Patents

Literature

281results about "Oscillations damping for weighing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

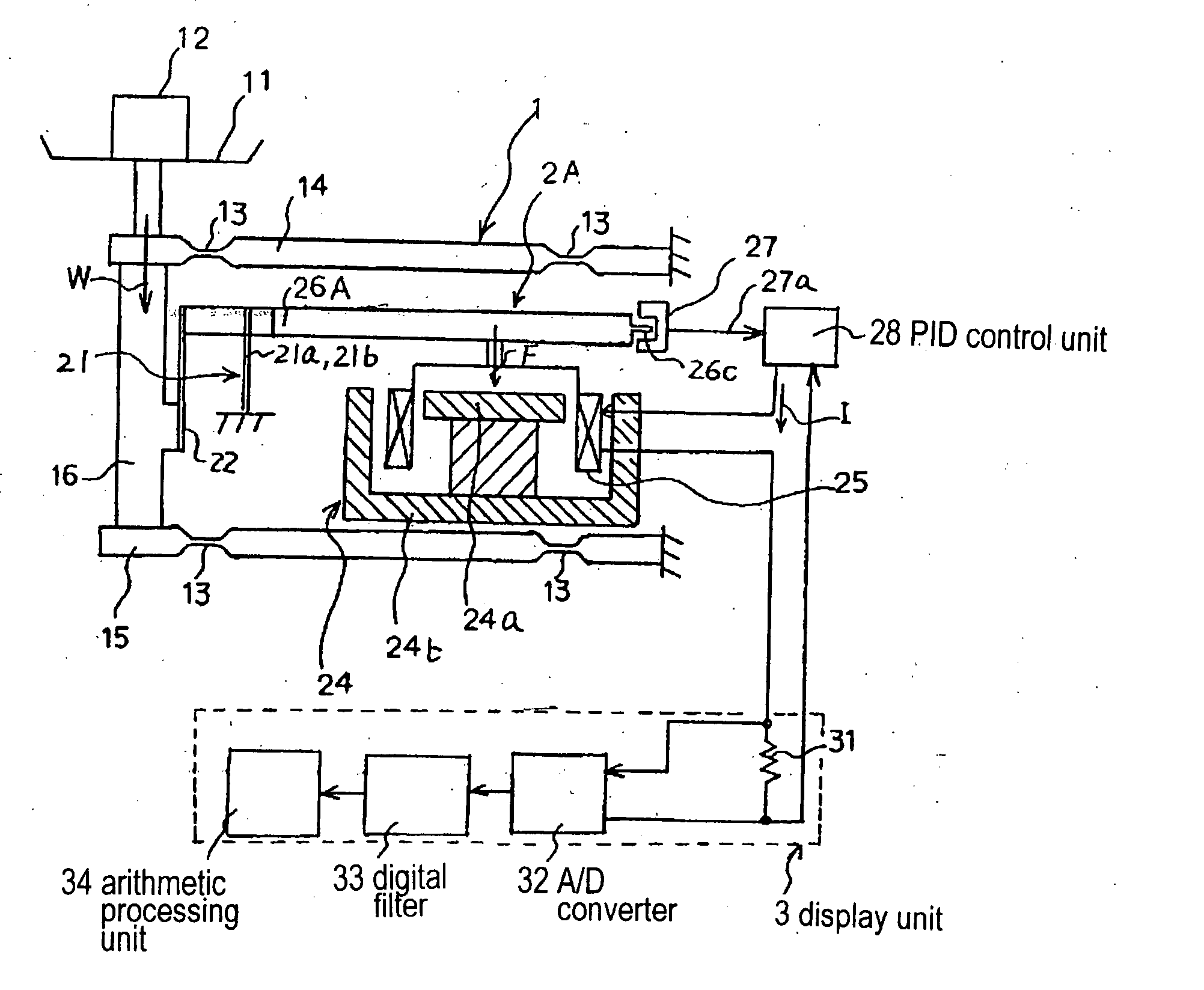

Weighing apparatus having an automatic filter adjusting capability

InactiveUS6271484B1Short response timeShort timeWeighing apparatus using elastically-deformable membersWeighing apparatus testing/calibrationDigital filterAutomatic filtering

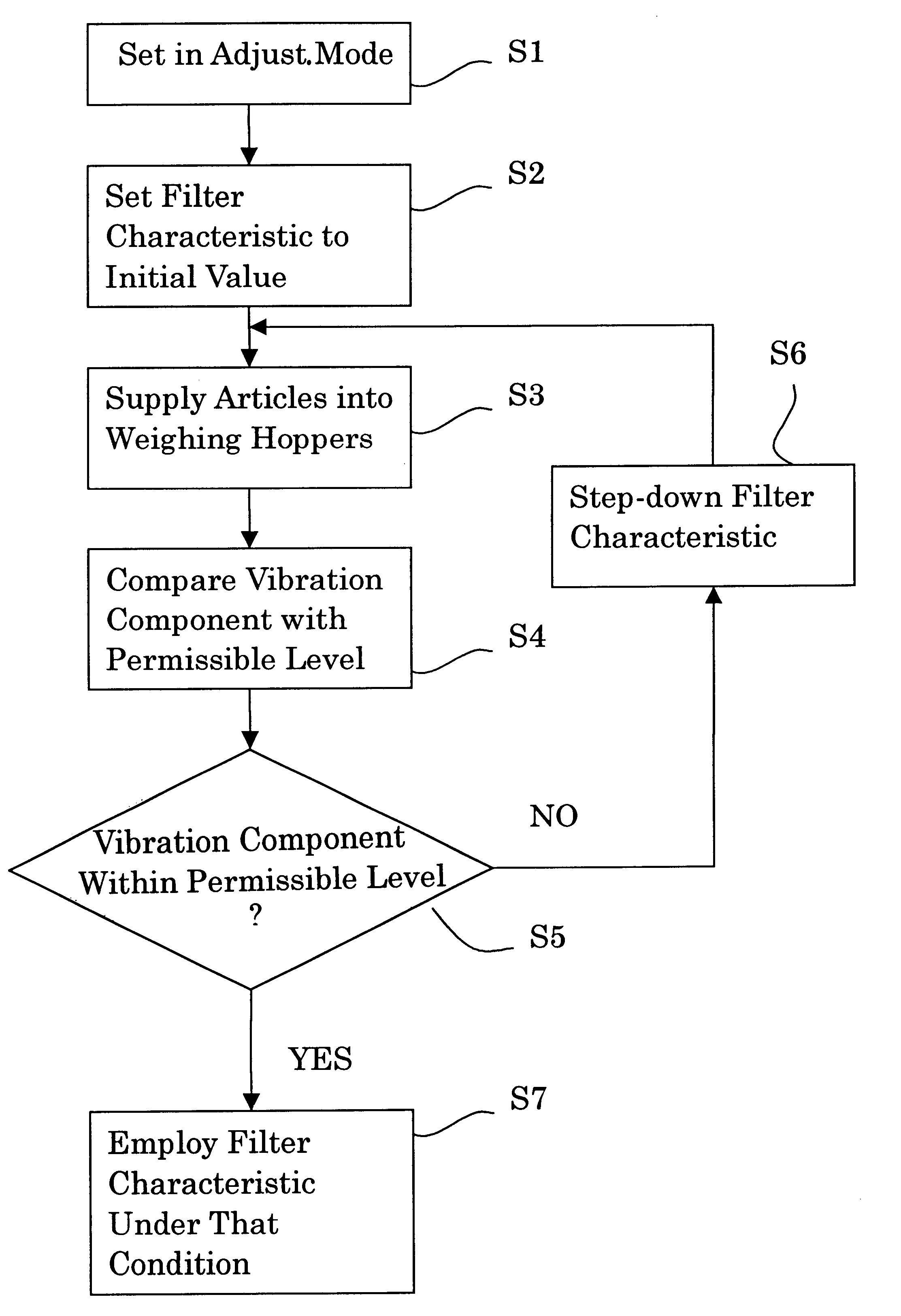

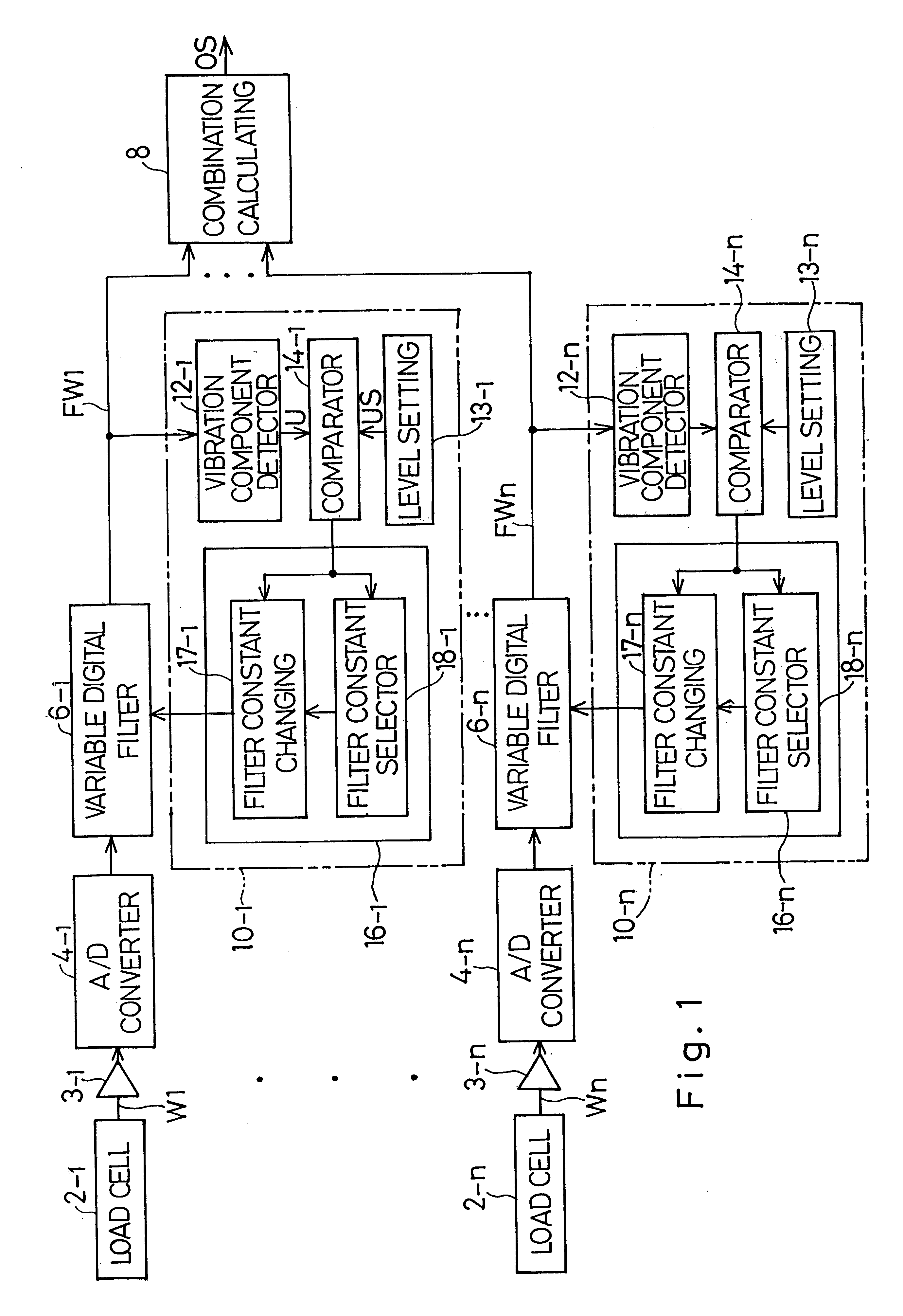

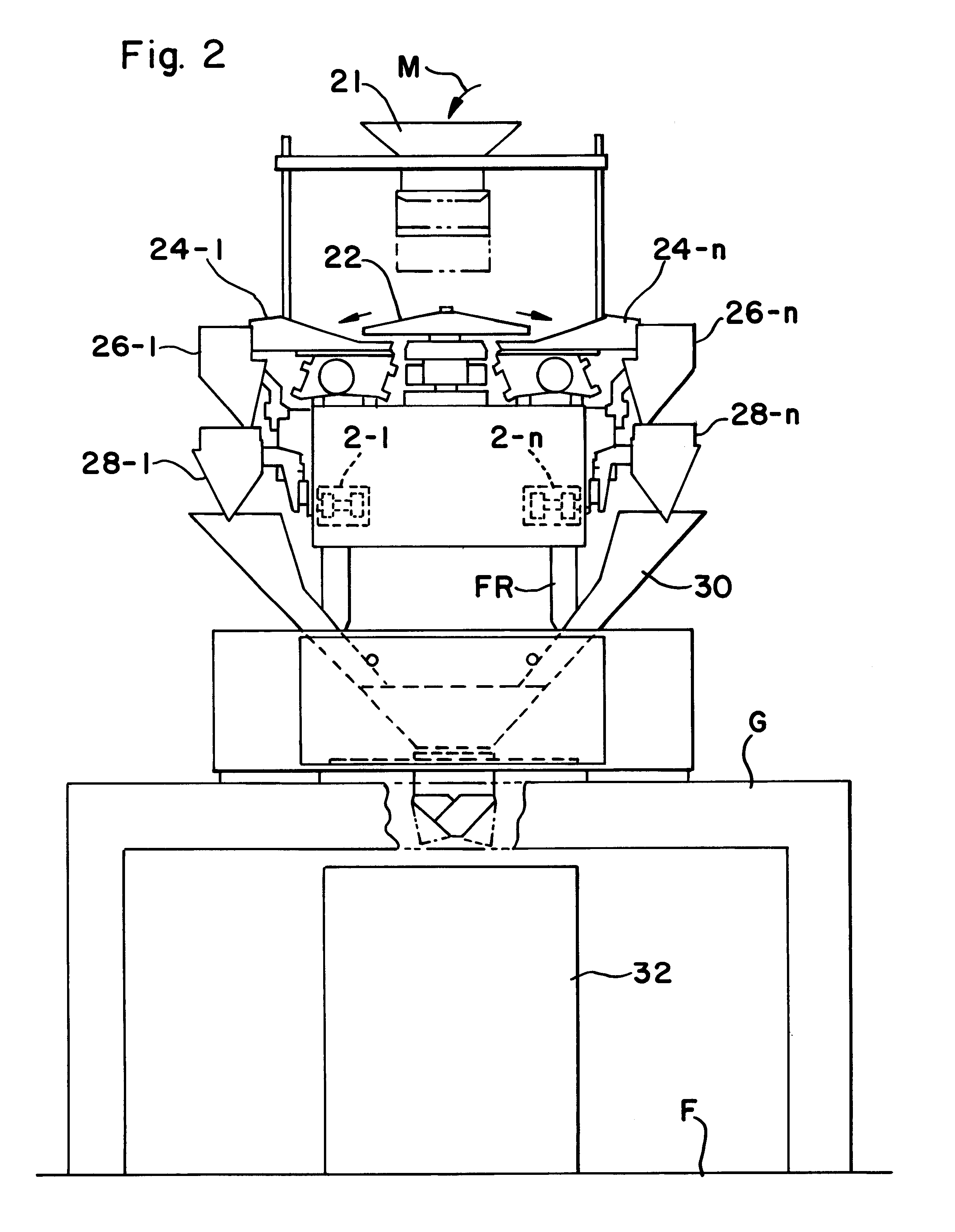

In order to provide a combination weighing apparatus having an automatic filter adjusting capability which is effective to secure a weighing accuracy and also to adjust a filter characteristic of a digital filter having a short response time, the filter characteristic is automatically adjusted, based on a result of comparison of respective vibration components U of filtered weight signals FW1 to FWn with a permissible level US of the vibration components, so that the respective vibration components U of the filtered weight signals FW1 to FWn can attain a value approximating to the permissible level US, but not exceeding the permissible level US. In this way, by damping the vibration components U down to a value within the permissible level US, the weighing accuracy can be secured and, on the other hand, by damping the vibration components U down to a value approximating to the permissible level US, the filter characteristic can be obtained quickly in a short time.

