Patents

Literature

65results about How to "Shorten weighing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

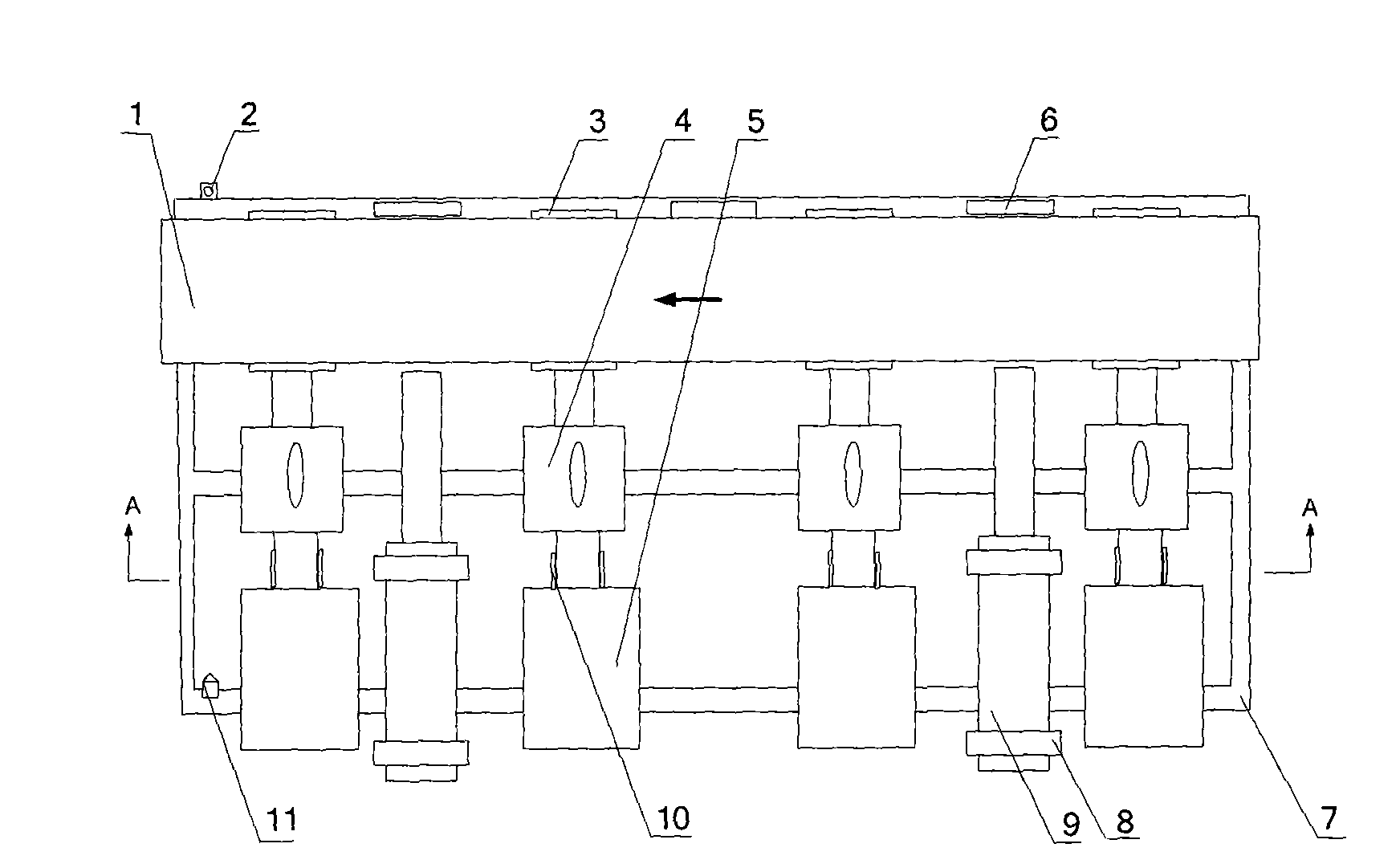

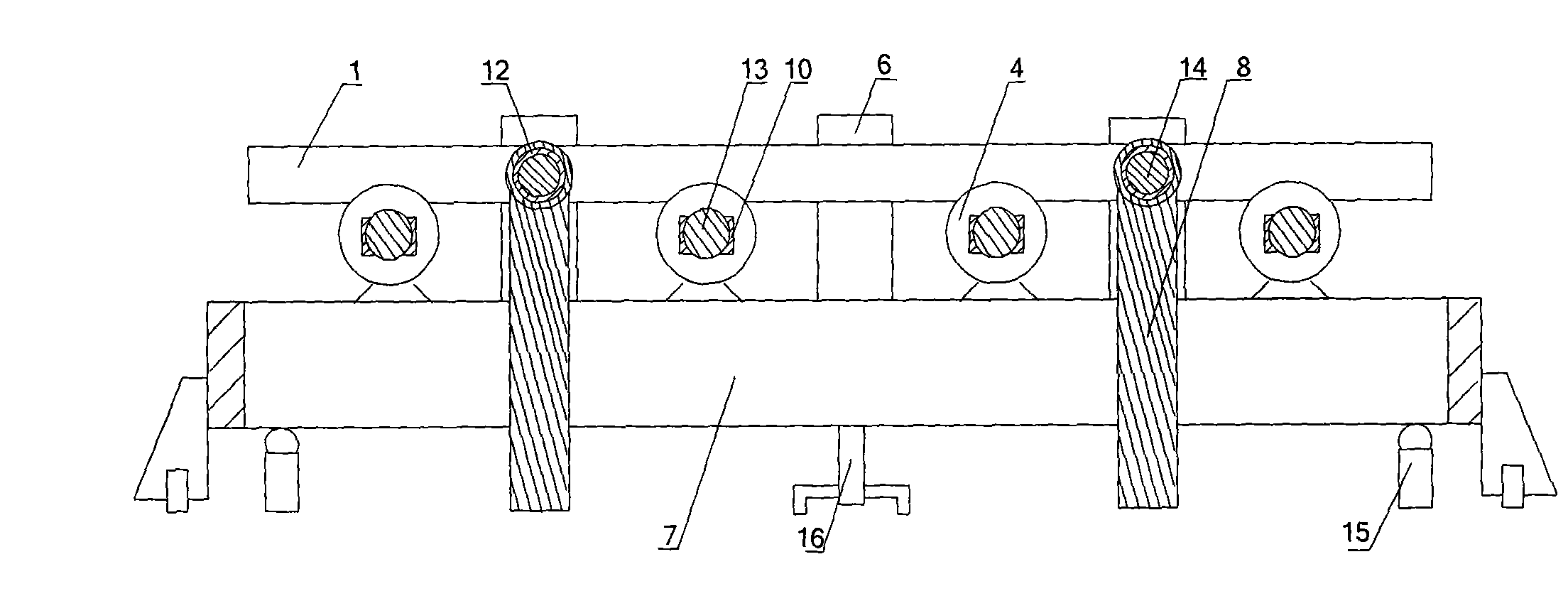

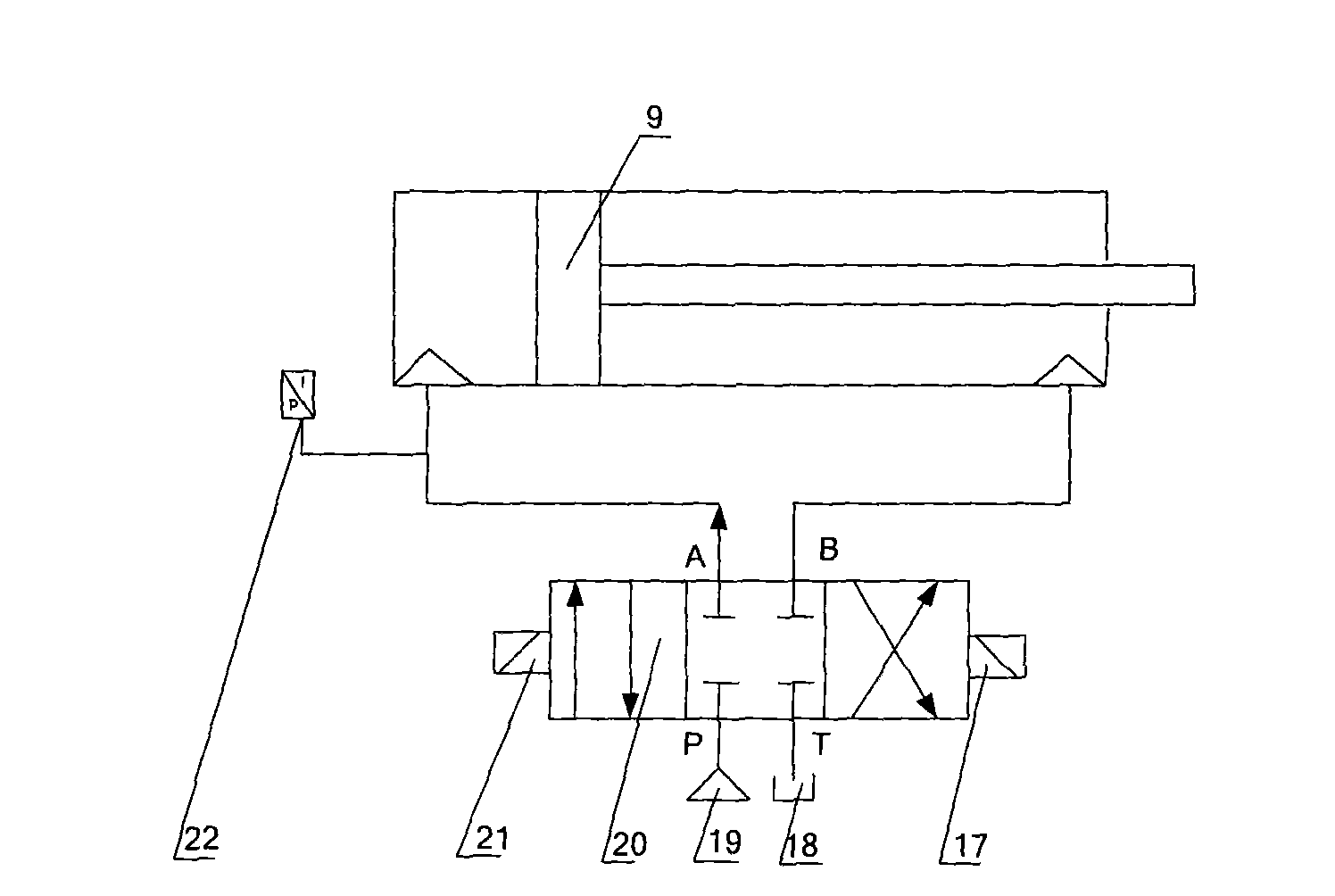

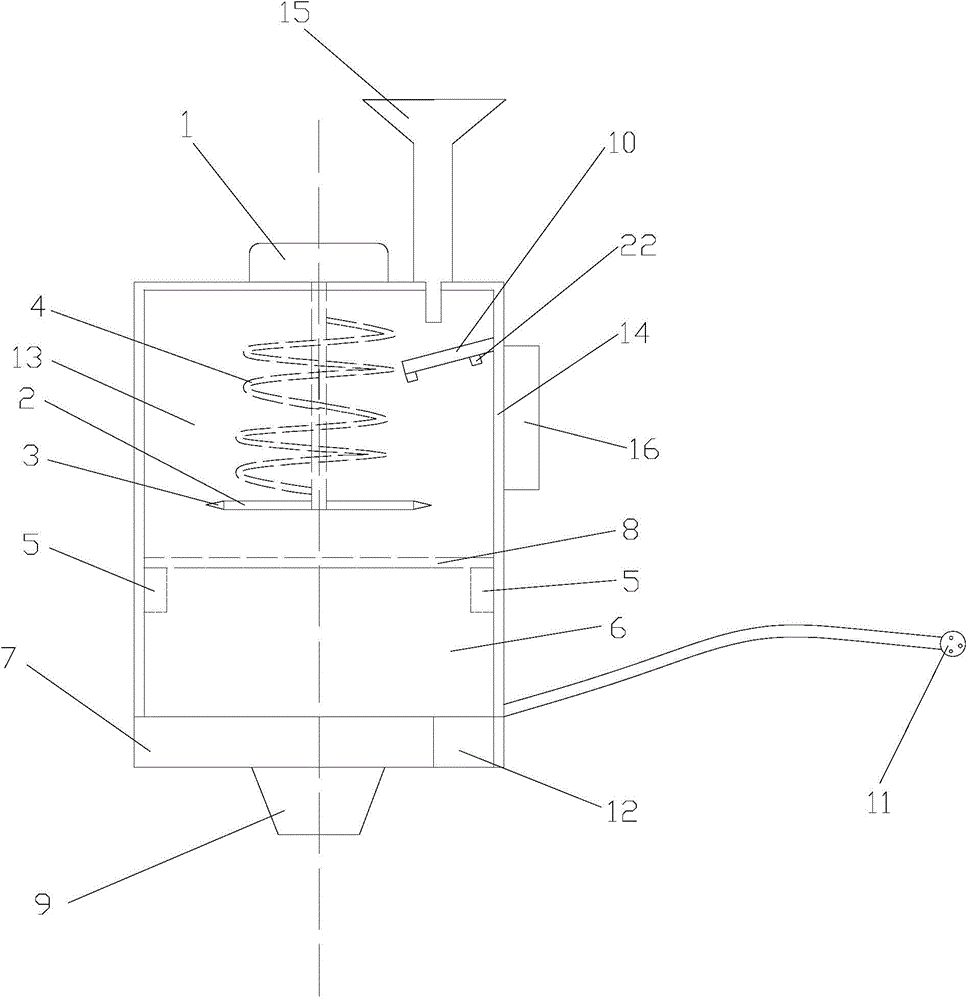

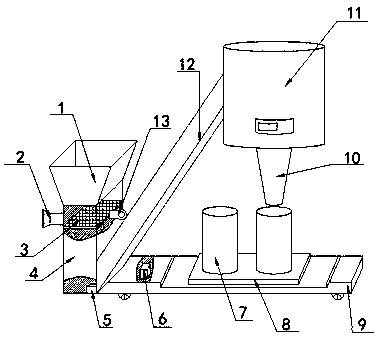

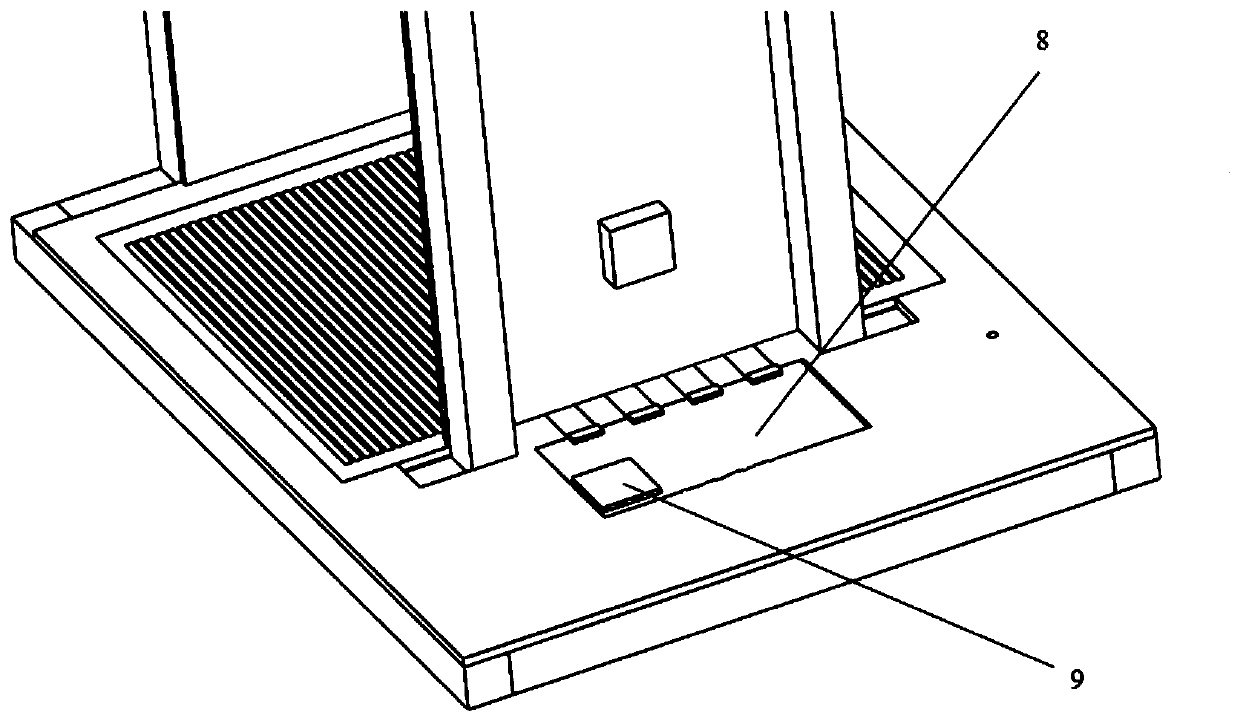

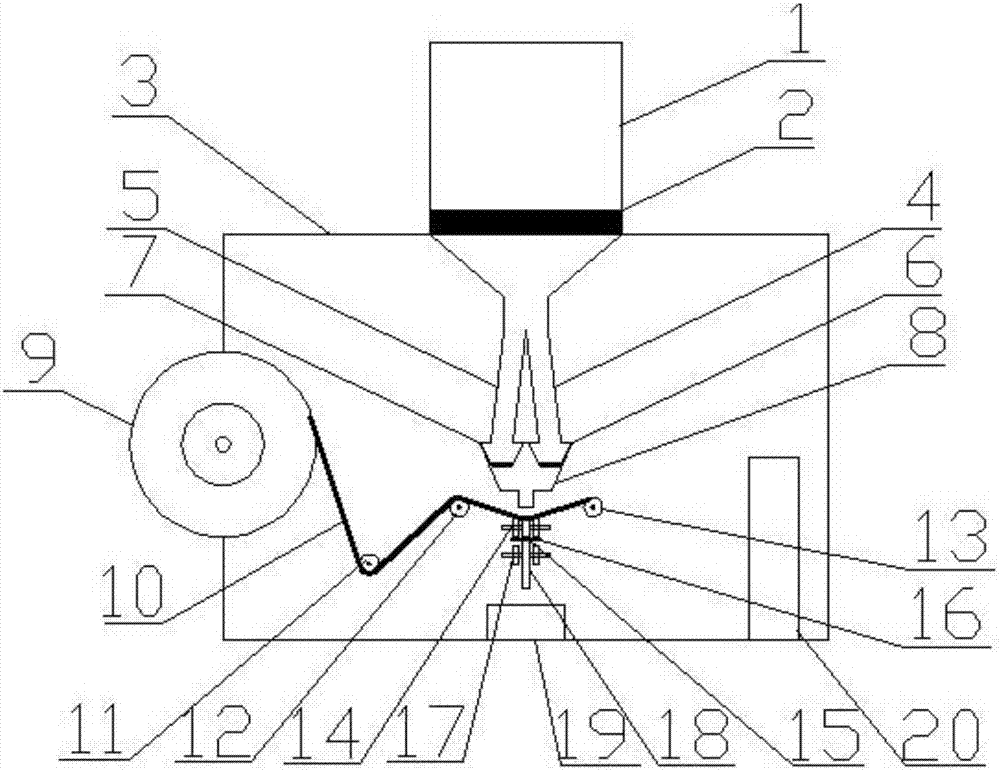

On-line steel billet weighting device

InactiveCN101634581AAvoid shockReduce shockWeighing relieving/arrestment mechanismsWeighing apparatus for continuous material flowInternal memoryDrive motor

The invention relates to an on-line steel billet weighting device which has the technical scheme that a weighting rack (7) is provided with 3-6 conveying rollers (3) and a driving motor (5); a motor control relay (25) and a brake control relay (26) which are respectively corresponding to the driving motor (5) and a brake (10) are respectively connected with a digital output channel DO of a PLC (24); 2-5 electromagnetic directional valves (20) are connected with a locating piston rod type hydraulic cylinder (9) by pipelines which are provided with pressure sensors (22), and each electromagnetic directional valve (20) and each pressure sensor (22) are respectively connected with the digital output channel DO and an analogue input channel AI of the PLC (24); four weighing sensors (15) and infrared receivers (2) the analogue input channel AI and a digital input channel DI of the PLC (24); control software is written into an internal memorizer of the PLC (24), and configuration software is written into an internal memorizer of a touch screen (23). The line steel billet weighting device has the characteristics of rapid on-line weighting, accuracy, small impact and low cost.

Owner:WUHAN UNIV OF SCI & TECH

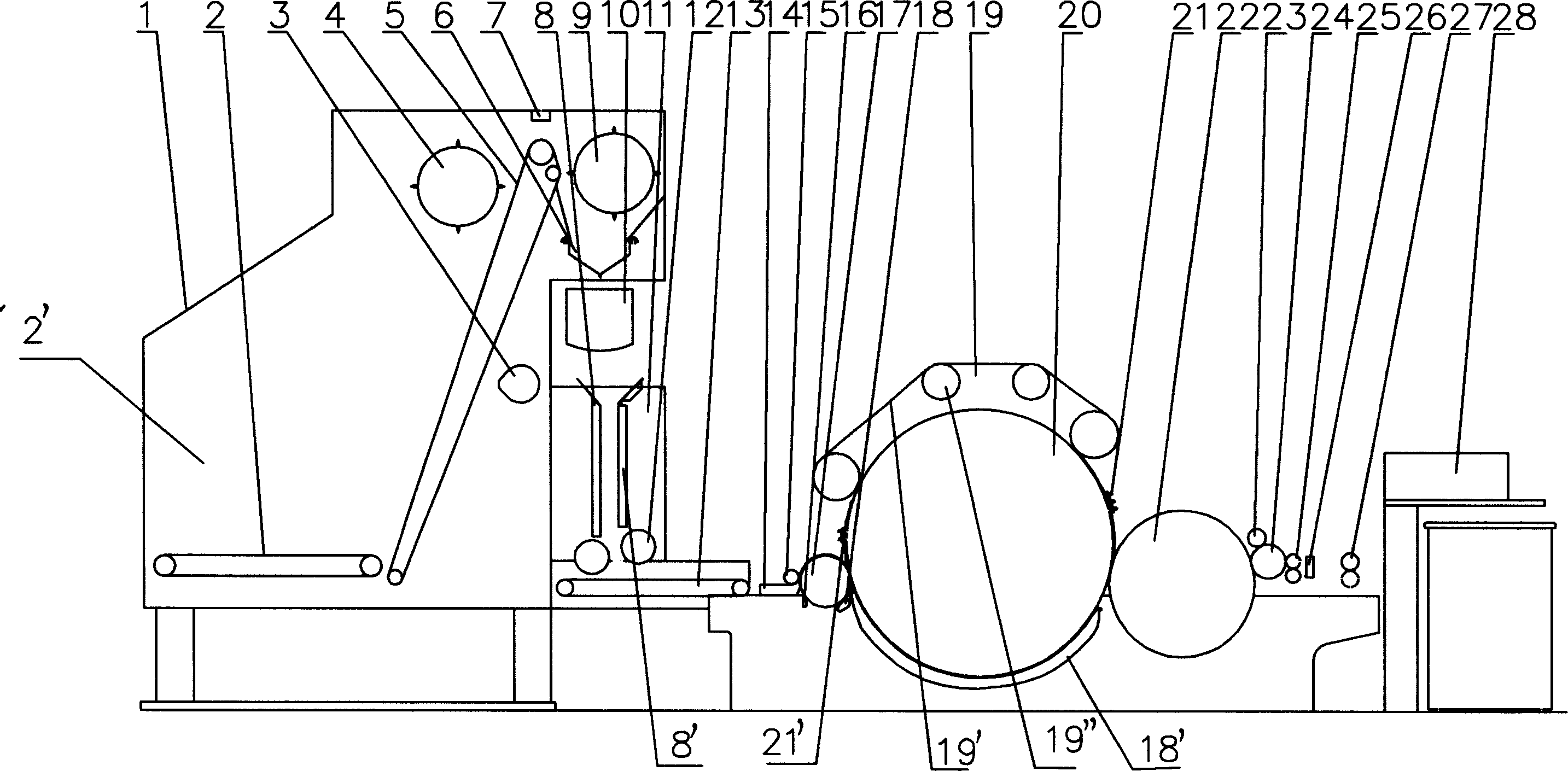

Semi-worsted cashmere piece-making machine

The semi-worsted cashmere top making machine includes mainly feeding unit, carding unit and top forming unit connected together. Material wool fiber is fed via the feeding unit to the carding unit, carded in the carding unit and formed into top in the top forming unit. The carding unit includes mainly cylinder and doffer and has rotary cover dehairing area set over the cylinder. The present invention has the features of good carding effect, high top quality, etc.

Owner:青岛东佳纺机(集团)有限公司

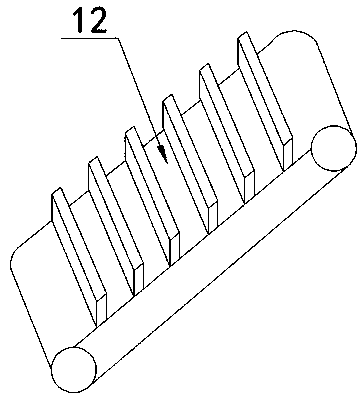

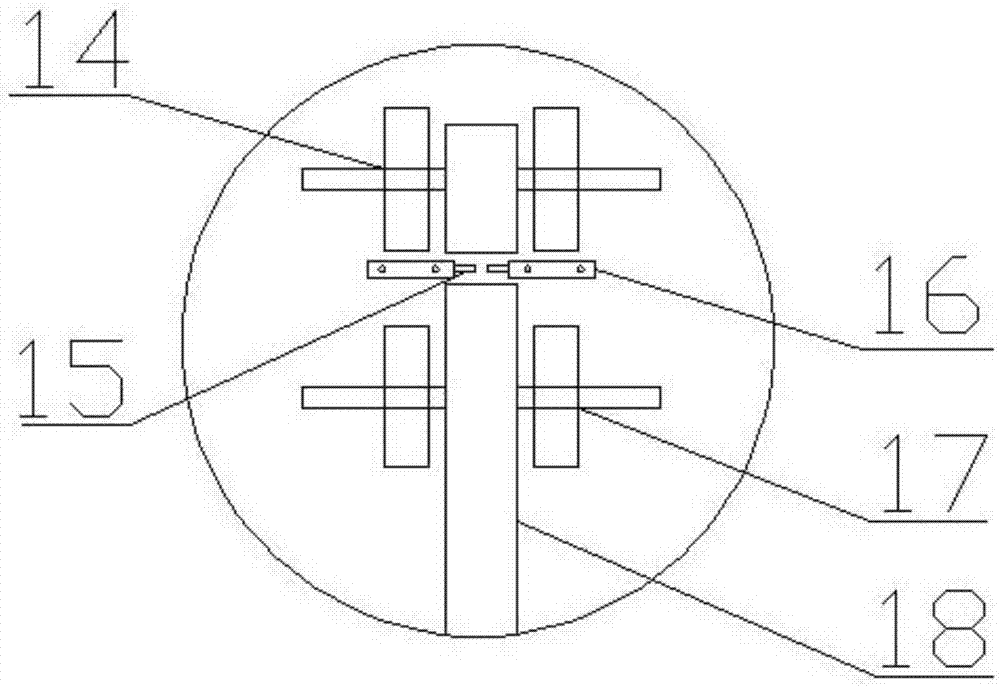

Batching system of concrete mixing plant

ActiveCN109049343AImprove practicalityIncrease productivityMixing operation control apparatusIngredients weighing apparatusEngineeringMechanical engineering

The invention relates to the technical field of concrete production equipment, and discloses a batching system of a concrete mixing plant. The batching system of the concrete mixing plant comprises amachine frame. A plurality of feeding hoppers and a weighing hopper are fixedly arranged on the machine frame, wherein the weighing hopper is used for weighing materials. A conveying assembly which isused for distinguishing and conveying materials to the weighing hopper is arranged on the machine frame. A material separating assembly is arranged in the weighing hopper, and comprises a cross, wherein the cross is fixedly arranged at the bottom of the weighing hopper. A stand column is fixedly arranged on the cross, sliding grooves are formed in the stand column and the inner wall of the weighing hopper, and a separating plate is connected with the interiors of the sliding grooves in a sliding mode. Insertion grooves are formed in the side wall of the weighing hopper and the separating plate, and insertion plates which are used for supporting materials to facilitate weighing are inserted into the insertion grooves in a connection and cooperation mode. By the adoption of the scheme, theinterior of the weighing hopper is divided into four weighing regions, first materials enter the weighing hopper and then accumulate on the separating plate to be weighed; subsequent materials enter different weighing regions in sequence, the increase quantity of the weight obtained through weighing is the weight of the materials, and therefore the function of distinguished weighing of the materials is fulfilled, the weighing time is shortened, and the production efficiency is improved.

