Patents

Literature

614results about How to "Load accurately" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

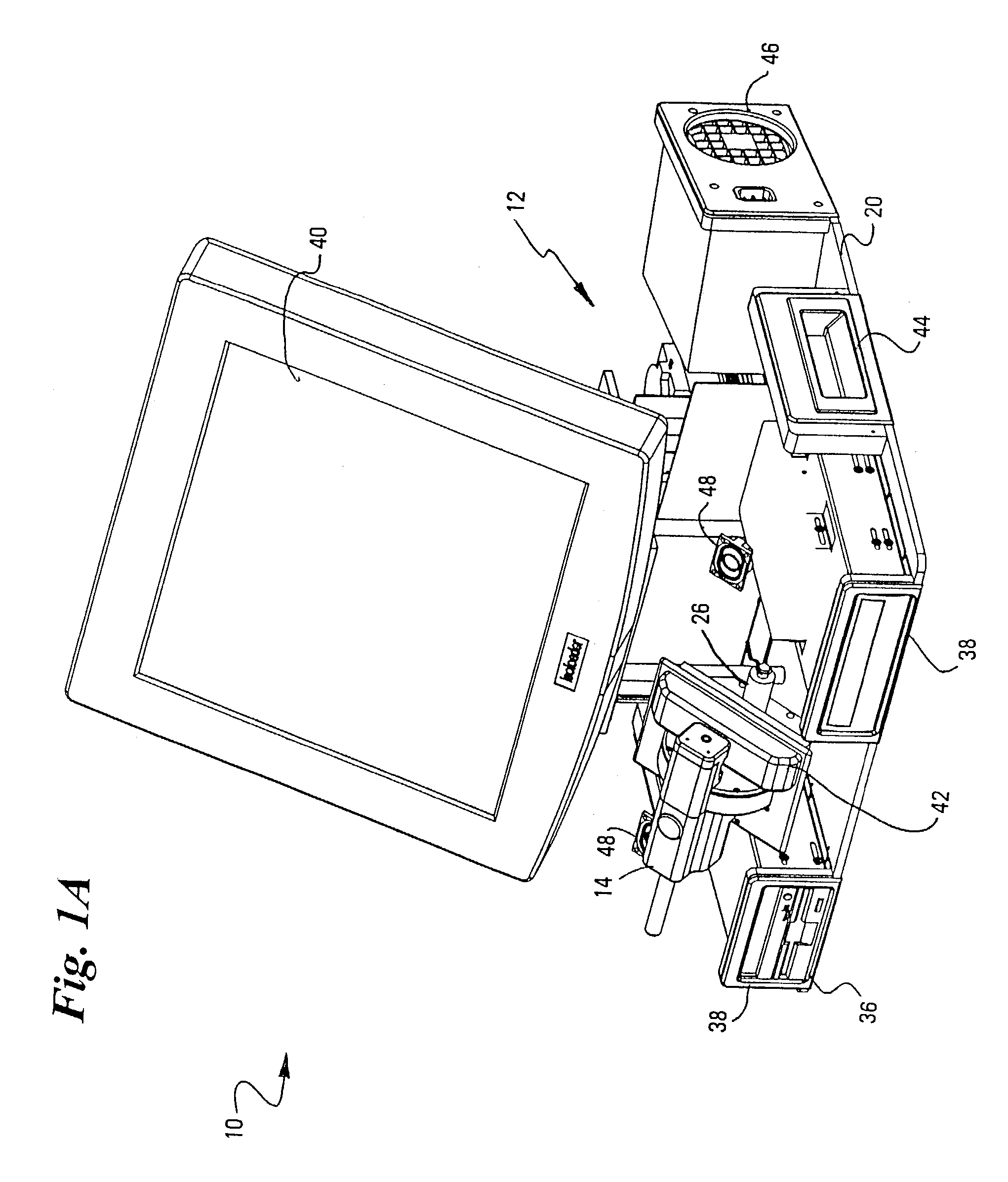

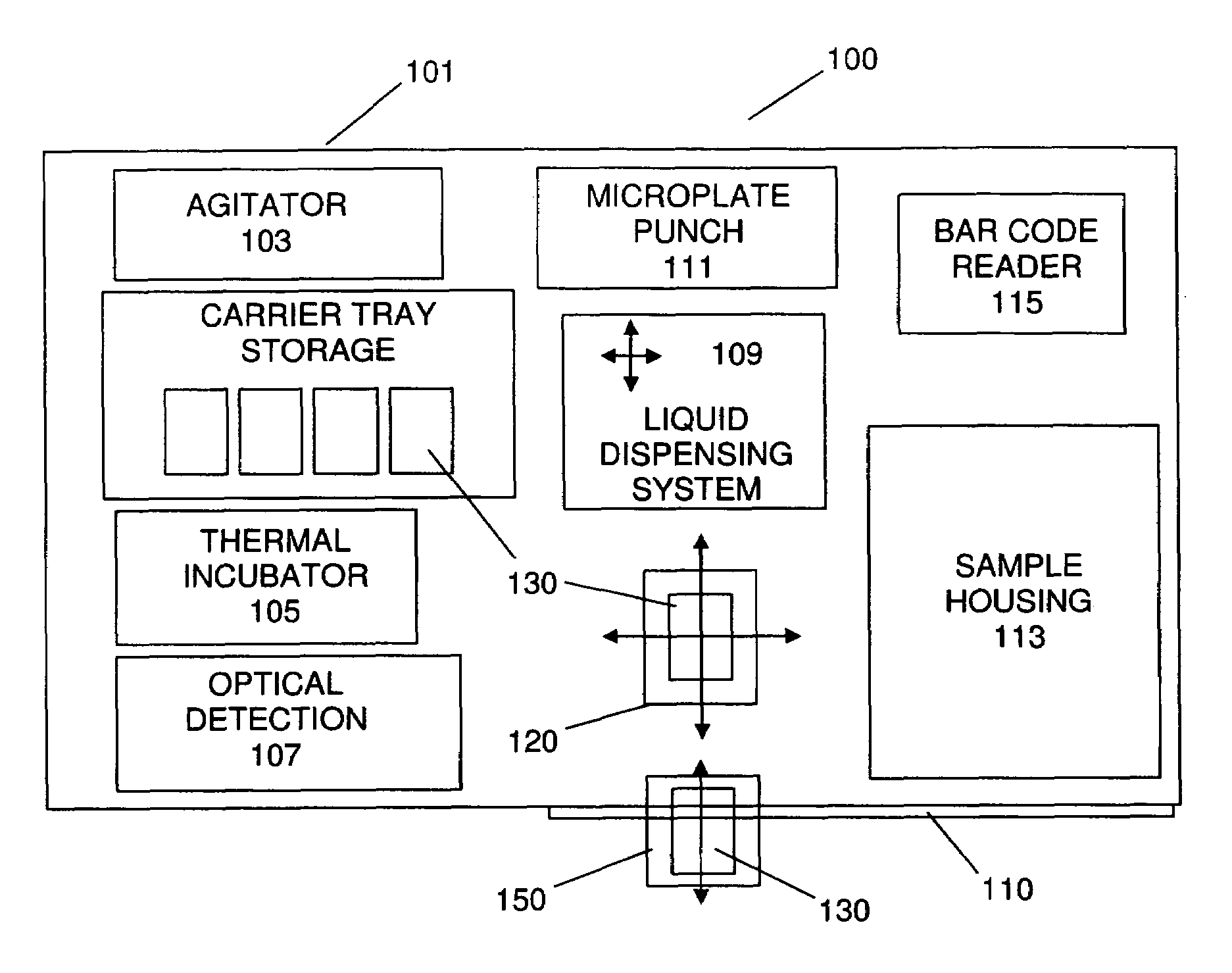

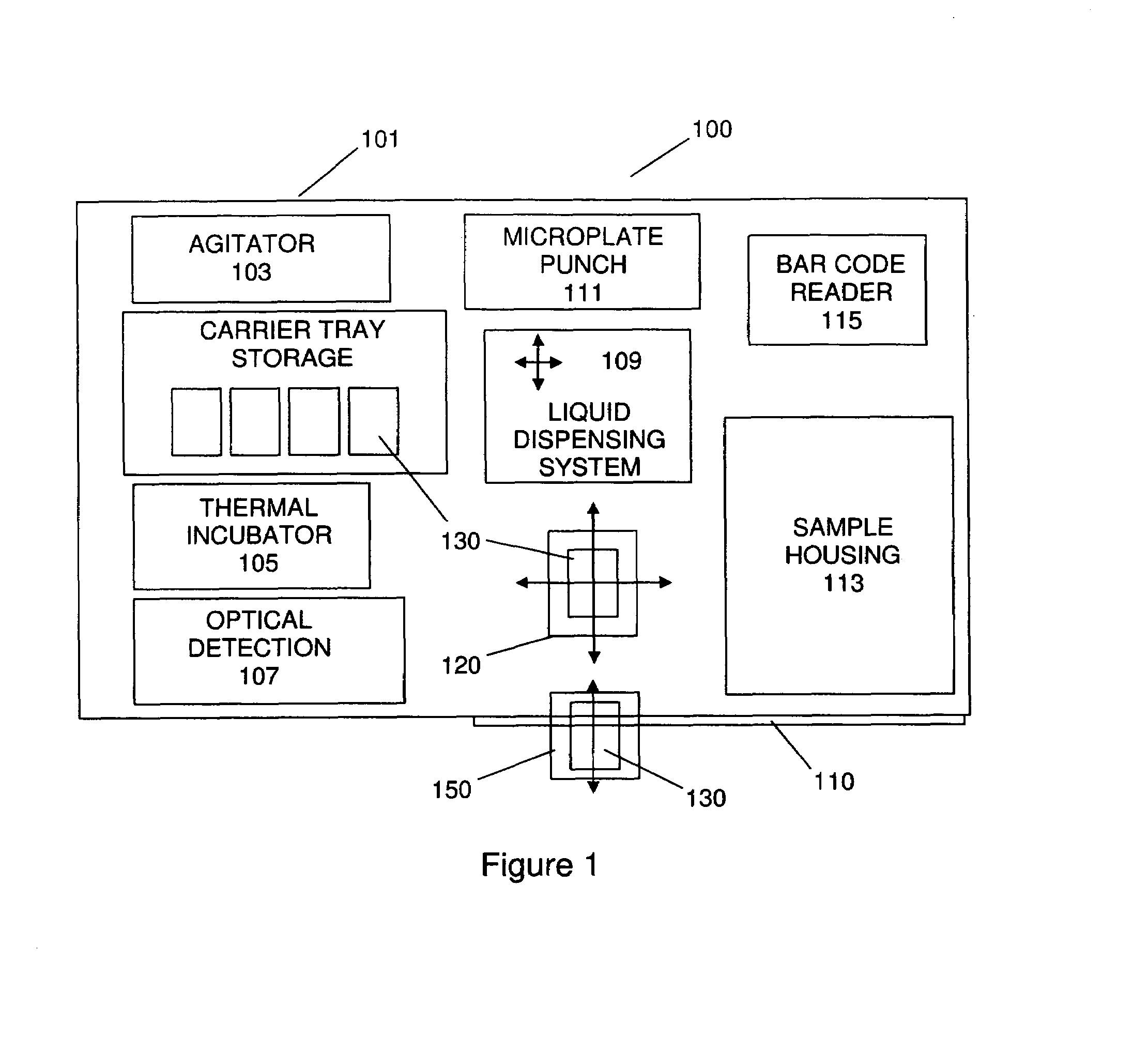

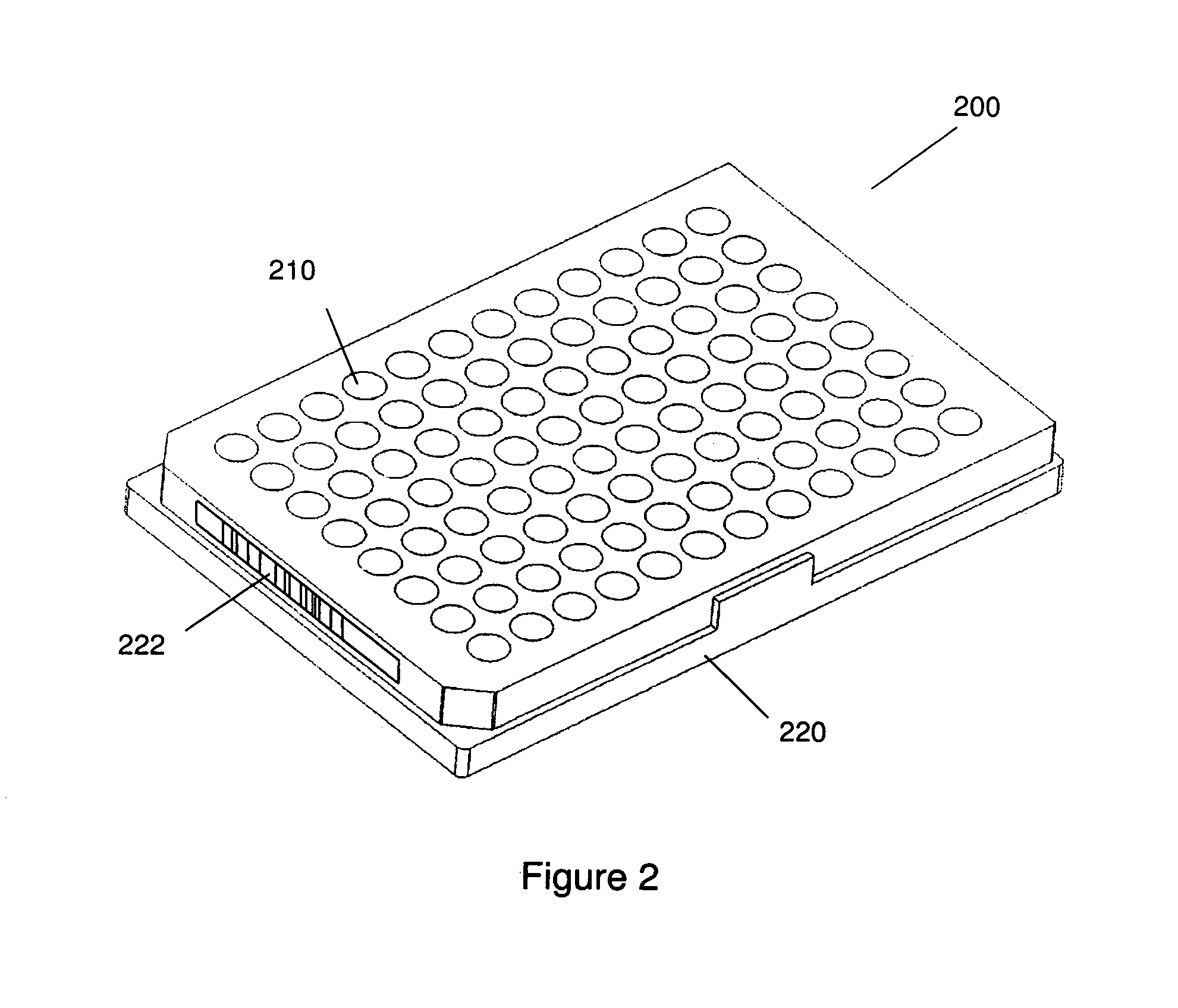

Automated analyzer

InactiveUS20060210435A1Minimal operator involvementEasy loadingBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid-crystal displayBarcode

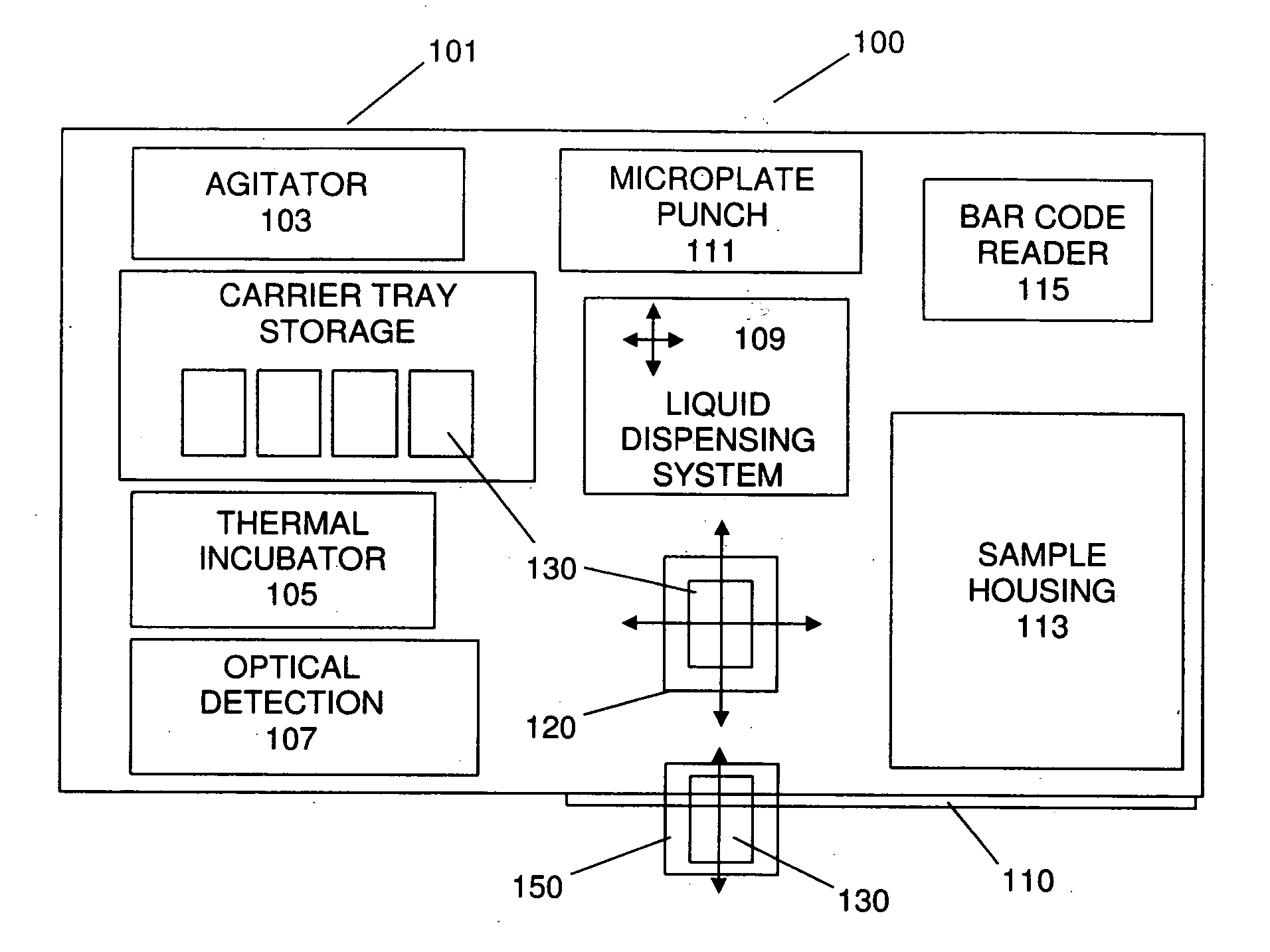

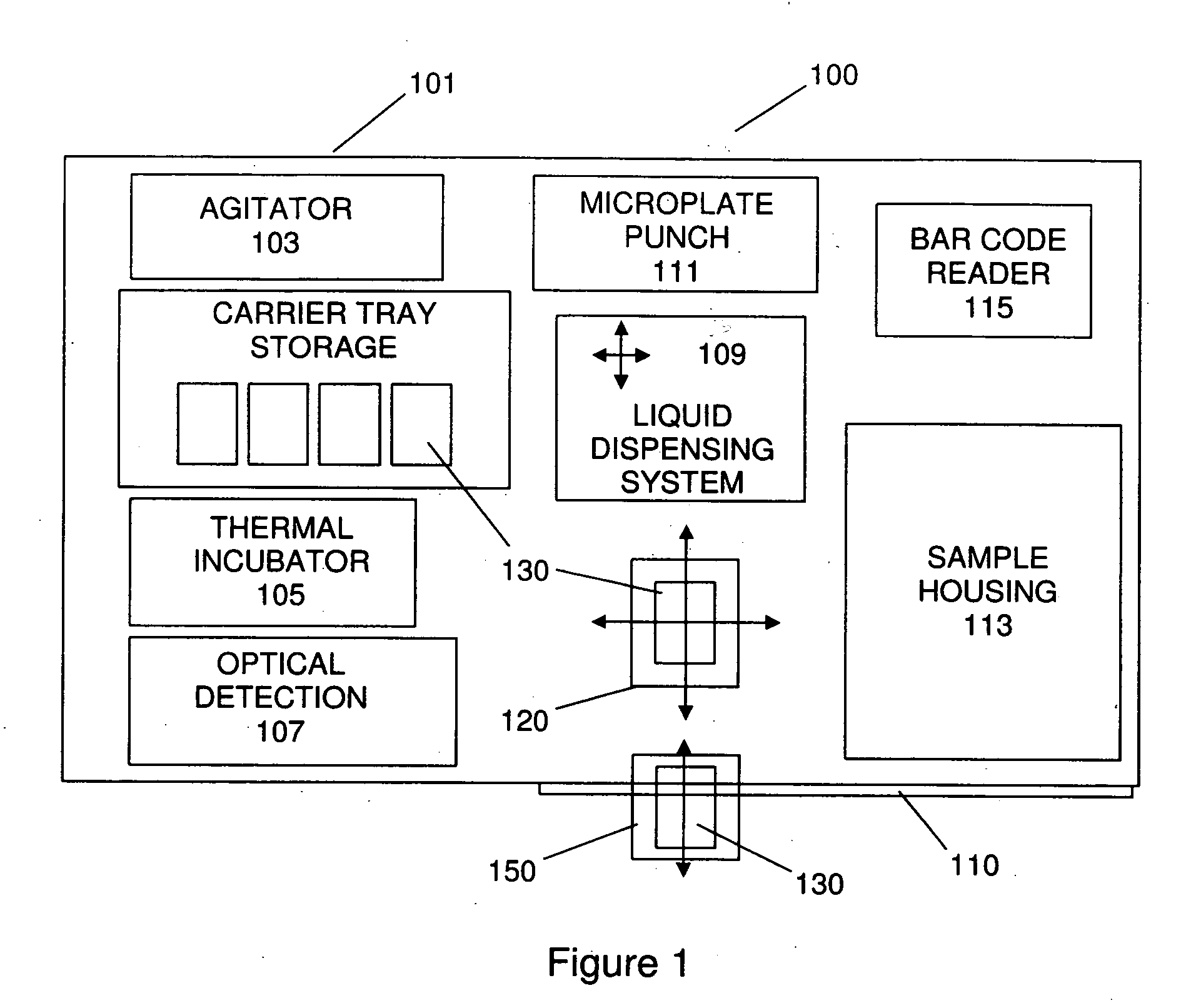

The present invention provides a bar-code driven, completely automated, microplate-based analyzer system for performing chemical, biochemical or biological assays. The analyzer is a modular, bench-top instrument that compactly integrates subsystems for sample dispensing, liquid handling, microplate transport, thermal incubation, vortexing, solid phase separation and optical reading. An internal processor is included for automating the instrument, and a user interface to facilitate communication with the operator via a touch-sensitive liquid-crystal display (LCD), and communicating with a remote network via multiple protocols. The analyzer includes firmware resident within the processing system and the user interface allows the operator to select pre-defined assay batch protocols and the user interface is configured in such as way so as to restrict an operator from programming the firmware.

Owner:NOVX SYST CANADA

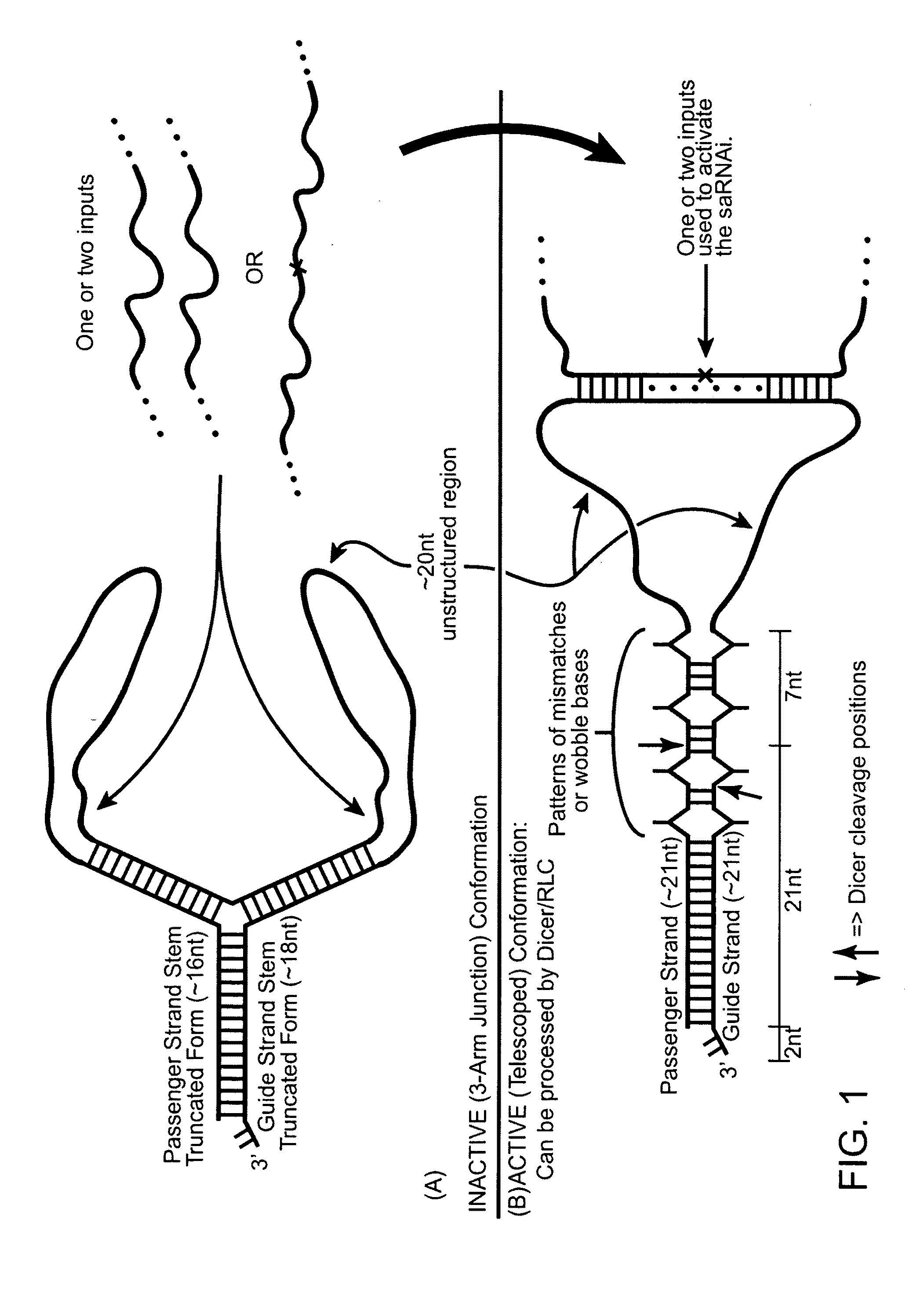

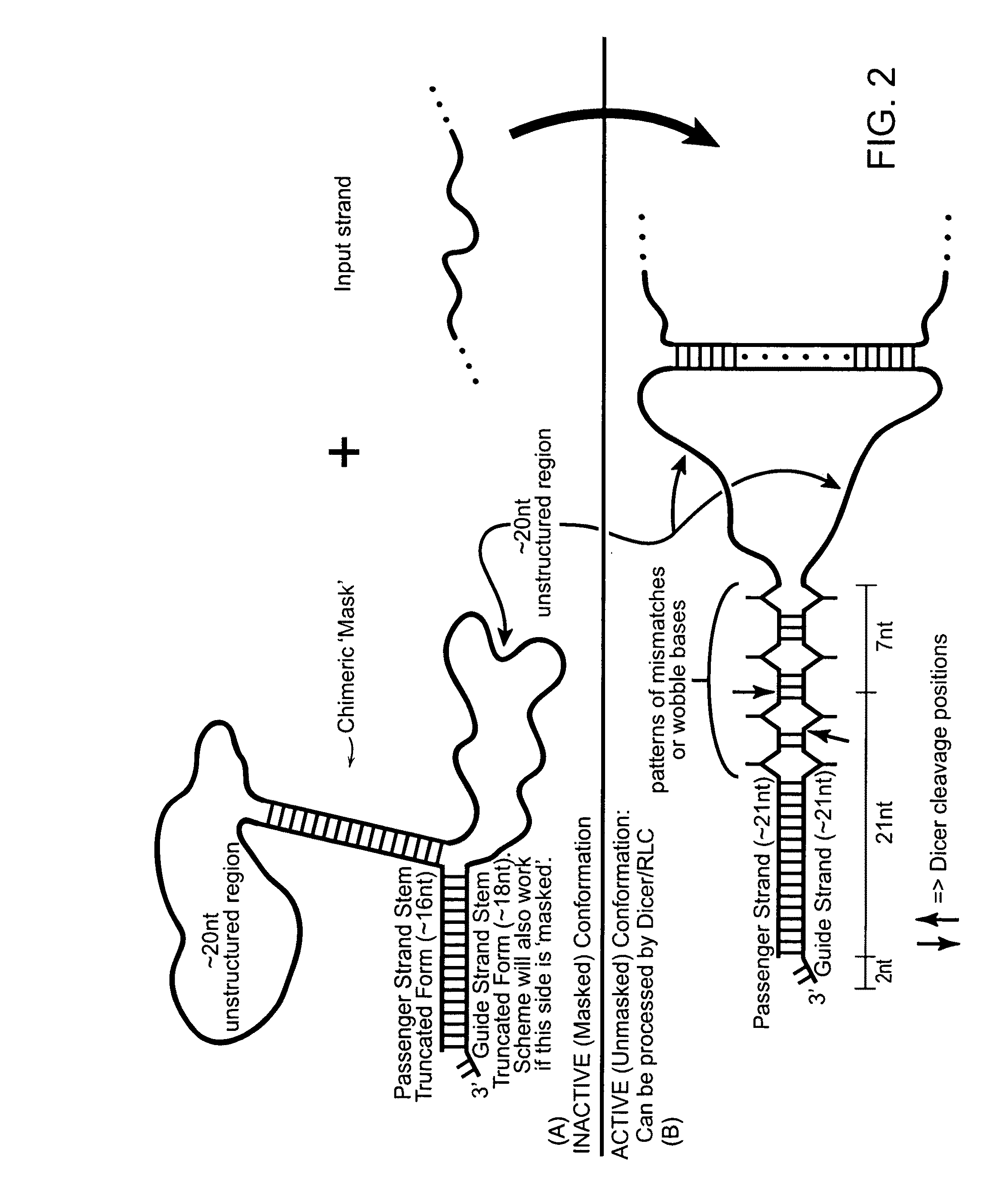

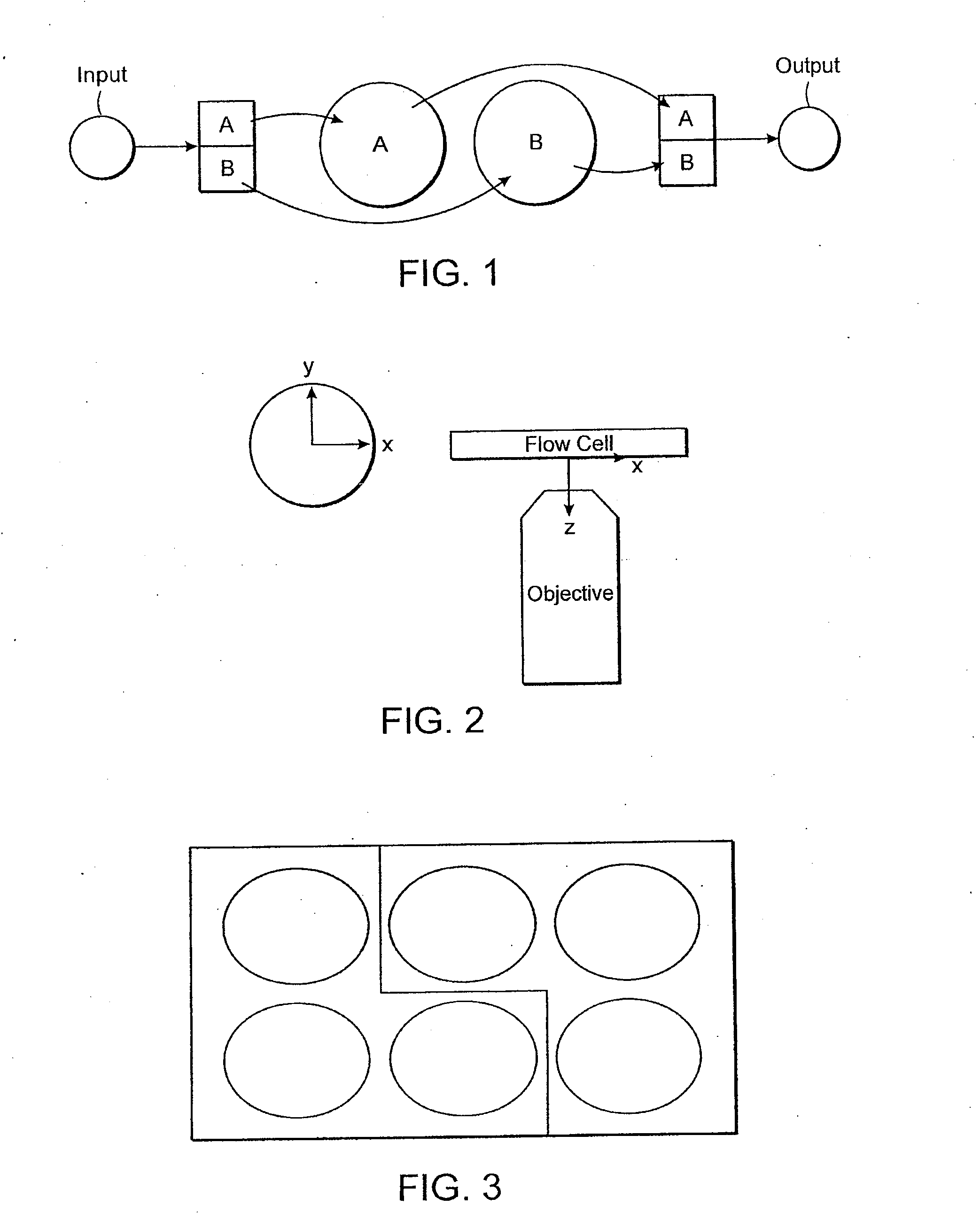

Signal activated RNA interference

ActiveUS20090234109A1Eliminate steric hindranceInhibits the degradation of the blocking sequenceSugar derivativesScreening processHomopolynucleotideDicer

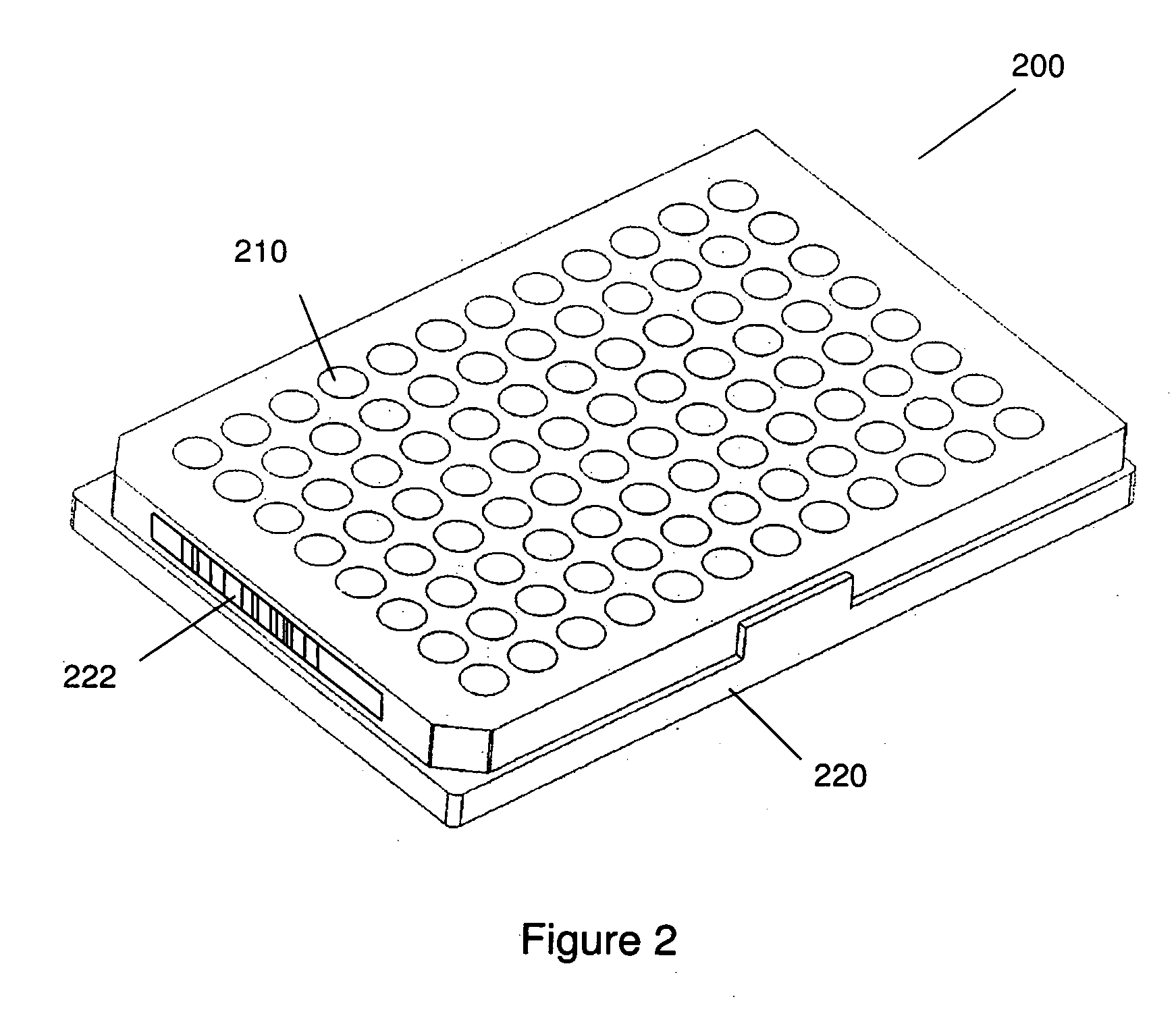

The invention provides compositions and methods for signal activated RNA interference (saRNAi), preferably in vivo. The invention provides polynucleotides that switches between an inactive form and an active form upon covalent or non-covalent interaction with one or more specific chemical signals, such as disease-specific mRNA, miRNA, or other cellular RNA products with sequences that characterize diseased states of the cell. The interaction between the subject polynucleotides and the signals is preferably mediated by hybridization, which exposes, facilitates the formation, and / or allows the formation of a substrate that can be processed by proteins of the RNAi pathway (such as Dicer). The input and output of multiple different polynucleotides of the invention can form an in vivo signaling network. In addition, the multiple input signals can be integrated to modulate the activity of the subject polynucleotides.

