Patents

Literature

129 results about "Nonlinear ultrasound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for non-linear ultrasonic online detection of early fatigue damage to metal material

InactiveCN101806778ARealize the whole process of fatigue detectionSolve misjudgmentMaterial analysis using acoustic emission techniquesFatigue damageSonification

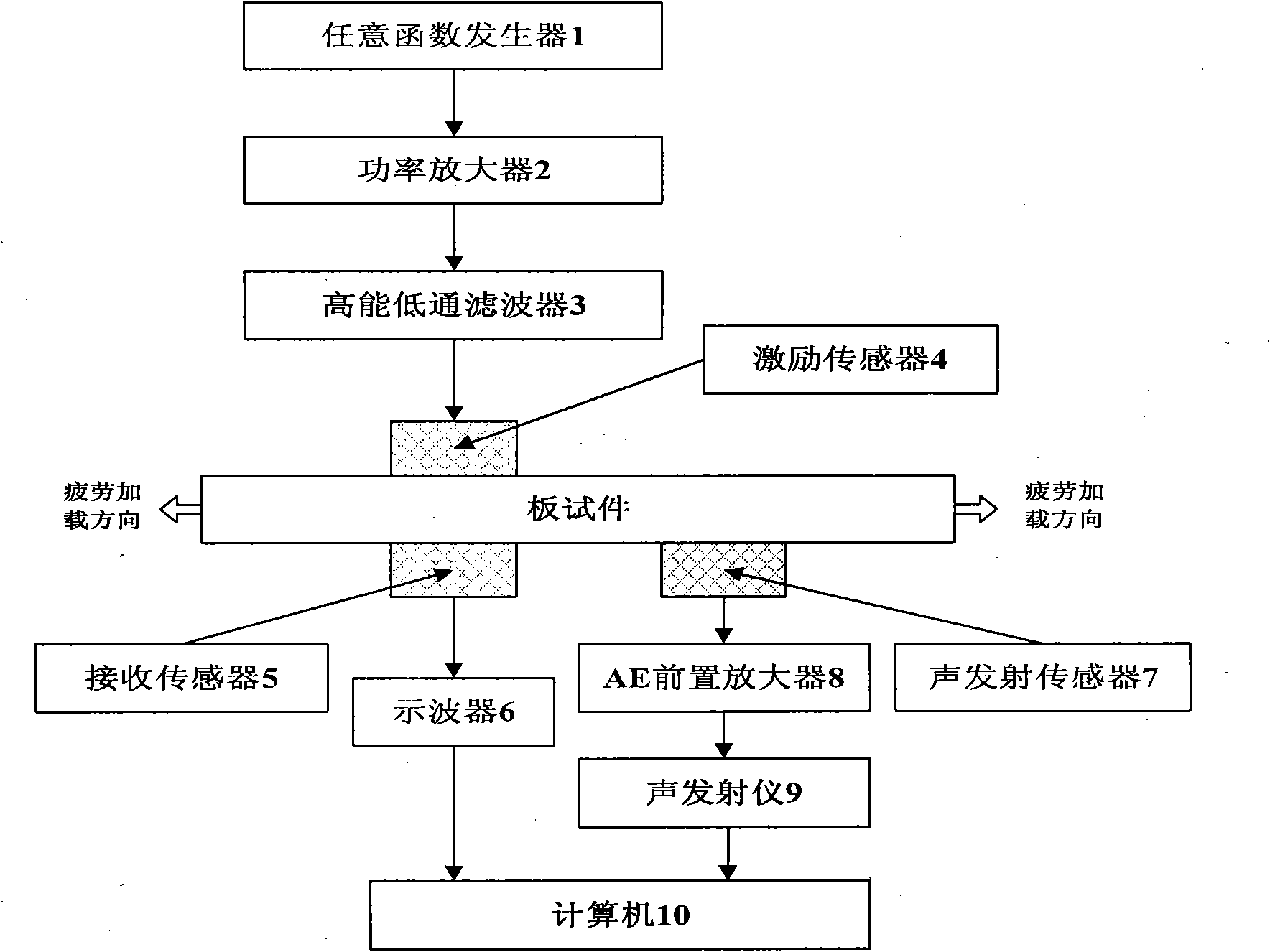

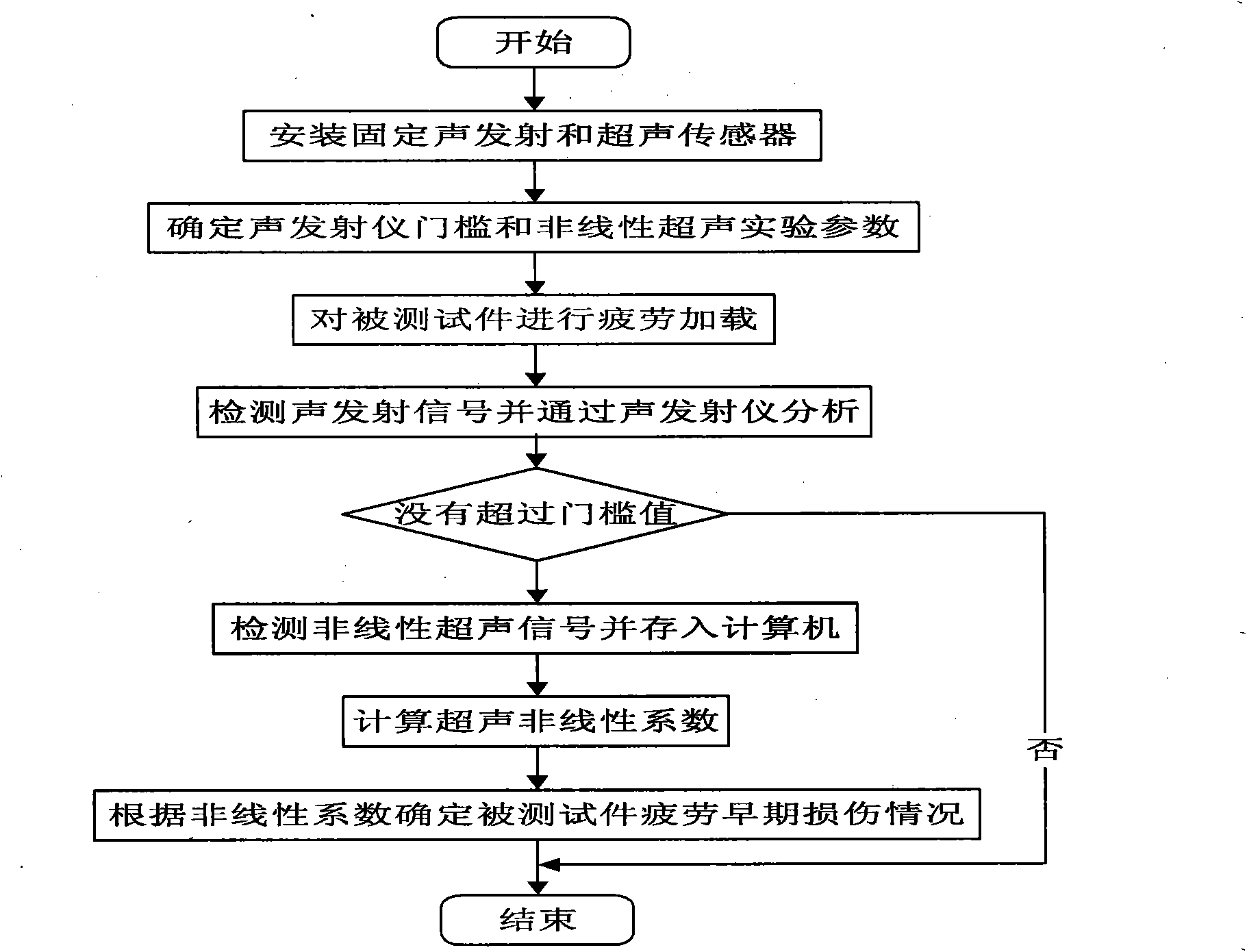

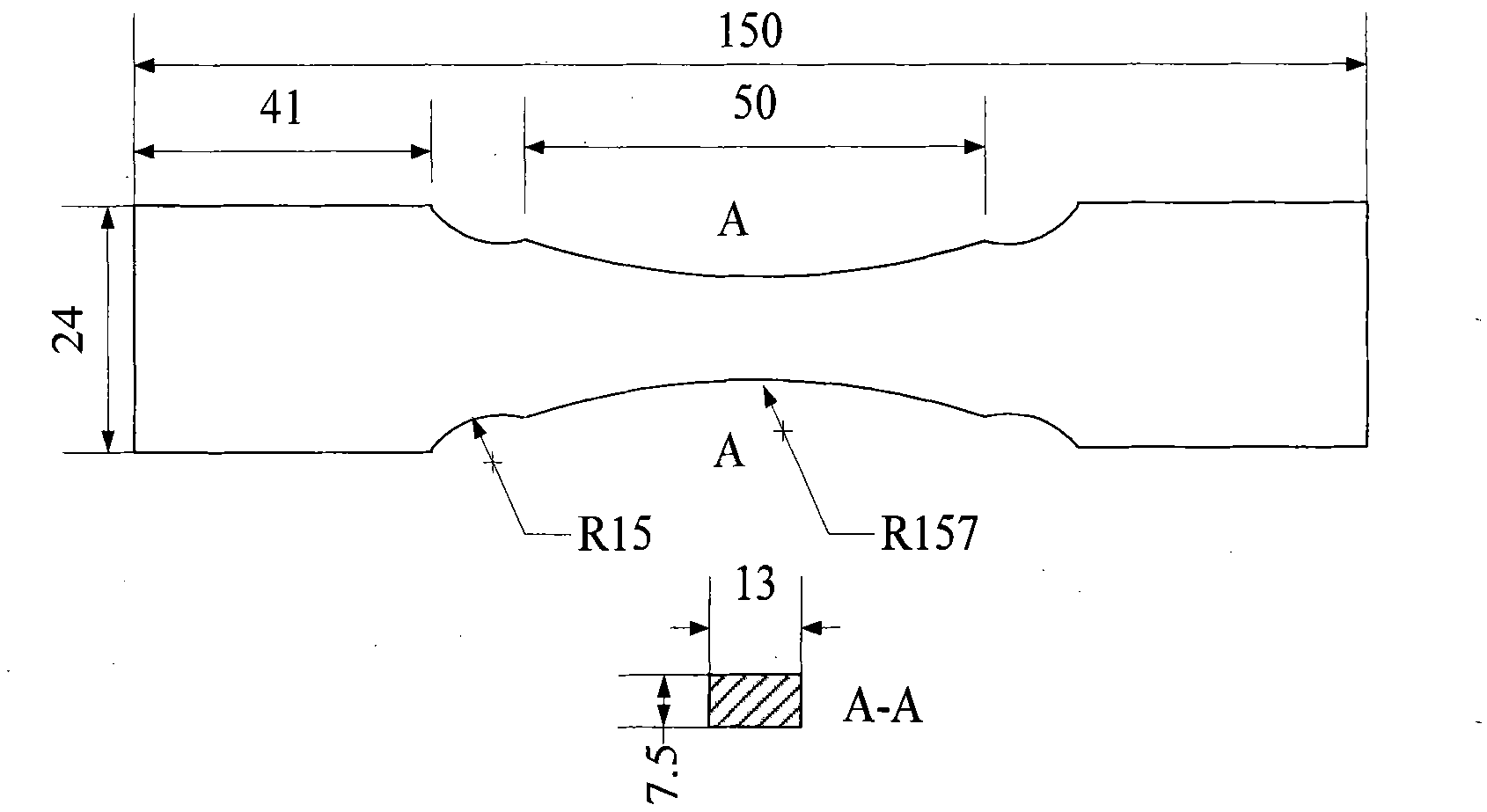

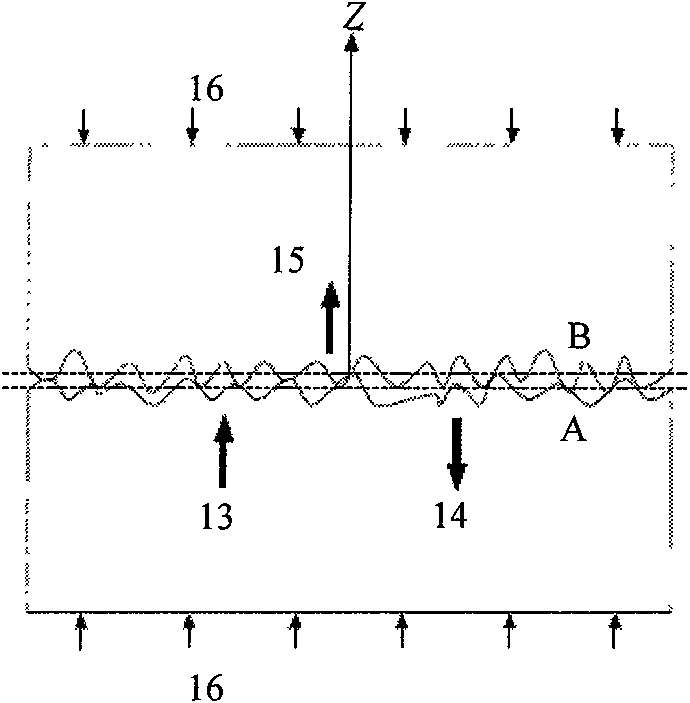

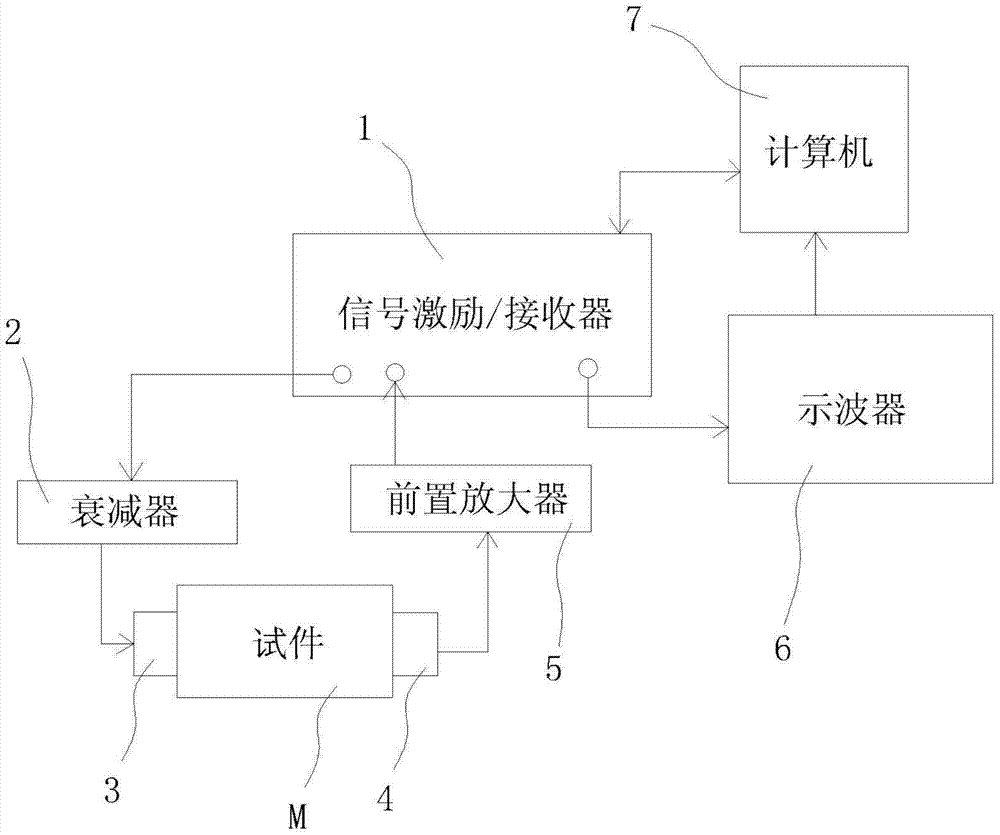

A method for the non-linear ultrasonic online detection of early fatigue damage to a metal material belongs to the field of nondestructive detection. The method comprises the following steps: determining an excitation signal parameter according to the thickness of a tested piece and inputting the parameter to an arbitrary function generator to generate a sound signal; determining a threshold value of an acoustic emission instrument according to the amplitude of a no-load noise signal; performing fatigue loading on the tested piece, continuously detecting an acoustic emission signal in real time with an acoustic emission sensor, amplifying the acoustic emission signal, inputting the acoustic emission signal into the acoustic emission instrument, and judging ring with the acoustic emission instrument when the amplitude of the acoustic emission signal exceeds the preset the threshold value of the acoustic emission instrument; detecting a non-linear ultrasonic signal at equal time interval if the acoustic emission instrument does not display the ring or the times of the continuous ring is not more than an empirical value; and stopping detection if the displayed ring times is more than the empirical value, because fatigue cracks are generated and develop. On the basis of non-linear ultrasonic nondestructive detection, the method of the invention introduces acoustic emission technique, so the method does not make incorrect judgment when detecting the early fatigue damage to the metal material and realizes continuous online detection.

Owner:BEIJING UNIV OF TECH

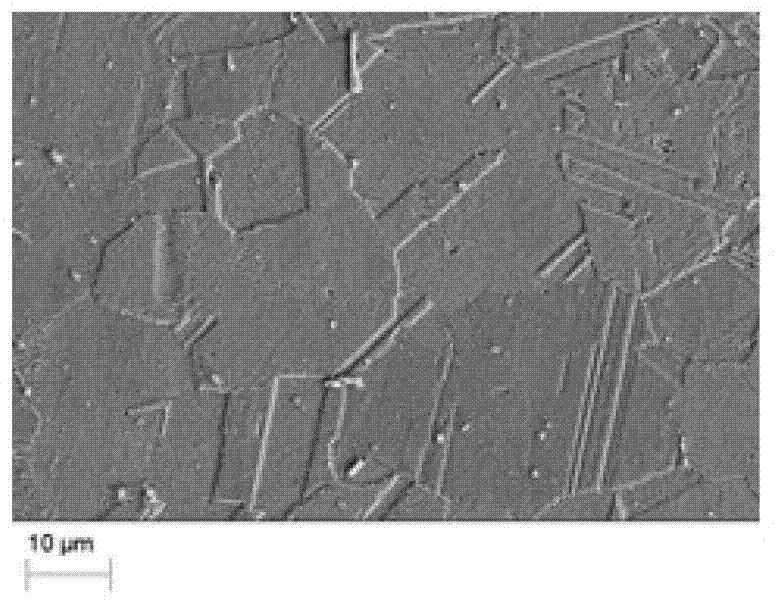

Imperfect interface contact state nonlinear ultrasonic evaluation method based on micro texture

ActiveCN101666780ARealize contact status evaluationHigh sensitivityAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalSonificationNonlinear ultrasound

The invention relates to an interface contact state nonlinear ultrasonic testing method which belongs to the nondestructive testing filed. The method comprises the following steps: determining the frequency and the periodicity of detection signals according to the size and the material performance of a test piece forming a contact interface; by applying different pressures to a rough interface, changing the contact state, and carrying out ultrasonic transmission detection test on the rough interface; by carrying out nonlinear least-squares approximation processing on testing data of the test,determining micro characteristic composite parameters of the interface, computing a first-order rigidity coefficient and a second-order rigidity coefficient which are used for expressing the characteristics of the rough interface, and realizing ultrasonic expression of the contact characteristics of different rough interfaces. In the invention, the nonlinear ultrasonic coefficients are adopted toexpress the contact characteristics of the interface, the nonlinear ultrasonic detection has higher sensitivity comparing with the linear ultrasonic; by combining the micro texture and the rigidity relation of the interface, the method enables the macroscopic property of the interaction of the ultrasonic and the contact interface to be associated with the microcosmic property of the contact surface, thereby evaluating contact states of different microcosmic interfaces.

Owner:BEIJING UNIV OF TECH

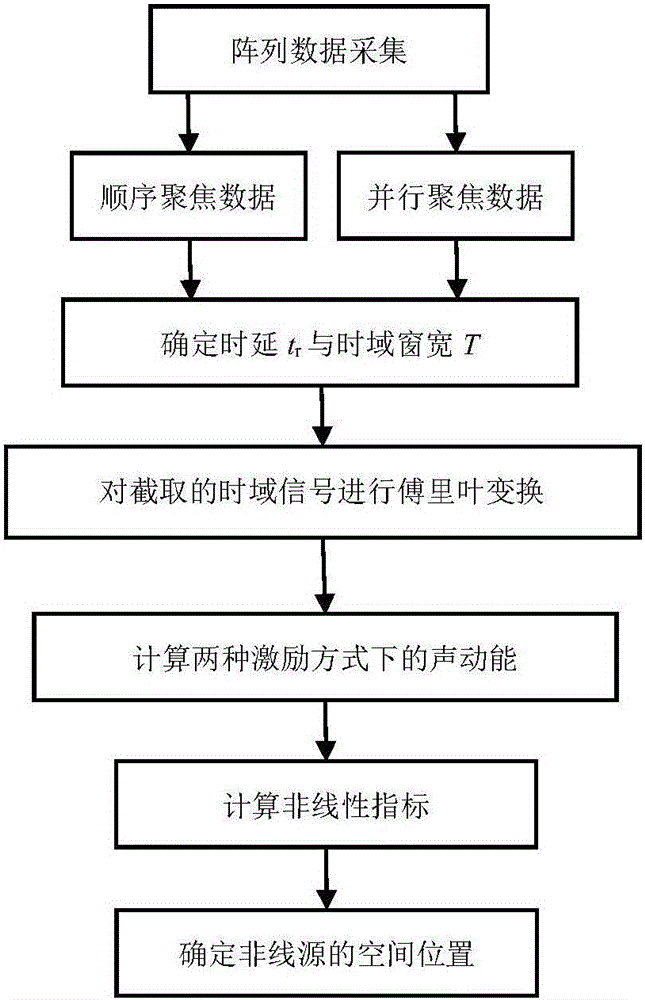

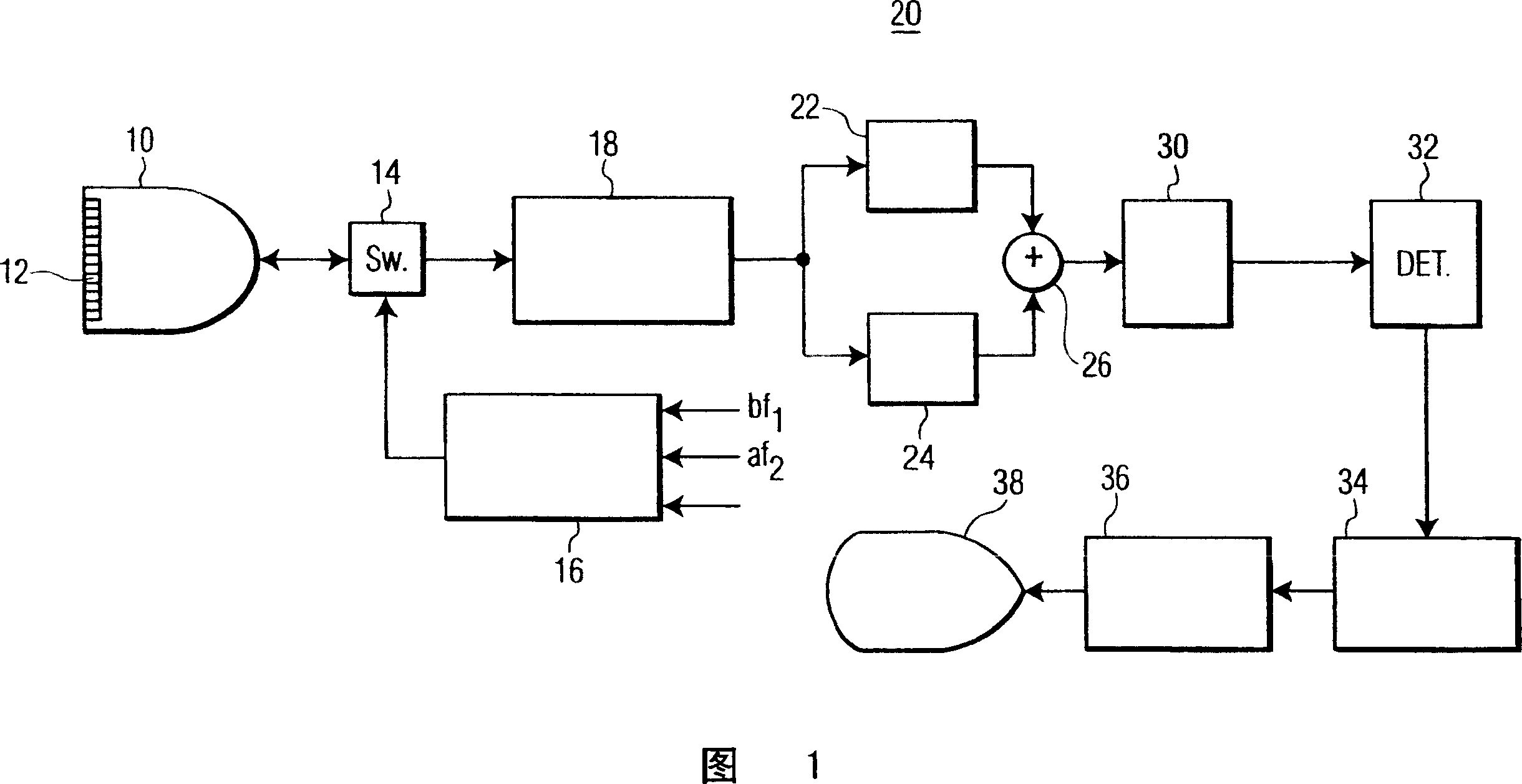

Nonlinear ultrasonic phased array imaging method for micro-crack detection

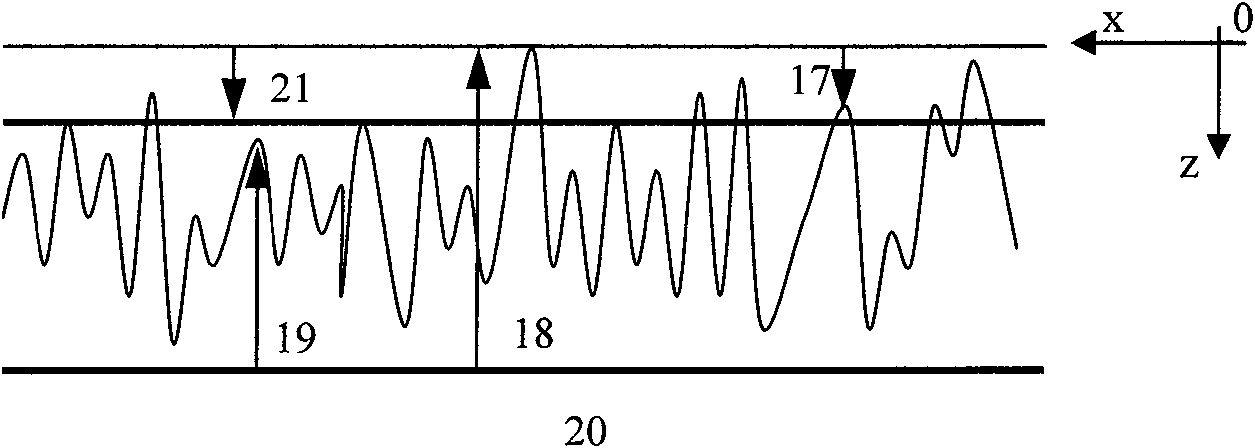

InactiveCN105004792AAnalysing solids using sonic/ultrasonic/infrasonic wavesTime domainRelative energy

The invention relates to a nonlinear ultrasonic phased array imaging method for micro-crack detection. According to the method, an ultrasonic phased array detection system is utilized to collect the detection signals in the sequence focusing mode and the parallel focusing mode, the appropriate receiving delay tr and the width T of the time-domain intercepting window are determined, the intercepted detection signals are subjected to Fourier transform, the sound kinetic energies Es and Ep of the sequence focusing method and the parallel focusing method and the relative energy difference gamma of the two focusing methods are respectively calculated, and the nonlinear source position is determined according to the gamma, ie., the micro-defect position.

