Synchrotron radiation in-situ imaging tensile testing machine simulating multiple environments and testing method thereof

A tensile testing machine and multi-environmental technology, applied in the direction of using radiation for material analysis, using stable tension/pressure to test material strength, etc., can solve the problem of low light source brightness, measurement accuracy and detection sensitivity need to be improved, optical signal detection Low signal-to-noise ratio and other issues to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

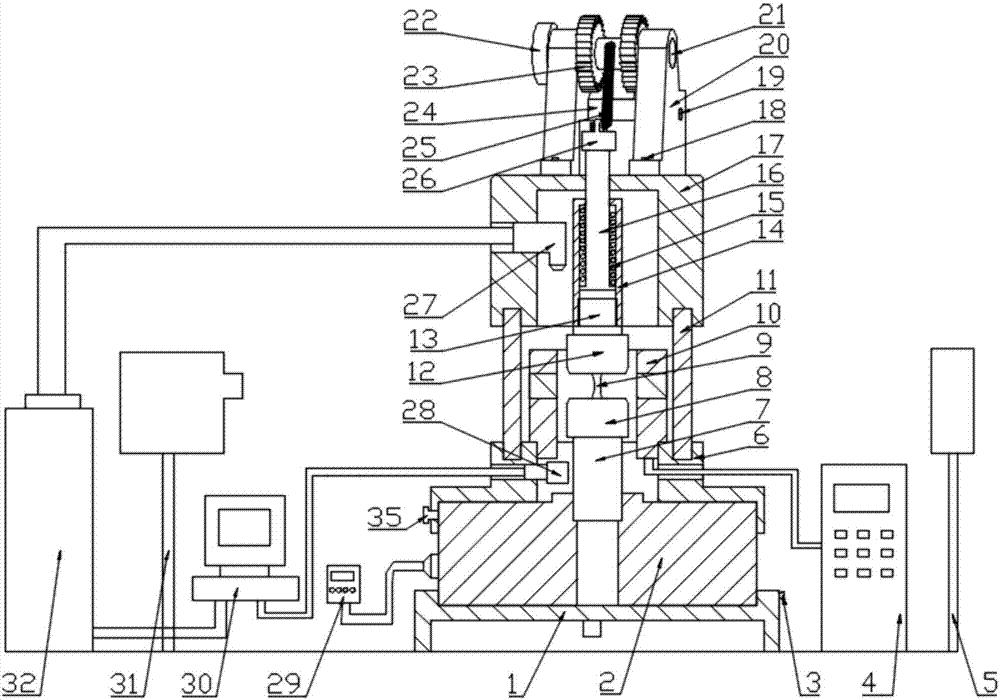

[0027] The bottom of the testing machine is a cylindrical single-pull base 1 that can rotate freely in 360 degrees. There is a groove under the single-pull base 1, and there is a small protrusion in the groove. The test bench is embedded in the groove under the single-pull base 1. Inside, the small protrusion is embedded in the cross-shaped gap of the test bench, so as to ensure that the single-pull base 1 rotates with the test bench. On the top of the single-pull base 1 is the digital display push-pull gauge 2, which is embedded in the groove on the upper part of the single-pull base 1 and fixed by the tightening screw 3 on the side of the single-pull base 1, and the digital display push-pull gauge 2 2 is also connected with the outer display screen 29 of the digital display push-pull gauge.

[0028] The top of the digital display push-pull gauge 2 is embedded in the groove below the connection platform 6 and fixed by the fastening screw 35 on the side of the connection platf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com