Patents

Literature

994 results about "Material type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Whereas material types are client level identification of materials. A material is created as a material type. They have their own number range and quite a bit of configuration can be done to segregate how different material types behave during transactions. Material types are for e.g. raw materials, finished goods.

Fiber adhesive material

InactiveUS20040071870A1Improve adhesion performanceMaterial nanotechnologySemiconductor/solid-state device detailsDielectricFiber

A fiber velvet comprising nano-size fibers or nanofibrils attached to micro-size fibers is disclosed. Methods of manufacturing the velvet as well as various uses of the velvet are also described. For example, the fiber velvet can be used as a thermal interface or as an adhesive material. The nanofibrils may be attached to a flat base or membrane, or may be attached to the tip portions of the micro-size or larger diameter fibers. Various attributes of the micro-size fibers and of the nano-size fibers, for example, geometry (e.g. size, length, packing density) material type (e.g. carbon, metal, polymer, or ceramic) and properties (e.g. conductivity, modulus, surface energy, dielectric constant, surface roughness) can be selected depending on the desired attributes of the fiber velvet. The nanofibrils have a diameter of less than about 1 micron, and may advantageously be formed from single walled and / or multi-walled carbon nanotubes.

Owner:KULR TECH

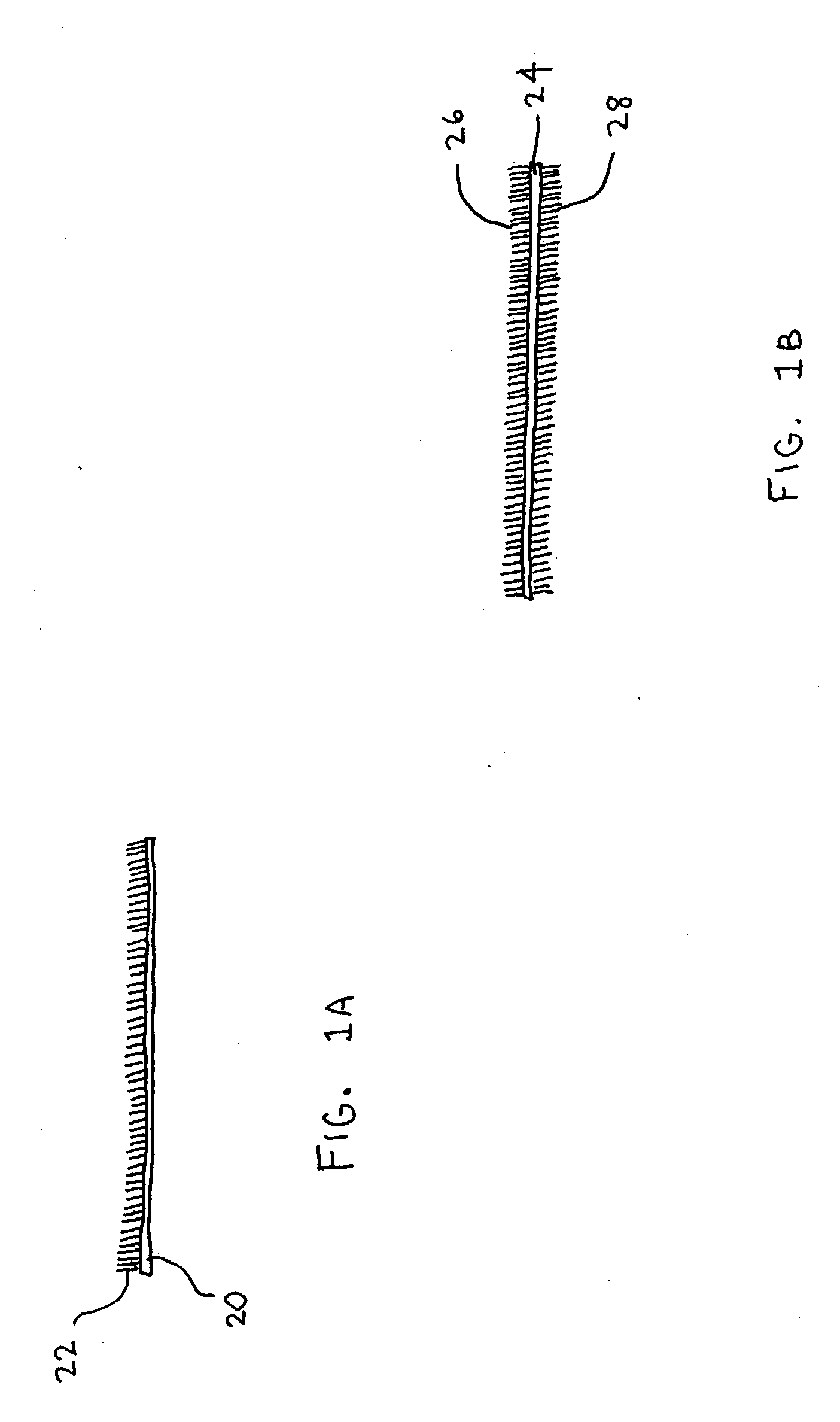

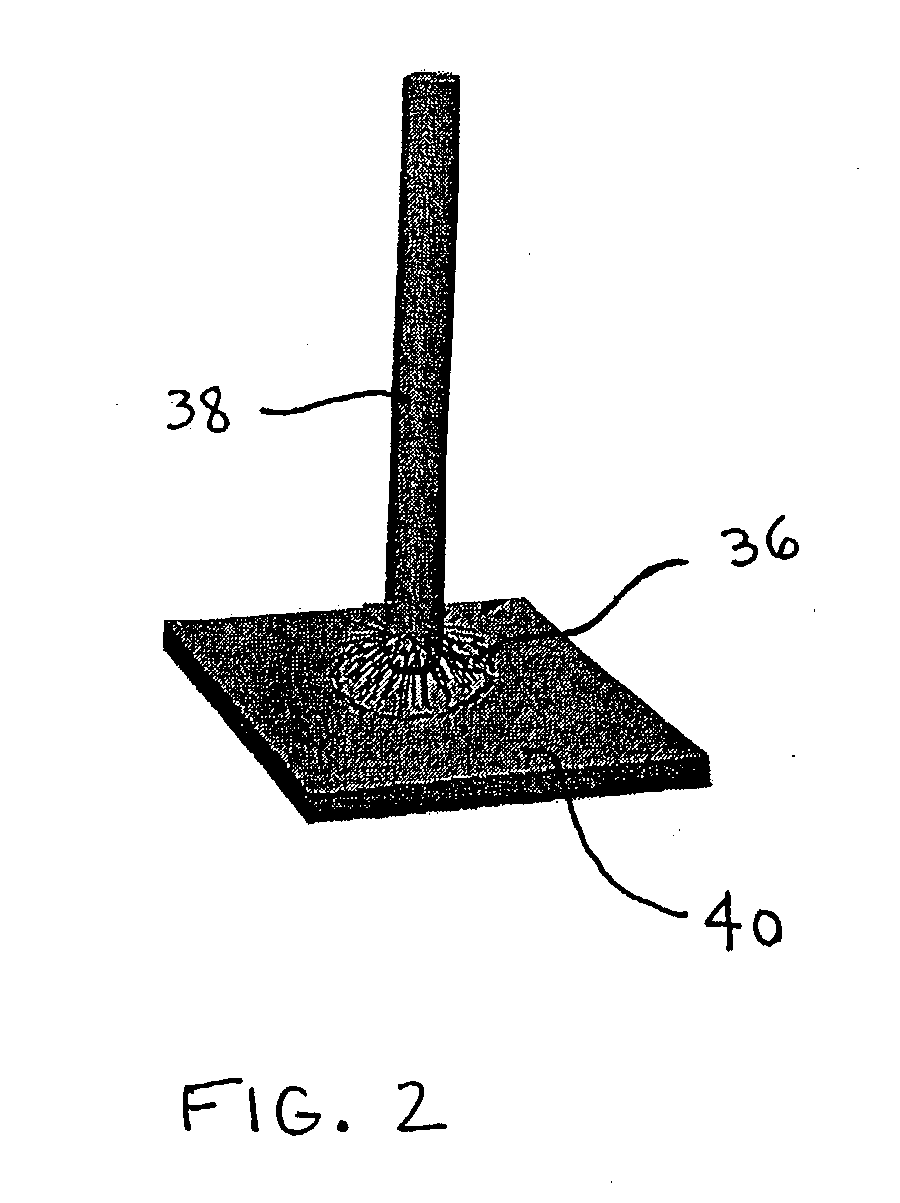

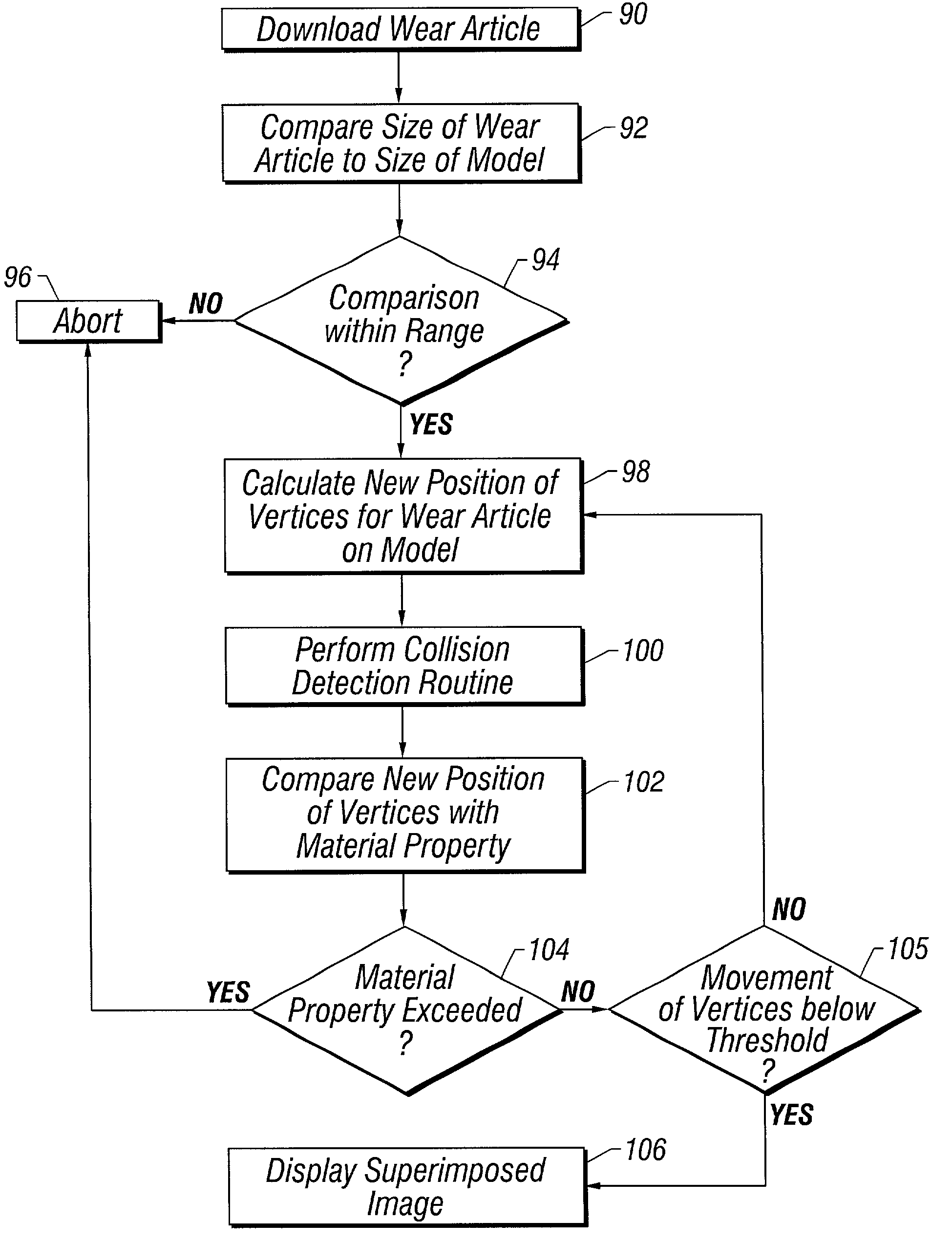

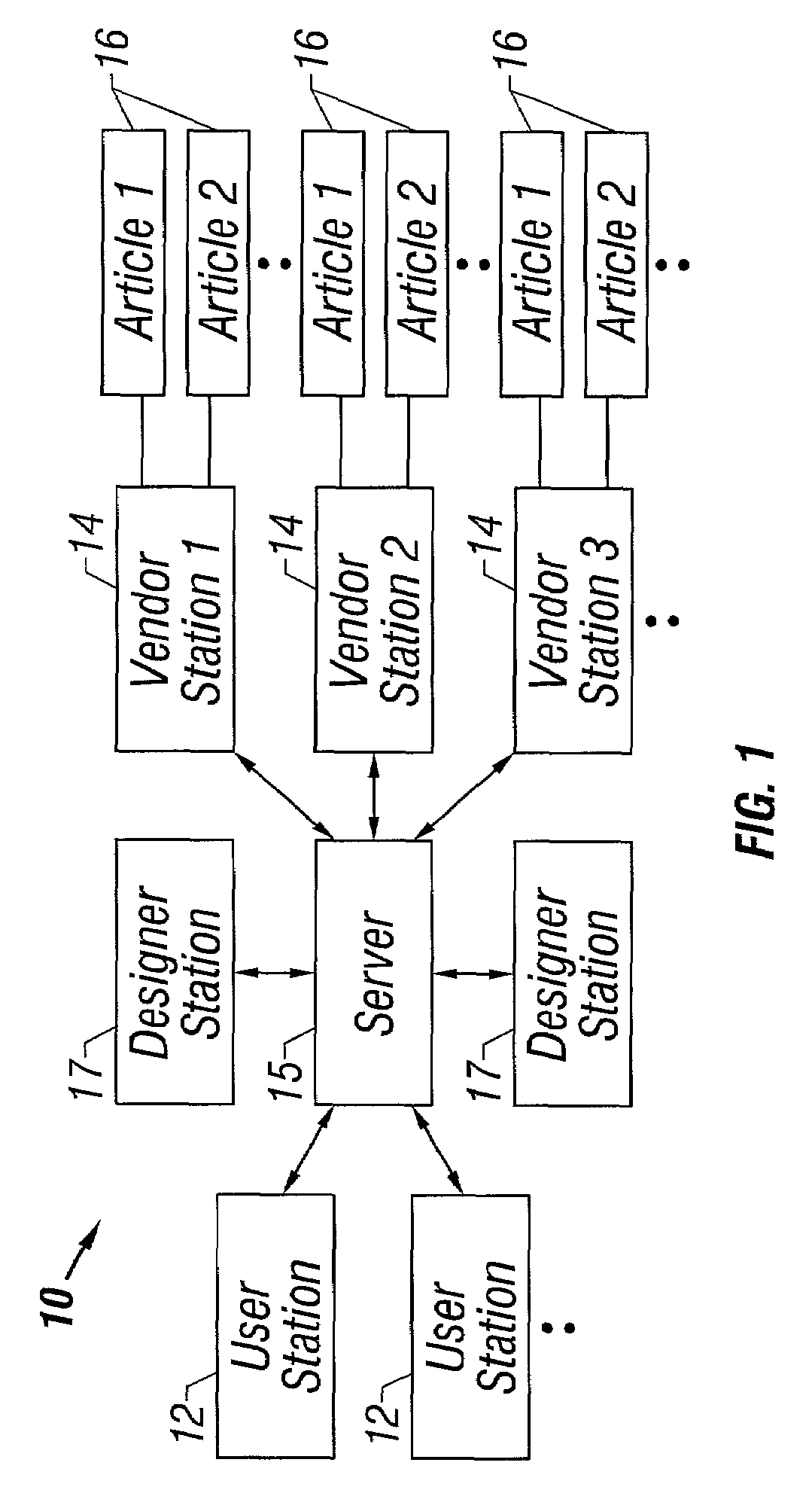

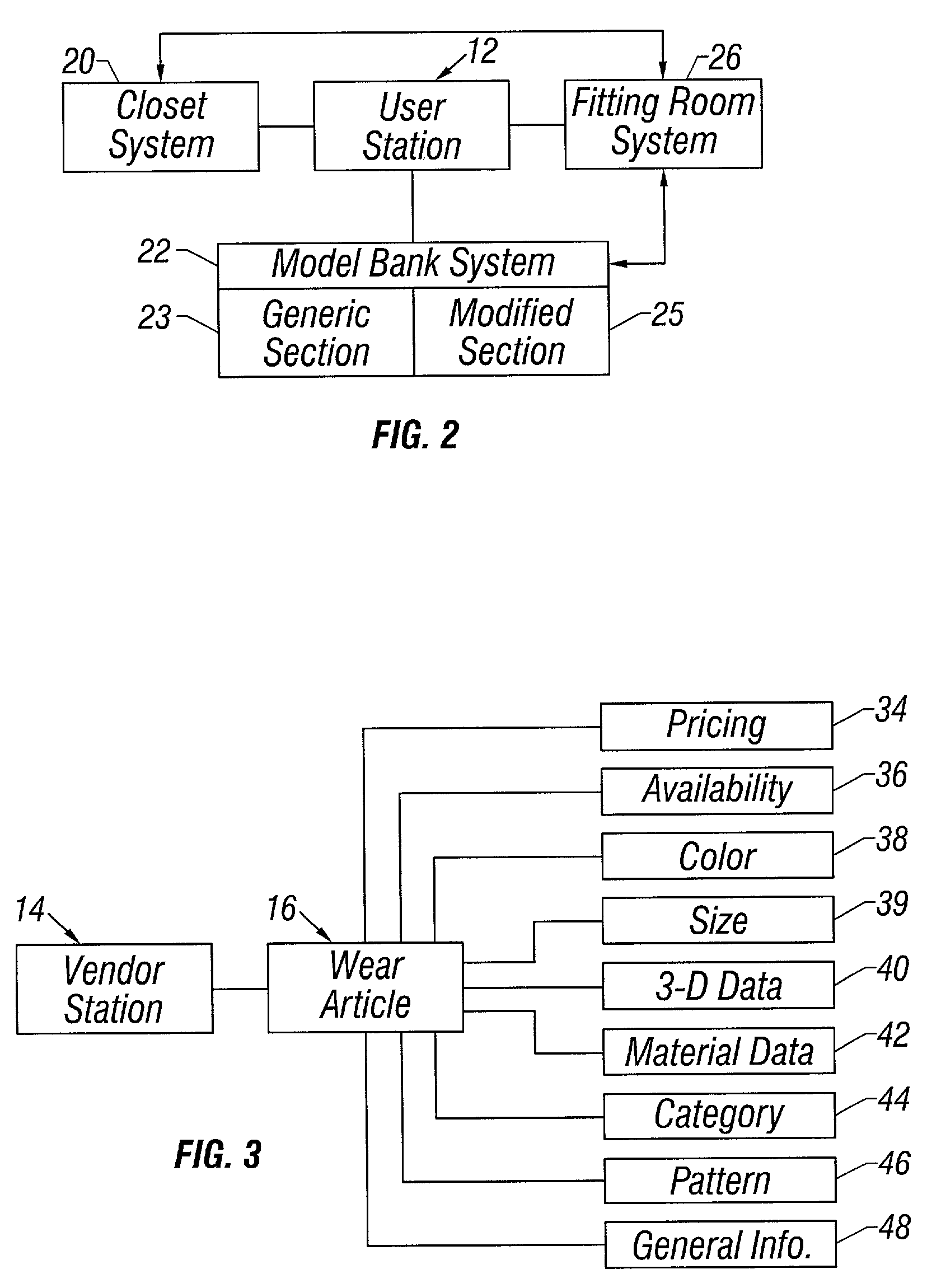

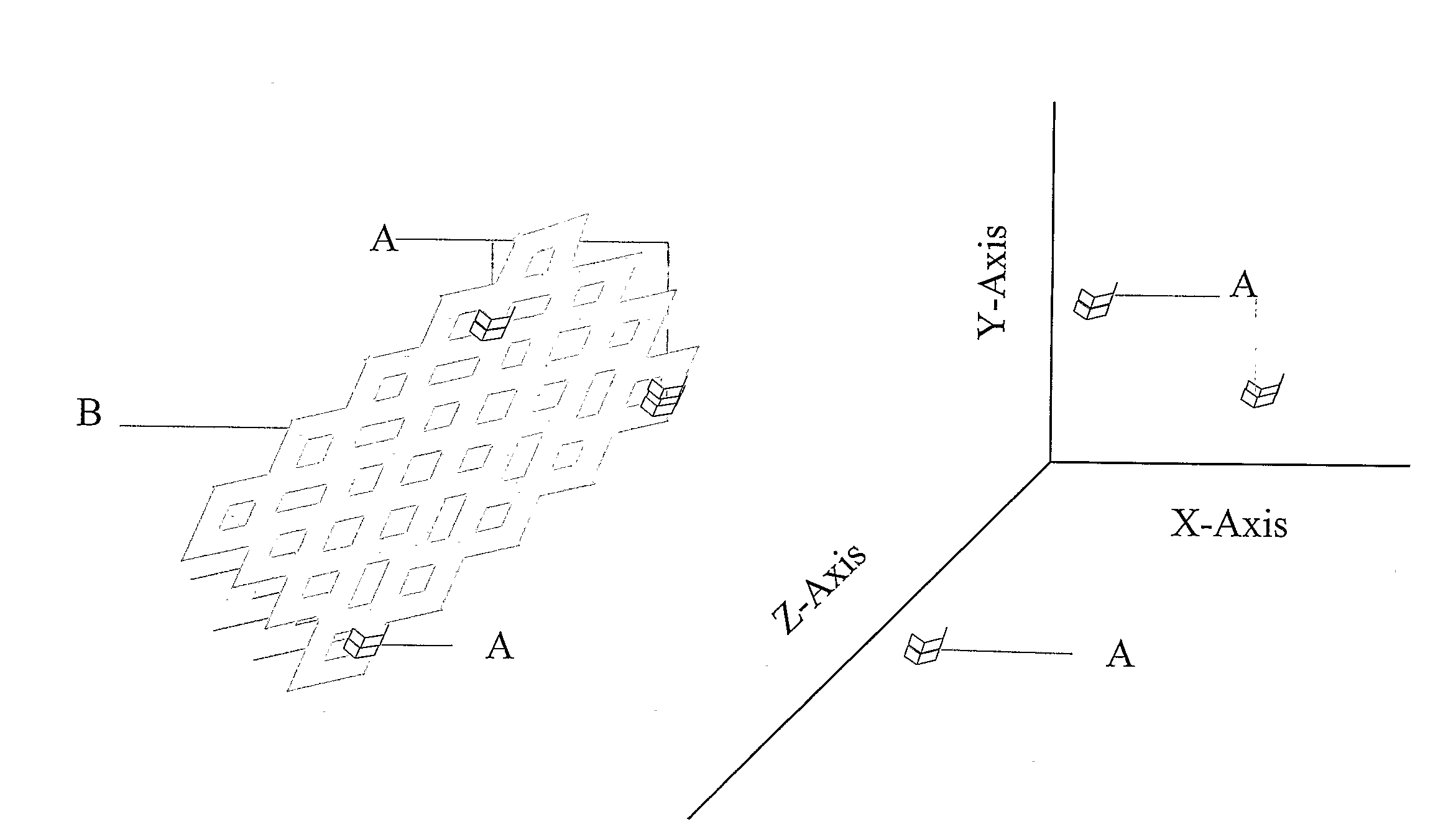

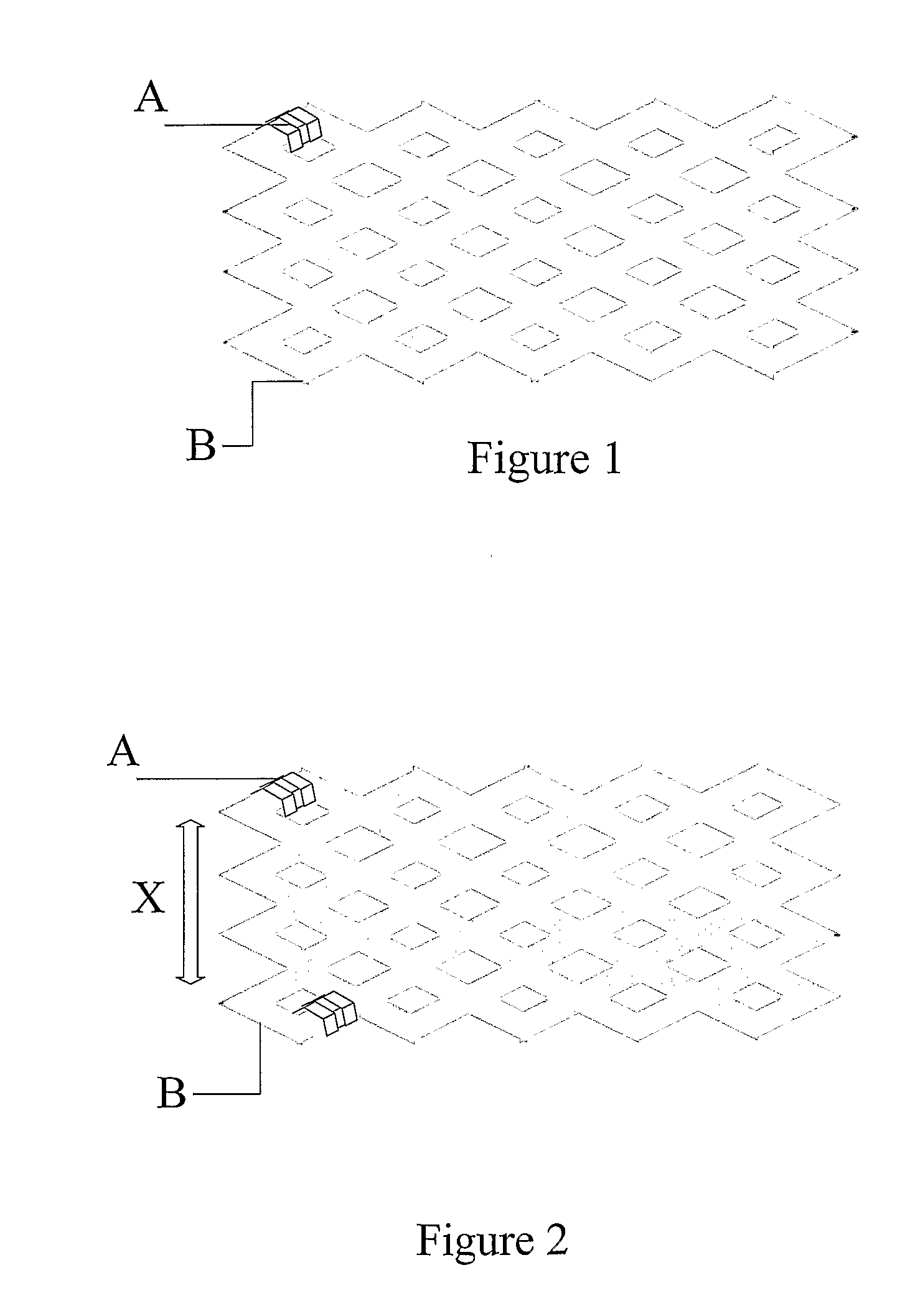

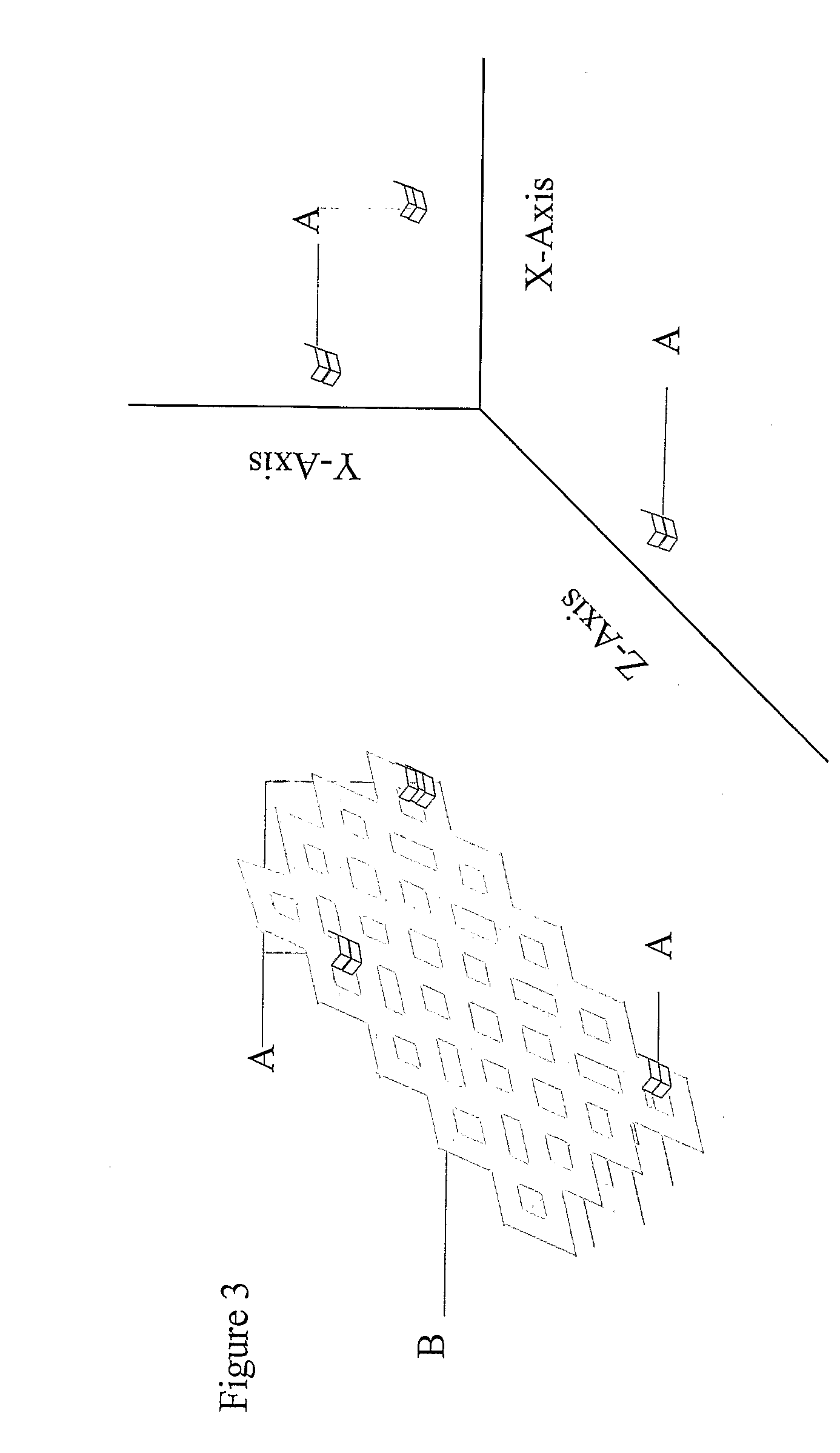

System and method for simulation of virtual wear articles on virtual models

InactiveUS7149665B2Reduce and eliminate needEasy to viewCathode-ray tube indicatorsComputation using non-denominational number representationMaterial typeComputer science

A system and method for designing a wear article for an object comprises providing a virtual three-dimensional model of the object, including first data representing three dimensions of the object. Virtual two-dimensional patterns representing different portions of the wear article are assembled into a virtual three-dimensional wear article. The virtual three-dimensional wear article includes second data representing three dimensions of the wear article. A material type is associated with one or more of the virtual patterns and the virtual three-dimensional wear article. The material type has third data representing at least one physical property of the material type. In order to display the virtual three-dimensional wear article on the virtual three-dimensional model, the first and second data are compared to determine the non-intersection of the virtual three-dimensional wear article with the virtual three-dimensional object. The virtual three-dimensional wear article is then conformed to the virtual three-dimensional model within constraints imposed by the third data. With this arrangement, the system and method enables the virtual wear article to stretch, flex, sag, etc., on the virtual model to better approximate the real-life fit and look of the wear article on an object during design of the wear article.

Owner:BROWZWEAR SOLUTIONS

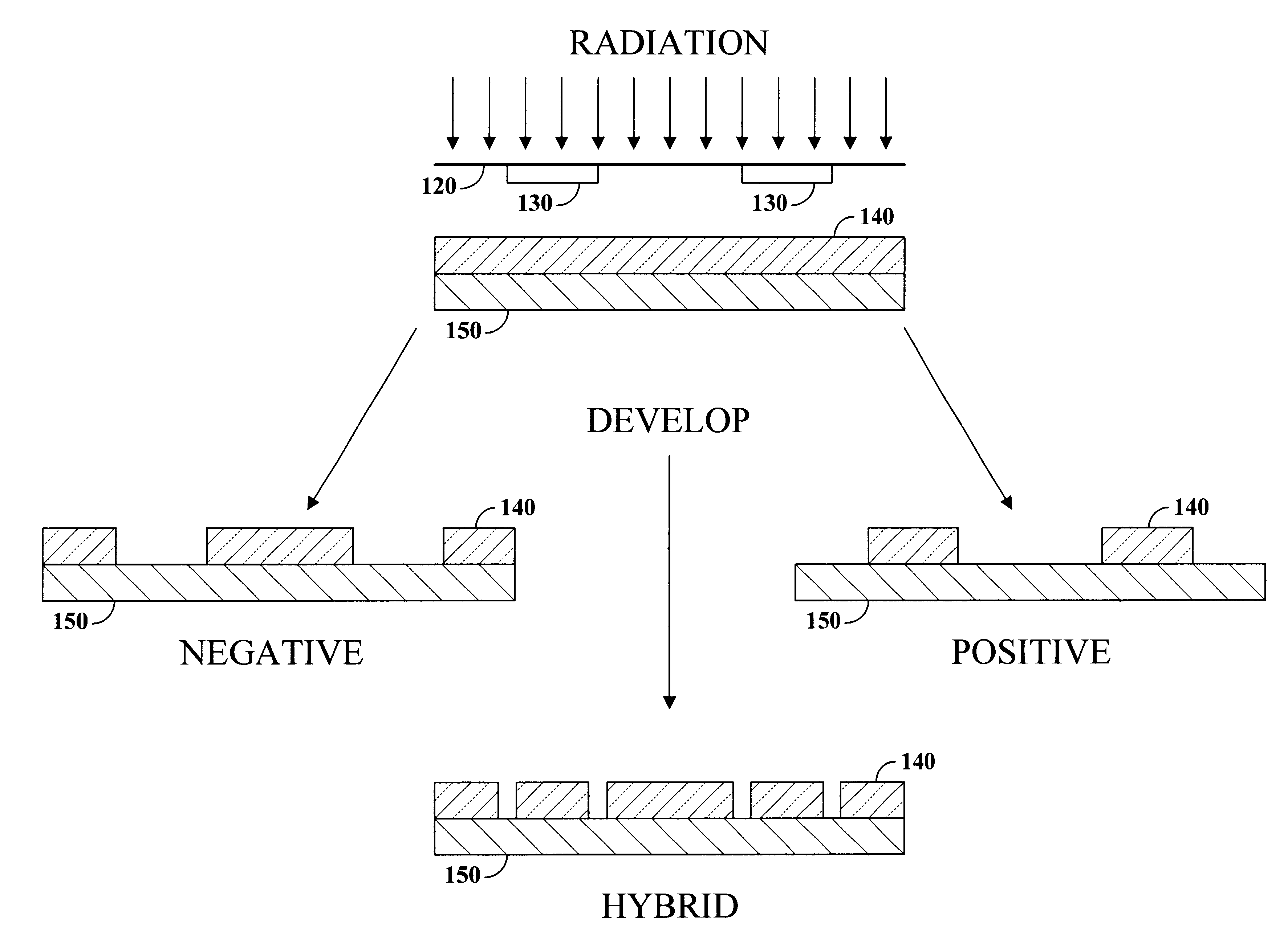

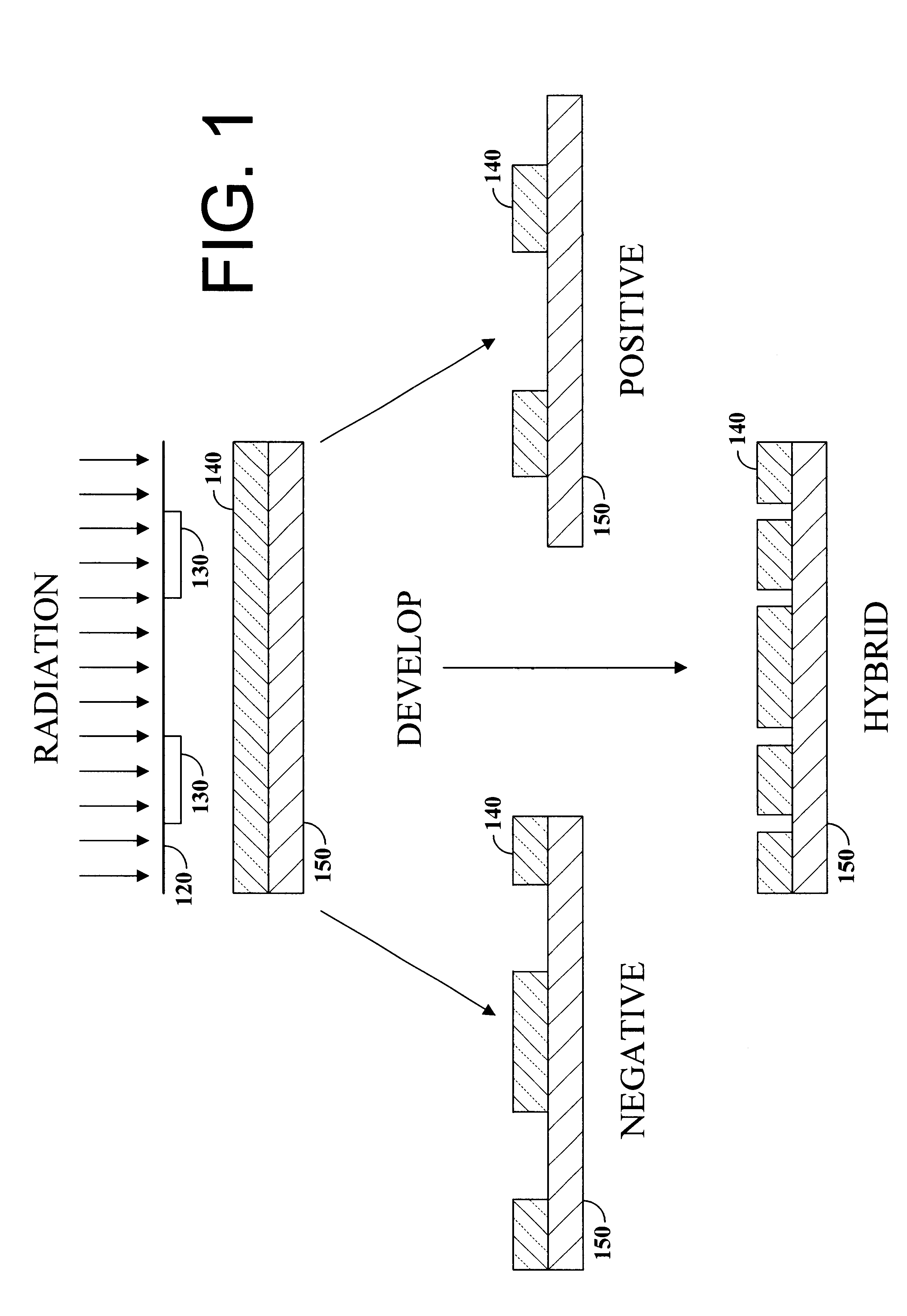

Hybrid resist based on photo acid/photo base blending

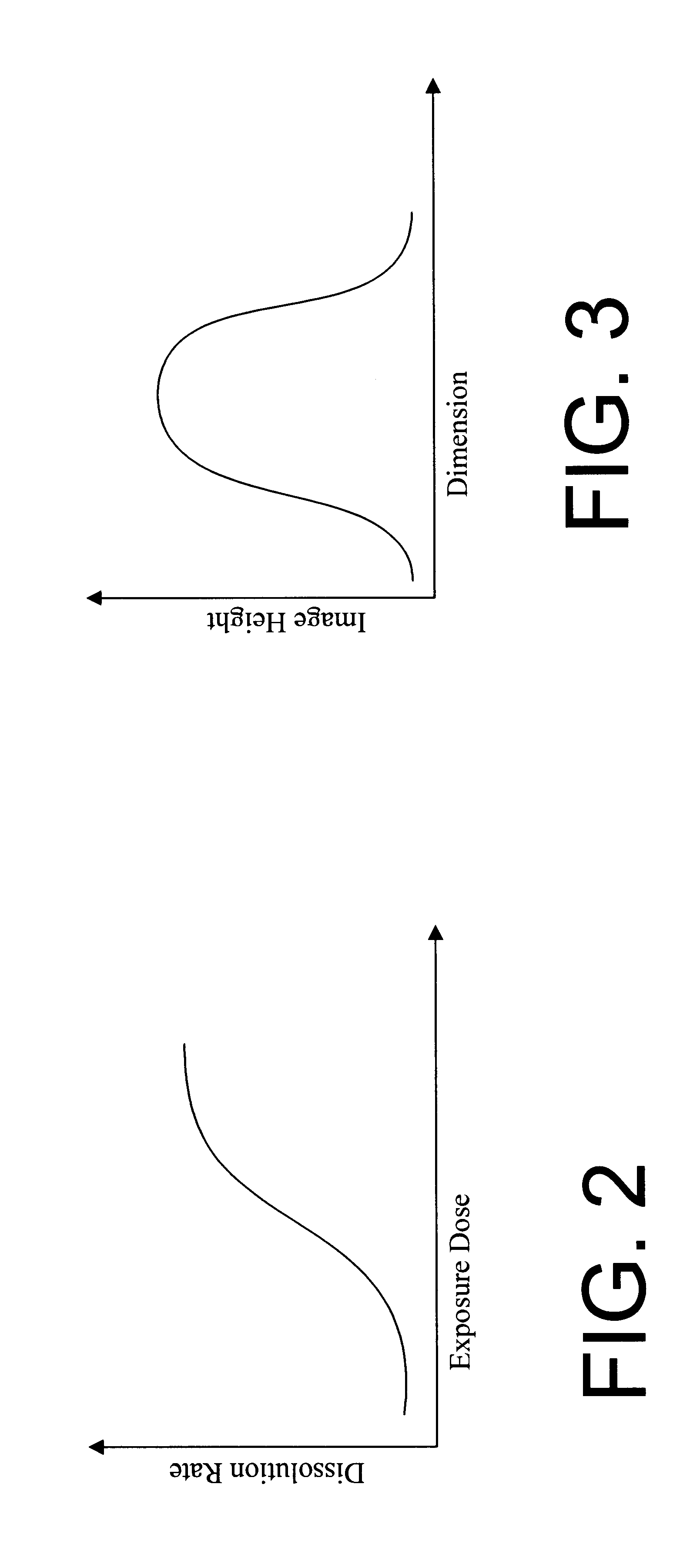

A photo resist composition contains a polymer resin, a first photo acid generator (PAG) requiring a first dose of actinic energy to generate a first photo acid, and a photo base generator (PBG) requiring a second dose of actinic energy, different from the first dose, to generate a photo base. The amounts and types of components in the photo resist are selected to produce a hybrid resist image. Either the first photo acid or photo base acts as a catalyst for a chemical transformation in the resist to induce a solubility change. The other compound is formulated in material type and loading in the resist such that it acts as a quenching agent. The catalyst is formed at low doses to induce the solubility change and the quenching agent is formed at higher doses to counterbalance the presence of the catalyst. Accordingly, the same frequency doubling effect of conventional hybrid resist compositions may be obtained, however, either a line or a space may be formed at the edge of an aerial image. Feature size may also be influenced by incorporating a quenching agent into the resist composition that does not require photo generation.

