Method for detecting microcracks of pipeline through frequency multiplication modulation and time reversal of nonlinear ultrasonic guided wave

A nonlinear ultrasonic and time-reversal technology, which is applied in the generation of ultrasonic/sonic/infrasonic waves, the analysis of solids using sonic/ultrasonic/infrasonic waves, and the material analysis using sonic/ultrasonic/infrasonic waves. Failure, safety hazards and other problems, to achieve the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0050] A method for detecting pipeline microcracks by frequency-multiplying modulated nonlinear ultrasonic guided wave time-reversal, comprising the following steps:

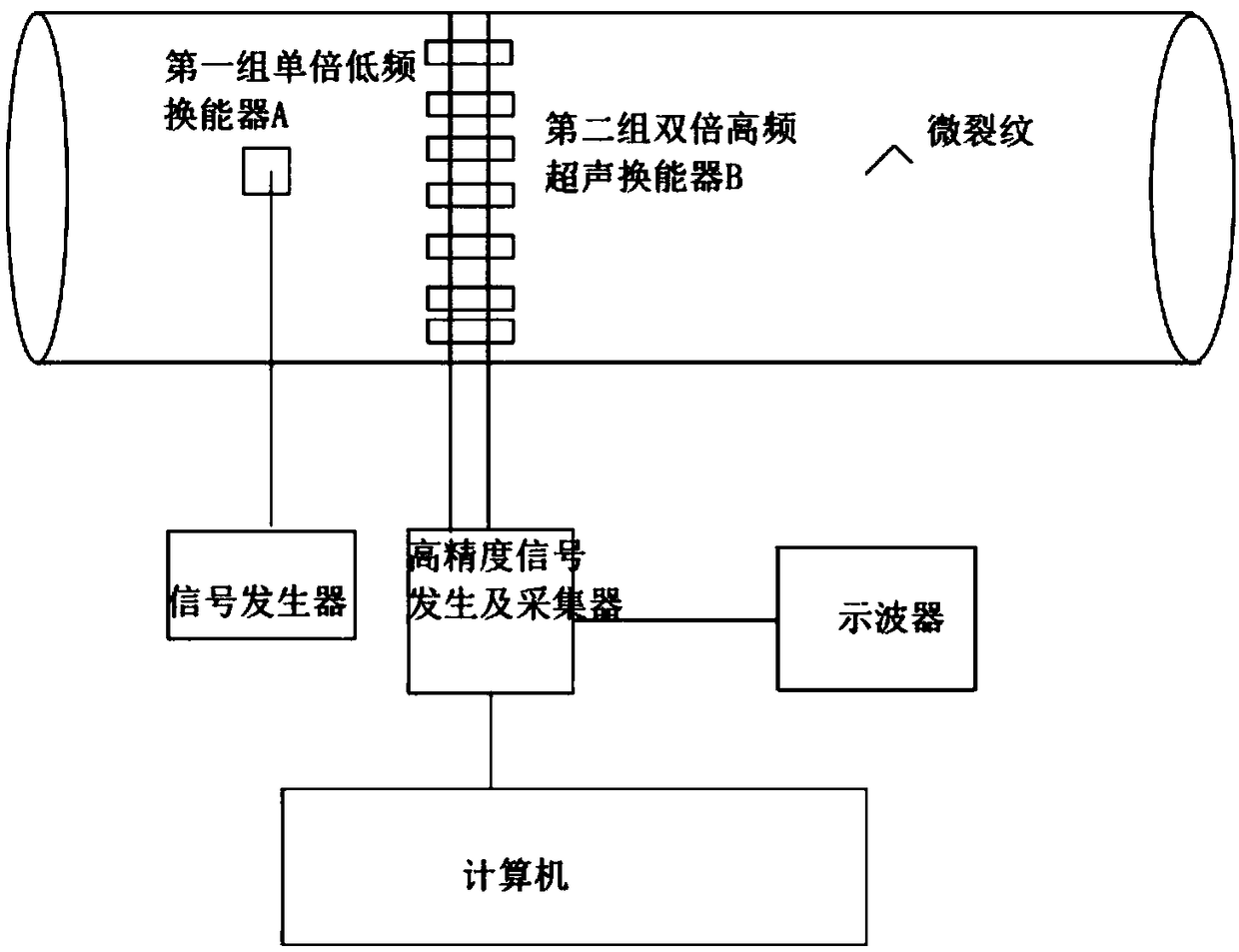

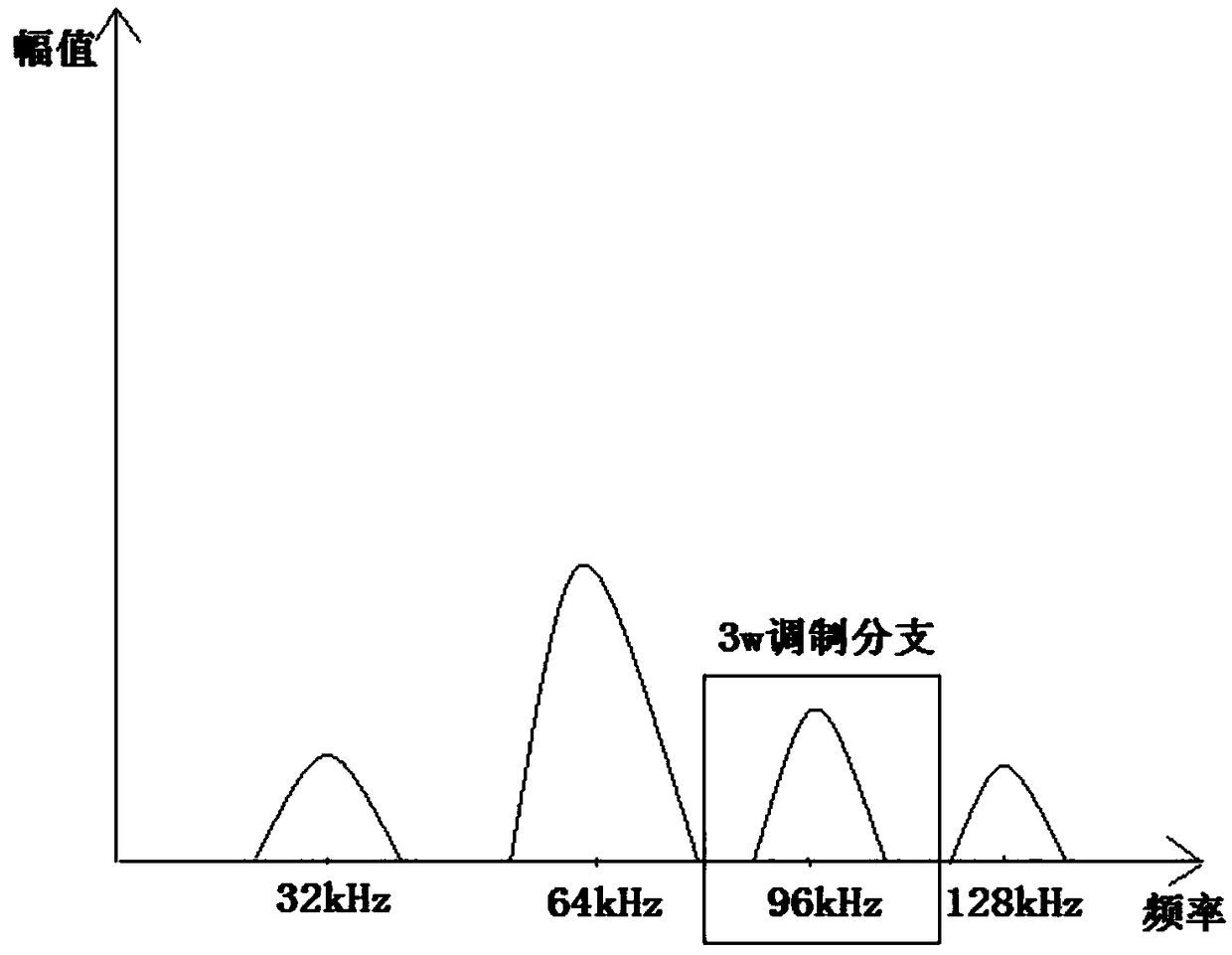

