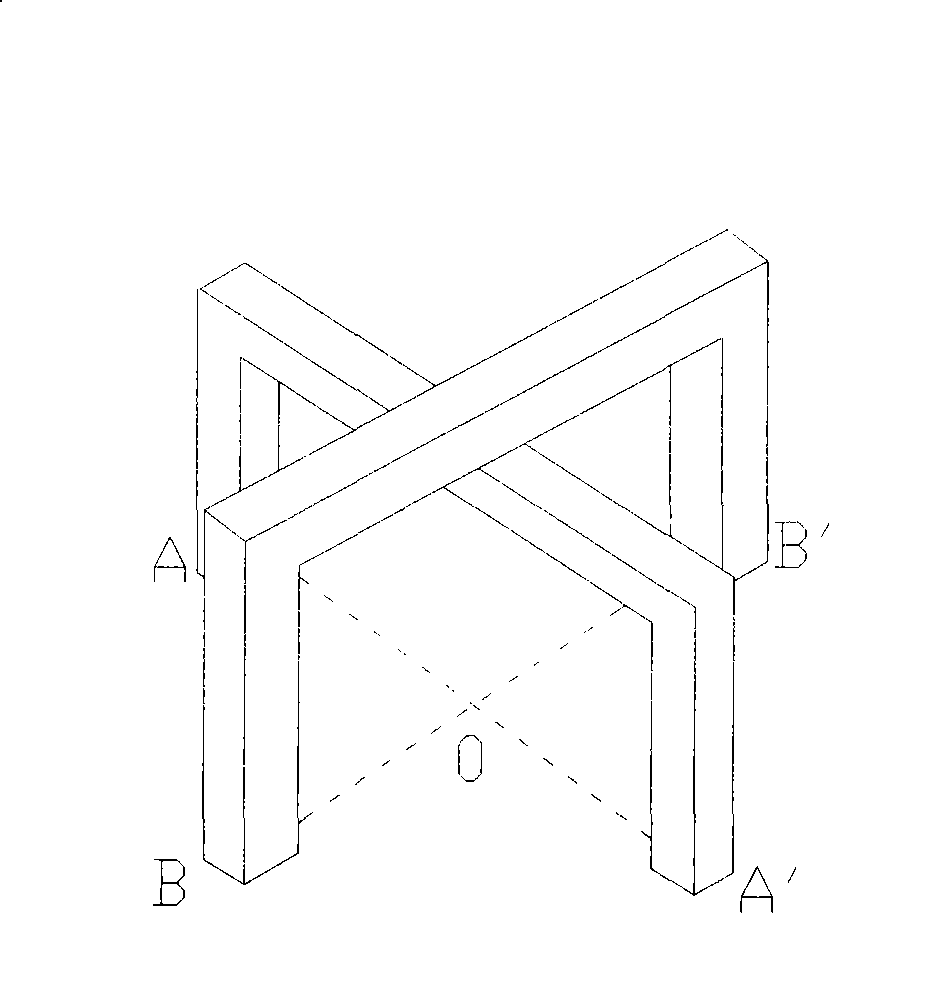

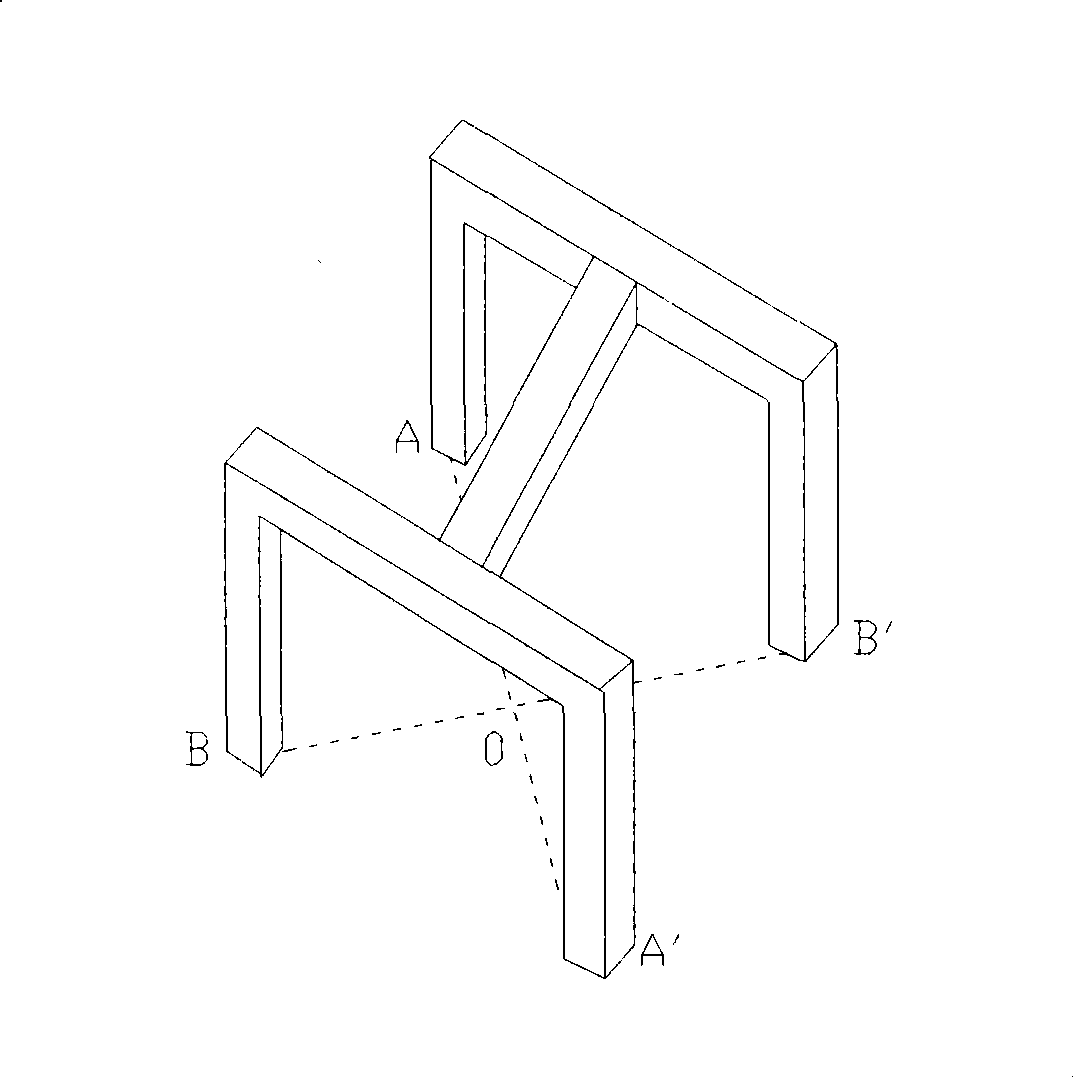

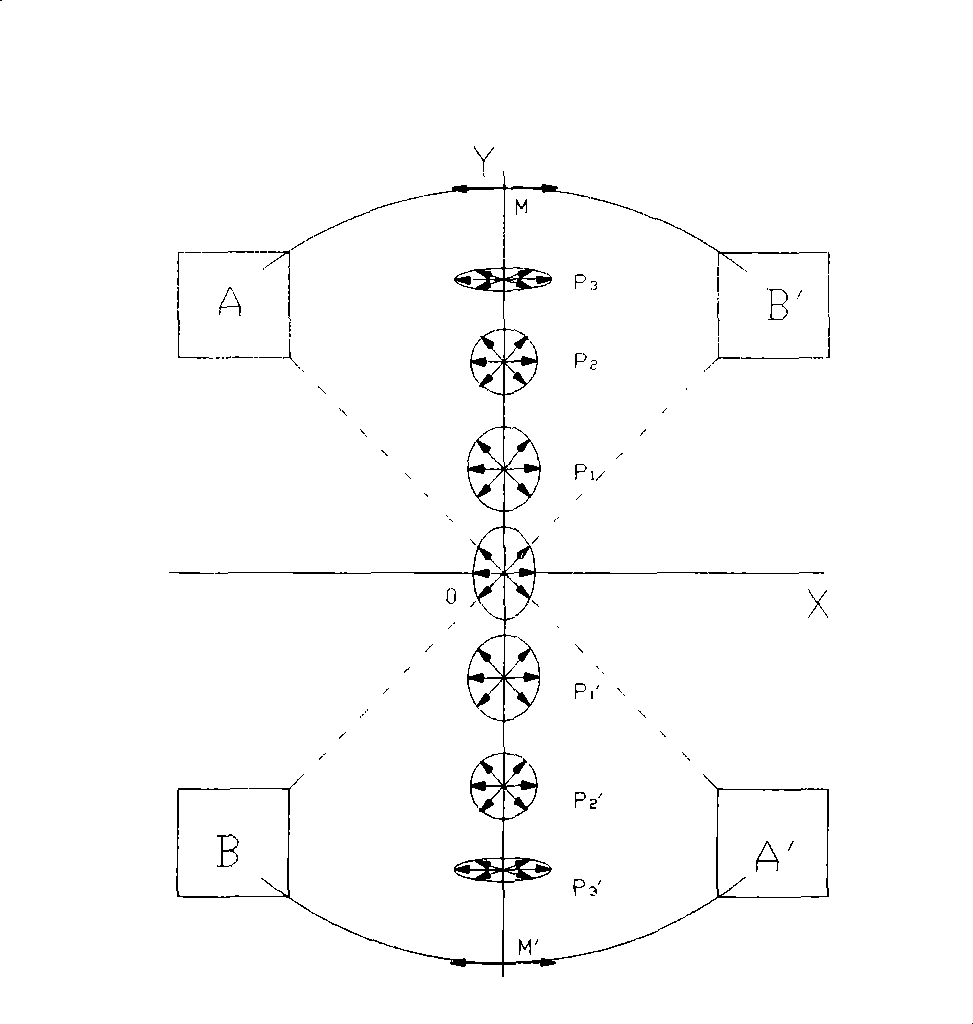

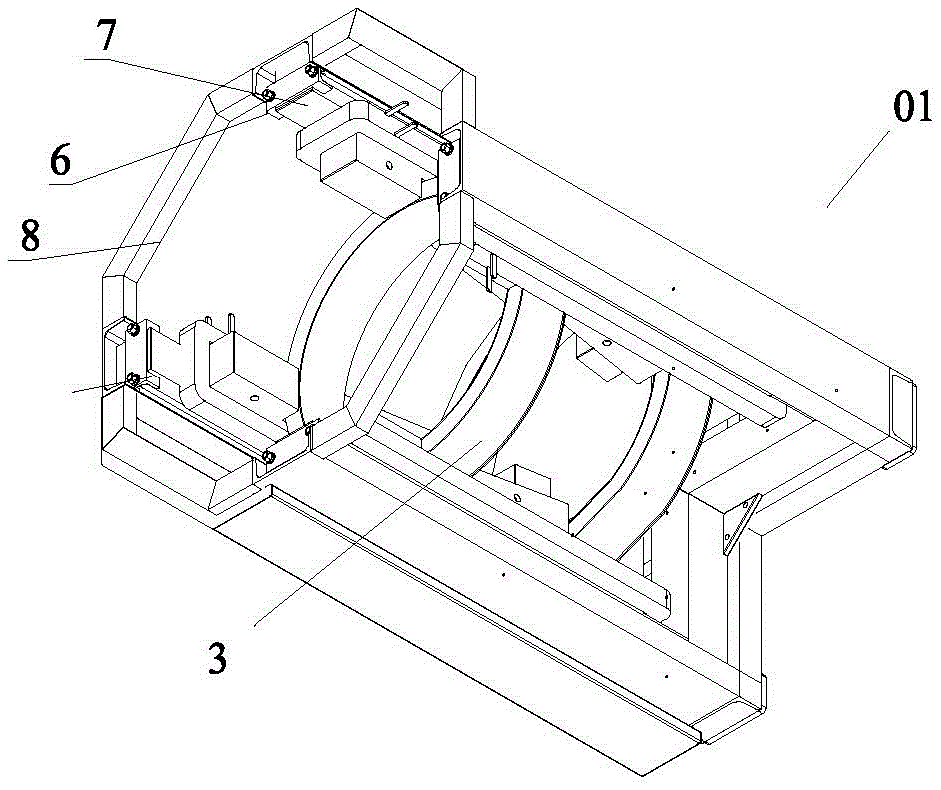

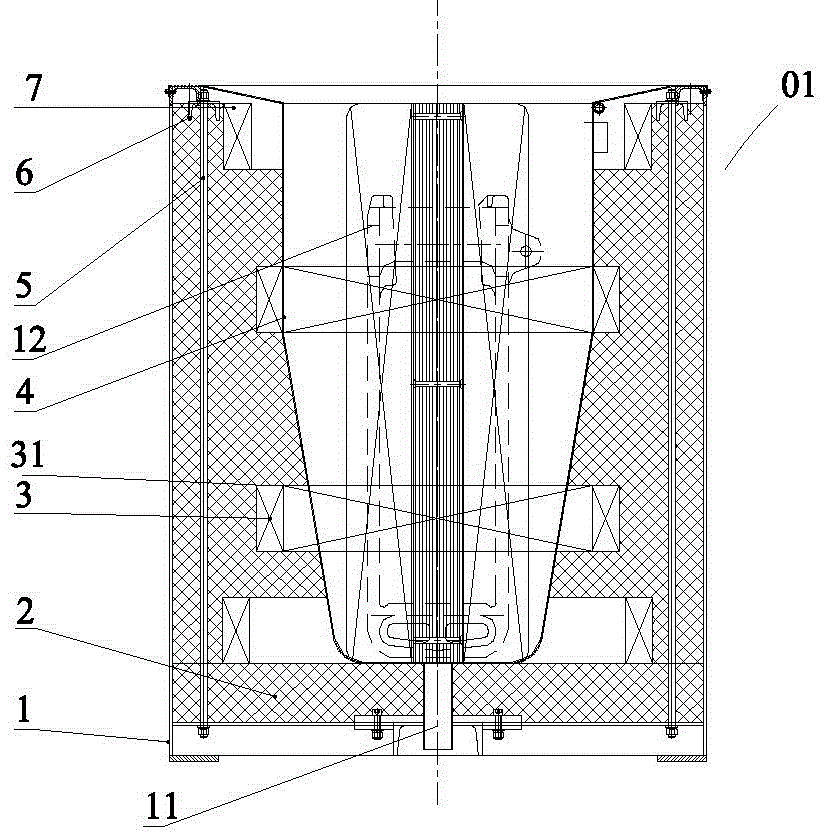

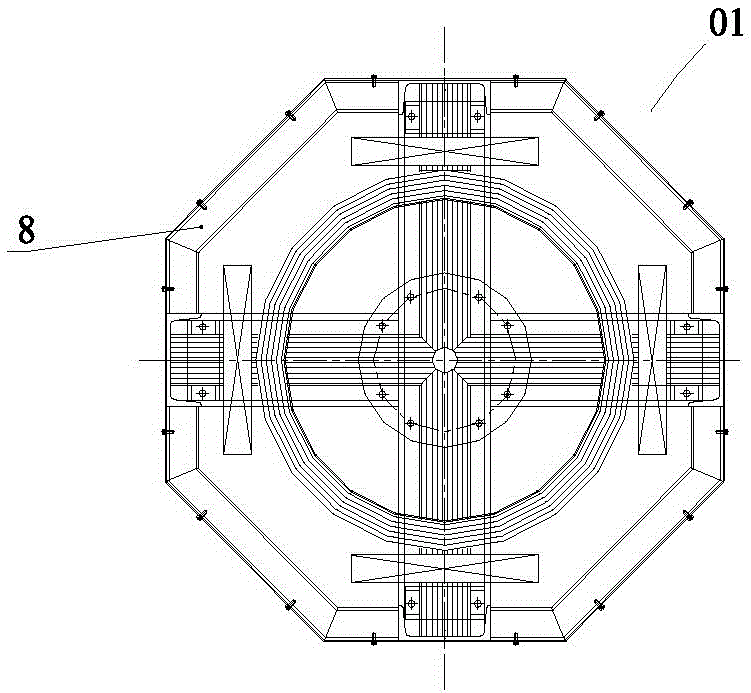

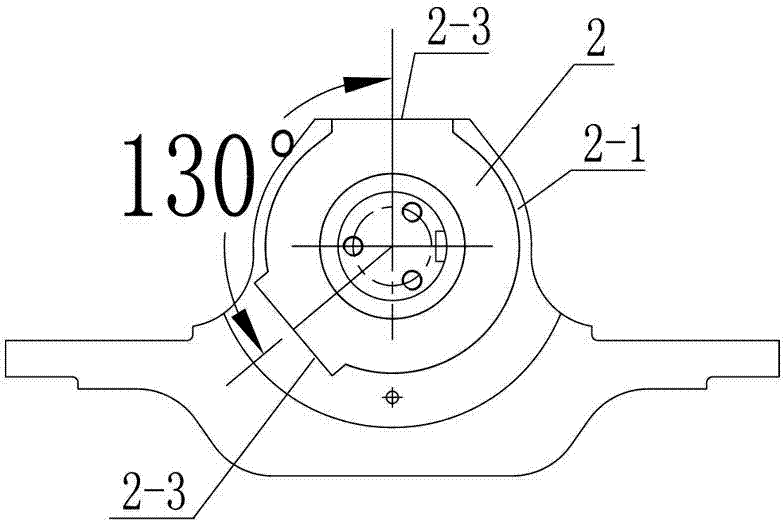

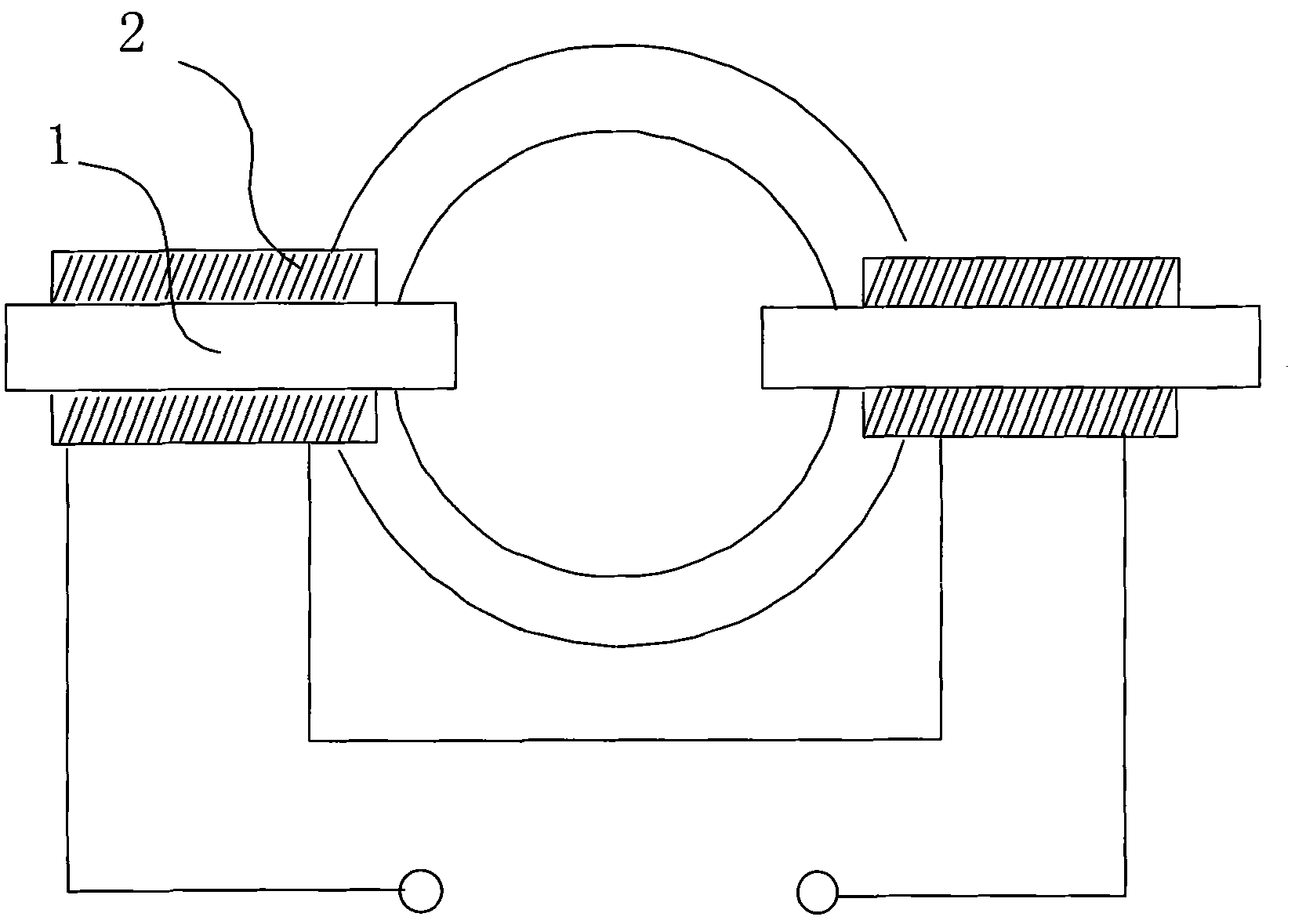

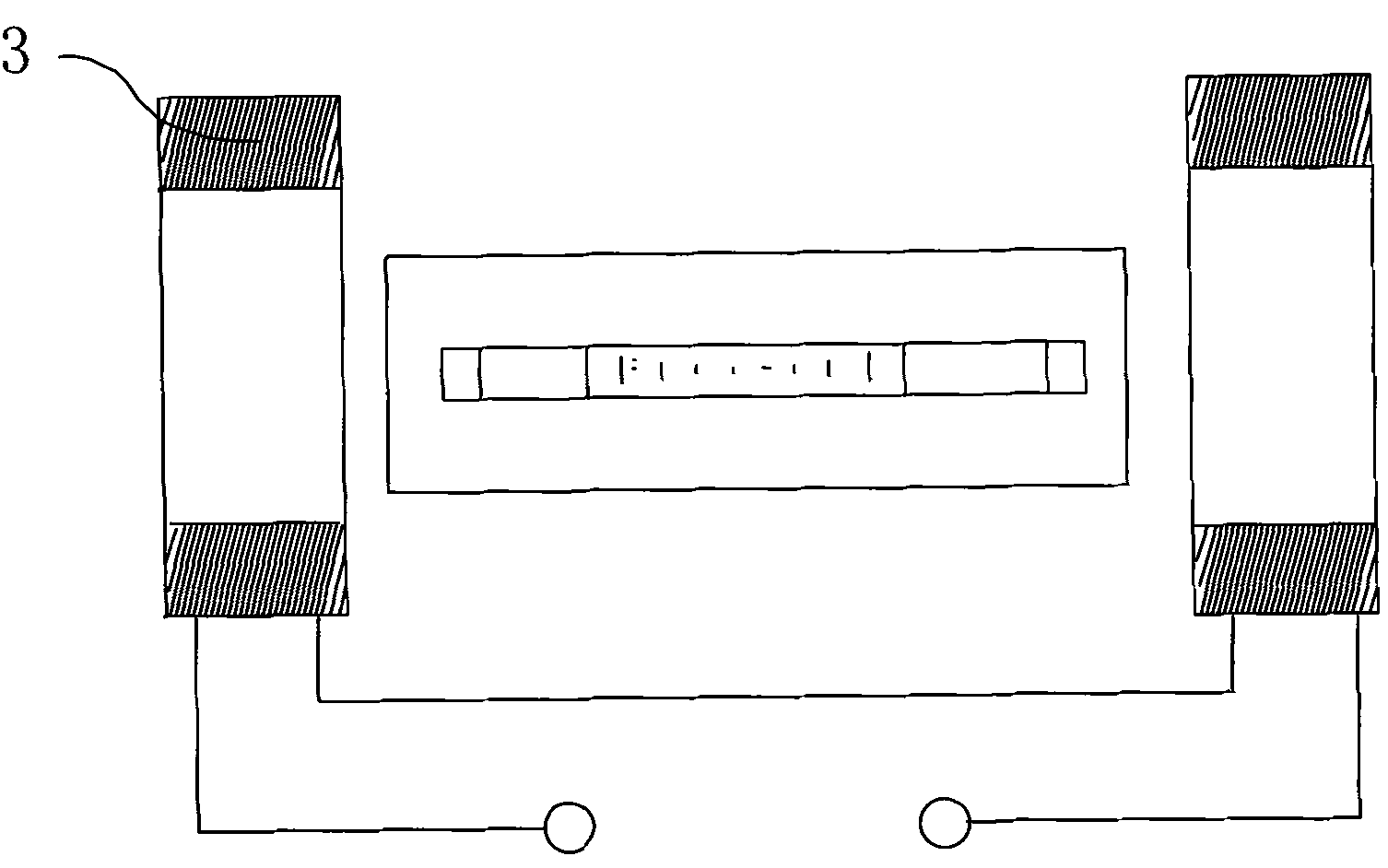

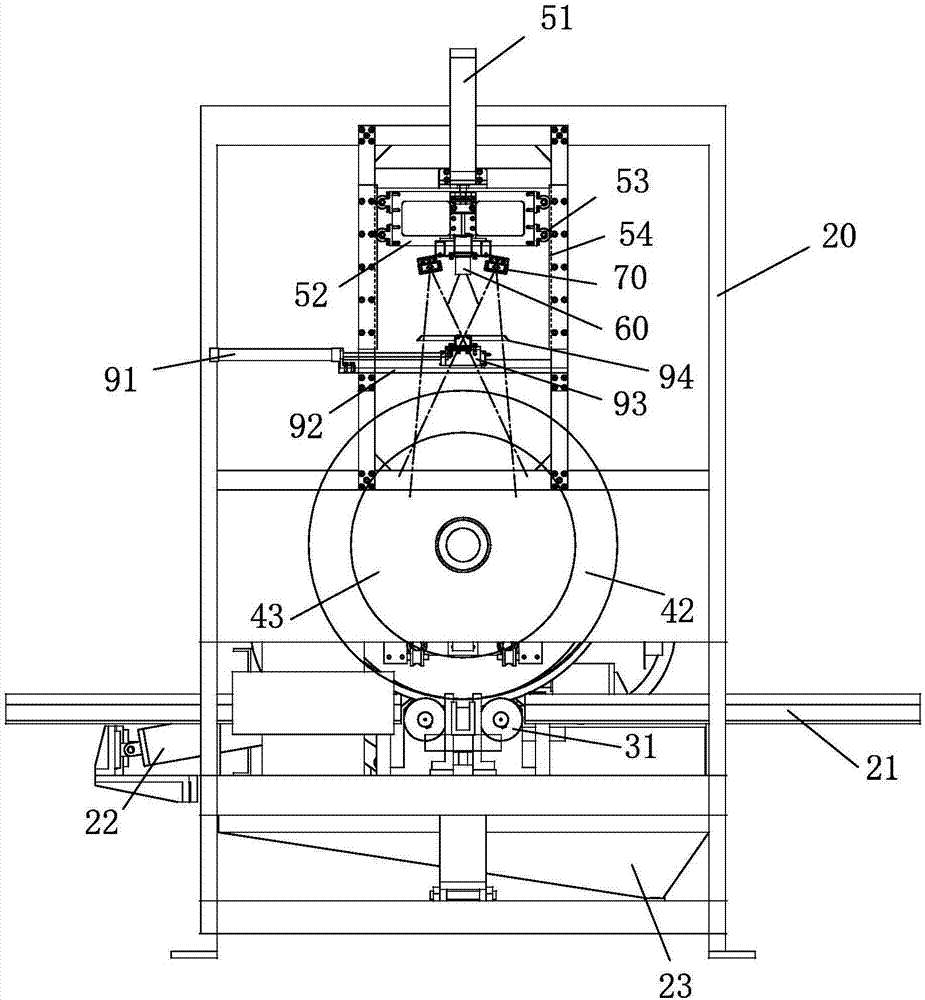

Telescopic cross magnet yoke fluorescent magnetic powder flaw detection machine

InactiveCN101435797ARealize the scaling functionWith telescopic functionMaterial magnetic variablesMagnetic polesUltimate tensile strength

The invention provides a telescopic crossed yoke fluorescent magnetic powder inspection machine. A crossed yoke comprises a fixed yoke parallel to the surface of a workpiece to be tested and a moving yoke perpendicular to the surface of the workpiece to be tested, the moving yoke passes through a sliding bushing and is in sliding connection with the fixed yoke, and the moving yoke is provided with a pressure spring. The invention successfully realizes that each magnetic pole of the magnetic powder inspection machine has telescopic function so as to closely contact the workpiece by dividing the crossed yoke into the fixed yoke and the moving yoke, thereby guaranteeing the magnetic-field intensity during the fault detection. The magnetic powder inspection machine is also provided with a CCD image acquisition device, and realizes the program control of working procedures of feeding, magnetization, CCD observation and discharge as well as on-line detection monitoring and automatic fault detection through the program control operation of a PLC.

Owner:瑞迪世纪(北京)探伤设备有限公司

Spiral seam submerged arc welded pipe manufacturing process

ActiveCN102284550ASmall sizeReduce cooling rateArc welding apparatusShielded metal arc weldingVisual inspection

