Patents

Literature

31 results about "Absorption contrast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

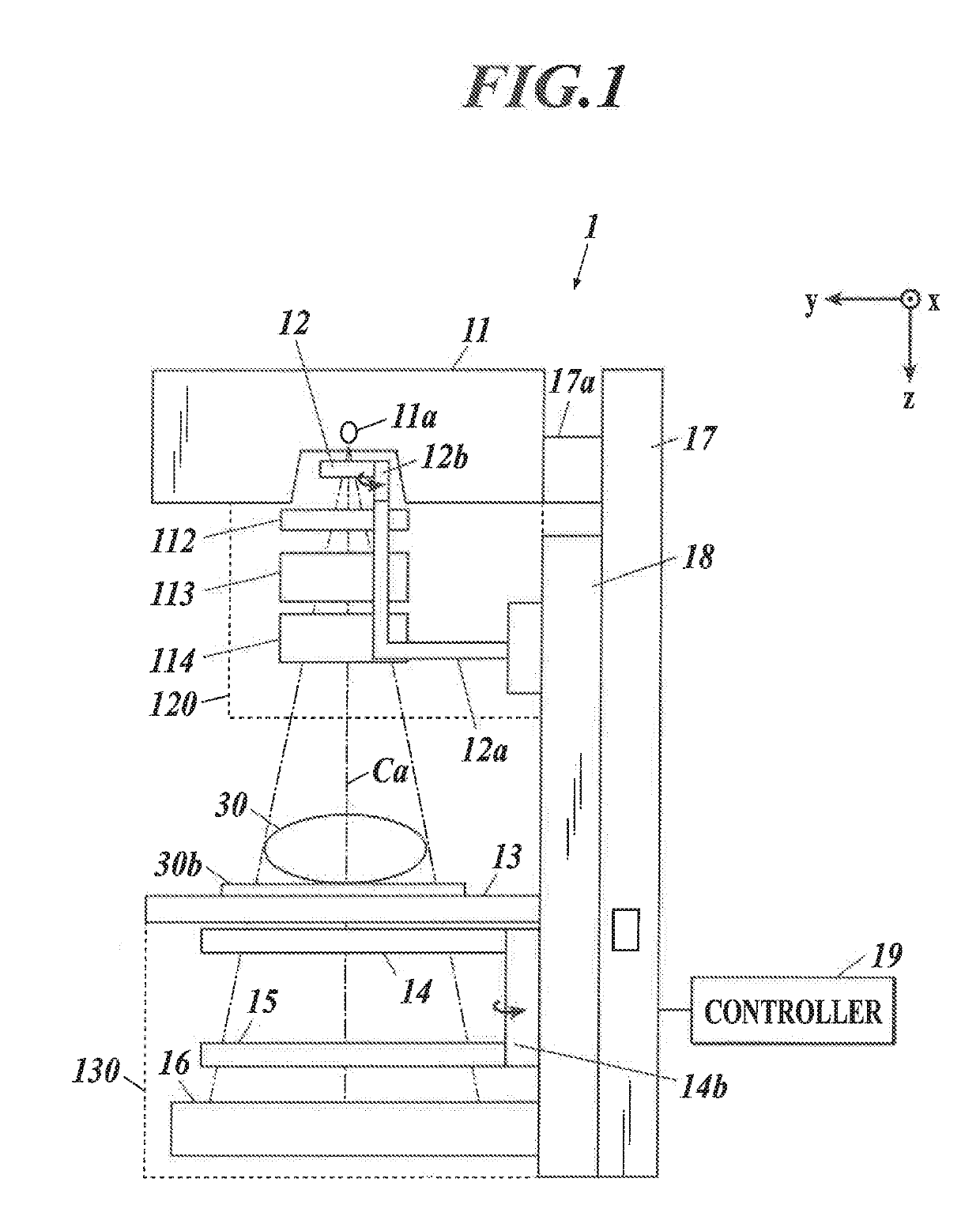

System and method for quantitative reconstruction of Zernike phase-contrast images

ActiveUS7787588B1Reduce artifactsMaterial analysis using wave/particle radiationGamma-ray/x-ray microscopesContrast transfer functionFull field

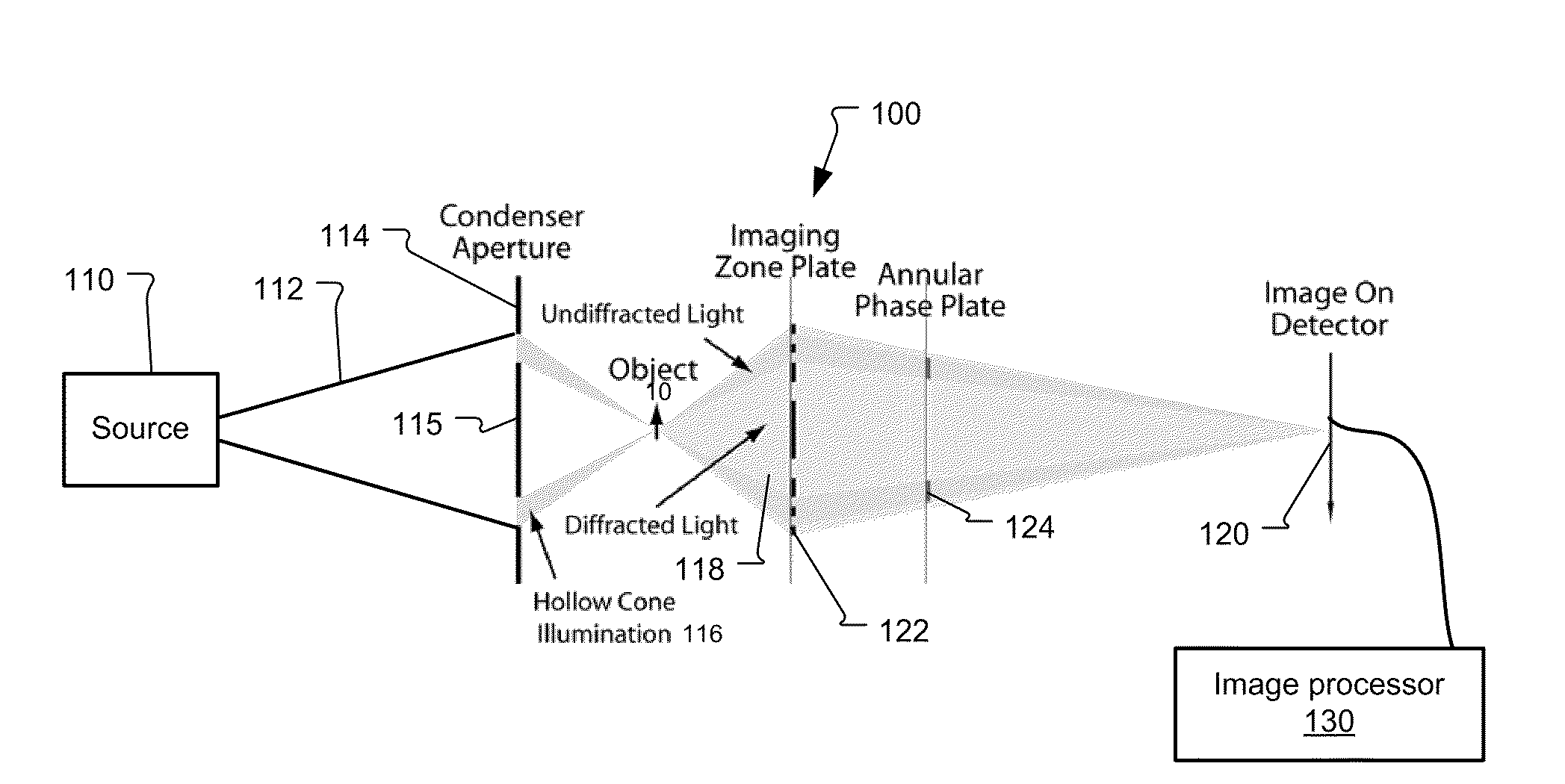

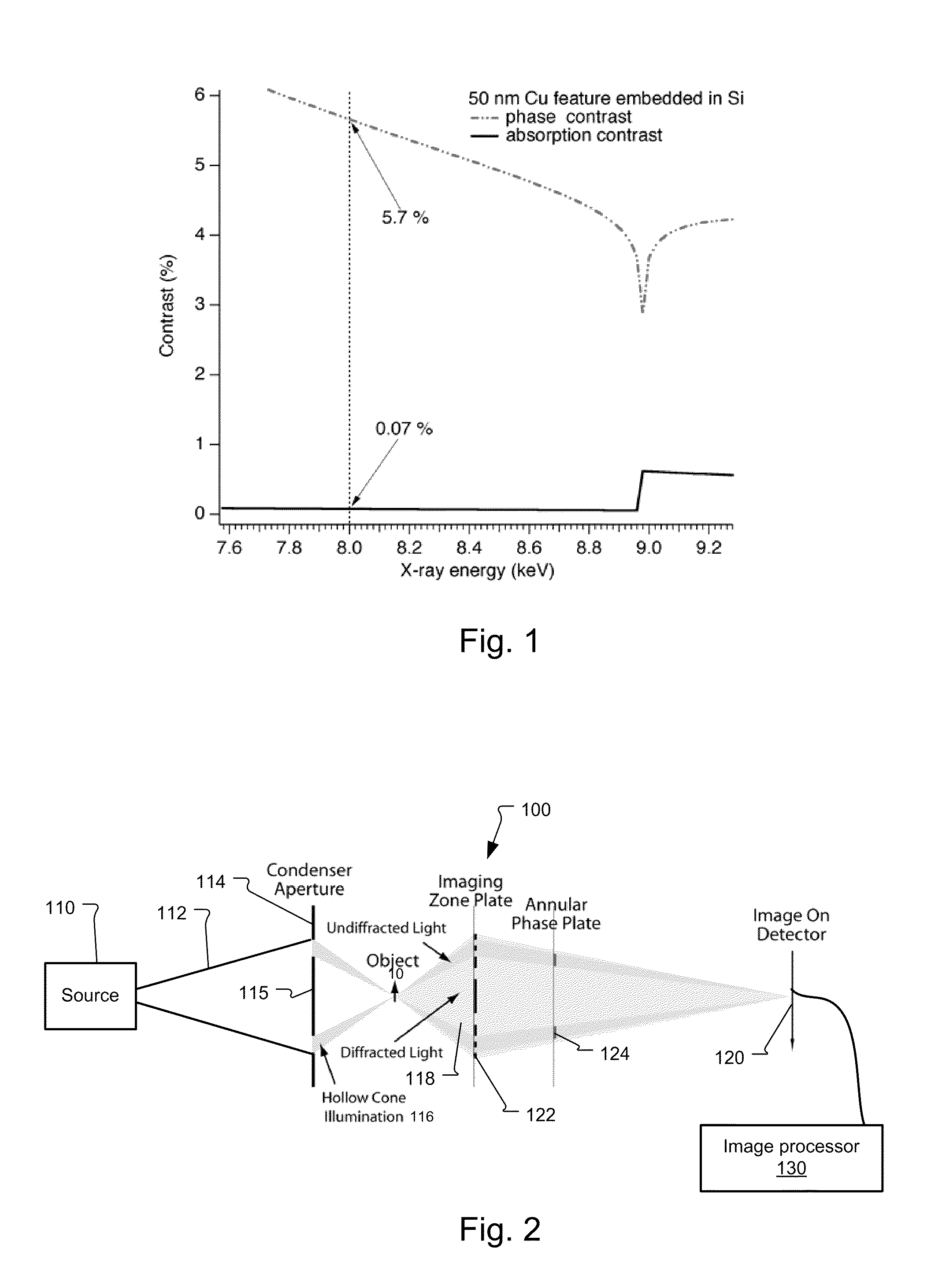

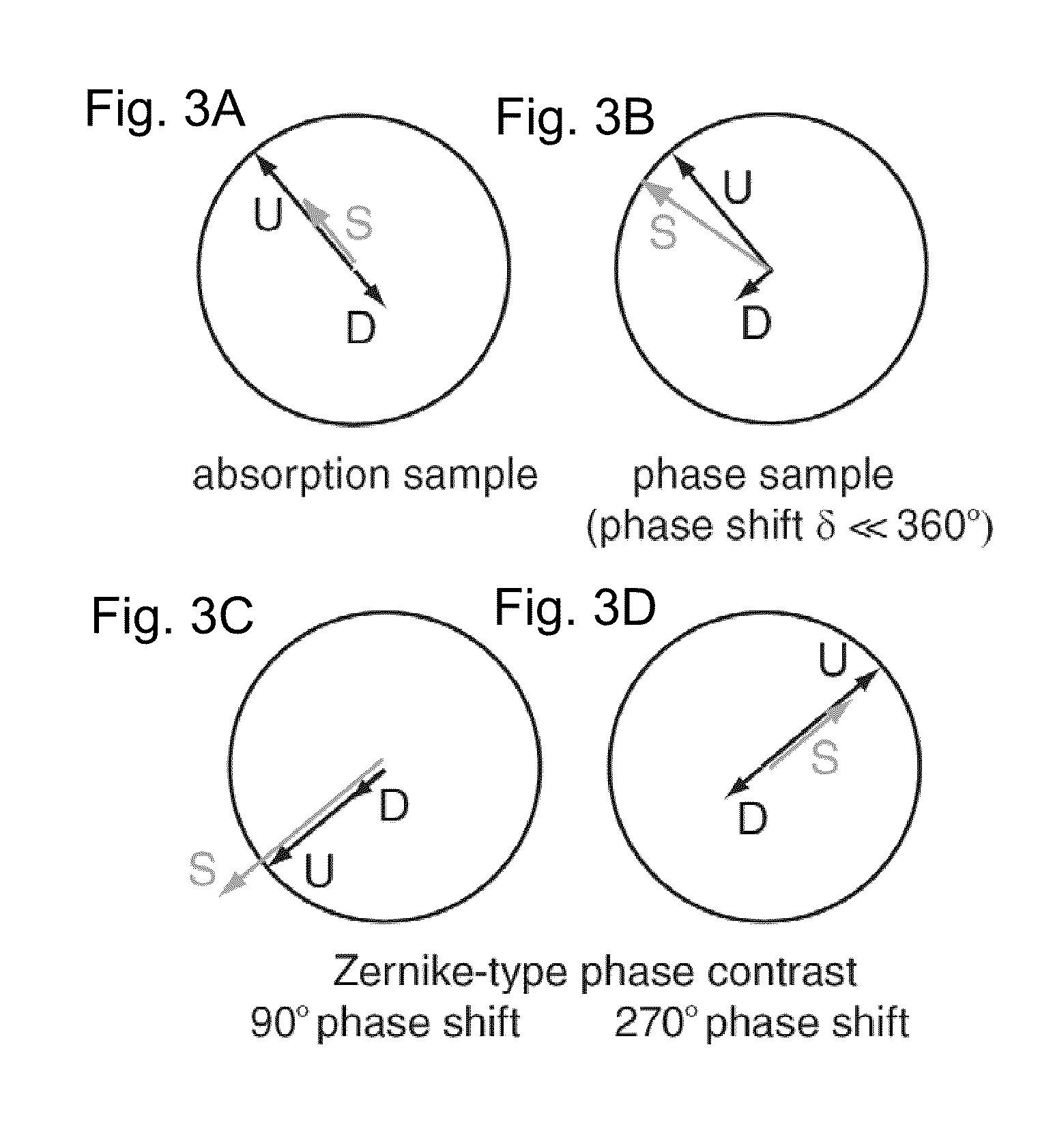

The principle of reciprocity states that full-field and scanning microscopes can produce equivalent images by interchanging the roles of condenser and detector. Thus, the contrast transfer function inversion previously used for images from scanning systems can be applied to Zernike phase contrast images. In more detail, a full-field x-ray imaging system for quantitatively reconstructing the phase shift through a specimen comprises a source that generates x-ray radiation, a condenser x-ray lens for projecting the x-ray radiation onto the specimen, an objective x-ray lens for imaging the x-ray radiation transmitted through the specimen, a phase-shifting device to shift the phase of portions of x-ray radiation by a determined amount, and an x-ray detector that detects the x-ray radiation transmitted through the specimen to generate a detected image. An image processor then determines a Fourier filtering function and reconstructs the quantitative phase shift through the specimen by application of the Fourier filtering function to the detected image. As a result, artifacts due to absorption contrast can be removed from the detecting image. This corrected image can then be used in generating three dimensional (3D) images using computed tomography.

Owner:CARL ZEISS X RAY MICROSCOPY

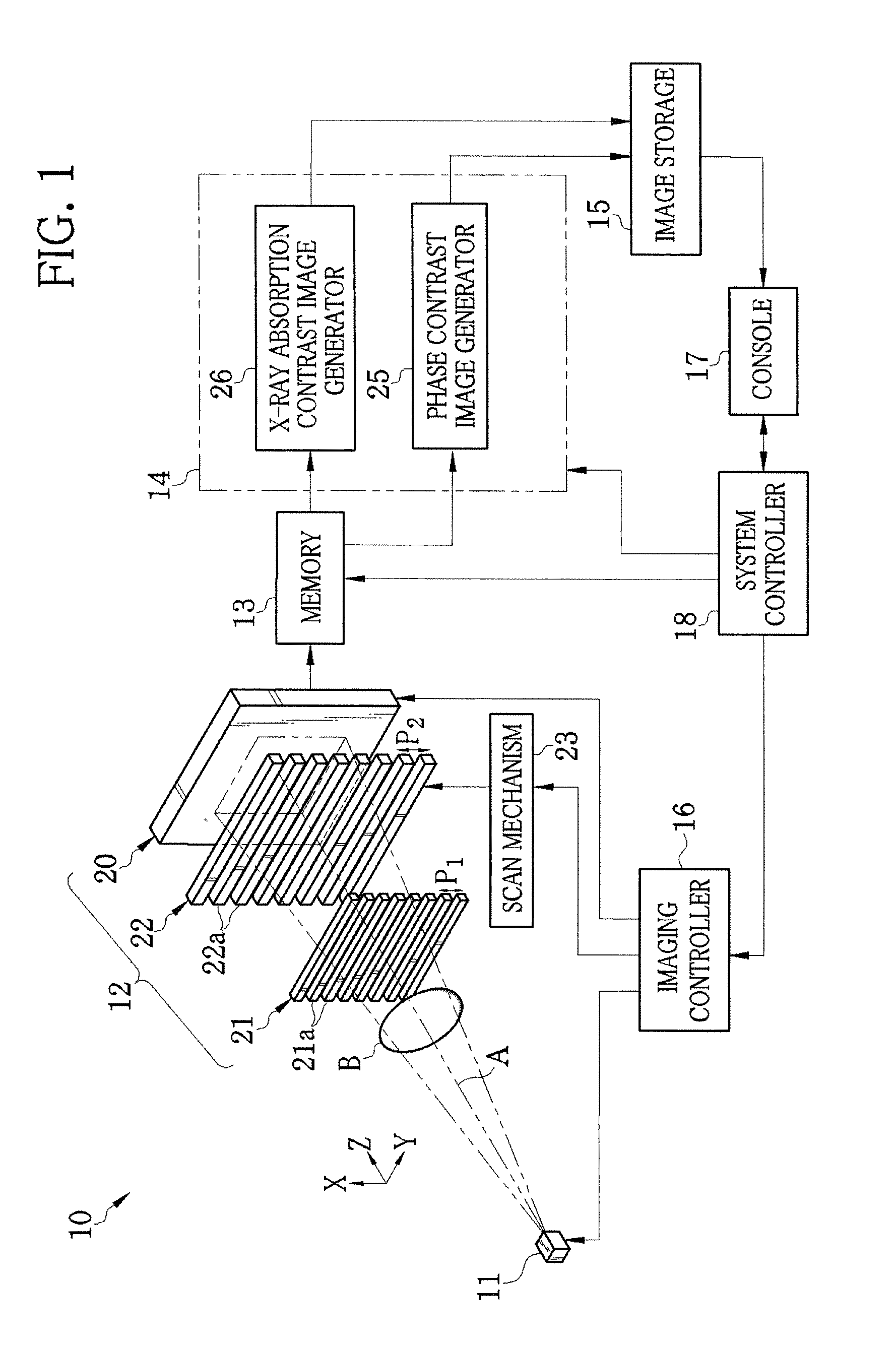

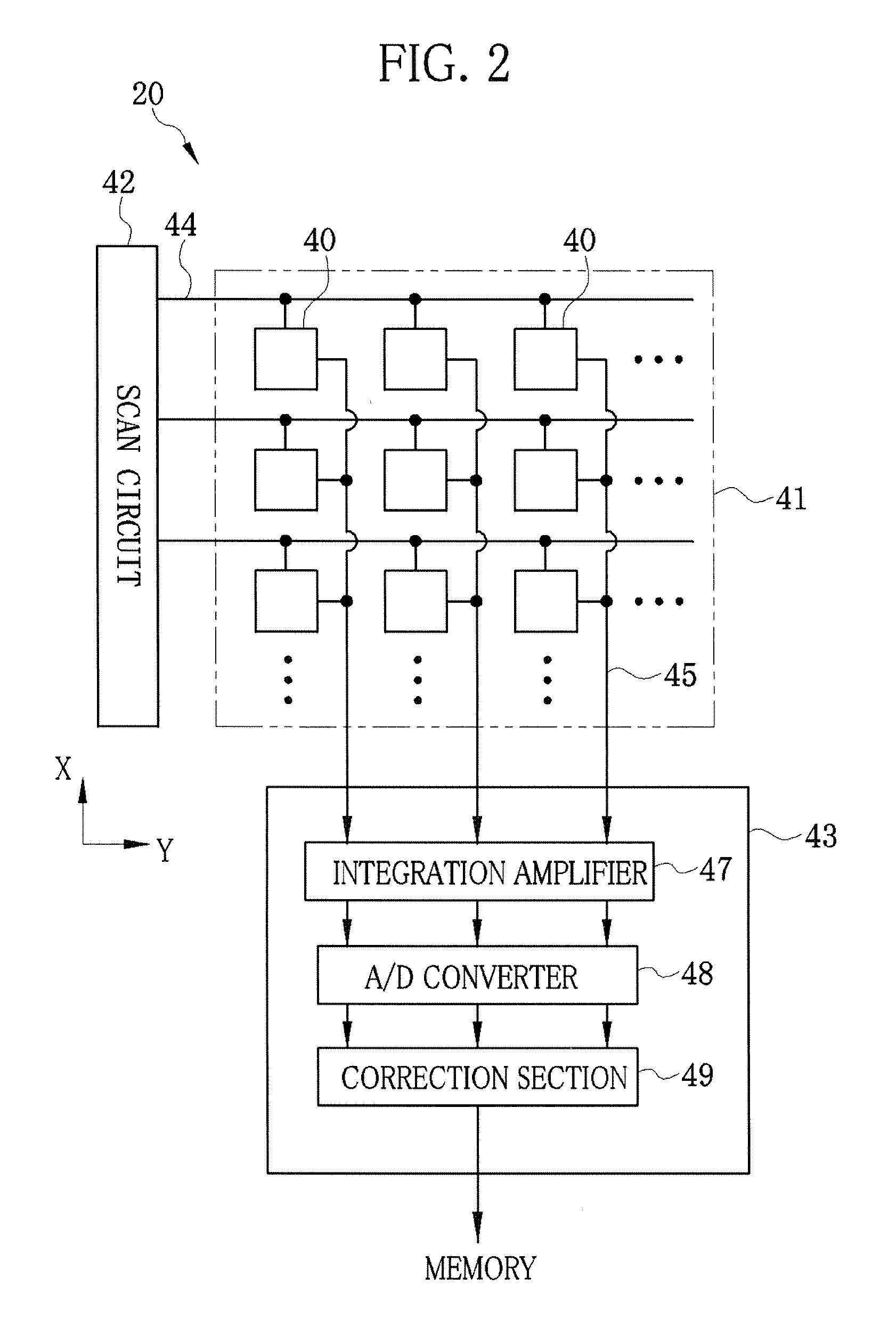

Radiation imaging system and method

InactiveUS20110243302A1Eliminate the effects ofEnhance the imageImaging devicesRadiation/particle handlingGratingAbsorption contrast

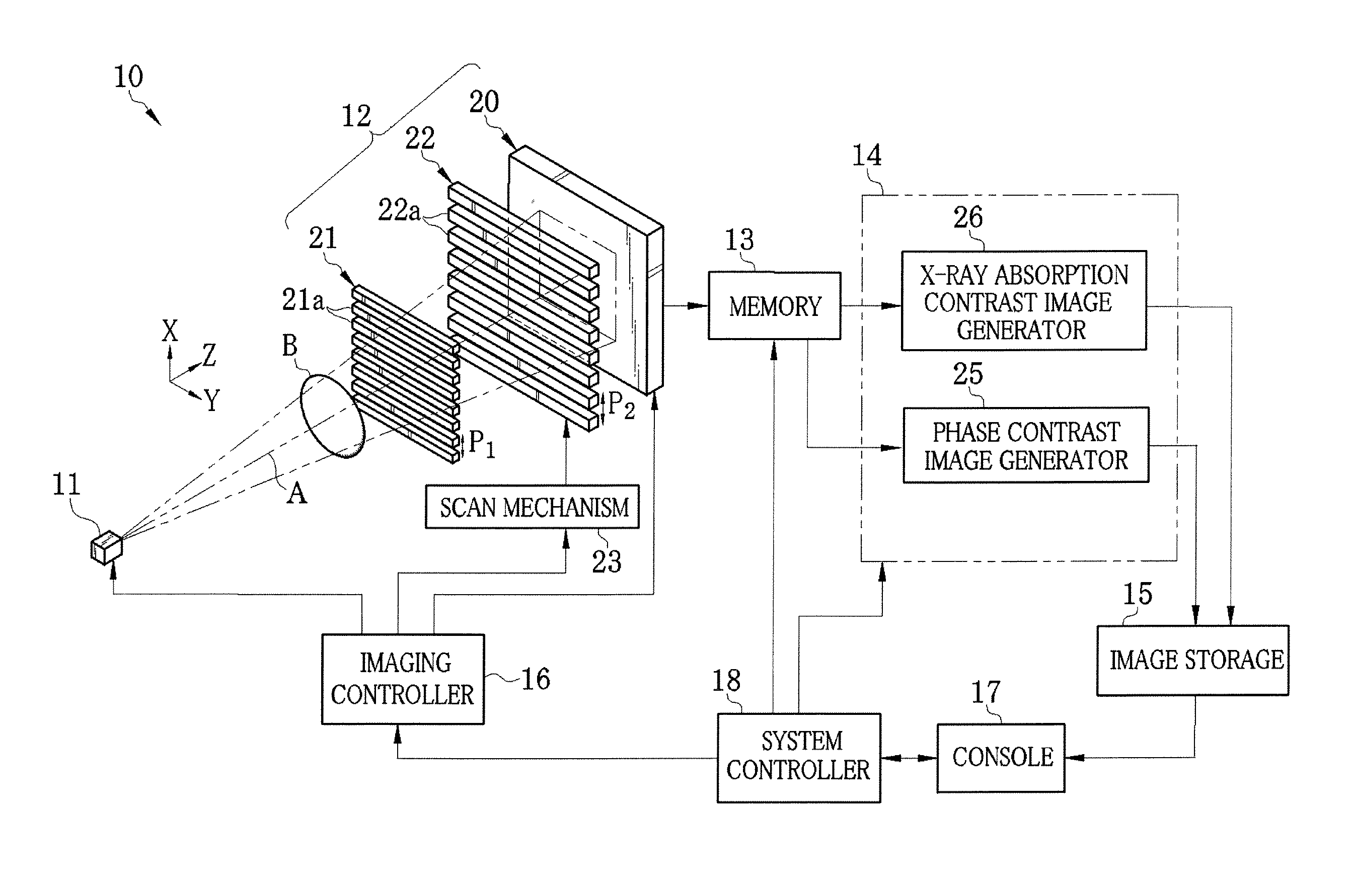

A radiation imaging system includes an X-ray source, first and second absorption gratins disposed in a path of X-rays emitted from the X-ray source, and an FPD. The second absorption grating is stepwise slid in an X direction relatively against the first absorption grating. Whenever the second absorption grating is slid, the FPD captures a fringe image and produces image data. A correction section corrects the image data for spatial variation of X-ray transmittance of the first and second absorption gratings. A phase contrast image generator produces a phase contrast image from the corrected image data. An X-ray absorption contrast image generator calculates a value related to an average of the corrected image data on a pixel-by-pixel basis, and produces an X-ray absorption contrast image from the value.

