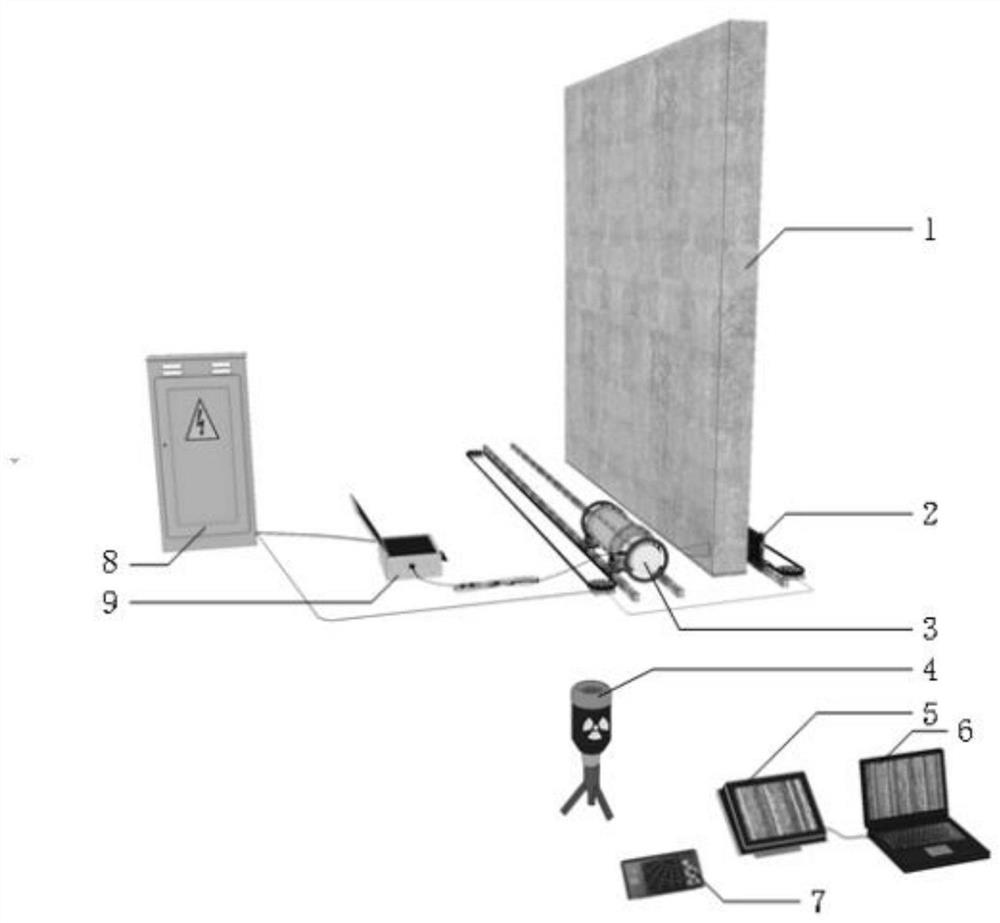

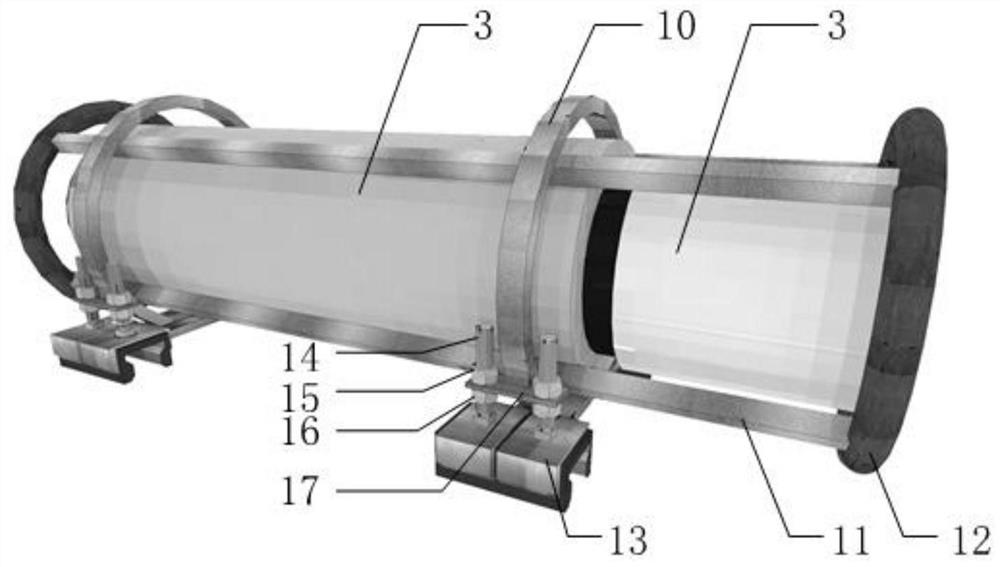

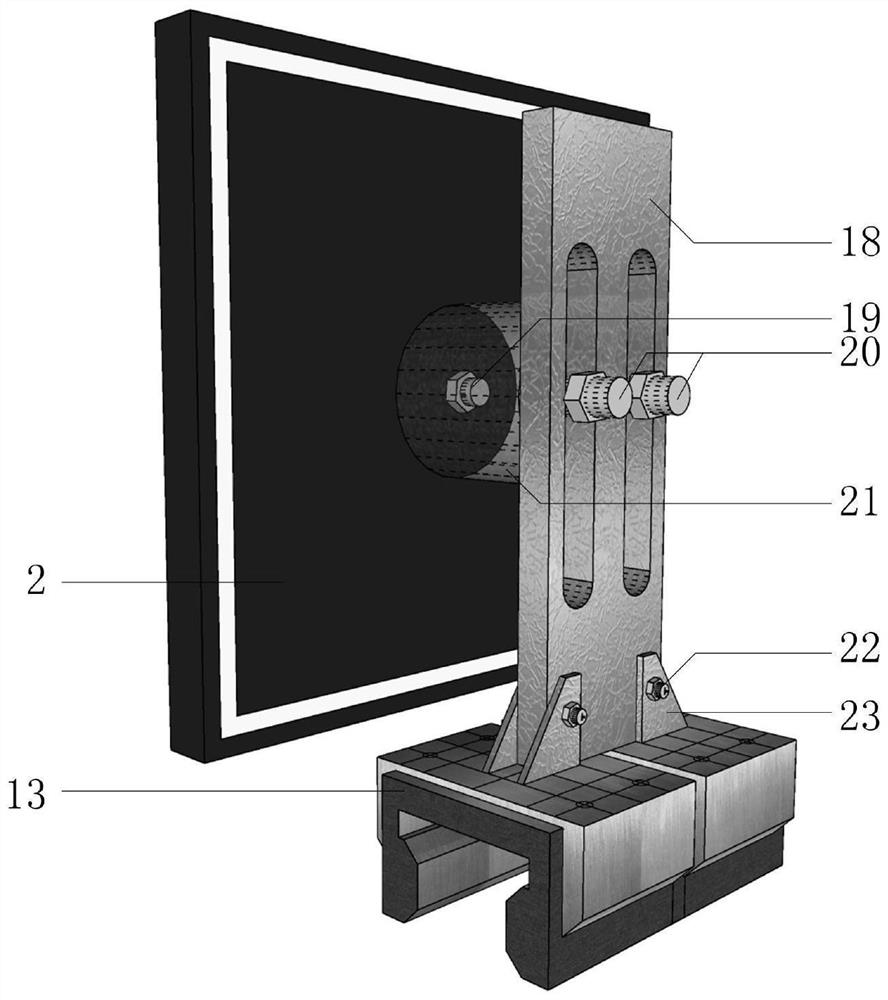

Sleeve grouting forming quality detection method based on X-ray absorption contrast improvement and detection device thereof

A technology for grouting and forming quality of sleeves, applied in measuring devices, material analysis using wave/particle radiation, instruments, etc. Large contrast difference, the effect of increasing the detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] As a preferred embodiment of the present invention, it comprises the following steps of mixing:

[0071] Step 1, take by weighing 2.5kg barium sulfate powder (barium sulfate powder purity is 99%, particle diameter is 5 μm), take by weighing 47.5kg grouting material, the sum of the two masses is 50kg, put the grouting material and barium sulfate powder into the mixer Medium pre-mixing, the stirring rate is 240r / min~280r / min, and the stirring time is 3min;

[0072] Step 2, after the stirring is completed, take out the mixed grouting material with a mass of about 15kg for use;

[0073] Step 3, add 6 liters of water to the mixer for stirring, the stirring rate is 150r / min, and the stirring time is 2min;

[0074] Step 4, add the mixed grouting material taken out in step 2 into the mixer for stirring, the stirring rate is 240r / min~280r / min, and the stirring time is 3min;

[0075] Step 5: After the preparation of the mixed grouting material is completed, stand still for 2 minu...

Embodiment 2

[0088] As a preferred embodiment of the present invention, it comprises the following steps of mixing:

[0089] Step 1, take by weighing 5kg barium sulfate powder (purity of barium sulfate powder is 99%, particle diameter is 5 μm), take by weighing 45kg grouting material, the sum of the quality of the two is 50kg, and the grouting material and barium sulfate powder are put into the mixer for pre-processing. Mixing, the stirring rate is 240r / min~280r / min, and the stirring time is 3min;

[0090] Step 2, after the stirring is completed, take out the mixed grouting material with a mass of about 15kg for use;

[0091] Step 3, add 6 liters of water to the mixer for stirring, the stirring rate is 150r / min, and the stirring time is 2min;

[0092] Step 4, add the mixed grouting material taken out in step 2 into the mixer for stirring, the stirring rate is 240r / min~280r / min, and the stirring time is 3min;

[0093] Step 5: After the preparation of the mixed grouting material is complet...

Embodiment 3

[0106] As a preferred embodiment of the present invention, it comprises the following steps of mixing:

[0107] Step 1, take by weighing 7.5kg barium sulfate powder (barium sulfate powder purity is 99%, particle diameter is 5 μm), take by weighing 42.5kg grouting material, the sum of the two masses is 50kg, put the grouting material and barium sulfate powder into the mixer Medium pre-mixing, the stirring rate is 240r / min~280r / min, and the stirring time is 3min;

[0108] Step 2, after the stirring is completed, take out the mixed grouting material with a mass of about 15kg for use;

[0109] Step 3, add 6 liters of water to the mixer for stirring, the stirring rate is 150r / min, and the stirring time is 2min;

[0110] Step 4, add the mixed grouting material taken out in step 2 into the mixer for stirring, the stirring rate is 240r / min~280r / min, and the stirring time is 3min;

[0111] Step 5: After the preparation of the mixed grouting material is completed, stand still for 2 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com