Patents

Literature

74 results about "Microstructure morphology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

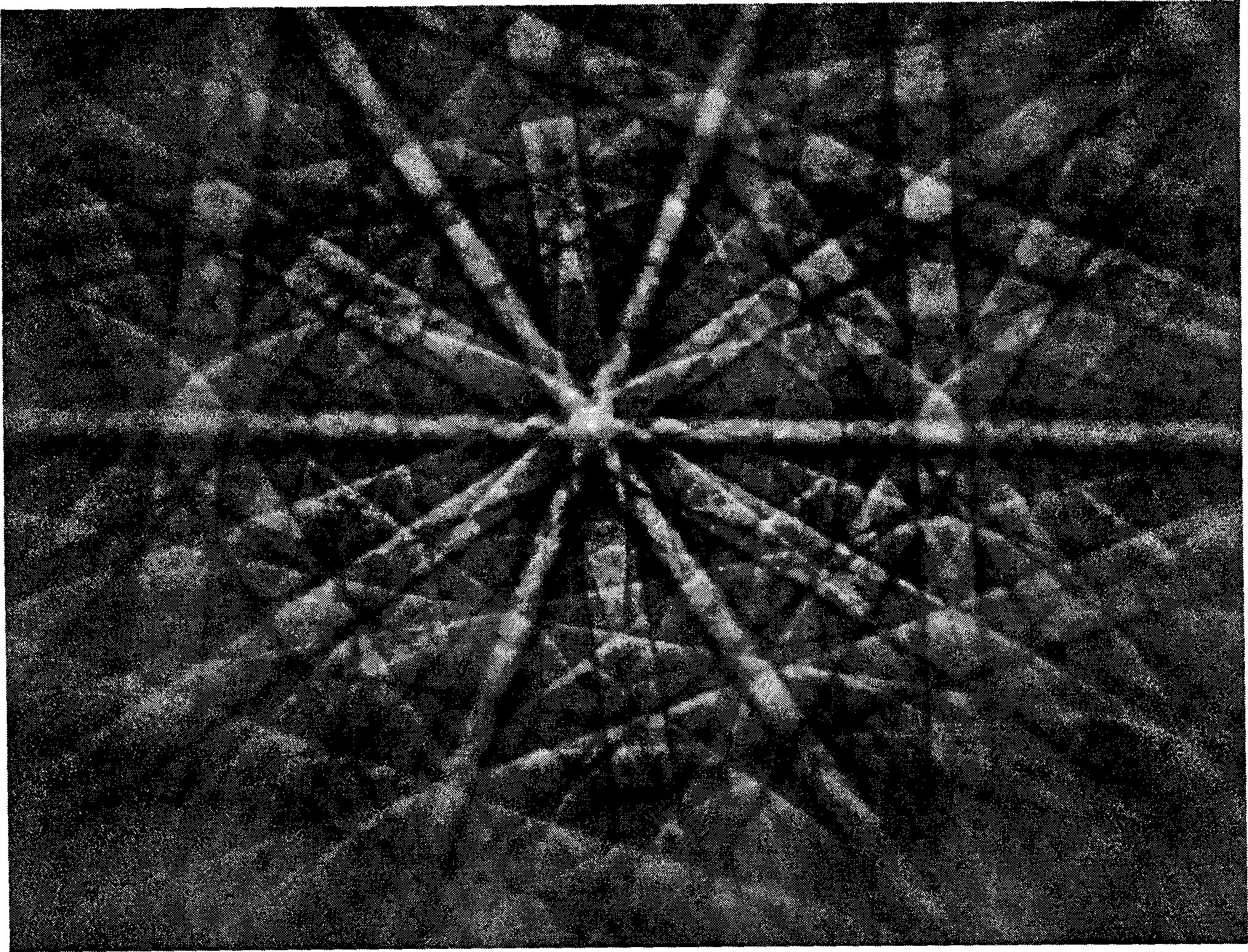

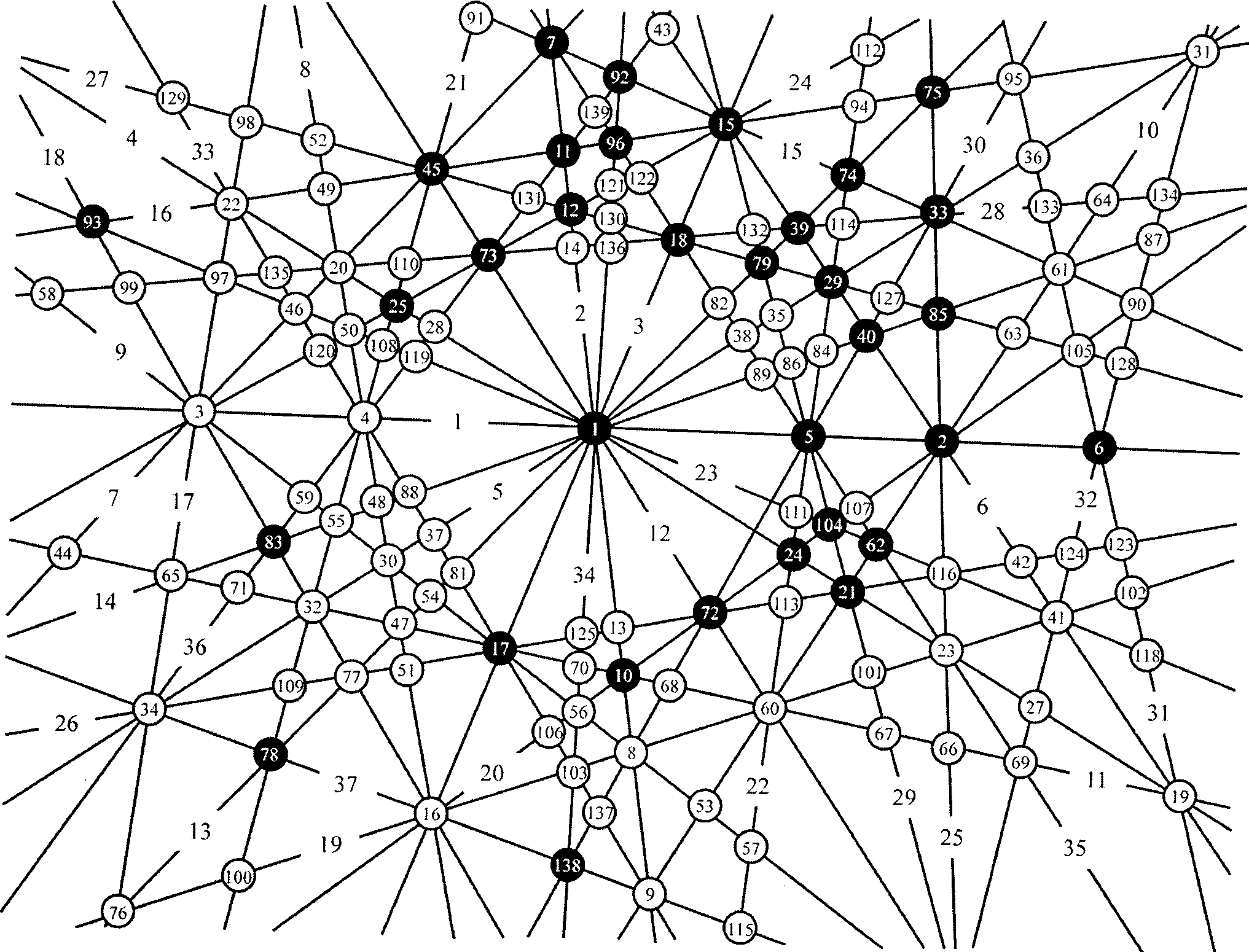

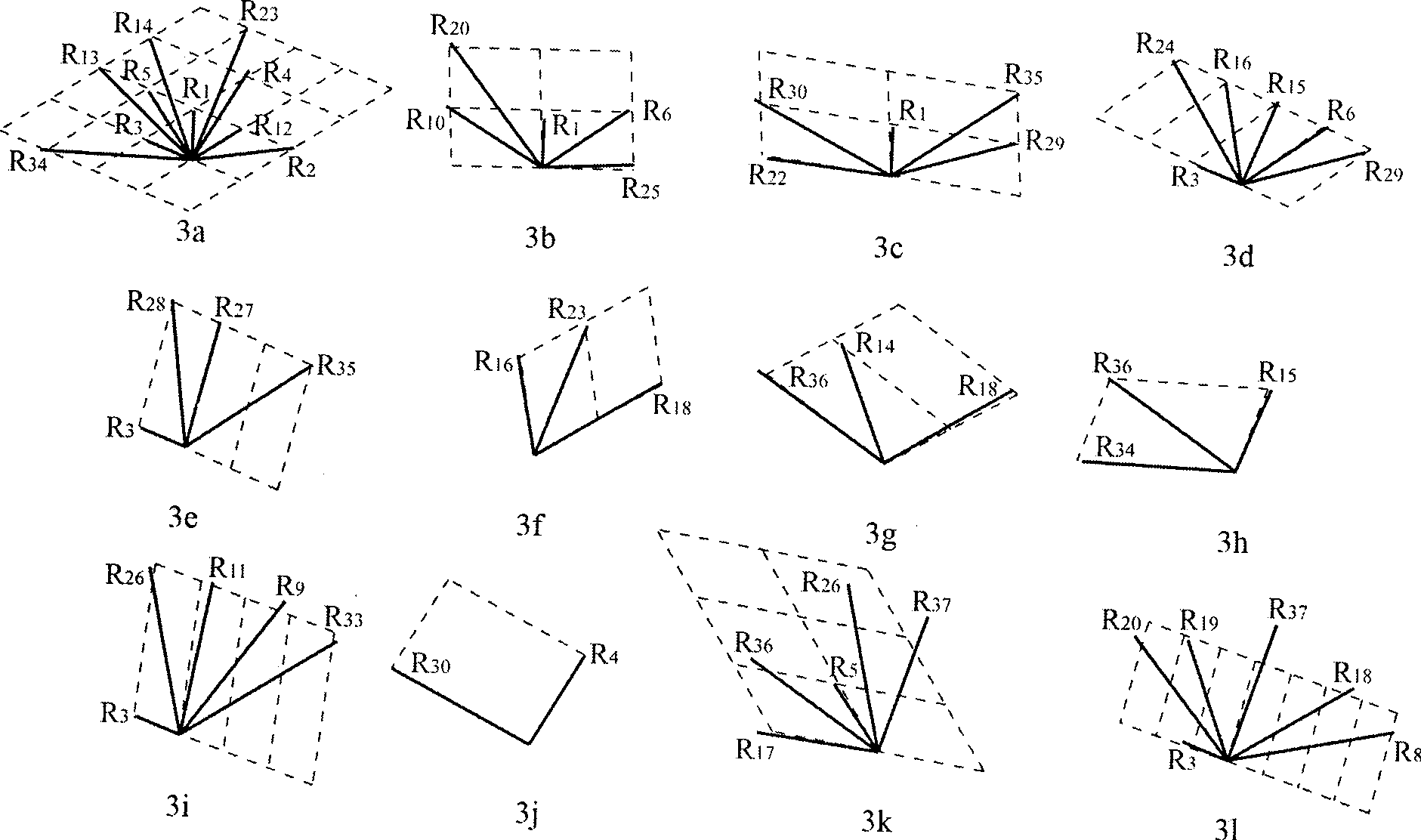

Method for determining unknown crystal Bravais lattice by electric back scattering diffraction

InactiveCN101413906ARealize analysisMaterial analysis using wave/particle radiationBravais latticeReal time analysis

The invention provides a method used for determining Bravais lattice of unknown crystal by electron backscatter diffraction. The invention is characterized in that the method comprises the steps as follows: 1) an electron backscatter diffraction spectrum is obtained and the crystal diffraction information in the diffraction spectrum is measured; 2) a two-dimensional reciprocal surface of the crystal is obtained; 3) a three-dimensional reciprocal primitive cell is reconstructed by the two-dimensional reciprocal surface; 4) the cell parameter of the three-dimensional reciprocal primitive cell s worked out according to the width of the Kikuchi band and the angle between the Kikuchi bands in the same Kikuchi electrode; 5) a reciprocal reduced cell of the crystal is solved; 6) the Bravais lattice of the crystal is determined in the reciprocal space; 7) the Bravais lattice of the crystal is determined. In the method, only a scanning electron microscope and an electron backscatter diffraction accessory are used to realize the analysis on unknown lattice of bulk crystals, and the exponential of the Kikuchi band and the Kikuchi electrode in the electron backscatter diffraction spectrum is marked at the same time. The method has no special requirement on the samples to be analyzed, is suitable for quickly analyzing bulk samples, and can be used for analyzing the microstructure morphologies and crystal structure in the buck samples.

Owner:SHANDONG UNIV OF TECH

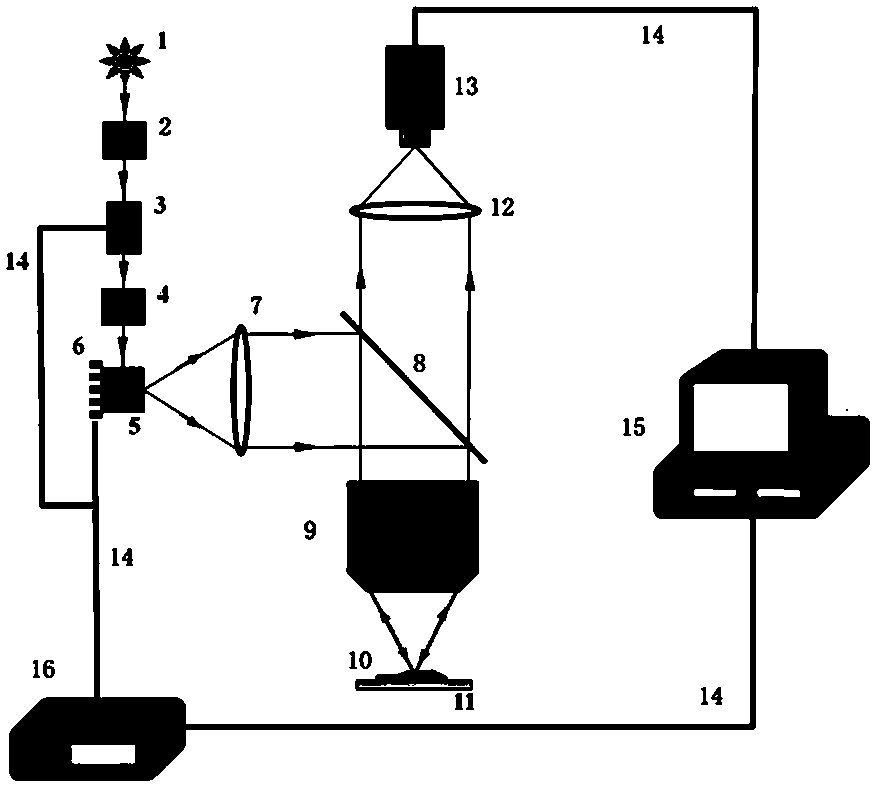

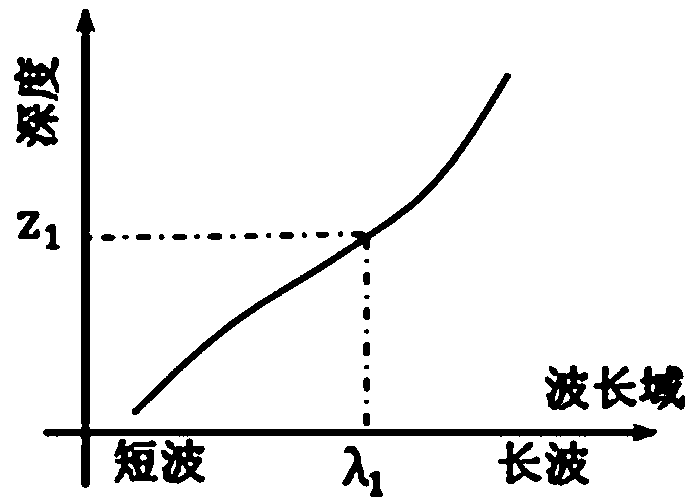

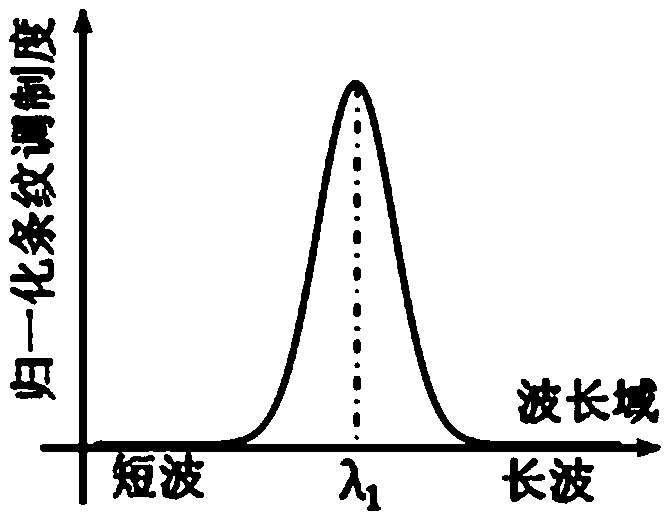

Method and device for measuring microstructure morphology based on spectral modulation depth coding

ActiveCN108844492AQuick measurementAccurate measurementUsing optical meansMeasurement deviceSpatial light modulator

The invention discloses a method and device for measuring microstructure morphology based on spectral modulation depth coding. An element to be measured and a spatial light modulator are conjugated atthe center wavelength of the spectral range used in the measurement; a beam folding coupler, the spatial light modulator, a collimating and expanding lens, a beam splitter, an axial non-achromatic microscope objective lens, an imaging lens and a color camera are in a common optical path structure. During the measurement, the pre-calibration of the corresponding relation of the 'spectral-depth' isfirstly carried out on a system device, and each frame monochromatic shift-phase fringe pattern reflected by the element to be measured is acquired by a measuring device, so as to obtain the modulation depth distribution of each monochromatic light fringe pattern related to the surface shape of the element to be measured, and the coded image is obtained; the 'spectrum-modulation depth' relation curve of each point on the surface to be measured is determined by using Gaussian, quasi-Gaussian or spline model fitting, the depth information of each point on the surface to be measured is demodulated, and the fast and precise measurement of the microstructure topography of the three-dimensional topography distribution of the element to tested, without mechanical scanning or contact, is completed.

Owner:SUZHOU UNIV

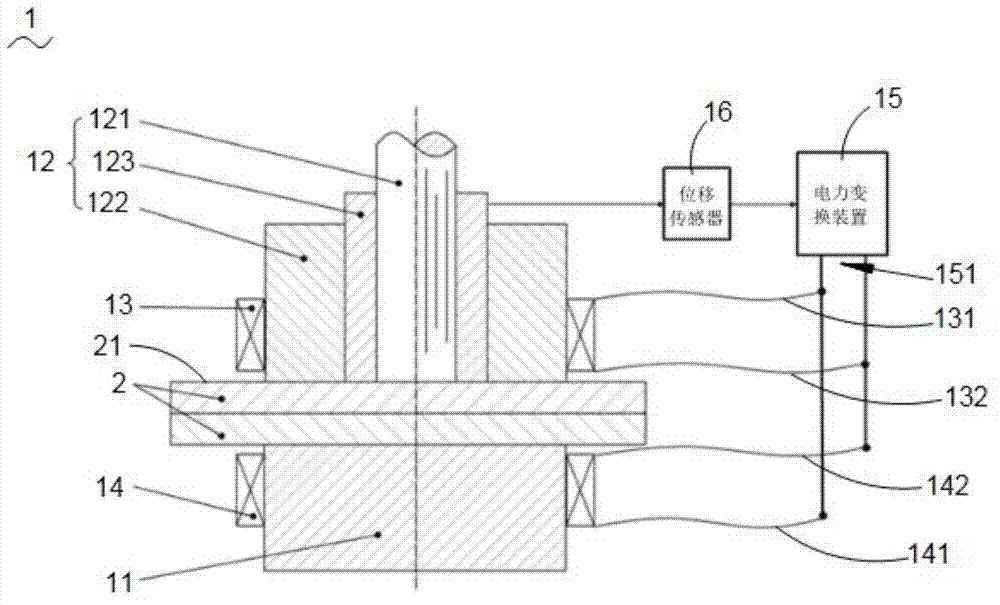

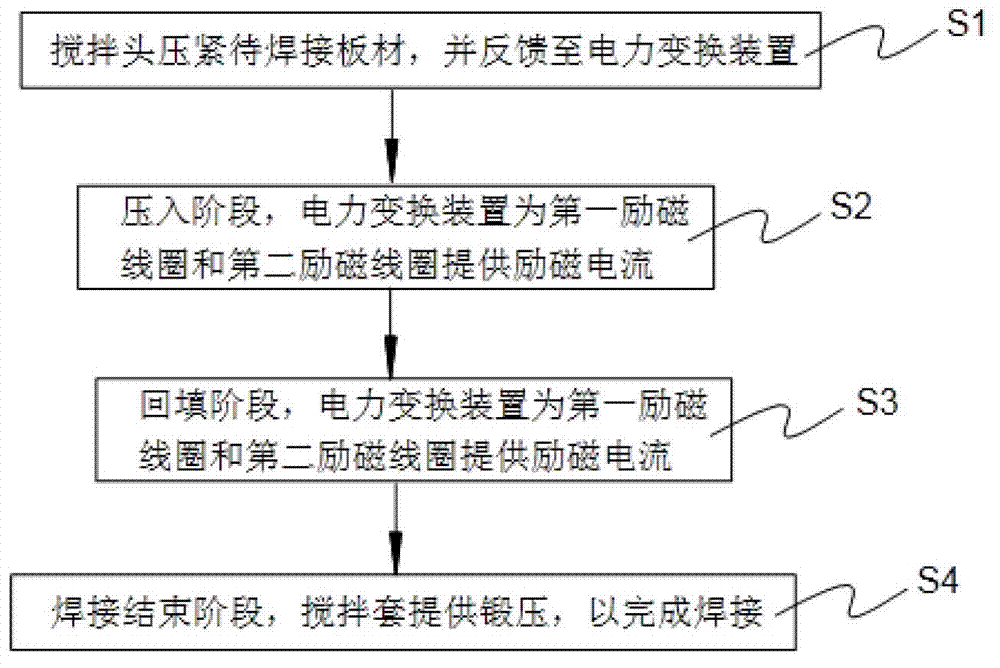

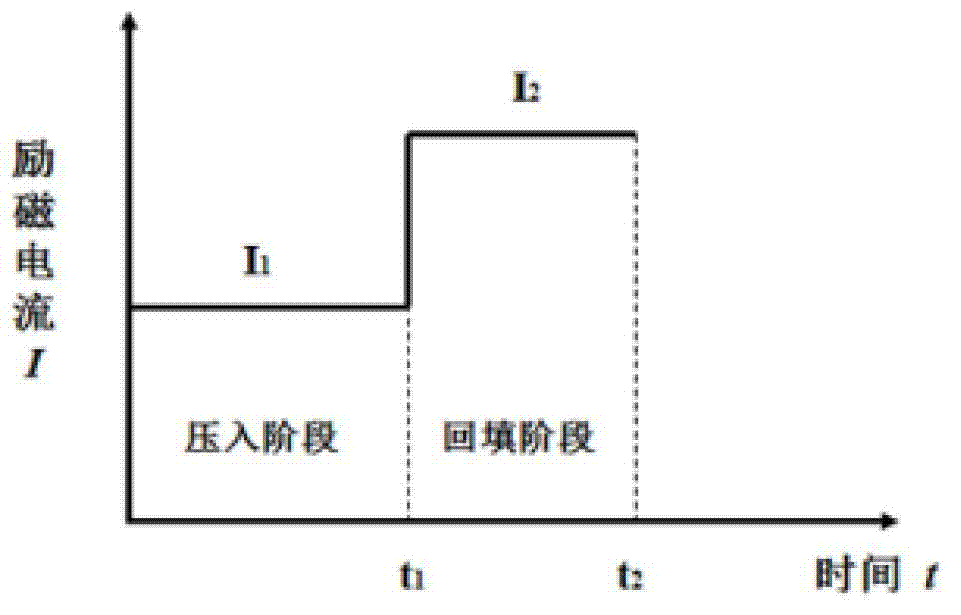

Electromagnetic friction stir spot welding device and method thereof

InactiveCN103170725AImprove plastic fluidityQuality improvementNon-electric welding apparatusElectricityMolten state

The invention relates to an electromagnetic friction stir spot welding device which comprises a welding cushion block, a stirring head, a stirring needle, a clamping sleeve, a stirring sleeve, a first excitation coil, a second excitation coil, a power transformation device and a displacement sensor, wherein the stirring needle is arranged at the inner layer of the stirring head, the clamping sleeve is arranged at the outer layer of the stirring head, the stirring sleeve is arranged between the stirring needle and the clamping sleeve, the first excitation coil and the second excitation coil are respectively arranged on the clamping sleeve and the welding cushion block and are symmetrically distributed, the power transformation device is electrically connected with the first excitation coil and the second excitation coil, and the displacement sensor is electrically connected with the stirring sleeve and the power transformation device. According to the electromagnetic friction stir spot welding device, the power transformation device provides a strong magnetic field for welding materials in a molten state in a pressing-in stage, a refilling stage and a forging and pressing process, and thus the plastic flow capacity of the welding materials in the molten state is remarkably improved, the welding condition of a joint is improved, a re-crystallized grain is further refined, the microstructure morphology of a spot welding joint is improved, and the quality of the spot welding joint is improved.