Owner:IBM CORP

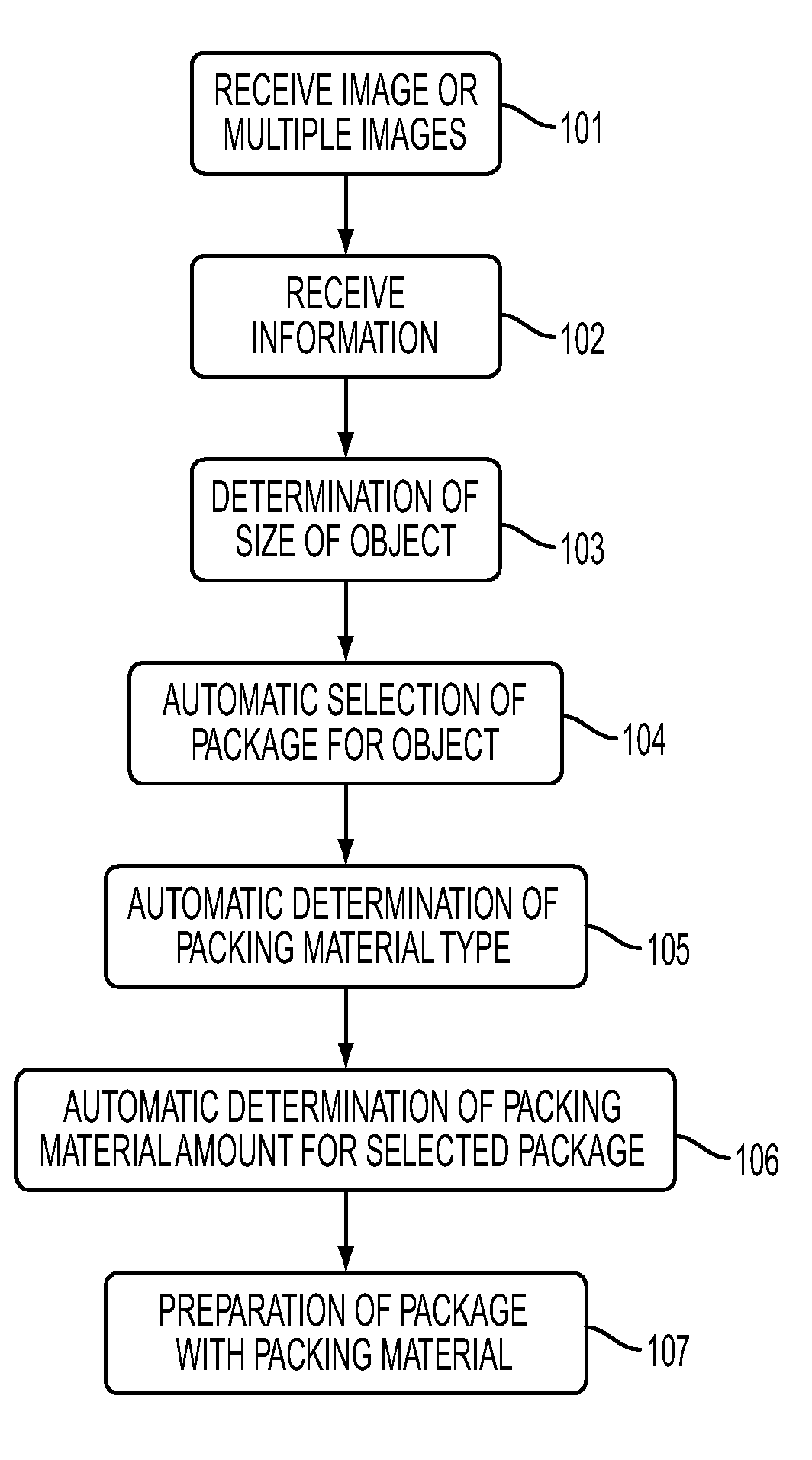

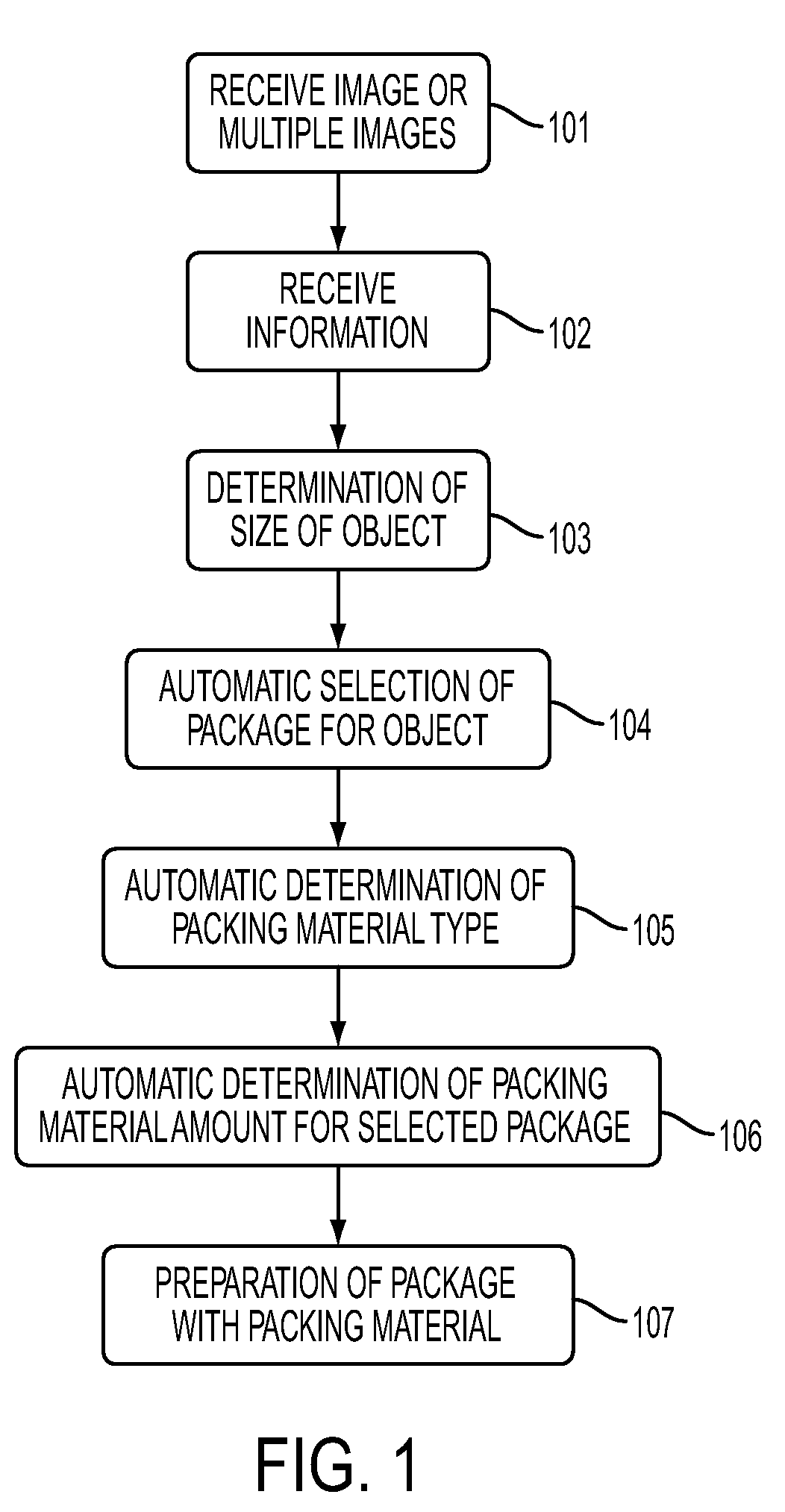

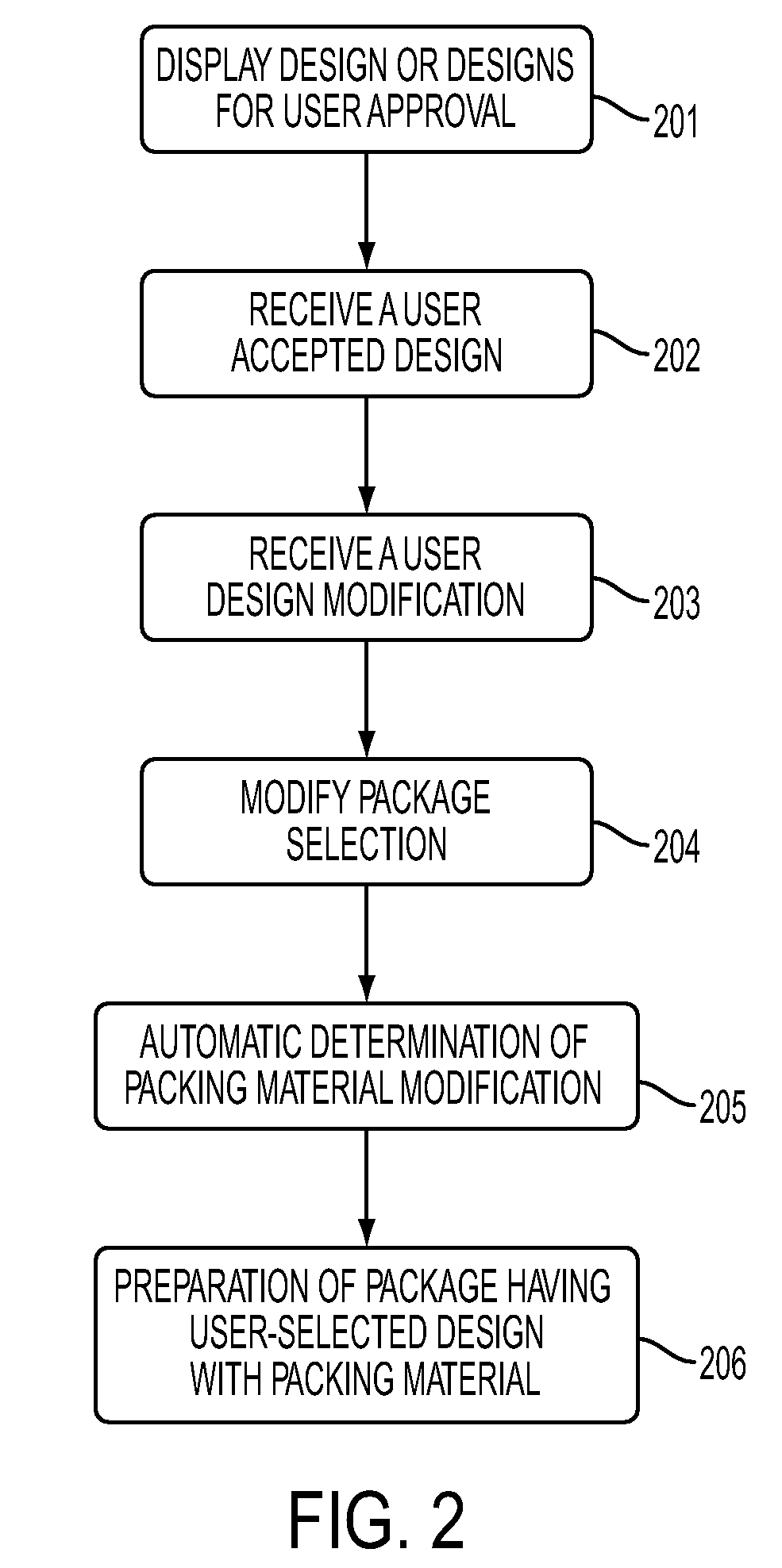

Custom packaging solution for arbitrary objects

Owner:XEROX CORP

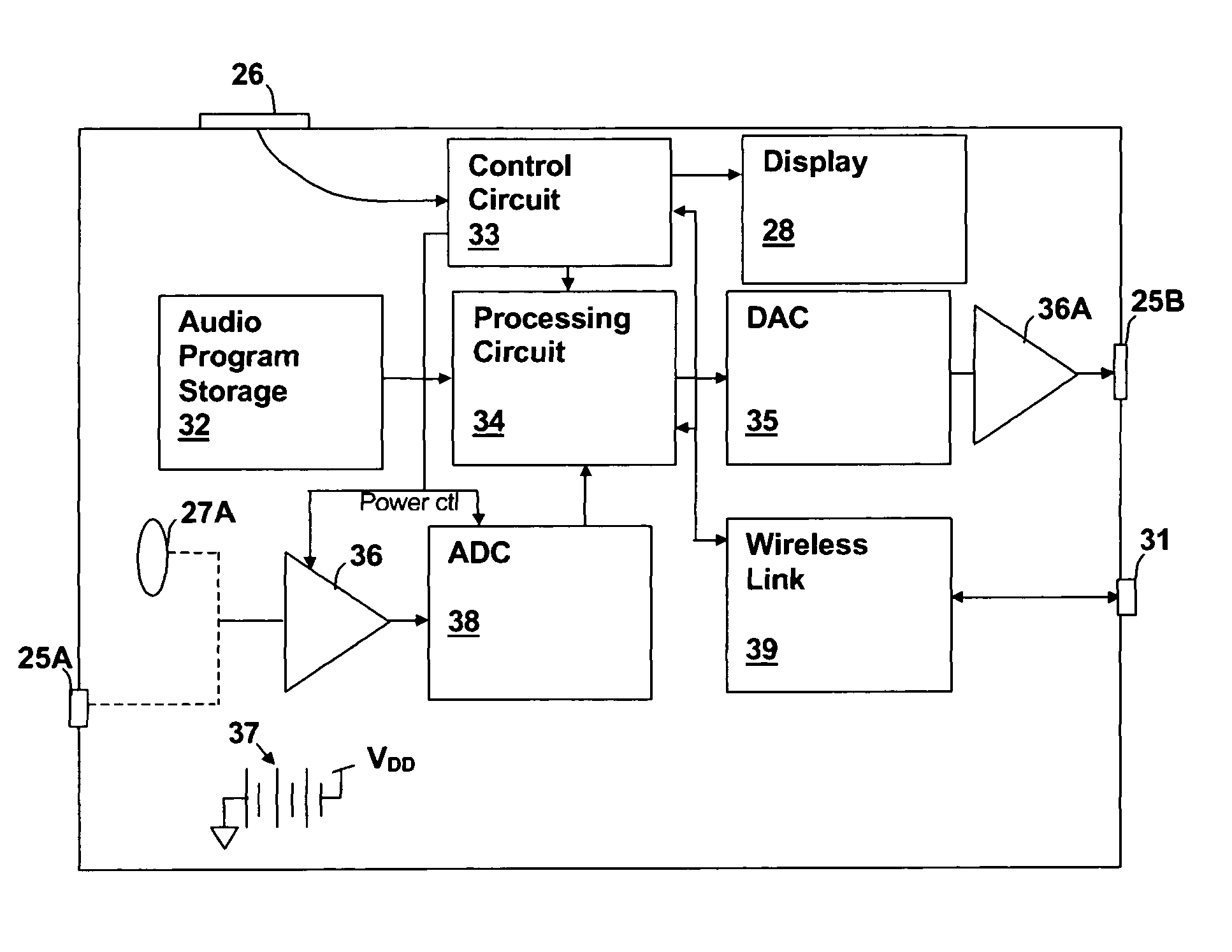

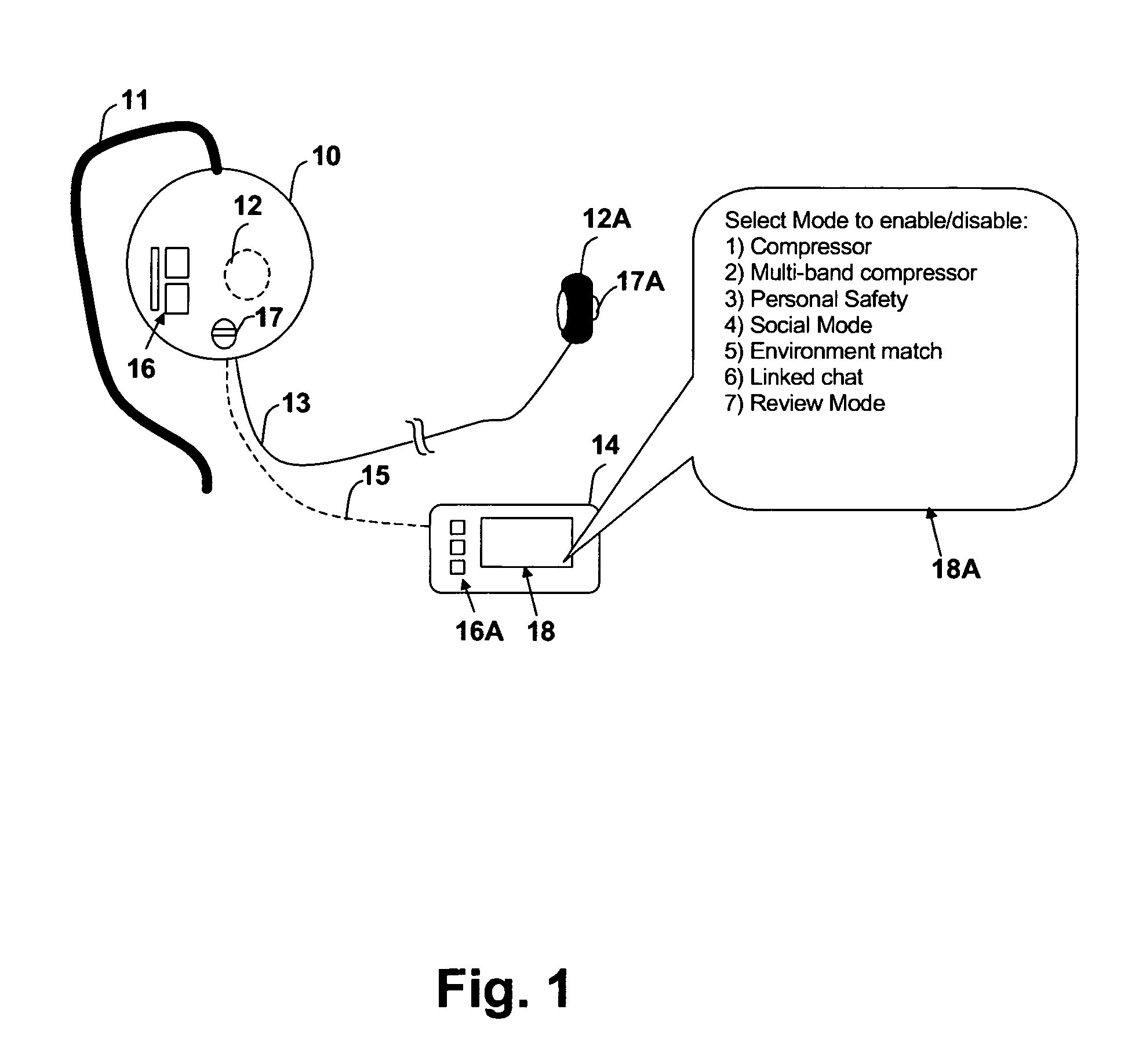

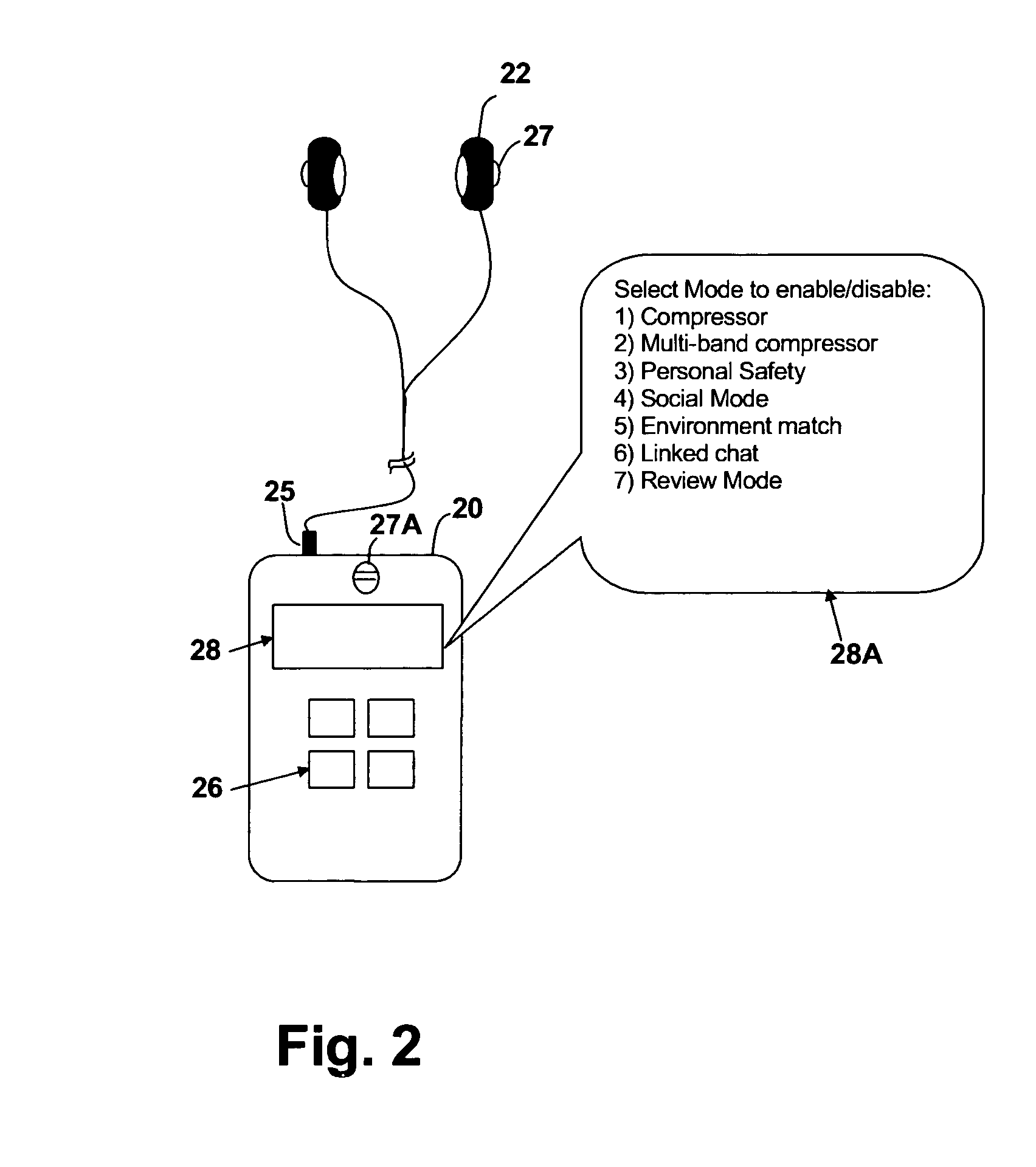

Personal audio playback device having gain control responsive to environmental sounds

ActiveUS7903825B1Lower Level RequirementsReduce rateGain controlEarpiece/earphone attachmentsMaterial typeEnvironmental sounds

A personal audio playback device having gain control responsive to environmental sounds provides for improved enjoyment of program material played back through headphones, while further providing features for personal safety and communications with others. A microphone is incorporated on the surface of the playback device, which includes an audio output connection for headphones and internal storage for audio program material. The entire device may be incorporated within the headphones, or the headphones may connect through a connector on the housing of the device. The gain, type or position of the program material is controlled in conformity with a detected characteristic of ambient sounds received by the microphone, which may be the amplitude of the signals in one or more frequency bands, or a particular type of sound, such as speech or vehicular sounds. Multiple modes are selectable for processing the audio, selecting program material type and / or re-positioning the program material.

