Patents

Literature

190 results about "Crack size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Critical crack size is the size of a flaw (crack) in a structure that causes failure at a particular stress level. Thus, the critical crack size can vary significantly with the type of material. In an ideally elastic (brittle) material, crack propagation occurs catastrophically if the crack size is above the critical size.

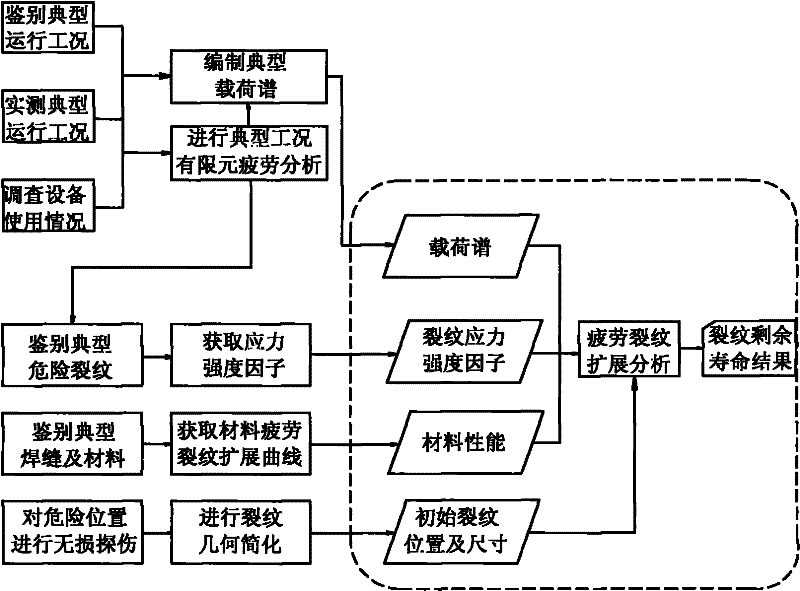

Method for estimating remaining fatigue life of main metal structure of crane

InactiveCN102221473AReflect duty cycleEstimating Fatigue LifeStructural/machines measurementUsing wave/particle radiation meansEstimation methodsEngineering

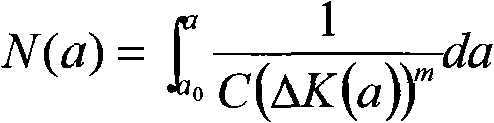

The invention relates to a method for estimating the remaining fatigue life of a main metal structure of a crane. The method is applied to the compiling of actually measured load spectrums, the measurement of material fatigue crack propagation curves, the nondestructive detection of hazardous locations and the estimation of the remaining fatigue life of the main metal structures of the large cranes at relatively higher working levels in shipyards, ports and the like, and is also applied to the estimation of the remaining fatigue life of the cranes of other types. The method comprises the following steps of: (1) acquisition of the load spectrum; (2) measurement of material performance; (3) detection of an initial crack location and an initial crack size; (4) acquisition of a crack stress intensity factor; and (5) estimation of the remaining fatigue life. In the method, factors such as the existence of a crack in the structure, the detection of the location and size of the actually crack, and the like are taken into account, and the nondestructive detection is performed on the hazardous location; therefore, the remaining fatigue life of the metal structure of the crane can be accurately estimated.

Owner:GUANGZHOU ACAD OF SPECIAL EQUIP INSPECTION& TESTING

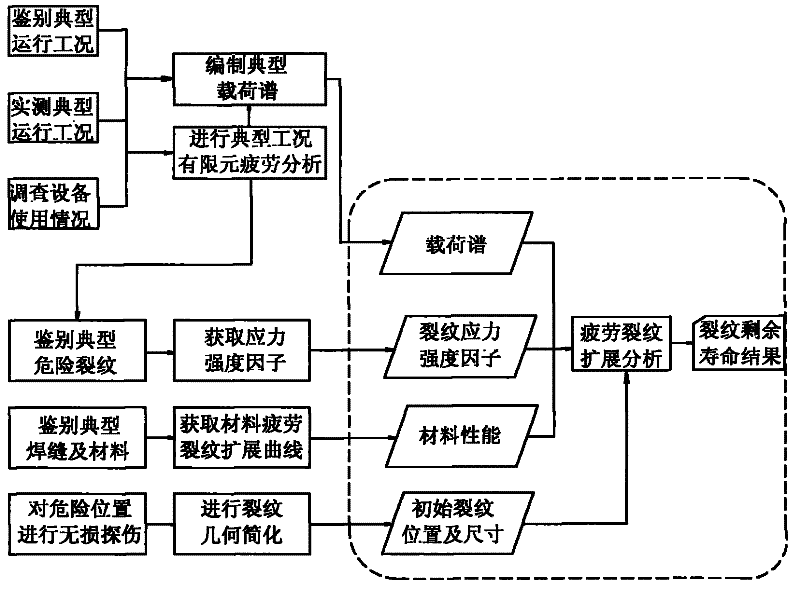

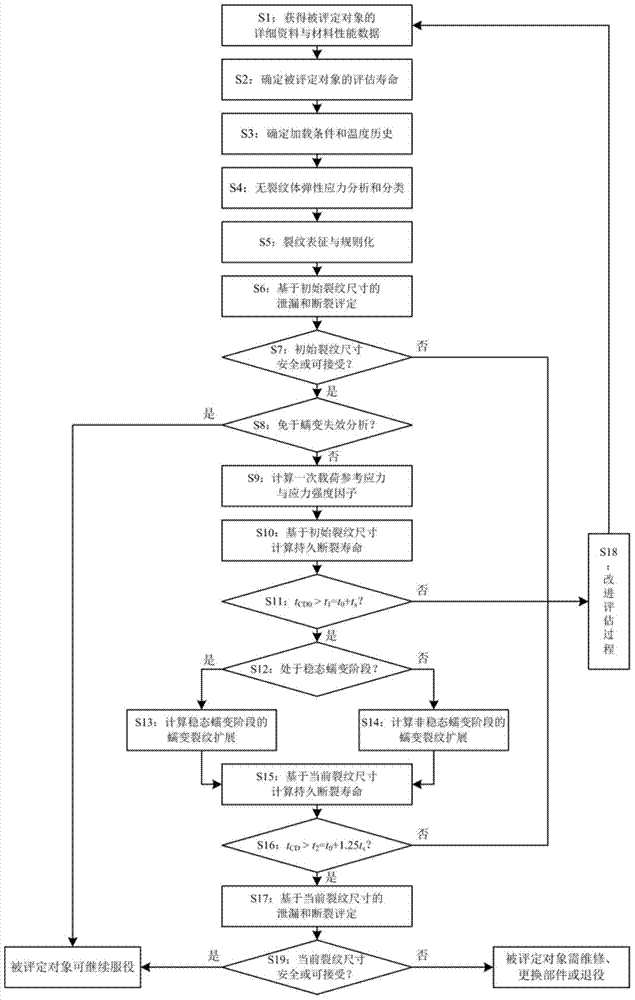

Safety assessment method for high-temperature pressure pipeline with crack type defects

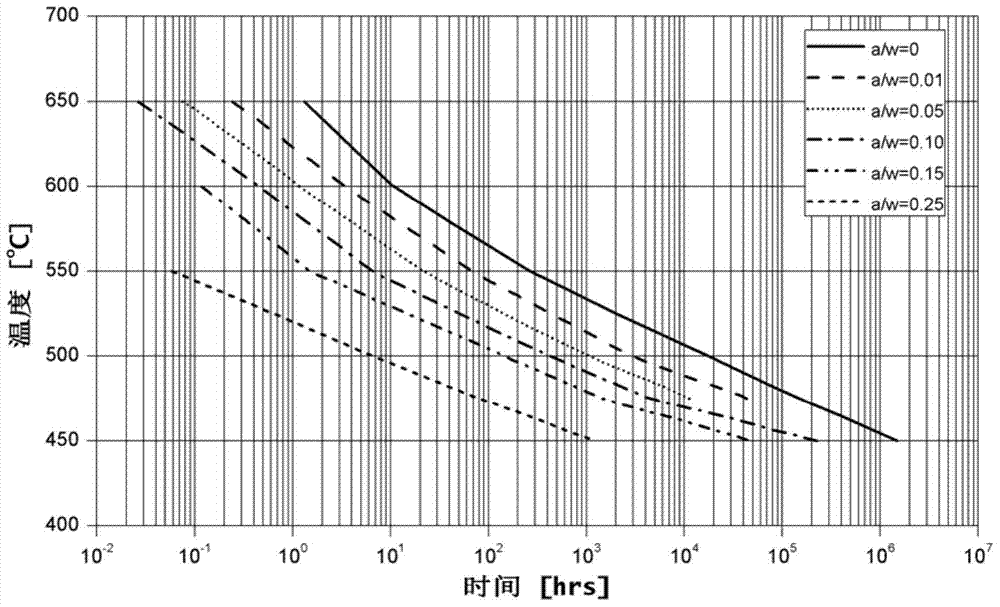

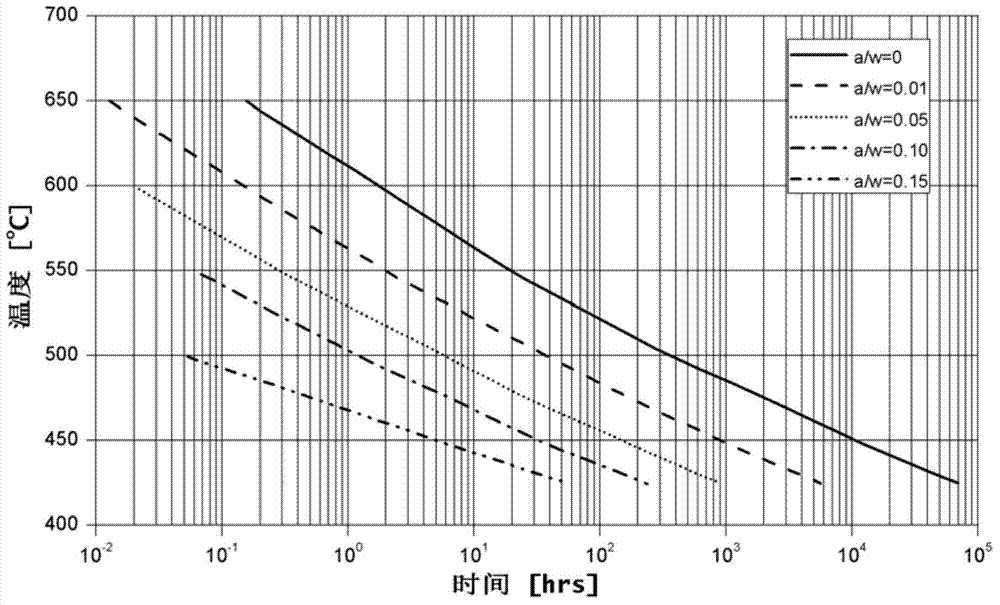

The invention discloses a safety assessment method for a high-temperature pressure pipeline with crack type defects. The safety assessment method for the high-temperature pressure pipeline with crack type defects includes steps that 1, gathering data; 2, definitely evaluating the life span; 3, determining load and temperature; 4, analyzing elastic stress; 5, characterizing crack; 6, assessing initial crack leakage and rupture; 7, judging whether the initial crack is safe; 8, judging whether the initial crack is free of creep analysis; 9, calculating reference stress and stress intensity factors; 10, calculating creep rupture life based on the initial crack size; 11, judging whether the creep rupture life is long enough; 12, judging whether the creep is steady creep; 13, calculating steady state creep crack growth; 14, calculating unsteady state creep crack growth; 15, calculating the creep rupture life based on the current crack size; 16, judging whether the current creep rupture life is long enough; 17, assessing the current crack leakage and rupture; 18, refining and evaluating; 19, judging whether the assessed object is safe. The safety assessment method for the high-temperature pressure pipeline with crack type defects can be used for assessing the safety of the high-temperature pressure pipeline with crack type defects under creep load effect.

Owner:HEFEI GENERAL MACHINERY RES INST

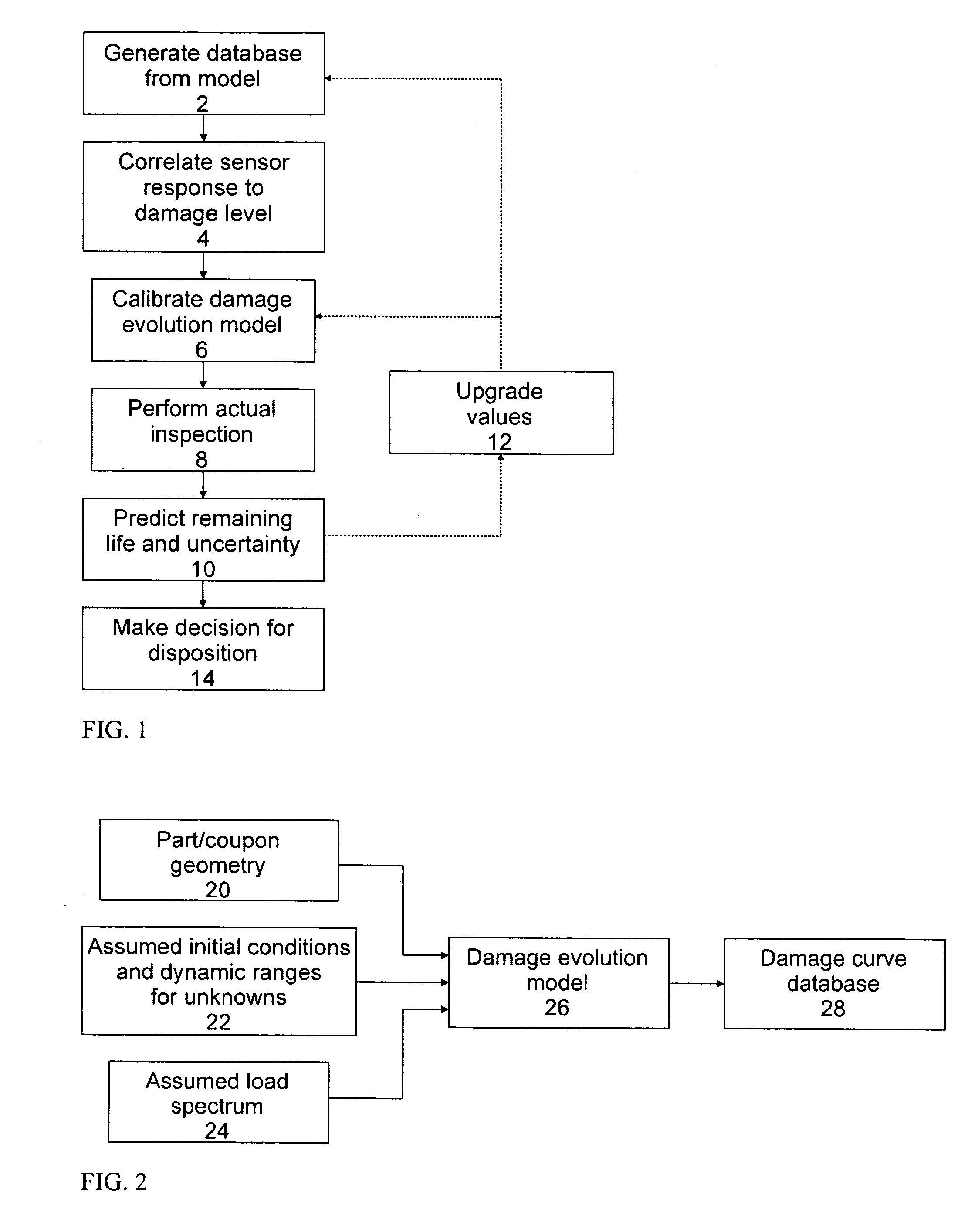

Remaining life prediction for individual components from sparse data

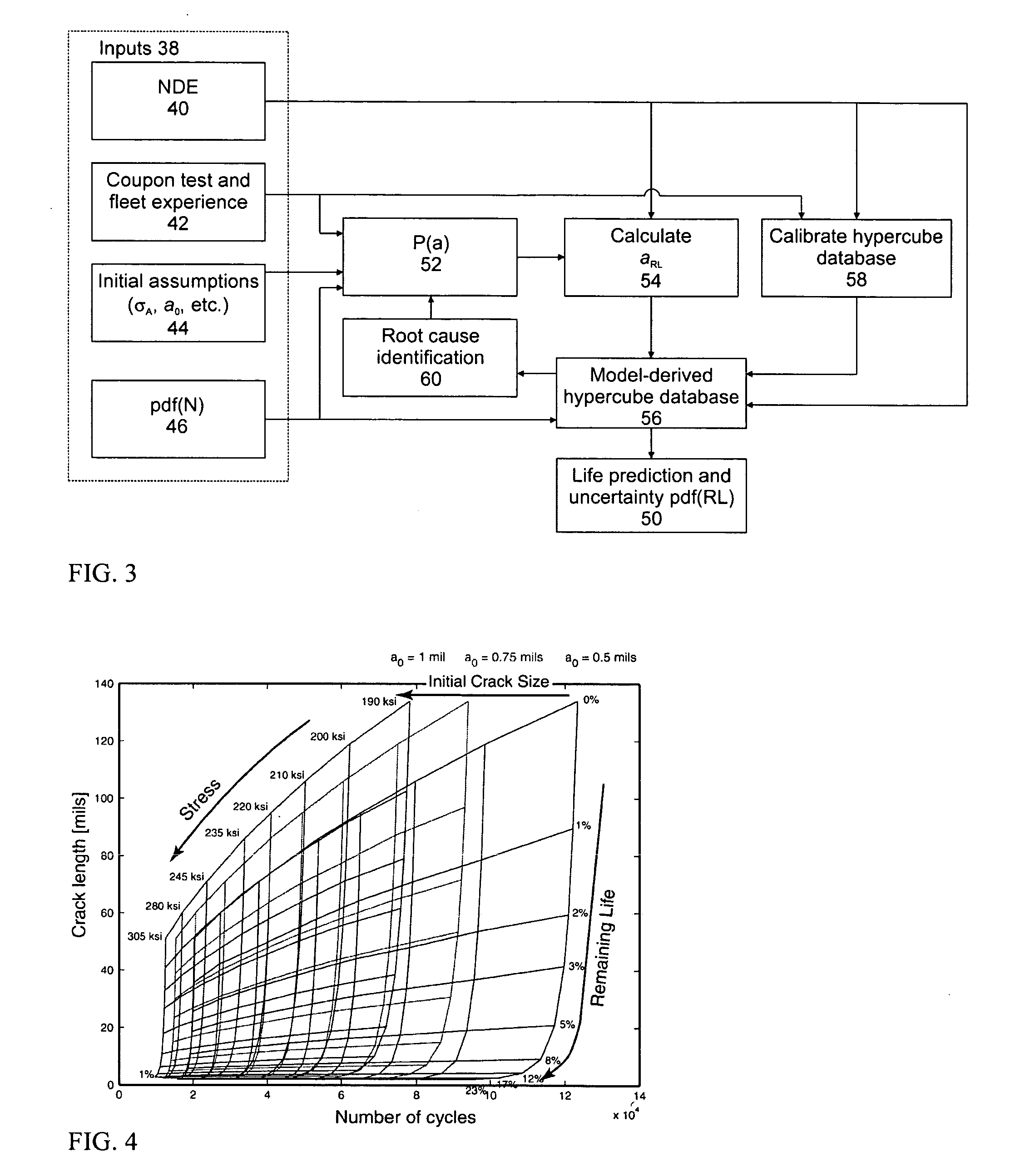

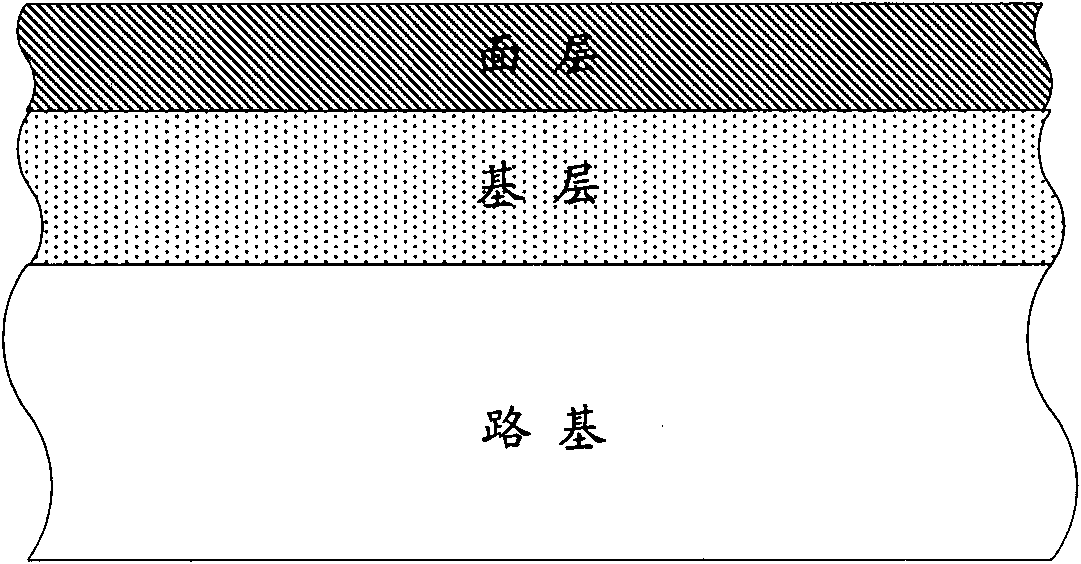

ActiveUS20070239407A1Effective calculationActive/predictive/anticipative controlElectric/magnetic roughness/irregularity measurementsRoot causeDecision taking