Owner:ISHIDA CO LTD

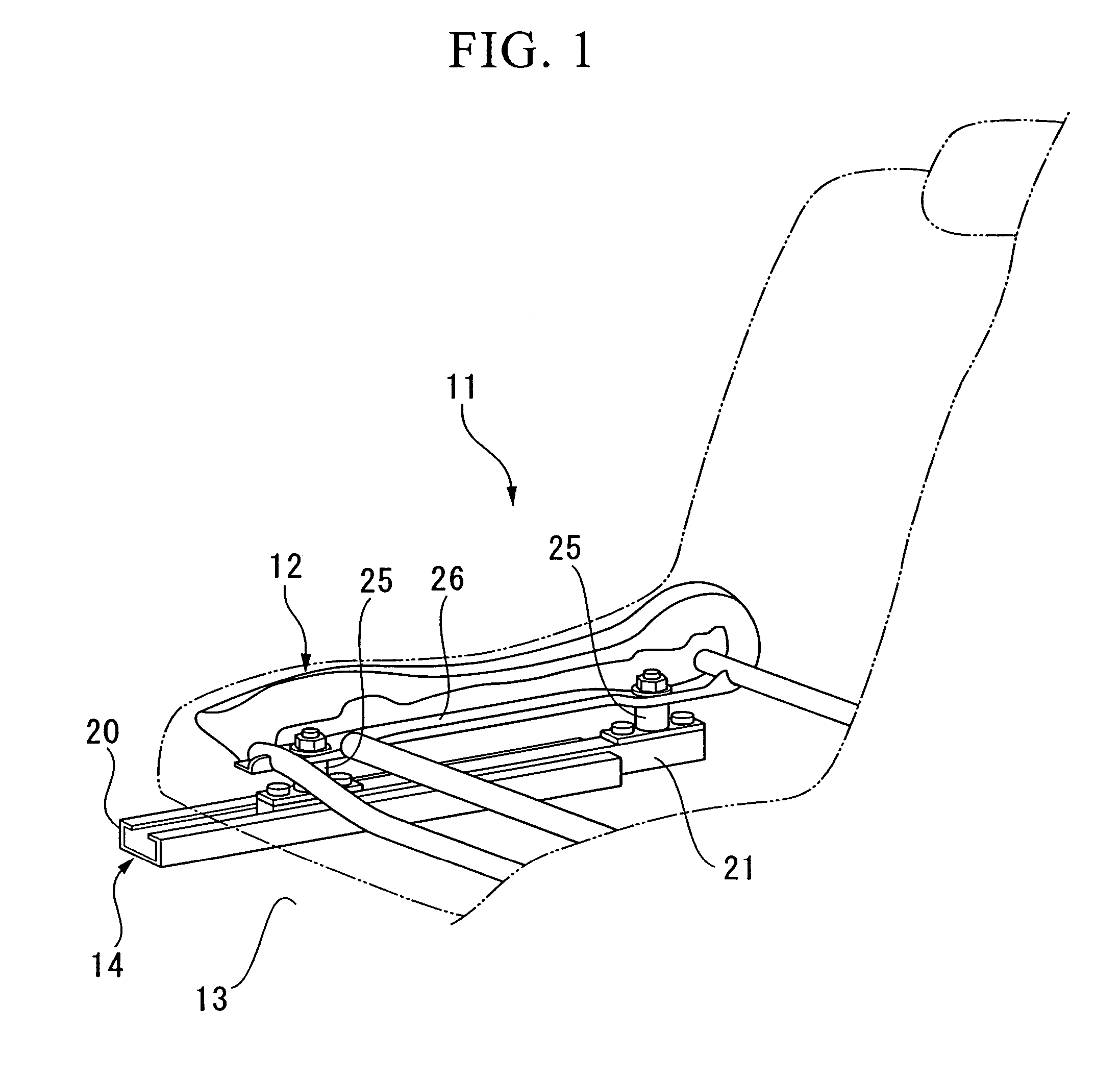

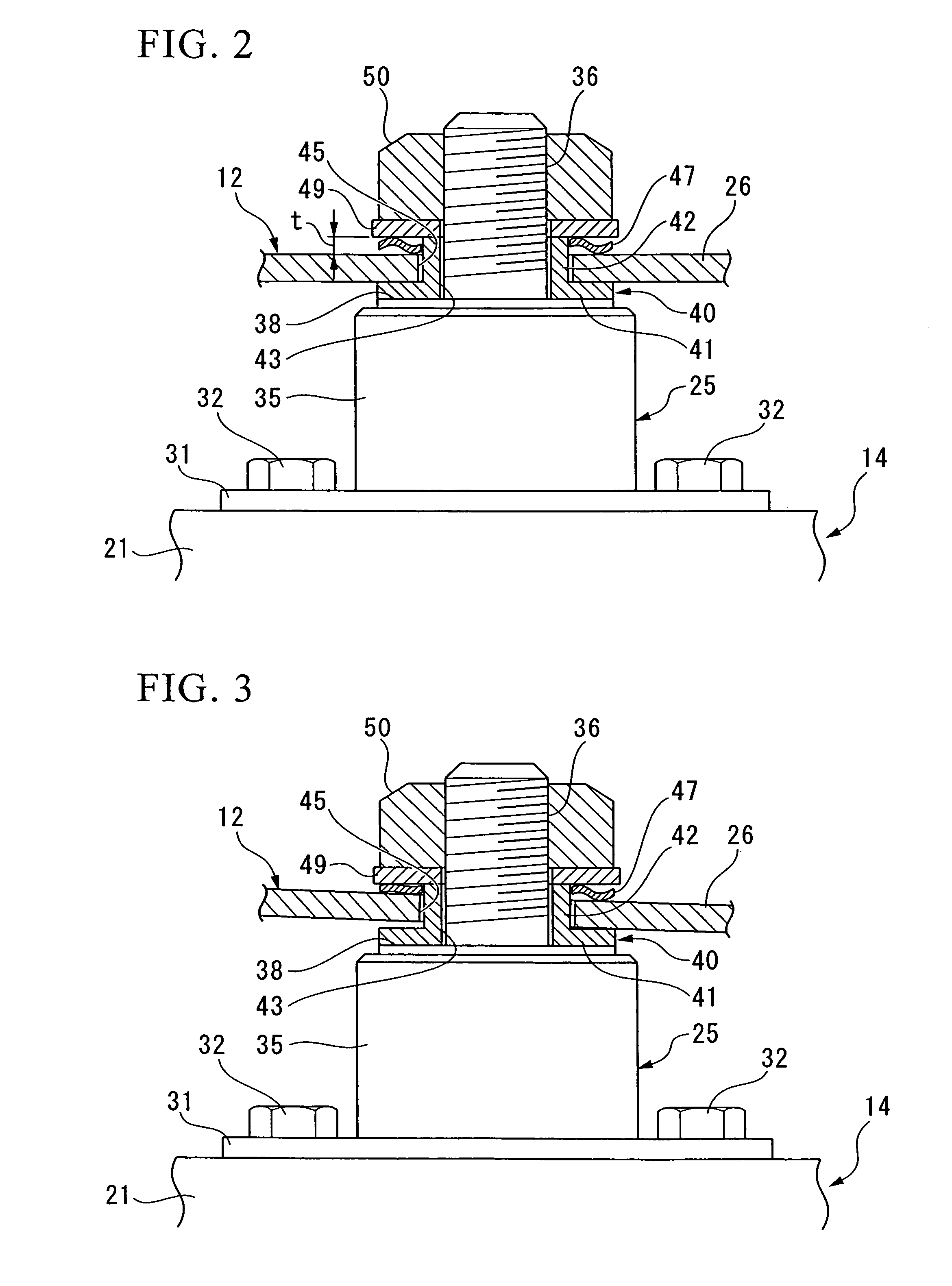

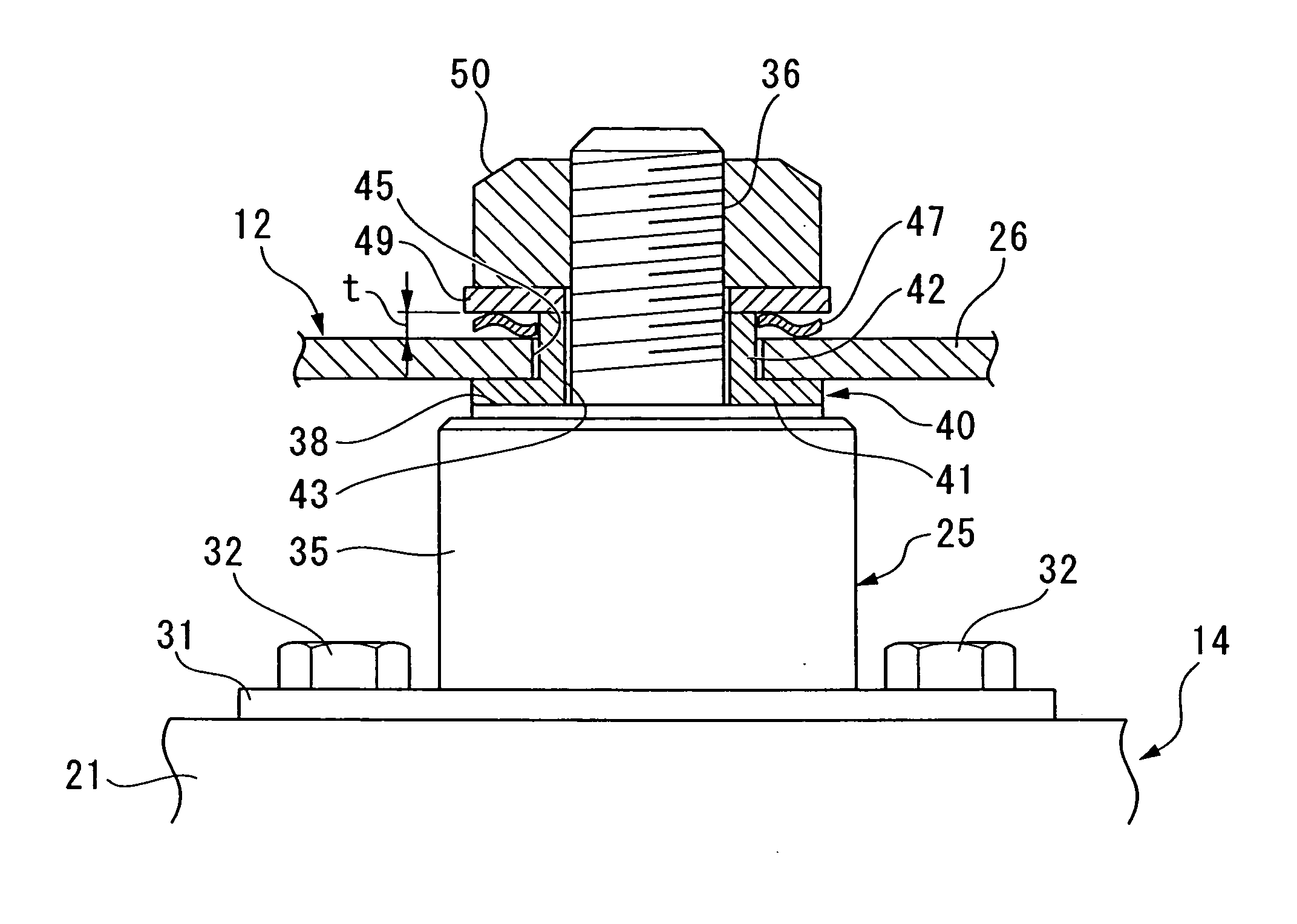

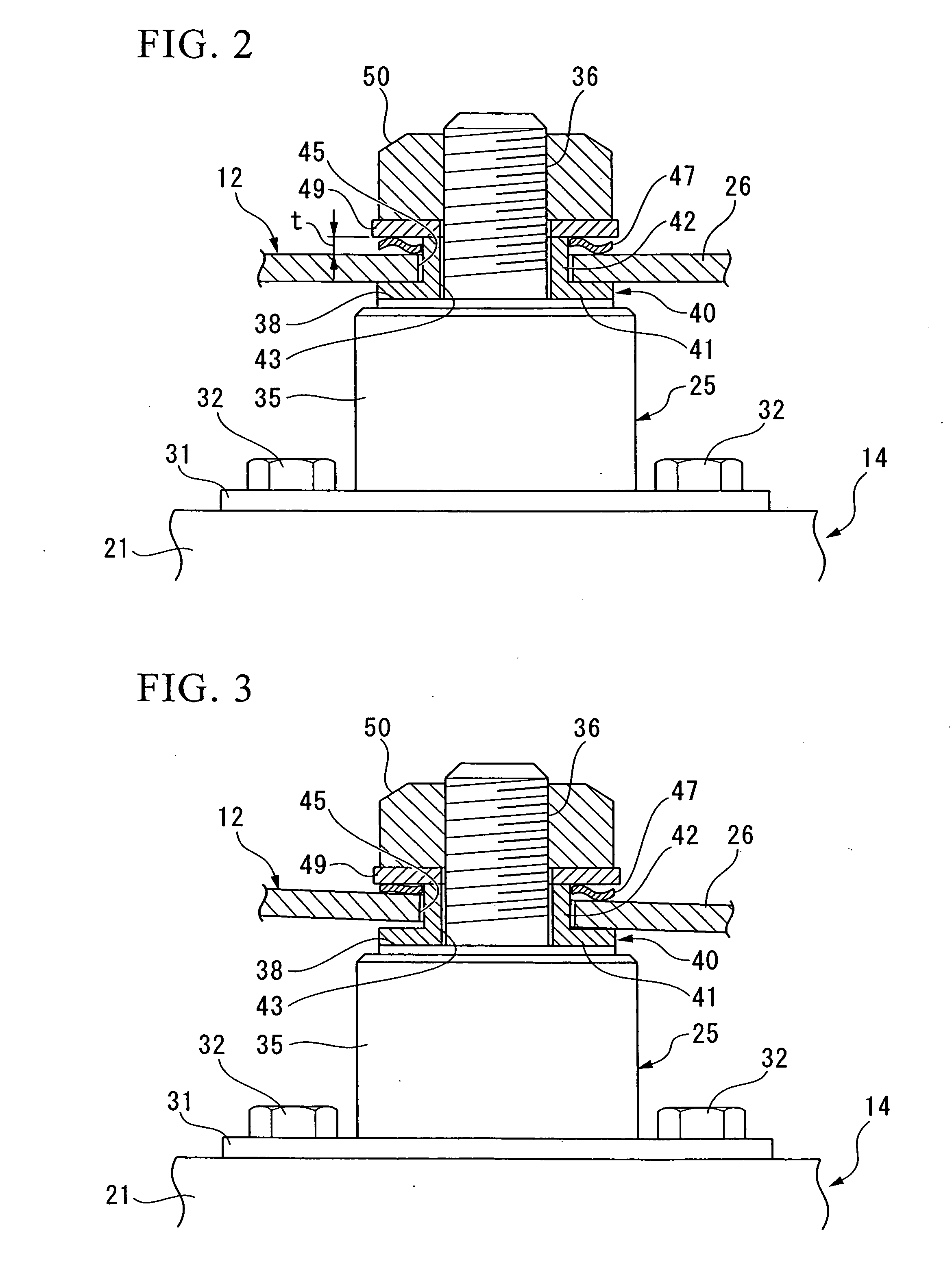

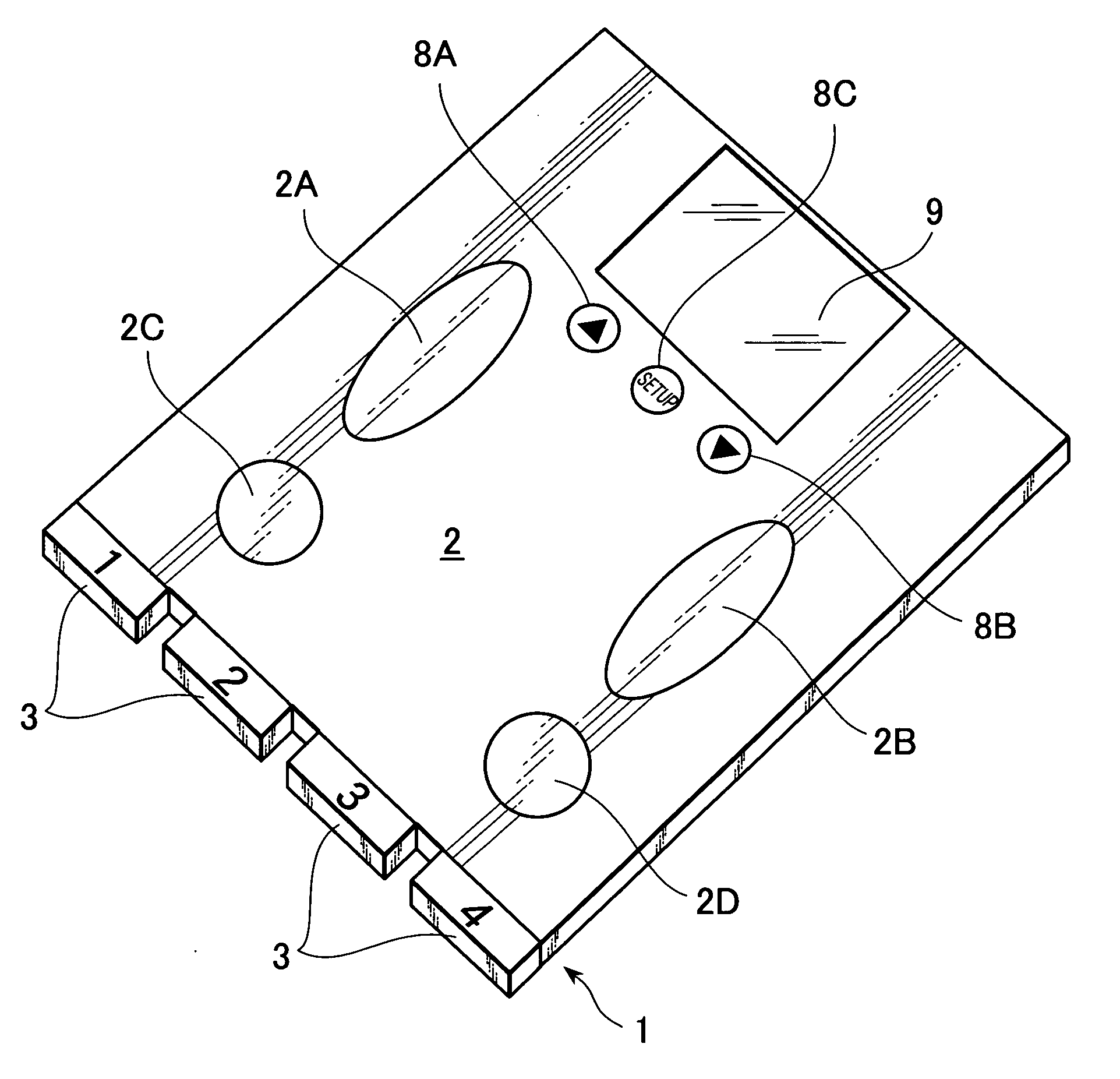

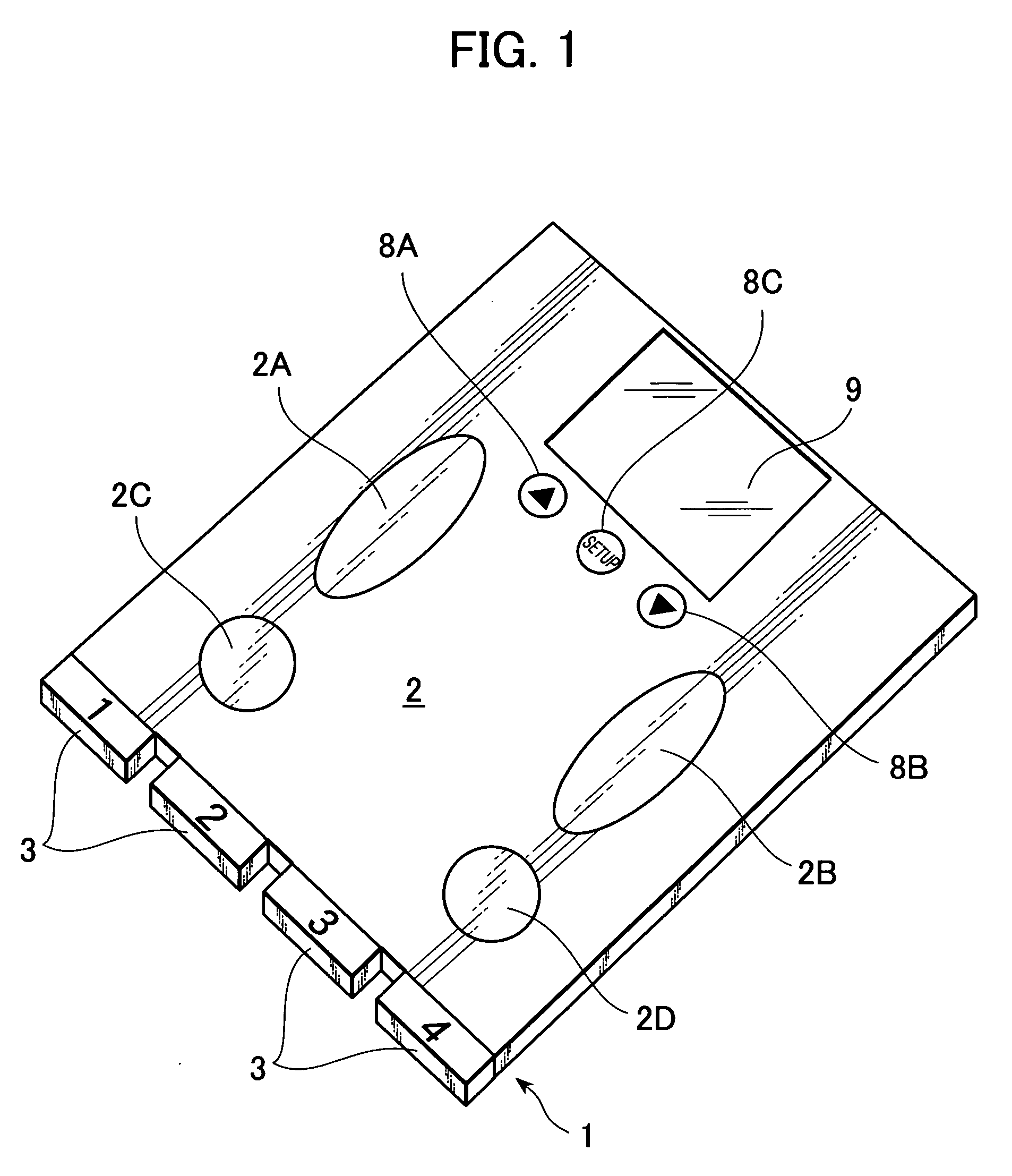

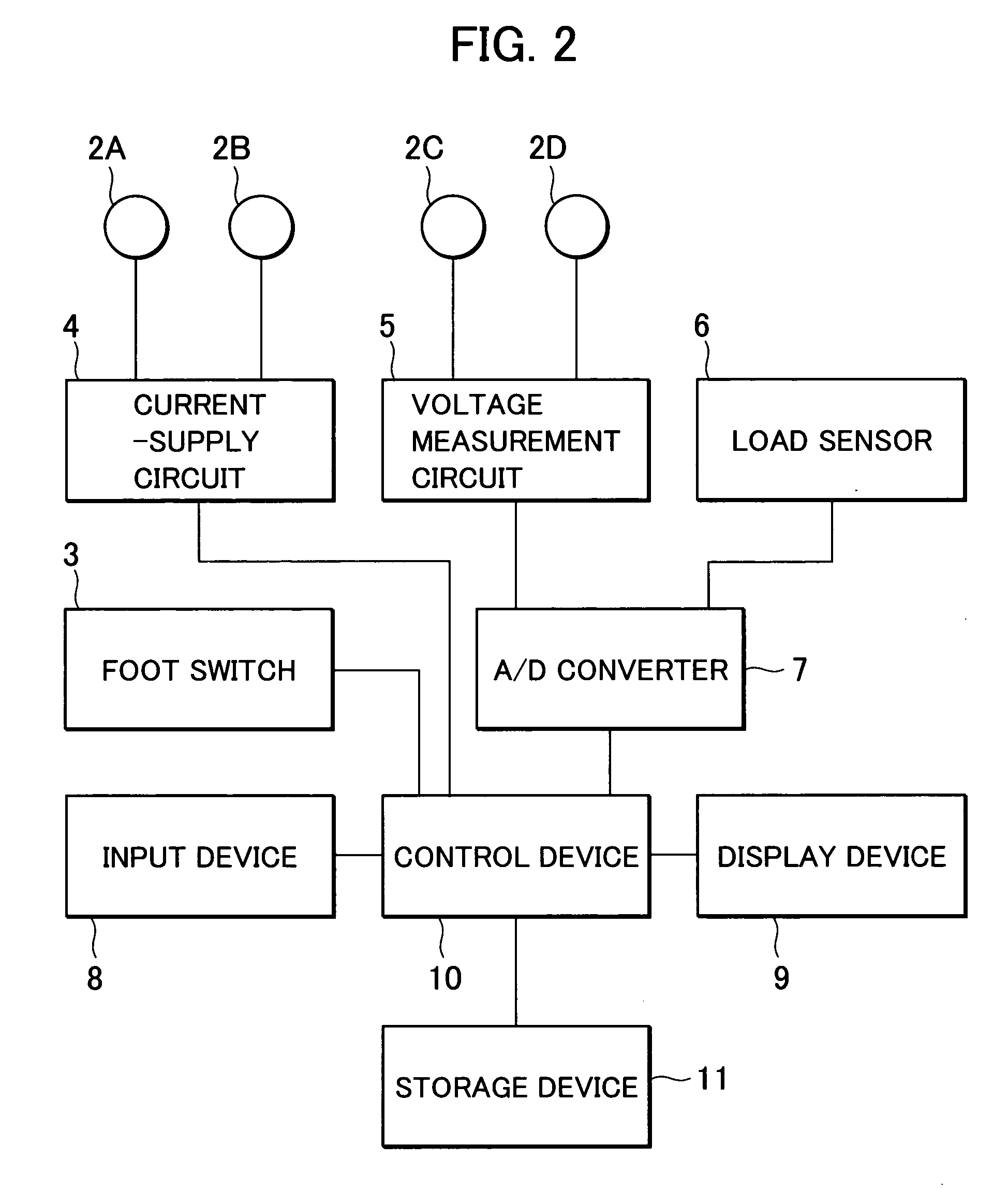

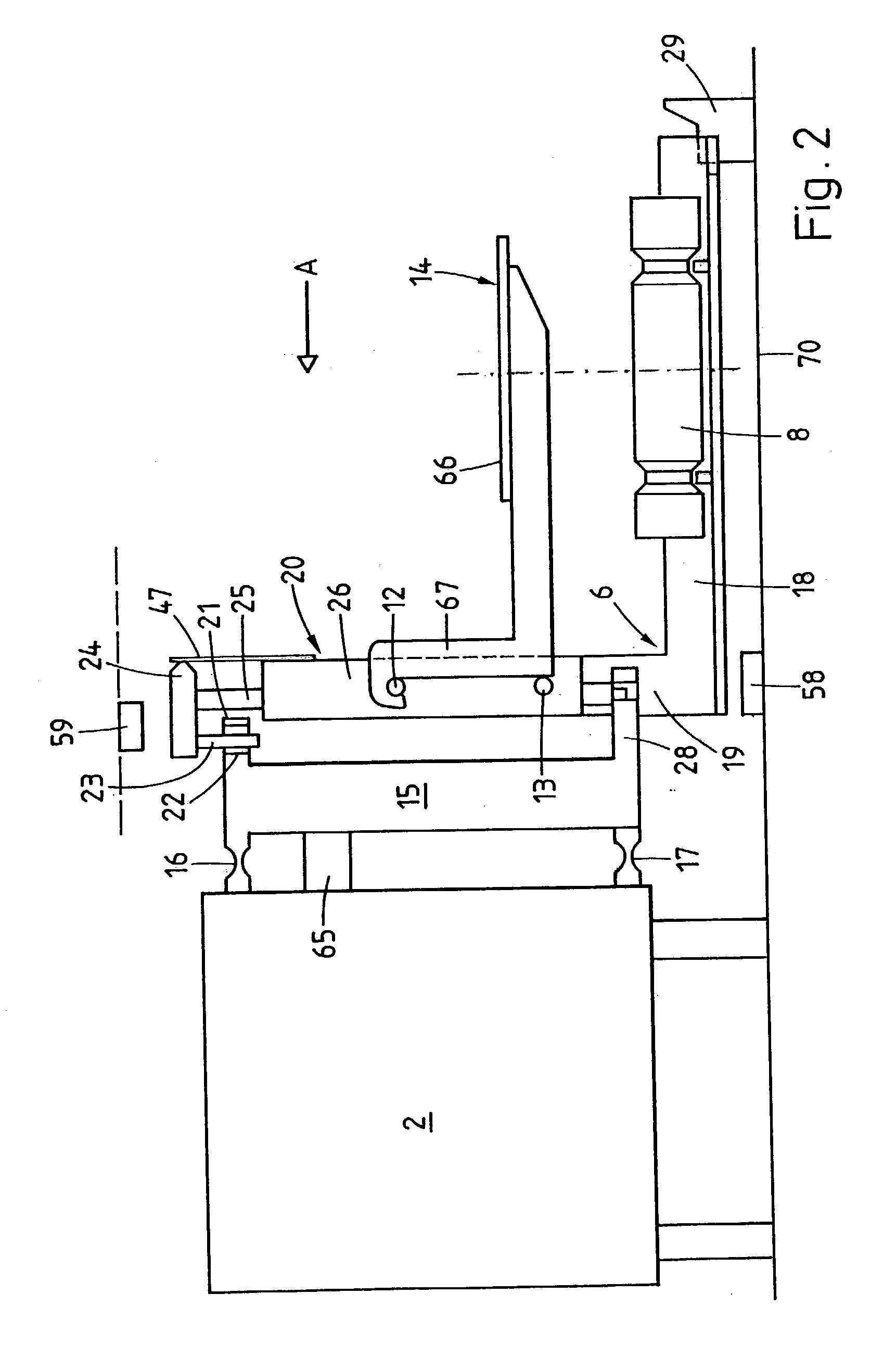

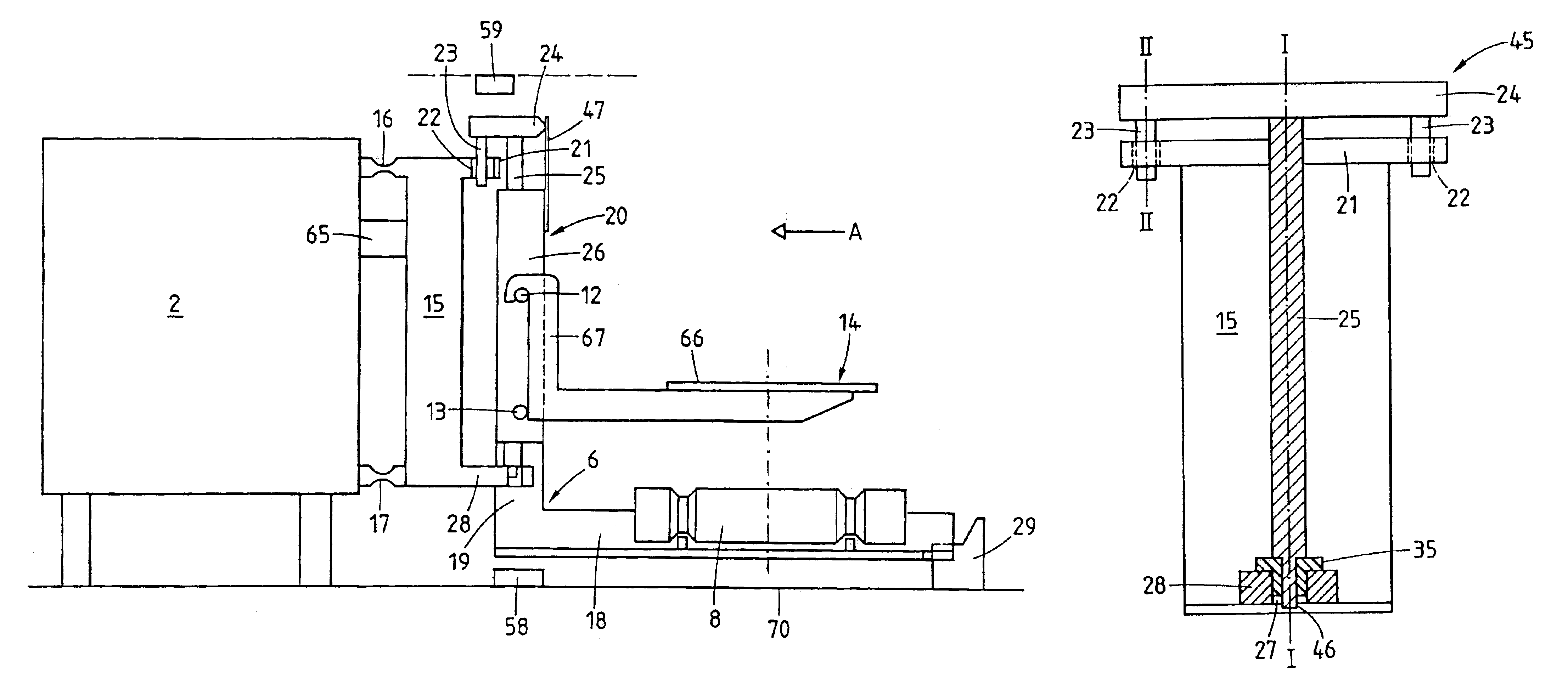

Load cell attachment structure

ActiveUS7373846B2Load accuratelyAccurate measurementLoad modified fastenersOscillations damping for weighingLoad sensingEngineering

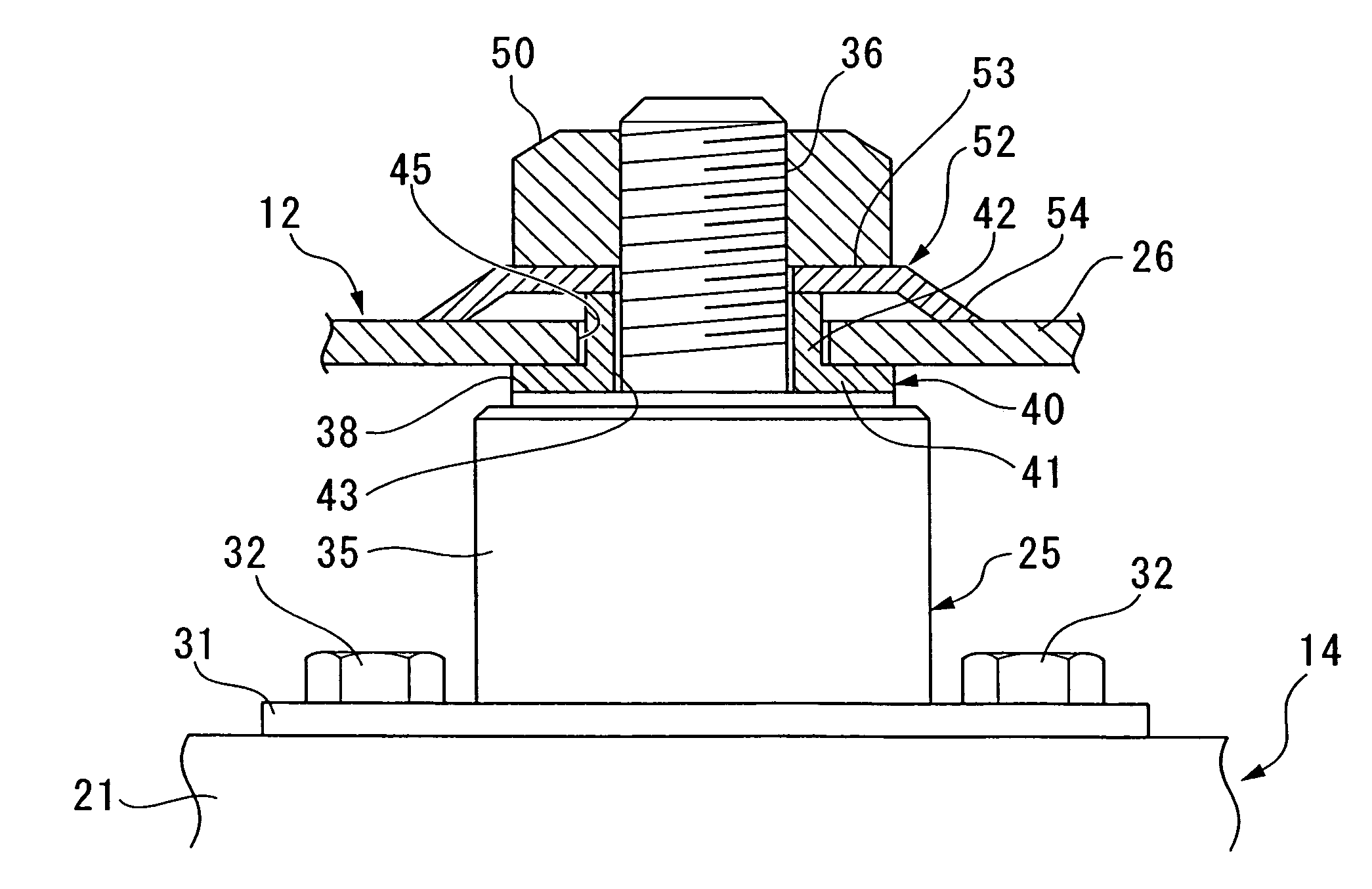

This load cell attachment structure includes a male screw which is formed on a load sensing part of the load cell, a nut which attaches the load cell to the attachment plate by engaging with the male screw, and a wave washer which is disposed between the attachment plate and the nut.

Owner:TS TECH CO LTD +1

Load cell attachment structure

ActiveUS20060048582A1Load accuratelyAccurate measurementLoad modified fastenersOscillations damping for weighingLoad sensingEngineering

This load cell attachment structure includes a male screw which is formed on a load sensing part of the load cell, a nut which attaches the load cell to the attachment plate by engaging with the male screw, and a wave washer which is disposed between the attachment plate and the nut.

Owner:TS TECH CO LTD +1

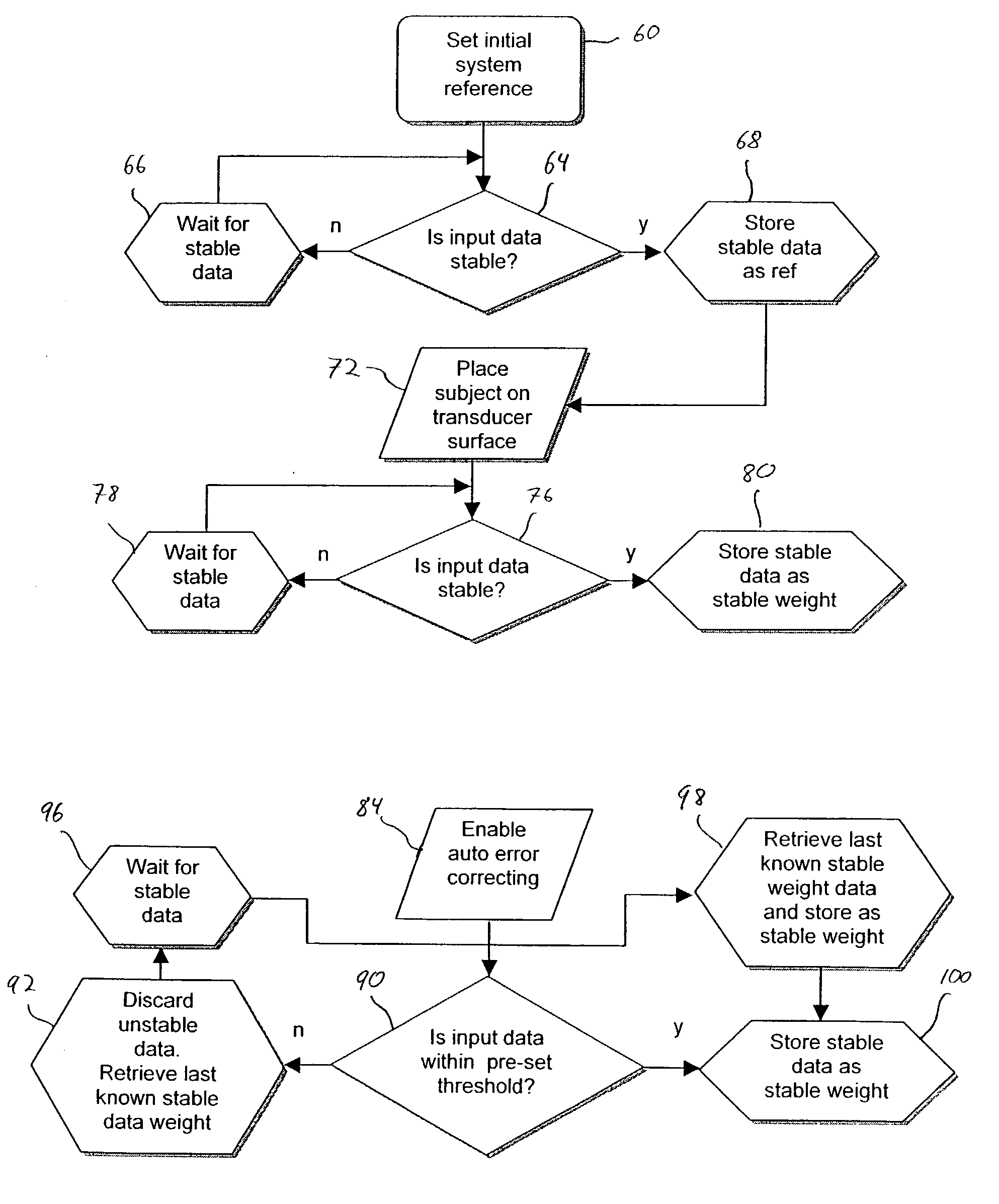

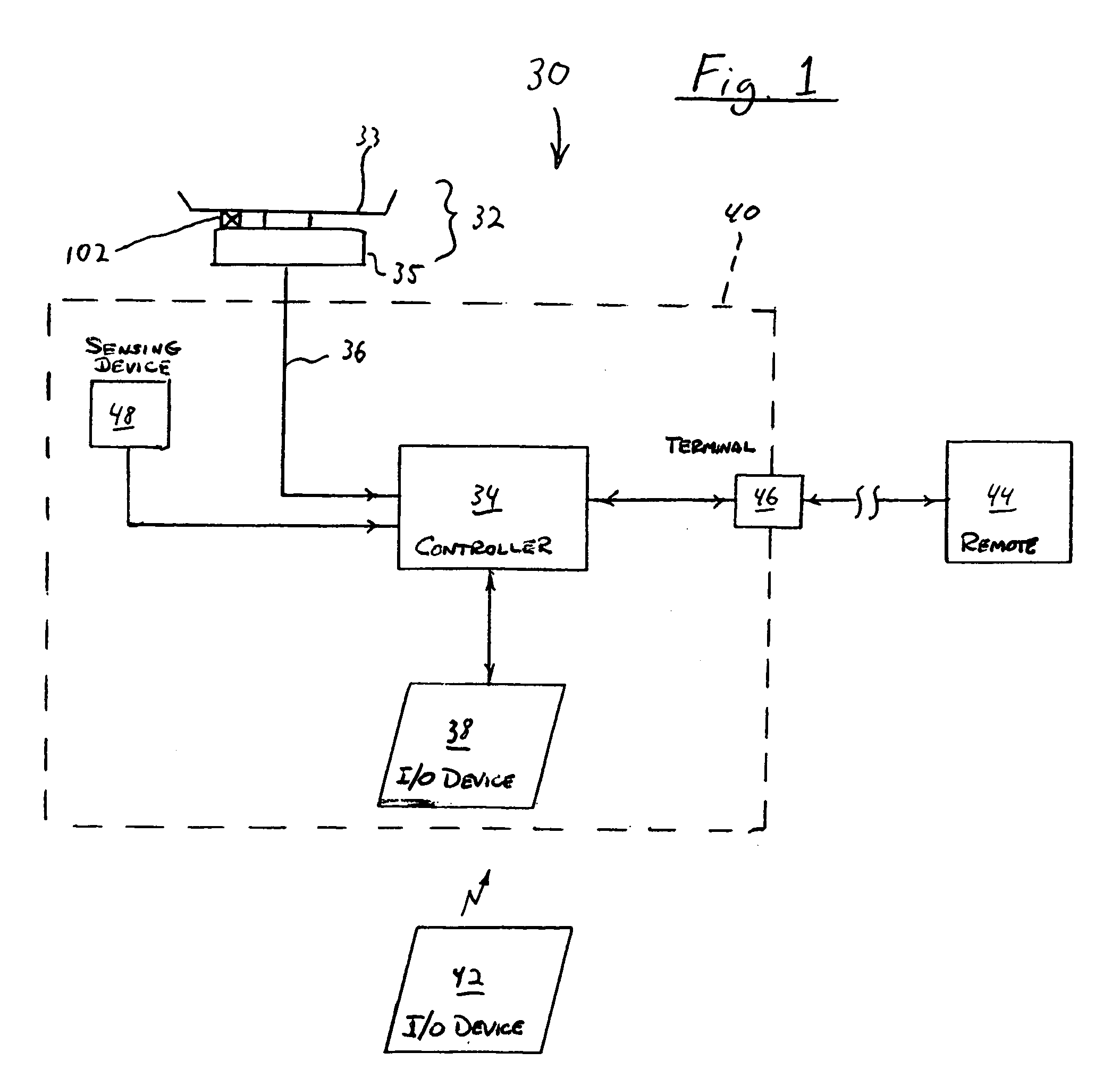

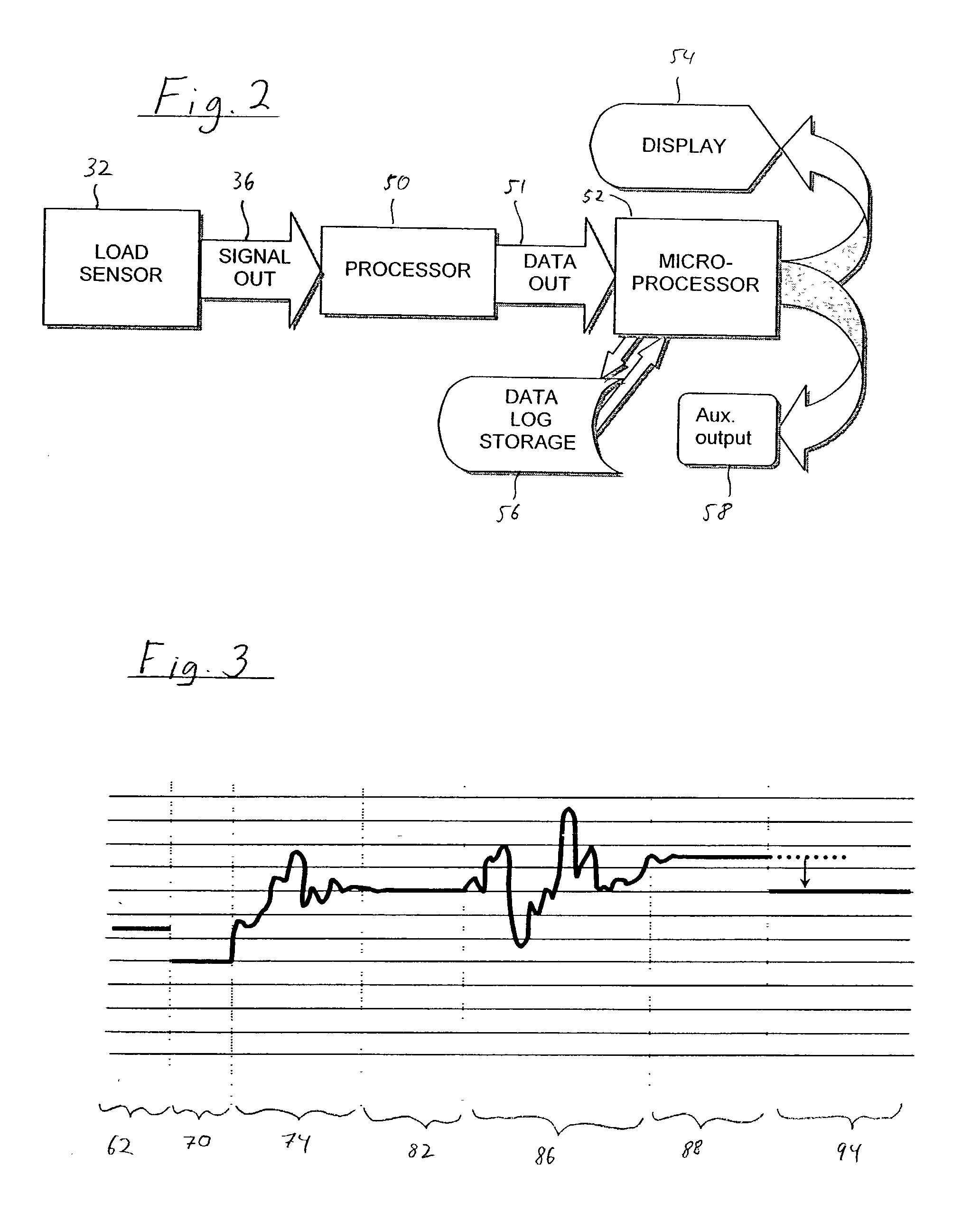

Weighing apparatus and method

InactiveUS6956175B1Reduce decreaseEliminate the problemWeighing apparatus testing/calibrationOscillations damping for weighingWeight shiftCollection system

A scale including an event data discrimination and collection system for continuously monitoring a weight of an infant placed on the scale platen, which may be configured as a bed. Load cells are used to continuously monitor infant weight from time placed on the scale platen, so that sudden apparent weight spikes sensed by the load cells but attributable to events involved in patient care may be discarded as artifact, while gradual weight changes reflective of infant physiology are accumulated by the scale controller and used to provide a current weight for the infant.

Owner:DALY PAUL C +1

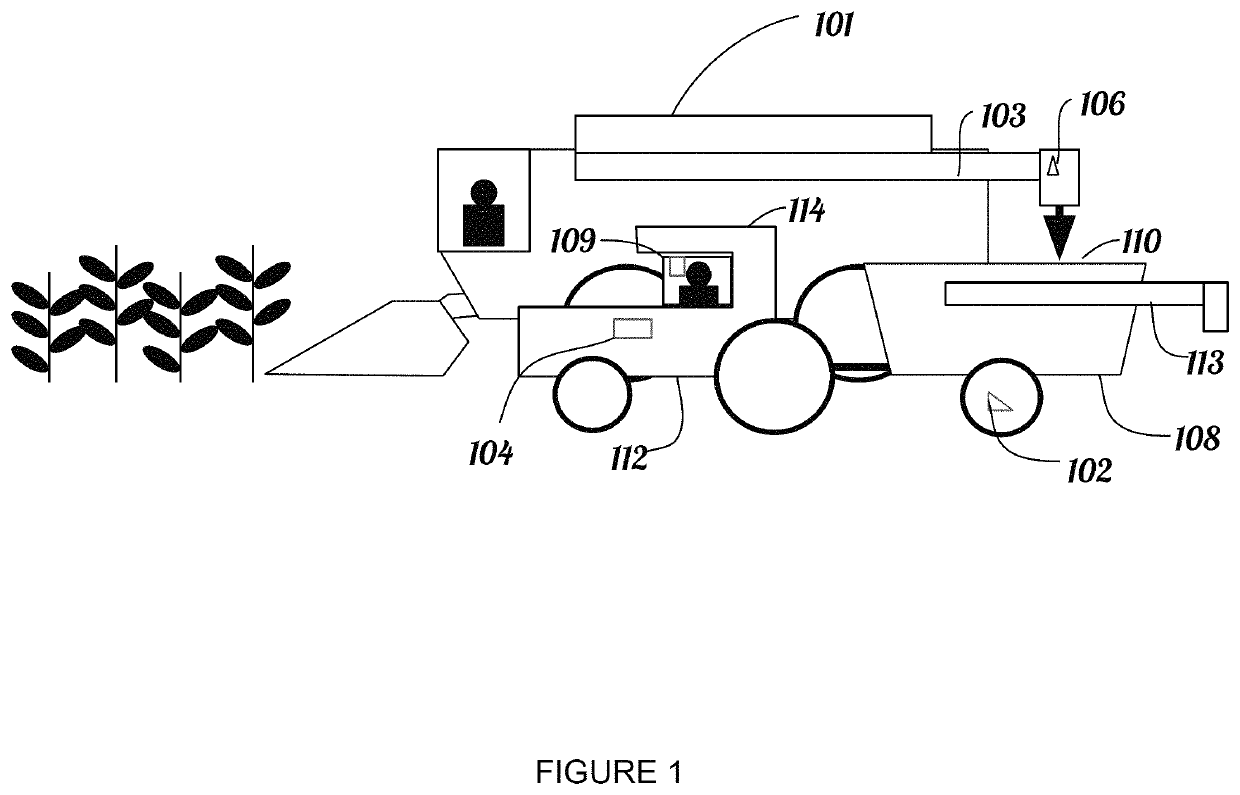

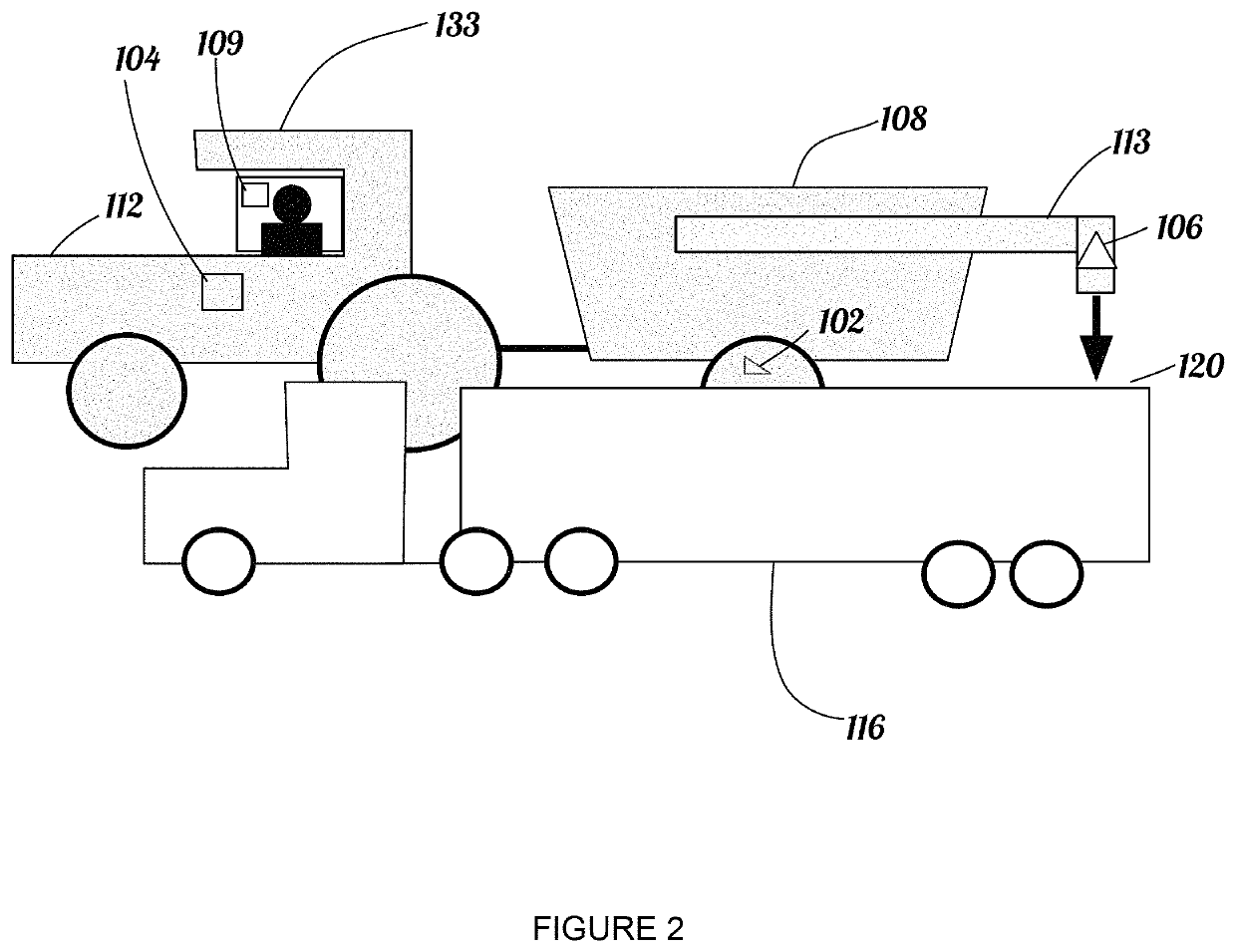

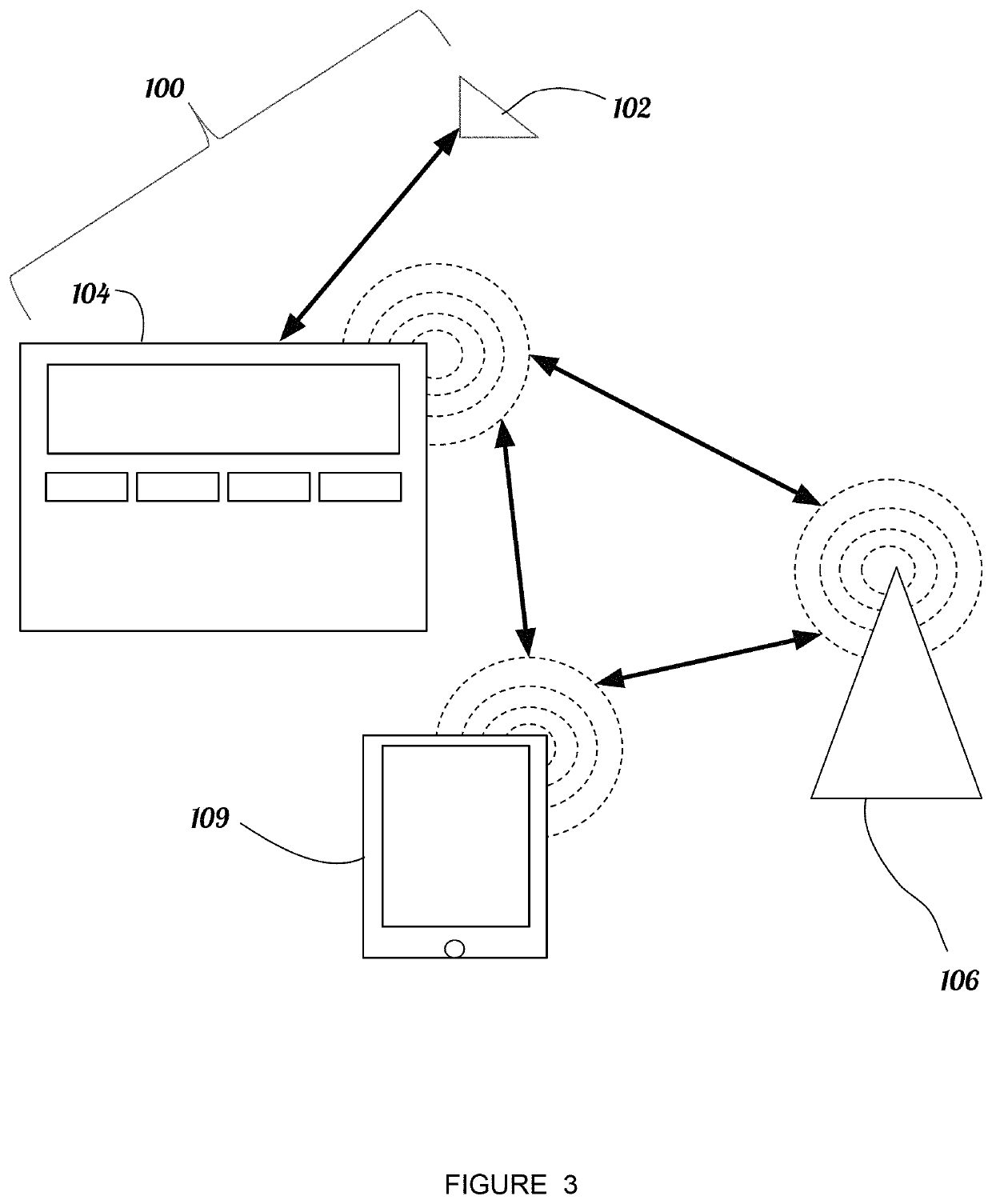

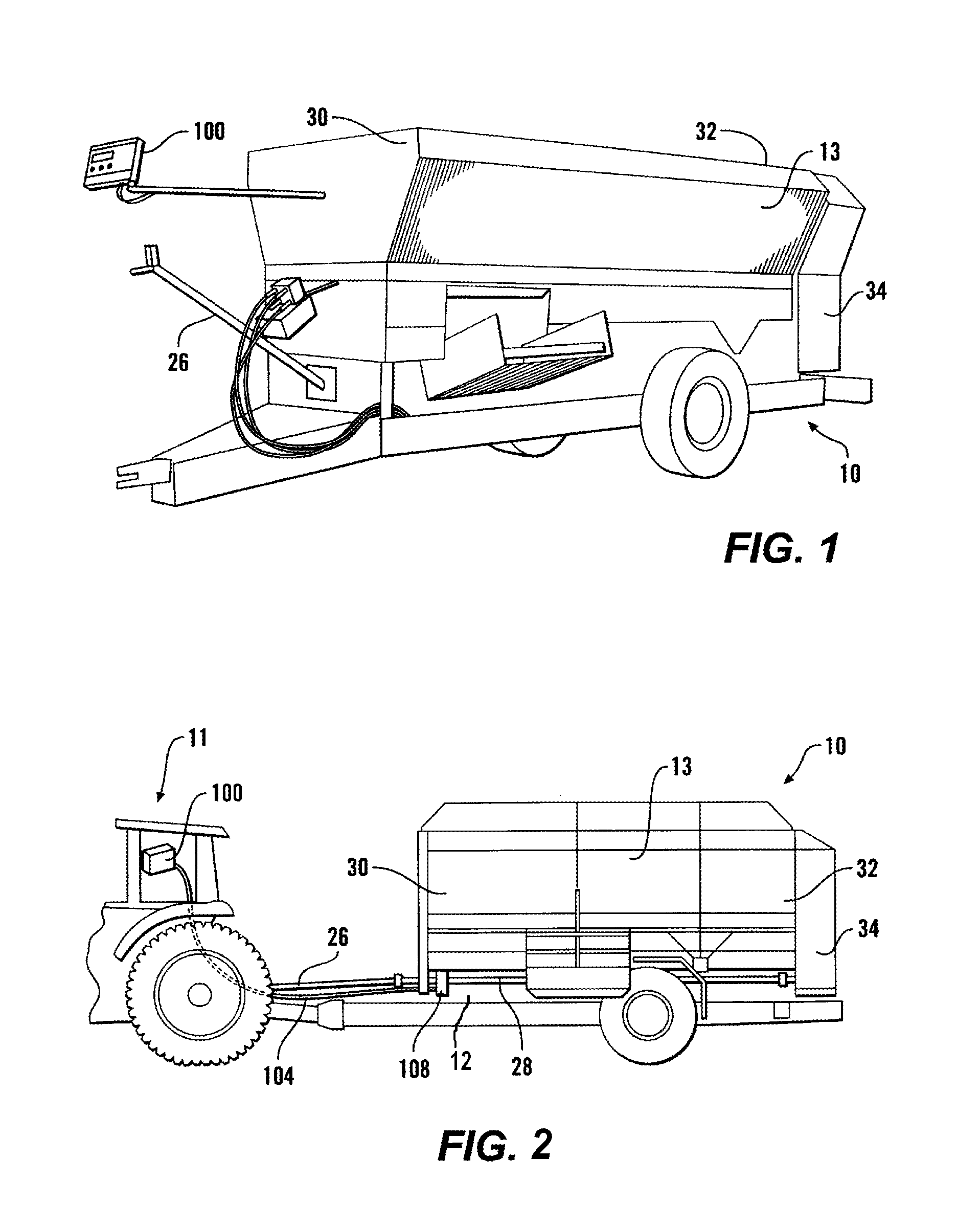

Scale controller with dynamic weight measurement

ActiveUS10677637B1Quick and easy placementQuick and easy and removalLoadersMowersControl engineeringControl theory

Owner:SCALE TEC LTD

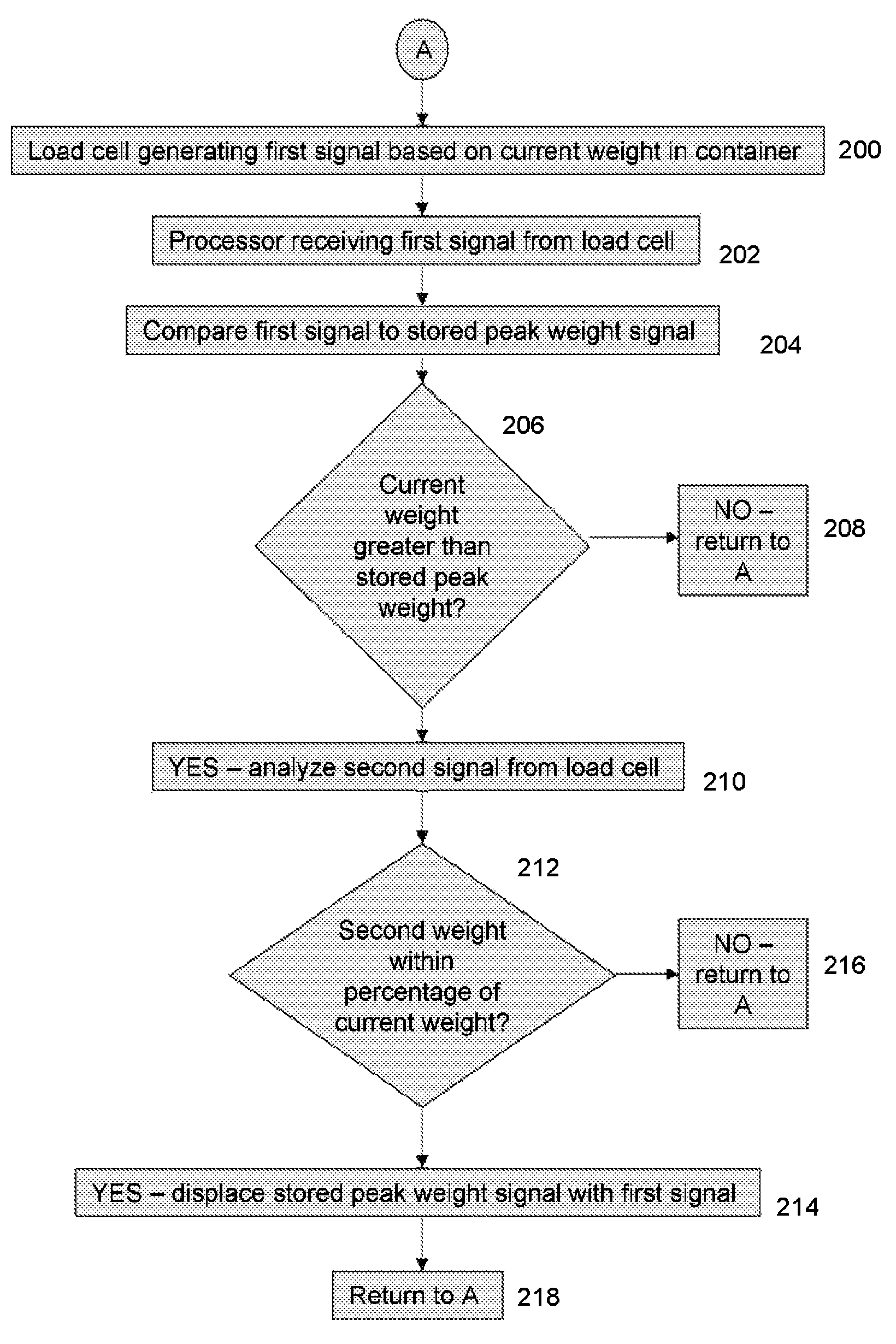

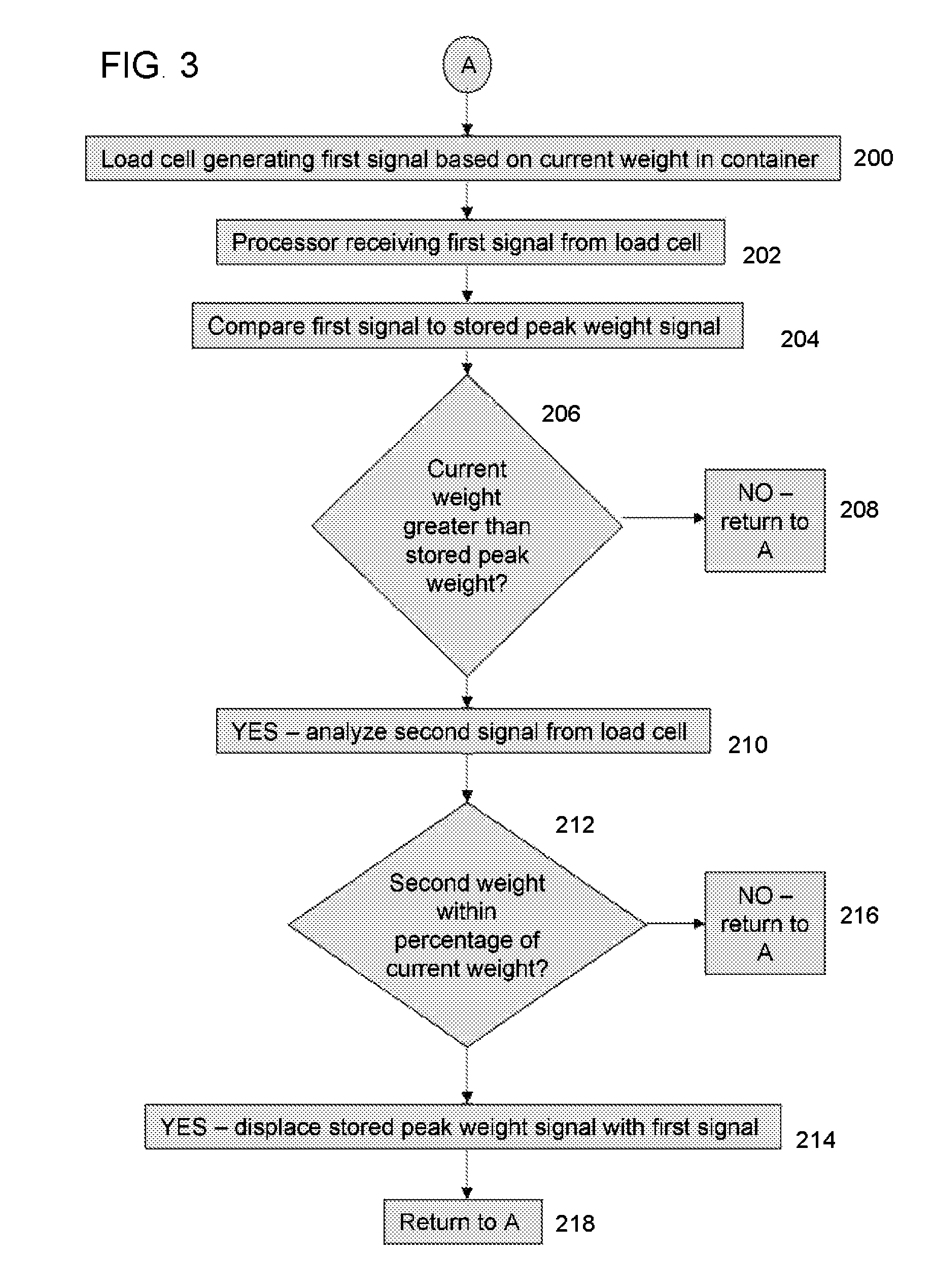

Peak weight detector and method

A peak weight detecting system and method which analyzes signals generated by a load cell indicating a load within a container. The signal indicates a weight which is compared with a stored peak weight. If the new weight exceeds the stored weight, the new weight is verified by comparison to a weight indicated by a second signal from the load cell. If the weights indicated by the first and second signals are within a specified percentage of each other, the weight indicated by the first signal may displace the stored peak weight and may be stored as a new peak weight.

