Material near-surface macro-micro defect integrated ultrasonic detection method based on spatial modulation laser ultrasonic sound spectrum

A technology of laser ultrasound and space modulation, which is applied in the use of sound waves/ultrasonic waves/infrasonic waves for material analysis, use of sound waves/ultrasonic waves/infrasonic waves for solid analysis, and material analysis. and other problems, to achieve the effect of improving detection coverage, good accessibility, and strong detection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

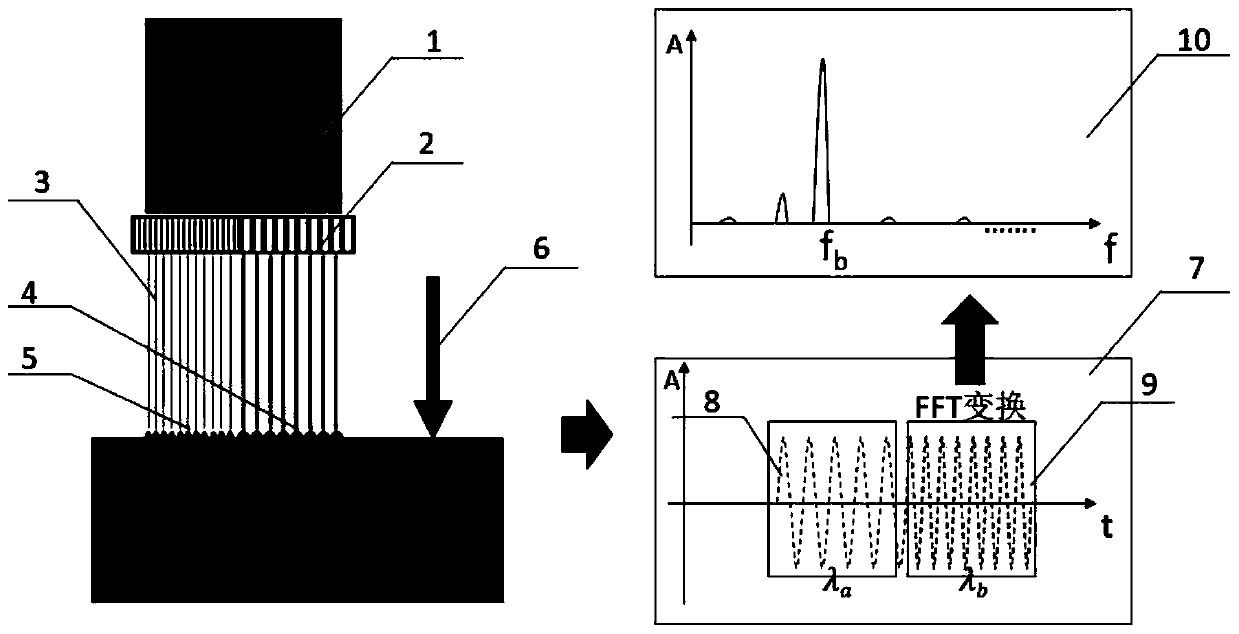

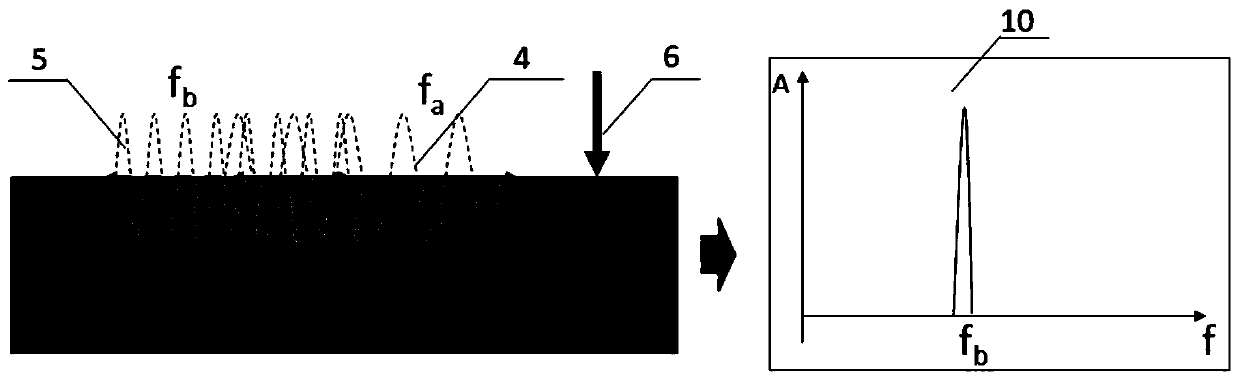

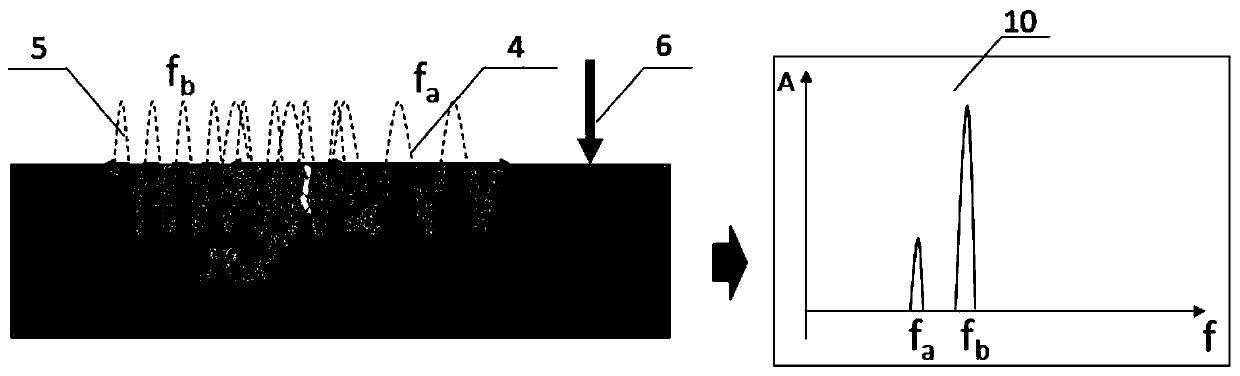

[0019] The present invention is an integrated ultrasonic detection method for macro and micro defects near the surface of materials based on spatially modulated laser ultrasonic sound spectrum, such as figure 1 As shown, first, the double-pitch optical mask 2 is used to make the high-energy pulsed laser beam 1 irradiated on the surface of the material to be tested form two kinds of grid-shaped laser spots 3 with periodic distribution, and simultaneously excite the laser beams with wavelengths λ and λ in the measured area. a and lambda b (respectively corresponding to the first center frequency f a and the second center frequency f b ) of the first row of ultrasonic surface waves 4 and the second row of ultrasonic surface waves 5, and then the laser ultrasonic detection unit 6 receives the surface wave signal 7 on the surface side of the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com