Patents

Literature

316 results about "Micro defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

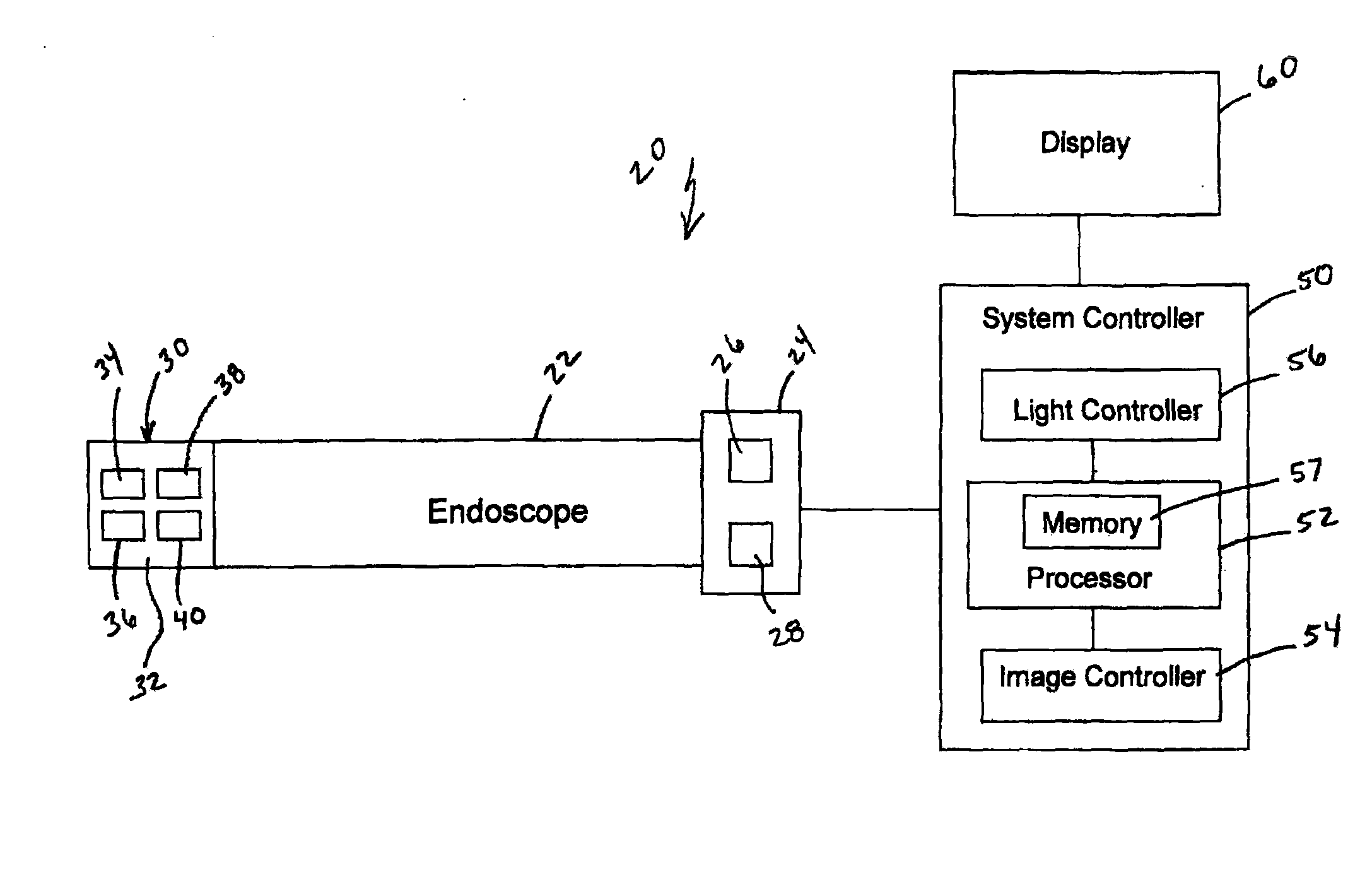

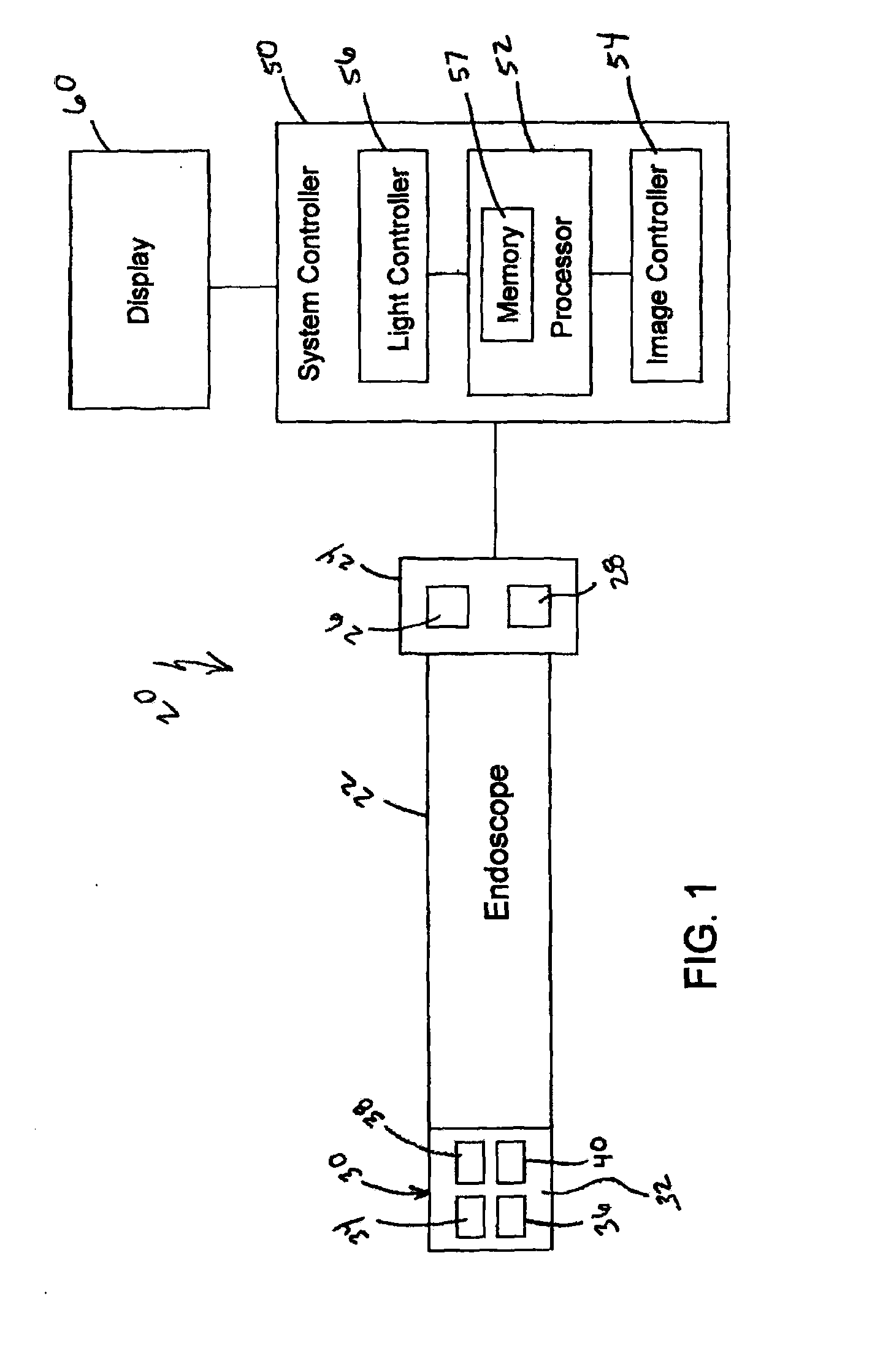

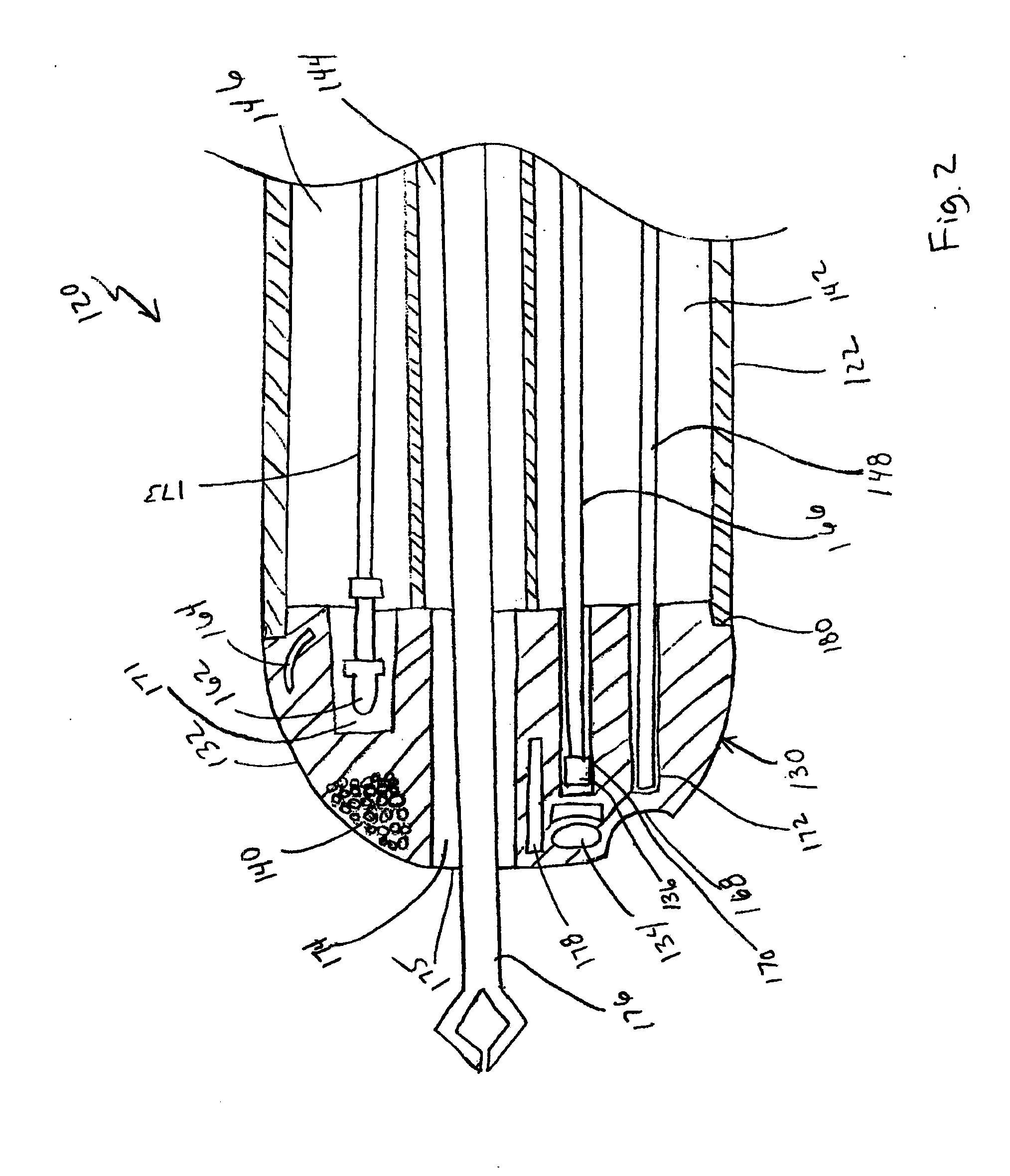

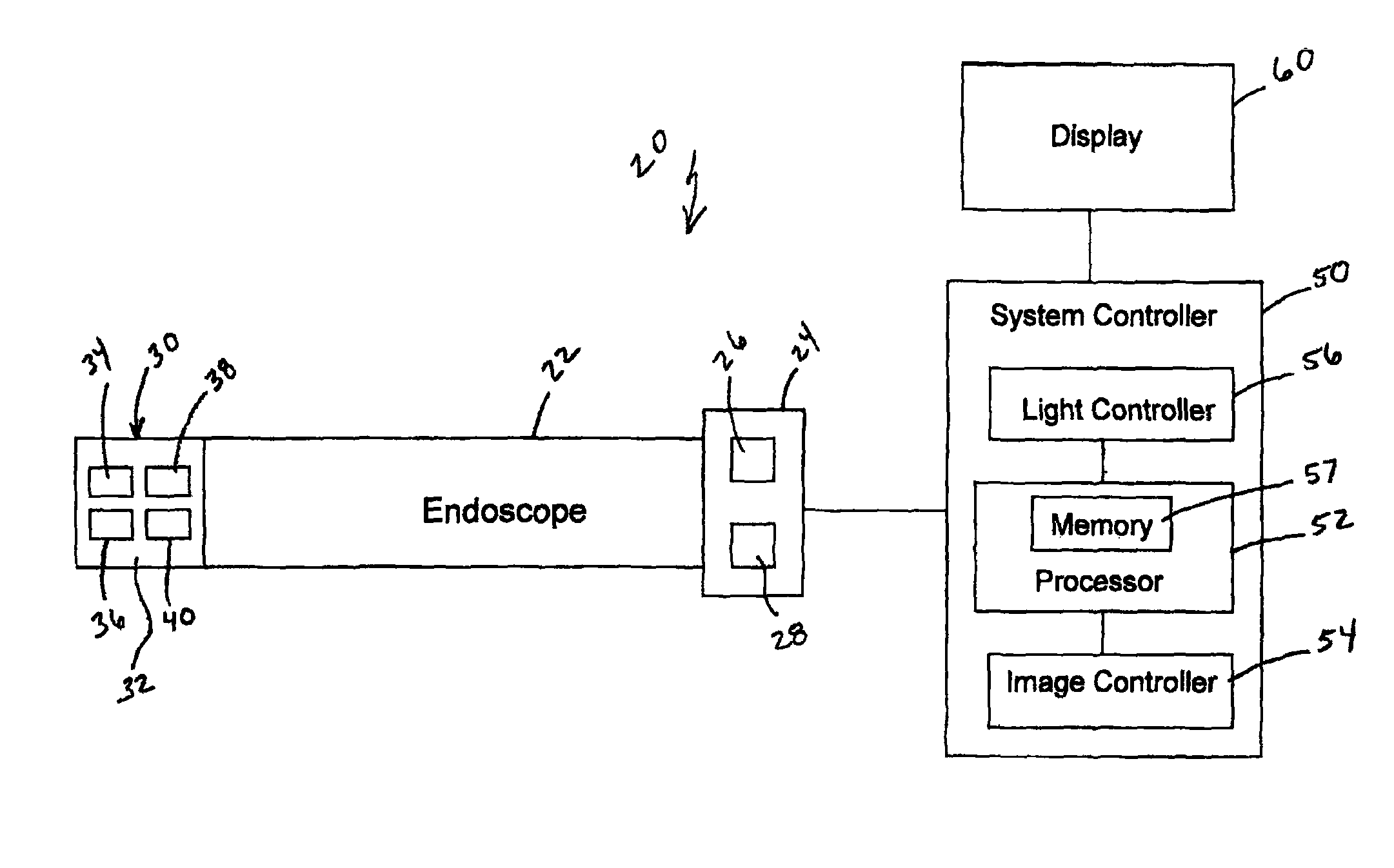

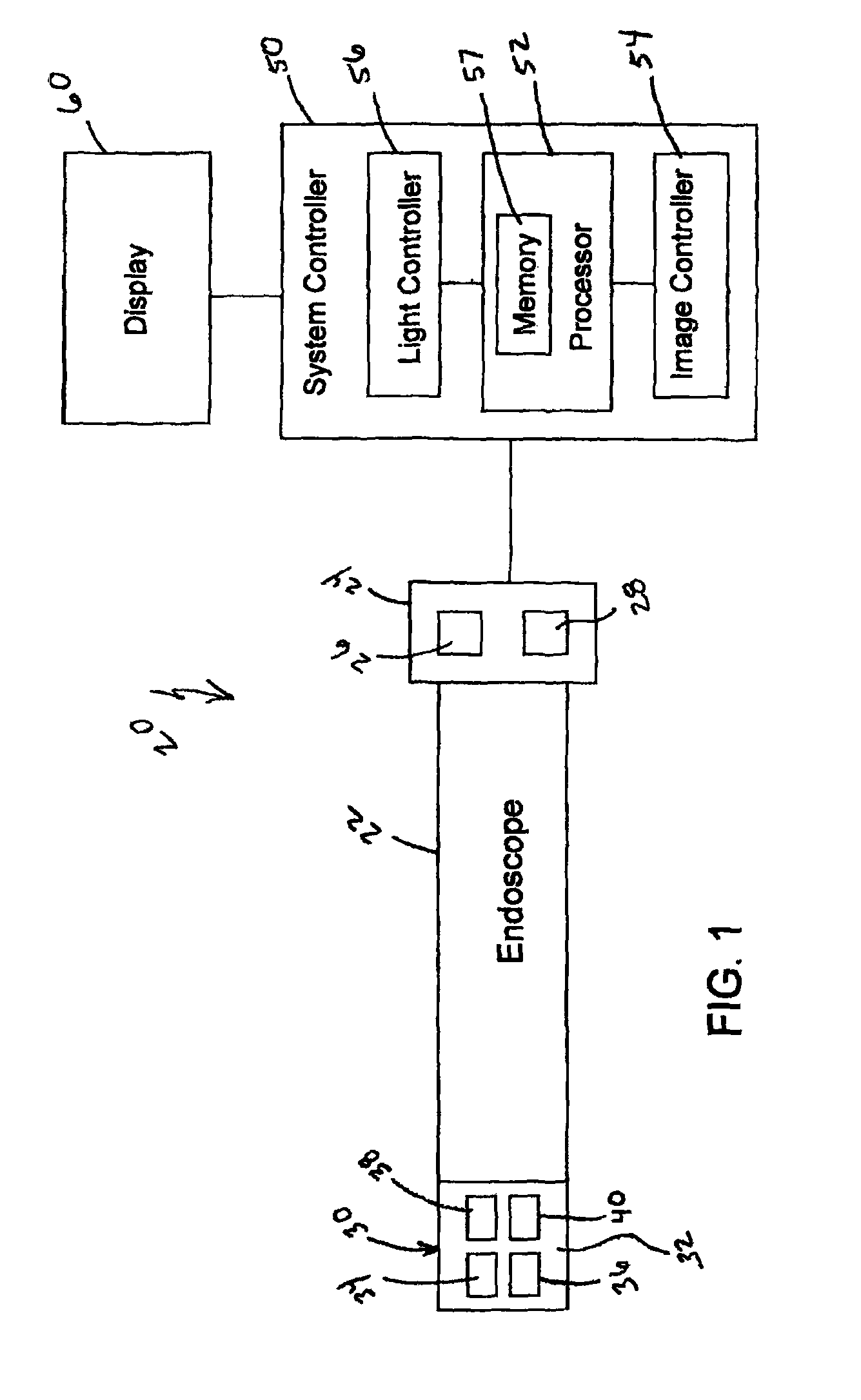

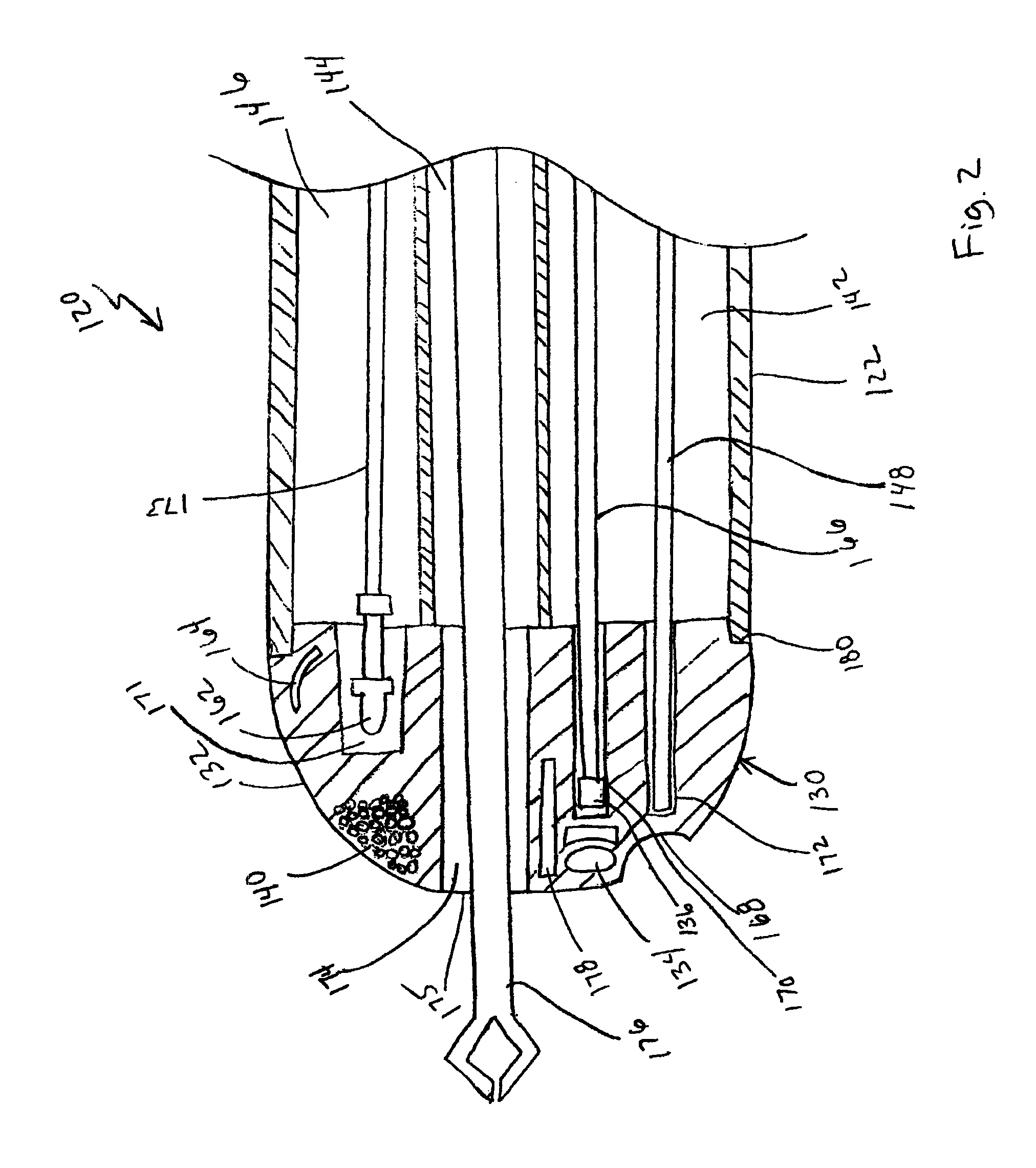

Endoscope with distal tip having encased optical components and display orientation capabilities

An apparatus according to one embodiment includes an endoscope tip including a housing that is monolithically formed of a transparent material. At least one optical component is at least partially encased within the housing. The optical component can be, for example, a light source, a fiber optic, an imaging sensor, a lens, a reflector or a light shield. In another embodiment, an apparatus includes an endoscope having a distal end portion that includes a housing. The housing is monolithically formed with a transparent material and a light source is at least partially encased within the housing. The housing also includes a micro-defects portion within the transparent material of the housing. The micro-defects portion is configured to provide a selected output shape of a beam of light produced by the light source.