Owner:CIRRUS LOGIC INC

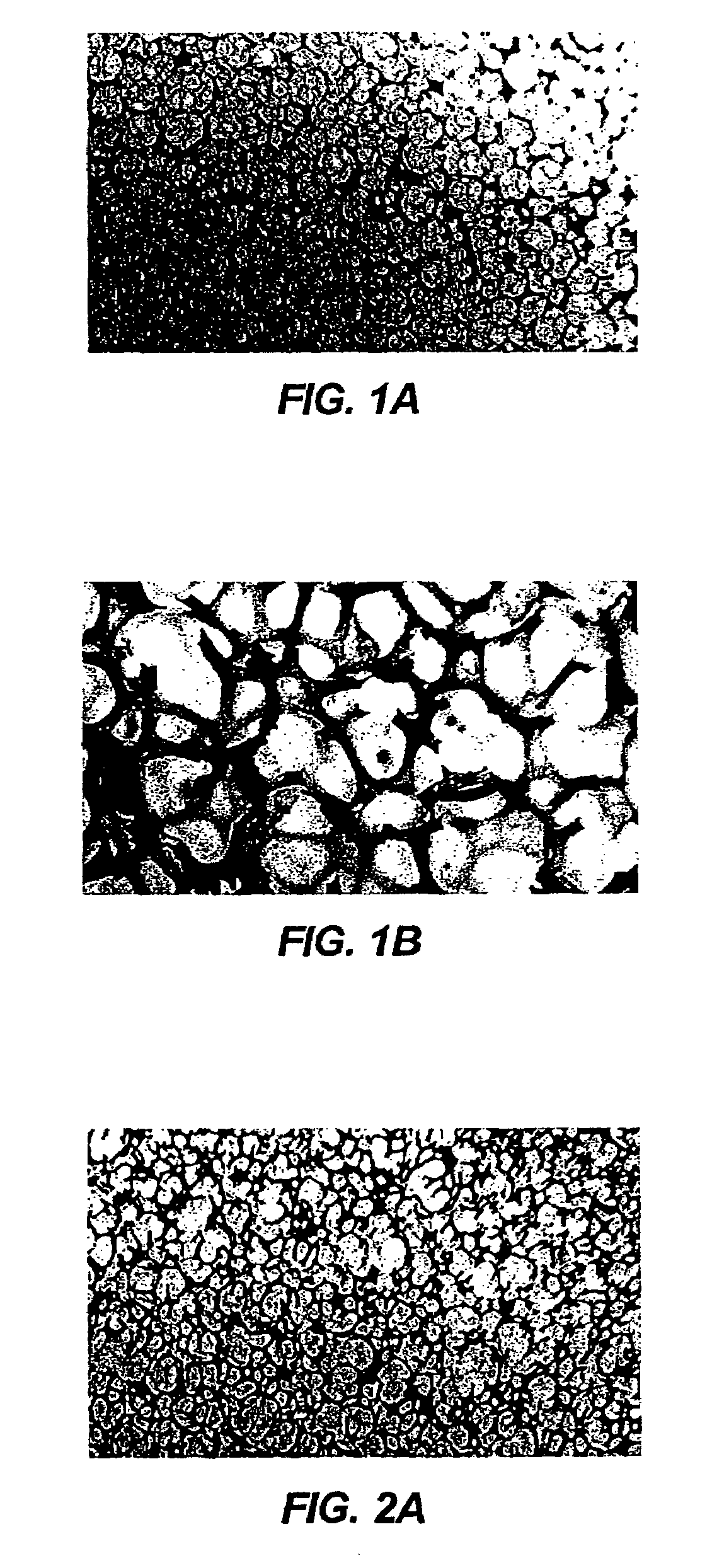

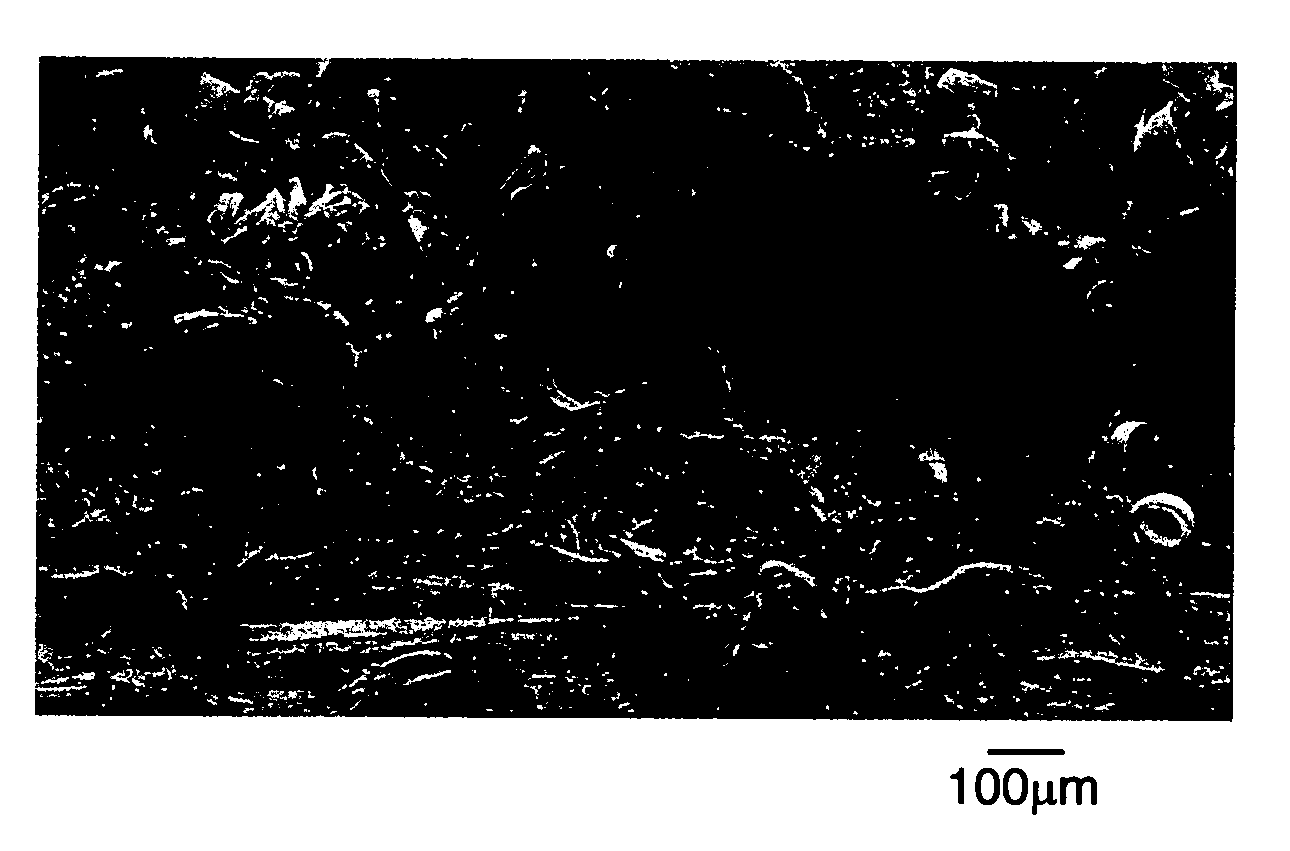

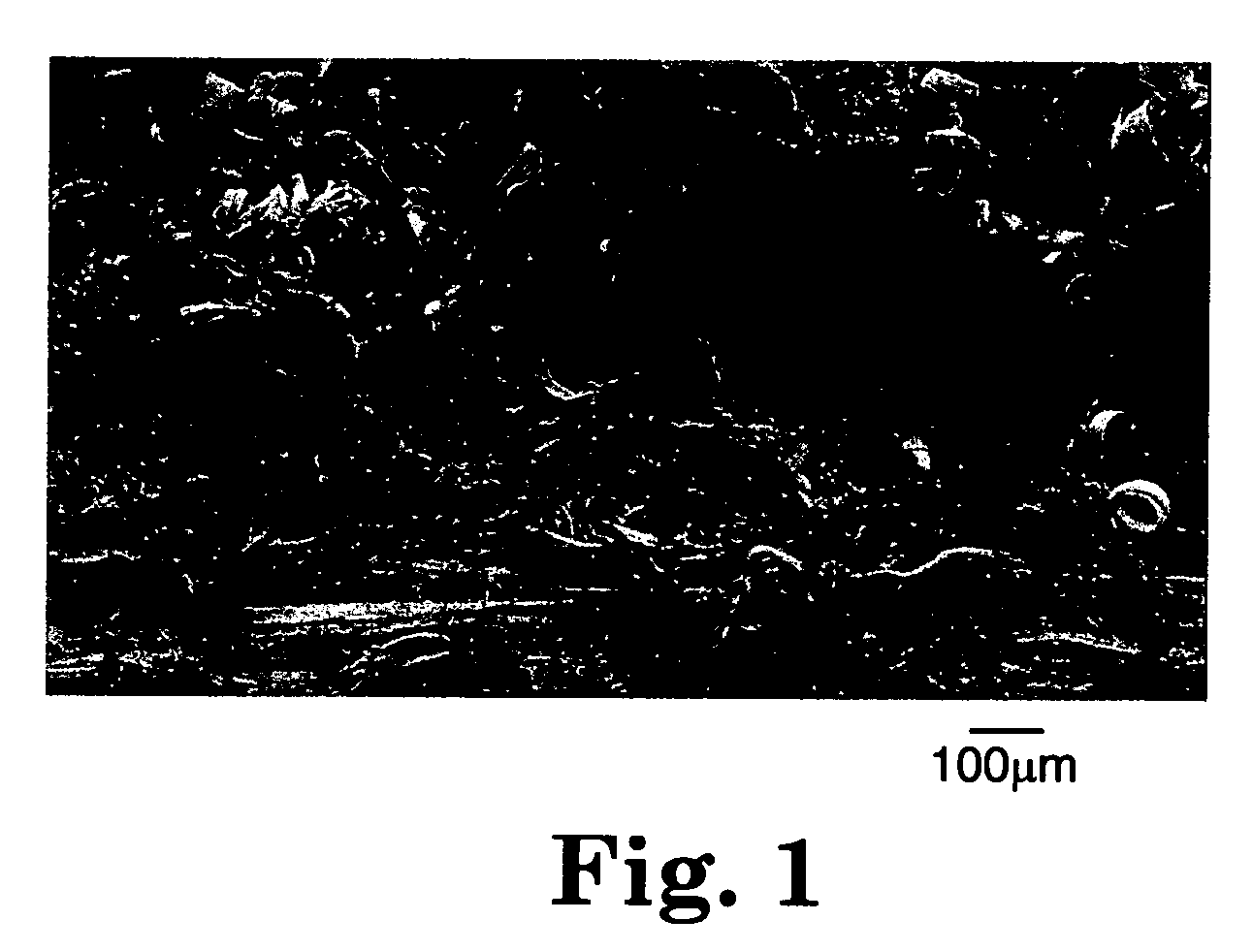

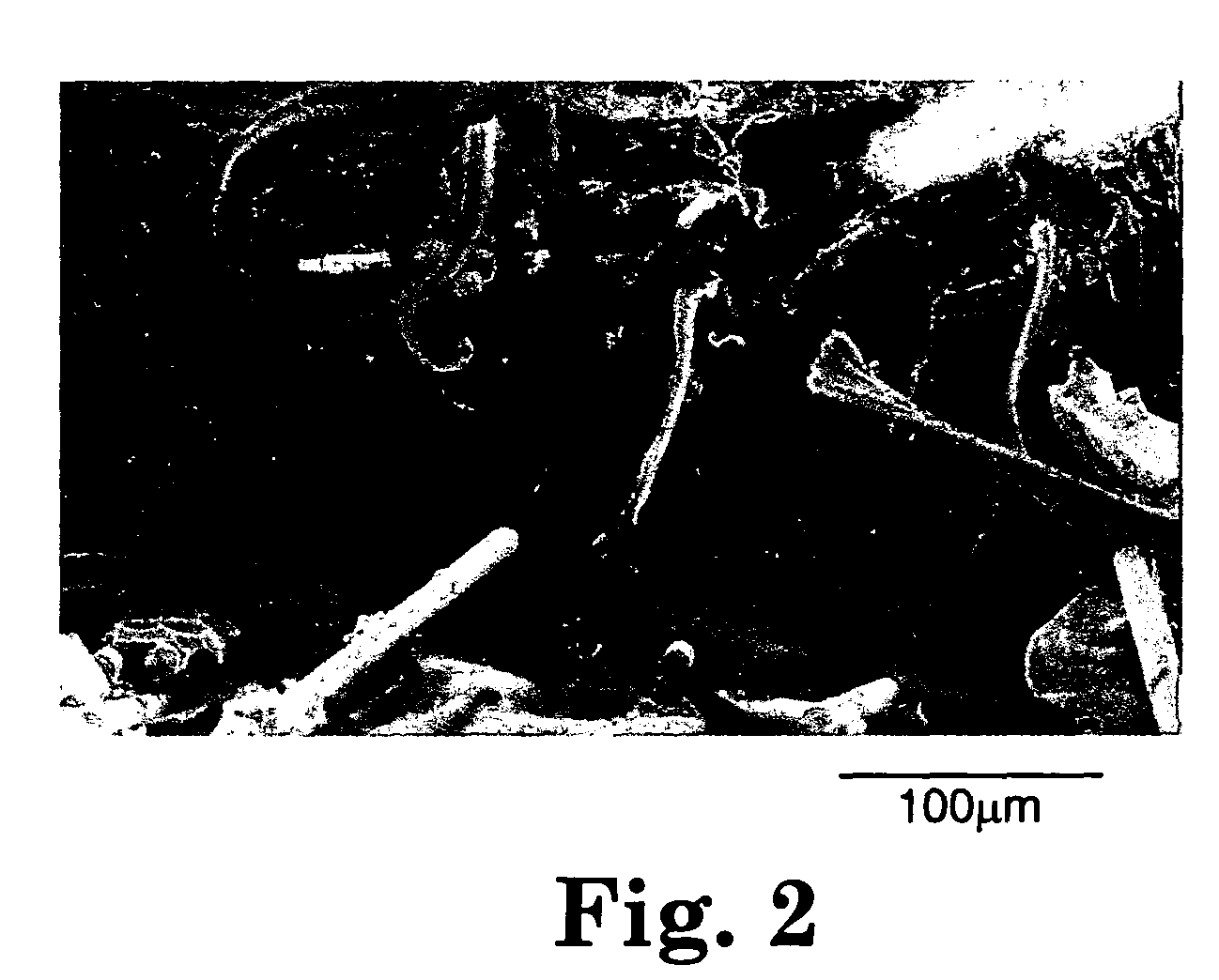

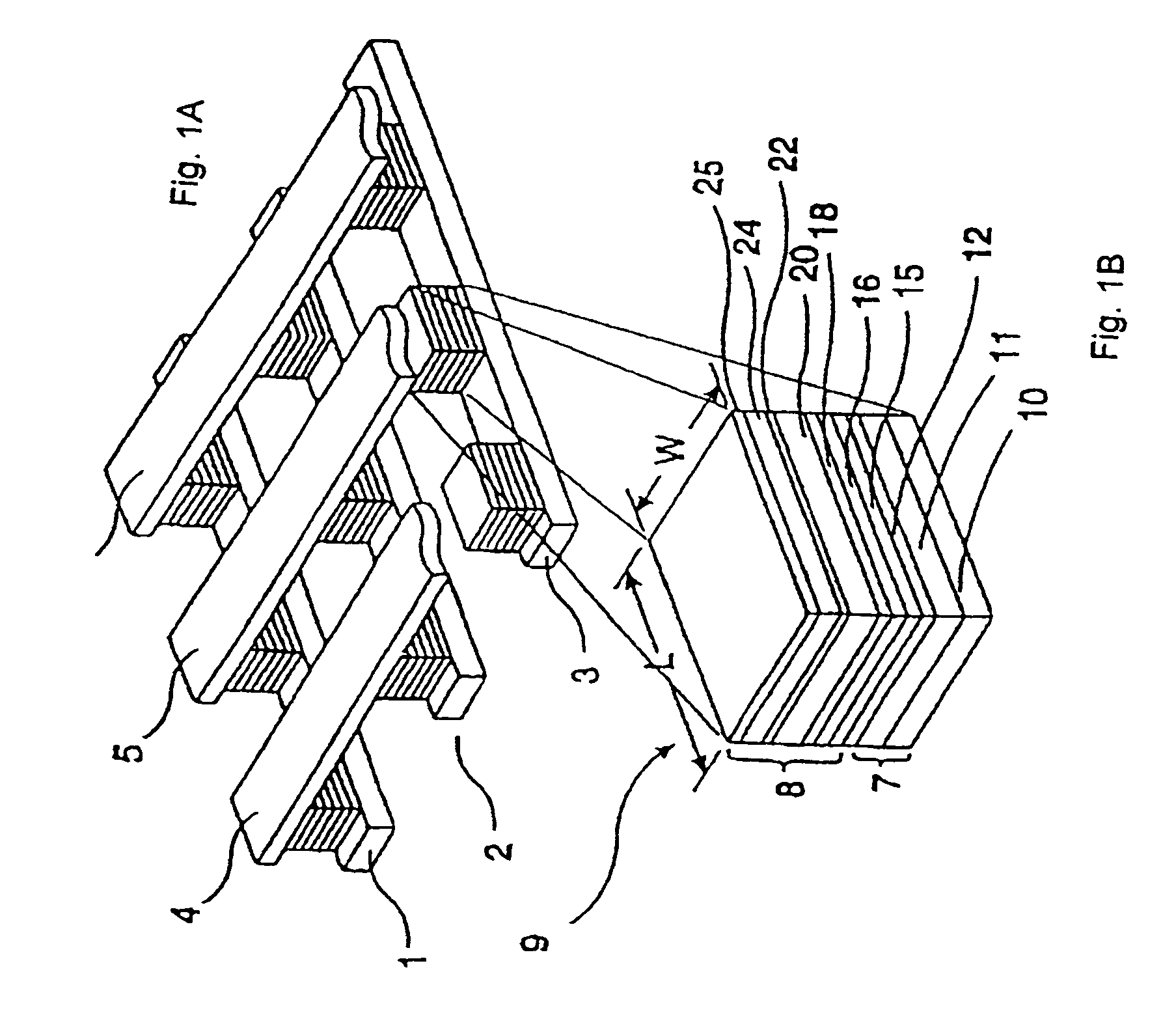

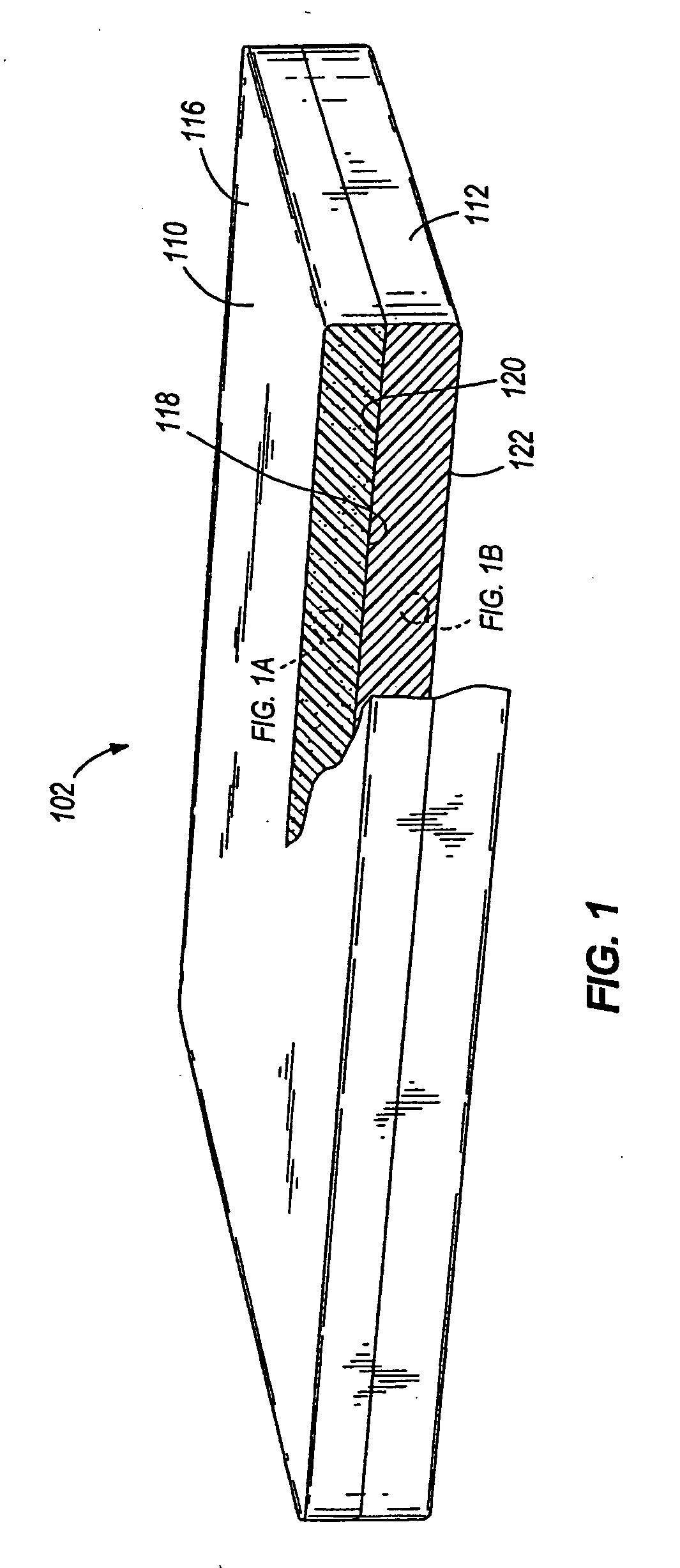

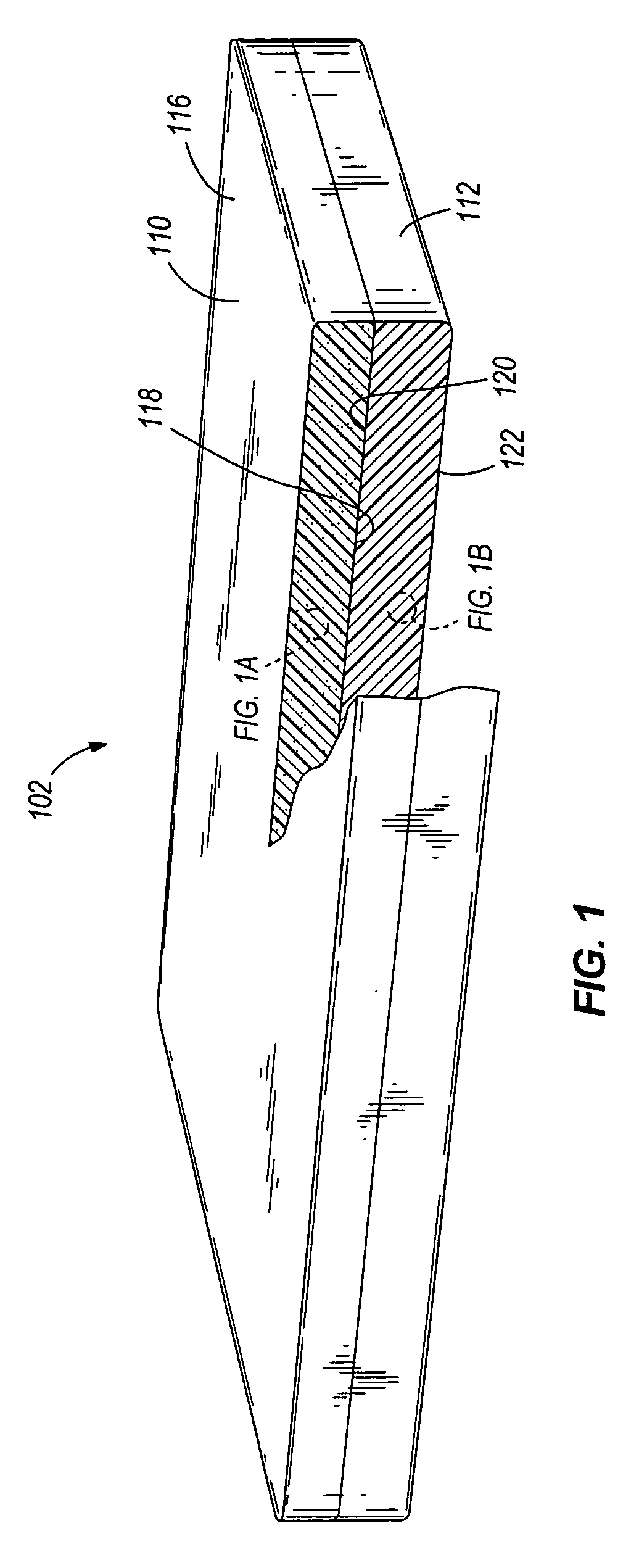

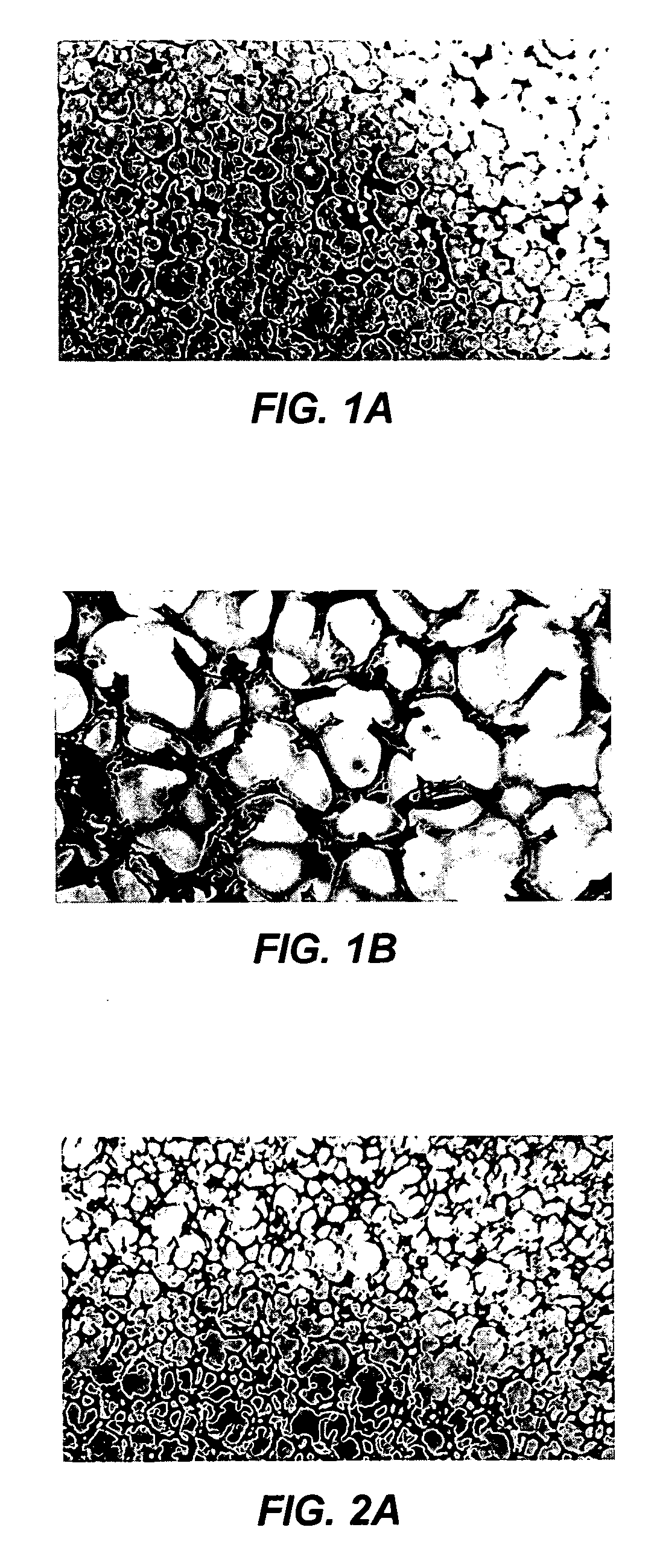

Composite articles reinforced with highly oriented microfibers

InactiveUS6630231B2Improve toughnessHigh strengthLamination ancillary operationsLayered product treatmentMaterial typePolymer science

A composite formed of a polymer matrix phase having a reinforcement phase including polymeric microfibers. The microfibers are preferably formed of a highly oriented polymer, having a high modulus value and a large surface area. The large surface area can serve to tightly bind the microfibers to the polymer matrix phase. The microfibers can be provided as a fully- or partially-microfibrillated film, as a non-woven web of entangled microfibers, or as a pulp having free fibers. The microfibers can be embedded in, or impregnated with, a polymer or polymer precursor. Some composite articles are formed from thermoset resins cured about a highly oriented polypropylene microfiber reinforcement phase, providing a strong, tough, moisture resistant article. One composite includes a matrix and reinforcement formed of the same material type and having substantially equal refractive indices, allowing the composite to be optically clear.

Owner:3M INNOVATIVE PROPERTIES CO

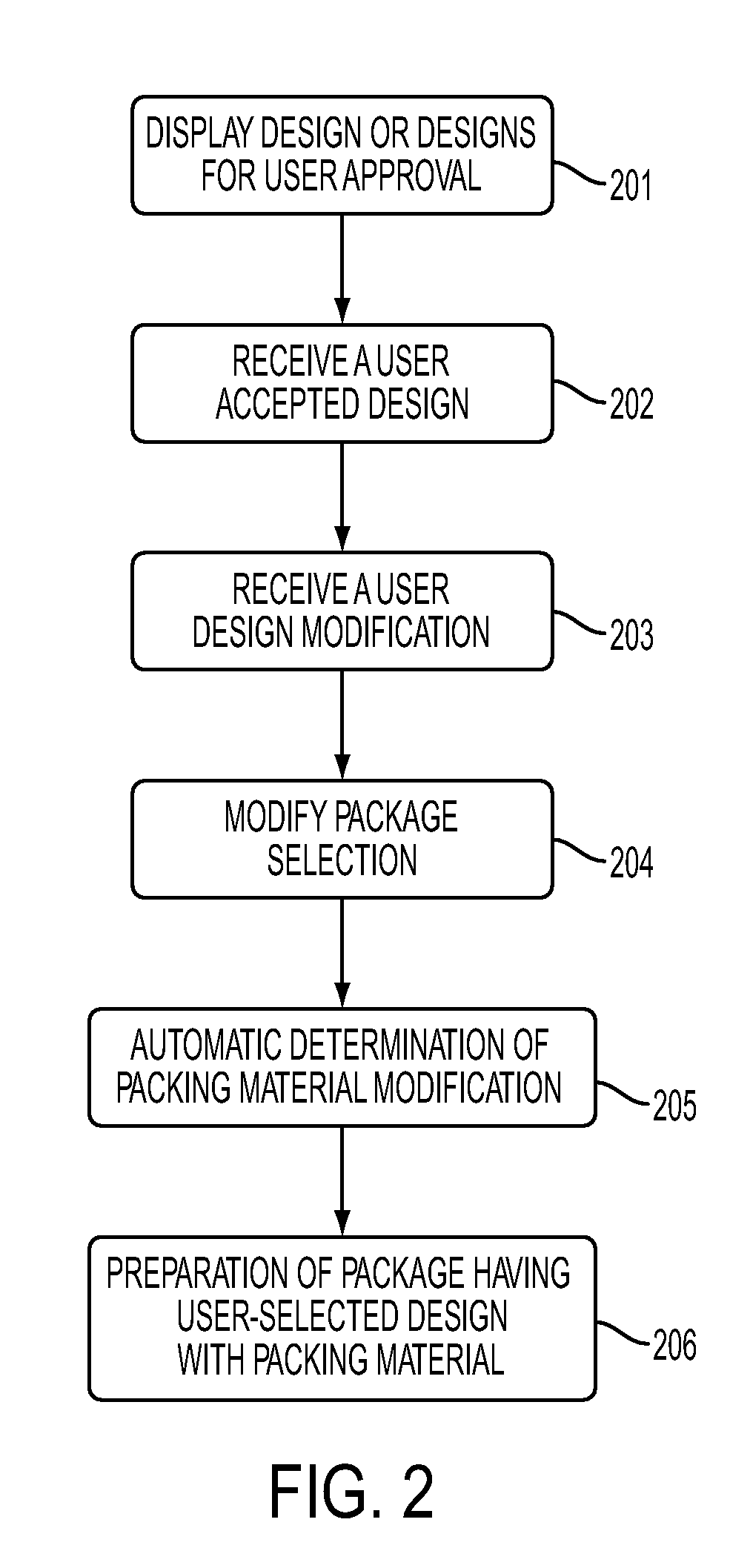

Custom packaging solution for arbitrary objects

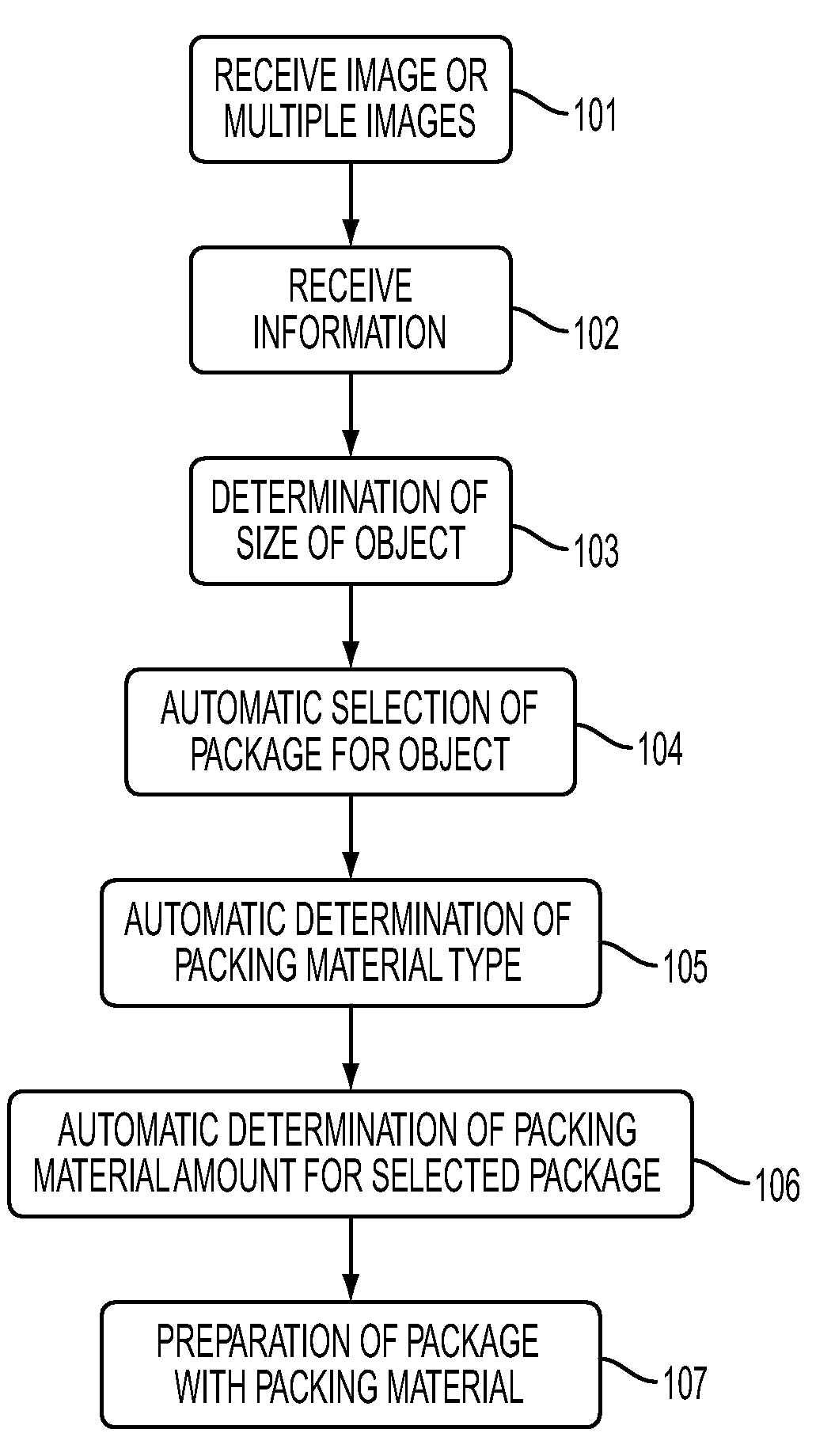

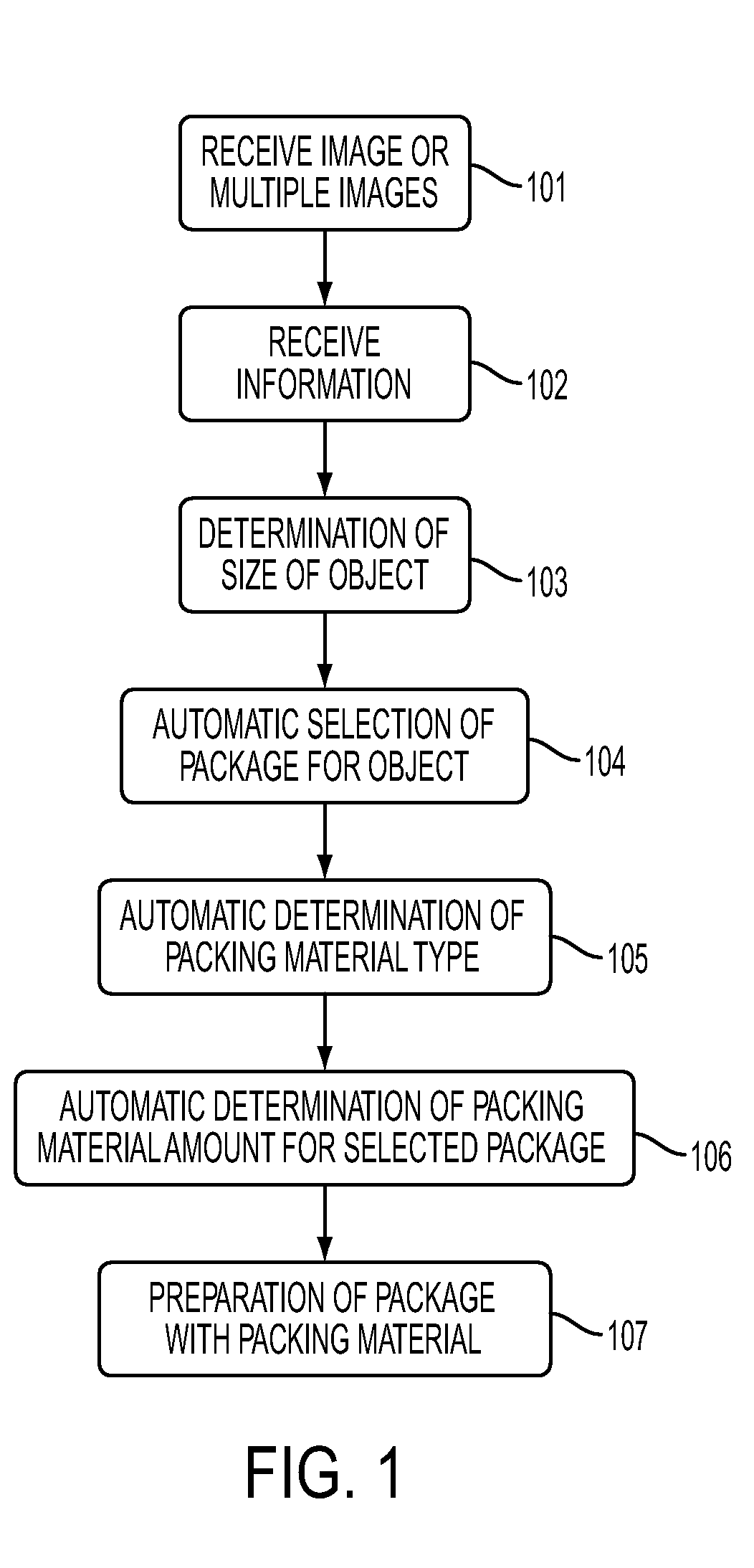

A method of producing a custom packaging system for arbitrary objects. A first image of an object to be packaged is received via an electronic user interface. Information relating to the material properties of the object may be received as well via the interface. A three dimensional size for the object is determined. At least one package for the object is automatically selected. Based on the material properties, a packing material type is automatically determined. Based upon the size and the selected package, a packing material amount is determined. Further printing options are permitted.

Owner:XEROX CORP

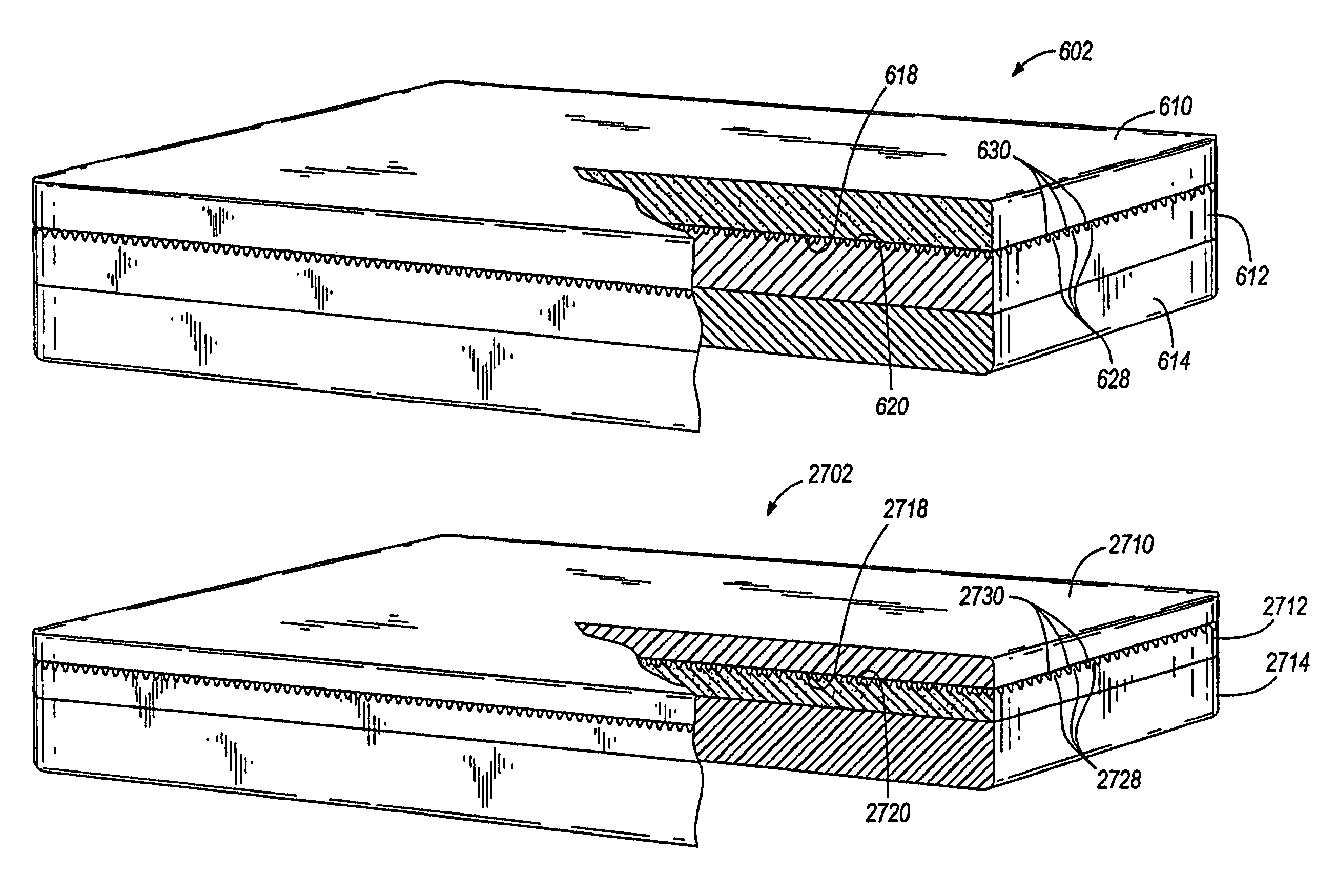

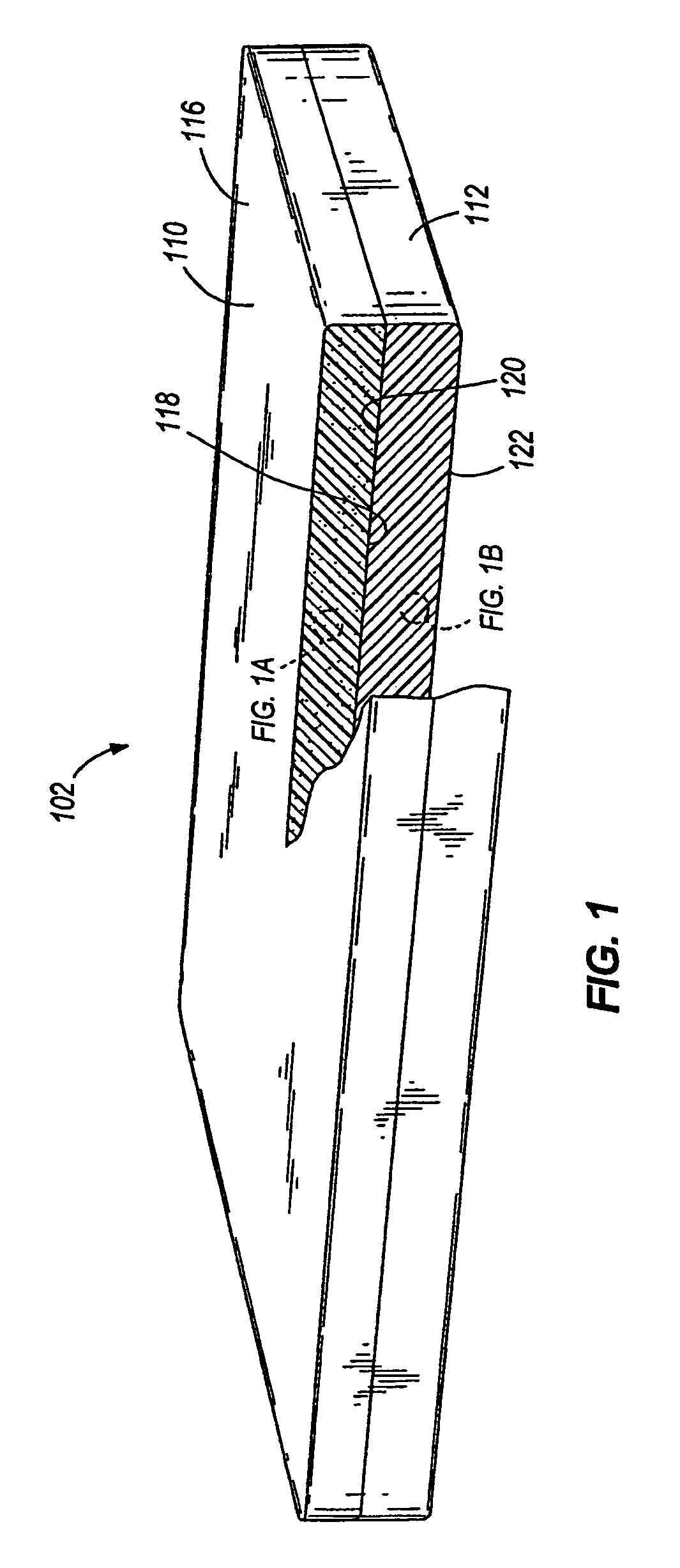

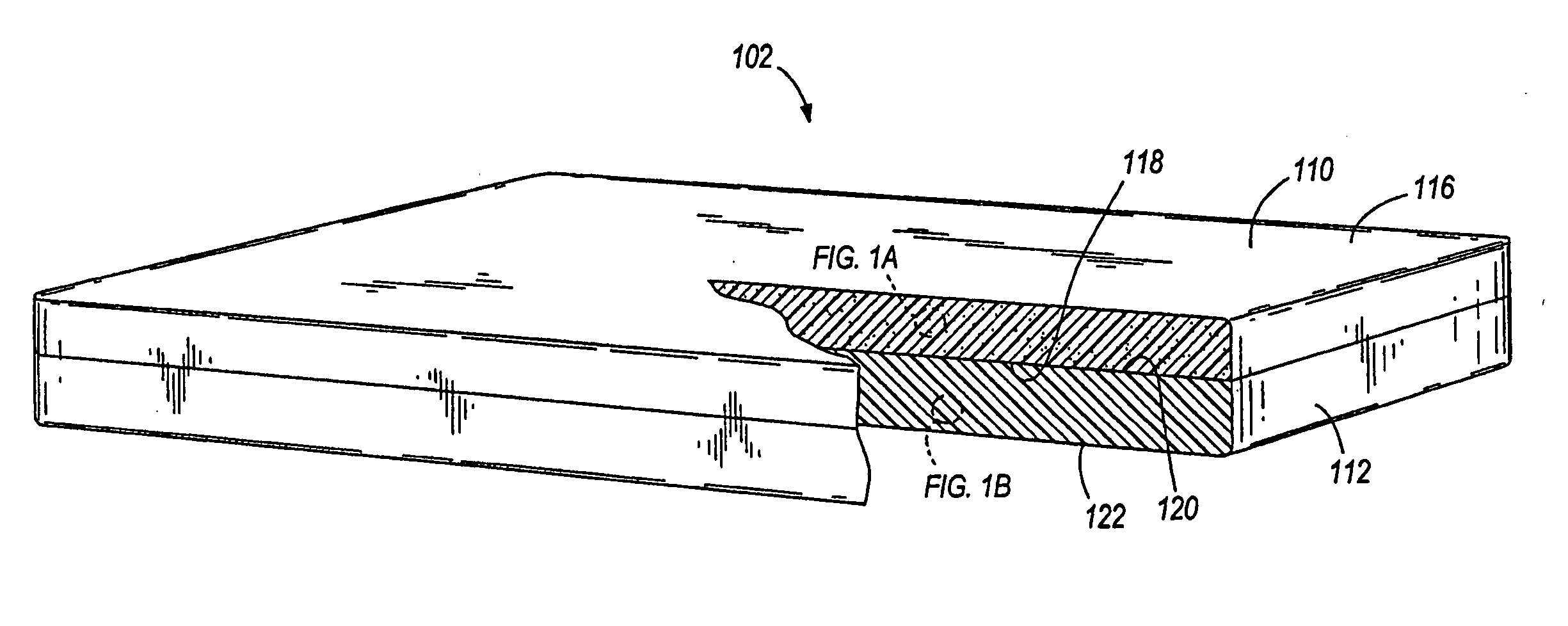

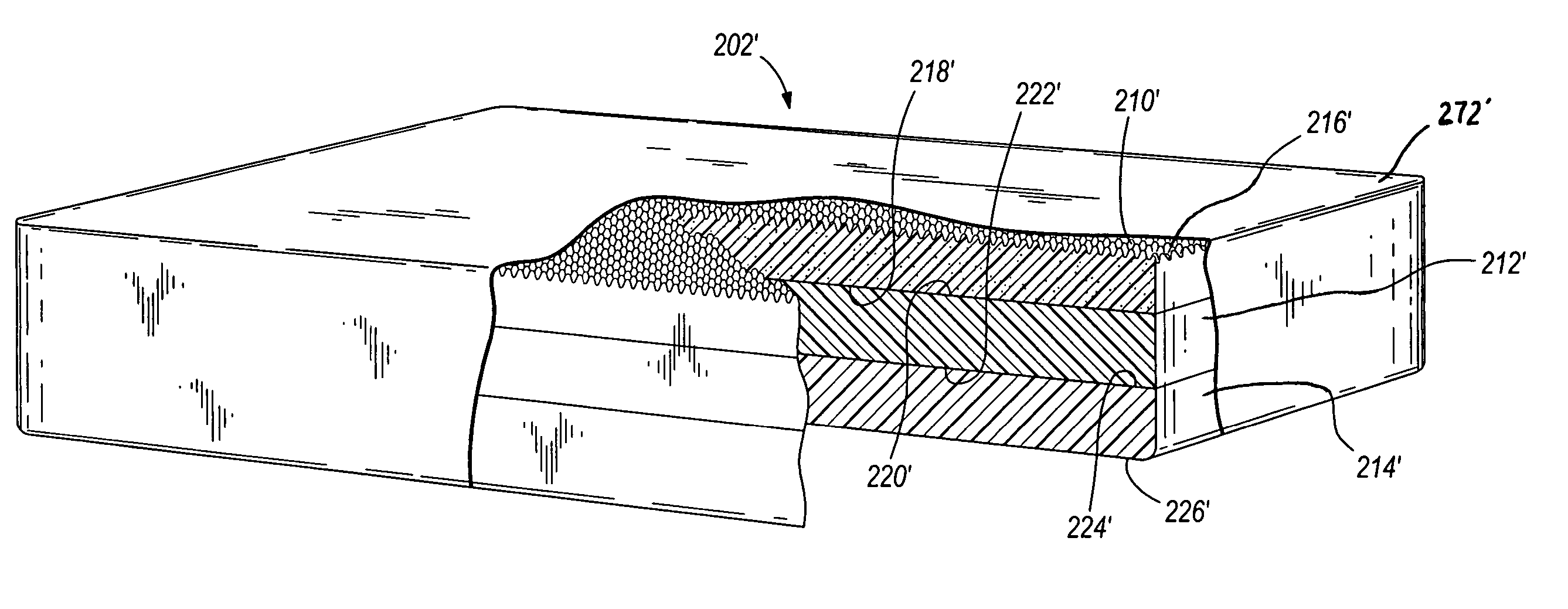

Reticulated material body support and method

A body support comprising at least one layer of flexible material having a reticulated cellular structure is disclosed. In some embodiments, one or more of these layers comprises reticulated visco-elastic foam, and has at least one material property responsive to temperatures in the range of a user's body heat. In these and other embodiments, one or more of the layers of flexible material comprises non-visco-elastic foam, and can be combined in a body support with one or more layers of visco-elastic foam. The body support can include one or more additional layers of other material types, including one or more layers of high-resilience polyurethane foam. Also, in those embodiments having two or more layers of material, one or more of the layers can have a profiled surface at least partially defining air flow paths through the body support.