Owner:FUJIFILM CORP

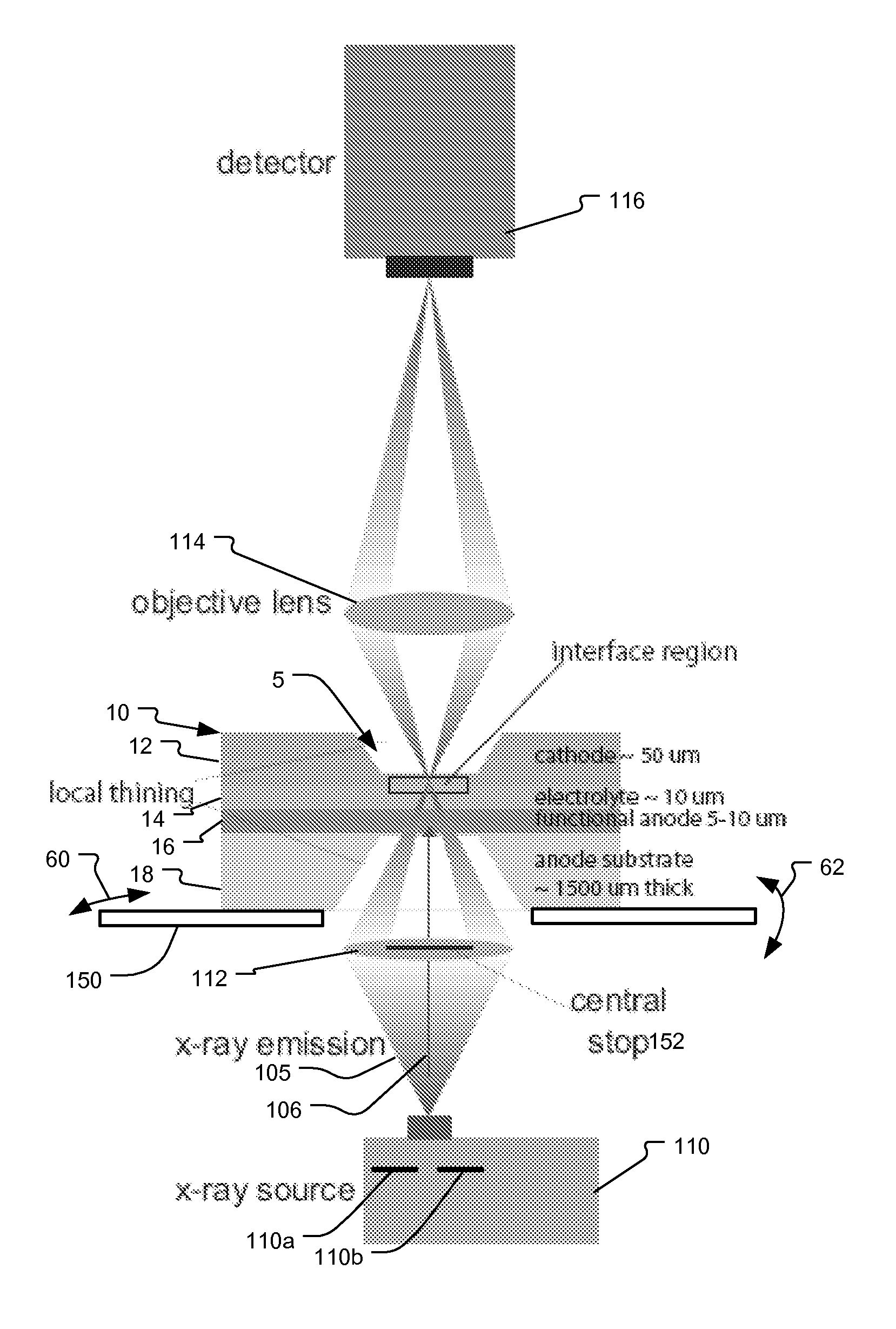

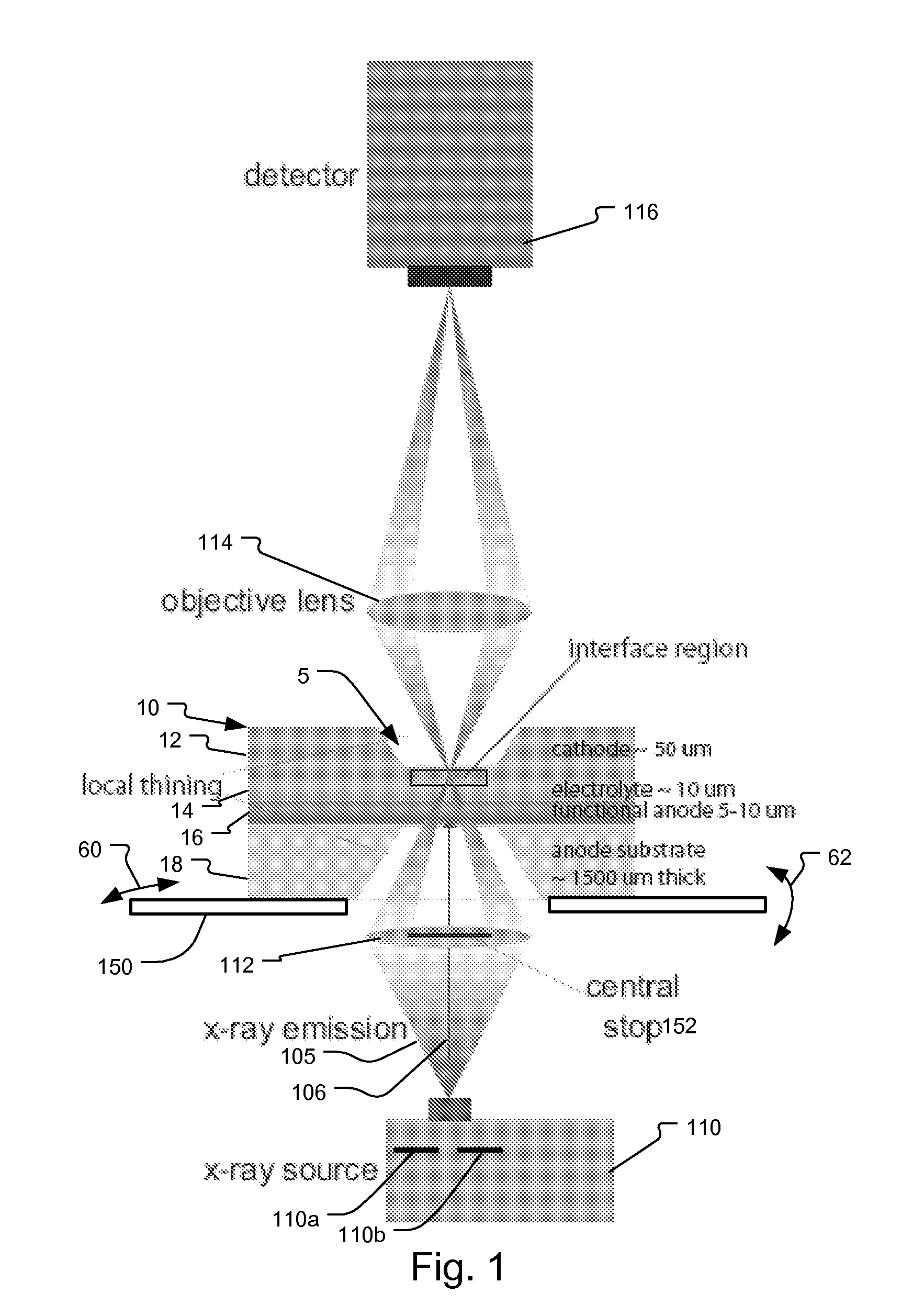

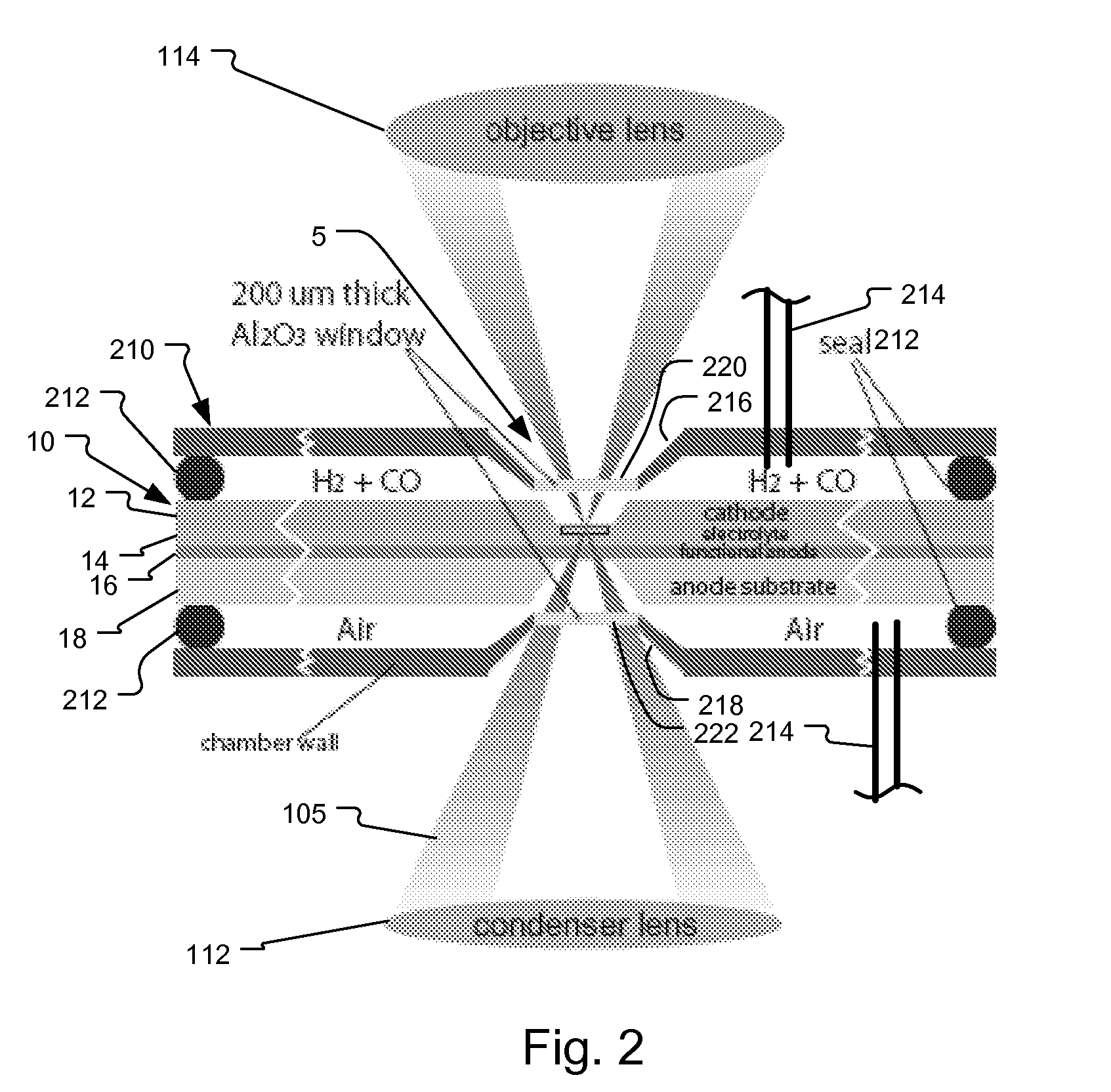

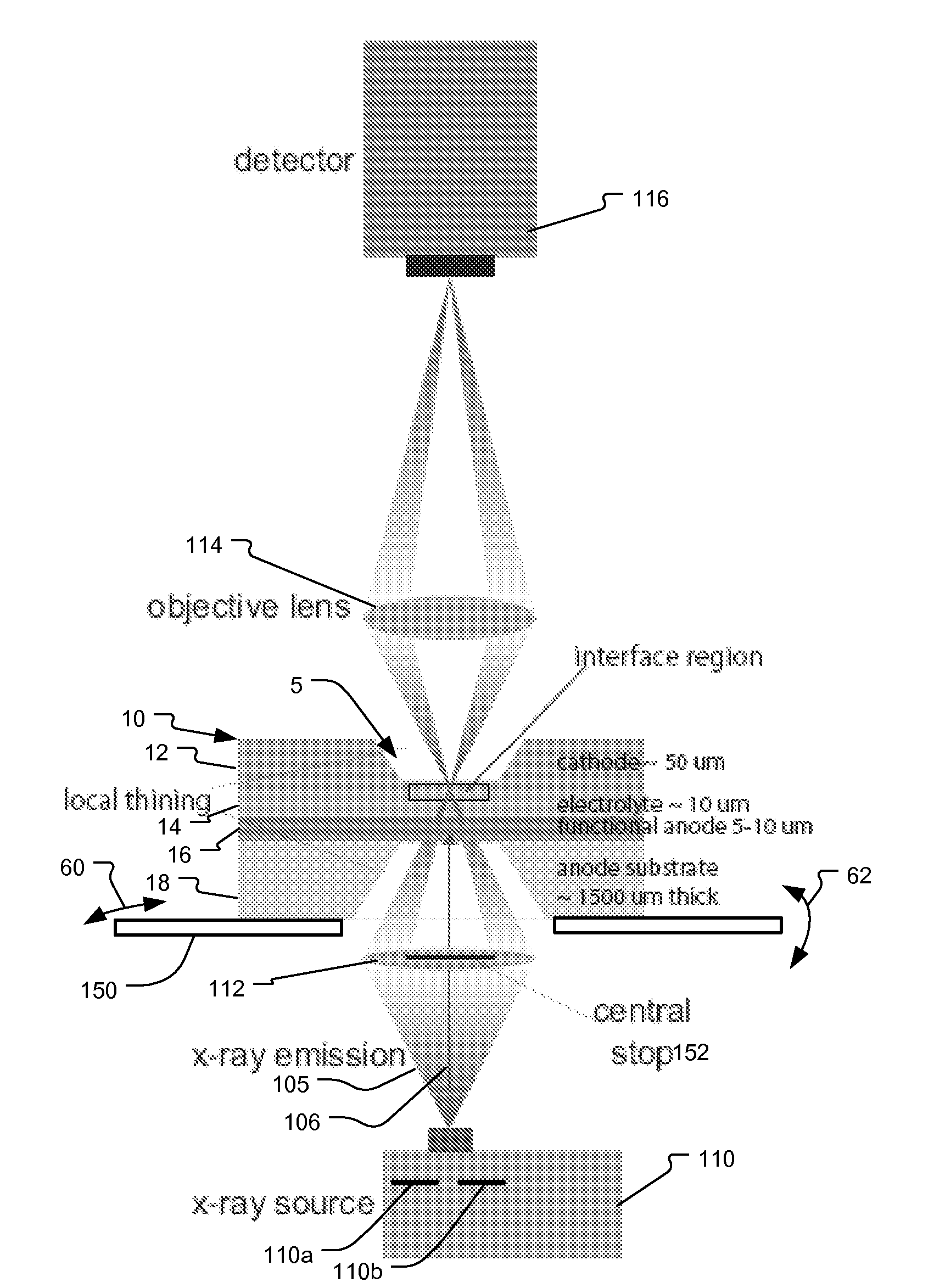

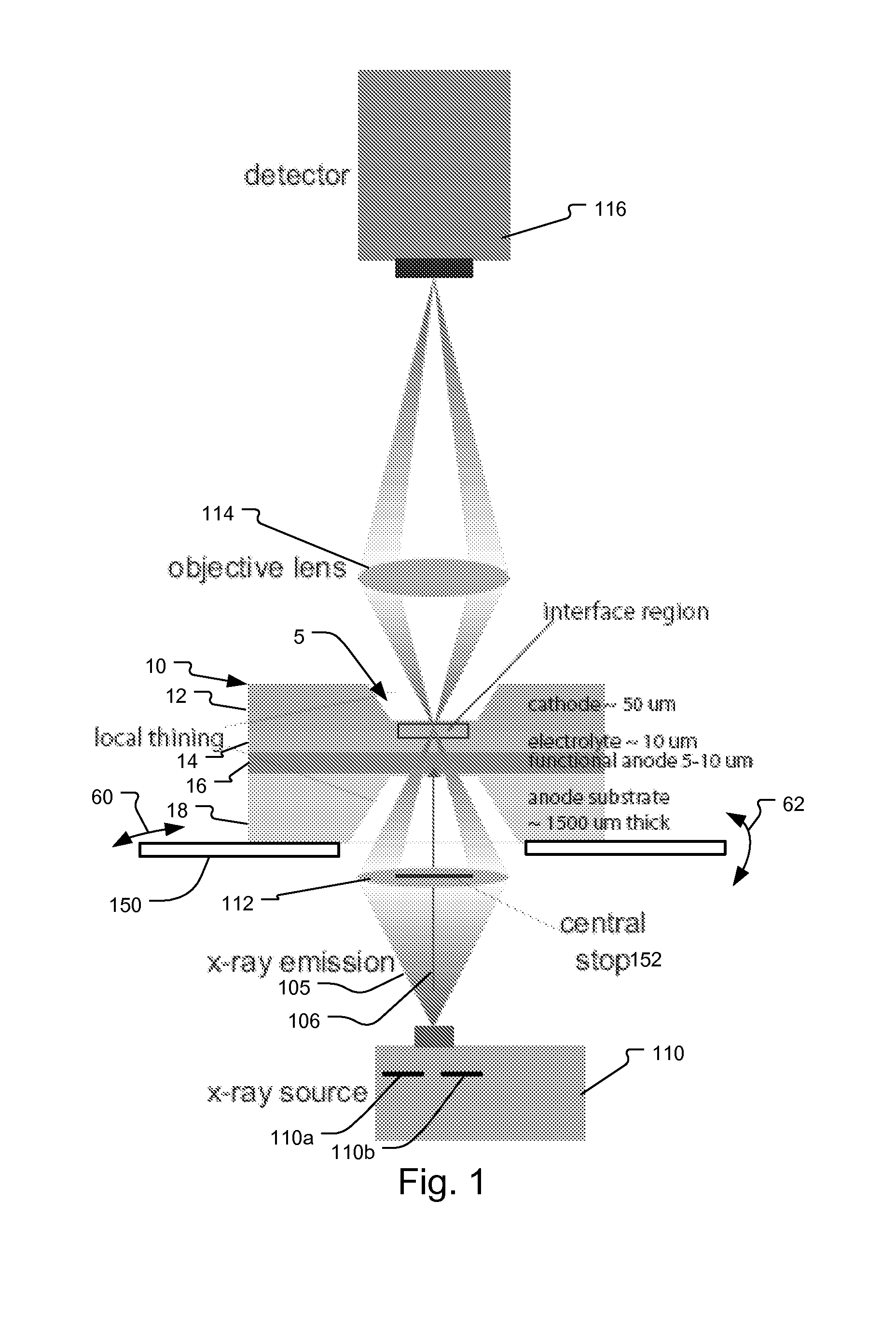

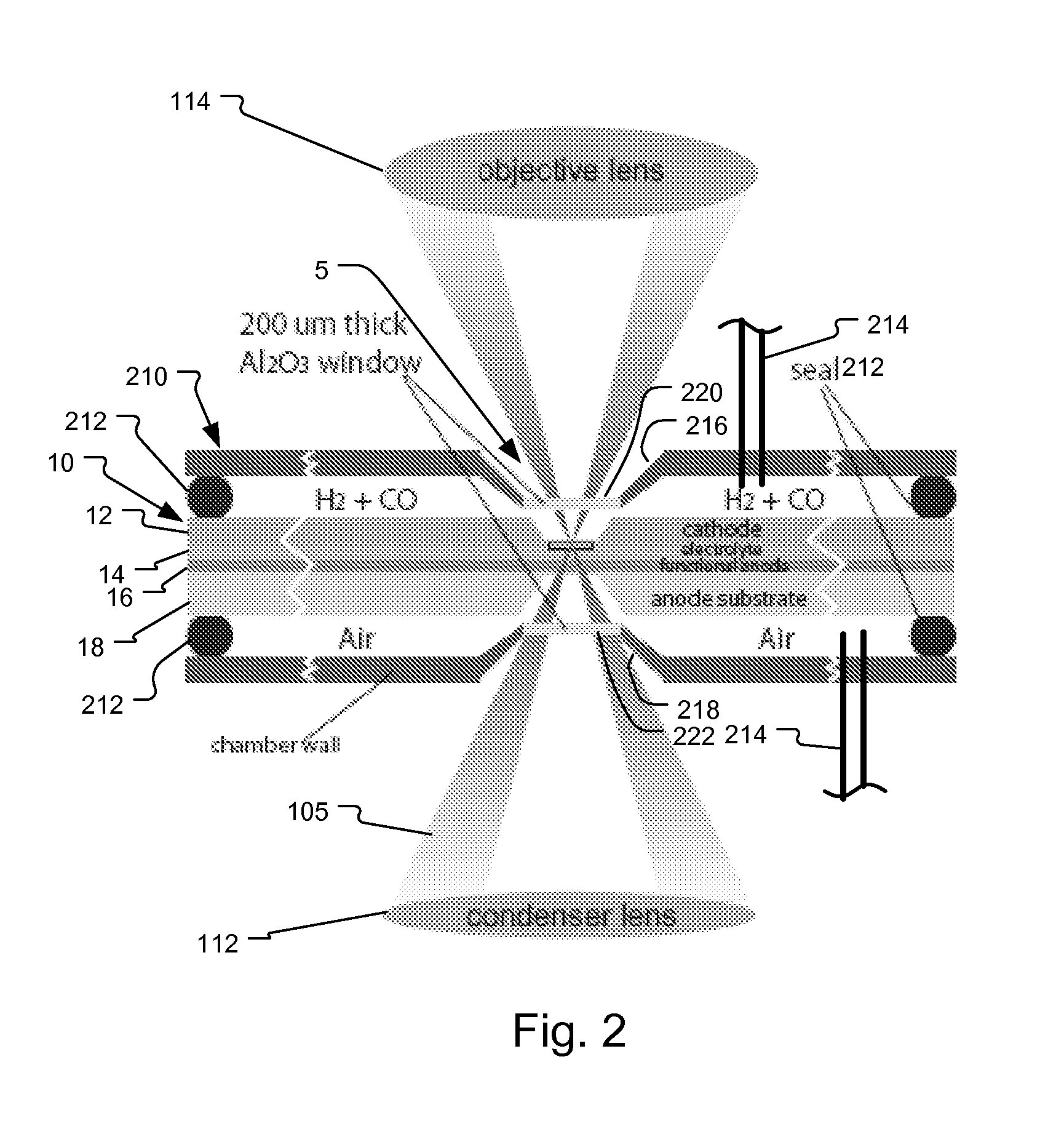

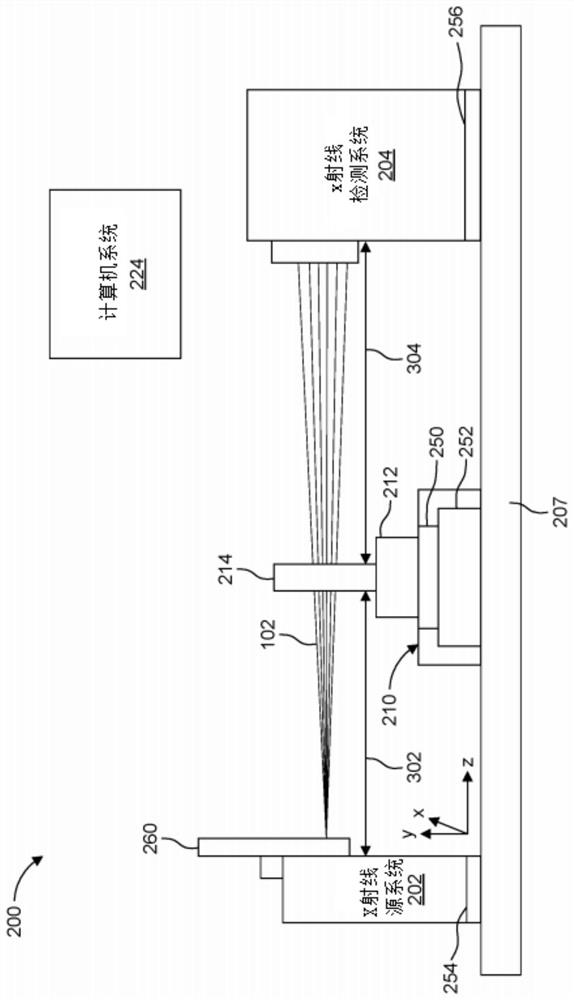

System and method for fuel cell material x-ray analysis

ActiveUS7499521B2Shorten development timeImprove reliabilityRadiation/particle handlingUsing wave/particle radiation meansHard X-raysMetrology

An imaging technology for fuel cells is based on x-ray microscopy. A metrology system images the electro-chemical interaction areas of solid-oxide fuel cells (SOFC) in-situ. This system takes advantage of both the penetrating power and elemental absorption contrast of hard x-ray radiation to image the internal interaction areas in a SOFC. The technology can further take advantage of the strong dependence of the x-ray absorption on material type and energy to distinguish the four major material types: cathode, electrolyte, air, and low-Z contaminants such as sulfur.

Owner:CARL ZEISS X RAY MICROSCOPY

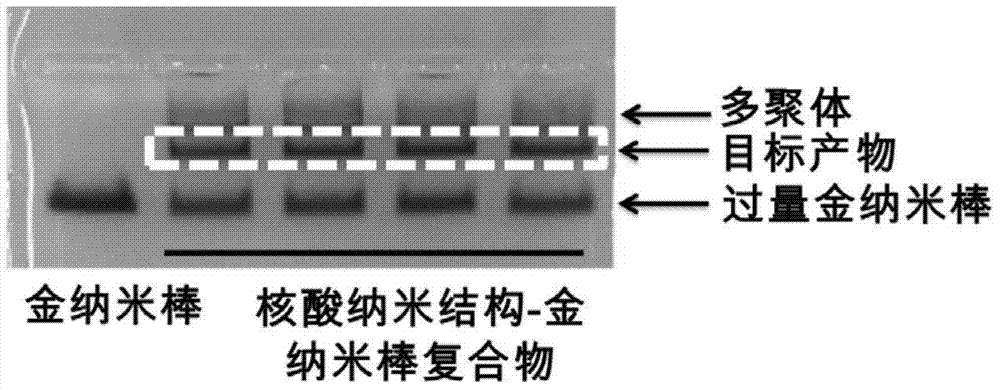

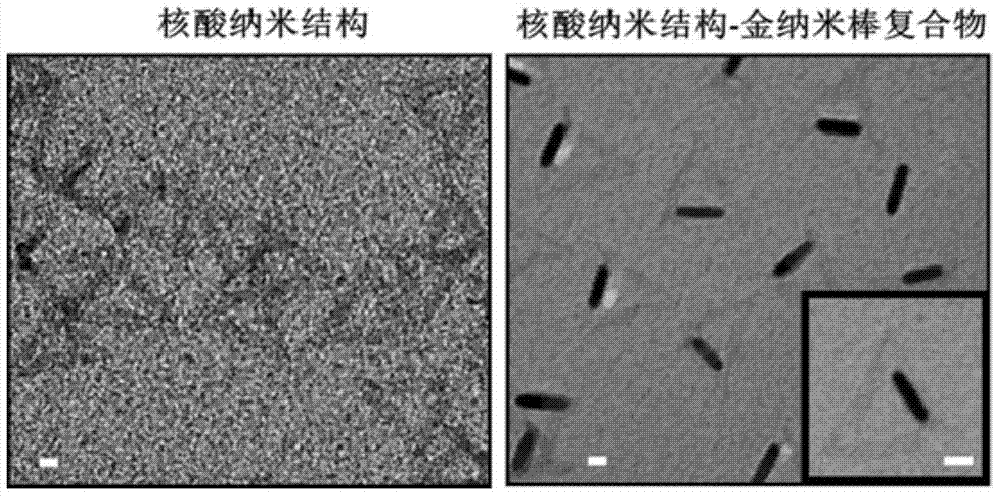

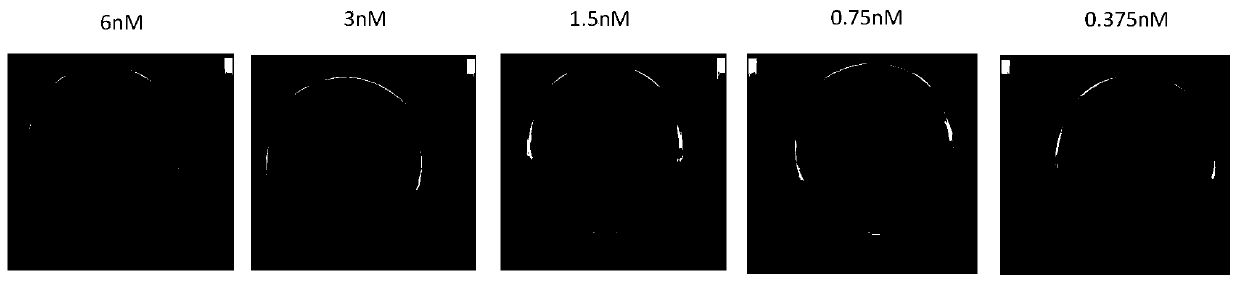

Nucleic acid nano structure carrier-precious metal photosensitive contrast agent composite for living organism photo-acoustic imaging, preparation method and applications thereof

InactiveCN104324375ARealize the combinationHigh Photoacoustic Imaging CapabilityEnergy modified materialsInorganic non-active ingredientsNano structuringWhole body

The invention discloses a nucleic acid nano structure carrier, a nucleic acid nano structure carrier-precious metal photosensitive contrast agent composite comprising the same, and preparation methods and applications of the carrier and the composite. The nucleic acid nano structure is a random two-dimensional and / or three-dimensional nano structure constructed by a DNA paper-folding technology. The precious metal components are used to carry out DNA modification on the surface of the carrier and selected from one or more of gold nano rods, gold nano shells, silver-coated gold nano rods, and gold nano cages. The provided composite is used as a photo-acoustic imaging probe, is capable of guaranteeing the absorption contrast enhancing effect of the photo-acoustic contrast agent which is coupled to the composite, and moreover can prominently improve the targeting performance of the contrast agent on tumors. Furthermore, the precious metal photosensitive components which are coupled to the carrier are enriched in the inner of tumor tissues, and thus the solved is the problems that conventional contrast agent is distributed over the whole human body or the contrast agent can only stay on the tumor surfaces. The preparation method has the advantages of simple technology, low cost, convenience, and easy application.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA +1

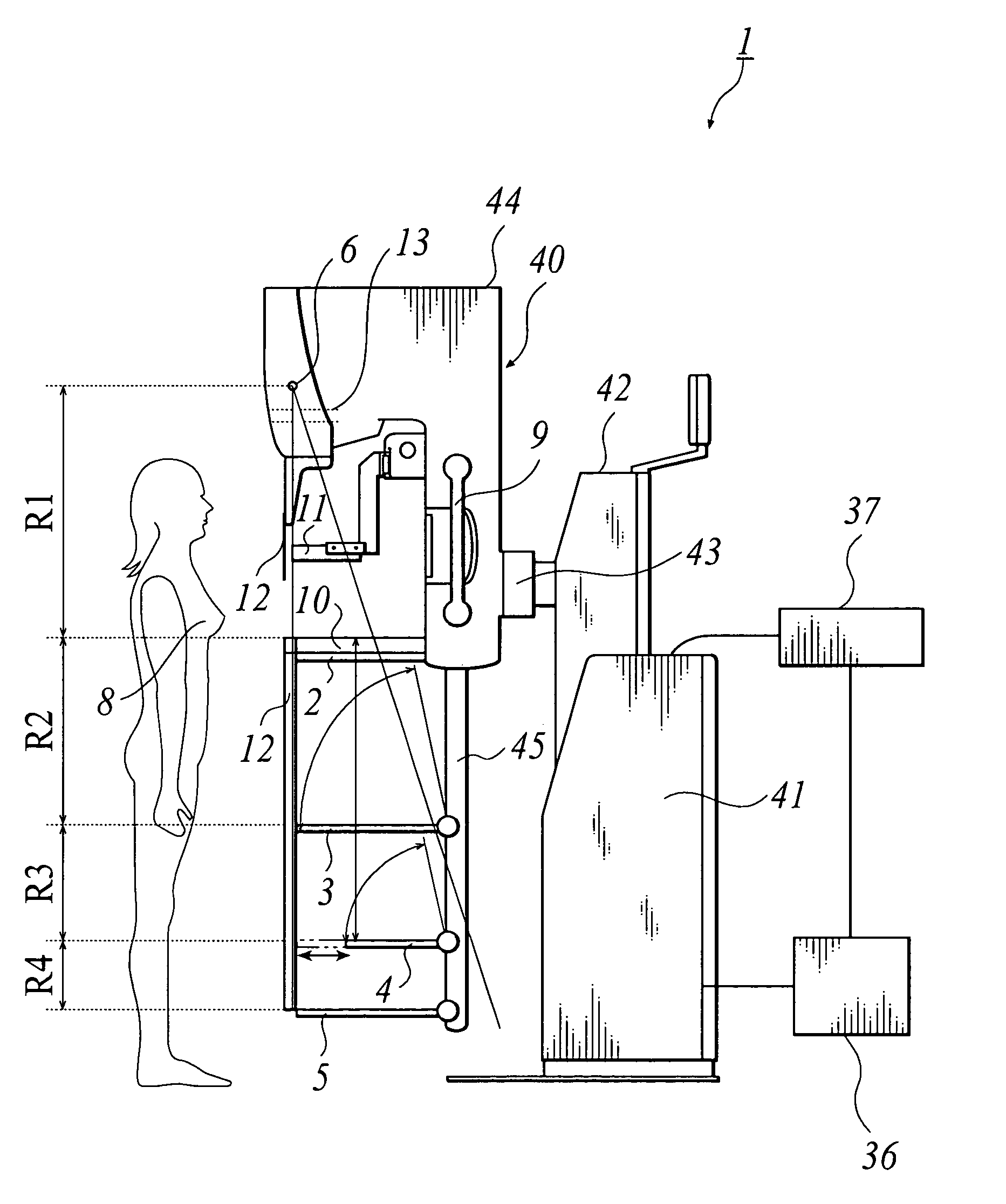

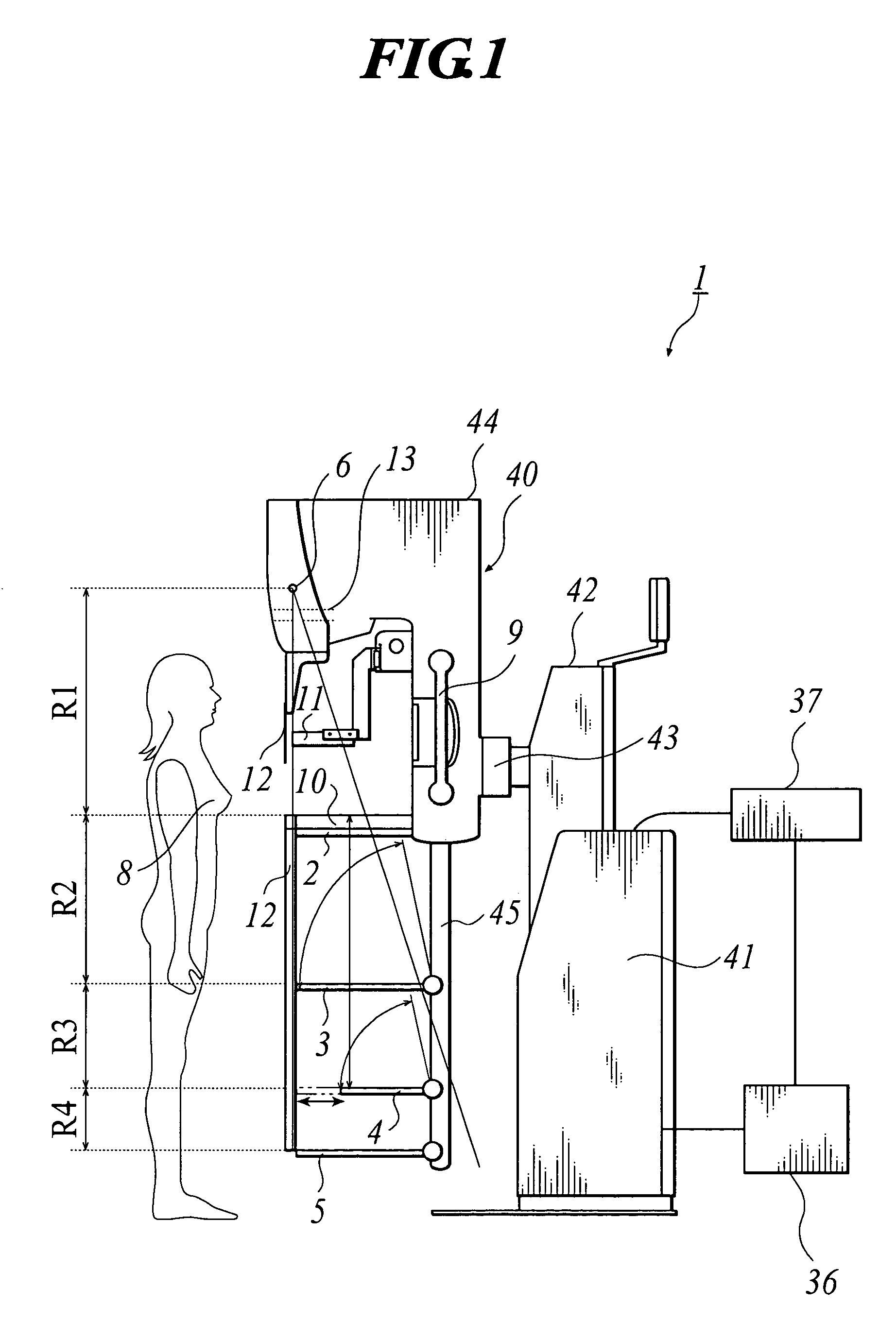

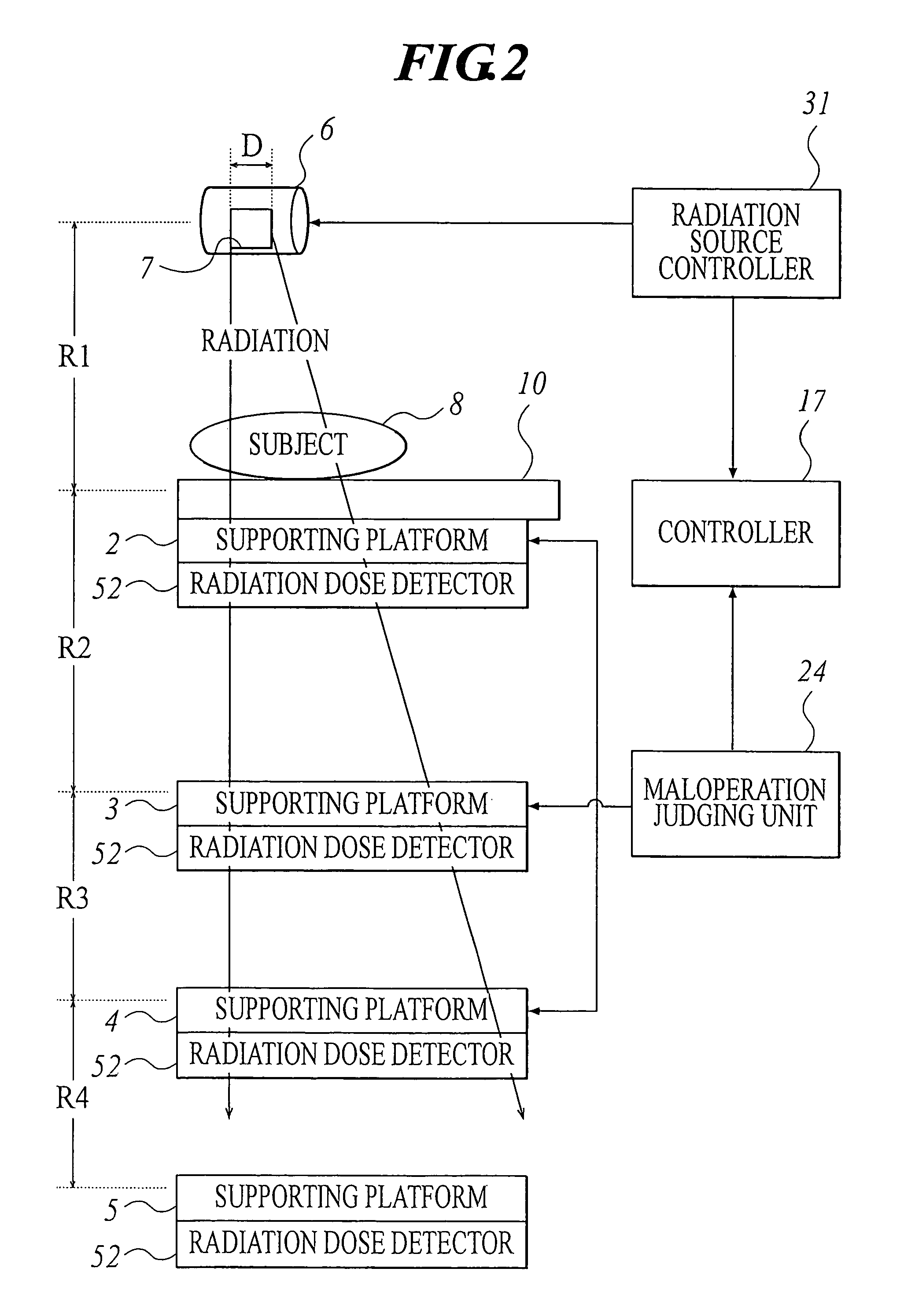

Radiation image radiographic apparatus

InactiveUS20040109530A1Easy to repeatEasy to switchVolume/mass flow measurementPatient positioning for diagnosticsAbsorption contrastSubject matter