The invention provides a manufacturing process of a spiral seam submerged arc welded pipe. The purpose of the present invention is achieved in this way: 1) raw material inspection, 2) stock preparation, 3) uncoiling, 4) leveling, 5) steel strip alignment, 6) disc shearing, 7) edge milling, 8) steel strip Delivery, 9) Steel strip edge pre-bending, 10) Forming, 11) Forming inspection, 12, 13) Internal and external automatic welding, 14, 15) Initial inspection, internal inspection, 16) Steel pipe cutting, 17) Manual repair welding, 18) X-ray inspection, 19) water pressure, 20) water pressure test inspection, 21) ultrasonic inspection, 22) magnetic particle inspection, 23) chamfering, 24) physical and chemical inspection of products, 25) finished product inspection, 26) spray marking. Submerged arc automatic welding can use large welding current, the arc heat is concentrated, the penetration depth is large, and the welding wire can be fed continuously, so its production efficiency is 5-10 times higher than that of manual arc welding; it saves materials and electric energy, and is environmentally friendly and harmless to the human body.

Owner:TIANJIN JINGHAI COUNTY XINGDA PIPE MFG

Grinder shell cover casting method

InactiveCN101134227AImpact flaw detectionGuaranteed sequential solidificationFoundry mouldsFoundry coresDivergence angleMaterials science

The present invention discloses method of casting end cap for mill. The present invention can ensure high casting quality by means of connecting external chill in thickness of 0.6-0.8 time the hot pitch circle diameter, applying the external chill with sand layer of 10-15 mm thickness, inwards shifting the hot pitch circle in the round corner region to avoid microscopic shrinkage to affect magnetic particle inspection, and ensuring the shrink passage with proper divergence angle for solidification in the order from far parts to the sink head.

