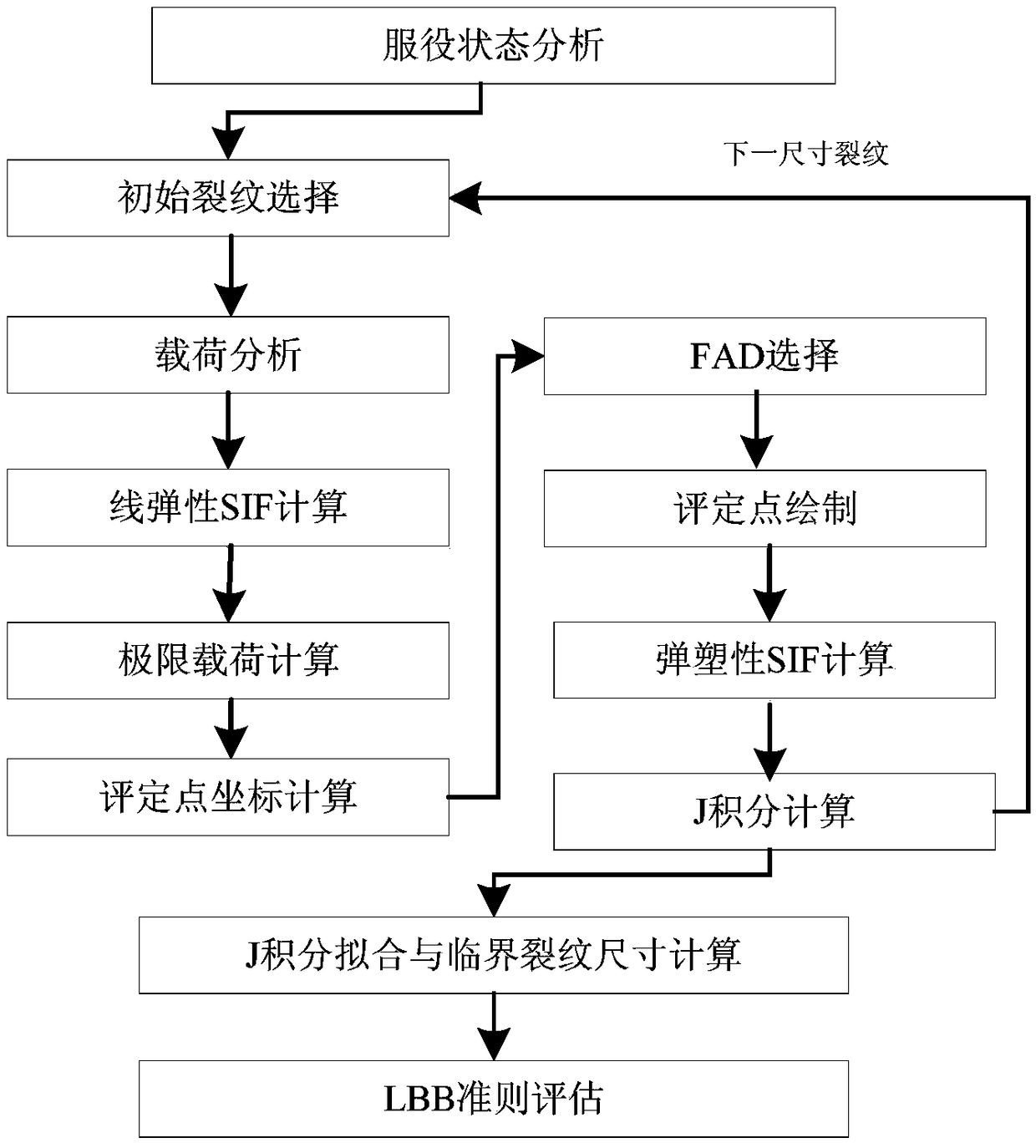

Leak before burst analysis method based on failure assessment diagram

An analysis method and load technology, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

