Wafer defect detection optimization method and device

A defect detection and optimization method technology, which is applied in the semiconductor field, can solve the problems of low sampling coverage and achieve the effect of improving sampling efficiency and sampling coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

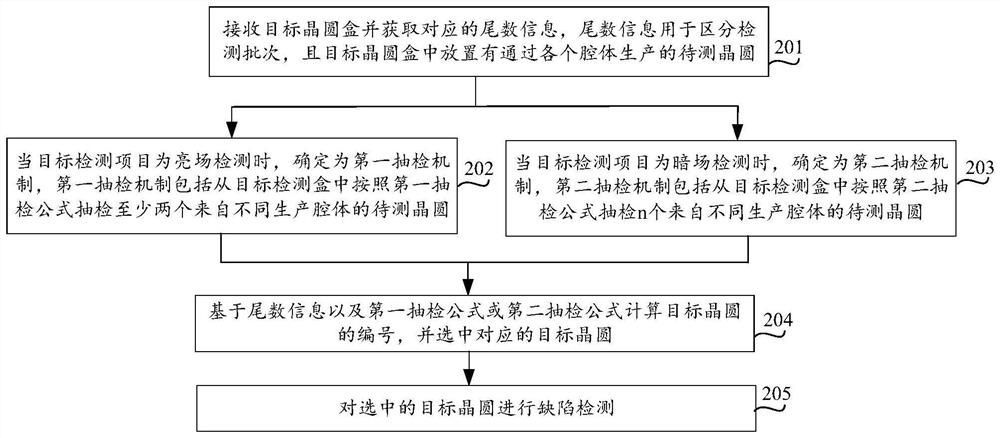

[0016] In order to make the objectives, technical solutions and advantages of the present application clearer, the embodiments of the present application will be further described in detail below with reference to the accompanying drawings.

[0017] As used herein, "plurality" refers to two or more. "And / or", which describes the association relationship of the associated objects, means that there can be three kinds of relationships, for example, A and / or B, which can mean that A exists alone, A and B exist at the same time, and B exists alone. The character " / " generally indicates that the associated objects are an "or" relationship.

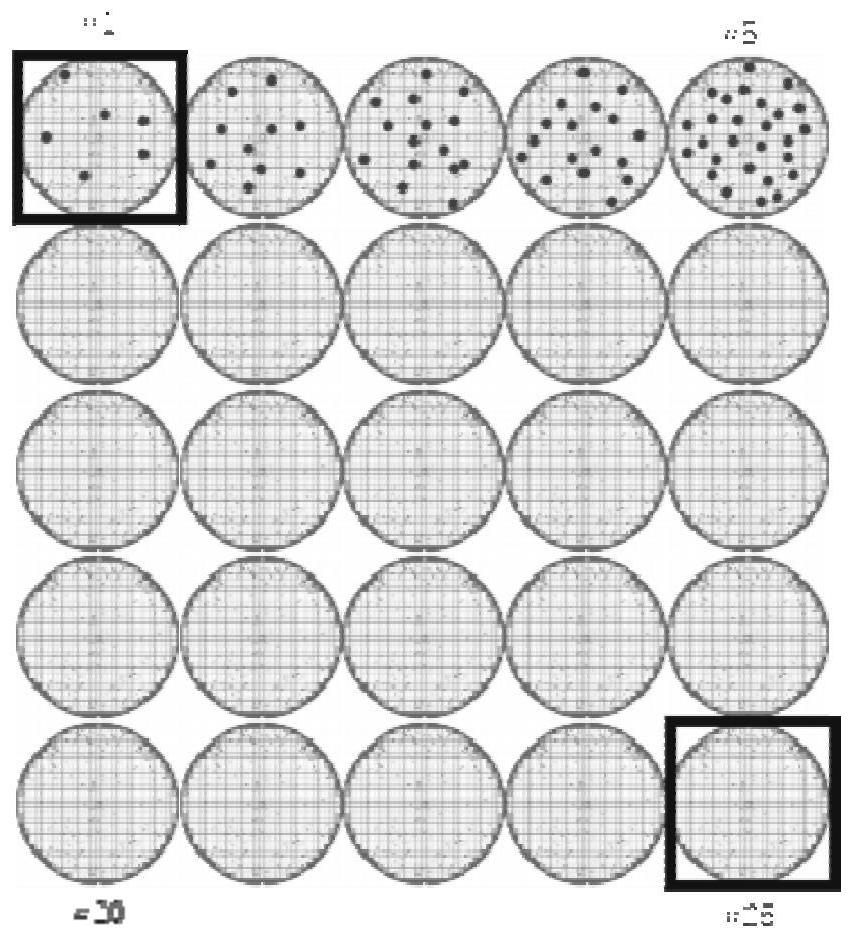

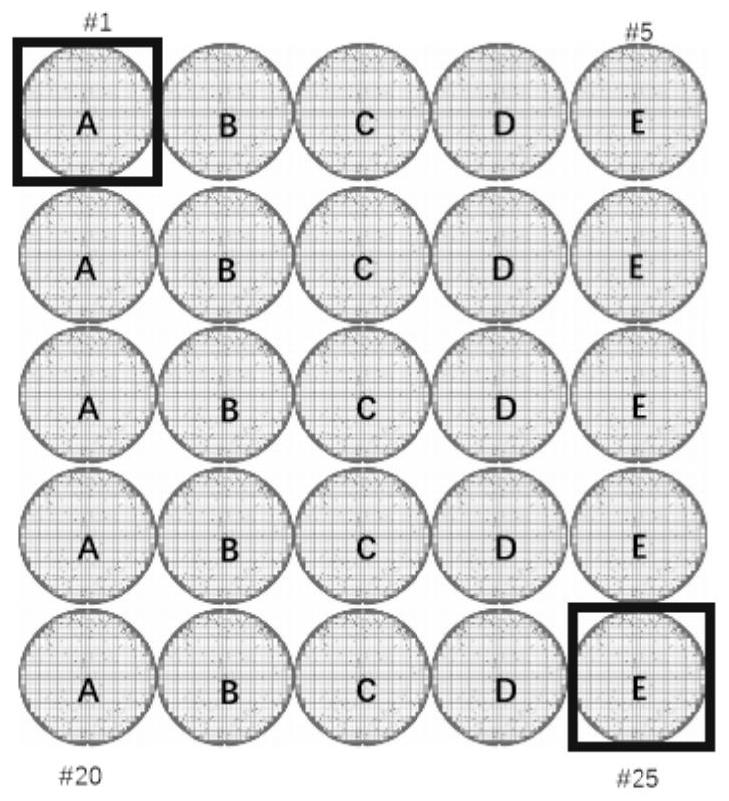

[0018] in related technologies such as figure 1 As shown, there are 25 wafers to be tested in the wafer cassette. These wafers to be tested are from different cavities of the production machine. The wafer batches produced in different cavities may have differences in accuracy and quality. The defect detection at the stage is to select the corr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com