Owner:CITIC HEAVY INDUSTRIES CO LTD

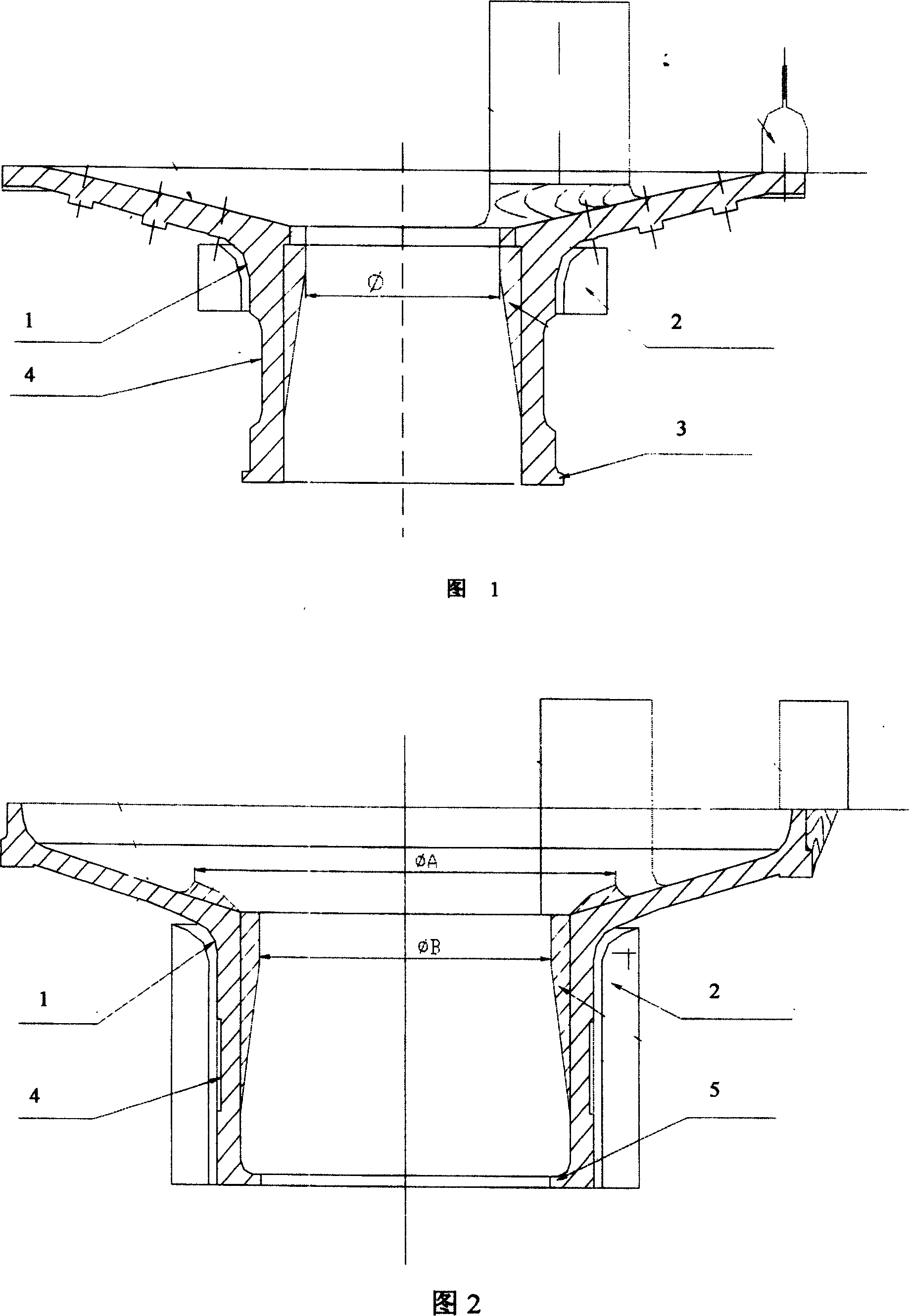

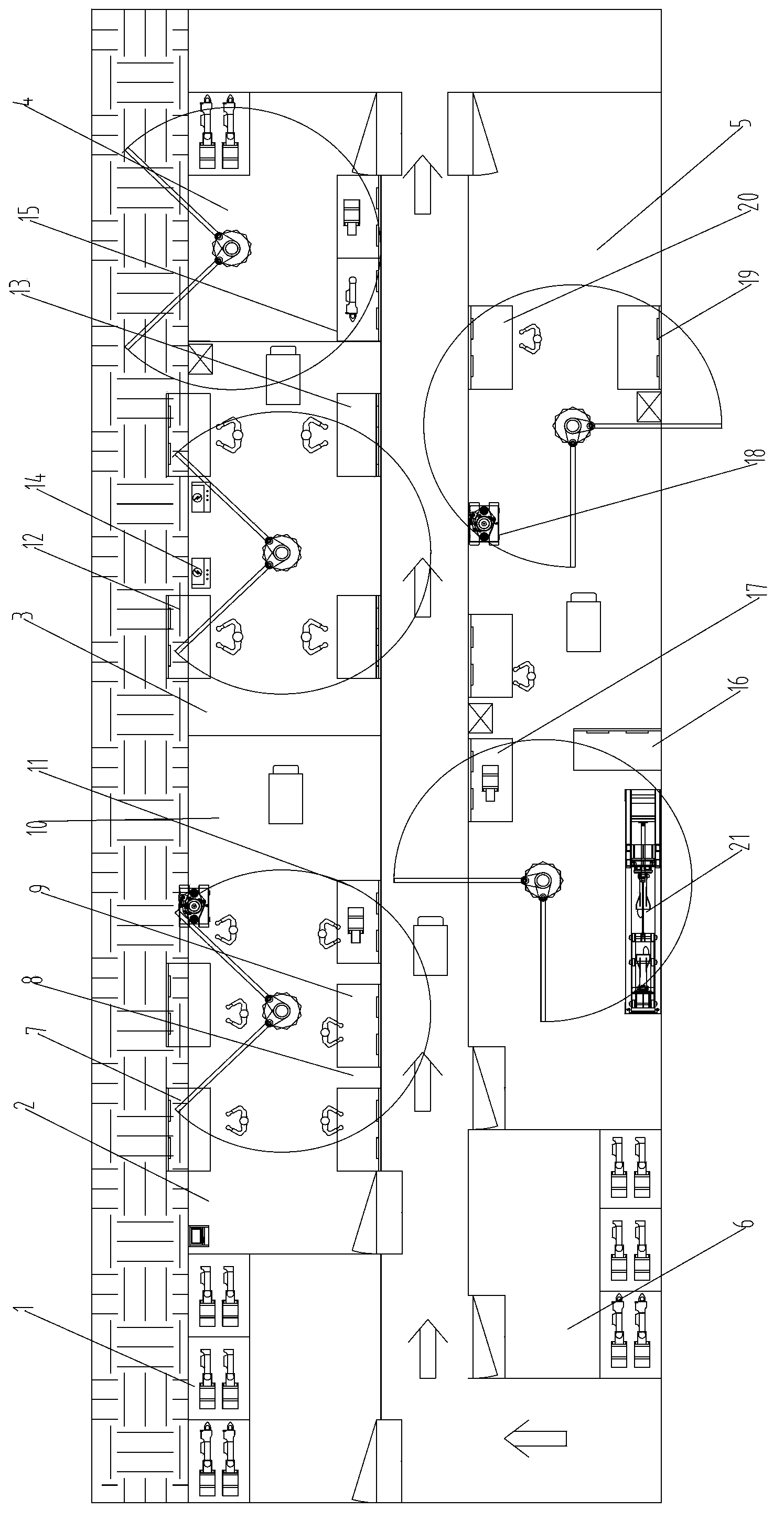

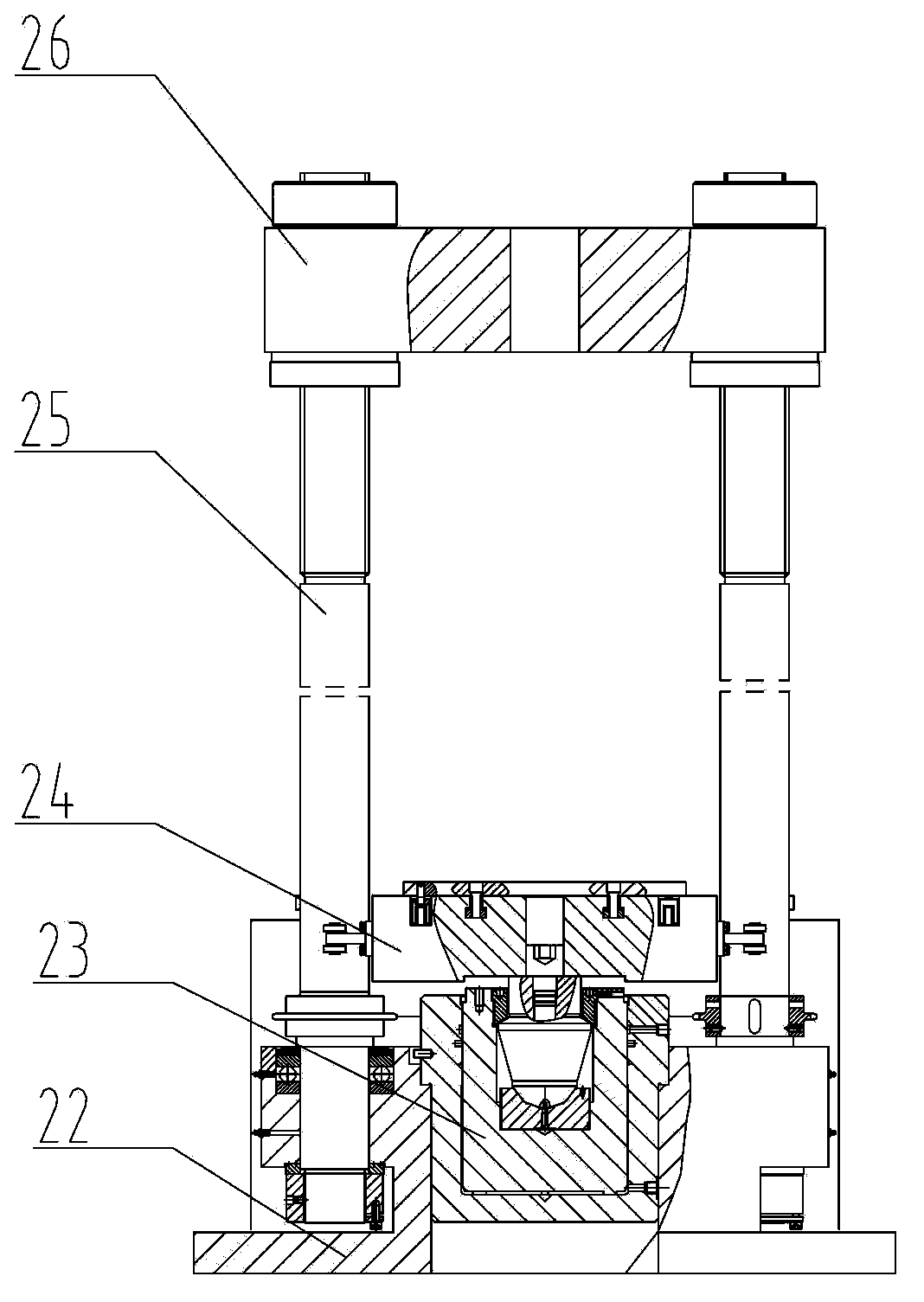

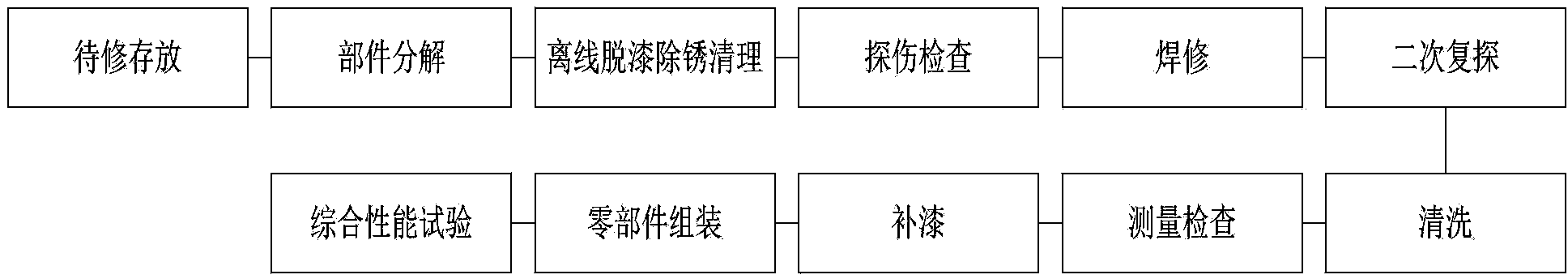

Inspection and repair line and method for bumper of coupler of motor train unit

ActiveCN103358087ASolve the problem of poor universality in maintenanceAdjustable operating spaceEngineeringReliability engineering

The invention relates to an inspection and repair line and method for a bumper of a coupler of a motor train unit. The inspection and repair line comprises a buffer for repair, a resolving and check area, a flaw detection area, a painting make-up area, an assembling test area and a qualified product storing area, wherein a plurality of dimensional storage racks are arranged in the buffer for repair; a resolving workbench, a coupler buffer resolving device, a coupler head resolving device, a bumper crushing pipe press-mounting machine and a bumper press-mounting machine are arranged in the resolving and check area; a flaw detection workbench, a measurement workbench and a mobile magnetic particle inspection machine are arranged in the flaw detection area; a painting make-up workbench and a temporary storage rack are arranged in the painting make-up area; an assembling workbench, a bumper assembling device, a bumper crushing pipe press-mounting machine, a coupler head assembling device, a coupler buffer assembling device and a coupler coupling testboard are arranged in the assembling test area.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

Magnetic particle flaw detector for irregular parts

PendingCN106404894AAccurate flaw detectionAddress diversityMaterial magnetic variablesMagnetic tension forceMulti path

The invention discloses a magnetic particle flaw detector for irregular parts. The magnetic particle flaw detector includes a rack, an iron core is fixed on the rack, multiple groups of longitudinal magnetization coils and multiple groups of circumferential magnetization coils in wire connection are fixed to the iron core, the longitudinal magnetization coils are in circular distribution along the horizontal circumferential direction, and the circumferential magnetization coils are in longitudinal extension distribution. During use of the magnetic particle flaw detector, workpieces are placed in a liquid collection bucket, when a magnetic suspension liquid is sprayed to irregular parts, the longitudinal magnetization coils and circumferential magnetization coils of the magnetic particle flaw detector provided by the invention can form a multipath three-dimensional magnetic field for magnetic particle flaw detection of the irregular parts. Compared with existing two-path magnetic field, the multi-path magnetic field can achieve more accurate flaw detection, also the irregular parts only need to be placed in the liquid collection basket, and no special clamping tool is needed, the diversity problem of irregular parts is solved, i.e. the magnetic particle flaw detector can be applicable to different irregular parts. Therefore, the magnetic particle flaw detector for irregular parts provided by the invention has the technical effects of precise flaw detection and good universality.