Owner:CALIFORNIA INST OF TECH

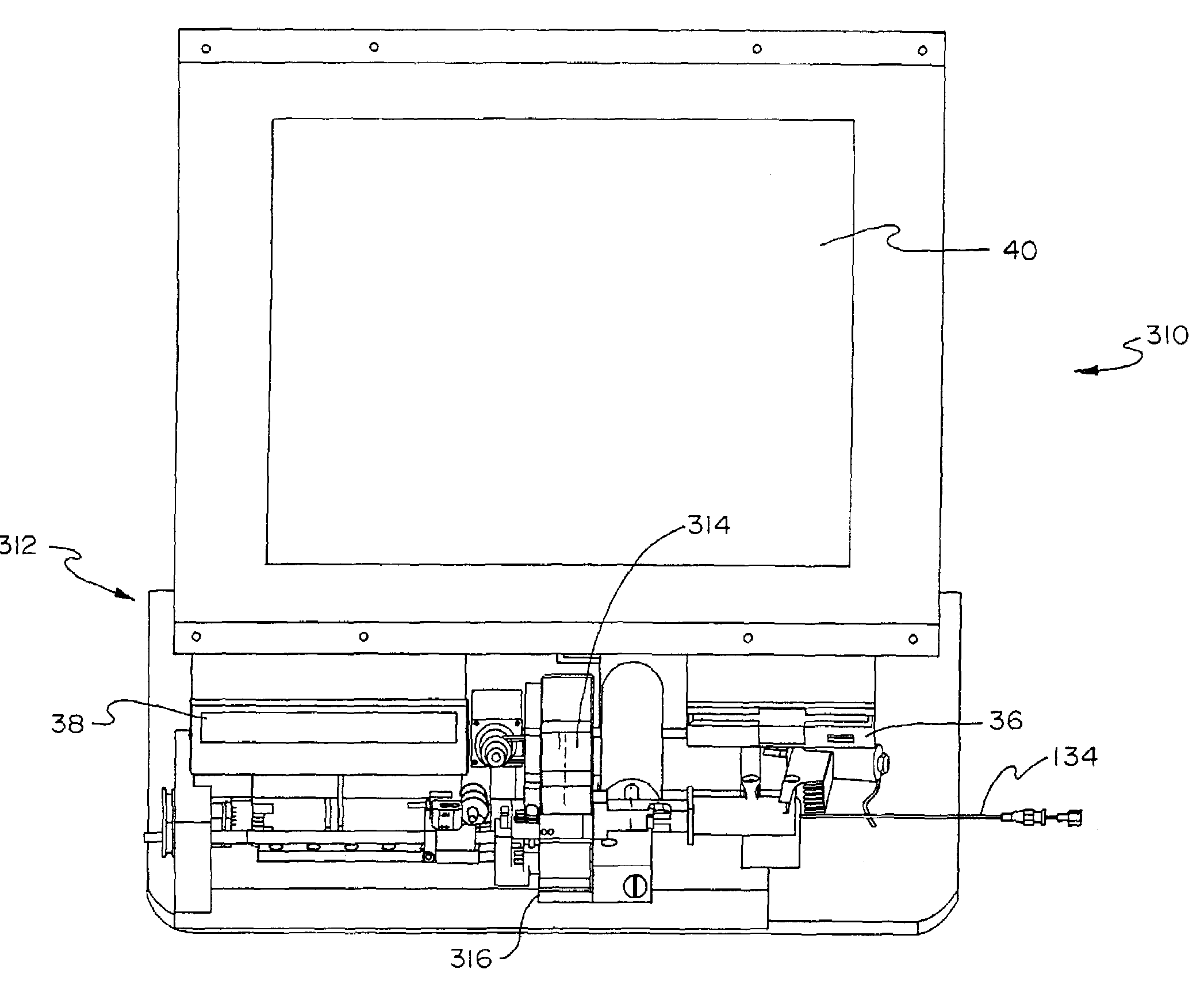

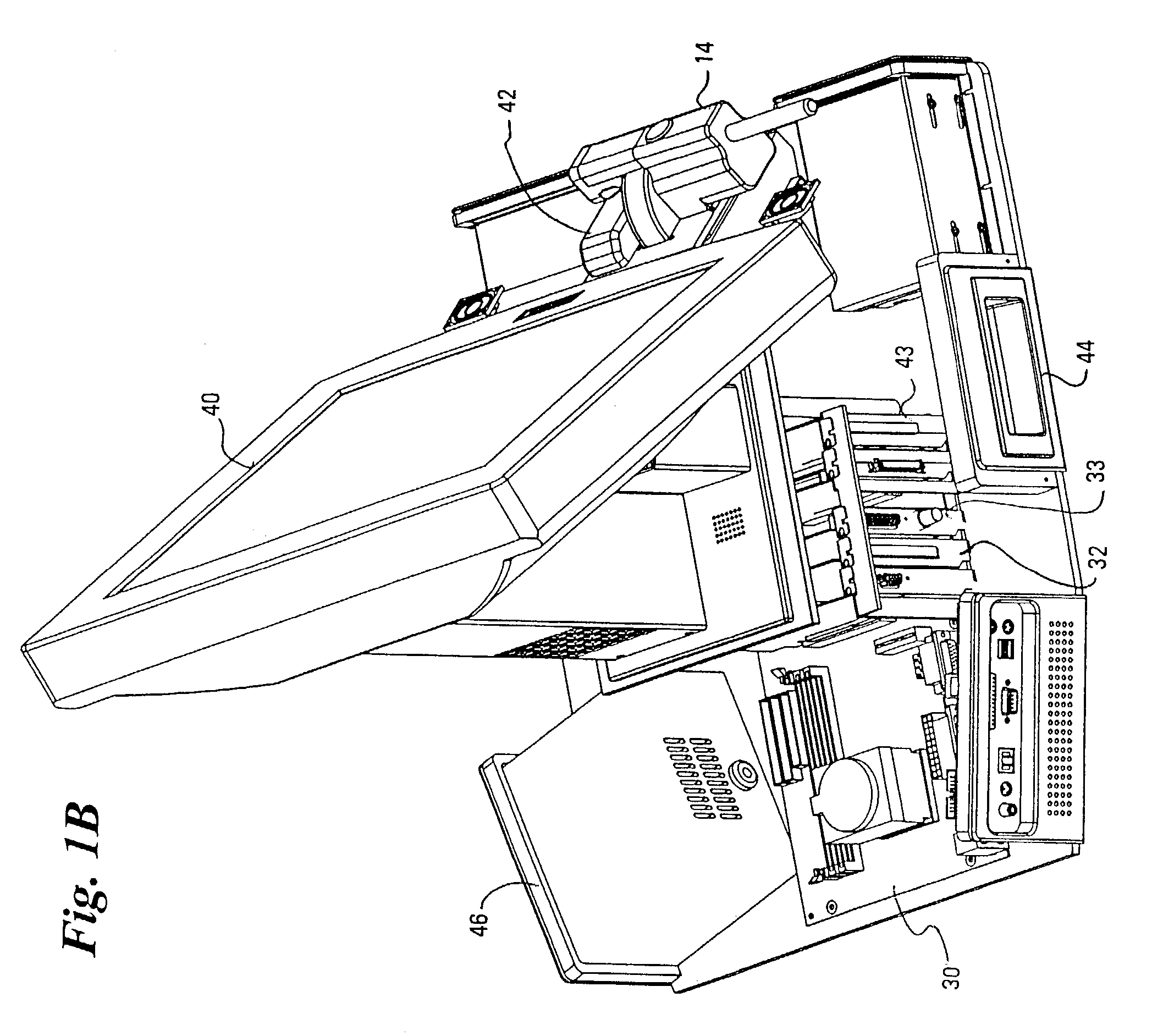

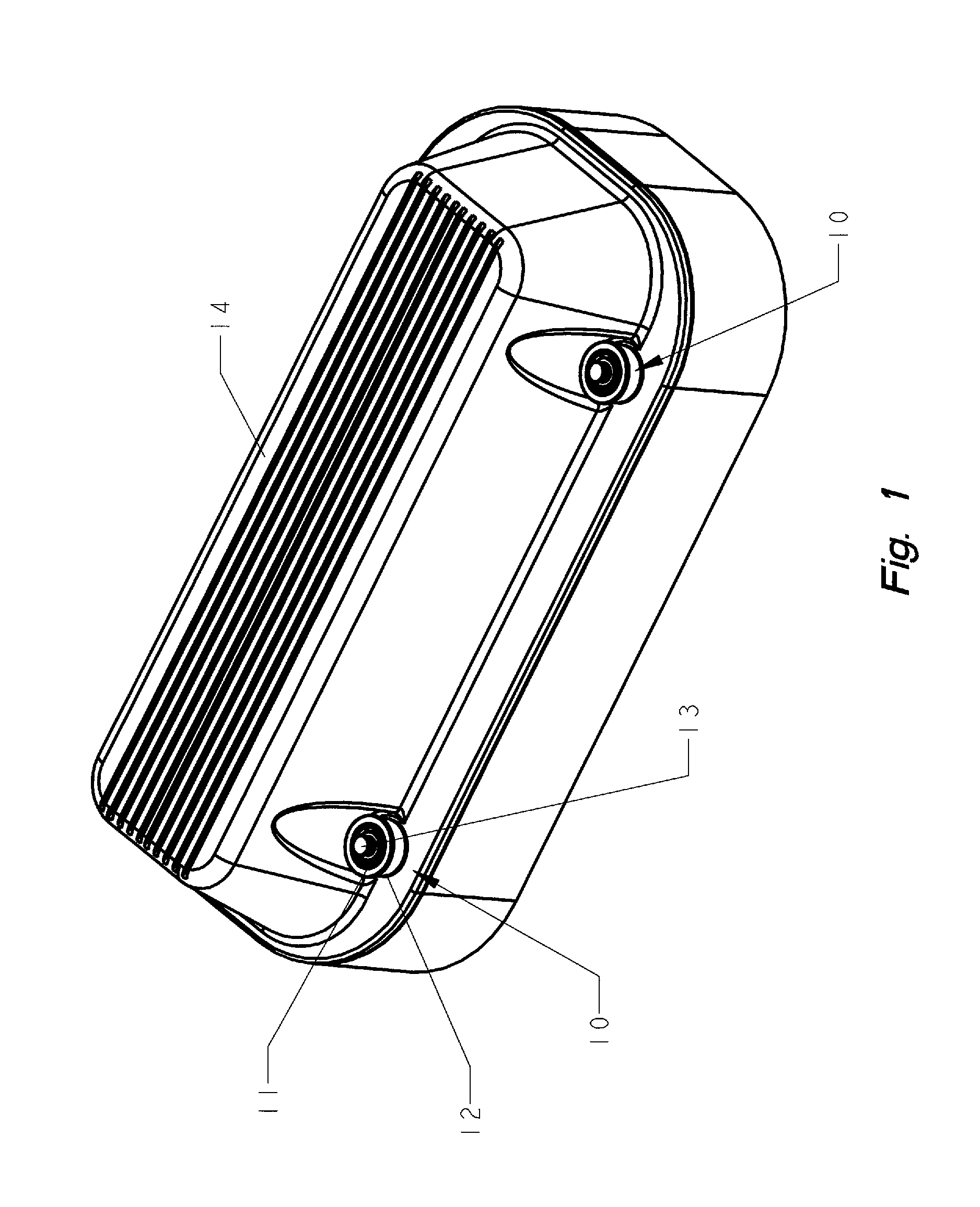

Automated radioisotope seed loader system for implant needles

InactiveUS7229400B2Minimize security issueSafe and efficientMedical devicesX-ray/gamma-ray/particle-irradiation therapyMovement controlAdemetionine

An automated system for loading low dose radioisotope seeds into a plurality of implant needles is comprised of a loading station into which a replaceable cartridge may be positioned. The cartridge is preloaded with a plurality of radioisotope seeds and a plurality of spacers. The cartridge has at least one aperture and preferably the radioisotope seeds and spacers are loaded around the periphery of a rotatable drum within the cartridge. The loading station has a cartridge receiving structure and an automated motion control system. When the cartridge is positioned in the cartridge receiving structure, the automated motion control system preferably drives a pair of stepper motors within the cartridge, one for rotating the rotatable drum and one for sliding a pushrod to selectively eject radioisotope seeds and spacers from the cartridge into each of a plurality of implant needles positioned so as to receive the radioisotopes seeds and spacers within the implant needle. In one embodiment, the implant needles are positioned tip first into the loading station, and once a predetermined arrangement of radioisotope seeds and spacers are loaded into the implant needle, a plug is positioned in the tip of the implant needle. Preferably, the automated system includes a computer processor having a touch screen user interface that is connected to and directs the operation of the automated motion control system to load the plurality of implant needles in accordance with a predetermined dose plan.

Owner:THERAGENICS CORP

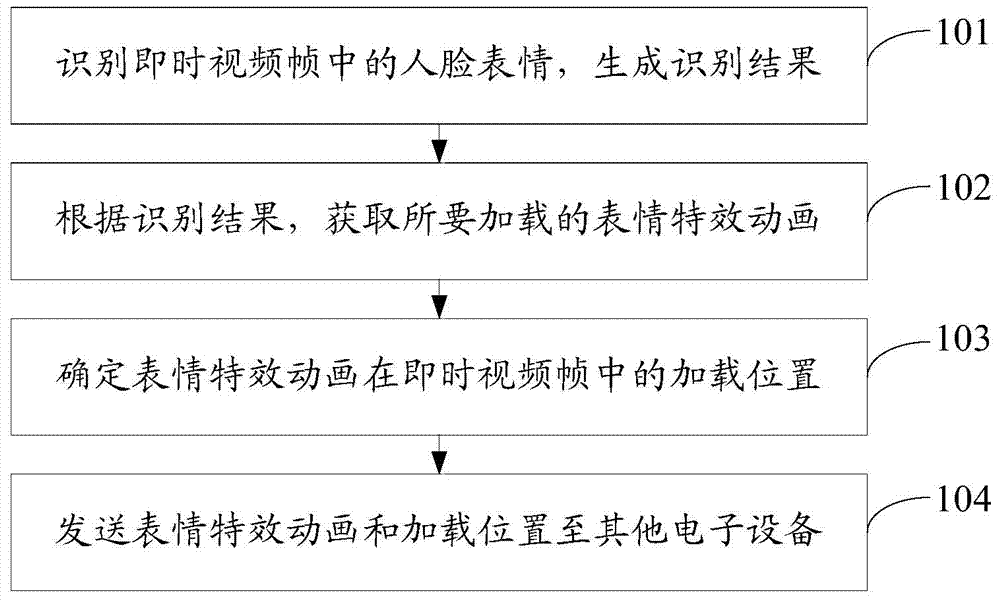

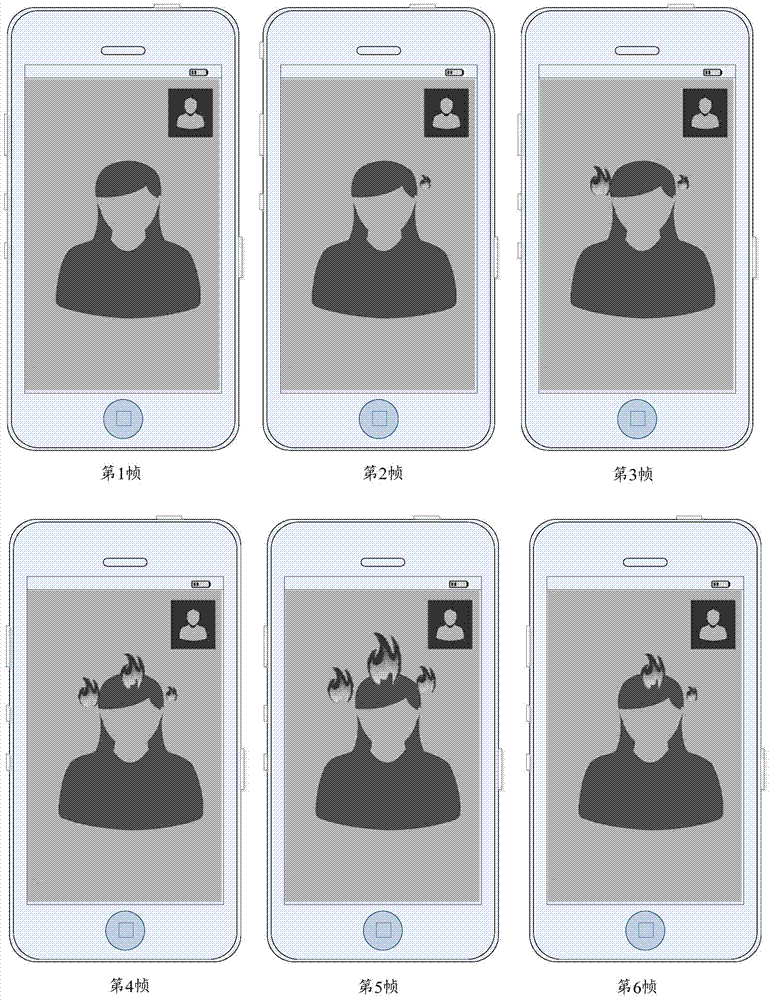

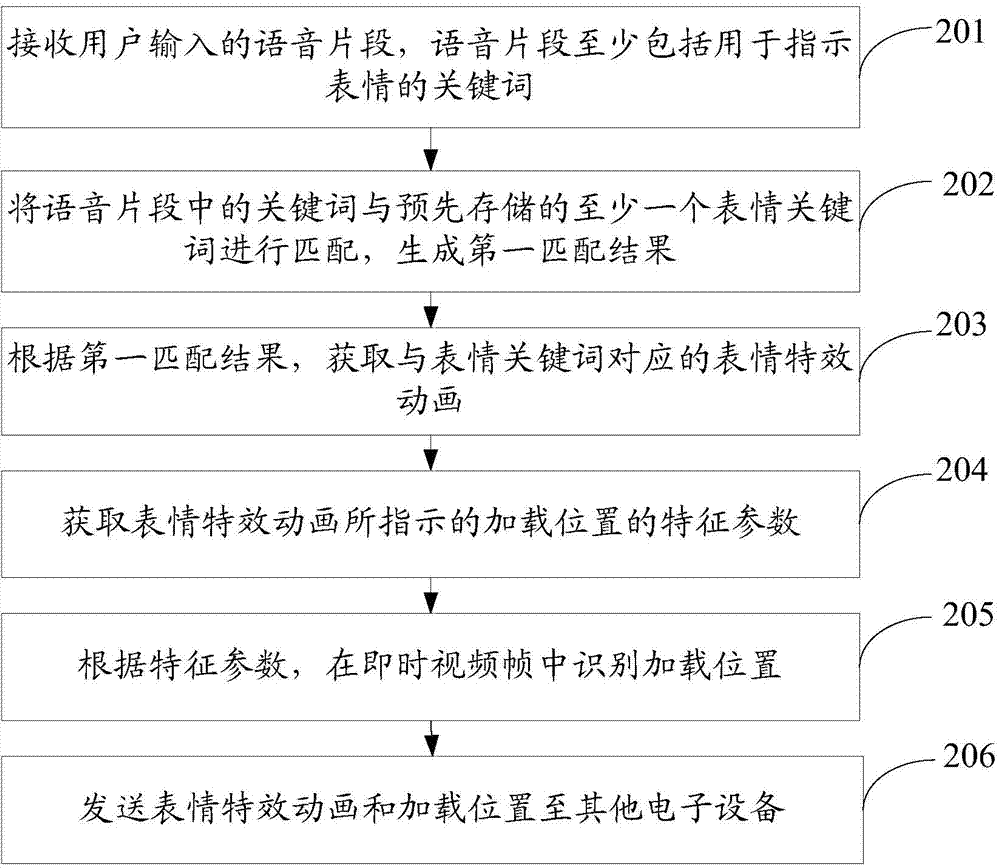

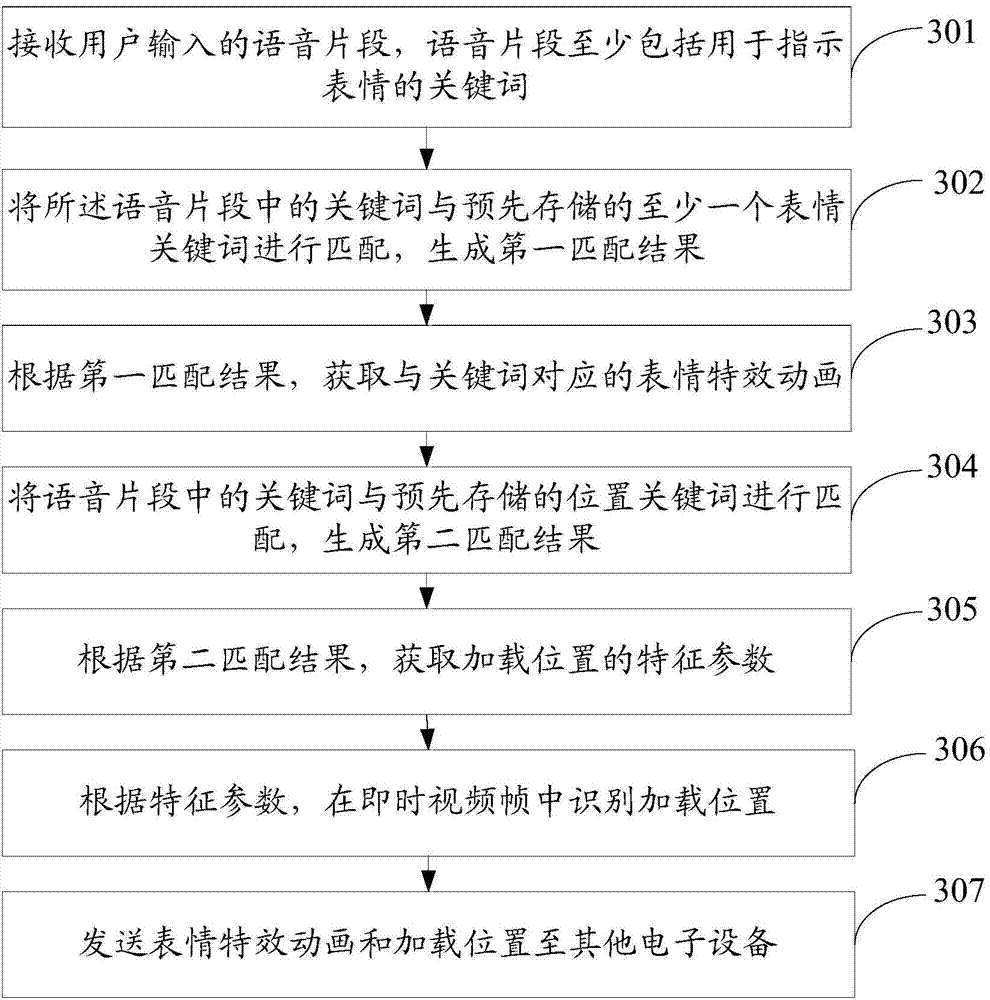

Method and electronic equipment for loading expression effect animation in instant video

InactiveCN104780339AMeet the needs of interactionLoad accuratelyCharacter and pattern recognitionAnimationPersonalizationAnimation

The invention discloses a method and electronic equipment for loading expression effect animation in an instant video, and belongs to the field of videos. The method comprises the following steps: distinguishing the expressions in frames of the instant video, and generating a distinguishing result; according to the distinguishing result, obtaining the expression effect animation which needs to be loaded; determining the loading position of the expression effect animation in the instant video; sending the expression effect animation and the loading position to other electric equipment; therefore, the individualized requirements of a user on instant video conversation are satisfied, the interaction form of the video is increased, and the user experience is improved.