Owner:武汉华强新型建筑材料有限公司

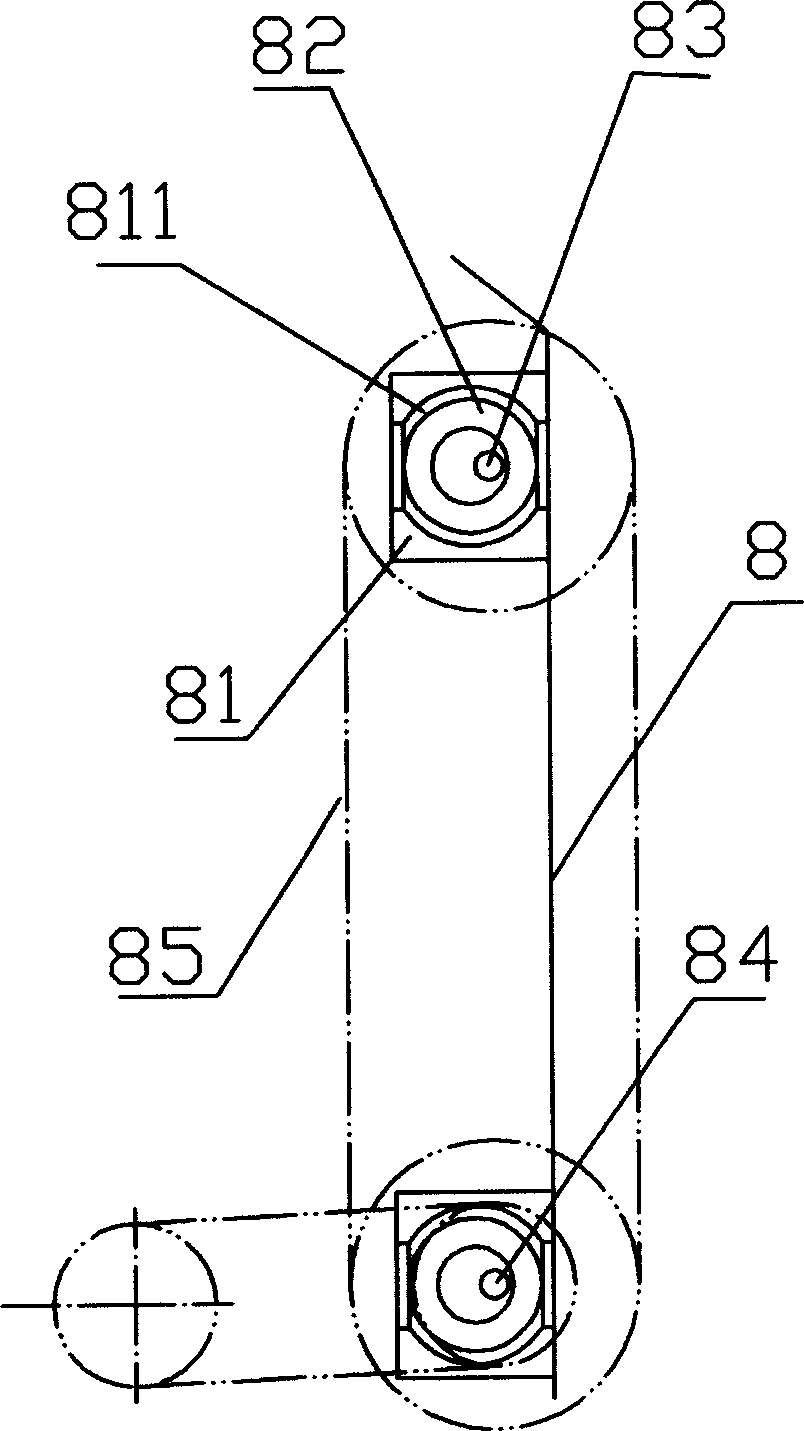

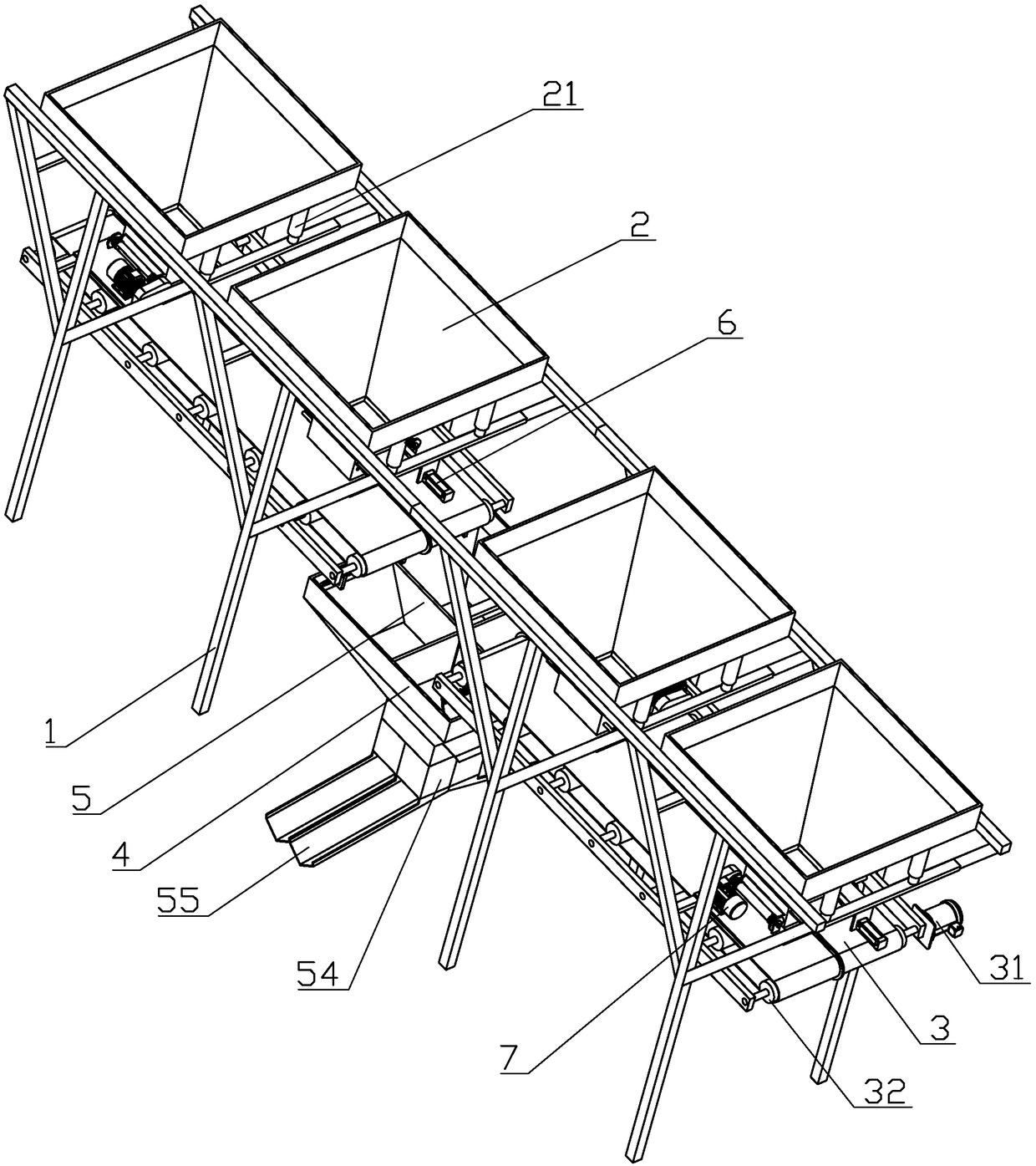

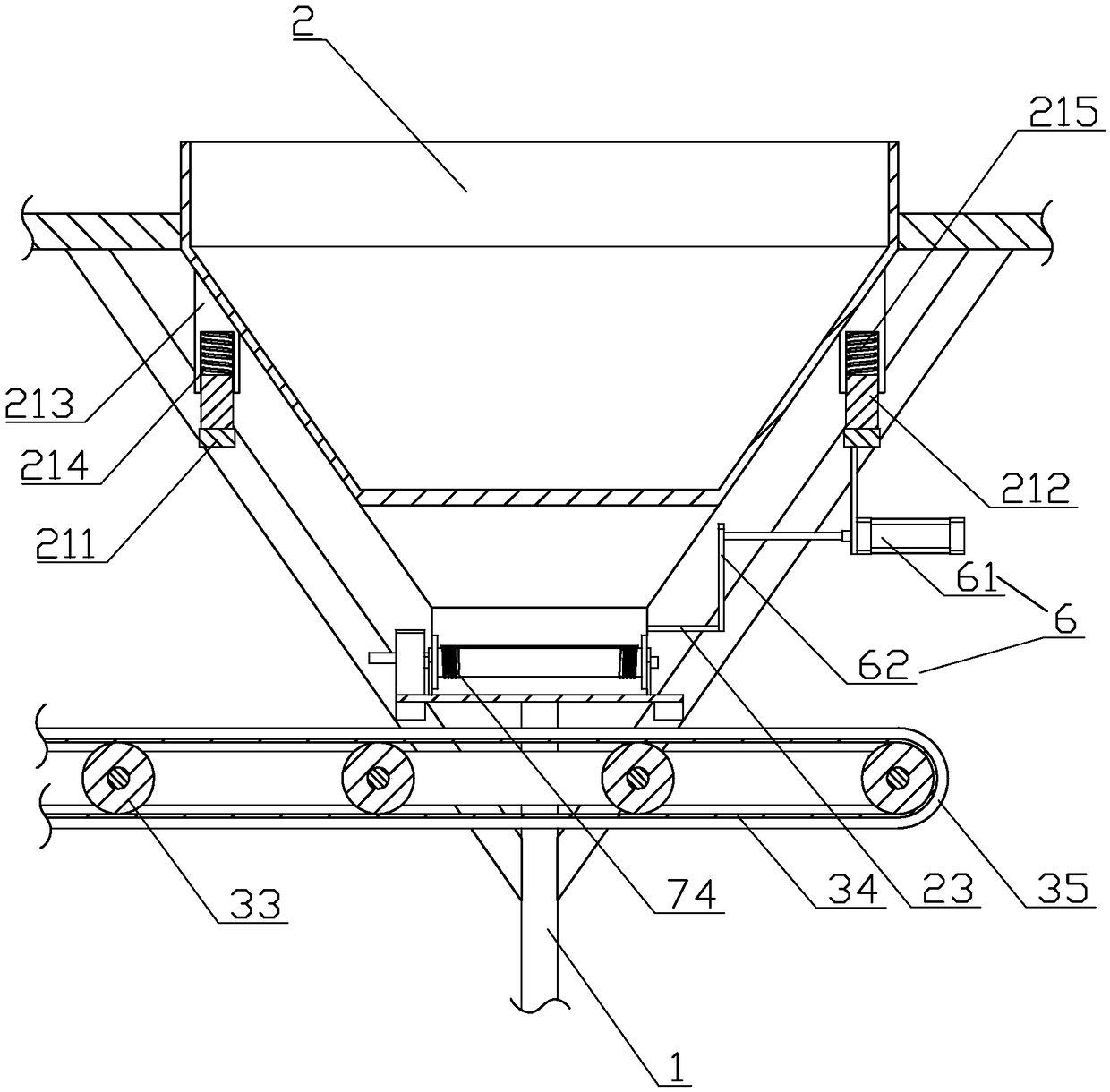

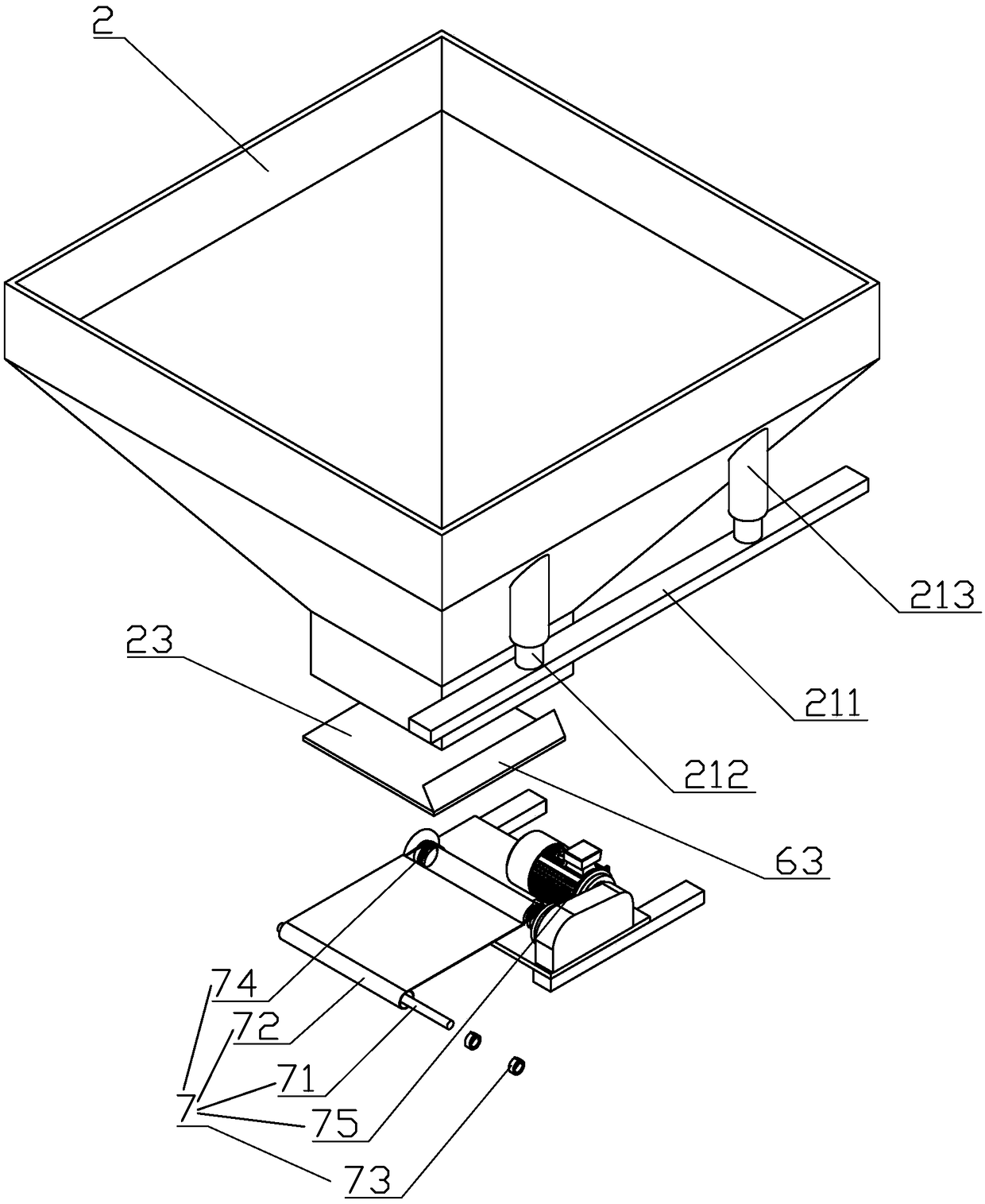

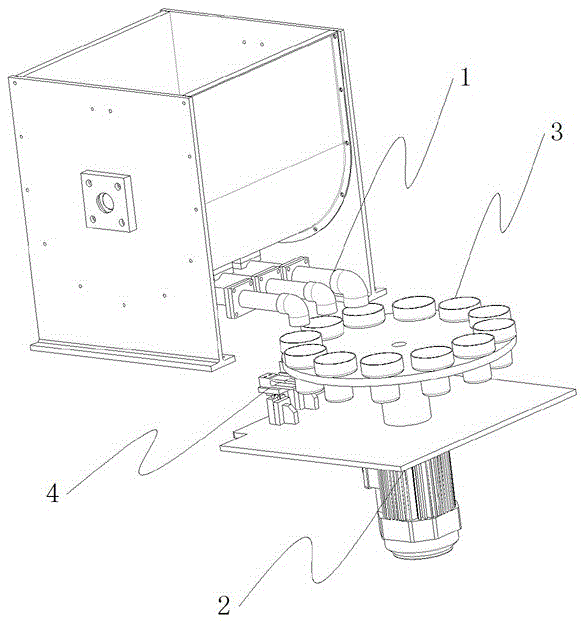

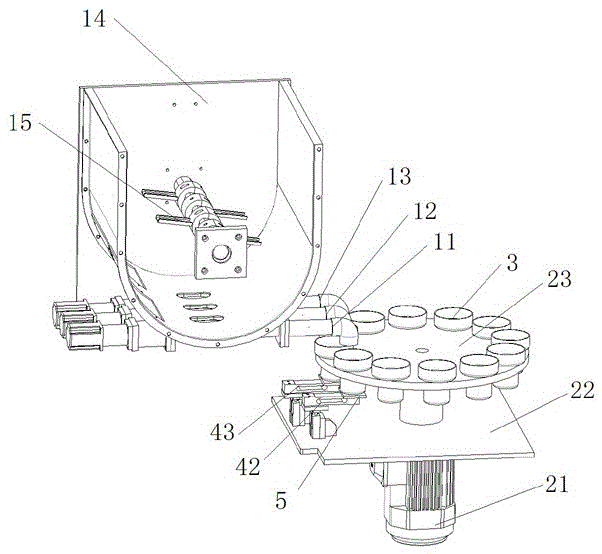

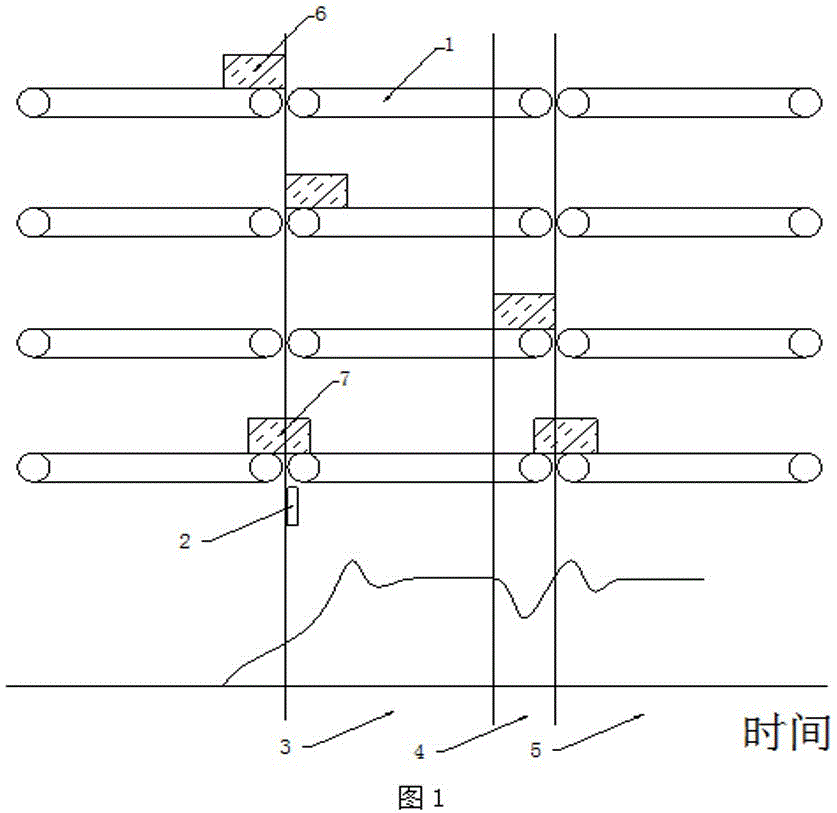

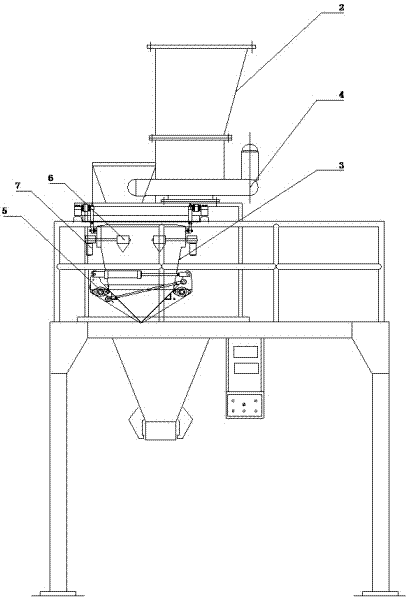

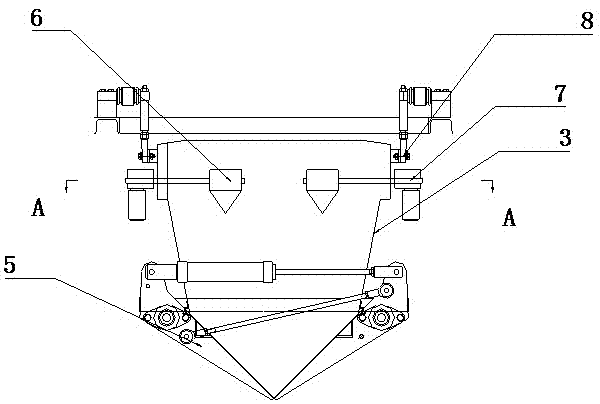

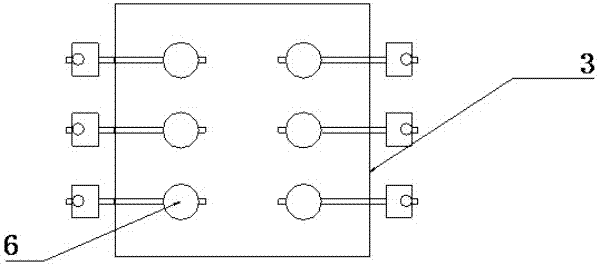

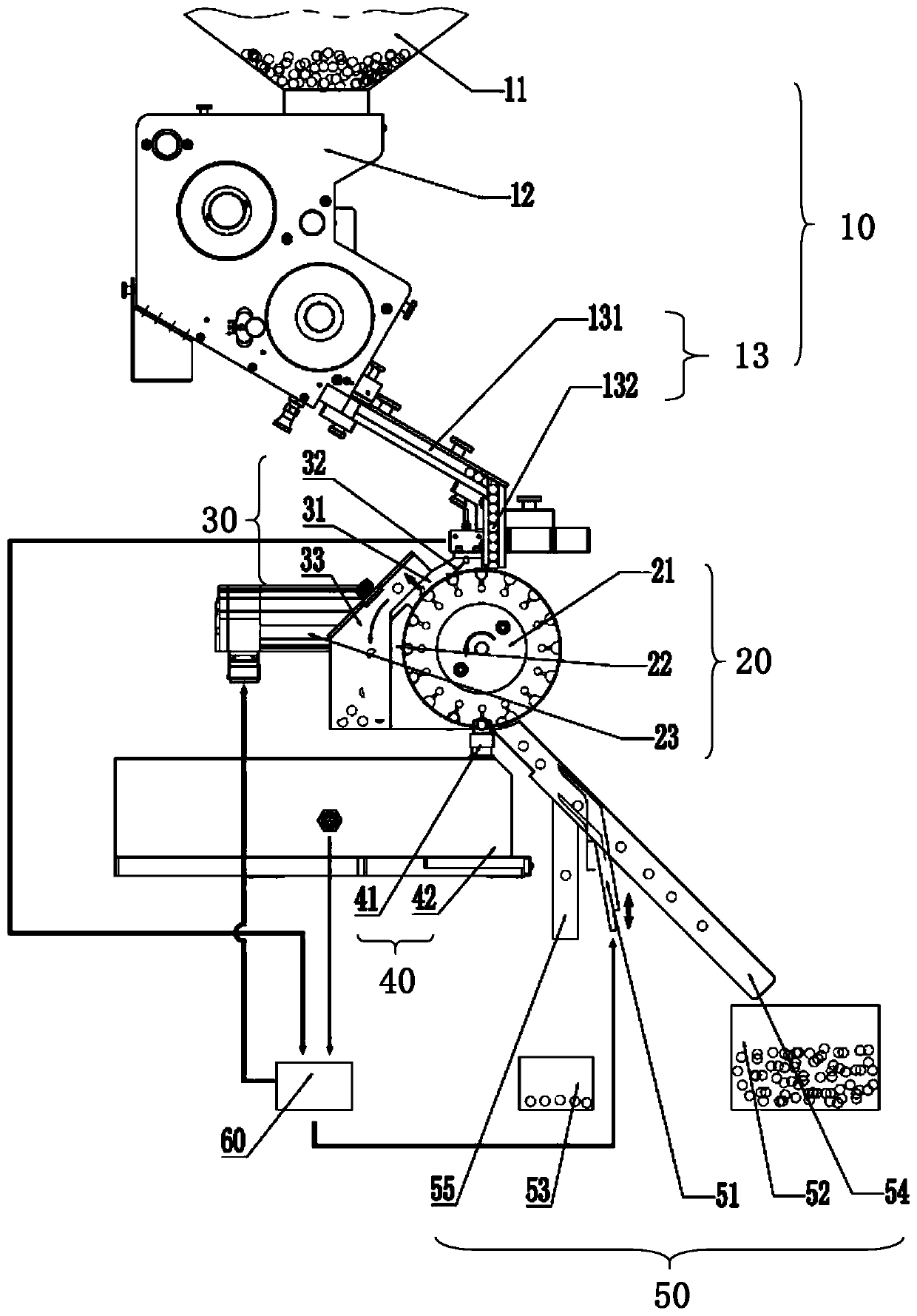

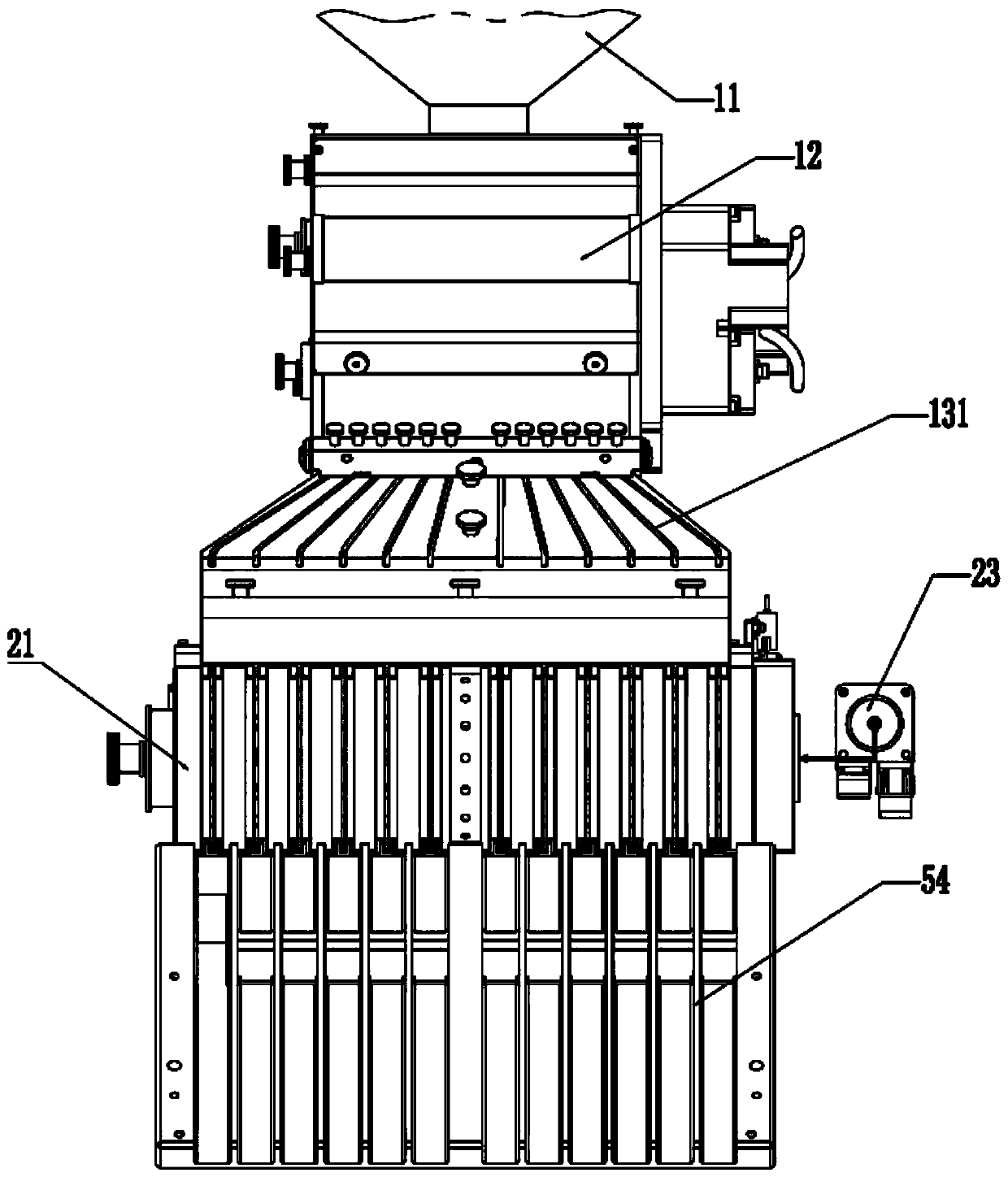

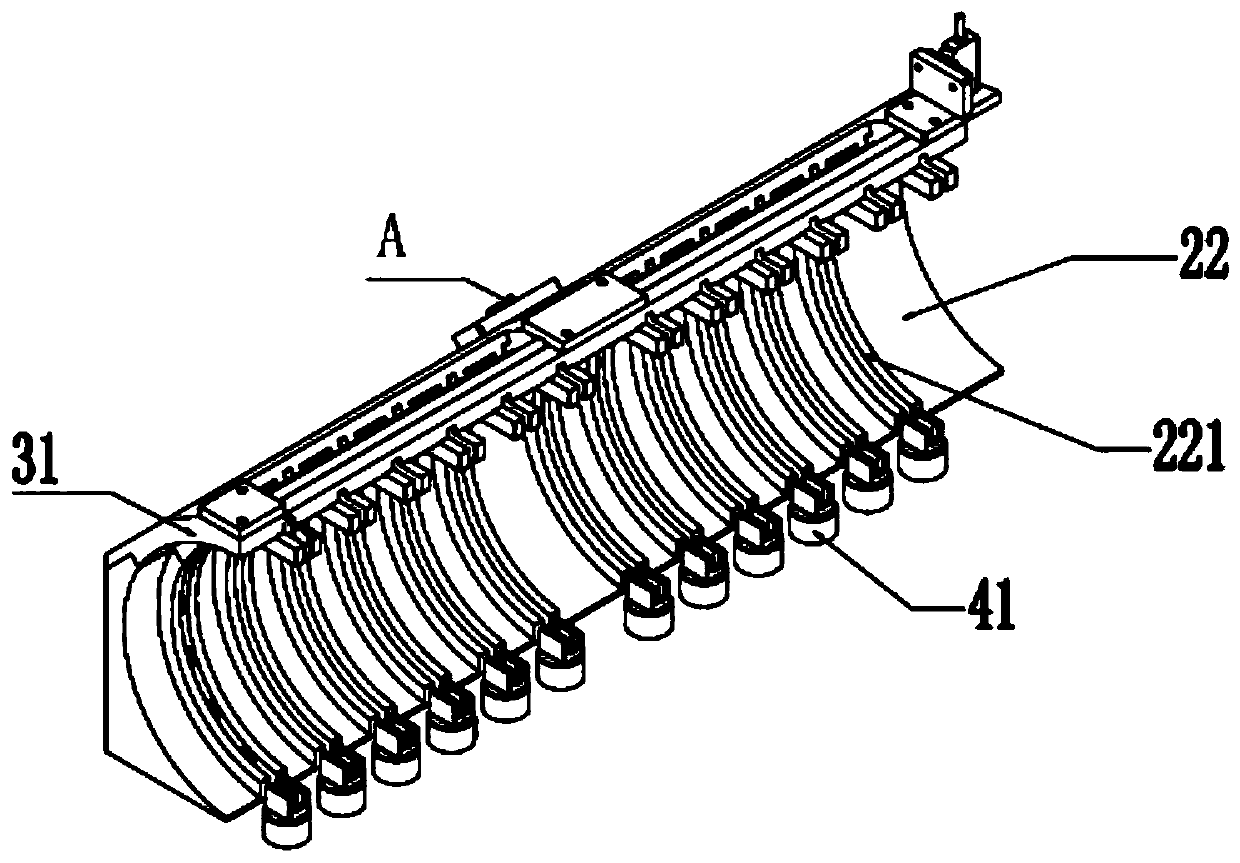

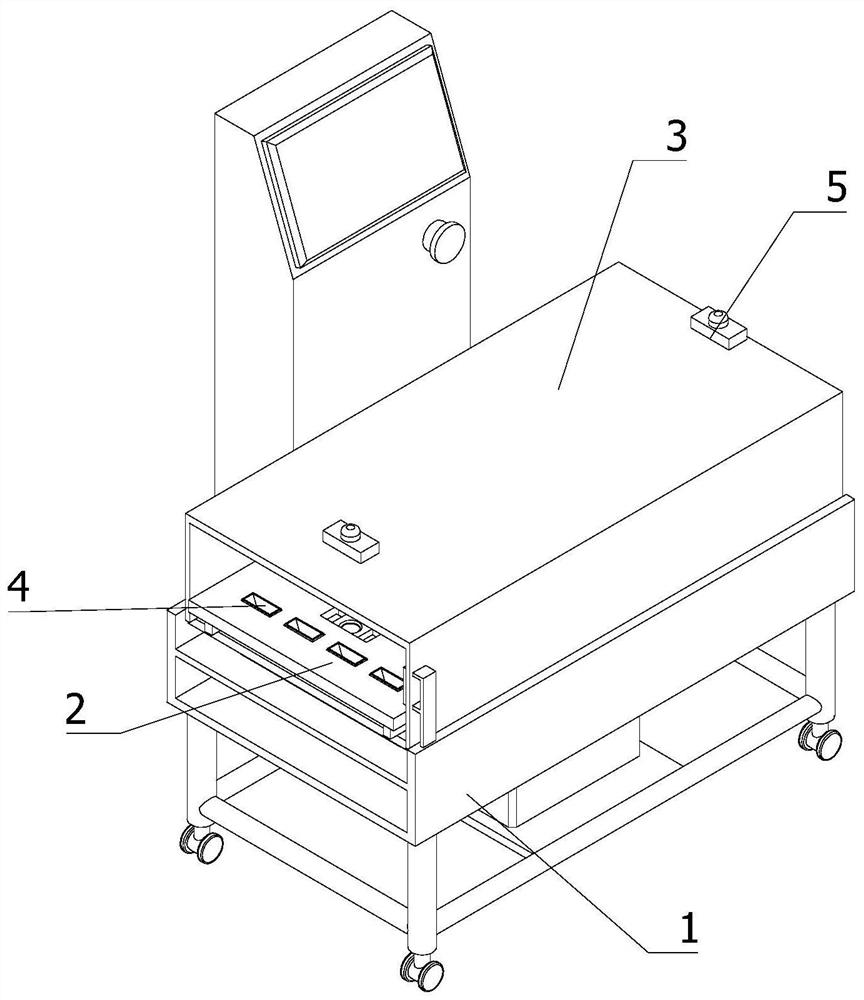

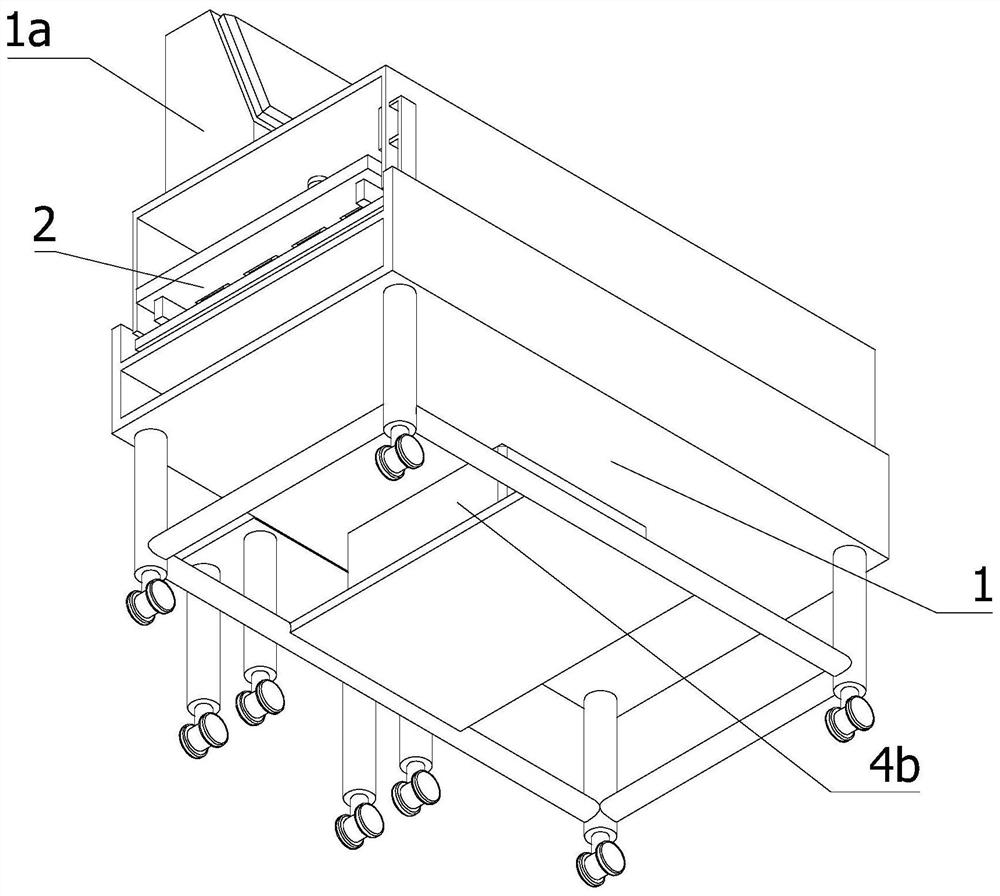

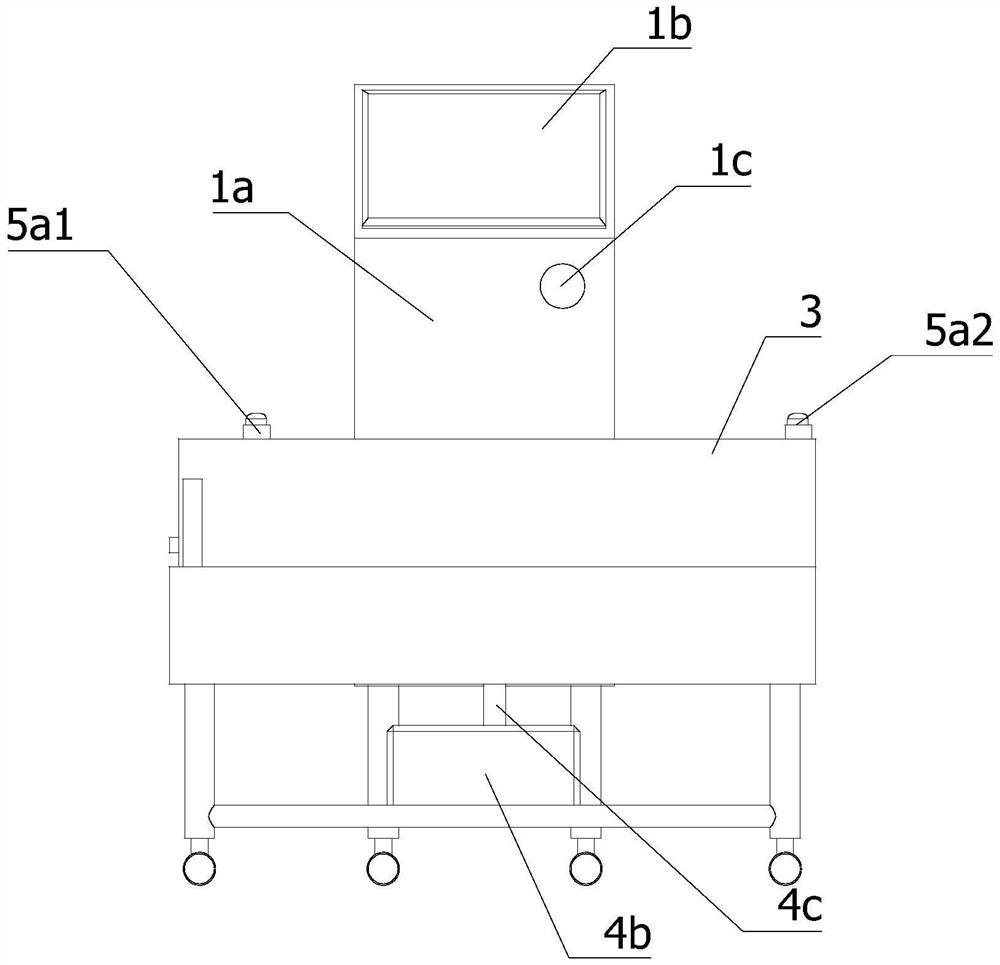

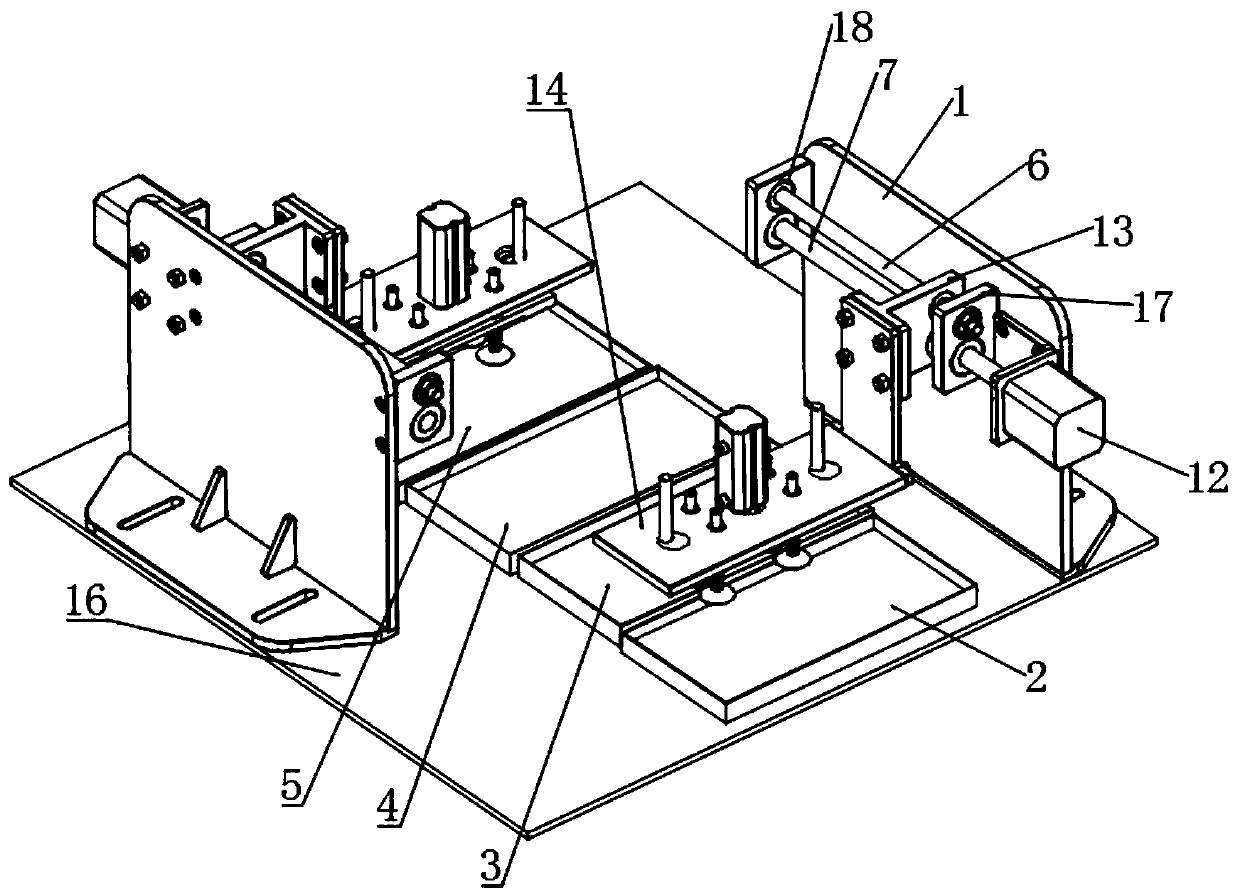

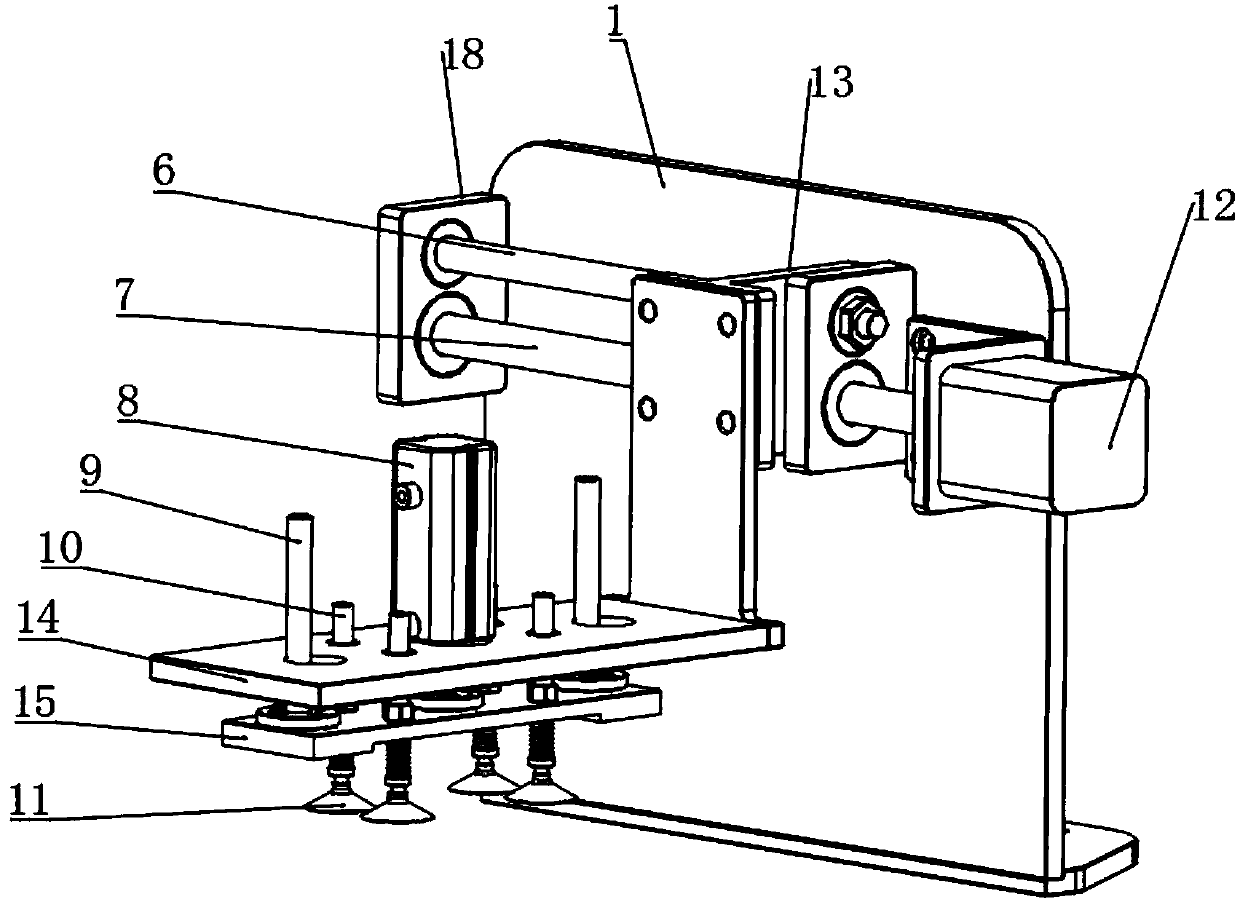

Multi-station weighing machine and method

ActiveCN105466533AShorten weighing timeFast weighingSpecial purpose weighing apparatusEngineeringMechanical engineering

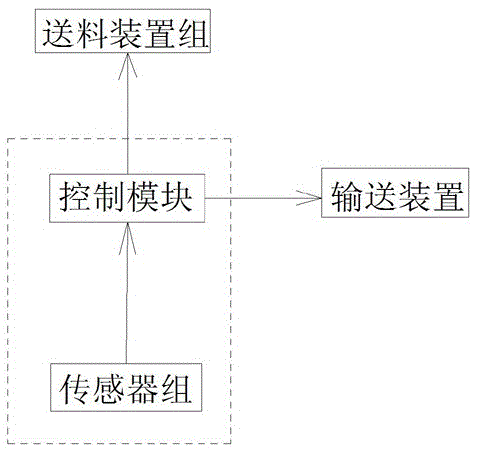

The invention discloses a multi-station weighing machine and method. The multi-station weighing machine is provided with a feeding device group, a conveying device, a material weighing container group and a control system. The feeding device group is provided with at least two feeding devices, and each feeding device is provided with a material inlet and a material outlet. The conveying device is provided with a plurality of conveying stations which are successively arranged in the arranging direction of the material outlet. The material weighing container group is composed of a plurality of material weighing containers, and each material weighing container is correspondingly installed on one conveying station. The control system is provided with a control module and a sensor group electrically connected with the control module, and the control module is electrically connected with the feeding device group and the conveying device. The multi-station weighing machine has the advantages that the weighing speed is high, the weighing precision is high, material overflow is prevented, the size is small, the cost is low, the operation is easy, the structure is simple, the maintenance is simple, etc.