Owner:SHEYANG SAIFU NDT EQUIP MFG

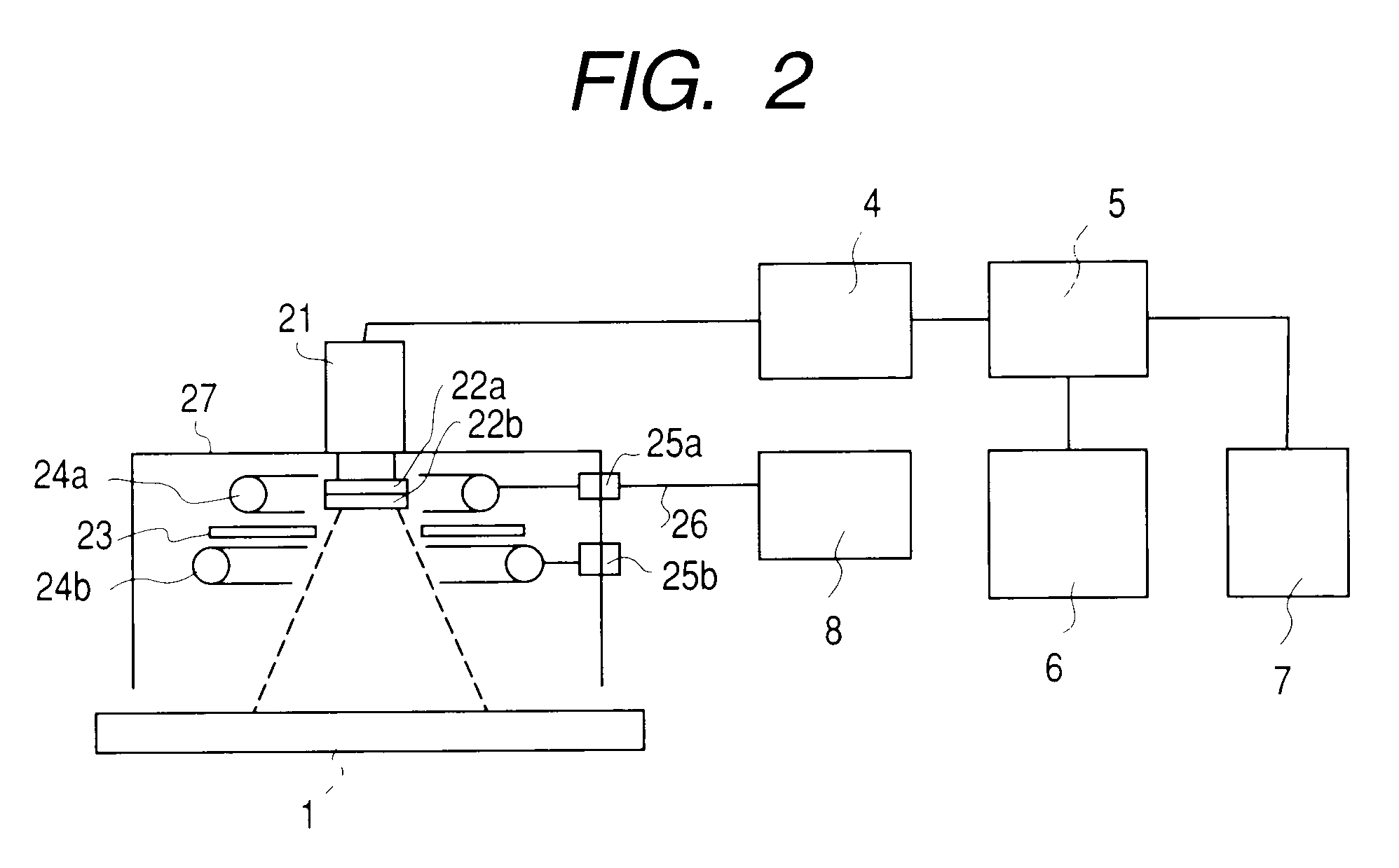

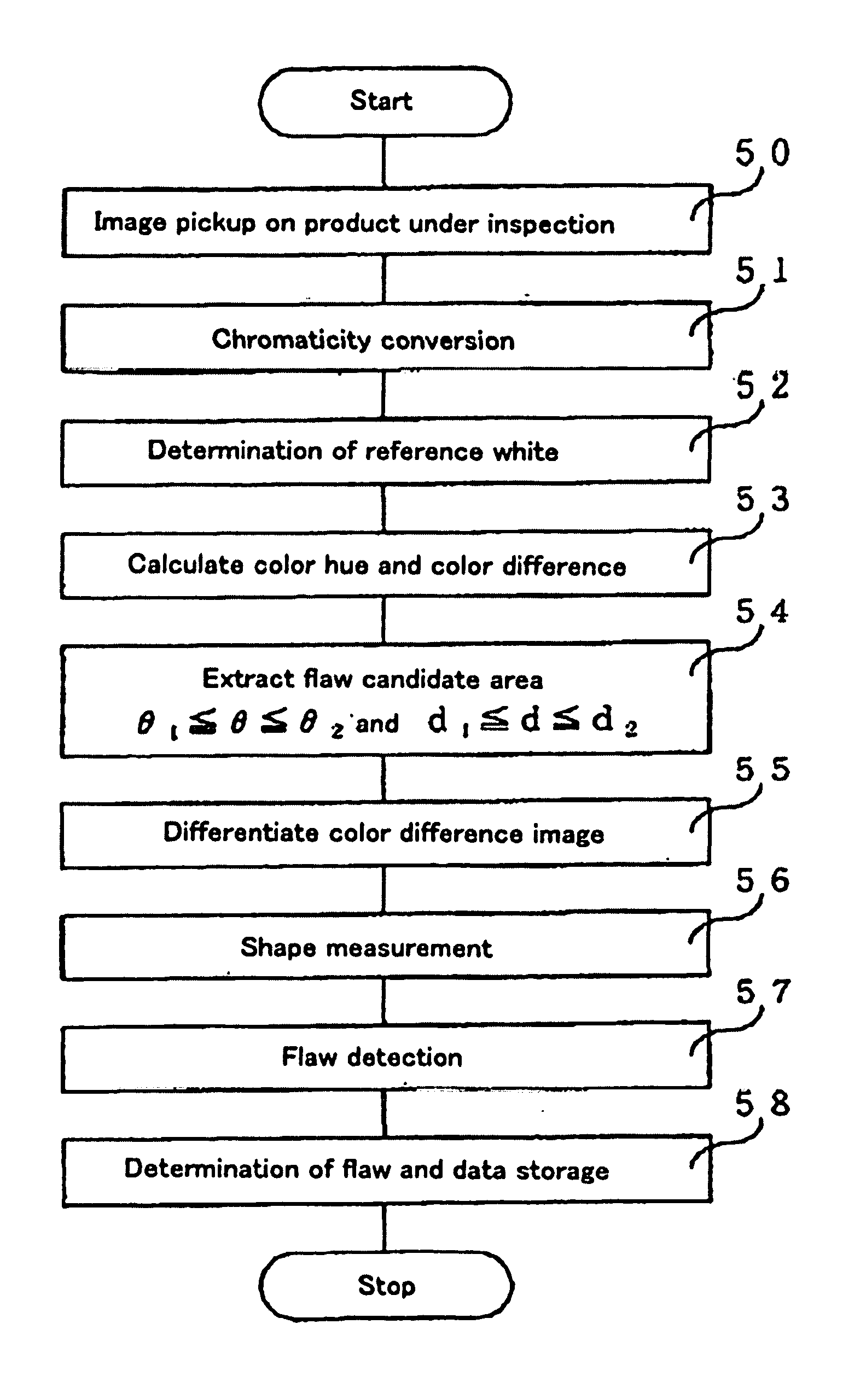

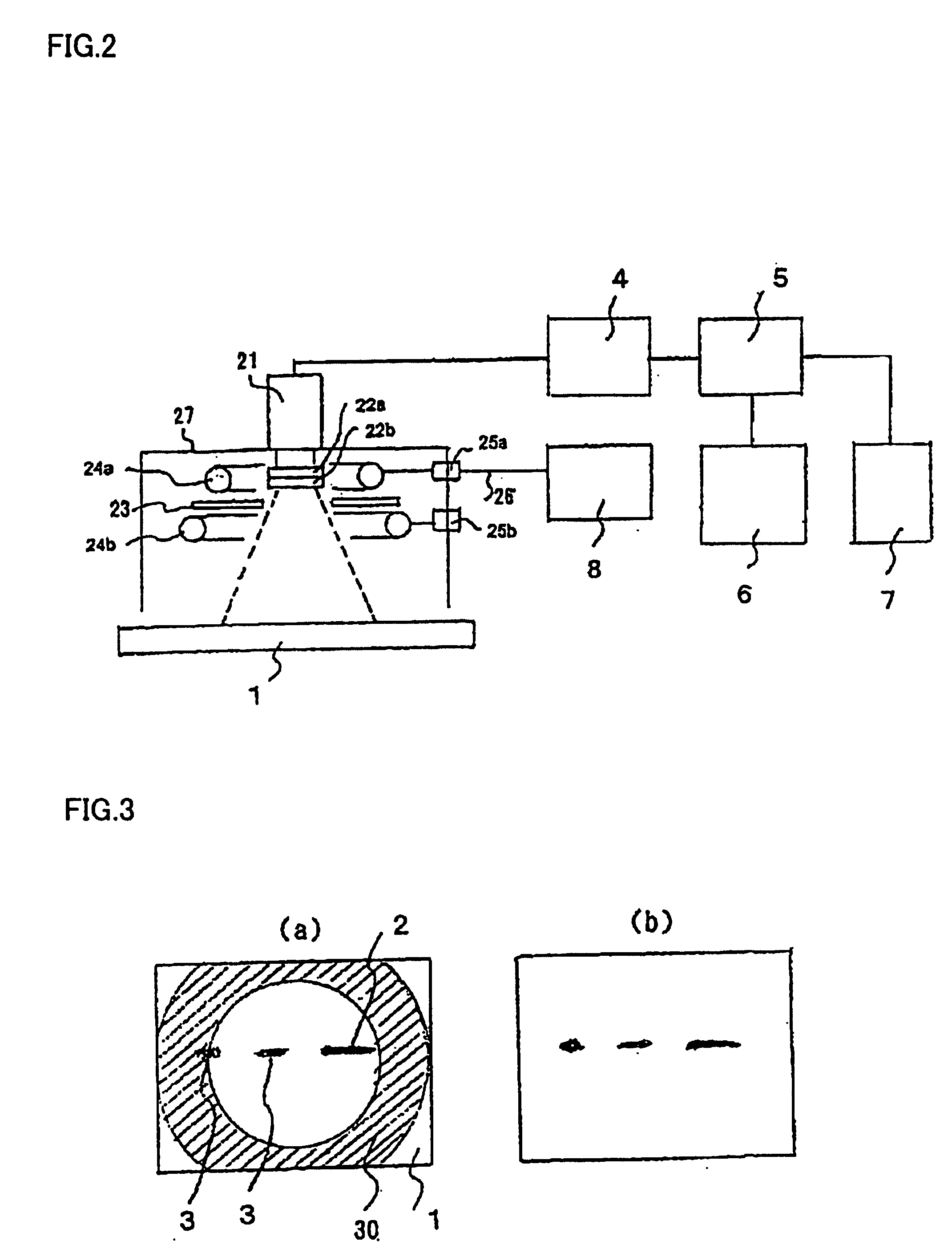

Method and apparatus for non-destructive testing

InactiveUS6975391B1Easy to findPhotometry using reference valueOptically investigating flaws/contaminationNon destructiveUltraviolet

Using an image signal acquired by picking up a sample to be inspected by a color video camera, penetrant inspection and magnetic-particle inspection, which are non-destructive inspections, are carried out so that deficiency candidates, including a pseudo deficiency, are automatically detected and displayed on a screen. A real deficiency can be detected from the displayed deficiency candidates. As image data is stored in memory means, information of a deficiency can be repeatedly reproduced on the screen. In the penetrant inspection, the chromaticity at each position on an image is acquired, a deficiency candidate is extracted based on the chrominance, and the deficiency is distinguished from a pseudo deficiency based on the differential value of the chrominance. A polarization filter eliminates regular reflection originating from illumination in the penetrant inspection, and an ultraviolet-rays cutting filter prevents noise in the magnetic-particle inspection. Both inspections can be carried out with a single probe.

Owner:RICOH PRINTING SYST +1

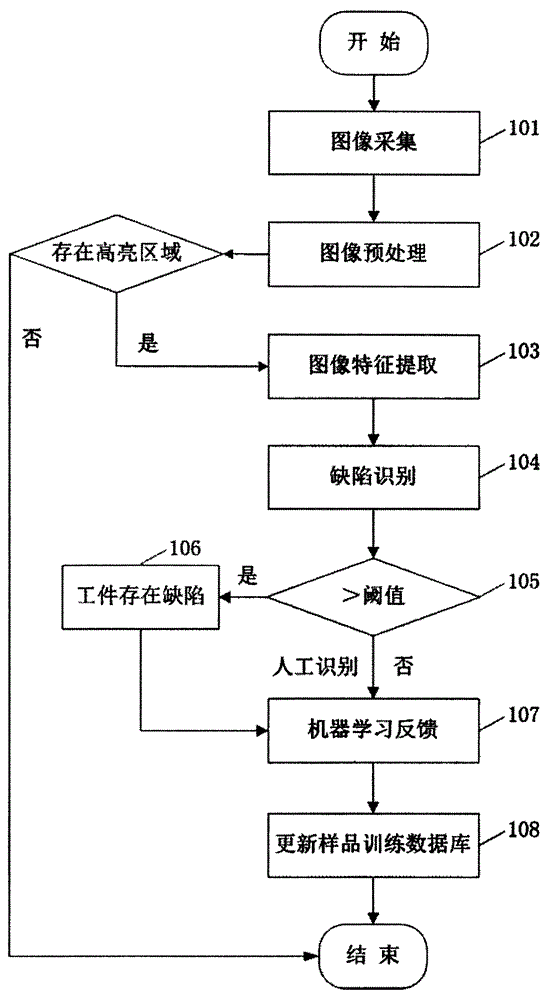

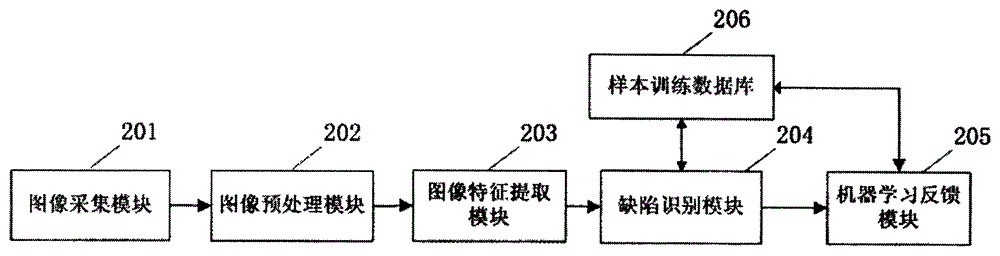

Automatic defect recognition method and system for magnetic particle testing

InactiveCN103984951AEasy to identifyImprove discrimination accuracyCharacter and pattern recognitionFeature extractionMaterial type

The invention discloses an automatic defect recognition method for magnetic particle testing. Whether a workpiece has defects or not is recognized by conducting image collecting, image preprocessing, image characteristic extraction, detect recognition and the like on the workpiece to be tested. The invention further discloses an automatic defect recognition system for magnetic particle testing. According to the automatic defect recognition technical scheme for magnetic particle testing, images are collected, discrimination of material types, the machining technique, magnetic particle detection process characteristics and other background knowledge of the workpiece and the rich experience of magnetic particle inspection personnel are combined, and thus the recognition rate and the discrimination accuracy of the workpiece are improved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Cognitive medical and industrial inspection system and method

ActiveUS9349098B1Low costSimplifies initial inspectionMedical simulationUltrasonic/sonic/infrasonic diagnosticsGamma rayCompanion animal