Owner:CHATGAME

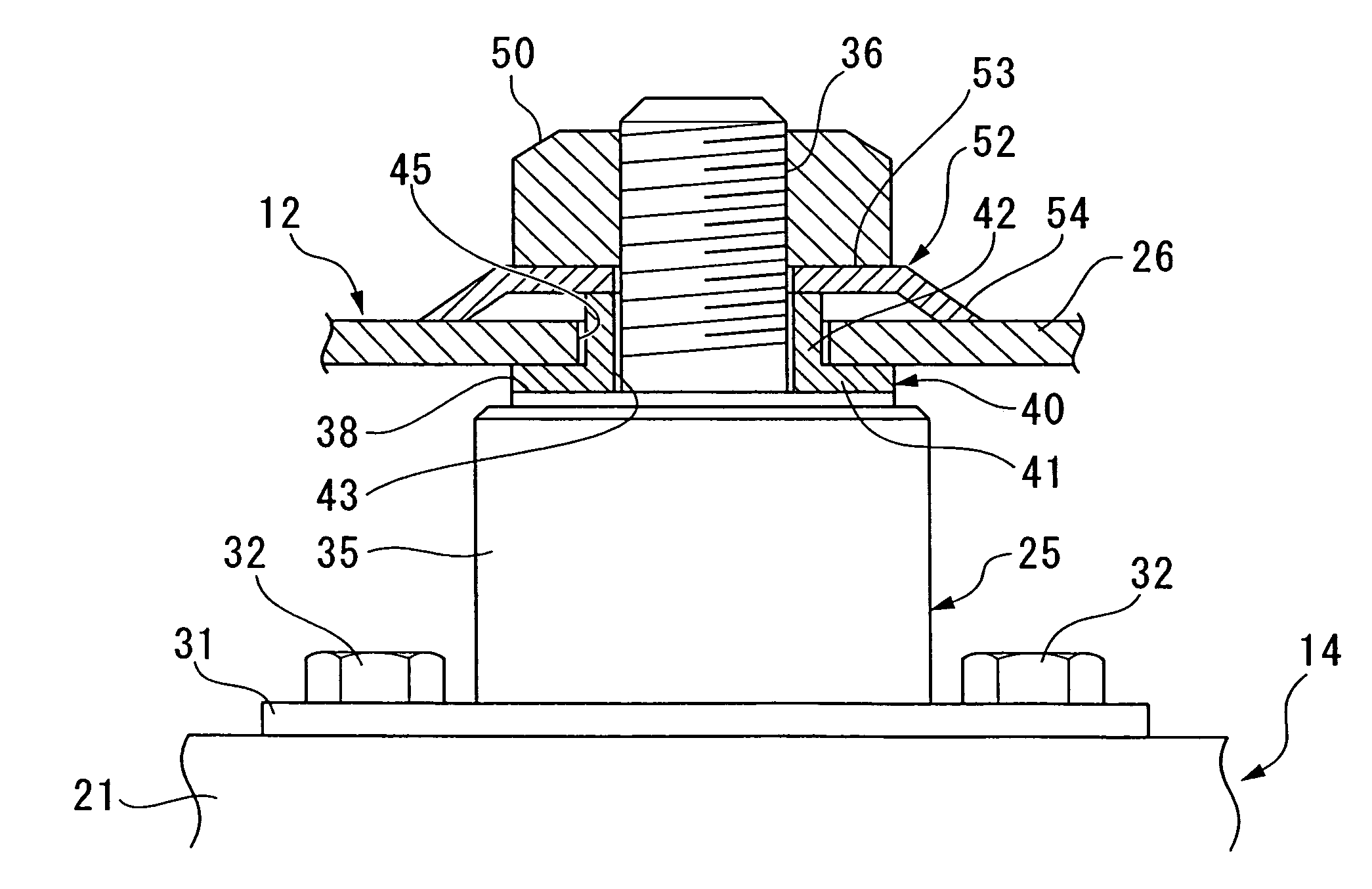

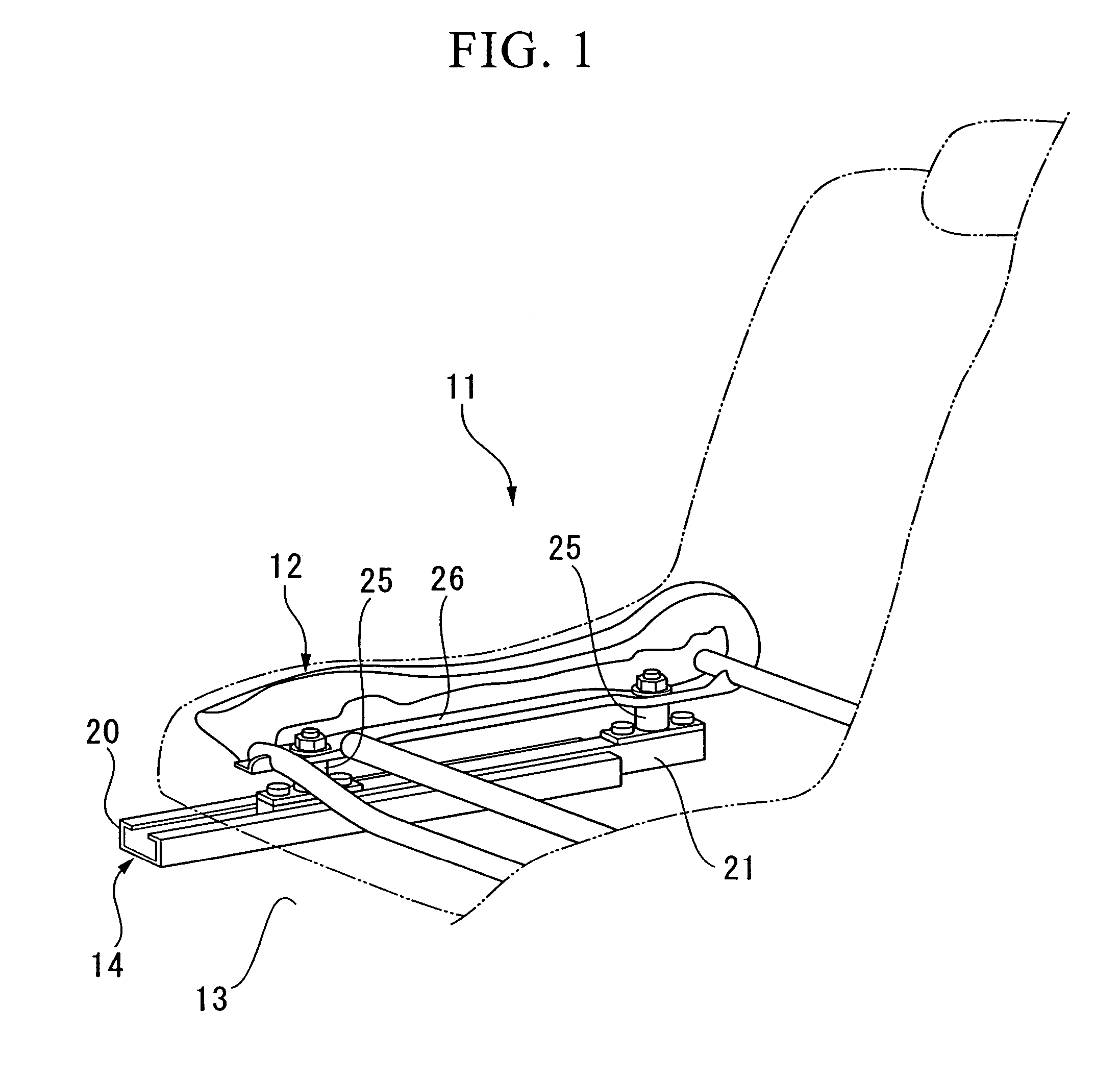

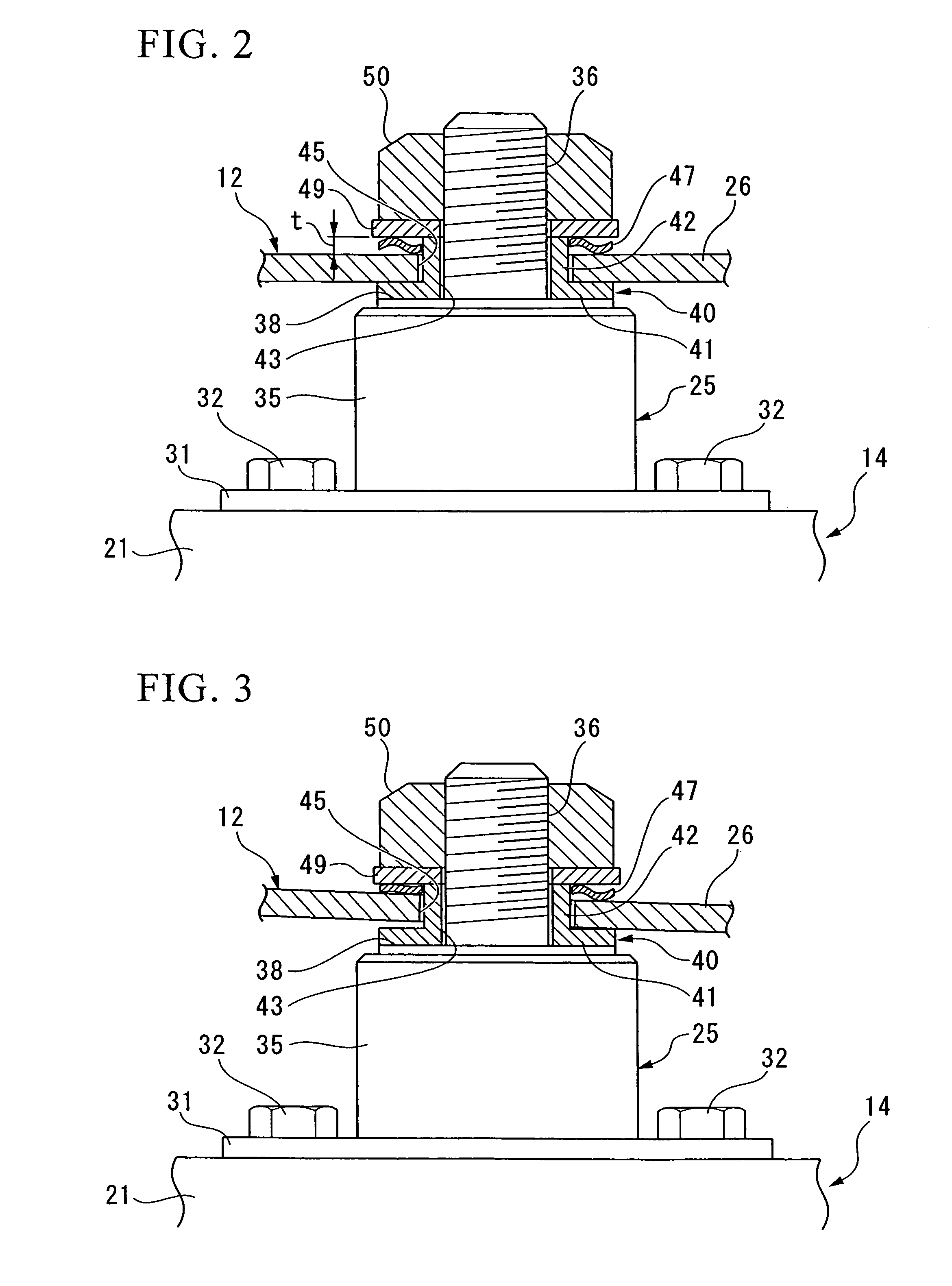

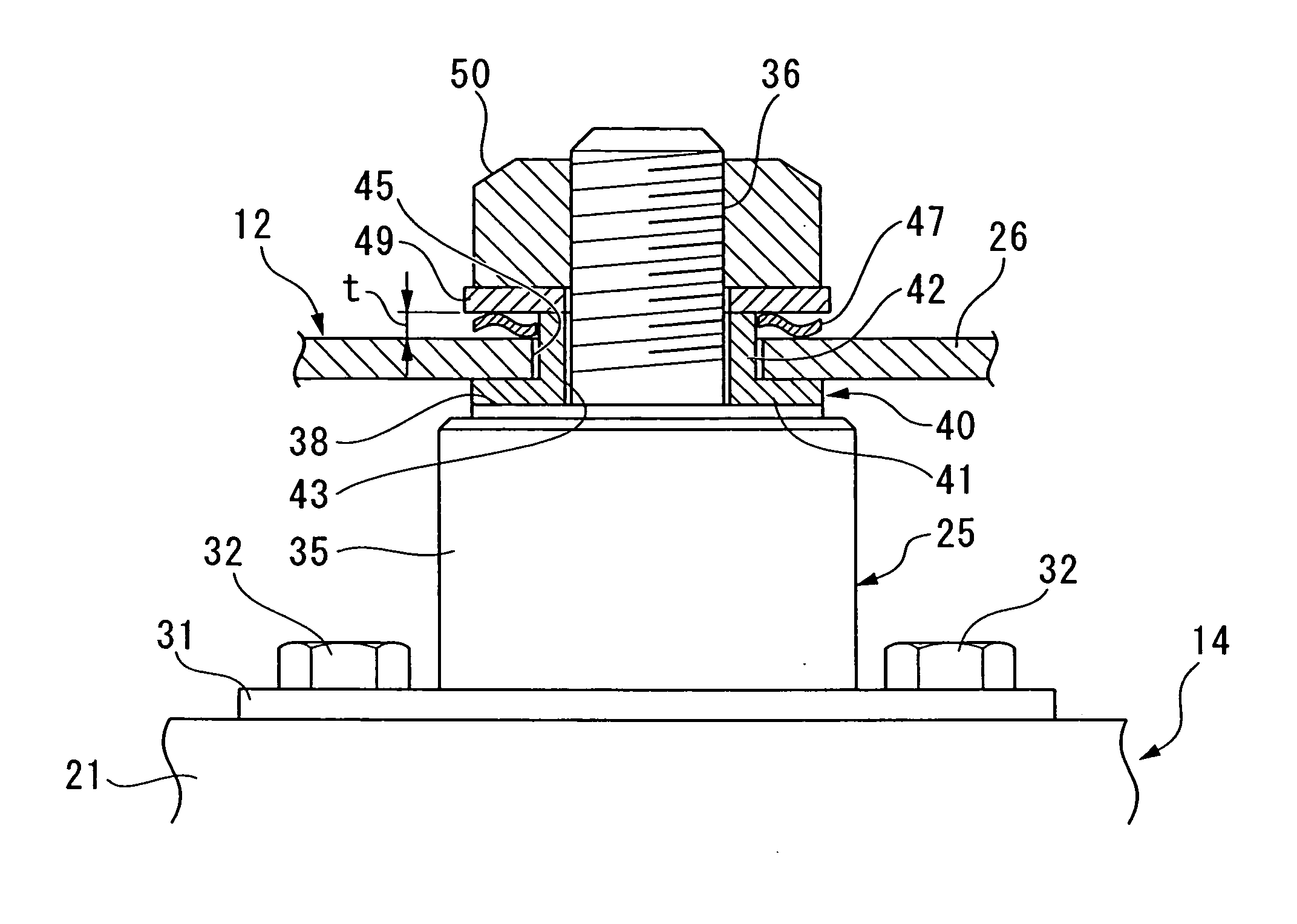

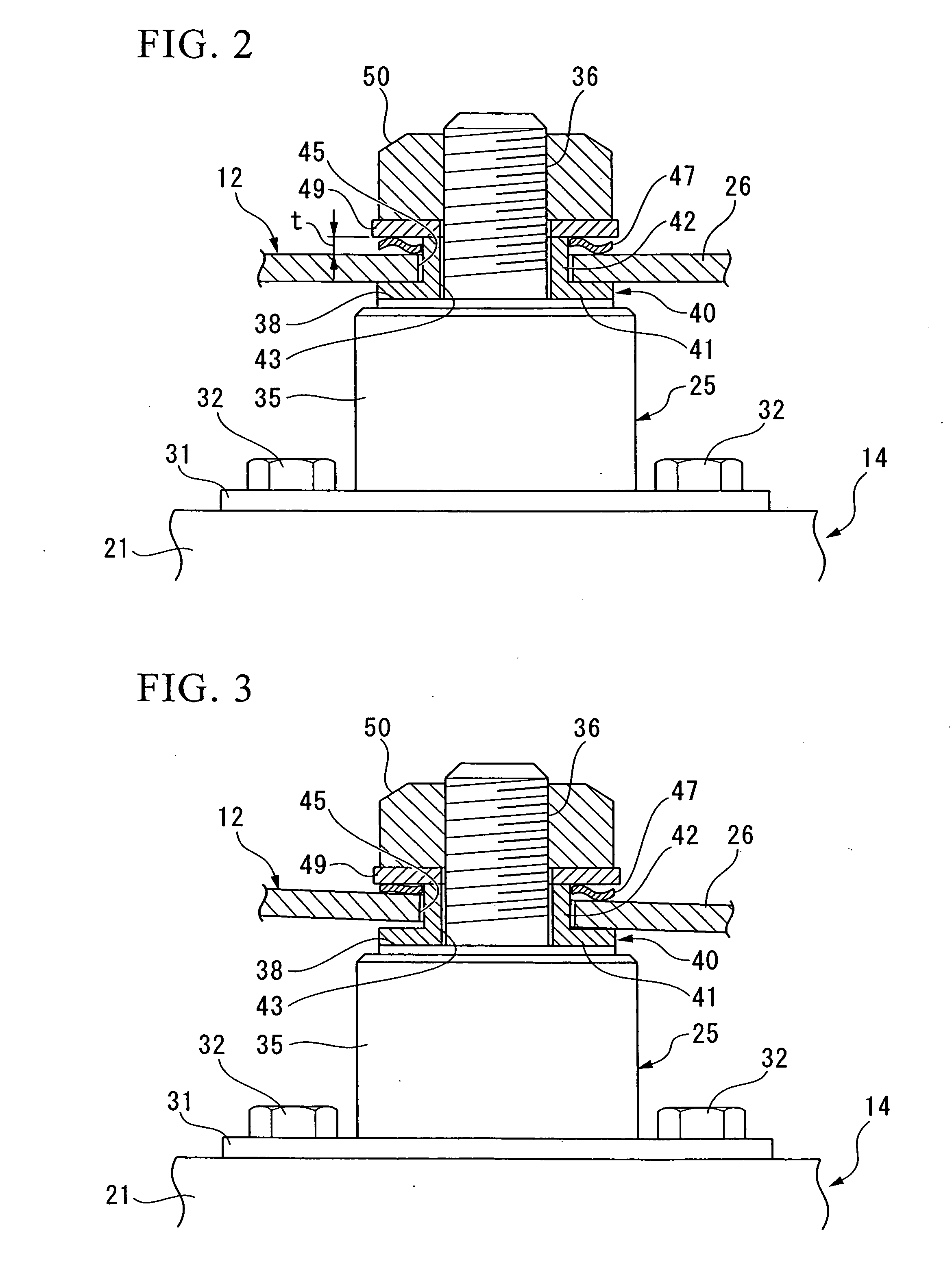

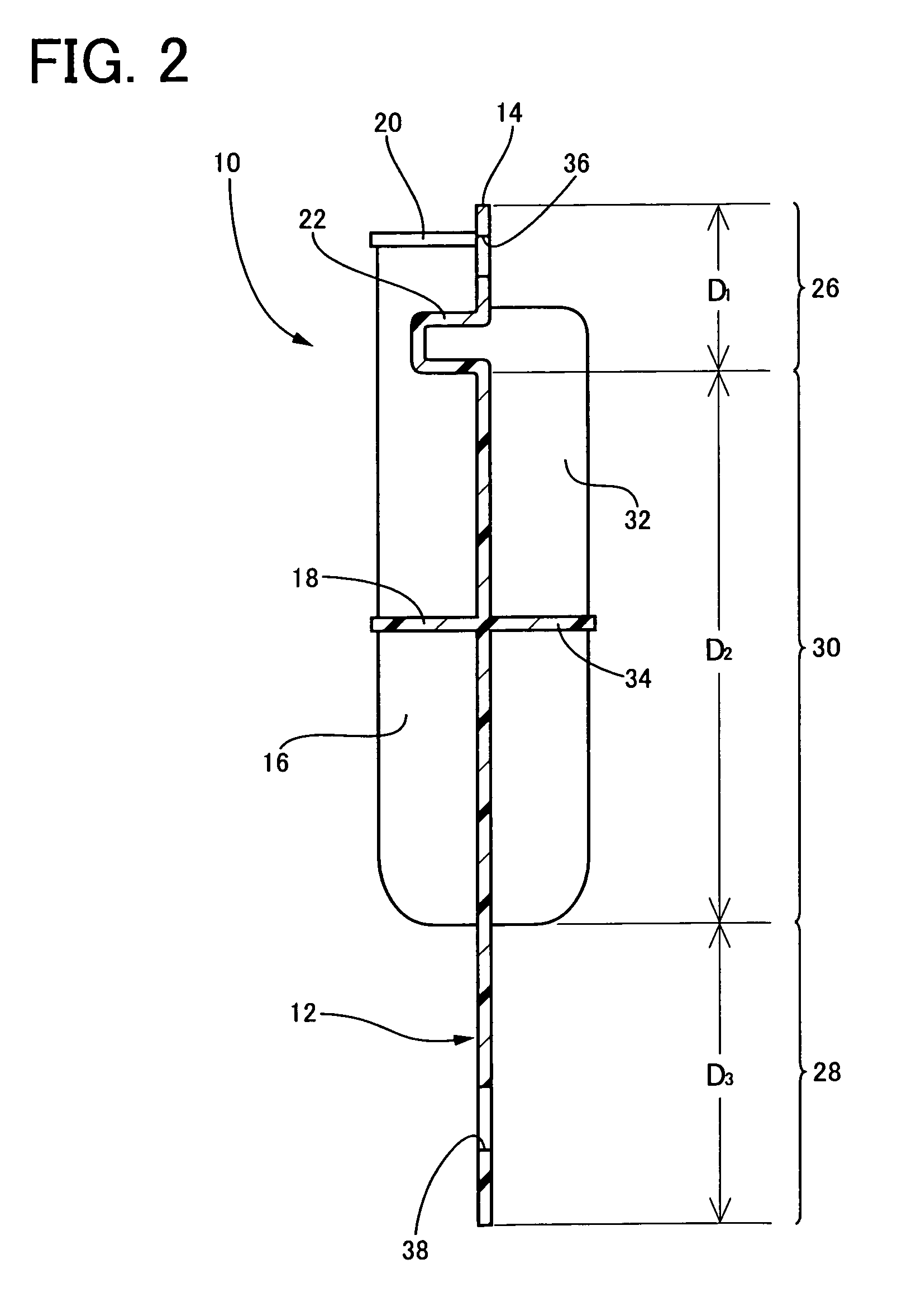

Load cell attachment structure

ActiveUS7373846B2Load accuratelyAccurate measurementLoad modified fastenersOscillations damping for weighingLoad sensingEngineering

This load cell attachment structure includes a male screw which is formed on a load sensing part of the load cell, a nut which attaches the load cell to the attachment plate by engaging with the male screw, and a wave washer which is disposed between the attachment plate and the nut.

Owner:TS TECH CO LTD +1

Automated analyzer

InactiveUS7666355B2Easy loadingImprove automationBioreactor/fermenter combinationsBiological substance pretreatmentsLiquid-crystal displayBarcode

The present invention provides a bar-code driven, completely automated, microplate-based analyzer system for performing chemical, biochemical or biological assays. The analyzer is a modular, bench-top instrument that compactly integrates subsystems for sample dispensing, liquid handling, microplate transport, thermal incubation, vortexing, solid phase separation and optical reading. An internal processor is included for automating the instrument, and a user interface to facilitate communication with the operator via a touch-sensitive liquid-crystal display (LCD), and communicating with a remote network via multiple protocols. The analyzer includes firmware resident within the processing system and the user interface allows the operator to select pre-defined assay batch protocols and the user interface is configured in such as way so as to restrict an operator from programming the firmware.

Owner:NOVX SYST CANADA

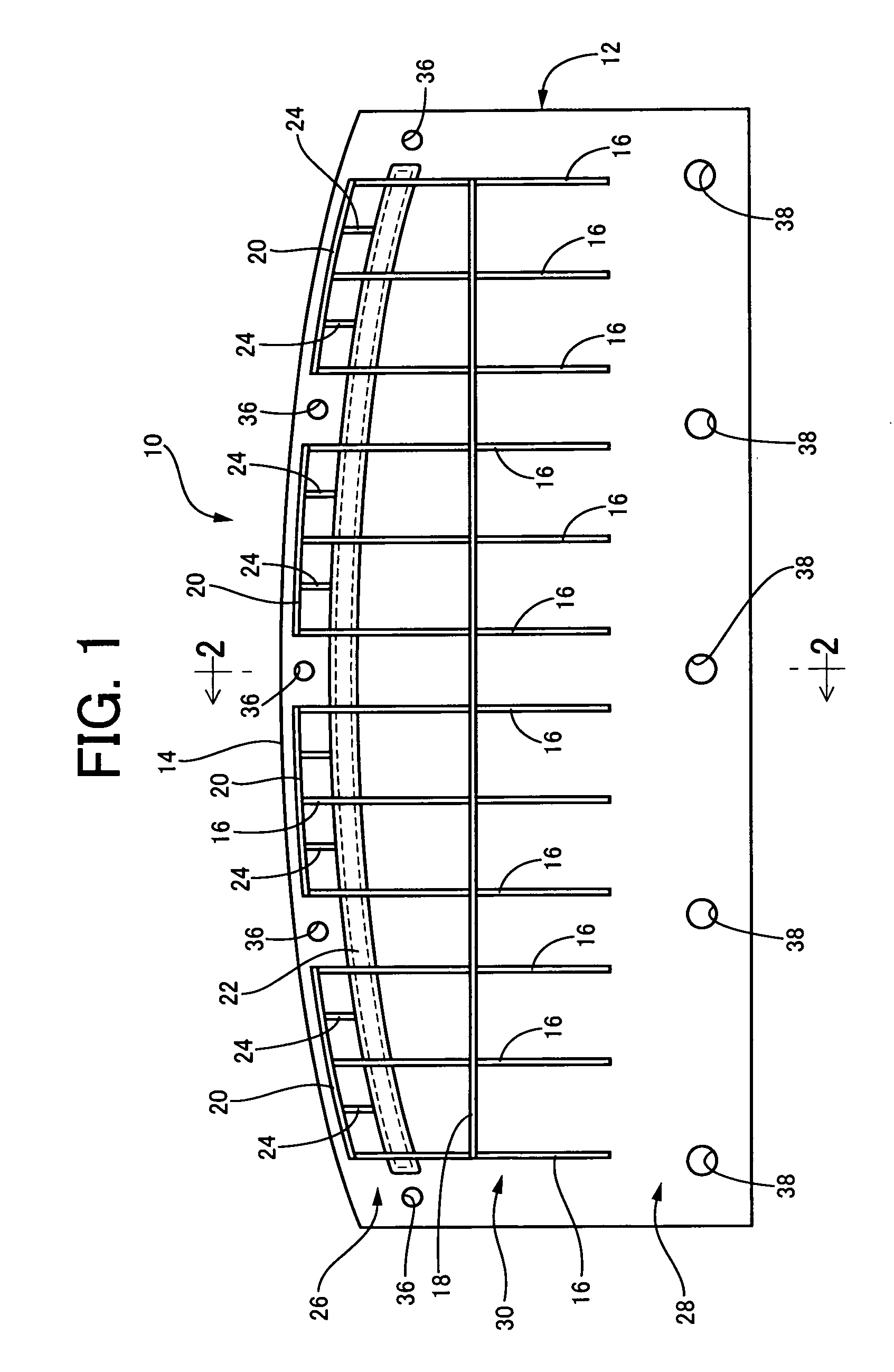

Load cell attachment structure

ActiveUS20060048582A1Load accuratelyAccurate measurementLoad modified fastenersOscillations damping for weighingLoad sensingEngineering

This load cell attachment structure includes a male screw which is formed on a load sensing part of the load cell, a nut which attaches the load cell to the attachment plate by engaging with the male screw, and a wave washer which is disposed between the attachment plate and the nut.

Owner:TS TECH CO LTD +1

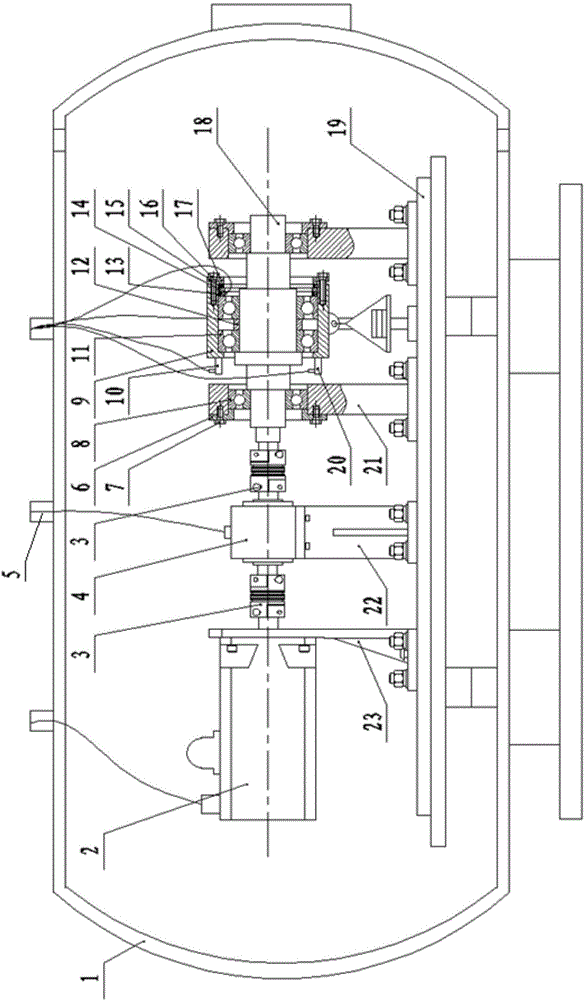

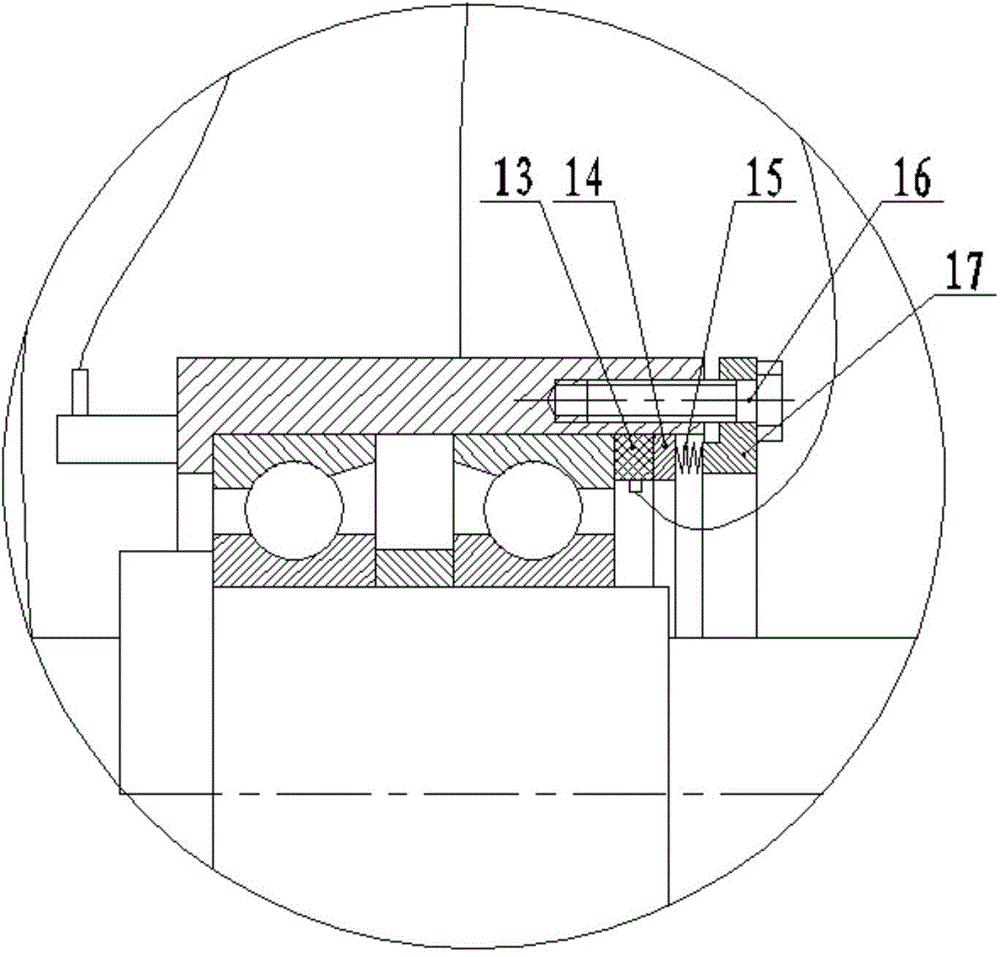

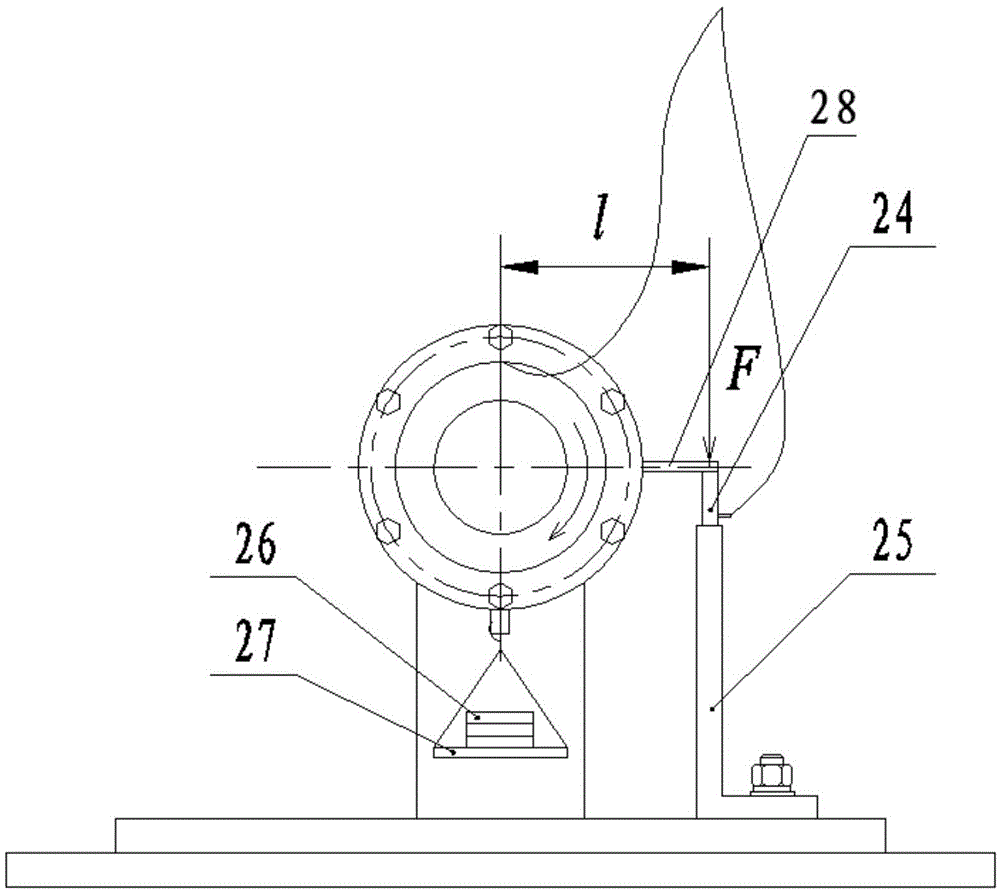

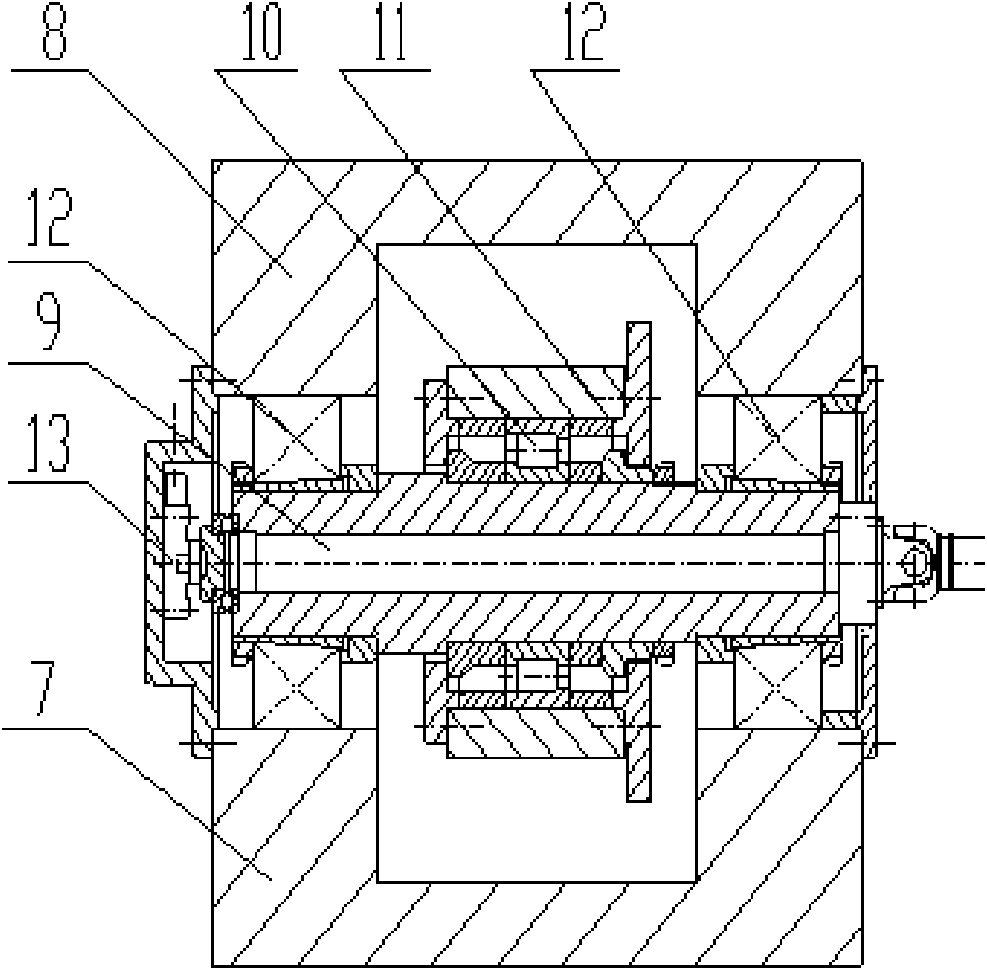

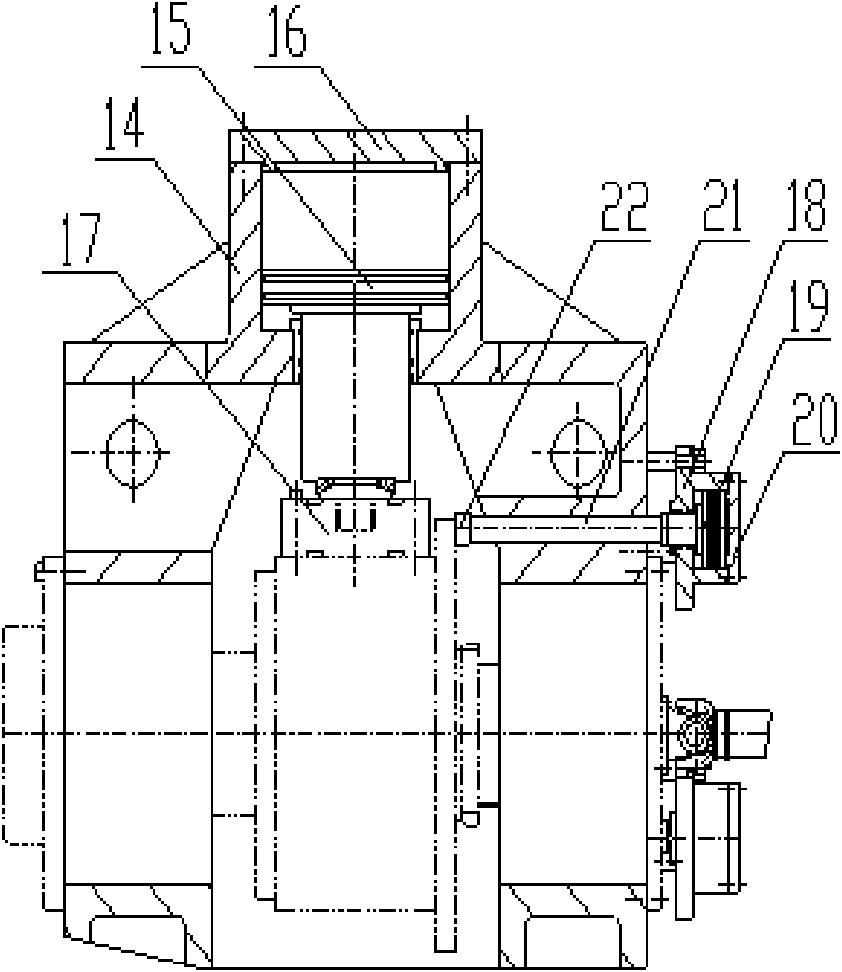

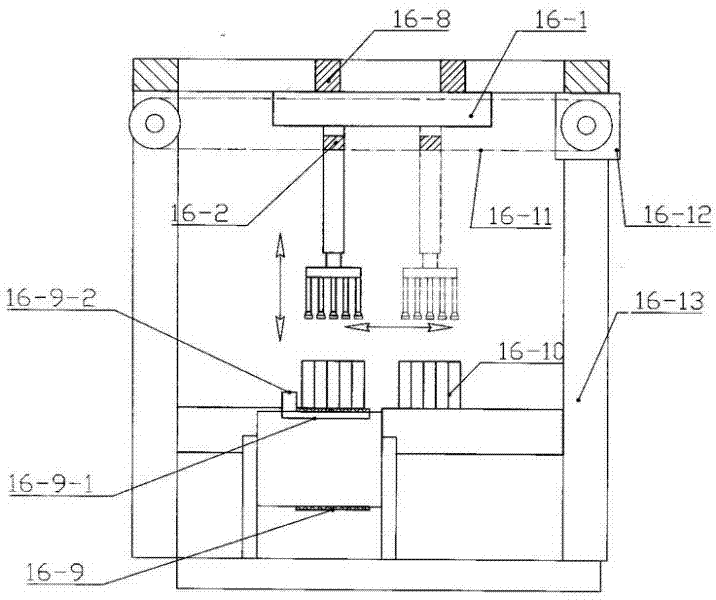

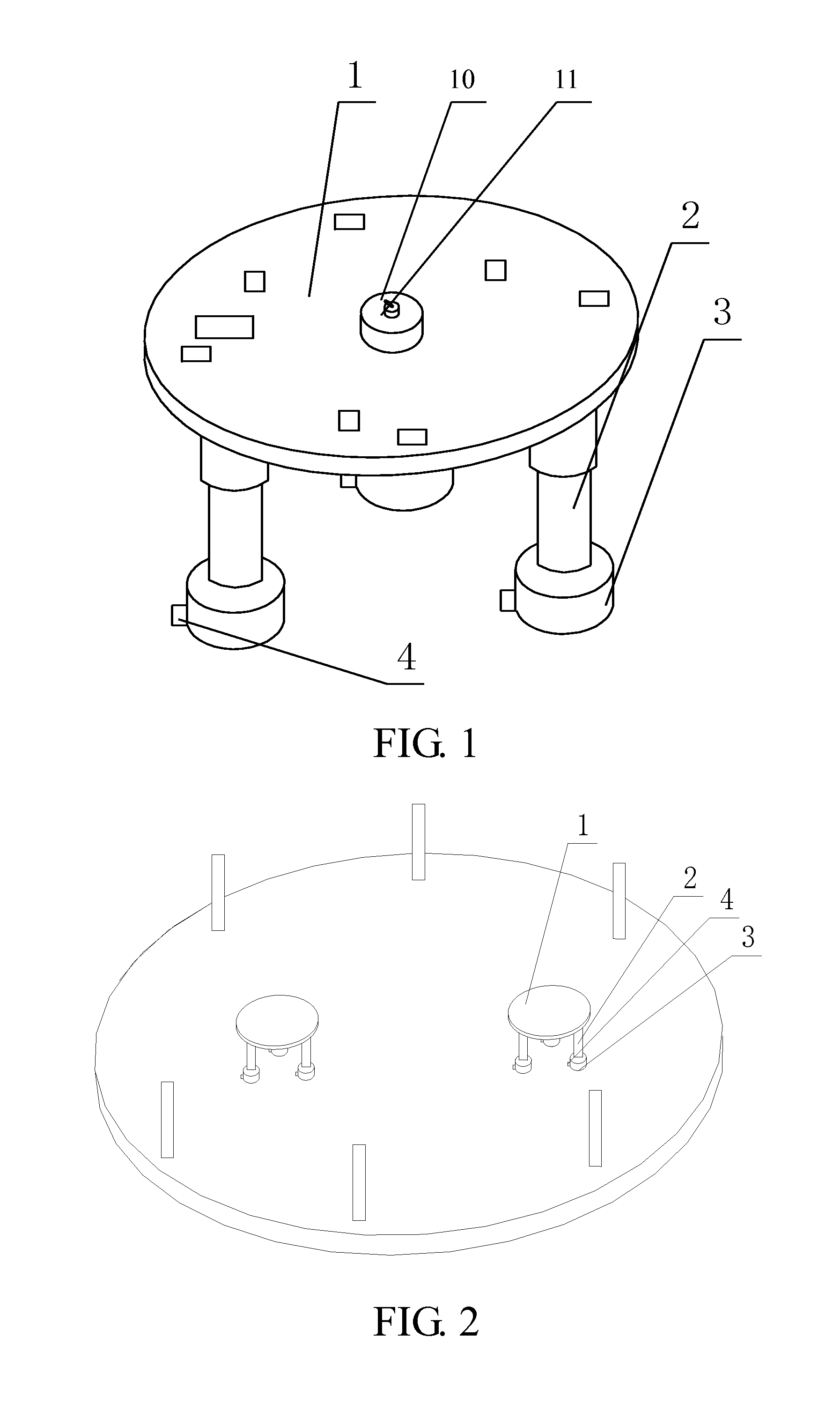

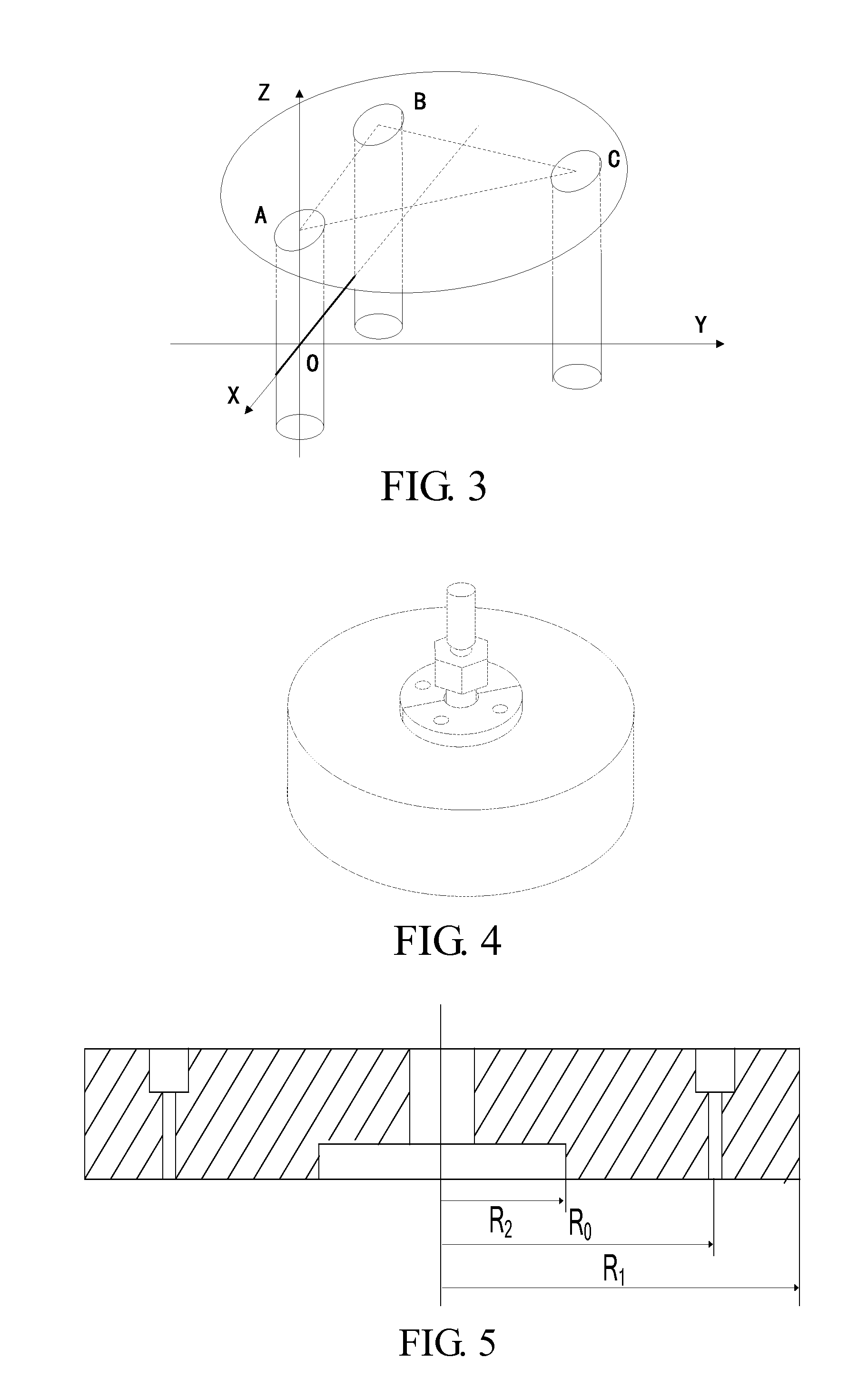

Space rolling bearing comprehensive performance experiment device

ActiveCN104568443ALoad accuratelyAccurate and stable loadingMachine bearings testingAviationFriction torque

The invention discloses a space rolling bearing comprehensive performance experiment device, relates to an experiment device and provides an experiment device capable of accurately measuring axial and redial united loads of a space rolling bearing and basic data including friction moment, bearing temperature rise, vibration and the like under different rotation speed working conditions. The space rolling bearing comprehensive performance experiment device can simultaneously conduct axial force and radial force accurate load on a measured bearing through an axial loading device and a radial loading device. A three-axis acceleration sensor is used for measuring radial, axial and peripheral vibration situations of the measured bearing. A temperature sensor is used for measuring the temperature rise situation of the measured bearing. A pressure sensor is used for measuring the friction moment of the measured bearing. An annular pressure sensor is used for measuring axial force borne by the measured bearing. Weights are used for marking radial force borne by the measured bearing. The space rolling bearing comprehensive performance experiment device can evaluate the comprehensive performance of the space rolling bearing and provide key scientific technical basis and test platform support for development of high-end bearings in the aerospace field of our country.