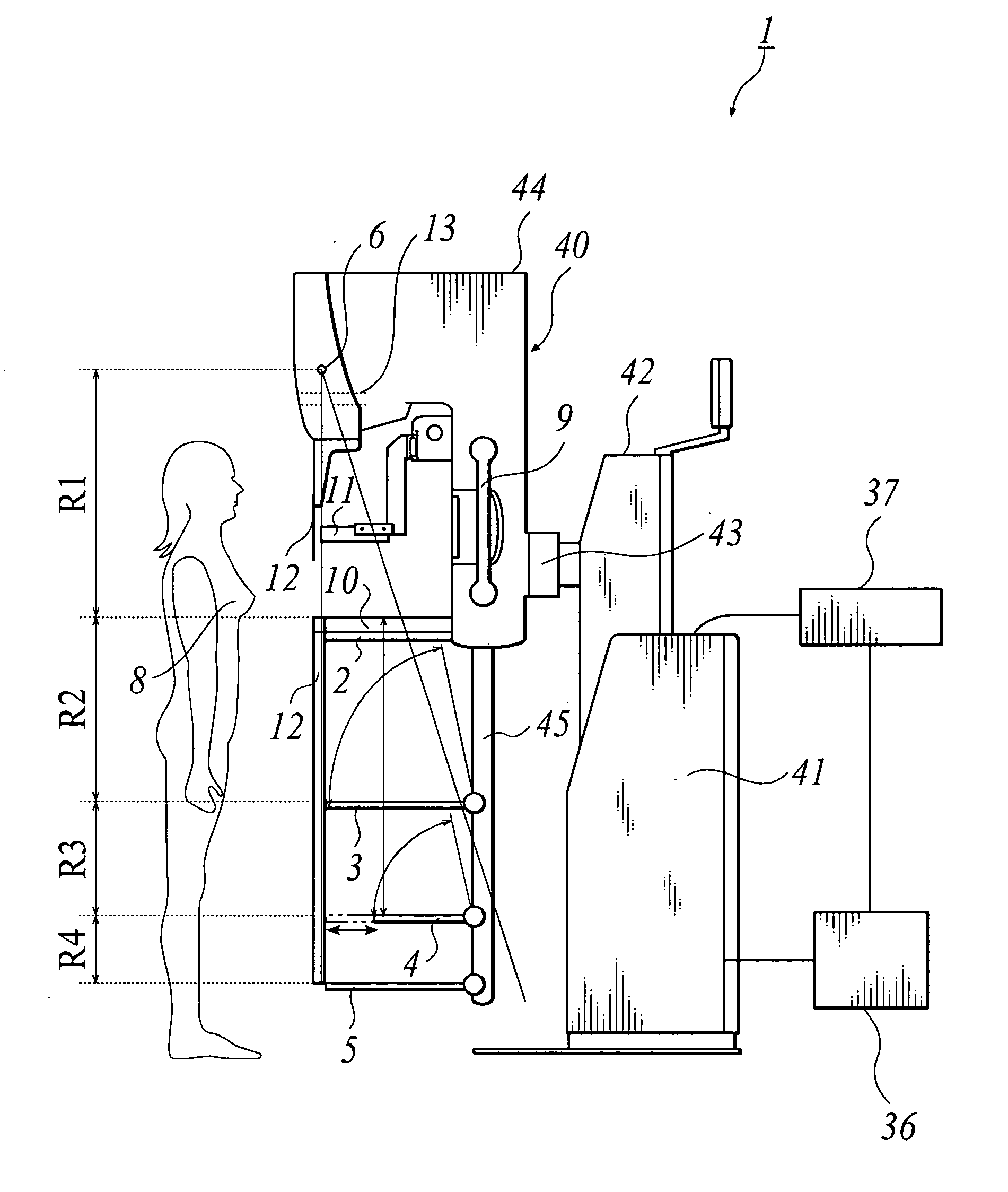

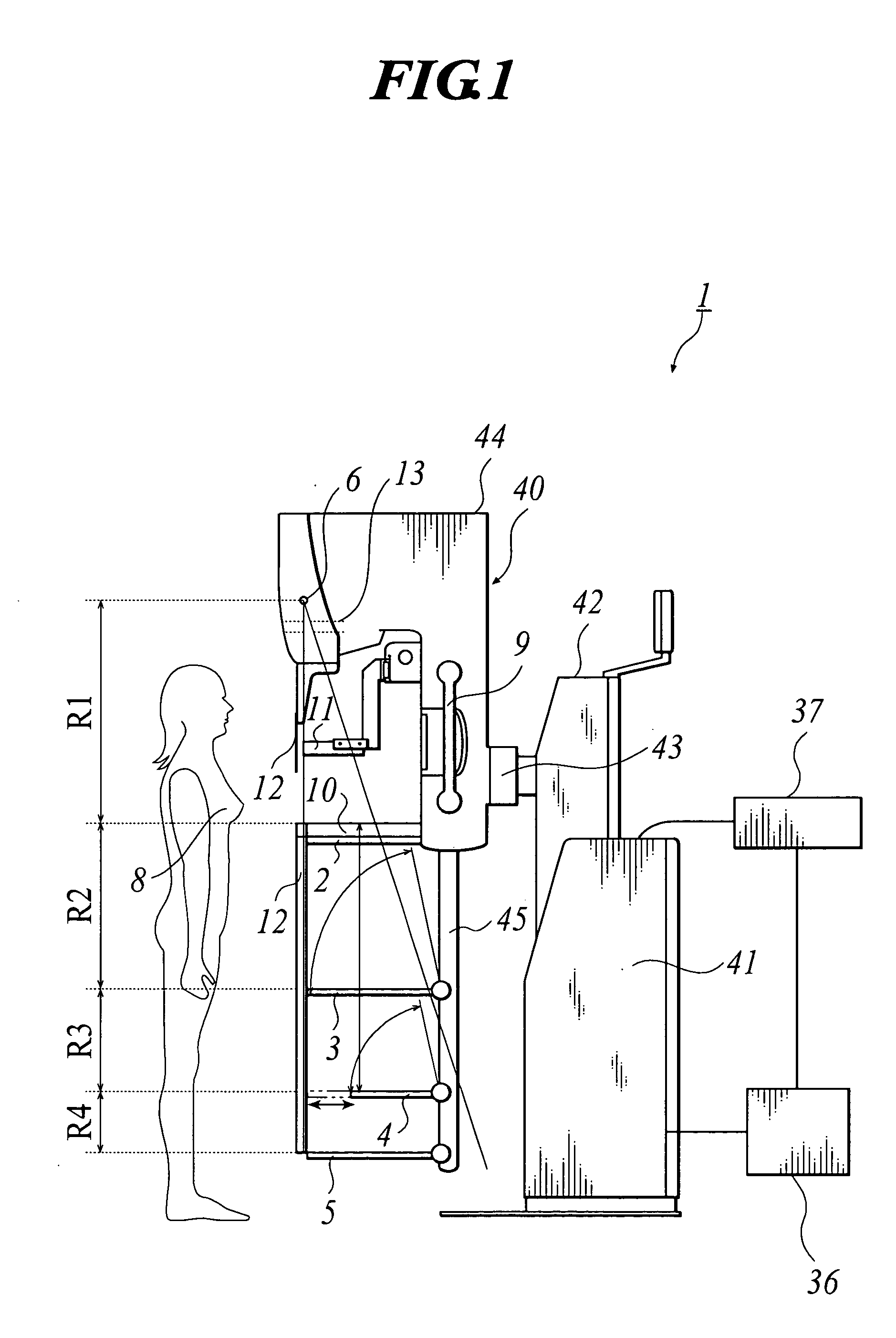

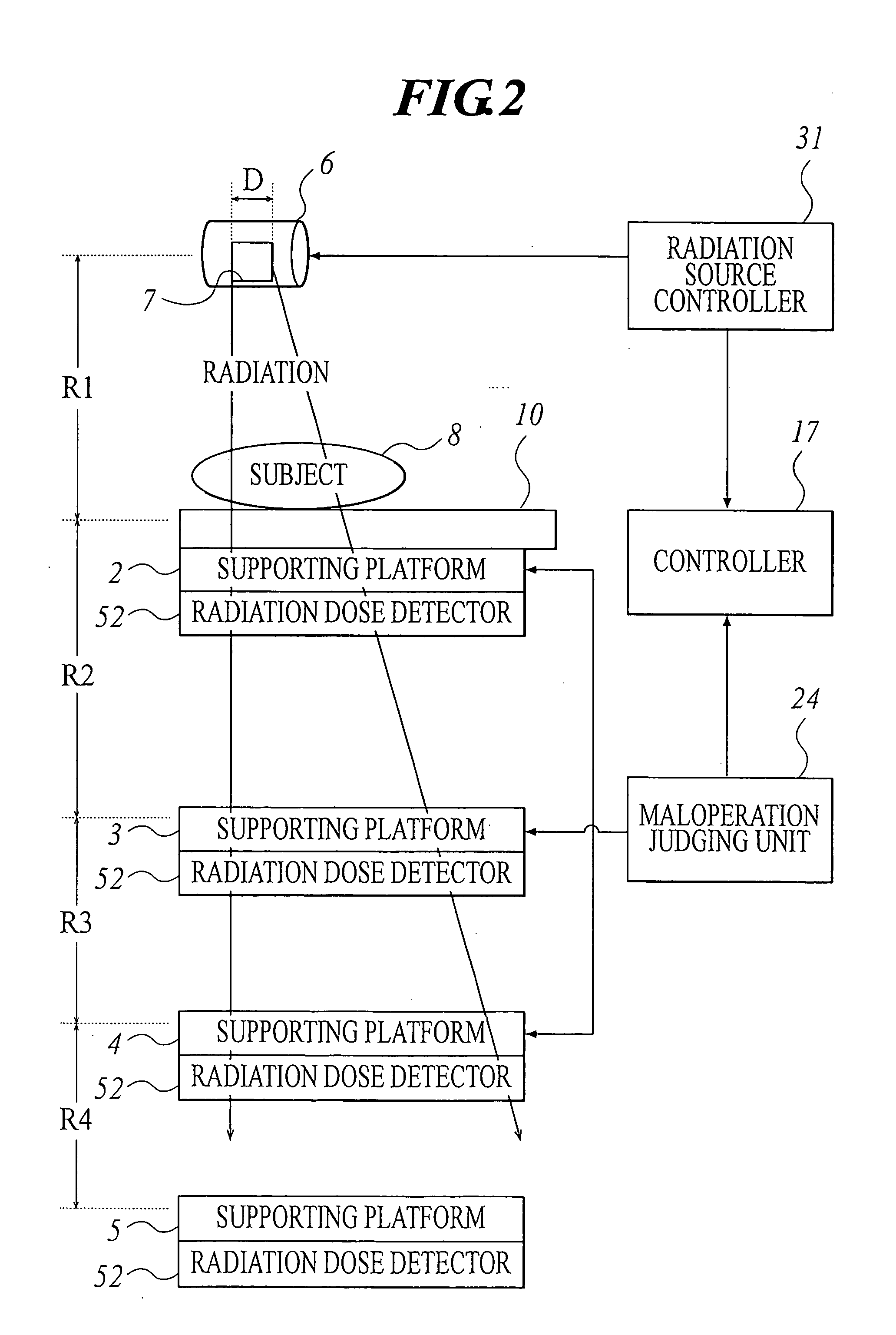

A user-friendly, inexpensive radiation image radiographing apparatus capable of easily switching between absorption contrast image radiography and phase contrast image radiography. The radiation image radiographing apparatus has: a radiation source; a subject platform for supporting a subject so as to face the subject to the radiation source; and a plurality of supporting platforms for supporting a radiation image information detecting member at a side opposite to the radiation source with respect to the subject platform, the radiation image information detecting member for detecting radiation image information based on radiation transmitted through the subject, wherein distances between the plurality of supporting platforms and the radiation source are different from each other.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

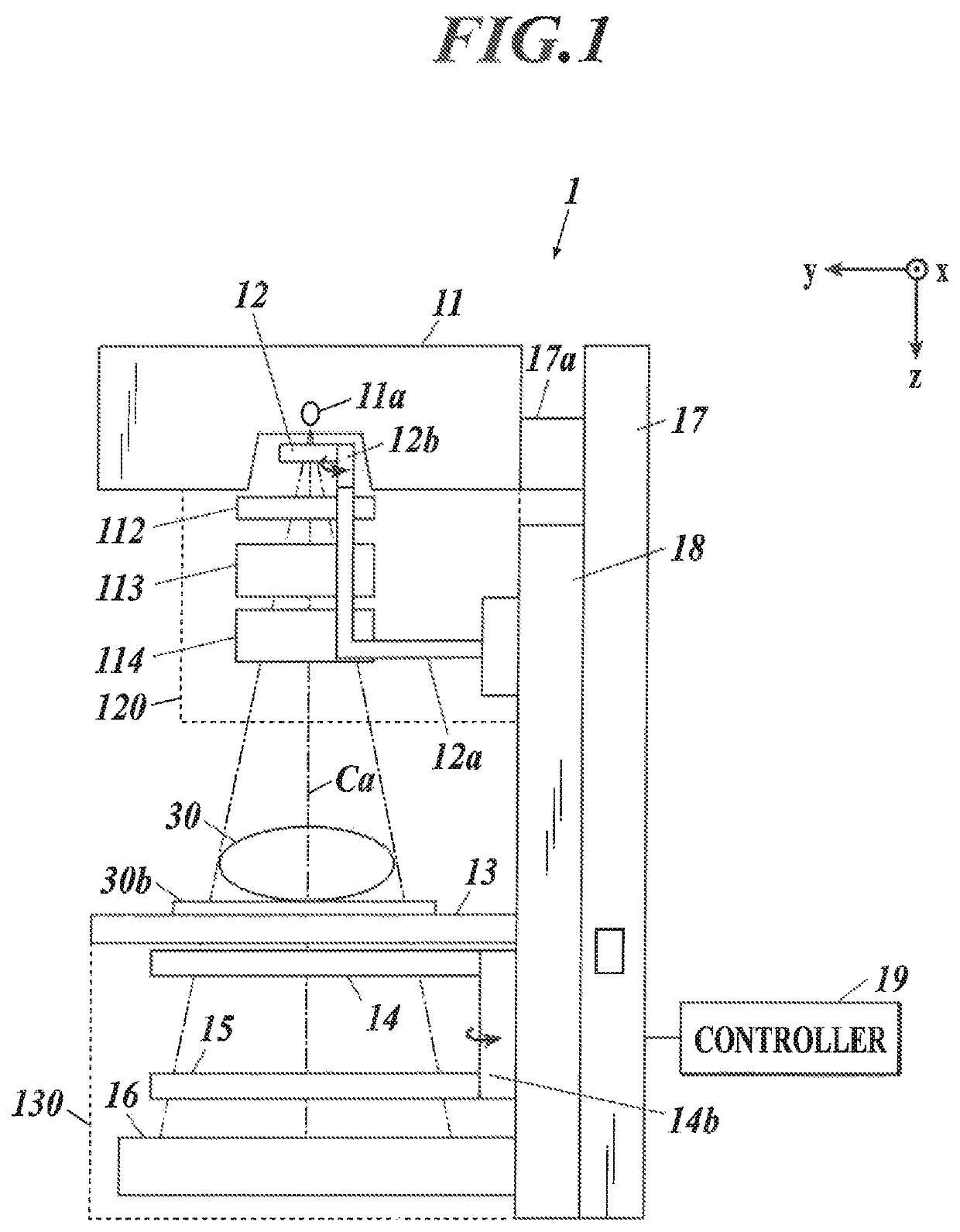

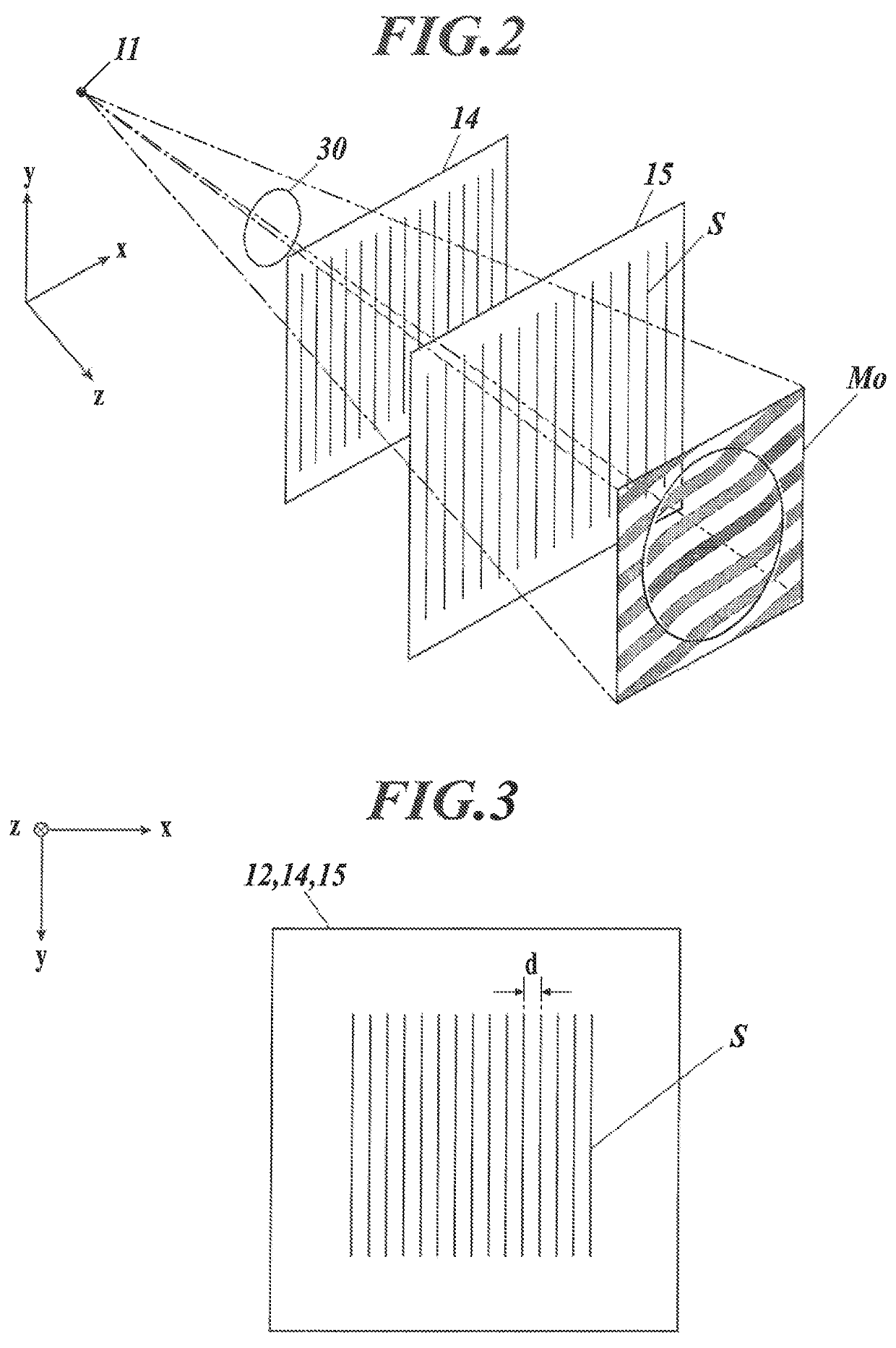

X-ray imaging system

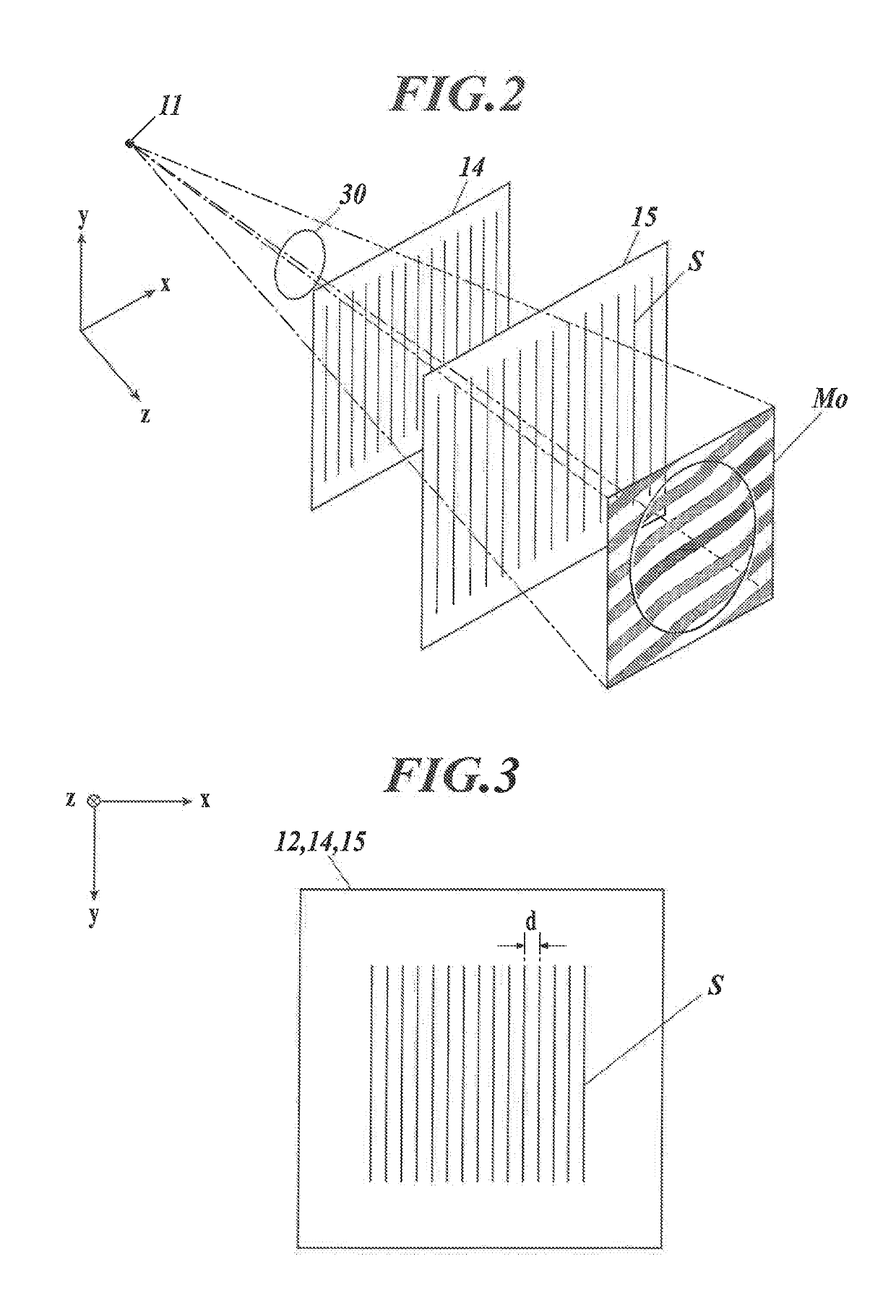

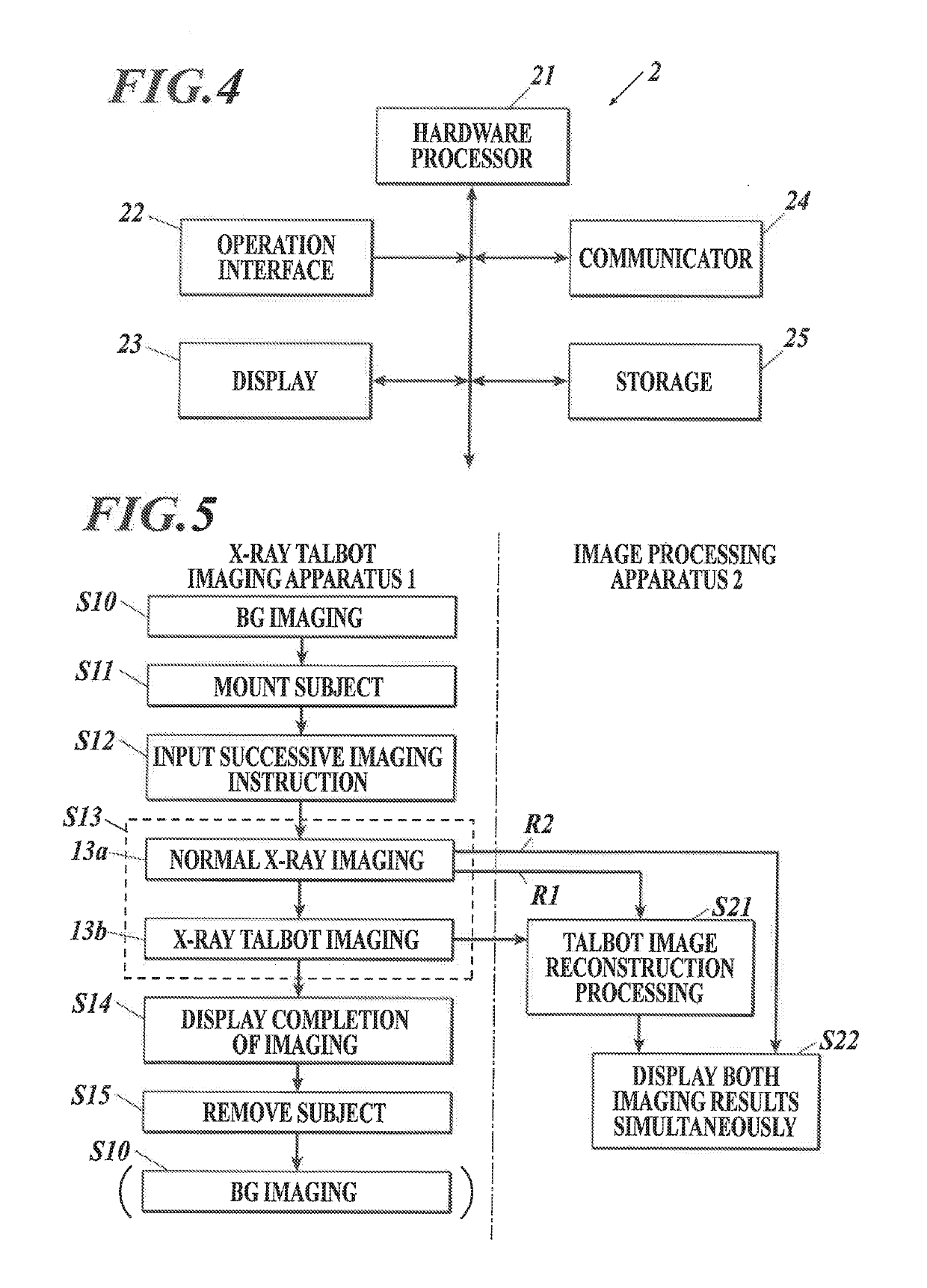

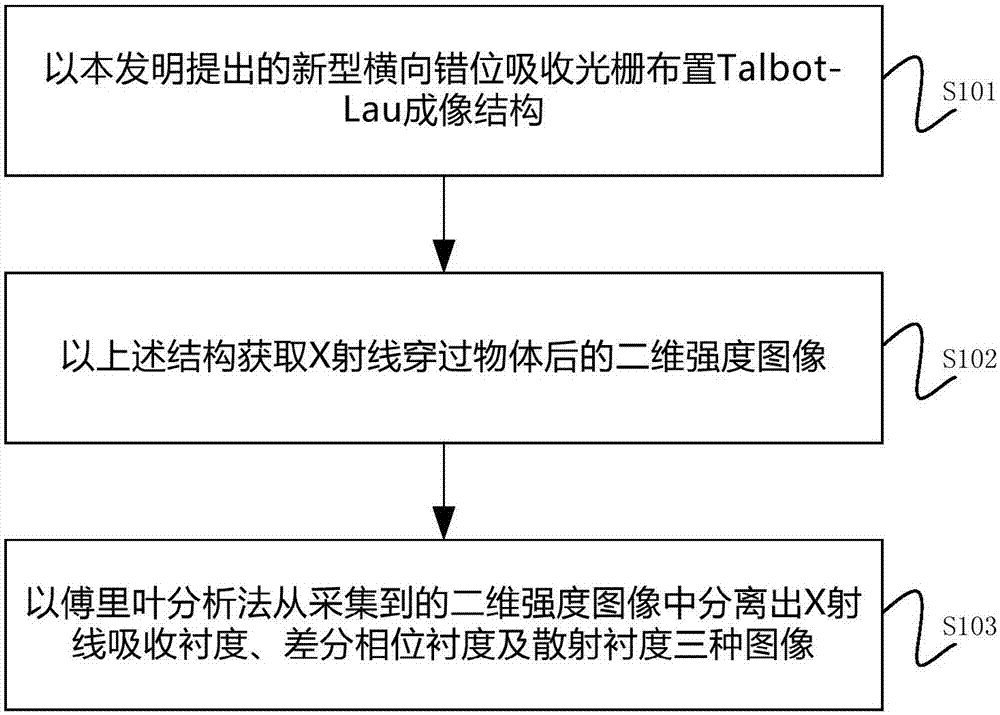

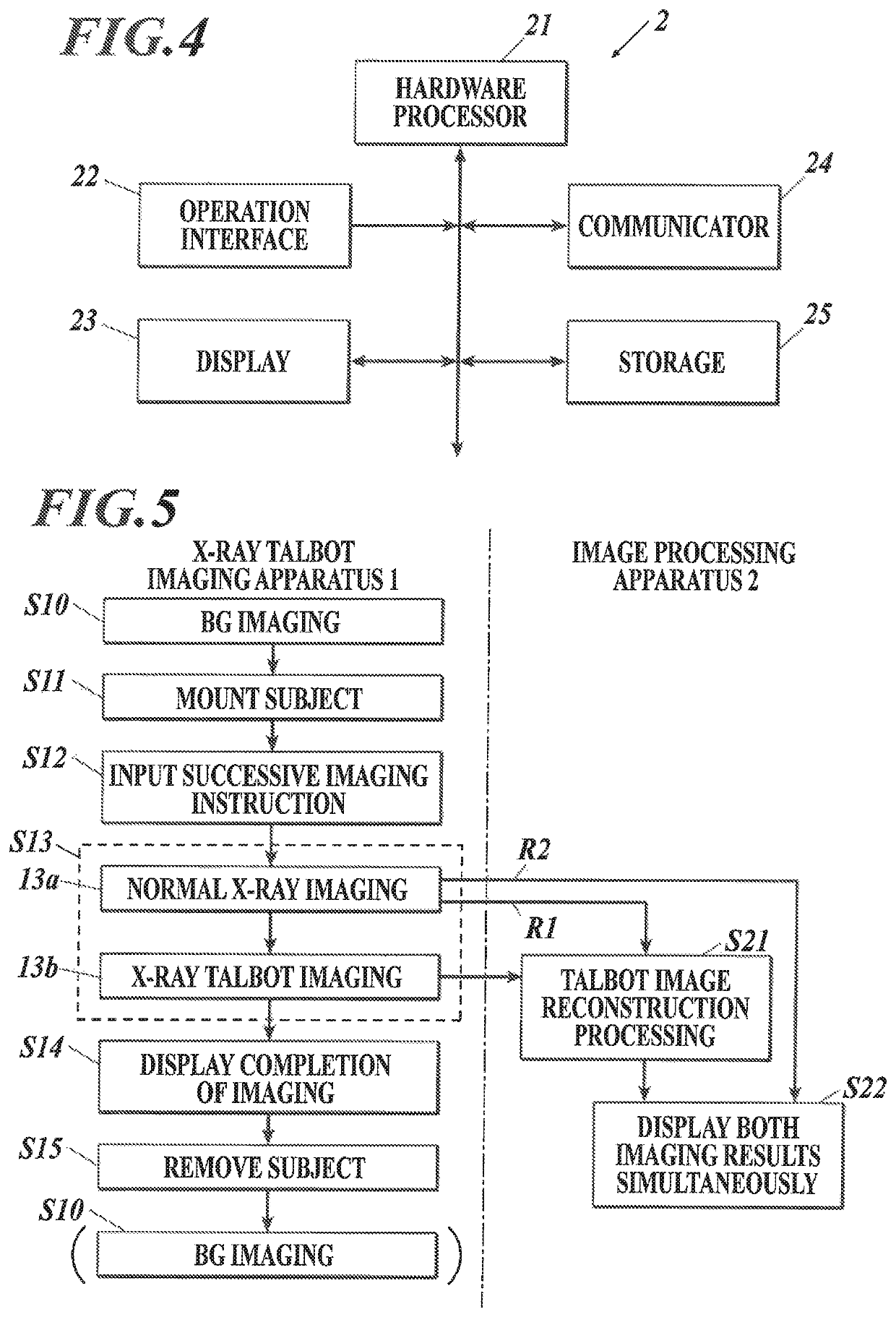

ActiveUS20190261935A1Patient positioning for diagnosticsForeign body detectionSoft x rayDifferential phase

An X-ray imaging system includes an X-ray Talbot; imaging apparatus and an image processing apparatus. The image processing apparatus generates reconstruction images from the moire image taken by the X-ray Talbot imaging apparatus. The reconstruction images include a differential phase image, an absorption image and a small-angle scattering image. The X-ray imaging system performs X-ray Talbot imaging and normal X-ray imaging. X-ray Talbot imaging includes setting an exposure energy of the X-ray Talbot imaging apparatus to a first exposure energy and taking the moire image with the X-ray detector. Normal X-ray imaging includes setting the exposure energy of the X-ray Talbot imaging apparatus to a second exposure energy and taking an absorption contrast image with the X-ray detector by normal X-ray imaging.