Owner:SHANGHAI DIANJI UNIV

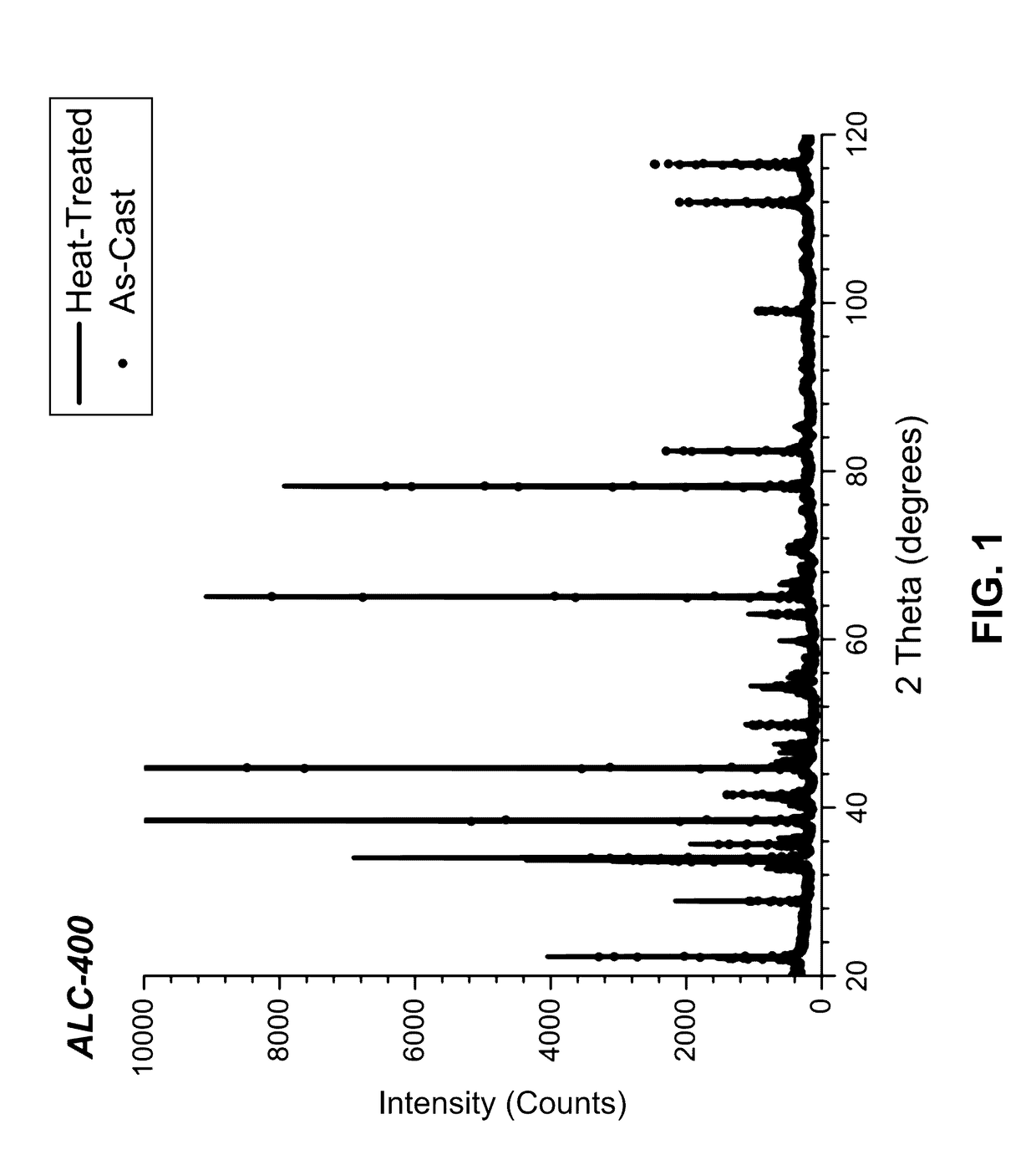

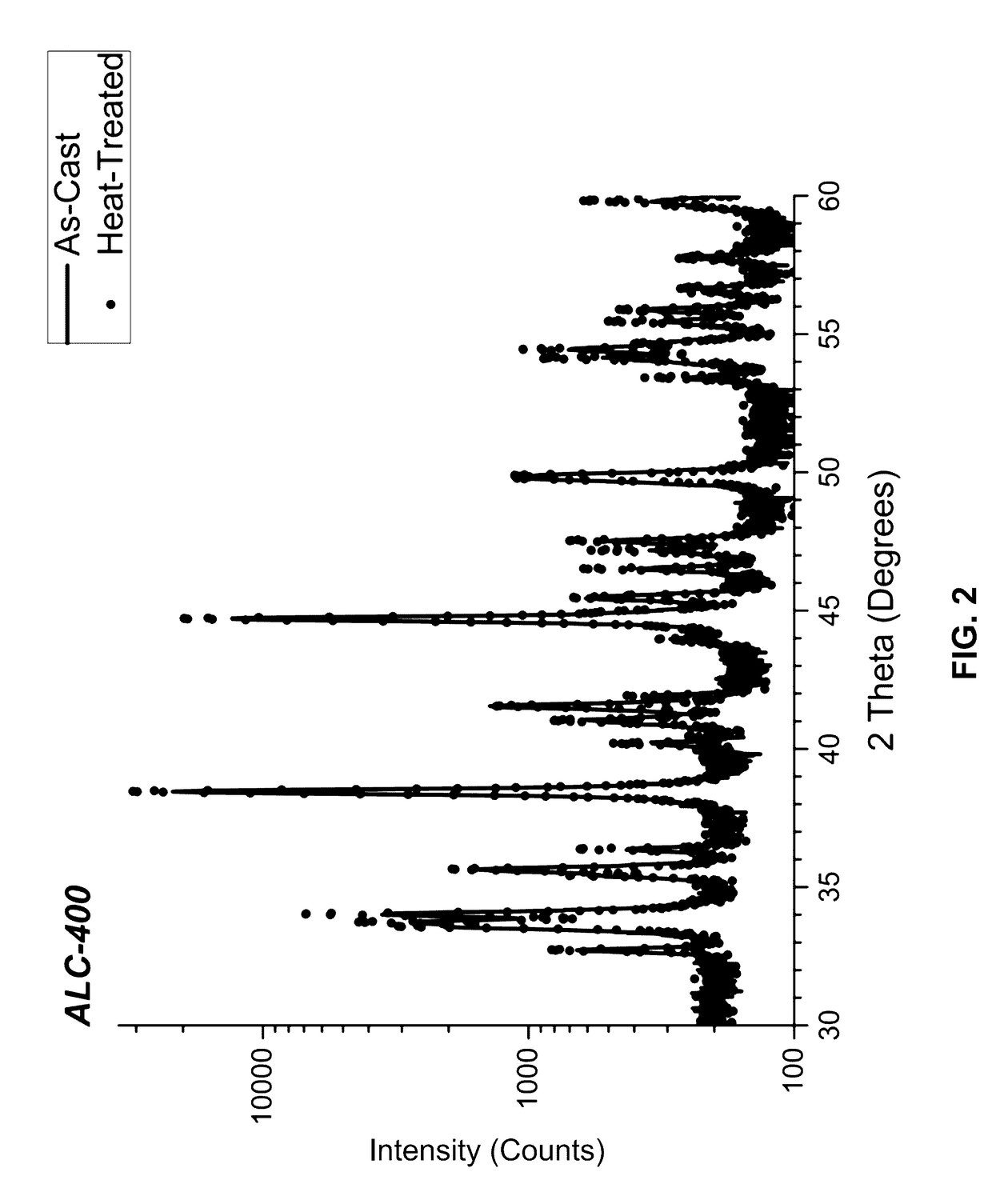

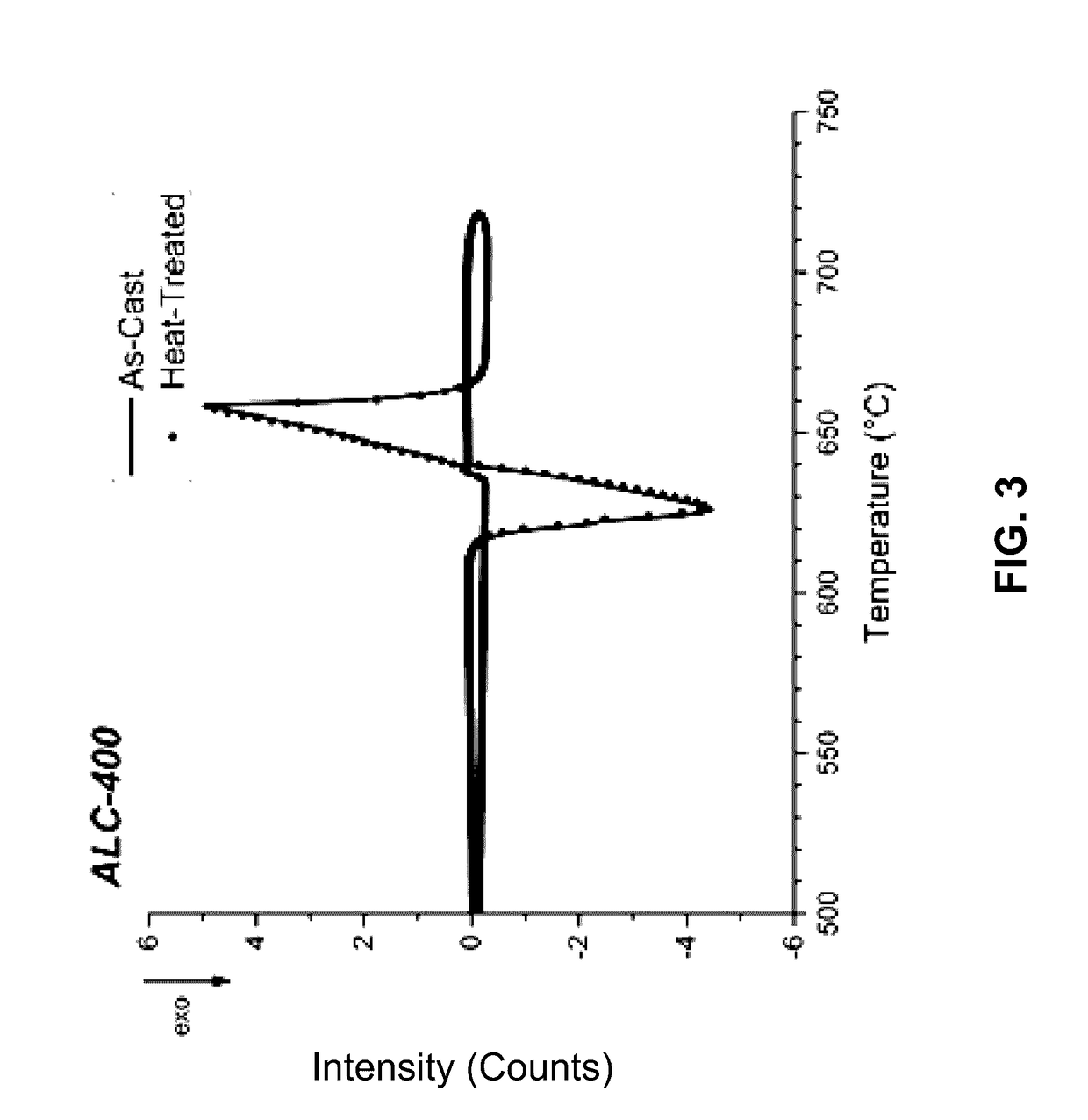

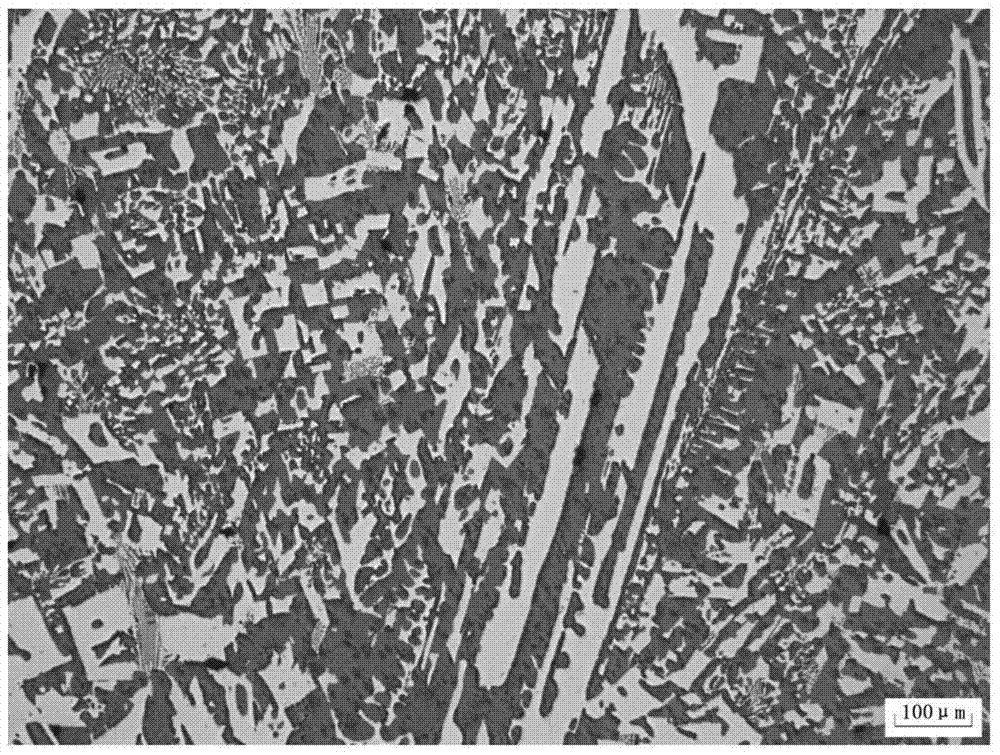

Castable High-Temperature Ce-Modified Al Alloys

A cast alloy includes aluminum and from about 5 to about 30 weight percent of at least one material selected from the group consisting of cerium, lanthanum, and mischmetal. The cast alloy has a strengthening Al11X3 intermetallic phase in an amount in the range of from about 5 to about 30 weight percent, wherein X is at least one of cerium, lanthanum, and mischmetal. The Al11X3 intermetallic phase has a microstructure that includes at least one of lath features and rod morphological features. The morphological features have an average thickness of no more than 700 um and an average spacing of no more than 10 um, the microstructure further comprising an eutectic microconstituent that comprises more than about 10 volume percent of the microstructure.

Owner:UT BATTELLE LLC +3

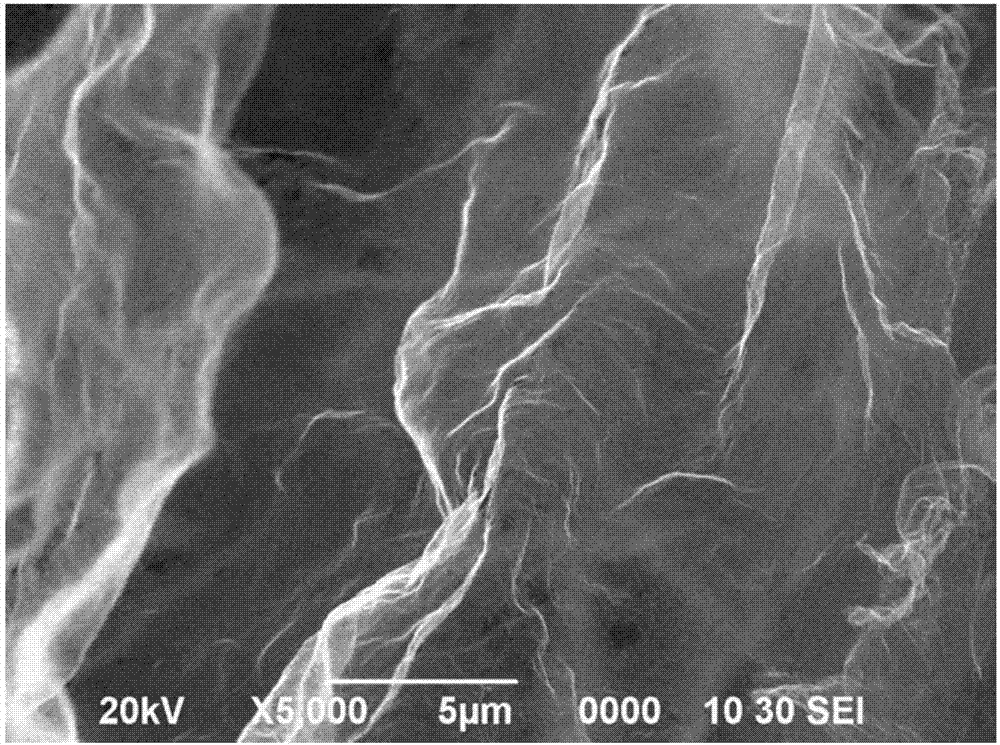

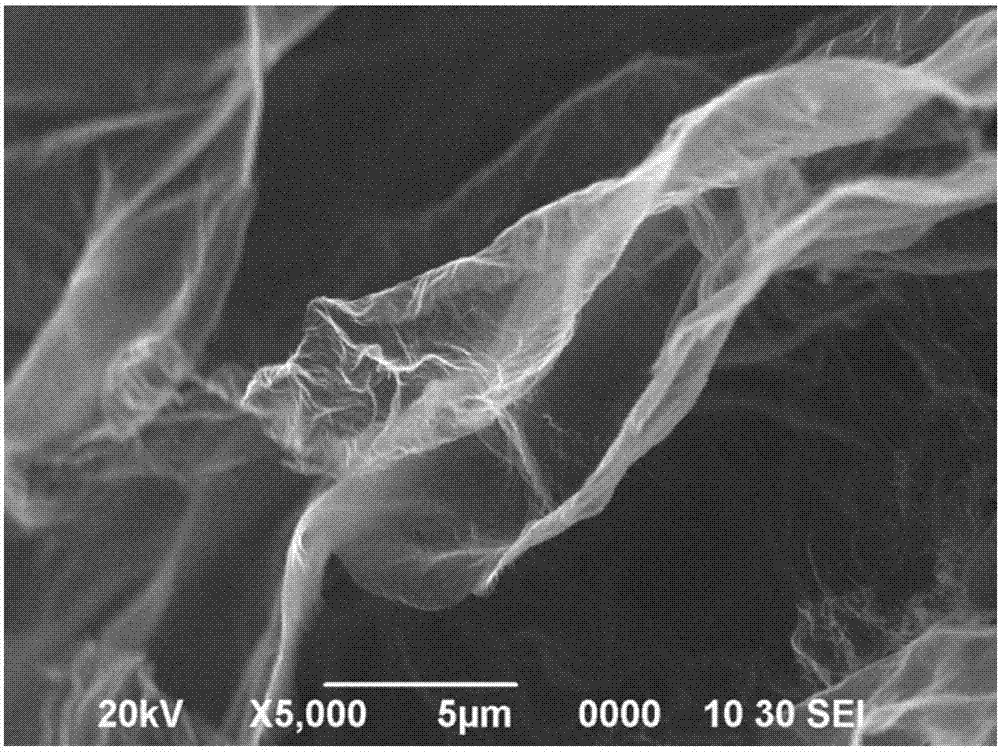

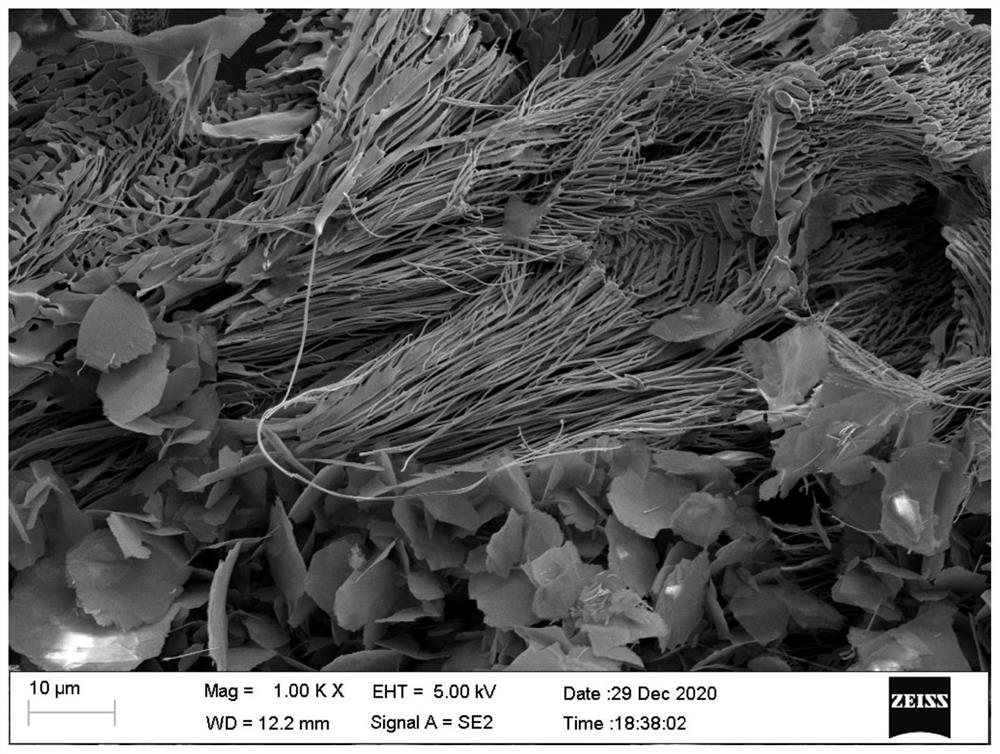

Preparation method of cellulose nanofiber/silk fibroin based porous nitrogen doped 2D carbon nanosheet electrode material

InactiveCN107331865AWide variety of sourcesLow costHybrid capacitor electrodesCell electrodesCelluloseFreeze-drying

The invention relates to a preparation method of a cellulose nanofiber / silk fibroin based porous nitrogen doped 2D carbon nanosheet electrode material and belongs to the technical field of carbon electrode materials. The preparation method of the cellulose nanofiber / silk fibroin based porous nitrogen doped 2D carbon nanosheet electrode material comprises steps as follows: a cellulose nanofiber suspension and a silk fibroin solution are mixed uniformly, and a compound suspension is obtained; the composite suspension is treated in hydrochloric acid steam for 1-12 h, and cellulose nanofiber / silk fibroin composite hydrogel is prepared; the cellulose nanofiber / silk fibroin composite hydrogel is frozen in liquid nitrogen for 5-60 DEG C and then freeze-dried, and composite aerogel is prepared; in the protective atmosphere, the composite aerogel is carbonized at 700-1,300 DEG C for 1-8 h and activated, and the cellulose nanofiber / silk fibroin based porous nitrogen doped 2D carbon nanosheet electrode material is obtained. The cellulose nanofiber / silk fibroin based porous nitrogen doped 2D carbon nanosheet electrode material prepared with the method has the characteristics of being large, good in flexibility, porous and the like and also has the microstructure morphology of 2D graphene morphology.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

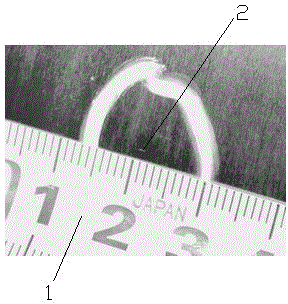

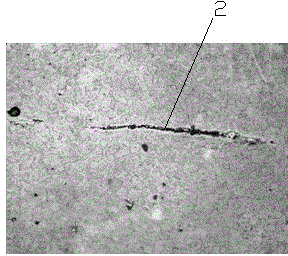

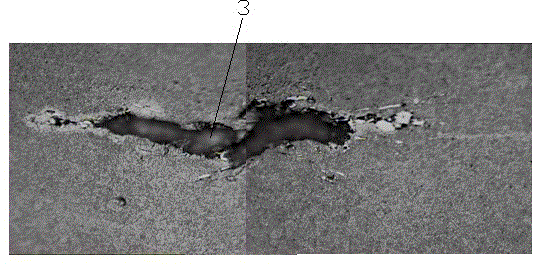

Qualitative detection method for cold roller surface micro linear defect

ActiveCN104422693AEasy to grindAvoid Aircraft Service AccidentsAnalysing solids using sonic/ultrasonic/infrasonic wavesPreparing sample for investigationFiberSand-paper

The present invention discloses a qualitative detection method for the cold roller surface micro linear defect. According to the qualitative detection method, ultrasonic surface wave and magnetic particle inspection is adopted to detect the cold roller surface; the micro linear defect is positioned by using a metallurgical defect positioning scale; the defect part is subjected to coarse grinding, fine grinding and polishing with sand paper and is corroded, the morphologies of the linear defect and the microstructure surrounding the linear defect are copied by using acetate fiber paper, and the defect is marked so as to complete the preparation of the defect morphology copying sheet; the defect morphology copying sheet is subjected to vacuum carbon spraying, the microstructure morphology of the defect is observed under a microscope, the change of the microstructure close to the defect is observed, and the characteristics of the defect morphology and the surrounding microstructure morphology are recorded; and according to the micromorphology characteristic of the micro linear defect and the characteristic of the microstructure surrounding the defect, the character of the roller surface linear defect is qualitatively judged. With the detection of the present invention, the qualitative judgment can be performed on the cold roller surface micro linear defect, such that the cold roller subsequent grinding treatment is convenient, the cold roller service accident is avoided, and the cold rolling quality of the plate is ensured.

