Patents

Literature

134results about "Weighing relieving/arrestment mechanisms" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weight-filling method, and a corresponding device

InactiveUS6073667ASuppress mutationAccurate weighingLiquid fillingWeighing apparatus using elastically-deformable membersEngineeringLoad cell

Owner:SERAC GROUP

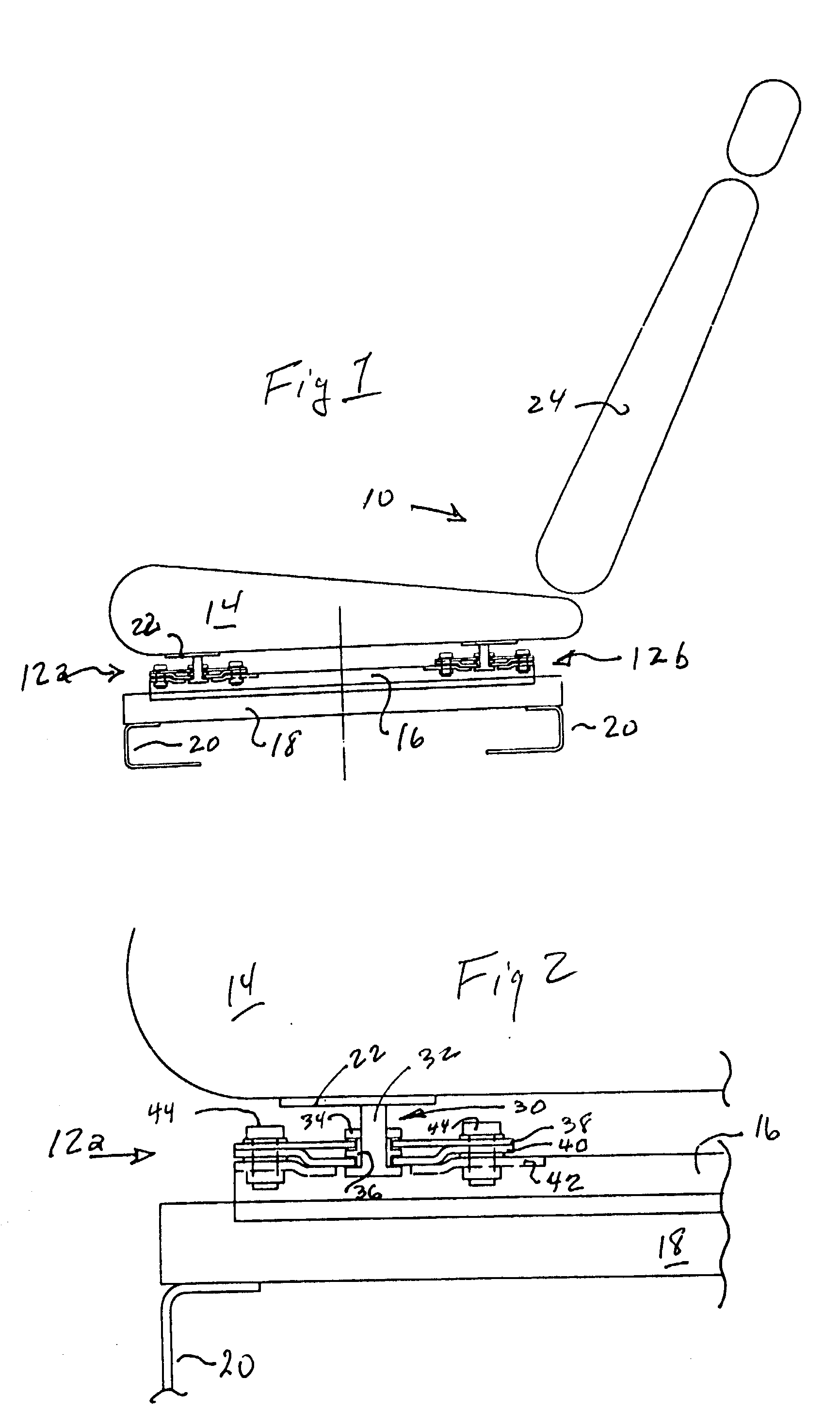

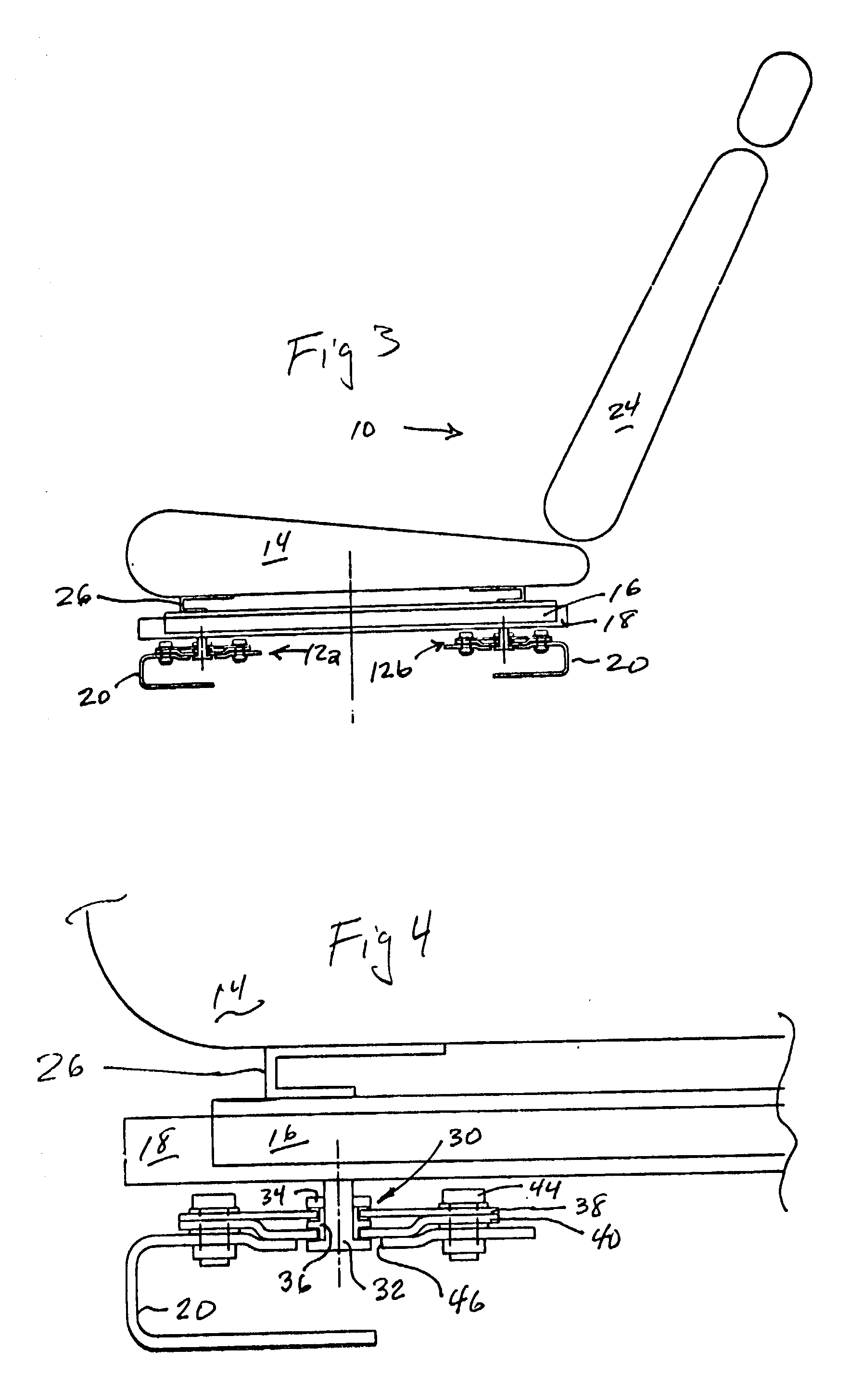

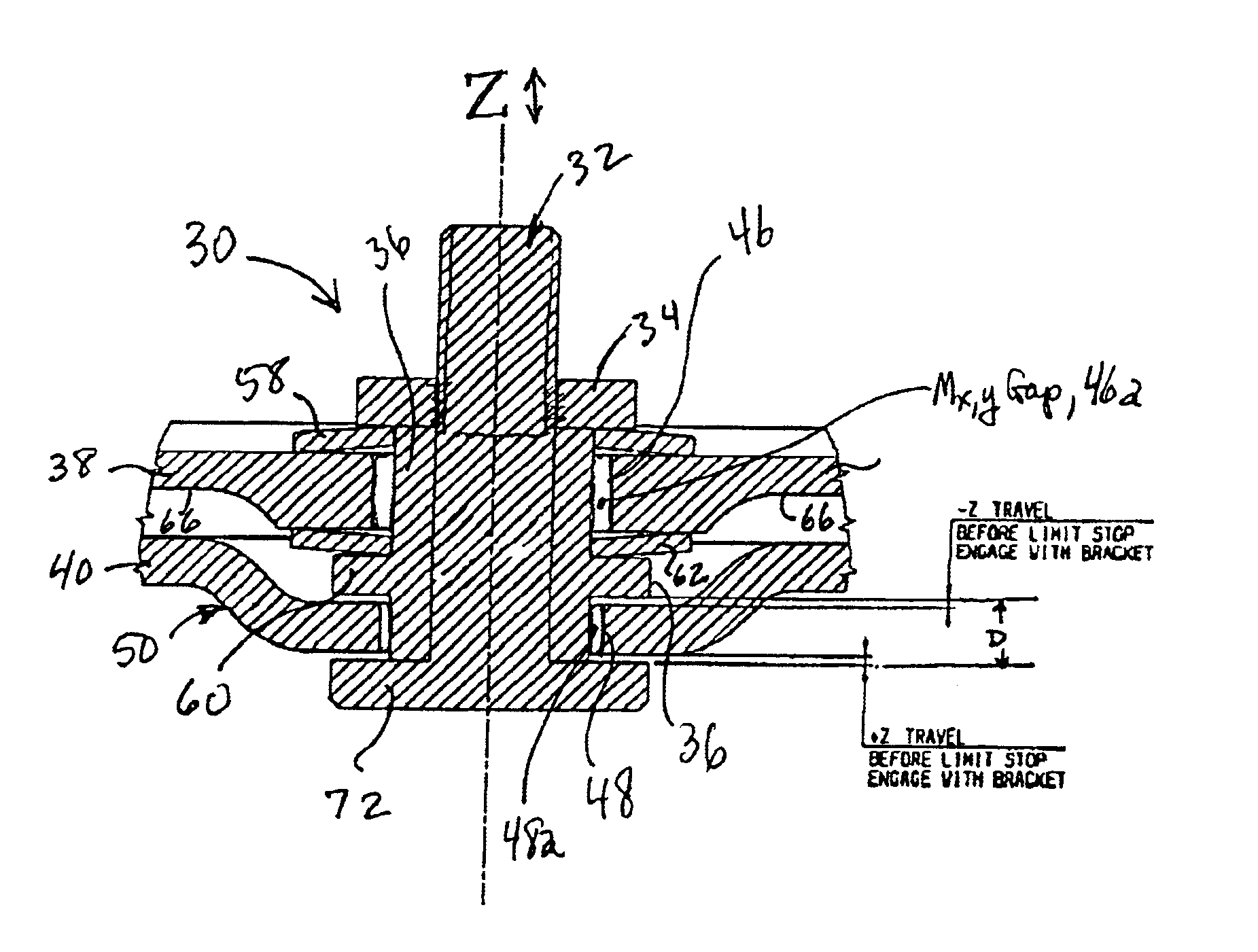

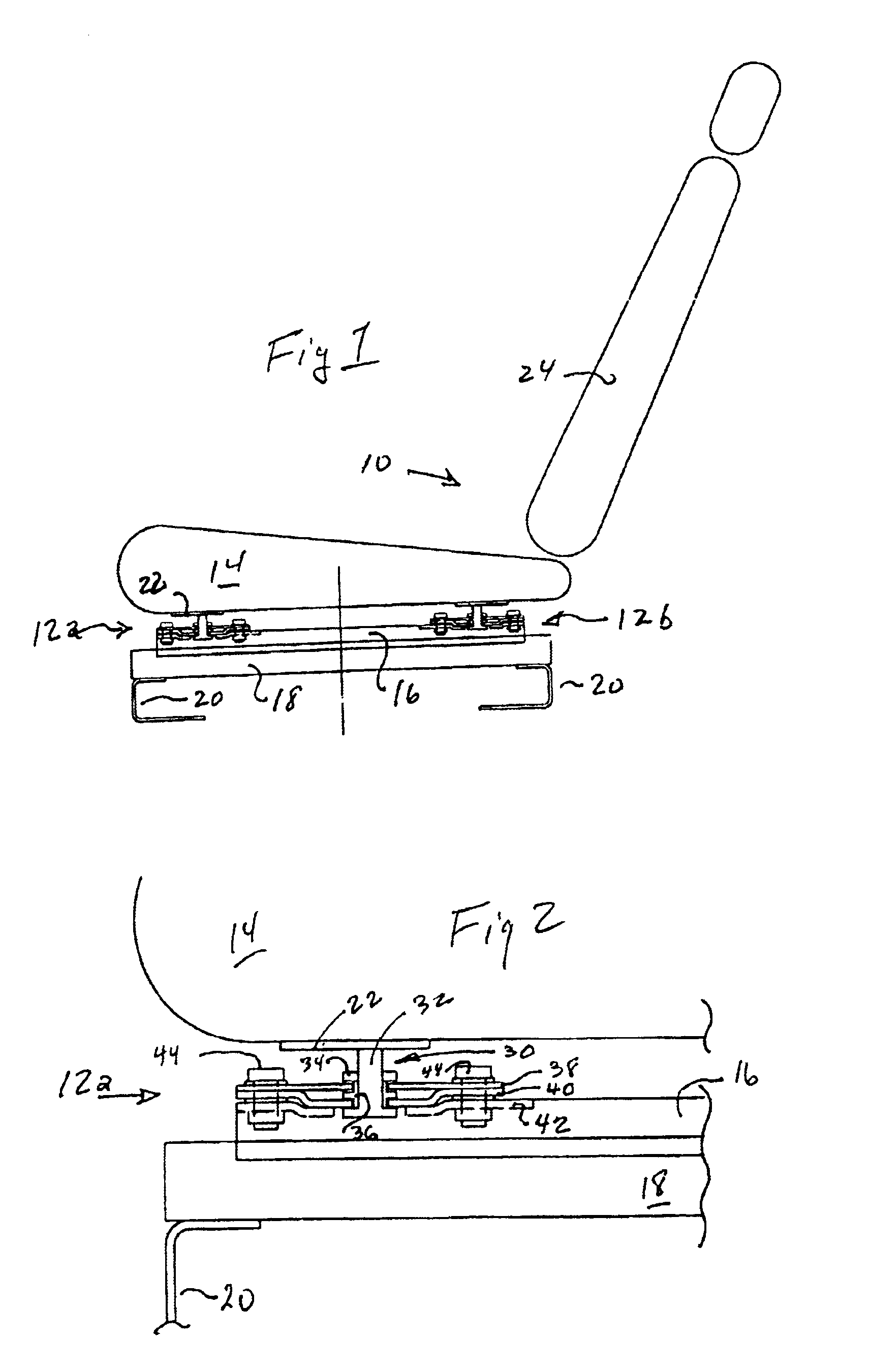

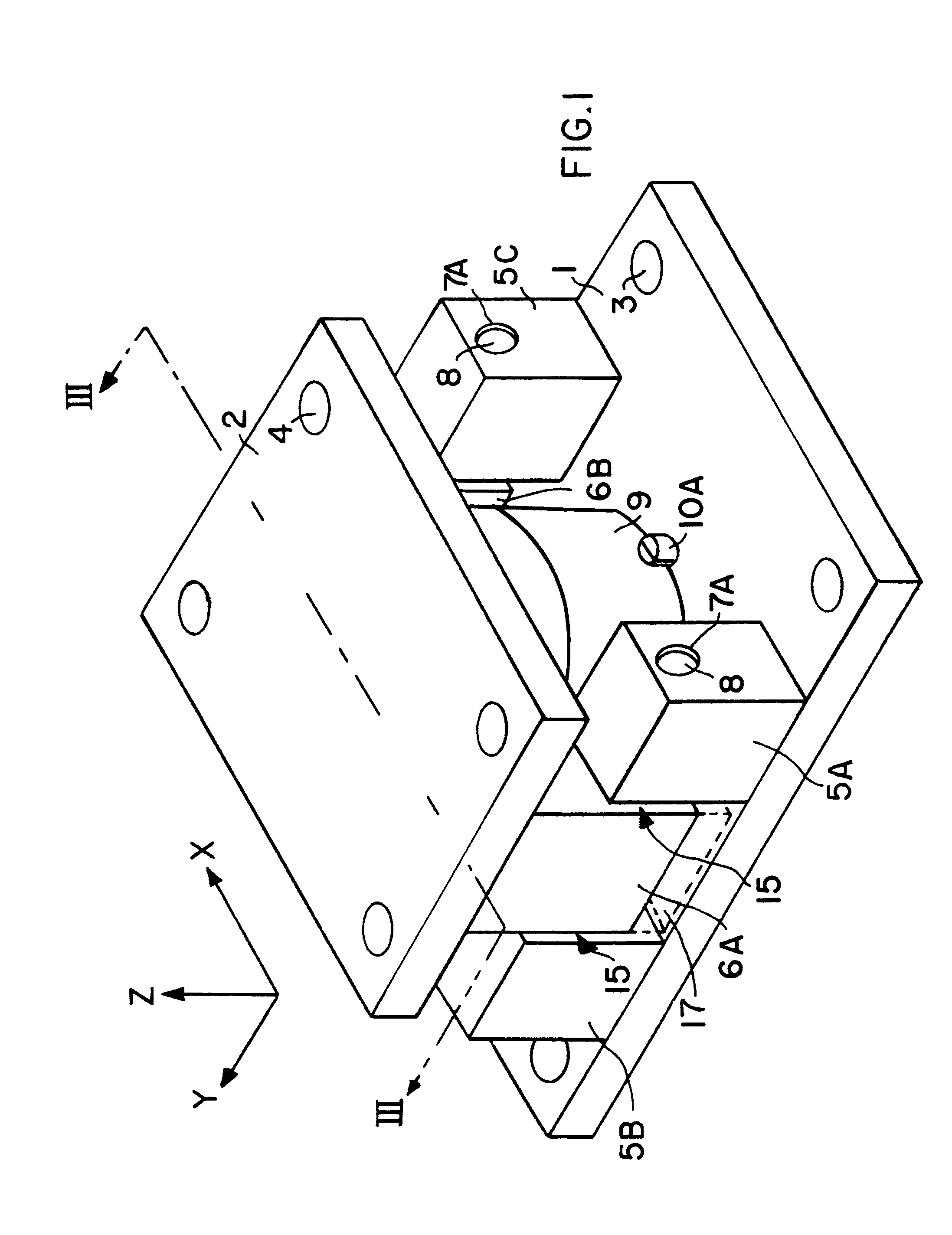

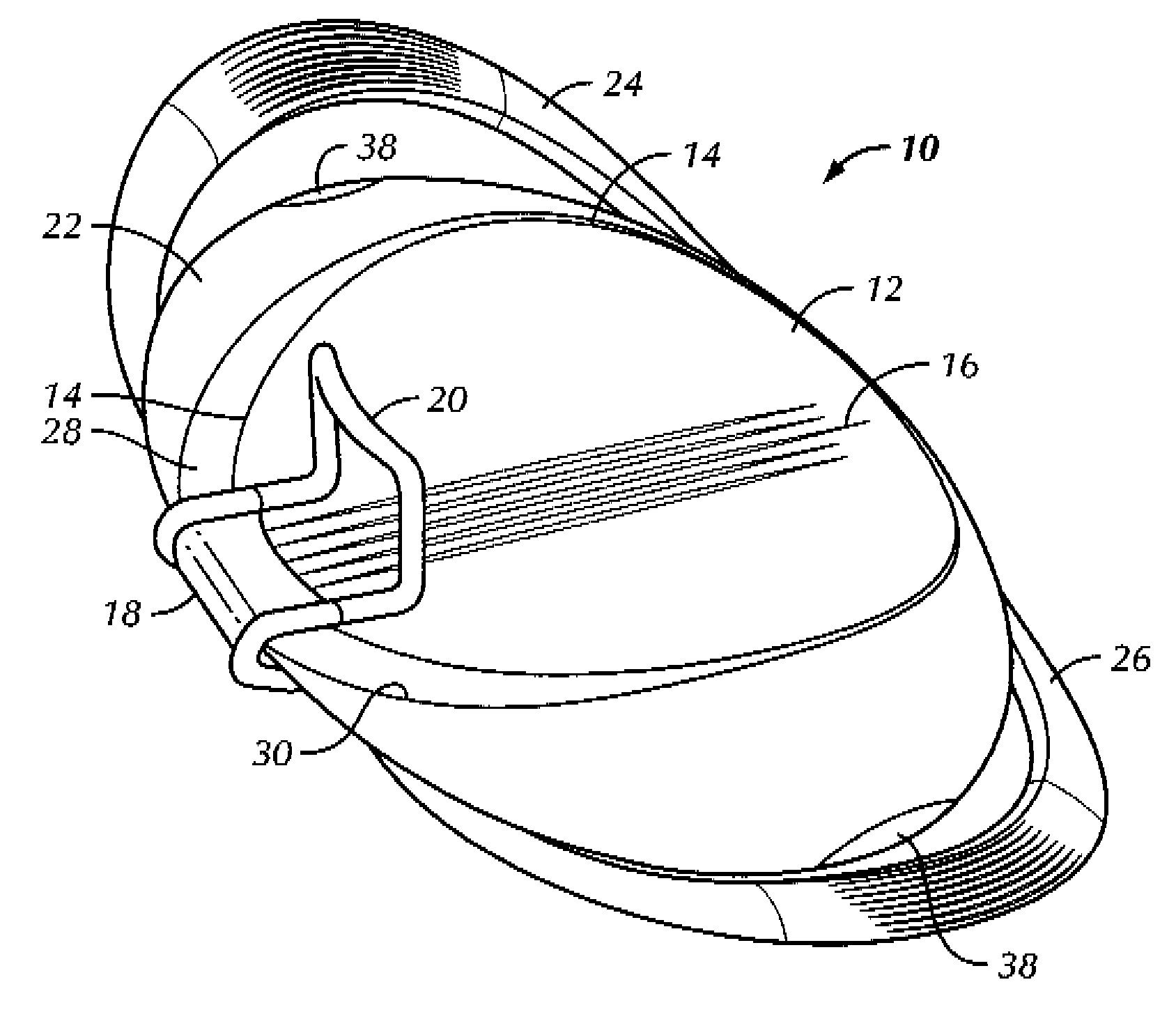

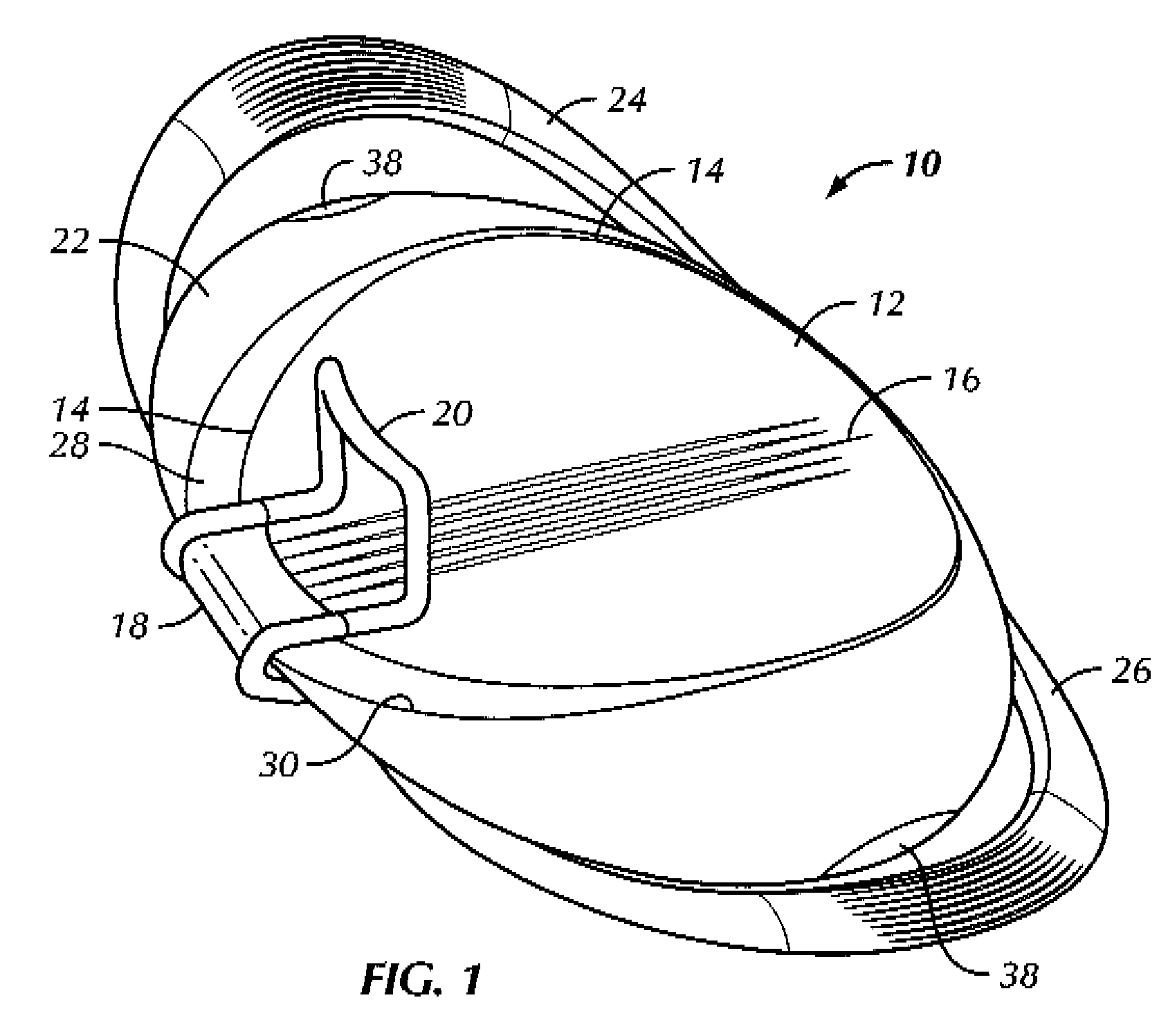

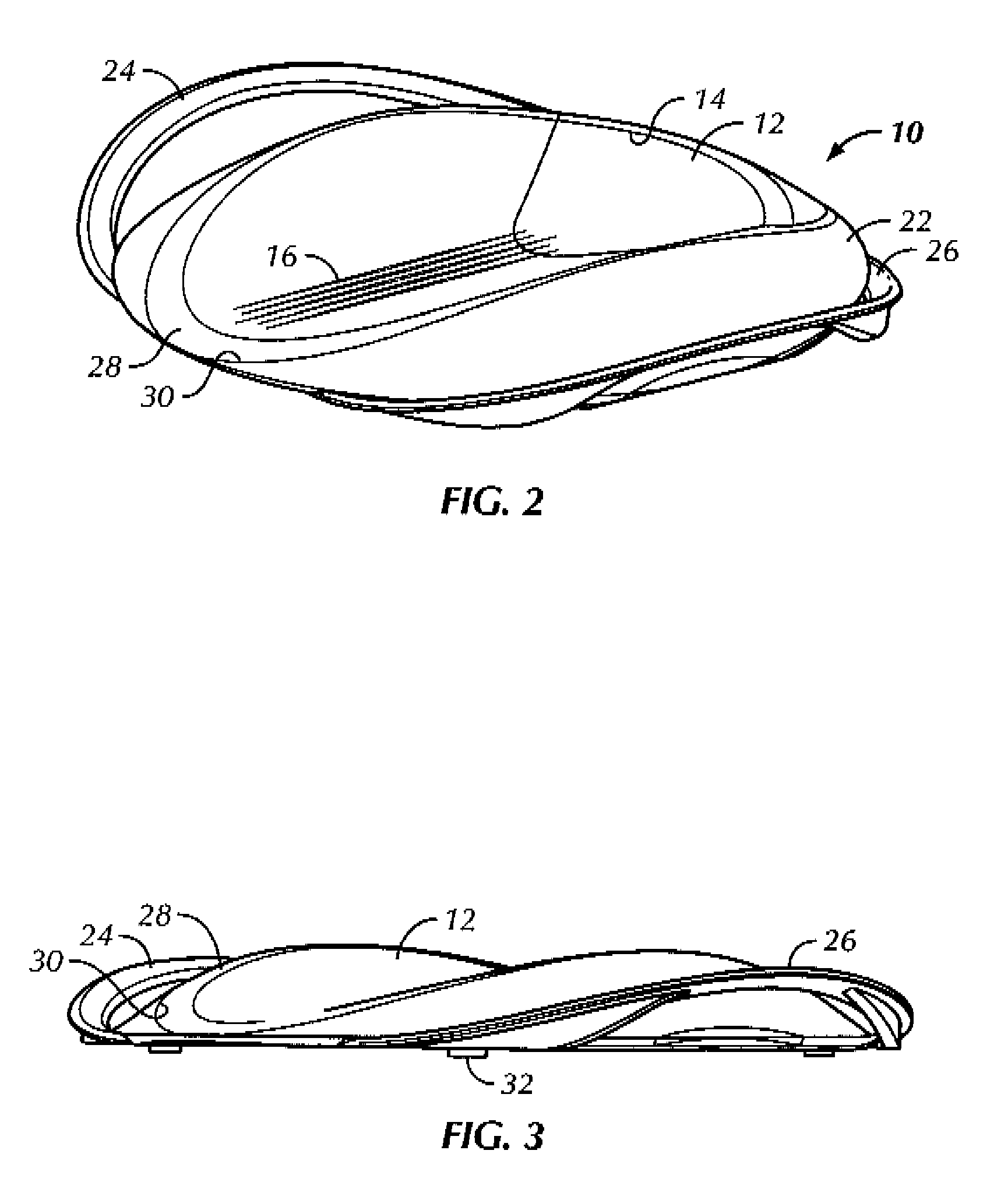

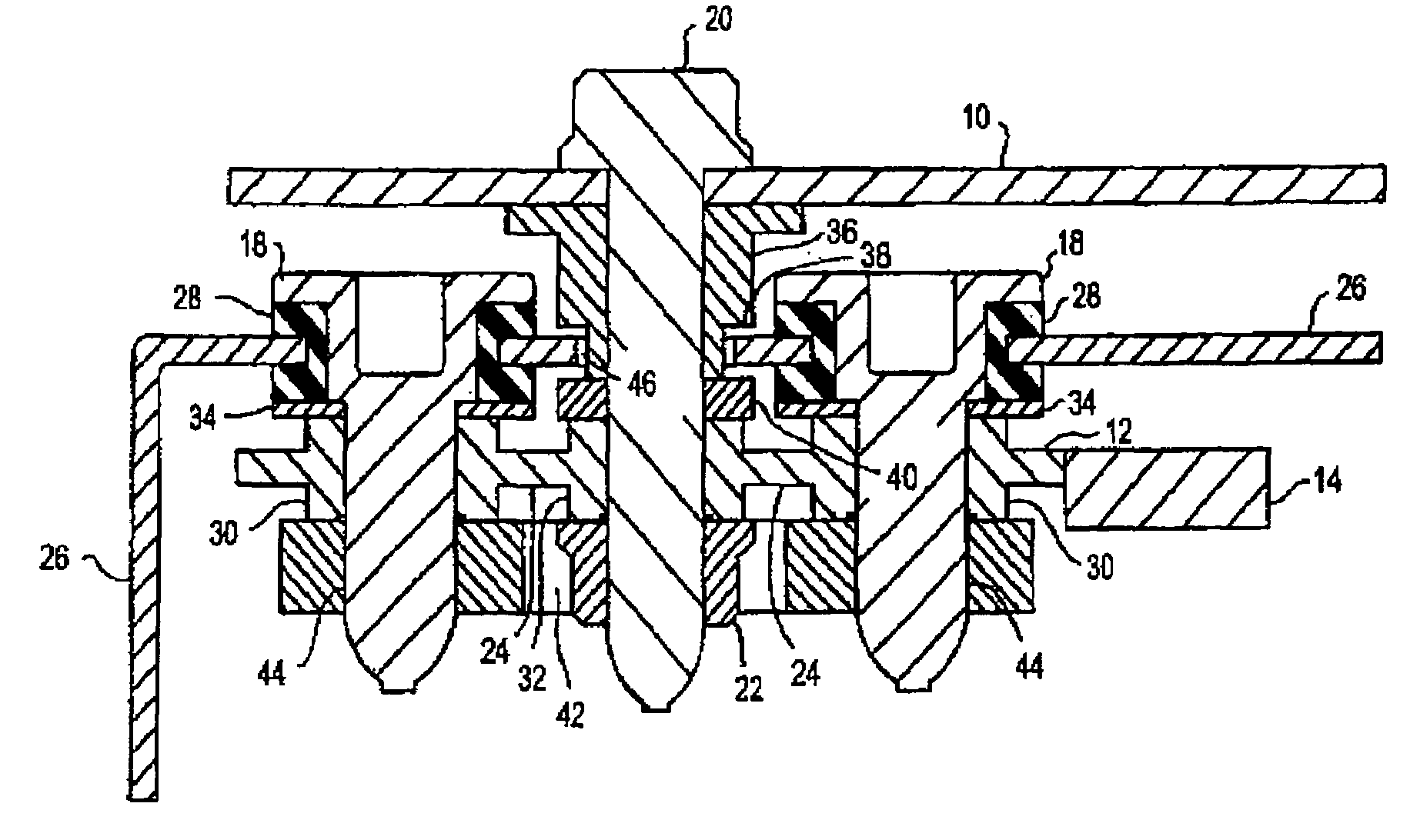

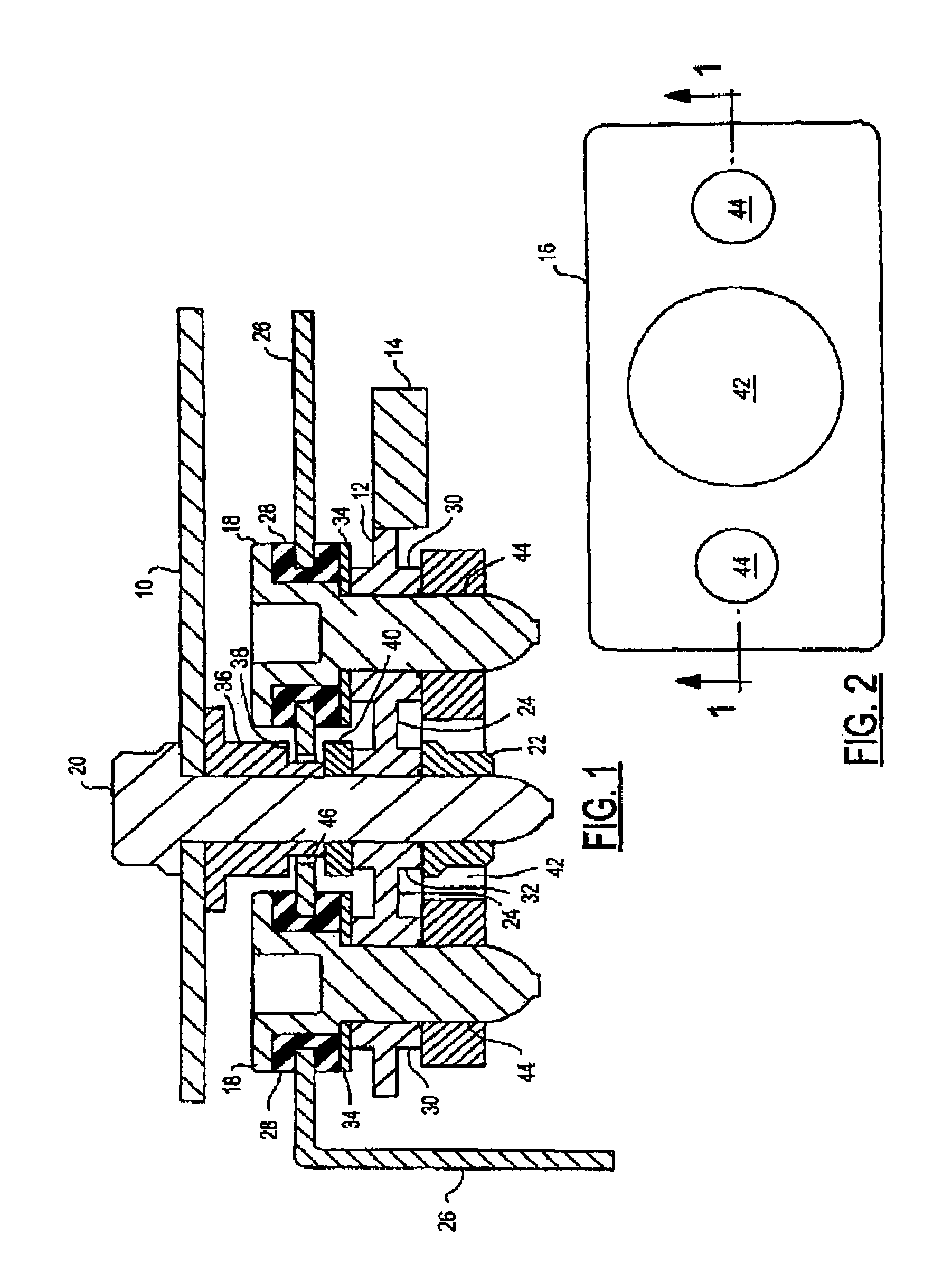

Weight sensors having centralized loose tolerance universal force and Mx/My moments overload stops

InactiveUS20030106723A1Increase angular travel permittedConvenient travelWeighing apparatus using elastically-deformable membersElectric devicesModularityAngular rotation

Automotive load cells having centralized, multi-axis, loose tolerance overload / limit stops provide improved strain gauge response. The modular, integrated stop assemblies magnify sensor substrate deflection by use of opposed concave (Belleville) springs are used in direct contact with the substrate to accommodate ±Z axis deflection and Mx / My moment angular rotation. A flanged guide member on the load stud permits a wide range of geometries. The substrate is thickened around the load stud hole and the outboard support bolt holes. Hollow rivets assist in design modularity. Strain gauges are placed at the yield zones symmetrically with respect to the X axis. The substrate hole Mx / My gap is larger than the stop bracket hole to insure a positive stop for Mx / My moments prior to yield. The inventive multi-axis stop assembly is used in any type load cell, including rectangular, thinned, notched, necked / dogbone, or cantilever substrates with any strain gauge layout configuration.

Owner:ROBERT BOSCH CORP

Weight sensors having centralized loose tolerance universal force and Mx/My moments overload stops

InactiveUS6916997B2Convenient travelReduce loadWeighing apparatus using elastically-deformable membersElectric devicesModularityAngular rotation

Automotive load cells having centralized, multi-axis, loose tolerance overload / limit stops provide improved strain gauge response. The modular, integrated stop assemblies magnify sensor substrate deflection by use of opposed concave (Belleville) springs are used in direct contact with the substrate to accommodate ±Z axis deflection and Mx / My moment angular rotation. A flanged guide member on the load stud permits a wide range of geometries. The substrate is thickened around the load stud hole and the outboard support bolt holes. Hollow rivets assist in design modularity. Strain gauges are placed at the yield zones symmetrically with respect to the X axis. The substrate hole Mx / My gap is larger than the stop bracket hole to insure a positive stop for Mx / My moments prior to yield. The inventive multi-axis stop assembly is used in any type load cell, including rectangular, thinned, notched, necked / dogbone, or cantilever substrates with any strain gauge layout configuration.