Owner:KONICA MINOLTA INC

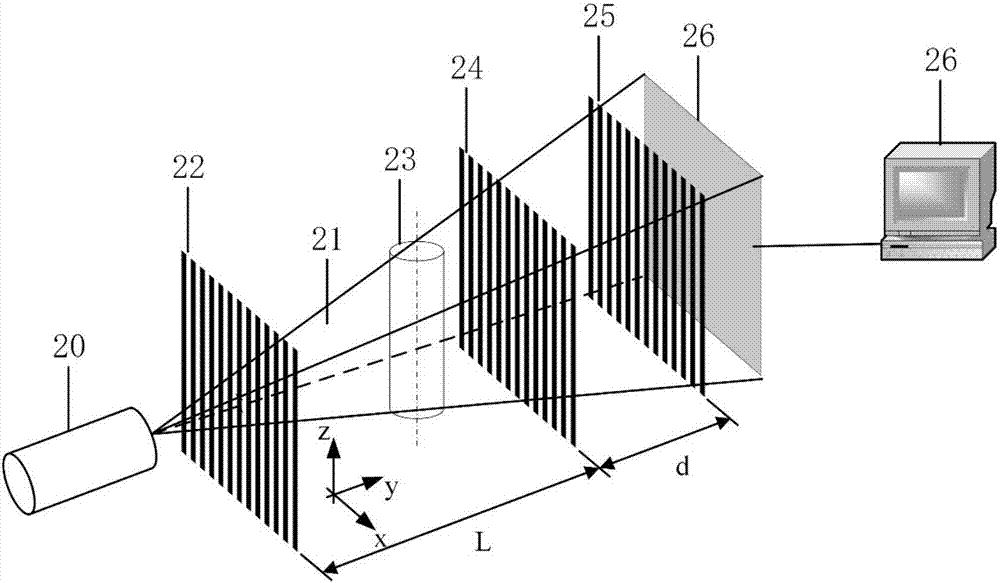

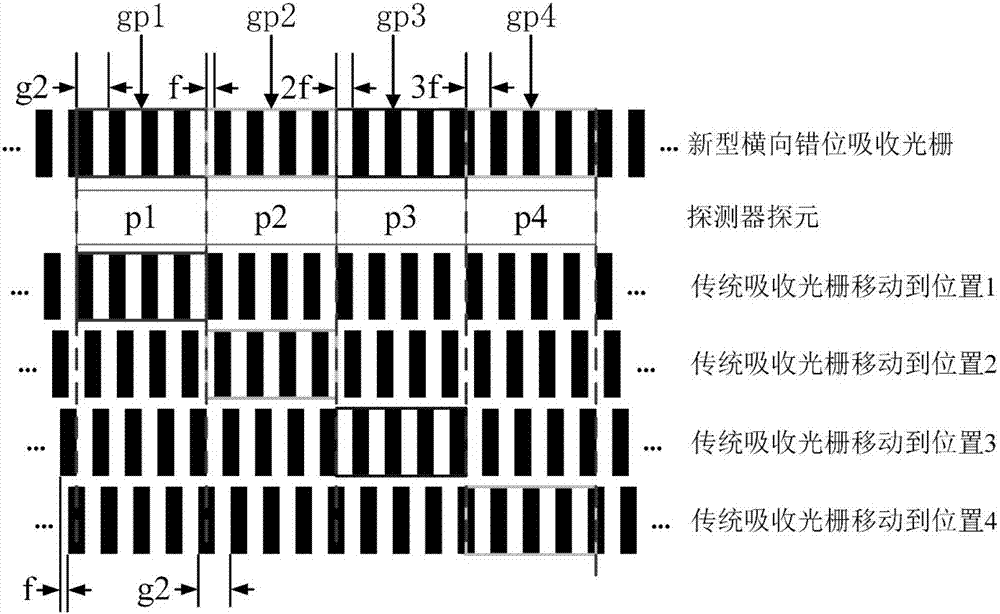

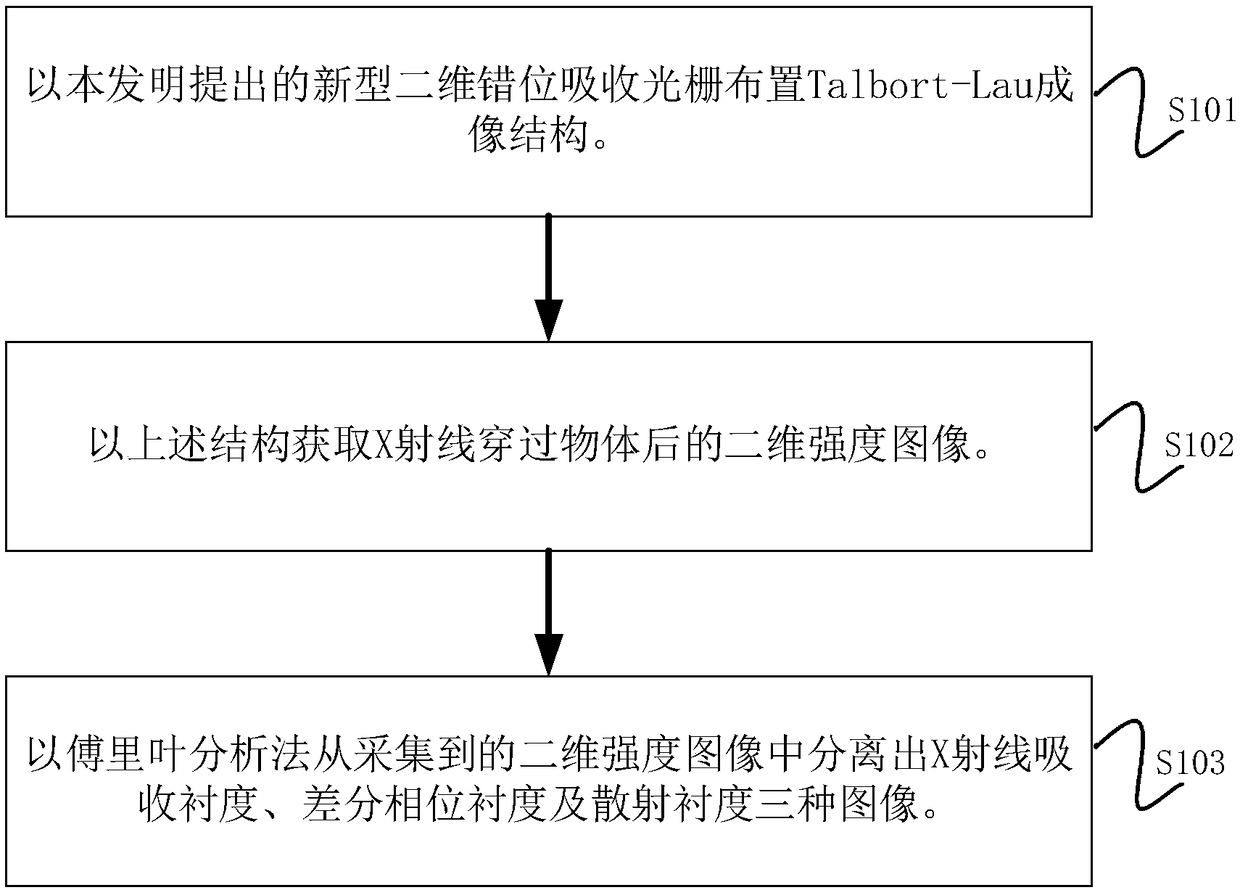

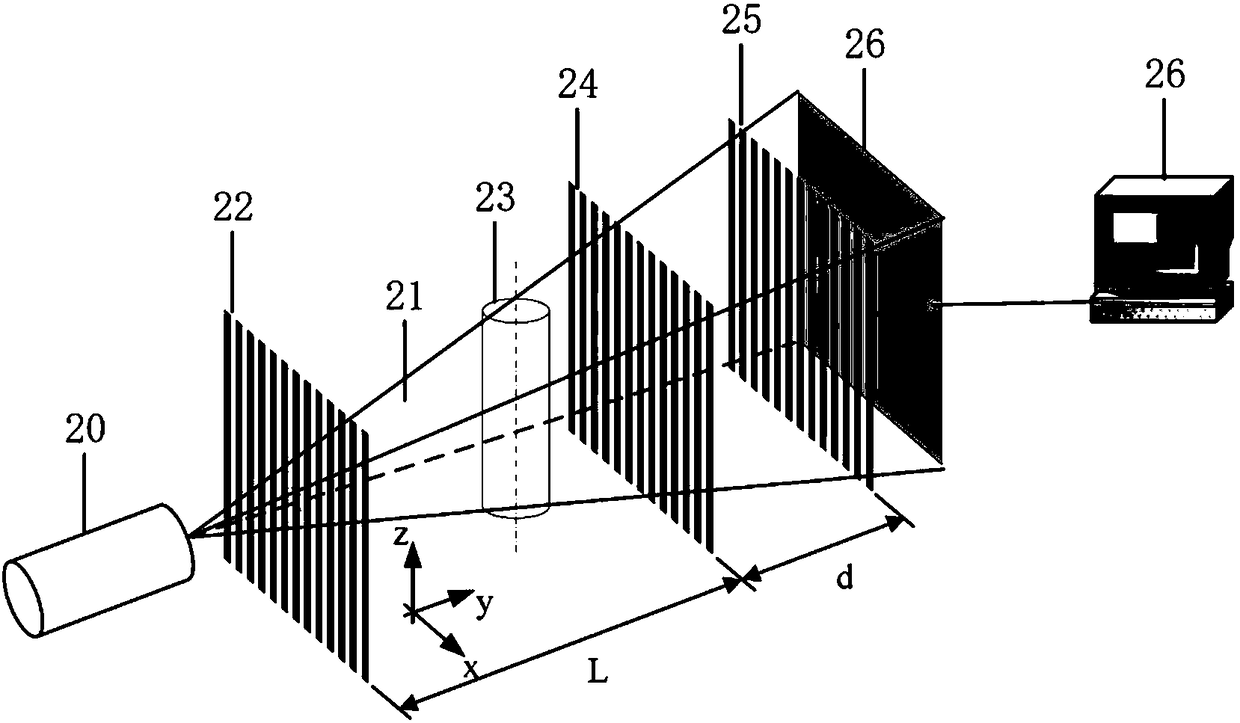

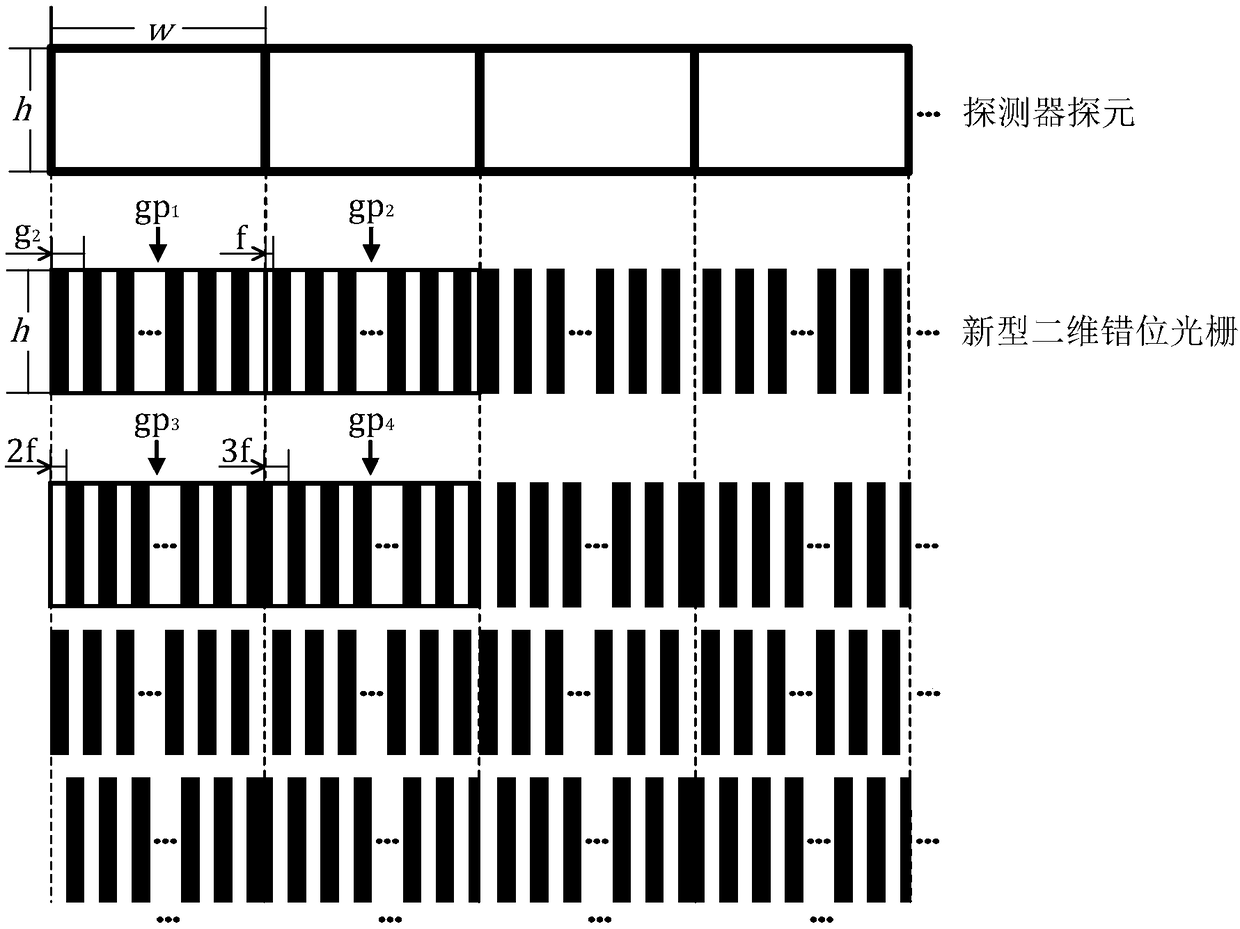

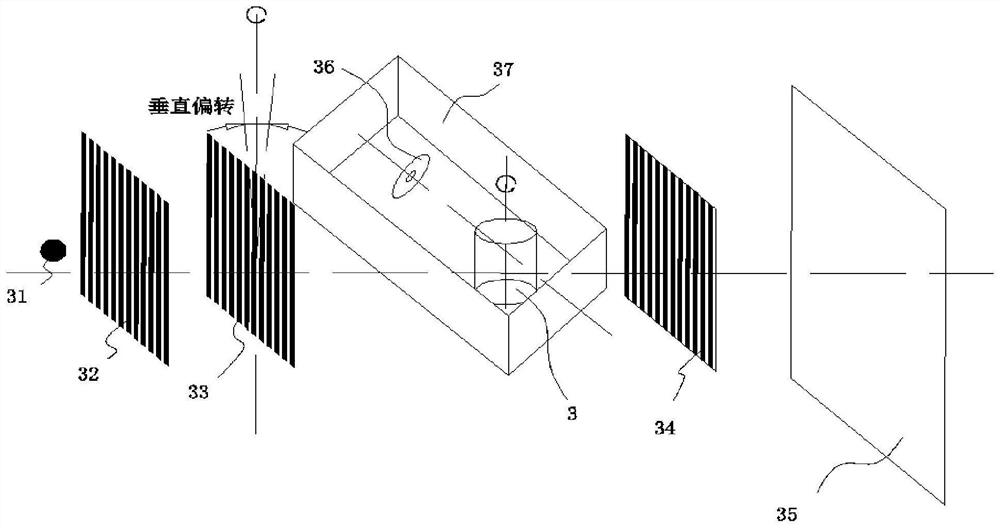

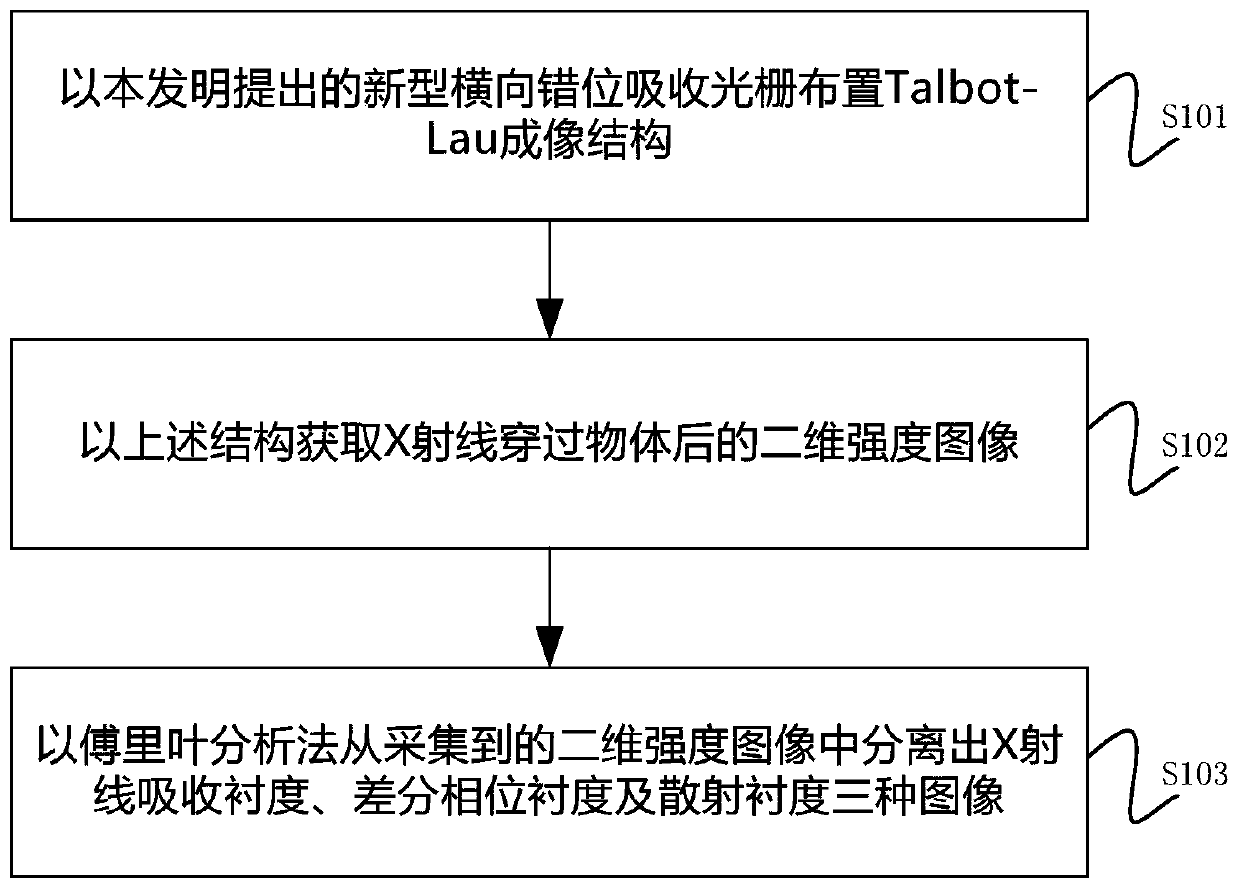

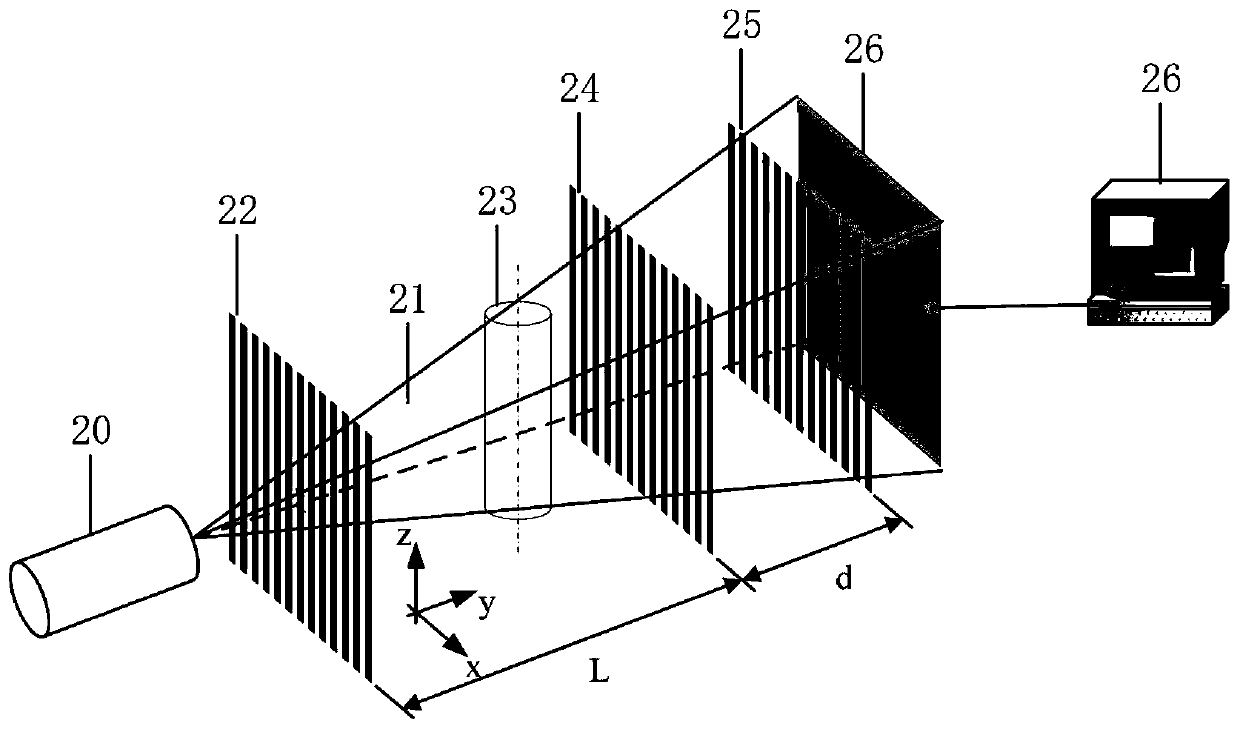

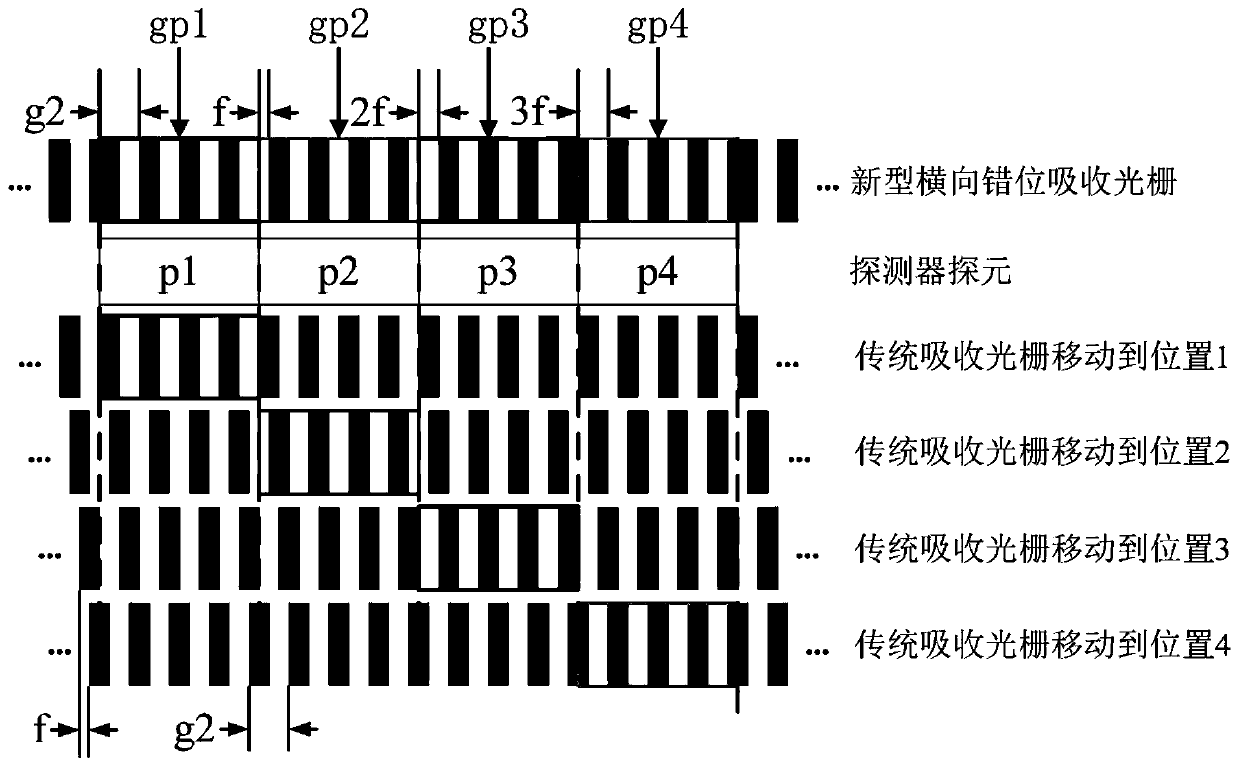

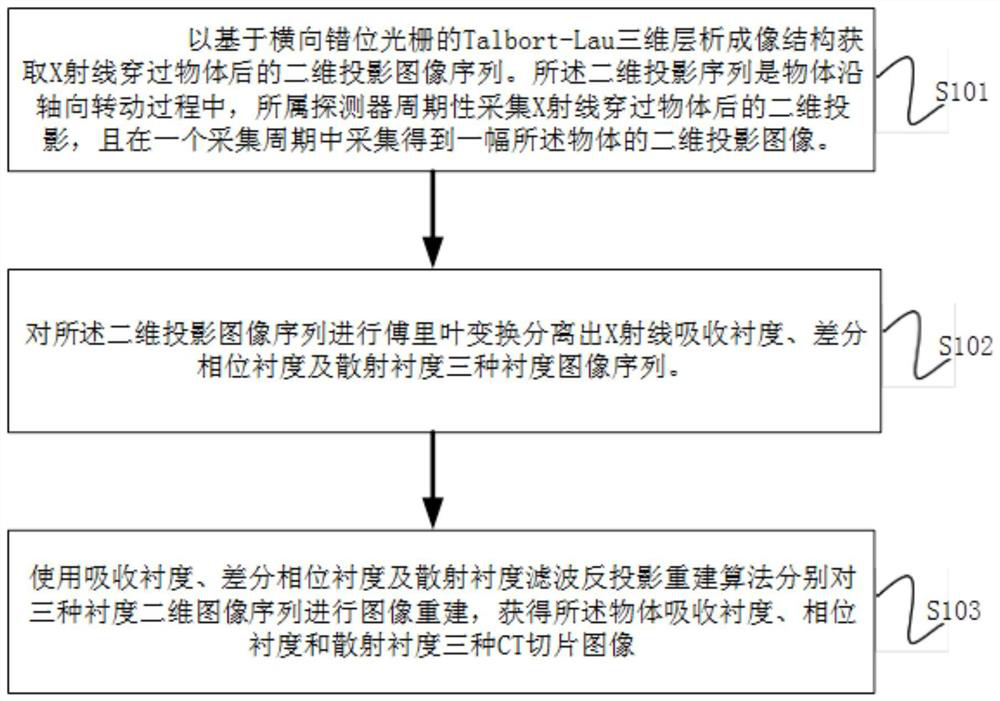

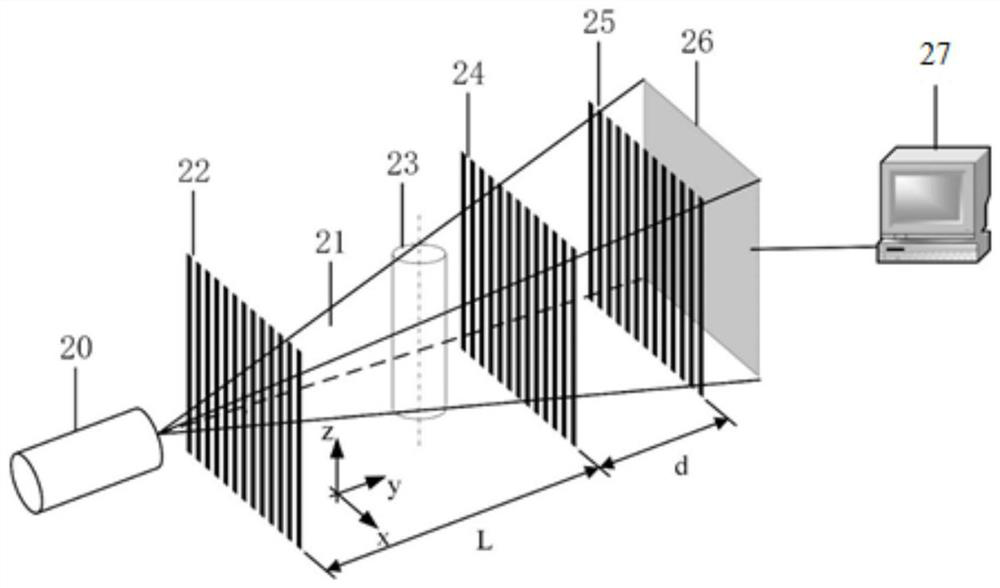

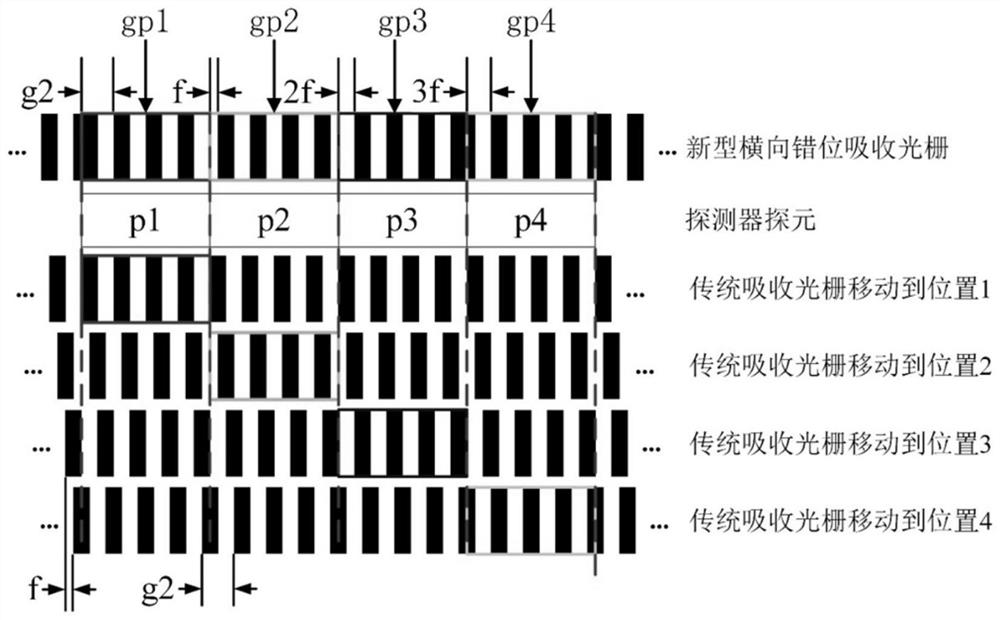

Transverse dislocated absorption grating-based X ray grating differential phase contrast imaging method and device

ActiveCN107144581ASolving the Multiple Exposure ProblemSimple stepsMaterial analysis by transmitting radiationSoft x rayAbsorption contrast

The invention discloses a transverse dislocated absorption grating-based X ray grating differential phase contrast imaging method and device. The method comprises the following steps: arranging a Talbot-Lau imaging structure by the novel transverse dislocated absorption grating disclosed by the invention; acquiring the two-dimensional intensity image after X ray penetrates through an object by the imaging structure; and separating the X ray absorption contrast image, differential phase contrast image and scattering contrast image from the acquired two-dimensional intensity image by the Fourier analysis method. Compared with the traditional method, the embodiment of the invention does not need to move the grating, three types of contrast images can be obtained by single exposure, so the imaging time is greatly shortened, the imaging dose is reduced and the imaging efficiency and stability of a system are improved.