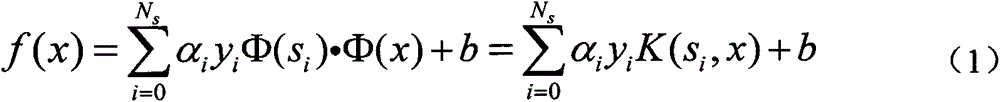

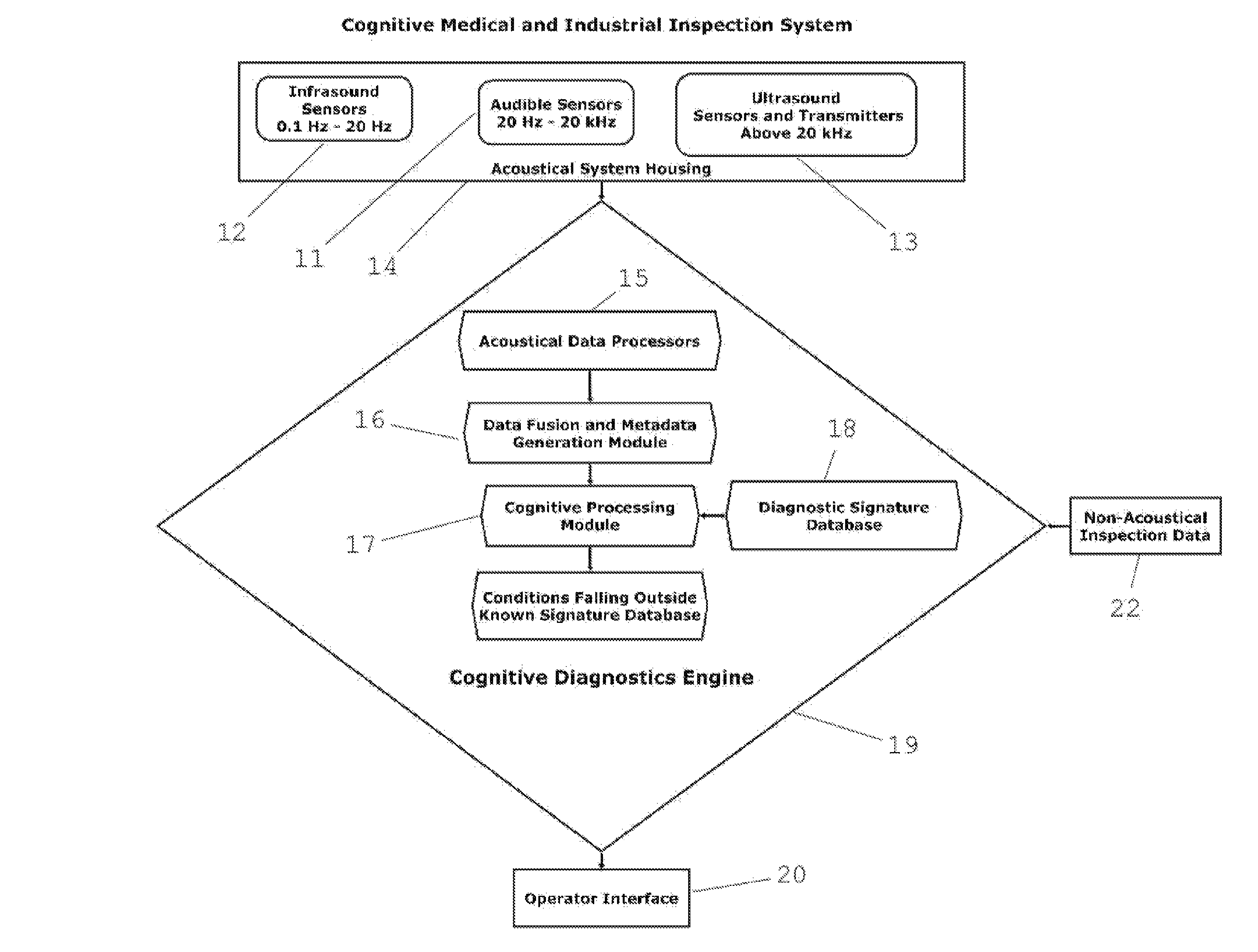

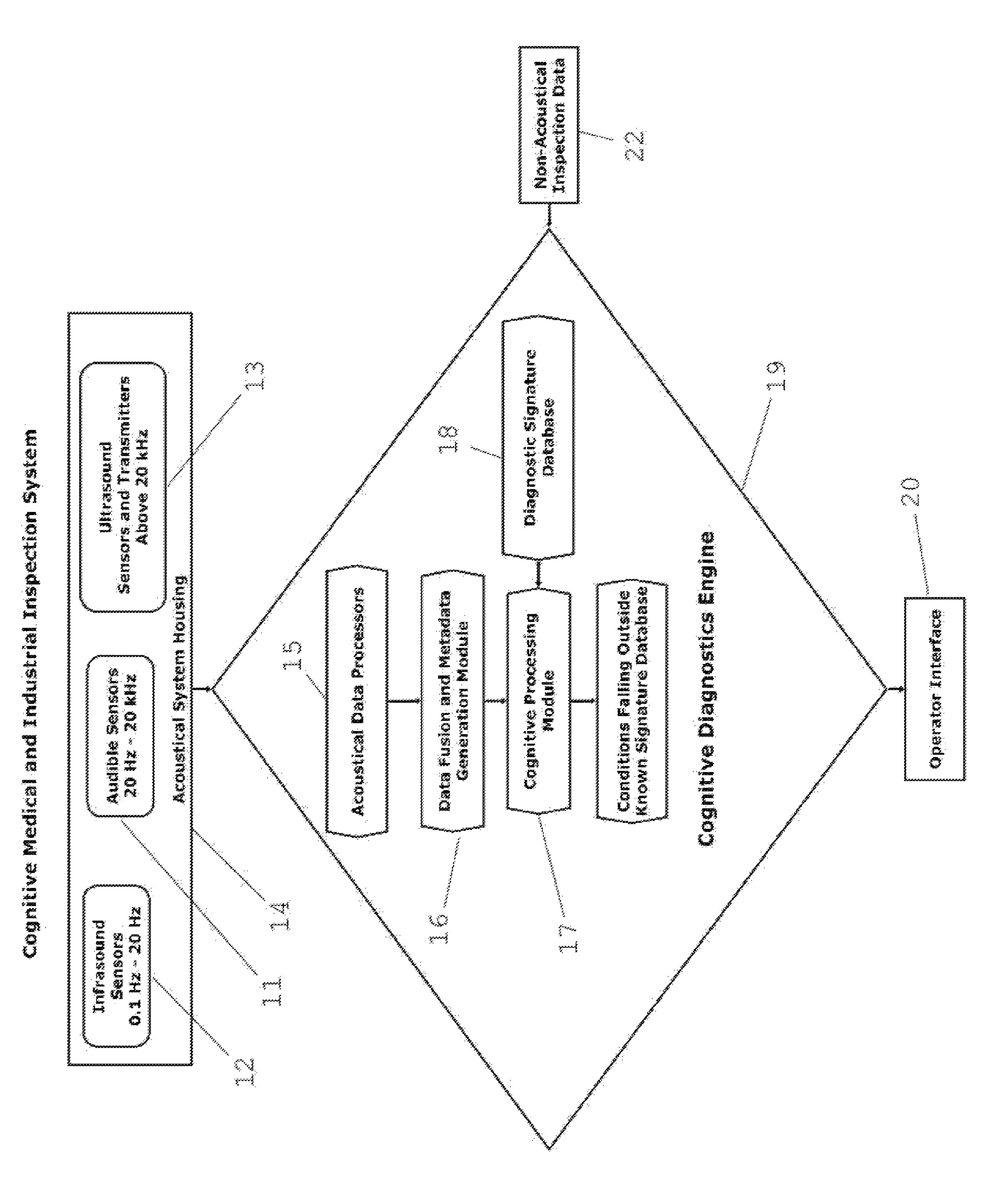

The present invention relates to inspection of medical patients including, but not limited to, phonocardiography, auscultation and ultrasound medical imaging and other non-acoustical inspection techniques; and industrial non-destructive testing and evaluation of materials, structural components and machinery; and more particularly to the incorporation of cognitive artificial intelligence into an inspection system and method that utilizes cognitive mathematical techniques which emulate the cognitive processing abilities of the human brain including, but not limited to, symbolic cognitive architectures and inference process algebras, to analyze data collected from infrasound acoustical sensors (0.1 Hz-20 Hz), audible acoustical sensors (20 Hz to 20 kHz), ultrasound acoustical sensors and transmitters above 20 kHz, data collected from other non-acoustical inspection devices and systems including, but not limited to electrocardiography (EKG), computed-tomography (CT), single photon emission computed tomography (SPECT), positron emission tomography (PET), magnetic resonance imaging (MRI), electromagnetic testing (ET), magnetic particle inspection (MT or MPI), magnetic flux leakage testing (MFL), liquid penetrant, radiographic (x-ray and gamma ray), eddy-current testing, low coherence interferometry, and combinations thereof (i.e., multi-modality inspection data); fuse this data resulting in the generation of new metadata; and then utilize cognitive mathematical techniques to interpret this data against inspection signatures that characterize conditions being diagnosed. The present invention has the ability to also identify and anticipate abnormal conditions that fall outside known inspection signature patterns; and communicate the inspection results to an operator thereby simplifying the initial inspection and diagnosis for medical patients and industrial objects; minimizing false negative and false positive initial inspection results and lowering costs.

Owner:1619235 ONTARIO LTD

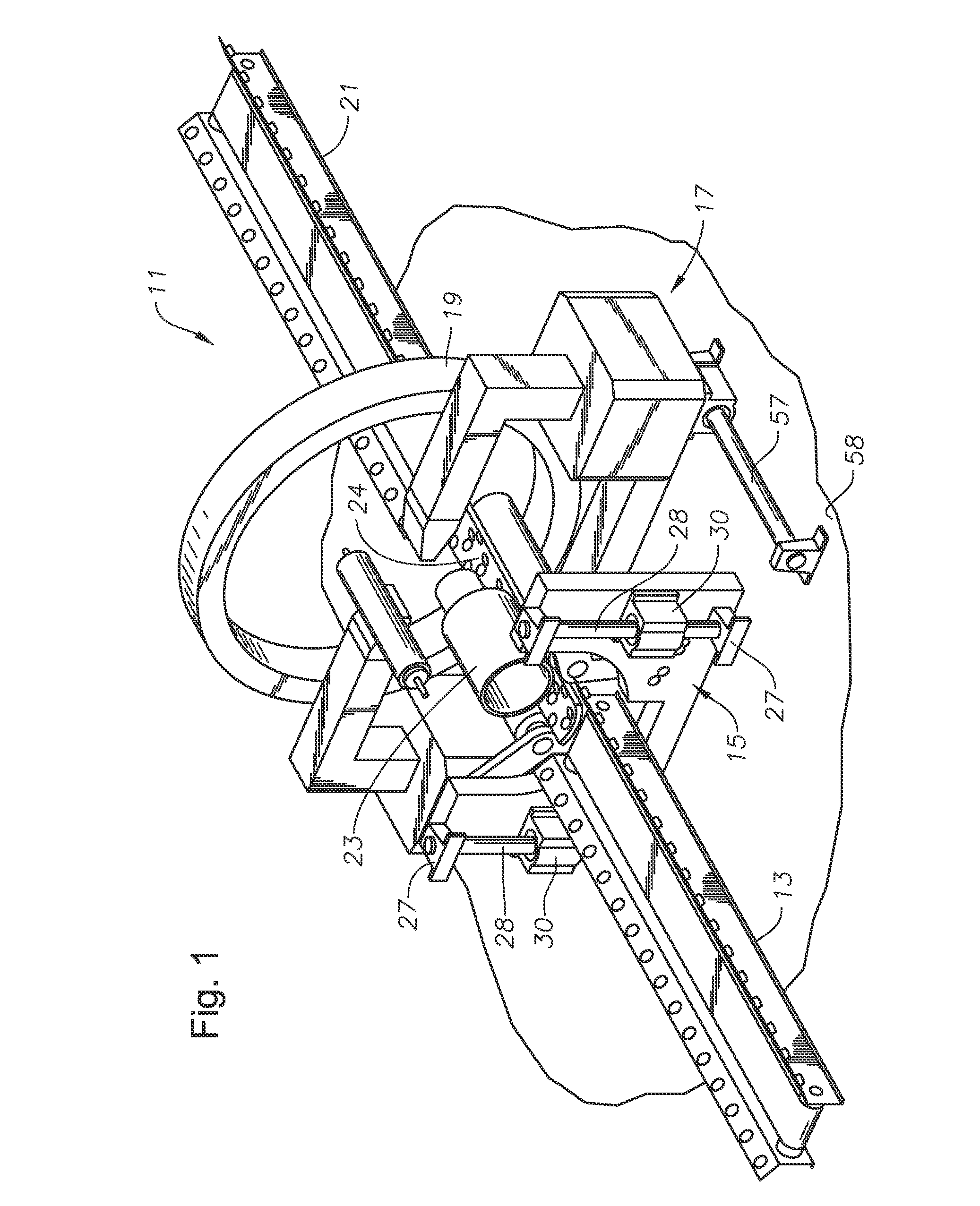

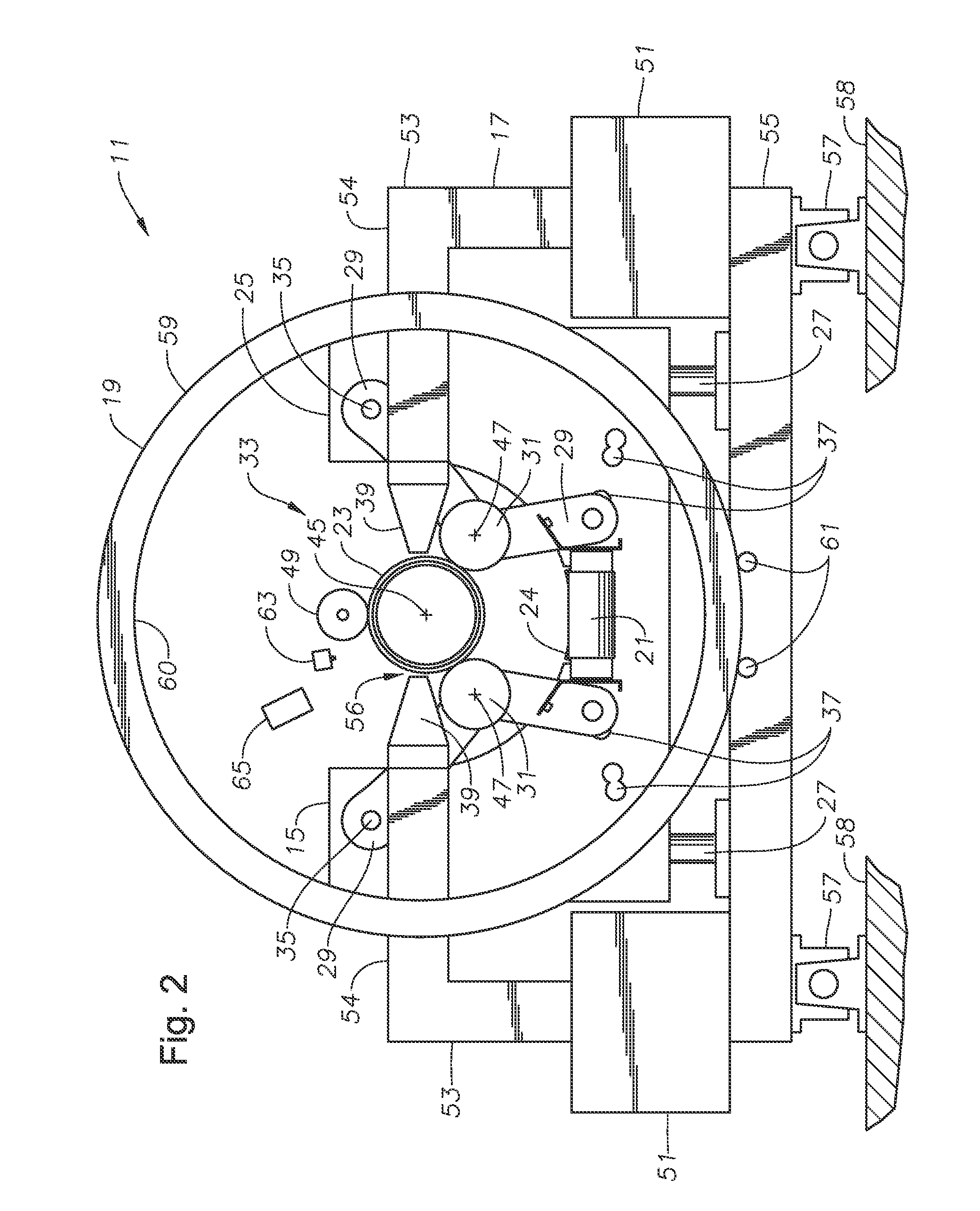

Method and apparatus for special end area inspection

ActiveUS8575923B1Avoid contactDamage to areaMagnetisation measurementsMaterial magnetic variablesMagnetic tension forceEngineering

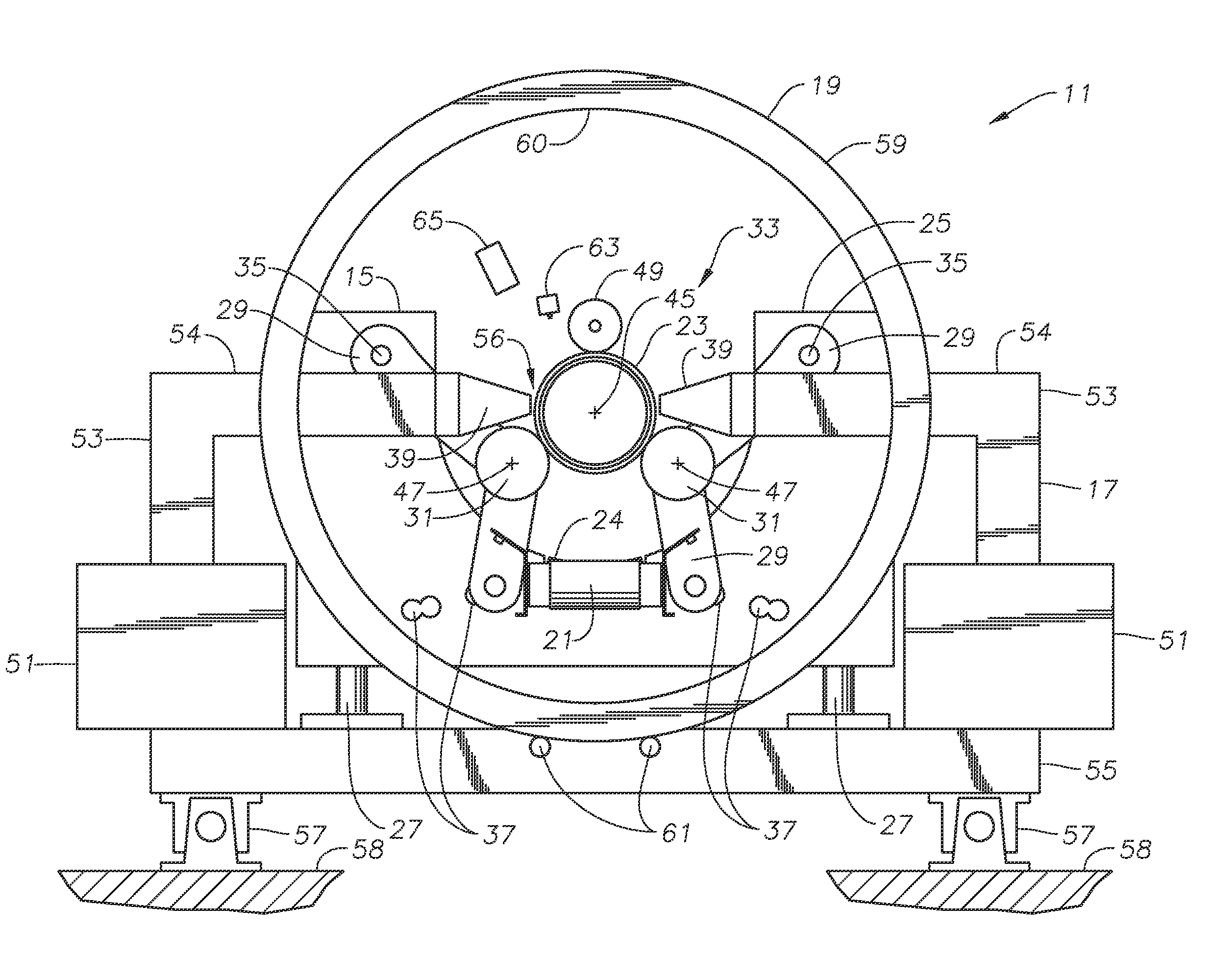

A magnetic inspection station for tubular members and methods for operating the same have a longitudinal flaw detection assembly adapted to pass a circumferential magnetic field through a tubular member and a transverse flaw detection assembly adapted to pass a longitudinal magnetic field through the tubular member. The magnetic fields cause congregation of a ferromagnetic particles sprayed on the tubular member in a magnetic particle inspection fluid. The congregation of ferromagnetic particles indicates a flaw in the tubular member. The magnetic inspection station includes a clamping apparatus positioned closely adjacent to the magnetic inspection station and adapted to support the tubular member within the magnetic inspection station and exert a compensating force on the tubular member to resist the magnetic forces generated by the longitudinal flaw detection assembly and the transverse flaw detection assembly.