Owner:ROBERT BOSCH CORP

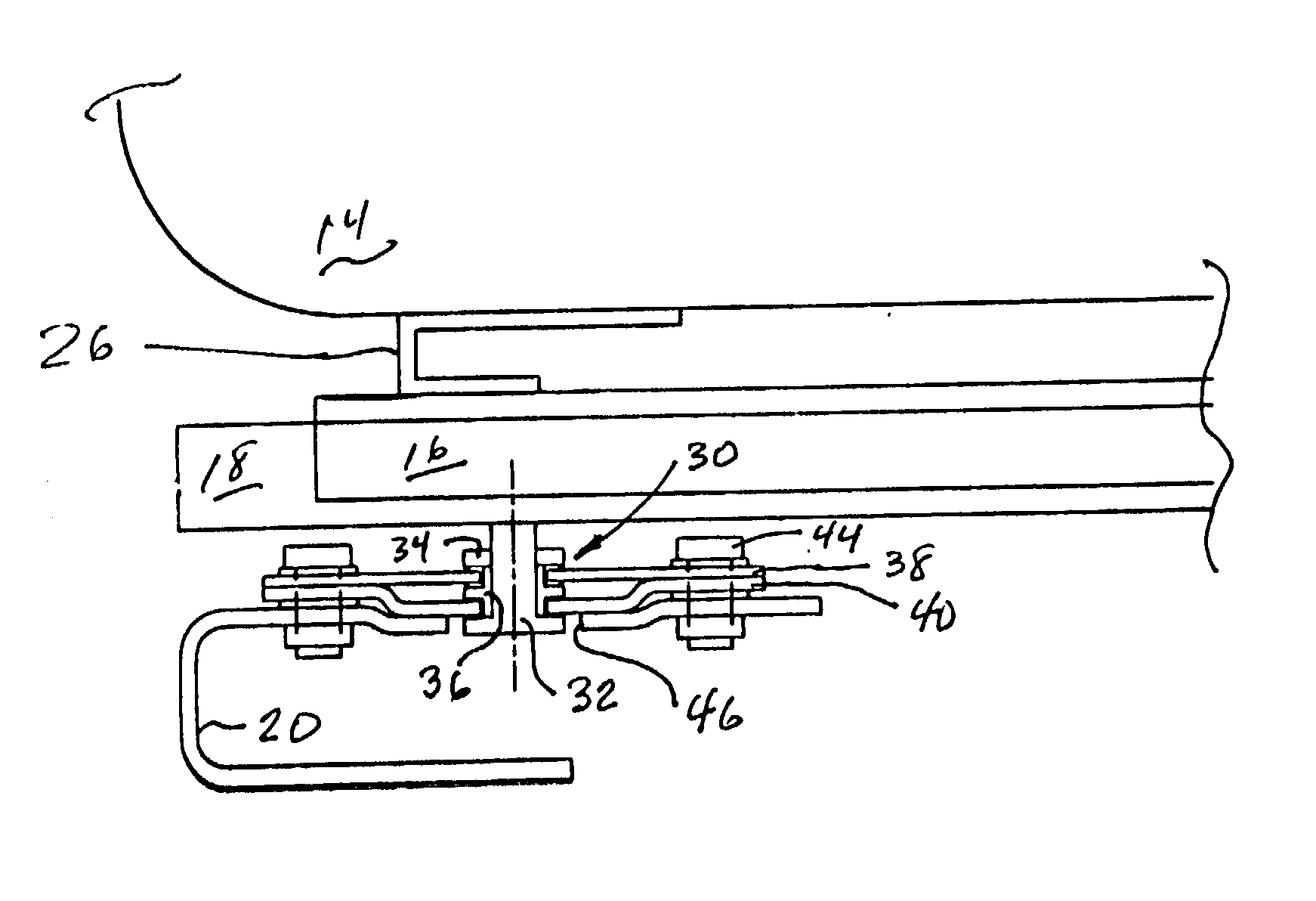

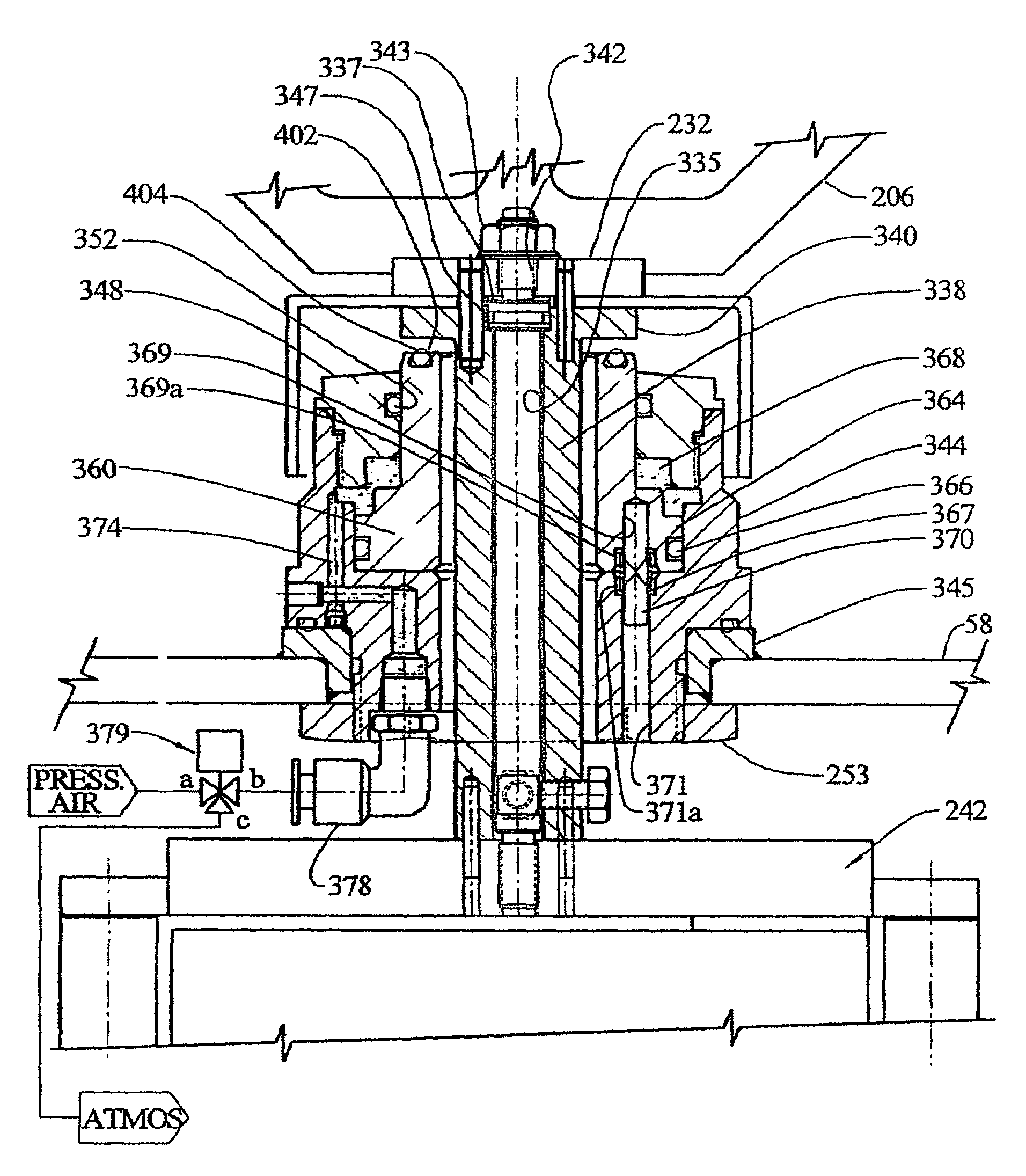

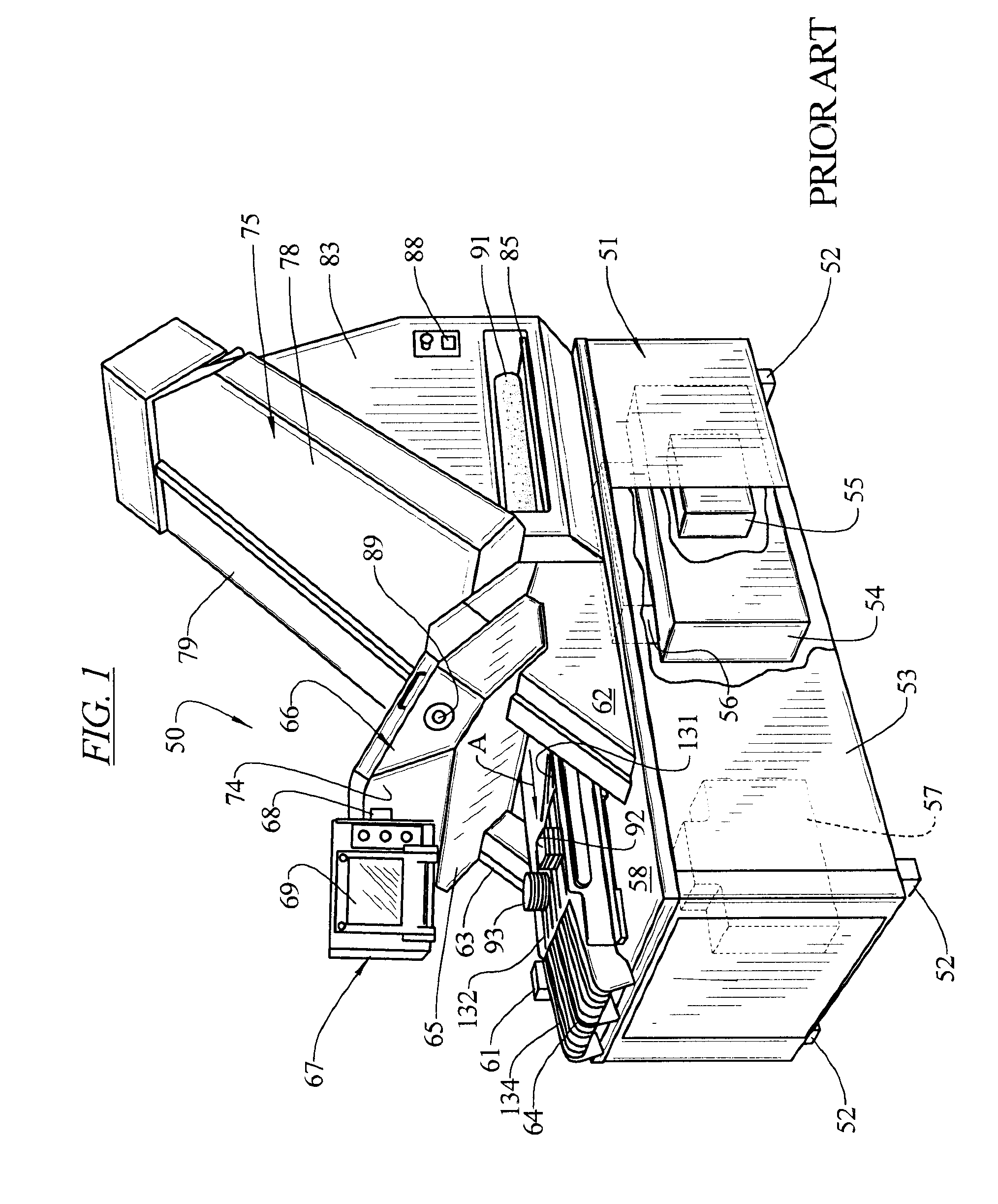

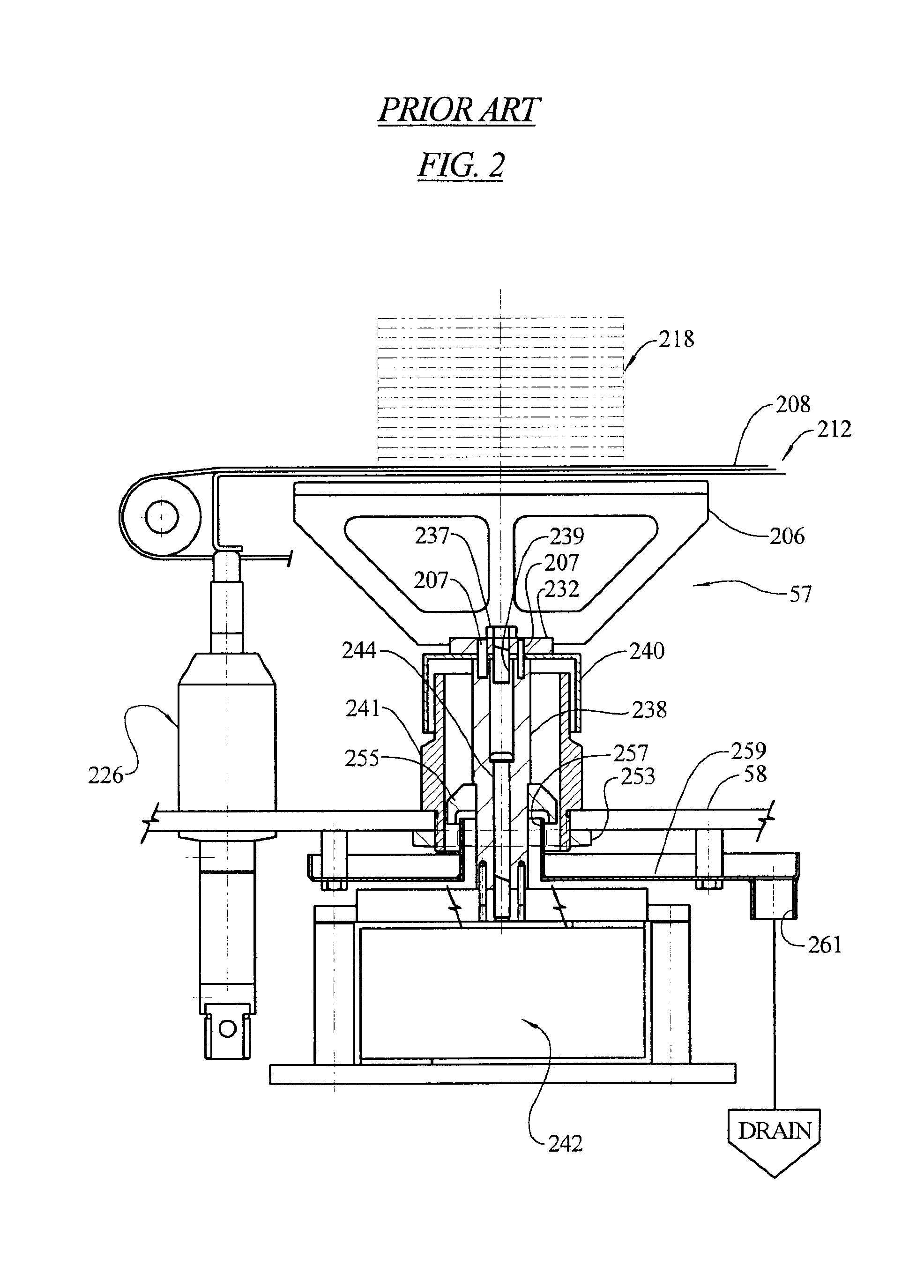

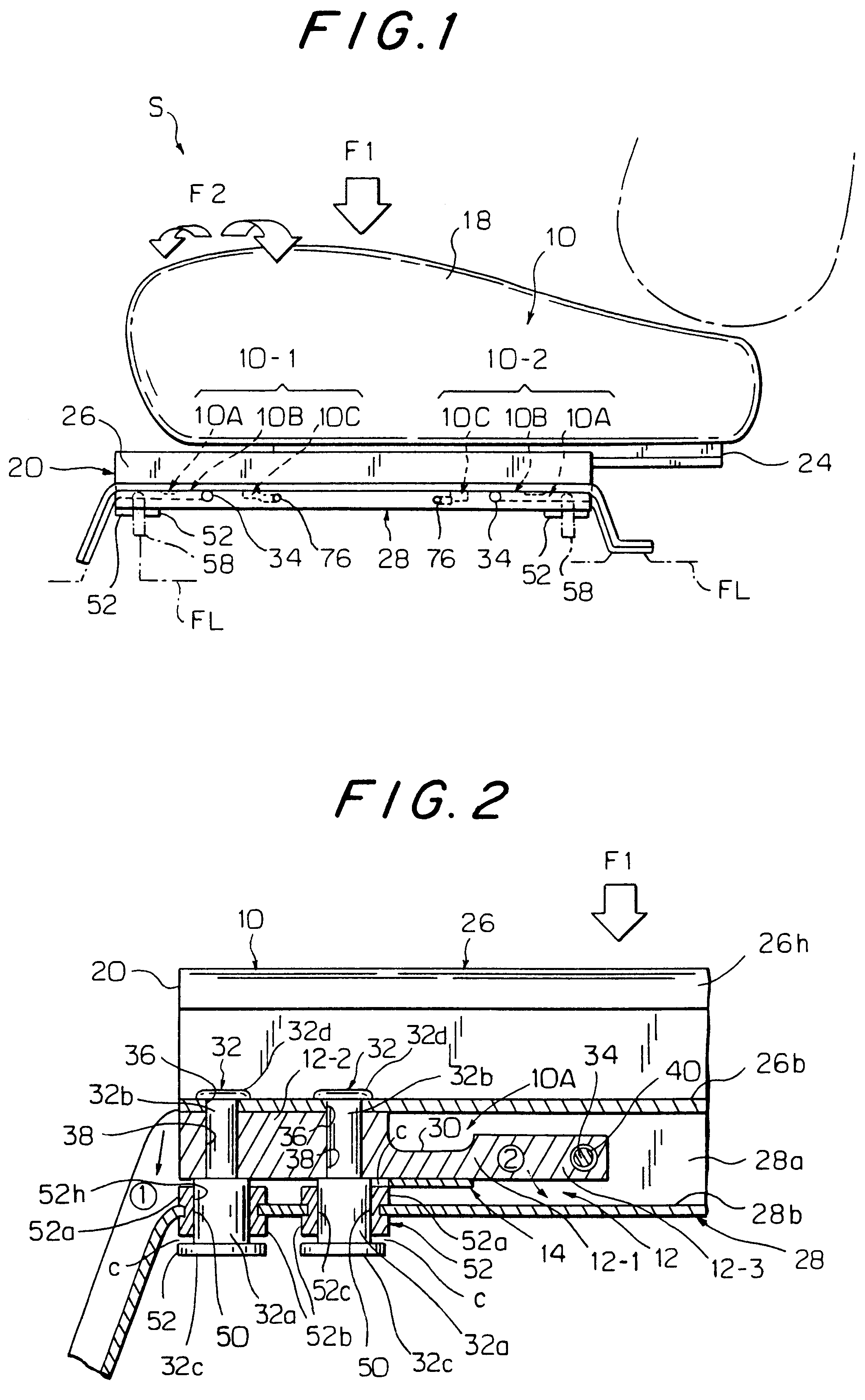

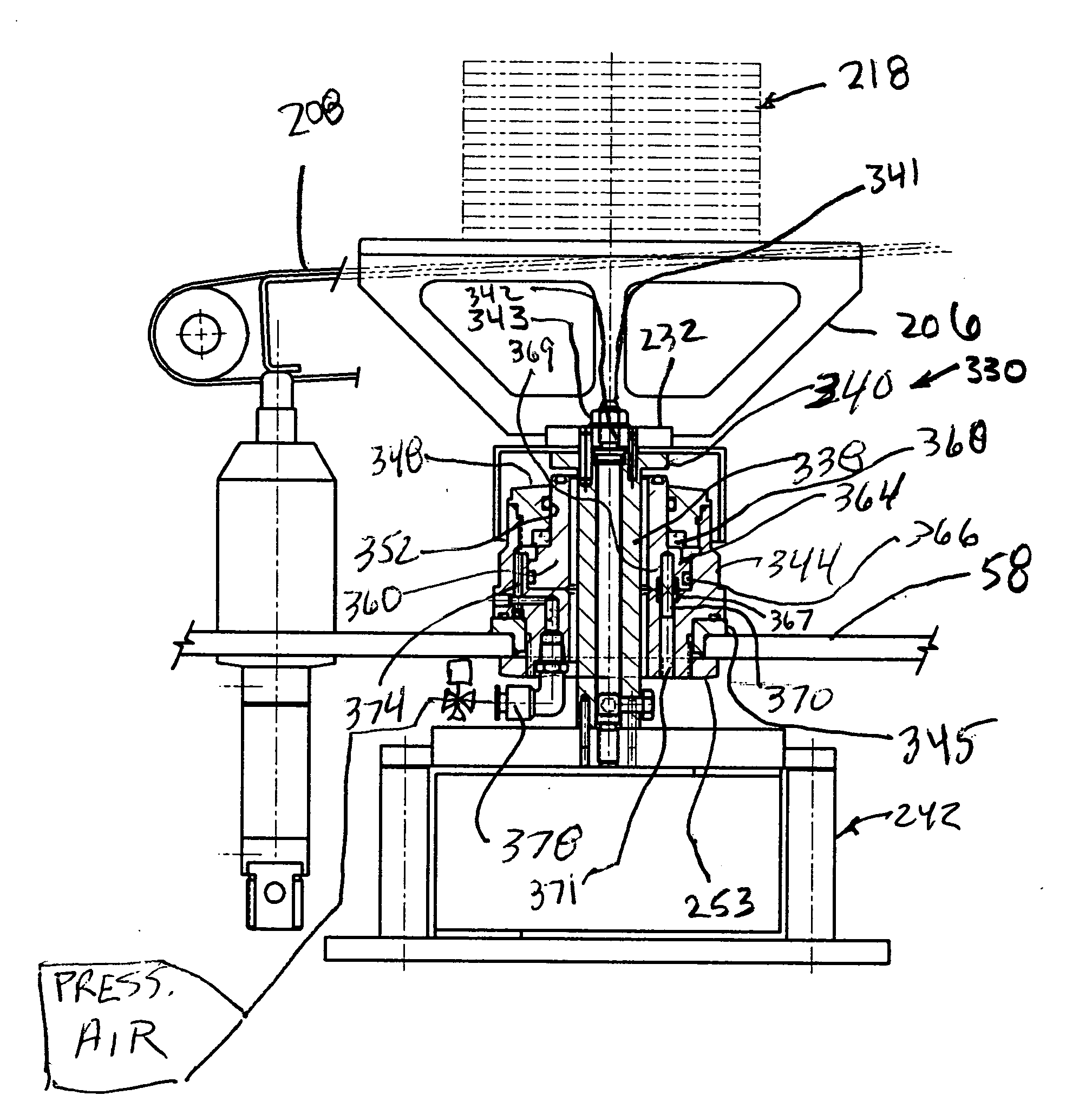

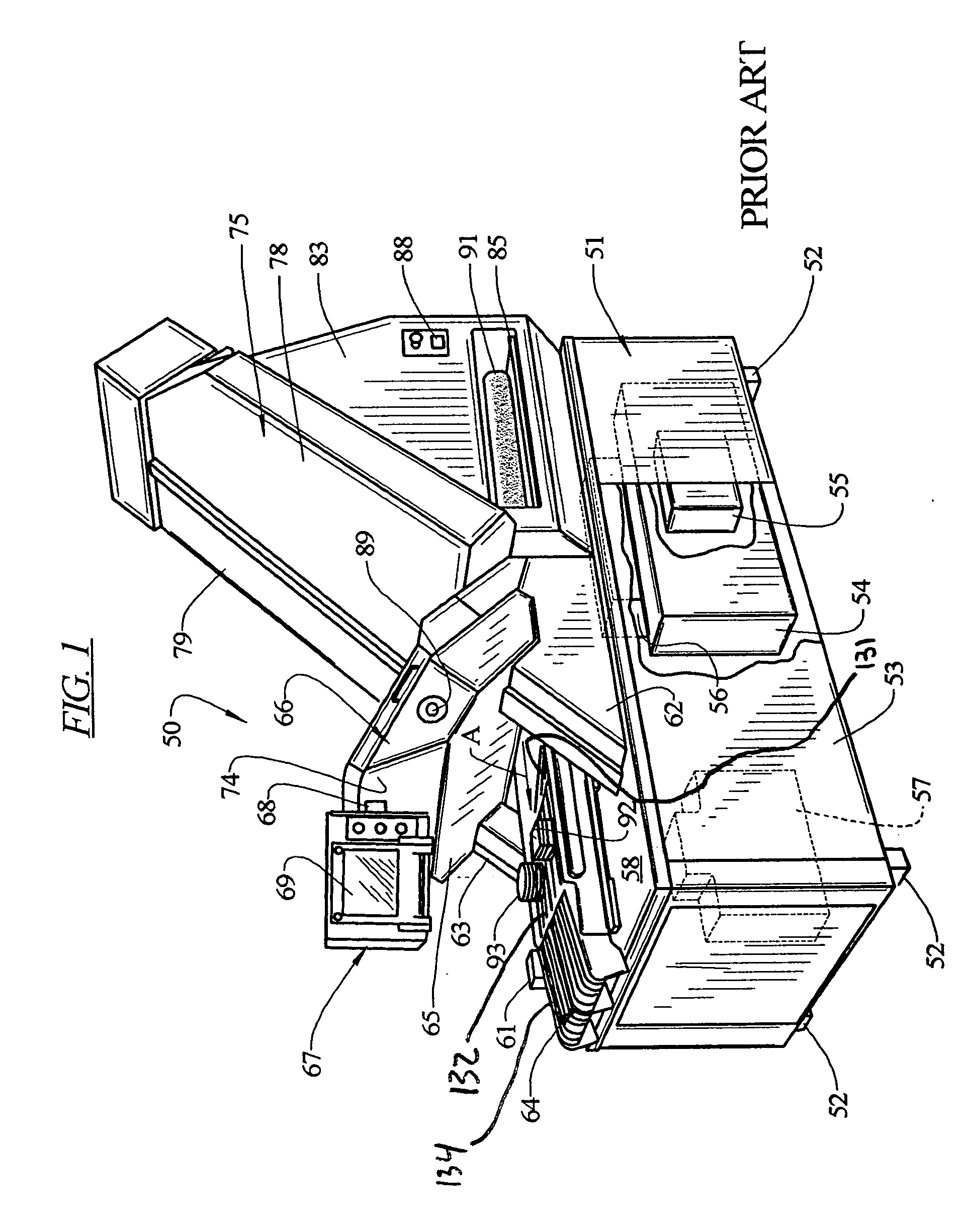

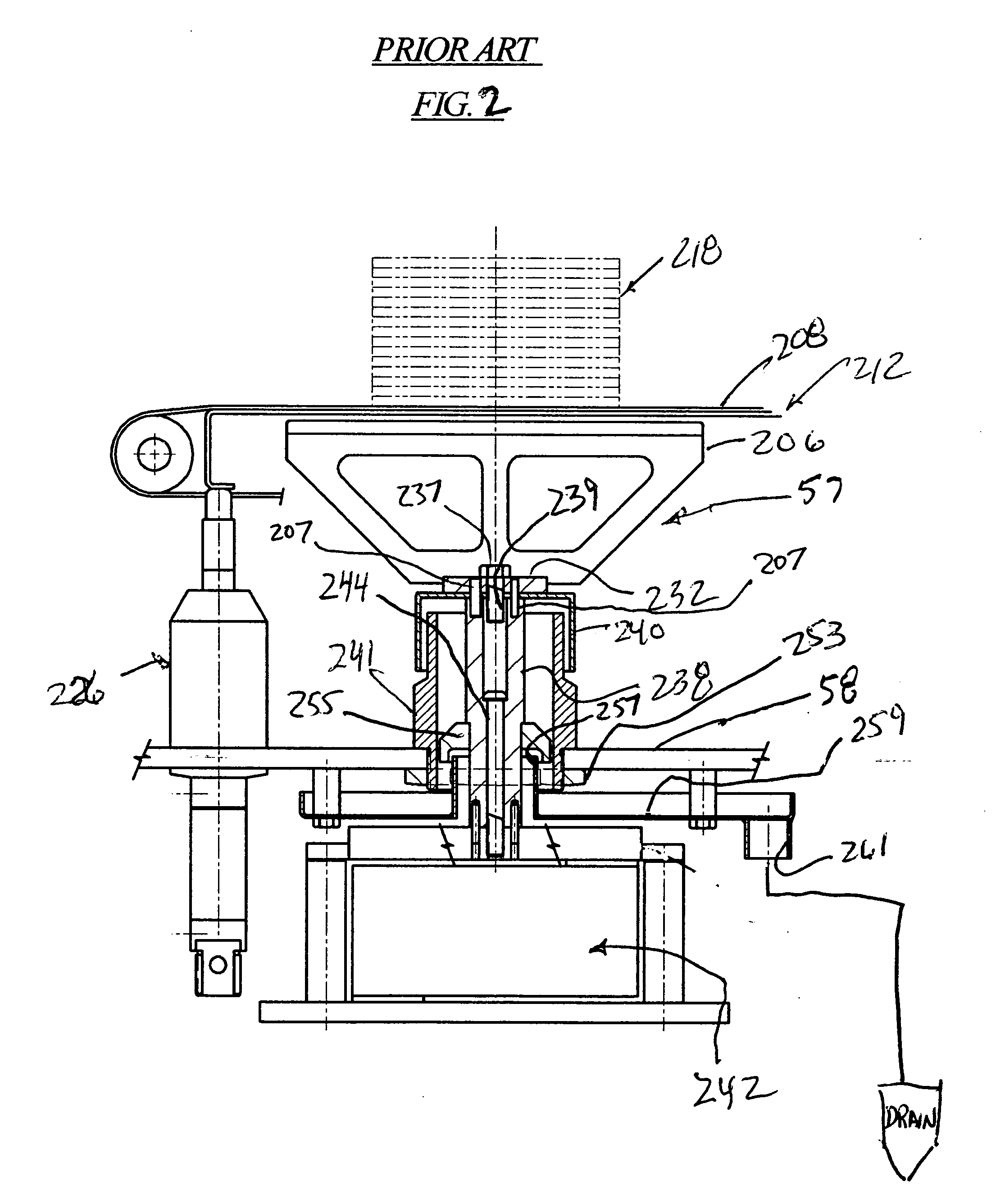

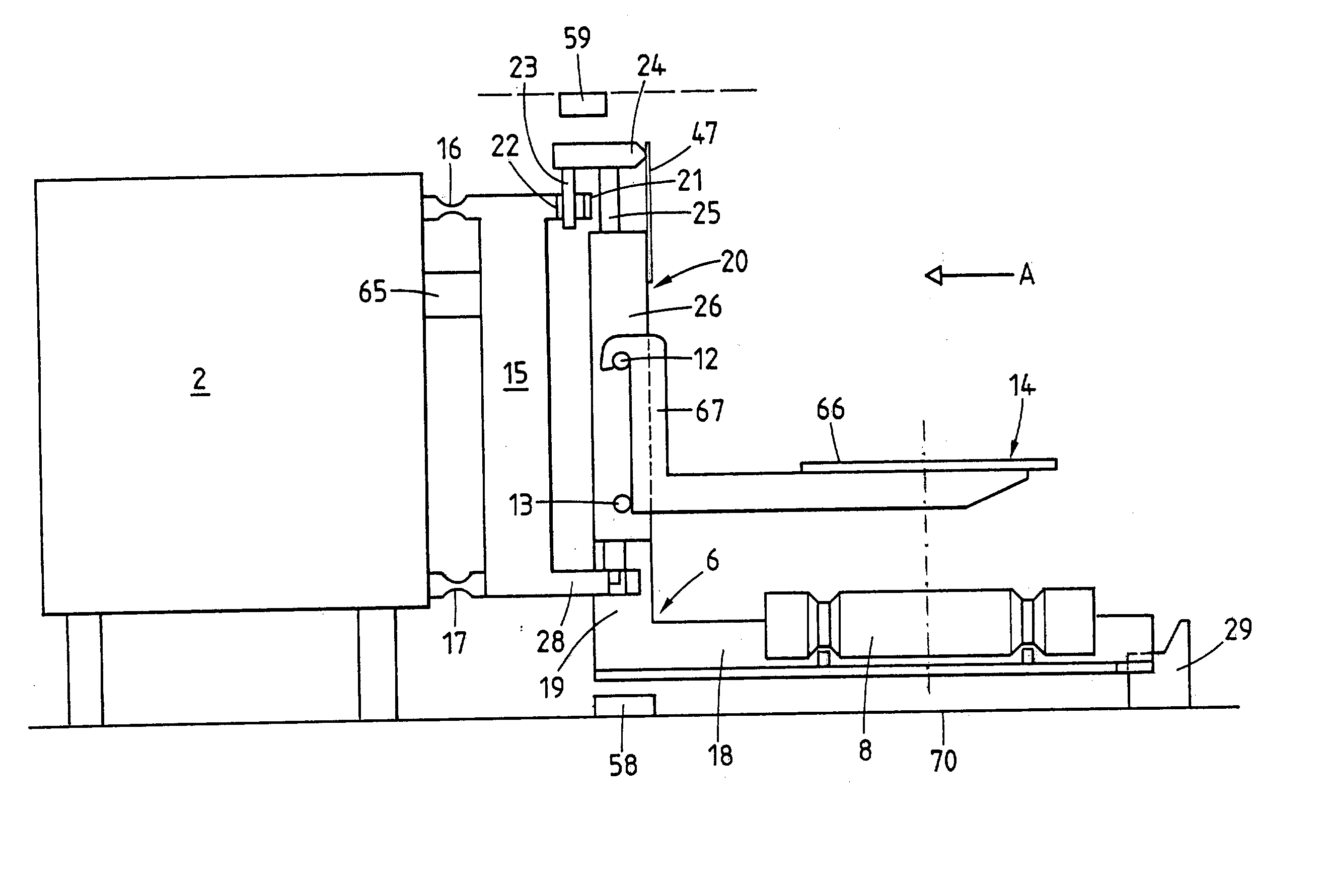

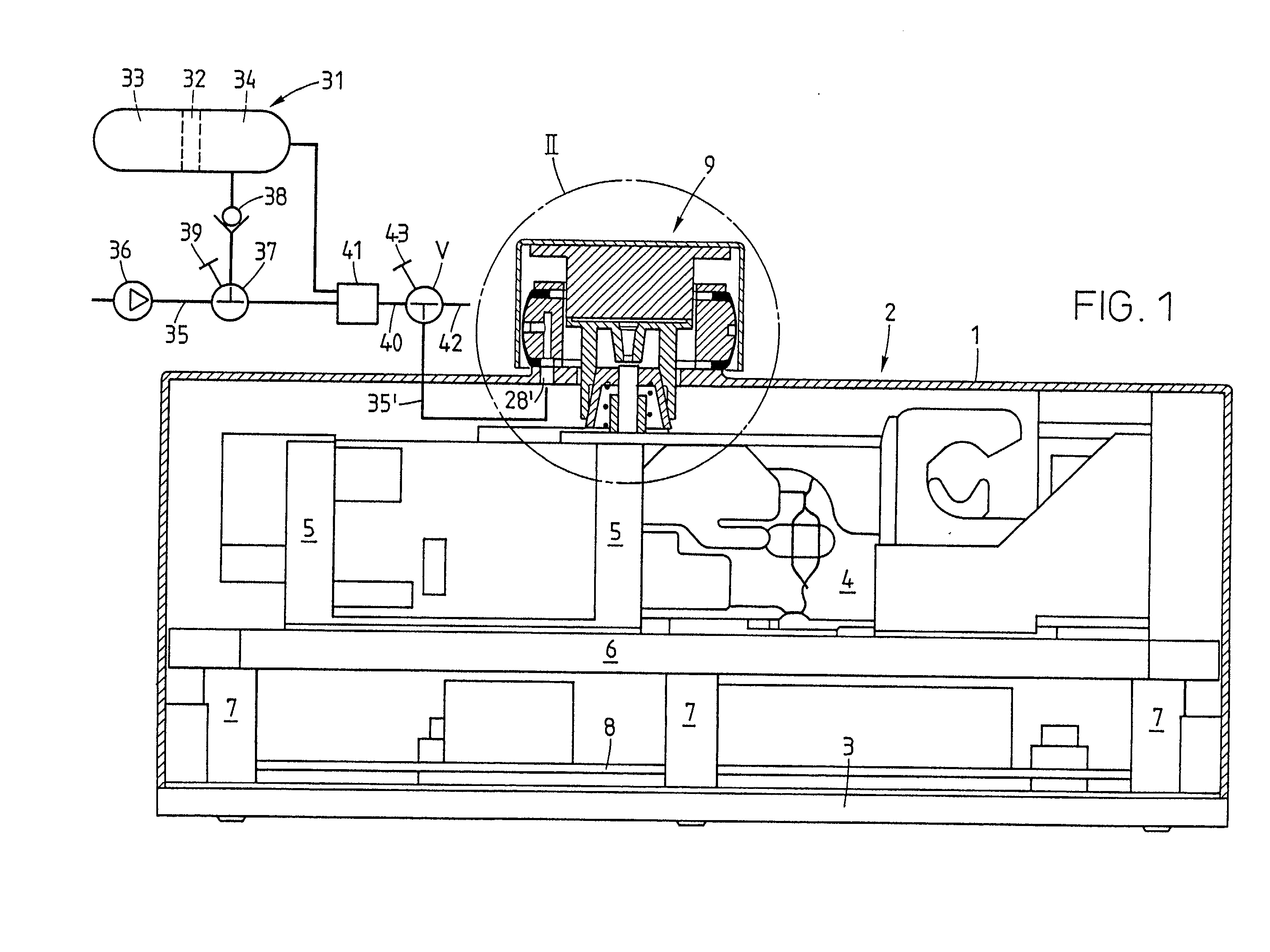

Automatic sealing arrangement for weigh scale for food processing apparatus

InactiveUS7411137B2Eliminate needWeighing relieving/arrestment mechanismsMetal working apparatusEngineeringVertical load

A sealing arrangement is provided for a product weigh scale for a food processing apparatus the weigh scale including a support for supporting a product, a member that carries the support, and a weight sensor that senses vertical load on the member. The sealing arrangement includes a seal surrounding the member beneath the support, the seal having a first sealing surface configured to be sealed against a cabinet, and a second sealing surface. The seal is movable between an inactive position wherein the second sealing surface is out of contact with the support and a sealing position wherein the second sealing surface seals against the support. The seal includes a stationary part having the first sealing surface and a sliding part having the second sealing surface. A plurality of springs urge the sliding part toward the sealing position and a source of pressurized fluid is injected between the sliding part and the stationary part to urge the sliding part toward the inactive position. The pressurized fluid has a sufficient pressure to overcome the urging of the springs and maintains the sliding part in the inactive position during normal operation of the scale, wherein upon loss of the supply of pressurized fluid, the springs cause the sliding part to assume the sealing position.