Owner:TEMPUR WORLD

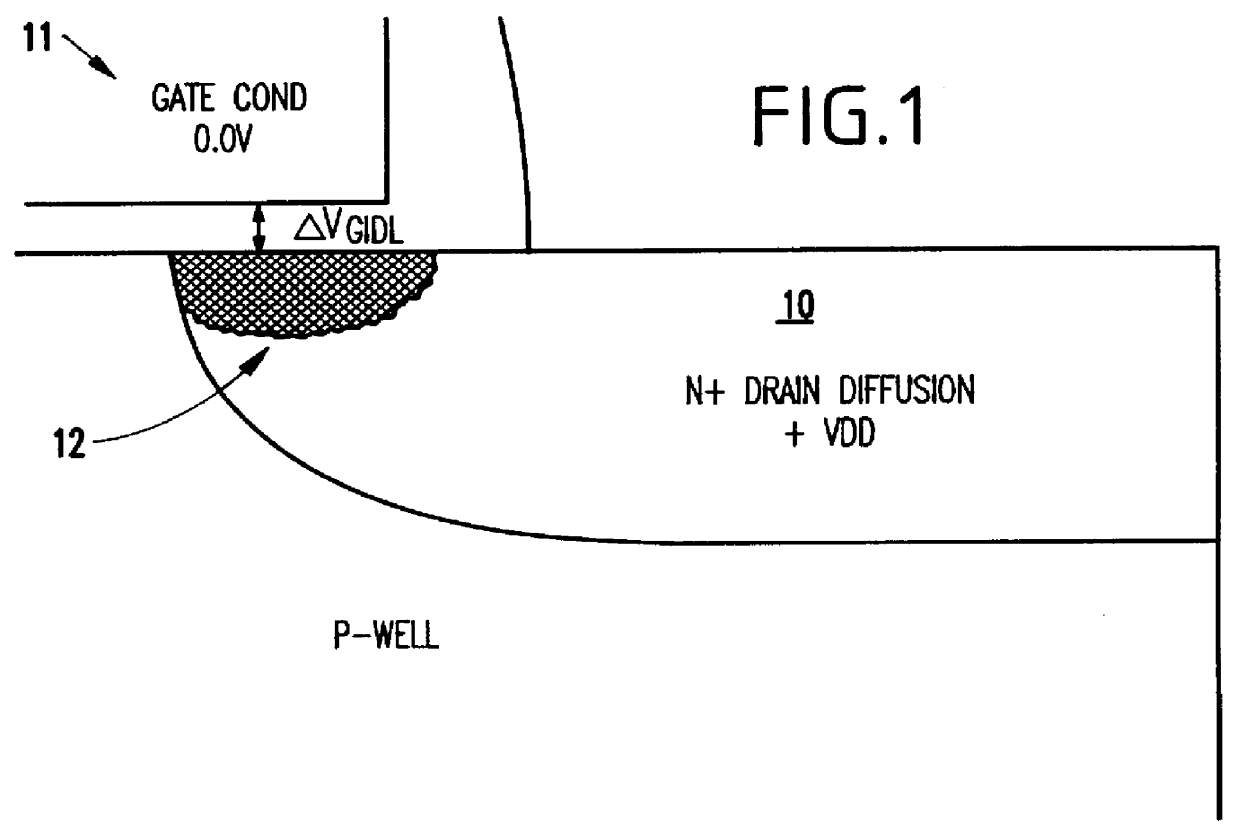

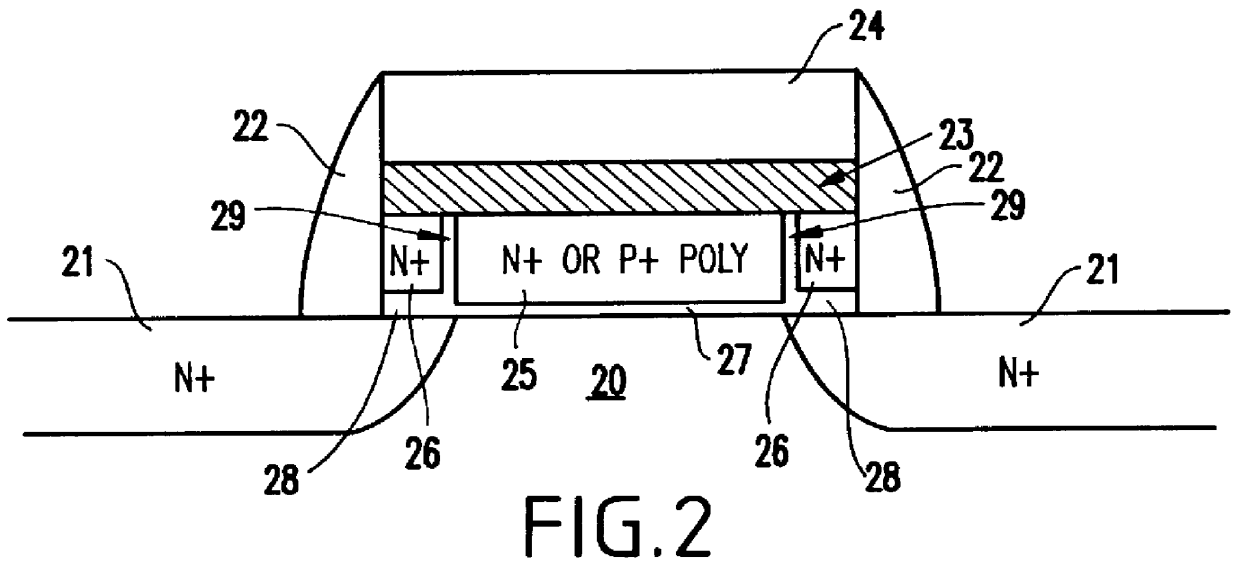

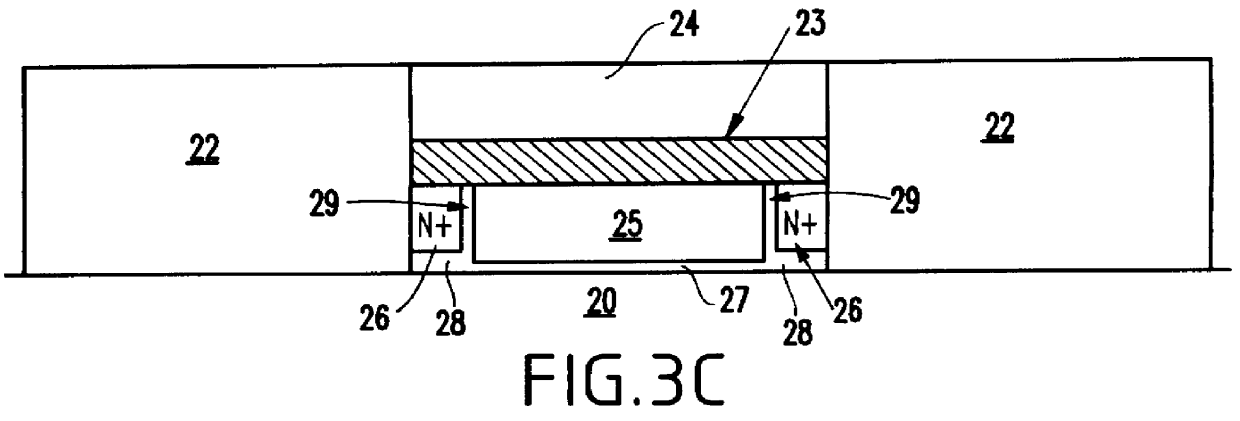

MOSFET structure and process for low gate induced drain leakage (GILD)

InactiveUS6097070ASemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETElectrical conductor

A structure and method for forming a metal oxide semiconductor field effect transistor structure comprises, a substrate having a gate-channel region and source and drain regions adjacent the gate-channel region, a gate insulator over the substrate, a central gate conductor positioned above the gate-channel region and over the gate insulator and outer gate conductors over the gate insulator and adjacent the central gate conductor, wherein the gate insulator has a first thickness under the central gate conductor and a second thickness greater than the first thickness under the outer gate conductors. The center and outer gate conductors may consist of different material types (i.e., different work functions). The polarity of the source-drain doping is independent of the polarity of the central or outer gate conductors.

Owner:GLOBALFOUNDRIES INC

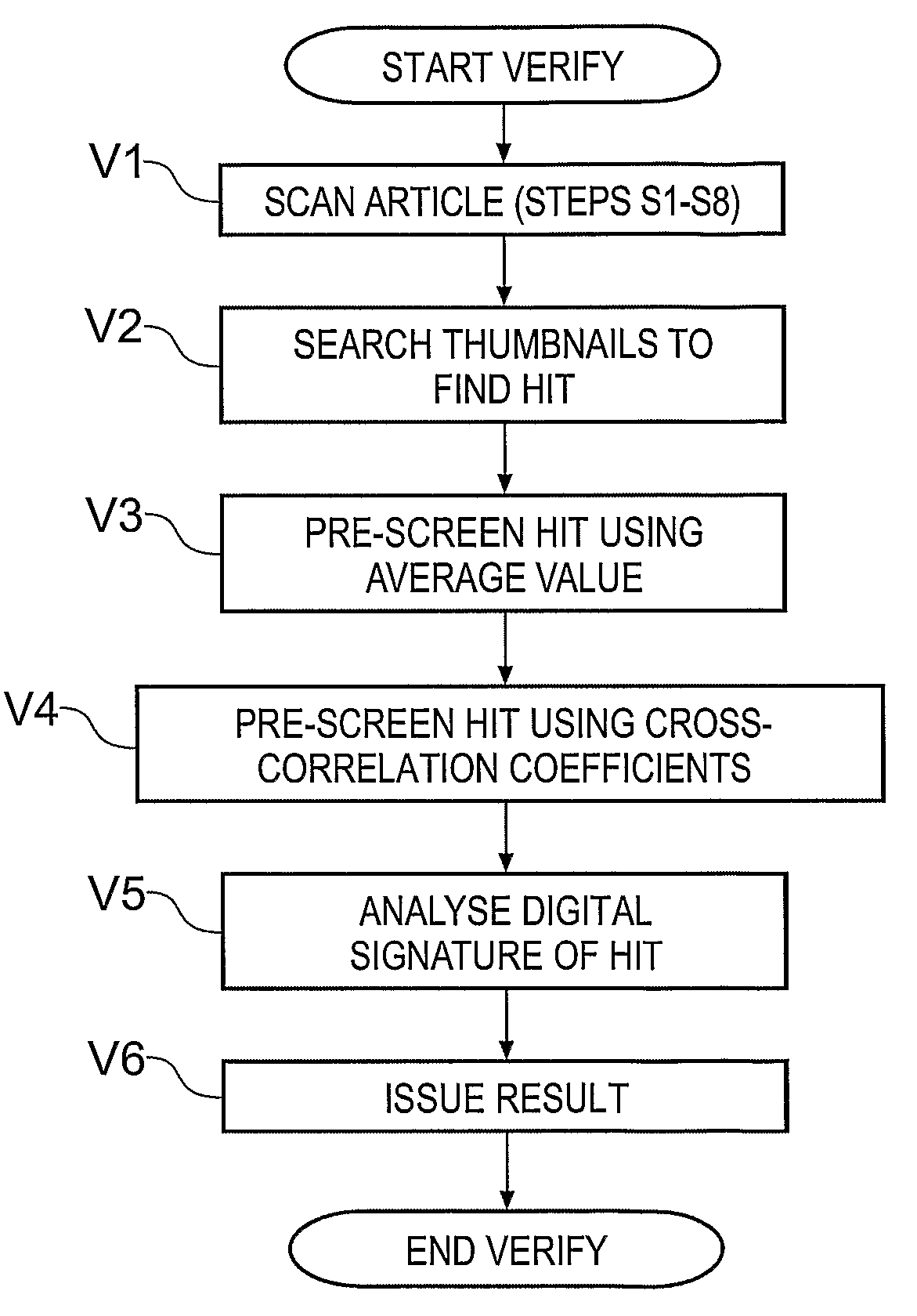

Authenticity verification methods, products and apparatuses

InactiveUS7853792B2Enhanced advantagePaper-money testing devicesUser identity/authority verificationCardboardMaterial type

Owner:INGENIA HLDG LTD

Method of monitoring positioning of polymer stents

The invention is directed to a polymer stent with one or more markers such that when the stent is placed within a lumen, the markers can be detected external to the body. The markers can also be used to monitor the stent position after placement and absorption of bioabsorbable stents. Further, the stent may comprise two markers used to determine the diameter of the stent in real time. It is also contemplated that the stent may comprise at least three markers. The use of at least three markers enables the three dimensional orientation of the stent to be determined at any time. The stent may also comprise markers such that the markers are located in regions with different in vivo lifetimes. It is also contemplated that the pattern and material type of markers on the stent may be used to determine the type of stent within a lumen or box.

Owner:ARTERIAL REMODELING TECH SA

Composite articles reinforced with highly oriented microfibers

InactiveUS7014803B2Improve toughnessAdded strength and stiffnessFilament/thread formingWood working apparatusMaterial typePolymer science

A composite formed of a polymer matrix phase having a reinforcement phase including polymeric microfibers. The microfibers are preferably formed of a highly oriented polymer, having a high modulus value and a large surface area. The large surface area can serve to tightly bind the microfibers to the polymer matrix phase. The microfibers can be provided as a fully- or partially-microfibrillated film, as a non-woven web of entangled microfibers, or as a pulp having free fibers. The microfibers can be embedded in, or impregnated with, a polymer or polymer precursor. Some composite articles are formed from thermoset resins cured about a highly oriented polypropylene microfiber reinforcement phase, providing a strong, tough, moisture resistant article. One composite includes a matrix and reinforcement formed of the same material type and having substantially equal refractive indices, allowing the composite to be optically clear.

Owner:3M INNOVATIVE PROPERTIES CO

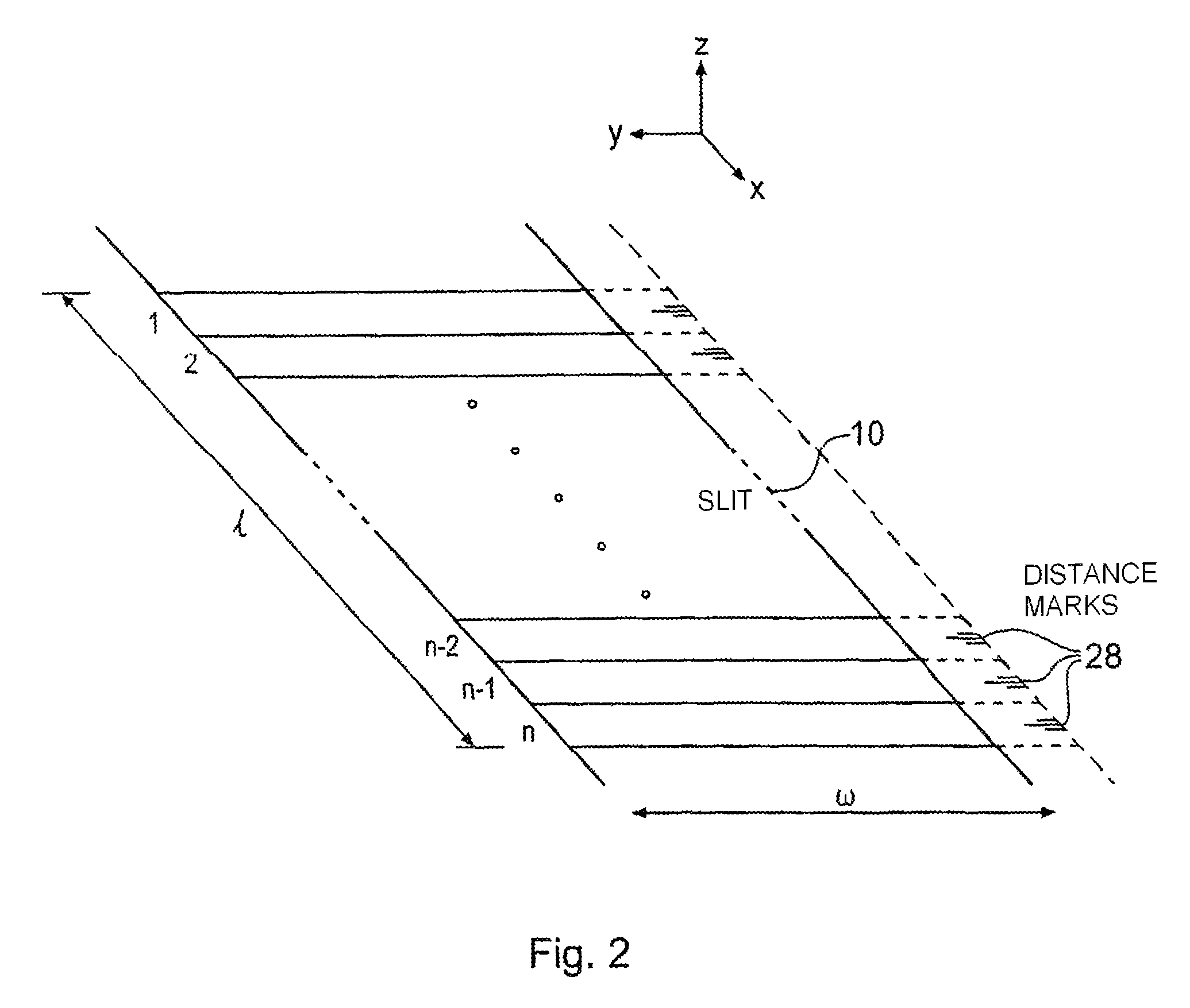

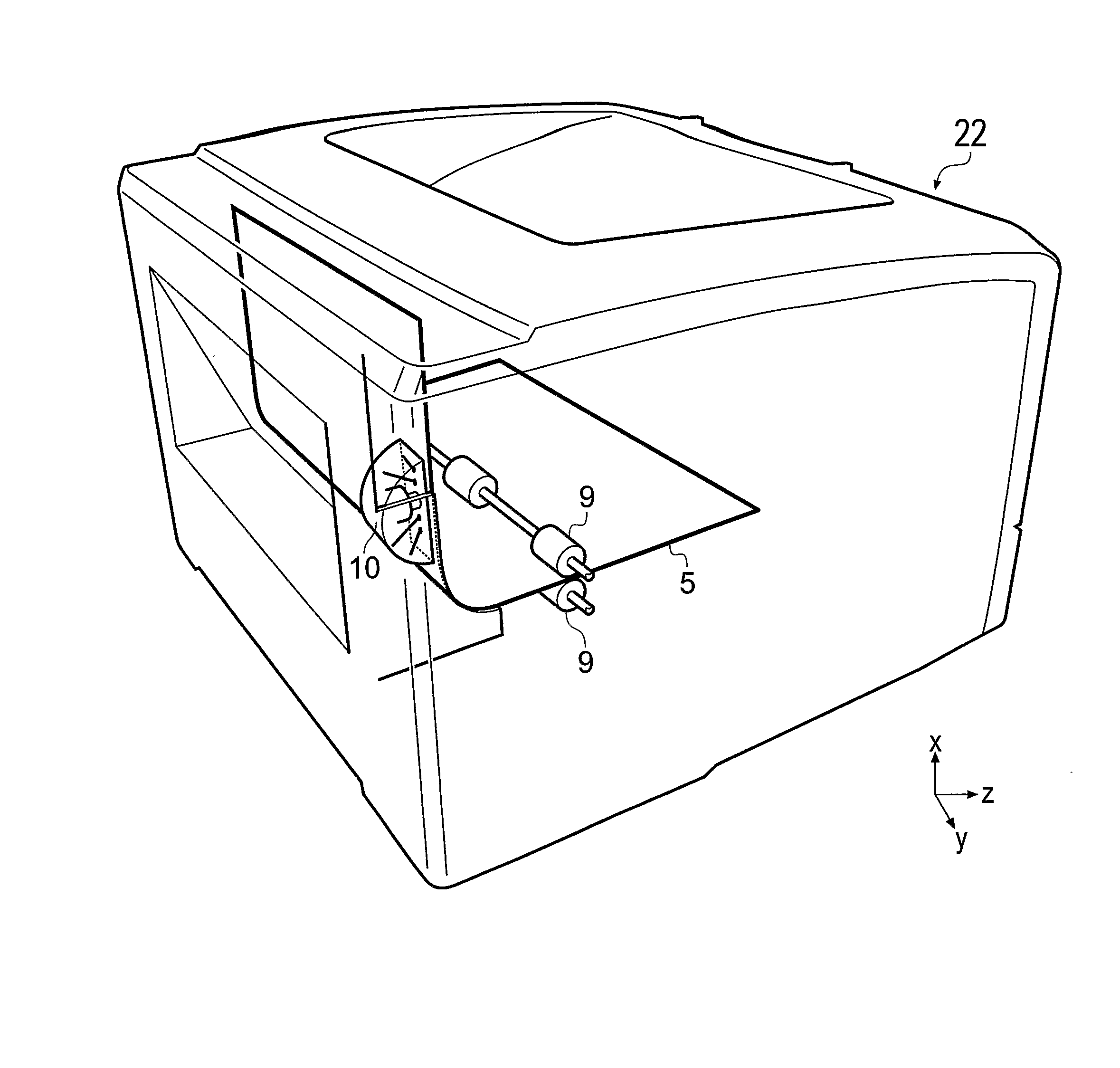

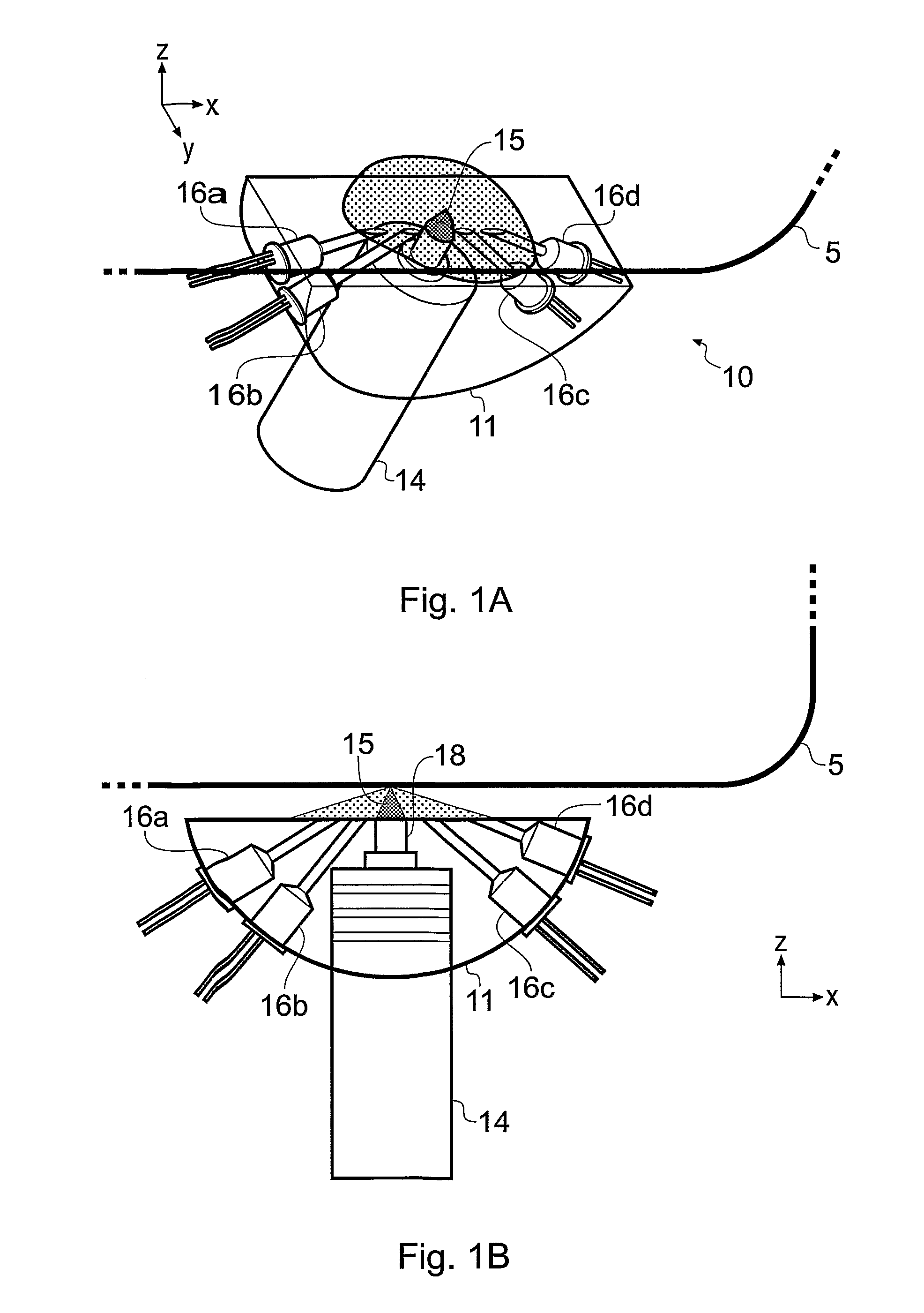

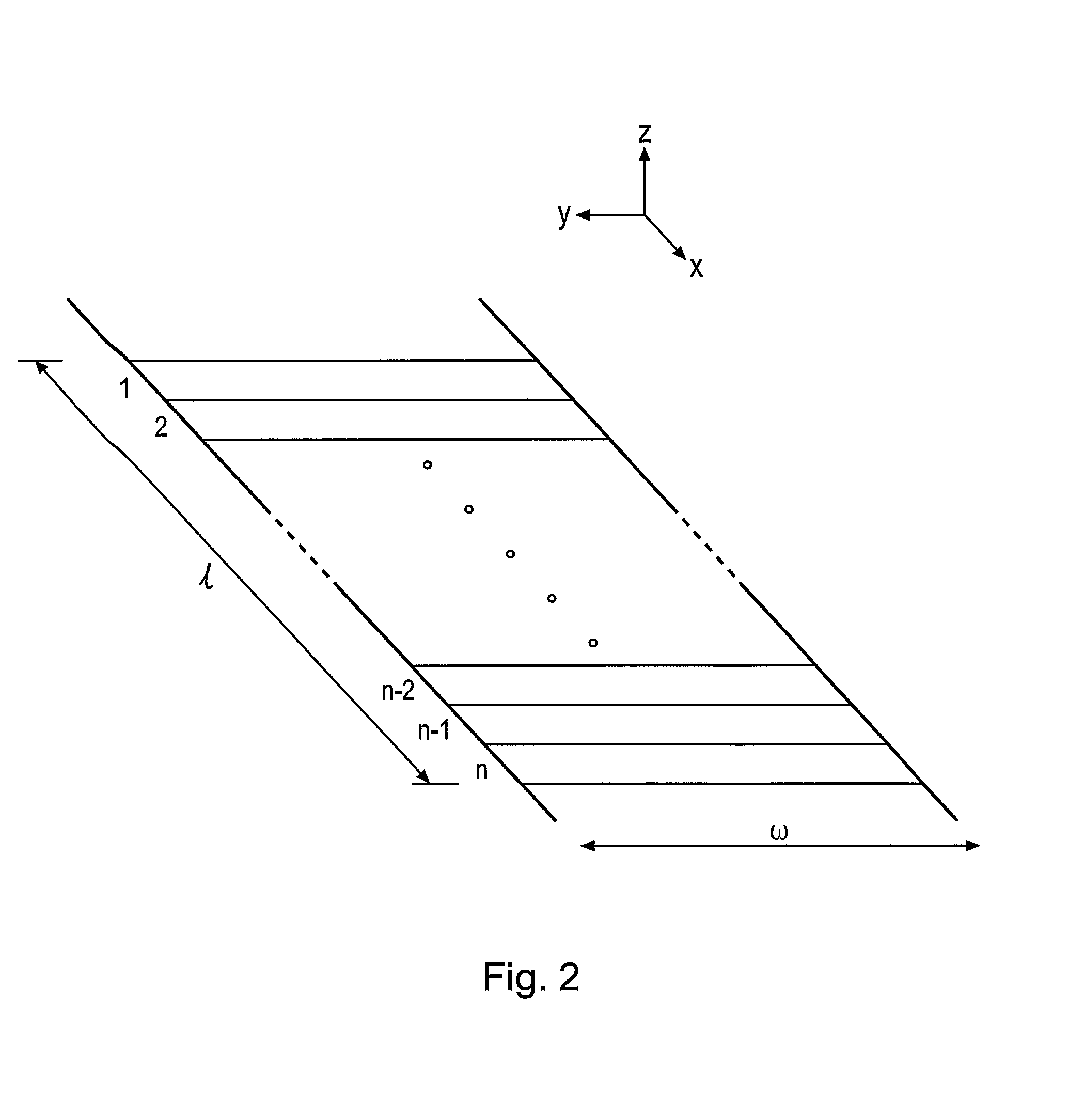

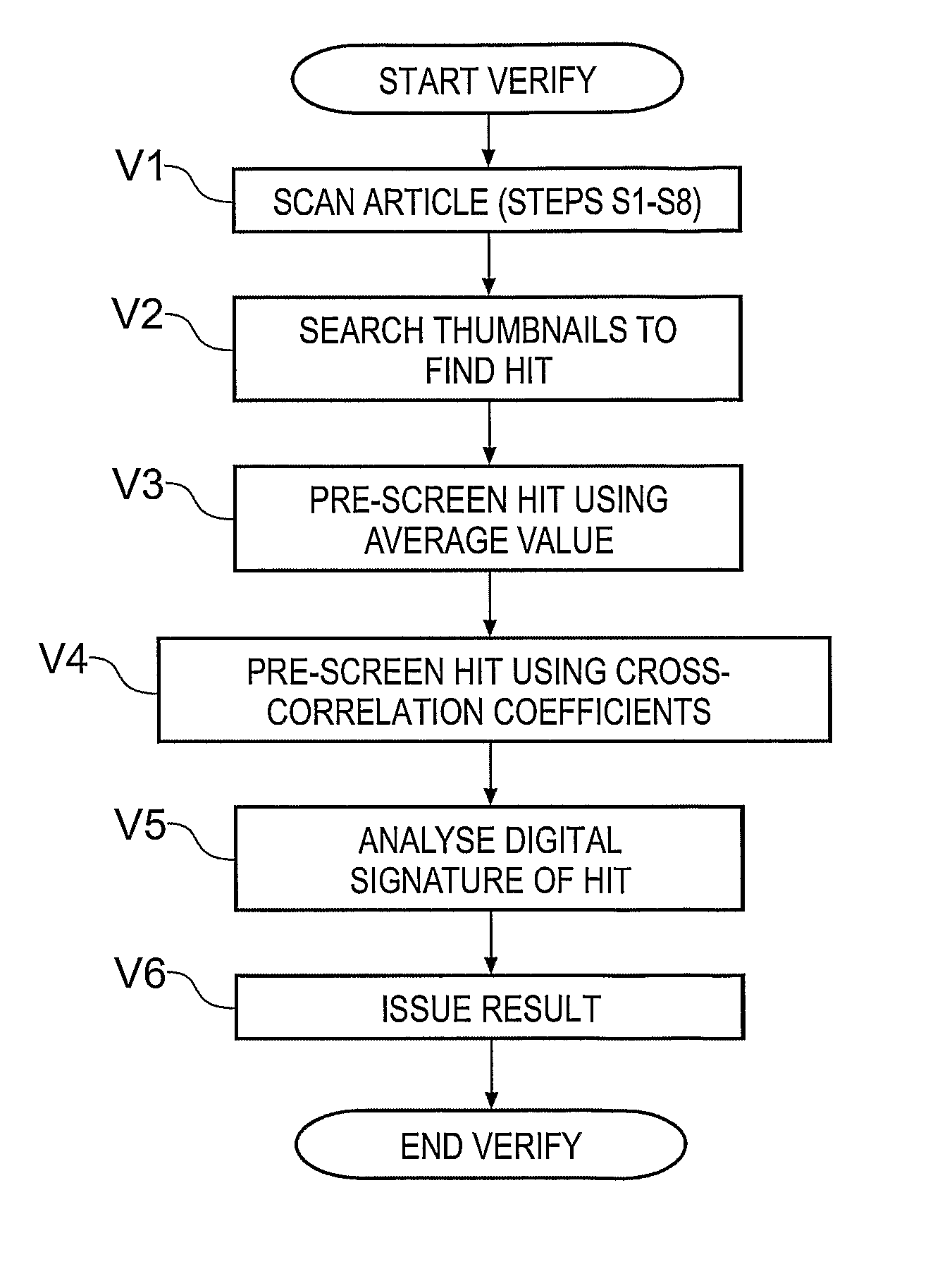

Methods and Apparatuses for Creating Authenticatable Printed Articles and Subsequently Verifying Them

InactiveUS20080002243A1Improve security levelImprove security systemInking apparatusPaper-money testing devicesCardboardMaterial type

A method and apparatus for determining a digital signature from an article made of paper, cardboard, plastic or many other material types. A coherent source directs a beam to illuminate the article and a detector arrangement collects data points from light scattered from many different parts of the article to collect a large number of independent data points, typically 500 or more. By collecting a large number of independent signal contributions specific to many different parts of the article, a digital signature can be computed that is unique to the area of the article that has been scanned. This measurement can be repeated whenever required to test authenticity of the article. Using this method, it has been discovered that it is essentially pointless to go to the effort and expense of making specially prepared tokens, since unique characteristics are measurable in a straightforward manner from a wide variety of every day articles.

Owner:INGENIA HLDG LTD

Authenticity verification methods, products and apparatuses

InactiveUS20070192850A1Enhanced advantageDigital data processing detailsUser identity/authority verificationCardboardMaterial type

A method and apparatus for determining a digital signature from an article made of paper, cardboard, plastic or many other material types. A coherent light source directs a beam to illuminate the article and a detector arrangement collects data points from light scattered from many different parts of the article to collect a large number of independent data points, typically 500 or more. By collecting a large number of independent signal contributions specific to many different parts of the article, a digital signature can be computed that is unique to the area of the article that has been scanned. This measurement can be repeated whenever required to test authenticity of the article. Using this method, it has been discovered that it is essentially pointless to go to the effort and expense of making specially prepared tokens, since unique characteristics are measurable a in a straightforward manner from a wide variety of every day articles.

Owner:INGENIA HLDG LTD

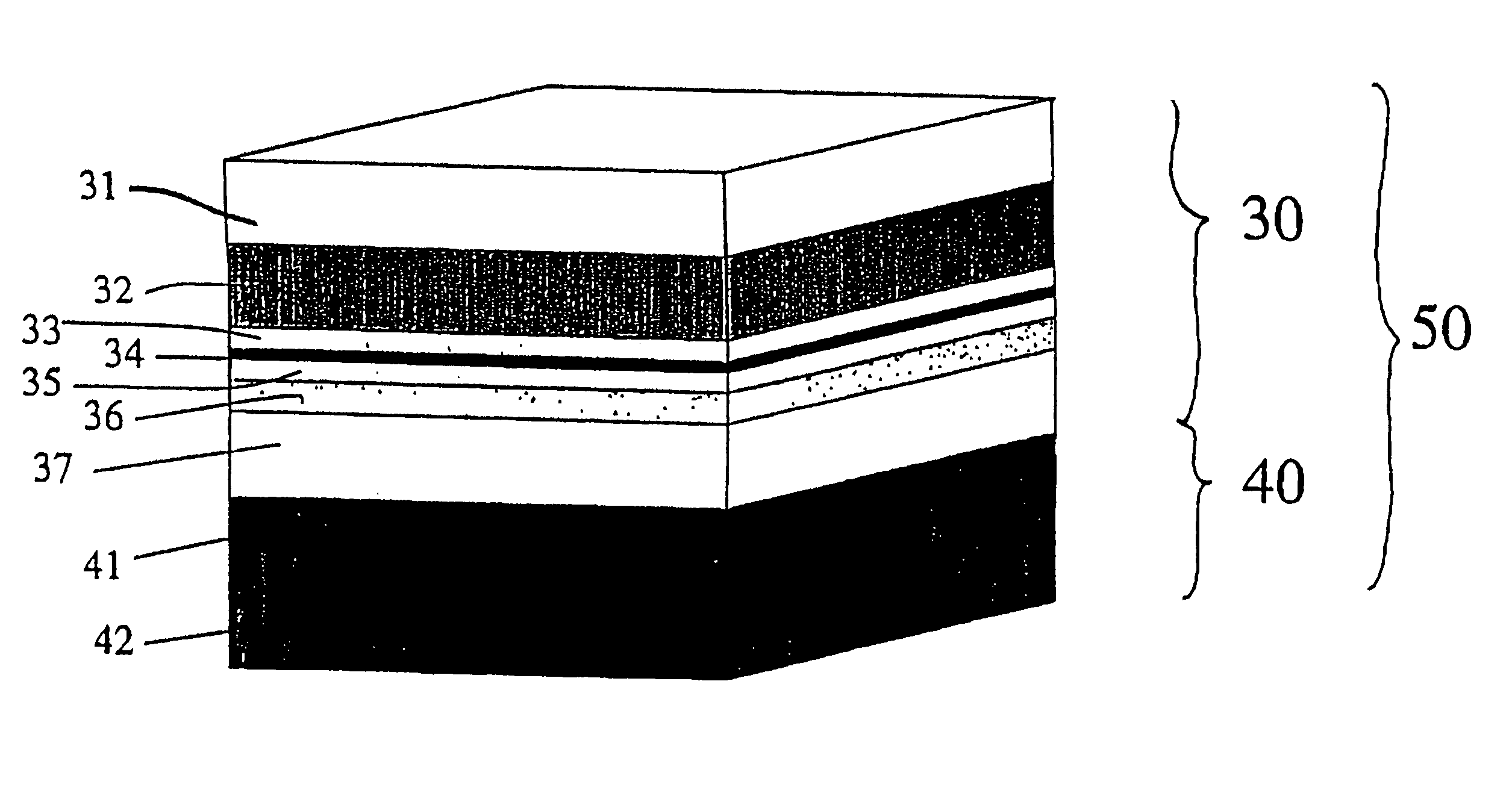

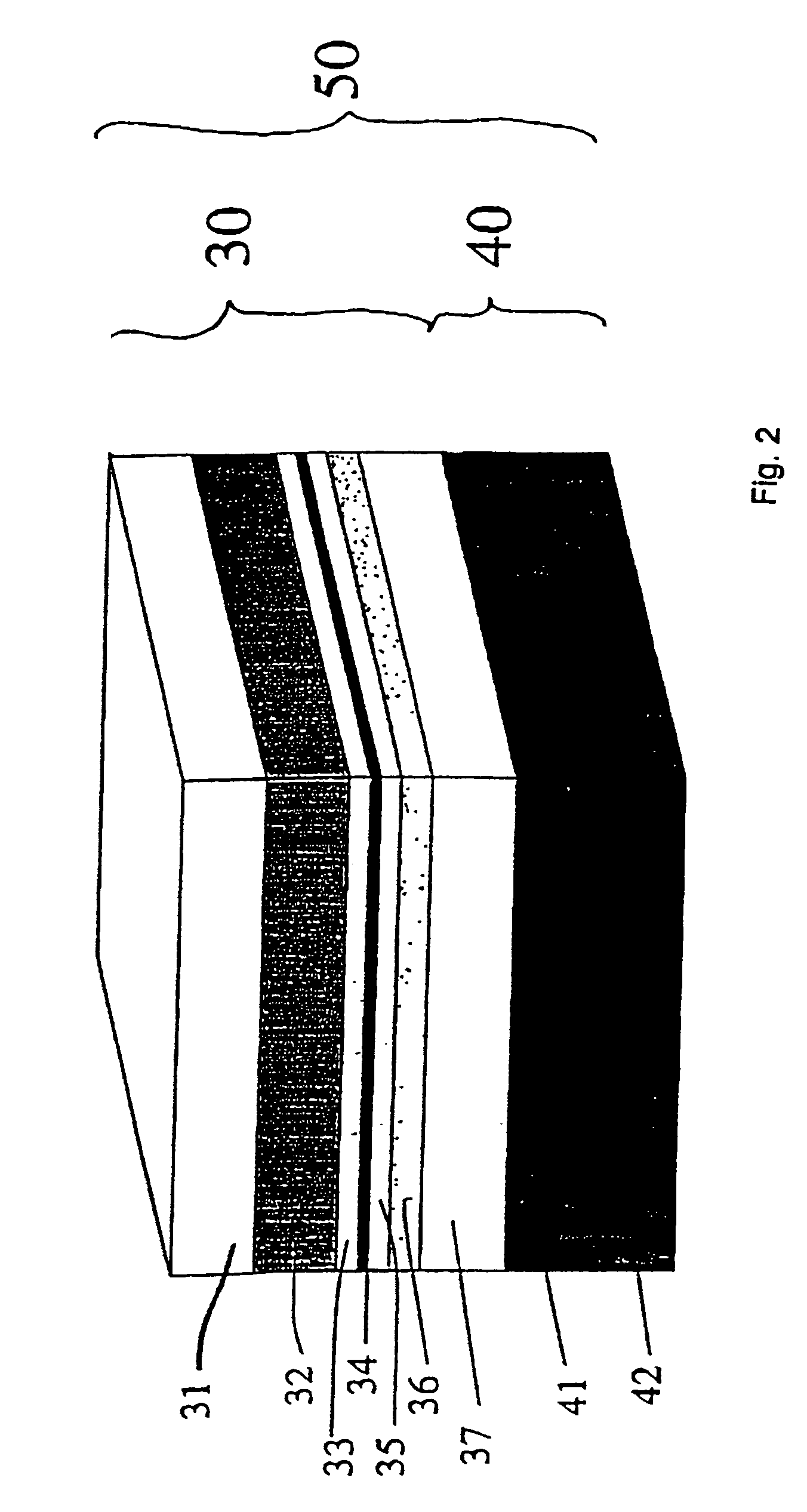

Magnetic storage device

InactiveUS7218550B2Reduce power consumptionReduce complexityRead-only memoriesDigital storageMagnetic storageZener diode

A magnetic storage device comprises an array of magnetic memory cells (50). Each cell (50) has, in electrical series connection, a magnetic tunnel junction (MTJ) (30) and a Zener diode (40). The MTJ (30) comprises, in sequence, a fixed ferromagnetic layer (FMF) (32), a non-magnetic spacer layer (33), a tunnel barrier layer (34), a further spacer layer (35), and a soft ferromagnetic layer (FMS) (36) that can change the orientation of its magnetic moment. The material type and thickness of each layer in the MTJ (30) is selected so that the cell (50) can be written by applying a voltage across the cell, which sets the orientation of the magnetic moments of the FMF (32) and FMS (36) relative to one another. The switching is effected by means of an induced exchange interaction between the FMS and FMF mediated by the tunneling of spin-polarised electrons in the MTJ (30). The cell (50) therefore has low power consumption during write operations allowing for fast writing and dense integration of cells (50) in an array. The mechanism used to control the array to write and sense the information stored in the cells (50) is simplified.