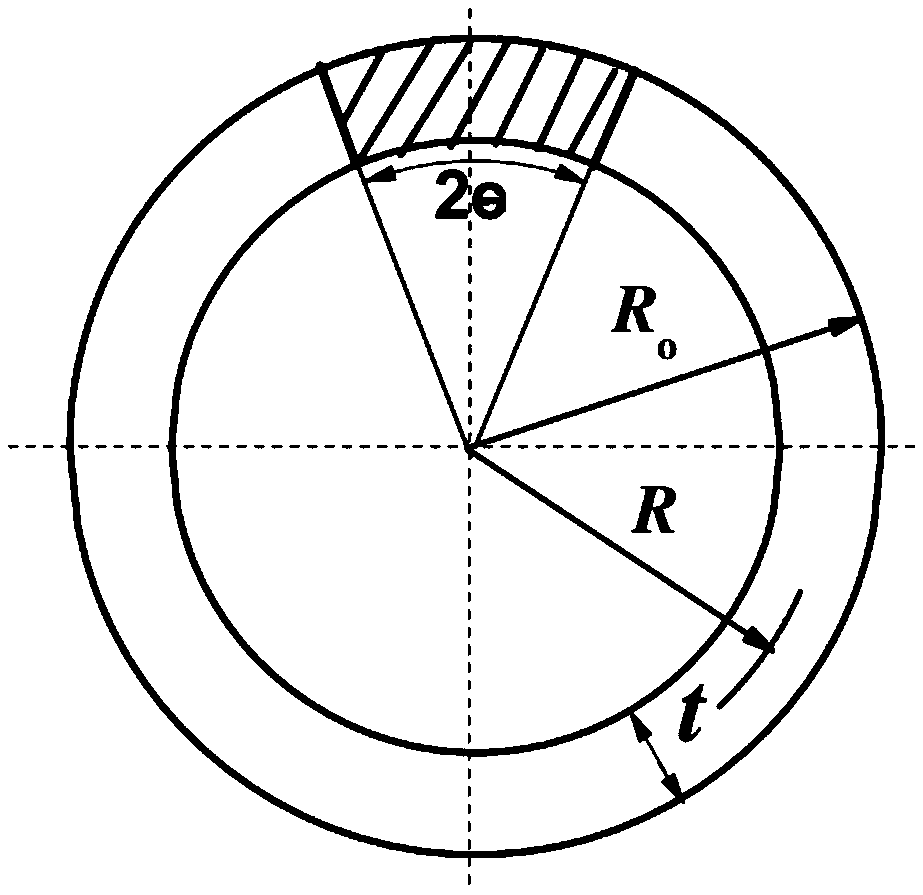

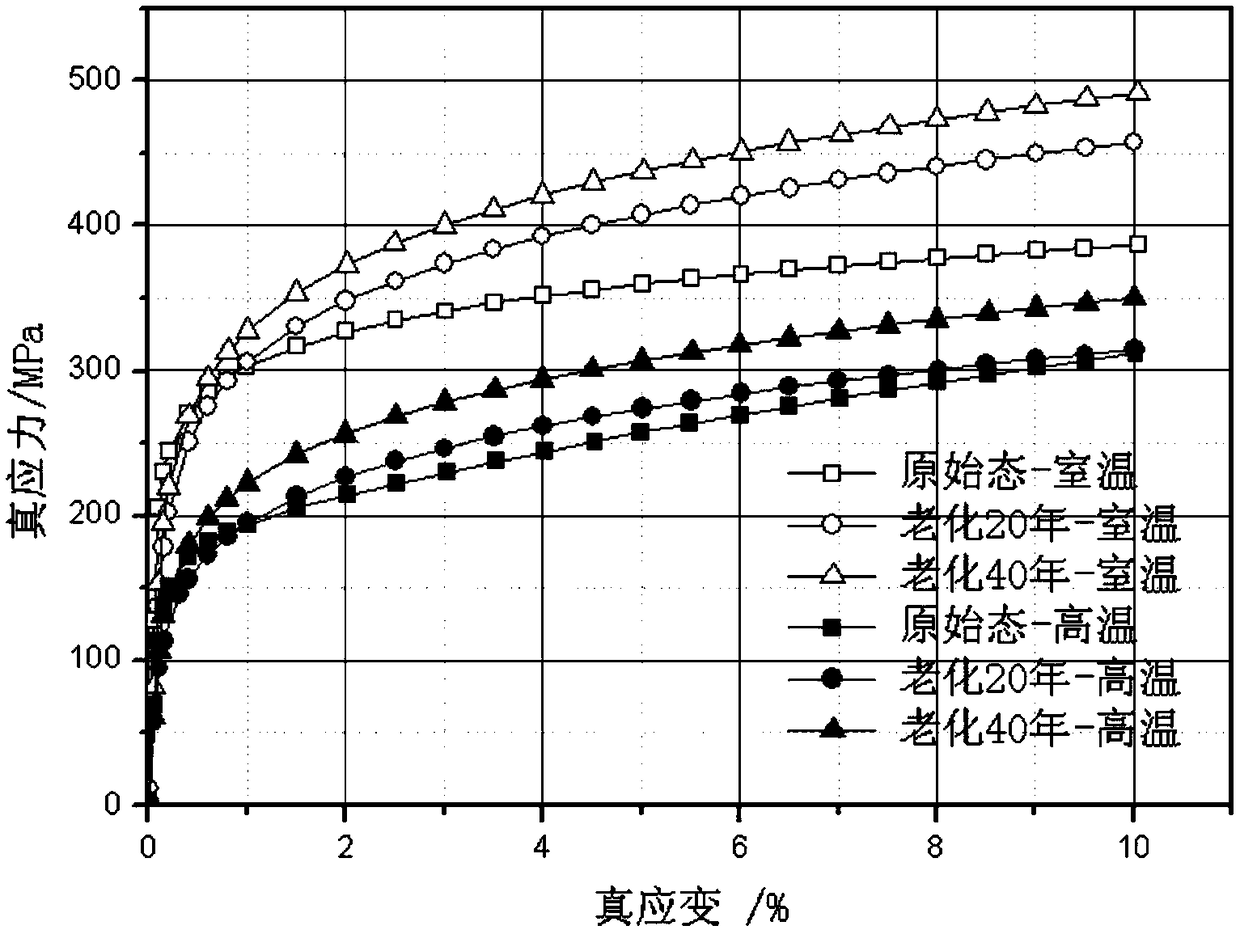

[0089] The pipe outer diameter R of the straight pipe section of an austenitic stainless steel casting o =814.5mm, pipe wall thickness t=72.5mm. The analysis process of LBB under certain working conditions is given here. Under this working condition, the main pipeline of the primary circuit has been in service for 40 years.

[0090] (1) Service status analysis

[0091] When the main pipeline of the primary circuit has been in service for 40 years, the elastic modulus E of the material is 180GPa, and the Poisson's ratio ν is 0.3.

[0092] (2) Initial crack selection

[0093] Such as figure 2 As shown, select a circumferential crack that initially penetrates the wall thickness, and the circumferential angle 2θ of the crack is 45 o (Crack length a=2θR o )

[0094] (3) Load analysis

[0095] Obtain the load information at room temperature at a certain moment in the working condition, and divide various loads into primary stress loads and secondary stress loads according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com