Owner:PROVISUR TECHNOLOGIES INC

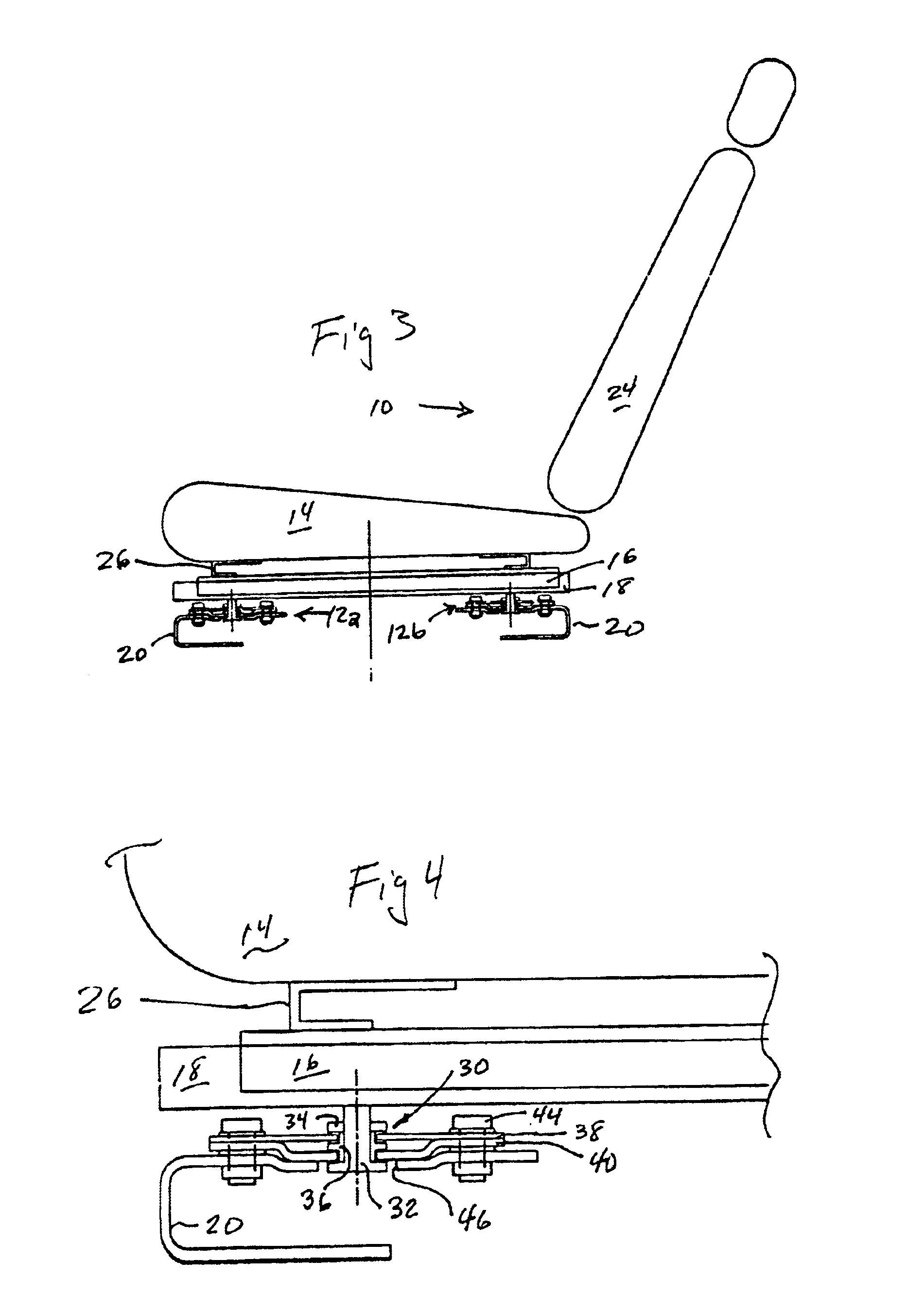

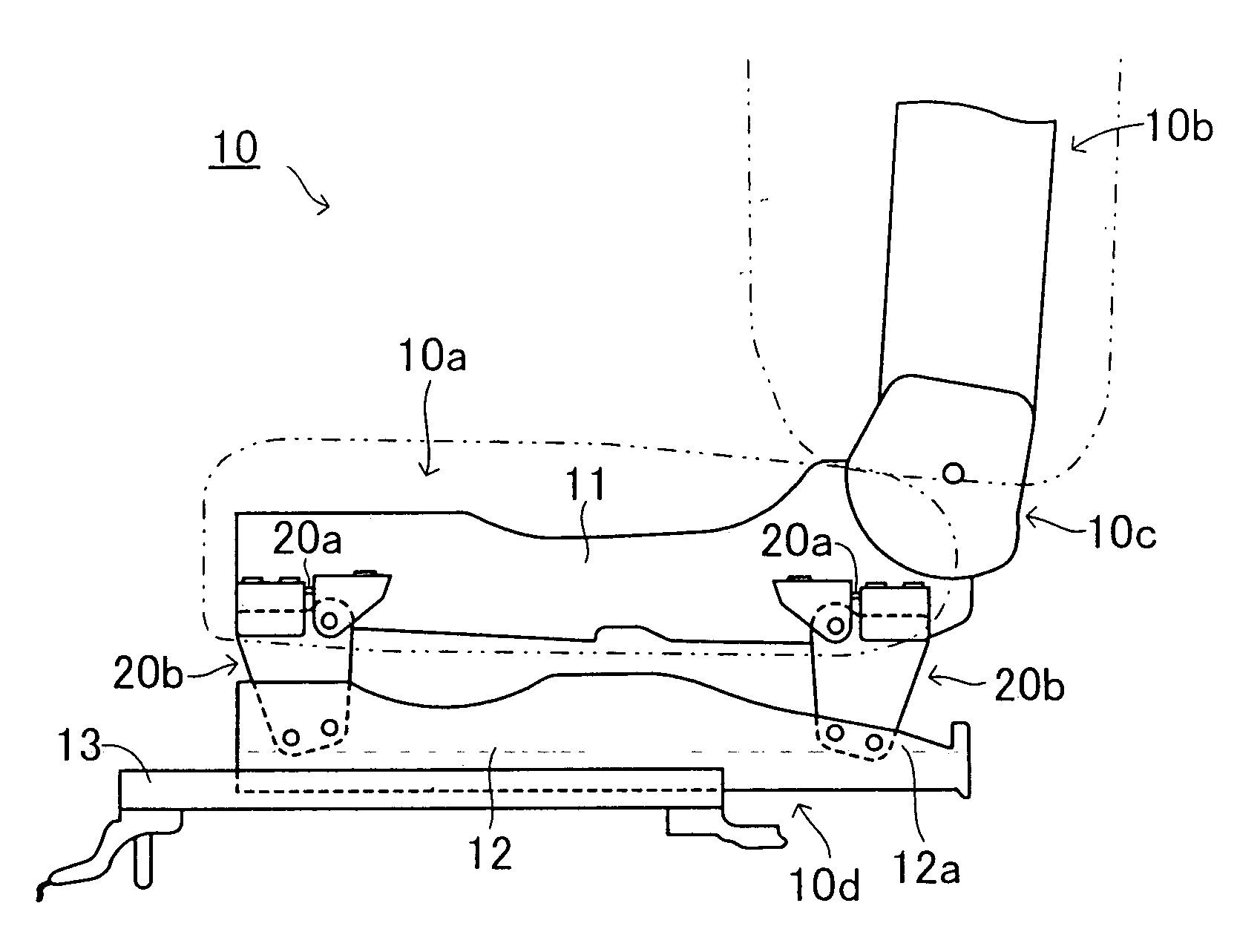

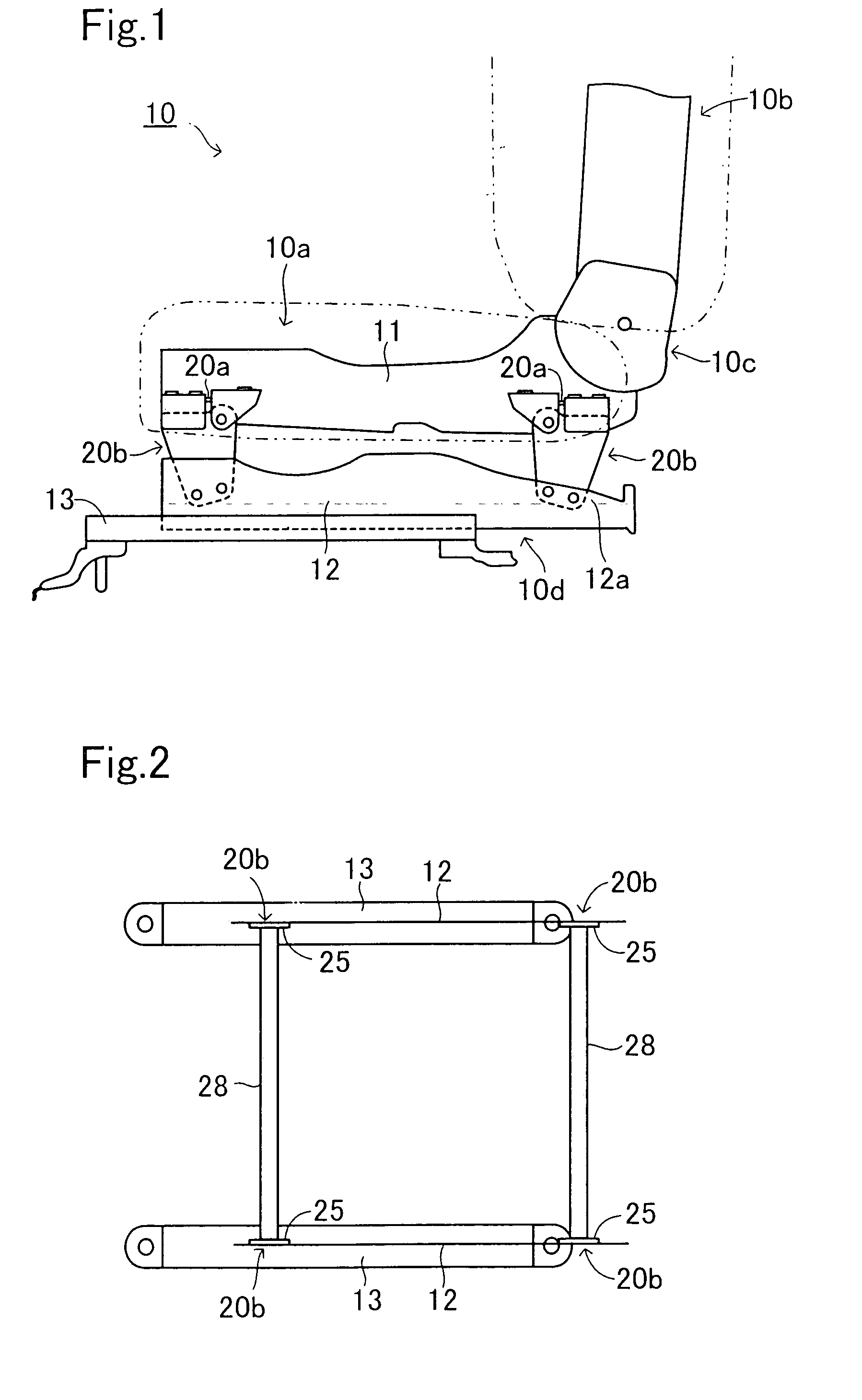

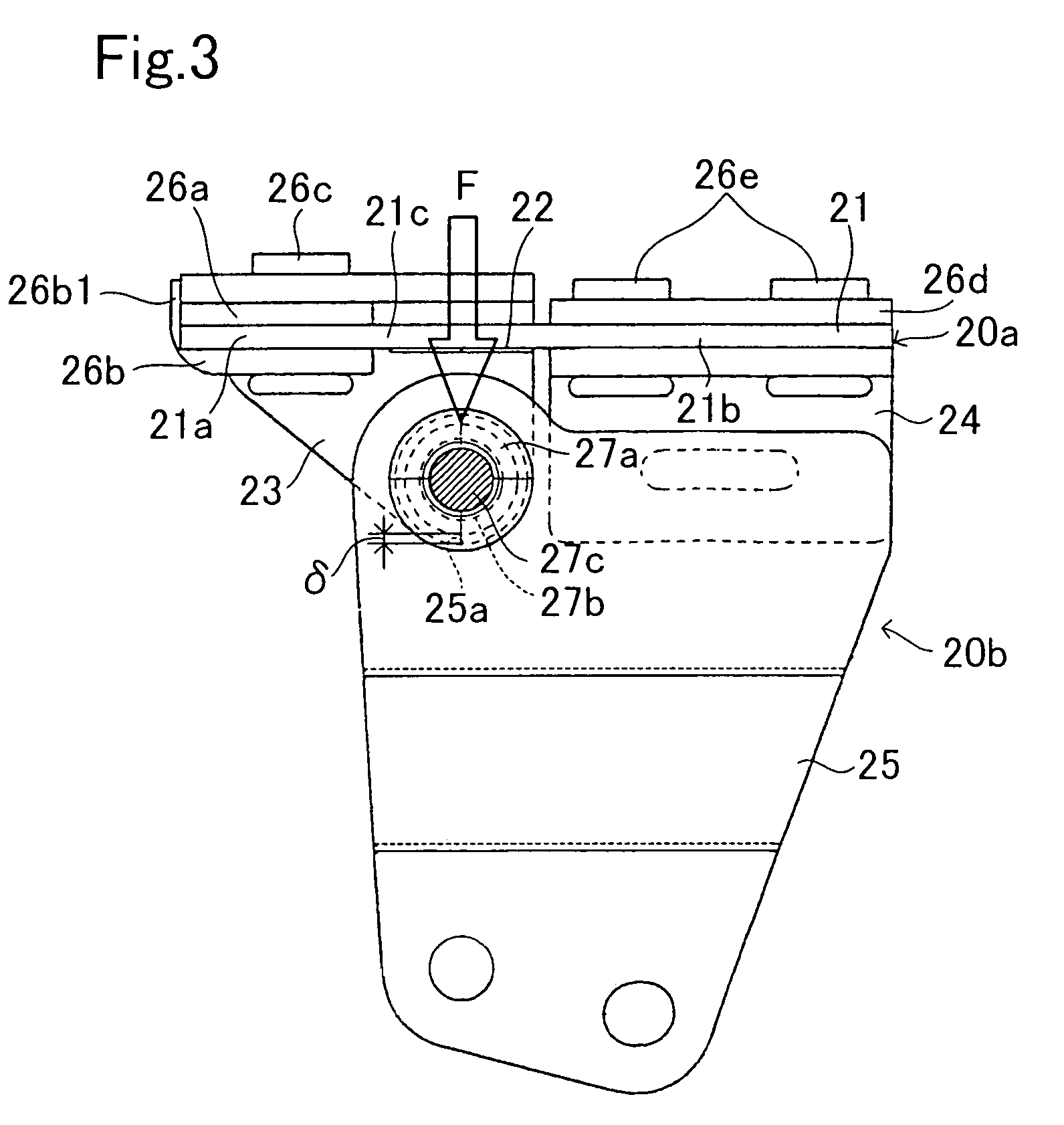

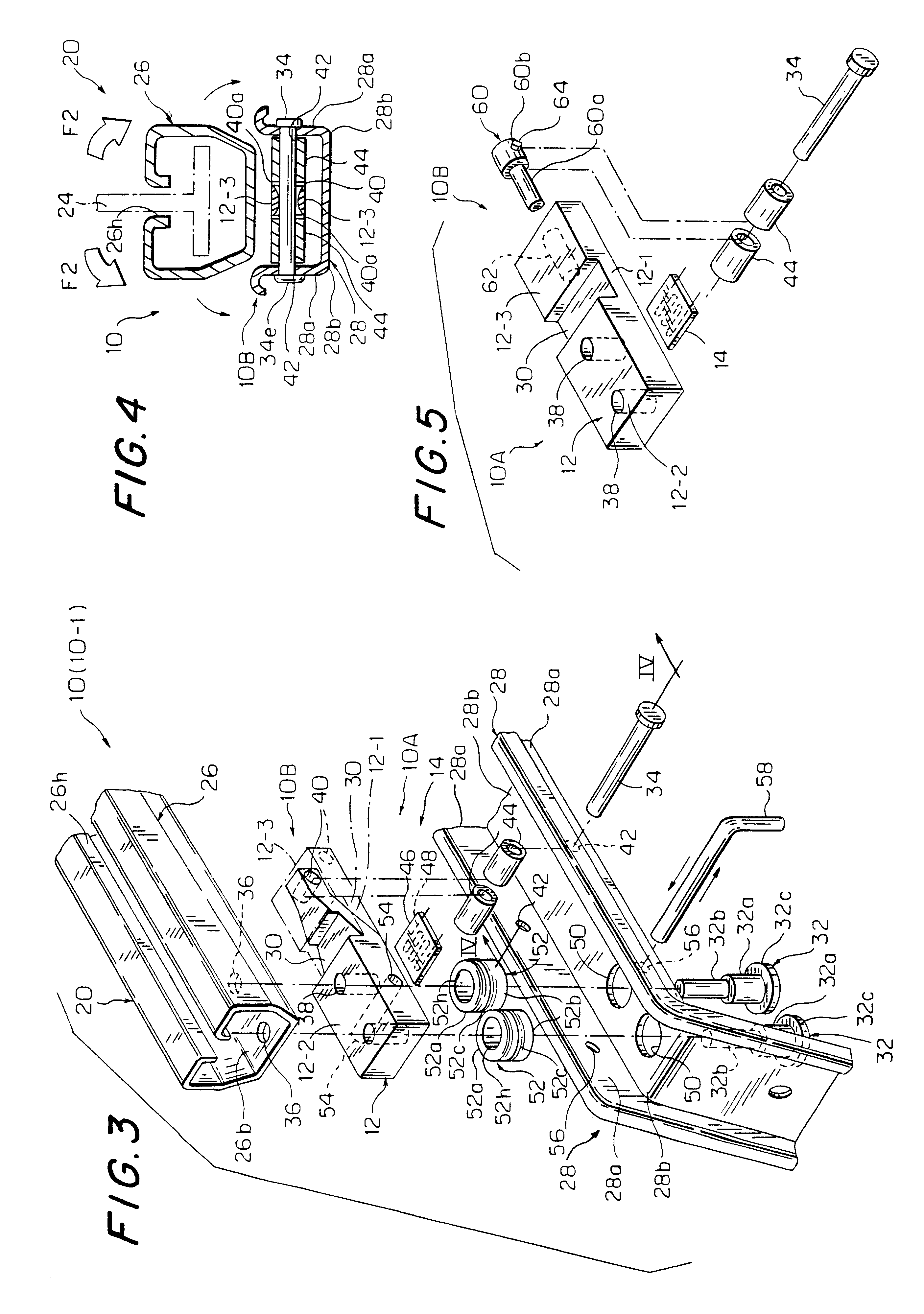

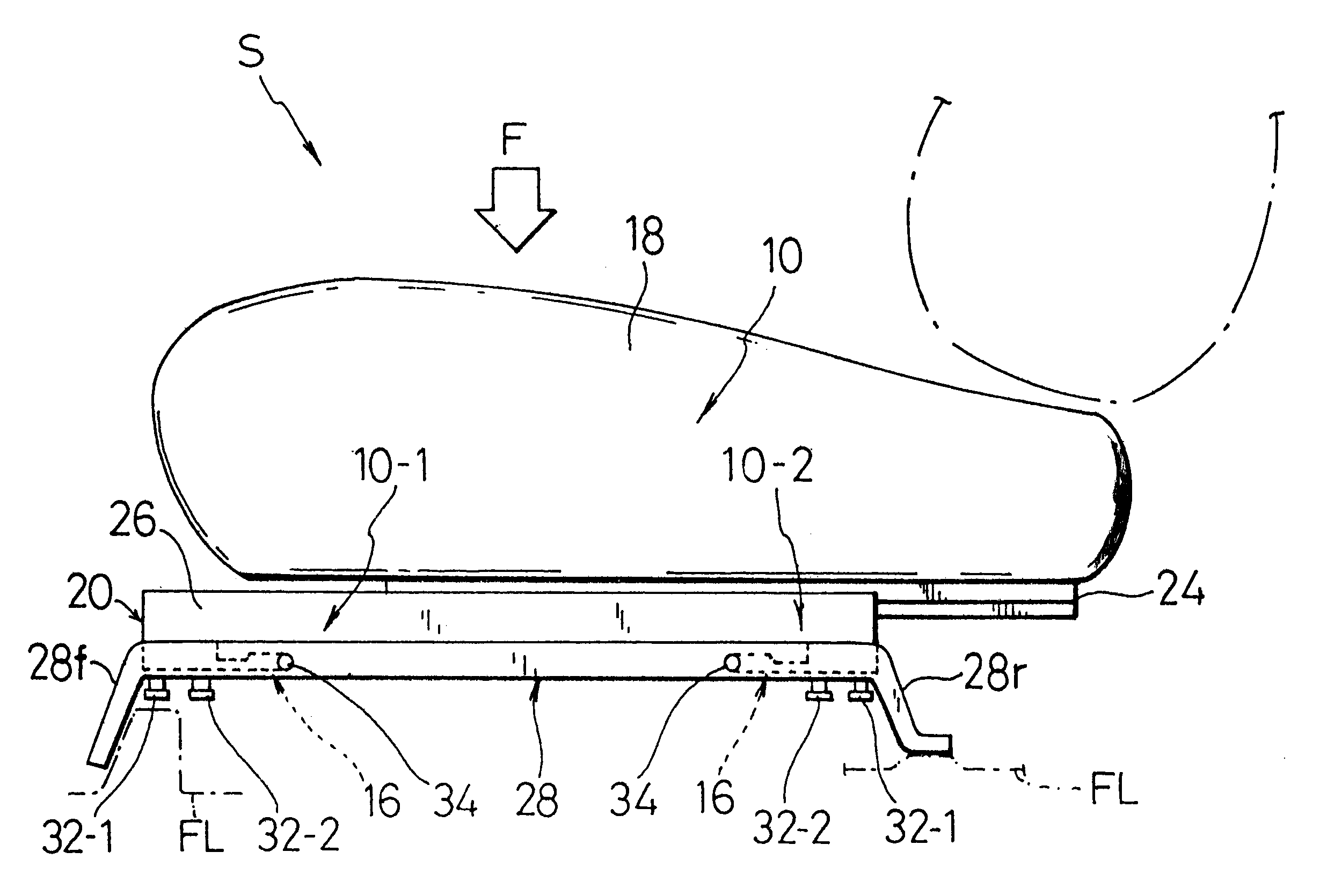

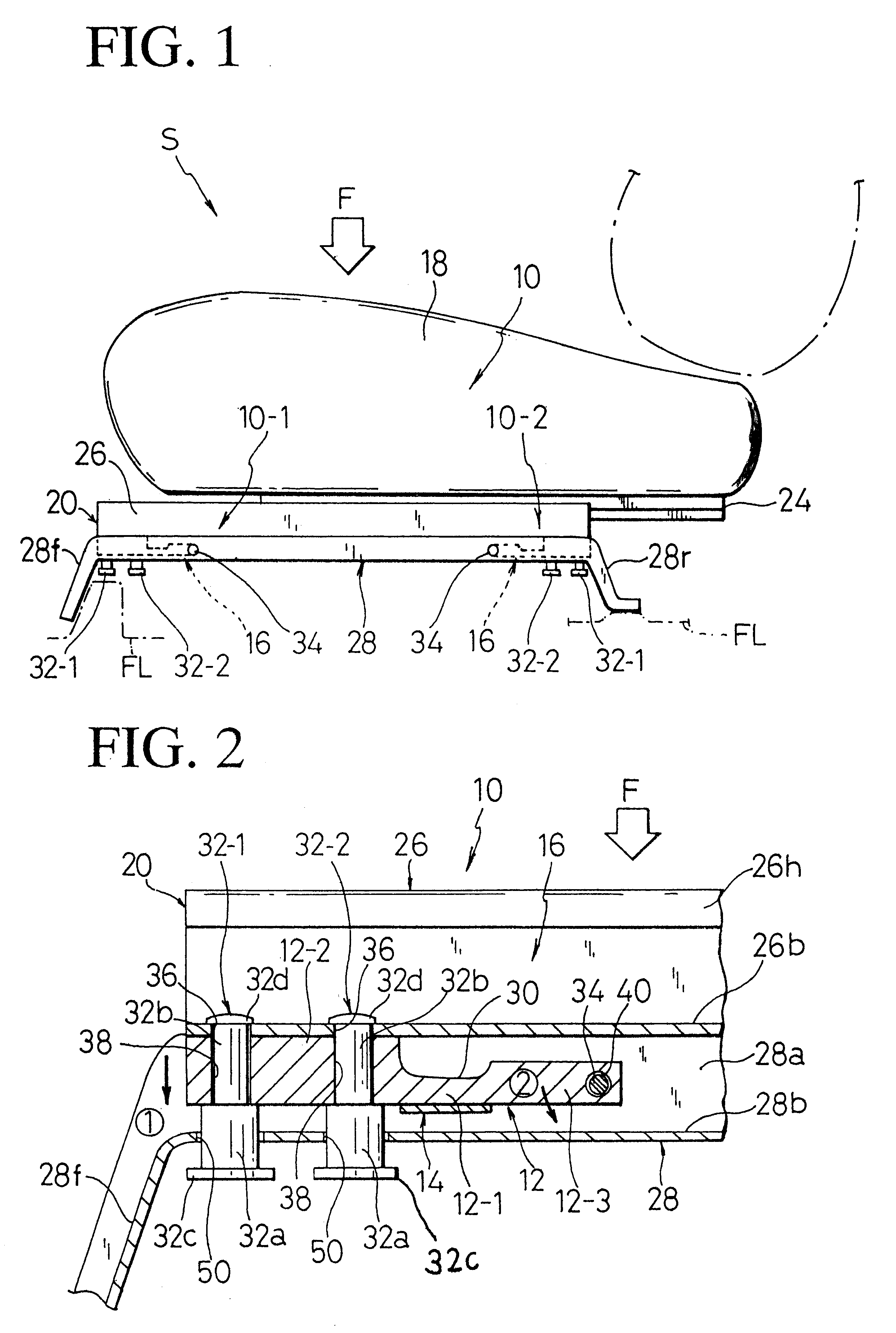

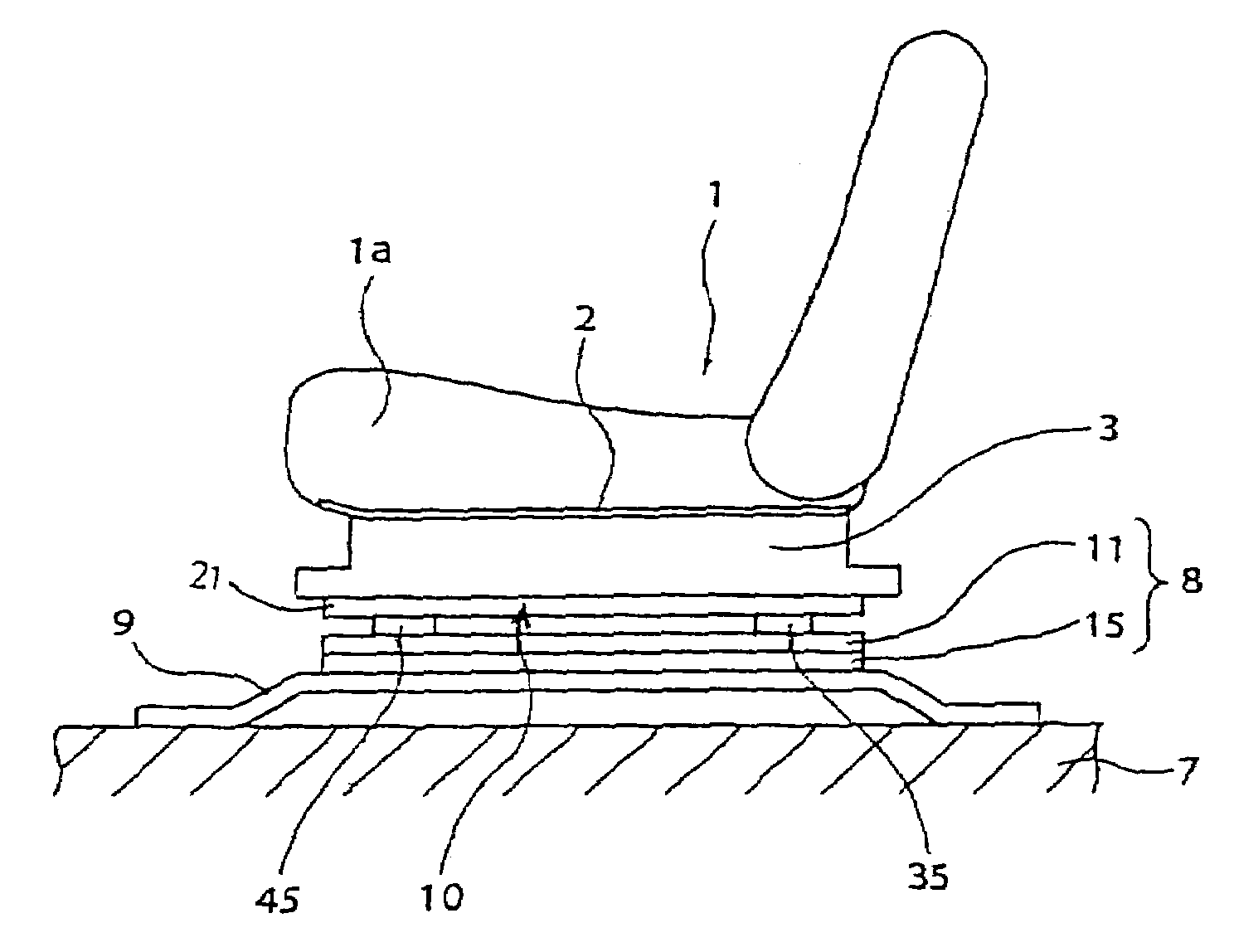

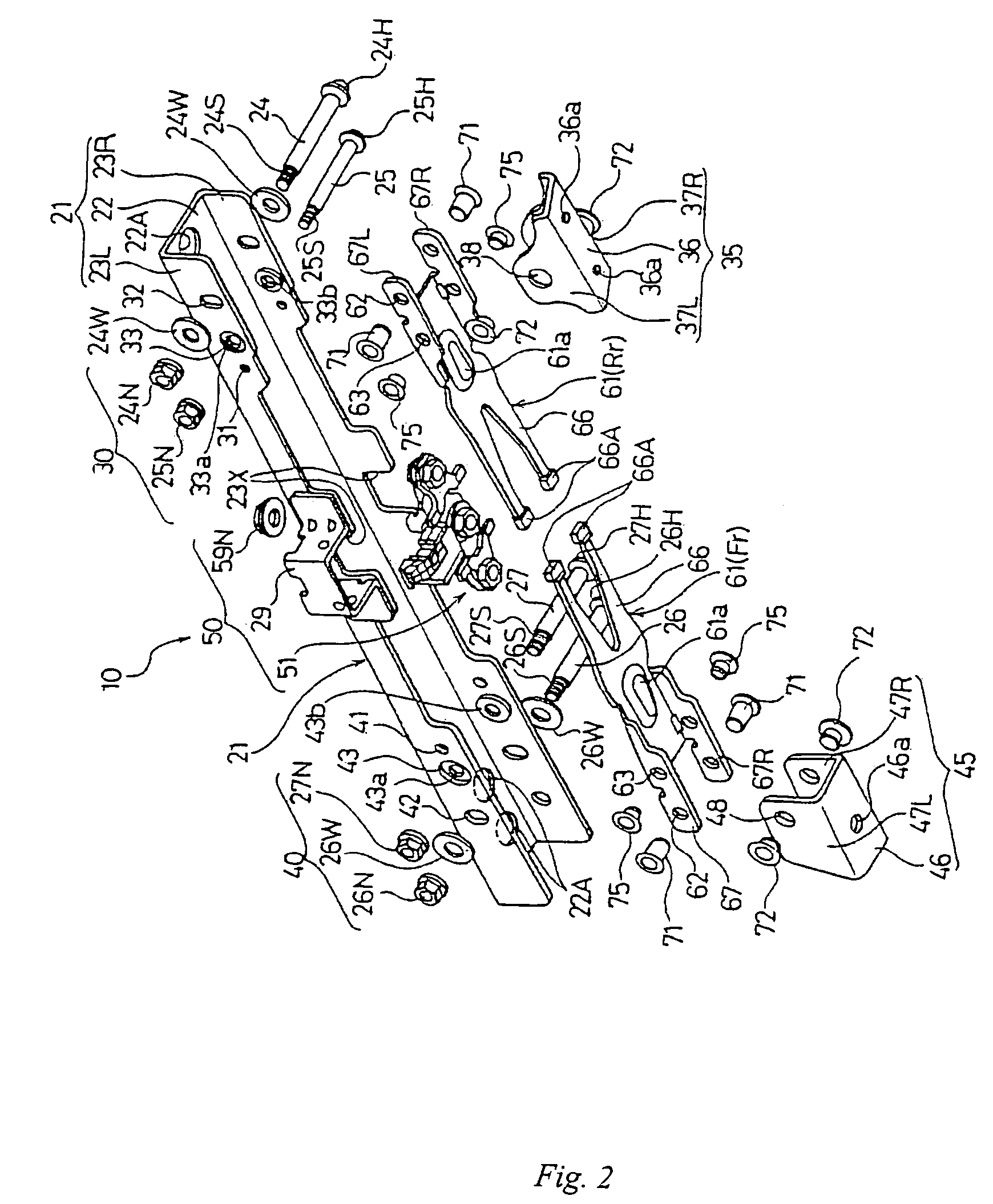

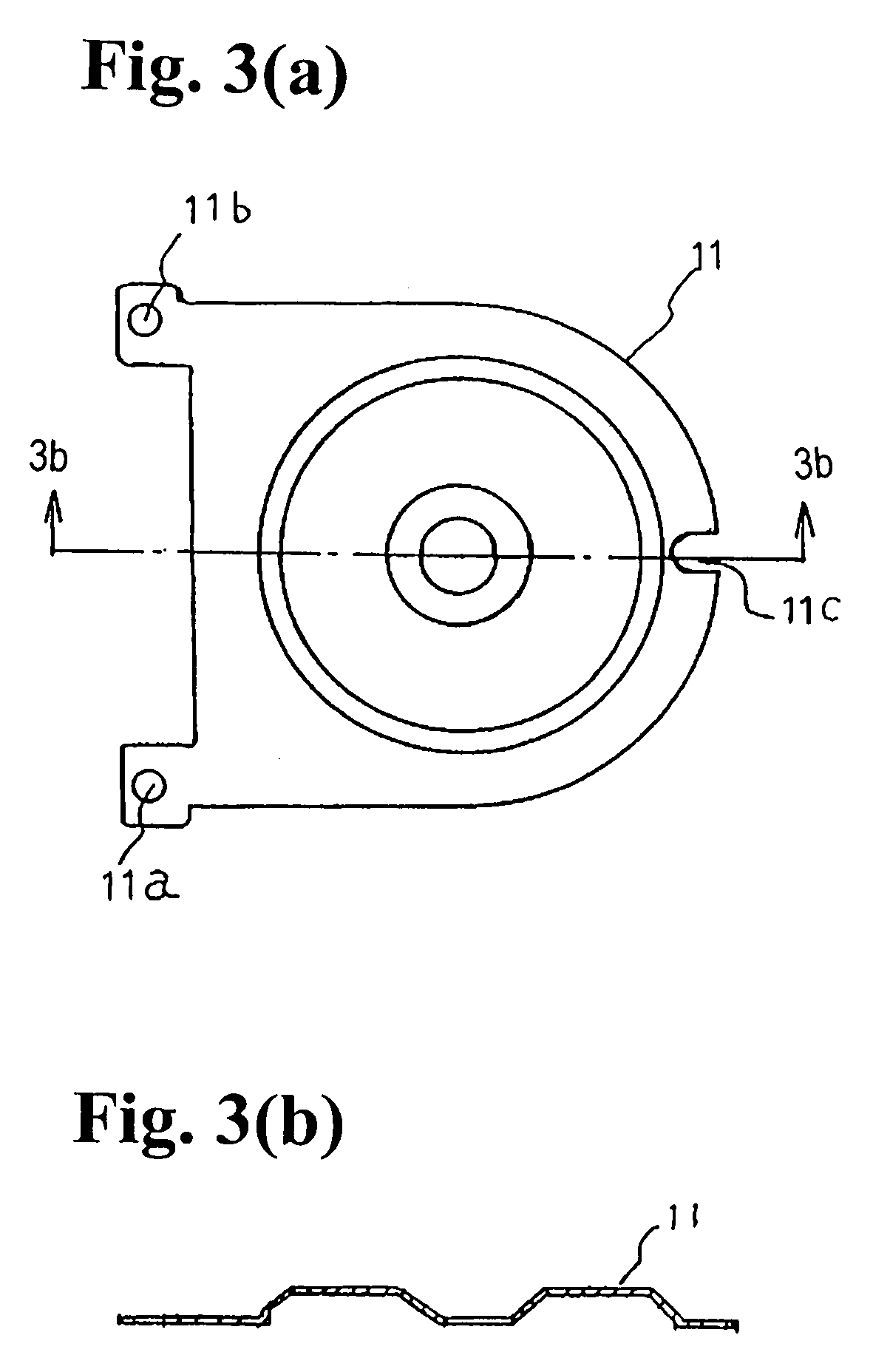

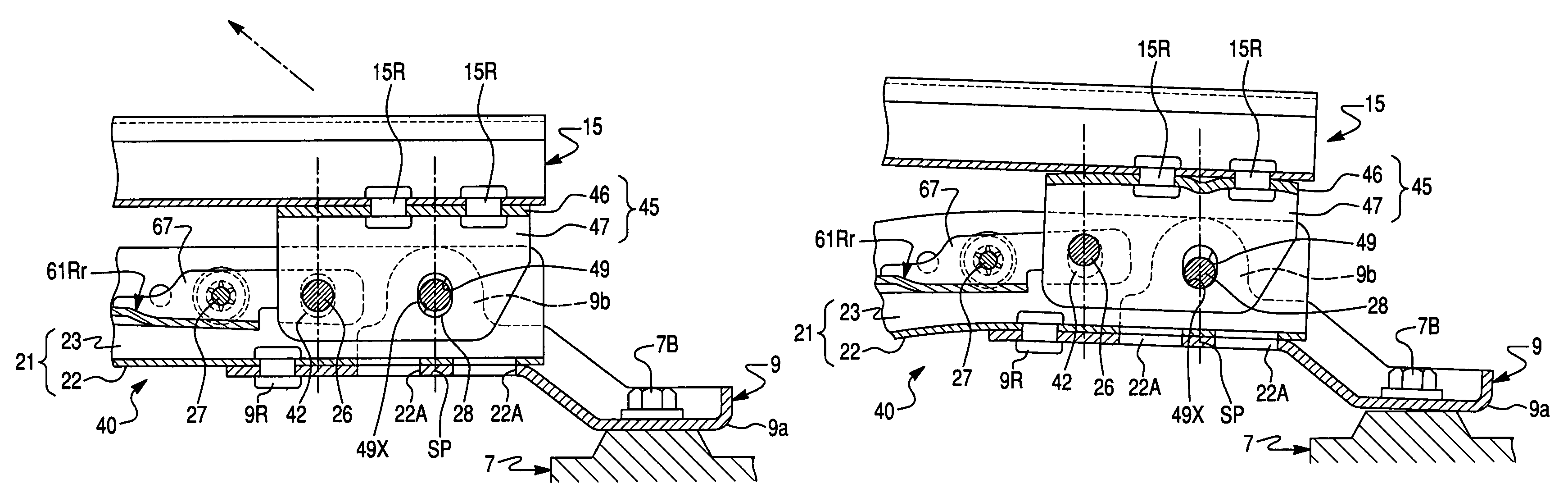

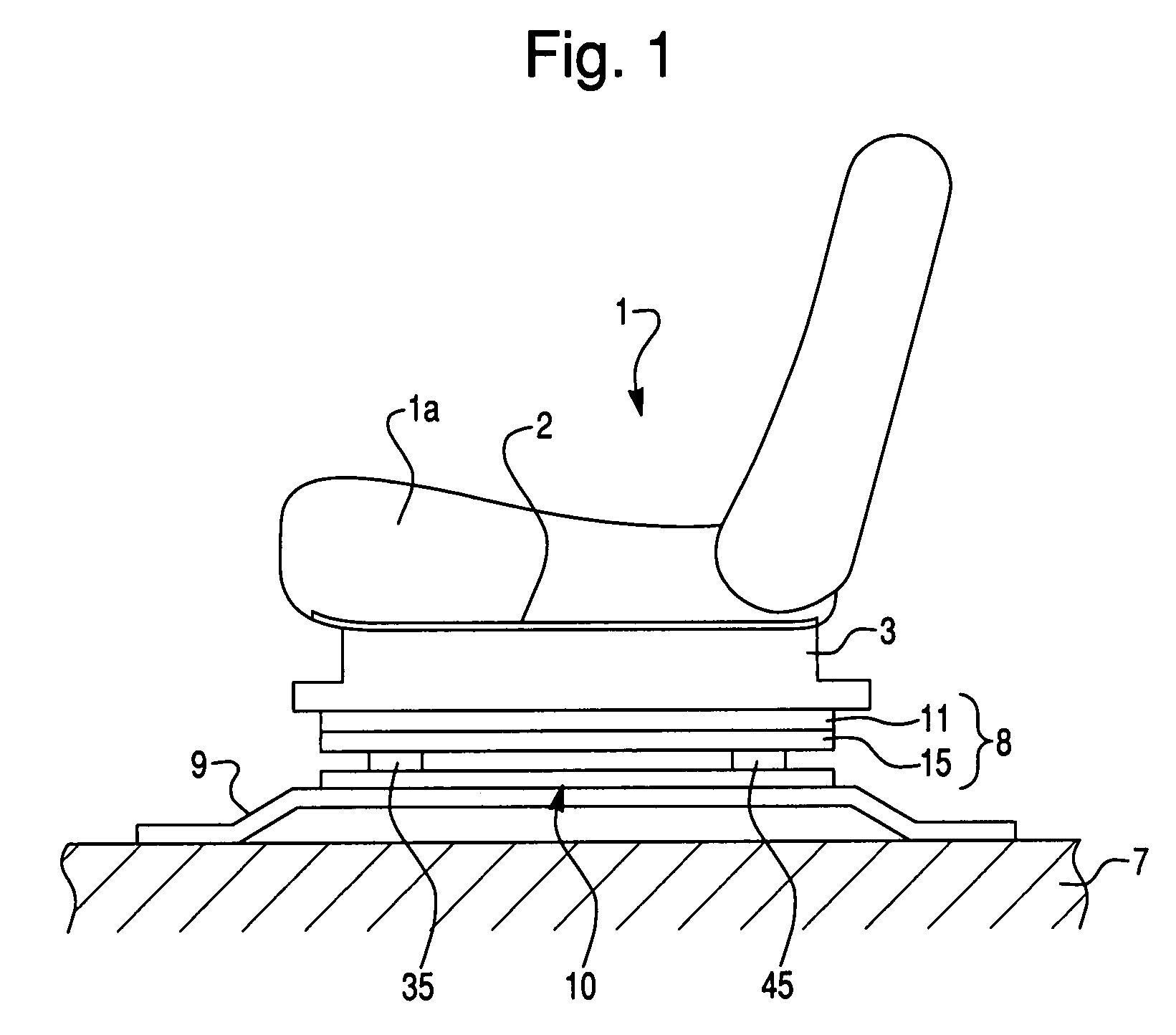

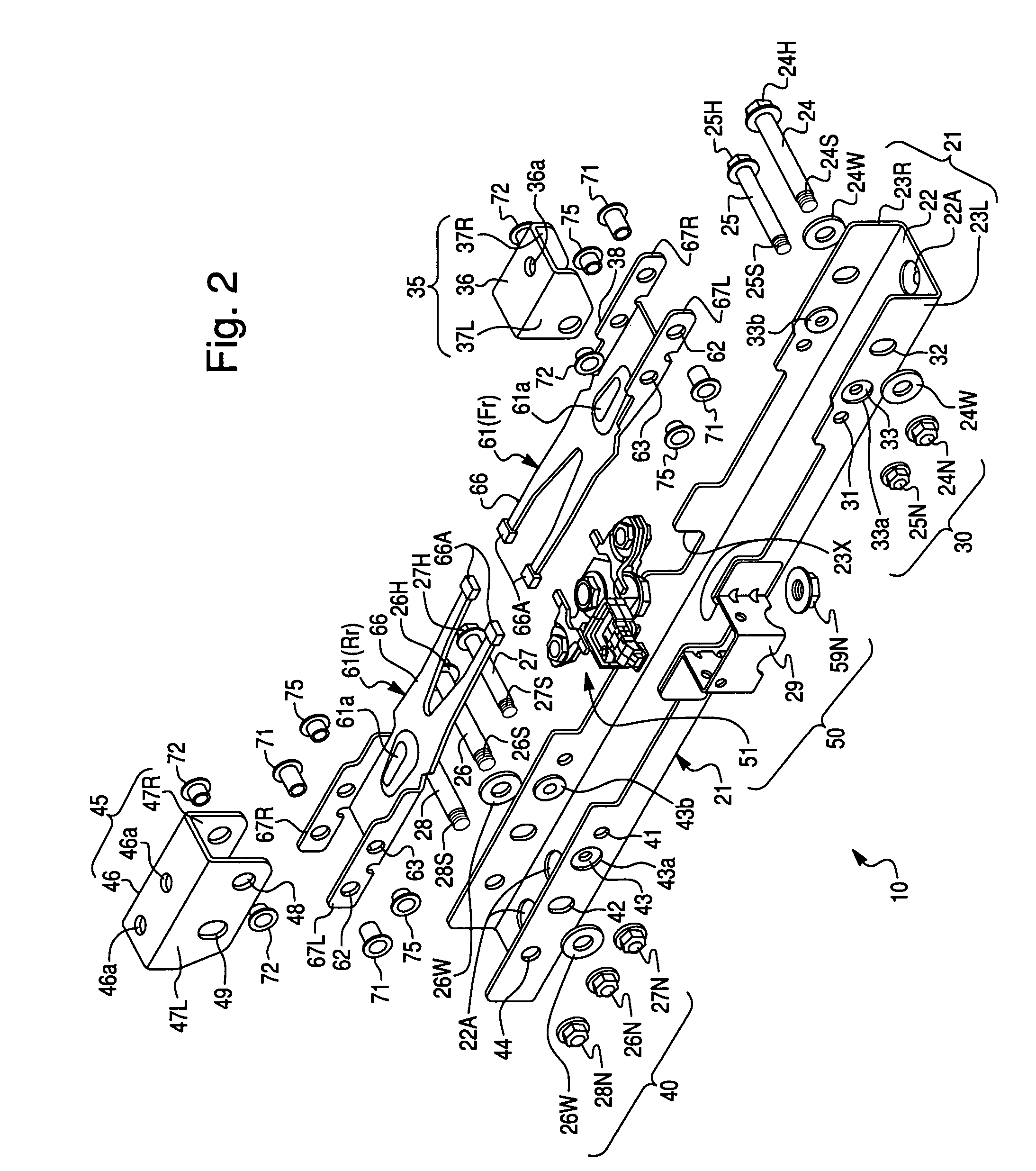

Attachment structure of a load sensor for a vehicle seat

InactiveUS6981717B2Accurate weighingReduce weightVehicle seatsBelt retractorsStrain gaugeAutomotive engineering

Owner:AISIN SEIKI KK

Load detection structure for vehicle seat

InactiveUS6520023B2Avoid distortionVehicle seatsWeighing apparatus using elastically-deformable membersEngineeringVertical load

A load detection structure in a vehicle seat with a support leg member, which includes a block member of rigid yet resilient recovery property and a strain gauge attached thereon. The block member is interposed between the seat and support leg member, such that a securing portion thereof is secured to the seat, whereas a pivotal end portion thereof is rotatably pivoted to the support leg member. The securing portion is displaced in a vertical direction due to a vertical load applied to the seat, while the pivotal end portion is rotated, so as to cause deflection in the block member, which is detected by the strain gauge. It may be so arranged that the block member is rotatable about its central axis, thereby being prevented against twist due to a lateral load applied to the seat. An auxiliary linkage is provided to insure preventing such twist of block member.

