On-line steel billet weighting device

A technology for weighing devices and steel billets, applied in the direction of measuring devices, weighing release/blocking mechanisms, and weighing equipment for continuous material flow, etc., can solve the problem of affecting the service life of conveying rollers, long weighing time, and affecting production rhythm And other problems, achieve the effect of shortening weighing time, low cost, fast and accurate online weighing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, which are not intended to limit the protection scope of the present invention.

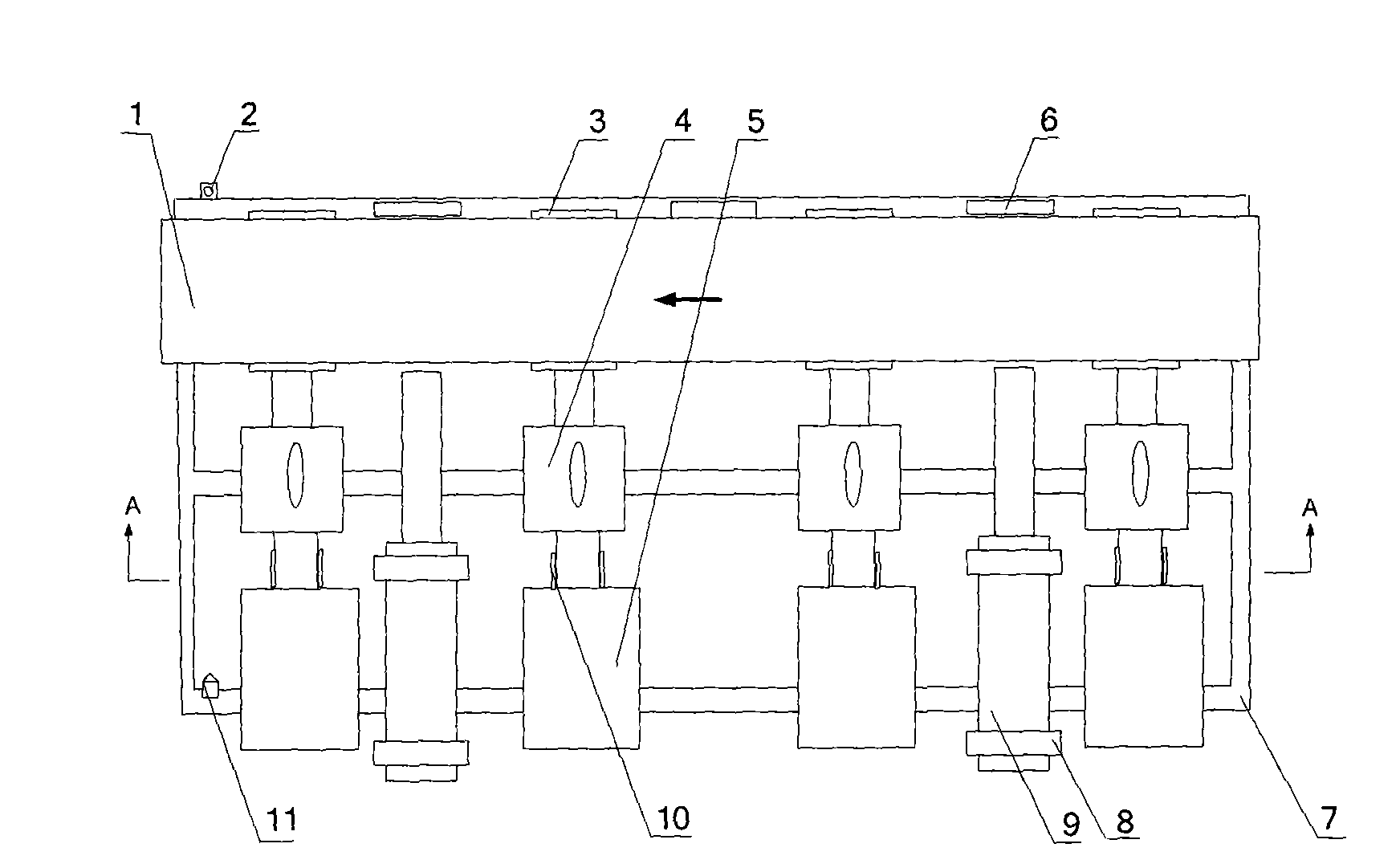

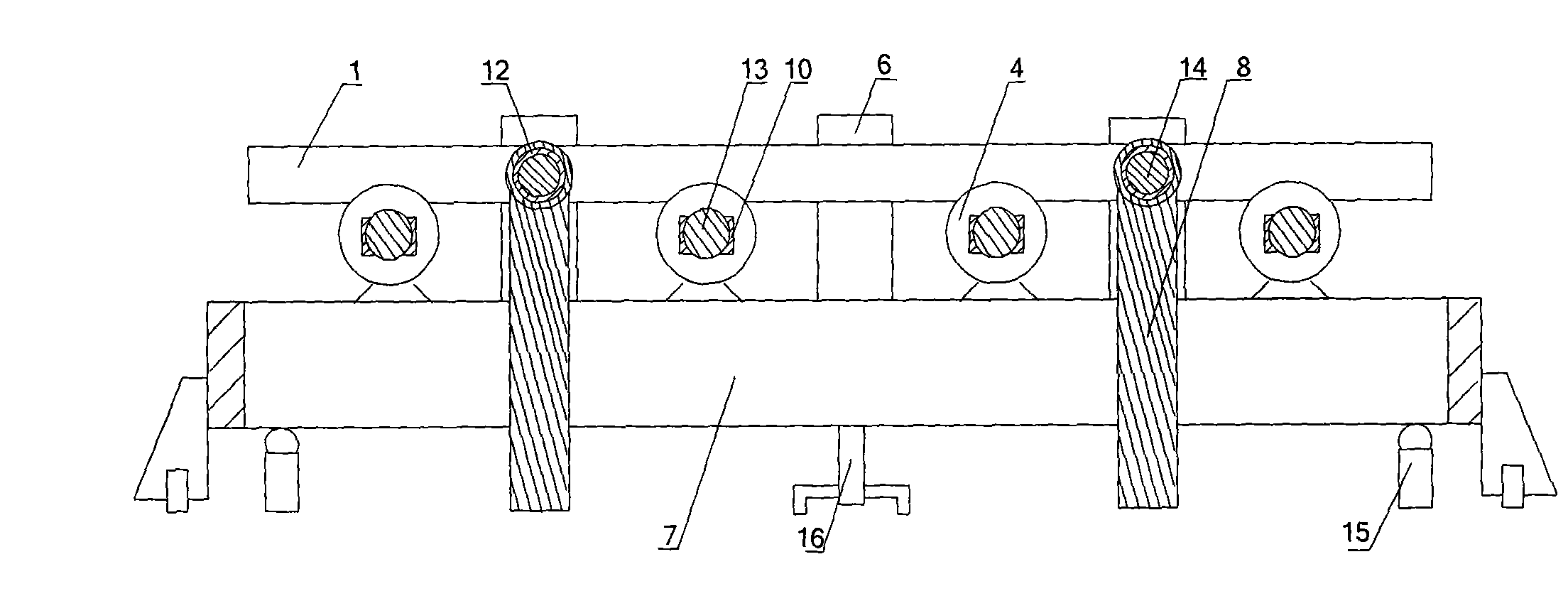

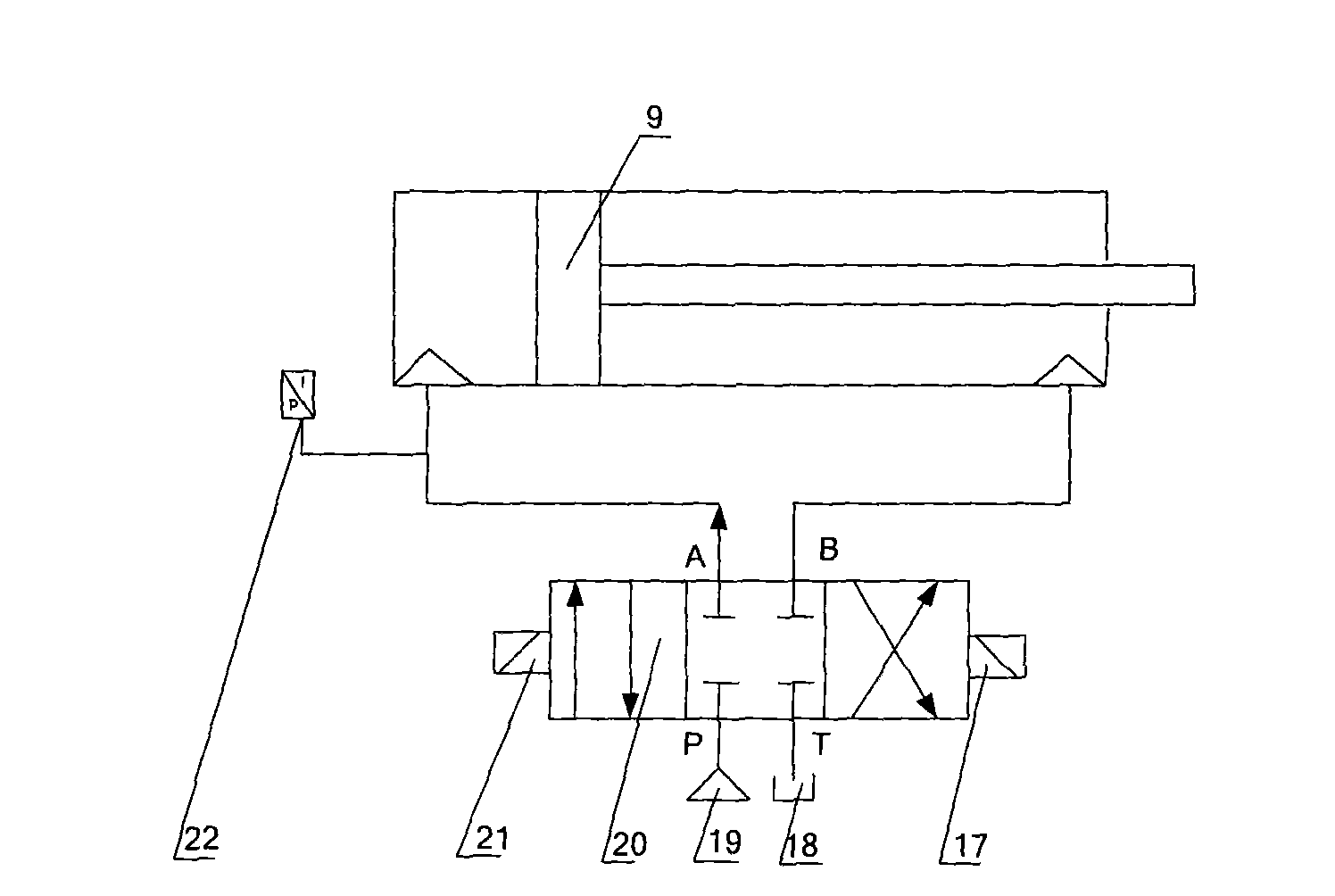

[0039] An online billet weighing device. Its mechanical parts such as figure 1 and figure 2 Shown: four conveying rollers 3 are evenly installed on the weighing platform 7, and the conveying rollers 3 and the steel billet conveying rollers 3 on the production line are arranged side by side to form a production conveying line. Each conveying roller 3 is correspondingly connected with a drive motor 5 by a shaft coupling 4, and the output shaft 13 of each drive motor 5 is equipped with a brake 10; Control relay 26 is electrically connected, such as Figure 4 As shown, each motor control relay 25 and each brake control relay 26 are respectively connected to the digital output channel DO of the PLC 24 .

[0040] 3 positioning baffles 6 such as figure 1 , 2 As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com