Owner:OILPATCH TECH

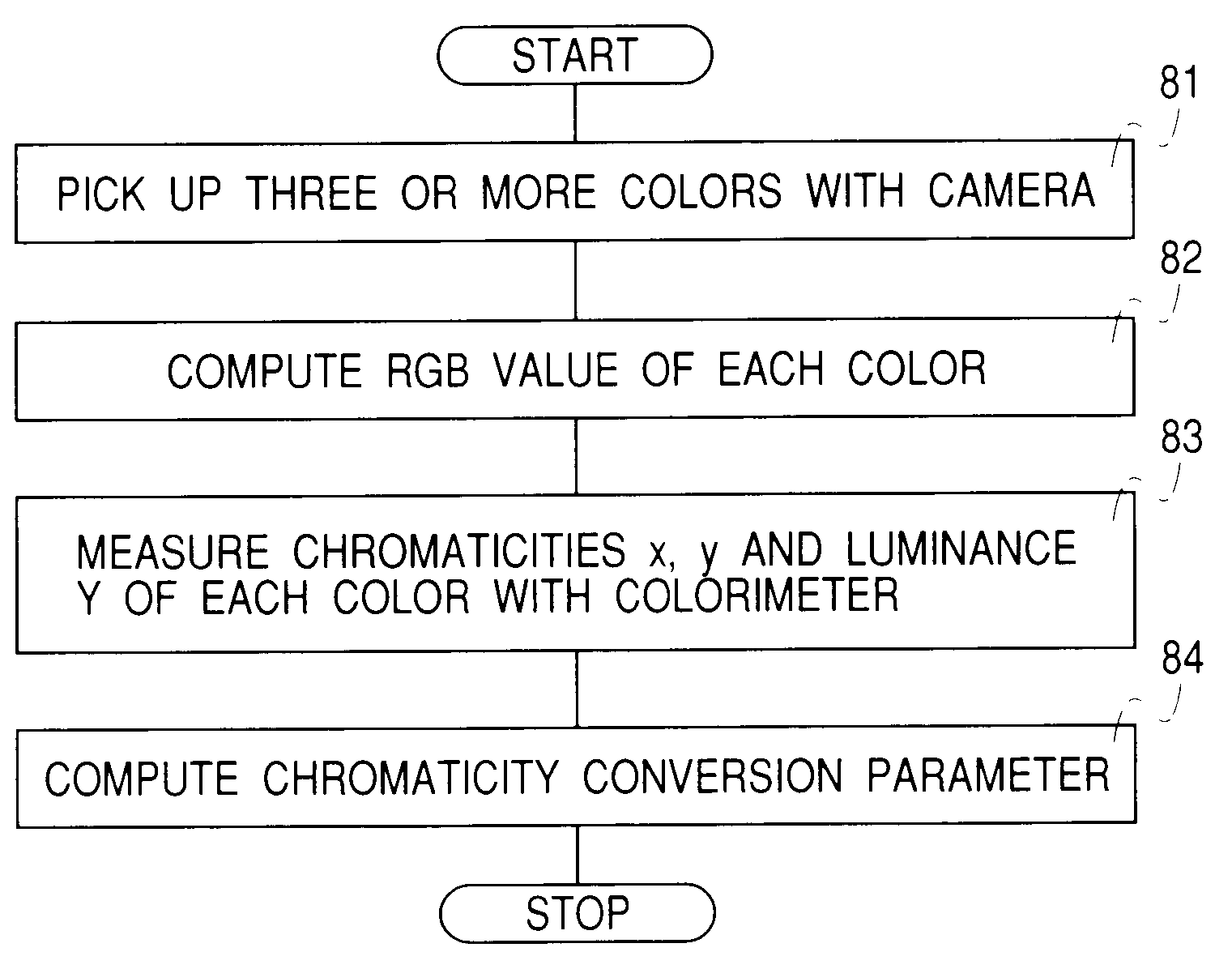

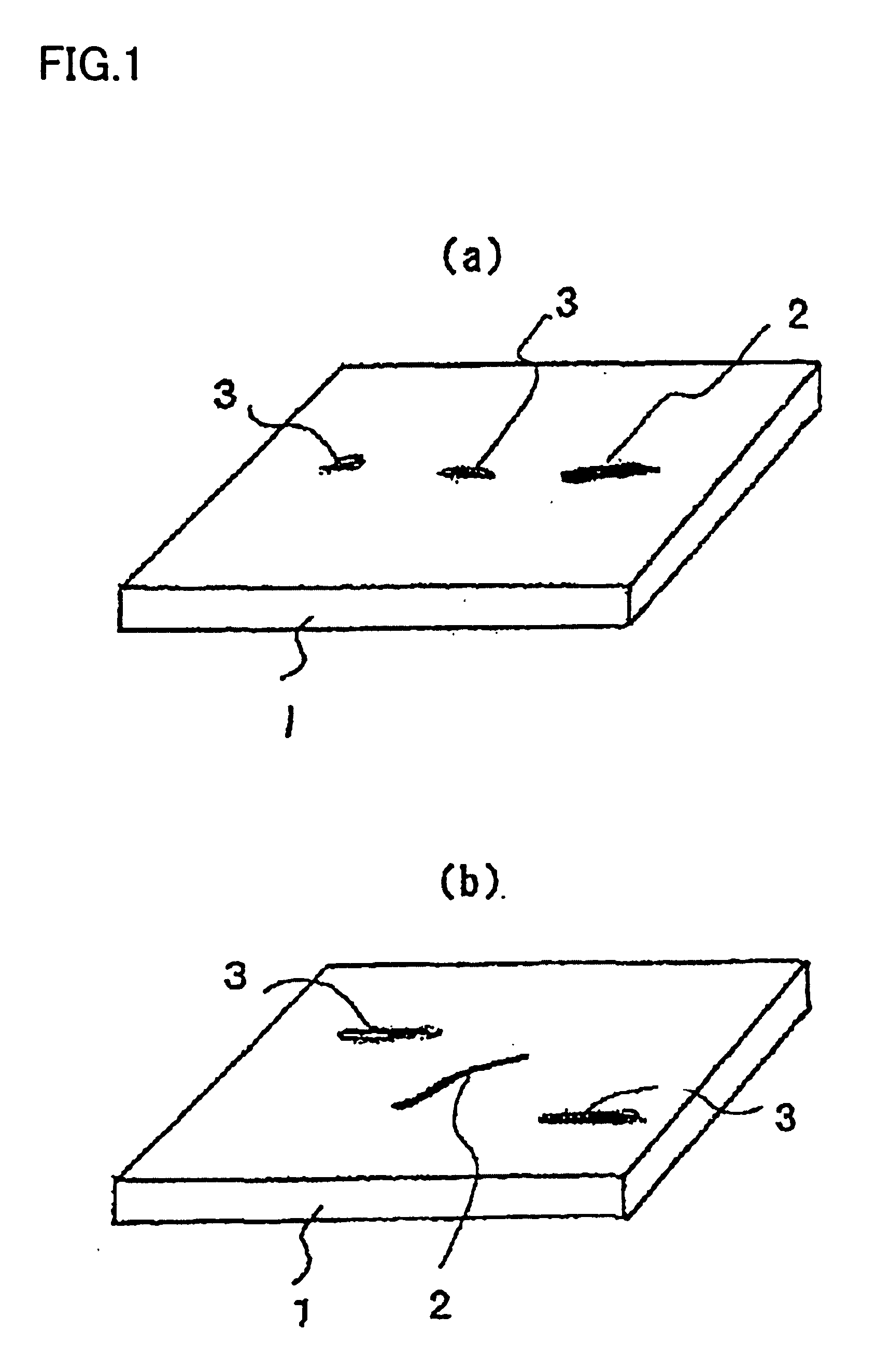

Nondestructive inspection method and apparatus

InactiveUS20050259861A1Easy to determineSimple processCharacter and pattern recognitionOptically investigating flaws/contaminationNon destructiveImage storage

The present invention relates to a method for inspecting a crack in a metal surface or the like, and, particularly, to an inspection method and apparatus for nondestructive inspection such as liquid penetrant inspection and magnetic particle testing. The present invention provides a flaw inspection method that essentially comprises the steps of illuminating a surface of a sample to be inspected, obtaining an image of the surface, characterizing a potential flaw on the inspected surface by processing the obtained image, displaying an image of the potential flaw, verifying that the potential flaw is a true flaw, and storing an image of the verified flaw in memory.

Owner:HITACHI-GE NUCLEAR ENERGY LTD

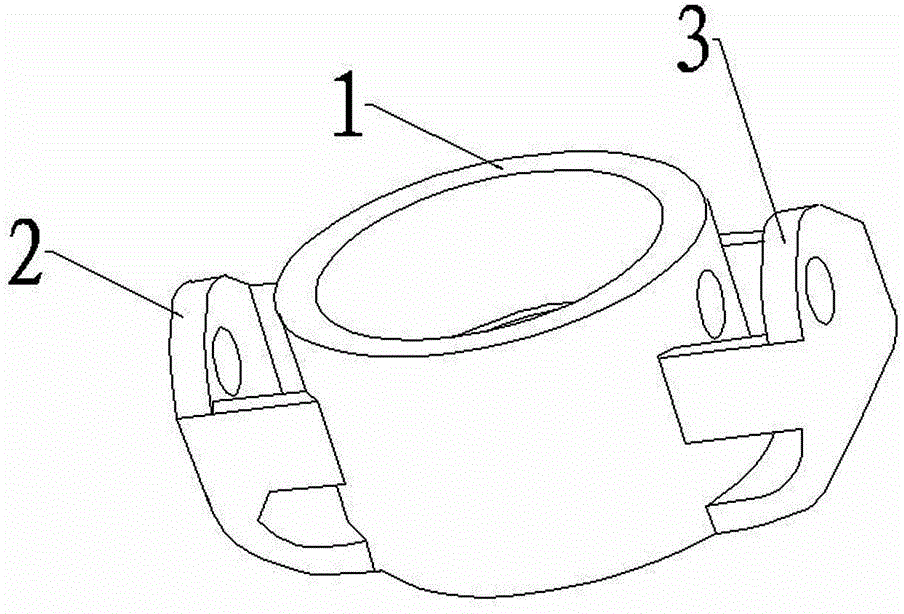

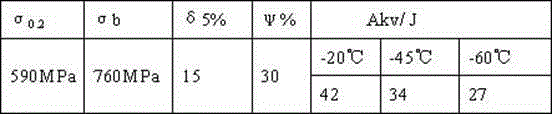

Manufacture technique of tap shells for polar drill rigs

The invention discloses a manufacture technique of tap shells for polar drill rigs. The manufacture technique incudes: (1) for forging, performing forging via upsetting, punching, broaching and forming to guarantee a forging fiber flow line under the conditions that heating temperature is 1270-1310 DEG C, initial forging temperature is 1100-1250 DEG C and terminal temperature is not lower than 850 DEG C, performing annealing after forging under the condition that the heating temperature is 880+ / -20 DEG C, and performing furnace cooling to enable tapping temperature not higher than 300 DEG C; (2) for heat treatment, normalizing at temperature of 880-900 DEG C prior to air cooling, quenching at temperature of 840-860 DEG C prior to oil cooling or cooling with a PAG quenching medium, tempering at temperature of 580+ / -40 DEG C prior to air cooling, performing subcritical quenching at temperature of 790+ / -10 DEG C prior to oil cooling or cooling with the PAG quenching medium, and tempering at temperature of 520-600 DEG C prior to air cooling; (3) for non-destructive inspection, finishing prior to machining a product according to size, and performing ultrasonic inspection and magnetic particle inspection, wherein the qualified level conforms to API Specification 8C standards. Compared with the prior art, the manufacture technique has the advantages that the tap shells manufactured with the technique have high strength to guarantee enough safety factor, adapt to polar regions (at the temperature of minus 60 DEG C) and meet the requirement on enough low temperature impact toughness so as to resist to the low-temperature environment of the polar regions.

Owner:RG PETRO MACHINERY GROUP

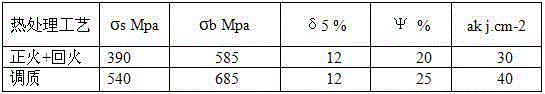

Manufacturing method of axle for low-floor vehicle

The invention relates to a manufacturing method of an axle for a low-floor vehicle. The method comprises the steps of selecting materials; preparing a blank; forging and pressing through a forging die to form; normalizing; roughly processing; ultrasonically detecting flaw; thermally processing; performing shot blasting; correcting; half finely processing; performing aging treatment; finely processing; performing magnetic particle inspection; spraying. The axle manufactured by the method for the low-floor vehicle is that a neck, a shaft head, a mounting seat and a shaft body are single parts formed as a whole; the axle is integrally formed by forging, has less defects, is basically free of defects such as air pores, air shots and shrinkage, high in yield, outstanding in performance, and high in mechanical performance; due to the serial of advantages, the integrally forged axle is suitable for mass production and use.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

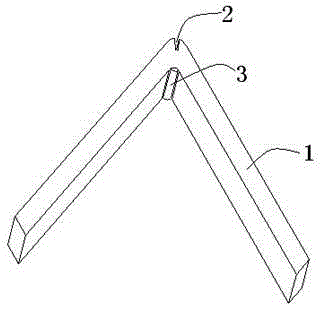

Method for compound magnetic powder flaw detection

InactiveCN101806774AAdapt to the requirements of magnetic particle testingAvoid sparkingMaterial magnetic variablesUltimate tensile strengthMagnetic particle inspection

The invention discloses a method for compound magnetic powder flaw detection, comprising the following steps: (1) pretreating; (2) magnetizing; (3) applying magnetic powder or magnetic suspension; (4) observing and recording a magnetic trace; (5) rating the flaw; (6) demagnetizing; and (7) post-treating. The magnetizing mode in the step (2) is circumferential closed magnet yoke magnetization and coil magnetization full sensing. The magnetic powder flaw detection method designed by the technical scheme of the invention has the advantage of high work efficiency, lightens the labor intensity of workers, avoids fire striking phenomenon, does not burn workpieces and has even magnetic field distribution.

Owner:SHEYANG SAIFU NDT EQUIP MFG

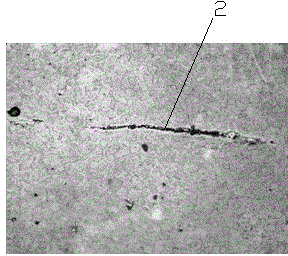

Qualitative detection method for cold roller surface micro linear defect

ActiveCN104422693AEasy to grindAvoid Aircraft Service AccidentsAnalysing solids using sonic/ultrasonic/infrasonic wavesPreparing sample for investigationFiberSand-paper

The present invention discloses a qualitative detection method for the cold roller surface micro linear defect. According to the qualitative detection method, ultrasonic surface wave and magnetic particle inspection is adopted to detect the cold roller surface; the micro linear defect is positioned by using a metallurgical defect positioning scale; the defect part is subjected to coarse grinding, fine grinding and polishing with sand paper and is corroded, the morphologies of the linear defect and the microstructure surrounding the linear defect are copied by using acetate fiber paper, and the defect is marked so as to complete the preparation of the defect morphology copying sheet; the defect morphology copying sheet is subjected to vacuum carbon spraying, the microstructure morphology of the defect is observed under a microscope, the change of the microstructure close to the defect is observed, and the characteristics of the defect morphology and the surrounding microstructure morphology are recorded; and according to the micromorphology characteristic of the micro linear defect and the characteristic of the microstructure surrounding the defect, the character of the roller surface linear defect is qualitatively judged. With the detection of the present invention, the qualitative judgment can be performed on the cold roller surface micro linear defect, such that the cold roller subsequent grinding treatment is convenient, the cold roller service accident is avoided, and the cold rolling quality of the plate is ensured.