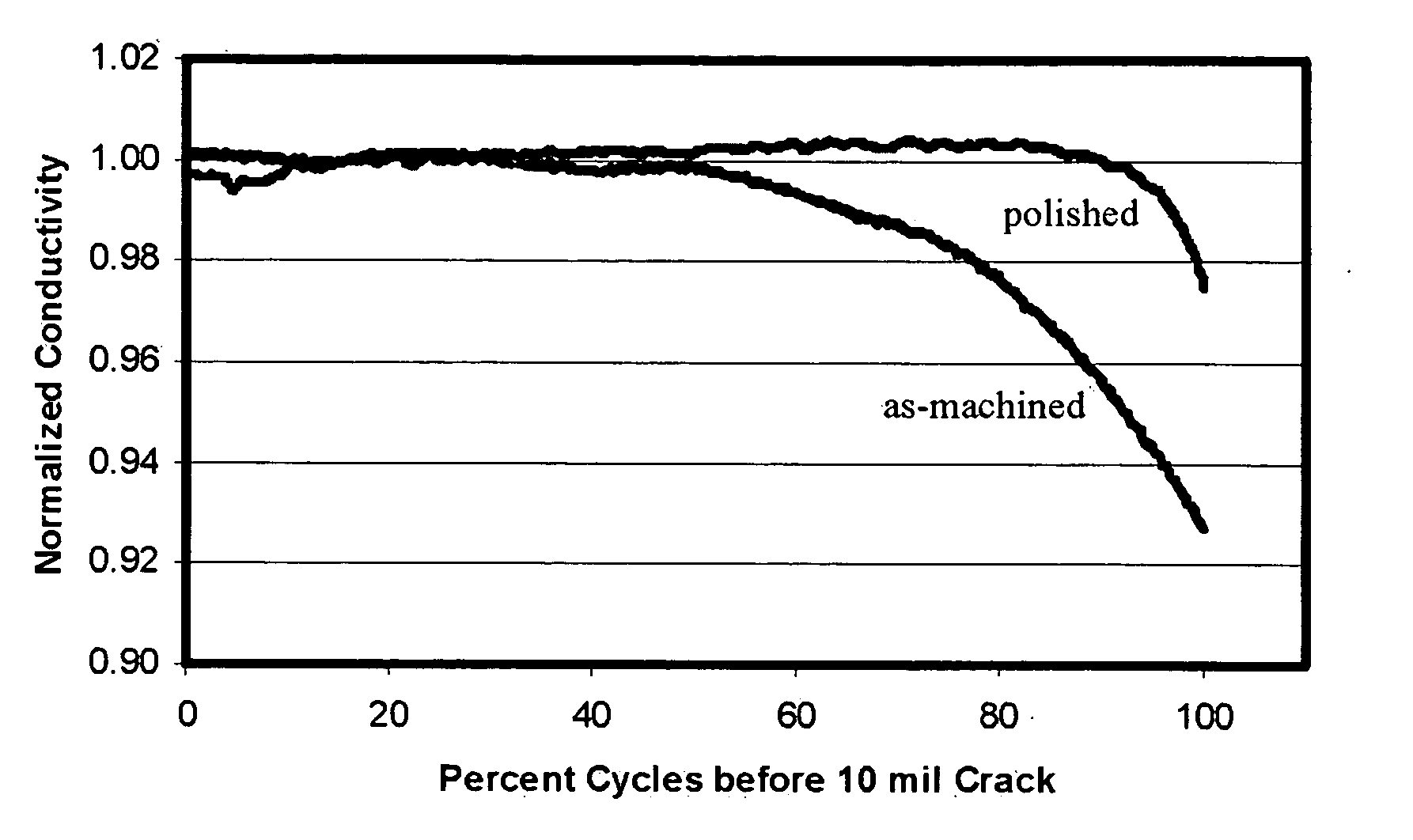

Predicting the remaining life of individual aircraft, fleets of aircraft, aircraft components and subpopulations of these components. This is accomplished through the use of precomputed databases of response that are generated from a model for the nonlinear system behavior prior to the time that decisions need to be made concerning the disposition of the system. The database is calibrated with a few data points, to account for unmodeled system variables, and then used with an input variable to predict future system behavior. These methods also permit identification of the root causes for observed system behavior. The use of the response databases also permits rapid estimations of uncertainty estimates for the system behavior, such as remaining life estimates, particularly, when subsets of an input variable distribution are passed through the database and scaled appropriately to construct the output distribution. A specific example is the prediction of remaining life for an aircraft component where the model calculates damage evolution, input variables are a crack size and the number of cycles, and the predicted parameters are the actual stress on the component and the remaining life.

Owner:JENTEK SENSORS

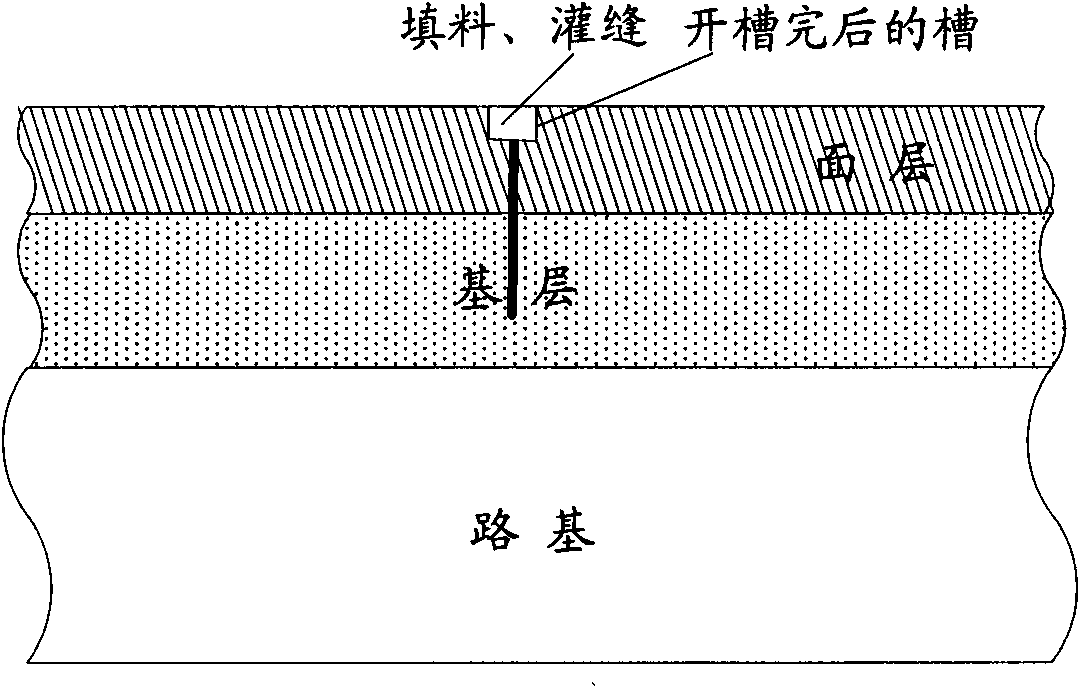

Method for repairing asphalt pavement cracks

The invention discloses a method for repairing asphalt pavement cracks, comprising the following steps: a. opening a trench: setting the trench size according to the crack size and opening the trench;b. cleaning the trench: cleaning disintegrating slags in the trench and dust at the periphery of the trench after finishing opening the trench; c. pouring a crack: pouring cold crack filling materialin the trench, and performing vibration operation on the cold crack filling material after crack pouring; d. filling materials: filling joint stones in the trench and performing vibration compactionoperation on the stones until the stones after vibration and compaction in the trench level with the pavement; and e. curing. By using the method in the invention, asphalt pavement cracks can be effectively repaired by cold-patch notching and vibration, the cracks and gaps at the periphery thereof can be completely closed, the materials in the trench can be integrated with the original asphalt pavement after repairing, thus having high strength, resisting water encroachment thoroughly, improving the service life of the asphalt pavement remarkably and saving investment on whole-life maintenancecosts of the asphalt pavement greatly.

Owner:交通部科学研究院

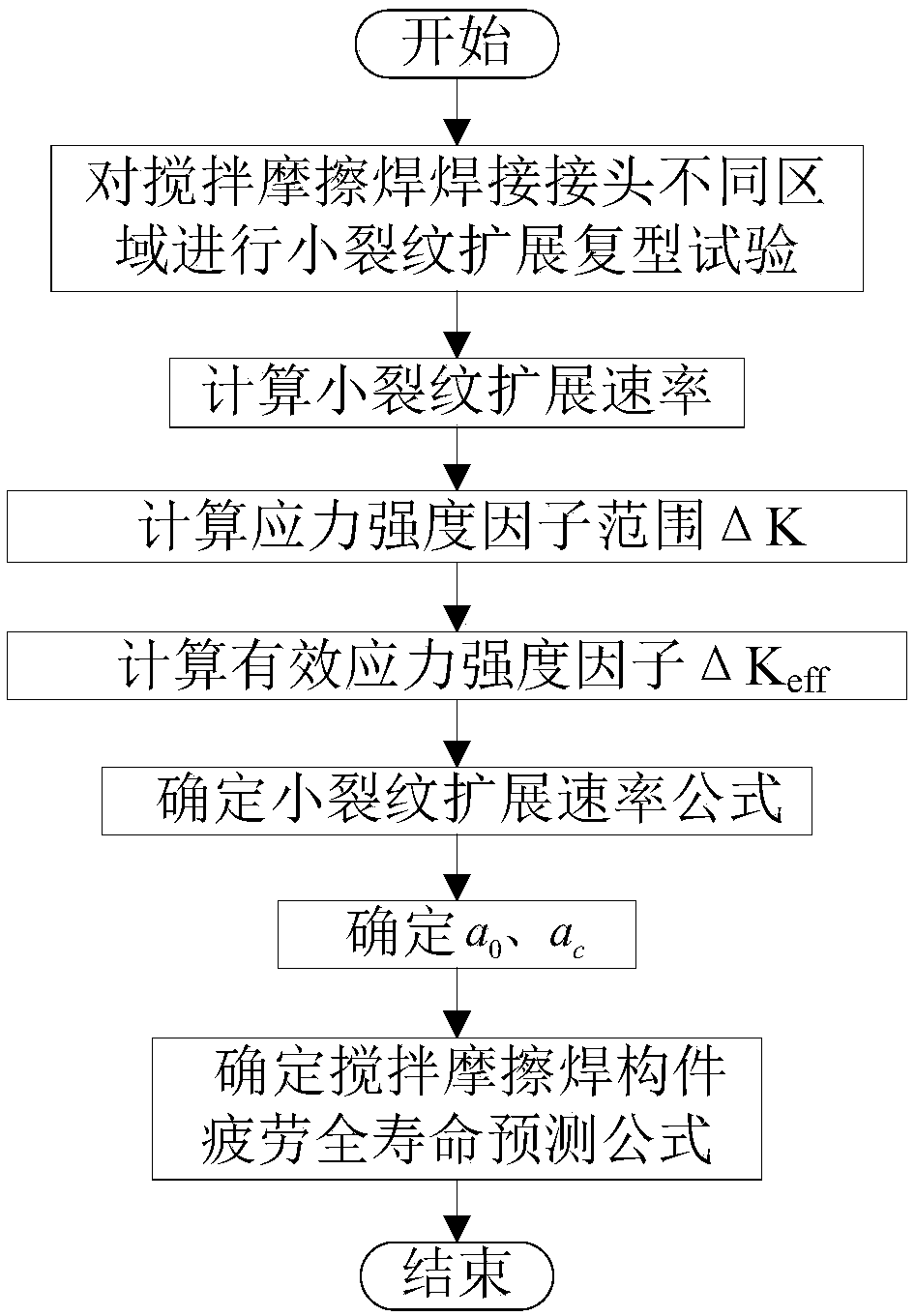

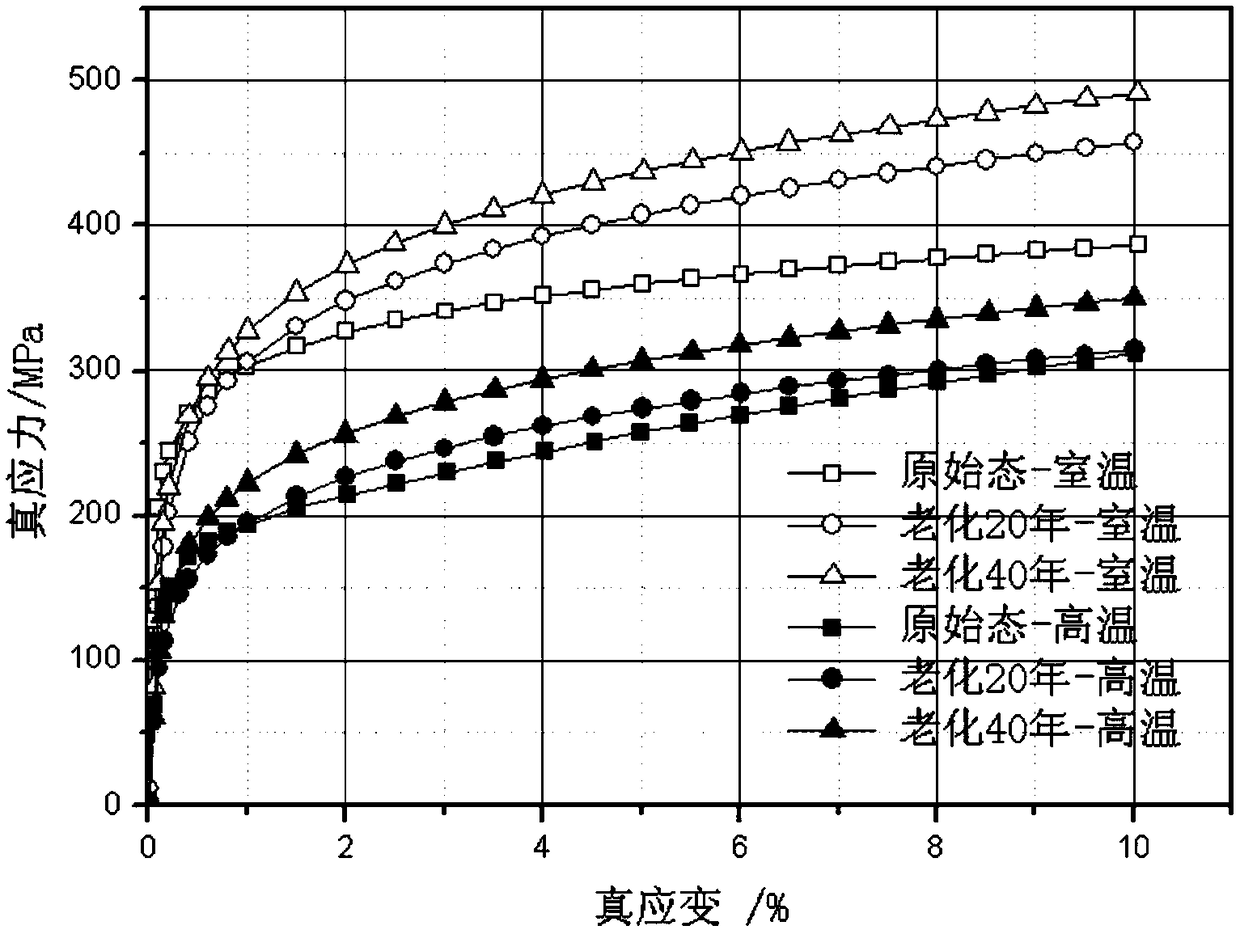

Fatigue life prediction method for friction stir welded component based on small crack propagation

ActiveCN108920792AEasy to calculateThe calculation method is accurateDesign optimisation/simulationSpecial data processing applicationsBone shapeMaterials science