Owner:SHANGHAI JINYI INSPECTION TECH

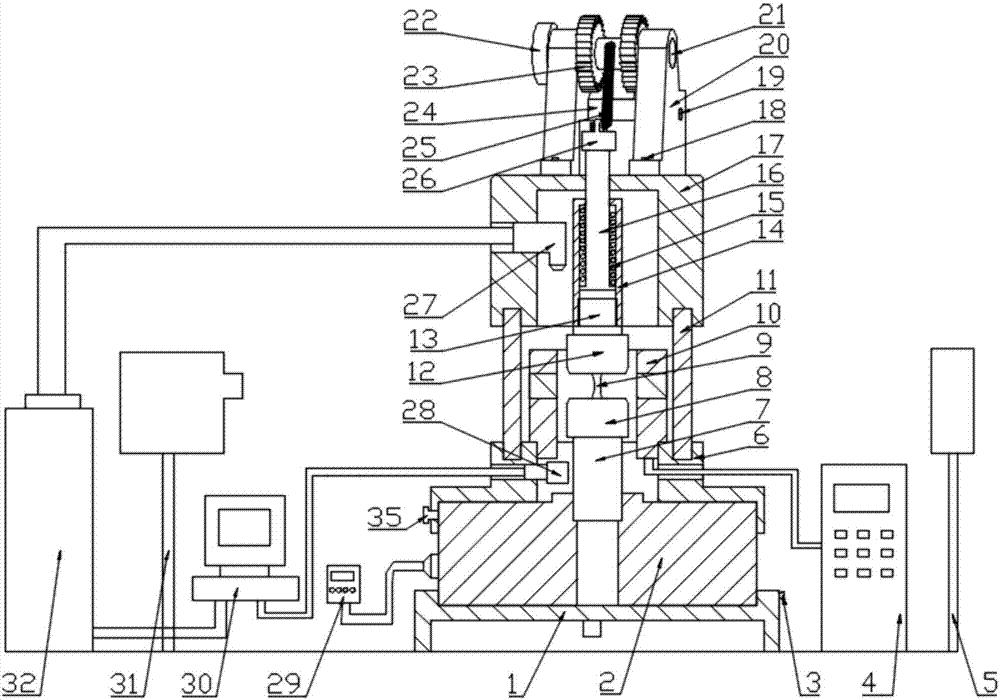

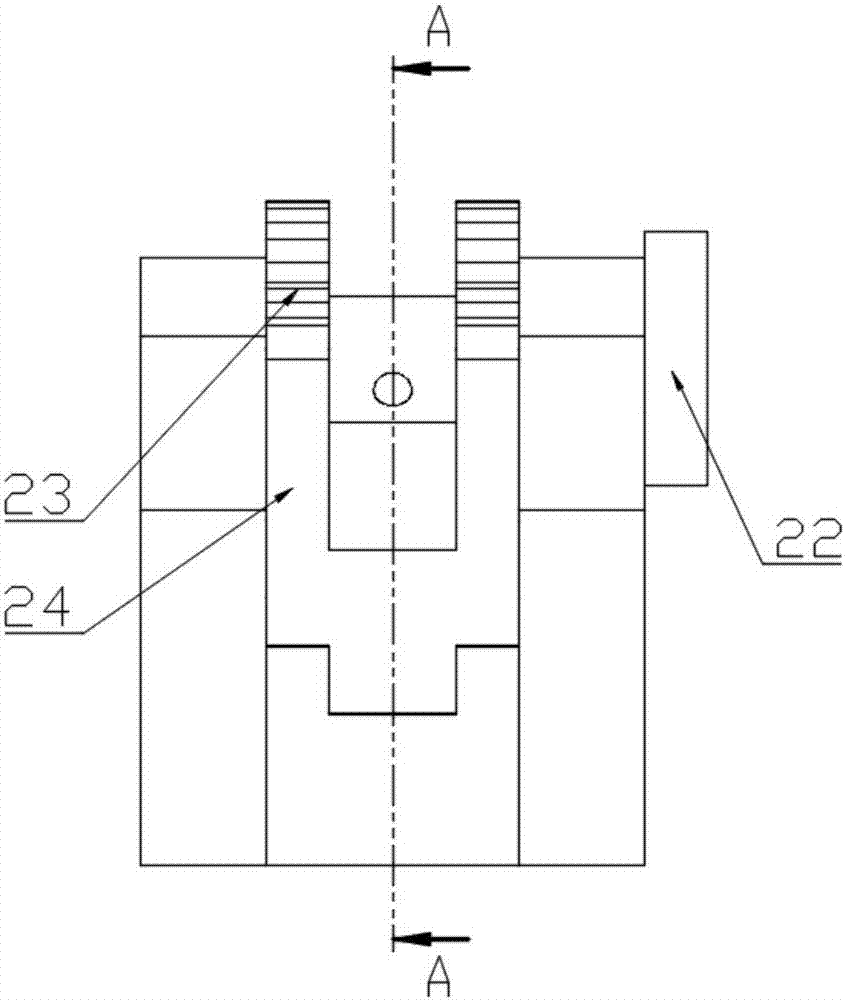

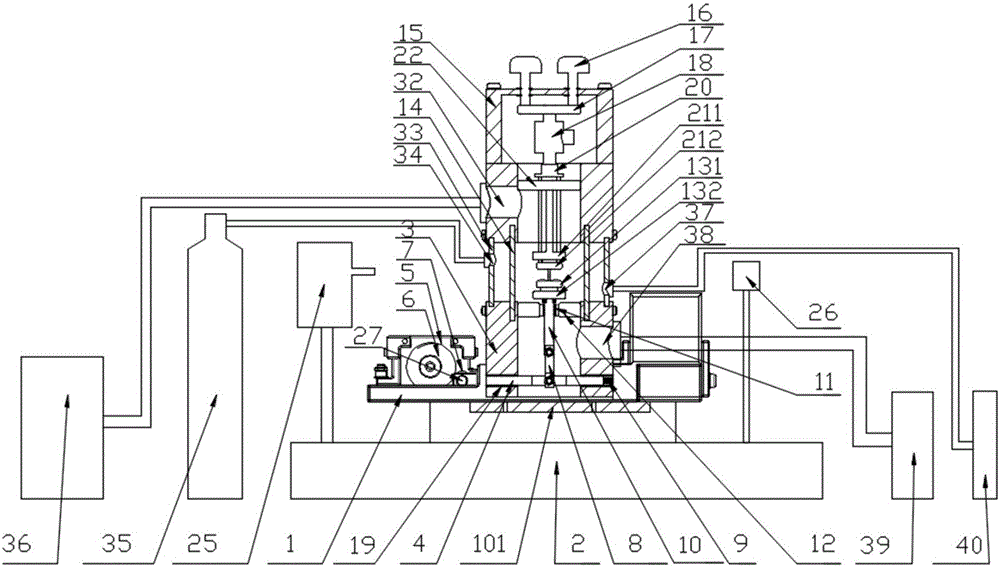

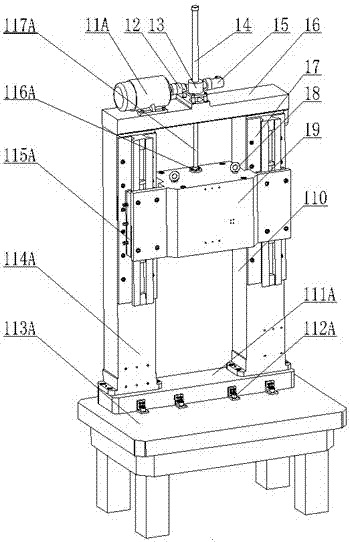

Synchrotron radiation in-situ imaging tensile testing machine simulating multiple environments and testing method thereof

ActiveCN107036888AImprove accuracyObserving the Microstructure MorphologyMaterial strength using tensile/compressive forcesMaterial analysis by transmitting radiationTemperature controlHigh humidity

The invention discloses a synchrotron radiation in-situ imaging tensile testing machine simulating multiple environments and a testing method thereof and belongs to the field of material tensile testing machine. The material tensile testing machine comprises a rotatable single-pull base, wherein a digital display pull and push dynamometer is arranged above the single-pull base and is fixedly connected with the lower portion of a lower clamp, the upper portion of an upper clamp is fixedly connected to a sleeve, a spring and a sleeve shaft are arranged in the sleeve, the top of the sleeve shaft is connected to the loading connection position of a loading mechanism, and the loading mechanism is provided with a ratchet wheel and a pawl for achieving a self-locking function. The testing machine is further provided with an in-situ imaging system, a humidification device and a temperature control device. The testing machine reasonably applies a dynamical tensile test and a synchrotron radiation imaging technique and conveniently obtains a three-dimensional image of the inside of a material, microstructure change and microcosmic deformation damage of material organization under complicated environments such as high temperature, low temperature, high humidity and rich oxygen can be obtained, and the microstructure morphology and defects of the material can be better observed.

Owner:SOUTHWEST JIAOTONG UNIV

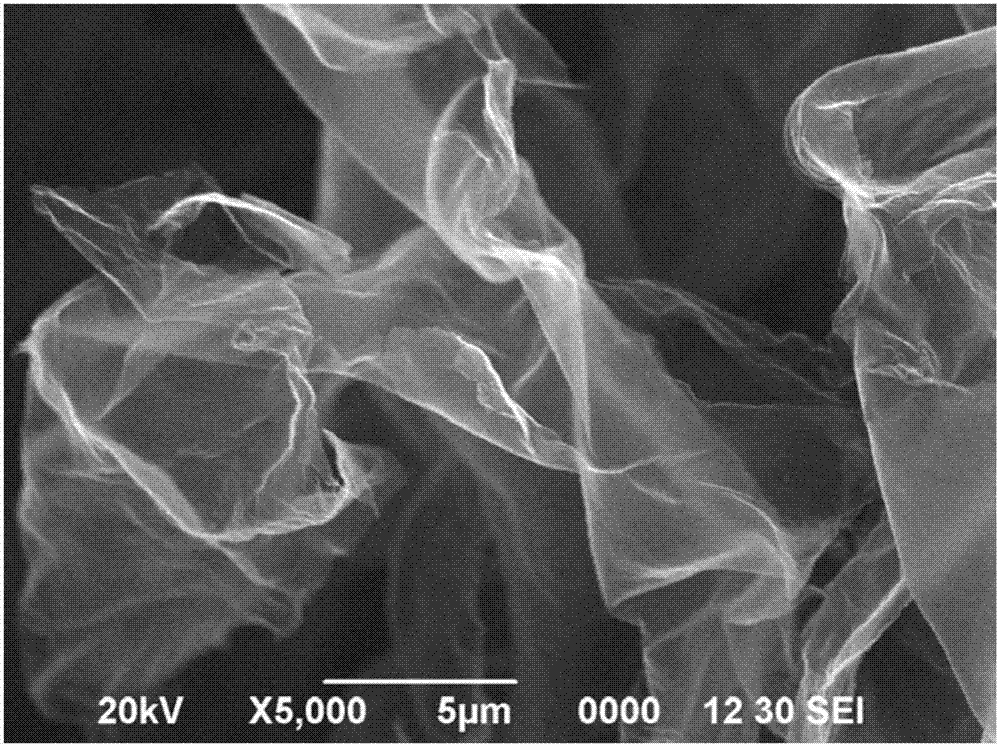

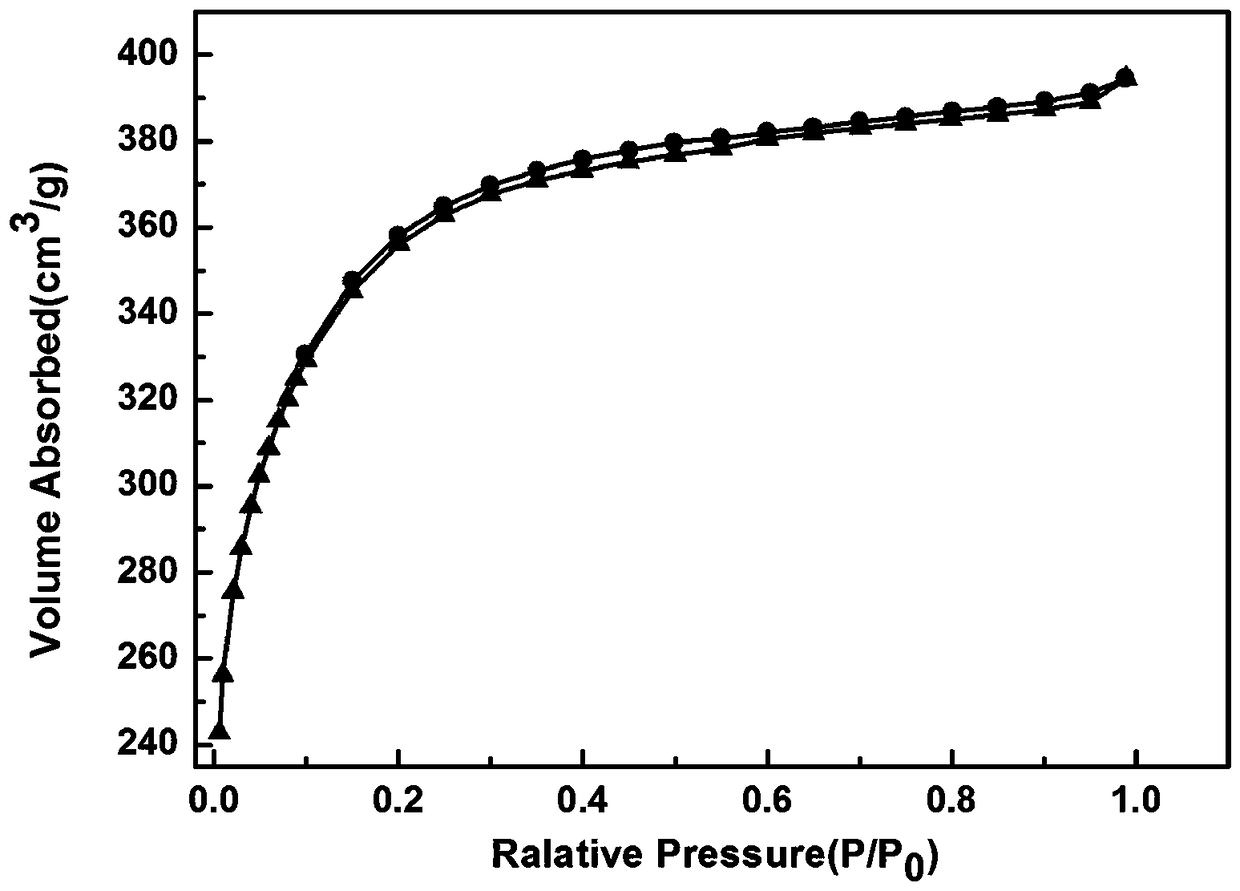

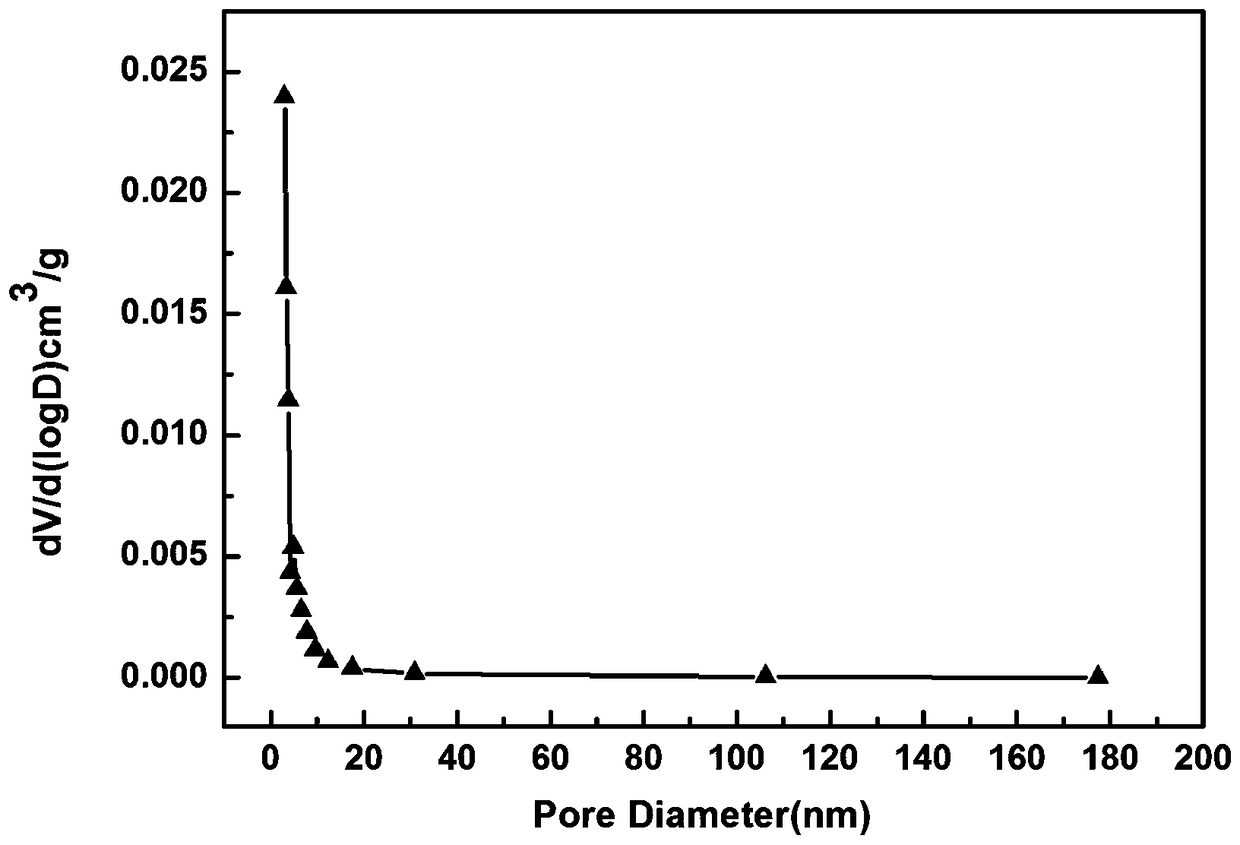

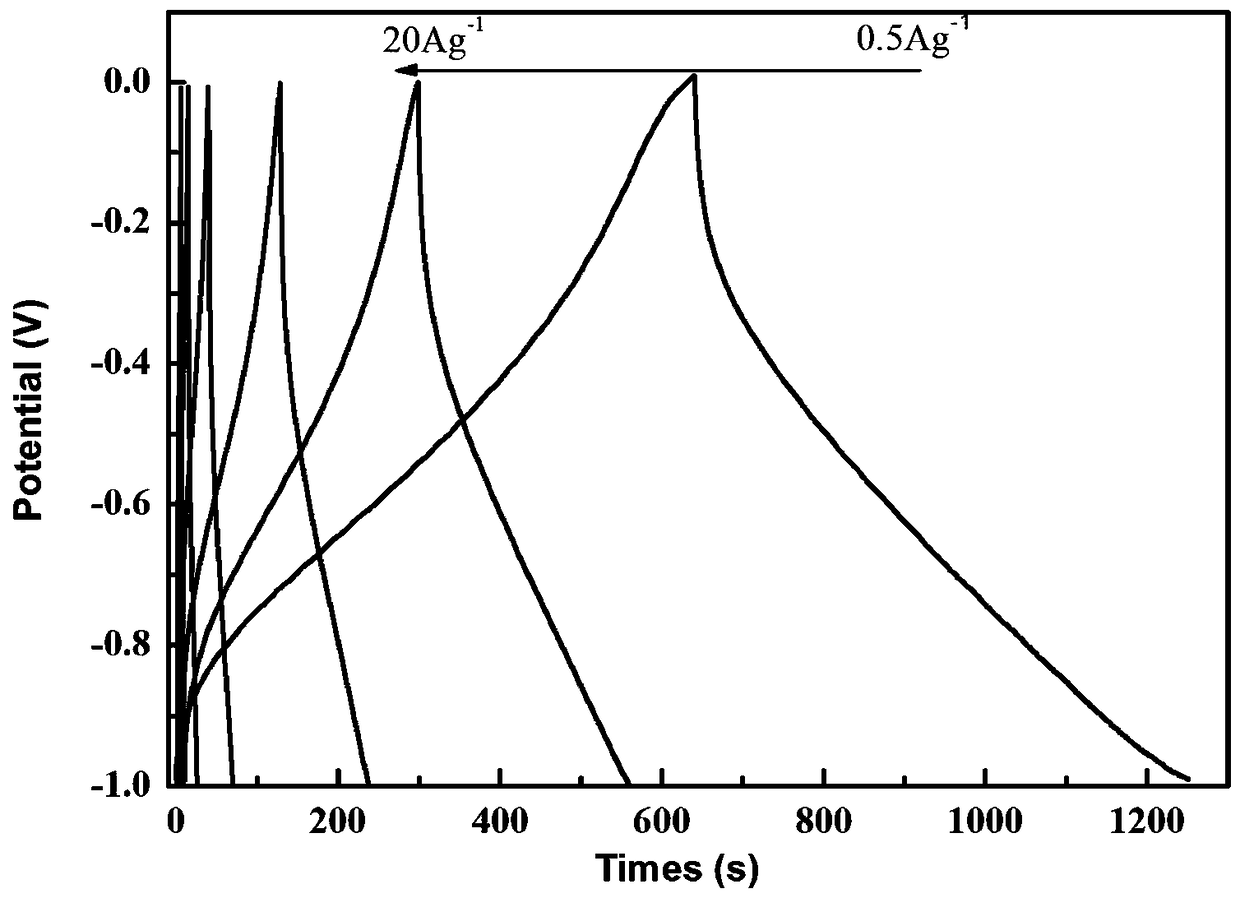

Nitrogen and boron co-doped porous carbon material and preparation method and application thereof

InactiveCN108597910AWidely distributedReduce wasteHybrid capacitor electrodesHybrid/EDL manufactureCapacitancePorous carbon

The invention discloses a nitrogen and boron co-doped porous carbon material. The nitrogen and boron co-doped porous carbon material is prepared by taking glucose, melamine and boric acid as raw materials, preparing a nitrogen and boron precursor after reaction and then performing calcination and activation. The specific surface area of the nitrogen and boron co-doped porous carbon material is (1,027-1,432) m<2> g<-1>, the average pore size distribution is 1.686-3.826 nanometers, and the micropore content accounts for 77-81%. The preparation method comprises the steps of 1) preparing the nitrogen- and boron-containing precursor; 2) activating the nitrogen- and boron-containing precursor; and 3) performing post-processing on the nitrogen- and boron-containing precursor. When the nitrogen and boron co-doped porous carbon material is used as a supercapacitor electrode material, the specific capacitance value is 230-309 F g<-1> when the current density is 0.5A G<-1>. The melamine has a unique and rich macropore framework structure, the microstructure morphology of the material is controlled, porous microstructure morphology in a honeycomb shape similar to cheese and with thick slice structure is obtained, so that the nitrogen and boron co-doped porous carbon material has favorable electrochemical performance. The nitrogen and boron co-doped porous carbon material has wide application prospect in the field of a supercapacitor, a fuel cell and the like.