Owner:BEIJING UNIV OF TECH

Metal plate micro-defect detection method based on nonlinear Lamb waves

PendingCN111044613AEffective representationCharacterize the flaws of the metal sheet under test for efficient characterizationAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalNon linear waveNonlinear ultrasound

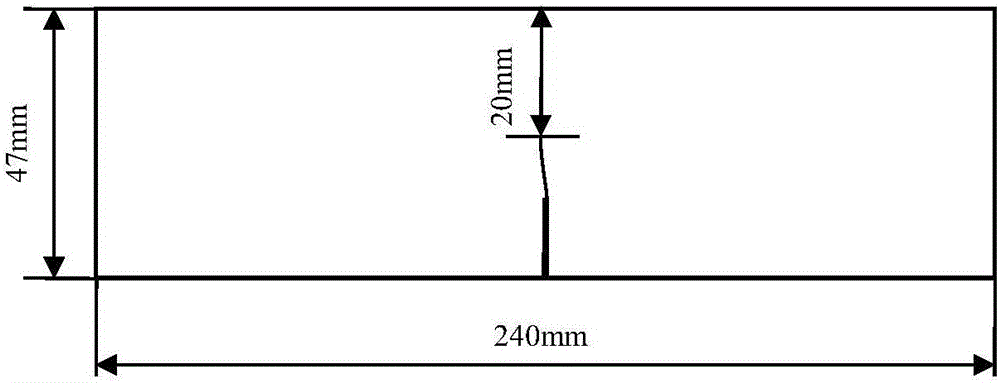

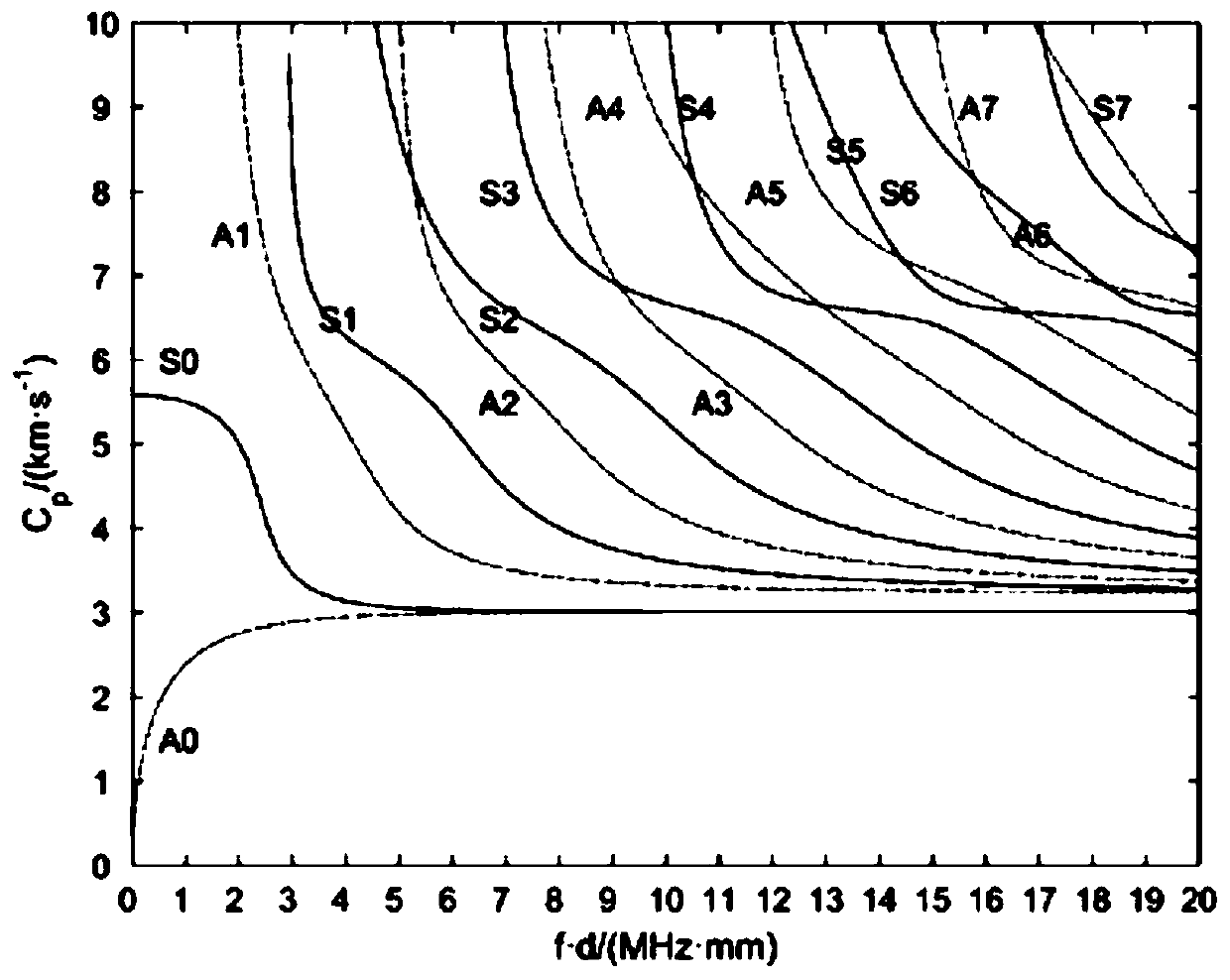

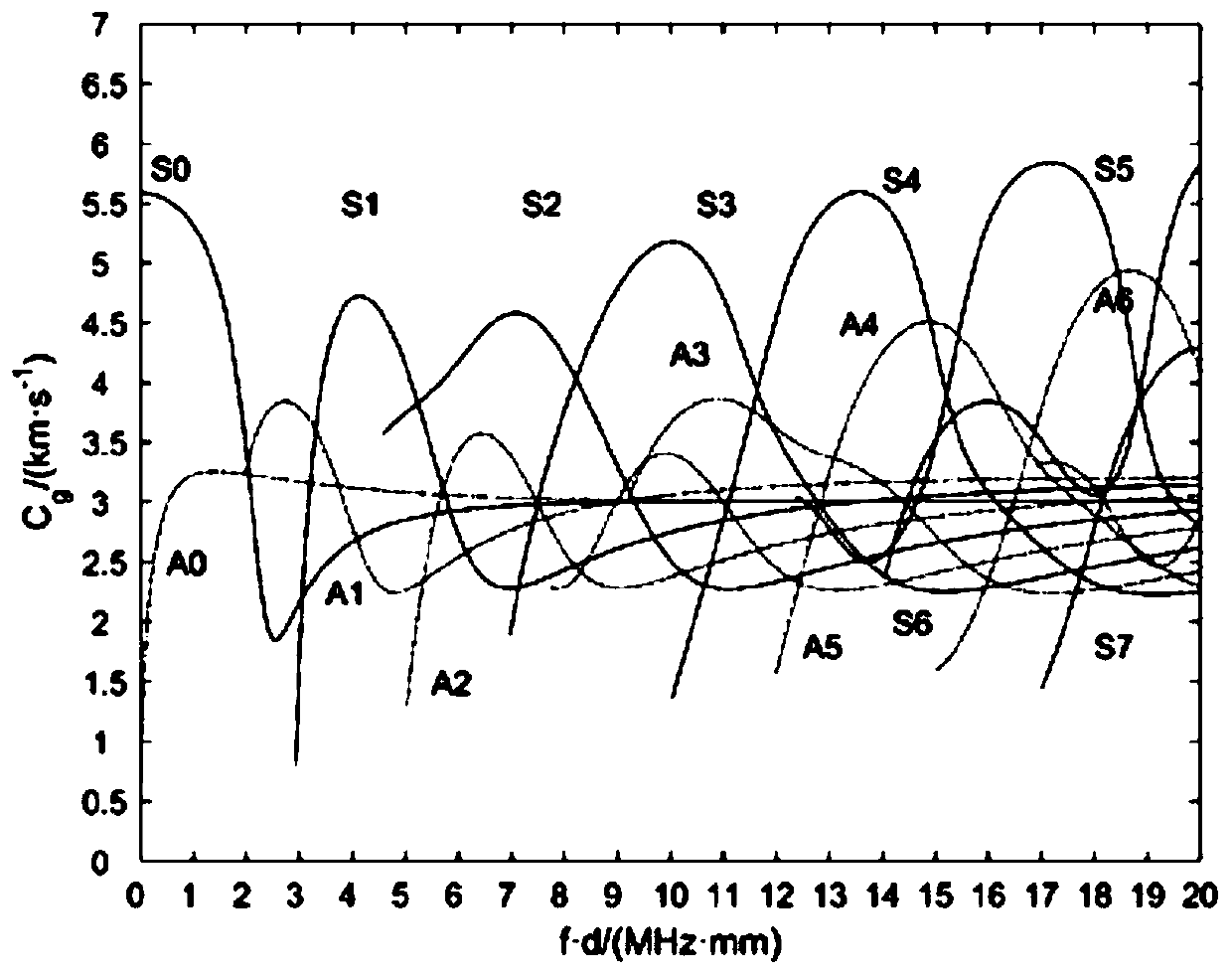

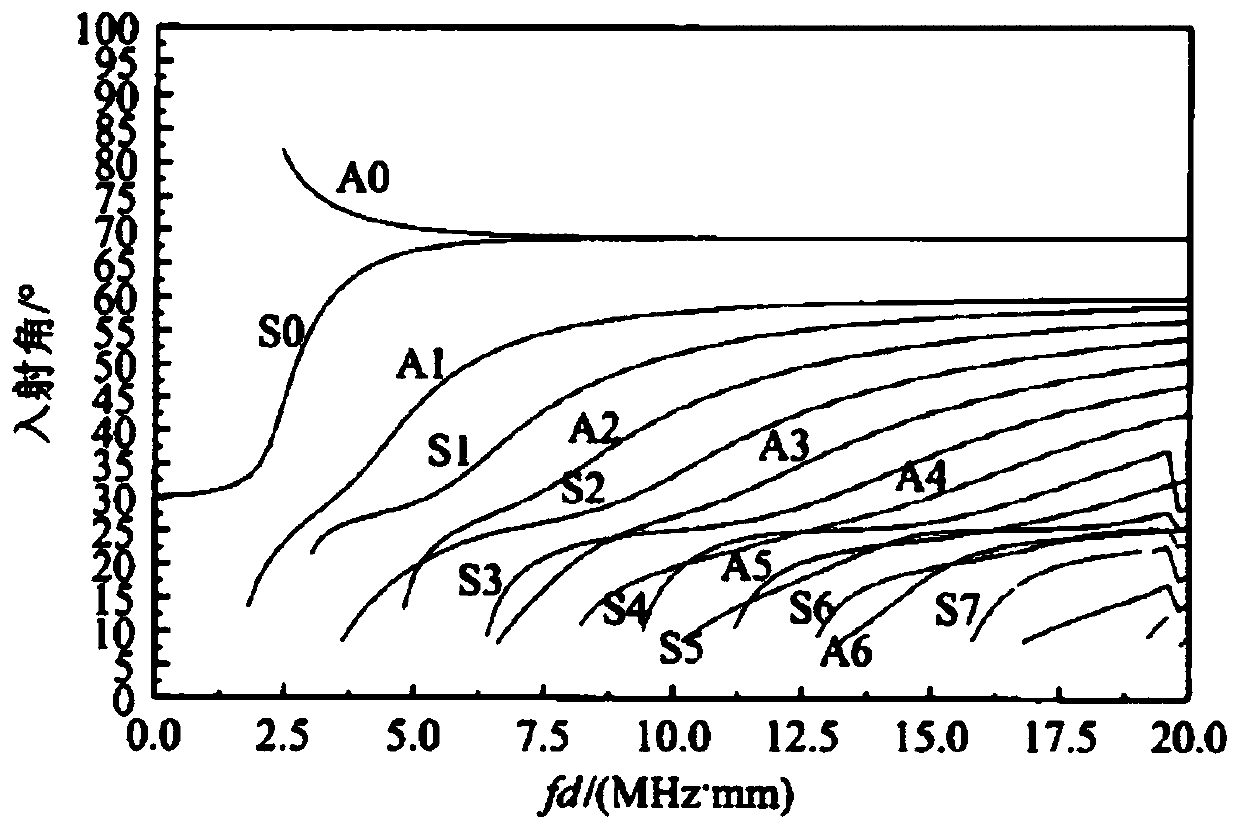

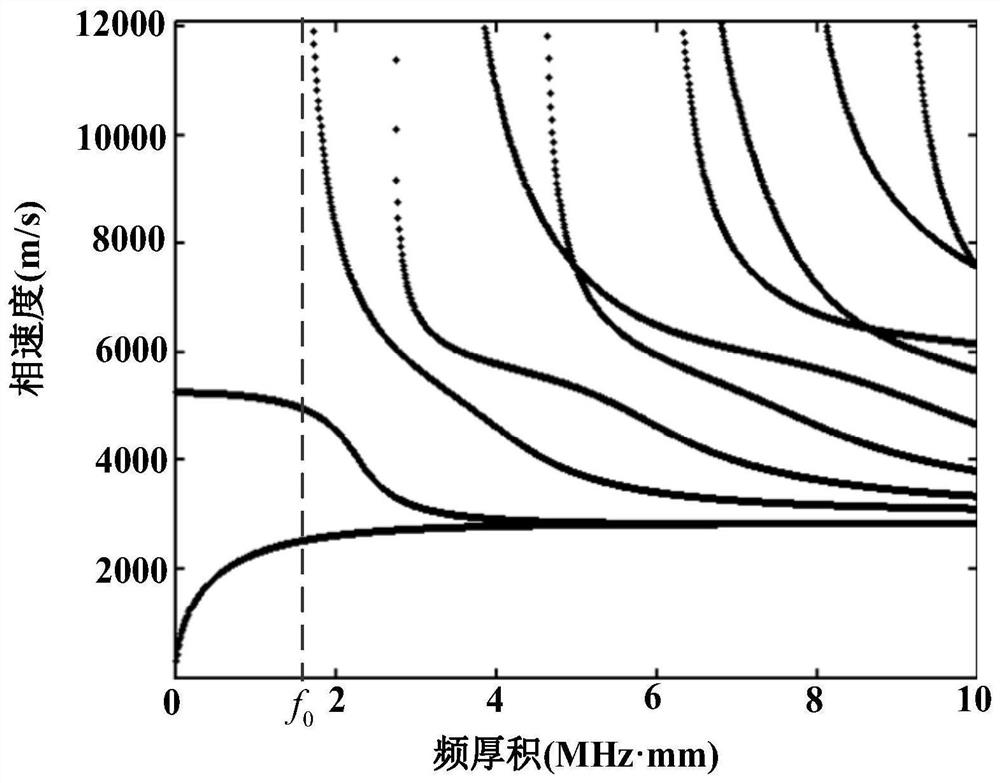

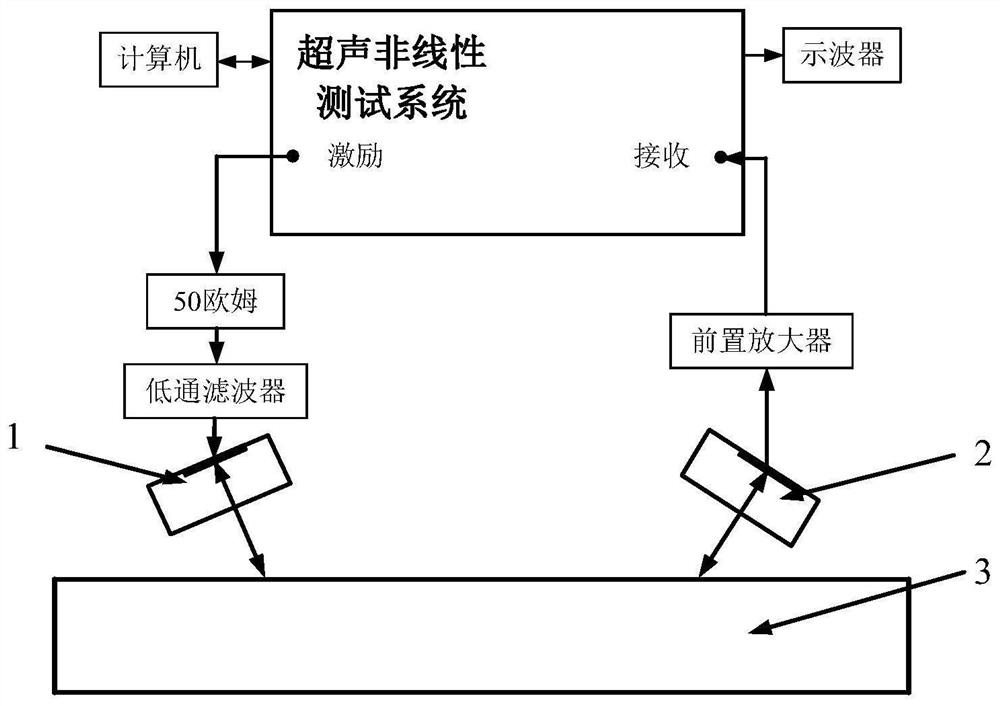

The invention provides a metal plate micro-defect detection method based on nonlinear Lamb waves. The metal plate micro-defect detection method comprises the following steps of: S1, acquiring a phasevelocity frequency dispersion curve and a group velocity frequency dispersion curve of a metal plate; S2, acquiring an excitation frequency, Lamb waves of a specific mode and an incident angle of theLamb waves of the specific mode as model parameters according to the phase velocity frequency dispersion curve and the group velocity frequency dispersion curve; S3, deriving a relative nonlinear coefficient beta' according to the Lamb waves of the specific mode in the S2, wherein the relative nonlinear coefficient beta' is used for representing the depth of a defect; S4, establishing a nonlinearultrasonic test system according to the model parameters; and S5, testing the metal plate according to the nonlinear ultrasonic test system established in the step S4, judging whether the relative nonlinear coefficient beta' is reliable or not, and if so, representing the defects of the tested metal plate by utilizing the relative nonlinear coefficient beta'. According to the metal plate micro-defect detection method, the relative nonlinear coefficient beta' represents the defects of the tested metal plate, the defects of the metal plate can be effectively represented, and the detection precision is improved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

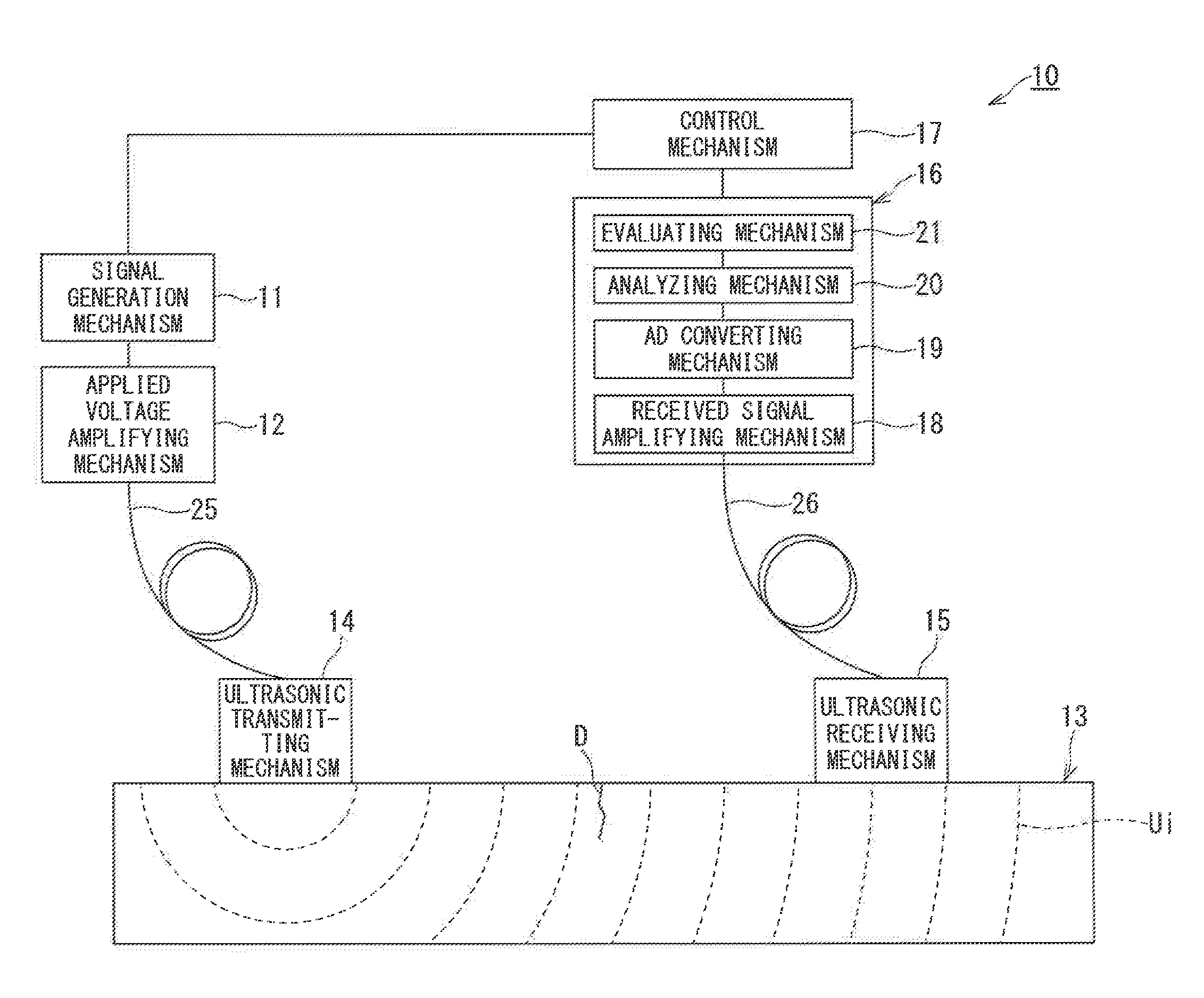

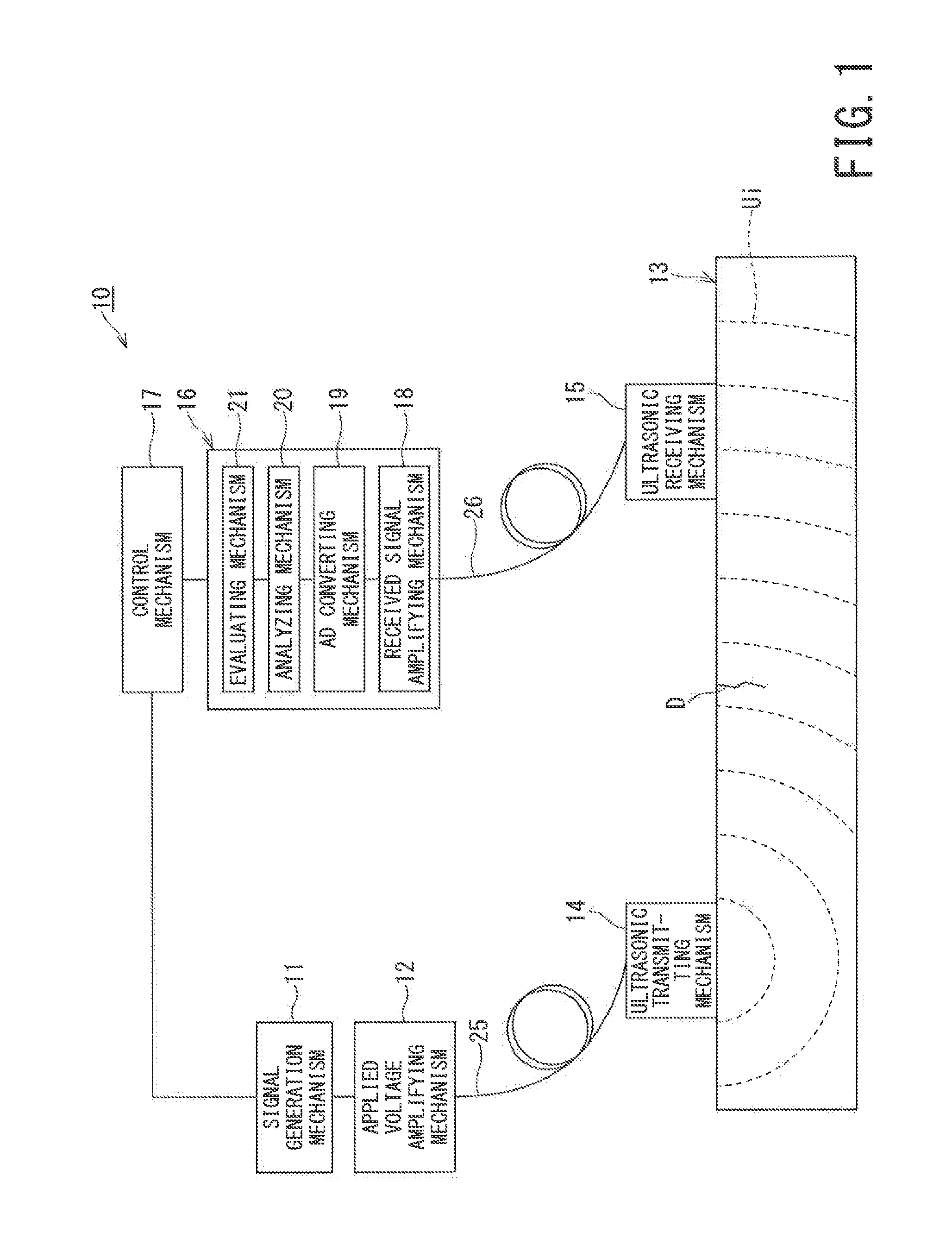

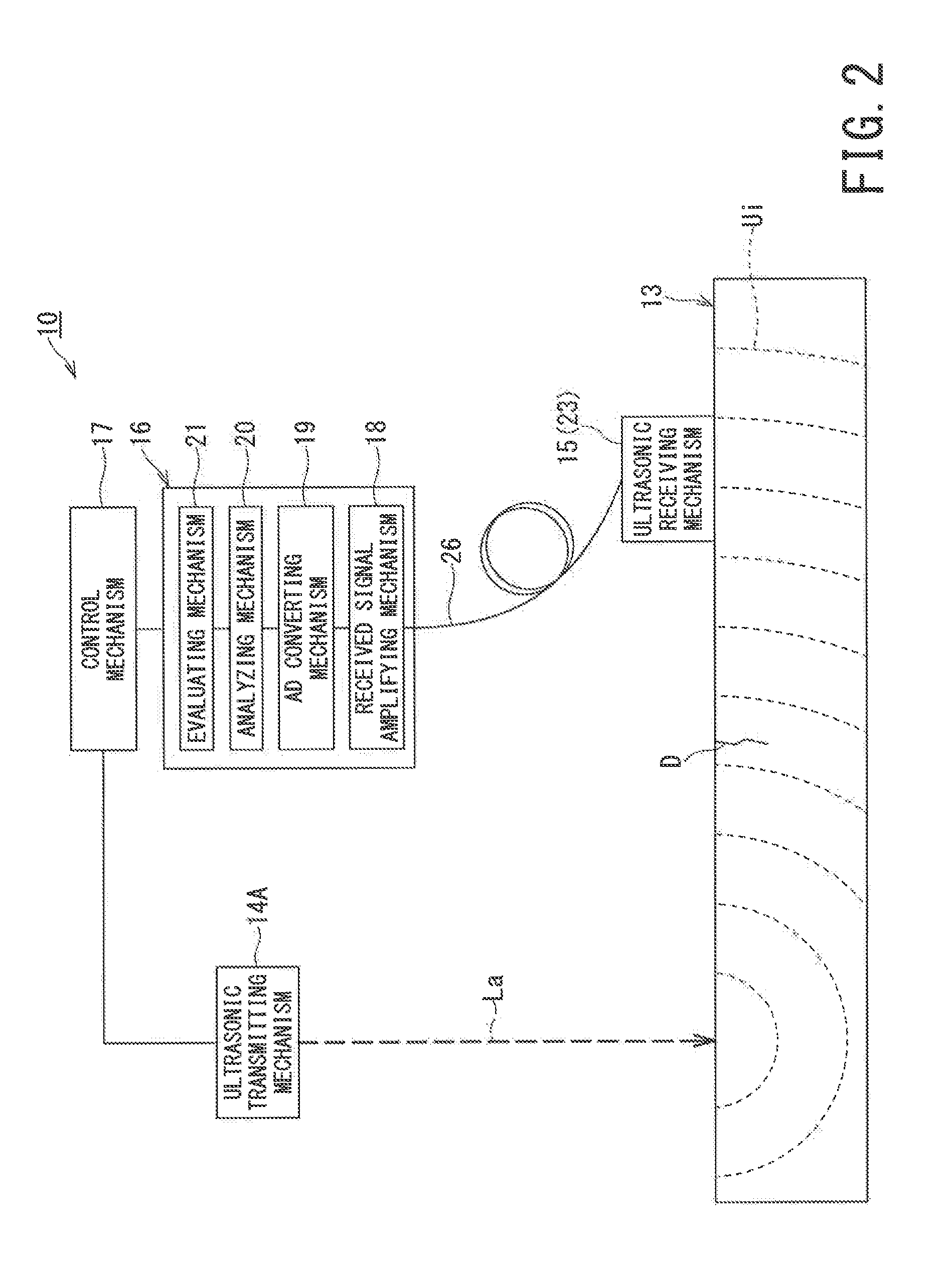

Ultrasonic Test Equipment and Evaluation Method Thereof

ActiveUS20140230556A1Wide rangeAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationData informationNonlinear ultrasound

An ultrasonic test equipment includes: a signal generating mechanism that generates a voltage waveform; an ultrasonic transmitting mechanism that excites ultrasonic vibrations having a lower frequency than a predetermined frequency to an object to be tested; an ultrasonic receiving mechanism that receives an ultrasonic response from the object to be tested; an AD converting mechanism that digitizes the received ultrasonic waveform; an analyzing mechanism that performs frequency analysis of the digital ultrasonic waveform digitized by the AD converting mechanism; an evaluating mechanism that extracts a variation of a nonlinear ultrasonic component from a frequency component of the digital ultrasonic wave obtained by the frequency analysis, compares the variation with defect data information in a defect information database, identifies a physical quantity of defect information of the object to be tested, and evaluates a defect in the object to be tested; and a control mechanism that partly or entirely controls a measurement system.

Owner:KK TOSHIBA

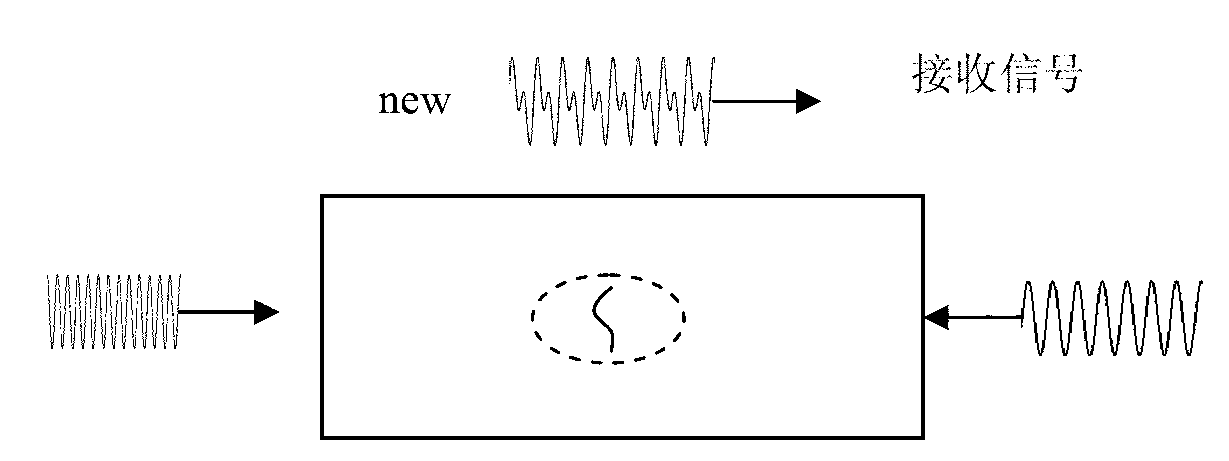

Method of applying Rayleigh waves in non-linear ultrasonic evaluation of surface damage of metal material

InactiveCN102426192AEasy to measureLong distanceAnalysing solids using sonic/ultrasonic/infrasonic wavesMetallic materialsNonlinear ultrasound

The invention relates to a method of applying Rayleigh waves in non-linear ultrasonic evaluation of surface damage of a metal material. The method comprises the following steps: 1) excitation and reception of Rayleigh waves; 2) detection of reliability of a testing system; 3) measurement of non-linear coefficients when the surface of a test piece has damage of different degrees; 4) repeatable operation of test. Compared to the method of using body waves for ultrasonic nondestructive test, the non-linear ultrasonic evaluation method provided in the invention has the characteristic that Rayleigh surface waves are especially suitable for measurement of non-linear coefficients of large-scale complex plate structures. According to the invention, it is only needed to carry out excitation and measurement of supersonic waves at one side of a structure during measuring, which enables measuring to be simple and easy; the Rayleigh surface waves have advantages favorable for measuring, e.g., concentration of energy on the surface of a structure, a long propagation distance, etc.; operation is simple and easy, so the method is especially suitable for on-site detection of structural elements; effective evaluation of early damage and degeneration of mechanical properties of a material structure can be realized by using the non-linear ultrasonic method.