Owner:BOSTON SCI SCIMED INC

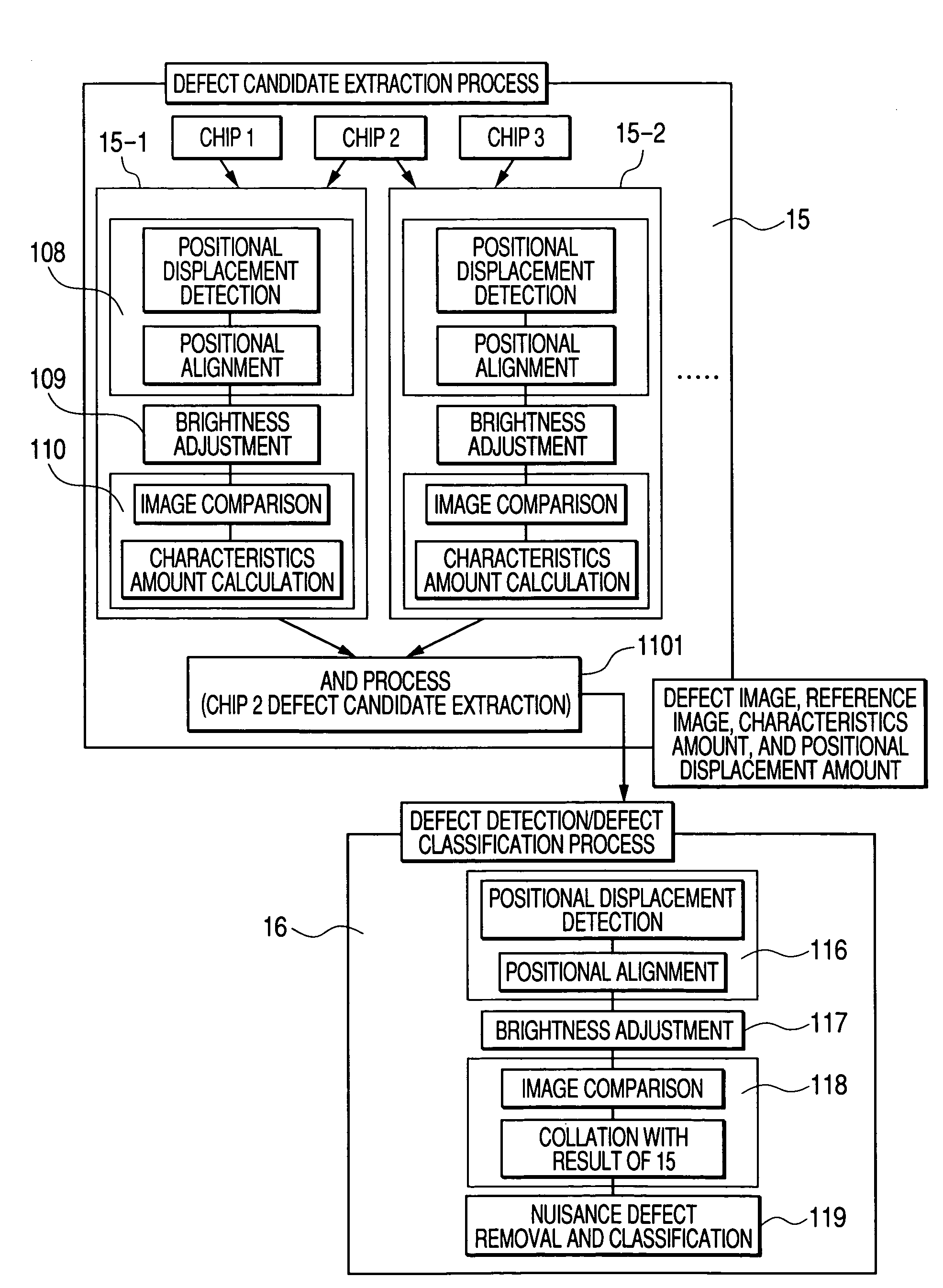

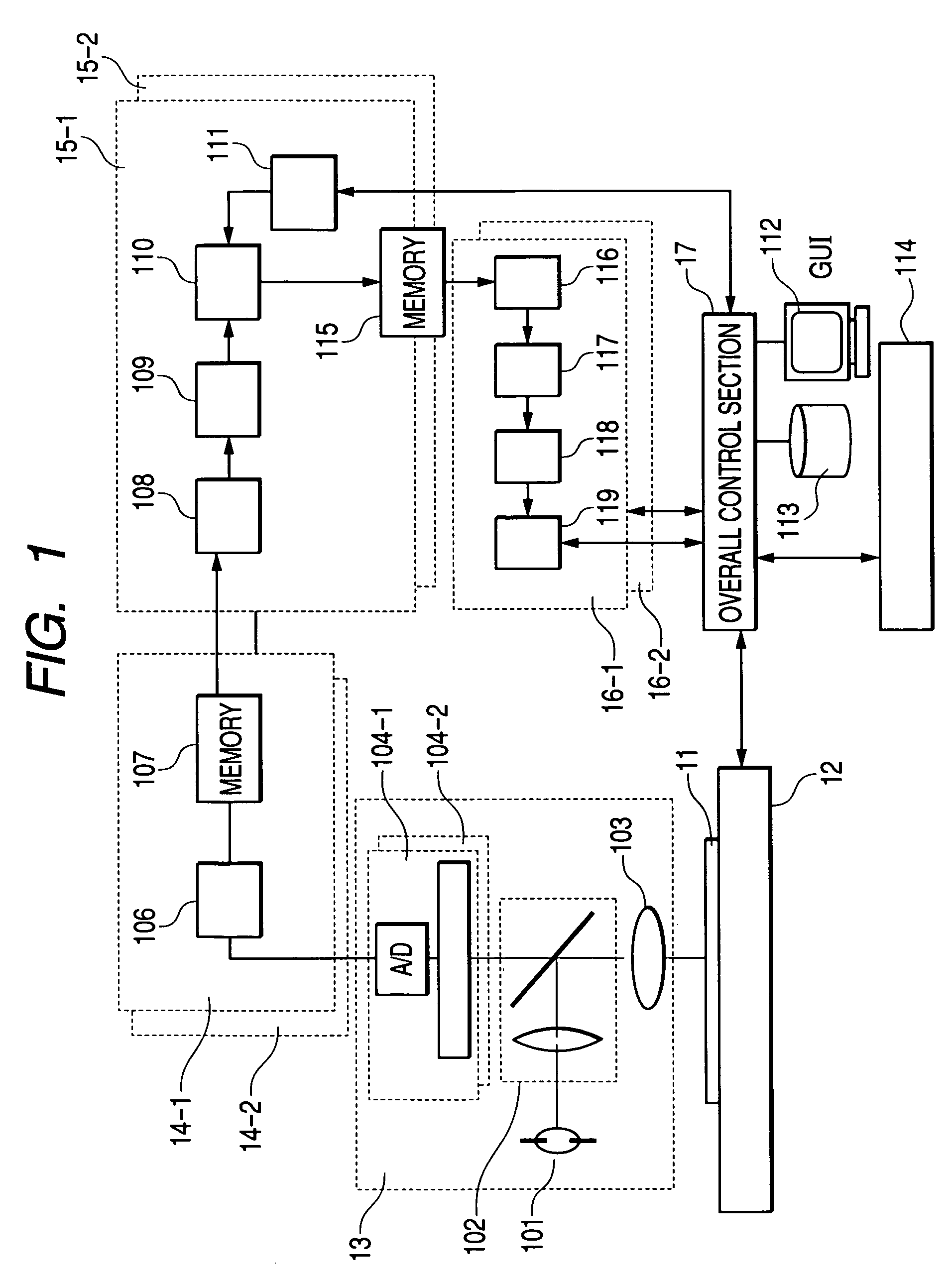

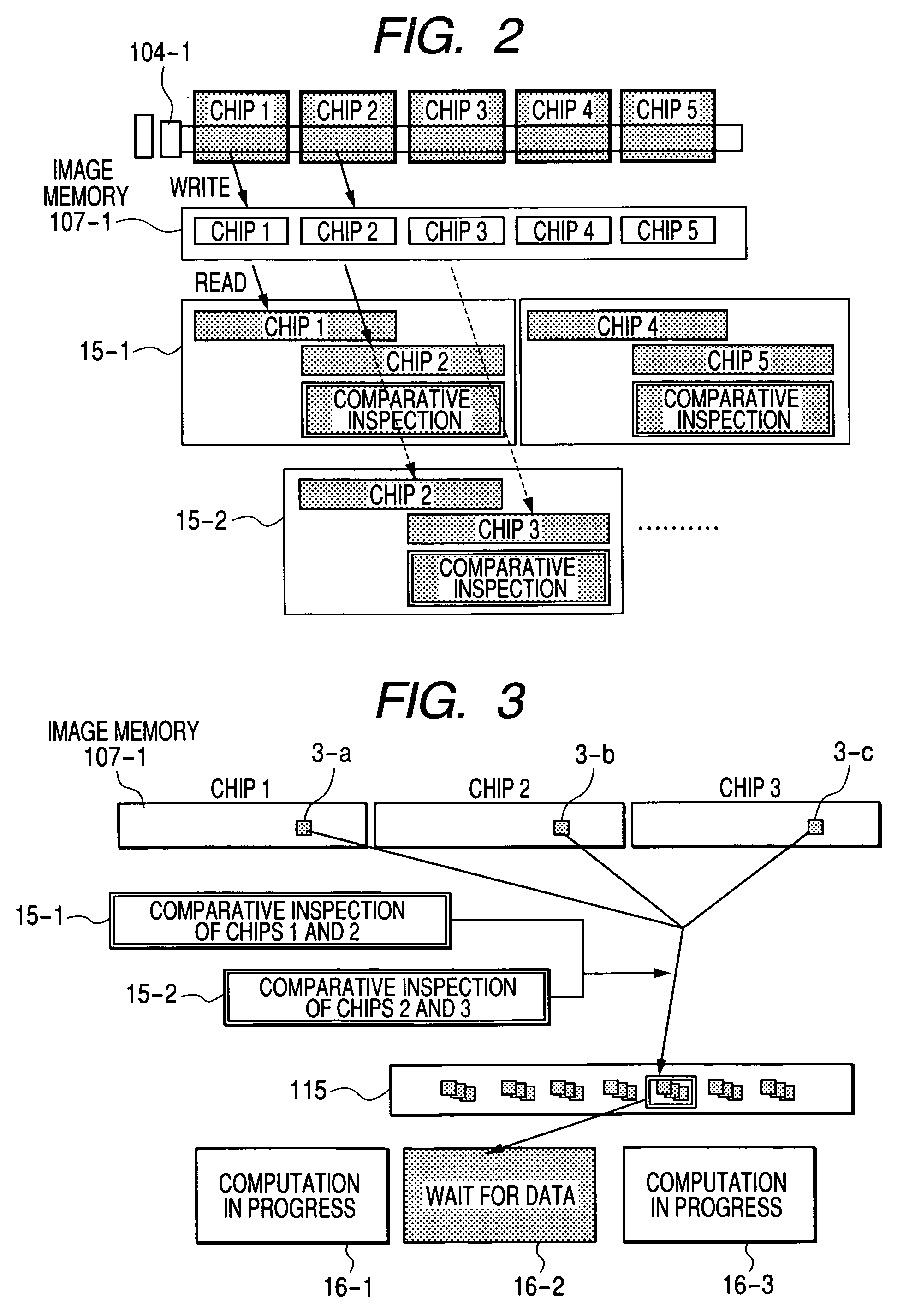

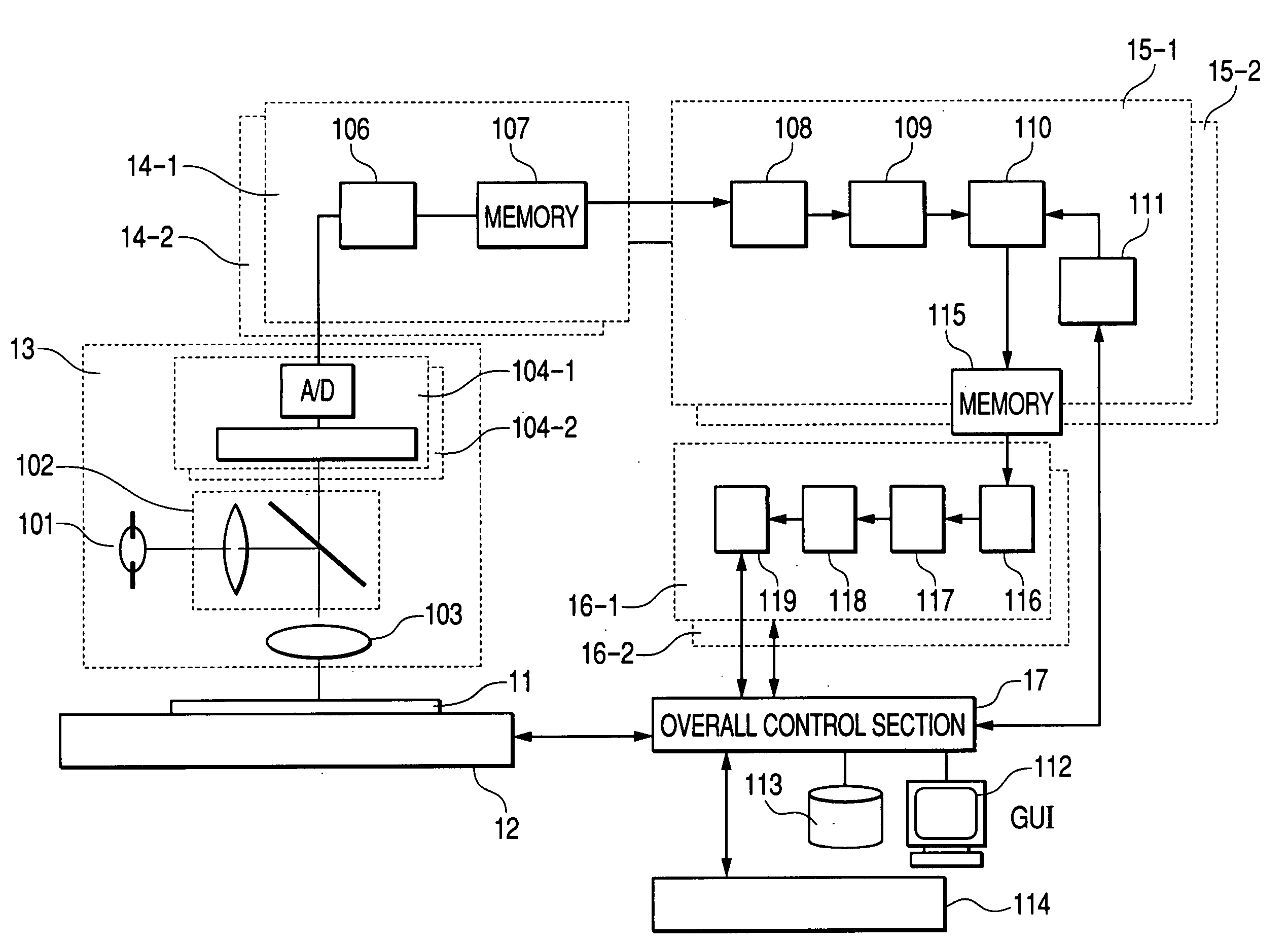

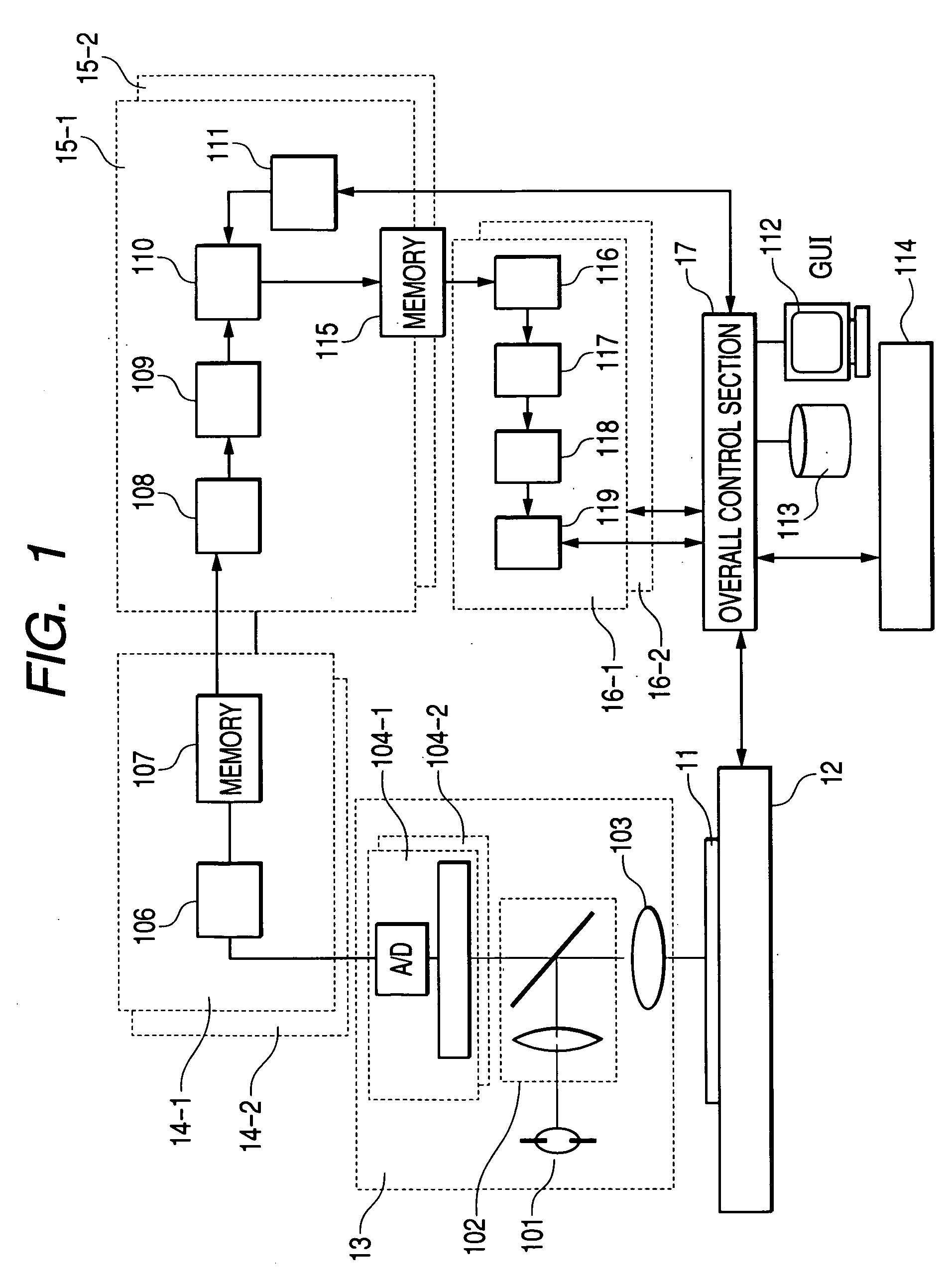

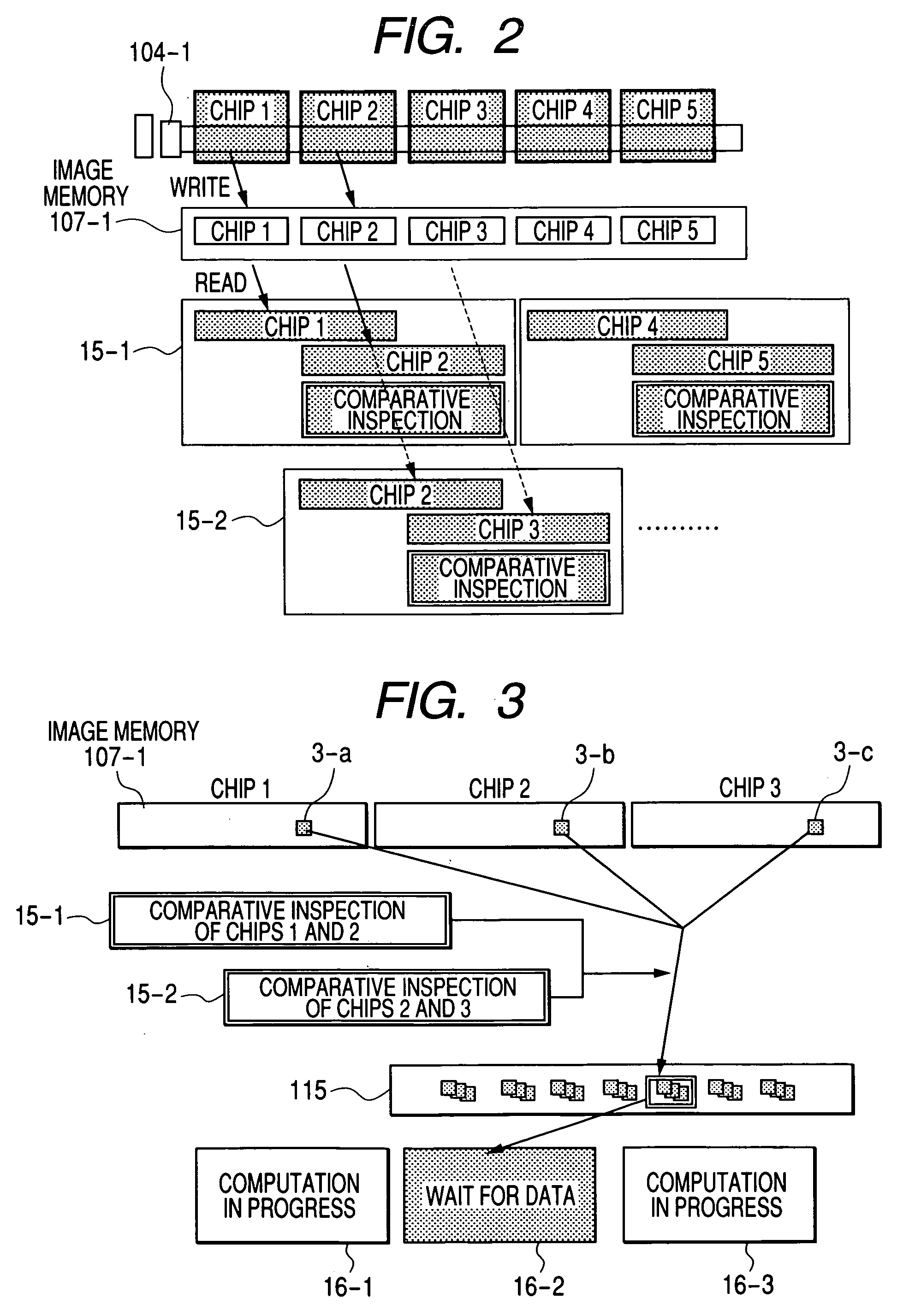

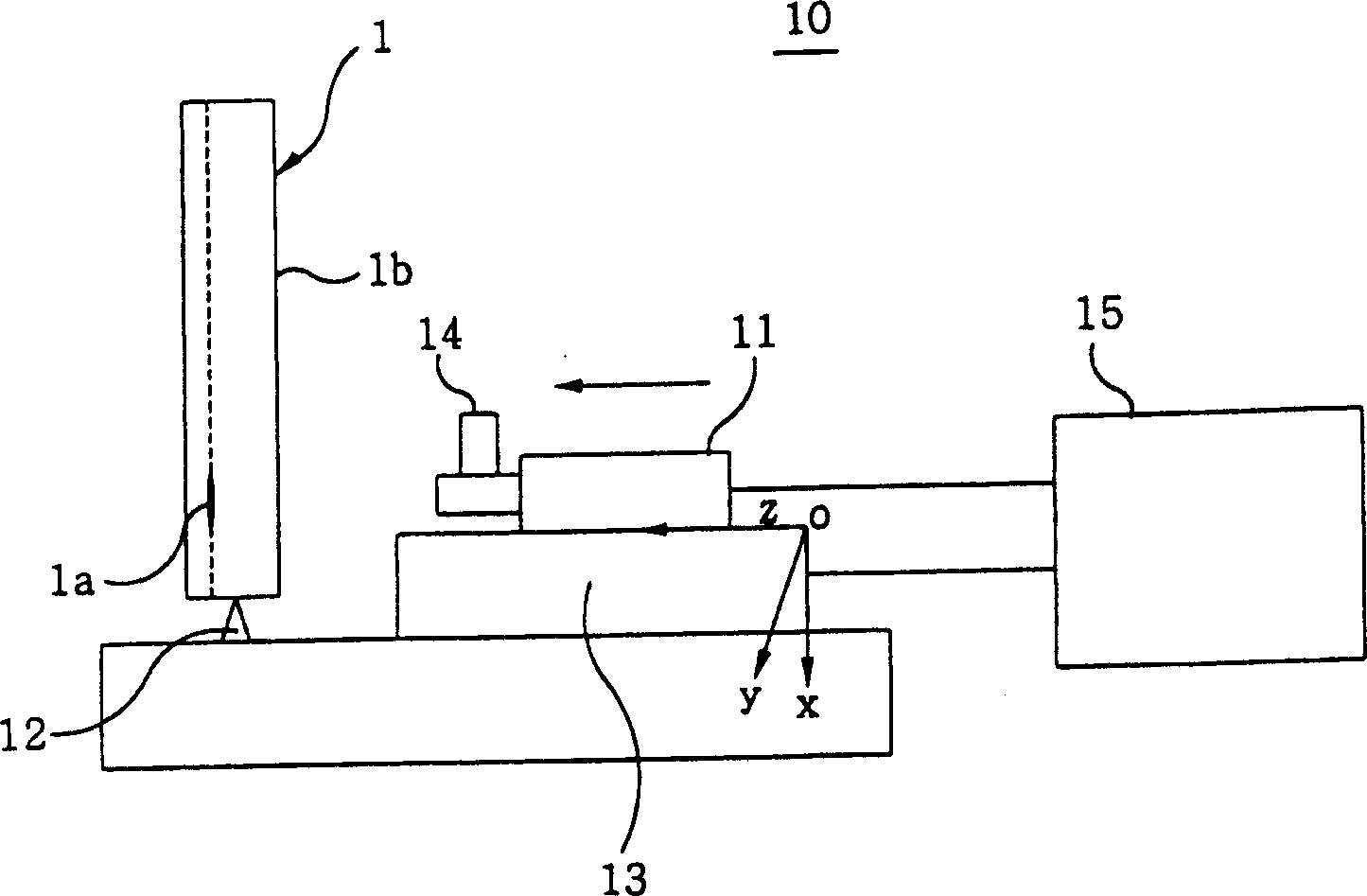

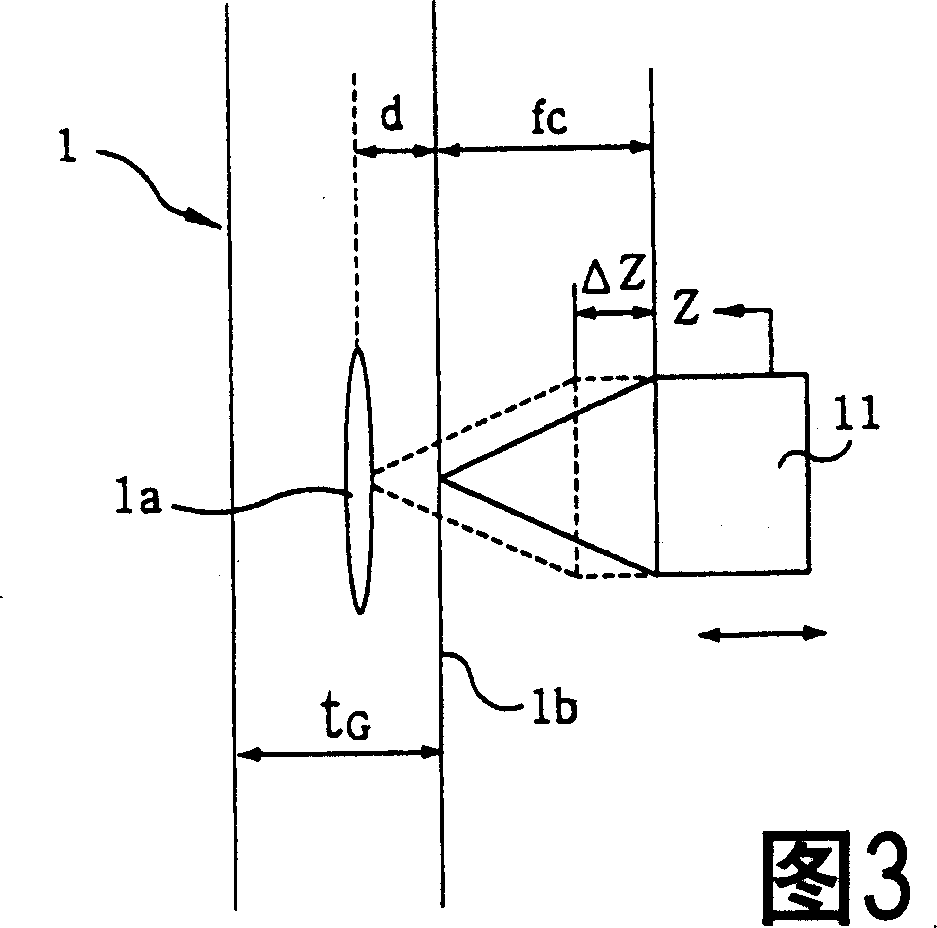

Method and apparatus for inspecting pattern defects

InactiveUS7388979B2High sensitivityIncrease speedImage enhancementImage analysisPattern recognitionComputer graphics (images)

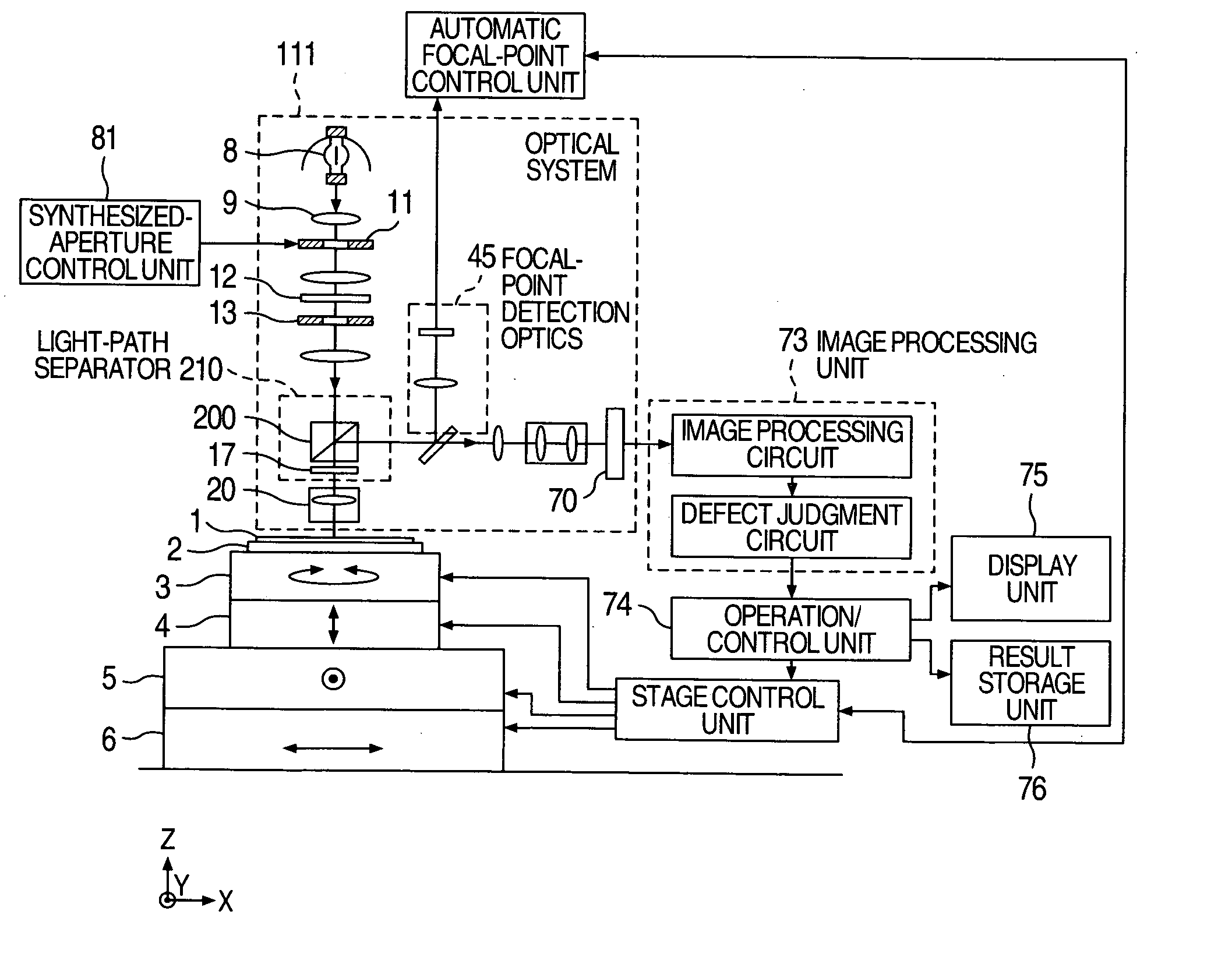

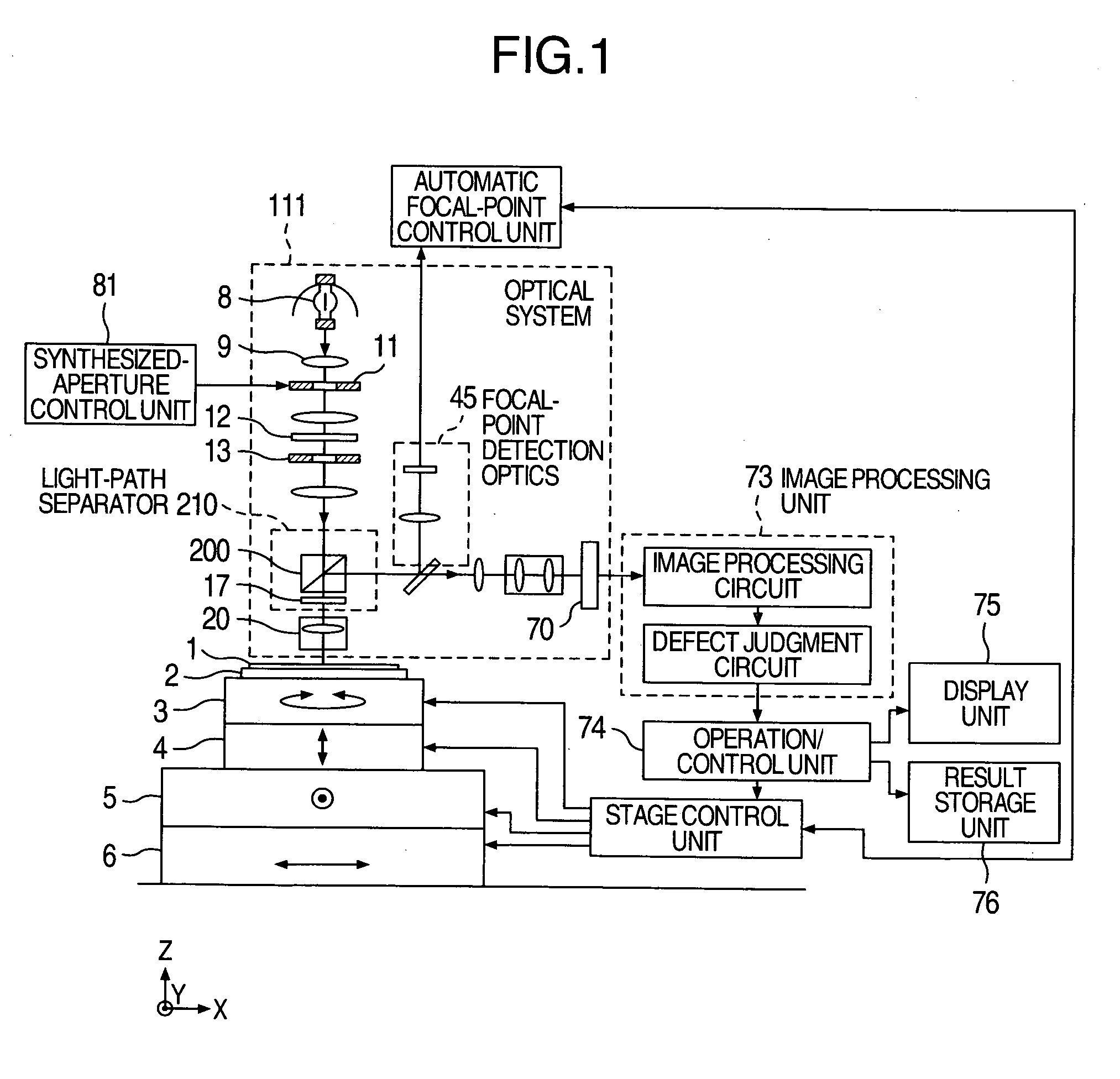

The present invention relates to a pattern defect inspection method and apparatus that reveal ultramicroscopic defects on an inspection target in which ultramicroscopic circuit patterns are formed, and inspect the defects with high sensitivity and at a high speed. The present invention provides a pattern inspection apparatus for comparing the images of corresponding areas of two formed patterns that should be identical with each other, and judging any mismatched image area as a defect. The pattern inspection apparatus includes means for performing an image comparison process on a plurality of areas in a parallel manner. Further, the pattern inspection apparatus also includes means for converting the gradation of the image signals of compared images in each of a plurality of different processes. Therefore, the present invention can properly detect defects even if the same patterns of compared images differ in brightness.

Owner:HITACHI HIGH-TECH CORP

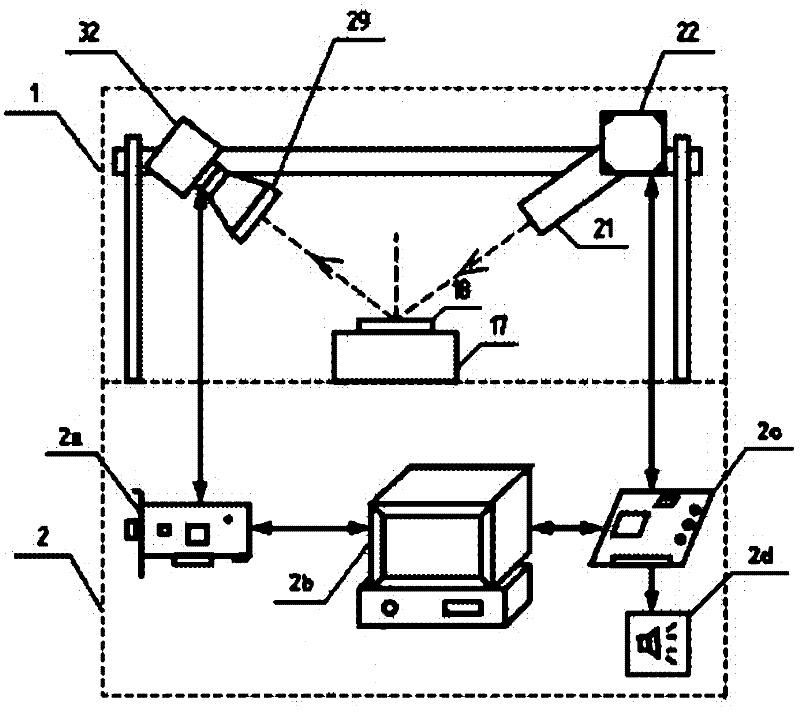

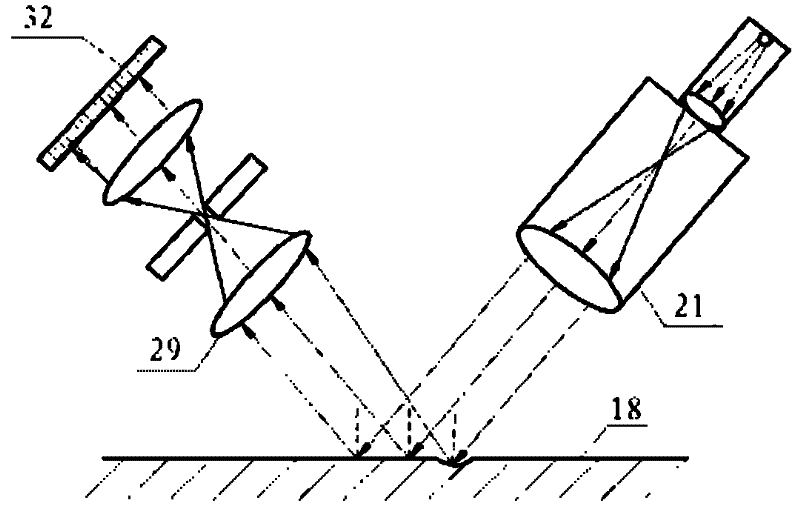

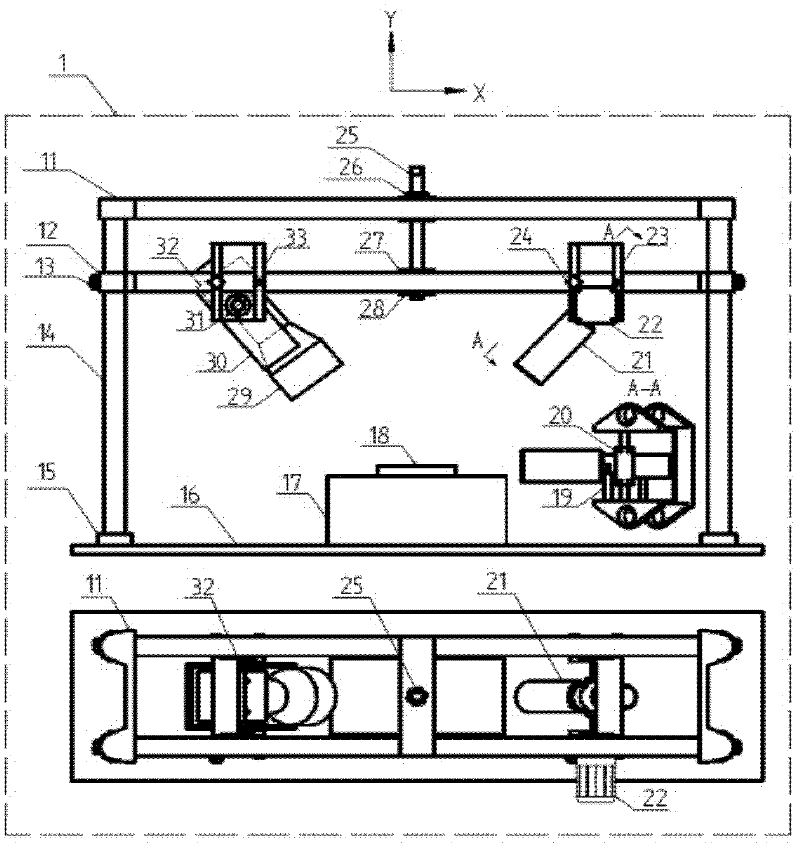

Device and method for detecting micro defects on bright and clean surface of metal part based on machine vision

ActiveCN102590218ARealize installation positioningEasy to operateOptically investigating flaws/contaminationEffect lightCcd camera

The invention relates to a device and method for detecting micro defects on the bright and clean surface of a metal part based on machine vision. The device comprises an imaging, positioning and adjusting mechanism and a processing unit, wherein the imaging, positioning and adjusting mechanism comprises a base plate, a guide rod, a fixed support, a sliding support, a stepping motor, a CCD (Charge Coupled Device) camera, a telecentric lens and parallel light sources, wherein the imaging and coaxial lighting of the CCD camera are primarily adjusted; an image collection card, an industrial personal computer, an equipment control card and an alarm are electrically connected in the processing unit and are used for collecting, transmitting, storing, processing, displaying and alarming image. The method comprises coaxial lighting adjustment and image processing, wherein coaxial lighting adjustment comprises the steps of triggering the equipment control card via software of the industrial personal computer to drive the stepping motor, and adjusting the rotating angles of the parallel light sources until the coaxial lighting condition is satisfied; and image processing comprises the steps of detecting defects on the internal surface of the detected part, respectively detecting large and small defects on the outer edge on the surface of the detected part, displaying the processing images in real time and judging the results.