Owner:DIGI STAR

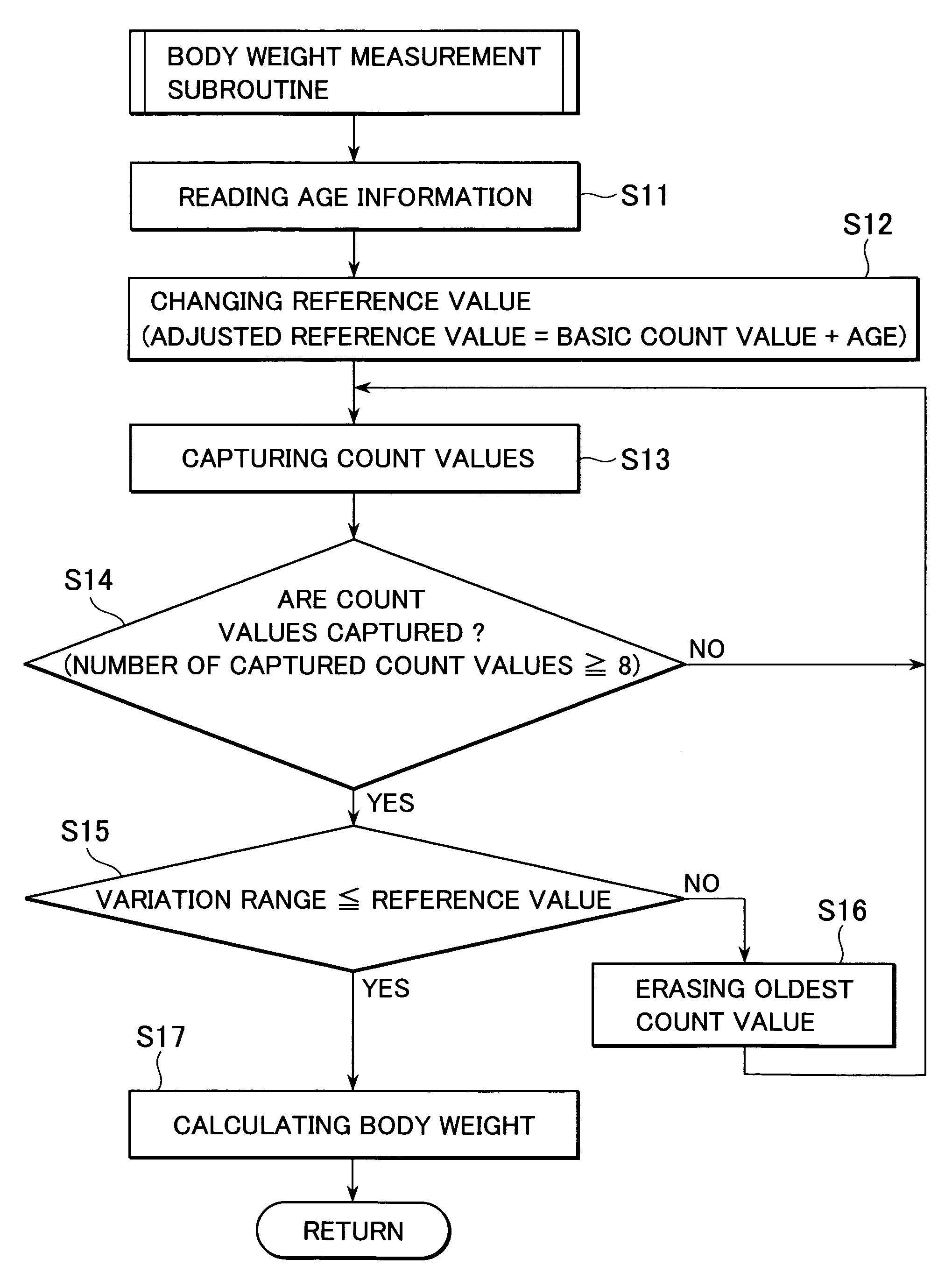

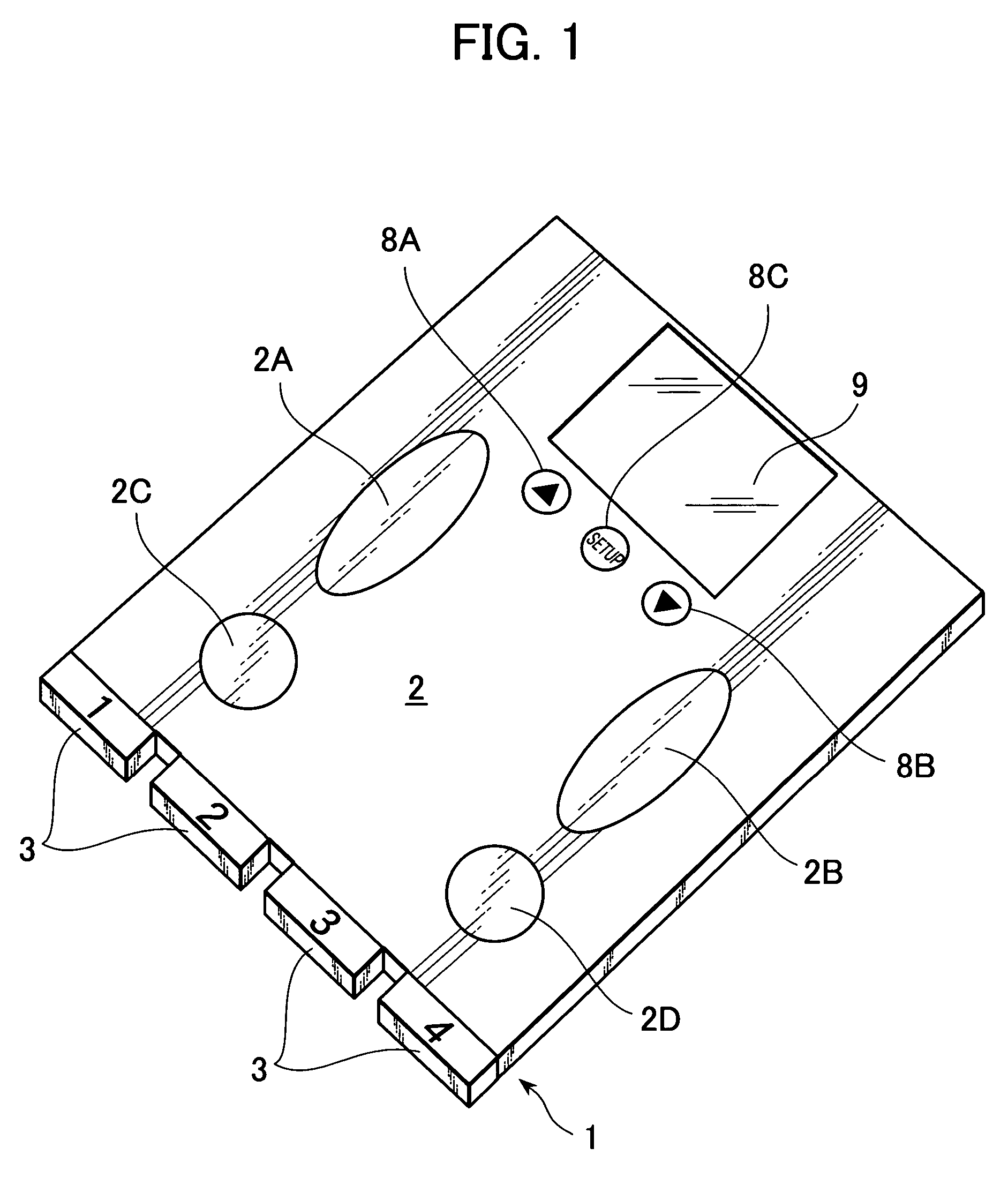

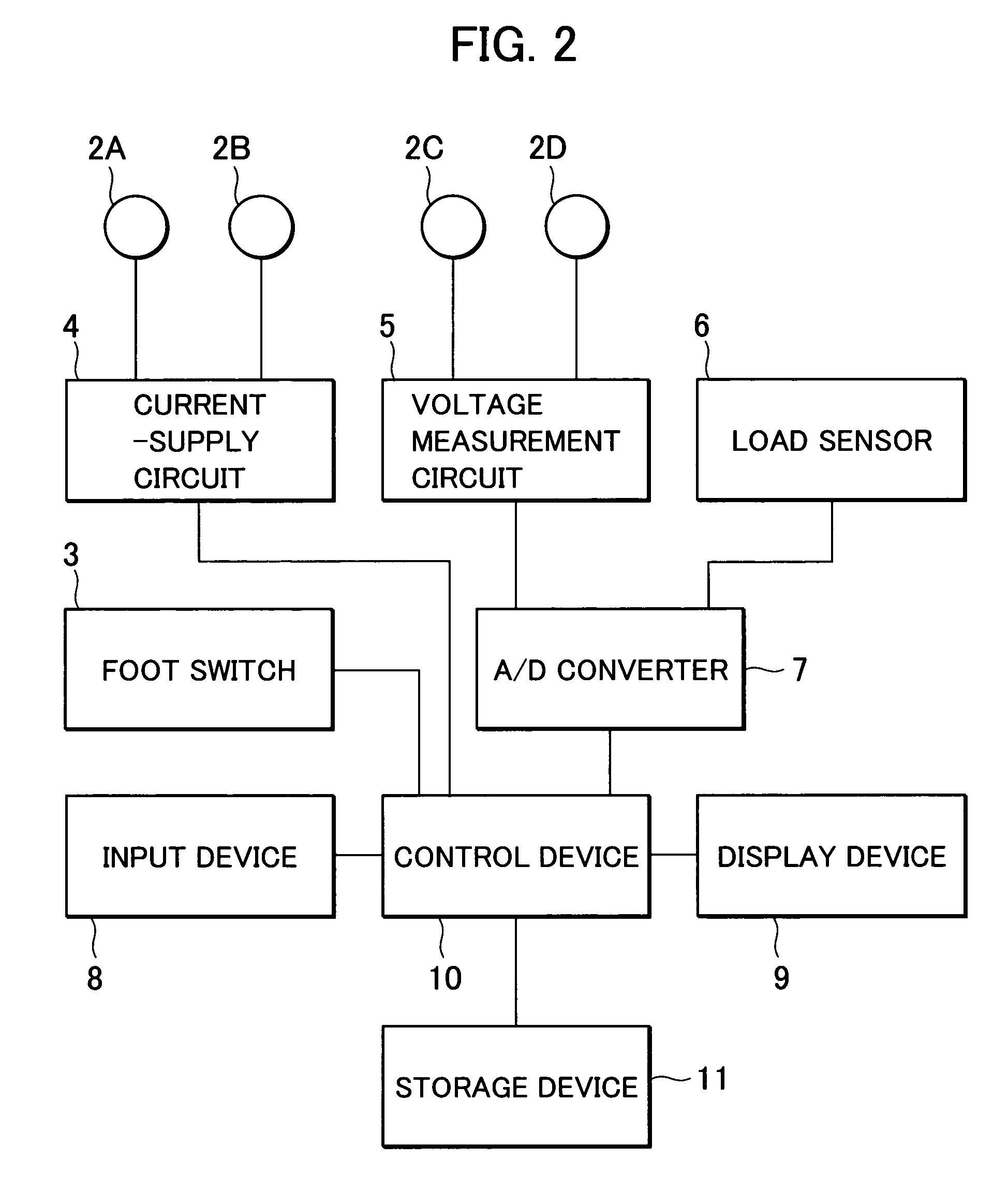

Digital measurement apparatus

InactiveUS7459644B2Avoid measurement errorsSimple wayWeighing apparatus testing/calibrationOscillations damping for weighingDigital dataFast measurement

Disclosed is a digital measurement apparatus including data capture means operable to continuously capture digital data about a target measurement item, validity determination means operable to compare the captured data with a reference value so as to determine whether all of the captured data are valid, and measurement-value calculation means operable, when all of the captured data are determined to be valid, to calculate a measurement value in accordance with the valid data, which is characterized by further comprising reference-value change means operable to change the reference value. The digital measurement apparatus of the present invention makes it possible to perform a speedy measurement.

Owner:TANITA CORP

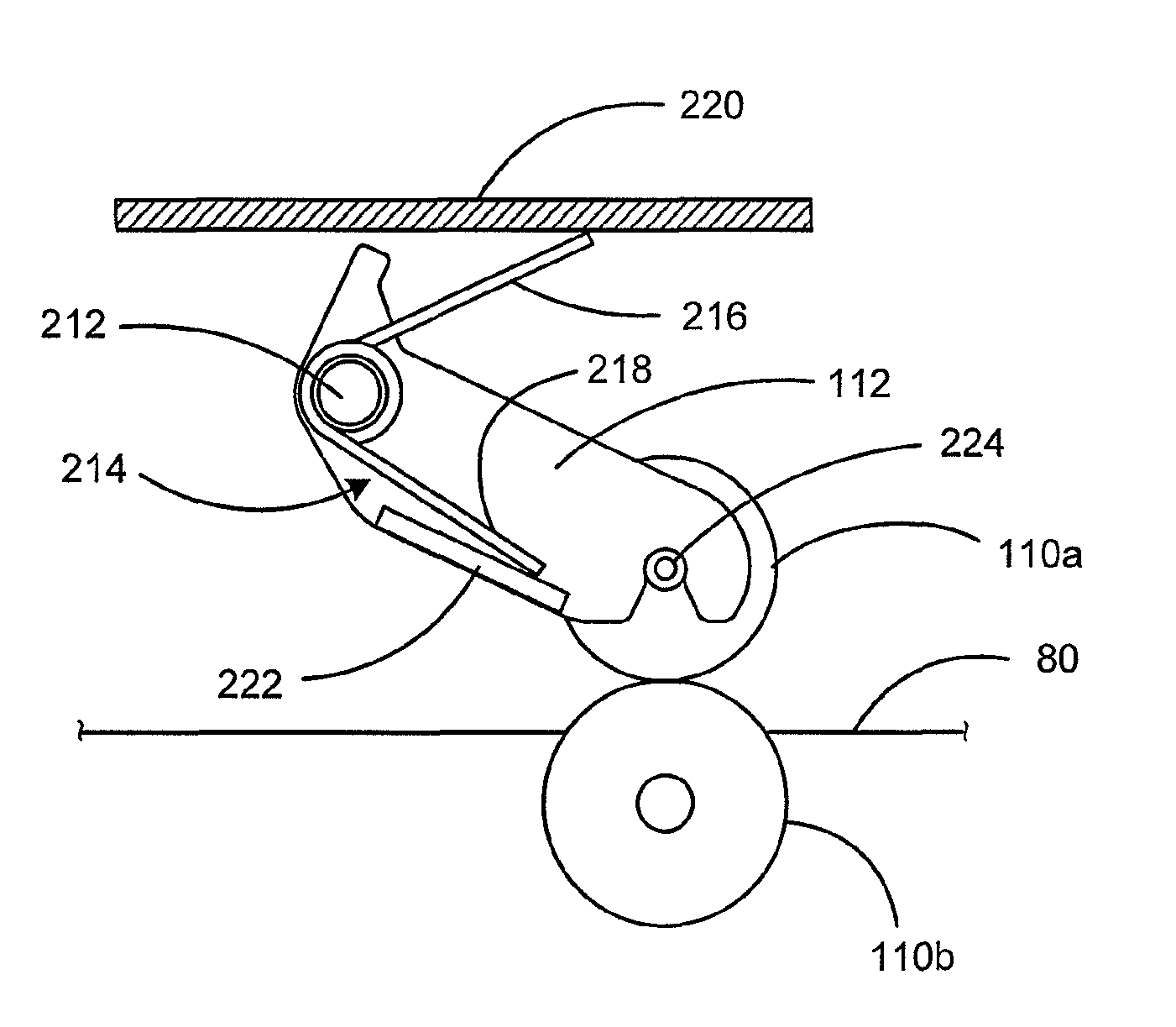

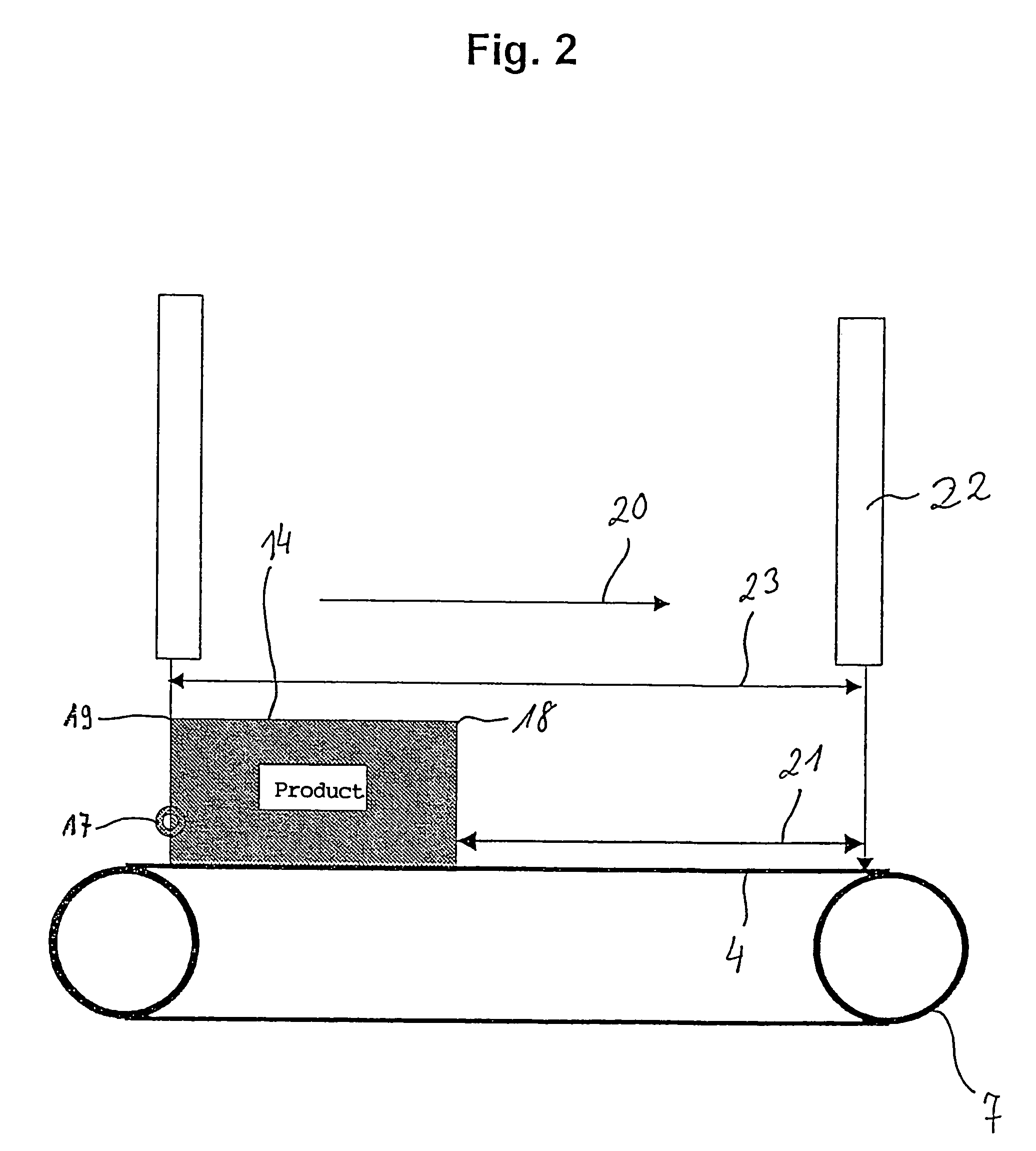

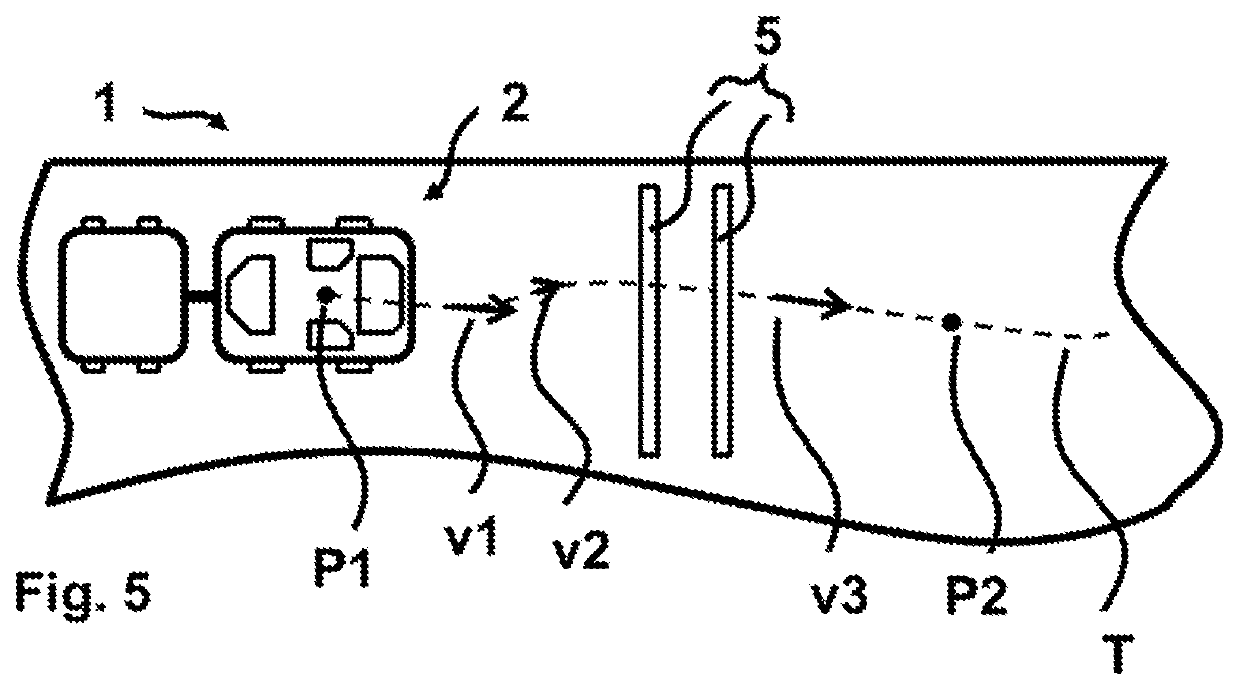

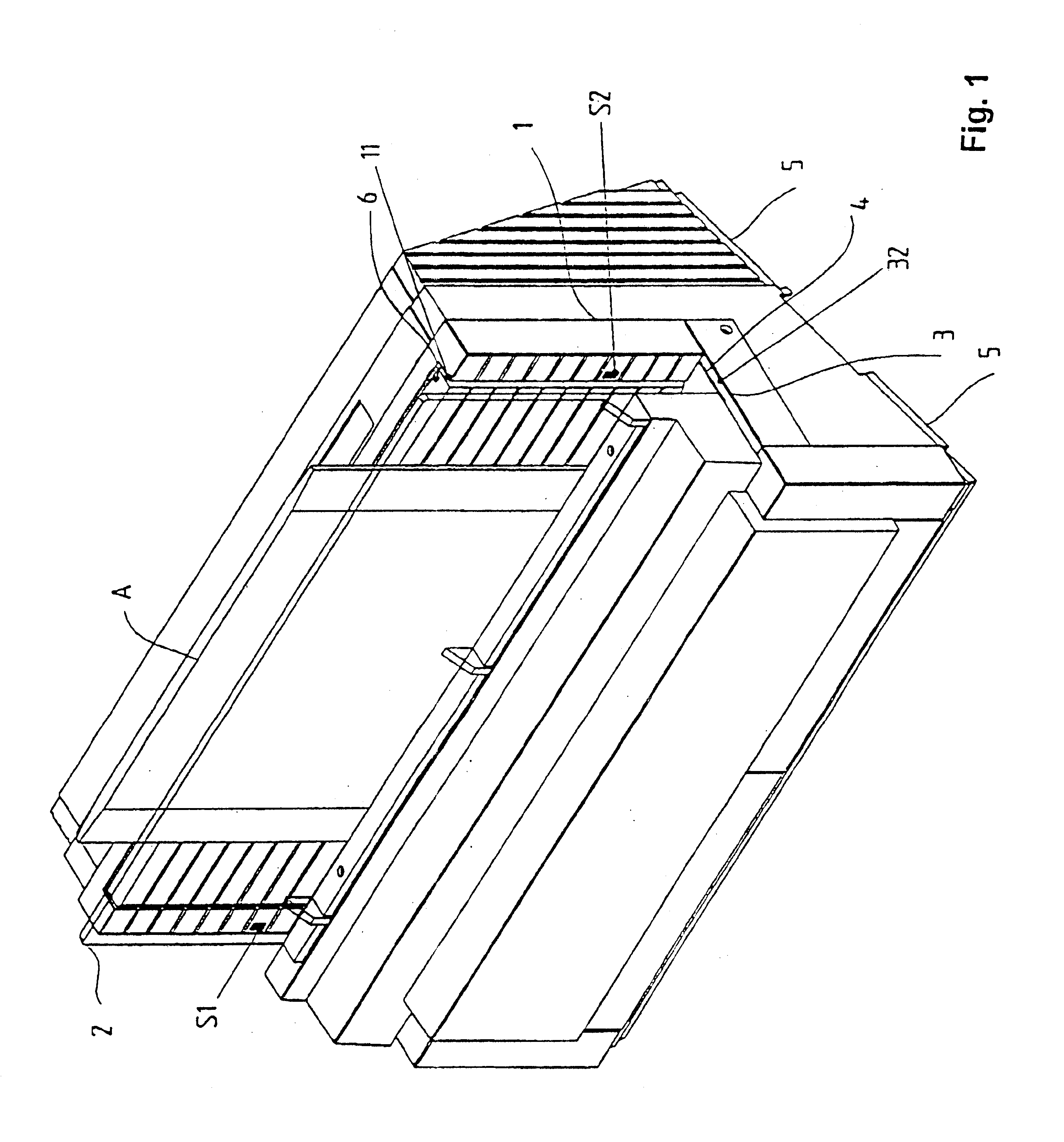

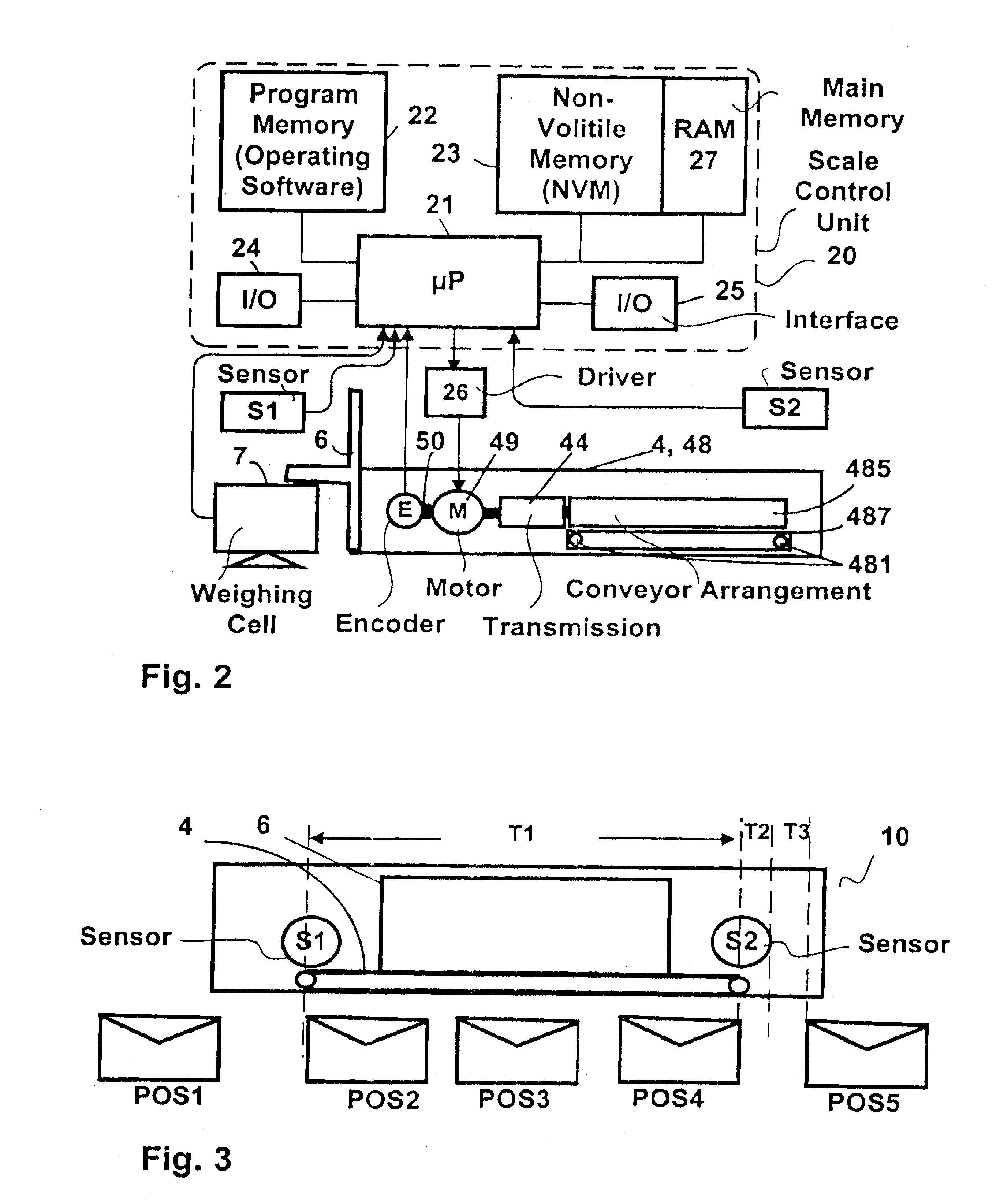

Mailing machine transport system with integral scale for weighing mail pieces where the contact force on the take away rollers is reduced to eliminate oscillations of the weighing platform

ActiveUS8148650B2Reduce oscillationFast weighingOscillations damping for weighingFranking apparatusTransport systemContact force

