Nonlinear ultrasonic phased array imaging method for micro-crack detection

An ultrasonic phased array and phased array technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of limited detection range, lack of nonlinear ultrasonic imaging methods, limited spatial average value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

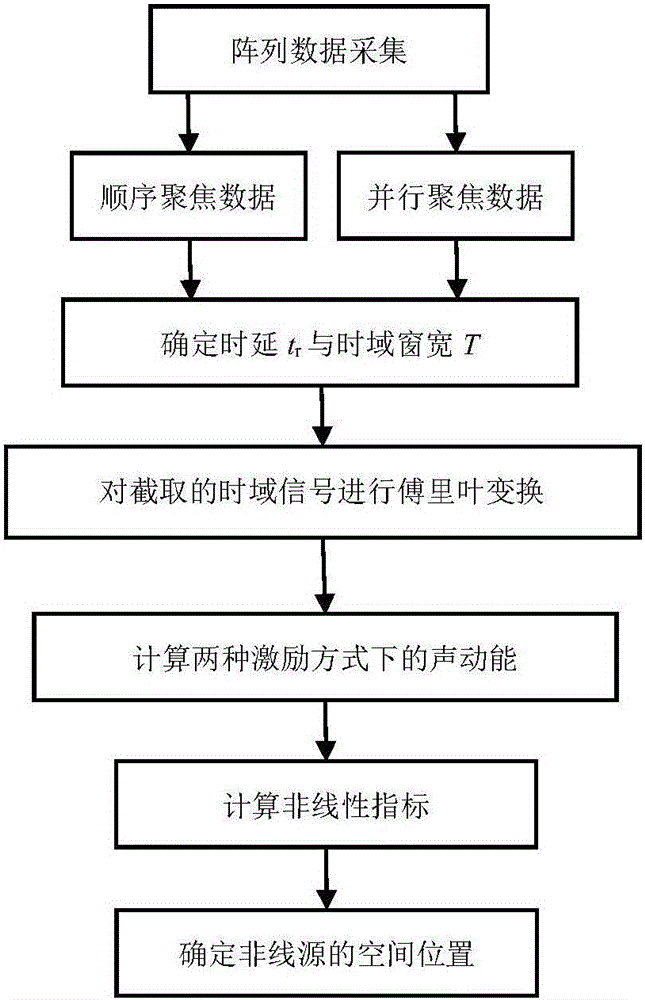

[0037] The effectiveness of the method of the present invention will be described in detail below using the data obtained from the detection experiment.

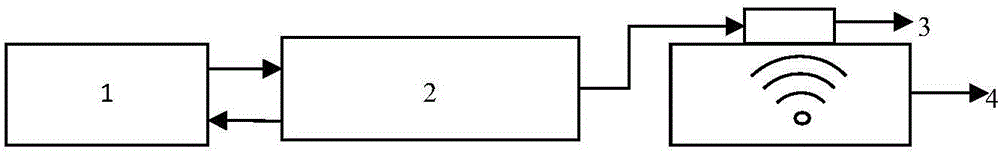

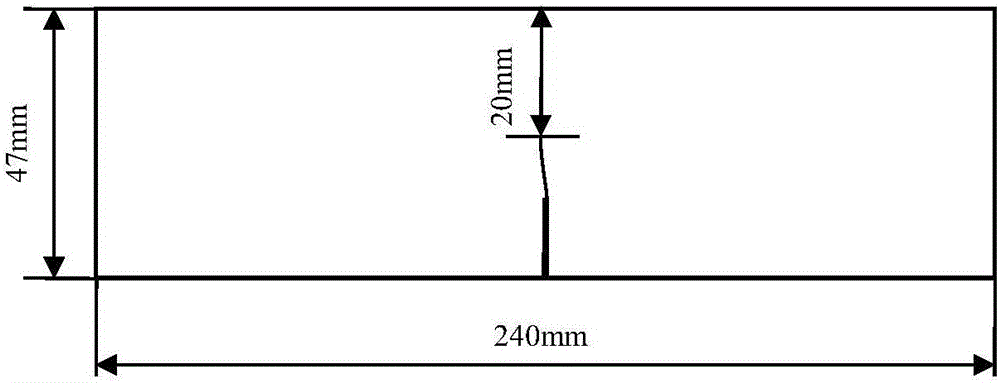

[0038] The test system used is figure 1 As shown, the linear array phased array probe used in the experiment, the model is 5L-32A5, and its parameters are shown in Table 1. The test piece such as Figure 4 As shown, the material is steel, the size is 240mm×47mm×25mm, there is a 20mm long wire-cut notch in the middle, and a fatigue crack with a length of about 9mm is processed at the top of the wire-cut by a fatigue testing machine, so the crack tip is 20mm away from the testing surface. The center frequency of the excitation signal is 5MHz, and the sampling frequency is 16.6MHz.

[0039] Table 1 Basic parameters of the probe

[0040]

[0041] Step 1: Use the ultrasonic phased array detection system to collect detection signals in the sequential focus and parallel focus modes;

[0042] (1) will be as figure 1 The ultr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com