Owner:BEIJING JIAOTONG UNIV

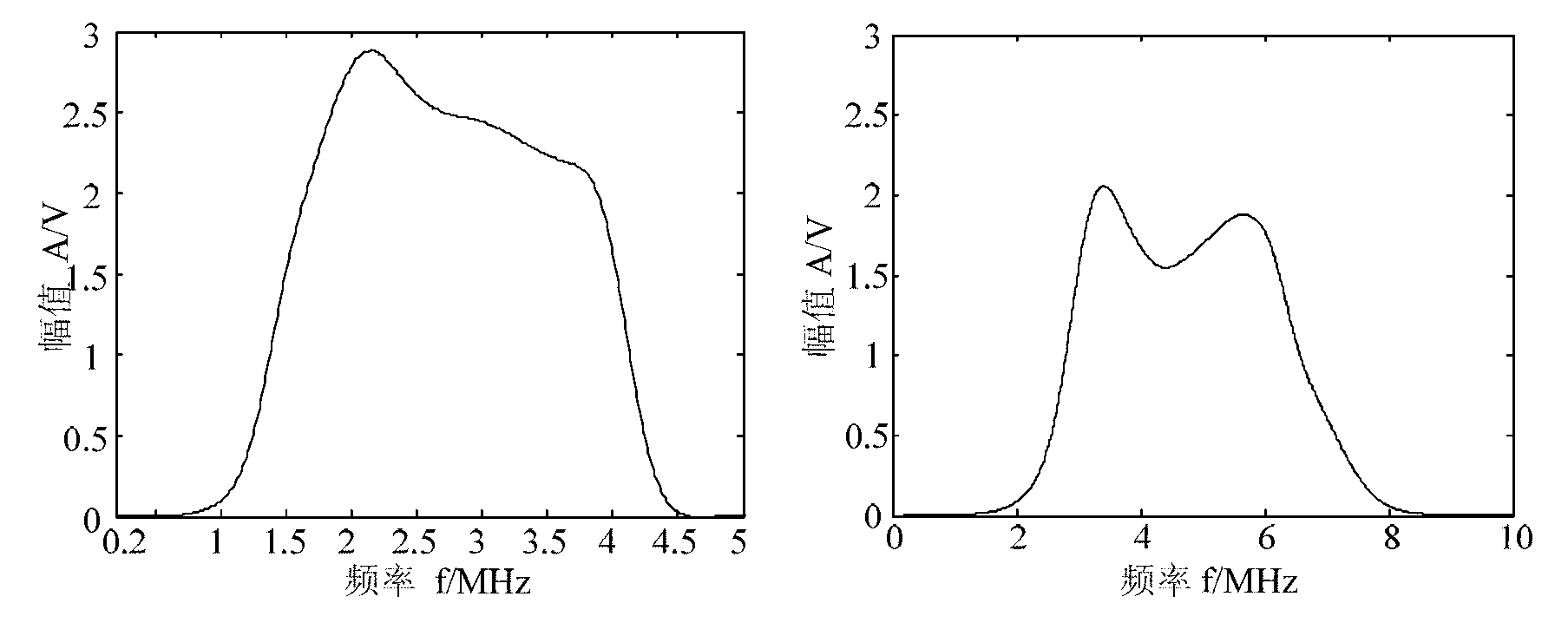

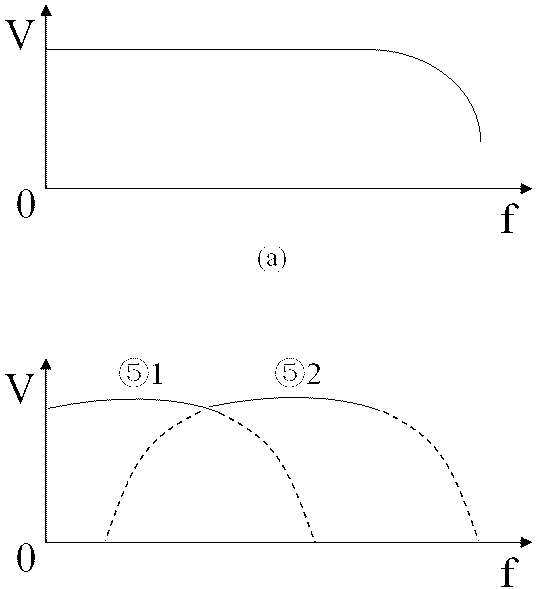

Frequency mixing nonlinear ultrasonic detection method for structure microcracks based on bispectrum analysis

ActiveCN102980945AAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationNonlinear ultrasound

The invention provides a frequency mixing nonlinear ultrasonic detection method for structure microcracks based on bispectrum analysis, and belongs to the detection field of nondestructive examination. The method comprises the steps of firstly, obtaining an amplitude-versus-frequency curve of an excited probe and an excited receiving probe through frequency sweep experiments, and determining probe excitation frequency or range according to the amplitude-versus-frequency curve; then, carrying out different lateral excitation frequency mixing mode experiments, tracking difference frequency and sum frequency signals, and determining an optimal frequency of the excitation signals according to amplitude-versus-frequency response characteristics of the difference frequency and sum frequency signals; performing bispectrum analysis on the time domain signals at the optimal frequency, and determining whether structure microcracks exist in a test piece or not according to whether mixing components appear in the bispectra or not; and scanning the length direction of a test piece and tracking the difference frequency and sum frequency signals by changing time delay of the excitation signals, and determining the positions of the structure microcracks according to the amplitude-versus-frequency response characteristics of the difference frequency and sum frequency signals. Influences on experimental results caused by nonlinearity of an experiment apparatus can be prevented by employing two probes to excite the signals; and the positions of the structure microcracks can be identified by making the two signals encountered through controlling the delay time of the excited signals.

Owner:BEIJING UNIV OF TECH

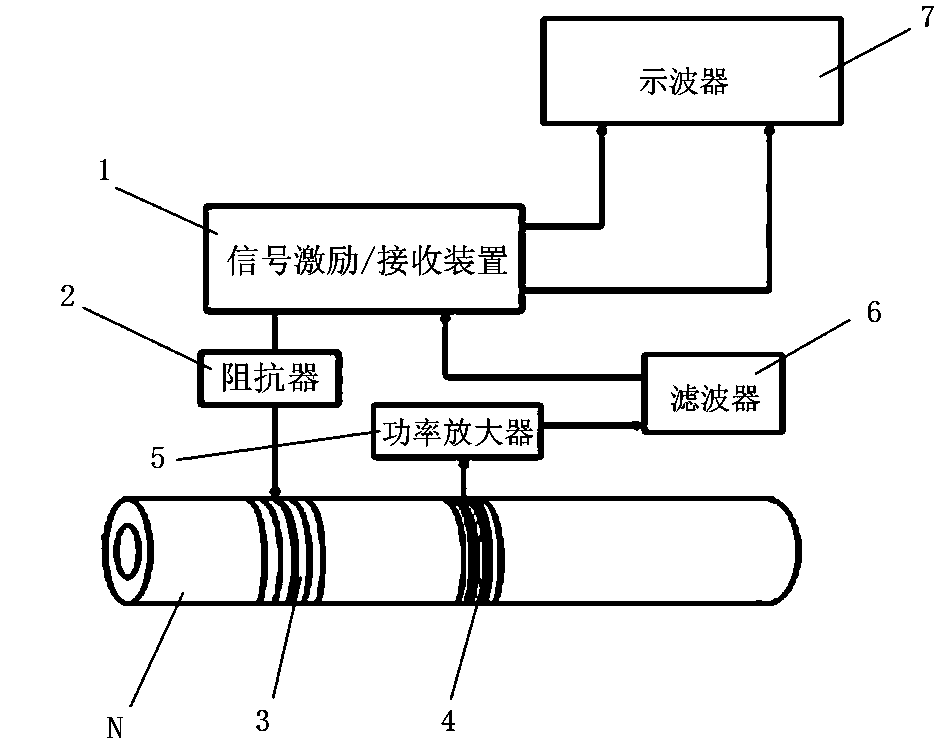

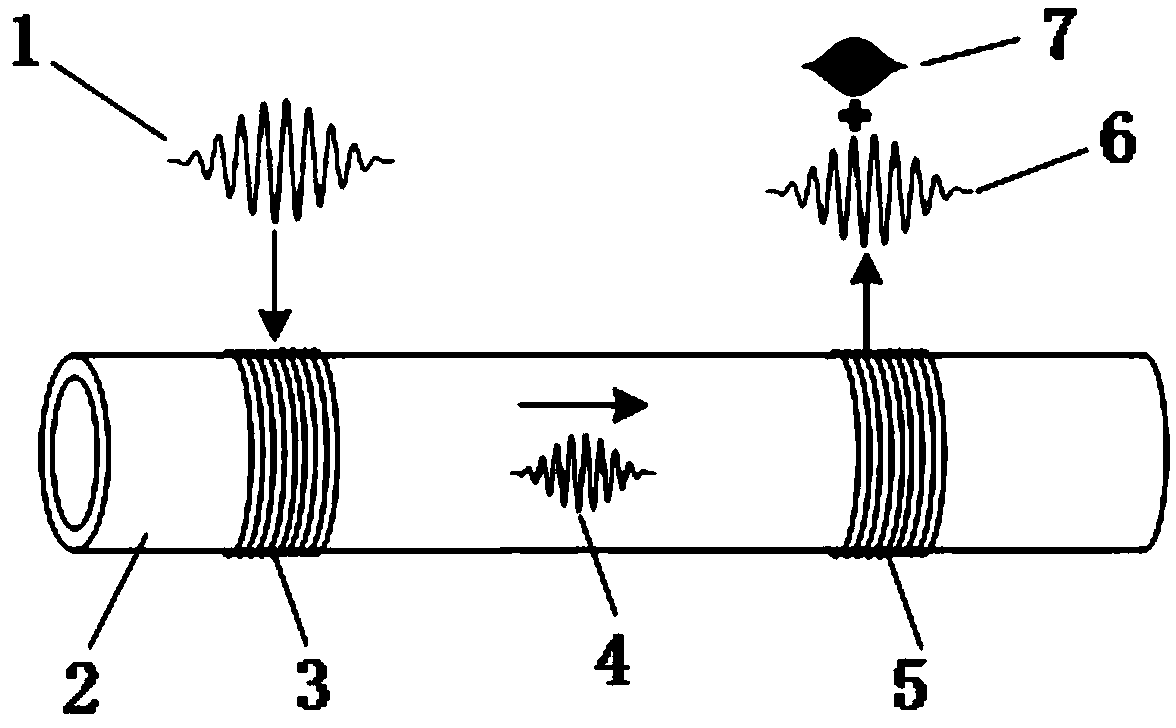

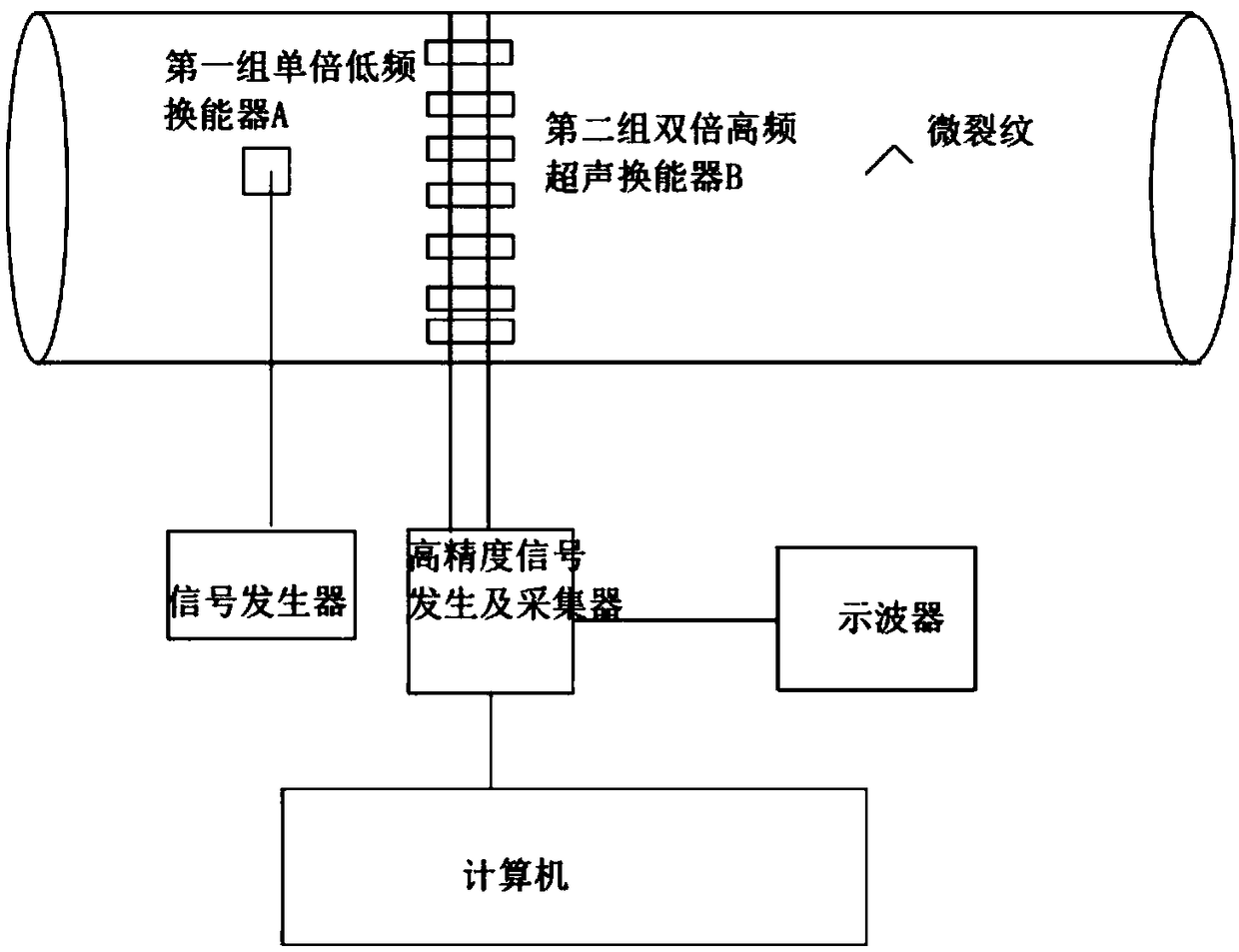

Nonlinear ultrasonic guided wave detection method and device for pipeline micro damage

InactiveCN103969339AEfficient receptionStable under pressureAnalysing solids using sonic/ultrasonic/infrasonic wavesHarmonicNonlinear ultrasound

The invention discloses a nonlinear ultrasonic guided wave detection method and a nonlinear ultrasonic guided wave detection device for pipeline micro damage. An exciting transducer capable of exciting single guided wave modal state and a matched receiving transducer are adopted, the transducers can wind a pipeline to excite axisymmetric modal states, the receiving efficiency of a second order harmonic signal is improved by a matching and corresponding receiving probe, the detection capacity of the system on second order harmonic waves of the guided waves is improved. The nonlinear change of a material is characterized by detecting the ratio of nonlinear response to propagation distance, nonlinear interference of instruments is effectively reduced, nonlinear ultrasonic guided wave evaluation of the pipeline material is realized, and nonlinear ultrasonic high sensitivity can be used for early detection of the pipeline micro defects.

Owner:XIAMEN UNIV

Nonlinear ultrasonic imaging detection method based on automatic scanning

ActiveCN103926320AHigh detection sensitivityImprove detection resolutionAnalysing solids using sonic/ultrasonic/infrasonic wavesSonificationImage detection

The invention belongs to the technical field of non-destructive detection, and relates to a nonlinear ultrasonic imaging detection method based on automatic scanning. The nonlinear ultrasonic imaging detection method is mainly implemented as follows: a nonlinear ultrasonic unit, nonlinear ultrasonic detection signal acquisition and nonlinear ultrasonic imaging. The nonlinear ultrasonic unit comprises an ultrasonic automatic scanning detection device, a transmitting transducer, a receiving transducer, an ultrasonic unit, a pre processor and the like. By the transmitting transducer and the receiving transducer a nonlinear ultrasonic detection signal is obtained. The nonlinear ultrasonic imaging includes imaging position data construction and imaging display, and comprises the following main steps: determining an automatic scanning mode, arranging and clamping parts, setting parameters, scanning for imaging and the like. Ultrasonic automatic scanning detection equipment with 1-6 coordinate freedom degrees is used for realizing high sensitivity and high resolution nonlinear ultrasonic automatic scanning imaging detection of the parts with different shaped, sized and structured, and the detection capability and reliability of clinging defects and micro defects can be significantly improved.

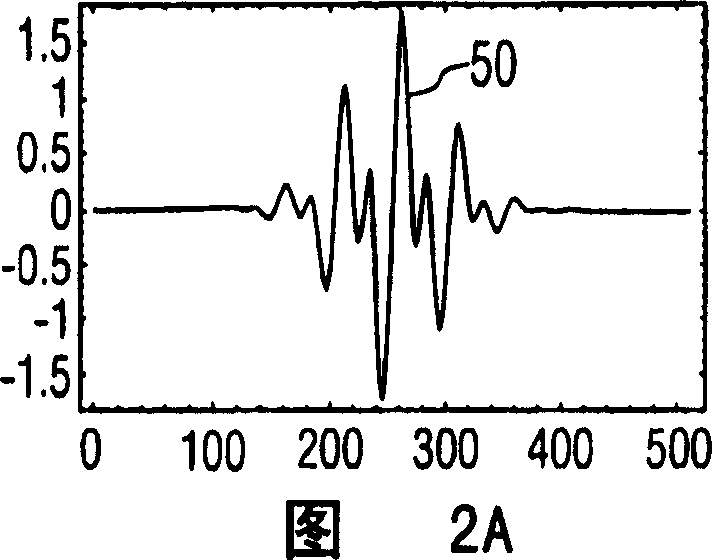

Owner:AVIC COMPOSITES

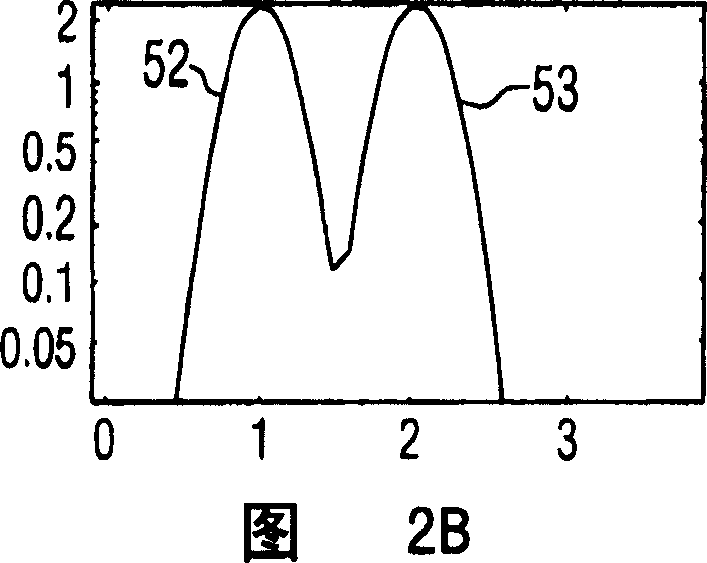

Nonlinear ultrasonic detection method for evaluating thermo-oxidative ageing of organic material

InactiveCN104764805ARealize non-destructive testingRealize continuous online monitoringAnalysing solids using sonic/ultrasonic/infrasonic wavesIntegratorNonlinear ultrasound

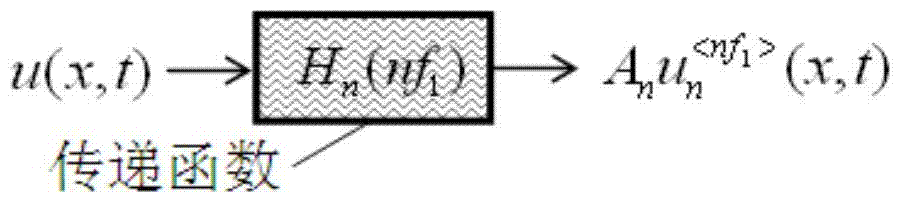

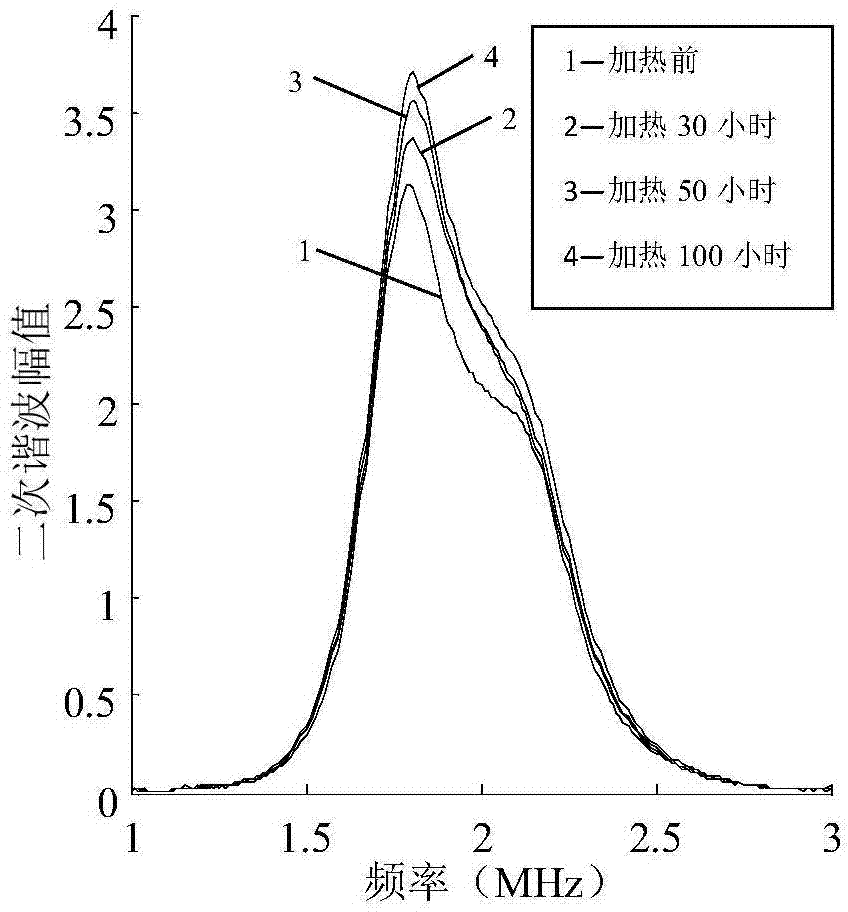

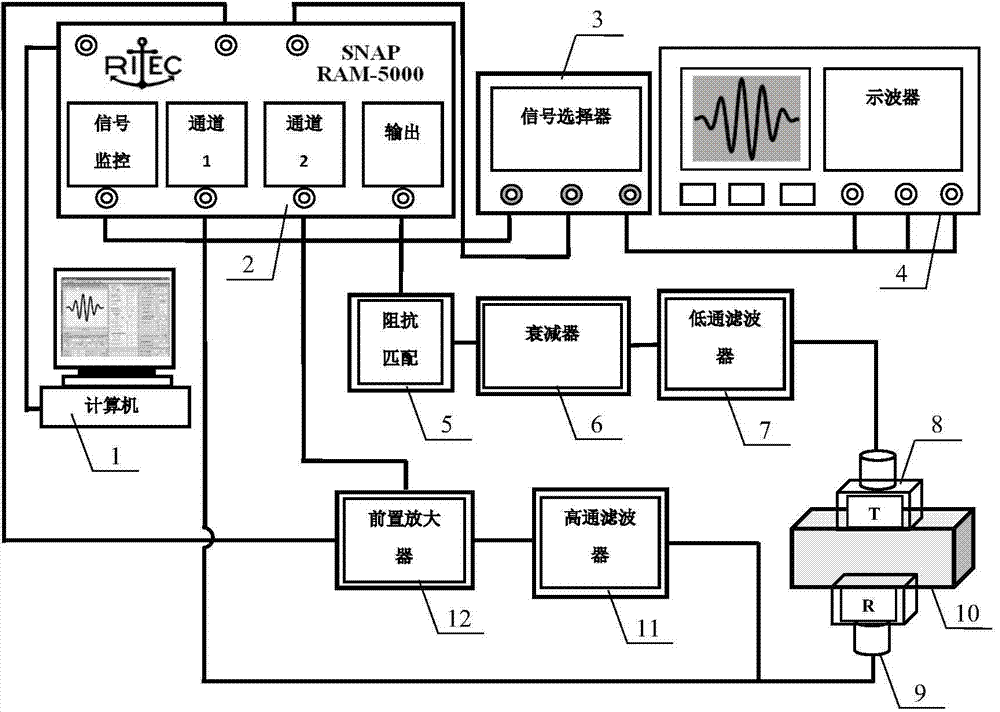

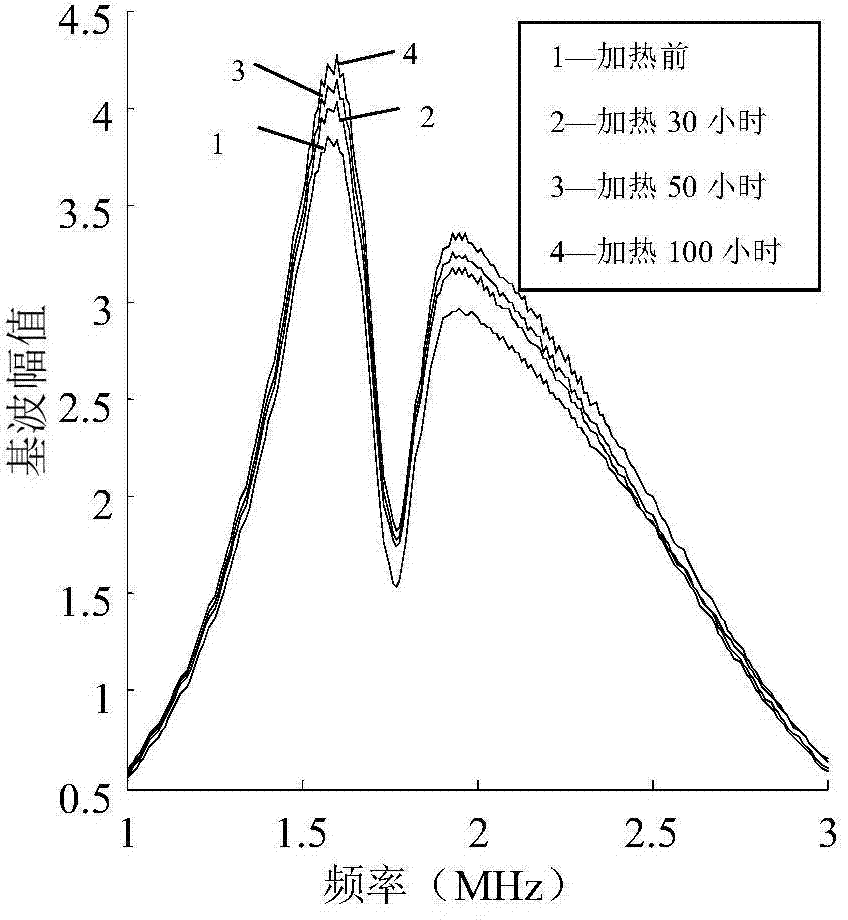

A nonlinear ultrasonic detection method for evaluating the thermo-oxidative ageing of an organic material comprises the following steps: building an organic material thermo-oxidative ageing damage nonlinear ultrasonic detection system based on a nonlinear acoustic detection system; respectively setting corresponding parameters of an excitation signal and a reception signal, and finely adjusting the corresponding parameters of the excitation signal and the reception signal by a time domain waveform signal observed and received by an oscilloscope; selecting the optimum work frequency range of a probe according to the frequency characteristic of the ultrasonic probe, and determining the initial frequency and the ending frequency of the swept frequency range; adjusting integrator gate parameters, carrying out frequency sweeping to obtain the change rule of an supersonic wave fundamental wave amplitude and a secondary harmonic amplitude with the frequency, and storing the change rule in a computer; calculating corresponding nonlinear coefficients of all frequency points in the swept frequency range, and calculating the accumulated nonlinear effect in the swept frequency range; and determining a corresponding relationship between the accumulated nonlinear effect and the thermo-oxidative ageing time of the organic material, and assessing the existence or not and the degree of the thermo-oxidative ageing damage of the organic material.