[0051] Step 1. Signal excitation: Two excitation ultrasonic transducer groups, the first group is single low frequency, the excitation frequency is 32kHz, and a single piezoelectric chip is glued to the side of the pipeline, which is group A; the second group is arranged in The piezoelectric ultrasonic transducer array distributed at equal intervals around the pipeline can control and excite the double high-frequency torsional mode T(0,1) mode, and the excitation frequency is 64kHz, which is group B;

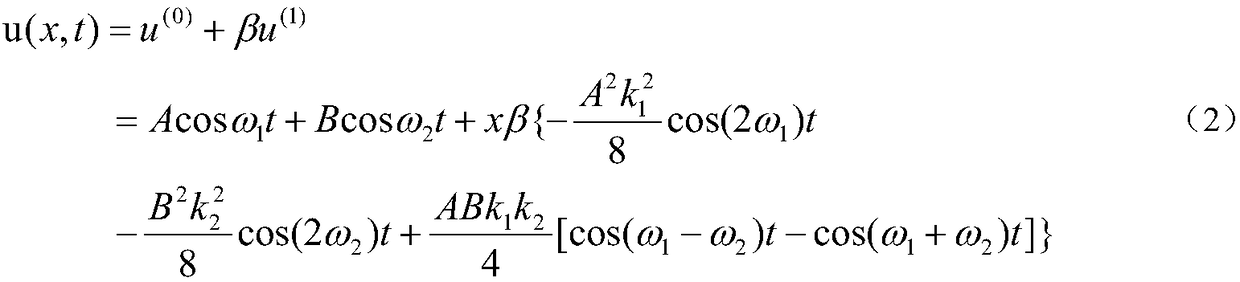

[0052] According to the nonlinear characteristics, the output displacement for an input mixed frequency signal is:

[0053] u (0) (x,t)=Acos(ω 1 t)+Bcos(ω 2 t) (1)

[0054] ω ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com