Owner:GUILIN UNIV OF ELECTRONIC TECH

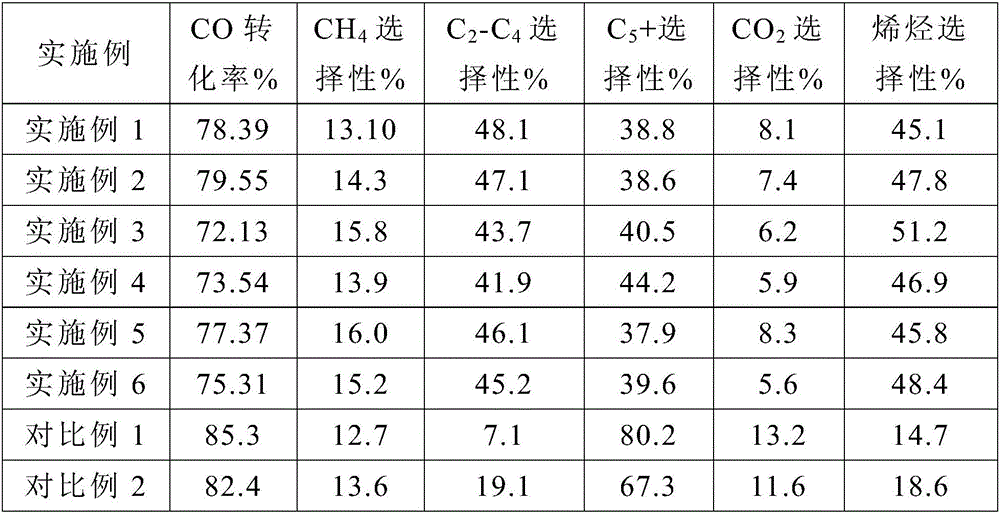

Multistage duct type cobalt-based Fischer-Tropsch synthesis catalyst with core-shell structure and preparation method of multistage duct type cobalt-based Fischer-Tropsch synthesis catalyst

ActiveCN105879899AExtended service lifeAvoid reunionMolecular sieve catalystsLiquid hydrocarbon mixture productionActive componentCobalt

The invention discloses a multistage duct type cobalt-based Fischer-Tropsch synthesis catalyst with a core-shell structure and a preparation method of the multistage duct type cobalt-based Fischer-Tropsch synthesis catalyst. The catalyst comprises a catalyst carrier S, a metal active component Co loaded on the catalyst carrier S and a shell layer zeolite membrane M which wraps the surface of the catalyst carrier S, wherein the catalyst carrier S is a mixture of one or two of SiO2 and Al2O3 according to an optional ratio, the microstructure form of SiO2 and Al2O3 is spherical, the specific surface area of the microstructure form is 160-290 m(2) / g, and the average particle size ranges from 10 meshes to 50 meshes; the shell layer zeolite membrane M is a cluster aggregation of H-ZSM-5 nano particles which are dispersed uniformly, the particle size range of the H-ZSM-5 nano particles is between 10 nm and 30 nm, the micropore aperture of the H-ZSM-5 is smaller than or equal to 2.0 nm, and gaps among the adjacent H-ZSM-5 nano particles are smaller than or equal to 100 nm; and the loading capacity of the metal active component Co accounts for 10-30% of the sum of the weight of the catalyst carrier S and the weight of the metal active component Co. The shell layer of the Fischer-Tropsch synthesis catalyst has a multistage duct and high catalyzing efficiency. Meanwhile, the preparation method is simple in technology and low in energy consumption.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

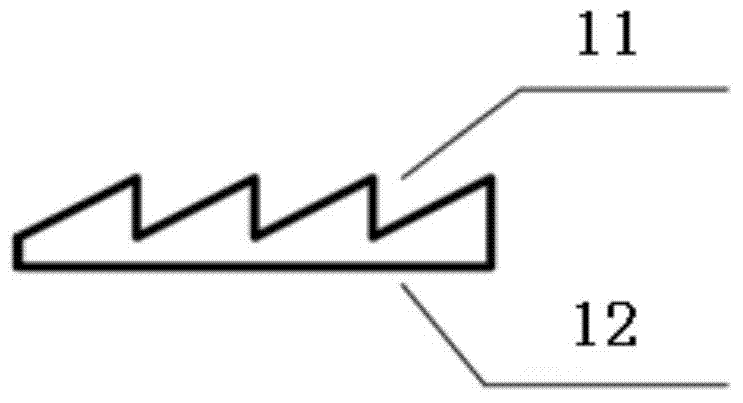

Assembly method of microstructure pressing triple prism made from PMMA polymer material

The invention relates to an assembly method of a microstructure pressing triple prism made from PMMA polymer material. The method comprises the following steps: welding a flat glass plate on the bottom surface of a PMMA pressing triple prism by an ultrasonic welding technology to enable the bottom surface of the PMMA pressing triple prism to be fixed on the flat glass plate; cutting the flat glass plate fixed on the PMMA pressing triple prism by a diamond cutting machine, wherein a free boundary exceeds the outline of the PMMA pressing triple prism; etching an assembly line on the inner layer of a lens of a common spherical mirror needing to be installed, wherein the assembly line is the same as the contour line of the flat glass plate; aligning a microstructure morphology layer of the PMMA pressing triple prism to the inner layer of the common spherical mirror, and welding the flat glass plate provided with the PMMA pressing triple prism on the assembly line by an ultrasonic welding technology; and carrying out edge polishing treatment.

Owner:浙江艾明德生物科技有限公司

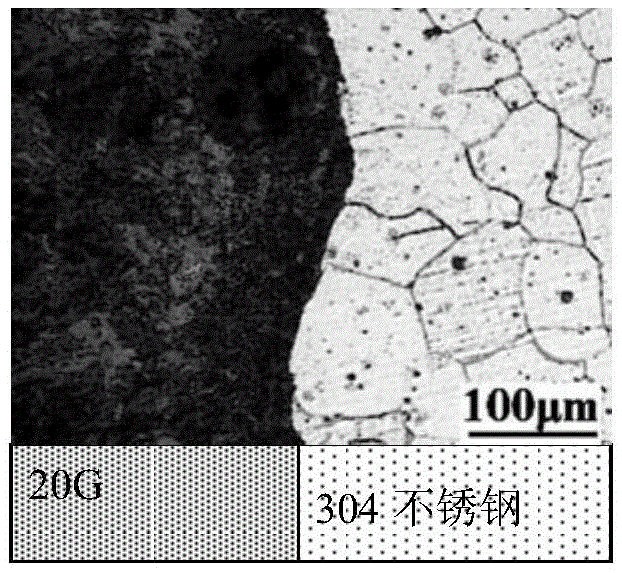

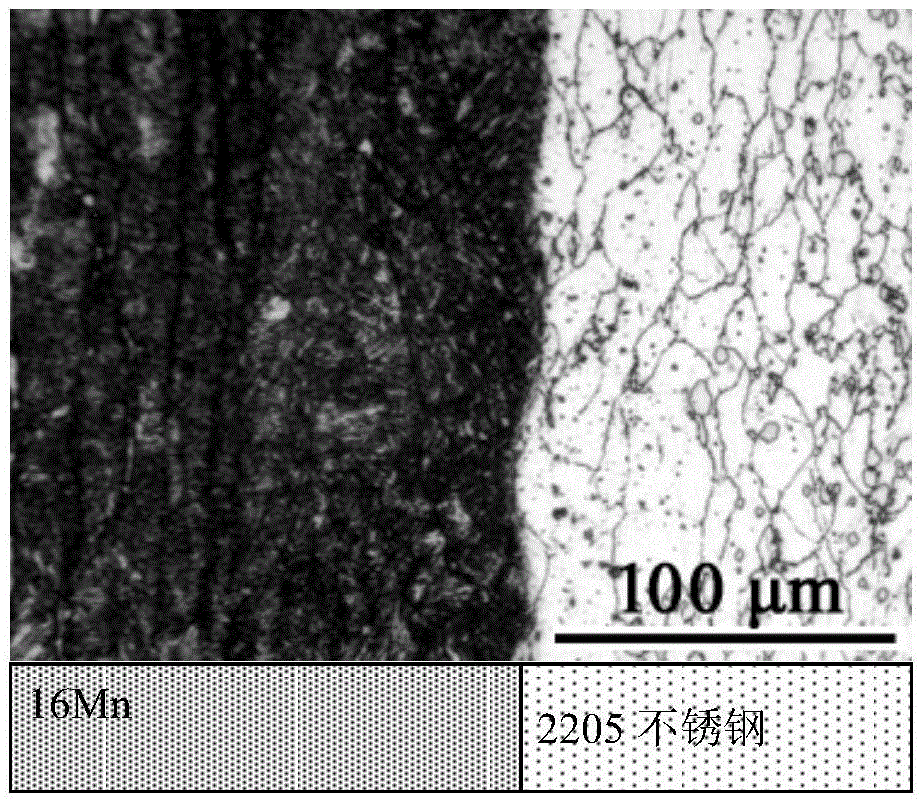

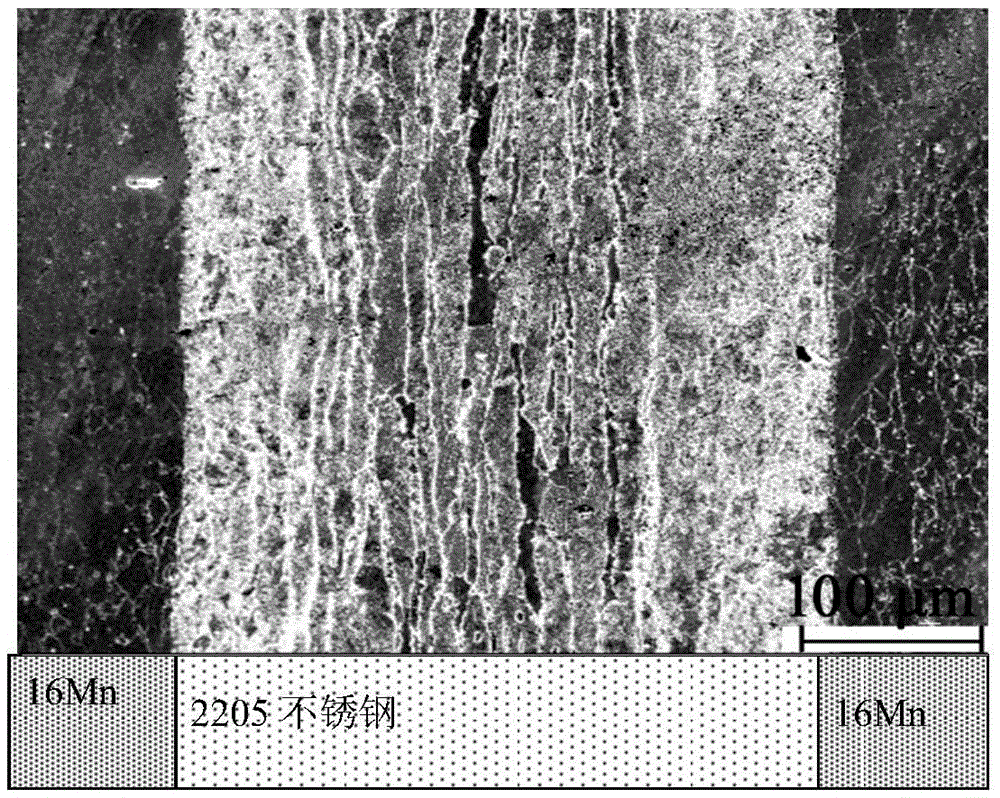

Metallurgical analysis etching method of layered metal composite material

The invention belongs to the technical field of metal material metallographic etching, and particularly relates to a metallurgical analysis etching method of layered metal composite material. The metallurgical analysis etching method employs electrolytic etching and chemical etching methods in order; and the microstructures of alloy components with different corrosion resistant performances in the layered metal composite material are displayed simultaneously, so as to analyze the phase composition, microstructure morphology, interface structure and grain size of components in each layer of the layered composite material.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

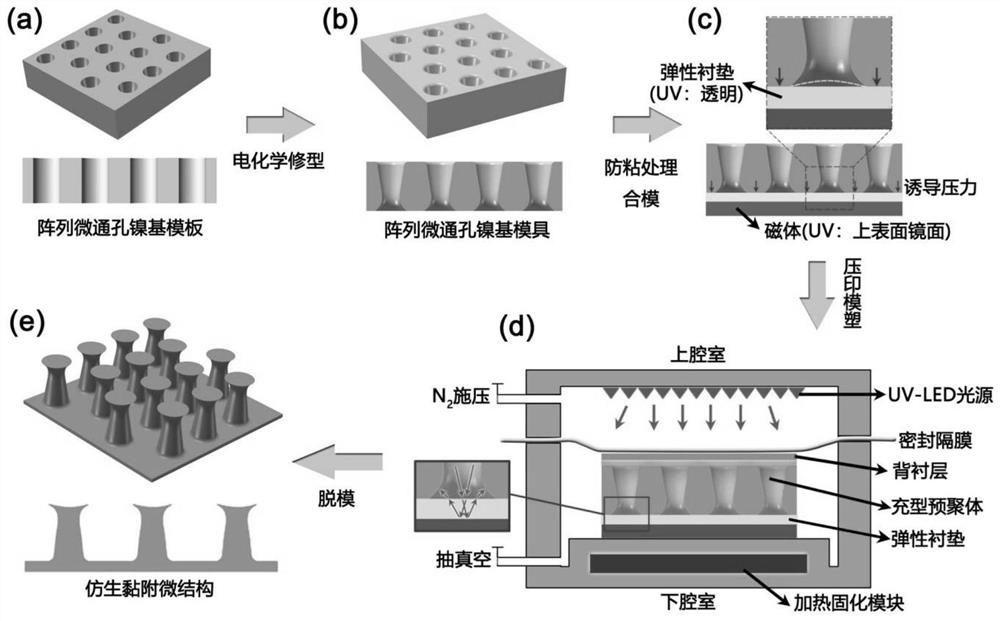

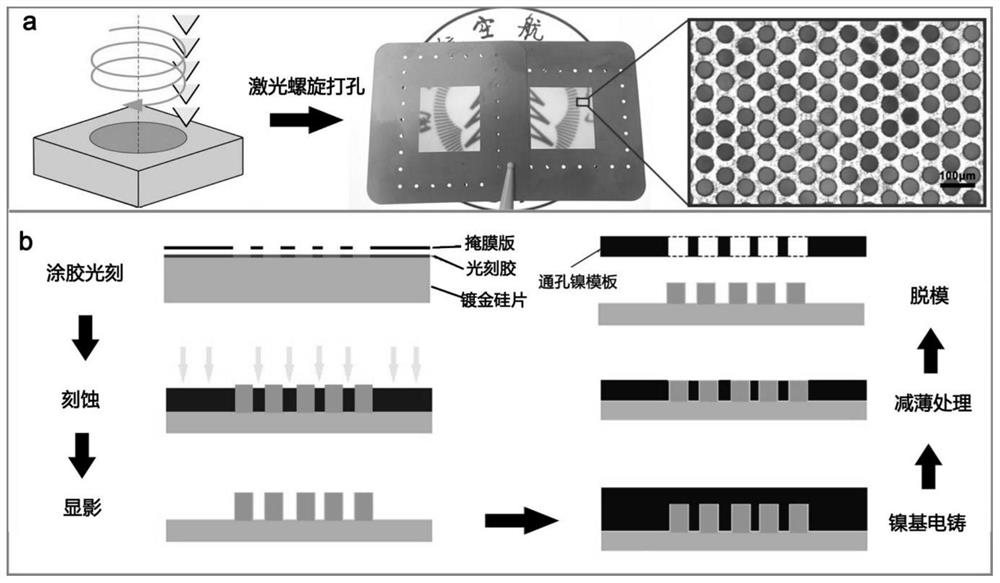

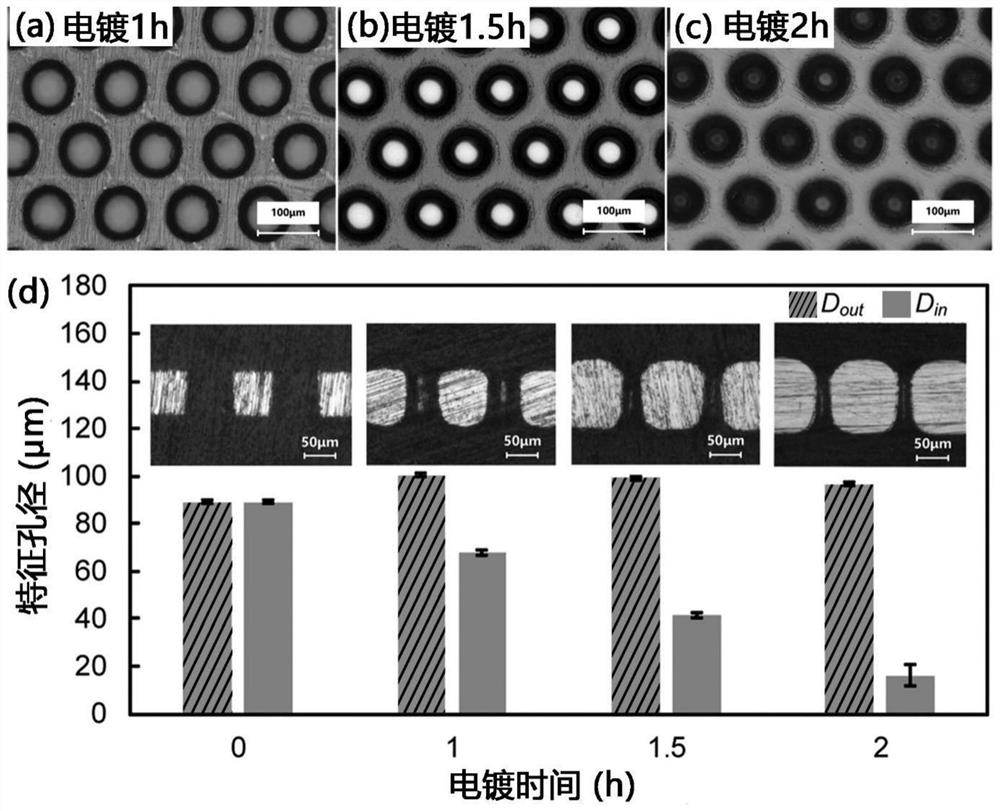

Flat pressing manufacturing method of bionic adhesion structure based on micro-via nickel-based mold

The invention discloses a flat pressing manufacturing method of a bionic adhesion structure based on a micro-via nickel-based mold. The method includes the steps of: preparing a nickel-based mold withan array of micro-vias; placing the nickel-based mold on an elastic liner in a magnetic assembly system; uniformly coating a backing with liquid prepolymer, and placing the side, coated with the liquid prepolymer, of the backing on the nickel-based mold; dividing a cavity into an upper cavity and a lower cavity by a sealing diaphragm, and uniformly pressing a backing layer by vacuumizing the lower cavity and inflating the upper cavity so as to achieve full filling of prepolymers with different viscosities; after completing filling, conducting curing and demolding, and obtaining the bionic adhesion material. The method contributes to the realization of an integrated molding process of a structure with a large depth-to-diameter ratio and an enlarged end; and the magnetic force-induced assembly system is combined with an electrochemical modification technology of the nickel-based mold to realize the omnidirectional controllable adjustment of the microstructure morphology of the bionic adhesive material. The method helps to improve the universality of the micro-nano imprint manufacturing technology for complex structures.

Owner:NANJING ADHESION TECH CO LTD +1

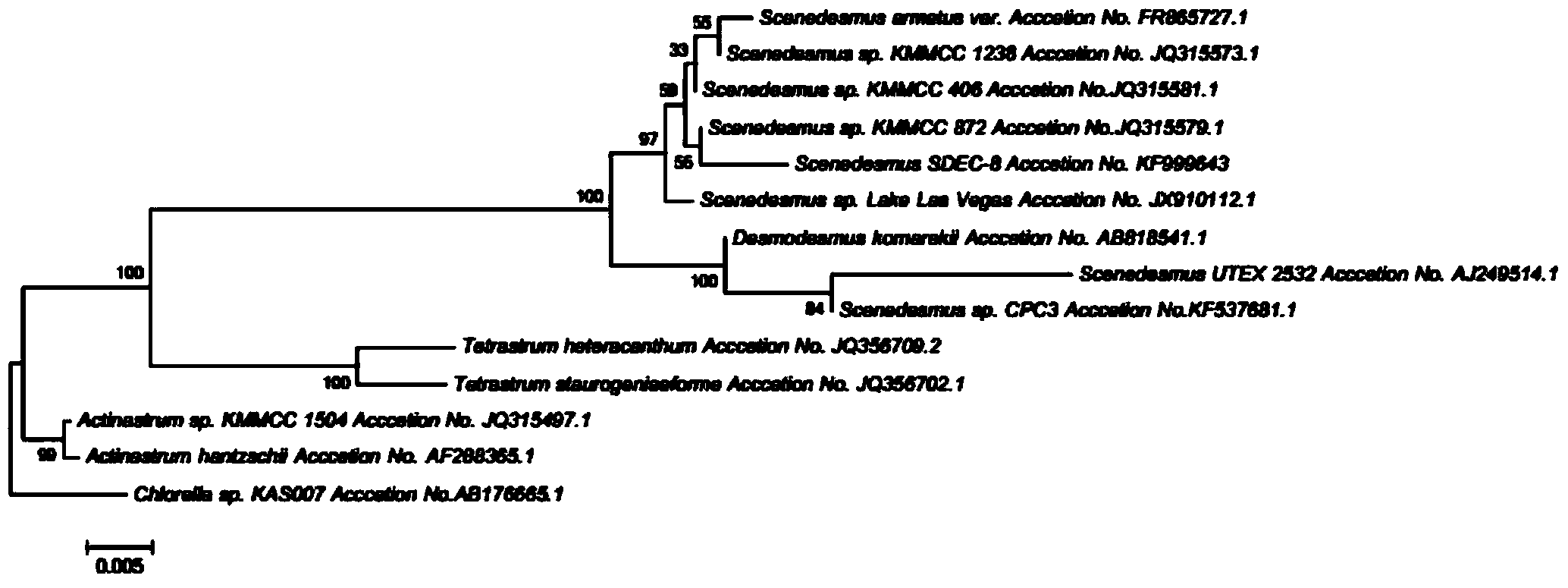

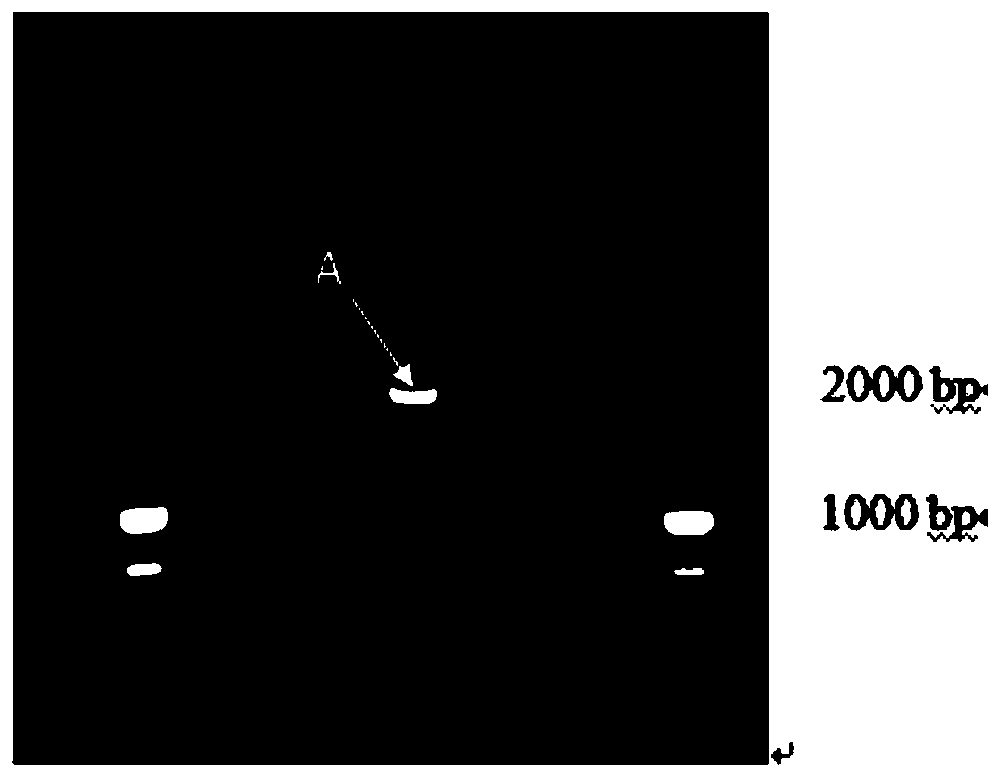

Scenedesmus capable of highly yielding oil as well as culture method and application thereof

InactiveCN104328053AWell mixedImprove light energy utilizationUnicellular algaeWater contaminantsBiodiesel feedstockSequence analysis

The invention relates to scenedesmus capable of highly yielding oil as well as a culture method and application thereof. An alga variety separated from a eutrophic water region is subjected to 18S rDNA sequence analysis and microstructure morphology identification so that the alga is determined as the member of Scenedesmus sp. and the sequence number is KF999043. The alga strain is named as Scenedesmus quadricauda SDEC-8 and is preserved in China Center for Type Culture Collection on October 8, 2014; and the preservation number is CCTCC NO: M2014448. An oil production culture method comprises the following steps: separating single alga cells of the Scenedesmus quadricauda SDEC-8 and carrying out aeration enlarged cultivation on obtained pure cells under laboratory conditions. The Scenedesmus quadricauda SDEC-8 contains rich high-quality oil; and the oil content can be up to 31.8% of the dry weight of the cells and the content of saturated fatty acids in fatty acids can be up to 80%, so that the Scenedesmus quadricauda SDEC-8 can be used as the raw material of biodiesel. Based on a high cetane number (61.38) and a low iodine number (29.38gI2 / 100g), the biodiesel prepared by taking the microalga as the raw material has good oxidization stability.