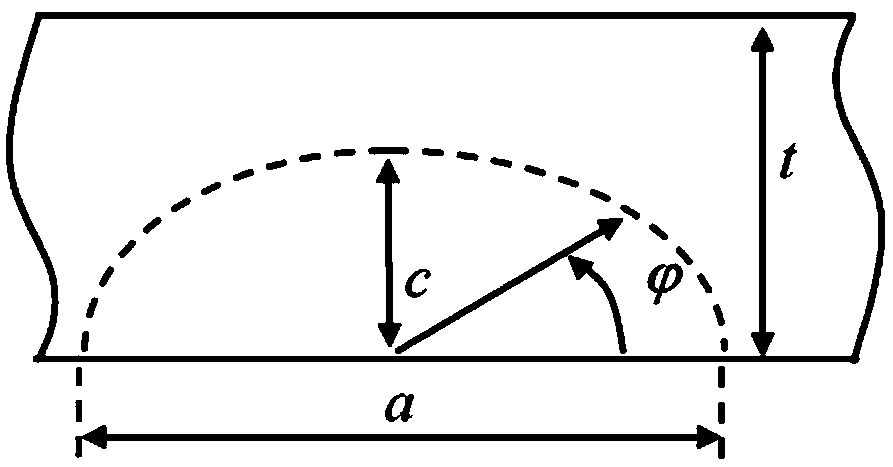

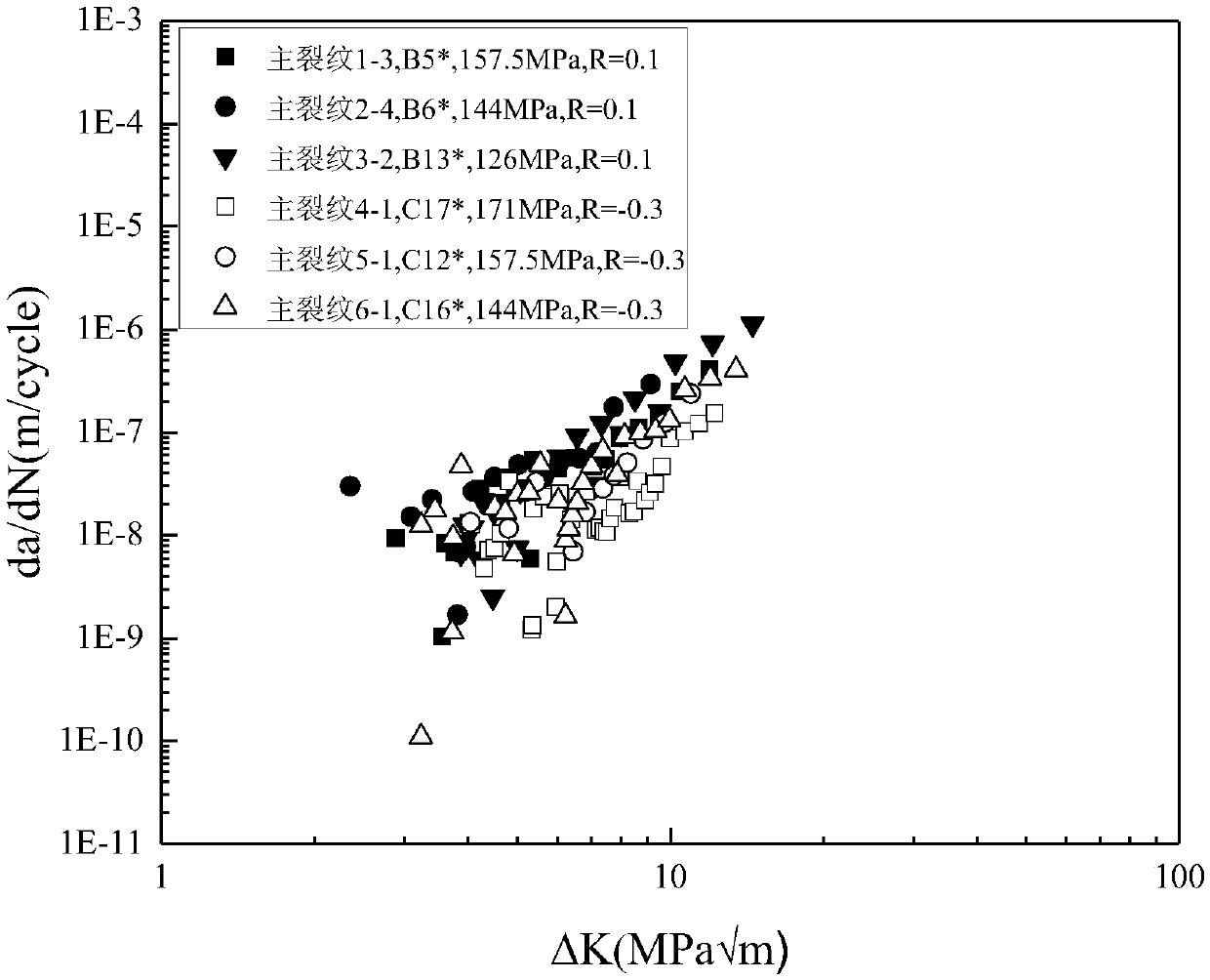

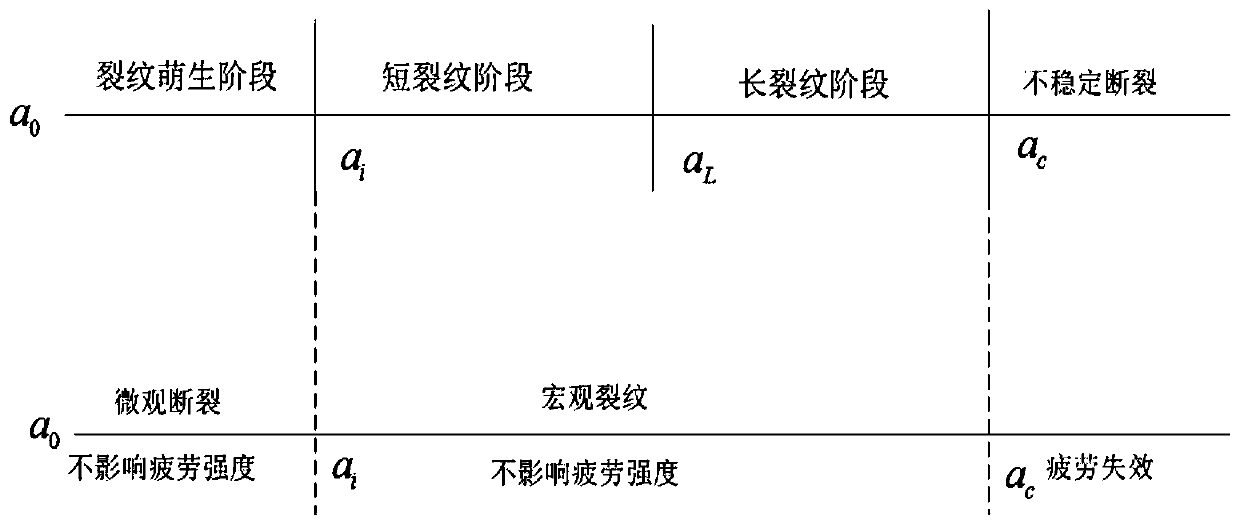

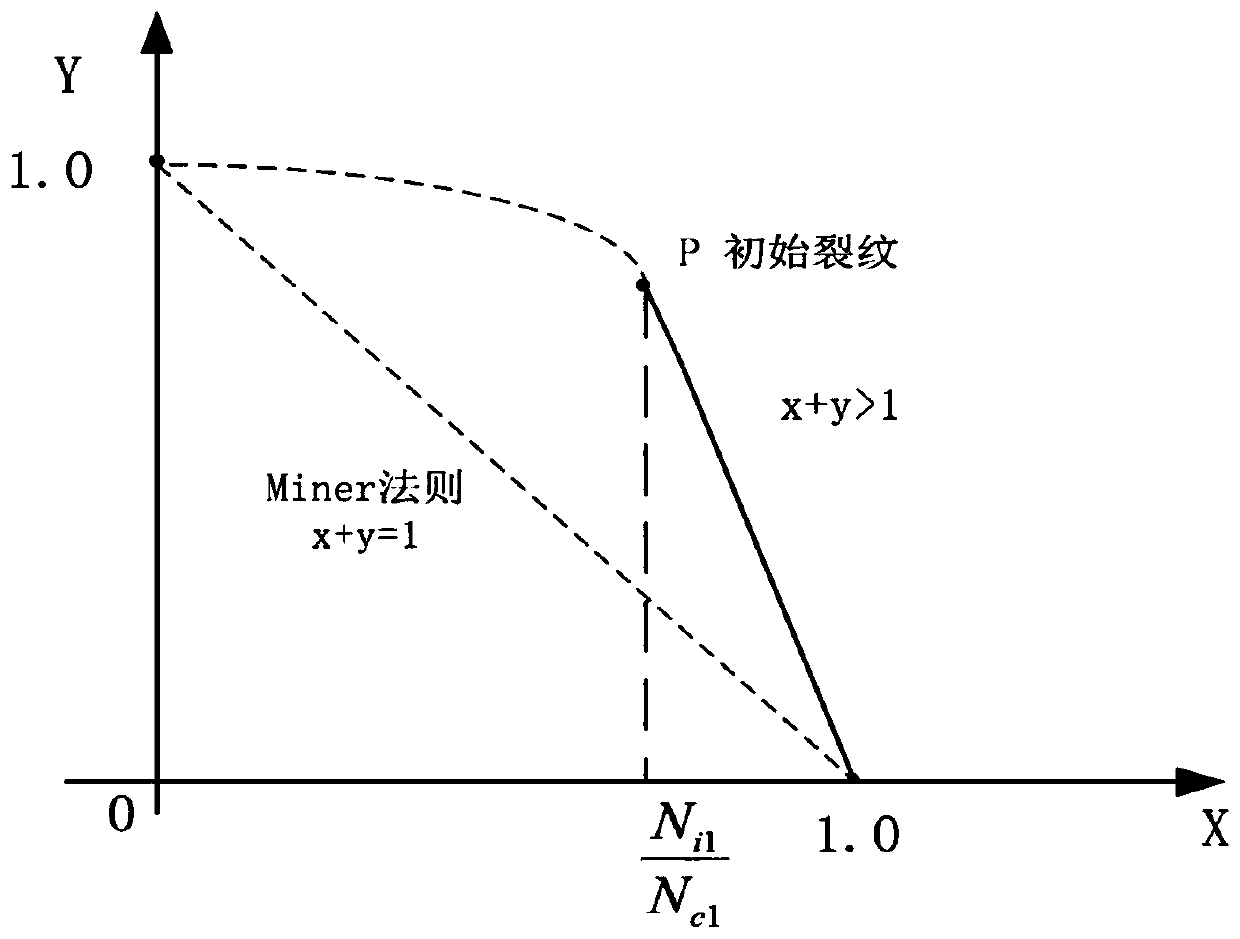

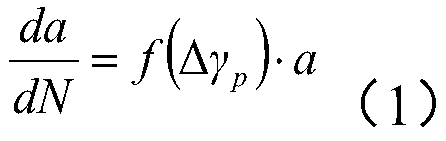

The invention discloses a fatigue life prediction method for a friction stir welded component based on small crack propagation, and belongs to the technical field of fatigue diagnosis and analysis ofmechanical structures. The method comprises the steps that a bone-shaped flat plate sample is prepared, fatigue small crack propagation replica tests under different stress loads and different stressratios are conducted on different areas of a joint, and a secant method is adopted for calculating the propagation rate of small cracks; a New-Raju model is adopted for calculating the stress intensity factor range of the small cracks of the joint; c values in the depth direction and a / 2 values in the vertical direction of semi-arc shapes of fatigue crack propagation zones in fracture shapes of different areas of the joint, and the depth-to-length ratio 2c / a of the cracks is calculated; a curve of the propagation rate of the cracks along with the change of the stress intensity factor range isdrawn; an effective stress intensity factor is calculated; a formula of the propagation rate of the small cracks is determined; an initial crack size a0 and a critical crack size ac are determined; the formula of the propagation rate of the small cracks is integrated to obtain the fatigue life of the welded component. By means of the scheme, the fatigue life of the friction stir welded component can be more easily and accurately predicted.

Owner:BEIJING UNIV OF TECH

Method for investigating fatigue crack expansion

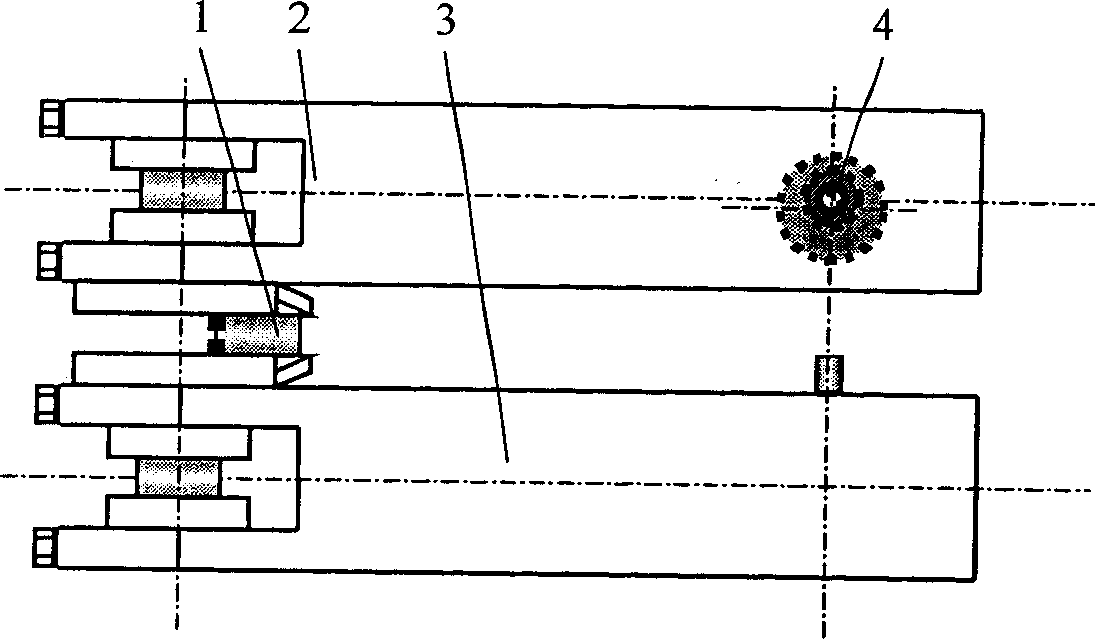

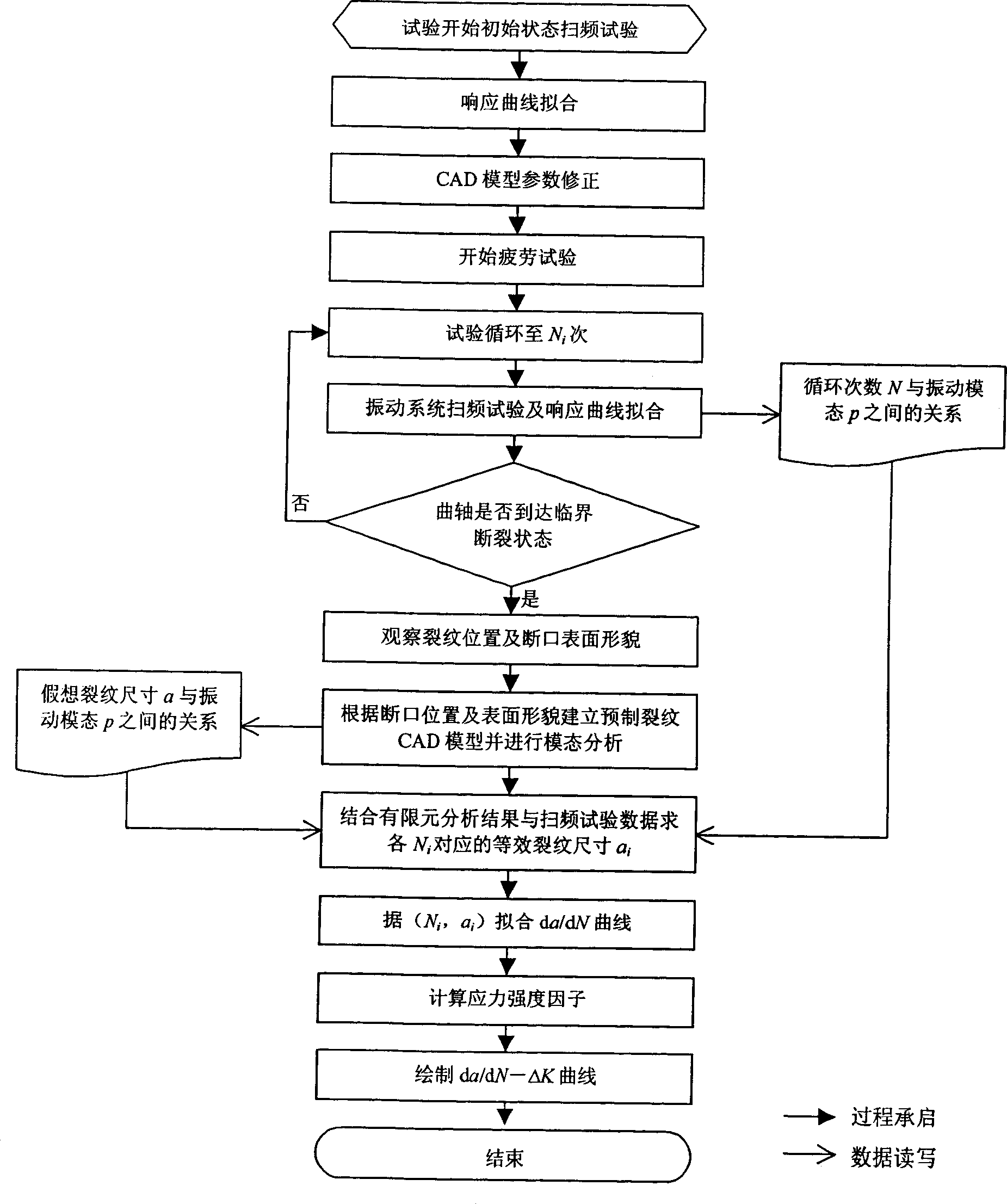

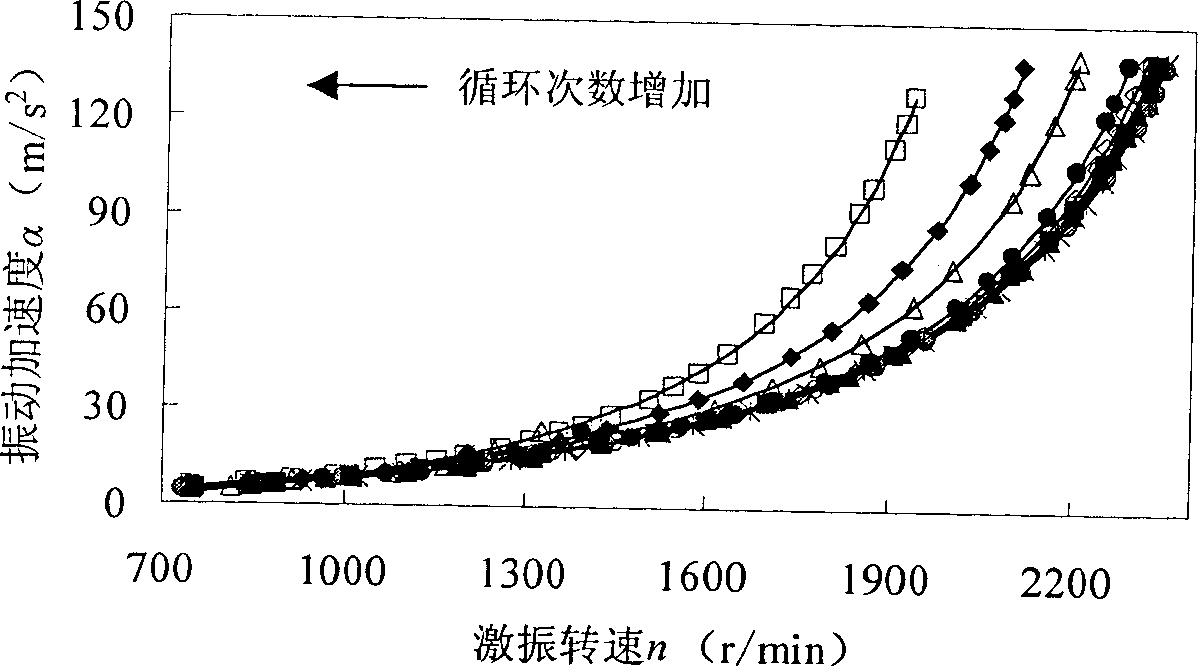

The invention discloses a fatigue crack extension testing method, making a sweeping test in the fatigue test course and obtaining the variation condition of vibration response of the test system varies with test piece crack extension on the forced vibration condition; using a numeric method to make sweeping data fitting and obtaining variation curve of resonant frequency with number of circulating times; after the test piece is broken, according to actually observed crack size and shape, prefabricating crack of a CAD model and making finite model analysis and obtaining a curve of resonant angular frequency of the system against test piece size, using the curve and able to obtain dynamic extension rule of test piece crack and then obtaining its curve of variation rate; and finally combining with calculation of stress strength factor range Delta K, and able to obtain a curve of crack extension rate.

Owner:ZHEJIANG UNIV

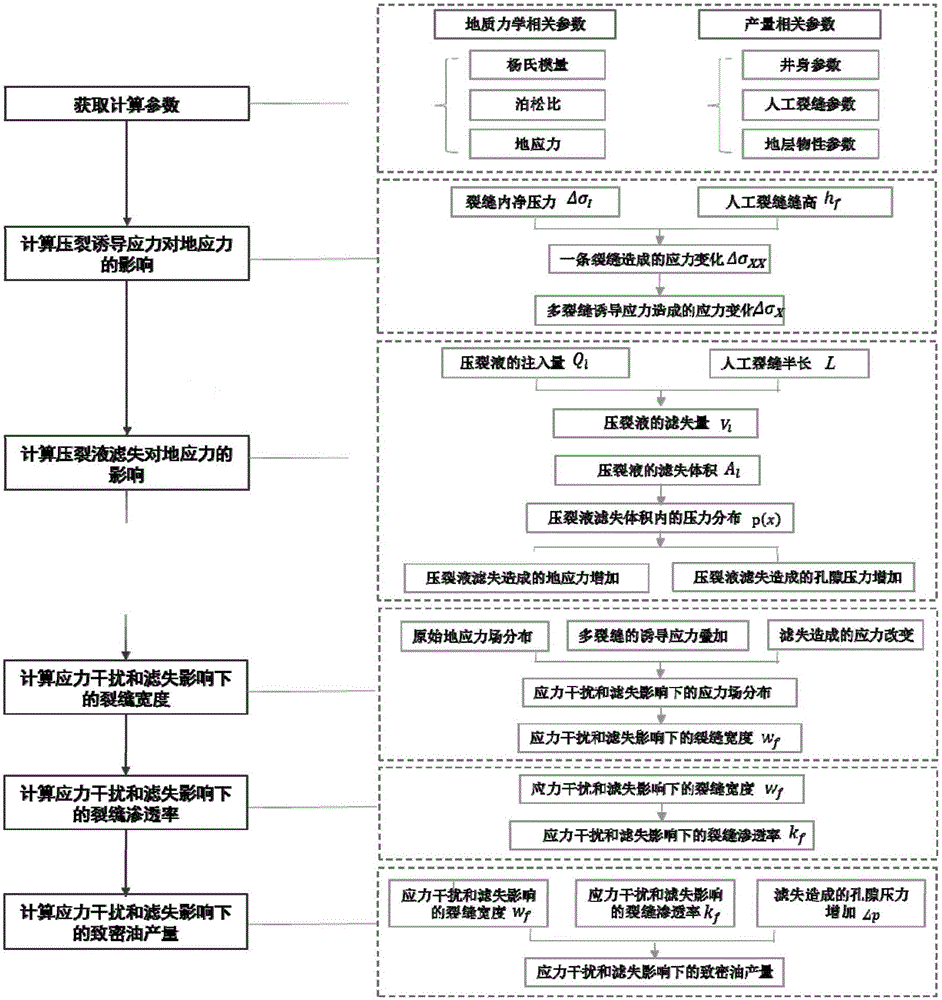

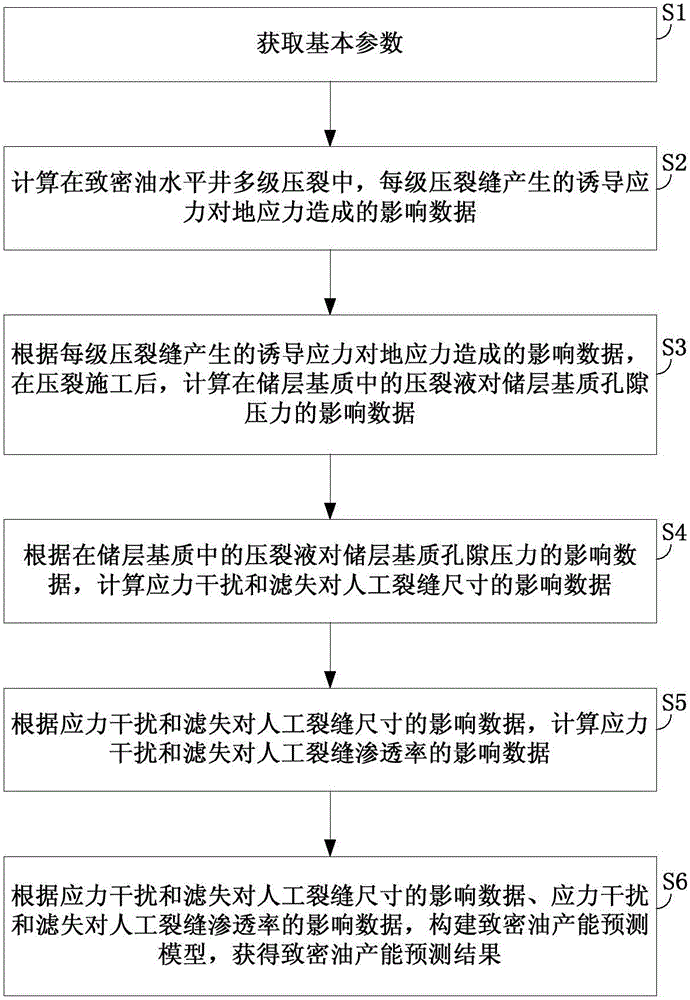

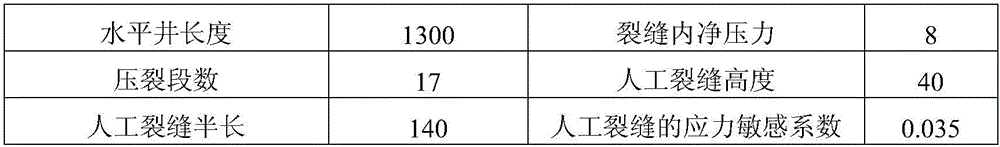

Tight oil productivity prediction method considering stress interference and fracturing fluid filtration loss and tight oil productivity prediction system thereof

The invention discloses a tight oil productivity prediction method considering stress interference and fracturing fluid filtration loss and a tight oil productivity prediction system thereof. The tight oil productivity prediction method comprises the steps that basic parameters are acquired; influence data of inducted stress generated by each stage of fracturing crack on ground stress in tight oil horizontal well multistage fracturing are calculated; the influence data of fracturing fluid in a reservoir matrix on reservoir matrix pore pressure are calculated after fracturing construction; the influence data of stress interference and filtration loss on the artificial crack size are calculated; the influence data of stress interference and filtration loss on artificial crack permeability are calculated; and a tight oil productivity prediction model is constructed and a tight oil productivity prediction result is acquired.

