Method and system for detecting and positioning micro-cracks based on ultrasonic phased array

A technology of ultrasonic phased array and positioning method, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids and process detection response signals. The effects of improved detection and positioning accuracy, high detection and positioning accuracy, high recognition rate and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

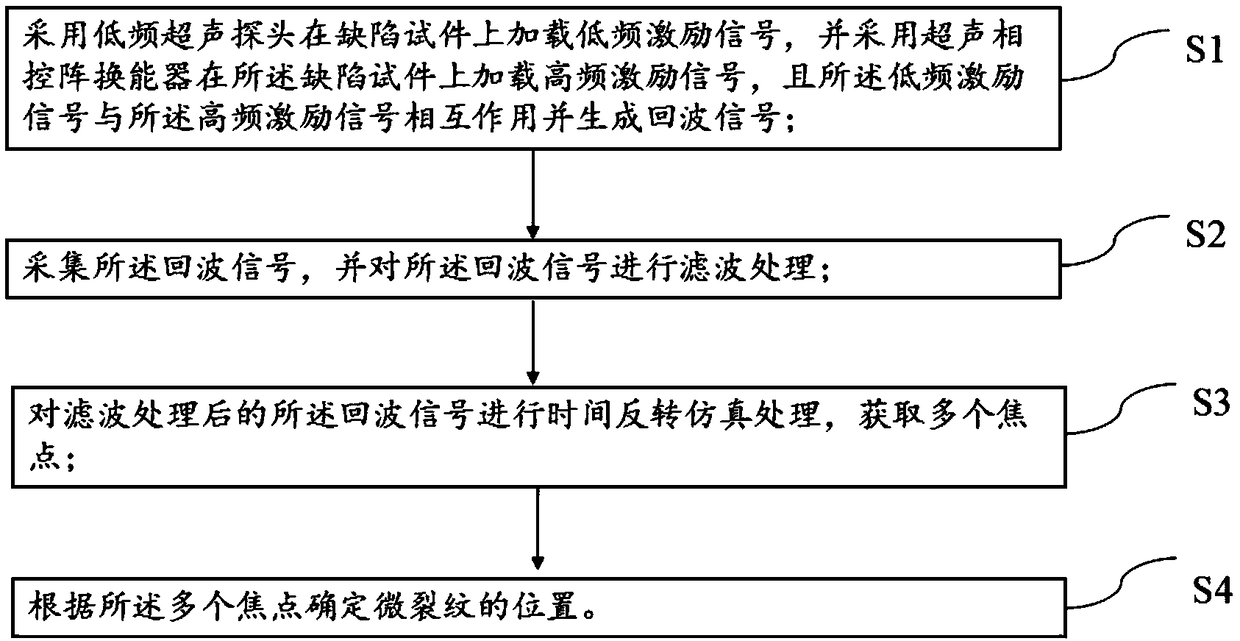

[0057] Embodiment one, as figure 1 As shown, it is a micro-crack detection and location method based on ultrasonic phased array of the present invention, comprising the following steps:

[0058] S1: Sampling a low-frequency ultrasonic probe to load a low-frequency excitation signal on the defect test piece, and using an ultrasonic phased array transducer to load a high-frequency excitation signal on the defect test piece, and the low-frequency excitation signal and the high-frequency excitation signal The signals interact and generate an echo signal;

[0059] S2: collecting the echo signal, and performing filtering processing on the echo signal;

[0060] S3: Perform time-reversal simulation processing on the filtered echo signal to obtain multiple focal points;

[0061] S4: Determine the position of the micro-crack according to the multiple focal points.

[0062] In this embodiment, an ultrasonic phased array based on vibration-acoustic modulation is used to excite high-fre...