Owner:TACHI S CO LTD

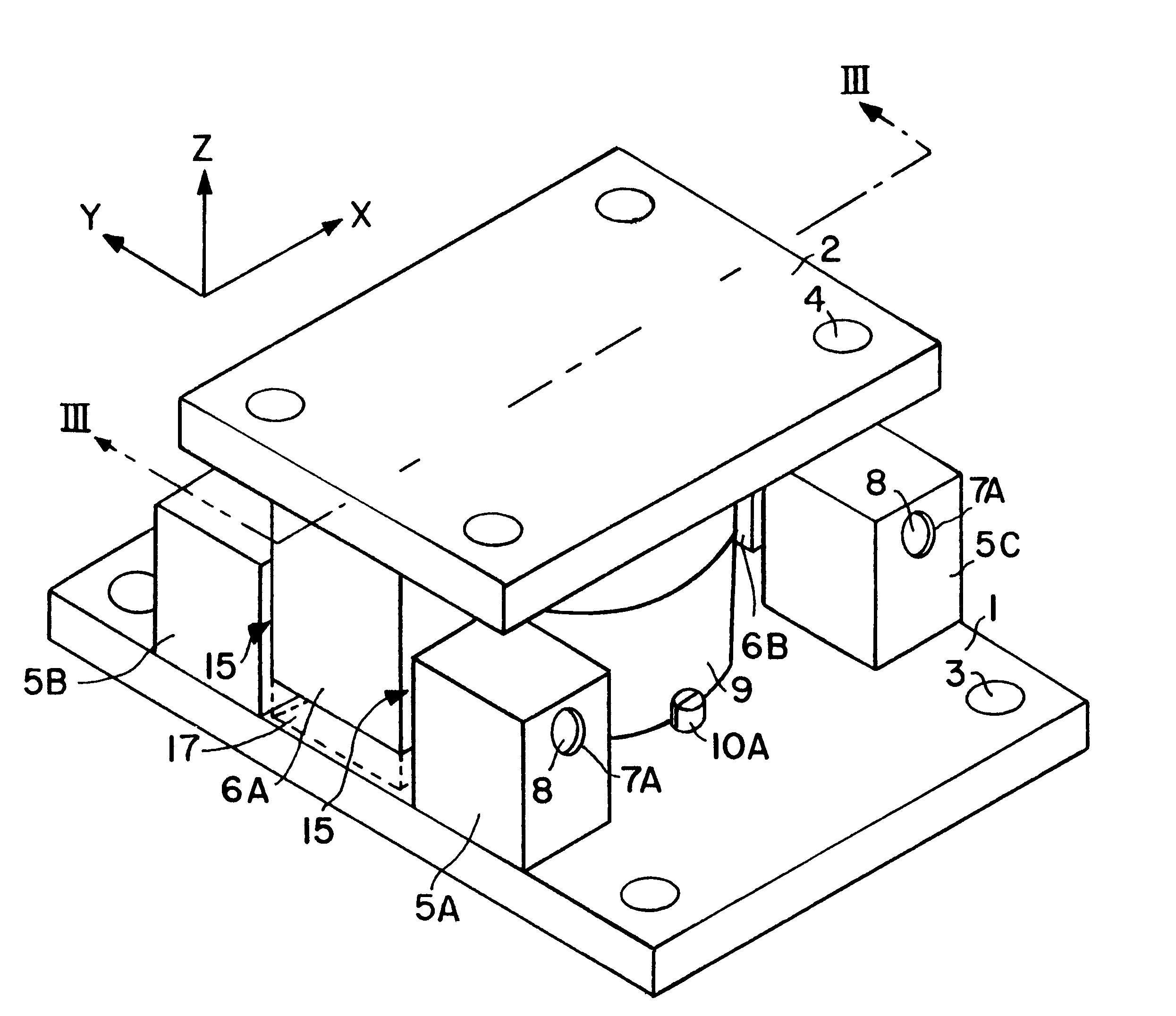

Tank weigh module with excess motion restraint

InactiveUS6331682B1Minimizes and eliminates lateral forceWeighing relieving/arrestment mechanismsFuel tankEngineering

A tank weigh module includes a bottom plate that has two lower stop blocks protruding upwardly therefrom, and a top plate that has an upper stop block protruding downwardly therefrom into a space between the two upper stop blocks with a block free play clearance therebetween. A restraining pin is arranged to extend through aligned pin receiving holes in all of the stop blocks. In the lower stop blocks, the holes provide a tight friction fit for the pin, while the hole in the upper stop block has a larger diameter and provides a pin free play clearance. Motion of the top plate relative to the bottom plate in the back-and-forth Y-direction is limited to the extent of the block free play clearance. Travel of the top plate in the side-to-side X-direction and in the uplift Z-direction is restrained by the extent of the pin free play clearance. Tilting and twisting about the X-, Y-, and Z-axes are also limited by the pin interacting with the blocks and the blocks interacting with each other. A load cell is secured in position between the top and bottom plates by two fixed securing pins and a third removable securing pin attached to the bottom plate, whereby the securing pins are angularly offset by 120° from each other. The weigh module has a simple construction, installation, and servicing, and provides protection against excess uplift, side loading, and tilting while allow complete free floating operation in a normal operating range.

Owner:HOTTINGER BALDWIN MEASUREMENTS

Automatic sealing arrangement for weigh scale for food processing apparatus

InactiveUS20070089581A1Eliminate needWeighing relieving/arrestment mechanismsMetal working apparatusVertical loadMechanical engineering

A sealing arrangement is provided for a product weigh scale for a food processing apparatus the weigh scale including a support for supporting a product, a member that carries the support, and a weight sensor that senses vertical load on the member. The sealing arrangement includes a seal surrounding the member beneath the support, the seal having a first sealing surface configured to be sealed against a cabinet, and a second sealing surface. The seal is movable between an inactive position wherein the second sealing surface is out of contact with the support and a sealing position wherein the second sealing surface seals against the support. The seal includes a stationary part having the first sealing surface and a sliding part having the second sealing surface. A plurality of springs urge the sliding part toward the sealing position and a source of pressurized fluid is injected between the sliding part and the stationary part to urge the sliding part toward the inactive position. The pressurized fluid has a sufficient pressure to overcome the urging of the springs and maintains the sliding part in the inactive position during normal operation of the scale, wherein upon loss of the supply of pressurized fluid, the springs cause the sliding part to assume the sealing position.

Owner:PROVISUR TECHNOLOGIES INC

High Capacity and High Resolution Scale

ActiveUS20090090564A1Weighing apparatus using counterbalanceWeighing apparatus using elastically-deformable membersImage resolutionEngineering

A scale can include a low capacity sensing mechanism operatively coupled to a load, wherein the low capacity sensing mechanism may detect movement of the load. A transfer mechanism can be operatively coupled to the low capacity sensing mechanism, wherein the low capacity sensing mechanism may enable the scale to weigh both relatively heavy loads and relatively light loads to a minor division resolution associated with the low capacity sensing mechanism.

