Patents

Literature

78 results about "Secondary stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Secondary stress (or obsolete: secondary accent) is the weaker of two degrees of stress in the pronunciation of a word; the stronger degree of stress being called primary. The International Phonetic Alphabet symbol for secondary stress is a short vertical line preceding and at the foot of the secondarily stressed syllable: as before the nun in proˌnunciˈation (the higher vertical line denotes primary stress). Another tradition in English is to assign acute and grave accents for primary and secondary stress: pronùnciátion.

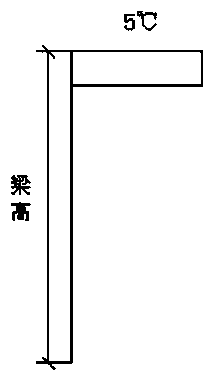

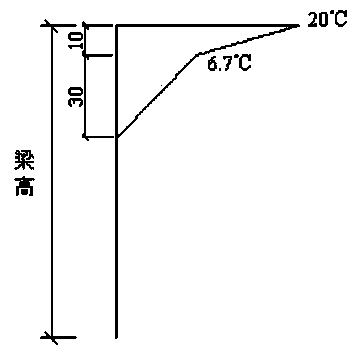

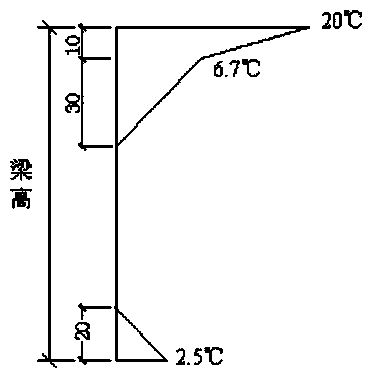

Finite element analysis method for temperature action on prestressed reinforced concrete continuous rigid frame bridge

ActiveCN104166792AAccelerated settlementEfficient solutionSpecial data processing applicationsStructural deformationElement analysis

The invention provides a finite element analysis method for the temperature action on a prestressed reinforced concrete continuous rigid frame bridge. The finite element analysis method is used for analyzing and calculating the stress and displacement distribution in the construction and finished bridge stage under different temperature gradient models, and provides references for designing and optimizing the prestressed reinforced concrete continuous rigid frame bridge. Through calculational analysis based on finite elements and the structural mechanics, the forward-calculation method is adopted for structural distortion and stress analysis according to the actual construction loading sequence of the bridge structure, so that the complex mechanics problem of box girder temperature self-stress, temperature secondary internal force in a prestressed reinforced concrete statically indeterminate structure and secondary stress of the temperature secondary internal force is solved easily, conveniently and efficiently, and the finite element analysis method has important practical value.

Owner:江苏中国科学院能源动力研究中心 +1

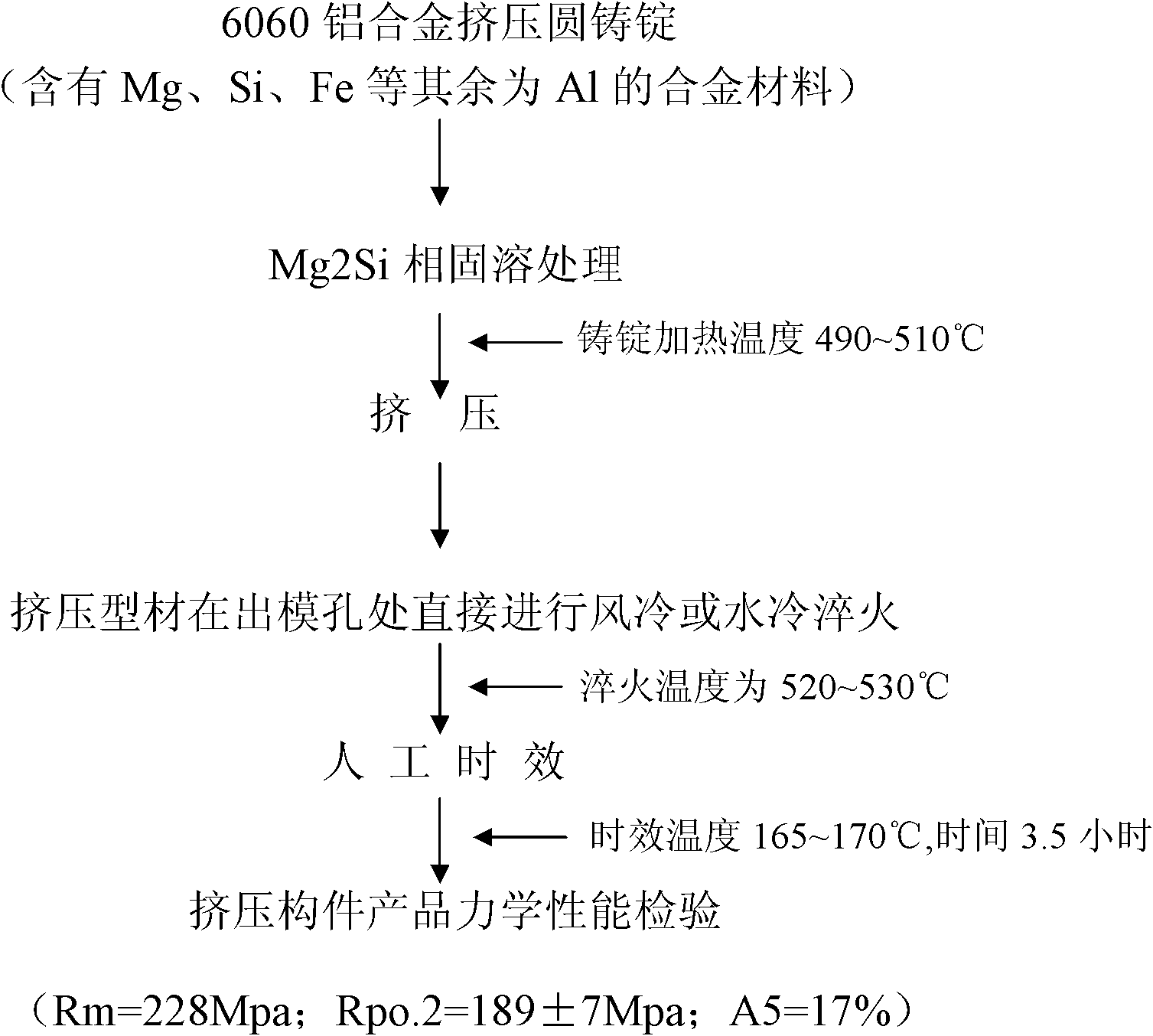

Aluminum alloy section of secondary stress member of automobile bumper and preparation method thereof

ActiveCN101984111AMeet the special requirements of mechanical propertiesControl the amount of precipitated phaseIngotThermal treatment

The invention relates to an aluminum alloy section of a secondary stress member of an automobile bumper and a preparation method thereof. The invention is characterized in that the 6060 aluminum alloy material of the member comprises the following components in parts by weight: 0.56-0.58 part of Mg, 0.32-0.35 part of Si, no more than 0.2 part of Fe, no more than 0.02 part of Mn, no more than 0.02 part of Cu, no more than 0.02 part of Ti, no more than 0.03 part of Zn, no more than 0.03 part of Cr, and the balance of Al. The preparation method comprises the following steps: preparing an aluminum alloy round ingot from the raw materials; extruding a section and placing the section in an aging thermal treatment furnace within 48 h, wherein the aging temperature is between 165 and 170 DEG C; and preserving heat for 3.5 h and then performing the aging thermal treatment. The invention has the beneficial effects that by introducing alloy elements, the precipitation phase number is selectively controlled and a proper amount of precipitation phase distribution is formed; the special requirements on the mechanical property of the secondary stress member of the automobile bumper can be satisfied; and batch production can be realized.

Owner:天津锐新昌科技股份有限公司

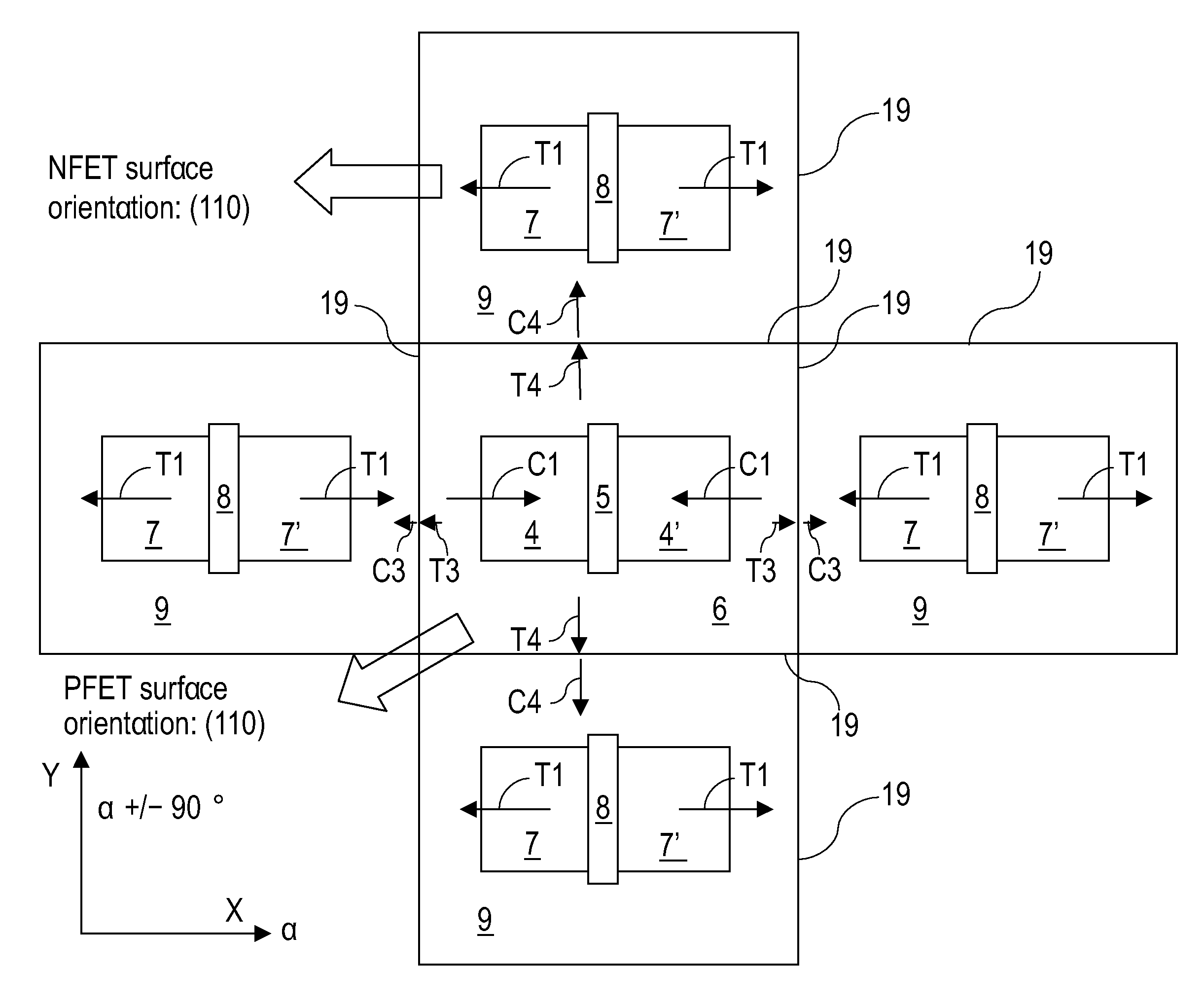

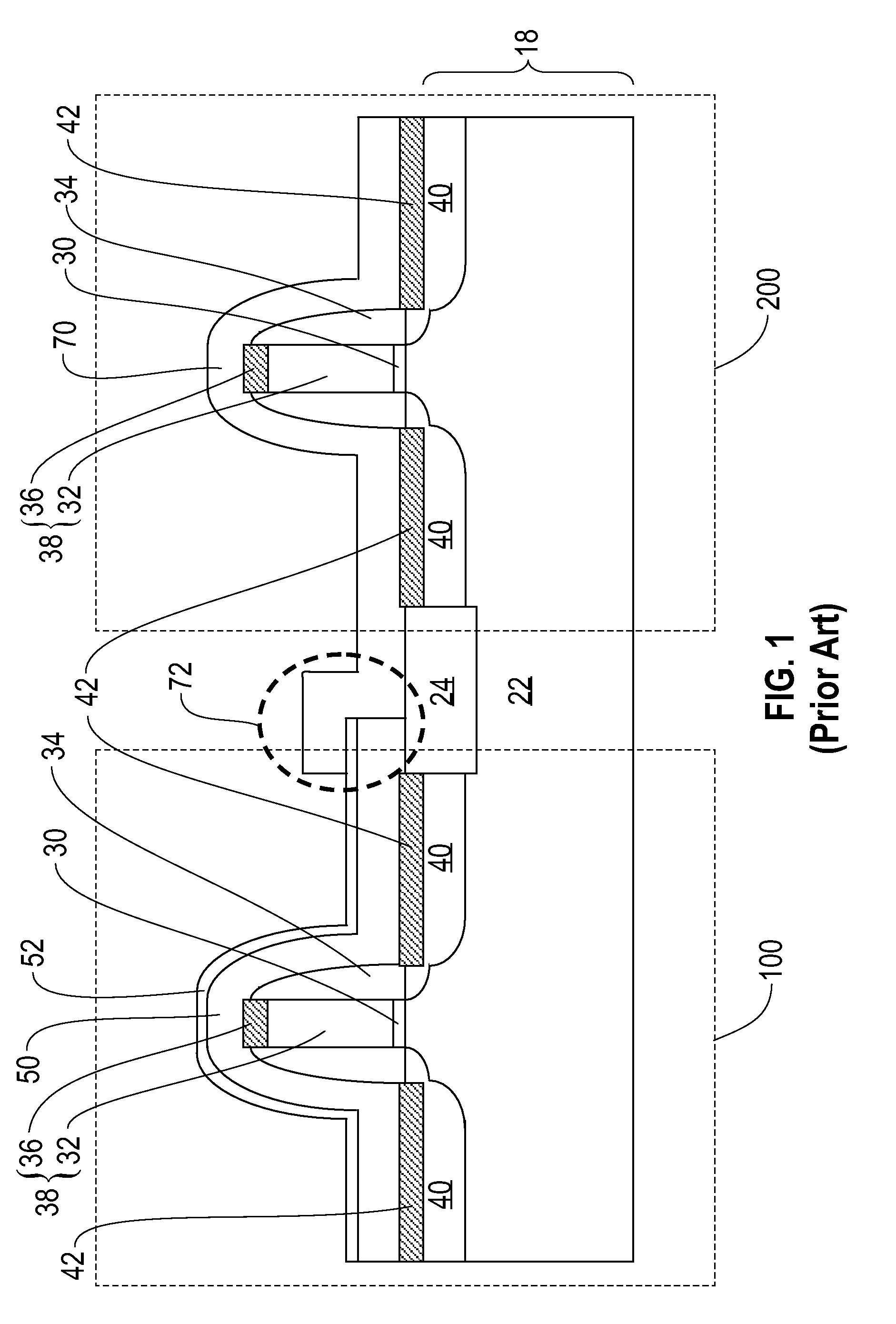

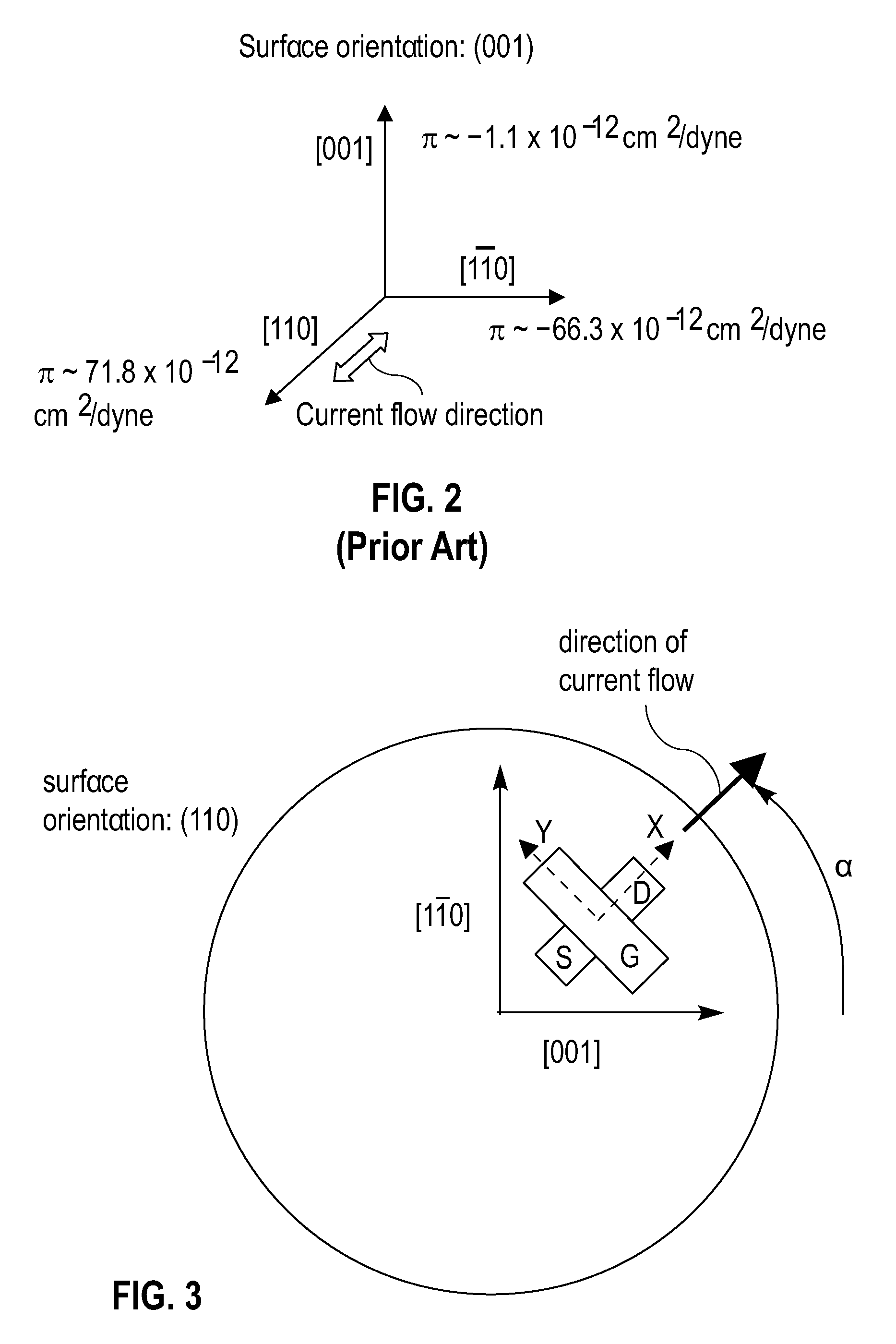

Orientation-optimized PFETS in CMOS devices employing dual stress liners

InactiveUS7525162B2Improve conductivitySolid-state devicesSemiconductor/solid-state device manufacturingIn planeCMOS

Owner:GLOBALFOUNDRIES INC

Method of preventing corrosion degradation using ni or ni-alloy plating

ActiveUS20090252883A1Prevent degradationPretreated surfacesLiquid/solution decomposition chemical coatingMachine partsPetrochemical

Disclosed herein is a method of preventing corrosion degradation in a defective region including an expansion transition region and / or an expansion region of a heat transfer tube of a steam generator in a nuclear power plant by using nickel (Ni) plating or nickel (Ni) alloy plating. The method can prevent various types of corrosion damage, such as pitting corrosion, abrasion, stress corrosion cracking, lead-induced stress corrosion cracking and the like, occurring during the operation of the steam generator, and particularly, pitting corrosion or primary and secondary stress corrosion cracking, so that the life span of the steam generator is increased, maintenance costs are reduced, and the operation rate of a nuclear power plant is increased, with the result that the unit cost of the production of electric power can be decreased, thereby improving economic efficiency. Further, the method can be usefully used to prevent the corrosion damage of parts and equipment of nuclear, hydroelectric or thermoelectric power plants or of petrochemical plants, and that of industrial and machine parts and equipment, and parts and equipment in a defense industry.