Owner:PETROCHINA CO LTD

Method and system of deterministic fatigue life prediction for rotor materials

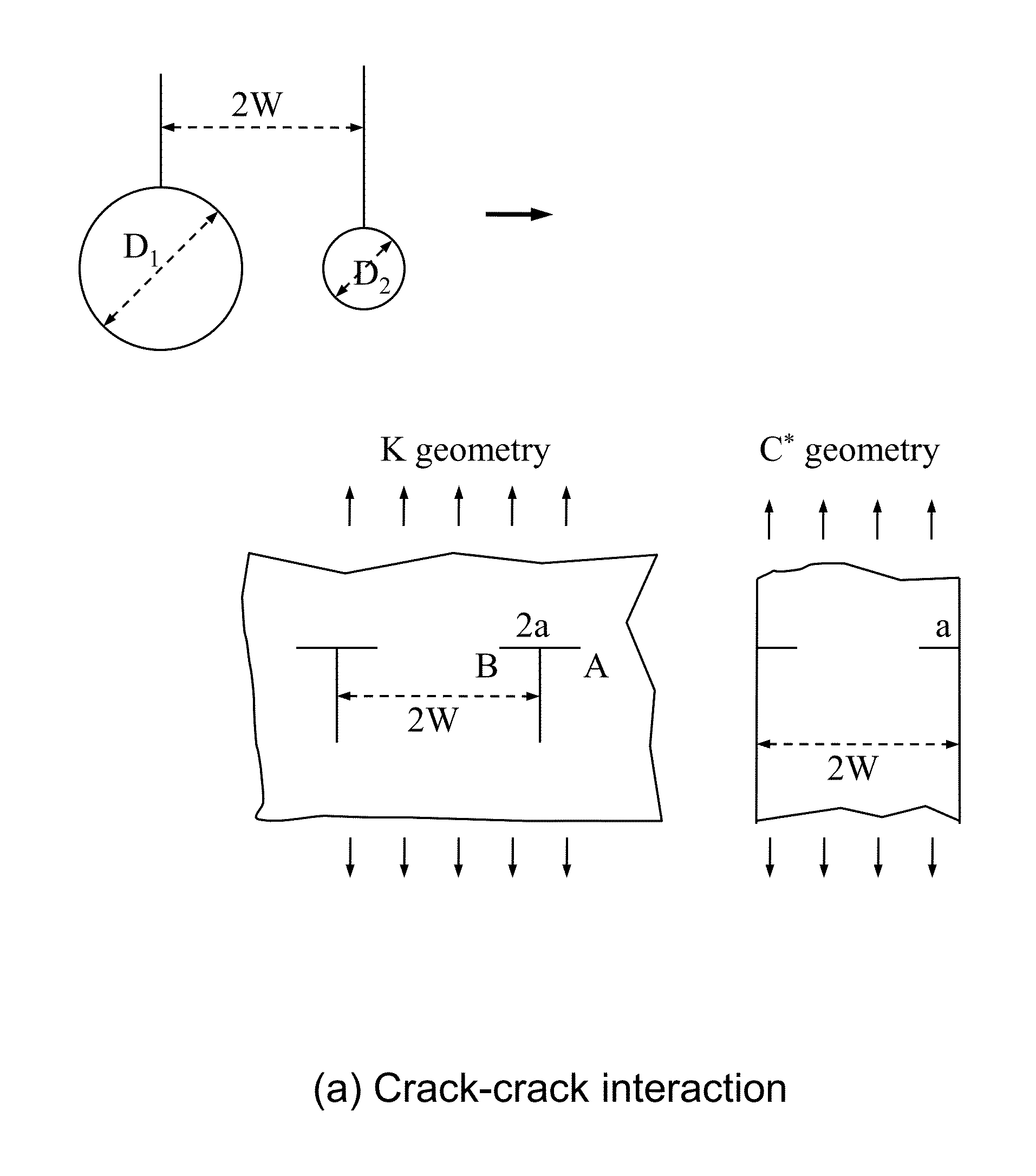

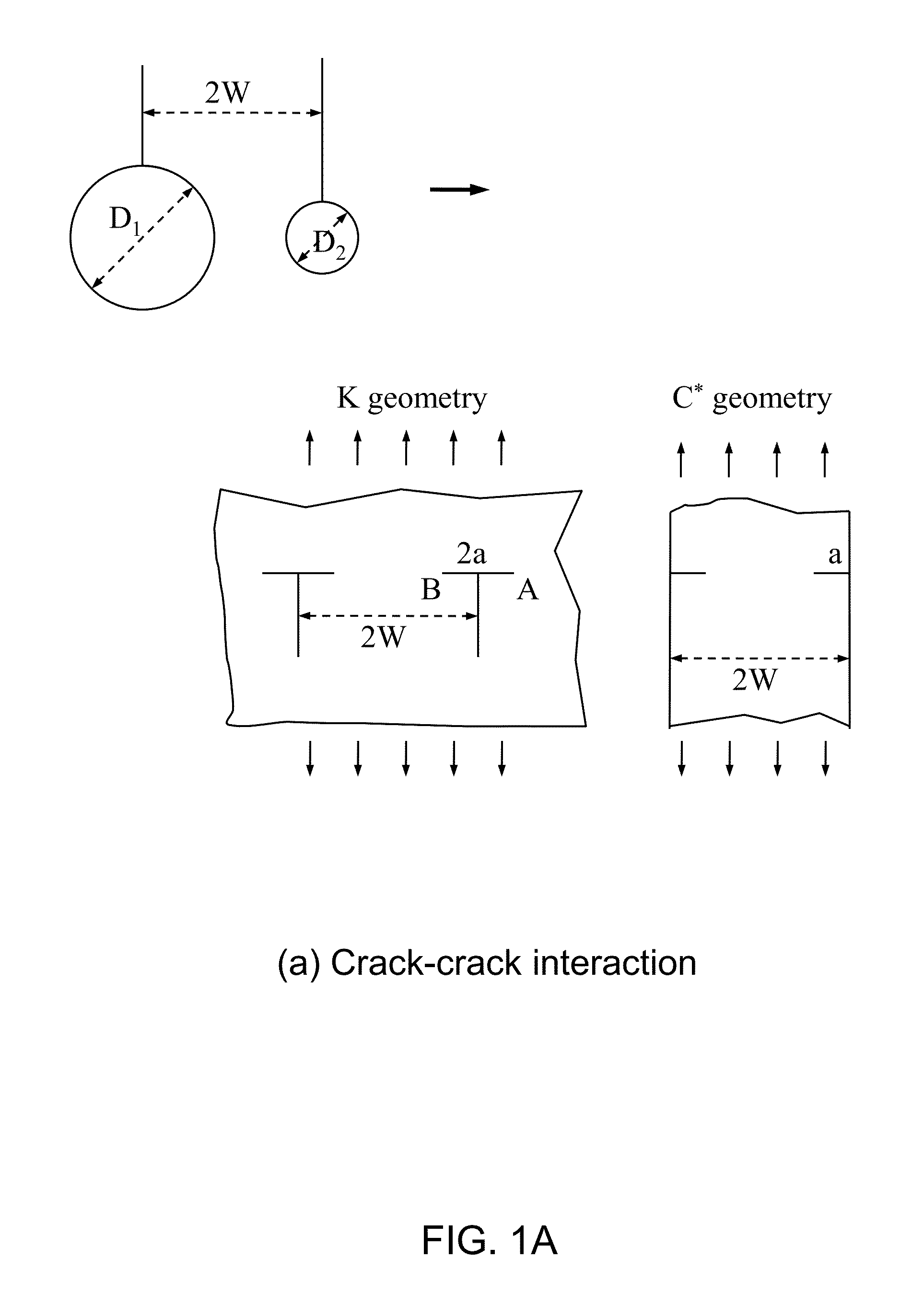

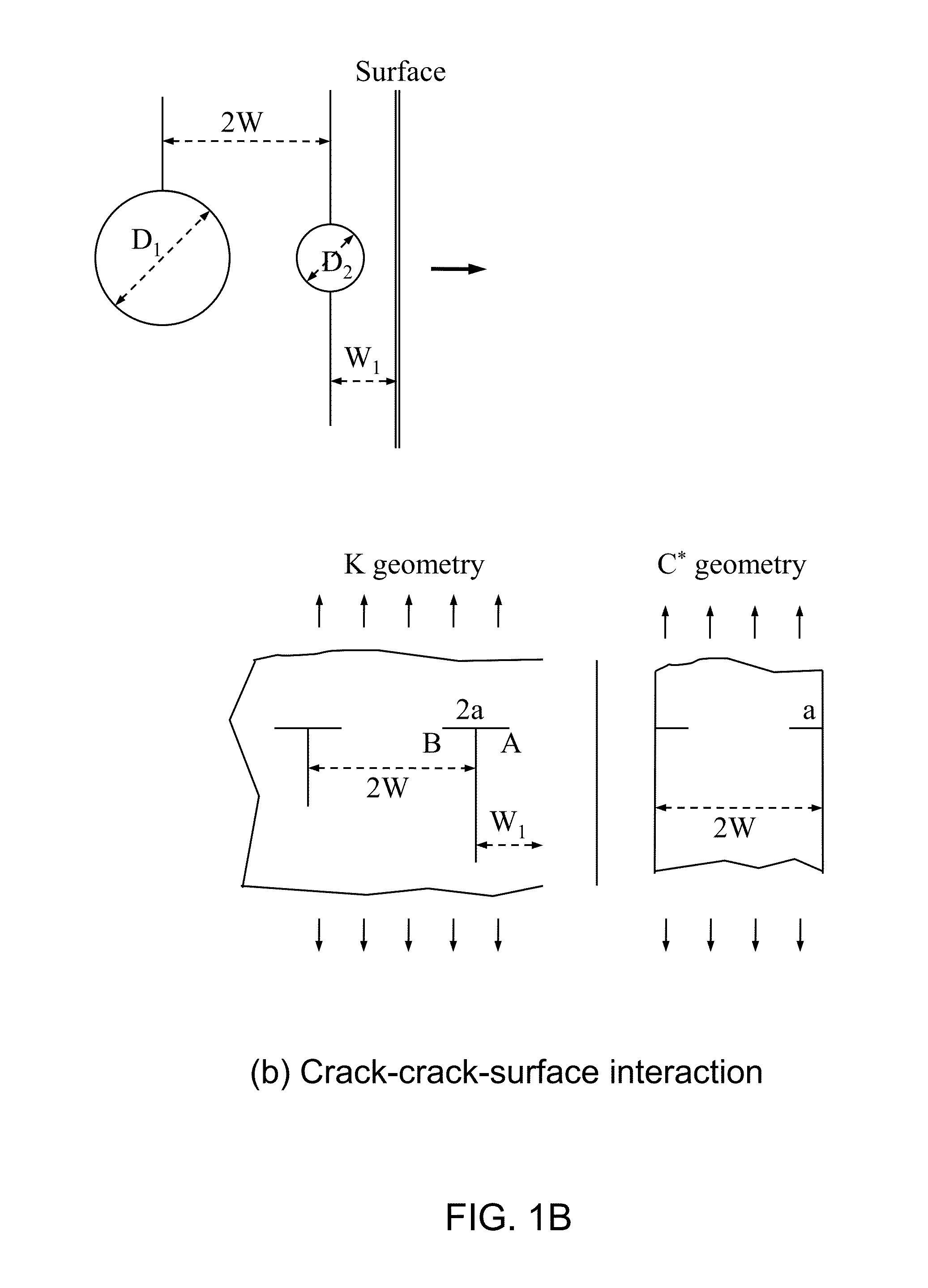

A method of fatigue life prediction including: calculating a critical crack size of an object of interest; identifying a first flaw in ultrasound data of the object of interest; determining that the first flaw interacts with a second flaw, the first flaw is to be merged with the second flaw, or the first flaw is isolated; calculating an initial crack size based on the determination; and calculating an increase in the initial crack size due to fatigue and creep to determine a number of load cycles until the initial crack size reaches the critical crack size.

Owner:SIEMENS ENERGY INC

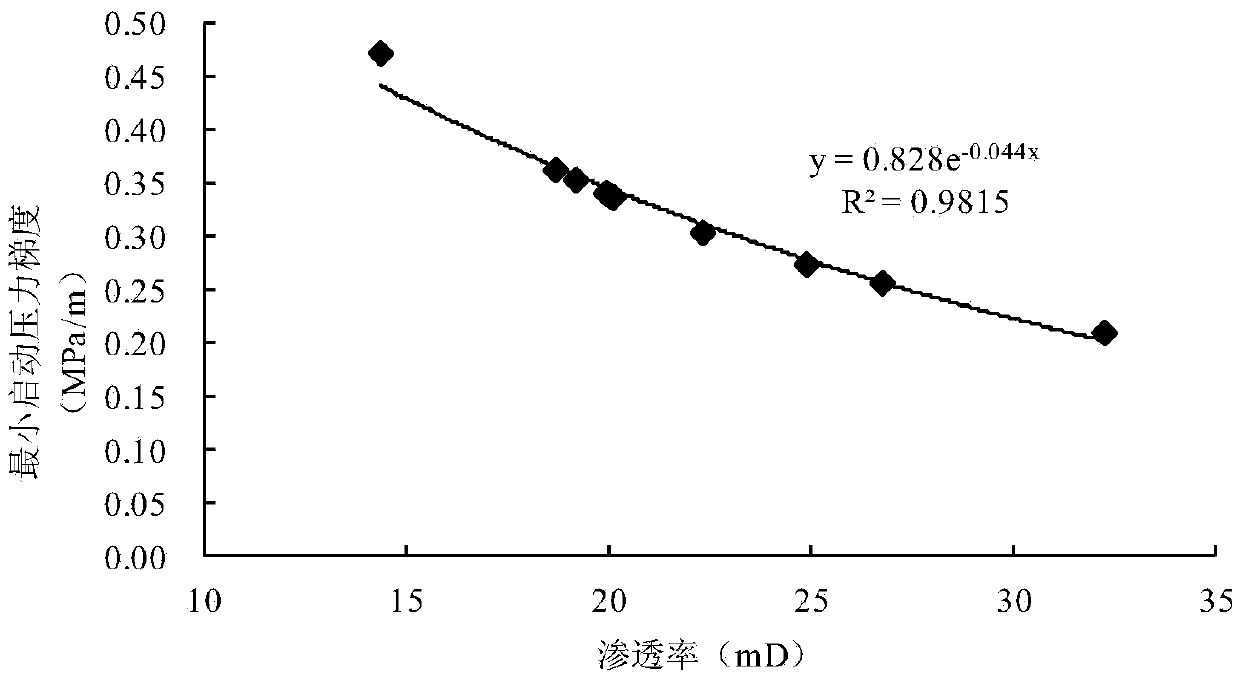

Experimental method for evaluating adaptability of plugging agent in low permeability crack rock core

The invention discloses a method for selecting a plugging agent most suitable for a low permeability crack rock core from plugging adjusting agents to be selected. The experimental method comprises the following steps that (1) low permeability crack rock core models are prepared, wherein cracks are manufactured with an artificial low permeability homogeneous columnar rock core and an artificial low permeability homogeneous square rock core as matrixes by referring to actual low permeability crack reservoirs, and a crack columnar rock core model and a crack square rock core model are manufactured; (2) the crack columnar rock core model or the crack square rock core model is taken as a physical model, the plugging performance of different plugging adjusting agents with the injection amount same as the crack size, and the breakthrough pressure gradient, the residual resistance factor and the plugging ratio of each plugging adjusting agent are worked out; firstly, the breakthrough pressure gradient of each plugging adjusting agent is compared with the minimum starting pressure gradient of the model, and the plugging agents with the breakthrough pressure gradients smaller than or equal to the minimum starting pressure gradient are removed; secondly, the plugging rate of the rest of the plugging adjusting agents are compared, and the plugging adjusting agent which larger the plugging rate is, larger the breakthrough pressure gradient is serves as the most adaptive plugging adjusting agent for the low permeability crack rock core.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

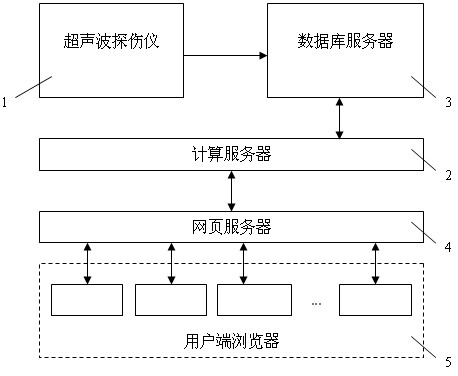

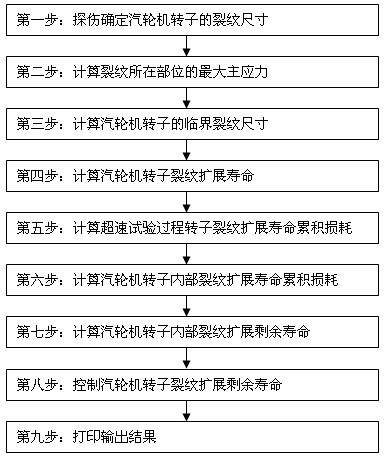

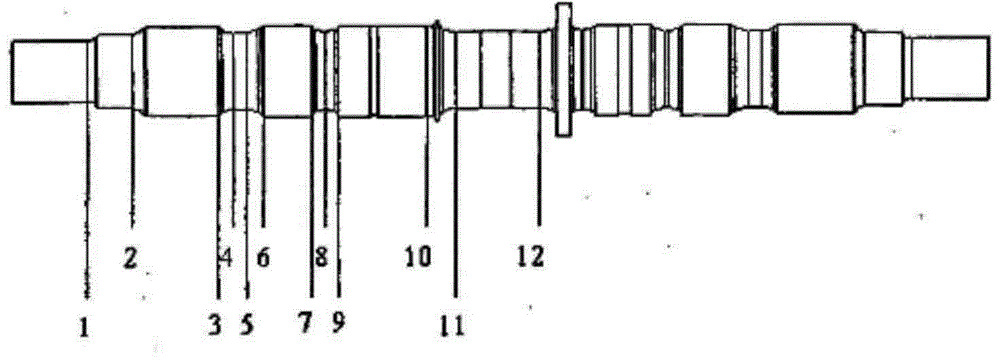

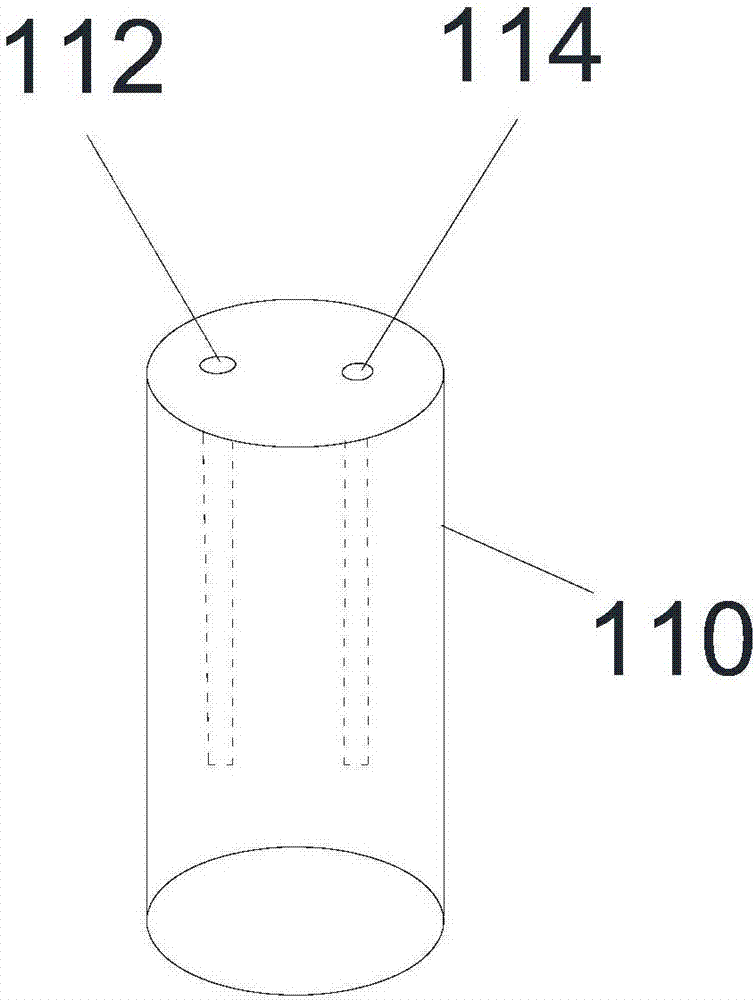

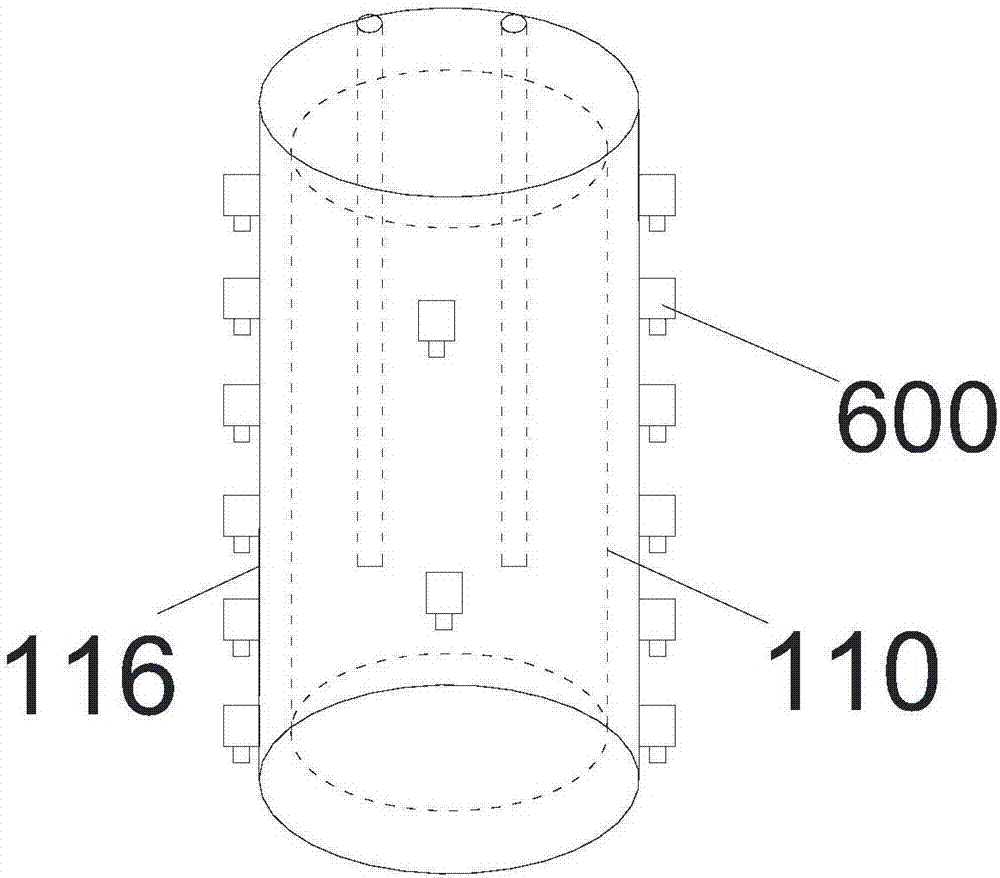

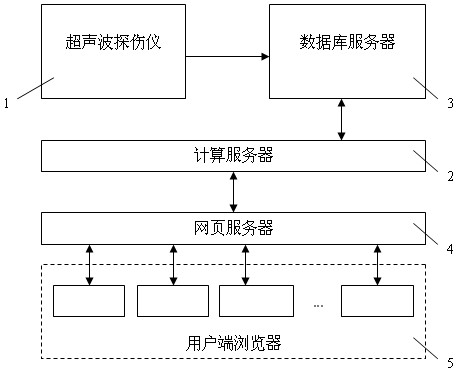

Device and method for monitoring crack propagation life of turbine rotor

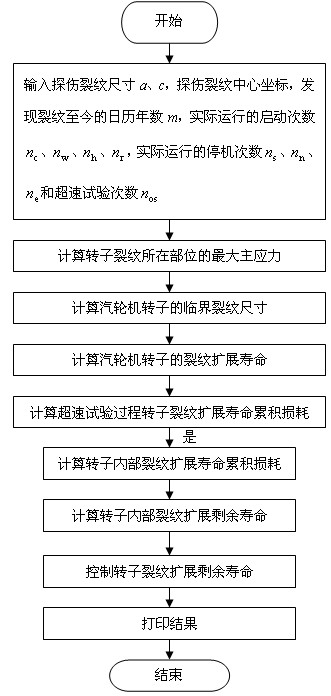

The invention provides a device and a method for monitoring internal crack propagation life of a turbine rotor. The method includes the specific steps of: flaw detection and determination of crack size of the turbine rotor; computation of maximum main stress of parts where the crack is; computation of a critical crack size of the turbine rotor; computation of crack propagation life of the turbine rotor; computation of accumulation loss of the crack propagation life of the rotor in an overspeed test process device; computation of the accumulation loss of the internal crack propagation life of the turbine rotor; computation of the internal crack propagation residue life of the turbine rotor; controlling the crack propagation residue life of the turbine rotor; and printing an output result. The device and the method have the advantages that: the residual crack propagation life of the turbine rotor can be calculated on line and monitored regularly; if the residual crack propagation life of the turbine rotor is relatively short, the residual crack propagation life of the turbine rotor is rationally used by immediately overhauling (A-level overhaul); therefore, a technical scheme that the residual crack propagation life of the turbine rotor is monitored regularly is achieved.