Owner:PITNEY BOWES INC

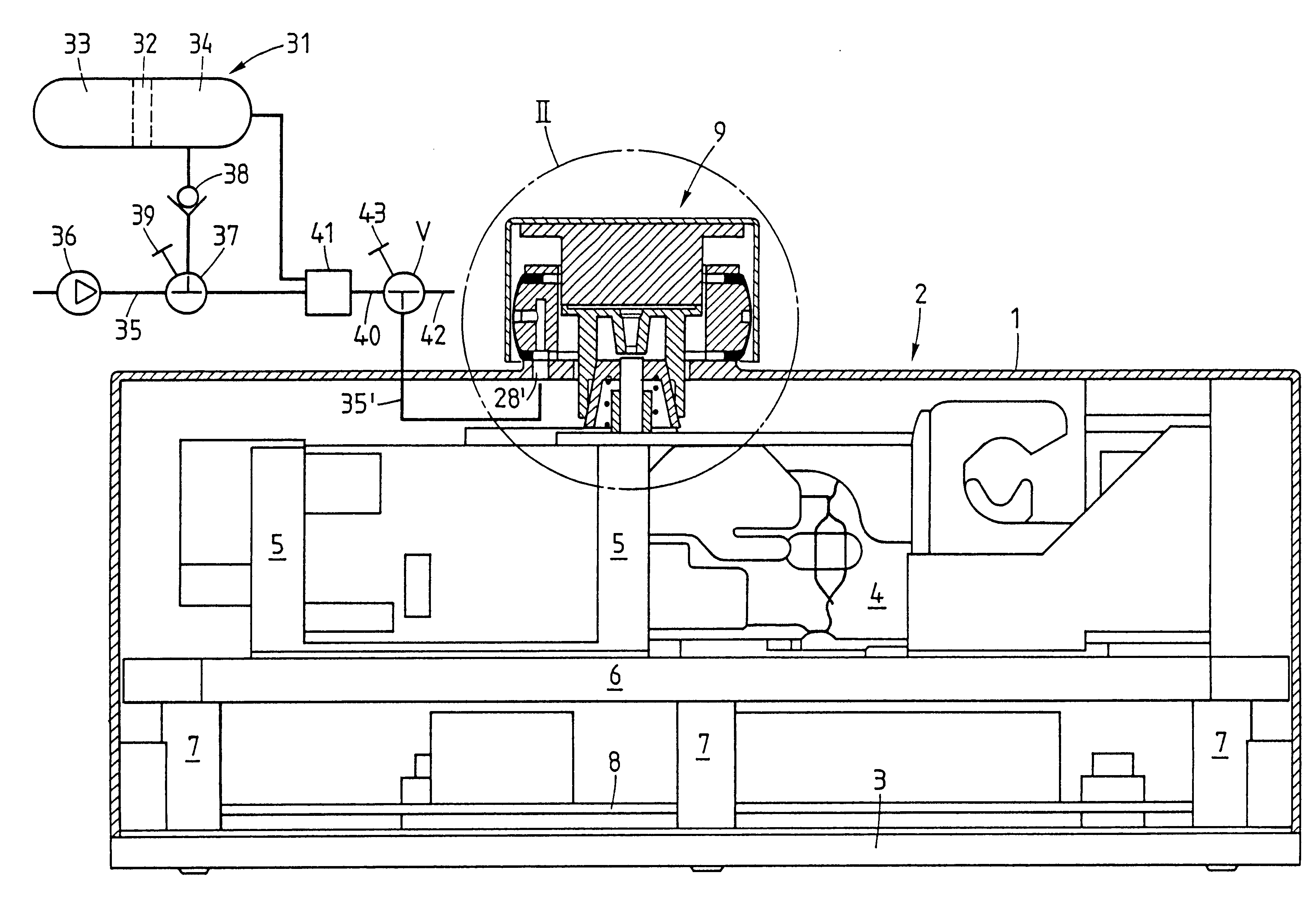

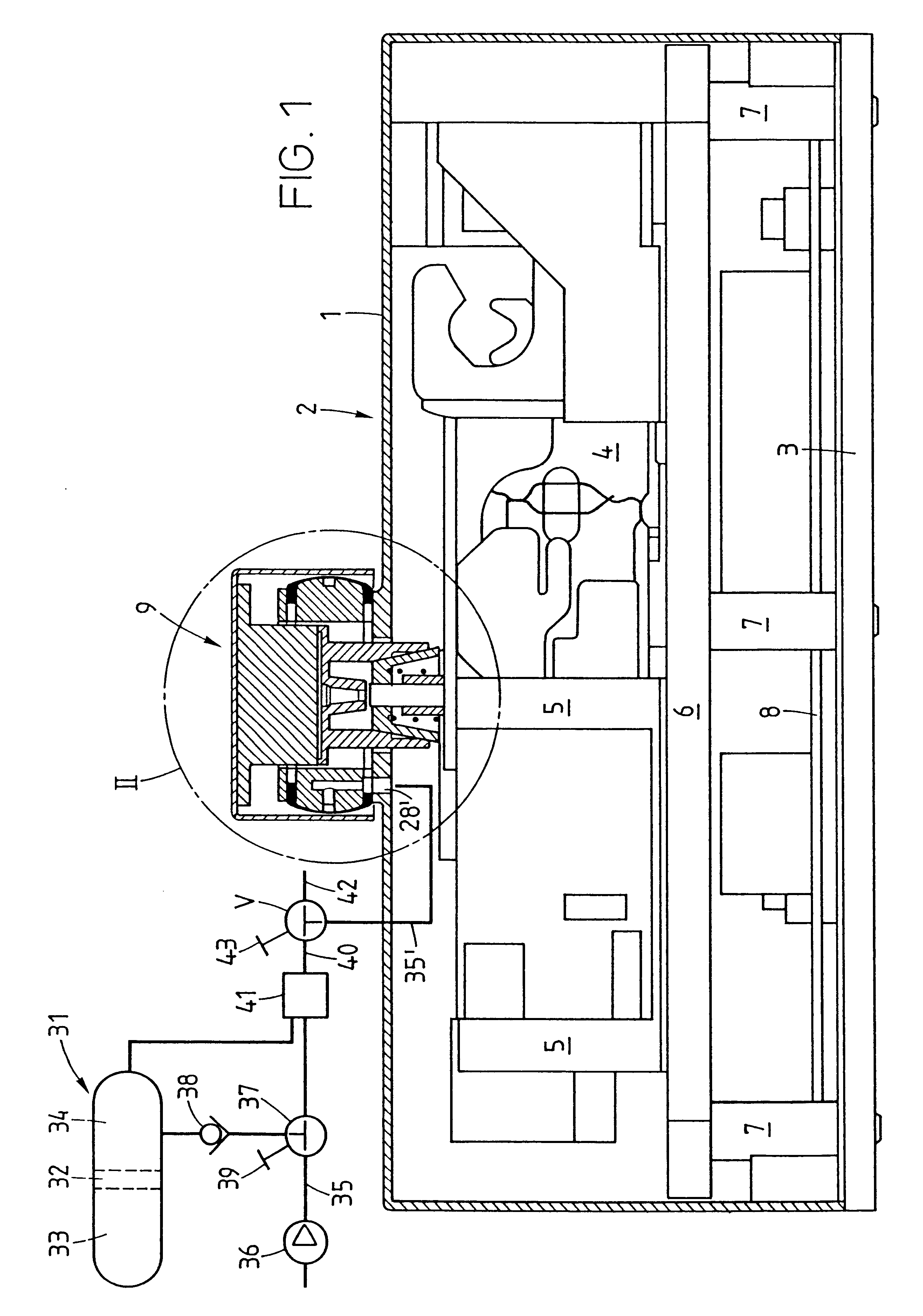

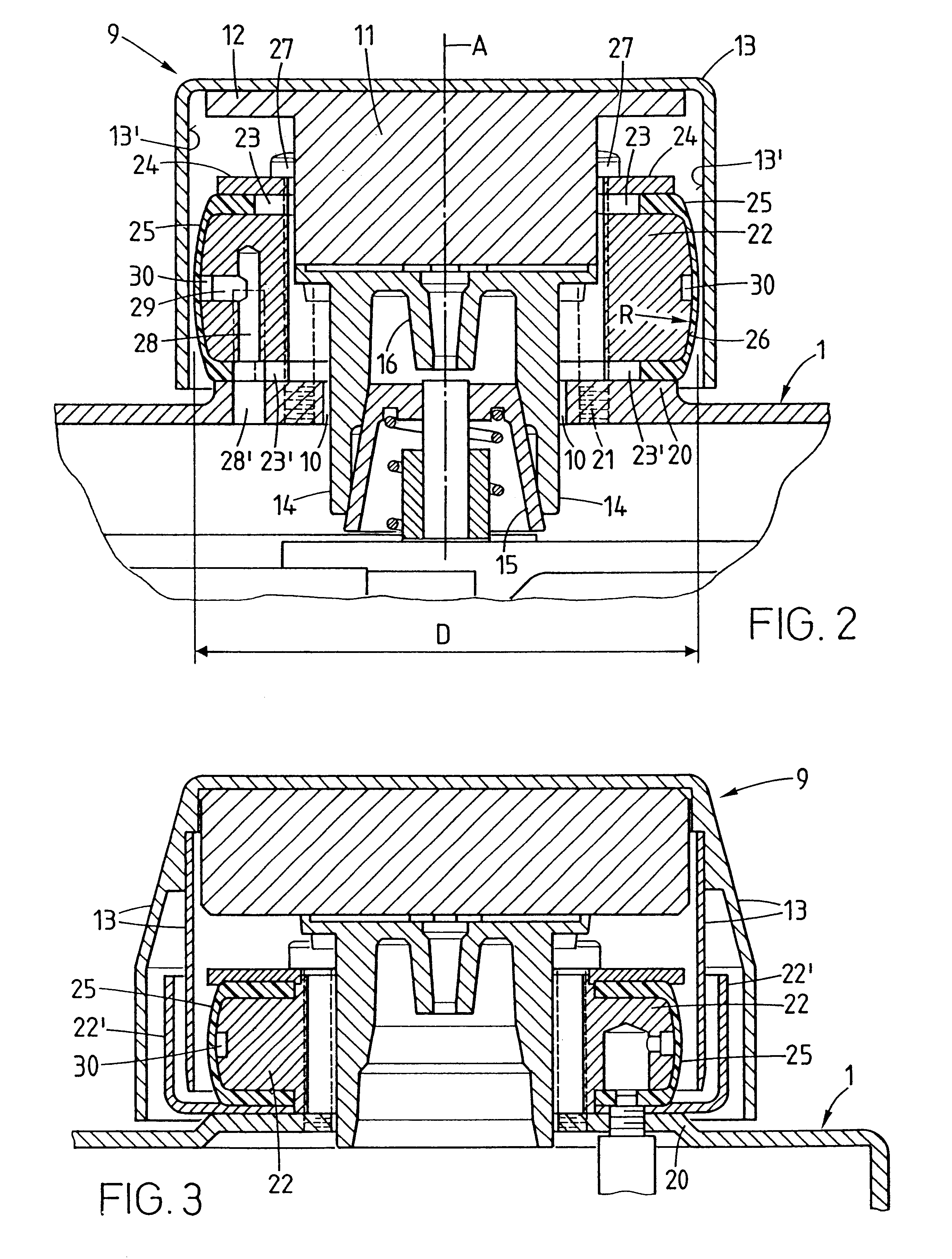

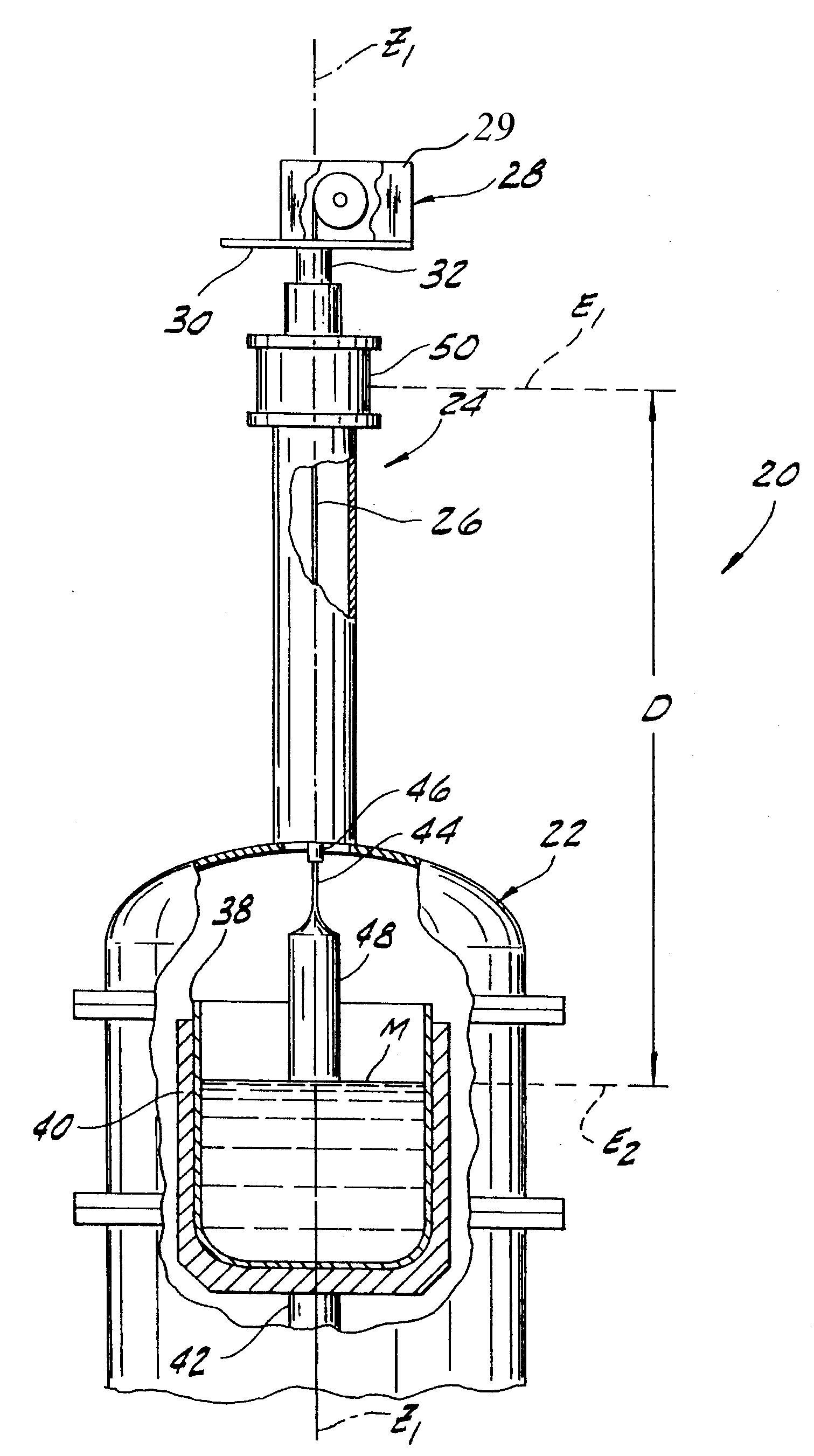

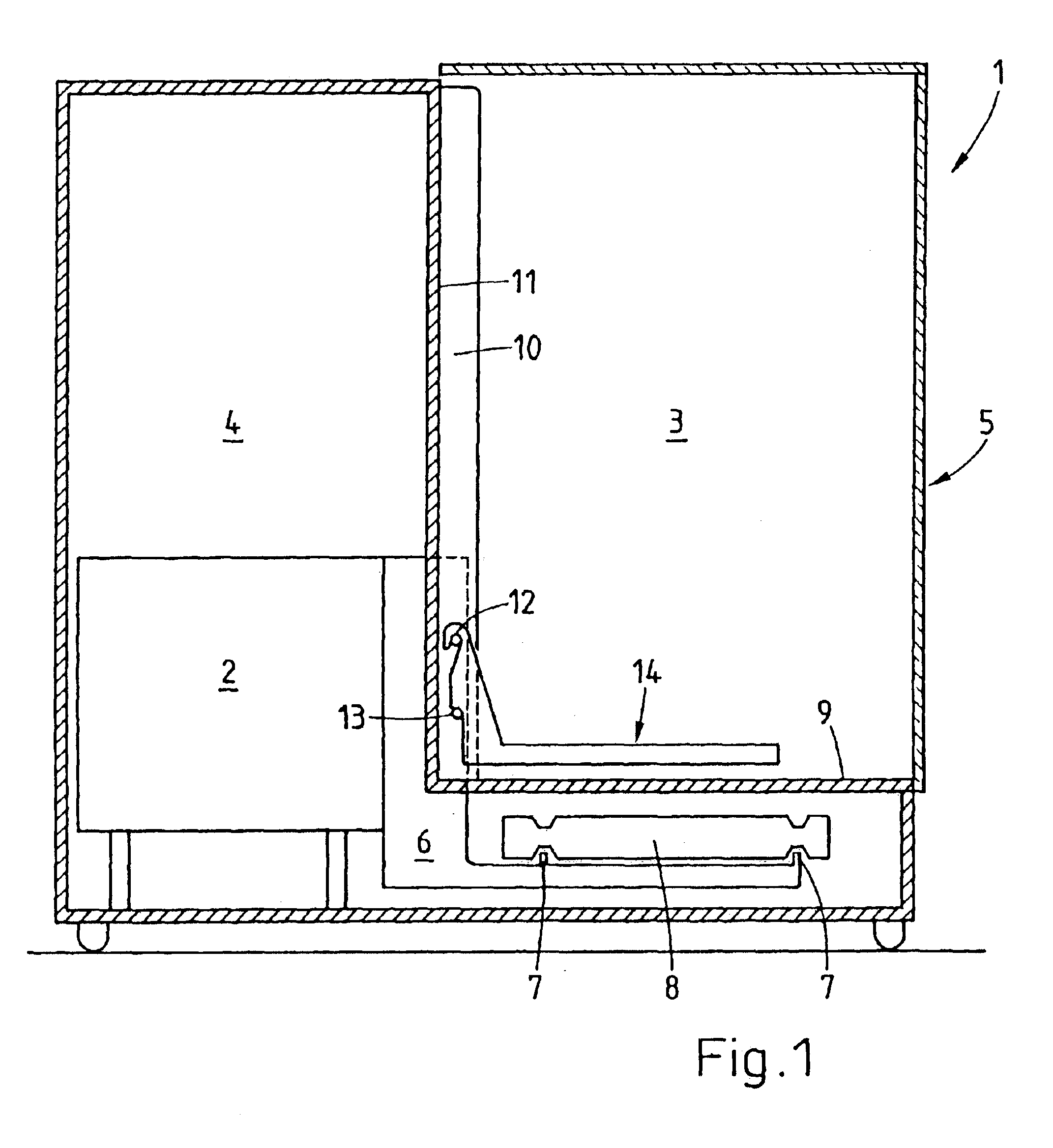

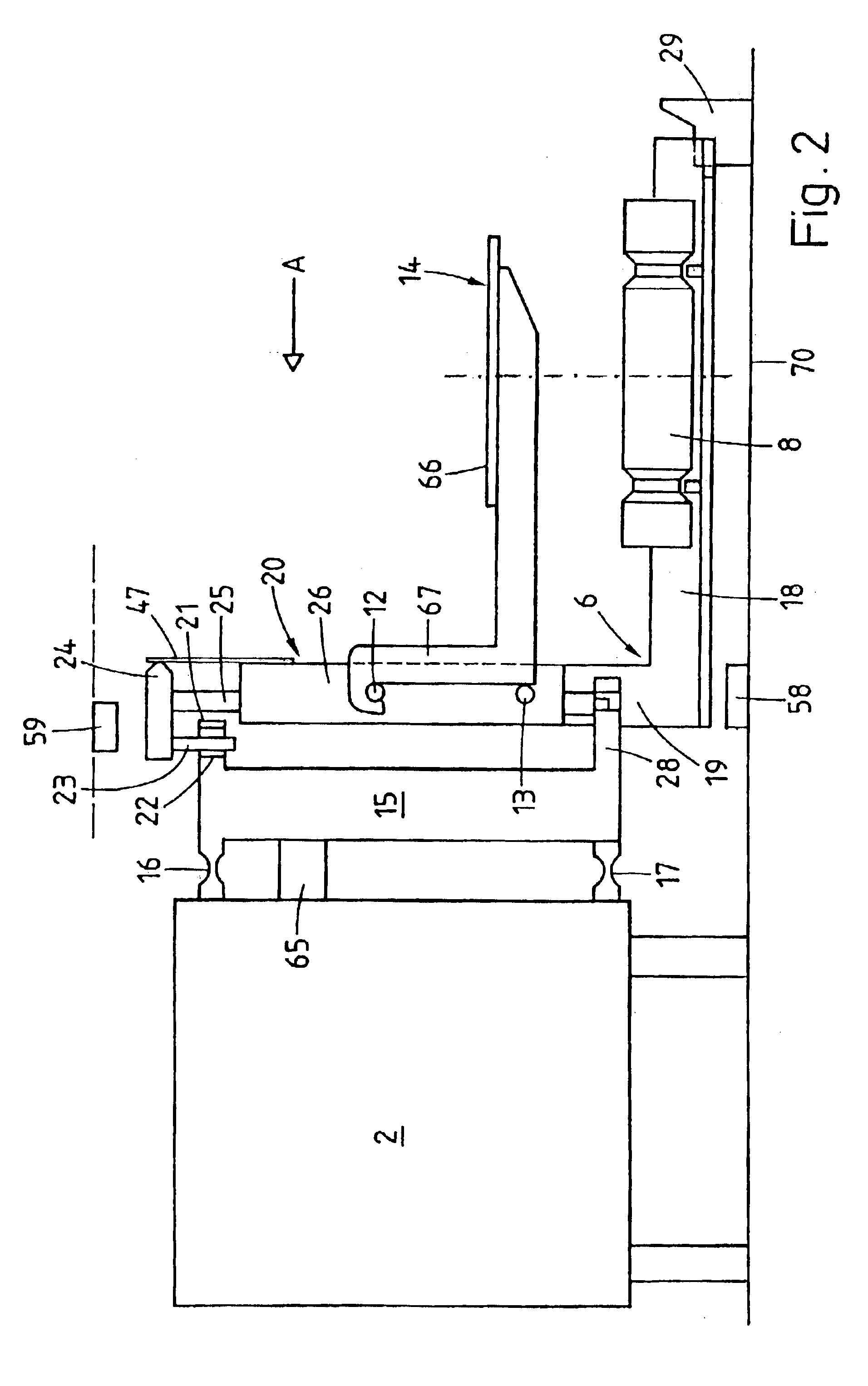

Weighing scale with a combined sealing and arresting device

InactiveUS6600112B2Preserving the accuracy of the scaleAccuracy and efficiencyWeighing relieving/arrestment mechanismsOscillations damping for weighingEngineeringGuide tube

A weighing scale has a housing (1) that encloses a force transducer (4). A load-transmitting member (9) is connected to the force transducer (4) and passes through an opening to the outside of the housing to transmit the weighing load to the force transducer. An elastic device is interposed between a fixed part that is attached to the housing (1) and a movable part that is attached to the load-transmitting member (9). The elastic device is preferably hollow and controllably expandable and contractible by injecting and removing a fluid through a conduit system (31-43) with a selectively switchable valve device.

Owner:METTLER TOLEDO GMBH

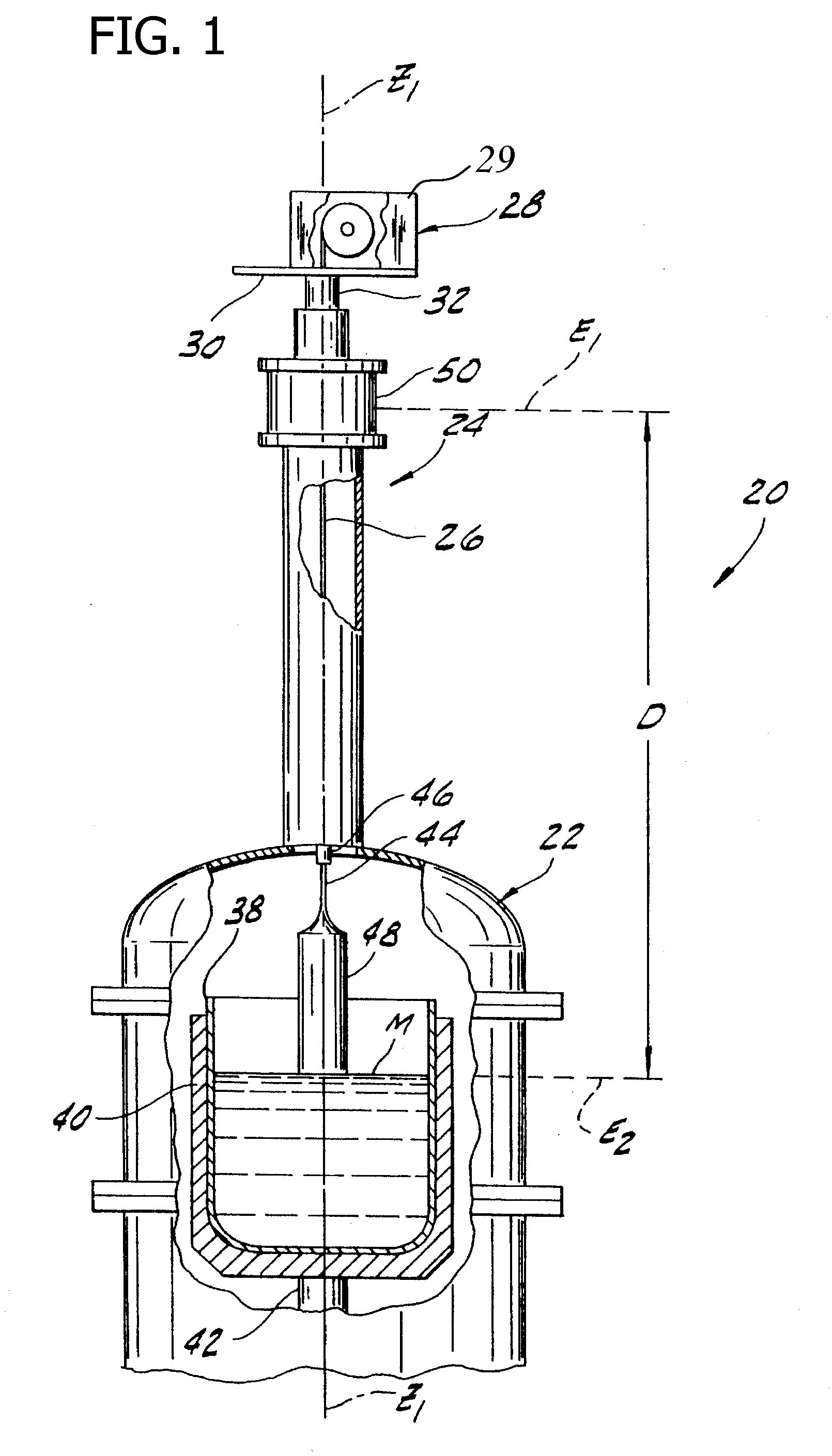

Systems for weighing a pulled object

Pulling systems are disclosed for measuring the weight of an object coupled to a first end of a cable. The cable is routed over a pulley suspended from a load cell. The force exerted by the cable on the pulley is used to calculate the weight of the object. The second end of the cable is coupled to a drum which when rotated pulls the object by wrapping the cable around the drum. An arm is coupled to the pulley at one end and to a frame at another end. A path traveled by the cable between the pulley and the drum is substantially parallel to a longitudinal axis of the arm. Horizontal force components are transmitted by the arm to the frame and do not affect a force component measured by the load cell, thus increasing the accuracy of the calculated weight of the object.

Owner:GLOBALWAFERS CO LTD

Method and device for weighing products

InactiveUS7405368B2Improve automationReduction of weighing resultOscillations damping for weighingWeighing apparatus for continuous material flowEngineeringMechanical engineering

Owner:METTLER TOLEDO GARVENS

Material unloading measurement method

Owner:SCALE TEC LTD

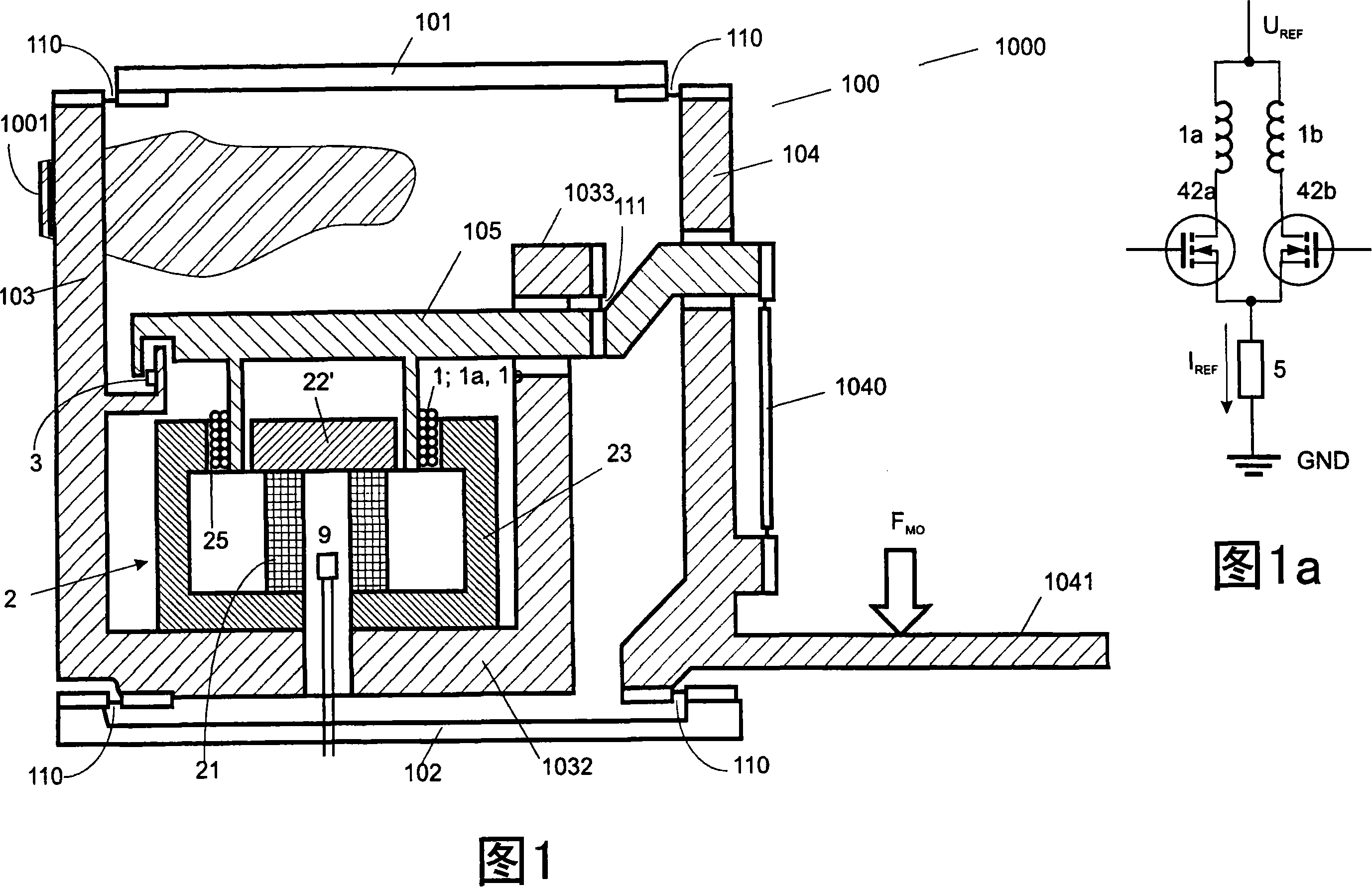

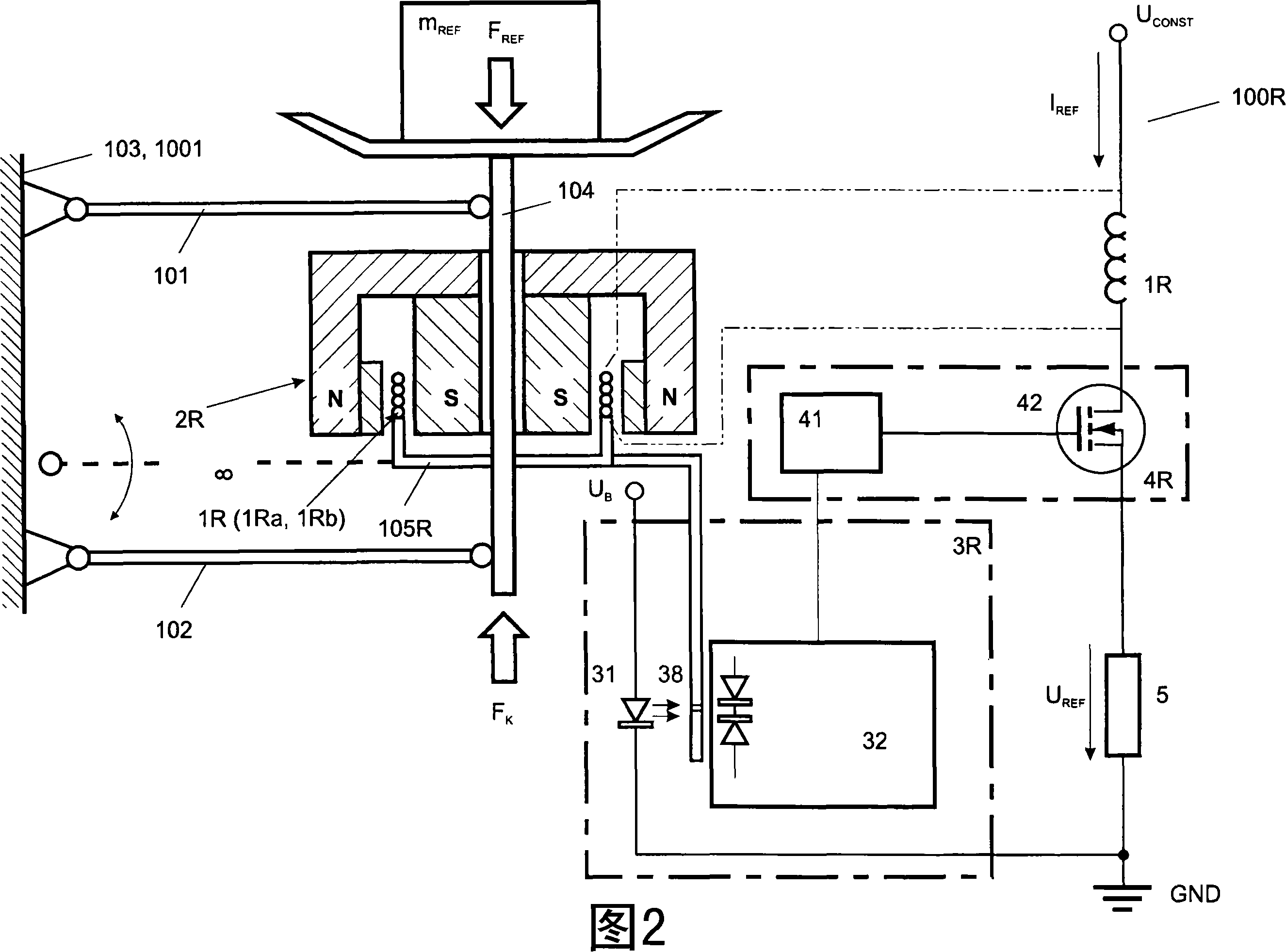

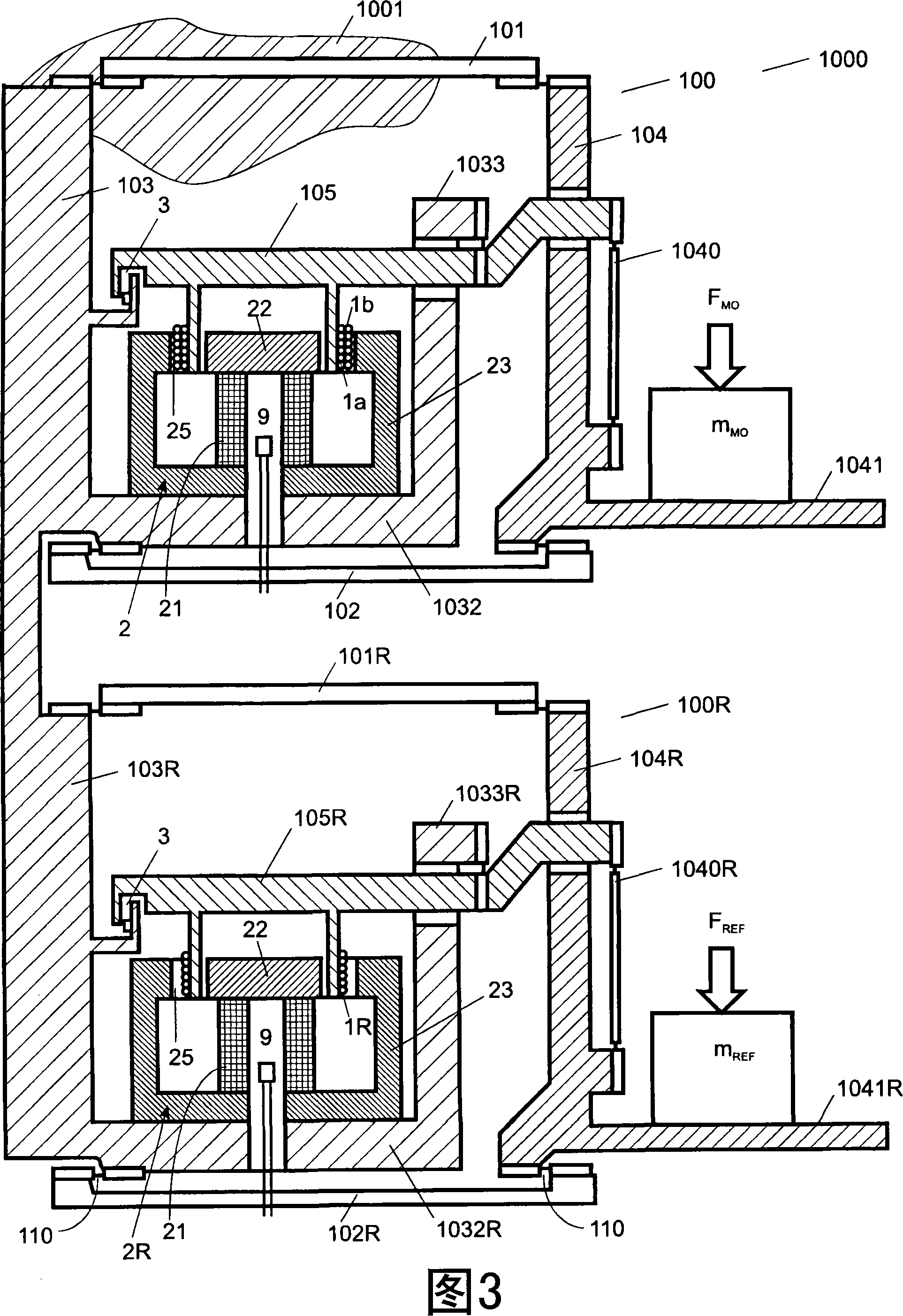

Force measuring device and reference unit

ActiveCN101140182ALow costCompact designWeighing apparatus testing/calibrationOscillations damping for weighingMagnetic tension forceReference current

A force-measuring device (1000) includes a measuring unit (100) and a reference unit (100R), wherein the reference unit (100R) is used to deliver a reference quantity, a reference current (IREF) or a reference voltage (UREF), by means of which the force (FMO) of a measurement object which is to be determined can be measured by the measuring unit (100). According to the invention, the reference unit (100) is a force-measuring device which is loaded with a reference mass (mREF) and which in accordance with the principle of electromagnetic force compensation generates a reference current (IREF) that can be regulated by means of a measuring-and regulating device (3R, 4R) in such a way that in a first reference coil (1R;1Ra) which is held by a reference lever (105R), the reference current (IREF) generates a magnetic field which cooperates with the magnetic field of a reference magnet (2R;2-2R) in such a way that a magnetic force is brought to bear on the reference lever (105R), wherein the force (FREF) of the reference mass (mREF) which is likewise acting on the reference lever can be compensated by said magnetic force.

Owner:METTLER TOLEDO INC

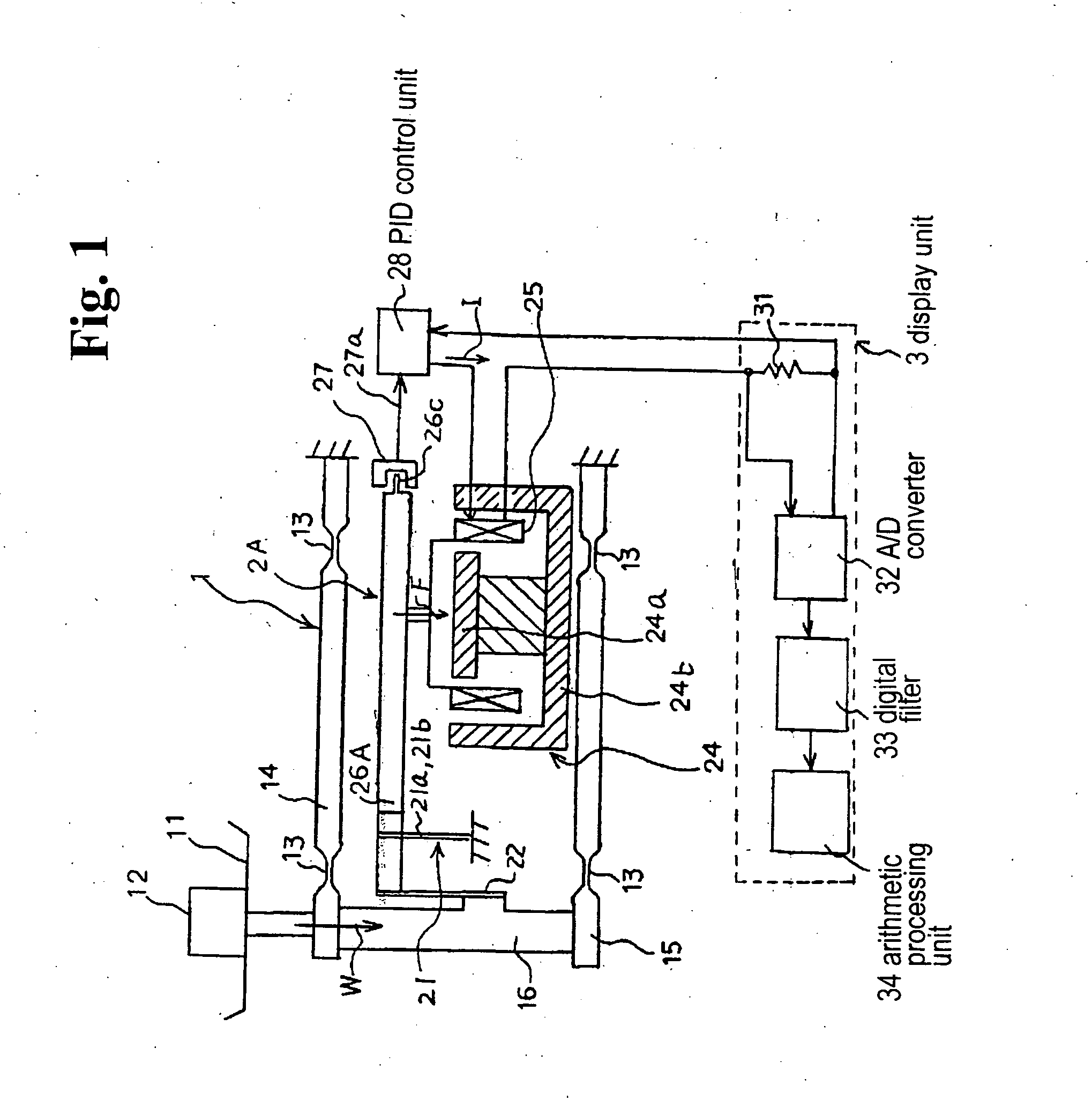

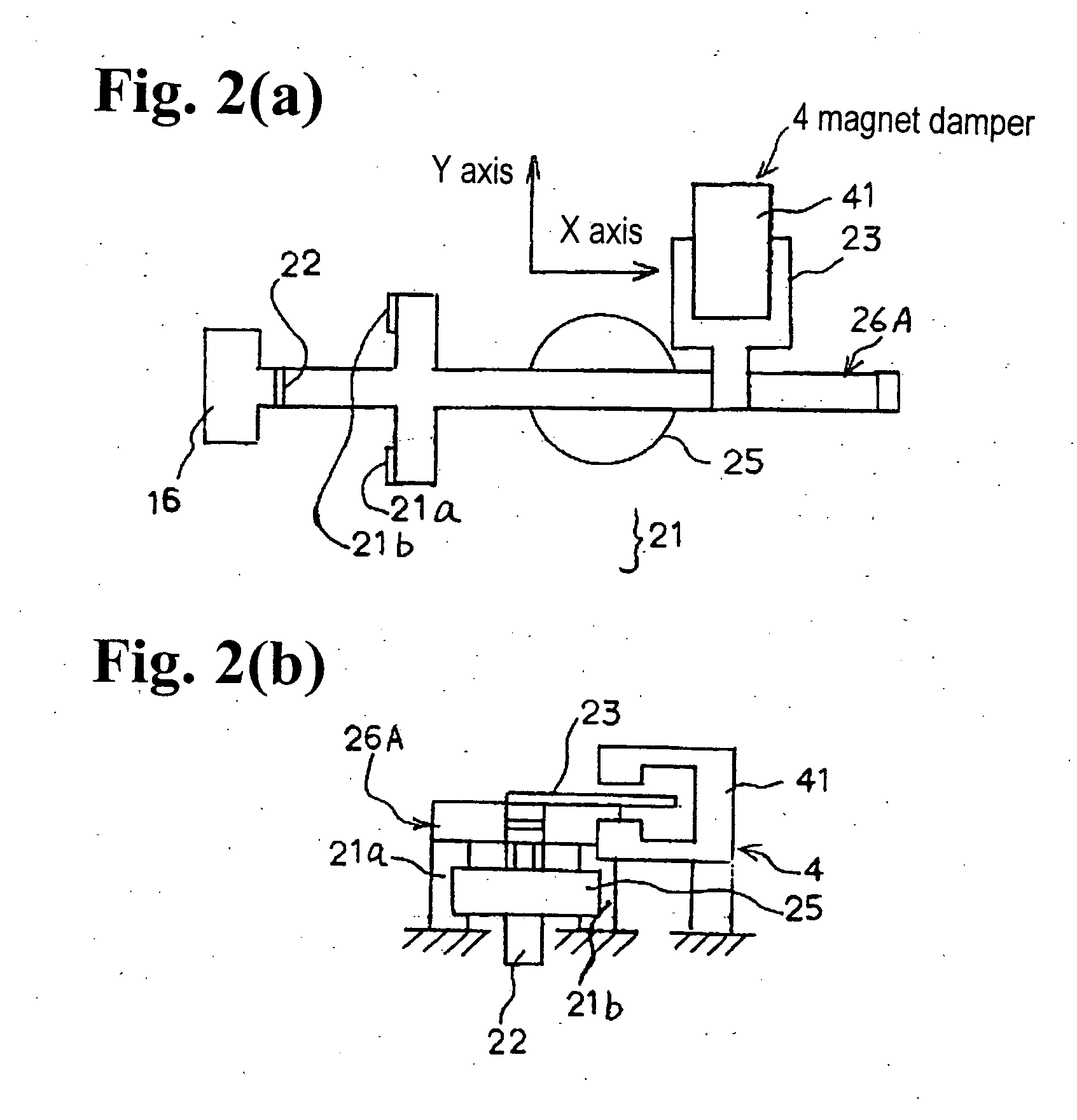

Electronic balance

InactiveUS20050205309A1Reduce vibrationEliminate the effects ofWeighing apparatus using counterbalanceWeighing apparatus using electromagnetic balancingEngineeringElectron

An electronic balance includes a load transmission mechanism for receiving an object to be measured, a magnetic field generator having a force coil for generating magnetic field, and a balance beam connected at one end to the load transmission mechanism and disposed adjacent to the magnetic field generator with a fulcrum interposed between a portion connected to the weight section and the magnetic field generator. An electromagnetic force generated by supplying current to the force coil is applied to the balance beam to obtain a weight of the object from the current flowing through the force coil in equilibrium with the load. A damper is attached to the balance beam to control vibration in at least one of a longitudinal direction of the balance beam and a horizontal direction perpendicularly intersecting therewith.

