In-situ micro mechanical test board

A test bench, miniature technology, applied in the direction of testing material strength by applying repetitive force/pulsation force, testing material strength by applying stable tension/compression, and measuring devices, which can solve the problem that the fatigue dynamic test cannot be realized and the driving structure is not ideal and other problems, to achieve the effect of fine control, reasonable and compact structure, and reduce the minimum value of strain rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

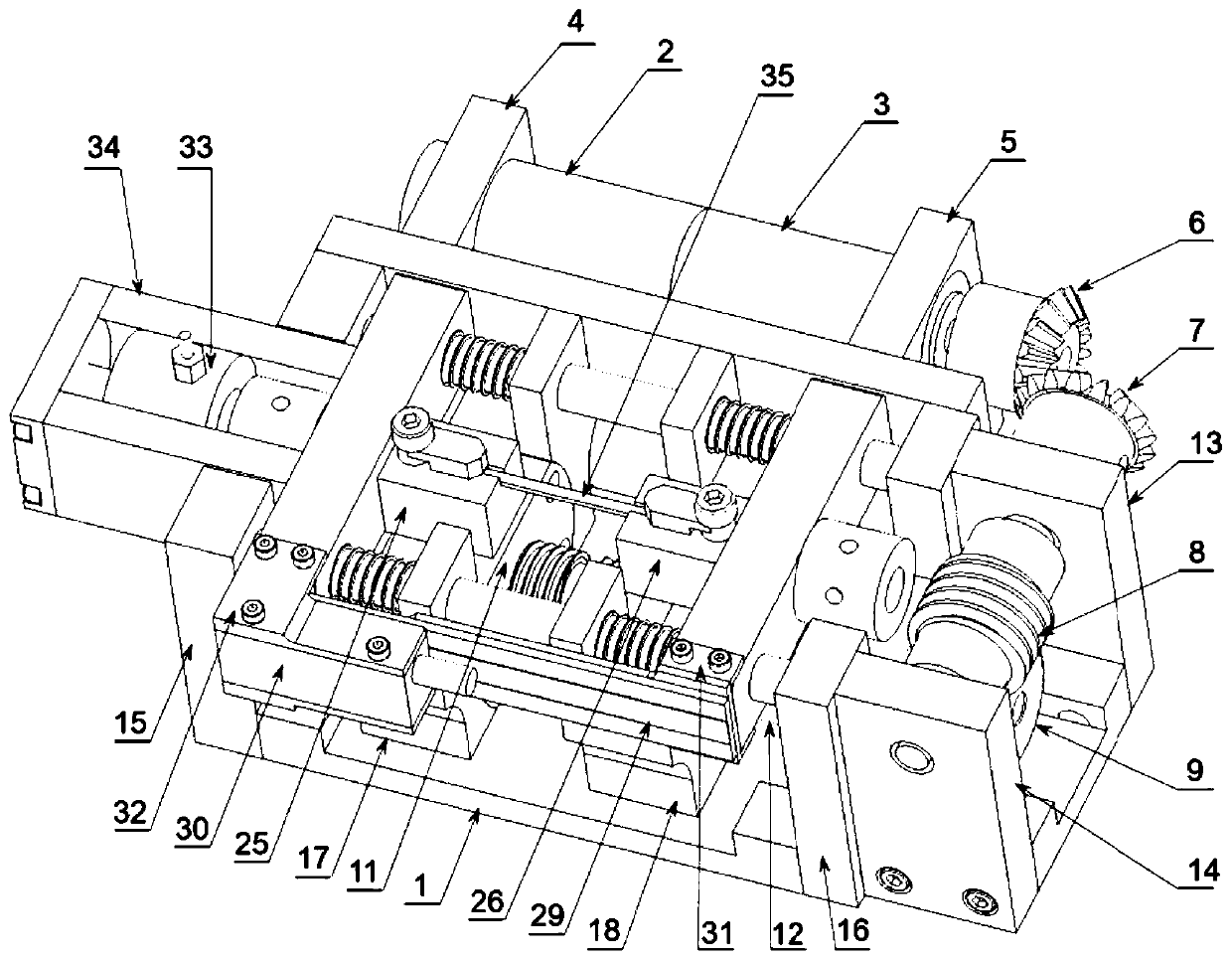

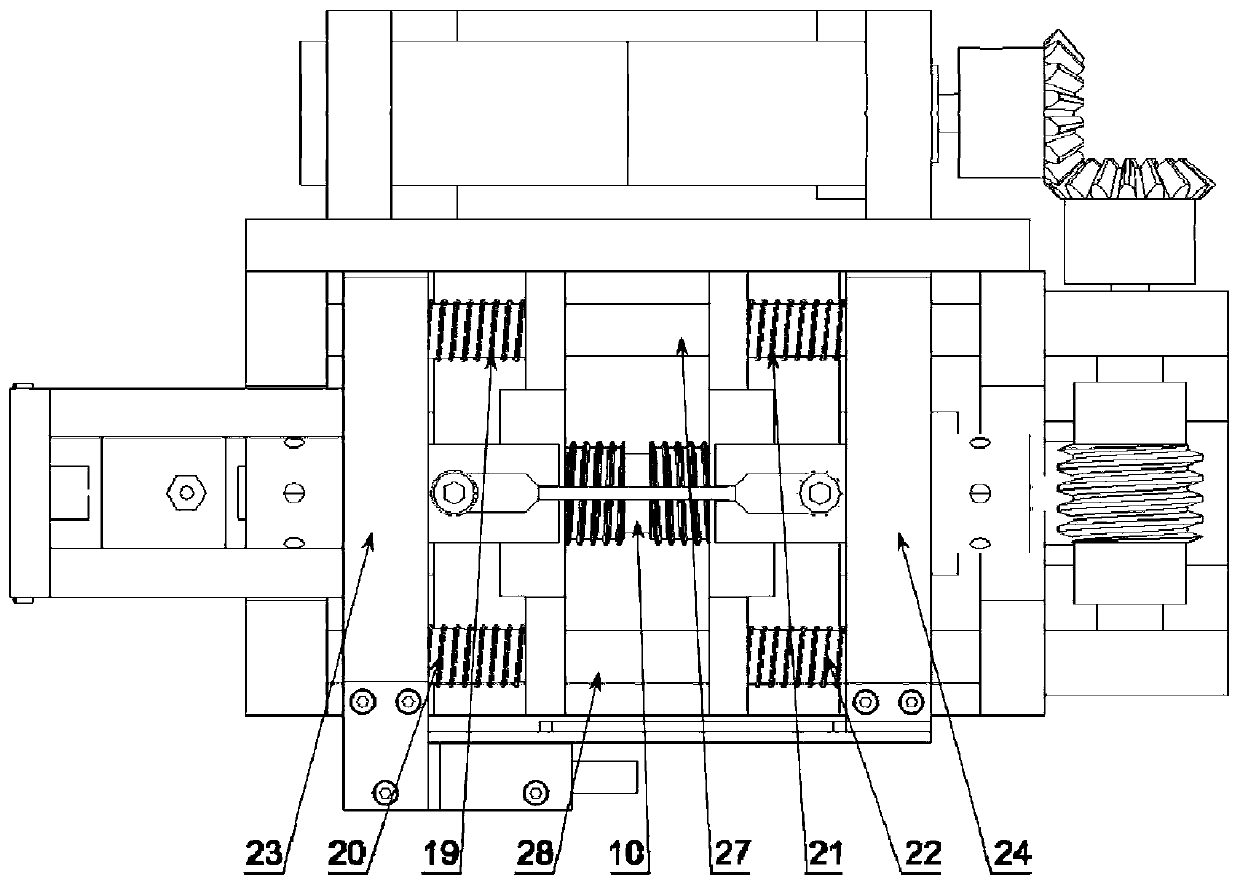

[0052] refer to Figure 1 to Figure 2 As shown, this embodiment provides a single-screw driven in-situ micro-mechanical test bench, including a motor actuator, a spring auxiliary loading mechanism, a position sensing mechanism, a force sensing mechanism and a base 1, and the output winding of the motor 2 The axial rotary motion is converted into the linear motion of the spring auxiliary loading mechanism through steering and transmission. The spring auxiliary loading mechanism applies the load on the tested sample 35, and the position sensing mechanism detects the relative position change of the spring auxiliary loading mechanism in real time and Given the deformation of the sample 35, the force sensing mechanism detects the stress value of the sample 35 in real time.

[0053] The motor actuator includes a motor 2, a reducer 3, a first motor support base 4, a second motor support base 5 and a transmission mechanism. The output end of the motor 2 is connected to the input end ...