Owner:BEIJING UNIV OF TECH

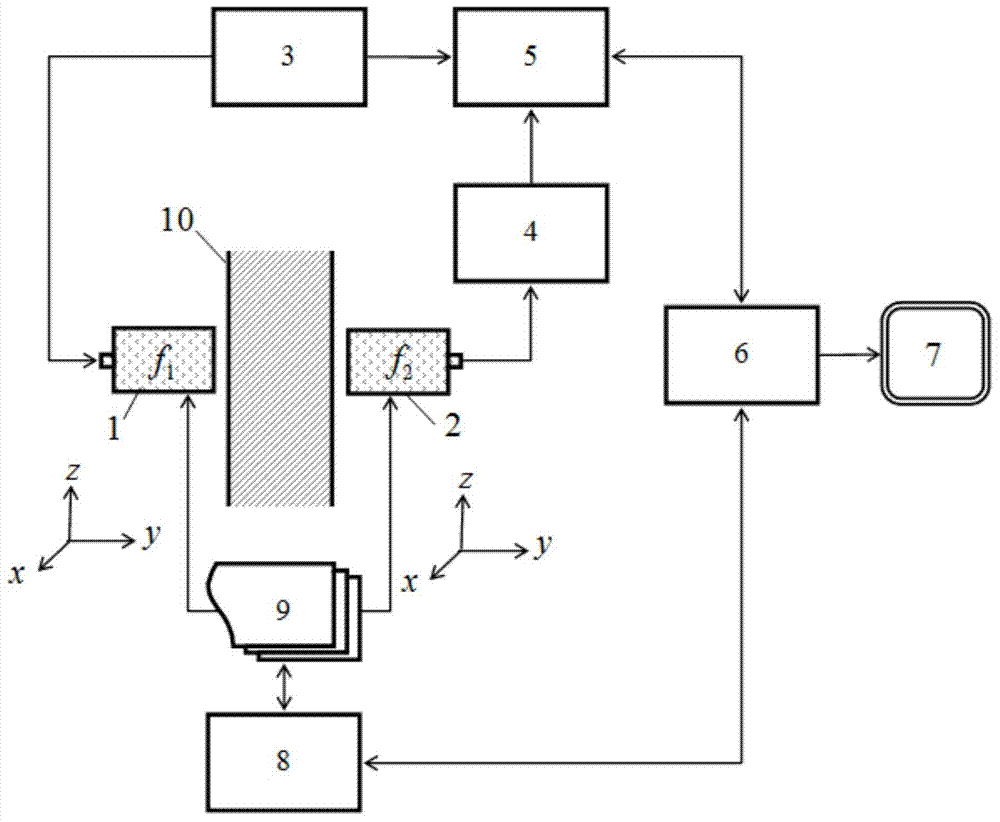

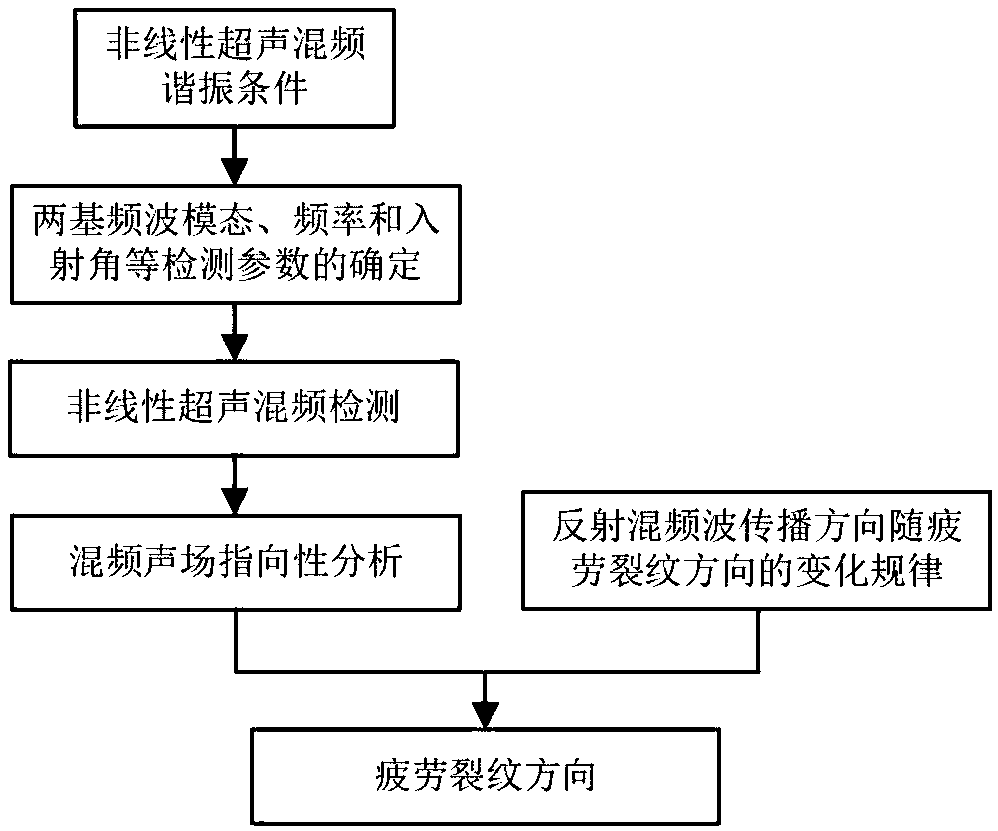

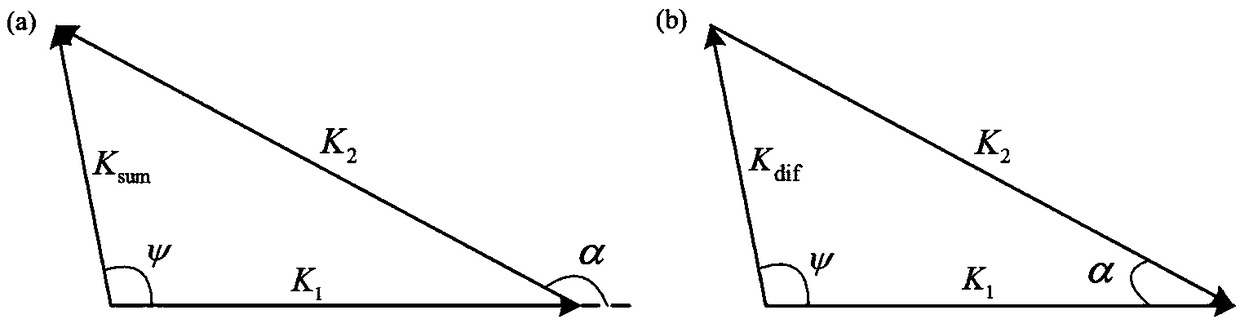

Nonlinear ultrasonic mixing method for testing in structural fatigue crack direction

ActiveCN108872393ASuppress the effects of non-linearityAnalysing solids using sonic/ultrasonic/infrasonic wavesStructural fatigueSonification

The invention discloses a nonlinear ultrasonic mixing method for testing in the structural fatigue crack direction, and belongs to the field of non-destructive testing. The method comprises the following steps: firstly, according to a tested object and a nonlinear ultrasonic mixing harmonic condition, determining the testing parameters such as the mode, frequency, incident angle and the like of two fundamental frequency waves; performing the nonlinear ultrasonic mixing testing of the structural fatigue crack; performing continuous wavelet transformation on testing signals in each annular receiving point, extracting the amplitudes of mixing waves, and performing the mixing sound field directivity analysis; finally, calculating the fatigue crack direction according to the change rule of thereflecting mixing wave propagation direction along with the fatigue crack direction.

Owner:BEIJING UNIV OF TECH

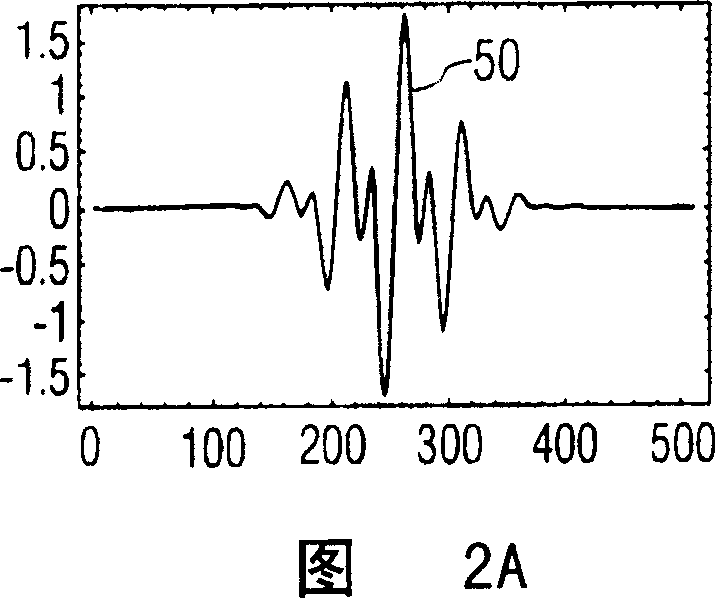

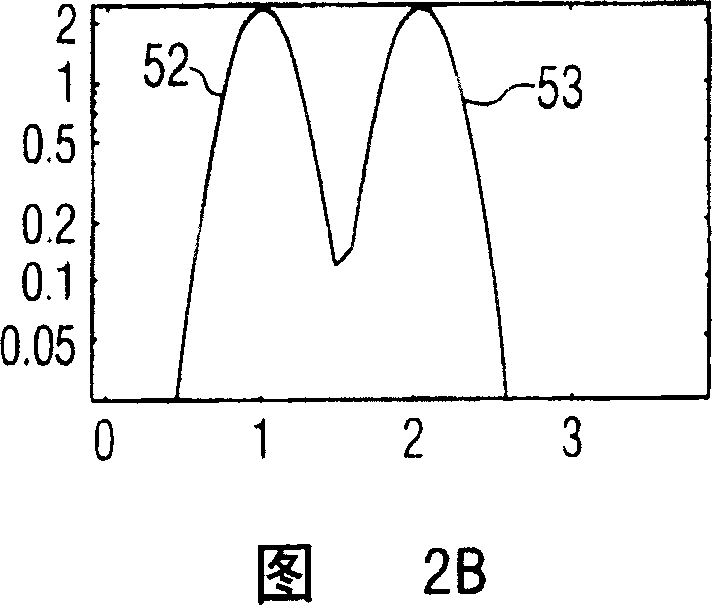

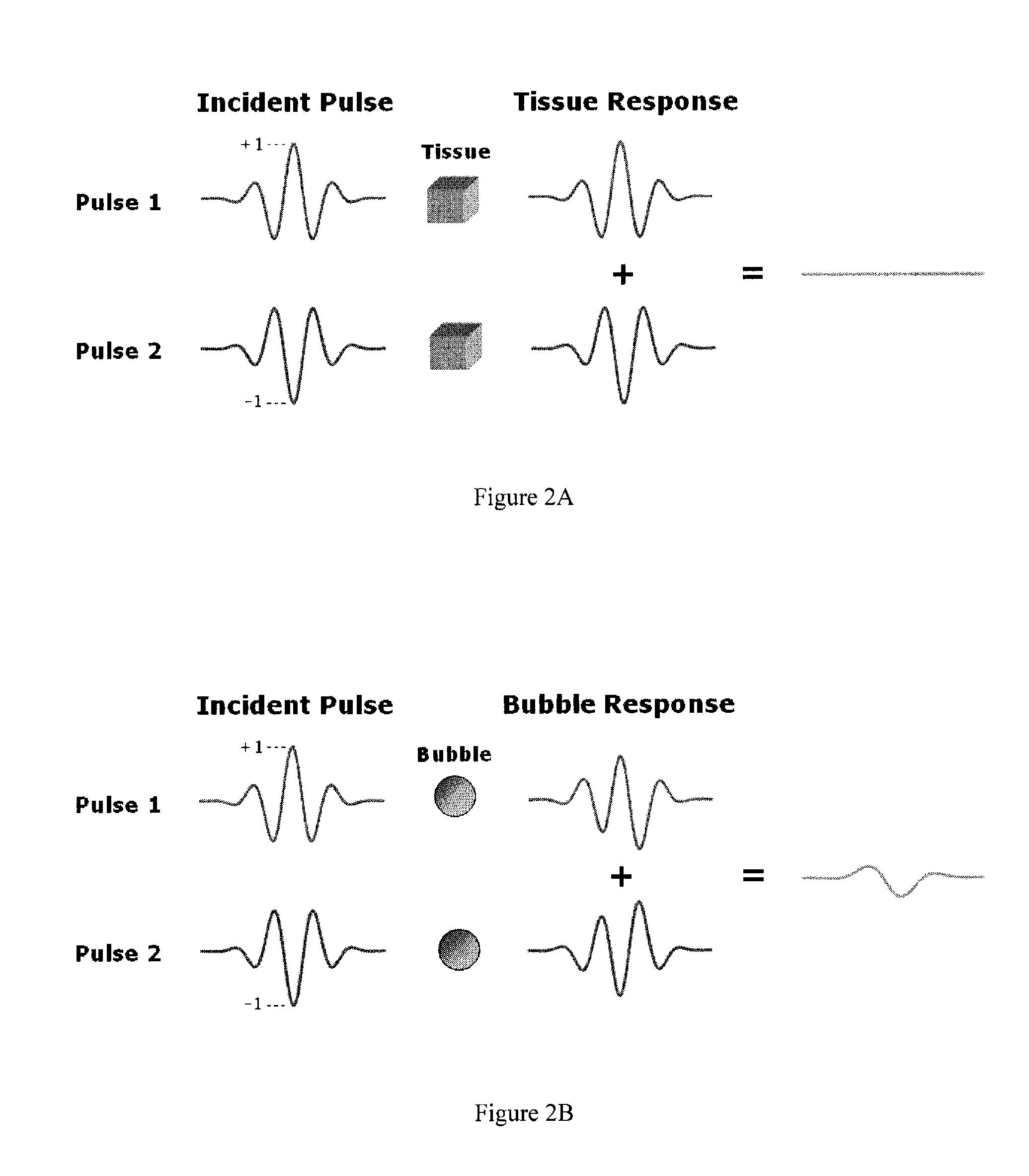

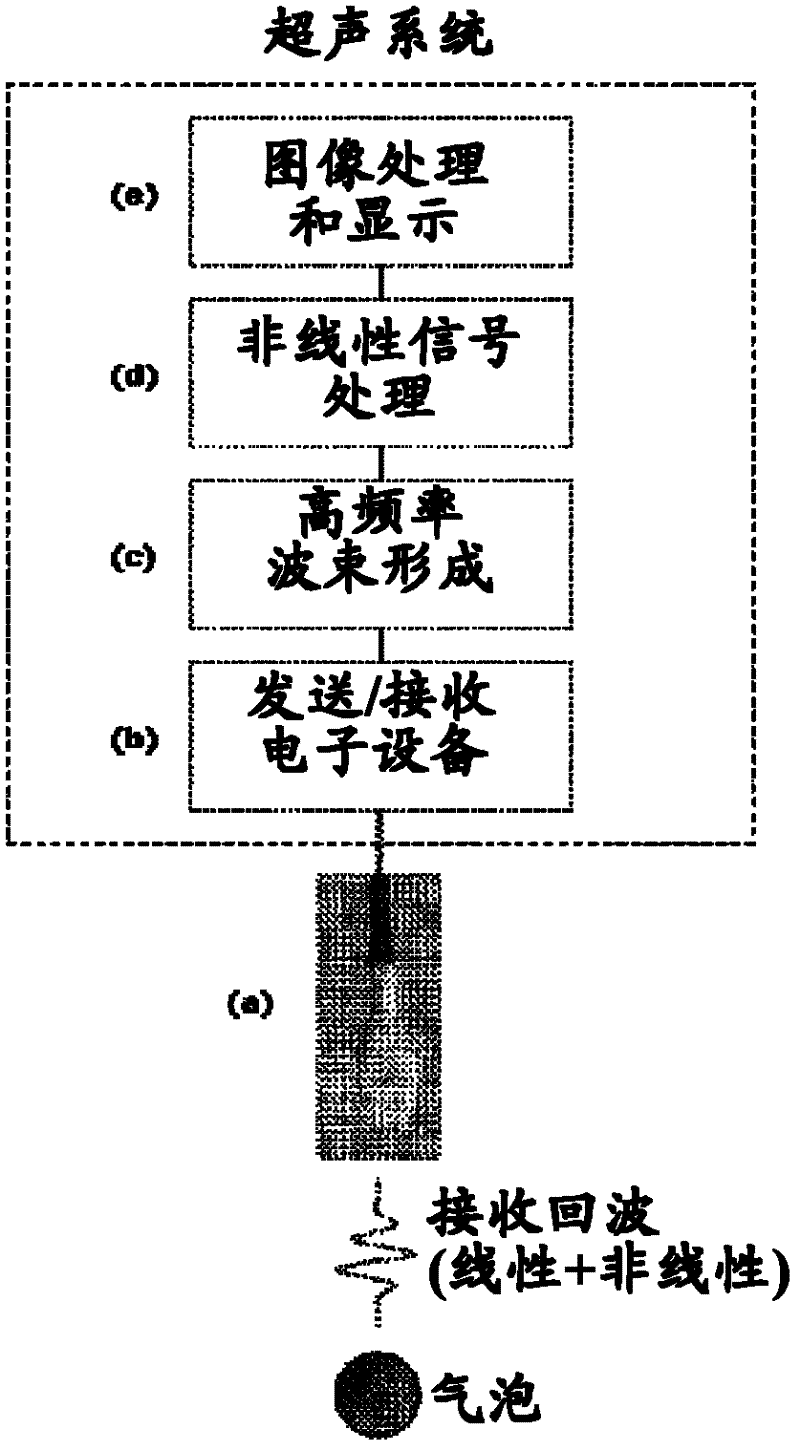

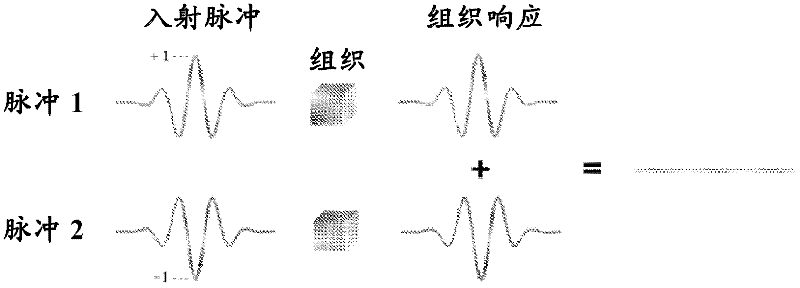

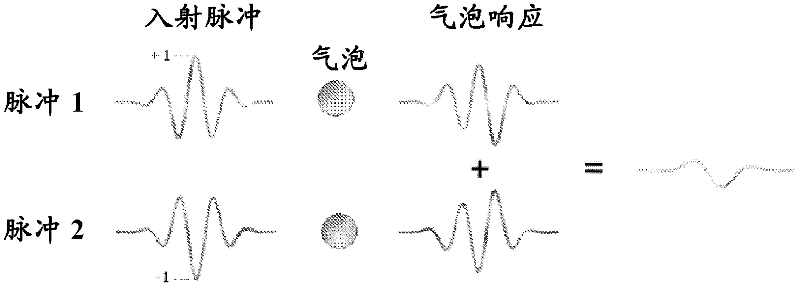

Non-linear ultrasonic diagnostic imaging using intermodulation component signals

InactiveCN1976635AUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsSonificationUltrasonic imaging

An ultrasonic imaging system transmits waveforms containing first and second major frequency components which are intermodulated by passage through a nonlinear medium or interaction with a contrast agent microbubble to produce a difference frequency component. In an illustrated embodiment the second major frequency is twice the frequency of the first major frequency, resulting in a difference frequency signal at the first major frequency. Two differently modulated transmit waveforms are transmitted and the difference frequency component is separated by pulse inversion.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

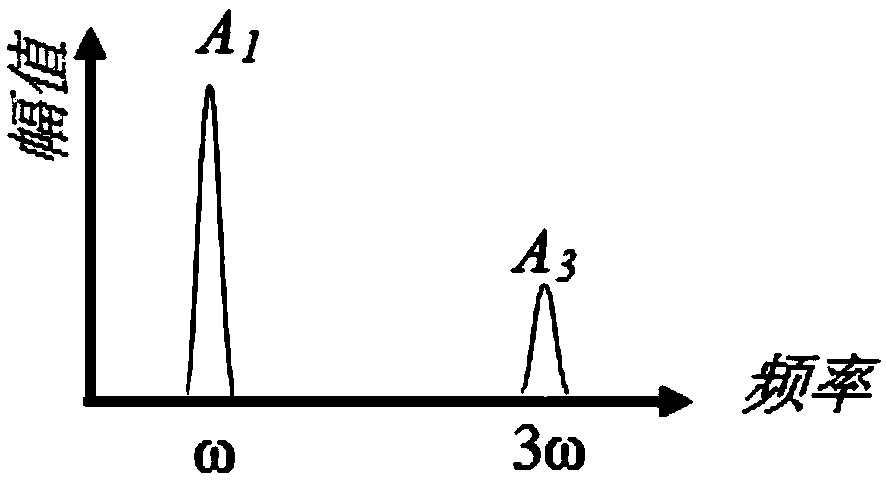

Nonlinear torsion modal ultrasonic guided-wave method used for evaluating metal circular tube microdamage

ActiveCN108872378AEffective evaluationHas a cumulative effectAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalNonlinear ultrasoundThird harmonic

The invention discloses a nonlinear torsion modal ultrasonic guided-wave method used for evaluating metal circular tube microdamage. Through a stimulation energy converter, single torsion modal ultrasonic guided-wave is stimulated in the circular tube; when the torsion modal ultrasonic guided-wave is spread in the circular tube, the torsion modal ultrasonic guided-wave and the microdamage of the circular tube mutually act to generate third harmonic with an accumulation effect; through a receiving energy converter, a fundamental frequency signal and third harmonic generated by the tube microdamage are received; an amplitude A1 and a third harmonic amplitude A3 of the fundamental frequency signal are obtained, an equivalent three-order nonlinear sound parameter [gamma'] is calculated, and the nonlinear ultrasonic guided-wave evaluation of the microdamage of the circular tube is evaluated. The nonlinear torsion modal ultrasonic guided-wave has a third harmonic accumulation effect on any point on a frequency dispersion curve, and therefore, the restriction that nonlinear longitudinal modal guided-wave only has the accumulation effect on certain points on the frequency dispersion curveis overcome. The damage states of circular tube construction members / materials can be effectively detected and evaluated, detection speed is high, detection cost is low, and detection accuracy is high.

Owner:XIAN UNIV OF SCI & TECH

Nonlinear ultrasonic diagnostic imaging using intermodulation product signals

InactiveCN1977186AUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsSonificationSquare waveform

An ultrasonic imaging system transmits waveforms containing first and second major frequency components which are intermodulated by passage through a nonlinear medium or interaction with a contrast agent microbubble to produce a difference frequency component. In an illustrated embodiment the transmit waveforms are square waves exhibiting only odd harmonic components. The first and third harmonic components are intermodulated by nonlinear effects to produce a difference frequency signal at the second harmonic frequency.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

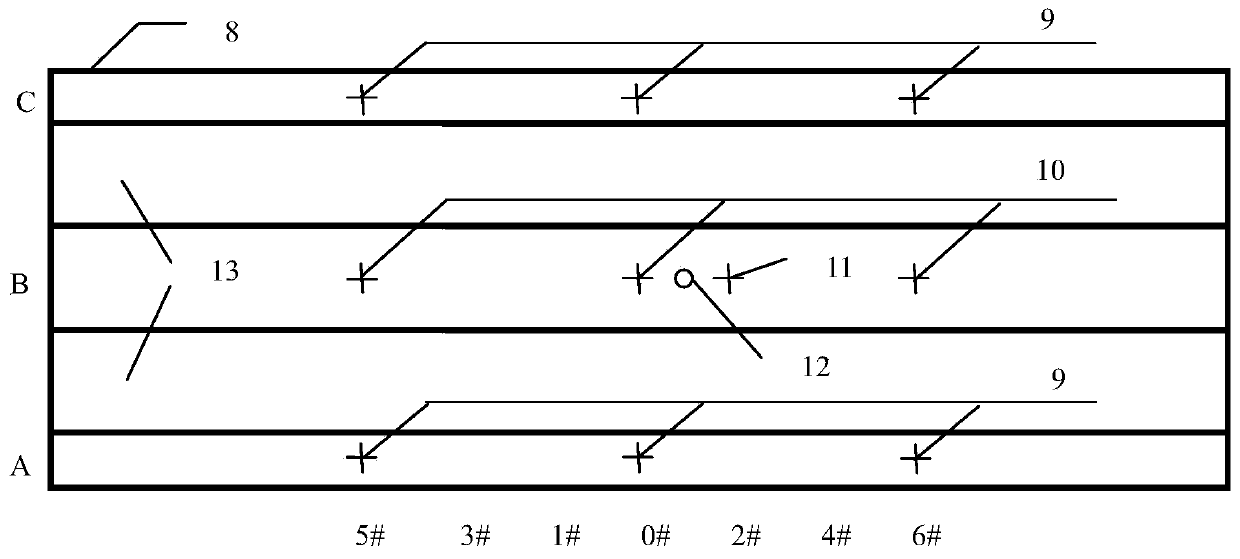

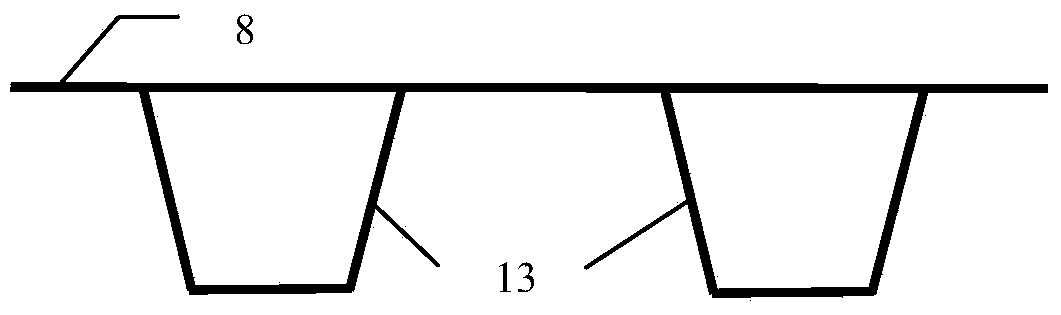

Testing device and testing method for recognizing weld defects of orthotropic steel bridge deck slab

InactiveCN103995051ASimple and fast operationMeet practical application requirementsAnalysing solids using sonic/ultrasonic/infrasonic wavesBridge deckNonlinear ultrasound