Owner:ZHUHAI HUALI FRICTION MATERIAL

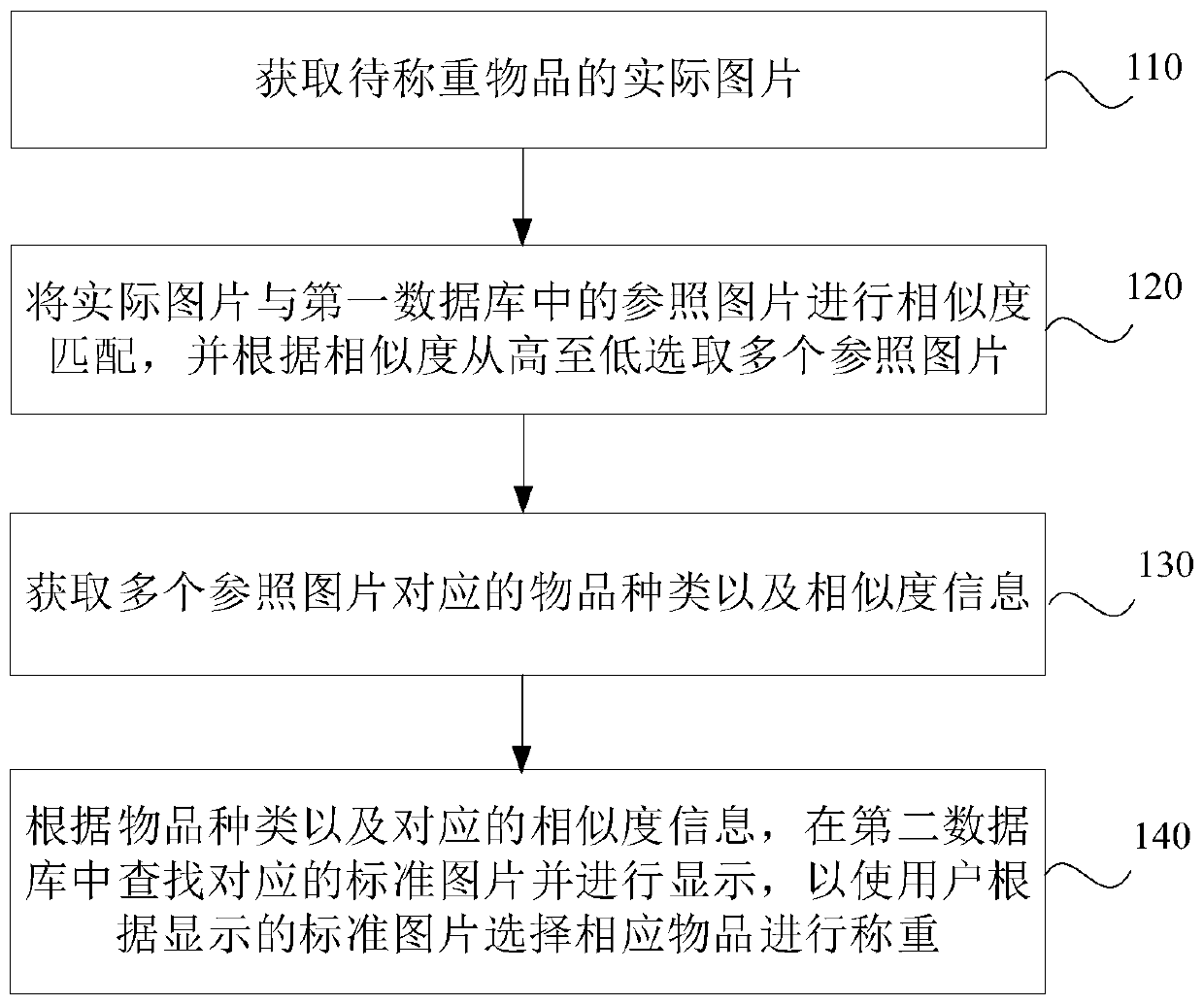

Self-service weighing method and system and computer readable storage medium

ActiveCN110793607AImprove the efficiency of self-service weighingShorten weighing timeCharacter and pattern recognitionSpecial purpose weighing apparatusEngineeringDegree of similarity

The invention relates to a self-service weighing method and system and a computer readable storage medium, wherein the self-service weighing method comprises the steps: an actual picture of a to-be-weighed object is acquired; the actual picture is subjected to similarity matching with reference pictures in a first database, and a plurality of reference pictures are selected based on similarity from high to low; object types corresponding to the plurality of reference pictures and similarity information are obtained; and corresponding standard pictures are searched in a second database and aredisplayed according to the object types and the corresponding similarity information, so that a user selects the corresponding object to be weighed according to the displayed standard picture. According to the weighing method provided by the invention, the reference pictures with relatively high similarity to the to-be-weighed objects are automatically identified for user selection, so that the self-service weighing efficiency can be improved, and the weighing time is saved.

Owner:ZHEJIANG DAHUA TECH CO LTD

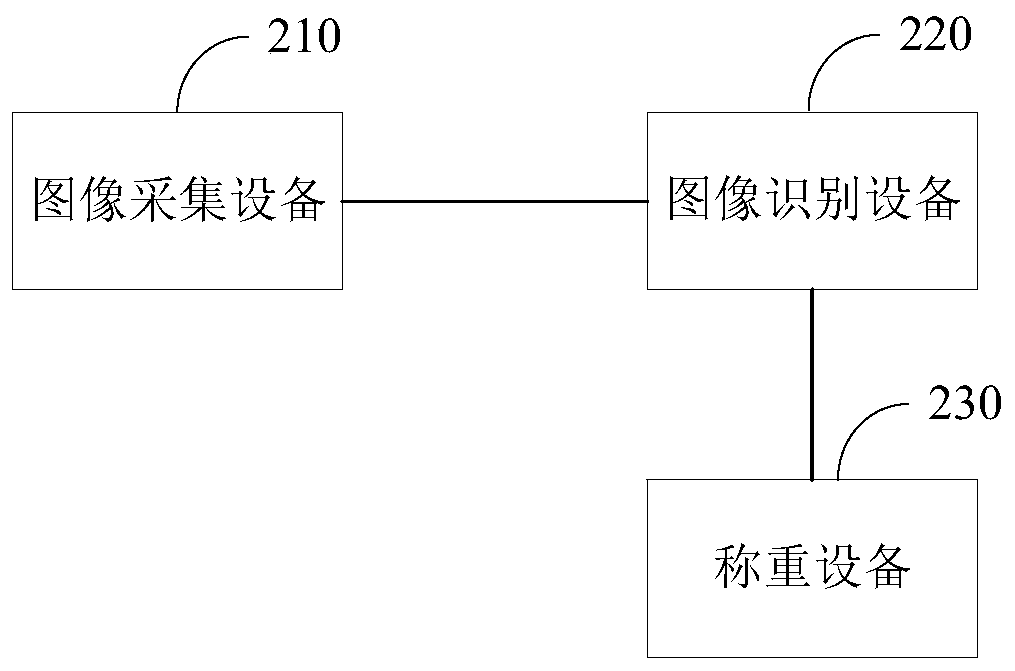

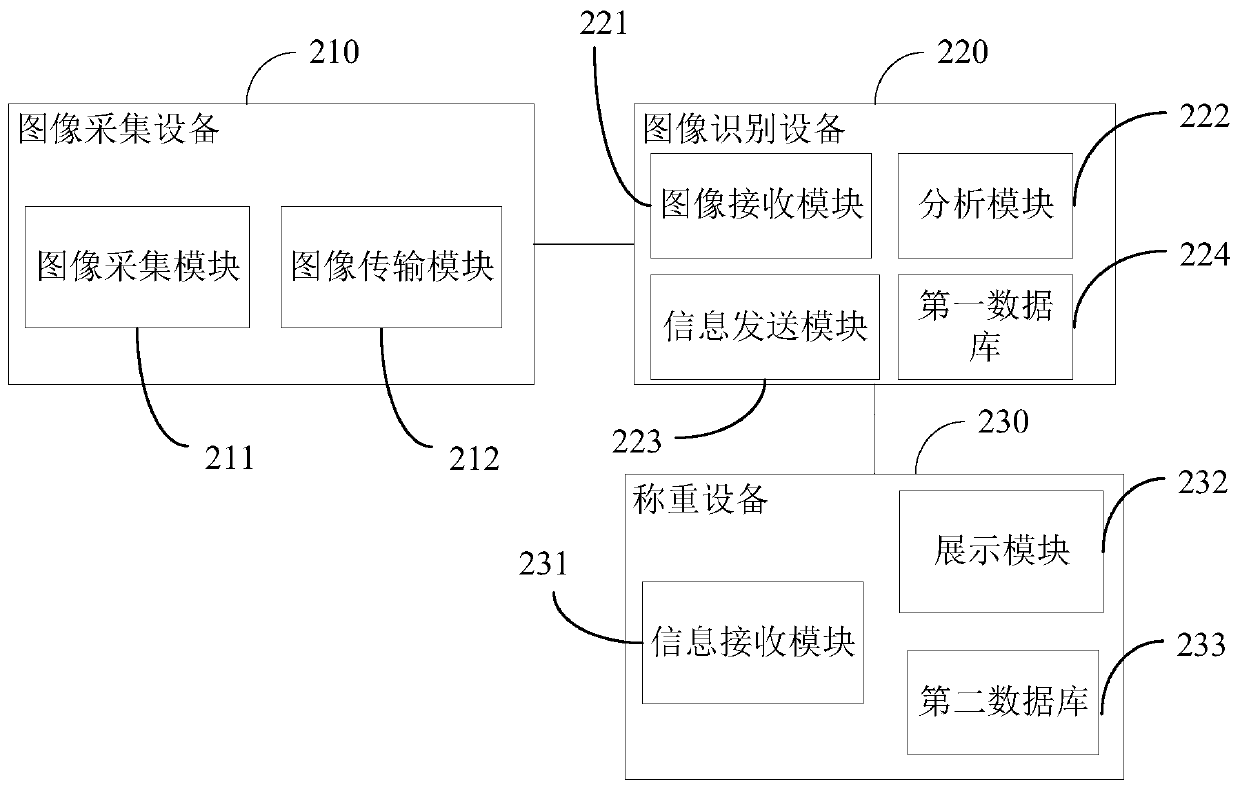

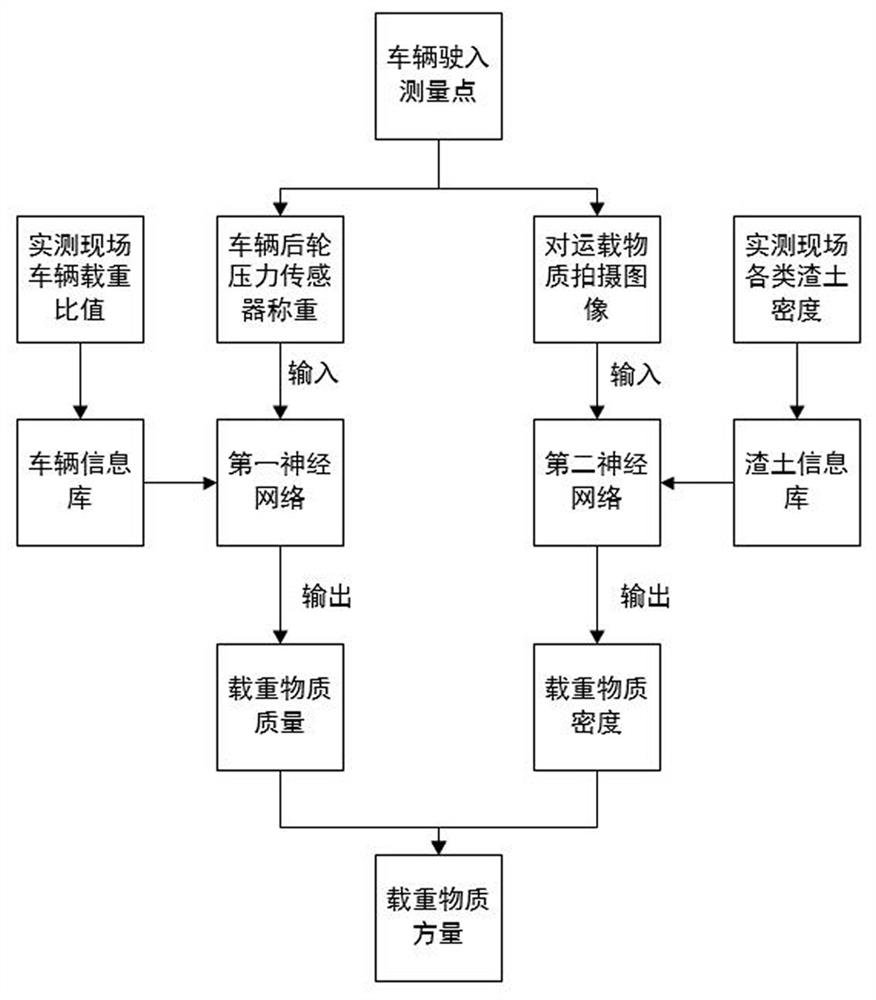

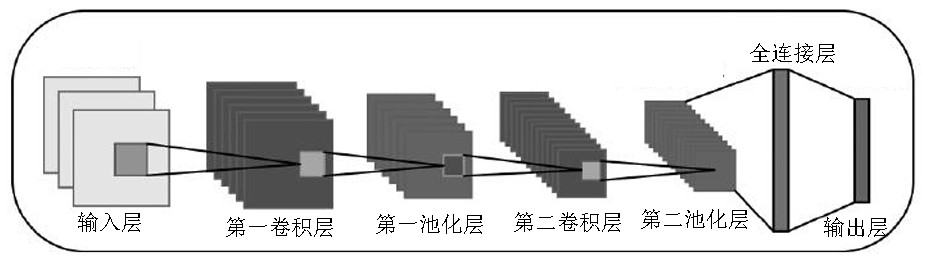

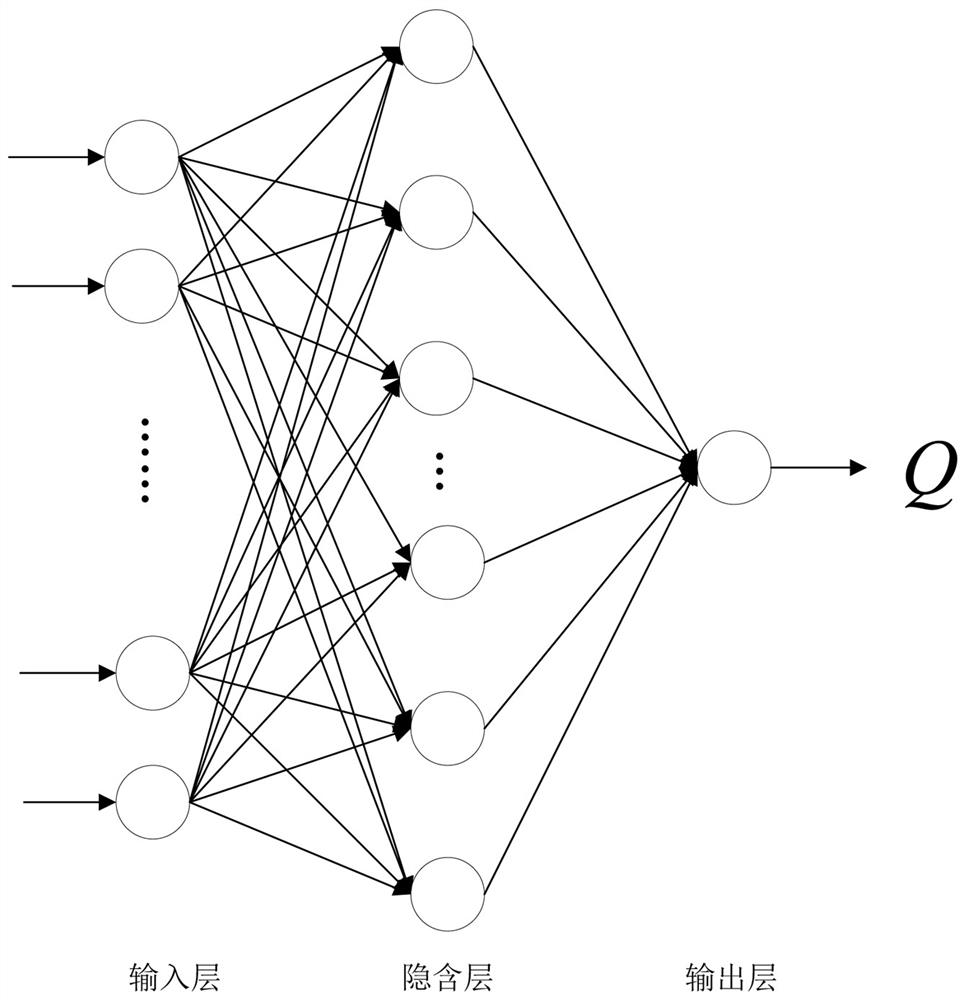

Muck truck earthwork volume calculation method based on convolutional neural network

PendingCN112232435ARealize automatic calculationImprove calculation accuracyEnsemble learningCharacter and pattern recognitionSoil scienceStructural engineering

The invention discloses a muck truck earthwork volume calculation method based on a convolutional neural network. The muck truck earthwork volume calculation method comprises the steps that rear wheels of a muck truck loaded with earthwork are weighed; a corresponding first neural network model is selected for the model of the muck truck, the rear wheel weighing value is input into the first neural network model, and the whole truck mass of muck loaded by the muck truck is obtained; the mass of the muck carried by the muck truck is calculated according to the whole truck mass of the muck loaded by the muck truck and the empty truck mass of the muck truck; an image of the muck carried by the muck truck is acquired, and the image is input into the second neural network model to obtain the density of the muck carried by the muck truck; and according to the muck mass and the muck density, the volume of muck carried by the muck truck, namely the earthwork carried by the muck truck is calculated. According to the invention, the first neural network model and the second neural network model are respectively used for calculating the weight of the whole muck truck and identifying the muck density, automatic calculation of the muck loading volume of the muck truck is achieved, manpower is replaced, time and labor are saved, and the calculation precision is high.

Owner:CHINA THREE GORGES UNIV

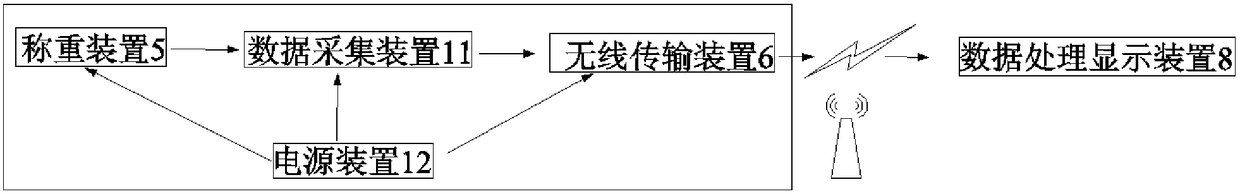

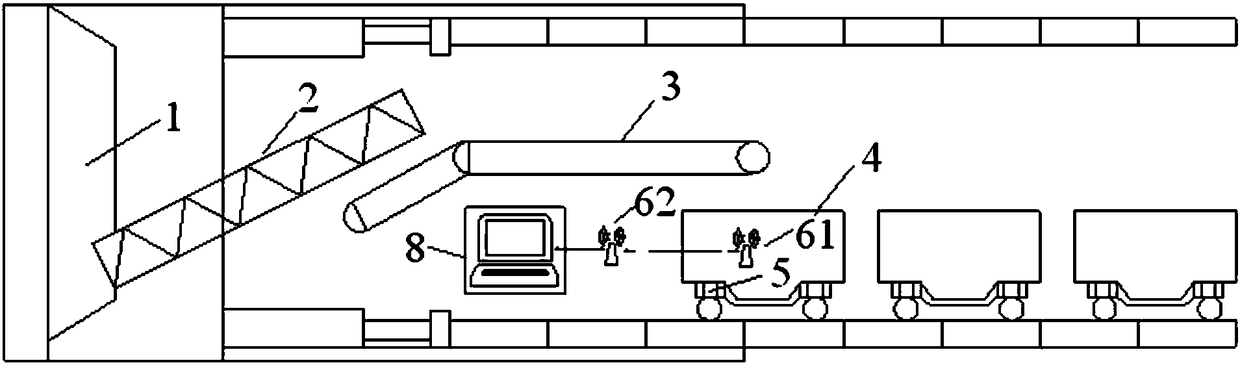

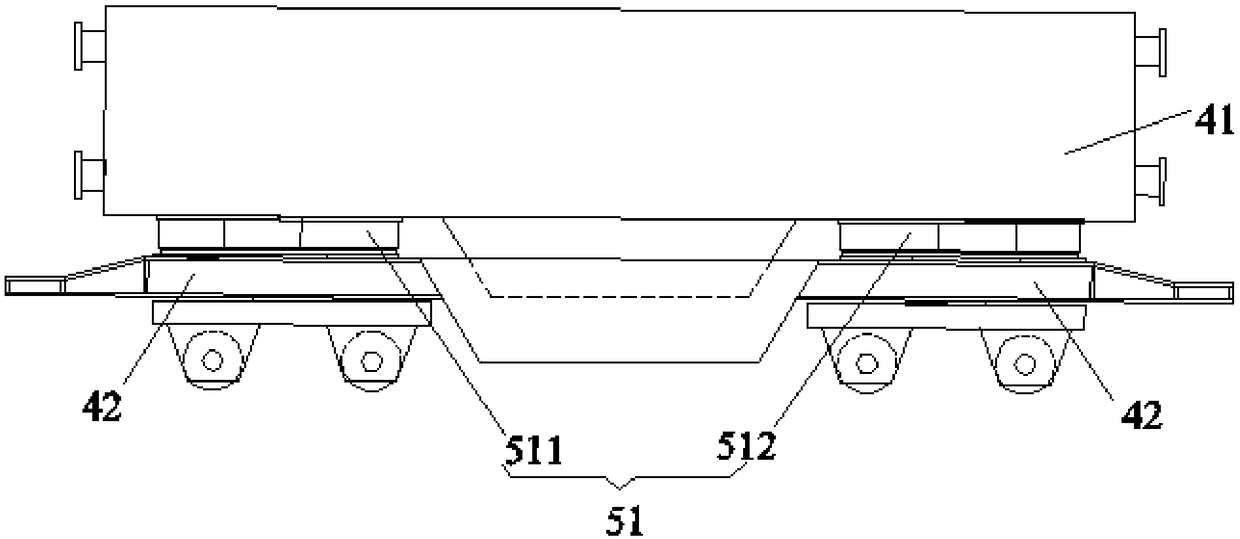

Shield tunnel engineering slag real-time weighing system and application method thereof

PendingCN108387302AShorten weighing timeAvoid lagWeighing auxillary devicesSpecial purpose weighing apparatusWireless transmissionSlag

The present invention discloses a shield tunnel engineering slag real-time weighing system and an application method thereof. The real-time weighing system comprises a weighing device, a data collection device, a wireless transmission device and a power device which are arranged below a slag hopper of a slag car, and a data processing display device arranged at a shield tunneling machine operationroom. The weighing device is configured to perform weighing of slag, the data collection device is configured to obtain weighing signals of the weighing device and transmit the data to the data processing and display device through the wireless transmission device, the data processing and display device is configured to perform processing and real-time display of the data, the power device is configured to supply power to the weighing device, the data collection device and the wireless transmission device. The application method comprises the steps of: filling slag into the slag hopper; triggering the weighing device to automatically perform weighing; obtaining the weighing signals of the weighing device through the data collection device, and transmitting the data to the processing and display device; and after the data processing and display device receives the weighing signals, converting the received weighing signals to figures, and displaying the figures on the display device.

Owner:NANNING RAIL TRANSIT +1

High-speed dynamic weighing system of automatic weight checker and work flow thereof

InactiveCN106323431AReduce labor costsSolve the problem of monopolizing the weighing platformSpecial purpose weighing apparatusHuman–machine interfaceMan machine

The invention discloses a high-speed dynamic weighing system of an automatic weight checker. The system comprises a dynamic weighing unit, a photoelectric sensor, a weighing sensor, a microprocessor circuit and a man-machine interface. The invention further discloses a work flow of the high-speed dynamic weighing system of the automatic weight checker. The high-speed dynamic weighing system of the automatic weight checker settles a problem of scale platform occupation by a single product in weighing by an existing automatic weight checker, and determines whether to start weighing of a next product through intelligent determining to a product state in the weighing process. Through the algorithm of the high-speed dynamic weighing system, the automatic weight checker allows overlapping of the product on the scale platform, thereby reducing weighing time of the single product, improving productivity, reducing labor cost of enterprise employees, and realizing wide application prospect.

Owner:上海芝研检测技术有限公司

Material weighing device and method

The invention discloses a material weighing device. The material weighing device comprises a rack. A hopper, a weighing hopper, a feeding mechanism and a feeding bin are arranged on the rack. A discharging mechanism is arranged in the weighing hopper and comprises taking-out hoppers and a discharging mechanism body. The multiple taking-out hoppers are different in size and are arranged on tracks with which materials on the feeding mechanism fall on the weighing hopper. The discharging mechanism body controls the materials in the taking-out hoppers to fall into the weighing hopper. According to the material weighing device and a material weighing method, a taking-out method is adopted, and the accurate materials are finally discharged; when the whole device runs, as a low-speed feeding link is removed, the weighing time is greatly saved, and the packaging efficiency is improved; although a discharging device is designed and a part of cost is increased, the material weighing accuracy is greatly improved, the automation degree is high, the indexes of the whole industry are increased, and the large market value is achieved.

Owner:李宝建

Balancing magnetic weighing instrument

InactiveCN1477377AReduced deformation rangeNo mechanicsWeighing apparatus using electromagnetic balancingMagnetic tension forceEngineering

The present invention relates to a balance magnetized weighing instrument for displaying weight of body by utilizing current of balance magnetized electromagnetic force. In its structure it utilizes light to detect the deformation of the elastic element, and the detected photoelectric signal is amplified to produce electromagnetic force to resist the deformation of the elastic element, and the intensity of the current of the electromagnetic force can be used for representing the weight of body, so that its weighing speed is quick and weighing result is accurate.

