Shield tunnel engineering slag real-time weighing system and application method thereof

A technology of engineering dregs and weighing system, which is applied in the field of tunnel engineering, can solve the problems of poor weighing effect of the front measurement method, failure to meet real-time monitoring requirements, and accuracy that cannot meet engineering requirements, etc., so as to shorten the weighing time of dregs , shorten the weighing time, eliminate the effect of complexity and delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

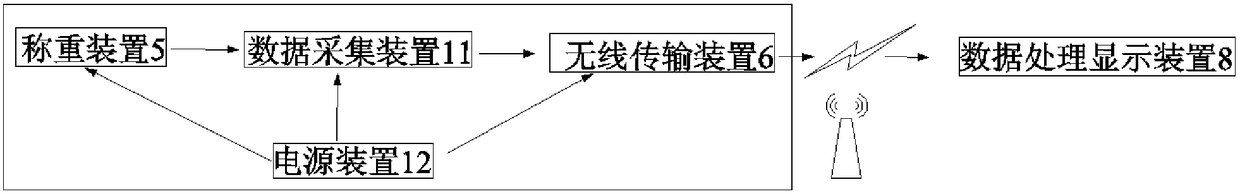

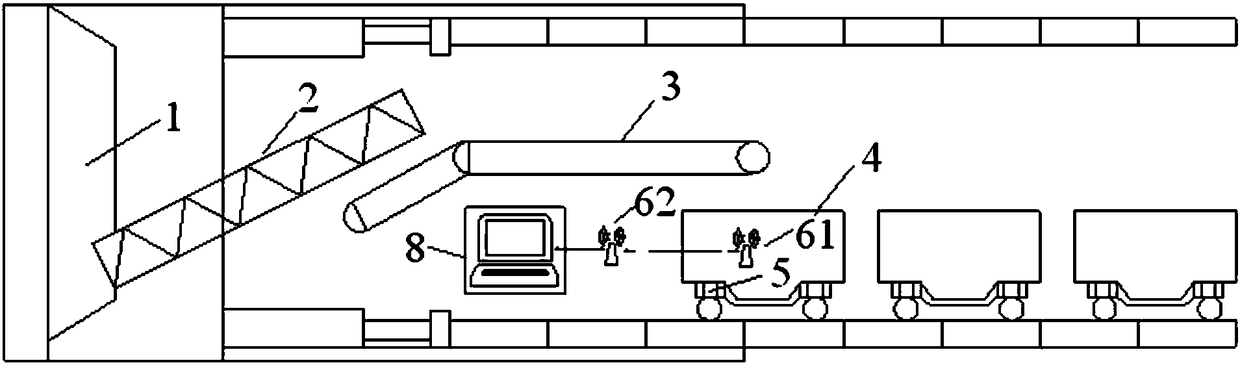

[0048] like figure 1 As shown, the present invention is a real-time weighing system for shield tunnel engineering dregs, including a weighing device 5, a data acquisition device 11, a wireless transmission device 6 and a power supply device 12 arranged under the dregs hopper 41 of the muck truck 4 , and the data processing and display device 8 arranged in the shield machine operating room, the weighing device 5 weighs the muck, the data acquisition device 11 obtains the weighing signal of the weighing device 5, and wirelessly The transmission device 6 transmits the data to the data processing and display device 8 , the data processing and display device 8 processes the data and displays it in real time, and the power supply device 12 is used to supply power to the weighing device 5 , the data acquisition device 11 and the wireless transmission device 6 .

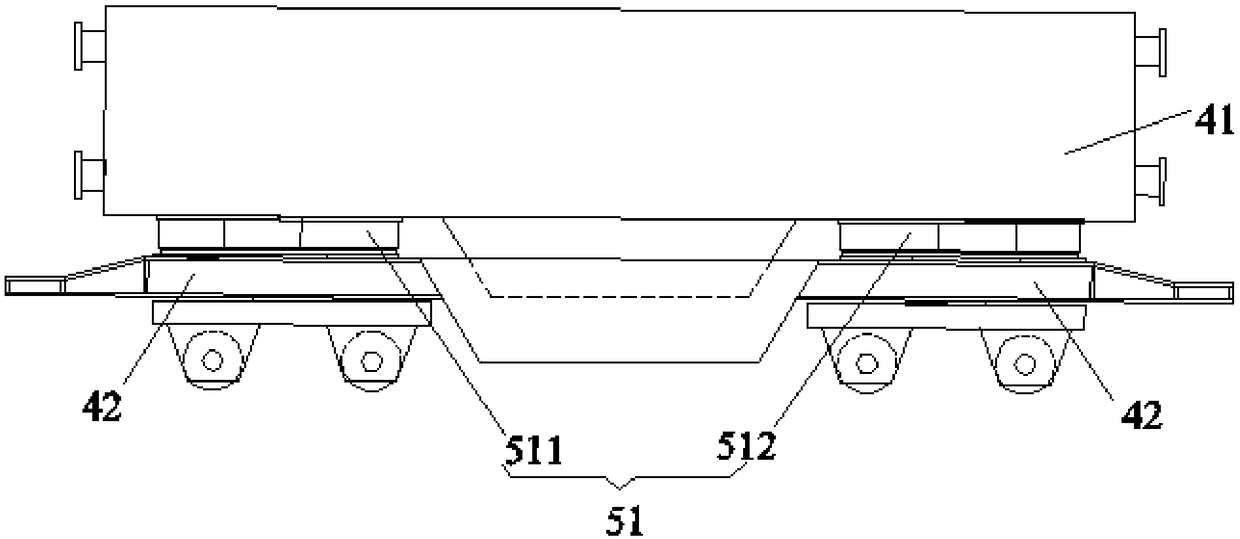

[0049] The weighing device 5 includes a weighing platform 51 between the slag hopper 41 and the mobile trolley 42, and a s...

Embodiment 2

[0059] like Figure 5 As shown, the present invention also discloses a method of using a real-time weighing system for shield tunnel engineering dregs, including any one of the above-mentioned real-time weighing systems for shield tunnel engineering dregs, and the usage method is as follows:

[0060] Step 1: Load slag, put the slag excavated from the excavated tunnel into the slag hopper. The excavated slag can be directly loaded into the slag hopper, or loaded into the slag hopper through a screw conveyor.

[0061] Step 2: Weighing. After the muck is full, trigger the weighing device to automatically weigh. The sensors installed on the left weighing platform and the right weighing platform respectively weigh the muck weight.

[0062] Step 3: signal collection and transmission, the data collection device obtains the weighing signal of the weighing device, and transmits the data to the data processing and display device through the wireless transmission device. Wherein, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com