Owner:QUADIENT TECH FRANCE

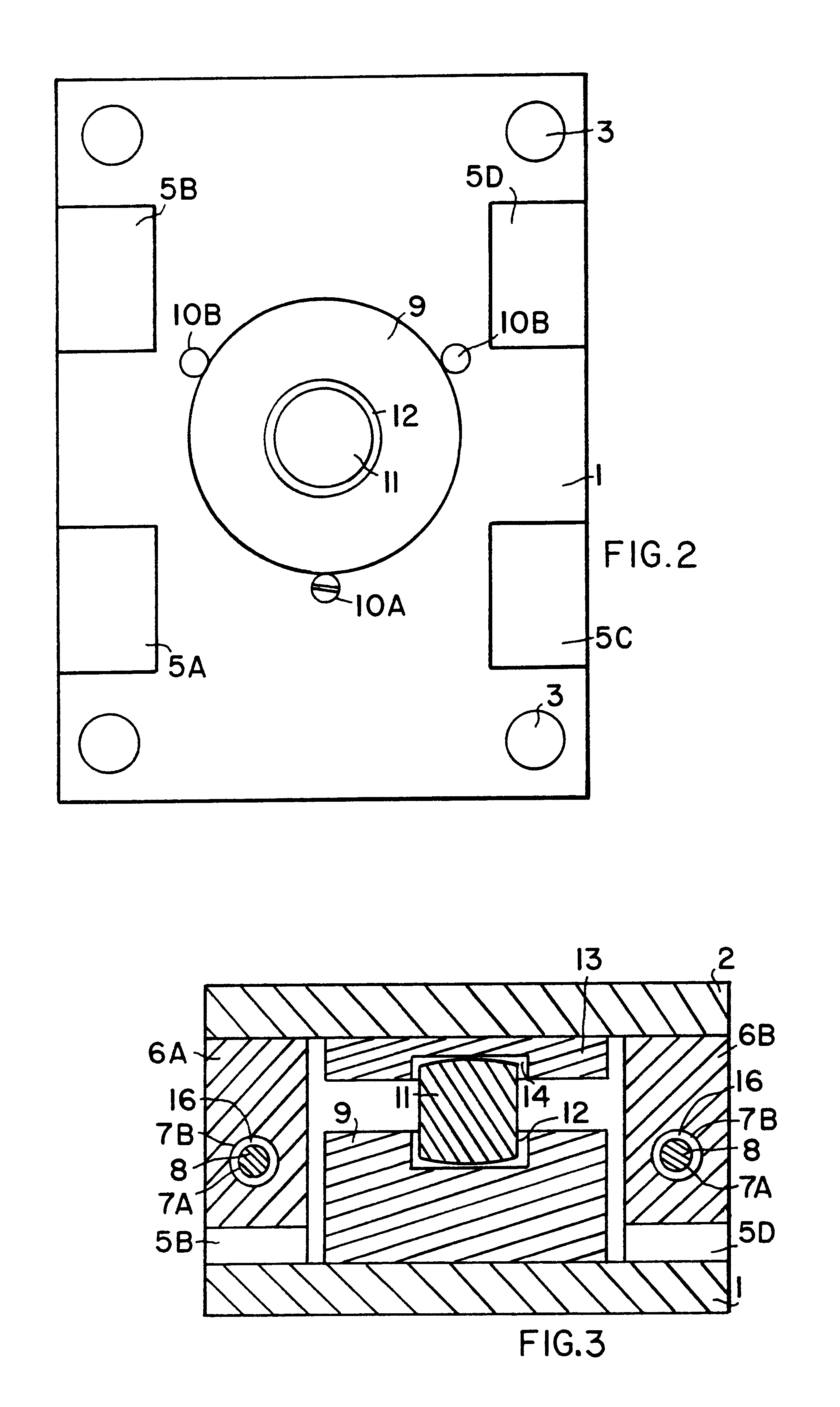

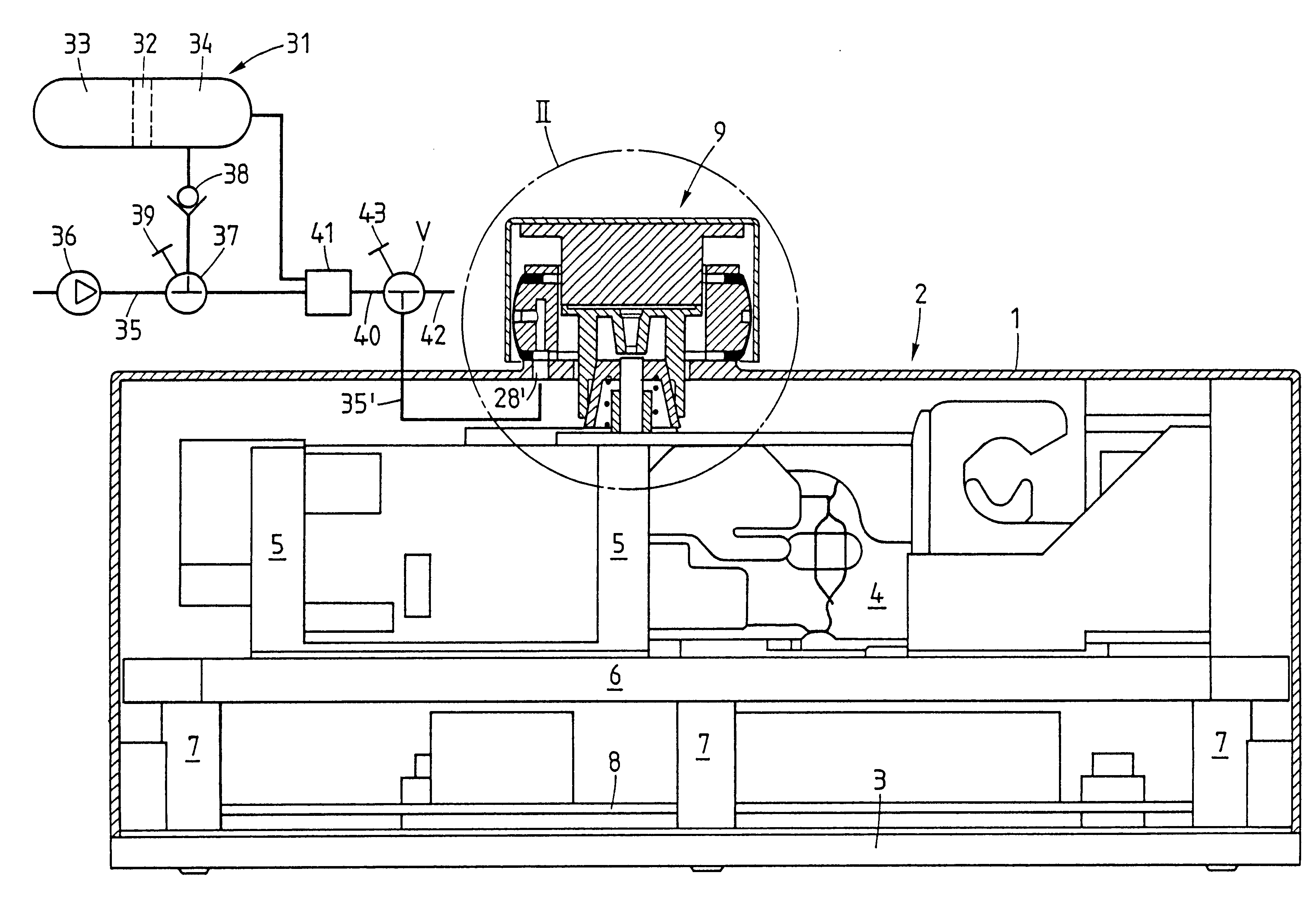

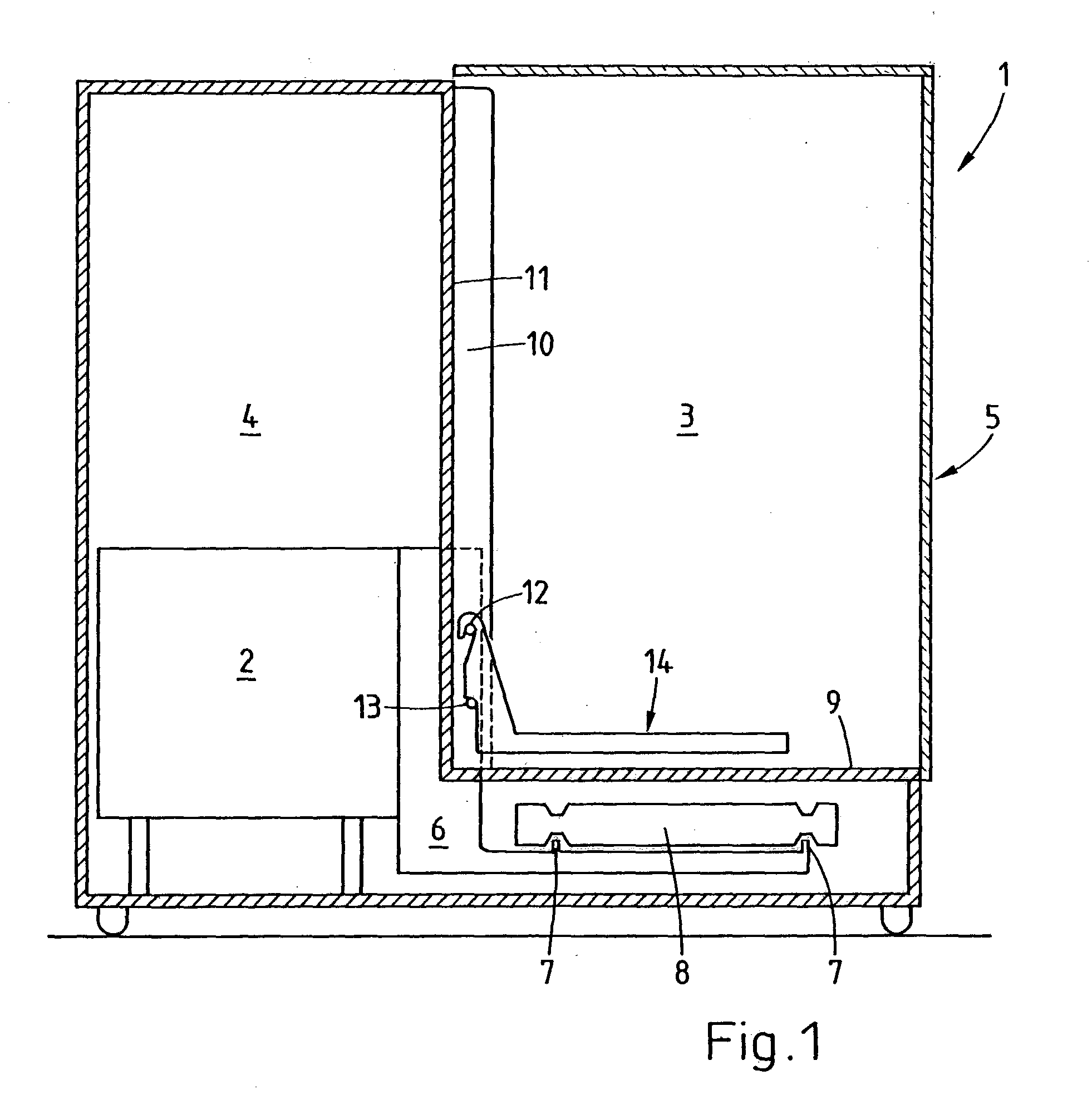

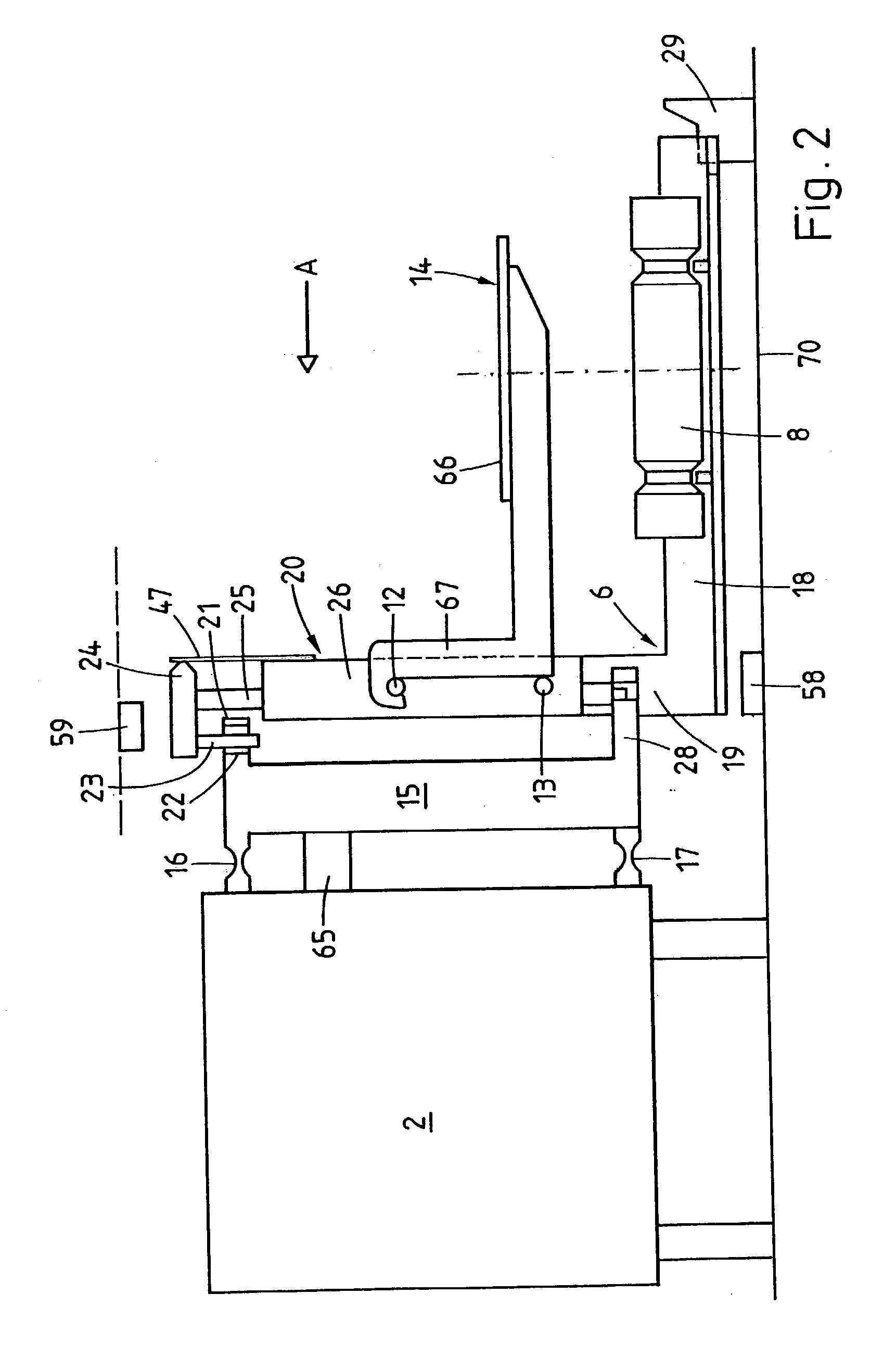

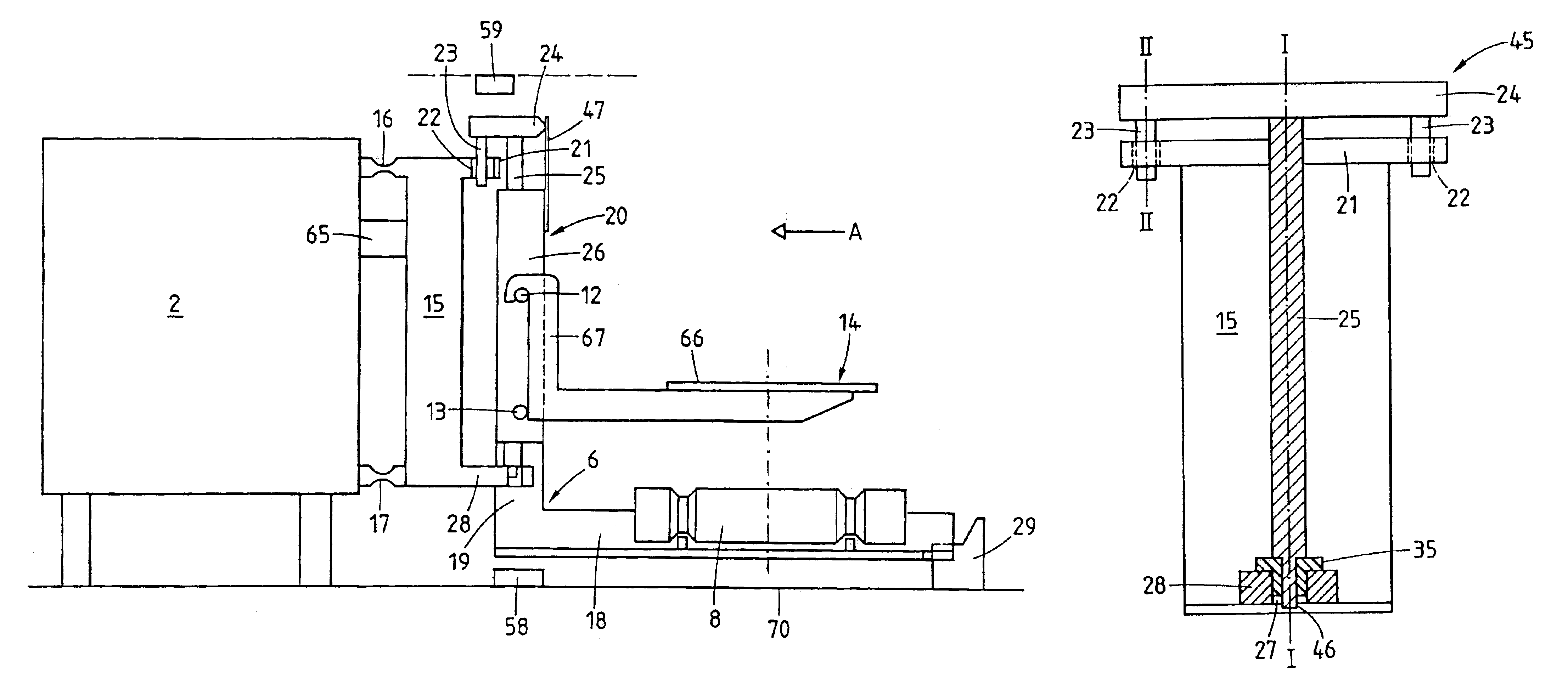

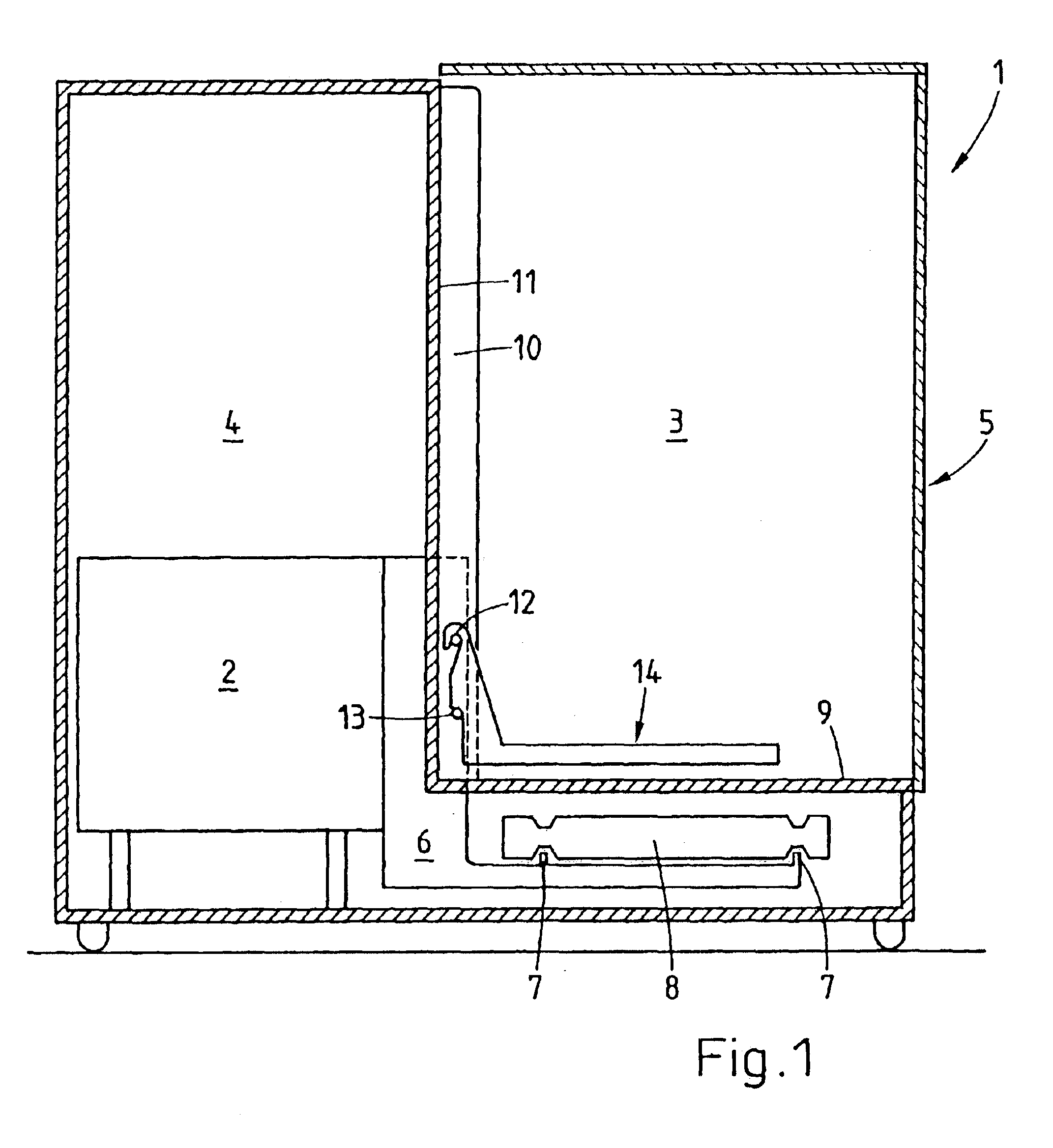

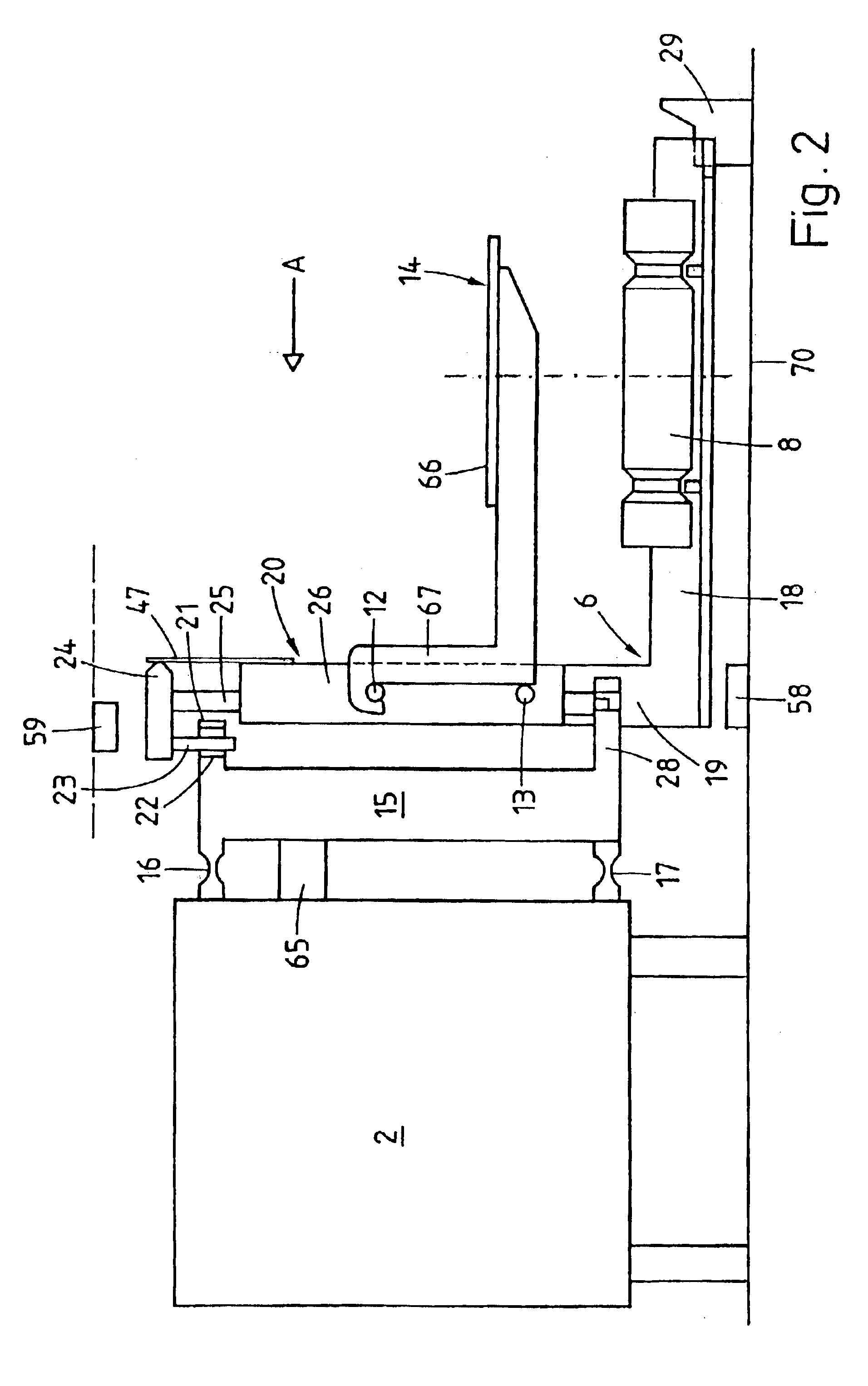

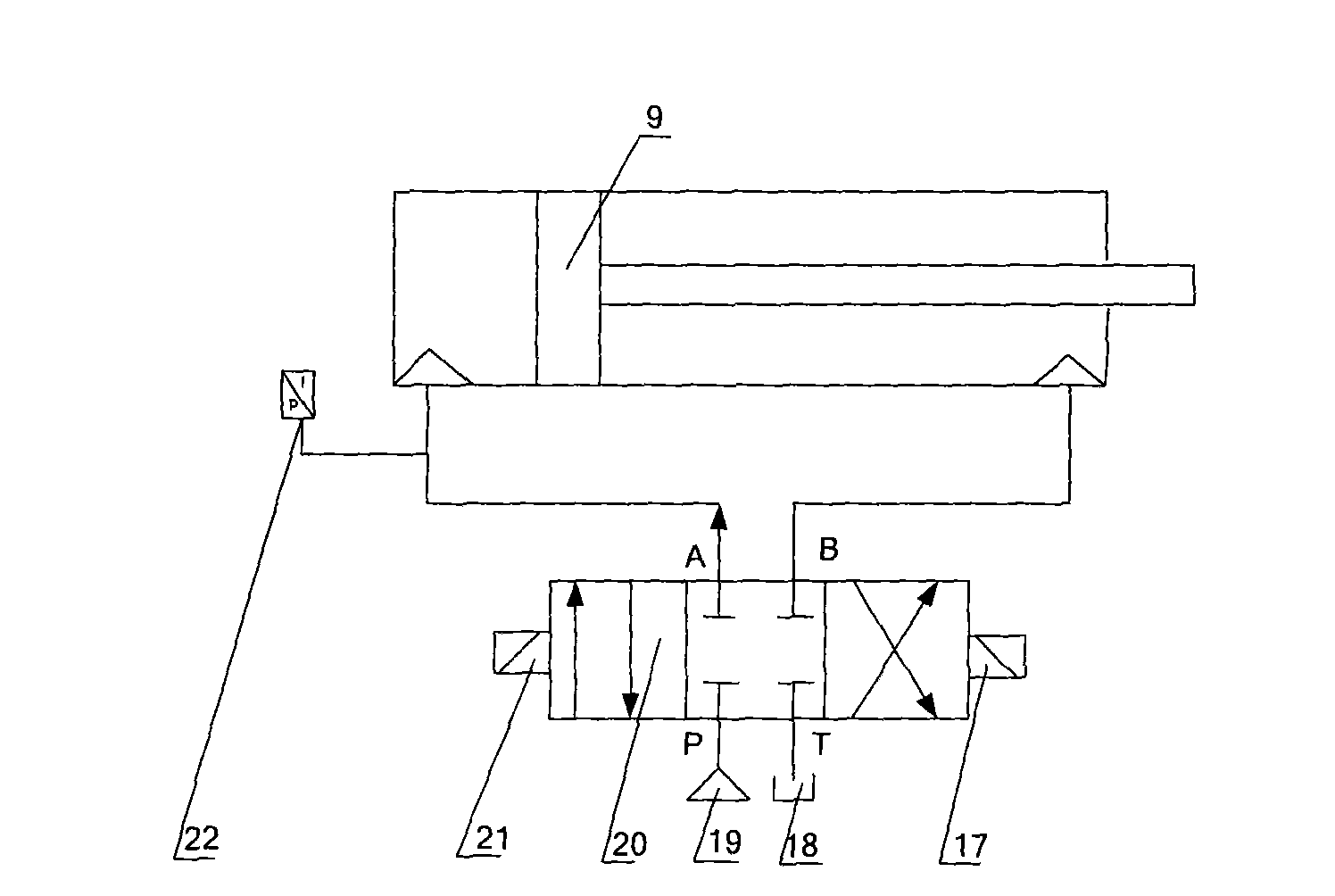

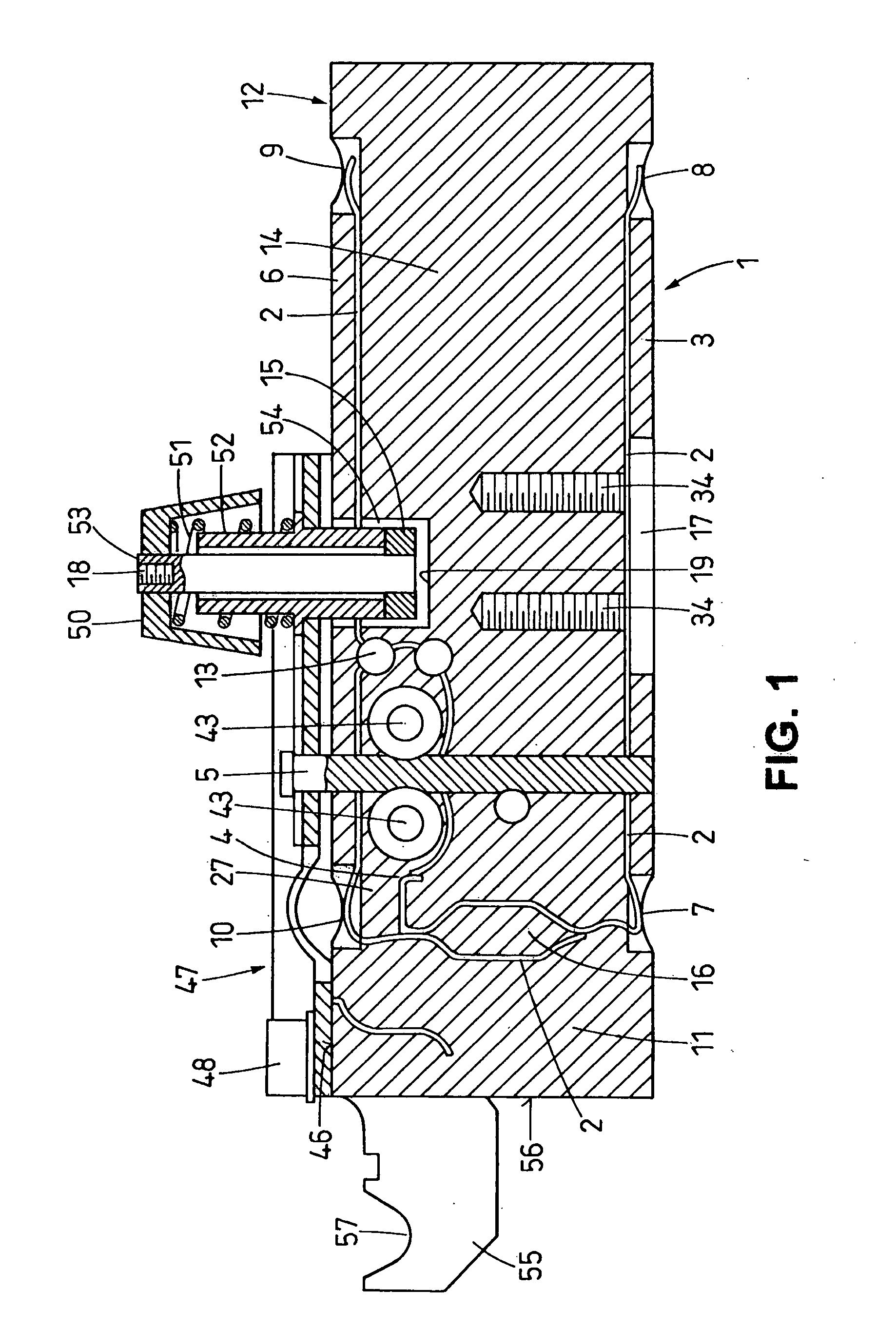

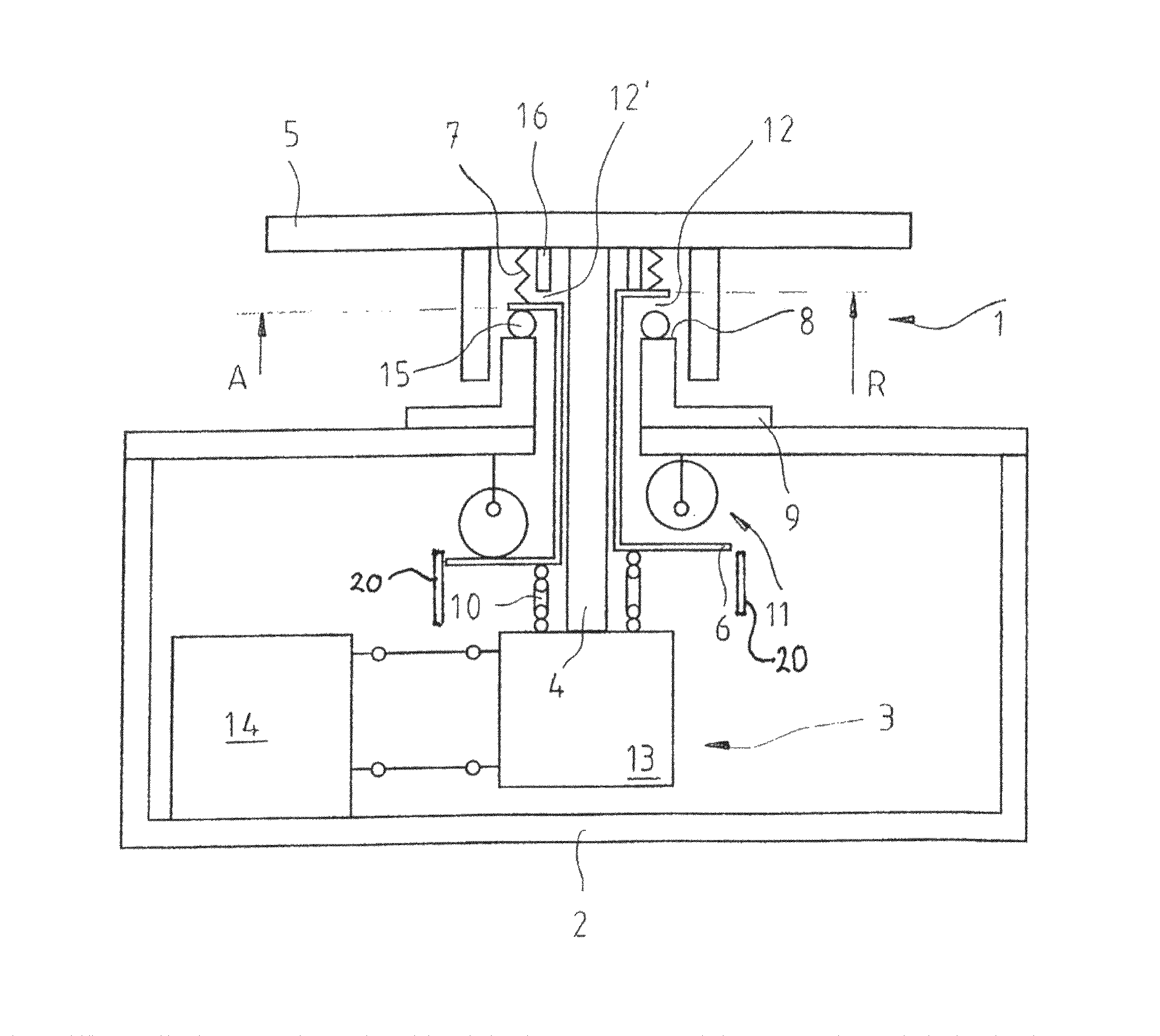

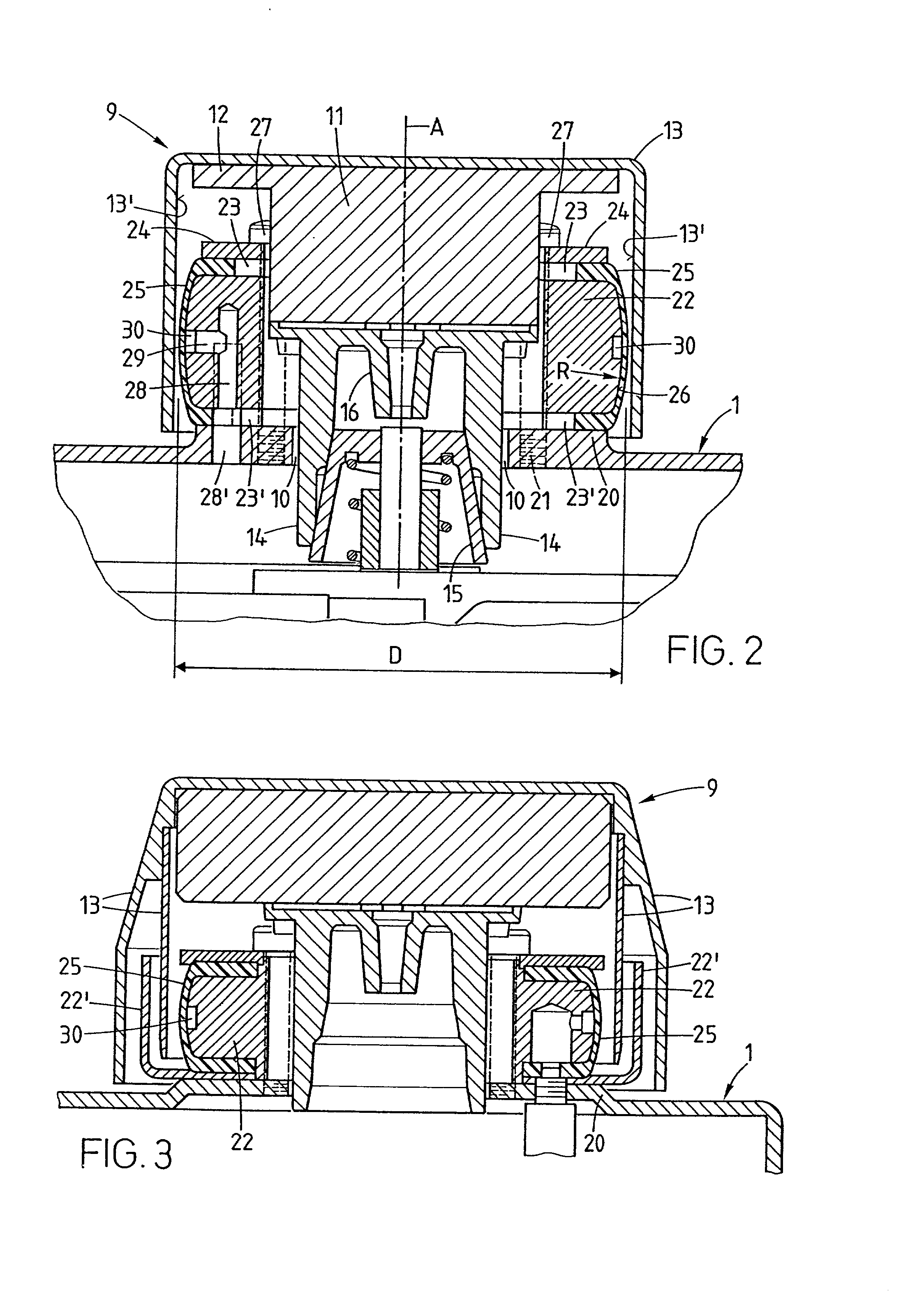

Weighing scale with a combined sealing and arresting device

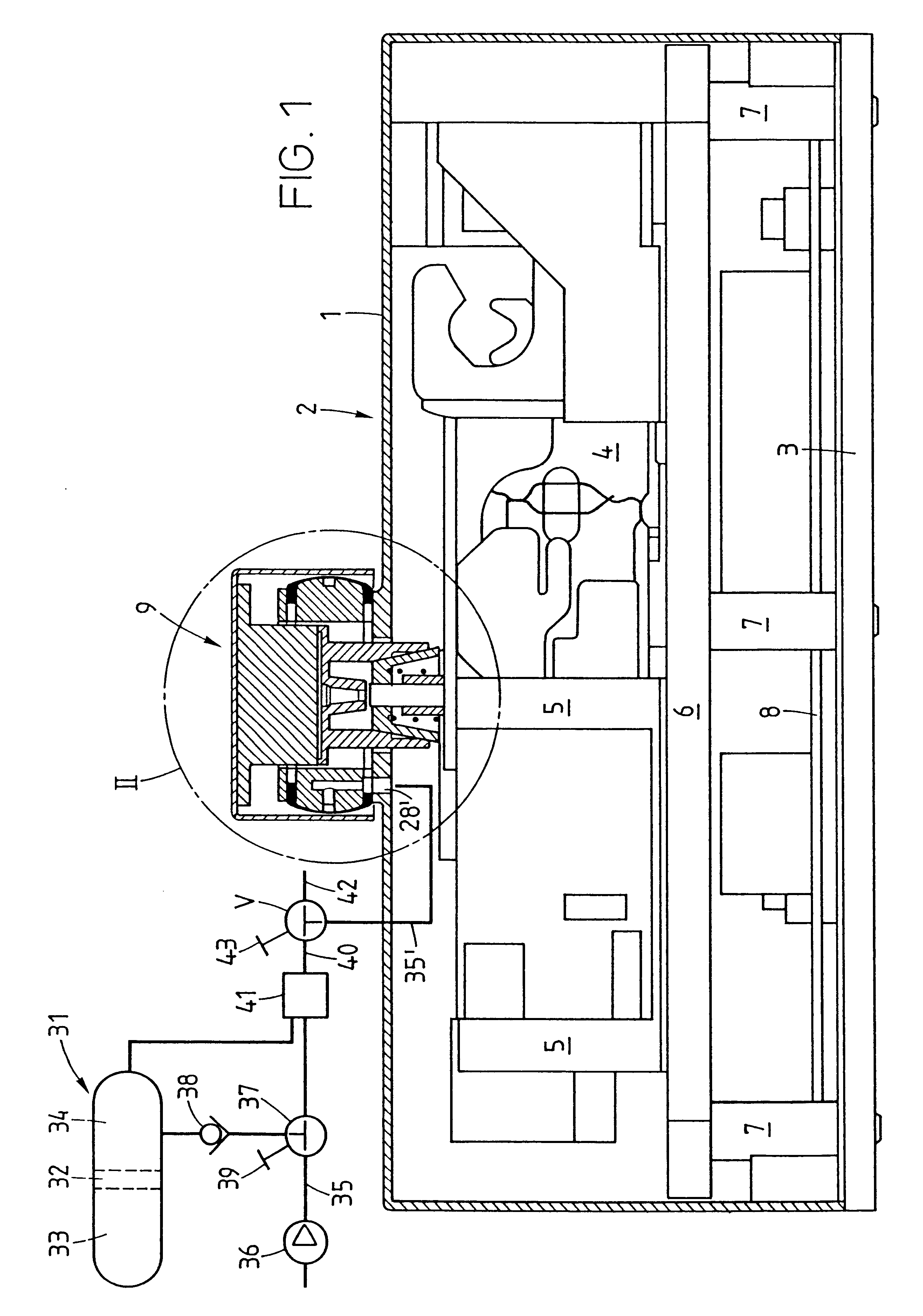

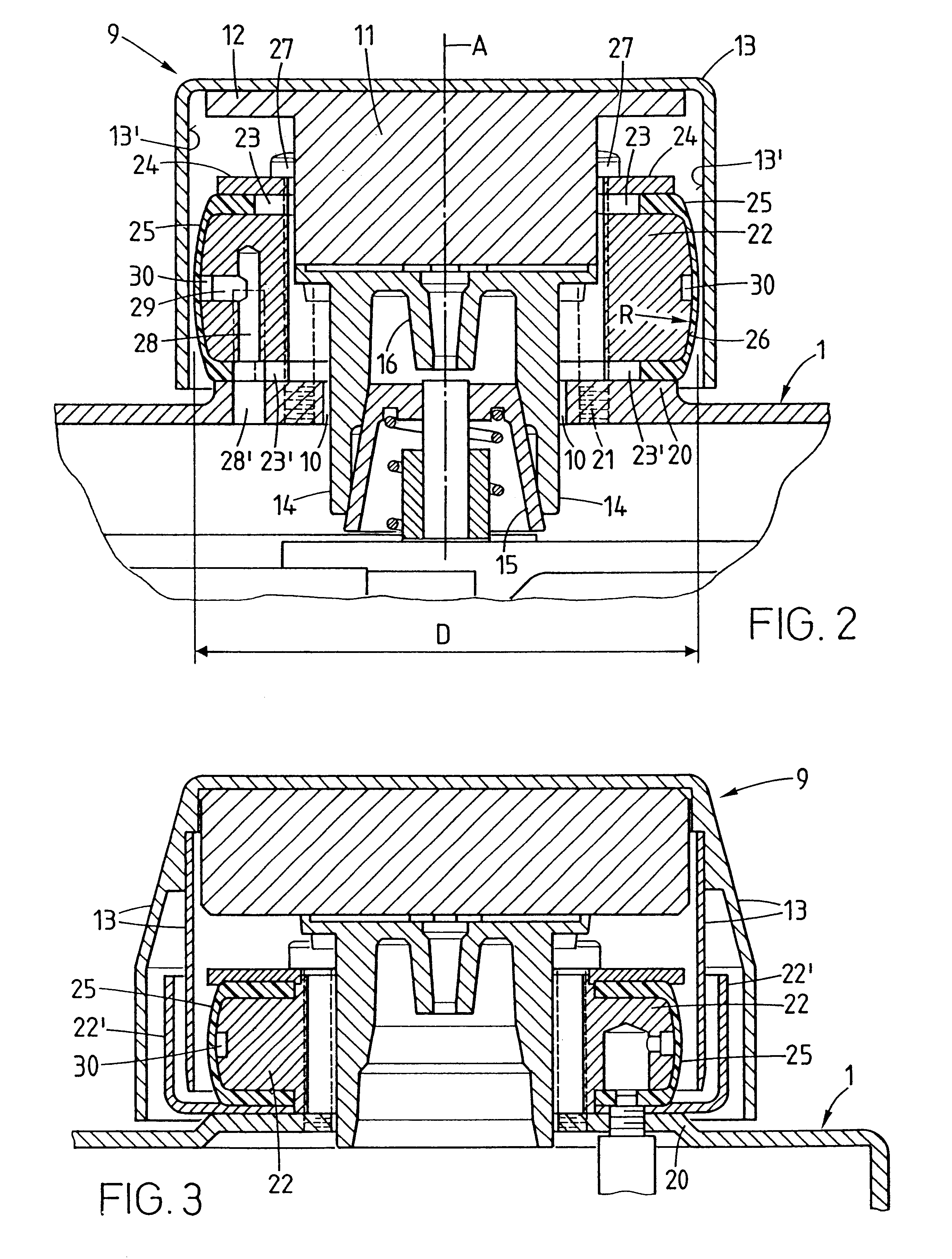

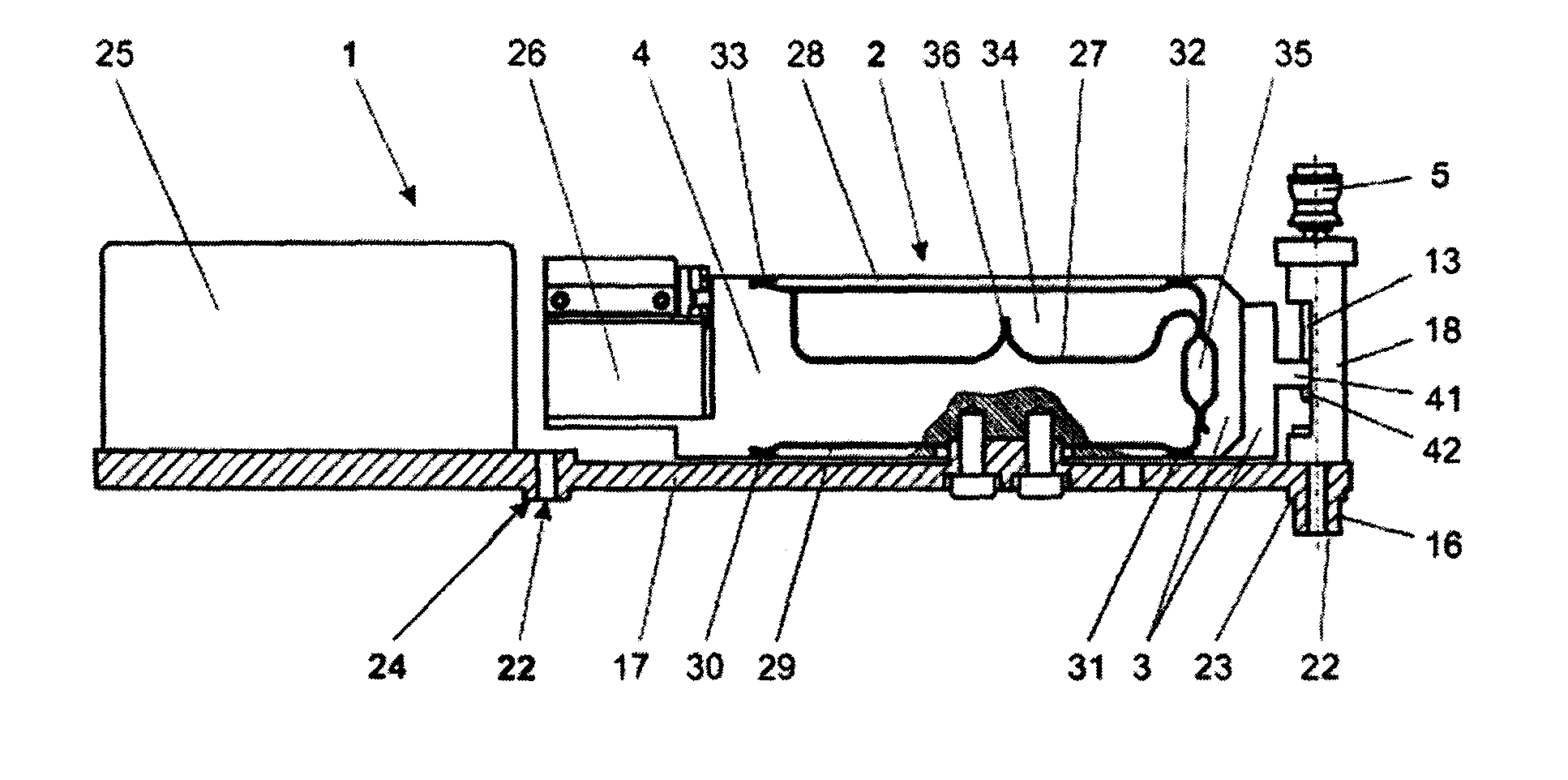

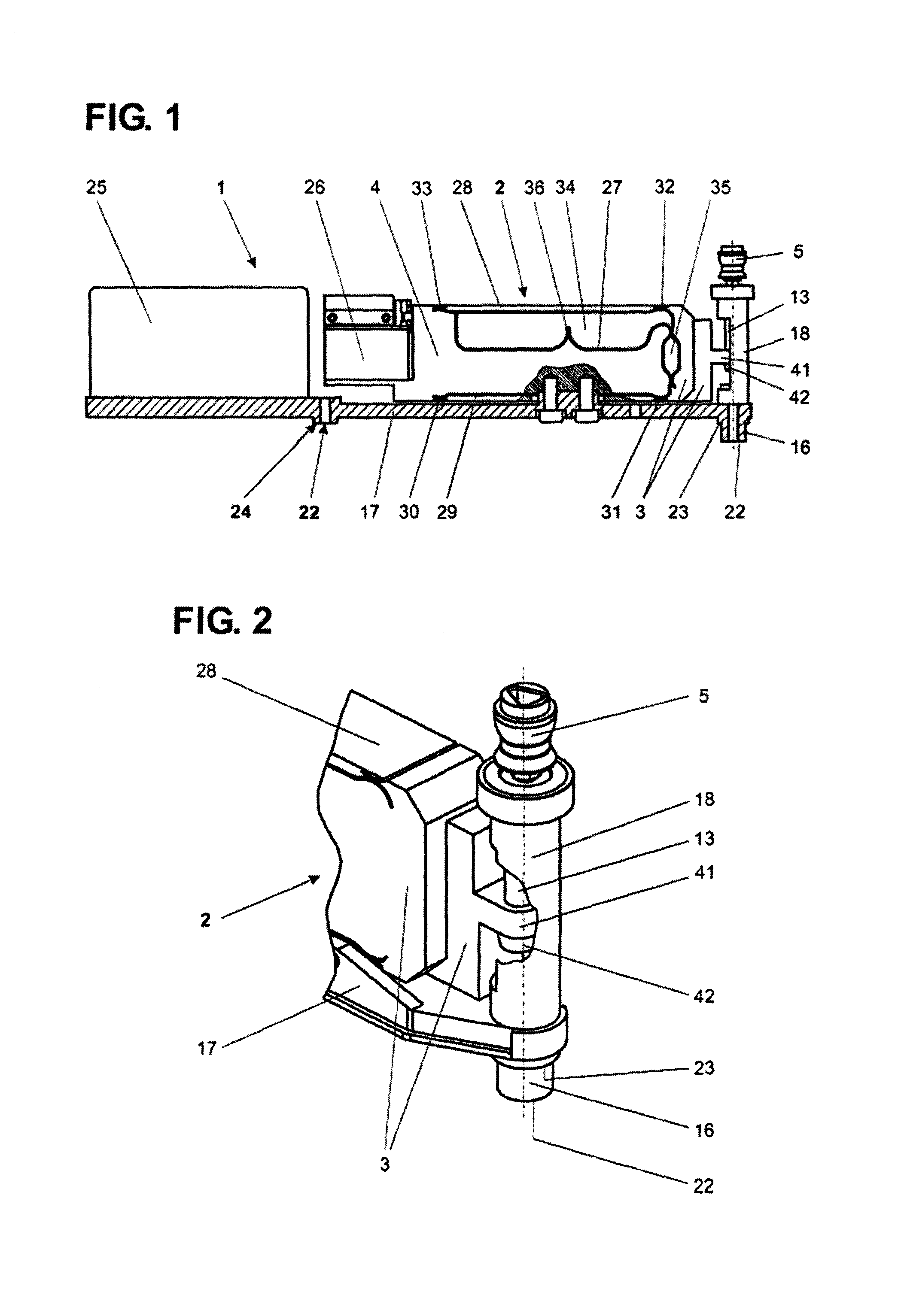

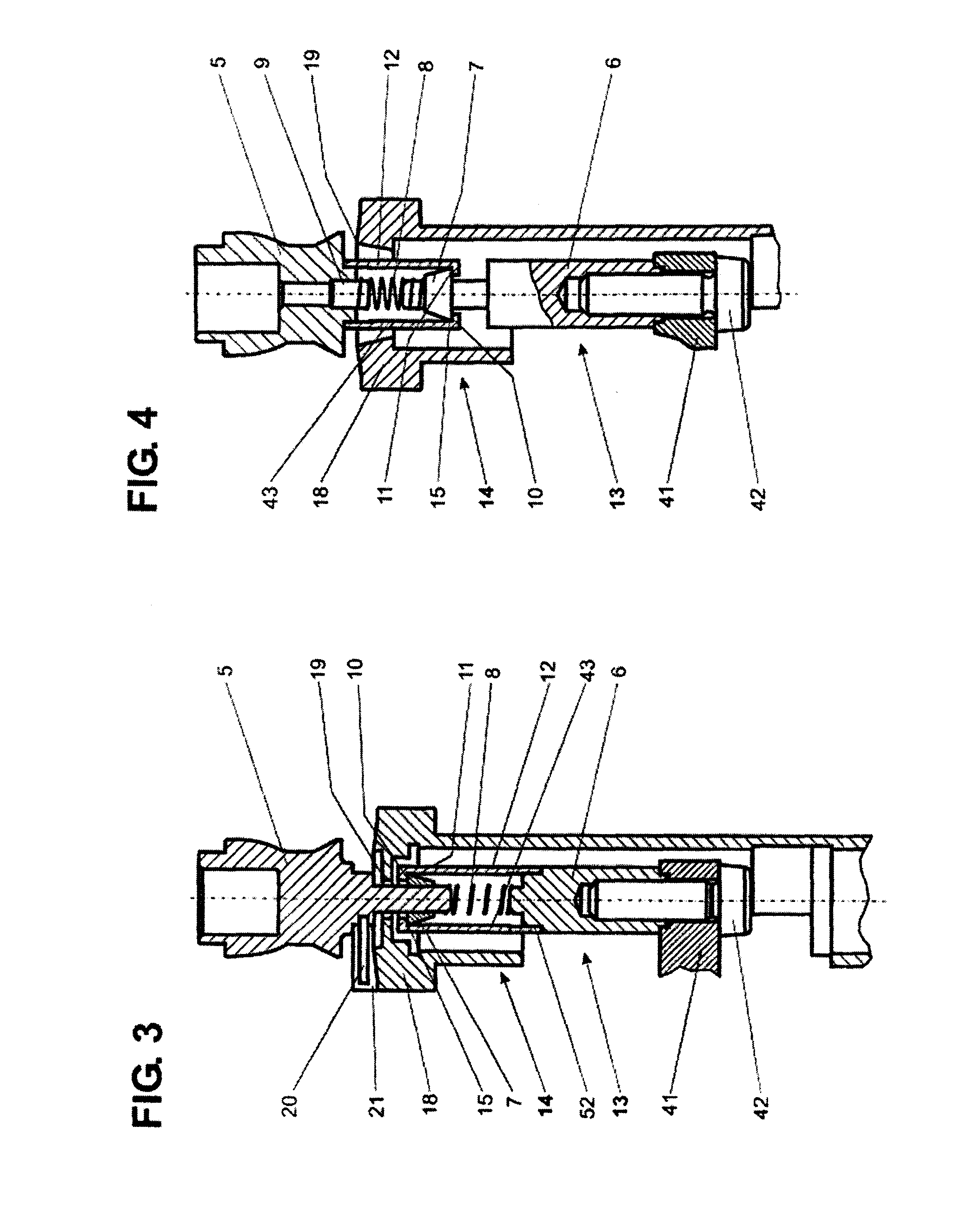

InactiveUS6600112B2Preserving the accuracy of the scaleAccuracy and efficiencyWeighing relieving/arrestment mechanismsOscillations damping for weighingEngineeringGuide tube

A weighing scale has a housing (1) that encloses a force transducer (4). A load-transmitting member (9) is connected to the force transducer (4) and passes through an opening to the outside of the housing to transmit the weighing load to the force transducer. An elastic device is interposed between a fixed part that is attached to the housing (1) and a movable part that is attached to the load-transmitting member (9). The elastic device is preferably hollow and controllably expandable and contractible by injecting and removing a fluid through a conduit system (31-43) with a selectively switchable valve device.

Owner:METTLER TOLEDO GMBH

Balance with a support element for coupling a weighing pan to a weighing cell

InactiveUS20030188897A1Yield easilyPrevent residual torquesWeighing apparatus using counterbalanceWeighing apparatus testing/calibrationCouplingCantilever

A balance includes a weighing cell with a vertically movable load receiver, a weighing pan to receive a weighing load, and a support element to couple the weighing pan to the vertically movable load receiver of the weighing cell. A cantilever arm with a seat for at least one calibration weight is solidly connected to the support element. The balance has a coupling arrangement that constrains the support element with low-friction mobility to the load receiver at three points forming a triangle in a plane that extends orthogonal to the symmetry plane of the weighing cell, wherein the triangle is symmetric to the symmetry plane of the weighing cell. Under the coupling arrangement, the support element is solidly supported on the load receiver in the direction in which the weighing load is acting.

Owner:METTLER TOLEDO GMBH

Balance with a T-shaped coupling arrangement that guides the support element onto a load receiver at three points forming a triangle

InactiveUS7012198B2Reduce frictionEasy to cleanWeighing apparatus using counterbalanceWeighing apparatus testing/calibrationCouplingEngineering

A balance includes a weighing cell with a vertically movable load receiver, a weighing pan to receive a weighing load, and a support element to couple the weighing pan to the vertically movable load receiver of the weighing cell. A cantilever arm with a seat for at least one calibration weight is solidly connected to the support element. The balance has a coupling arrangement that constrains the support element with low-friction mobility to the load receiver at three points forming a triangle in a plane that extends orthogonal to the symmetry plane of the weighing cell, wherein the triangle is symmetric to the symmetry plane of the weighing cell. Under the coupling arrangement, the support element is solidly supported on the load receiver in the direction in which the weighing load is acting.