Owner:WUHAN UNIV OF TECH

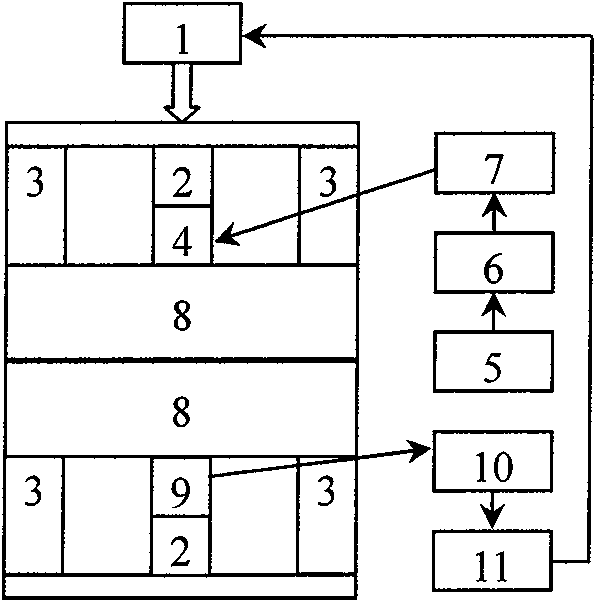

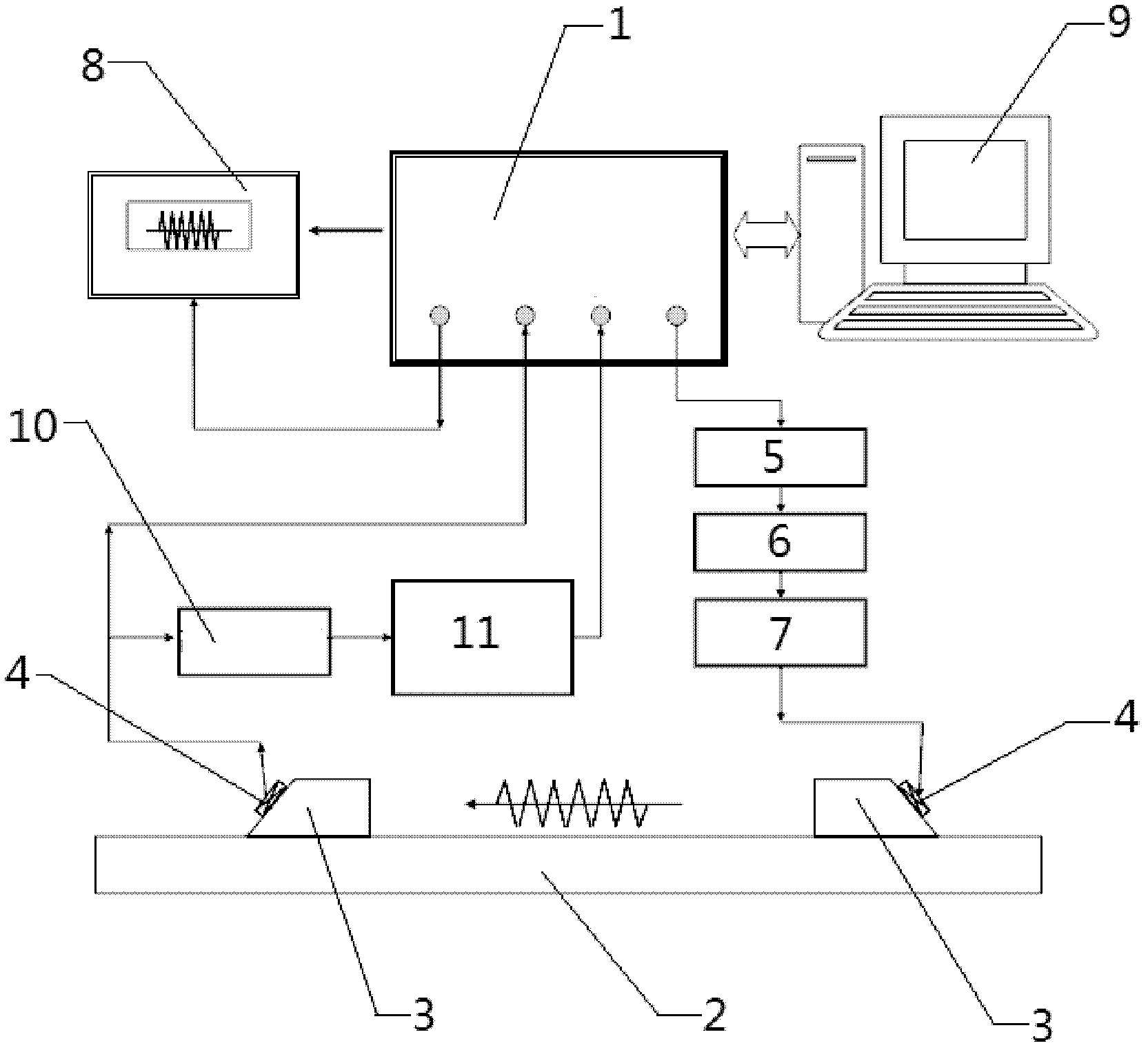

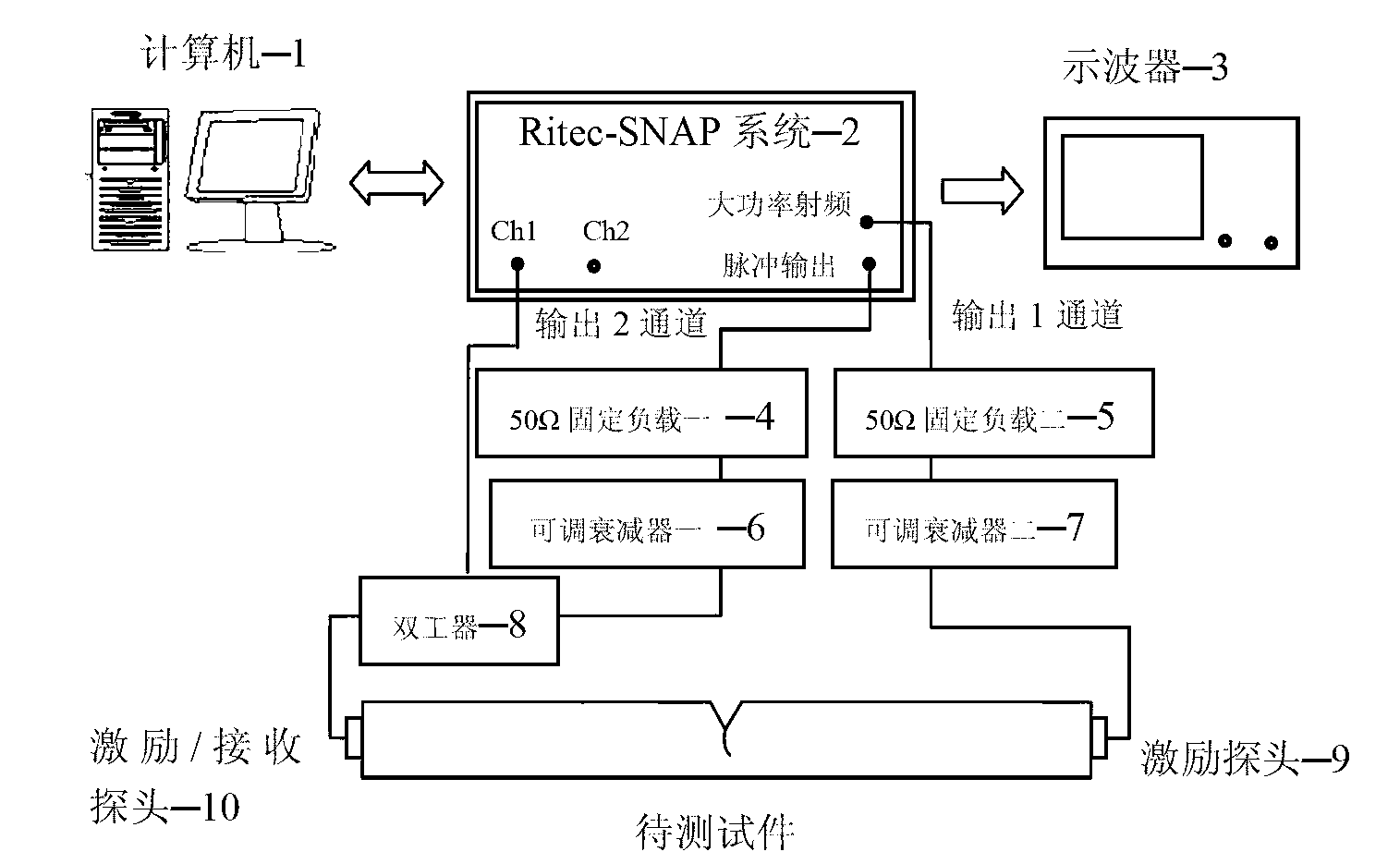

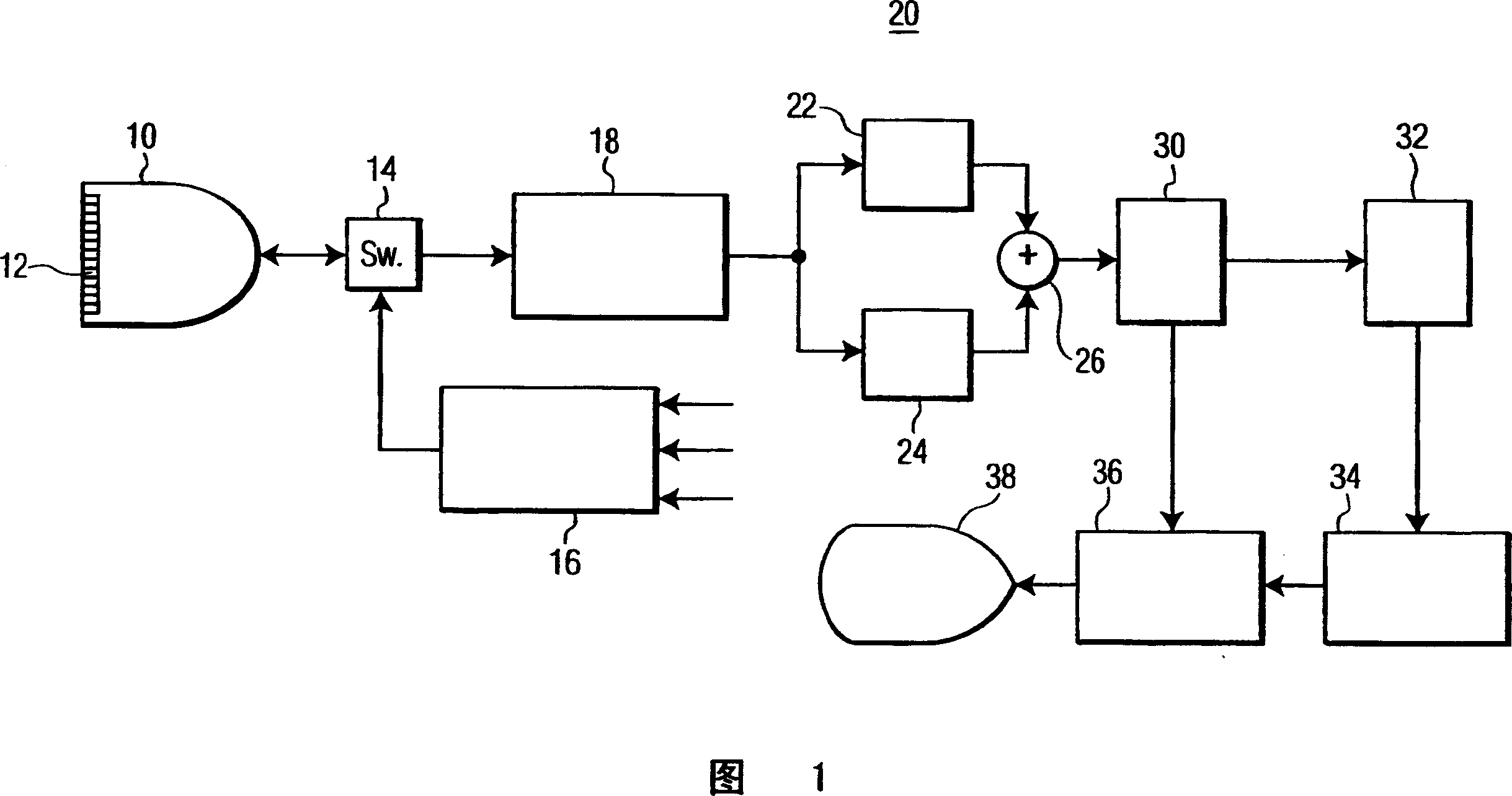

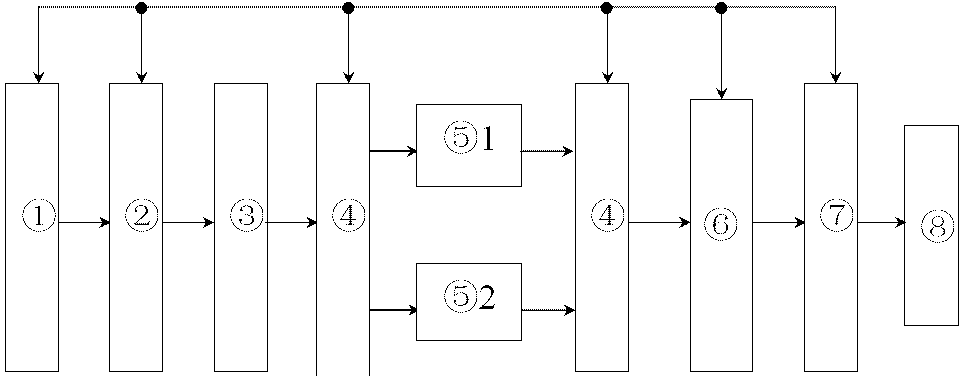

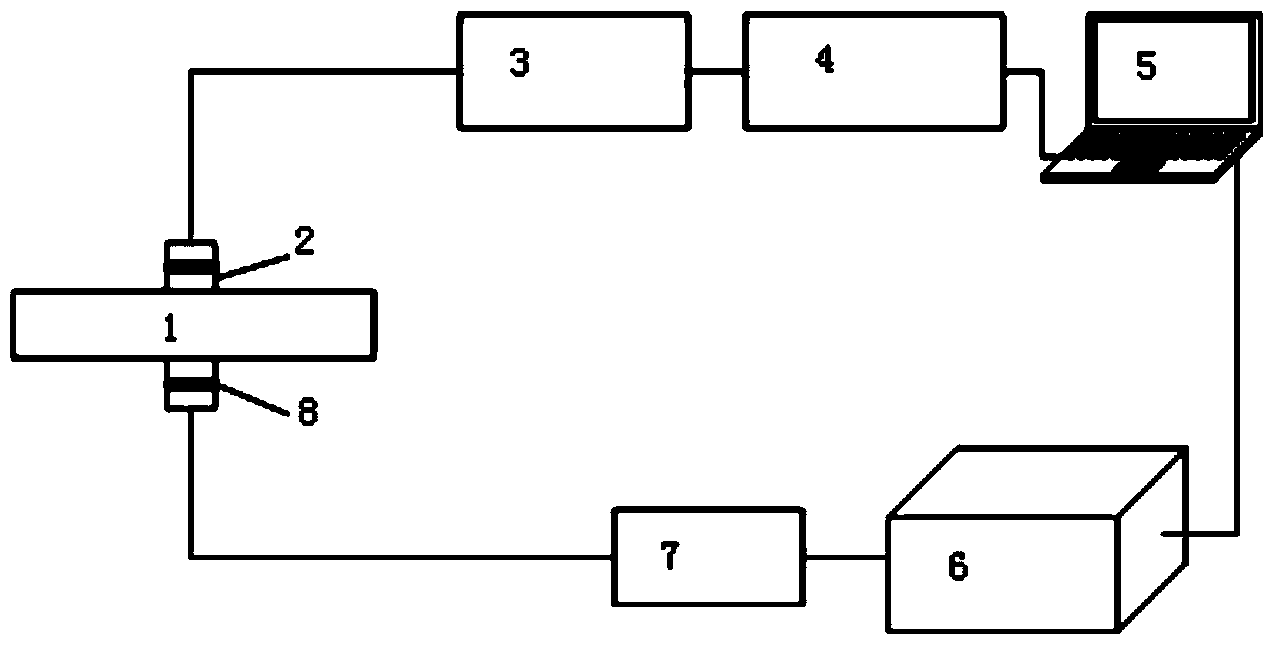

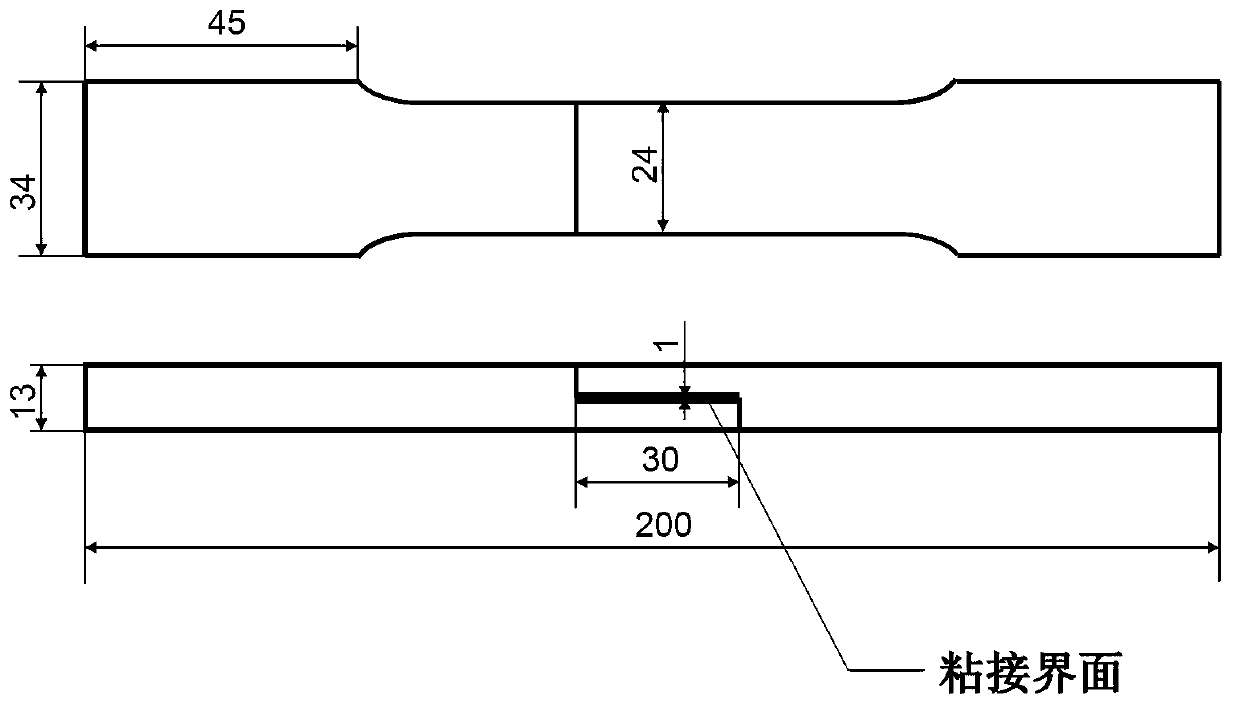

Nonlinear ultrasound system used for detecting super austenitic stainless steel inter-granular corrosion

InactiveCN103323525ARapid identification of intergranular corrosion degreeImprove detection efficiencyAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalNonlinear ultrasoundSteel tube

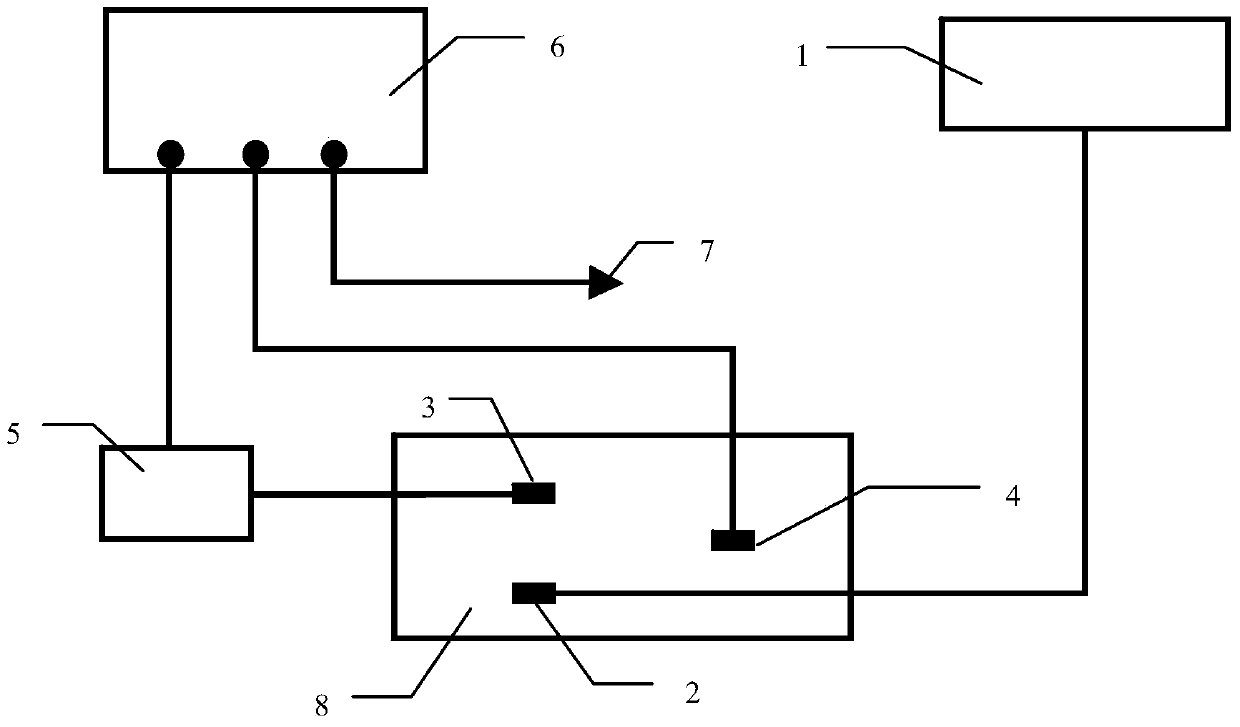

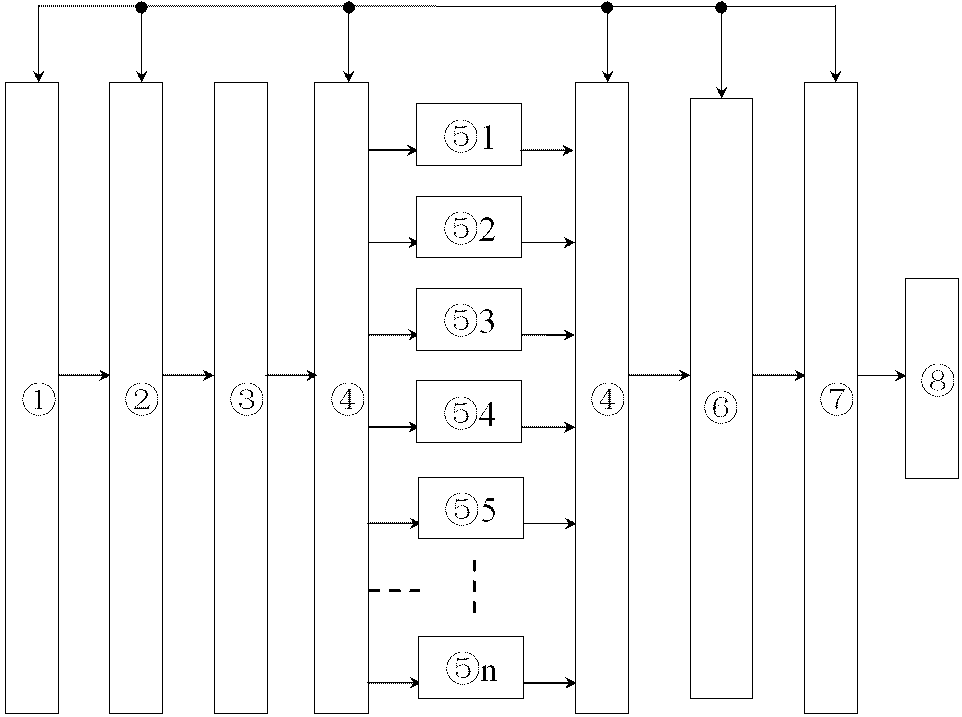

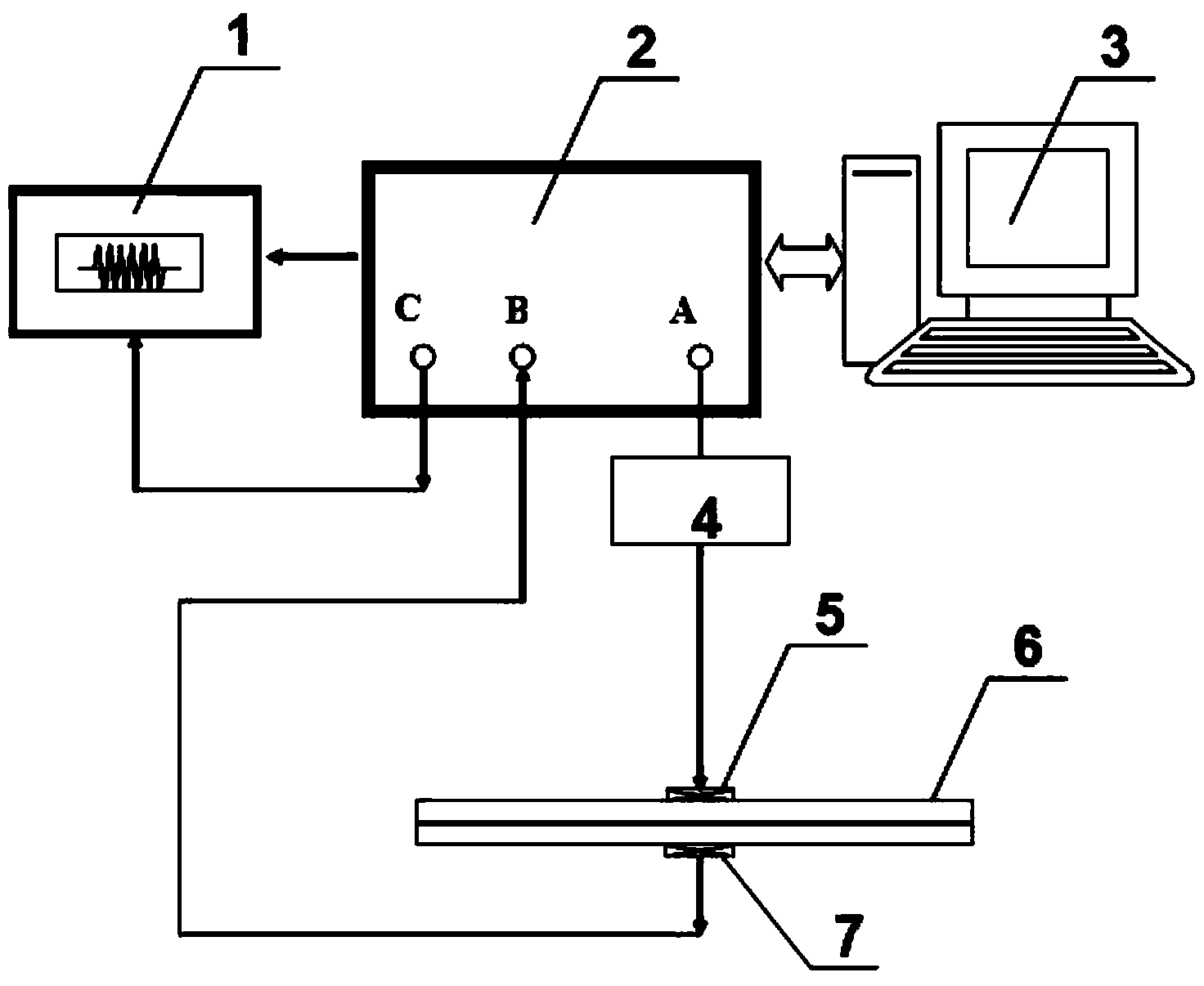

The invention relates to a nonlinear ultrasound system used for detecting super austenitic stainless steel inter-granular corrosion. The system comprises a host computer (1), an excitation and receiving module (2), a power amplification module (3), a multi-channel switching circuit (4), an ultrasound transmitting probe (5), and an ultrasound receiving probe (6). The excitation and receiving module (2) is composed of a DSP chip (21), a synchronization module (22), an excitation board (23), and a receiving board (24). The DSP chip is connected with the host computer and outputs to the synchronization module and the excitation board, and the DSP chip reads the signals of the receiving board. With the synchronization module, the signals of DSP are respectively outputted to the excitation board and the receiving board. The excitation board outputs to the ultrasound transmitting probe through the power amplification module and the multi-channel switching circuit. The receiving board reads the signals of the ultrasound transmitting probe through the multi-channel switching circuit. The invention also relates to a nonlinear ultrasonic method for detecting Super304H steel tube inter-granular corrosion by using the system.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

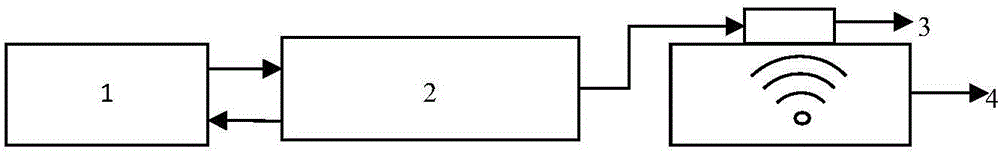

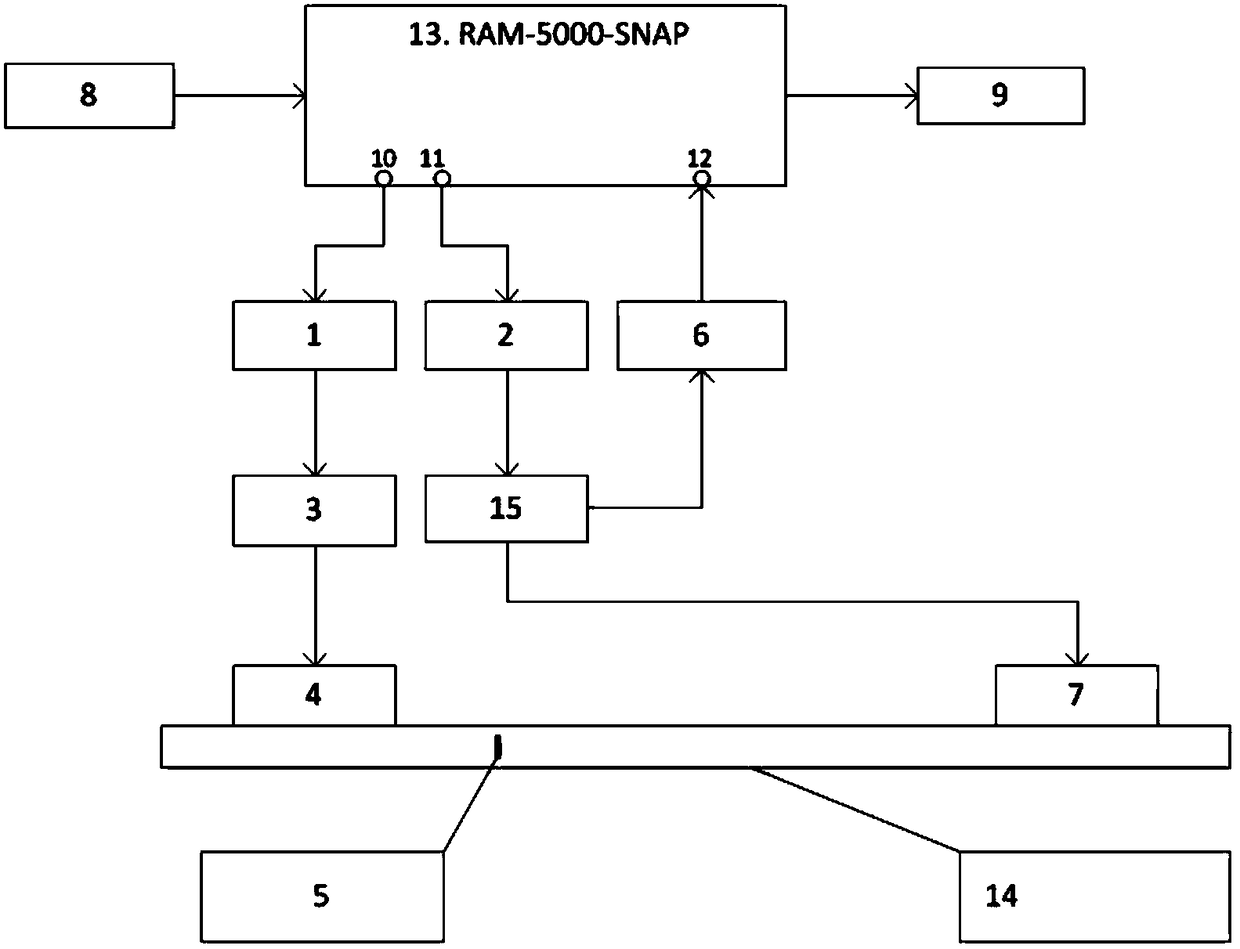

Realization method of nonlinear ultrasonic test instrument analog amplifying circuit and realization device thereof

ActiveCN102969996AMeet the hardware requirementsMultiple-port networksAnalysing solids using sonic/ultrasonic/infrasonic wavesBandpass filteringTwo band

The invention discloses a realization method of a nonlinear ultrasonic test instrument analog amplifying circuit and a realization device of the nonlinear ultrasonic test instrument analog amplifying circuit. The device comprises an arbitrary waveform generator, a variable power amplifier, a broadband ultrasonic sensor, two sets of multi-channel switches, at least two band-pass filter amplifiers, at least one A / D (analog to digital) convertor, an FPGA (field programmable gata array) signal integration processing unit, a microprocessing system and a displayer. The adopted method comprises the following steps of: stimulating and receiving samples at different frequency ranges repeatedly or for once, carrying out hardware compensation, and carrying out integration processing in a concentrated way. The disadvantages of the existing instrument can be overcome, the required ultra-broadband amplifying power of the ultrasonic instrument can be obtained, and each hardware requirement of a nonlinear ultrasonic nondestructive testing technology can be met.