Owner:SHIMADZU CORP

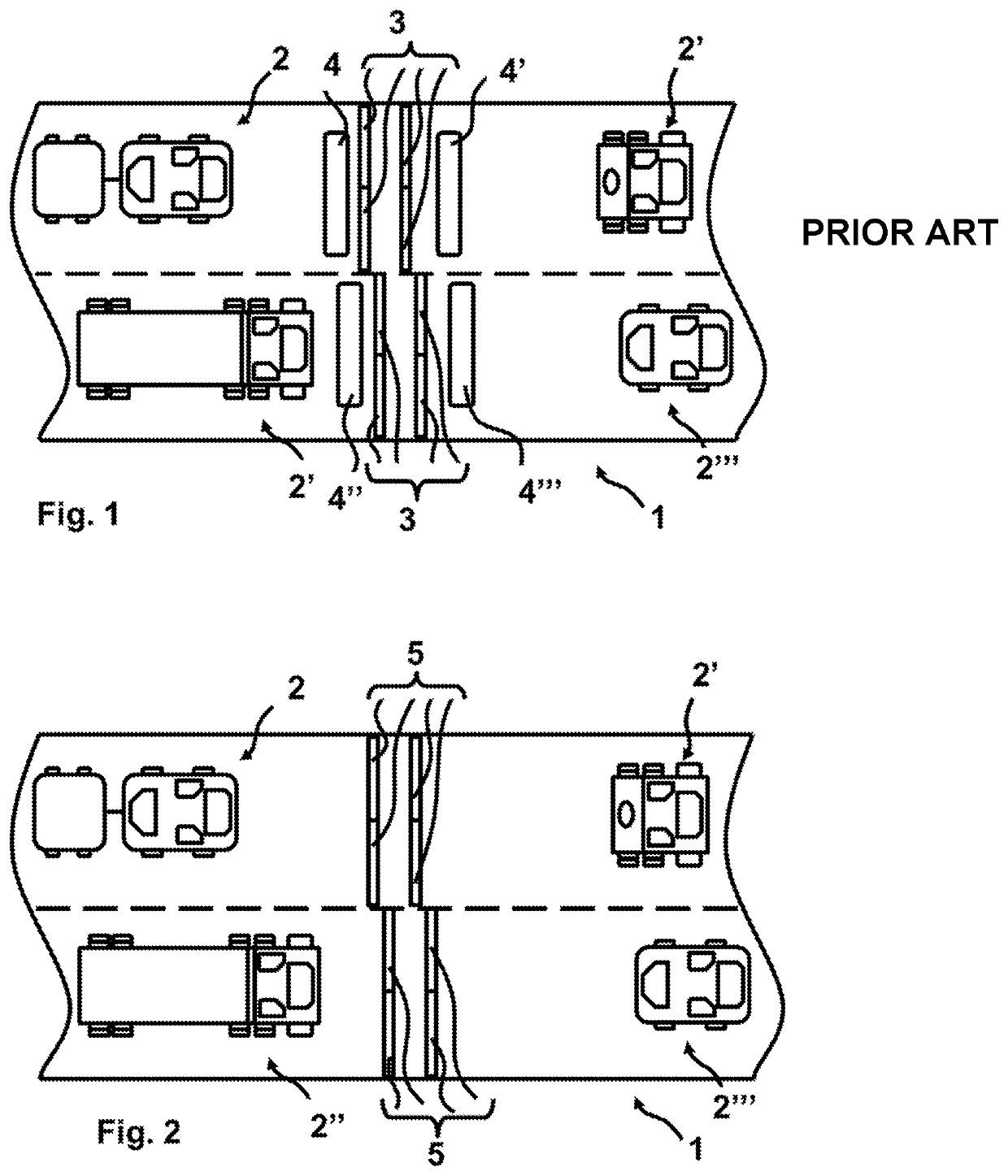

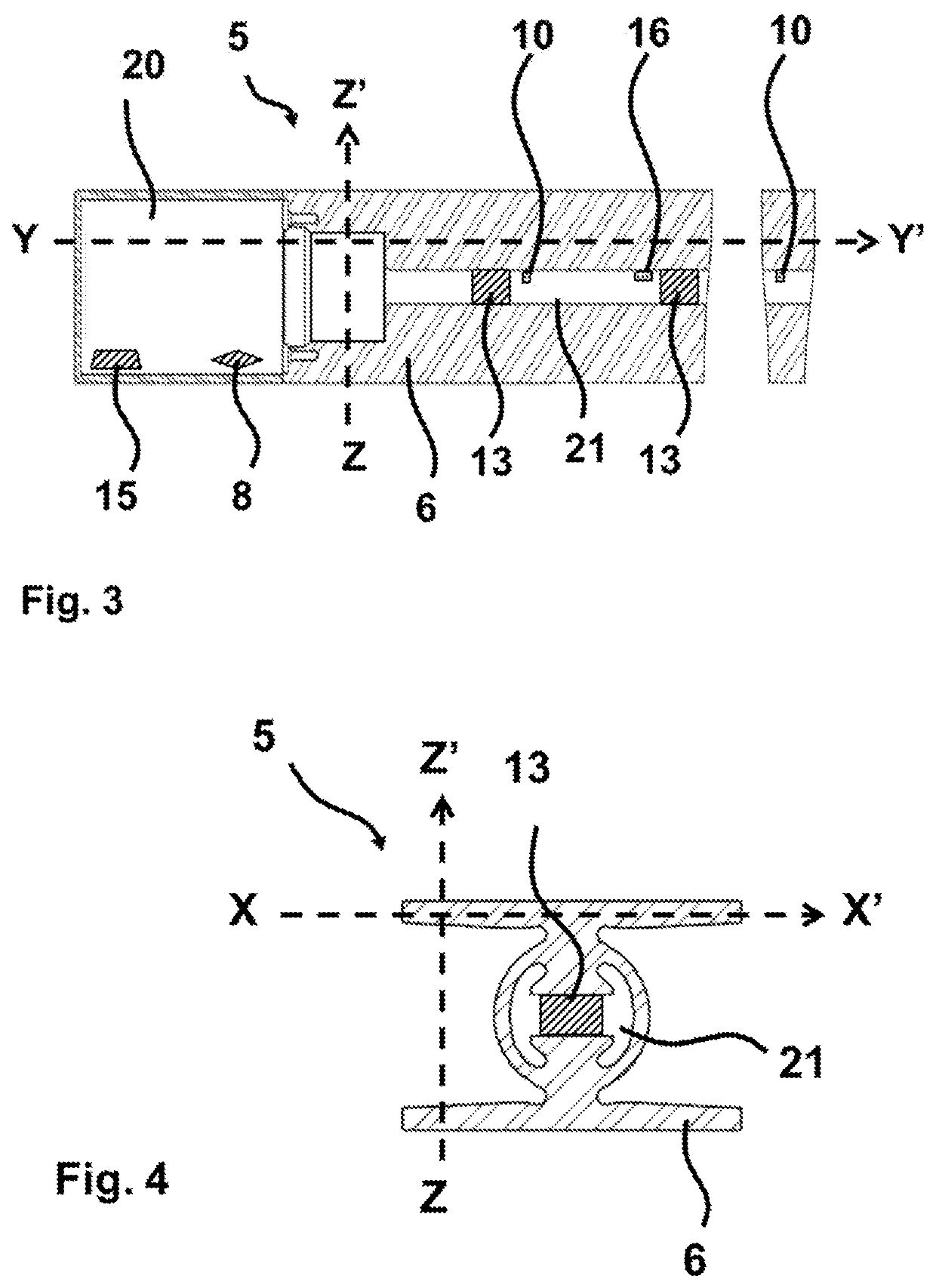

Wim sensor comprising electro-acoustic transducers

ActiveUS20210181010A1Reduction in cost and installation effortImprove accuracyOscillations damping for weighingSpecial purpose weighing apparatusTransducerEngineering

The invention relates to a WIM sensor for detecting loads of vehicles on a roadway segment when a wheel of a vehicle crosses the WIM sensor arranged flush with the roadway surface in the roadway segment. The WIM sensor is formed as an elongated profile along a longitudinal axis and defines a space therein. A force sensor configured to generate a force sensor signal corresponding to a dynamic ground reaction force when the wheel crosses the force sensor is arranged in the space. An electro-acoustic transducer is arranged in the space and configured to measure sound waves and accordingly generate a transducer signal.

Owner:KISTLER HLDG AG

Digital measurement apparatus

InactiveUS20060096789A1Simple wayHigh precisionWeighing apparatus testing/calibrationOscillations damping for weighingDigital dataFast measurement

Disclosed is a digital measurement apparatus including data capture means operable to continuously capture digital data about a target measurement item, validity determination means operable to compare the captured data with a reference value so as to determine whether all of the captured data are valid, and measurement-value calculation means operable, when all of the captured data are determined to be valid, to calculate a measurement value in accordance with the valid data, which is characterized by further comprising reference-value change means operable to change the reference value. The digital measurement apparatus of the present invention makes it possible to perform a speedy measurement.

Owner:TANITA CORP

Method and system for reducing errors in vehicle weighing systems

InactiveUS20090125273A1High trafficLess effortDigital computer detailsWeighing apparatus testing/calibrationIn vehicleEngineering

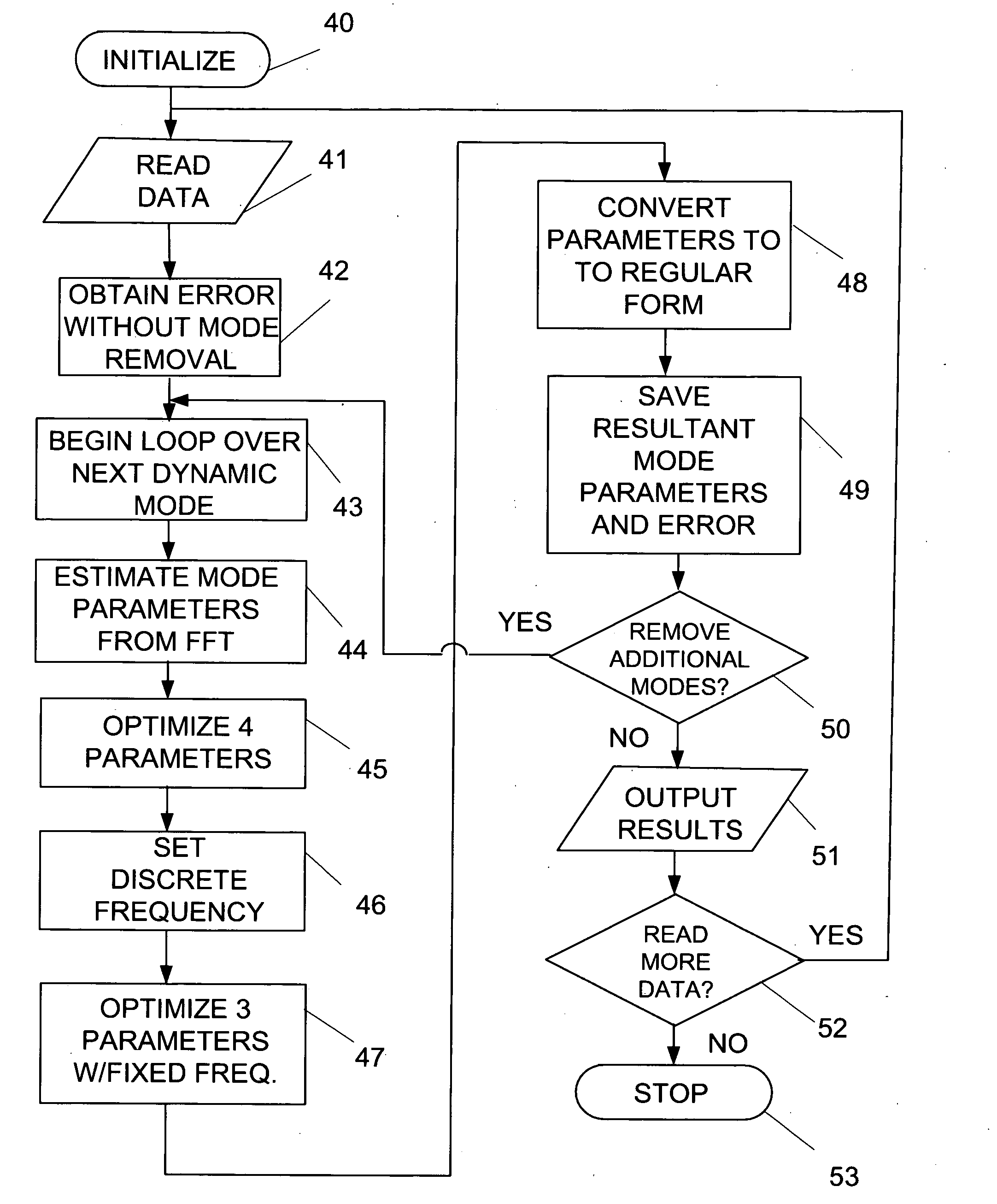

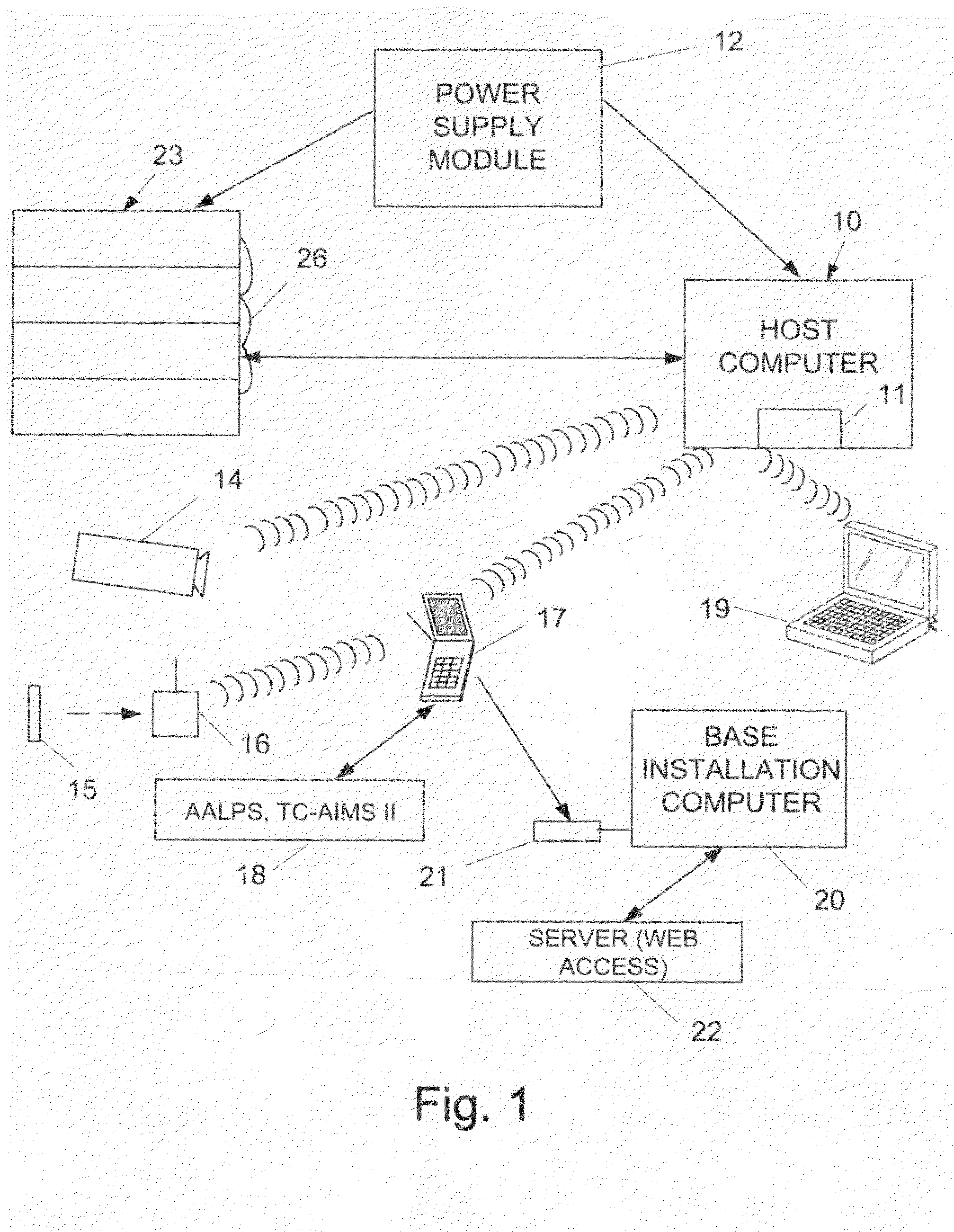

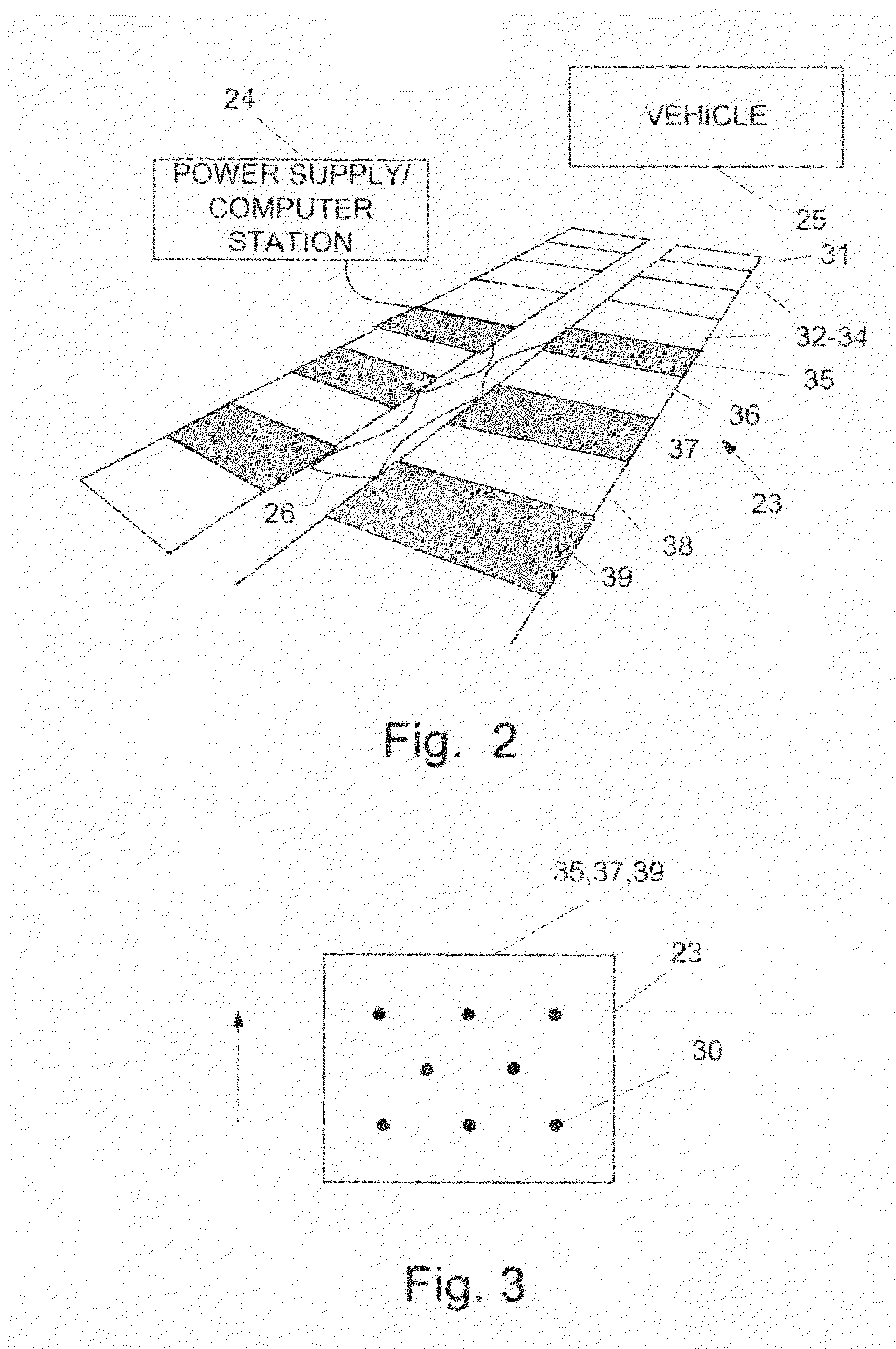

A method and system (10, 23) for determining vehicle weight to a precision of <0.1%, uses a plurality of weight sensing elements (23), a computer (10) for reading in weighing data for a vehicle (25) and produces a dataset representing the total weight of a vehicle via programming (40-53) that is executable by the computer (10) for (a) providing a plurality of mode parameters that characterize each oscillatory mode in the data due to movement of the vehicle during weighing, (b) by determining the oscillatory mode at which there is a minimum error in the weighing data; (c) processing the weighing data to remove that dynamical oscillation from the weighing data; and (d) repeating steps (a)-(c) until the error in the set of weighing data is <0.1% in the vehicle weight.

Owner:UT BATTELLE LLC

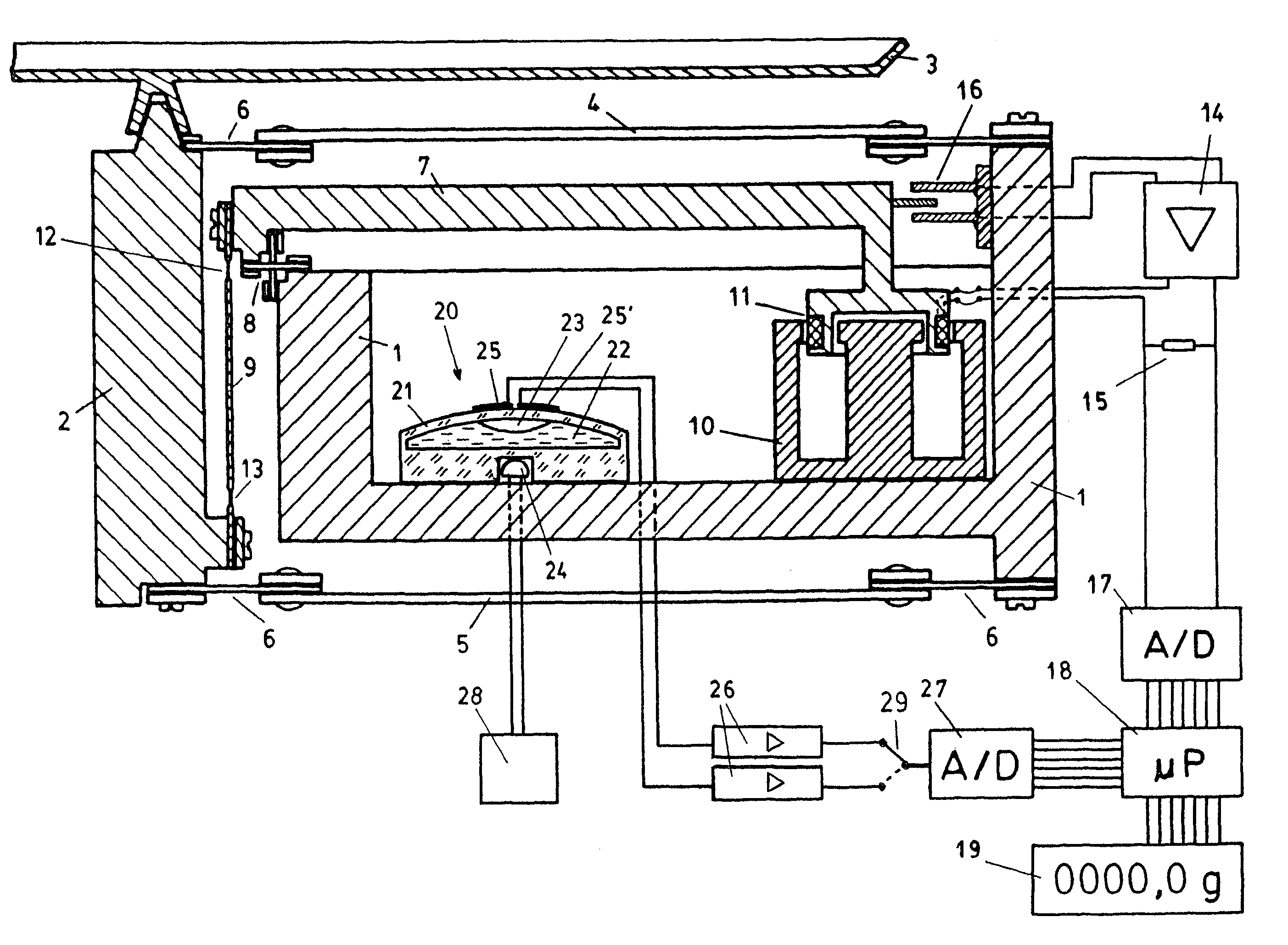

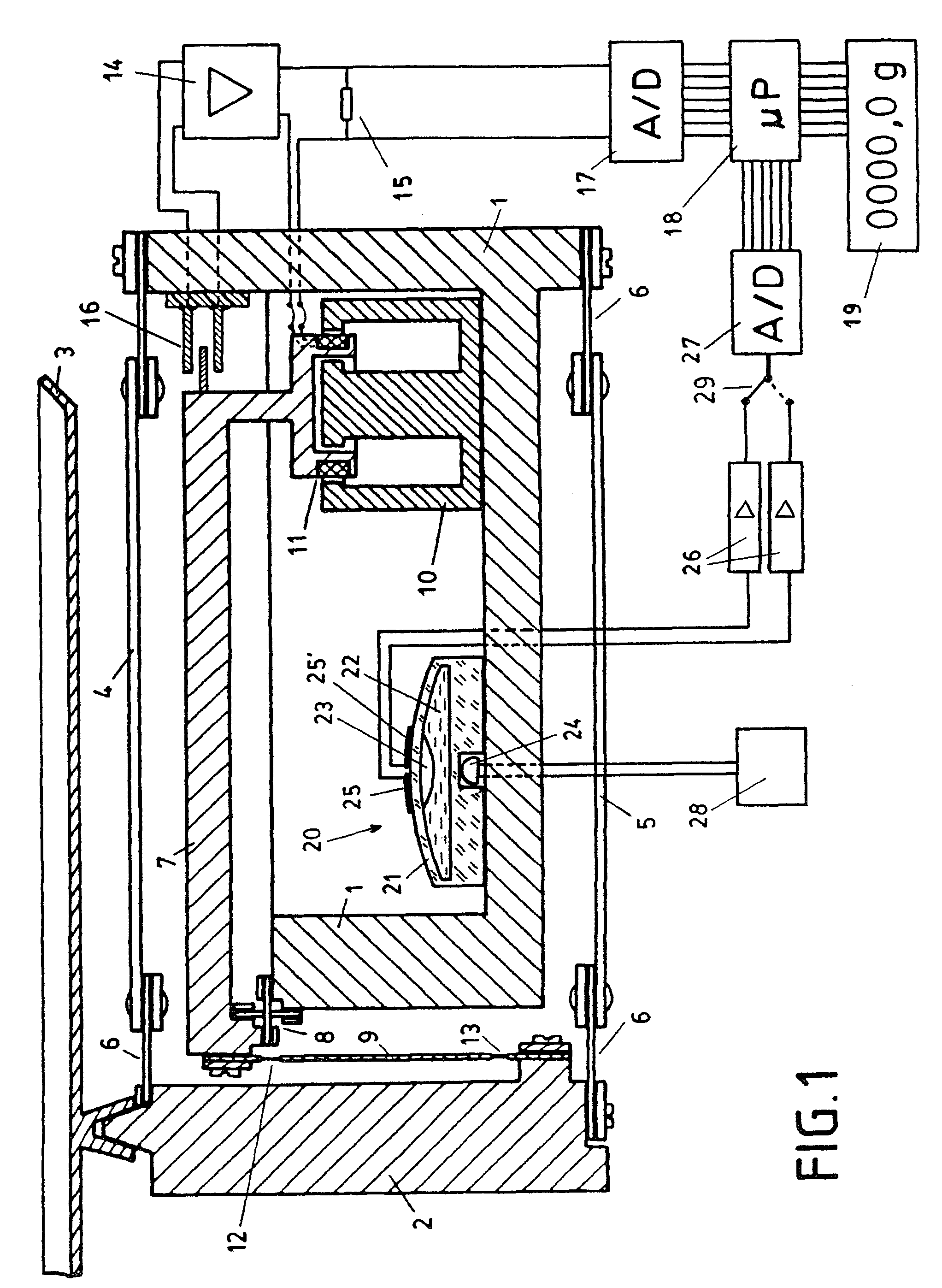

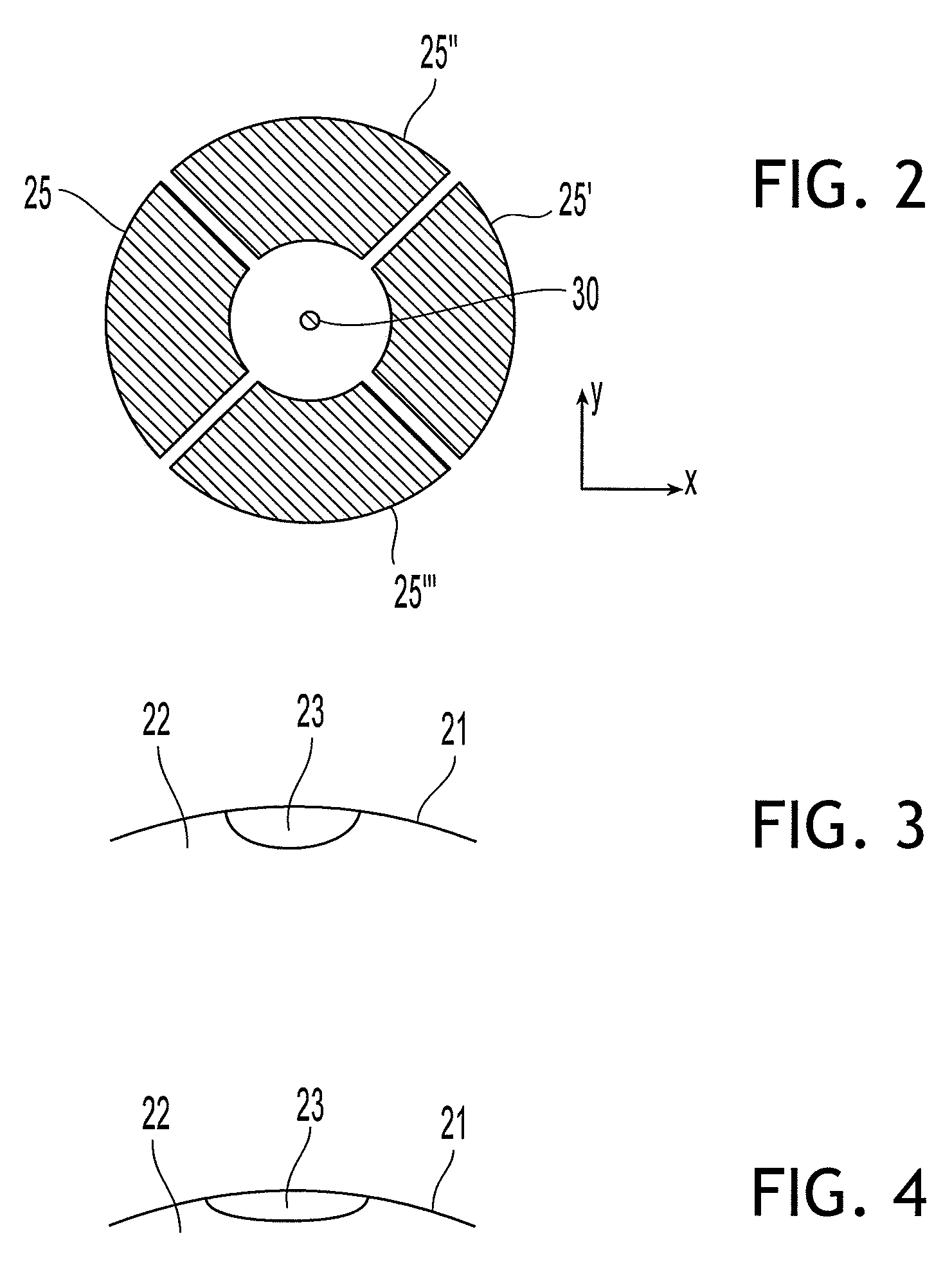

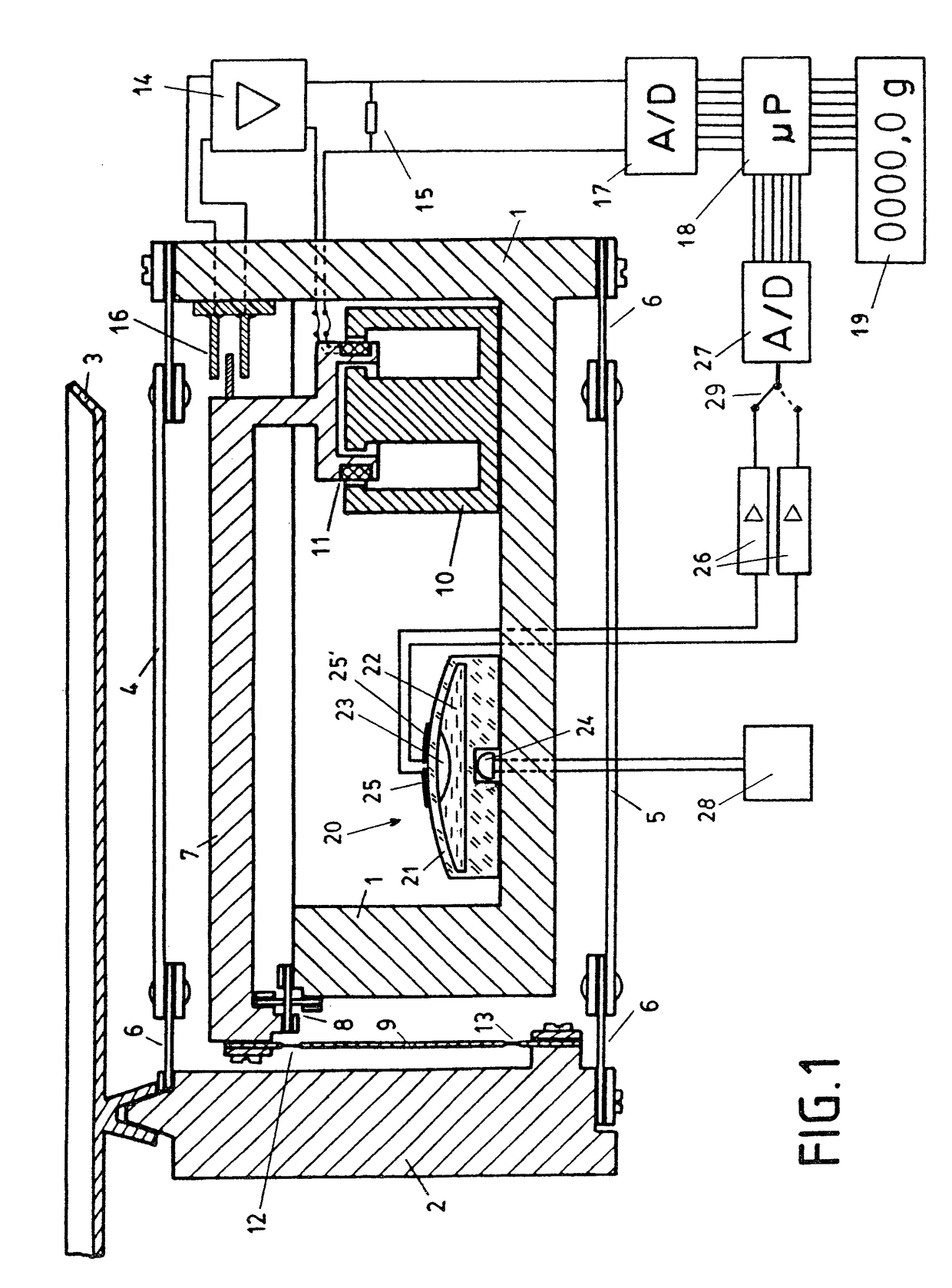

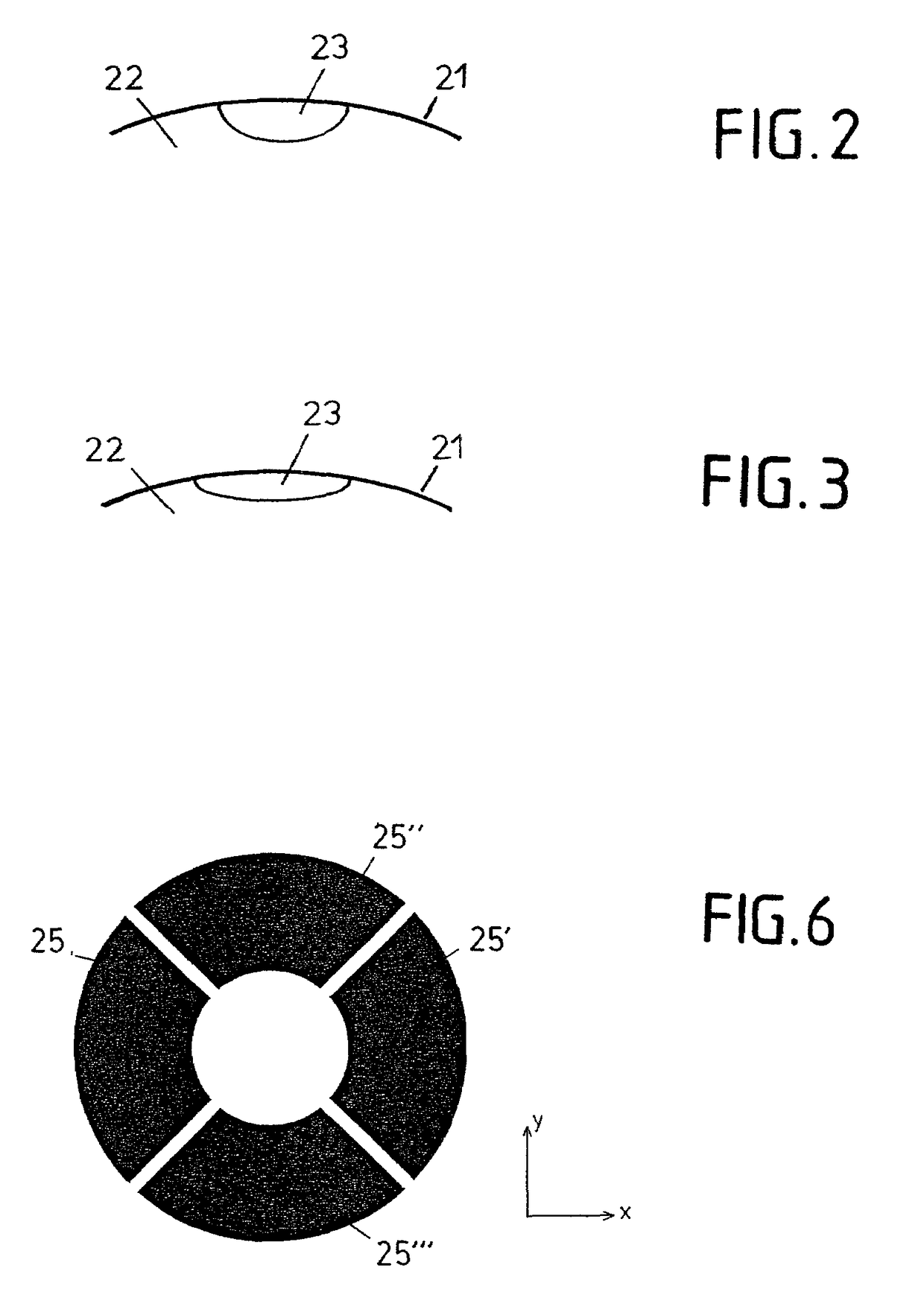

Electronic scale comprising a bubble level

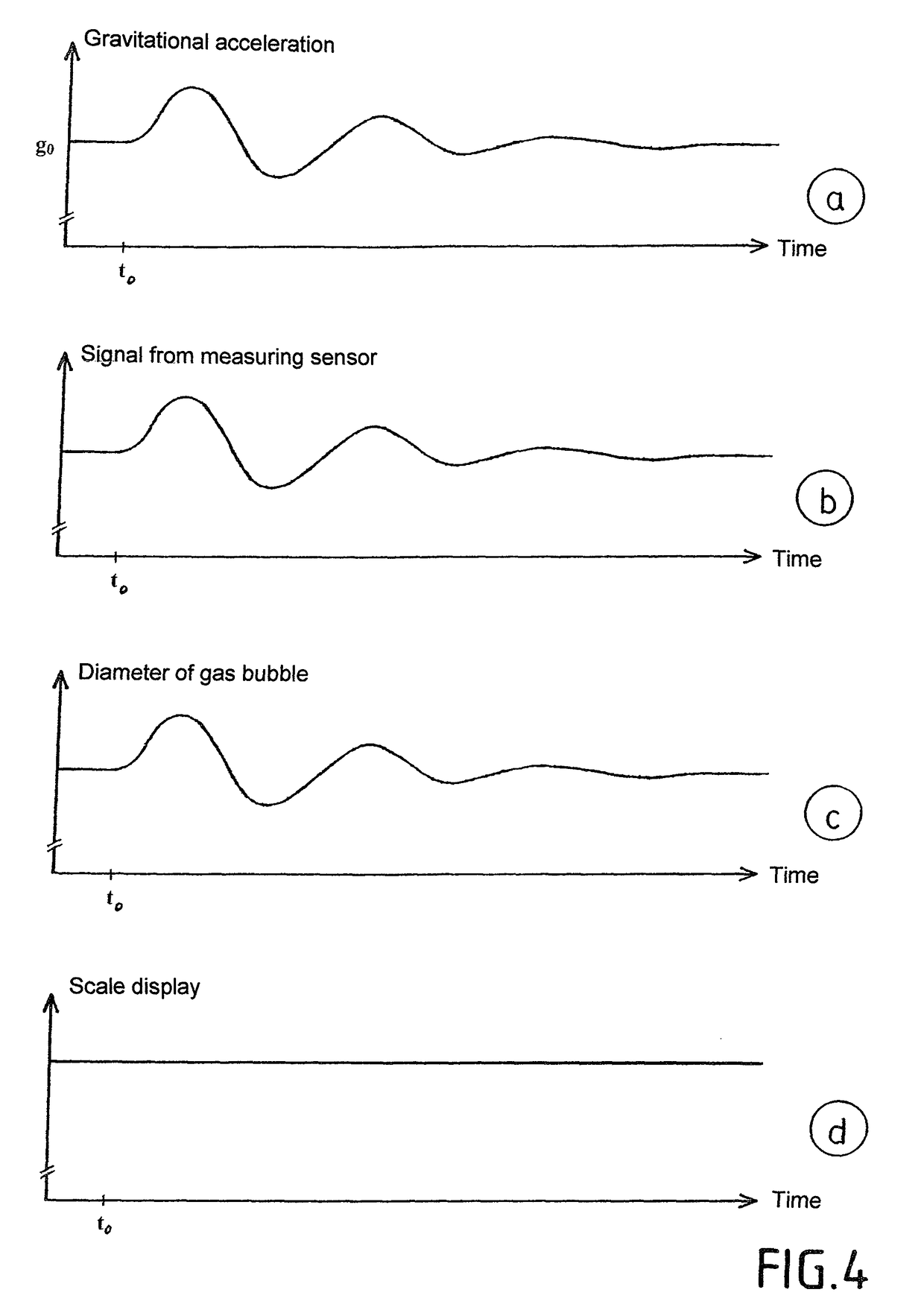

InactiveUS7964806B2Vibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesVertical vibrationDigital signal processing

An electronic scale having a measuring sensor (1 . . . 16), a digital signal processing unit (18), a digital display (19), a bubble level (20), which includes a container (21) that is partially filled with a liquid (22) while forming a gas bubble (23), and circuit component or program routine in the digital signal processing unit (18) for detecting a displacement of the gas bubble (23). An additional circuit component or program routine detects the diameter of the gas bubble (23). The diameter of the gas bubble changes due to vertical vibrations of the scale. The signal from the measuring sensor (1 . . . 16) falsified by vibrations can thus be corrected by the digital signal processing unit (18) by calculation, making use of the diameter signal.