Owner:SICHUAN UNIV

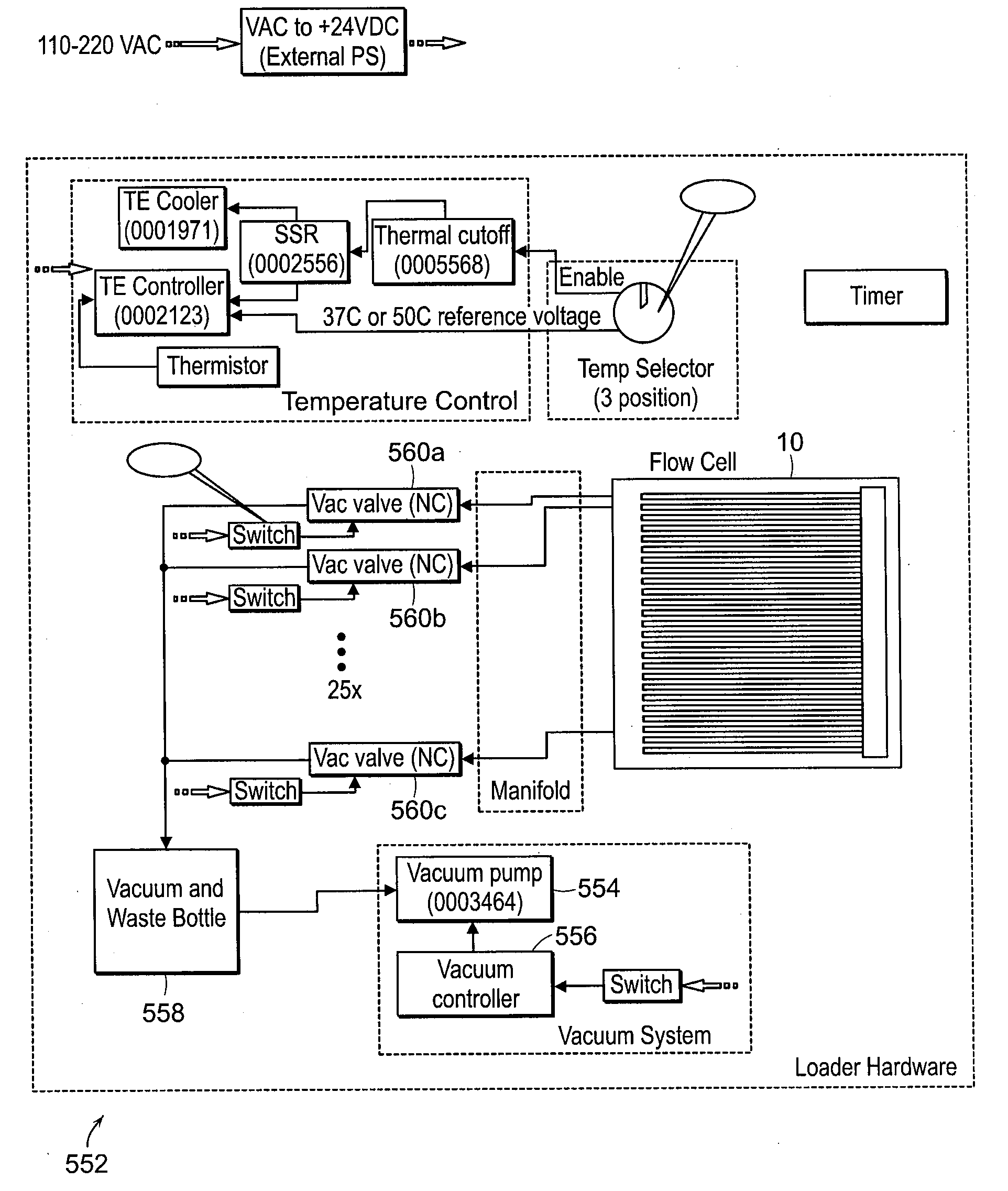

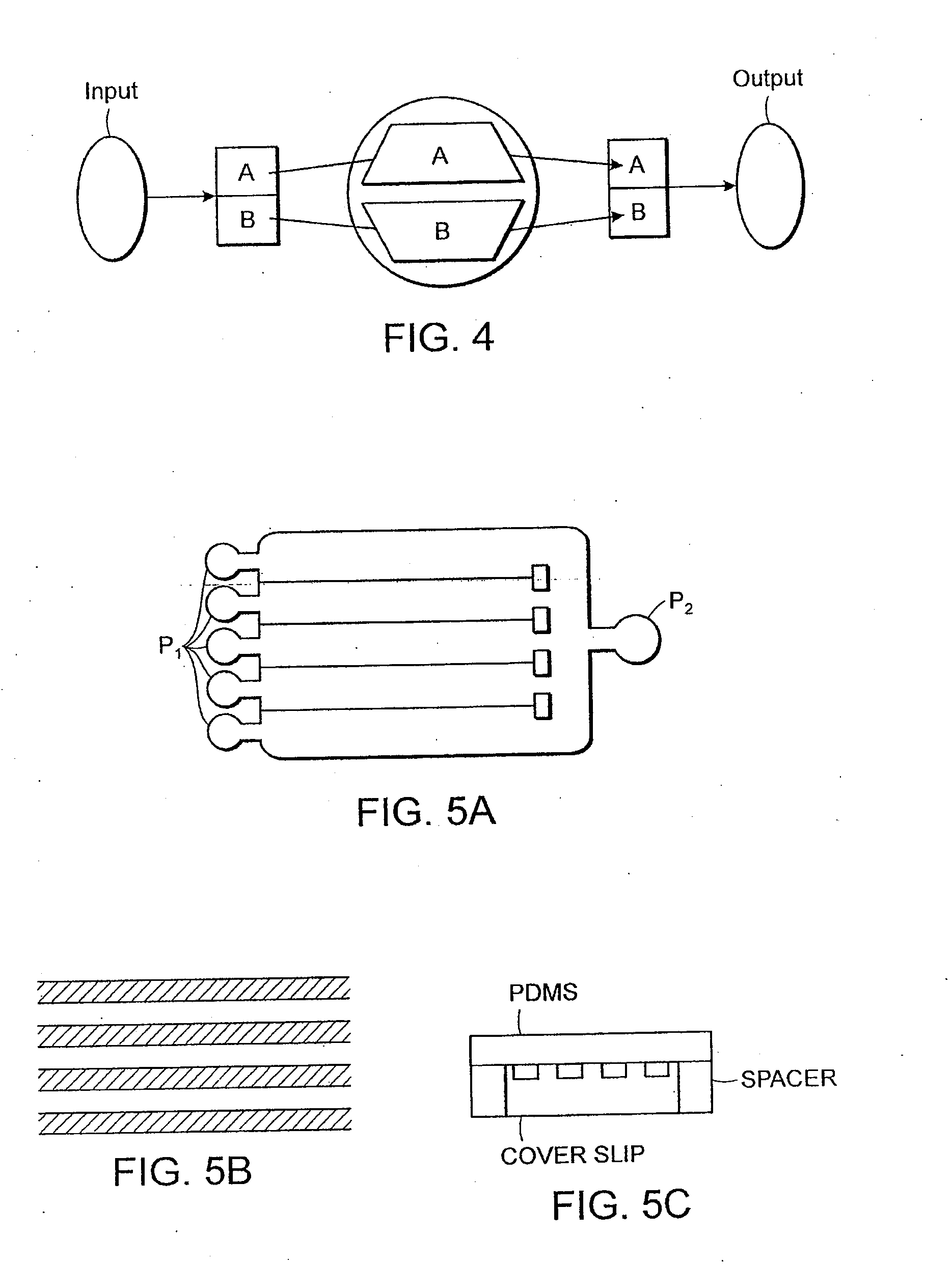

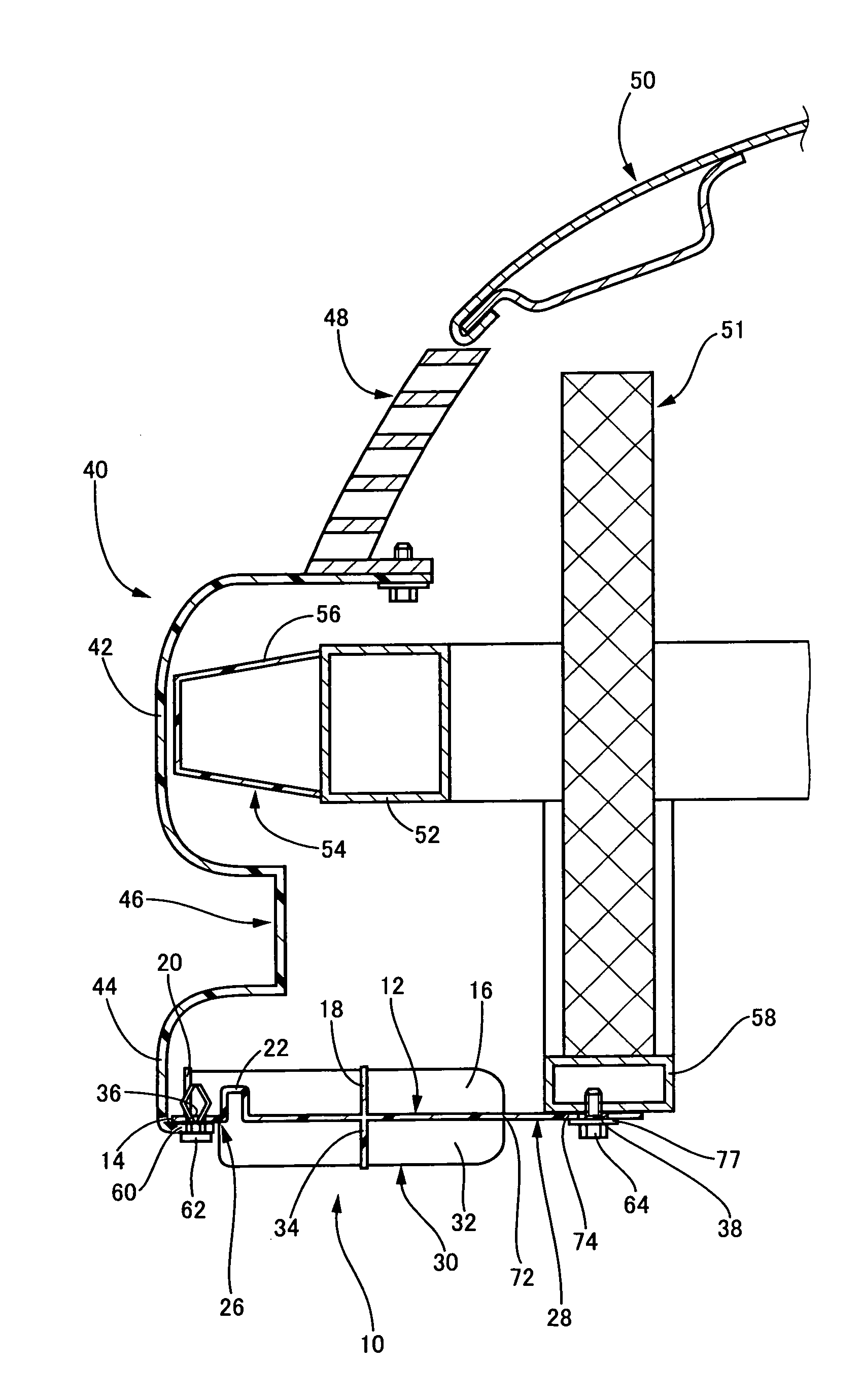

Sample loading and recovery

InactiveUS20080219890A1Avoid pollutionReduce cross contaminationBioreactor/fermenter combinationsBiological substance pretreatmentsFlow cellEngineering

A apparatus and method for loading a sample into a microfluidic flow cell allows for more precise loading, reduced cross-contamination, and more efficient use of samples to be analyzed. The system for loading a sample into a flow cell includes a flow cell defining a plurality of individually isolated channels through which fluid can flow. The flow cell also defines an inlet port and an outlet port for each of the channels. The system also includes a base that defines a chamber for receiving the flow cell, a cover pivotally attached to the base, and a passive vacuum source for pulling a volume through the flow cell. The method of loading a sample includes inserting the flow cell into the sample loading apparatus, placing a sample in at least one of the wells of the loading block, activating a vacuum source fluidly coupled to the outlet ports to pull the sample into the channel, and optionally aspirating the unused sample from the well.

Owner:FLUIDIGM CORP

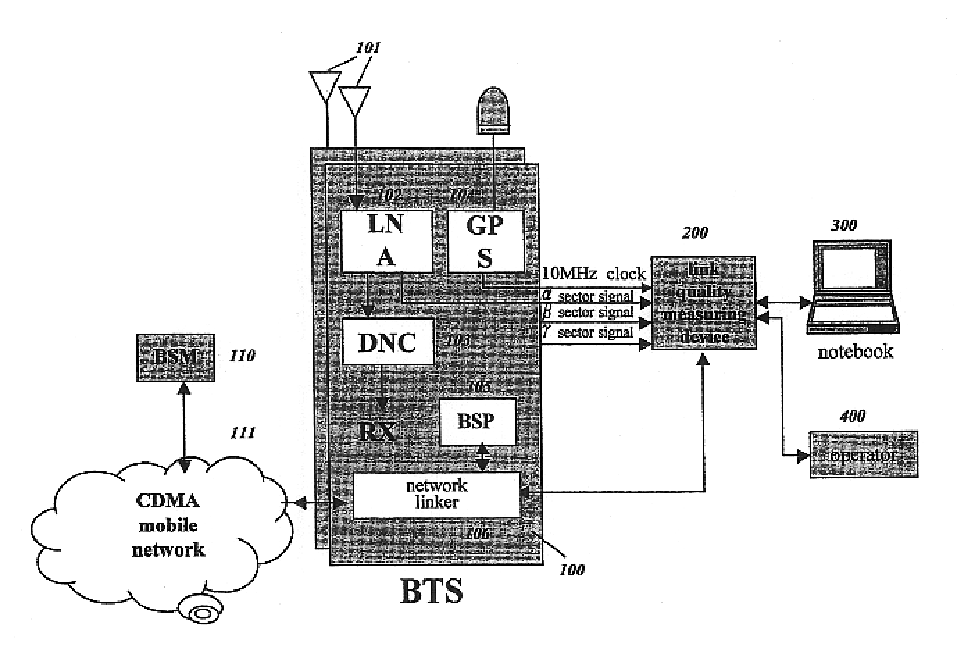

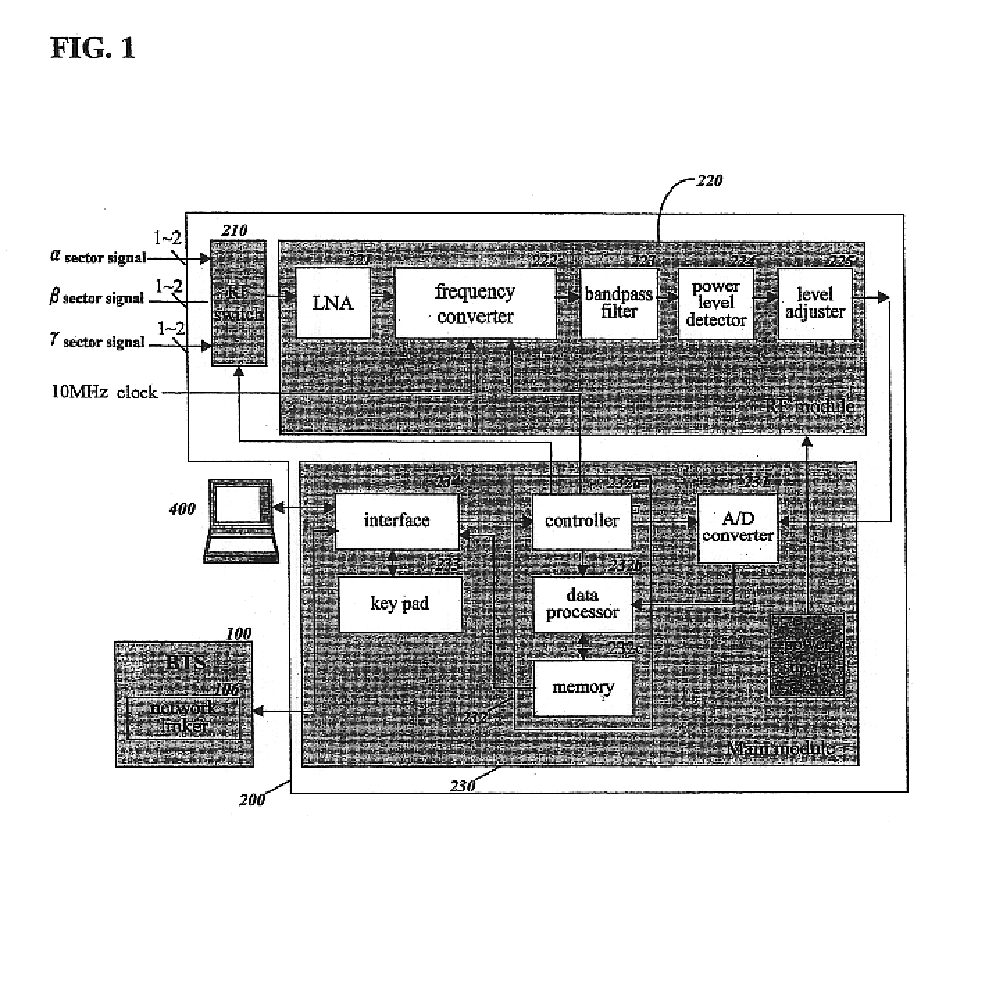

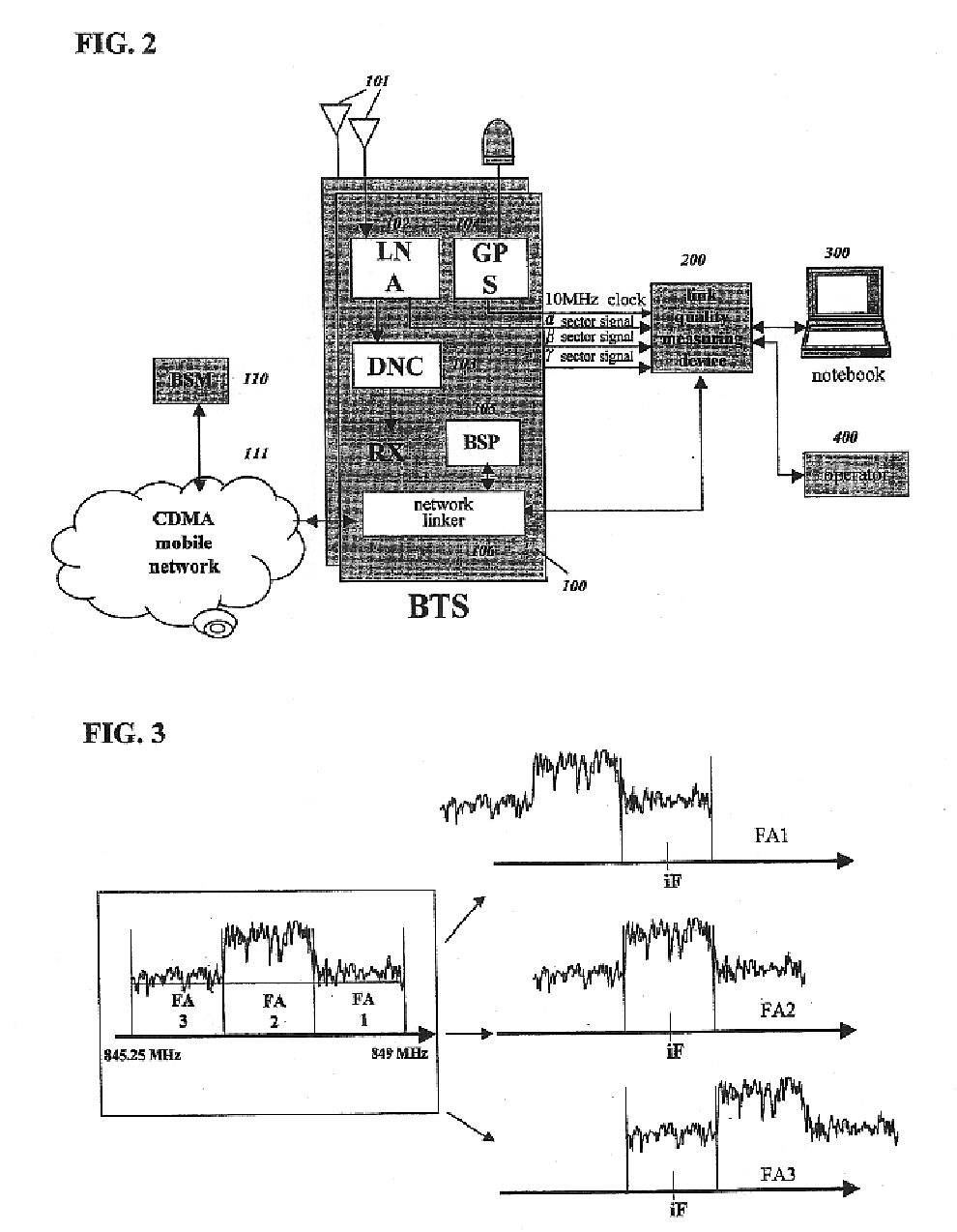

Apparatus and method for measuring quality of a reverse link in a CDMA system

InactiveUS6760567B1Load accuratelyAccurate qualityReceivers monitoringError preventionNormal densityMobile station

An apparatus and method for measuring the quality of a reverse link and the load of a base station (BTS) in a CDMA mobile telecommunication system. The apparatus and method periodically detect the power of a receiving signal from a mobile station to a BTS, constructs a practical statistical distribution curve for a power ratio of signal to interference, compares the practical distribution curve with the theoretical distribution curve pre-constructed based upon the parameter condition of a BTS, and determines the quality of a reverse link based upon the difference between the distribution curves. The link-quality measuring device has a power detecting unit for detecting the power of signals received by a BTS; a converter for digitizing the detected power; a controlling unit constructing a PDF (Probability Density Function) and / or a CDF (Cumulative Distribution Function) for a ratio of a received power to a background noise power using the digitized data, comparing the constructed function with the theoretical PDF and / or CDF for the ratio which is pre-calculated based upon various values of input parameters, and acquiring the traffic load according to the compared result; and data entering unit for receiving the values for the input parameters provided from an operator or an external device.

Owner:SK TELECOM CO LTD

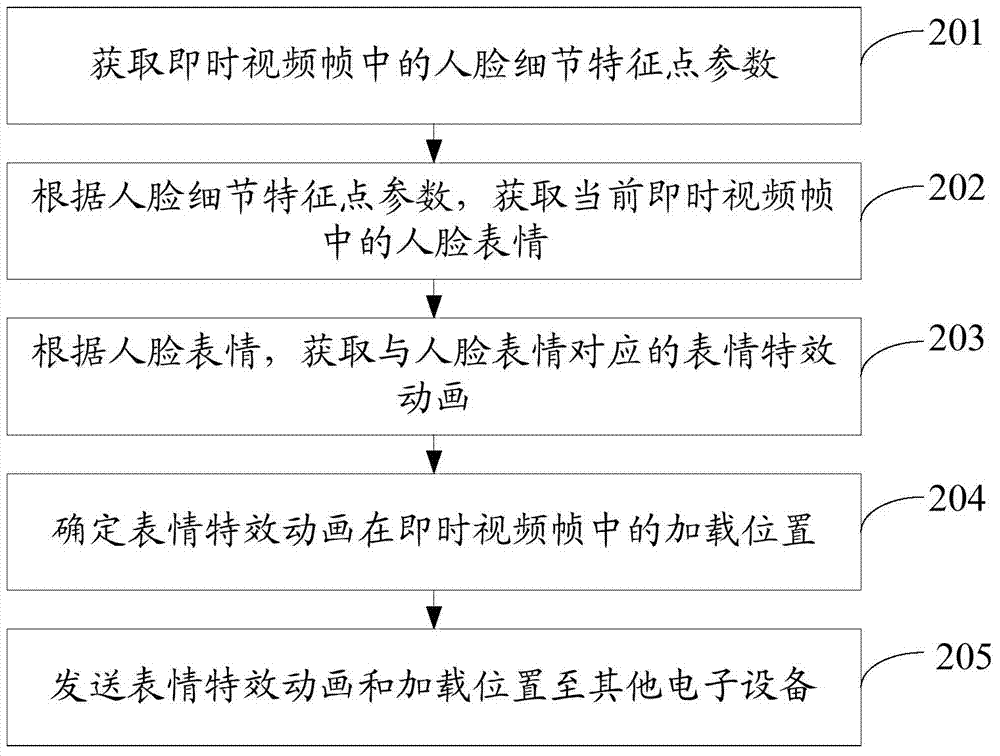

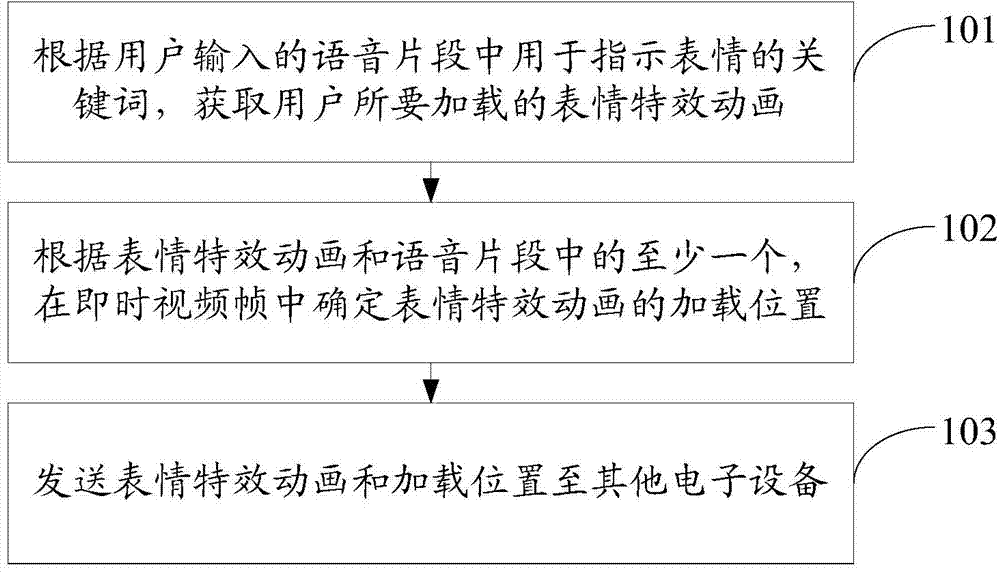

Method and electronic equipment for loading expression effect animation in instant video

InactiveCN104780338ALoad accuratelyMeet the needs of interactionTwo-way working systemsAnimationPersonalizationAnimation

The invention discloses a method and electronic equipment for loading expression effect animation in an instant video, and belongs to the field of videos. The method comprises the following steps: according to key words for indicating expressions in video clips input by a user, obtaining the expression effect animation which is needed to be loaded by the user; according to at least one of the expression effect animation and the video clips, determining the loading position of the expression effect animation in the instant video; sending the expression effect animation and the loaded position to other electric equipment; therefore, the individualized requirements of the user on instant video conversation are satisfied, the interaction form of the video is increased, and the user experience is improved.

Owner:CHATGAME

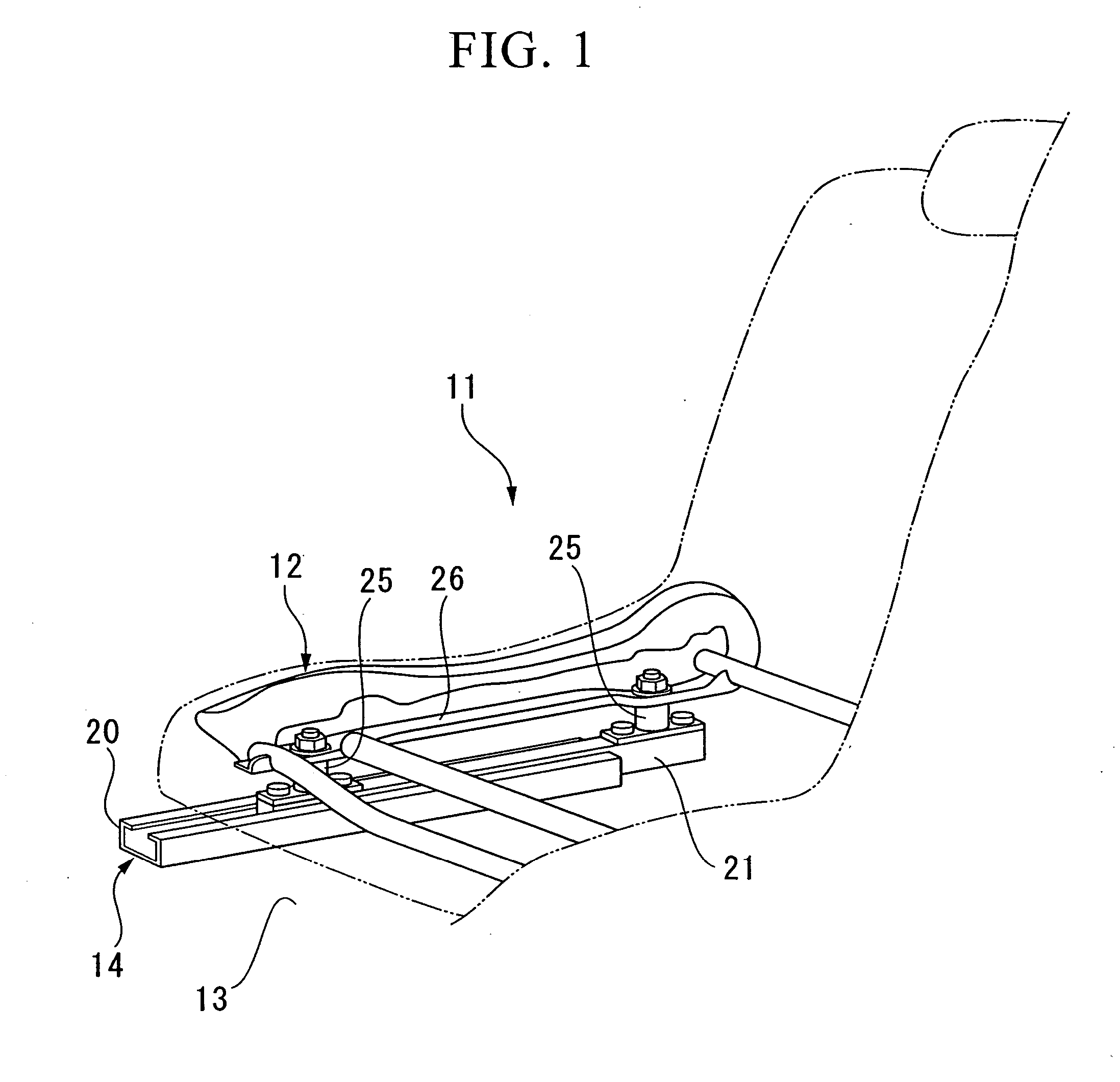

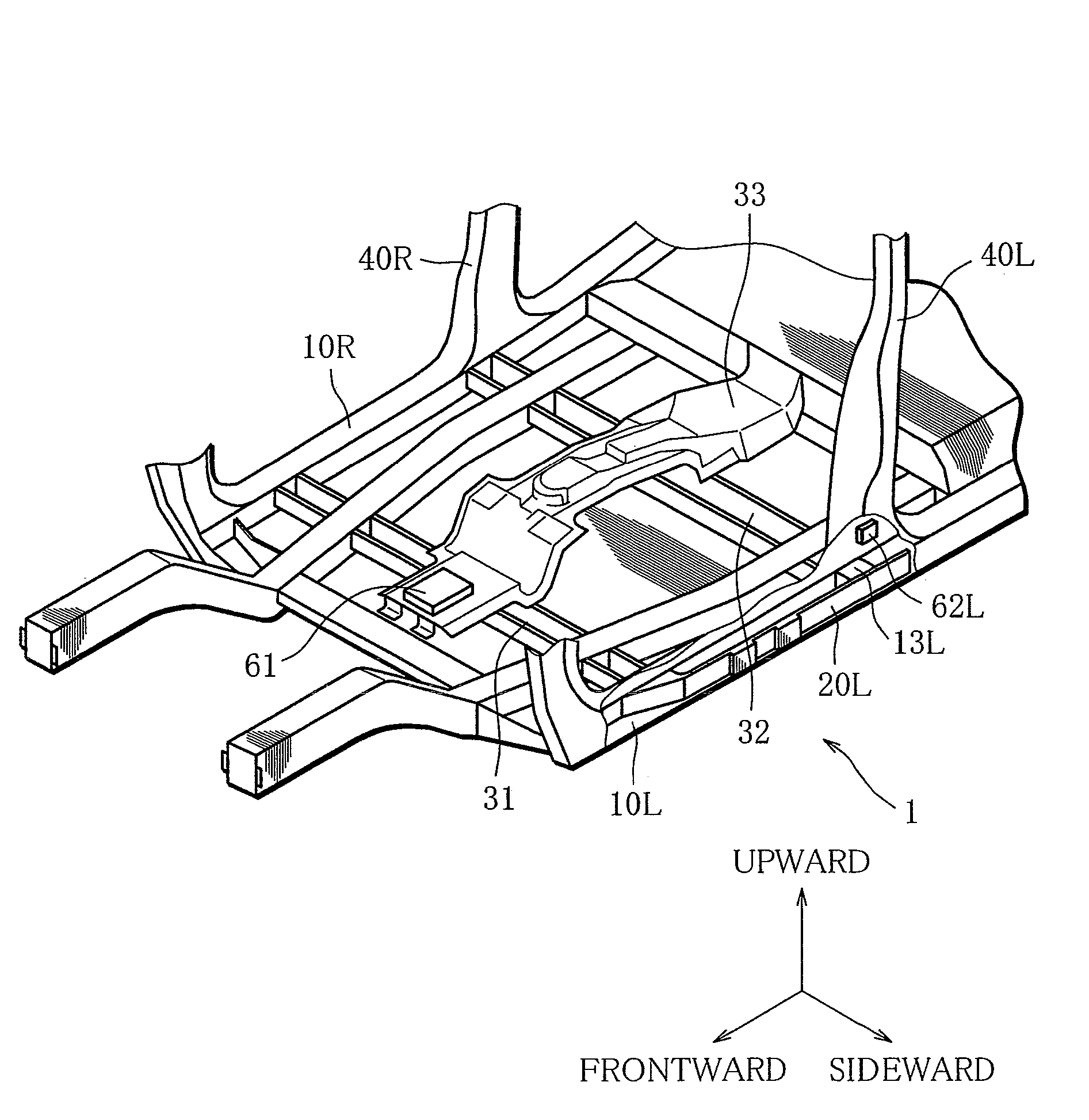

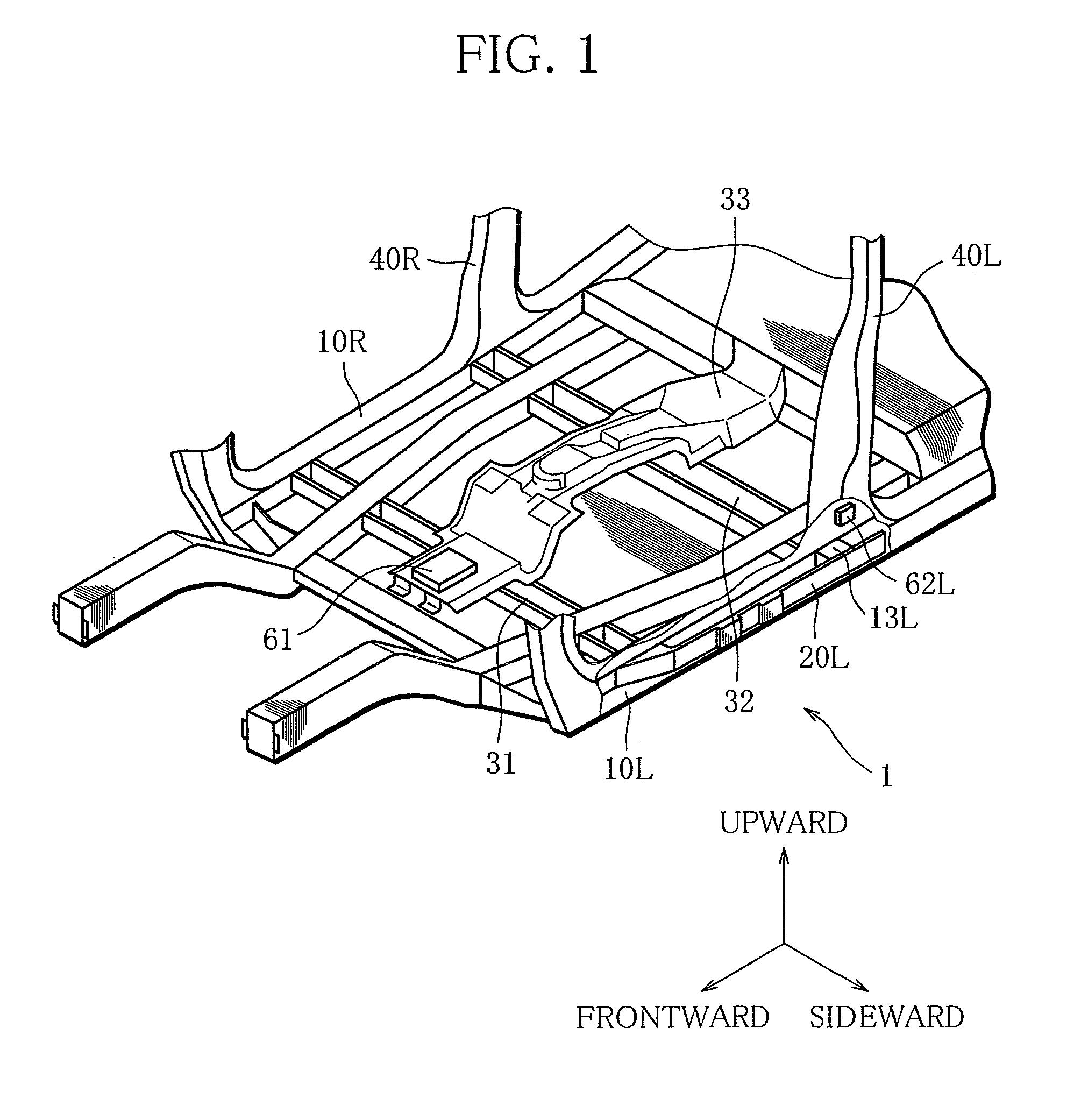

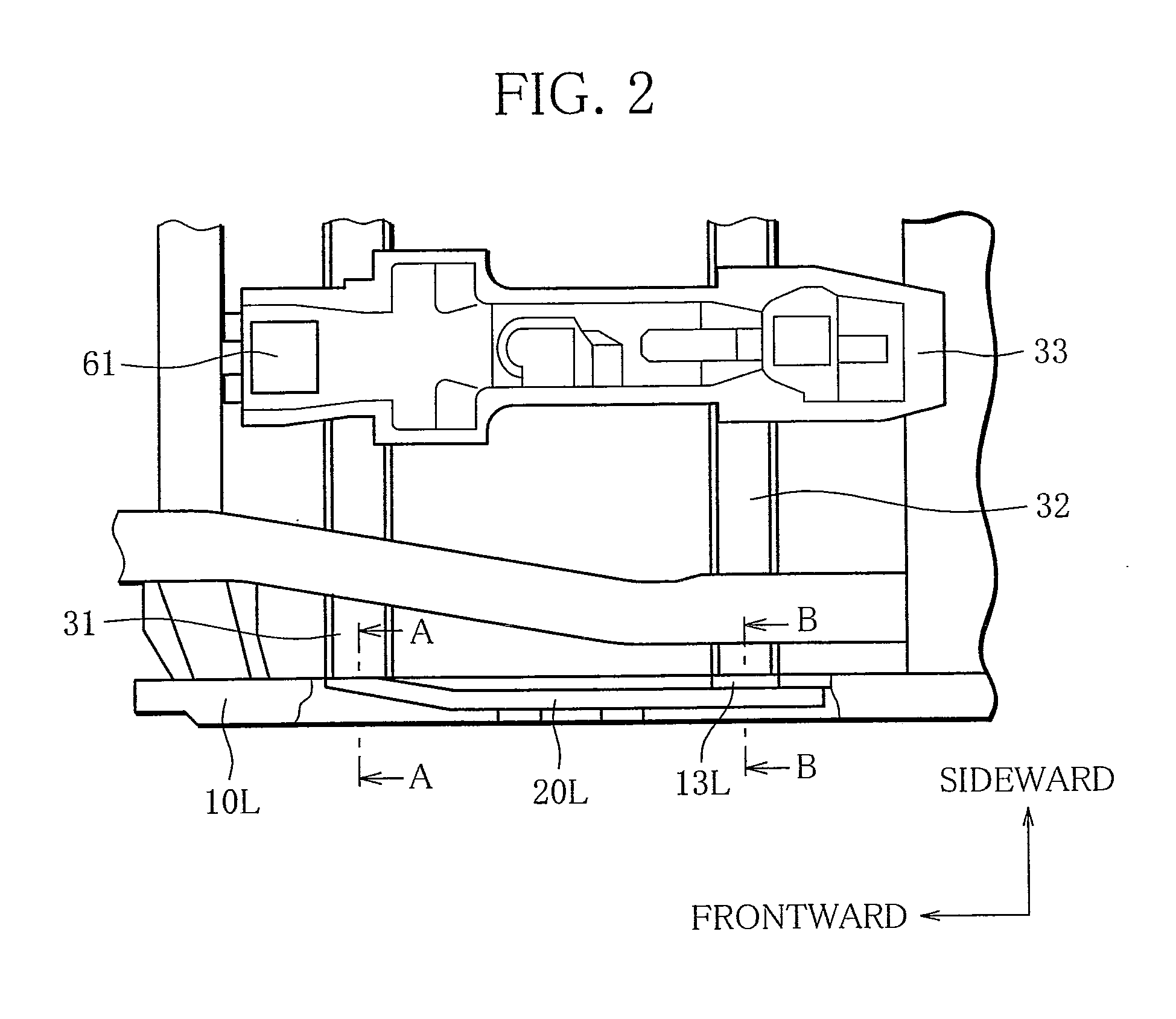

Vehicle impact detection system

ActiveUS20100231002A1Accurately transmitting loadLoad accuratelyVehicle seatsUnderstructuresVehicle detectionMechanical engineering

A side sill beam having a shape of an arch concave outwards in a vehicle-width direction is placed in a side sill, and includes first and second ends welded to joining areas with front and rear floor cross members, respectively. A first impact detection element that detects an impact from the outside in the vehicle-width direction is disposed near the joining areas of the side sill and the front or rear floor cross member, and a second impact detection element that detects an impact from the outside in the vehicle-width direction is disposed offset from the first impact detection element in a vehicle front-rear direction as viewed in the vehicle-width direction.