Owner:安徽中科智能高技术有限责任公司

Method and apparatus for inspecting pattern defects

InactiveUS20050147287A1High sensitivityIncrease speedImage enhancementImage analysisPattern recognitionTwo-form

The present invention relates to a pattern defect inspection method and apparatus that reveal ultramicroscopic defects on an inspection target in which ultramicroscopic circuit patterns are formed, and inspect the defects with high sensitivity and at a high speed. The present invention provides a pattern inspection apparatus for comparing the images of corresponding areas of two formed patterns that should be identical with each other, and judging any mismatched image area as a defect. The pattern inspection apparatus includes means for performing an image comparison process on a plurality of areas in a parallel manner. Further, the pattern inspection apparatus also includes means for converting the gradation of the image signals of compared images in each of a plurality of different processes. Therefore, the present invention can properly detect defects even if the same patterns of compared images differ in brightness.

Owner:HITACHI HIGH-TECH CORP

Micro defects in semi-conductors

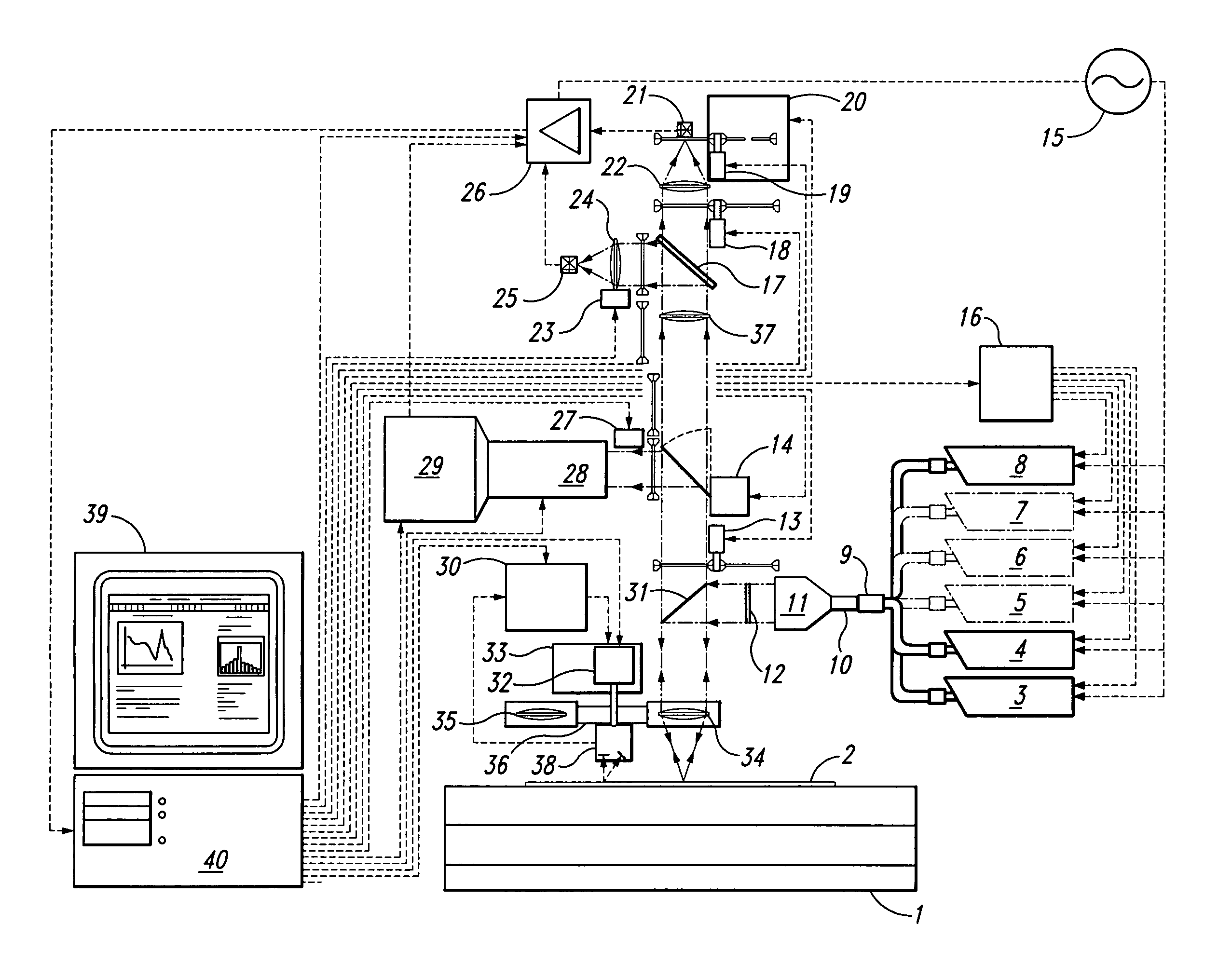

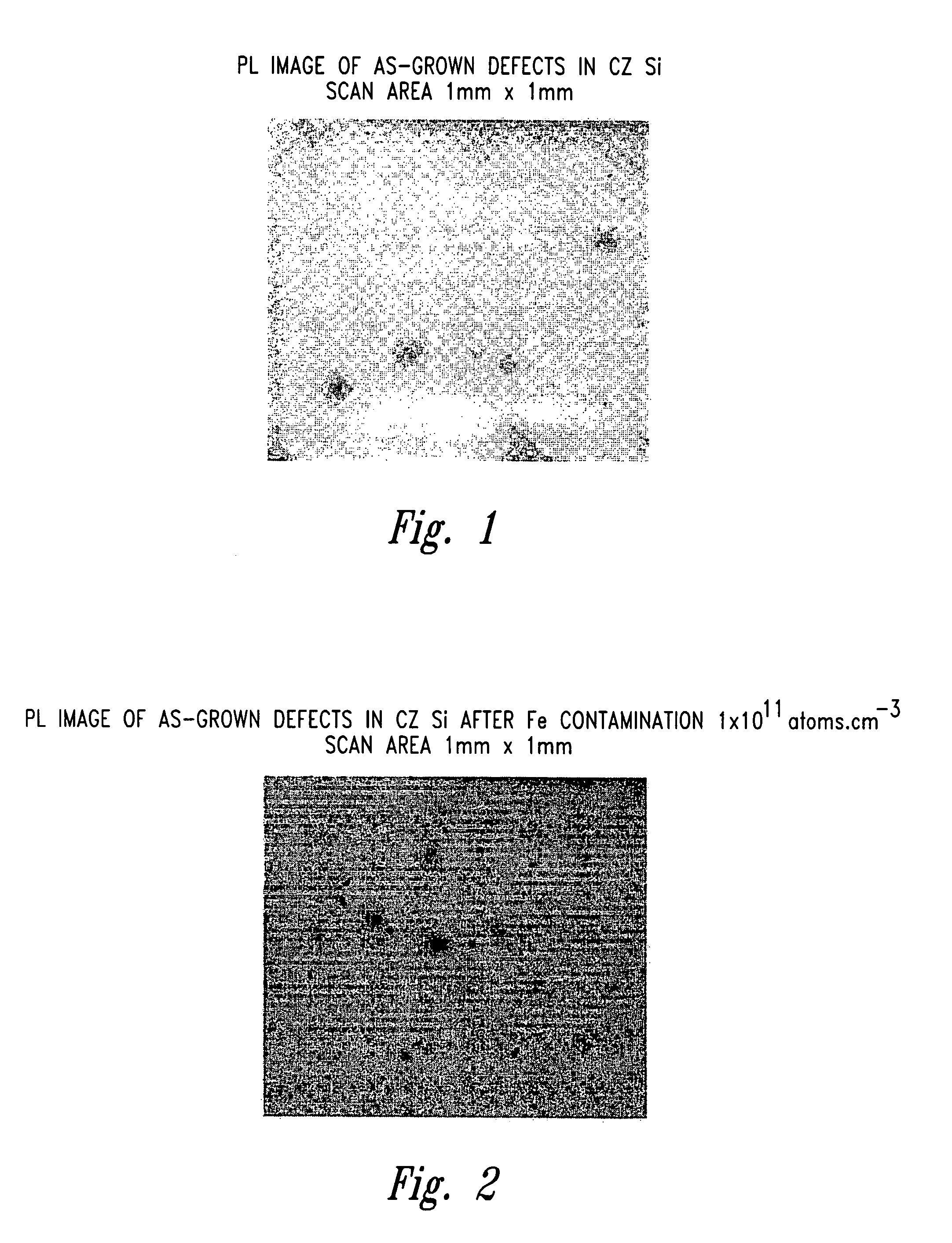

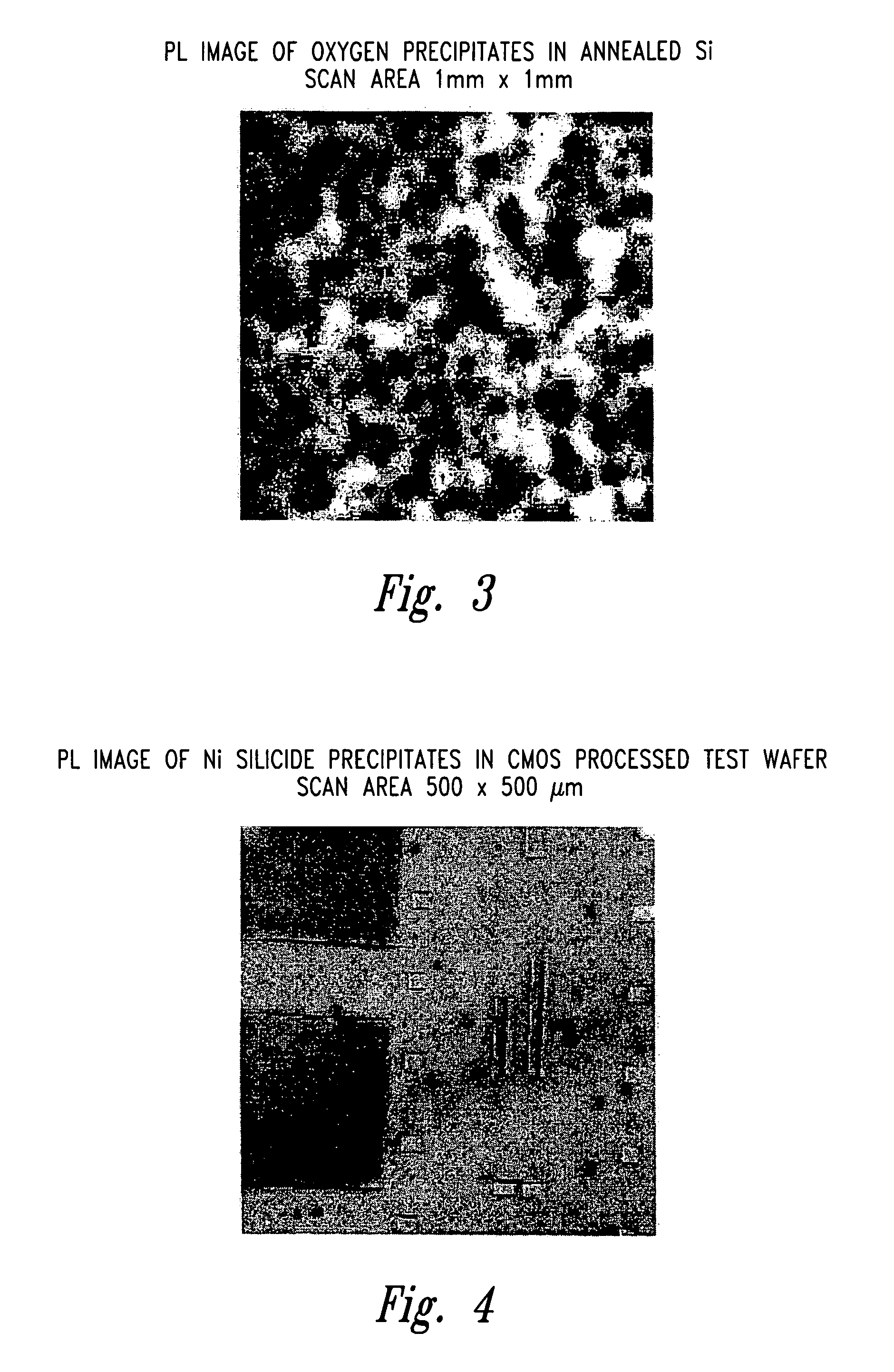

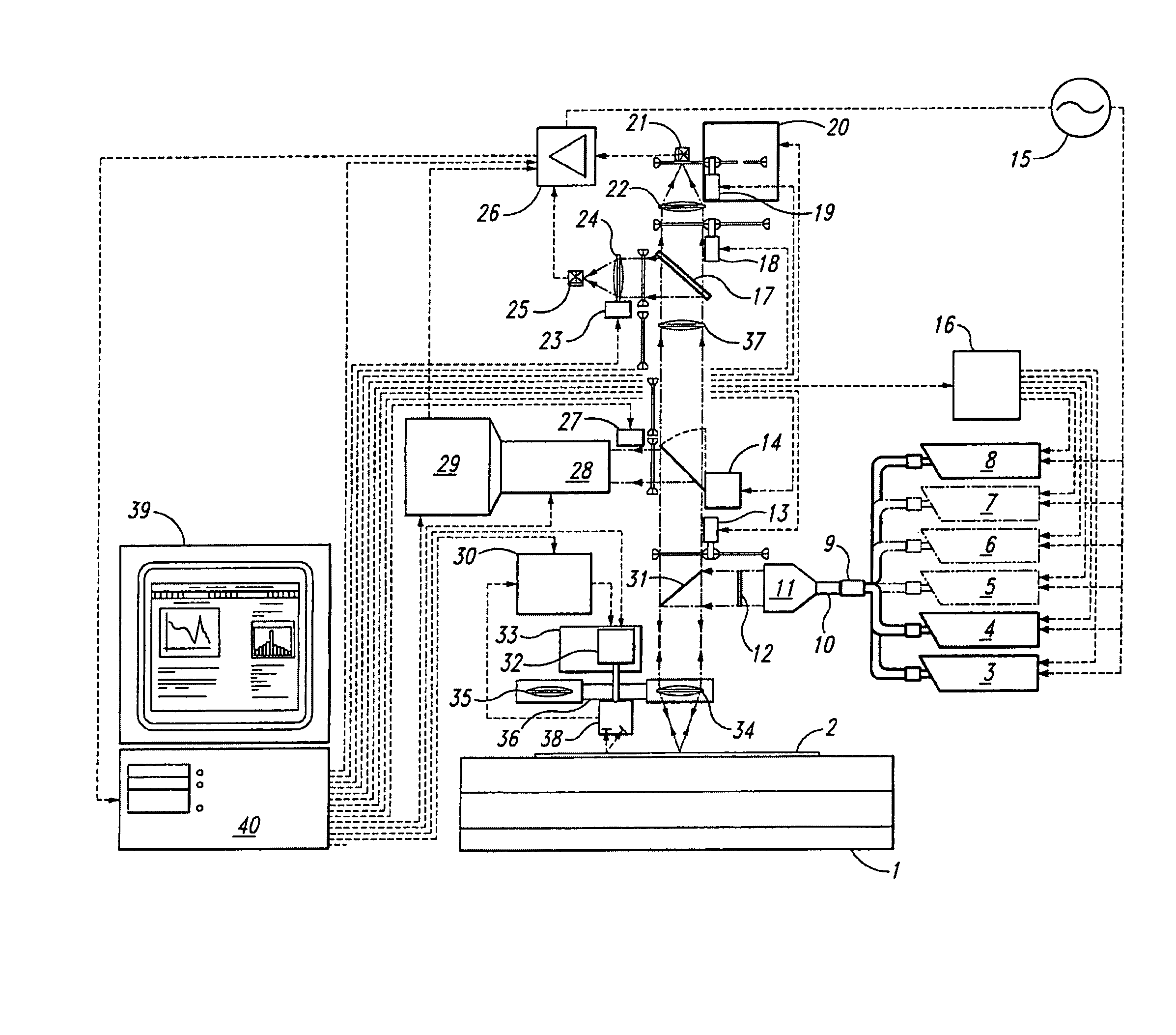

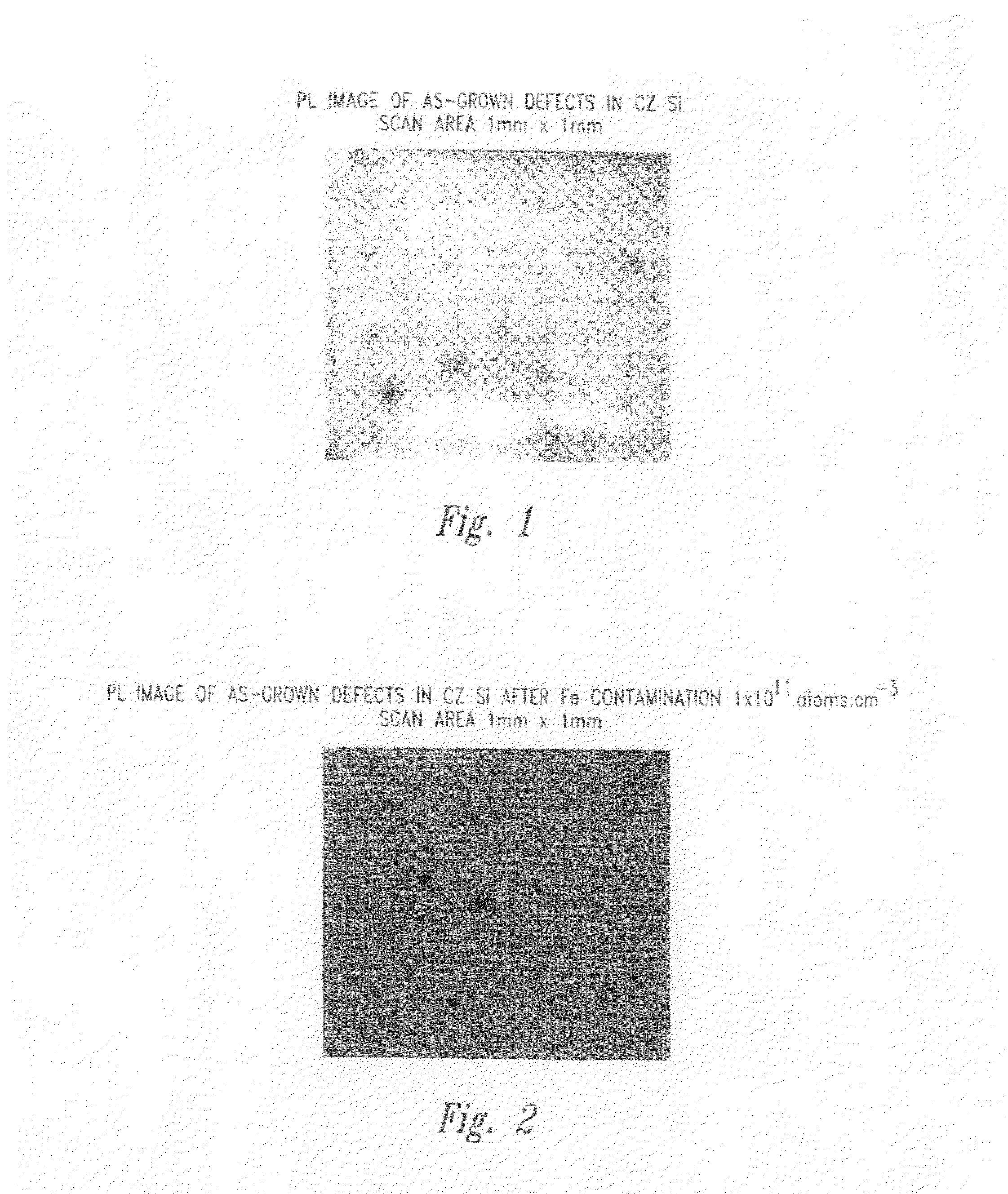

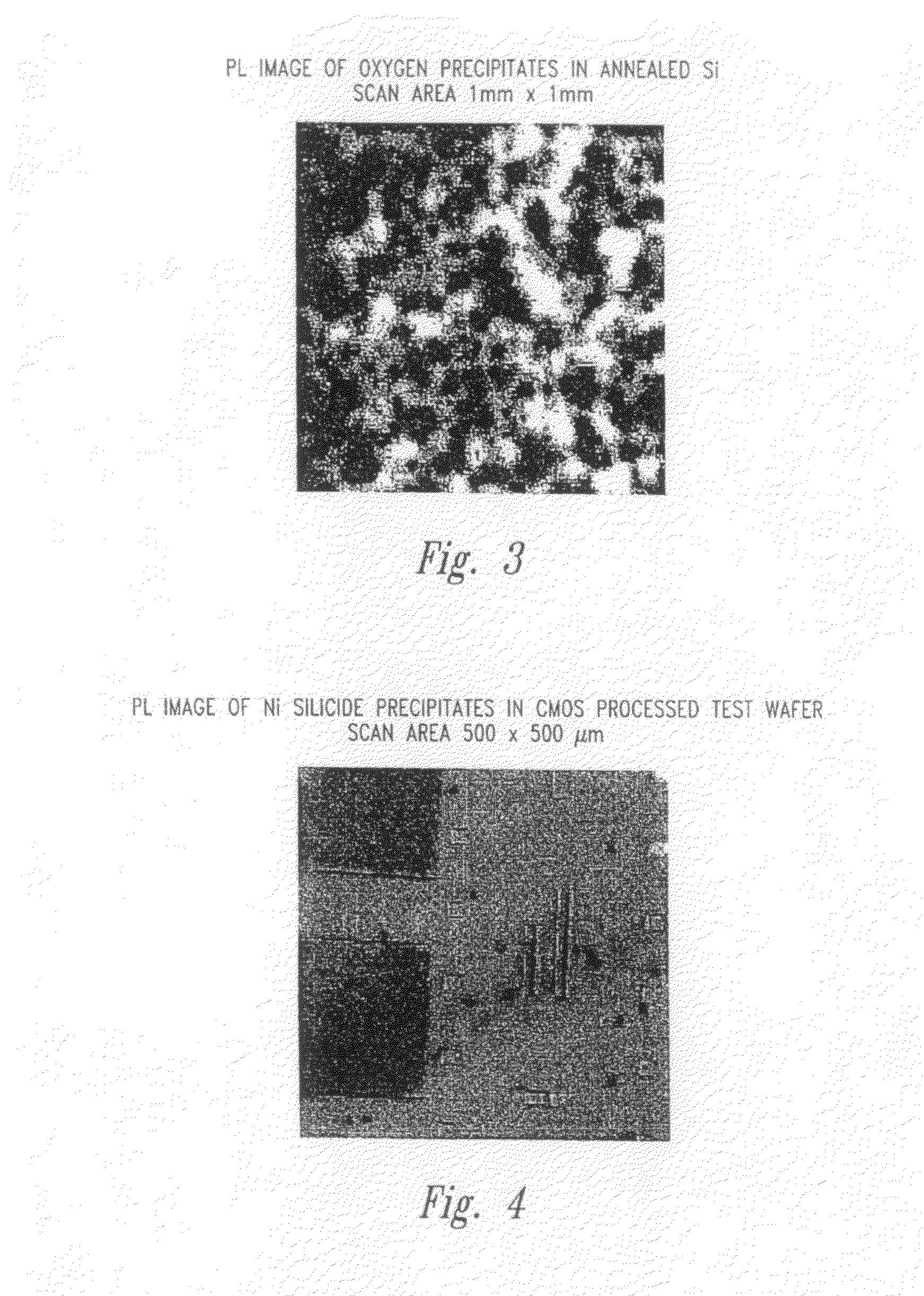

InactiveUS7113276B1Spectrum investigationSemiconductor/solid-state device testing/measurementHigh concentrationPhotoluminescence

The invention relates to a method and apparatus for detecting defects in a semiconductor or silicon structure at room temperature, and in an efficient time, using photoluminescence. The invention employs the use of a high intensity beam of light preferably having a spot size between 0.1 mm–0.5 microns and a peak or average power density of 104–109 w / cm2 with a view to generating a high concentration of charge carriers, which charge characters detect defects in a semiconductor by interacting with same. These defects are visible by producing a photoluminescence image of the semiconductor. Several wavelengths may be selected to identify defects at a selective depth as well as confocal optics may be used.

Owner:NANOMETRICS

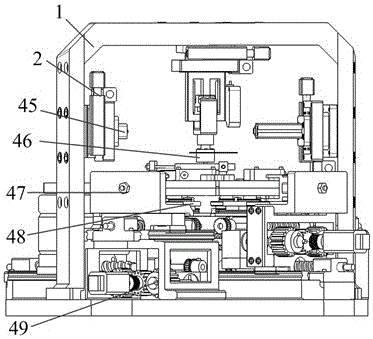

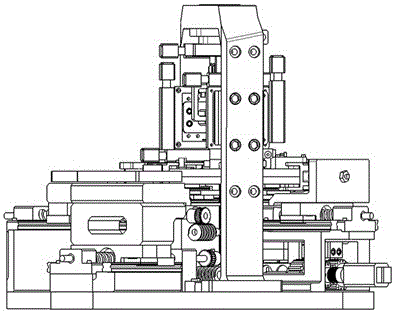

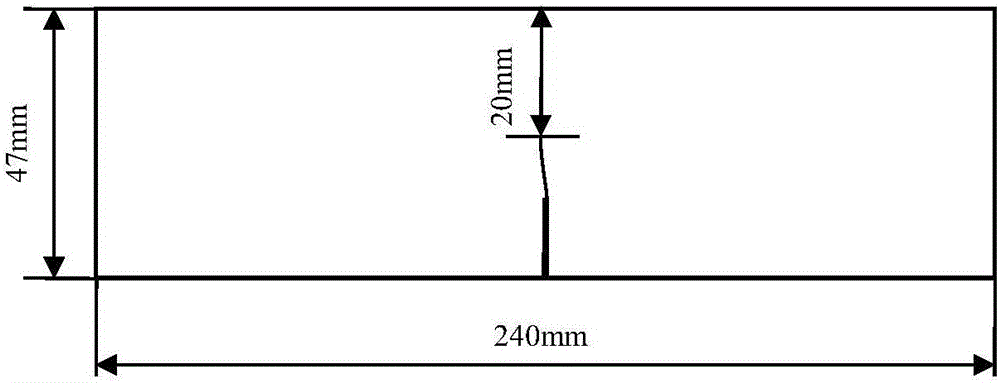

Material mechanical property in-situ testing system and method in dynamic and static load spectrum

ActiveCN106226152AImprove compatibilityCompact structureMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesEngineeringMultiple modes

The invention relates to a material mechanical property in-situ testing system and method in a dynamic and static load spectrum, and belongs to the field of mechanical tests. The system integrates the following functions: a static testing function of biaxial drawing and shearing in an orthogonal plane, a shearing static testing function, a double shaft pull-pull mode fatigue testing function, and a static / dynamic press testing function. A complicated static / dynamic load spectrum can be established. Multi-mode composite load mechanical property evaluation can be performed on a film material or a block material, for example: high-cycle fatigue tests based on double-shaft pre-stretching load and impact press tests based on double-shaft stretching-shearing pre-load. At the same time, special defects are pre-fabricated on the central area and cross shaped arm area of a test piece; the analysis functions of a variable-zoom optical imaging system or a digital speckle strain analysis system can be utilized; the provided system and method can also be used to research the deformation behavior and cracking expansion rules of micro defects in a component under a multi-dimensional stress, and an evaluation tool is provided for performance degradation rules of products and optimized preparation method of materials.