Owner:KOREA ATOMIC ENERGY RES INST +1

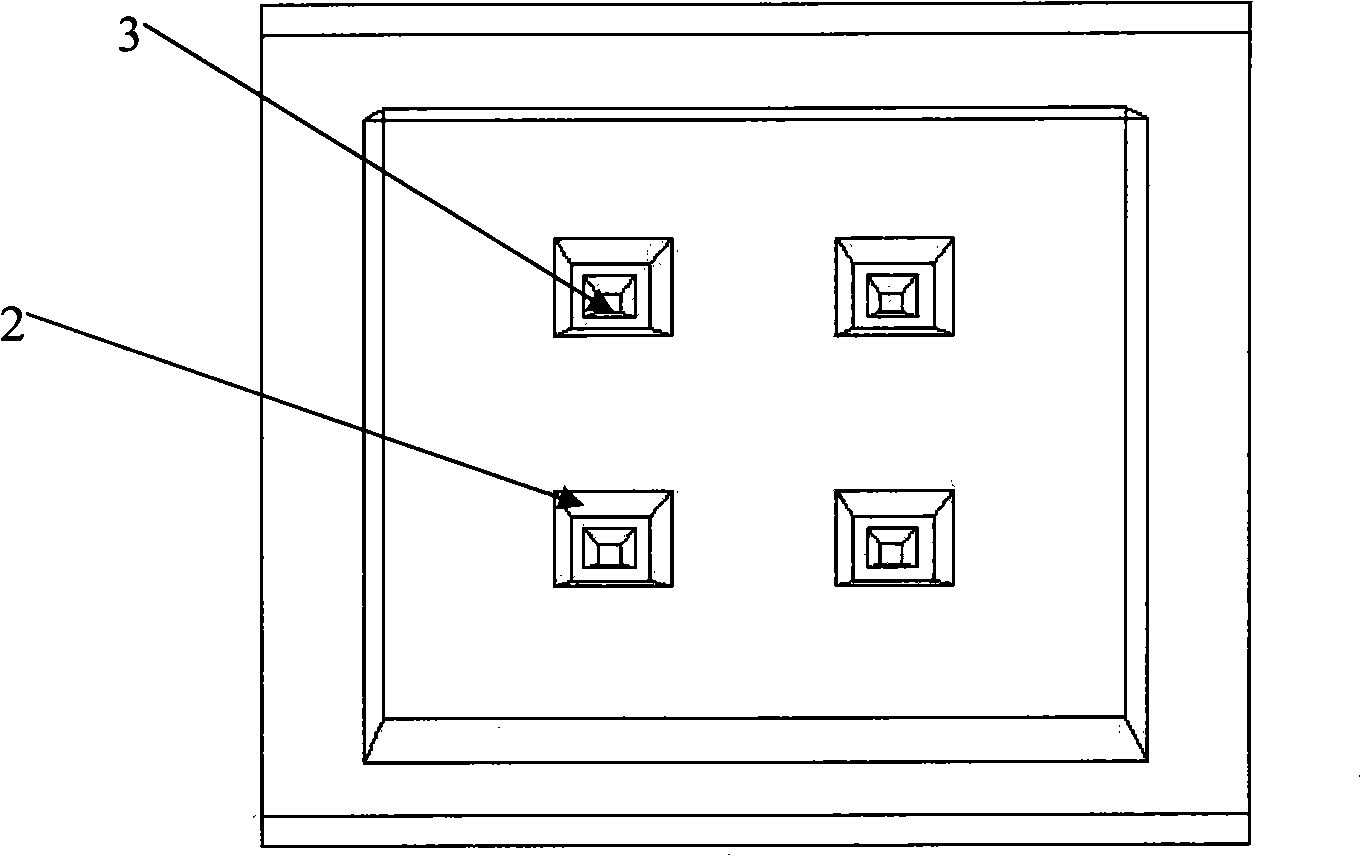

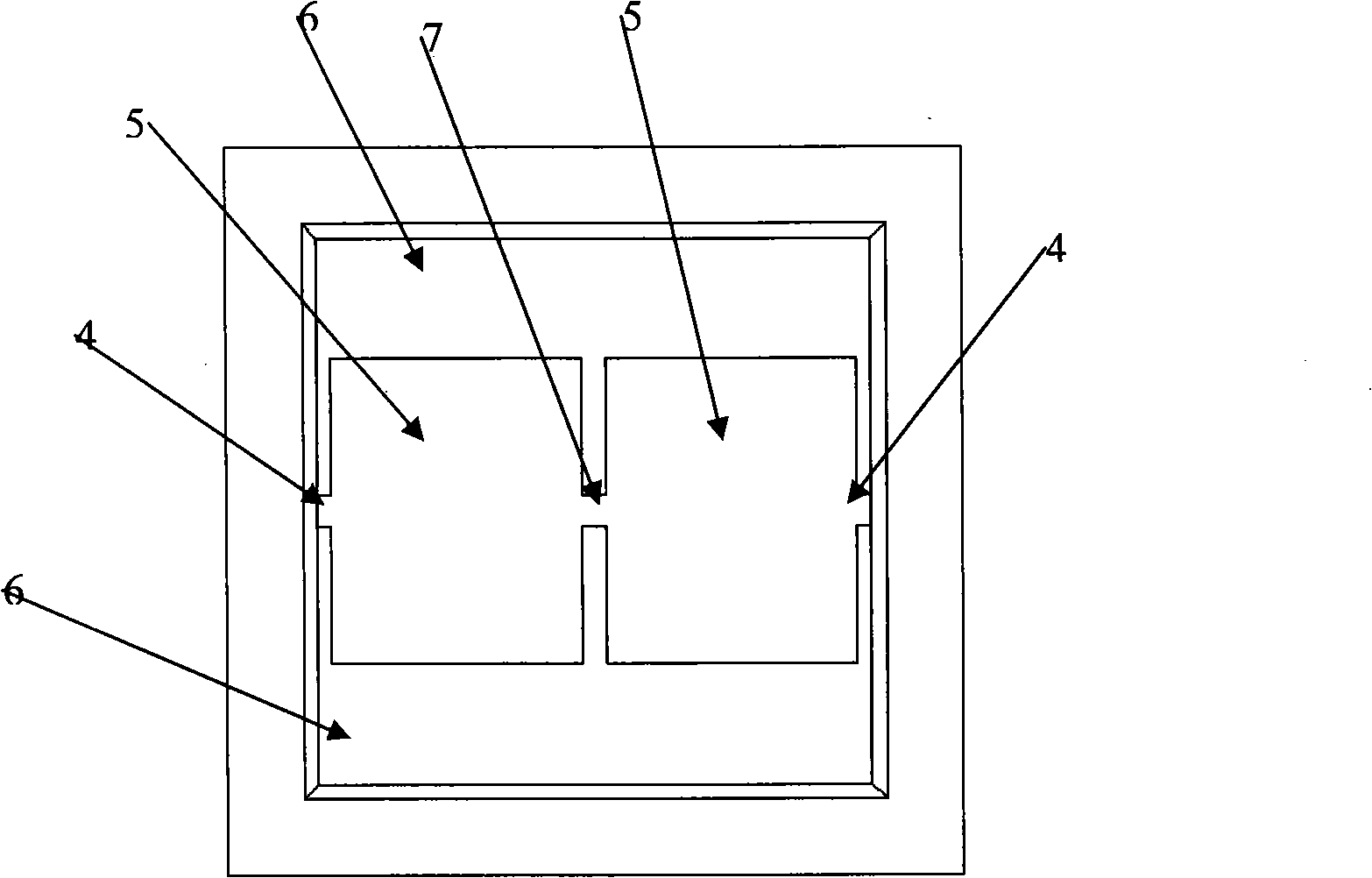

Nano-silicon thin-membrane four-island-beam-membrane sensor chip and preparation method thereof

InactiveCN101922984AHigh sensitivityImprove linearityFluid pressure measurement using ohmic-resistance variationDecorative surface effectsStress concentrationEngineering

The invention relates to an ultra-micro pressure sensor, in particular to a nano-silicon thin-membrane four-island-beam-membrane sensor chip and a preparation method thereof. The sensor chip is square, monocrystalline silicon is adopted as a chip material, and nano-silicon is taken as a sensitive thin resistance material; the effective area of the chip is square, the back surface consists of four big islands and four small islands, and the small islands are positioned on the big islands; and the front surface of the effective chip area consists of a central beam, two edge beams, two flat membrane areas and two beam membrane areas, and resistors made of the nano-silicon material are arranged on the central beam and the edge beams. The sensor chip utilizes the advantages of a double-island beam membrane and combines the islands with the beams, thereby playing the effect of secondary stress concentration and improving the sensitivity and the linearity of a sensor; and the four resistors are respectively placed on the central beam and the edge beams, thereby transforming the stress of the resistors to the change of the resistance. The resistance change at the middle and the edges has the equal size and the reverse symbols, and the ultra-micro pressure measurement is realized by adopting the excitation of a constant current source through a Wheatstone bridge.

Owner:JIANGSU UNIV

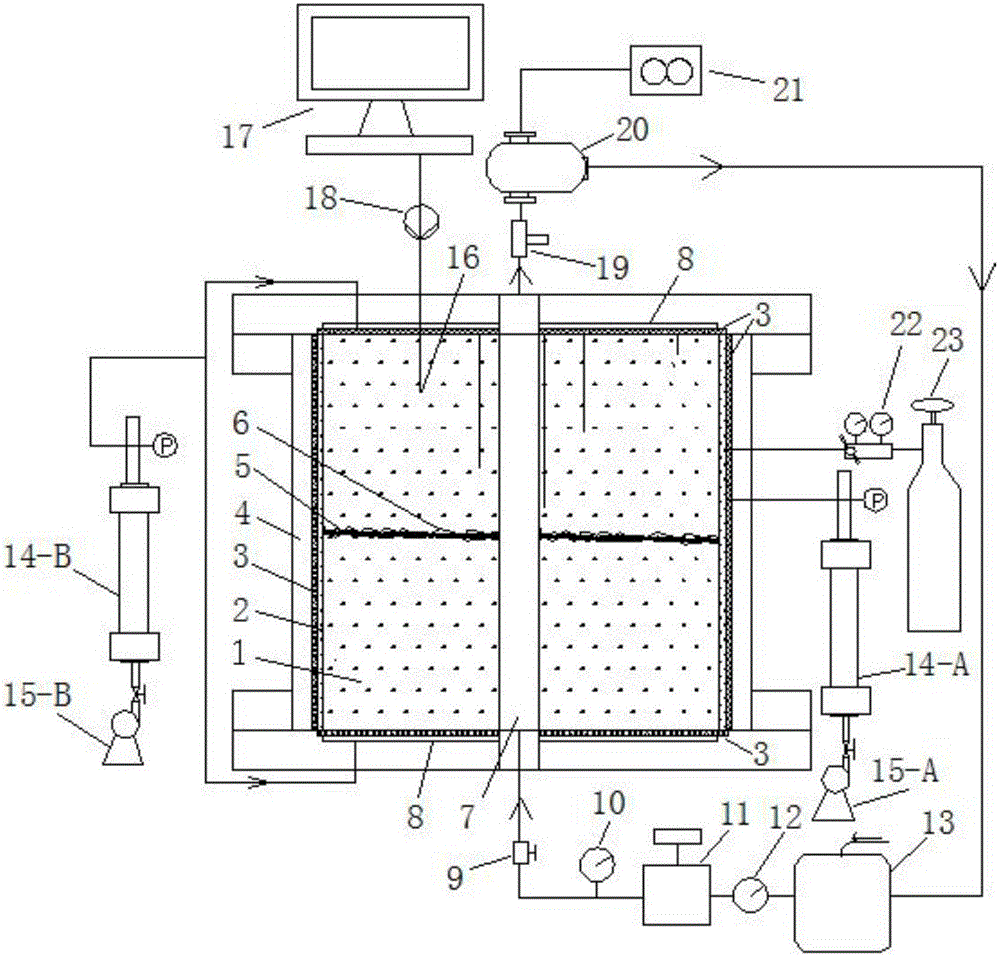

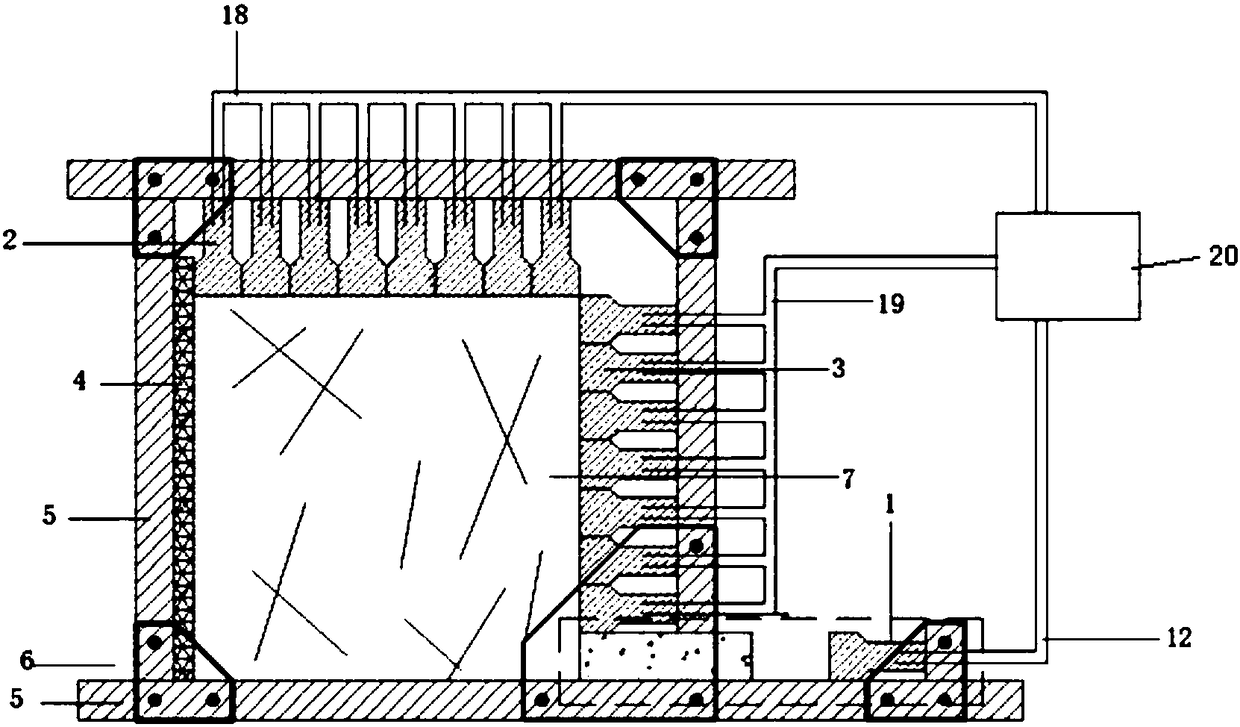

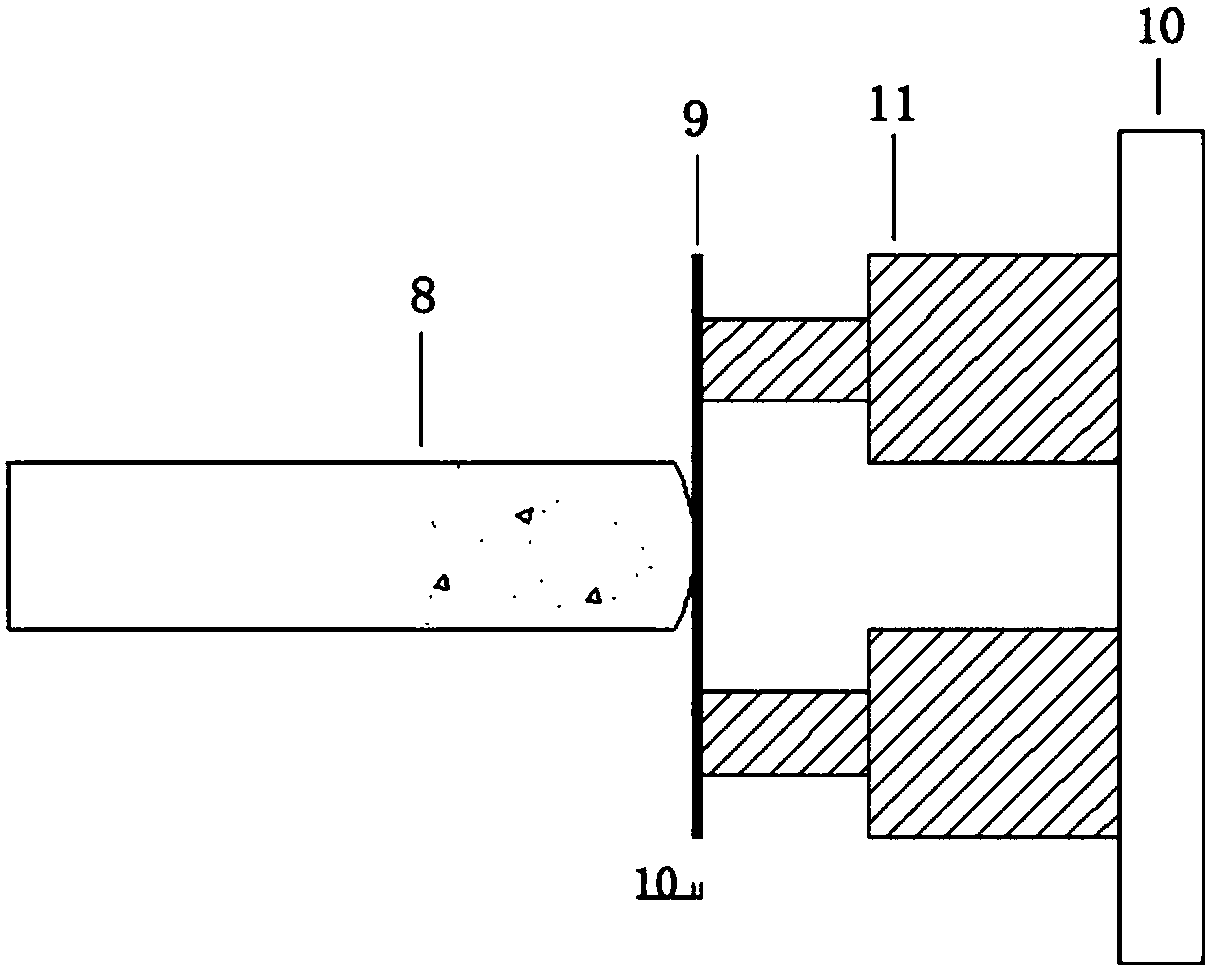

Crack-substrate coupling flow damage evaluating device and method by simulating formation conditions

ActiveCN105756674AIntuitive simulation of damage processSimulated damage process is clearBorehole/well accessoriesElectrical resistance and conductanceRock core

The invention discloses a crack-substrate coupling flow damage evaluating device and method by simulating formation conditions. The device mainly consists of a kettle body 4, a rock core 1, a crack 6, a simulated well 7, a pressurized capsule 3, a resistance probe 16, a pressure sensor 18, a data collecting system 17 and a work liquid circulation system, wherein the rock core 1 is arranged in the kettle body 4; the pressurized capsule 3 wraps the periphery of the rock core; the kettle body is provided with an axial pressure injecting opening, a peripheral pressure injecting opening and a gas inlet; the crack 6 and the simulated well 7 are arranged in the rock core; nine drilling holes extending into the rock core are distributed in the rock core; the resistance probe 16 is arranged in the drilling holes; the resistance probe 16 is connected with the pressure sensor 18; the resistance probe and the pressure sensor are connected with the data collecting system 17; the simulated well 7 is connected with the work liquid circulation system. The circum-well secondary stress condition and the formation radial flow of a crack-substrate system are simulated for determining the damage degree of the crack-substrate system by the device. The device and the method have the advantages that the principle is reliable; the operation is convenient; scientific and accurate quantitative reservoir damage evaluation can be made.

Owner:SOUTHWEST PETROLEUM UNIV +1

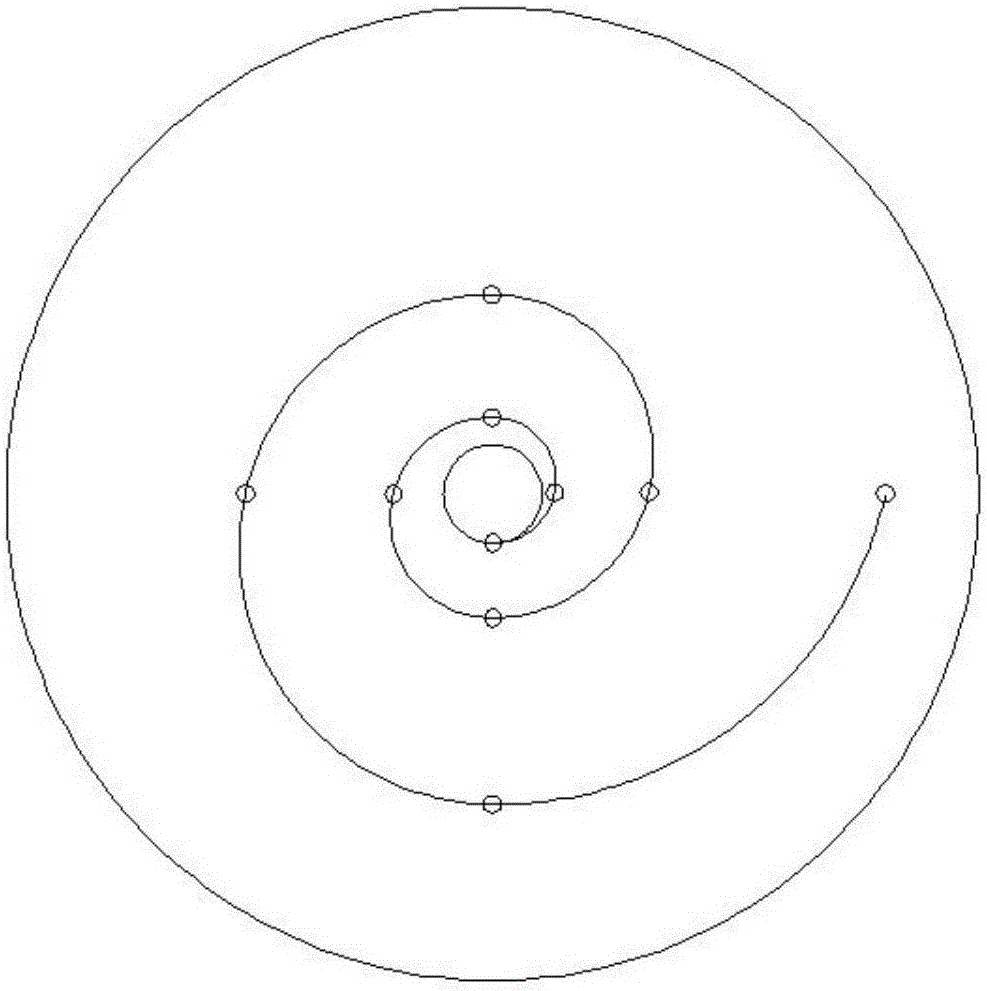

Processing technology of arc-shaped spring

ActiveCN102501009ASmall thermal relaxation rateLarge momentary torqueFurnace typesHeat treatment furnacesStress reliefMaterials science

The invention relates to a processing technology of a large-radian arc-shaped spring. The processing technology is characterized by comprising the following procedures of: spring coiling: primary stress relief annealing; spring grinding; spring bending into an arc-shaped spring; secondary stress relief annealing; shot blasting; hot-strong pressing; sorting; angular rigidity and torque test; fatigue life test; and surface antirust treatment. According to the forming technology of the arc-shaped spring provided by the invention, the arc-shaped spring with the free angle of being more than 45 degrees can be effectively formed, the thermal relaxation rate of the spring is less than 2%, the instantaneous torque is large, the fatigue life is 1 million times, and the technical problems of low finished product rate and incapability for normal use of the large-radian arc-shaped spring in the prior art are solved.