Owner:SARTORIUS LAB INSTR GMBH & CO KG

Balance with a support element for coupling a weighing pan to a weighing cell

InactiveUS20030188897A1Yield easilyPrevent residual torquesWeighing apparatus using counterbalanceWeighing apparatus testing/calibrationCouplingCantilever

A balance includes a weighing cell with a vertically movable load receiver, a weighing pan to receive a weighing load, and a support element to couple the weighing pan to the vertically movable load receiver of the weighing cell. A cantilever arm with a seat for at least one calibration weight is solidly connected to the support element. The balance has a coupling arrangement that constrains the support element with low-friction mobility to the load receiver at three points forming a triangle in a plane that extends orthogonal to the symmetry plane of the weighing cell, wherein the triangle is symmetric to the symmetry plane of the weighing cell. Under the coupling arrangement, the support element is solidly supported on the load receiver in the direction in which the weighing load is acting.

Owner:METTLER TOLEDO GMBH

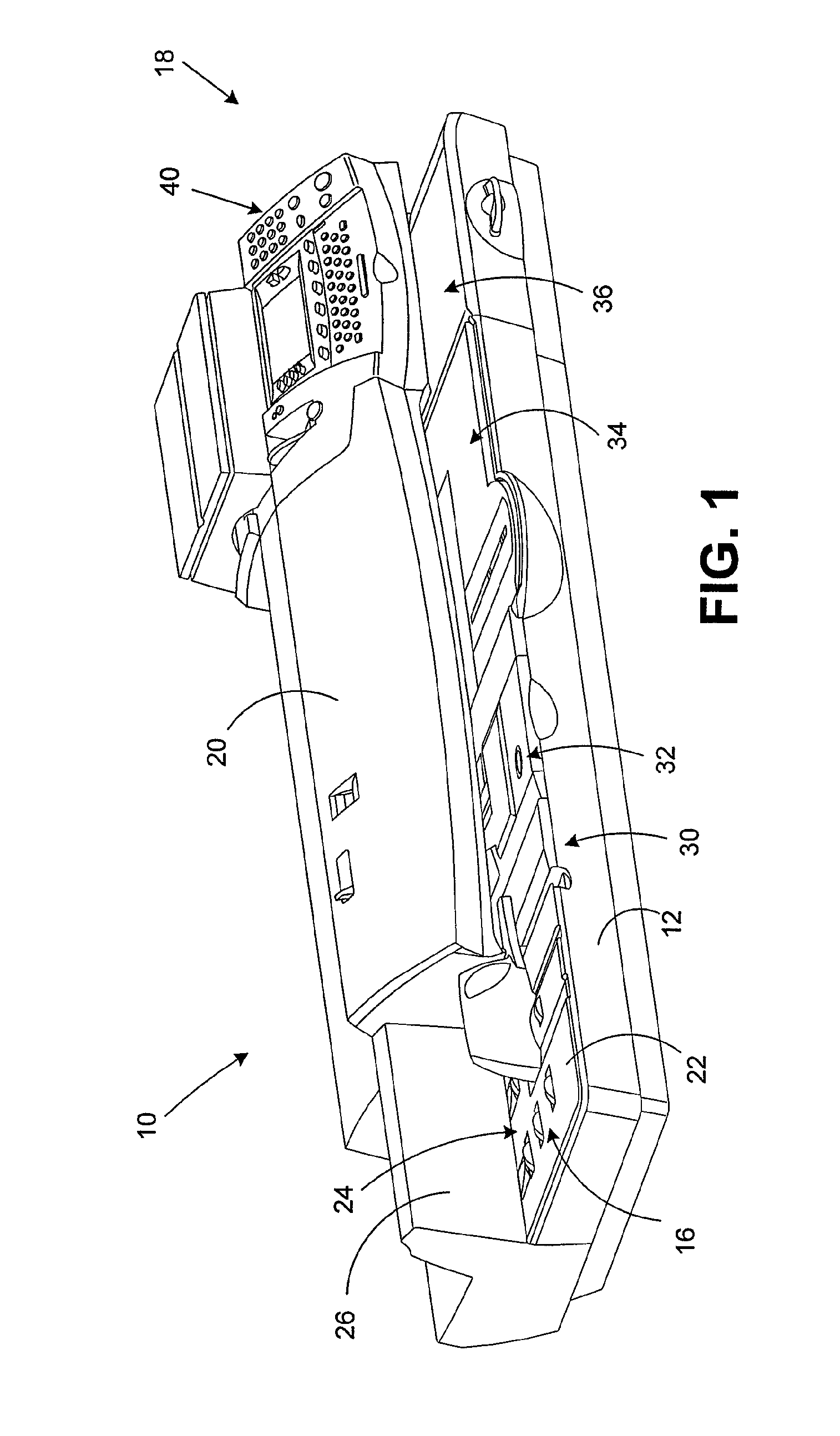

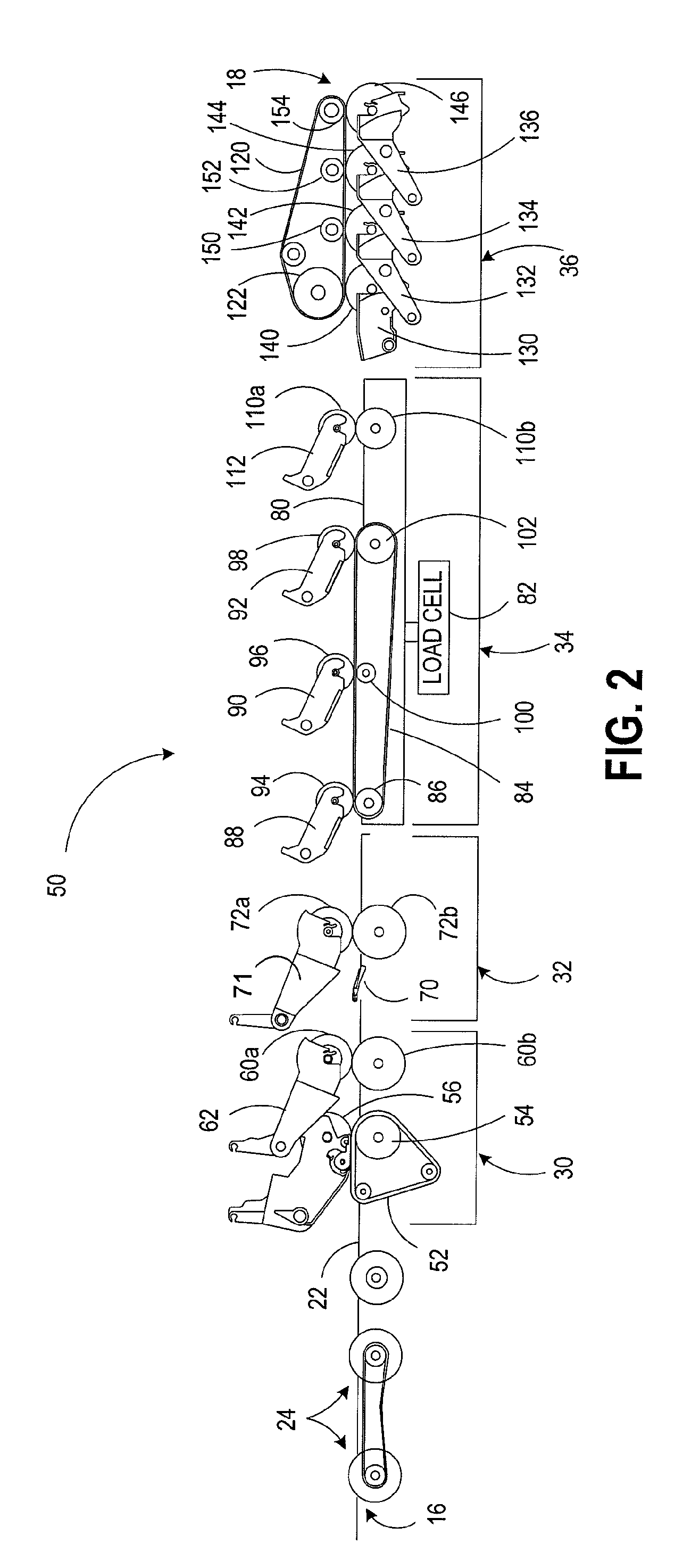

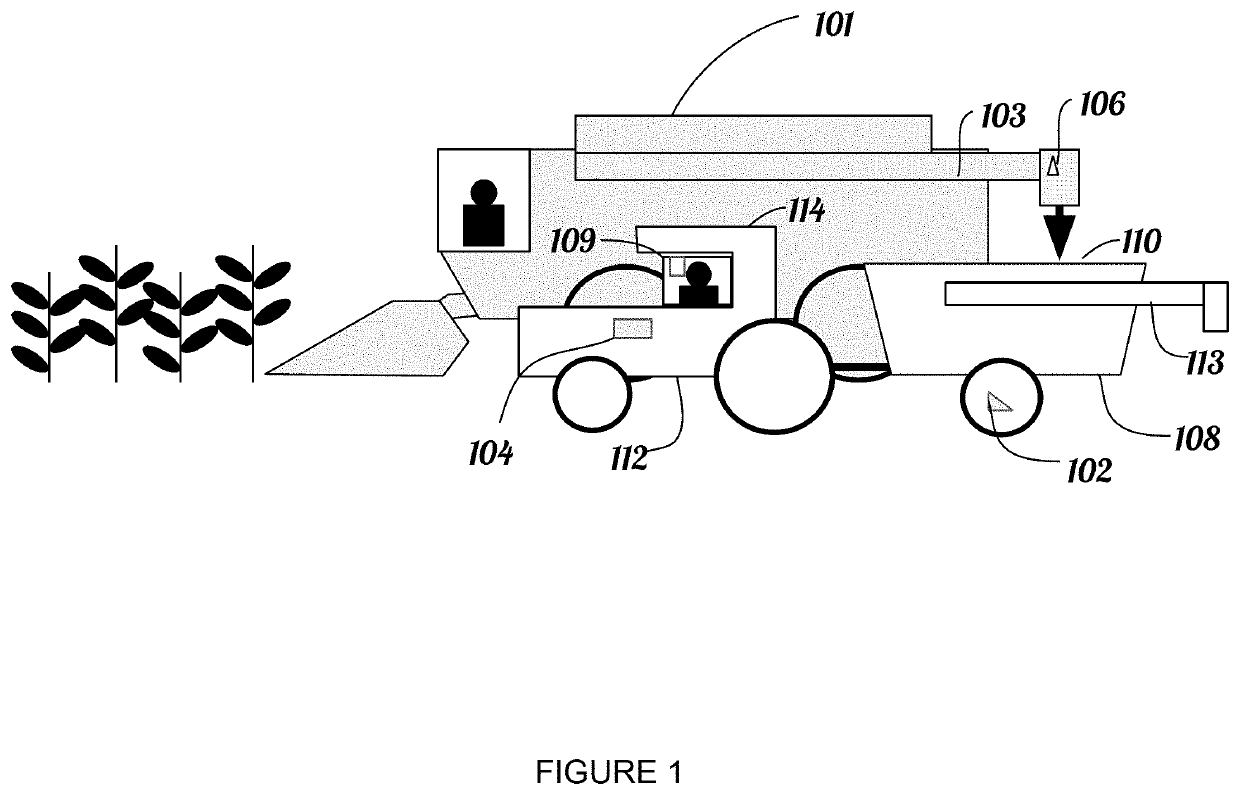

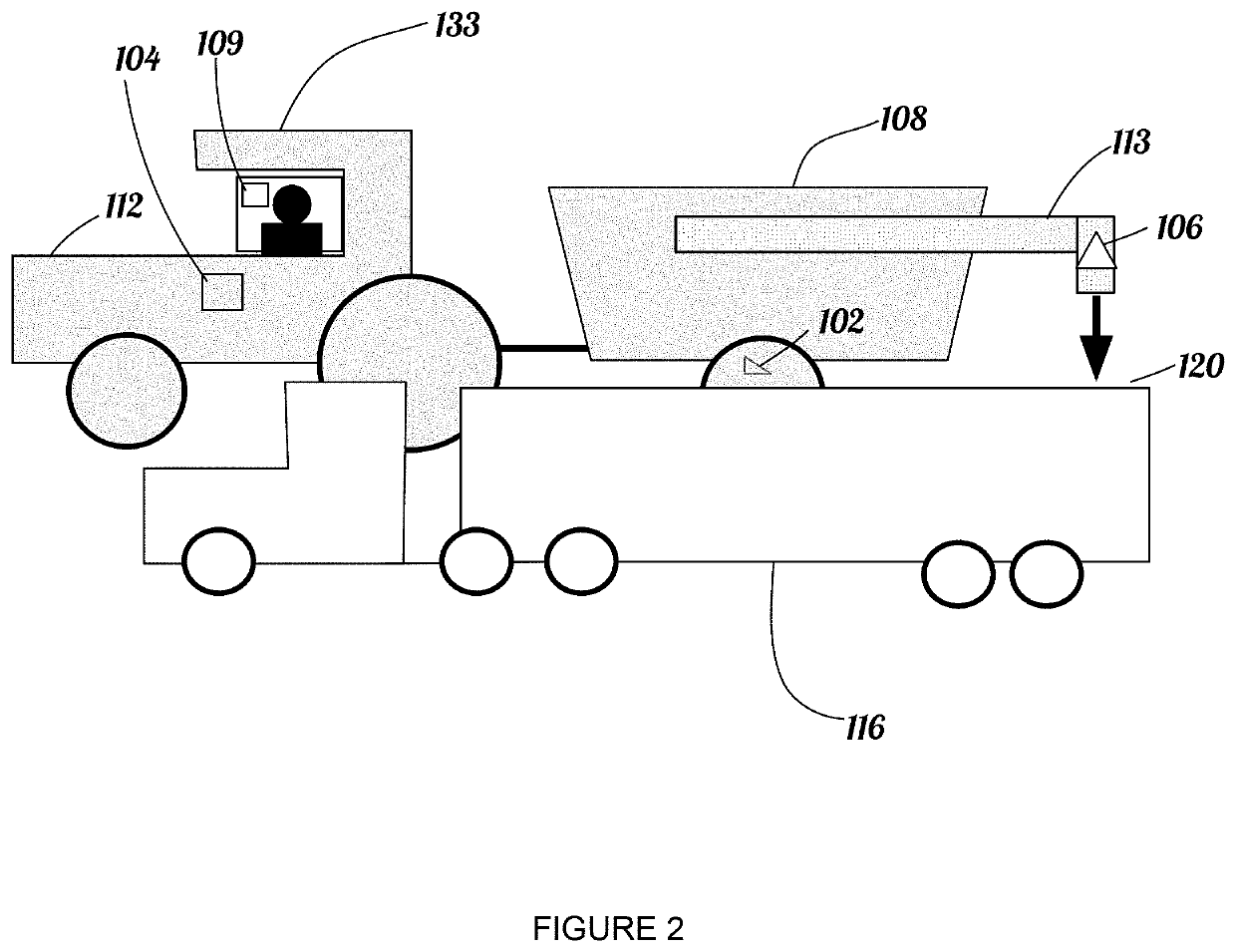

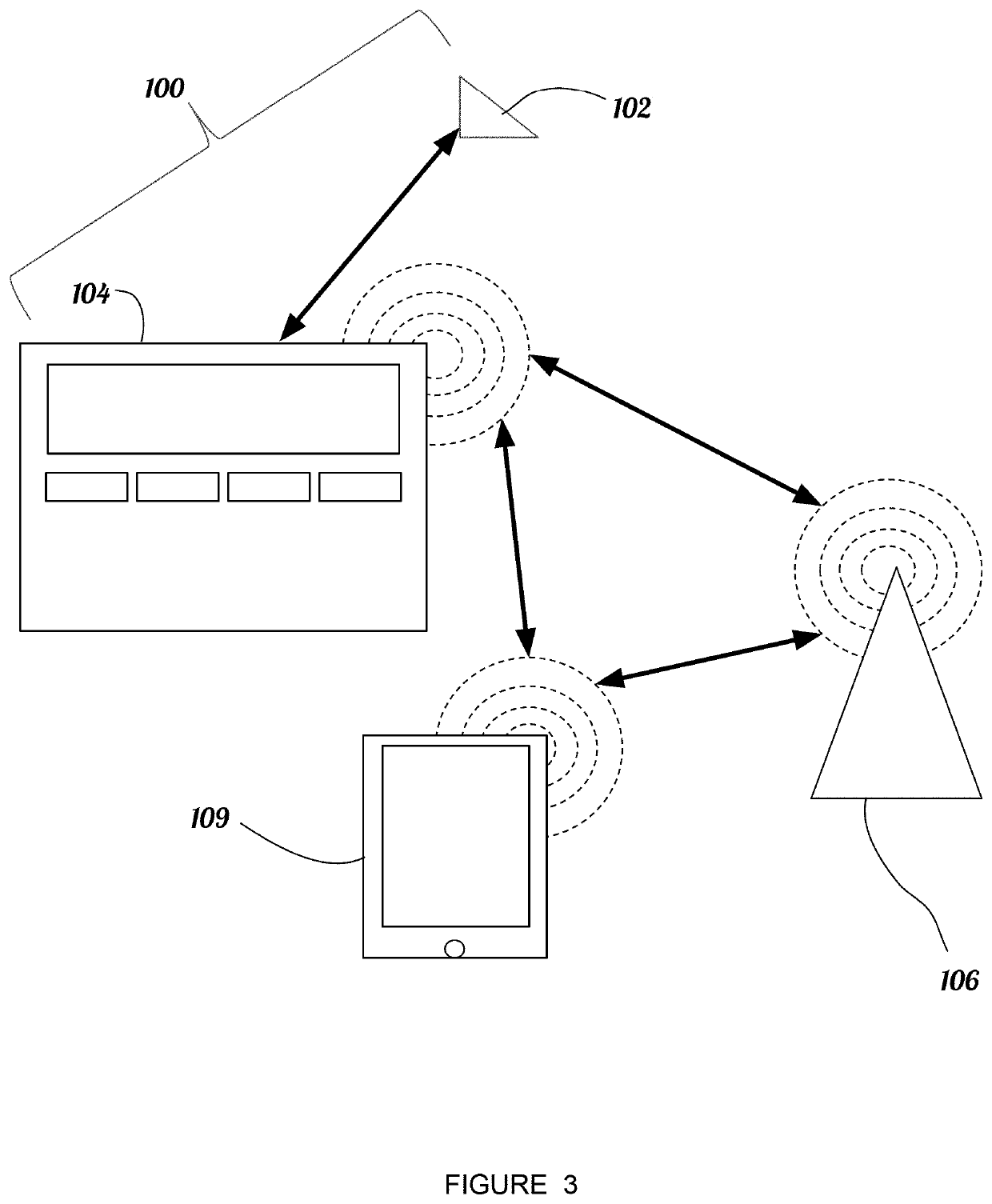

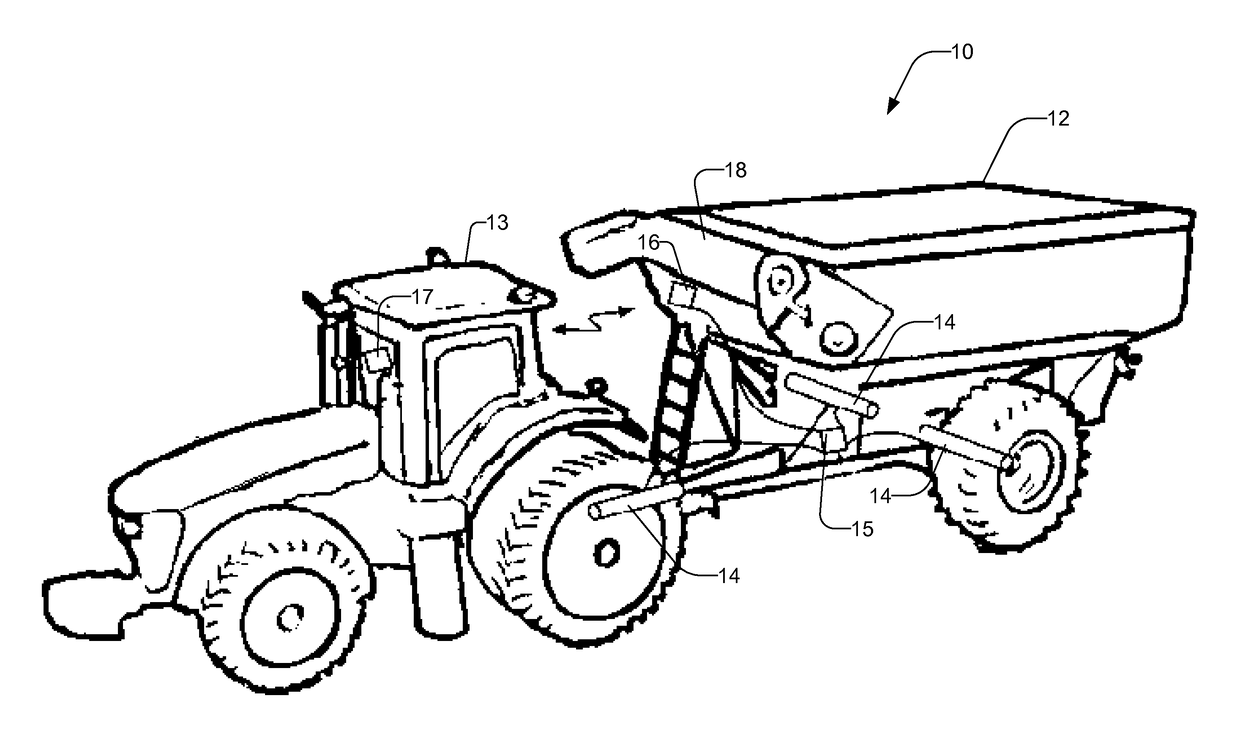

System and method for measuring grain cart weight

ActiveUS9983048B1Enhancing display location diversityCompensation effectOscillations damping for weighingWeighing indication devicesAccelerometerLow-pass filter

A system of detecting loading and unloading of mobile containers such as grain carts utilizes two low pass filters to determine whether the contents of the container are changing by subtracting one filter signal from the other, and using the sign of the difference. Weighing performance is improved by utilizing accelerometers to compensate for measurement dynamics and non-level orientation. Failure and degradation of weight sensors is detected by testing sensor half bridges. Loading and unloading weights can be tied to specific vehicles by utilizing RF beacons.

Owner:BITSTRATA SYST INC

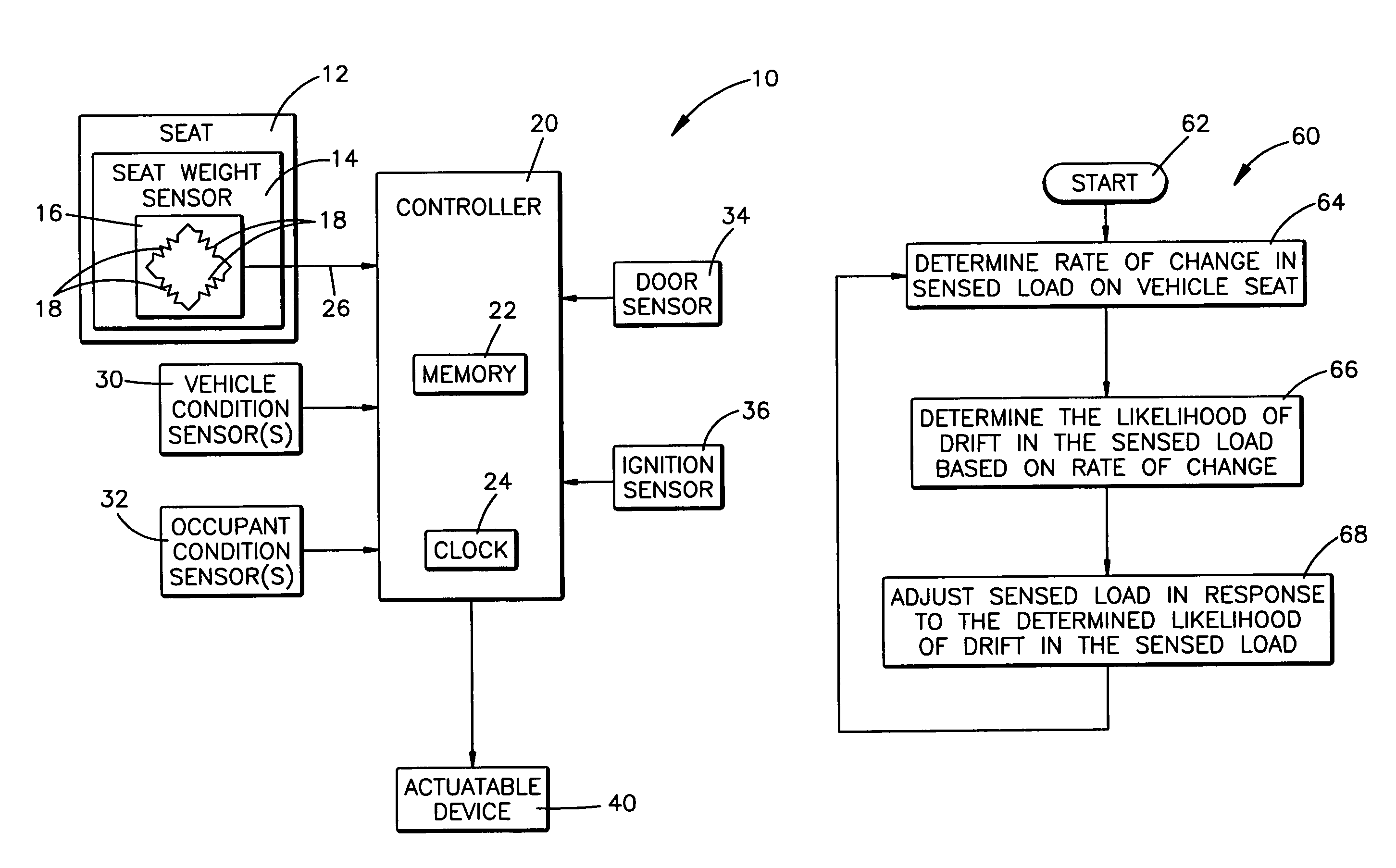

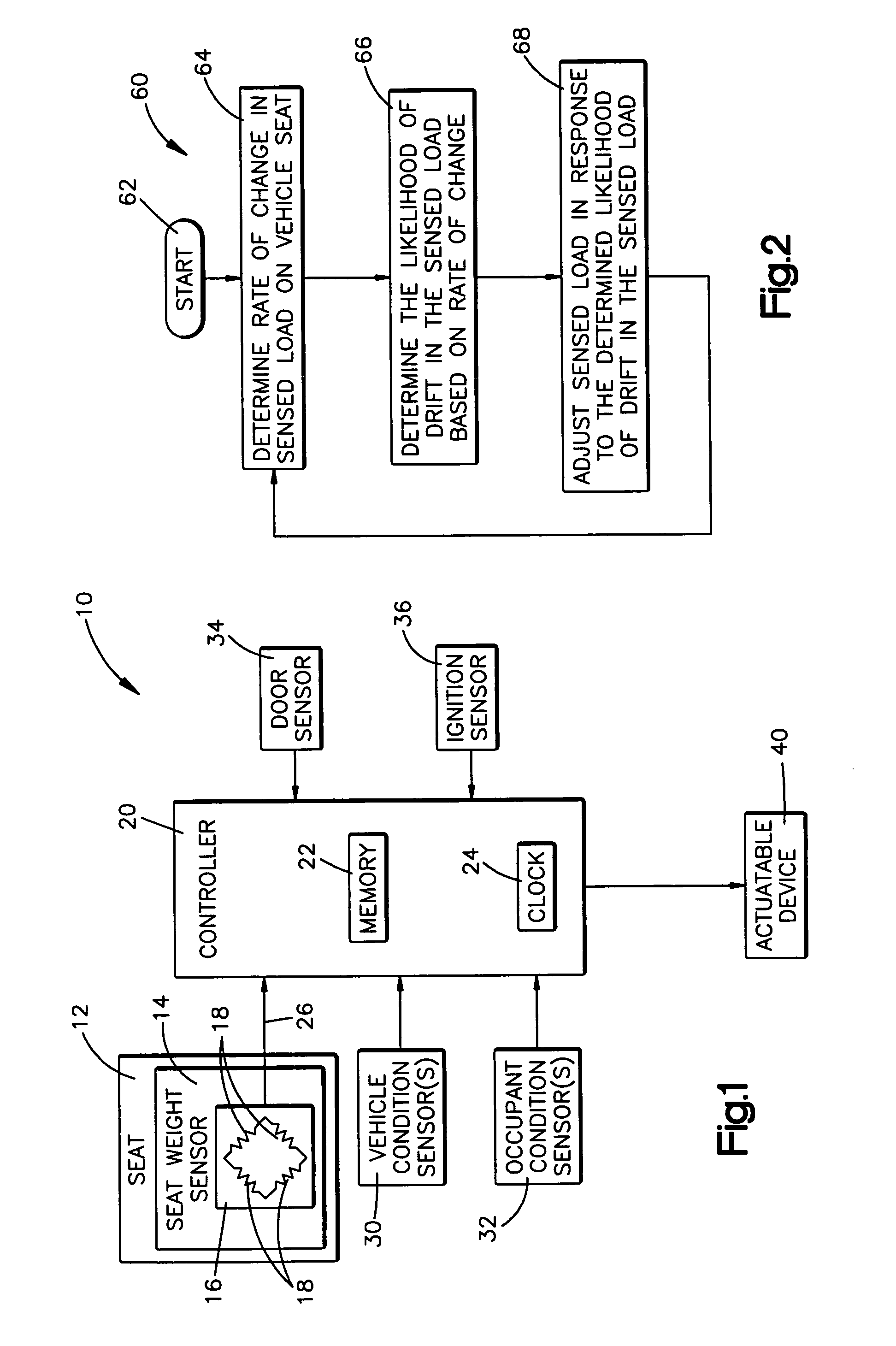

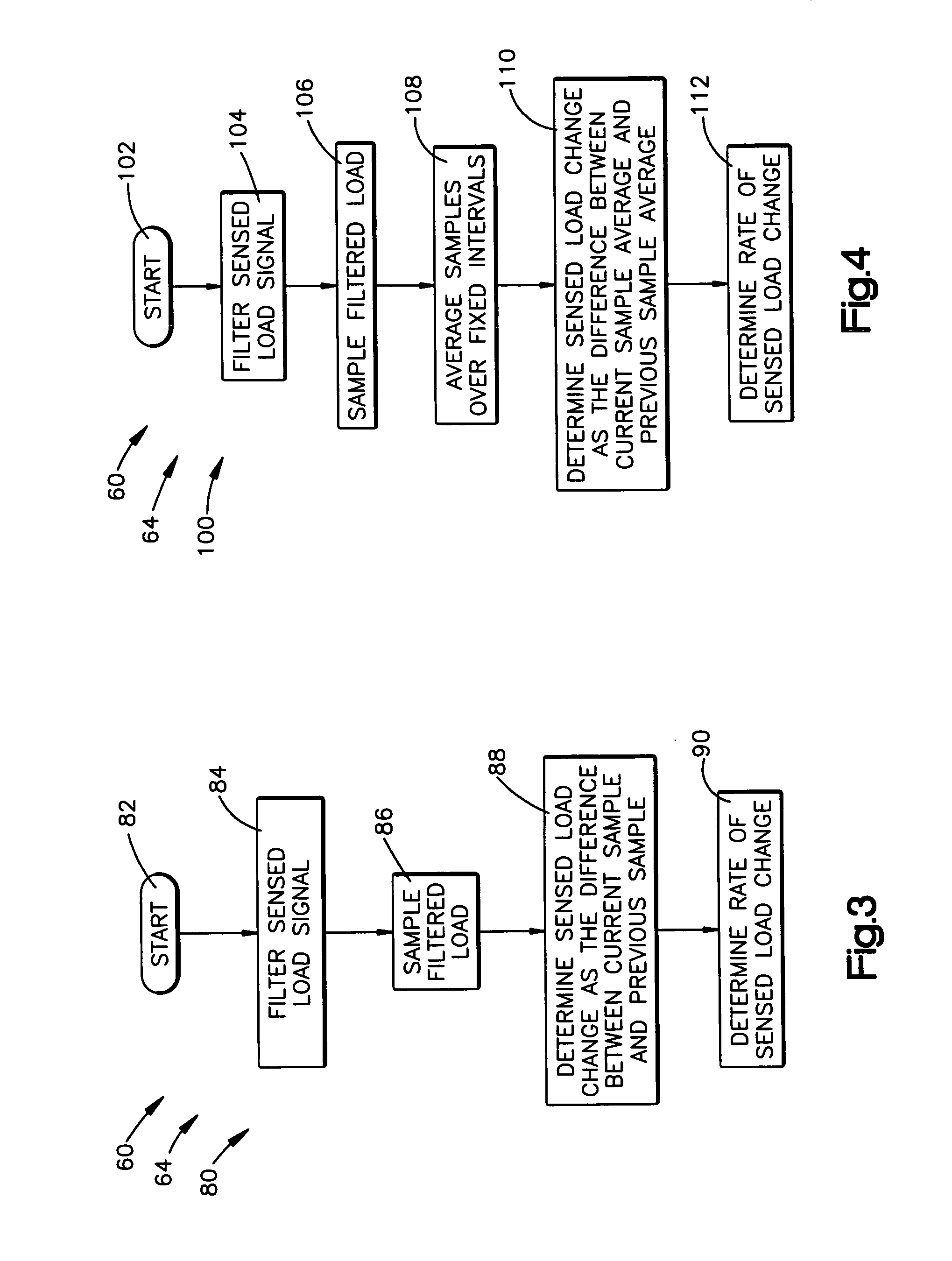

System and method for drift compensation in a seat load sensing system

A method (60) for adjusting a sensed load W(s) of a vehicle seat weight sensing system (10) includes the step (64) of determining a rate of change {dot over (W)}(t),{dot over (W)}avg in the sensed load. The method (60) also includes the step (66) of determining the likelihood of drift in the sensed load W(s) in response to the determined rate of change {dot over (W)}(t),{dot over (W)}avg.

Owner:TRW AUTOMOTIVE US LLC

Balance with a T-shaped coupling arrangement that guides the support element onto a load receiver at three points forming a triangle

InactiveUS7012198B2Reduce frictionEasy to cleanWeighing apparatus using counterbalanceWeighing apparatus testing/calibrationCouplingEngineering

A balance includes a weighing cell with a vertically movable load receiver, a weighing pan to receive a weighing load, and a support element to couple the weighing pan to the vertically movable load receiver of the weighing cell. A cantilever arm with a seat for at least one calibration weight is solidly connected to the support element. The balance has a coupling arrangement that constrains the support element with low-friction mobility to the load receiver at three points forming a triangle in a plane that extends orthogonal to the symmetry plane of the weighing cell, wherein the triangle is symmetric to the symmetry plane of the weighing cell. Under the coupling arrangement, the support element is solidly supported on the load receiver in the direction in which the weighing load is acting.

Owner:METTLER TOLEDO GMBH

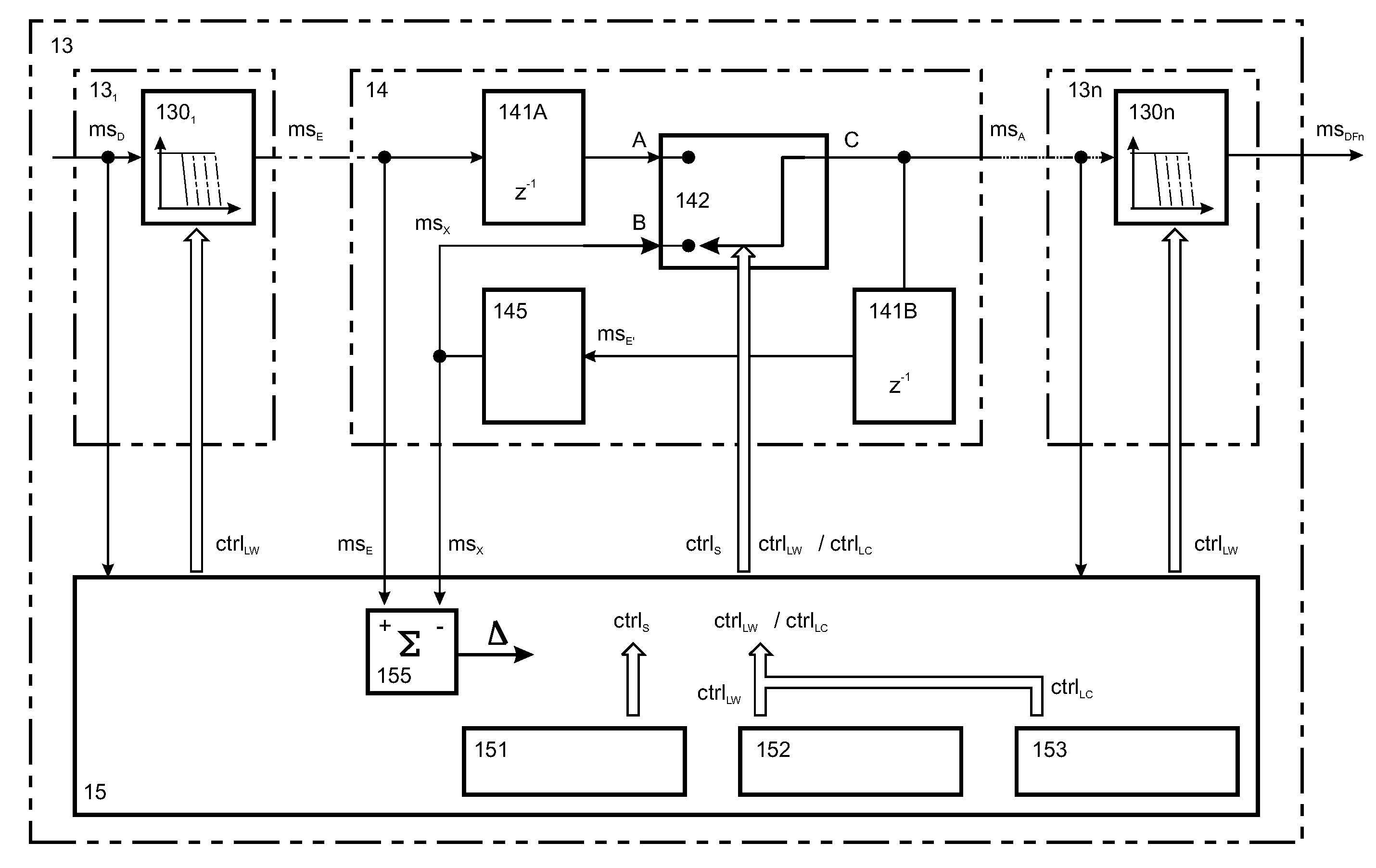

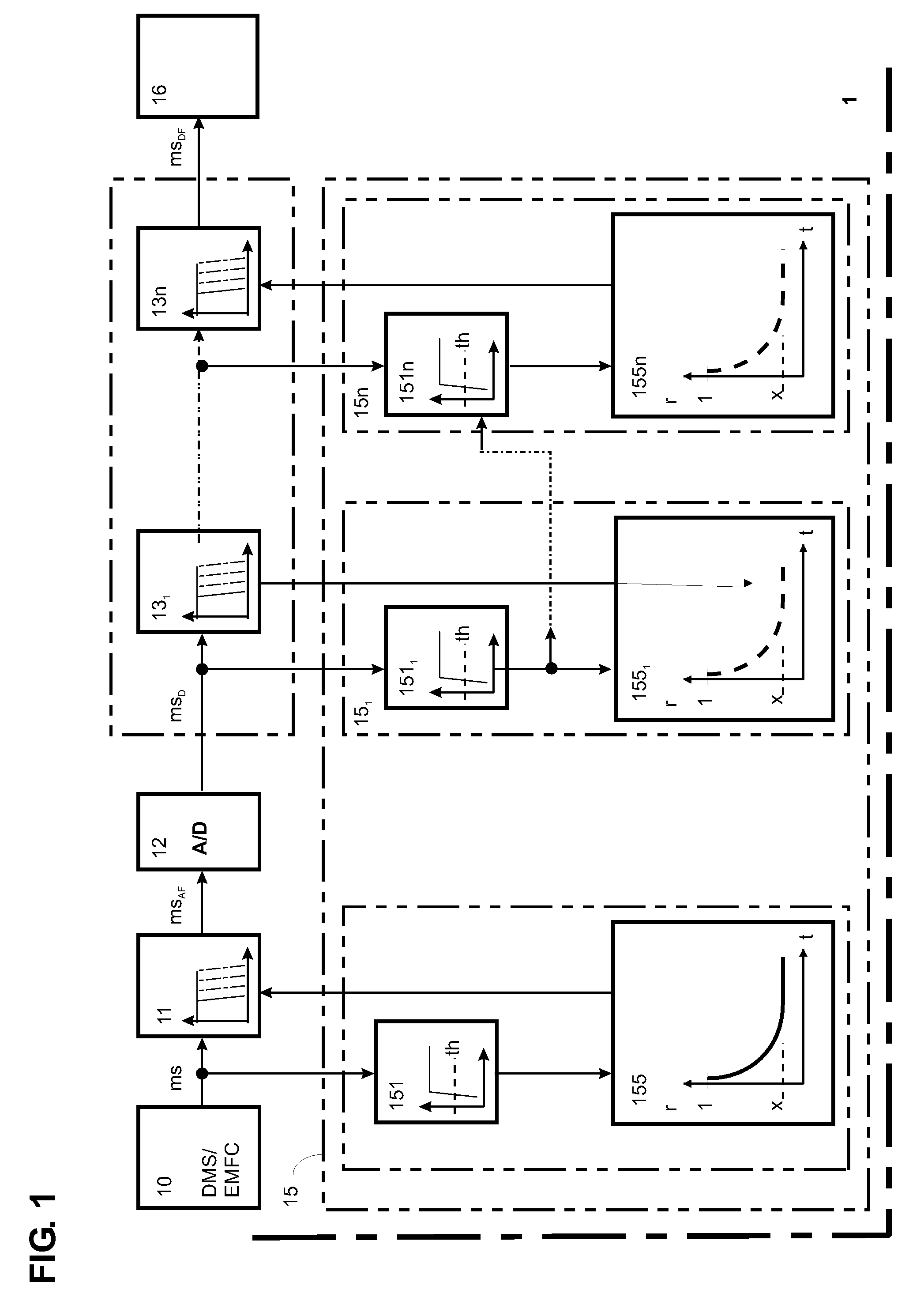

Method for processing the output signal of a measurement transducer, and force-measuring device

ActiveUS20070271056A1Simple signal processingReliable detection and suppressionTesting/calibration apparatusForce measurementMeasurement deviceTransducer

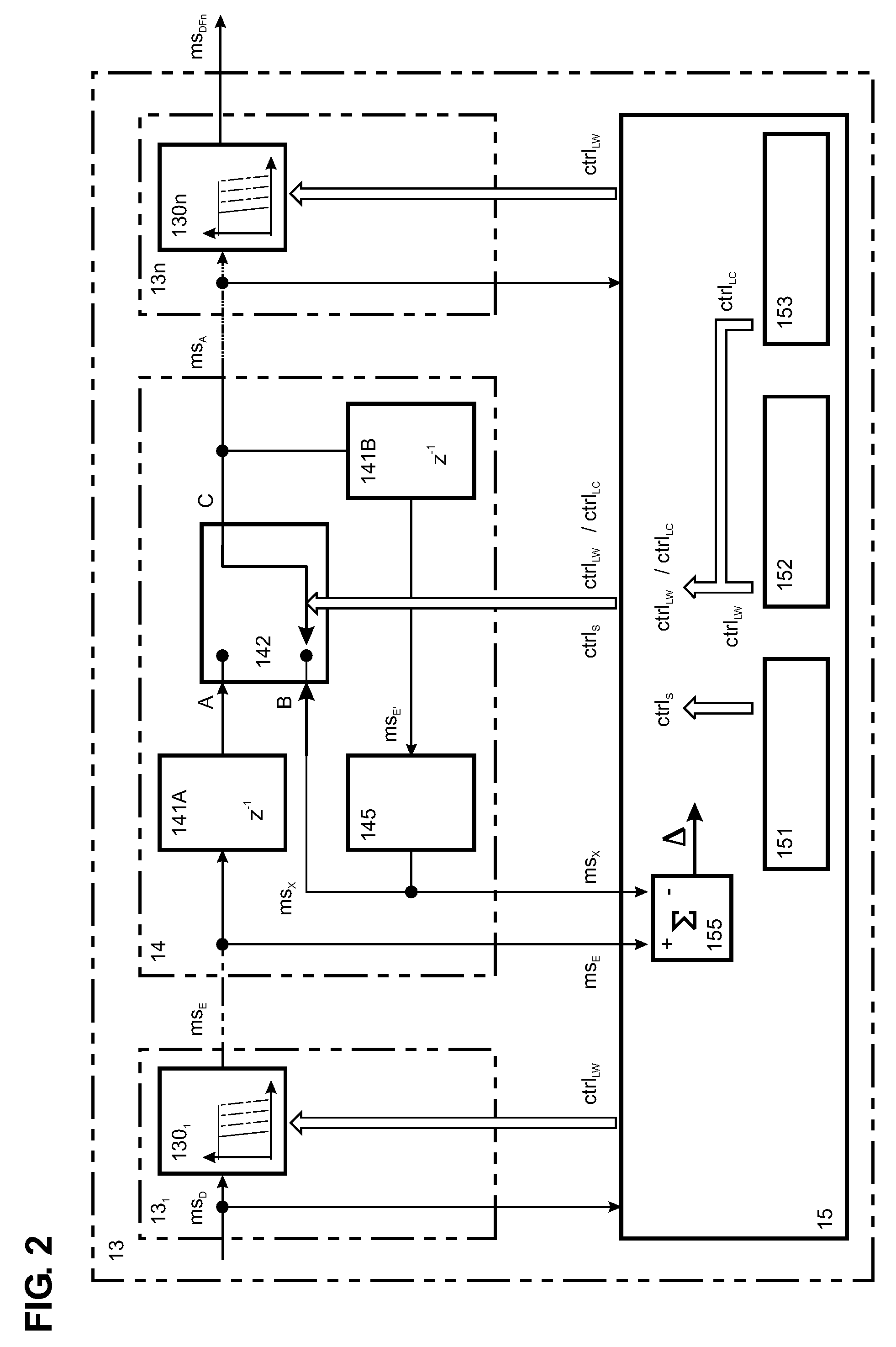

The output signal from a measuring transducer in a force-measuring device is processed by filtering a measuring signal (ms), representing a load that is acting on the transducer, to suppress interfering signal portions caused by extraneous influences including mechanical disturbances, or changes of the load. The measuring signal (msE) passes through a first delay element (141A) to a measurement value unit (145) which holds the value of the currently received measuring signal (msE), a mean value based on the most recent values of the measuring signal, or an expected value (msE) based on the most recent values of the measuring signal. The measuring signal (msE) is monitored for signal disturbances using a first detector module (151). After detection, a switching means (142) is actuated and the output signal (msX) of the measurement value unit is processed further, if applicable, and sent to the output end of the device, instead of the currently received measuring signal (msE).