Owner:EDDYSUN (XIAMEN) ELECTRONICS CO LTD

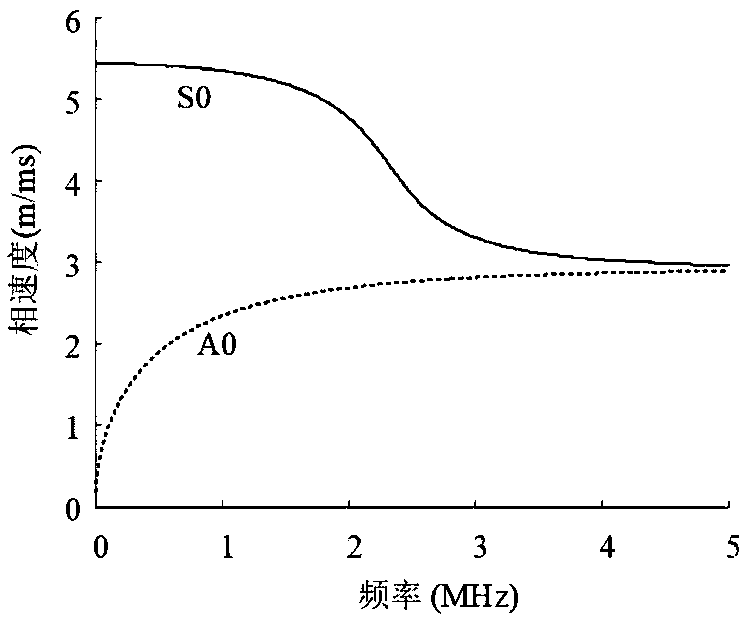

Air coupling Lamb wave nonlinear ultrasonic stress detection method, system and device for fiber reinforced composite material

PendingCN114061805AStructural solutionSolve the problem of broken performanceForce measurementNonlinear ultrasoundAir coupled

The invention discloses an air coupling Lamb wave nonlinear ultrasonic stress detection method, system and device for a fiber reinforced composite material, and belongs to the field of ultrasonic stress detection. Traditional nonlinear ultrasonic stress detection has system errors, and special fiber material stress detection causes damage to the structure and performance of a material. The air coupling Lamb wave nonlinear ultrasonic stress detection method comprises: obtaining a pure Lamb wave mode by processing a to-be-detected fiber reinforced composite material, and the pure Lamb wave comprising a symmetric mode S0 and an antisymmetric mode A0; determining an antisymmetric mode A0 group velocity according to the frequency dispersion curve, and carrying out air coupling ultrasonic detection according to the antisymmetric mode A0; performing air coupling ultrasonic detection on the to-be-detected fiber reinforced composite material to obtain a relative nonlinear coefficient of the to-be-detected fiber reinforced composite material sample, namely obtaining the to-be-detected fiber reinforced composite material sample to realize stress characterization. According to the invention, the influence of a coupling agent is eliminated, the flexibility of stress detection of the fiber reinforced composite material is enhanced, and the detection efficiency is improved.

Owner:HARBIN INST OF TECH

Nonlinear ultrasonic heat treatment process evaluation and optimization method and device

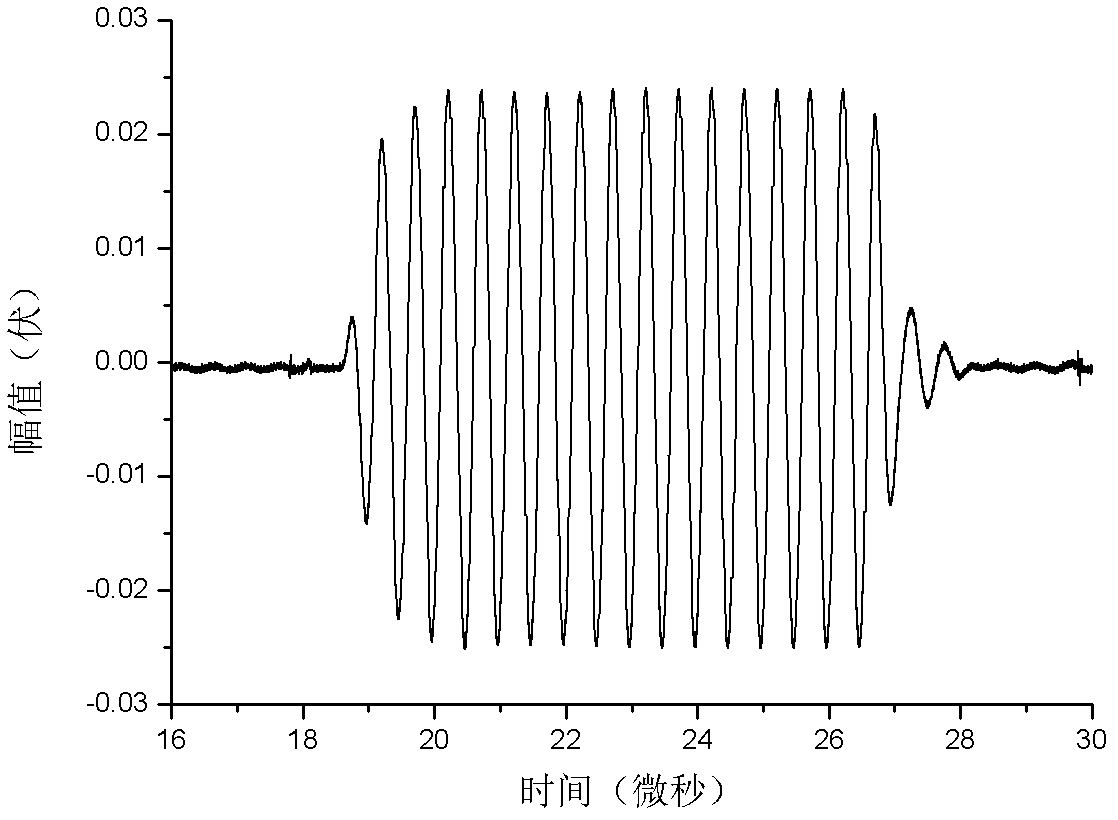

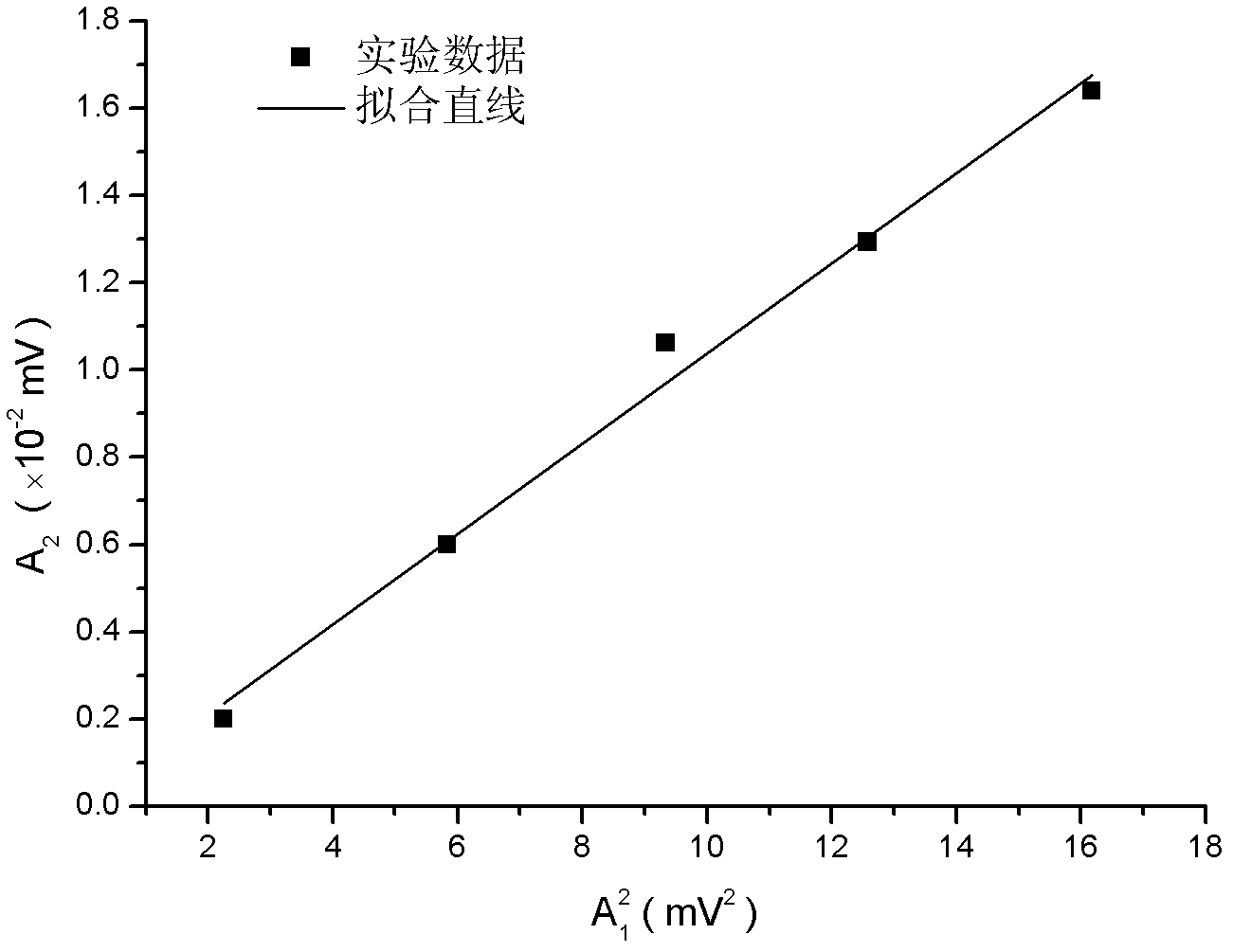

ActiveCN103940910AImprove performanceUniform structureAnalysing solids using sonic/ultrasonic/infrasonic wavesHarmonicNonlinear ultrasound

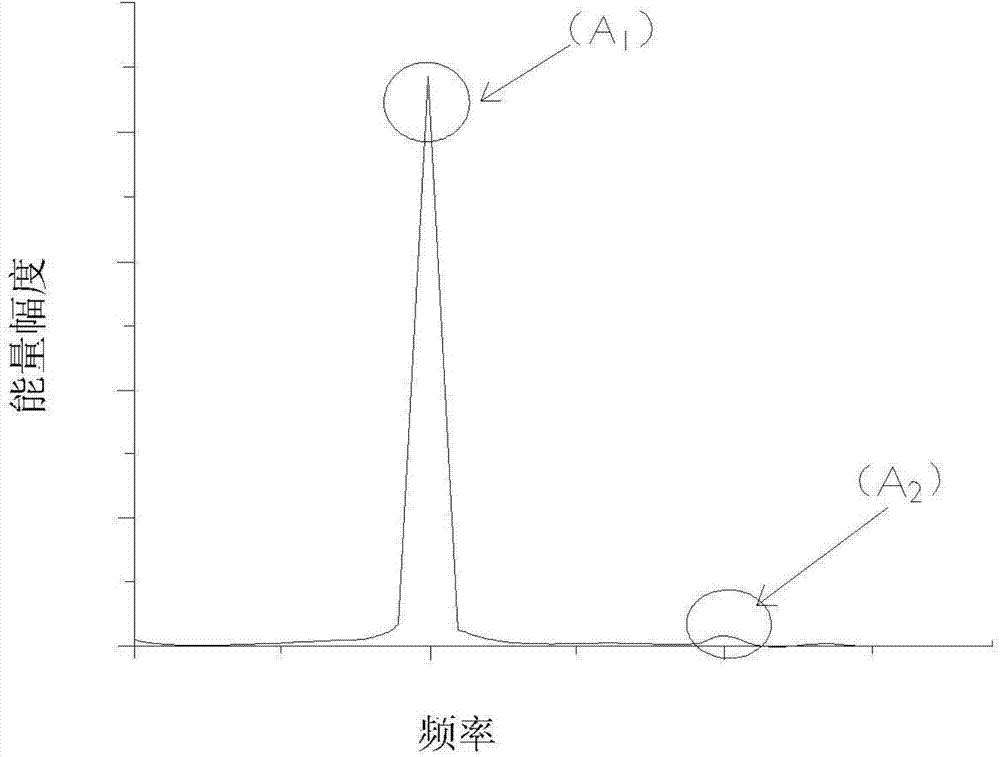

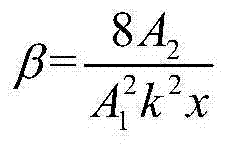

The invention discloses a nonlinear ultrasonic heat treatment process evaluation and optimization method and device. The method comprises the following steps: acquiring an ultrasonic baseband signal A1 propagated in a test piece and amplitude A2 of second harmonics, and calculating a nonlinear acoustic parameter beta' of the test piece, wherein the expression is as shown in the specification; and comparing the difference between nonlinear acoustic parameters of an untreated material and a material subjected to different heat treatment processes based on the obtained relative nonlinear acoustic parameter beta'. The better the heat treatment process is, the more uniform the interior structure of the material subjected to heat treatment is, the performance is greatly improved, and the acoustic nonlinear response of ultrasonic propagation is low. The microstructure of the material can be changed based on heat treatment, a direct correlation exists between the nonlinear response of ultrasonic propagation and the microstructure of the material. According to the method, the heat treatment process effects can be nondestructively, rapidly and effectively evaluated, and the related parameters of heat treatment process are optimized and perfected.

Owner:XIAMEN UNIV

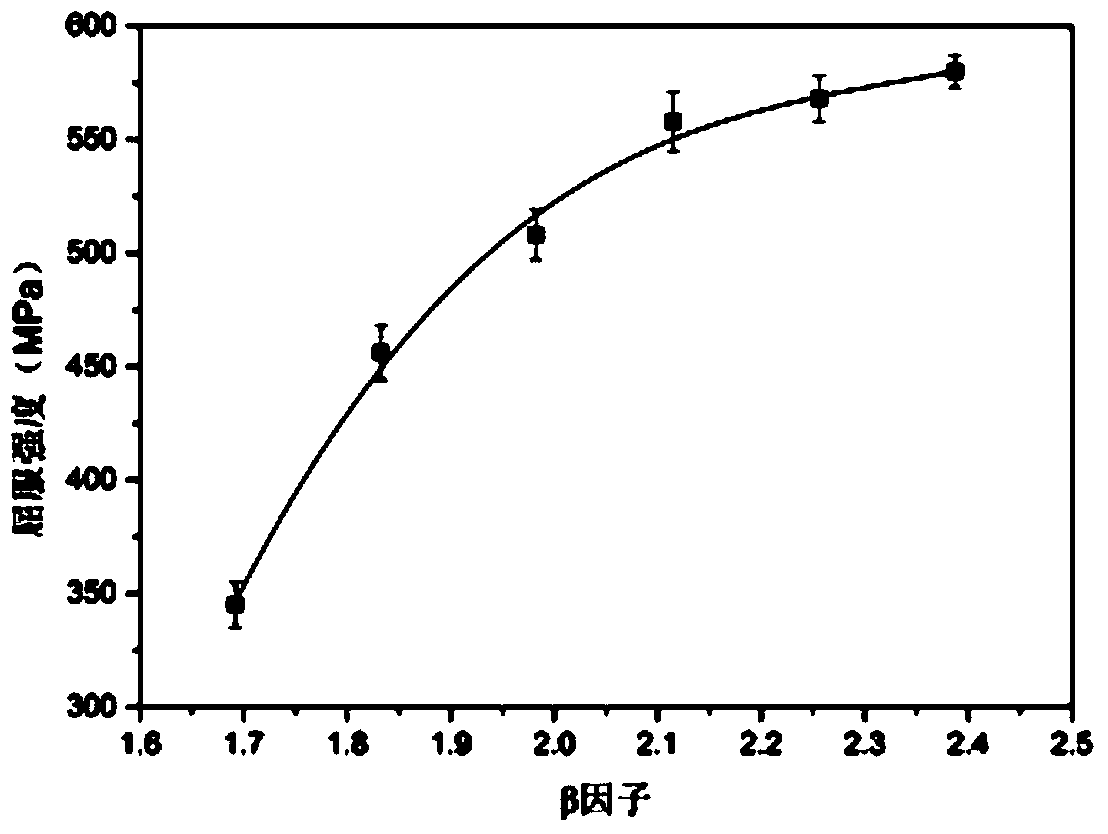

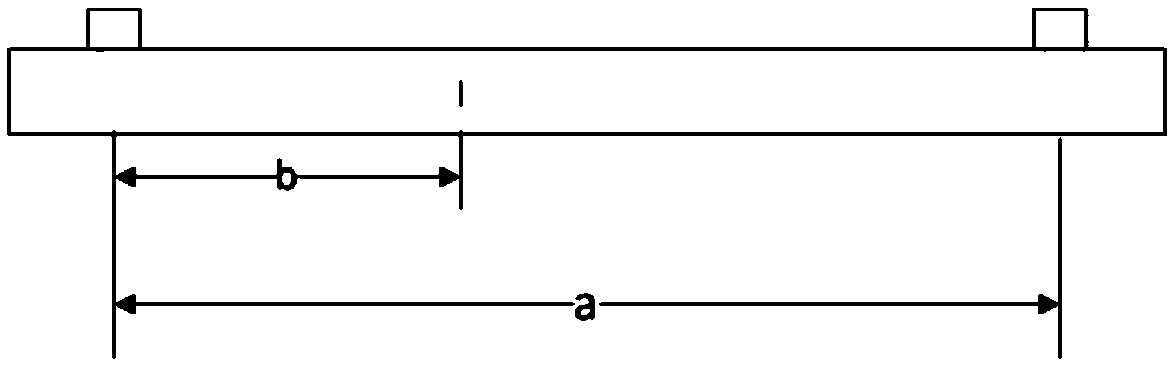

Method for measuring yield strength of Q345 low alloy steel by using nonlinear ultrasonic technique

InactiveCN103713052AYield strength reflectsFast measurementAnalysing solids using sonic/ultrasonic/infrasonic wavesMetallurgyCold hardening

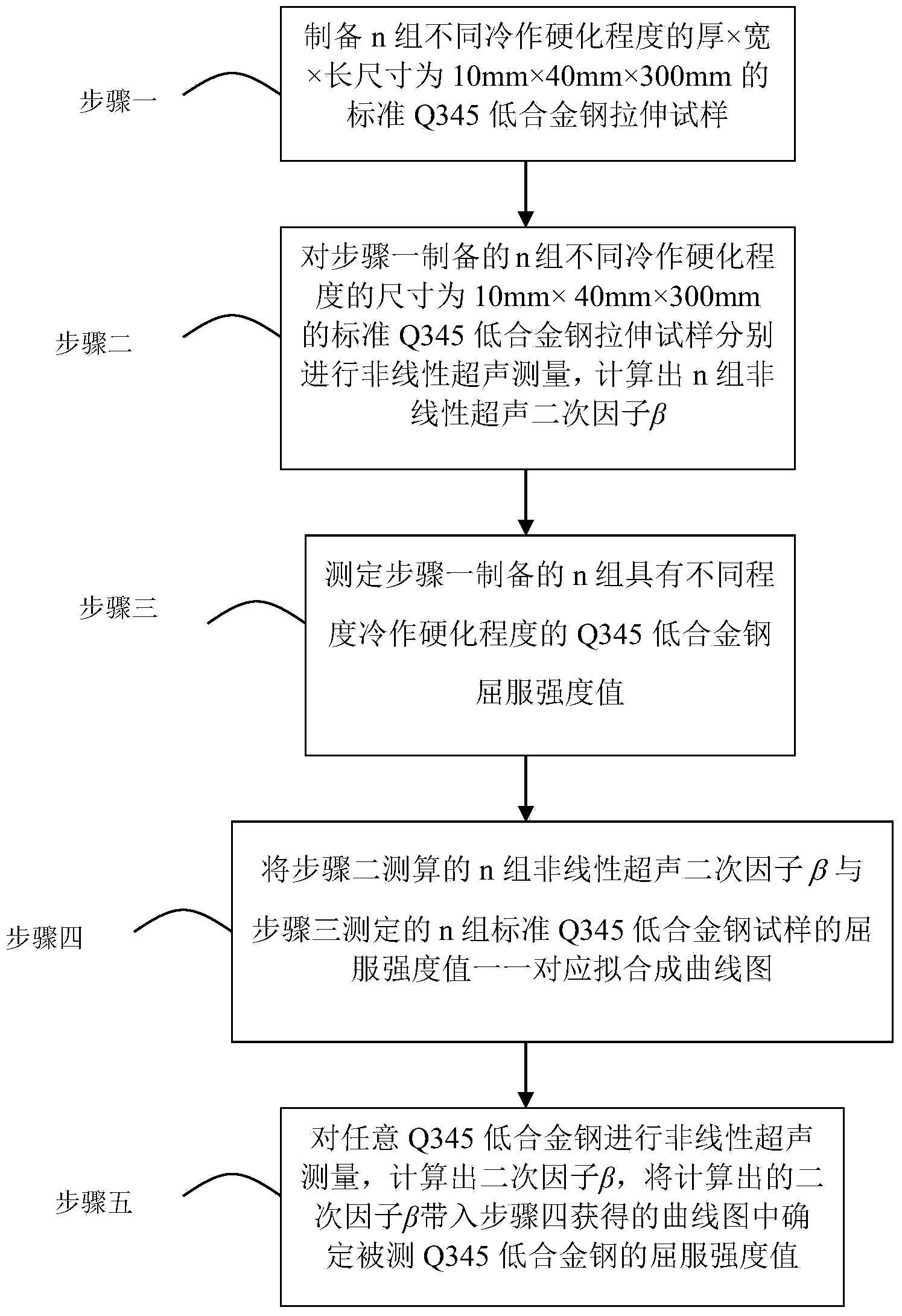

The invention discloses a method for measuring yield strength of Q345 low alloy steel by using a nonlinear ultrasonic technique, which relates to methods for measuring yield strength of Q345 low alloy steel. The method for measuring yield strength of Q345 low alloy steel by using nonlinear ultrasonic technique provided by the invention is used for solving the problems that a traditional steel yield strength measurement method is destructive and the measurement speed is low. The method comprises the following steps: 1. preparing n groups of standard Q345 low alloy steel tensile samples with different cold hardening degrees and with thickness*width*length sizes of 10mm *40mm*300mm; 2. calculating n groups of nonlinear ultrasonic secondary factors beta; 3. measuring the yield strength values of n groups of Q345 low alloy steel; 4. fitting a curve graph; 5. measuring the yield strength value of any Q345 low alloy steel; and the method disclosed by the invention is applied to the field of measurement of yield strength of Q345 low alloy steel.

Owner:STATE GRID CORP OF CHINA +1

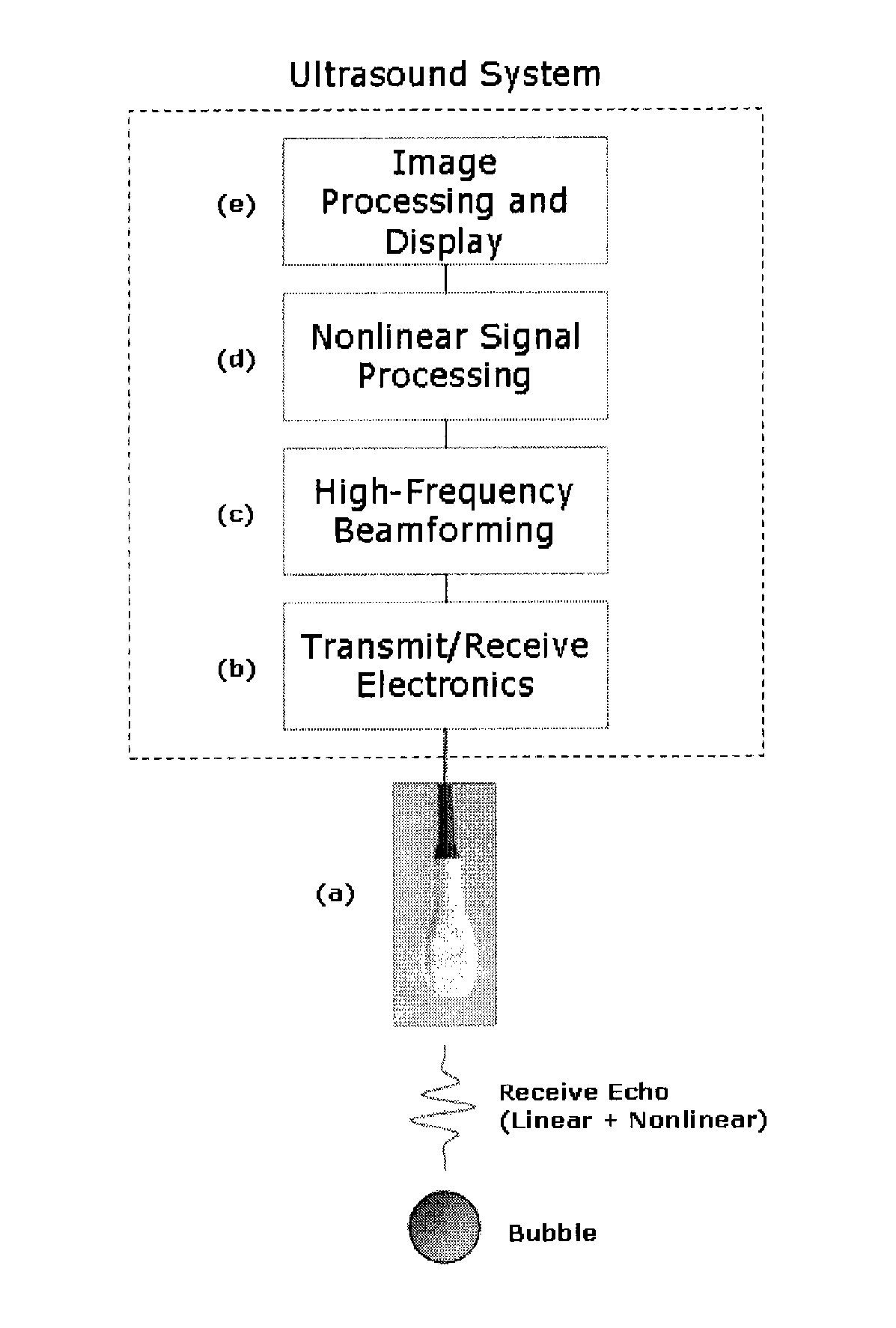

Method for nonlinear imaging of ultrasound contrast agents at high frequencies

InactiveUS20100298709A1High sensitivityReal-time visualizationBlood flow measurement devicesInfrasonic diagnosticsBandpass filteringSonification

This invention employs multiple ultrasound pulse firings of either alternating phase and / or amplitude to detect nonlinear fundamental and subharmonic signals from microbubble contrast agents within living tissue, at high frequencies (≧15 MHz), e.g., with a linear array transducer. It can be shown that the contrast-to-tissue ratio (CTR) decreases with increasing ultrasound frequency because of nonlinear ultrasound propagation in tissue. However, using the subharmonic signal in addition to the nonlinear fundamental harmonic component, rather than the conventional second harmonic used at lower frequencies, provides appreciable signal strength to overcome the limitations of nonlinear tissue propagation. Additionally, the method provides for the ability to switch, at some desired frequency above 20 MHz, into a purely alternating phase inversion acquisition, in combination with bandpass filtering of the subharmonic frequency band, minimizing the losses in CTR as the frequency increases. This maintains contrast sensitivity for more limited fields of view, as penetration depth will be limited at higher frequencies. Thus, within the same micro-ultrasound imaging system, many applications of microbubble detection can be achieved with a wide range of frequencies that covers both resolution and sensitivity requirements.