Owner:SONY CORP

Reticulated material body support and method

A body support comprising at least one layer of flexible material having a reticulated cellular structure is disclosed. In some embodiments, one or more of these layers comprises reticulated visco-elastic foam, and has at least one material property responsive to temperatures in the range of a user's body heat. In these and other embodiments, one or more of the layers of flexible material comprises non-visco-elastic foam, and can be combined in a body support with one or more layers of visco-elastic foam. The body support can include one or more additional layers of other material types, including one or more layers of high-resilience polyurethane foam. Also, in those embodiments having two or more layers of material, one or more of the layers can have a profiled surface at least partially defining air flow paths through the body support.

Owner:TEMPUR WORLD

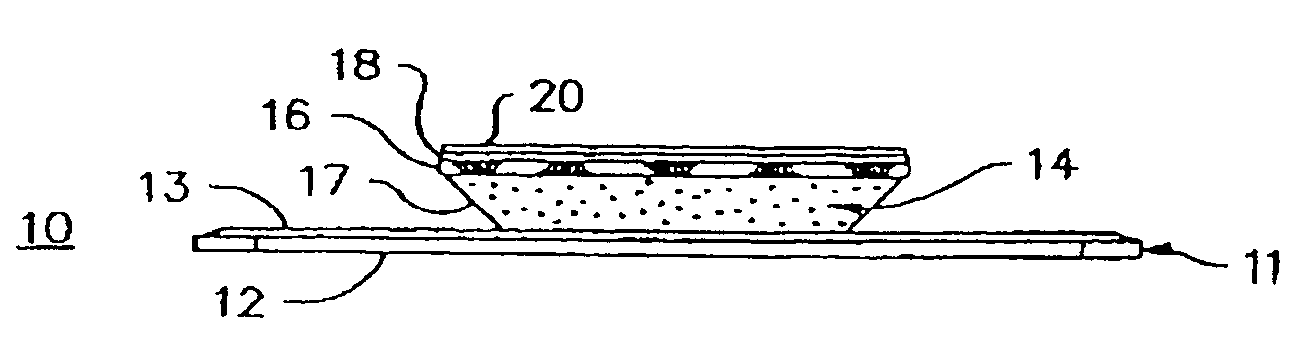

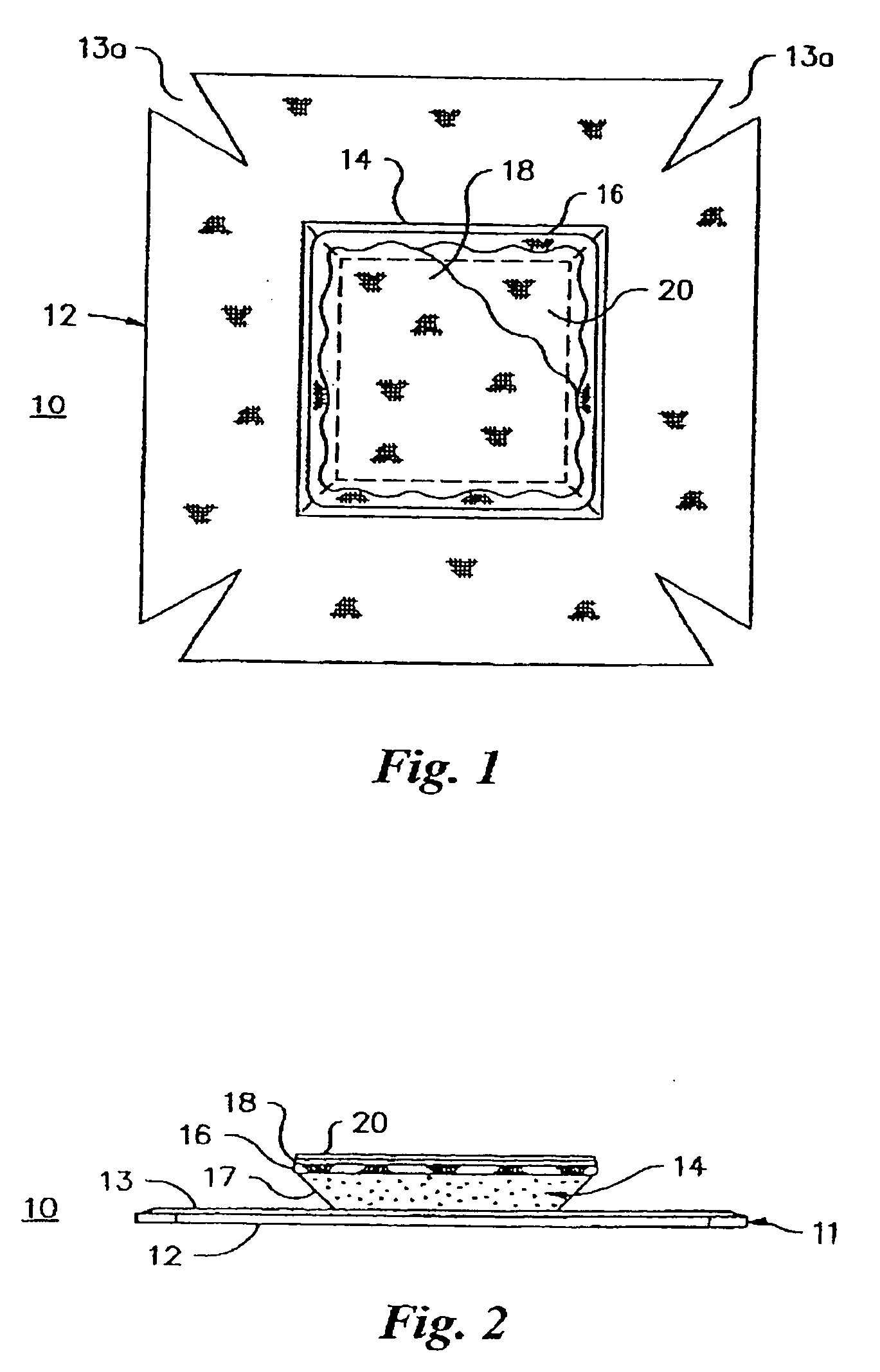

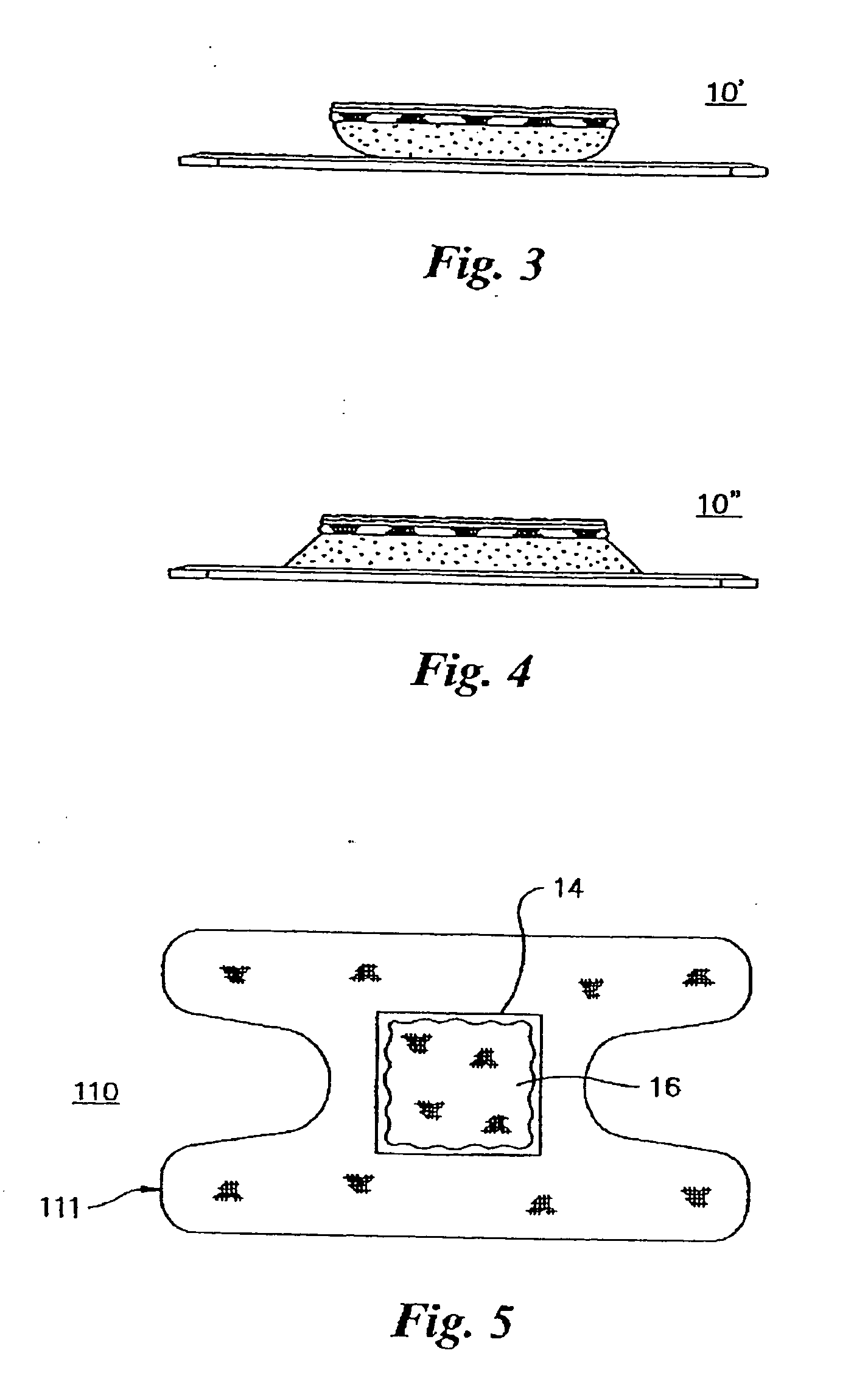

Devices and methods of treatment of wounds and burns and related impaired blood circulation problems

A device for treating wounds on an individual is disclosed. The device includes a flexible foam, a treatment suitable for treating the wound placed in relative proximity to the foam, and a flexible fabric with recoverable properties substantially circumferencing the wound and the treated foam. The flexible fabric maintains the treated foam in substantial proximity to the wound to allow the treatment to treat the wound. A bandage suitable for treating wounds on an exterior limb is disclosed. The bandage includes a butterfly shaped flexible fabric, at least one Hook and loop material type fastener attachment located on the edge of the butterfly shaped flexible fabric, at least two foam layers located axially in the center of the butterfly shaped flexible fabric, and a medication suitable for treating the wound proximately located with respect to at least a first of the at least two foam layers. The butterfly shaped flexible fabric is suitable to be wrapped around the limb and fastened using the at least one Hook and loop material type fastener attachment, and the wrapped fabric maintains the at least two foam layers in proximate location with the wound such that the medication is located appropriately with the wound to provide treatment.

Owner:ABRAMS LEONARD

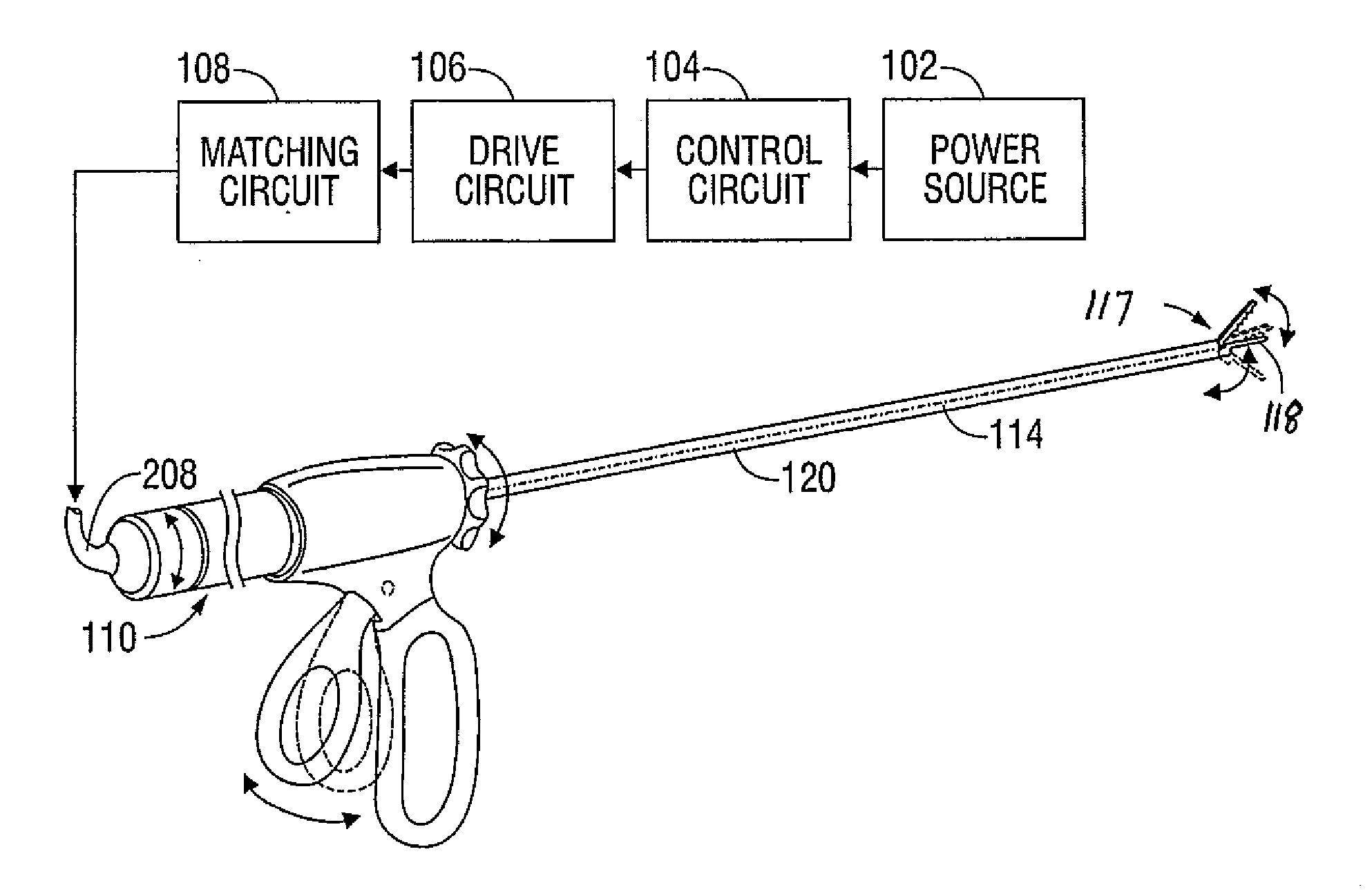

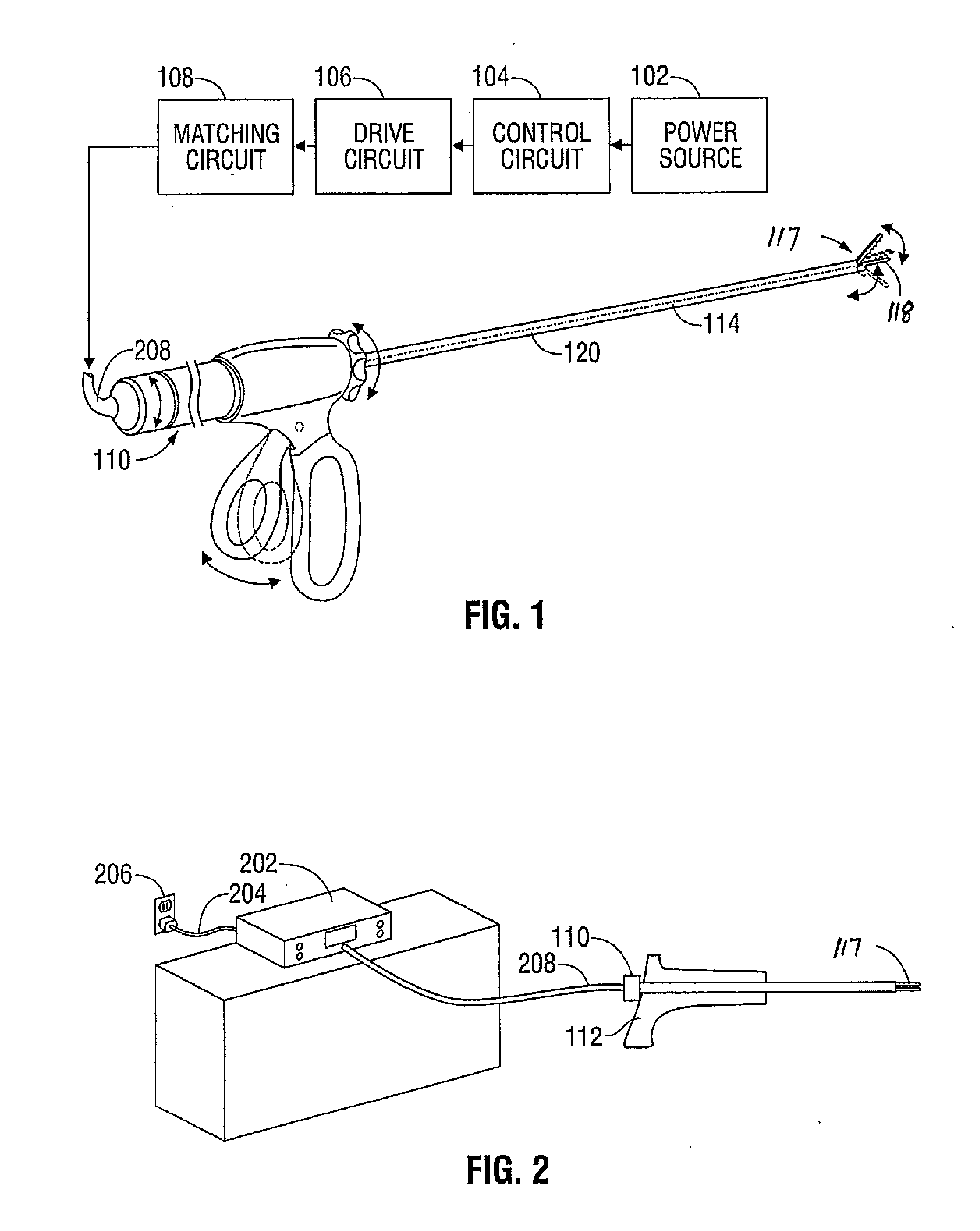

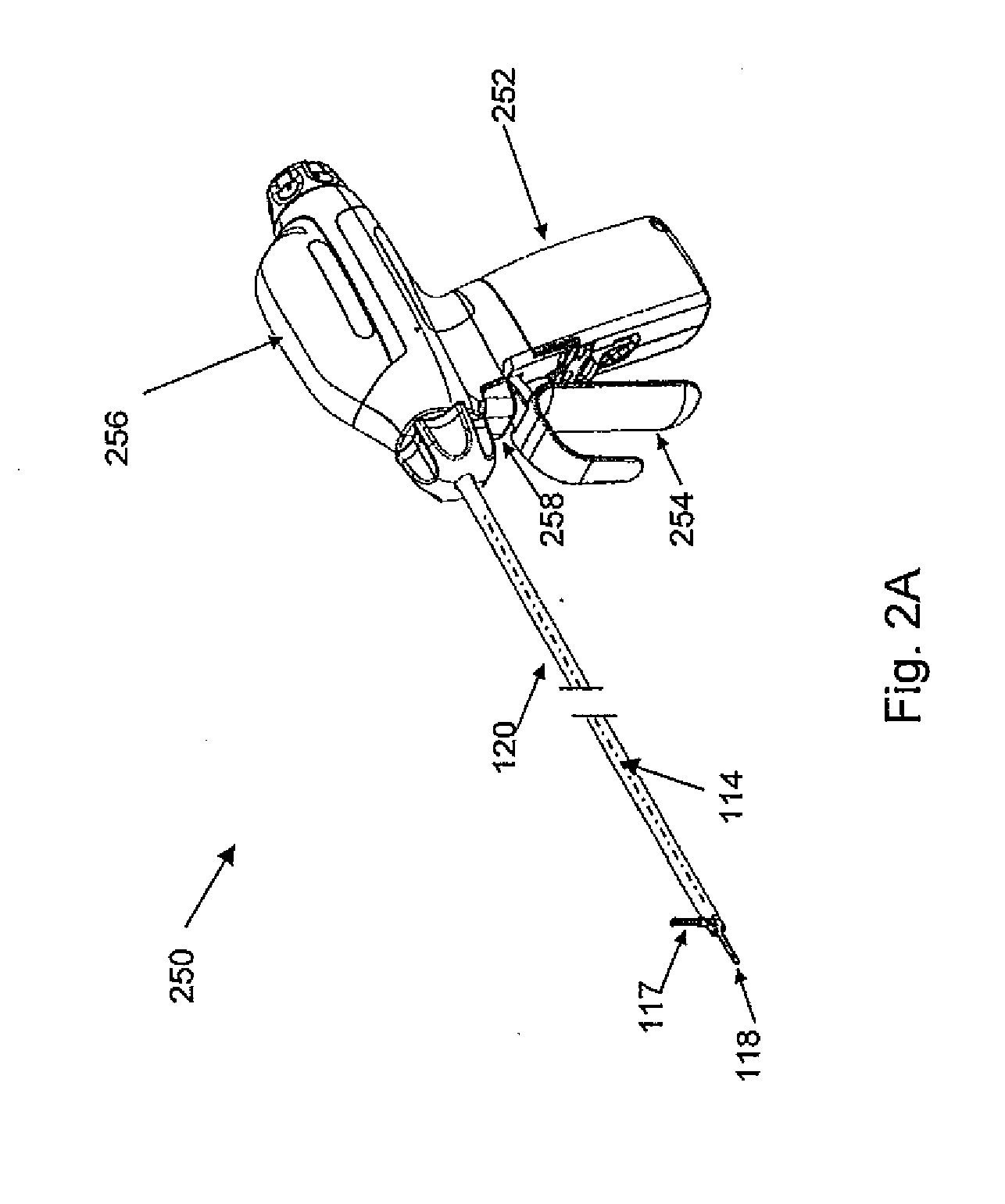

Temperature estimation and tissue detection of an ultrasonic dissector from frequency response monitoring

ActiveUS20130331874A1Simple methodSurgeryProcessing detected response signalMicrocontrollerMaterial type

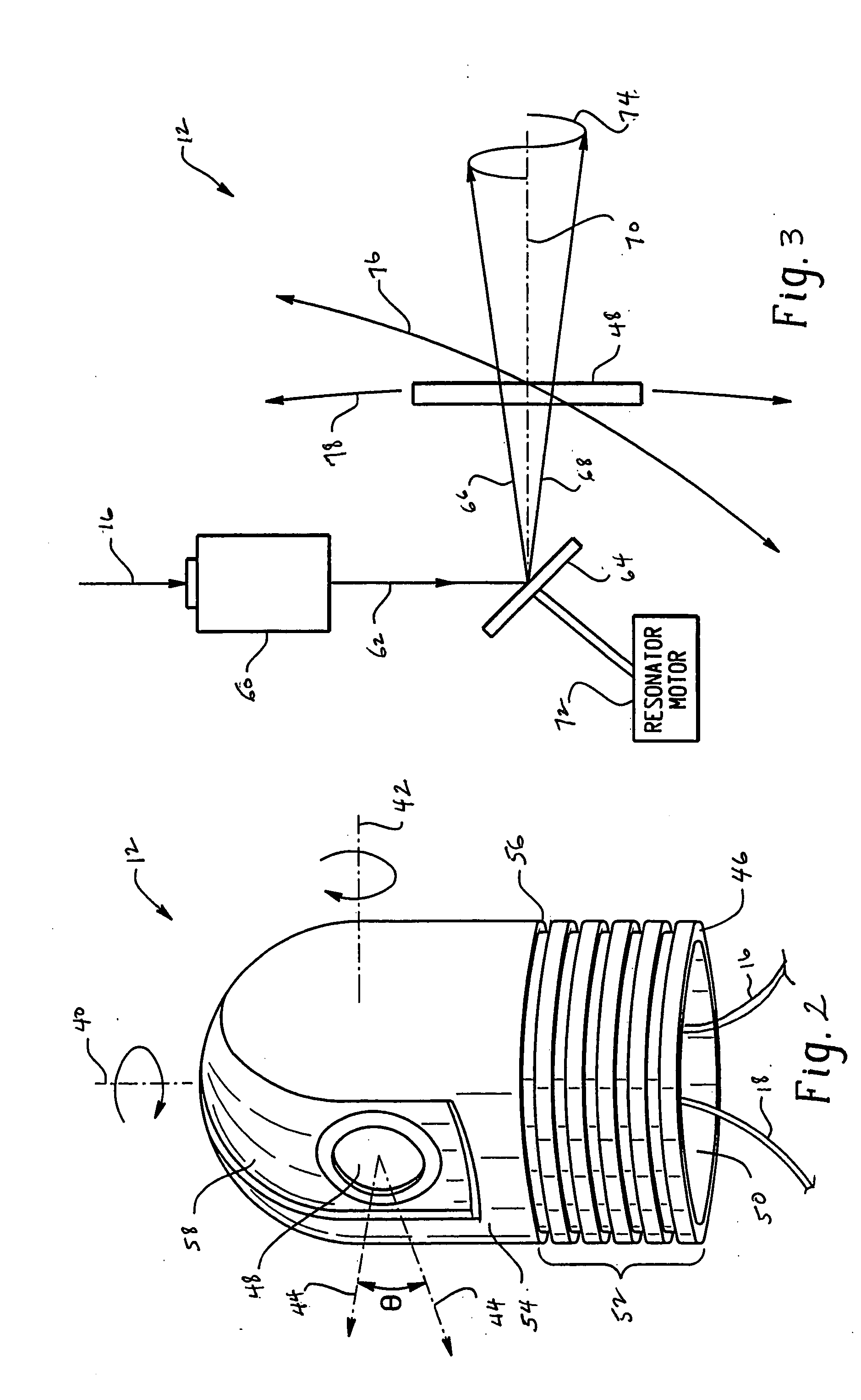

An ultrasonic surgical apparatus and method, the apparatus including a signal generator outputting a drive signal having a frequency, an oscillating structure, receiving the drive signal and oscillating at the frequency of the drive signal, and a bridge circuit, detecting the mechanical motion of the oscillating structure and outputting a signal representative of the mechanical motion. The ultrasonic surgical apparatus also includes a microcontroller receiving the signal output by the bridge circuit, the microcontroller determining an instantaneous frequency at which the oscillating structure is oscillating based on the received signal, and determining a frequency adjustment necessary to maintain the oscillating structure oscillating at its resonance frequency, the microcontroller further determining the quality (Q value) of the signal received from the bridge circuit and determining material type contacting the oscillating structure.

Owner:TYCO HEALTHCARE GRP LP

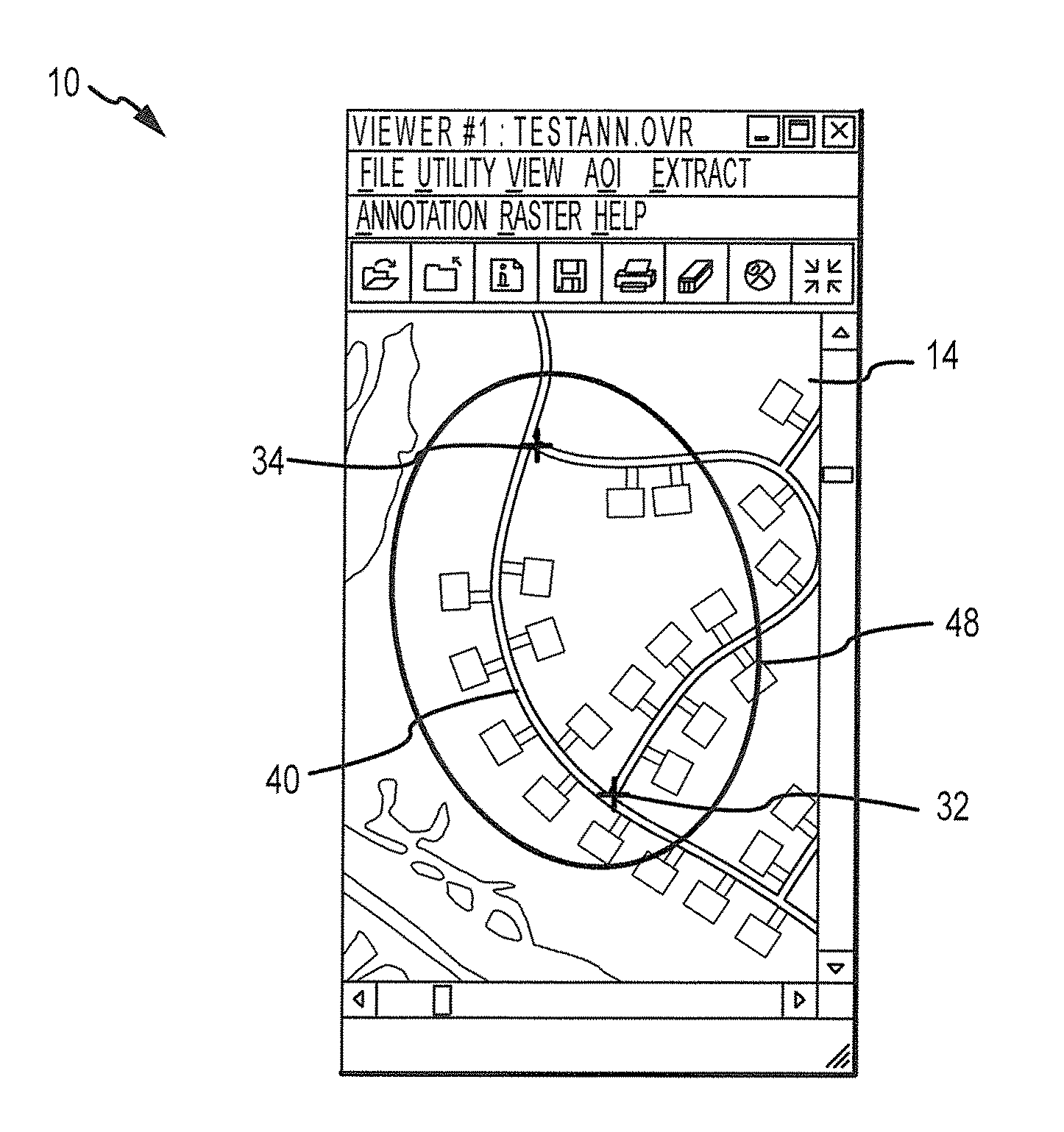

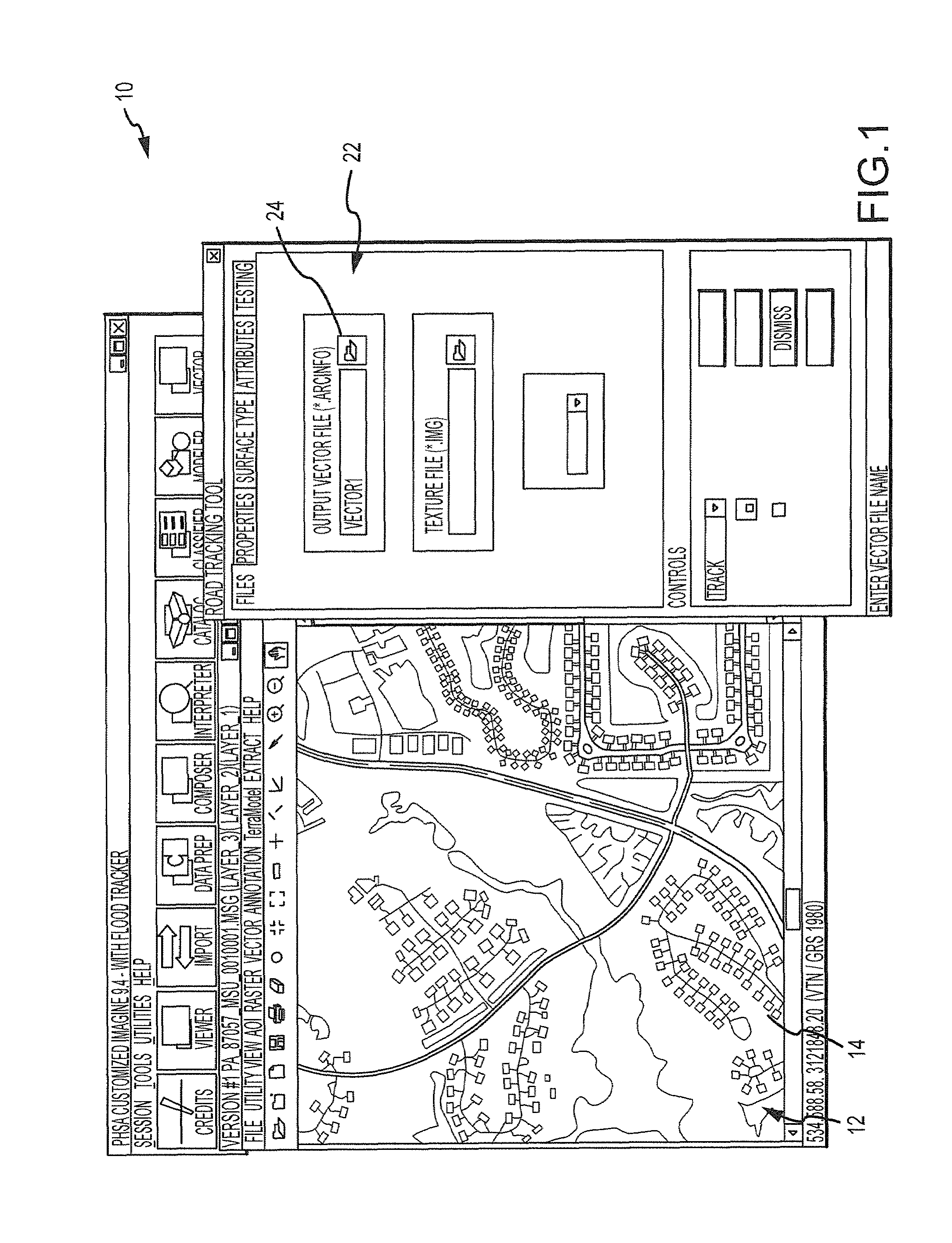

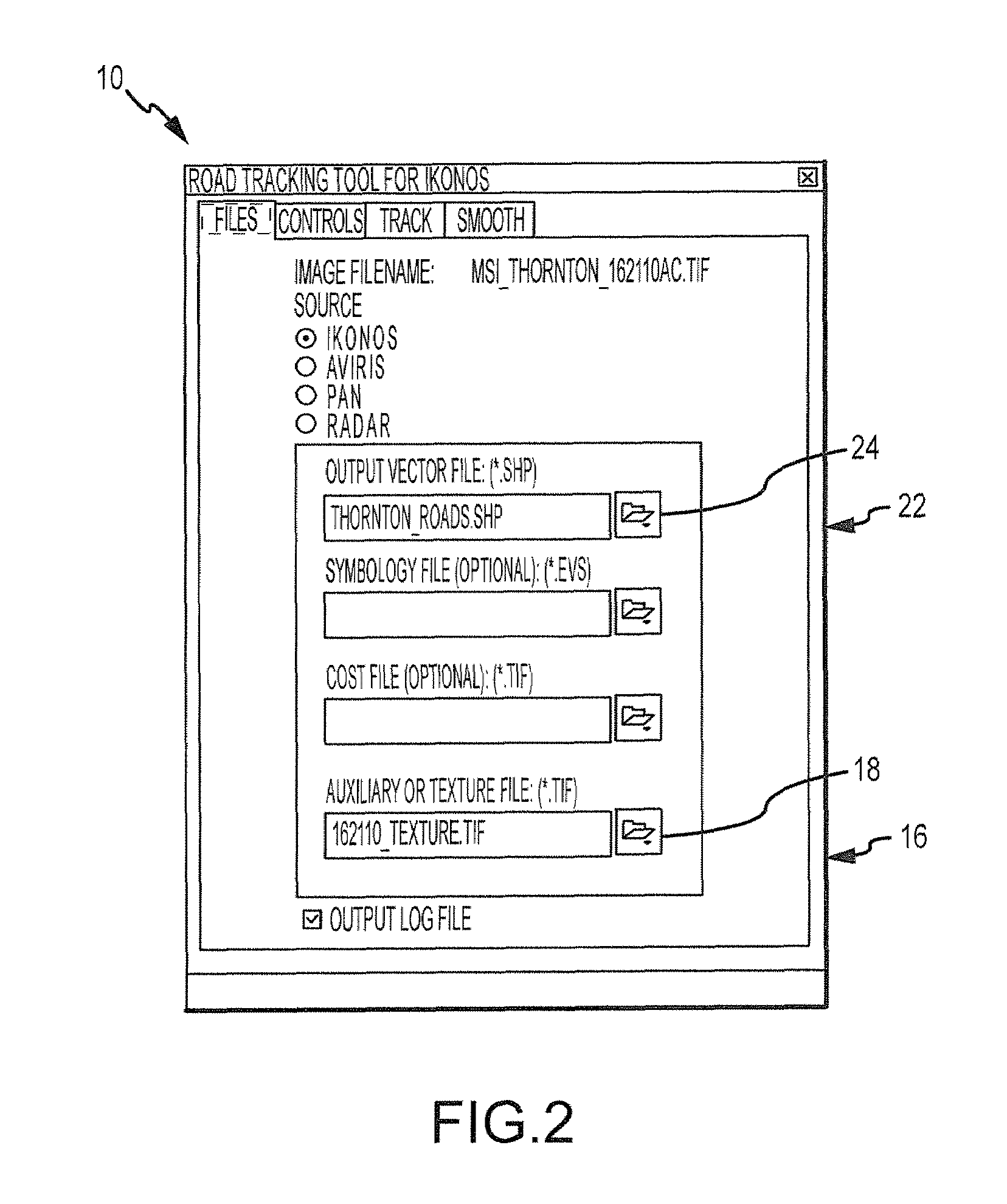

Semi-automatic extraction of linear features from image data

A method for extracting a linear feature from remotely sensed imagery, including selecting by user interface anchor points for the linear feature, the anchor points being identified with a geographic location; using image-based logic to automatically calculate a vector set associated with the anchor points, the vector set comprising a path associated with the linear feature; automatically attributing a material type to the path; automatically attributing a geometry to the path; selecting by user interface anchor points for a successive linear feature; using image-based logic to calculate a successive vector set associated with the anchor points for the successive linear feature, the successive vector set comprising a successive path; using a geometric relationship between the vector set and the successive vector set to automatically adjust the vector set to create an adjusted vector set, the adjusted vector set correcting the path associated with the first linear feature.