Owner:SHANDONG UNIV

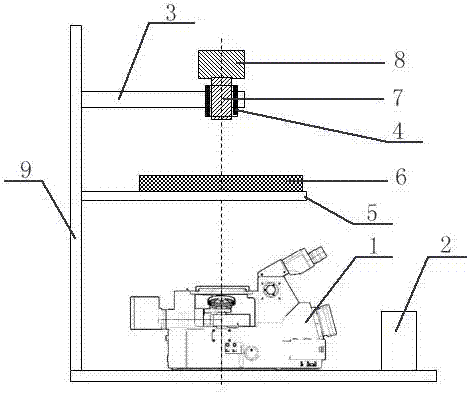

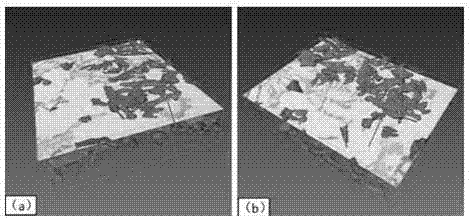

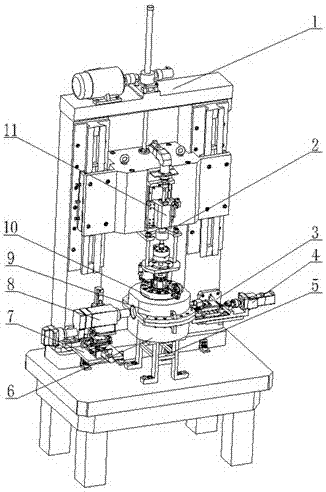

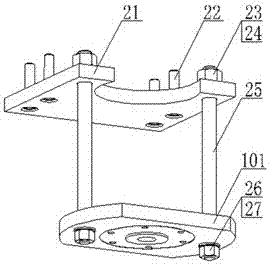

Apparatus for highly-efficiently reconstructing three-dimensional microstructure morphology of material, and reconstruction method thereof

ActiveCN107314928AReduce manpowerReduce material consumptionPreparing sample for investigationMaterial analysis by optical meansAutofocusHorizontal orientation

The invention belongs to the technical field of material characterization, and especially relates to an apparatus for highly-efficiently reconstructing the three-dimensional microstructure morphology of a material, and a reconstruction method thereof. The problem of time and labor consuming and low efficiency existing in the prior art are solved in the invention. The apparatus comprises a metallographic microscope, a camera, a sample clamping assembly and a polishing assembly, the metallographic microscope is inverted, the camera is an autofocus camera, the sample clamping assembly comprises a supporting rod capable of rotating in a horizontal direction and a clamp movably arranged at the end portion of the supporting rod, and the polishing assembly comprises a supporting rack capable of rotating in the horizontal direction and a polishing disc horizontally arranged on the supporting rack; and the clamp opens up and down, the cross section of the clamp has a noncircular shape, a sample with a noncircular cross section is clamped in the clamp, a balancing weight is arranged on the upper end surface of the sample, at least one radial dimension of the cross section of the clamp is smaller than the radial dimension of the cross section of the balancing weight, and the lower end surface of the sample and the disc surface of the polishing disc are located in the same horizontal plane.

Owner:XIAN TECHNOLOGICAL UNIV

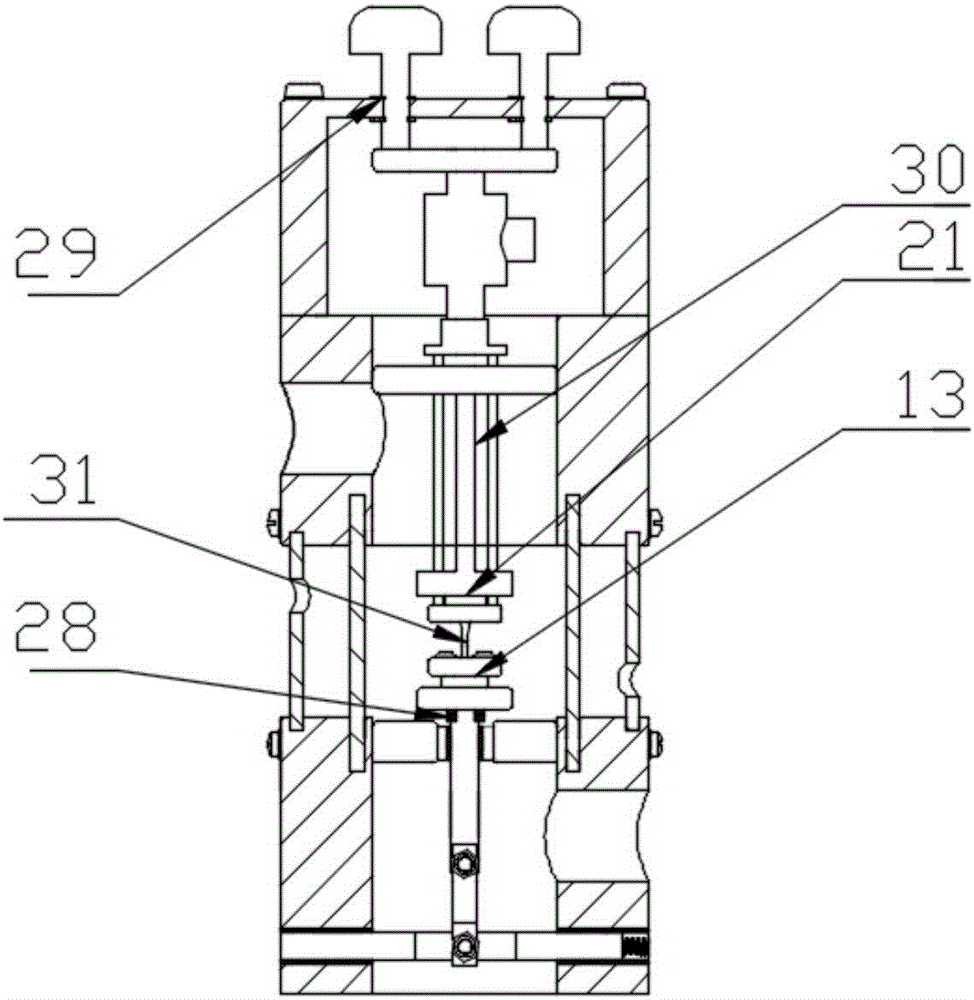

Synchrotron radiation in-situ imaging fatigue testing machine comprising temperature control mechanism and testing method of synchrotron radiation in-situ imaging fatigue testing machine

ActiveCN106680121AObserving the Microstructure MorphologyObserve defectsMaterial strength using repeated/pulsating forcesTemperature controlNitrogen

The invention discloses a synchrotron radiation in-situ imaging fatigue testing machine comprising a temperature control mechanism and a testing method of the synchrotron radiation in-situ imaging fatigue testing machine, and belongs to the field of fatigue testing machines. The synchrotron radiation in-situ imaging fatigue testing machine comprising the temperature control mechanism comprises a base and a top cover, wherein the bottom of a bottom plate is inlaid in a synchrotron radiation light source platform in a cross manner; a clamping mechanism is arranged on the cylindrical base of the synchrotron radiation light source platform; and the temperature control mechanism is arranged between the base and the cylindrical top cover. The testing method comprises the following steps: clamping a sample between an upper clamp and a lower clamp; then fixing an inner enclosure and an outer enclosure well; feeding temperature control air flow and nitrogen to the inner side and the outer layer of the inner enclosure of the testing machine to control the temperature of the sample and prevent water spray from being produced on the enclosure; and then starting a servo motor, applying vertical reciprocating loading to the sample, and acquiring pressure by using a load sensor. The testing machine can analyze fatigue properties of the sample at different temperatures, and microstructure morphology and defects of a material can be observed well.

Owner:SOUTHWEST JIAOTONG UNIV

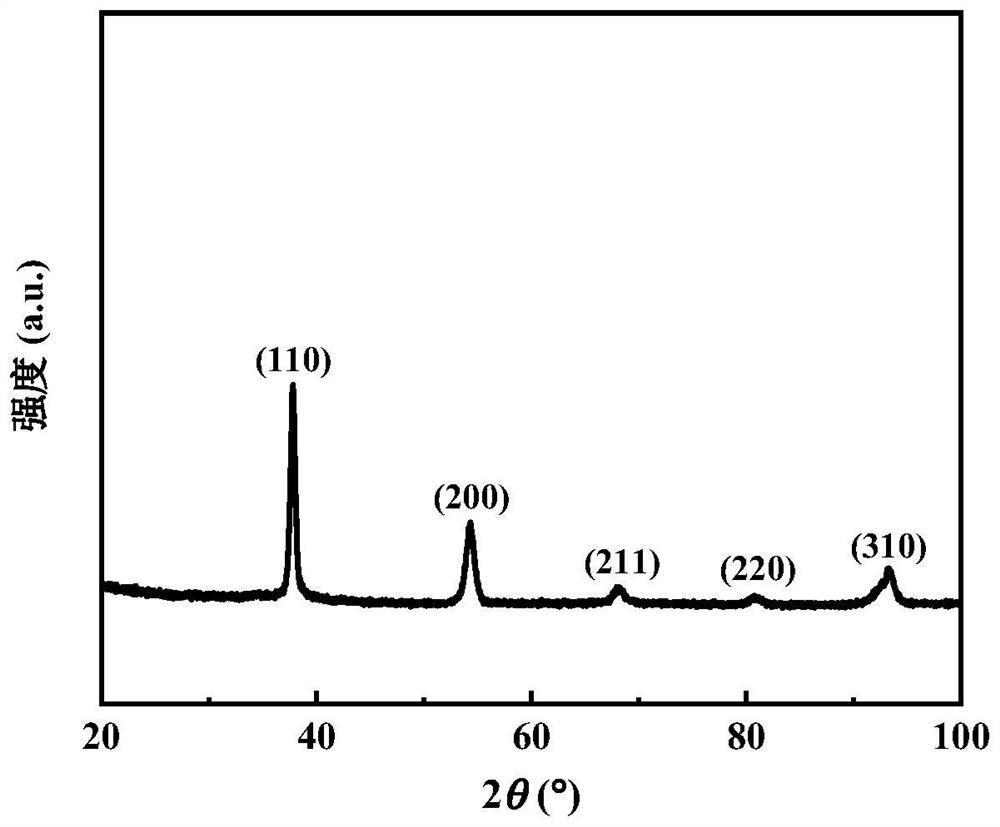

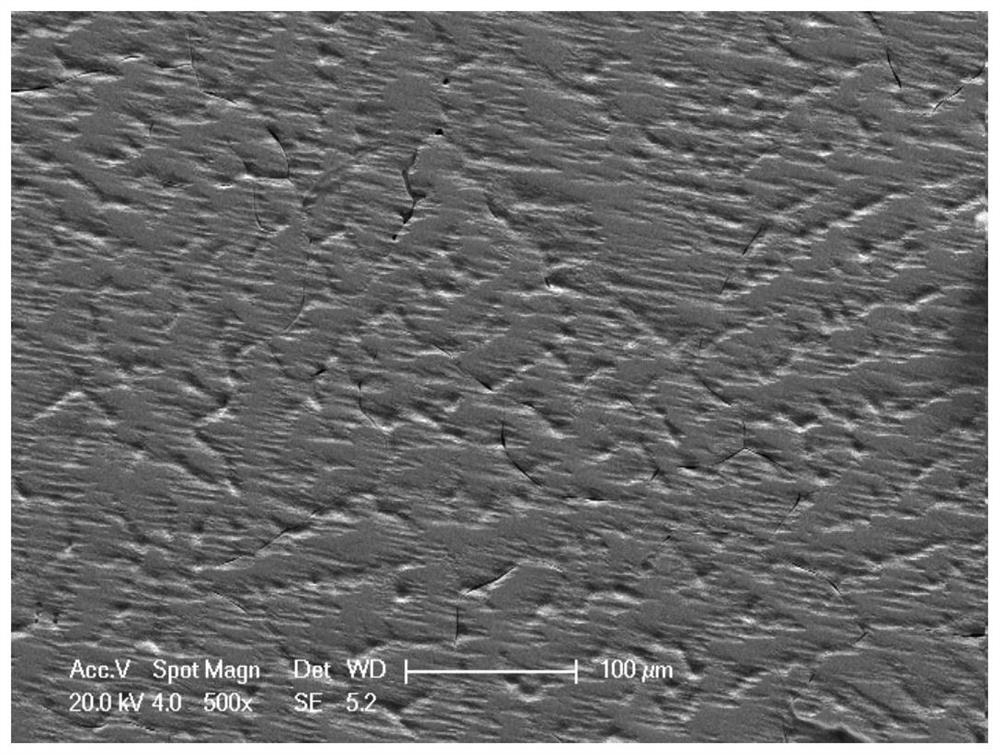

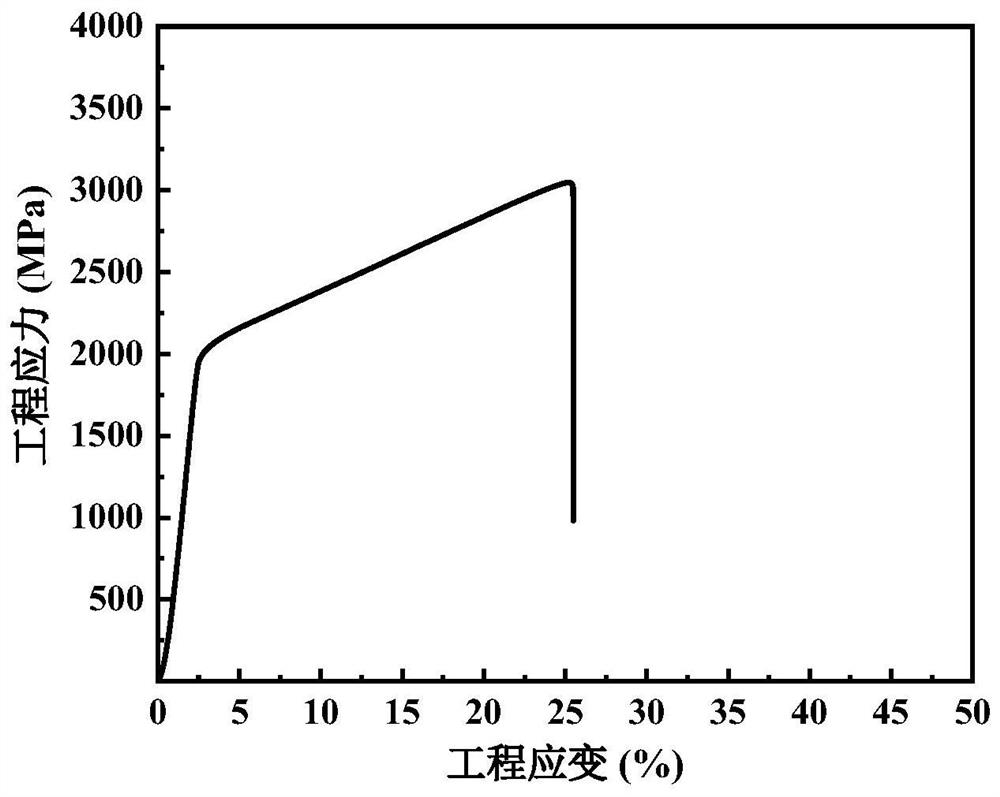

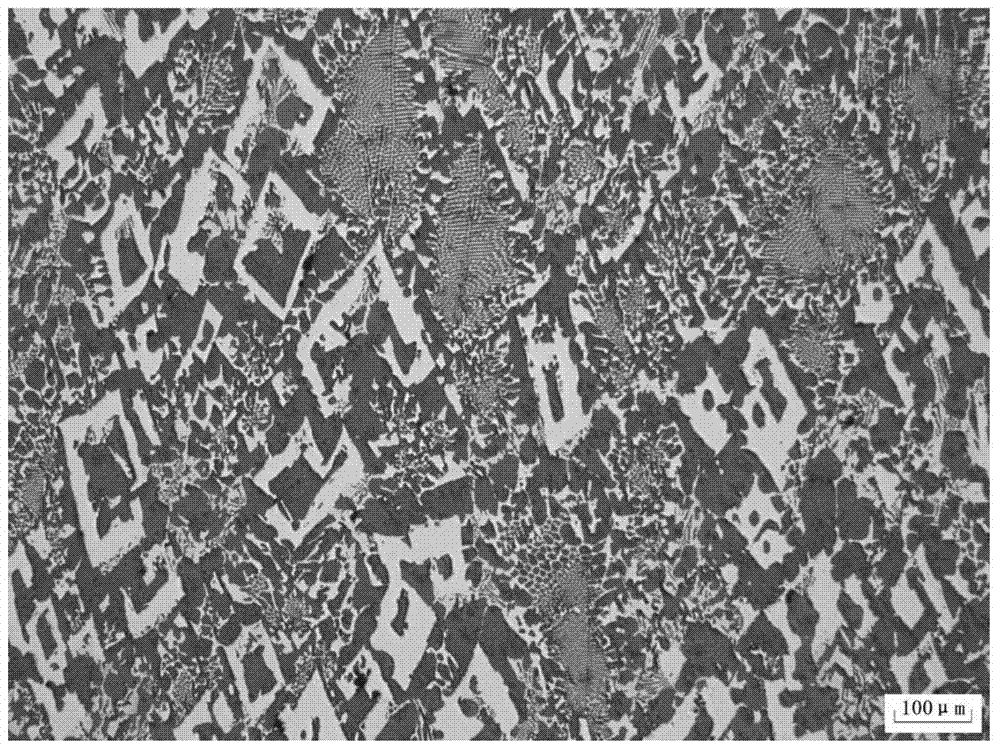

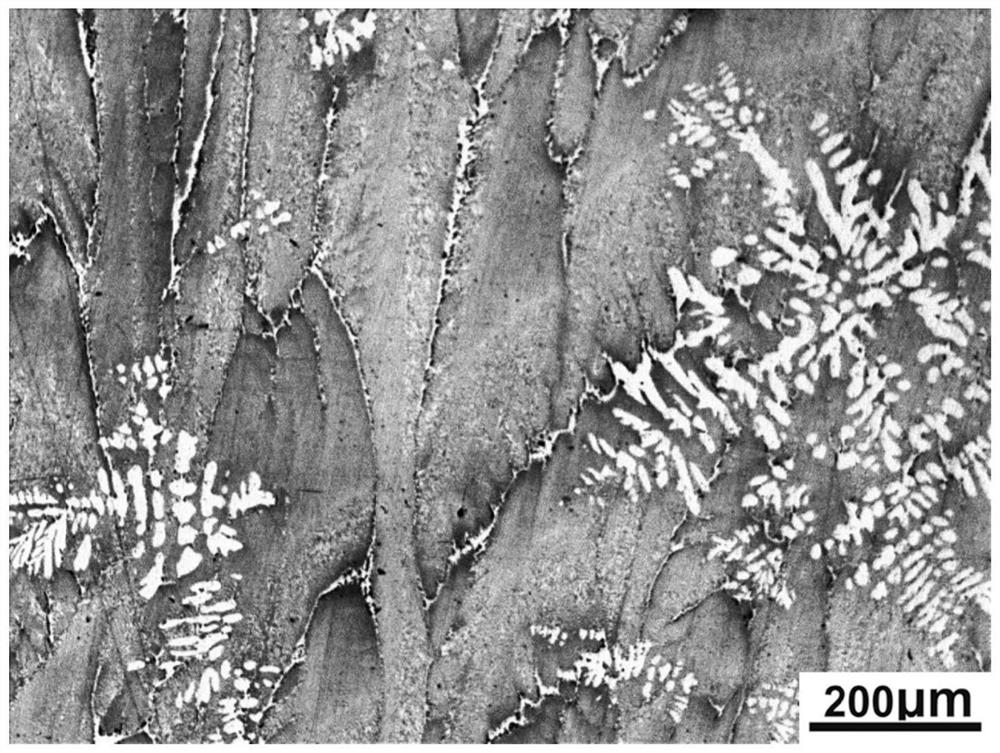

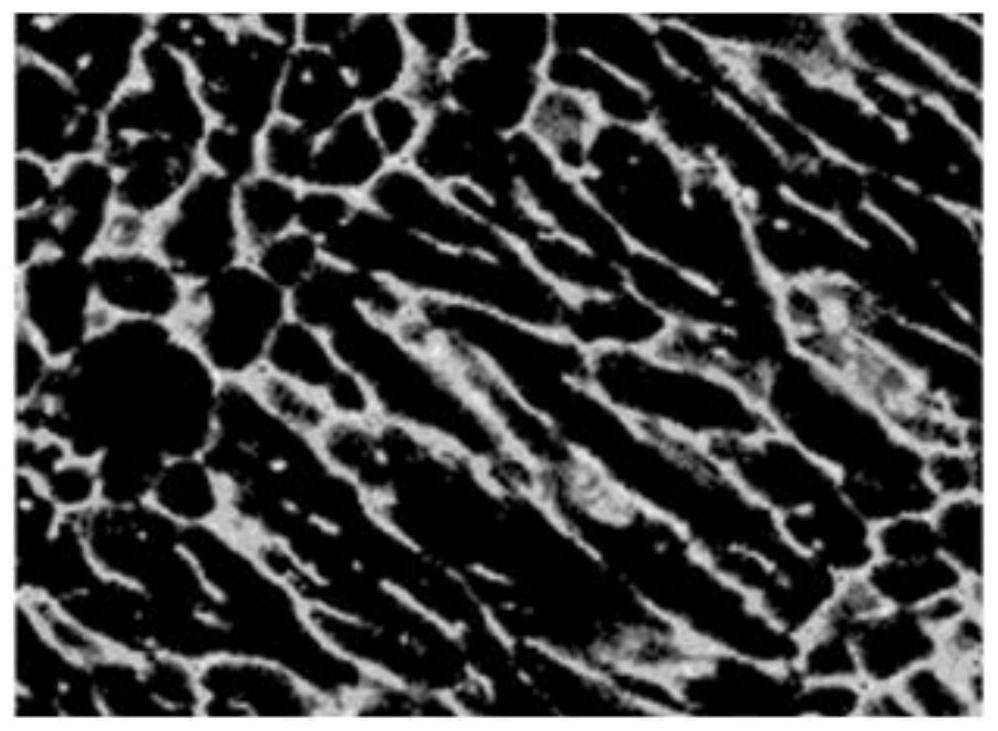

Ceramic phase reinforced refractory high-entropy alloy composite materials and preparation method thereof

ActiveCN113789464AExcellent room temperatureImprove mechanical propertiesHigh entropy alloysAlloy composite

The invention relates to ceramic phase reinforced refractory high-entropy alloy composite materials and a preparation method thereof, and belongs to the technical field of material science and engineering. A series of ceramic phase reinforced refractory high-entropy alloy composite materials are prepared by adding a ceramic phase and using a non-consumable vacuum arc melting furnace. The preparation method is simple in process and convenient to operate; and the alloy is of a single BCC structure, the microstructure morphology is mainly dendritic crystals, interstitial atoms are introduced while a nanometer second phase is introduced, so that the average grain size is obviously reduced compared with a matrix refractory high-entropy alloy, the room-temperature and high-temperature mechanical properties are obviously improved, and the alloy has excellent high-temperature structure stability at the temperature of 800 DEG C. According to the ceramic phase reinforced refractory high-entropy alloy composite materials and the preparation method thereof, the service temperature of mechanical engineering equipment and parts can be obviously improved, the ceramic phase reinforced refractory high-entropy alloy composite materials are expected to replace nickel-based superalloys, and have a wide application prospect in the fields of aerospace, traffic transportation, petrochemical industry, mechano-electronics, automobile manufacturing and the like.