Owner:HANGZHOU FUCHUN SPRING

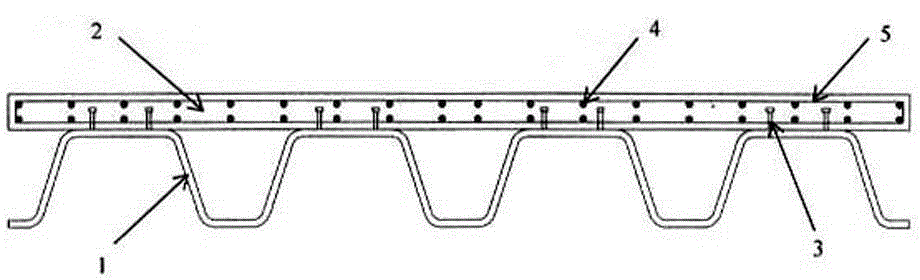

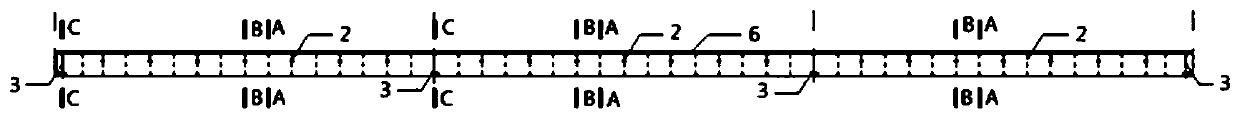

Composite bridge deck applied to long-span bridges and city bridges

ActiveCN104594194ALow costEase of large-scale standardized productionBridge structural detailsWater-setting substance layered productBridge deckWeld seam

The invention discloses a composite bridge deck applied to long-span bridges and city bridges. The composite bridge deck comprises a bridge deck body, wherein the bridge deck body is formed through combining a lower wave-shaped steel plate and an upper concrete slab; shear connectors which are symmetrically welded to wave crests of the wave-shaped steel plate upwards extend into the concrete slab; reinforcing steel bars and annular hoop reinforcements which are used for bundling up the reinforcing steel bars are arranged at the middle part of the concrete slab in a balanced manner. According to the composite bridge deck, the characteristics of the wave-shaped steel plate and the characteristics of the concrete slab are combined together, properties of materials are fully utilized, the flexural bearing capacity is enough under heavy loads, the deformation is small enough under the action of concentrated loads, and too-large secondary stress resulting from weld seams can be avoided; a top plate of a steel bridge deck is replaced with the concrete slab, so that the construction cost of a bridge floor system can be reduced; the quantity of welding is very small, so that the damage to the bridge deck caused by defects of a welding process can be reduced; due to the wrinkling effect of the wave-shaped steel plate, the problem that the deformation of the steel plate and the deformation of concrete are non-synchronous can be greatly solved, and the cracking of the transverse bridge direction of the bridge deck is avoided.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

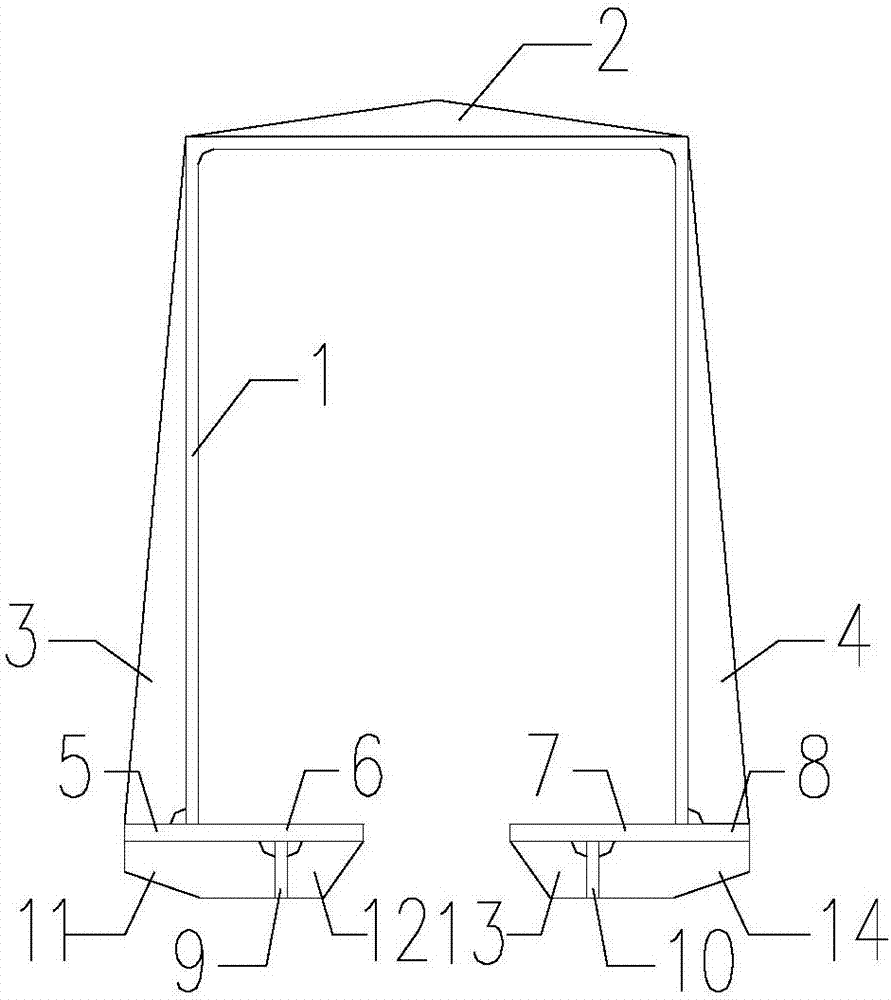

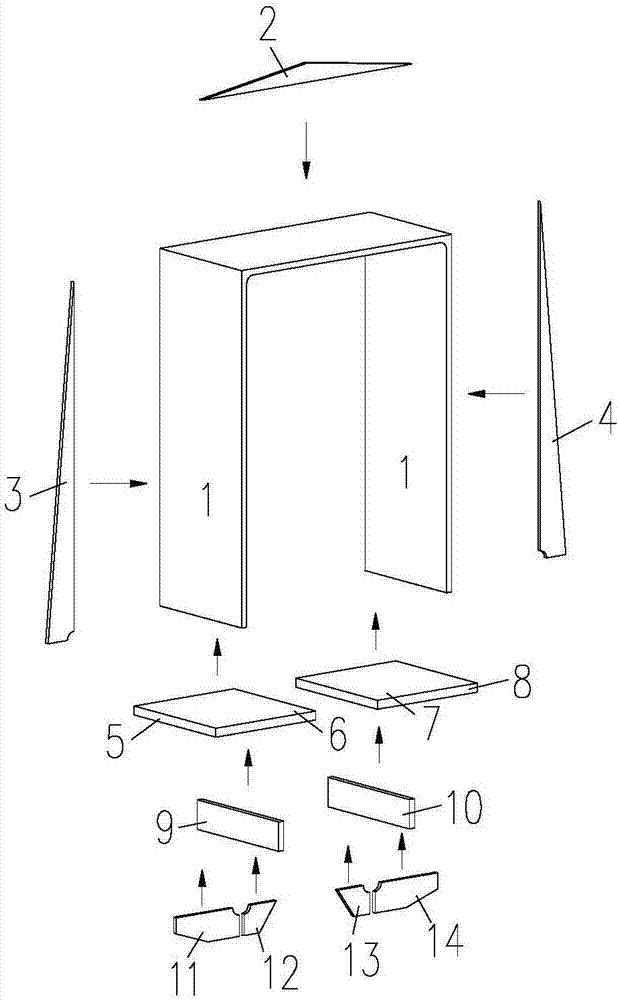

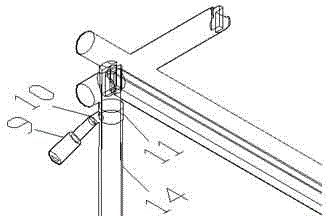

Inverse U-shaped overhead monorail traffic track girder and processing technology thereof

The invention discloses an inverse U-shaped overhead monorail traffic track girder which comprises a track girder U-shaped body and bottom plates, wherein the bottom plates include a first bottom plate and a second bottom plate, and the first bottom plate and the second bottom plate are welded at the bottom of the track girder U-shaped body; the first bottom plate comprises a first track girder bottom outer flange and a first track girder bottom inner flange; the second bottom plate comprises a second track girder bottom outer flange and a second track girder bottom inner flange, and the second track girder bottom outer flange and the second track girder bottom inner flange are fixed; and the track girder U-shaped body is molded by rolling or bending. The track girder disclosed by the invention is convenient for construction transportation and field installation, the flatness of the inner section of the track girder is guaranteed, and the comfort degree is high. According to the invention, primary and secondary stress regions are divided, wherein the track girder bottom flanges which have relatively large stress can be integrally molded by rolling or bending by adopting relatively thick steel plates, and the other regions which have relatively small stress can be integrally molded by rolling or bending by adopting relatively small-thickness steel plates, thereby being favorable for reducing the steel consumption, reducing the welding workload and improving the processing and manufacturing efficiency.

Owner:CHINA MCC5 GROUP CORP

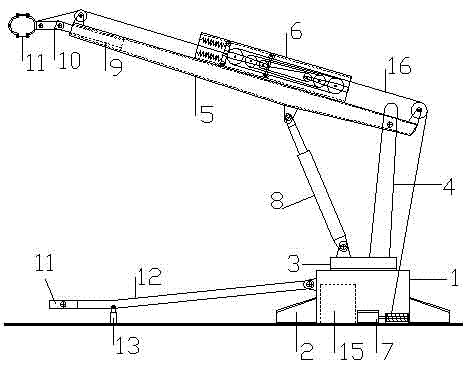

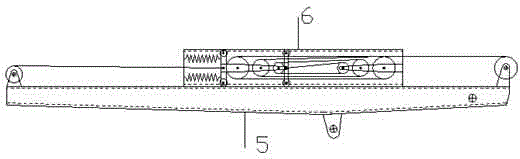

Historic building slanting timber frame tensioning jacking resetting device

InactiveCN103982051AFacilitate conductionAchieve steeringBuilding repairsStress concentrationUniversal joint

The invention provides a historic building slanting timber frame tensioning jacking resetting device which comprises a box body, a ground support, a round bearing table, mechanism arms composed of a vertical arm and a cross arm, a linear displacement amplifying device and an electric winch, an auxiliary jack, a power jack, a universal joint and a variable hoop which are arranged in the box body. A jacking system composed of a hydraulic pump station with a proportional pressure dividing valve and a large-stroke jack and a tensioning system composed of the electric winch, a steel strand and the linear displacement amplifying device are utilized to conduct tensioning and jacking resetting operation on a historic building slanting timber frame. Force transfer condition between the back shore system and the timber frame to be repaired is effectively improved through the universal joint and the variable hoop to achieve steering of a correction force system, secondary stress is greatly reduced in the correction, stress performance of a column head is improved, the column head is protected, and secondary damage caused by concentrated stress caused by the fact that the force system directly acts on the column head in the correction is avoided.

Owner:YANGZHOU UNIV

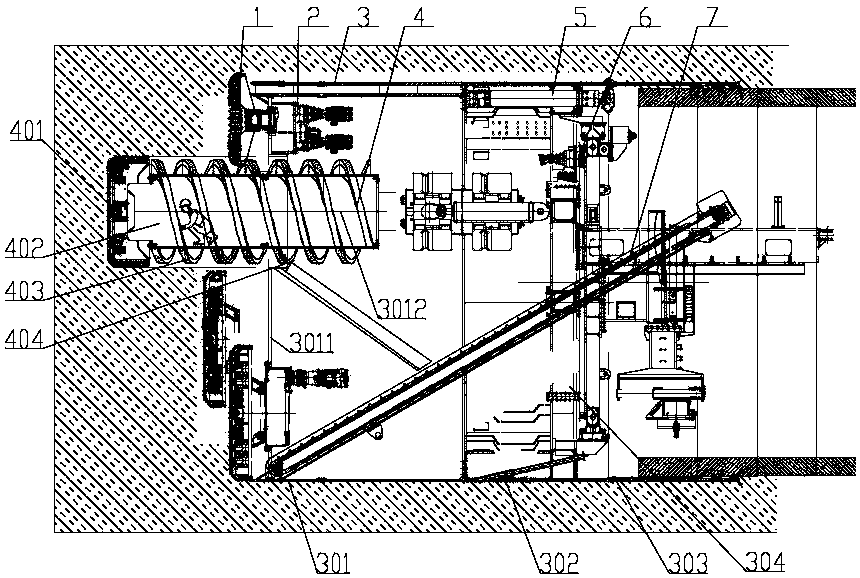

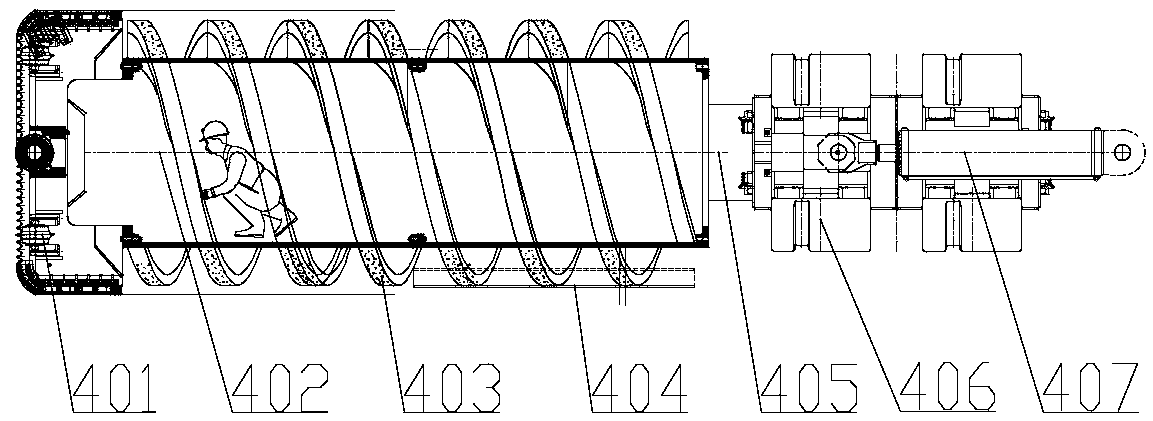

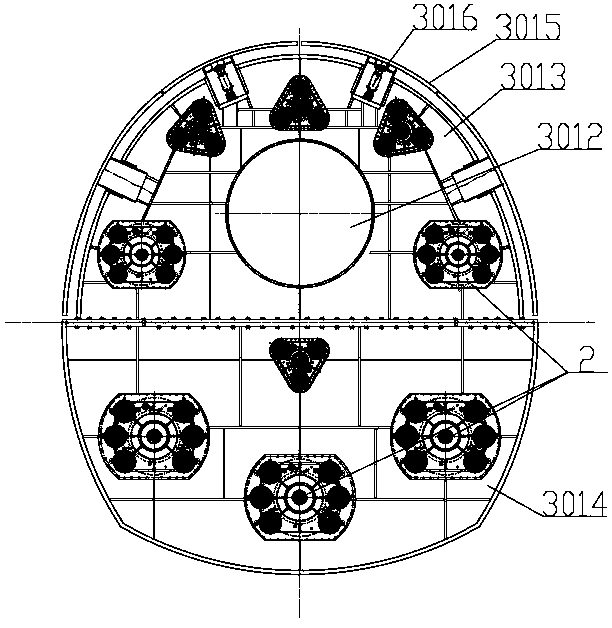

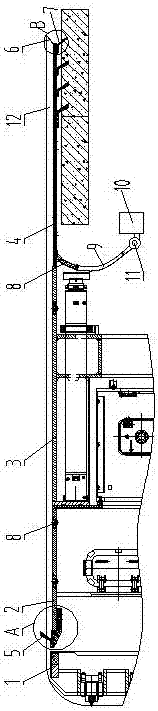

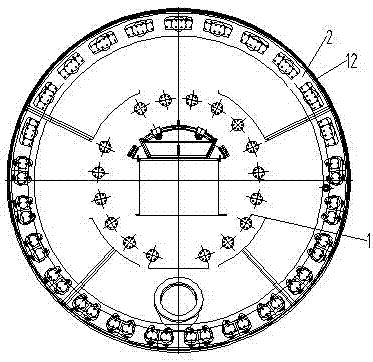

Shield machine suitable for high crustal stress soft rock stratum

The invention provides a shield machine suitable for high crustal stress soft rock stratum. The machine comprises a cutter device and a shield body, the shield body is internally provided with a frontshield partition plate, the front shield partition plate is provided with an advanced tunneling passage, the advanced tunneling passage is internally provided with an advanced tunneling device, the advanced tunneling device includes an advanced tunneling cutter, a spiral blade shaft, a guide rail, advanced tunneling drive, an advanced support device and an advanced propulsion device, the advancedtunneling cutter is connected to the spiral blade shaft, the spiral blade shaft is connected to an advanced drive device, the advanced propulsion device is arranged between the advanced drive deviceand the advanced support device, the advanced support device is supported on the shield body, and the guide rail is arranged at the advanced tunneling passage. The machine has the advantages that themachine not only facilitates the early release of the energy accumulated in a rock body, but also utilizes an expansion and contraction function of the shield body to achieve secondary stress release,and achieves integrated construction of horseshoe-shaped full-section excavation, slag discharge and lining machinery of the high crustal stress soft rock stratum.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