Owner:MAXAR INTELLIGENCE INC

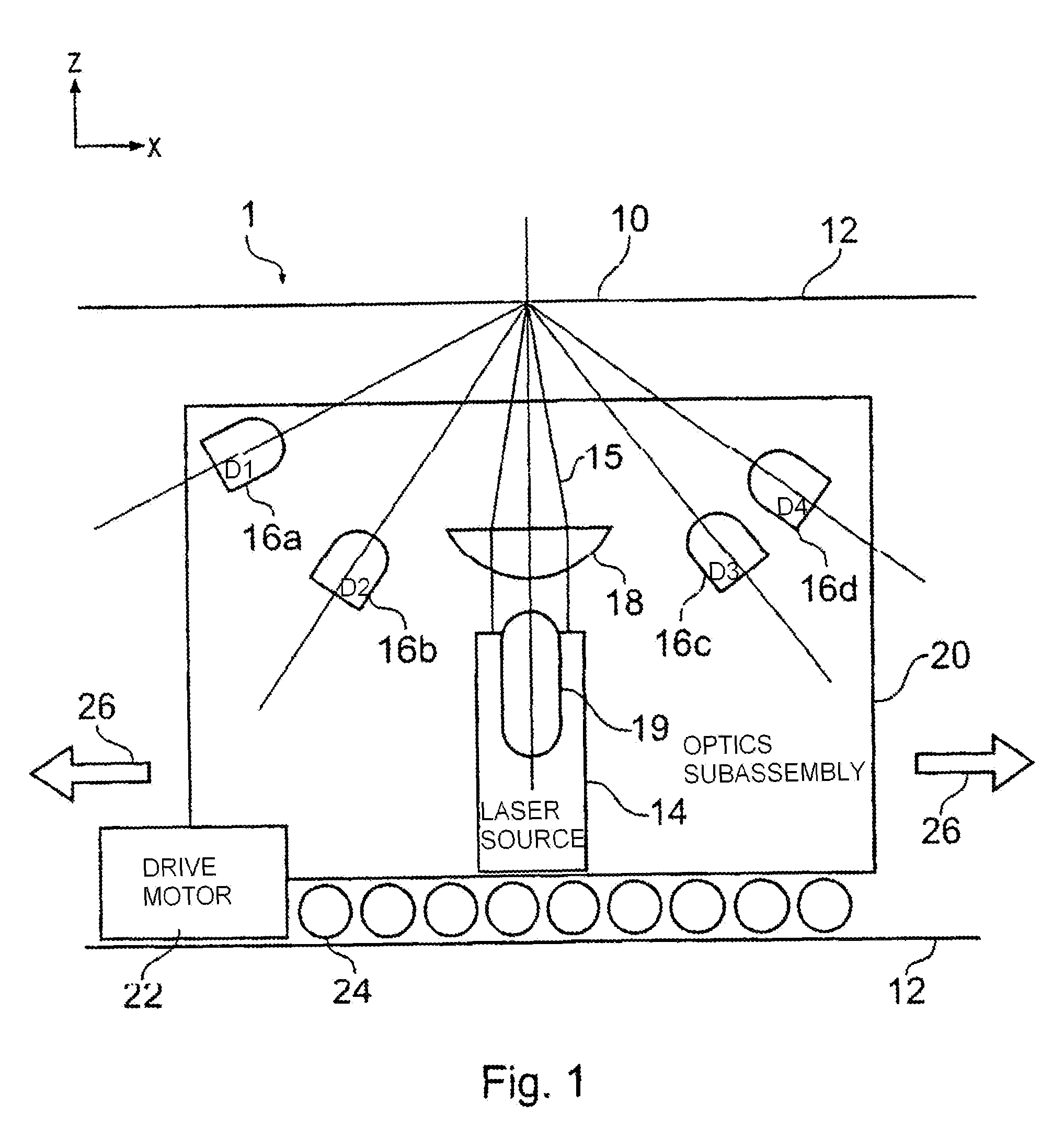

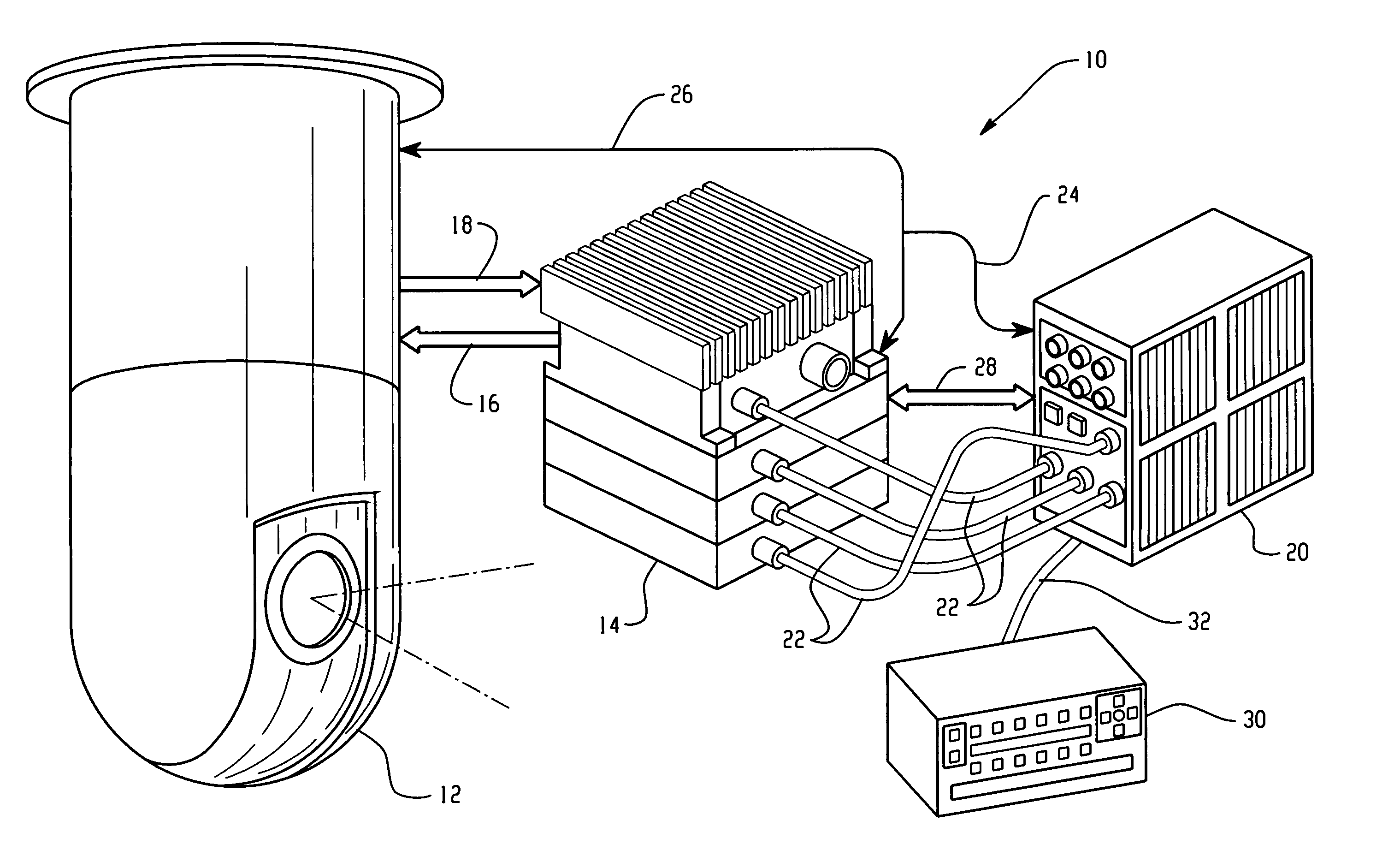

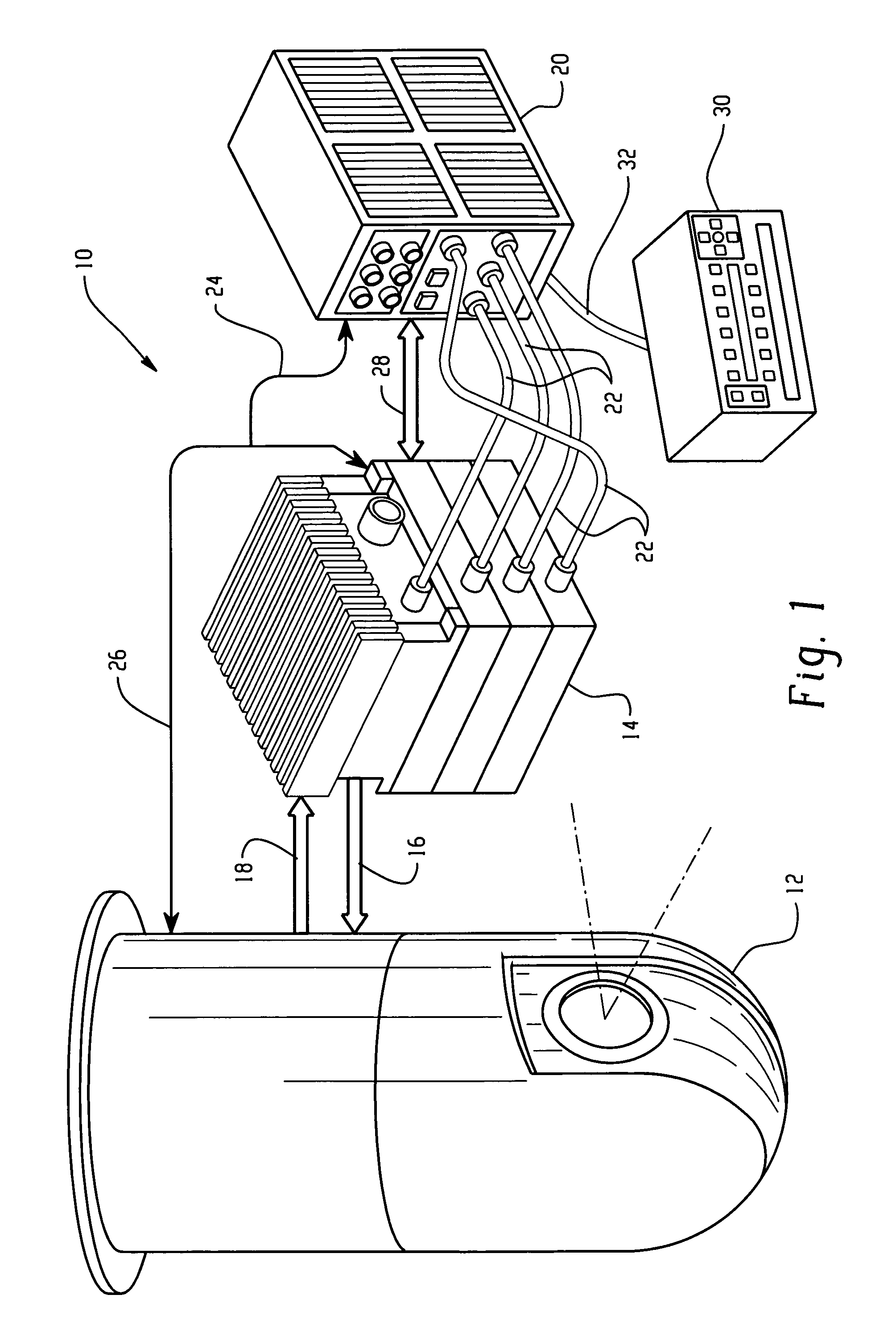

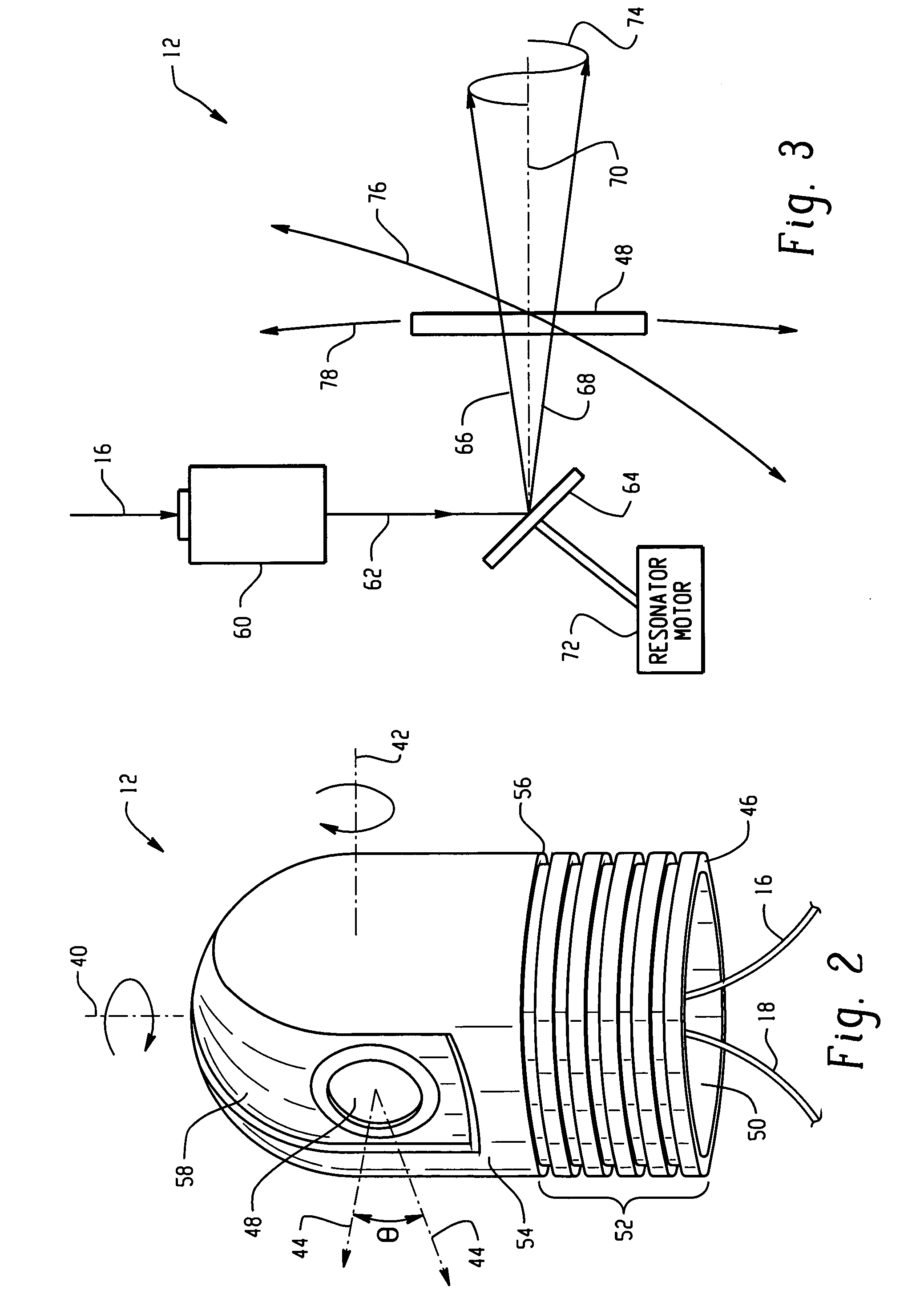

System and method of identifying an object in a laser beam illuminated scene based on material types

Owner:ROSEMOUNT AEROSPACE

Material reservation distribution system and method

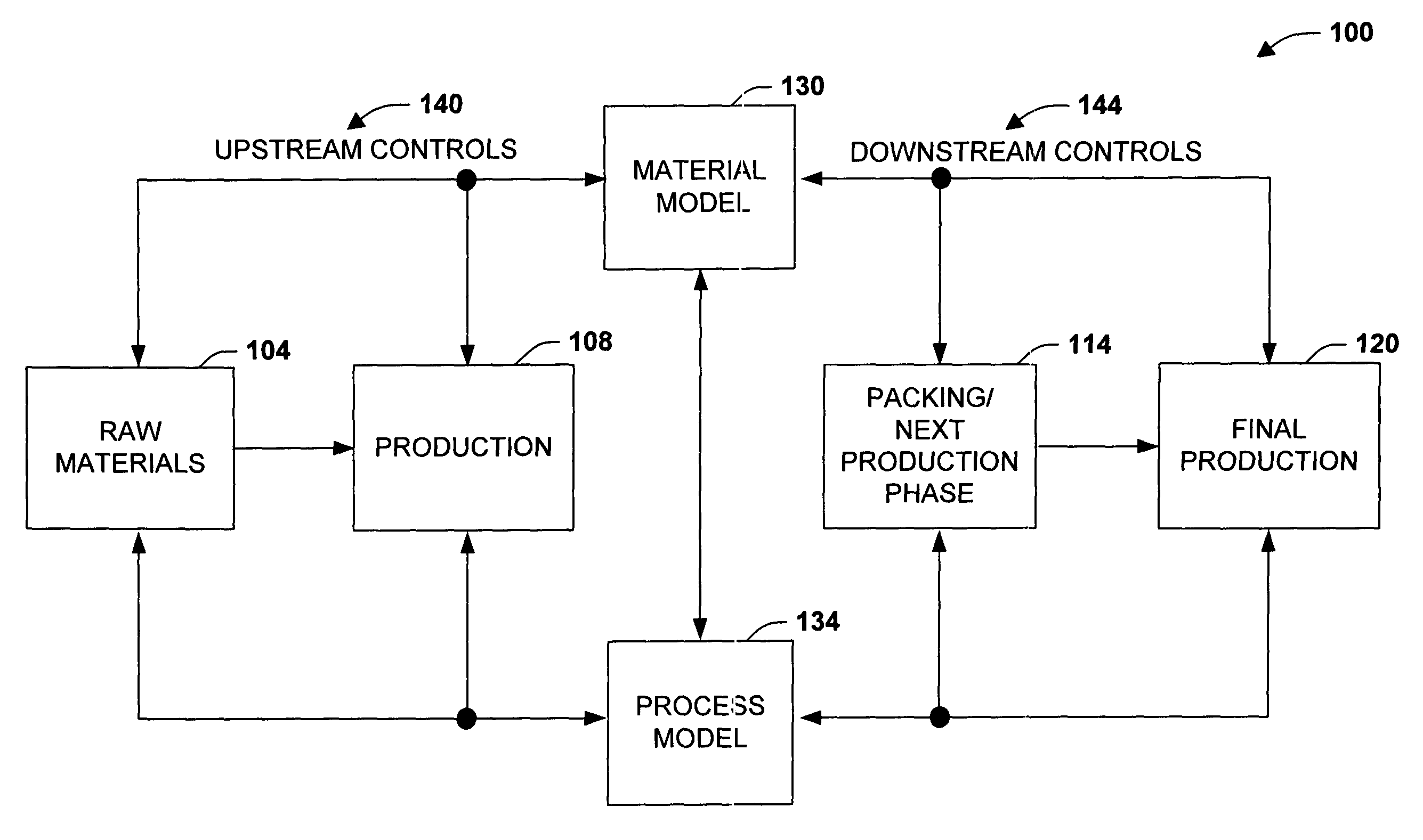

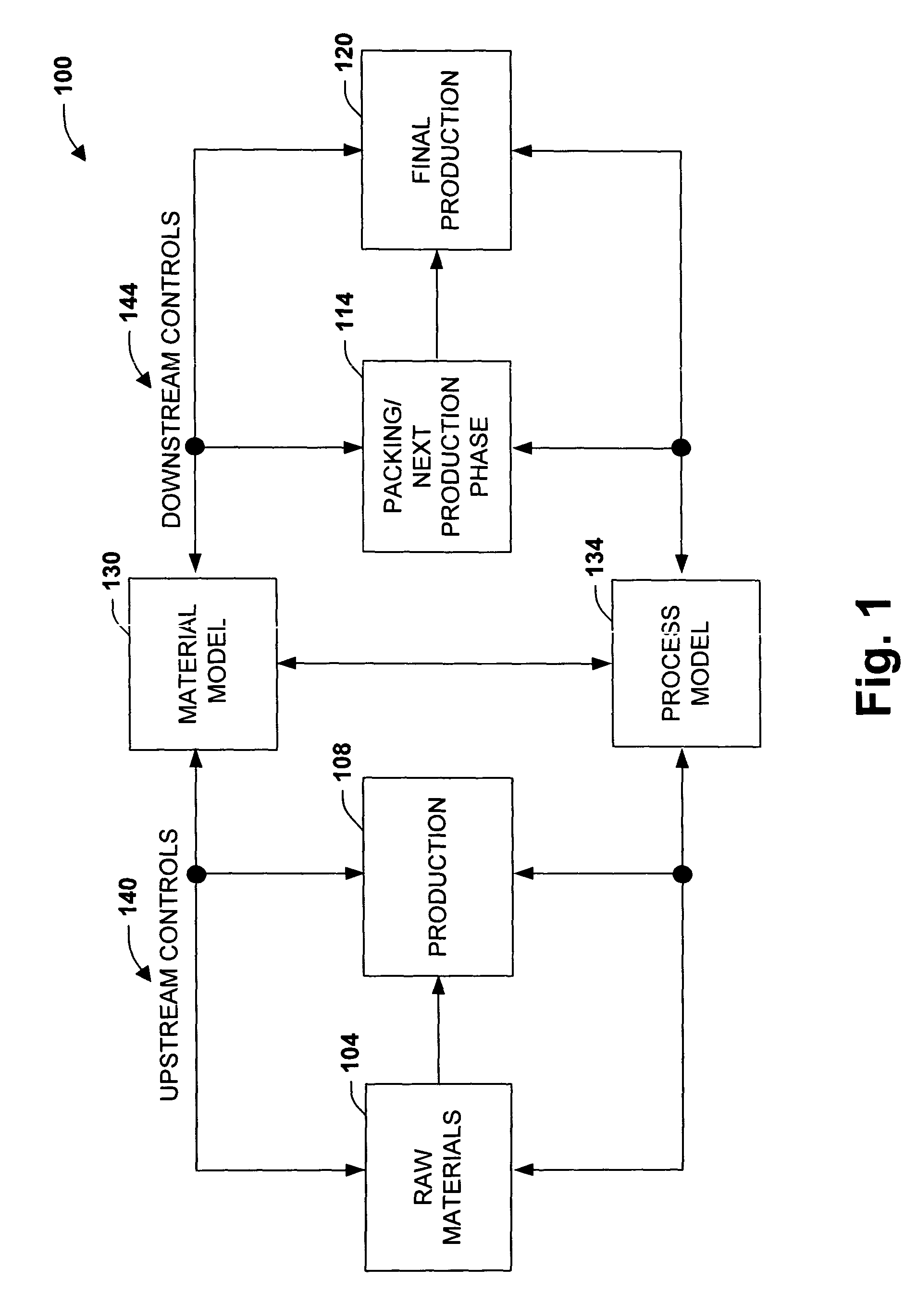

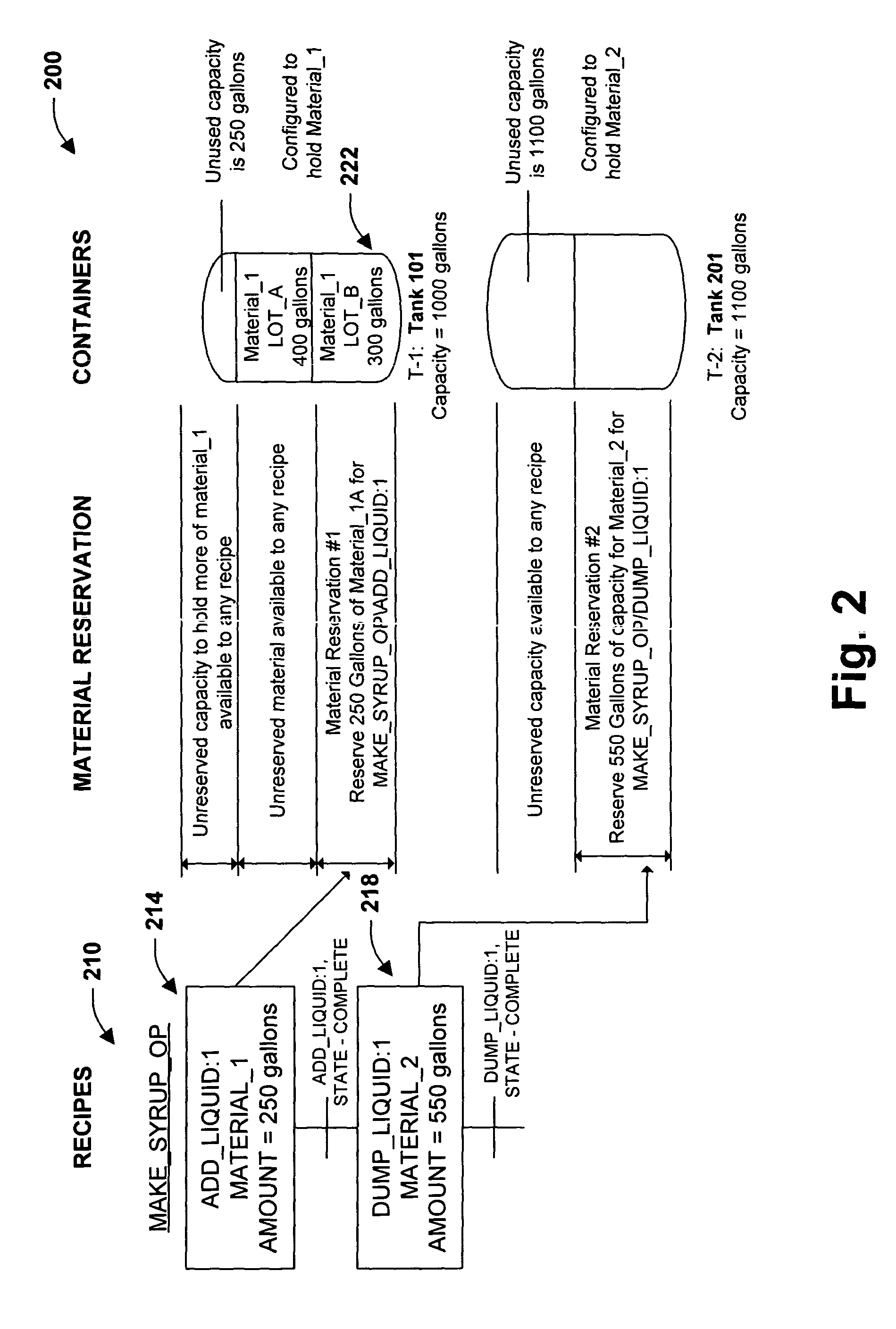

InactiveUS20050065626A1Easy to optimizeEfficient managementProgramme controlHand manipulated computer devicesBatch processingManufacturing operations

The present invention relates to a system and methodology facilitating material-driven processing in an industrial controller environment. Various models supported by database objects are provided to automatically and dynamically map inventory systems / processes to control systems / process such as in batch or recipe operations. A material model is provided that tracks to an inventory database and includes such aspects as defining material types and containers to house such materials. An area model maps the material model to possible units and equipment modules to process the materials. These models include phased-based parameters that define amounts of material that flow into and out of a determined area for processing the materials. Before, during and / or after automated manufacturing operations, object binding operations occur between material-based servers associated with an inventory system and batch servers associated with a process-control system. Such binding includes Just-In-Time or on-demand binding at run time, and relates material requirements of a recipe (or batch) to the units and equipment that are available to produce the recipe.

Owner:ROCKWELL AUTOMATION TECH

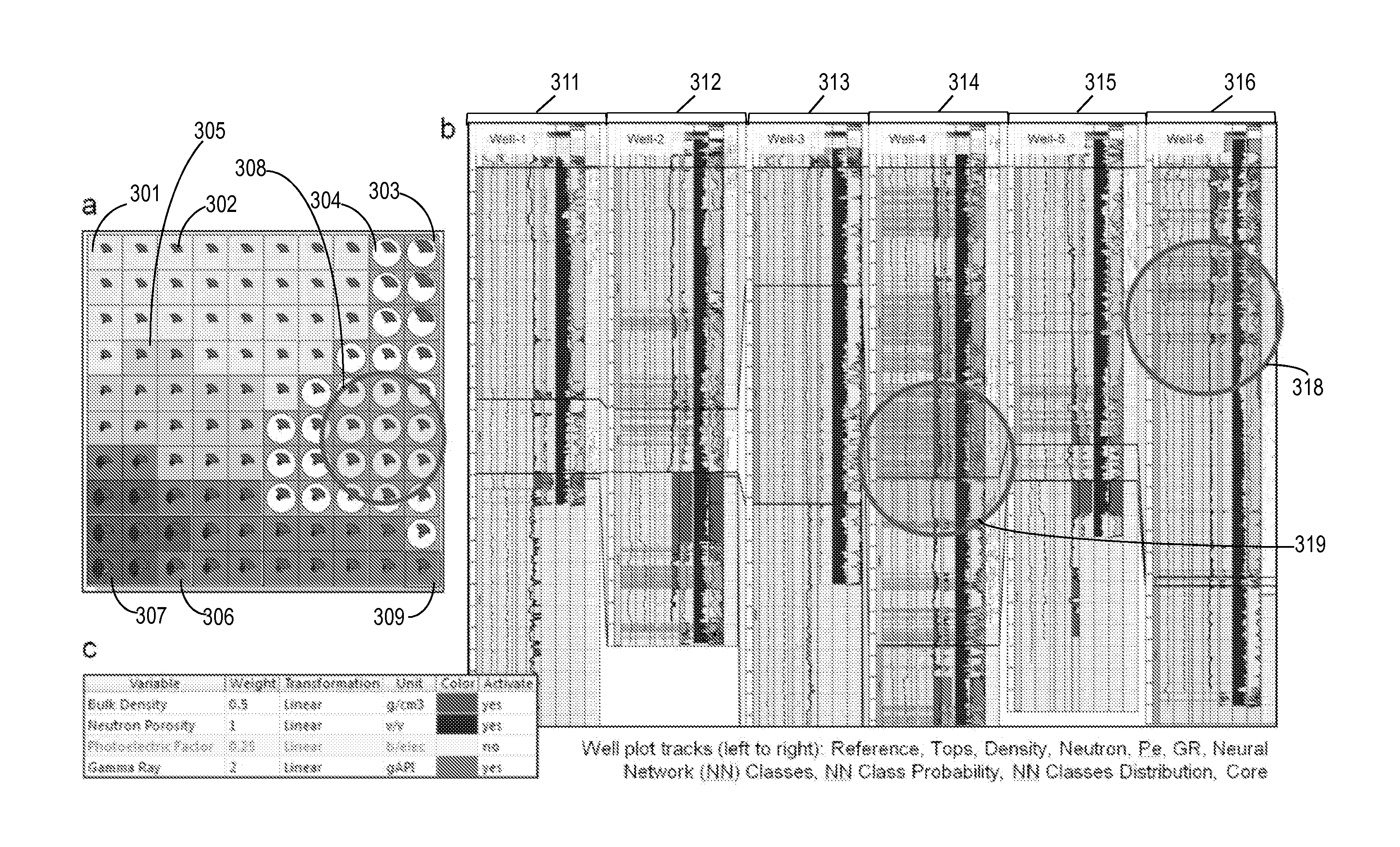

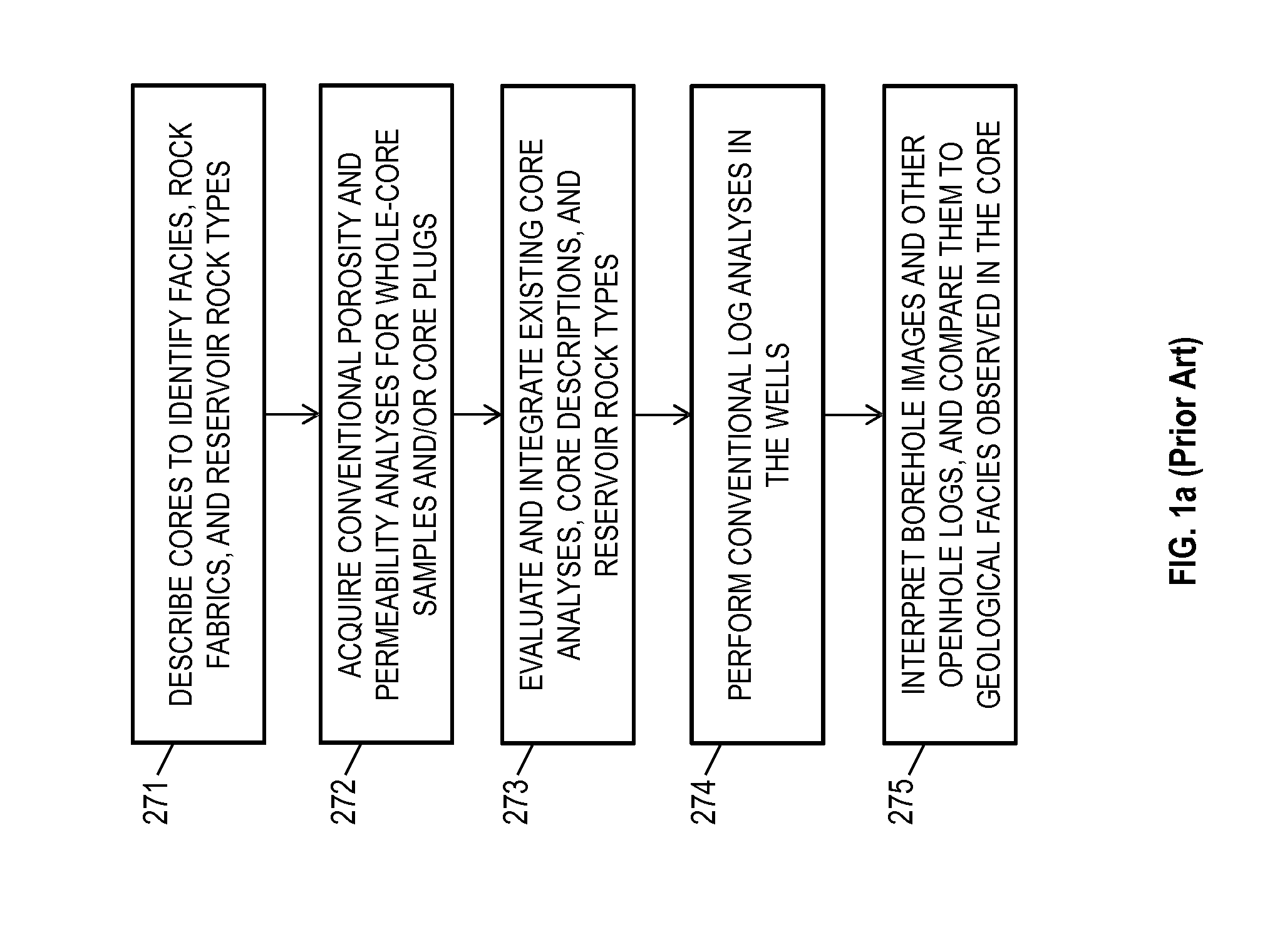

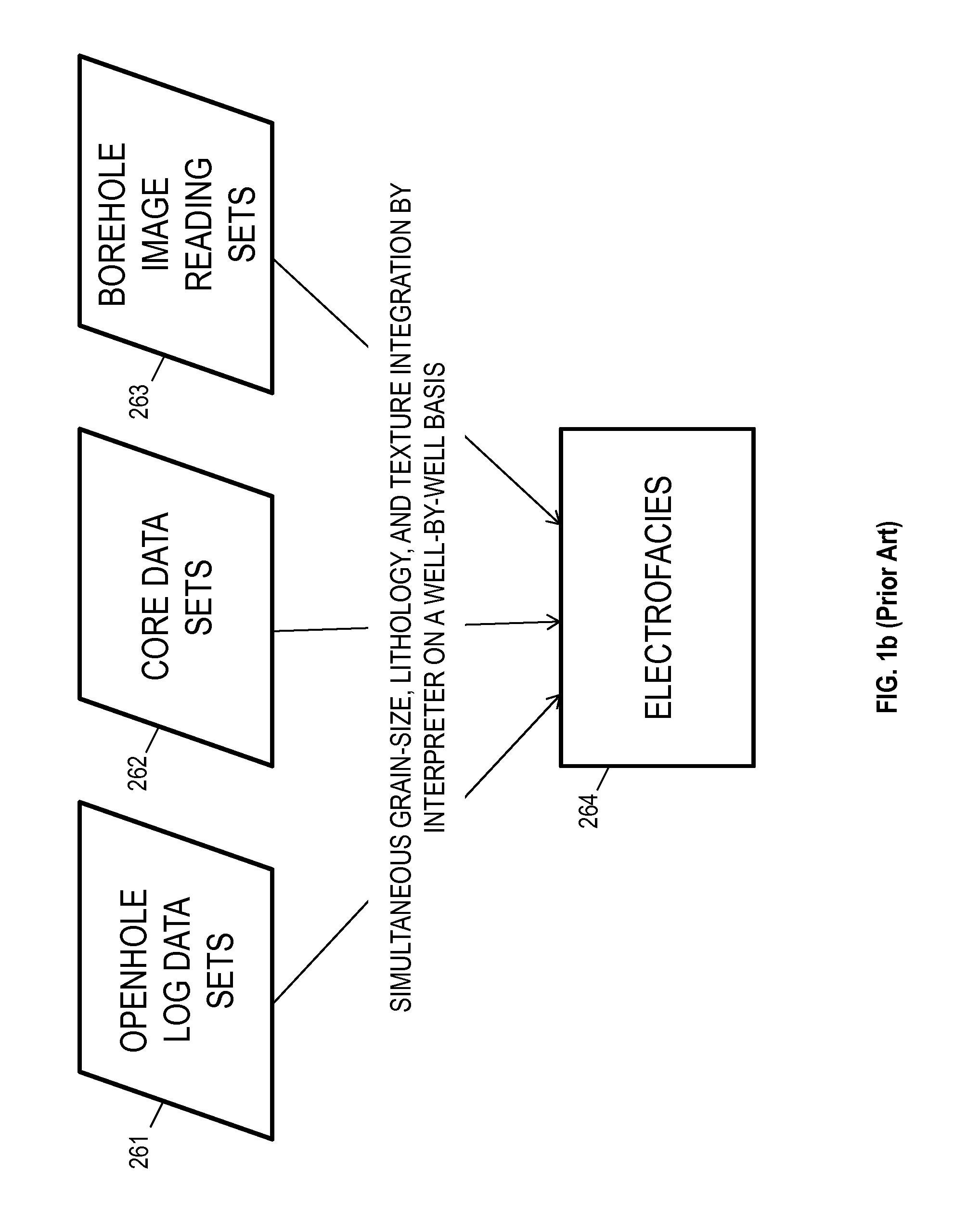

Systems, methods, and computer medium to produce efficient, consistent, and high-confidence image-based electrofacies analysis in stratigraphic interpretations across multiple wells

ActiveUS20150241591A1Improve consistencyEasy to explainElectric/magnetic detection for well-loggingBiological neural network modelsHydrocotyle bowlesioidesImaging data

Embodiments of systems, computer-implemented methods, and non-transitory computer-readable medium having one or more computer programs stored therein are provided to enhance borehole image analysis associated with a hydrocarbon reservoir. A neural network mapping process can first be performed, responsive to openhole log data and core data, to thereby generate a material-type scheme. Then, an image-based petrophysical analysis process can distribute and calibrate borehole image data, responsive to the core data and material-type scheme. Consequently, an approximated material type and an approximated grain size can be produced for each borehole image reading. The openhole log data, the core data, the material-type scheme, and the approximated material types and grain sizes, for example, can then be displayed to thereby increase consistency in categorizing subsurface material associated with hydrocarbon wells by material type and enhance interpretation of subsurface material texture, fabric, and features to predict subsurface material composition of the hydrocarbon reservoir.