Owner:VISUALSONICS

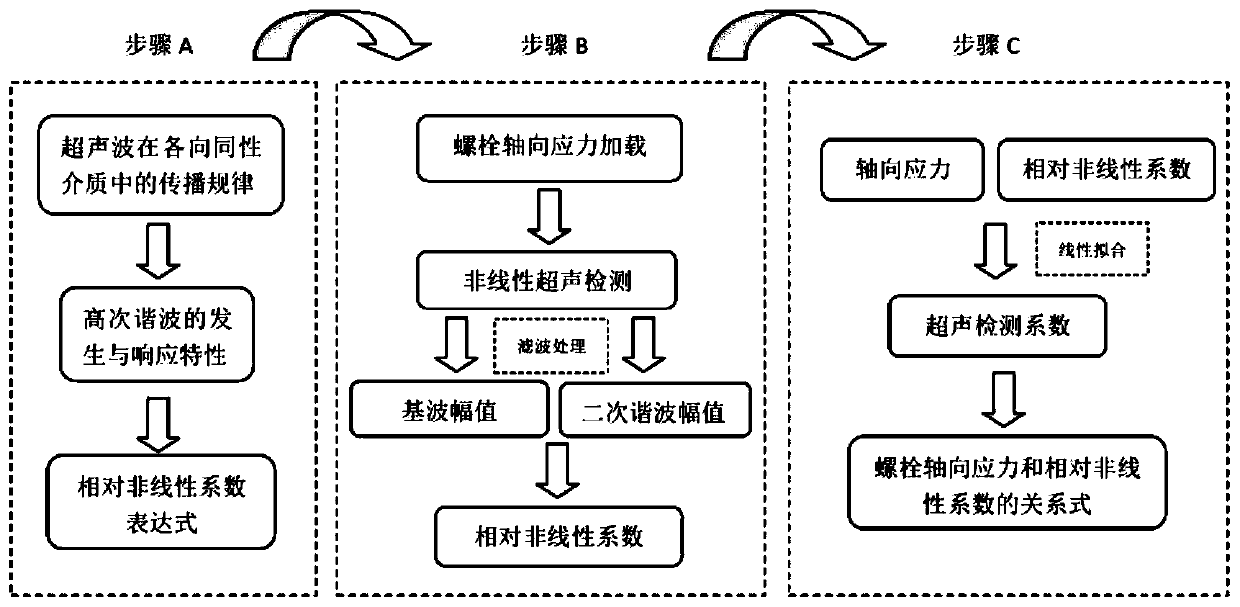

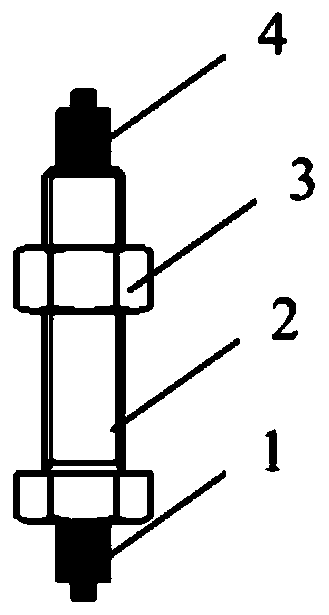

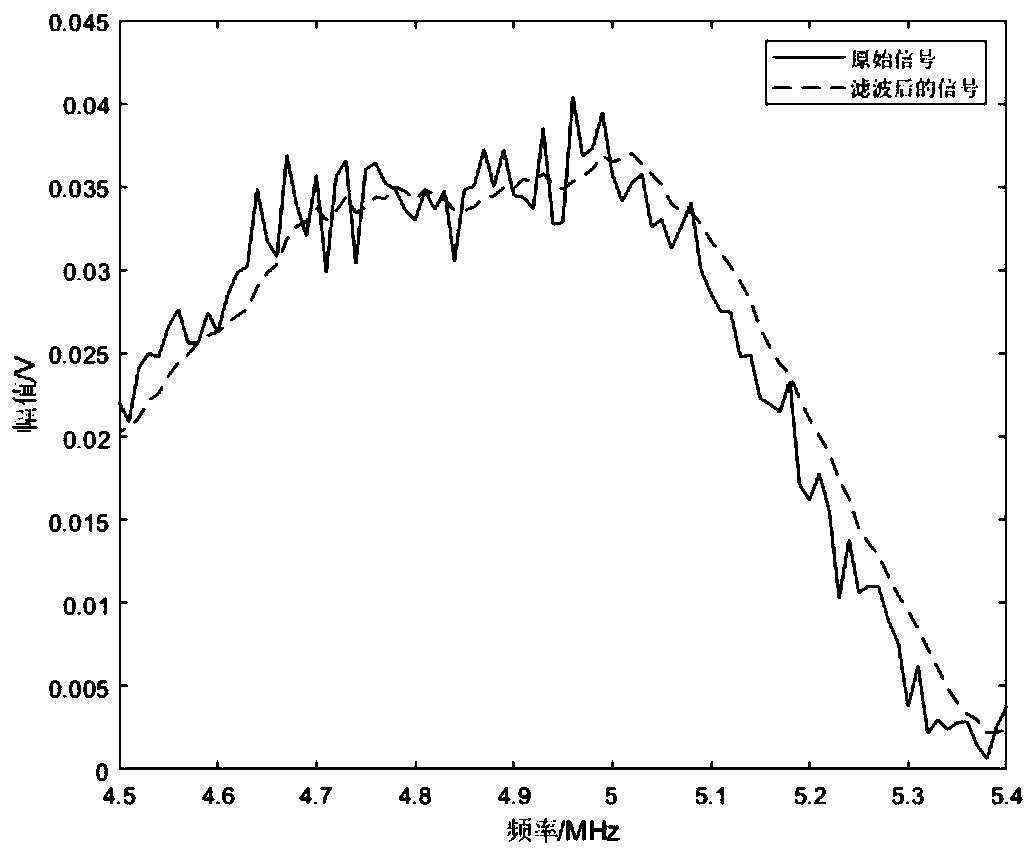

Nonlinear ultrasonic detection method for axial stress of bolt

InactiveCN111442869AImprove accuracyAvoid measuringMeasurement of force componentsNonlinear ultrasoundEngineering

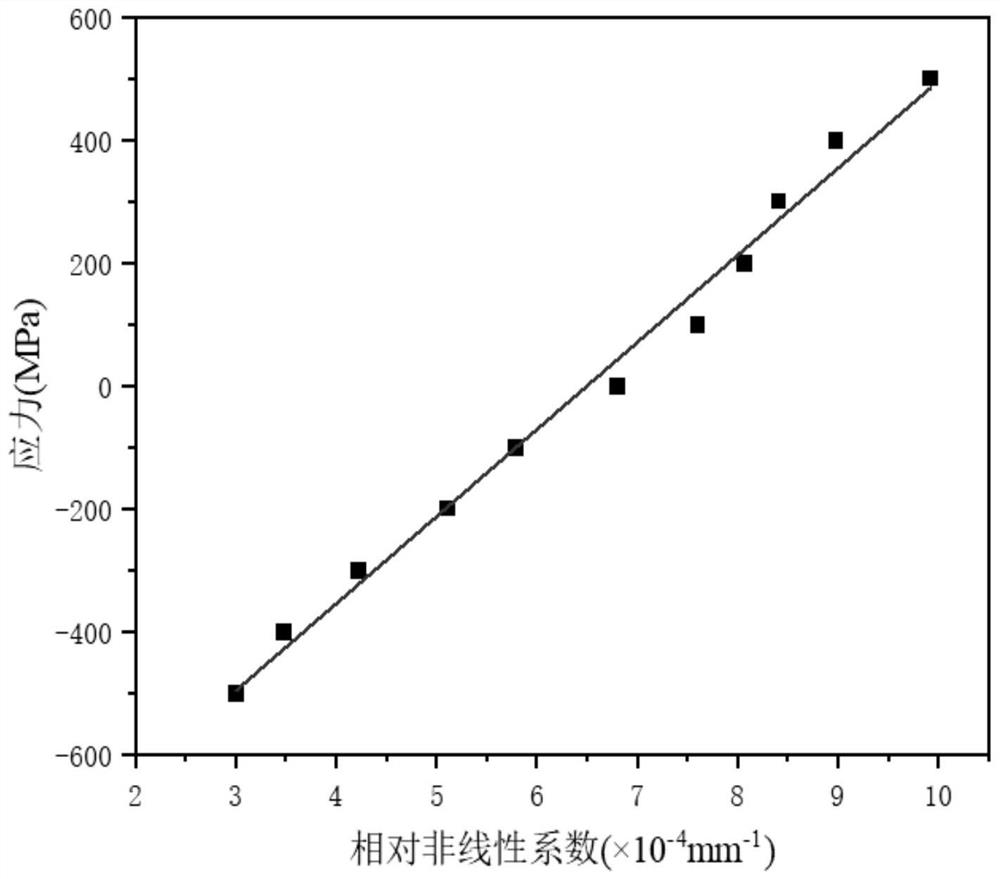

The invention provides a nonlinear ultrasonic detection method for axial stress of a bolt. The method comprises the following implementation steps: step A, establishing a relation model between a second harmonic amplitude and a fundamental wave amplitude on the basis of a propagation theory of ultrasonic waves in an isotropic medium to obtain an expression of relative nonlinear coefficients; stepb, carrying out an axial stress loading experiment on a bolt sample, carrying out nonlinear ultrasonic detection, and calculating relative nonlinear coefficients under different stress states; and step c, fitting the loaded axial stress and the corresponding relative nonlinear coefficients, determining an ultrasonic detection coefficient of the axial stress of the bolt, and finally obtaining a relational expression of the axial stress of the bolt and the relative nonlinear coefficients. By means of the steps, nonlinear ultrasonic detection of the axial stress of the bolt can be realized, the axial stress of the bolt can be rapidly and accurately detected with the method, and the accuracy and the practicability of the axial stress detection technology of the bolt are improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

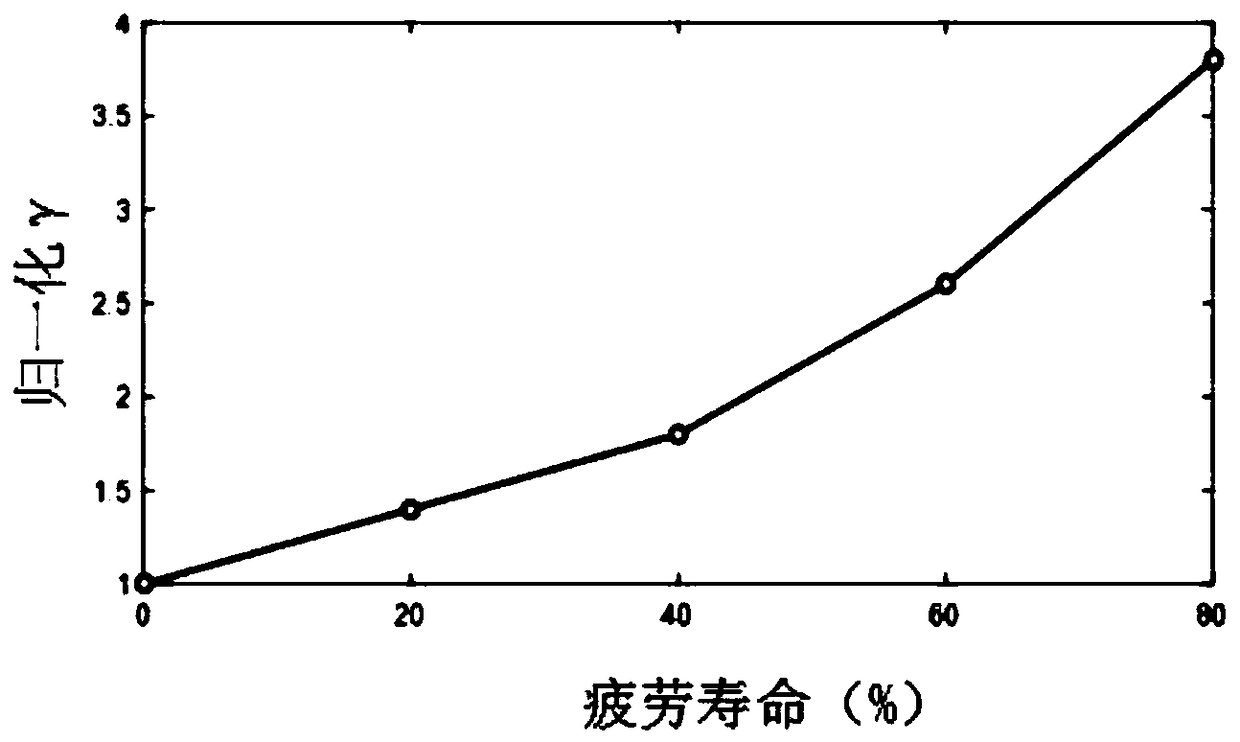

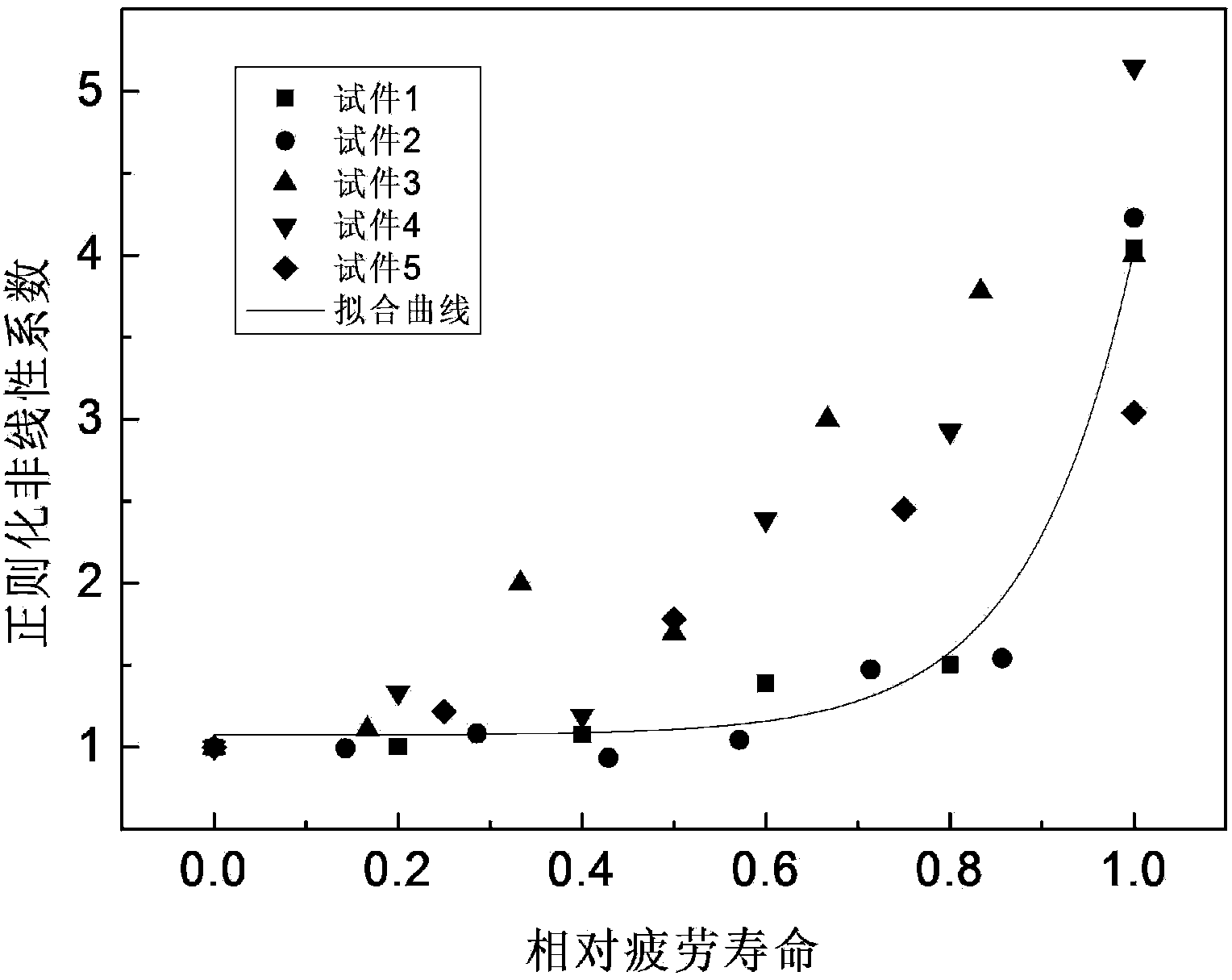

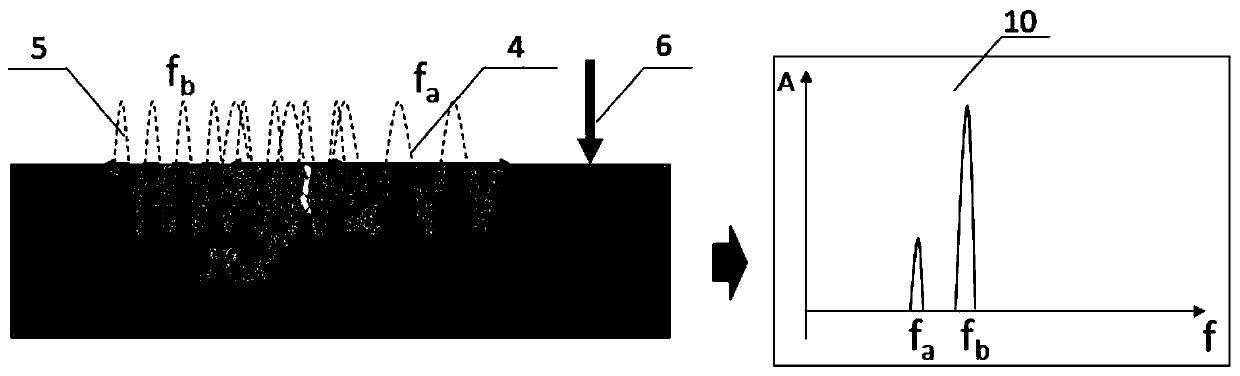

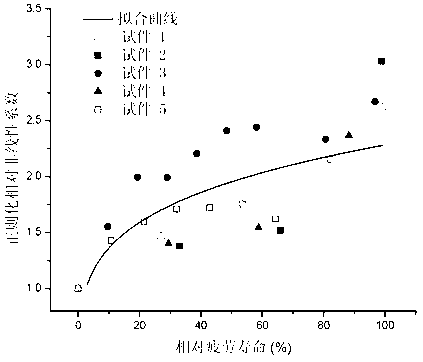

Nonlinear ultrasound evaluating method for impact fatigue damage of metal bonding interface

InactiveCN103776902AGuaranteed safe operationAnalysing solids using sonic/ultrasonic/infrasonic wavesFatigue damageUltrasound attenuation

The invention discloses a nonlinear ultrasound evaluating method for impact fatigue damage of a metal bonding interface, belonging to the field of ultrasonic nondestructive detection. According to the nonlinear ultrasound evaluating method, the defect of insensitivity in material mechanical performance degradation by parameters such as sound velocity, attenuation and impedance of ultrasonic waves is overcome, and the impact damage degree is objectively evaluated through a nonlinear coefficient. A testing method comprises the steps: firstly, testing an initial nonlinear coefficient of a material bonding interface, secondly, performing an impact test on a bonding structure, determining a nonlinear coefficient once every impacting for a certain times until the bonding structure is damaged; and regularizing the nonlinear coefficient, and establishing a curve relationship of the regularized nonlinear coefficient and the relative fatigue life. As a result, the regularized nonlinear coefficient is increased with the increase of the relative fatigue life. According to the nonlinear ultrasound evaluating method, a fatigue life relation of the metal bonding structure under an impact is established, an effective nondestructive detection method is provided for a large industrial bonding facility bearing the impact in future, and a great significance is obtained for ensuring the safety operation of industrial equipment and predicting the service life of the equipment.

Owner:BEIJING JIAOTONG UNIV

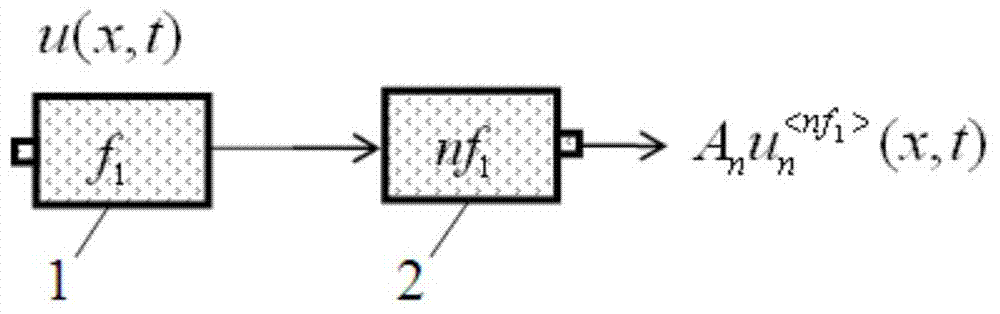

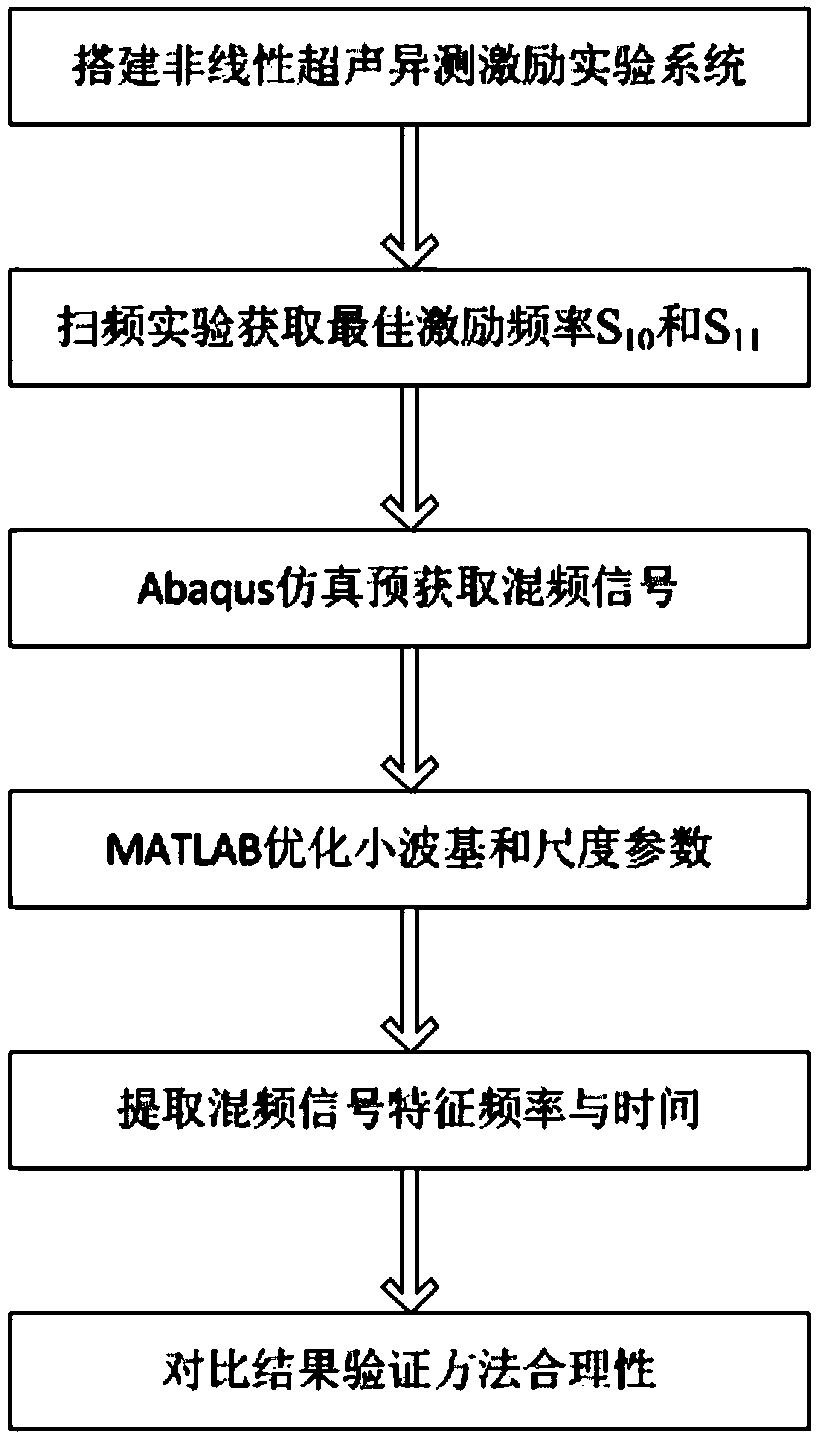

Wavelet-based microcrack location method by utilizing nonlinear ultrasonic opposite-side exciting mixing frequency

InactiveCN108709934AReduce wasteIncrease profitAnalysing solids using sonic/ultrasonic/infrasonic wavesFatigue damageTime–frequency analysis

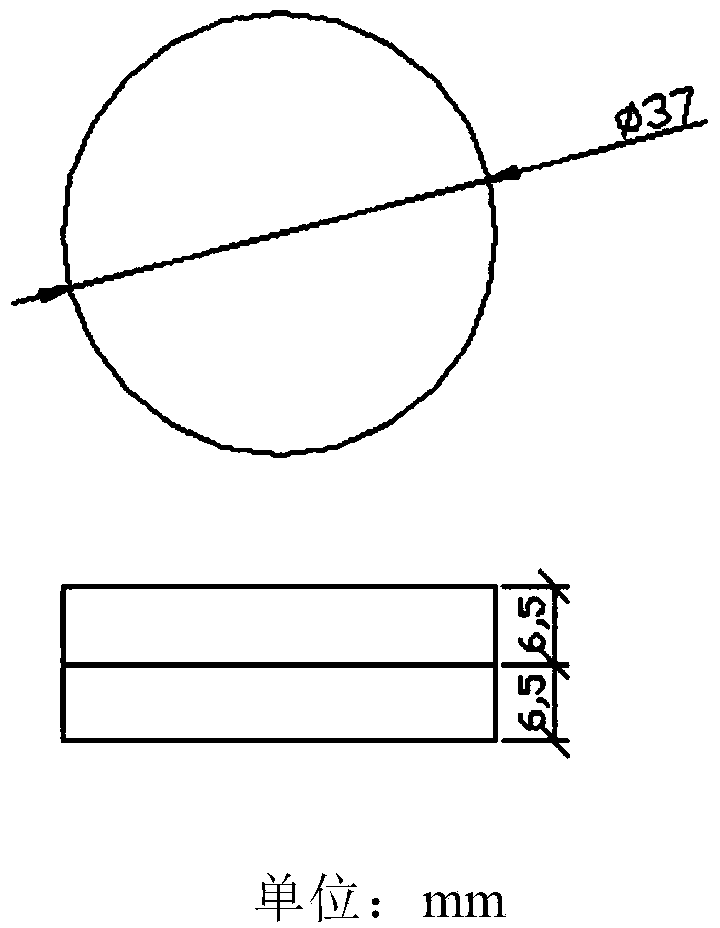

The invention discloses a wavelet-based microcrack location method by utilizing nonlinear ultrasonic opposite-side exciting mixing frequency. The wavelet-based microcrack location method includes: respectively arranging a first sensor and a second sensor on two sides of a to-be-tested piece to form nonlinear opposite-side lamb wave excitation; acquiring a mixing frequency signal generated, by a fatigue crack existing in the to-be-tested piece, under the action of opposite-side excitation; by means of wavelet transformation, subjecting the mixing frequency signal to time-frequency analysis, andextracting characteristic frequency and emerging time of the characteristic frequency to realize recognition and location of a fatigue damage structure. The wavelet-based microcrack location method has the advantages that the wavelet transformation theory and the MATLAB (matrix laboratory) software are combined and applied to a nondestructive testing field, a method for detecting and locating microcracks in metal sheets from a time-frequency analysis angle is provided; by combining excitation with experiment and optimizing parameters continuously, the optimal parameters capable of representing the characteristic frequency of the mixing frequency signal can be acquired, and accuracy and feasibility of a wavelet transformation based nonlinear opposite-side lamb wave exciting mixing frequency locating method are indicated in a result.