Owner:SHANGHAI JINYI INSPECTION TECH

Plasma arc fusion covering repair method for continuous casting rollers

The invention discloses a plasma arc fusion covering repair method for continuous casting rollers. The plasma arc fusion covering repair method includes steps of preliminarily examining a continuous casting roller; removing a fatigue layer of the surface of the continuous casting roller; performing magnetic particle inspection and ultrasonic inspection; preparing mixed alloy powder of Ni45 and WC (wolfram carbide) according to a proportion by a mechanical powder mixer; mixing and stirring the mixed alloy powder and white emulsion according to a proportion; coating the mixed alloy powder on the surface of a base material of the continuous casting roller, scanning the pre-coated alloy powder by a single plasma arc channel via plasma arc fusion covering equipment to form an alloy layer; and finely finishing the continuous casting roller by a lathe or a grinder to obtain a continuous casting roller meeting technical requirements. Compared with the prior art, the plasma arc fusion covering repair method has the advantages of capabilities of obviously prolonging the service life of the continuous casting roller and reducing alloy consumption, high heat resistance and controllability, simplicity in process, low cost and energy consumption, and the like.

Owner:QINHUANGDAO GERUIDE ENERGY SAVING TECH SERVICE

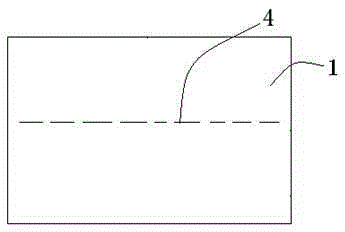

Magnetic powder flaw detection technology

InactiveCN105758932ALow experience requirementEasy to operateMaterial magnetic variablesMagnetic polesPre treatment

The invention discloses a magnetic powder flaw detection technology comprising the following procedures: 2), a flaw detection device; 3), a test piece; and 4), a magnetic powder flaw detection operation procedures comprising the steps: (1) pre-treatment; (2) magnetization: e, when a magnetic yoke is adopted for flaw detection, the distance between two poles is in a range of 75-150 mm, the effective flaw detection range of the detection is 1 / 4 of the distance of the magnetic poles at two sides of the magnetic poles, and the cover area of the magnetic yoke at each time of movement is not less than 25 mm; and f, the above methods all adopt continuous ways, magnetization is carried out for three times for 0.5-2 seconds at each time, the interval time is not more than 1 second, and after the application of a magnetic suspending liquid or a magnetic powder is stopped for 1 second, magnetization (power failure) can be stopped; (3) magnetic marks require to be observed immediately after being formed, and the magnetic marks require to be observed under natural light or lamp light under which the magnetic marks can be clearly identified; and (4) demagnetization is carried out. The technology has the advantages of simple operation, low requirements on operator experience and high product quality.

Owner:CHONGQING XUNSHENG LOCOMOTIVE PARTS CO LTD

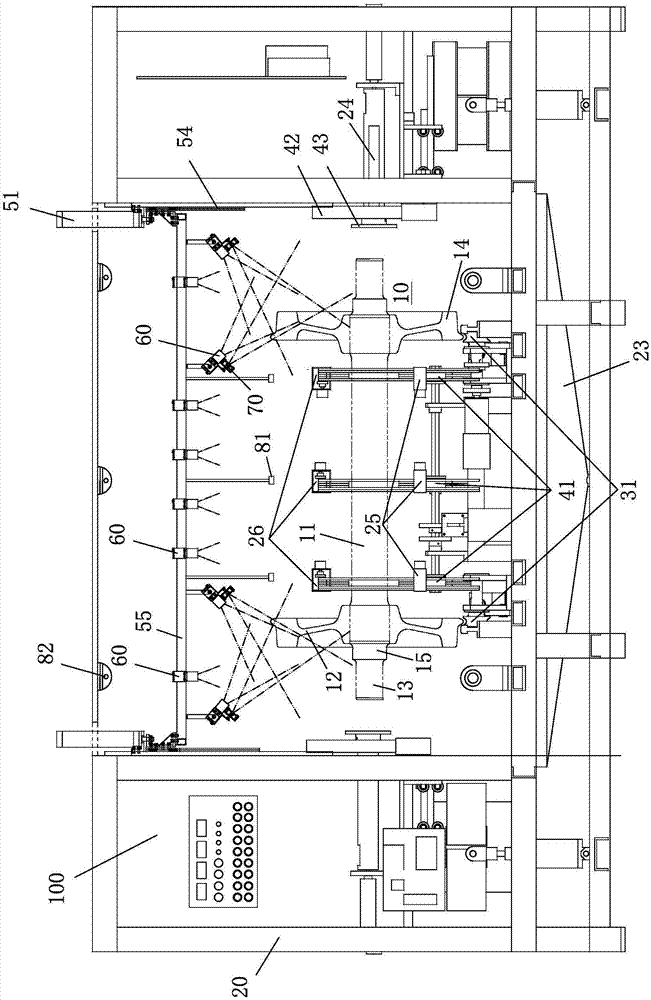

Automated imaging magnetic particle flaw detector of railway axle and flaw detection method

ActiveCN107238657ARealize automatic identificationImplement automatic pasting recordsMaterial magnetic variablesIlluminanceUltraviolet

The invention discloses an automated imaging magnetic particle flaw detector of a railway axle and a flaw detection method. The flaw detector comprises a frame, a work piece feeding mechanism, a work piece delivering mechanism, a rotating mechanism, a magnetic suspension fluid spraying system, an axle circumferential magnetizing mechanism, and an axle longitudinal magnetizing mechanism. The automated imaging magnetic particle flaw detector further comprises a high-definition camera and an ultraviolet ray lamp for collecting magnetic traces of the axle body, a high-definition camera and an ultraviolet ray lamp for collecting magnetic traces of an axle neck and a dustproof plate, and a high-definition camera and an ultraviolet ray lamp for collecting magnetic traces at inside and outside of a wheel web plate of the axle; all high-definition camera and ultraviolet ray lamps are installed on a vertically moveable lifting device; an ultraviolet illuminometer is further installed on the lifting device. The automated imaging magnetic particle flaw detector is fast in flaw detecting speed, high in result accuracy, small in mistakes and omissions; the defected magnetic trace image can be displayed, the flaw detection result can be traced; moreover, the flaw detectors have good working environment and low labor intensity; the flaw detector can solve problems existed in the existing magnetic powder flaw detection technology.

Owner:北京博力加机电技术有限公司 +1

Roll processing flaw detecting method

InactiveCN101113971AExtended service lifeImprove processing efficiencyMaterial magnetic variablesElectricityEngineering

The invention provides a crack detection method of roll dressing, the steps of which is that: scrapping the surface of the rolls after processing; connecting magnetic particle detector to the electricity; spraying black oil magnetic suspension on the defectoscopy of the roll surface; opening the switch of the magnetic particle detector and adjusting the angle of the two contact heads and being positioned at the black oil magnetic suspension sprayed. After observation of the roll surface, magnetic powder can be found at the crack if crack exists; then carrying on flaw inspection in a plurality of different places on the roll surface, the process should be continued if crack is observed until no crack is detected. The invention has the beneficial effects that tiny crack on the roll surface is efficiently detected after roll processing by the detection method. Then appropriate procession can be continued which not only cuts down the loss during raising the processing capacity blindly, but also avoiding the short service life of rolls caused by not eliminating the cracks completely.

Owner:TIANJIN PIPE GROUP CORP

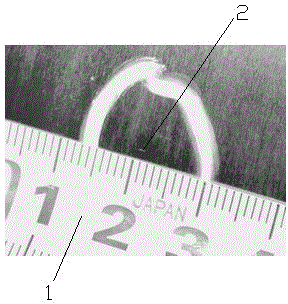

Manufacturing method of test block having surface artificial crack defect used for magnetic particle testing

InactiveCN105353028AIncrease awarenessCrack direction controllablePreparing sample for investigationMaterial magnetic variablesStructural engineeringNondestructive testing

The invention discloses a manufacturing method of a test block having surface artificial crack defect used for magnetic particle testing. The manufacturing method includes processing a sawing groove on the test block with a sawing machine, welding a weld joint on the test block directly beneath the sawing groove; bending the test block to cause a crack with the weld joint as a center line, restoring the test block to be horizontal; processing the sawing groove to be a U-shaped bevel; welding and filling the U-shaped bevel; polishing the weld joint to flush with a base material, rewelding the weld joint; and polishing again the weld joint to flush with the base material test block. The manufacturing method can manufacture the test block having surface artificial crack defect rapidly, is suitable for magnetic particle nondestructive testing method, and has important meaning in training the magnetic particle inspection personnel, testing and researching the flaw detection material property, and improving the understanding of the magnetic particle detection signal. The prepared surface crack of the test block is different with the artificial defect of a flaw detection standard test block, and the crack defect is real and easily available.

Owner:HEFEI UNIV OF TECH +1

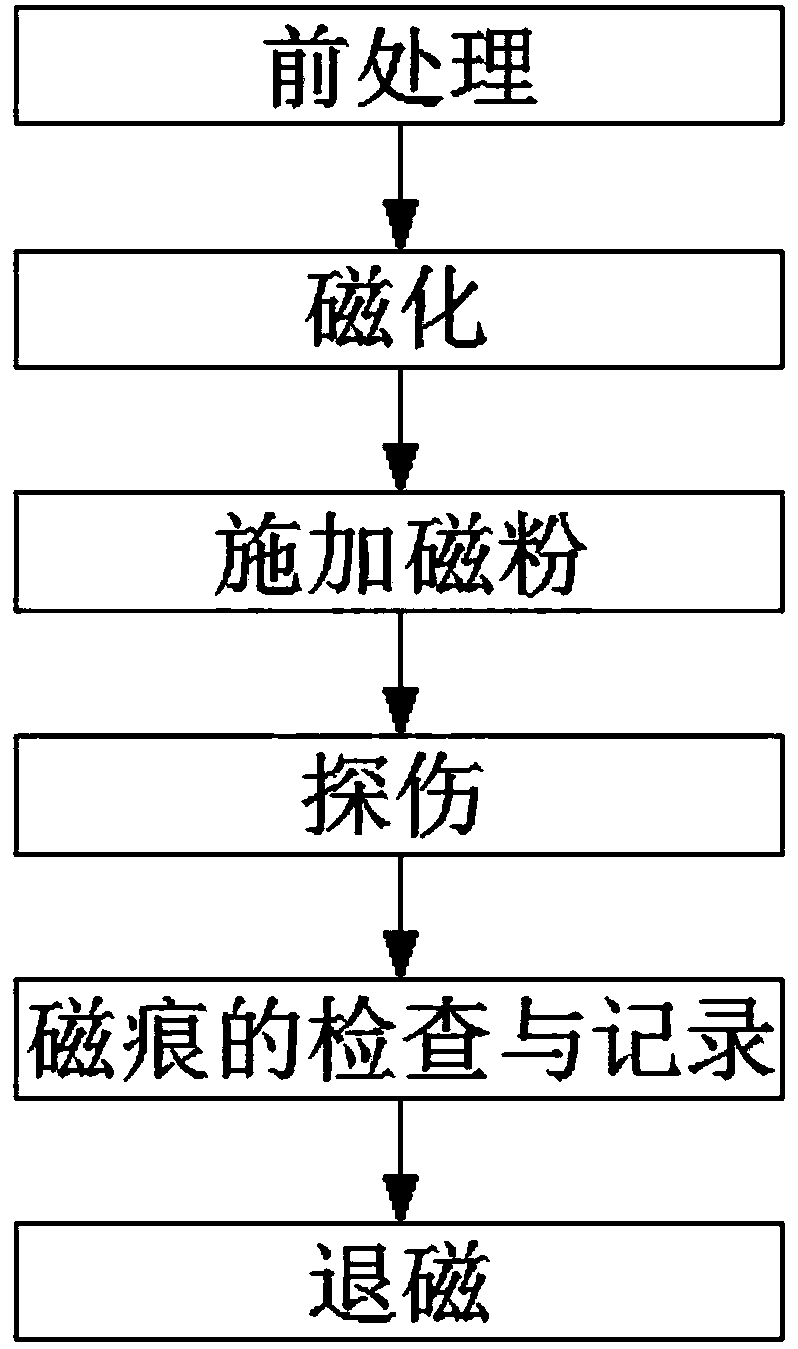

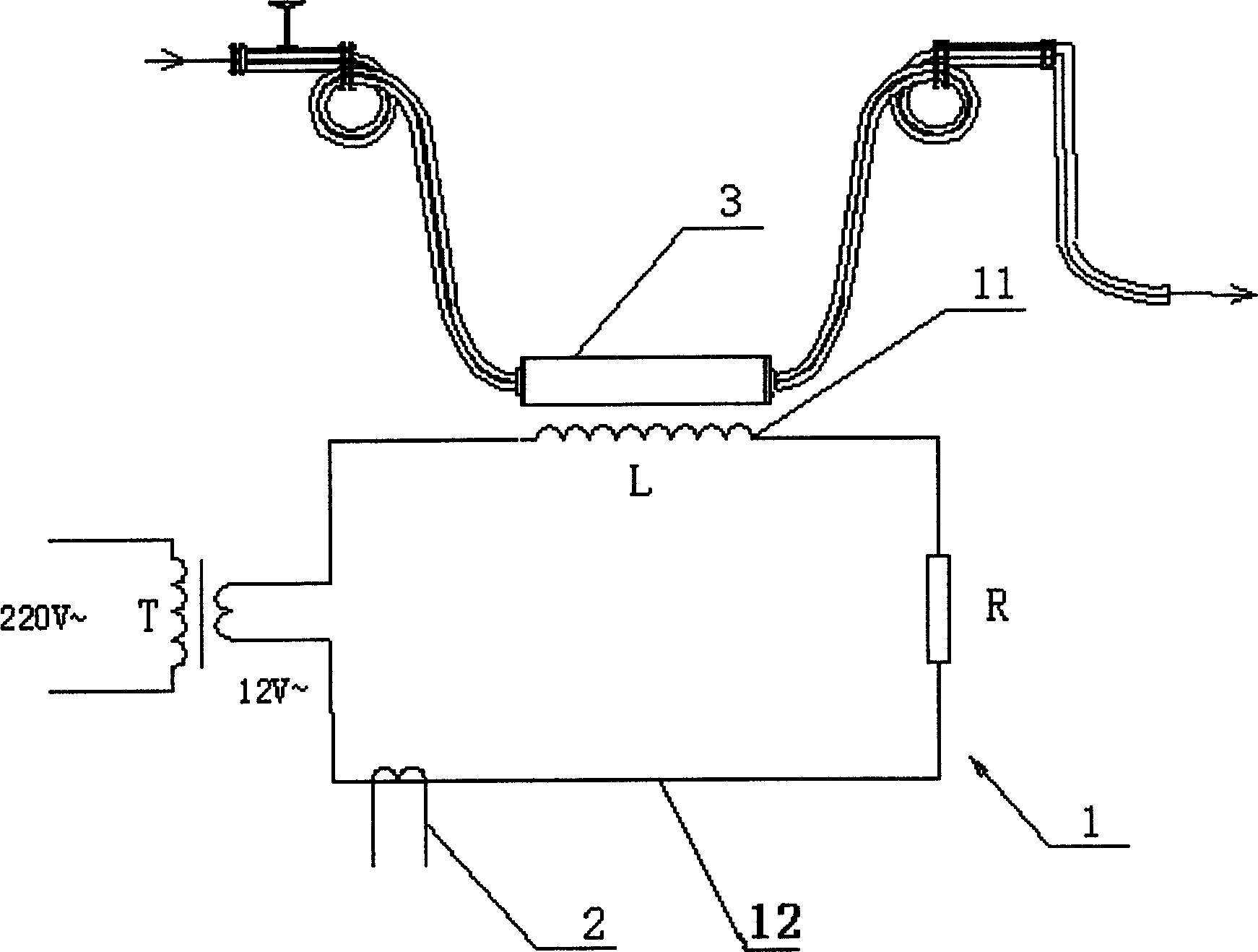

High-frequency impulse magnetic powder inspection method

InactiveCN108120763AImprove stabilityImprove flaw detection efficiencyMaterial magnetic variablesPre treatmentMaterials science

The invention discloses a high-frequency impulse magnetic powder inspection method and belongs to the technical field of magnetic powder inspection. The high-frequency impulse magnetic powder inspection method comprises the following steps: S1, pre-treatment: cleaning the surface of a workpiece to be inspected thoroughly to remove attachments on the surface of the workpiece, and cleaning and drying the workpiece; S2, magnetization: putting the workpiece in an electrified coil to magnetize the surface of the workpiece; S3, magnetic powder application: uniformly applying the magnetic powder to an inspection surface in an effective inspection range, wherein the magnetic powder is adsorbed to defective parts, then electrifying an instant current to the workpiece, and pouring a magnetic suspension for 2-3 times after power off; S4, inspection: inspecting the surface of the workpiece by using an electromagnetic probe which outputs high frequency impulse signals; S5, examination and recordingof magnetic traces; and S6, demagnetization: detecting the demagnetized workpiece with a magnetometer, and carrying out inspection with the high frequency impulse signals. The method is high in stability, low in cost and high in inspection efficiency, the detection precision is improved, and the method is convenient to operate and meets the production demands.