Owner:BEIHANG UNIV

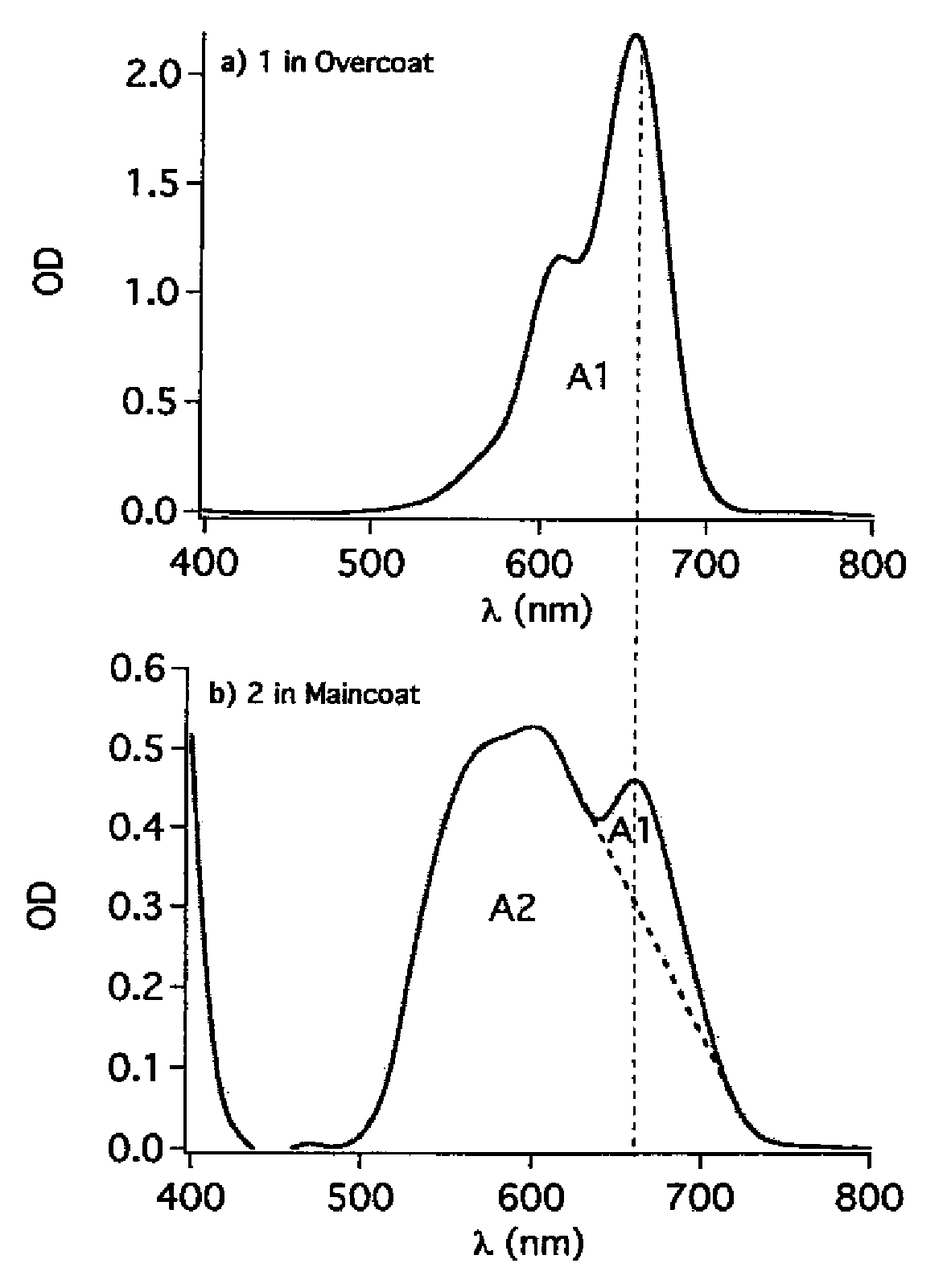

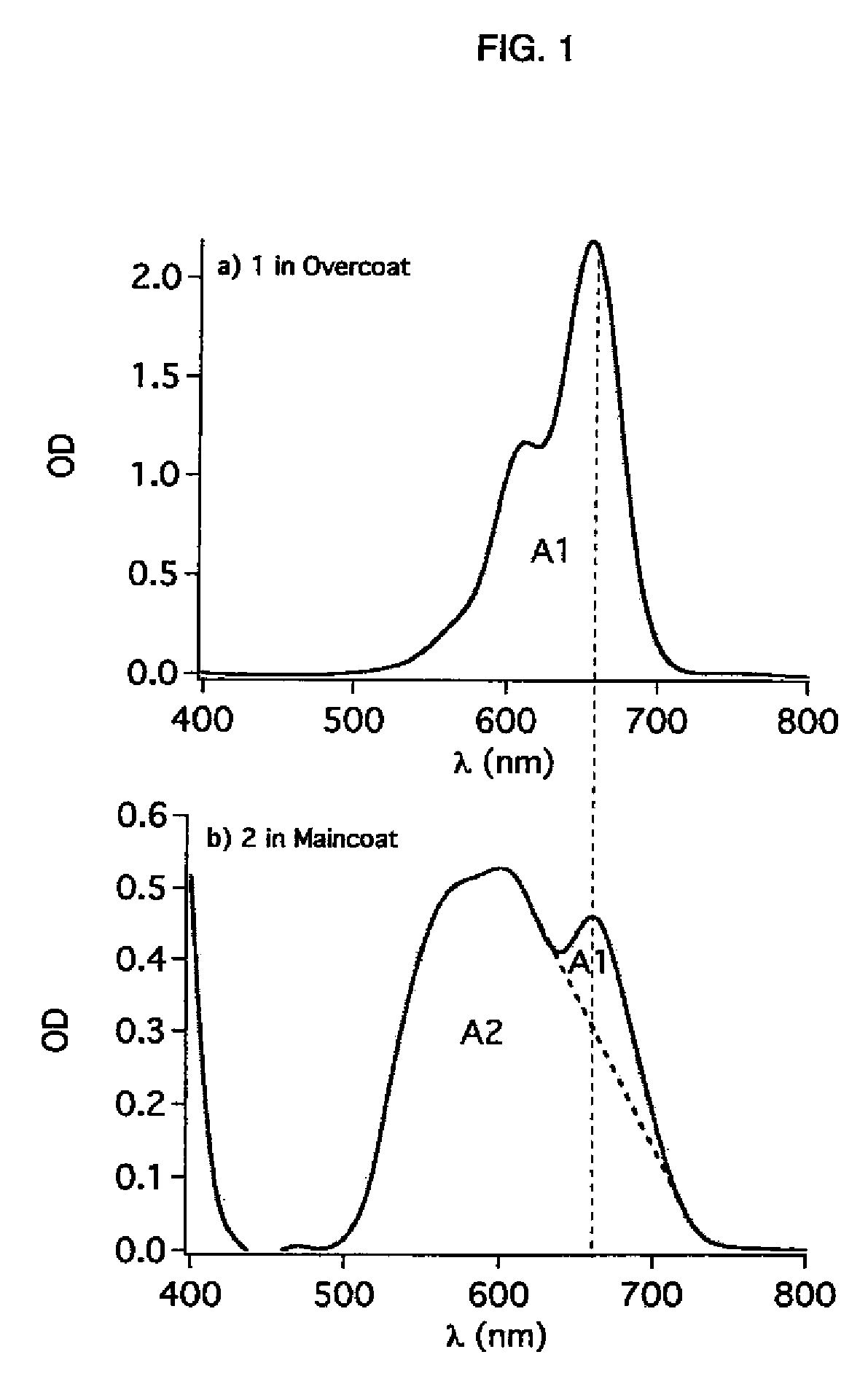

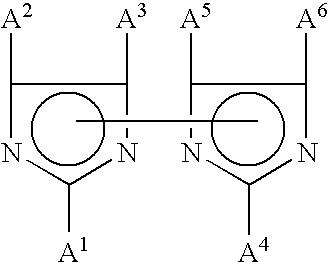

Negative-working imageable elements

InactiveUS8034538B2Improve adhesionGood lookingPhotosensitive materialsRadiation applicationsAbsorption contrastContrasting dye

Negative-working imageable element can be used to prepared lithographic printing plates. These elements include a water-soluble contrast dye having a λmax in the range of from about 450 to about 750 nm and having an absorption that is lower than 10% with respect to the absorption of the radiation absorbing compound in the element at the wavelength used for exposure. The contrast dye is present in sufficient H-aggregation such that less than 40% of the entire absorption spectrum from the contrast dye is contributed by it in non-H-aggregated form.

Owner:EASTMAN KODAK CO

Radiation image radiographic apparatus

InactiveUS7103140B2Easily radiographingEasy to implementVolume/mass flow measurementPatient positioning for diagnosticsAbsorption contrastRadiographic equipment

A user-friendly, inexpensive radiation image radiographing apparatus capable of easily switching between absorption contrast image radiography and phase contrast image radiography. The radiation image radiographing apparatus has: a radiation source; a subject platform for supporting a subject so as to face the subject to the radiation source; and a plurality of supporting platforms for supporting a radiation image information detecting member at a side opposite to the radiation source with respect to the subject platform, the radiation image information detecting member for detecting radiation image information based on radiation transmitted through the subject, wherein distances between the plurality of supporting platforms and the radiation source are different from each other.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

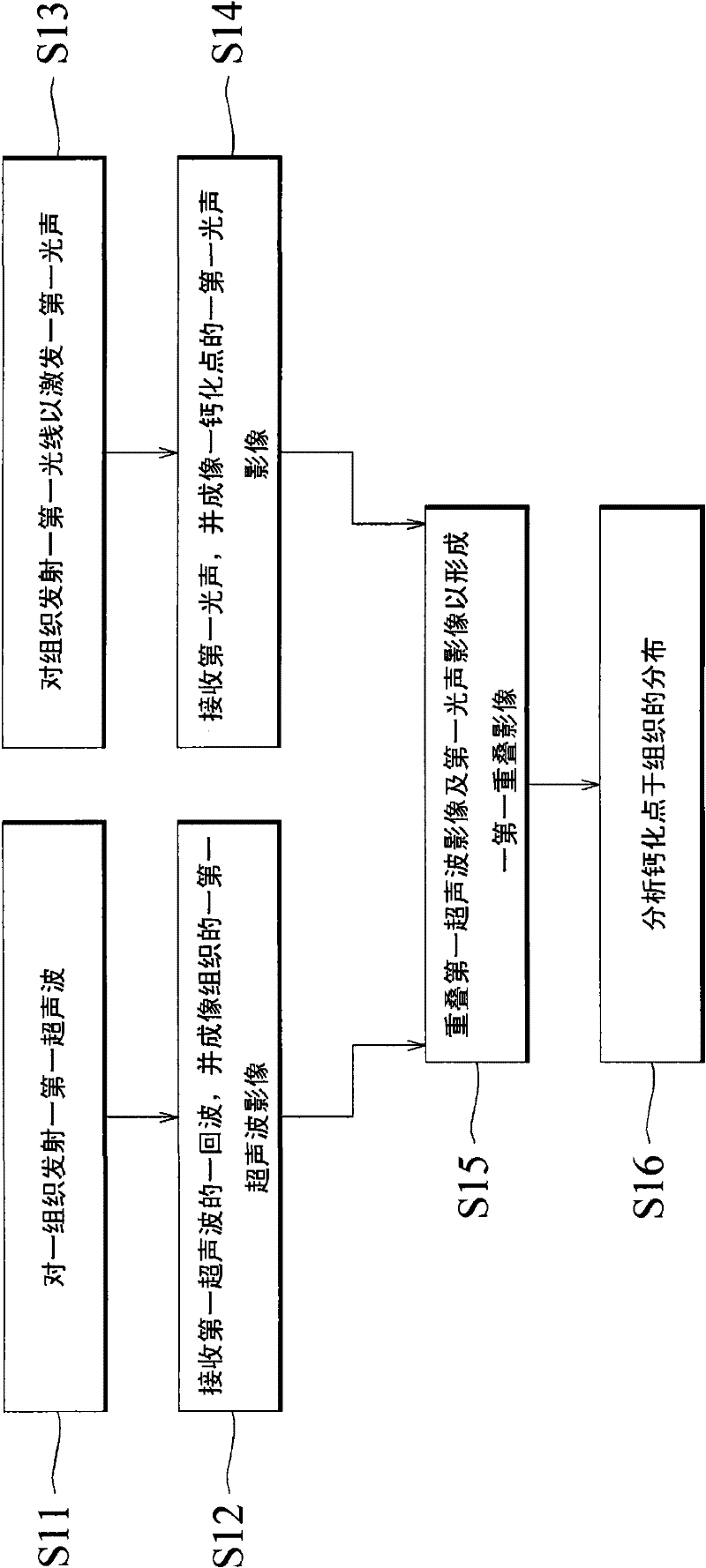

Calcification imaging method and system

InactiveCN102240213AImprove securityUltrasonic/sonic/infrasonic diagnosticsDiagnostic recording/measuringNon-ionizing radiationAbsorption contrast

The invention provides a calcification imaging method and system. The calcification imaging method comprises the following steps of: transmitting a first ultrasonic wave to a tissue; receiving the echo wave of the first ultrasonic wave and forming the first ultrasonograph of the tissue; transmitting a first light ray onto the tissue to excite a first optical sound; receiving the first optical sound and forming a first optical sound image of a calcification; and overlapping the first ultrasonograph with the first optical sound image to form a first overlapped image for imaging the distribution condition of the calcification in the tissue. Compared with ultrasonic wave and X-ray mammography, the image obtained by the invention has the advantages of no speckle noise, high optical absorption contrast and high ultrasonic wave spatial resolution, and the used light source is non-ionizing radiation, thus having higher safety.

Owner:NATIONAL TSING HUA UNIVERSITY

System and Method for Fuel Cell Material X-Ray Analysis

ActiveUS20080165924A1Shorten development timeImprove reliabilityRadiation/particle handlingUsing wave/particle radiation meansMetrologyHard X-rays

An imaging technology for fuel cells is based on x-ray microscopy. A metrology system images the electrochemical interaction areas of solid-oxide fuel cells (SOFC) in-situ. This system takes advantage of both the penetrating power and elemental absorption contrast of hard x-ray radiation to image the internal interaction areas in a SOFC. The technology can further take advantage of the strong dependence of the x-ray absorption on material type and energy to distinguish the four major material types: cathode, electrolyte, air, and low-Z contaminants such as sulfur.

Owner:CARL ZEISS X RAY MICROSCOPY

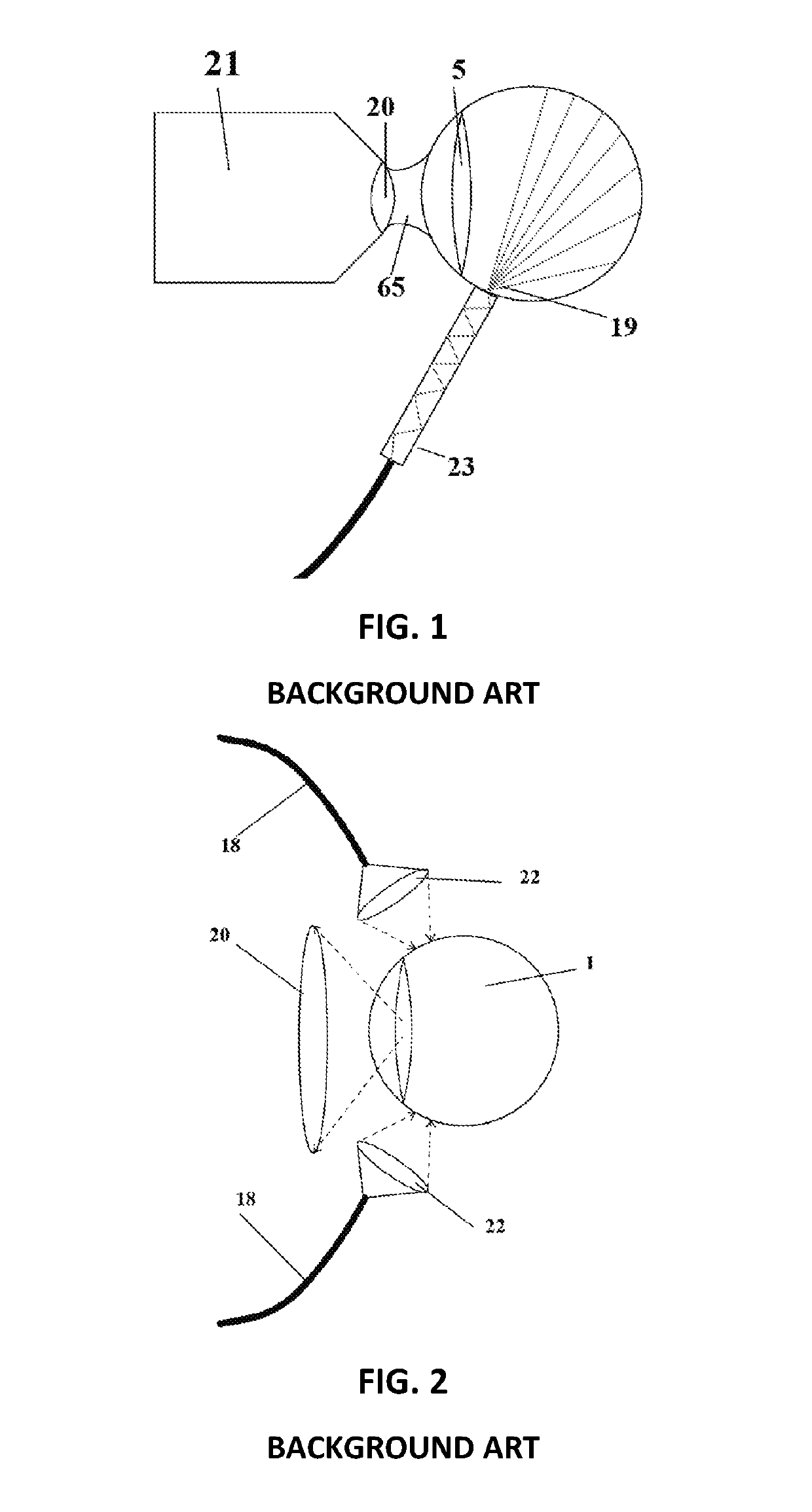

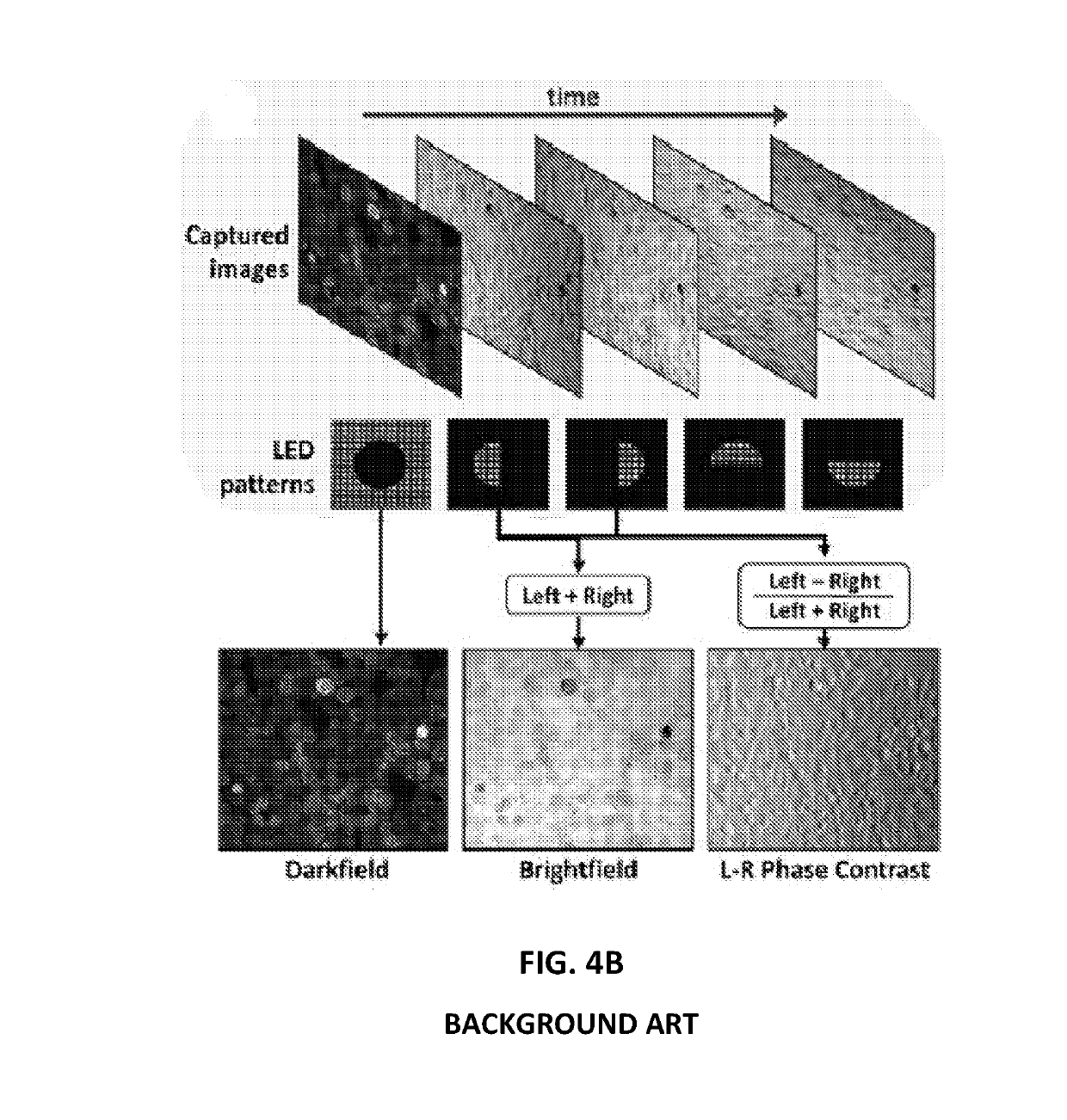

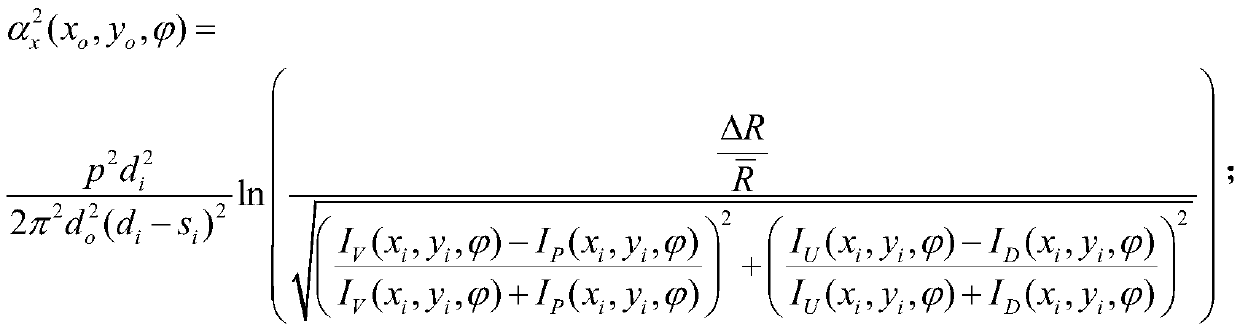

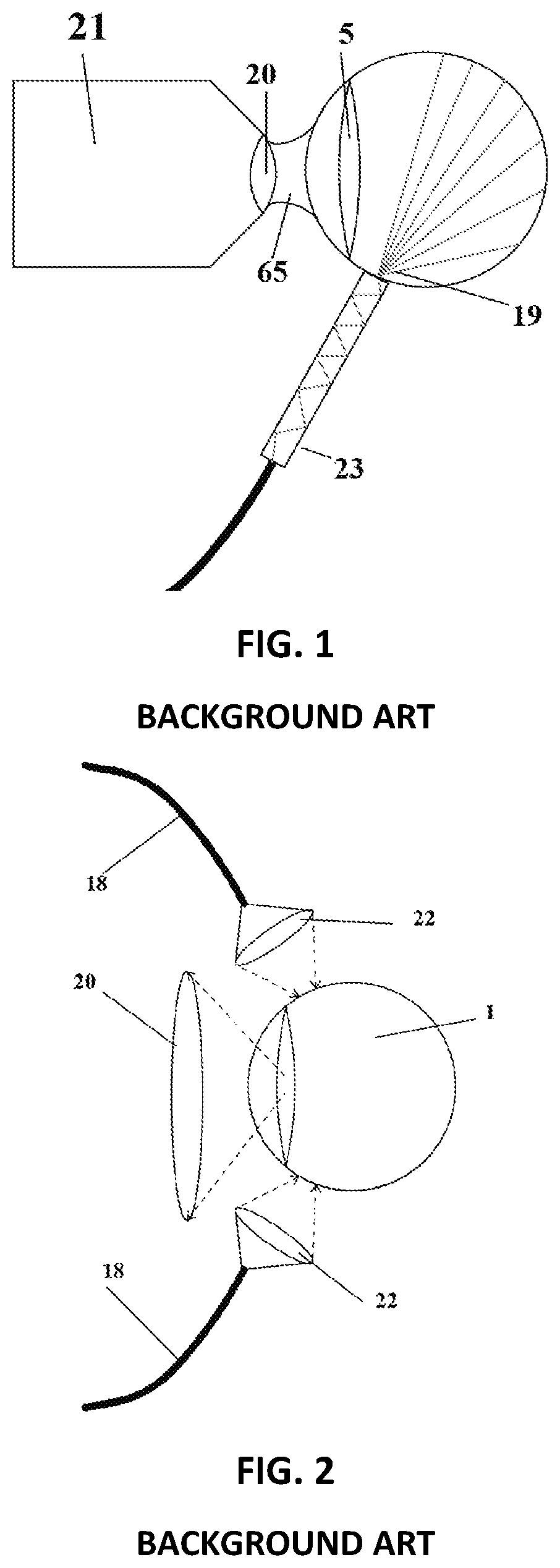

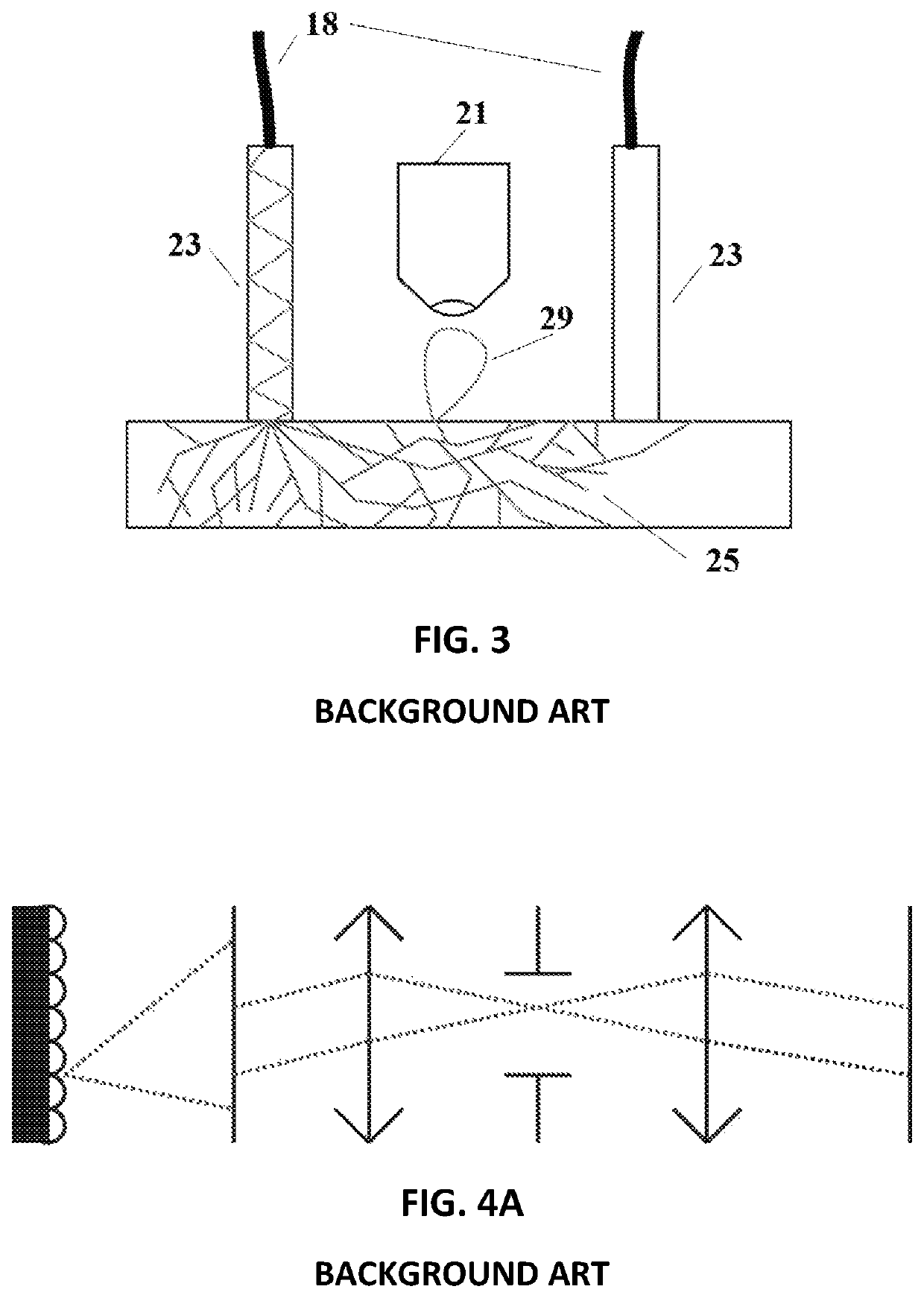

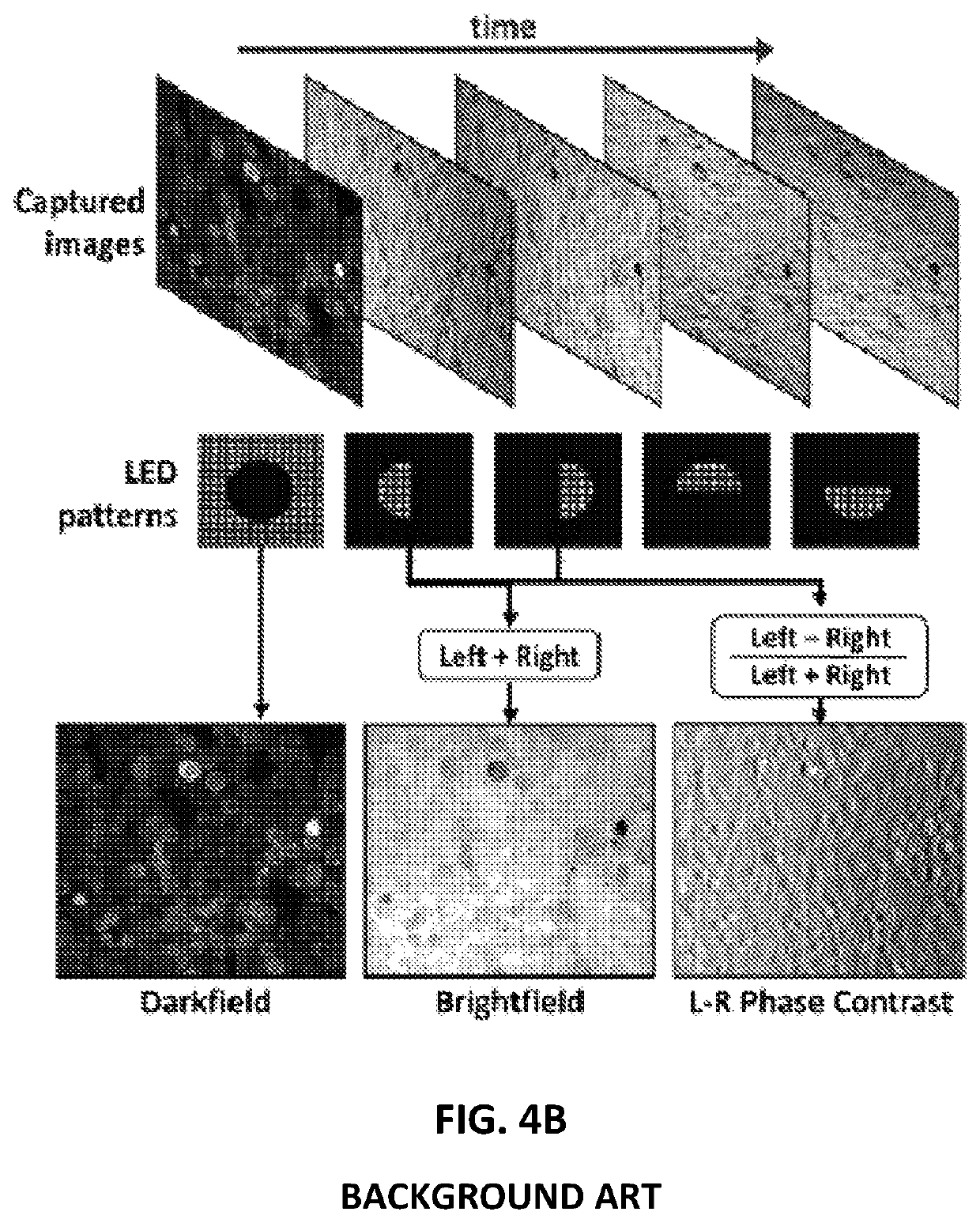

System, method and apparatus for retinal absorption phase and dark field imaging with oblique illumination

A method for imaging a tissue of an eye, the method including the steps of providing oblique illumination to the eye by a plurality of light emitting areas of a light delivery device, the plurality of light emitting areas being independently controllable and arranged to direct light towards at least one of a retina and an iris of the eye, causing an output beam from light backscattered from the at least one of the retina and the iris by the oblique illumination, capturing the output beam with an imaging system to provide a sequence of images of a fundus of the eye, and retrieving a phase and absorption contrast image from the sequence of images of the fundus, wherein the sequence of images of the fundus of the step of capturing is obtained by sequentially turning on one or more of the plurality of light emitting areas at a time in the step of providing the oblique illumination.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

X-ray grating differential phase contrast imaging method and device based on two-dimensional dislocation absorption grating

InactiveCN108469443ASolving the Multiple Exposure ProblemSimple stepsMaterial analysis using radiation diffractionSoft x rayAbsorption contrast

The invention discloses an X-ray grating differential phase contrast imaging method and device based on a two-dimensional dislocation absorption grating. The method comprises the following steps: arranging a Talbot-Lau imaging structure according to a novel two-dimensional dislocation absorption grating provided in the invention; acquiring a two-dimensional intensity image of X rays passing through an object by virtue of the previous structure; and separating three images from the acquired two-dimensional intensity image by a Fourier analysis method, namely an X-ray absorption contrast image,a differential phase contrast image and a scattering contrast image. Compared with the traditional method, the method in the embodiment of the invention has the advantages that the grating does not need to be moved, the three contrast images can be acquired by virtue of single exposure, the imaging time is greatly shortened, the imaging dose is reduced, and the imaging efficiency and stability ofthe system are improved.

