Layout method for multi-station small powder automatic weighing system

A technology of automatic weighing and layout method, applied in the directions of weighing, measuring devices, instruments, etc., can solve the problems of unreduced labor intensity, increased equipment footprint, low equipment utilization, etc., to reduce equipment investment, reduce The equipment covers an area and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Utilize the layout method of the multi-station powder automatic weighing system designed by the present invention, according to the newly-built certain tire factory configuration 1 masterbatch production matching small powder automatic weighing system, now design the layout of the automatic weighing system:

[0038] Collect information on the weight of materials required in different formulas produced by tire factories and the number of weighing times of materials, and estimate the output data of the weighing formula (abbreviated as PF) from the production plan (taking the average monthly output as an example) and the types of weighing materials in the formula ( Abbreviate FL) information, set up the database of weighing times of each material of each formula, obtain Table 1;

[0039] Table I:

[0040]

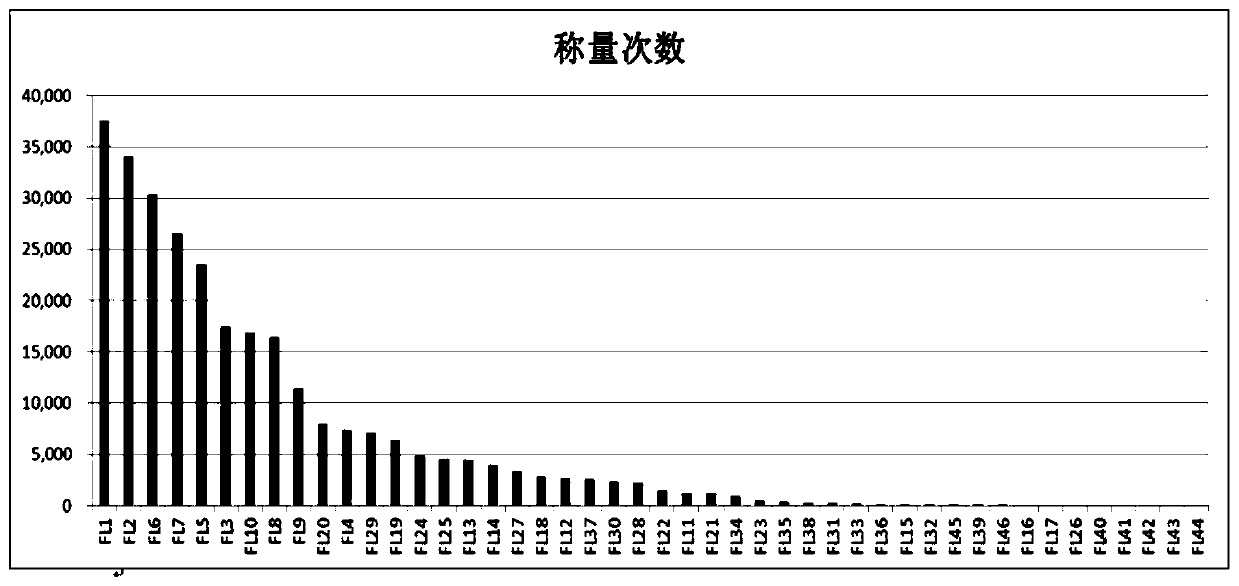