Owner:JILIN UNIV

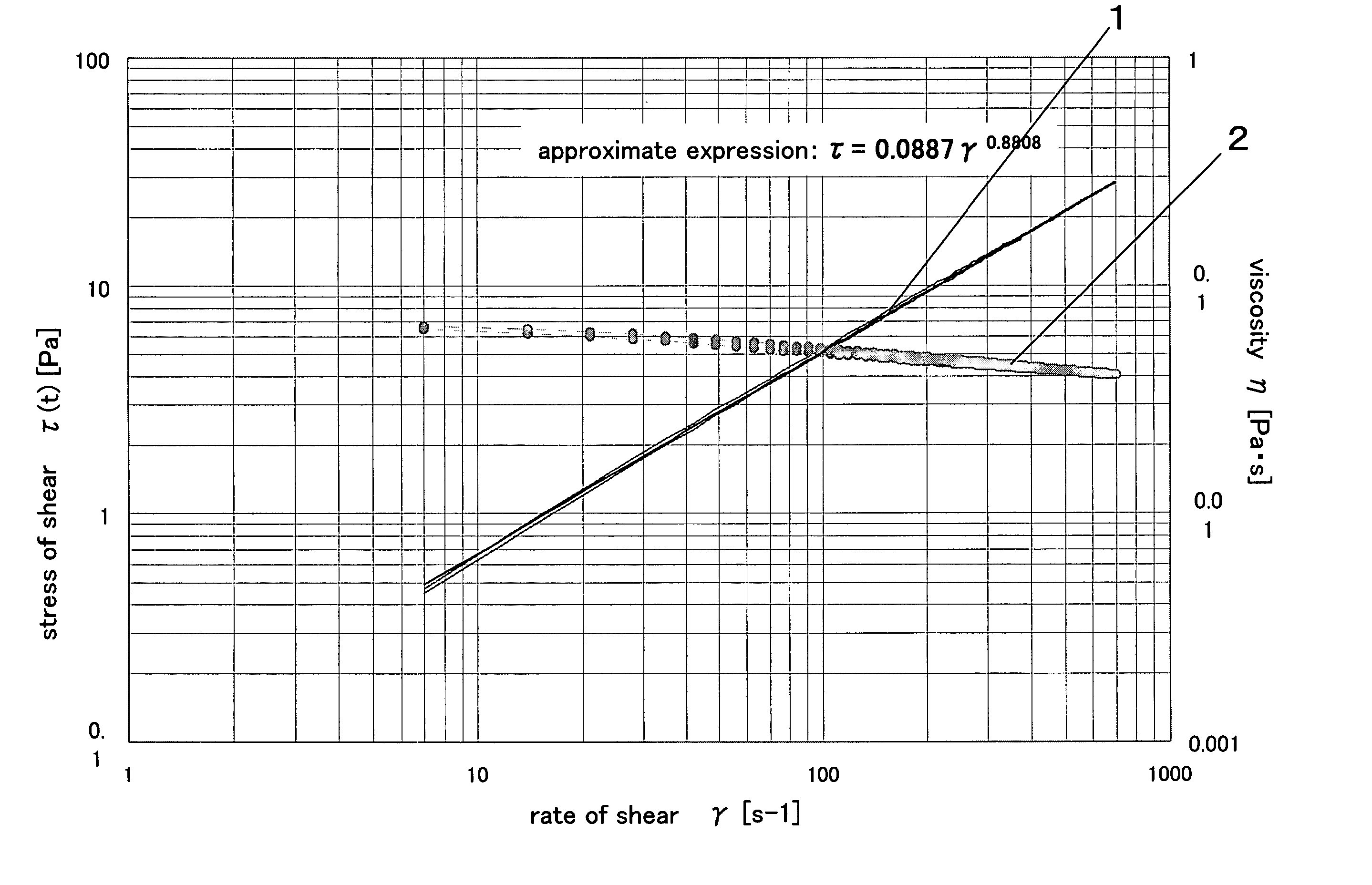

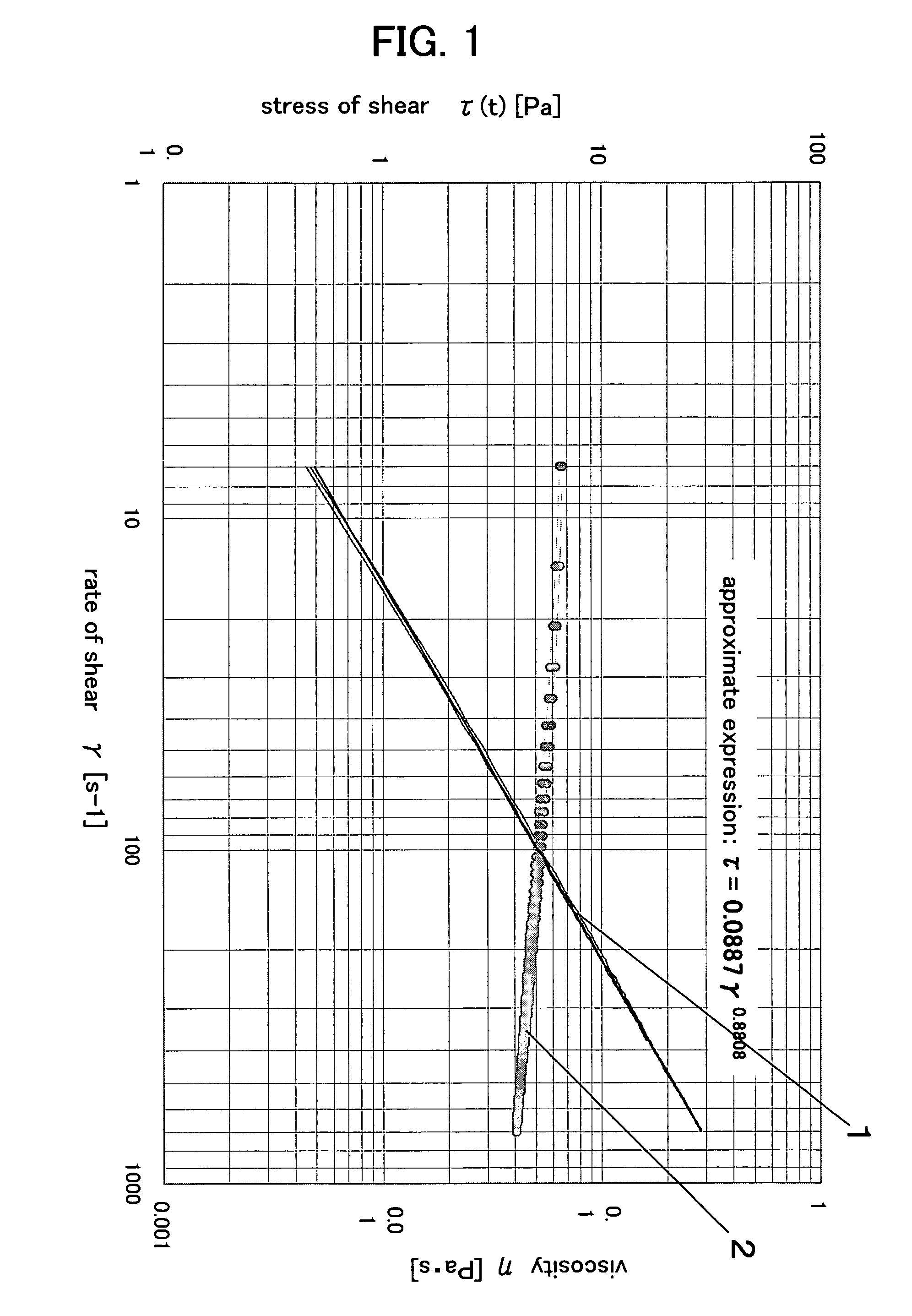

Correction ink for micro defect of color pattern, color filter, method for correcting micro defect of color pattern, and process for producing ink

InactiveUS20040130606A1Increase freedomSolve the lack of densityErasing devicesMeasurement apparatus componentsSolventColor filter array

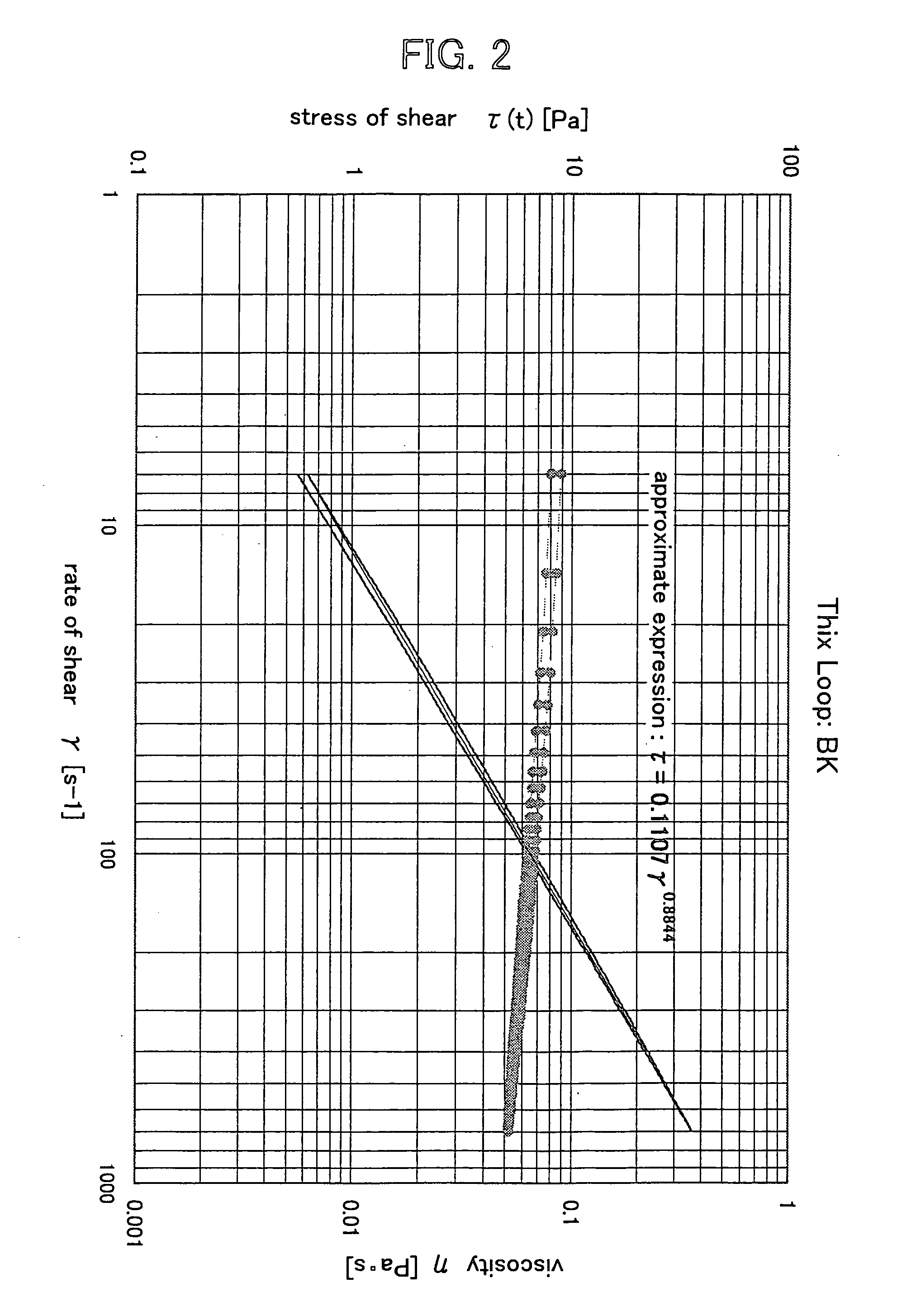

A correction ink of the present invention is used for correcting a micro defect in a color pattern, which comprises a coloring agent, polymer, monomer having reactivity functional group and a solvent, wherein an amount of the solvent is from 25% by weight to 70% by weight of the whole ink, and a viscosity is from 40 to 300 mPa.sec.

Owner:DAI NIPPON PRINTING CO LTD

Apparatus and method for defect inspection

InactiveUS20060262297A1High sensitivitySharp contrastOptically investigating flaws/contaminationEngineeringPupil

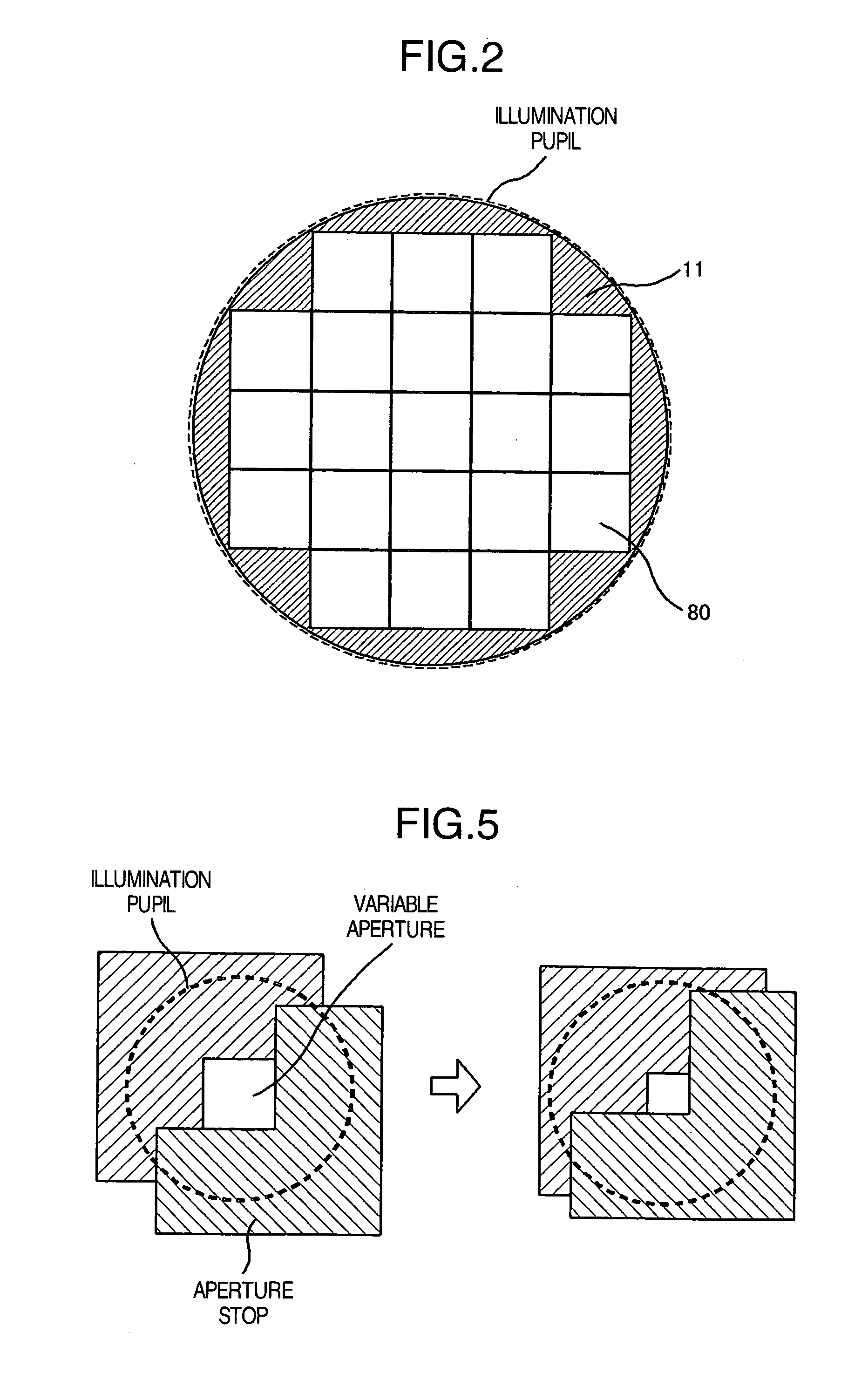

In the conventional methods for enhancing defect detection sensitivity by improving the resolving power, if a microscopic pattern, which is a high spatial-frequency structure as is the case with a microscopic defect, has become the brightest portion, the gray-scale contrast of the microscopic defect will be enhanced. At the same time, however, the gray-scale contrast of the microscopic pattern will also be enhanced simultaneously. Consequently, there has existed a problem that it is impossible to enhance the microscopic-defect detection sensitivity further than that. In the present invention, an aperture stop which is divided into a plurality of small apertures is located on an illumination pupil plane. Then, light-shield / light-transmission for each small aperture is controlled independently of each other. This control allows an inspection-target object to be illuminated at only an incident angle at which the gray-scale contrast of the microscopic defect will be emphasized more sharply.

Owner:HITACHI HIGH-TECH CORP

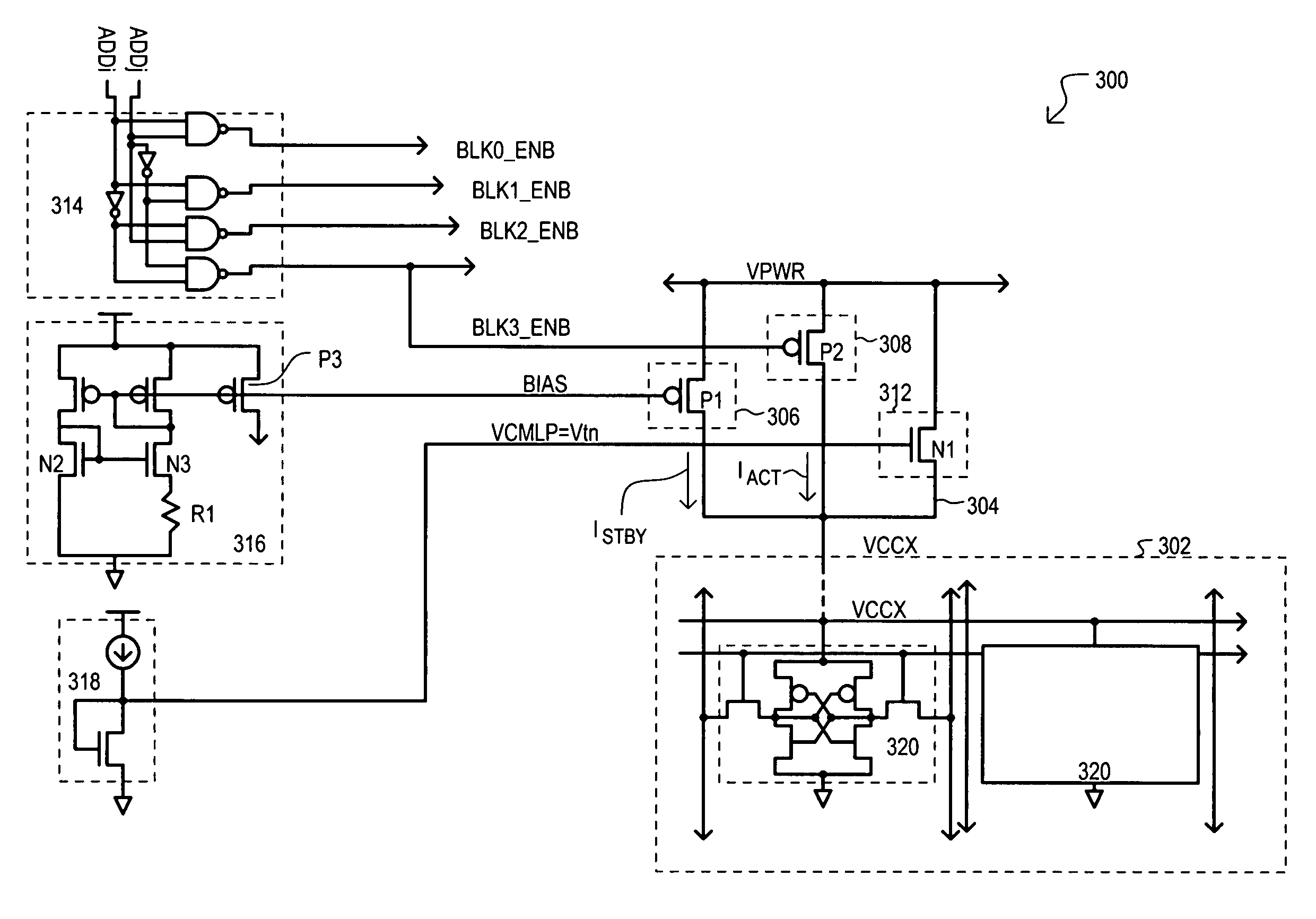

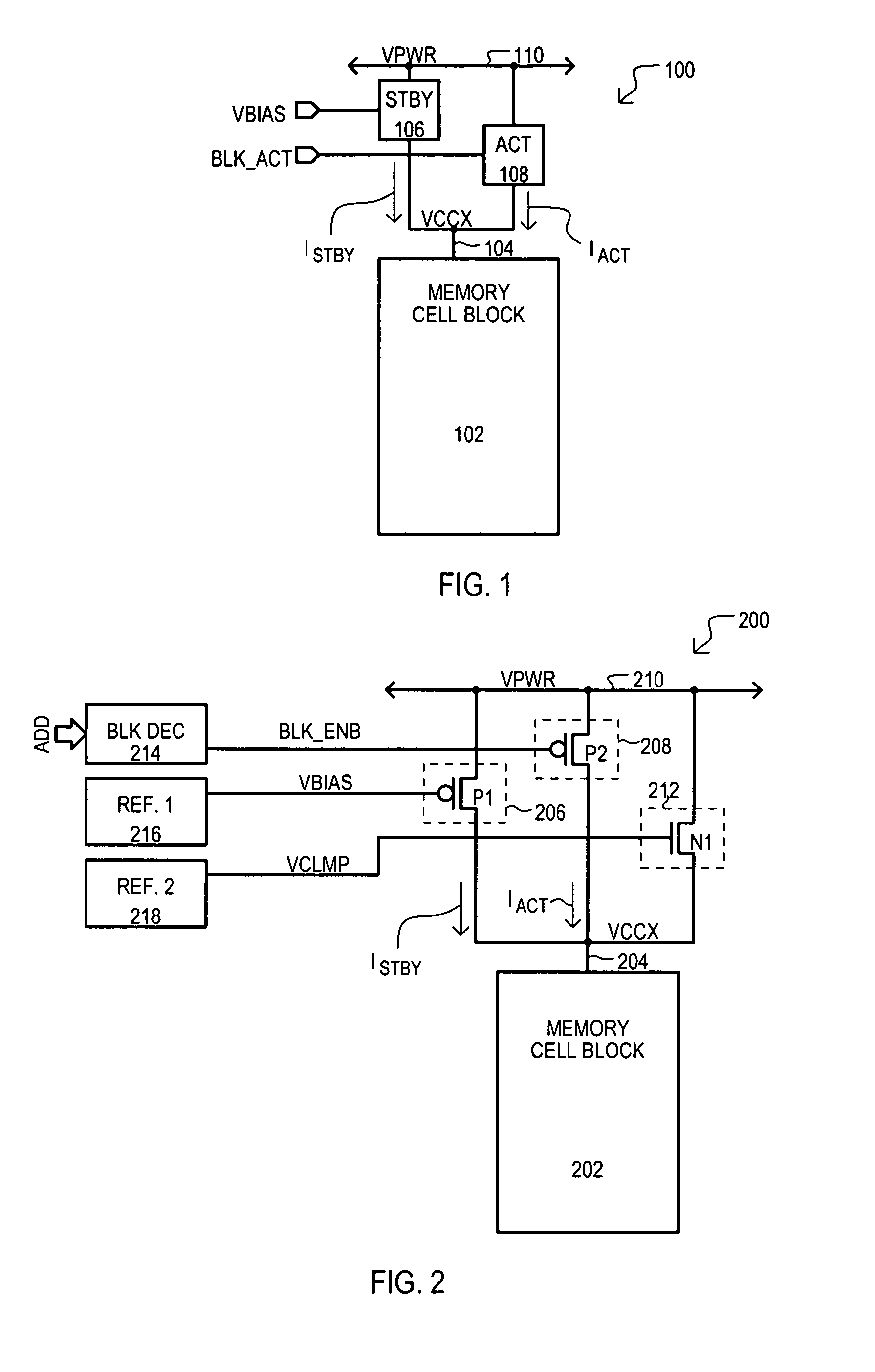

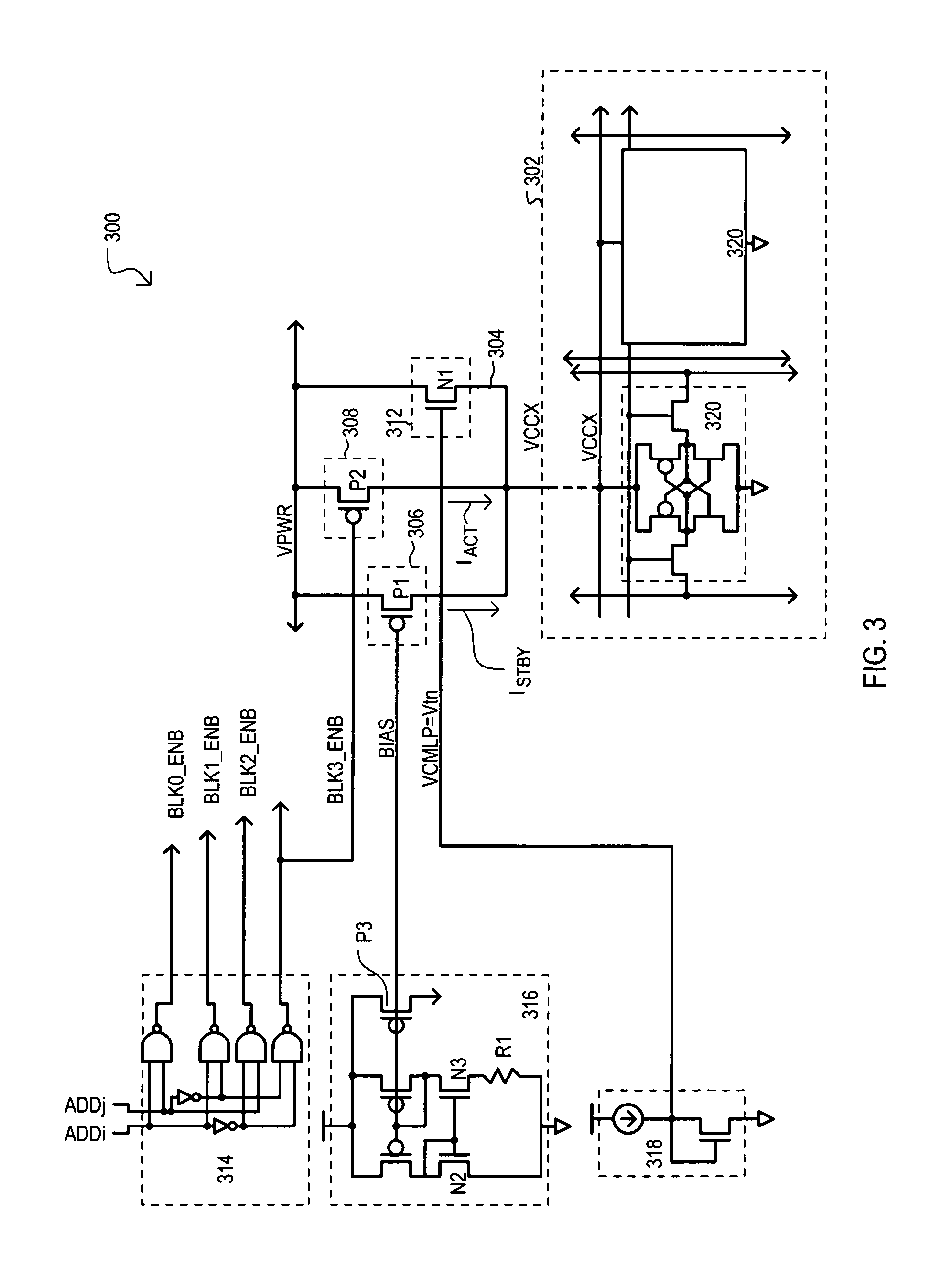

Current source architecture for memory device standby current reduction

A memory device (200) can include a memory cell block (202), a standby current source (206), an active current source (208), and a clamping device (212). In a standby mode, a standby current source (206) can provide constant standby current ISTBY to memory cell block (202) via block supply node (204). In an active mode, active current source (208) can provide current to accommodate current necessary for active operations (e.g., accessing the memory cell block). A clamping circuit (212) can provide additional current in the event a block supply node (204) potential VCCX collapses due to the presence of micro-defects. In addition, compensation for process variation can be achieved by a self regulating well (454) to source (404) back bias that can modulate the threshold voltage of p-channel transistors of memory cells within the well (454), reducing overall leakage.

Owner:INFINEON TECH LLC

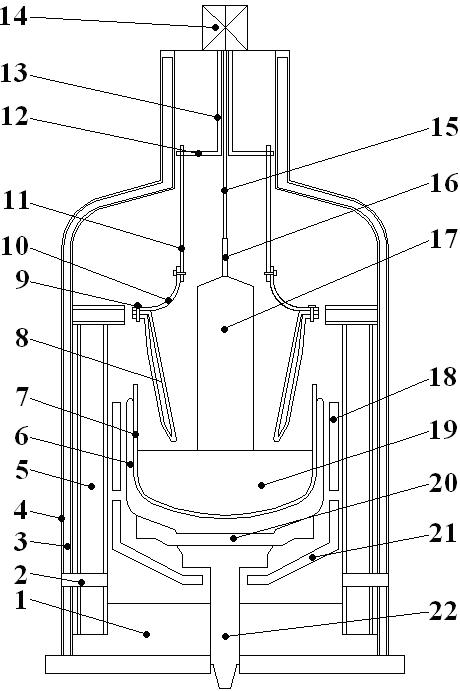

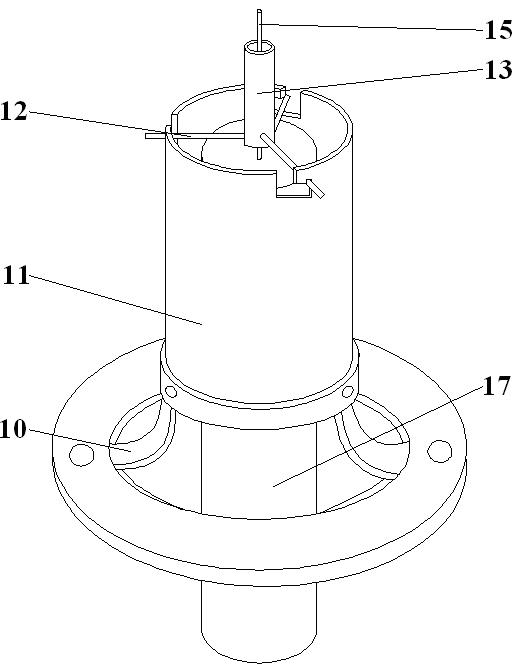

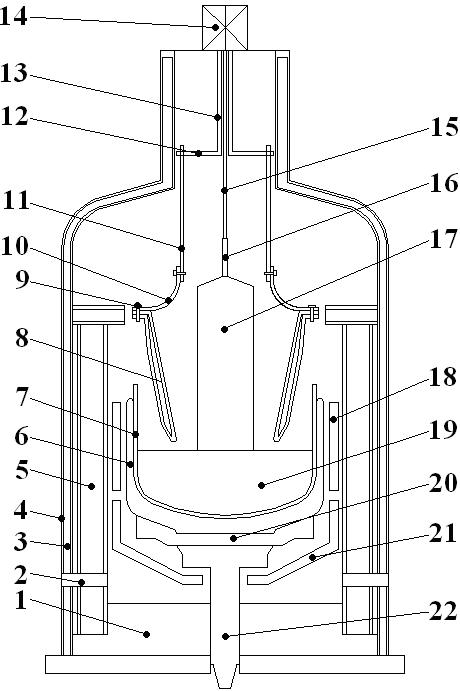

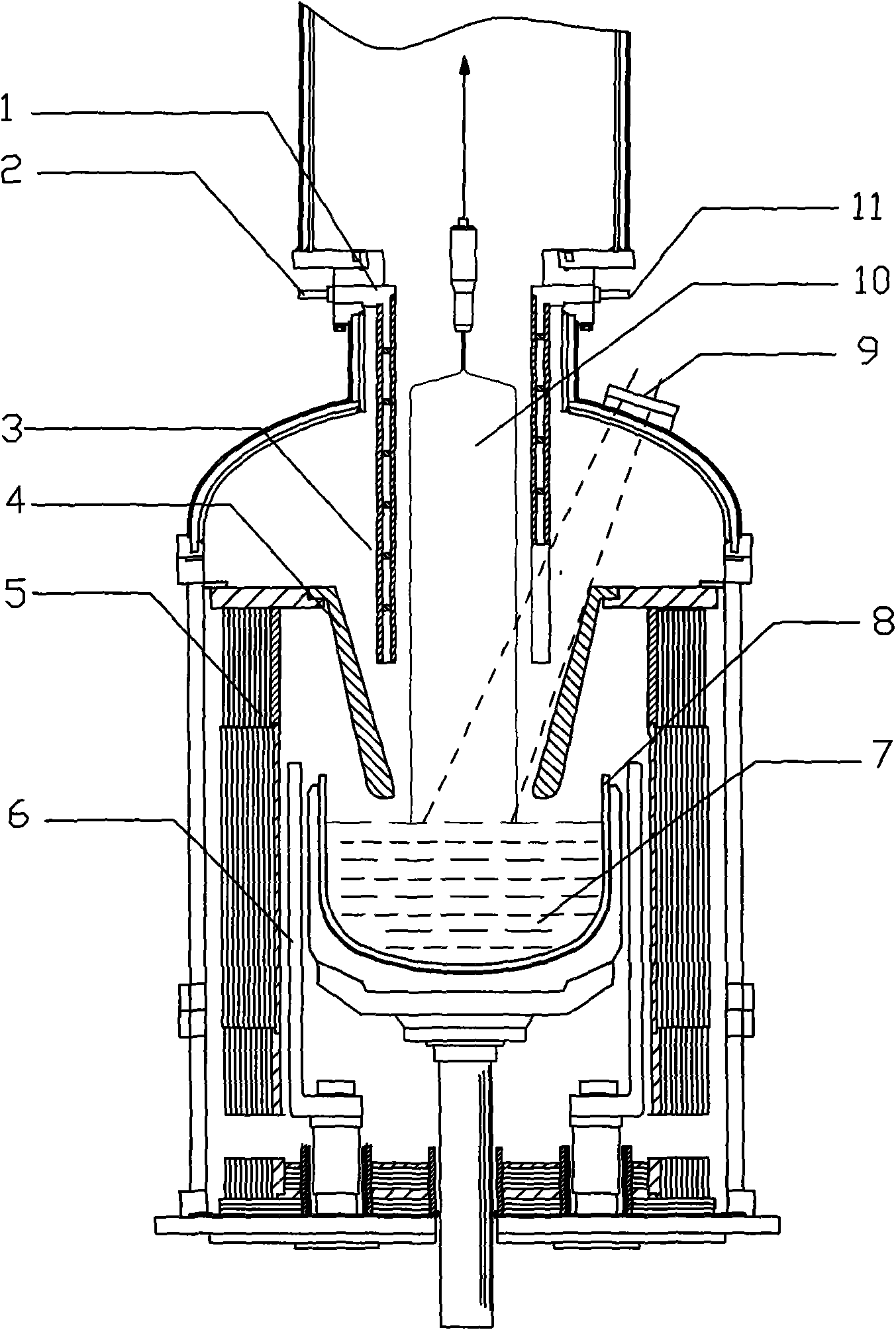

Dual-heater mobile-heat-shield type Czochralski crystal growing furnace

ActiveCN102162123AReduce the presence of impuritiesReduce microdefectsBy pulling from meltSemiconductor materialsSingle crystal

The invention discloses semiconductor material growing equipment, and in particular relates to a Czochralski crystal growing furnace for semiconductor single crystal growth. In the invention, the downward motion of a heat shield is used to replace the upward motion of a crucible, so that the crucible can only rotate and not ascend any more, thus, one degree of freedom is reduced and the system complexity is decreased; by adopting dual heaters respectively located at the bottom and the side face of the crucible respectively to control the growth of a crystal by aiming at different stages respectively, the temperature gradient control of the crystal and melt is more convenient; the relative positions between the crucible and the heaters are kept parallel and unchanged, and the heat radiation of the heaters is directly used for baking the crucible, so that the heat transfer efficiency is greatly improved in comparison with that in a traditional method in which the crucible in the traditional single crystal furnace is constantly away from a heating zone; and a flow guiding cylinder is used for guiding argon gas to carry out enhanced heat exchange on the crystal, so that an convection vortex of the argon gas above the melt is inhibited, thus, impurities and micro-defects in the crystal are favorably reduced and the consumption level of the argon gas is decreased.