Owner:MITSUBISHI MOTORS CORP

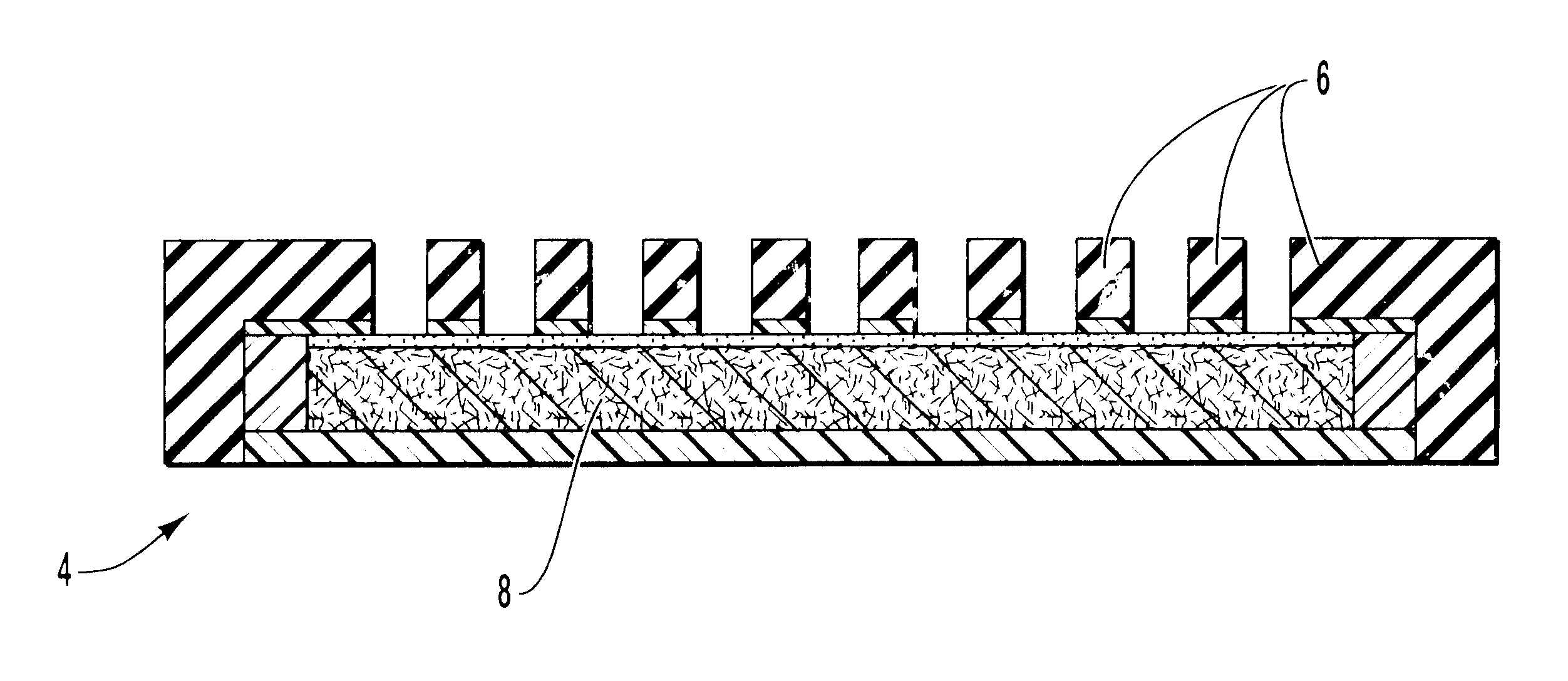

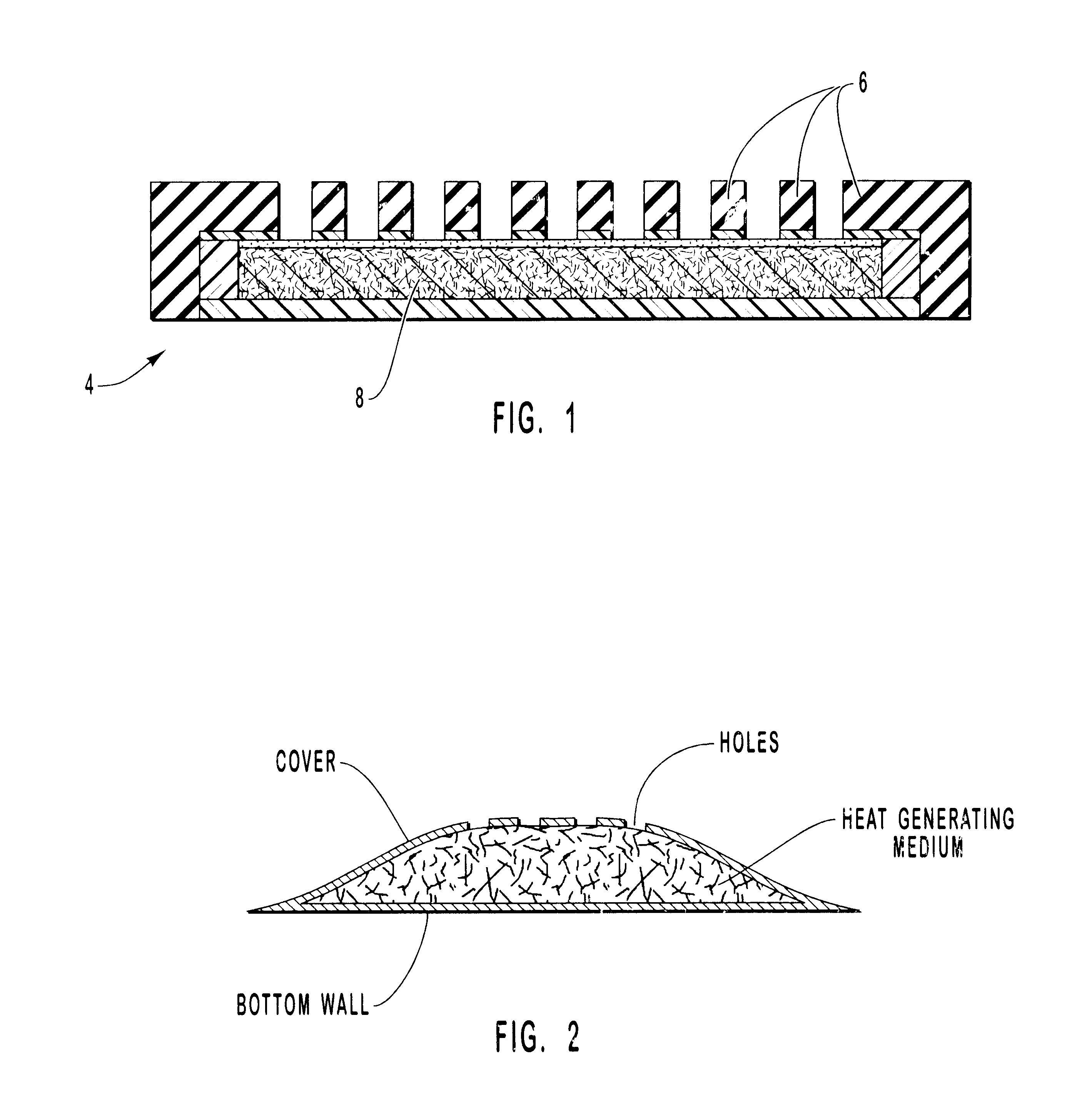

Method for manufacturing a heat generating apparatus

InactiveUS6453648B1Even heat distributionPrevent oxidationSolid materialLiquid materialActivated carbonEngineering

Owner:NUVO RES

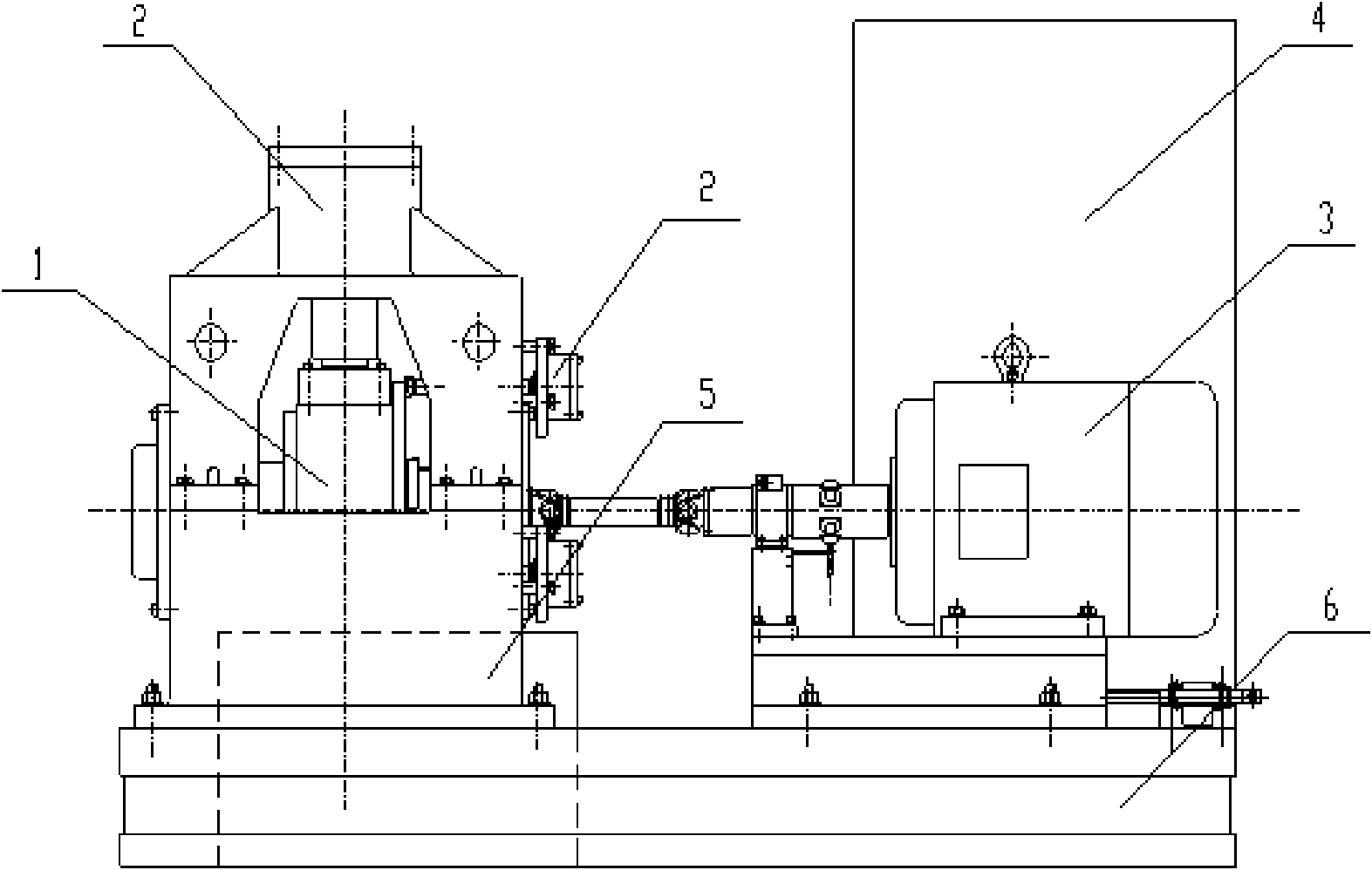

Large bearing testing machine

InactiveCN101660970ALoad accuratelyImprove structural rigidityMachine bearings testingWork measurementProper timeTest procedures

The invention belongs to the technical field of bearing tests, in particular to a large bearing testing machine. The large bearing test machine is characterized by consisting of a test unit, a loadingunit, a drive unit, a control unit, a hydraulic power unit and a workbench. The loading unit, the drive unit and the control unit are arranged on the workbench, the test unit is arranged on the loading unit, the hydraulic power unit is arranged behind the workbench and connected with the loading unit, the control unit is matched with the test unit, the loading unit, the drive unit, and the hydraulic power unit respectively. The test unit is used for receiving a large bearing for test, the loading unit applies radial load, axial load and capsizing moment to the test bearing, the drive unit drives the test bearing to rotate at a specified rotation speed and torque, and the control unit controls electrical operation and protection, monitors test operation, analyzes test procedures and results, and give feedbacks at proper time.

Owner:汇洲智能技术集团股份有限公司

Pedestrian protection apparatus, and method of tuning load characteristic of the apparatus

ActiveUS7597383B2Increase impactLoad accuratelyVehicle seatsDeflectorsEngineeringMechanical engineering

In a pedestrian protection apparatus installed in a lower part of a front of a vehicle, a plate extends in a longitudinal direction of the vehicle, and includes a front section having at least a portion protruding from the front of the vehicle, a rear section fixed to the vehicle, and a center section provided between the front and rear sections. The front section is more rigid than the rear section, and the center section is less rigid than the front section and more rigid than the rear section.

Owner:KOJIMA PRESS IND CO LTD

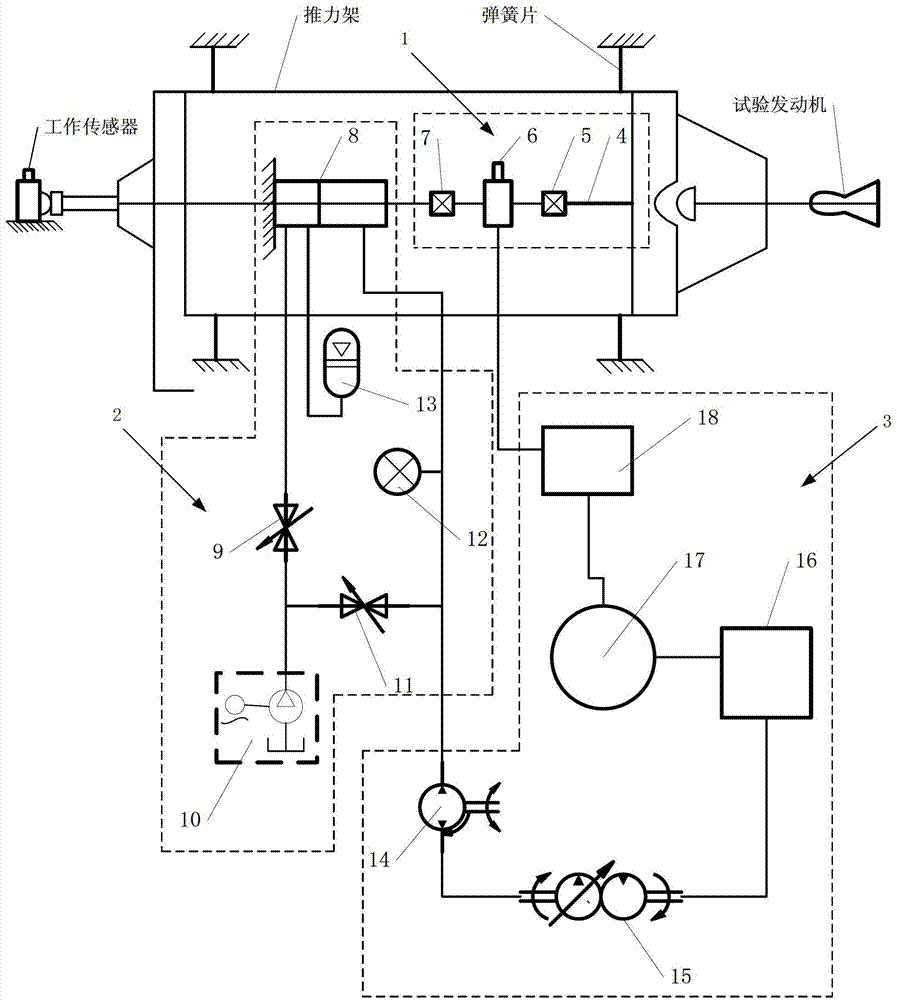

Thrust rack in-situ calibration system

InactiveCN102818676AImprove calibration accuracyHigh calibration stabilityEngine testingForce/torque/work measurement apparatus calibration/testingElectricityHydraulic cylinder

The invention discloses a thrust rack in-situ calibration system, which comprises a standard sensor assembly, a hydraulic system and a loading and unloading control system, wherein the standard sensor assembly comprises a sensor pull rod, a front universal flexible element, a standard sensor and a back universal flexible element, the hydraulic system comprises a hydraulic cylinder, a press cavity oil filling valve, a hand lifting pump, a pulling cavity oil filling valve, an electric joint pressure meter and a pressure cavity energy accumulator, the loading and unloading control system comprises a self control pump, a wide frequency servo motor, a pulse automatic tracking system, a computer and a collecting card, the in-situ thrust calibration system controls the work of the self control pump through the pulse automatic tracking system and the wide frequency servo motor, in addition, measurement signals of the standard sensor are fed back to the computer, the computer transmits the pulse signals to the pulse automatic tracking system through software operation, the automatic loading and unloading on the standard sensor by the hydraulic cylinder is realized, in addition, the necessary time can be stabilized, the loading stability can reach 0.004 percent F.S per 30 minutes (or longer time).

Owner:BEIHANG UNIV

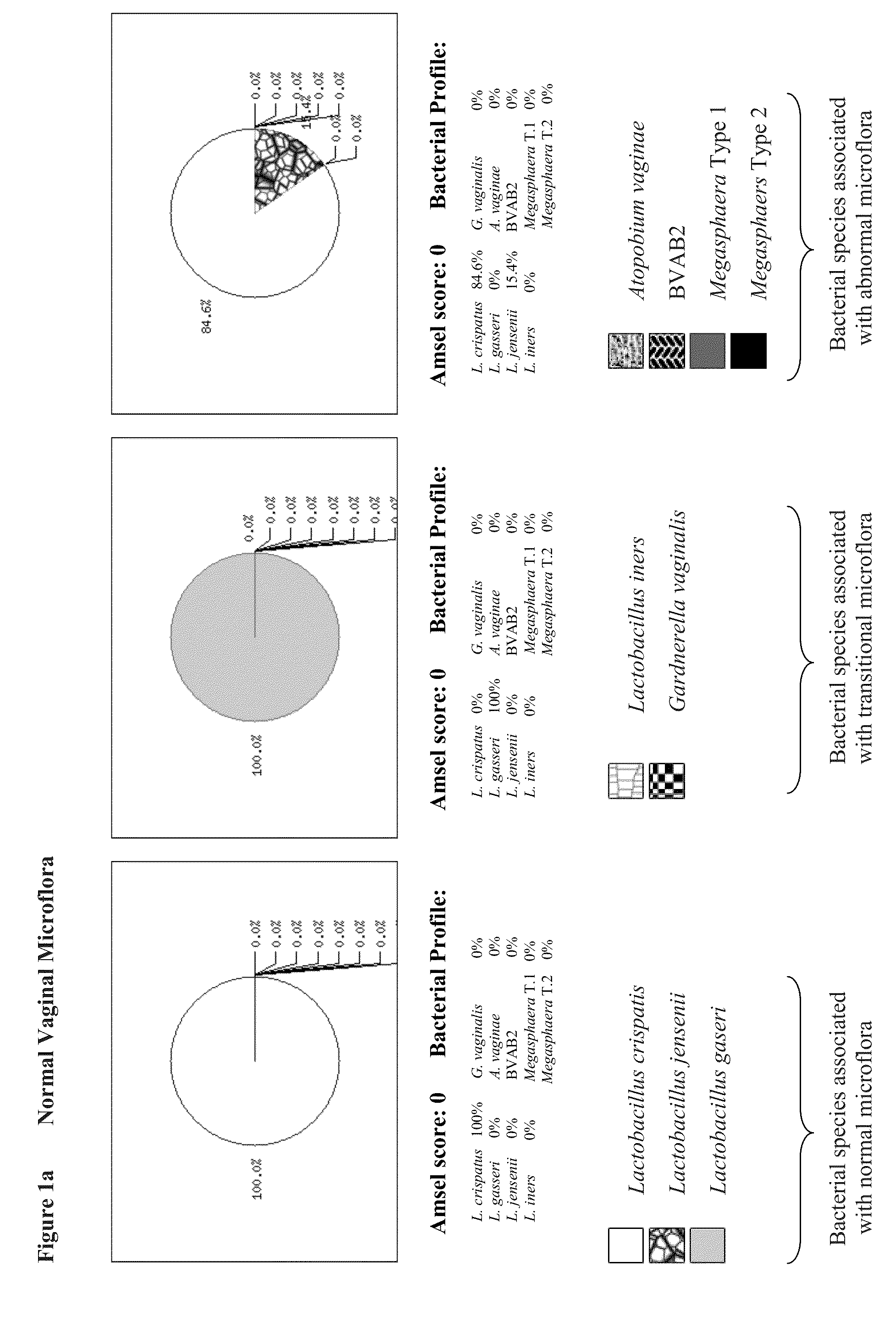

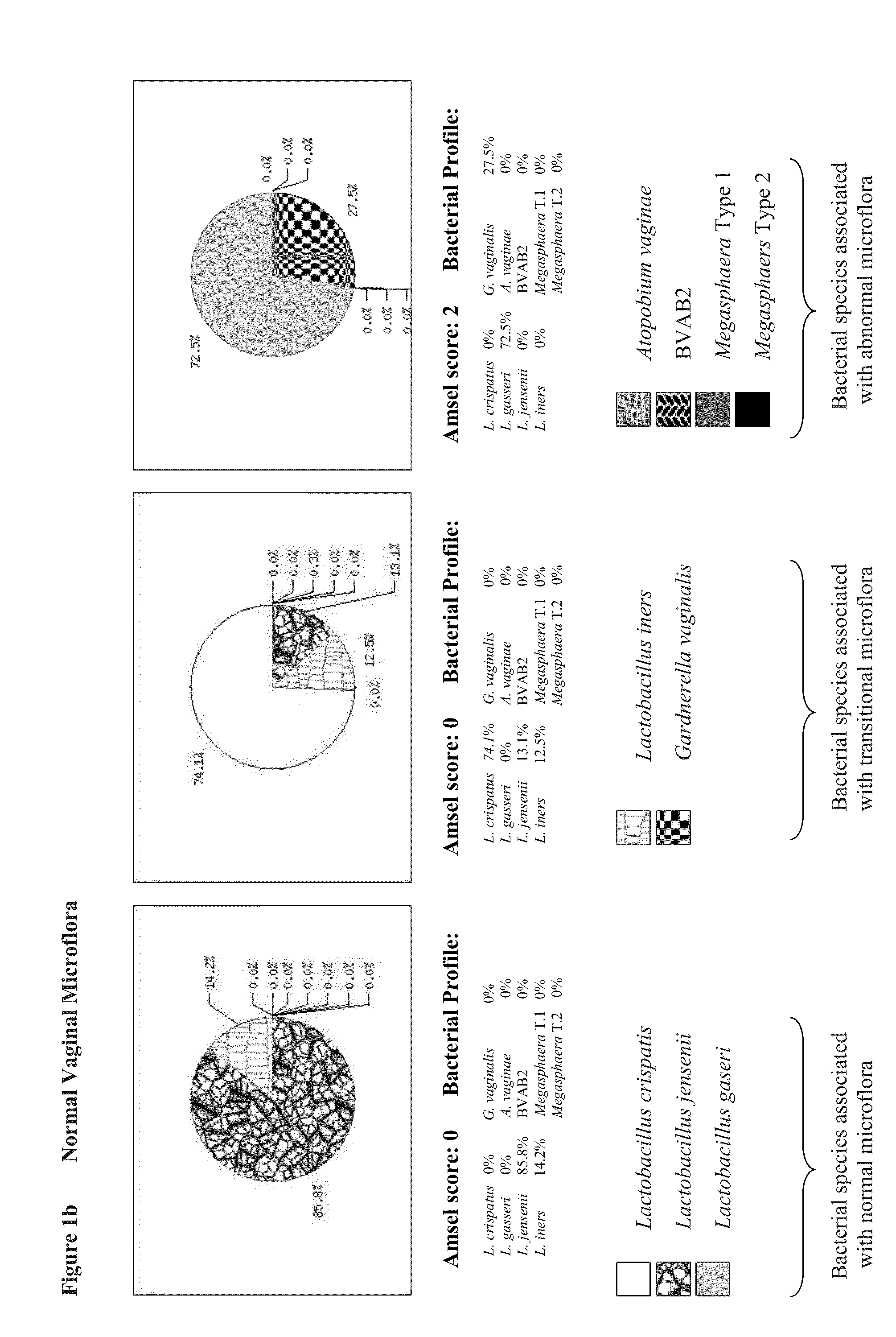

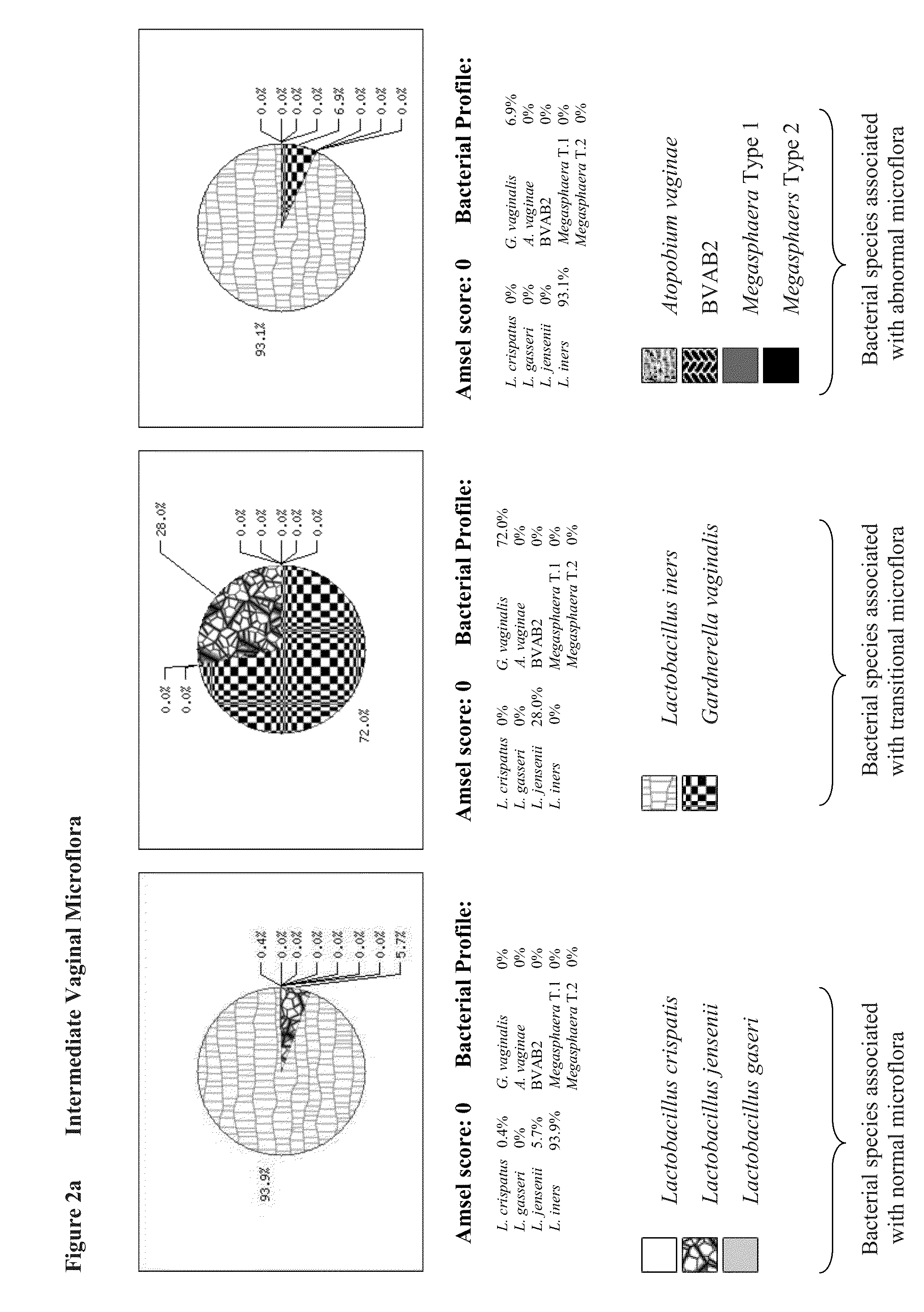

Quantitation and profiling of vaginal microflora

InactiveUS20130316922A1High cytokine levelReduces bacterial vaginosis recurrenceNucleotide librariesMicrobiological testing/measurementQuantitative assessmentGardnerella vaginalis DNA

Disclosed are methods of quantifying microflora in vaginal samples. Quantitative assessment of vaginal microflora by real-time PCR to create a profiling of Lactobacillus species, Gardnerella vaginalis, Atopobium vaginae, Megasphaera Type 1 and Type 2 and BVAB2 permits evaluation of bacterial vaginosis. Kits containing reagents for quantitative assessment of microflora are also disclosed.