Owner:上海虎能电器有限公司

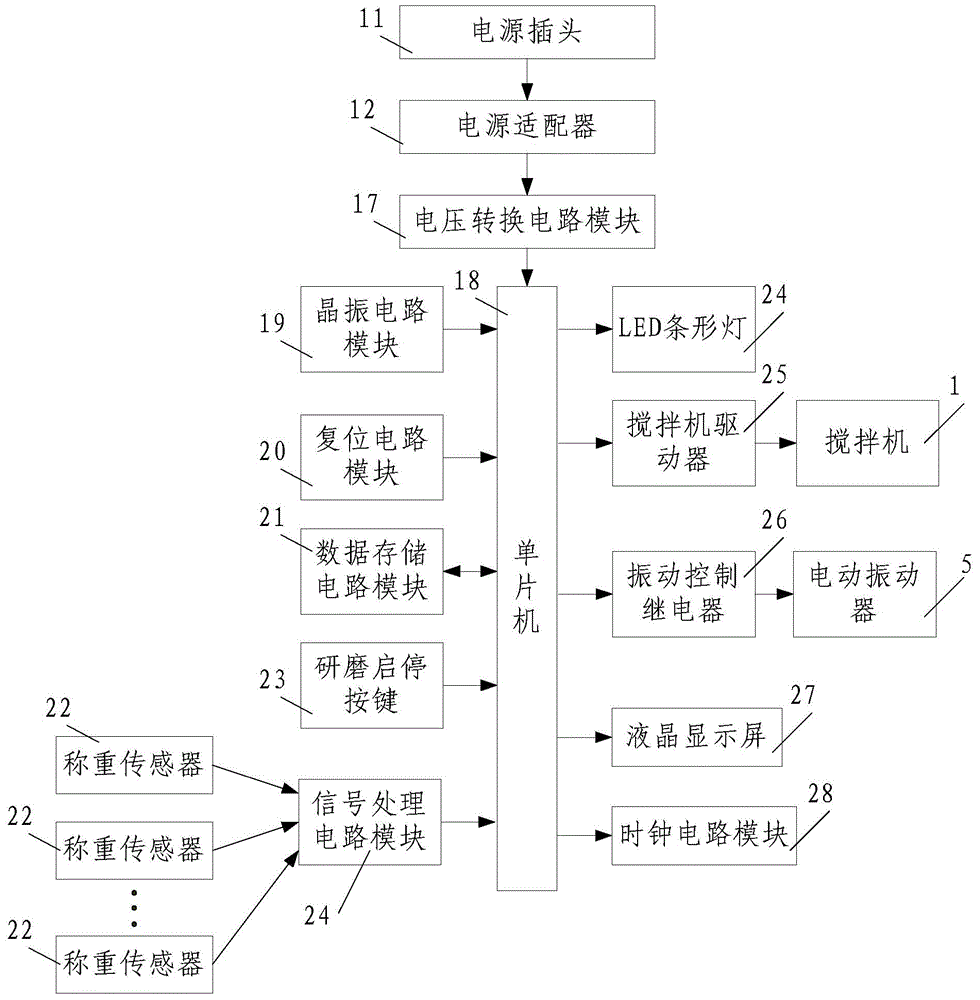

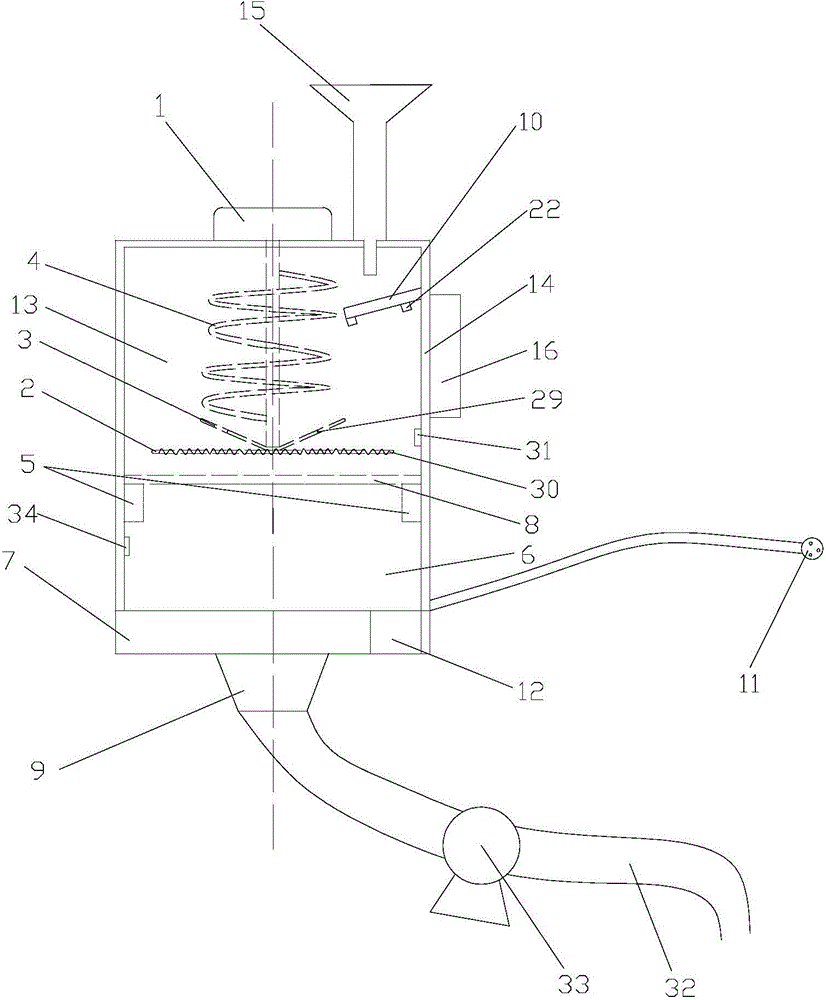

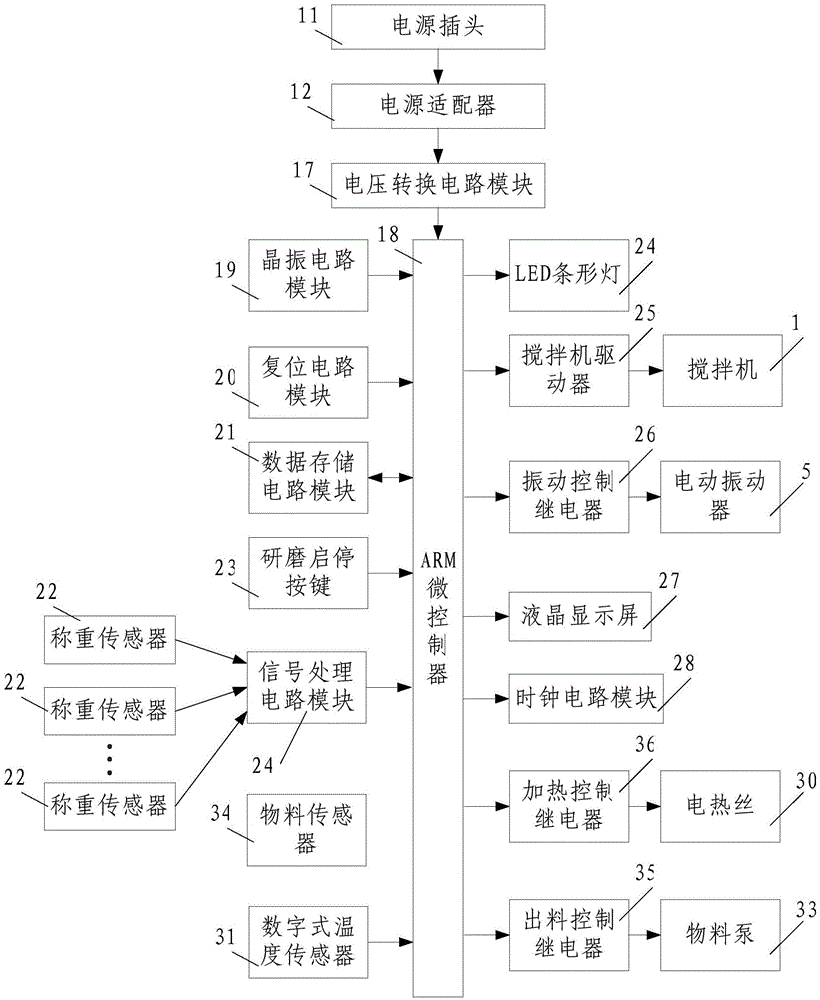

Automatic coarse cereal food flour mill with automatic weighing function

InactiveCN105728124ASimple structureReasonable designGrain treatmentsMicrocontrollerVibration control

The invention discloses an automatic coarse cereal food flour mill with an automatic weighing function. The automatic coarse cereal food flour mill comprises a coarse cereal food flour mill main body and a coarse cereal food flour mill controller. The coarse cereal food flour mill main body comprises a frame, a casing, a feeding hopper, a stirrer, a stirring propeller, a stirring breaking cutter, a cutter head, a weighing plate, multiple weighing sensors, a filter sieve, an electric vibrator, a material outlet, a power adapter and a battery socket. The coarse cereal food flour mill controller comprises a singlechip, a voltage conversion circuit module, a crystal oscillation circuit module, a reset circuit module, a data storage circuit module, grinding starting and stopping keys, a clock circuit module, a signal processing circuit module, a LED, a stirrer driving device and a vibration control relay. The automatic coarse cereal food flour mill has a simple structure and a reasonable design, is convenient for implementation, has a low cost, can be operated conveniently, is healthy and environmentally friendly, has high milling efficiency, good effects and good practicability and is convenient for promotion and application.

Owner:XIAN ZHONGZHI HUIZE PHOTOELECTRIC TECH

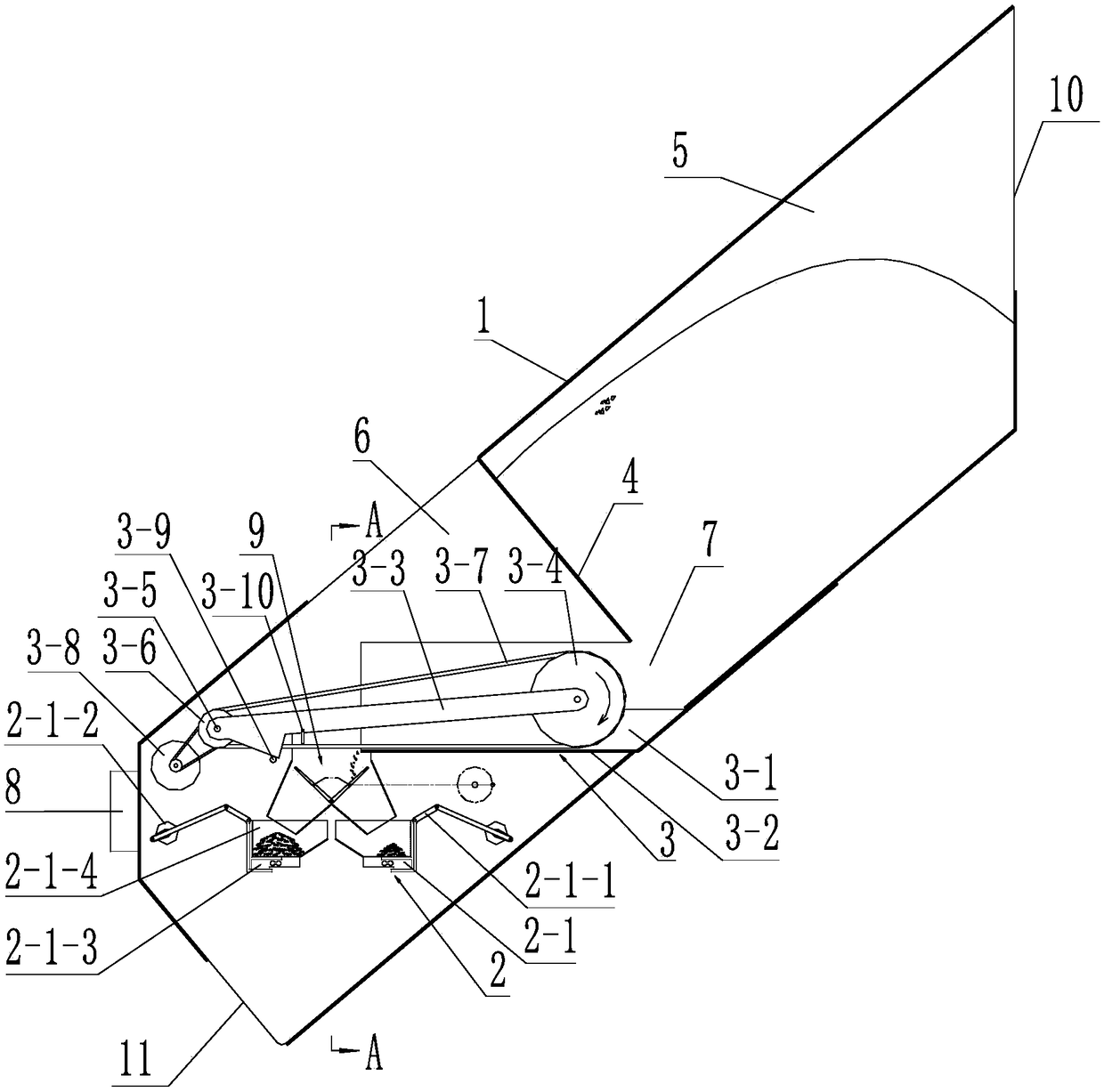

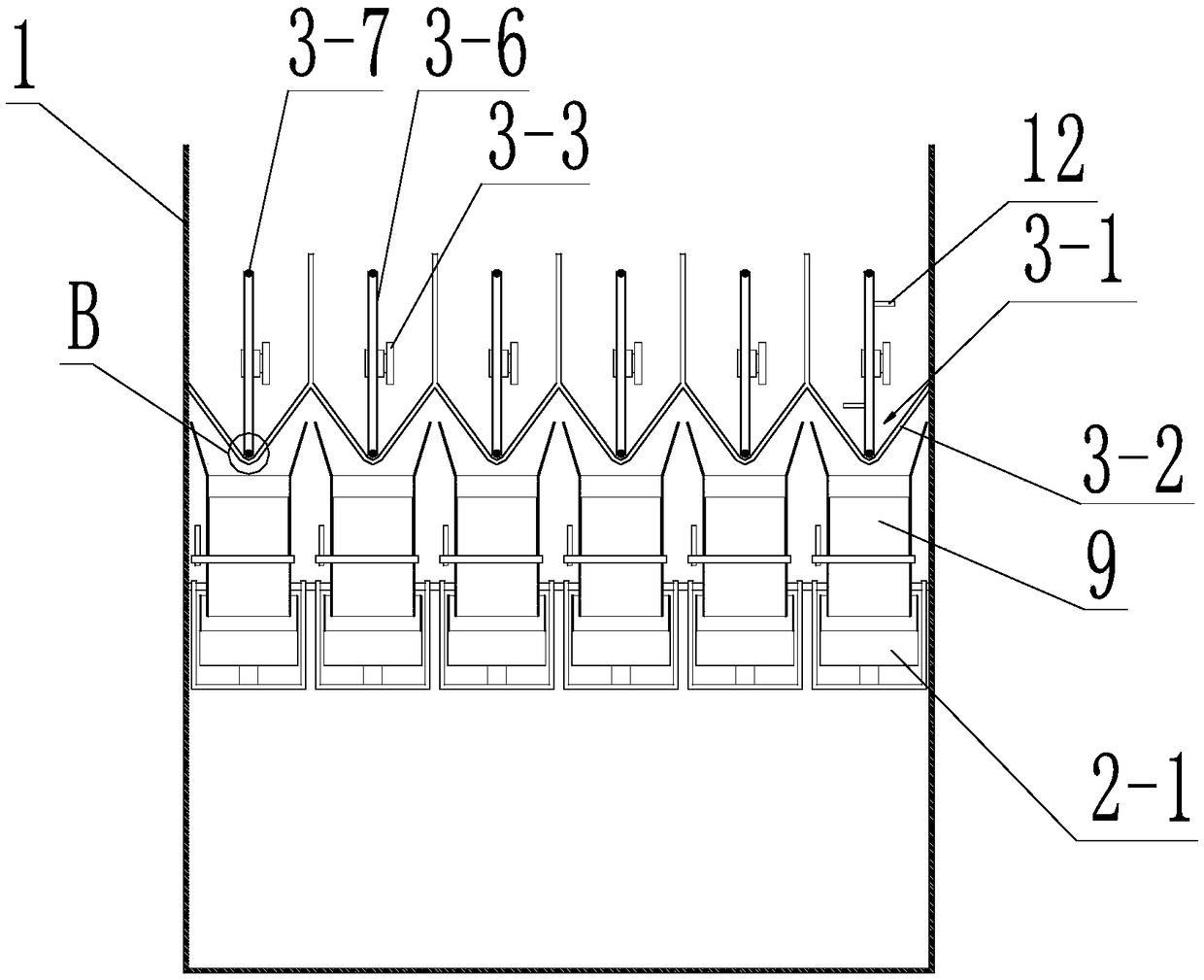

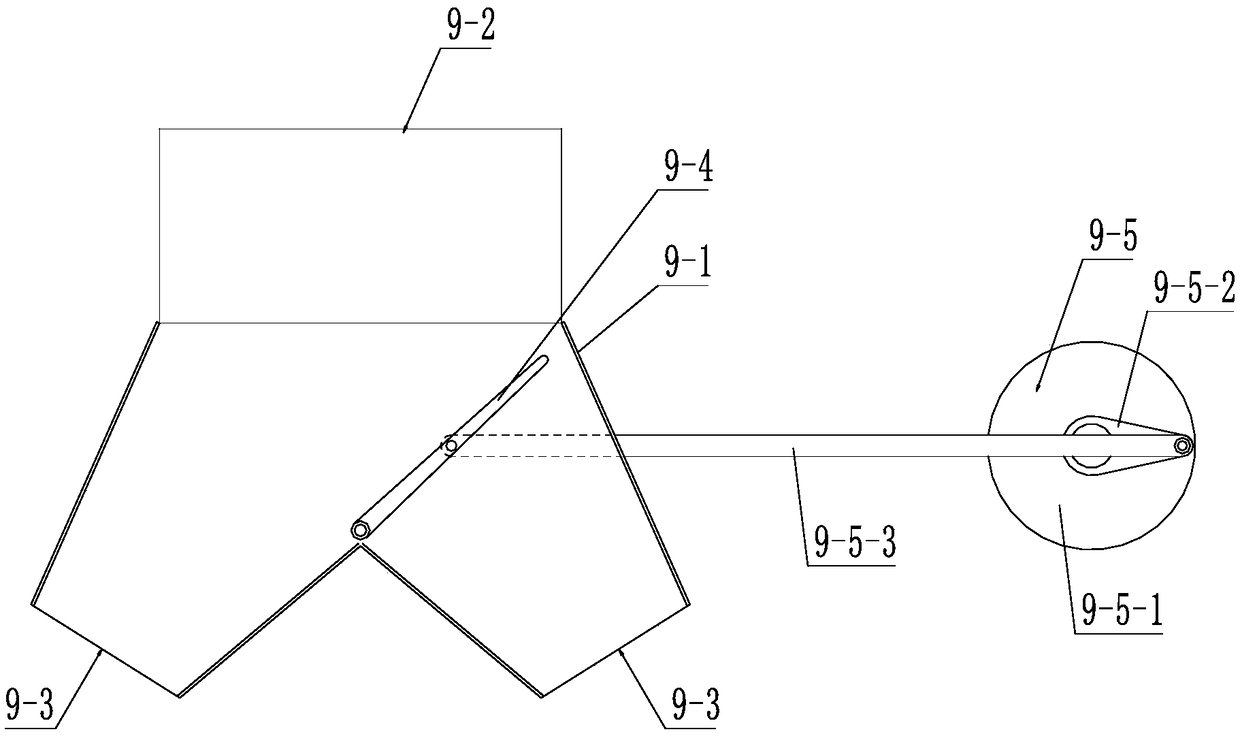

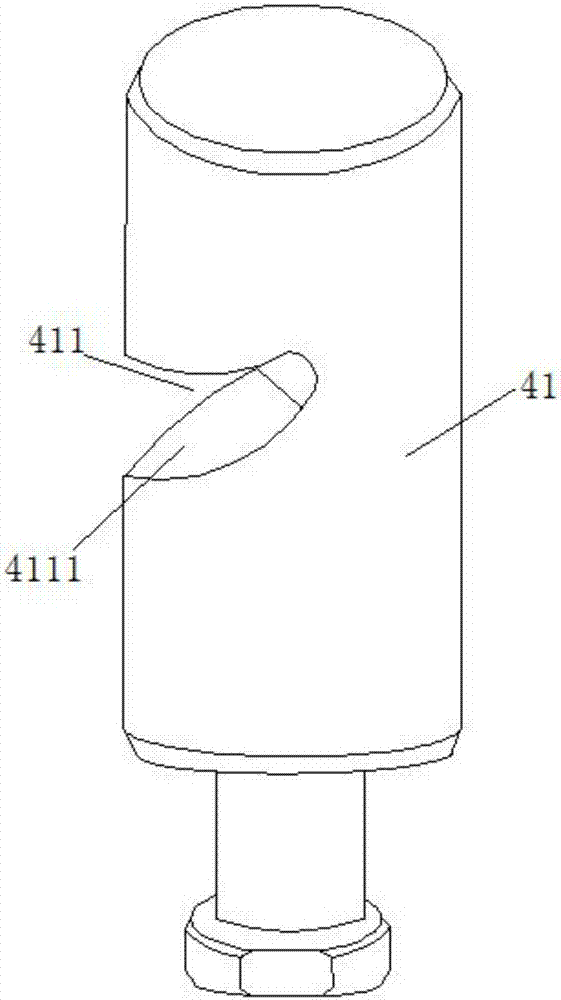

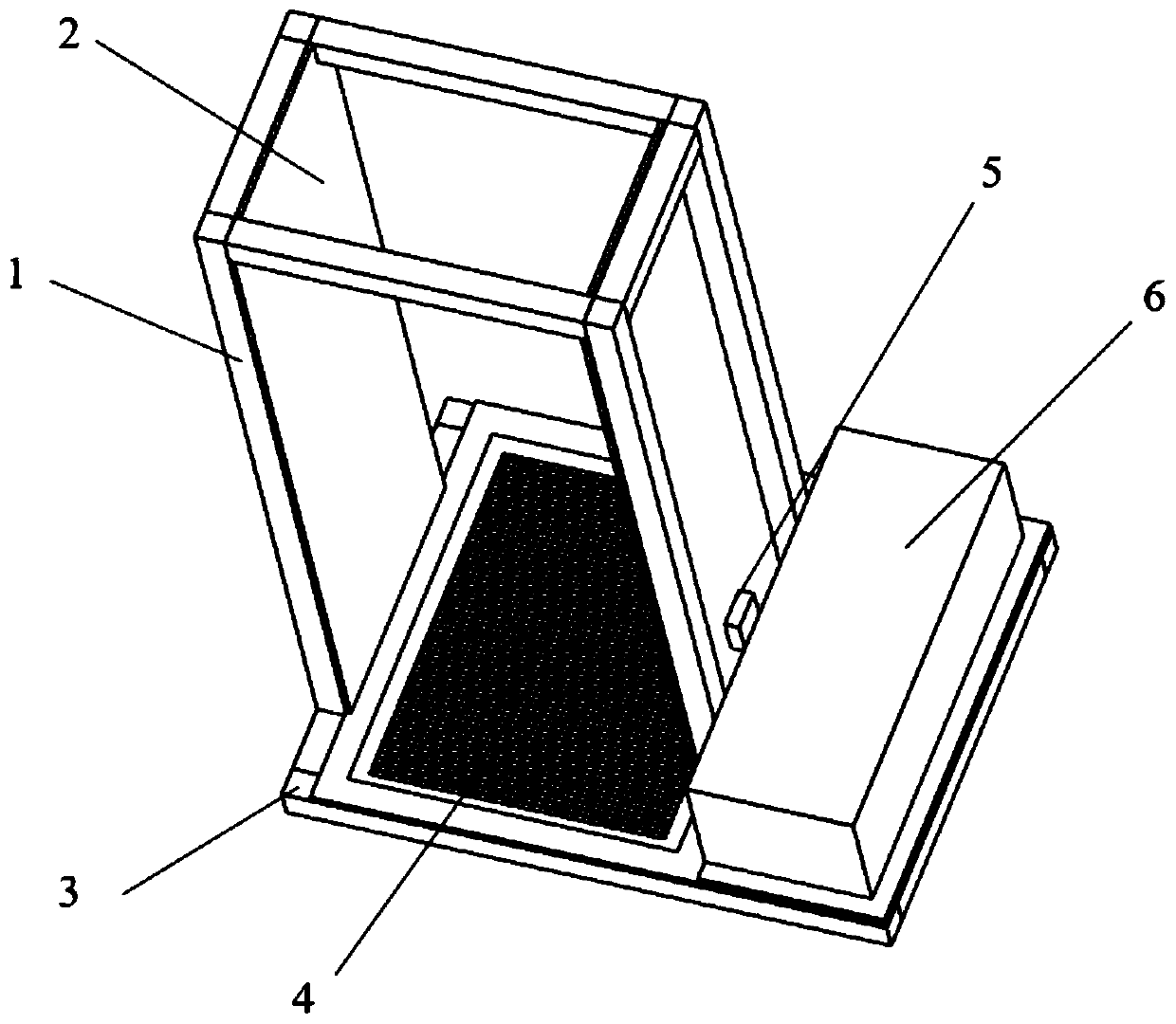

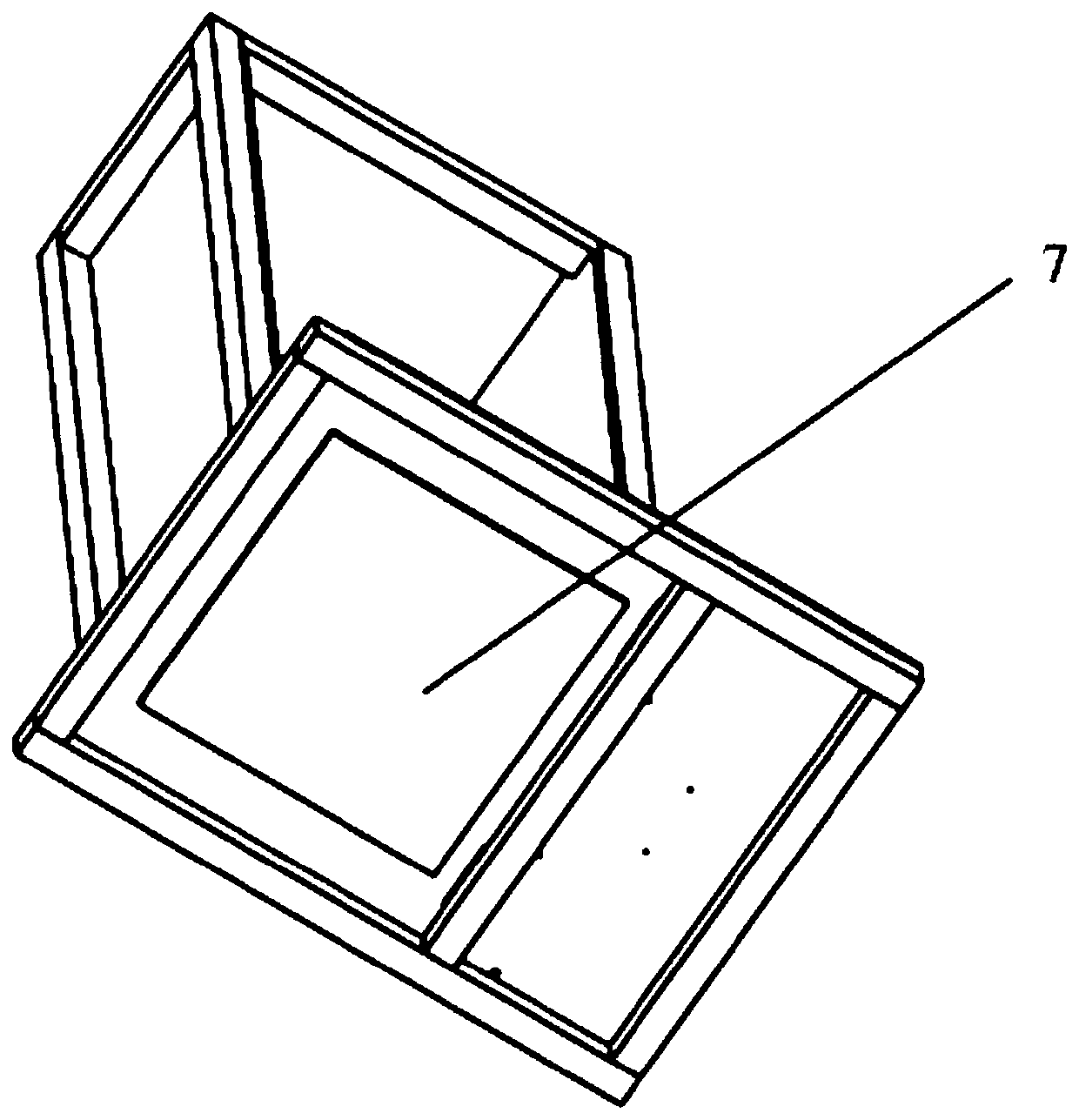

Automatic weighing unit bin and automatic weighing method for bulk traditional Chinese medicine decoction pieces

PendingCN109141591AWeighing time shortenedReduced weighing accuracyWeighing apparatus with automatic feed/dischargeMedicineTraditional Chinese medicine

The invention relates to an automatic weighing unit bin and an automatic weighing method for bulk traditional Chinese medicine decoction pieces. The unit bin includes a medicine bin, a weighing systemand a medicine supply device. The upper part of the medicine bin is a medicine storage chamber. The bottom of the medicine storage chamber is provided with a medicine outlet. The medicine supply device transfers traditional Chinese medicine in the medicine storage chamber to the weighing system for weighing. The weighing system is composed of a plurality of weighing devices. Each weighing deviceindividually weighs. The medicine supply device separately supplies the medicine for each weighing device. The weighing method adopts a method of weighing with multiple weighing devices based on the unit bin so as to improve the weighing speed, calculates a weighing tray combination that meets total quality requirements of the traditional Chinese medicine by arrangement and combination of some ofthe weighing trays, and simultaneously discharges the medicine for the weighing trays in the combination to obtain a dose of the traditional Chinese medicine that meets weight requirements. The weighing efficiency of the traditional Chinese medicine decoction pieces can be effectively improved by using the unit bin and the weighing method.