Owner:SOUTHEAST UNIV

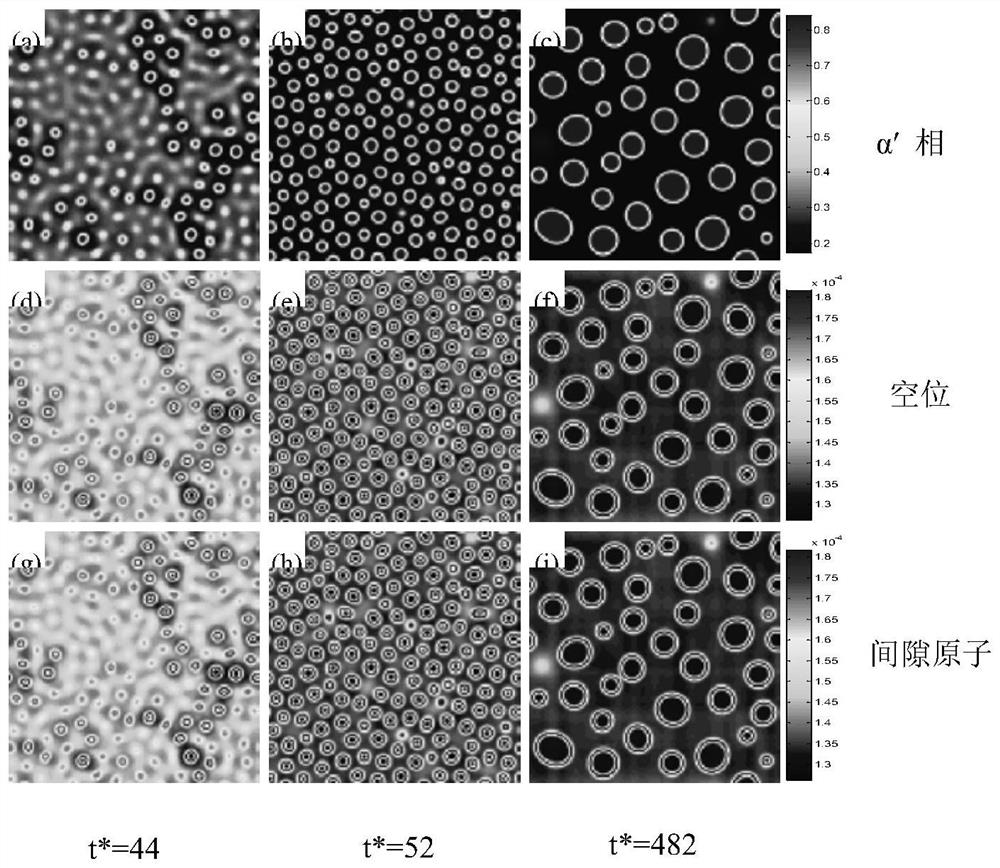

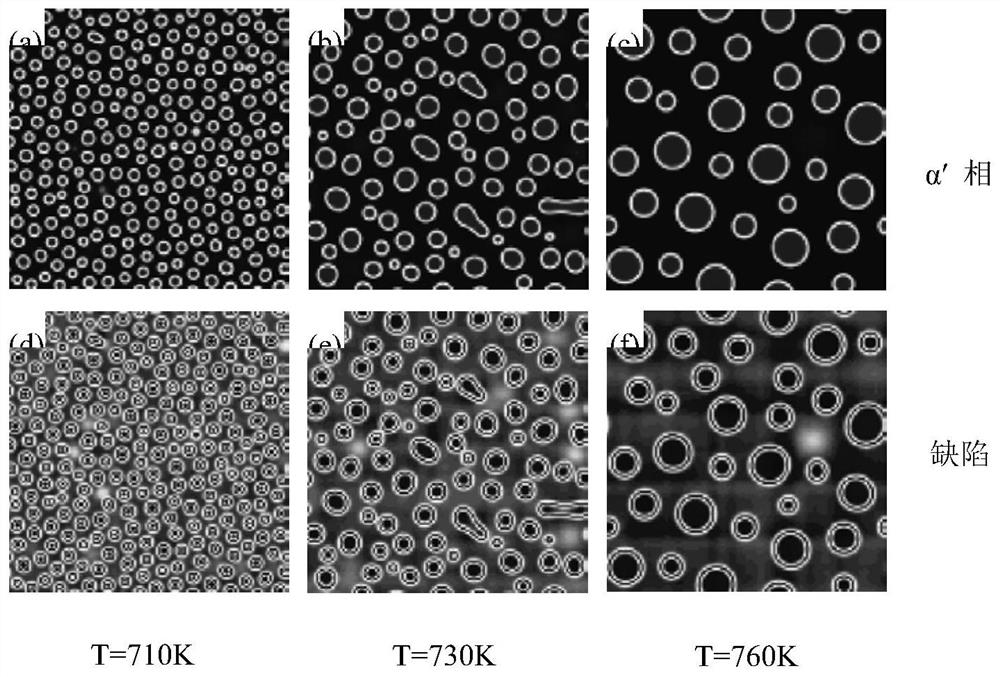

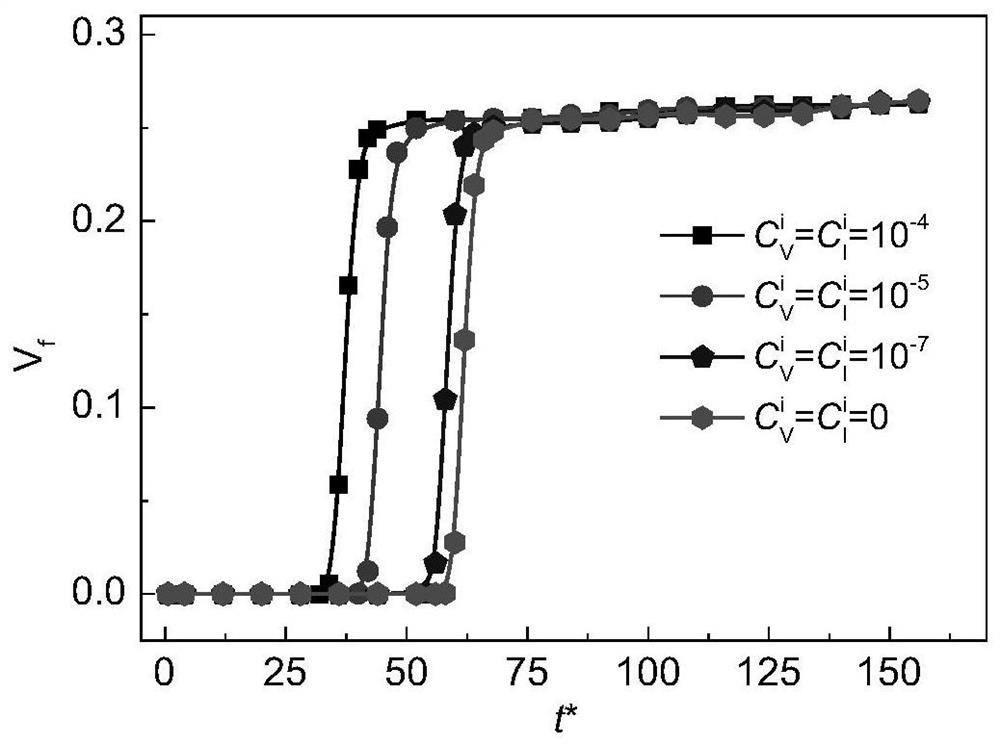

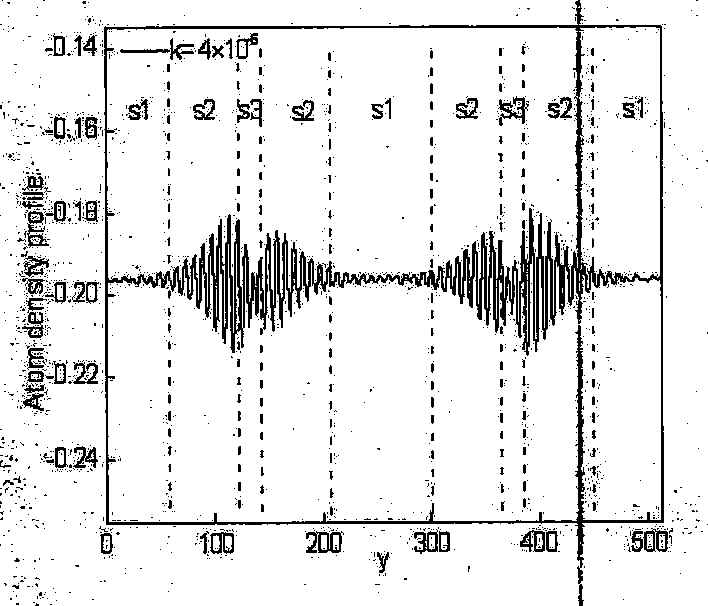

Phase field simulation method for co-evolution of defects and nanophases under irradiation

ActiveCN111899819AMake up for limitationsEasy to parseDesign optimisation/simulationComputational materials scienceFree energiesThermodynamic free energy

The invention relates to a phase field simulation method for co-evolution of defects and nanophases under irradiation. The phase field simulation method comprises the following steps: characterizing the evolution of a system by using the thermodynamic free energy of an alloy; establishing total free energy of a defect-alloy system under irradiation; establishing a phase field equation for co-evolution of defects and nanophases under irradiation, and realizing simulation and representation of evolution of alloy defects and nano-phases under irradiation; analyzing the changes of the microstructure morphology of the defects and the nanophases under the condition that an irradiation temperature and a defect concentration change so as to obtain the evolution rules of the defects and precipitated nanophases under irradiation; and analyzing the volume fraction changes of the defects and the nanophases to obtain the influence rules of different irradiation temperatures and defect concentrations on the formation and evolution dynamics of the defects and the nanophases. The invention provides the phase field simulation method for co-evolution of the defects and the nanophases under irradiation, so an interaction relationship between the defects and phase decomposition under irradiation can be obtained, and guidance is provided for the design and service safety of alloy materials under irradiation.

Owner:NANJING UNIV OF SCI & TECH

Performance determination method for anti-coking coating of boiler heating surface tube

InactiveCN106289137AEffective detection performanceInnovative designMaterial thermal conductivityUsing wave/particle radiation meansTest platformMicro morphology

The invention discloses a performance determination method for an anti-coking coating of a boiler heating surface tube, which comprises the steps of 1) measuring the coating thickness, and determining the coating thickness uniformity; 2) carrying out microstructure morphology inspection on the coating, and determining the micro-morphology and the phase structure; 3) performing a thermal shock test on the coating, and determining the cold-hot alternating resistance capacity of the coating; 4) testing heat transfer characteristics of the coating; and 5) performing a coking and slagging test in a test platform, and determining the coking and slagging resistance performance of the coating under a laboratory condition. The method disclosed by the invention can comprehensively determine anti-coking effects of the coating, provides a determination system for authenticating the performance of the anti-coking coating, and is simple and reliable.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD

Multi-element microalloyed high-strength heat-resistant rare earth magnesium alloy and preparation method thereof

The invention provides a rare earth magnesium alloy. The rare earth magnesium alloy is a modified Mg-Gd-Y-Zr series rare earth magnesium alloy. The as-cast metallographic structure of the rare earth magnesium alloy is provided with an Mg5Gd phase with a round edge; and or the extruded metallographic structure of the rare earth magnesium alloy has a small granular precipitated phase, and the radial size of the granules is 10-150 nm. The microstructure morphology of the alloy is improved through a multi-element microalloying method, the microstructure morphology of the alloy material is improved by adding trace Ag and Sc in a specific proportion, the age hardening and grain refinement effects are improved, and then excellent room-temperature and high-temperature mechanical properties are obtained. On the premise that the total amount of rare earth is not increased, the strength performance index is high, good plasticity is reserved, engineering application is easy to achieve, and the requirements of the current fields of aerospace, missile military industry, rail transit and the like for the mechanical property of a light structural material under the room-temperature and high-temperature environment can be met.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for determining performance of high-temperature sulfur corrosion prevention coating of water-cooling wall of boiler

InactiveCN106018708AEffective detection performanceInnovative designMaterial thermal conductivityWeather/light/corrosion resistancePorosityAdditive ingredient

The invention discloses a method for determining performance of a high-temperature sulfur corrosion prevention coating of a water-cooling wall of a boiler. The method comprises the following steps: (1) analyzing chemical constituents of raw materials of the coating, and testing alloy ingredients and contents of the raw materials; (2) measuring the thickness of the coating, and determining the thickness uniformity of the coating; (3) carrying out energy spectrum analysis and microstructure morphology testing on the coating, and determining micromorphology, porosity and phase composition; (4) testing the bonding strength of the coating, and determining the bonding strength of the coating and a water-cooling wall tube; (5) carrying out thermal shock test on the coating, and determining temperature cycling resistance of the coating; (6) carrying out high-temperature sulfur corrosion test on the coating, and determining the comprehensive performance of the high-temperature sulfur corrosion prevention coating; and (7) carrying out thermal transfer characteristic test on the coating. By the method, the high-temperature sulfur corrosion prevention effect of the coating can be evaluated comprehensively, and a determining system for identifying the performance of the high-temperature sulfur corrosion prevention coating is provided and is simple and reliable.

Owner:GUODIAN NANJING ELECTRIC POWER TEST RES CO LTD

Method for preparing large-size micro-groove bionic antifouling coating by template imprinting method

PendingCN112756233ANo crackNo sheddingPretreated surfacesSpecial surfacesCoated surfaceCoating microstructure

The invention relates to a method for preparing a large-size micro-groove bionic antifouling coating by a template imprinting method. The method comprises the following steps that a specific bionic microstructure morphology is etched on a plane template or a roller template through laser, the microstructure template is coated with a release agent, then the bionic microstructure template is directly imprinted on the surface of a surface-dried antifouling coating to be subjected to overturning and forming, the bionic antifouling coating with the microstructure morphology is obtained, and then the bionic antifouling coating with the large-area microstructure is prepared through multiple times of imprinting of the microstructure plane template or continuous rolling imprinting of the microstructure roller template. The method can be carried out under the room temperature condition, the requirement for preparation conditions is low, operation is easy, and preparation of the large-area coating microstructure surface can be achieved; and the prepared bionic antifouling coating has the advantages of uniform surface microstructure morphology, no crack, no shedding, and good antifouling effect.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

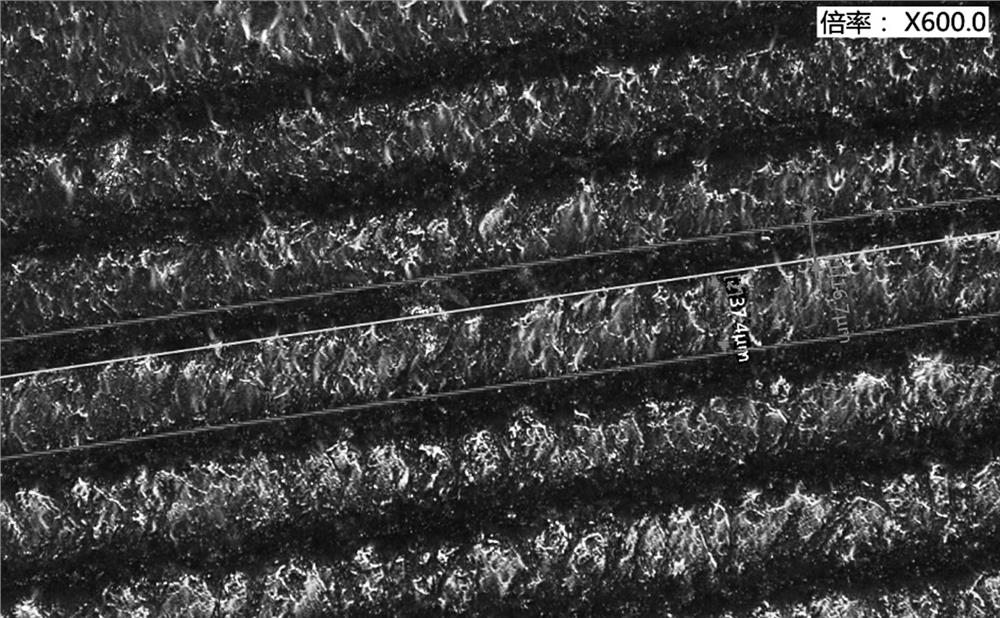

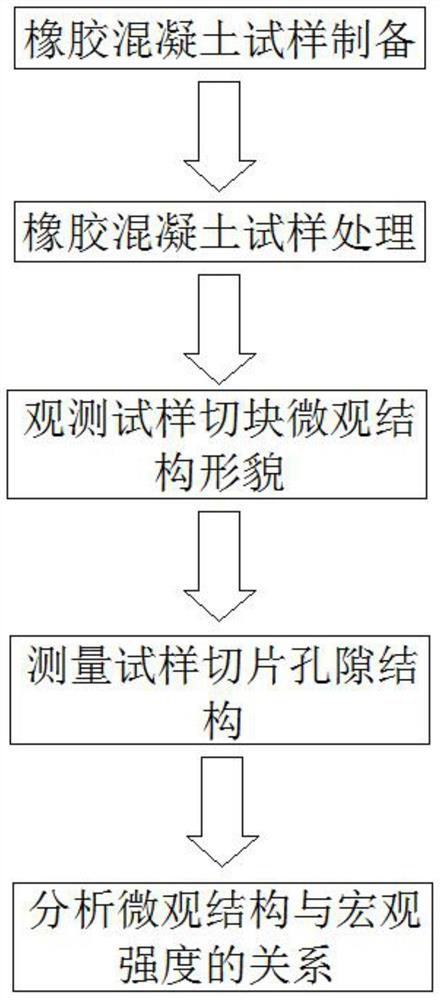

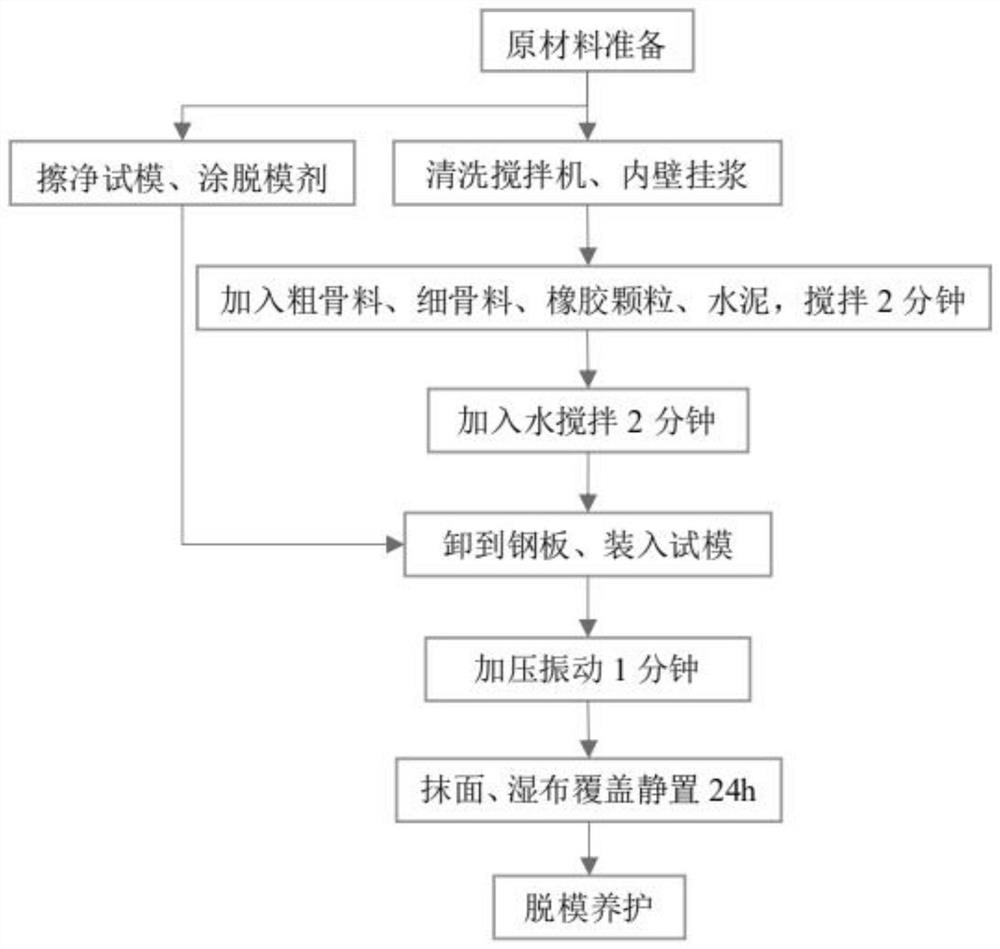

Quantitative analysis method for rubber concrete microstructure

ActiveCN111610213AAnalytical methods are scientific and rigorousMaterial analysis using wave/particle radiationSolid waste managementMacroscopic scaleScanning electron microscope

The invention discloses a quantitative analysis method for a rubber concrete microstructure. The quantitative analysis method comprises the steps of preparing a rubber concrete sample, treating the rubber concrete sample, observing the microstructure morphology of sample dices, measuring the pore structure of sample slices, and analyzing the relationship between the microstructure and macroscopicstrength. According to the invention, microstructure observation is carried out on the sample dices through a scanning electron microscope system; measuring the pore structure on the sample slices through a linear wire method; then, a hydraulic servo universal testing machine is used for carrying out a compressive strength test on the rubber concrete; therefore, the influence of the microstructureof the rubber concrete on the macroscopic strength of the rubber concrete is obtained through analysis of a microstructure test and a macroscopic mechanical performance test, and great help is provided for performance prediction and improvement of the rubber concrete in aspects of water conservancy, civil engineering, traffic and like; and the analysis method provided by the invention is scientific and rigorous, and conforms to the reality, and the analyzed conclusion are representative.

Owner:ZHENGZHOU UNIV

Method for simulating influence of heating technology on premelting and melting of crystal boundaries by aid of crystal phase-field process

The invention relates to a method for simulating the influence of a heating technology on premelting and melting of crystal boundaries by the aid of a crystal phase-field process, and belongs to the field of technologies for simulating crystals. The method includes steps of (1), building a crystal phase-field model, in other words, building the crystal phase-field model on the basis of an idea of the traditional phase-field process, introducing a periodic function form into the model, and setting periodic partial-time average atomic densities as order parameters to obtain a free energy function expression of crystals; (2), determining a numerical process and calculation parameters. The method has the advantages that premelting and melting microstructure morphology at different heating rates is researched by the aid of a simulated calculation process and the crystal phase-field process, the widths of liquid-phase films at the crystal boundaries are quantitatively calculated by an excess mass process when the crystal boundaries are premelted and melted at the different heating rates, accordingly, the widths of the liquid-phase films at the crystal boundaries are quantified when the crystal boundaries are premelted and melted, structural relations among numerical values of the widths of the liquid-phase films and the atomic crystal boundary structures are illustrated, and an effect is perfect.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