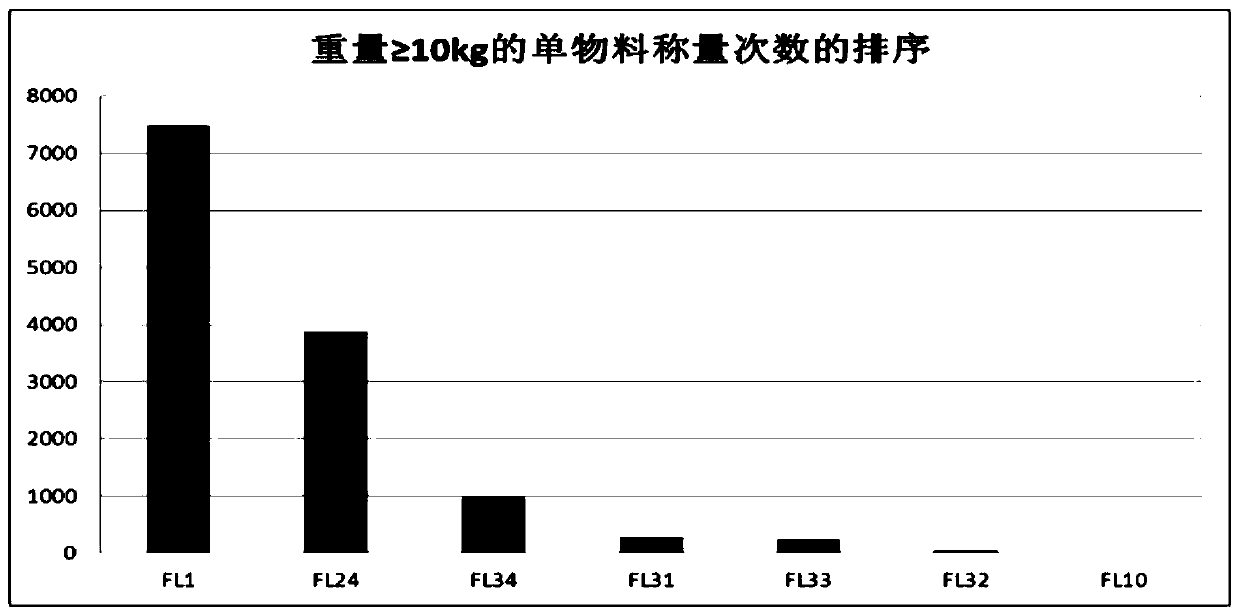

[0041] Use the sum method to get the total weighing times of materials in all formulas, sort in descending order according to the total weighing times of each material...

Embodiment 2

[0055] Embodiment 2, optimizing the material variety layout in the original small powder automatic weighing system, without changing the equipment layout and weighing material variety;

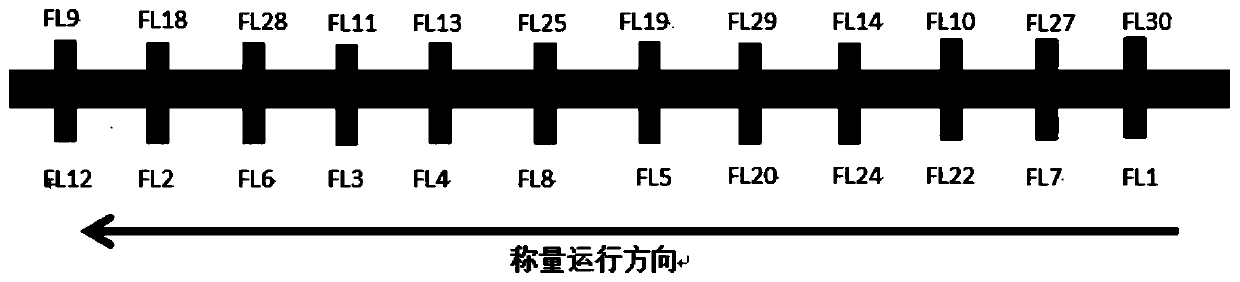

[0056] It is known that the factory has 12 kinds of materials (abbreviation: FL) in the multi-station small powder automatic weighing system for masterbatch production, and two of them share a weighing scale for weighing. The current layout is as follows Figure 4 As shown, collect the existing weighing formula output data (with the monthly average output as an example) and the weighing material variety information in the formula, establish a database of weighing times for each material in each formula, and obtain Table 6;

[0057] Table six:

[0058]

[0059] Calculate the number of weighing times between materials in all formulas. Table 7 shows the calculation results of FL1 and other powders, and Table 8 shows the calculation results of FL2 and other powders. Others will not be repeated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com