Owner:张家港建辰机械科技有限公司

Household intelligent small-sized flour mill

InactiveCN105728151ASimple structureReasonable designGrain treatmentsVibration controlSignal processing circuits

The invention discloses a household intelligent small-sized flour mill which comprises a whole grain food flour mill body and a whole grain food flour mill controller, wherein the whole grain food flour mill body comprises an engine base, a shell, a feeding hopper, a stirring machine, a spiral stirring impeller, a stirring crushing head, a heating wire, a digital temperature sensor, a weighing plate, a plurality of weighing sensors, a filter sieve, an electric vibrator, a material outlet, a material output hose, a material pump, a power adapter and a power plug; and the whole grain food flour mill controller comprises an ARM microcontroller, a data storage circuit module, a grinding starting-stopping button, a clock circuit module, a signal processing circuit module, a material sensor, a liquid crystal display, a stirring machine driver, a vibration control relay, a discharge control delay and a heating control delay. According to the household intelligent small-sized flour mill, the design is reasonable, the implementation is convenient, the cost is low, the utilization operation is convenient, health and environmental protection are achieved, the four milling efficiency is high, the effect is good, the practicability is high, and popularization and application are facilitated.

Owner:XIAN ZHONGZHI HUIZE PHOTOELECTRIC TECH

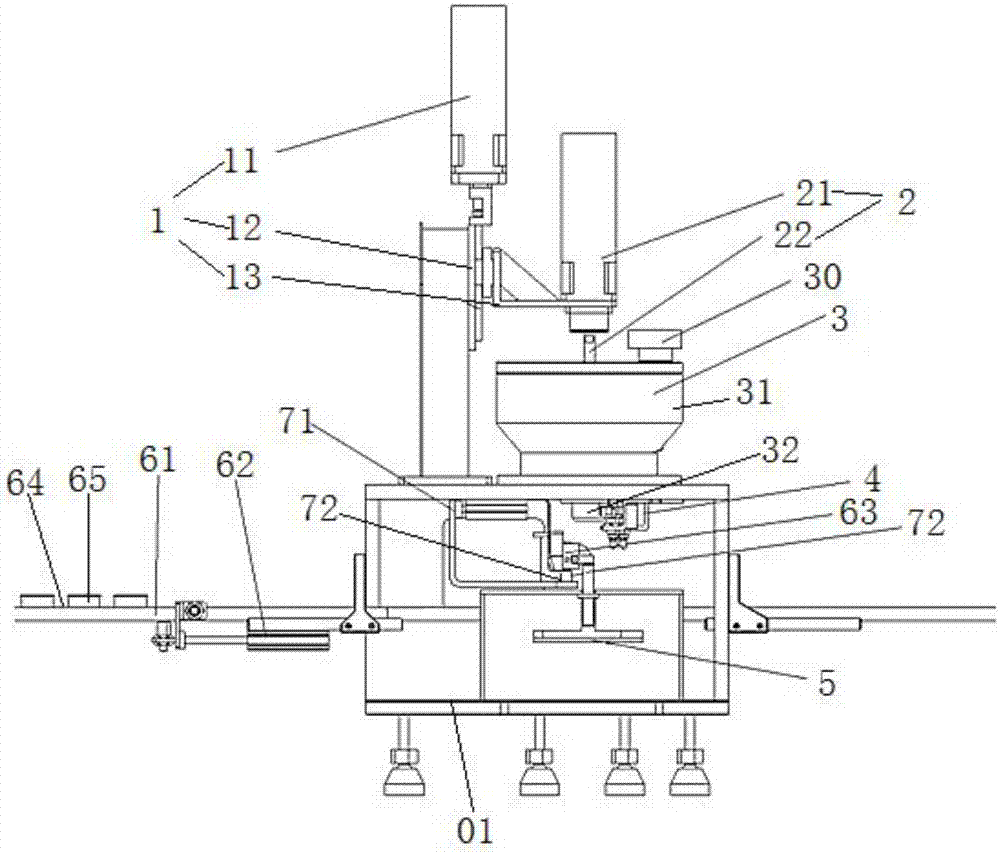

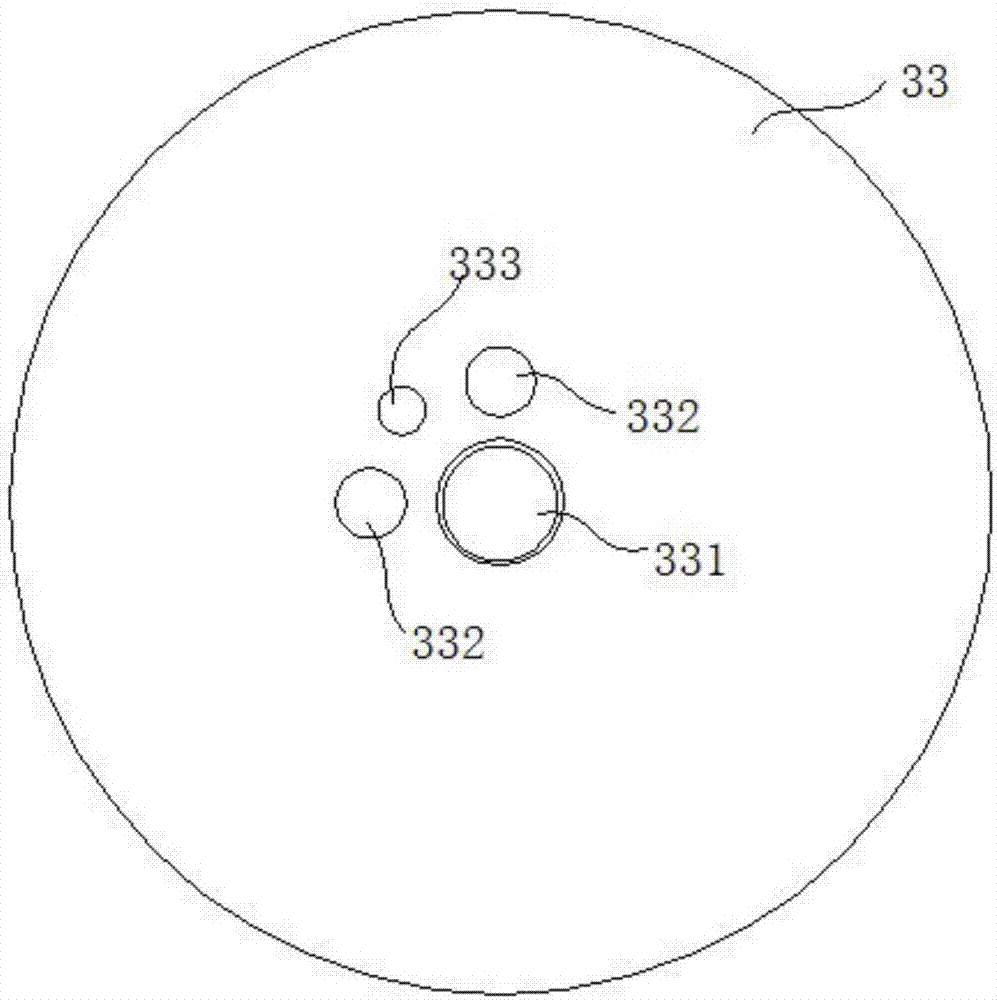

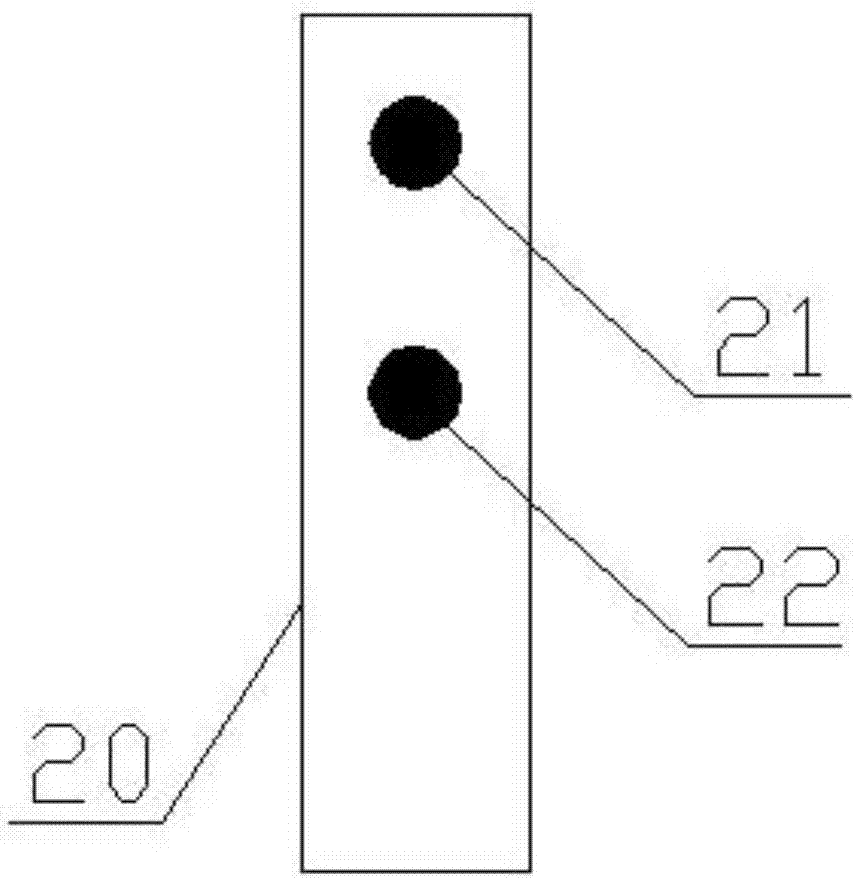

Automatic microscale throttling powder weighing device and weighing method

ActiveCN107144328AEfficient automatic weighing toolPrecise automatic weighing toolBio-packagingWeighing apparatus for materials with special property/formTransfer mechanismAutomation

The invention relates to the technical field of automatic metering and specifically relates to an automatic microscale throttling powder weighing device and weighing method. The device includes a device body and a material holding mechanism and a weighing mechanism arranged on the device body. The upper part of the material holding mechanism is provided with a lift mechanism and a stirring mechanism whose height adjustment is performed by the lift mechanism. The lower part of the material holding mechanism is provided with a hopper transfer mechanism. The material holding mechanism includes a material holding bin and a material collecting ring, a material adding hopper arranged on the upper part of the material accommodating bin and a throttling device arranged in the bottom of the material accommodating bin. The throttling device is provided with a throttling hole. The hopper transfer mechanism includes a transfer hopper. The weighing mechanism includes a weighing support and an electronic scale. The weighing support is connected with the transfer hopper and the electronic scale. The electronic scale realizes powder weighing through weighing weight change of the transfer hopper. The scheme provided by the invention has technical features of high weighing automation level, high weighing efficiency and good weighing accuracy for microscale weighing of power-shaped solid.

Owner:西安航晨机电科技股份有限公司

Small product weighing device

PendingCN111174879AGuaranteed accuracyShorten weighing timeWeighing apparatus with automatic feed/dischargeSortingControl cellProcess engineering

The invention relates to a small product weighing device. The device comprises a feeding mechanism, a conveying and transferring mechanism, a fragment removing mechanism and a weighing mechanism, wherein the feeding mechanism comprises a hopper, a stirring mechanism and a sequencing mechanism, the conveying and transferring mechanism comprises a transferring hub, a guiding seat and a servo motor,the fragment removing mechanism comprises a guiding fork, a triggering mechanism, an air blowing device and a collecting box a, and the weighing mechanism comprises a weighing platform and a weighingsensor; the discharging mechanism comprises a discharging sliding groove a, a discharging sliding groove b, a removing door, a collecting box b and a collecting box c; the device further comprises a control unit, the trigger mechanism and the weighing sensor transmit signals to the control unit, the control unit can send instructions to the air blowing device, the servo motor and the removing door, and products meeting the weight requirement and products not meeting the weight requirement are separated. The problem that disturbance airflow is generated around the weighing platform due to vacuum leakage and the problem that the production efficiency is affected due to the fact that the stabilization time is long when small products are weighed are solved.

Owner:SHANGHAI QUNTIN-TECH CO LTD

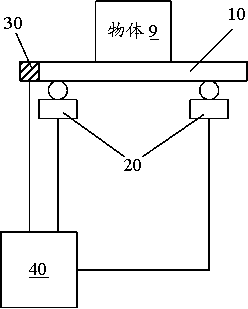

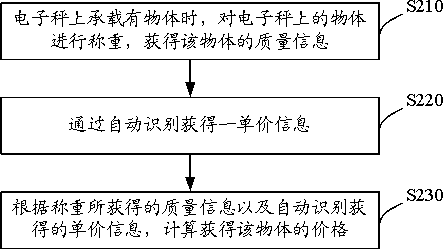

Electronic scale and pricing method thereof

InactiveCN104165678AReduce laborReduce labor intensitySpecial purpose weighing apparatusTotal priceLoad cell

The invention discloses an electronic scale and a pricing method of the electronic scale. The defects that when an existing electronic scale is used, because unit price codes need to be manually input, the labor amount is large, efficiency is low, and error is likely to happen. The electronic scale comprises a scale body, a weighing sensor, a recognizer and a load measuring device, wherein the weighing sensor is arranged to weigh articles on the scale body when the scale body bears the articles so that mass information of the articles can be obtained, the recognizer is arranged to recognize the obtained unit price information, and the load measuring device is arranged to obtain the price of the articles according to the mass information and the unit price information. Due to the electronic scale and the pricing method of the electronic scale, the unit price information of the articles on the electronic scale can be automatically obtained, the price is automatically calculated according to the unit price information, the labor amount and the labor intensity of a user can be substantially reduced, weighing time is obviously shortened, operating efficiency is remarkably improved, the error probability is reduced in the weighing and pricing process, and accuracy of the unit price information and the total price is guaranteed.

Owner:QINGDAO SHANGHUI INFORMATION TECH

Electronic weighing medicine spoon device

InactiveCN110918151AEasy, quick and efficient operationEasy to operate and controllableSpatulasSpecial purpose weighing apparatusElectrical connectionStress sensors

The invention relates to an electronic weighing medicine spoon device. A first assembly is of a shell-shaped structure with an opening in one end, and supporting parts are arranged at the opening of the first assembly in longitudinal symmetry. One end of a second assembly is arranged in the first assembly in a penetrating mode, the second assembly is in multi-point contact or linear contact with the supporting parts of the first assembly, and a medicine spoon fixing part is arranged at the other end of the second assembly and used for fixing a medicine spoon. A pressure sensor, an integrated circuit board and a power source are arranged in the first assembly, and a display screen and a switch are arranged on the shell of the first assembly. The pressure sensor is fixed in the first assembly and arranged above the end, located in the first assembly, of the second assembly. The integrated circuit board is in power supply connection with the power source. and the integrated circuit boardis electrically connected with the pressure sensor, the display screen and the switch. The device is convenient, quick and efficient to operate, and is simpler, more convenient and controllable in operation than decrement weighing when being used for weighing a reagent which is easy to deteriorate in air, so that the weighing time is shortened, and the weighing error is reduced.

Owner:FUJIAN NORMAL UNIV

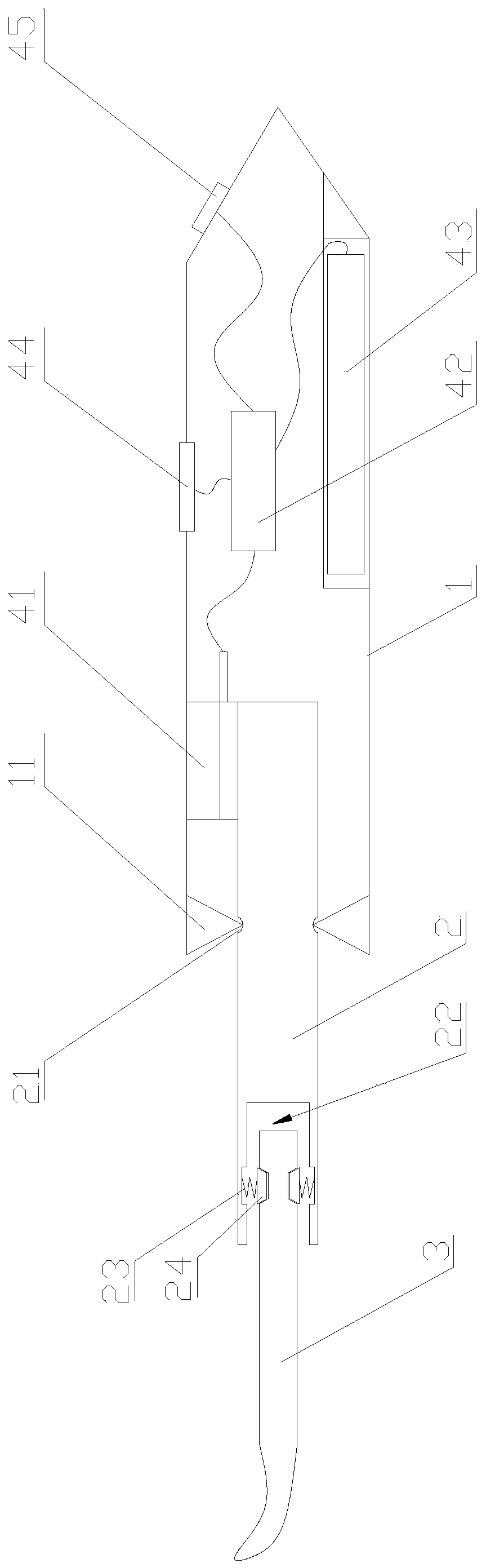

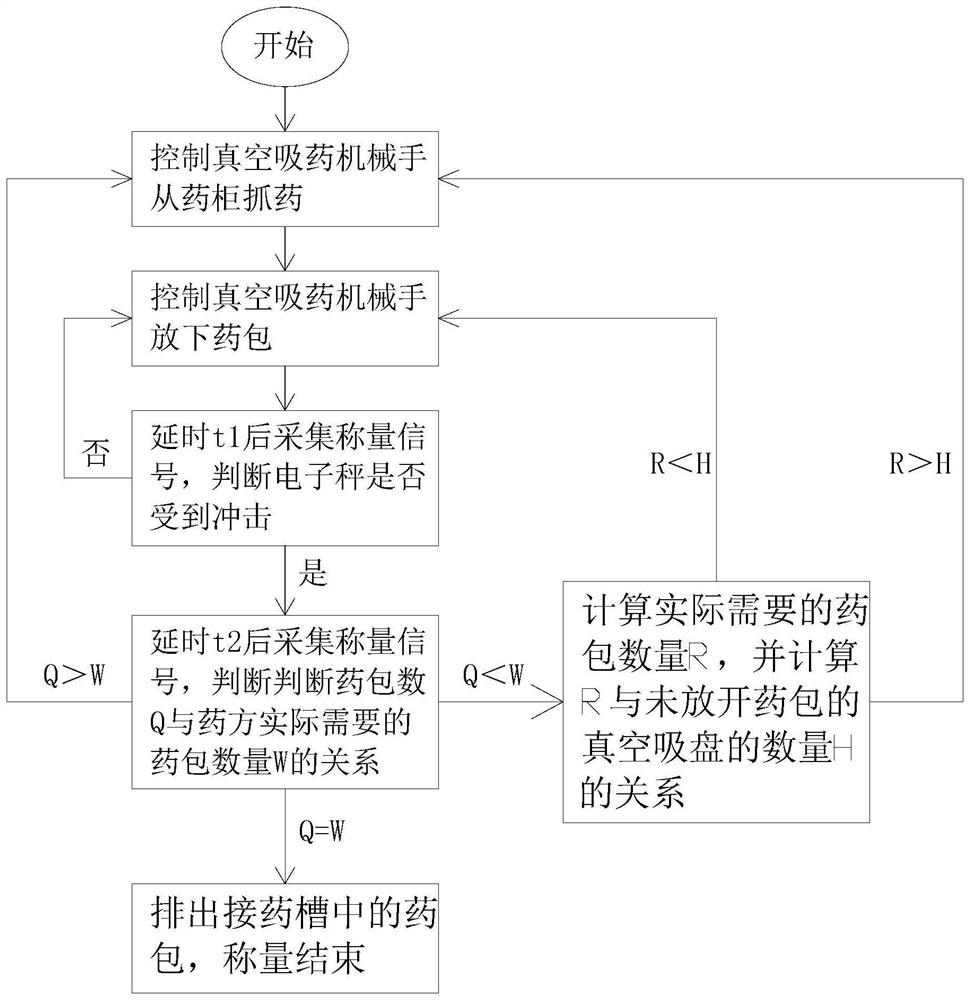

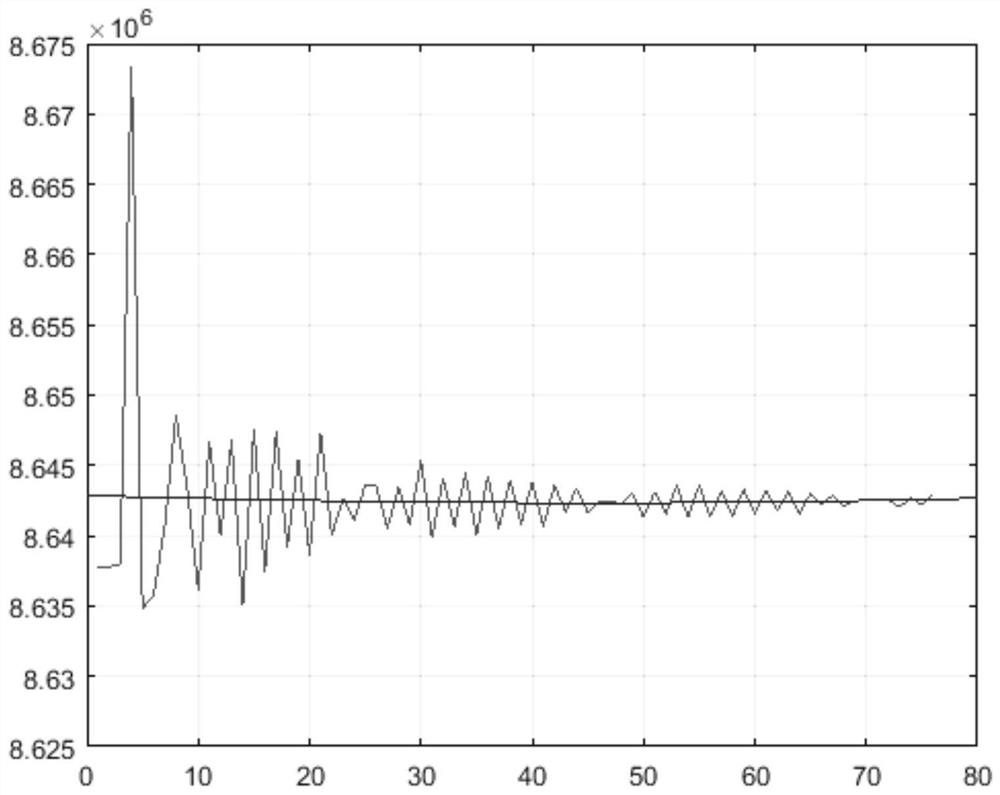

Dynamic weighing method for bulk small-package traditional Chinese medicines

ActiveCN111854908AImprove weighing efficiencyImprove drug grasping efficiencyComplex mathematical operationsSpecial purpose weighing apparatusProcess engineeringTraditional Chinese medicine

The invention discloses a dynamic weighing method for bulk-bag small-package traditional Chinese medicines. The method comprises the following steps: 1) controlling a vacuum medicine suction manipulator to grab a medicine bag from a medicine cabinet; 2) controlling a vacuum suction disc on the vacuum medicine suction manipulator to release the grabbed medicine bag; 3) acquiring a weighing signal of an electronic scale after a delay time t1, calculating the difference between the acquired weighing signal and the weighing signal before the vacuum suction disc releases the medicine bag, judging whether the electronic scale is impacted by the medicine bag according to the calculation result, if the judgment result is that the electronic scale is impacted by the medicine bag, executing the step4 downwards, and otherwise, skipping to execute the step 2; and 4) acquiring the weighing signal of the electronic scale after a delay time t2, and judging the number of the medicine bags on the electronic scale according to the acquired weighing signal. According to the invention, the dynamic weighing method for the bulk small-package traditional Chinese medicine can shorten the weighing time and improve the medicine grabbing efficiency.