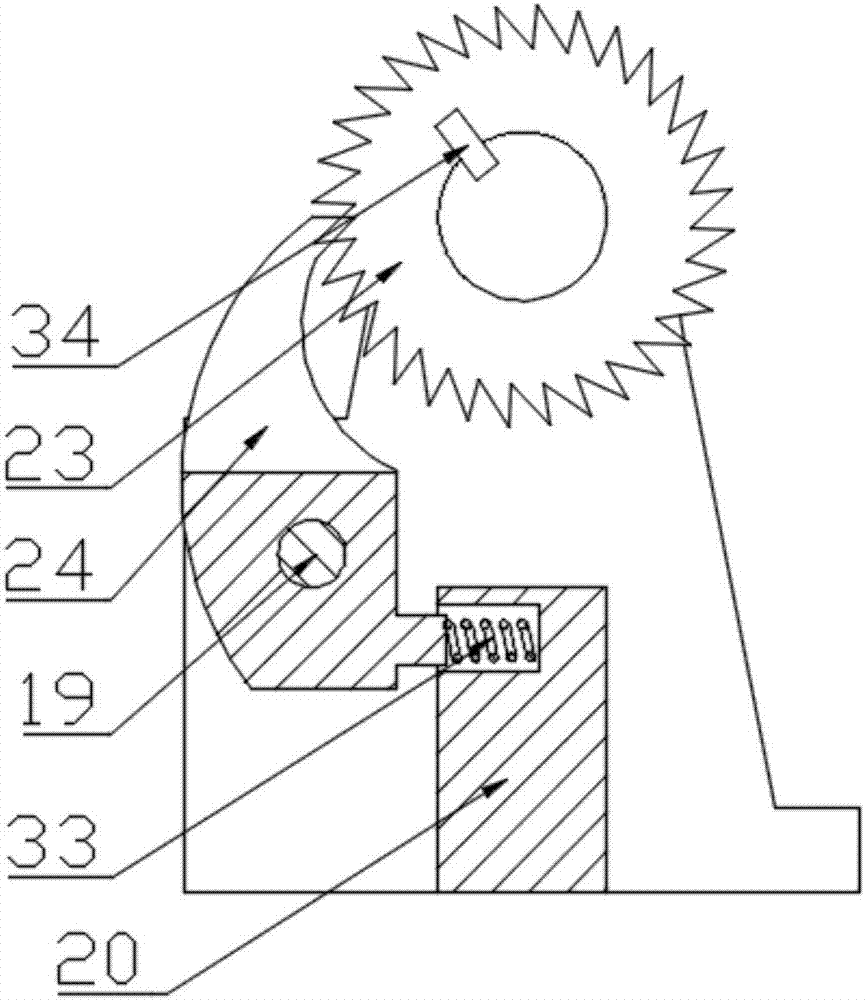

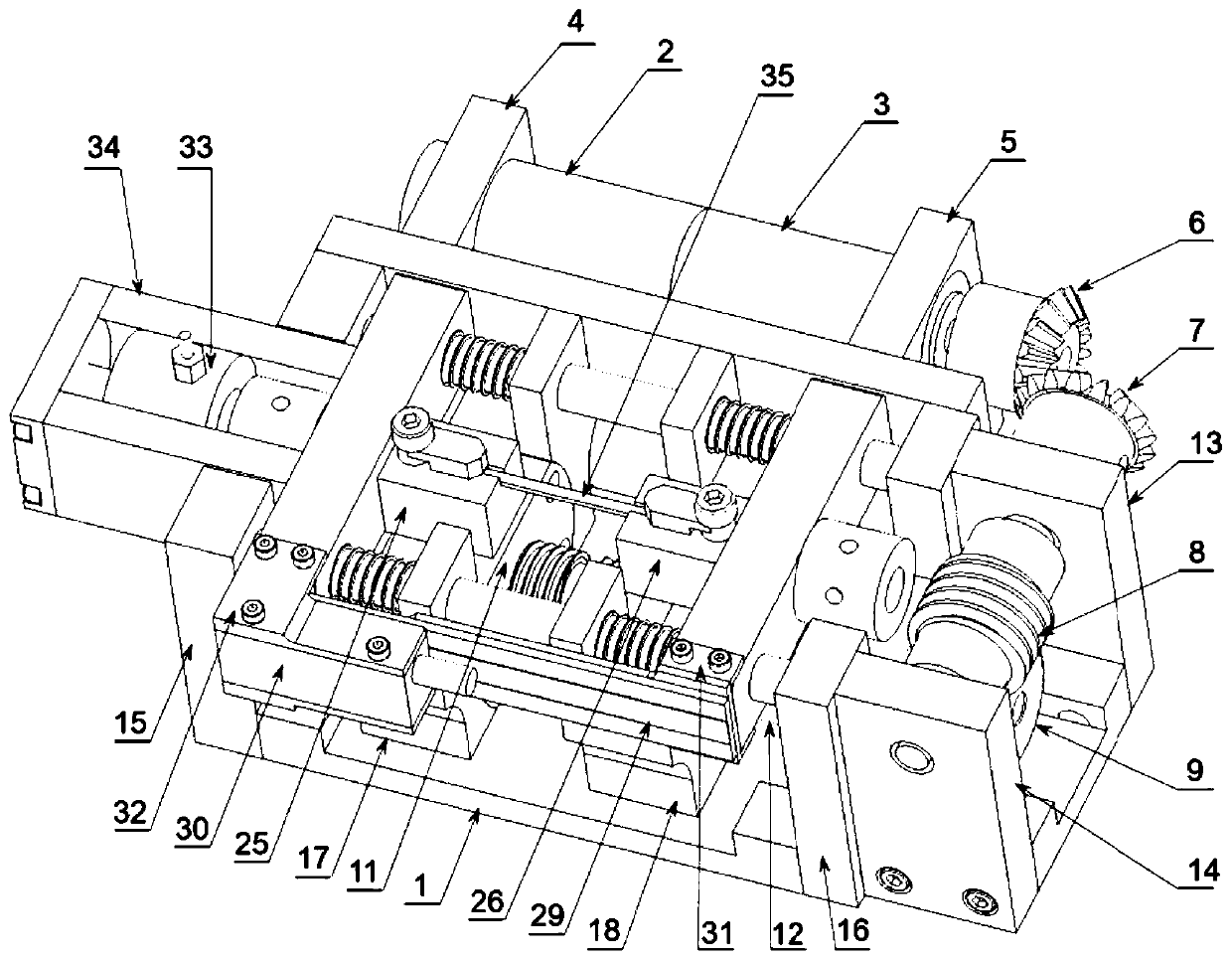

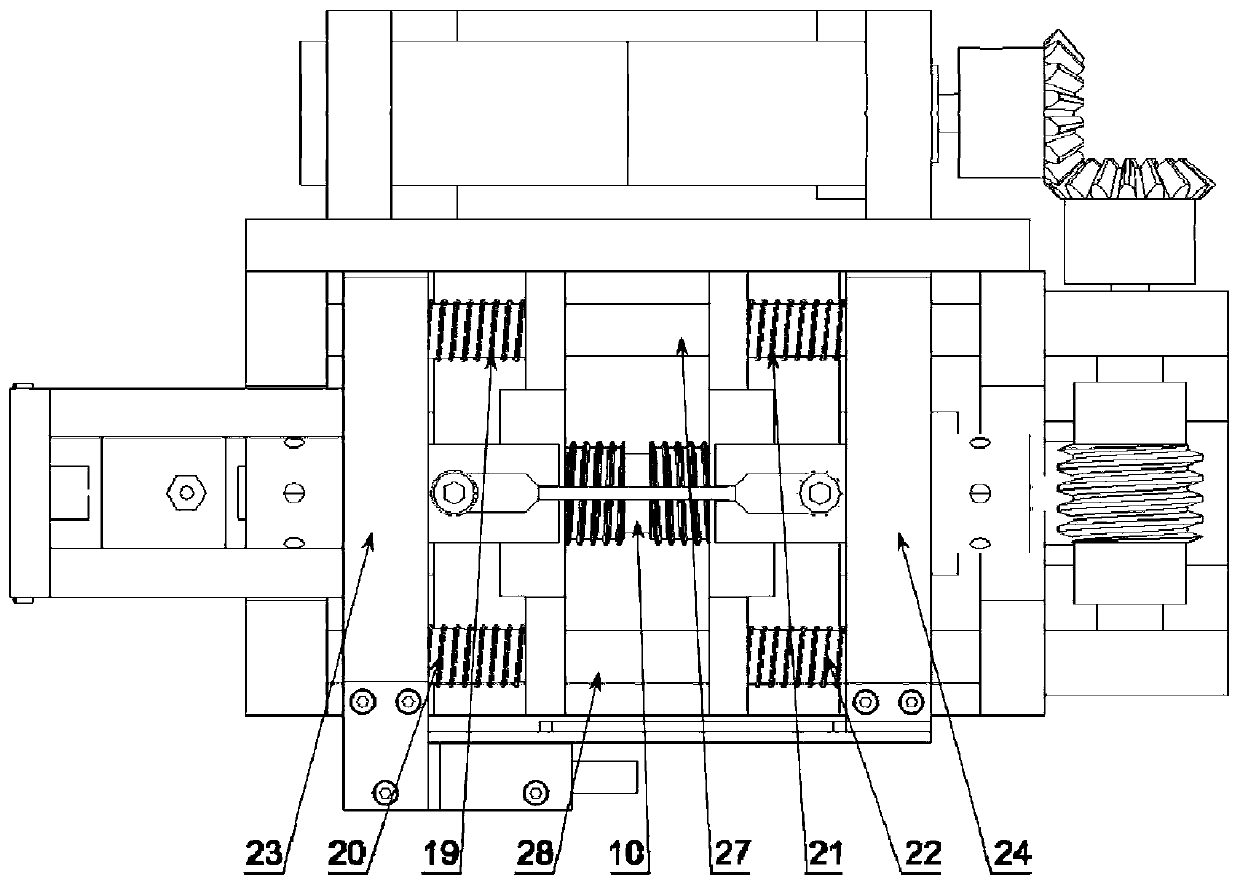

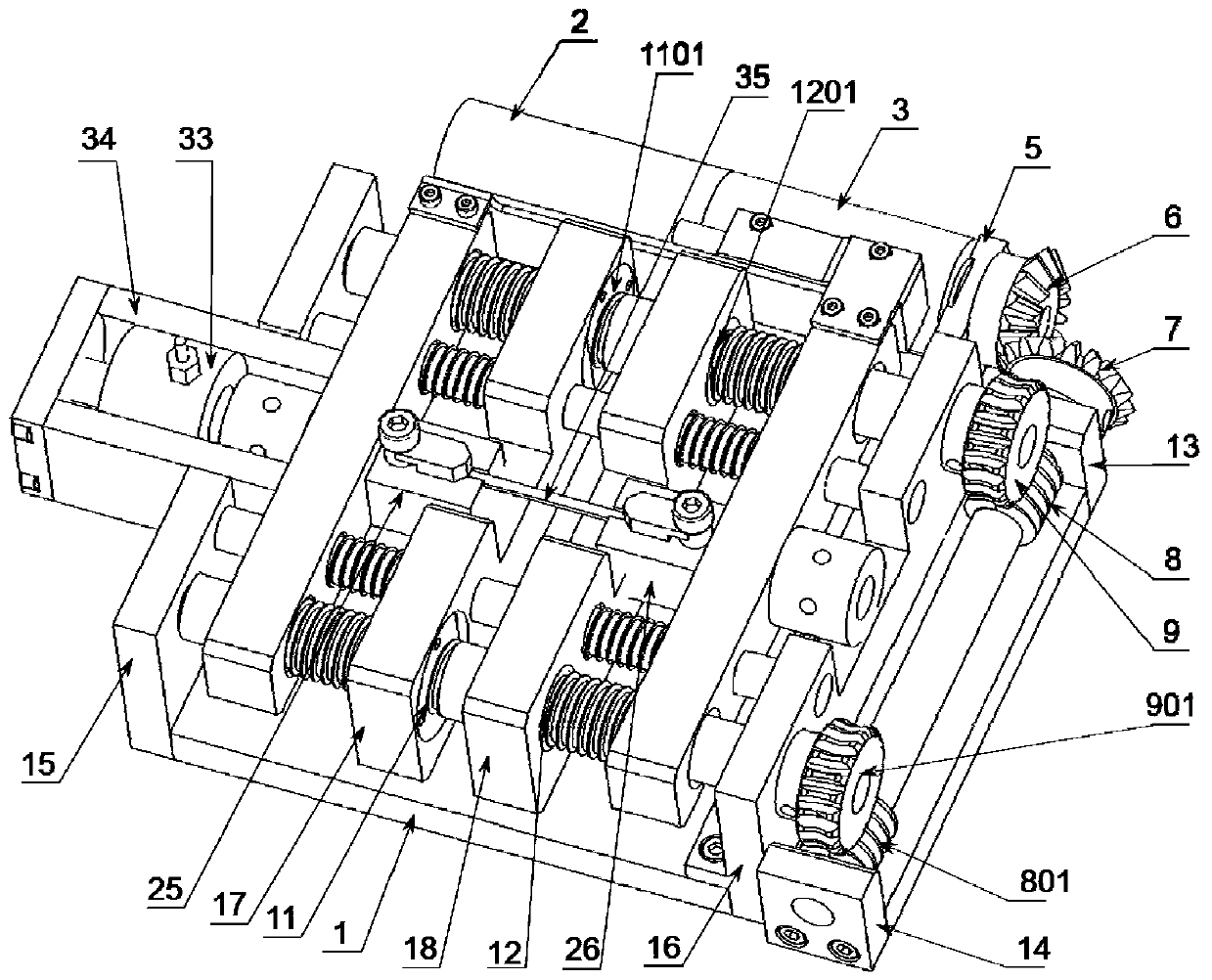

In-situ micro mechanical test board

ActiveCN110487628AAchieving fatigue loadingCompact and reasonable structureMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesLinear motionChemical composition

The invention relates to the technical field of in-situ characterization of mechanical properties and microstructure of materials and provides an in-situ micro mechanical test board. The test board comprises a motor execution mechanism, a spring auxiliary loading mechanism, a position sensing mechanism, a force sensing mechanism and a base, wherein the motor execution mechanism is fixed on the base, rotation output of a motor around the axial direction is converted into linear motion of the spring auxiliary loading mechanism through steering and transmission, the spring auxiliary loading mechanism applies a load to a sample, the position sensing mechanism detects the relative position variation, namely the sample deformation quantity, of the spring auxiliary loading mechanism in real time,and the force sensing mechanism detects a stress value borne by the sample in real time. The test board is advantaged in that a clamp supporting frame and a lead screw nut pair are elastically connected in the axial direction of a lead screw, on the basis, a load oscillator is additionally arranged, so fatigue performance testing of the sample and in-situ characterization of the microstructure morphology, chemical components, the crystal structure and the phase structure information of the material under the action of the fatigue load can be realized, the structure is reasonable and compact,and fine control under a force control mode is facilitated.

Owner:杭州源位科技有限公司

Corrosive agent for Nb - Si material microstructure specimens and an electrolyte corrosion technique

ActiveCN104846426AConvenient organizationImprove the speedPreparing sample for investigationElectrolysisPhysical metallurgy

The invention relates to a corrosive agent for Nb - Si material microstructure specimens and an electrolyte corrosion technique which belongs to metallographic analysis of physical metallurgy field. The invention uses solution of H3PO4 and H2O, and the volume is 98% H3PO4 : H2O is 1 to 99. The polished Nb - Si material is used as positive pole, and stainless as negative pole. Direct current source is used to process electrolyte corrosion, and then Nb - Si material microstructure specimens is made, and thus the composition phases and microstructure morphology of the Nb - Si material can be rapid and conveniently analyzed via an optical microscope.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Quasi-in-situ experimental method for dynamic shear deformation and failure behavior of metallic material

InactiveCN108254264AFix the issue of not being able to load again under the same conditionsSolve the problem that continuous sampling cannot be observedMaterial strength using steady shearing forcesExperimental methodsMetallic materials

The invention belongs to a quasi-in-situ experimental method for dynamic shear deformation and failure behaviors of a metal material in the technical field of material dynamic mechanical experiments.The specific steps of the experimental method are as follows: (1) preparing a mortarboard type sample and polishing the side surface, and observing the microstructure and morphology and the grain orientation of the sample before deformation; (2) performing dynamic shear loading on the sample; (3) performing quasi-in-situ observation on the microstructure and morphology and the grain orientation ofthe sample after the loading; (4) performing dynamic loading again on the sample at a same strain rate to increase the total strain; and (5) repeating step (3) to step (4) until the sample is destroyed; the microstructure morphology and the grain orientation information observed by the method are further analyzed for reduction of change of the microstructure during dynamic shear deformation and failure process. By using the disclosed research and analysis method of the present invention, the dynamic shear deformation and failure behaviors of the metal material at a strain rate of 10<4>s<-1> to 10<5>s<-1> can be revealed.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