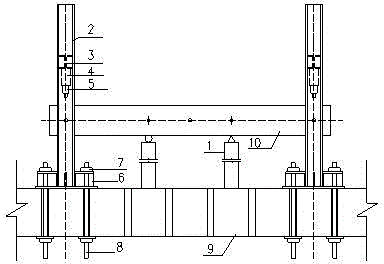

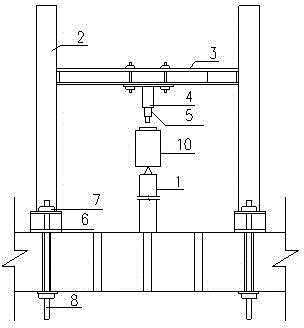

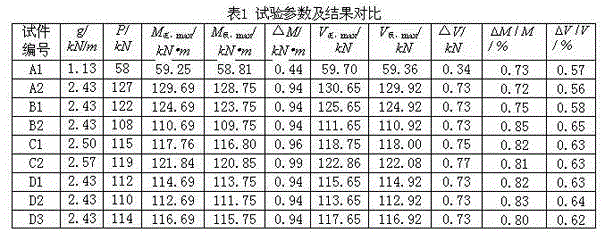

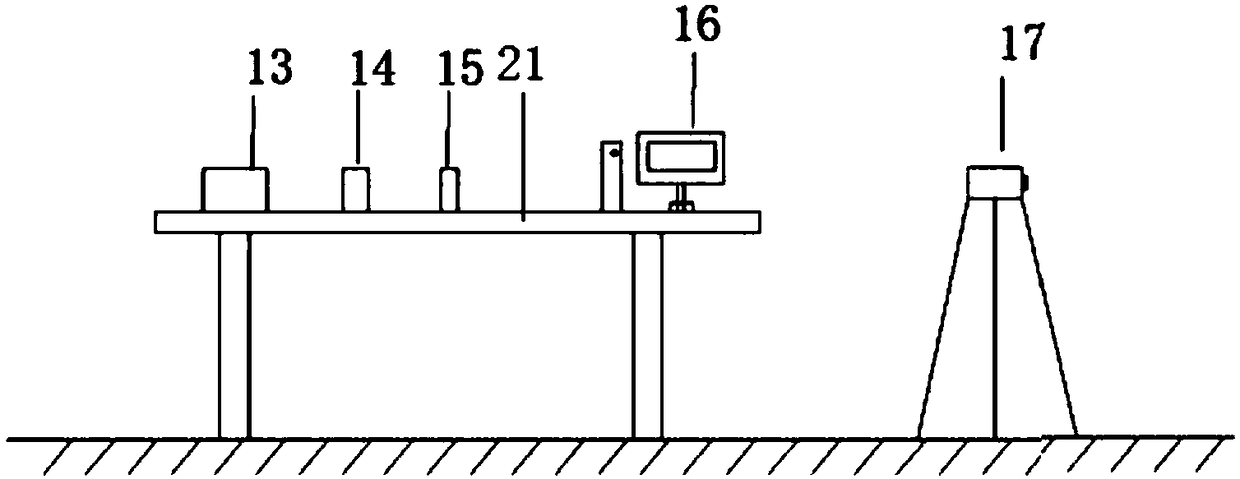

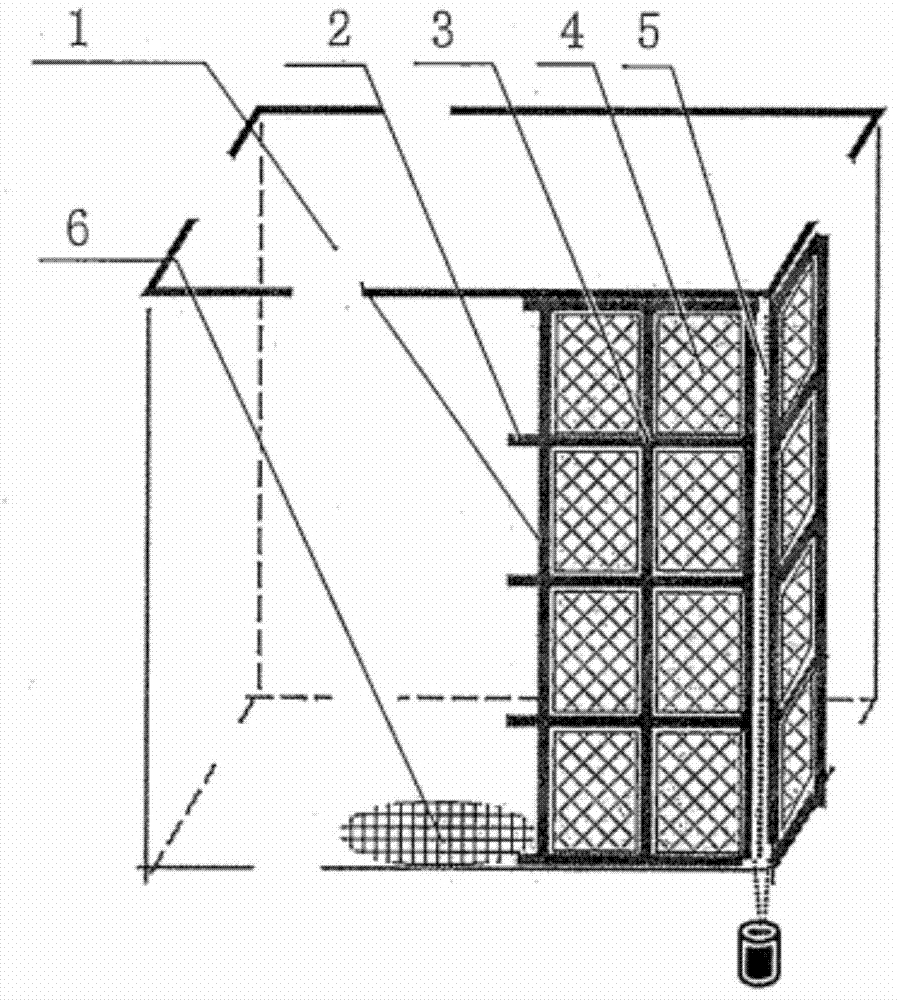

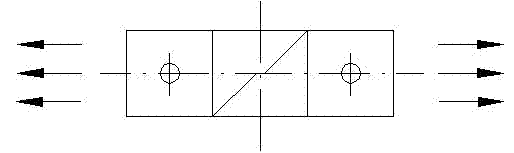

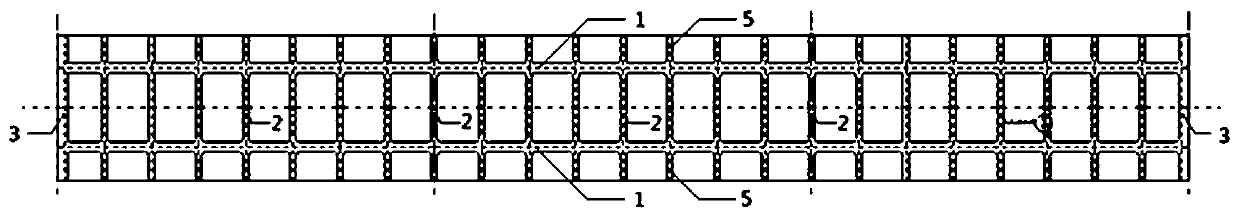

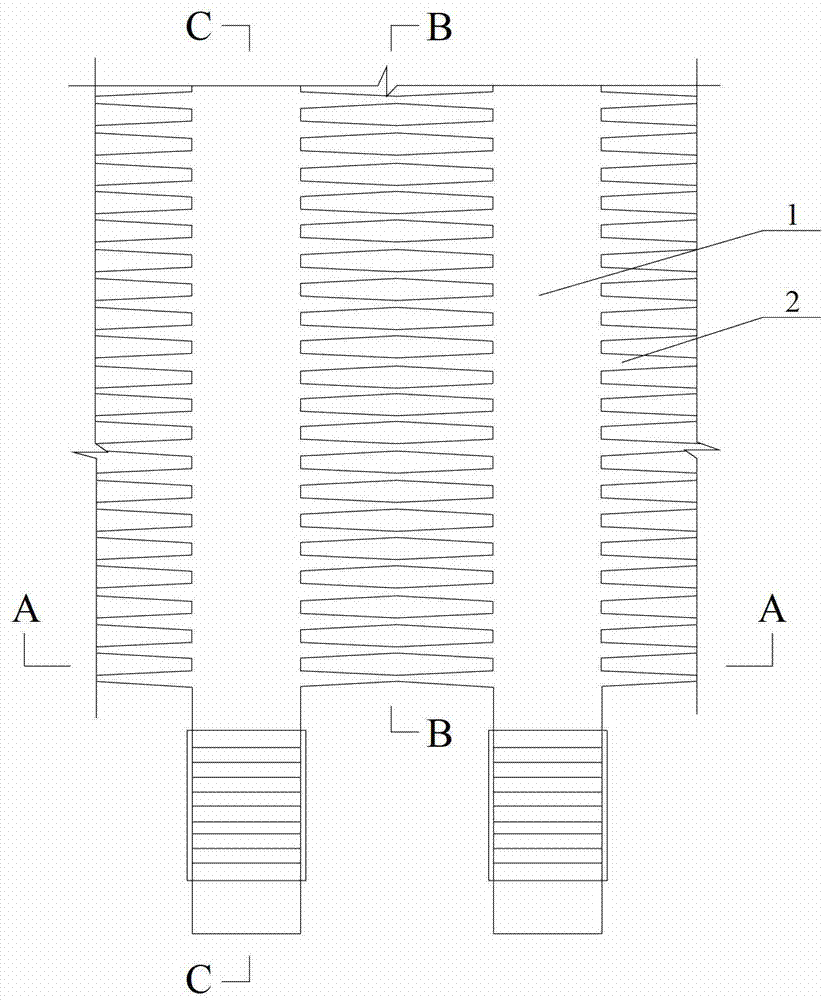

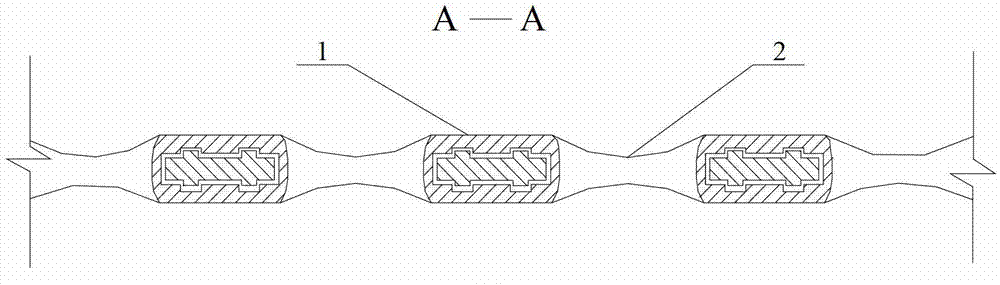

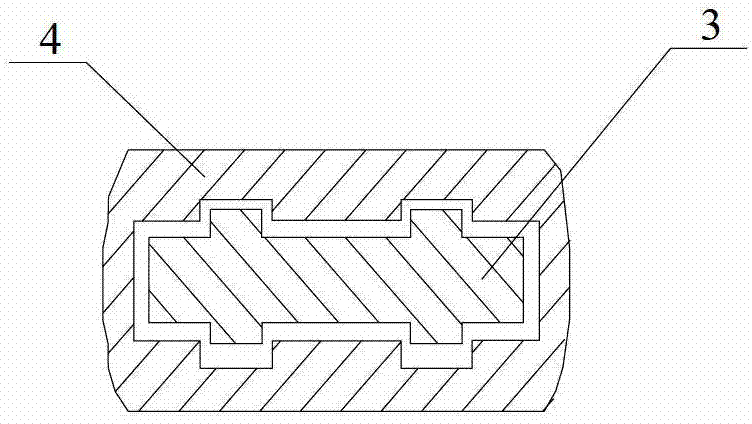

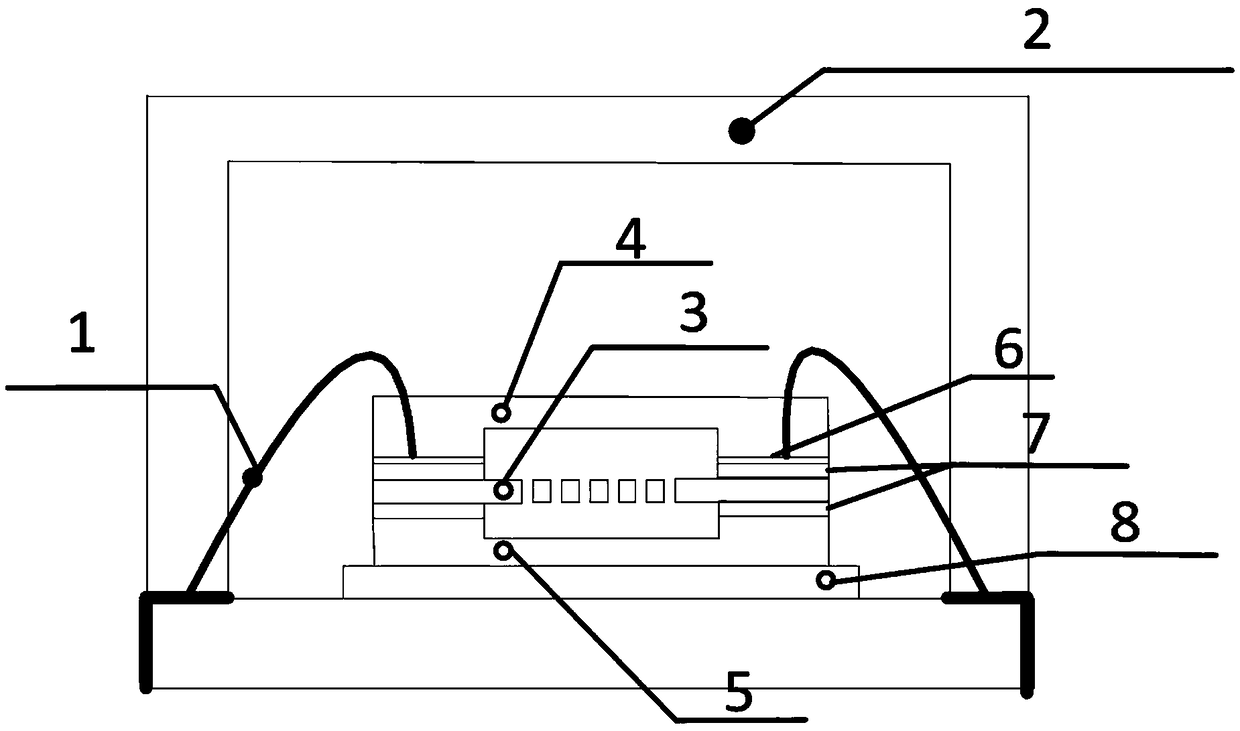

Secondary stress loading test device convenient for reinforcing structure under constant load and manufacturing method of secondary stress loading test device

InactiveCN104359764ASimple structureLow costMaterial strength using tensile/compressive forcesConstant loadTest beam

The invention relates to a secondary stress loading test device convenient for reinforcing a structure under a constant load. The secondary stress loading test device convenient for reinforcing the structure under the constant load comprises a base fixedly connected with a rigid ground, wherein heavy frames are arranged at the two sides of the base, a support is arranged at the lower part of each heavy frame, each support is fixedly connected with the rigid ground, each heavy frame is provided with a cross beam parallel to the rigid ground, a jack is hung upside down on each cross beam, each jack is vertical to the rigid ground and is provided with a force sensor, a test beam is arranged between each jack and the base, and each test beam is hinged with each jack and the base. The secondary stress loading test device convenient for reinforcing the structure under the constant load has the beneficial effects that an initial load can be applied to each test beam by virtue of a loading device, U-shaped increased cross section method reinforcing is carried out on a test piece under the condition that the initial load is kept constant, the working condition that the actual structure is reinforced under the initial stress can be fully simulated, the secondary stress loading test device convenient for reinforcing the structure under the constant load can be applied to a bending and shear reinforcing test of a reinforced concrete beam, the structure is simple and the cost is low.

Owner:FUZHOU UNIV

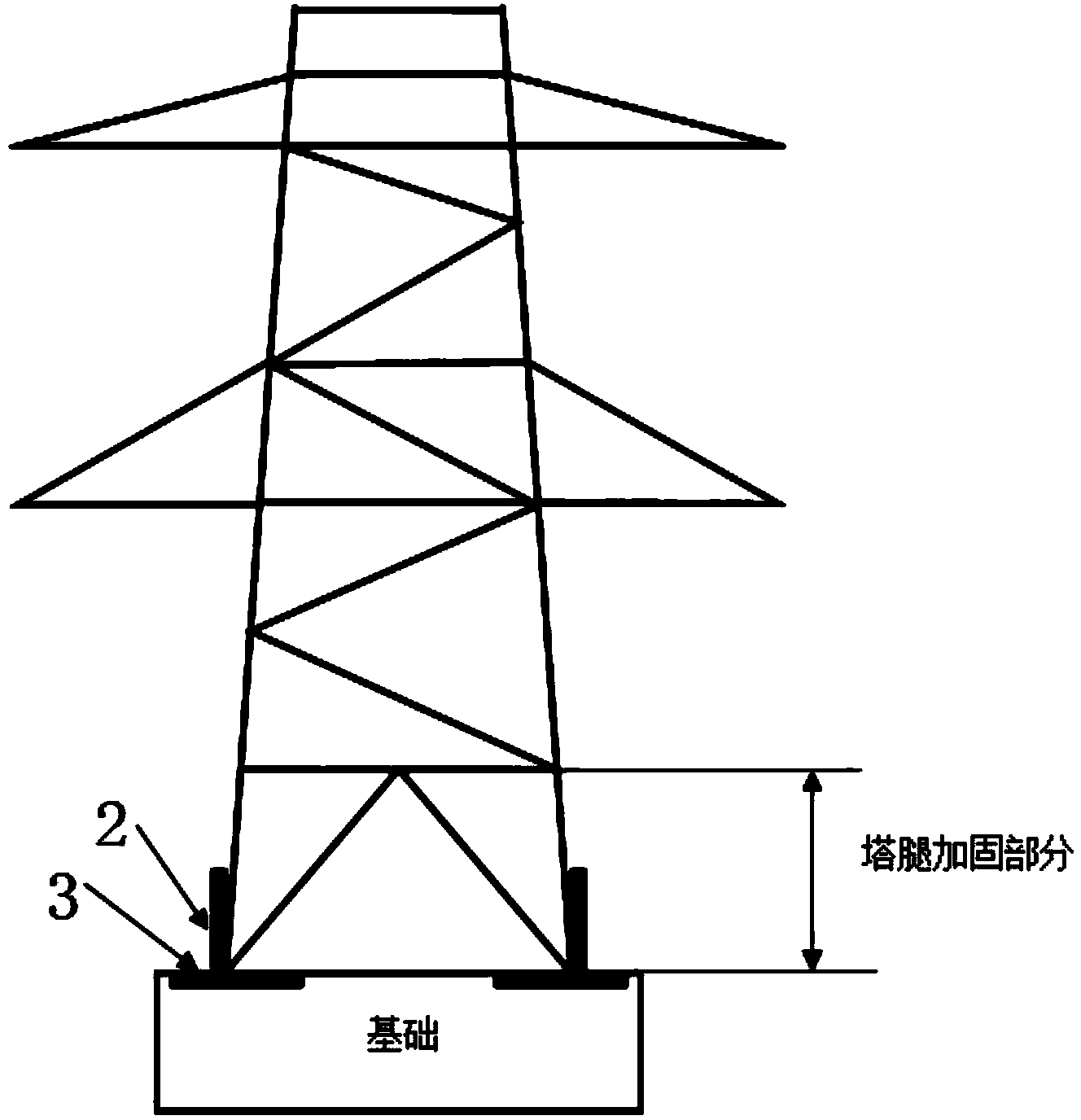

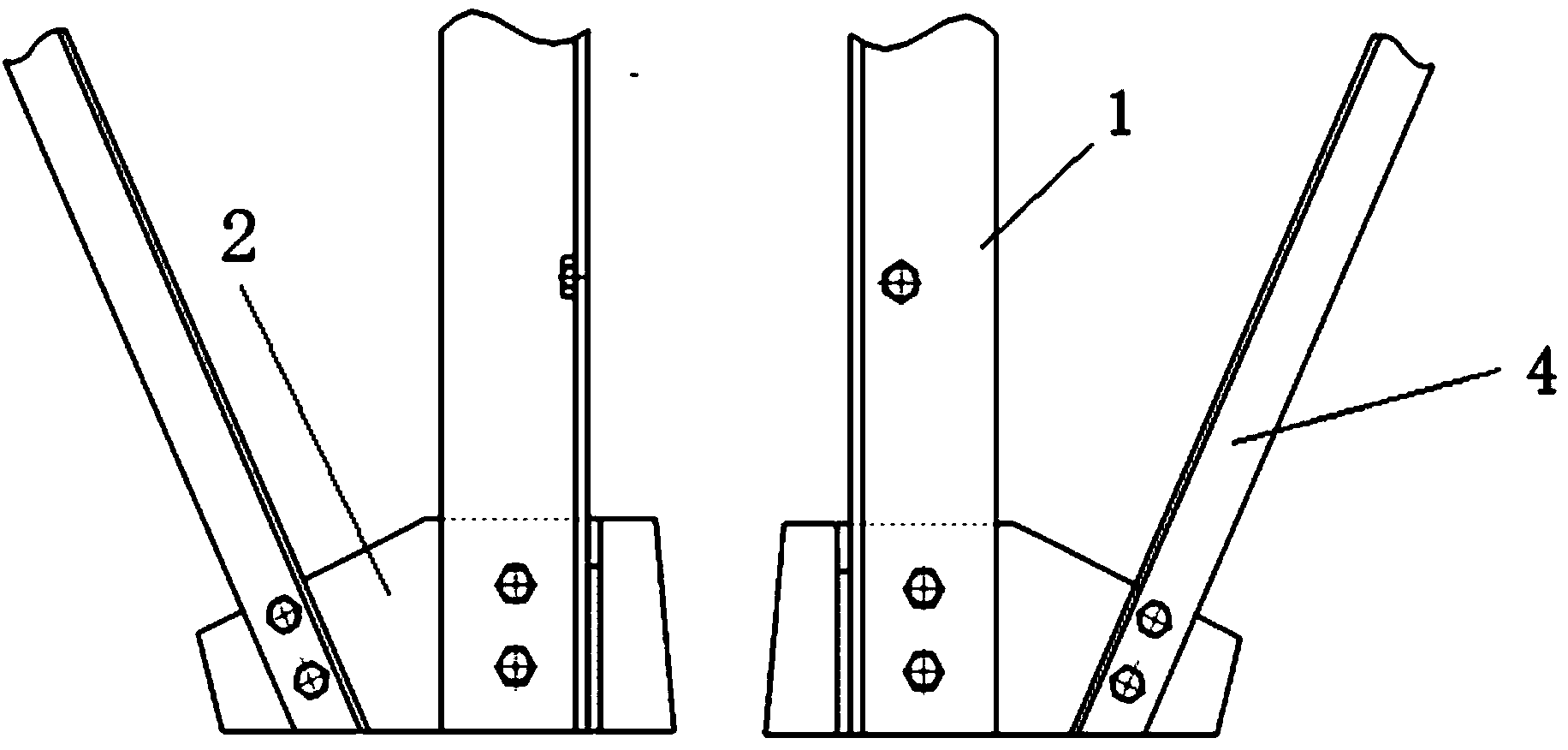

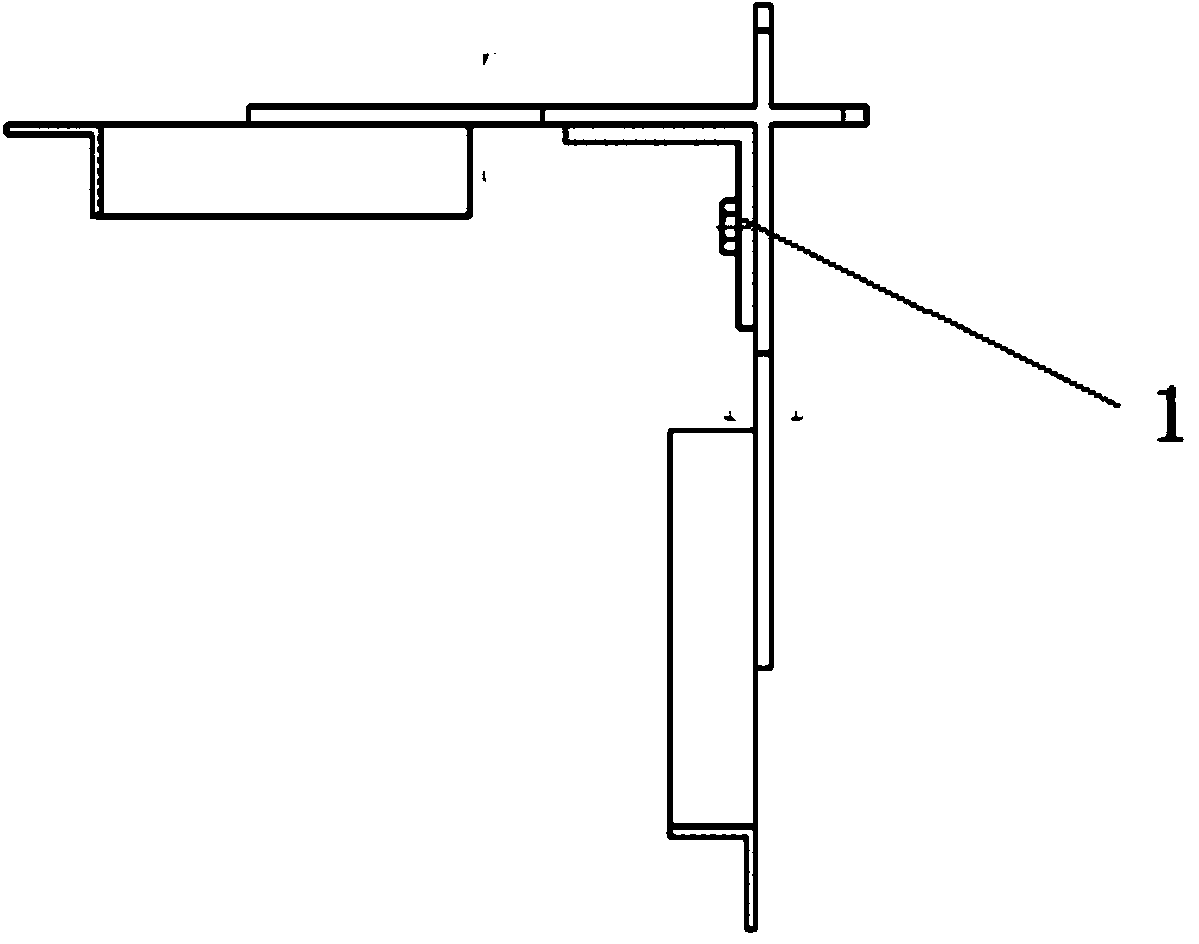

Method for field welding and strengthening of power transmission line steel angle tower leg

ActiveCN103883154AAvoid the hidden danger of weakening strengthImprove hardened securityTowersWelding apparatusLap jointEngineering

The invention discloses a method for field welding and strengthening of a power transmission line steel angle tower leg. In terms of a ZGU (7727) 110 kilovolt double-loop straight line tower type, a new steel angle tower leg is welded and attached to the surface of an original component in a covering mode by the adoption of a welding mode for strengthening, so that the defects existing in an existing steel angle tower leg strengthening method are avoided; newly added steel angles are directly connected together with the original component through a welded connection mode, firm metallurgical bonding is formed, tapping processing is not needed, intensity weakening hidden danger caused by tapping is avoided, and strengthening security is improved. The welded connection technology is adopted, metallurgical bonding is carried out on strengthening steel angles and original steel angles, the secondary stress phenomenon caused by bolt force transfer is avoided, and the strengthening effect can be improved to the maximum degree. The welded lap joint technology is adopted in the strengthening method, special-shaped plates are reasonably selected to connect and strengthen principal materials and tower leg sleeve plates, and therefore the strengthening steel angles can be easily arranged.