Owner:JIANGYIN YONGXING MACHINERY MFG

Magnetic powder concentration sensor of magnetic suspension

InactiveCN1712949AImprove detection accuracyMaterial magnetic variablesCurrent transducerEngineering

A transducer of magnetic powder concentration in magnetic suspension is prepared by forming inductive coil loop by connecting electric inductive coil with current sensing wire in series, setting nonmagnetic conduction tube in inductive coil of inductive coil loop as one nonmagnetic conduction tube end used as inlet of magnetic suspension and another used as outlet of said suspension, sheathing current transducer on current sensing wire of inductive coil loop.

Owner:曾德文

Detection system for welding lines and detection method used by detection system for welding lines

The invention discloses a detection system for welding lines. The detection system is used for detecting the welding lines in a linear closed space and comprises a moving platform and a detection device which is arranged on the moving platform; the detection device comprises a polishing device, a magnetic powder flaw detection device and a camera; the moving platform can enter the closed space; the polishing device is used for polishing the welding lines in the closed space; the magnetic powder flaw detection device is used for performing magnetic powder flaw detection on the welding lines after polishing; and the camera is used for collecting images of the magnetic powder flaw detection process of the welding lines. For the detection system, aiming at structural features of the linear closed space, a brand-new detection manner is adopted, the detection system can enter the closed space for welding line detection; the detection process is transmitted by image collection, so that the qualified and unqualified conditions of the welding lines can be judged in a visualized manner; and the operation is convenient, the detection speed is high, and the efficiency is high. The invention also discloses a detection method used by the detection system for the welding lines.

Owner:WUHAN LIXIN AUTOMATION TECH CO LTD

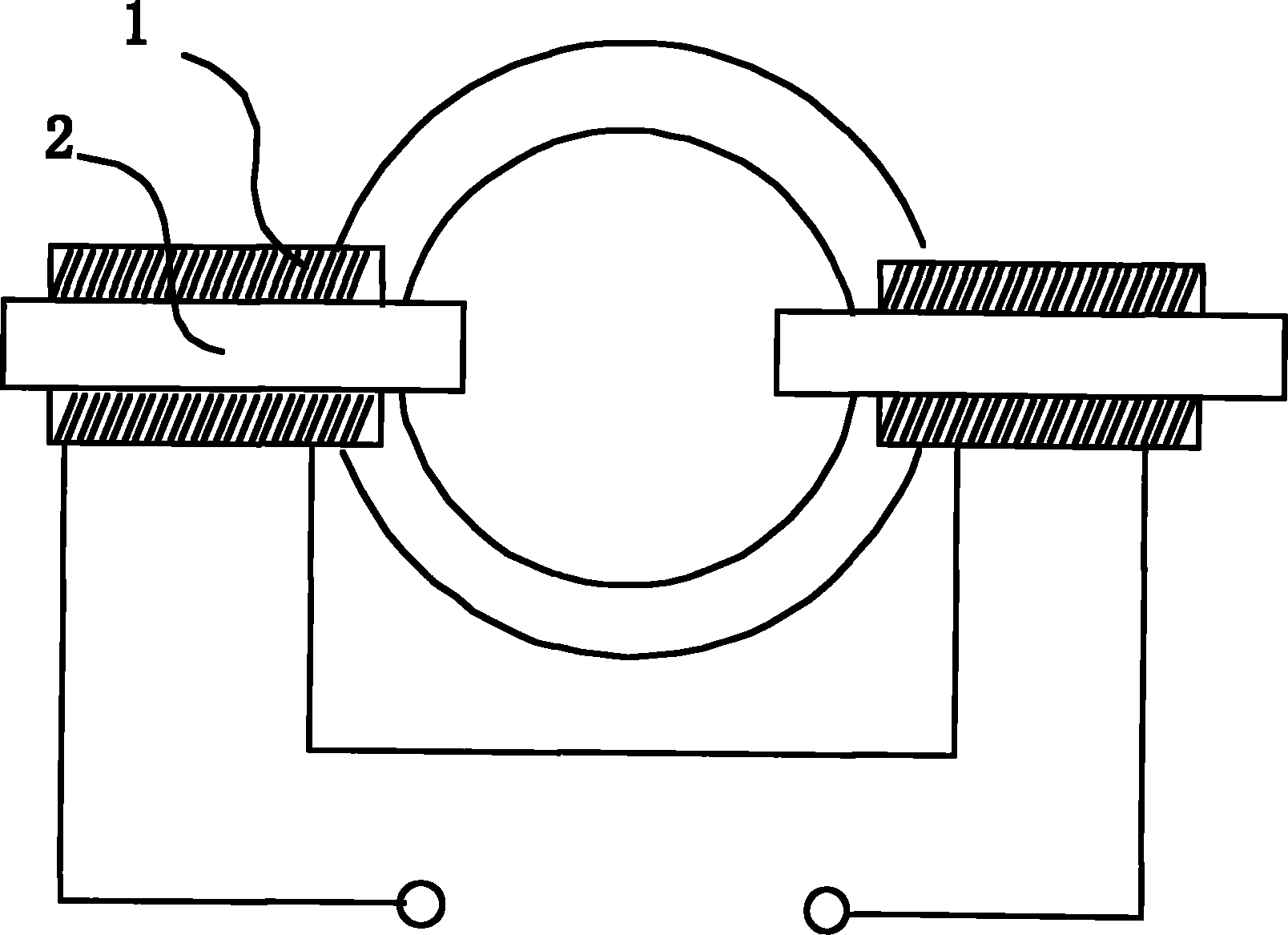

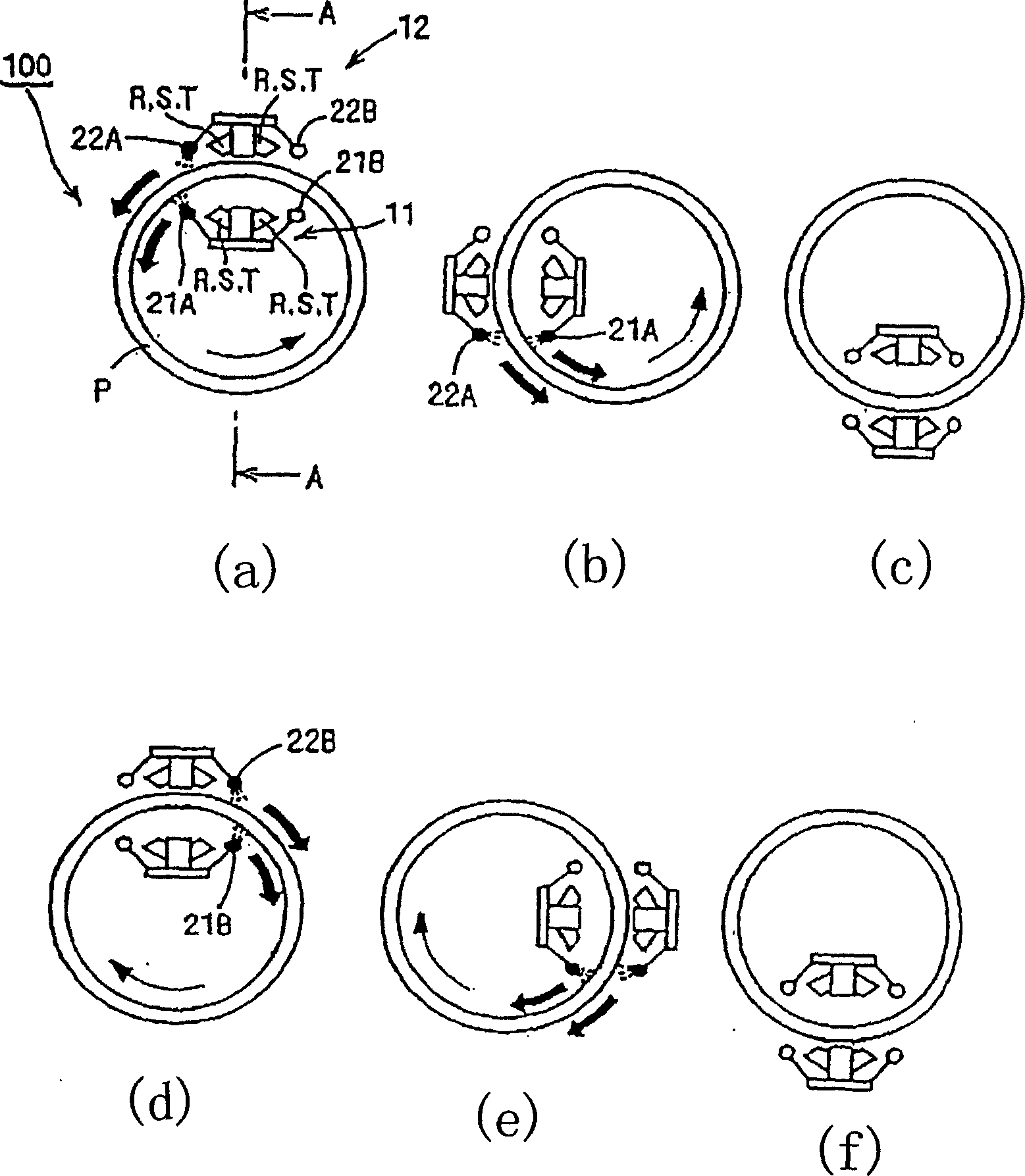

Method and device for flaw detection of magnetic powder

InactiveCN1752746APrevent grindingPrevent disappearingMaterial magnetic variablesActuatorTest material

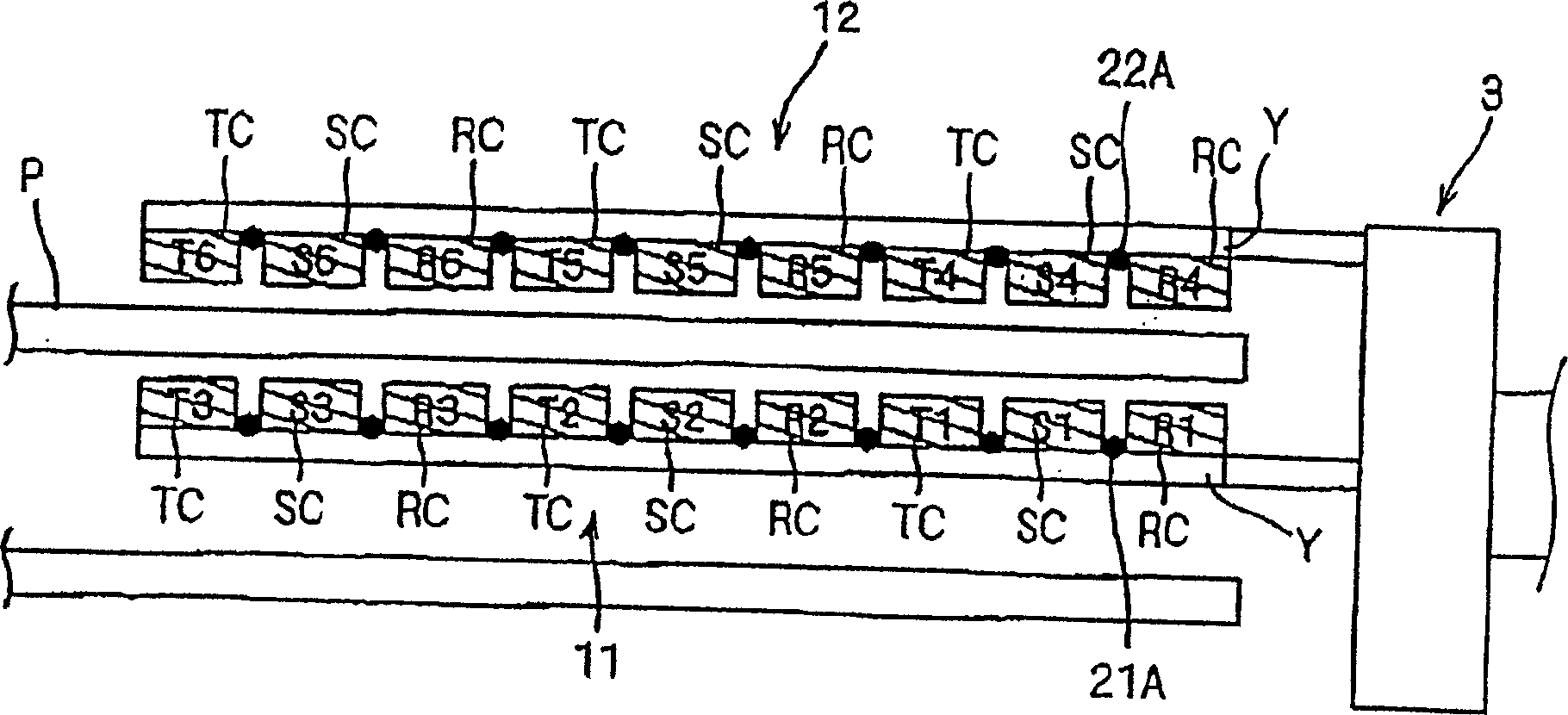

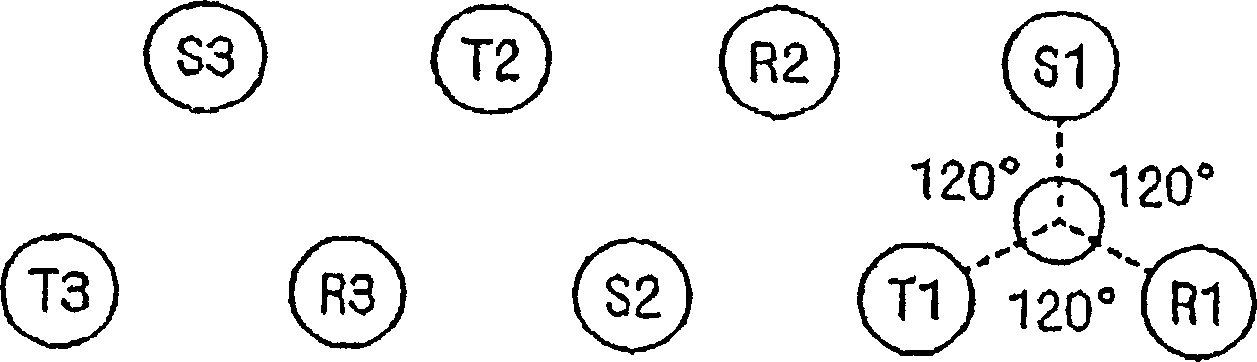

To provide a method and a system for magnetic particle inspection which can achieve high-precision magnetic particle inspection by forming clearer magnetic particle patterns. This magnetic particle inspection system 100 is equipped with magnetizing equipment 11, 12 which allows rotating magnetic field to act on surface P of horizontally-arranged tubular test material, nozzle actuators 21A, 21B, 22A, 22B for sprinkling magnetic powder liquid on surface of the test material, and a driving mechanism 3 which allows these magnetizing equipment and nozzle actuators to be rotated integrally about the central axis of the test material along its circumferential direction. The nozzle actuators are respectively provided on both ends in the traveling direction of the magnetizing equipment, to sprinkle magnetic powder liquid from the nozzle actuators mounted on the end of the same directional side as the magnetic powder flowing direction; while the driving mechanism moves the magnetizing equipment toward the same direction as the sprinkled magnetic powder flowing direction so that traveling speed of the magnetizing equipment is nearly equal to the flowrate of the magnetic powder liquid immediately, after being sprinkled.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com