Owner:METTLER TOLEDO GMBH

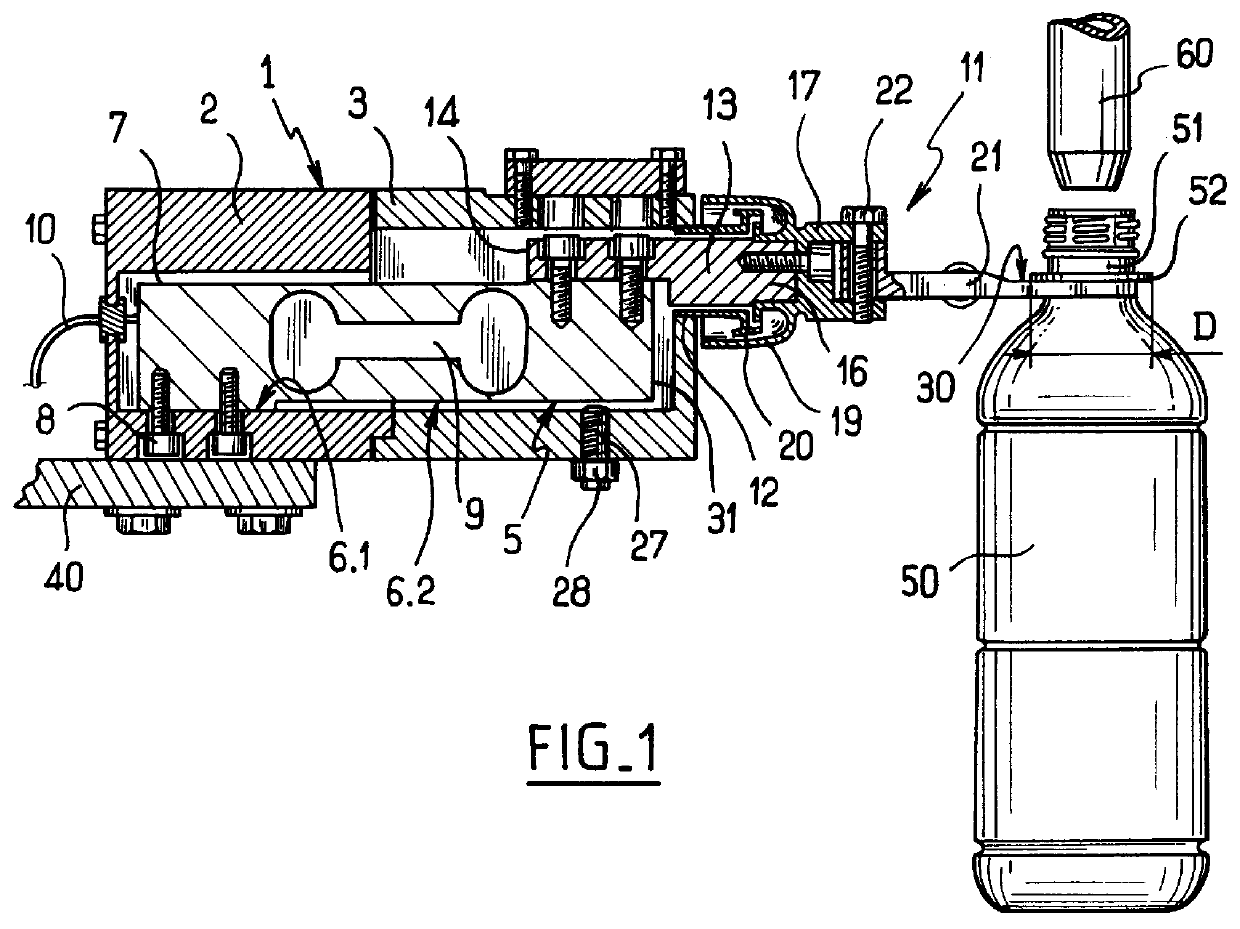

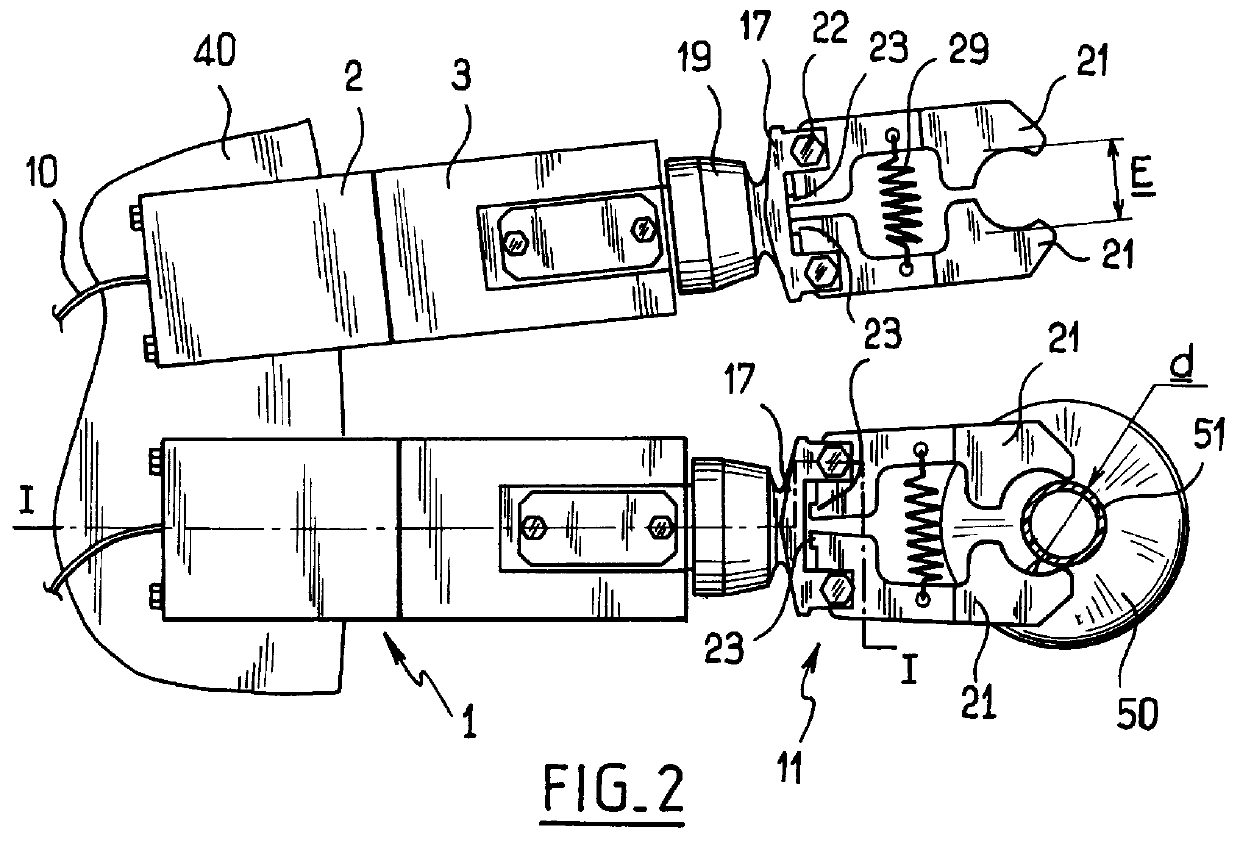

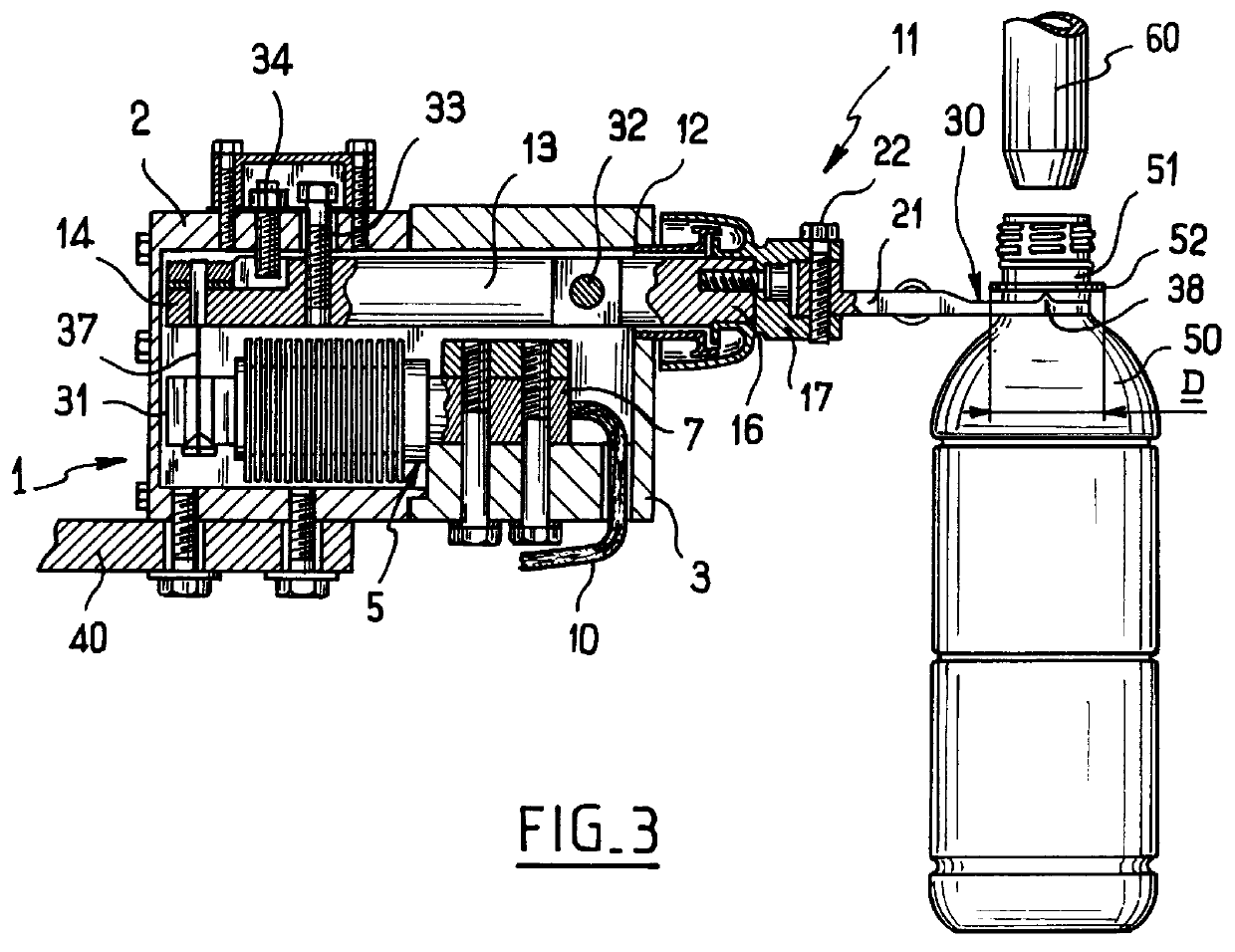

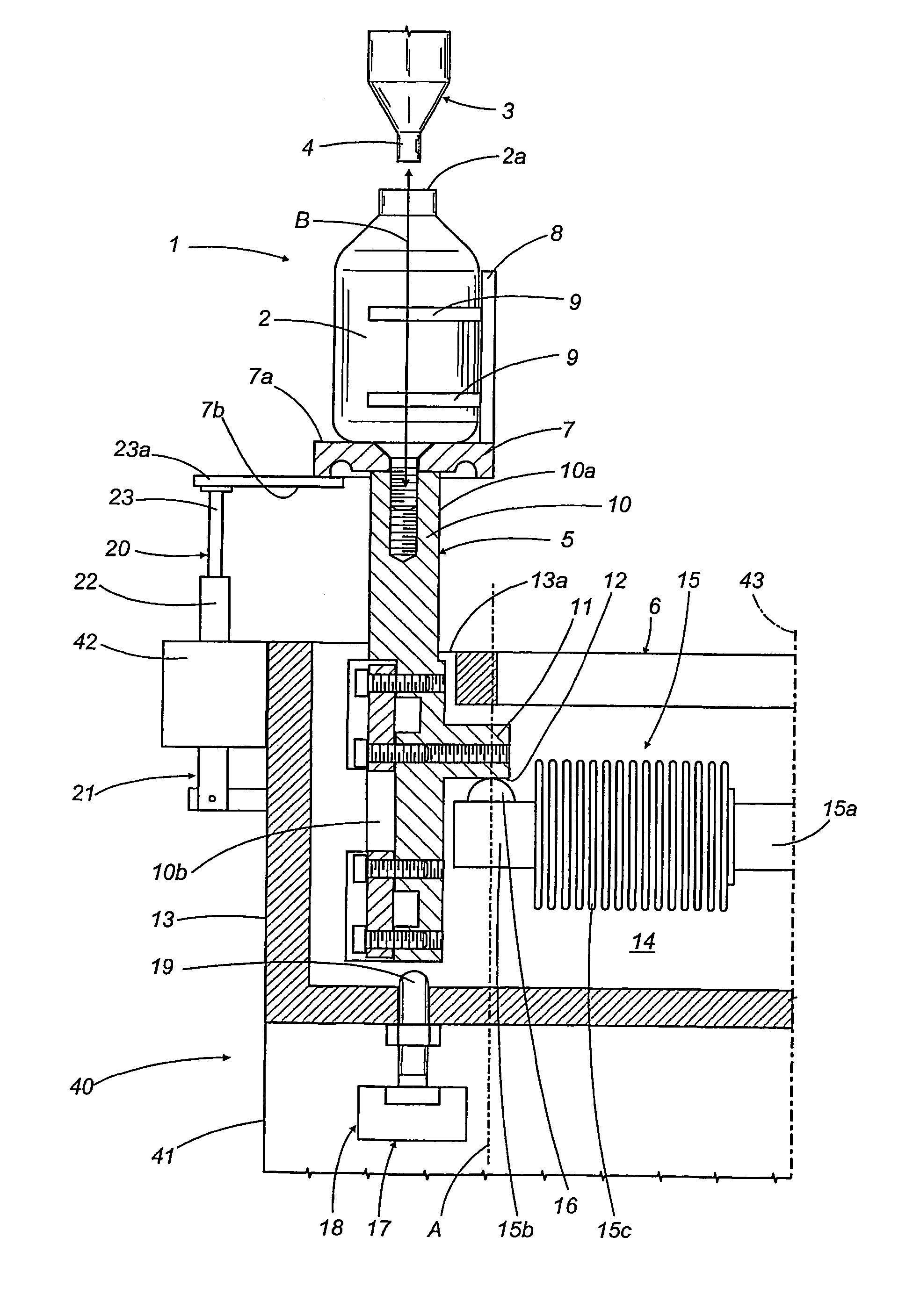

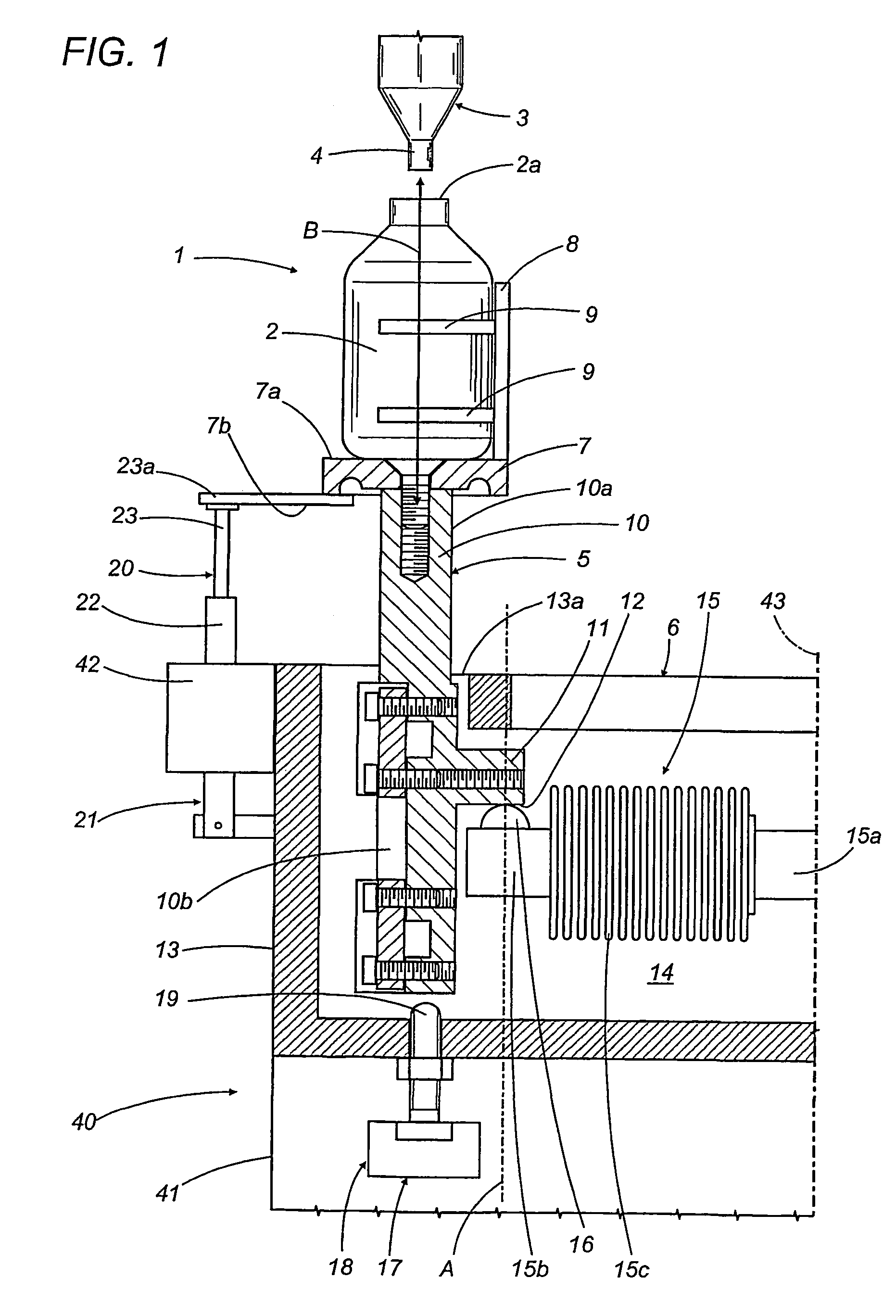

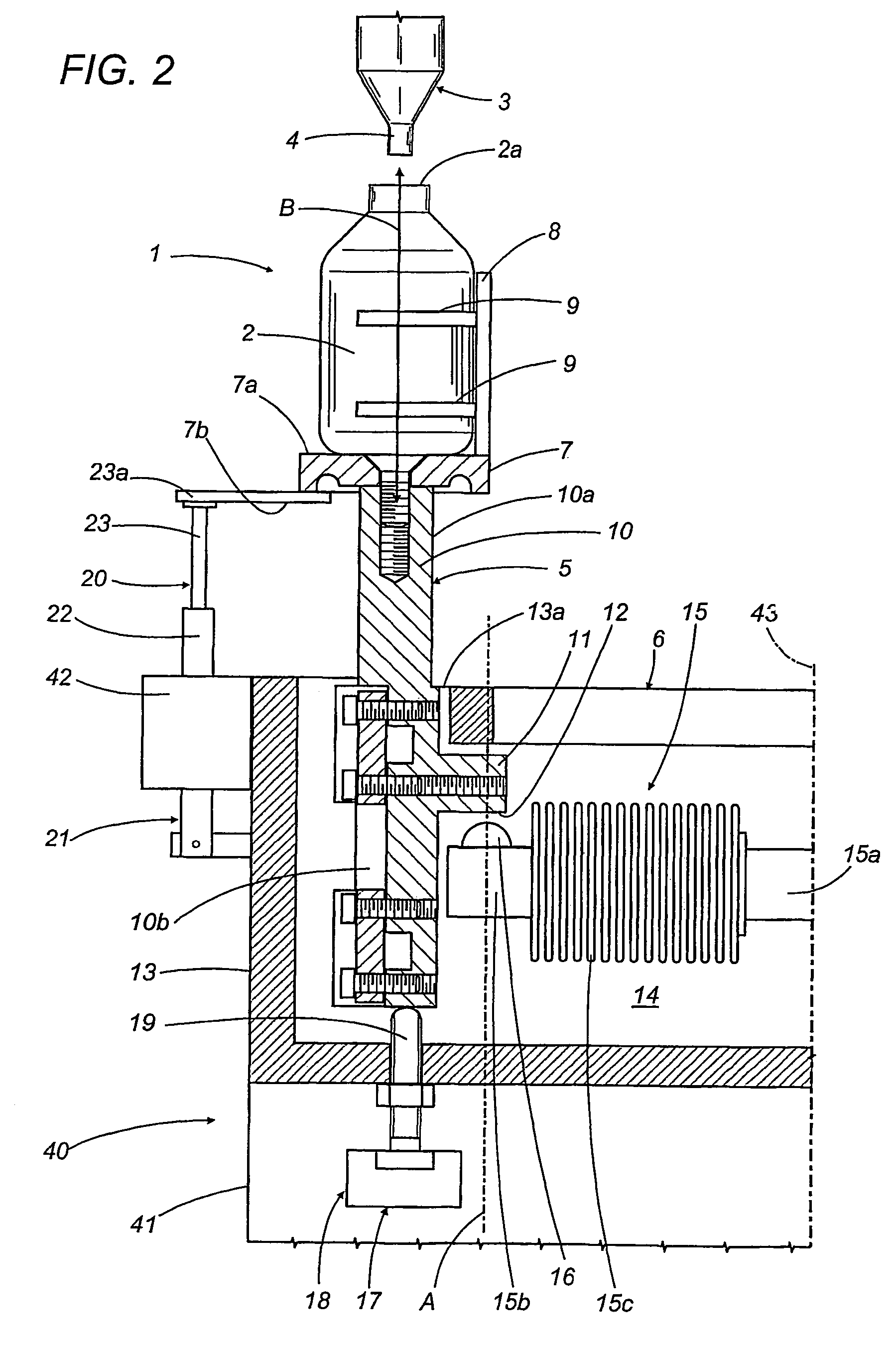

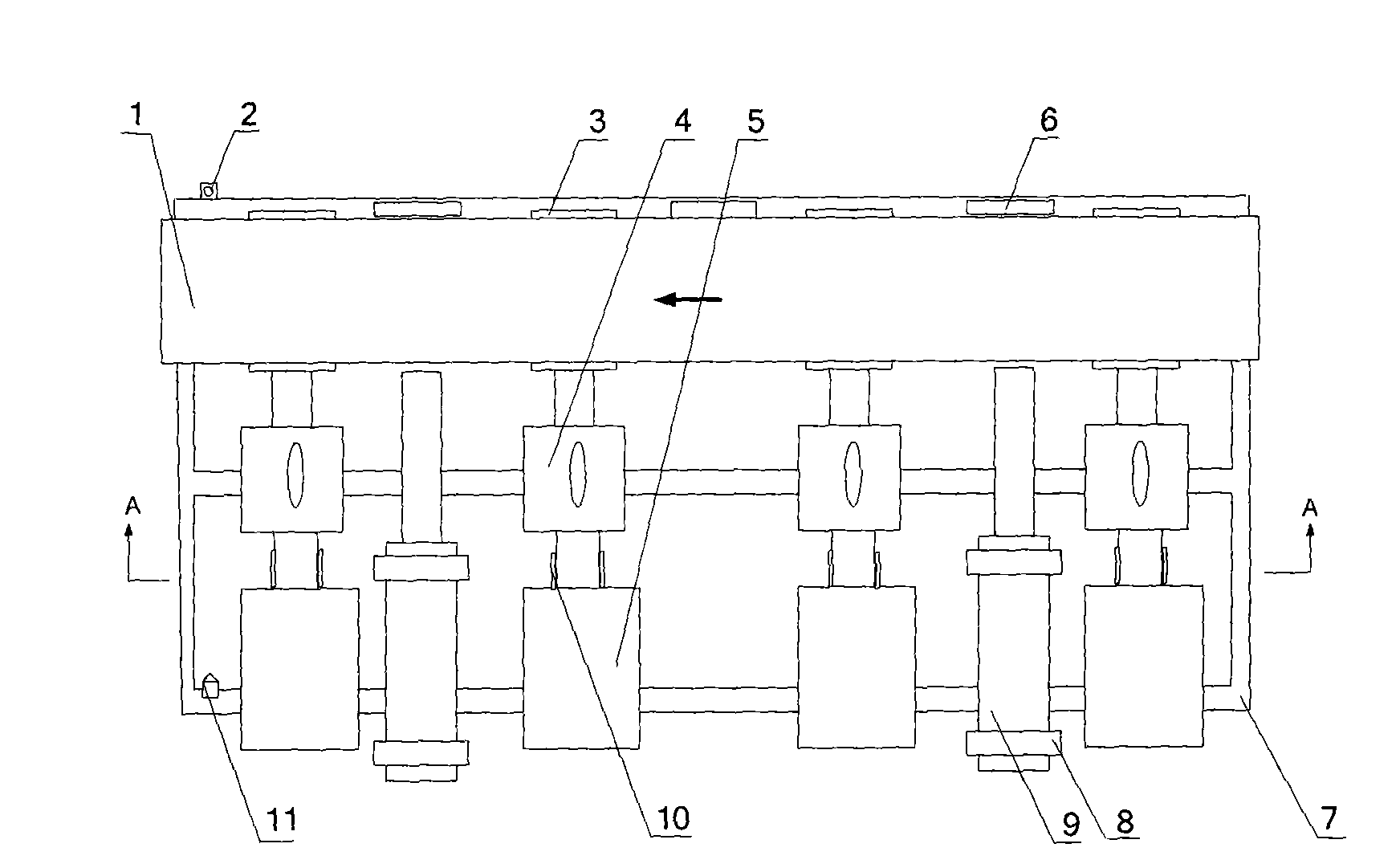

Head and a process for filling containers with powder material

InactiveUS7048018B2Accurate quantityWeighing relieving/arrestment mechanismsSolid materialEngineeringDynamometer

A filler head (1) carried by the carousel of a rotary powder filling machine comprises a dispensing element (3) by which a predetermined quantity of powder material is directed into a container (2) positioned on a platform assembly (7, 5) carried by a hollow frame (13); the dispensing element (3) is interlocked to a dynamometer (15) housed in the cavity (14) of the frame (13) and controllable thus during the step of filling the container (2). The platform support (5) is associated with a first actuator (18) mounted at the bottom of the frame (13) and designed to separate the selfsame support (5) from the dynamometer (15), also with a second actuator (21) by which the container (2) is caused to shake in a direction (B) that causes the powder material to settle in the container (2) during the filling operation.

Owner:AZIONARIA CONSTR MASCH AUTOMATICHE A C M A SPA

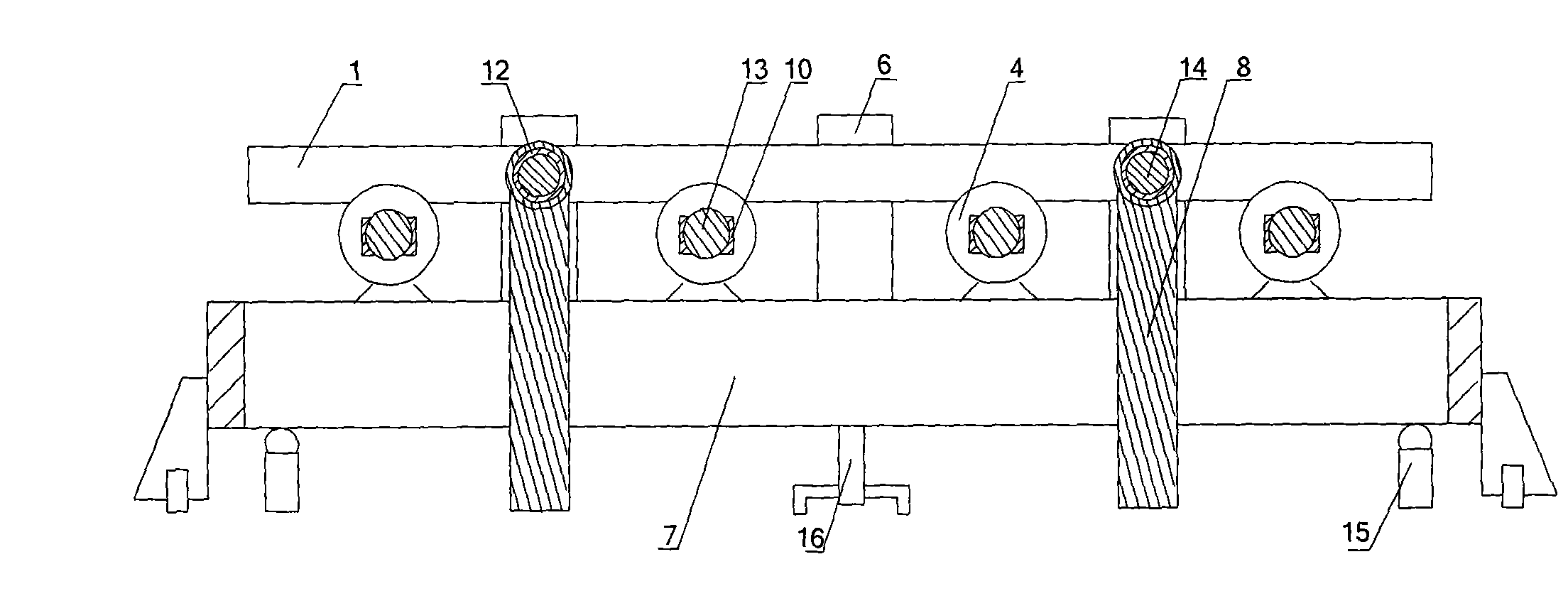

On-line steel billet weighting device

InactiveCN101634581AAvoid shockReduce shockWeighing relieving/arrestment mechanismsWeighing apparatus for continuous material flowInternal memoryDrive motor

The invention relates to an on-line steel billet weighting device which has the technical scheme that a weighting rack (7) is provided with 3-6 conveying rollers (3) and a driving motor (5); a motor control relay (25) and a brake control relay (26) which are respectively corresponding to the driving motor (5) and a brake (10) are respectively connected with a digital output channel DO of a PLC (24); 2-5 electromagnetic directional valves (20) are connected with a locating piston rod type hydraulic cylinder (9) by pipelines which are provided with pressure sensors (22), and each electromagnetic directional valve (20) and each pressure sensor (22) are respectively connected with the digital output channel DO and an analogue input channel AI of the PLC (24); four weighing sensors (15) and infrared receivers (2) the analogue input channel AI and a digital input channel DI of the PLC (24); control software is written into an internal memorizer of the PLC (24), and configuration software is written into an internal memorizer of a touch screen (23). The line steel billet weighting device has the characteristics of rapid on-line weighting, accuracy, small impact and low cost.

Owner:WUHAN UNIV OF SCI & TECH

Load detection structure for vehicle seat

InactiveUS6640653B1Easy to assembleLow costElectric devicesPedestrian/occupant safety arrangementEngineeringStrain gauge

A load detection structure in a vehicle seat with a support leg member, which includes a rigid yet resilient block member having a pivotal end portion, a thin intermediate portion, and a securing portion in which pin (s) is / are provided, and a strain gauge attached to the thin intermediate portion of block member. The support leg member has at least one first hole formed in the bottom wall thereof and two second holes formed in the respective two vertical walls thereof. The block member is arranged between the seat and support leg member, such that the securing portion thereof of is fixed via one end of the pin (s) to the seat, with another end of the pin (s) extending through the at least one first hole, while the pivotal end portion of block member is rotatably connected with the support leg member by fitting two flanged collars in the two second holes, respectively, and then inserting a pivot pin through those two flanged collars and second holes.

Owner:TACHI S CO LTD

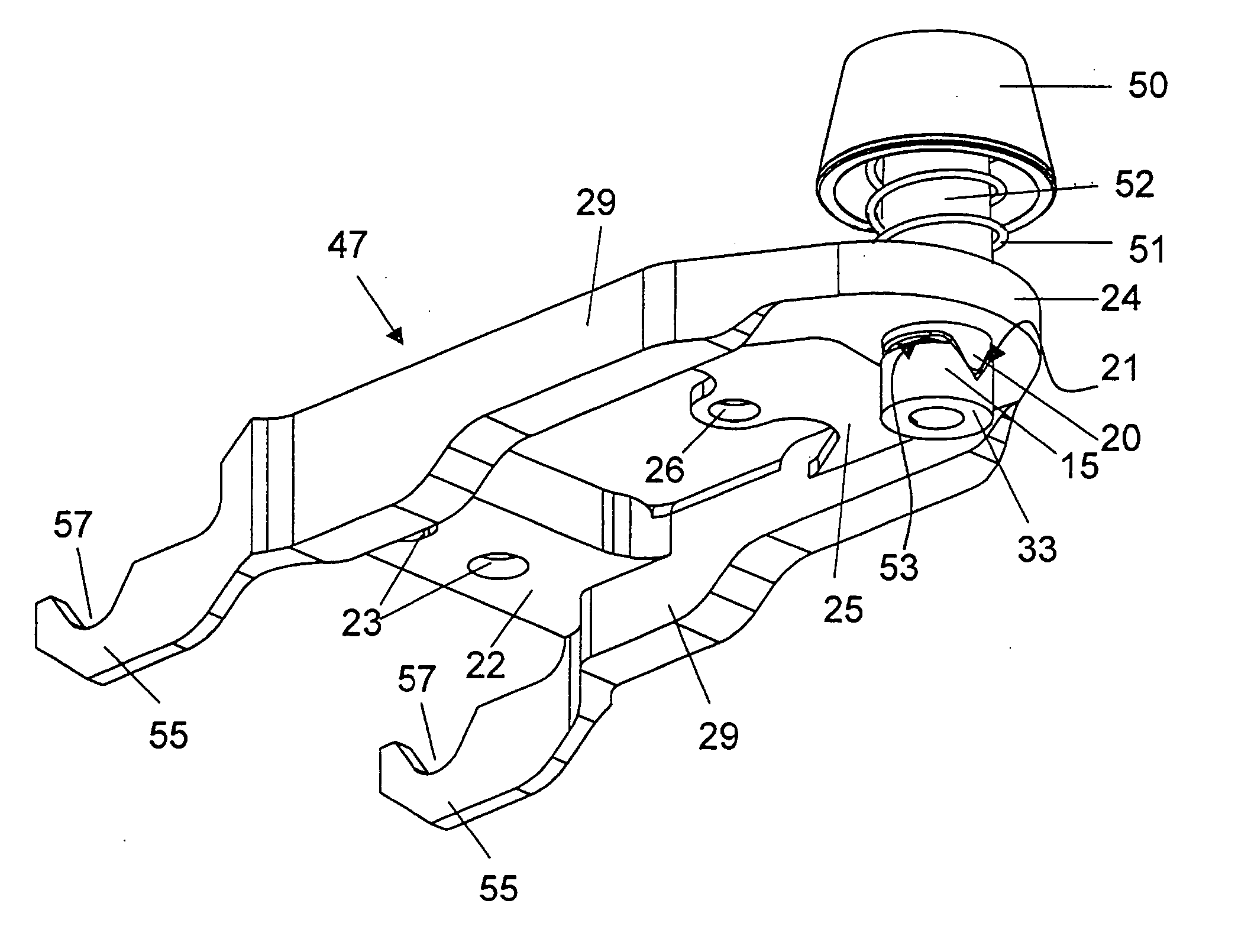

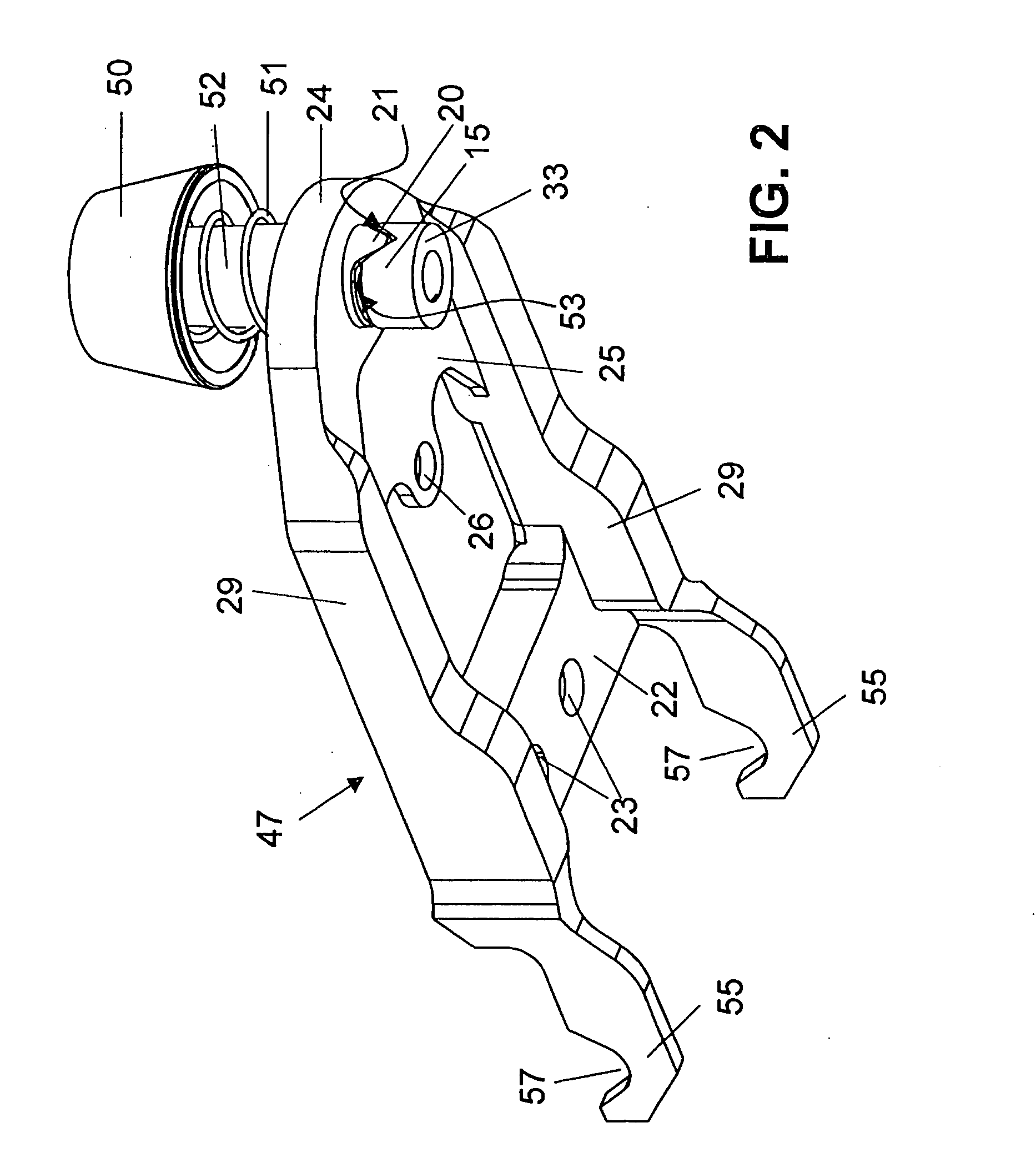

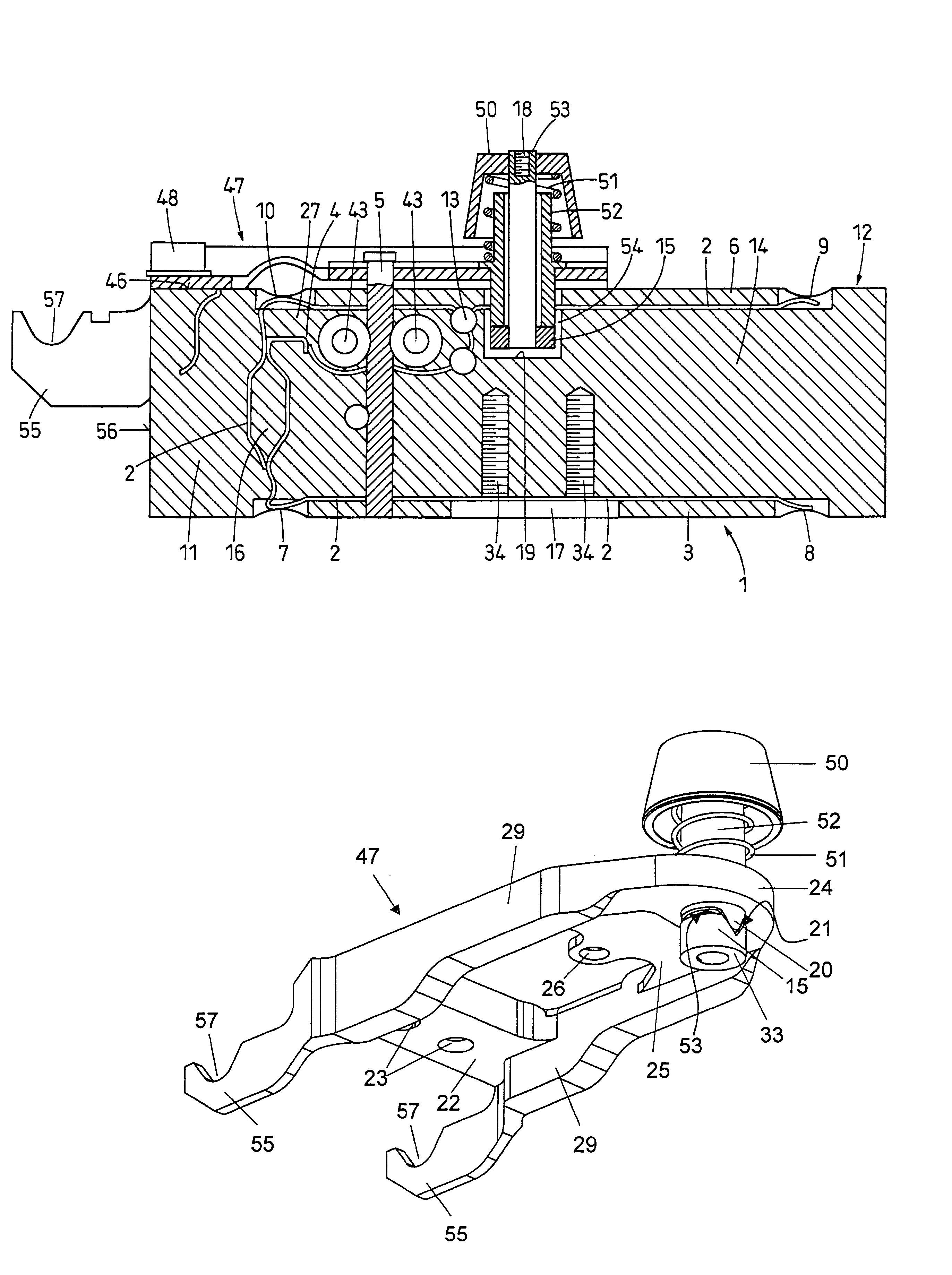

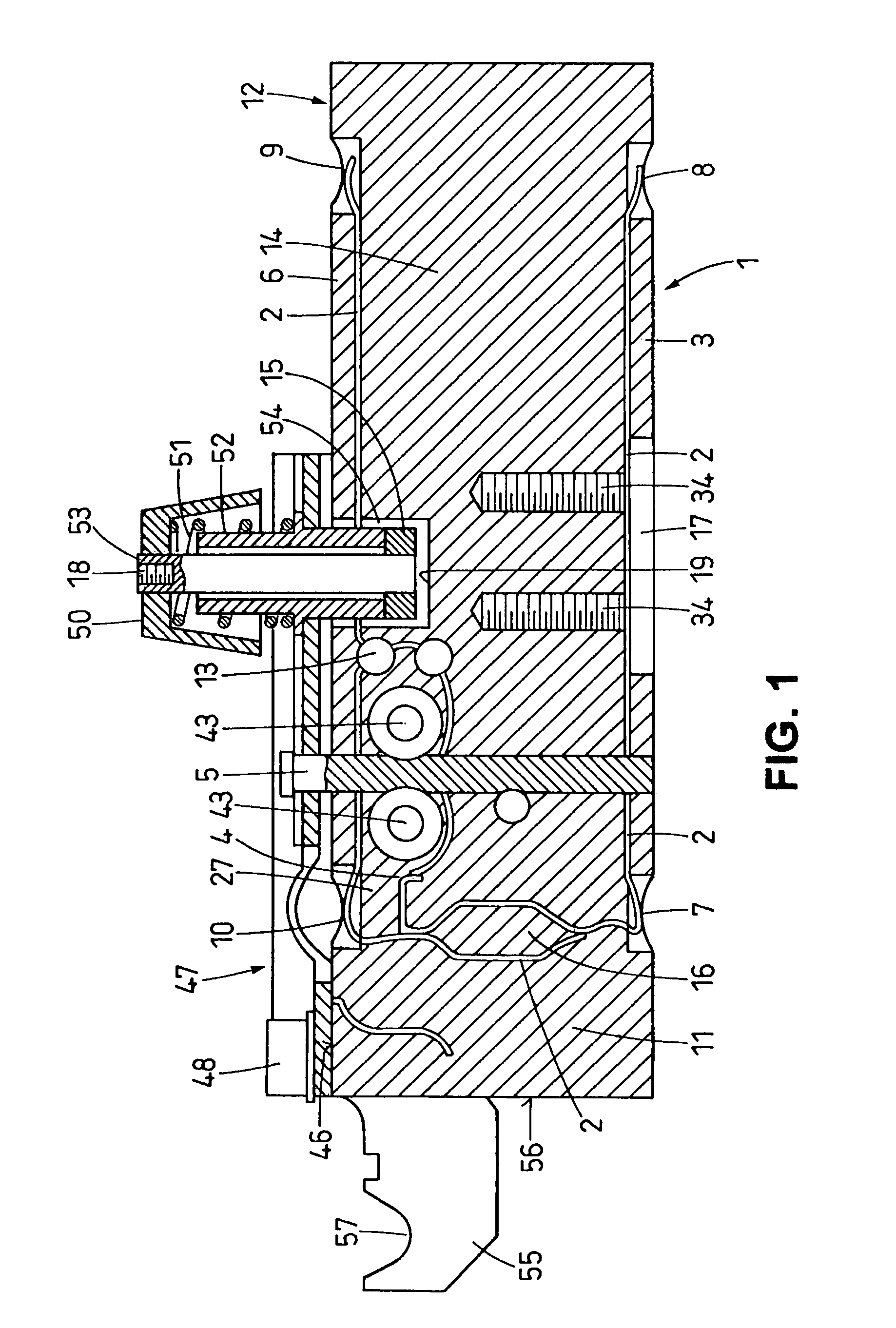

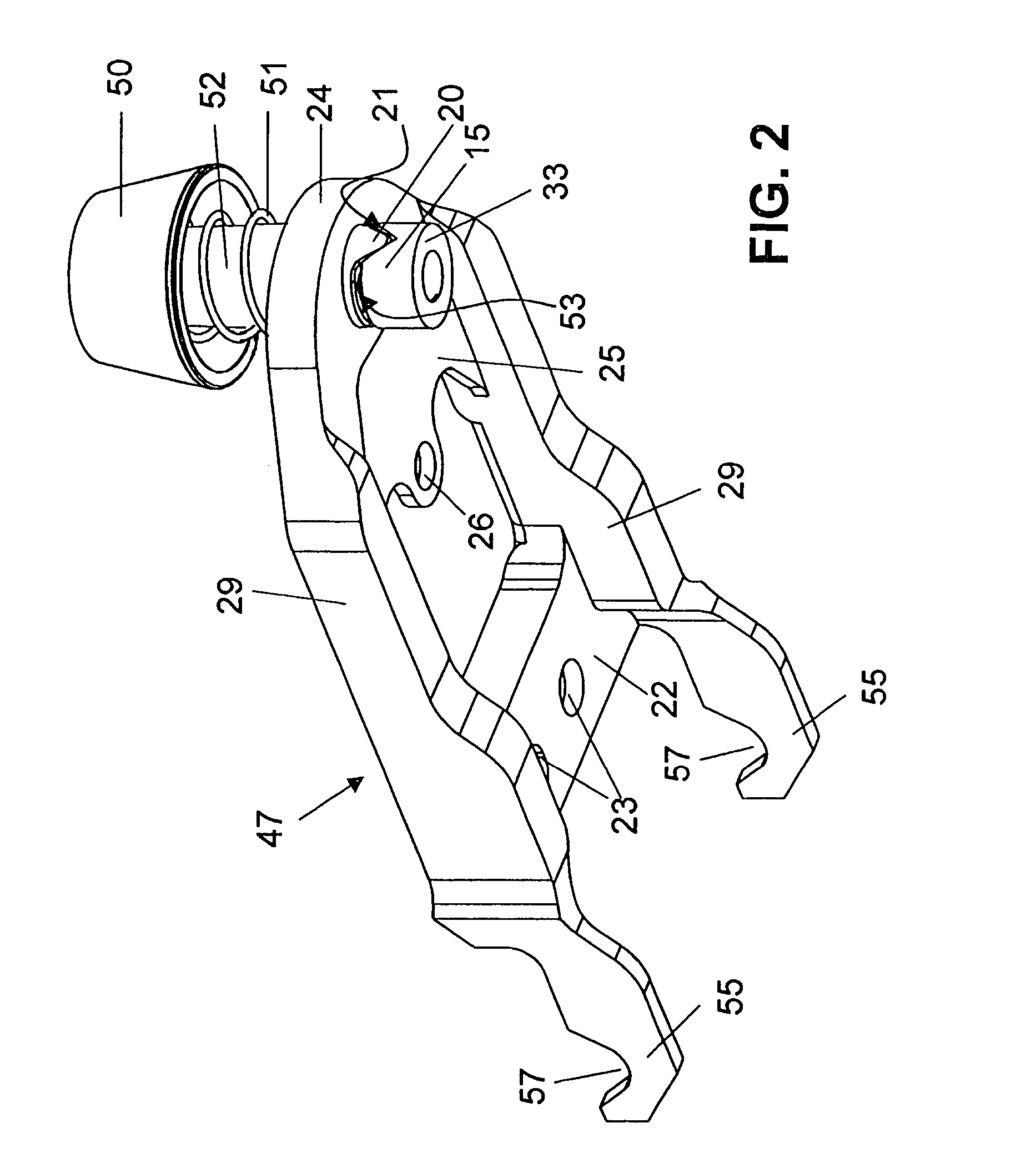

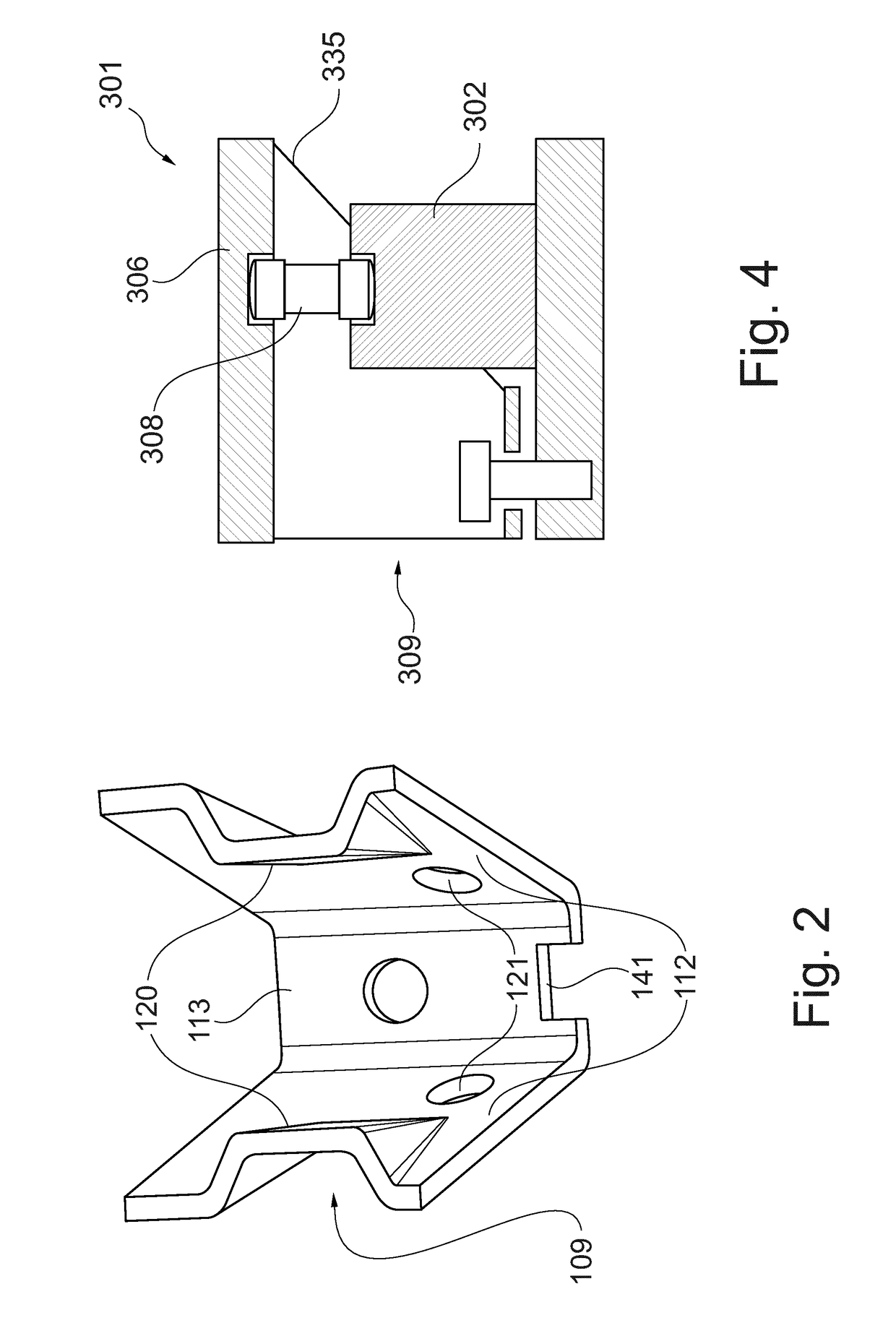

Weighing pan carrier with overload protection device

InactiveUS20050045388A1Avoid irreversible deformationMaintaining engagementWeighing relieving/arrestment mechanismsOscillations damping for weighingEngineeringLoad cell

A weighing pan carrier (47) for a balance with a weighing pan and with a weighing cell that includes a load-receiving portion (11) and a stationary portion (12) has an overload protection device against excessive vertically directed forces that is releasably engaged with the weighing pan carrier. The weighing pan carrier (47) is fastened to the load-receiving portion (11) of the weighing cell and has on the other hand a fixed connection to the weighing pan. The weighing pan carrier (47) has a torque safety feature, which is integrated in the overload protection device and provides protection against excessive forces acting tangentially on the weighing pan and / or on the weighing pan carrier (47) in a direction perpendicular to the direction of the weighing load.

Owner:METTLER TOLEDO GMBH

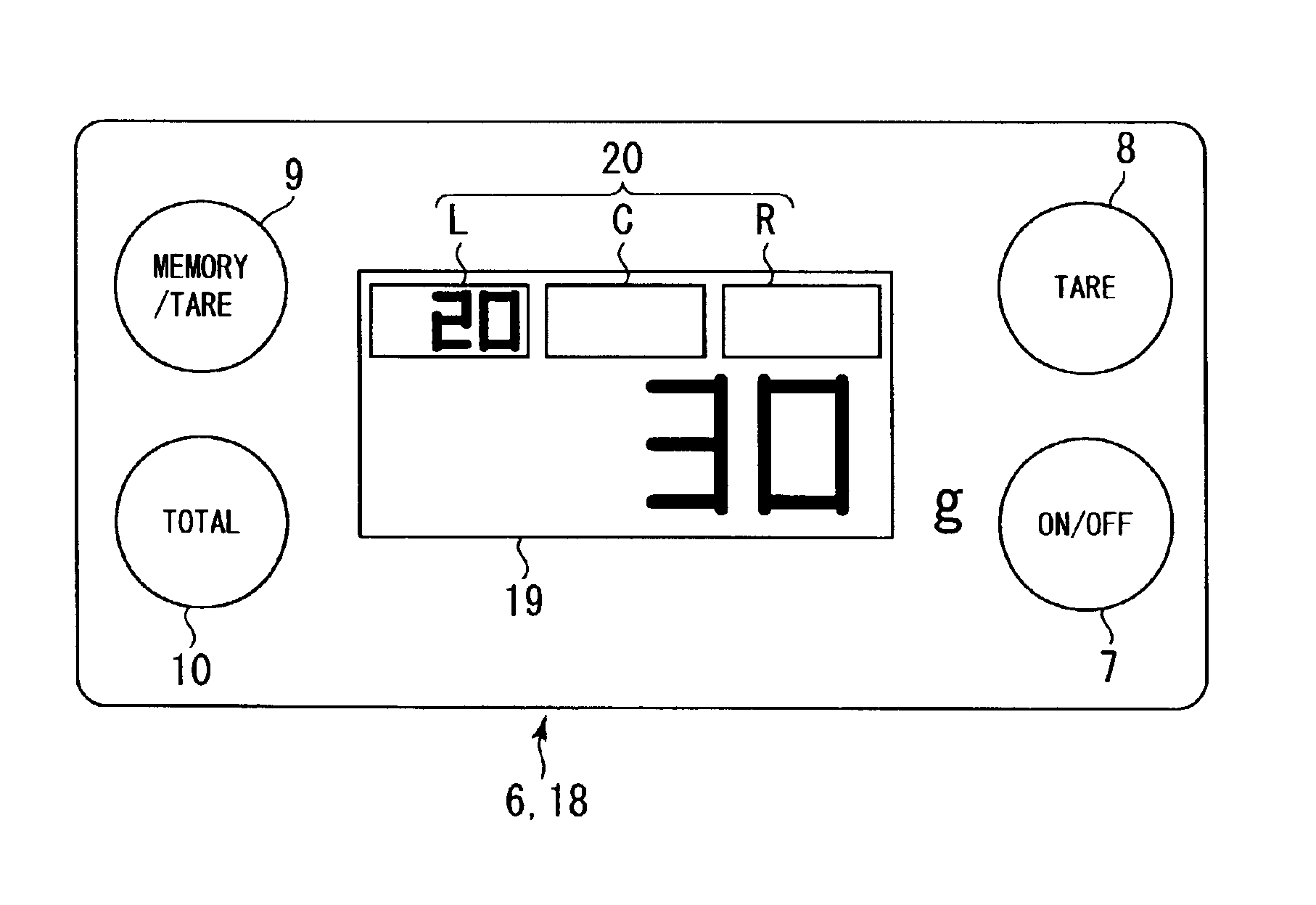

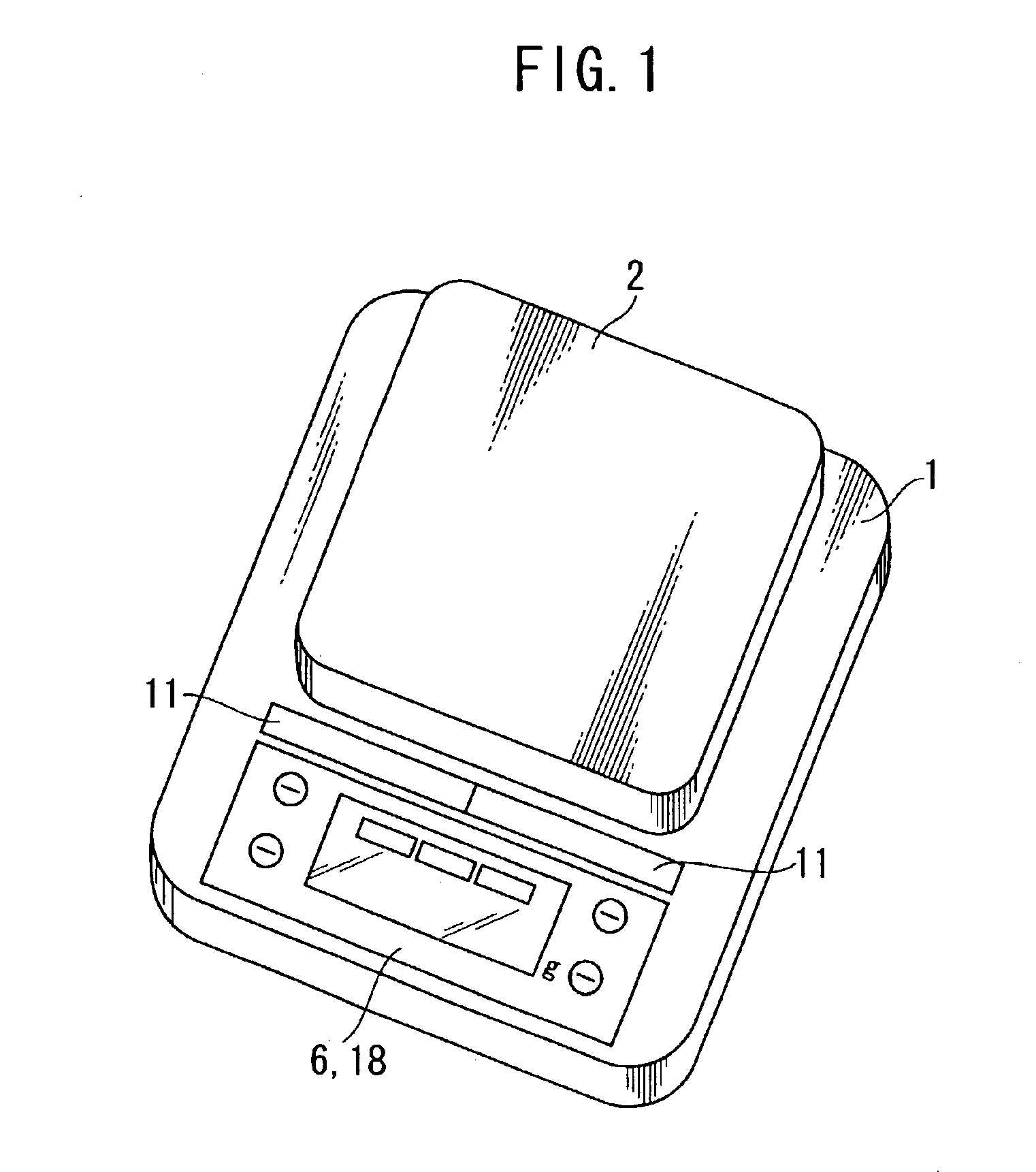

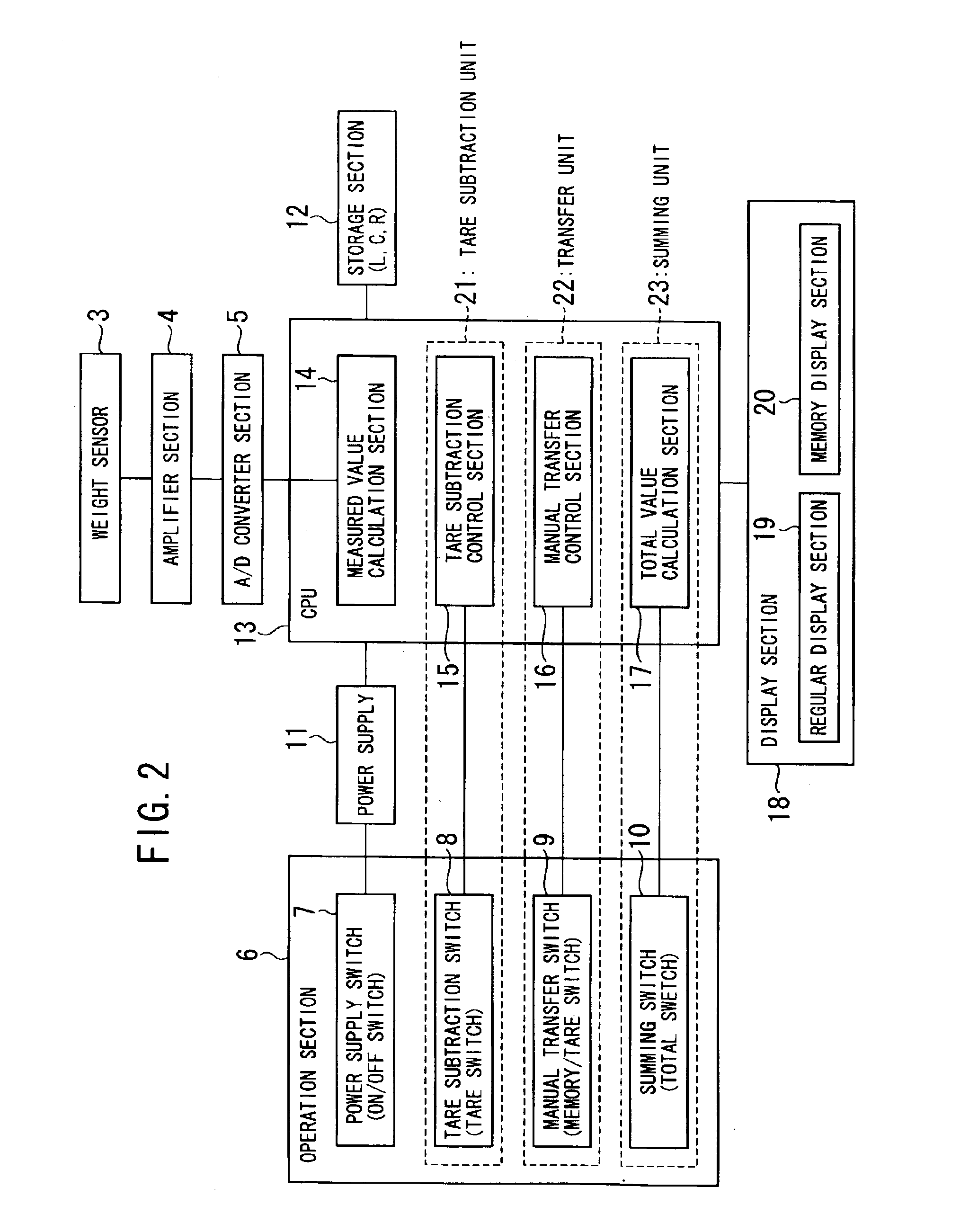

Scale with memory display function

A scale equipped with a memory display section comprises, separately from a regular display section 19 for indicating a current measured value, additionally a memory display section 20 for indicating the current measured value as a previously measured value in a series of consecutive measurements, wherein a transfer unit 22 executes such a transfer operation that the current measured value indicated in the regular display section 19 can be indicated in the memory display section 20 as the previously measured value in a series of consecutive measurements. A person in charge of measurement no more needs to take the trouble of remembering in the brain or taking notes of the previously measured values in a series of consecutive measurements, such as an incremental measurement, but the current measuring work can be carried out simply by a visual recognition.