Owner:STATE GRID CORP OF CHINA +2

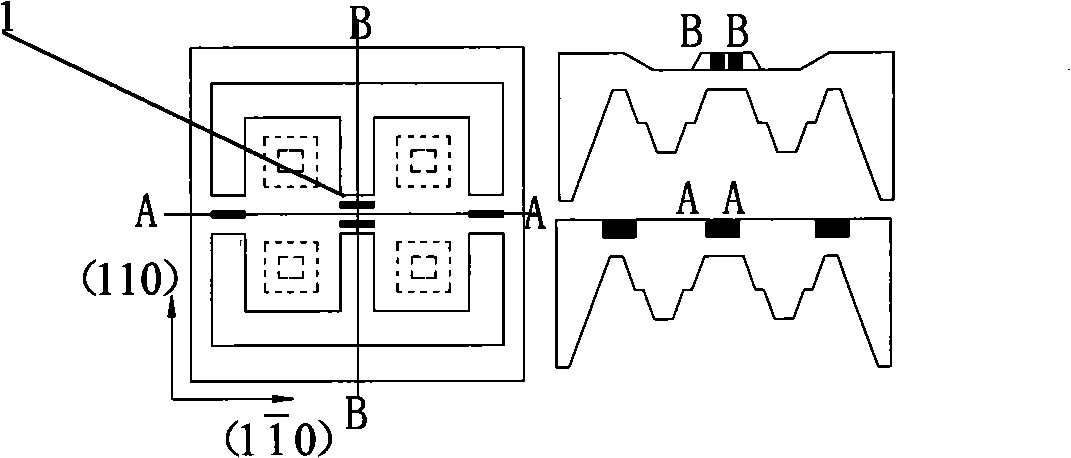

Orientation-optimized pfets in CMOS devices employing dual stress liners

InactiveUS20090065867A1Minimize tensile stressBig advantageSolid-state devicesSemiconductor/solid-state device manufacturingCMOSTensile strain

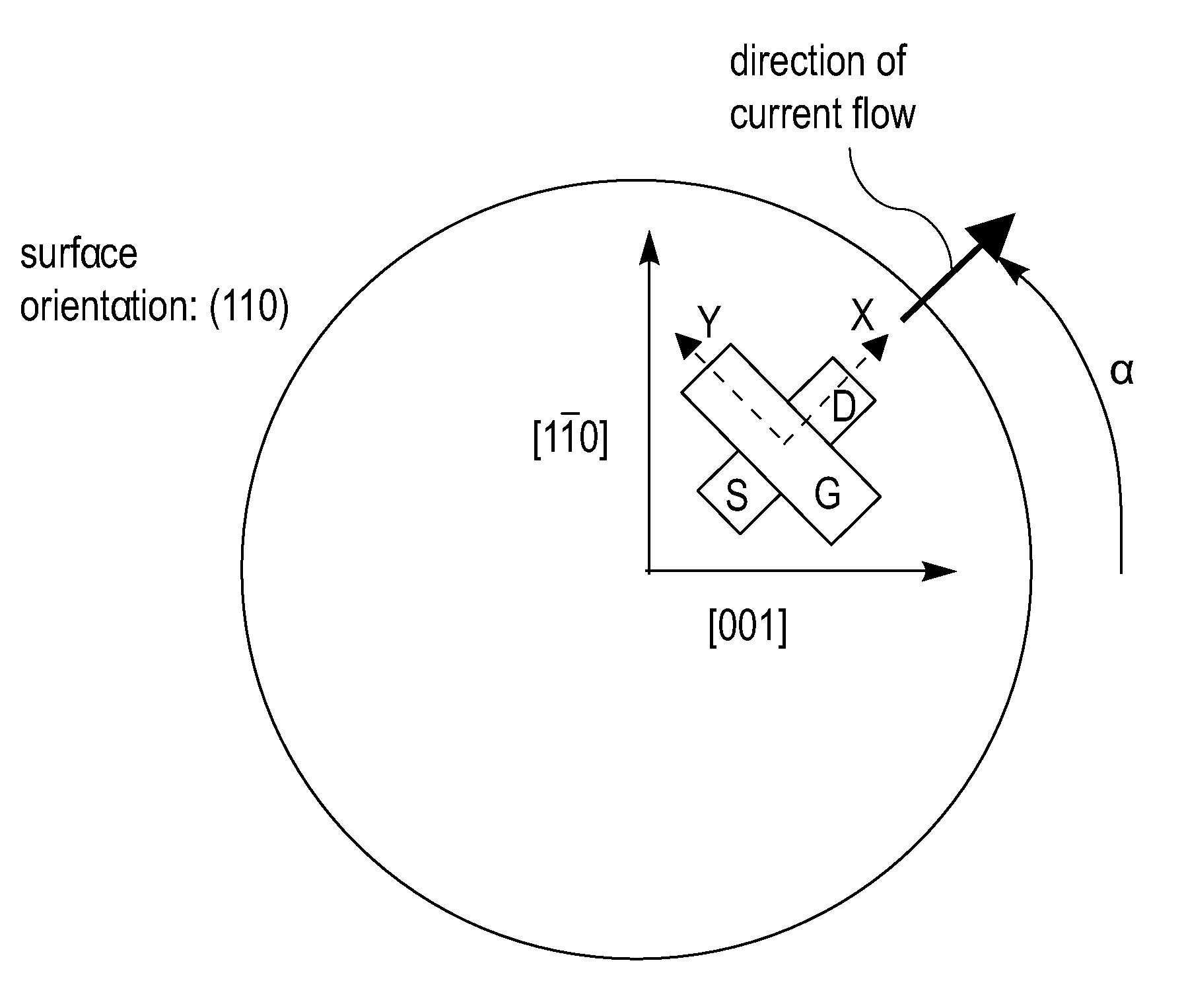

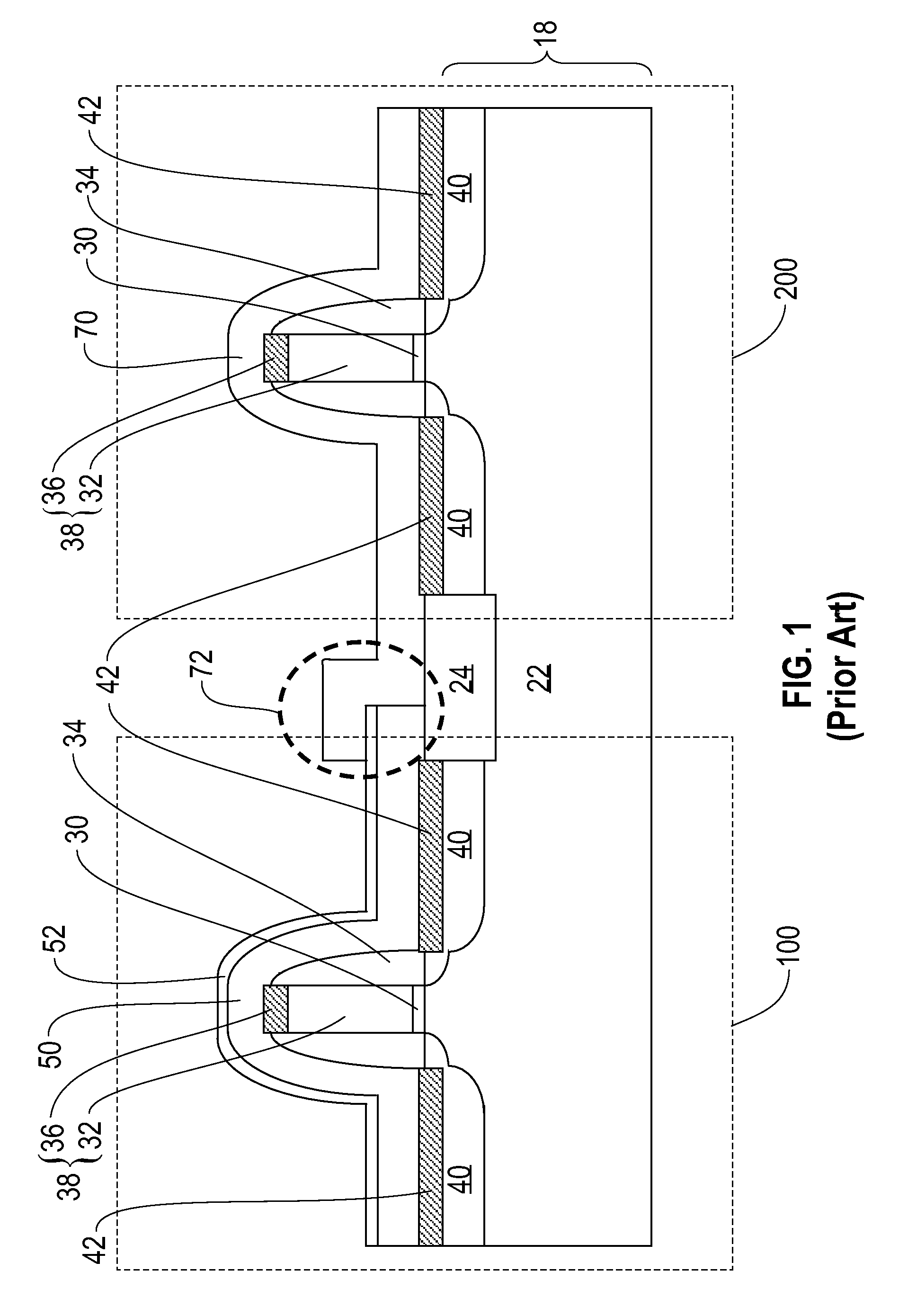

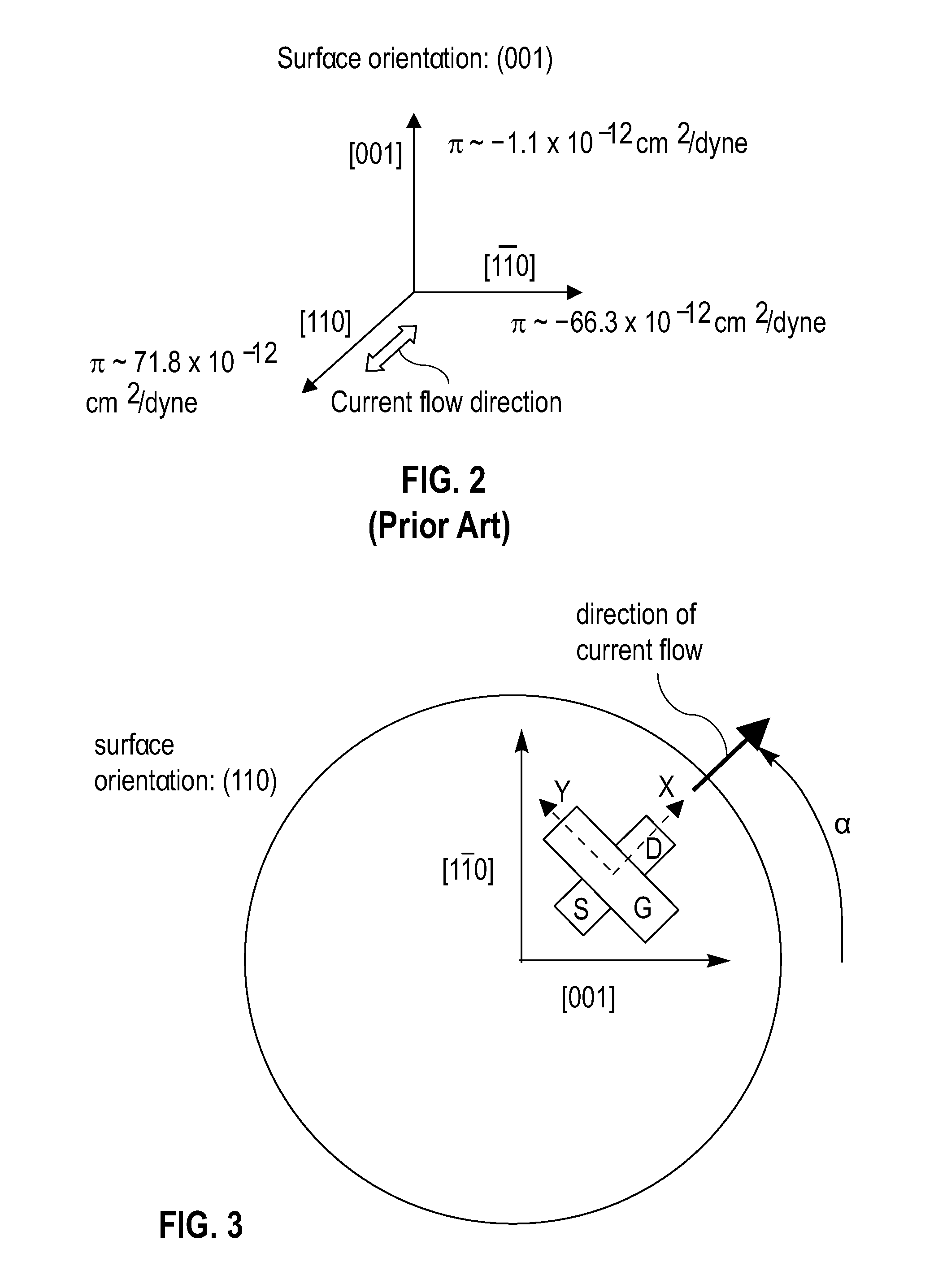

A PFET is provided on a silicon layer having a (110) surface orientation and located in a substrate. A compressive stress liner disposed on the gate and source / drain regions of the PFET generates a primary longitudinal compressive strain along the direction of the PFET channel. A tensile stress liner disposed on at least one NFET located transversely adjacent to the PFET generates a primary longitudinal tensile strain along the direction of the NFET channel. A secondary stress field from the at least one NFET tensile liner generates a beneficial transverse tensile stress in the PFET channel. The net benefits of the primary compressive longitudinal strain and the secondary tensile transverse stress are maximized when the azimuthal angle between the direction of the PFET channel and an in-plane [1 10] crystallographic direction in the (110) silicon layer is from about 25° to about 55.

Owner:GLOBALFOUNDRIES INC

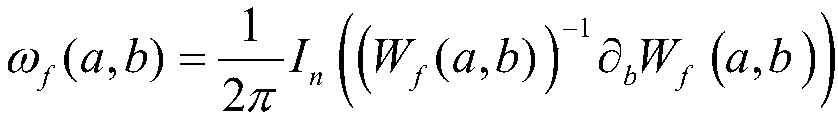

Transient unloading test simulation system for deep fractured rock mass under high confining pressure

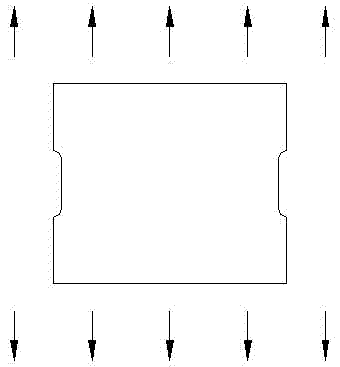

ActiveCN108535115AIn line with the actual unloading situationReveal mechanical behaviorMaterial strength using tensile/compressive forcesTest benchPetrology

The invention discloses a transient unloading test simulation system for deep fractured rock mass under a high confining pressure. The system mainly comprises a rock mass model, a support frame body,a test bench, a horizontal loading device, a vertical loading device, a loading and unloading device and a monitoring device, wherein the rock mass model is arranged in the support frame body, and thesupport frame body is arranged on the test bench; the bottom and left side of the rock mass model are jointed with the inner wall surface of the support frame body, and the right side of the rock body model is connected with an output end of the horizontal loading device; the top of the rock body model is connected with the vertical loading device; the loading and unloading device passes throughthe support frame body, and is connected with the lower part of the right side face of the rock mass model; an input end of the monitoring device is connected with the rock mass model. The transient unloading test simulation system for deep fractured rock mass under the high confining pressure has the beneficial effects that the system can realize a simulation test capable of simulating the following two mechanisms: transient redistribution, caused by transient unloading of surrounding rock, of a secondary stress field during blasting excavation; local damage possibly caused by quasi-static change of secondary stress field due to surrounding rock creep; therefore, the transient adjustment of the secondary stress field is realized, and the system is more in line with actual unloading situation in a project.

Owner:WUHAN UNIV OF TECH

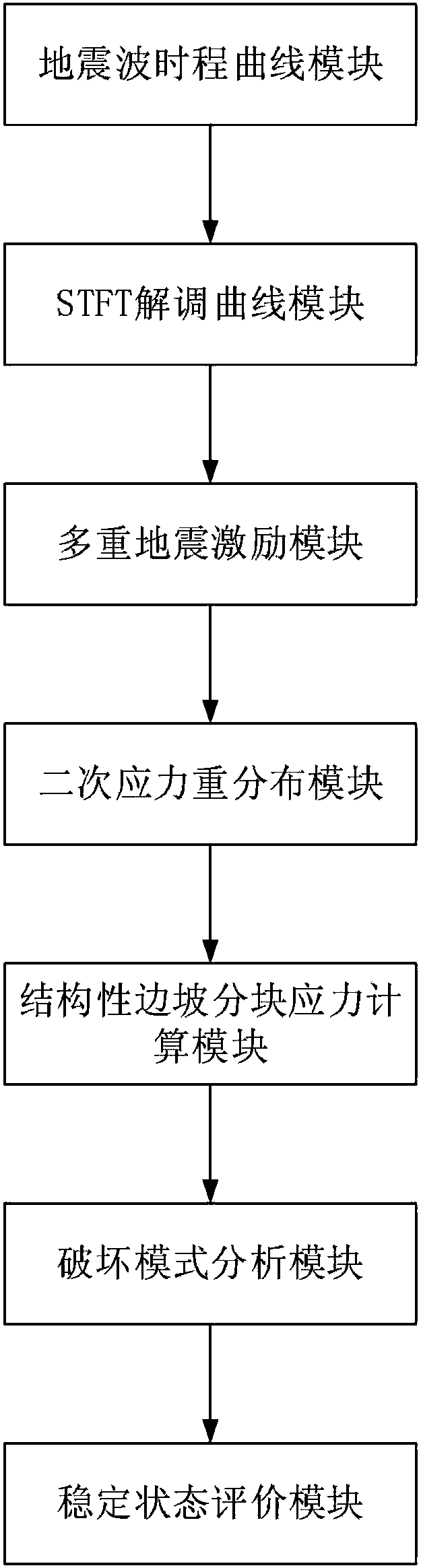

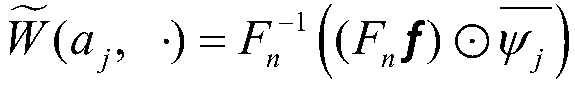

Novel layered slope earthquake damage instability calculating system and method based on energy demodulation frequency spectrum

The embodiment of the invention provides a novel layered slope earthquake damage instability calculating system and method based on an energy demodulation frequency spectrum, and relates to the geological technical field; the system comprises the following parts: a seismic wave time travel curve module used for obtaining a seismic wave time travel curve; a STFT demodulation curve module used for obtaining reflection wave and penetrated wave each order typical frequency time travel curve and energy spectrum curve; a multi-earthquake excitation module used for carrying out multi-earthquake excitations in a frequency domain; a secondary stress redistribution module used for calculating secondary stress redistribution; a structural slope partitioning stress calculation module used for solvingthe average stress state on each interface, drawing a sliding mass structural surface stress field, horizontally and transversely stripping the slope, and solving the lower sliding force and anti-sliding force of corresponding positions on the strip interfaces; a damage mode analysis module used for analyzing damage modes; a stability state evaluation module used for evaluating stability states. The method and system are high in calculating efficiency and accuracy.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Modular splicing type copper alloy stretching net box and assembling method thereof

ActiveCN104756904AImprove integrityIncrease elasticityClimate change adaptationPisciculture and aquariaPolyesterFiber

The invention relates to a modular splicing type copper alloy stretching net box and n assembling method thereof. The modular splicing type copper alloy stretching net box comprises a vertical main stressing high-strength polyester fiber belt main framework tape standard part and a horizontal secondary stressing high-strength polyester fiber belt secondary framework tape standard part which are fixed at a crisscross connecting point to form a grid shaped single-side net box tape framework which has the characteristics of flexibility and elasticity; a prefabricated copper alloy stretching net standard module is assembled into each frame of the grid shaped single-side net box tape framework through a prefabricated quick connecting part to form the modular splicing type net box body single-edge side net; two side edges of the single-edge side net are connected through the quick connecting part, or a plurality of single-edge side nets are provided with corner flexible connecting adapting standard parts and bottom nets and then assembled to be a copper alloy stretching net box body. The modular splicing type copper alloy stretching net is applicable to modular and standard production and convenient to be quickly mounted in the sea; a marine breeding net can be maintained well and prevented from being attached by marine fouling organisms; the inside and outside water of the net box body can be exchanged well.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