Owner:JIANGSU UNIV

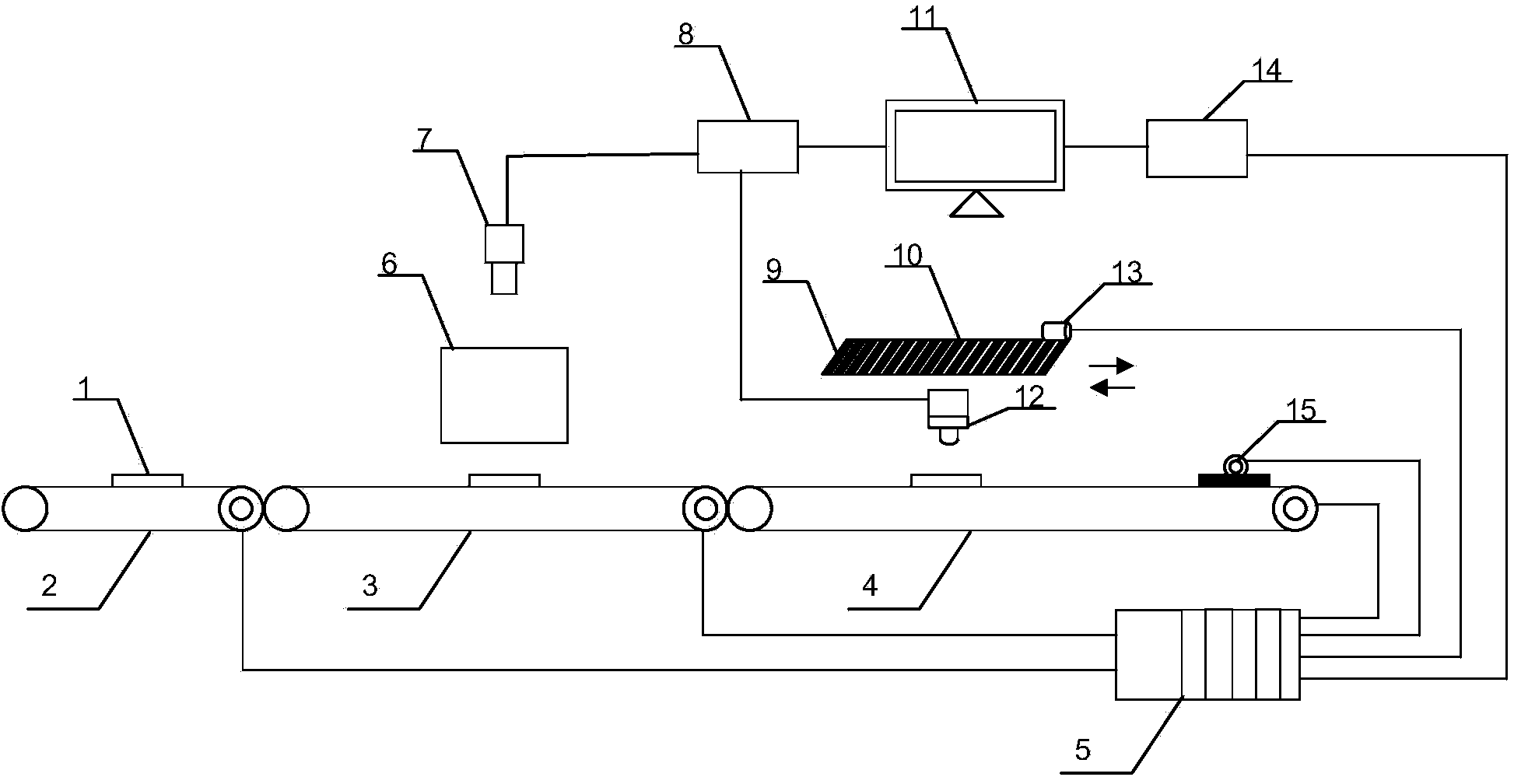

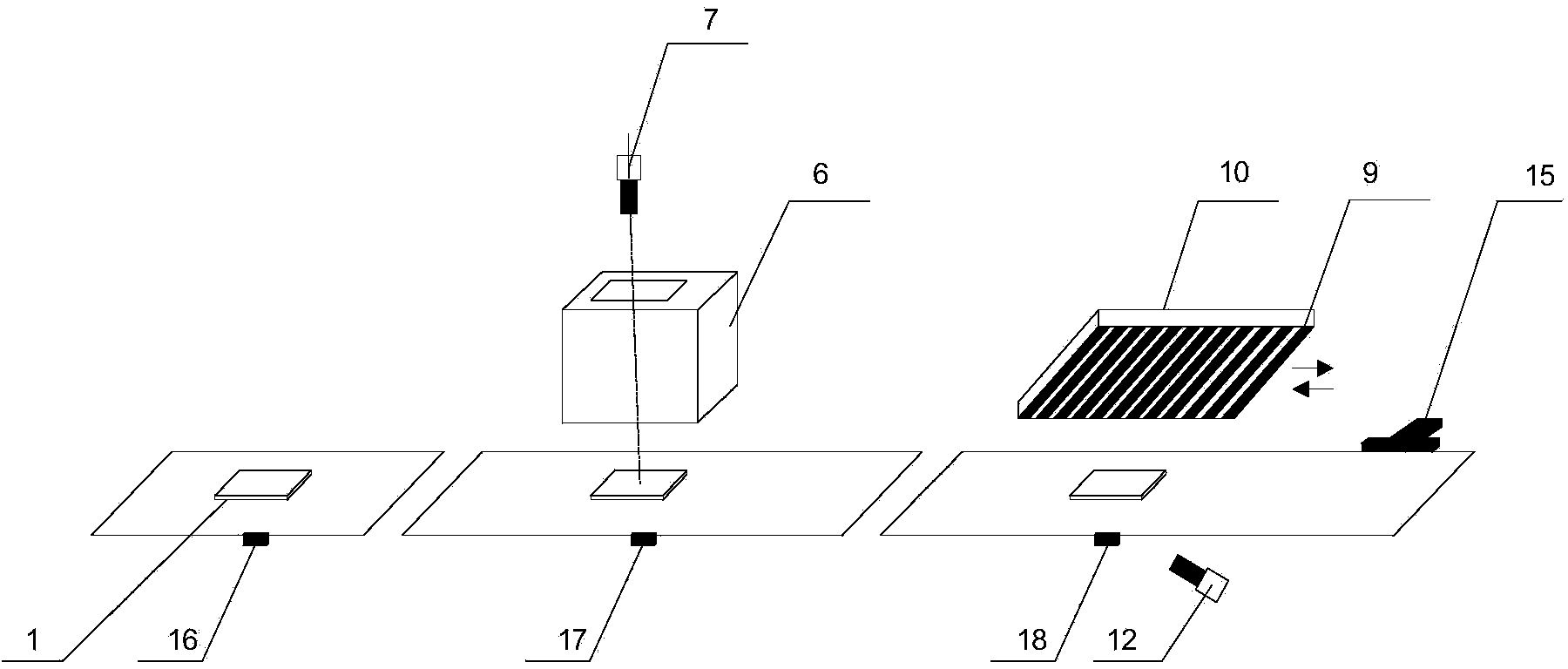

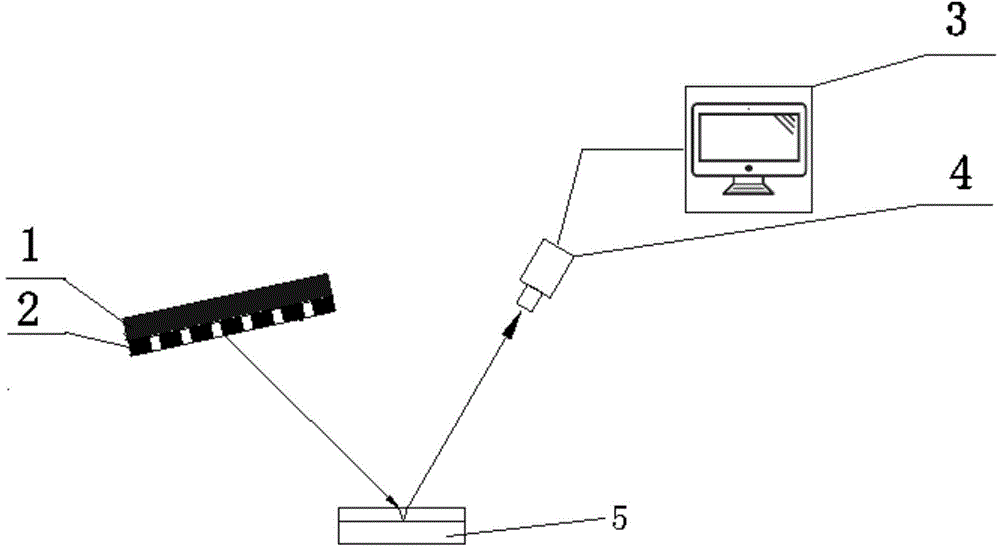

Machine-vision-based method and device for intelligently detecting surface micro-defects of product

InactiveCN104237252ASolve onlineSolve real-time detectionOptically investigating flaws/contaminationGratingMachine vision

The invention discloses a machine-vision-based method and a machine-vision-based device for intelligently detecting surface micro-defects of a product. The device comprises a first conveying belt, a second conveying belt, a third conveying belt and a conveying belt driving device, wherein the conveying belt driving device is controlled by a PLC (Programmable Logic Control) system; photoelectric sensors are correspondingly arranged on both sides of the three conveying belts; a coaxial light source and a camera A are arranged on the second conveying belt; the camera A is connected with an image acquisition card, an industrial personal computer, a DAQ (Data Acquisition) card and the PLC system; a non-uniform light source composed of a grating and a parallel light source is arranged above the third conveying belt; a camera B is arranged above the side of the third conveying belt and connected with the image acquisition card; a servo motor of the parallel light source is connected with the PLC system; a defective product elimination unit is arranged at the side edge of the tail of the third conveying belt. By the cooperation of two stations, fine defects can be detected efficiently and accurately, and particularly, the effect of detecting the surface defects of mirror-surface-like products through the grating and the non-uniform light source at the second station is excellent.

Owner:SOUTH CHINA UNIV OF TECH +1

Micro defects in semi-conductors

The invention relates to a method and apparatus for detecting defects in a semiconductor or silicon structure at room temperature, and in an efficient time, using photoluminescence. The invention employs the use of a high intensity beam of light preferably having a spot size between 0.1 mm 0.5 microns and a peak or average power density of 104-109 w / cm2 with a view to generating a high concentration of charge carriers, which charge characters detect defects in a semiconductor by interacting with same. These defects are visible by producing a photoluminescence image of the semiconductor. Several wavelengths may be selected to identify defects at a selective depth as well as confocal optics may be used.

Owner:ONTO INNOVATION INC

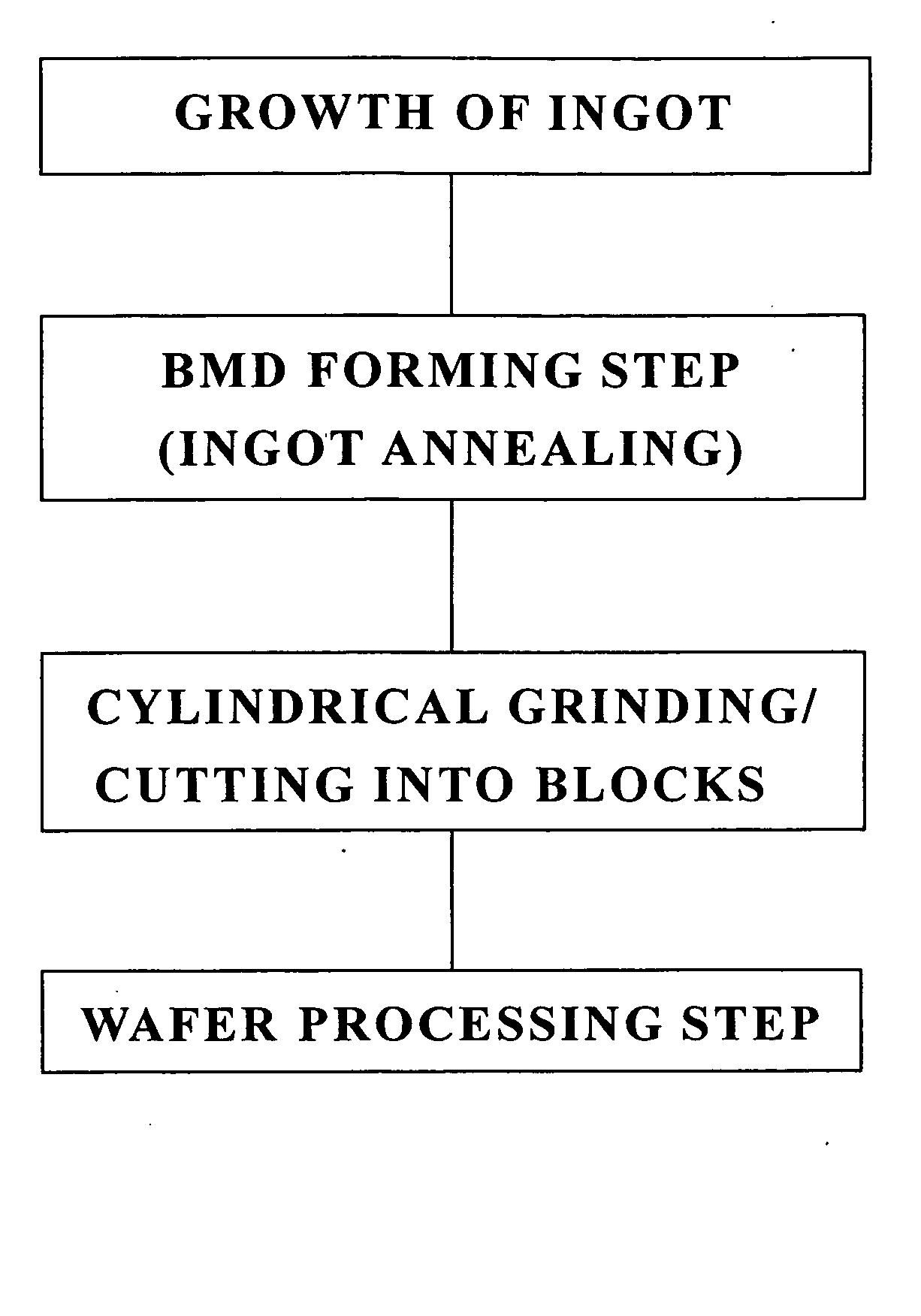

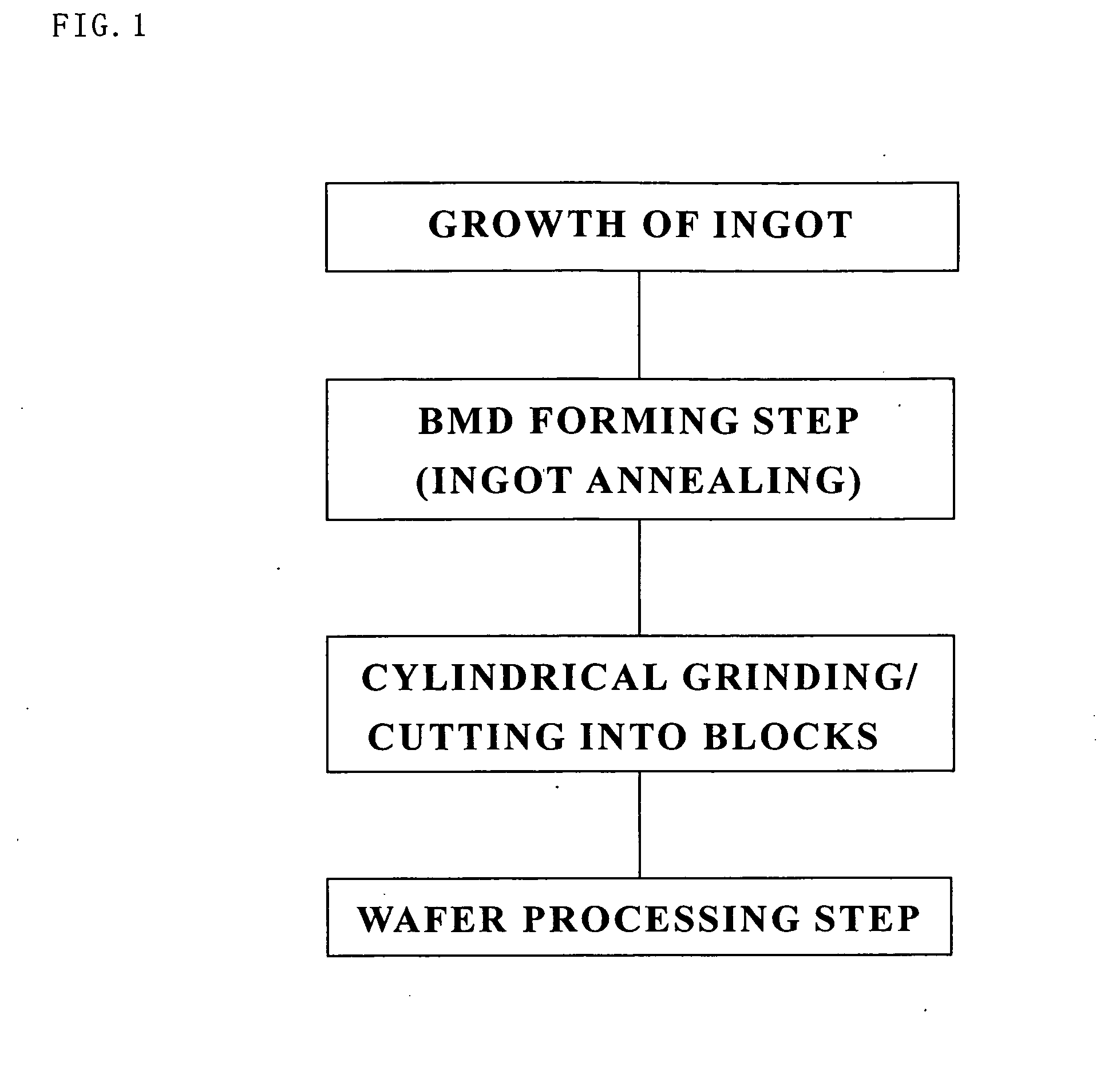

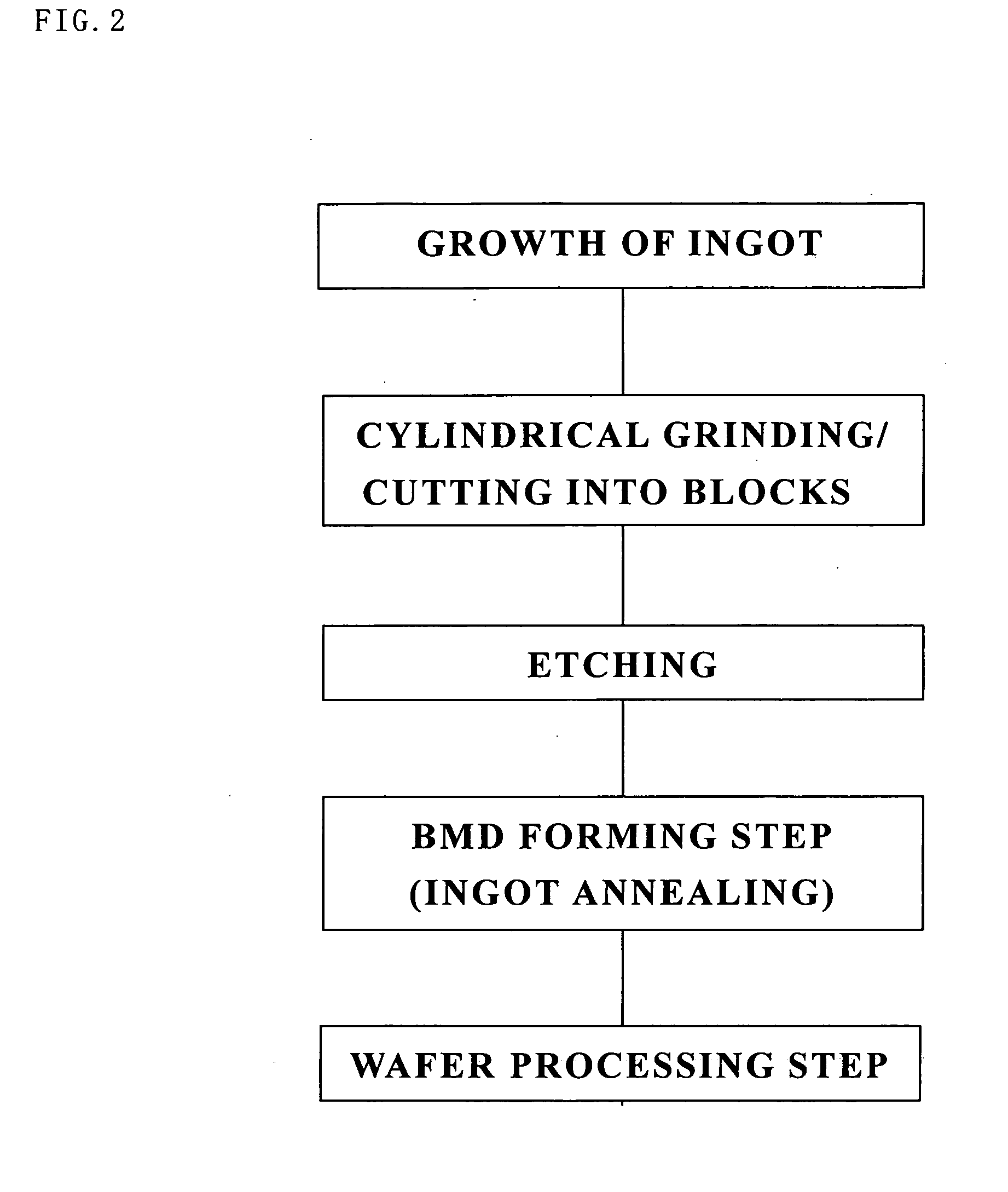

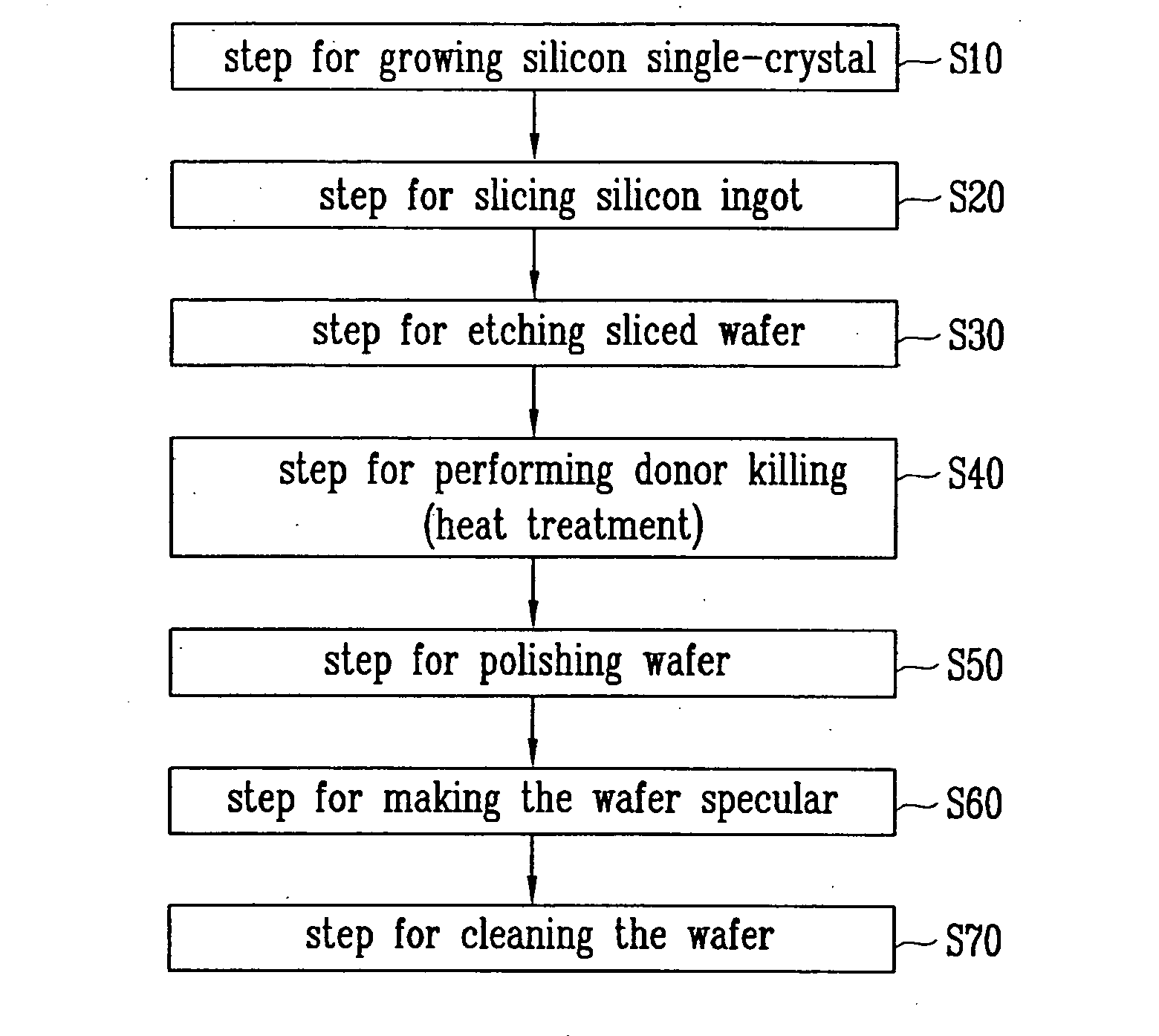

Method for producing a wafer

InactiveUS20060150894A1Improve abilitiesAvoid small quantitiesPolycrystalline material growthAfter-treatment detailsProduction rateWafering

The present invention is a method for producing a wafer comprising, at least, a BMD forming step of subjecting a silicon single crystal in a state of an ingot to heat treatment thereby to form bulk micro defects (BMDs) inside, and a wafer processing step of processing the ingot in which the bulk micro defects (BMDs) was formed into wafers. Thereby, there can be provided a method for producing a wafer, wherein heat treatment for providing IG capability in production of wafer can be shortened and wafers with high IG capability can be produced in large quantity. Also, the present invention can further comprise a wafer heat-treating step of subjecting the processed wafer to heat treatment, or an epitaxial growth step of forming an epitaxial layer on the wafer. Thereby, there is improved productivity of annealed wafers or epitaxial wafers that are excellent in gettering capability.

Owner:SHIN-ETSU HANDOTAI CO LTD

Method for repairing micro-defects inside metal materials

The invention discloses a method for repairing micro-defects inside metal materials which can repair the micro-defects inside the metal materials so as to improve the performance of the metal materials without affecting the thermal deformation of the metal materials. The method comprises the following steps: putting the metal material to be repaired in an external physical field excitation device capable of generating a pulsed magnetic field and a pulsed electric field, and selecting the appropriate field treatment process for processing according to the magnetic property of the metal material and the configuration type of the microscopic defect inside the substrate. In this way, the in-situ repair of internal defects of metal materials can be realized by pulsed magnetic field and pulsed electric field induction. Therefore, the plastic toughness of metal materials is improved, the strength of materials can be increased, the abrasion resistance of materials can be greatly improved, the initiation of microcracks can be restrained and expansion of the microcracks can be delayed, and the fatigue life of the materials can be significantly prolonged. In addition, the whole repair process will not cause significant temperature rise and thermal deformation of the metal material.

Owner:WUHAN JINGTAI TECH CO LTD +1

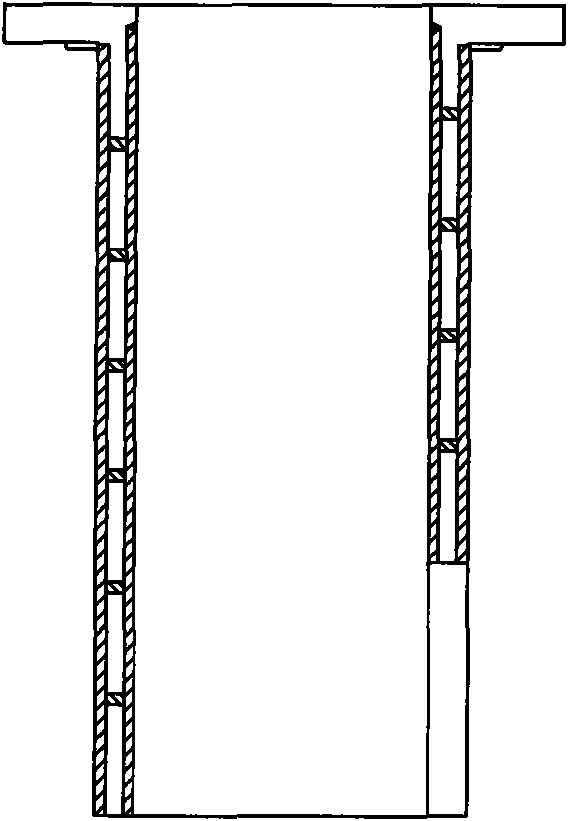

Vertical pulling silicon single crystal growing furnace with water-cooling jacket

InactiveCN101575731AHeat dissipation fastFast growthPolycrystalline material growthBy pulling from meltCooling effectEngineering

The invention relates to a device for preparing silicon single crystal and aims at providing a vertical pulling silicon single crystal growing furnace with a water-cooling jacket. The growing furnace comprises a heater, a quartz crucible and a heat insulating device. The above of the quartz crucible is provided with a thermal shielding device which guards a single crystal rod lifting region; the tube-shaped water-cooling jacket is arranged between the thermal shielding device and the single crystal rod lifting region; and the water-cooling jacket is a hollow jacket device, the interior of which is a channel for cooling water to flow and provided with a water inlet pipe and a water outlet pipe. The newly grown high temperature part of the single crystal rod is cooled by the water-cooling jacket, and large temperature difference ensures the single crystal rod to dissipate heat rapidly, and the growing speed of the single crystal rod can increase nearly one time. As the heat on the growing interface of the single crystal rod can be led away by the single crystal rod, the power consumption of the heater can be reduced greatly and the micro defect of the crystal can be reduced. If the temperature of the used cooling water is lower, the cooling effect is better.