Owner:SHANGHAI POWER EQUIP RES INST

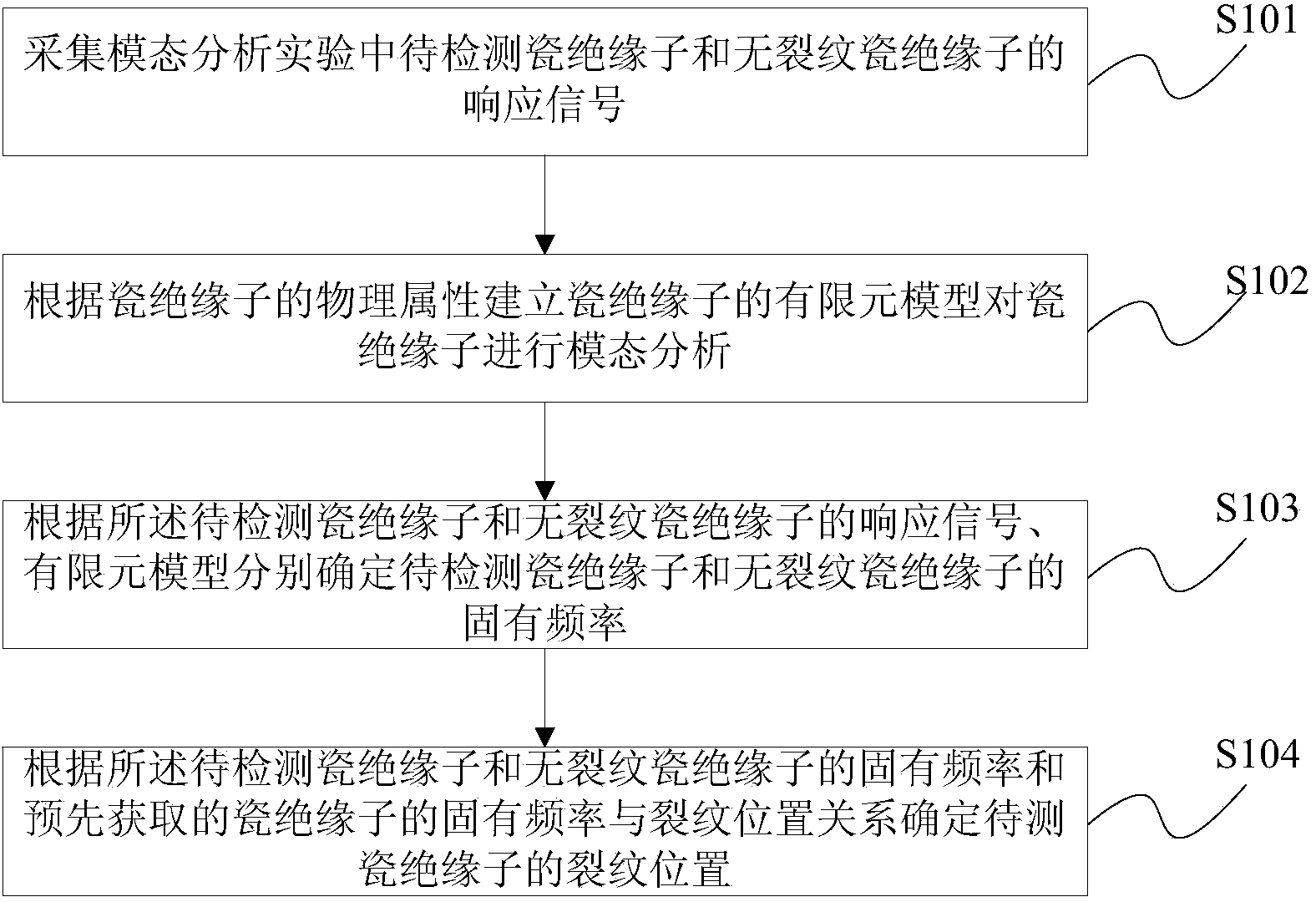

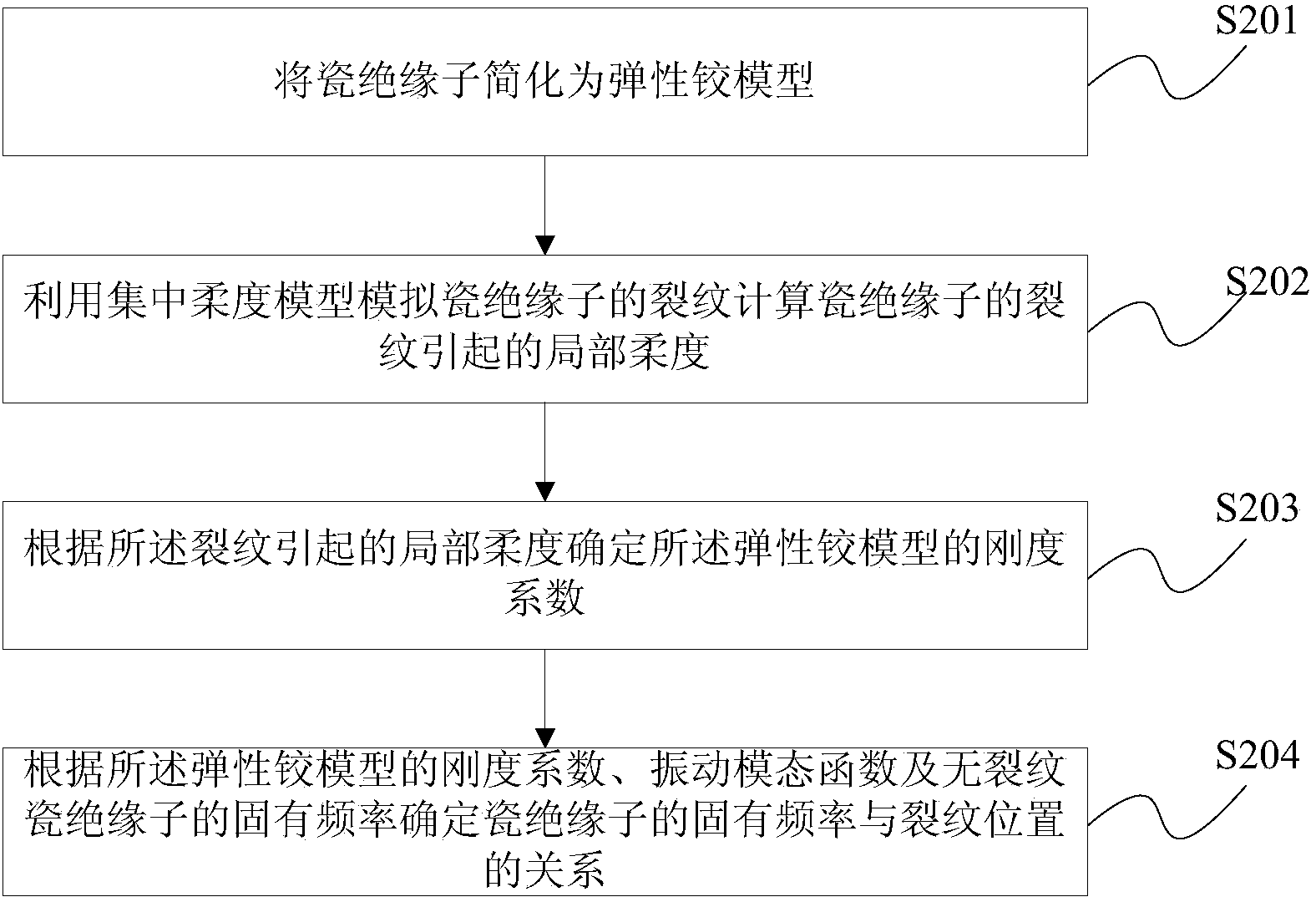

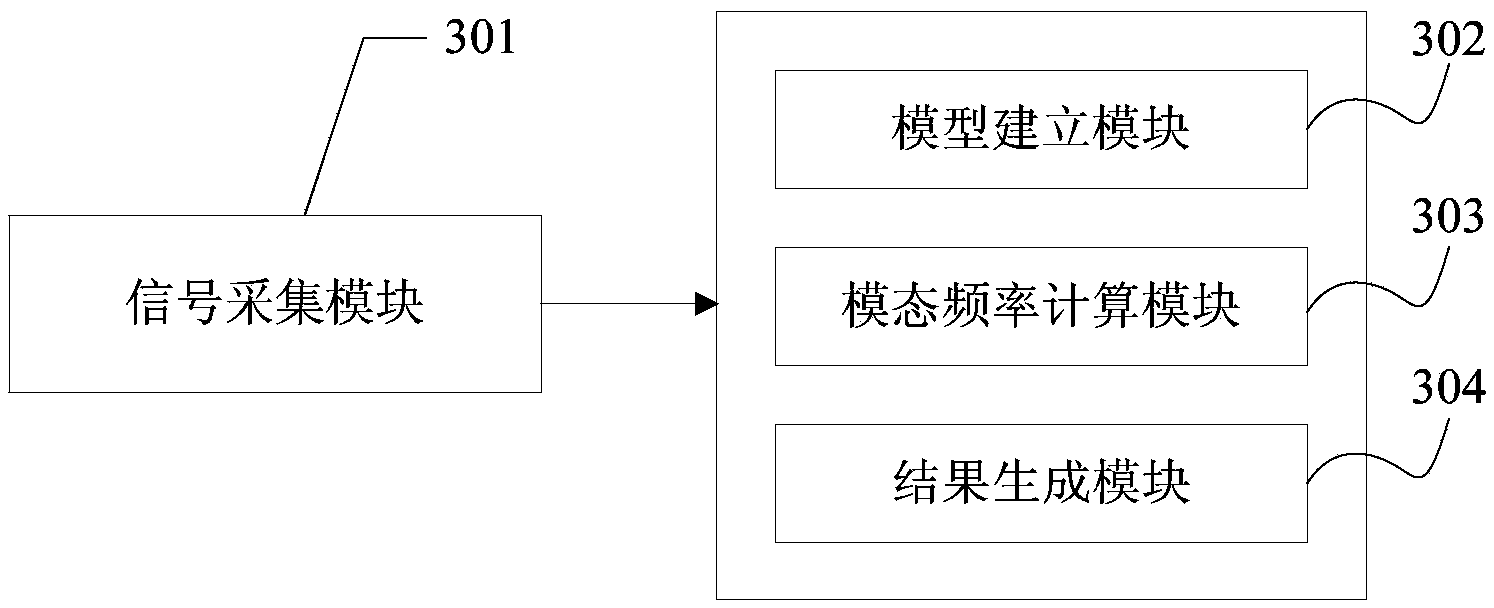

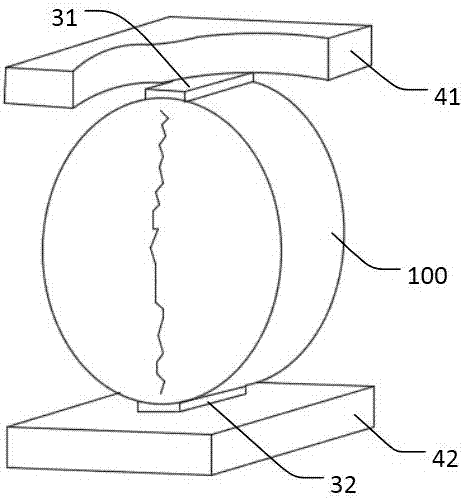

Method, device and system for detecting crack of insulator

ActiveCN103543209AImprove safety and reliabilityAnalysing solids using sonic/ultrasonic/infrasonic wavesElement modelCrazing

The invention provides a method, a device and a system for detecting a crack of an insulator. The method comprises the steps of acquiring response signals of a porcelain insulator to be detected and a crack-free porcelain insulator in a modal analysis experiment; establishing a finite element model of the porcelain insulator to perform modal analysis to the porcelain insulator according to the physical property of the porcelain insulator; determining the inherent frequencies of the porcelain insulator to be detected and the crack-free porcelain insulator according to the response signals of the porcelain insulator to be detected and the crack-free porcelain insulator and the finite element model respectively; and determining the crack position of the porcelain insulator to be detected according to the relation of the inherent frequencies of the porcelain insulator to be detected and the crack-free porcelain insulator, the inherent frequency of the porcelain insulator, acquired in advance, and the crack position. According to the invention, the finite element model of the cracked porcelain insulator is established to analyze the influence of different crack positions and crack sizes on the inherent frequency of the porcelain insulator, so that the purpose of detecting the crack of the porcelain insulator is achieved, and the safety and the reliability of the porcelain insulator are improved.

Owner:STATE GRID CORP OF CHINA +2

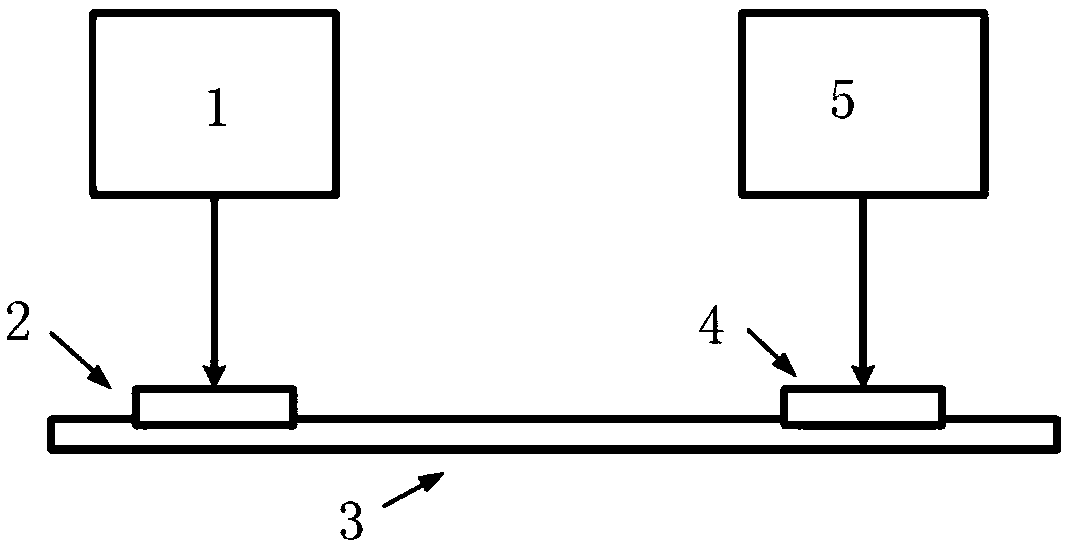

Ultrasonic nondestructive detection method of material mico-crack expanded size

InactiveCN109283247AAvoid Serious Impact on SecurityThe detection process is fastAnalysing solids using sonic/ultrasonic/infrasonic wavesReference sampleFatigue damage

The invention provides an ultrasonic nondestructive detection method of material micro-crack expanded size. The method comprises the following steps: constructing a measurement system; manufacturing multiple reference samples, and performing repeated fatigue test on each reference sample; performing metallographic observation after each fatigue test so as to obtain a micro-crack length of each reference sample, and performing ultrasonic nonlinear Lamb wave measurement to compute a nonlinear parameter beta0 of each reference sample; obtaining a nonlinear parameter-fatigue life curve, marking micro-crack sizes corresponding to various points on the curve; performing nonlinear ultrasonic Lamb wave measurement on the to-be-tested sample to obtain the nonlinear parameter beta0, and finding outthe point corresponding to the nonlinear parameter beta0 in the above curve, and finding the length of the micro-crack corresponding to the point. A relationship of the micro-crack size and the nonlinear parameter is used for judging the micro-crack length and representing the fatigue damage, in-service equipment cannot be damaged, and the micro-crack state of the material on active can be quicklydetected at low cost.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing simulated stress corrosion crack with controllable crack size and conductivity

ActiveCN105823661AEasy to operateEasy to implementPreparing sample for investigationCrazingMachined surface

Provided is a method for preparing a simulated stress corrosion crack with the controllable crack size and conductivity. The method comprises the steps that firstly, two stainless steel test blocks are machined, and a pit flaw with a certain size and shape is pre-buried in a to-be-welded face of one test block according to the size of a real stress corrosion crack; then the pre-buried pit is filled with a selected high temperature resisting material with proper conductivity according to the conductivity of the real crack, and the two test blocks are welded together through the solid phase welding technology to obtain a welded test piece; the part, above the pre-buried flaw area, of the welded test piece is cut out, the machined surface flaw test piece can be used for eddy current testing experiments, and the real stress corrosion crack is simulated. The simulated test piece prepared through the method can effectively replace a stress corrosion crack test piece complex in actual shape and hard to prepare, the advantages of being easy to operate and achieve, low in cost and controllable in crack size and conductivity are achieved, and the test piece can be widely applied to a detectability certification system of a stress corrosion crack quantitative eddy current testing method.