Owner:MEDICAL DIAGNOSTIC LAB

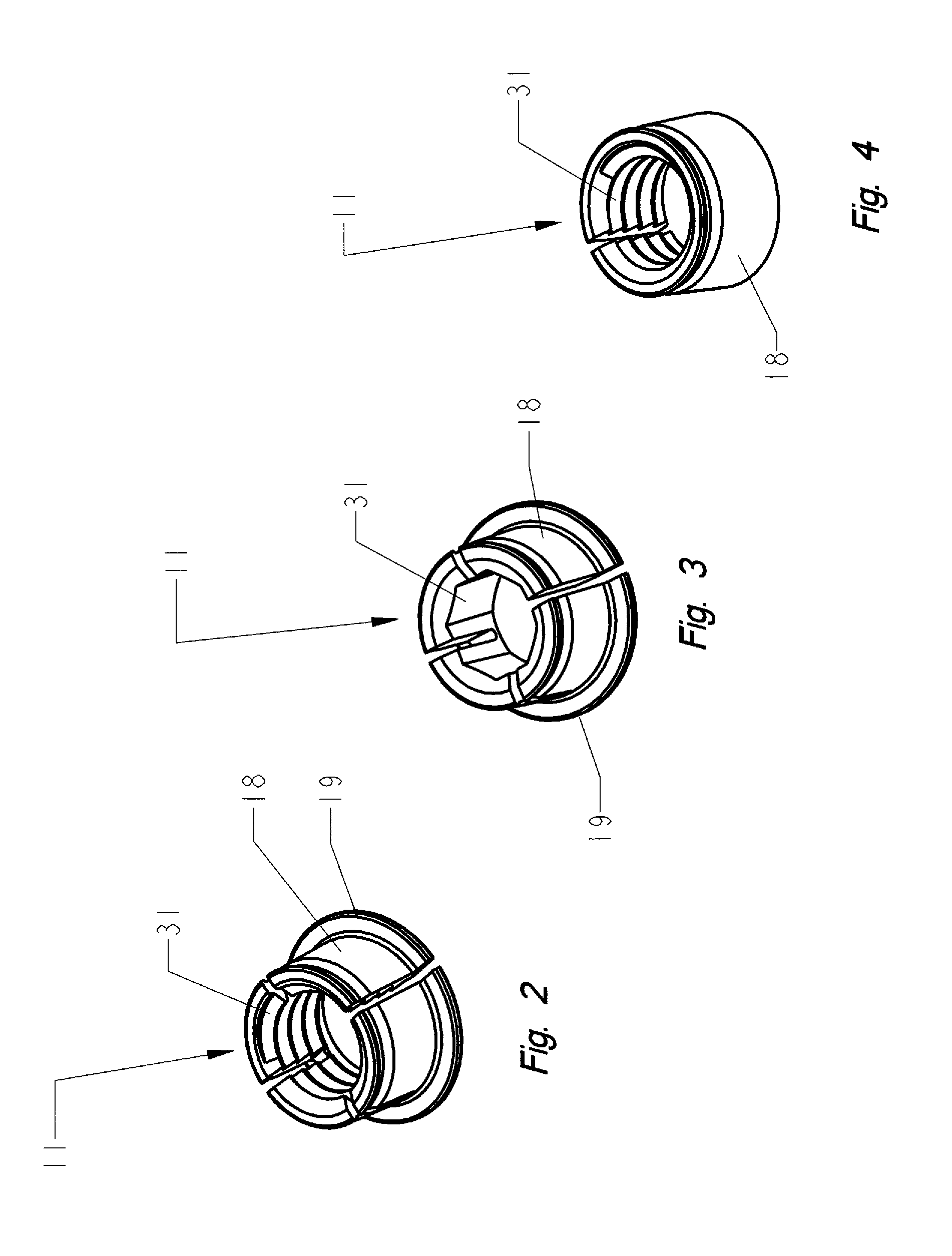

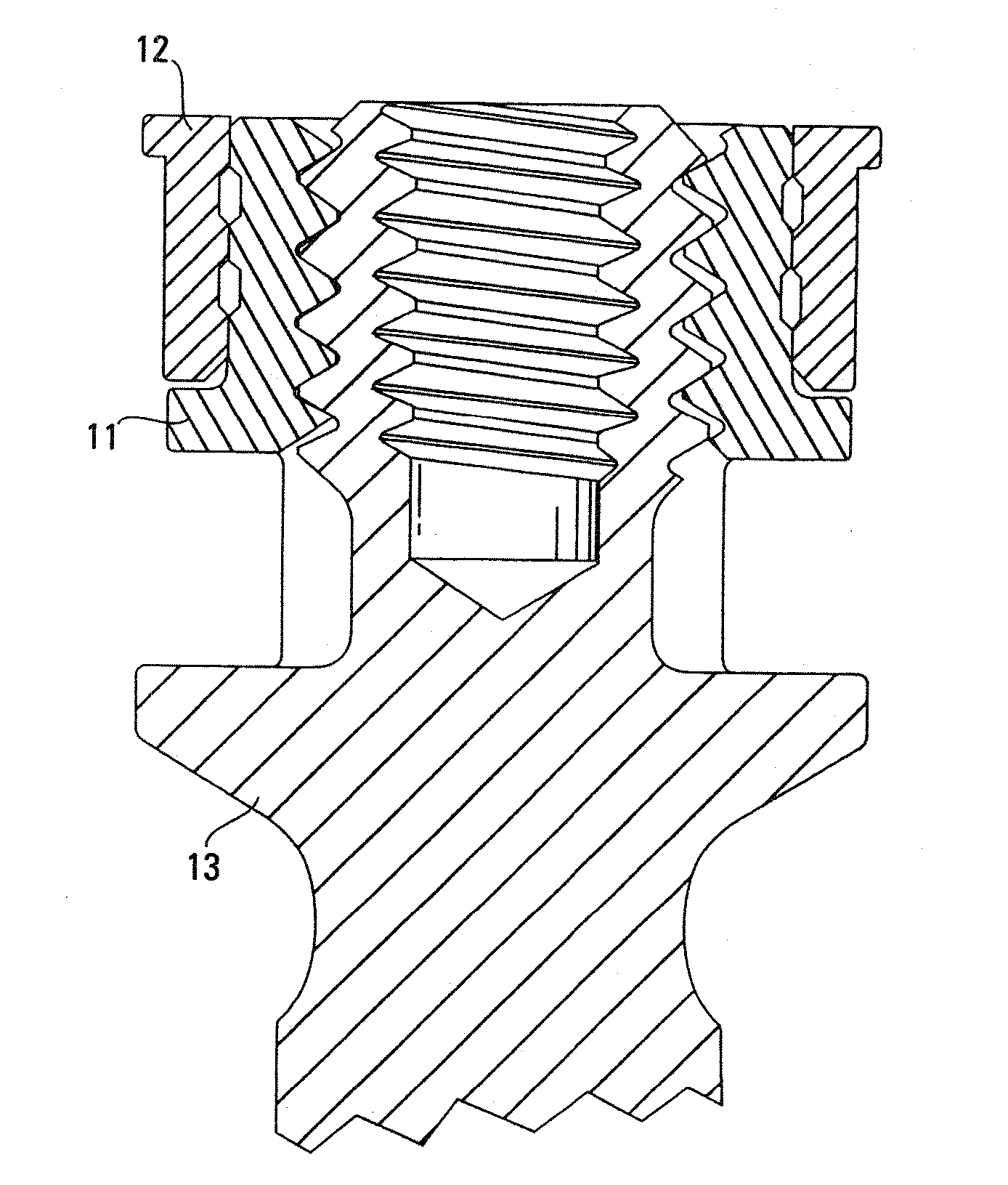

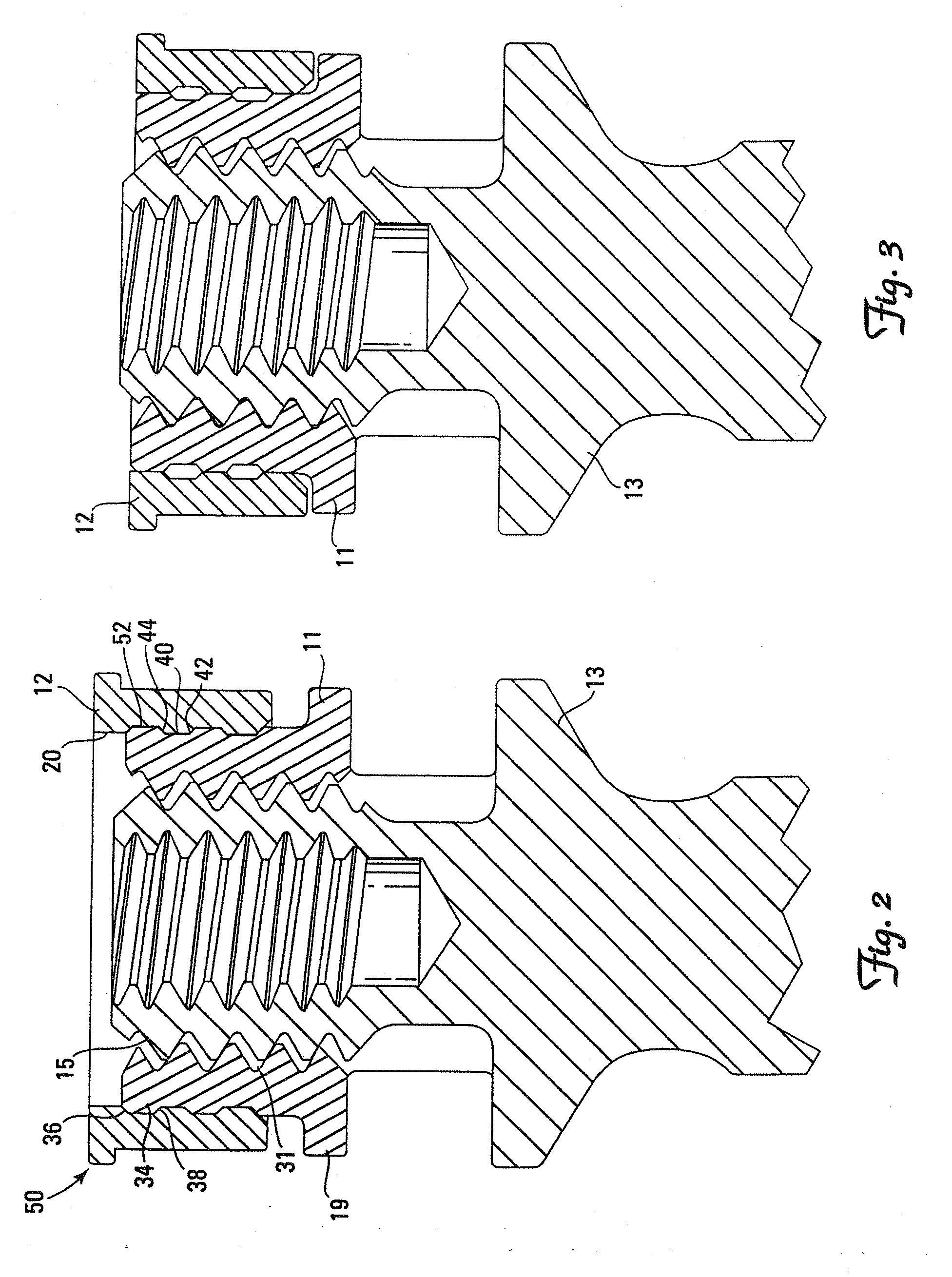

Linear fastener system and method for use

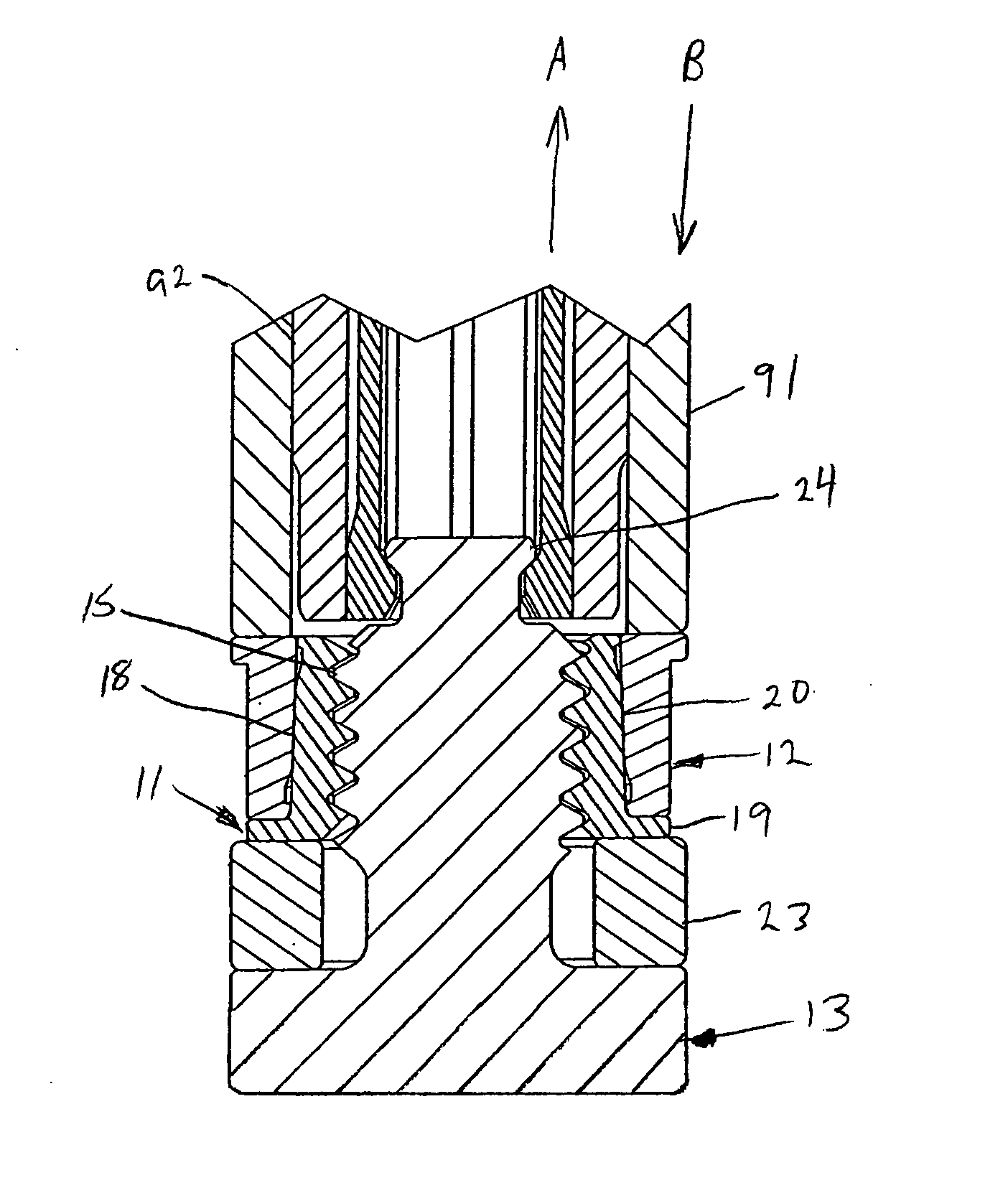

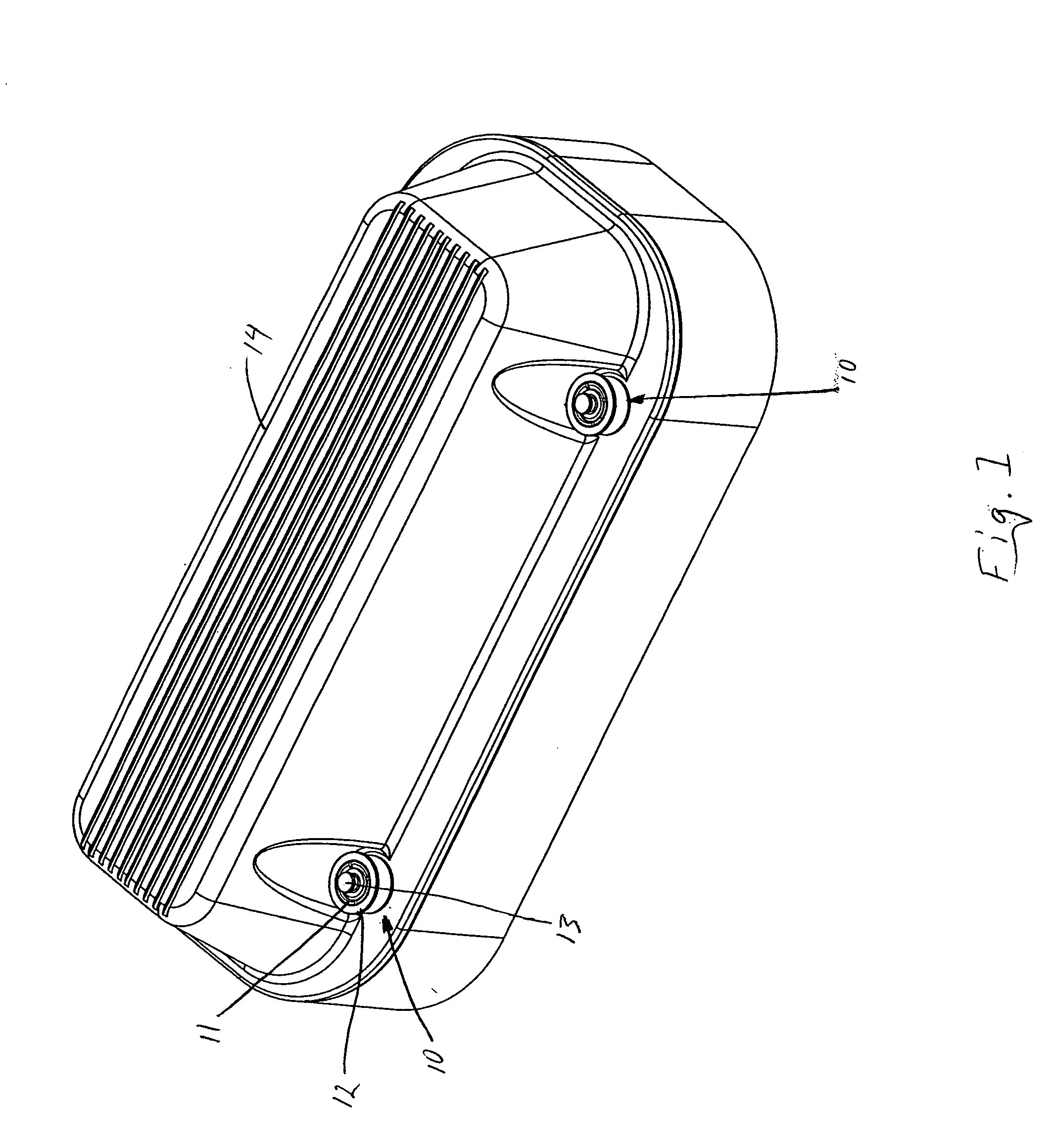

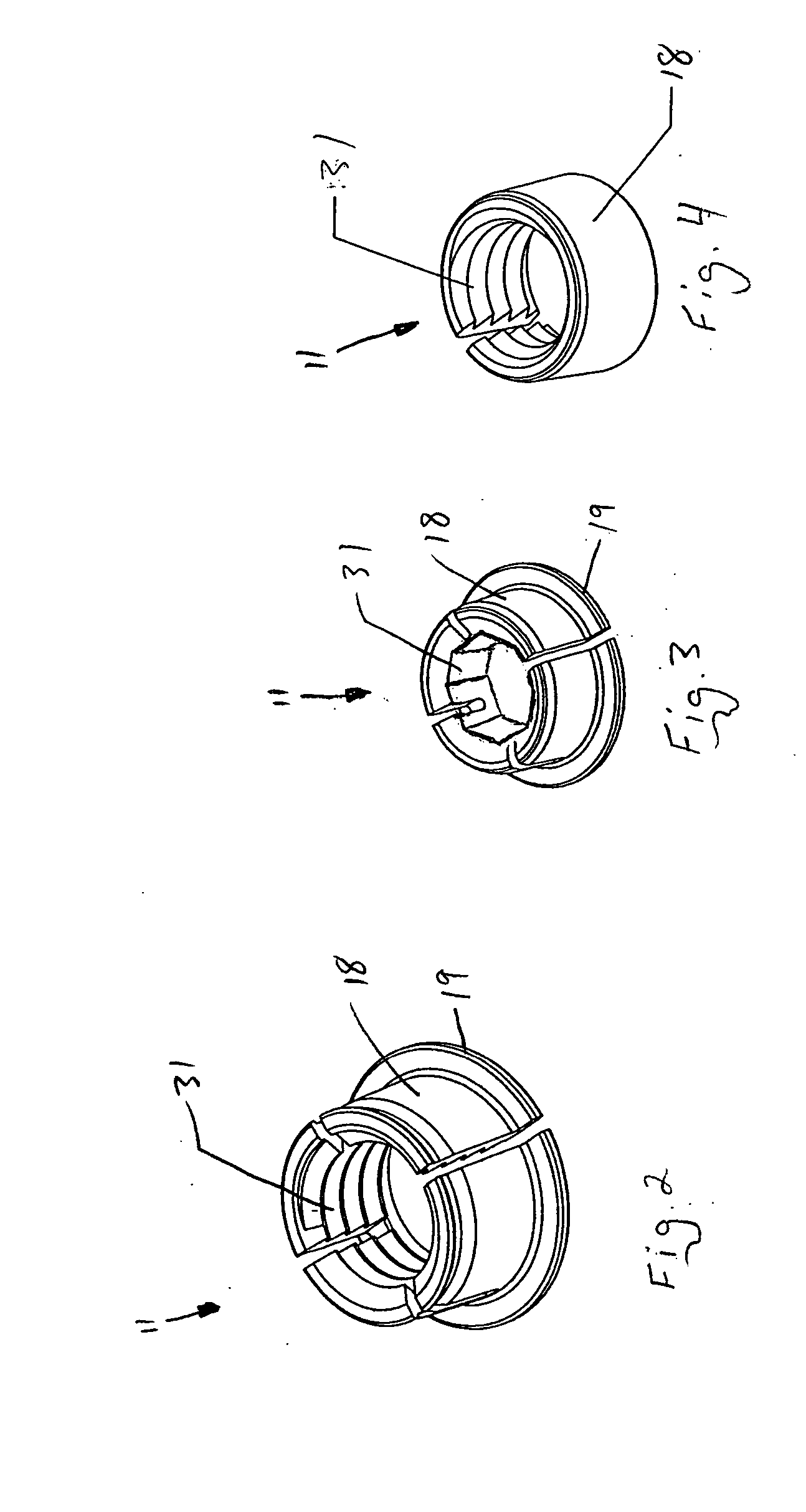

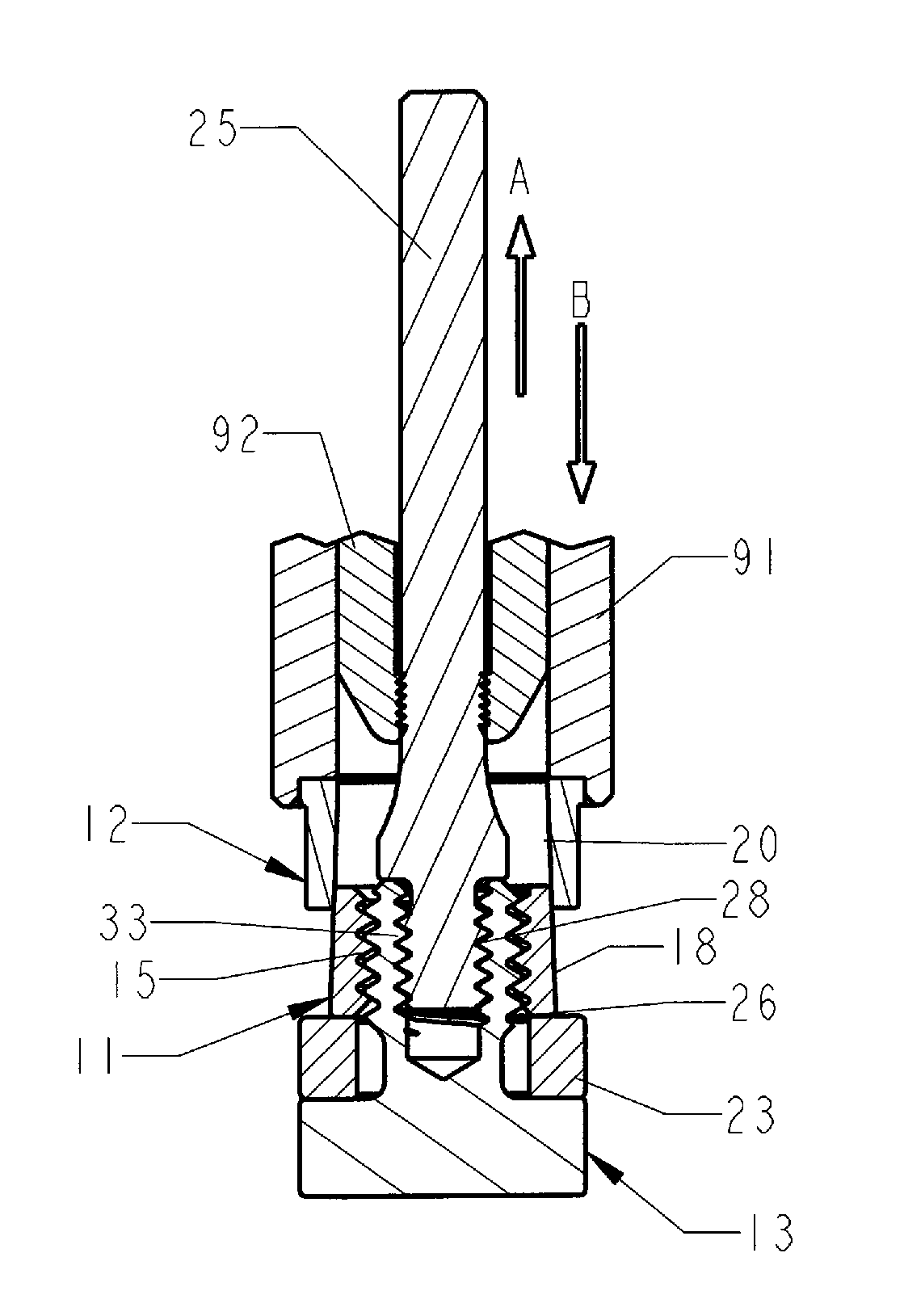

ActiveUS20050053423A1Rapid linear engagementFor quick disengagementSuture equipmentsNutsCompression memberBiomedical engineering

The present invention provides a linear fastening system capable of rapid engagement and disengagement. More specifically, the system utilizes a cooperating collet member and a compression ring member which are constructed and arranged to slip easily over a shank member. The fastener system is secured by sliding a compression member in a linear overlapping fashion over the collet member thereby utilizing the conical surfaces to compress the collet member to grip the outer surface of the shank member. In this manner, the linear fastener system is capable of providing a secure connection between multiple components without the need to apply rotational torque to the assembly.

Owner:SPINAL

Linear fastener system and method for use

InactiveUS7981143B2Rapid linear engagement and disengagementLoad accuratelySuture equipmentsNutsCompression memberBiomedical engineering

The present invention provides a linear fastening system capable of rapid engagement and disengagement. More specifically, the system utilizes a cooperating collet member and a compression ring member which are constructed and arranged to slip easily over a shank member. The fastener system is secured by sliding a compression member in a linear overlapping fashion over the collet member thereby utilizing the conical surfaces to compress the collet member to grip the outer surface of the shank member. In this manner, the linear fastener system is capable of providing a secure connection between multiple components without the need to apply rotational torque to the assembly.

Owner:SPINAL

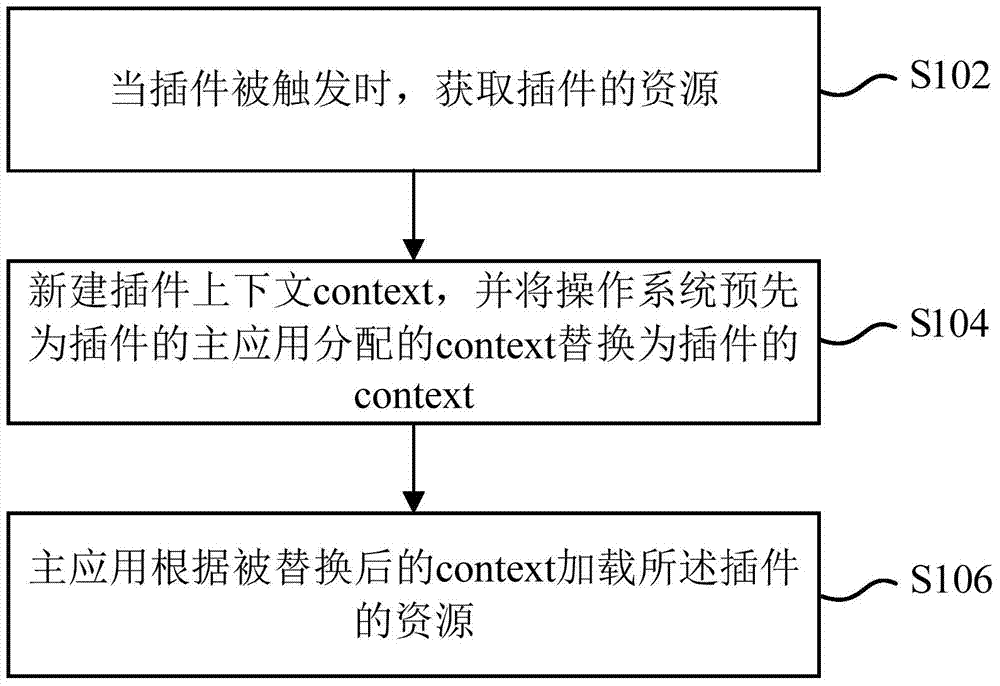

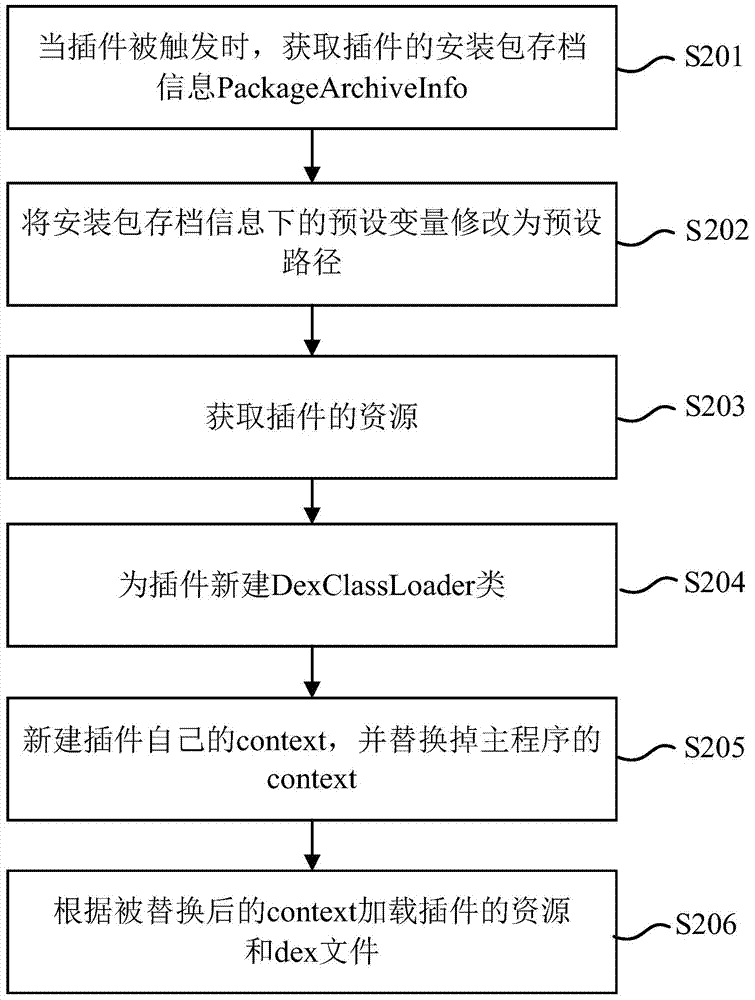

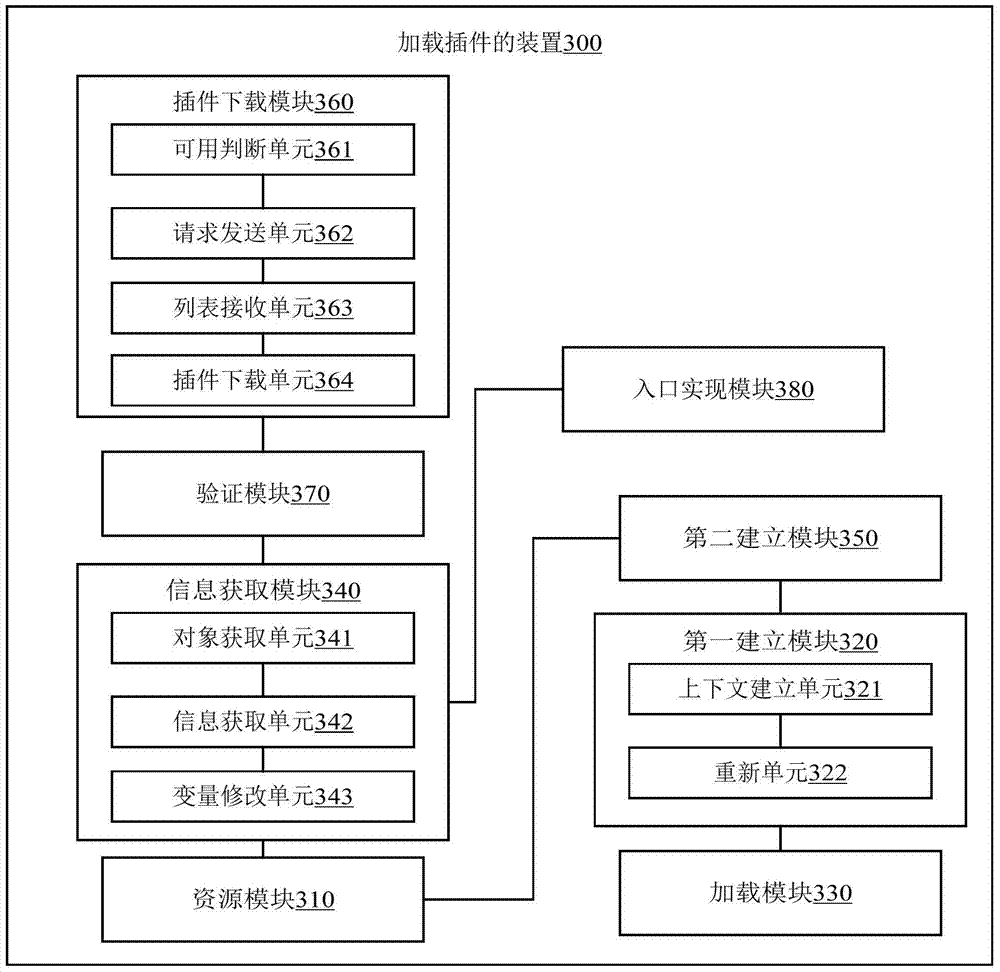

Method, device and mobile terminal for loading plugin

ActiveCN104731625ALoad accuratelySolve the problem that the resources of the plugin cannot be loadedProgram loading/initiatingDatabase

The invention provides a method, device and mobile terminal for loading a plugin and relates to the field of computers. The embodiment of the method comprises the steps that when the plugin is triggered, the resources of the plugin are obtained, the context of the plugin is created, the context which is allocated to a main application of the plugin by an operation system is replaced with the context of the plugin, and according to the replaced context, the resources of the plugin are loaded. By means of the method, the problem that under an Android original system, the resources of the plugin can not be loaded due to the fact that the context of the plugin can not be obtained, the method has no effect on other objects generated by the system, the compatibility problem does not occur, and even if evolvement happens to the system, the plugin can still be loaded correctly.

Owner:BEIJING QIHOO TECH CO LTD

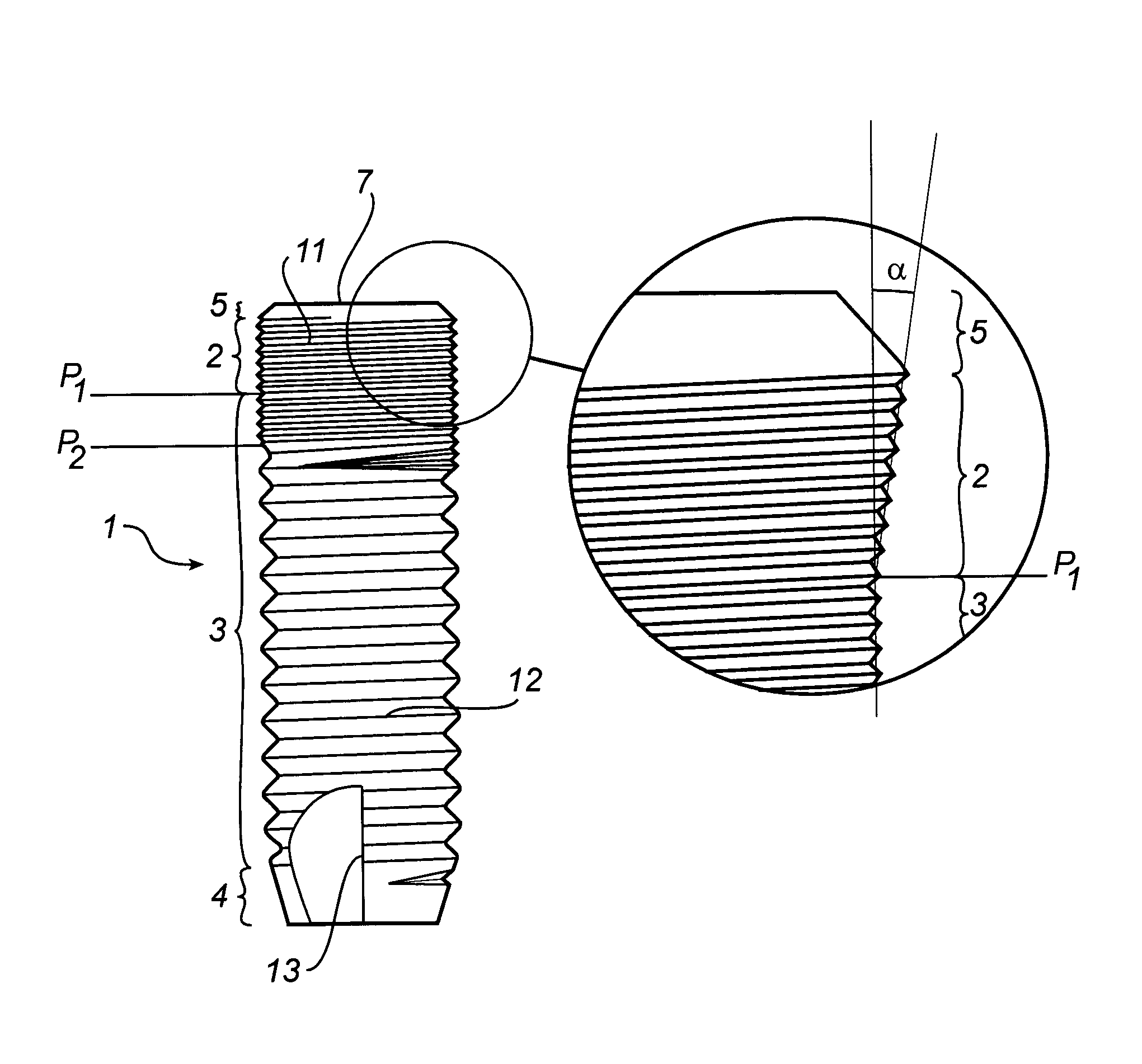

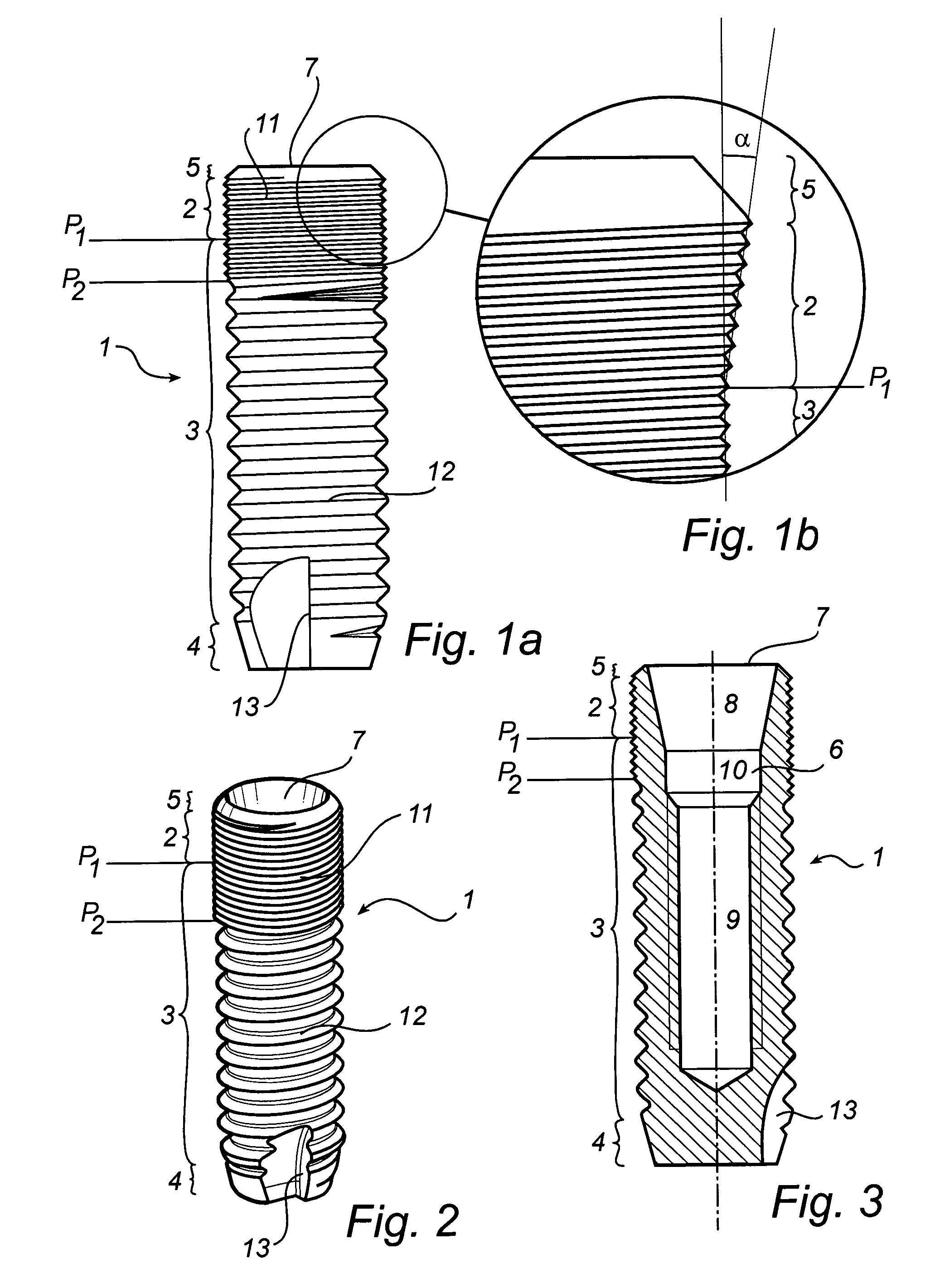

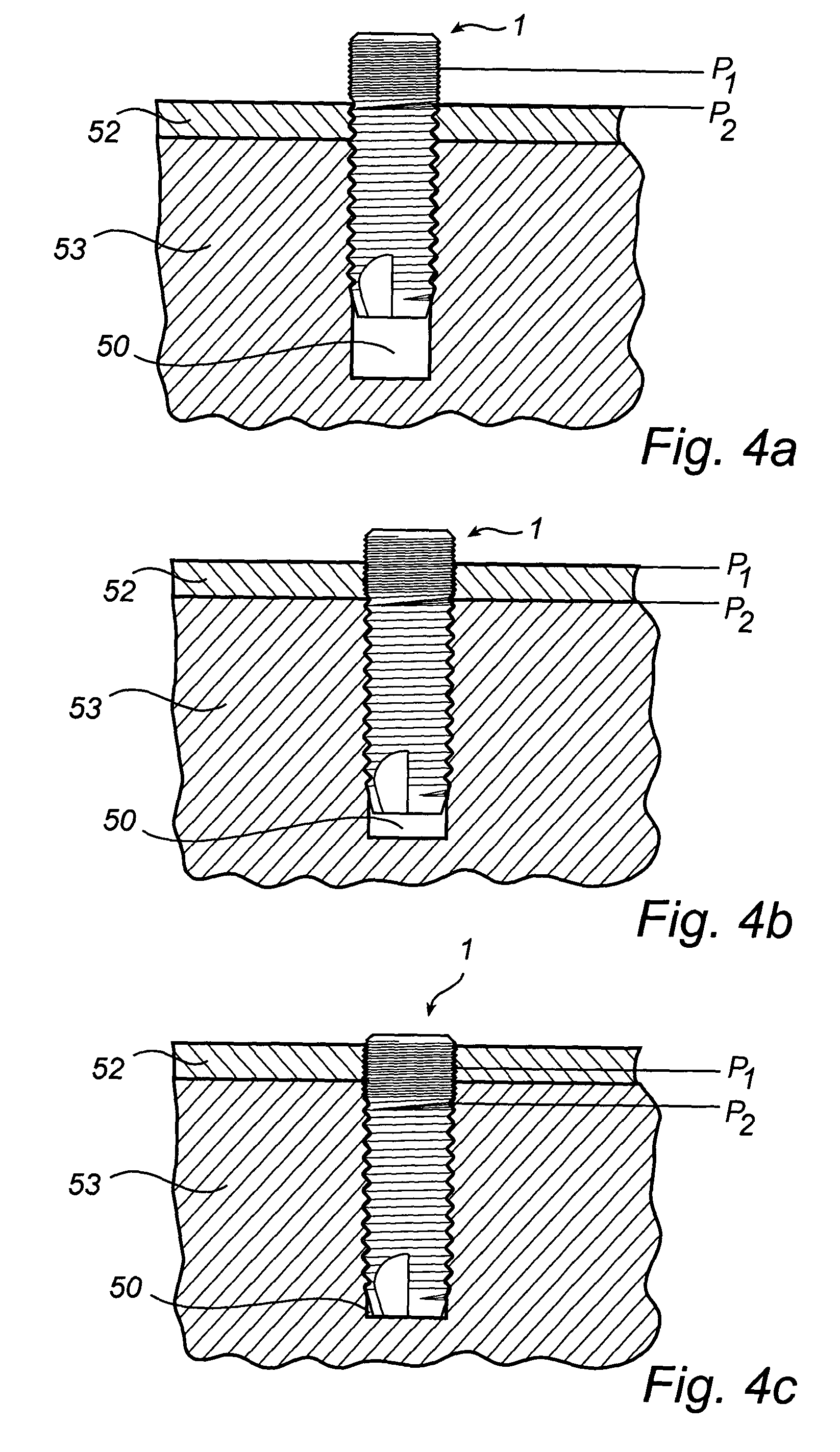

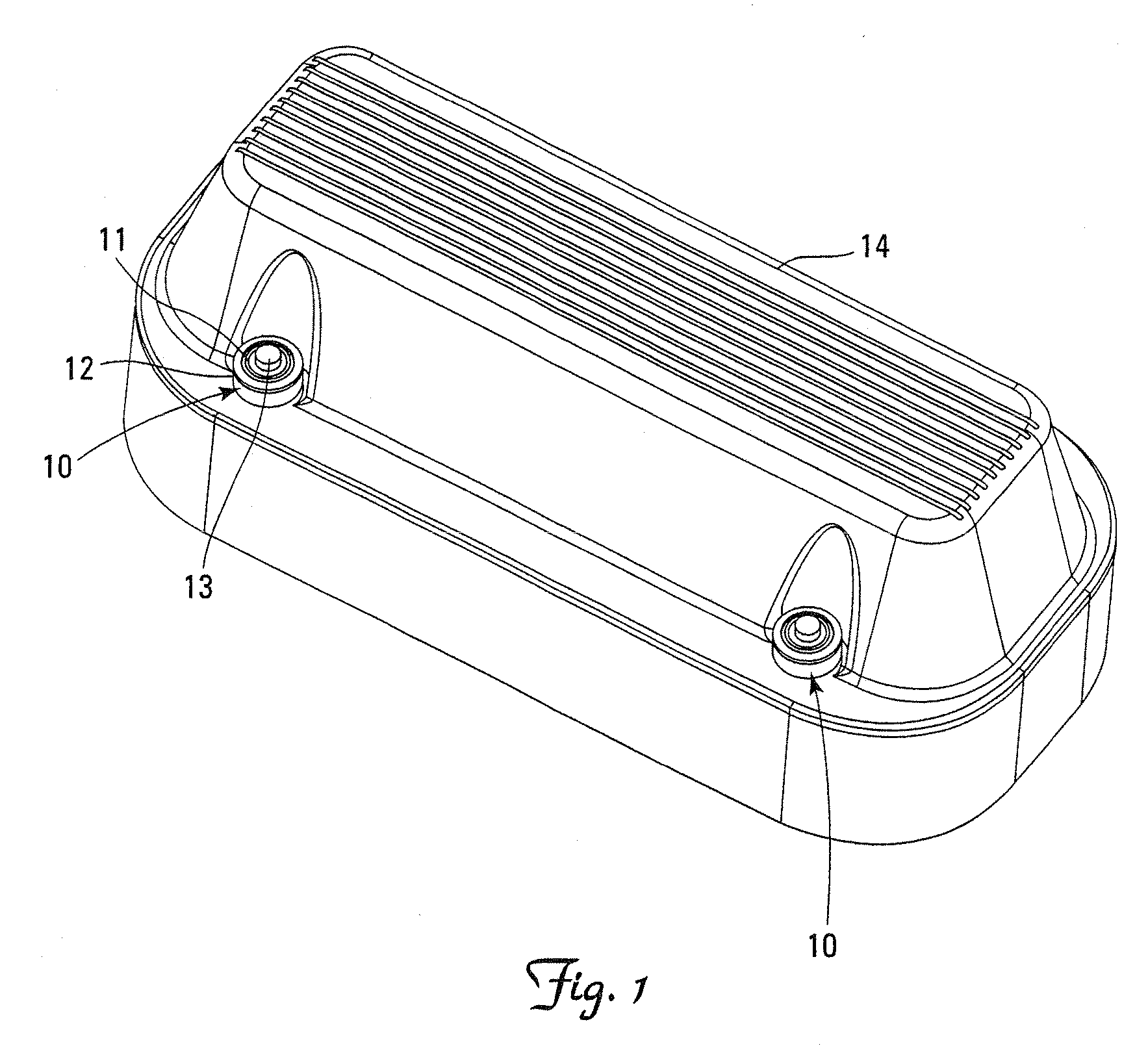

Implant, arrangement comprising an implant, and method for inserting said implant in bone tissue

InactiveUS8029285B2Easy to installReduce decreaseSuture equipmentsDental implantsBone tissueBone Cortex

The present invention relates to a screw implant (1) for insertion into a bore hole (50) arranged in bone tissue, said implant having a cancellous portion (3), and a cortical portion (2) having an axial length such that, when installed in the bore hole (50), the engagement of said cortical portion (2) with the bone tissue will generally be confined to the cortical bone tissue layer (52). Said cortical portion (2) presents an outer surface which is threaded for accomplishing said engagement, and has an outer design such that, when being screwed into said bore hole under action of a screwing torque, said cortical portion (2) acts so as to increase the compression of the cortical bone tissue only, in essentially radial directions of the implant, resulting in a distinct increase of the screwing torque needed for screwing the implant (1). Said increase is usable as an indication that the implant (1) is in place or nearly in place in the bore hole.The invention also relates to an arrangement comprising an implant and a bore hole, and a method for insertion of an implant into a bore hole.