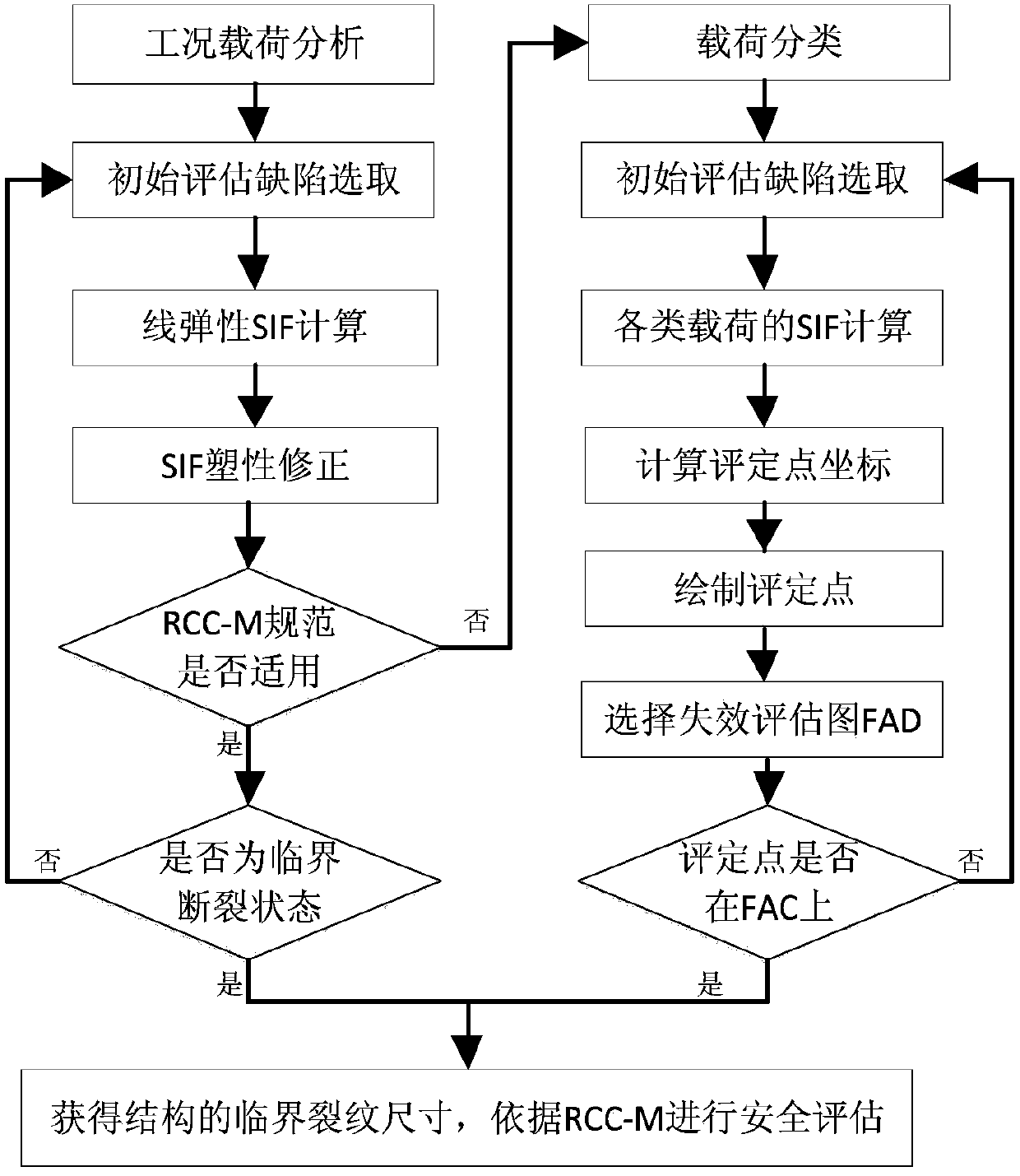

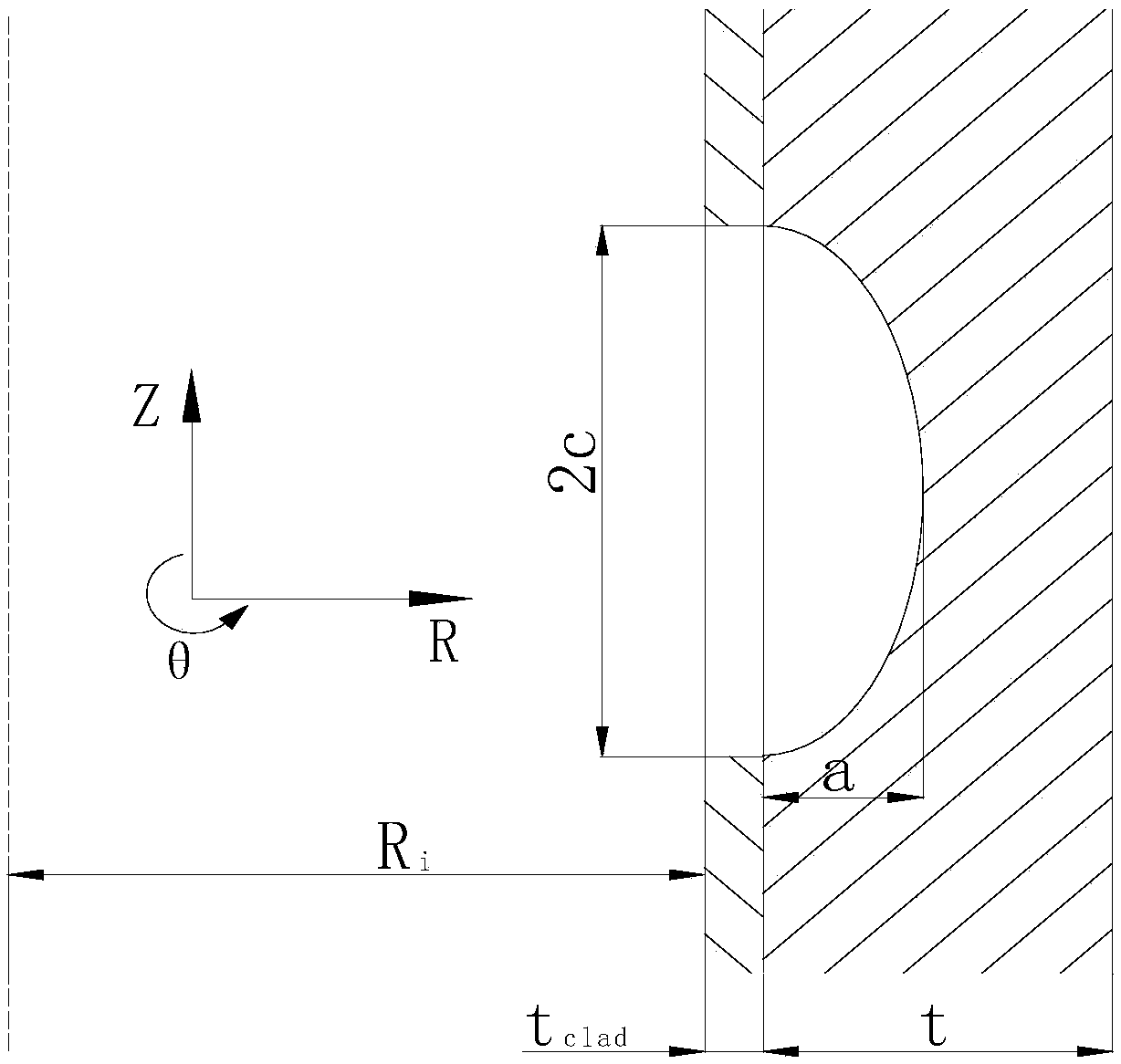

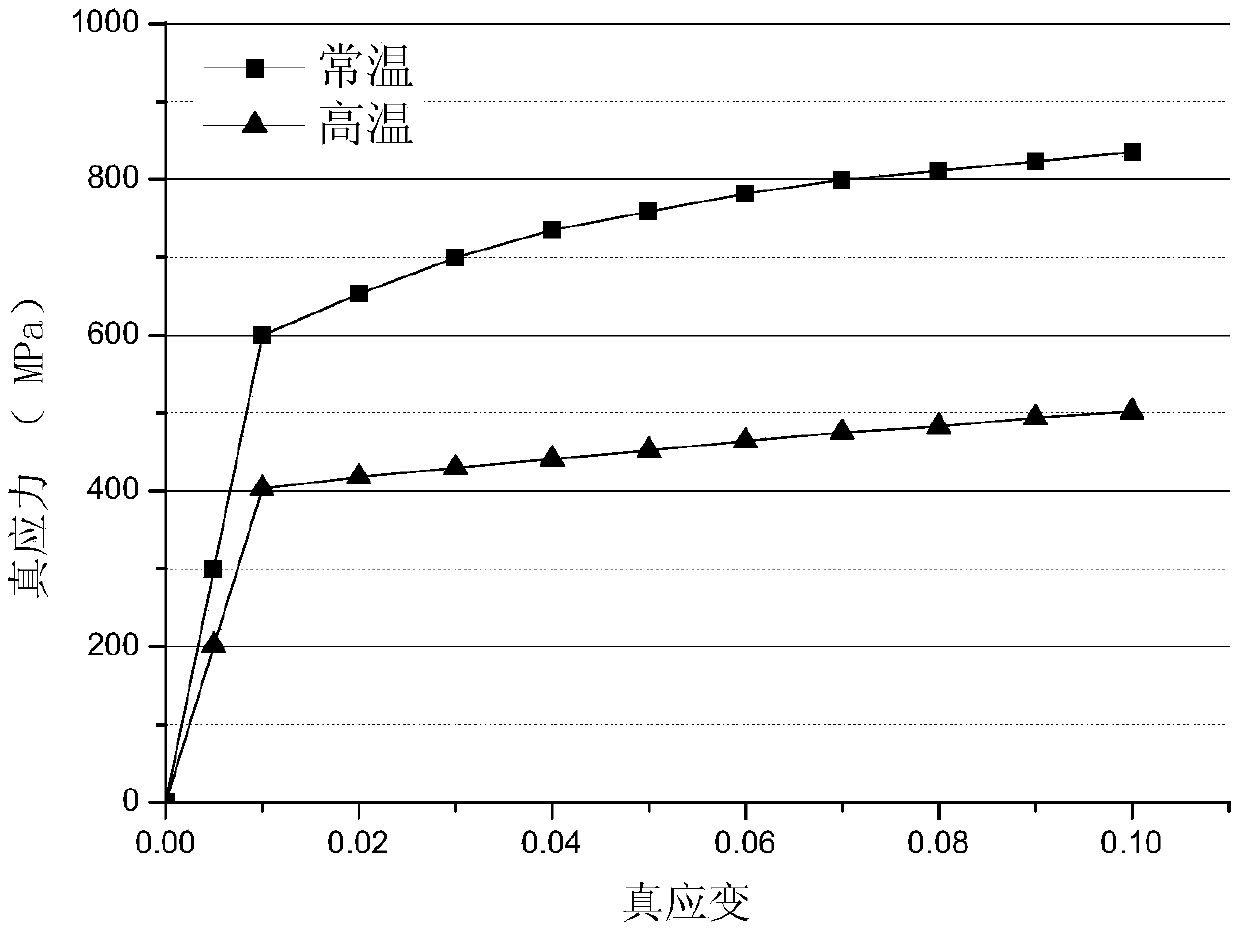

Method for simplifying analysis of elastic-plastic fractures of RPV under extreme accident conditions based on RCC-M specification

The invention relates to a method for simplifying analysis of elastic-plastic fractures of a reactor pressure vessel (RPV) under extreme accident conditions based on RCC-M specification. The method comprises the following steps: (a) analyzing loads of extreme accident conditions and dividing various loads into primary stress loads and secondary stress loads by determining whether the loads have influence on plastic instability of the structure; (b) determining types and shape parameters of fissures according to RCC-M specification; (c) obtaining material property parameters of RPV and calculating a linear elastic stress intensity factor, wherein the linear elastic stress intensity factor is sum of stress intensity factors caused by the primary stress loads and the secondary stress loads in transient state; and (d) judging whether the RCC-M specification is applied to plastic correction of the linear elastic stress intensity factor, assessing by using the technology when the plastic correction of the linear elastic stress intensity factor exceeds the application range of the RCC-M specification so as to improve accuracy of analysis of fracture-containing defects of RPV.

Owner:SUZHOU NUCLEAR POWER RES INST +4

Veneer special for wood blade of classical ceiling fan and preparation method for plywood

ActiveCN102514052ASmall degree of deformationHigh strengthLaminationLamination apparatusCeiling fanPulp and paper industry

The invention discloses a veneer special for a wood blade of a classical ceiling fan and a preparation method for the plywood. The preparation method comprises the following steps of: preparing materials, wherein thickness difference between a eucalyptus core veneer and a eucalyptus long-center veneer is not more than 0.3mm; assembling; hot-pressing, namely performing hot-pressing on a three-layer blank veneer subjected to cold repair; hot stacking for 24 to 72 hours to cure glue water and eliminate stress; cutting an edge, supplying putty, sanding and veneering; hot-pressing the veneered 5-layer veneer; cooling, and hot staking for 2 to 3 days; cutting an edge; performing humidifying and formaldehyde pollution resistant posttreatment; eliminating secondary stress; and performing surface treatment and wood grain filling to obtain the veneer special for the wood blade of the classical ceiling fan. The veneer special for the wood blade of the classical ceiling fan has the advantages of small deformation, high integral strength, flat and smooth surface and no torn grains.

Owner:王佐生

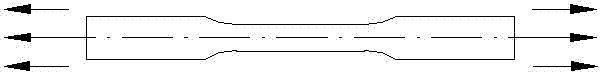

Method for measuring volume distribution of retained austenite in transformation induced plasticity (TRIP) steel stamped part

InactiveCN102680388AGood formabilityGive full play to the effect of phase transformation induced plasticityUsing mechanical meansMaterial analysisTRIP steelApplication areas

The invention relates to the field of performance measurement of steel stamped parts and in particular to a method for measuring the volume distribution of retained austenite in a transformation induced plasticity (TRIP) steel stamped part. The method for measuring the volume distribution of retained austenite in the TRIP steel stamped part comprises the following steps of: firstly classifying the deformations into four standard deformation modes; then deducing the law of retained austenite transformation under a complicated strain path according to the plastic deformation theory; and finally calculating the volume content of retained austenite of each point on the part after deformation according to the main and secondary strain magnitudes. The method can be used for obtaining the volume content of retained austenite only by measuring the main and secondary stresses of the stamped part; has the advantages of simplicity of implementation, accurate result and low time and economic costs; and provides a basis for improving the formability of the TRIP steel by improving the part shape and the process addendum and / or the design of draw beads, so as to take full advantage of the effect of transformation induced plasticity of the TRIP steel and increase the application range of the TRIP steel.

Owner:BAOSHAN IRON & STEEL CO LTD

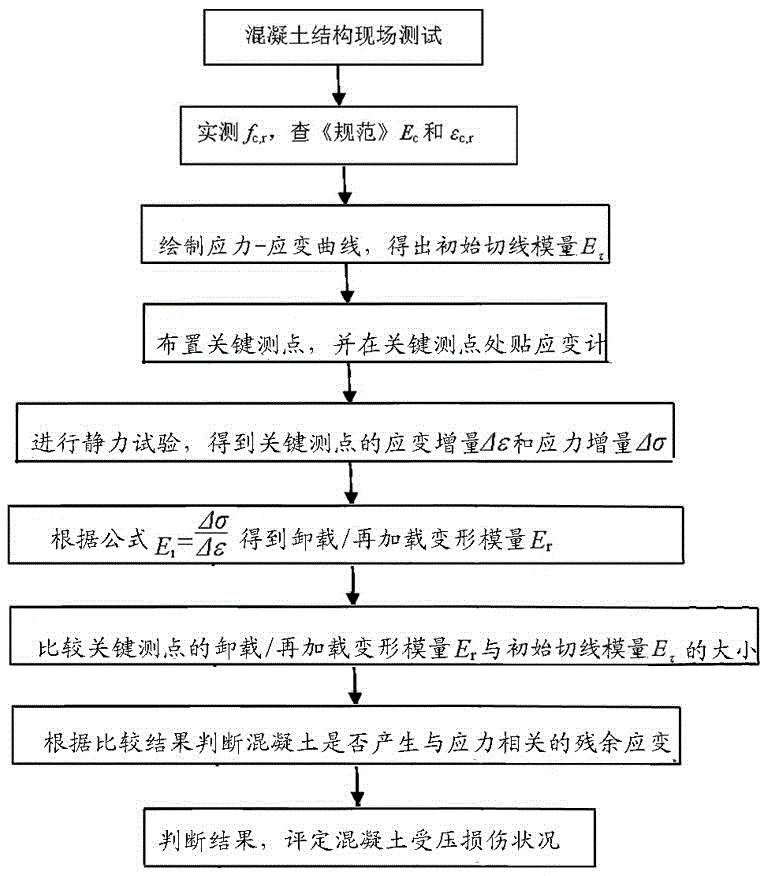

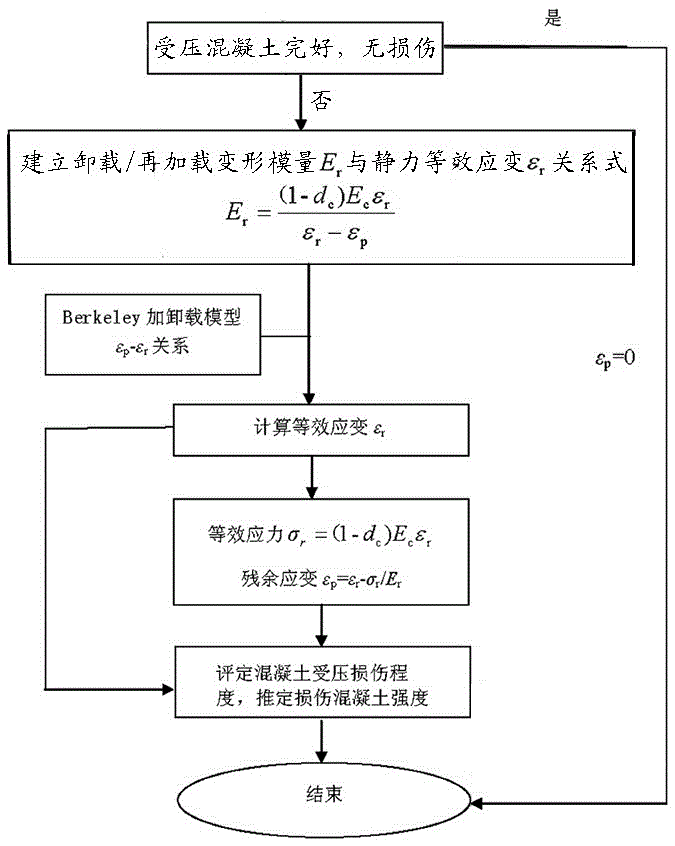

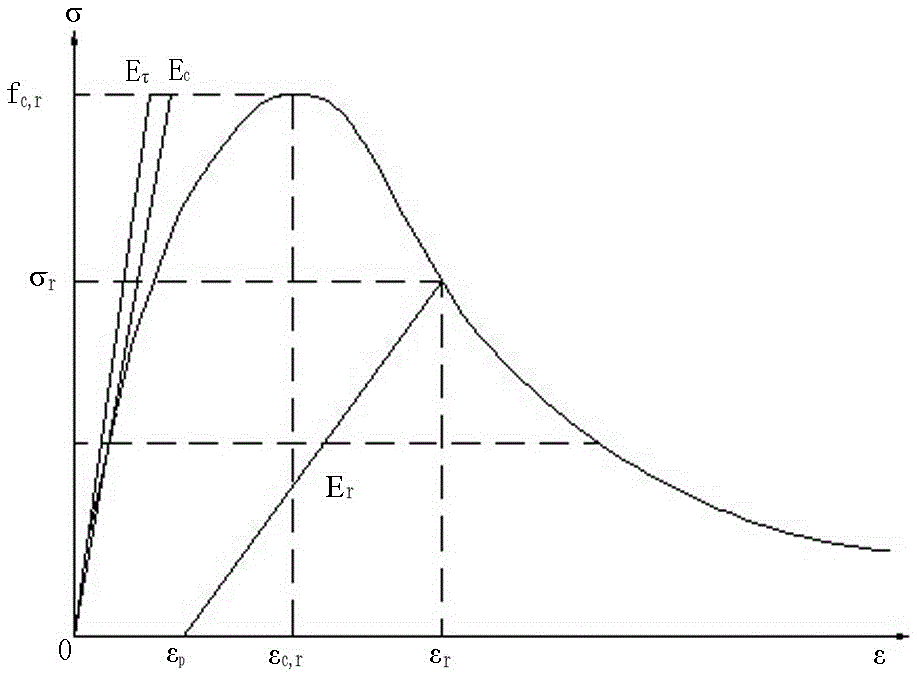

Existing structure concrete fatigue residual strain testing method based on deformation modulus

ActiveCN106404534AHigh precisionAvoid affecting the mechanical performance of the structureMaterial strength using tensile/compressive forcesResidual strainDeformation modulus

The invention provides an existing structure concrete fatigue residual strain testing method based on a deformation modulus. An actual concrete stress-strain curve is established through testing and analyzing mechanical parameters of concrete on a representative secondary stress component; at a maximum compressive strain part of a key section of a main stress component, a concrete unloading / reloading deformation modulus is tested; static-force equivalent strain and static-force equivalent stress corresponding to the concrete unloading / reloading deformation modulus are calculated according to a strain equivalent principle, so that concrete fatigue residual strain is obtained. By adopting the existing structure concrete fatigue residual strain testing method provided by the invention, the technical problem that the residual strain cannot be obtained by a traditional field testing method is solved, and stressed concrete damage degree evaluation standards, concrete static-force equivalent strain indexes and concrete post-damage predicted strength based on the residual strain,are given.

Owner:BEIJING MUNICIPAL ENG RES INST

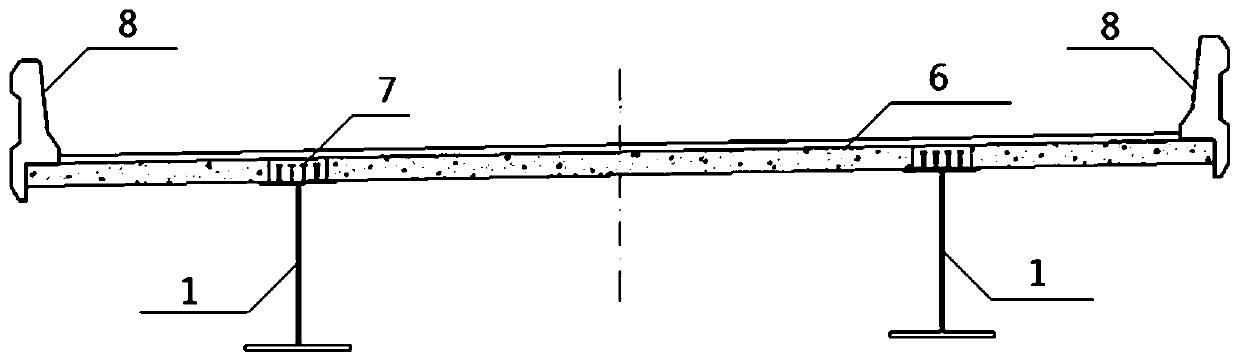

Bearing reaction force detection method for I-shaped steel-concrete composite beam

PendingCN110220626AMake sure emptyAccurate measurementApparatus for force/torque/work measurementSupport pointComposite beams

The invention particularly relates to a bearing reaction force detection method for an I-shaped steel-concrete composite beam. The composite beam comprises a steel girder, a concrete deck slab, and shear studs, wherein the steel girder comprises two I-shaped girders, mid-span small crossbeams, supporting point large crossbeams, and cantilever arm crossbeams; and the steel girder is integrated withthe concrete deck slab through the shear studs, so that a composite structure is formed. The bearing reaction force detection method is characterized in that an oil jack and a displacement meter arearranged in the position of each supporting point of the I-shaped steel-concrete composite beam; and the jacks simultaneously carry out jacking to reach a certain height, complete disengagement of allsupporting seats of the entire steel girder is ensured, and the bearing reaction force of each jack is measured in a static status. The method has the advantages that through the conventional instruments and equipment such as the jacks and the displacement meters, as well as simple technical measures, the bearing reaction force of the I-shaped steel-concrete composite beam can be precisely measured, so that technical guarantees can be provided for subsequent bearing reaction force correction and secondary stress adjustment.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Anti-jamming single-shield TBM main machine structure and anti-jamming method thereof

ActiveCN107218050AReduce deformation rateImprove applicabilityHydro energy generationTunnelsAnti jammingEngineering

The invention discloses an anti-jamming single-shield TBM main machine structure and an anti-jamming method thereof. The anti-jamming single-shield TBM main machine structure and the anti-jamming method thereof are used for solving the technical problem that in the prior art, jamming is easily caused on single-shield TBM faults, crushed zones and other poor stratums. The anti-jamming single-shield TBM main machine structure comprises a cutterhead. The cutterhead is connected with a shield body. The shield body comprises a front shield, a middle shield and a tail shield which are sequentially connected. Multiple detachable front shield check pulp brushes are arranged at the front end of the front shield, multiple upper tail brushes and multiple lower tail brushes are arranged on the shield wall of the rear end of the tail shield, the upper tail brushes correspond to the front shield check pulp brushes, multiple trigger mud connectors are arranged on the shield walls in the front shield and the tail shield, the trigger mud connectors are connected with a mud storage tank through a mud pipe, and a mud conveying pump is arranged on the mud pipe. The positions between dug cavity walls and the shield body are filled with trigger mud, a stress field generated after the cavity walls are dug is converted into a tertiary stress state from a secondary stress field, the stratum deformation rate is reduced accordingly, a single-shield TBM can smoothly and stably pass through a crushed stratum, and construction quality and construction safety are guaranteed.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