Owner:TANITA CORP

Sealing mechanism

ActiveUS8525051B2Improve sealingEngine sealsWeighing relieving/arrestment mechanismsEngineeringMechanical engineering

Owner:WIPOTEC WIEGE UND POSITIONIERSYSTEME GMBH

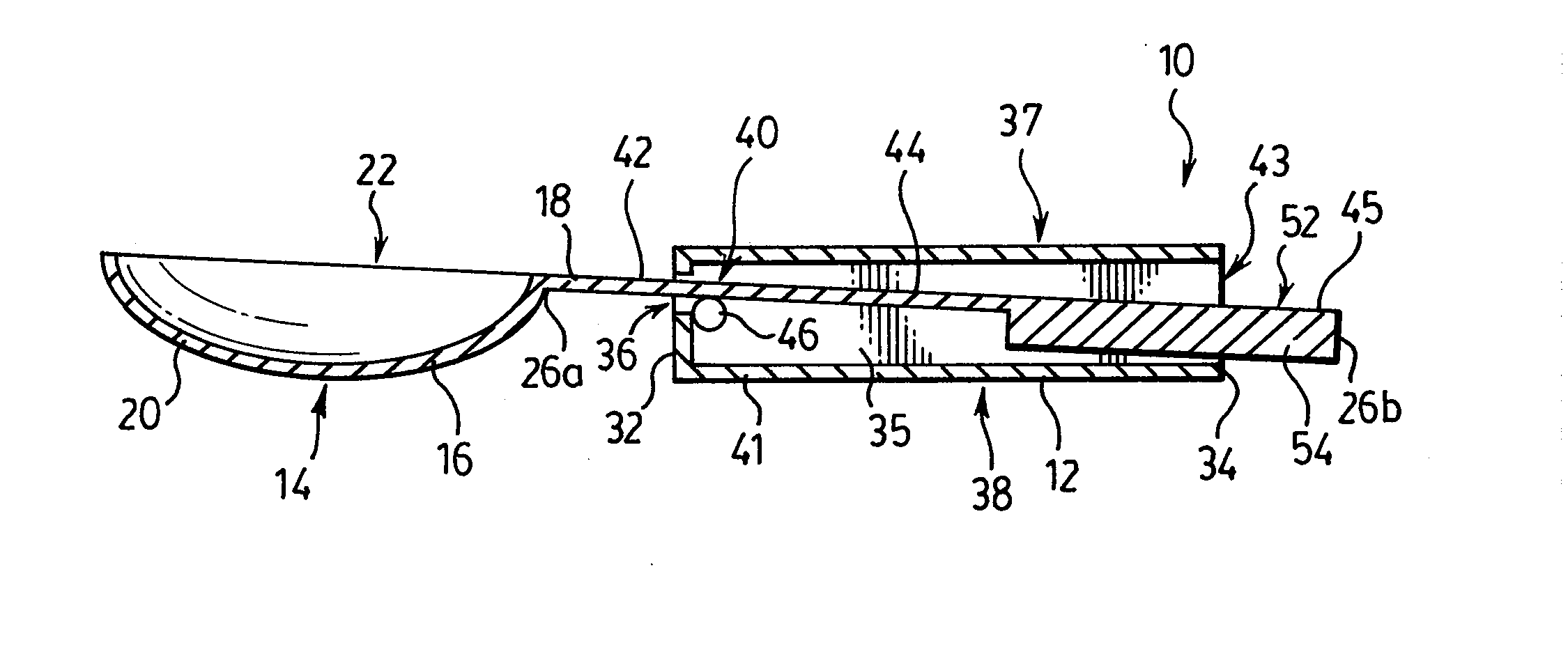

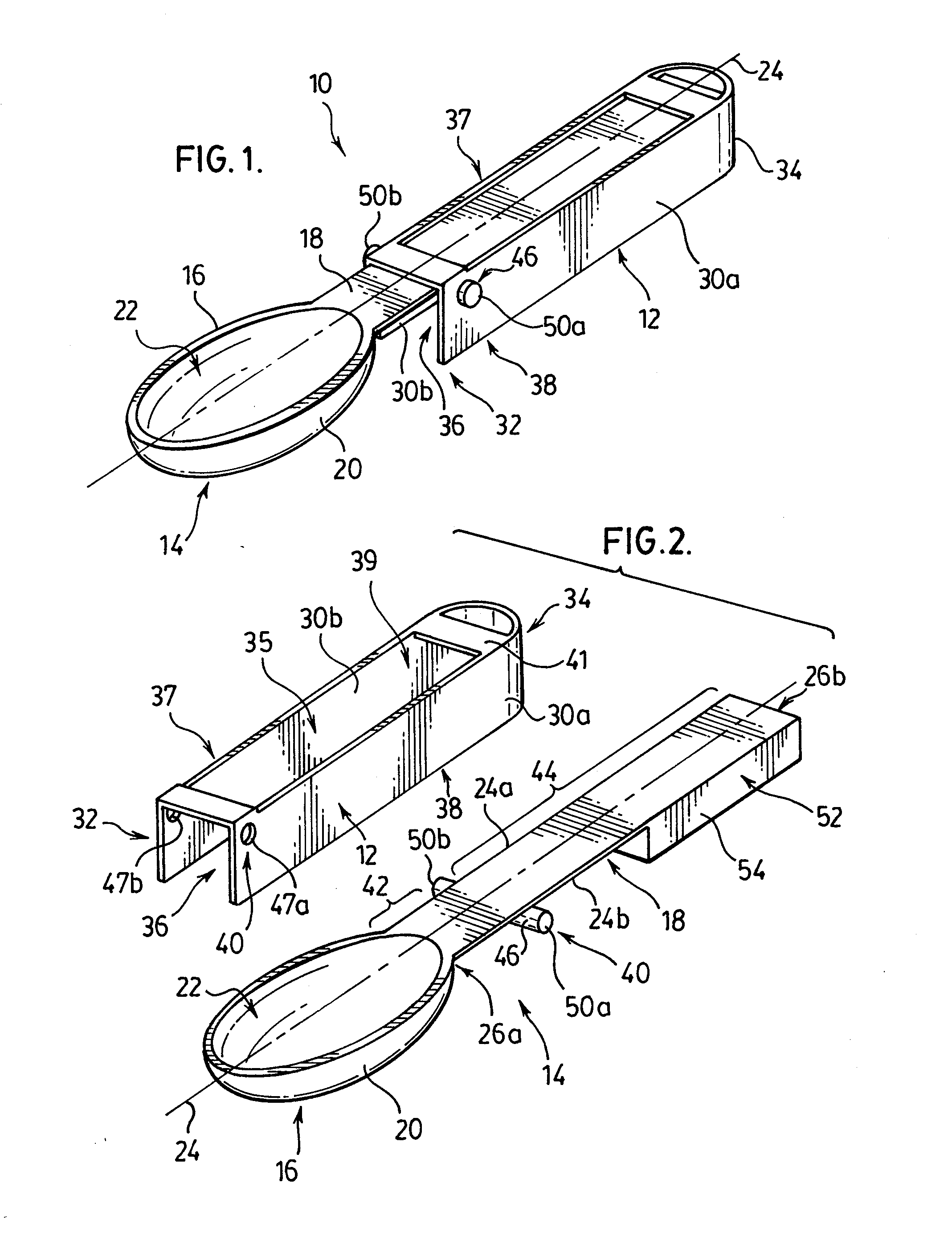

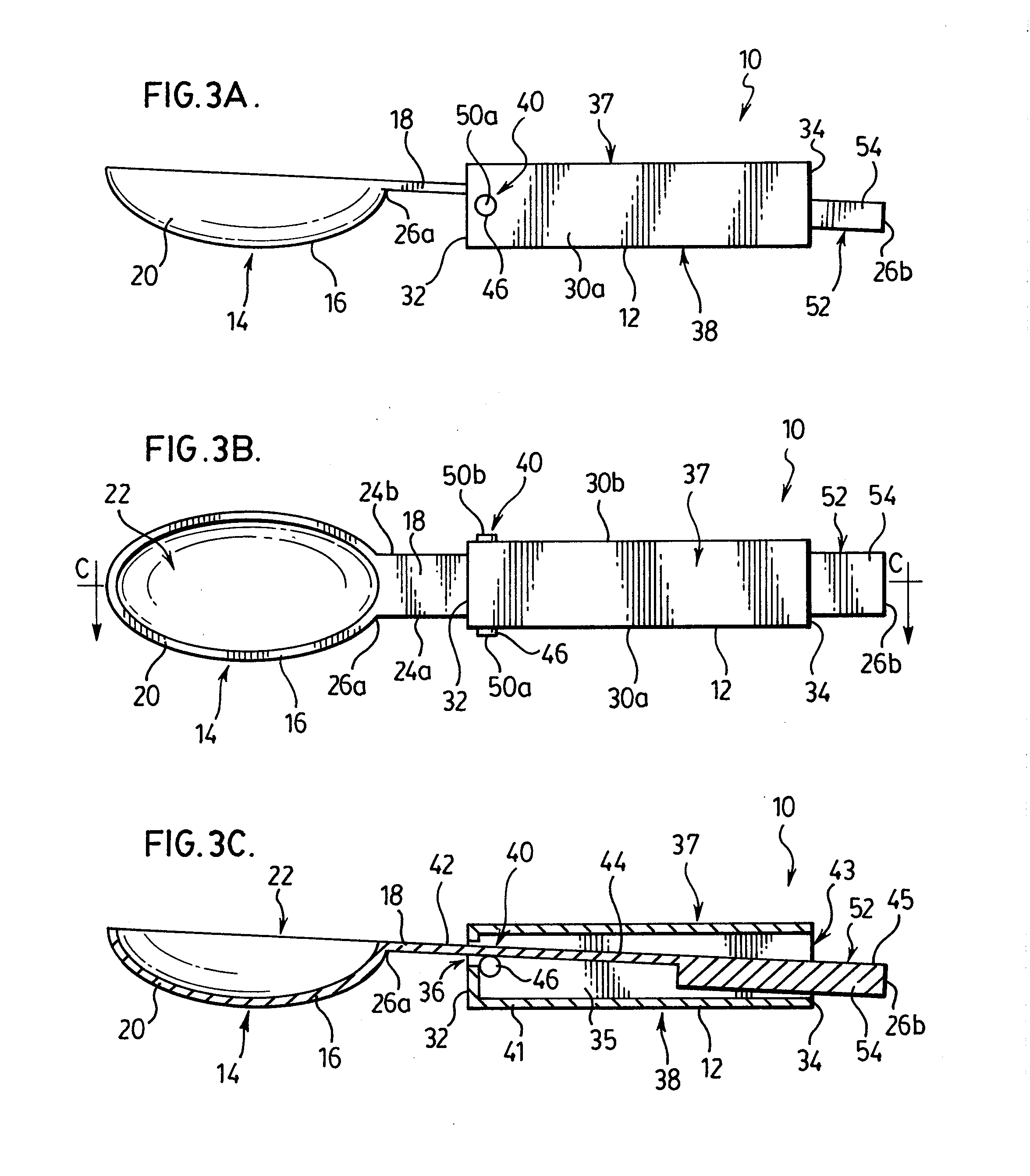

Weighing serving implement

InactiveUS20090133940A1Accurate measurementResistant to heat and waterWeighing apparatus using counterbalanceWeighing relieving/arrestment mechanismsMechanical engineering

A weighing serving implement is disclosed. The weighing serving implement has a head to serve food and is mounted to a mount at a pivot point. The pivot point provides a mechanical balance and facilities a rugged and washable design.

Owner:WOODS CHARLES

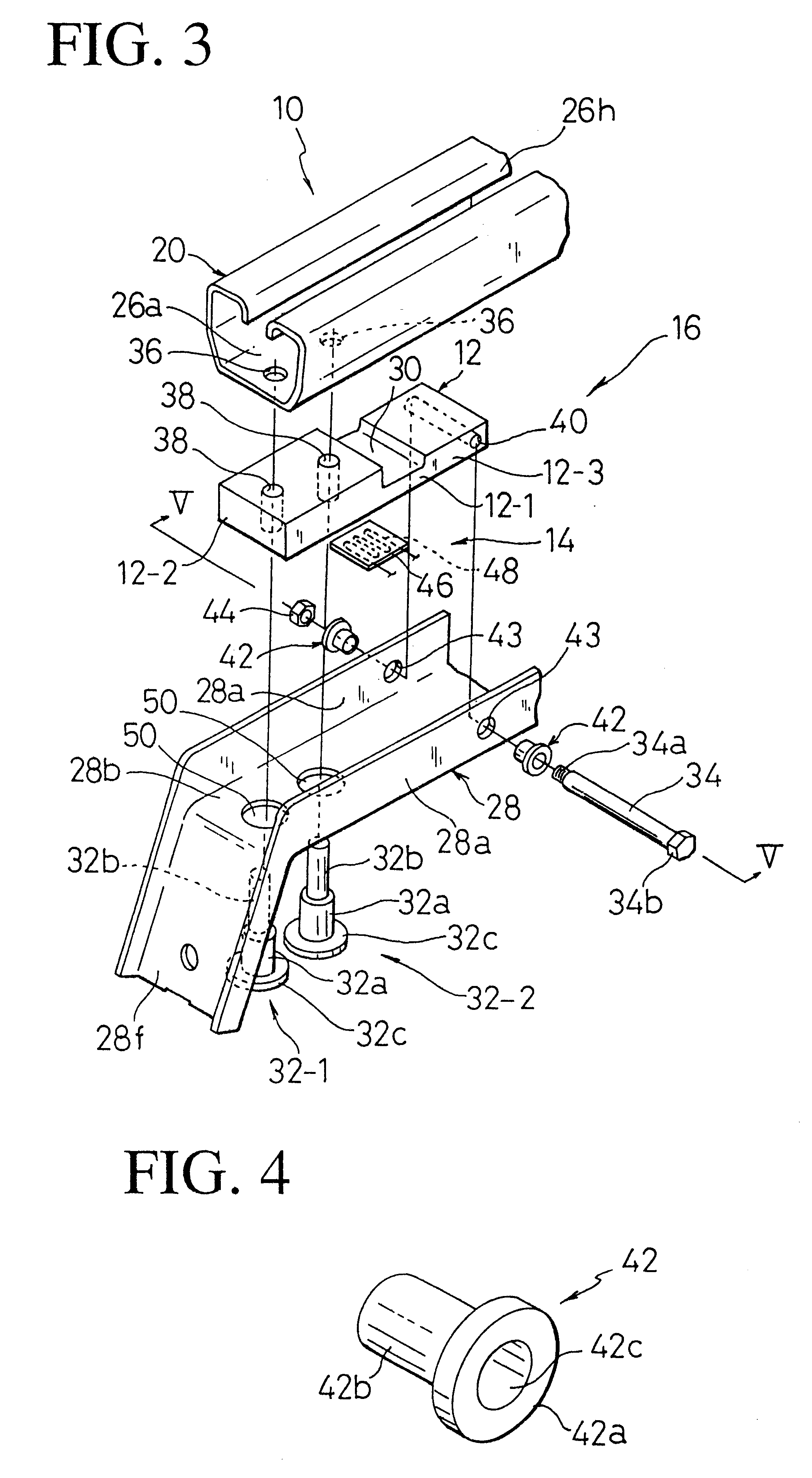

Weighing module with precisely-positionable overload protection device

ActiveUS20060289207A1Affect resultProtection overloadWeighing apparatus using counterbalanceWeighing relieving/arrestment mechanismsTransverse forceOperating environment

A weighing module 1 has a force-transmitting linkage 13 arranged between the load-receiving portion 3 of the weighing cell 2 and the load receiver 5, with an overload protection device that precisely maintains its position being an integral part of the force-transmitting linkage 13. By means of a positioning element 7, 107, 207, the load receiver 5 is positioned without play relative to the load-receiving portion 3 in the plane that extends orthogonal to the load direction, and the load receiver 5 is also guided in the load direction without play. When forces in excess of the pre-tension force of the elastic element 8 act on the load receiver 5, the latter has the capability of being displaced in the load direction and to tip in all directions that are orthogonal to the load direction. The housing part 18 serves to delimit at least the range of linear downward deflection as well the tipping movement of the load receiver 5 when the load receiver 5 is exposed to transverse forces and to overloads. The rotation constraint 20 is rigidly connected to the load receiver 5 and engages a housing-connected recess 21. To position the load receiver 5 relative to its operating environment, a positioning device 16 is provided, whose central longitudinal axis coincides with the central longitudinal axis of the load receiver 5.

Owner:METTLER TOLEDO GMBH

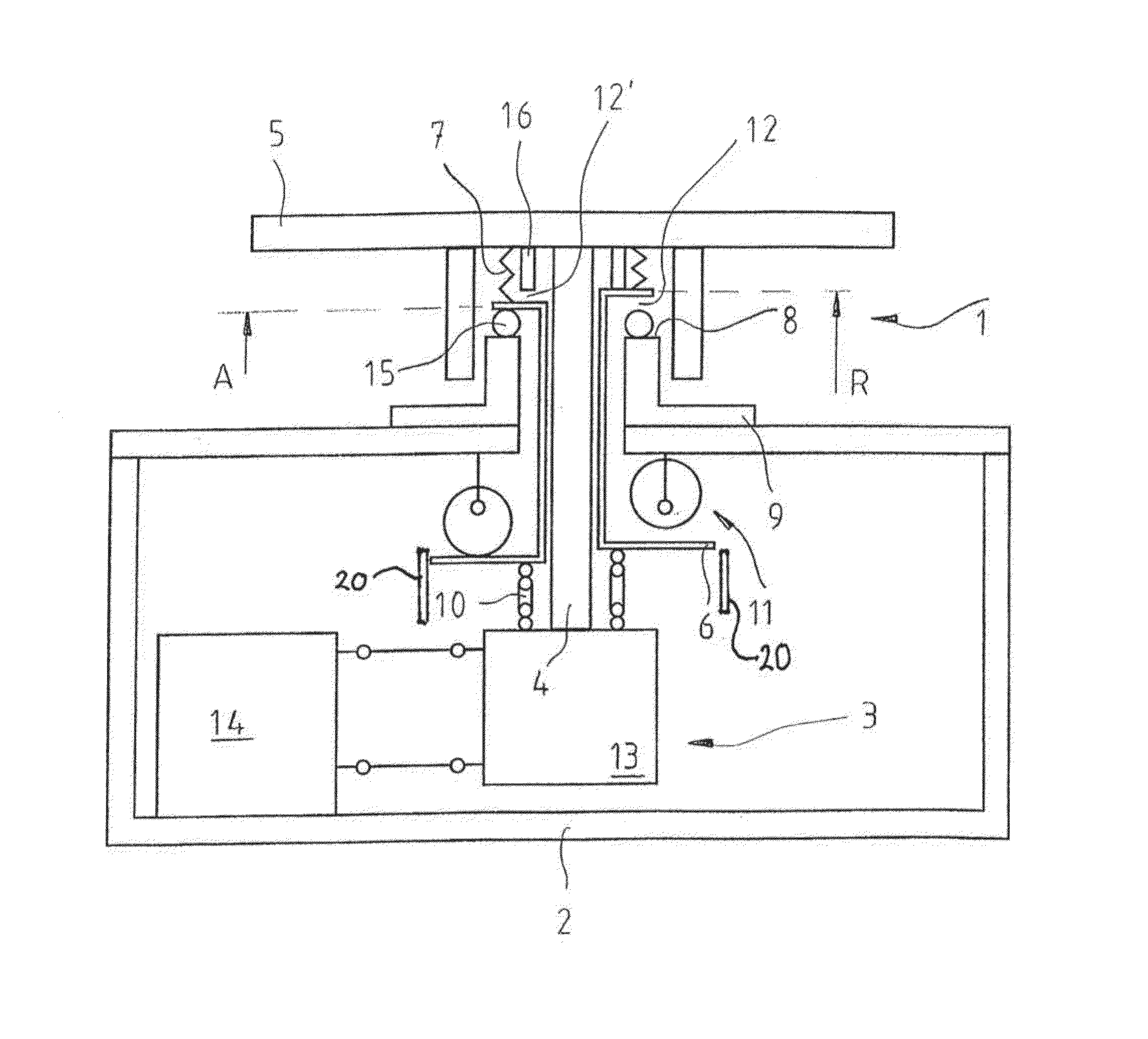

Weighing scale with a combined sealing and arresting device

InactiveUS20010027882A1Accuracy and efficiencyPreserving the accuracy of the scaleWeighing relieving/arrestment mechanismsOscillations damping for weighingStructural engineeringMechanical engineering

A weighing scale has a housing (1) that encloses a force transducer (4). A load-transmitting member (9) is connected to the force transducer (4) and passes through an opening to the outside of the housing to transmit the weighing load to the force transducer. An elastic device is interposed between a fixed part that is attached to the housing (1) and a movable part that is attached to the load-transmitting member (9). The elastic device is preferably hollow and controllably expandable and contractible by injecting and removing a fluid through a conduit system (31-43) with a selectively switchable valve device.

Owner:METTLER TOLEDO GMBH

Weighing pan carrier with overload protection device

InactiveUS6958453B2Avoid irreversible deformationMaintaining engagementWeighing relieving/arrestment mechanismsOscillations damping for weighingMechanical engineeringEngineering

A weighing pan carrier (47) for a balance with a weighing pan and with a weighing cell that includes a load-receiving portion (11) and a stationary portion (12) has an overload protection device against excessive vertically directed forces that is releasably engaged with the weighing pan carrier. The weighing pan carrier (47) is fastened to the load-receiving portion (11) of the weighing cell and has on the other hand a fixed connection to the weighing pan. The weighing pan carrier (47) has a torque safety feature, which is integrated in the overload protection device and provides protection against excessive forces acting tangentially on the weighing pan and / or on the weighing pan carrier (47) in a direction perpendicular to the direction of the weighing load.

Owner:METTLER TOLEDO GMBH

Easy mount base for mobility scale

InactiveUS7763813B2Weighing relieving/arrestment mechanismsSpecial purpose weighing apparatusEngineeringMechanical engineering

Owner:INNOVISION DEVICES

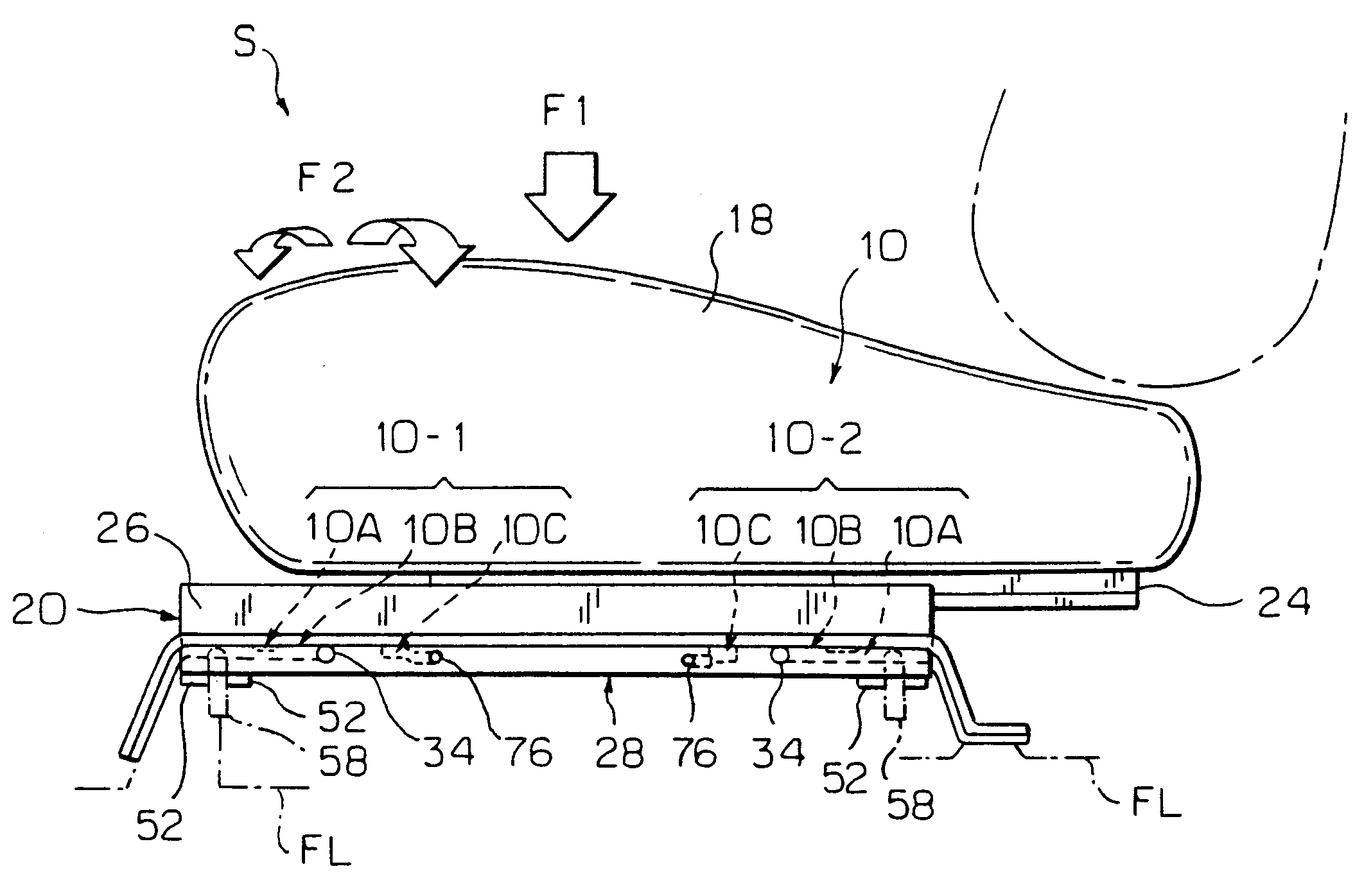

Seat-load measuring apparatus

ActiveUS7096745B2Avoid assembly stressHigh measurement accuracyVehicle seatsPedestrian/occupant safety arrangementMeasurement deviceEngineering

Owner:JOYSON SAFETY SYST JAPAN GK

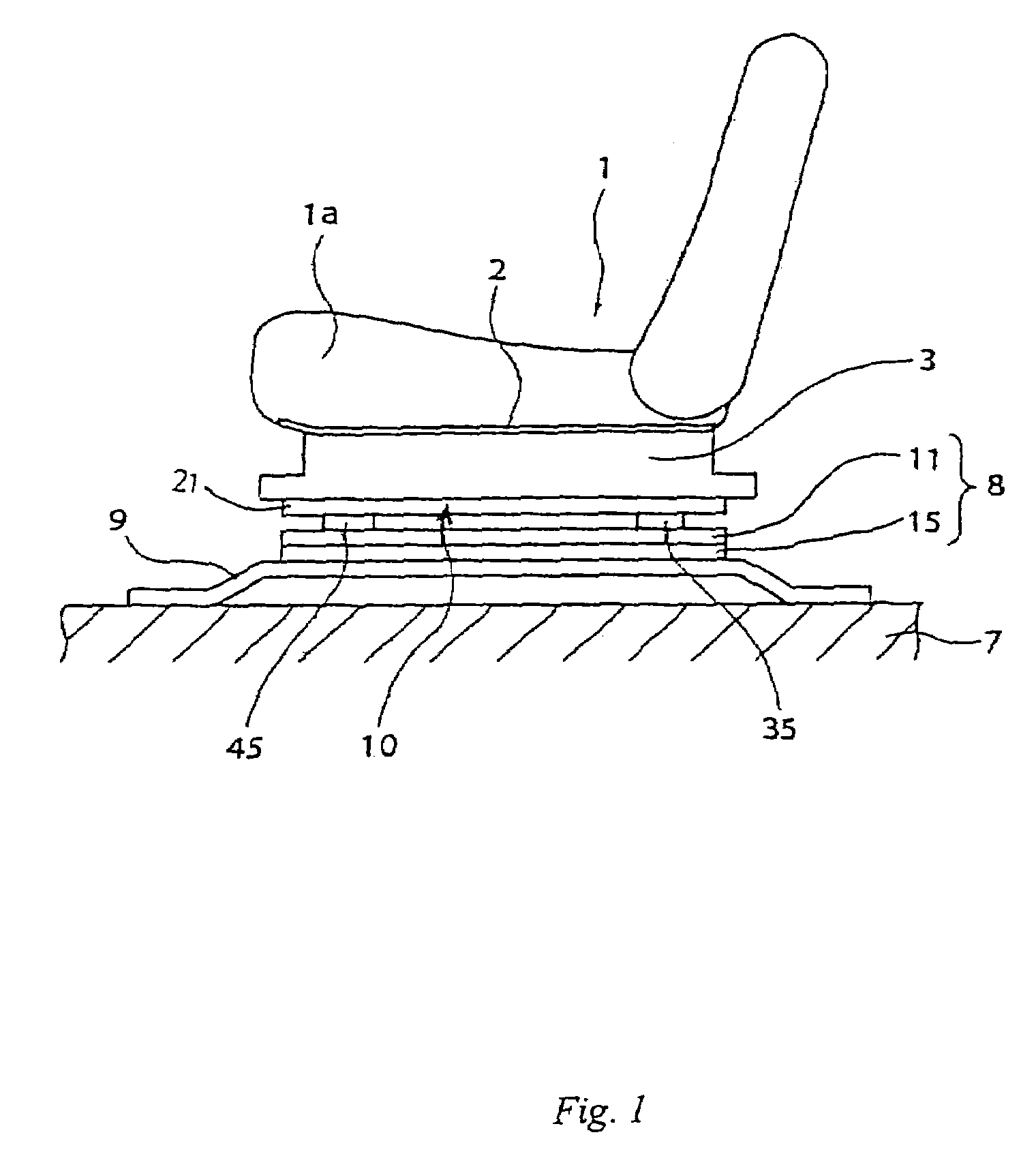

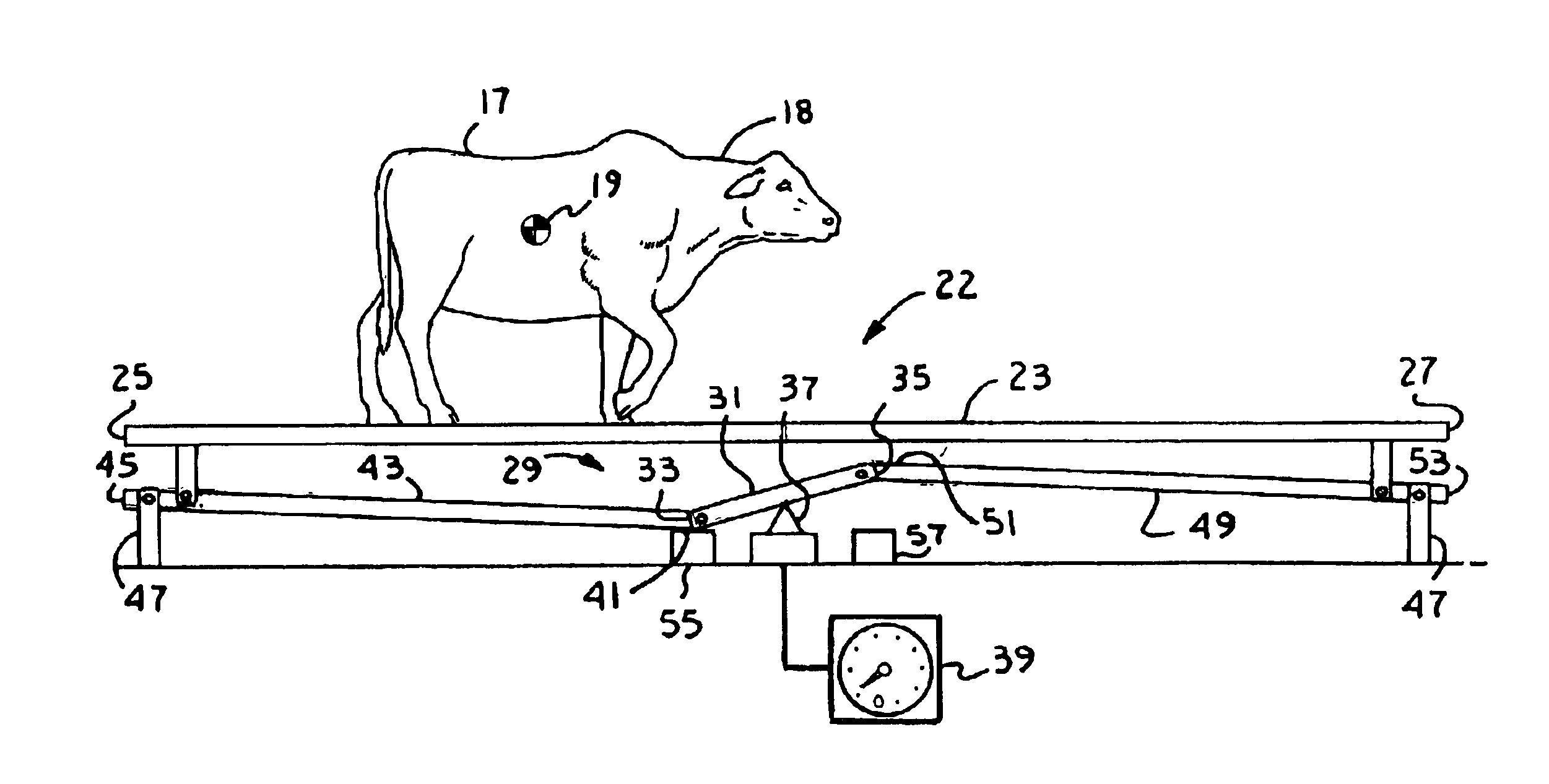

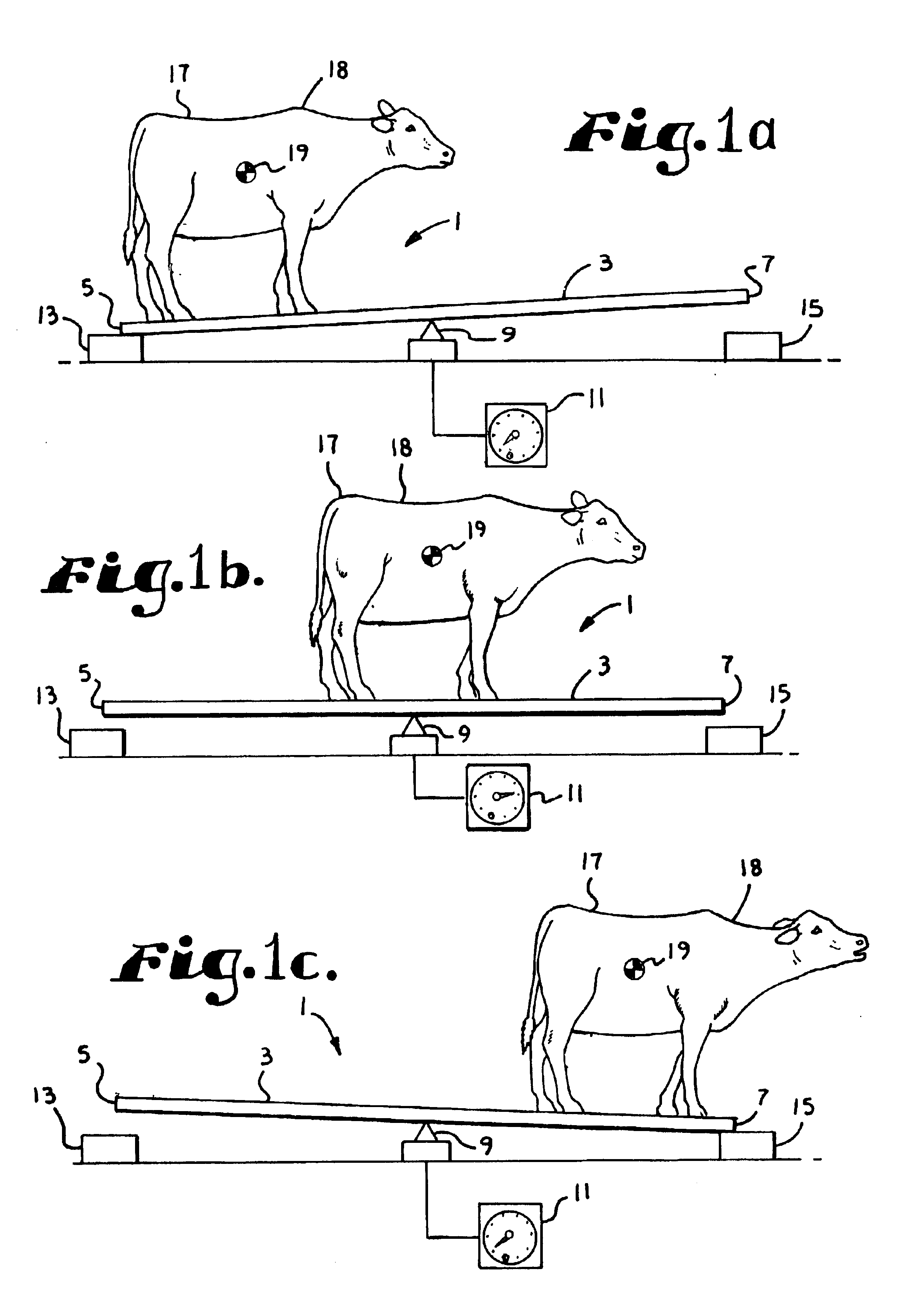

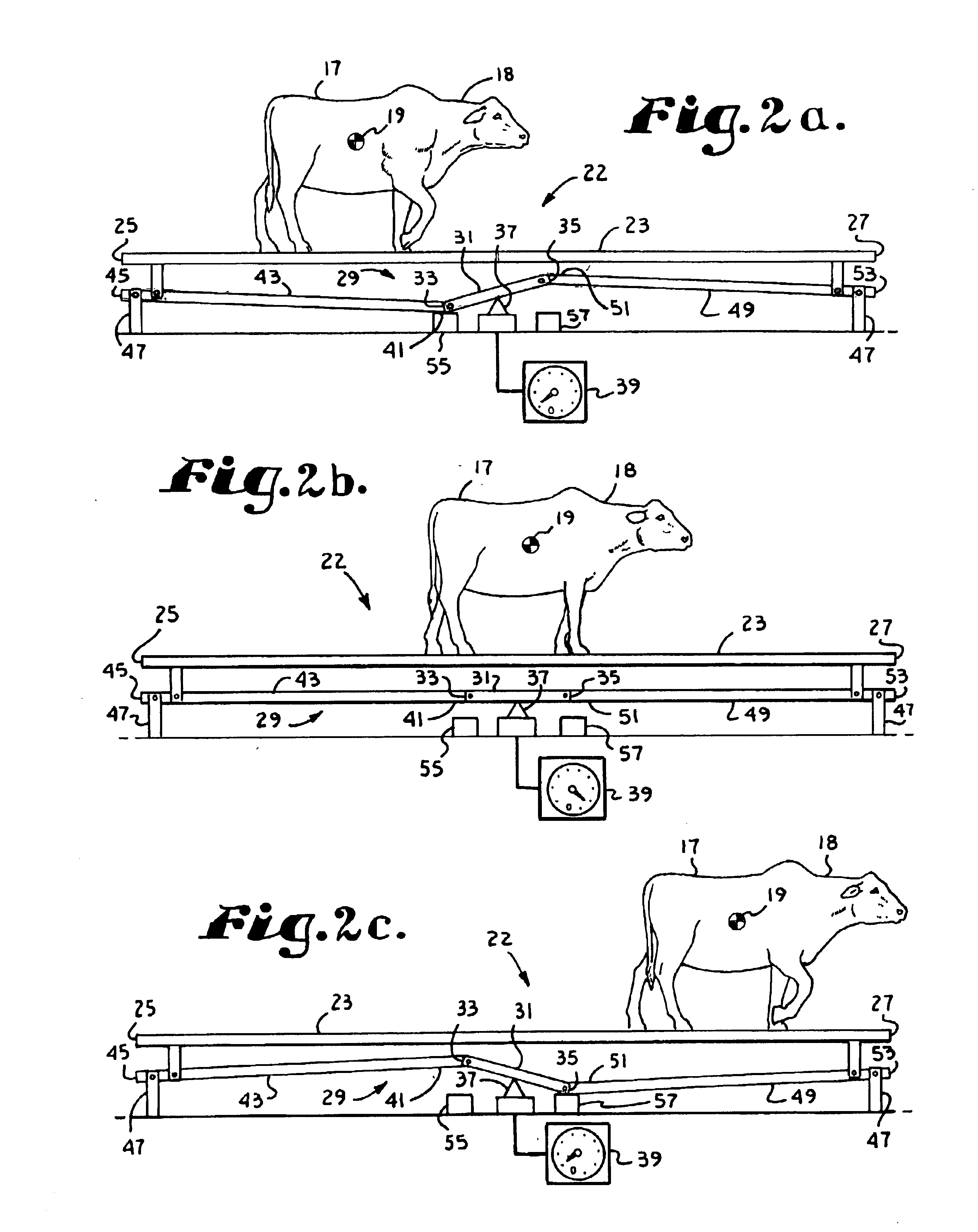

Tipping balance scale for weighing moving objects

InactiveUS6838625B2Reduce shock loadRestricts downward movementWeighing relieving/arrestment mechanismsWeighing apparatus for materials with special property/formEngineeringTransverse axis

A scale 1 for weighing moving loads 17 includes a weighing platform 3 having an entrance end 5 and an exit end 7. The platform 3 is pivotal about a transverse axis 9 between the entrance end 5 and exit end 7. A first limit stop 13 is engageable to limit downward movement of the entrance end 5 and a second limit stop 15 is engageable to limit downward movement of the exit end 7. A weighing device 11 is connected to the platform 3 and is operable to provide an indication of the weight of a load 17 supported on the platform 3 when neither the first limit stop 13 nor the second limit stop 15 is engaged.