Owner:SAUDI ARABIAN OIL CO

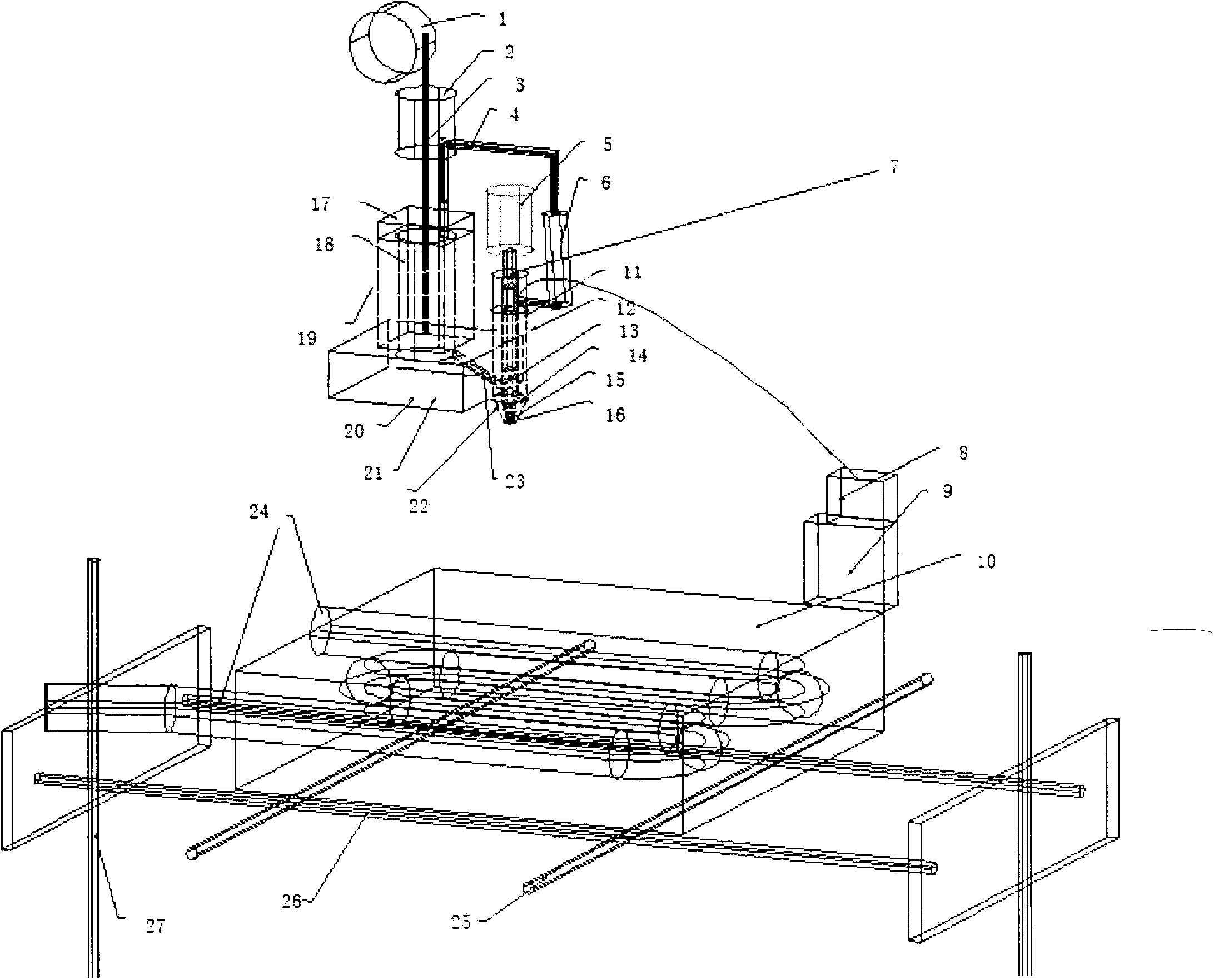

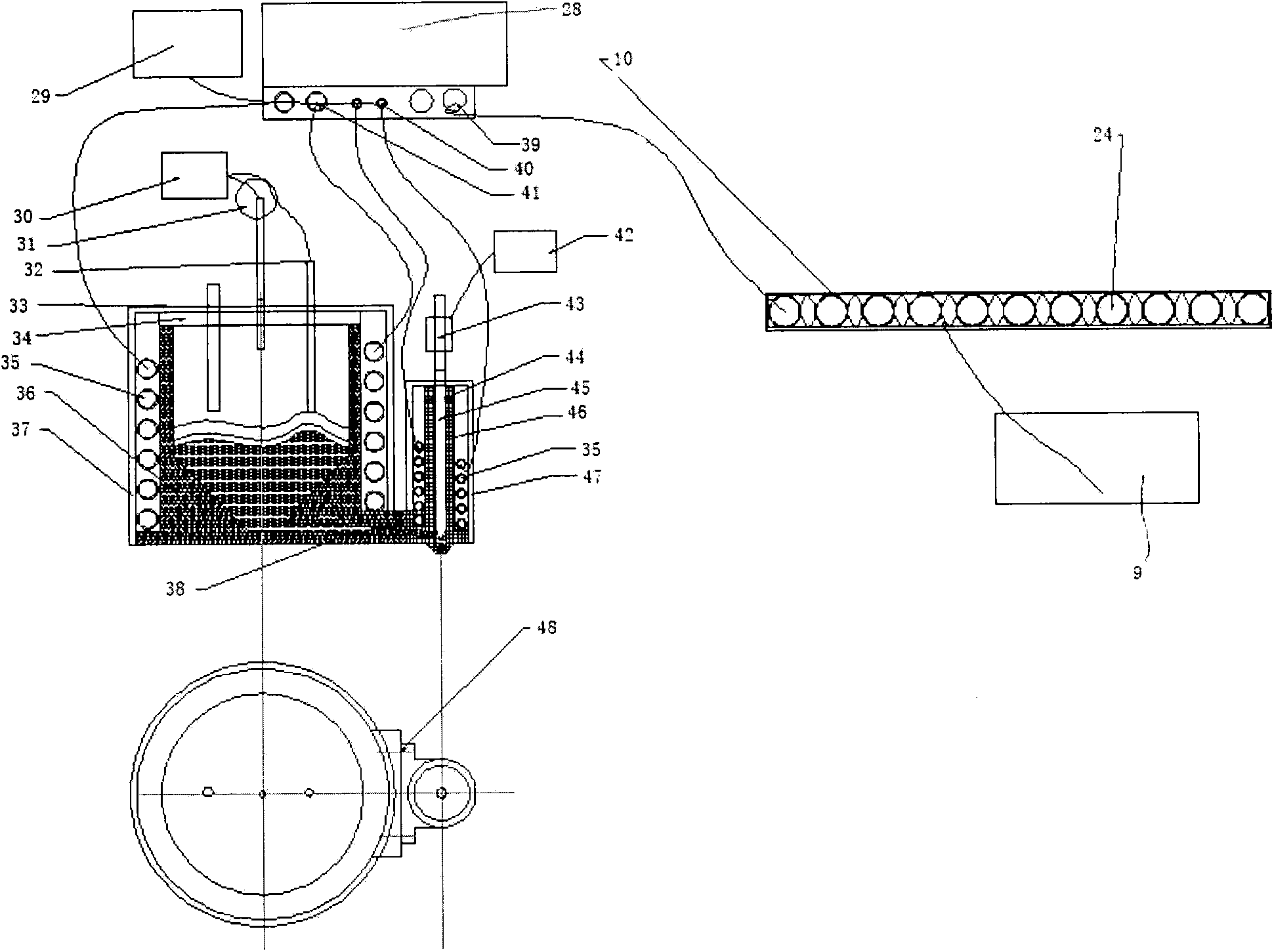

Three-dimensional (3D) metal printer

InactiveCN103551572AAdditive manufacturing apparatusIncreasing energy efficiencyMetallic materialsLiquid metal

The invention discloses a three-dimensional (3D) metal printer. A printing head integrating a ceramic melting furnace and a liquid metal ejector is a key technology for the 3D metal printer. The printing head is made of high temperature resistant ceramic or graphite material, a water cooling eddy current coil is installed on an outer layer, the melting furnace is filled with inert gas to protect liquid metal, and the ejector is a reciprocating type plunger pump. The water cooling eddy current coil is electrified with high-frequency current, and heating power can be adjusted through a high-frequency controller according to factors such as material types, model requirements and processing speeds. The inert gas keeps a certain pressure while protecting the molten metal, flow of the liquid metal is facilitated, and metal residue in the plunger pump and the melting furnace is removed by means of gas simultaneously during shutdown. Besides application to the 3D metal printer, the printing head can also be used for devices for die-cast molding and injection molding of metal material and the like.

Owner:王璐瑶

Reticulated material body support and method

A body support comprising a top layer of flexible visco-elastic material having an exposed convoluted top surface is disclosed. The flexible visco-elastic material can have a reticulated or non-reticulated cellular structure. In some embodiments, one or more other layers of the body support comprises reticulated visco-elastic foam, and can have at least one material property responsive to temperatures in the range of a user's body heat. In these and other embodiments, one or more of the other layers of flexible material comprises non-visco-elastic foam, and can be combined in a body support with one or more layers of visco-elastic foam. The body support can include one or more layers of other material types, including one or more layers of high-resilience polyurethane foam.

Owner:TEMPUR WORLD

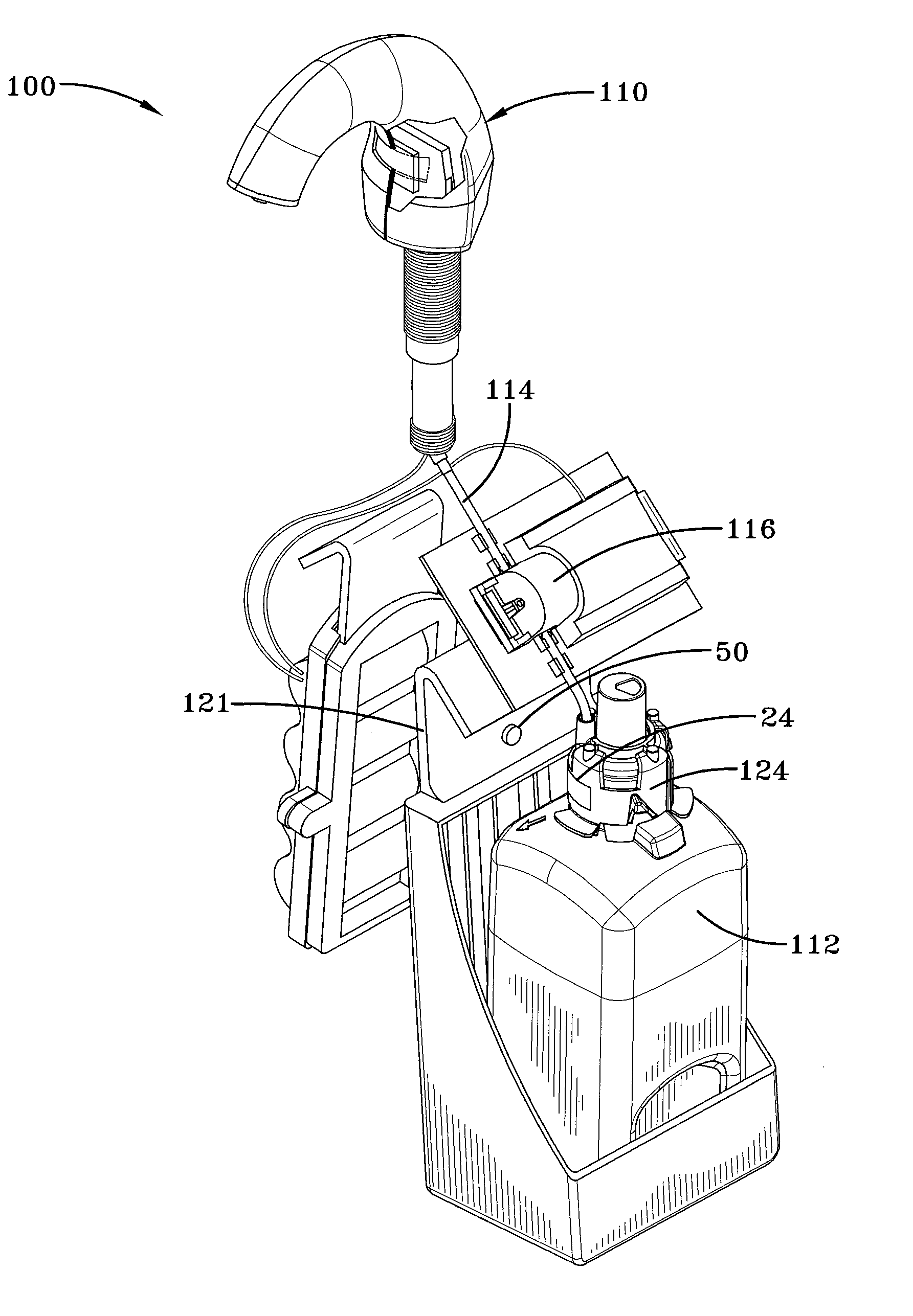

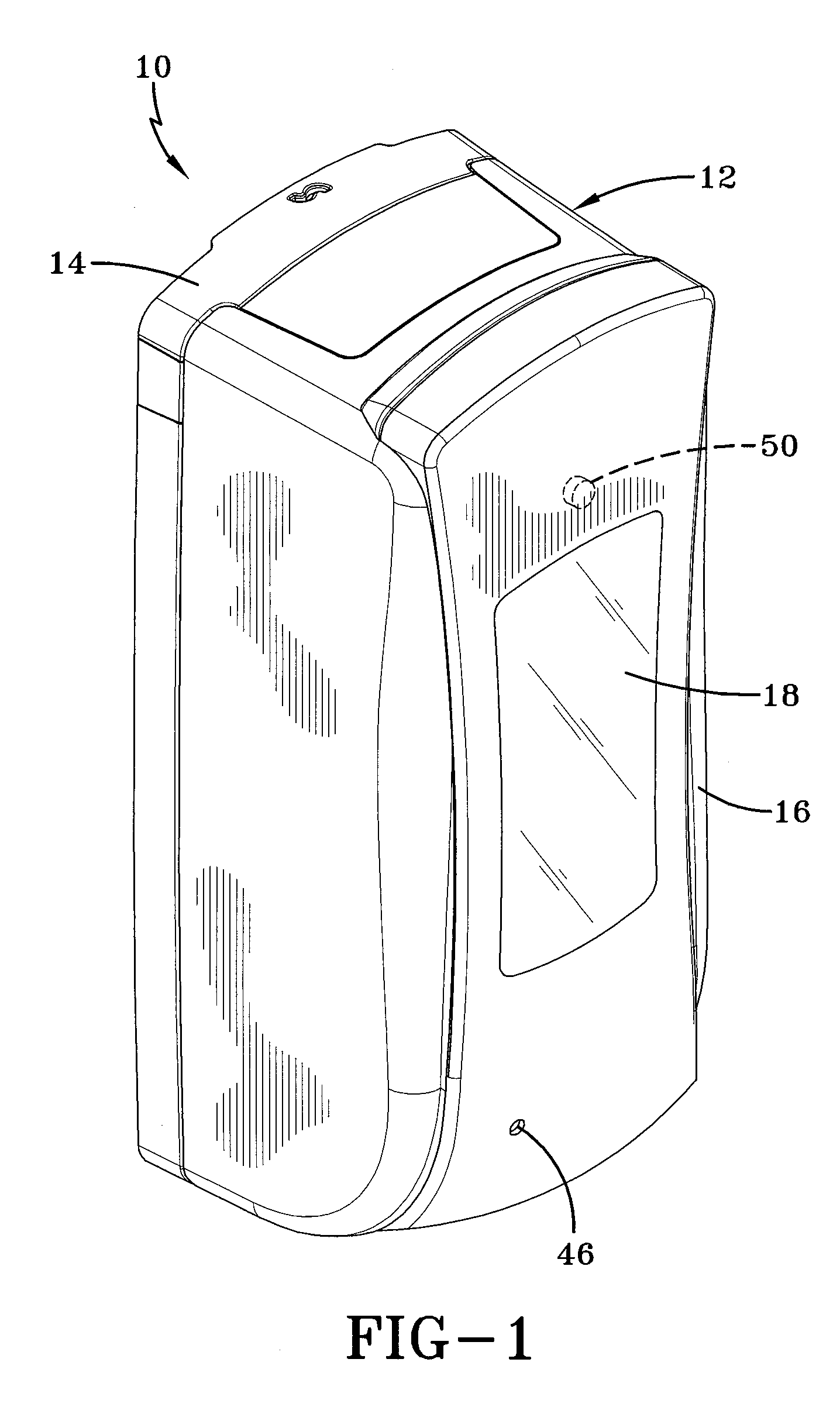

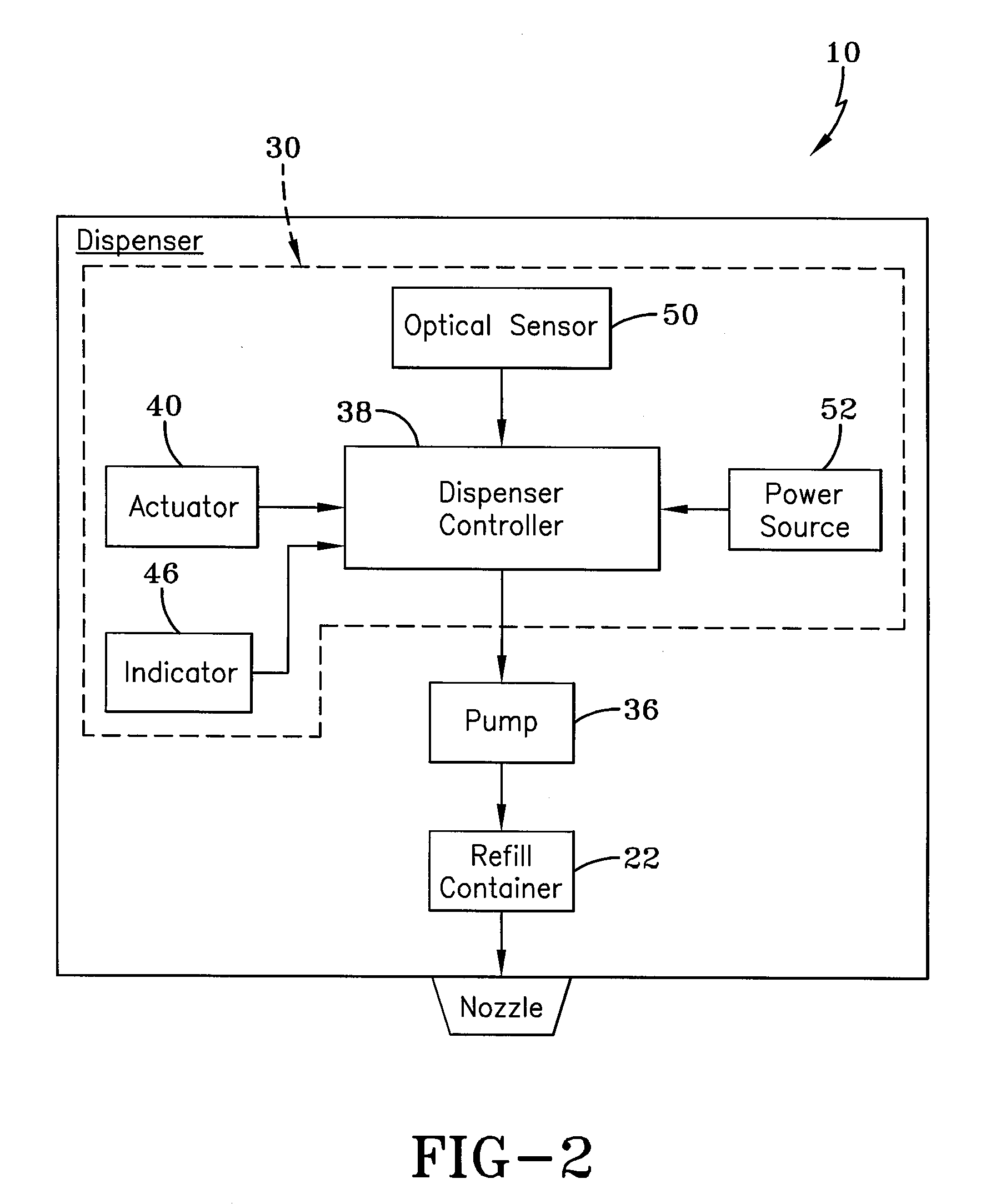

Dispenser with optical keying system

A dispenser with an optical keying system includes a housing that is configured to carry a removable refill container that contains an amount of material, such as soap, for example. The removable refill container includes microscopic indicia that is visually-imperceptible to a human, which includes an authorization code, as well as a reference code that identifies various attributes associated with the refill container, such as its size, material type, and date of manufacture. Finally, the dispenser includes an optical sensor that is configured to read the authorization code defined by the microscopic or visually-imperceptible indicia to determine whether the refill container is authorized for use with the dispenser.

Owner:GOJO IND INC

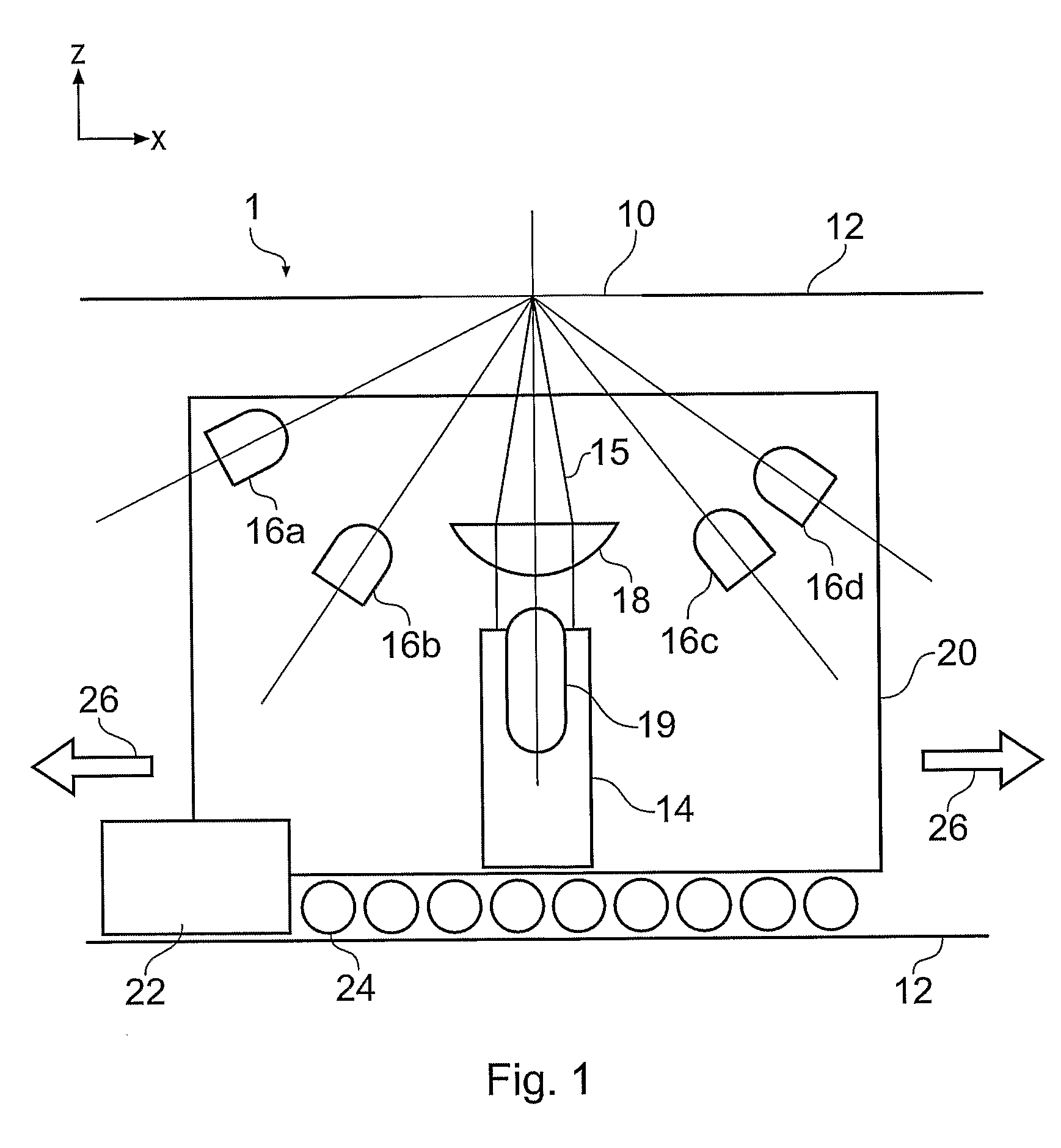

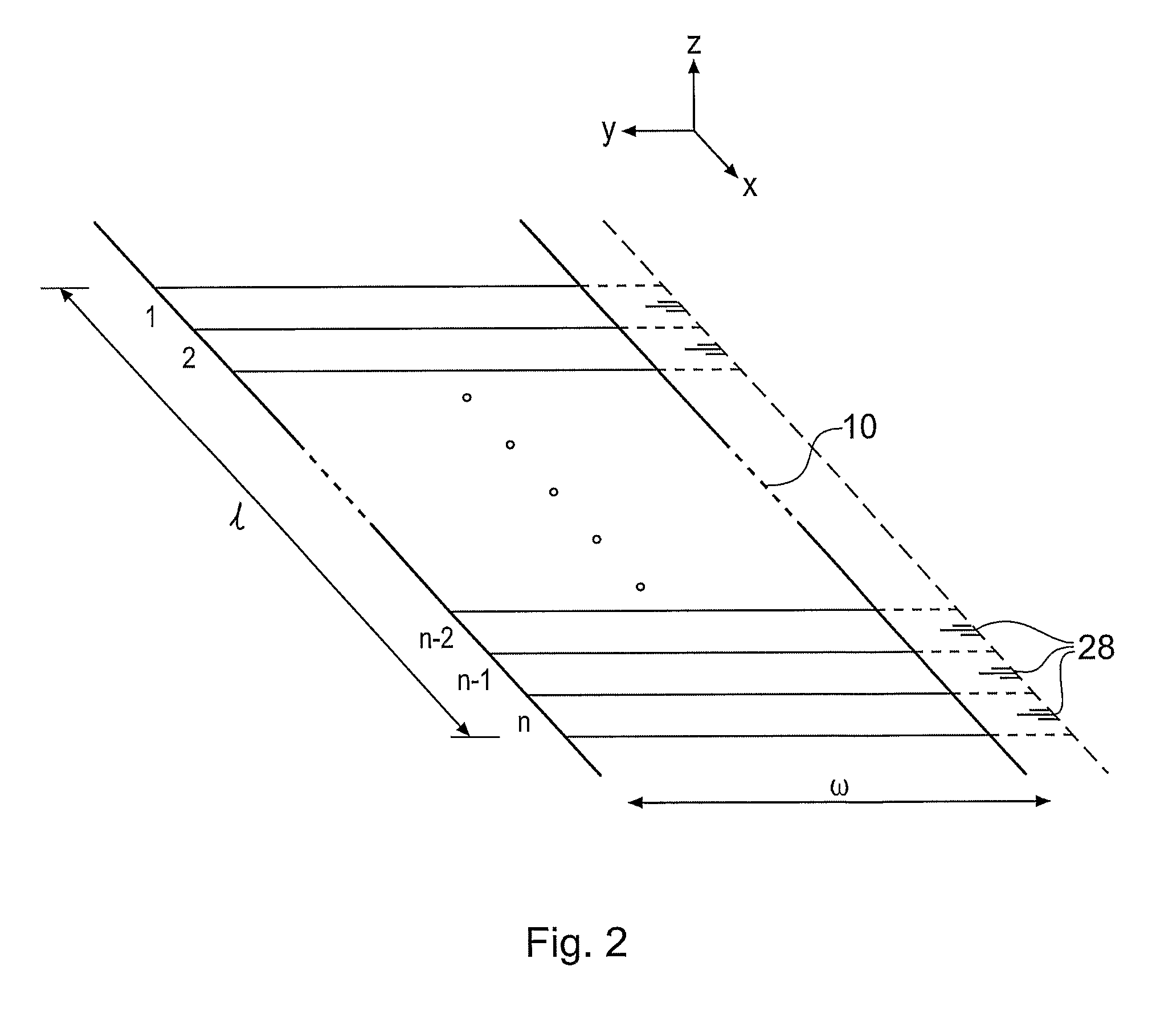

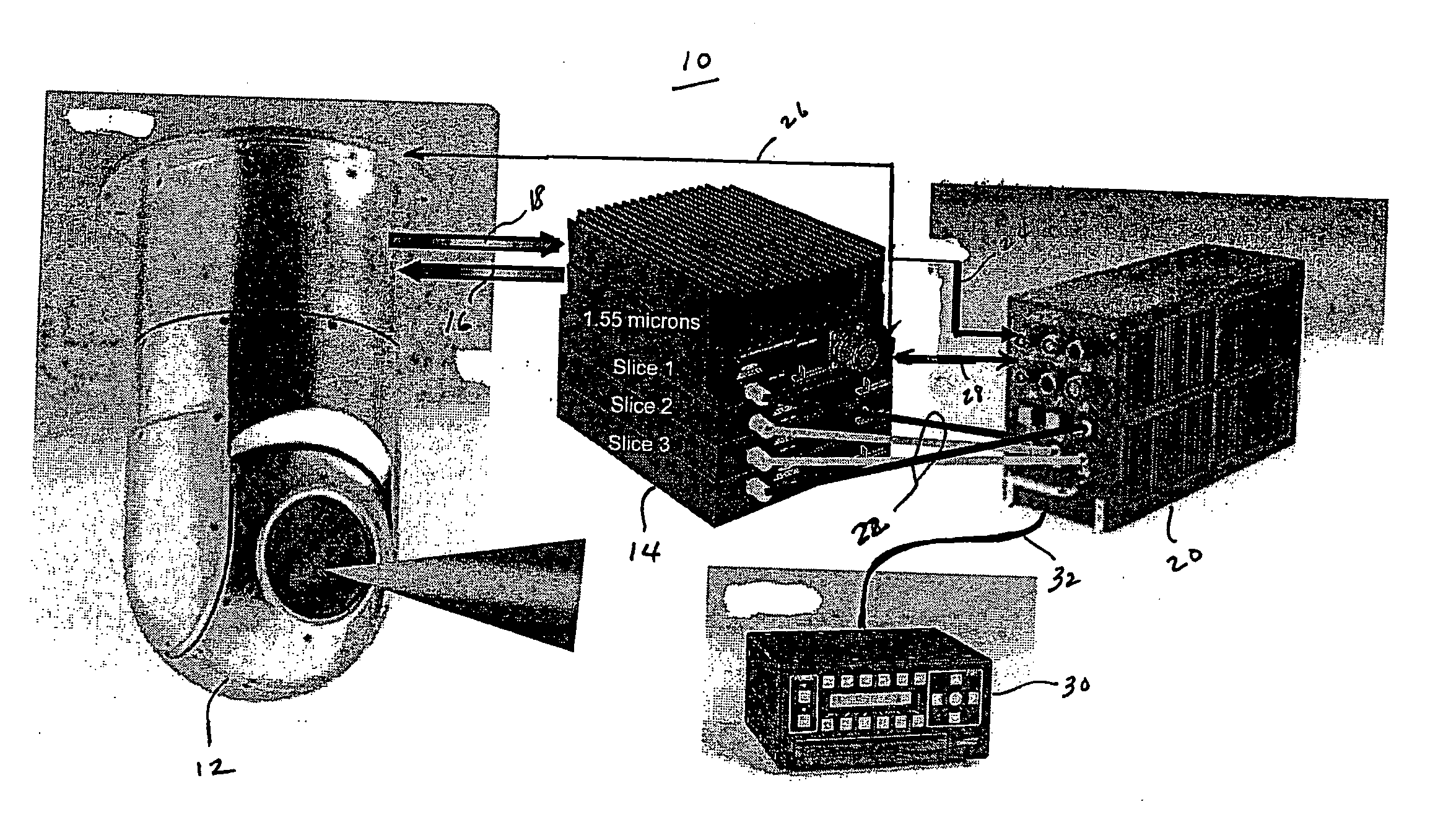

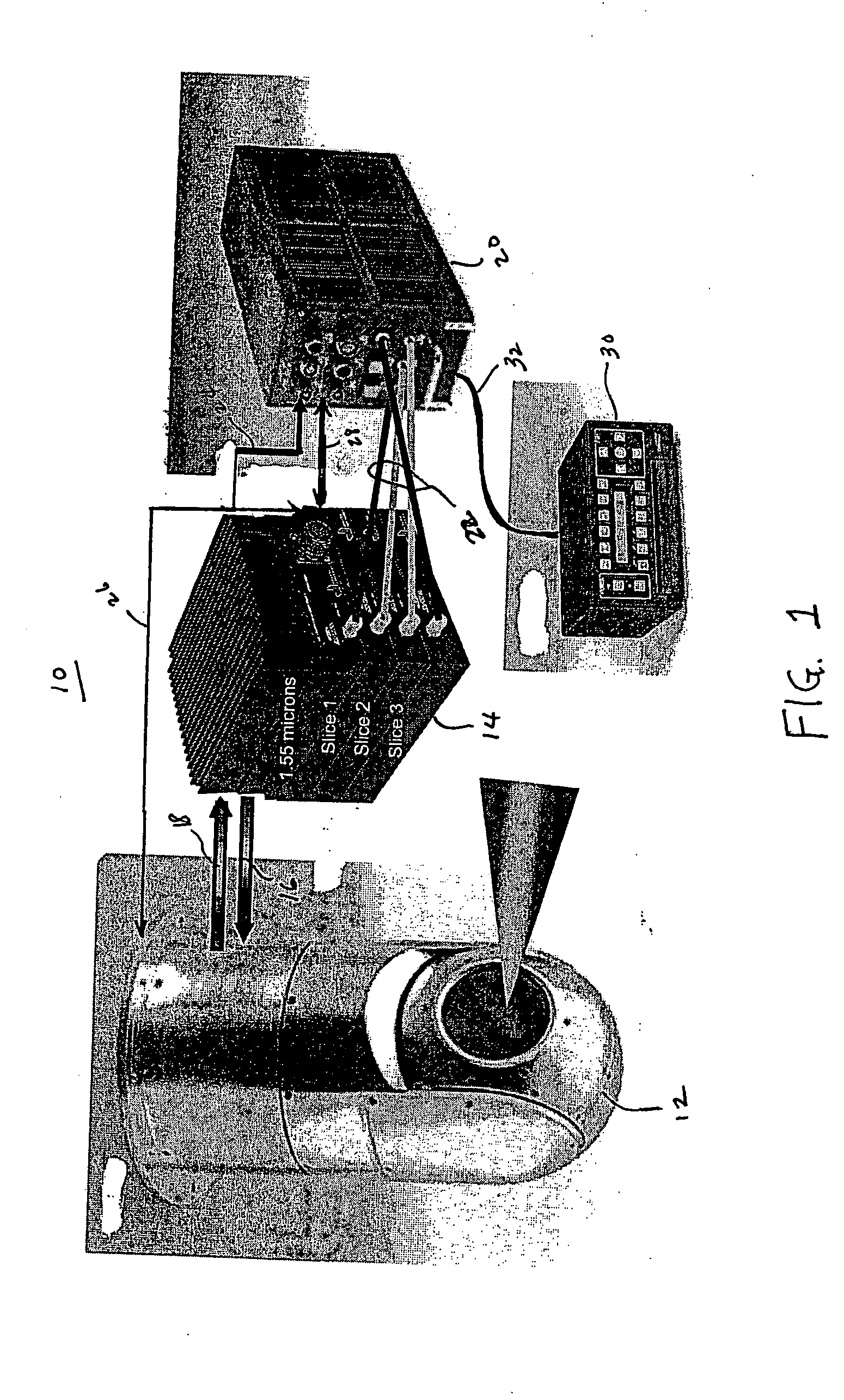

System and method of identifying an object in a laser beam illuminated scene based on material types

A method of identifying an object in a laser beam illuminated scene based on material types comprises the steps of: emitting a pulsed beam of laser energy, each beam pulse comprising a plurality of different discrete wavelength emission components; illuminating a predetermined scene with the pulsed beam; receiving return laser pulses from objects within the illuminated scene, each return laser pulse comprising return components corresponding to the plurality of different discrete wavelength emission components; determining spectral reflectance values for the plurality of return components of each return laser pulse; determining a material type for each return laser pulse of the illuminated scene based on the plurality of reflectance values of the corresponding return pulse; indexing each determined material type to a position in the illuminated scene; and identifying an object in the illuminated scene based on material types and indexed positions thereof in the scene. A counterpart system for carrying out the method is also disclosed.