Owner:哈尔滨智海睿核能源科技有限公司

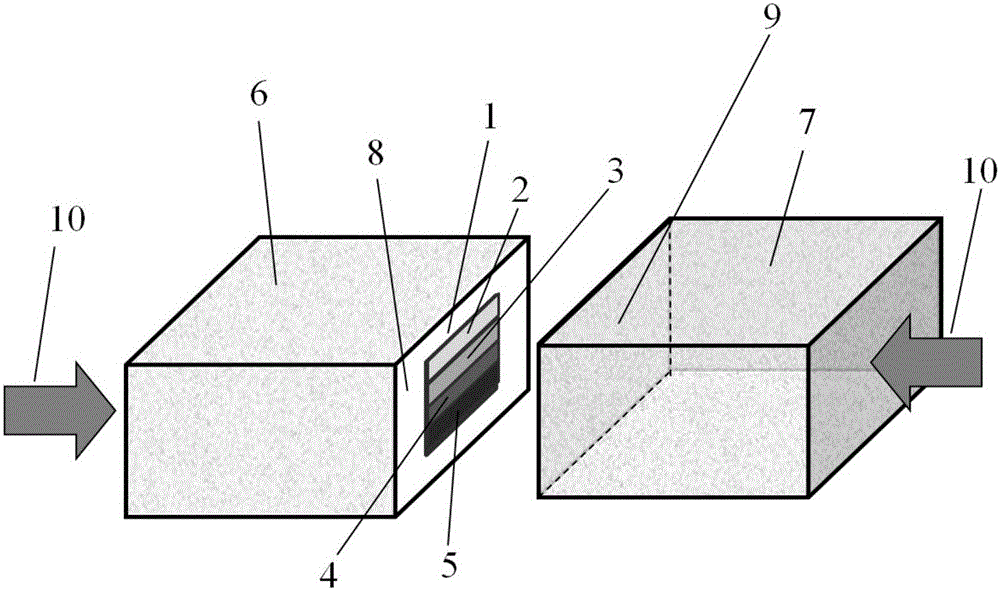

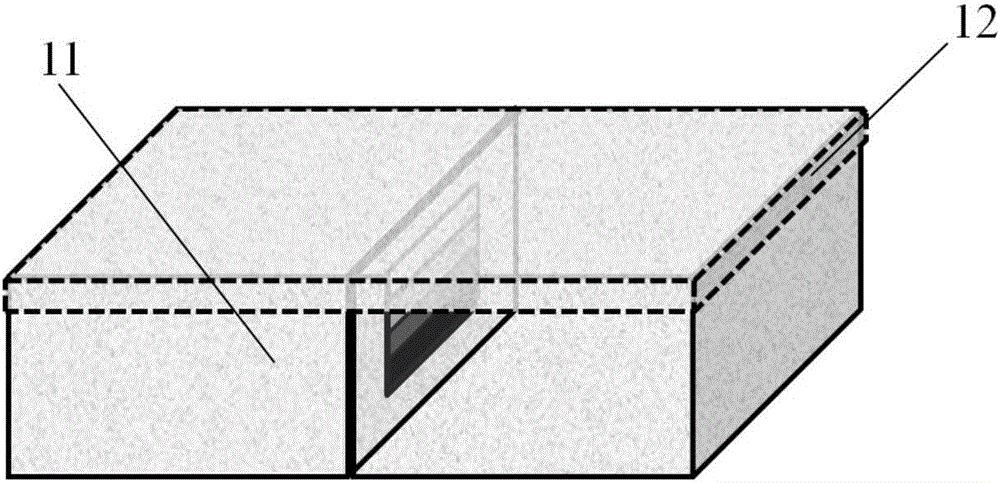

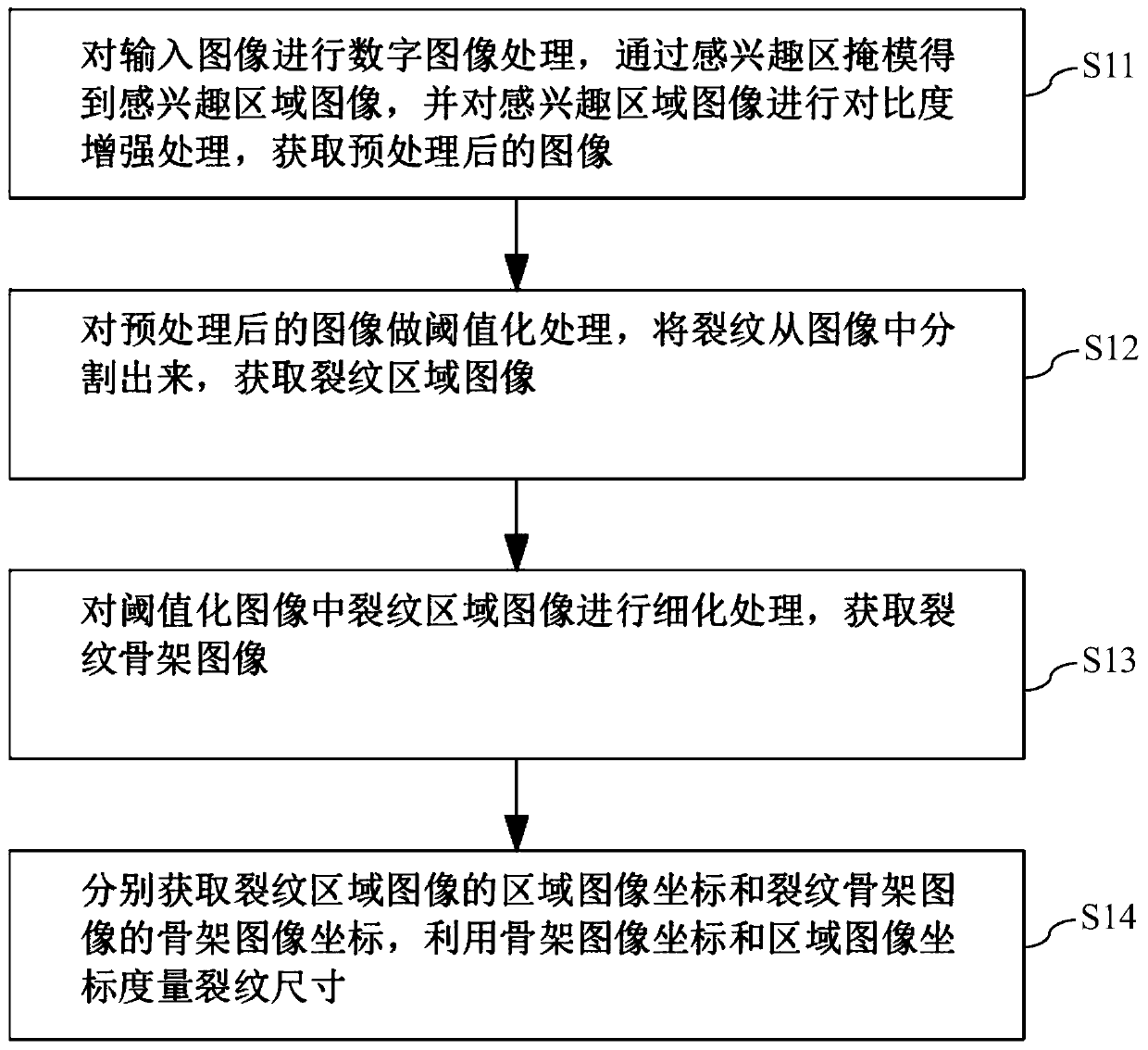

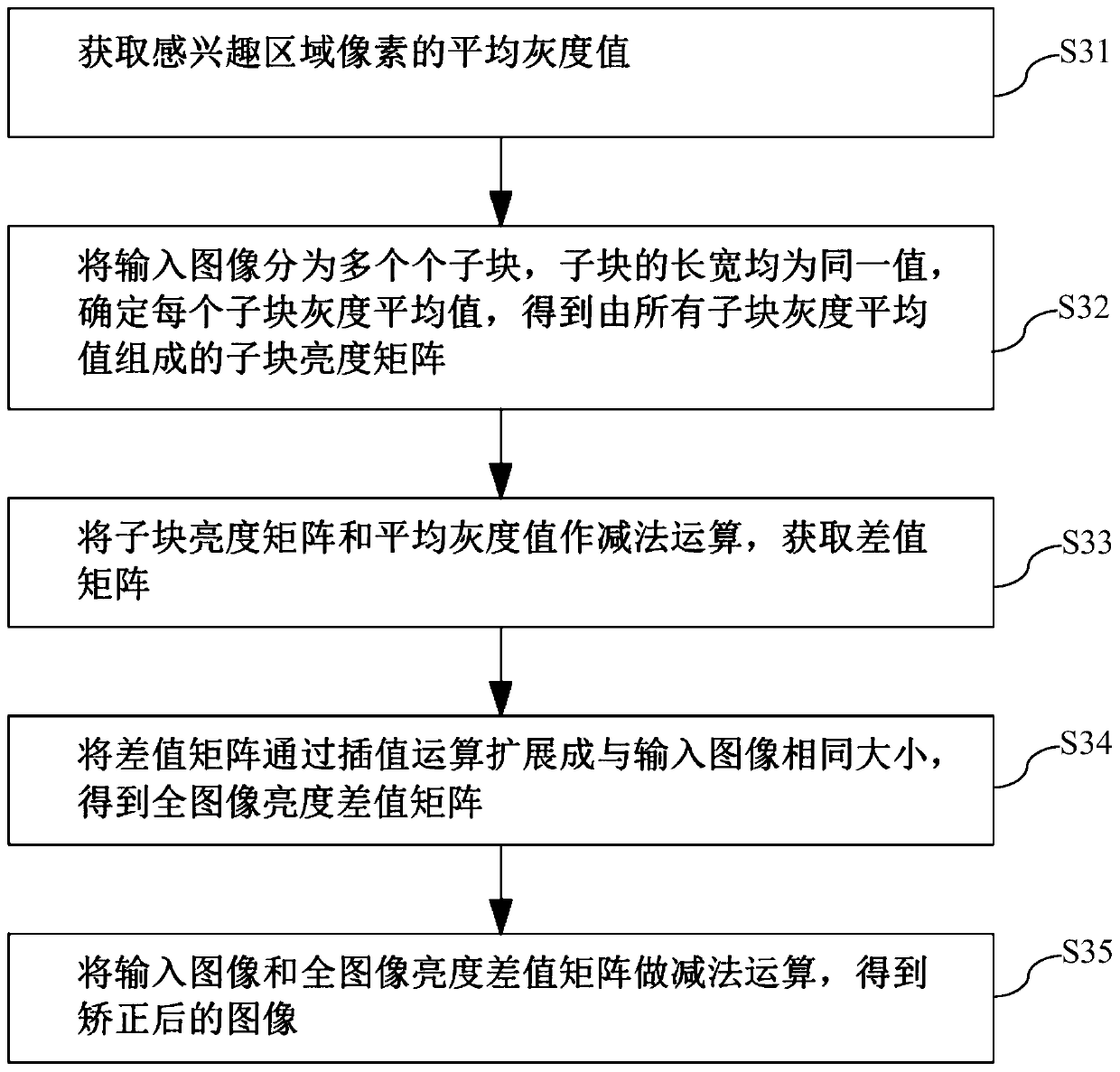

Crack size measurement method and device based on digital image and electronic device

PendingCN109886921AAccurate detection metricsImage enhancementImage analysisImaging processingLow speed

The embodiment of the invention discloses a crack size measurement method based on a digital image, which is used for crack detection and measurement, and comprises the following steps of carrying outdigital image processing on an input image, obtaining an interested region image through an interested region mask, and carrying out contrast enhancement processing on the interested region image toobtain a preprocessed image; performing threshold processing on the preprocessed image, and segmenting the crack from the image to obtain a crack area image; carrying out refining processing on the crack region image in the threshold image to obtain a crack skeleton image; acquiring the area image coordinates of the crack area image and the skeleton image coordinates of the crack skeleton image respectively, and measuring the crack size by using the skeleton image coordinates and the area image coordinates, so that the problems of low speed and inaccurate measurement of the existing crack measurement method are avoided, and the material can be rapidly and accurately detected and measured.

Owner:新而锐电子科技(上海)有限公司

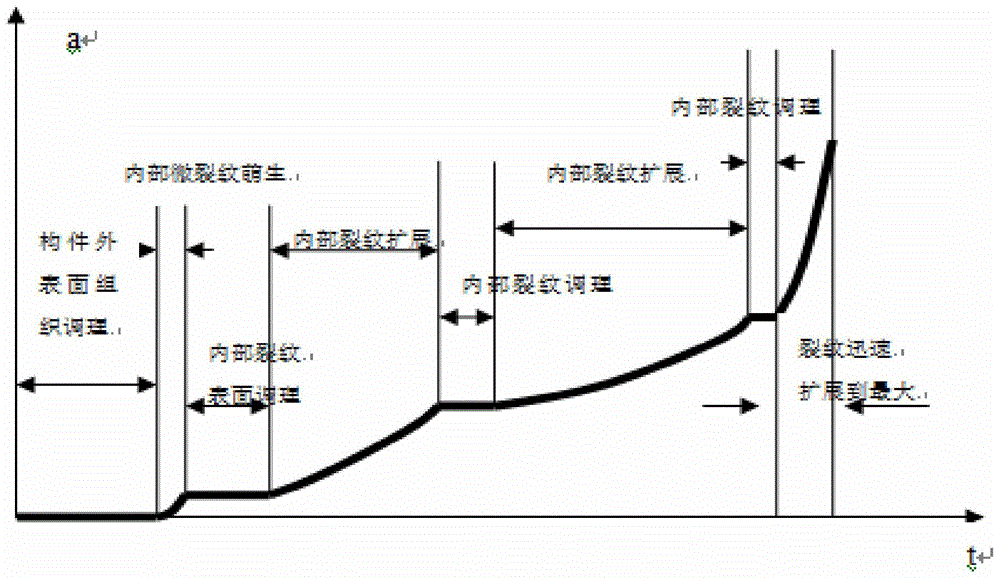

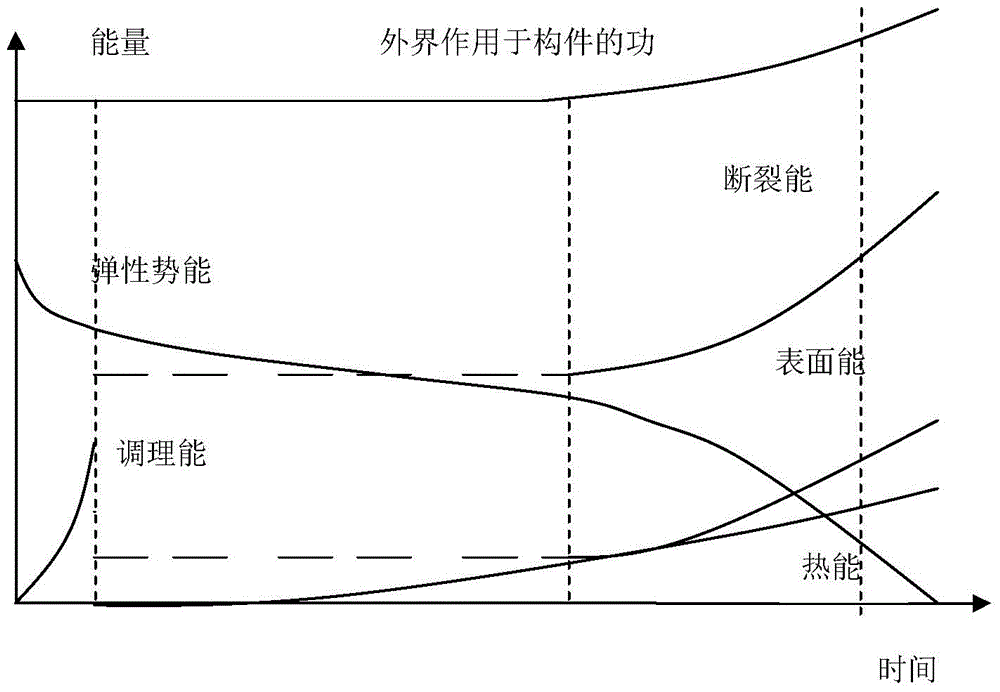

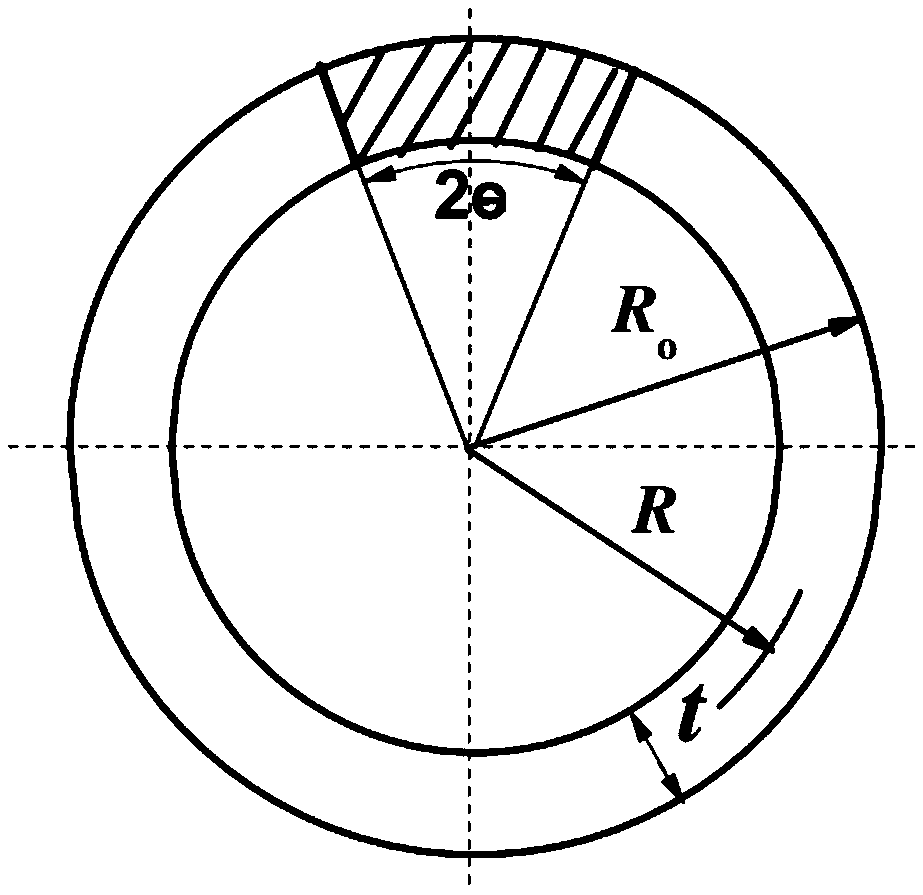

Method for calculating ultrahigh-cycle fatigue crack initiation time

The invention belongs to the fields of quantitative description and life calculation and analysis of ultrahigh-cycle fatigue damage coupling mechanisms of iron system materials and in particular relates to a method for calculating ultrahigh-cycle fatigue crack initiation time. The method comprises the following steps: by adopting principles such as an energy conservation principle, elastic mechanics and fracture mechanics, taking a hollow shaft as an example, establishing a three-dimensional transient temperature field, providing a quantitative model and time calculation method in the ultrahigh-cycle fatigue crack initiation process under the coupling effect, giving novel crack initiation basis, and performing allowable stress design reasoning. The propagation of cracks is discontinuous, the change of outside action time and change of the crack length are in the same direction, and the change speed is influenced by surface energy and yield limit. The scheme has the advantages that the method is based on the quantitative model of the crack initiation under the multi-factor coupling effect when the material interior crack size is zero. The method directly contributes to estimating the observable crack scale and crack initiation time in actual production and is scientific.

Owner:SOUTHEAST UNIV +1

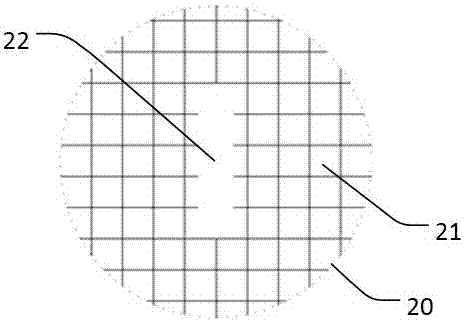

Method for prefabricating cement-based sample crack, prefabricated sample and prefabricating system

The invention discloses a method for prefabricating a cement-based sample crack, a prefabricated sample and a prefabricating system. A configuration net which can form a fracture through removing net wires so as to produce a weak area is manufactured, and is put in the prefabricated sample during a process of casting to form the prefabricated sample, so that when the prefabricated sample is loaded by a pressure testing machine, not only can a crack size and a crack position of the prefabricated sample be controlled through the configuration net, but also the advantage of enabling the formed crack to get close to a crack produced by real stress cracking of concrete is realized.

Owner:SHENZHEN UNIV

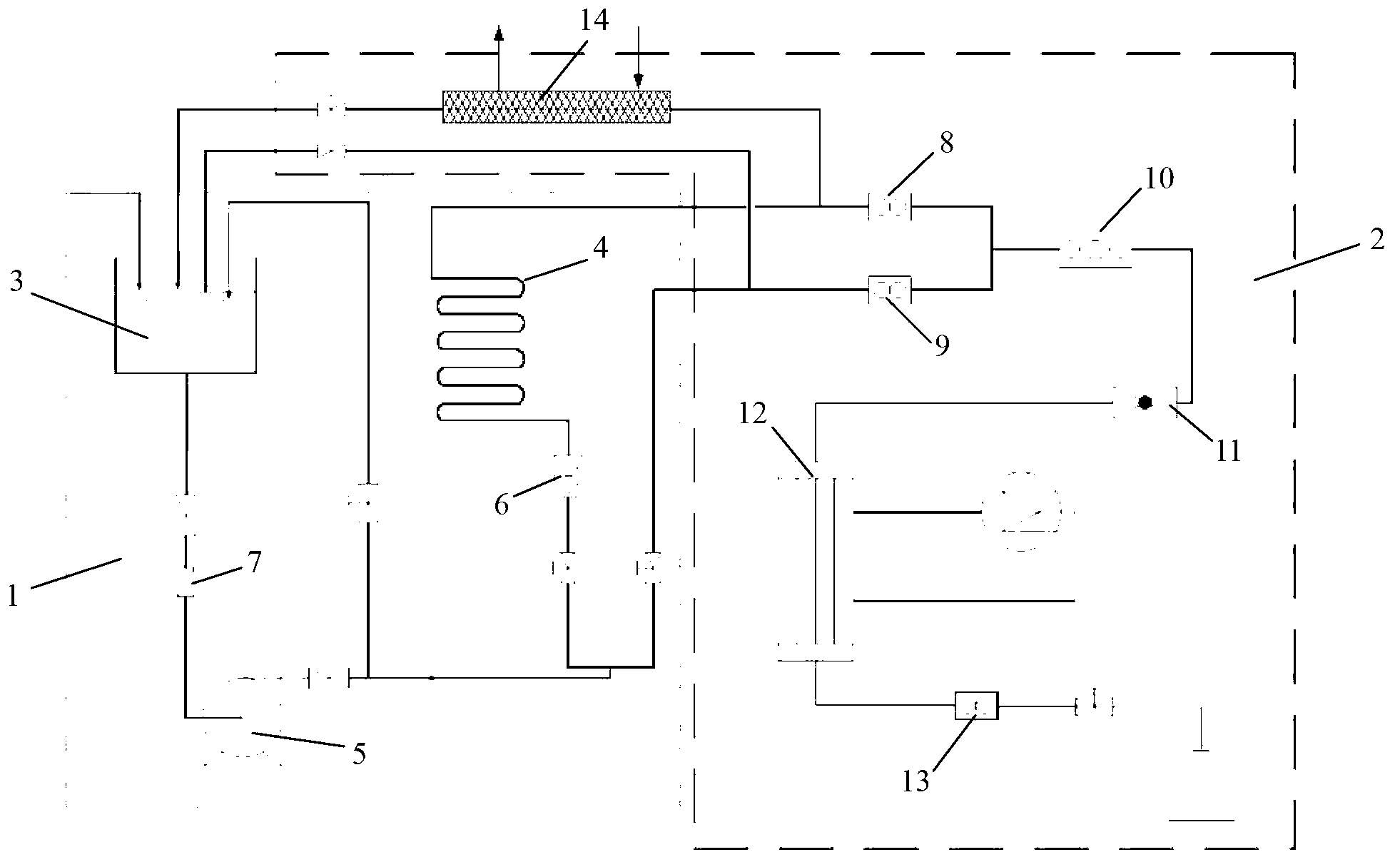

Method and system for testing nuclear power station pipeline leakage rate

The invention relates to a method and a system for testing nuclear power station pipeline leakage rate. The method includes: generating corresponding media with a medium generator; measuring medium mass through a mass flowmeter; cooling media, which is mixed by a mixer and flowed out from a test section, with a condensing device, measuring the media with the mass flowmeter, comparing measured mass with input mass, and regarding the measuring result as creditable if measured mass equals to or is close to the input mass; otherwise, repeating the test; and cutting open the test section, detecting crack surface roughness and a runner, using the detecting value as input of a leakage rate program, and comparing difference between the result of the leakage rate program and the measuring result. Crack size is simulated to build relation of flow and defined size, leakage test under actual working conditions can be performed aiming at actual cracks, and leakage amount of different load and crake forms can be measured.