Owner:OSTERMANN JERRY L

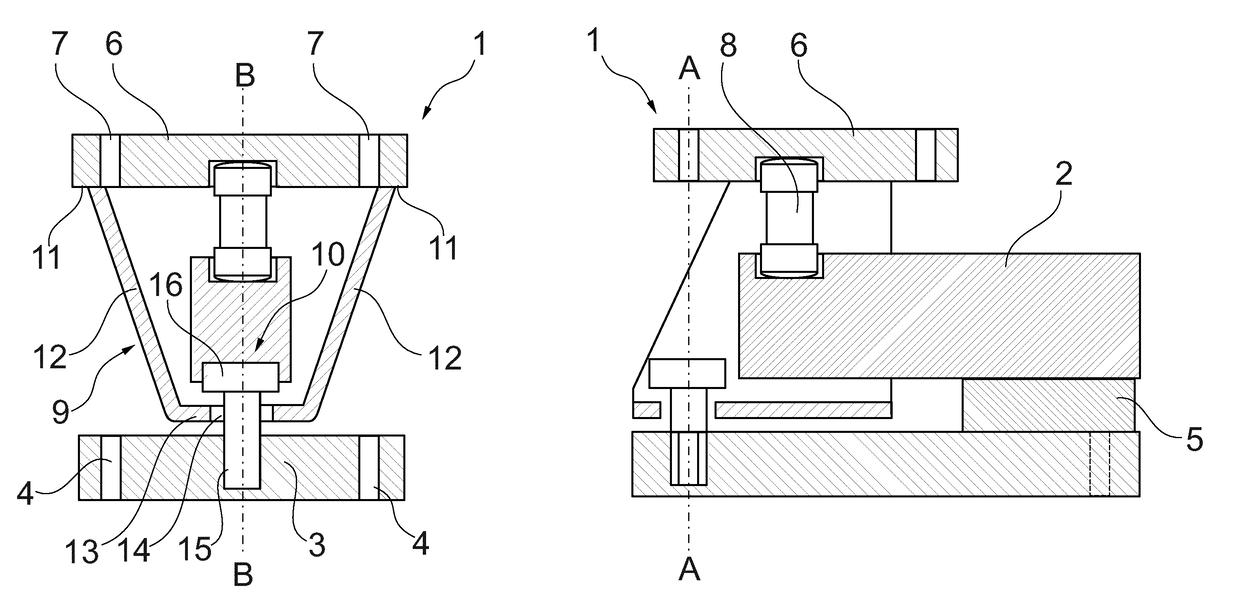

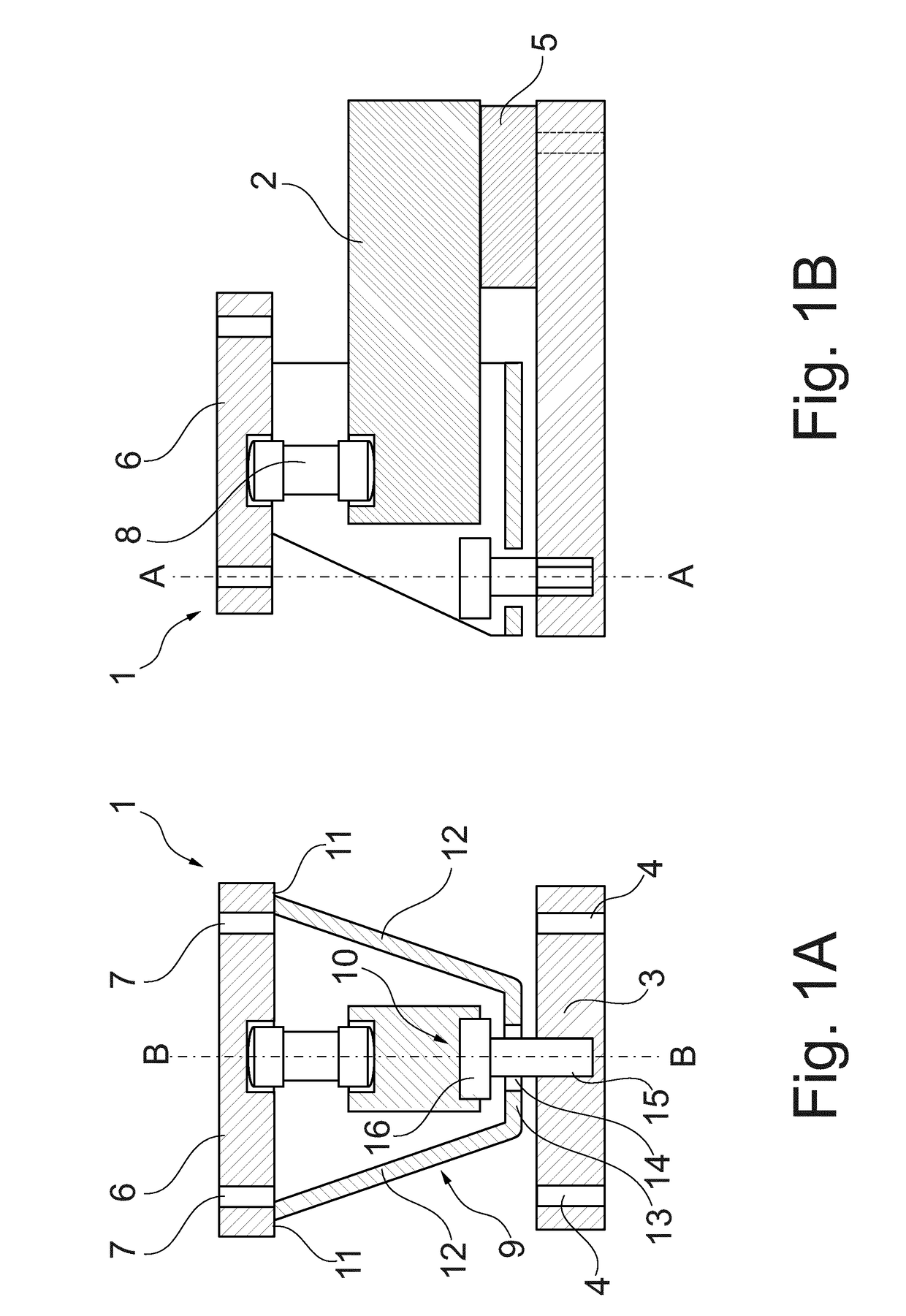

Load cell weigh module hat limits horizontal floating movement of the top plate

ActiveUS9612150B2Easy visual inspectionReduce accumulationWeighing relieving/arrestment mechanismsEngineeringLoad cell

A weigh module (1) includes a load cell (2), a base plate (3), a top plate (6), a force-transmitting member (8) serving to transmit the weighing force from the top plate (6) to the load cell (2), and movement-restricting means (9, 10) which serve to limit the horizontal floating movement of the top plate (6) relative to the base plate (3) within a confined range of free play and to transmit lateral force components directly from the top plate (6) to the base plate (3). One part of the movement-restricting means (9, 10) has the form of a channel whose top edges (11) are rigidly connected to the top plate (6) and whose flat bottom extends parallel to the base plate (3) at a clear distance from the latter. The other part of the movement-restricting means (9, 10) is a bolt whose shaft (15) is anchored in the base plate (3) and passes with all-around clearance through a passage (14) in the channel bottom (13), and whose head (16) is larger than the passage (14) and arranged above the channel bottom (13) with a vertical clearance gap from the latter.

Owner:METTLER TOLEDO GMBH

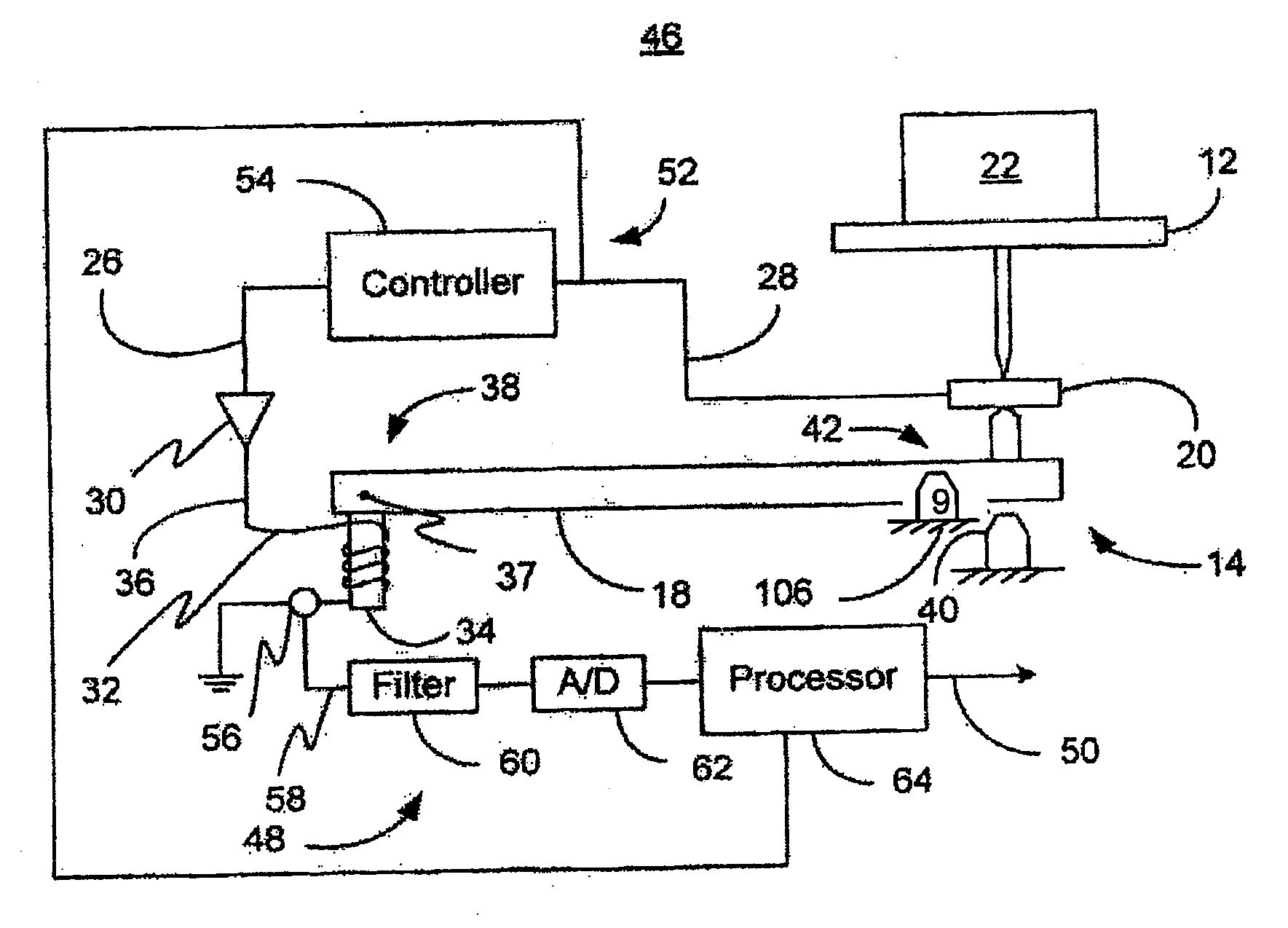

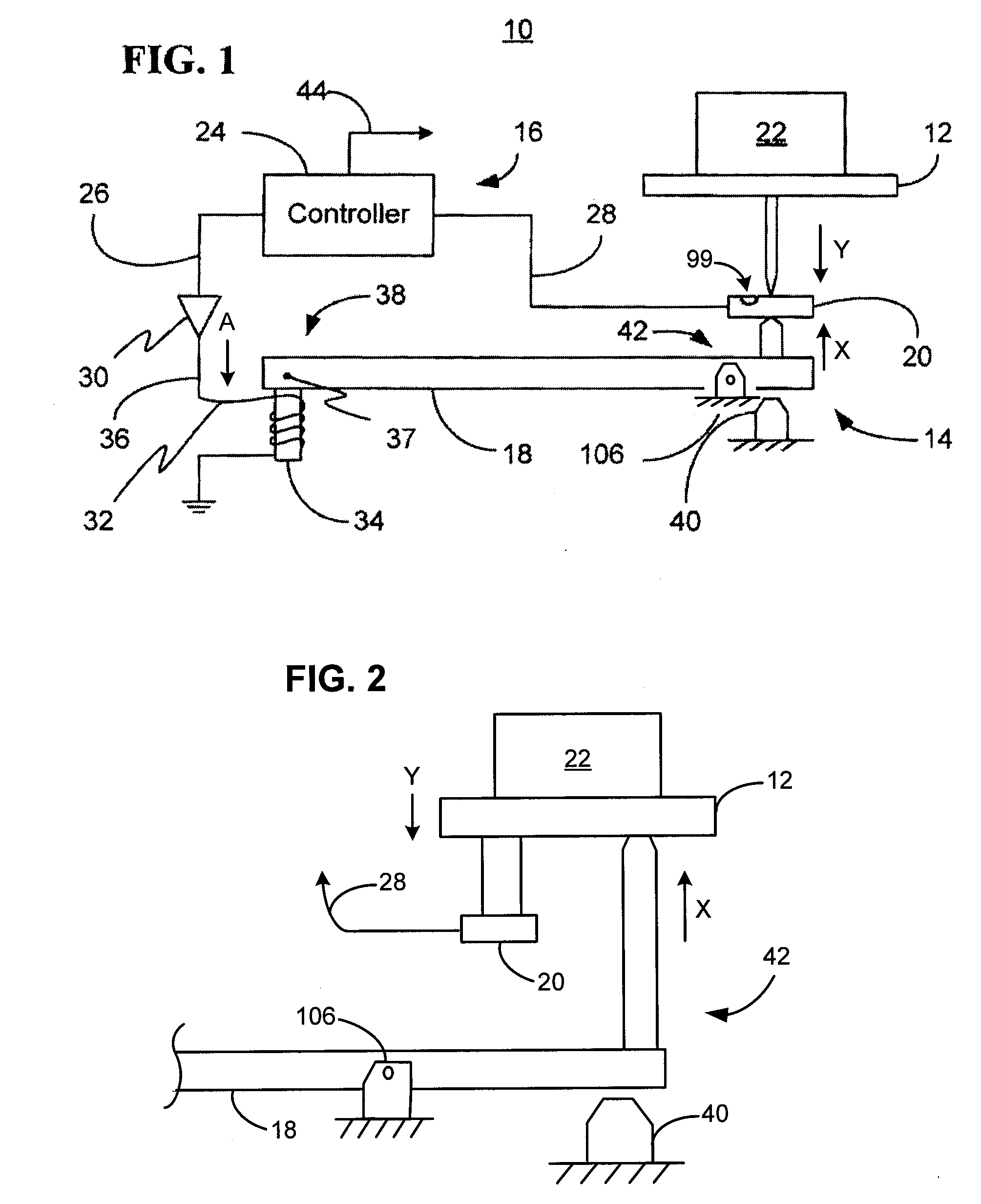

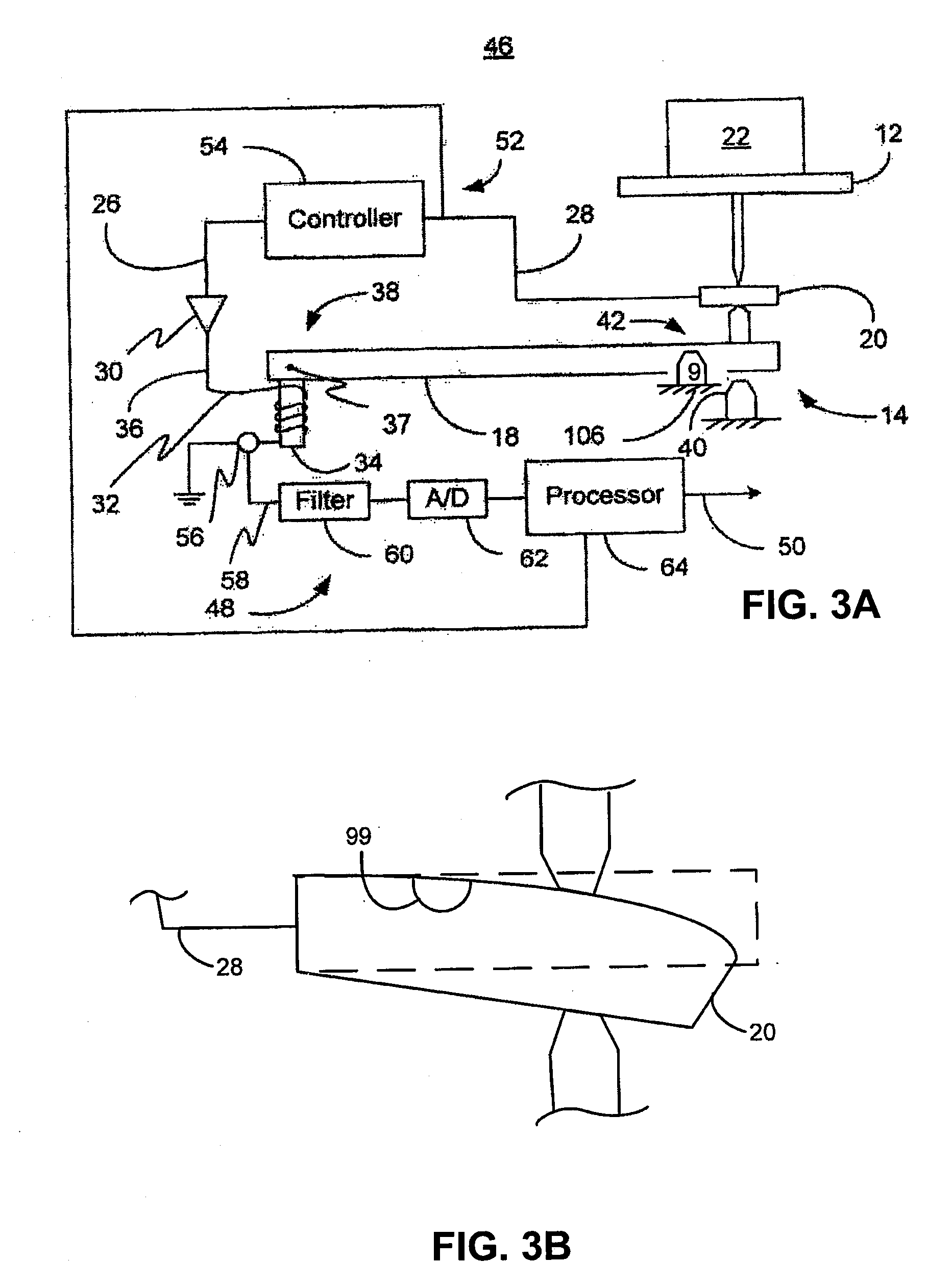

Load limiter for strain gauge occupant classification sensor

InactiveUS7297880B2Restrict movementPreventing further displacementPedestrian/occupant safety arrangementWeighing relieving/arrestment mechanismsEngineeringStrain gauge

Owner:FCA US

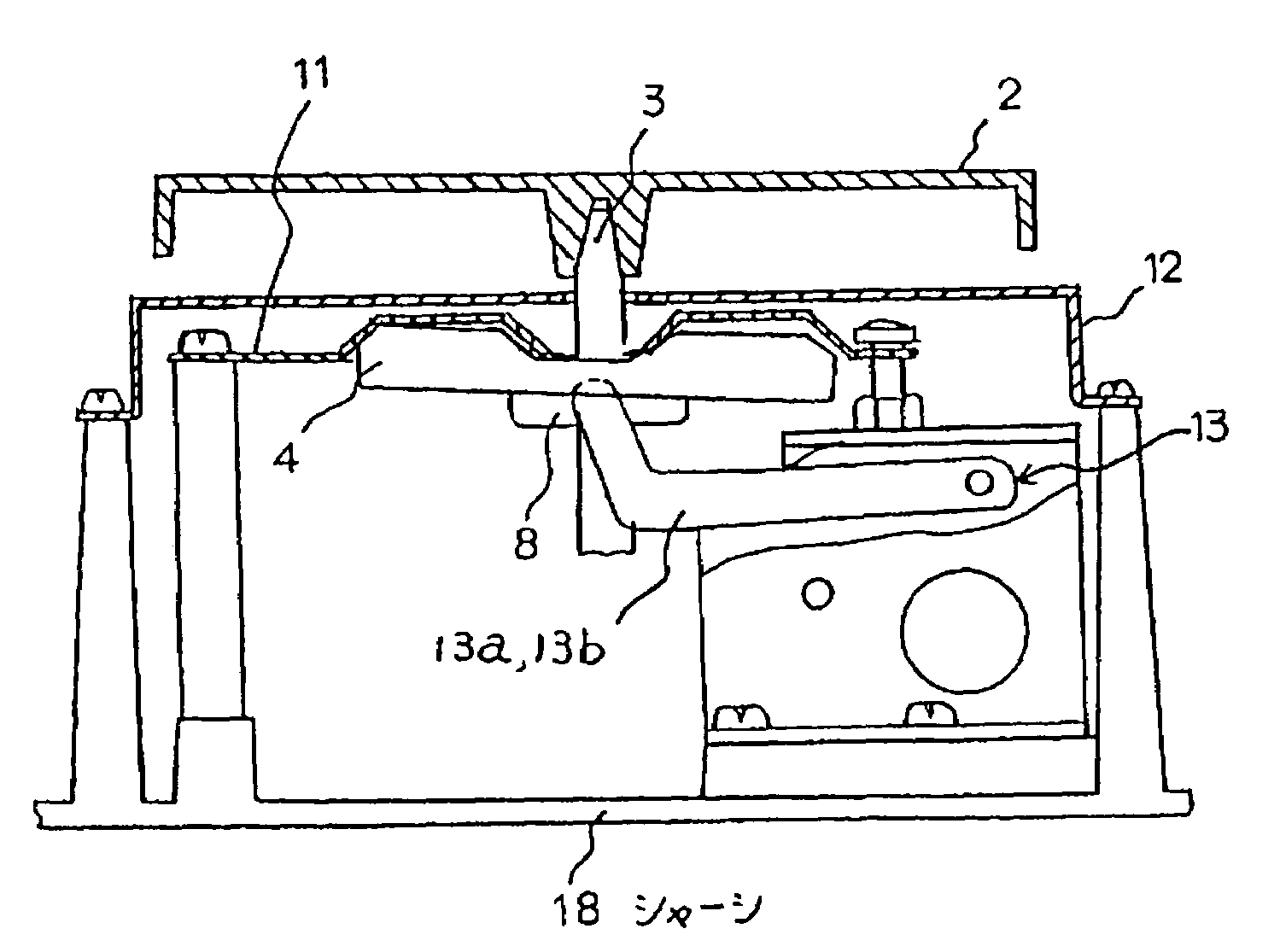

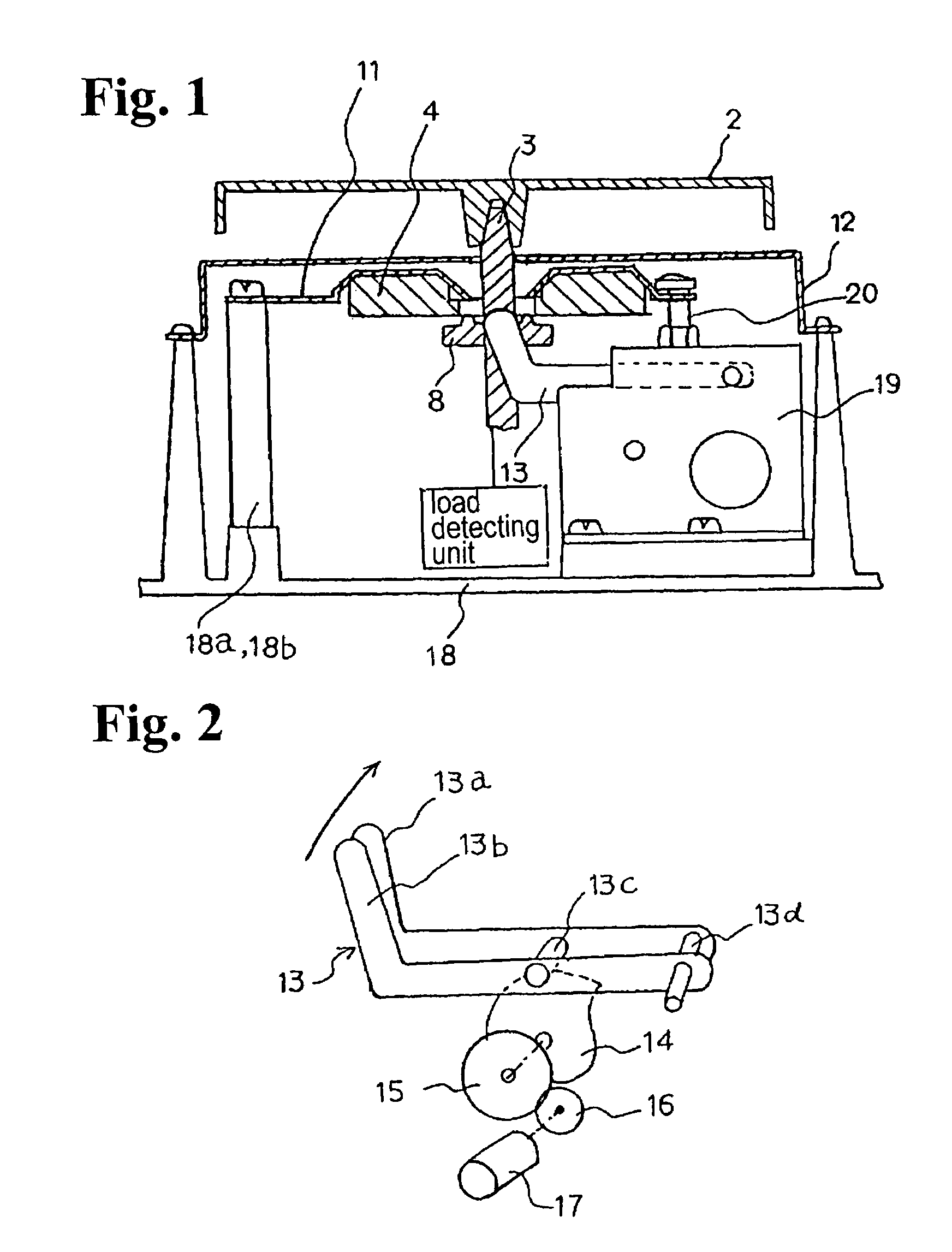

Electronic balance

InactiveUS7176389B2Simple structureLow costWeighing apparatus testing/calibrationWeighing relieving/arrestment mechanismsEngineeringSensitivity coefficient

An electronic balance includes a sample plate for placing a sample, a load detecting unit for determining a weight of the sample, a sensitivity calibration mechanism having a calibration weight disposed under the sample plate for applying a load of the calibration weight to the load detecting unit, a weight holding member with a spring property for holding the calibration weight when the load of the calibration weight is not applied to the load detecting unit, and a pressing member disposed above the weight holding member for restricting an upper movement of the weight holding member. The load detecting unit converts a load of the sample placed on the sample plate into an electrical signal according to a sensitivity coefficient to determine the weight of the sample. The sensitivity coefficient is calibrated when the load of the calibration weight is applied to the load detecting unit.

Owner:SHIMADZU CORP

Seat load measuring apparatus

InactiveUS7399932B2Improve compatibilityEfficient productionElectric devicesPedestrian/occupant safety arrangementMobile vehicleEngineering

Owner:JOYSON SAFETY SYST JAPAN KK

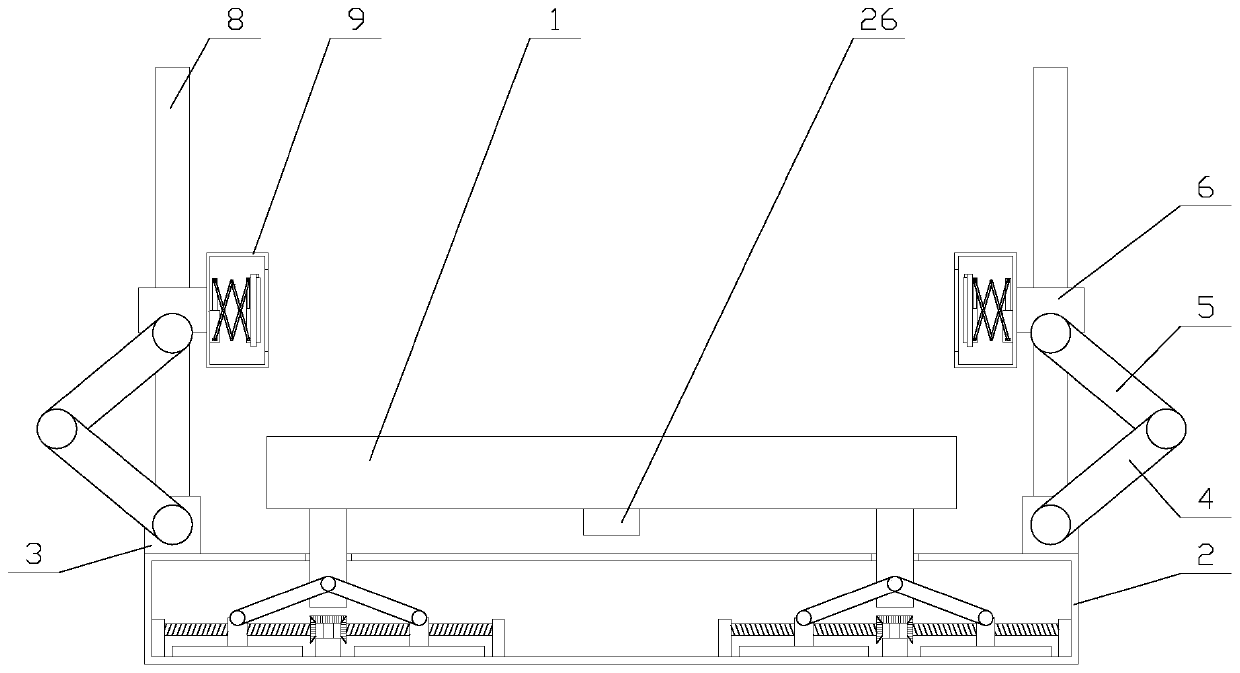

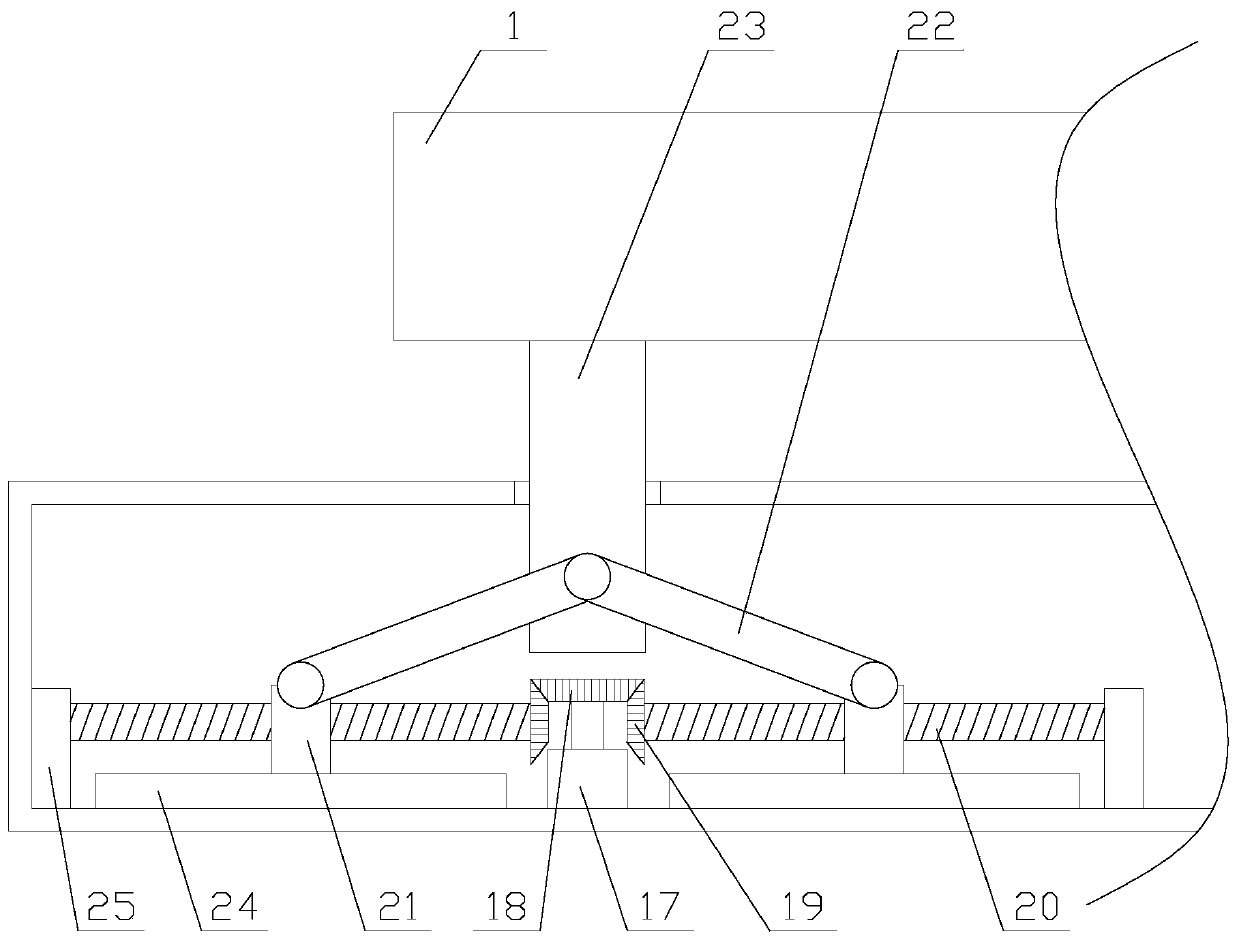

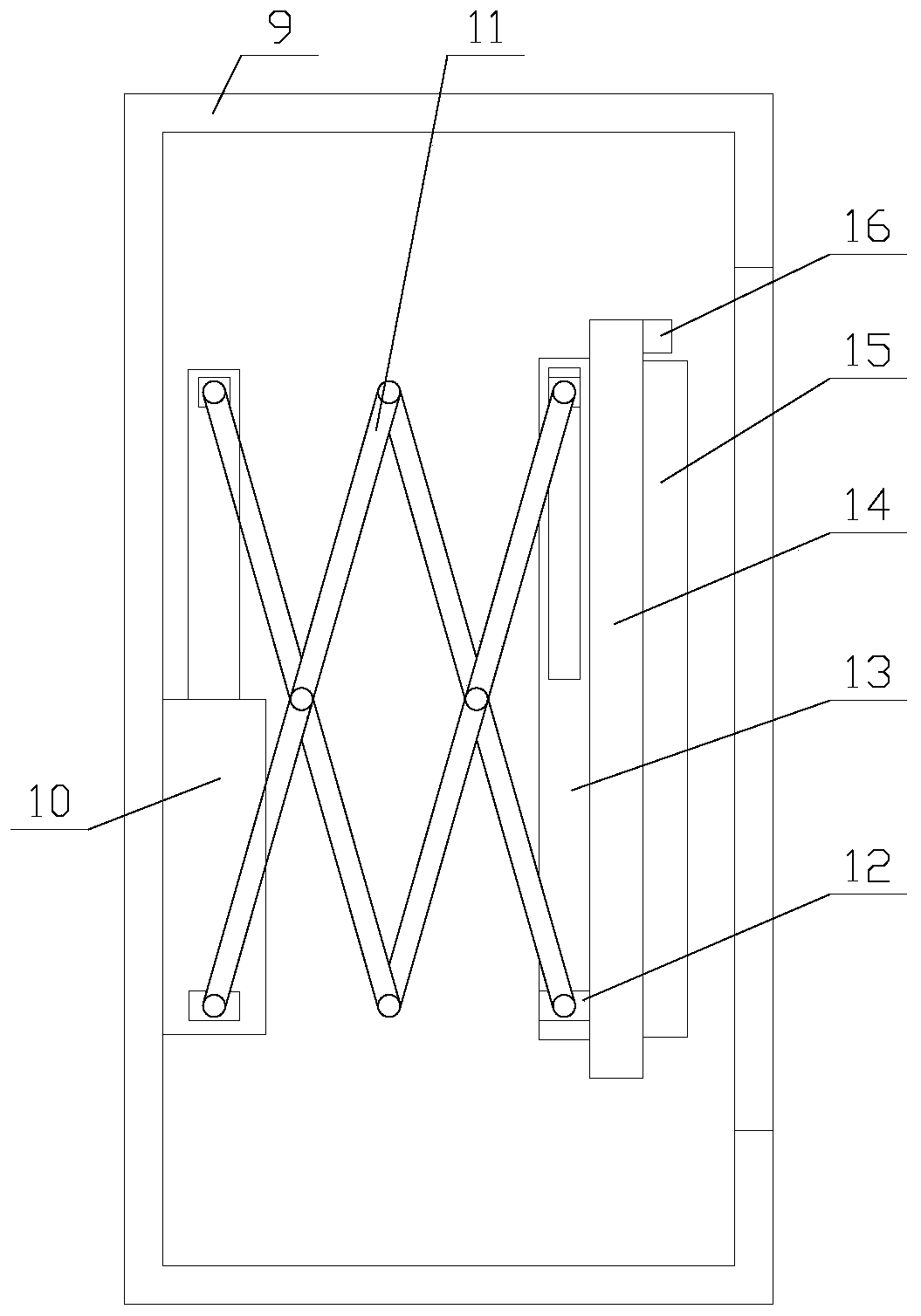

Stable weighing device with leveling function

InactiveCN109855715AImprove reliabilityImprove practicalityWeighing relieving/arrestment mechanismsLeveling mechanismBevel gear

The invention relates to a stable weighing device with a leveling function. The stable weighing device comprises a pedestal, a platform, two stabilizing mechanisms and four leveling mechanisms. The leveling mechanisms include leveling rods and adjusting assemblies; each adjusting assembly includes a first motor, a drive bevel gear and two adjustment units; and the adjustment units include lead screws, sliding blocks, driven bevel gears and adjusting rods. The stabilizing mechanisms include lifting assemblies and fixation boxes; fixation assemblies are arranged in the fixation boxes; and each fixation assembly includes a cylinder, a telescopic frame, a moving plate, a fixation plate and two hinge blocks. According to the stable weighing device, with the leveling mechanisms, the platform canbe leveled to avoid platform inclination and protect the weighing precision; and with the stabilizing mechanisms, a measured object is fixed and thus the shaking of the measured object on the platform or separation from the platform is avoided and thus the good weighing effect is guaranteed.

Owner:刘晓慧

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com