Owner:ROSEMOUNT AEROSPACE

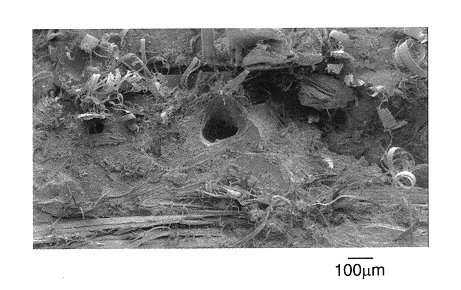

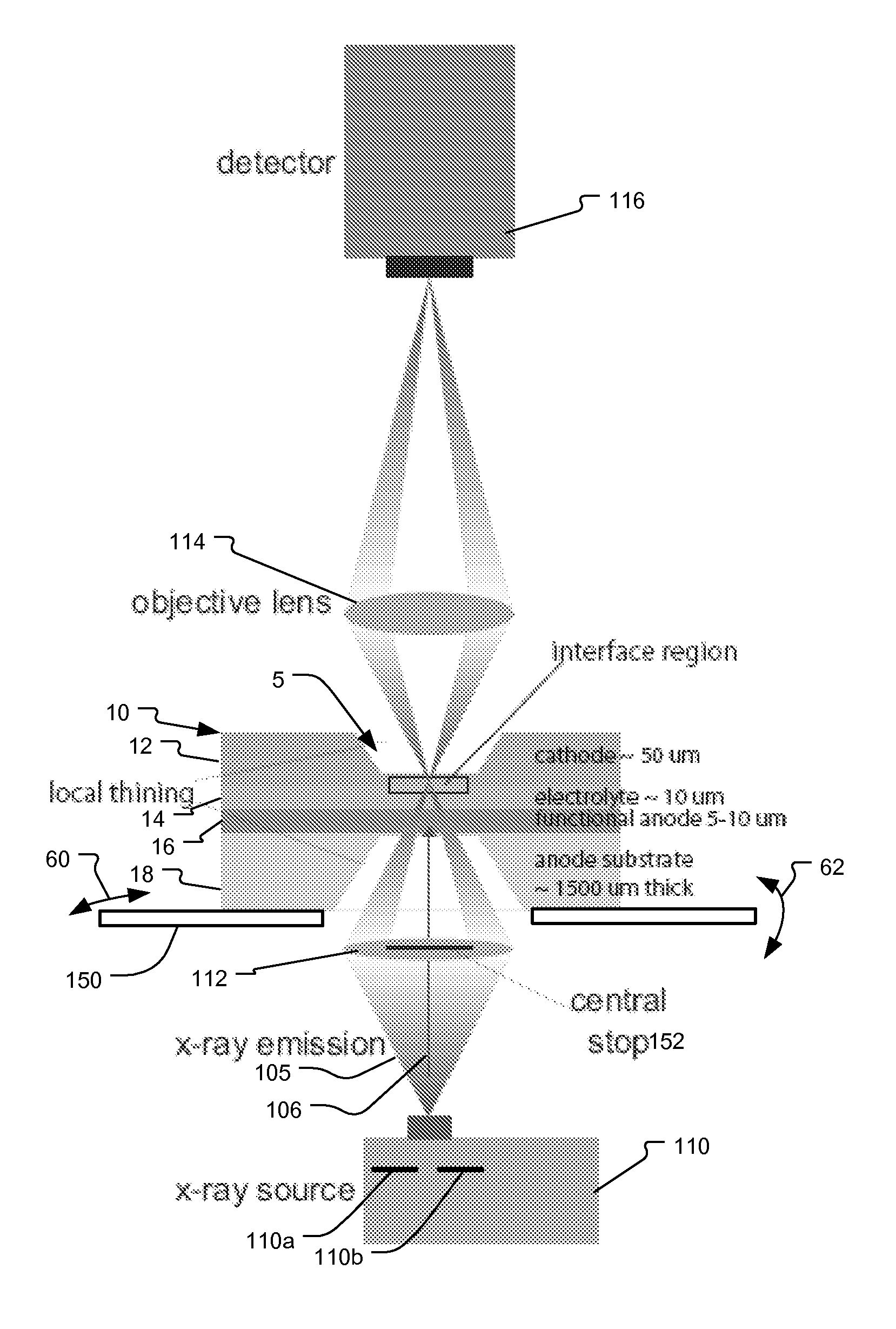

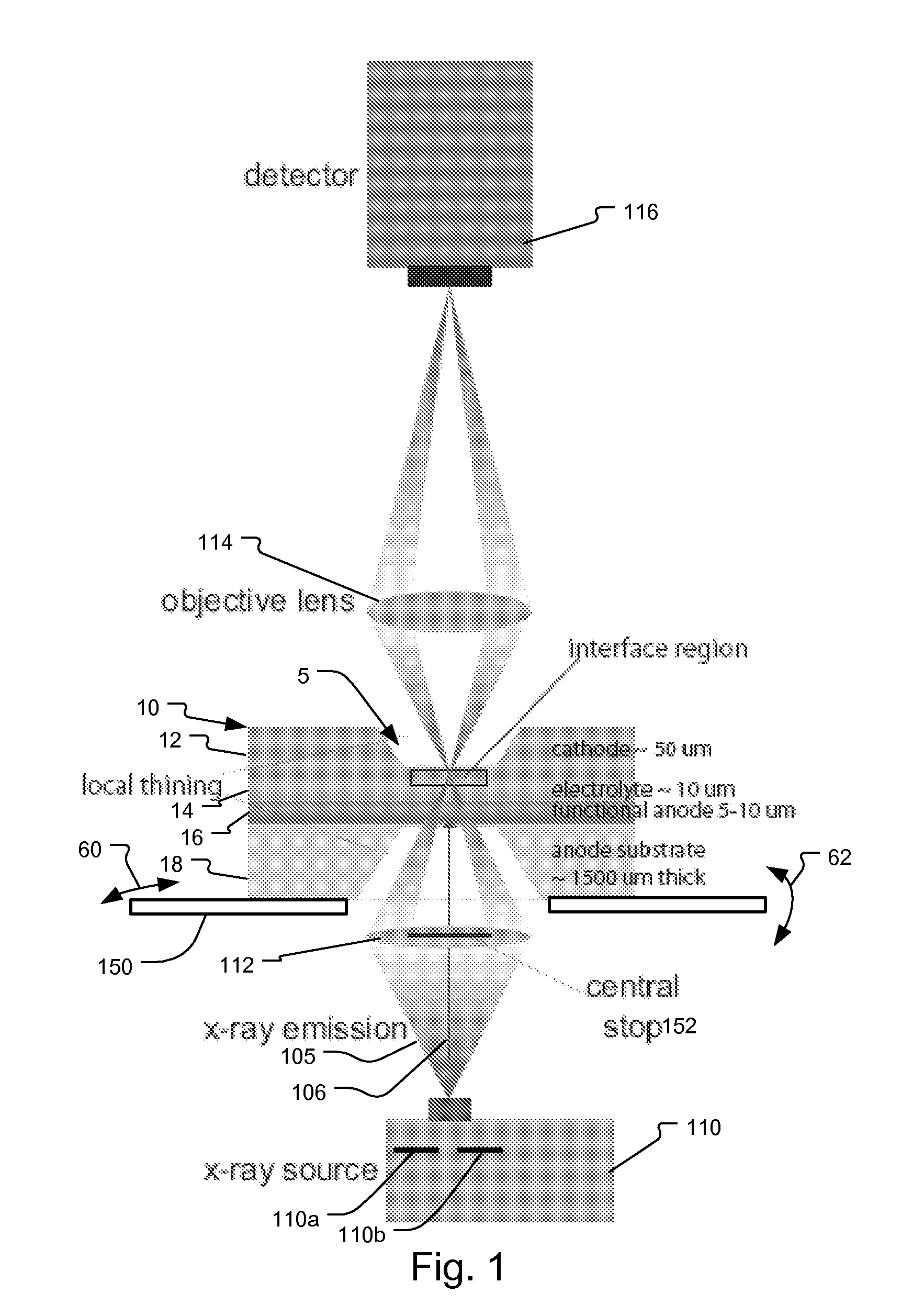

System and method for fuel cell material x-ray analysis

ActiveUS7499521B2Shorten development timeImprove reliabilityRadiation/particle handlingUsing wave/particle radiation meansHard X-raysMetrology

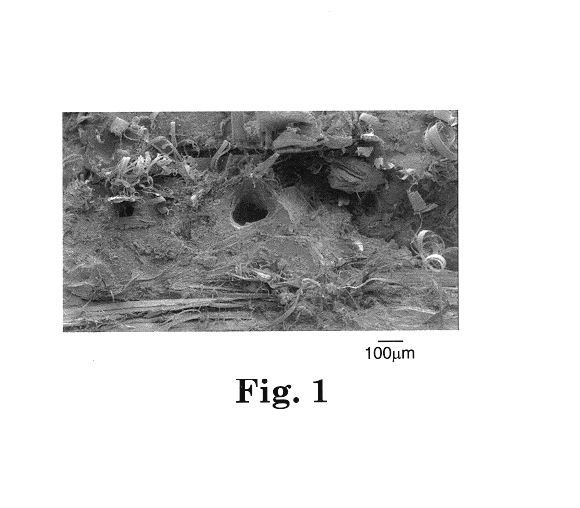

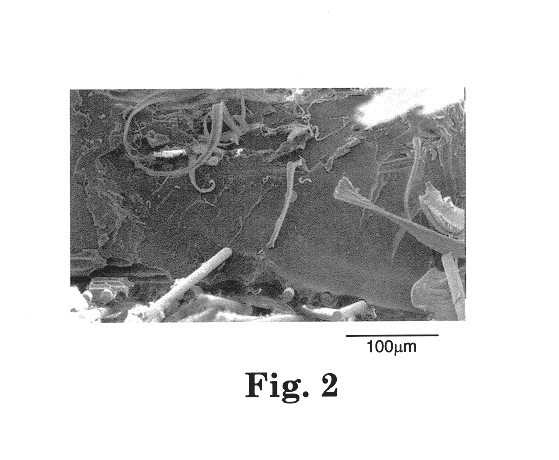

An imaging technology for fuel cells is based on x-ray microscopy. A metrology system images the electro-chemical interaction areas of solid-oxide fuel cells (SOFC) in-situ. This system takes advantage of both the penetrating power and elemental absorption contrast of hard x-ray radiation to image the internal interaction areas in a SOFC. The technology can further take advantage of the strong dependence of the x-ray absorption on material type and energy to distinguish the four major material types: cathode, electrolyte, air, and low-Z contaminants such as sulfur.

Owner:CARL ZEISS X RAY MICROSCOPY

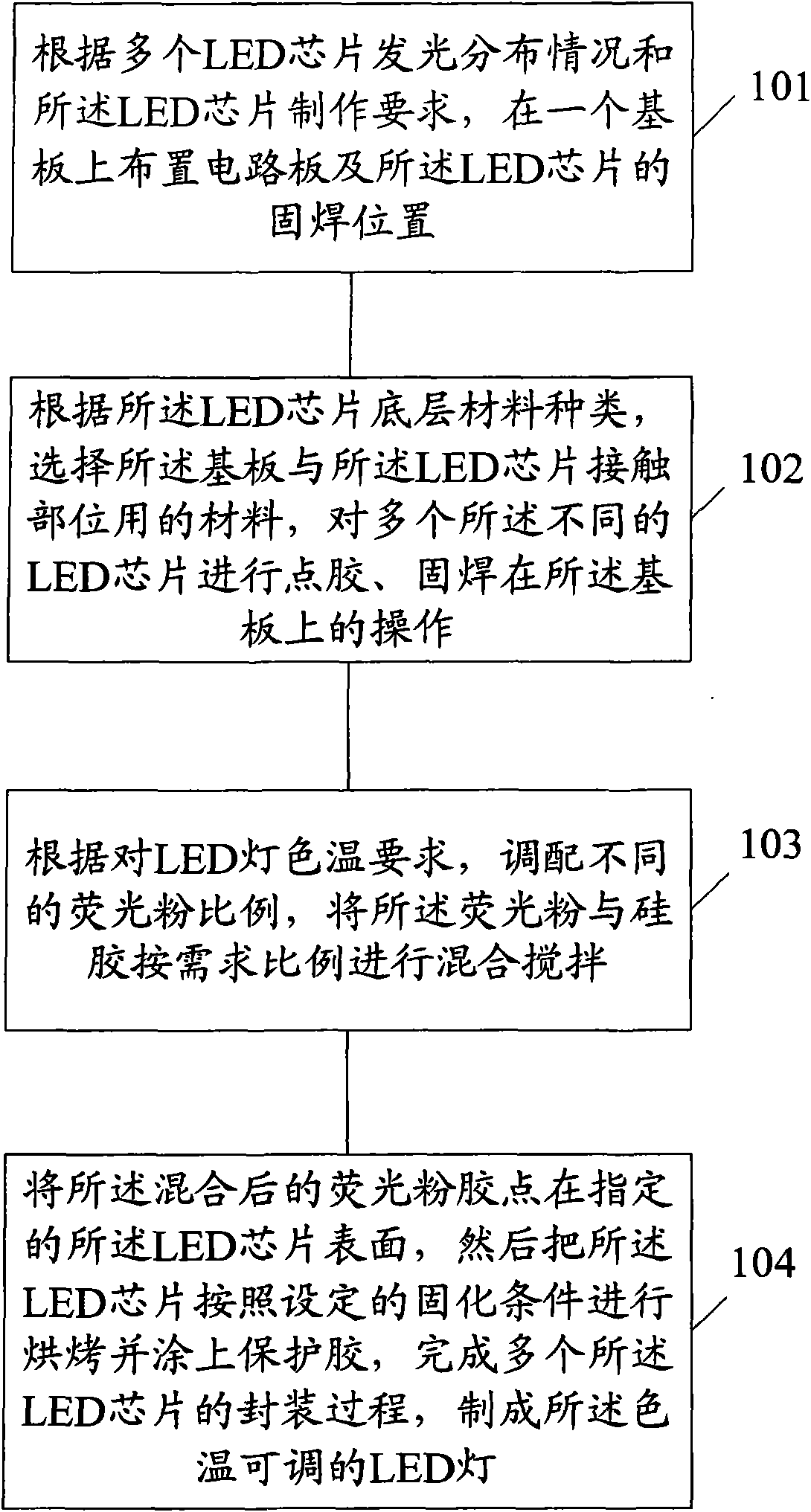

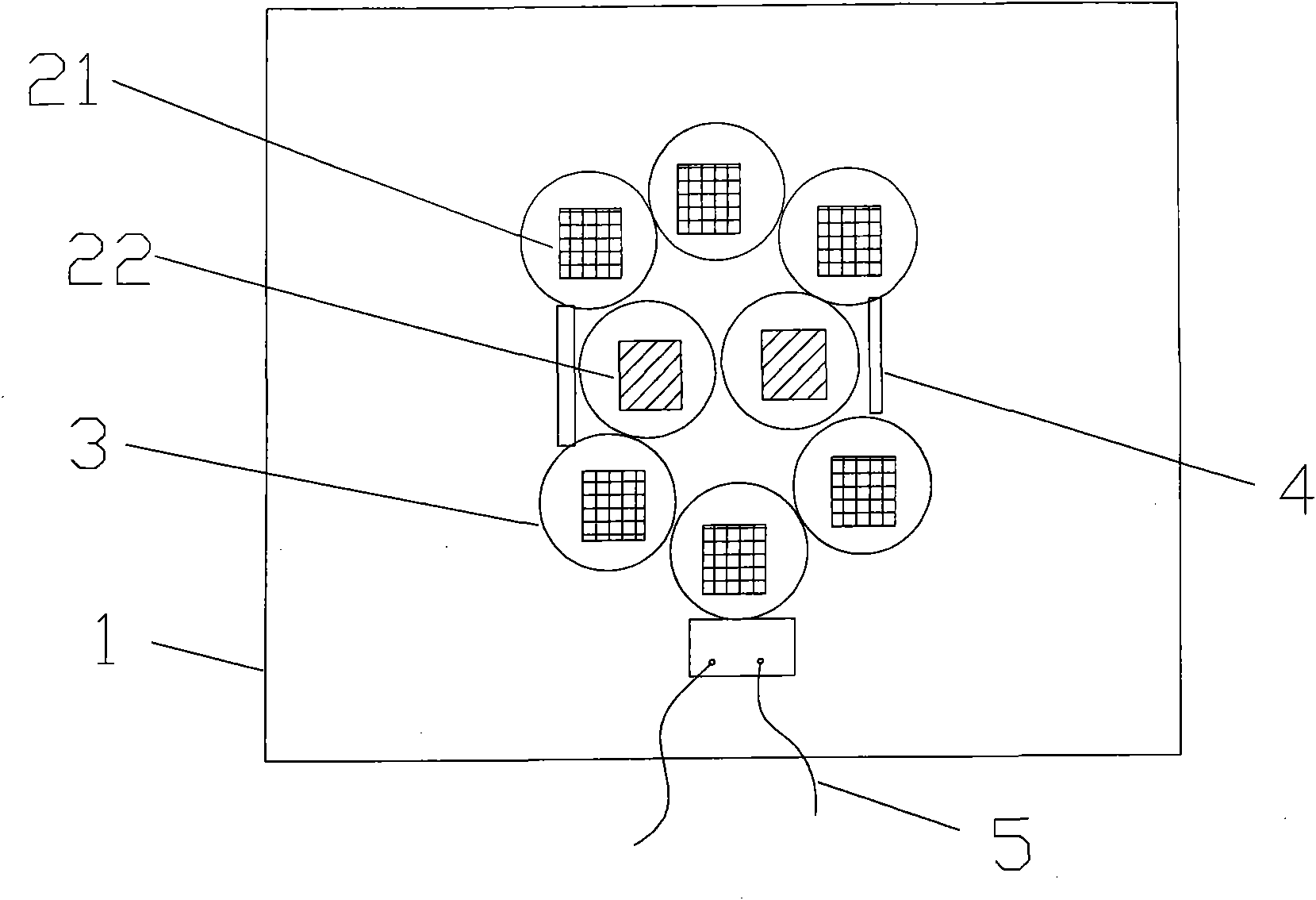

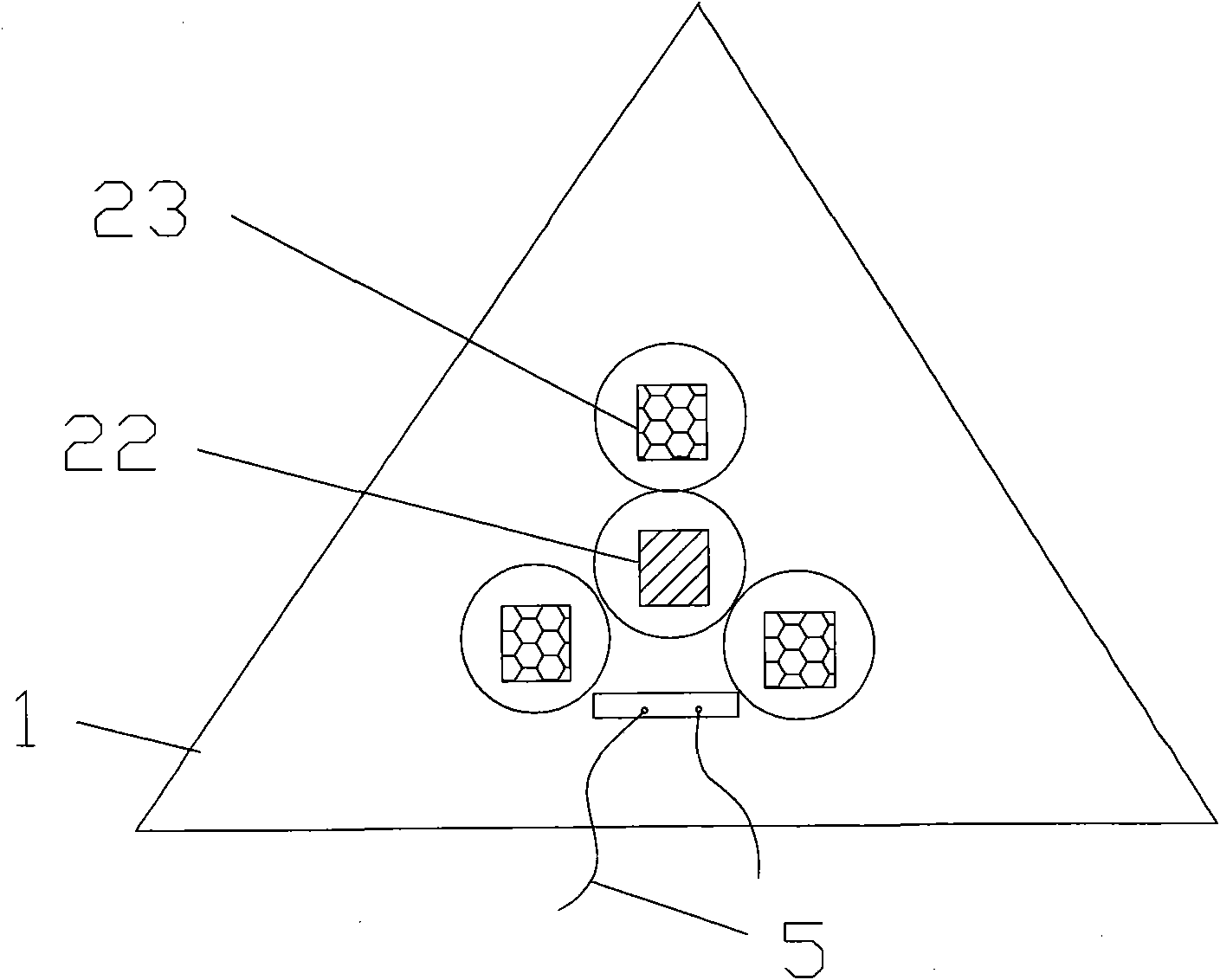

Method for manufacturing color temperature tunable LED lamp and LED lamp

InactiveCN101592291AHigh color rendering indexImprove luminous efficiencyLine/current collector detailsPoint-like light sourceMaterial typeColor rendering index

The invention discloses a method for manufacturing a color temperature tunable LED lamp and the LED lamp. The method comprises the following steps: distributing a circuit board and fixed welding positions of LED chips on a substrate according to the luminance distribution conditions and manufacturing requirements of a plurality of LED chips; selecting a material for contact positions of the substrate and the LED chips according to material types of base layers of the LED chips, and carrying out adhesive dispensing and fixed welding on the substrate; blending different proportions of fluorescent powder according to the color temperature requirement of the LED lamp, and mixing and stirring the fluorescent powder and silica gel according to the required proportion; dispensing the mixed fluorescent powder gel on the surfaces of the LED chips; and baking the LED chips, coating with protective adhesive, and completing the encapsulation process of the plurality of LED chips. The manufacturing method has advanced process and easily controlled flow. The color temperature tunable LED lamp has good color rendering index and high luminous efficiency, and the color rendering index and the luminous efficiency cannot be reduced because of the change of the color temperature.

Owner:GUANGDONG SEEDCOM ELECTRICAL & LIGHTING +1

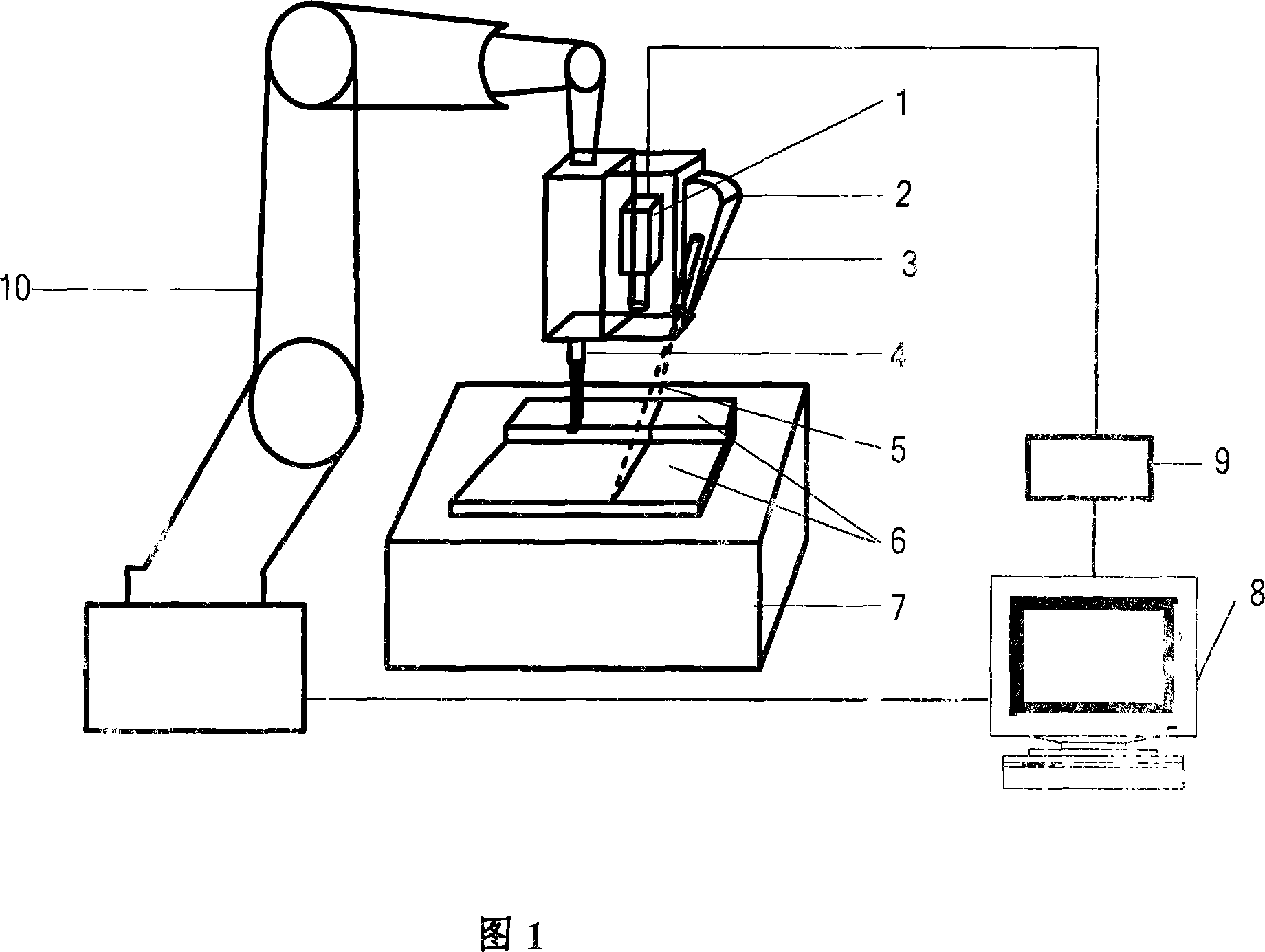

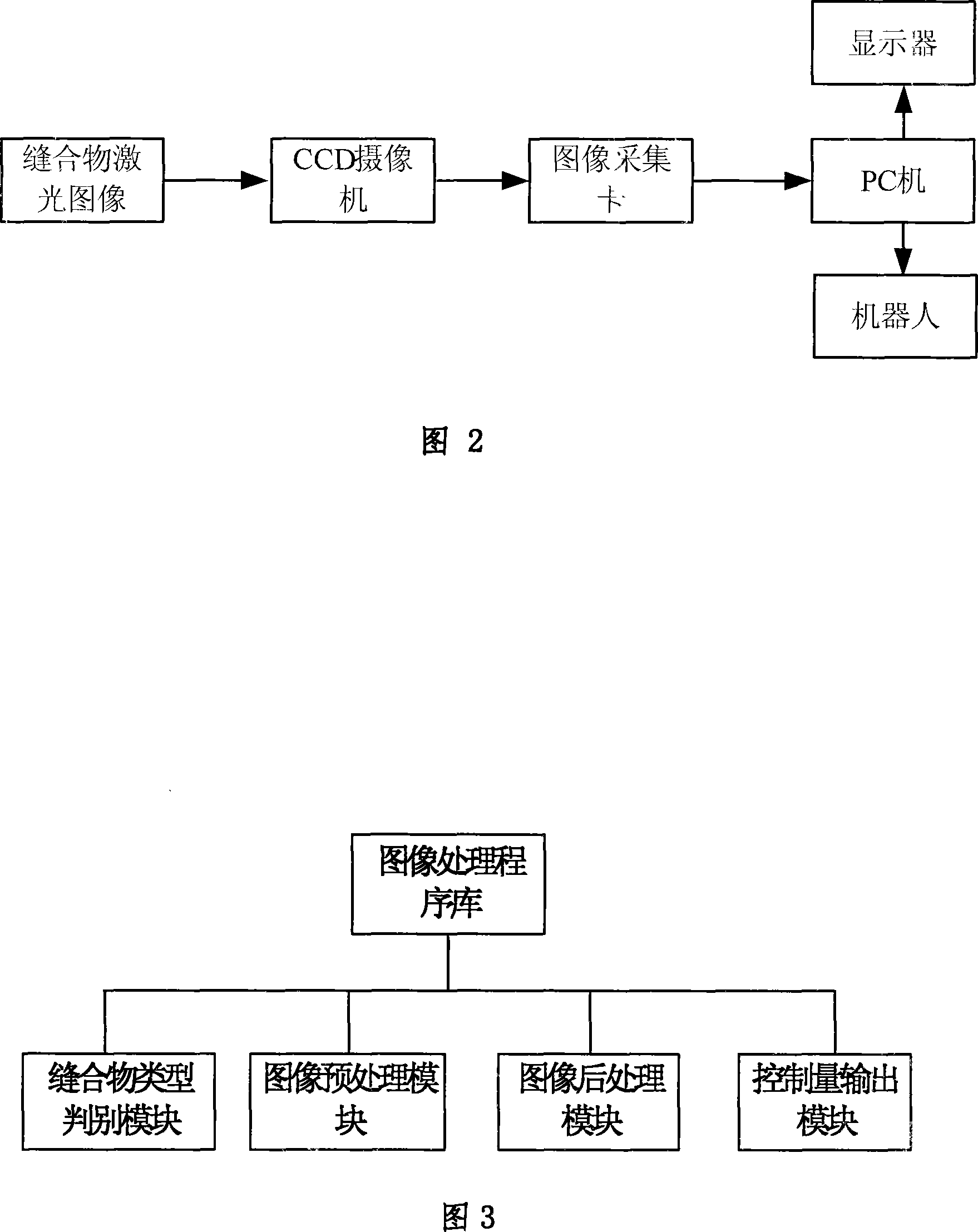

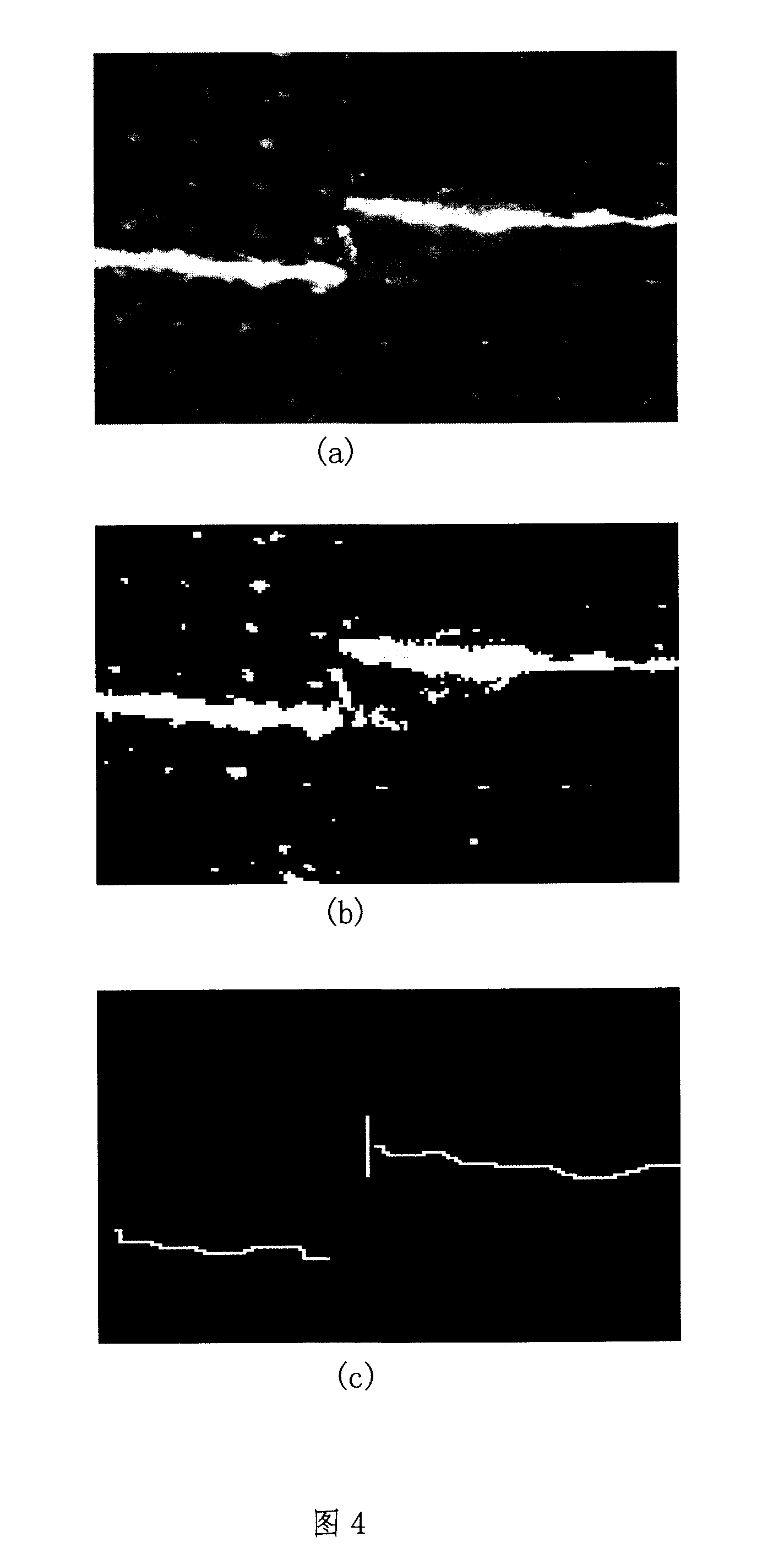

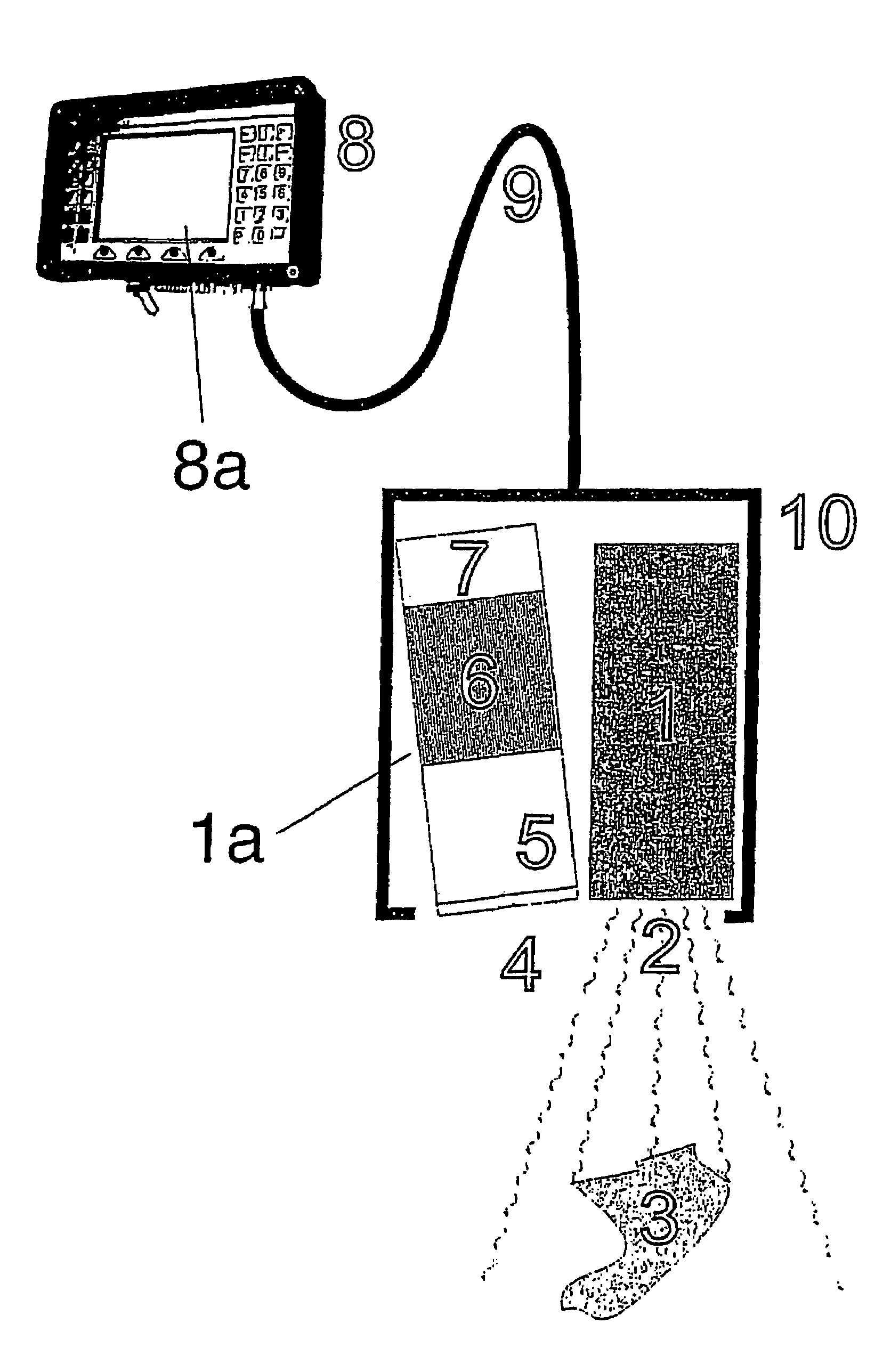

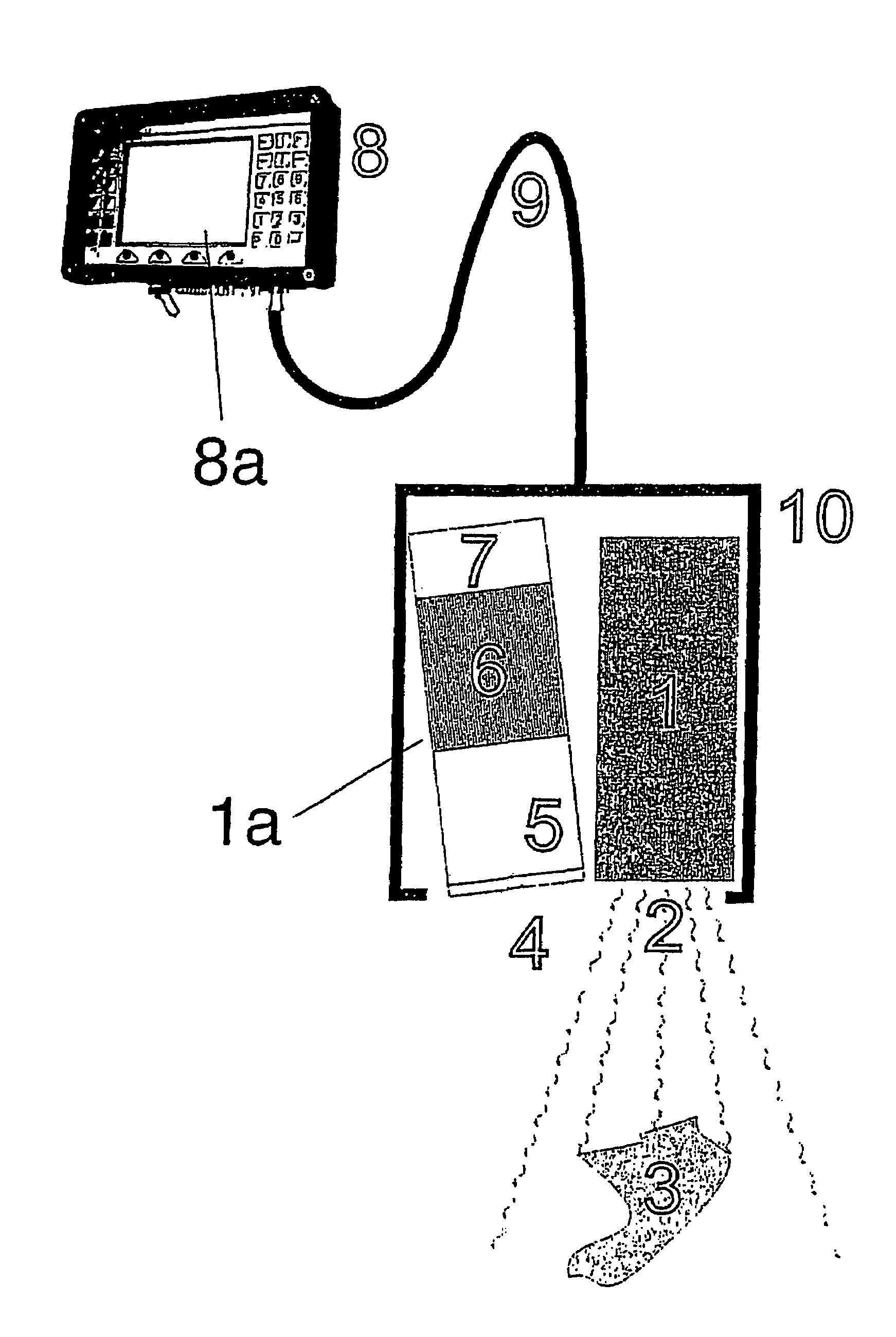

Robot sewing system for three-dimensional composite material perform

InactiveCN101205662AOvercome flexibilityOvercome errorProgramme-controlled manipulatorSewing apparatusImage post processingEngineering

The invention relates to a 3D composite material prefabrication piece robot sewing system, which comprises a robot, a single-face sewing machine, a structured light vision sensor and an image processing unit; the single-face sewing machine is connected with a shell of the structure light vision sensor and fixed at the tail end of an arm of the robot; the structured light vision sensor comprises a laser and a CCD video camera which are respectively fixed inside an shell of the structured light vision sensor, the included angle of a light axis centerline of the CCD video camera and a laser structure light surface of the laser is 30 to 60 degrees, which is perpendicular with the work-piece surface of a sewing material; the image processing unit comprises an image acquisition card, a PC machine and an image processing program library, the image processing program library comprises a sewing material type identification module, an image pre-processing module, an image post-processing module and a control capacity output module; the CCD video camera is connected with the image acquisition card through an video data line, the image acquisition card is arranged inside a main board slot of the PC machine, the PC machine is connected with the robot through a serial port.

Owner:TIANJIN POLYTECHNIC UNIV

Apparatus and a method for visualizing target objects in a fluid-carrying pipe

ActiveUS7675029B2Information obtainedSurveyX-ray spectral distribution measurementMaterial typeHigh energy

An apparatus for recording and displaying images of and identifying material types in a target object in a fluid carrying conduit includes a downhole unit. The downhole unit includes a controllable light source, the controllable light source structured to emit high energy photons. The downhole unit further includes a sensor unit structured to detect the high energy photons that are backscattered from the target object and to generate signals in response to the detected high energy photons. The apparatus also includes a control and display unit that includes a signal transmitter and a viewing screen structured to display at least one two-dimensional image that is generated using the signals from the sensor unit.

Owner:VISURAY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com