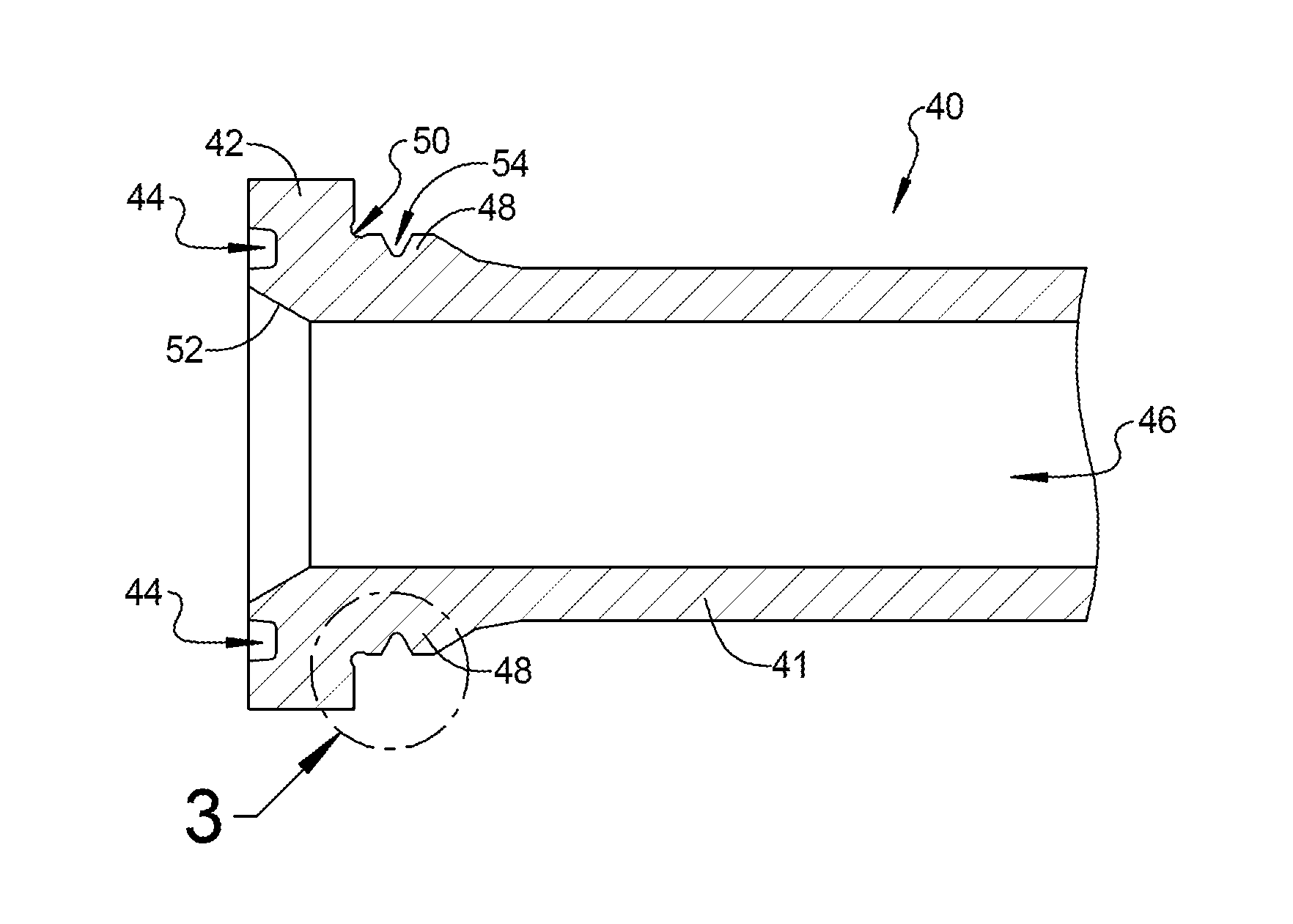

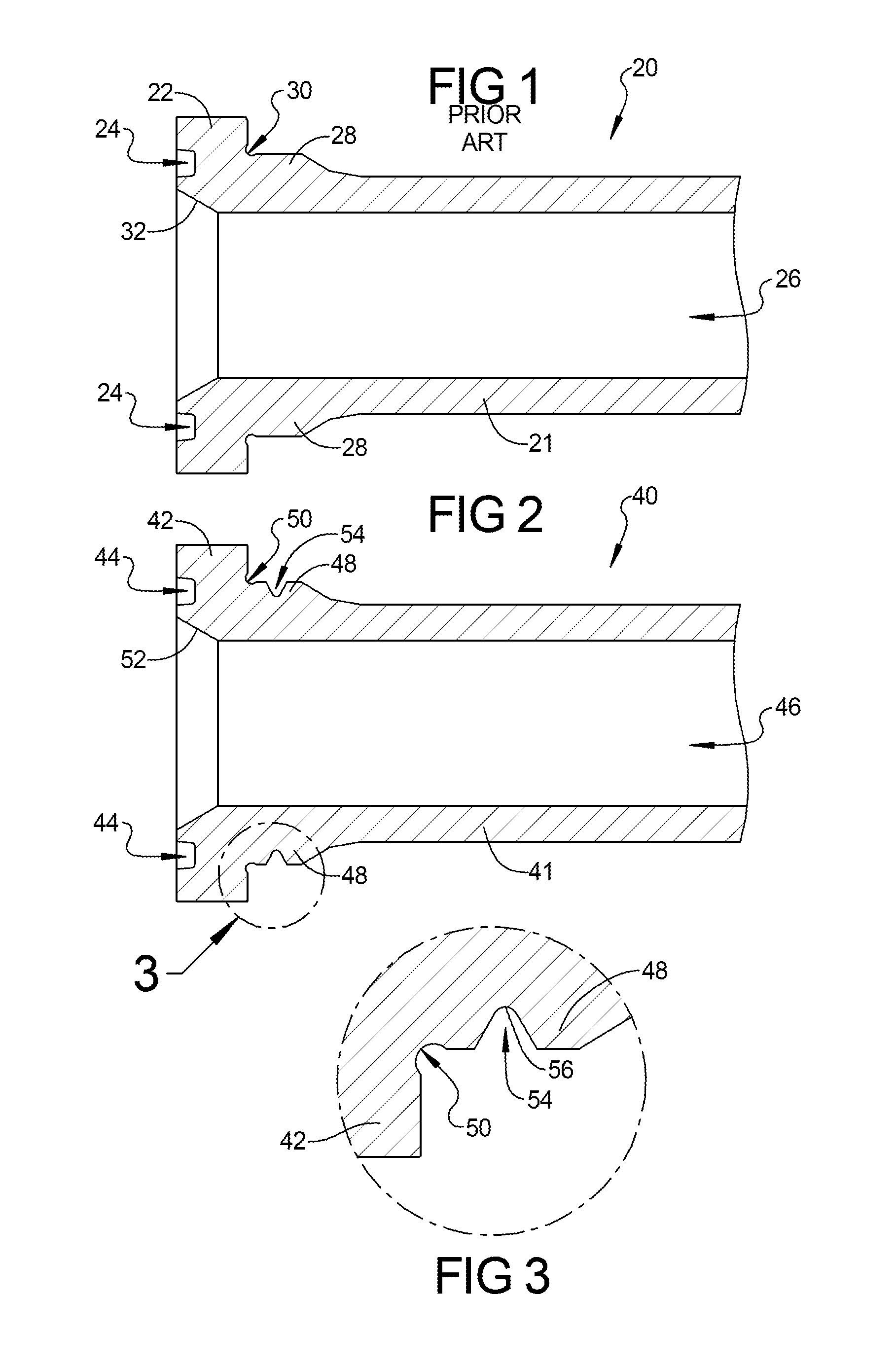

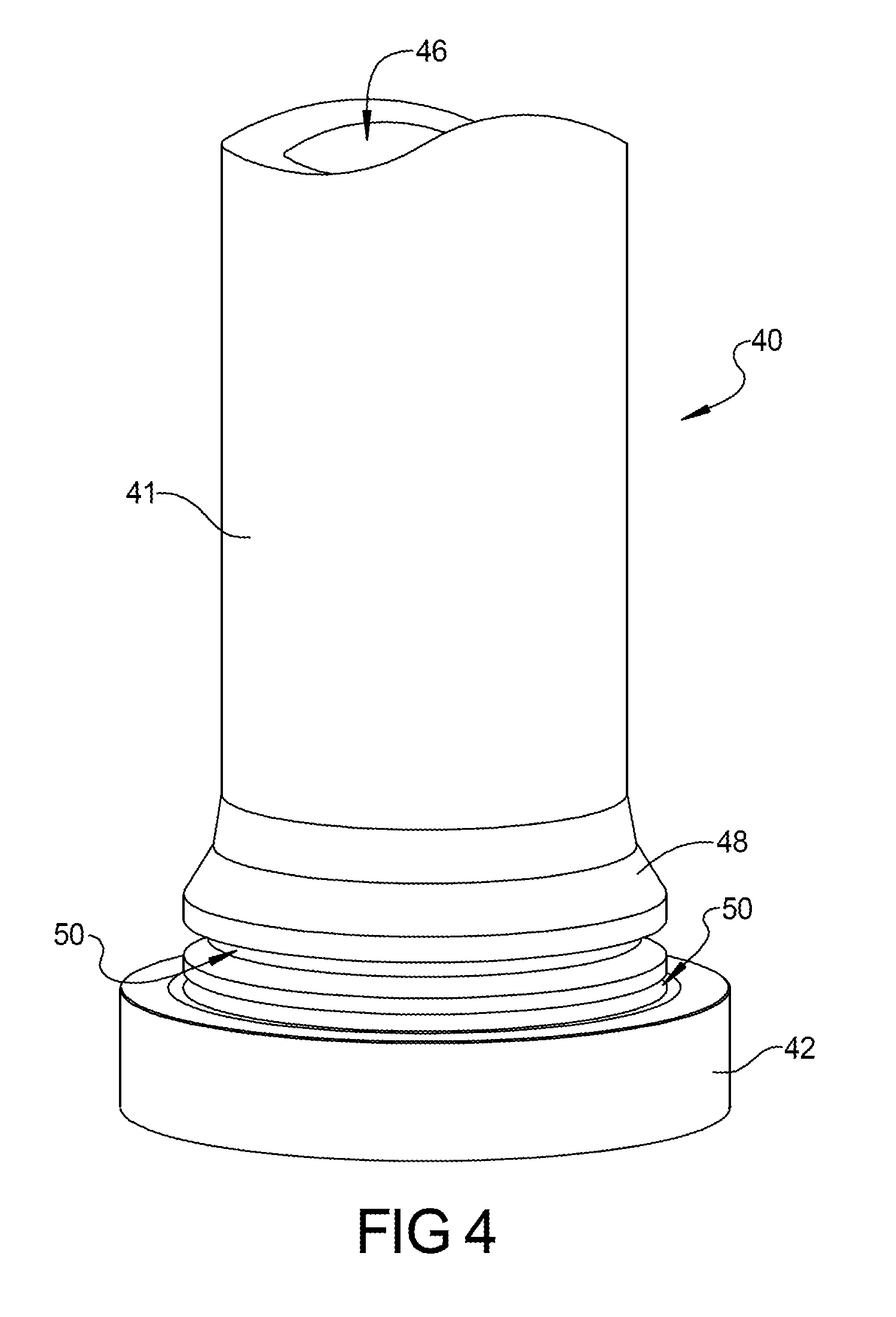

Hydraulic flange connection

A hydraulic flange connection formed on a tube having a first groove formed in the outside of the flange at a first stress area and a second groove formed in the outside surface of the flange at a secondary stress area and extending in a direction substantially perpendicular to a central cavity formed in the tube.

Owner:EATON CORP

Engineering calculation method of flexible thin tube sheet

ActiveCN101847172ACalculation results are fastEasy calculationSpecial data processing applicationsTemperature differenceEngineering

The invention discloses an engineering calculation method of a flexible thin tube sheet, comprising the following steps: determining the wall temperature of a heat exchange tube and the design temperature of a channel box; according to the technological condition, optimizing the tube pitch of key structural parameter and the wall thickness of the heat exchange tube; analyzing and processing a calculation result; if secondary stress is out of limit under the combined action of the tube, shell side pressure and temperature difference load, forbidding considering the calculation result of nonexistent operation working condition; and if the primary stress is out of limit under the combined action of the tube and the shell side pressure, converting the secondary stress into the primary stress for controlling. The invention has the positive effect on making up the shortcomings because of adopting two calculation methods for designing flexible thin tube sheets for a long term, i.e. the defects of limited applicable range or long consumed calculation time, high calculation cost and complex calculation process. The method has wide applicable range, high calculation speed, simple calculation process and safe and reliable calculation result and conforms to the requirements of national energy saving and consumption reduction as well as cost saving for enterprises.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

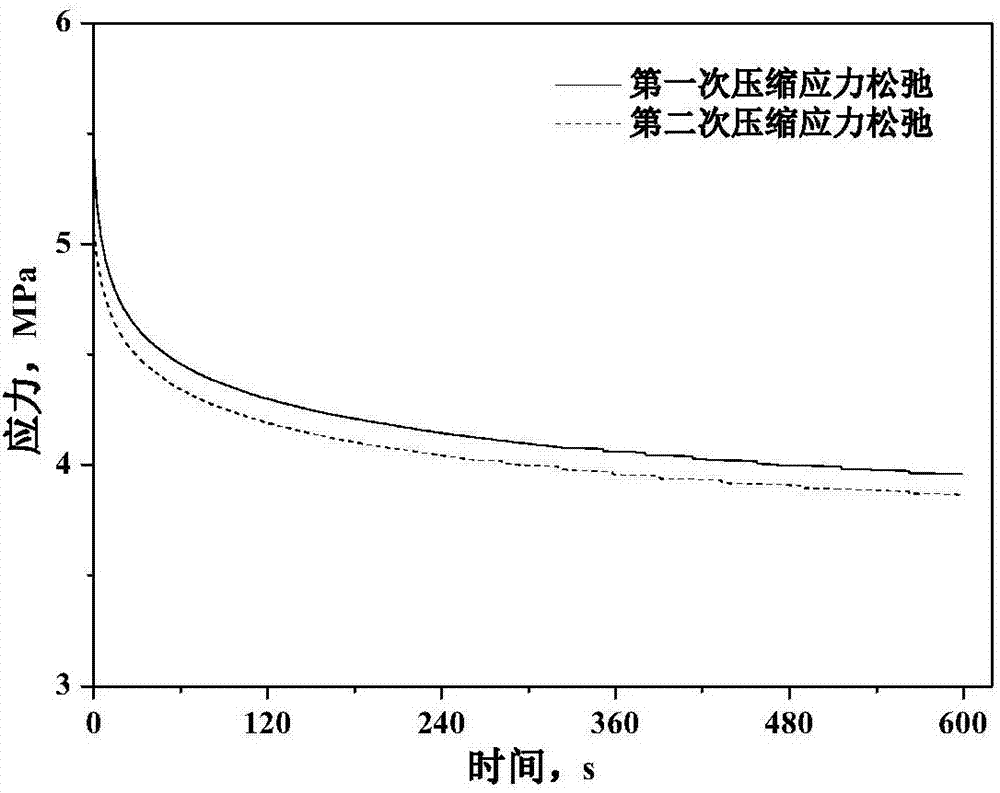

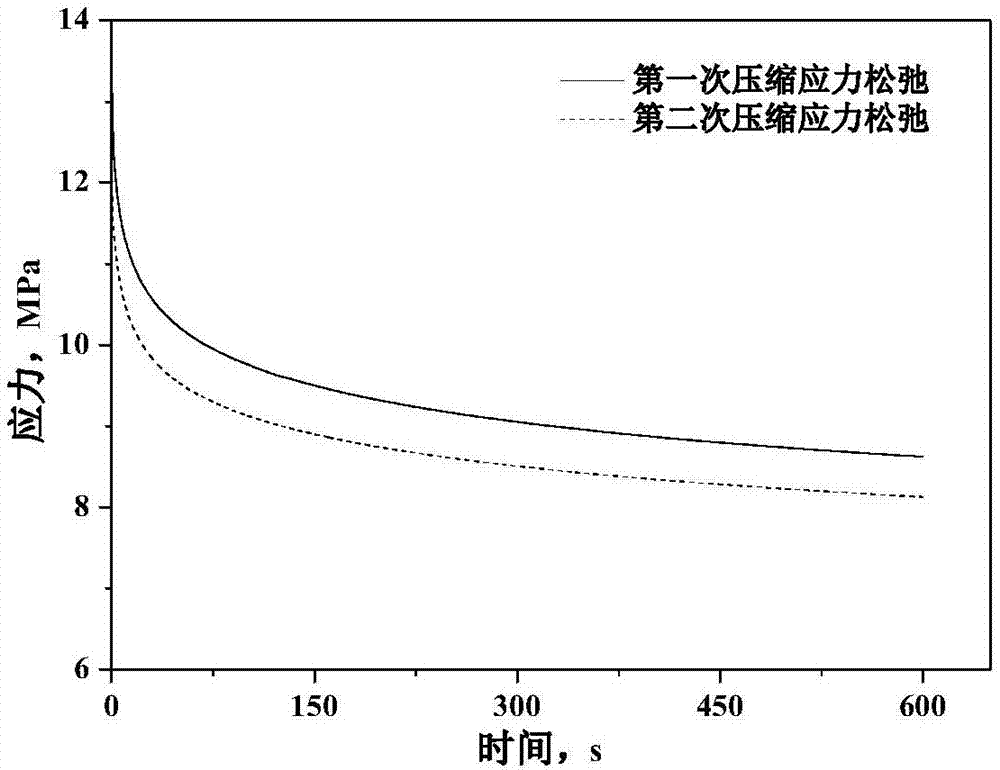

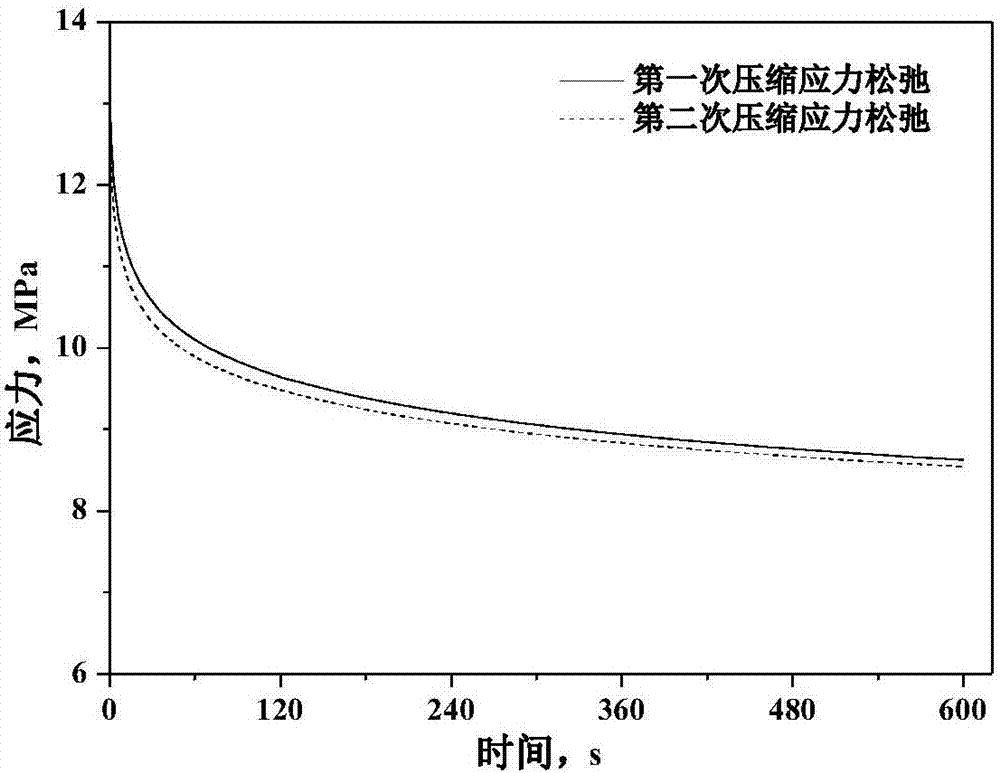

Thermoplastic vulcanizate compression stress relaxation reversible recovery behavior characterization method

The invention relates to a thermoplastic vulcanizate compression stress relaxation reversible recovery behavior characterization method, which provides an effective method for qualitative and quantitive characterization of reversible recovery. The characterization method comprises the steps of a, applying a compression strain on a sample, measuring a primary stress relaxation behavior, wherein the initial height of the sample is h0, and the height becomes hs when the sample is compressed to the stipulated strain; b, after finishing the primary test, carrying out heat treatment on the sample, and then cooling to the room temperature, wherein the height is h1, and the compression set is recorded as shown in the below figure; c, carrying out secondary compression stress relaxation test on the heat-treated sample, and by adopting the h1 as a baseline, applying the same strain of the primary test; d, reading the maximum stress in a stress relaxation curve, wherein the maximum stress recovery rate is equal to (the secondary stress relaxation maximum stress / the primary stress relaxation maximum stress) x 100 percent; e, qualitatively judging a reversible recovery degree according to a close degree of two-time stress relaxation behavior curves; and quantitatively judging the reversible recovery degree according to the compression set and the maximum stress recovery rate.

Owner:QINGDAO UNIV OF SCI & TECH

Non-adhesion prestressing reinforcement material

InactiveCN102877468AImprove support capacityIncrease constraintsArtificial islandsRoadwaysPre stressPolyvinyl chloride

The invention provides a non-adhesion prestressing reinforcement material. A main stressed part comprises an internal reinforcement material and an outer layer reinforcement material; the internal reinforcement material is arranged inside the outer layer reinforcement material; the outer layer reinforcement material is made of polypropylene or polyvinyl chloride high molecular polymer; the internal reinforcement material is a high-elasticity modulus reinforcement material; and a lubricating agent is filled between the internal reinforcement material and the outer layer reinforcement material. According to the non-adhesion prestressing reinforcement material, the supporting effect of the reinforcement material on a soil body can be improved through the high-elasticity modulus reinforcement material in a tensioning inner layer. Therefore, the constraint of reinforcement belts on the soil body is increased, and the vertical deformation of filled earth is reduced; the non-adhesion prestressing reinforcement material can slide between the inner layer and an outer layer, so that the soil body cannot be driven to move towards the two sides in the tensioning process; and a composite material is formed by the outer layer reinforcement material and the soil body, so that the deformation of the soil body is further constrained. By mutually connecting a secondary stressed part with the main stressed part, the deformation of the soil body among the reinforcement belts on the same layer can be coordinated.