Owner:ASTRA TECH SE

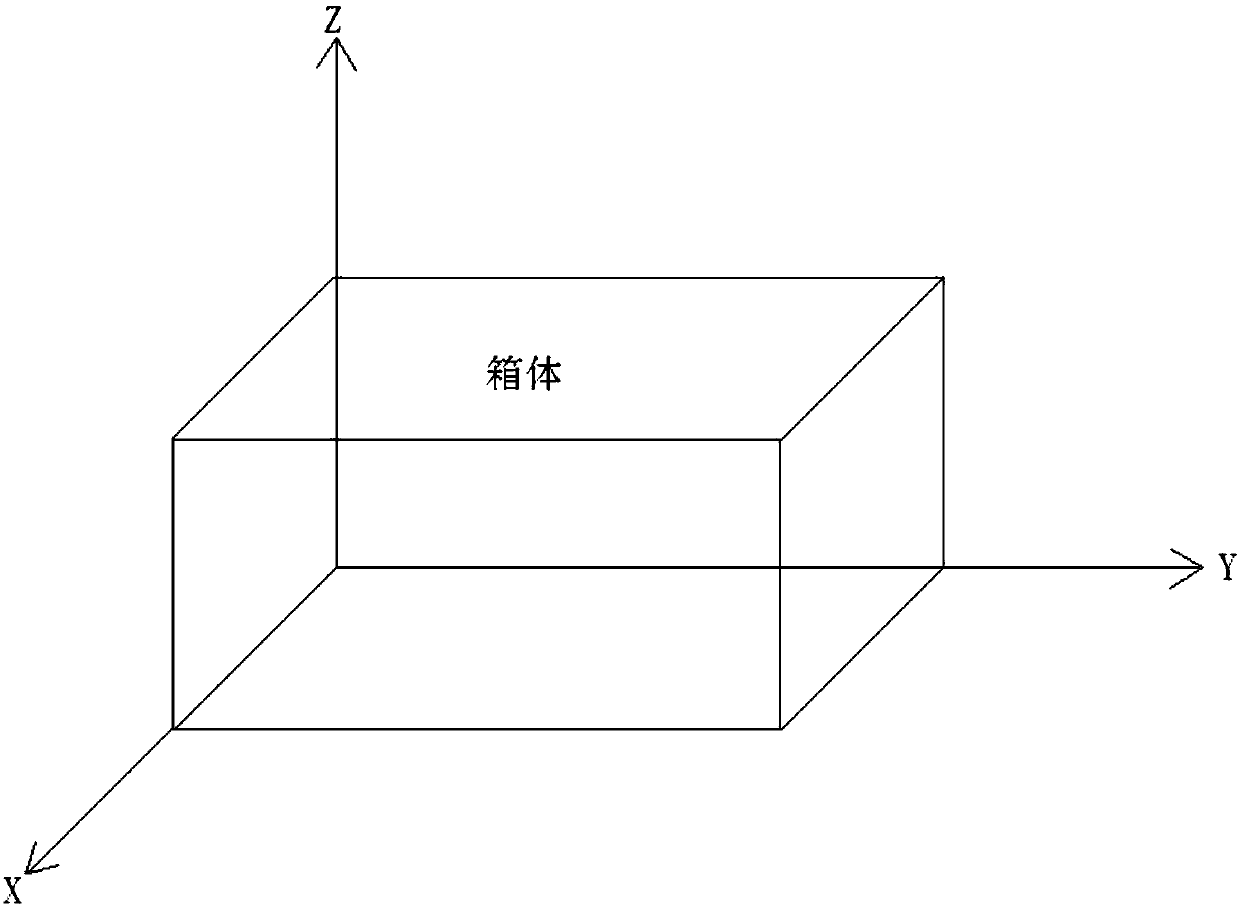

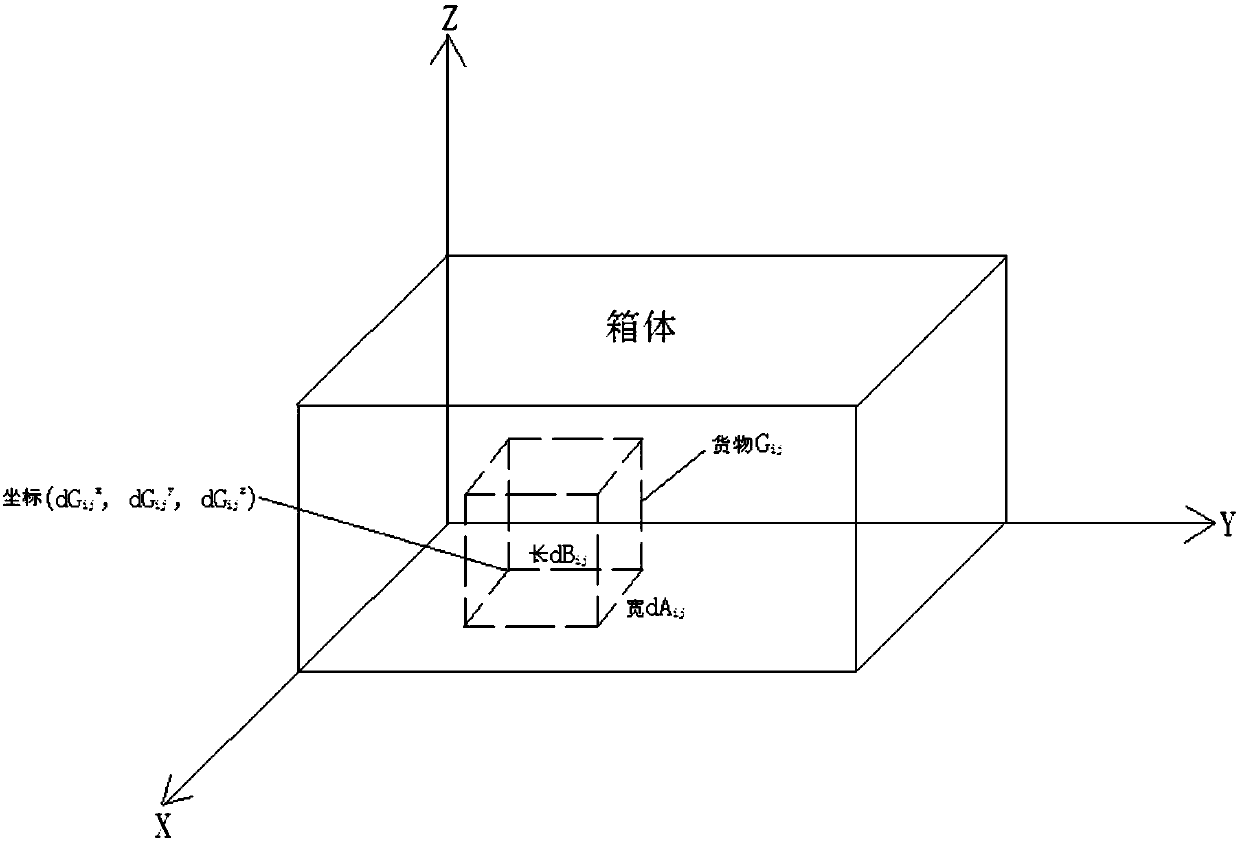

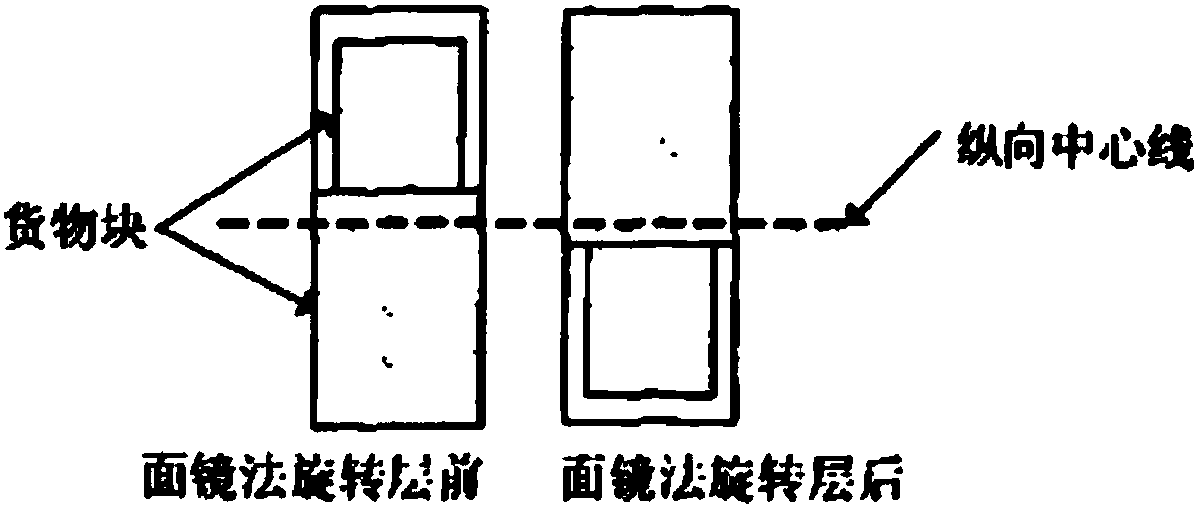

An algorithm for intelligently generating a case loading scheme based on multiple constraint conditions

The invention provides an algorithm for intelligently generating a case loading scheme based on multiple constraint conditions. The algorithm is characterized by, one the basis of combining actual situation of case loading and fully considering main factors influencing case transport safety and case loading utilization rate, constructing a case balance loading optimization model, designing a corresponding solution algorithm, that is, a case loading algorithm comprising a balance adjustment algorithm, and providing a three-dimensional graph case loading scheme. Results show that the system cancalculate the case balance loading scheme of cargos in a case body quickly and efficiently, and can guide on-site workers to load the cargos quickly and accurately.

Owner:国家粮食和物资储备局山东局八三二处

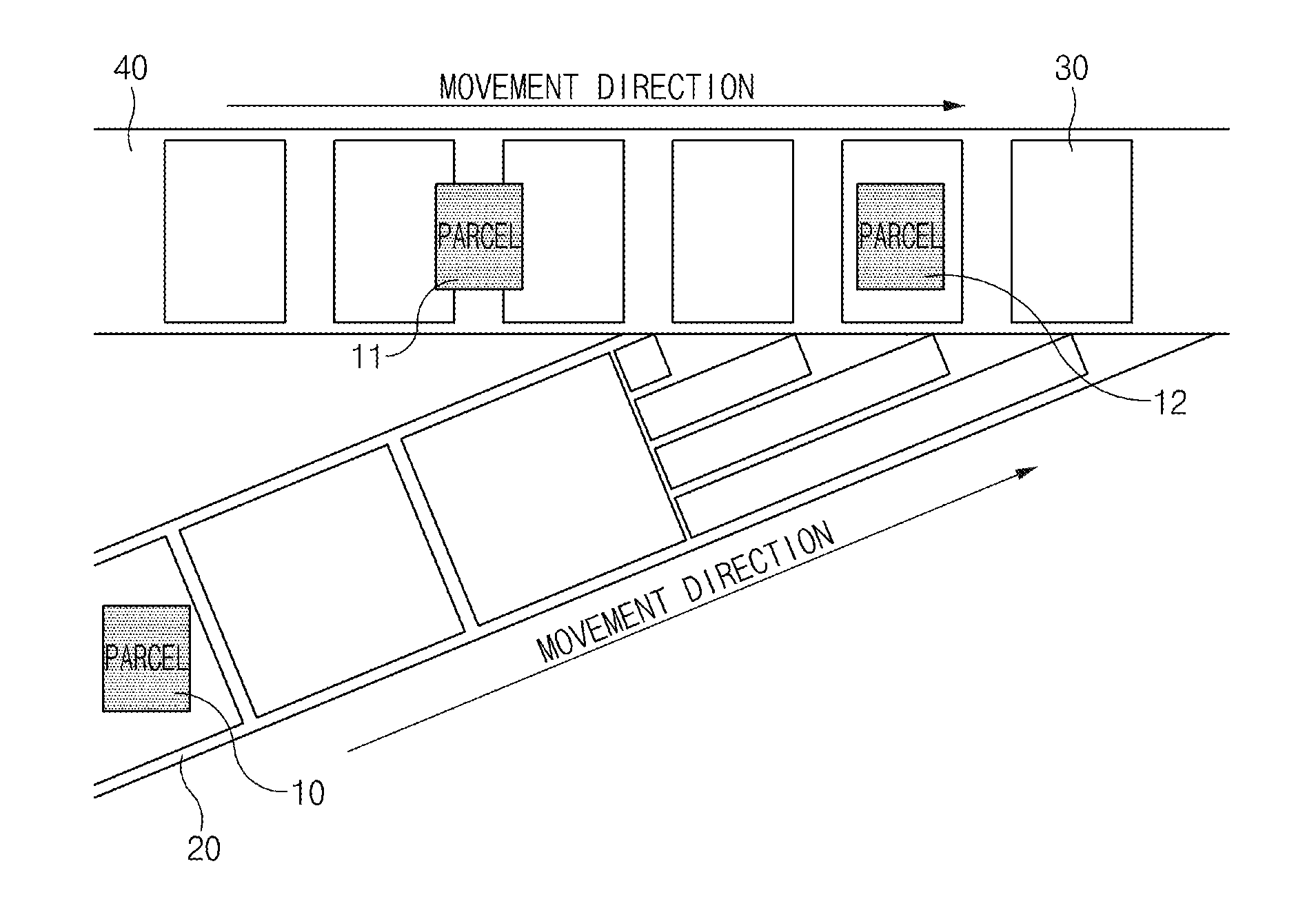

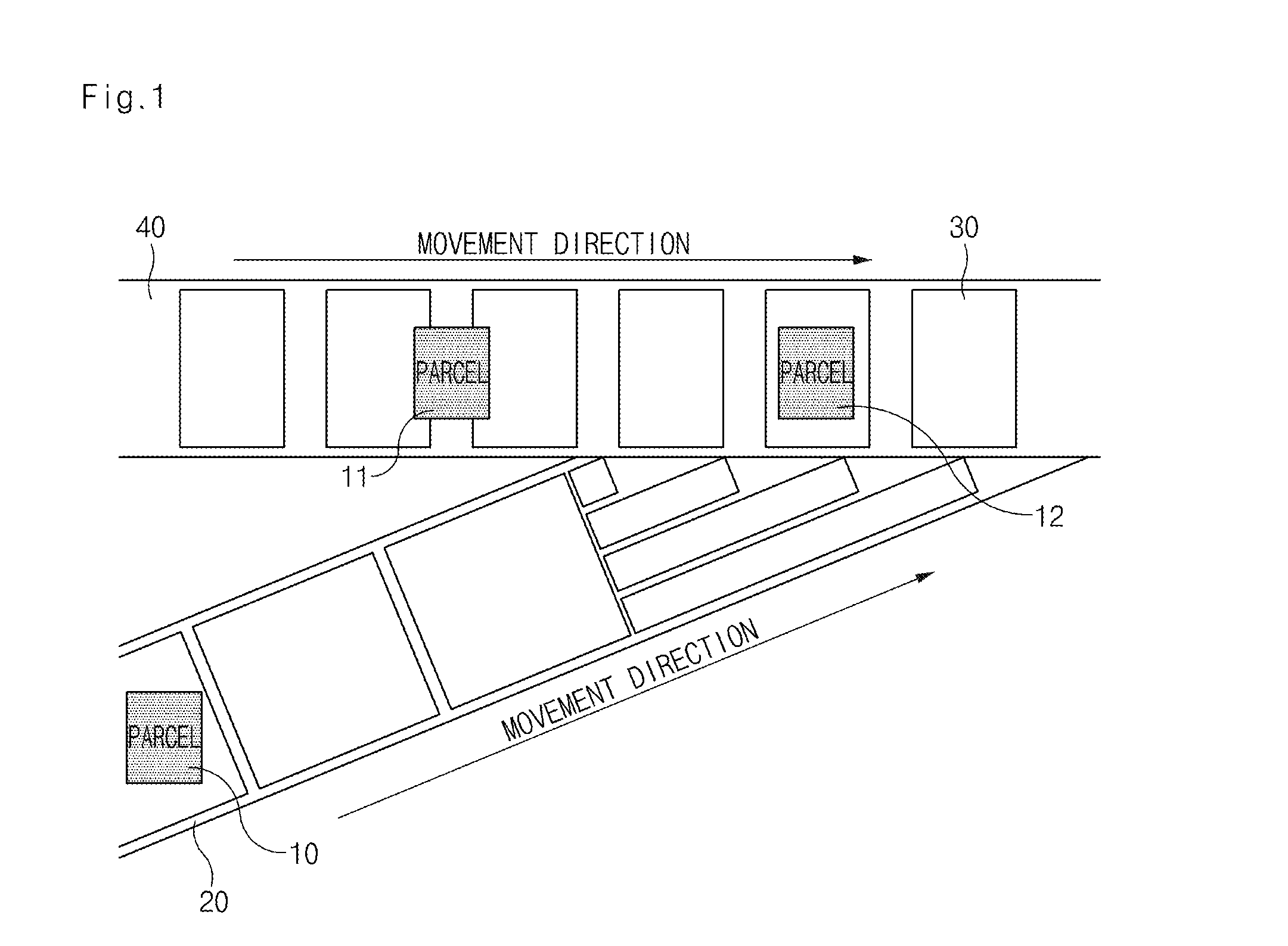

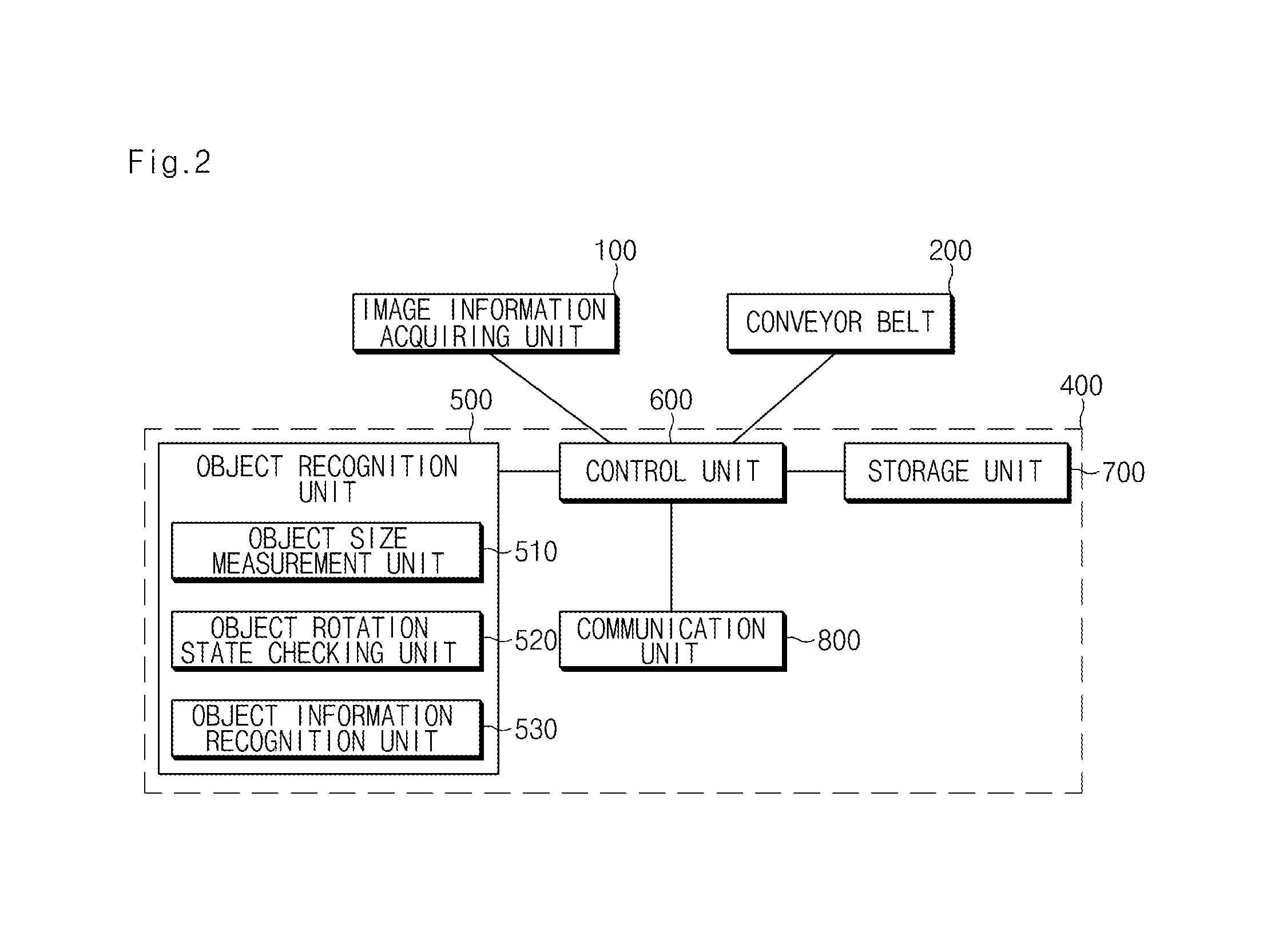

System for loading parcel and method thereof

InactiveUS20150360877A1Efficient loadingEvenly arrangedImage enhancementConveyorsComputer graphics (images)Transmission belt

Disclosed is a system for loading a parcel, which loads an object on a loading transportation vehicle through a conveyor belt of a loading unit, including: an image information acquiring unit which acquires image information acquired by photographing the parcel on the conveyor belt; an object recognition unit which measures the size of the object from the image information and calculates a rotation state of the object; and a control unit which controls the speed of the conveyor belt according to the size and the rotation state of the object.

Owner:ELECTRONICS & TELECOMM RES INST

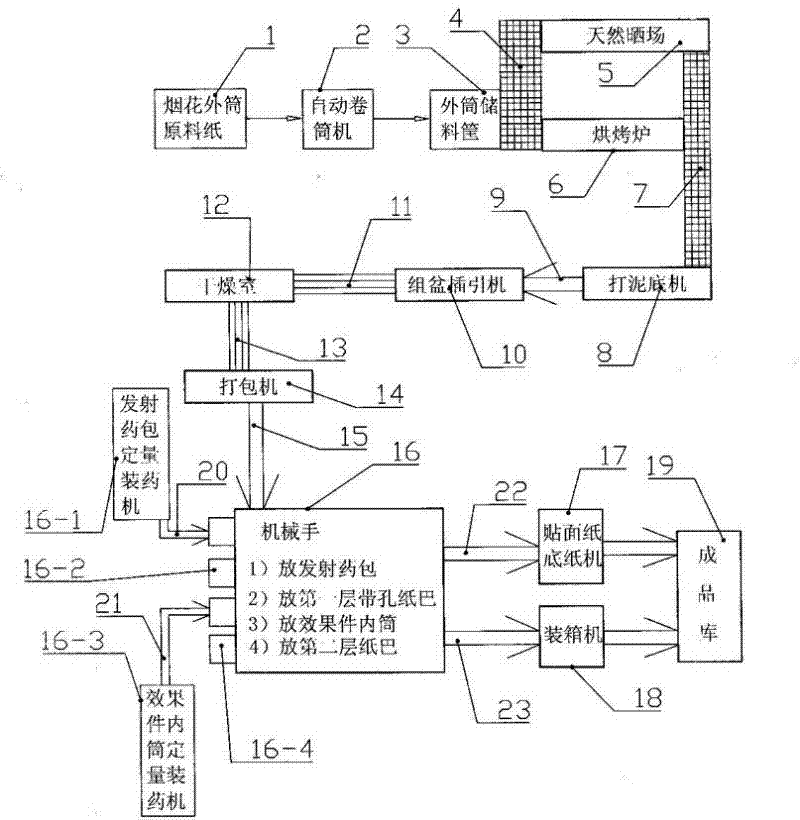

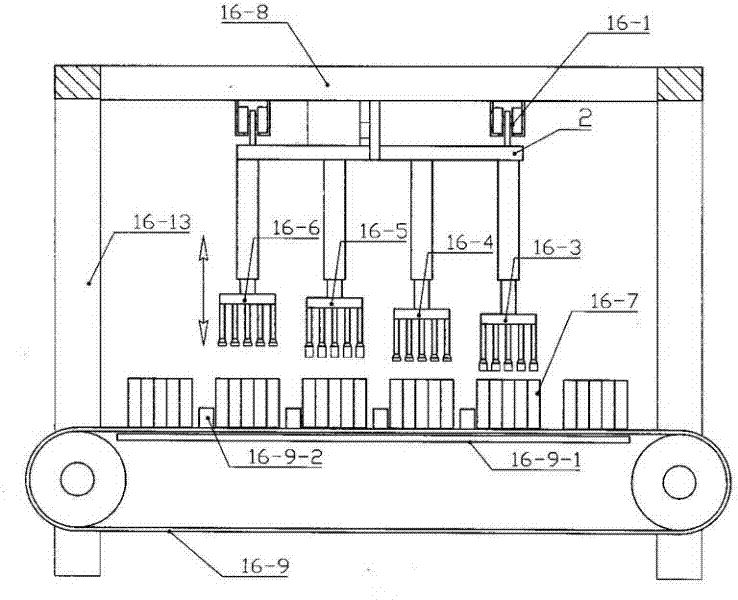

Flexible automatic production system for combined firework

InactiveCN102645135AAccurate and timely deliveryGuarantee quality and efficiencyFireworksFireworksPhotoelectric conversion

The invention relates to a flexible automatic production system for combined fireworks, which comprises an automatic tube rolling machine, a conveyer, a mud filling machine, a cake assembling and fuse inserting machine, a wrapping machine and a manipulator. The system is characterized in that firstly tubes are rolled through the automatic tube rolling machine and are stored in a tube storage basket, the tubes are fed to the mud filing machine for mud filling, cake assembling and fuse inserting after the tubes are dried, then the tubes are wrapped and reinforced by the wrapping machine, the tubes are righted and fed to the inlet port of the manipulator, propelling charges, effect part tubes, a first paper layer and a second paper layer are sequentially filled into the tubes after cake assembling, face paper and labels are stuck, products are boxed and sealed by a boxing and sealing machine and then the finished products are conveyed by the conveyer to a finished product warehouse; and materials among equipment of the entire system are conveyed by adopting the conveyer, and the loading position and the unloading position of each equipment are provided with photoelectrical conversion switches which are used for controlling the startup and the shutdown of the conveyer. Since the materials in the system are conveyed by the conveyer and the startup and shutdown of the conveyer are controlled by the photoelectric conversion switches, the materials are accurately conveyed in time, the product quality and the production efficiency are guaranteed, and the defects that manual handling in the past is time-consuming and labor-consuming and safety accidents are apt to occur are avoided.

Owner:柳真

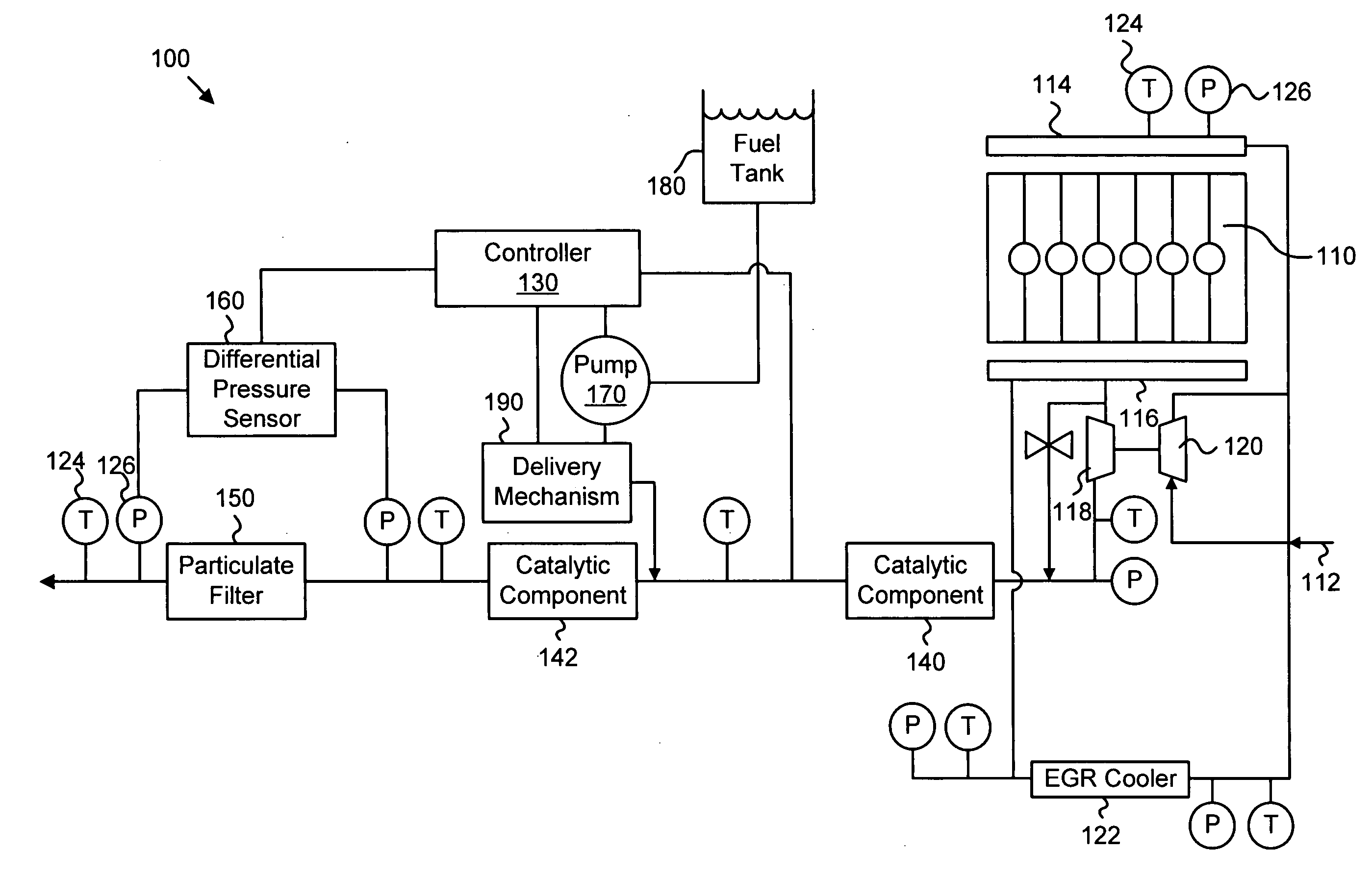

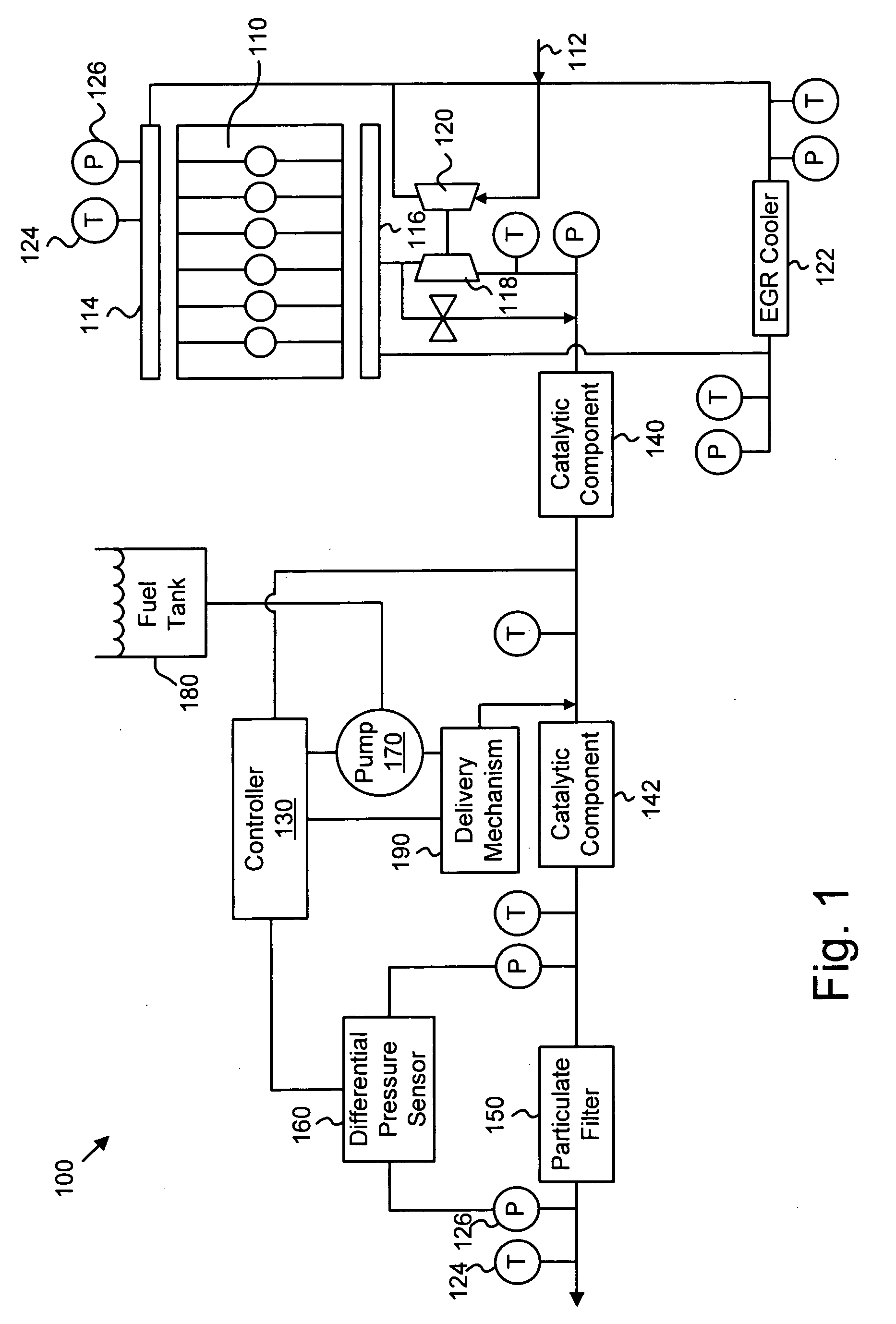

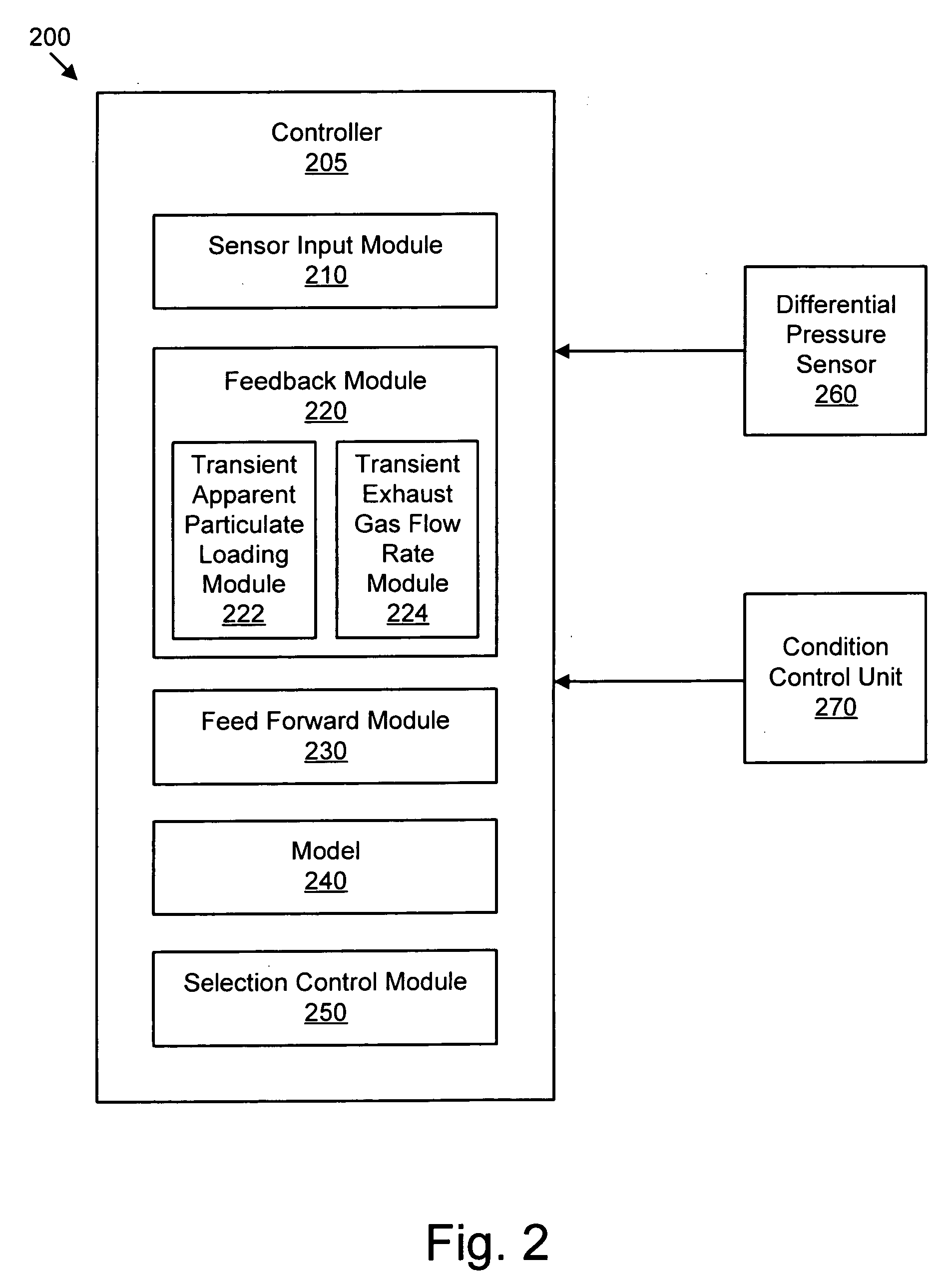

Apparatus, system, and method for determining the distribution of particulate matter on a particulate filter

ActiveUS20070056271A1Easy to determineLoad accuratelyNon-fuel substance addition to fuelInternal combustion piston enginesParticulatesDifferential pressure

An apparatus, system, and method are disclosed for determining the distribution of particulate matter on a particulate filter. The apparatus, in one embodiment, determines a first distribution of particulate matter by comparing the pressure change across the particulate filter with a change in engine operating conditions. The apparatus may include an input module for receiving input corresponding to engine operating conditions and input from a differential pressure sensor and a feedback module to determine a first distribution of particulate matter. The apparatus may further include a feed forward module for determining a particulate distribution trend and a selection control module to combine the first distribution of particulate matter with the particulate distribution trend to determine a second distribution of particulate matter. The distribution may be defined as a uniform distribution factor in certain embodiments.