Owner:METTLER TOLEDO GMBH

System and method for count by weight correction

InactiveUS20090301791A1Improve trustAccurate measurementOscillations damping for weighingWeighing apparatus for materials with special property/formTransducerElectric signal

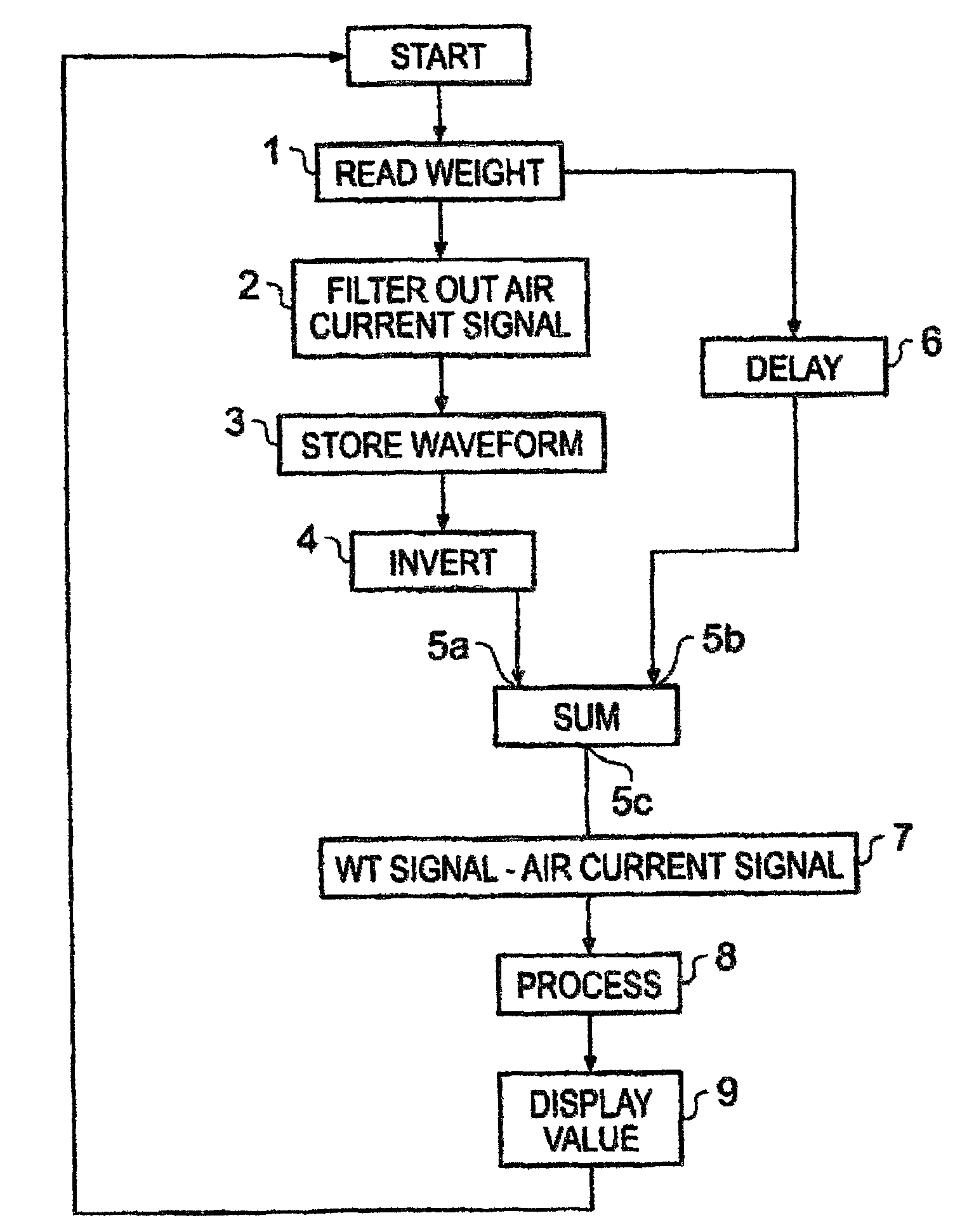

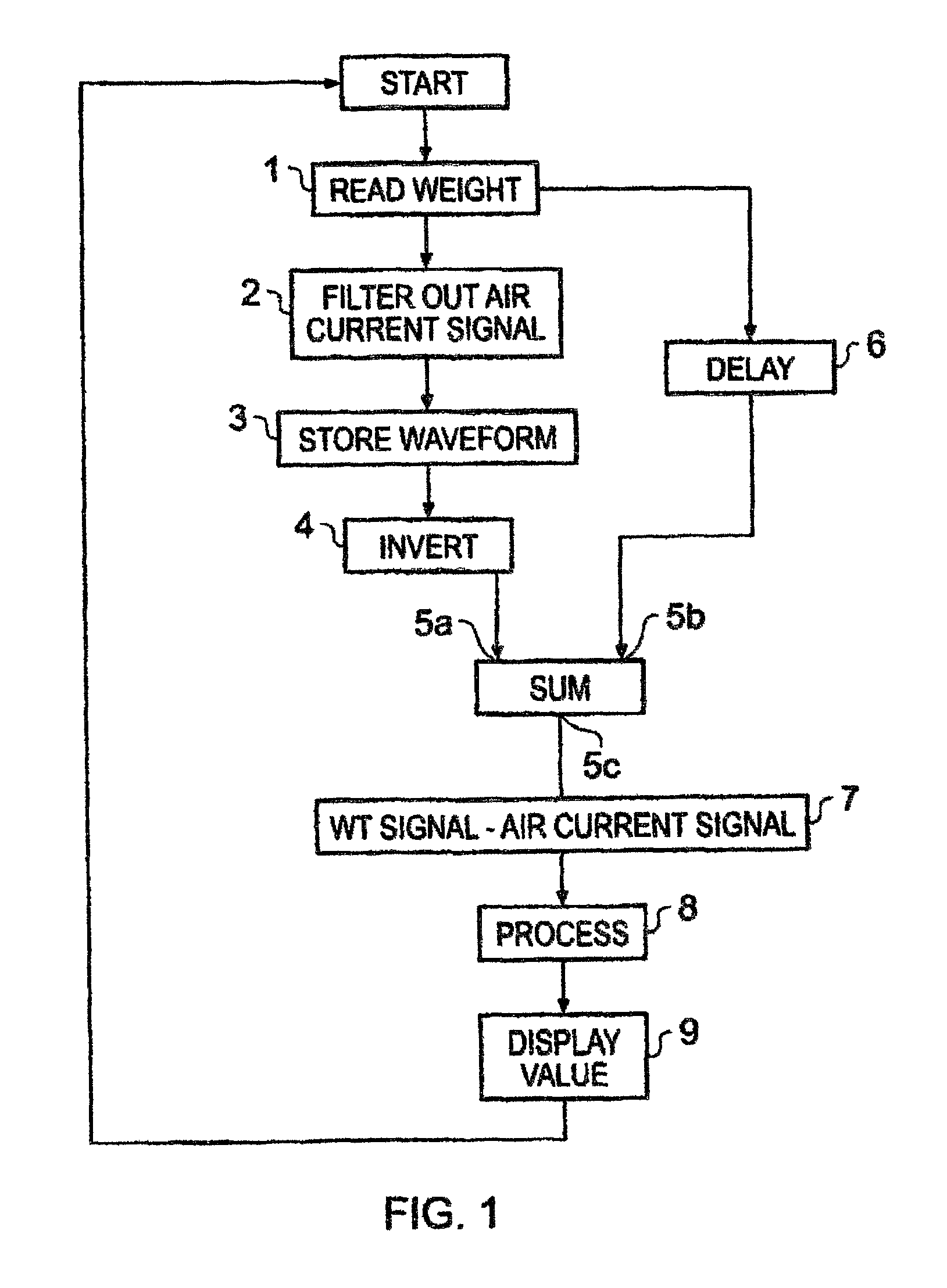

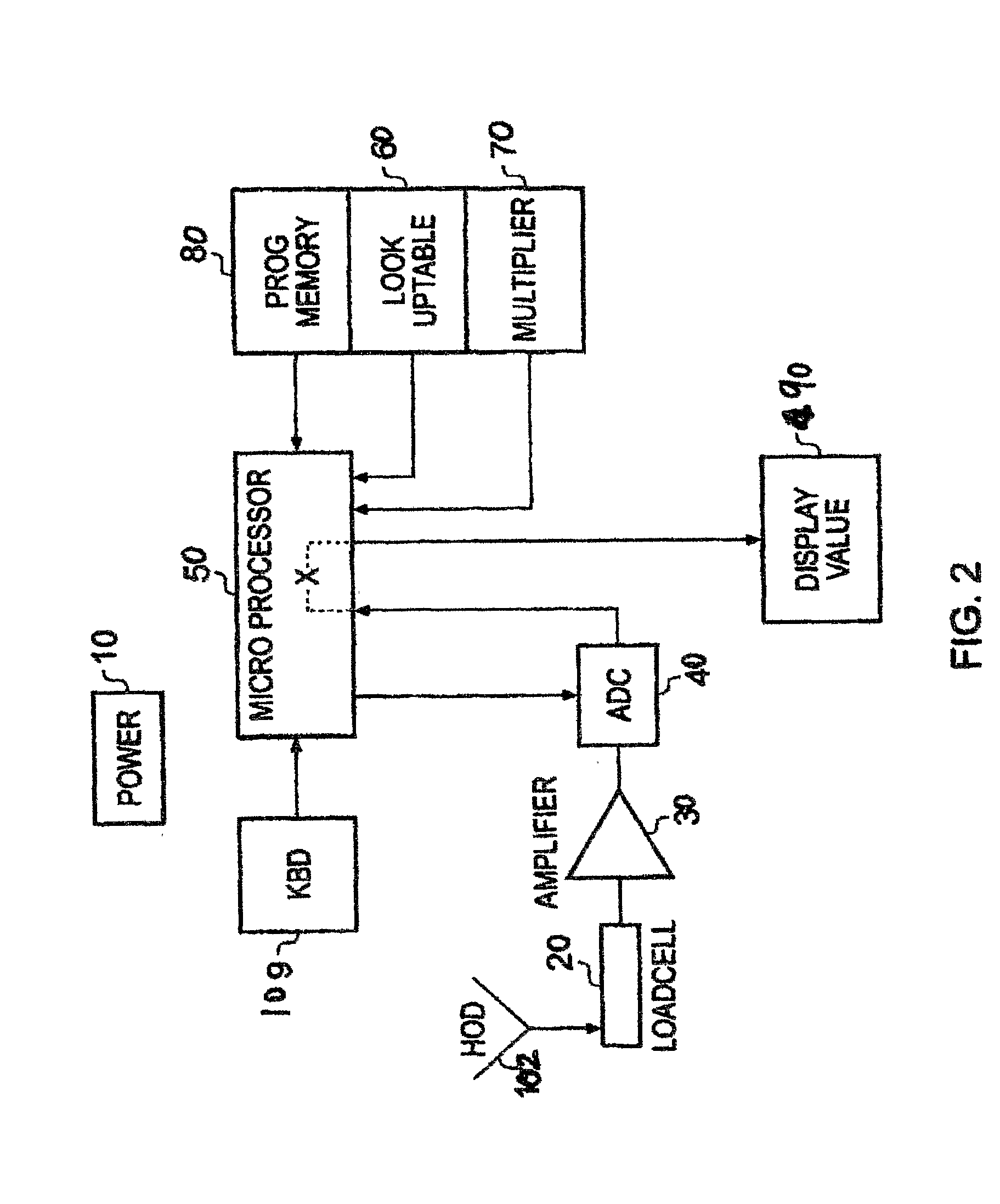

A method and apparatus for counting nominally identical articles employs weighing apparatus, which comprises a load hod (102) for holding a number of articles to be weighed and a load transducer (20) responsive to loading of the hod (102) to produce a derived electrical signal indicative of the apparent weight of articles in the hod (102). The signal is susceptible to fluctuation as a result of local air currents acting on the hod (102) or on the articles contained therein. The transducer derived signal is filtered to extract a component signal representative of such fluctuation. After further processing, the filtered component signal is used to correct the original transducer signal thereby to indicate the true weight of articles in the hod (102). The number of articles in the hod (102) is then determined by dividing the true weight indication by an expected average weight of an article. Fluctuations in the transducer signal due to air currents may also be removed by a system of validation of the signals depending on whether or not they are within range limits based on a running average.

Owner:MCPHAIL DUNCAN +2

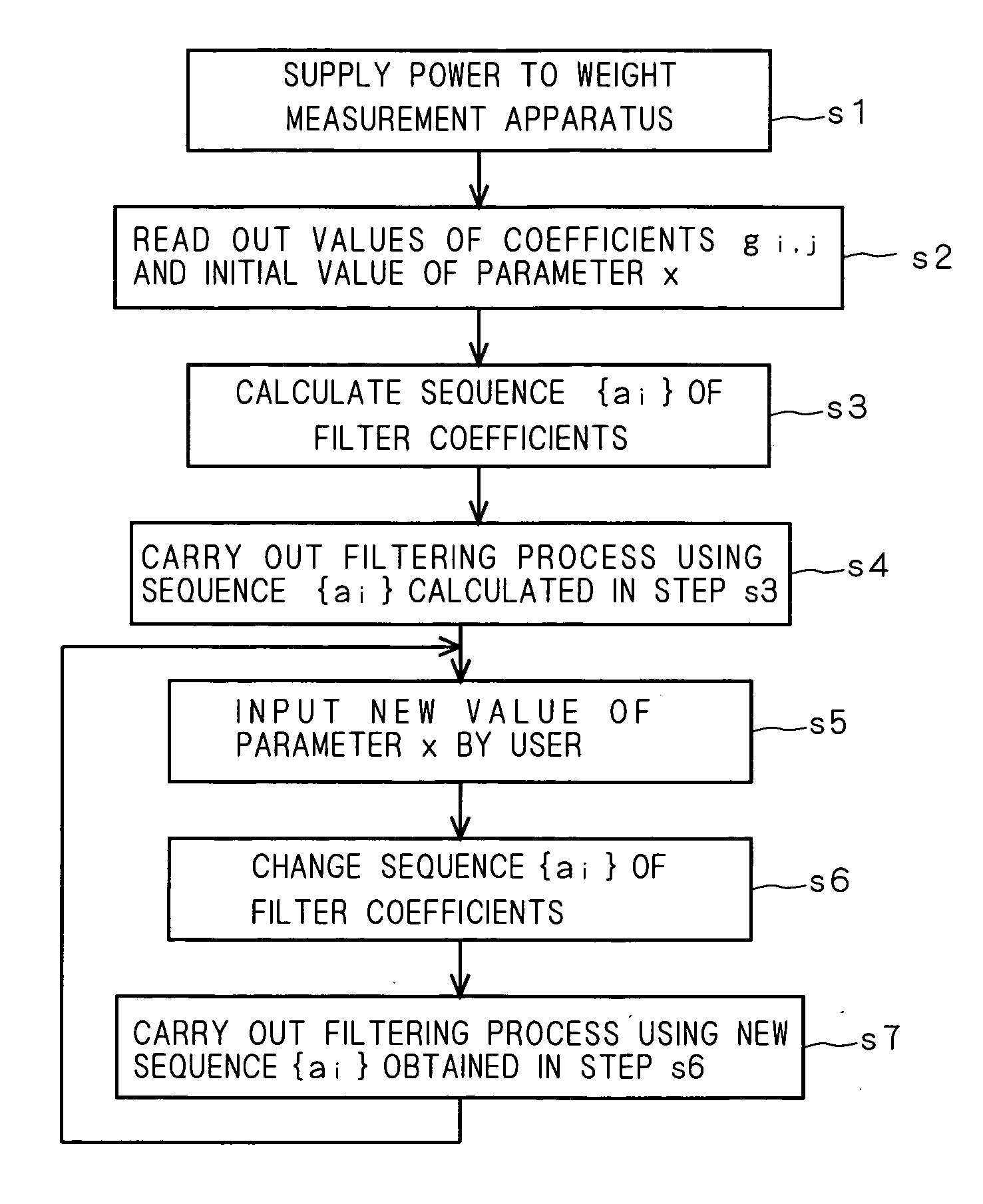

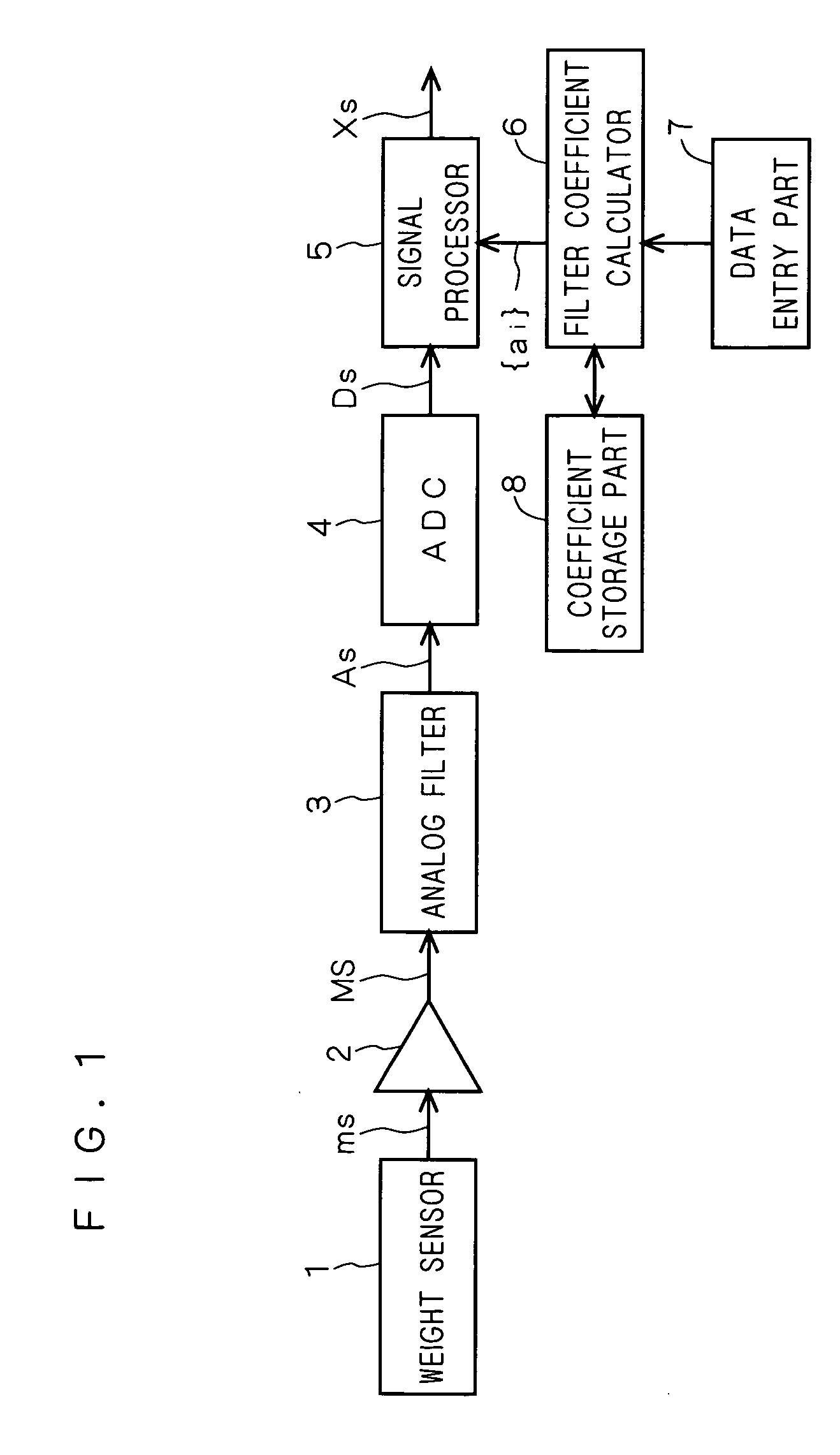

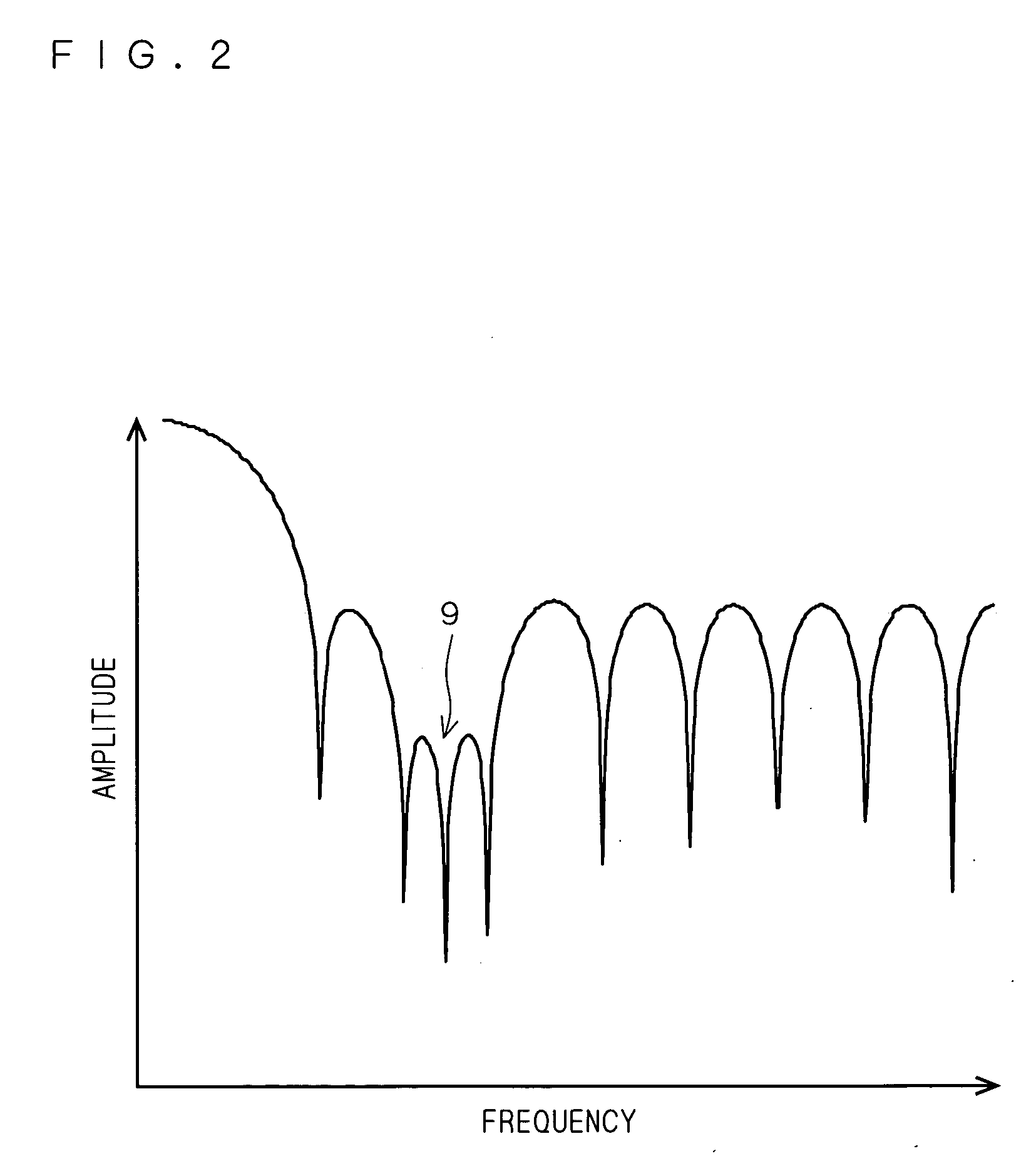

Noise eliminating apparatus, weight measurement apparatus, method of eliminating noise, and method of designing digital filter

InactiveUS20070095123A1Increasing scale of circuitImprove scaleTesting/calibration apparatusDigital technique networkFrequency spectrumMeasurement device

A filter coefficient calculator of a weight measurement apparatus calculates filter coefficients using a predetermined arithmetic expression and outputs them to a signal processor. The signal processor carries out a filtering process on a weighing signal using the filter coefficients. The arithmetic expression includes a spectrum parameter specifying a band position of an attenuation band where attenuation must be locally enhanced. A user can input a value of the parameter via a data entry part. Each band is specified by the spectrum parameter not as the lowest limit value of a normalized angular frequency, but as the amount of deviation (the amount of displacement) from its center frequency.

Owner:ISHIDA CO LTD

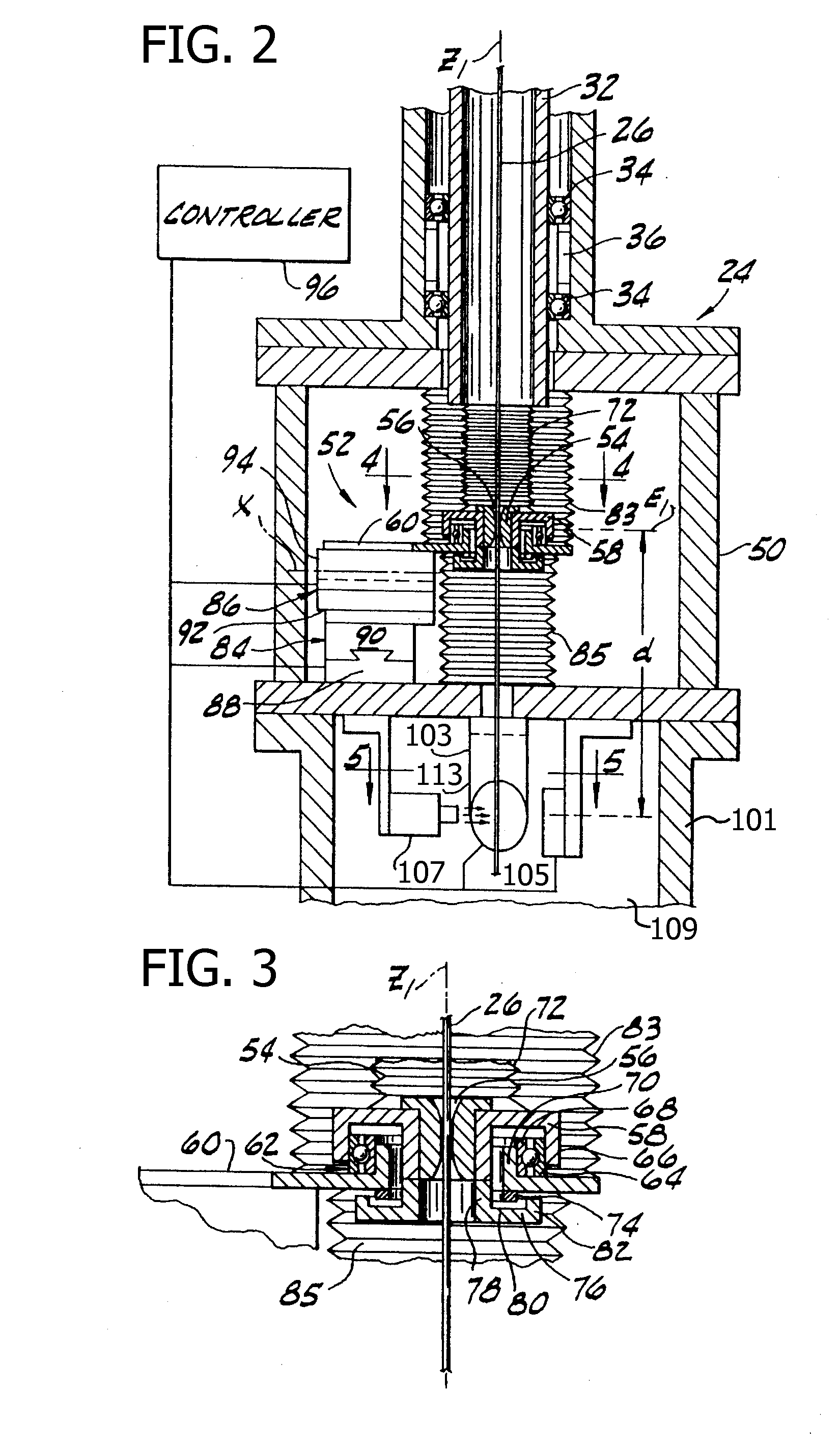

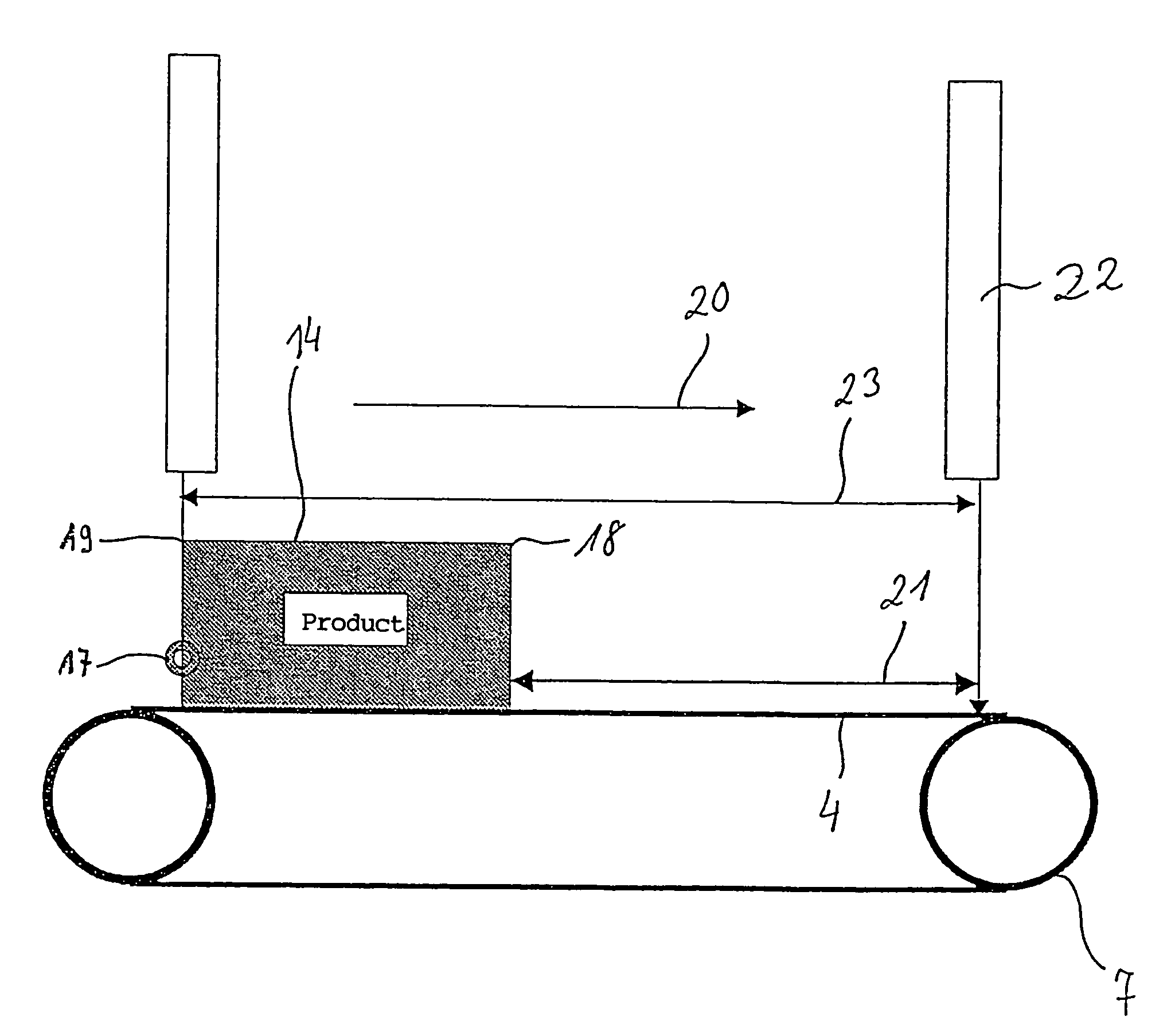

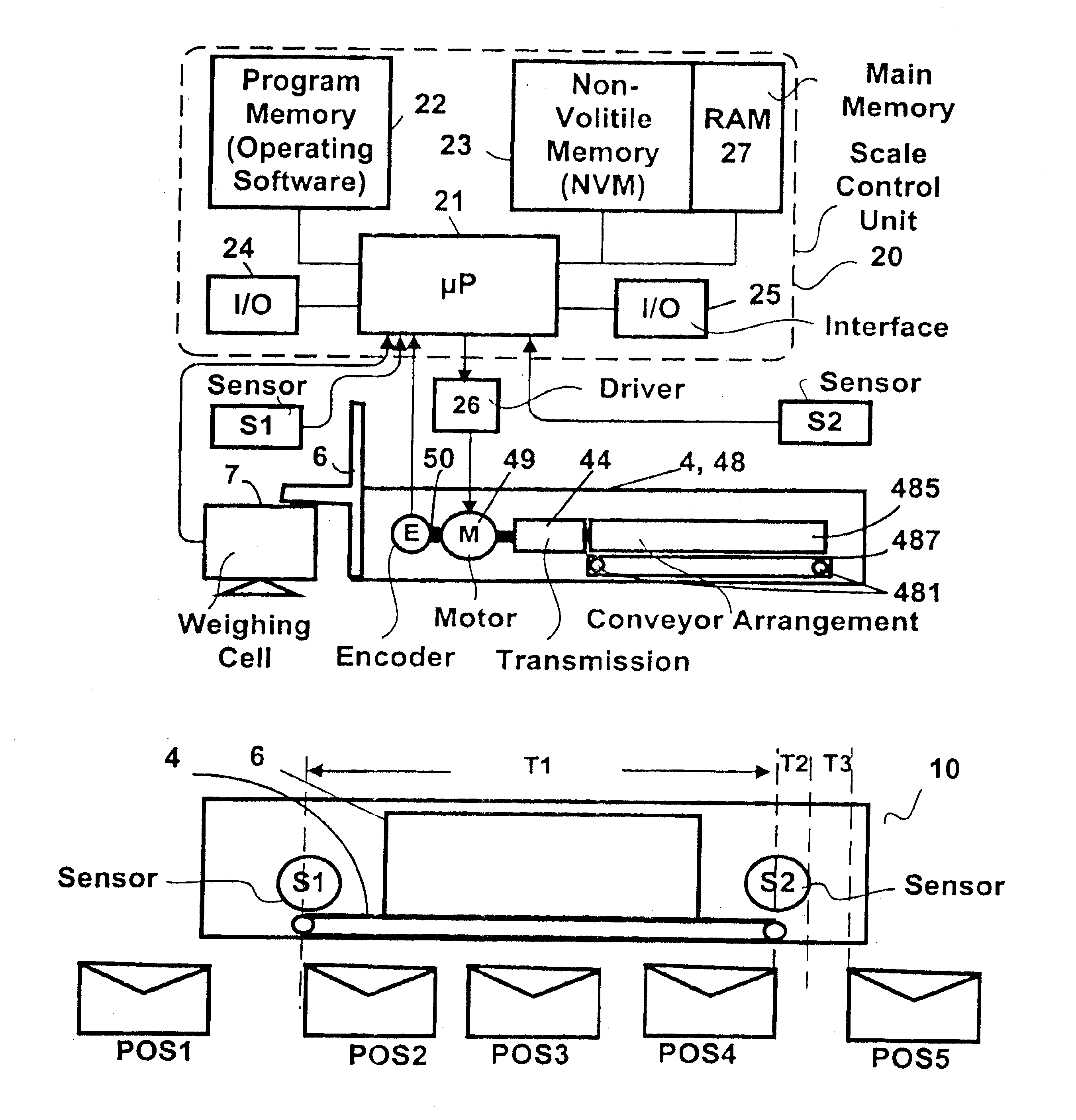

Method and arrangement for determining a weight with a dynamic scale

InactiveUS6907409B1Known disadvantageAvoid disadvantagesOscillations damping for weighingFranking apparatusLimit valueIndustrial engineering

A dynamic scale has a conveyor, a weighing pan, a weighing cell, sensors and an electronic control unit that, in addition to controlling the conveyor means (4), implements an evaluation of a number measured weight values that are obtained from the weighing cell and performs a measured value correction on the basis of specific parameters, and supplies a corrected weight value to a postage meter machine via an interface. A method for a control of the conveyor, evaluation of the measured values from the weighing cell, and formulation of a valid output weight value includes an overload check that is made by comparing a measured weight value lying in the middle of the number of measured values to at least one overload limit value, and formation of a decision parameter from the measured values, in a validity check, for comparison to at least one shutoff criterion. If the validity check determines that the measured values from the weighing cell are valid, they are used to form the output weight value.