Embodiment 2

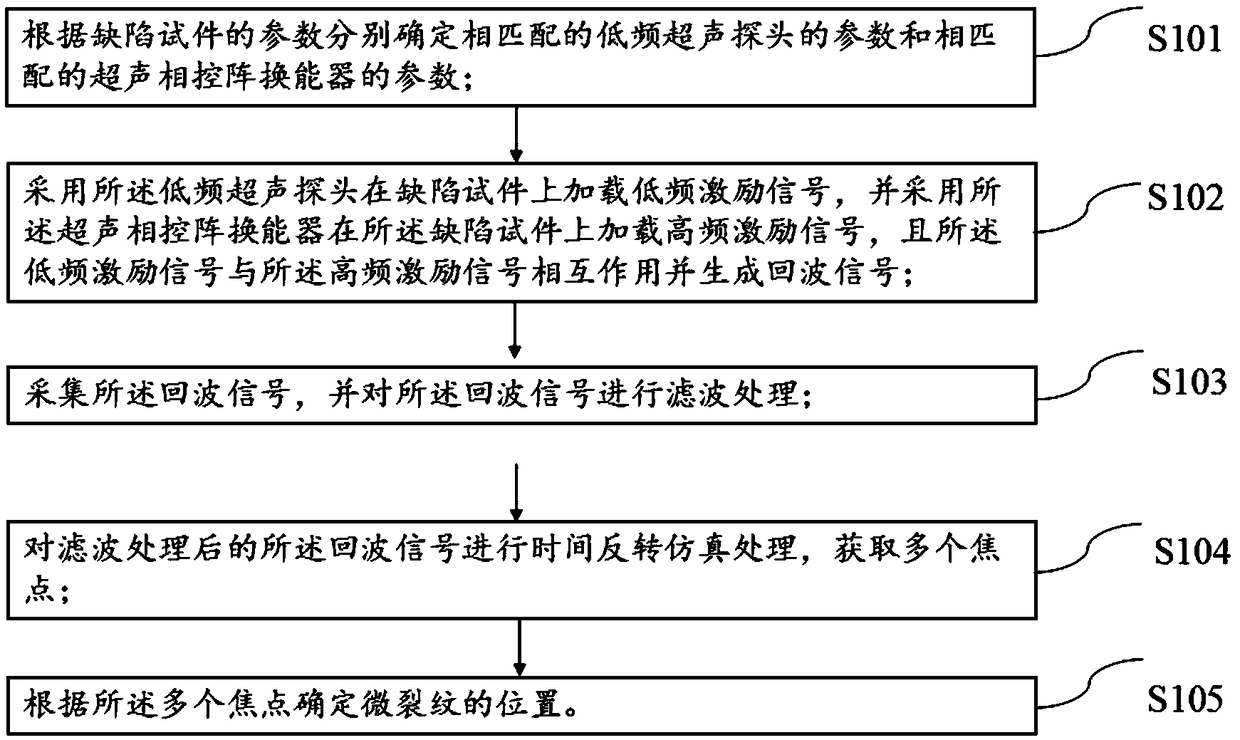

[0063] Embodiment two, such as figure 2 Shown is another embodiment of a micro-crack detection and location method based on ultrasonic phased array of the present invention, comprising the following steps:

[0064] S101: Determine the matched parameters of the low-frequency ultrasonic probe and the ultrasonic phased array transducer respectively according to the parameters of the defective test piece.

[0065] In this embodiment, a carbon steel plate with a length of 200 mm, a width of 200 mm, and a thickness of 20 mm is selected as a defect test piece, and the defect test piece contains a microcrack inside. In this steel plate, the propagation velocity of the transverse wave is 3200m / s, and the propagation velocity of the longitudinal wave is 5900m / s, so it is determined that the center frequency of the low-frequency ultrasonic probe in this embodiment is 0.5MHz, and the sampling frequency is 100MHz. The transducer contains 64 vibration elements, and the center frequency of...

Embodiment 3

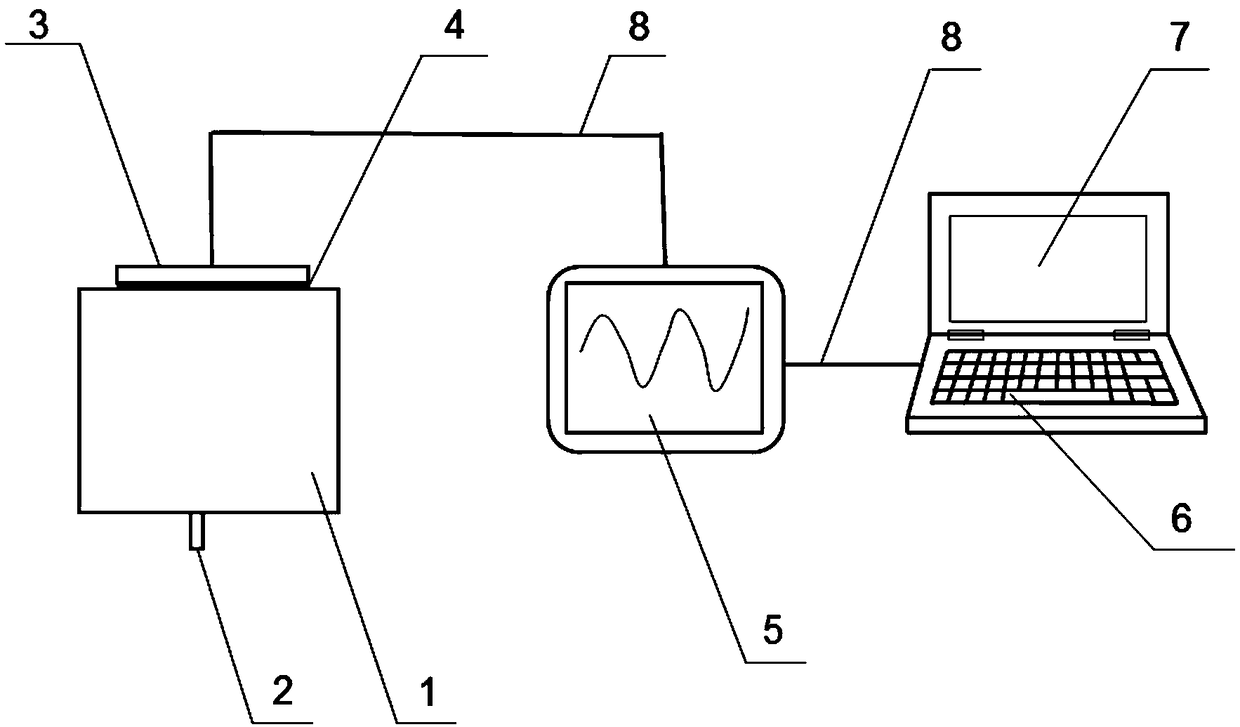

[0090] Embodiment three, as image 3 As shown, it is a structural schematic diagram of a micro-crack detection and positioning system based on ultrasonic phased array of the present invention, including a defect test piece 1, a low-frequency ultrasonic probe 2, an ultrasonic phased array transducer 3, a signal acquisition device 5, Processor 6;

[0091] The low-frequency ultrasonic probe 2 is arranged under the defect test piece 1 and faces the defect test piece 1, and the low-frequency ultrasonic probe 2 is used to load a low-frequency excitation signal on the defect test piece 1; the ultrasonic phase The controlled array transducer 3 is arranged above the defect test piece 1 and facing the defect test piece 1, and the ultrasonic phased array transducer 3 is used to load the high frequency excitation signal on the defect test piece 1 ; The signal acquisition device 5 is electrically connected with the low-frequency ultrasonic probe 1 and the ultrasonic phased array transduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com