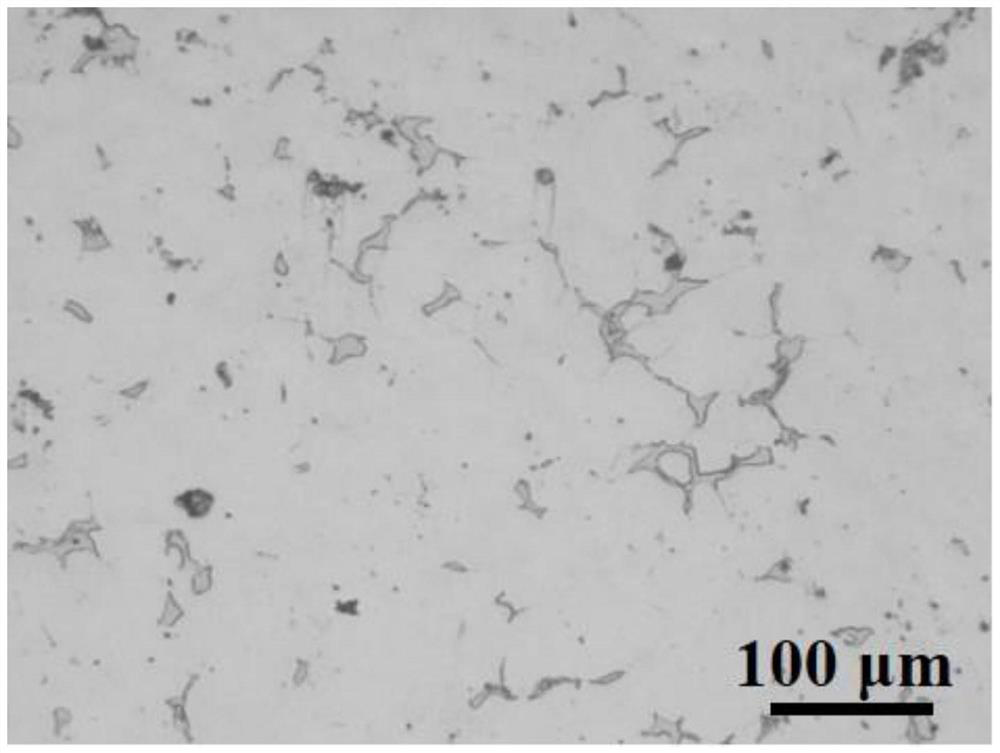

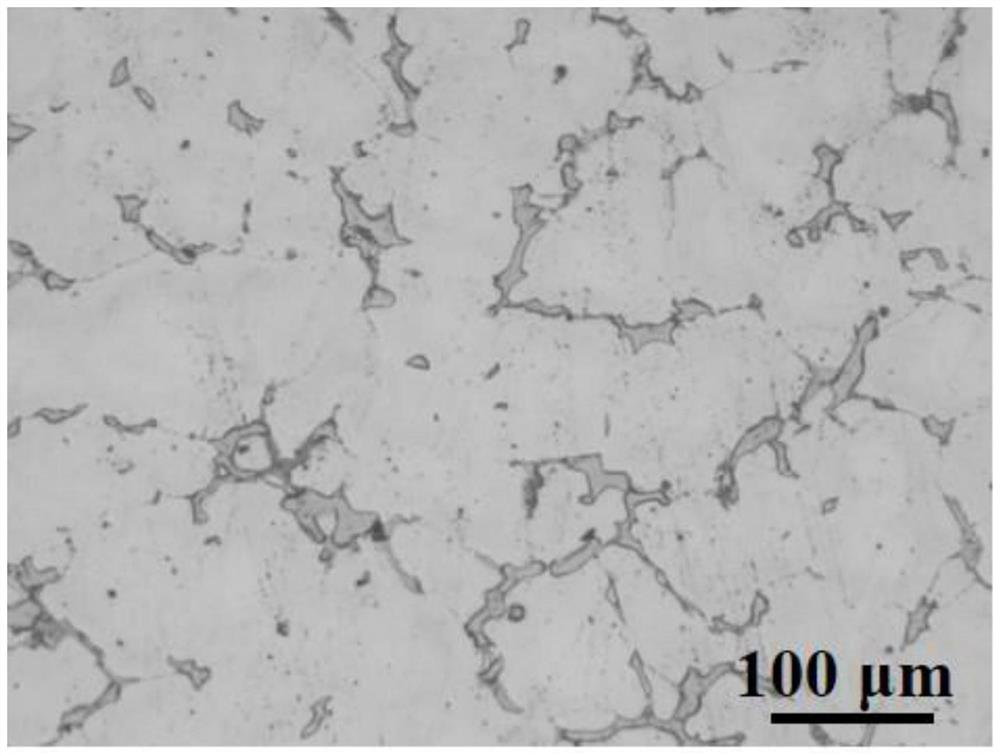

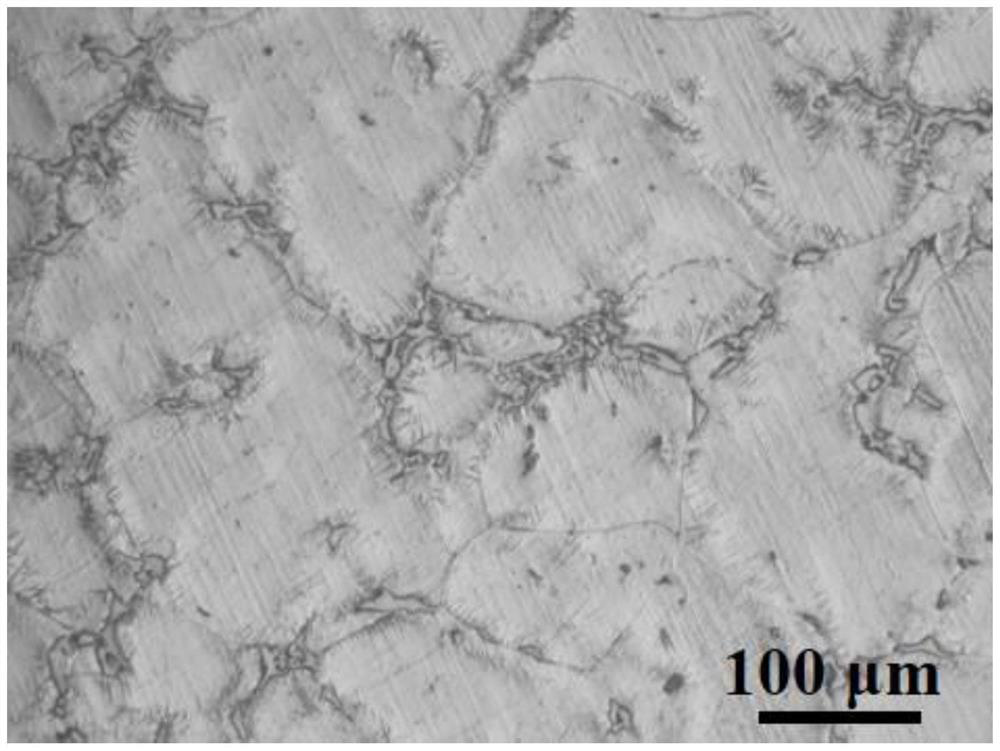

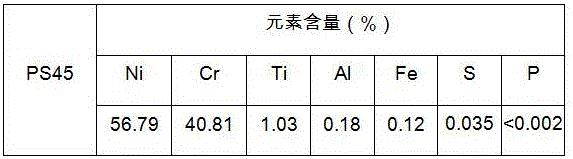

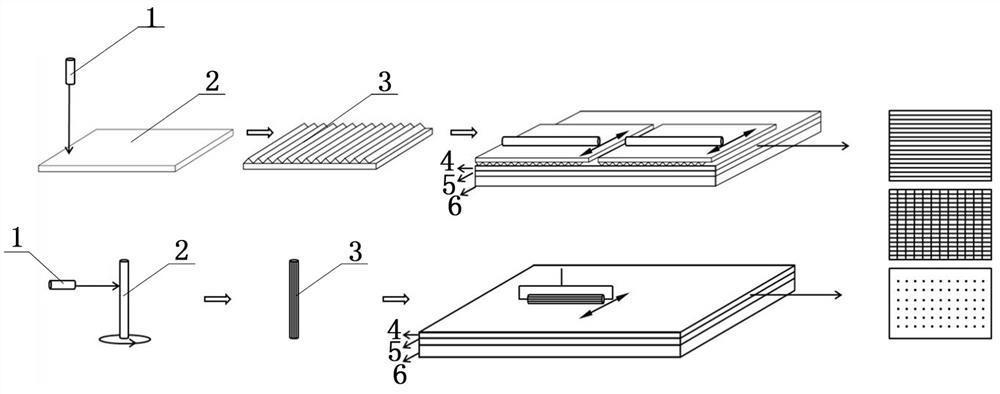

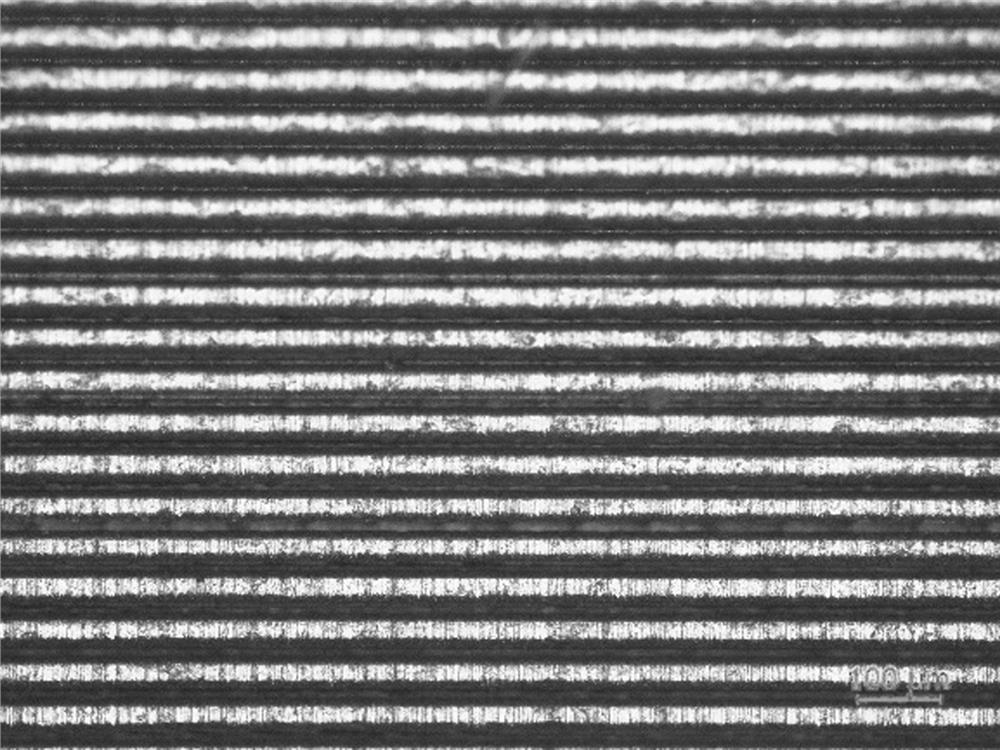

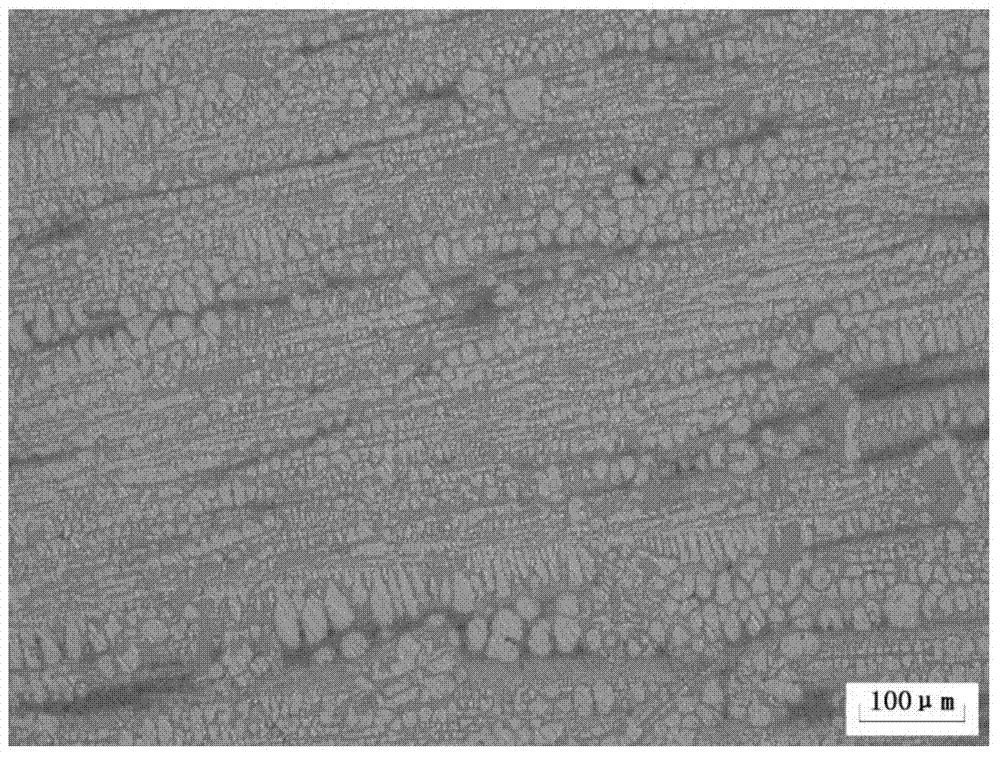

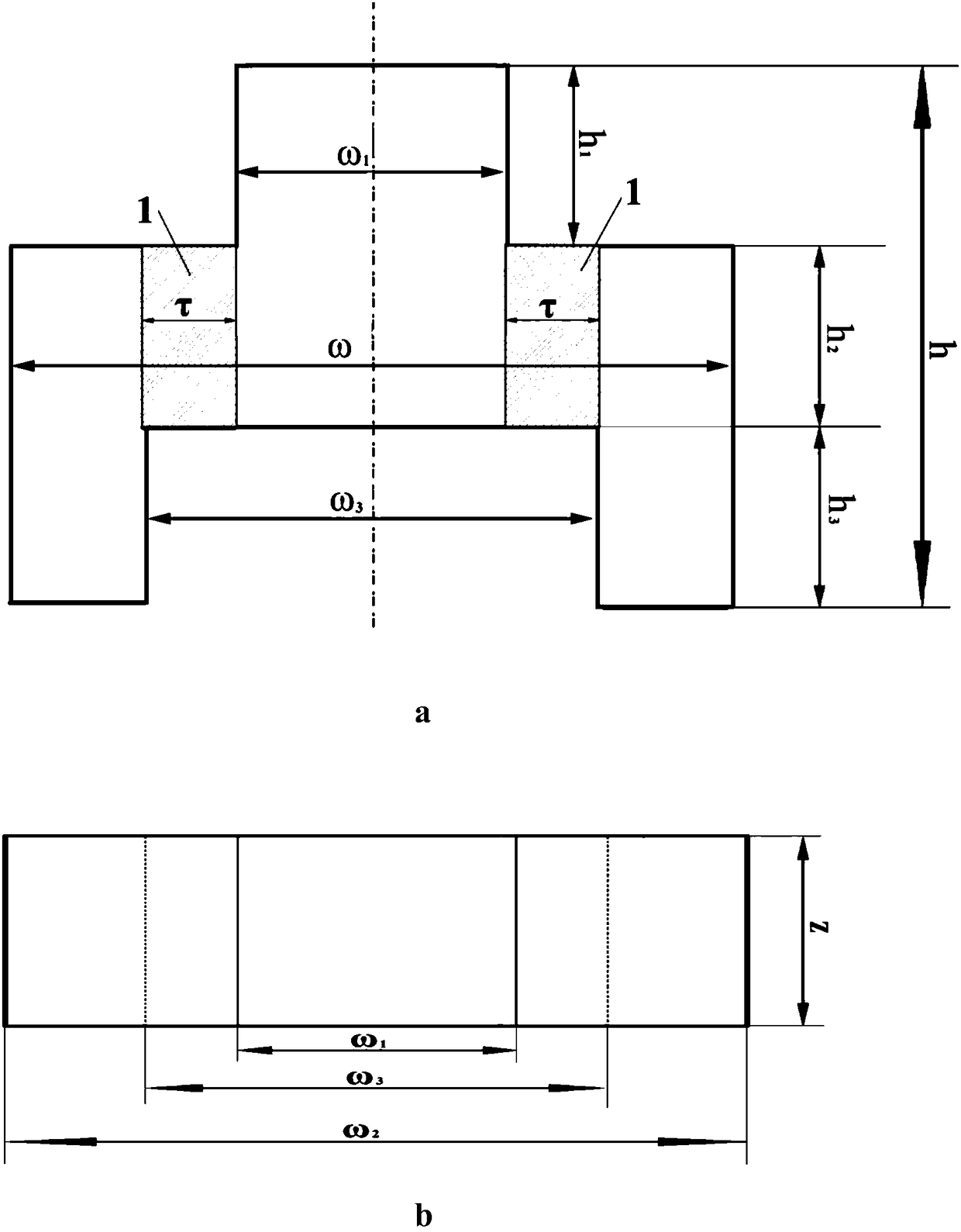

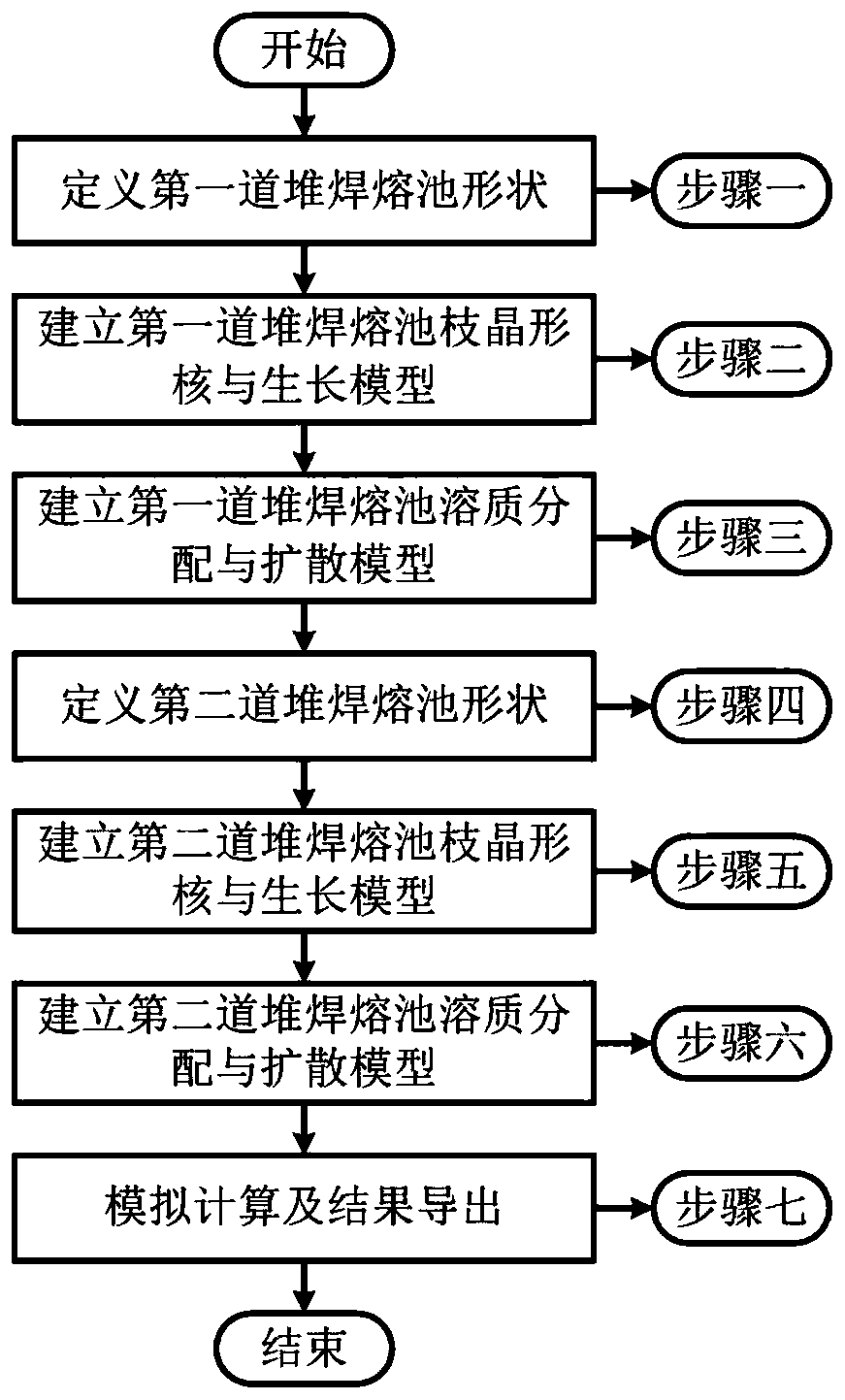

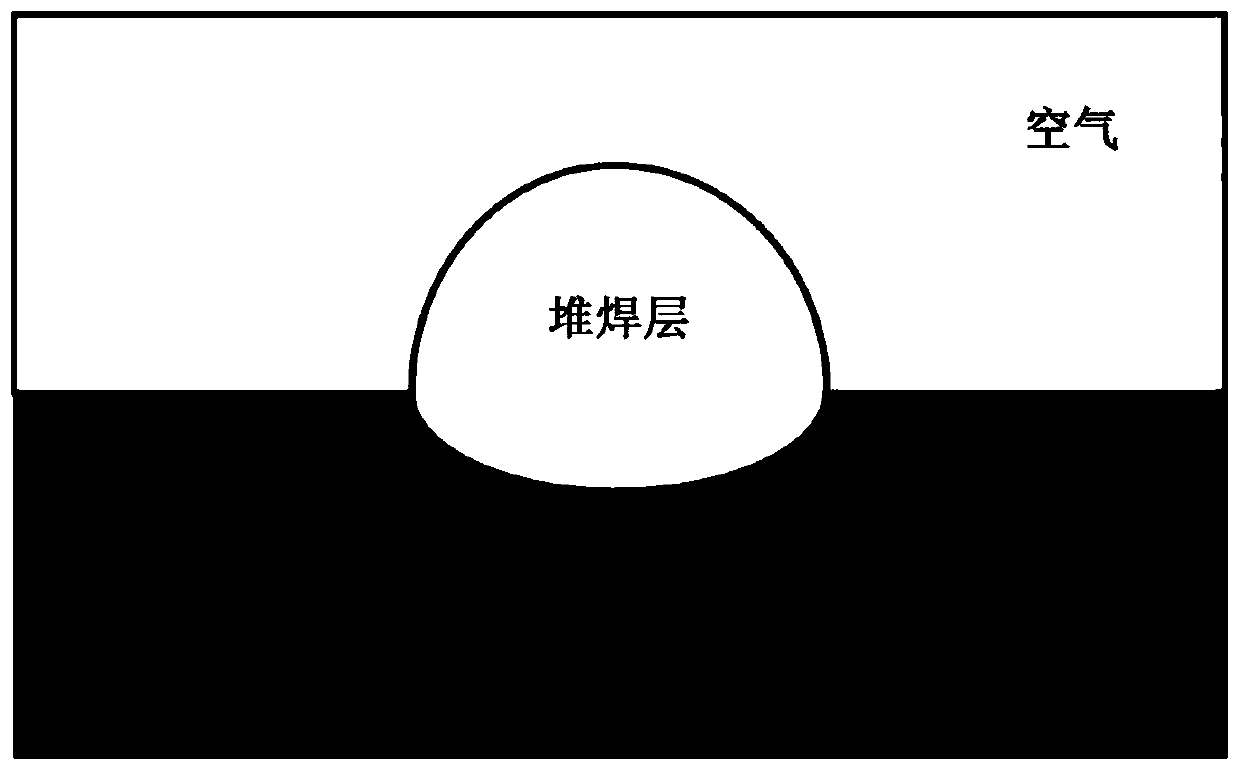

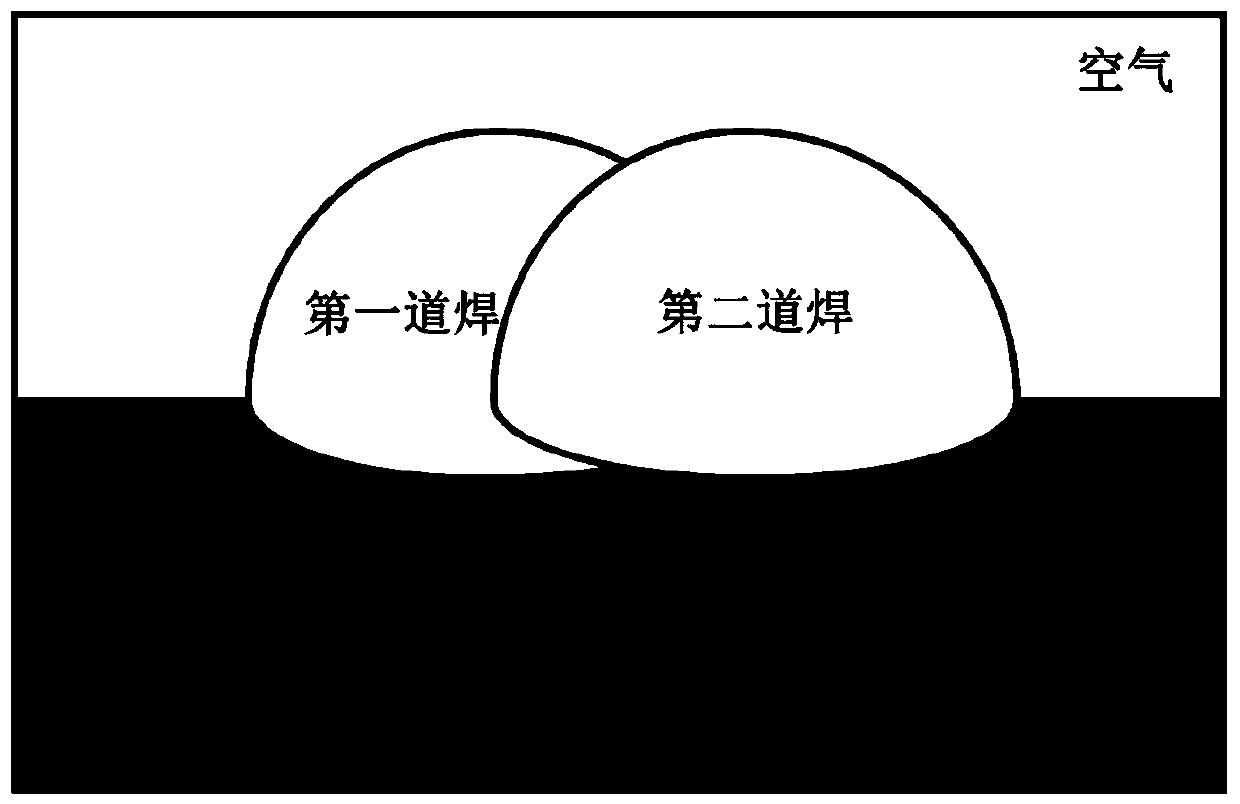

Dendritic crystal growth numerical simulation method in nickel-based alloy multi-pass surfacing process

ActiveCN111261241AServe as a referenceShort time consumingComputational materials scienceInstrumentsAlloyCrystal growth

The invention discloses a dendritic crystal growth numerical simulation method in a nickel-based alloy multi-pass surfacing process. The method comprises the following specific steps: defining the shape of a first surfacing welding pool, and establishing a dendrite nucleation and growth model and a solute distribution and diffusion model, secondly, defining the shape of a second surfacing weldingpool on the basis of the first surfacing welding, establishing a dendrite nucleation and growth model and a solute distribution and diffusion model, finally writing a computer program, inputting alloythermophysical parameters and various welding process parameters, importing simulation calculation software, and performing calculation to obtain a simulation result. Compared with experimental research, the method consumes less time and saves more maternal and labor resources, influences of microstructure morphology evolution, solute concentration distribution, welding current, welding voltage,thermal disturbance amplitude and other parameters on dendritic crystal growth in the nickel-based alloy multi-pass surfacing process can be simulated, and therefore a certain reference effect is achieved for selection and formulation of the nickel-based alloy multi-pass surfacing welding process.

Owner:XIAN UNIV OF TECH

Material performance testing device for key nuclear material under complex service environment

PendingCN107462468ASimulate the realSimple structureWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesEngineeringStructural engineering

Owner:JILIN UNIV

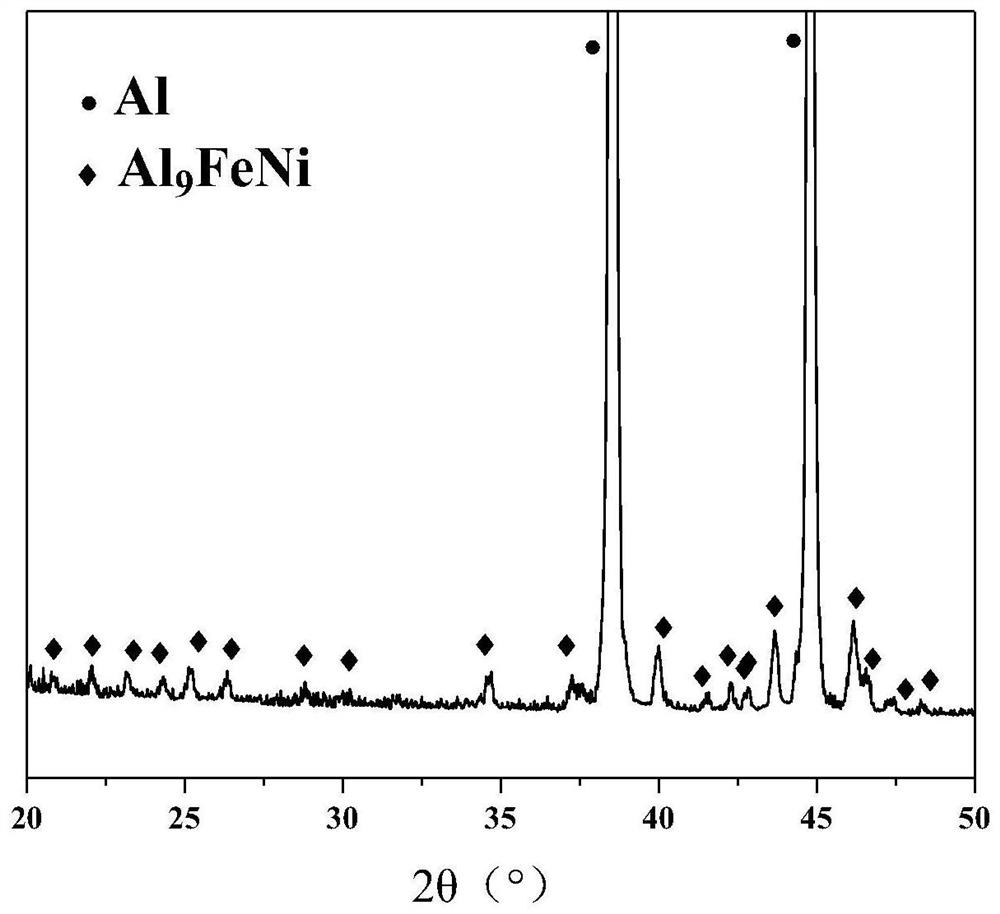

High-thermal-conductivity and low-expansion wrought aluminum alloy and preparation method thereof

ActiveCN113502419ALittle impact on thermal conductivityThermal balance optimizationSemiconductor/solid-state device detailsSolid-state devicesThermal dilatationMicrostructure morphology

The invention belongs to the technical field of wrought aluminum alloys and discloses a high-thermal-conductivity and low-expansion wrought aluminum alloy and a preparation method thereof. The wrought aluminum alloy comprises the following components in percentage by mass: 1.5-2.5% of Fe, 1.0-2.0% of Ni, 0-0.5% of Yb, 0-0.5% of Mg and the balance of Al, wherein Yb and Mg are not 0 at the same time; the wrought aluminum alloy is obtained by performing mechanical vibration casting on a melt; or after mechanical vibration casting is completed, annealing treatment and rolling deformation treatment are carried out. The invention further discloses a preparation method of the wrought aluminum alloy. According to the high-thermal-conductivity and low-expansion wrought aluminum alloy and the preparation method thereof, Yb and / or Mg compound modification and vibration casting are used for improving the microstructure morphology of the alloy; and multi-target balance optimization of the heat-conducting property, the thermal expansion coefficient and the mechanical performance of the alloy is achieved. The wrought aluminum alloy has high thermal conductivity, low expansibility and high mechanical performance.

Owner:SOUTH CHINA UNIV OF TECH +1

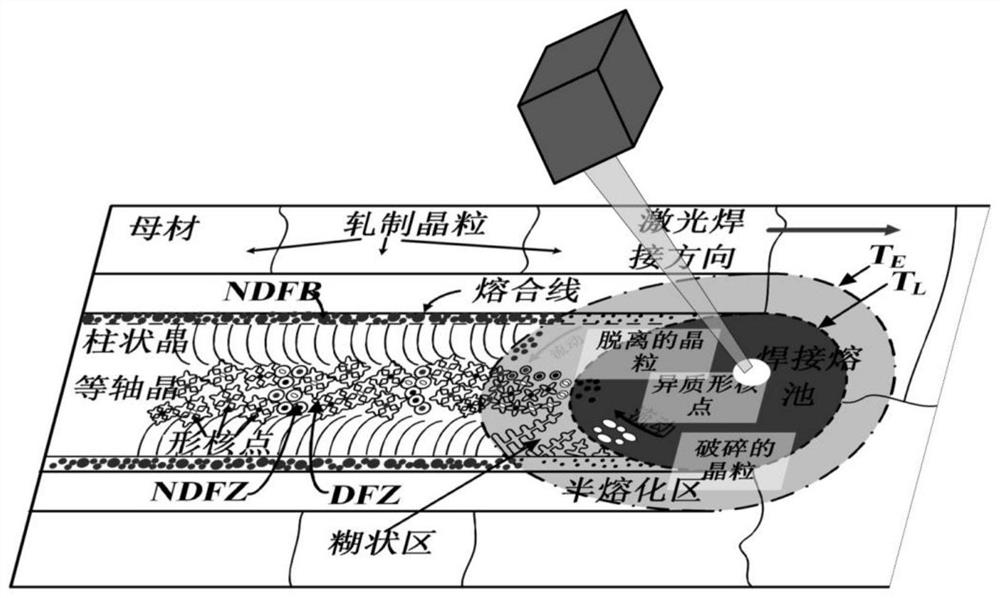

Method for analyzing microstructure nucleation mechanism of laser welding seam

ActiveCN111982618AGood repeatabilityImprove accuracyPreparing sample for investigationTesting metal structuresEquiaxed crystalsWeld seam

The invention belongs to the technical field related to laser welding, and discloses a method for analyzing a microstructure nucleation mechanism of a laser welding seam. The method comprises the following steps: (1) performing laser welding, namely test welding, on a sample 1, and analyzing the microstructure morphology and distribution of the obtained laser welding seam; meanwhile, using TIG welding for conducting one-pass pre-welding and n-pass pre-welding on the sample 2-1 and the sample 2-2 correspondingly, then conducting test welding on weld joints formed through pre-welding correspondingly, and conducting metallographic representation on the obtained overlapped weld joints correspondingly; wherein the sample 1, the sample 2-1 and the sample 2-2 are made of the same material; wherein n is a positive integer greater than or equal to 3; (2) comparing the equiaxed crystal quantity and distribution of the laser weld joint and the overlapped weld joint area of the sample 1, and pre-identifying the nucleation mechanism of the weld joint according to the comparison result; and (3) performing confirmation according to the pre-identification result so as to analyze and obtain a nucleation mechanism. According to the invention, the accuracy and repeatability of a nucleation mechanism are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com