Owner:ZHEJIANG JINGSHENG MECHANICAL & ELECTRICAL

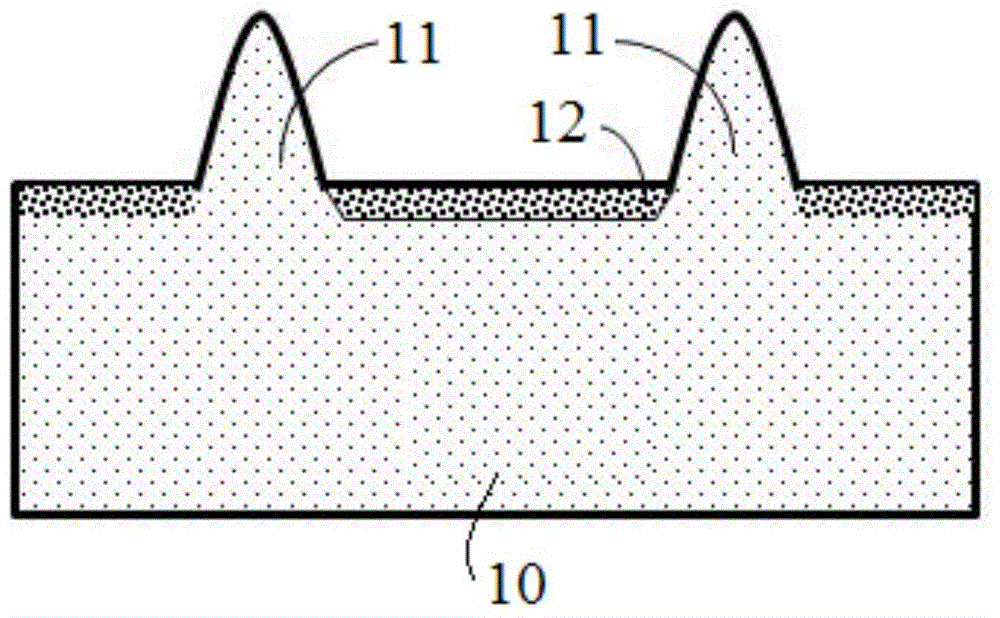

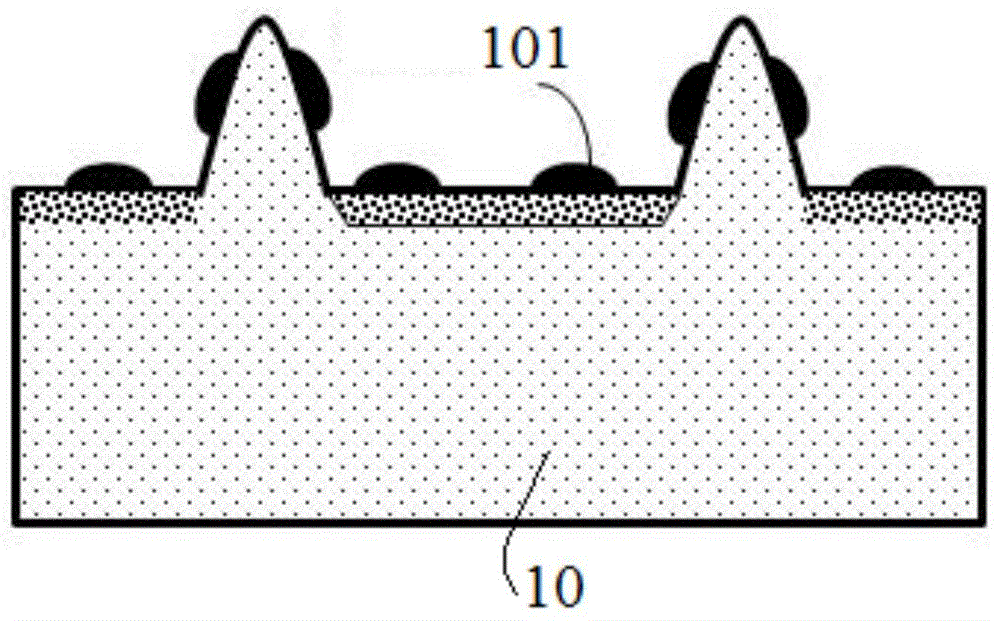

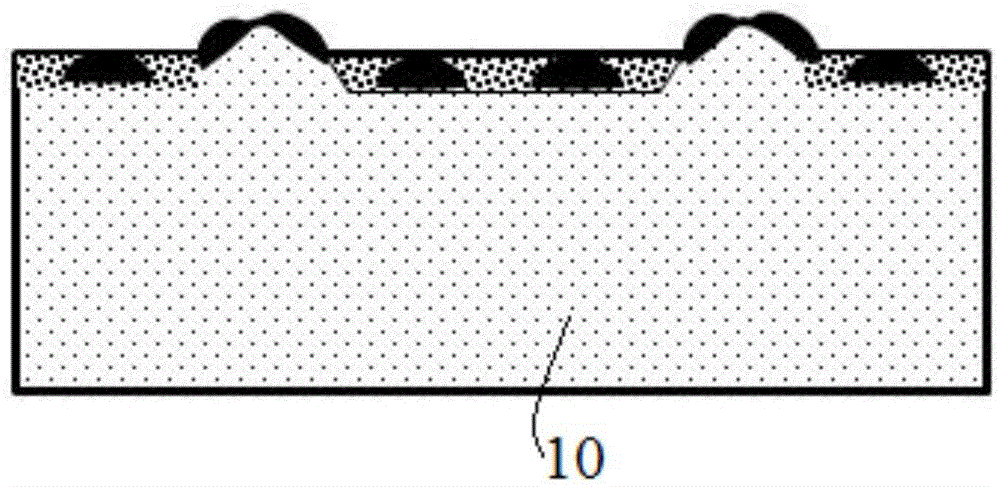

Surface treatment method and texturing method for diamond wire cutting silicon wafers

ActiveCN104900509AImprove conversion efficiencyAvoid difficultiesFinal product manufactureSemiconductor/solid-state device manufacturingWire cuttingMetal particle

The invention discloses a surface treatment method and a texturing method for diamond wire cutting silicon wafers. The surface of a diamond wire cutting silicon wafer is covered with an amorphous silicon layer caused by cutting, and line marks are densely distributed on the surface of the diamond wire cutting silicon wafer. The surface treatment method comprises the following steps: cleaning and pre-treating a diamond wire cutting silicon wafer; putting the cleaned and pre-treated diamond wire cutting silicon wafer in mixed solution containing metal ions, oxidizing agent and etching agent, and carrying out metal ion adhesion, SiO2 generation through oxidation, and catalytic chemical etching reaction in sequence; cleaning the etched silicon wafer with first cleaning fluid, second cleaning fluid and deionized water respectively, and removing metal particles, an oxide layer and chemical residues on the surface of the silicon wafer; and cleaning the silicon wafer to obtain a silicon wafer which has no line marks and contains a micro-defect amorphous layer. According to the invention, a diamond wire cutting silicon wafer can be effectively textured through a regular process, and the conversion efficiency of a crystalline silicon solar cell prepared with the textured silicon wafer is improved.

Owner:JIA XING SHANGNENG PHOTOVOLTAIC MATERIALS SCI & TECH CO LTD

Endoscope with distal tip having encased optical components and display orientation capabilities

An apparatus according to one embodiment includes an endoscope tip including a housing that is monolithically formed of a transparent material. At least one optical component is at least partially encased within the housing. The optical component can be, for example, a light source, a fiber optic, an imaging sensor, a lens, a reflector or a light shield. In another embodiment, an apparatus includes an endoscope having a distal end portion that includes a housing. The housing is monolithically formed with a transparent material and a light source is at least partially encased within the housing. The housing also includes a micro-defects portion within the transparent material of the housing. The micro-defects portion is configured to provide a selected output shape of a beam of light produced by the light source.

Owner:BOSTON SCI SCIMED INC

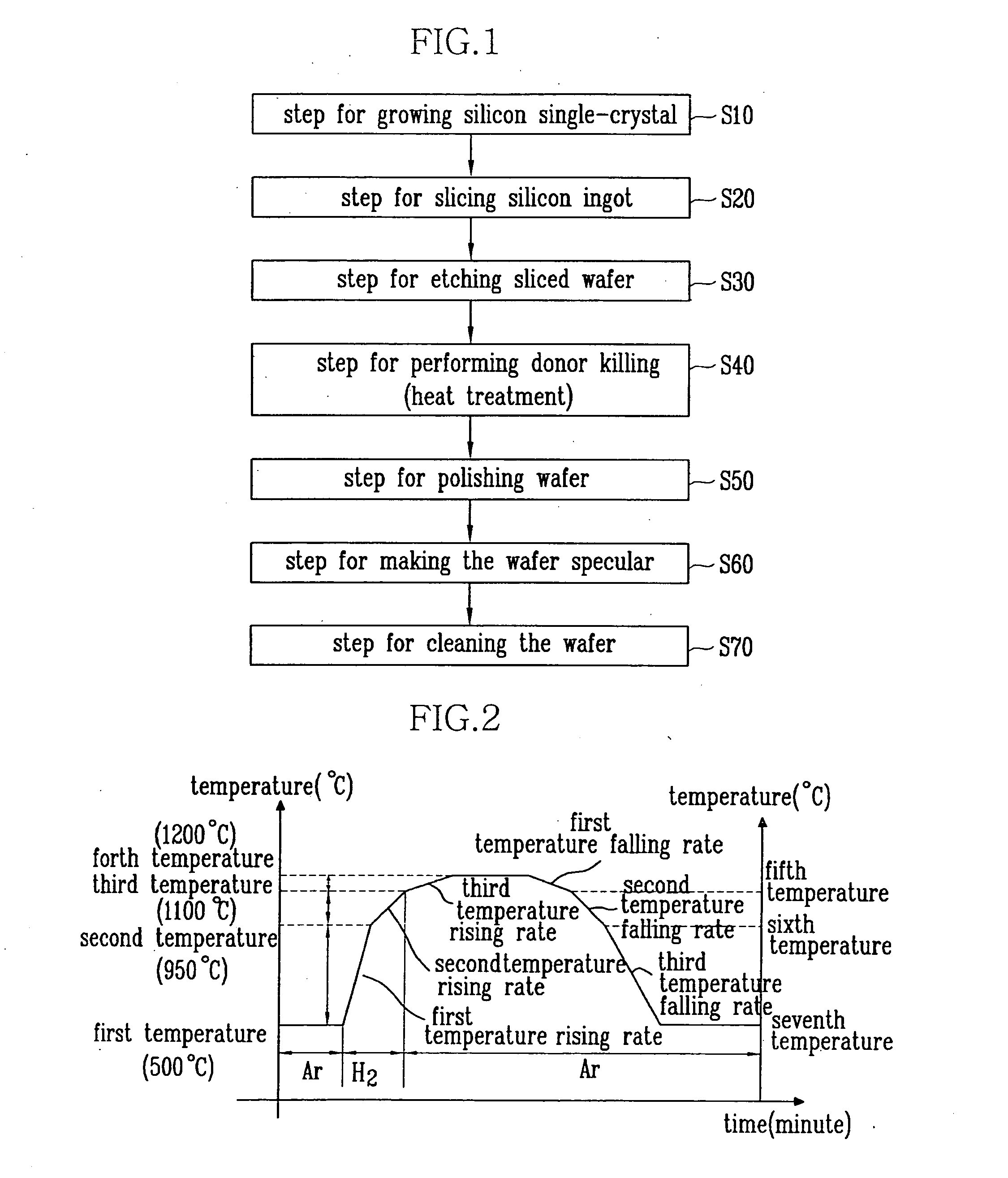

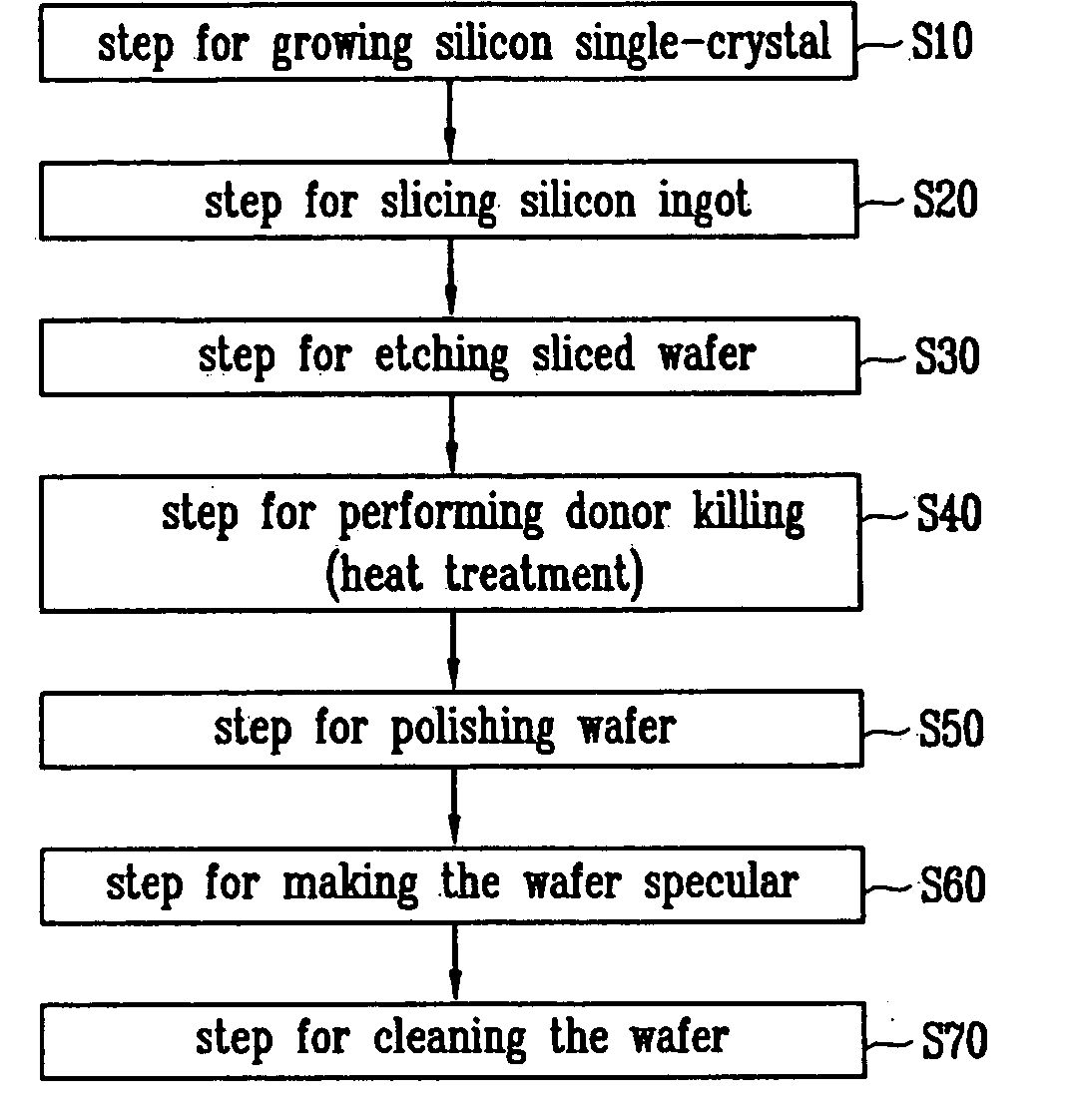

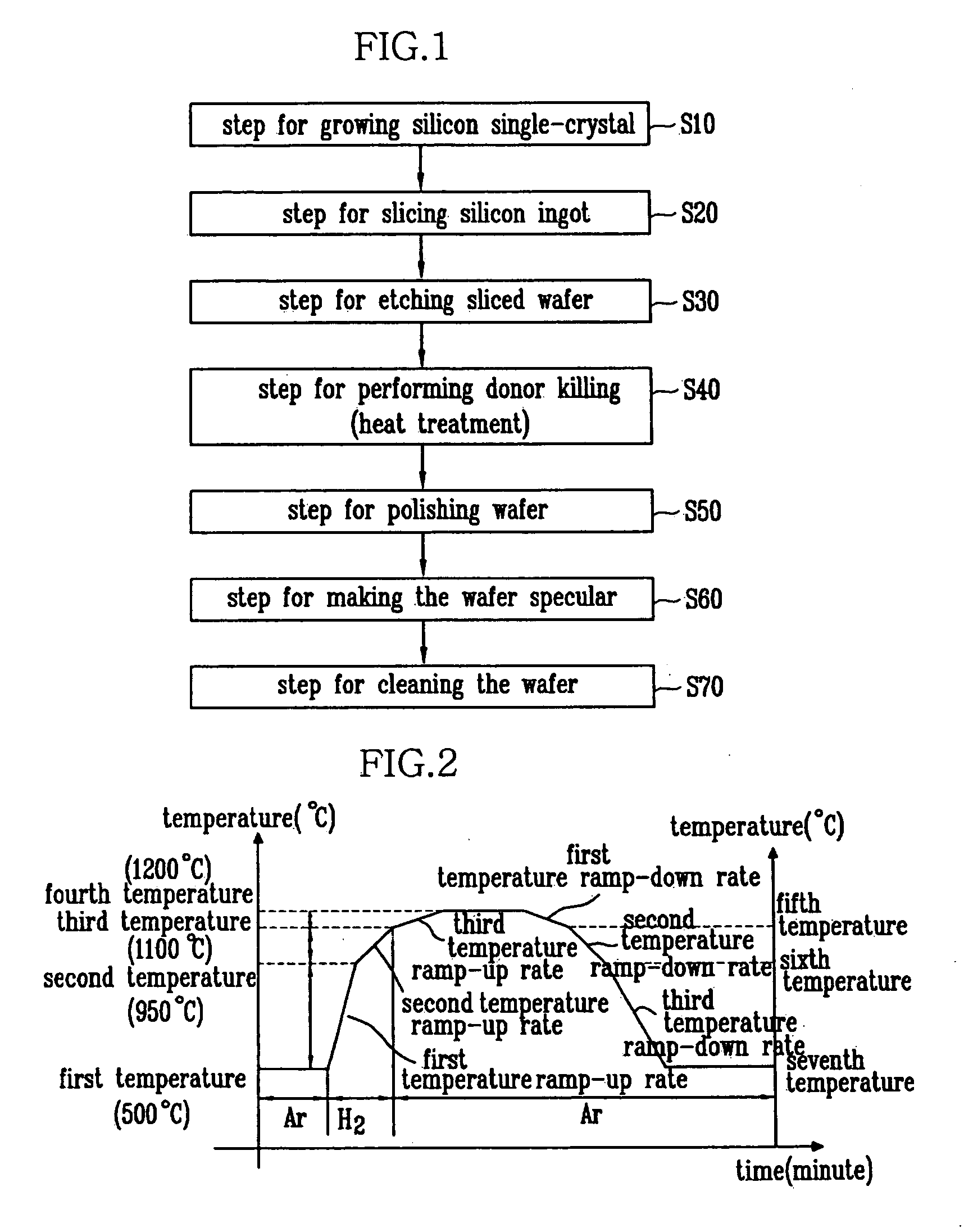

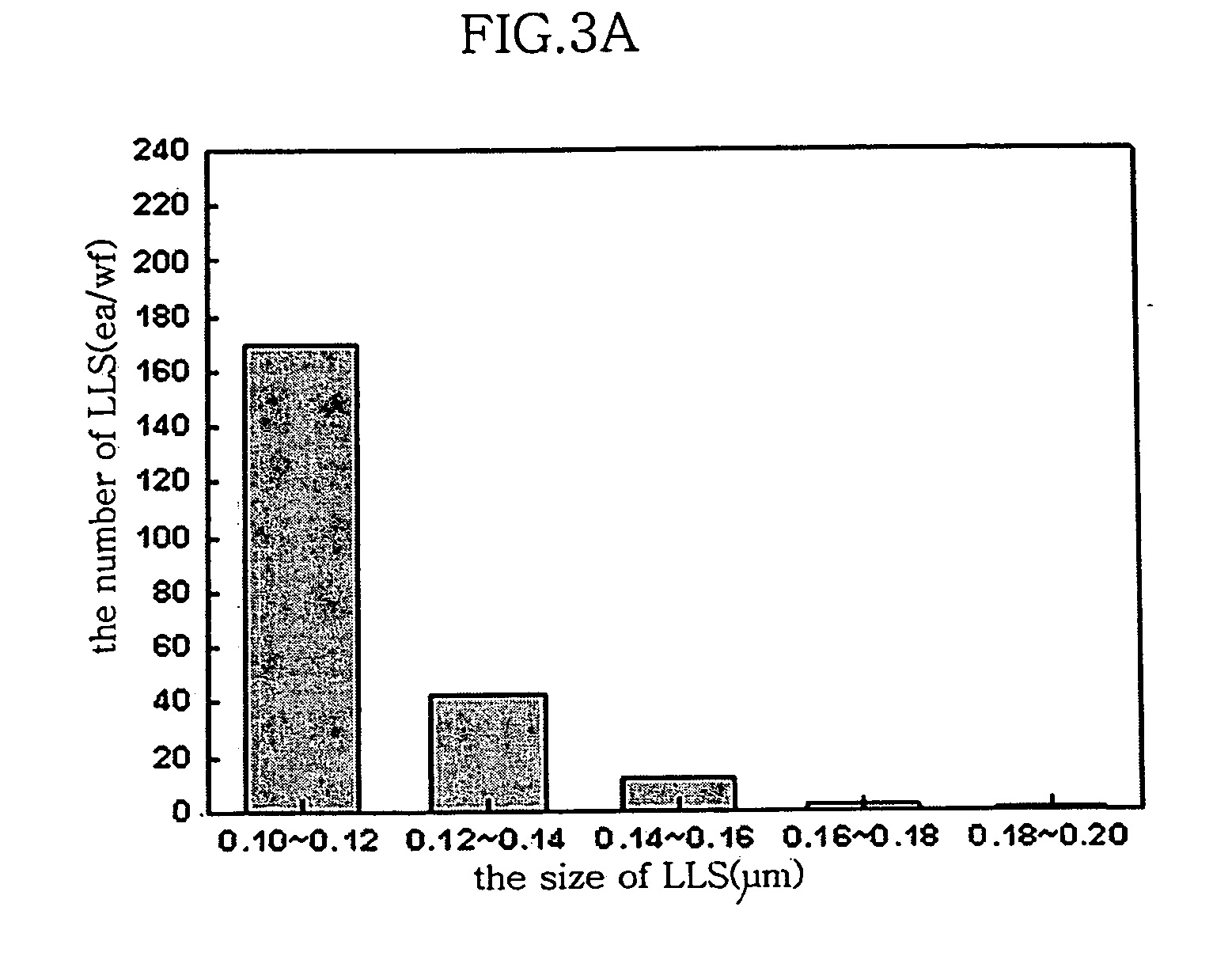

Method for manufacturing silicon wafer

InactiveUS20070169688A1Generates damageIncrease precipitated oxygenPolycrystalline material growthAfter-treatment detailsHigh densityMetal impurities

A method for manufacturing a high quality annealed wafer which has both a uniform and high density bulk micro defect (BMD) in a bulk zone disposed between front and rear denuded zones (DZ), which increases the effect of gettering metal impurities such as Fe, Cu and etc., and which provides a defect free zone in the active region of device.

Owner:LG SILTRON

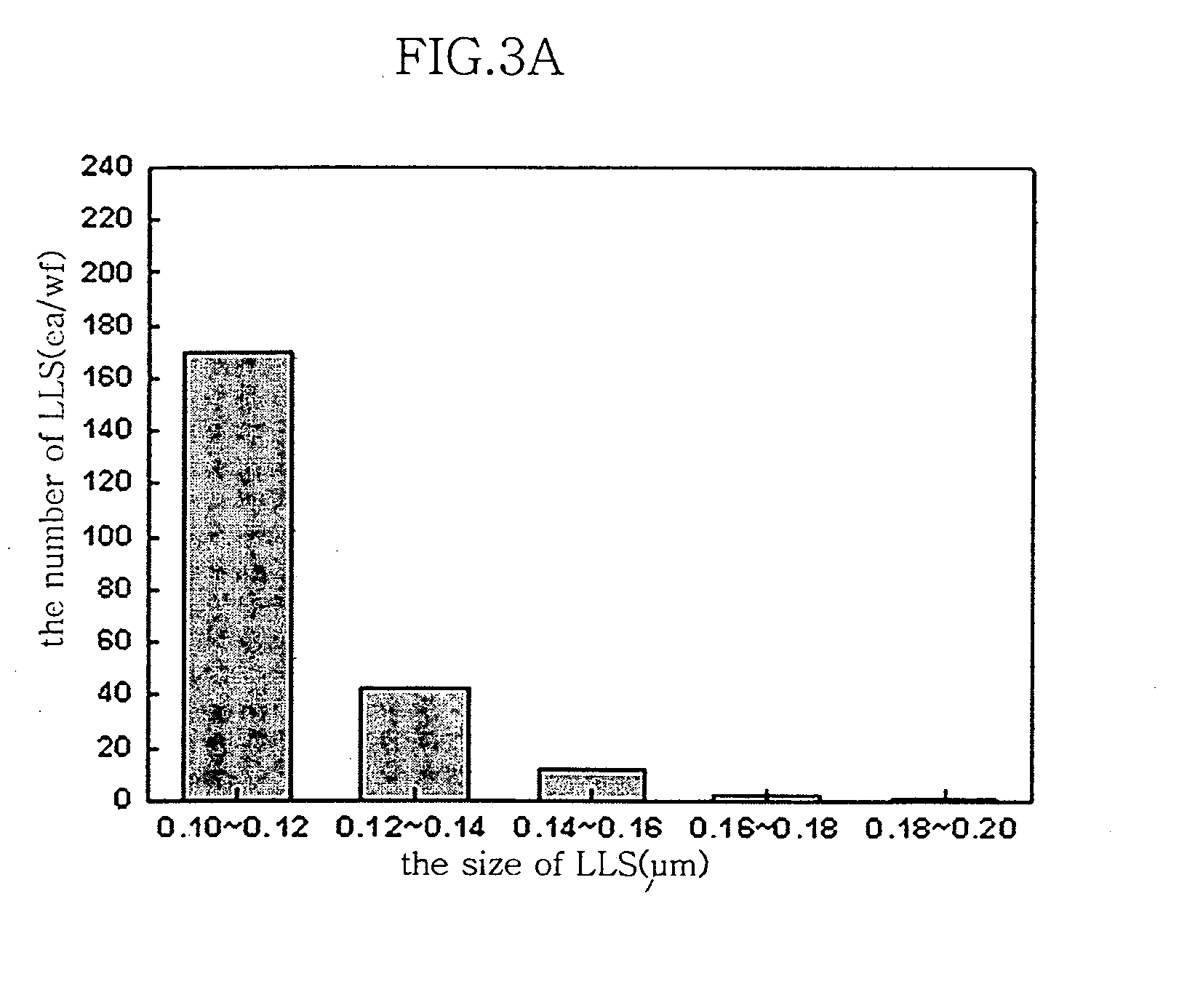

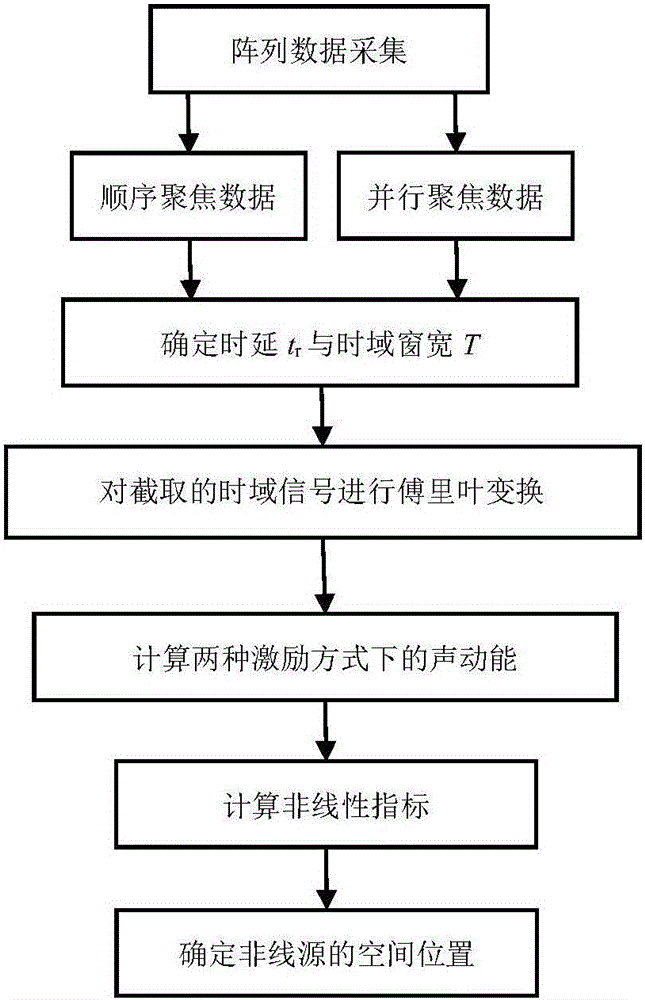

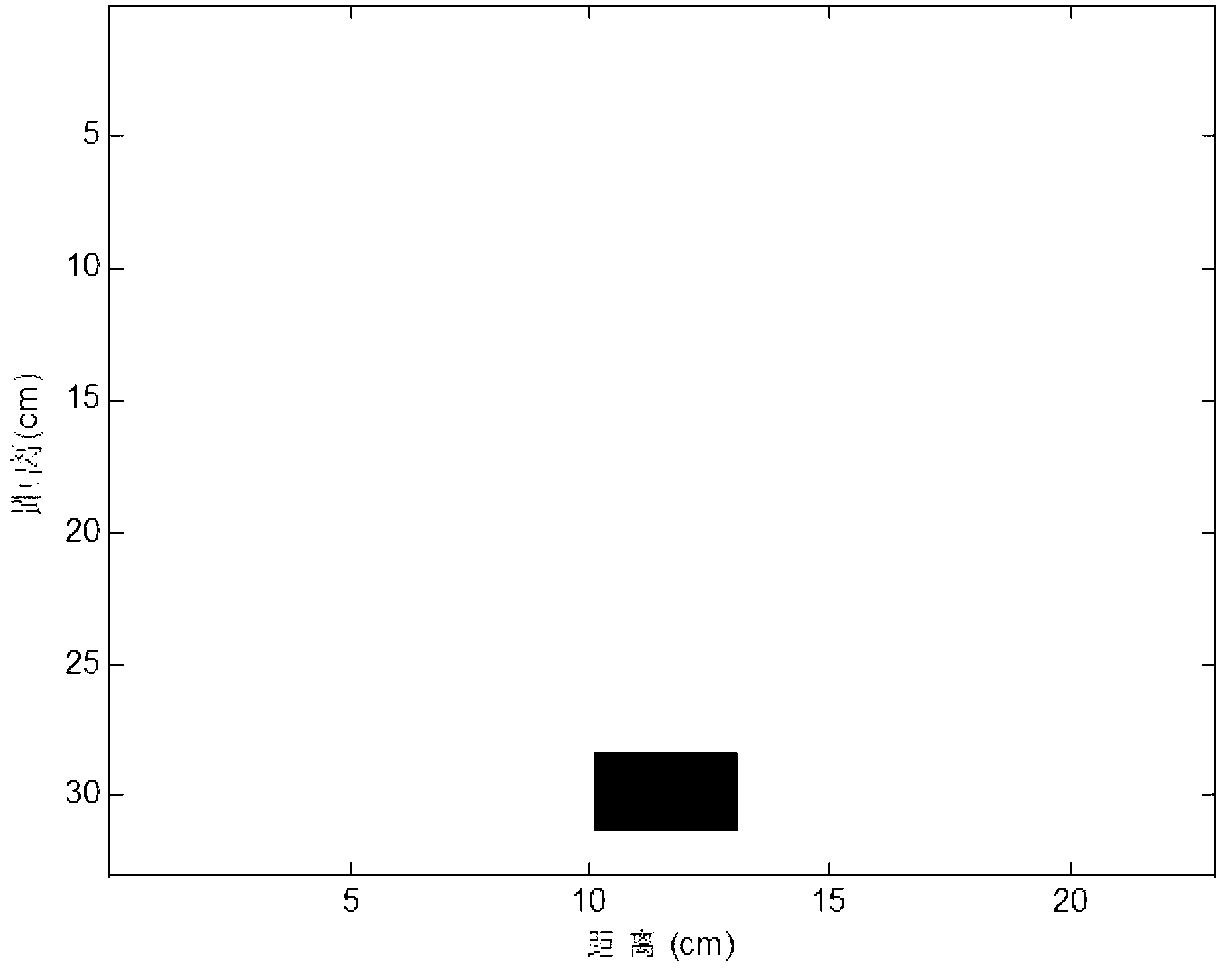

Nonlinear ultrasonic phased array imaging method for micro-crack detection

InactiveCN105004792AAnalysing solids using sonic/ultrasonic/infrasonic wavesTime domainRelative energy

The invention relates to a nonlinear ultrasonic phased array imaging method for micro-crack detection. According to the method, an ultrasonic phased array detection system is utilized to collect the detection signals in the sequence focusing mode and the parallel focusing mode, the appropriate receiving delay tr and the width T of the time-domain intercepting window are determined, the intercepted detection signals are subjected to Fourier transform, the sound kinetic energies Es and Ep of the sequence focusing method and the parallel focusing method and the relative energy difference gamma of the two focusing methods are respectively calculated, and the nonlinear source position is determined according to the gamma, ie., the micro-defect position.