Owner:CUMMINS INC

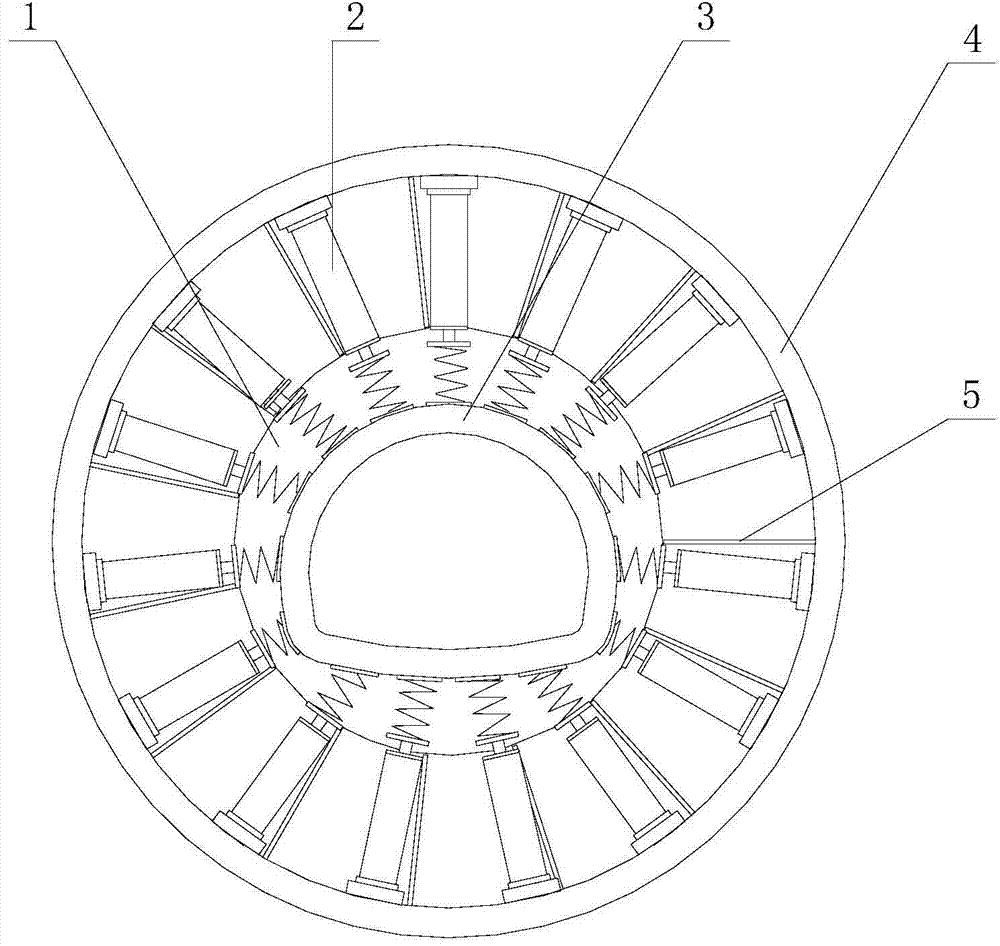

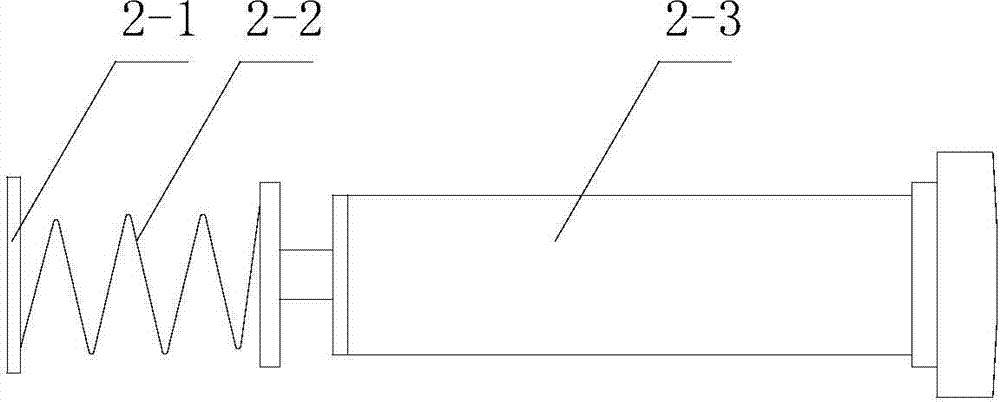

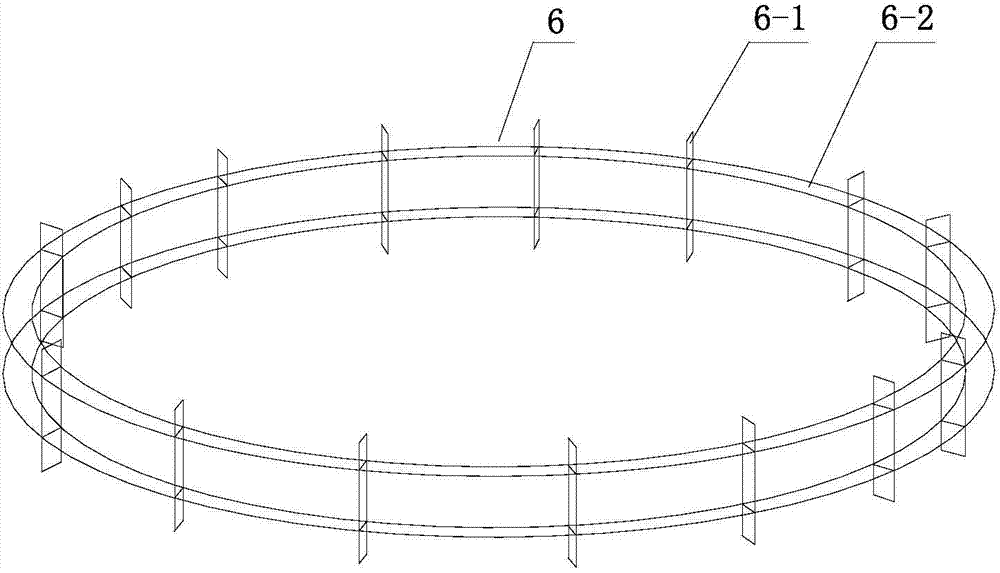

Load equipment of tunnel lining structural mechanics property simulation test device

InactiveCN104748993ALoad accuratelyMeet the test requirementsStructural/machines measurementNumerical controlStress conditions

The invention relates to load equipment of a tunnel lining structural mechanics property simulation test device. According to the arrangement, a tunnel lining is arranged on a displacement limitation face plate, a load mechanism is radially arranged on the outer surface of the tunnel lining, and the other end of the load mechanism is fixed on an outer retainer plate; the load mechanism is composed of cushion plates, springs and hydraulic jacks, the cushions are arranged along the outer wall of the tunnel lining, the springs are radially arranged on the outer walls of the cushion plates and allow the cushion plates to be connected with the hydraulic jacks, the hydraulic jacks are normally arranged on the outer surface of the tunnel lining, and cylinders of the hydraulic jacks are fixed on the inner wall of the outer retainer plate; under variable work conditions such as different lining types and thickness and different stress conditions, mechanics property simulation is effectively achieved; during the loading, the numerical control hydraulic jacks are adopted to ensure strength and position of stress applied to the lining, bringing convenience to the following data analysis and research, and accordingly the tunnel lining structural mechanics property changes are effectively simulated.

Owner:CHANGAN UNIV

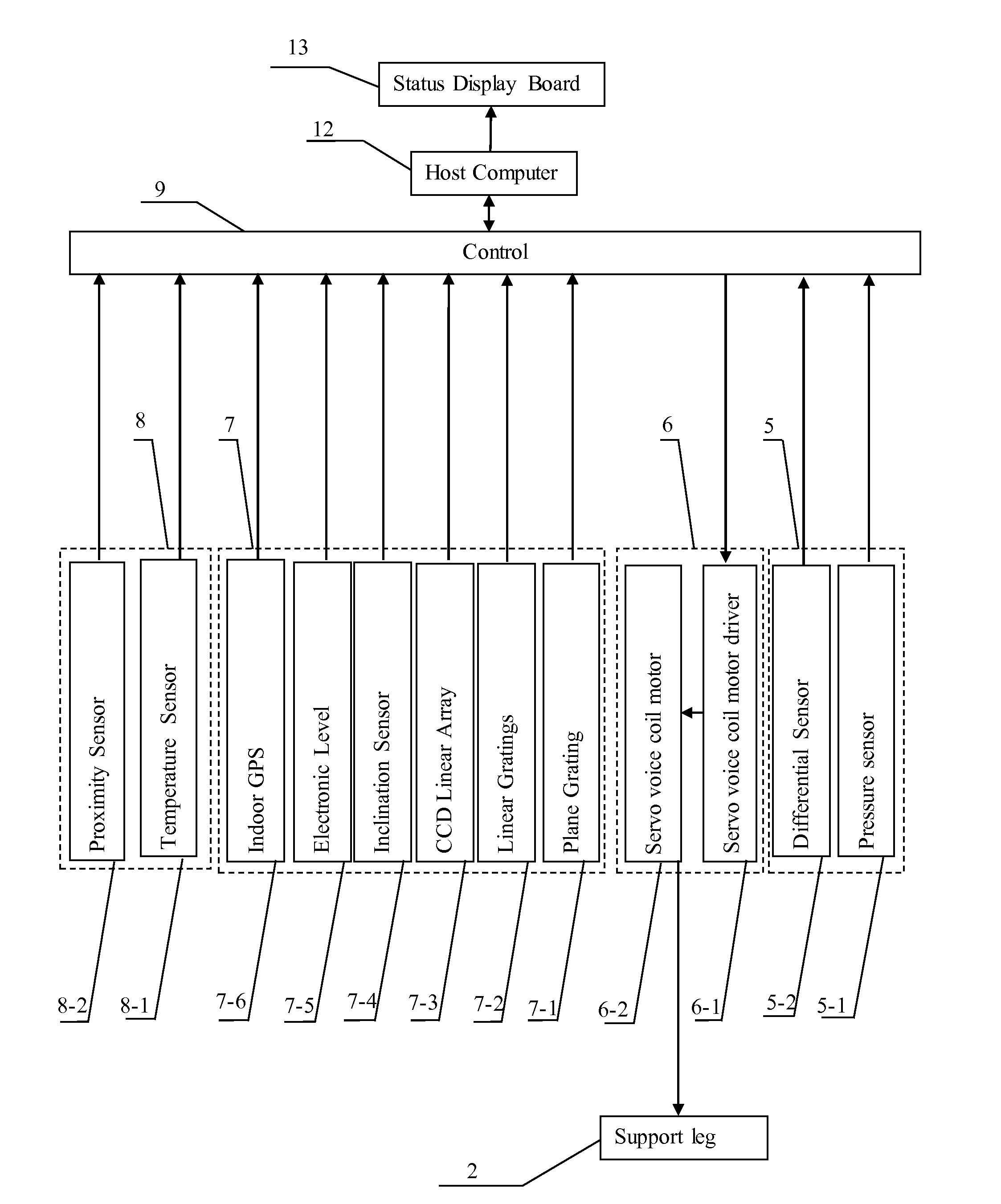

Measurement Control System for Multi-Shaft Supported Air Floatation Platform

ActiveUS20160124437A1Increased load-bearing capacityIncreased accuracy levelComputer controlStands/trestlesGratingProximity sensor

A measurement control system for a multi-shaft supported air floatation platform, the system comprising a load feedback unit (5), an execution unit (6), a position measurement unit (7), a safety protection unit (8), a controller (9), a rotating motor (10), and a linear light source 11; the load feedback unit comprises M pressure sensors (5-1) and four differential sensors (5-2); the execution unit comprises M servo voice coil motors (6-1) and M servo voice coil motor drivers (6-2); the position measurement unit comprises a plane grating (7-1), M linear gratings (7-2) a linear array CCD (7-3), a tilt sensor (7-4), M electronic levels (7-5), and an indoor GPS (7-6); the safety protection unit comprises 2M proximity sensors (8-1) and M temperature sensors (8-2); and the linear array CCD consists of no few then six CCDs. The system solves the problems of leveling limitations and narrow application range of existing supporting platforms.

Owner:HARBIN INST OF TECH

Precise linear fastener system and method for use

InactiveUS20070286703A1Rapid linear engagement and disengagementPrecise and secure and reproducible connectionNutsCompression memberLinearity

The present invention provides a linear fastening system capable of rapid engagement and disengagement. More specifically, the system utilizes a cooperating collet member and a compression ring member which are constructed and arranged to slip easily over a shank member. The fastener system is secured by linearly traversing a compression member in an overlapping fashion over the collet member thereby utilizing ribbed surfaces to compress the collet member to grip the outer surface of the shank member. In this manner, the linear fastener system is capable of providing a precise, secure, and reproducible connection between multiple components without the need to apply rotational torque to the assembly.

Owner:ORTHO INNOVATIONS +1

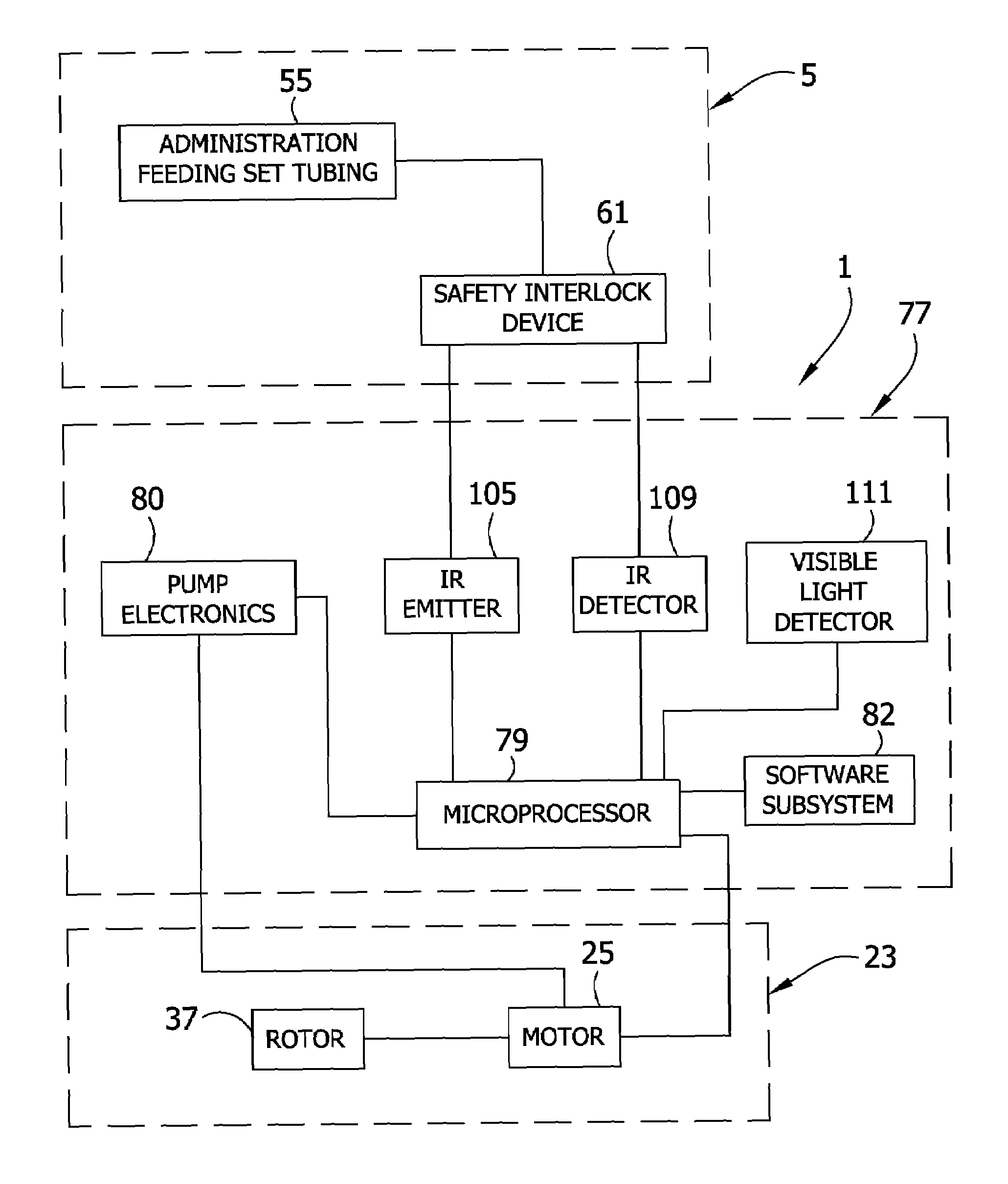

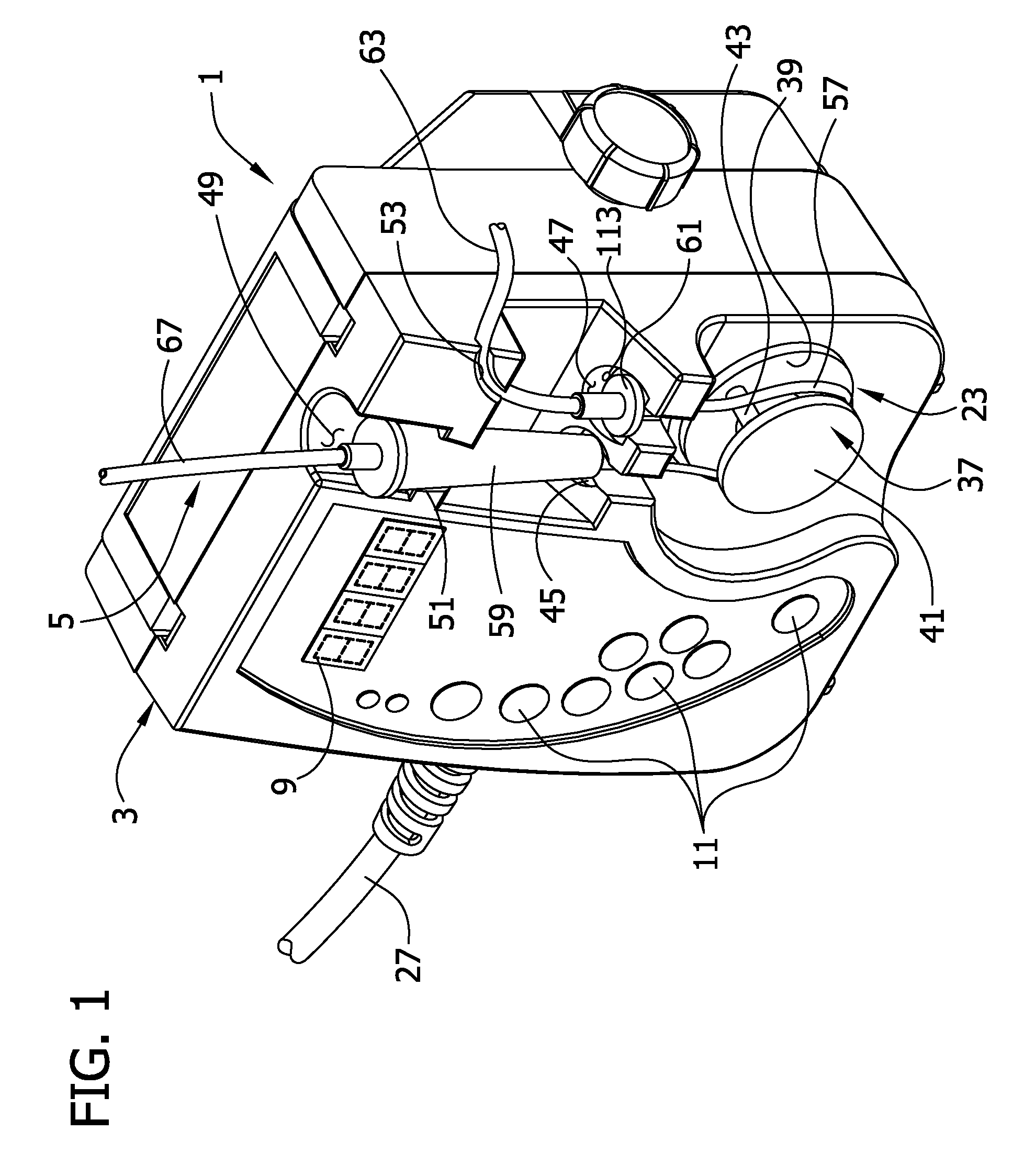

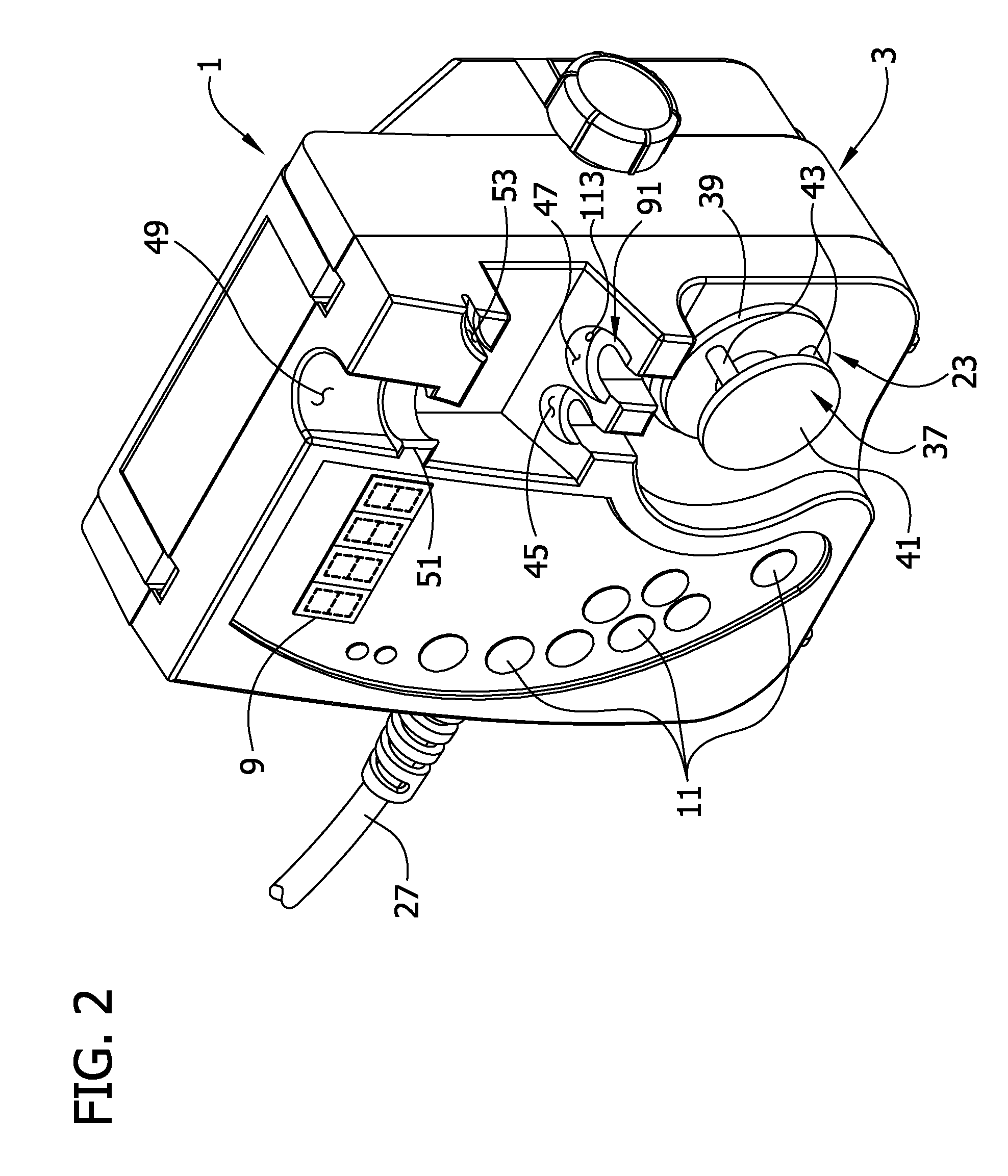

Pump Set with Safety Interlock

A pump set for use with a pump to deliver a supply of liquid to a patient. The feeding set has a conduit for the nutrient liquid and a safety interlock device associated with the conduit. The pumping apparatus has a pumping device and a control system for controlling operation of the pump. An electromagnetic radiation source is operatively connected to the control system of the pump for emitting an electromagnetic radiation signal in a direction for striking the safety interlock device of the feeding set. The safety interlock device is adapted to affect the direction of the electromagnetic radiation. An electromagnetic radiation detector is operatively connected to the control system for receiving the electromagnetic radiation signal when the direction is affected by the safety interlock device, and providing an indication to the control system that the feeding set conduit is properly positioned in the feeding pump.

Owner:KPR U S LLC

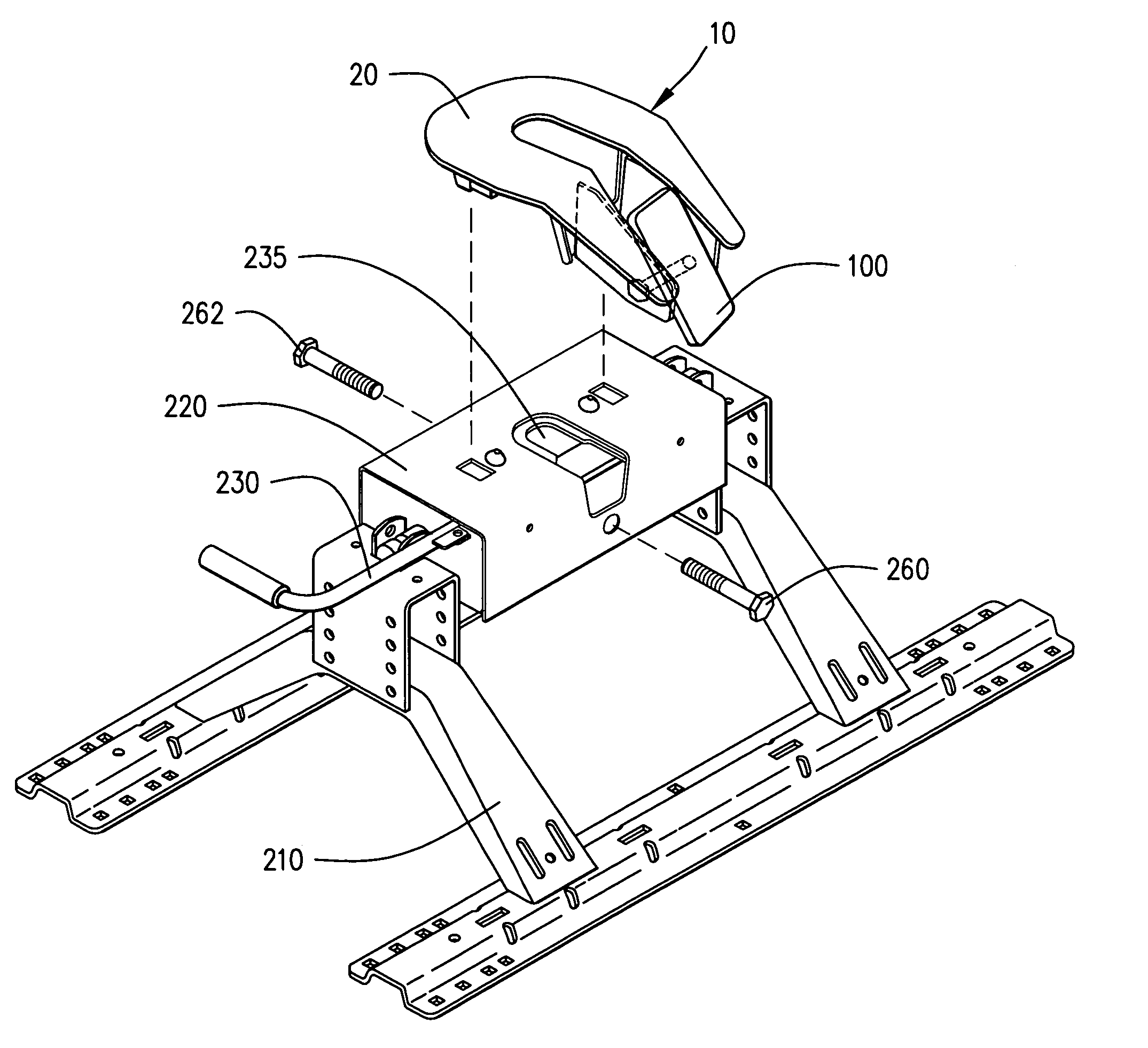

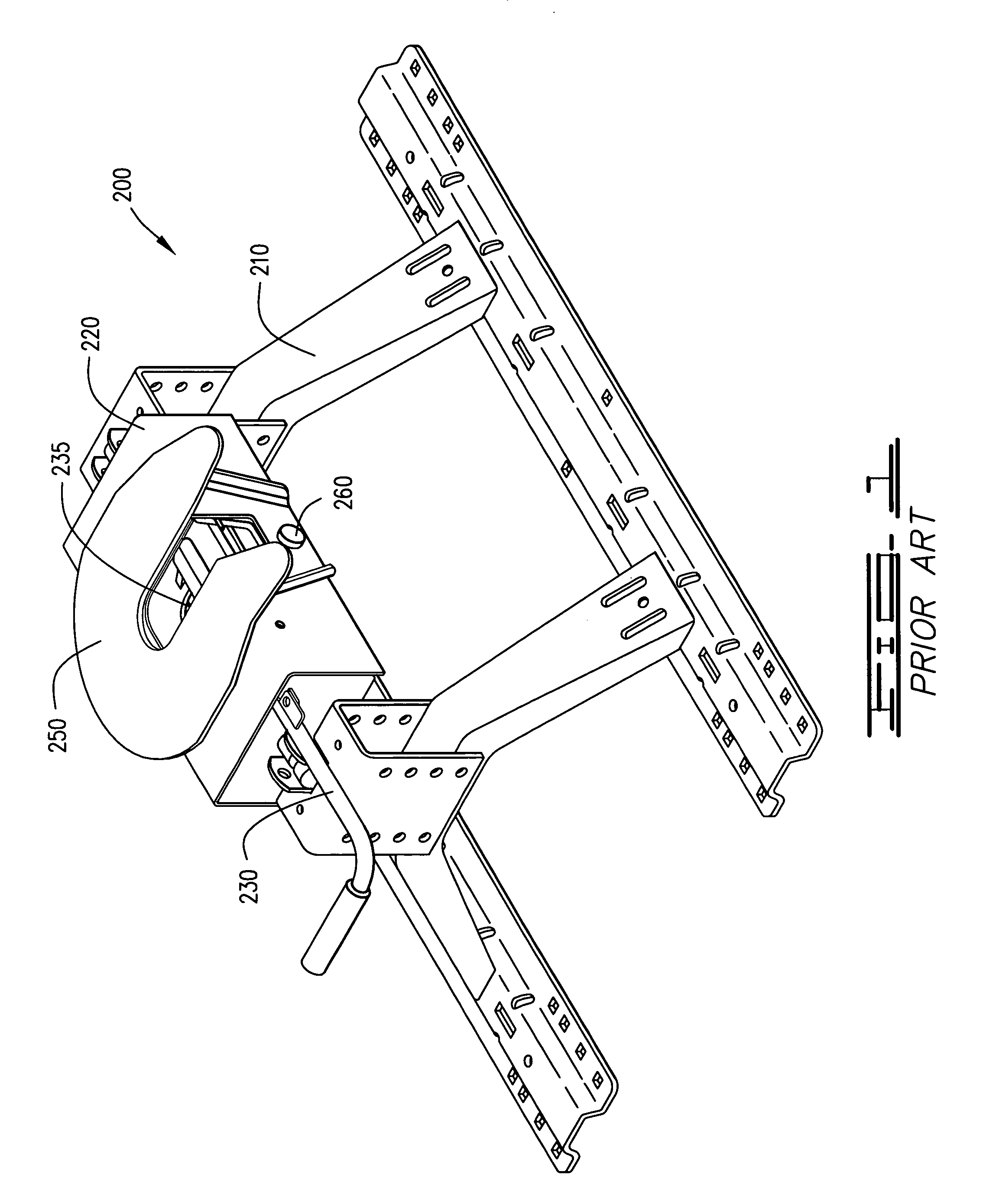

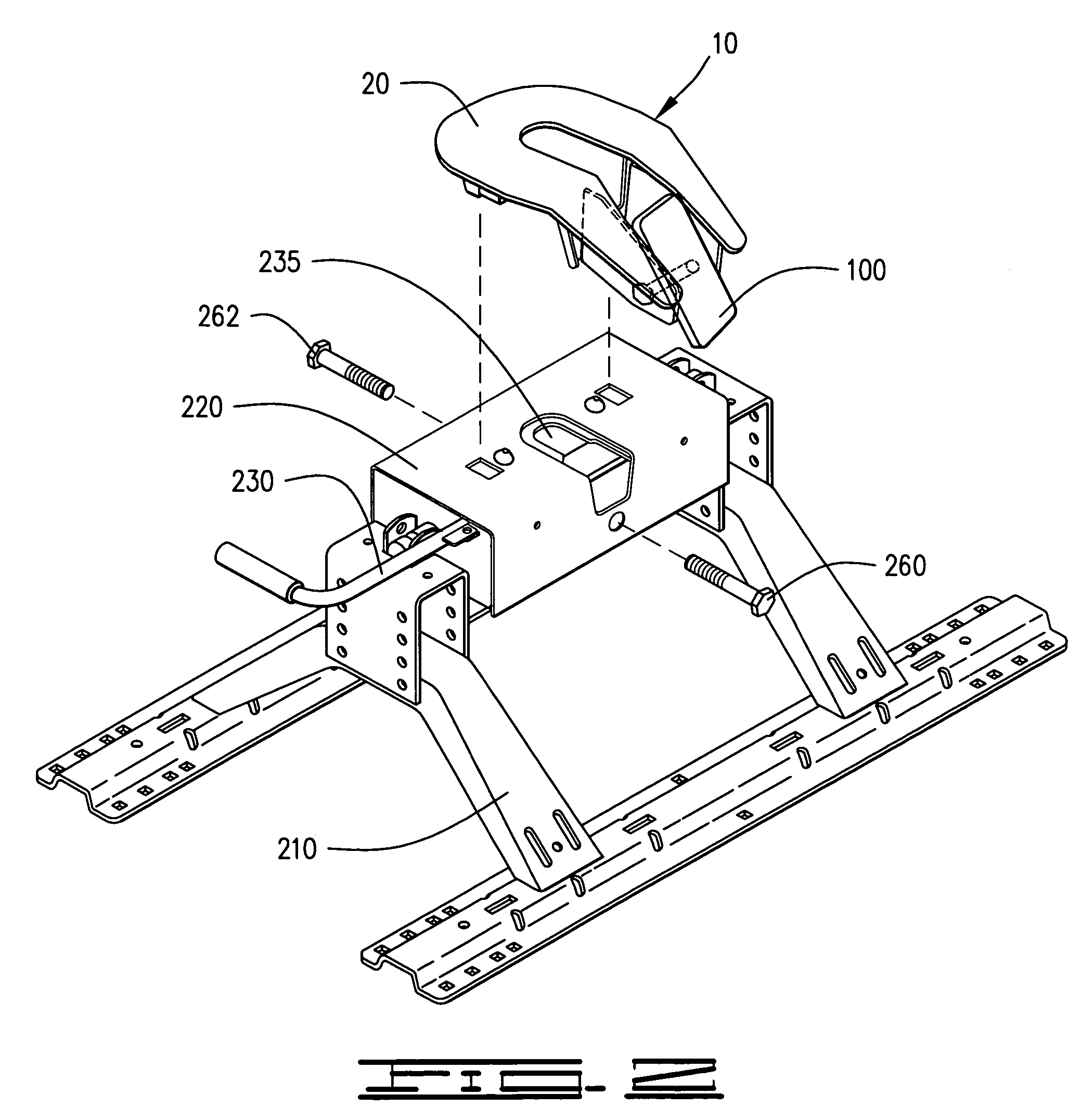

Fifth wheel hitch device with pivotal locking ramp

ActiveUS7100935B1Improve device integrationGood removal effectAutomatic initiationsTractor-trailer combinationsEngineeringTruck

A improved detachable fifth wheel hitch device with a pivotal locking ramp, which replaces a supplied fifth wheel hitch plate device attached to a truck or pickup mounted fifth wheel hitch base, provides an extended collar hitch plate above a kingpin receiver channel incorporating a pivotal locking ramp directing a kingpin into the kingpin receiver channel, over the pivotal locking ramp during loading, the pivotal locking ramp returning to an erect position, blocking removal of the kingpin once past the pivotal locking ramp unless the kingpin is raised vertically out of the kingpin receiver channel, thus preventing unintentional release of the kingpin from the kingpin receiver channel during loading, unloading or transport.

Owner:AUTOMATIC EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com