Owner:CHINA NUCLEAR POWER ENG CO LTD +1

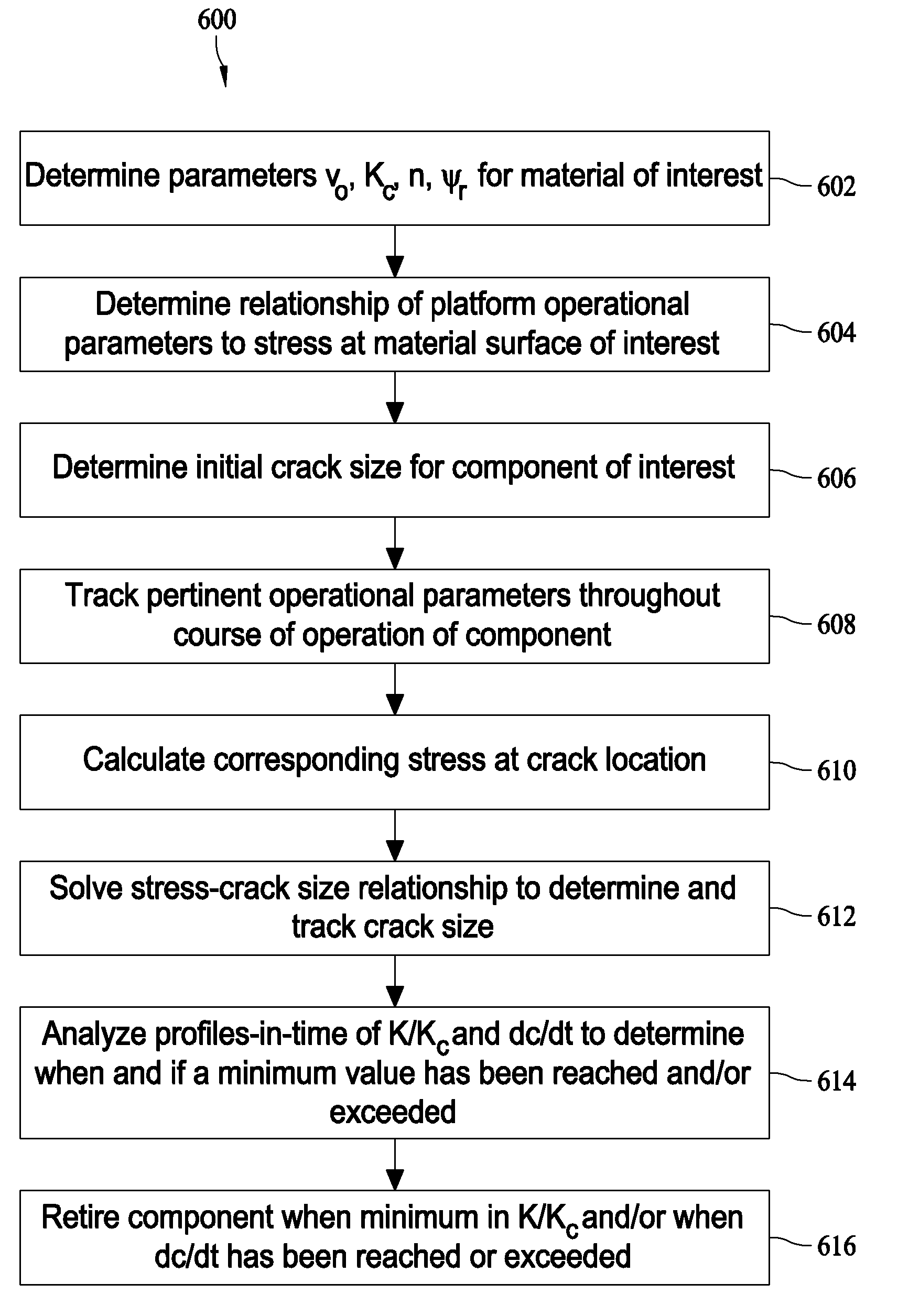

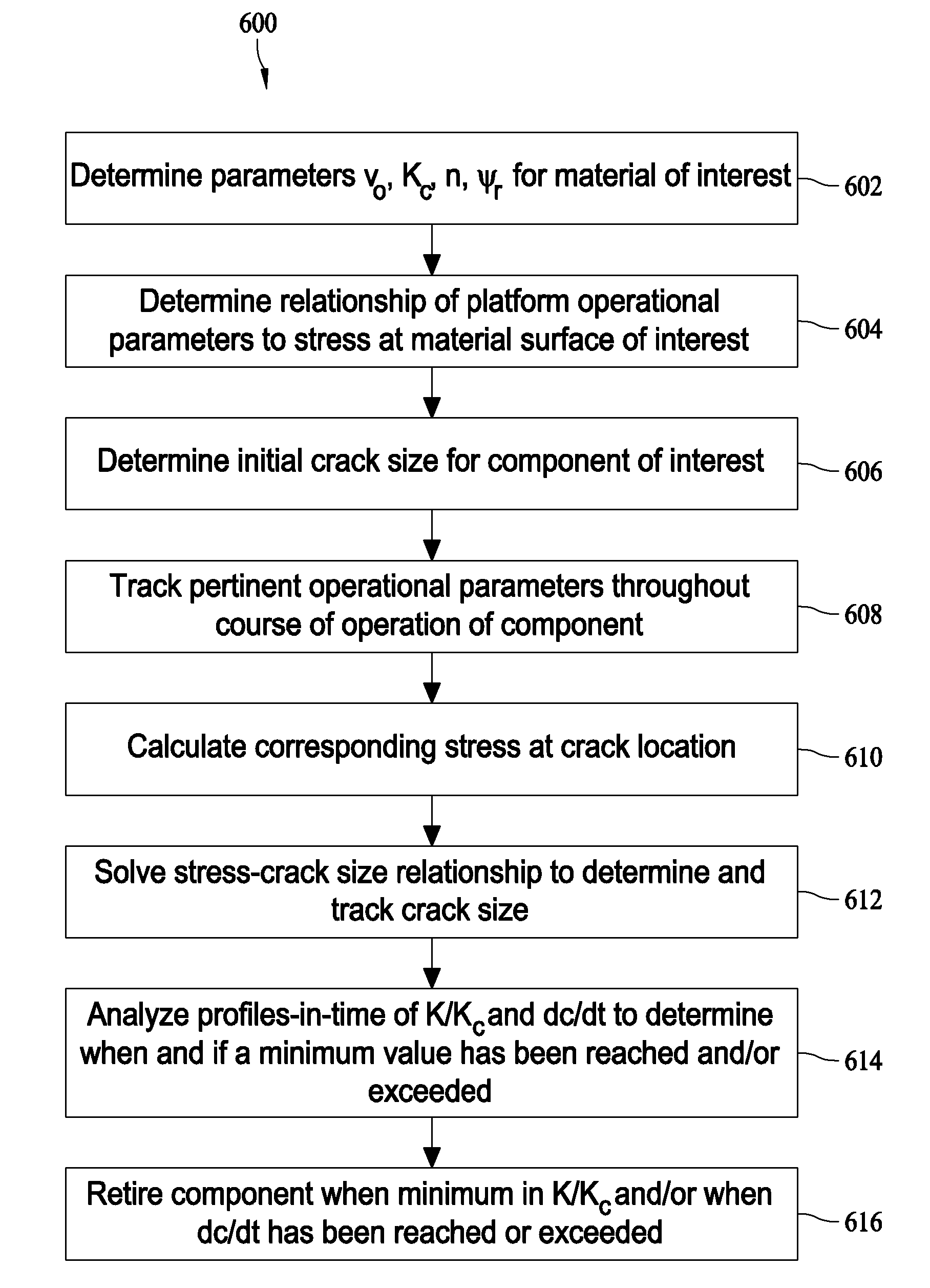

Method and systems for estimating remaining service life of a component subject to stress

A method is described for determining when a ceramic component on a platform should be replaced. The method includes determining the parameters vo, Kc, n, and ψr for the component, where vo and n are empirically determined parameters, Kc is a critical stress intensity factor, ψr is a geometry factor for the material in the form of the component, determining a relationship of between platform operational parameters to the generation of stress at the surface of interest of the component, determining an initial crack size of a crack within the component at installation, tracking operational parameters of the platform throughout a course of usage of the component, calculating the corresponding stress at the crack location due to the tracked operational parameters, and calculating a numerical solution that illustrates a crack growth rate velocity and tracks a size of the crack over time.

Owner:THE BOEING CO

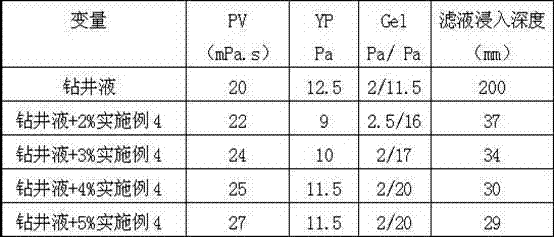

Broad-spectrum deformable while-drilling leak-proof sealing agent

The invention relates to a broad-spectrum deformable while-drilling leak-proof sealing agent which comprises the following components in percentage by weight: 40-60% of amorphous plugging material, 15-25% of ultrafine expanding material, 5-10% of elastic tire rubber particle and 20-35% of reinforcer ultrafine calcium carbonate powder. The amorphous plugging material is amorphous slag powder, and the ultrafine expanding material is ultrafine konjaku powder, ultrafine bamboo powder or ultrafine natural rubber powder. The sealing agent has the advantages of high sealing efficiency and high acid solubility, is independent of leak layer pores and crack size, and can be used for while-drilling leak-proof sealing for permeable and cracking non-reservoirs and reservoirs.

Owner:DAQING PETROLEUM ADMINISTRATION

Processing method of alloy surface micro-cracks

InactiveCN102642177AExtended peening timeReduce processing timeAbrasion apparatusSurface finishHardness

The invention relates to a processing method of alloy surface micro-cracks. The aimed micro-crack size range is that the depth is smaller than 0.8 mm, the width is smaller than 0.2 mm, and the length is smaller than 2 mm. A compressive stress layer is formed on the periphery of the alloy surface cracks by using liquid shot-peening repair method, so that micro-cracks with lower depth are eliminated directly, the size of cracks with deeper depth become small, closure effects are produced, spreading rate of the surface micro-cracks is effectively reduced, the surface rigidity and toughness are increased, and components serve continuously; and deformation of alloy after processing is small, and the surface fineness is high. The method is applied in the repair of alloy surface micro-cracks, the operation of the device is flexible, and the process is simple; and limits to workpiece size, operation site and space are small, the processing efficiency is high, energy is saved, and the method is clean and pollution-free.

Owner:DALIAN UNIV OF TECH

Method and systems for estimating remaining service life of a component subject to stress

ActiveUS8255171B2Plug gaugesMachine gearing/transmission testingUltimate tensile strengthCritical stress

A method for determining when a ceramic component on a platform should be replaced. The method includes determining parameters for the ceramic component, the parameters include empirically determined a critical stress intensity factor, and a geometry factor for the ceramic component. The method also includes determining a relationship between platform operational parameters to the generation of stress at the surface of interest of the ceramic component, determining an initial crack size of a crack within the ceramic component at installation, tracking operational parameters of the platform throughout a course of usage of the ceramic component, calculating the corresponding stress at the crack location due to the tracked operational parameters, and calculating a numerical solution that illustrates a crack growth rate velocity and tracks a size of the crack over time. The ceramic component is replaced based on the crack growth rate velocity and the size of the crack.

Owner:THE BOEING CO

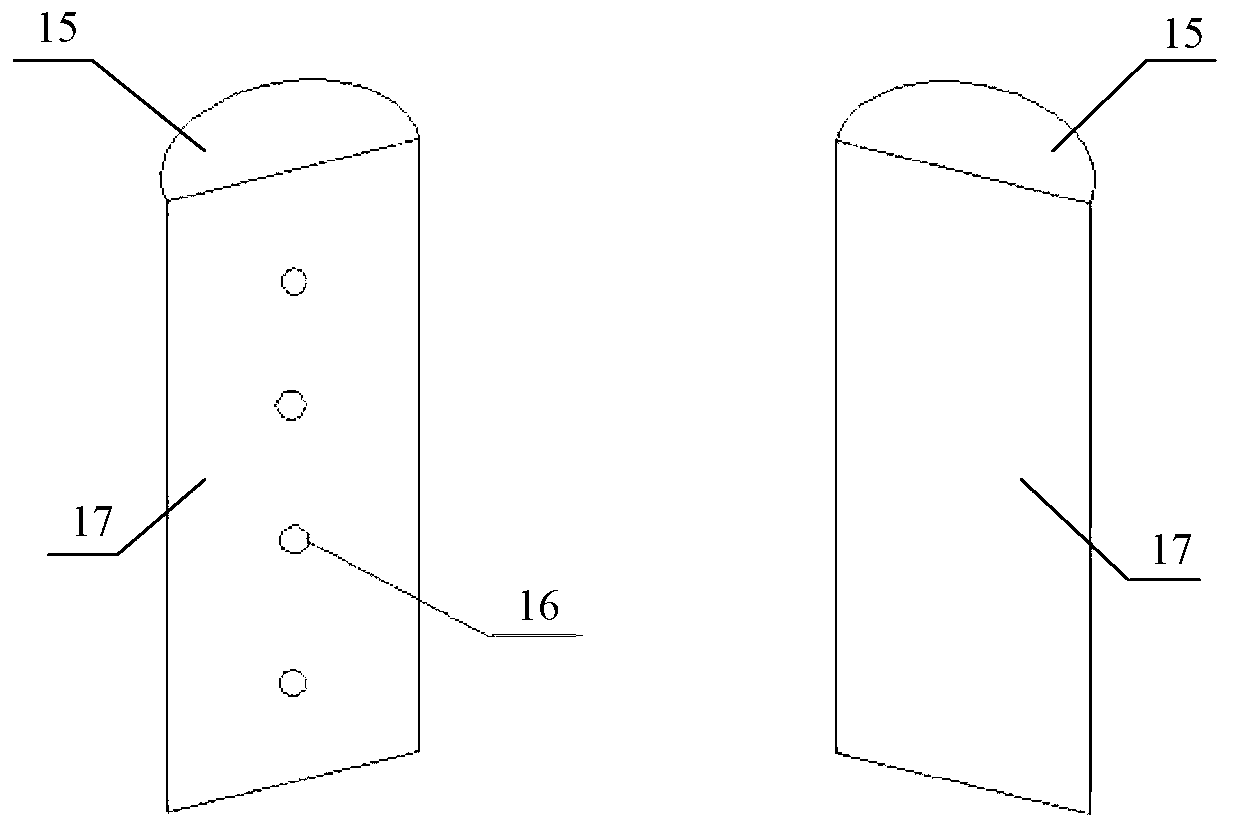

Method for making longitudinal cracks in simulated test block welding seams

ActiveCN104729901AIncrease success rateLow costPreparing sample for investigationNon destructiveMetallic materials

The invention discloses a method for making longitudinal cracks in simulated test block welding seams. The method comprises the following steps: prefabricating and welding, machining, cracking by adopting a mechanical method, trimming by adopting a mechanical processing method, teaming and selecting a teaming part welding method. Compared with an existing method for making longitudinal cracks in a simulated test block, the method disclosed by the invention has the advantages that additives are not added, and a metal material of the welding seams is adopted. The operation method is simple and practical, easy to grasp, and wide in scope of application. The made cracks are high in success rate and low in cost. The made cracks have topographic characteristics which are almost the same as those of true cracks, and are even consistent with those of true cracks, so that the characteristics of the true cracks can be reflected. The dimensions, namely height, length and generated positions, of the cracks are easy to control, the precision is high and the dimensions of the generated cracks easily meet requirements within an error range. The method disclosed by the invention is suitable for being applied as a simulated test block crack processing method for non-destructive testing of test pieces.

Owner:田国良

Method for estimating crack initiation dimension values

PendingCN110059432AMaterial strength using steady shearing forcesDesign optimisation/simulationEstimation methodsElastic plastic

The invention provides a method for estimating a crack initiation dimension value, which comprises the following steps: obtaining a formula of short crack fatigue life based on an elastic-plastic fracture mechanical method, and establishing a basic model of a fatigue crack initiation dimension; and improving the basic model of the fatigue crack initiation size according to a calculation method ofthe fatigue crack initiation life, the total fatigue life and the invalid crack size to obtain a prediction model of the fatigue crack initiation size.

Owner:SHANGHAI UNIV OF ENG SCI

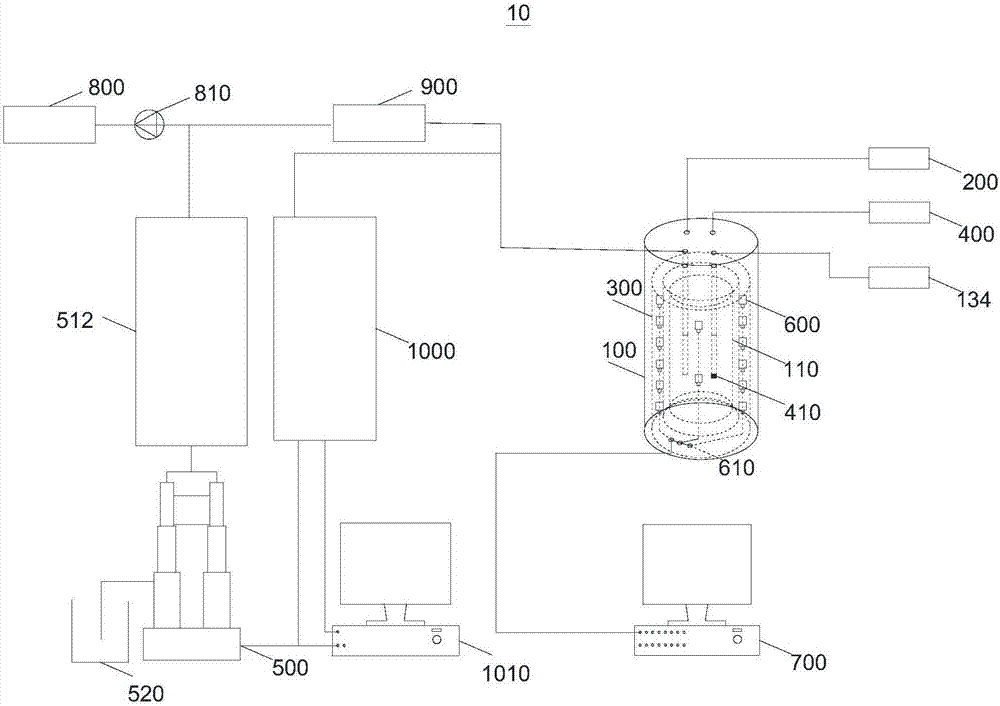

Testing device and simulation method of enhanced type terrestrial heat exploitation simulation

InactiveCN106872651AImprove efficiencyIncrease productivityMaterial analysis using acoustic emission techniquesAcoustic emissionNew energy

The invention relates to the field of design and manufacturing of new energy source development testing equipment and provides a testing device and a simulation method of enhanced type terrestrial heat exploitation simulation, aiming at solving the problem in the prior art that a complete set of equipment for simulating high-temperature and high-pressure environments does not exist. The testing device of the enhanced type terrestrial heat exploitation simulation, provided by the embodiment of the invention, is provided with a first pump and a heating device and is used for simulating underground high-temperature and high-pressure environments with different depths; the testing device is further provided with a second pump for providing high-temperature liquid for a liquid feeding hole of a test sample in a testing space and is provided with a plurality of acoustic emission sensors which are mounted in an manner of surrounding the test sample, are used for positioning an acoustic emission event and carrying out wave-velocity tomographic imaging and are used for monitoring positions of cracks and an evolution law of crack sizes. The testing device of the enhanced type terrestrial heat exploitation simulation, provided by the embodiment of the invention, can obtain testing data which has relatively great effect on optimization of production parameters and improvement of the production efficiency in actual field production.

Owner:CHONGQING UNIV

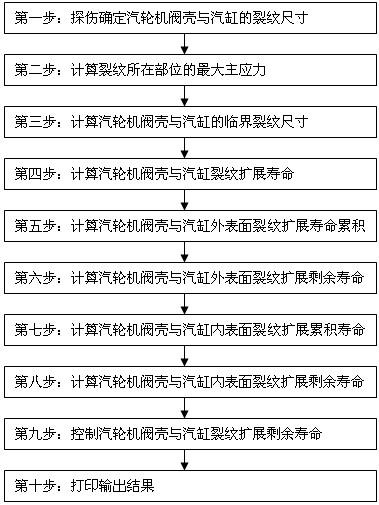

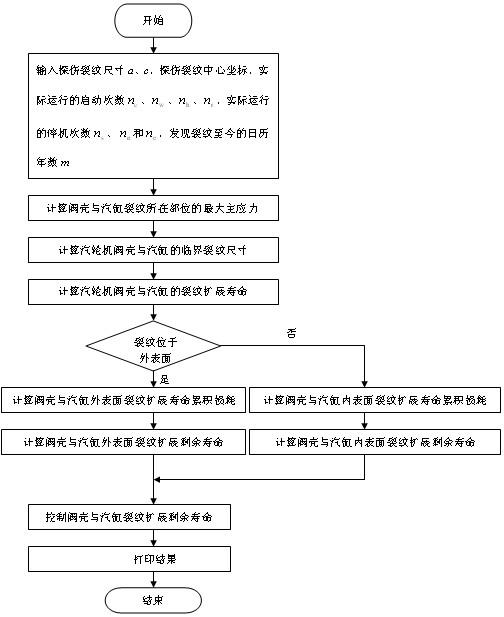

Device for monitoring service lives of valve casing of steam turbine and crack propagations of cylinder and method

The invention provides a device and a method for monitoring crack propagation life of a valve casing and a cylinder of a turbine. The method includes the specific steps of: flaw detection and determination of crack size of the valve casing and the cylinder of the turbine; computation of maximum main stress, a critical crack size, a crack propagation life, outer surface crack propagation life accumulation loss, an outer surface crack propagation residue life, inner surface crack propagation life accumulation loss, and an inner surface crack propagation residue life of parts where the crack is; controlling the crack propagation residue life of the turbine valve casing and cylinder; and printing an output result. The device has the advantages that online calculation and regular monitoring of the crack propagation residual life of the valve casing and the cylinder of the turbine are realized, if the crack propagation residual lives of the valve casing and the cylinder of the turbine are over short, scheduled heavy repair (A-level repair) is arranged in time so as to reasonably utilize the crack propagation residual lives of the valve casing and the cylinder of the turbine, and a technical effect of regularly monitoring the crack propagation residual lives of the valve casing and the cylinder of the turbine is achieved.

Owner:SHANGHAI POWER EQUIP RES INST

Area selection-based automatic crack size measurement method

InactiveCN103528527AReduce the difficulty of measurementImprove working environmentUsing optical meansEngineeringMechanical engineering

The invention relates to a construction inspection technique, in particular to an area selection-based automatic crack size measurement method which is used for detecting the sizes of cracks on various facilities including buildings and bridges. The method includes the following steps: (1) a crack image is acquired and converted into a single-channel grey image; (2) the grey image is dotted and captured; (3) the image is divided into a foreground part and a background part; (4) a checking image, the length and width of which are 2 and the reference point of which is (0, 0), is applied for traversing; the image is eroded in a single step once each time when traversing is finished, and eroding frequency S1 is counted; (5) the binarized crack image is reversed, so that the crack is detailed, and the image is then reversed; (6) the detailing of the crack is improved; and a crack pixel number S2 is counted; (7) a single-step erosion width and a single-pixel width is determined: a equal to W1 divided by S1; and b equal to L1 divided by S2; (8) the maximum width and length of the crack is worked out: W equal to S1 multiplied by a, and L equal to S2 multiplied by b.