Owner:BEIJING UNIV OF TECH

Silicon wafer and method for manufacturing the same

InactiveUS20050247259A1Generates damageIncrease precipitated oxygenPolycrystalline material growthAfter-treatment detailsHigh densityMetal impurities

A method for manufacturing a high quality annealed wafer which has both a uniform and high density bulk micro defect (BMD) in a bulk zone disposed between front and rear denuded zones (DZ), which increases the effect of gettering metal impurities such as Fe, Cu and etc., and which provides a defect free zone in the active region of device.

Owner:LG SILTRON

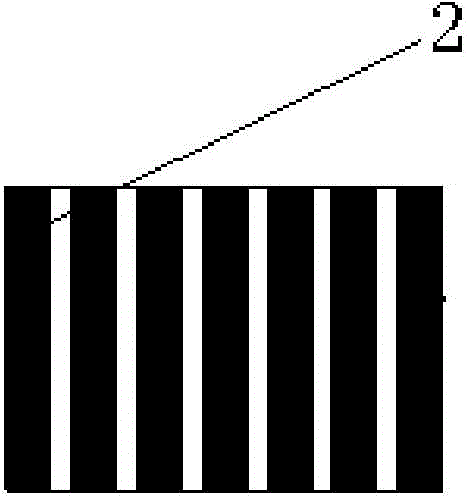

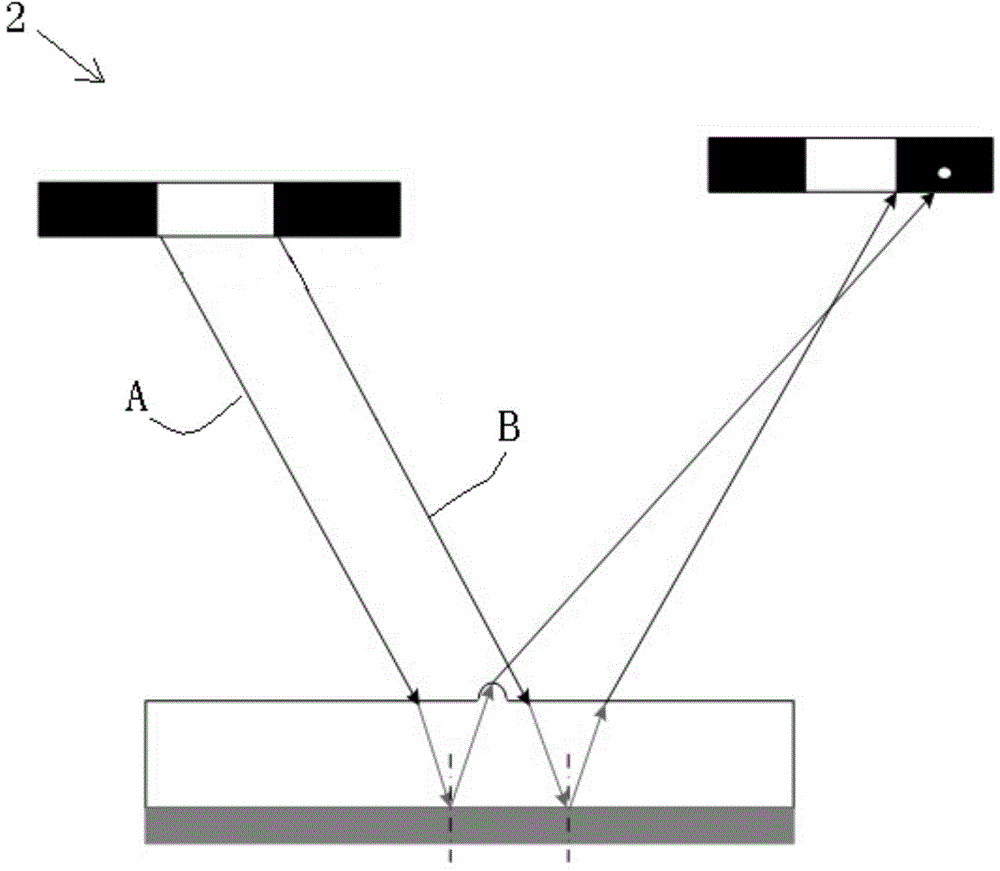

Mirror-like object surface optical imaging device and imaging method thereof

InactiveCN104101611AGood optical imaging effectSolve the shortcomings of high reflectionOptically investigating flaws/contaminationGratingImaging problem

The invention discloses a mirror-like object surface optical imaging device and an imaging method thereof. The device comprises a parallel light source, a grating, a camera, a computer and a light source controller for controlling the parallel light source. The camera is connected to the computer. The parallel light source and the grating cooperate to generate a non-uniform light source with light and dark stripes. According to refraction and reflection principles of light, by moving the non-uniform light source, the light and dark stripes can scan the total surface of a scanned object, and the camera is employed to acquire a same position on the object surface continuously in a movement period so as to obtain series of pictures, and subjecting the series of pictures to morphological dilation treatment, and then synthesizing a final target pictures. The device and the method provided by the invention solve the unable imaging problem due to too small mirror-like object surface defects and high reflections, and mirror-like object surface micro-defects and a background can form significant contrast, the noise is small, the gray value difference is great, and defect segmentation can be easy.

Owner:SOUTH CHINA UNIV OF TECH

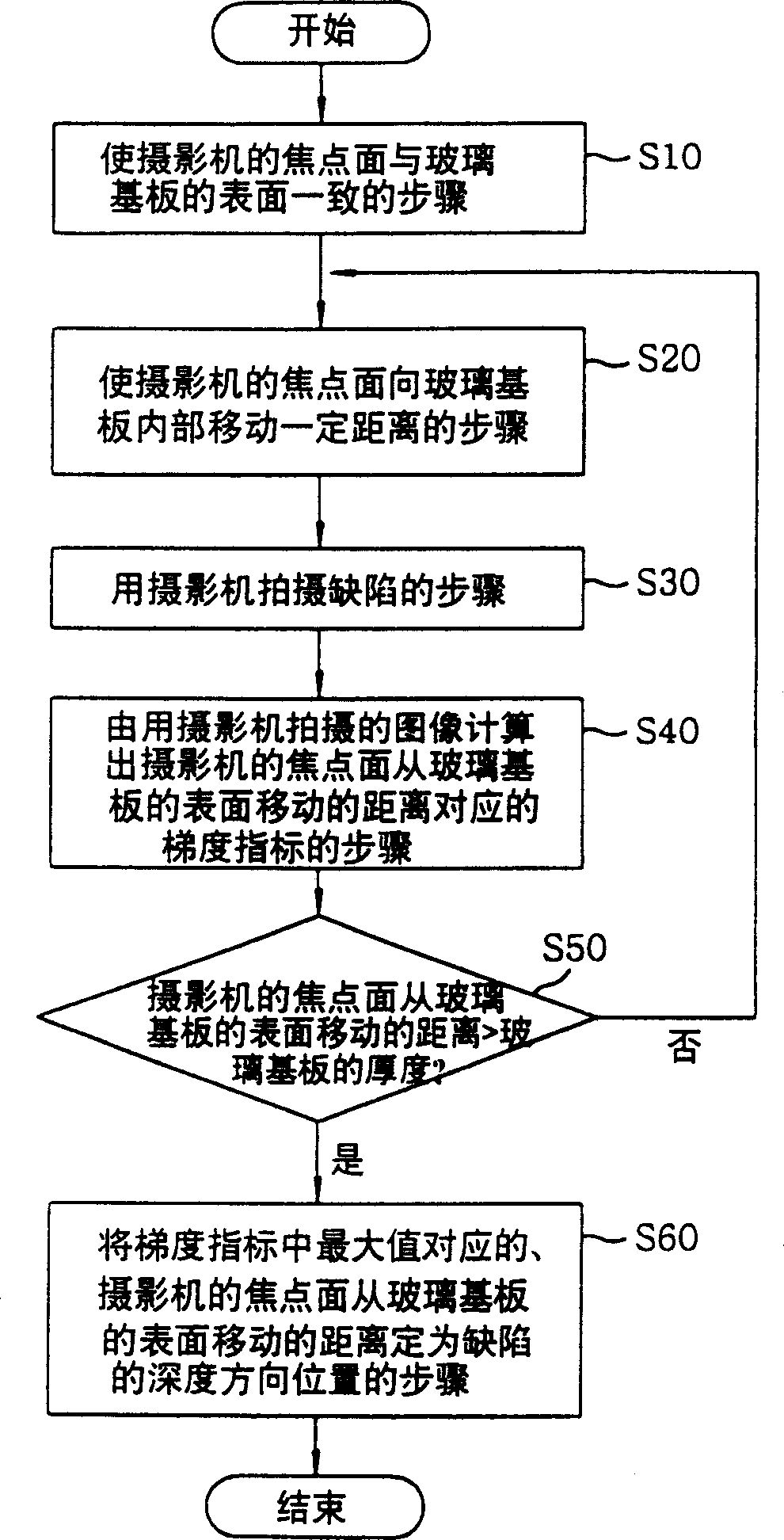

Internal flaw position detecting method in depth direction for glass base plate

ActiveCN1573319ACorrect and immediate judgment of good and badMaterial analysis by optical meansUsing optical meansIlluminanceDepth direction

To enable accurate and quick decision on the quality of a glass substrate, by precisely calculating the position of a defect in the depth direction, based on the image of a defect photographed, while moving the focal surface of a camera from the surface of the glass substrate to the inside, to obtain a clear image of a micro defects. The focal point of the camera is made to coincide with the position of a defect on the surface of the glass substrate; the gradient of illuminance in color in a boundary between the defect and the background thereof is calculated as a gradient index GI value with respect to a traveled distance from the glass surface, by using the image with the defect photographed, while the focal plane of a camera is moved from the surface of the glass substrate to the back side; the traveled distance, corresponding to the maximum of the gradient index GI value is determined as the position of the defect in the depth direction.

Owner:SAMSUNG CORNING PRECISION MATERIALS CO LTD

Polishing solution capable of improving surface quality of polished phase transition material

ActiveCN102516878AImprove surface qualityHeat-exchange elementsPolishing compositions with abrasivesSurface roughnessPhase-change material

The invention provides a chemically mechanical polishing solution for a phase transition memory. The polishing solution comprises, calculated by a total weight of the polishing solution, 0.1-30 wt% of polishing particle, 0.01-10 wt% of oxidizing agent, 0.001-5 wt% of surface improving agent and aqueous medium. Using the polishing solution provided by the invention to carry out polishing treatment on a phase transition memory member can obviously improve surface quality of the polished phase transition material and realize control on low surface roughness less than 1 nm and micro defects (corrosion pit, residual, scratch and polishing mist, etc.).

Owner:SHANGHAI XINANNA ELECTRONICS TECH +1

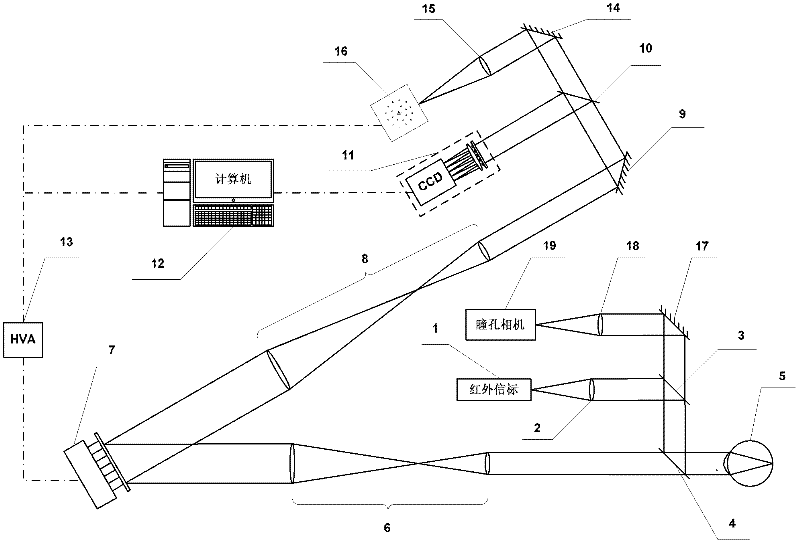

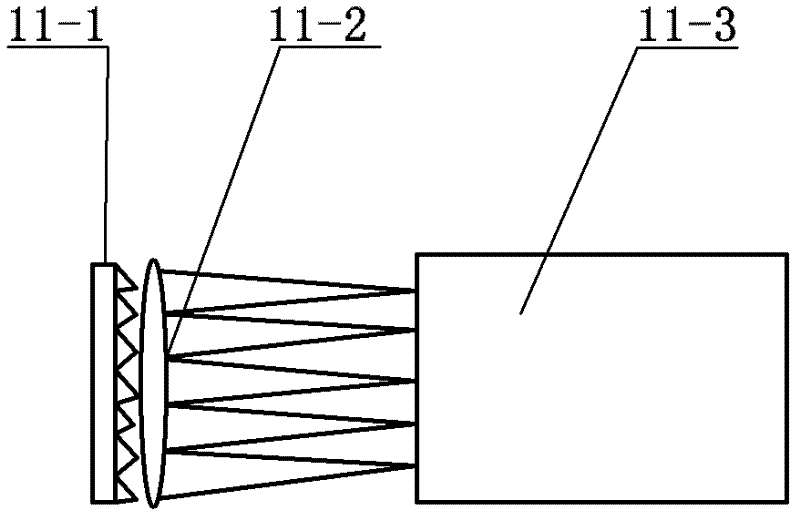

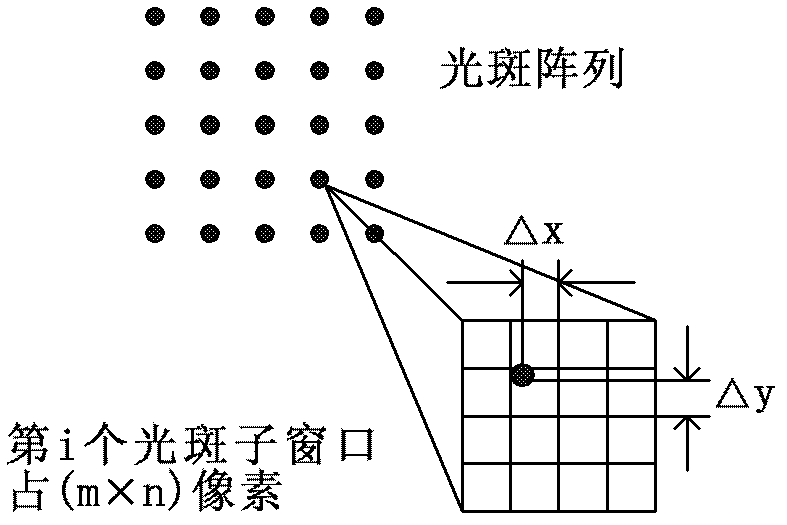

An Adaptive Optics Micro Perimeter

InactiveCN102283633AReduce stimulus redundancyFacilitate the detection of subtle visual field defectsEye diagnosticsPupil diameterDisease

An adaptive optics microperimetry, infrared beacon emits infrared light to the pupil of the subject, the Hartmann wavefront sensor measures the wavefront aberration of the human eye carried by the reflected light of the fundus, and the computer calculates the control voltage based on the measured aberration , driving the wavefront corrector to correct the aberration of the human eye. After the aberration correction is completed, the fixed optotype for fixing the line of sight of the examinee and the optical stimulation optotype for providing optical stimulation to the fundus of the examinee are displayed at a plurality of predetermined positions on the stimulus optotype display device. The pupil camera uses the infrared light emitted by the infrared light source in front of the eye to capture the subject's human eye pupil image and calculate the pupil diameter. The computer controls the change of the optical stimulus visual target according to the change of the subject's pupil diameter, and measures the subject's field of vision. The invention has high reliability, reduces the stimulus redundancy caused by the aberration of the human eye in the visual field test, is beneficial to discover early micro-perspective defects, and provides a powerful tool for the evaluation of the micro-perspective defects of the human eye and the diagnosis of related diseases.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI +1

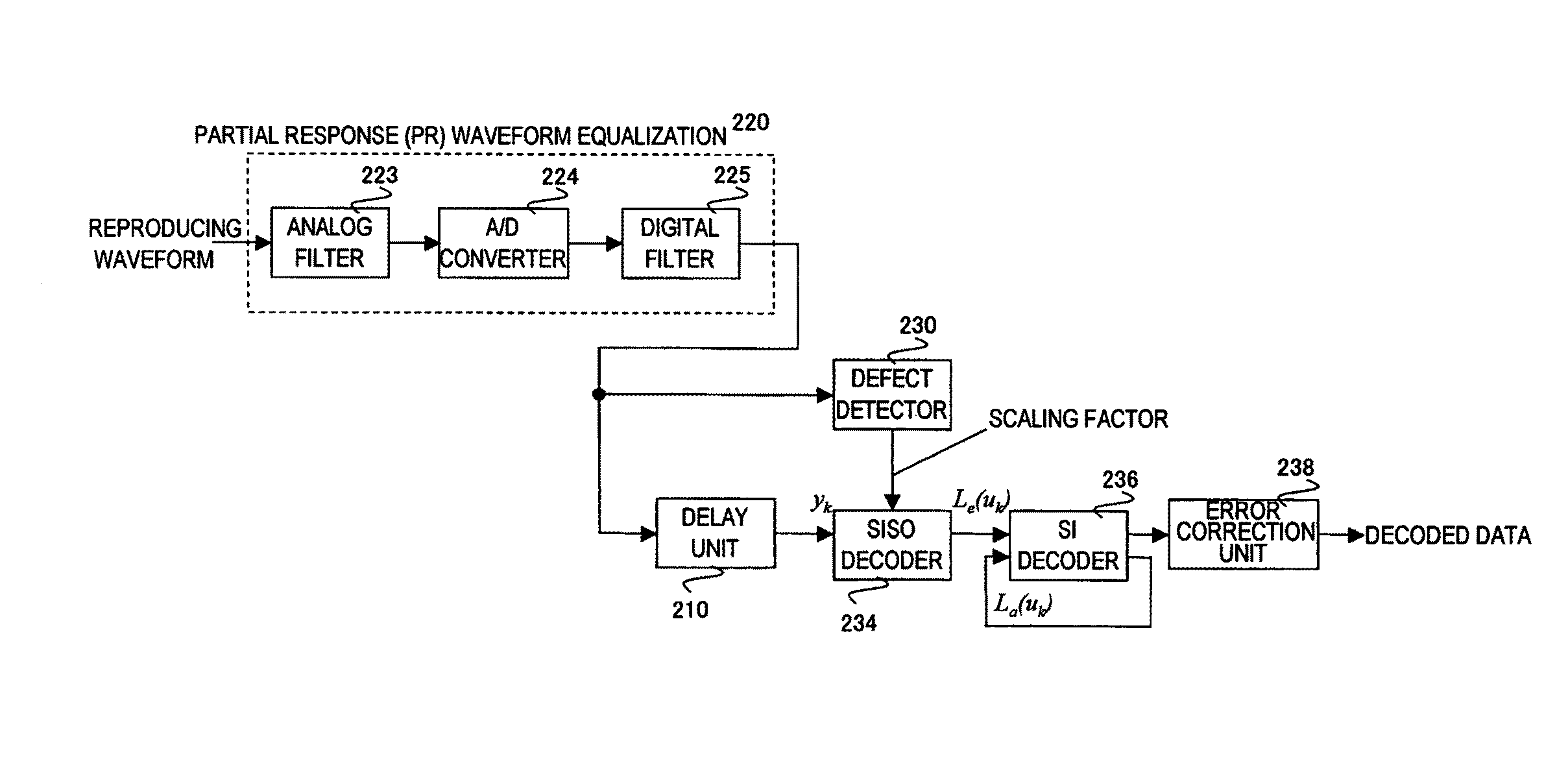

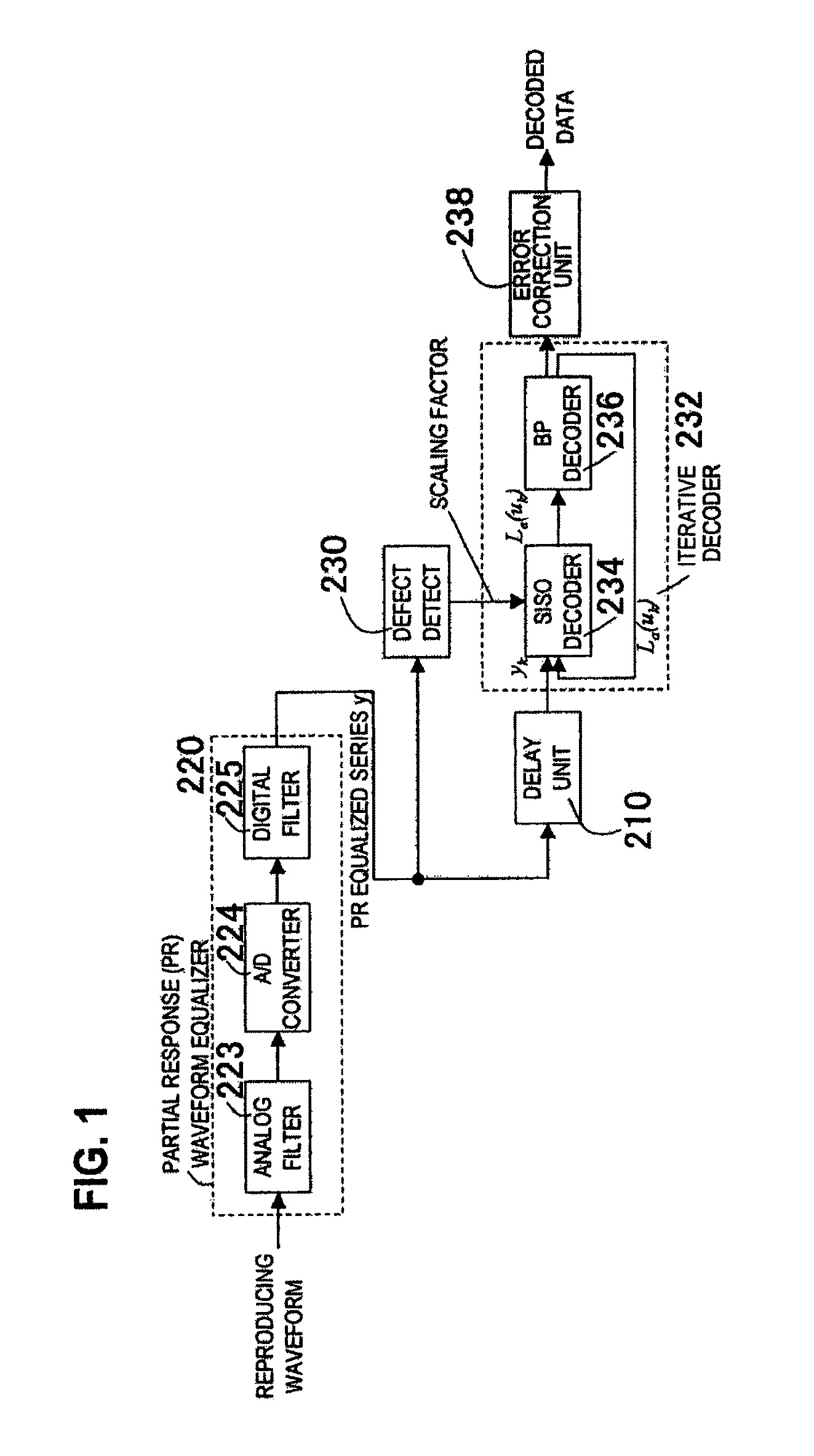

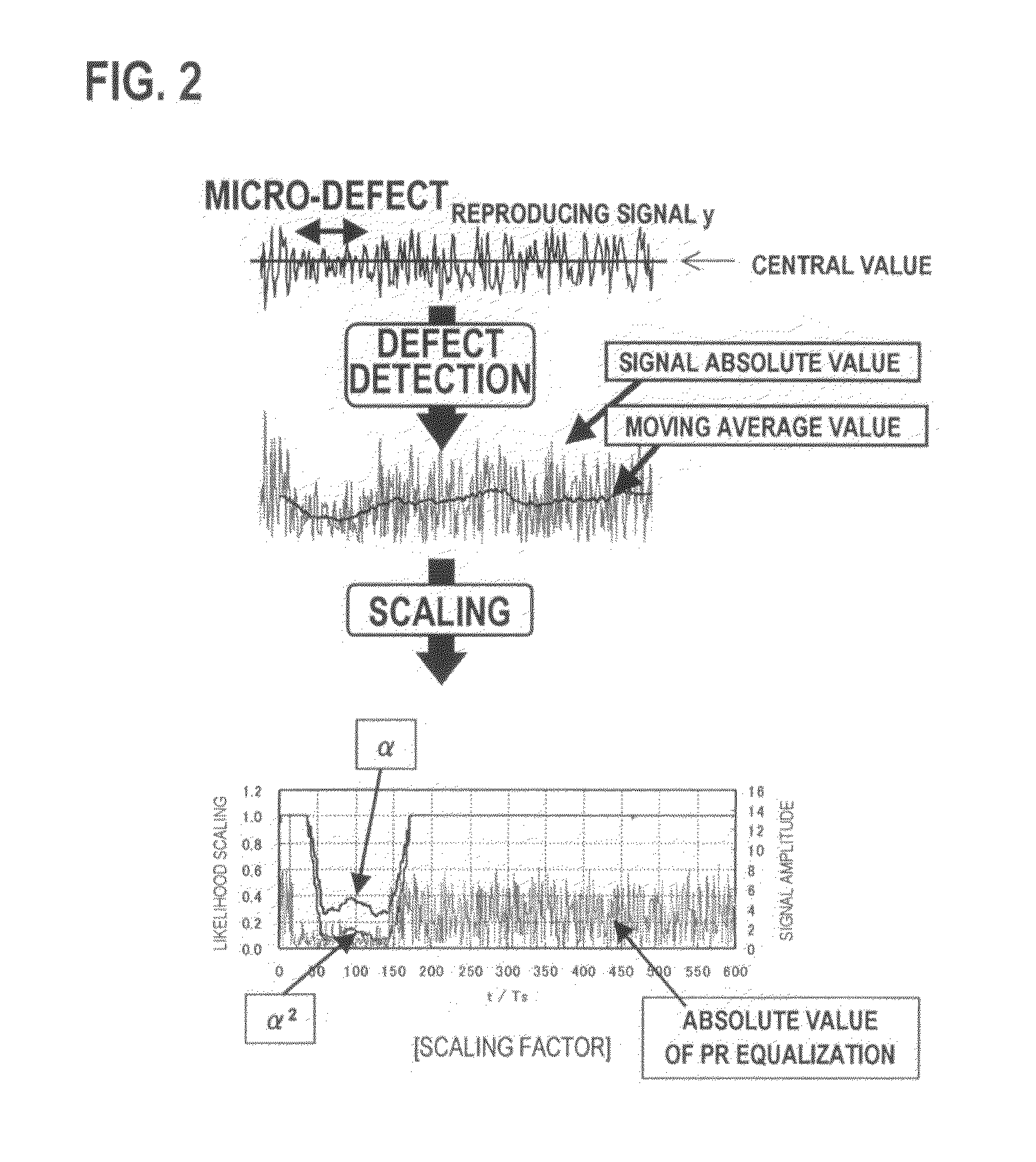

Decoder and reproducing device

InactiveUS8015499B2Suppress error propagationError propagationData representation error detection/correctionCode conversionMoving averageDependability

A reproducing device performs decoding by propagating the reliability, and detects micro medium defects to correct the reliability information. The decoder has an internal decoder, external decoder and a defect detector which calculates a moving average value of a soft-input signal, acquires a scaling factor from this, and manipulates the reliability information of the internal decoder. Since micro-defects can be detected accurately and the reliability information of the internal decoder is manipulated, error propagation due to micro defects can be suppressed.