Owner:BEIHANG UNIV

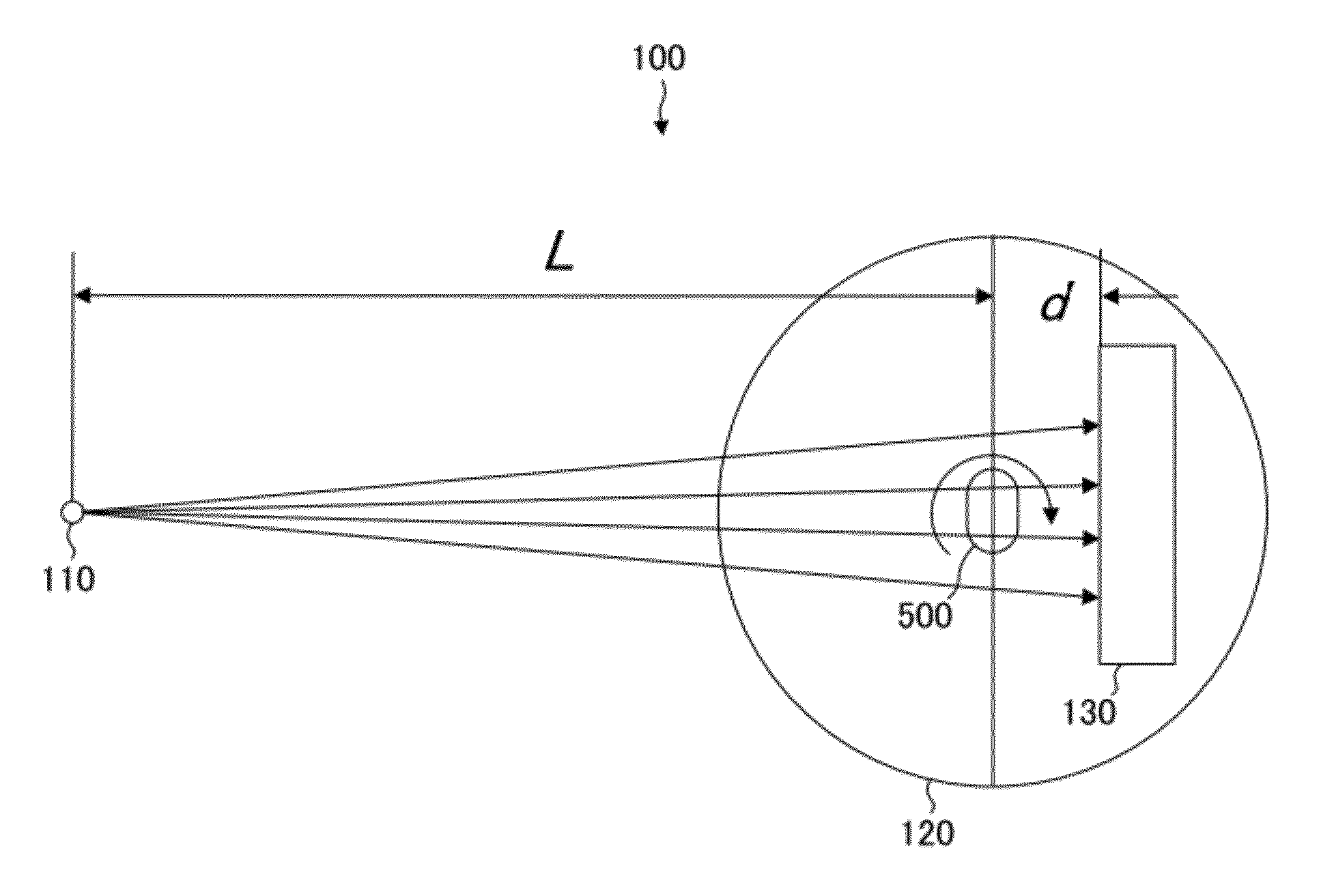

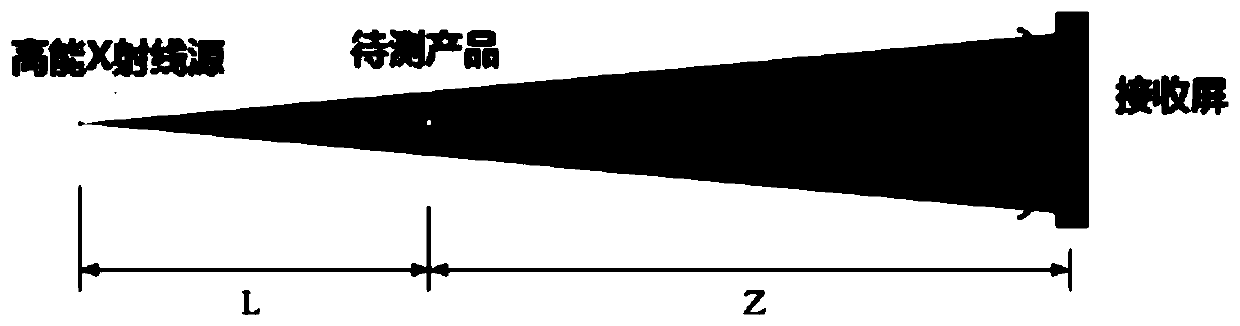

X-ray image photographing method and x-ray image photographing apparatus

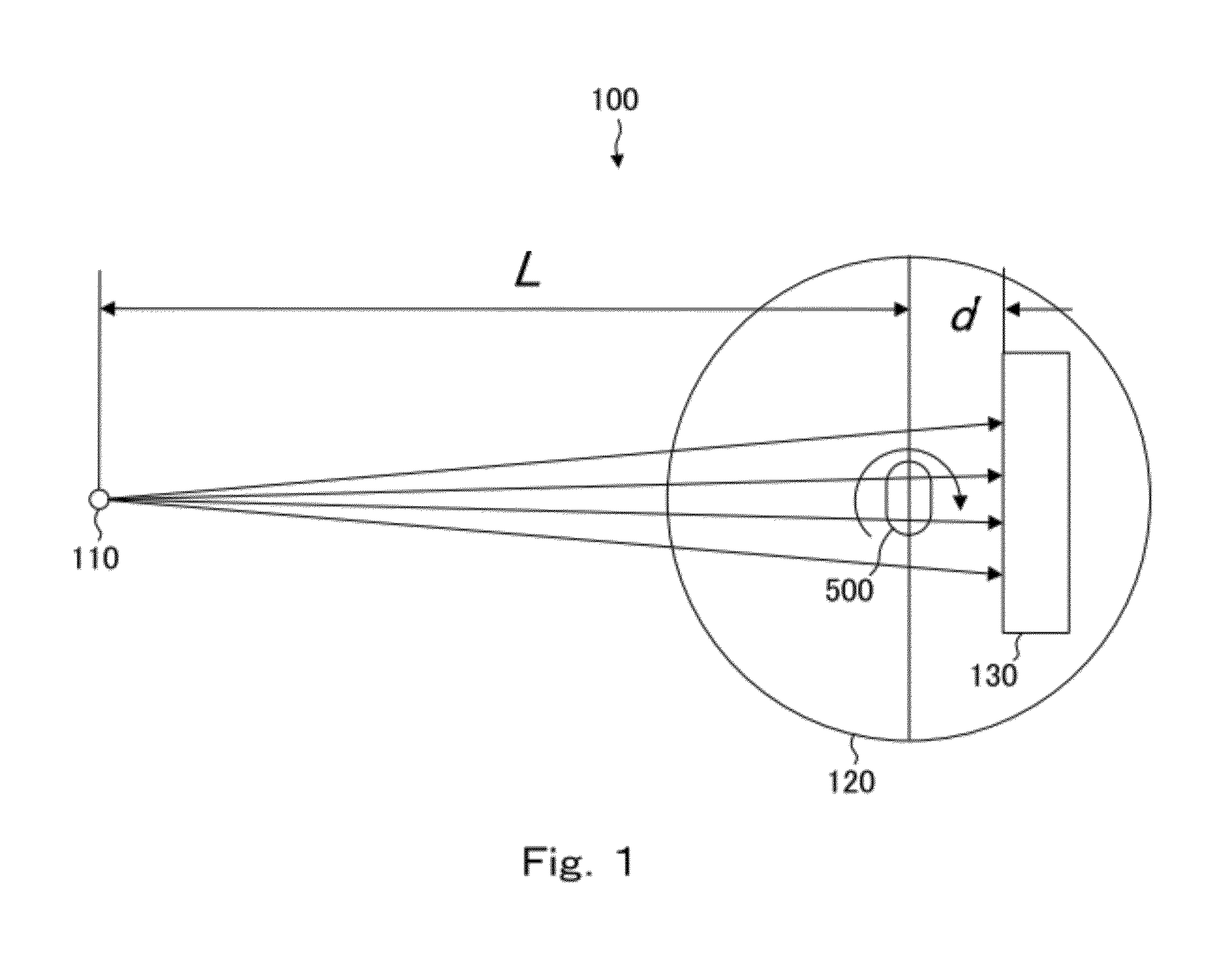

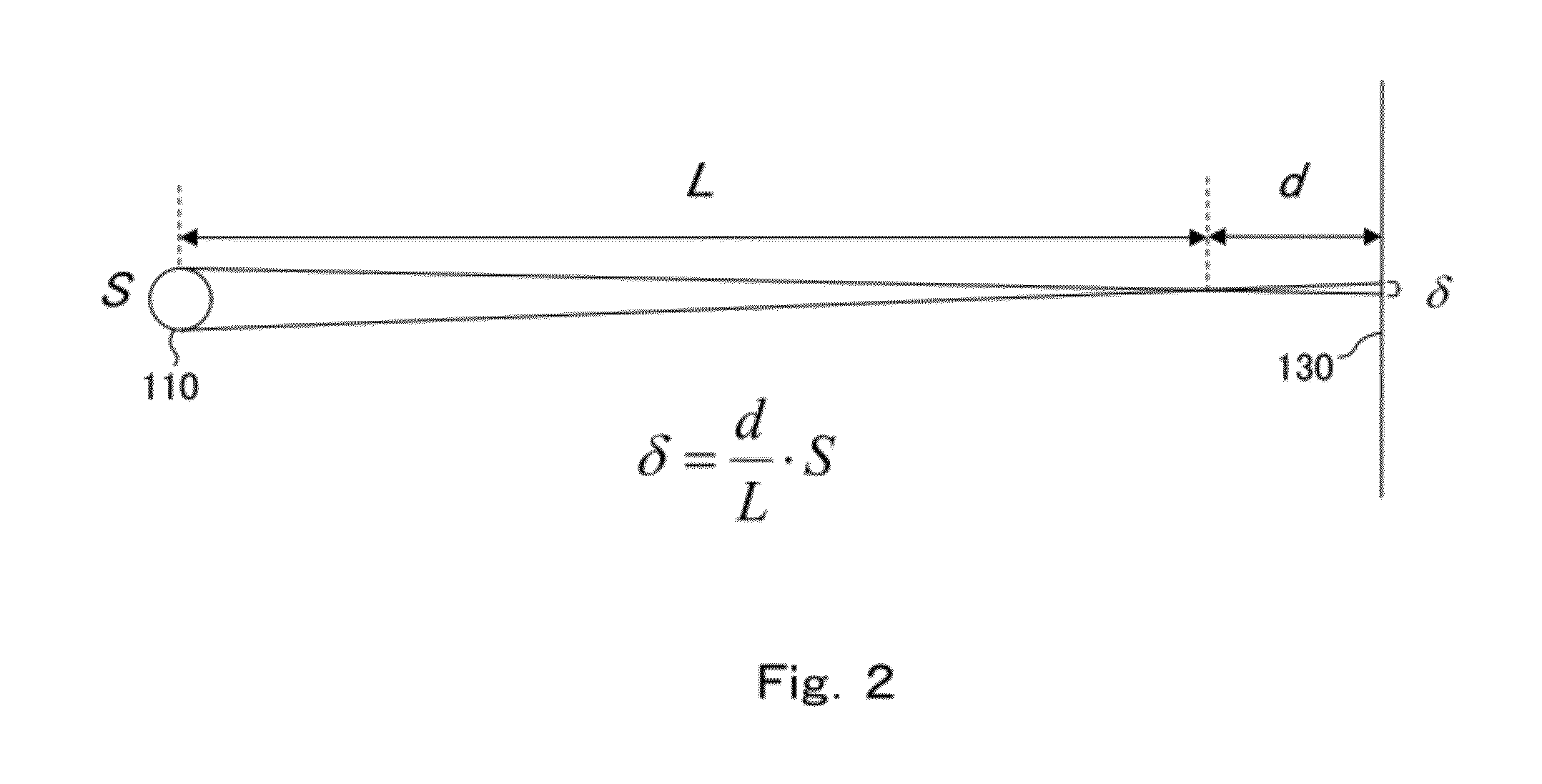

ActiveUS20120087470A1Short timeEasy to quantifyMaterial analysis by transmitting radiationRadiation diagnosticsFine structureImage resolution

An X-ray image photographing method and apparatus is capable of photographing a high resolution phase contrast image and a high resolution absorption contrast image in a short time by finely adjusting the distance between a specimen and a detector with respect to an X-ray source.The method enables photographing a fine structure with high space resolution while using an X-ray source having a finite size, and d / L is sufficiently smaller than 1, when L is a distance from an X-ray source to a specimen and d is a distance from the specimen to a detector.

Owner:EXXON RES & ENG CO +1

Phase contrast image generation method and system

ActiveCN109215094ARadiation diagnosis data transmissionImage enhancementObject basedAbsorption contrast

The present application provides a system and method for generating a phase contrast image based on an absorption contrast image. The method may include acquiring an absorption contrast image of the first object. The method may further include acquiring a phase contrast image generation model, wherein the phase contrast image generation model may be associated with at least one absorption contrastimage sample of the second object and at least one phase contrast image sample of the second object. The method may further include executing the phase contrast image generation model to generate a phase contrast image of the first object based on the absorption contrast image of the first object.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

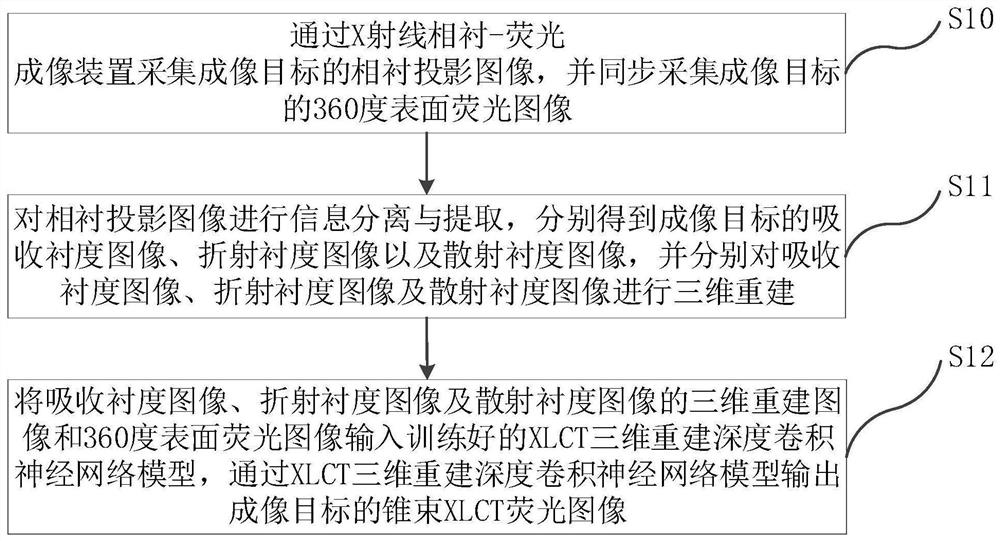

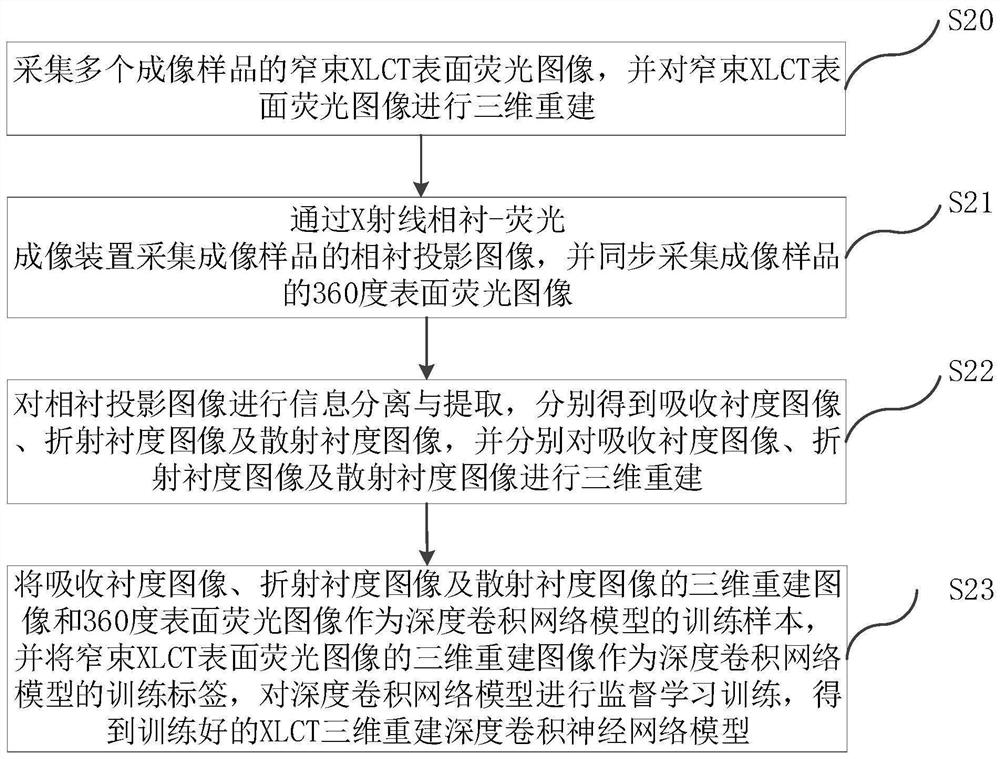

Cone-beam X-ray fluorescence imaging method and system, terminal and storage medium

ActiveCN113367717AReduce morbidityPromote migrationComputerised tomographsTomographyProjection imageRadiology

The invention relates to a cone-beam X-ray fluorescence imaging method and system, a terminal and a storage medium. The method comprises the following steps: acquiring a phase contrast projection image of an imaging target through an X-ray phase contrast-fluorescence imaging device, and synchronously acquiring a surface fluorescence image of the imaging target; performing information separation and extraction on the phase contrast projection image to obtain an absorption contrast image, a refraction contrast image and a scattering contrast image of the imaging target, and performing three-dimensional reconstruction on the absorption contrast image, the refraction contrast image and the scattering contrast image respectively; inputting the three-dimensional reconstruction images of the absorption contrast image, the refraction contrast image and the scattering contrast image and the surface fluorescence image into the trained XLCT three-dimensional reconstruction deep convolutional neural network model, and outputting a cone beam XLCT fluorescence image of the imaging target through the XLCT three-dimensional reconstruction deep convolutional neural network model. According to the method, the ill-conditioned degree of solving the cone-beam XLCT three-dimensional reconstruction equation can be effectively reduced, and rapid and high-resolution cone-beam X-ray fluorescence imaging is realized.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

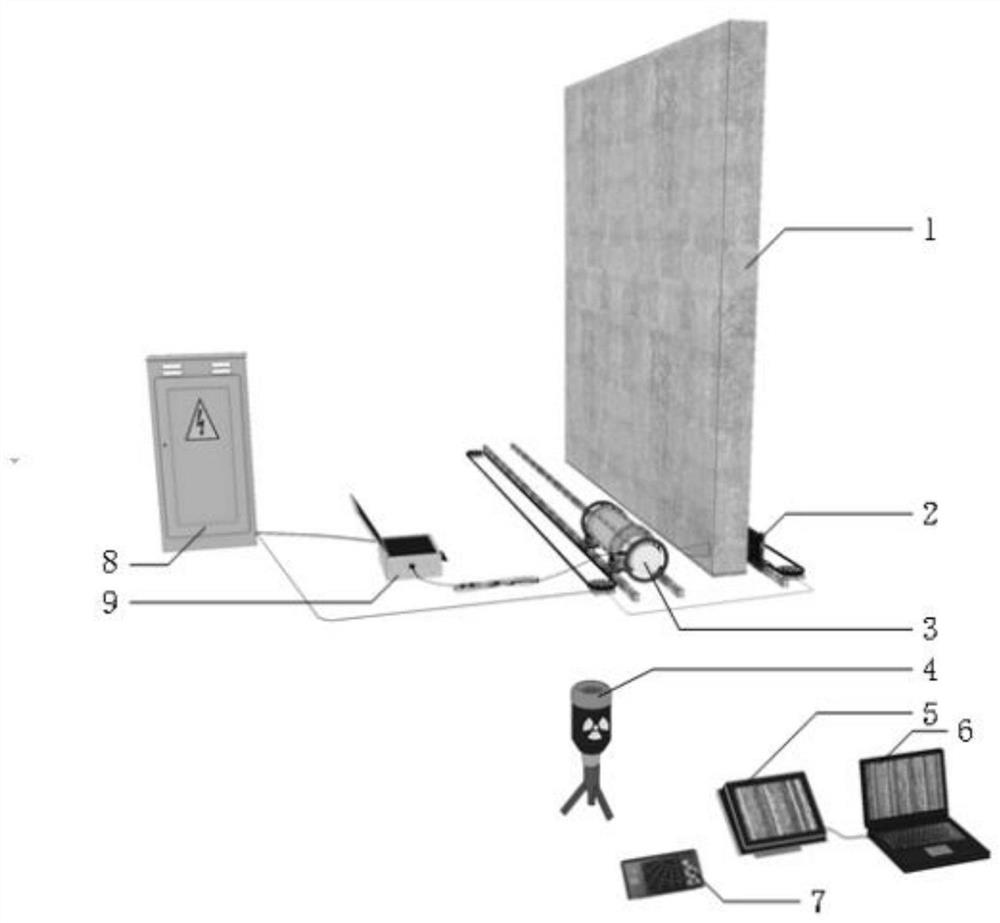

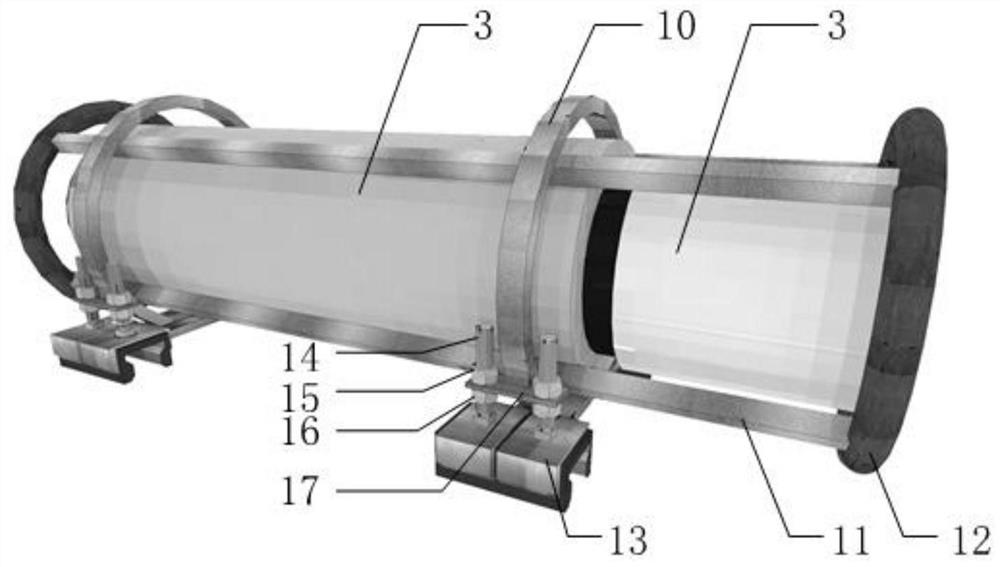

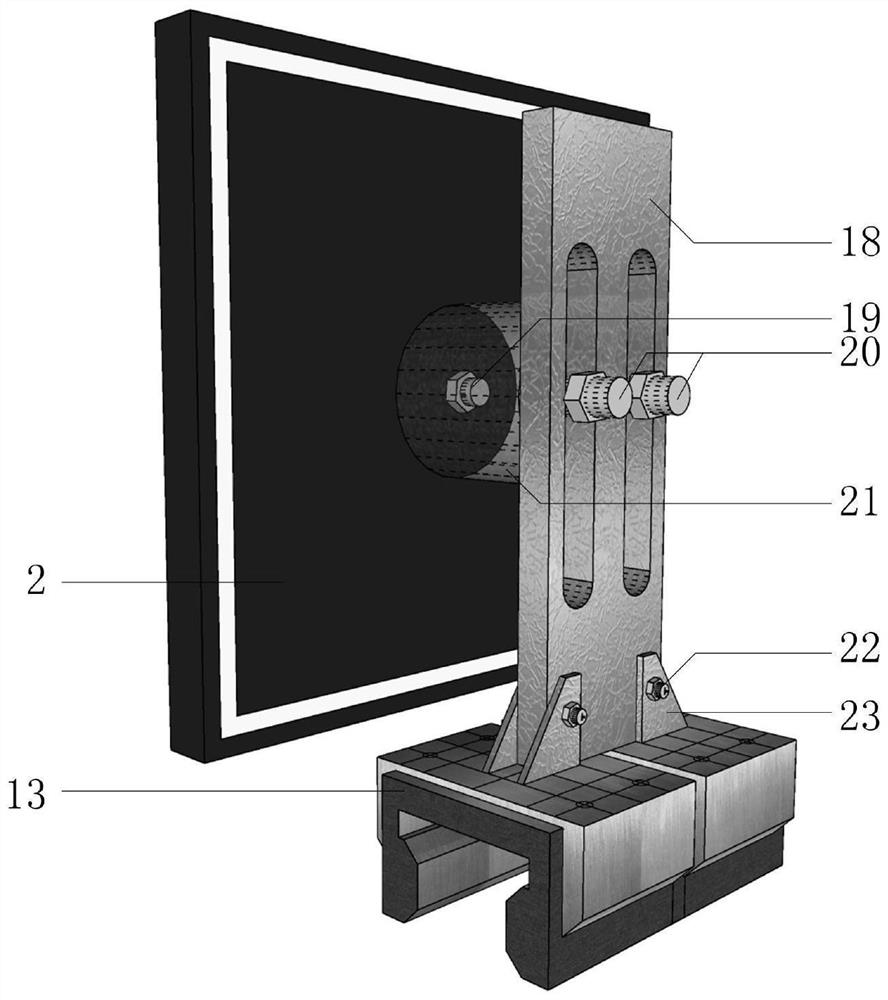

Sleeve grouting forming quality detection method based on X-ray absorption contrast improvement and detection device thereof

PendingCN114577828AImprove absorption contrastIncrease the contrast differenceMaterial analysis using wave/particle radiationAbsorption contrastX-ray

The invention relates to the technical field of nondestructive testing of building structures, and discloses a sleeve grouting forming quality detection method based on improvement of X-ray absorption contrast, which comprises the following steps: mixing: putting a grouting material and barium sulfate powder into a stirrer for premixing at the stirring speed of 240-280 r / min for 3 minutes, and after stirring is completed, putting the grouting material and barium sulfate powder into the stirrer for pre-mixing; and taking out about 30% by mass of the mixed grouting material for later use, and adding water accounting for 12% of the sum of the mass of the mixed grouting material into the stirrer for stirring. According to the method, the barium sulfate powder is added into the grouting material, and the barium sulfate powder and the grouting material are fully mixed, so that the absorption contrast of the mixed slurry to X rays is improved, the contrast difference between the grouting material and grouting defects is increased, and accurate judgment of the grouting fullness and the grouting node internal defects is realized; compared with the conventional X-ray detection, the portable X-ray detector has the advantages that the technical progress is realized, and meanwhile, the portable X-ray detector has popularization performance.