Owner:北京交通大学长三角研究院

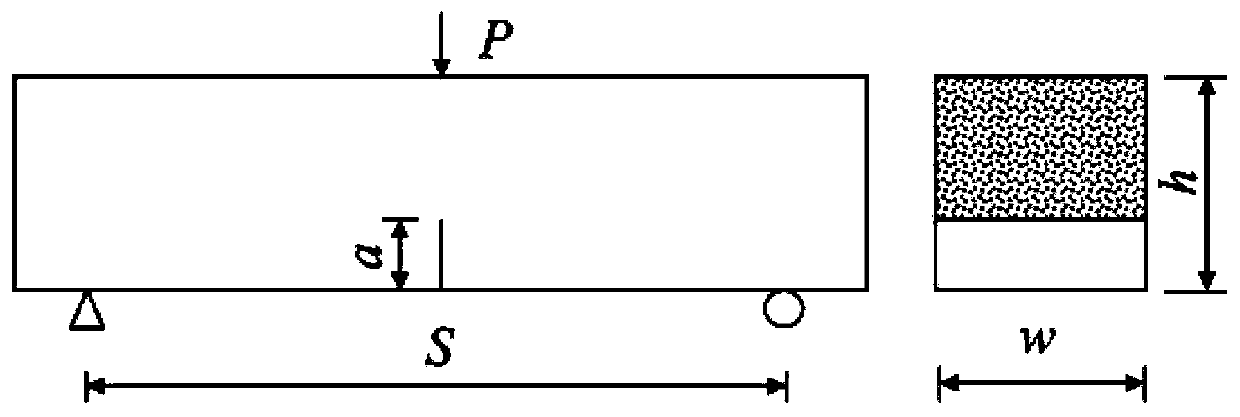

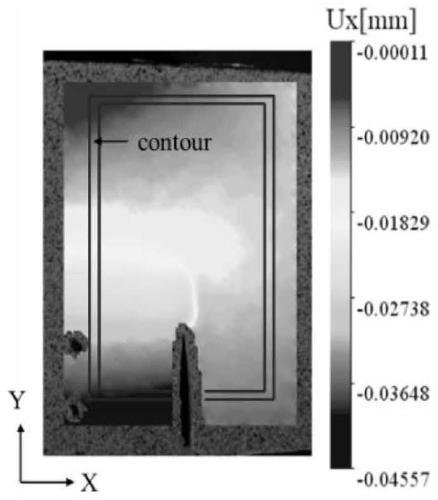

Heterogeneous material crack stress intensity factor calculation method applying DIC technology

ActiveCN111398057AImprove general performanceImprove efficiencyMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesCrazingStress intensity factor

The invention discloses a heterogeneous material crack stress intensity factor calculation method applying a DIC technology. The heterogeneous material crack stress intensity factor calculation methodcomprises the steps of: preparing a standard compression or tensile test piece of a heterogeneous material, carrying out unidirectional compression or stretching on the standard compression or tensile test piece to obtain an elastic modulus and a Poisson's ratio; preparing a heterogeneous material standard fracture test piece with cracks, and preparing speckles for carrying out a DIC test on thesurface of peripheral regions of the cracks; implementing a fracture experiment on the test piece to obtain a displacement field and a crack size of the region near a crack tip under different loads;selecting different integral paths, dividing subunits in an integral region, and calculating J-integral values of the subunits; performing filtering processing on the J-integral values, then performing superposition to obtain J-integral values on the integral paths, and converting the J-integral values into stress intensity factors K; repeating the above steps, calculating J-integral values underdifferent loads / displacements, and acquiring the stress intensity factor K at each loading moment. The heterogeneous material crack stress intensity factor calculation method has the advantages of high efficiency, high precision, high universality and the like.

Owner:SOUTH CHINA UNIV OF TECH

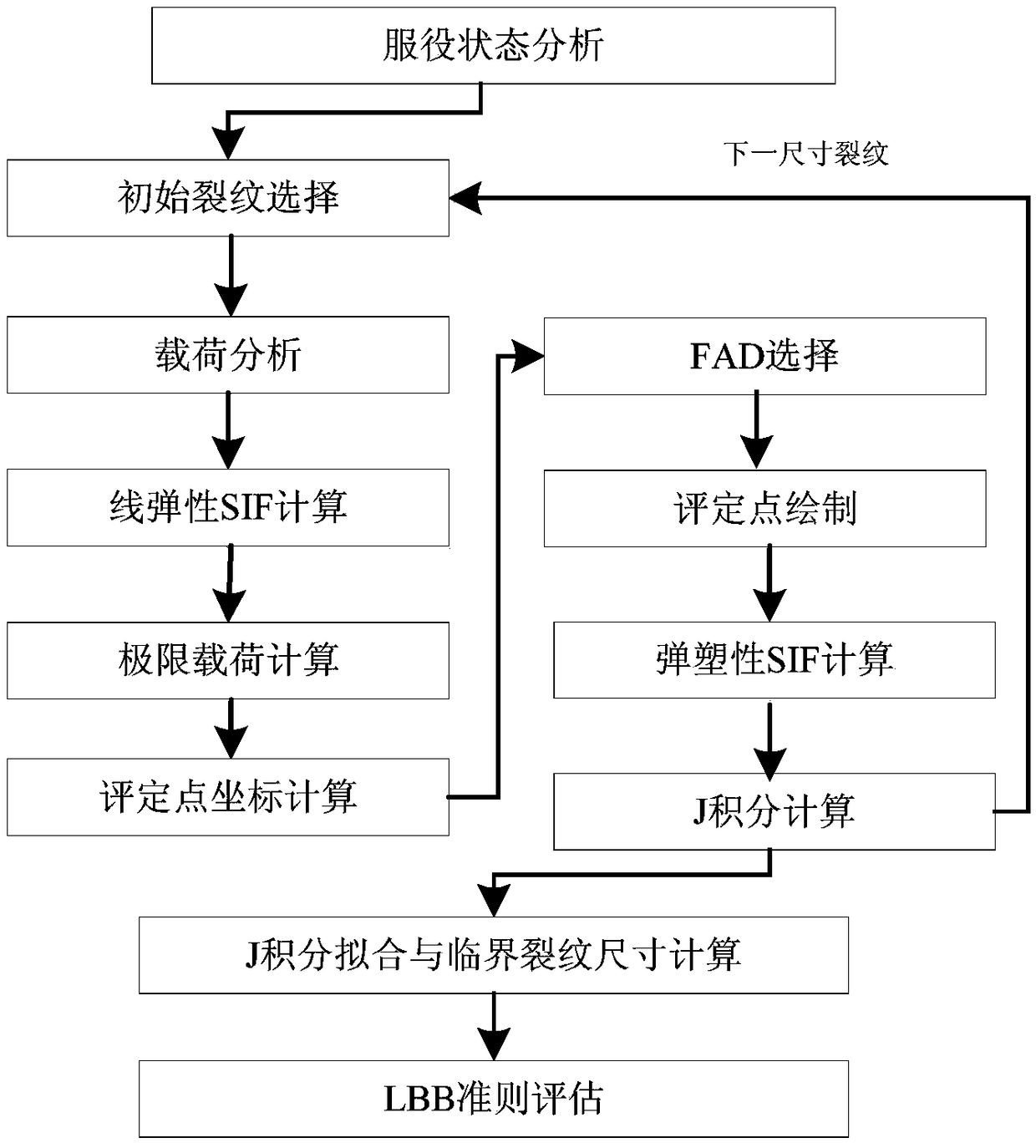

Leak before burst analysis method based on failure assessment diagram

ActiveCN108710721ADesign optimisation/simulationSpecial data processing applicationsFailure assessmentElement model

The present invention relates to a leak before burst (LBB) analysis method based on a failure assessment diagram (FAD). The method comprises the following steps: (a) service state analysis; (b) initial crack selection; (c) load analysis; (d) line elastic stress intensity factor (SIF) calculation; (e) ultimate load analysis; (f) evaluation point coordinate calculation; (g) FAD selection; (h) evaluation point drawing; (i) elastoplastic SIF calculation; (j) J-integral calculation; (k) calculation and fitting of the J-integral of different cracks; (l) calculation of the structural failure criticalcrack size; (m) calculation of the structural critical leakage crack size; and (n) LBB criterion evaluation. According to the method provided by the present invention, based on the FAD theory, defects that the theoretical basis of elastoplastic analysis in the existing norms is insufficient, the existing J-integral calculation manual has a limited application scope, the finite element modeling analysis process is complicated, and the processes for calculating the structural failure critical crack size and the structural critical leakage crack size are complicated, and the like are overcome, and a FAD-based LBB analysis basis is provided.

Owner:SUZHOU NUCLEAR POWER RES INST +4

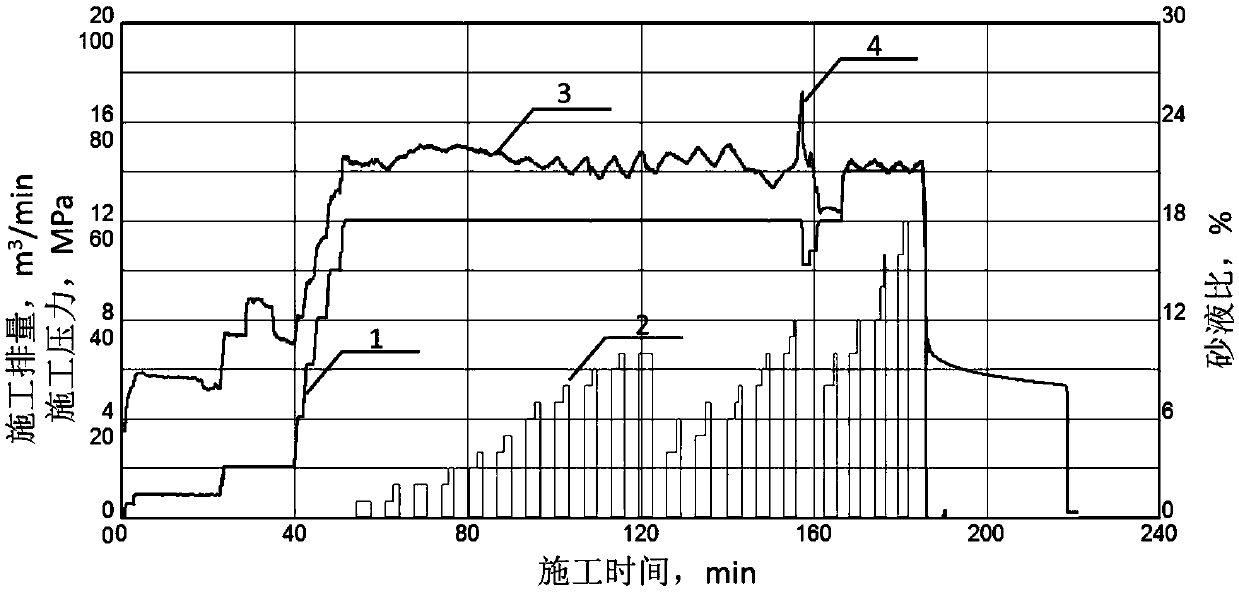

Critical sand plug fracturing method for improving crack complexity

ActiveCN110344799AIncrease net pressureImprove steering performanceFluid removalHorizontal stressCalcium in biology

The invention discloses a critical sand plug fracturing method for improving crack complexity. The method includes the following steps: (1) formation evaluation before fracturing; (2) preferable selection of viscosity of pre-crack generation fracturing fluid; (3) application of different viscosity fracturing fluid to generate cracks of different sizes at different stages; (4) preferable selectionof dosage proportion and particle size of a proppant matching the different crack sizes; (5) design of a bench type slug sanding mode; (6) implementation of a critical sand plug fracturing process; and (7) other construction steps and a flowback and production process. The method realizes the effective promotion of net pressure and an induced stress field in the whole process of one-time sand fracturing, thereby reducing a horizontal stress difference of two directions of a formation at different positions of a main crack to make the opening of natural cracks or micro cracks filled with calcium easier. The main crack turns and then communicates and intersects with the natural cracks or the micro cracks, thereby maximizing the complexity of the whole crack system and further improving the crack reconstruction volume and single well production.

Owner:CHINA PETROLEUM & CHEM CORP +1

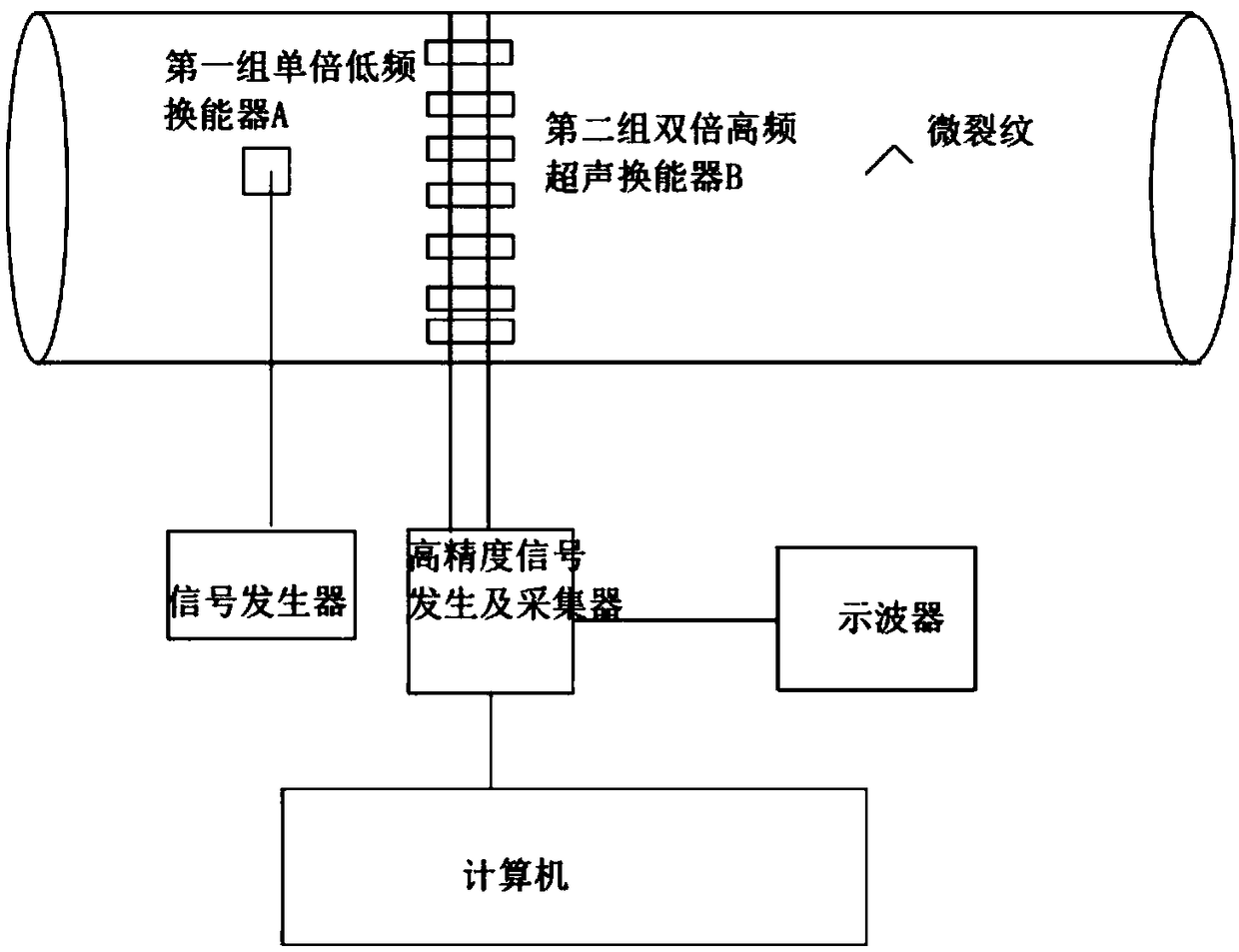

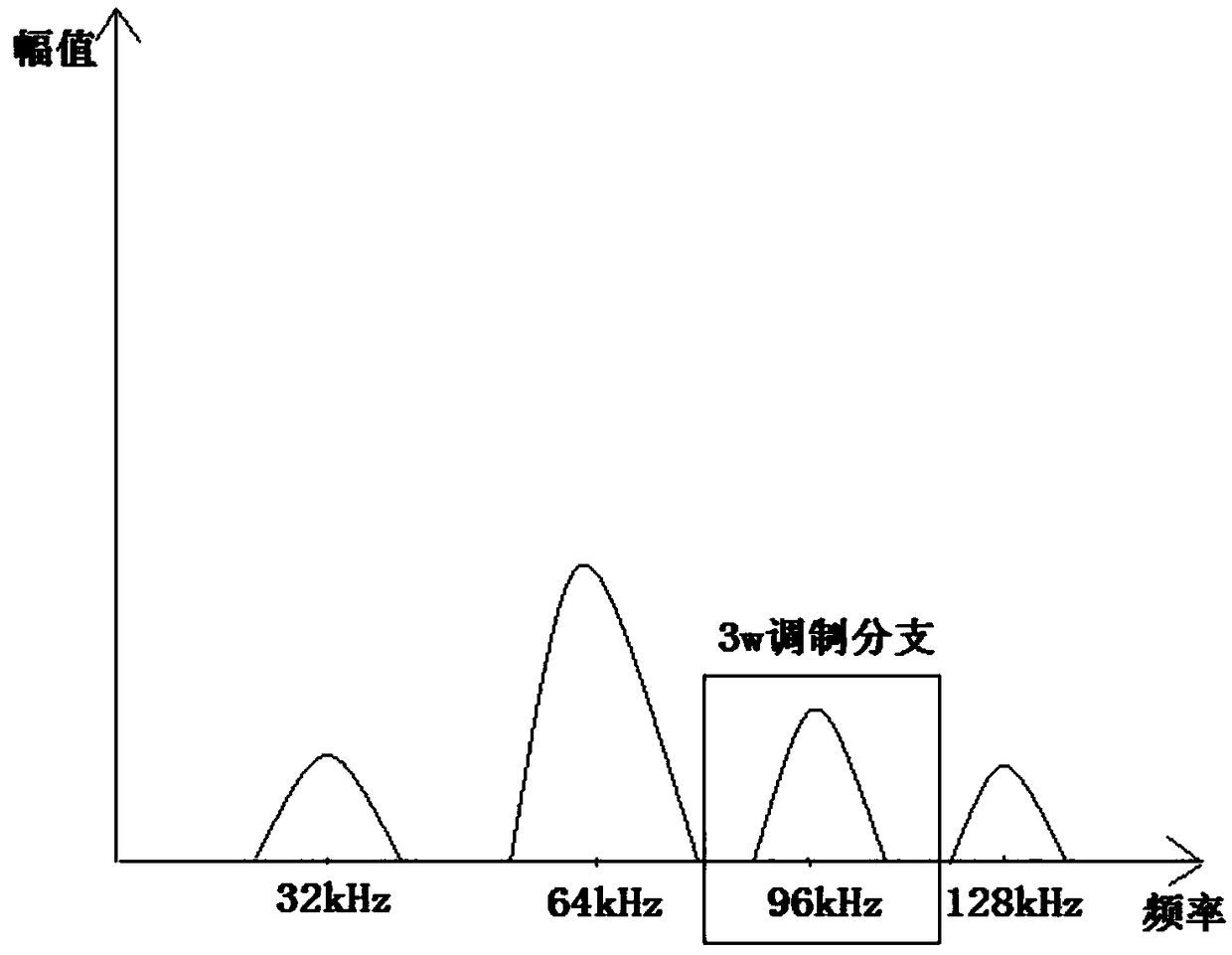

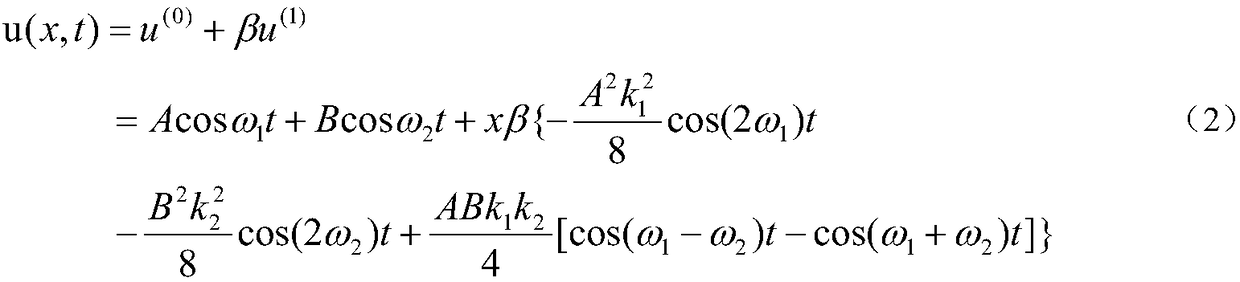

Method for detecting microcracks of pipeline through frequency multiplication modulation and time reversal of nonlinear ultrasonic guided wave

ActiveCN109187754AAchieving Adaptive FocusQuick checkAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic/sonic/infrasonic wave generationSonificationNonlinear ultrasound

The invention discloses a method for detecting micro-cracks of a pipeline through a frequency multiplication modulation and time reversals of a nonlinear ultrasonic guided wave, and belongs to the field of nondestructive detection. The method comprises the following steps: 1) signal excitation: using two groups of emission ultrasonic transducers, wherein a first group of emission ultrasonic transducer excitating a single low-frequency, and a second group of emission ultrasonic transducer excitating a double high-frequency; 2) signal reception: the second group of emission transducer simultaneously receiving signals as a reception transducer; 3) nonlinear analysis: selecting a time reversal window function according to a sound field modulation side lobe frequency of omega1+omega2=3omega1; 4) signal time reversal: reversing intercepted time reversal signals, and sending the intercepted time reversal signals by the excitation signal transducers; and 5) energy focusing: focusing the signals at the micro-cracks. According to the method for detecting micro-cracks of the pipeline through the frequency multiplication modulation and time reversals of the nonlinear ultrasonic guided wave, the identification of micro-cracks is realized by utilizing the advantages that the propagation distance of the ultrasonic guided wave is long and the nonlinear ultrasound is highly sensitive to micro-cracks, meanwhile utilizing the characteristic of adaptive focusing of the time reversal algorithm; and the crack size is determined by utilizing a nonlinear ultrasonic parameter.

Owner:山东省特种设备检验研究院集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com