Owner:HUNAN UNIV

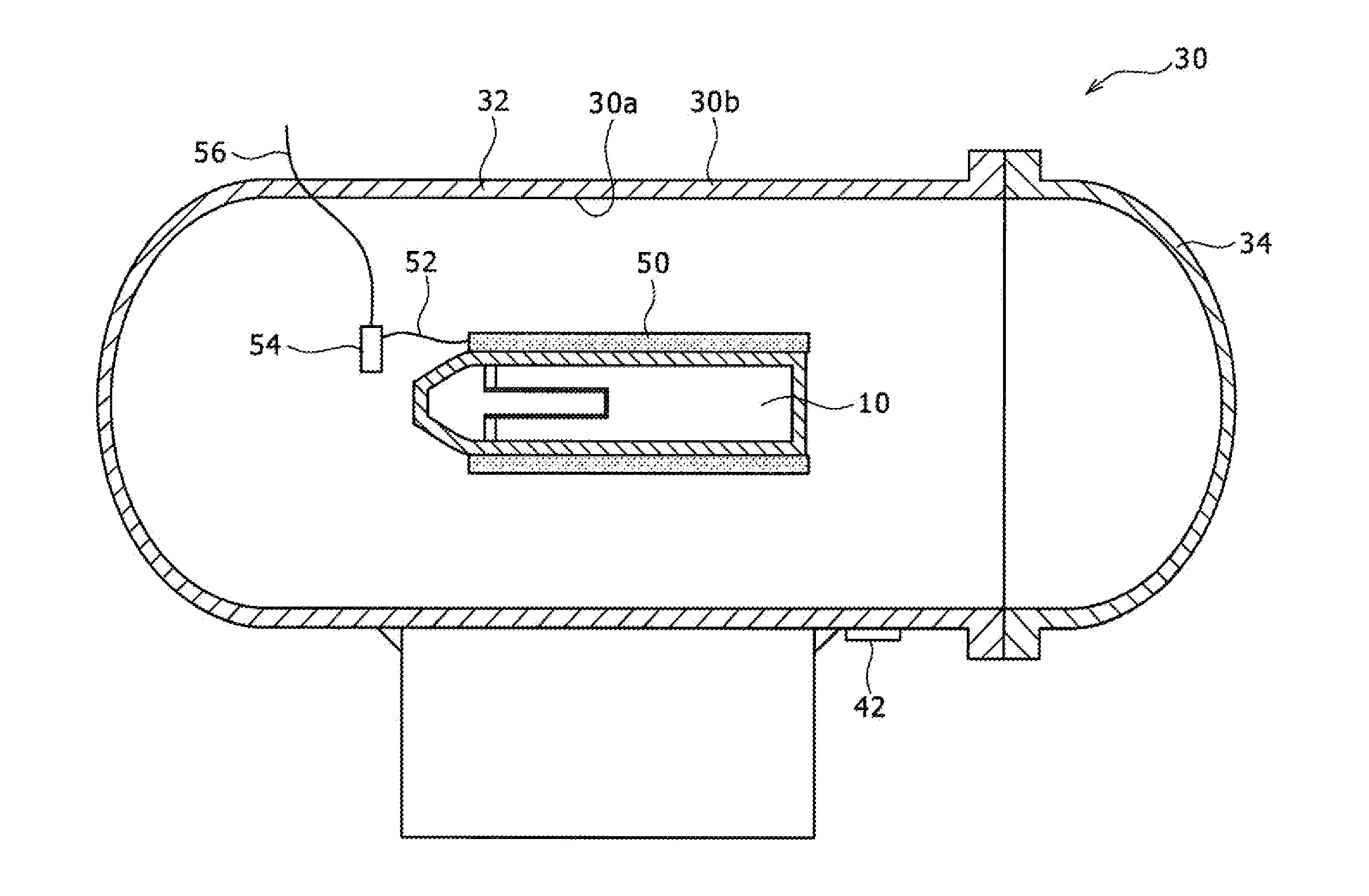

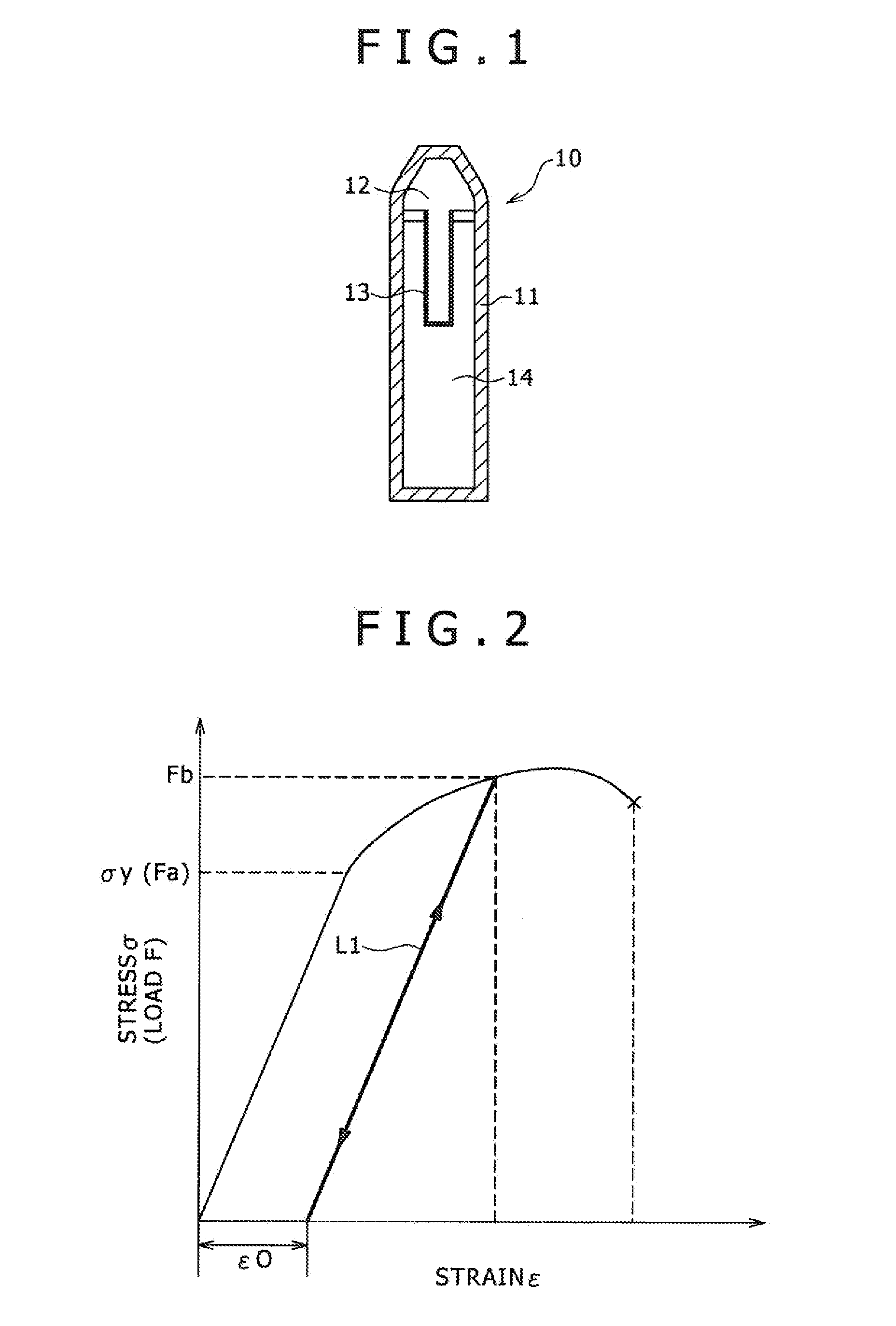

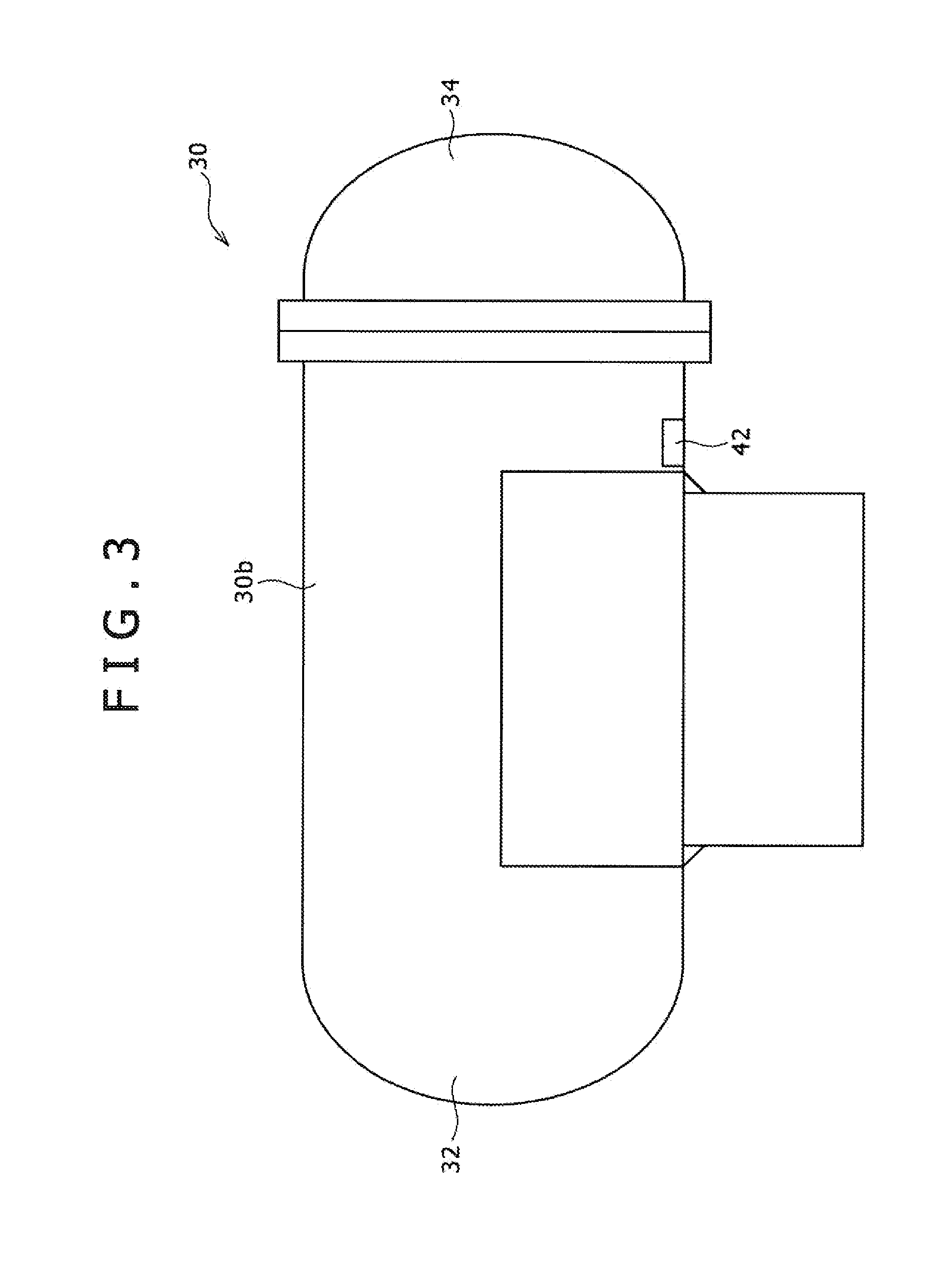

Blast treatment method

Provided is a blast treatment method with which the object to be treated can be treated more reliably and efficiently. This method includes: a step wherein an explosive is detonated inside a pressure vessel (30) comprising an elasto-plastic metal, thereby imparting to the pressure vessel (30) an initial load wherein the primary + secondary stress generated in at least a portion of the structural parts of the pressure vessel becomes a stress that is included in a plastic region exceeding the elastic region, thereby generating a shakedown state in the pressure vessel (30); and a subsequent step wherein a treatment explosive (50) is detonated within the pressure vessel (30), thereby blasting the object (10) to be treated.

Owner:KOBE STEEL LTD

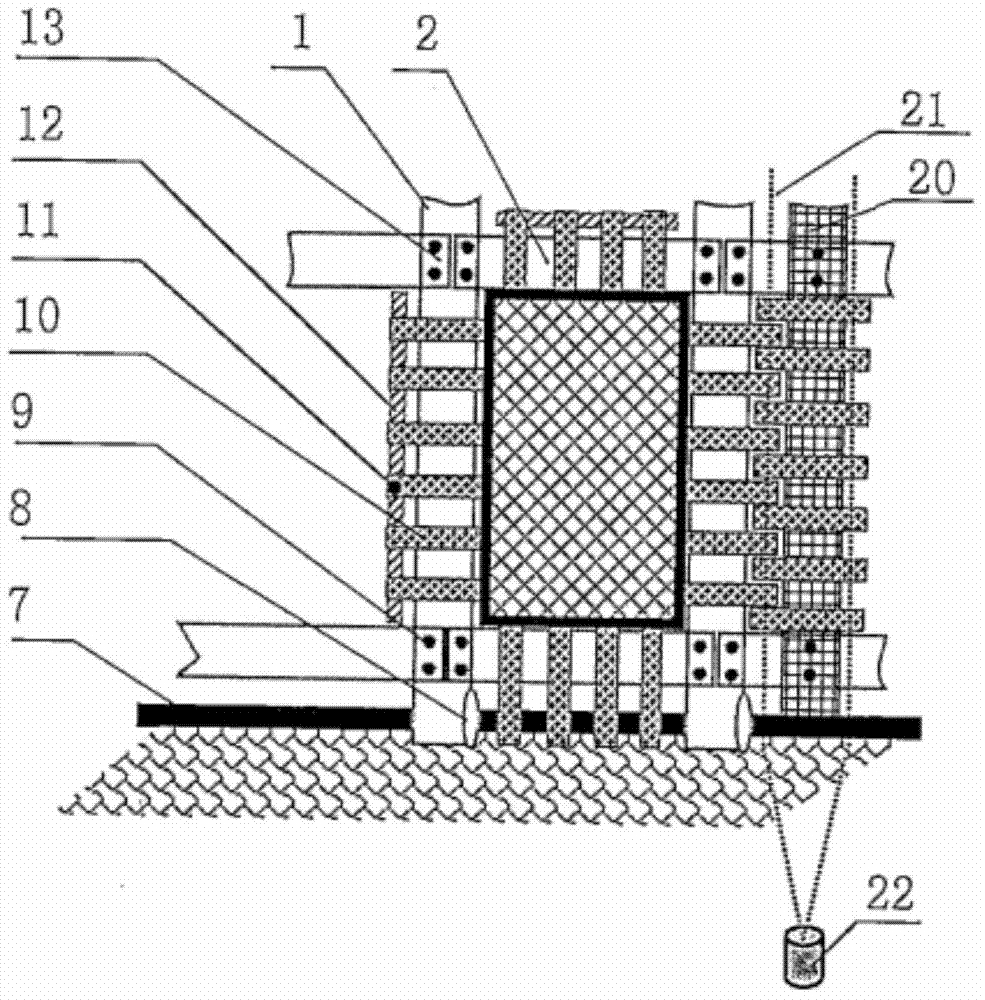

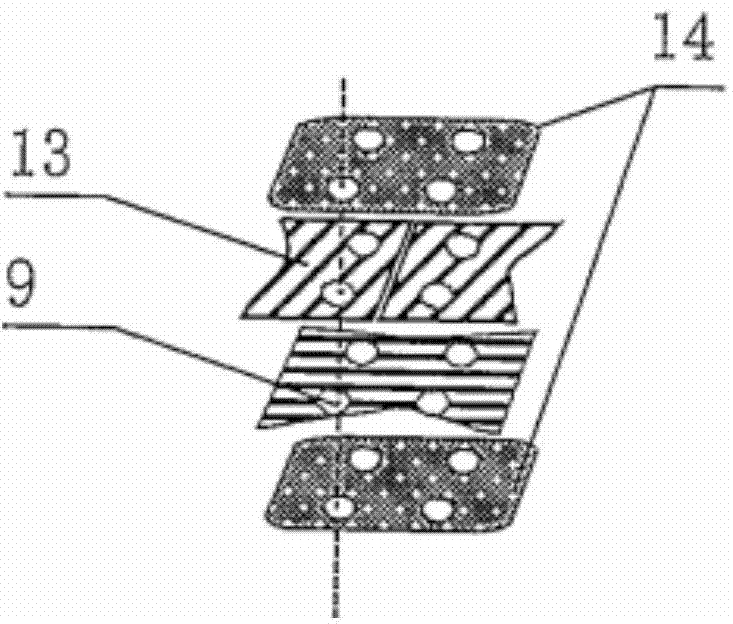

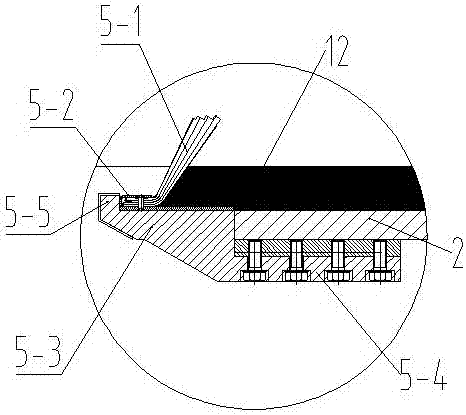

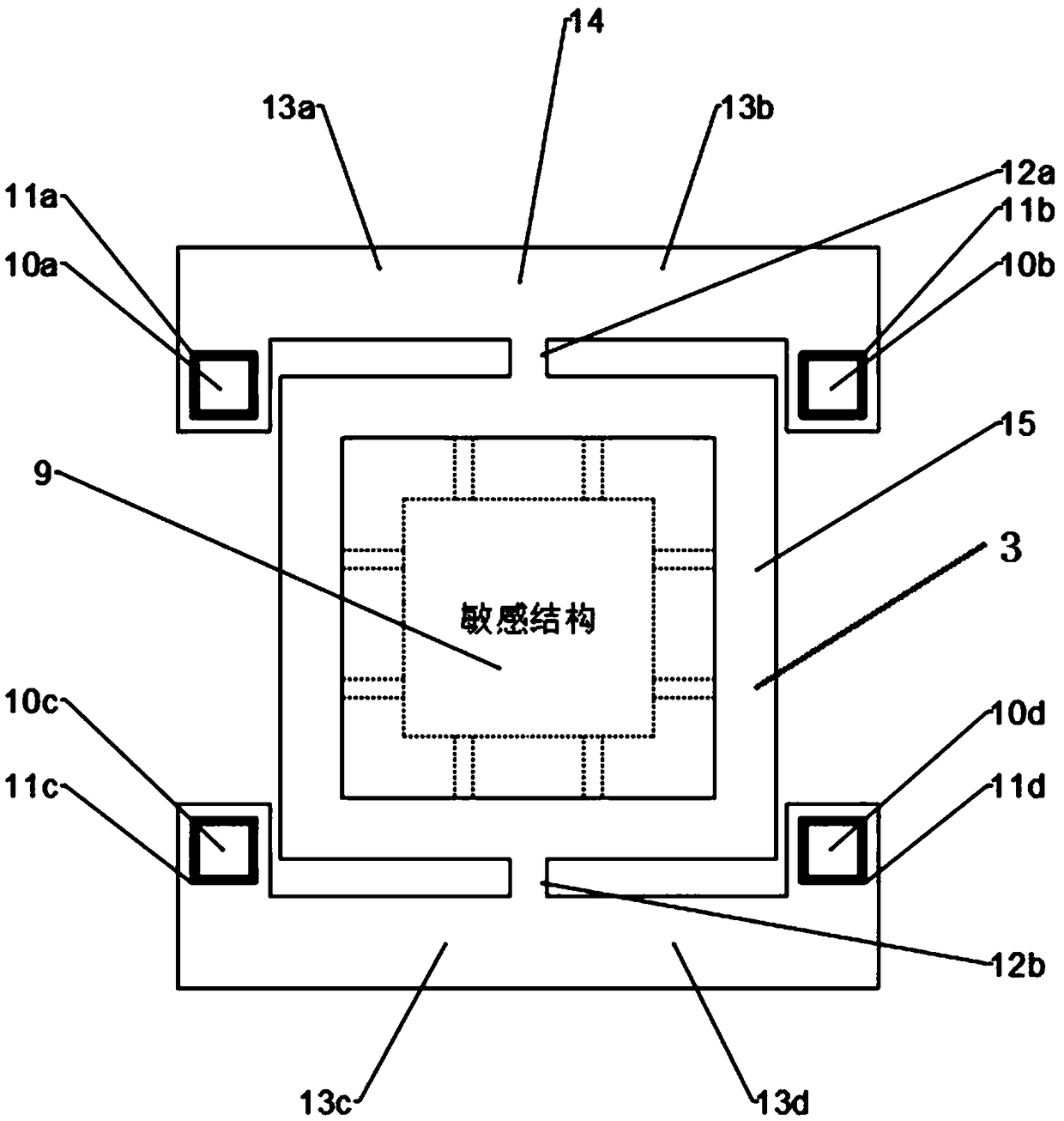

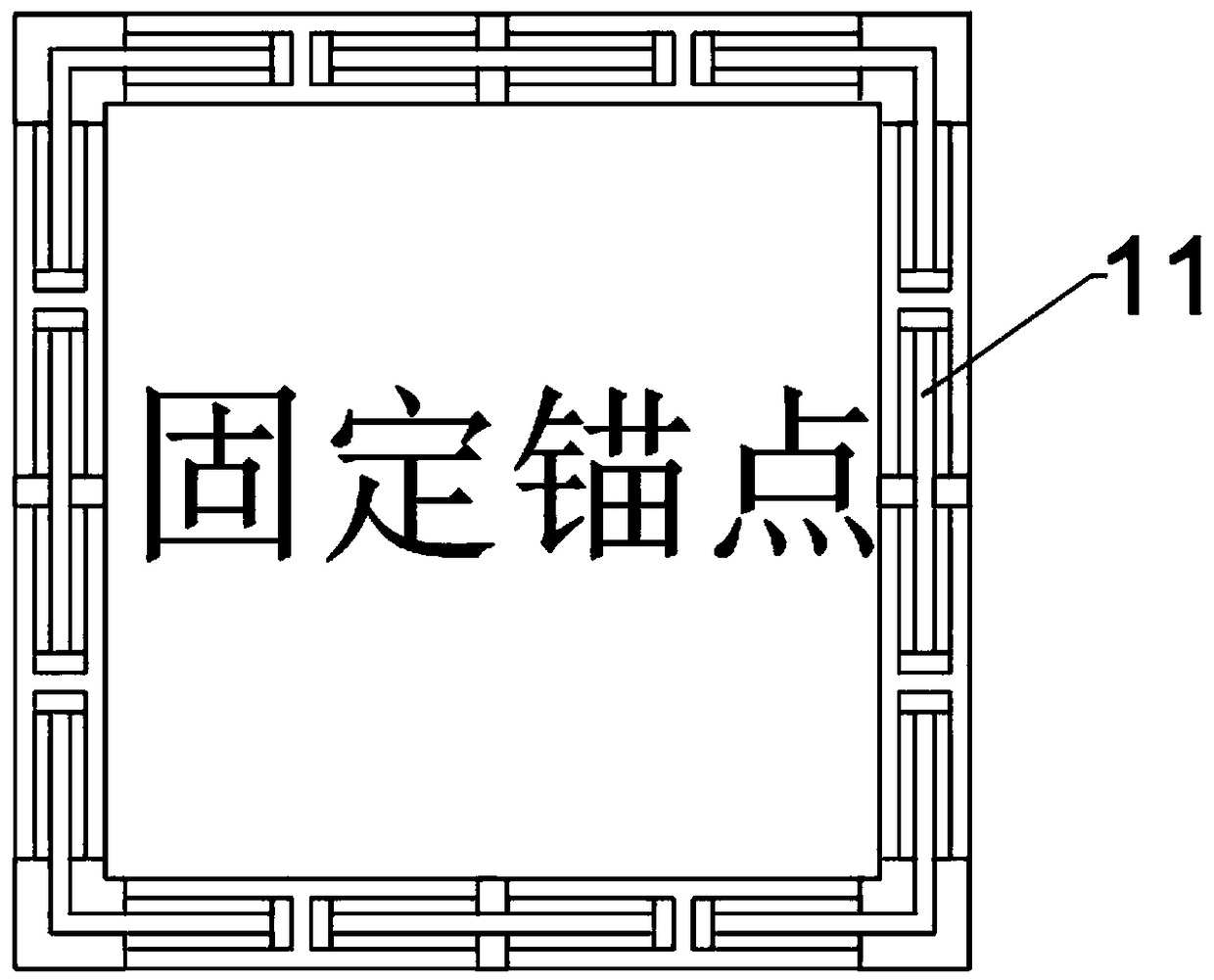

Secondary stress isolation structure applied to MEMS force sensitive device

PendingCN109110724ASimple structureSimple processTelevision system detailsImpedence networksUltrasound attenuationStress concentration

The invention discloses a secondary stress isolation structure (3) applied to a MEMS force sensitive device. The structure comprises an external framework structure (14) and a force sensitive structure (9) arranged in the external framework structure (14). The external framework structure (14) comprises an internal framework (15). The upper and lower ends of the internal framework (15) are connected to corresponding stress attenuation beams (13) through at least one stress concentration beam (12). The stress attenuation beams (13) are connected to fixed anchor points (10) located in flexible connections (11) through the plurality of flexible connections (11). In the invention, secondary stress release can be realized; the flexible connections (11) are first order stress isolation; the stress attenuation beams (13) and the stress concentration beam (12) are stubby stiffening bars, form a transition framework and are taken as secondary stress isolation; and stresses generated during a sensitive structural technology and a packaging process can be isolated on a sensitive structural layer.

Owner:NANJING UNIV OF SCI & TECH

Cold drawing method for medium-carbon steel bar

The invention relates to a cold drawing method for a medium-carbon steel bar, in particular to a cold drawing method for processing a medium-carbon steel bar blank into required specifications. The medium-carbon steel bar is manufactured by using the medium-carbon steel bar blank with the total deformation rate more than or equal to 30 percent through the steps of primary drawing, primary stress annealing treatment, secondary drawing, secondary stress annealing treatment, straightening treatment, nondestructive inspection and the like. The method can save material and reduce energy consumption.

Owner:WUXI TIANCHEN COLD DRAWING STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com