Owner:CHINA CONSTR THIRD ENG BUREAU GRP CO LTD

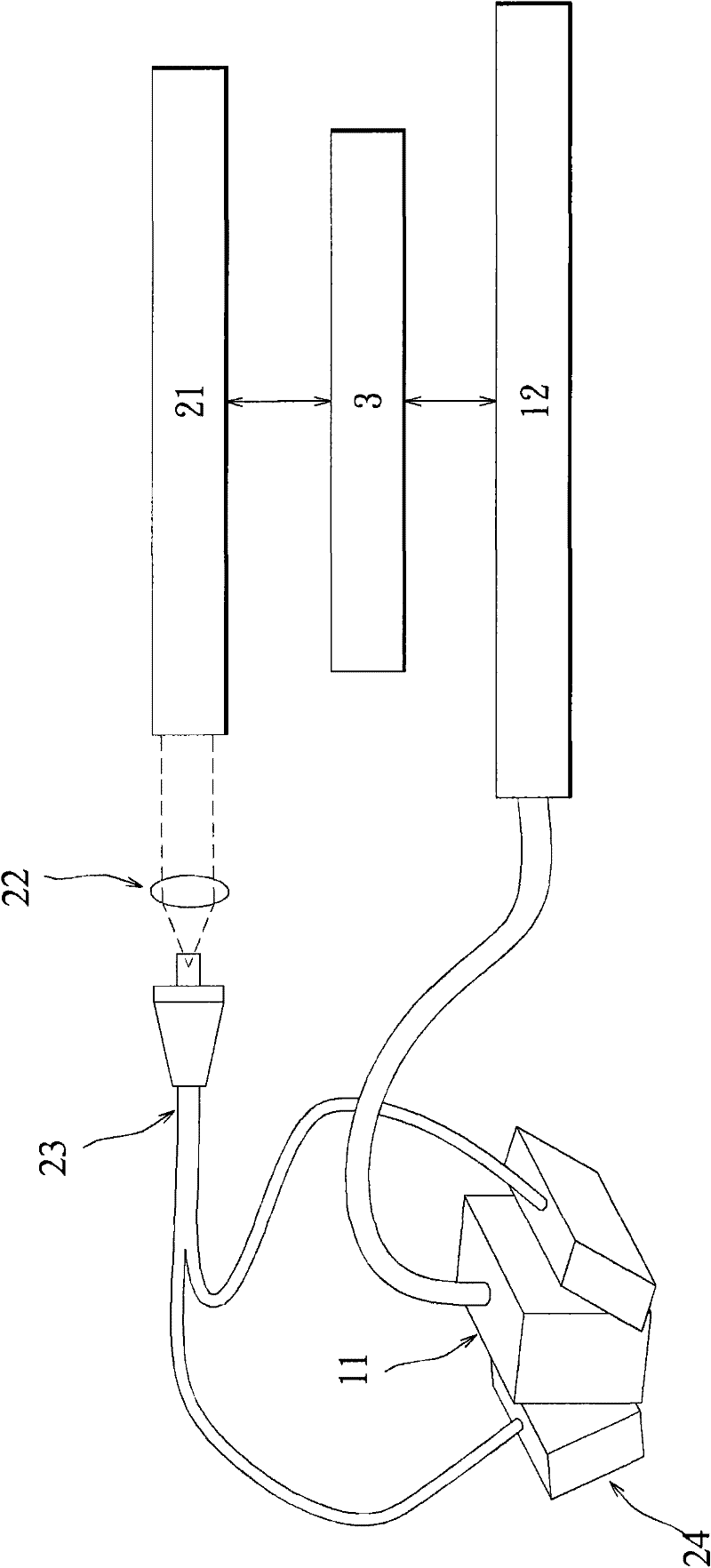

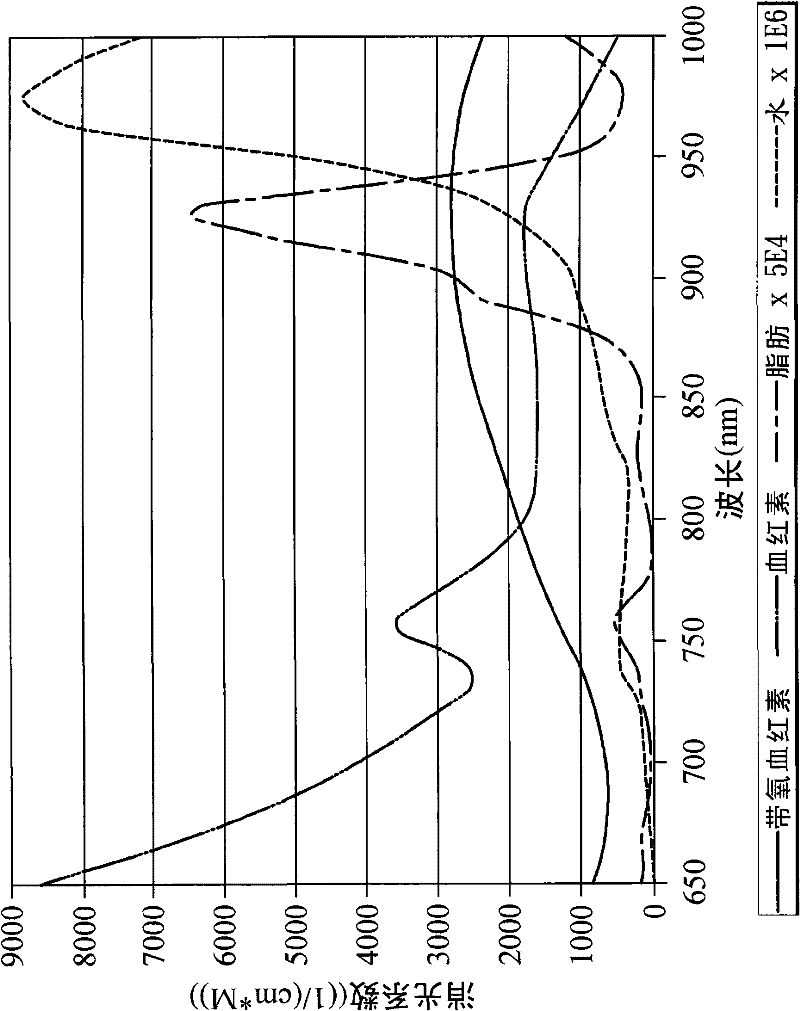

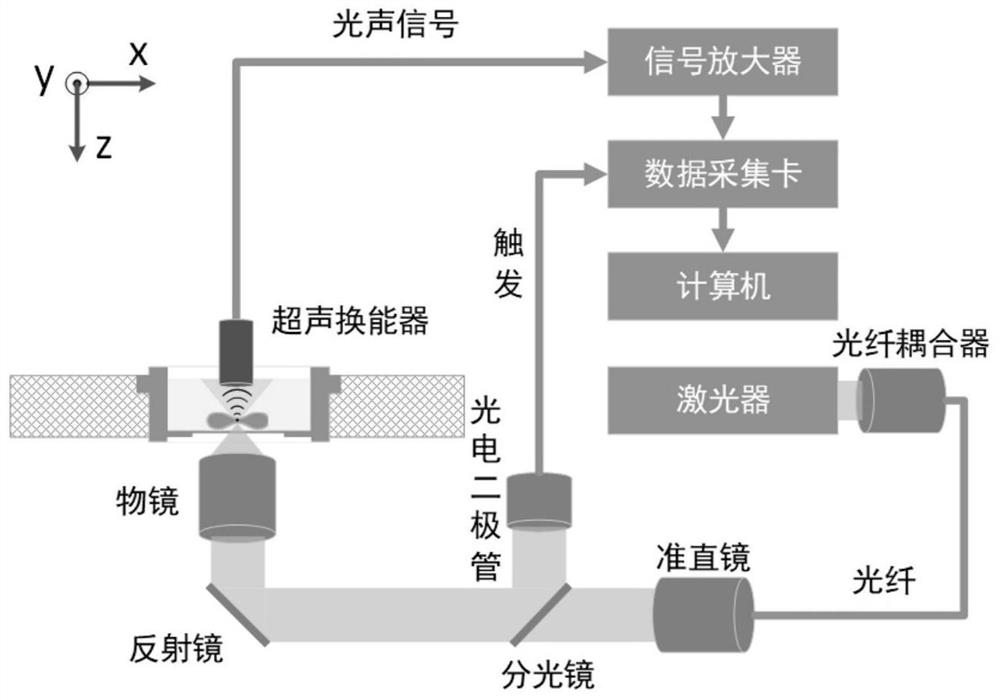

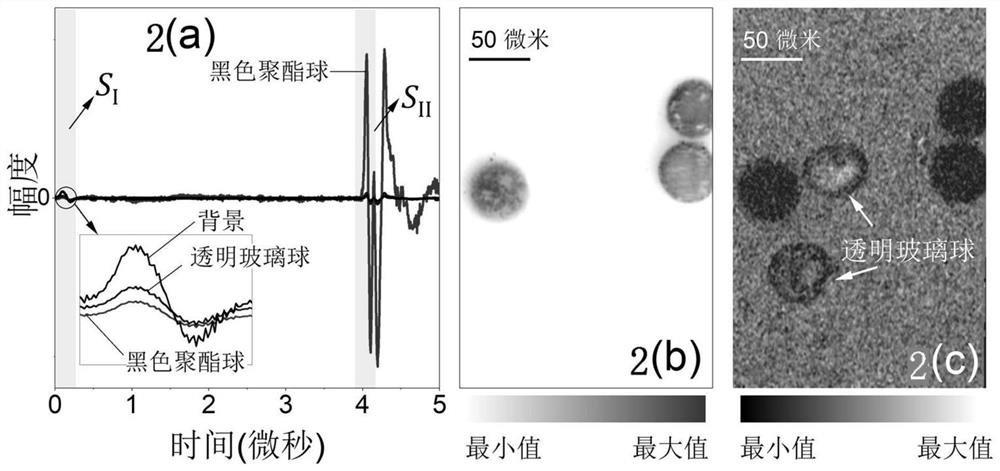

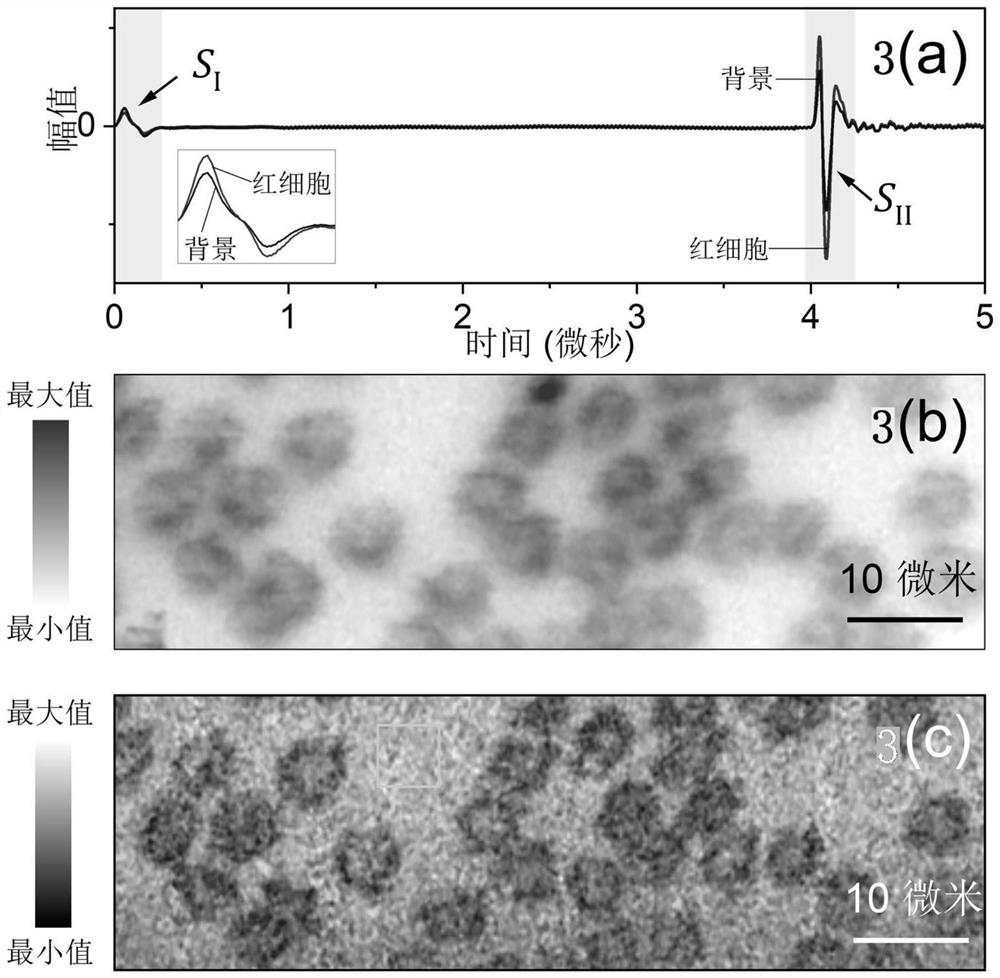

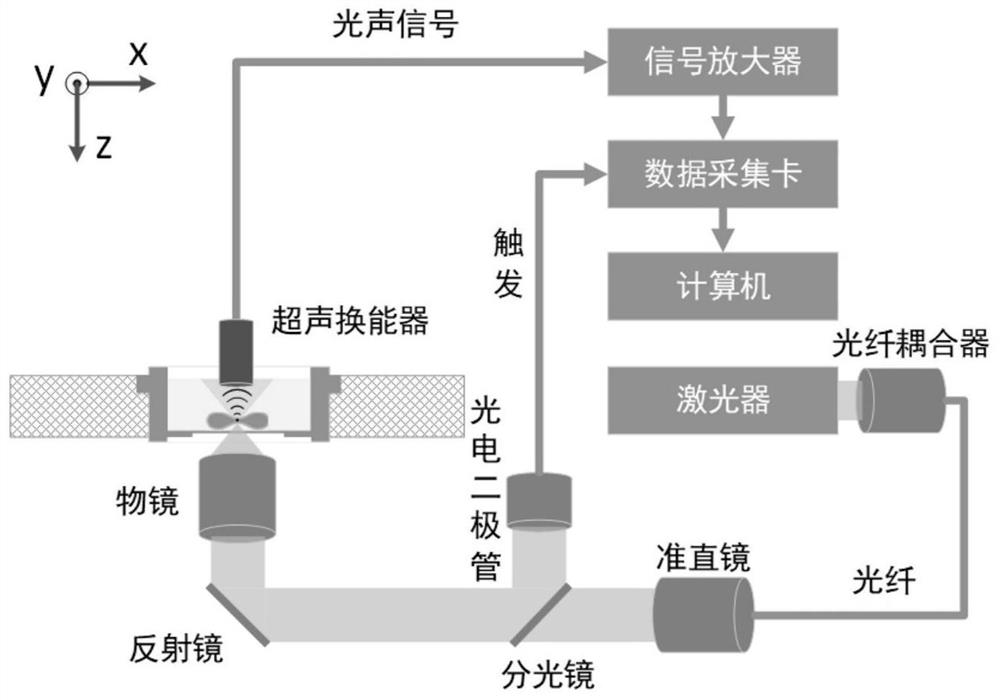

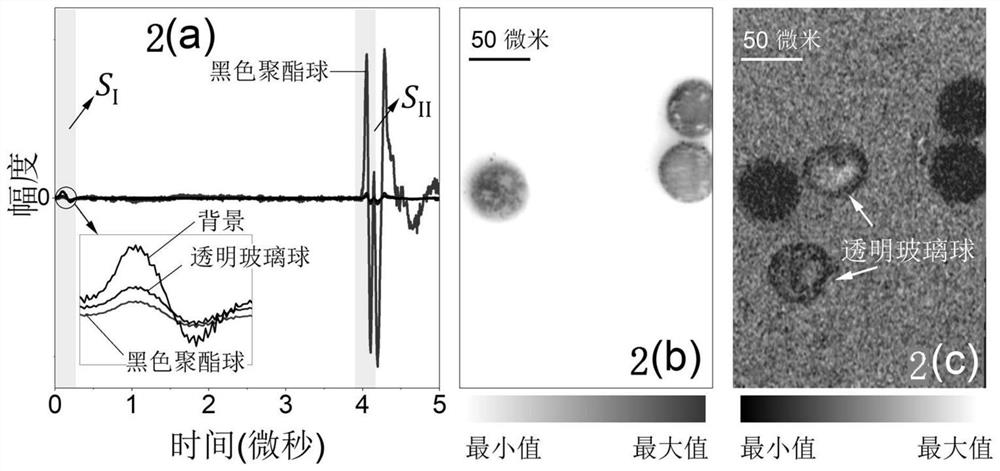

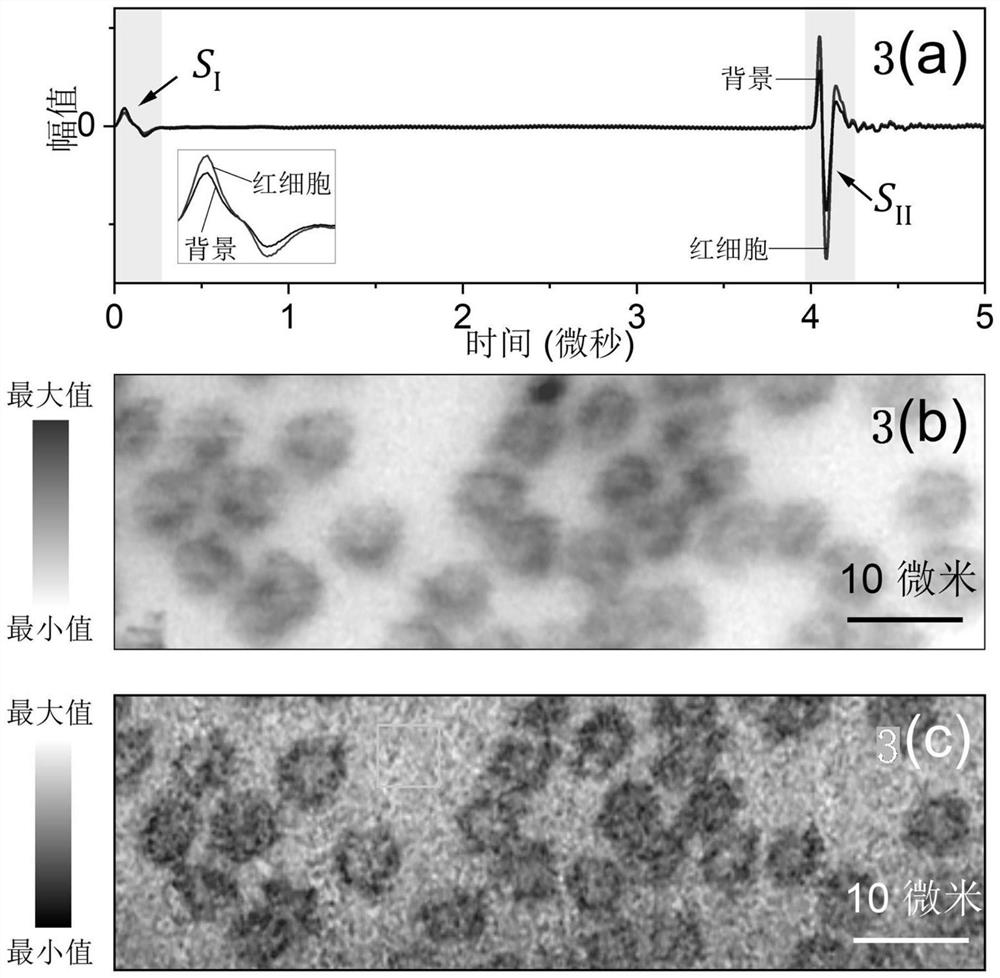

Microscopic imaging method for simultaneously obtaining light absorption contrast and light scattering contrast

ActiveCN111693465ARealization of Light Scattering-Light Absorption Dual Mode Microscopic ImagingAvoid influenceScattering properties measurementsColor/spectral properties measurementsMicro imagingUltrasonic sensor

The invention discloses a microscopic imaging method for simultaneously obtaining light absorption contrast and light scattering contrast. The method comprises the following steps: focusing pulse laser on a sample, absorbing part of the pulse laser by the sample, exciting an ultrasonic signal due to a photoacoustic effect, and receiving the ultrasonic signal through an ultrasonic transducer whichis confocal with a microscope objective and coaxially arranged to obtain an image with light absorption contrast; and meanwhile, using residual pulse laser penetrating through the sample irradiates the surface of the same ultrasonic transducer after being scattered and absorbed by the sample, so as to excite another ultrasonic signal, receiving the ultrasonic signal by the ultrasonic transducer, and obtaining an image with light scattering contrast. According to the invention, for any imaging point on the sample, light scattering-light absorption bimodal microimaging can be realized at the same time only by one-time light excitation; moreover, the method is a high-resolution imaging technology without an exogenous marker, avoids possible influence of a marker on the properties of the sample, and has higher usability and practicability.

Owner:NANJING UNIV

X-ray imaging system

ActiveUS10695019B2Patient positioning for diagnosticsForeign body detectionImaging processingRadiology

An X-ray imaging system includes an X-ray Talbot imaging apparatus and an image processing apparatus. The image processing apparatus generates reconstruction images from the moire image taken by the X-ray Talbot imaging apparatus. The reconstruction images include a differential phase image, an absorption image and a small-angle scattering image. The X-ray imaging system performs X-ray Talbot imaging and normal X-ray imaging. X-ray Talbot imaging includes setting an exposure energy of the X-ray Talbot imaging apparatus to a first exposure energy and taking the moire image with the X-ray detector. Normal X-ray imaging includes setting the exposure energy of the X-ray Talbot imaging apparatus to a second exposure energy and taking an absorption contrast image with the X-ray detector by normal X-ray imaging.

Owner:KONICA MINOLTA INC

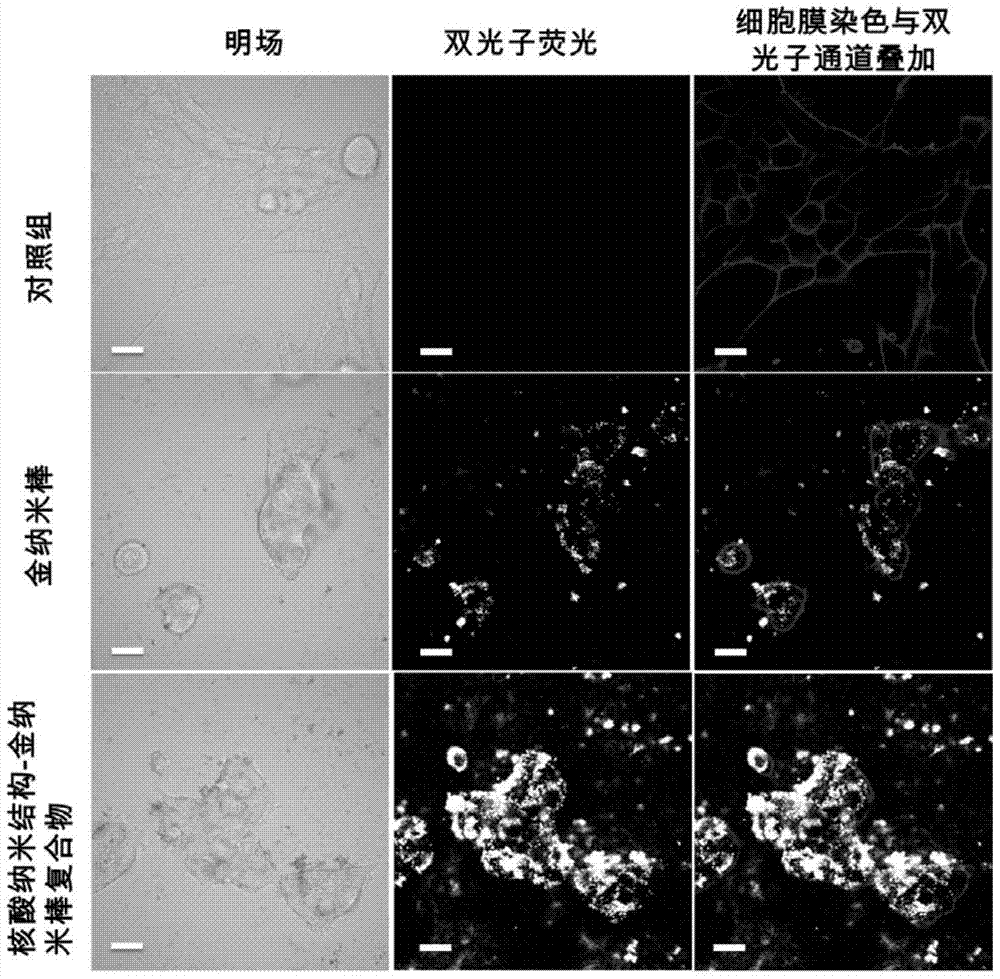

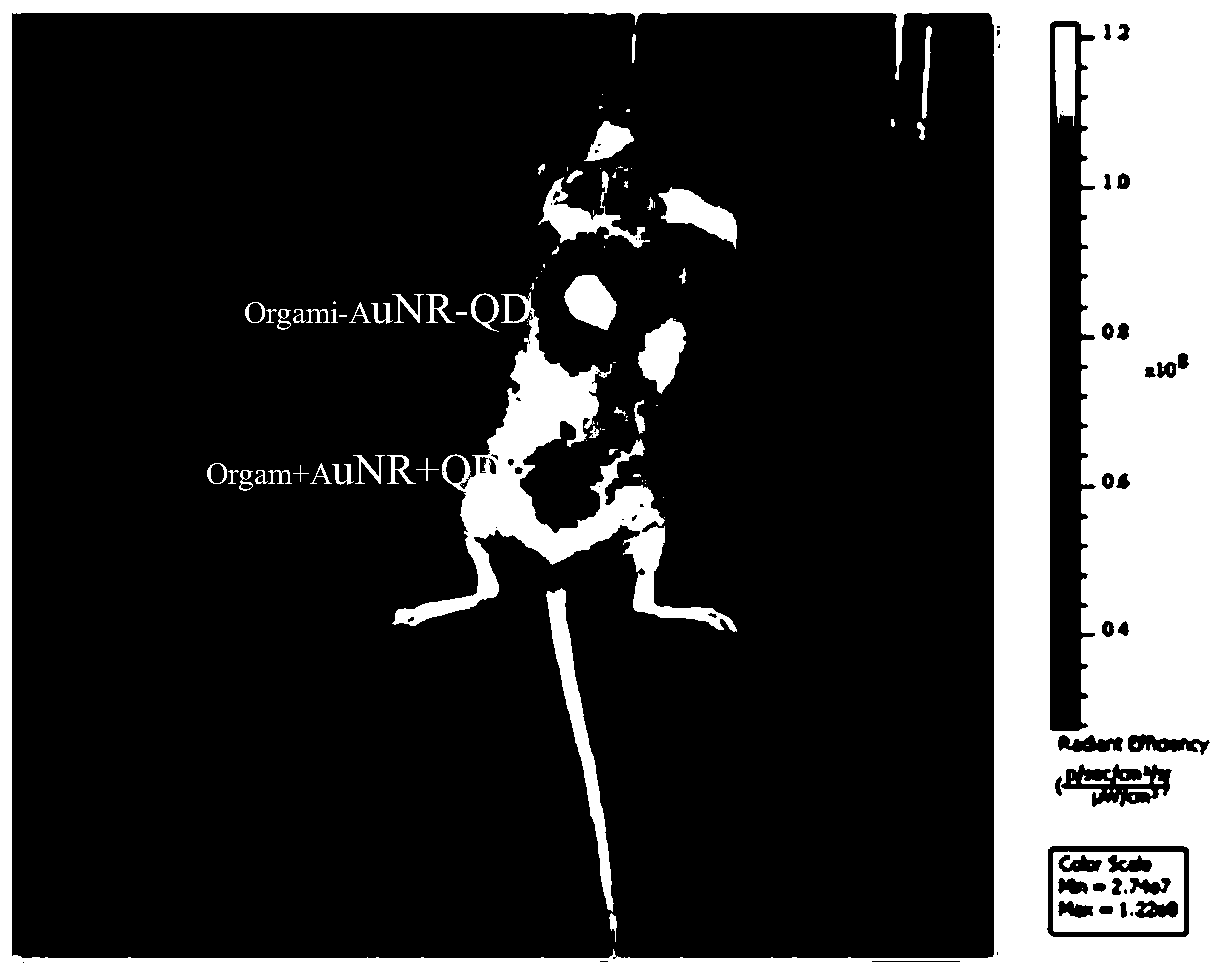

A dual-mode molecular imaging probe integrating optics and photoacoustics and its preparation method and application

ActiveCN106620725BPowder deliveryGeneral/multifunctional contrast agentsGold nanorodMolecular imaging

The invention relates to an optical and opto-acoustic integration dual-mode molecular image probe as well as a preparation method and application thereof. The optical and opto-acoustic integration dual-mode molecular image probe is formed by a nucleic acid nanostructure-gold nanorod-quantum dot compound; the nucleic acid nanostructure is of a two-dimensional and / or three-dimensional nano structure constructed on the basis of a DNA origami technology; the gold nanorod is subjected to surface DNA modification. The nucleic acid nanostructure-gold nanorod-quantum dot compound serving as the optical and opto-acoustic image probe can ensure that the coupled opto-acoustic absorption and comparison effect is enhanced; furthermore, loaded quantum dots are extremely high in optical imaging quality, so that the detection sensitivity can be obviously improved, and the living imaging detection time is prolonged. The material preparation method is simple in process, low in cost, convenient and feasible.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

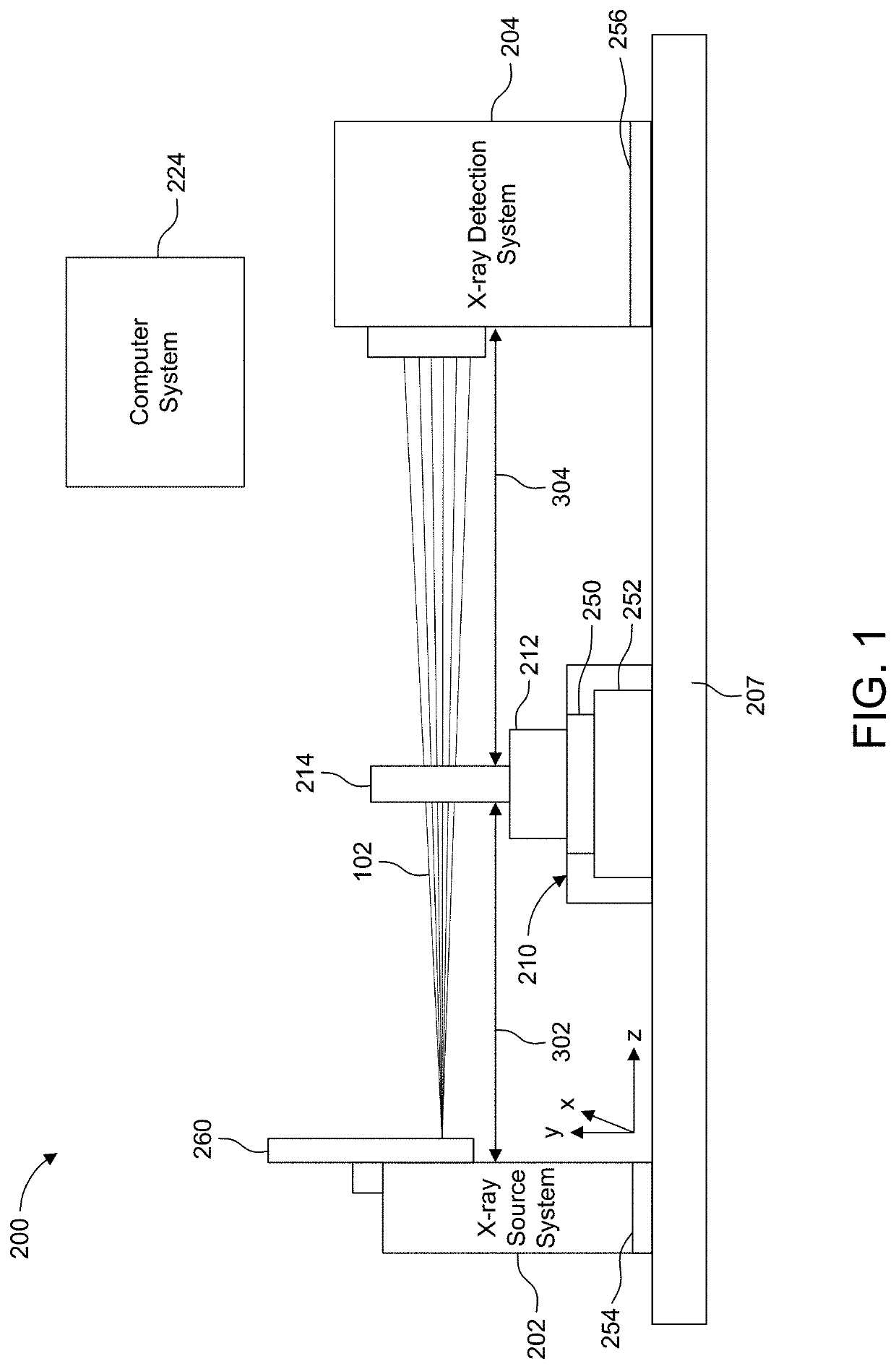

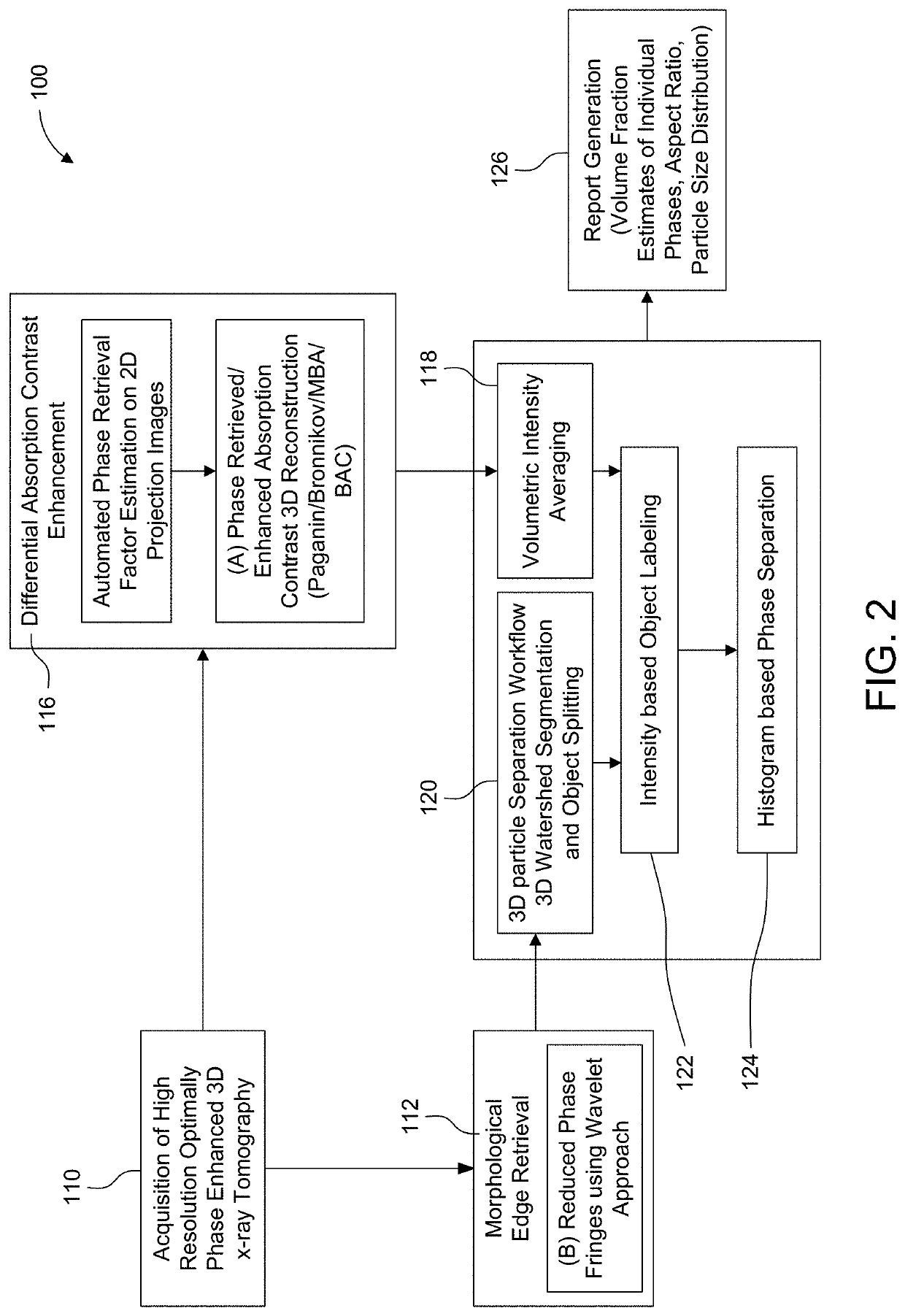

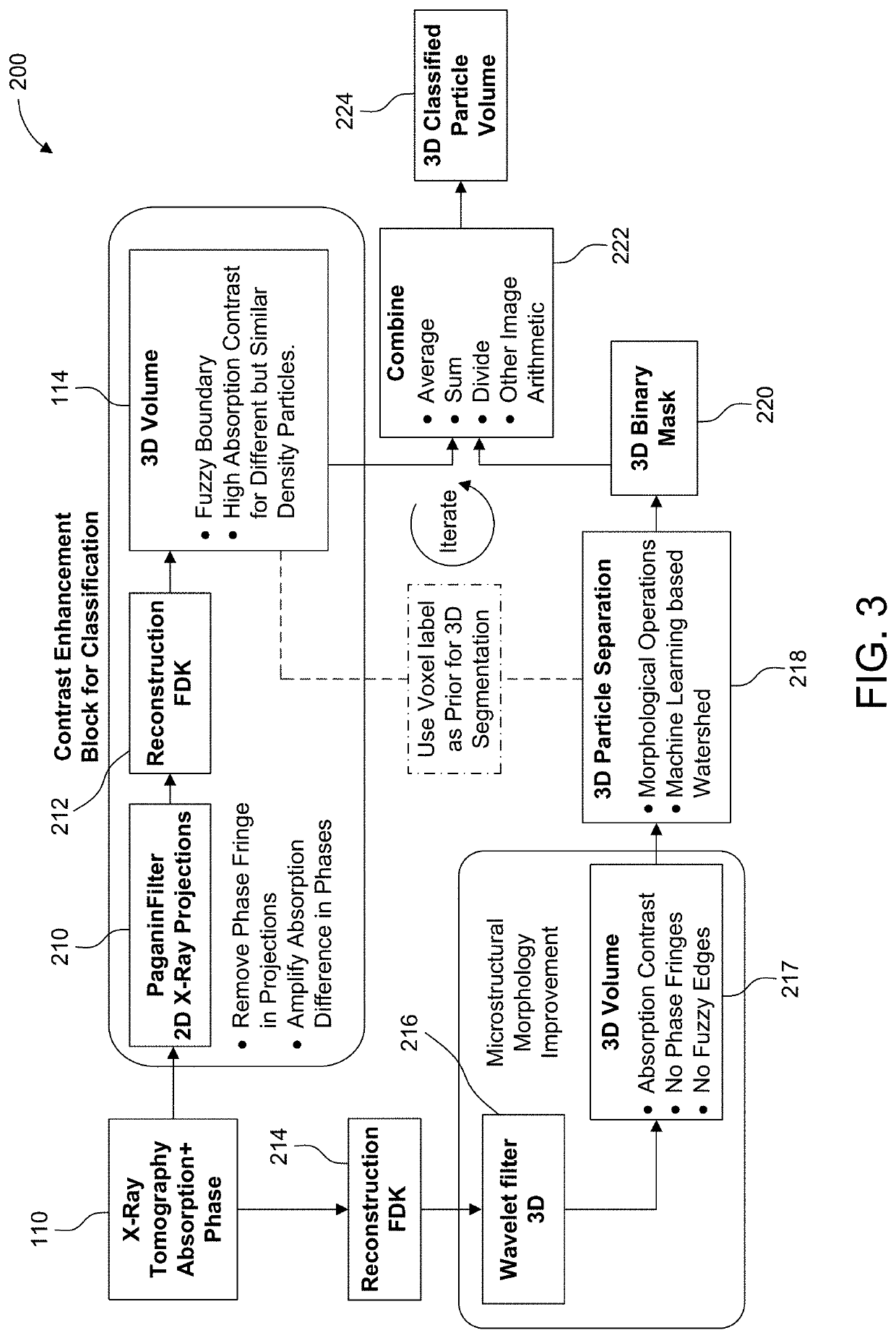

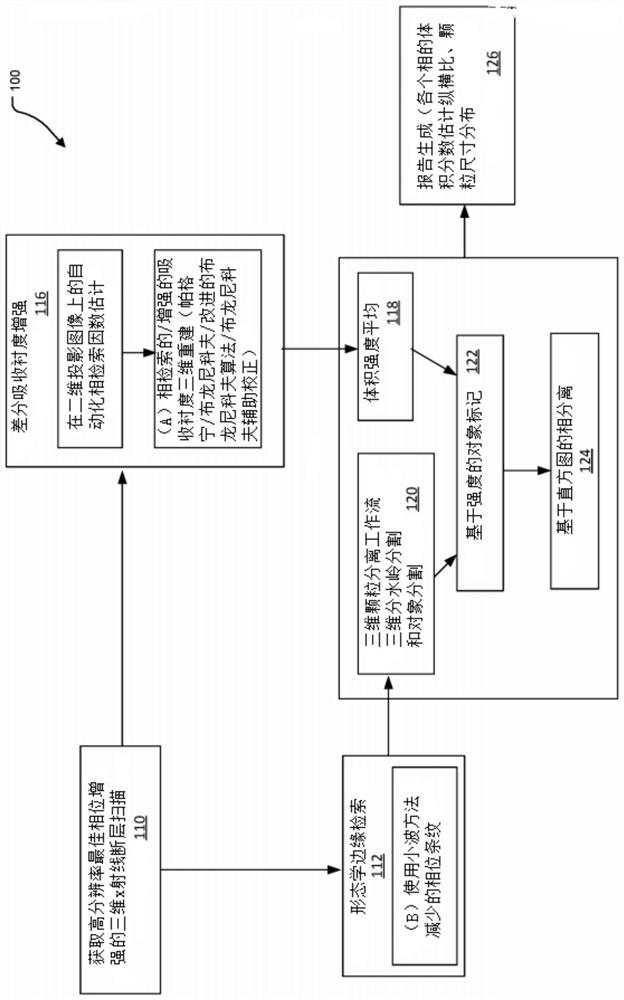

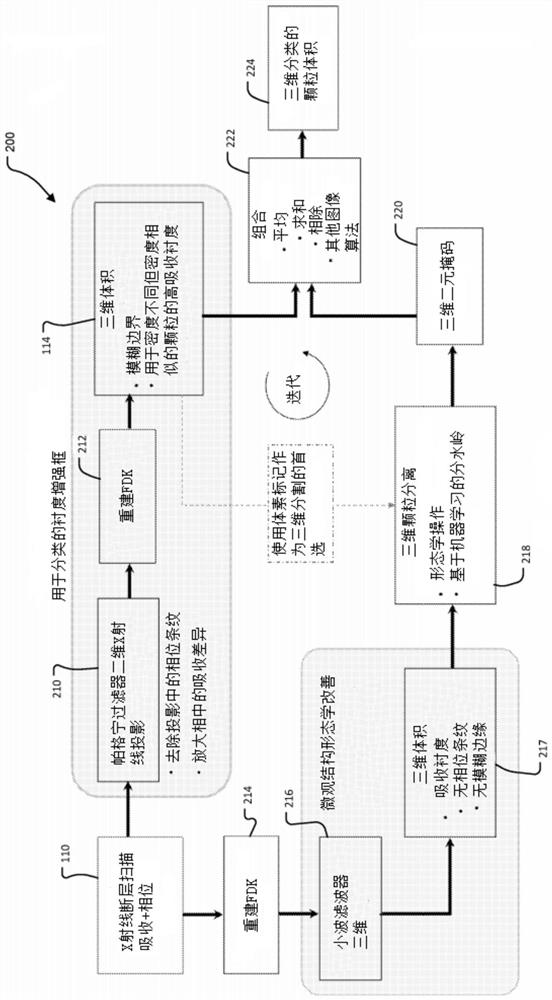

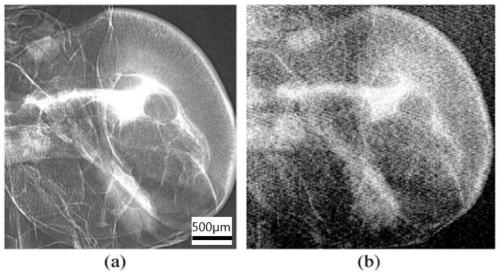

Edge Phase Effects Removal Using Wavelet Correction and Particle Classification Using Combined Absorption and Phase Contrast

ActiveUS20220366620A1Fast volumetric classificationMaximize signal to noiseImage enhancementReconstruction from projectionImaging processingAbsorption contrast

An x-ray microscopy method that obtains a classification of different particles by distinguishing between different material phases through a combination of image processing involving morphological edge enhancement and possibly resolved absorption contrast differences between the phases along with optional wavelet filtering.