Owner:FRANCOTYP POSTALIA

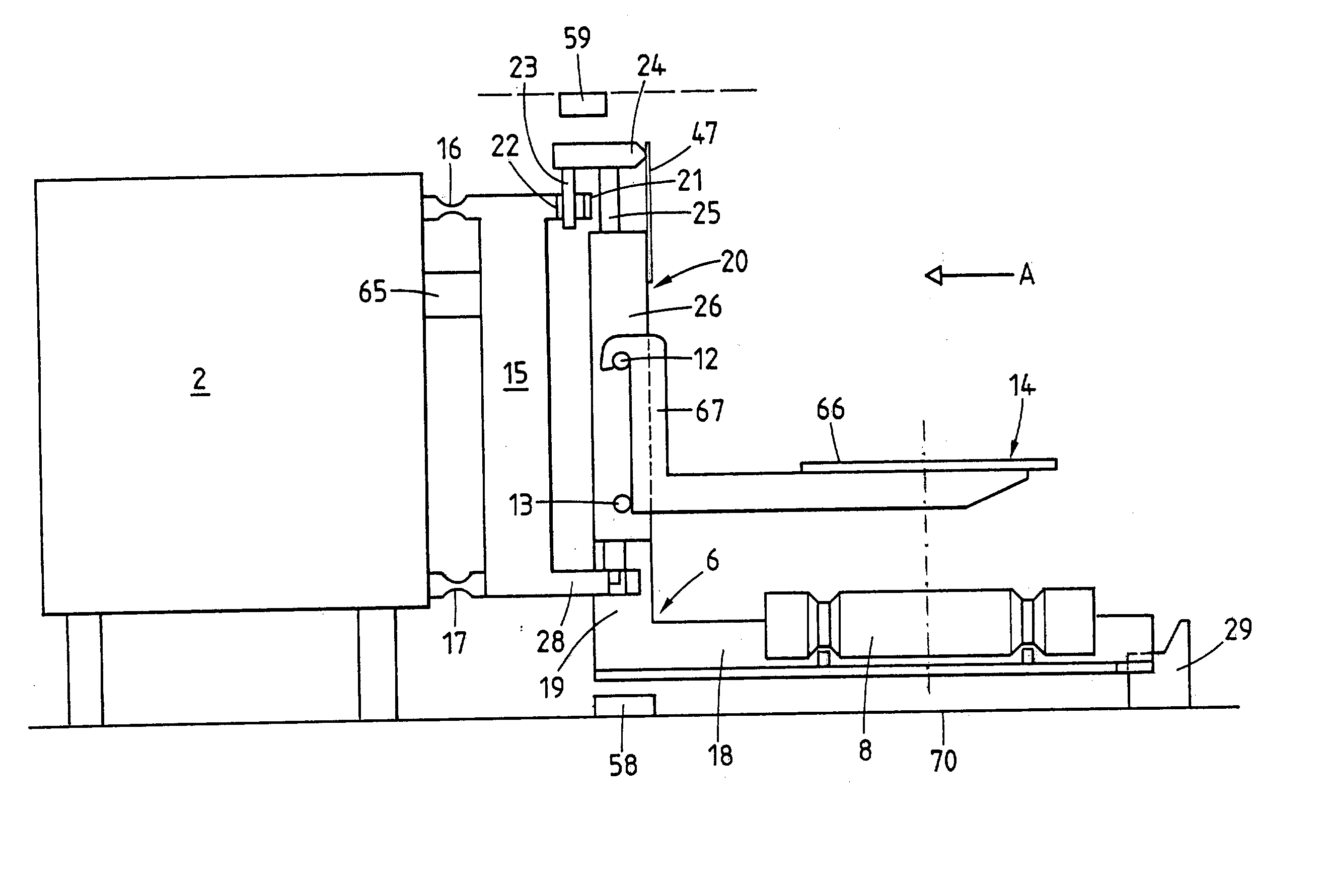

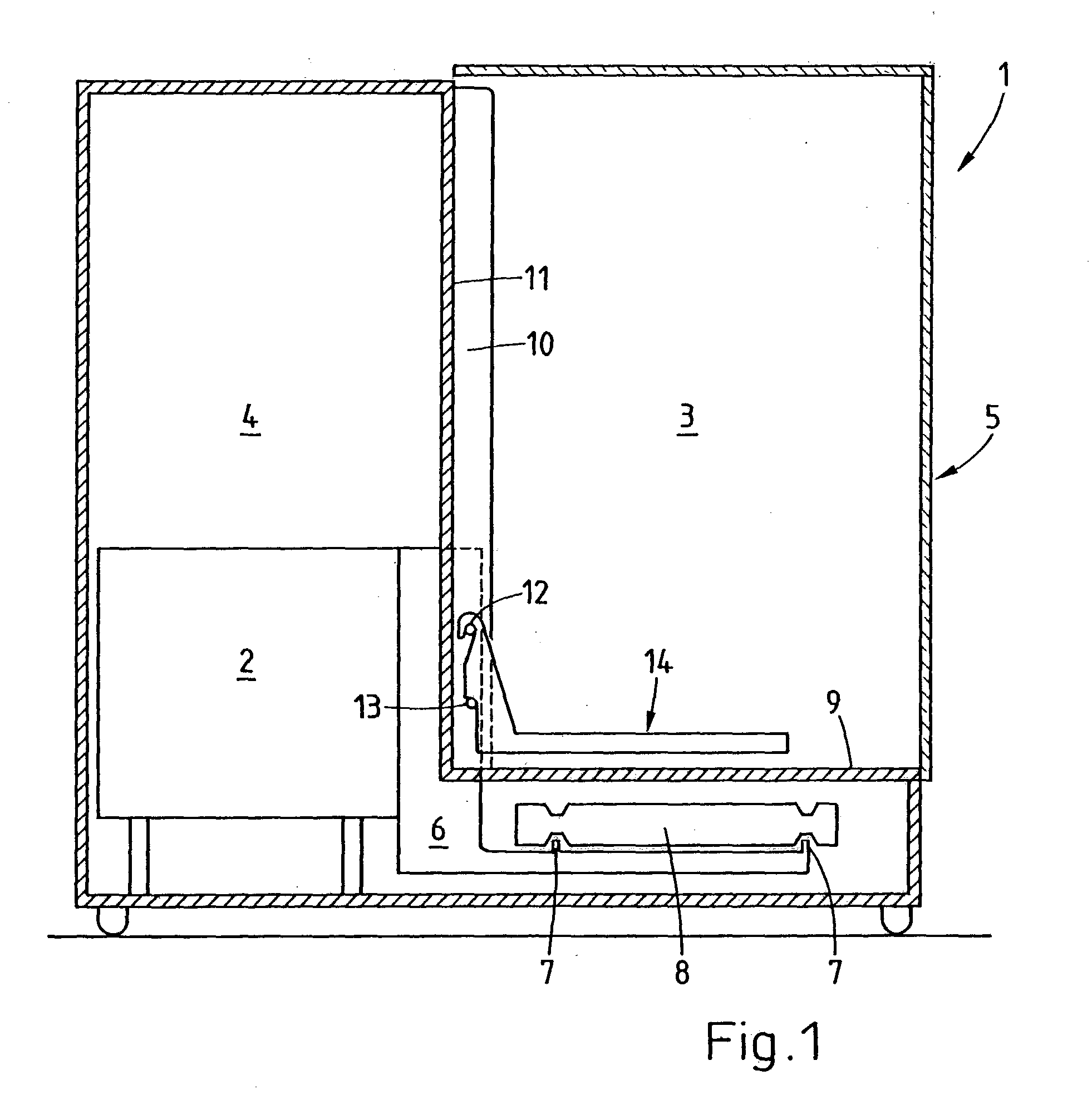

Electronic scale comprising an inclinometer and corresponding signal evaluation method

InactiveUS7906737B2Vibration measurement in solidsMaterial analysis by observing immersed bodiesDigital signal processingSignal correction

An electronic scale having a measuring sensor (1 . . . 16), a digital signal processing unit (18), a digital display (19) and an inclinometer (40). The inclinometer derives a signal for the tilt of the scale from the difference of at least two signals. The digital signal processing unit (18) is provided with an additional circuit component or program routine that adds the two signals and, by way of this cumulative signal, corrects the vibration-distorted signal of the measuring sensor (1 . . . 16). A plurality of inclinometers enables the simultaneous detection of momentary gravitational acceleration. For example, in an electric bubble level, the gas bubble moves out of place when tilted and the diameter of the gas bubble changes when the gravitational acceleration changes. The scale thus provides an additional signal for correcting the influence of disturbances with minimum complexity.

Owner:SARTORIUS LAB INSTR GMBH & CO KG

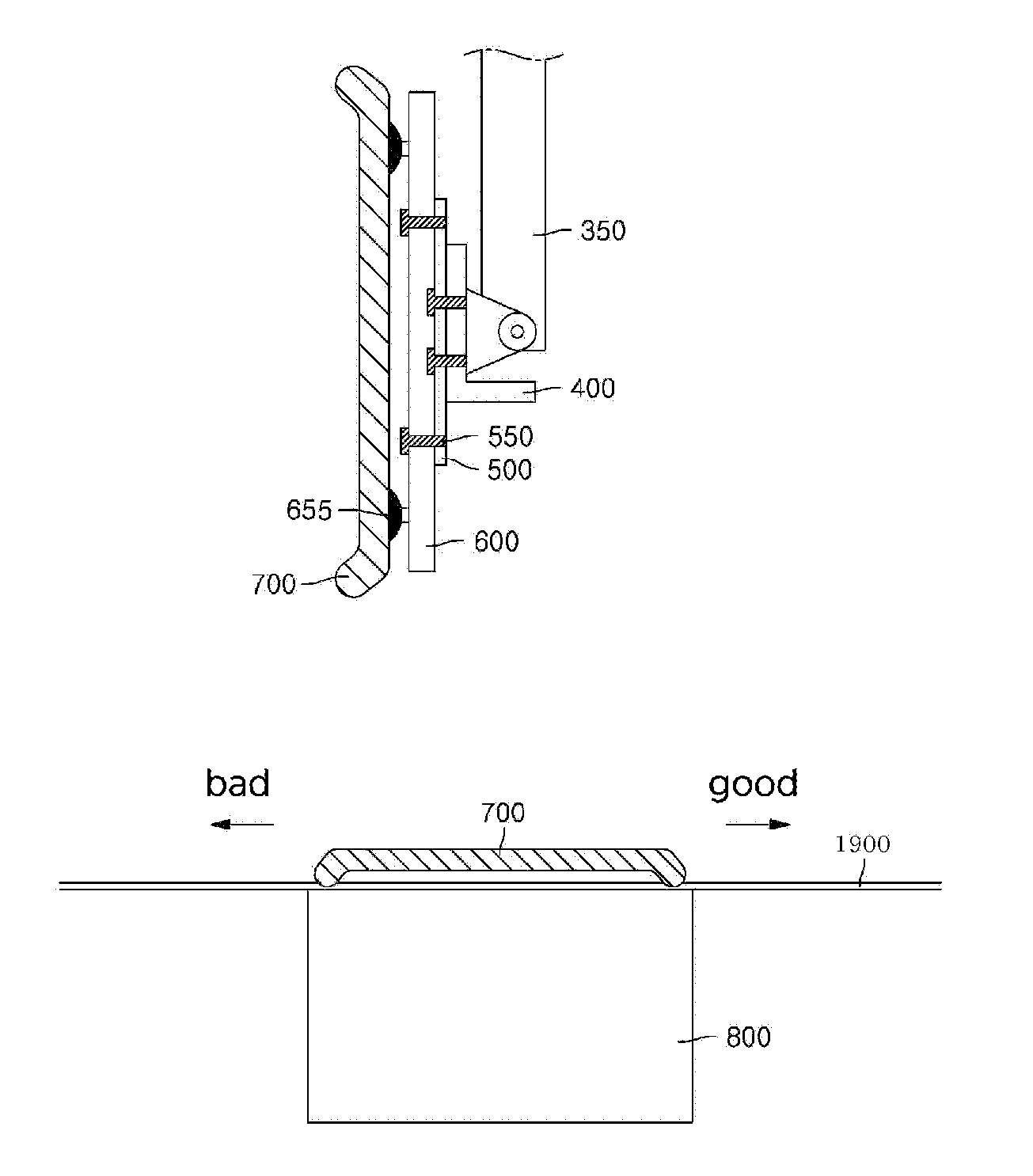

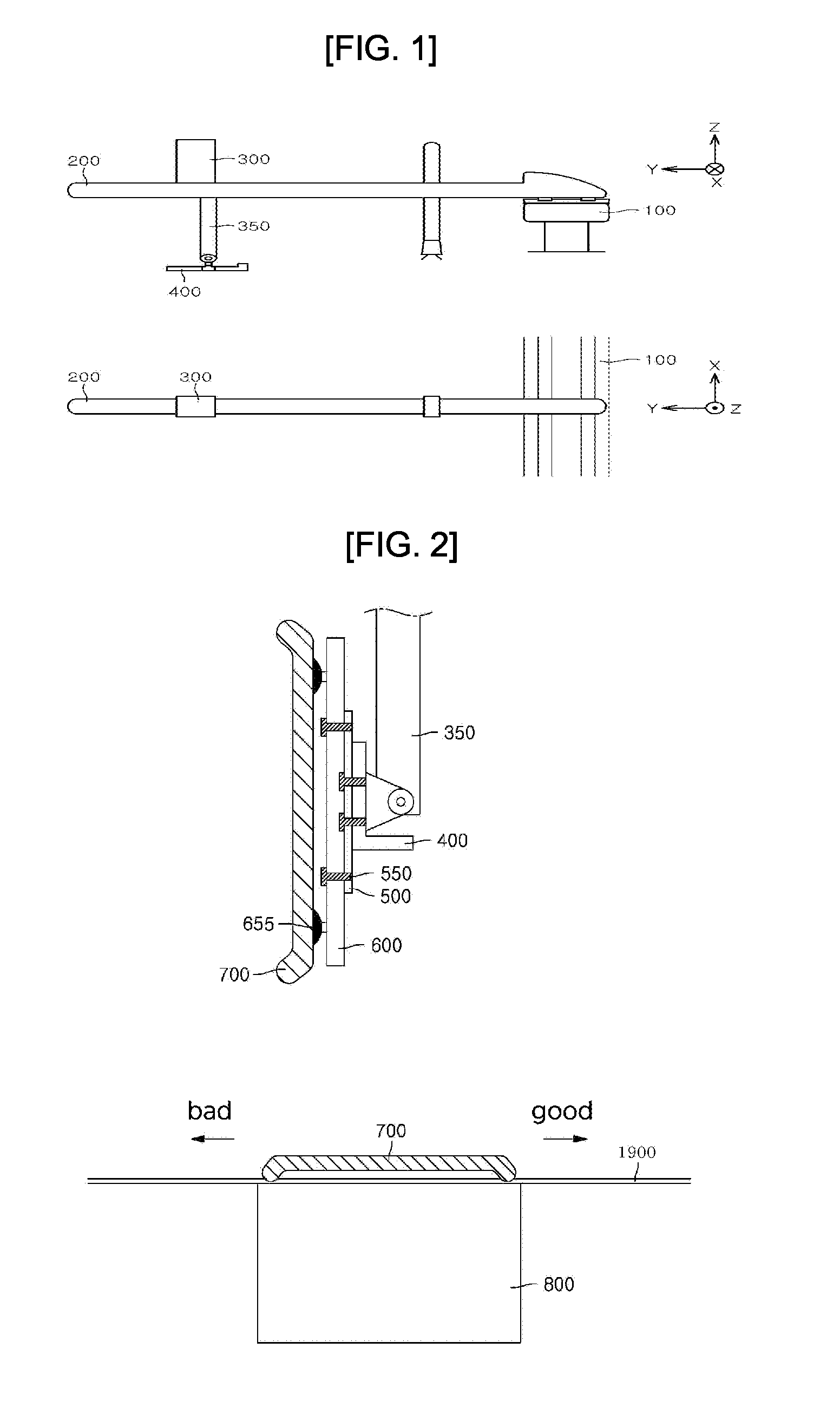

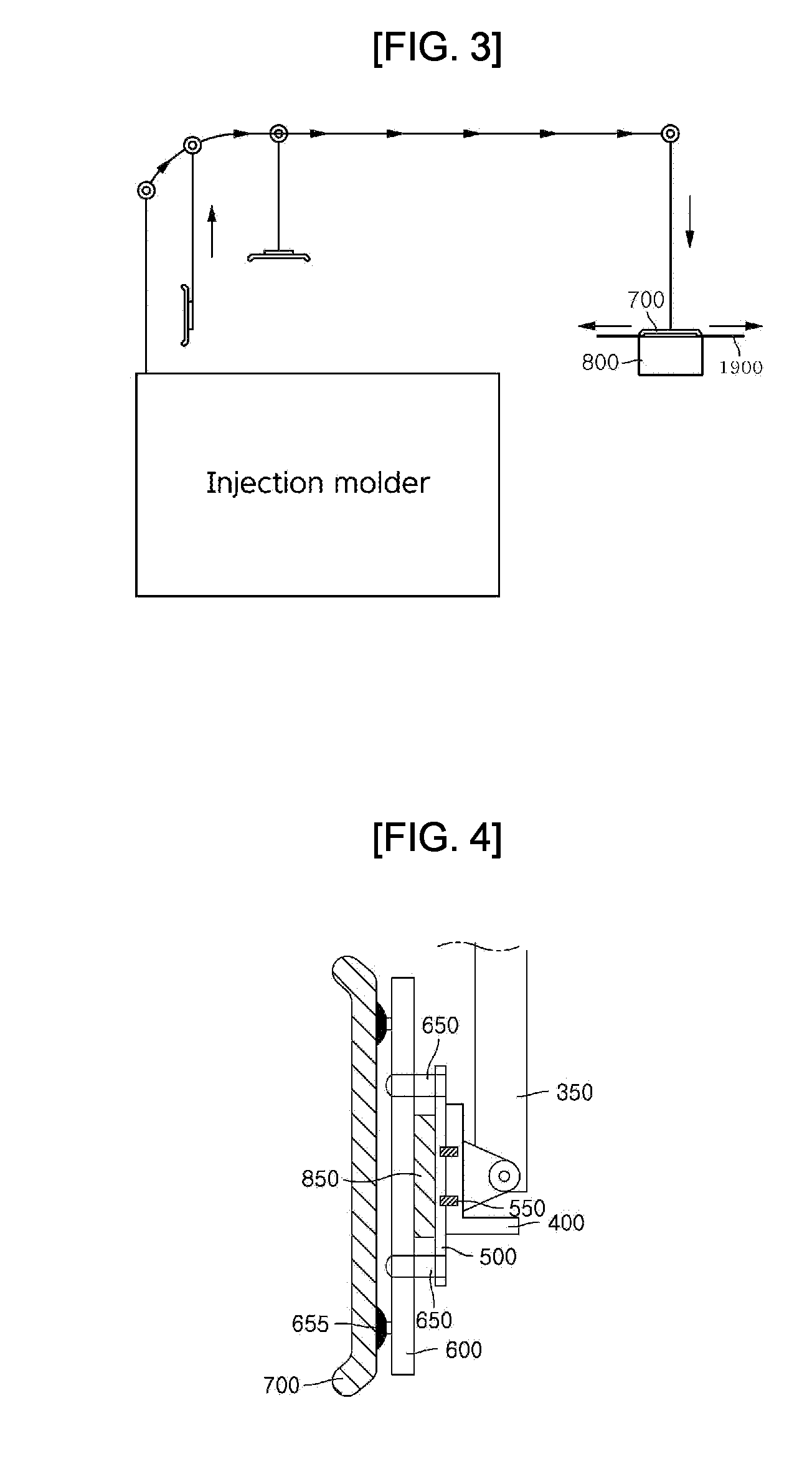

Take-out robot with function of sensing weight of injection molded product

ActiveUS20150314507A1Low costOptimize space utilizationProgramme-controlled manipulatorMouldsEngineeringVertical load

Provided is a take-out robot including a load cell in a rotating unit to allow an injection molded product to be attached to an adhesive unit, measure a weight of the injection molded product, and determine whether the injection molded product is desirable or faulty. A chucking device of measuring the weight may be installed to prevent a vertical load during the taking out and a force during the conveying from being applied to the load cell, and allow the force to be applied to the load cell only when reaching a weight measuring point. Further, a cut portion may be formed to have a stepped boundary surface in the load cell and thus, a stopper function may be performed against bending deflection of the load cell when a load is applied so that the load cell may be protected without an additional chucking device of measuring the weight.

Owner:HANYANG ROBOTICS

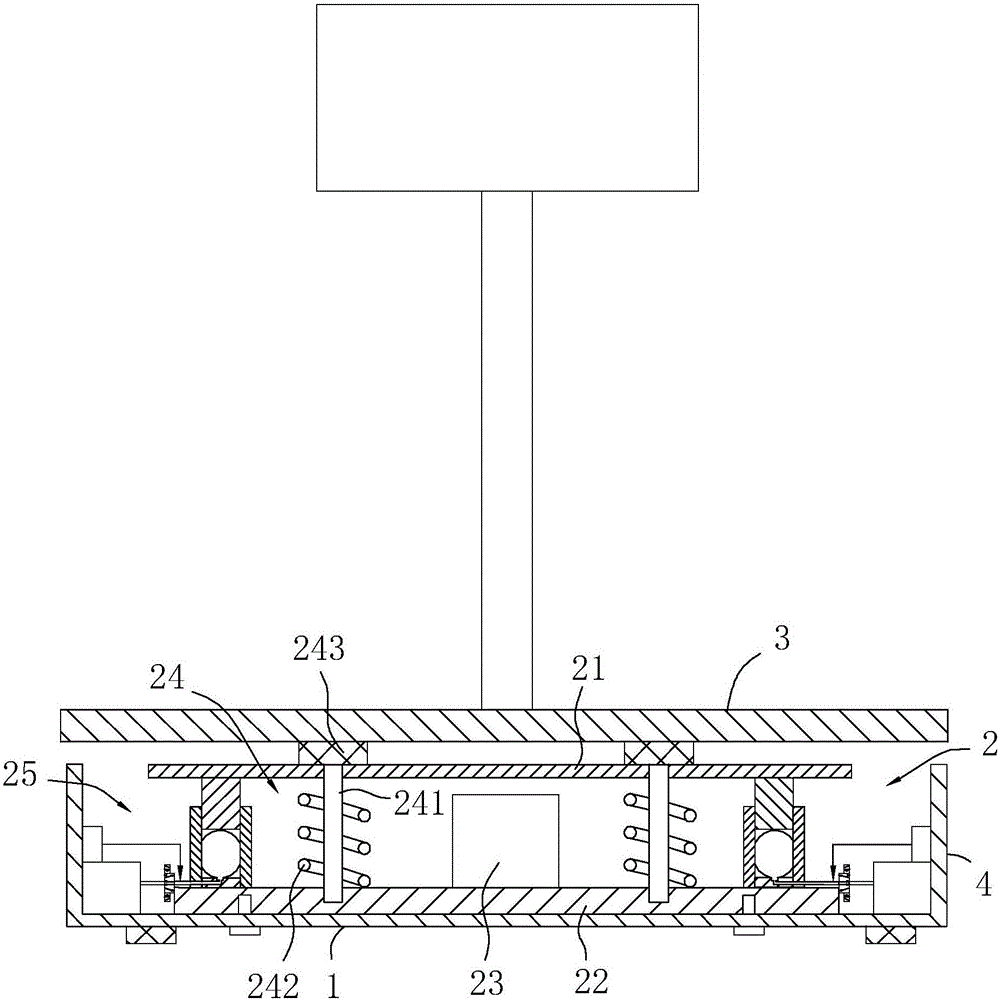

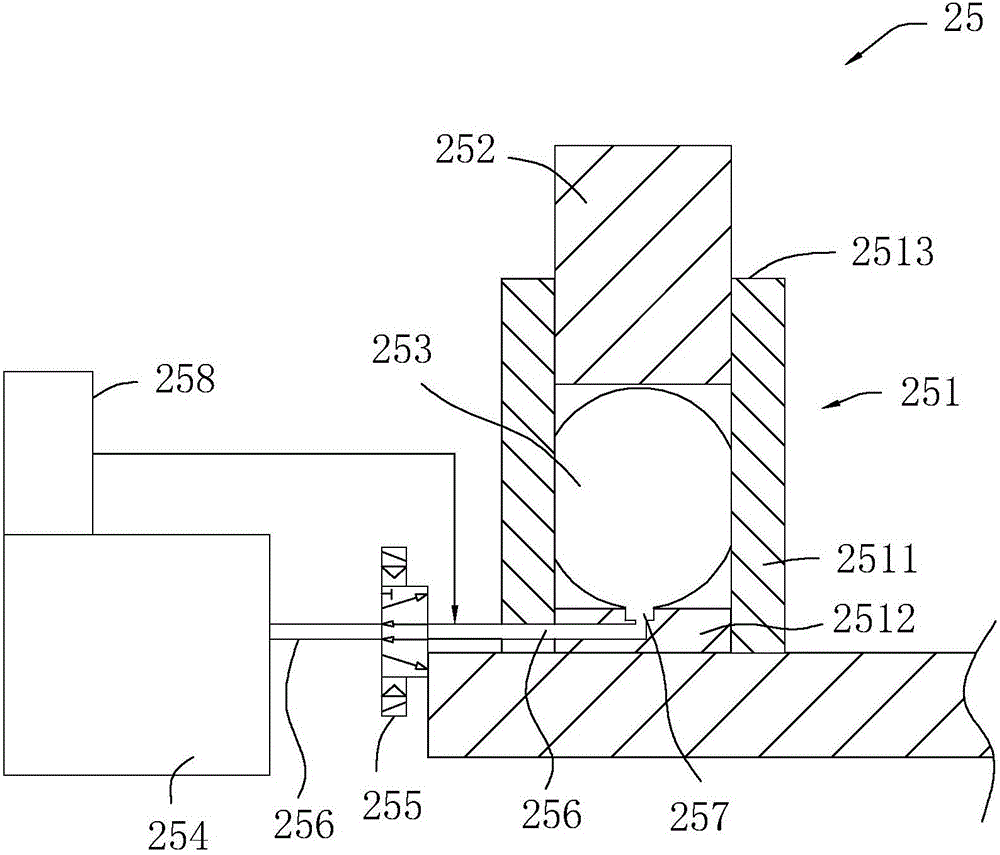

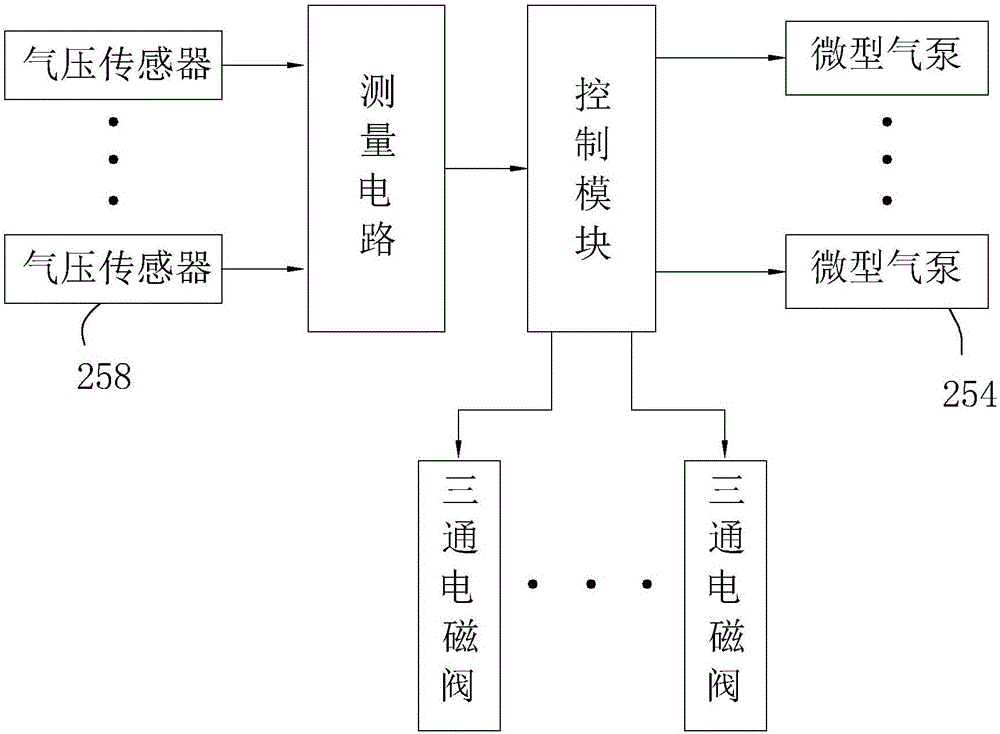

Electronic platform scale and weighing method thereof

ActiveCN106840353AExtended service lifeLow costOscillations damping for weighingElectricitySolenoid valve

The invention discloses an electronic platform scale and a weighing method thereof. According to the technical scheme, the electronic platform scale comprises a base, a scale shelf and a platform scale plate, wherein the scale shelf comprises a buffering assembly, a baroceptor, and a control module, the scale shelf makes contact with a top bar earlier that a weighing sensor does, the buffering assembly comprises a supporting casing pipe, a top block which is slidably installed in the supporting casing pipe and abuts against the top bar, the interior of the supporting casing pipe is provided with an inflating body which abuts against the top block, the inflating body is provided with a gas nipple, and the gas nipple is connected to a solenoid valve through an air tube; the baroceptor is used for detecting air pressure in the inflating body and converting the air pressure into an air pressure electric signal through a measuring circuit; the control module is used for receiving the air pressure electric signal and obtaining weight data through operation and conversion. If the weight data is smaller than maximum weighting data of the electronic platform scale, the solenoid valve is controlled to be breakover so that air inside the inflating body can be released, the inflating body is filled with air, which plays a buffering effect, and avoids damages of the weighing sensor caused when the weighing sensor is shocked due to transient contact of the top bar and the weighing sensor.

Owner:浙江润达检测科技有限公司

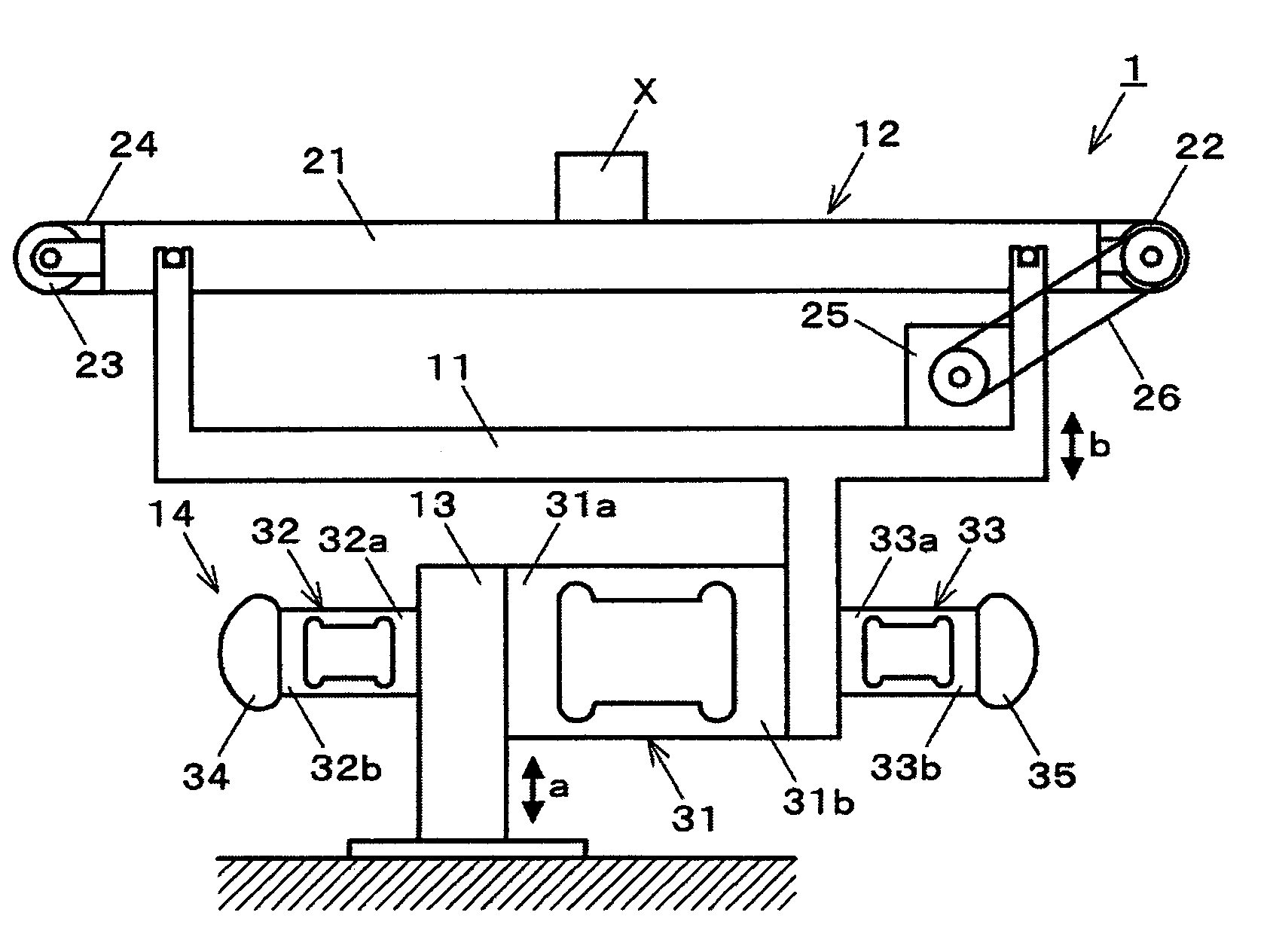

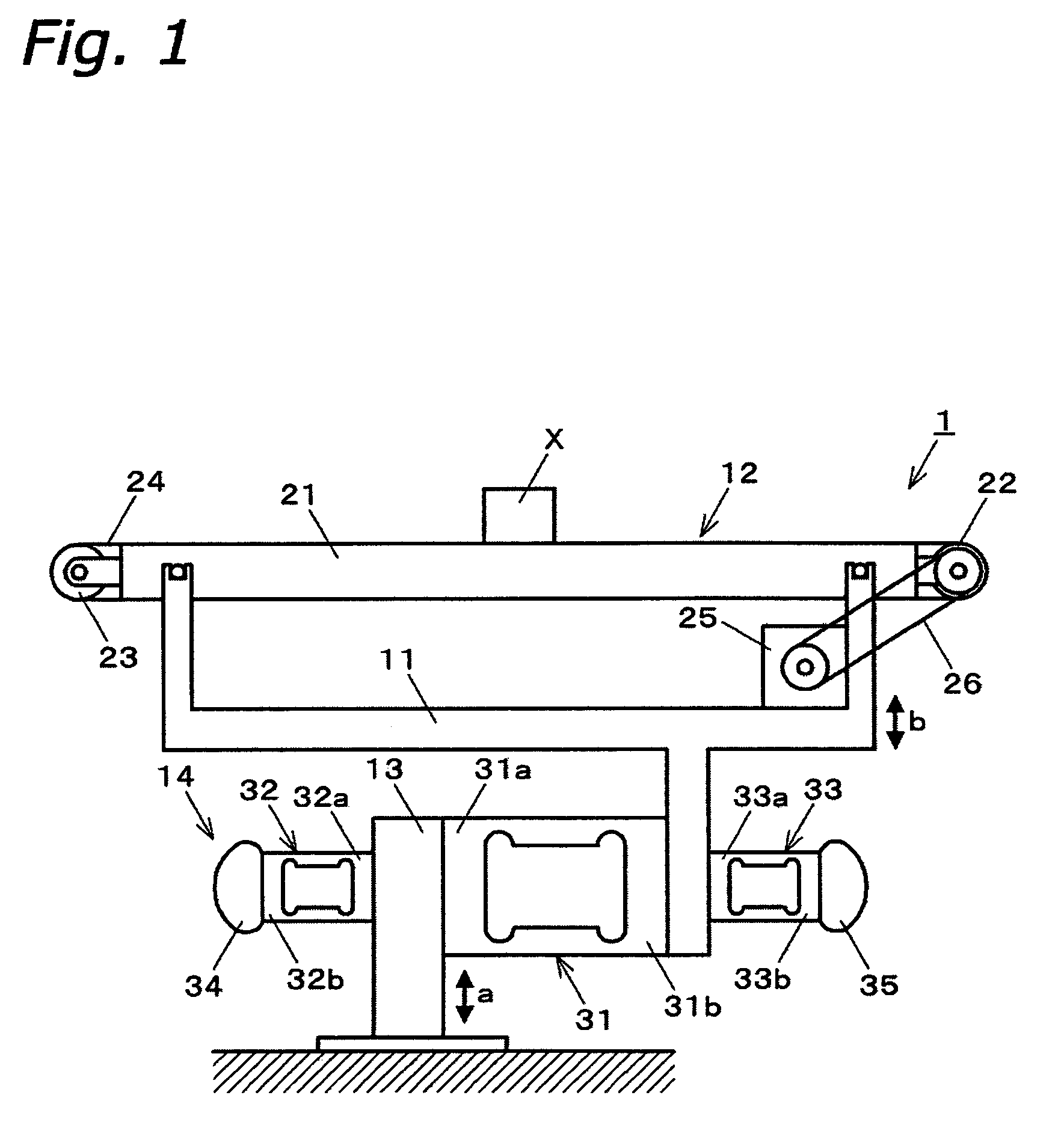

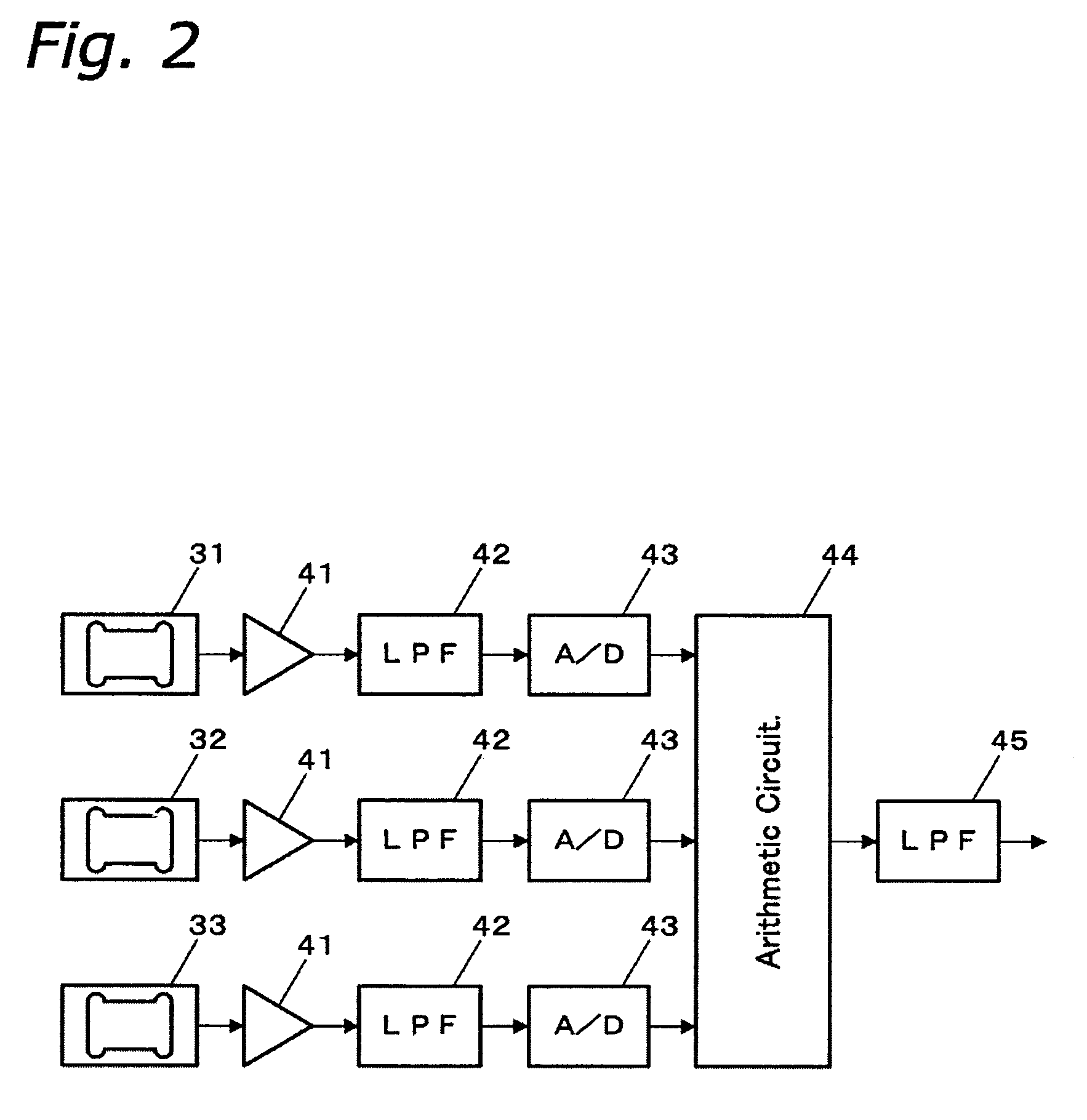

Weight detecting apparatus with vibrational sensors attached to both the free end and the fixed end of the load cell

InactiveUS6987227B2Exclude influenceEasy to detectAmplifier modifications to reduce noise influenceDigital computer detailsMotor vibrationEngineering

The weight detecting apparatus includes a weight detecting load cell having a fixed end fixed to a fixed base arranged on a floor and a free end bearing a weight of an object, a first vibration detecting load cell arranged on the fixed end side of the weight detecting load cell for detecting a vibration component on the fixed end side, i.e., a floor vibration component, and a second vibration detecting load cell arranged on the free end side of the weight detecting load cell for detecting a motor vibration component on the free end side, i.e., the motor vibration component. The weight detecting apparatus precisely detects the weight of the object by removing the vibration component from the detection signal of the weight detecting load cell based on the detection signals of the respective load cells.

Owner:ISHIDA CO LTD

Popular searches

Electrical measurements Testing/calibration of speed/acceleration/shock measurement devices Weighing apparatus with automatic feed/discharge Special data processing applications Screws Apparatus for force/torque/work measurement Force measurement by elastic gauge deformation Strength properties Diagnostic recording/measuring Sensors

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com