Owner:TIANJIN UNIV

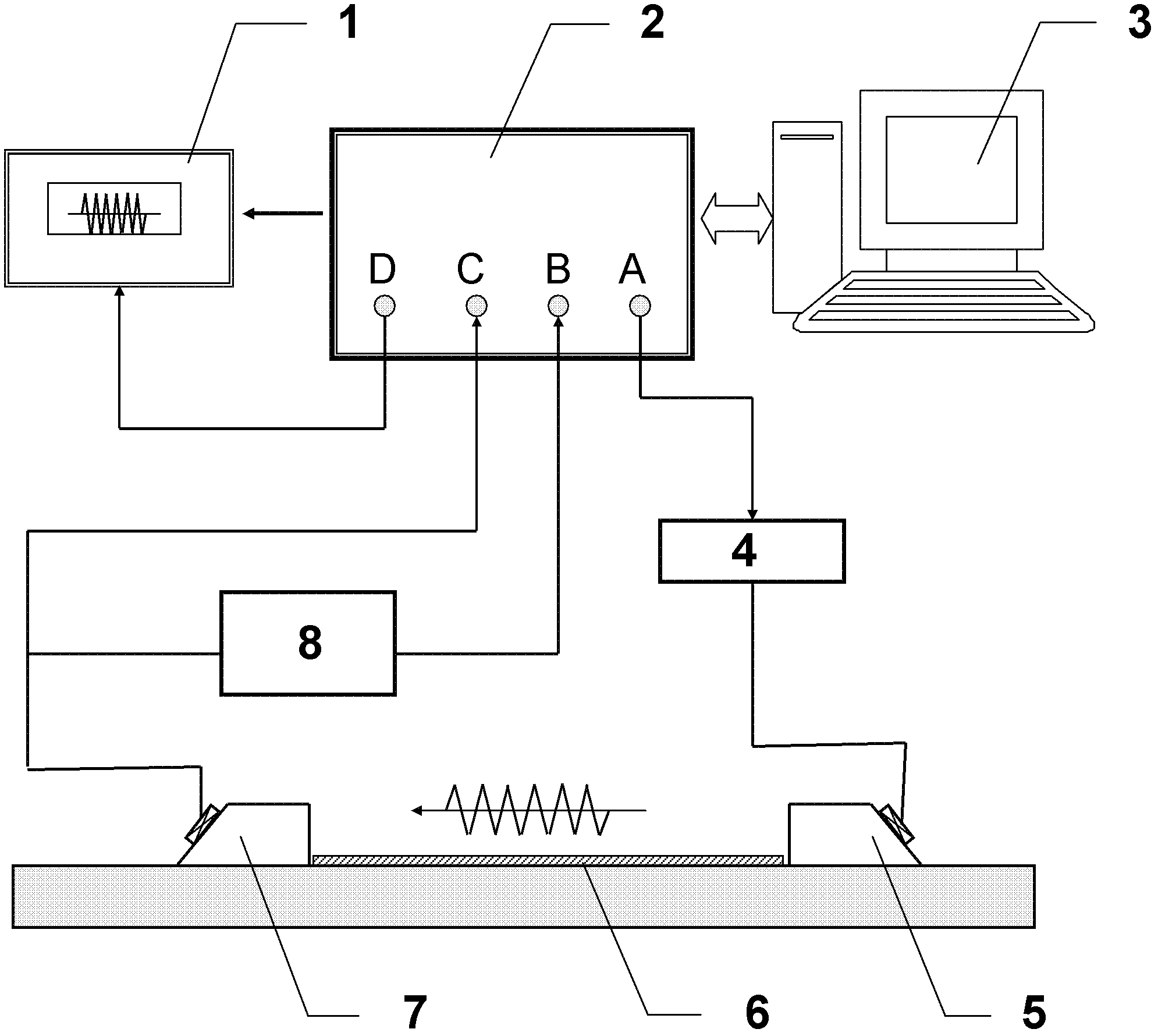

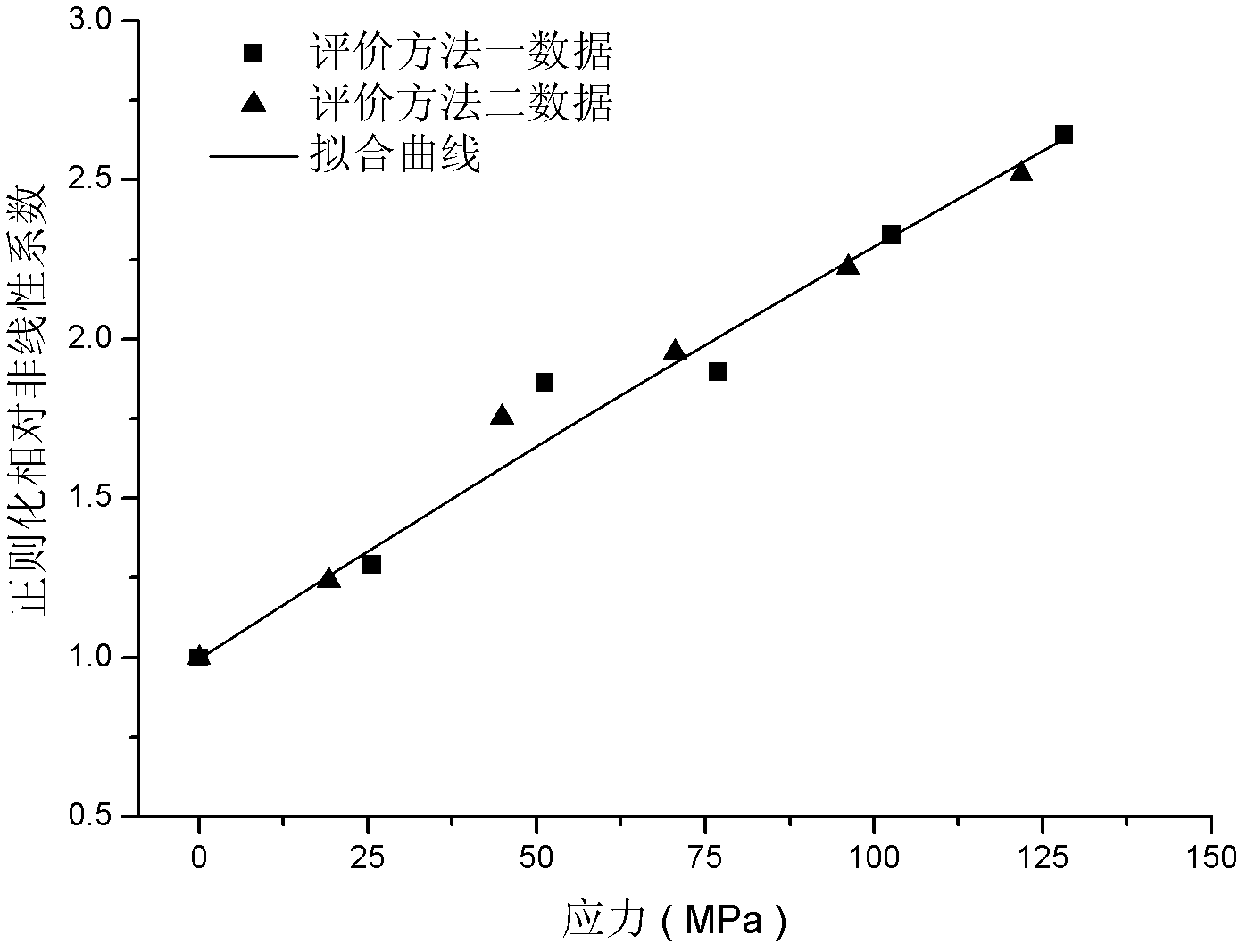

Nonlinear ultrasonic evaluation method of metal material plating damage

InactiveCN102621227AEnsure the safety of industrial operationAvoid major operational accidentsAnalysing solids using sonic/ultrasonic/infrasonic wavesMetallic materialsNonlinear ultrasound

The invention provides a nonlinear ultrasonic evaluation method of metal material plating damage, which relates to metal material plating damage testing so as to determine the damage degree of the plating. The method comprises the following steps of: selecting a plating test piece; testing the plating test piece by using a nonlinear ultrasonic testing system so as to obtain an initial relative nonlinear coefficient; carrying out loading on the plating test piece for five times so as to obtain five loaded stresses; carrying out nonlinear ultrasonic testing on the five loaded plating test pieces so as to obtain five relative nonlinear coefficients; dividing the relative nonlinear coefficients by the initial relative nonlinear coefficient so as to regularize the relative nonlinear coefficients as vertical coordinates; representing the initial and five regularized relative nonlinear coefficient values in a coordinate by using the stresses as horizontal ordinates so as to obtain a relationship curve diagram between the regularized relative nonlinear coefficients and the stresses, wherein damage exists in the plating test piece during regularizing the relative nonlinear coefficient of more than 1 and less than the regularized relative nonlinear coefficient when the plating has a crack; and the larger the relative nonlinear coefficient is and the larger the damage degree is.

Owner:BEIJING JIAOTONG UNIV

A method for nonlinear imaging of ultrasound contrast agents at high frequencies

InactiveCN102458257ABlood flow measurement devicesInfrasonic diagnosticsBandpass filteringSonification

This invention employs multiple ultrasound pulse firings of either alternating phase and / or amplitude to detect nonlinear fundamental and subharmonic signals from microbubble contrast agents within living tissue, at high frequencies (=>15 MHz), e.g., with a linear array transducer. It can be shown that the contrast-to-tissue ratio (CTR) decreases with increasing ultrasound frequency because of nonlinear ultrasound propagation in tissue. However, using the subharmonic signal in addition to the nonlinear fundamental harmonic component, rather than the conventional second harmonic used at lower frequencies, provides appreciable signal strength to overcome the limitations of nonlinear tissue propagation; Additionally, the method provides for the ability to switch, at some desired frequency above 20 MHz, into a purely alternating phase inversion acquisition, in combination with bandpass filtering of the subharmonic frequency band, minimizing the losses in CTR as the frequency increases.

Owner:VISUALSONICS

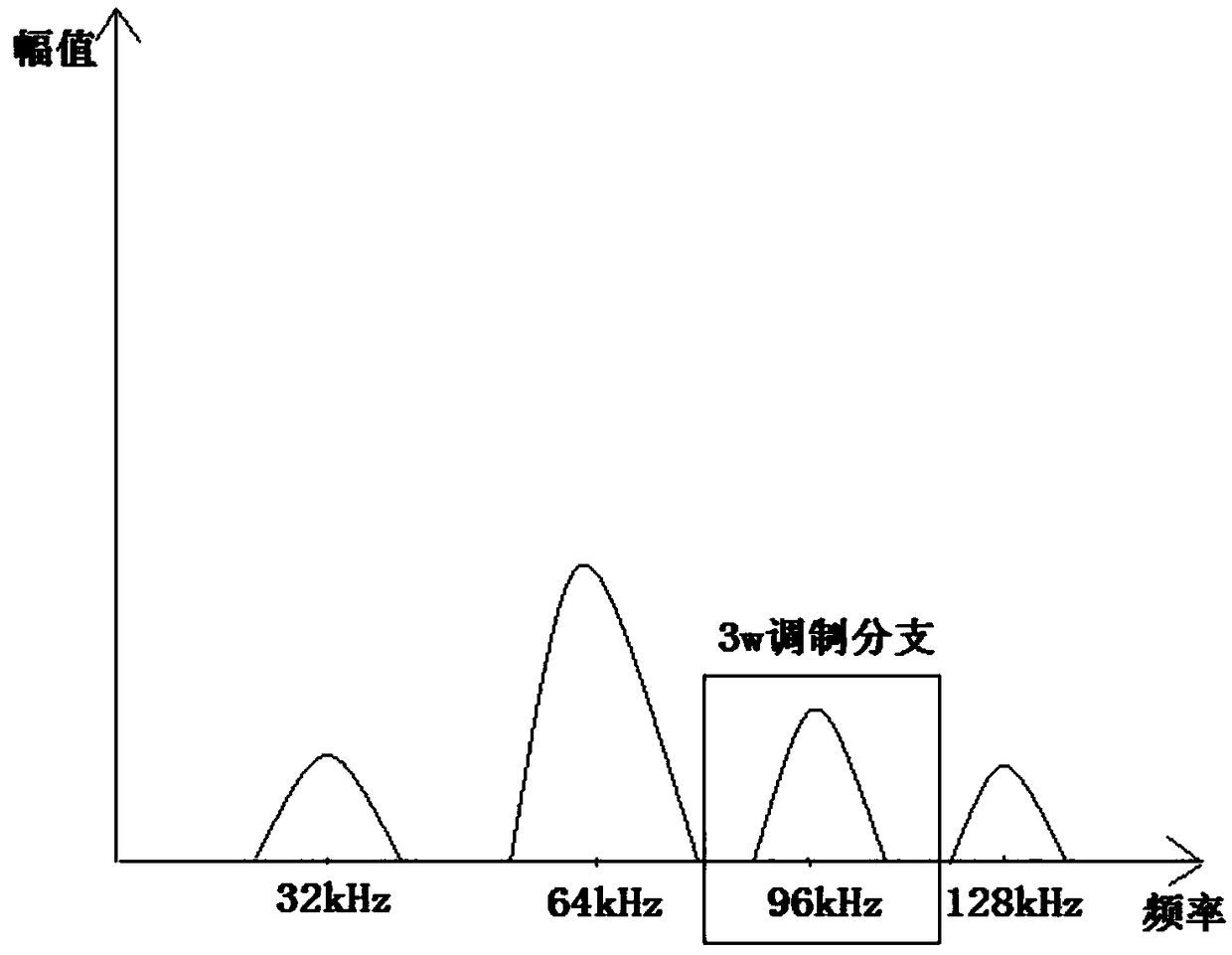

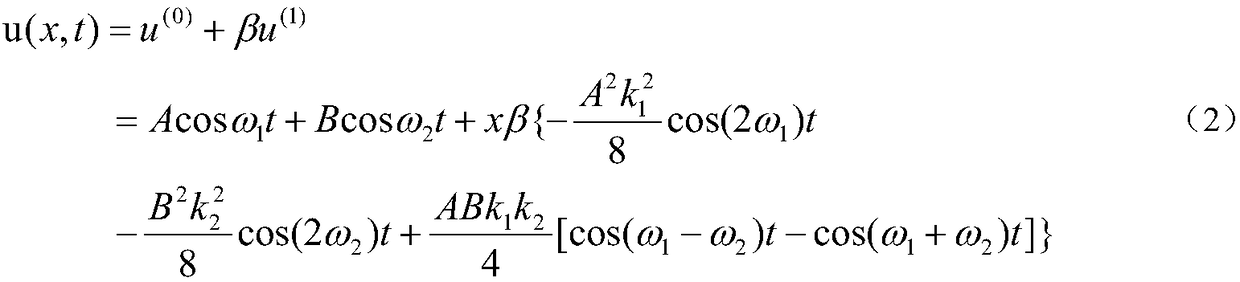

Method for detecting microcracks of pipeline through frequency multiplication modulation and time reversal of nonlinear ultrasonic guided wave

ActiveCN109187754AAchieving Adaptive FocusQuick checkAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationSonificationNonlinear ultrasound

The invention discloses a method for detecting micro-cracks of a pipeline through a frequency multiplication modulation and time reversals of a nonlinear ultrasonic guided wave, and belongs to the field of nondestructive detection. The method comprises the following steps: 1) signal excitation: using two groups of emission ultrasonic transducers, wherein a first group of emission ultrasonic transducer excitating a single low-frequency, and a second group of emission ultrasonic transducer excitating a double high-frequency; 2) signal reception: the second group of emission transducer simultaneously receiving signals as a reception transducer; 3) nonlinear analysis: selecting a time reversal window function according to a sound field modulation side lobe frequency of omega1+omega2=3omega1; 4) signal time reversal: reversing intercepted time reversal signals, and sending the intercepted time reversal signals by the excitation signal transducers; and 5) energy focusing: focusing the signals at the micro-cracks. According to the method for detecting micro-cracks of the pipeline through the frequency multiplication modulation and time reversals of the nonlinear ultrasonic guided wave, the identification of micro-cracks is realized by utilizing the advantages that the propagation distance of the ultrasonic guided wave is long and the nonlinear ultrasound is highly sensitive to micro-cracks, meanwhile utilizing the characteristic of adaptive focusing of the time reversal algorithm; and the crack size is determined by utilizing a nonlinear ultrasonic parameter.

Owner:山东省特种设备检验研究院集团有限公司

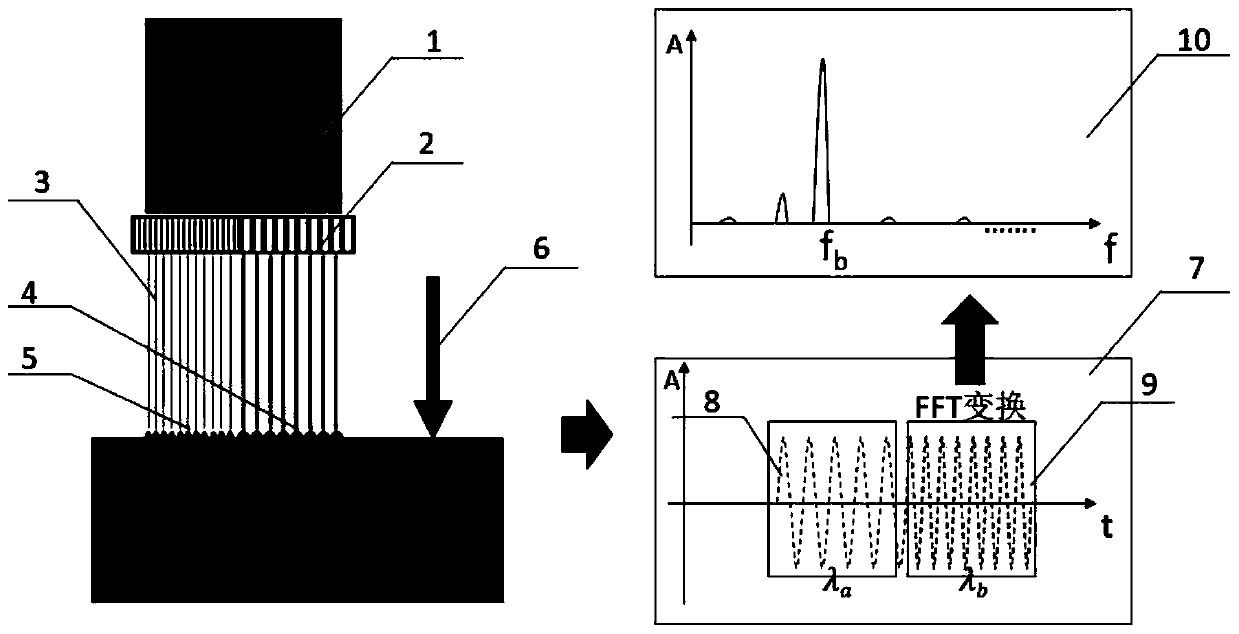

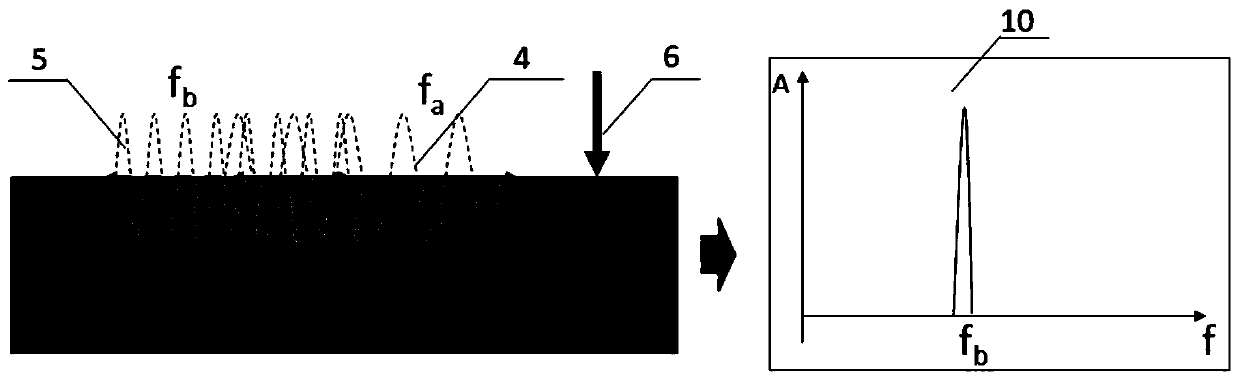

Material near-surface macro-micro defect integrated ultrasonic detection method based on spatial modulation laser ultrasonic sound spectrum

ActiveCN111505116AImprove detection coverageIntegrated detection realizationAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalFrequency spectrumSignal on

The invention discloses a material near-surface macro-micro defect integrated ultrasonic detection method based on a spatial modulation laser ultrasonic sound spectrum. Firstly, a double-spacing optical mask plate is used for enabling a high-energy pulse laser beam irradiated to the surface of a measured material to form two kinds of periodically distributed grid-shaped laser spots; two columns ofultrasonic surface waves with different frequencies are excited at the same time in a measured area. Linear or non-linear interaction occurs in a measured area; the laser ultrasonic detection unit receives a surface wave signal on one side of the surface; fourier transform is carried out on the rear half section of the received surface wave signal pulse sequence to obtain a spatial modulation laser ultrasonic frequency spectrum curve, and finally integrated detection of linear ultrasonic and nonlinear ultrasonic is achieved according to the two fundamental frequencies in the frequency spectrum and the components of the nonlinear frequency mixing components of the fundamental frequencies.

Owner:XI AN JIAOTONG UNIV

Ultrasonic nondestructive evaluation of early-stage fatigue damage of bonding interface

InactiveCN103278567AEnsure the safety of industrial operationAvoid major operational accidentsAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalFatigue damageFatigue loading

The invention relates to an ultrasonic nondestructive evaluation of the early-stage fatigue damage of a bonding interface, and relates to a method for evaluating the early-stage fatigue damage of the bonding interface by utilizing an ultrasonic detecting technology. The method comprises the following steps: selecting a test specimen with a bonding structure; measuring the initial nonlinear coefficient of the bonding interface by utilizing a nonlinear ultrasonic testing system; carrying out the tensile fatigue loading on the test specimen and performing nonlinear ultrasonic testing for every thirty times until the test specimen is damaged; dividing the number of the final fatigue loading times by the number of the fatigue loading times, so as to obtain the value of the relative fatigue life; dividing the initial nonlinear coefficient by the nonlinear coefficient, so as to perform normalization; then repeating the operations by selecting another four test specimens; and by taking the normalized nonlinear coefficient as the y-coordinate and the value of the relative fatigue life as the x-coordinate, expressing the normalized nonlinear coefficient values of the five test specimens in the coordinate, so as to obtain a fitting relationship curve chart of the normalized nonlinear coefficient and the relative fatigue life, wherein the greater the normalized nonlinear coefficient is, the more serious the fatigue damage degree of the bonding interface is.

Owner:BEIJING JIAOTONG UNIV

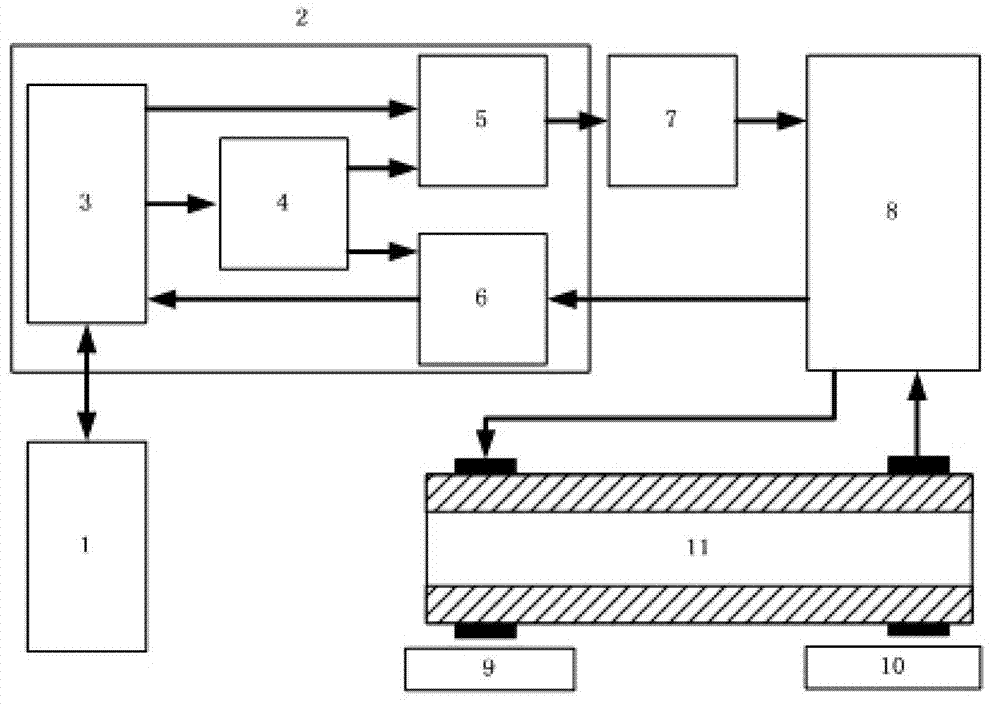

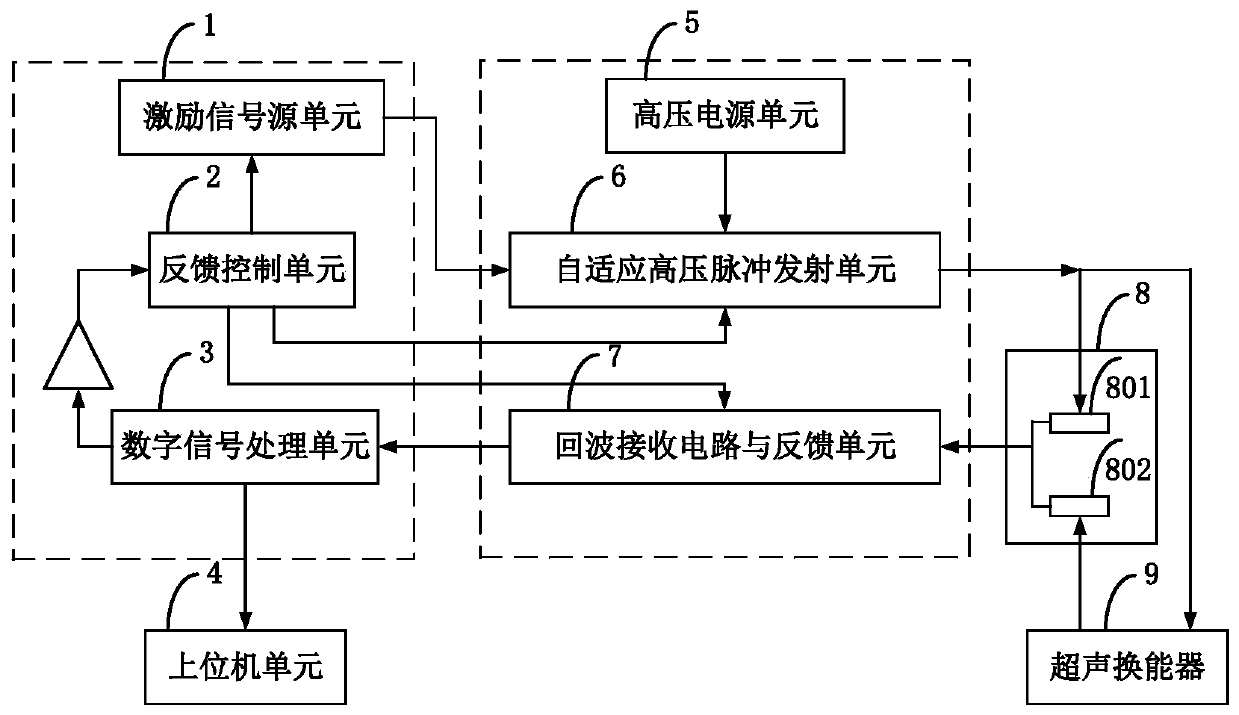

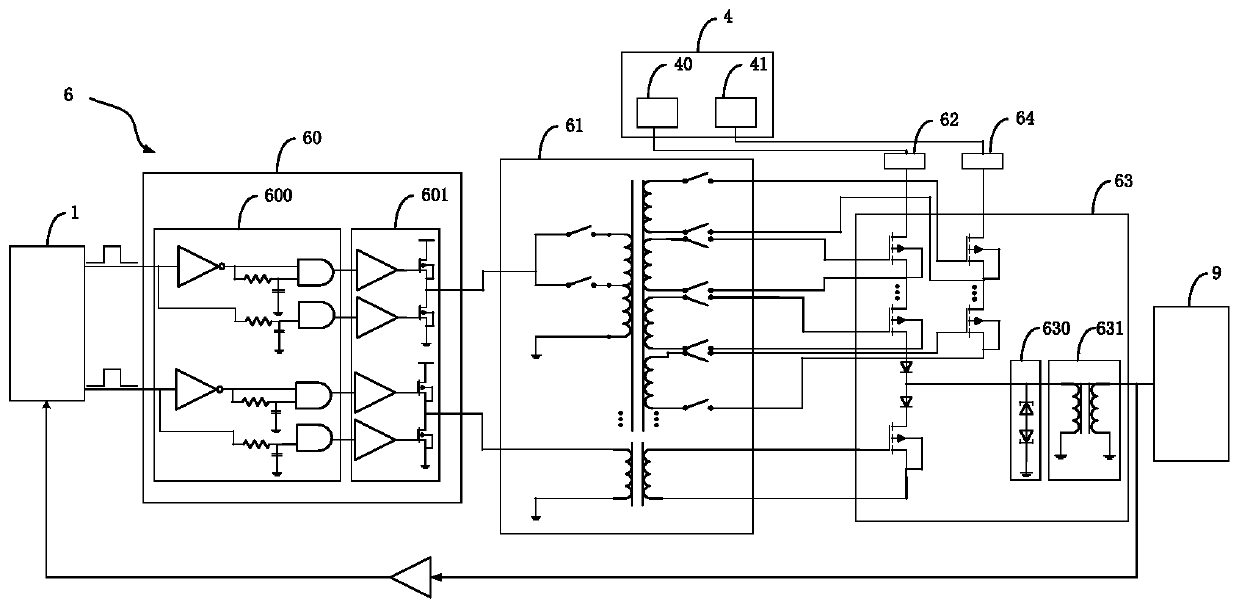

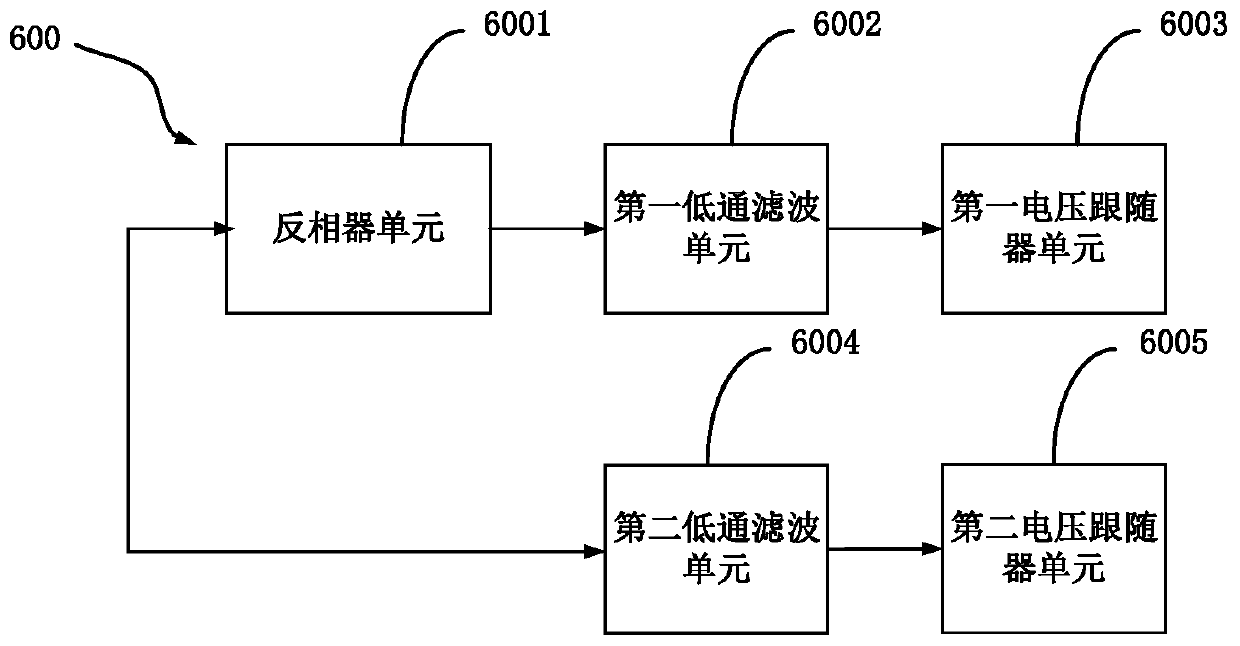

High-power self-adaptive ultrasonic pulse emission and nonlinear ultrasonic guided wave measurement device

ActiveCN111157623AGuaranteed stabilityEnsure safetyAnalysing solids using sonic/ultrasonic/infrasonic wavesResponse signal detectionDigital signal processingVoltage pulse

The invention discloses a high-power self-adaptive ultrasonic pulse emission and nonlinear ultrasonic guided wave measurement device. The device comprises an excitation signal source unit, a self-adaptive high-voltage pulse emission unit, an echo receiving circuit and feedback unit, a digital signal processing unit and a feedback control unit. The output end of the excitation signal source unit isconnected with the input end of the self-adaptive high-voltage pulse transmitting unit and used for providing excitation signals of the system. The output end of the self-adaptive high-voltage pulsetransmitting unit is connected with the input ends of the ultrasonic transducer, the echo receiving circuit and the feedback unit through the switch unit. The output ends of the echo receiving circuitand the feedback unit are connected with the input end of the digital signal processing unit, and the output end of the digital signal processing unit is connected with the input end of the feedbackcontrol unit. According to the invention, the intensity of a transmitted signal and the sensitivity of a received signal can be improved, the noise influence is inhibited, and the characteristics of various ultrasonic transducers are adapted.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com