Embodiment 2

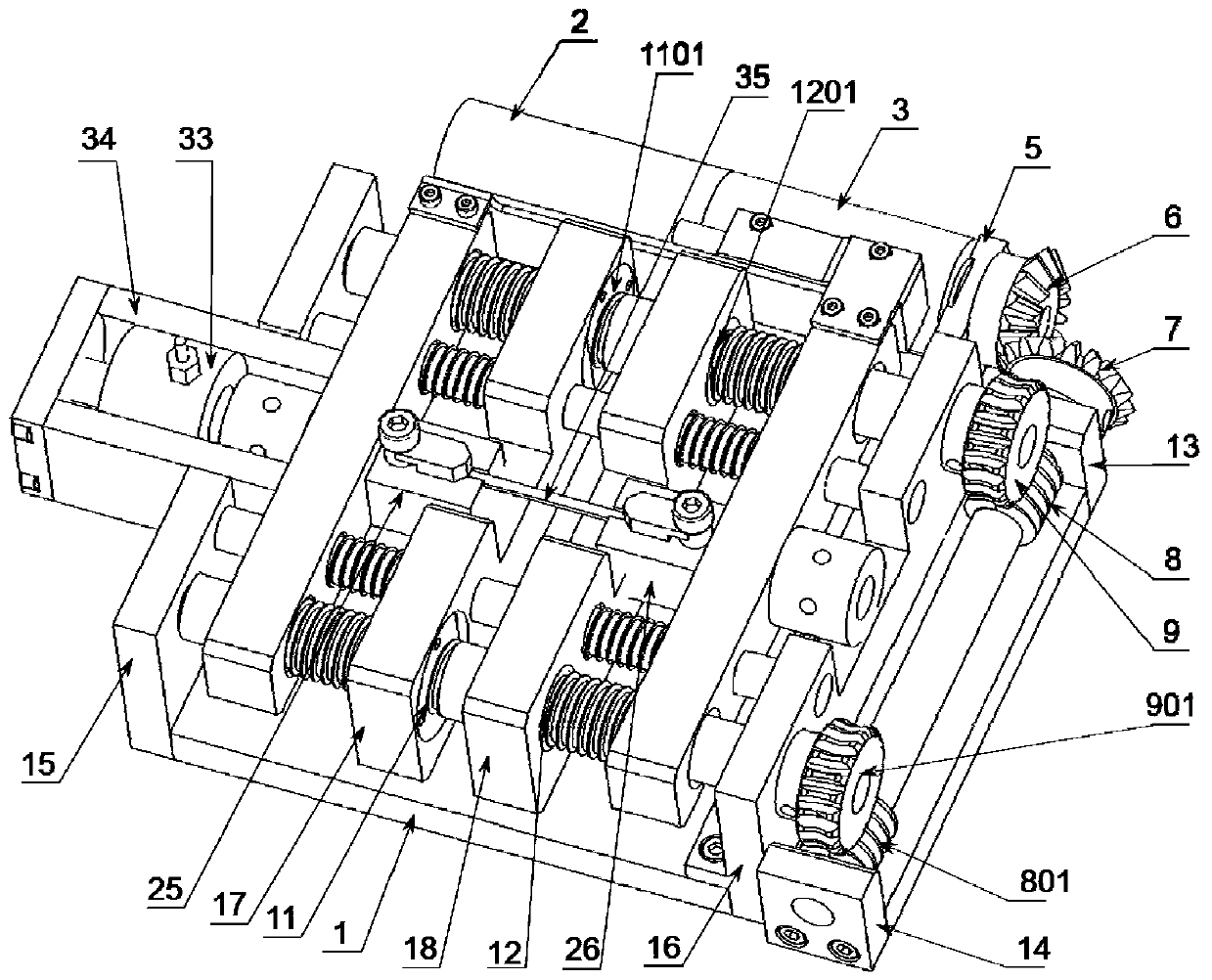

[0061] refer to Figure 3 to Figure 4 As shown, this embodiment provides a double-screw-driven in-situ micro-mechanical test bench. The structure of this embodiment is basically the same as that of Embodiment 1. The difference is that it adopts a transmission mechanism with double screws. The transmission mechanism includes a driving wheel 6, a driven wheel 7, a first worm 8, a second worm 801, a first Worm wheel 9, second worm wheel 901, first screw mandrel 10, second screw mandrel 1001, first nut 11, second nut 12, third nut 1101, fourth nut 1201, first worm screw support seat 13, second worm screw The supporting base 14 , the first screw supporting base 15 and the second screw supporting base 16 .

[0062] The first worm 8 and the second worm 801 are arranged at the two ends on the same worm shaft, and the worm shaft is installed on the first worm support seat 13 and the second worm support seat 14, above the middle part of the first worm 8 and the second worm 801 The fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com