Tea packaging equipment

A packaging equipment and tea technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of low production efficiency, easy pollution of tea leaves, and uneven weight, so as to improve operating efficiency, save weighing time, and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

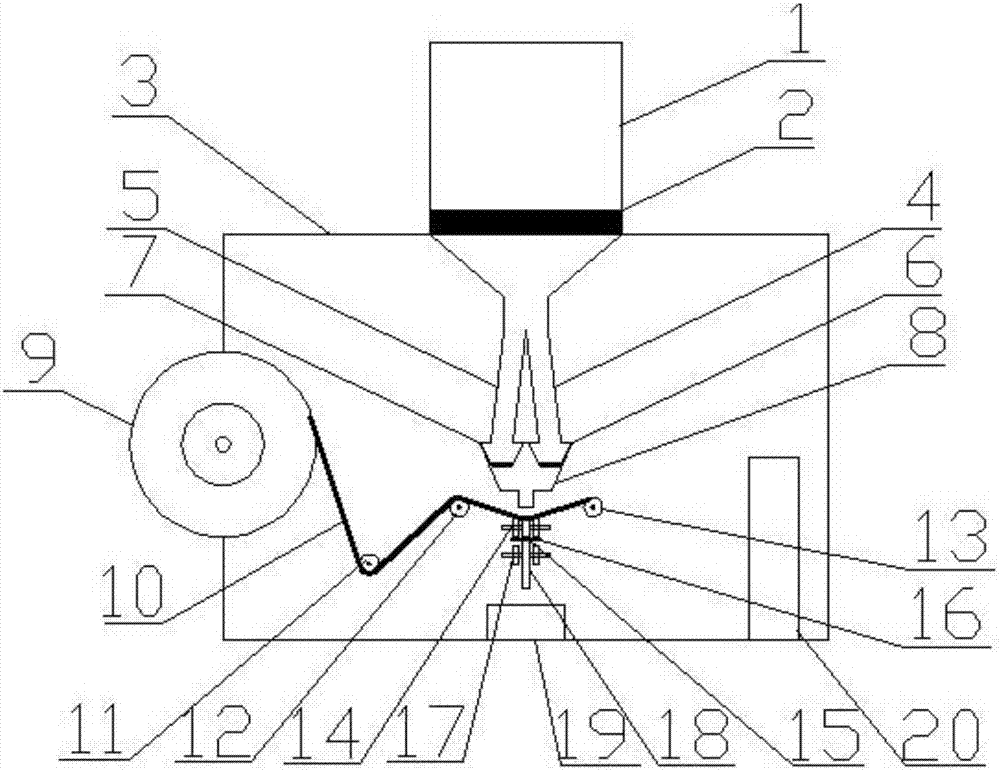

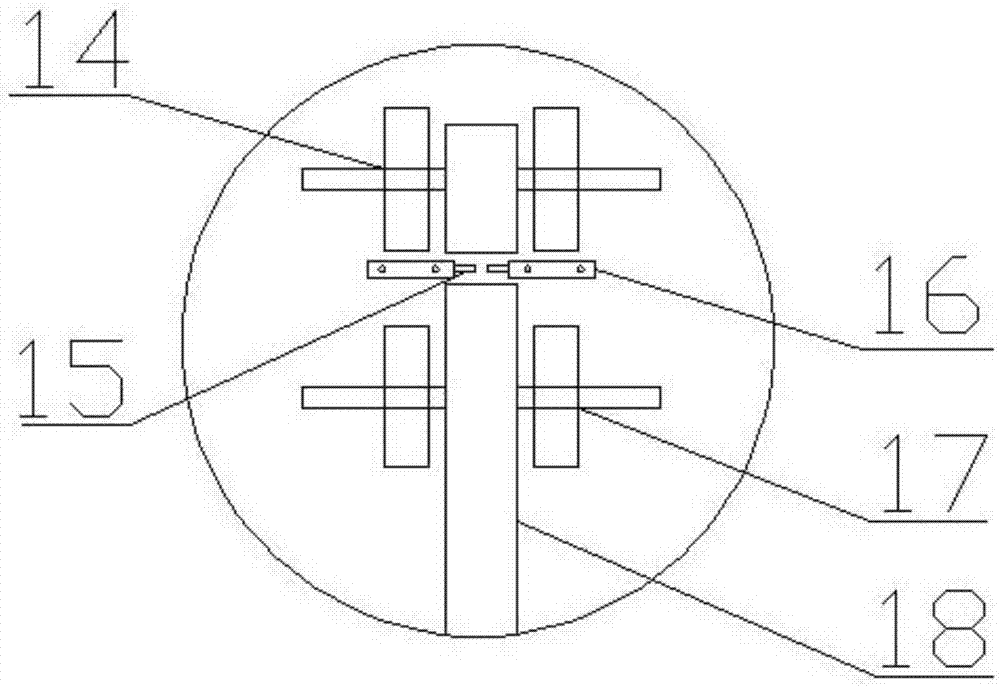

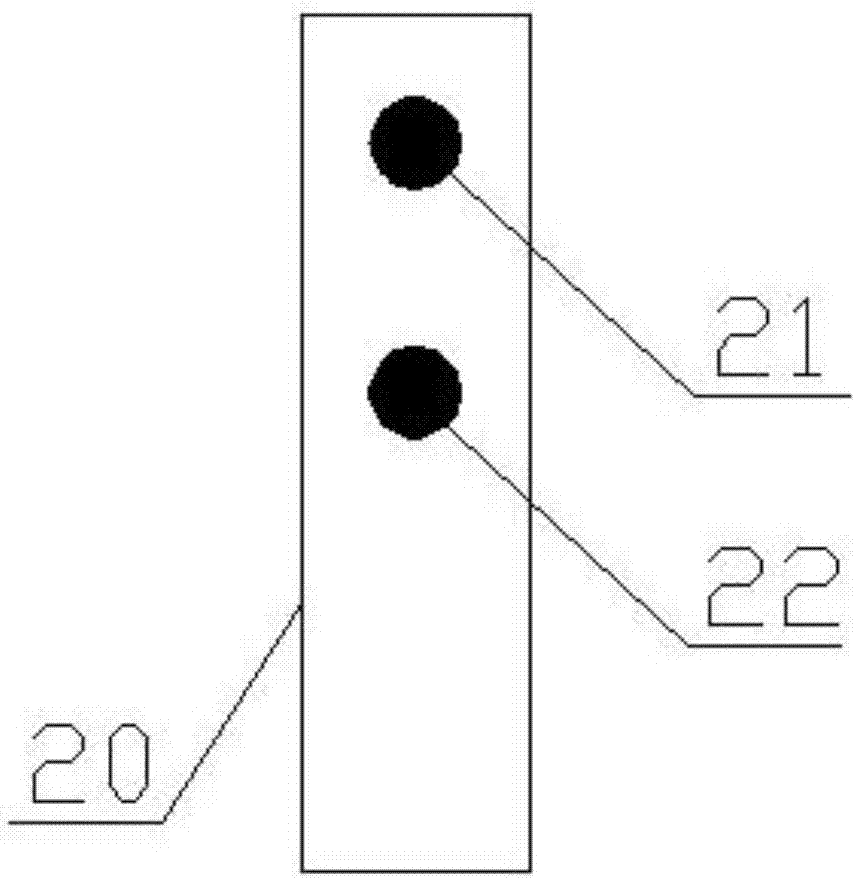

[0016] figure 1 A specific embodiment of the present invention is shown: a tea packaging equipment, including a frame 3, a heating device 2, an automatic feeding device, a plastic film winding box 9, a plastic film 10, a roller shaft, a heat sealing device, a cutting device, an outlet Material channel 18, material receiving box 19 and intelligent controller 20, automatic feeding device includes hopper 1, left material channel 5, right material channel 4, left weighing hopper 7, right weighing hopper 6 and total lower hopper 8, Hopper 1 is fixedly installed on the frame 3, left and right feeding passages 5 and 4 are symmetrically arranged below the feeding hopper 1, a left weighing hopper 7 is arranged below the left feeding passage 5, and a weighing hopper is arranged below the right feeding passage 4. The right weighing hopper 6, the left weighing hopper 7 and the right weighing hopper 6 are provided with a total lower hopper 8; the heating device 2 is arranged below the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com