Owner:FUJITSU LTD

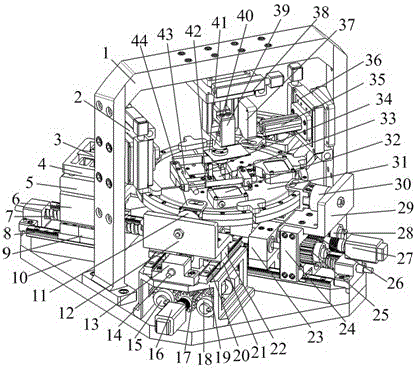

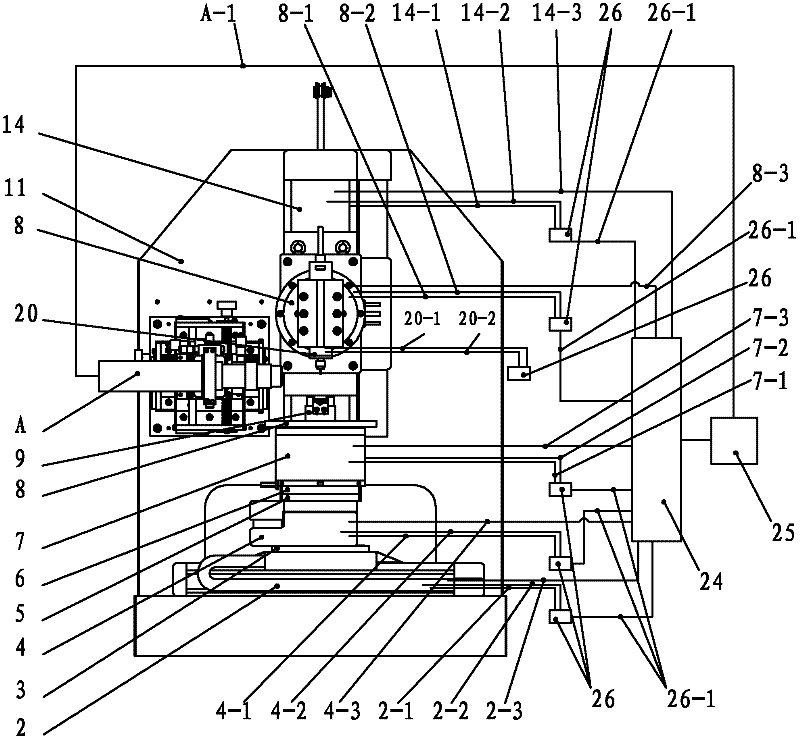

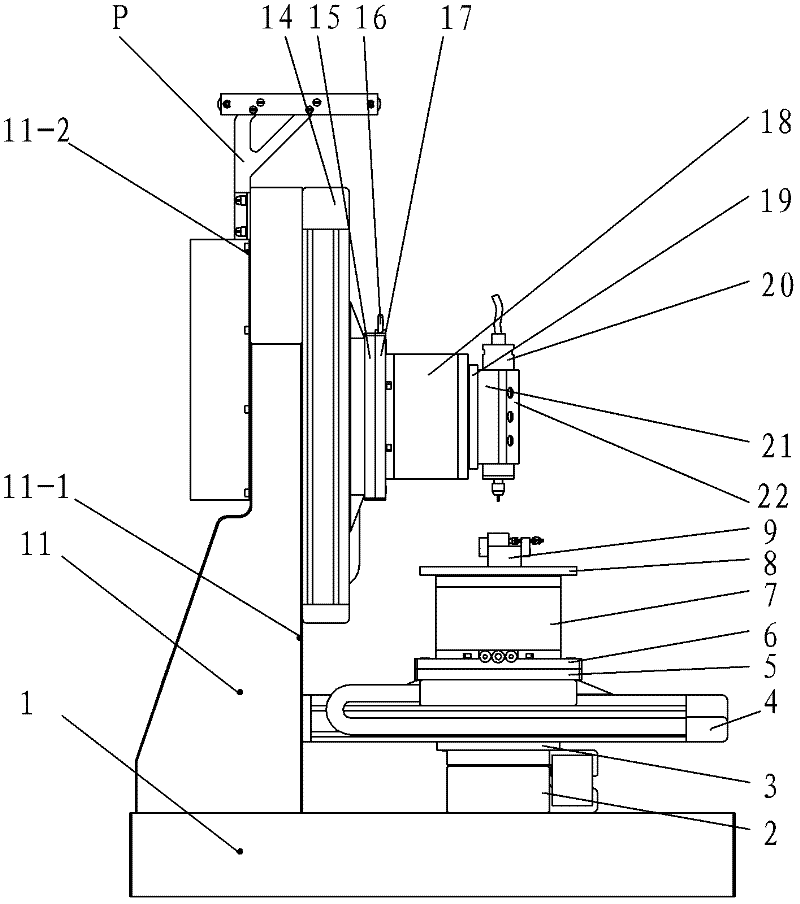

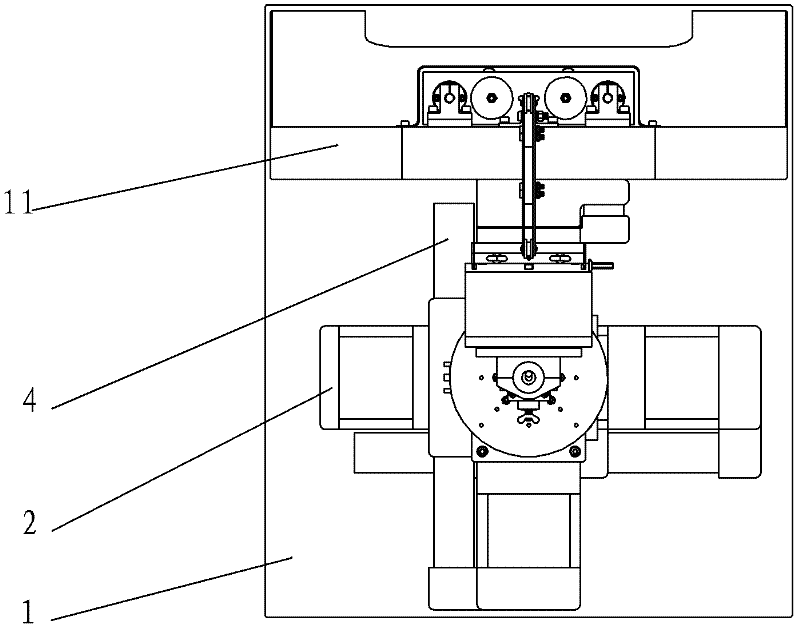

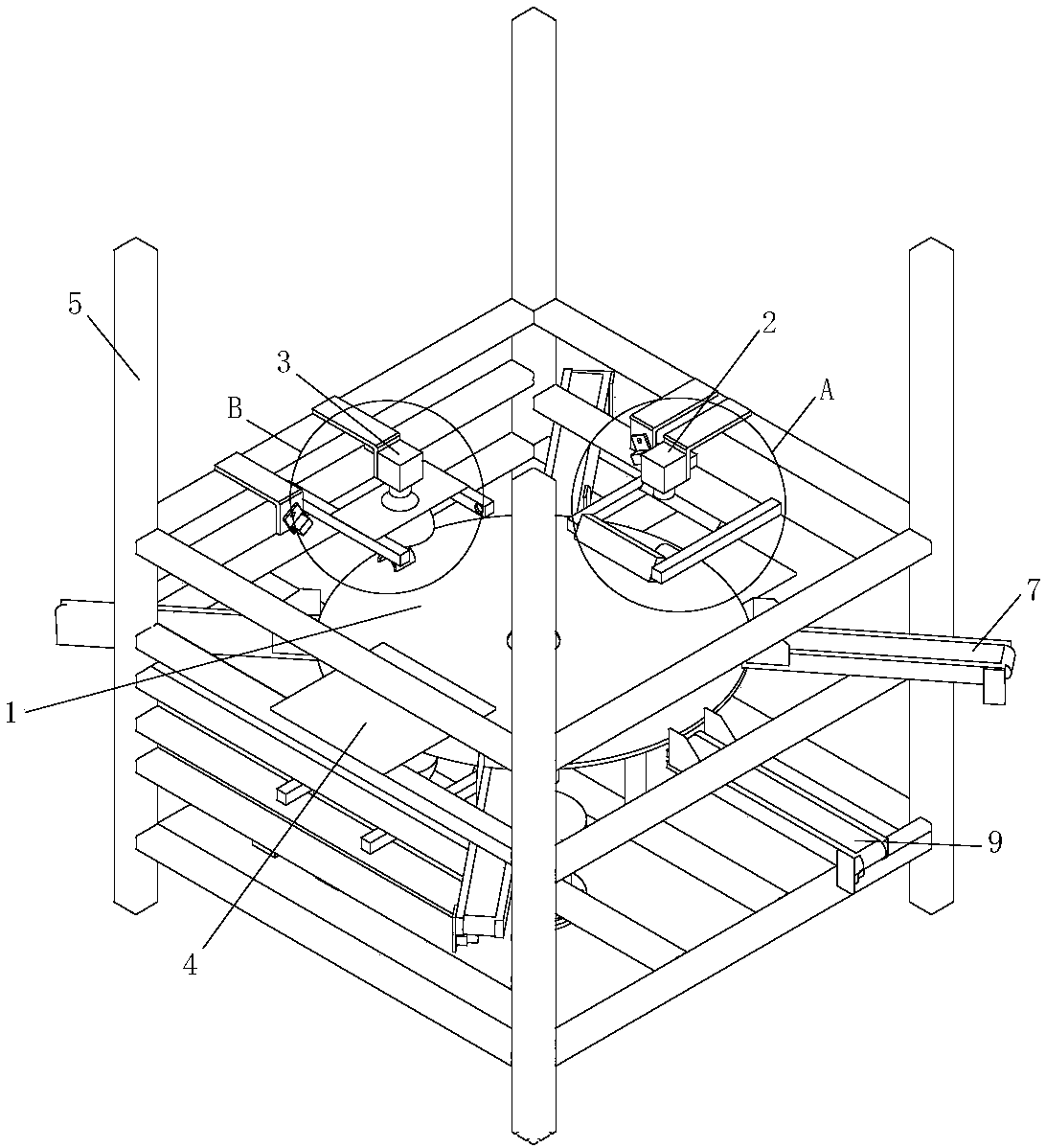

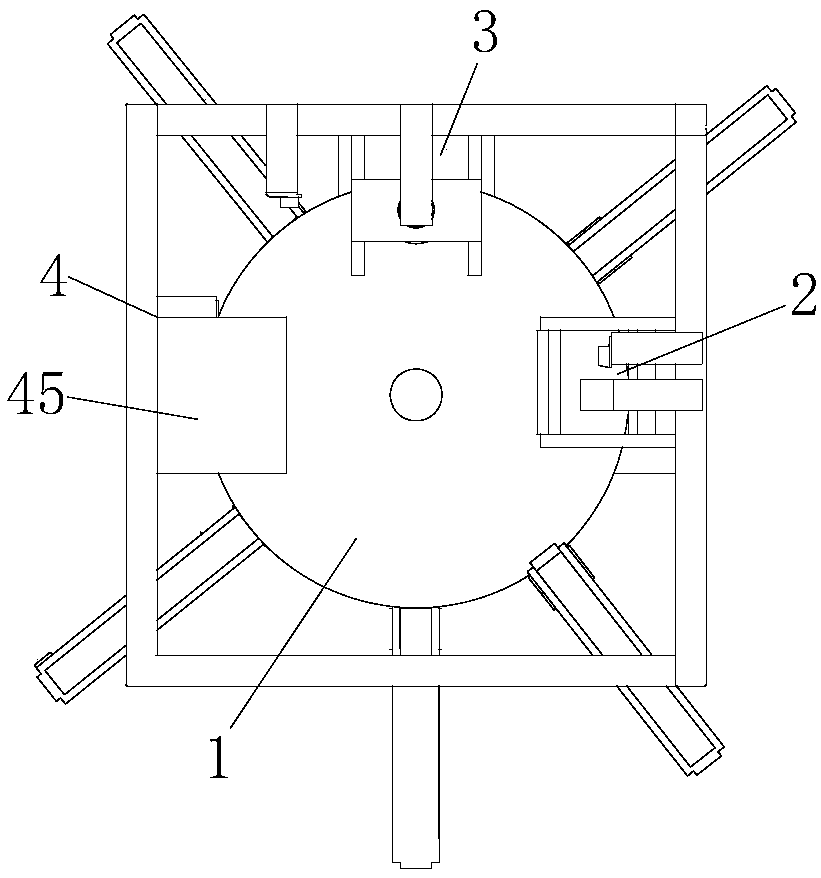

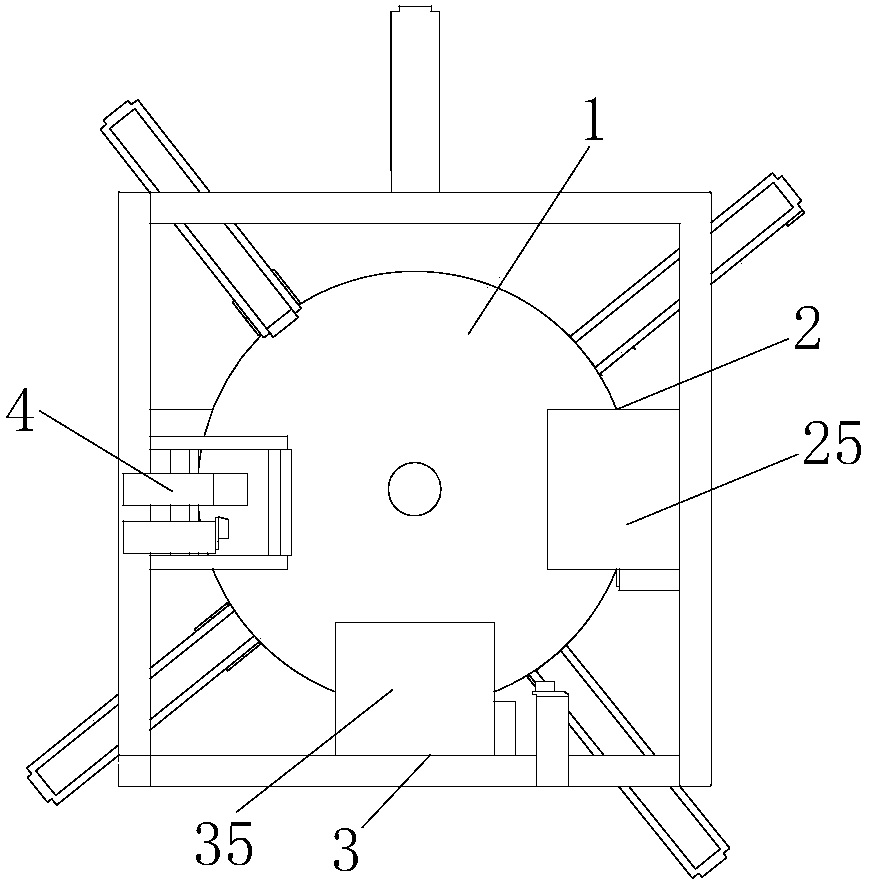

Multi-axis linkage mechanical device used for finely repairing micro-defects on surface of optical element

ActiveCN102380913AAccurate observationWorking accessoriesStone-like material working toolsElectricityLaser target

The invention provides a multi-axis linkage mechanical device used for finely repairing micro-defects on a surface of an optical element and relates to a mechanical device for repairing the optical element. The mechanical device is used for solving the problem of the growth of micro-defects generated during a high-energy beam intense laser targeting process of the optical element. A vertical element is vertically mounted on a plate base; an X-axis linear unit is mounted on the plate base; the X-axis linear unit is connected with a Y-axis linear unit through an XY linear unit connector; the Y-axis linear unit is connected to a C-axis rotating unit through two connectors; an operating platform is mounted on the C-axis rotating unit; a fixture body is mounted on the operating platform; a Z-axis linear unit is mounted on the vertical element; the Z-axis linear unit is connected to a B-axis rotating unit through two connectors; a spindle connector is mounted on the B-axis rotating unit; an electric spindle clamping fixture is mounted between a first spindle clamping element and a second spindle clamping element; and a CCD (Charge Coupled Device) tool setter and a monitoring device are mounted on a main mounting surface of the vertical element. The multi-axis linkage mechanical device is used for repairing the surface of the optical element.

Owner:HARBIN INST OF TECH

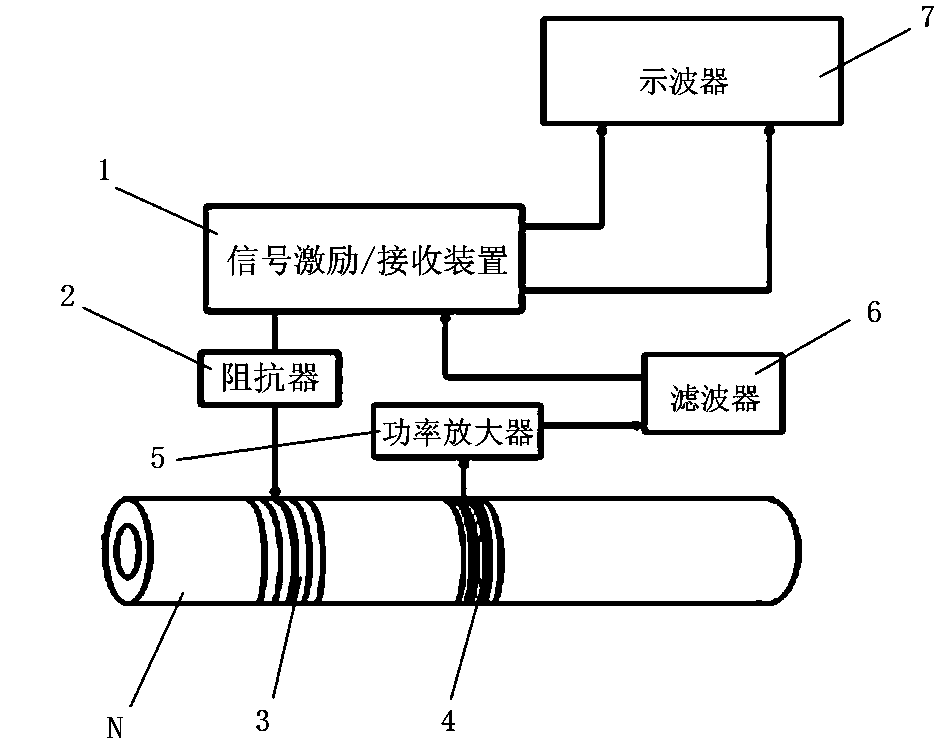

Nonlinear ultrasonic guided wave detection method and device for pipeline micro damage

InactiveCN103969339AEfficient receptionStable under pressureAnalysing solids using sonic/ultrasonic/infrasonic wavesHarmonicNonlinear ultrasound

The invention discloses a nonlinear ultrasonic guided wave detection method and a nonlinear ultrasonic guided wave detection device for pipeline micro damage. An exciting transducer capable of exciting single guided wave modal state and a matched receiving transducer are adopted, the transducers can wind a pipeline to excite axisymmetric modal states, the receiving efficiency of a second order harmonic signal is improved by a matching and corresponding receiving probe, the detection capacity of the system on second order harmonic waves of the guided waves is improved. The nonlinear change of a material is characterized by detecting the ratio of nonlinear response to propagation distance, nonlinear interference of instruments is effectively reduced, nonlinear ultrasonic guided wave evaluation of the pipeline material is realized, and nonlinear ultrasonic high sensitivity can be used for early detection of the pipeline micro defects.

Owner:XIAMEN UNIV

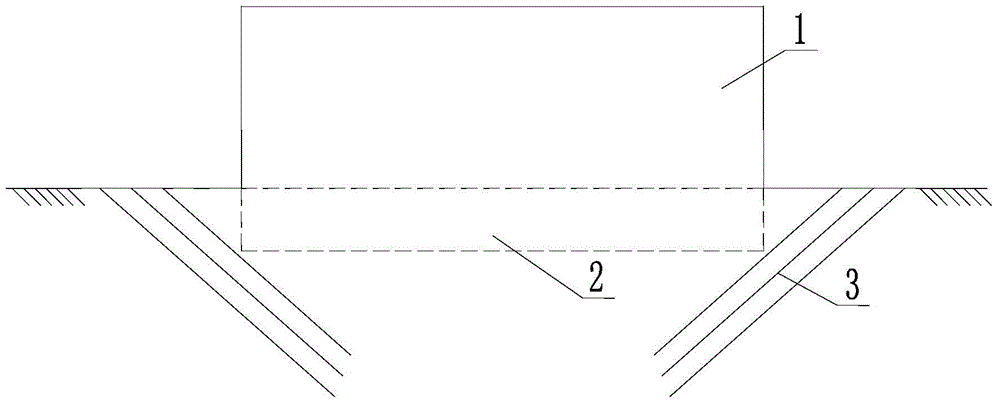

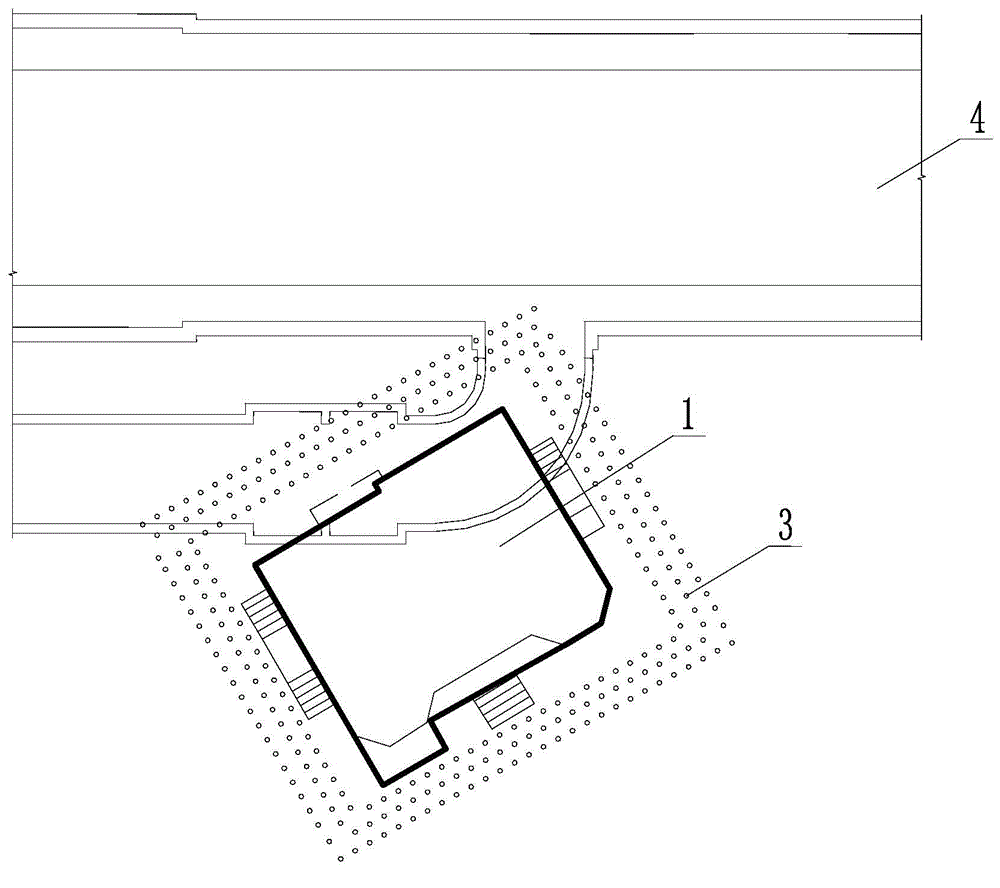

Construction method for subway tunnel penetrating through building in fractured rock stratum

The invention discloses a construction method for a subway tunnel penetrating through a building in a fractured rock stratum. The construction method mainly comprises the following steps: firstly utilizing a deep hole grouting process to reinforce a stratum; excavating a tunnel by circularly utilizing mechanical excavation and explosion, and after the excavation of a tunnel face is completed, immediately performing primary support in an anchor rod, bar-mat reinforcement, shotcrete and grid combined support manner till the tunnel penetrates through the building; finally performing grouting reinforcement of a tunnel inner deep hole sleeve valve tube. According to the construction method, by utilizing central mechanical excavation and circumferential smooth blasting techniques, the disturbance of the penetrating-tunnel explosion construction to the fractured rock stratums is reduced, the expansion and growth of rock body internal micro-defects are effectively controlled, the expanding and shaking losses to the building are avoided; due to the field vibration speed monitoring, the explosion vibration speed of a to-be-tested point of the building is within 10 mm / s, which meets the standard requirements.

Owner:SHANDONG UNIV OF SCI & TECH

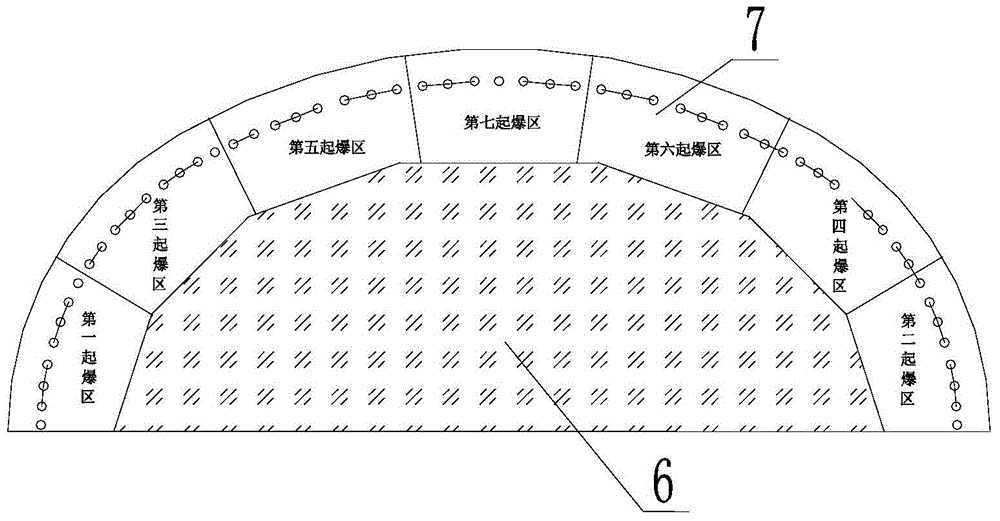

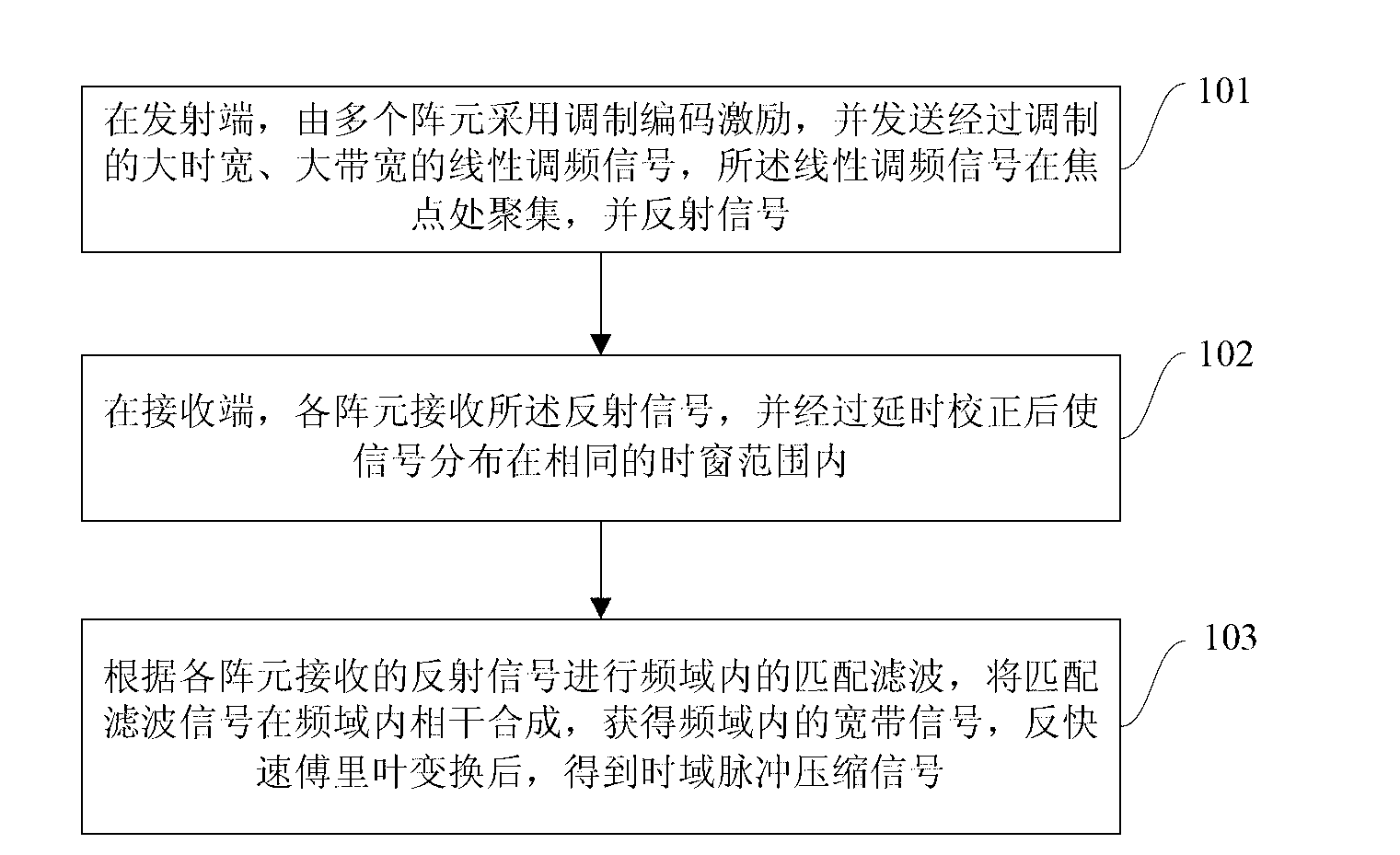

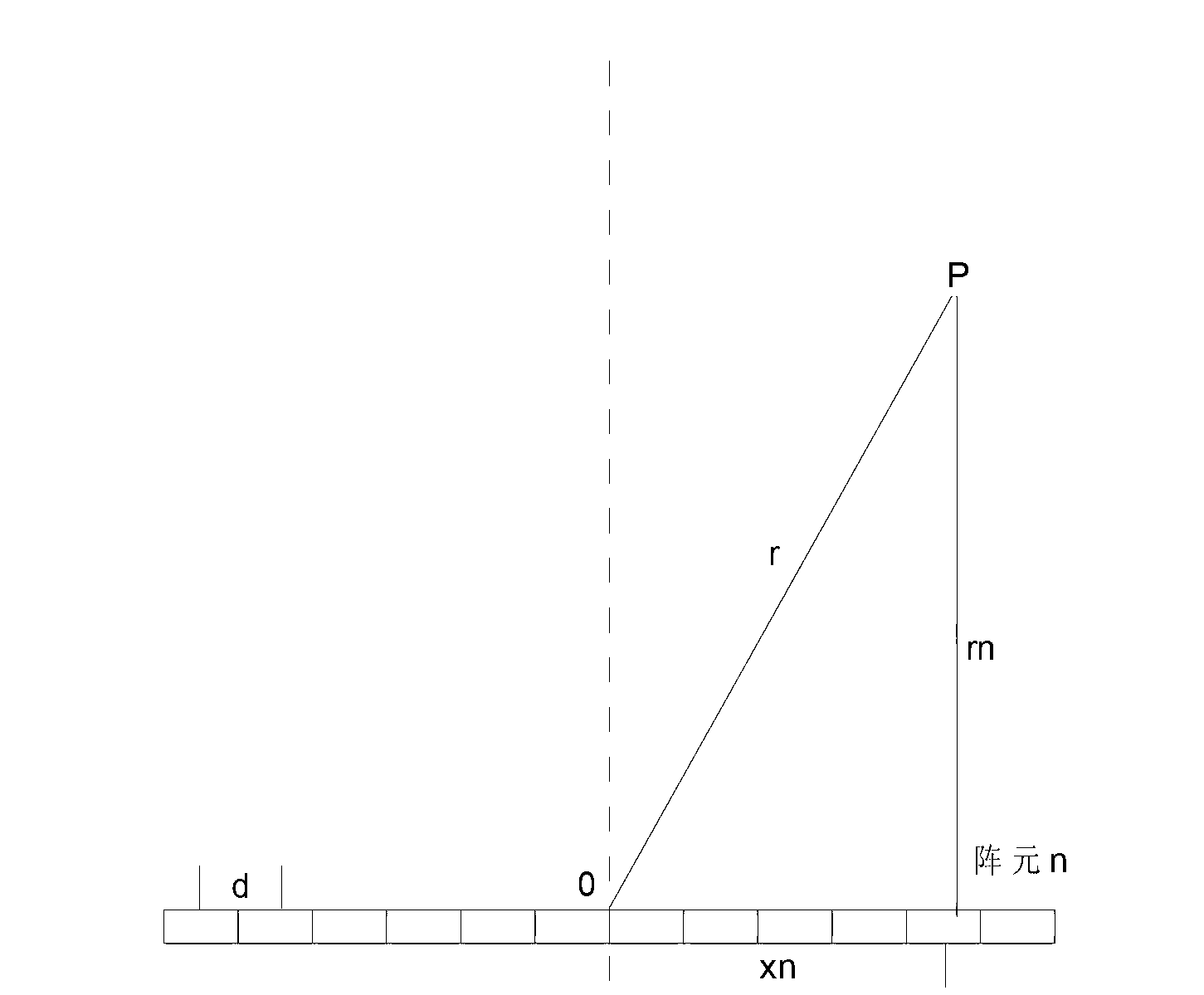

Defect defecting method based on wide frequency band ultrasonic phase array

InactiveCN103175893AHigh resolutionRealize accurate detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesArray elementPhased array transducer

The invention discloses a defect defecting method based on a wide frequency band ultrasonic phase array, which is applied to an ultrasonic phase array transducer consisting of multiple array elements. The defect defecting method comprising the steps of: exciting by multiple array elements by adopting modulation codes, transmitting modified big-timewidth and big-bandwidth linear frequency modulation signals at a transmitting end, gathering the linear frequency modulation signals at a focal point and reflecting the signals; receiving the reflected signals at a receiving end by each array element and distributing the delayed and corrected signals within a same time window range; and implementing matched-filtering within a frequency domain according to the reflected signals received by each array element, coherently combining the matched-filtered signals within the frequency domain to obtain bandwidth signals within the frequency domain, and implementing inverse fast Fourier transform, thus obtaining time domain pulse compression signals. By virtue of the method, the bandwidth of the transmitted signals can be increased and the pulse compression signals with high resolution can be obtained, so that micro defects can be accurately detected.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

Visual detection method for micro-defects on surface of magnetic tile

PendingCN108230324AMethod stableEasy maintenanceImage enhancementImage analysisComputer visionVisual perception

The invention provides a visual detection method for micro-defects on the surface of a magnetic tile. The method comprises the steps of reading a magnetic tile image, detecting magnetic tile image defects, obtaining a defect region K of the magnetic tile image, and judging whether or not the area of the defect region K is greater than a first set value; detecting the magnetic tile image defects, obtaining a second-class defect effect map of the magnetic tile image, and judging whether or not the length of the second-class defect effect map is greater than a second set value; detecting the magnetic tile image defects, obtaining a circular degree of a communication domain pixel of an edge detection image Q' of the magnetic tile image, and judging whether or not the circular degree of the communication domain pixel of the edge detection image Q' is greater than a third set value, wherein whether or not the defects of the magnetic tile belong to three types can be judged through the threejudgement processes. The visual detection method for the micro-defect on the surface of the magnetic tile is high in adaptability to illumination changes and magnetic tile type changes; various different types of defects of the magnetic tile can all be detected; compared with magnetic tile defect images obtained by means of traditional methods, the magnetic tile defect image obtained by means of the method is clearer and more accurate.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com