Owner:CHONGQING UNIV

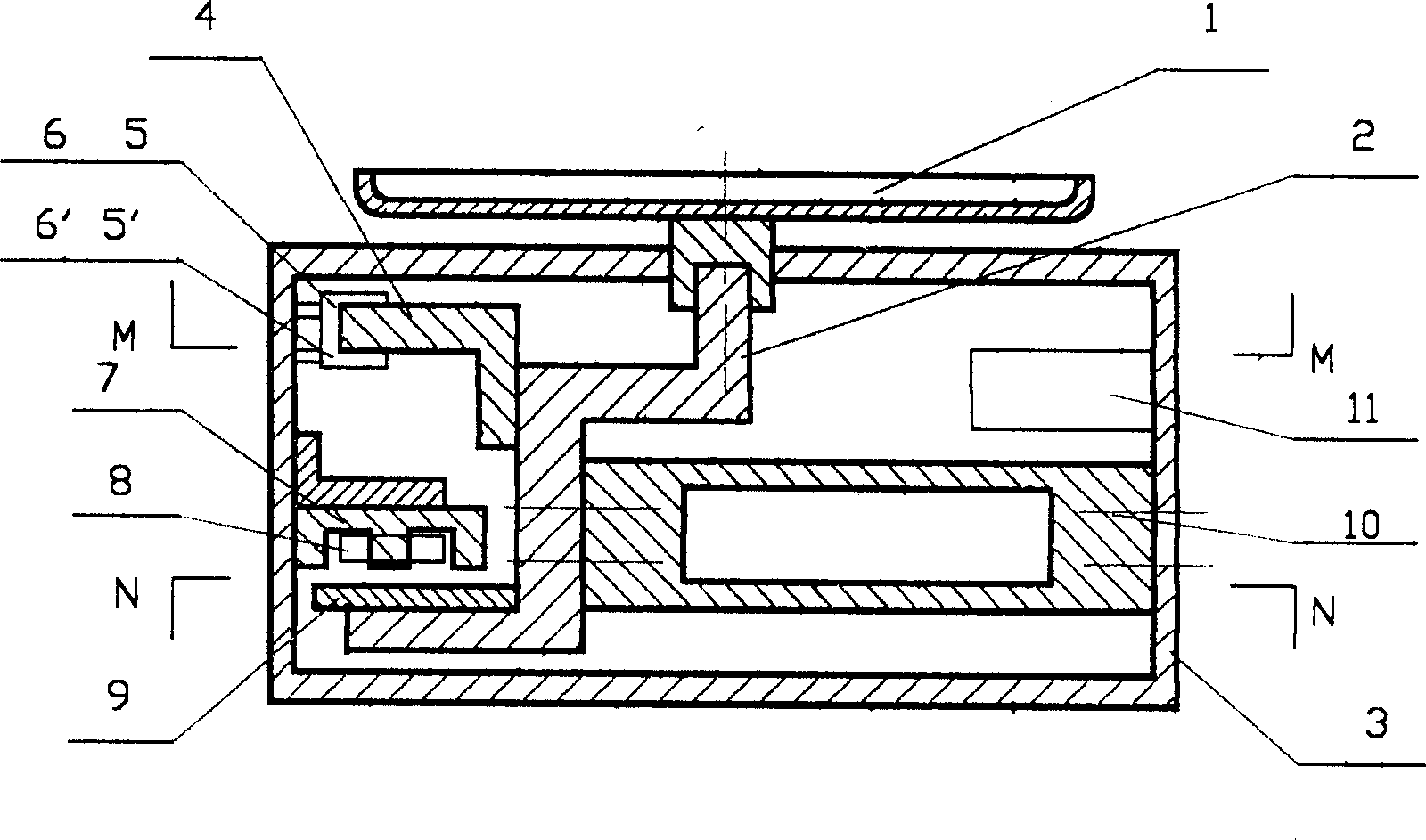

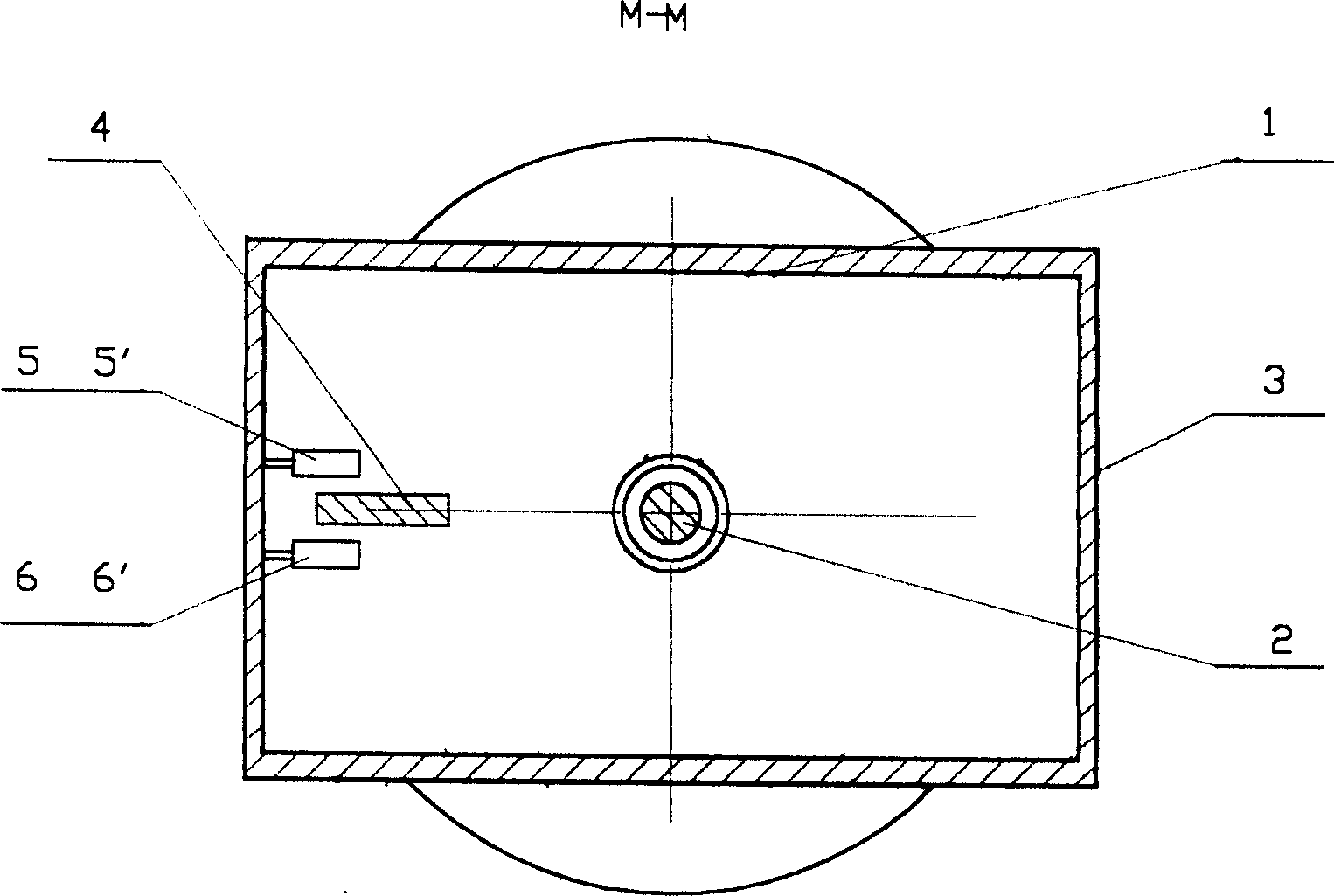

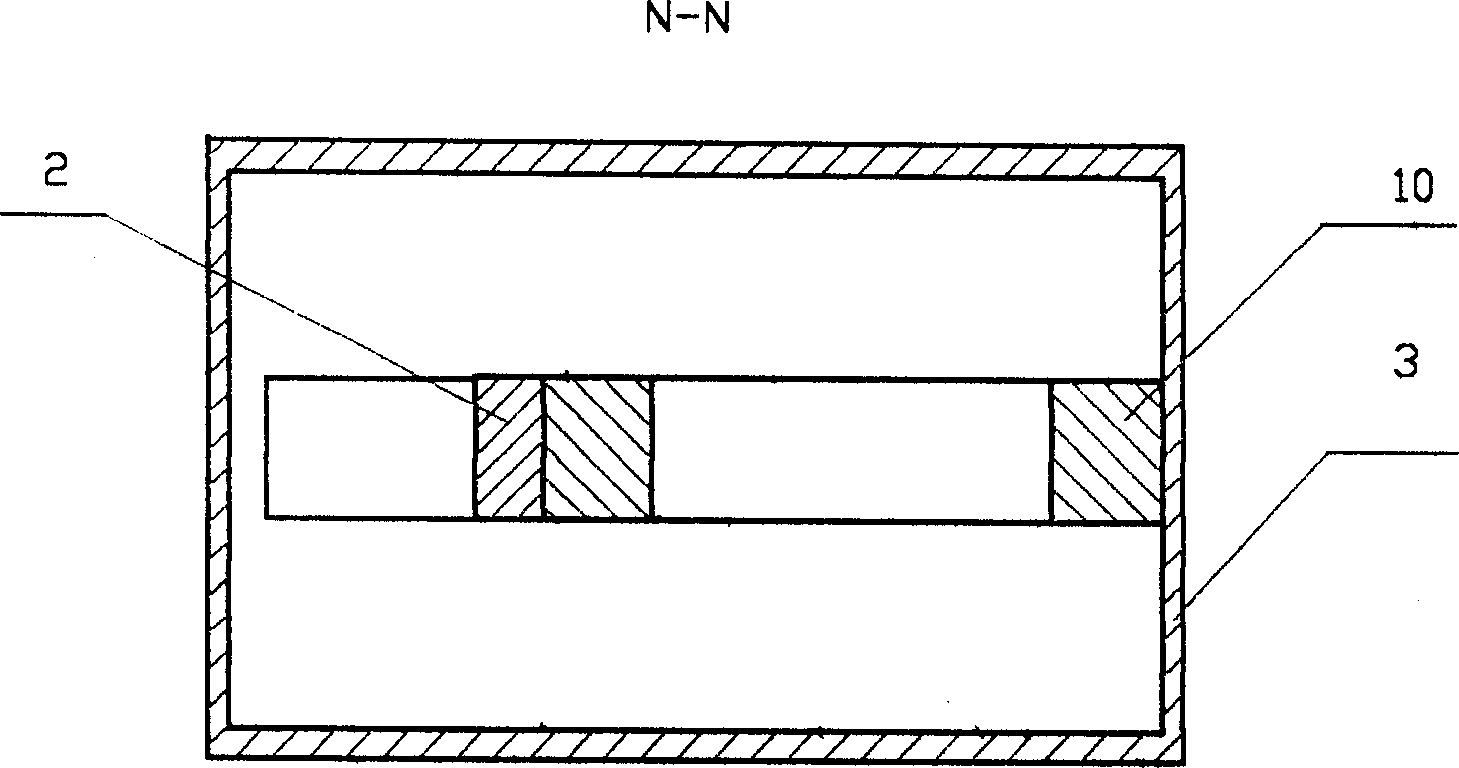

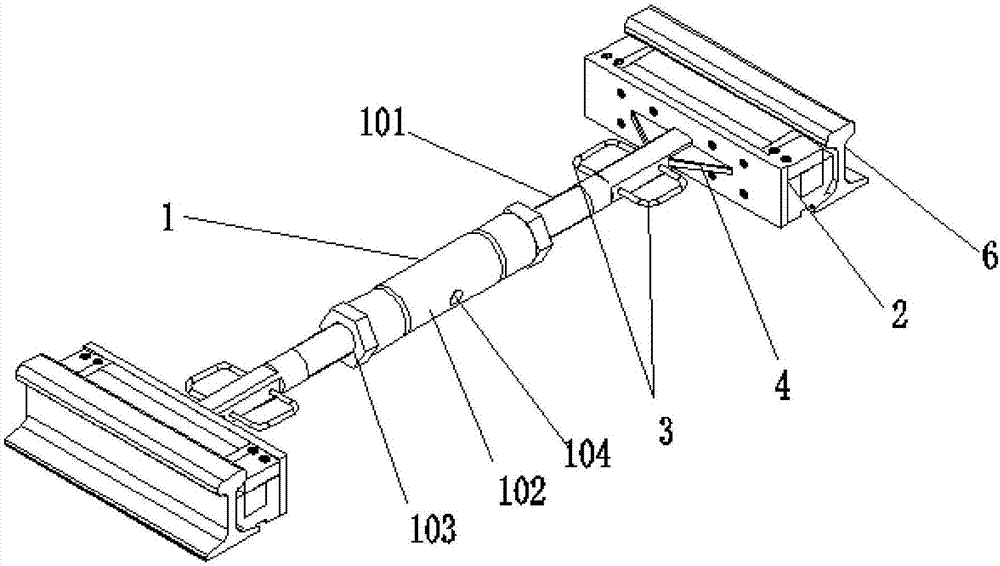

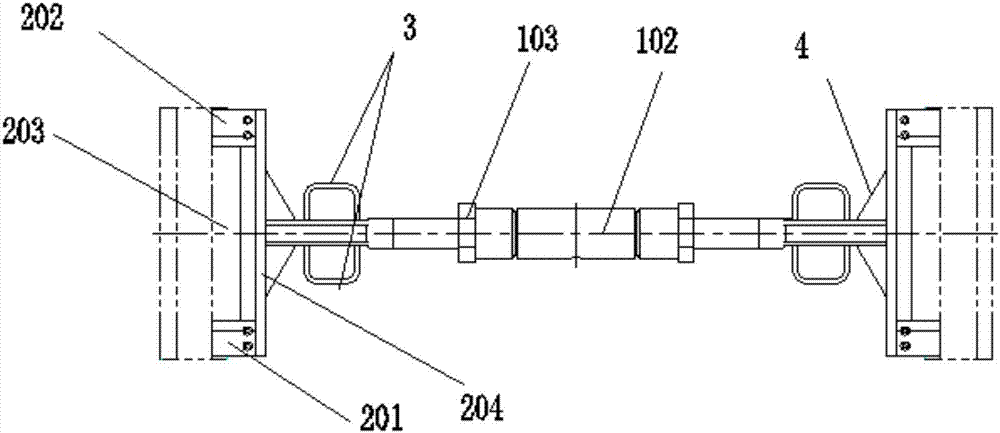

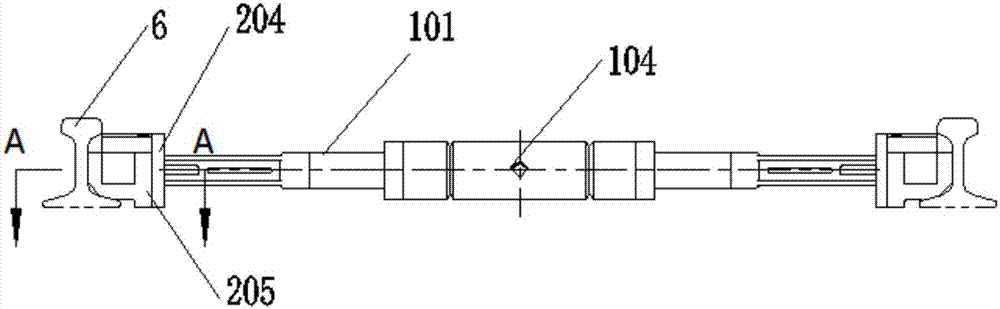

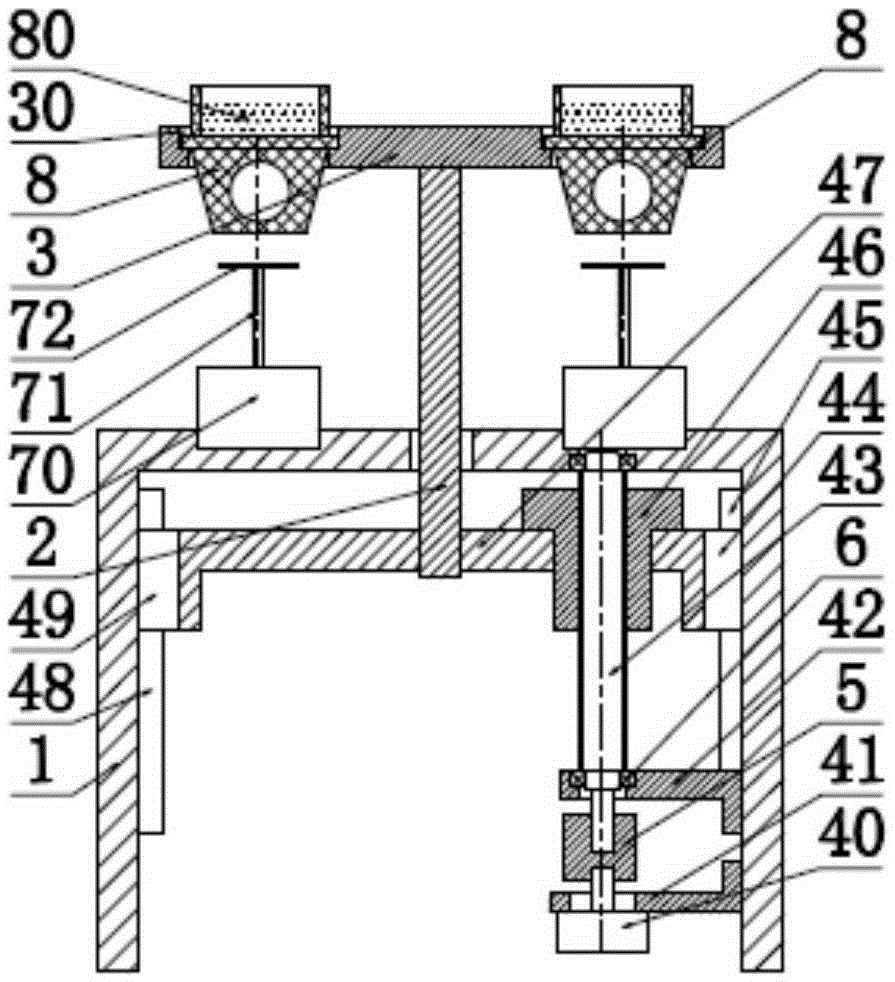

Portable subway vehicle weighing device

PendingCN107402058ASimple structureReduce volumeSpecial purpose weighing apparatusTruckMechanical engineering

The invention provides a portable subway vehicle weighing device which includes a screw adjusting unit, support platforms, and sensors. The two ends of the screw adjusting unit are fixedly connected with the two support platforms. The screw adjusting unit can drive the support platforms to move to the two ends or to the middle. The sensors are fixedly arranged inside the support platforms. The beneficial effects are as follows: the portable subway vehicle weighing device is simple, small and light; the position of the device can be adjusted at any time in a simpler and more labor-saving manner, and thus, the device can adapt to various subway vehicles with different wheel bases and lengths between truck centers; and a single wheel is weighed using multiple sensors, and the weighing range and weighing efficiency of the weighing device are improved.

Owner:TIANJIN LOCOMOTIVE CO LTD

Weighing device for grain purchasing

InactiveCN109029657ALow costEasy to useGas current separationWeighing apparatus for materials with special property/formSolenoid valveEngineering

The invention discloses a weighing device for grain purchasing. The device comprises a feeding throat, an impurity outlet, a solenoid valve and a humidity sensor, wherein a feeding cylinder is arranged at a lower side of a discharging port, a filter net is arranged at the inside of the feeding cylinder, a left side of the filter net is provided with the impurity outlet, a right side of the filternet is provided with an air blower, the air blower and the impurity outlet are located on the same straight line, the lower side of the filter net is provided with a first motor, the right side of thefirst motor is provided with a feeding machine, the right side of the feeding machine is provided with a weighing barrel, the lower side of the weighing barrel is provided with the discharging port,the inside of the weighing barrel is provided with a weighing inner barrel, the humidity sensor is arranged at the inside of the weighing inner barrel, the lower side of the weighing inner barrel is provided with two symmetrical connection rods, the lower side of the connection rods is provided with a weight sensor, and the solenoid valve is arranged between the two connection rods. The weighing device for grain purchasing can be used for impurity removing, weighing and humidity detection for the grain, and complete multiple operations through one equipment, thus, cost is reduced, and the weighing device for grain purchasing is more convenient to use.

Owner:YANGZHOU BAODA RUBBER & PLASTIC PROD

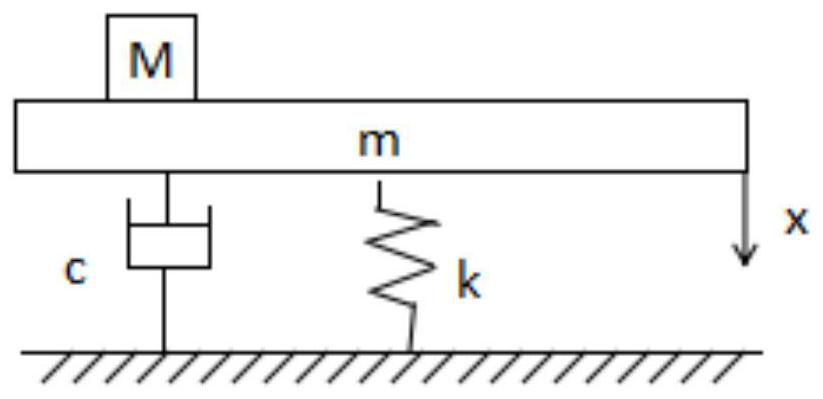

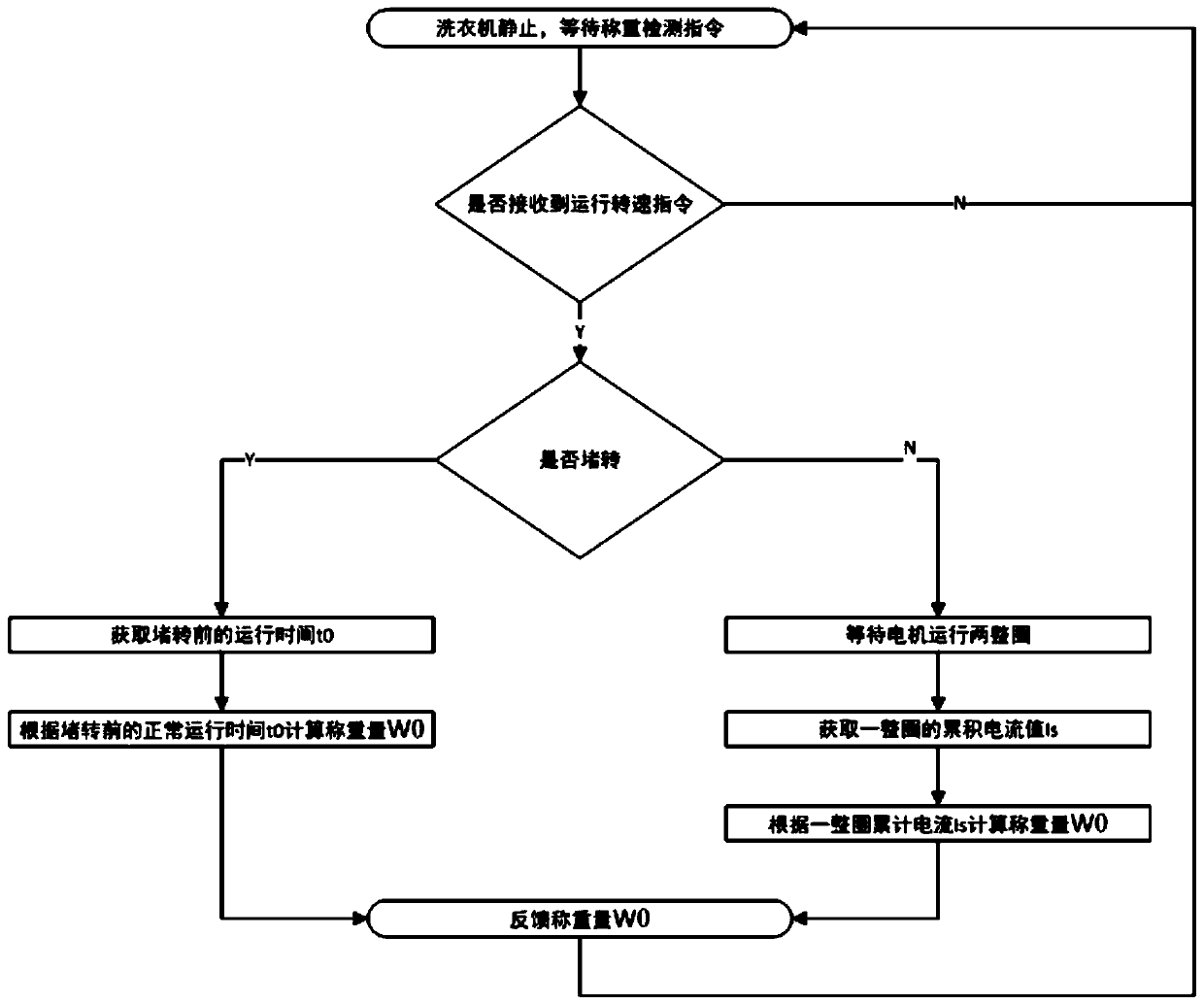

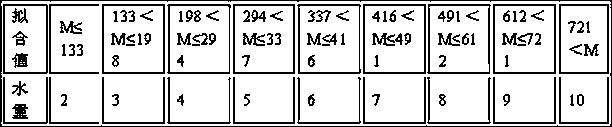

Weighing method applied to non-sensor pulsator washing machine

ActiveCN110284299AReduce material costShorten the time required for weighingOther washing machinesControl devices for washing apparatusElectricityEngineering

The invention discloses a weighing method applied to a non-sensor pulsator washing machine and belongs to the technical field of household appliances. The washing machine is the pulsator washing machine and comprises a motor for driving an inner drum to rotate and an upper computer MCU electrically connected with the motor, the pulsator washing machine rotates multiple times before washing is started, and in the period, whether or not the motor is in a blocked operation state is judged; if yes, the operation time of the motor is acquired; if the motor normally operates, an accumulation current value of the motor during a whole circle of operation is calculated; according to the two states, by using the operation time or accumulation current value of the motor, the weight is obtained through weighing and transmitted to the upper computer MCU, and the upper computer MCU gives a proper water level. According to the weighing method, for the pulsator washing machine, under the condition of not additionally increasing the material cost, garments in the drum can be weighed, the upper computer MCU automatically gives the proper water level, and the operation difficulty of a user is lowered.