Owner:CARL ZEISS X RAY MICROSCOPY

X-ray grating differential phase contrast imaging method and device based on laterally dislocated absorption grating

ActiveCN107144581BSolving the Multiple Exposure ProblemSimple stepsMaterial analysis using wave/particle radiationSoft x rayDifferential phase

Owner:BEIHANG UNIV

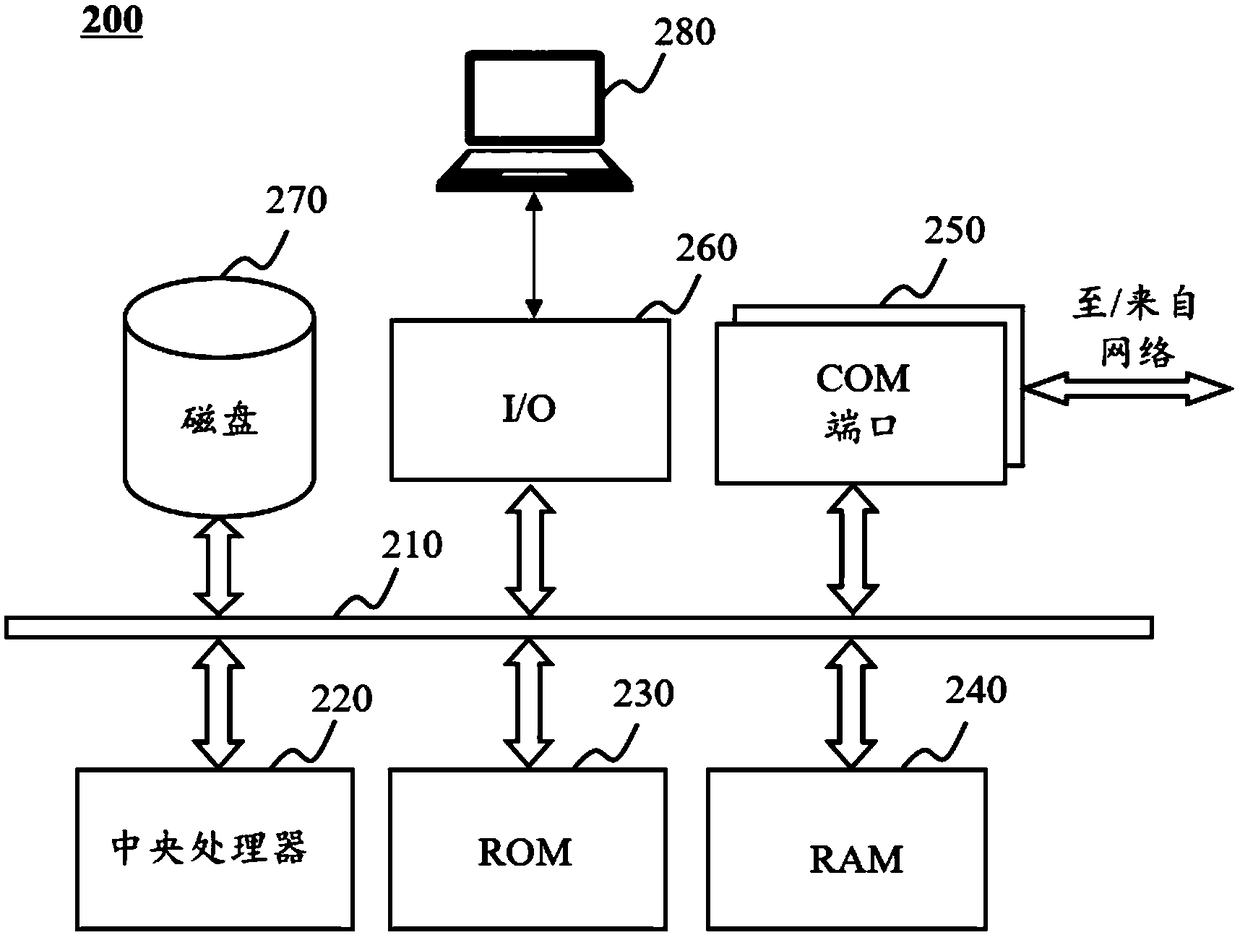

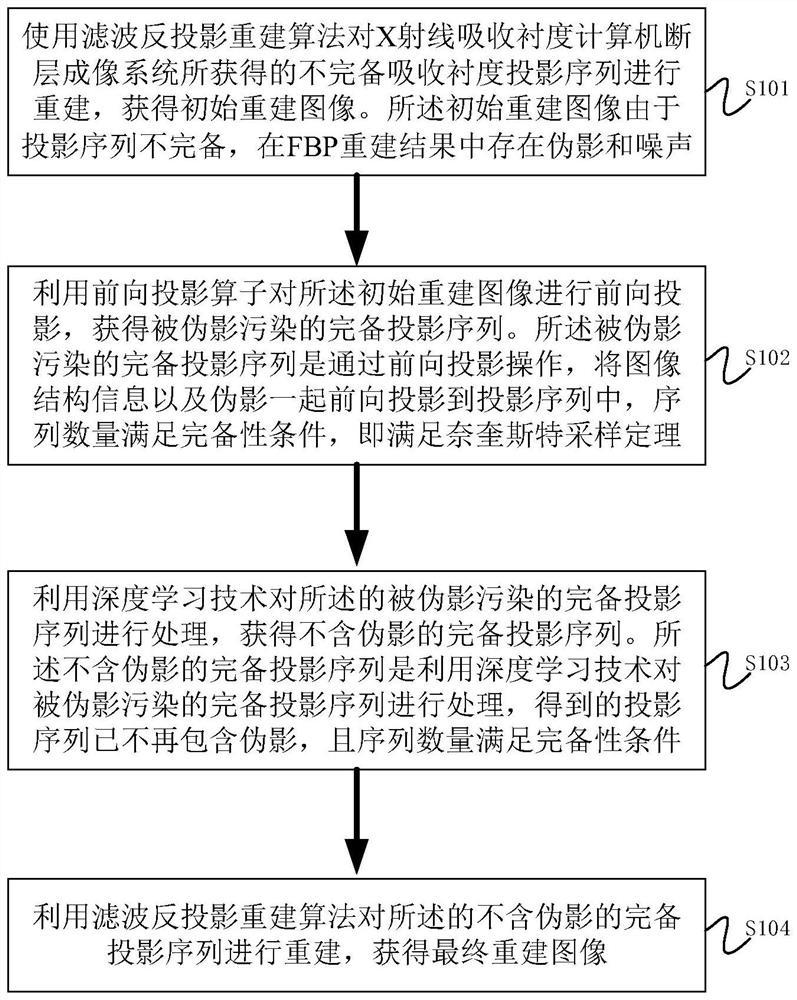

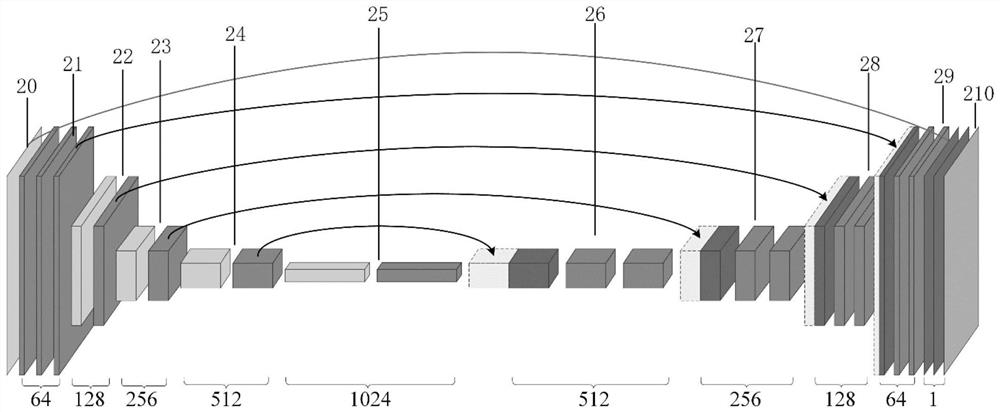

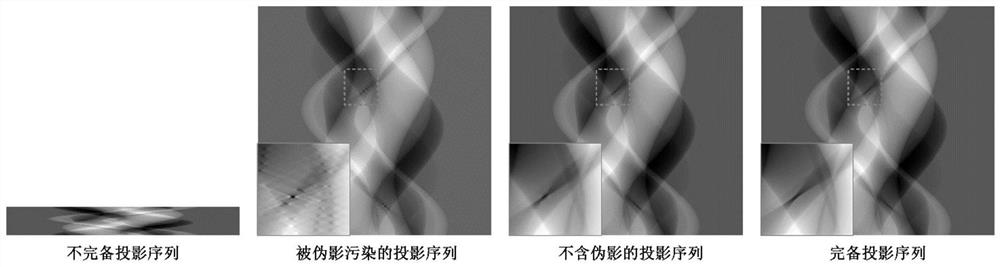

A Deep Learning-Based Method for Incomplete Data Reconstruction of X-ray Absorption Contrast Computed Tomography

ActiveCN110751701BThe calculation process is simpleCalculation speedReconstruction from projectionMaterial analysis using wave/particle radiationPattern recognitionImaging quality

The invention discloses a method for reconstructing incomplete data of X-ray absorption contrast computed tomography based on deep learning. The method comprises the following steps: using a filtering back-projection reconstruction algorithm to obtain an initial reconstruction image; performing forward projection on the above-mentioned initial reconstruction image Obtain the projection sequence polluted by artifacts; use deep learning technology to process the above-mentioned projection sequence contaminated by artifacts to obtain a projection sequence without artifacts; use the filtered back-projection reconstruction algorithm to reconstruct the above-mentioned projection sequence without artifacts, Obtain the final reconstruction result image. Compared with the traditional incomplete data reconstruction method, the embodiment of the present invention has a simple calculation process, fewer parameters that need to be manually set, faster calculation speed, and higher image quality.

Owner:BEIHANG UNIV +1

Three-dimensional cone-beam computed tomography method and device based on laterally misaligned gratings

ActiveCN108680589BPrevent steppingSolve the problem of multiple exposureMaterial analysis using wave/particle radiationAbsorption contrastBack projection

The invention discloses an X-ray grating differential phase contrast three-dimensional cone-beam computer tomography method and device based on a laterally dislocated grating. The method includes: arranging a Talbot-Lau three-dimensional cone-beam tomography structure with a laterally dislocated absorption grating; The two-dimensional intensity image sequence after the X-ray passes through the object is obtained with the above structure; the X-ray absorption contrast, differential phase contrast and scattering contrast are separated from the collected two-dimensional intensity image by Fourier analysis. Image sequence: Using the absorption contrast, differential phase contrast and scattering contrast filter back projection reconstruction algorithms to reconstruct the three contrast image sequences to obtain the three contrast CT slice images of the object. The invention does not need to step the absorption grating, and can obtain three kinds of contrast CT slice images with the traditional X-ray attenuation-based CT scanning method, which greatly reduces the imaging time, reduces the imaging dose, and improves the imaging efficiency and stability of the system sex.

Owner:BEIHANG UNIV

Edge phase effect removal using wavelet correction and particle classification using combined absorption and phase contrast

ActiveCN114762003AImage enhancementReconstruction from projectionImaging processingAbsorption contrast

An x-ray microscopy method obtains a classification of different particles by distinguishing between different material phases in conjunction with image processing including morphological edge enhancement and potentially distinguishable differences in absorption contrast between the phases, and optionally wavelet filtering.

Owner:卡尔蔡司有限公司

A Microscopic Imaging Method to Obtain Double Contrast of Light Absorption and Light Scattering Simultaneously

ActiveCN111693465BReduce absorptionReduce scatterScattering properties measurementsColor/spectral properties measurementsMicro imagingMicroscopic image

The invention discloses a microscopic imaging method for obtaining double contrast of light absorption and light scattering at the same time. The pulsed laser is focused on the sample, and the sample absorbs part of the pulsed laser, and the ultrasonic signal is excited due to the photoacoustic effect. 1. The ultrasonic transducer arranged coaxially receives the ultrasonic signal and obtains an image with light absorption contrast; at the same time, the remaining pulsed laser light that passes through the sample is scattered and absorbed by the sample, and then irradiates on the same surface of the ultrasonic transducer, and then Another ultrasound signal is excited and received by the ultrasound transducer, from which an image with light scattering contrast can be obtained. For any imaging point on the sample, the present invention can realize light scattering-light absorption dual-mode microscopic imaging at the same time with only one optical excitation; moreover, this method is a high-resolution imaging technology without exogenous labeling, avoiding The possible influence of the marker on the properties of the sample is understood, and it has high ease of use and practicability.

Owner:NANJING UNIV

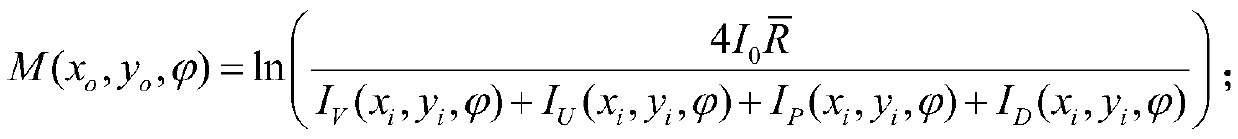

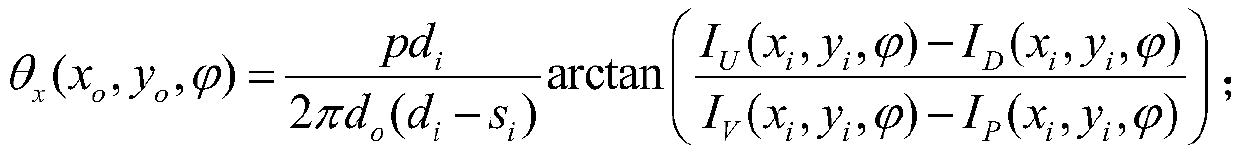

Nano-CT 3D Imaging Method with Three Quantitative Imaging Mechanisms

ActiveCN108169257BMaterial analysis using wave/particle radiationAbsorption contrastRefractive index

The invention discloses a nanometer CT three-dimensional imaging method using three quantitative imaging mechanisms. The method comprises taking a valley macrophotograph, an upslope macrophotograph, apeak macrophotograph and a downslope macrophotograph of a sample at different angles on the image plane of an X-ray differential phase contrast microscope according to an angle signal response imaging mechanism, rebuilding a two-dimensional absorption contrast image, a two-dimensional refraction contrast image and a two-dimensional scattering contrast image of the sample at different angles on the object plane of the X-ray differential phase contrast microscope according to three quantitative imaging mechanisms, and rebuilding a linear absorption coefficient three-dimensional image, a linearscattering coefficient three-dimensional image, a refractive index real attenuation rate three-dimensional image and a refractive index real attenuation rate derivative three-dimensional image of thesample according to inverse Radon conversion. The method can realize three-dimensional imaging of whole cells with diameters of 5 micrometers or more and has the nanometer scale resolution rate.

Owner:济南汉江光电科技有限公司

System, method and apparatus for retinal absorption phase and dark field imaging with oblique illumination

A method for imaging a tissue of an eye, the method including the steps of providing oblique illumination to the eye by a plurality of light emitting areas of a light delivery device, the plurality of light emitting areas being independently controllable and arranged to direct light towards at least one of a retina and an iris of the eye, causing an output beam from light backscattered from the at least one of the retina and the iris by the oblique illumination, capturing the output beam with an imaging system to provide a sequence of images of a fundus of the eye, and retrieving a phase and absorption contrast image from the sequence of images of the fundus, wherein the sequence of images of the fundus of the step of capturing is obtained by sequentially turning on one or more of the plurality of light emitting areas at a time in the step of providing the oblique illumination.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

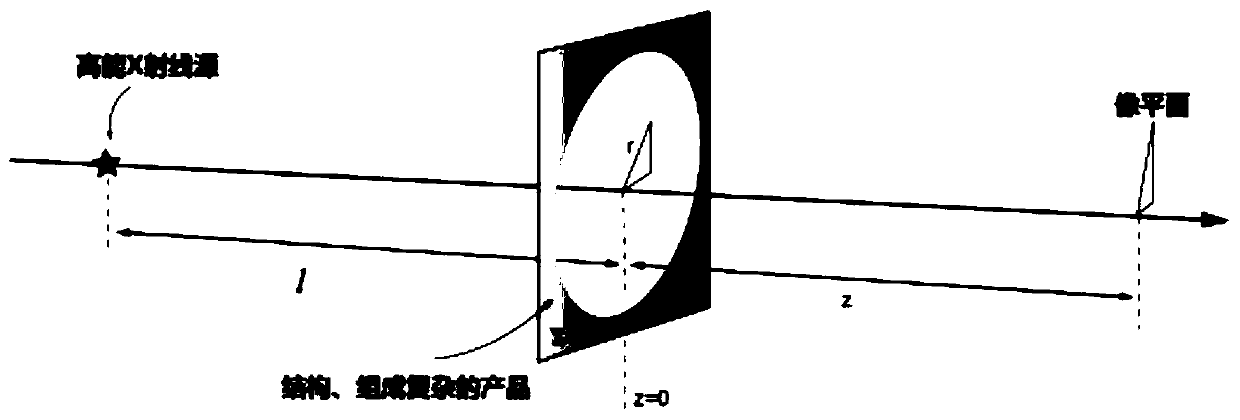

High-energy X-ray CT device based on phase contrast imaging and imaging method

PendingCN111289545AReduce the impactImprove manufacturing precisionMaterial analysis using wave/particle radiationCt technologyImage resolution

The invention discloses a high-energy X-ray CT device based on phase contrast imaging and an imaging method. The high-energy X-ray CT device comprises a high-energy X-ray source, a sample table and animaging device, wherein the high-energy X-ray source is a high-energy X-ray punctuality light source, is an irradiation light source of a sample and is used for directionally emitting and irradiatingand transmitting the sample; the sample table is used for placing a sample, and after the high-energy X-ray source penetrates through the sample, transmitted X-rays are transmitted in a fluctuation mode and are coherently superposed on an image plane behind the sample to form photon intensity information containing phase and amplitude information; and the imaging device is arranged on an image plane behind the sample and is used for converting photon intensity information into an image signal. According to the method, the problems that the quality of the obtained CT image is not ideal and thespatial resolution is poor due to the existing CT technology based on high-energy X-ray absorption contrast, particularly, the resolution of the obtained image of the micro gap in the product is verylow, the micro gap is visible and unmeasurable, and the micro defects are difficult to distinguish are solved.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

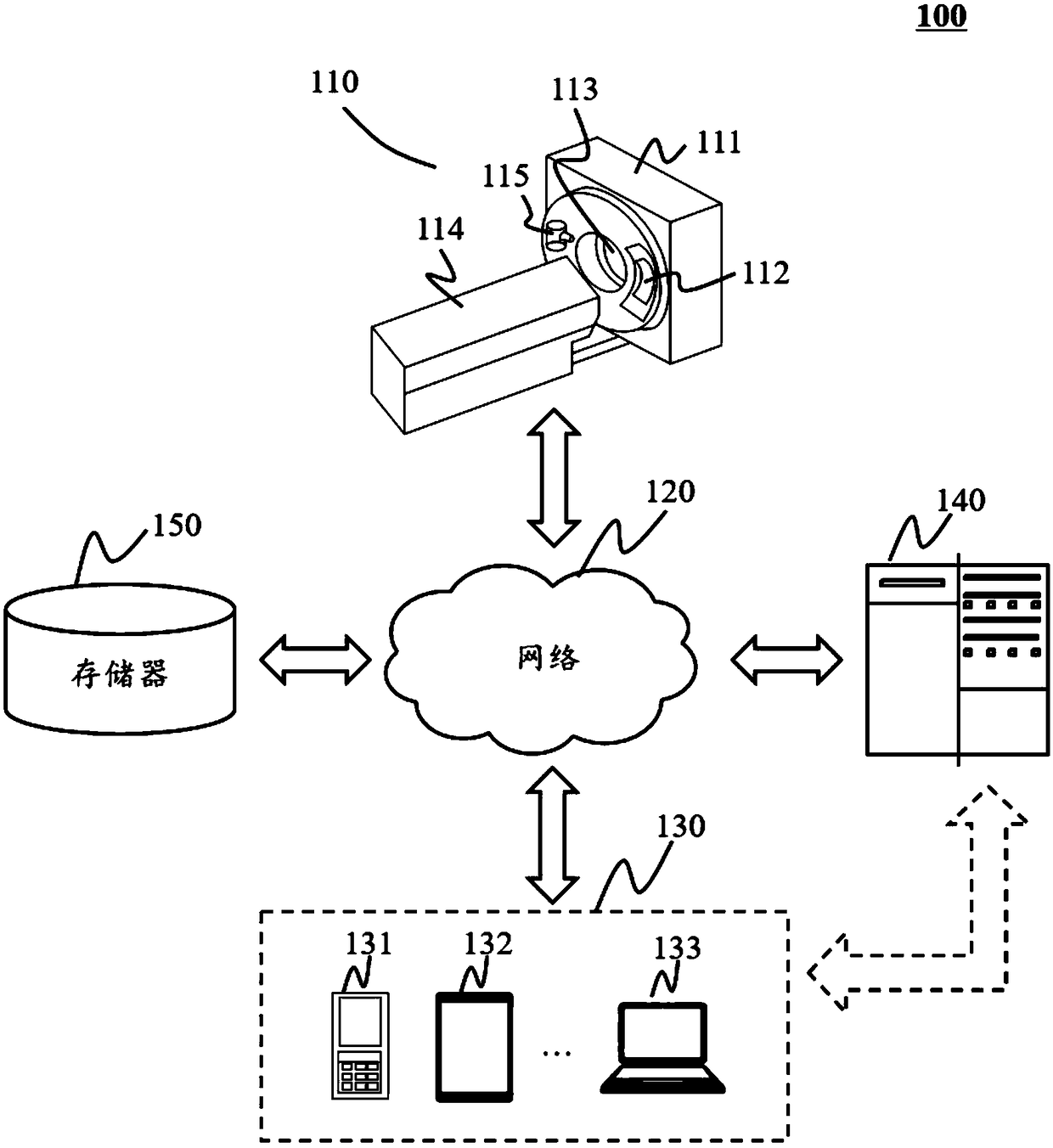

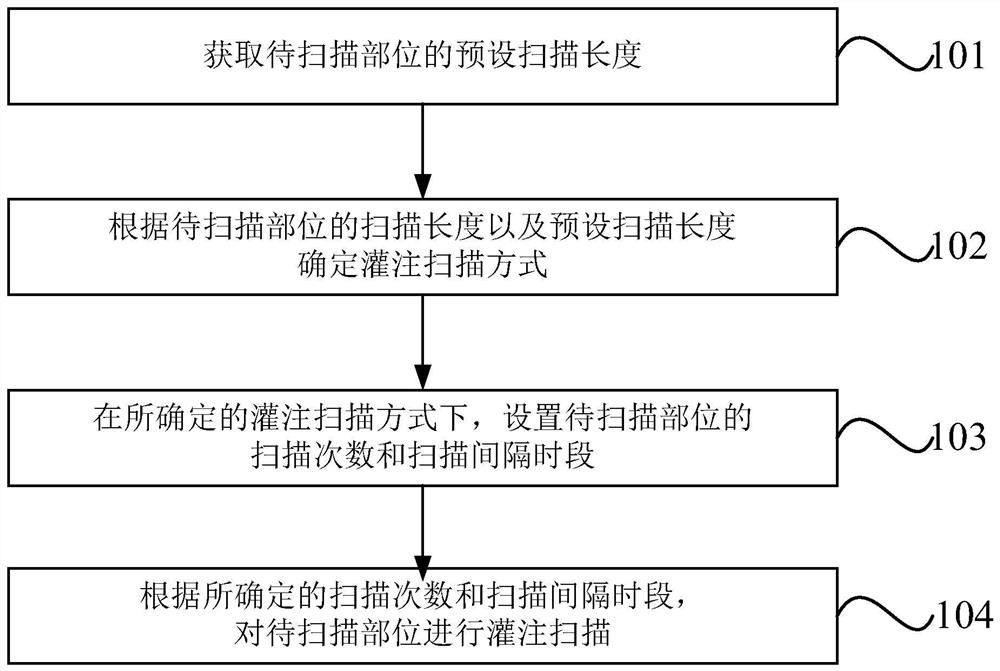

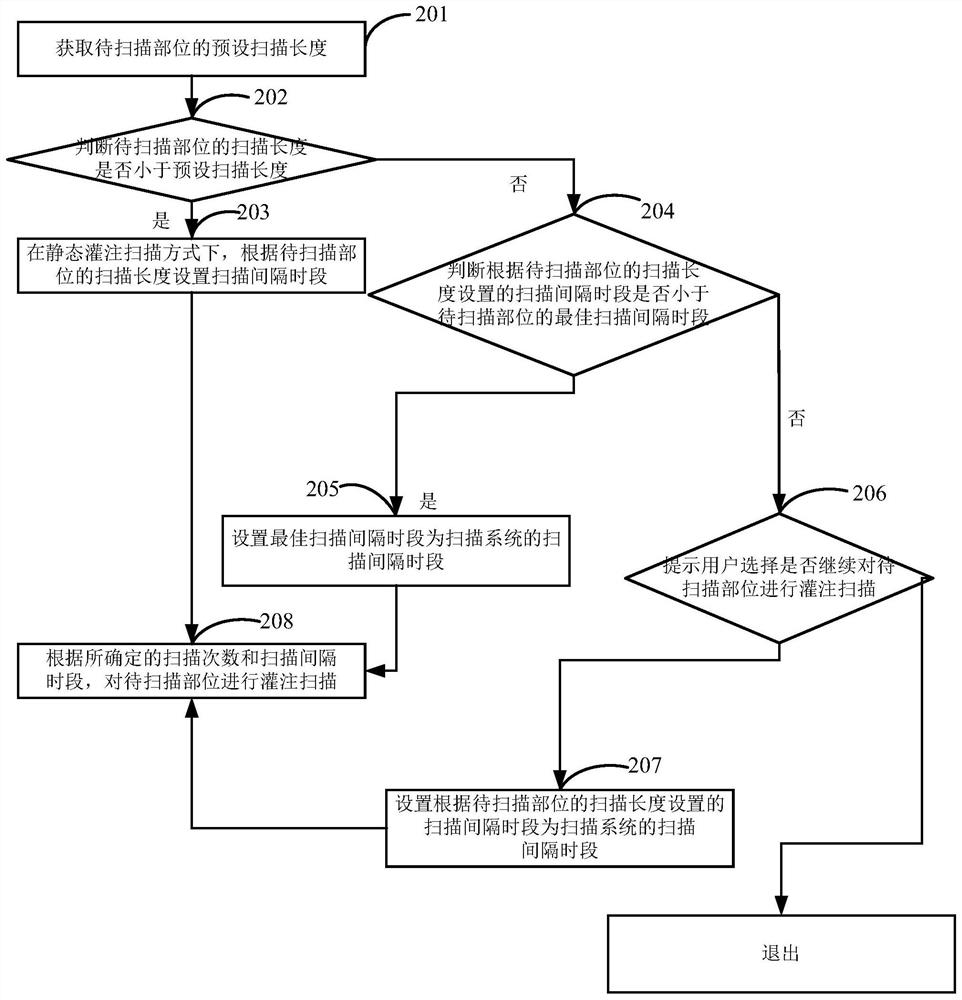

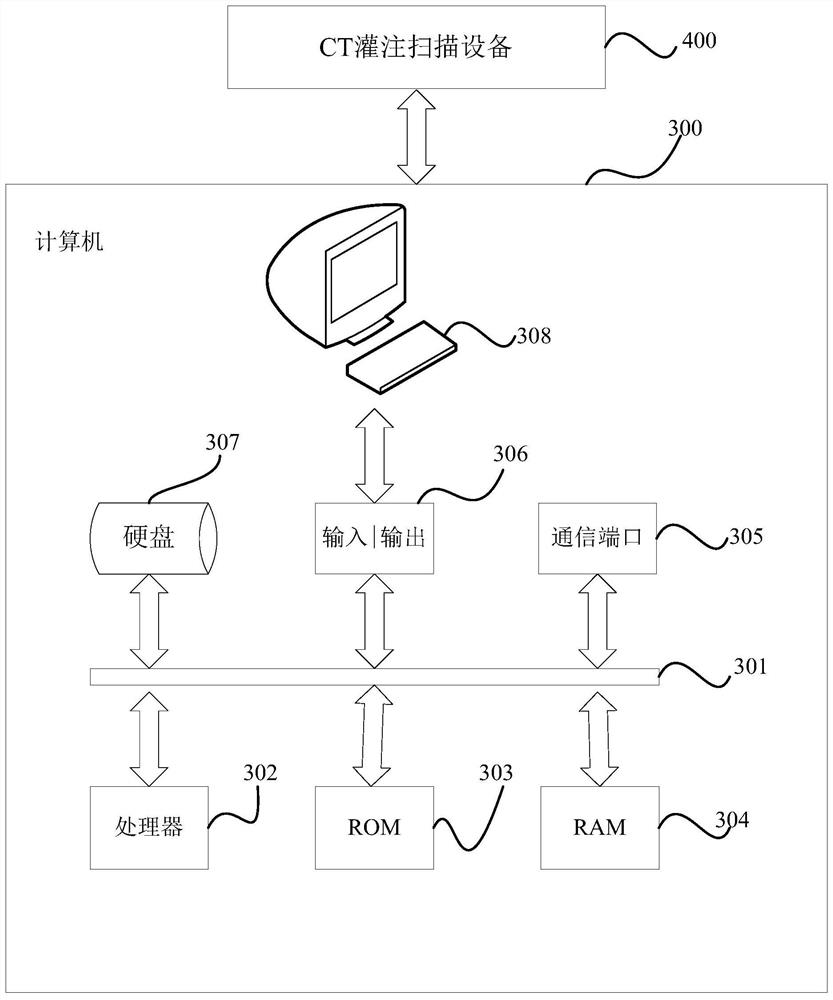

CT perfusion scanning method, system and storage medium

ActiveCN108095751BReduce the amount of absorbed contrast agentReduce harmComputerised tomographsTomographyContinuous scanningAbsorption contrast

The present invention relates to a CT perfusion scanning method, system and storage medium, including obtaining the scanning length of the part to be scanned; determining the perfusion scanning mode according to the scanning length of the part to be scanned and the preset scanning length, and the perfusion scanning mode includes static Perfusion scanning and dynamic perfusion scanning; in the determined perfusion scanning mode, setting the number of scans and the scanning interval of the part to be scanned; performing perfusion scanning on the part to be scanned according to the determined number of scans and the scanning interval , which can prevent the scan interval manually selected by the user from being too large or too small, so that the set time interval for continuous scanning of the same part, that is, the scan interval, is more accurate. On the premise of ensuring that the image of CT perfusion scan is clear, it can be minimized. The number of consecutive scans of the same part reduces the amount of contrast agent absorbed by the patient, thereby reducing the harm to the patient.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com