Owner:上海景能电气有限公司

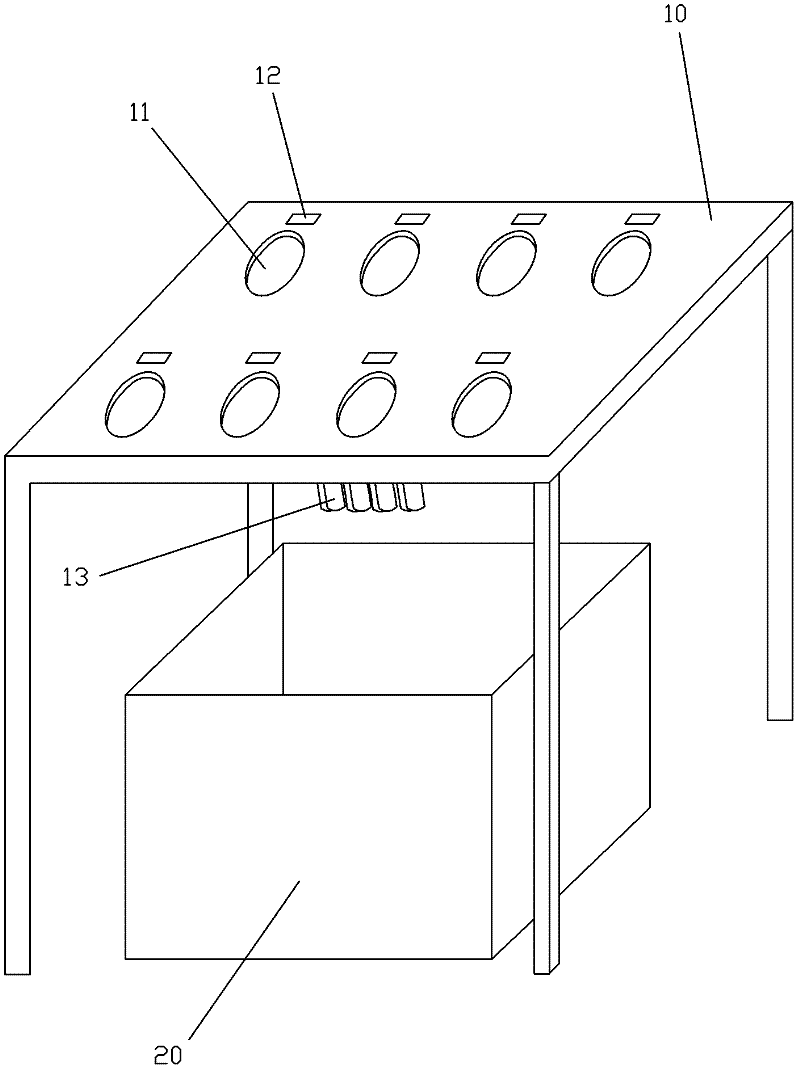

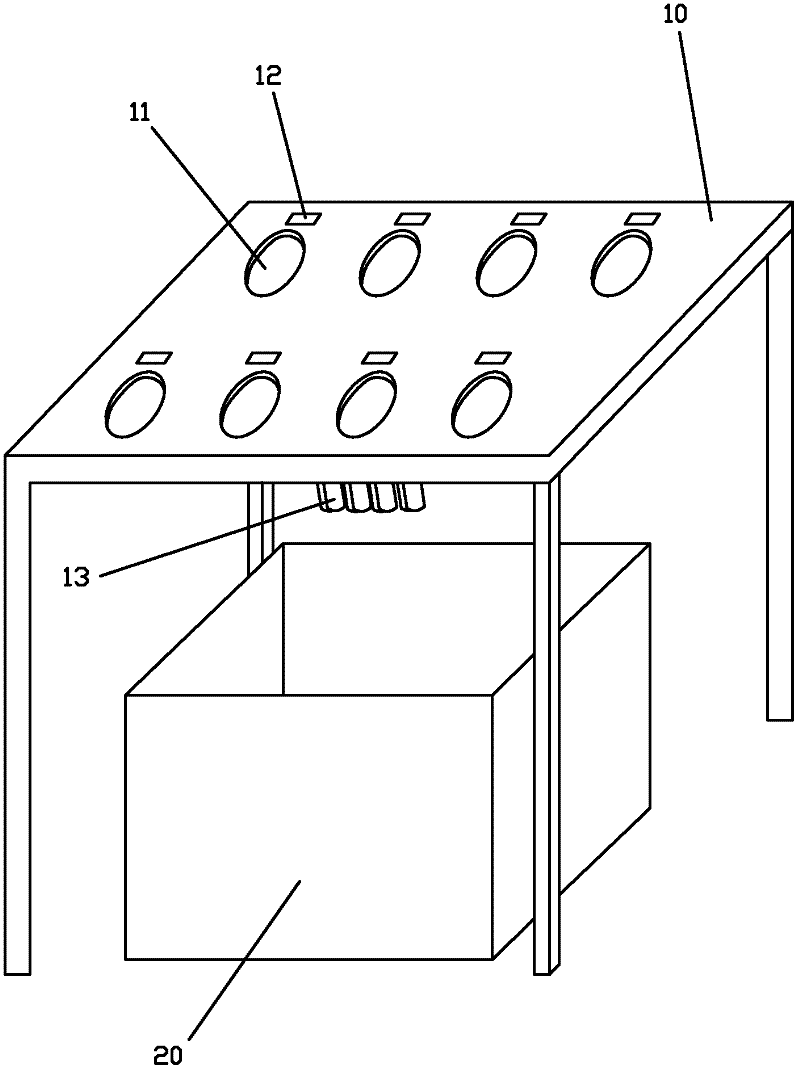

Dispensing device for traditional Chinese medicine

A dispensing device for traditional Chinese medicine is disclosed, which comprises a workbench, wherein a medicine bag placing groove is disposed below the workbench; a plurality of medicine holes are disposed on the bench surface of the workbench; a medicinal material channel is connected below each medicine hole; and the outlet of the medicinal material channel is aligned to the medicine bag placing groove. Compared with the prior art, the dispensing device for traditional Chinese medicine disclosed by the invention is convenient for pharmacist to weigh medicinal materials, capable of saving weighing time and the waiting time of the patient, and worth to be greatly popularized and used.

Owner:永春县博发生物医药投资有限责任公司

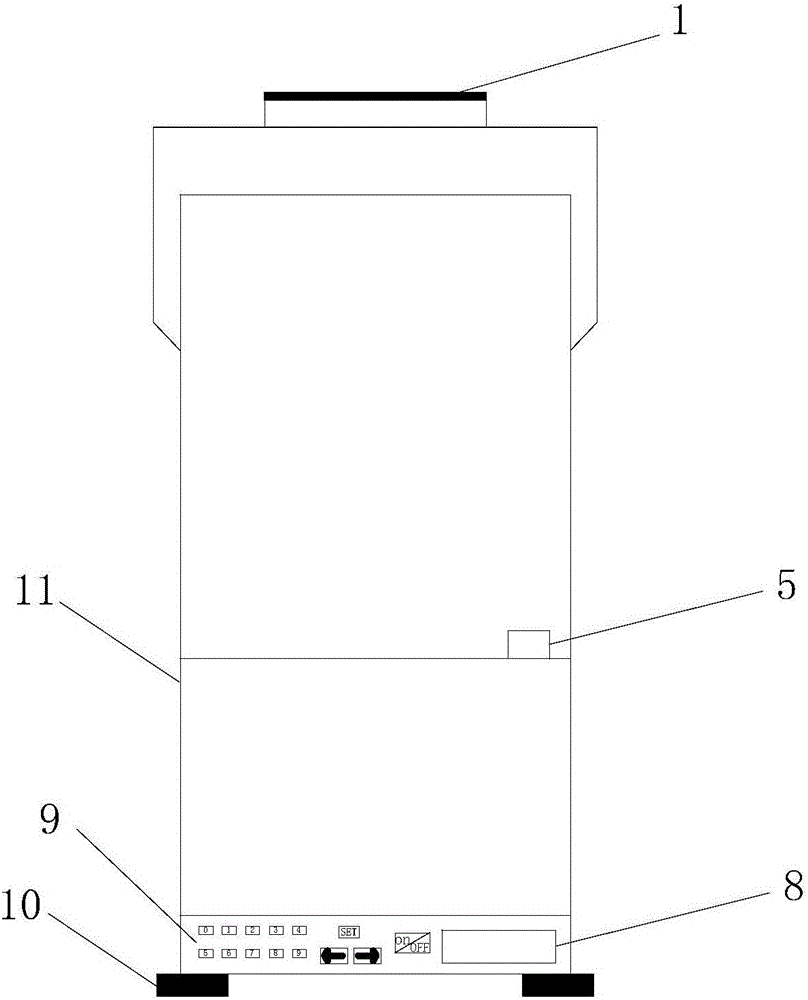

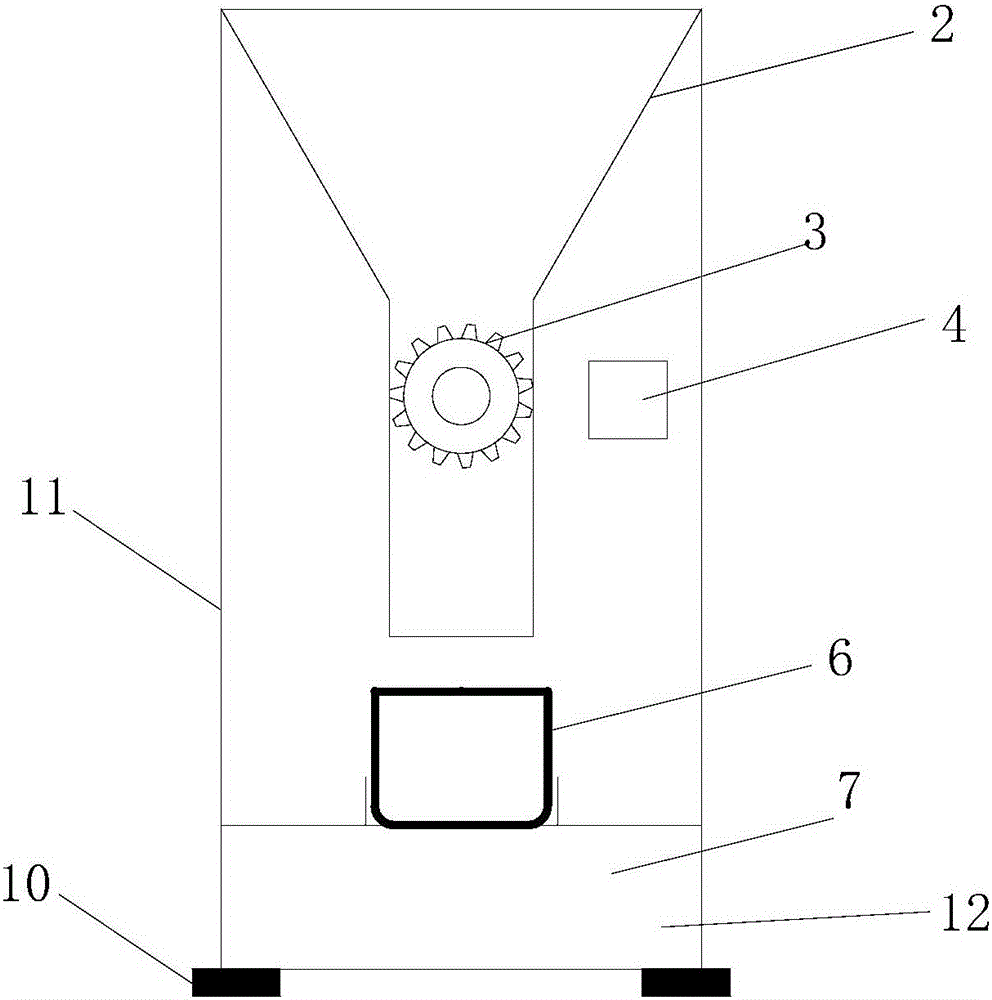

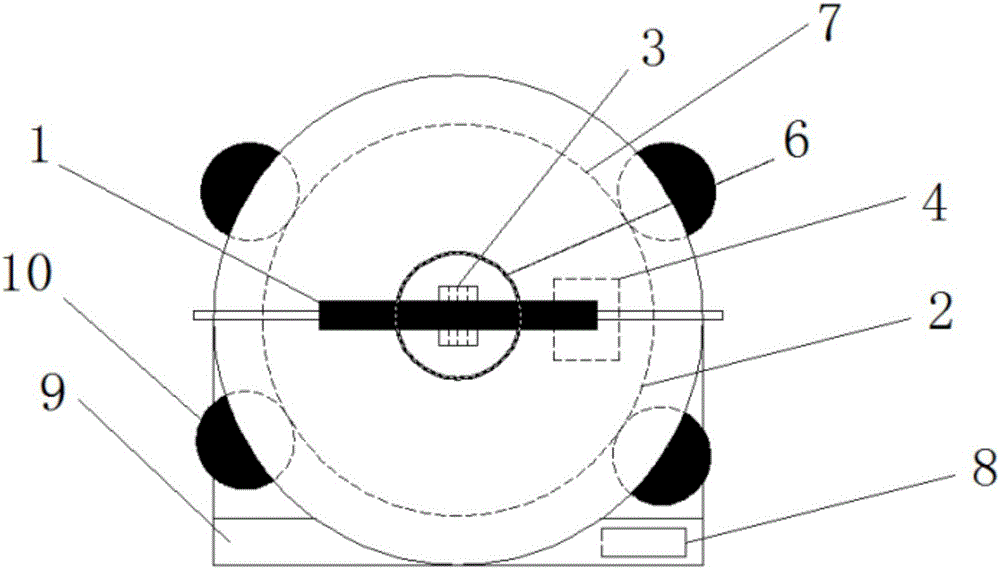

Automatic microweighing system and method

ActiveCN105651365AShorten weighing timeImprove efficiencyWeighing apparatus for materials with special property/formEngineeringGravitation

The invention discloses an automatic microweighing system and method. The system comprises a sample adding hopper, a gear, a controller, a movable door, a sample cup, a gravity sensor, a base and a shell. The base is arranged at the bottom of the shell. The sample adding hopper is arranged inside the shell. The top of the sample adding hopper is used as a feed inlet. The bottom of the sample adding hopper is provided with the sample cup used for containing materials. The neck of the sample adding hopper is provided with the gear controlled by the controller to rotate. The gear is in interference fit with the neck of the sample adding hopper, so that materials in a horn opening in the sample adding hopper are completely blocked to the position above the gear when the gear is not rotated; when the gear rotates, the materials in the horn opening in the sample adding hopper are clamped by tooth grooves between gear teeth to the position below the gear and fall into the sample cup; the sample cup is arranged on the gravity sensor. According to the automatic micro-weighing system and method, weighing time is greatly shortened, efficiency is improved, fine control over samples is achieved, and weighing precision is improved; microweighing is automatically carried out, human input is greatly reduced, operation is convenient, durability and persistence are achieved.

Owner:ZHEJIANG UNIV

Cargo and vehicle in-factory and out-factory dispatching management method

PendingCN113505973AShorten weighing timeInspection is accurateResourcesSensing by electromagnetic radiationBarcodeMobile phone

The invention provides a cargo and vehicle in-factory and out-factory dispatching management method, which comprises the following steps that A, a two-dimensional code / bar code is pasted at the exposed position of a cargo, and the two-dimensional code or bar code contains the type, quality, batch number and weight information of the cargo; B, a cargo pickup vehicle enters the parking lot and collects vehicle information of the goods picking vehicle; and C, the information management host obtains order information, carries out loading on a vehicle corresponding to the cargo information on the two-dimensional code / bar code according to the order, or generates an order according to the cargo information on the two-dimensional code / bar code and the vehicle information after loading is completed. and D, the information of the cargo pickup vehicle is acquired, whether the order is completed or not is judged; if so, a gate is opened to let the pickup vehicle to leave; and if not, the gate is opened after the order is completed. According to the scheme, the two-dimensional code / bar code can be scanned through the mobile phone terminal to obtain information such as the quality and the type of the cargo, so that the cargo can be reasonably distributed to the corresponding cargo pickup vehicle.

Owner:TONGLING NON FERROUS METAL GROUP CORP

Conveying device capable of sorting agricultural products according to weight

ActiveCN113714128AFast and accurate weighing operationAvoid weighing effectsSortingAgricultural scienceControl system

The invention relates to the field of agricultural product weighing equipment, in particular to a conveying device for sorting agricultural products according to weight. The conveying device comprises a rack, a mounting plate, a protective cover, a blowing mechanism and a detection mechanism, wherein a weighing channel is formed between the mounting plate and the protective cover; a control system is fixedly mounted at one side of the rack, and the control system is electrically connected with the blowing mechanism and the detection mechanism; the blowing mechanism comprises blowing heads, a blowing driving box and a communicating pipe; a plurality of first mounting grooves for mounting the blowing heads are uniformly formed in the mounting plate; the detection mechanism comprises an offset detection assembly and a counter; and the offset detection assembly and the counter are mounted on the protective cover. The agricultural products are weighed in a blowing weighing manner, at least three-level classification can be conducted on the agricultural products, the influence of friction on agricultural product weighing is avoided, so that the detection precision is improved; and the detection device is not in contact with the agricultural products during detection, so that the possibility that the agricultural products are polluted is reduced, and the practicability is improved.

Owner:广东广垦绿色农产品有限公司

Intelligent continuous stress-free weighing system and method for geese

ActiveCN111238614AAvoid stress responseShorten weighing timeWeighing apparatus using elastically-deformable membersWeighing apparatus for materials with special property/formAnimal scienceImage manipulation

The invention discloses an intelligent continuous stress-free weighing system and method for geese. The weight of the breeding geese is obtained by collecting the data of the breeding geese on the array type piezoresistive film sensors when the breeding geese pass through the access door and conducting data processing and fitting, the stress reaction to the breeding geese during manual weighing isavoided, and compared with other intelligent weighing, the weighing time is shortened, and the weighing efficiency and accuracy are improved. An intelligent network model is adopted to recognize walking gaits of geese, moving target detection and image processing are carried out through legs of breeding geese, and a gait cycle chart is generated. A residual network idea is introduced, so that theconvergence speed of the network is increased, and the individual recognition rate is improved. The dynamic continuous stress-free acquisition module for goose body quality data adopts an array piezoresistive film sensor, so that the weight can be read in the walking process of a breeding goose, the stress reaction is avoided, an analog switch chip is used for selectively outputting an analog signal, the switching speed is high, and the data reading efficiency and accuracy are improved.

Owner:YANGZHOU UNIV

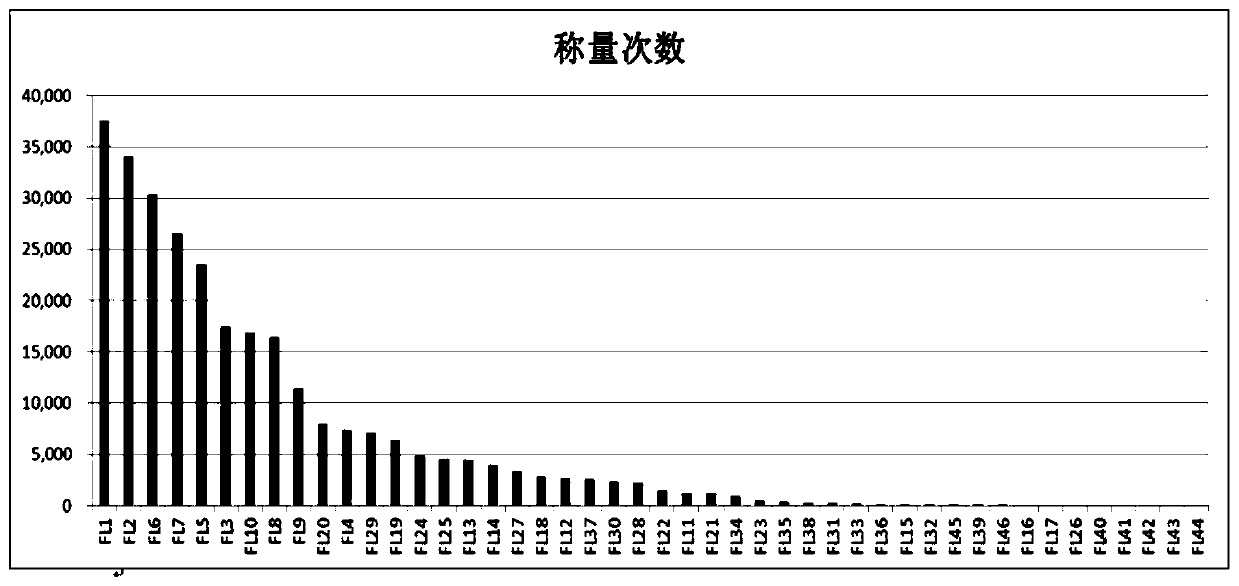

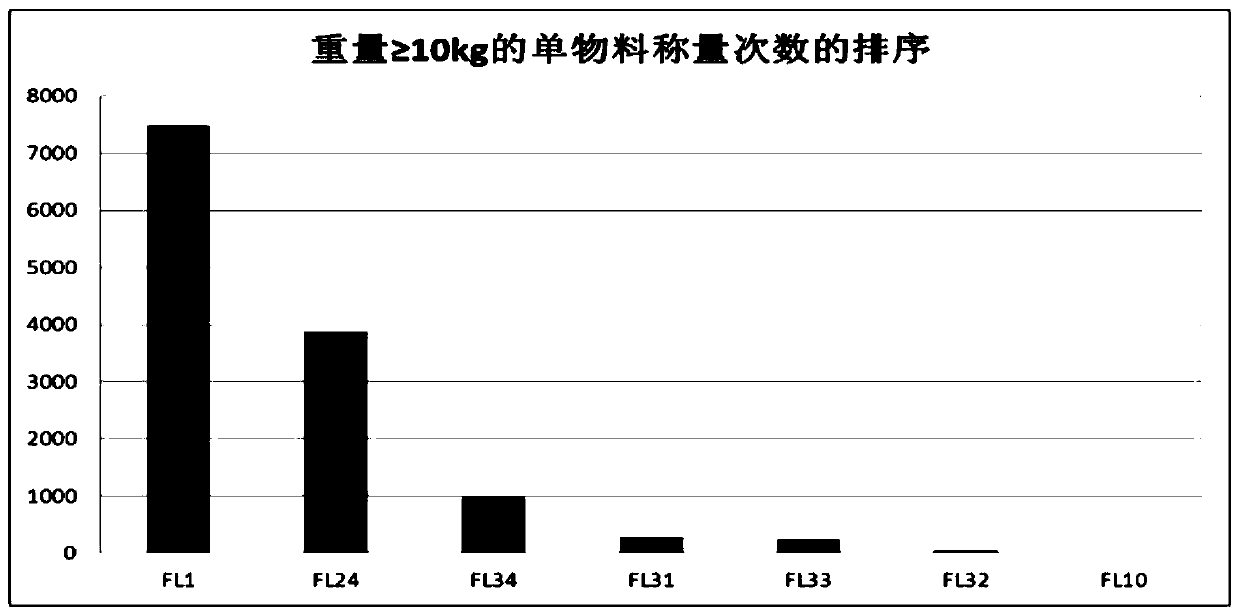

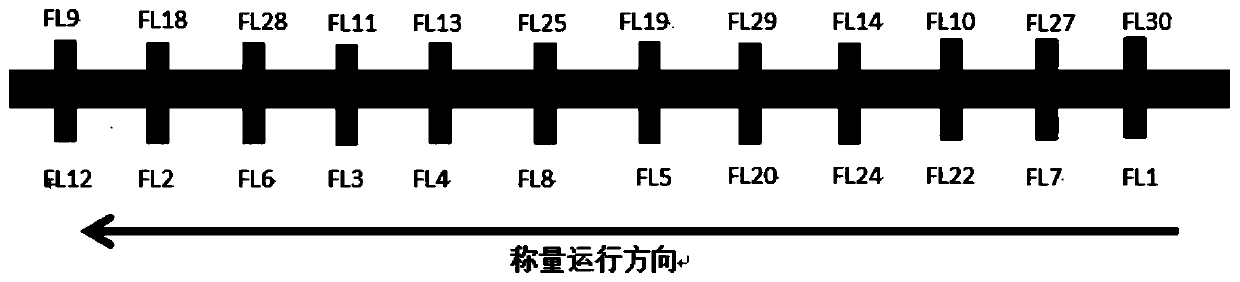

Layout method for multi-station small powder automatic weighing system

ActiveCN110361083AShorten weighing timeLess investmentSpecial purpose weighing apparatusMaterial typeEngineering

The invention provides a layout method for a multi-station small powder automatic weighing system. The method comprises the steps that the weight of materials required in different recipes and the information of the number of times of material weighing are collected; sorting is carried out according to the weighing times and weight of the materials; according to the sorting information of the weighing times of the materials, the type of the materials to be weighed, the quantity and the number of weighing scales are selected; the arrangement of the material types and the weighing scales is selected according to the weighing times and weight of the materials; and the optimal material type and the arrangement of the weighing scales are calculated and designed according to the weighing times of the materials. According to the invention, the existing method of relying on experience to design material types arranged in the automatic weighing system and the layout of the material types is changed; and the method can be used to reduce equipment investment, reduce equipment floor space, improve the utilization of existing equipment, reduce the waiting time of weighing, shorten the weighingtime of a formula bag, and improve the work efficiency.

Owner:GITI RADIAL TIRE (ANHUI) CO LTD

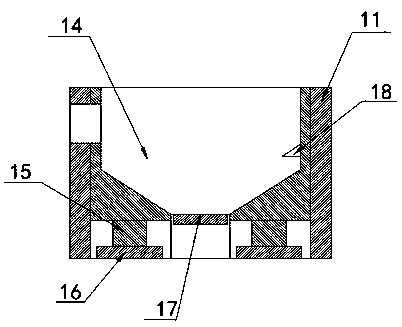

Crucible elevating circumferential parallel weighing apparatus used for aldrin sulfur detector

InactiveCN105334132AShorten weighing timeFast Parallel WeighingMaterial weighingCircular discCrucible

The invention discloses a crucible elevating circumferential parallel weighing apparatus used for aldrin sulfur detector, and belongs to the field of analysis equipment of sulfur content in soft-coal inflammable substances. The apparatus comprises four weighing modules installed on a U-shaped frame, a first guide rail, a second guide rail, a first slide block, a second slide block, a stepping motor installed on a motor frame, a lead screw of which one end is installed on the U-shaped frame and the other end is installed on a support under the lead screw, a rolling nut installed on the lead screw, a nut frame installed on the rolling nut, an elevating rod installed on the nut frame, and an elevating disc installed on the elevating rod; and the four weighing modules are same in structure, and each weight module comprises a balance, a balance ejector rod, and a weighing plate installed on the balance ejector rod. The crucible elevating circumferential parallel weighing apparatus used for aldrin sulfur detector is compact in structure, good in motion stability, free of manual intervention and capable of realizing rapid parallel weighing of multiple axisymmetrically-arranged crucibles.

Owner:CHANGZHOU UNIV

Tea packaging equipment

InactiveCN107487491ASimple structureEasy to operateWrapper twisting/gatheringSolid materialEngineeringPlastic film

The invention discloses tea packaging equipment. The tea packaging equipment comprises a rack, a heating device, an automatic feeding device, a plastic film coiling box, a plastic sealing film, a roll shaft, a hot sealing device, a cutting device, a discharging channel, a receiving box and an intelligent controller. The automatic feeding device comprises a feeding hopper, a left feeding channel, a right feeding channel, a left weighing hopper, a right weighing hopper and a total discharging hopper; the hot sealing device comprises a horizontal hot sealing device body and a vertical hot sealing device body; the cutting device comprises a blade and a knife rest; and the intelligent controller is provided with a temperature adjusting switch and a weighing set switch. The tea packaging equipment is high in packaging efficiency and good in packaging effect and saves time and labor; tea is dried and not prone to being affected with damp; and the left feeding channel, the right feeding channel, the left weighing hopper and the right weighting hopper discharge tea alternately, the weighing time is shortened, and the operation efficiency of the packaging equipment is improved.

Owner:ANHUI XINXUTANG TEA CO LTD

Weighing and sorting device for cell pole pieces

The invention discloses a battery pole piece weighing and sorting device, which comprises an operating table, on which a support frame is arranged, on which a guide rod parallel to the table surface of the operating table and a driving screw are arranged, and the driving screw One end is connected with a servo motor, the guide rod and the transmission screw are slidably connected with a slider, the slider is connected with a support plate 1, a cylinder is arranged on the support plate 1, the piston rod of the cylinder is connected with a support plate 2, and the support plate 2 passes through The vacuum connecting rod is connected with a vacuum suction cup; the middle part of the operation table is equipped with a discharge tray, an electronic scale, a qualified sheet tray and an unqualified sheet tray, and the vacuum suction cup is located on the discharge tray, electronic scale, qualified sheet tray and unqualified sheet Above the plate, the electronic scale, the air cylinder and the servo motor are connected to a plc controller for communication. Beneficial effects of the present invention: the weight of the pole piece of the battery cell can be weighed conveniently and quickly, and at the same time, qualified and unqualified pole pieces are classified, the weighing time of the pole piece is shortened, the problem of slow weighing is solved, and manpower is saved.

Owner:SHANXI CHANGZHENG POWER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com